Page 1

ENGINE

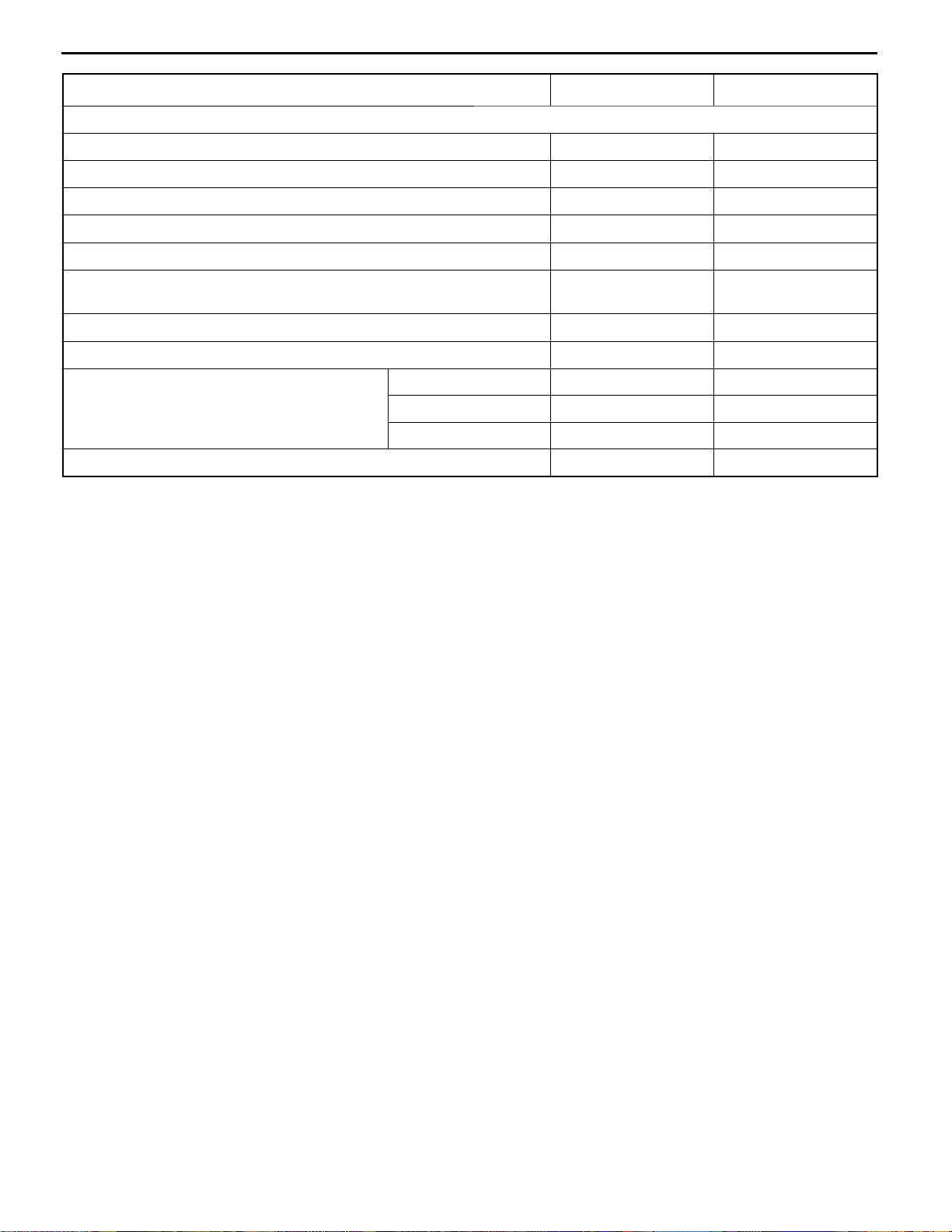

4G1 SERIES

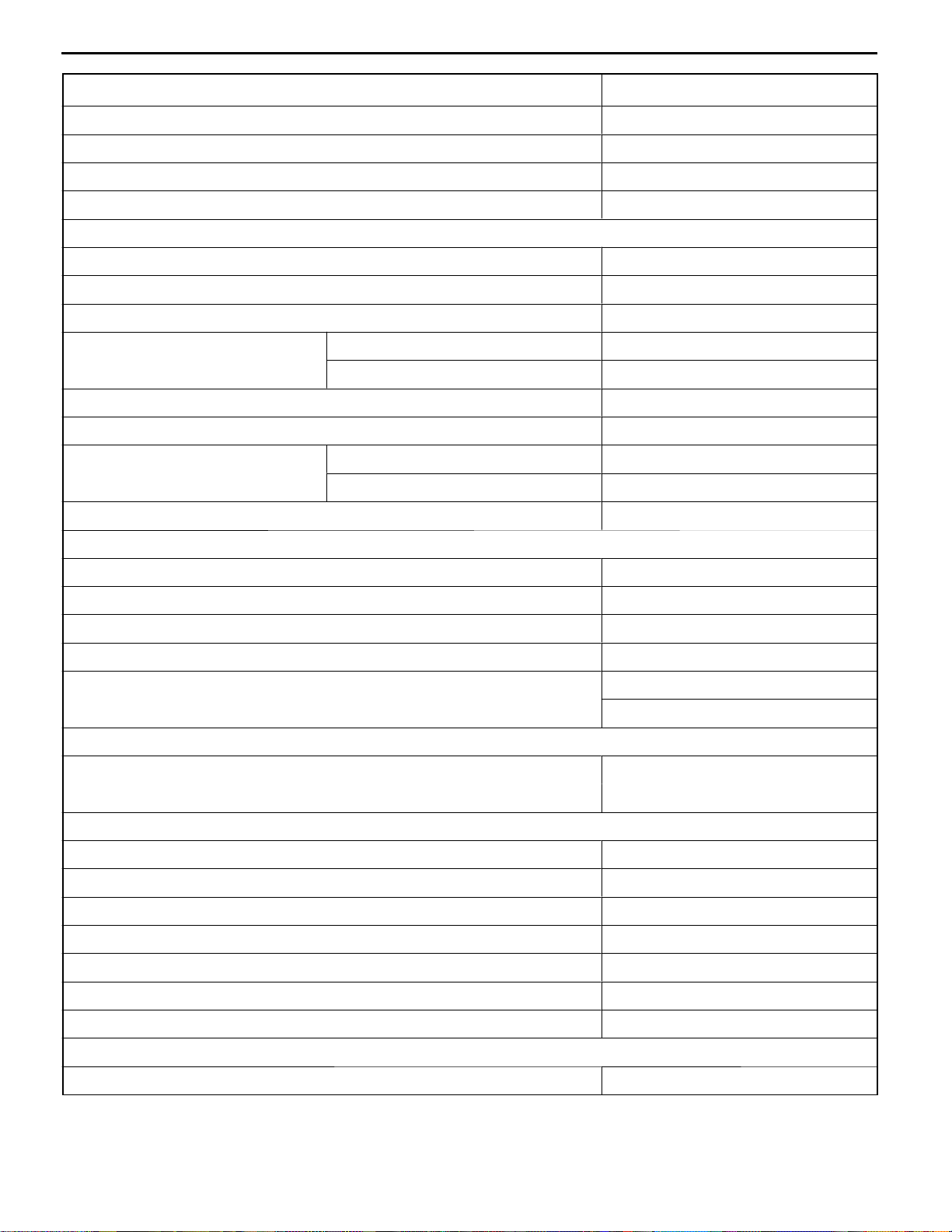

CONTENTS

11A-0-1

GENERAL INFORMATION 11A-0-3

1. SPECIFICATIONS 11A-1-1

SERVICE SPECIFICATIONS 11A-1-1

REWORK DIMENSIONS 11A-1-3

TORQUE SPECIFICATIONS 11A-1-4

NEW TIGHTENING METHOD-BY USE OF BOLTS TO BE

TIGHTENED IN PLASTIC AREA 11A-1-6

SEALANT 11A-1-6

FORM-IN-PLACE GASKET 11A-1-7

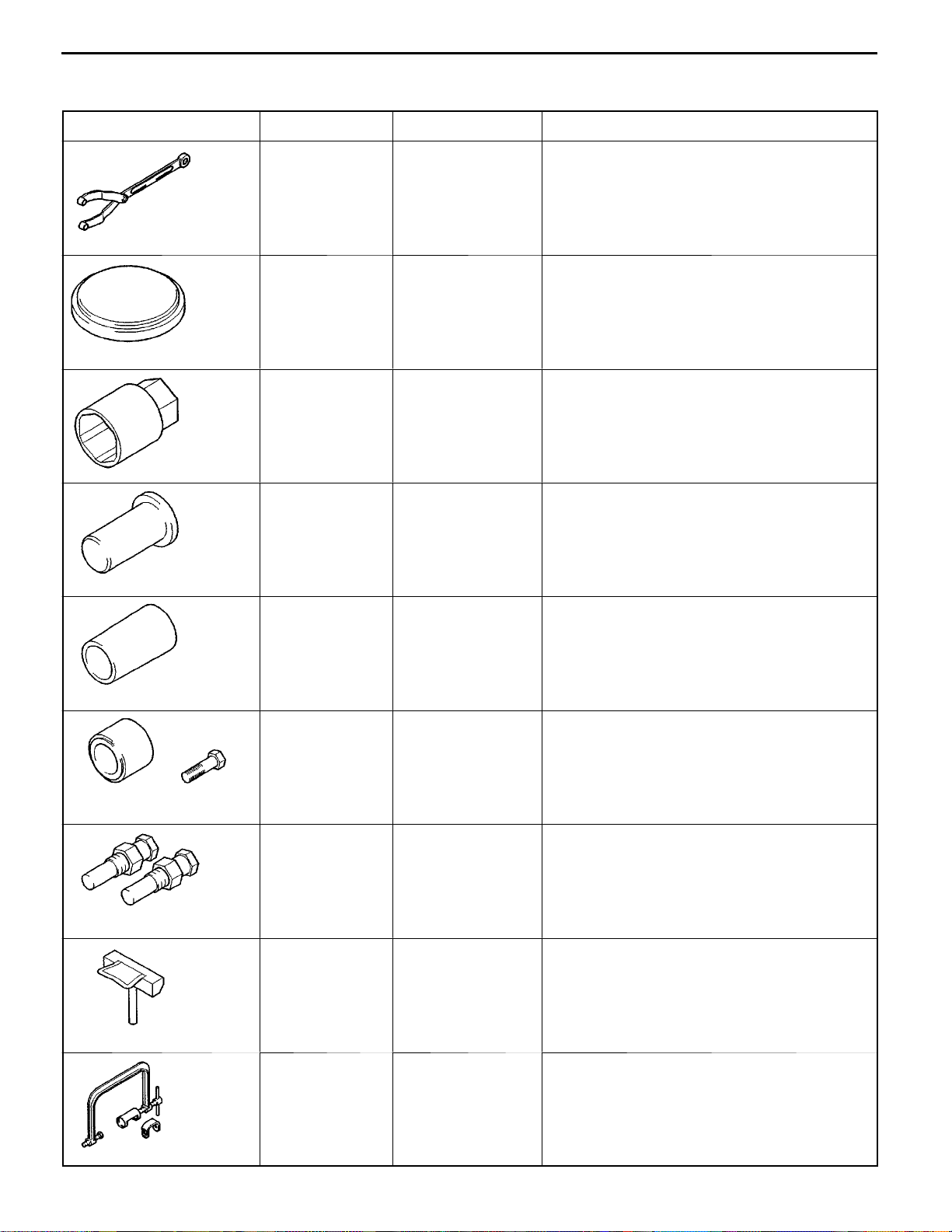

2. SPECIAL TOOLS 11A-2-1

3. ALTERNATOR AND IGNITION SYSTEM 11A-3-1

4. TIMING BELT 11A-4-1

5. FUEL AND EMISSION CONTROL SYSTEM 11A-5-1

6. WATER PUMP AND WATER HOSE 11A-6-1

7. INTAKE AND EXHAUST MANIFOLD 11A-7-1

8. ROCKER ARMS AND CAMSHAFT 11A-8-1

........................................................

......................................................

...........................................

.................................................

....................................

........................................

.....................................

...............................

......................................

.................................................

........................

....................

.............................

............................

..............................

9. CYLINDER HEAD AND VALVES 11A-9-1

10. OIL PUMP AND OIL PAN 11A-10-1

11. PISTON AND CONNECTING ROD 11A-11-1

12. CRANKSHAFT, CYLINDER BLOCK 11A-12-1

E

Nov. 1995Mitsubishi Motors Corporation

.......................................

.................................

..............................

...........................

