Page 1

ENGINE

6A1 SERIES

CONTENTS

11A-0-1

GENERAL INFORMATION

1.SPECIFICATIONS

SERVICE SPECIFICATIONS

REWORK DIMENSIONS

TORQUE SPECIFICATION

NEW TIGHTENING METHOD - BY USE OF BOLTS TO BE

TIGHTENED IN PLASTIC AREA

SEALANTS

FORM-IN-PLACE GASKET (FIPG)

2.SPECIAL TOOLS

3.DRIVE BELT

4.TIMING BELT

5.FUEL AND EMISSION CONTROL PARTS

6.IGNITION SYSTEM

7.WATER PUMP AND WATER PIPE

8.INTAKE MANIFOLD AND EXHAUST MANIFOLD

.....................................................

.....................................................

....................................................

...........................................

...............................................

..................................

.......................................

....................................

..............................

............................

................................................

......................

..............................................

..............................

..............

11A-0-3

11A-1-1

11A-1-1

11A-1-3

11A-1-4

11A-1-7

11A-1-7

11A-1-8

11A-2-1

11A-3-1

11A-4-1

11A-5-1

11A-6-1

11A-7-1

11A-8-1

9.ROCKER ARM AND CAMSHAFT <SOHC>

10.ROCKER COVER AND CAMSHAFT <MIVEC>

11.ROCKER ARM AND ROCKER SHAFT CAP <MIVEC>

12.CYLINDER HEAD AND VALVES

13.OIL PUMP CASE AND OIL PAN

14.PISTON AND CONNECTING ROD

15.CRANKSHAFT, CYLINDER BLOCK, FLYWHEEL

AND DRIVE PLATE

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

..............................................

....................

.................

........

................................

................................

..............................

11A-9-1

11A-10-1

11A-11-1

11A-12-1

11A-13-1

11A-14-1

11A-15-1

Page 2

11A-0-2

NOTES

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 3

6A1 ENGINE (E-W) -

General Information

GENERAL INFORMATION

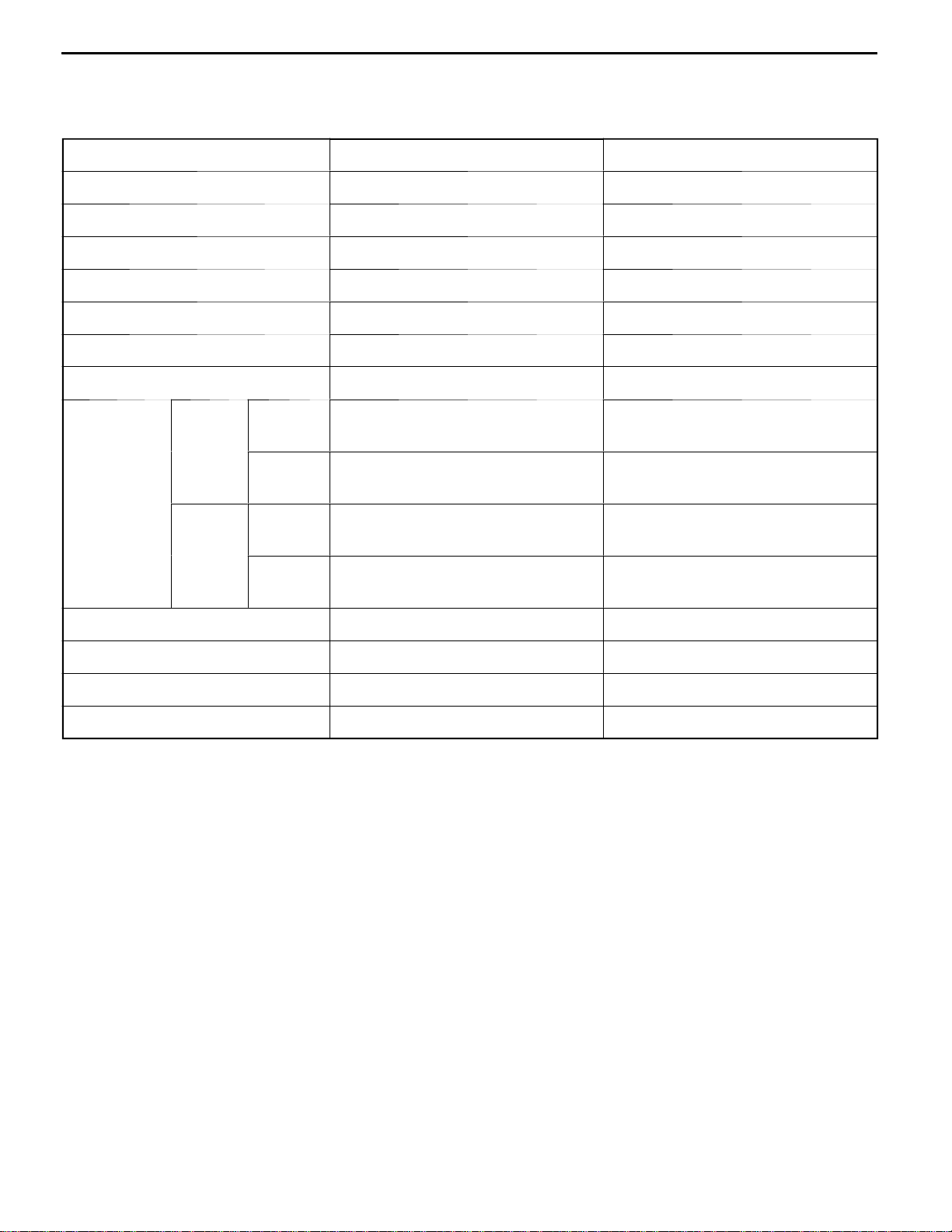

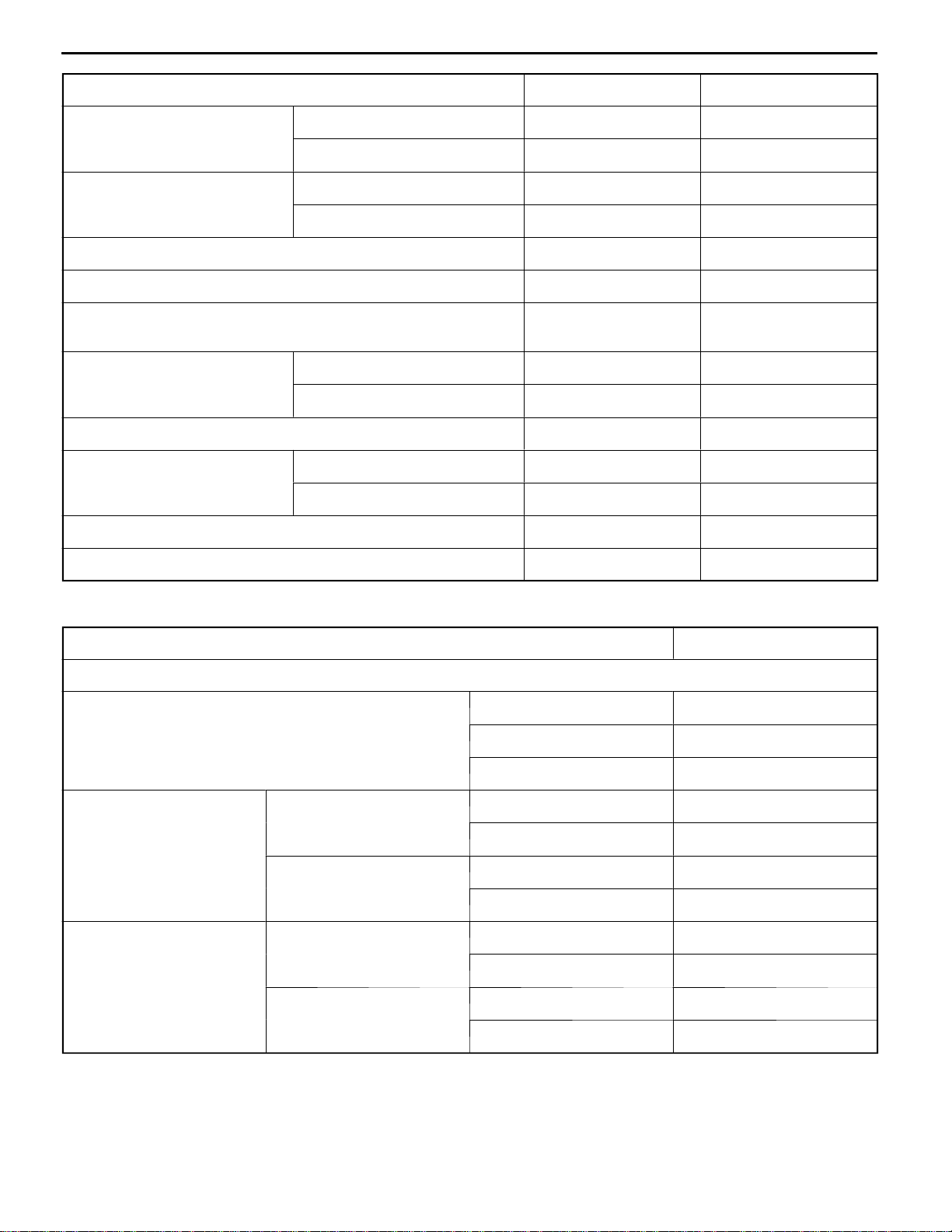

GENERAL SPECIFICATIONS

Descriptions 6A12 6A13

11A-0-3

Type 60è V, OHV, SOHC (for each bank)

Number of cylinders 6 6

Combustion chamber Pentroof type

Total displacement dm

Cylinder bore mm

Piston stroke mm

Compression ratio or 9.0*

V alve timing (Low-speed cam)

Lubrication system Pressure feed, full-flow filtration Pressure feed, full-flow filtration

Intake

valve

Exhaust

valve

3

Opens

(BTDC)

Closes

(ABDC)

Opens

(BBDC)

Closes 15è

(ATDC)

60è V, OHV, DOHC (for each bank)

Pentroof type

1,998 2,498

78.4 81.0

69.0 80.8

10.0 9.5*

15è

37.5è

(High-speed cam)

41è

(Low-speed cam)

82.5è

(High-speed cam)

41è

(Low-speed cam)

75è

(High-speed cam)

(Low-speed cam)

30è

(High-speed cam)

1 2

15è

53è

53è

15è

Oil pump type Trochoid type Trochoid type

Cooling system Water-cooled forced circulation Water-cooled forced circulation

Water pump type Centrifugal impeller type Centrifugal impeller type

NOTE

1

*

: Europe and Hong Kong

2

*

: GCC and Export

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 4

6A1 ENGINE (E -W) -

Specifications

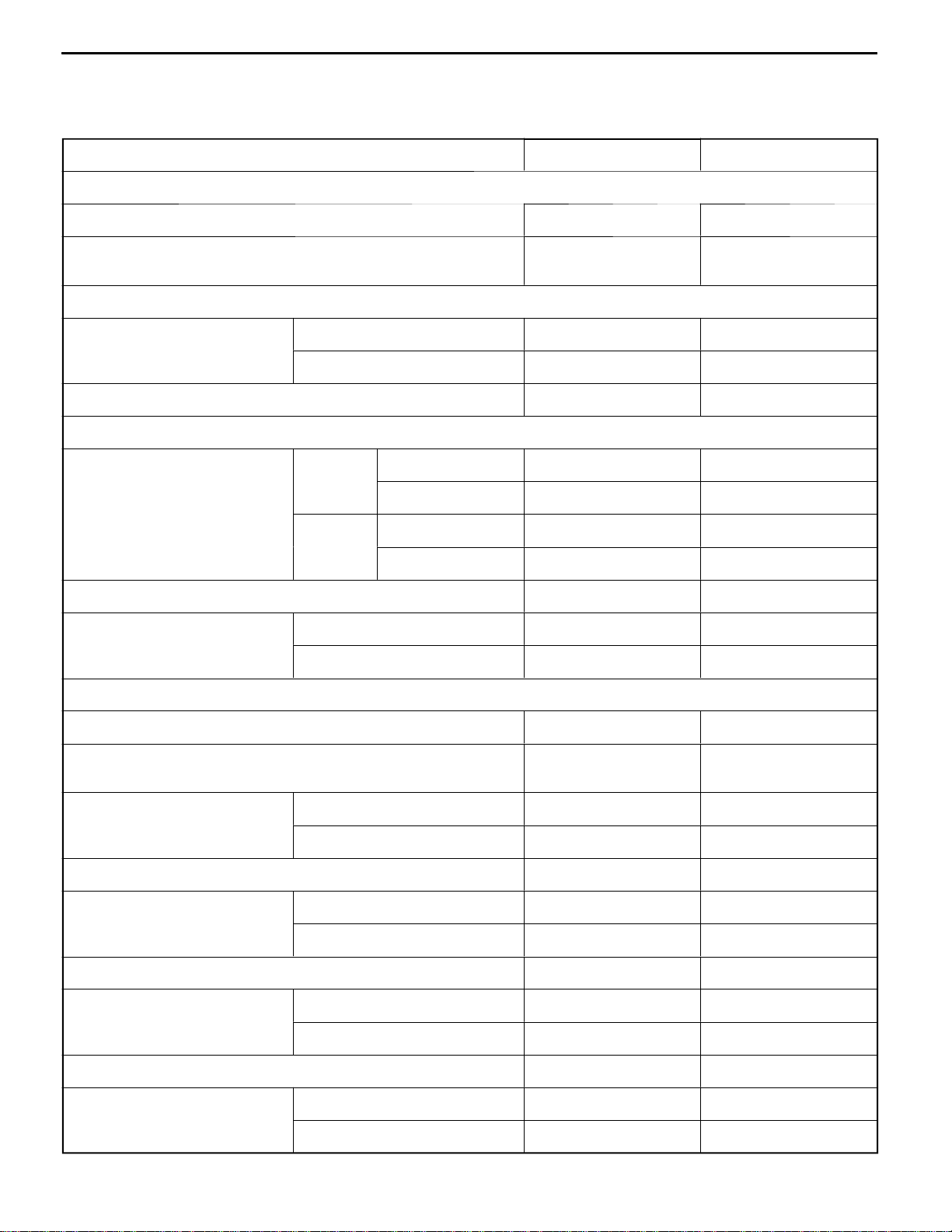

1. SPECIFICATIONS

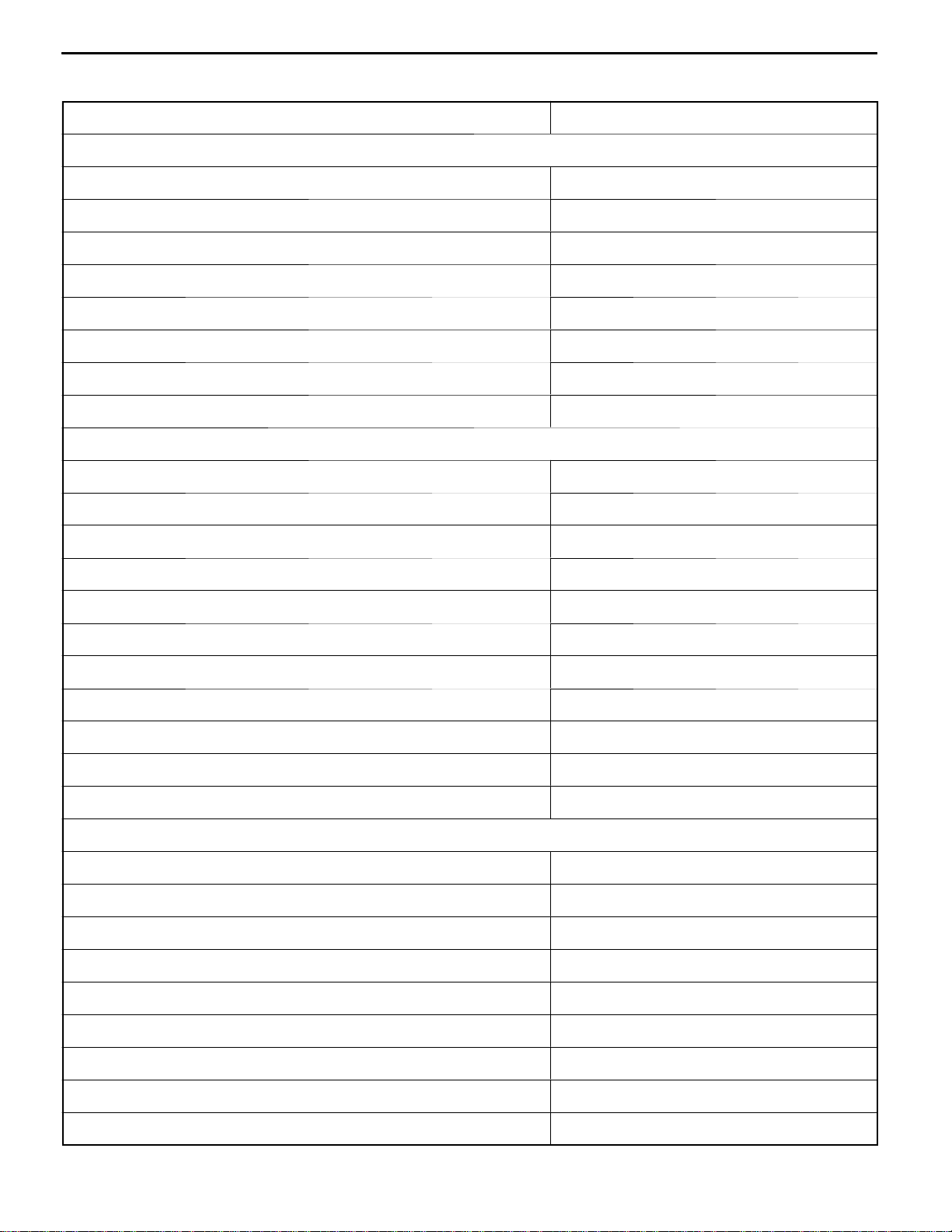

SERVICE SPECIFICATIONS

Items Standard value Limit

Timing belt

Auto tensioner rod projection mm 12.0 -

11A-1-1

Auto tensioner rod pushed-in amount (when pushed with a force of 98 - 196 N) mm

Rocker arm and camshaft <SOHC>

Camshaft cam height mm

Camshaft journal diameter mm

Rocker cover and camshaft <MIVEC>

Camshaft cam height mm (Low-speed cam)

