Page 1

Page 2

Page 3

Introduction of <CNC 70 Series Maintenance Training> Course

Course name : CNC 70 Series maintenance

Maximum number

of trainees

: 5

Aim of the course : to learn about maintenance of CNC 70 Series

Intended trainees : Engineers in charge of NC machine tool maintenance

Textbook to use : CNC 70 Series Maintenance Course

NC model to use : CNC 70 Series

Curriculum (One-day course)

Date Time Contents

Day ( ) Month ( )

Orientation

9:15

NC system hardware configuration

to

Maintenance and diagnosis screens

12:00

Data input/output operation and practice

NC alarms and part replacement practice

13:00

to

NC setup and practice

Drive system maintenance and part

The entry of

participation

record

16:30

replacement practice

Drive system alarms and their remedies

Page 4

Page 5

Preface

This textbook is designed to be used in "CNC 70 Series maintenance training course".

Operations and procedures described in this textbook are basically standard ones. Therefore, they

may be different from yours, depending on your NC model, machine tool builder , machine type, and so

on. Before you carry out actual maintenance such as part replacement, we recommend you to consult

with our service center.

As this textbook has been written based mostly on the following manuals, please refer to them for the

details.

• 700/70 Series Instruction Manual..................................................................IB-1500041

• 700/70 Series Setup Manual......................................................................... IB-1500123

• 70 Series Connection Manual.......................................................................IB-1500253

• MDS-D/DH Series Instruction Manual...........................................................IB-1500024

• MDS-D-SVJ3/SPJ3 Series Instruction Manual.............................................. IB-1500192

Page 6

Page 7

Contents

1. 70 Series System Configuration.........................................................................................................................1

1.1 NC Configuration...........................................................................................................................................1

1.2 System Configuration ....................................................................................................................................2

1.2.1 System Basic Configuration Drawing......................................................................................................2

1.2.2 General Connection Diagram..................................................................................................................3

1.2.3 List of Configuration Units.......................................................................................................................5

1.2.3.1 Control Unit: FCU7-MU521/FCU7-MU522........................................................................................5

1.2.3.2 Display Unit: FCU7-DU120-12/FCU7-DU140-12/FCU7-DU140-32 .................................................5

1.2.3.3 Operation Panel I/O Unit: FCU7-DX7xx............................................................................................6

1.2.3.4 Keyboard Unit: FCU7-KB024/ FCU7-KB044....................................................................................7

1.2.3.5 Remote I/O Unit:

FCUA-DX100/FCUA-DX110/FCUA-DX120/FCUA-DX140/FCUA-DX101/FCUA-DX111/

FCUA-DX121/FCUA-DX141.........................................................................................................................7

1.2.3.6 Scan I/O Card: HR357/HR347..........................................................................................................7

1.2.3.7 Card-sized I/O Card: HR361/HR371/HR381/HR383........................................................................8

1.2.3.8 External Power Supply Unit: PD25/PD27.........................................................................................8

2. Maintenance Screens.........................................................................................................................................9

2.1 Input/Output Screen ......................................................................................................................................9

2.1.1 Changing the Valid Area........................................................................................................................12

2.1.2 Selecting a Device, Directory and File..................................................................................................13

2.1.3 Transferring a File .................................................................................................................................20

2.1.4 Comparing Files (Compare)..................................................................................................................22

2.1.5 Formatting an External Device..............................................................................................................23

2.1.6 List of File Names..................................................................................................................................23

2.2 All Backup Screen........................................................................................................................................24

2.2.1 Performing a Backup Operation............................................................................................................26

2.2.2 Performing a Restore Operation...........................................................................................................26

2.2.3 Setting Automatic Backup.....................................................................................................................27

2.2.4 Backing up the SRAM...........................................................................................................................28

2.3 Absolute Position Setting Screen................................................................................................................30

2.3.1 Selecting the Axis..................................................................................................................................32

2.3.2 Carrying Out Dogless-type Zero Point Initialization ..............................................................................33

2.3.3 Carrying Out Dog-type Zero Point Initialization.....................................................................................41

2.3.4 Precautions............................................................................................................................................41

3. Diagnosis Screens............................................................................................................................................44

3.1 System Configuration Screen......................................................................................................................44

3.2 Option Display Screen.................................................................................................................................47

3.3 I/F Diagnosis Screen ...................................................................................................................................48

3.3.1 Displaying the PLC Device Data...........................................................................................................51

3.3.2 Carrying Out Modal Output ...................................................................................................................52

3.3.3 Carrying Out One-shot Output ..............................................................................................................53

3.4 Drive Monitor Screen...................................................................................................................................54

3.4.1 Servo Axis Unit Display Items...............................................................................................................56

3.4.2 Spindle Unit Display Items.....................................................................................................................59

3.4.3 Display Items for the Power Supply Unit...............................................................................................68

3.4.4 Display Items for the Synchronous Error ..............................................................................................70

3.4.5 Clearing the Alarm History.....................................................................................................................71

3.5 NC Memory Diagnosis Screen (NC Memory Diagn Screen) ......................................................................72

3.5.1 Writing/Reading the Data Using the NC Data Designation...................................................................74

3.6 Alarm Screen ...............................................................................................................................................75

3.6.1 Alarm History .........................................................................................................................................77

3.7 Self Diagnosis Screen .................................................................................................................................79

4. NC's Maintenance Check and Replacement Procedure..................................................................................83

4.1 Maintenance Items ......................................................................................................................................83

4.1.1 Escutcheon............................................................................................................................................83

4.1.2 LCD Panel.............................................................................................................................................84

Page 8

4.1.3 Compact Flash/IC card..........................................................................................................................84

4.2. H/W Replacement Methods........................................................................................................................85

4.2.1 Durable Parts.........................................................................................................................................85

4.2.1.1 Control unit battery..........................................................................................................................85

4.2.1.2 Backlight..........................................................................................................................................87

4.2.2 Unit........................................................................................................................................................89

4.2.2.1 Control Unit.....................................................................................................................................89

4.2.2.2 Display Unit.....................................................................................................................................91

4.2.2.3 Keyboard unit..................................................................................................................................92

4.2.2.4 DX Unit............................................................................................................................................94

4.2.3 Compact Flash ......................................................................................................................................95

4.2.3.1 Front Compact Flash.......................................................................................................................95

5. NC Setup Procedures.......................................................................................................................................96

5.1 Setup Procedure after SRAM Clear ............................................................................................................96

5.1.1 Outline of Hardware Configuration........................................................................................................96

5.1.2 Outline of Setup Procedures.................................................................................................................97

5.2 Setup Details ...............................................................................................................................................99

5.2.1 Erasing the backed up data (SRAM).....................................................................................................99

5.2.2 Inputting the Parameters.....................................................................................................................100

5.2.2.1 When There is No Parameter File ................................................................................................100

5.2.2.2 When a Parameter File is Av ailable..............................................................................................101

5.2.2.3 Parameter Screens.......................................................................................................................102

5.2.3 Formatting the File System .................................................................................................................113

5.2.4 Integrated Time Display.......................................................................................................................114

5.2.4.1 Setting the Integrated Time...........................................................................................................115

5.2.4.2 Setting the Time Display Selection...............................................................................................116

5.2.5 Credit System......................................................................................................................................117

5.2.6 Absolute Position Detection System ...................................................................................................119

5.2.6.1 Dog-type Reference Position Return Operation...........................................................................119

5.2.6.2 Starting up the Absolute Position Detection System.....................................................................120

5.2.7 PLC Switch Function...........................................................................................................................122

5.2.7.1 Turning PLC Switches ON/OFF....................................................................................................123

5.3 7-segment LED's Alarm/Status Indication .................................................................................................124

5.3.1 Outline.................................................................................................................................................124

5.3.2 Status Display......................................................................................................................................124

5.3.3 Alarm Display ......................................................................................................................................124

5.3.4 Notes...................................................................................................................................................125

5.3.5 Example of alarm display....................................................................................................................126

6. Drive Unit Maintenance...................................................................................................................................134

6.1 MDS-D/DH Series......................................................................................................................................134

6.1.1 Part system connection diagram.........................................................................................................134

6.1.2 Maintenance........................................................................................................................................135

6.1.2.1 Inspections....................................................................................................................................135

6.1.2.2 Service parts.................................................................................................................................135

6.1.2.3 Adding and replacing units and parts............................................................................................136

6.1.2.3.1 Replacing the drive unit..........................................................................................................136

6.1.2.3.2 Replacing the unit fan.............................................................................................................137

6.1.2.3.3 Replacing the battery..............................................................................................................138

6.1.2.3.4 Replacing the fuse..................................................................................................................140

6.2 MDS-D-SVJ3/SPJ3 Series........................................................................................................................141

6.2.1 Part system connection diagram.........................................................................................................141

6.2.2 Maintenance........................................................................................................................................142

6.2.2.1 Inspections....................................................................................................................................142

6.2.2.2 Service parts.................................................................................................................................142

6.2.2.3 Adding and replacing units and parts............................................................................................143

6.2.2.3.1 Replacing the drive unit..........................................................................................................143

6.2.2.3.2 Replacing the unit fan.............................................................................................................144

6.2.2.3.3 Replacing the battery..............................................................................................................145

7. Servo System Maintenance............................................................................................................................146

7.1 D/A output specifications for servo drive unit ............................................................................................146

7.1.1 MDS-D/DH Series...............................................................................................................................146

Page 9

7.1.1.1 D/A output specifications...............................................................................................................146

7.1.1.2 Setting the output data..................................................................................................................147

7.1.1.3 Setting the output magnification....................................................................................................148

7.1.2 MDS-D-SVJ3 Series............................................................................................................................149

7.1.2.1 D/A output specifications...............................................................................................................149

7.1.2.2 Setting the output data..................................................................................................................150

7.1.2.3 Setting the output magnification....................................................................................................151

7.2 Vibration Suppression................................................................................................................................152

7.2.1 Notch filte.............................................................................................................................................152

8. Spindle System Maintenance .........................................................................................................................153

8.1 D/A output specifications for spindle drive unit..........................................................................................153

8.1.1 MDS-D/DH Series...............................................................................................................................153

8.1.1.1 D/A output specifications...............................................................................................................153

8.1.1.2 Setting the output data..................................................................................................................154

8.1.1.3 Setting the output magnification....................................................................................................156

8.1.2 MDS-SPJ3 Series ...............................................................................................................................157

8.1.2.1 D/A output specifications...............................................................................................................157

8.1.2.2 Setting the output data..................................................................................................................158

8.1.2.3 Setting the output magnification....................................................................................................160

8.2 Diagnostic Procedure When Vibration/Noise Occurs................................................................................161

8.2.1 How to judge whether the cause is on machine side or control unit side...........................................161

8.2.2 How to judge PLG trouble...................................................................................................................161

8.2.3 How to check PLG waveform..............................................................................................................162

8.2.3.1 Configuration of serial detector TS5691.......................................................................................162

8.2.3.2 Adjust A and B phase signals........................................................................................................163

8.2.3.3 Check Z phase signal....................................................................................................................164

8.3 Adjustment of Orientation Stop Position....................................................................................................166

9. Servo/Spindle's T roubleshooting.....................................................................................................................167

9.1 MDS-D/DH Series......................................................................................................................................167

9.1.1 Points of caution and confirmation......................................................................................................167

9.1.1.1 LED display when alarm or warning occurs..................................................................................168

9.1.2 Protective functions list of units...........................................................................................................169

9.1.2.1 List of alarms.................................................................................................................................169

9.1.2.2 List of warnings.............................................................................................................................173

9.1.3 Troubleshooting...................................................................................................................................176

9.1.3.1 Troubleshooting at power ON.......................................................................................................176

9.1.3.2 Troubleshooting for each alarm No...............................................................................................177

9.1.3.3 Troubleshooting for each warning No...........................................................................................200

9.1.3.4 Parameter numbers during initial parameter error........................................................................202

9.1.3.5 Troubleshooting the spindle system when there is no alarm or warning......................................203

9.2 MDS-D-SVJ3/SPJ3 Series........................................................................................................................205

9.2.1 Points of caution and confirmation......................................................................................................205

9.2.1.1 LED display when alarm or warning occurs..................................................................................206

9.2.2 Protective functions list of units...........................................................................................................207

9.2.2.1 List of alarms.................................................................................................................................207

9.2.2.2 List of warnings.............................................................................................................................210

9.2.3 Troubleshooting...................................................................................................................................213

9.2.3.1 Troubleshooting at power ON.......................................................................................................213

9.2.3.2 Troubleshooting for each alarm No...............................................................................................214

9.2.3.3 Troubleshooting for each warning No...........................................................................................232

9.2.3.4 Parameter numbers during initial parameter error........................................................................234

9.2.3.5 Troubleshooting the spindle system when there is no alarm or warning......................................235

10. Appendix.......................................................................................................................................................237

10.1 List of Alarms...........................................................................................................................................237

10.1.1 Operation Alarms...............................................................................................................................237

10.1.2 Stop Codes........................................................................................................................................245

10.1.3 Servo/Spindle Alarms........................................................................................................................249

10.1.4 MCP Alarm ........................................................................................................................................258

10.1.5 System Alarms ..................................................................................................................................268

10.1.6 Absolute Position Detection System Alarms.....................................................................................274

10.1.7 Distance-coded Reference Scale Errors...........................................................................................277

Page 10

10.1.8 Messages during Emergency Stop ...................................................................................................278

10.1.9 Computer Link Errors........................................................................................................................280

10.1.10 User PLC Alarms.............................................................................................................................281

10.1.1 1 Network Service Errors....................................................................................................................283

10.2 RS-232C I/O Device Parameter Setting Examples.................................................................................284