PWEE9520

Page 2

11A-0-2

NOTES

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 3

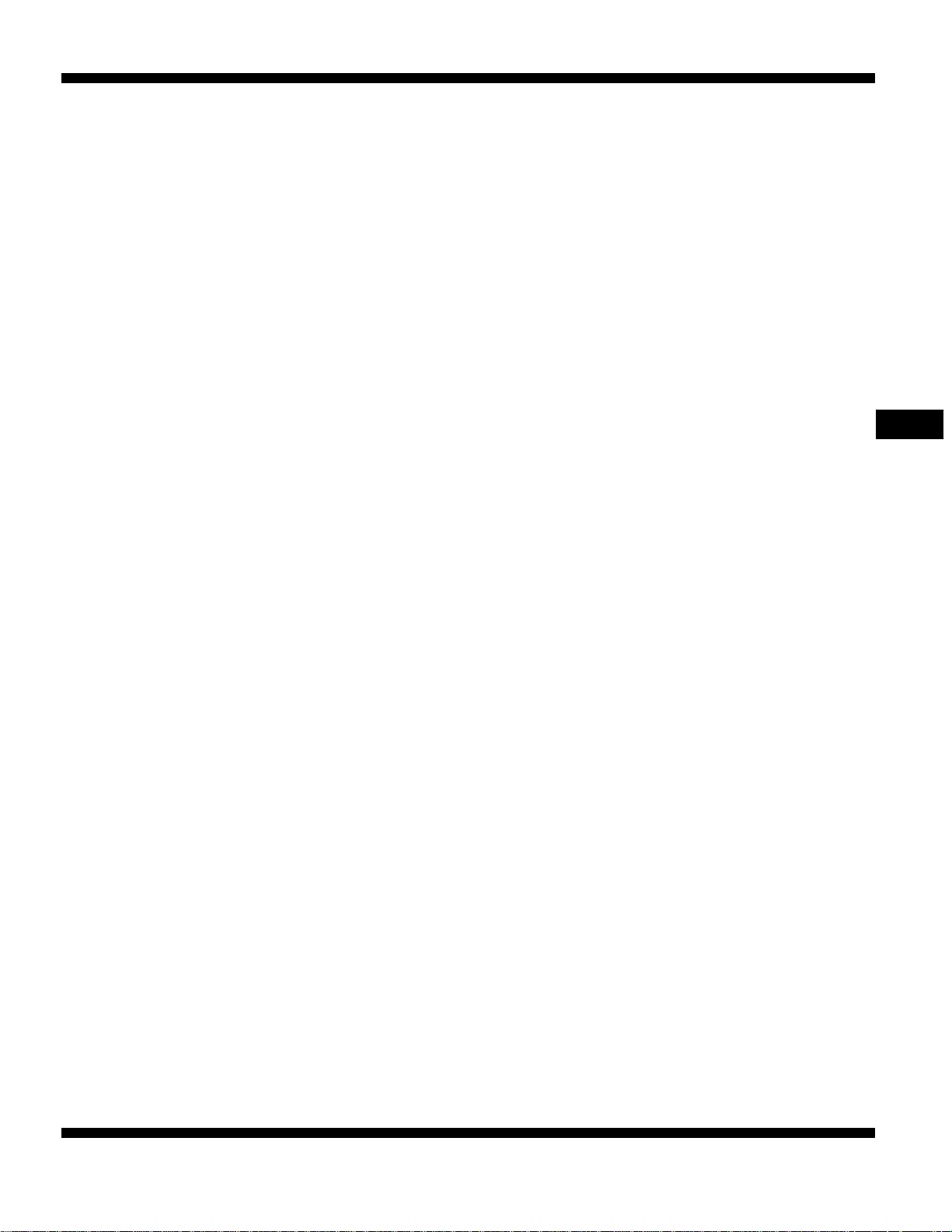

4G1 ENGINE (E-W) -

GENERAL INFORMATION

General Information

11A-0-3

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 4

11A-0-4

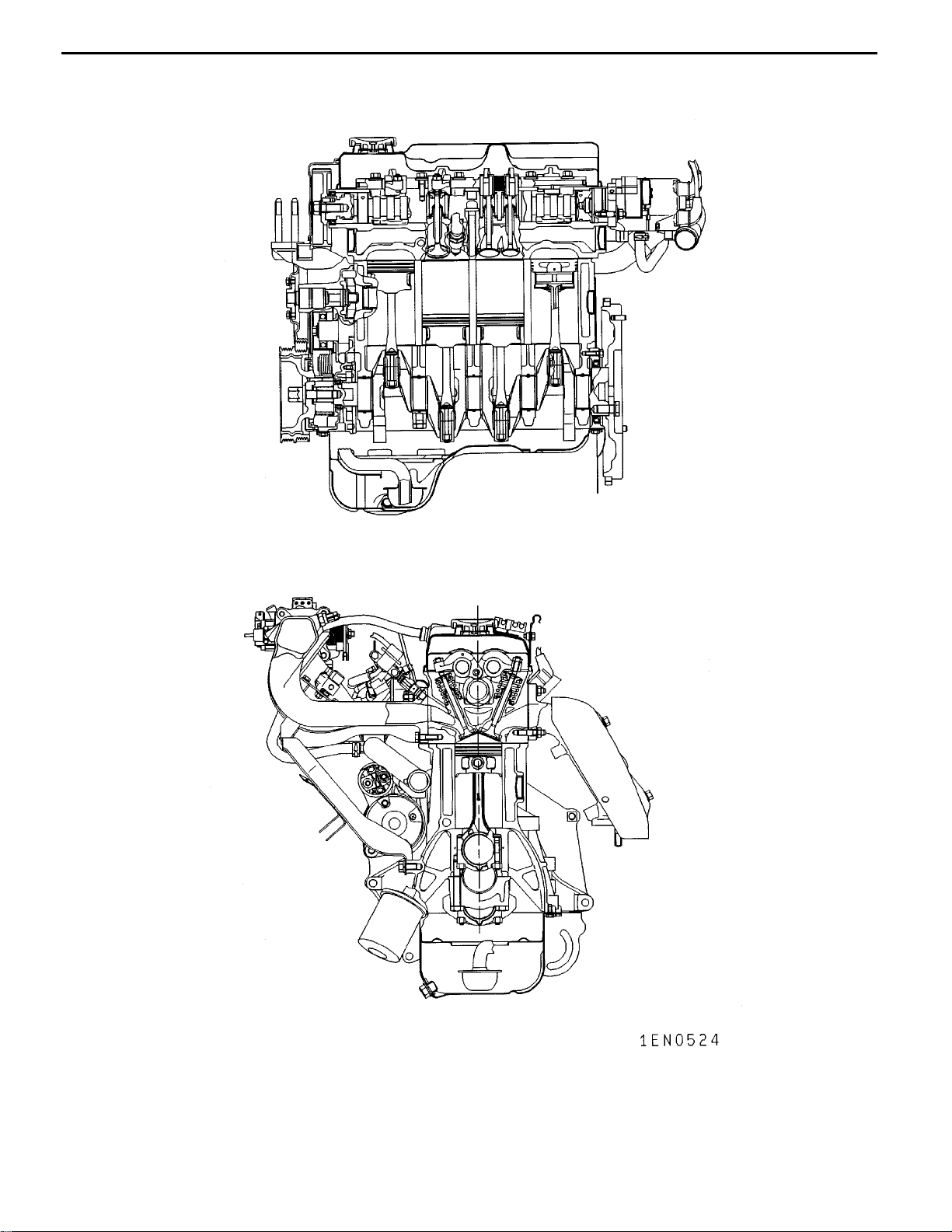

4G1 ENGINE (E-W) -

General Information

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 5

4G1 ENGINE (E-W) -

General Information

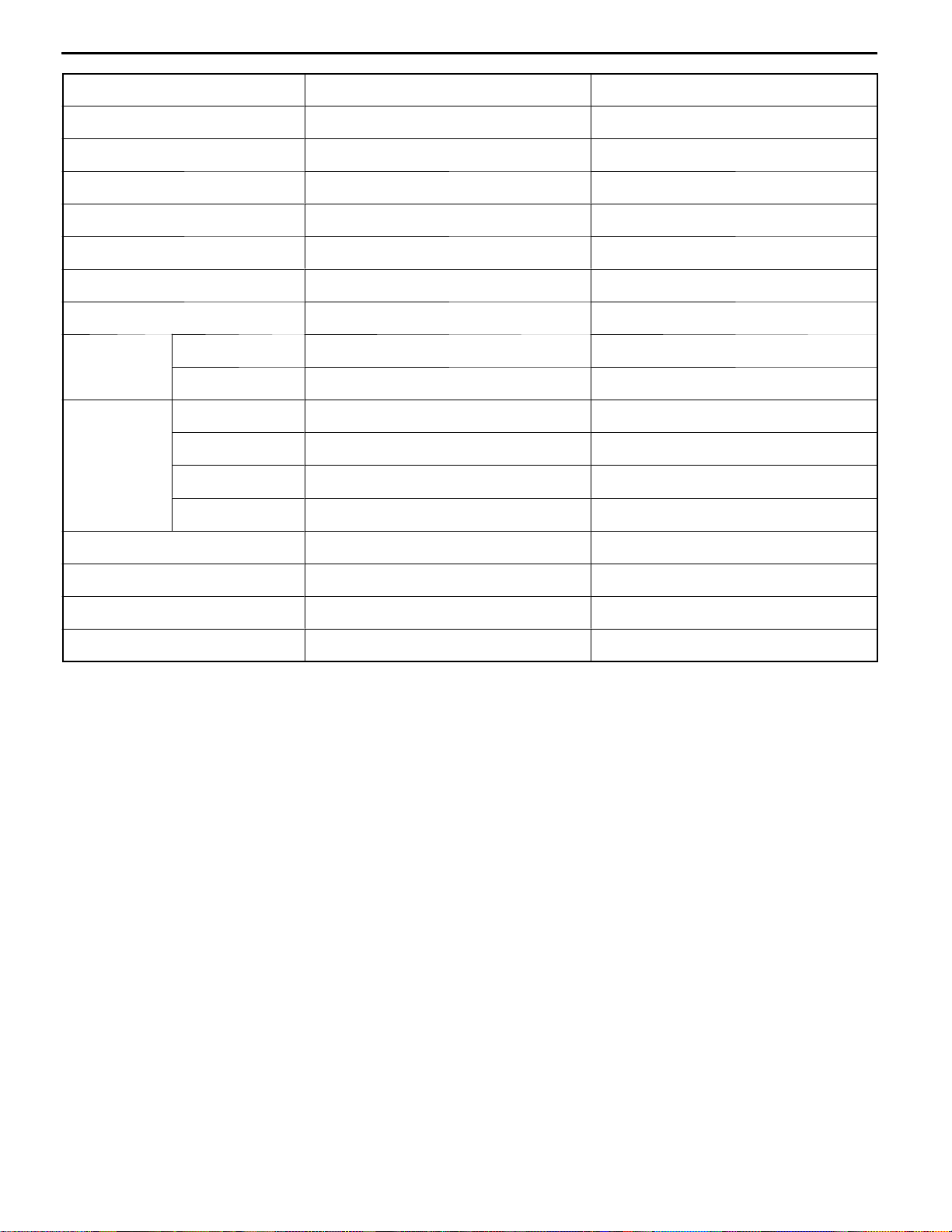

Descriptions 4G13 12-VALVE- CARBURETOR 4G13 12-VALVE- MPI

Type In-line OHV, SOHC In-line OHV, SOHC

Number of cylinders 4 4

Combustion chamber Pentroof type Pentroof type

11A-0-5

Total displacement dm

3

1,299 1,299

Cylinder bore mm 71.0 71.0

Piston stroke mm 82.0 82.0

Compression ratio 9.5 9.5

Number of Intake 8 8

valves

Exhaust 4 4

V alve timing Intake opens BTDC 14

Intake closes ABDC 48

Exhaust opens BBDC 55

Exhaust closes ATDC 13

_

_

_

_

BTDC 19

ABDC 43

BBDC 60

ATDC 8

_

_

_

_

Lubrication system Pressure feed, full-flow filtration Pressure feed, full-flow filtration

Oil pump type Trochoid type Trochoid type

Cooling system Water-cooled, forced circulation Water-cooled, forced circulation

Water pump type Centrifugal impeller type Centrifugal impeller type

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 6

11A-0-6

4G1 ENGINE (E-W) -

General Information

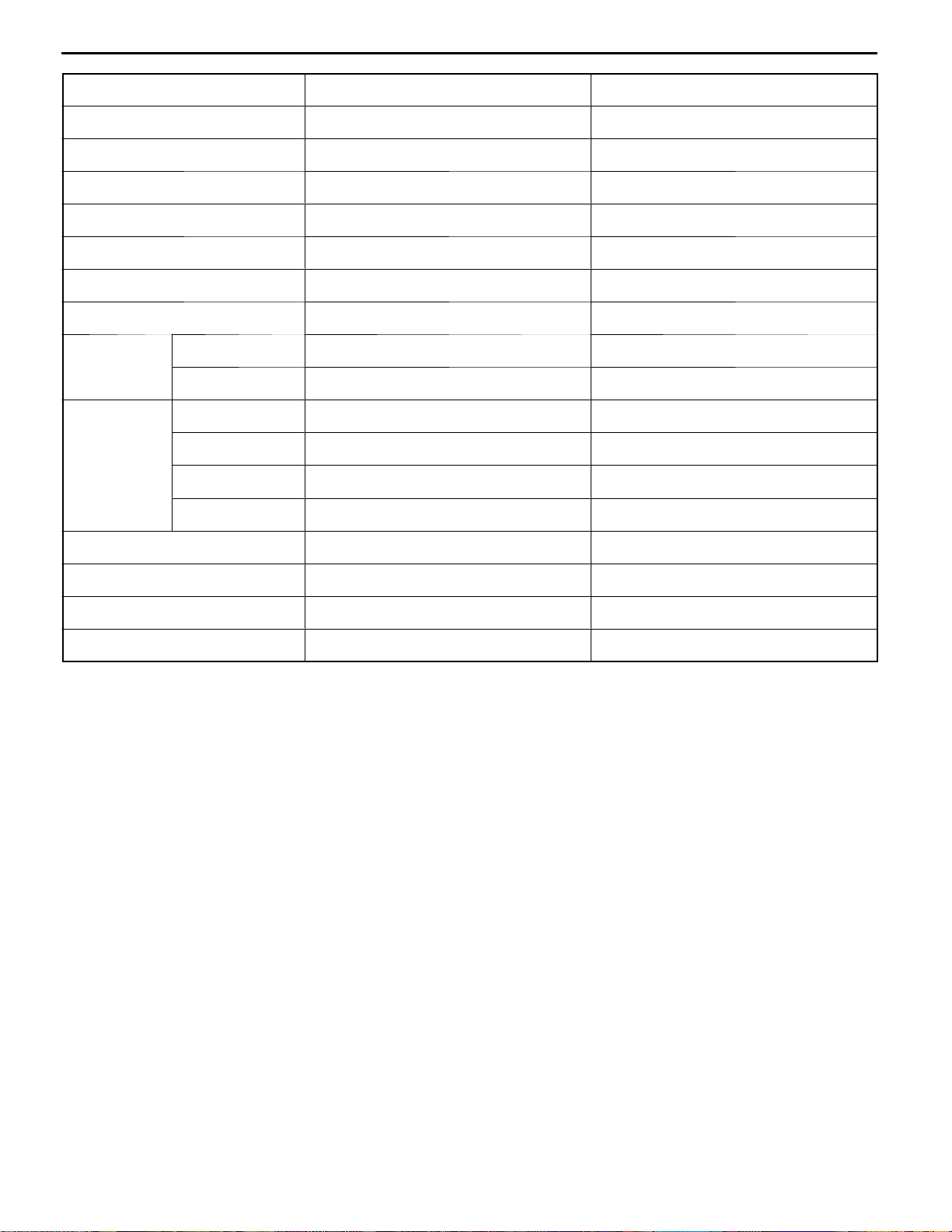

Descriptions 4G13 16-VALVE- MPI 4G18 16-VALVE- MPI

Type In-line OHV, SOHC In-line OHV, SOHC

Number of cylinders 4 4

Combustion chamber Pentroof type Pentroof type

Total displacement dm

3

1,299 1,584

Cylinder bore mm 71.0 76.0

Piston stroke mm 82.0 87.3

Compression ratio 10 9.5

Number of Intake 8 8

valves

Exhaust 8 8

V alve timing Intake opens BTDC 17

Intake closes ABDC 39

Exhaust opens BBDC 49

Exhaust closes ATDC 7

_

_

_

_

BTDC 17

ABDC 39

BBDC 49

ATDC 7

_

_

_

_

Lubrication system Pressure feed, full-flow filtration Pressure feed, full-flow filtration

Oil pump type Trochoid type Trochoid type

Cooling system Water-cooled, forced circulation Water-cooled, forced circulation

Water pump type Centrifugal impeller type Centrifugal impeller type

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 7

4G1 ENGINE (E-W) -

General Information

Descriptions 4G15-CARBURETTOR 4G15-MPI

Type In-line OHV, SOHC In-line OHV, DOHC

Number of cylinders 4 4

Combustion chamber Semi spherical type Pentroof type

11A-0-7

Total displacement dm

3

1,468 1,468

Cylinder bore mm 75.5 75.5

Piston stroke mm 82.0 82.0

Compression ratio 9.0 9.5

Number of Intake 8 8

valve

Exhaust 4 8

V alve timing Intake opens BTDC 14

Intake closes ABDC 48

Exhaust opens BBDC 55

Exhaust closes ATDC 13

_

_

_

_

BTDC 16

ABDC 40

BBDC 45

ATDC 15

_

_

_

_

Lubrication system Pressure feed, full-flow filtration Pressure feed, full-flow filtration