Camshaft journal diameter mm

Valve clearance mm

Cylinder head and valve

Intake 35.20 34.70

Exhaust 34.70 34.20

Intake 34.34 33.84

(High-speed cam)

Exhaust 34.40 33.90

Intake 0.10 Exhaust 0.13 -

(Low-speed cam)

(High-speed cam)

1.0 or less

45 -

36.46 35.96

35.86 35.36

26 -

Flatness of cylinder head gasket surface mm - Cylinder head gasket surface grinding limit (including grinding of

cylinder block gasket surface) mm

Cylinder head overall height SOHC - 120.1 -

mm

MIVEC

Cylinder head bolt nominal length mm

V alve margin mm

Valve stem diameter mm

V alve stem-to-guide clearance

mm

V alve face angle

V alve stem projection mm

Intake 1.0 0.5

Exhaust 1.3 0.8

Intake 0.02 - 0.05 0.10

Exhaust

SOHC 48.45 48.95

MIVEC 48.40 48.90

Less than 0.03

119.9

119.6 119.8

- -

- 96.4

6.0 -

0.04 - 0.07 0.15

45è - 45.5è -

-

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 5

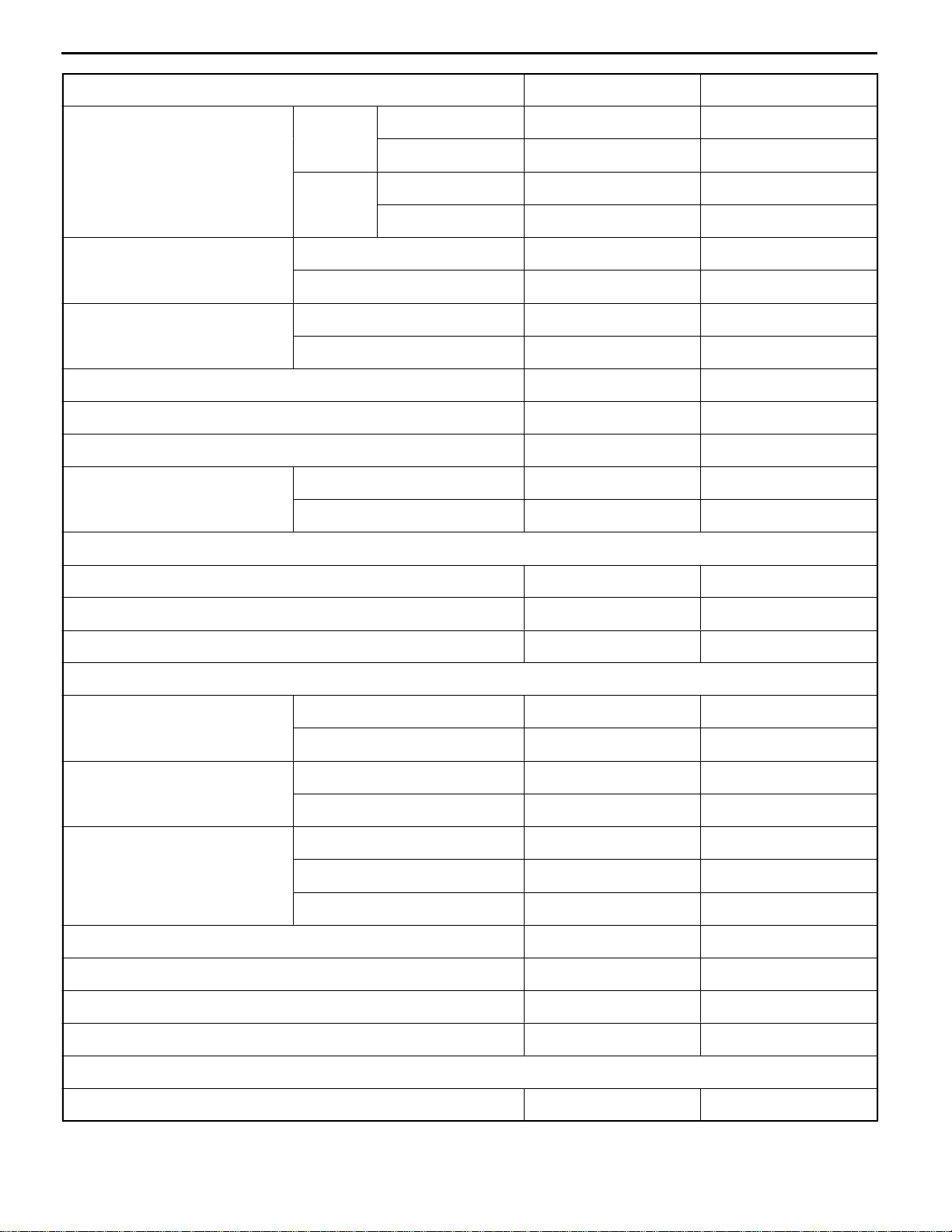

11A-1-2

6A1 ENGINE (E-W) -

Specifications

Items Limit

Overall valve length mm 113.02 112.52

V alve spring free height mm

V alve

height N/mm

Valve spring squareness

Valve seat contact width mm

V alve guide internal diameter mm

Valve guide projection mm

spring load/installed SOHC 265/43.4 -

Intake SOHC

MIVEC

Exhaust SOHC

MIVEC

SOHC 49.9 48.9

MIVEC 51.5 50.5

MIVEC 255/44.5 -

SOHC 14.0 MIVEC 19.0 -

Standard value

112.37 111.87

115.32 114.82

110.74 110.74

2è 4è

0.9 - 1.3 -

6.6 -

Oil pump case and oil pan

Oil i 0.06 - 0.18 -

pump t p clearance mm

Oil 0.04 - 0.10 -

pump side clearance mm

Oil 0.10 - 0.18 0.35

pump body clearance mm

Piston and connecting rod

Piston outside diameter mm

Piston ring side clearance mm No.1 ring

Piston ring end gap mm No.1 ring

Piston pin outside diameter mm Piston pin press-in load (at room temperature) N -

6A12 78.4 6A13 81.0 -

0.02 - 0.06 -

No.2 ring

No.2 ring

Oil ring 0.20 - 0.50 1.0

0.02 - 0.06 -

0.20 - 0.35 0.8

0.35 - 0.50 0.8

19.0

4,900 - 14,700

Crankshaft pin oil clearance mm 0.02 - 0.05 0.1

Connecting rod big end side clearance mm 0.4

Crankshaft, cylinder block, flywheel and drive plate

Crankshaft end play mm 0.05 - 0.25 0.4

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

0.10 - 0.25

Page 6

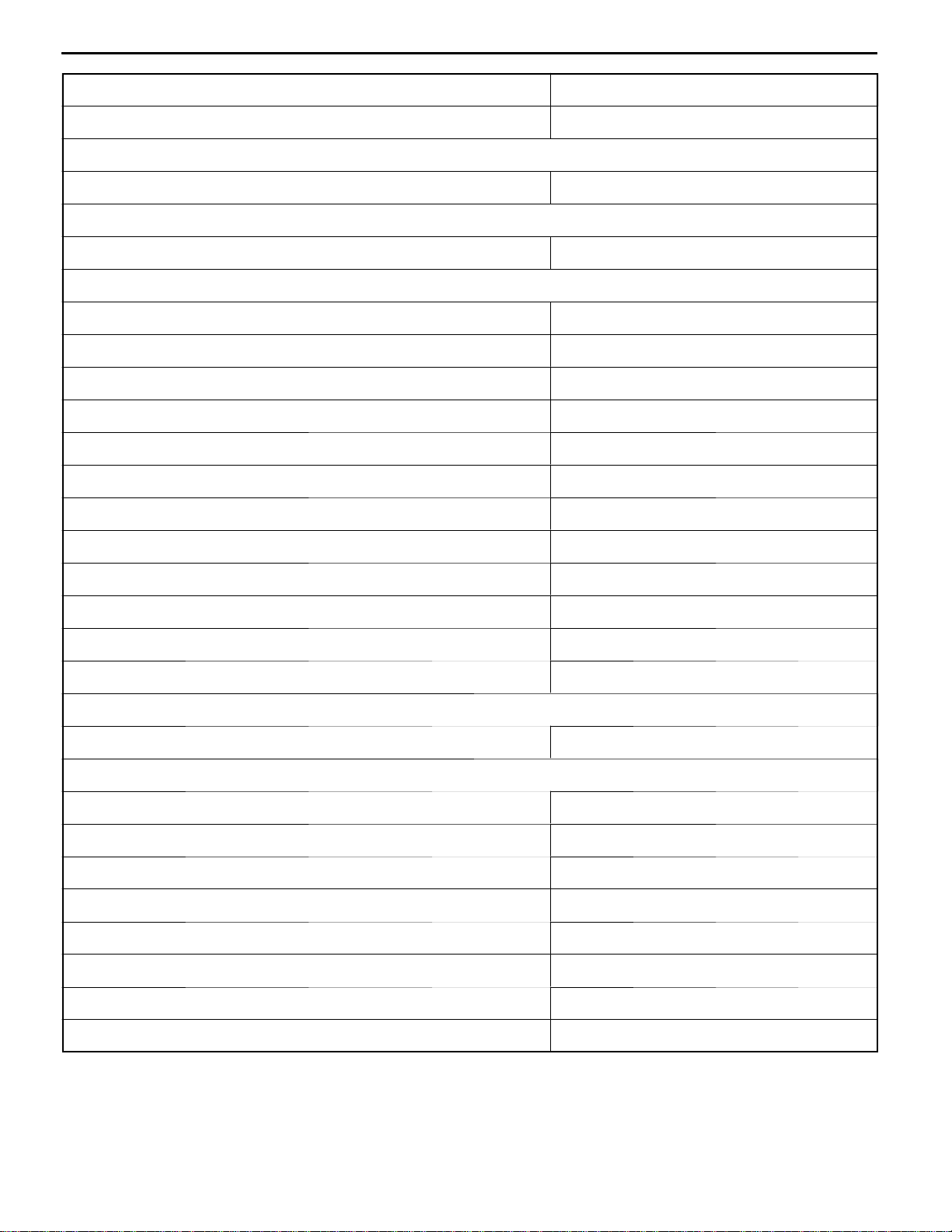

6A1 ENGINE (E-W) -

Specifications

11A-1-3

Items Limit

Crankshaft journal diameter 6A12 53.0 -

mm

6A13

Crankshaft pin diameter mm

Crankshaft journal oil clearance mm

Cylinder block gasket surface flatness mm

Cylinder block gasket surface grinding limit (including grinding of

cylinder head gasket surface) mm

Cylinder block overall height

mm

Cylinder block cylindricity mm 0.01 or less

Cylinder block internal diame- 6A12 78.4 -

ter mm

Bearing cap bolt nominal length mm 71.1

6A12 43.0 6A13 51.0 -

6A12 190.0 6A13

6A13 81.0 -

Standard value

56.0 -

0.02 - 0.04 0.1

0.05 -

- 0.2

209.0 -

-

-

Piston-to-cylinder clearance mm 0.02 - 0.04 -

REWORK DIMENSIONS

Item Standard

Cylinder head and valves

Cylinder head oversize valve guide hole diameter mm 0.05 O.S. 11.05 11.07

0.25 O.S. 11.25 11.27

0.50 O.S. 11.50 11.52

Oversize intake valve seat 0.3 O.S.

ring hole diameter mm

Oversize exhaust valve SOHC 27.80 - 27.82

seat ring diameter mm

SOHC 29.80 - 29.82

0.6 O.S.

MIVEC 32.30 - 32.32

MIVEC 29.80 - 29.82

0.3 O.S.

0.6 O.S.

0.3 O.S.

0.6 O.S.

0.3 O.S.

-

-

-

30.10 - 30.12

32.60 - 32.62

28.10 - 28.12

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

0.6 O.S.

30.10 - 30.12

Page 7

11A-1-4

6A1 ENGINE (E-W) -

Specifications

TORQUE SPECIFICATION

Items Nm

Alternator and drive belt

Alternator pivot nut 44

Alternator bolt 21

Oil level gauge guide 23

Tensioner pulley 15

Engine hanger 23

Tensioner pulley bracket A 45

Crankshaft bolt 182

Engine cover 3

Timing belt

Timing belt front cover 11

Engine support bracket 49

Angle sensor 9

Angle sensor connector bracket 11

Tensioner pulley 48

Tensioner arm 24

Auto tensioner 21

Camshaft sprocket bolt 88

Idler pulley 35

Timing belt rear cover 11

Angle sensor connector bracket 11

Fuel and emission control parts

Air intake plenum stay 18

Connector bracket 11

EGR valve 22

Throttle body 12

Air intake plenum 18

Delivery pipe 12

Fuel pipe 9

Fuel pressure regulator 9

Alternator bracket 23

K

Feb. 1997 Mitsubishi Motors Corporation

PWEE9622

Page 8

6A1 ENGINE (E-W) -

Items Nm

Ignition system

Spark plug 25

Water cover (SOHC) 11

Distributor (SOHC) 13

Ignition failure sensor (MIVEC) 10

Condenser bracket assembly (MIVEC) 5

Ignition coil (MIVEC) 10

Water pump and water pipe

Engine hanger (MIVEC) 11

Engine coolant temperature gauge unit 11

Engine coolant temperature sensor 29

Heater pipe (SOHC) 23

Specifications

11A-1-5

Water inlet fitting 18

Water outlet fitting 18

Thermostat housing 23

Water pipe 13

Water pump 23

Intake manifold and exhaust manifold

Intake manifold 17

Heat protector 13

Exhaust manifold stay 44

Exhaust manifold 49

Rocker arm and camshaft <SOHC>

Rocker cover 4

Rocker arm and rocker shaft 31

Thrust case 24

Rocker arm and camshaft <MIVEC>

Rocker cover 4

Oil control valve holder 9

Cam cap 24

Bearing cap M6 11

Bearing cap M8 24

K

Feb. 1997 Mitsubishi Motors Corporation

PWEE9622

Page 9

11A-1-6

Items Nm

6A1 ENGINE (E-W) -

Specifications

Arm spring holder

Rocker arm and rocker shaft cap <MIVEC>

Rocker shaft cap 11

Cylinder head and valves

Cylinder head bolt 20 + 120è + 120è

Oil pan and oil pump

Oil pressure switch 10

Oil filter cover 21

Water hose 30

Bolt 68

Drain plug 39

Oil level sensor 9

Oil pan 7

Oil screen 19

11

Baffle plate 9

Relief plug 44

Oil pump case 14

Oil pump case cover 12

Piston and connecting rod

Connecting rod 18 + 90è - 100è

Crankshaft, cylinder block, flywheel and drive plate

Detonation sensor 23

Idler pulley bracket 35

Flywheel bolt 98

Drive plate bolt 98

Rear plate 11

Bell housing cover 9

Oil seal case 11

Bearing cap bolt 25 + 90è - 100è

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 10

6A1 ENGINE (E-W) -

Specifications

11A-1-7

NEW TIGHTENING METHOD - BY USE OF BOLTS TO BE TIGHTENED IN PLASTIC AREA

A new type of bolts, to be tightened in plastic area, is currently used in some parts of the engine. The

tightening method for the bolts is different from the conventional one. Be sure to observe the method

described in the text when tightening the bolts.

Service limits are provided for the bolts. Make sure that the service limits described in the text are strictly

observed.

J Areas where the bolts are in use:

(1) Cylinder head bolts

(2) Main bearing cap bolts

(3) Connecting rod cap bolts

J Tightening Method

After tightening the bolts to the specified torque, tighten them another 90è to 100è, or 240è (twice

120è). The tightening method varies on different areas. Observe the tightening method described

in the text.