Page 11

1. 70 Series System Configuration

C

A

A

1. 70 Series System Configuration

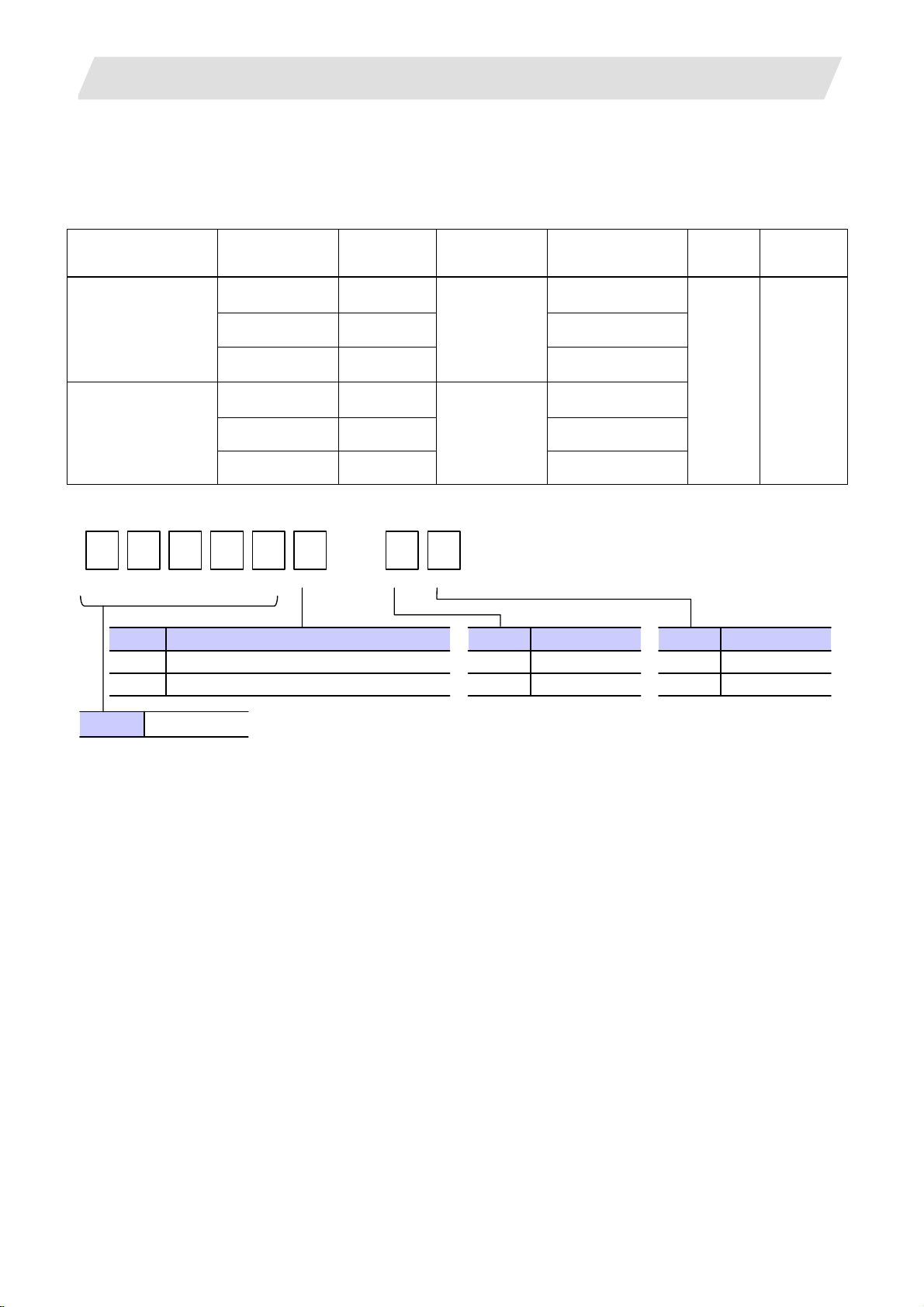

1.1 NC Configuration

70 Series configuration

MITSUBISHI CNC 70

Type A

MITSUBISHI CNC 70

Type B

F

System model

name

FCA70P-2A 8.4" LCD FCU7-DU120-12

FCA70P-4A 10.4" LCD FCU7-DU140-12

FCA70H-4A 10.4" LCD

FCA70P-2B 8.4" LCD FCU7-DU120-12

FCA70P-4B 10.4" LCD FCU7-DU140-12

FCA70H-4B 10.4" LCD

7 0 P

-

Display

size

4

Control unit

name

FCU7-MU522

FCU7-MU521

1.1 NC Configuration

Display unit name

FCU7-DU140-32

FCU7-DU140-32

Machine

type

Common

to M/L

System #

BND-

1009W000

Hardware type Code

Panel-in type (without touch panel specification)

P

Panel-in type (with touch panel specification)*

H

M70 Series FCA70

* Reserved for future expansion

There are six types of M70 H/W configurations

Display unit sizeCode

8.4 inch 2

10.4 inch 4

Type Code

Type A A

Type B B

1

Page 12

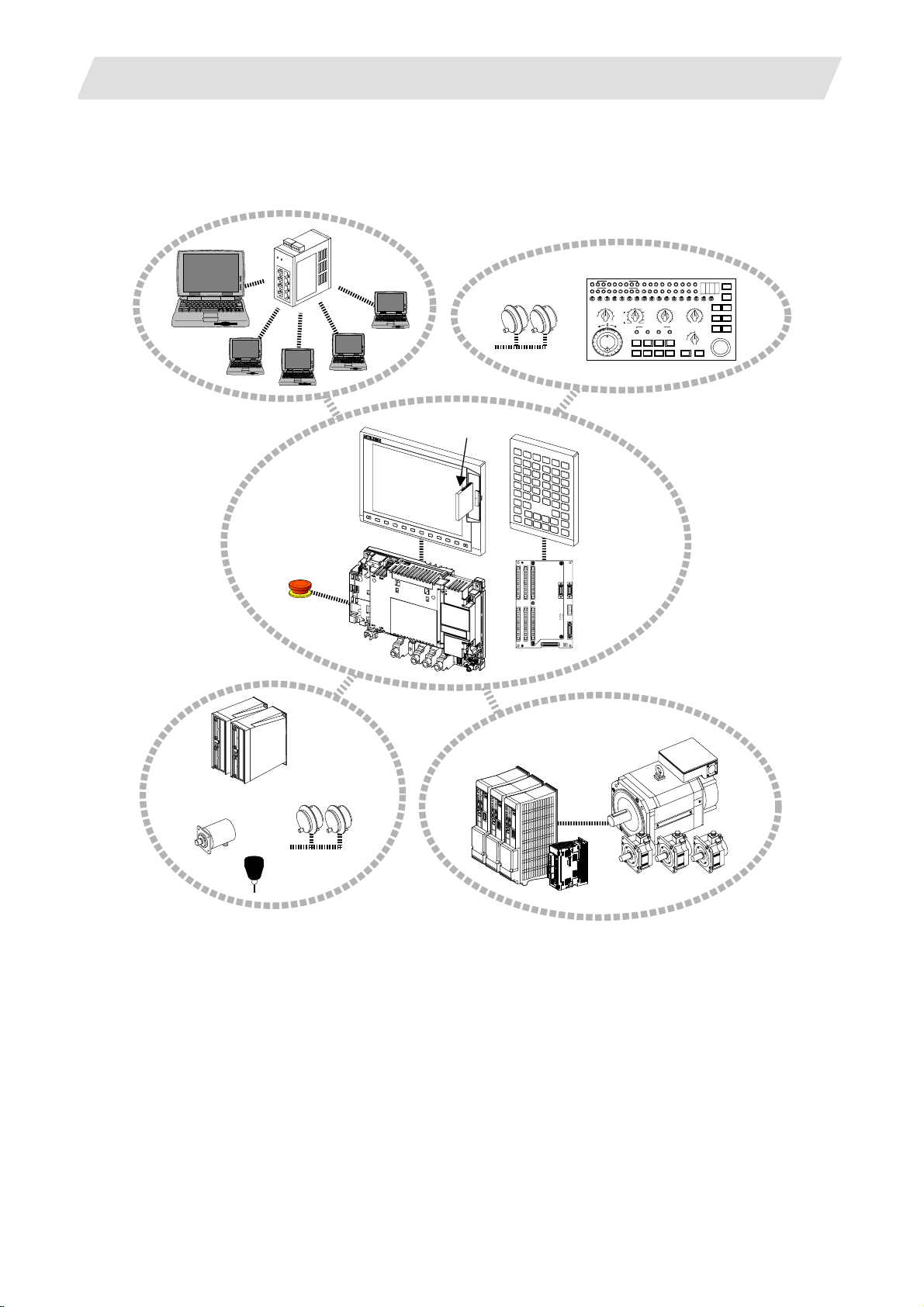

1. 70 Series System Configuration

1.2 System Configuration

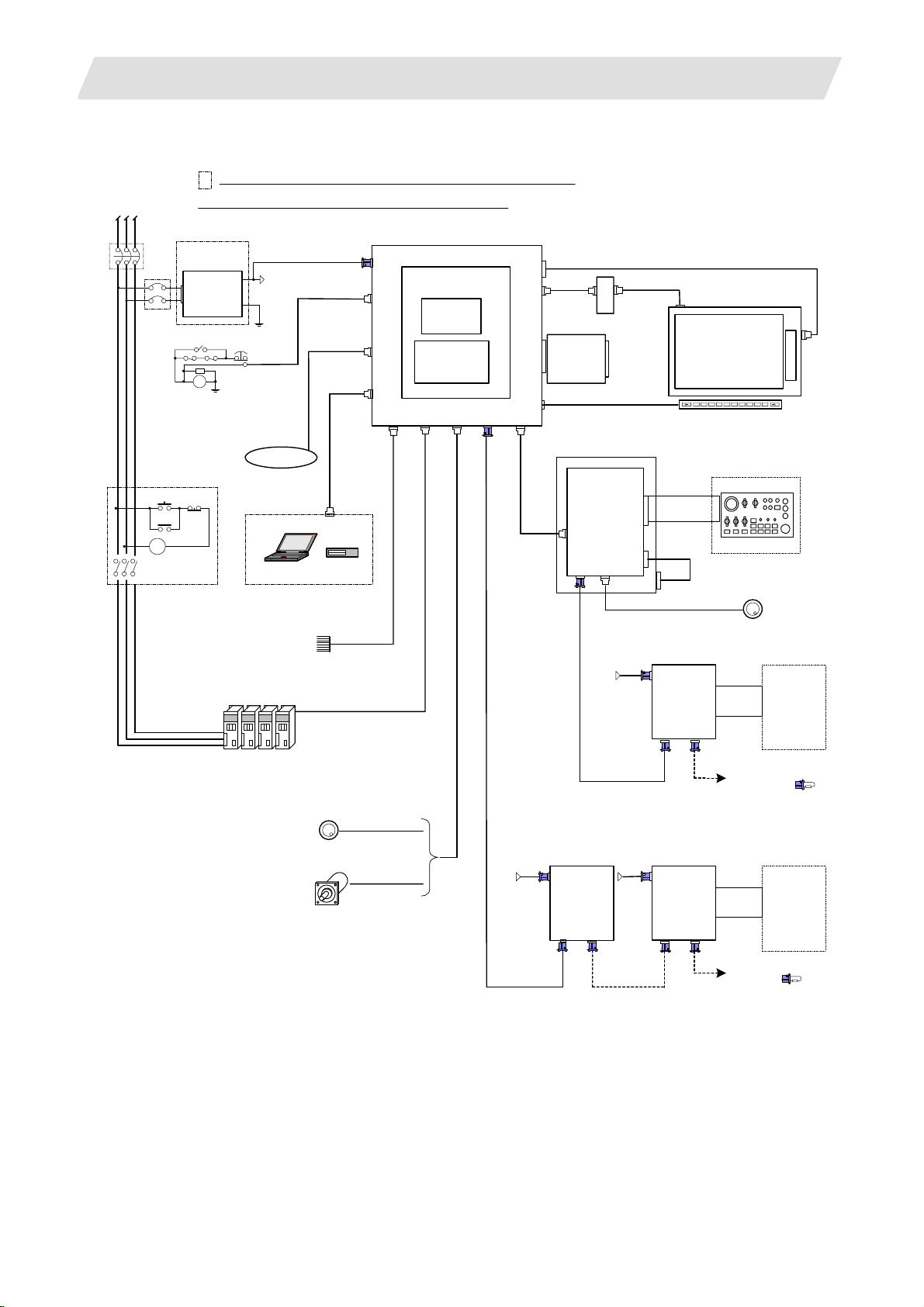

1.2.1 System Basic Configuration Drawing

Ethernet

hub

Personal

computer

Display unit

CF card I/F

Manual pulse

generator

1.2 System Configuration

Machine operation panel

MF MCODEDATA

TF TCODEDATA

SW1 SW9 SW10 SW11 SW12 SW13 OVSL OVC SRN F1DSW8SW7SW6SW5SW4SW3SW2

10

1

-+

Keyboard unit

100

1000

5000

10000

50000

100000

AL1 AL2 AL3 AL4 TAP DEN OP SA MA

SFLED29LED30 LED31LED32 LED33LED34LED35LED36

RAP ID

STEP

R-P OINTRETURN

JOG

X

HANDLE

MEM

Y

MDI

Z

TAPE

4

1STREFERENCEPOSITIO N

+X +4+Z+Y

-X -4-Z-Y FEEDHOLDCYCLESTART

MANUAL FEEDRATE

100

52

27

20

10

REACHED

DEGITALSWITCH

RESET

CUTTIN GFEEDRATEOVERRIDEMODE SELECTHANDLE/STEPMULTIPLICATION

520

100

720

110

270

90

1000

80

120

200

130

1400

70

140

2000

60

MACHINELOCK

2700

50

150

160

40

3700

30

170

5200

2

180

20

7200

10

190

1

10000

mm/mi n

%

0

0

SIN GLEBLOCK

200

14000

RAPIDTRAVERSEOVERRID E

4ZYX

100

50

25

EMERGENCYSTOP

1

ON

OFF

FIN

MSTLOCK

DRYRUN

Control unit

Operation panel

I/O unit

Synchronous feed

encoder

Emergency

stop switch

Remote I/O

unit

Manual pulse

generator

Servo/Spindle drive units

MDS-D/DH Series

MDS-D-SVJ3/SPJ3 Series

Skip

(Note 1) Control unit is mounted on the back side of the display unit.

(Note 2) Operation panel I/O unit is mounted on the back side of the keyboard unit.