Oil pump type Trochoid type Trochoid type

Cooling system Water-cooled, forced circulation Water-cooled, forced circulation

Water pump type Centrifugal impeller type Centrifugal impeller type

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 8

NOTES

Page 9

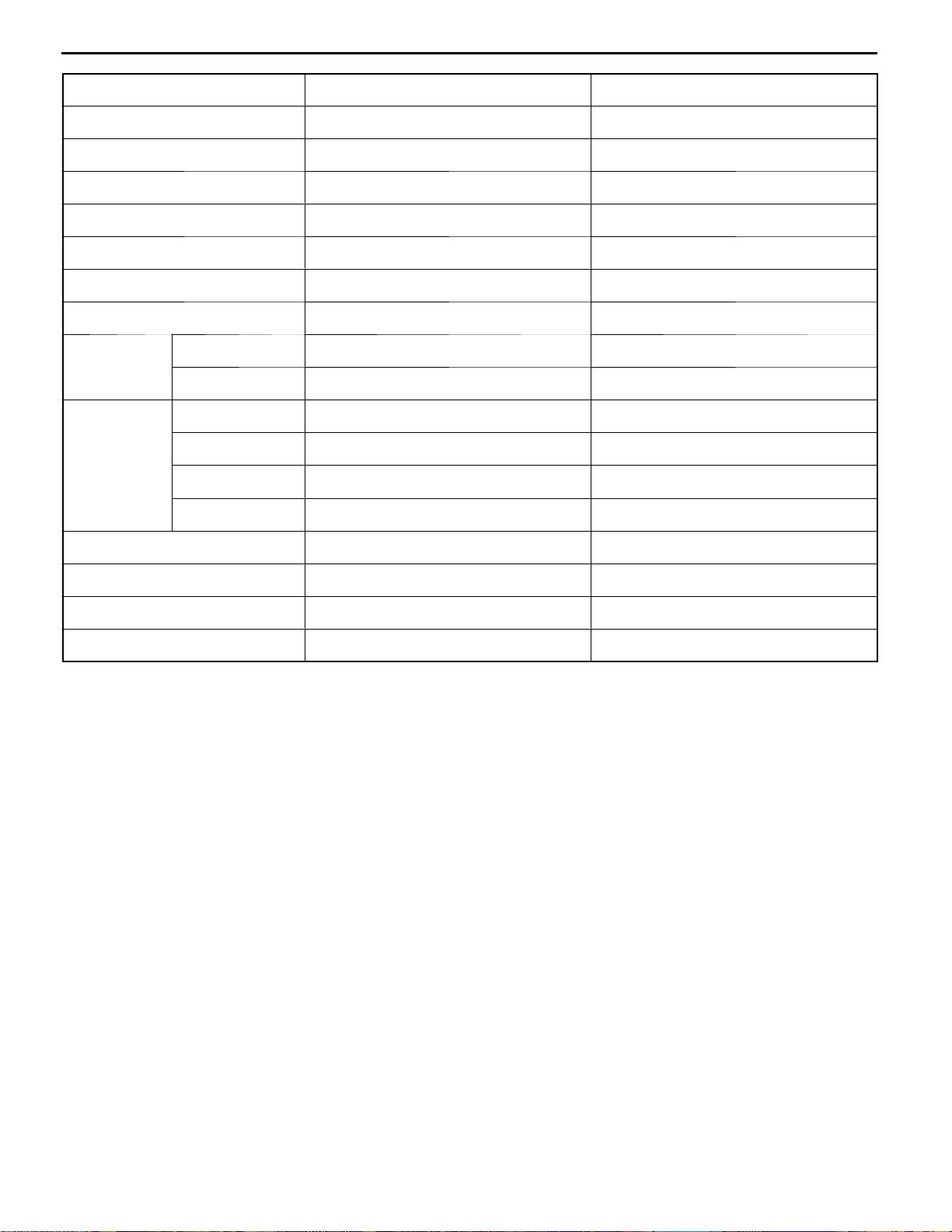

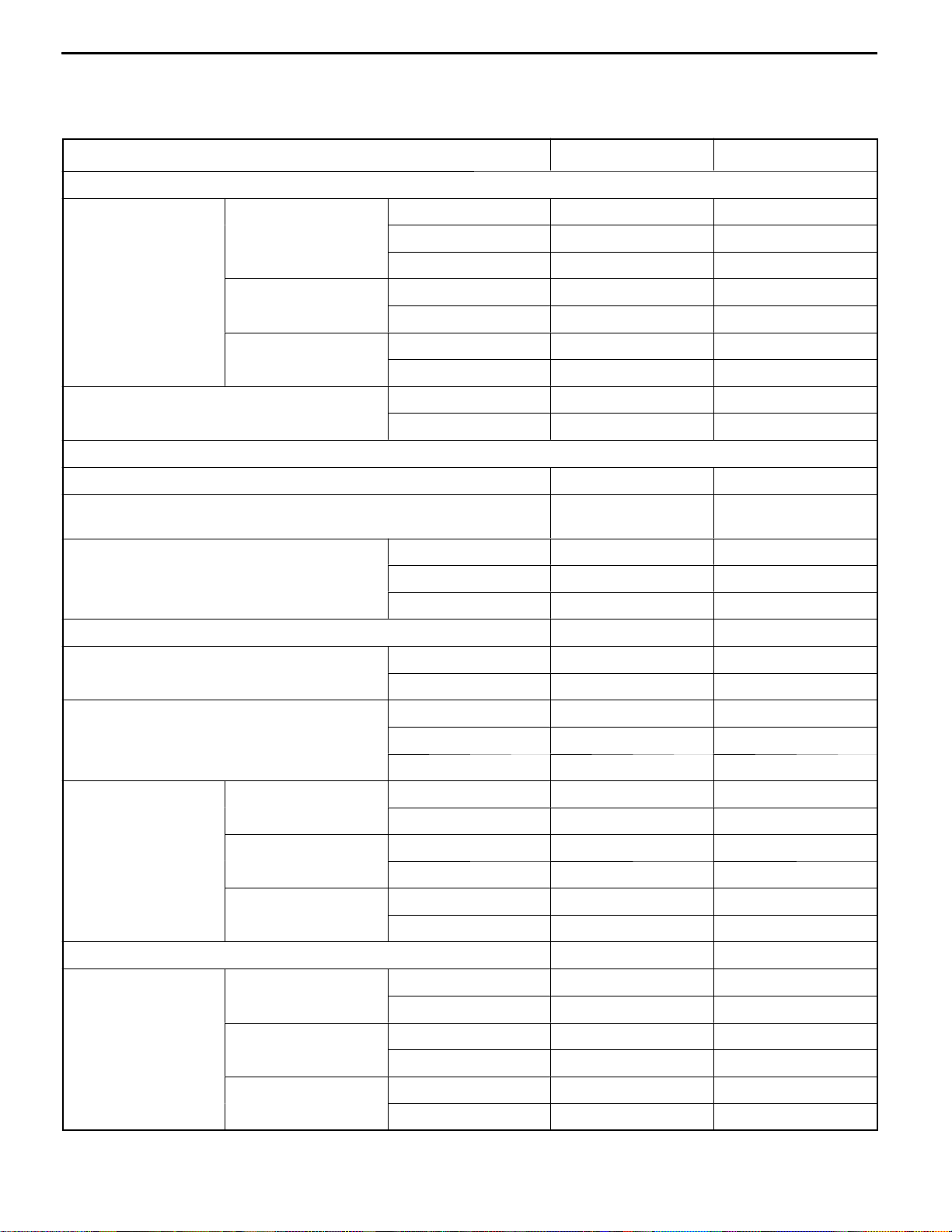

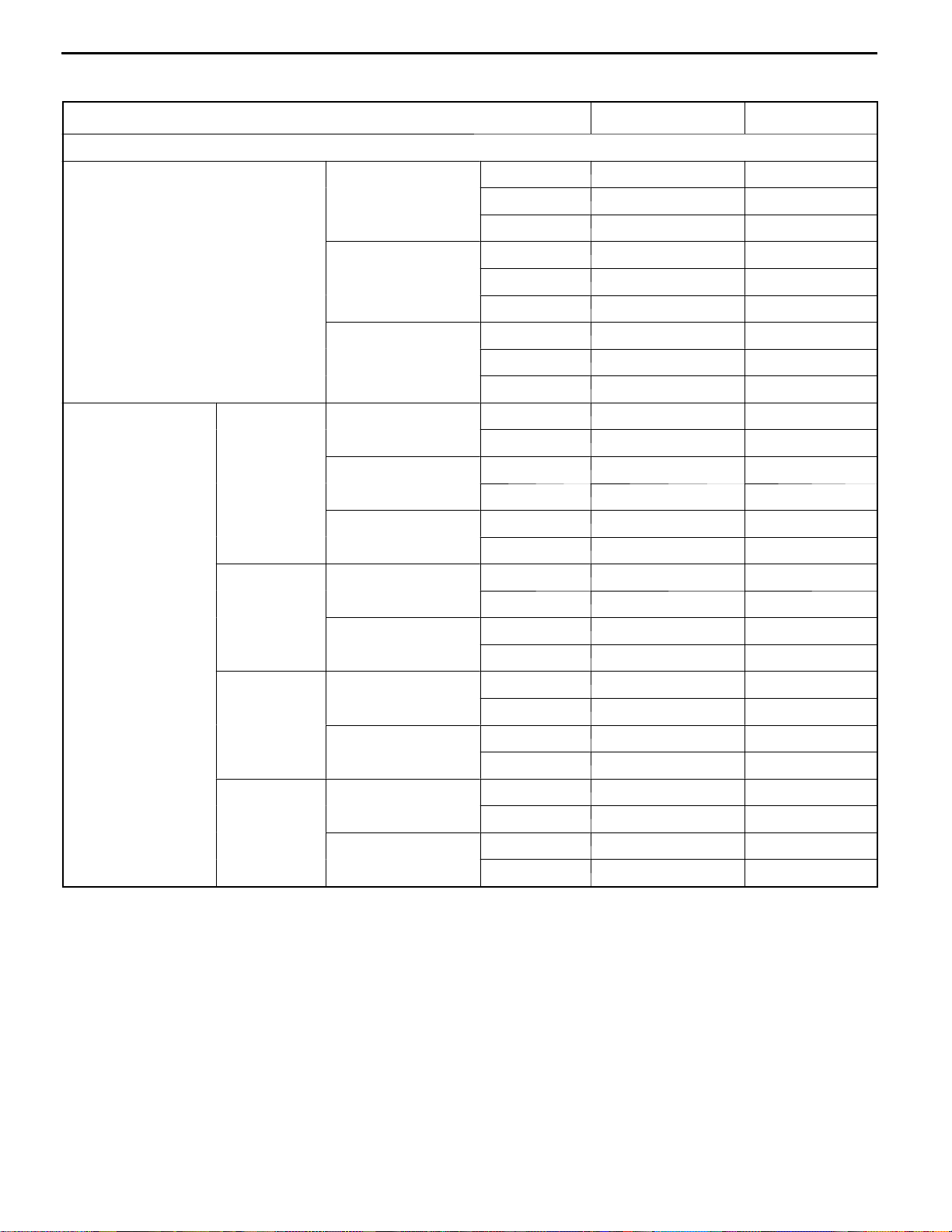

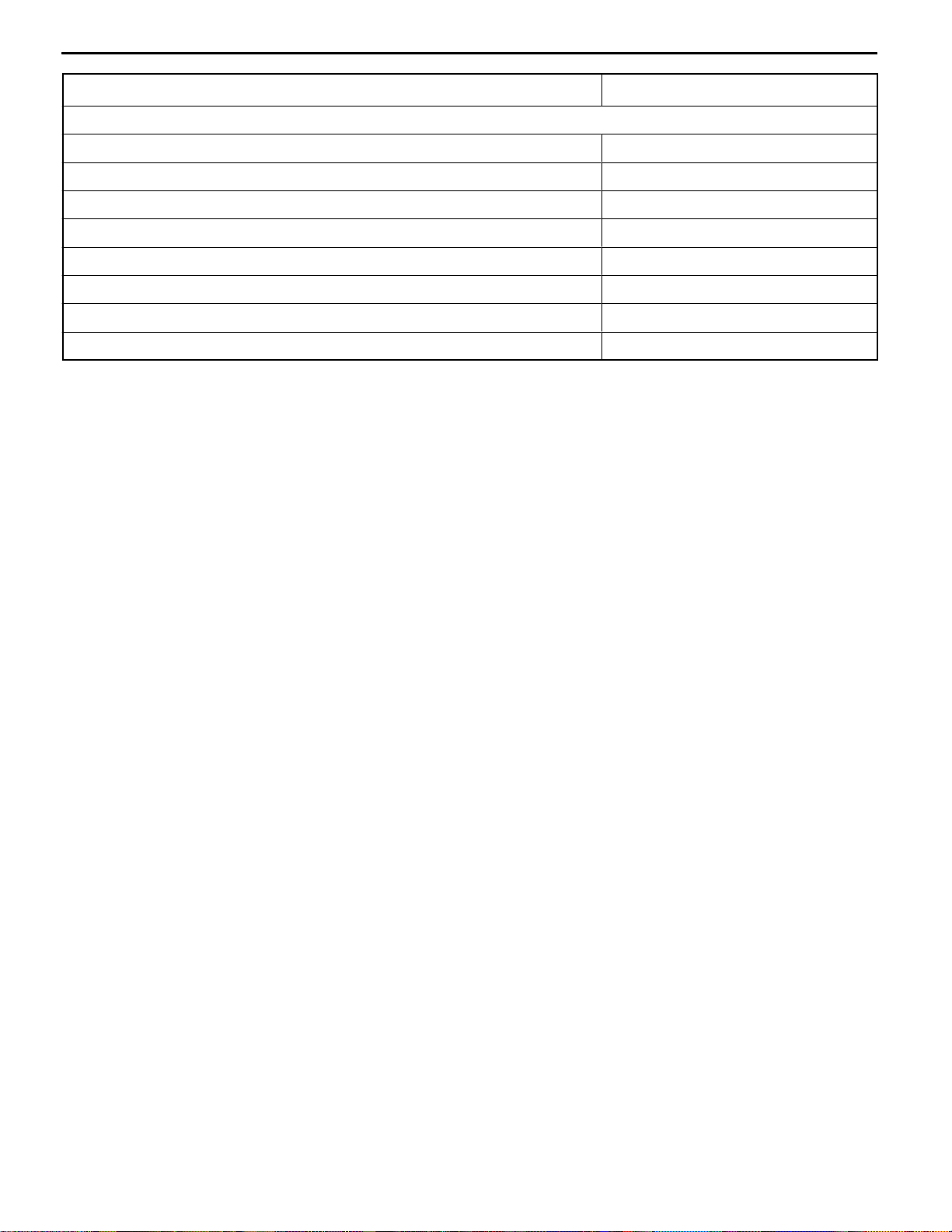

4G1 ENGINE (E-W) -

Specifications

1. SPECIFICATIONS

SERVICE SPECIFICATIONS

Item Standard Limit

Rocker arms, rocker shafts, and camshaft

11A-1-1

Camshaft cam SOHC 12-VALVE

height mm

SOHC 16-VALVE

DOHC

Camshaft journal diameter mm

Cylinder head and valves

Flatness of cylinder head gasket surface mm 0.05 or less -

Cylinder head gasket surface grinding limit (including grinding of

cylinder block gasket surface) mm

Cylinder head overall height mm

Cylinder head bolt nominal length mm - 103.2

V alve margin mm

Intake (primary) 38.78 38.28

Intake (secondary) 38.78 38.28

Exhaust 39.10 38.60

Intake 36.99 36.49

Exhaust 36.85 36.35

Intake 34.67 38.28

Exhaust 34.26 38.60

SOHC 45.93- 45.94 -

DOHC 25.95- 25.97 -

- 0.2

SOHC 12-VALVE 106.9- 107.1 -

SOHC 16-VALVE 119.9- 120.1 -

DOHC 131.9- 132.1 -

Intake 1.0 0.5

Exhaust 1.5 1.0

Valve stem diameter mm

V alve stem-to-guide SOHC 12-VALVE

clearance mm

SOHC 16-VALVE

DOHC

V alve face angle 45_- 45.5

V alve stem projec- SOHC 12-VALVE

tion mm

SOHC 16-VALVE

DOHC

SOHC 12-VALVE 6.6 -

SOHC 16-VALVE 5.5 -

DOHC 5.5 -

Intake 0.020- 0.050 0.10

Exhaust 0.050- 0.085 0.15

Intake 0.020 - 0.047 0.10

Exhaust 0.030 - 0.062 0.15

Intake 0.020- 0.047 0.10

Exhaust 0.030- 0.062 0.15

Intake 43.70 44.20

Exhaust 43.30 43.80

Intake 53.21 53.71

Exhaust 54.10 54.60

Intake 48.80 49.30

Exhaust 48.70 49.20

_

-

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

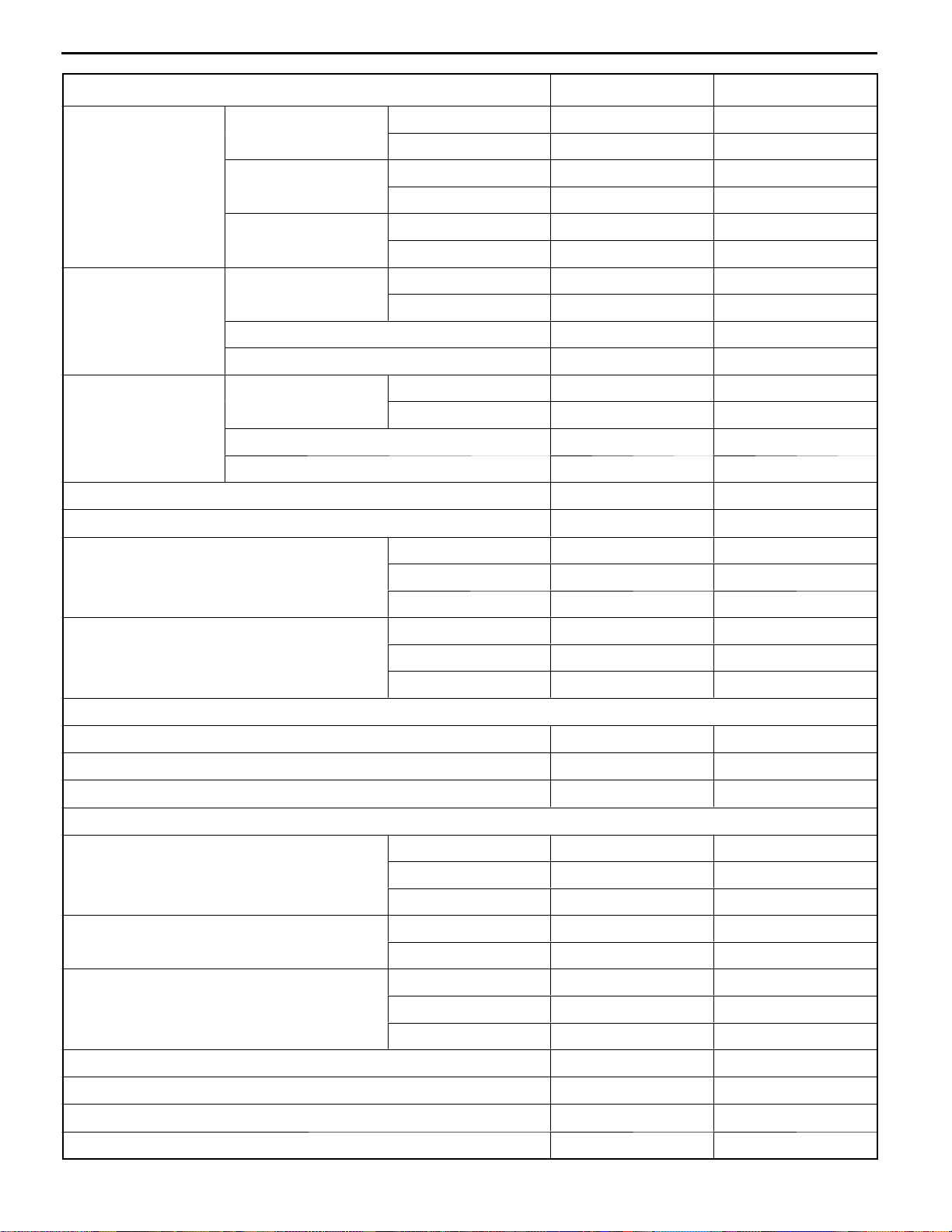

Page 10

11A-1-2

4G1 ENGINE (E-W) -

Specifications

Item LimitStandard

Overall valve length SOHC 12-VALVE

mm

SOHC 16-VALVE

Intake 100.75 100.25

Exhaust 101.05 105.55

Intake 111.56 111.06

Exhaust 114.71 114.21

DOHC

Intake 106.35 105.85

Exhaust 106.85 106.35

V alve spring free SOHC 12-VALVE

height mm

Intake 46.1 45.6

Exhaust 46.8 46.3

SOHC 16-VALVE 50.9 50.4

DOHC 49.1 48.6

Valve spring load/ SOHC 12-VALVE

installed height N/

mm

mm

Intake 226/40.0 -

Exhaust 284/39.6 -

SOHC 16-VALVE 216/44.2 -

DOHC 177/40.0 -

Valve spring squareness 2

_

Valve seat contact width mm 0.9- 1.3 -

V alve guide internal diameter mm

SOHC 12-VALVE 6.6 -

_

4

SOHC 16-VALVE 5.5 -

DOHC 5.5 -

Valve guide projection mm

SOHC 12-VALVE 17.0 -

SOHC 16-VALVE 23.0 -

DOHC 23.0 -

Oil pump and oil pan

Oil pump tip clearance mm 0.06- 0.18 -

Oil pump side clearance mm 0.04 - 0.10 -

Oil pump body clearance mm 0.10- 0.18 0.35

Pistons and connecting rods

Piston outside diameter mm

4G13 71.0 -

4G15 75.5 -

4G18 76.0 -

Piston ring side clearance mm

No. 1 ring 0.02- 0.06 -

No. 2 ring 0.02- 0.06 -

Piston ring end gap clearance

No. 1 ring 0.20- 0.35 0.8

No. 2 ring 0.35- 0.50 0.8

Oil ring 0.20- 0.50 1.0

Piston pin O. D. mm 18.0 -

Piston pin press-in load (at room temperature) N 4,900 - 14,700 -

Crankshaft pin oil clearance mm 0.02- 0.04 0.1

Connecting rod big end side clearance mm 0.10- 0.25 0.4

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 11

4G1 ENGINE (E-W) -

Specifications

Item Standard Limit

Crankshaft and cylinder block

Crankshaft end play mm 0.05- 0.18 0.25

Crankshaft journal diameter mm 48.0 -

Crankshaft pin diameter mm 42.0 -

Crankshaft journal oil clearance mm 0.02- 0.04 0.1