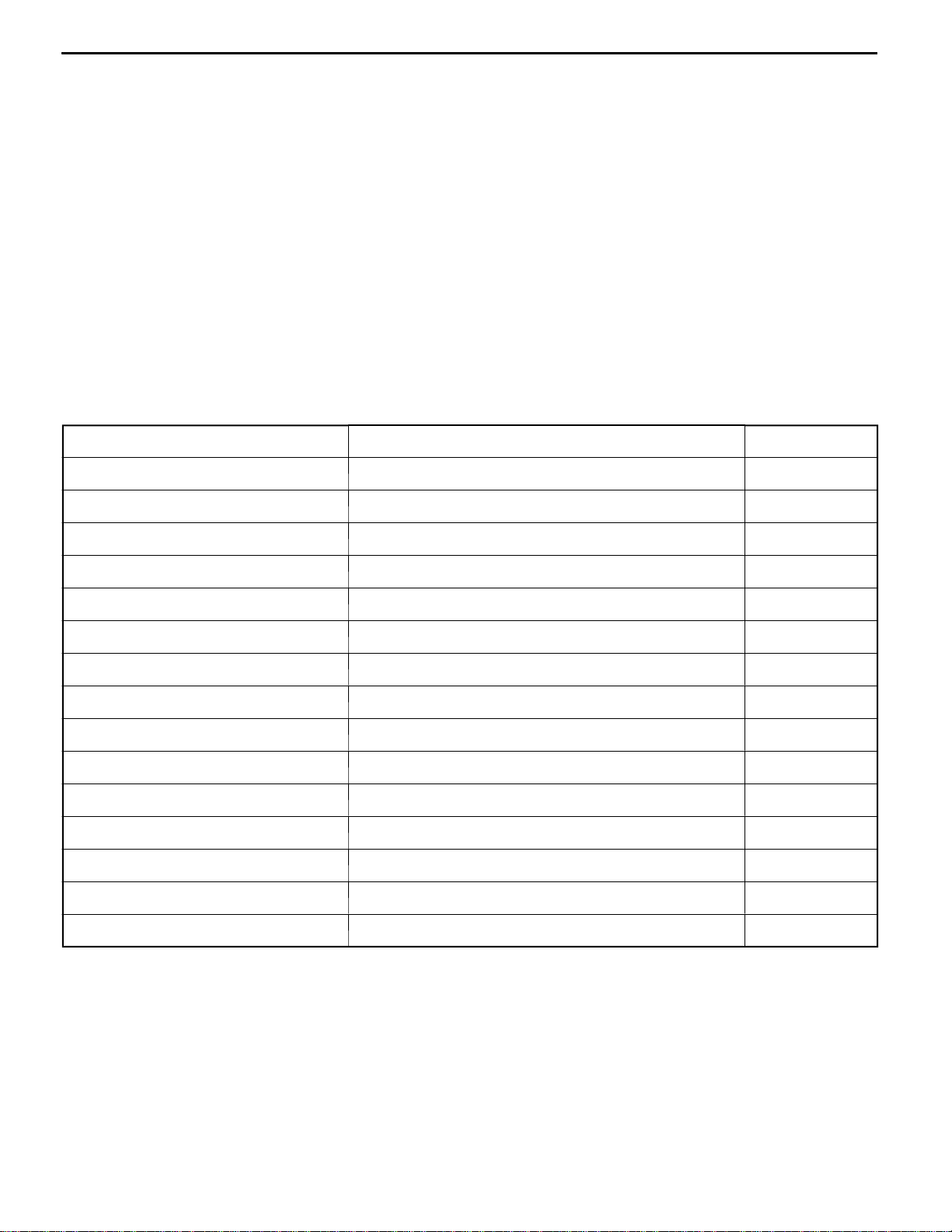

SEALANTS

Item

Water pump*

Water outlet fitting*

Engine coolant temperature sensor

Engine coolant temperature gauge unit

Camshaft bearing 3M ATD Part No. 8660 or equivalent As required

Cam cap 3M ATD Part No. 8660 or equivalent As required

Oil control valve 3M ATD Part No. 8660 or equivalent As required

Camshaft holder* Mitsubishi Genuine Part No. MD970389 or equivalent As required

Rocker cover 3M ATD Part No. 8660 or equivalent As required

Oil pump case* Mitsubishi Genuine Part No. MD970389 or equivalent As required

Oil pan*

Oil pressure switch 3M ATD Part No. 8660 or equivalent As required

Oil seal case* Mitsubishi Genuine Part No. MD970389 or equivalent

Specified sealant Quantity

Mitsubishi Genuine Part No. MD970389 or equivalent

Mitsubishi Genuine Part No. MD970389 or equivalent As required

3M Nut Locking Part No. 4171 or equivalent

3M ATD Part No. 8660 or equivalent As required

Mitsubishi Genuine Part No. MD970389 or equivalent As required

As required

As required

As required

Drive plate bolt 3M Nut Locking Part No. 4171 or equivalent As required

Flywheel bolt 3M Nut Locking Part No. 4171 or equivalent As required

*: parts sealed by foam-in-place gasket (FIPG)

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 11

11A-1-8

6A1 ENGINE (E-W) -

Specifications

FORM-IN-PLACE GASKET (FIPG)

The engine has several areas where the form-in-place gasket (FIPG) is in use. To ensure that the gasket

fully serves its purpose, it is necessary to observe some precautions when applying the gasket. Bead

size, continuity and location are of paramount importance. Too thin a bead could cause leaks. Too thick

a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing of the

fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary to

apply the gasket evenly without a break, while observing the correct bead size.

The FIPG used in the engine is a room temperature vulcanisation (RTV) type a n d is supplied in a 100-gram

tube (Part No. MD970389 or MD997110). Since the RTV hardens as it reacts with the moisture in the

atmospheric air, it is normally used in the metallic flange areas. The FIPG, Part No. MD970389, can

be used for sealing both engine oil and coolant, while Part No. MD997110 can only be used for engine

oil sealing.

Disassembly

The parts assembled with the FIPG can be easily disassembled without use of a special method. In

some cases, however, the sealant between the joined surfaces may have to be broken by lightly striking

with a mallet or similar tool. A flat an d thin gasket scraper may be lightly hammered in between the

joined surfaces. In this case, however, care must be taken to prevent damage to the joined surfaces.

For removal of the oil pan, the special tool “Oil Pan Remover” (MD998727) is available. Be sure to use

the special tool to remove the oil pan.

Surface Preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper

or wire brush. Check to ensure that the surfaces to which the FIPG is to be applied is flat. Make sure

that there are no oils, greases and foreign substances deposited on the application surfaces. Do not

forget to remove the old sealant remained in the bolt holes.

Form-in-Place Gasket Application

When assembling parts with the FIPG, you must observe some precautions, but th e procedures is very

simple as in the case of a conventional precut gasket.

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the

bolt hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is

hardened. While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When

the parts are mounted, make sure that the gasket is applied to the required area only. In addition, do

not apply any oil or water to the sealing locations or start the engine until a sufficient amount of time

(about one hour) has passed after installation is completed.

The FIPG application procedure may vary on different areas. Observe the procedure described in the

text when applying the FIPG.

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 12

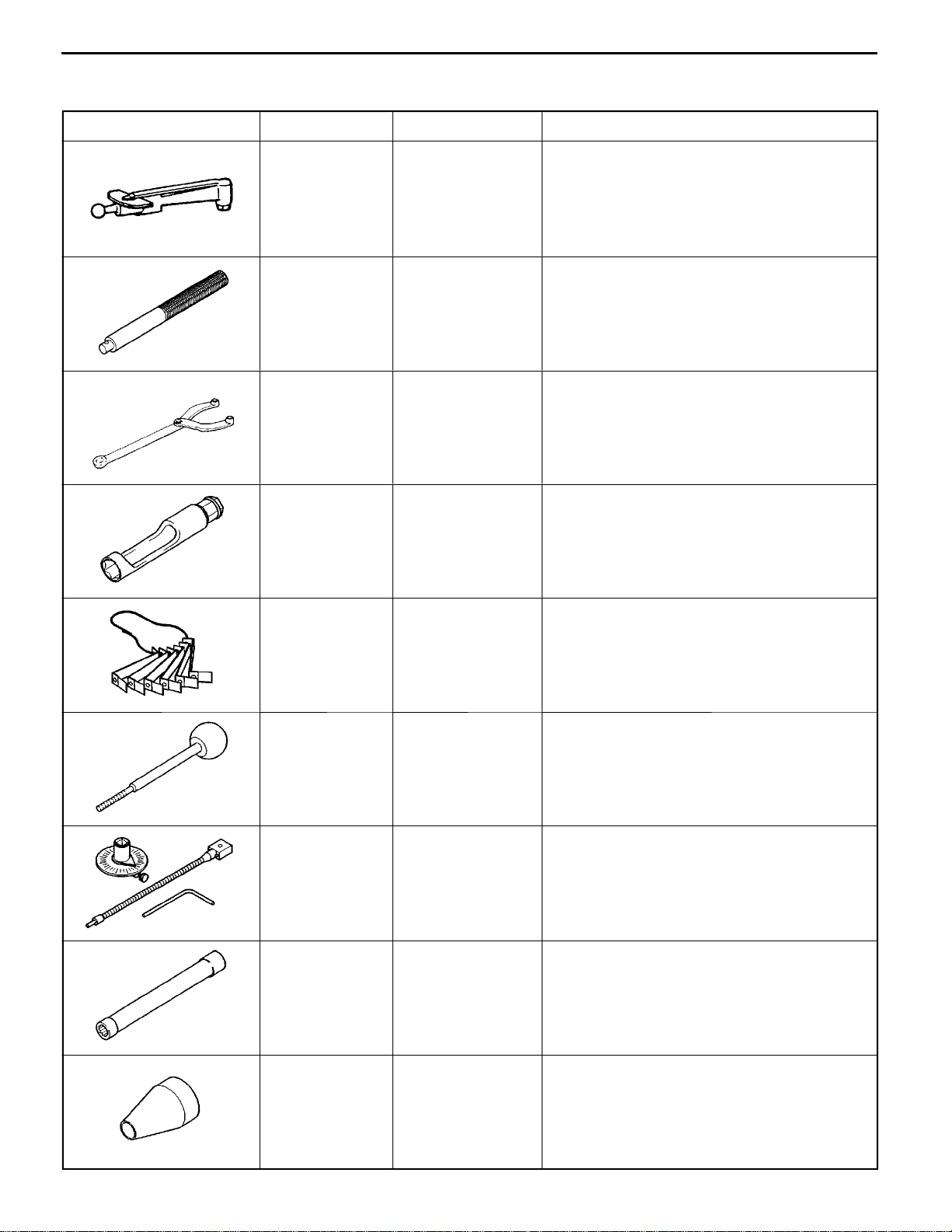

2. SPECIAL TOOLS

6A1 ENGINE (E-W) -

Special Tools

11A-2-1

Tool

Number Name Use

MB990685

MB990938 Handle

MB990767 Crankshaft pulley

MB991477

Torque wrench Adjustment of timing belt tension

Use with MD998776

Holding camshaft sprocket when loosening

holder

Valve adjusting Adjustment of valve clearance (MIVEC)

wrench

and tightening of bolt.

Use with MD998719

MB991478

MB991479

MB991614

MB991653

Valve adjusting

wrench feeler

gauge set

Rocker arm

piston checker

Angle gauge Tightening cylinder head bolt

Cylinder head bolt Tightening and loosening of cylinder head bolt

wrench

Adjustment of valve clearance (MIVEC)

Adjustment of valve clearance (MIVEC)

MB991659

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Guide D Removal of piston pin (Use with MD998780)

Page 13

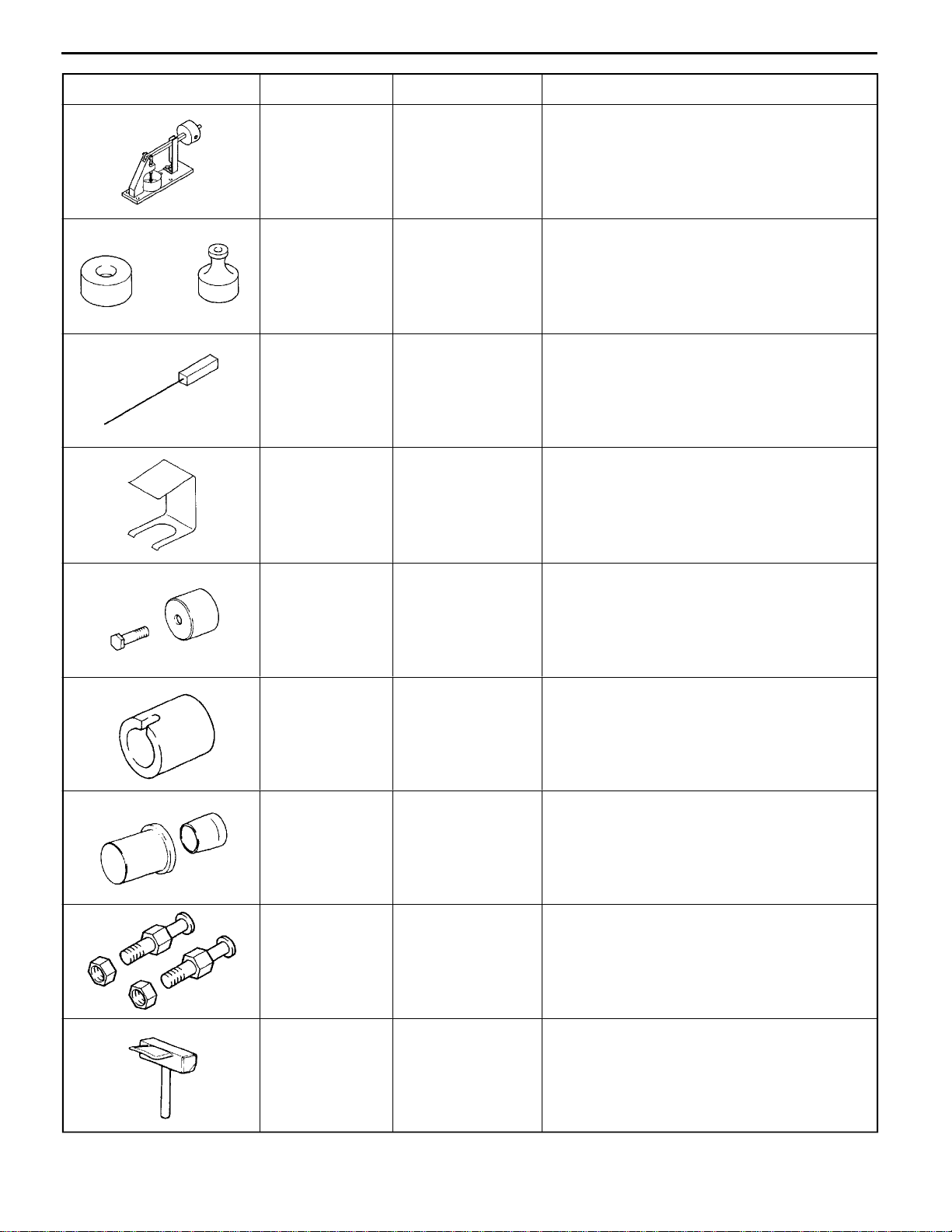

11A-2-2

6A1 ENGINE (E-W) -

Special Tools

Tool Use

MD998440

MD998441

MD998442 Ai Ai

MD998443

NameNumber

Leak-down tester Leak-down test of lash adjuster

Lash adjuster r bleeding of lash adjuster

retainer

r bleed wire r bleeding of lash adjuster

Lash adjuster Retainer for holding lash adjuster in rocker arm

holder

Ai

at time of removal and installation of rocker arm

and rocker shaft assembly

MD998713

MD998716

MD998717 il

MD998719 Pulley holder pin

Camshaft oil seal Installation of camshaft oil seal

installer

Crankshaft wrench Rotation of crankshaft when installing piston

Crankshaft front o

seal installer

(2)

and timing belt.

Installation of crankshaft front oil seal

Use with MB990767

MD998727

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Oil pan remover Removal of oil pan