Motors

2

Page 13

1. 70 Series System Configuration

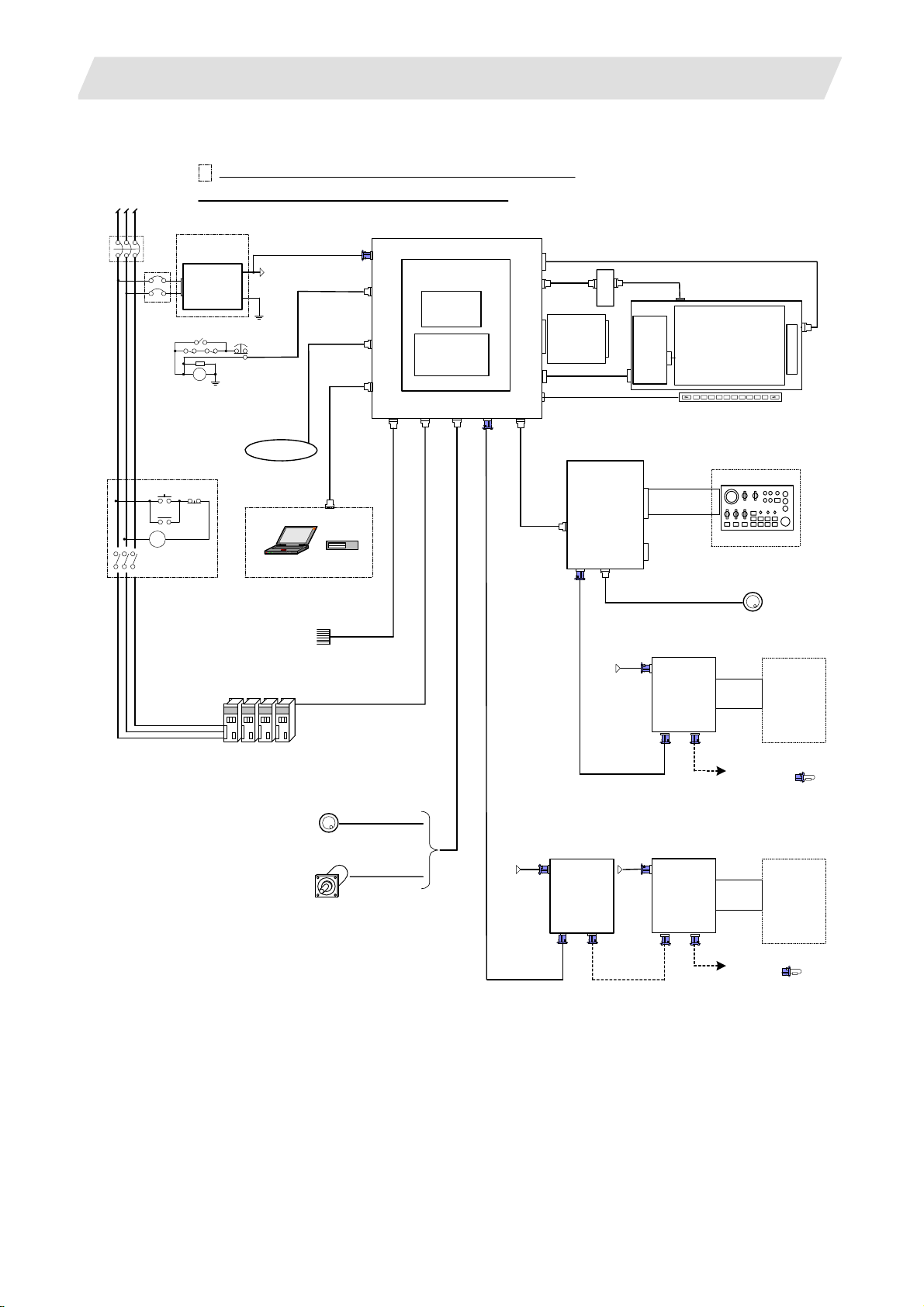

1.2.2 General Connection Diagram

(1) Without Touch Panel

Dotted lines indicate the sections prepared by machine tool builder.

RST

No-fuse breaker(NFB)

NFB

MC

MC

The name with brackets <> indicates the cable for the unit.

24VDC

stabilized power

supply

DCOUT

ACIN

OT release switch

RA

ON OFF

MC

FG

EMG

FG

24VDC

FG

Network

Sensor signals

Max. 8 pints

F070

F120

G300/G301

RS232C Device

Skip signal input

1ch

USER 2ch

1ch: F034

2ch: F035

FCUA-R030

G395/G396/G380

CNC control unit

FCU7-MU521/522

DCIN

Main card HN76x

EMG

LAN

Memory card

Expansion

SIO

OPT

SKIP ENC

HN4xx

card

HN75x

RIO1

LCD

INV

FRONT

MENU

CG71

G011

max. 0.5m

<8.4-type: G097>

<10.4-type: G098>

<F480>

Backlight inverter

Front CF

card

HN791

Keyboard unit

FCU7-KB024/44

Operation panel

I/O unit

FCU7-DXxxx

CG3x

CG71

RIO3 MPG

1.2 System Configuration

<10.4-type: G482>

Display unit

8.4-type FCU7-DU120-12

10.4-type FCU7-DU140-12

(VGA:640×480)

Menu key

Machine operation panel

F351

<G402>

NCKB

Manual pulse generator

DI-L/R

RIO2RIO1

2ch

R300

Machine

control

relay/contact

24VDC

F070

12V:F320/F321

5V:F023/F024

Remote I/O unit

DCIN

FCUA-DX1xx

Spindle/Servo Drive Units

MDS-D/DH/SVJ3/SPJ3

Manual pulse generator

Sync. Encoder

2ch

5V:G023/G024

1ch

FCUA-R050/054

24VDC 24VDC

F070

FCUA-R211

/SH41

FCUA-R211

/SH41

Remote I/O unit

DCIN

FCUA-DX1xx

RIO2

RIO1

F070

FCUA-R211

/SH41

Remote I/O unit

DCIN

FCUA-DX1xx

DI-L/R

RIO2RIO1

To the next remote

I/O or terminator

Machine

control

relay/contact

R300

To the next remote I/O

or terminator

3

Page 14

1. 70 Series System Configuration

(2) With Touch Panel

Dotted lines indicate the sections prepared by machine tool builder.

RST

No-fuse breaker(NFB)

NFB

MC

MC

The name with brackets <> indicates the cable for the unit.

24VDC

stabilized power

supply

DCOUT

ACIN

OT release switch

RA

ON OFF

MC

FG

EMG

FG

24VDC

FG

Network

Sensor signals

Max. 8 pints

F070

F120

G300/G301

RS232C Device

Skip signal input

1ch

USER 2ch

1ch: F034

2ch: F035

FCUA-R030

G395/G396/G380

CNC control unit

FCU7-MU521/522

DCIN

Main card HN76x

EMG

LAN

Memory card

Expansion

SIO

OPT

SKIP ENC

HN4xx

card

HN75x

RIO1

LCD

INV

FRONT

TEST

MENU

CG71

G011

max. 0.5m

<G098>

<F480>

Backlight

inverter

Front CF

card

HN791

Operation panel

FCU7-DXxxx

CG71

RIO3 MPG

1.2 System Configuration

<G482>

HN244

Touch panel display unit

FCU7-DU140-32

<G422>

I/O unit

TPIN

TESTIN

CG3x

NCKB

Remote I/O unit

24VDC

F070

(VGA:640×480)

F351

12V:F320/F321

5V:F023/F024

DCIN

FCUA-DX1xx

DI-L/R

RIO2RIO1

Menu key

Machine operation panel

2ch

R300

Manual pulse generator

Machine

control

relay/contact

Spindle/Servo Drive Units

MDS-D/DH/SVJ3/SPJ3

Manual pulse generator

Sync. Encoder

2ch

5V:G023/G024

1ch

FCUA-R050/054

24VDC 24VDC

F070

FCUA-R211

/SH41

FCUA-R211

/SH41

Remote I/O unit

DCIN

FCUA-DX1xx

RIO2

RIO1

F070

FCUA-R211

/SH41

Remote I/O unit

DCIN

FCUA-DX1xx

DI-L/R

RIO2RIO1

To the next remote

I/O or terminator

Machine

control

relay/contact

R300

To the next remote I/O

or terminator

4

Page 15

1. 70 Series System Configuration

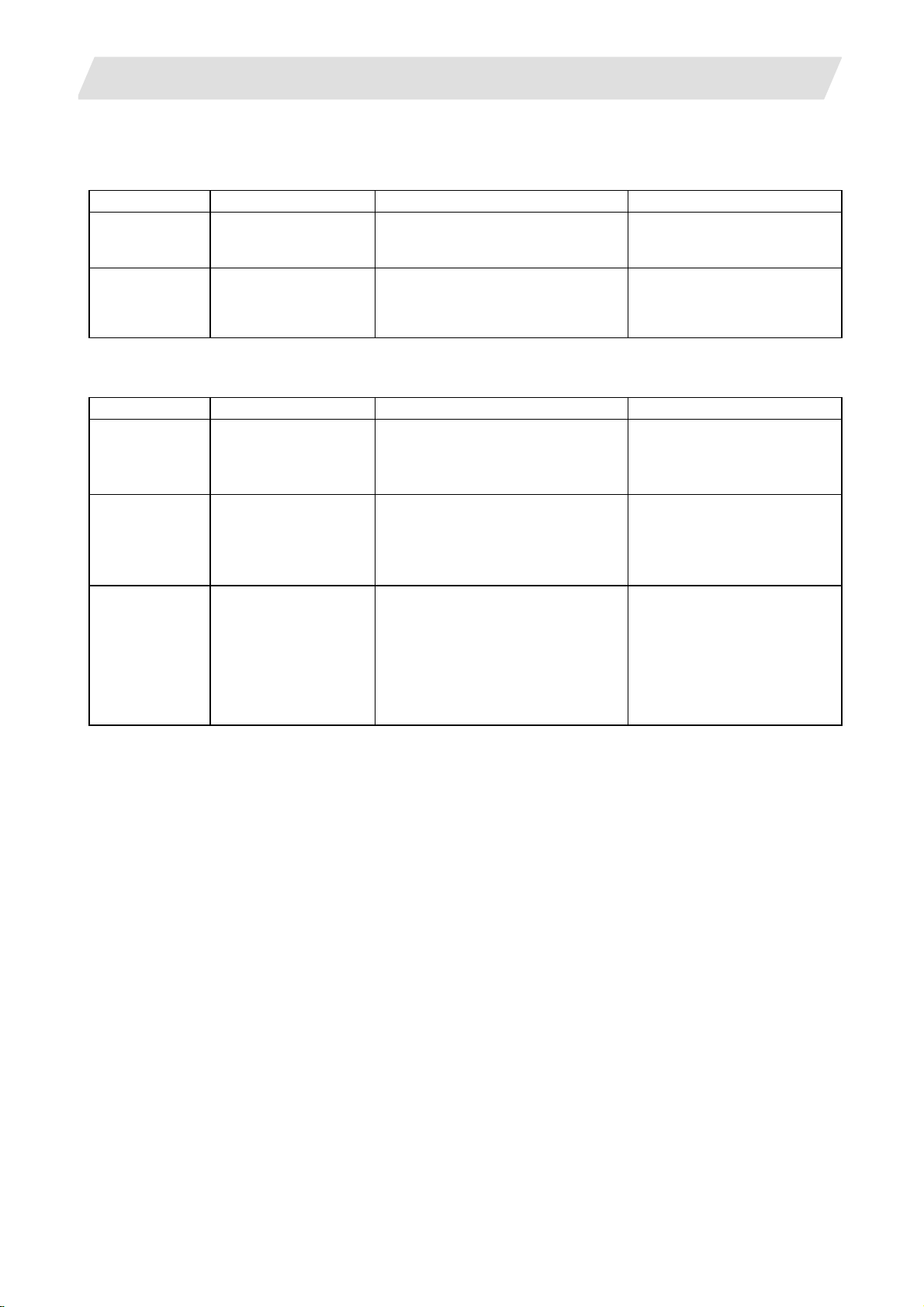

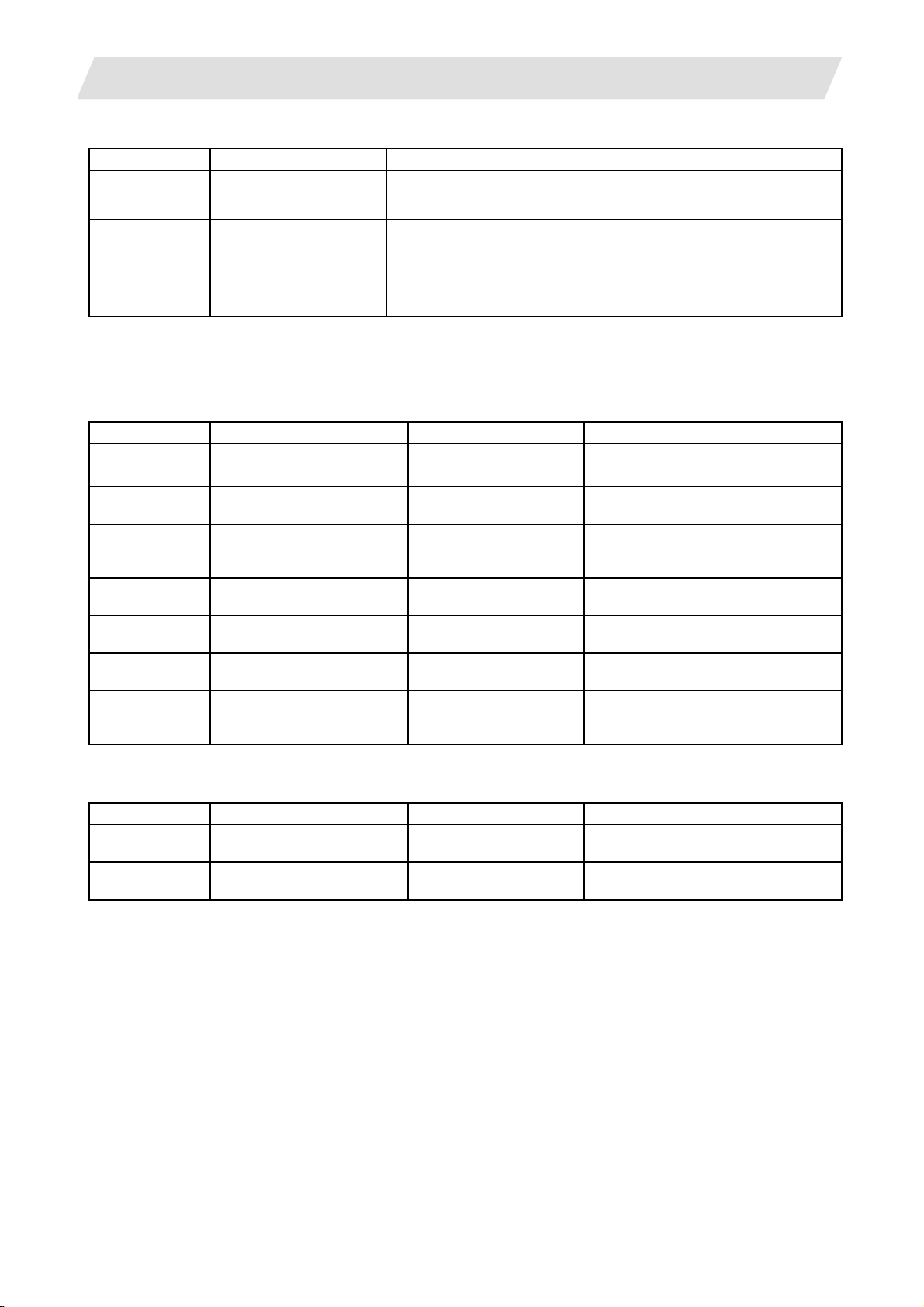

1.2.3 List of Configuration Units

1.2.3.1 Control Unit: FCU7-MU521/FCU7-MU522

Type Function Configuration element Details

FCU7-MU521 NC functions and

display controller

FCU7-MU522 NC functions and

display controller

Main control card (HN761)