Cylinder block gasket surface flatness mm 0.05 or less -

11A-1-2a

Cylinder block gasket surface grinding limit (including grinding of

- 0.2

cylinder head gasket surface) mm

Cylinder block overall height mm 256 -

Cylinder block cylindricity mm 0.01 -

Cylinder block I. D. mm

4G13 71.0 -

4G15 75.5 -

4G18 76.0 -

Piston-to-cylinder clearance mm 0.02-0.04 -

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 12

11A-1-2b

4G1 ENGINE (E-W) -

Specifications

Intentionally blank

E

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation AddedPWEE9520-A

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 13

4G1 ENGINE (E-W) -

Specifications

REWORK DIMENSIONS

Item Standard Limit

Cylinder head and valves

11A-1-3

Cylinder head oversize valve guide SOHC 12-VALVE

hole diameter mm

SOHC 16-VALVE

DOHC

Oversize valveseat SOHC Intake (primary)

ring hole diametermm12-VALVE

mm

Intake (secondary)

Exhaust

SOHC Intake

16-VALVE

<4G13>

<4G13>

Exhaust

0.05 O. S. 12.050- 12.068 -

0.25 O. S. 12.250- 12.268 -

0.50 O. S. 12.500- 12.518 -

0.05 O. S. 10.550- 10.568 -

0.25 O. S. 10.750- 10.768 -

0.50 O. S. 11.000 - 11.018 -

0.05 O. S. 10.550- 10.568 -

0.25 O. S. 10.750- 10.768 -

0.50 O. S. 11.000 - 11.018 -

0.3 O. S. 27.300- 27.325 -

0.6 O. S. 27.600- 27.625 -

0.3 O. S. 32.300- 32.325 -

0.6 O. S. 32.600- 32.625 -

0.3 O. S. 35.300- 35.325 -

0.6 O. S. 35.600- 35.625 -

0.3 O. S. 28.300- 28.321 -

0.6 O. S. 28.600- 28.621 -

0.3 O. S. 26.300- 26.321 -

SOHC Intake

16-VALVE

<4G18>

<4G18>

Exhaust

DOHC Intake

Exhaust

0.6 O. S. 26.600- 26.621 -

0.3 O. S. 30.300- 30.321 -

0.6 O. S. 30.600- 30.621 -

0.3 O. S. 28.300- 28.321 -

0.6 O. S. 28.600- 28.621 -

0.3 O. S. 31.300- 31.325 -

0.6 O. S. 31.600- 31.625 -

0.3 O. S. 27.800- 27.825 -

0.6 O. S. 28.100- 28.125 -

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

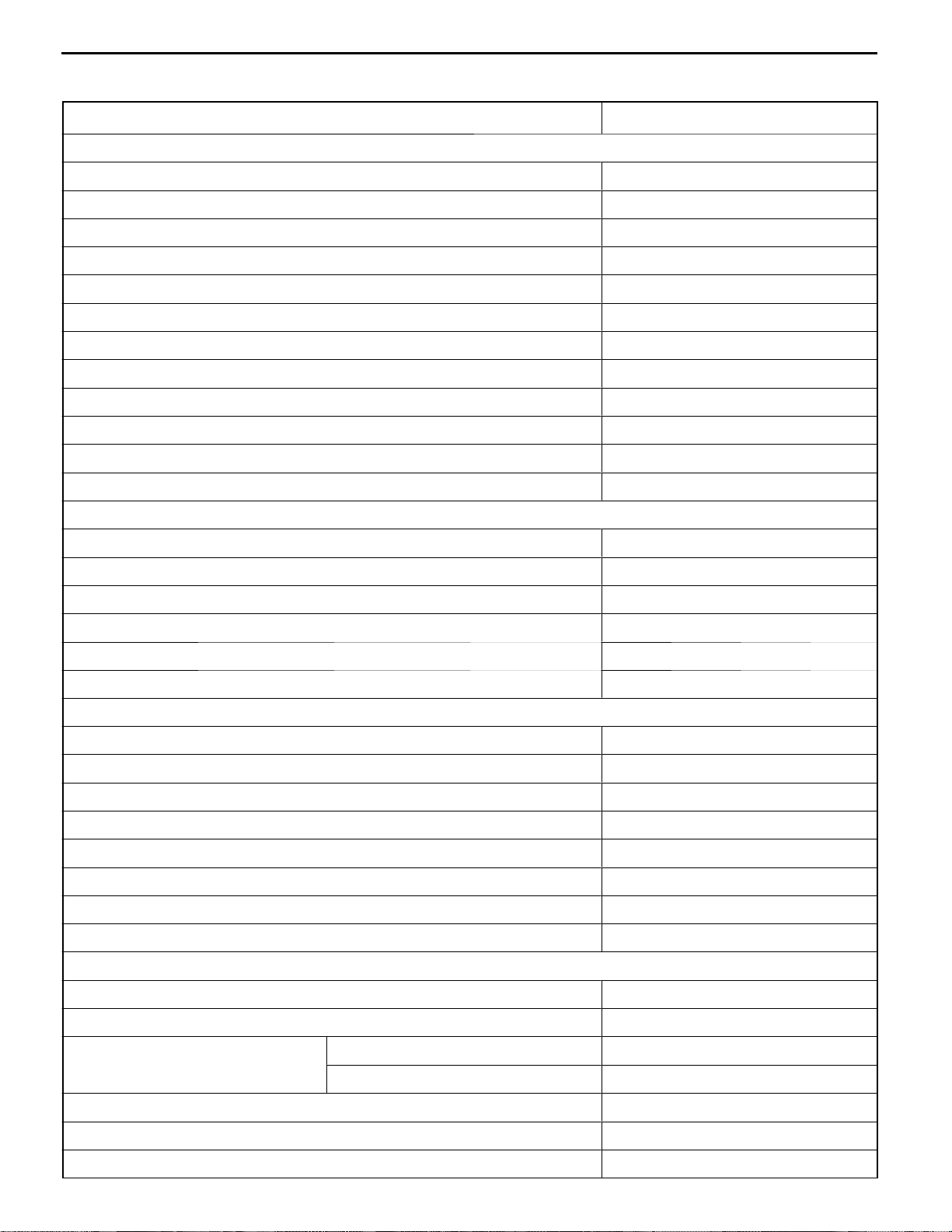

Page 14

11A-1-4

4G1 ENGINE (E-W) -

Specifications

TORQUE SPECIFICATIONS

Item Nm

Alternator and ignition system

Water pump pulley bolt 9

Alternator brace (alternator side) 22

Alternator brace (tightened with water pump) 23

Alternator pivot bolt 44

Oil level gauge guide 23

Crankshaft bolt 125

Spark plug 25

Distributor 11

Ignition coil 10

Camshaft position sensor 9

Camshaft position sensor support 13

Camshaft position sensing cylinder 21

Timing belt

Timing belt cover 11

Timing belt tensioner 23

Crankshaft angle sensor (Rear wheel drive) 9

Engine support bracket (left) 35

Idler pulley 35

Camshaft sprocket bolt 88

Fuel system

Delivery pipe 11

Fuel pressure regulator 9

Throttle body 18

Fuel pump 11

Breather tube 22

Carburetor 17

Air temperature sensor 13

EGR valve 21

Water pump

Water inlet fitting 22

Water inlet pipe assembly 12

Water inlet pipe

M6 12

M8 25

Fitting (Rear wheel drive) 23

Water outlet fitting (Rear wheel drive) 23

Thermostat case 23

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 15

4G1 ENGINE (E-W) -

Specifications

Item Nm

Thermo valve 27

Water temperature gauge unit 11

Water temperature sensor 29

Water pump 13

Exhaust manifold and intake manifold

Boost sensor 5

Solenoid valve assembly 9

Intake manifold 17

11A-1-5

Intake manifold stay (MPI)

M8 17

M10 21

Intake manifold stay (carburetor) 29

Exhaust manifold cover 29

Exhaust manifold

M8 17

M10 29

Oxygen sensor 44

Rocker arms, rocker shafts, and camshaft

Fuel pump cover 12

Rocker cover 4

Rocker shaft assembly 31

Adjusting screw 15

Bearing cap

24

11

Cylinder head and valves

Cylinder head bolt 20 + 90_+90

_

Tighten to 49 Nm, then completely loosen and retighten as described.