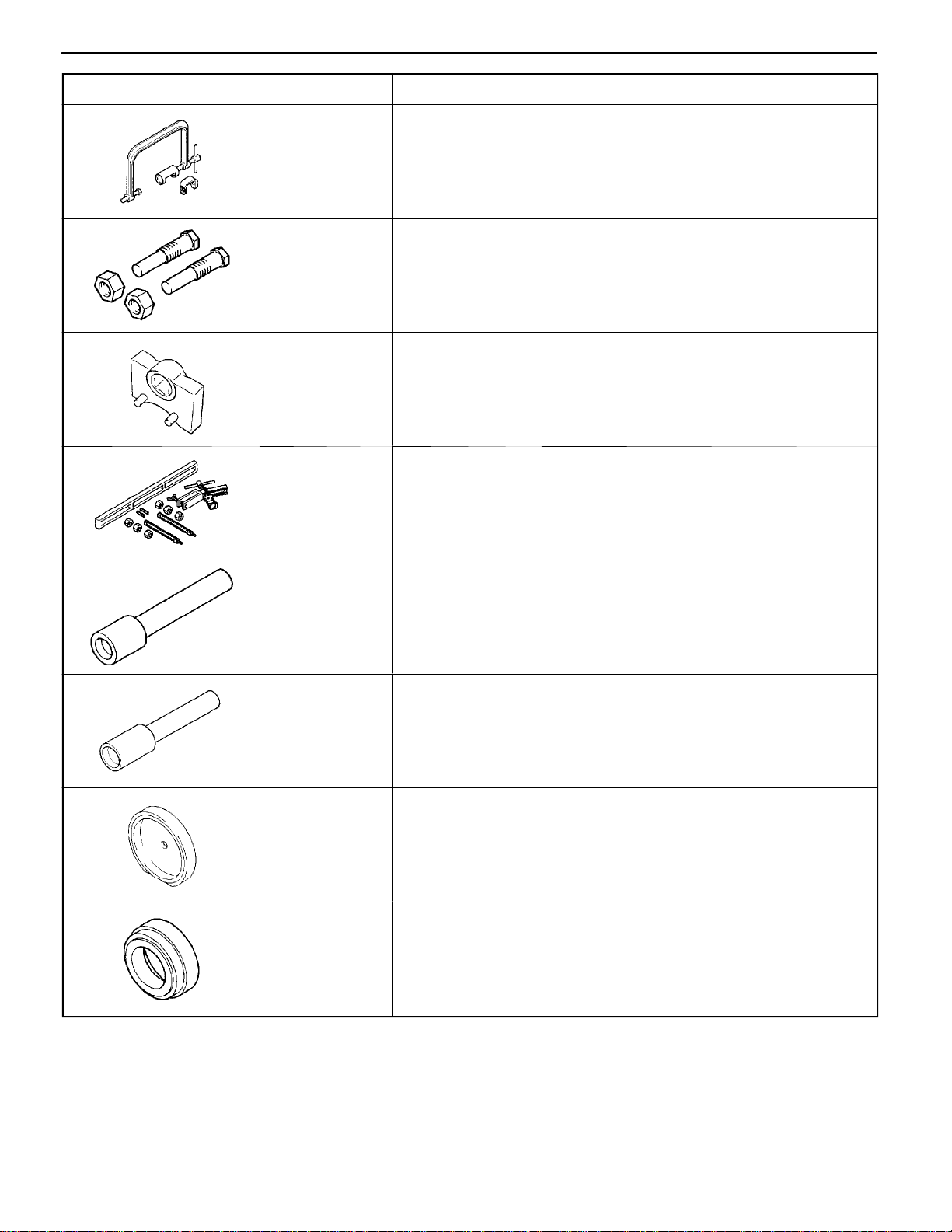

Page 14

6A1 ENGINE (E-W) -

Special Tools

11A-2-3

Tool Use

MD998735

MD998754 Pin

MD998767

MD998772

NameNumber

Valve spring Compression of valve spring

compressor

Use with MB990767

Tensioner pulley

socket wrench

Valve spring Removal and installation of valve and related

compressor parts

Adjustment of timing belt tension

MD998774 stem seal

MD998775 stem seal

MD998776 il

MD998777

V alve Installation of valve stem seal

installer

V alve Installation of valve stem seal

installer

Crankshaft rear o

seal installer

Camshaft oil seal

installer adapter

Installation of crankshaft rear oil seal

Use with MB990938

Installation of camshaft oil seal

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

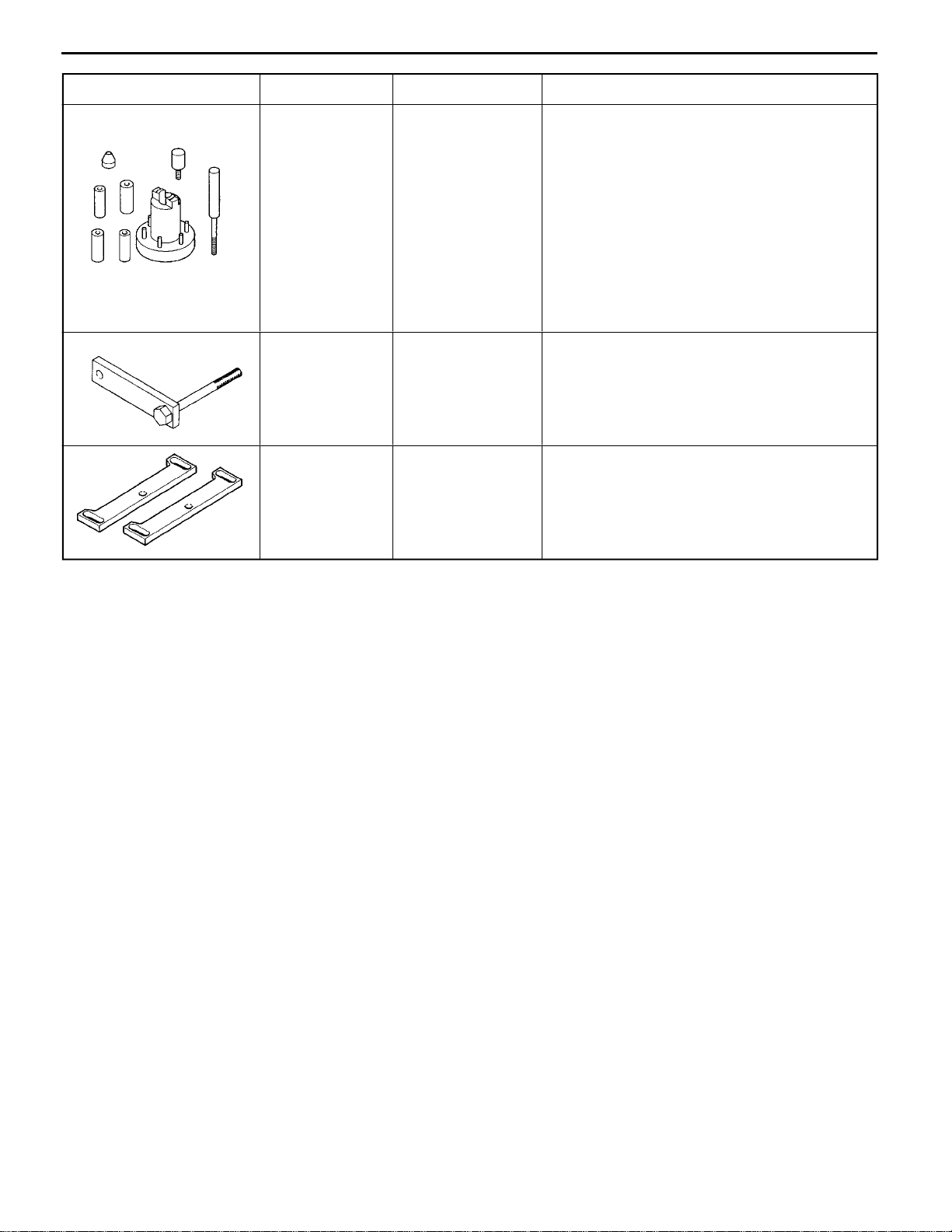

Page 15

11A-2-4

6A1 ENGINE (E-W) -

Special Tools

Tool Use

MD998780

MD998781

MD998784

NameNumber

SETTING TOOL

Piston p

Flywheel stopper Holding flywheel and drive plate

Valve spring Compression of valve spring (MIVEC)

compressor

adapter

in

Removal and installation of piston pin

(Use with MD998772)

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 16

6A1 ENGINE (E-W) -

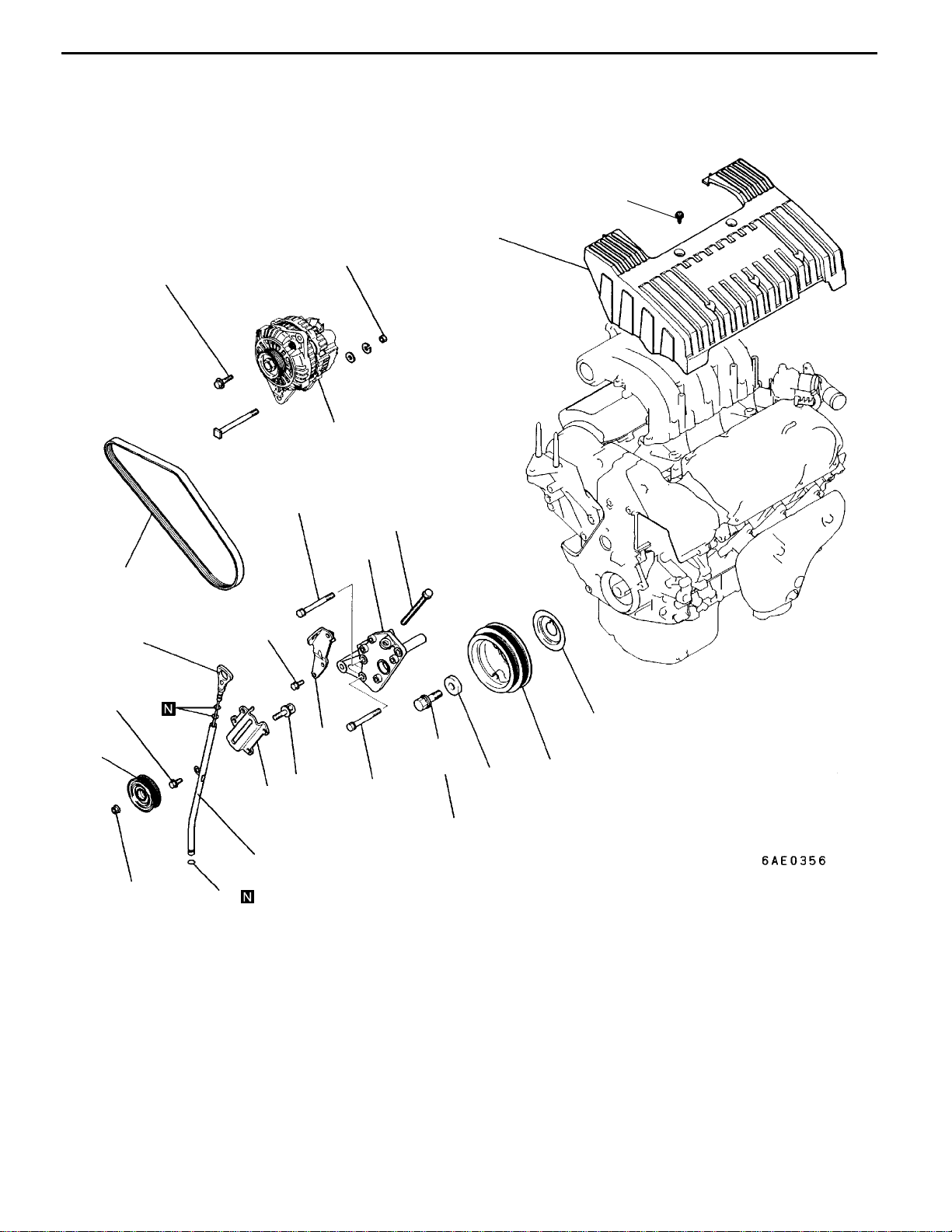

3. DRIVE BELT

REMOVAL AND INSTALLATION <SOHC>

44 Nm

21 Nm

2

16

Drive Belt

3Nm

11A-3-1

1

23 Nm

6

15 Nm

3

23 Nm

5

44 Nm

8

4

10

7

11

9

44 Nm

12

182 Nm

13

15

14

Removal steps

1. Drive belt 9. T ensioner pulley bracket B

2. Alternator 10. Adjusting stud

3. Oil level gauge (dipstick) 11. Adjusting bolt

4. Oil level gauge guide G

5. O-ring 13. Special washer

6. Tensioner pulley 14. Crankshaft pulley

7. Engine hanger 15. Flange

8. Tensioner pulley bracket A 16. Engine cover

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

++

A

G 12. Crankshaft bolt

A

Page 17

11A-3-2

6A1 ENGINE (E-W) -

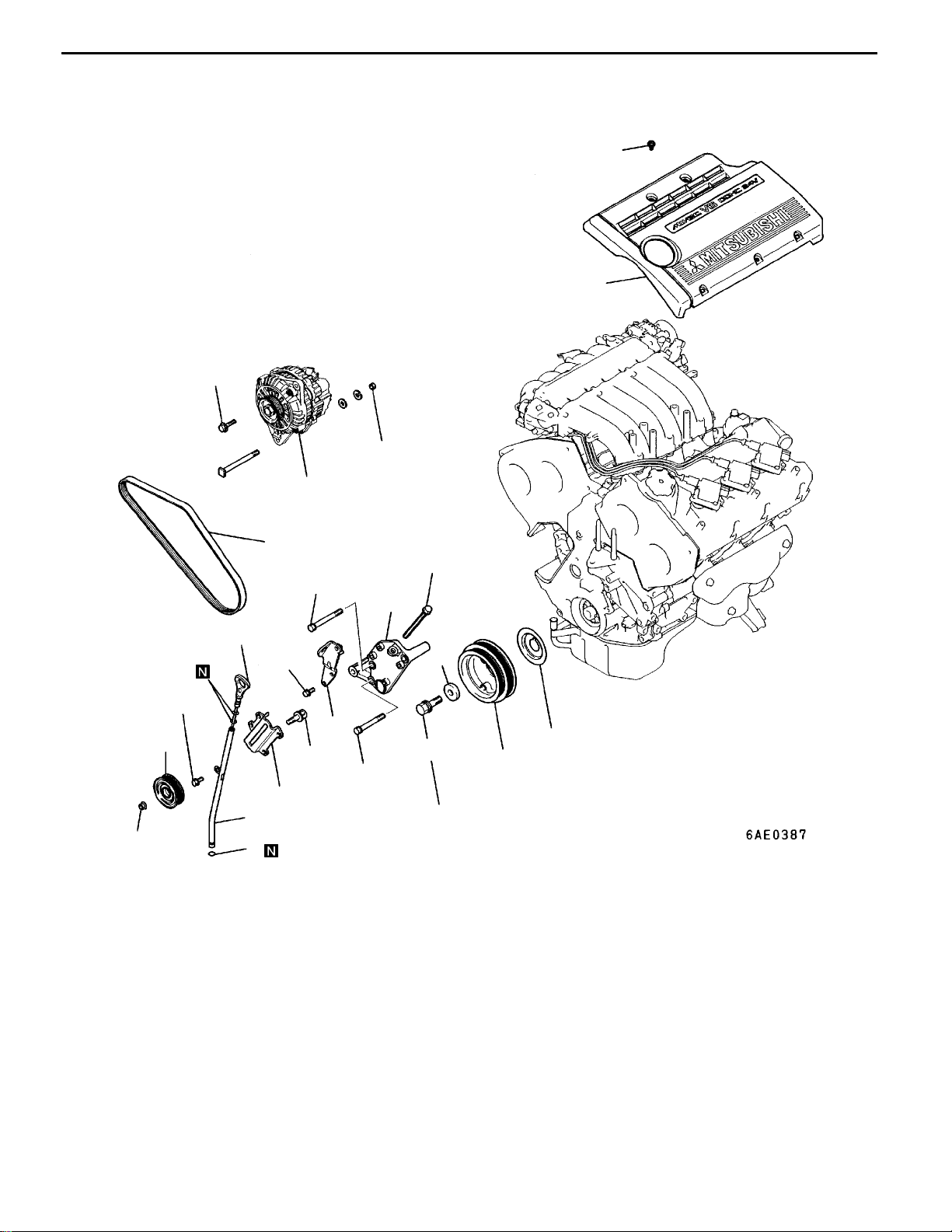

REMOVAL AND INSTALLATION <MIVEC>

21 Nm

44 Nm

2

Drive Belt

3Nm

16

23 Nm

15 Nm

1

11

44 Nm

9

3

12

13

15

14

23 Nm

7

6

10

44 Nm

8

4

182 Nm

5

Removal steps

1. Drive belt 9. T ensioner pulley bracket B

2. Alternator 10. Adjusting stud

3. Oil level gauge (dipstick) 11. Adjusting bolt

4. Oil level gauge guide G

5. O-ring 13. Special washer

6. Tensioner pulley 14. Crankshaft pulley

7. Engine hanger 15. Flange

8. Tensioner pulley bracket A 16. Engine cover

++

A

G 12. Crankshaft bolt

A

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 18

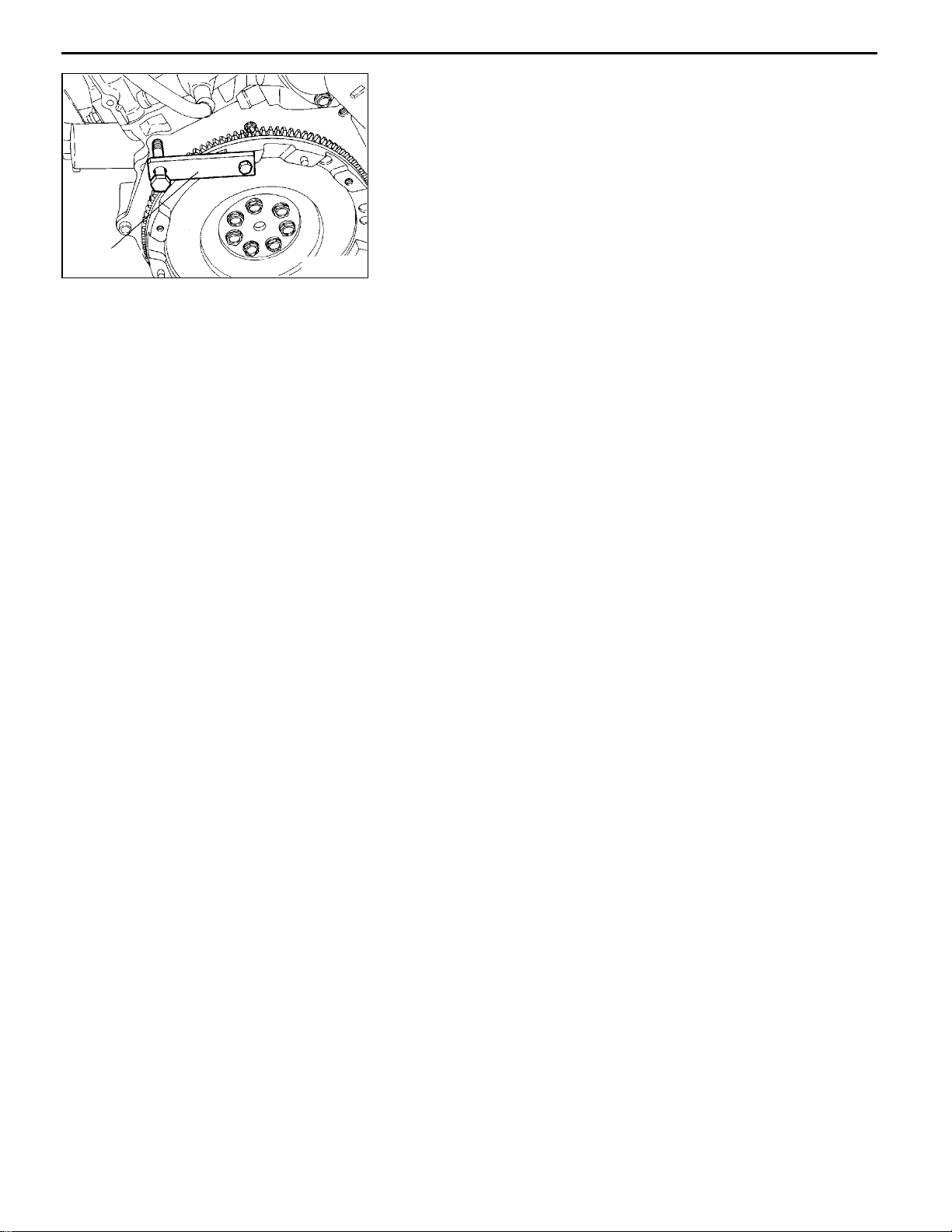

MD998781

6A1 ENGINE (E-W) -

REMOVAL SERVICE POINTS

G

A+ CRANKSHAFT PULLEY BOLT REMOVAL

(1) Hold the flywheel or drive plate in position with the special

tool before removing the crankshaft pulley bolts.

INSTALLATION SERVICE POINTS

+

AG CRANKSHAFT PULLEY BOLT INSTALLATION

(1) Hold the flywheel or drive plate in position with the special

6AE0039

tool before installing the crankshaft pulley bolts.