Memory card (HN451)

CF I/F Card (HN791)

Main control card (HN761)

Memory card (HN451)

Expansion card (HN751)

CF I/F Card (HN791)

1.2.3.2 Display Unit: FCU7-DU120-12/FCU7-DU140-12/FCU7-DU140-32

Type Function Configuration element Details

FCU7-DU120-12 8.4-type color TFT LCD panel

Backlight inverter (84PW031)

Menu keys

G097 cable

FCU7-DU140-12 10.4-type color TFT LCD panel

Backlight inverter (104PW161)

Menu keys

G098 cable

G482 cable

FCU7-DU140-32 10.4-type color TFT LCD panel

touch panel Backlight inverter (104PW161)

Menu keys

Touch panel

Touch panel control card (HN244)

G098 cable

G422 cable

G482 cable

1.2 System Configuration

Export Trade Control Ordinance

and Foreign Trade Ordinance

noncompliant unit

Export Trade Control Ordinance

and Foreign Trade Ordinance

noncompliant unit

CF card I/F is normally equipped

with the control unit.

CF card I/F is normally equipped

with the control unit.

CF card I/F is normally equipped

with the control unit.

5

Page 16

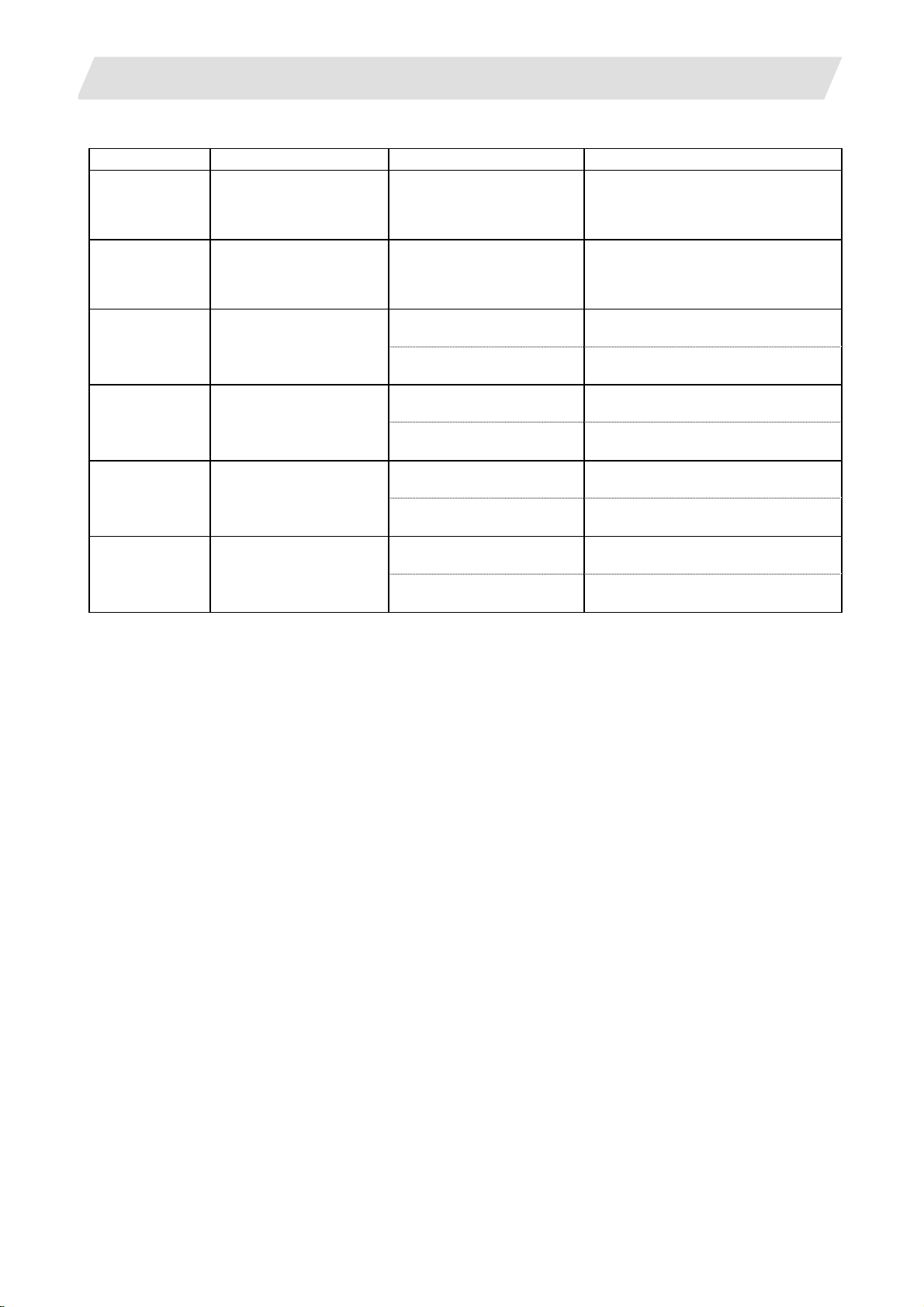

1. 70 Series System Configuration

1.2.3.3 Operation Panel I/O Unit: FCU7-DX7xx

Type Function Configuration element Details

FCU7-DX710 DI/DO Sink/source input

DO sink output

Base card

Terminator

(HN341)

(R-TM)

1.2 System Configuration

DI/DO = 64 points/64 points + MPG 2ch

FCU7-DX711 DI/DO Sink/source input

DO source output

FCU7-DX720 DI/DO Sink/source input

DO sink output

FCU7-DX721 DI/DO Sink/source input

DO source output

DO sink output

DO source output

Base card

Terminator

Base card

Terminator

Add-on card (HN361) DI/DO = 32 points/16 points + AO 1ch

Base card

Terminator

Add-on card (HN371) DI/DO = 32 points/16 points + AO 1ch

Base card

Terminator

Add-on card (HN362) DI/DO = 32 points/32 points

Base card

Terminator

Add-on card (HN372) DI/DO = 32 points/32 points

(HN351)

(R-TM)

(HN341)

(R-TM)

(HN351)

(R-TM)

(HN341)

(R-TM)

(HN342)

(R-TM)

DI/DO = 64 points/64 points + MPG 2ch

DI/DO = 64 points/64 points + MPG 2ch

DI/DO = 64 points/64 points + MPG 2ch

DI/DO = 64 points/64 points + MPG 2chFCU7-DX730 DI/DO Sink/source input

DI/DO = 64 points/64 points + MPG 2chFCU7-DX731 DI/DO Sink/source input

(Note 1) Operation panel I/O unit is mounted on the back side of the keyboard unit

FCU7-KB024/KB026/KB044.

(Note 2) Operation panel I/O unit for 700 Series is not available.

6

Page 17

1. 70 Series System Configuration

1.2 System Configuration

1.2.3.4 Keyboard Unit: FCU7-KB024/ FCU7-KB044

Type Function Configuration element Details

FCU7-KB024 8.4-type display keyboard Escutcheon, key switch Connect with G011 cable from control unit.

Sheet keys G402 cable Mounting method: Mount on front panel

FCU7-KB026 8.4-type display keyboard Escutcheon, key switch Connect with G011 cable from control unit.

Clear keys G402 cable Mounting method: Mount on front panel

FCU7-KB044 10.4-type display keyboard Escutcheon, key switch Connect with G011 cable from control unit.

Sheet keys G402 cable Mounting method: Mount on front panel

1.2.3.5 Remote I/O Unit: FCUA-DX100/FCUA-DX110/FCUA-DX120/FCUA-DX140/FCUA-DX101/FCUA-DX111/ FCUA-DX121/FCUA-DX141

Type Function Configuration element Details

FCUA-DX100 Sink/source input + sink output RX31 1 DI/DO = 32 points/32 points

FCUA-DX110 Sink/source input + sink output RX31 1+RX321-1 DI/DO = 64 points/48 points

FCUA-DX120 Sink/source input + sink output

+ analog output

FCUA-DX140 Sink/source input + sink output

+ analog input/output

FCUA-DX101 Sink/source input + source

output

FCUA-DX111 Sink/source input + source

output

FCUA-DX121 Sink/source input + source

output + analog output

FCUA-DX141 Sink/source input + source

output + analog input/output

RX311+RX321 DI/DO = 64 points/48 points

+ analog output 1 point

RX311+RX341 DI/DO = 32 points/32 points

+ analog input 4 points

+ analog output 1 point

RX312 DI/DO = 32 points/32 points

RX312+RX322-1 DI/DO = 64 points/48 points

RX312+RX322 DI/DO = 64 points/48 points

+ analog output 1 point

RX312+RX341 DI/DO = 32 points/32 points

+ analog input 4 points

+ analog output 1 point

1.2.3.6 Scan I/O Card: HR357/HR347

Type Function Configuration element Details

HR357 Scan I/O (source) HR357 Scan DI/DO = 64 points/64 points

DI/DO = 32 points/32 points

HR347 Scan I/O (sink) HR347 Scan DI/DO = 64 points/64 points

DI/DO = 32 points/32 points

7

Page 18

1. 70 Series System Configuration

1.2 System Configuration

1.2.3.7 Card-sized I/O Card: HR361/HR371/HR381/HR383

Type Function Configuration element Details

HR361 DI16 (sink/source)

+DO16 (sink)

HR371 DI32 (sink/source)

+DO16 (source)

HR381 AO x 1 HR381 AO x 1

HR383 AI x 4+AO x 1 HR383 AI x 4+AO x 1

HR361 DI/DO = 16 points/16 points

HR371 DI/DO = 16 points/16 points

1.2.3.8 External Power Supply Unit: PD25/PD27

Type Function Configuration element Details

PD25 External power supply with

power supply ON/OFF

function

PD27 External power supply with

power supply ON/OFF

function

Power supply card

Case set

Power supply card

Case set

Input 200VAC

Output 24VDC (3A)

Input 200V to 400VAC

Output 24VDC (8A)

8

Page 19

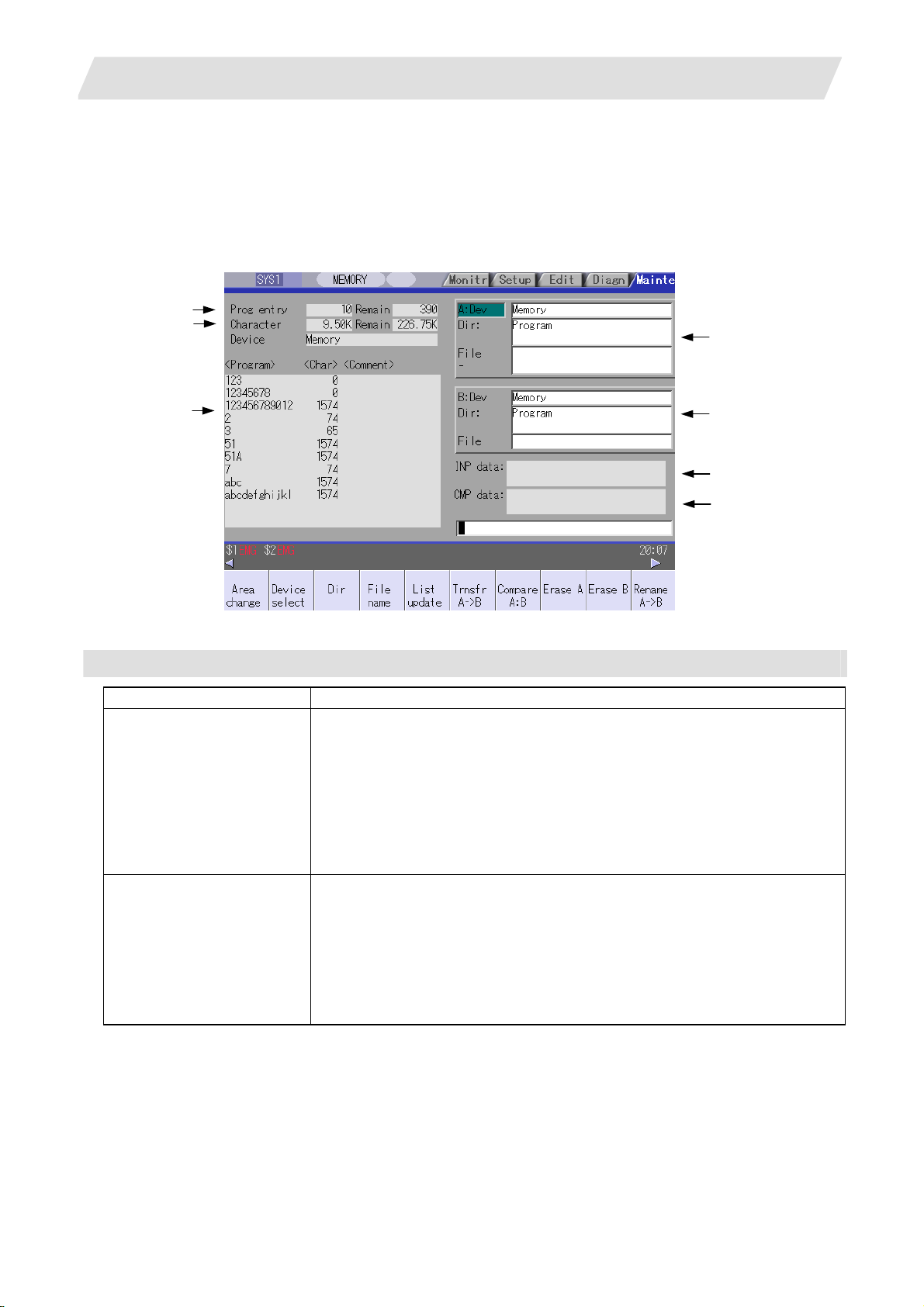

2. Maintenance Screens

2.1 Input/Output Screen

2. Maintenance Screens

2.1 Input/Output Screen

The Input/Output screen is used to carry out NC data input/output between the NC internal memory and the

external input/output devices.