Oil pump and oil pan

Transmission stay 23

Oil pan 7

Drain plug 39

Oil screen 18

Front case 13

Relief plug 44

Oil pump cover 10

Pistons and connecting rods

Connecting rod nut 17 + 90_to 100

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

_

Page 16

11A-1-5a

4G1 ENGINE (E-W) -

Specifications

Item Nm

Crankshaft and cylinder block

Flywheel 132

Drive plate 132

Rear plate 10

Bell housing cover 10

Rear oil seal case 11

Bearing cap bolt 51

Oil pressure switch 18

Knock sensor 23

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 17

4G1 ENGINE (E-W) -

Specifications

11A-1-5b

Intentionally blank

E

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation AddedPWEE9520-A

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 18

11A-1-6

4G1 ENGINE (E-W) -

Specifications

NEW TIGHTENING METHOD USING PLASTIC REGION TIGHTENING BOLTS

Parts of the engine use plastic region tightening bolts. The tightening procedure for these is different

from that of conventional bolts and is described in relevant parts of this manual. Note that plastic region

tightening bolts have fixed service limits. These limits are indicated in relevant parts of this manual and

must be strictly observed.

Plastic region tightening bolts are used for the following applications:

D

(1) Cylinder head bolts

(2) Connecting rod cap bolts

The tightening procedure is basically as follows:

D

After tightening a bolt to the specified torque, tighten it by a further 90_+90_or by a further 90–100°.

The exact tightening procedure differs depending on the bolt and is described in relevant parts of

this manual.

SEALANTS

Item Specified sealant Quantity

Water pump Mitsubishi Genuine Part No. MD970389 or equivalent As required

Thermo valve Mitsubishi Genuine Part No. MD970389 or equivalent As required

Engine coolant temperature sensor 3M Nut Locking Part No. 4171 or equivalent As required

Engine coolant temperature gauge unit 3M ATD Part No. 8660 or equivalent As required

Camshaft bearing cap 3M ATD Part No. 8660 or equivalent As required

Semi-circular packing 3M ATD Part No. 8660 or equivalent As required

Rocker cover 3M ATD Part No. 8660 or equivalent As required

Front oil seal case Mitsubishi Genuine Part No. MD970389 or equivalent As required

Oil pump Mitsubishi Genuine Part No. MD970389 or equivalent As required

Oil pressure switch 3M ATD Part No. 8660 or equivalent As required

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 19

4G1 ENGINE (E-W) -

Specifications

11A-1-7

FORM-IN-PLACE GASKET

The engine has several areas where the form-in-place gasket (FIPG) is in use. To ensure that the gasket

fully serves its purpose, it is necessary to observe some precautions when applying the gasket. Bead

size, continuity and location are of paramount importance. Too thin a bead could cause leaks. Too thick

a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing of the

fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary to

apply the gasket evenly without a break, while observing the correct bead size.

The FIPG used in the engine is a room temperature vulcanization (RTV) type and is supplied in a 100-gram

tube (Part No. MD970389 or MD997110). Since the RTV hardens as it reacts with the moisture in the

atomospheric air, it is normally used in the metallic flange areas. The FIPG, Part No. MD970389, can

be used for sealing both engine oil and coolant, while Part No. 997110 can only be used for engine

oil sealing.

Disassembly

The parts assembled with the FIPG can be easily disassembled without use of a special method. In

some cases, however, the sealant between the joined surfaces may have to be broken by lightly striking

with a mallet or similar tool. A flat and thin gasket scraper may be lightly hammered in between the

joined surfaces. In this case, however, care must be taken to prevent damage to the joined surfaces.

For removal of the oil pan, the special tool “Oil Pan Remover” (MD998727) is available. Be sure to use

the special tool to remove the oil pan. <Except aluminium die-cast oil pans>

Surface Preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper

or wire brush. Check to ensure that the surfaces to which the FIPG is to be applied is flat. Make sure

that there are no oils, greases and foreign substances deposited on the application surfaces. Do not

forget to remove the old sealant remained in the bolt holes.

Form-In-Place Gasket Application

When assembling parts with the FIPG, you must observe some precautions, but the procedures is very

simple as in the case of a conventional precut gasket.

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the

bolt hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is

hardened. While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When

the parts are mounted, make sure that the gasket is applied to the required area only. In addition, do

not apply any oil or water to the sealing locations or start the engine until a sufficient amount of time

(about one hour) has passed after installation is completed.

The FIPG application procedure may vary on different areas. Observe the procedure described in the

text when applying the FIPG.

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 20

NOTES

Page 21

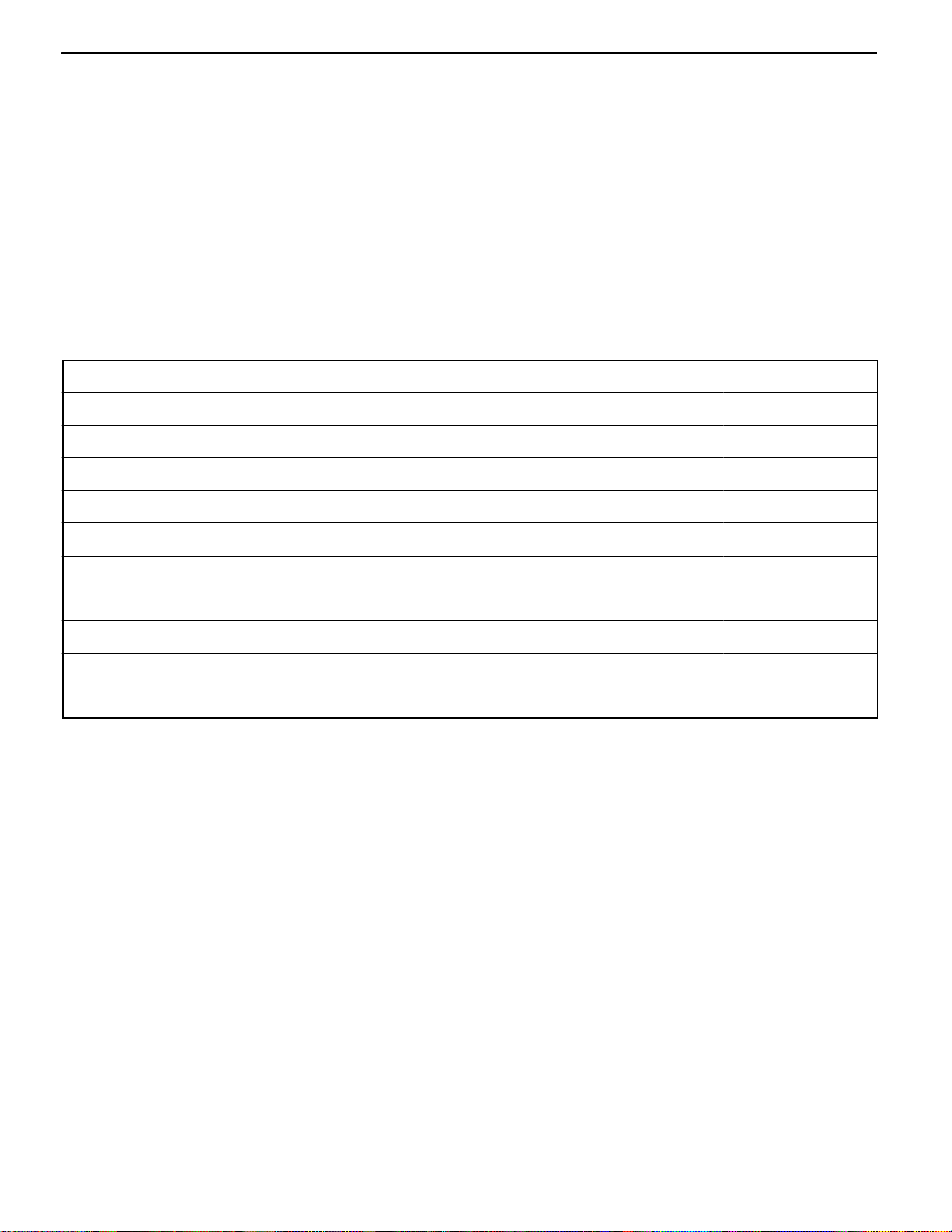

4G1 ENGINE (E-W) -

Special Tools

2. SPECIAL TOOLS

Tool Number Name Use

MB990767 End yoke holder Holding camshaft sprocket when loosening or

11A-2-1

tightening bolt (used with MD998715)

MD99801 1 Crankshaft rear oil

seal installer

MD998054 Oil pressure switch

wrench

MD998304 Crankshaft front oil

seal installer

MD998305 Crankshaft front oil

seal guide

Installation of crankshaft rear oil seal

Removal and installation of oil pressure switch

Installation of crankshaft front oil seal

Guide for installation of crankshaft front oil seal

MD998713 Camshaft oil seal

installer

MD998715 Pin (2-off) Holding camshaft sprocket when loosening or

MD998727 Oil pan remover Removal of oil pan

MD998735 Valve spring com-

pressor

Installation of camshaft oil seal

tightening bolt (used with MB990767)

Compression of valve springs

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 22

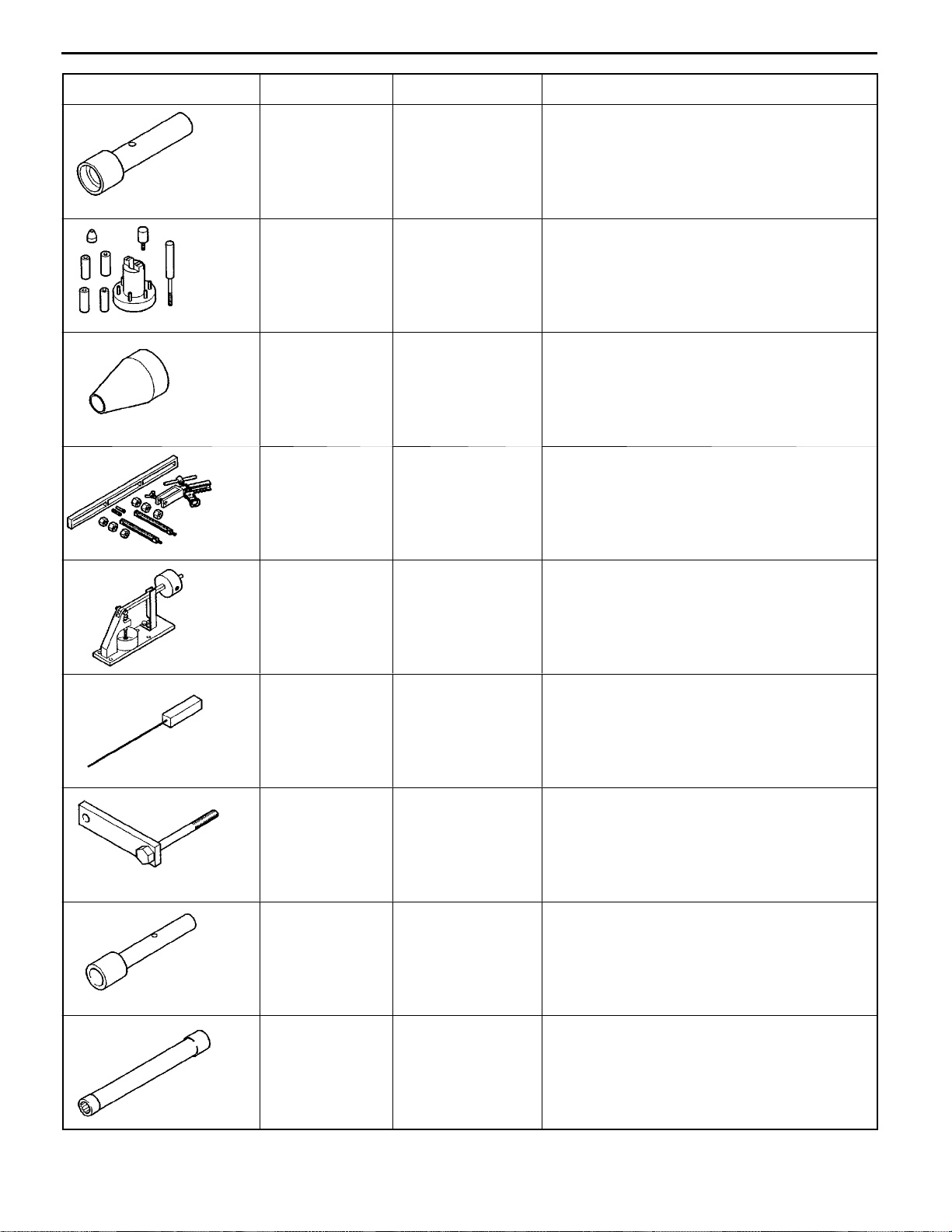

11A-2-2

Tool UseNameNumber

4G1 ENGINE (E-W) -

Special Tools

MD998760 Valve stem seal

installer

MD998780 Piston pin setting

Installation of valve stem seals

(SOHC 12-VALVE)

Removal and press-fitting of piston pins

tool

MB991659 Guide-D Guide for removal and press-fitting of piston

pins

MD998772 Valve spring com-

Compression of valve springs

pressor

MD998440 Leak-down tester Testing of automatic lash adjusters

(DOHC)

MD998442 Air bleed wire Testing of automatic lash adjusters

(DOHC)

MD998781 Flywheel stopper Locking flywheel in fixed position

MB991671 Valve stem

installer

Press-fitting of valve stem seals

(SOHC 16-VALVE, DOHC)

MB991653 Cylinder head bolt

Removal and installation of cylinder head bolt

wrench (10)