Drive Belt

11A-3-3

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 19

6A1 ENGINE (E-W) -

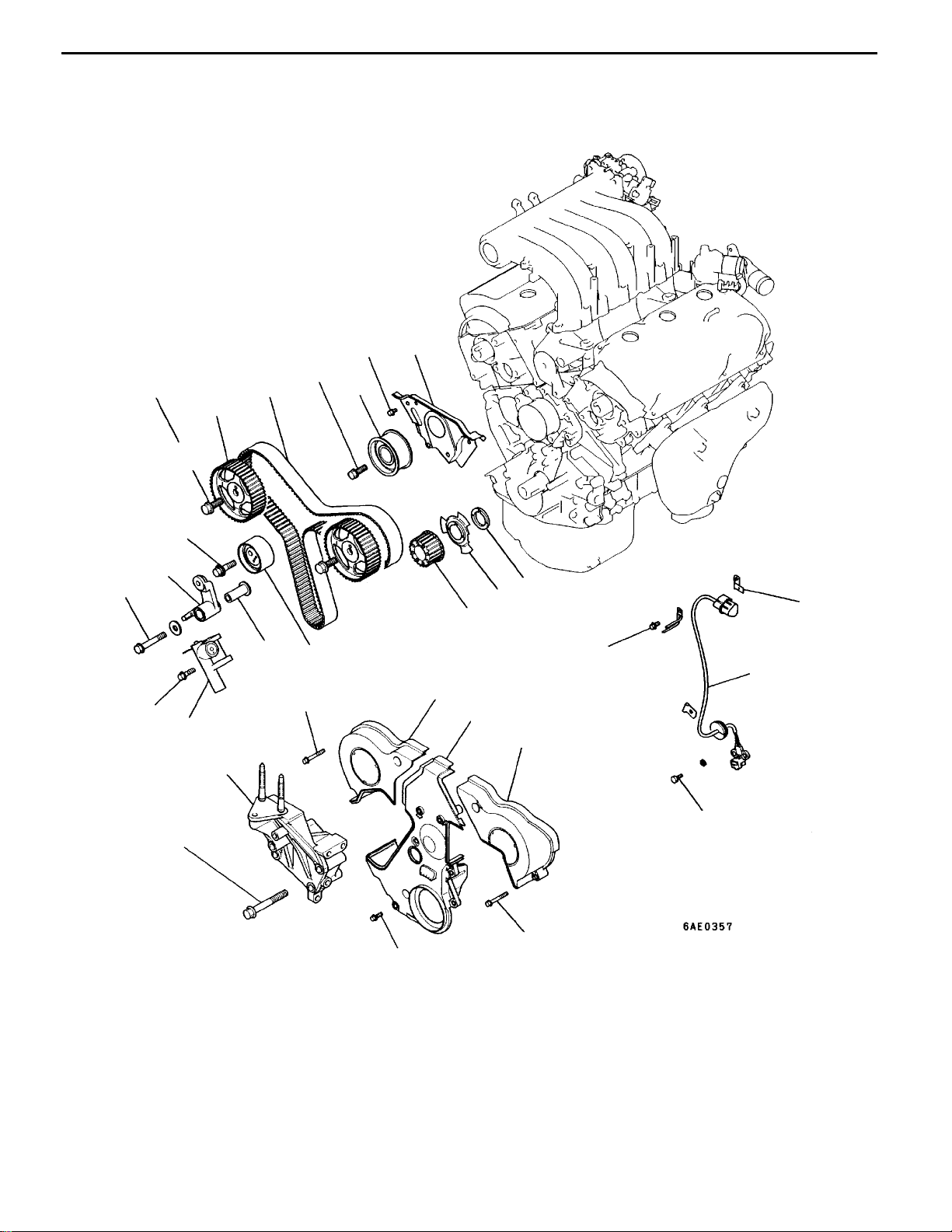

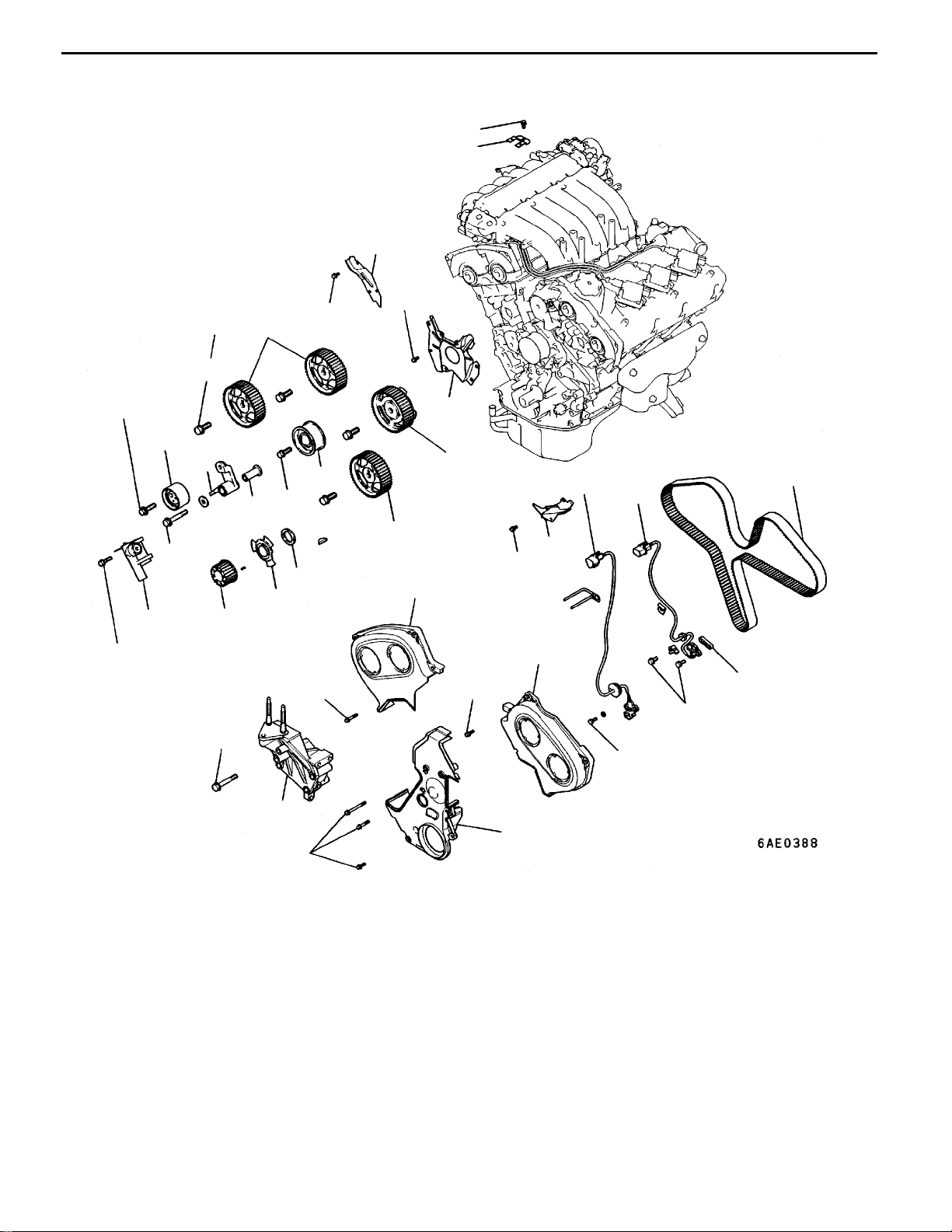

4. TIMING BELT

REMOVAL AND INSTALLATION <SOHC>

Timing Belt

11A-4-1

88 Nm

24 Nm

21 Nm

14

48 Nm

8

10

15

4

6

9

35 Nm

7

11 Nm

11 Nm

16

17

1

11

3

12

13

18

11 Nm

5

2

49 Nm

11 Nm

Removal steps

1. Timing belt front cover, upper right +BG 10. Auto tensioner

2. Timing belt front cover, upper left 11. Crankshaft sprocket

3. Timing belt front cover, lower 12. Sensing plate

4. Engine support bracket 13. Crankshaft spacer

5. Angle sensor G

GA++

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

G 6. Timing belt 15. Camshaft sprocket

C

7. Tensioner pulley 16. Idler pulley

8. Tensioner arm 17. Timing belt rear cover, center

9. Tensioner spacer 18. Connector bracket

11 Nm

++

B

9Nm

G 14. Camshaft sprocket bolt

A

Page 20

11A-4-2

6A1 ENGINE (E-W) -

REMOVAL AND INSTALLATION <MIVEC>

12 Nm

23

21

Timing Belt

48 Nm

22 Nm

12

9

44 Nm

88 Nm

16

10

13

49 Nm

11

17

35 Nm

14

11 Nm

19

15

11 Nm

11 Nm

17

1

22

18

9Nm

11 Nm

2

20

5

8

6

7

9Nm

9Nm

4

11 Nm

Removal steps

1. Timing belt front cover, upper right

2. Timing belt front cover, upper left

3. Timing belt front cover, lower

4. Engine support bracket

5. Angle sensor

6. Angle sensor

7. Spacer

GA++

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

G

8. Timing belt

D

9. Tensioner pulley

10. Tensioner arm

11. Tensioner spacer

+

G 12. Auto tensioner

B

3

GB++

13. Crankshaft sprocket

14. Sensing plate

15. Washer

G 16. Camshaft sprocket bolt

A

17. Camshaft sprocket

18. Camshaft sprocket with sensing

plate

19. Idler pulley

20. Timing belt rear cover, left

21. Timing belt rear cover, right

22. Timing belt rear cover, center

23. Connector bracket

Page 21

6A1 ENGINE (E-W) -

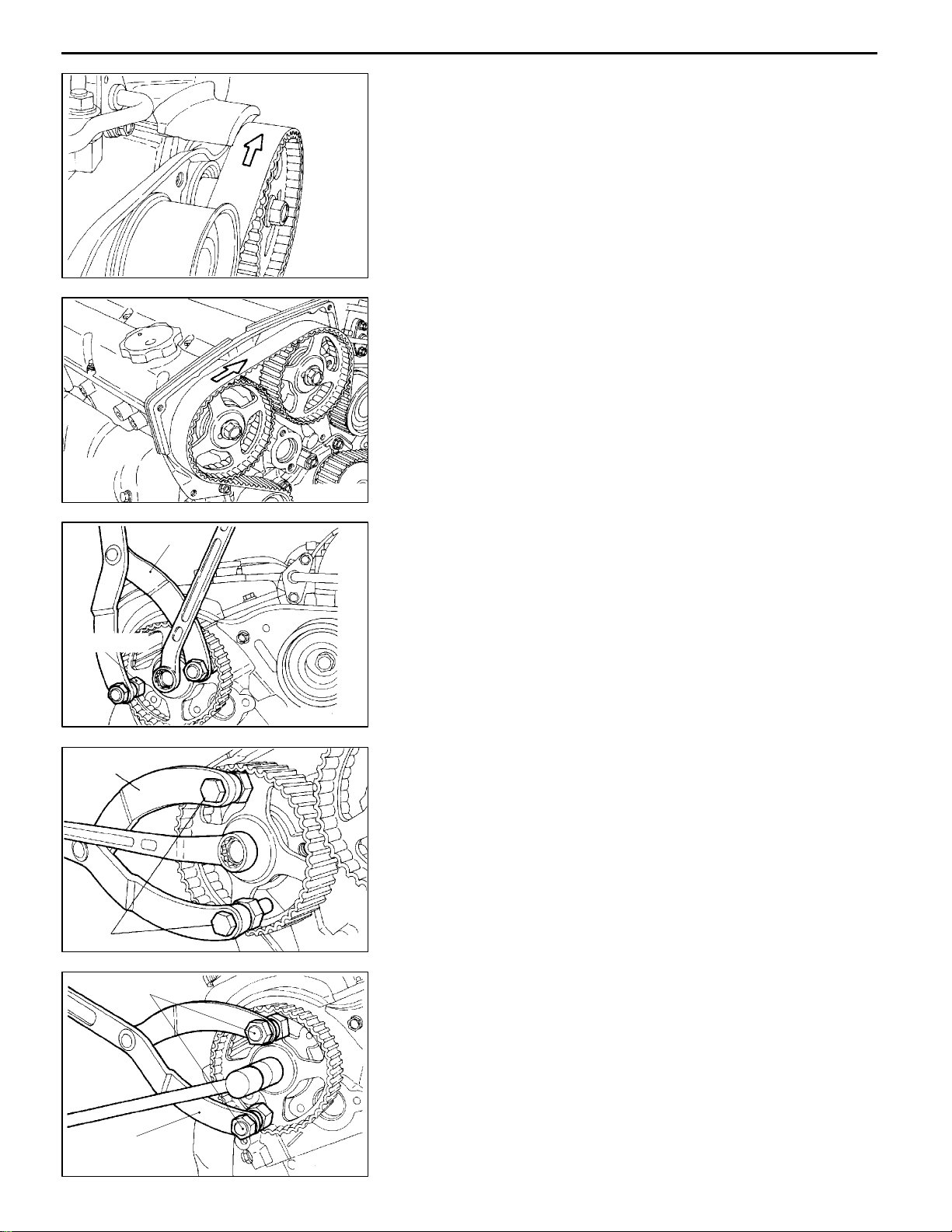

REMOVAL SERVICE POINTS

G

A+ TIMING BELT REMOVAL

(1) Mark the belt running direction for reference in

reinstallation.

(2) Loosen the bolt that secures the tensioner pulley to

remove the timing belt.

6AE0135

Timing Belt

11A-4-3

MD998719

MB990767

MD998754

MB990767

6AE0044

6AE0137

6AE0045

G

B+ CAMSHAFT SPROCKET BOLT REMOVAL

MD998719

MB990767

6AE0138

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

INSTALLATION SERVICE POINTS

+

AG CAMSHAFT SPROCKET BOLT INSTALLATION

Page 22

11A-4-4

MD998754

6A1 ENGINE (E-W) -

Timing Belt

MB990767

(B)

(A)

6AE0048

6AE0049

+

BG AUTO TENSIONER SETTING

(1) Set the auto tensioner in a vice, while making sure it

is not tilted.

(2) Slowly close the vice to force th e rod in until the set

hole (A) of the rod is lined up with the set hole (B) of

the cylinder.

(3) Insert a 1.4 mm wire in the set hole.

(4) Remove the auto tensioner from the vice.

6AE0050

+

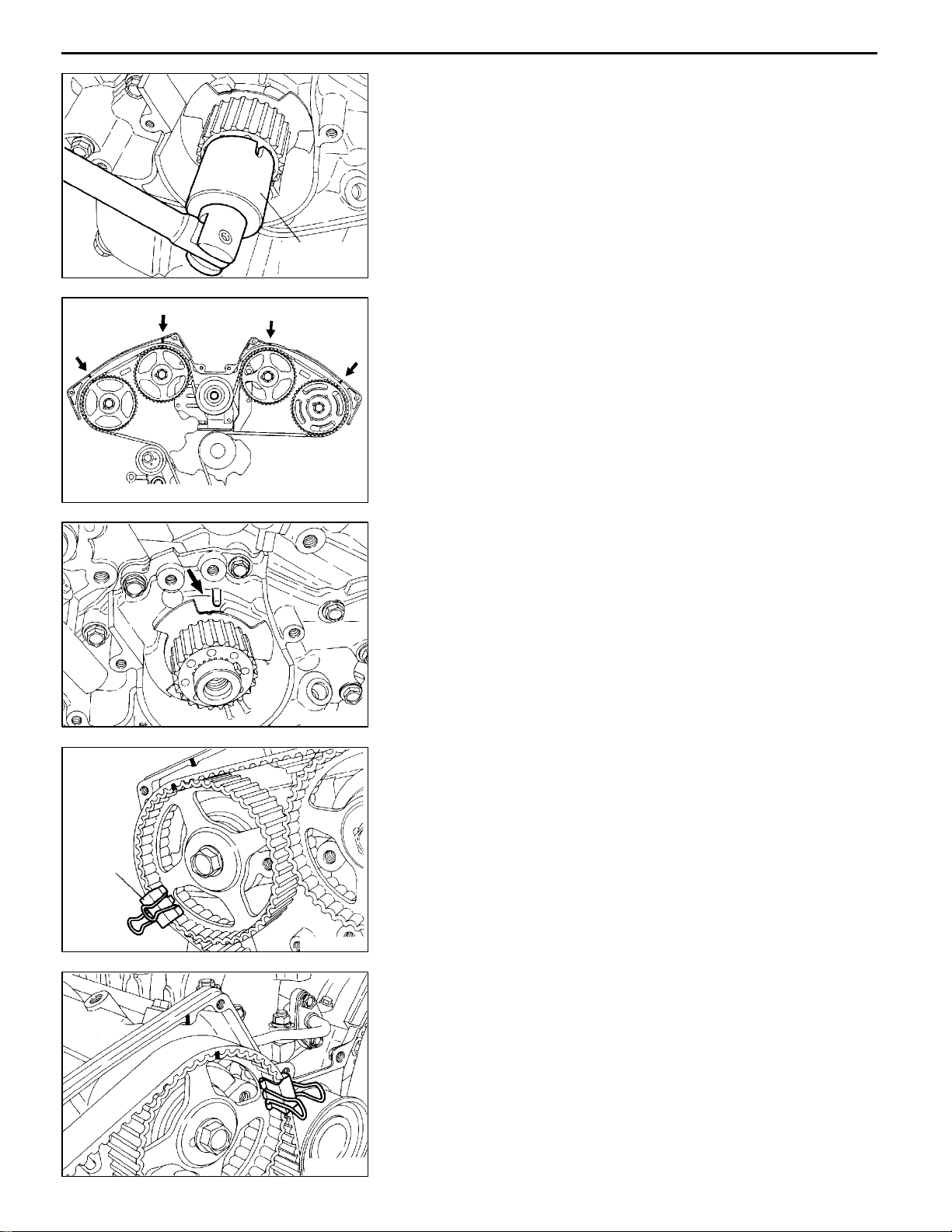

CG TIMING BELT INSTALLATION

(1) Turn the crankshaft sprocket so that its timing mark will

be away from the mating timing mark by approx. three

teeth.

Caution

J

6AE0329

Timing mark

6AE0358

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

(2) Bring the timing marks of the camshaft sprockets as shown

in the illustration.

If the timing marks are aligned, the piston is

brought to the TDC. When the camshaft is turned

under this condition, the valves may interfere with

the piston.