Here, the hard disk built into the NC device is also treated as external devices.

In 70 series, only "Memory", "Memory card", "Serial", "Ethernet" and "Anshin-net server" can be used.

(1)

(2)

(4)

(3)

Display items

Display item Details

(1) Number of programs

registered and remainder

(Note 1)

(2) Number of memory

characters and remainder

(Note 1)

(5)

(6)

(7)

This displays the registration information of machining program of the selected

device.

Number of programs registered :

This displays the number of programs previously registered as user machining

programs.

Remainder :

This displays the remaining number of programs that can be registered.

When "Memory" is selected as the device, the total of the number of programs

registered and the remainder is the maximum number of registrations set in the

specifications.

This displays the number of characters of the machining program of the selected

device.

Number of memory characters :

This displays the number of characters previously registered as user machining

programs.

Remainder :

This displays the remaining number of characters that can be registered. The total

of the number of memory characters and the remainder is the maximum number of

memory characters set in the specifications.

9

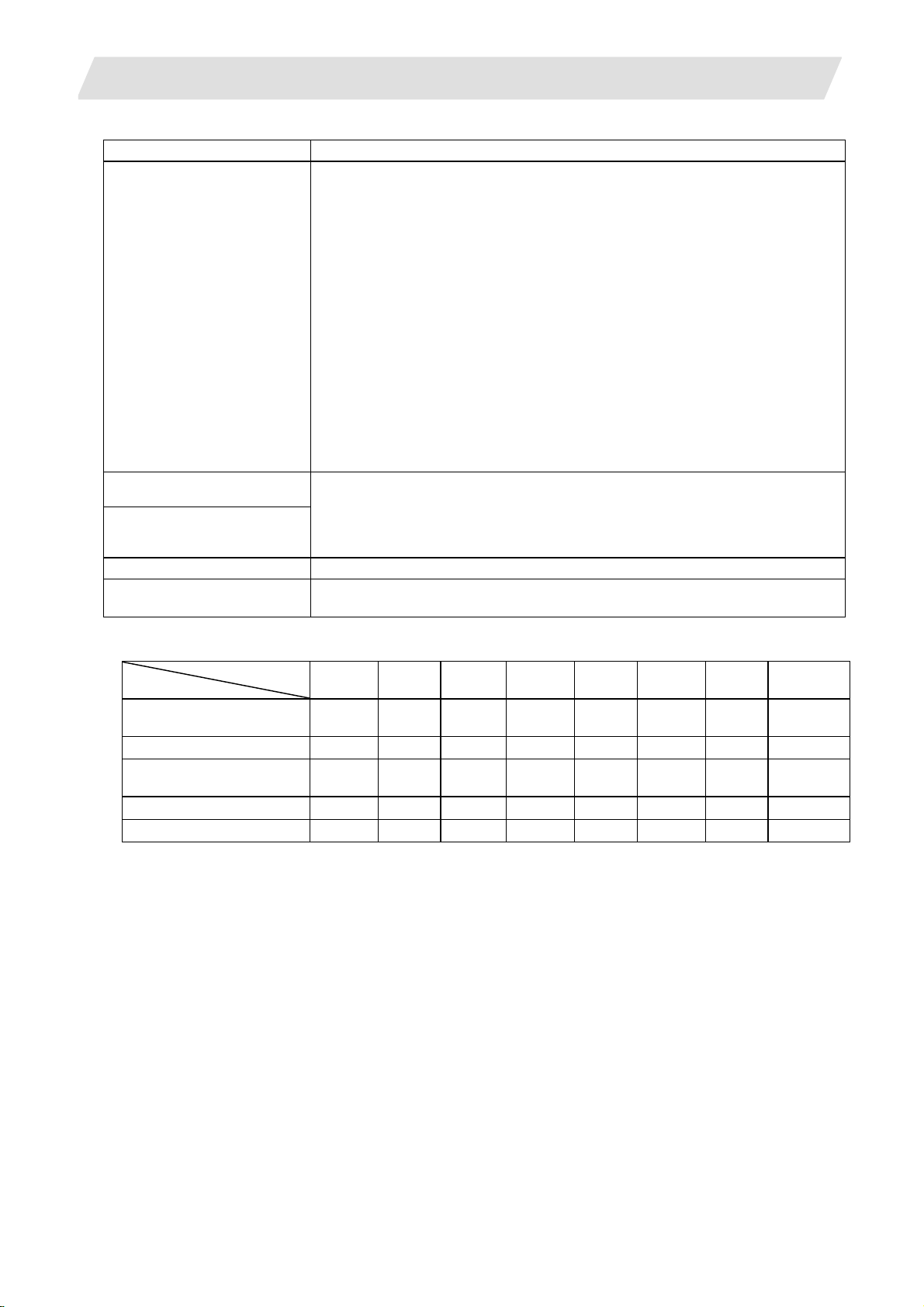

Page 20

2. Maintenance Screens

2.1 Input/Output Screen

Display items Details

List (Note 2)

(3)

(4) File setting column A

(5) File setting column B

(6) Input data This displays the data being transferred.

(7) Comparison data This displays the data being compared. If an error occurs during comparison, the

(Note 1) Depending on the device, some items are not displayed.

Device

Display item

Number of programs

registered

Remainder

Number of memory

characters

Remainder

List

* : When the Ethernet parameter "#97*1 Host n no tot al siz" is set to 1, the number of host memory

characters will not appear .

(Note 2) The list does not appear when using serial.

This displays a contents list (directory and file name) of the directory in the setting

column (file setting column A or B) where the cursor is currently located.

Program :

When "Memory" is selected for the device, this displays the file name (program No.)

of the machining programs already registered. The file names are displayed in

order from the smallest number, from 1 to 99999999. When a device other than

memory is selected, this displays the file name and directory to be included in the

directory that is set in the current setting column.

When the number of characters exceeds 12, the excess is indicated as "*".

Character :

The size of each file (when memory is selected for the device, the number of

characters in the machining program). When directory is selected, this displays

"DIR".

Comment :

This displays the comment (up to 17 alphanumeric characters and symbols) of

each file.

The date which the file is updated is displayed for the HD, FD, memory card, DS or

Ethernet.

When the number of characters exceeds 17, the excess is not displayed.

This sets the device, directory, and file name of the target file for transfer, compare,

erasing, etc., operations.

When transferring, the file name of the transfer origin file is set. When renaming, the

file name before renaming is set. When erasing, the erasing range is set. When the

number of characters exceeds 28, the excess is not displayed.

block with the error is displayed.

×

×

×

×

Memory

card

{ { { {

{ {

{ {

{ { { {

DS Ethernet FD

{ *

×

{ : Displayed × : Not displayed

Memory HD Serial

{ {

{

{ {

{ {

{ {

× × × × × × ×

{

{

Anshin-net

server

×

×

×

×

10

Page 21

2. Maintenance Screens

Menus

Menu Details Type Reference

Area

change

Device

select

Dir

File

name

List

update

Transfr

A→B

Compare

A:B

Erase A

Erase B

Rename

A→B

Comment

nondisp

Dir

create

Merge

B→A

FD

format

MemCrd

format

DS

format

Warning

cancel

Stop

This changes the setting area to file setting column A (transfer origin)

or file setting column B (transfer destination). The display of the valid

area (A or B) is highlighted.

This displays the submenu of the machining program storage area.

When the submenu is selected, the device is confirmed, and if a

directory exists it is set in the root.

The memory is selected as the default.

This menu sets the directory that carries out input/ output operations,

and is on standby for input. Note that when memory is selected for the

device, the directory can be selected from the submenu.

This menu sets the file name that carries out input/ output operations,

and is on standby for input. When memory is selected for the device,

setting is not necessary if the directory is not the program.

This updates the list. The list of the directly selected in the currently

valid file setting column (A/B) is updated.

This copies the file in file setting column A (transfer origin) to the file

setting column B (transfer destination). (The transfer origin file is not

changed.) A message appears during transfer and when the transfer

is completed.

This compares the files in file setting column A (transfer origin) and file

setting column B (transfer destination).

This erases the file in file setting column A.

(Note) The NC memory (excluding programs), serial and Ethernet

This erases the file in file setting column B.

(Note) The NC memory (excluding programs), serial and Ethernet

This changes the name of the file in file setting column A (transfer

origin) to the name of the file in file setting column B (transfer

destination).

(Note) The same device must be selected for A and B.

The NC memory (excluding programs) and serial cannot be renamed.

This changes whether to show or hide the comment field. B

This creates a new directory in the directory of the currently valid file

setting column (A/B).

The directory can be created when HD, FD, memory card or DS is

selected for the device.

The file contents in the file setting column B are added to the file in the

file setting column A. (The file in the file setting column B is not

changed.)

(Note) The NC memory (excluding programs), serial and Ethernet

This formats the FD.

This menu is only for 700 series.

The formats the front IC card.

This formats the NC compact flash memory.

This menu is only for 700 series.

This cancels a warning from network service. C

This interrupts the process (transfer, compare, etc.) during execution. C -

(host file) cannot be erased.

(host file) cannot be erased.

(host file) cannot be merged.

A

2.1 Input/Output Screen

C 2.1.1 Changing the Valid

Area

A 2.1.2 Selecting a

Device, Directory, and

File

A

A

C -

B 2.1.3 Transferring a File

C 2.1.4 Comparing Files

(Compare)

B

B

B

A

B

A

2.1.5 Formatting an

External Device

A

11

Page 22

2. Maintenance Screens

2.1 Input/Output Screen

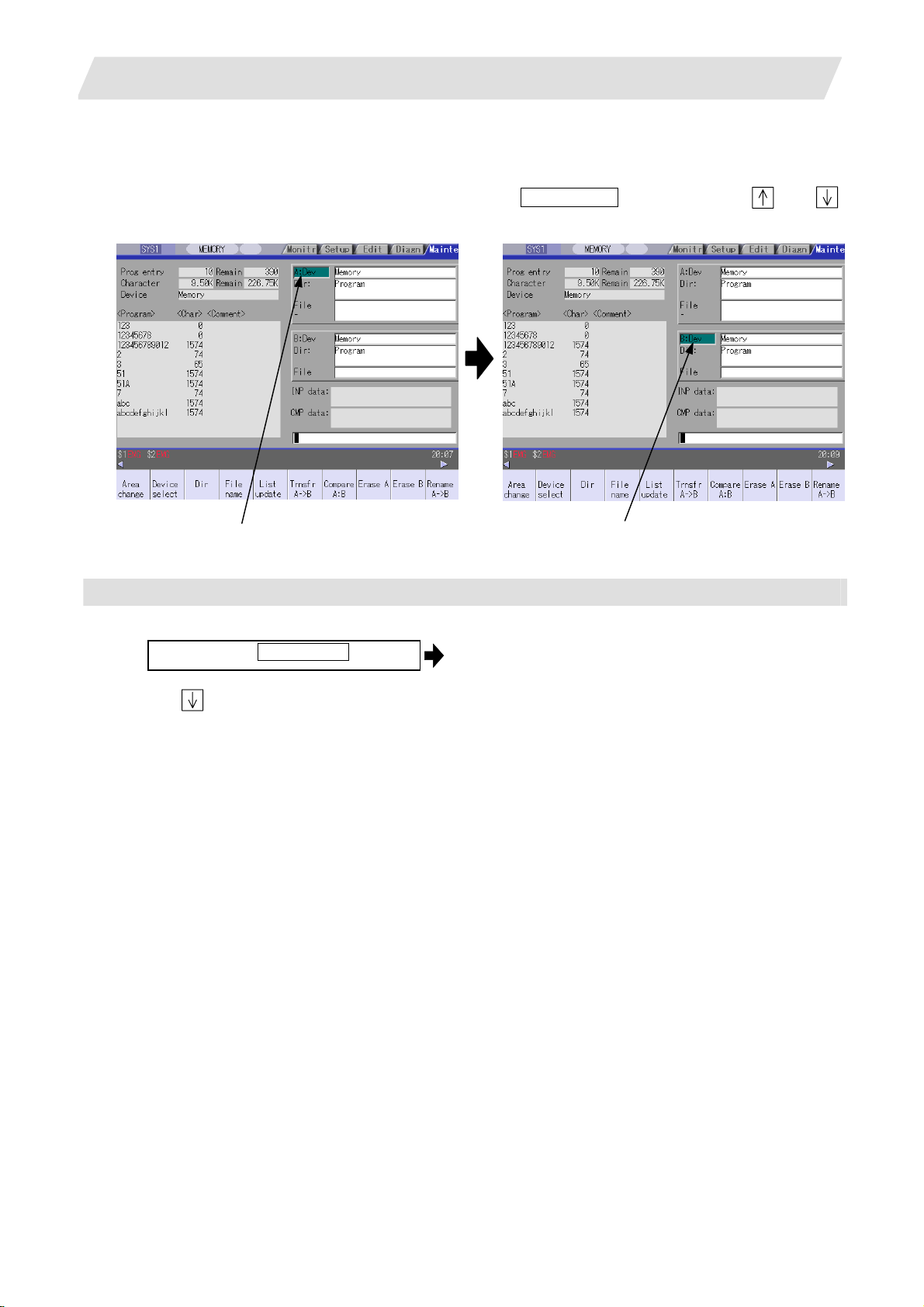

2.1.1 Changing the Valid Area

When setting the file setting field A or B device, directory and file name on this screen, the area containing

these must be valid.