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 23

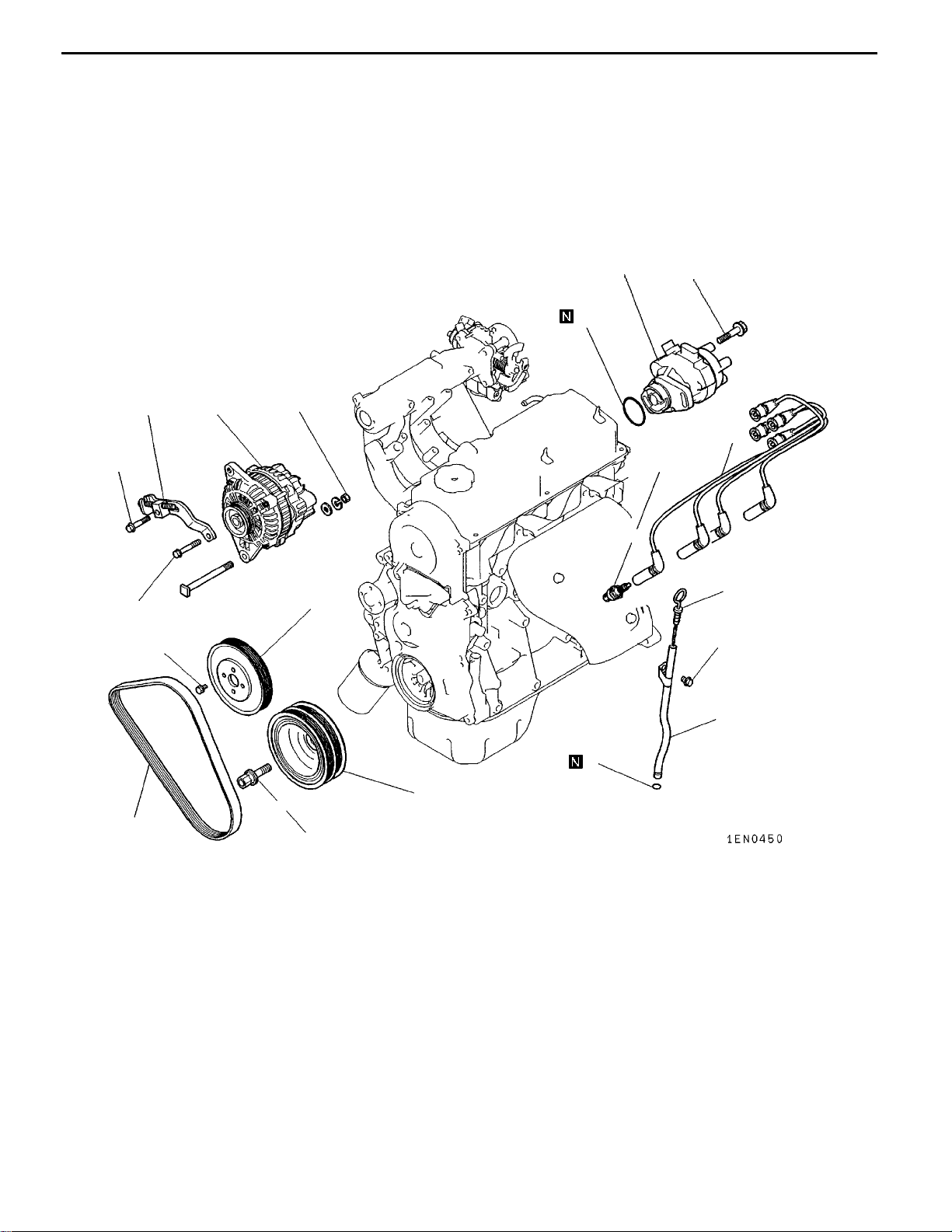

4G1 ENGINE (E-W) -

Alternator and Ignition System

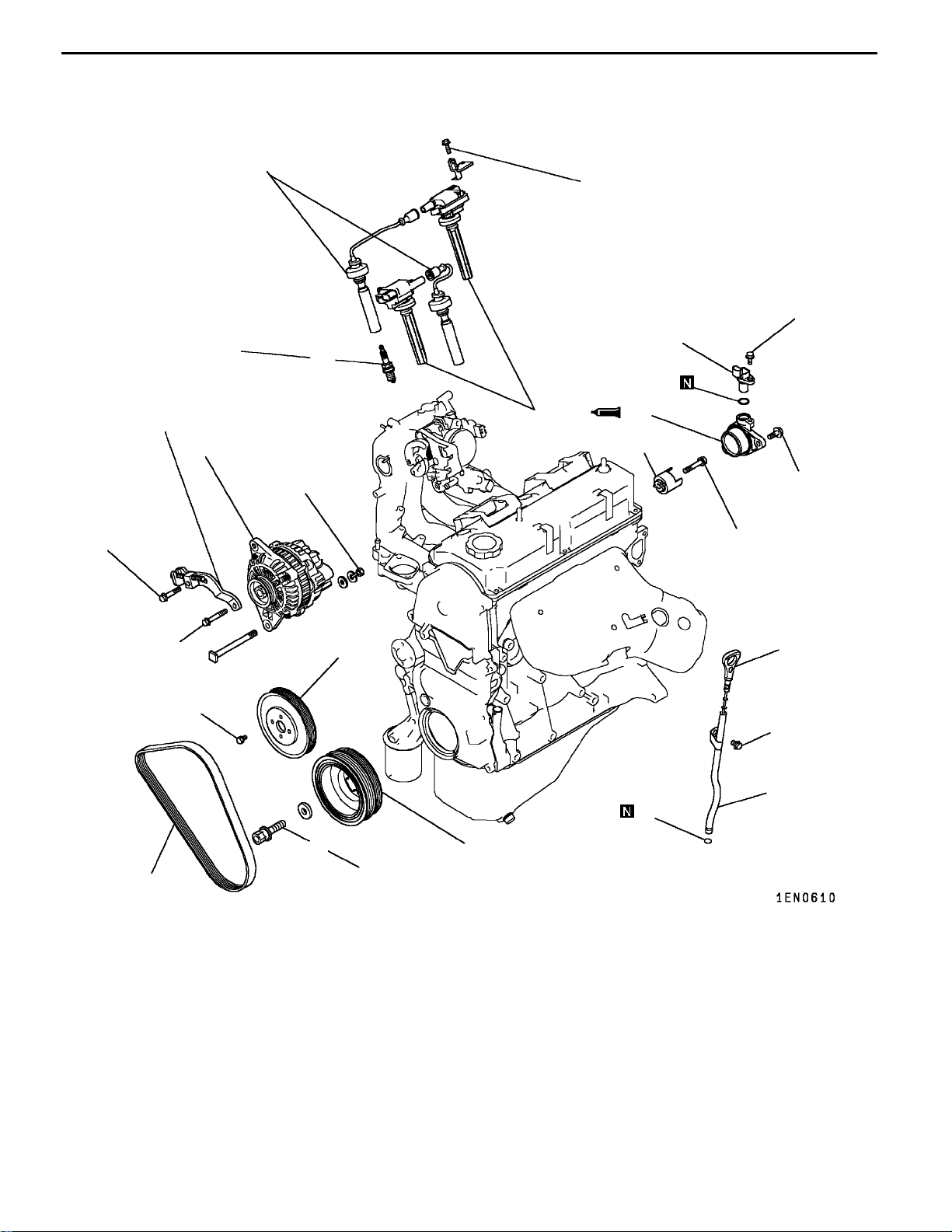

3. ALTERNATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION <SOHC 12-VALVE>

11A-3-1

22 Nm

23 Nm

6

9Nm

12

12 Nm

13

7

44 Nm

10

25 Nm

11

1

5

23 Nm

2

4

AA""BA

E

E

8

123 Nm

Removal steps

1. Oil level gauge

2. Oil level gauge guide

3. O-ring

4. Drive belt*

5. Water pump pulley

6. Alternator brace

7. Alternator

8. Crankshaft bolt

9. Crankshaft pulley

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

9

PWEE9520

PWEE9520-A

3

10. Spark plug cable

11. Spark plug

"AA

NOTE

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

12. Distributor

13. O-ring

Page 24

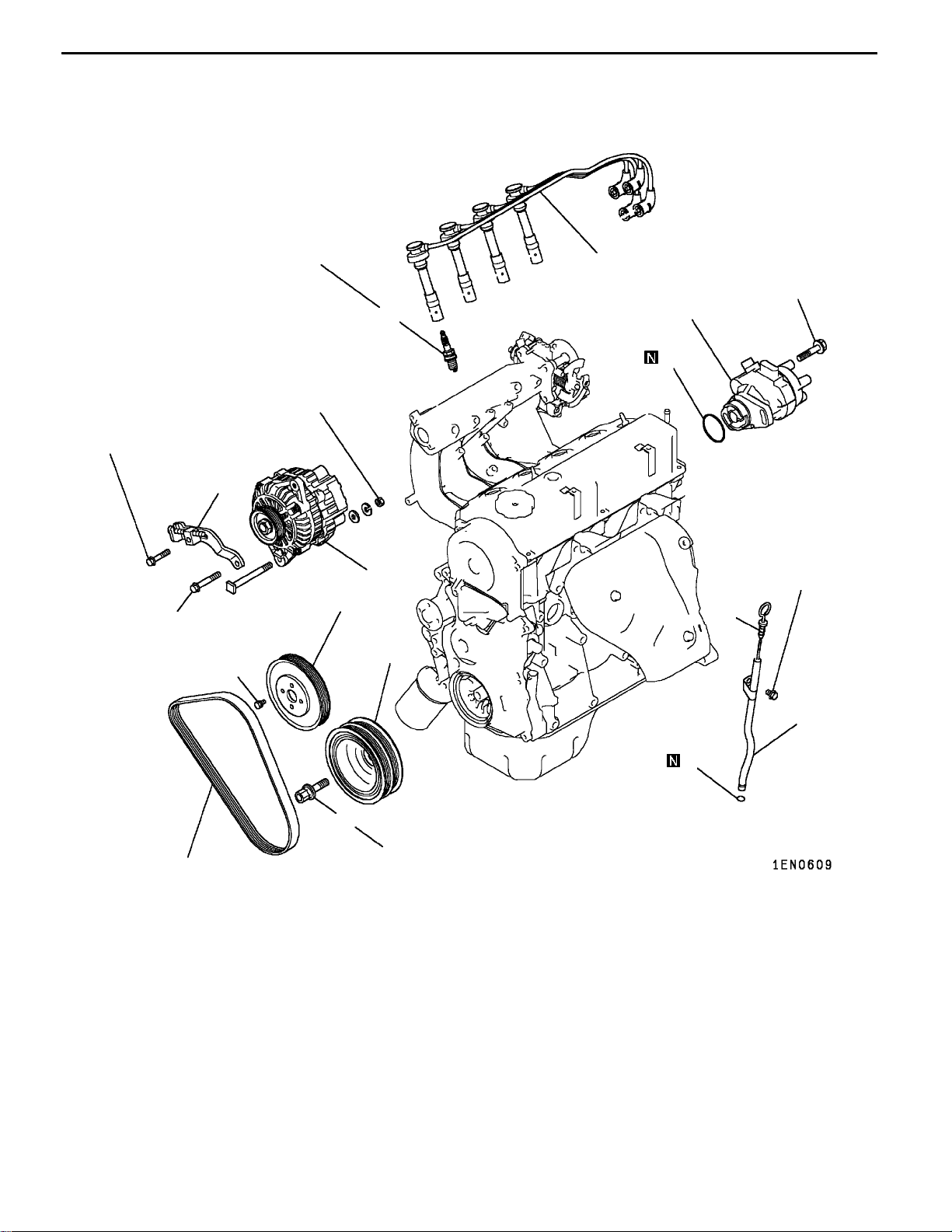

11A-3-1a

4G1 ENGINE (E-W) -

Alternator and Ignition System

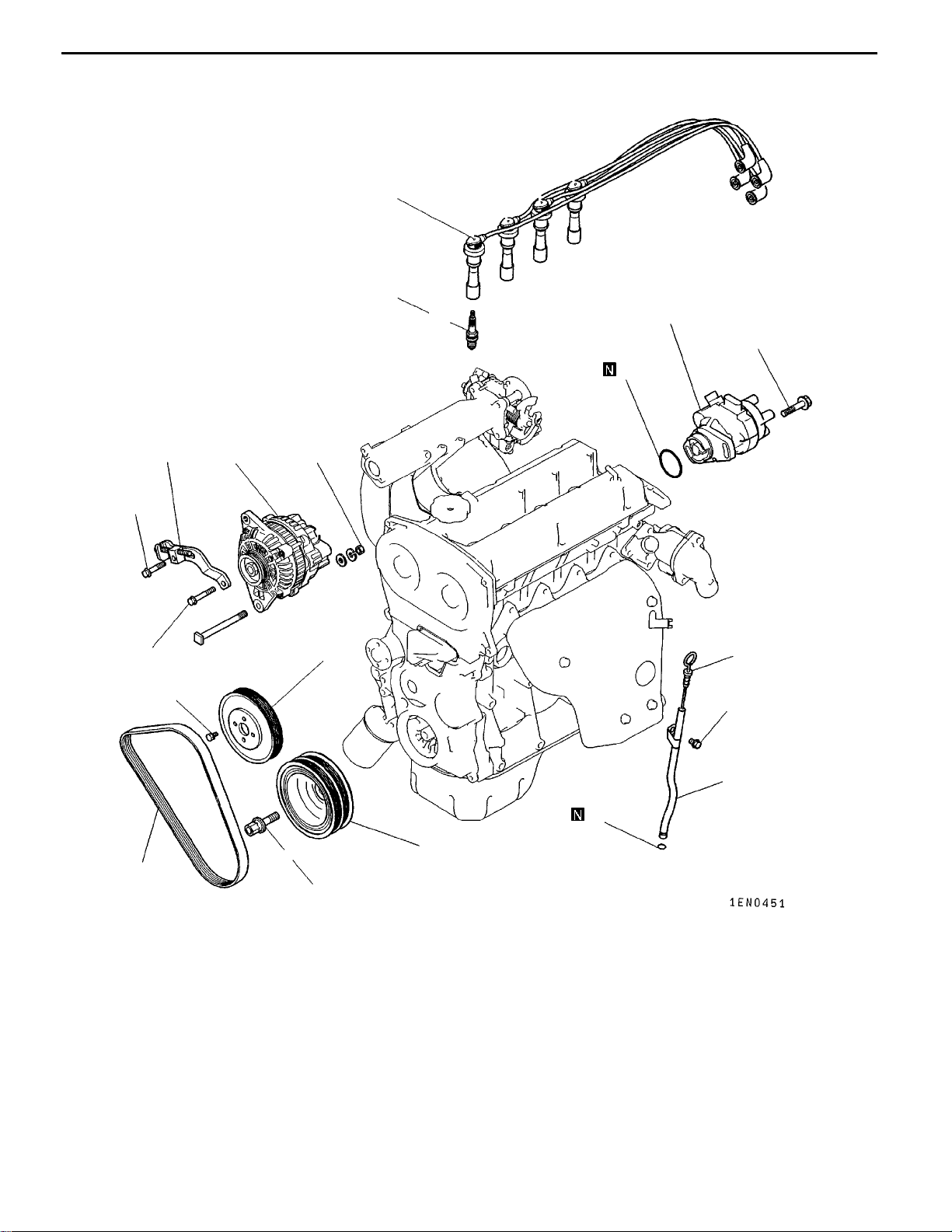

REMOVAL AND INSTALLATION <SOHC 16-VALVE-FRONT WHEEL DRIVE>

22Nm

23 Nm

6

9Nm

25 Nm

44 Nm

10

12 Nm

11

12

13

7

23 Nm

5

1

9

AA""BA

4

Removal steps

1. Oil level gauge

2. Oil level gauge guide

3. O-ring

4. Drive belt*

5. Water pump pulley

6. Alternator brace

7. Alternator

8. Crankshaft bolt

9. Crankshaft pulley

2

3

8

125 Nm

10. Spark plug cable

11. Spark plug

"AA

NOTE

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

12. Distributor

13. O-ring

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 25

4G1 ENGINE (E-W) -

Alternator and Ignition System

REMOVAL AND INSTALLATION <SOHC 16-VALVE-REAR WHEEL DRIVE>

10

10 Nm

25Nm

12

13

11A-3-1b

9Nm

22Nm

6

23 Nm

4

9Nm

11

7

44 Nm

5

14

15

13 Nm

21 Nm

1

23 Nm

2

3

8

125 Nm

9

AA""BA

E

E

Removal steps

1. Oil level gauge

2. Oil level gauge guide

3. O-ring

4. Drive belt*

5. Water pump pulley

6. Alternator brace

7. Alternator

8. Crankshaft bolt

9. Crankshaft pulley

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

NOTE

PWEE9520

PWEE9520-A

10. Spark plug cable

11. Ignition coil

12. Spark plug

13. Cam position sensor

"CA

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

14. Cam position sensor support

15. Cam position sensing cylinder

Page 26

11A-3-2

4G1 ENGINE (E-W) -

Alternator and Ignition System

REMOVAL AND INSTALLATION <DOHC>

10

25 Nm

11

12

11 Nm

13

22Nm

23 Nm

4

6

9Nm

7

44 Nm

5

1

23 Nm

2

3

8

103 Nm

9

AA""BA

E

Removal steps

1. Oil level gauge

2. Oil level gauge guide

3. O-ring

4. Drive belt*

5. Water pump pulley

6. Alternator brace

7. Alternator

8. Crankshaft bolt

9. Crankshaft pulley

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

10. Spark plug cable

11. Spark plug