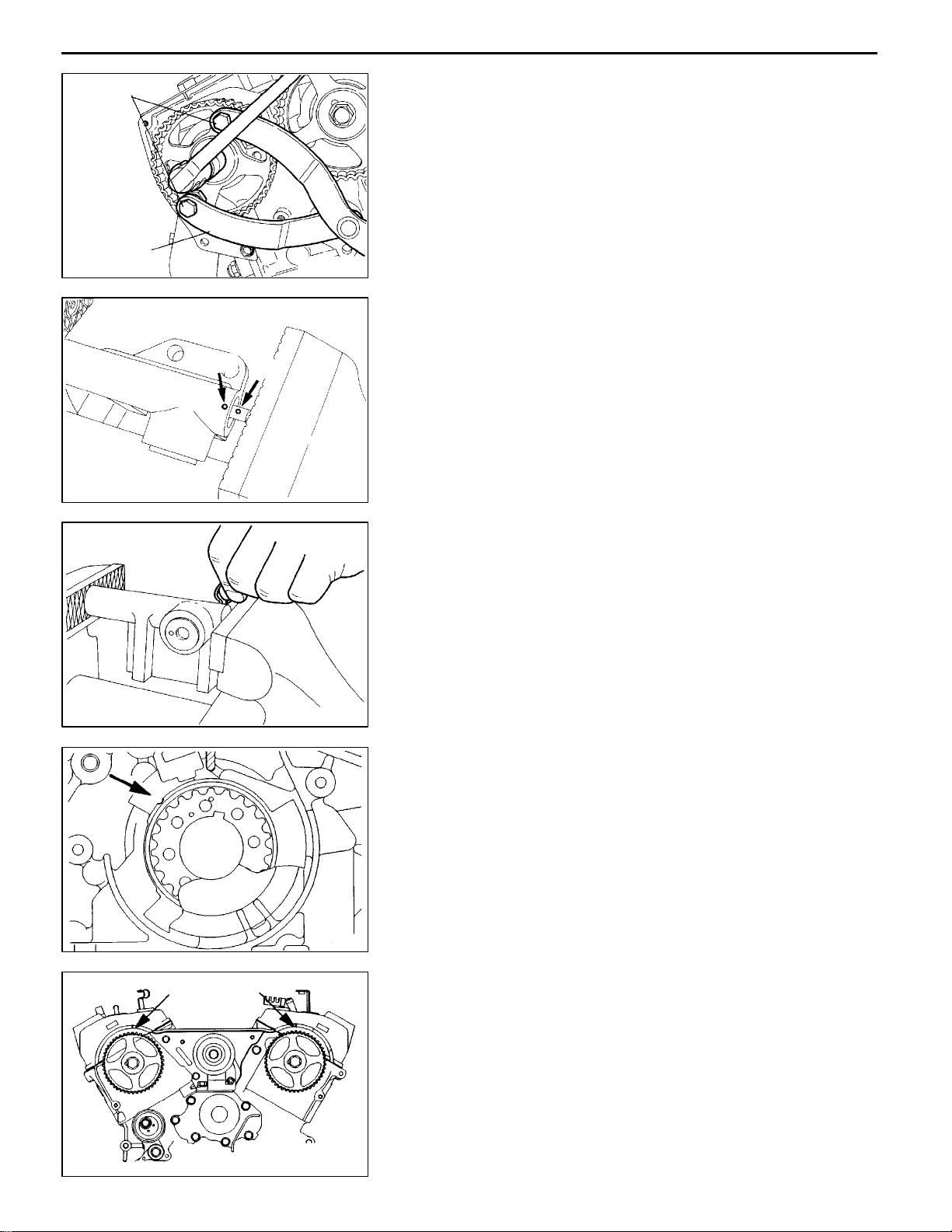

Page 23

6A1 ENGINE (E-W) -

(3) Align the timing mark on the crankshaft sprocket with

that on the cylinder block side.

(4) Fit the timing belt on the sprockets in the following order:

1) Fit the timing belt on the crankshaft sprocket and

then, while giving tension to the belt, fit it on the

water pump sprocket.

2) Fit the belt on the left bank camshaft sprocket.

3) Fit the belt on the idler pulley while keeping it tight.

4) Align the timing mark on the right bank camshaft

sprocket with the mark on the cylinder block, a nd

6AE0331

then fit the belt on the camshaft sprocket.

Caution

J

The camshaft sprockets are prone to rotate. Avoid

giving excessive tension to the timing belt when

it is fitted.

Timing Belt

11A-4-5

MB990685

MD998767

5) Make sure that the left bank portion of the belt is

not slack when the belt is fitted on the tensioner pulley.

If it is slack, remove the belt and fit it again beginning

with the first step.

6AE0143

(5) Move the tensioner pulley in the direction of the arrow

and hold it in raised position by tightening the tensioner

pulley bolt.

(6) Check that all timing marks are aligned correctly.

(7) Turn the crankshaft counterclockwise a quarter turn.

(8) Turn back the crankshaft clockwise until the timing marks

align again.

6AE0057

(9) Install the special tool and a torque wrench of 0 - 5

Nm to the tensioner pulley.

(10)Torque the tensioner pulley to 3 Nm with the torque

wrench.

(11) While holding the tensioner pulley, tighten the center bolt

to specification.

(12)Turn the crankshaft clockwise 2 turns and let it stand

for about 5 minutes.

6AE0058

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 24

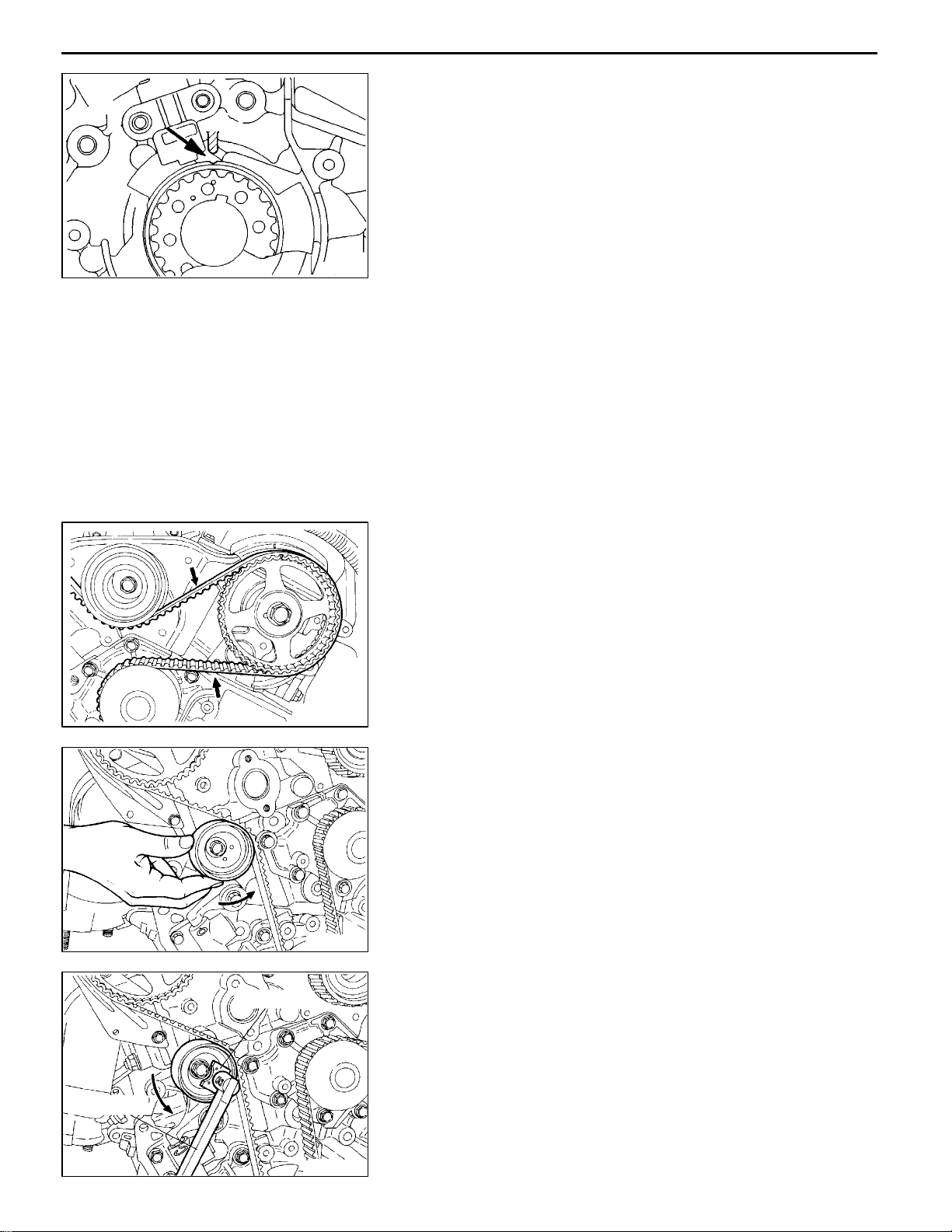

11A-4-6

6A1 ENGINE (E-W) -

+

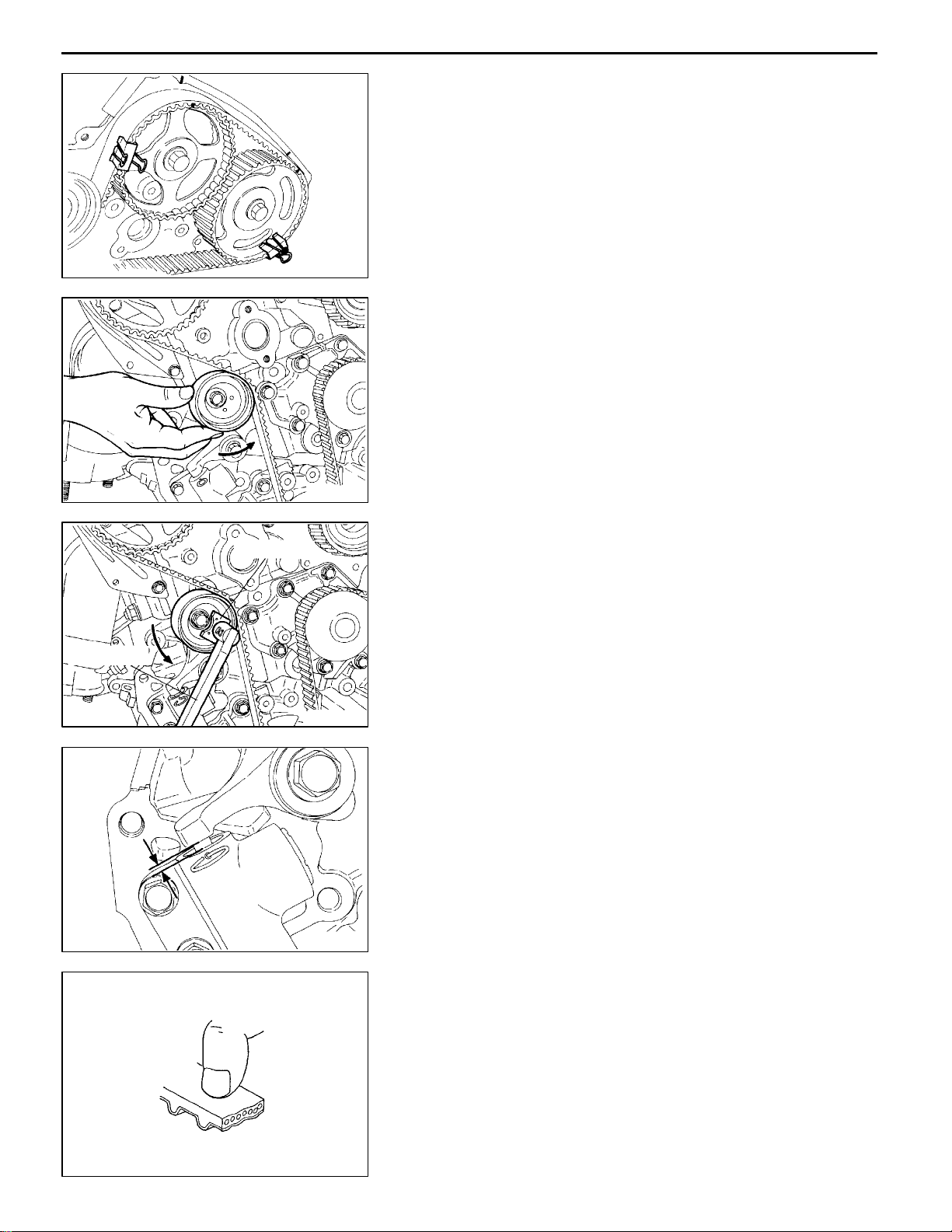

DG TIMING BELT INSTALLATION

(1) Turn the crankshaft sprocket so that its timing mark will

be away from the mating timing mark by approx. three

teeth.

Caution

J

MD998716

6AE0051

(2) Bring the timing marks of the camshaft sprockets as shown

in the illustration.

Caution

J

Timing Belt

If the timing marks are aligned, the piston is

brought to the TDC. When the camshaft is turned

under this condition, the valves may interfere with

the piston.

If one of the camshaft sprockets on the right bank

is turned with the timing mark on the other

sprocket aligned, there may be danger for the

intake and exhaust valves to interfere with each

other.

Paper clip

6AE0311

6AE0053

6AE0054

(3) Align the timing mark on the crankshaft sprocket with

the mating timing mark, and then turn the crankshaft

counterclockwise by one tooth.

(4) Place the timing belt over the sprockets in the following

method.

Caution

J

The camshaft sprockets on the right bank can

turn very easily because of the valve spring

tension. Use care not to allow your fingers to get

caught between the sprockets.

)

Align the timing mark of the right bank exhaust

1

camshaft sprocket with the mating timing mark and

hold the timing belt on the sprocket with a paper

clip.

)

Align the timing mark of the intake camshaft sprocket

2

and place the timing belt around that sprocket. Then,

clip the belt at th e location shown.

Caution

J

The camshaft sprockets can turn easily and

do not give excessive tension to the timing

belt.

3) Place the timing belt around the idler pulley.

6AE0055

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 25

6A1 ENGINE (E-W) -

4) On the left bank, make sure that the timing marks

of the camshaft sprockets are aligned and then hold

the timing belt on these sprockets with paper clips.

5) Place the timing belt around the water pump pulley.

6) Place the timing belt around the crankshaft sprocket.

7) Place the timing belt around the tensioner pulley.

6AE0056

(5) Move the tensioner pulley in the direction of the arrow

and hold it in raised position by tightening the tensioner

pulley bolt.

(6) Check that all timing marks are aligned correctly.

(7) Turn the crankshaft counterclockwise a quarter turn.

(8) Turn back the crankshaft clockwise until the timing marks

align again.

Timing Belt

11A-4-7

MB990685

MD998767

6AE0057

6AE0058

6AE0059

(9) Install the special tool and a torque wrench of 0 - 5

Nm to the tensioner pulley.

(10)Torque the tensioner pulley to 3 Nm with the torque

wrench.

(11) While holding the tensioner pulley, tighten the center bolt

to specification.

(12)Turn the crankshaft clockwise 2 turns and let it stand

for about 5 minutes.

(13)Make sure that the wire, which has been inserted when

installing the auto tensioner, can be removed easily.

Belt tension should be acceptable if the wire can be easily

removed. Remove the wrench. The belt tension can also

be verified by checking the protrusion amount of the auto

tensioner rod which should conform to the following.

Standard value: 3.8 - 4.5 mm

(14)If the wire cannot be removed easily or the rod protrusion

is not up to specification, repeat steps (9) through (12)

to obtain the correct tension.

INSPECTION

TIMING BELT

Replace belt if any of the following conditions exist.

(1) Hardening of back rubber.

Back side is glossy without resilience and leaves no indent

when pressed with fingernail.

8EN0066

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 26

11A-4-8

6A1 ENGINE (E-W) -

Timing Belt

Peeling

Cracks

Rounded edge

Abnormal wear

(Fluffy strand)

Rubber exposed

Cracks

Cracks

1EN0249

8EN0067

(2) Cracks on rubber back.

(3) Cracks or peeling of canvas.

(4) Cracks on tooth bottom.

(5) Cracks or belt sides.

(6) Abnormal wear of belt sides. The sides are normal if

they are sharp as if cut by a knife.

(7) Abnormal wear on teeth.

(8) Missing tooth.

Tooth missing

and canvas

fiber exposed

“L”

98 196 N

-

8EN0068

6AE0046

Stroke

AUTO-TENSIONER

(1) Check for oil leaks. If oil leaks are evident, replace the

auto-tensioner.

(2) Check the rod end for wear or damage and replace the

auto-tensioner if necessary.

(3) Measure the rod projection length “L”. If the reading is

outside the standard value, replace the auto tensioner.

Standard value “L”: 12 mm

(4) Press the rod by a force of 98 to 196 N and measure

the rod stroke. If the measured value exceeds the standard

value, replace the tensioner.

Standard value: 1 mm or less

6EN1033

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 27

6A1 ENGINE (E-W) -

Fuel and Emission Control Parts

5. FUEL AND EMISSION CONTROL PARTS

REMOVAL AND INSTALLATION <SOHC>

11A-5-1

12 Nm

6

22 Nm

3

18 Nm

4

10

18 Nm

1

11

17

18 Nm

12 Nm

2

18 Nm

18 Nm

18

21

7

16

20

15

14

5

8

9

9Nm

19

13

+

23 Nm

22

Removal steps

1. Air intake plenum stay, front

2. Air intake plenum stay, rear

3. EGR valve

4. Gasket

5. Vacuum pipe

6. Throttle body

G

7. Gasket

C

8. Air intake plenum

9. Gasket

10. Control harness

11. Delivery pipe and injector

9Nm

12

12. Insulator

13. Insulator

+

G 14. Injector

B

15. Grommet

16. O-ring

17. Fuel pipe

18. O-ring

+

G 19. Fuel pressure regulator

A

20. O-ring

21. Delivery pipe

22. Alternator bracket

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 28

11A-5-2

6A1 ENGINE (E-W) -

Fuel and Emission Control Parts

REMOVAL AND INSTALLATION <MIVEC>

18 Nm

1

14

18 Nm

21

2

10

14 Nm

22

8.8 Nm

11

11 Nm

6

12 Nm

25

8

20

17

18 Nm

9

24

19

18

18 Nm

11 Nm

7

13

9Nm

23

16

12 Nm

3

4

5

12

15

+

23 Nm

26

Removal steps

1. Air intake plenum stay, front

2. Air intake plenum stay, rear

3. Vacuum pipe

4. Throttle body

G

5. Gasket

C

6. Connector bracket

7. Connector bracket

8. Accelerator cable bracket

9. Ignition failure sensor

10. Air temperature sensor

11. Gasket

12. Air intake plenum

13. Gasket

9Nm

14. Control harness

15. Delivery pipe and injector

16. Insulator

17. Insulator

+

G 18. Injector

B

19. Grommet

20. O-ring

21. Fuel pipe

22. O-ring

+

G 23. Fuel pressure regulator

A

24. O-ring

25. Delivery pipe

26. Alternator bracket

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 29

6A1 ENGINE (E-W) -

Fuel and Emission Control Parts

11A-5-3

INSTALLATION SERVICE POINTS

+

AG FUEL PRESSURE REGULATOR INSTALLATION

(1) Apply spindle oil or gasoline to the new O-ring installed

on the fuel pressure regulator.