The display area can be changed by pressing the menu key ( Area change ) or the cursor key

After changing, the data setting operation is valid in that area.

and .

File setting field A is valid. File setting field B is valid.

Changing the valid file setting field

When file setting field A (top) is valid

(1)

Press the menu Area change .

This can also be changed with the cursor

key .

The file setting field B (bottom) is validated.

12

Page 23

2. Maintenance Screens

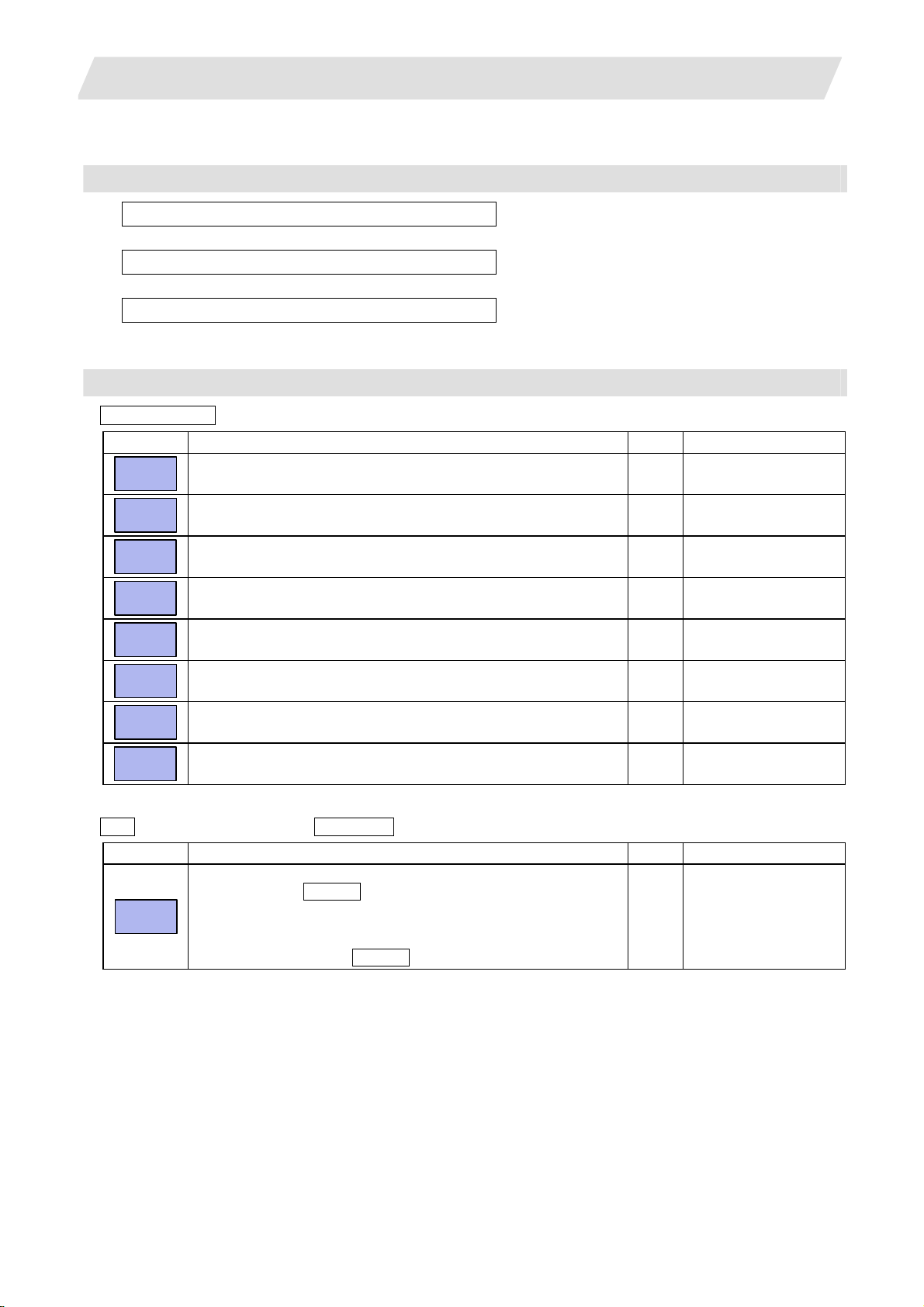

2.1.2 Selecting a Device, Directory and File

File selection sequence

Designate the device where the target file is located.→ Select from the sub menu.

↓

Designate the directory with a full path.

↓

Designate the file name.

Menu used

Device select menu's submenus

Menu Details Type Reference

Memory

HD

Serial

Memory

card

DS

Ethernet

FD

Anet

server

Dir (other than memory) and File name menu submenus

Menu Details Type Reference

From

list

This selects the NC memory (program, parameter, user PLC, NC

data).

This selects the hard disk.

This menu is only for 700 series.

This selects the RS-232C device (PC, tape, etc.). C -

This selects the front IC card. C -

This selects the NC compact flash memory.

This menu is only for 700 series.

This selects the Ethernet-connected host computer. C -

This selects the floppy disk.

This menu is only for 700 series.

This selects the Anshin-net server. C

The cursor appears in the list display. The list contents can be

selected with the INPUT key.

When a directory is selected, the contents of the selected directory

are displayed in the list. Continued selection is possible.

When a file name is selected, the file name is temporarily displayed in

the input area. When the INPUT key is pressed again, it is fixed.

2.1 Input/Output Screen

Input the full path or select from the list.

→

→ Input the file name or select from the list.

C -

C -

C -

C -

A -

13

Page 24

2. Maintenance Screens

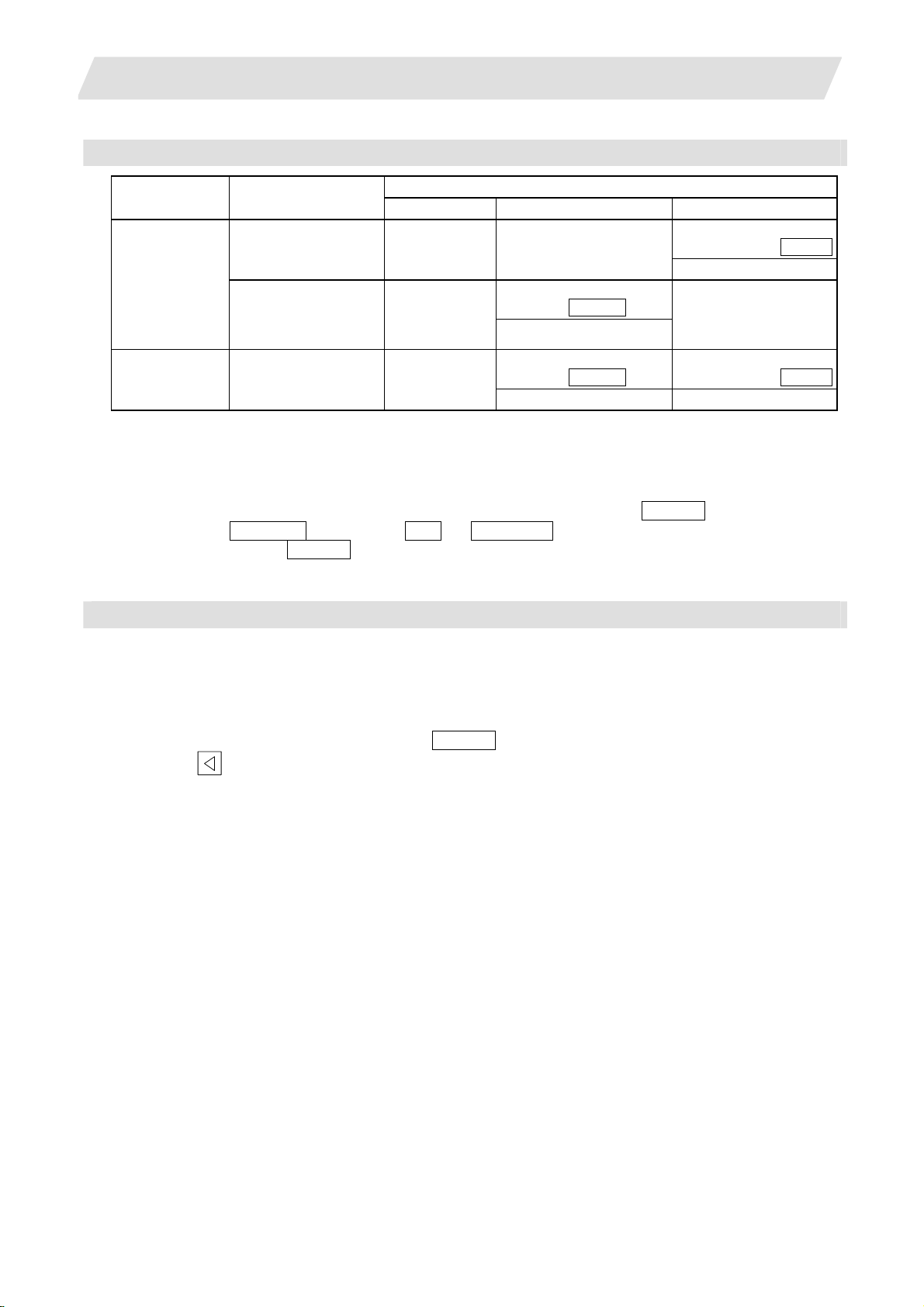

Selecting methods for device, directory, and file name

Device Designation target file

NC memory Select from the

Other than the

• Machining program

•

User macro

Fixed cycle

•

machining program

Device Directory File name

submenu

Select from the list

Select from the

submenu

2.1 Input/Output Screen

Designation method

-

(Default)

Key input in the input area,

and press INPUT

Select from the submenu

Key input in the input

area, and press INPUT

-

(Fixed)

Other than the

NC memory

Select from the list Select from the list

All Select from the

submenu

Key input in the input area,

and press INPUT

Key input in the input

area, and press INPUT

The device can be selected from the submenu. (The devices that can be used will differ depending on the

specifications.)

One of the following methods can be used to designate the directory (for devices other than the NC memory)

and file name.

• Set the directory path (full path) or file name in the input area, and press the INPUT key.

• Press submenu From list of the menu Dir or File name . Move the cursor to the target directory or

file name, and press the INPUT key.

A wild card (*) can be used when selecting a file name.

Notes when selecting a file

(1) During directory and file name setting, the designated directory, path or file name will be set, even if it

does not actually exist. This will not cause an error. Note that the previously set directory is overwritten.

(2) Whe n a file in the NC memory other than a machining program is designated, it is not necessary to set the

file name. (The file name is fixed.)

(3) Whe n a file name is selected from the menu, it first is displayed in the input area. However, at this time th e

file name has not yet been fixed. Press the INPUT key again to fix the file name.

(4) When the

key is pressed when setting a file name, the file name in the input area is erased.

(5) When a fixed cycle program is designated, the basic common parameters "#1166 fixpro" must be set.

Select "Memory" for the device, and "Program" for the directory.

14

Page 25

2. Maintenance Screens

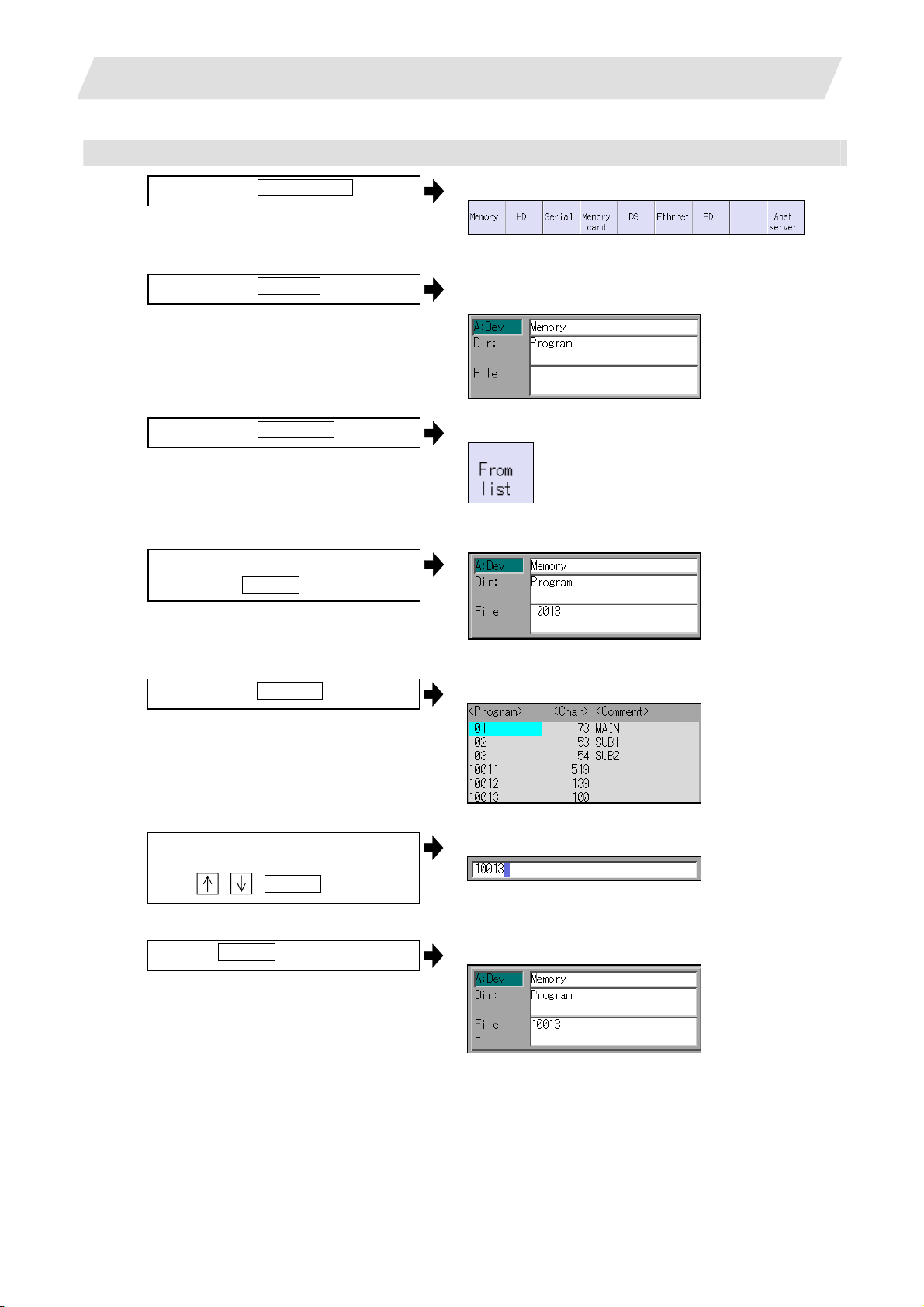

Selecting an NC memory program

(1)

Press the menu Device select .