"AA

NOTE

*: For details of adjustment, refer to the relevant model’s

chassis workshop manual.

12. Distributor

13. O-ring

Page 27

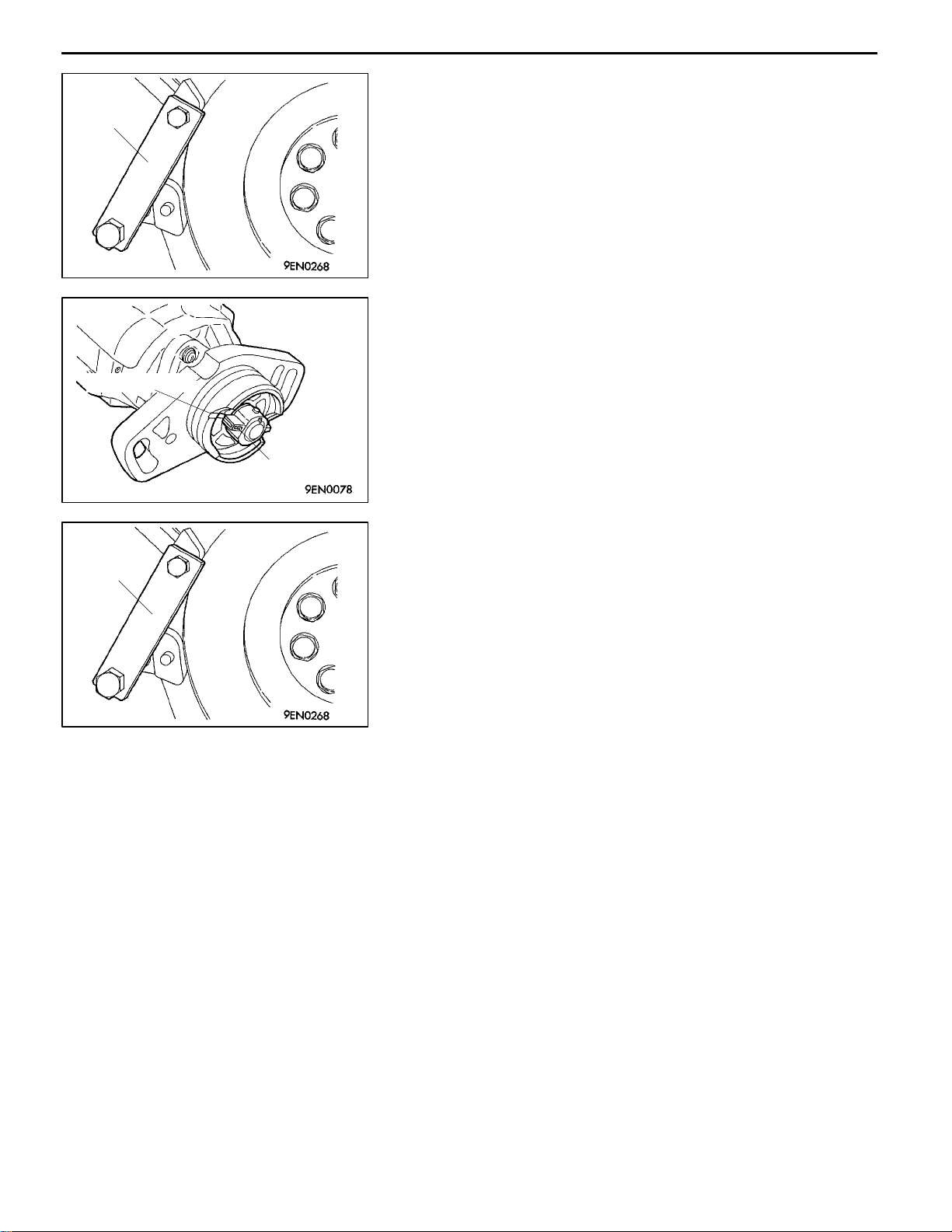

MD998781

Alignment mark

4G1 ENGINE (E-W) -

REMOVAL SERVICE POINT

AA"

(1) Lock the flywheel or drive plate in position using the special

INSTALLATION SERVICE POINTS

"AA

(1) Turn the crankshaft clockwise until cylinder No. 1 is at

(2) Align the alignment marks on the distributor housing and

(3) Fit the distributor onto the engine, aligning the stud bolts

Alignment mark

Alternator and Ignition System

11A-3-3

CRANKSHAFT BOLT REMOVAL

tool shown in the illustration, then loosen the crankshaft

bolts.

DISTRIBUTOR INSTALLATION

top dead center on its compression stroke.

coupling.

with the slots in the distributor mounting flange.

MD998781

"BA

CRANKSHAFT BOLT INSTALLATION

(1) Lock the flywheel or drive plate in position using the special

tool shown in the illustration, then tighten the crankshaft

bolts.

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 28

NOTES

Page 29

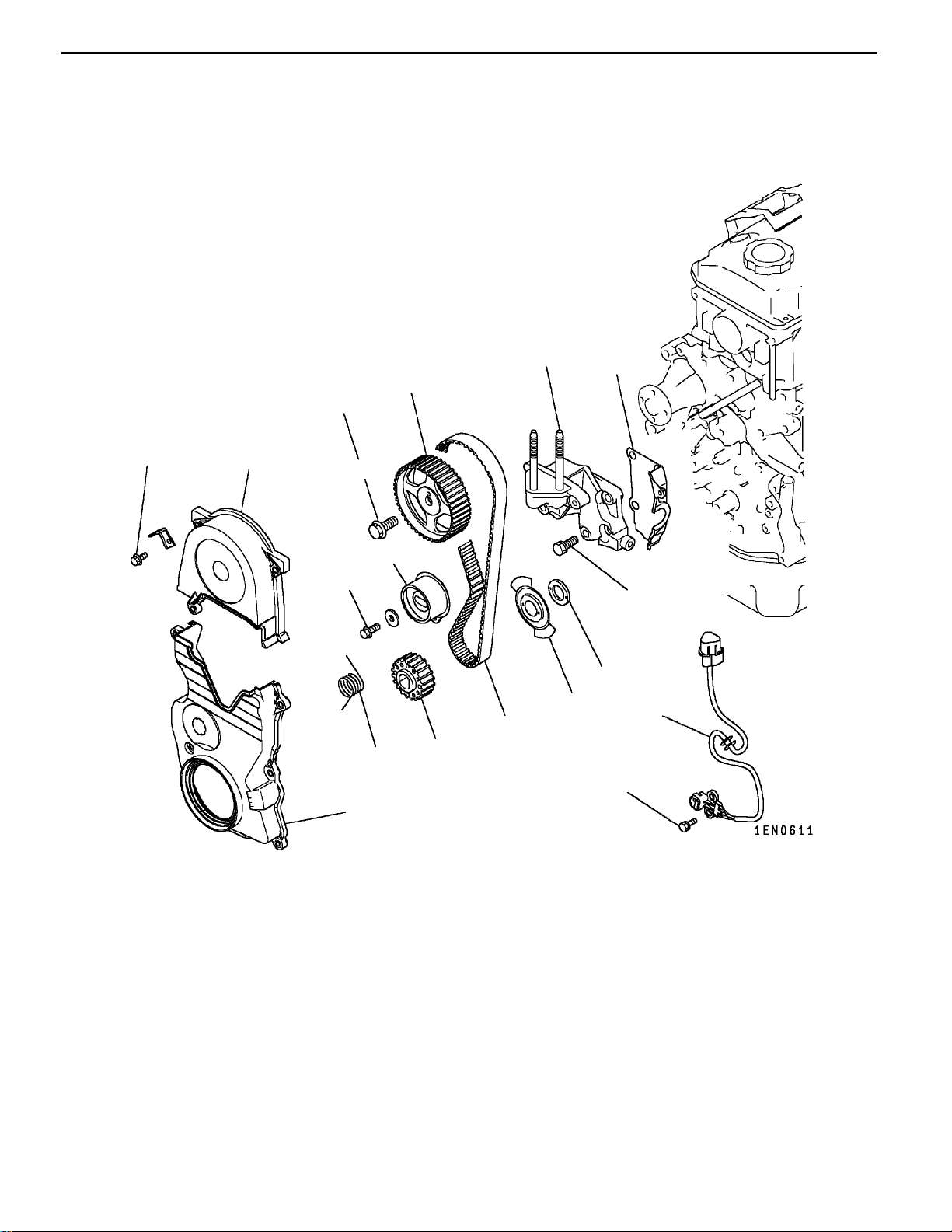

4G1 ENGINE (E-W) -

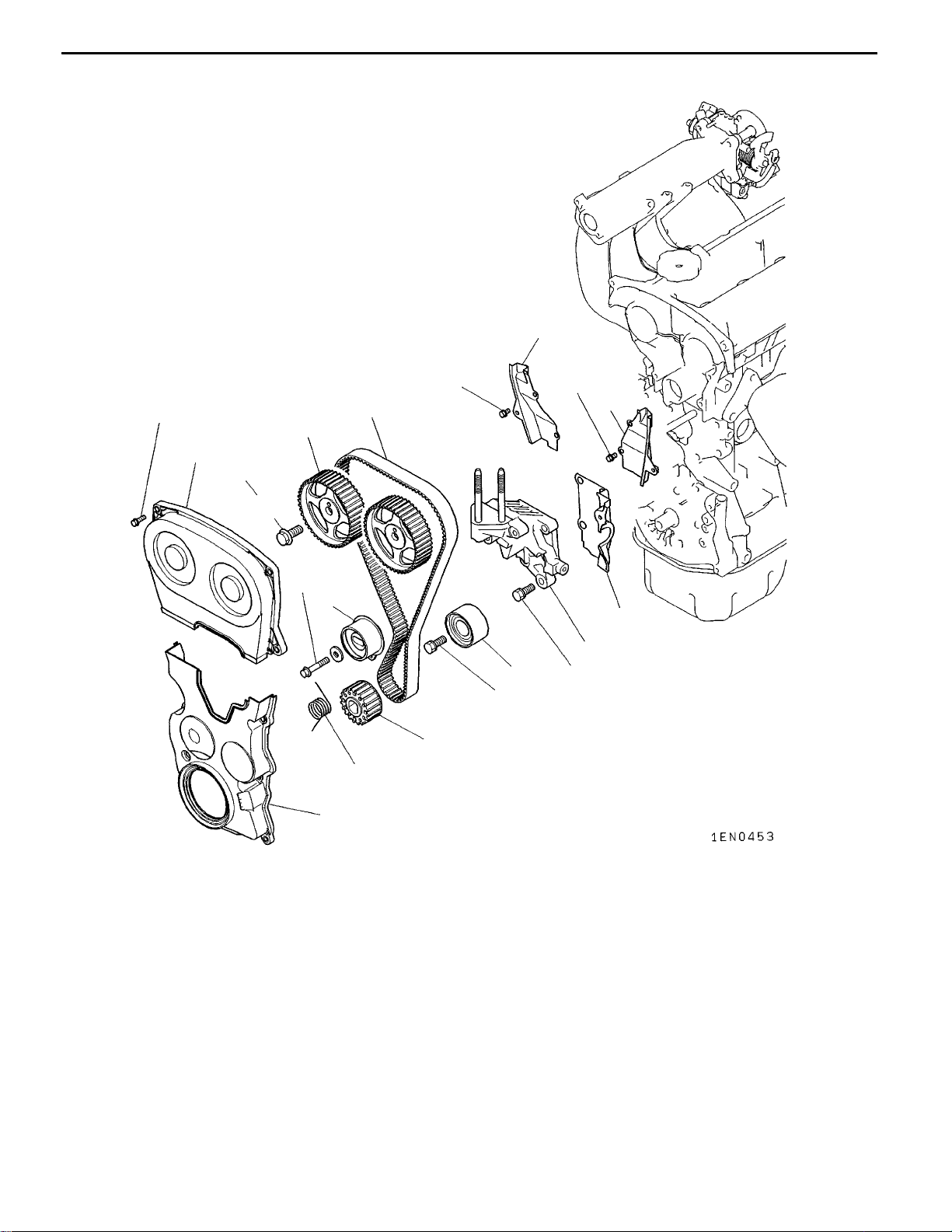

4. TIMING BELT

REMOVAL AND INSTALLATION <SOHC>

Timing Belt

11A-4-1

11 Nm

12

13

11

88 Nm

1

10

5

23 Nm

35 Nm

8

9

6

3

4

7

9Nm

AA""CA

"BA

"BA

E

E

E

2

Removal steps

1. Timing belt upper cover

2. Timing belt lower cover

3. Timing belt

4. Tensioner spring

5. Timing belt tensioner

6. Crankshaft angle sensor

<Rear wheel drive>

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation RevisedPWEE9520-A

Dec. 1998Mitsubishi Motors Corporation Revised

AB""AA

PWEE9520

PWEE9520-A

7. Crankshaft sprocket

8. Spacer <Rear wheel drive>

9. Sensing blade <Rear wheel drive>

10. Camshaft sprocket bolt

11. Camshaft sprocket

12. Engine support bracket

13. Timing belt rear cover

Page 30

11A-4-2

4G1 ENGINE (E-W) -

REMOVAL AND INSTALLATION <DOHC>

Timing Belt

12

11 Nm

11 Nm

3

11 Nm

13

9

1

88 Nm

8

23 Nm

5

11

10

6

35 Nm

35 Nm

7

4

2

AA""DA

AA""BA

AA""BA

E

Removal steps

1. Timing belt upper cover

2. Timing belt lower cover

3. Timing belt

4. Tensioner spring

5. Timing belt tensioner

6. Idler pulley

7. Crankshaft pulley

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

AB""AA

8. Camshaft sprocket bolt

9. Camshaft sprocket

10. Engine support bracket

11. Timing belt rear cover (lower)

12. Timing belt rear cover (right)

13. Timing belt rear cover (left)

Page 31

MD998715

4G1 ENGINE (E-W) -

MB990767

Timing Belt

11A-4-3

REMOVAL SERVICE POINTS

AA"

(1) Using pliers, grip t he tensioner spring projection (marked

(2) Remove the timing belt tensioner.