(2) Insert the fuel pressure regulator in the delivery pipe.

(3) Make sure that the fuel pressure regulator turns smoothly;

then align the threaded holes and tighten the regulator

bolts to specification.

6AE0061

6AE0062

Caution

J

If the regulator does not turn smoothly, the O-ring

probably gets caught somewhere in the delivery

pipe. In such a case, remove the fuel pressure

regulator and reinsert it into the delivery pipe.

Check it again for smooth rotation before securing.

+

BG INJECTOR INSTALLATION

(1) Install new grommet and O-ring on the injector.

(2) Apply spindle oil or gasoline to the O-ring of the injector.

(3) While turning the injector in both directions, install it in

the delivery pipe.

(4) Make sure that the injector turns smoothly.

Caution

J

If the injector does not turn smoothly, the O-ring

probably gets caught somewhere in the delivery

pipe. In such a case, remove the injector and

reinsert it into the delivery pipe. Check it again

for smooth rotation.

(5) On the right bank, align the marks on the injector and

delivery pipe.

+

Projection

6AE0277

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

CG GASKET INSTALLATION

(1) Locate the projection on the gasket as shown.

Page 30

6A1 ENGINE (E-W) -

6. IGNITION SYSTEM

REMOVAL AND INSTALLATION <SOHC>

1

Ignition System

11A-6-1

25 Nm

2

4

13 Nm

11 Nm

3

Removal steps

1. Spark plug cable

2. Spark plug

3. Water cover

+

G 4. Distributor

A

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 31

11A-6-2

6A1 ENGINE (E-W) -

REMOVAL AND INSTALLATION <MIVEC>

Ignition System

1.0 Nm

25 Nm

3

1

2

Removal steps

1. Spark plug cable

2. Ignition coil

3. Spark plug

INSTALLATION SERVICE POINT

+

AG DISTRIBUTOR INSTALLATION

Alignment mark

6AE0151

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

(1) Turn the crankshaft clockwise to bring the No. 1 cylinder

piston to the compression stroke top dead center.

(2) Align the mark on the distributor housing with the mark

on the coupling.

(3) Install the distributor while aligning the coupling key with

the keyway in the camshaft end.

Page 32

6A1 ENGINE (E-W) -

Water Pump and Water Pipe

7. WATER PUMP AND WATER PIPE

REMOVAL AND INSTALLATION <SOHC>

11A-7-1

18 Nm

5

4

6

14

23 Nm

13 Nm

3

13

10

29 Nm

1112

2

9

1

23 Nm

11 Nm

18 Nm

8

7

23 Nm

15

Removal steps

+

G

1. Engine coolant temperature gauge

F

+

G

E

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

unit

2. Engine coolant temperature sensor

3. Water hose

4. Water hose

5. Heater pipe

6. O-ring

7. Water inlet fitting

+

G 8. Thermostat

D

+

G 9. Water outlet fitting

C

10. Thermostat housing

11. Gasket

+

G 12. O-ring

B

+

G 13. Water pipe

B

+

G 14. O-ring

B

+

G 15. Water pump

A

Page 33

11A-7-2

6A1 ENGINE (E-W) -

Water Pump and Water Pipe

REMOVAL AND INSTALLATION <MIVEC>

8

5

13

13 Nm

12

18 Nm

11

4

10

18 Nm

23 Nm

1

29 Nm

9

3

7

2

18 Nm

6

11 Nm

23 Nm

+

+

+

14

Removal steps

1. Engine hanger

G

2. Engine coolant temperature gauge

F

G

E

G

D

unit

3. Engine coolant temperature sensor

4. Water hose

5. Water hose

6. Water inlet fitting

7. Thermostat

+

G 8. Water outlet fitting

C

9. Thermostat housing

10. Gasket

+

G 11. O-ring

B

+

G 12. Water pipe

B

+

G 13. O-ring

B

+

G 14. Water pump

A

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 34

6A1 ENGINE (E-W) -

Water Pump and Water Pipe

11A-7-3

3mm

diameter

bead sealant

3mm

diameter

bead sealant

6AE0067

INSTALLATION SERVICE POINTS

+

AG SEALANT APPLICATION TO WATER PUMP

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent

+

BG WATER PIPE / O-RING INSTALLATION

(1) Wet the O-ring (with water) to facilitate assembly.

Caution

J

Keep the O-ring free of oil or grease.

J

Secure the water pipe after the thermostat housing

has been installed.

+

CG SEALANT APPLICATION TO WATER OUTLET

FITTING

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent

6AE0068

+

DG THERMOSTAT INSTALLATION

Jiggle valve

(1) Install the thermostat so that the jiggle valve will be located

in the thermostat housing as shown.

6AE0069

+

EG SEALANT APPLICATION TO ENGINE COOLANT

Specified sealant:

6AE0070

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

TEMPERATURE SENSOR

3M Nut locking Part No. 4171 or equivalent

Page 35

11A-7-4

6A1 ENGINE (E-W) -

+

6AE0071

Water Pump and Water Pipe

FG SEALANT APPLICATION TO ENGINE COOLANT

TEMPERATURE GAUGE UNIT

Specified sealant:

3M ATD Part No. 8660 or equivalent

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 36

6A1 ENGINE (E-W) -

Intake Manifold and Exhaust Manifold

8. INTAKE MANIFOLD AND EXHAUST MANIFOLD

REMOVAL AND INSTALLATION <SOHC>

11A-8-1

13 Nm

49 Nm

3

5

44 Nm

6

4

17 Nm

1

2

7

9

13 Nm

Removal steps

1. Intake manifold

2. Gasket

3. Heat protector, right

4. Exhaust manifold stay

5. Exhaust manifold, right

6. Gasket

7. Heat protector, left

8. Exhaust manifold, left

9. Gasket

8

49 Nm

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 37

11A-8-2

6A1 ENGINE (E-W) -

Intake Manifold and Exhaust Manifold

REMOVAL AND INSTALLATION <MIVEC>

13 Nm

49 Nm

3

5

17 Nm

1

2

6

7

9

44 Nm

4

13 Nm

Removal steps

1. Intake manifold

2. Gasket

3. Heat protector, right

4. Exhaust manifold stay

5. Exhaust manifold, right

6. Gasket

7. Heat protector, left

8. Exhaust manifold, left

9. Gasket

8

49 Nm

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 38

6A1 ENGINE (E-W) -

Rocker Arm and Camshaft <SOHC>

9. ROCKER ARM AND CAMSHAFT <SOHC>

REMOVAL AND INSTALLATION

4Nm

1

2

11A-9-1

31 Nm

6

5

11

3

8

7

9

8

7

8

14

9

7

9

12

10

12

13

12

24 Nm

15

16

17

4

Removal steps

1. Rocker cover 10. Rocker arm shaft

2. Rocker cover gasket

3. Oil seal

+

G 4. Oil seal 13. Rocker arm shaft

GA++

GA++

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

D

G

5. Rocker arm and rocker shaft

C

G

6. Rocker arm and rocker shaft

C

+

G 7. Rocker shaft spring

C

8. Rocker arm A

9. Rocker arm B

Apply engine oil to all

moving parts before

installation.

+

G 11. Lash adjuster

B

12. Rocker arm C

+

G 14. Lash adjuster

B

15. Thrust case

16. O-ring

+

G 17. Camshaft

A

Page 39

11A-9-2

For right bank

For left bank

6A1 ENGINE (E-W) -

MD998443

6AE0160

6AE0180

Rocker Arm and Camshaft <SOHC>

REMOVAL SERVICE POINT

G

A+ ROCKER ARMS AND ROCKER ARM SHAFTS

REMOVAL

(1) Before removing rocker arms and shafts assembly, install

the special tool as illustrated to prevent adjuster from

dropping.

INSTALLATION SERVICE POINTS

+

AG CAMSHAFT INSTALLATION

(1) Apply engine oil to journals and cams of the camshaft

before installation.

Be sure to install the correct camshafts on t he correct

bank.

Do not confuse the intake camshaft with the exhaust

one.

+

BG LASH ADJUSTER INSTALLATION

(1) Immerse the lash adjuster in clean diesel fuel.

(2) Using the special tool (air bleed wire), move the plunger

up and down 4 or 5 times while pushing down lightly

on the check ball in order to bleed out the air.

MD998442

Diesel

fuel

6EN0421

(3) Insert the lash adjuster to rocker arm, being careful not

to spill the diesel fuel. Then use the special tool to prevent

adjuster from falling while installing it.

MD998443

Lash adjuster

6AE0161

+

CG ROCKER SHAFT SPRING / ROCKER ARMS AND

(1) Temporarily tighten the rocker shaft with the bolt so that

all rocker arms on the inlet valve side do not push the

valves.

(2) Fit the rocker shaft spring from the above and position

it so that it is right angles to the plug guide.

NOTE

Install the rocker shaft spring before installing the exhaust

6AE0162

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

side rocker arms and rocker arm shaft.

ROCKER ARM SHAFT INSTALLATION

Page 40

Right bank

6A1 ENGINE (E-W) -

6AE0163

MD998713

Rocker Arm and Camshaft <SOHC>

11A-9-3

NOTE

Install the rocker shaft spring before installing the exhaust

side rocker arms and rocker arm shaft.

(3) Remove the special tool for securing the lash adjuster.

(4) Make sure that the notch in the rocker arm shaft is in

the direction as illustrated.

+

DG CAMSHAFT OIL SEAL INSTALLATION

(1) When installing the left bank camshaft oil seal, use the

special tool to prevent interference with the knock pin.

Left bank

MD998713

6AE0164

MD998777

6AE0181

9EN0058

INSPECTION

CAMSHAFT

(1) Measure the cam height (lobe diameter) and, if the limit

is exceeded, replace the camshaft.

Standard value:

35.20 mm

34.91 mm

Limit:

34.70 mm

34.41 mm

...........................................

.......................................

...........................................

.......................................

Exhaust side

Exhaust side

Intake side

Intake side

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 41

11A-9-4

6A1 ENGINE (E-W) -

Rocker Arm and Camshaft <SOHC>

LASH ADJUSTER LEAK DOWN TEST

Caution

J

The lash adjuster is a precision part. Keep it free

from dust and other foreign matters.

J

Do not disassemble lash adjuster.

J

When cleaning lash adjuster, use clean diesel fuel

only.

MD998442

MD998441

MD998440

Diesel fuel

Graduations = 1 mm

6EN0186

(1) Immerse the lash adjuster in clean diesel fuel.

(2) While lightly pushing down inner steel ball using the special

tool (Air bleed wire MD998442), move the plunger up

and down four or five times to bleed air.

Use of the special tool (Retainer MD998441) helps

facilitate the air bleeding of the rocker arm mounted type

lash adjuster.

(3) Remove the special tool (Air bleed wire MD998442) and

press the plunger. If the plunger is hard to be pushed

in, the lash adjuster is normal. If the plunger can be pushed

in all the way readily, bleed the lash adjuster again an d

test again.

If the plunger is still loose, replace the lash adjuster.

Caution

J

Upon completion of air bleeding, hold lash

adjuster upright to prevent inside diesel fuel from

spilling.

(4) After air bleeding, set lash adjuster on the special tool

(Leak down tester MD998440).

(5) After plunger has gone down somewhat [0.2 - 0.5 mm],

measure time taken for it to go down 1 mm. Replace

if measured time is out of specification.

Standard value: 4 - 20 seconds/1 mm

Lash adjuster

6EN0187

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

(Diesel fuel at 15 - 20èC)

Page 42

6A1 ENGINE (E-W) -

Rocker Cover and Camshaft <MIVEC>

10. ROCKER COVER AND CAMSHAFT <MIVEC>

REMOVAL AND INSTALLATION

4Nm

1

11 Nm

2

24 Nm

24 Nm

9Nm

11A-10-1

8

3

24 Nm

Apply engine oil to all

moving parts before

installation.

11 Nm

24 Nm

10

9

11

4

11 Nm

9

12

13

6

14

5

7

Removal steps

+

G 1. Rocker cover +CG 8. Oil control valve

G

2. Rocker cover gasket

3. Oil seal

+

G

4. Circuit packing

F

+

G

5. Oil seal

E

+

G

6. Camshaft holder

D

+

G

7. Semi-circular packing

D

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

+

G 9. Cam cap

B

10. Oil control valve holder

+

G 11. Camshaft bearing cap

B

12. Arm spring holder

13. Arm spring

+

G 14. Camshaft

A

Page 43

11A-10-2

6A1 ENGINE (E-W) -

Left bank

camshaft

Right bank

camshaft

6AE0229

Rocker Cover and Camshaft <MIVEC>

INSTALLATION SERVICE POINT

+

AG CAMSHAFT INSTALLATION

(1) Intake valve camshaft and exhaust valve camshaft can

be identified by their diameters at the portions indicated

in the illustration.

Intake valve camshaft: 25 mm

Exhaust valve camshaft: 30 mm

EX

Dowel p

in

IN

EXIN

Dowel p

Right

bank

Left

bank

in

6AE0230

6AE0233

(2) Before installing each camshaft, apply engine oil to its

journals and cams.

(3) The camshaft dowel pins must be positioned as shown

in the illustration.

+

G

B

CAMSHAFT BEARING CAP CAM CAP

/

INSTALLATION

(1) Apply sealant to the illustrated points of the

camshaft

holders.

Specified sealant:

3M ATD part No. 8660 or equivalent

(2) Install the bearing caps and cam caps correctly according

to the “I” (intake) and “E” (exhaust) marks as well as

the stamped cap numbers a nd front marks.

(3) Tighten the bolts in the sequence of the numbers shown

in the illustration.

Cap No.

Intake

Exhaust

Cap No.

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Front mark

6AE0308

Page 44

Protrusion

6A1 ENGINE (E-W) -

6AE0236

Screw

Rocker Cover and Camshaft <MIVEC>

+

CG OIL CONTROL VALVE INSTALLATION

11A-10-3

(1) Apply the specified sealant to the area shown.

Specified sealant:

3M ATD Part No. 8660 or equivalent

+

DG SEMI-CIRCULAR PACKING / CAMSHAFT

HOLDER INSTALLATION

(1) Make sure that the retainer of each adjusting screw is

fitted correctly.

Groove

Retainer

Pad

6AE0237

6AE0238

Caution

J

If the protrusion on the retainer is not correctly

fitted in the groove of the screw, the pad could

slip off the retainer.

(2) Apply 3 mm thick bead of foam-in-place gasket (FIPG)

to the gasket surface of the camshaft holder.

Caution

J

Since the FIPG could cause blocking of engine

oil passages, be careful not to apply FIPG to other

locations than specified.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent

(3) Install the semi-circular packings.

(4) Raise the rocker arms until the rollers come into contact

with the cams, and install the camshaft holder.

(5) Tighten the bolts in the order indicated in the illustration.

106248

(6) Check the torque of the Q-marked bolts. See section +BG

for the checking order.

(7) Verify that the pad of each adjusting screw is in place.

7 3 1 5 9

6AE0239

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 45

11A-10-4

Right bank

MD998713

Left bank

6A1 ENGINE (E-W) -

6AE0306

MD998777

MD998713

6AE0307

Rocker Cover and Camshaft <MIVEC>

+

EG CAMSHAFT OIL SEAL INSTALLATION

(1) When installing the left bank camshaft oil seal, use the

special tool to prevent interference with the knock pin.

10 mm

10 mm

12

MD998713

10 mm

6AE0241

Sealant application

areas

6AE0242

+

FG CIRCULAR PACKING INSTALLATION

+

GG ROCKER COVER INSTALLATION

(1) Apply the specified sealant to the area shown.

Specified sealant:

3M ATD Part No. 8660 or equivalent

INSPECTION

OIL CONTROL VALVE

(1) Connect a 12VDC power supply between terminals (1)

and (2) of the oil control valve and check if the valve

operates smoothly.

+ -

6AE0206

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 46

6A1 ENGINE (E-W) -

High-speed cam (H)

Valve

16 mm

6AE0227

9N0058

Rocker Cover and Camshaft <MIVEC>

11A-10-5

CAMSHAFT

(1) Measure the cam heights. If the specified limit is exceeded,

replace the camshaft.

NOTE

Each camshaft has an identification mark on its rear end

surface.

( ) Limit

: Identification mark Standard value

IN (3) 34.34 mm 33.84 mm

EX (C) 34.40 mm 33.90 mm

L

H

L

H

36.46 mm 35.96 mm

35.86 mm 35.36 mm

Identification

mark location

21 mm

Low-speed

cam (L)

6AE0228

VALVE CLEARANCE ADJUSTMENT

NOTE

Adjust the valve clearance for each cylinder and for both

intake and exhaust valves with the piston at the compression

stroke top dead center.

(1) Bring the No. 1 cylinder piston into the compression stroke

top dead center.

(2) Use th e special tool to loosen the adjusting screw.

Thickness gauge

MB991477

6AE0285

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

(3) Insert a thickness gauge of the thickness specified below

between the low-speed cam (narrow cam) and roller.

Intake

Exhaust

(4) Screw in on e of the two adjusting screws until it comes

into contact with the valve (when the turning torque

changes).

....................................................

.................................................

0.10 mm

0.13 mm

Page 47

11A-10-6

MB991479

6A1 ENGINE (E-W) -

Piston

Rocker Cover and Camshaft <MIVEC>

(5) Screw in the other adjusting screw until it comes into

contact with the valve (when the turning torque changes),

and then tighten the lock nut.