(2)

Press the menu Memor y .

2.1 Input/Output Screen

The following menu appears.

(When specifications of all devices is valid.)

"Memory" appears in the device name, and the default

"Program" appears in the directory.

(3)

Press the menu File name .

<When inputting the file name from the input area>

(4)

Input the file name

10013 INPUT

<When selecting the file name from the list>

(4)-1

Press the menu From list .

(4)-2 Move the cursor to file name to be

selected, and fix.

, , INPUT

The following menu appears.

The cursor appears in the list.

The selected file name appears in the input area.

(4)-3

Press the INPUT key.

The selected file name appears.

15

Page 26

2. Maintenance Screens

Designating multiple files

(1) Designating multiple serial files

Multiple serial files can be transferred, compared and erased in the file setting column A. Set as follows

in this case.

File : First file name

- : Last file name

(2) Using a wild card

A wild card (* ) can be used in the file name.

(Note) When serial or Anshin-net server is used, multiple files cannot be compared.

:

File

-

*

All files will be selected.

2.1 Input/Output Screen

Selecting an NC memory file other than a program

(1)

Press the menu Device select .

(2)

Press the menu Memor y .

(3)

Select the menu Dir .

(4)

Press the menu Tool offset .

The following menu appears.

(When specifications of all devices is valid.)

"Memory" appears in the device name, and "Program"

appears as the default in the directory.

The following menu appears.

The directory and file name appear.

(Note) The file name for each directory is fixed. Refer to "2.1.6 List of file names" for the file names.

16

Page 27

2. Maintenance Screens

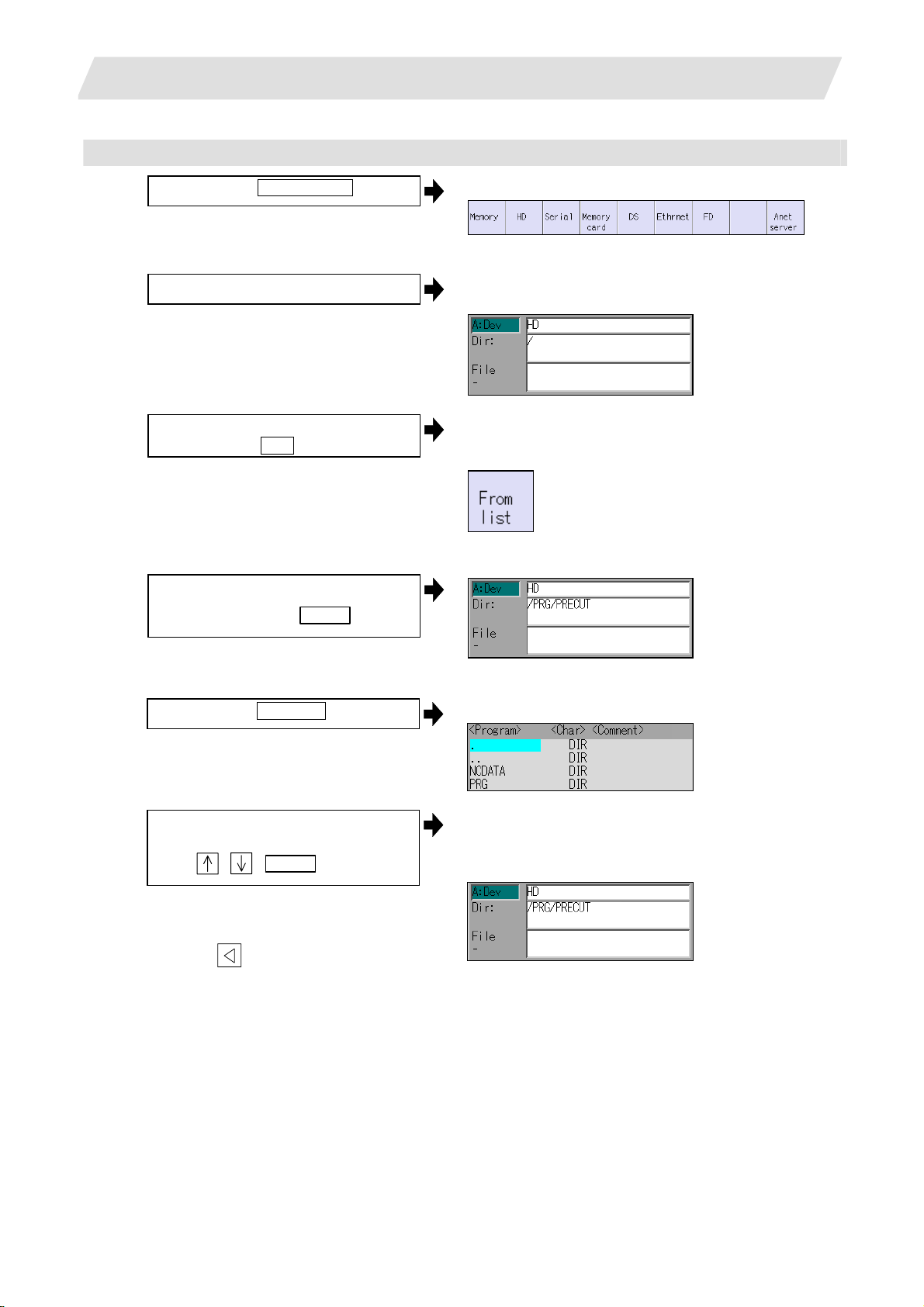

Selecting a device file other than the NC memory

(1)

Press the menu Device select .

(2) Select a device .

2.1 Input/Output Screen

The following menu appears.

(When specifications of all devices is valid.)

The device name appears. The root directory is

selected as the default.

(3)

Designate the directory.

Select the menu Dir

<When inputting the directory from the input area>

(4)

Input the directory path as a full path.

/PRG/PRECUT INPUT

<When selecting the directory from the list >

(4)-1

Press the menu Fr om list

(4)-2 Move the cursor to directory to be

selected, and fix.

, , INPUT

The mode changes to the mode for inputting the

directory name.

The following menu appears.

The cursor appears in the list.

The selected directory appears in the data setting

column.

The contents of the selected directory appear in the

list.

Repeat this operation until the target

directory is reached.

When the target directory is reached,

press the

inputting the directory.

key and quit the mode for

17

Page 28

2. Maintenance Screens

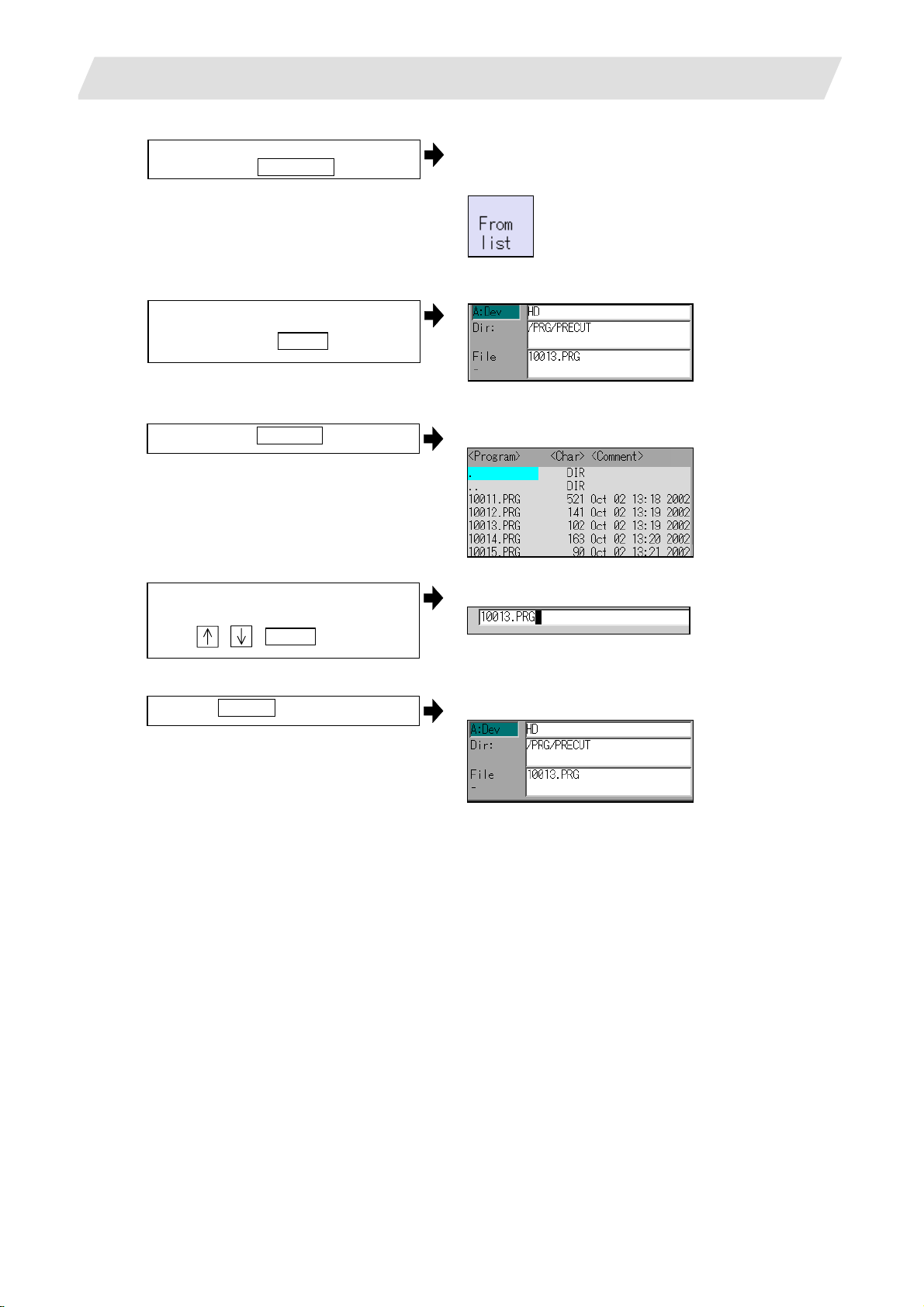

(5) Designate the file n ame.

Press the menu File name

<When inputting the file name from the input area>

(6)

Input the file name

10013.PRG INPUT

2.1 Input/Output Screen

The mode changes to the mode for inputting the file

name.

The following menu appears.

<When selecting the file name from the list>

(6)-1

Press the menu From list .

(6)-2 Move the cursor to file name to be

selected, and fix.

, , INPUT

(6)-3

Press the INPUT key.

The cursor appears in the list.

The selected file name appears in the input area.

The selected file name appears.

18

Page 29

2. Maintenance Screens

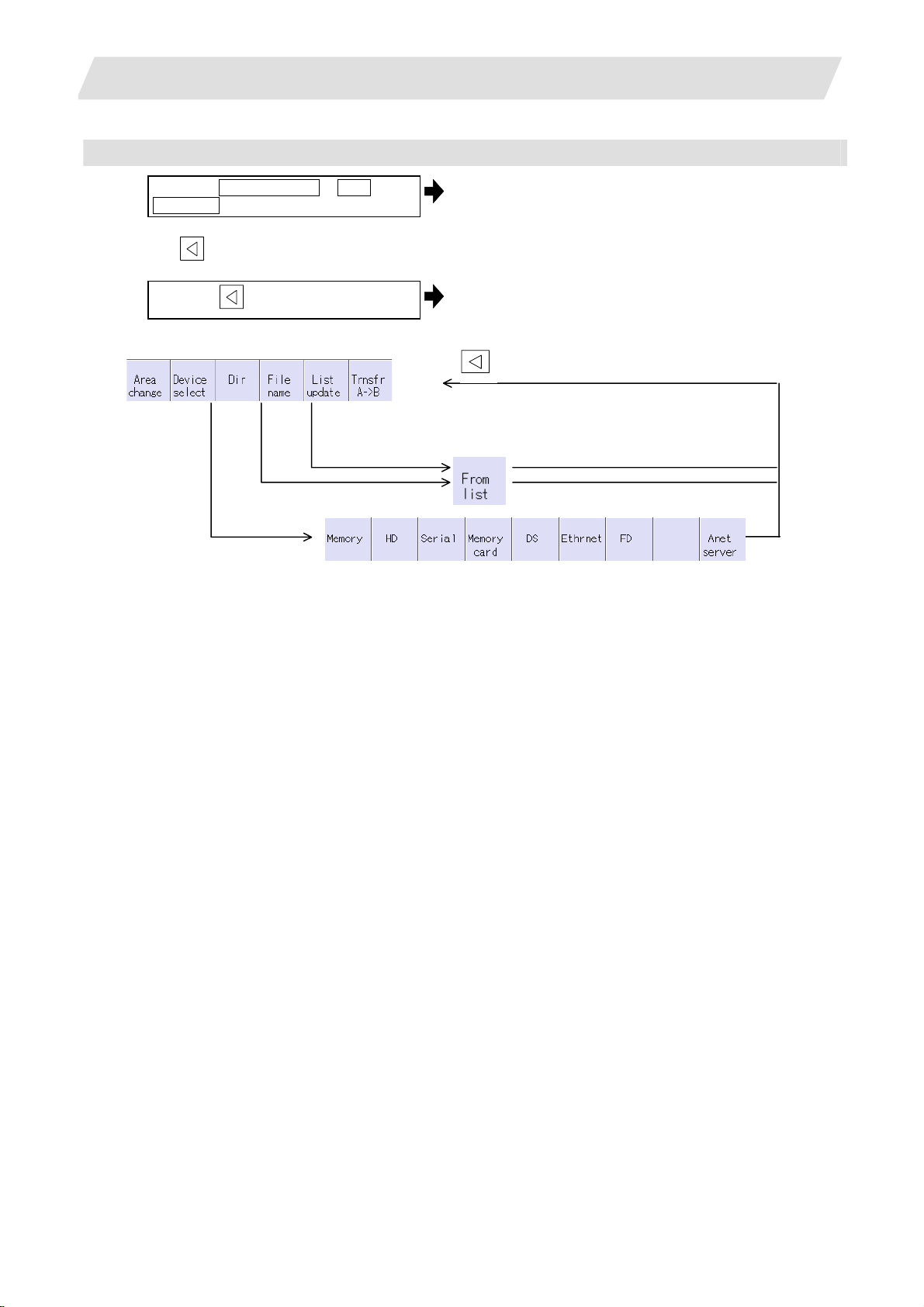

Canceling the input mode

(1)

Press the Device Select , Dir or

File name .