(6) Loosen the adjusting screw that was screwed in first

slightly (until the turning torque becomes almost zero).

Screw in the adjusting screw until it comes into contact

with the valve again (when the turning torque changes)

and tighten the lock nut.

(7) Remove the thickness gauge.

(8) Screw the special tool into the top of piston of the rocker

arm “H”, and pull up the tool to make sure that the piston

can be lifted smoothly by hand.

(9) Perform valve clearance adjustments for other cylinders

by turning every time the crankshaft through 120è (60è

in camshaft sprocket angle) and following the above steps

(2) through (8). Perform the adjustments in the following

order of cylinder number:

No. 2 ç No. 3 ç No. 4 ç No. 5 ç No. 6

6AE0286

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 48

6A1 ENGINE (E-W) -

Rocker Arm and Rocker Shaft Cap <MIVEC>

11. ROCKER ARM AND ROCKER SHAFT CAP <MIVEC>

REMOVAL AND INSTALLATION

11A-11-1

16

13

18

7

17

9

10

14

15

19

5

6

21

20

12

11

13

2

22

21

20

4

12

11

20

21

13

11

12

4

3

1

11 Nm

8

4

Removal steps

+

G 1. Rocker shaft cap

B

2. Seal cap A

3. Seal cap C

4. Intake rocker arm assembly A

5. Nut

6. Adjusting screw

7. Intake rocker arm H

8. Piston H

9. Piston spring H

10. Intake T-lever

+

G 11. Spring guide

A

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Apply engine oil to all

moving parts before

installation.

12. Wave washer

13. Exhaust rocker arm assembly A

14. Nut

15. Adjusting screw

16. Exhaust rocker arm H

17. Piston H

18. Piston spring H

19. Exhaust T-lever L

+

G 20. Spring guide

A

21. Wave washer

22. Camshaft holder

Page 49

11A-11-2

6A1 ENGINE (E-W) -

Rocker Arm and Rocker Shaft Cap <MIVEC>

T-lever

Either side may be out

6

5

Waved washer

2

1

Spring guide

4

3

Concave

side

6AE0247

10

8

7

9

6AE0249

INSTALLATION SERVICE POINTS

+

AG SPRING GUIDE INSTALLATION

(1) Install the spring guide with the concave side toward

the rocker arm. The waved washer may be installed with

either side out.

+

BG ROCKER SHAFT CAP INSTALLATION

(1) Tighten the bolts in the sequence shown.

(2) Make sure that each rocker arm moves smoothly.

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 50

6A1 ENGINE (E-W) -

Cylinder Head and Valves

12. CYLINDER HEAD AND VALVES

REMOVAL AND INSTALLATION <SOHC>

5

12

16

19

11

4

6

13

20

17

15

1

14

10

11A-12-1

8

9

2

3

18

7

Apply engine oil to all

moving parts before

installation.

Removal steps

GA++

GB++

GB++

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

G 1. Cylinder head bolt

D

2. Cylinder head

3. Cylinder head gasket

G 4. Retainer lock

C

5. Valve spring retainer

+

G 6. Valve spring

B

7. Intake valve

G 8. Retainer lock

C

9. Valve spring retainer

+

G 10. Valve spring

B

GC++

GC++

11. Exhaust valve

G 12. Valve stem seal

A

13. Valve spring seat

G 14. Valve stem seal

A

15. Valve spring seat

16. Intake valve guide

17. Exhaust valve guide

18. Intake valve seat

19. Exhaust valve seat

20. Cylinder head

Page 51

11A-12-2

6A1 ENGINE (E-W) -

REMOVAL AND INSTALLATION <MIVEC>

1

5

9

10

15

8

14

17

Cylinder Head and Valves

4

12

6

13

16

Apply engine oil to all

moving parts before

installation.

18

7

19

20

11

2

3

Removal steps

GA++

GB++

GB++

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

G 1. Cylinder head bolt

D

2. Cylinder head

3. Cylinder head gasket

G 4. Retainer lock

C

5. Valve spring retainer

+

G 6. Valve spring

B

7. Intake valve

G 8. Retainer lock

C

9. Valve spring retainer

+

G 10. Valve spring

B

G

+ 11. Exhaust valve

D

GC++

GC++

G 12. Valve stem seal

A

13. Valve spring seat

G 14. Valve stem seal

A

15. Valve spring seat

16. Intake valve guide

17. Exhaust valve guide

18. Intake valve seat

19. Exhaust valve seat

20. Cylinder head

Page 52

6A1 ENGINE (E-W) -

Cylinder Head and Valves

11A-12-3

<SOHC>

MB991653

<MIVEC>

MB991653

<SOHC>

6AE0166

6AE0408

REMOVAL SERVICE POINTS

PRECAUTION FOR REMOVED PARTS

Keep removed parts in order according to the cylinder number

and intake/exhaust side.

G

A+ CYLINDER HEAD BOLT REMOVAL

(1) Using the special tool, loosen the cylinder head bolts.

Loosen evenly, little by little.

G

B+ RETAINER LOCK REMOVAL

(1) Store removed valves, springs and other parts, tagged

to indicate their cylinder Nos. and location for reassembly.

<MIVEC>

MD998772

MD998735

MD998772

6AE0167

MD998784

6AE0253

6EN1068

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 53

11A-12-4

6A1 ENGINE (E-W) -

G

C+ VALVE STEM SEAL REMOVAL

(1) Do n ot reuse removed valve stem seals.

6AE0082

G

D+ VALVE HANDLING PRECAUTIONS

(1) Sodium reacts violently with water or moisture generation

(2) Handling of Sodium-filled Exhaust Valves

(3) How to Neutralize Sodium

Cylinder Head and Valves

heat and liberating hydrogen. It must be handled with

utmost care because otherwise the following dangerous

conditions may result:

Loss of eyesight if sodium gets in eyes.

Burns if sodium contact skin.

Fire hazard.

Sodium-filled exhaust valves are not dangerous and may

be handled in the same way as ordinary valves unless

they are broken.

Never try to break the valves and expose sodium to the

air. When worn exhaust valves are to be discarded, have

them disposed of by a salvage company equipped with

special disposal system, notifying them that the valves

contain sodium.

Should the exhaust valves be broken, neutralize sodium

using the method described below, and discard the valves

in the same way as ordinary valves.

Place a container filled with more than 10 liters of water

in a well ventilated large space.

Wear rubber gloves and goggles, and carefully take out

broken valves from the cylinder head.

Put a broken valve in the water-filled container and quickly

get away from the container at least 2 or 3 m.

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 54

Stem seals for intake

valves: Silver

<SOHC>

MD998774

6A1 ENGINE (E-W) -

INSTALLATION SERVICE POINTS

Stem seals

for exhaust

valves: Black

7EN0763

+

AG VALVE STEM SEAL INSTALLATION

(1) Install the valve spring seat.

(2) Use the special tool to fit a new stem seal on the valve

Cylinder Head and Valves

11A-12-5

guide.

NOTE

Valve stem seals for intake valves are different from those

for exhaust valves. They are identified by colors of their

spring sections as follows:

Stem seals for intake valves: Silver

Stem seals for exhaust valves: Black

Caution

J

Do not reuse the valve stem seal.

J

Always use the special tool to install the valve

stem seal. If the seal is improperly fitted, engine

oil may work its way down along the valve stem.

<MIVEC>

Painted

end

6AE0169

MD998775

6AE0409

Spring

retainer

Stem seal

Spring

seat

6EN0437

+

BG VALVE SPRING INSTALLATION

(1) Install the valve spring with the painted e nd on the rocker

arm side.

+

<SOHC>

CG RETAINER LOCK INSTALLATION

(1) The valve spring, if excessively compressed, causes the

bottom end of retainer to be in contact with, and damage,

the stem seal.

MD998772

6AE0167

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 55

11A-12-6

<MIVEC>

6A1 ENGINE (E-W) -

MD998784

Cylinder Head and Valves

MD998772

MD998735

Length of shank

6AE0253

6EN1068

9EN0251

+

DG CYLINDER HEAD BOLT INSTALLATION

(1) When installing the cylinder head bolts, check that the

shank length of each bolt meets the limit. If the limit is

exceeded, replace the bolts.

Limit: max. 96.4 mm

(2) Install the washers as illustrated.

(3) Apply engine oil to the bolt threads and washers.

(4) Retighten the loosened bolts to a torque of 20 Nm in

the specified tightening sequence.

6AE0392

MB991614

(5) Make paint marks on the cylinder head bolts and cylinder

head.

(6) Give a 120è turn to th e bolts in the specified tightening

sequence.

Caution

120

è

J

J

6AE0339

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

If the bolts are tightened by an angle of less than

120è, they may not hold the cylinder head with

sufficient strength.

If a bolt is overtightened, completely remove all

the bolts and carry out the installation procedure

again from step (1).

Page 56

6A1 ENGINE (E-W) -

INSPECTION

CYLINDER HEAD

(1) Check the cylinder head gasket surface for flatness by

(2) If the service limit is exceeded, correct to meet the

6AE0083

Cylinder Head and Valves

11A-12-7

using a straightedge and thickness gauge.

Standard value: 0.03 mm

Limit: 0.2 mm

specification.

Grinding limit: *0.2 mm

*Includes/combined with cylinder block grinding

Cylinder head height (Specification when new):

119.9 - 120.1 mm <SOHC>

119.6 - 119.8 mm <MIVEC>

Valve seat

contact

Margin

6EN0542

VALVE

(1) Check the valve face for correct contact. If incorrect, reface

using a valve refacer. Valve should make a uniform contact

with the seat at the centre of valve face.

(2) If the margin is smaller than the service limit, replace

the valve.

Standard value mm

Intake 1.0 0.5

Exhaust 1.3 0.8

Limit mm

(3) Measure the overall height of the valve. If the specified

limit is exceeded, replace the valve.

Intake SOHC

MIVEC

Exhaust SOHC

MIVEC

Standard value

mm

113.02 112.52

112.37 111.87

115.32 114.82

110.74 110.74

Limit mm

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 57

11A-12-8

6A1 ENGINE (E-W) -

VALVE SPRING

Out of square

(1) Measure the valve spring’s free height. If the measurement

Cylinder Head and Valves

is less than specified, replace the spring.

Free

height

1EN0264

Valve stem end

Valve stem

projection

Standard value

mm

SOHC 49.9 48.9

MIVEC 51.5 50.5

Limit mm

(2) Measure the squareness of the spring. If the measurement

exceeds the specified limit, replace the spring.

Standard value: 2b or less

Limit: 4

b

VALVE SEAT

(1) Assemble the valve, then measure the valve stem

projection between the end of the valve stem and the

spring seating surface. If the measurement exceeds the

specified limit, replace the valve seat.

Valve

guide

Spring seating

surface

DEN0212

1EN0279

Standard value Limit mm

mm

48.45SOHC 48.95

MIVEC 48.40 48.90

VALVE GUIDE

(1) Measure the clearance between the valve guide and valve

stem. If the limit is exceeded, replace the valve guide

or valve, or both.

Standard value:

Intake: 0.02 - 0.05 mm

Exhaust: 0.04 - 0.07 mm

Limit:

Intake: 0.10 mm

Exhaust: 0.15 mm

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 58

6A1 ENGINE (E-W) -

Cylinder Head and Valves

11A-12-9

0.9 -

65

b

15

b

Cut away

1.3 mm

Valve seat

height

44

0.5 -

b

1.0 mm

44

0.9 -

b

0.5 -

1.3 mm

65

15

b

1EN0105

1.0 mm

1EN0274

VALVE SEAT RECONDITIONING PROCEDURE

(1) Before correcting the valve seat, check the clearance

between the valve guide and valve. If necessary, replace

b

the valve and/or valve guide.

(2) Using the appropriate special tool or seat grinder, correct

the valve seat to achieve the specified seat width and

angle.

(3) After correcting the valve seat, lap the valve and valve

seat using lapping compound. Then, check the valve

stem projection (refer to VALVE SEAT in INSPECTION).

VALVE SEAT REPLACEMENT PROCEDURE

(1) Cut the valve seat to be replaced from the inside to thin

the wall thickness. Then, remove the valve seat.

(2) Rebore the valve seat hole in the cylinder head to a

selected oversize valve seat diameter.

Intake valve seat hole diameter

0.3 O.S. <SOHC>: 29.80 - 29.82 mm

<MIVEC>: 32.30 - 32.32 mm

0.6 O.S. <SOHC>: 30.10 - 30.12 mm

<MIVEC>: 32.60 - 32.62 mm

Exhaust valve seat hole diameter

0.3 O.S. <SOHC>: 27.80 - 27.82 mm

<MIVEC>: 29.80 - 29.82 mm

0.6 O.S. <SOHC>: 28.10 - 28.12 mm

<MIVEC>: 30.10 - 30.12 mm

Oversize valve seat

hole diameter

1EN0275

(3) Before fitting the valve seat, either heat the cylinder head

up to approximately 2 50bC or cool the valve seat in liquid

nitrogen, to prevent the cylinder head bore from galling.

(4) Correct the valve seat to the specified width and angle.

VALVE GUIDE REPLACEMENT

(1) Force the valve guide out toward the cylinder block using

a press.

(2) Machine the valve guide hole in the cylinder head to

the size of the oversize valve guide to be installed.

Caution

J

Do not use the valve guide of the same size as

the removed one.

Valve guide hole diameters in cylinder head

0.05 O.S.: 11.05 - 11.07 mm

0.25 O.S.: 11.25 - 11.27 mm

0.50 O.S.: 11.50 - 11.52 mm

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 59

11A-12-10

6A1 ENGINE (E-W) -

Cylinder Head and Valves

<SOHC>

14 mm

<DOHC>

19 mm

19 mm

1EN0106

6AE0254

(3) Press-fit the valve guide until it protrude specified value

(SOHC: 14 mm, DOHC: 19 mm) as shown in t he

illustration.

Caution

J

Press the valve guide from the cylinder head top

surface.

J

Valve guide for intake valve and that for exhaust

valve are different in length. (45.5 mm for intake

valve; 50.5 mm for exhaust valve)

(4) After the valve guide has been installed, insert a new

valve to check for smooth sliding motion.

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 60

6A1 ENGINE (E-W) -

Oil Pump Case and Oil Pan

13. OIL PUMP CASE AND OIL PAN

REMOVAL AND INSTALLATION <SOHC>

11A-13-1

Apply engine oil to all

moving parts before

installation.

22

14 Nm

21

1

10 Nm

25

26

18

44 Nm

12 Nm

20

19

14

24

23

17

16

19 Nm

15

9Nm

8

4

30 Nm

5

7Nm

6

2

7

21 Nm

68 Nm

3

39 Nm

10

9

9Nm

Removal steps

+

G 1. Oil pressure switch

I

+

G 2. Oil filter

H

3. Oil filter cover

4. Water hose (for Europe and GCC)

5. Water pipe (for Europe and GCC)

6. Water pipe (for Europe and GCC)

7. Bolt (for Europe and GCC)

+

G 8. Oil cooler (for Europe and GCC)

G

9. Drain plug

+

G 10. Gasket

F

11. Oil level sensor (For Europe)

12. Cover

+

G 13. Oil pan lower

D

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

11

12

7Nm

13

7Nm

+

G 14. Oil pan upper

D

15. Buffle plate

16. Oil screen

17. Gasket

18. Relief plug

19. Relief spring

20. Relief plunger

+

G 21. Oil seal

C

+

G 22. Oil pump case

B

23. O-ring

24. Oil pump case cover

+

G 25. Outer rotor

A

+

G 26. Inner rotor

A

Page 61

11A-13-2

6A1 ENGINE (E-W) -

REMOVAL AND INSTALLATION <MIVEC>

17

18

14

Oil Pump Case and Oil Pan

2

21 Nm

14 Nm

13

1

10 Nm

39 Nm

11

10

4

12

15

44 Nm

19 Nm

6

5

16

12 Nm

9

3

7Nm

8

7

7Nm

Apply engine oil to all

moving parts before

installation.

Removal steps

+

G

1. Oil pressure switch

I

+

G

2. Oil filter

H

3. Oil filter cover

4. Drain plug

+

G

5. Gasket

GA++

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

F

G

6. Oil pan

E

7. Oil screen

8. Gasket

9. Buffle plate +AG 18. Inner rotor

10. Relief plug

11. Relief spring

12. Relief plunger

+

G 13. Oil seal

C

+

G 14. Oil pump case

B

15. O-ring

16. Oil pump case cover

+

G 17. Outer rotor

A

Page 62

6A1 ENGINE (E-W) -

REMOVAL SERVICE POINT

G

MD998727

(1) Knock the special tool deeply between the oil pan and

(2) Hitting the side of the special tool, slide th e special tool

6AE0087

INSTALLATION SERVICE POINTS

+

(1) Apply engine oil to the rotors. Then, install the rotors

Oil Pump Case and Oil Pan

11A-13-3

A+ OIL PAN REMOVAL

the cylinder block.

along the oil pan to remove it.

AG INNER ROTOR / OUTER ROTOR INSTALLATION

ensuring that the alignment dots made at disassembly

are properly aligned.

3 mm diameter

bead sealant

MD998717

6AE0091

6AE0092

6AE0093

+

BG SEALANT APPLICATION TO OIL PUMP CASE

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent

+

CG OIL SEAL INSTALLATION

(1) Apply engine oil to the oil seal lip.

Using the special tool, knock the oil seal into the oil pump

case.

Mitsubishi Motors Corporation Feb. 1997 PWEE9622

K

Page 63

11A-13-4

6A1 ENGINE (E-W) -

+

(1) Clean the cylinder block and oil pan gasket application

(2) Install the oil pan within 15 minutes after FIPG has been

Oil Pump Case and Oil Pan

DG OIL PAN INSTALLATION <SOHC>

surfaces.

applied to the entire flange surfaces of the oil pan.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent

4

f

Bolt

hole

4 diametermm

bead sealant

Groove

+

EG OIL PAN INSTALLATION <MIVEC>

(1) Clean the cylinder block and oil pan gasket application

surfaces.

(2) Install the oil pan within 15 minutes after FIPG has been