To cancel the data input at this time, press

the key.

(2)

Press the

Main menu

key.

2.1 Input/Output Screen

The submenu appears.

The details in the input area are erased, and the main

menu appears.

The details in the data input area are erased.

Submenu

(When specifications of all devices is valid.)

19

Page 30

2. Maintenance Screens

2.1.3 Transferring a File

Operating method

(1)

Press the menu Area change , and

select file setting column A.

(2) Designate the transfer origin device,

directory and file name.

(3)

Press the menu Area ch ange , and

select file setting column B.

(4) Designate the transfer destination device,

directory and file name.

(5)

Press the menu Trnsfr A ->B .

(6)

Press Y or INPUT .

2.1 Input/Output Screen

The designated file appears.

Multiple files can be designated in the file setting

column A. Designate the first and last file name of the

target range. A wildcard "*" can be designated for the

file name.

The designated file appears.

A message appears to confirm the transfer.

The file transfer starts. The data being transferred

appears in the input data display column.

A message appears when the transfer is completed.

INP data :

CMP data :

Caution

!

" ; ", "EOB", "%", and “EOR” are symbols used for explanation. The actual codes for ISO are "CR, LF" ("LF")

!

and "%".

The programs created on the Edit screen are stored in the NC mem ory in a "CR, LF" format, however, the

programs created with external devices such as the FD or RS-232C may be stored in an "LF" format.

The actual codes for EIA are "EOB (End of Block)" and "EOR (End of Record)".

G91 G28 XYZ;

F1000;

!

To prevent the influence of data loss and data transformation over the line, always carry out data

comparison after transferring a machining program.

20

Page 31

2. Maintenance Screens

Notes

(1) Notes related to transferring in general

(a) Depending on the type of file, some data cannot be transferred during automatic operation. Do not

transfer during automatic operation.

(b) When the capacity of the transfer destination is reached during file transfer, only the data transferred

up to that point is registered as a file, and an error will result.

(c) During input to the NC memory or comparison, if the file format size on the NC memory side differs

from the other side file format size (when the maximum number of registrations differs between the

NC memory and the other side), processing is carried out matched to the small er size.

(Ex. 1) If a format size of 200 files is input for a format size of 1000 NC files, 200 files are registered.

(Ex. 2) If a format size of1000 files is input for a format size of 200 NC files, the files up to the 200th

file are registered and an error message appears. (The remaining files are not registered.)

(d) Up to 223 files, including the directory, can be registered in the FD's root directory.

(2) Notes when transferring machining program files

(a) For the serial, always set feed (Null) at both ends of the "EOR" code at the head and end. If "EOB"

etc., is directly after "EOR", the operation may not execute normally due to the input buffer influence

during the next input operation.

(b) The transfer speed is slower if there are many registrations.

(c) The size of one block of the machining program should be 250 characters or less.

(d) When using tape, carry out parity V adjustment to improve the reliability of the tape format. Then use

with the input/output parameter "Parity V" validated.

(e) When the machine tool builder macro and fixed cycle program are input to NC memory, change the

program type with the parameter "#1166 fixpro". Also, set in the Input/Output screen as follows.

Device: Memory, Directory: Program

(f) Transferring or verifying the multiple files between the external device connected serially and that

other than the serial connection.

(g) With machining program created before the MELDAS500 Series, "EOB" is registered as "LF".

However, wh en these programs are stored in the 700/70 Series NC memory, "EOB" will be converted

to "CR LF", and the number of characters will increase. Thus, when all of the machining programs

output from an MELDAS500 Series or earlier NC, having the same specifications as the maximum

memory capacity, are stored in the 700/70 Series NC memory, the memory capacity may be

exceeded.

(h) When the file to be transferred (input) is running or in "program restarting" mode, the operation

message "Executing automatic operation" or "Program restarting" is displayed and file will not be

transferred (input).

(3) Notes when transferring tool offset data files

(a) If an error occurs during offset data transfer, an error message appears on the screen, and the

transfer operation is interrupted.

(4) Notes when transferring parameter files

(a) In the same manner as when setting in the Parameter screen, there are parameters validated

immediately after input, and parameters validated after a restart. Restart when a parameter file has

been transferred to the NC memory.

(b) When a parameter file is transferred to the NC memory, the setting value of the input/output

parameters is also changed. Before transferring next time, set the input/output parameters again.

(c) System parameters can be transferred from the NC memory to an external device, but cannot be

transferred from an external device to the NC memory.

2.1 Input/Output Screen

21

Page 32

2. Maintenance Screens

(5) Notes when transferring common variable data files

(a) If the variable value is 100000 or more or less than 0.0001 when transferring common variable data,

it is expressed with an exponential expression.

(6) Notes when transferring tool life data files

(a) When tool life data is output from the NC memory, the file information is inserted at the first and last

of the file.

First file information : Number of registered tools (P No.) and the maximum number of possible

registrations (T No.)

Last file information : Finish code

(7) Notes when transferring auxiliary axis parameter files (700 series only)

(a) When the auxiliary axis parameters are input to the NC memory, the same parameter data is

simultaneously transferred to the drive unit. If transferred errors by some causes occur, the

parameter data may be not matched between NC memory data and drive unit.

(8) Notes when transferring sampling data file

(a) When the output form is set as 8-digit hexadecimal number and the parameter

"#1004 ctrlunit" is set to "E (1nm)", accurate data can be output just within 1m.

When the output data length exceeds 1m, lower 32 bits of the sampling data will be output.

2.1.4 Comparing Files (Compare)

Operation method

(1)

Press the menu Area change , and

select file setting column A.

(2) Designate the device, directory and file

name to be compared.

(3)

Press the menu Area change , and

select file setting column B.

(4) Designate the other side device, directory

and file name to be compared.

(5)

Press the menu Compare A:B .

The designated file name appears.

The designated file name appears.

The file comparison starts. The data being compared

appears in the comparison data display column.

A message appears when the comparison is

completed.

If a comparison error occurs, the block with the error is

displayed in the comparison data display column on

the screen.

2.1 Input/Output Screen

(Note) Files that can be compared are text files only.

Correct outcome will not be obtained through binary file comparison.

22

Page 33

2. Maintenance Screens

2.1 Input/Output Screen

2.1.5 Formatting an External Device

Operation method (Formatting an FD) [700 series only]

(1) Insert a floppy disk in the FD drive, and

press FD format .

(2)

Press Y or INPUT .

A message confirming the formatting appears.

The FD is formatted.

A message appears when the formatting is completed.

(Note 1) The FD is formatted with FAT (1.44MB).

(Note 2) The volume label is set when formatting the FD.

Operation method (Formatting a memory card)

(1)

Press the menu MemCrd format .

(2)

Press Y or INPUT .

A message confirming the formatting appears.

The memory card is formatted.

A message appears when the formatting is completed.

(Note 1) The memory card is formatted with FAT16.

(Note 2) The volume label is set when the memory card is formatted.

Operation method (Formatting a DS) [700 series only]

First, press the menu DS format . Refer to "Formatting a memory card" for following operations.

(Note 1) The DS is formatted with FAT16.

(Note 2) Only the DS formatted with FAT16 can be used. The DS with NTF S cannot be used.

(Note 3) As for the DS formatted with NTFS, reformat it with FAT formatted by Windows to use.

(NC cannot convert NTFS partition to FAT formatted.)

(Note 4) The volume label is not set even when the DS is formatted.

2.1.6 List of File Names

There is a directory for each type of data in the NC memory.

Each directory and file name (fixed) in the NC memory is shown below.

Do not change the extensions (.XXX) when storing in a device other than the NC memory.

Data type NC memory directory path Fixed file name

Machining program /PRG/USER (Program No.)

Fixed cycle program /PRG/FIX (Program No.)

Parameters

Parameters [User, machine] (Text format)

Auxiliary axis parameter (700 series only)

User PLC /LAD USERPLC.LAD

NC data

Tool compensation amount data

Tool life management data

Common variable data

SRAM data

System configuration data /DGN ASSEMBLY.INF

Decryption code /RLS P ASSCODE. DAT

Sampling data /LOG NCSAMP.CSV

Machine data /DGN COMPO.STA

/PRM

ALL.PRM

AUXAXIS.PRM

/DAT

TOOL.OFS

TLIFE.TLF

COMMON.VAR

SRAM.BIN

23

Page 34

2. Maintenance Screen

2.2 All Backup Screen

2.2 All Backup Screen

This screen is used to perform batch backups of NC memory data to an external device, and batch

restoration of that data to the NC memory.

Data backed up by the automatic backup function can also be restored.

Data which has been automatically backed up can be selected only when the device set by the "#8919 Auto

backup device" parameter setting is selected.

(1)

(2)

Display items

(3)

(5)

Display item Details

(1) Device name This displa ys the selected device name.

(2) Data name This displays the data name being backed up/restored.

System data, ladder, and APLC data are displayed.

(3) Execution status This displays the processing execution status.

Processing is executed in the system data, ladder, and APLC data order.

(Note 1)

(4) Warning message T his displays messages at the start and end of backup/restore processing.

(5) Backup list This displays the backup date list.

This date is the system data time stamp.

Backup area Explanation

Auto 1

2

3

Data that was automatically backed

up. Display in the backup date

descending order. The latest three

generations of data are displayed.

(4)

Backup

format

Auto

Manual Data that was backed up on this

screen.

Master data Data that was backed up on this

screen. Generally, this is the factory

settings data.

The above data can be selected at restore processing. (Note 2)

Manual

Manual

(Note 1) "APLC data" cannot be backed up/restored if the optional "APLC" is disabled.

(Note 2) The "Auto 1 to 3" data display when the device set by the "#8919 Auto backup device" parameter is

selected.

24

Page 35

2. Maintenance Screen

Menus

Menu Detail Type Reference

Device

select

Backup

Restore

Stop

2.2 All Backup Screen

This displays the sub-menu for "Device" selection. C

This executes backup processing. A 2.2.1 Performing a

This executes restore processing. A 2.2.2 Performing a

This stops processing. C

Backup Operation

Restore Operation

25

Page 36

2. Maintenance Screen

2.2.1 Performing a Backup Operation

Operation methods

(1)

Press the menu Backup .

(2) Move the cursor to select the area.

Press the INPUT key.

(3)

Press Y or INPUT key.

2.2.2 Performing a Restore Operation

Operation methods

(1)

Press the menu Restore .

(2) Move the cursor to select the file.

Press the INPUT key.

(3)

Press Y or INPUT key.

2.2 All Backup Screen

The menu is highlighted.

An operation message "Select directory to

backup" appears.

An operation message "OK? (Y/N)" appears.

(Note) Auto 1 to 3 cannot be selected.

Backup operation begins.

An operation message "Backupping" appears.

When the backup is completed without error, an

operation message "Backup complete" appears.

The menu is highlighted.

An operation message "Select directory to

restore" appears.

An operation message "OK? (Y/N)" appears.

Restore operation begins.

An operation message "Restoring" appears.

When the restoration is completed without error,

an operation message "Restore complete"

appears.

26

Page 37

2. Maintenance Screen

2.2 All Backup Screen

2.2.3 Setting Automatic Backup

When you validate automatic back up function, NC memory data can be backed up automatically.

(1) Parameter setting

By setting the below parameters on operation parameter screen, the automatic back up function will be

validated.

# Item Contents Setting range (unit)

8915 Auto backup day 1

8916 Auto backup day 2

8917 Auto backup day 3

8918 Auto backup day 4

8919 Auto backup device This sets the automatic backup target device. 0: DS

When the NC power is ON after the designated

date was passed over, the automatic backup is

executed.

When -1 is set to "Auto backup day 1", the

automatic backup is executed every turning NC

power ON.

When 0 is set to all on "Auto backup day 1" to "4",

the automatic backup is not executed. It is possible

to specify the designated date up to 4 days for a

month.

-1 to 31

(-1 can be set for "Auto

backup day 1" only.)

1: HD

2: Memory card

(1)

(2)

(3)

(5)

(4)

(5) Backup list This displays the backup date list.

This date is the system data time stamp.

Backup area Explanation

Auto 1

2

3

Data that was automatically backed

up. Display in the backup date

descending order. The latest three

generations of data are displayed.

Backup

format

Auto

27

Page 38

2. Maintenance Screen

2.2.4 Backing up the SRAM

(1)

Press the menu SRAM backup .

(2)

Press Y or INPUT .

Press a key other than Y or

INPUT to cancel the backup.

2.2 All Backup Screen

A message appears to confirm the backup execution.

The backup is executed.

<700 series>

The data is backed up into "D:¥ NCFILE ¥ SRAM.BIN"

on the HD.

(If SRAM.BIN already exists, the original file will be

saved as SRAM.BAK.)

<70 series>

The data is backed up into the memory card.

28

Page 39

2. Maintenance Screen

Menus

Menu Details Type Reference

Psswd

input

PLC

stop

All

backup

System

setup

Adjust

S-ana

To

Abs pos

AUX

test

Collect

set

Format

T-life

format

Serial

No.Set

Console

exec

To

In/out

To

param

SRAM

backup

HMI

Quit

This changes the screen related to the maintenance by setting the

password.

This forcible stops the PLC ladder process. If this menu key is pressed

in the stopped state, the stop is canceled.

This backs up (saves) or restores (reloads) the file such as SRAM etc.

to designated device.

This automatically executes necessary parameter setting for driving

servomotor only by setting necessary minimum item.

This changes the screen to that for adjusting the spindle analog

output.