(3) If the timing belt is to be reused, chalk an arrow on the

AB"

(1) Using the special tools shown in the illustration, lock the

(2) Loosen the camshaft sprocket bolt.

TIMING BELT / TENSIONER SPRING / TIMING

BELT TENSIONER REMOVAL

“A” in the diagram)and remove it from the oil pump case

stopper. Then, remove the tensioner spring.

belt to indicate the direction of rotation before removing

it. This will ensure the timing belt is fitted correctly when

reused.

CAMSHAFT SPROCKET BOLT REMOVAL

camshaft sprocket in position.

Crack

Separation

Cracked tooth base

Rounded edge

Crack

Cracked side

INSPECTION

1. TIMING BELT

Check the timing belt closely. Replace the belt with a new

one if any of the following defects is evident:

(1) Hardened backing rubber (the backing rubber is glossy,

non-elastic, and so hard that scratching with fingernails

leaves no mark)

(2) Surface cracks in the backing rubber

(3) Splits in the canvas and/or separation of the canvas a n d

rubber

(4) Cracks at the bases of teeth

(5) Cracks in the side of the belt

(6) Abnormal wear on the belt’s sides

NOTE

The sides of the belt are normal if they are sharp as

if cut by a knife.

Abnormal wear

(exposed core wire)

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 32

11A-4-4

Canvas worn exposing

rubber

Missing tooth

4G1 ENGINE (E-W) -

(7) Abnormal wear on teeth

Initial stage:

Canvas worn (fluffy canvas fibers, rubbery texture gone,

white discoloration, canvas texture indistinct)

Final stage:

Canvas worn, exposing rubber (tooth width reduced)

(8) Missing teeth

2. TENSIONER PULLEY AND IDLER PULLEY

(1) Check that the pulleys turn smoothly without play and

are not abnormally noisy. Replace either or both of the

pulleys if necessary.

Timing Belt

MD998715

MB990767

Timing belt

tensioner

INSTALLATION SERVICE POINTS

"AA

(1) Using the special tools shown in the illustration, lock the

(2) Tighten the camshaft sprocket bolt to the specified torque.

"BA

(1) Lock the timing belt tensioner in the illustrated position.

(2) Fit one of the tensioner spring projections over the hooked

CAMSHAFT SPROCKET BOLT INSTALLATION

camshaft sprocket in position.

TIMING BELT TENSIONER / TENSIONER SPRING

INSTALLATION

portion of the timing belt tensioner and fit the tensioner

onto the oil pump case.

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 33

4G1 ENGINE (E-W) -

(3) Grip the other tensioner spring projection and fit it onto

the oil pump case lug as shown in the illustration.

(4) Move the timing belt tensioner in the direction shown

and temporarily tighten the bolt.

Timing Belt

11A-4-5

"CA

TIMING BELT INSTALLATION

(1) Align the camshaft timing mark with the timing mark on

the cylinder head.

(2) Align the crankshaft timing mark with the timing mark

on the front case.

(3) Keeping the tension side of the timing belt tight, fit the

timing belt onto the crankshaft sprocket, camshaft

sprocket, and tensioner pulley in that order.

(4) Loosen the tensioner pulley mounting bolts by 1/4 to

1/2 of a turn an d allow the tensioner spring to apply tension

to the timing belt.

(5) Turn the crankshaft twice in the normal rotating direction

(clockwise) and check that the timing marks are correctly

aligned.

Caution

This procedure utilizes the camshaft’s driving torque

to apply tension evenly to the timing belt. Be sure

to turn the crankshaft as described above. Do not

turn the crankshaft in reverse.

(6) Tighten the tensioner pulley mounting bolts.

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 34

11A-4-6

4G1 ENGINE (E-W) -

Timing Belt

"DA

TIMING BELT INSTALLATION

(1) Place the camshaft sprocket timing marks at the positions

shown.

NOTE

After aligning the sprocket timing marks, let go of the

sprockets. The exhaust camshaft sprocket will rotate by

one tooth in the direction shown and remain stable in

this position.

(2) Align the crankshaft timing mark with the timing mark

on the front case.

(3) Turn the exhaust camshaft sprocket in the direction shown

and fit the timing belt with the timing marks aligned.

(4) Use a bulldog clip to prevent the timing belt teeth from

jumping.

(5) Fit the timing belt onto the idler pulley, crankshaft sprocket,

and tensioner pulley in that order.

NOTE

When fitting the belt, keep the camshaft sprocket timing

marks correctly aligned a nd keep the tension side of the

belt tight.

1

(6) Loosen the tensioner pulley mounting bolts by

/4to1/

2

of a turn and allow t he tensioner spring to apply tension

to the timing belt.

(7) Remove the bulldog clip.

(8) Turn the crankshaft twice in the normal rotating direction

(clockwise) and check that the timing marks are correctly

aligned.

Caution

This procedure utilizes the camshaft’s driving torque

to apply tension evenly to the timing belt. Be sure

to turn the crankshaft as described above. Do not

turn the crankshaft in reverse.

(9) Tighten the tensioner pulley mounting bolts.

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 35

4G1 ENGINE (E-W) -

Fuel and Emission Control Systems

5. FUEL AND EMISSION CONTROL SYSTEMS

REMOVAL AND INSTALLATION <SOHC-CARBURETOR>

17 Nm

8

9

11A-5-1

7

11 Nm

22 Nm

3

10

21 Nm

11

2

4

12

5

6

1

Removal steps

1. Breather tube

2. Fuel hose

3. Fuel pump

4. Gasket

5. Insulator

6. Gasket

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

7. Carburetor

8. Upper gasket

9. Spacer

10. Lower gasket

11. EGR valve (vehicles with automatic

transmission for GCC only)

12. Gasket

Page 36

11A-5-2

4G1 ENGINE (E-W) -

Fuel and Emission Control Systems

REMOVAL AND INSTALLATION <SOHC-MPI>

11 Nm

9Nm

3

11

18 Nm

1

6

9

5

4

10

8

2

21 Nm

7

12

13

"BA

Removal steps

1. Throttle body assembly

2. Gasket

3. Fuel return pipe

4. Fuel pressure regulator

5. O-ring

6. Insulator

7. Insulator

"AA

15

8. Injector

9. O-ring

10. Grommet

11. Delivery pipe

12. EGR valve

13. Gasket

14. Air temperature sensor

15. Gasket

14

18 Nm

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 37

4G1 ENGINE (E-W) -

Fuel and Emission Control Systems

REMOVAL AND INSTALLATION <SOHC-REAR WHEEL DRIVE>

9Nm

11A-5-2a

4

9Nm

3

11 Nm

18 Nm

11

2

5

10

9

6

1

21 Nm

8

7

12

13

Removal steps

1. Throttle body assembly

2. Gasket

3. Fuel return pipe

"BA

E

E

4. Fuel pressure regulator

5. O-ring

6. Insulator

7. Insulator

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

"AA

8. Injector

9. O-ring

10. Grommet

11. Delivery pipe

12. EGR valve

13. Gasket

Page 38

11A-5-2b

4G1 ENGINE (E-W) -

Fuel and Emission Control Systems

Intentionally blank

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 39

4G1 ENGINE (E-W) -

Fuel and Emission Control Systems

REMOVAL AND INSTALLATION <DOHC>

11 Nm

11A-5-3

9Nm

3

11

18 Nm

1

6

2

9

5

4

10

8

7

Removal steps

1. Throttle body assembly

2. Gasket

3. Fuel return pipe

"BA

E

4. Fuel pressure regulator

5. O-ring

6. Insulator

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

"AA

7. Insulator

8. Injector

9. O-ring

10. Grommet

11. Delivery pipe

Page 40

11A-5-4

4G1 ENGINE (E-W) -

Fuel and Emission Control Systems

INSTALLATION SERVICE POINTS

"AA

(1) Fit a new O-ring and grommet onto the injector.

(2) Apply spindle oil or gasoline to the injector O-ring.

(3) Fit the injector onto the delivery pipe, turning it to the

(4) Check that the injector rotates smoothly.

INJECTOR INSTALLATION

left and right as it goes in.

Caution

If the injector does not rotate smoothly, its O-ring

may be binding. If this occurs, remove the injector

from the delivery pipe, check the O-ring, and re-insert

the injector.

"BA

FUEL PRESSURE REGULATOR INSTALLATION

(1) Apply a little new engine oil to the O-ring, then insert

the fuel pressure regulator into the delivery pipe, taking

care not to damage the O-ring.

Caution

Ensure that no engine oil enters the delivery pipe.

(2) Check that the fuel pressure regulator rotates smoothly.

If it does not rotate smoothly, the O-ring may be binding.

If this occurs, remove the fuel pressure regulator, check

the O-ring for damage, then re-insert the regulator into

the delivery pipe.

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 41

4G1 ENGINE (E-W) -

Water Pump and Water Hose

6. WATER PUMP AND WATER HOSE

REMOVAL AND INSTALLATION <SOHC-CARBURETOR>

11A-6-1

3

12 Nm

1

2

27 Nm

4

27 Nm

11 Nm

22 Nm

12

5

11

6

8

7

9

23 Nm

10

14

13

"FA

"FA

"DA

13 Nm

Removal steps

1. Water hose

2. Water hose

3. Water hose

4. Thermo valve (engines with EGR)

5. Thermo valve

6. Water temperature gauge unit

7. Water inlet fitting

"CA

"BA

"BA

"BA

"AA

8. Thermostat

9. Thermostat case

10. Gasket

11. Water inlet pipe

12. O-ring

13. O-ring

14. Water pump

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 42

11A-6-2

4G1 ENGINE (E-W) -

Water Pump and Water Hose

REMOVAL AND INSTALLATION <SOHC-MPI>

12 Nm

10

12

11

2

29 Nm

7

6

22 Nm

3

11 Nm

4

8

9

5

23 Nm

1

13 Nm

Removal steps

1. Water hose

2. Water hose

"EA

"DA

"CA

E

3. Water temperature sensor

4. Water temperature gauge unit

5. Water inlet fitting

6. Thermostat

7. Thermostat case

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

"BA

"BA

"BA

"AA

8. Gasket

9. Water inlet pipe

10. O-ring

11. O-ring

12. Water pump

Page 43

4G1 ENGINE (E-W) -

Water Pump and Water Hose

11A-6-2a

REMOVAL AND INSTALLATION <SOHC 16-VALVE-MPI-FRONT WHEEL DRIVE>

2

12 Nm

1

9

12 Nm

10

13 Nm

12

11

29 Nm

23 Nm

3

8

7

4

6

5

11 Nm

22 Nm

Removal steps

1. Water hose

2. Water hose

"EA

"DA

"CA

E

E

3. Water temperature sensor

4. Water temperature gauge unit

5. Water inlet fitting

6. Thermostat

7. Thermostat case

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

"BA

"BA

"BA

"AA

8. Gasket

9. Water inlet pipe

10. O-ring

11. O-ring

12. Water pump

Page 44

11A-6-2b

4G1 ENGINE (E-W) -

Water Pump and Water Hose

REMOVAL AND INSTALLATION <SOHC 16-VALVE-MPI-REAR WHEEL DRIVE>

25 Nm

29 Nm

11 Nm

1

12 Nm

11

2

12 Nm

23 Nm

5

6

10

7

9

3

8

4

12

23 Nm

13 Nm

Removal steps

1. Water hose

2. Water hose

"EA

"DA

E

E

3. Water temperature sensor

4. Water temperature gauge unit

5. Water outlet fitting

6. Gasket

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

"CA

"BA

"BA

"AA

7. Thermostat

8. Fitting

9. Gasket

10. Water inlet pipe

11. O-ring

12. Water pump

Page 45

4G1 ENGINE (E-W) -

Water Pump and Water Hose

REMOVAL AND INSTALLATION <DOHC>

12 Nm

11A-6-3

12 Nm

10

2

11

1

29 Nm

8

7

3

22 Nm

9

6

12

23 Nm

4

5

11 Nm

13 Nm

Removal steps

1. Water hose

2. Water hose

"EA

"DA

"CA

E

3. Water temperature sensor

4. Water temperature gauge unit

5. Water inlet fitting

6. Thermostat

7. Thermostat case

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

"BA

"BA

"BA

"AA

8. Gasket

9. Water inlet pipe

10. O-ring

11. O-ring

12. Water pump

Page 46

11A-6-4

4G1 ENGINE (E-W) -

INSTALLATION SERVICE POINTS

"AA

(1) Apply a 3 mm bead of form-in-place gasket (FIPG) to

Water Pump and Water Hose

WATER PUMP INSTALLATION

the mounting surface.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent.

"BA

O-RING / WATER PIPE INSTALLATION

(1) Replace the water inlet pipe O-rings with new ones, then

apply water to the O-rings so that they can be inserted

easily into the water pump and thermostat case.

Caution

1. Donotapply engine oil or any otheroilysubstance

to the O-rings.

2. Secure the water pipe after the thermostat case

has been installed.

"CA

THERMOSTAT INSTALLATION

(1) Fit the thermostat such that its jiggle valve is at the top.

"DA

WATER TEMPERATURE GAUGE UNIT

INSTALLATION

(1) If the water temperature gauge unit is to be reused, apply

the specified sealant to its thread.

Specified sealant:

3M ATD Part No. 8660 or equivalent.

"EA

WATER TEMPERATURE SENSOR INSTALLATION

(1) If the water temperature sensor is to be reused, apply

the specified sealant to its thread.

Specified sealant:

3M Nut Locking Part No. 4171 or equivalent.

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 47

4G1 ENGINE (E-W) -

Water Pump and Water Hose

11A-6-5

"FA

THERMO VALVE INSTALLATION

(1) If the thermo valve is to be reused, apply the specified

sealant to its thread.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent.

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 48

NOTES

Page 49

4G1 ENGINE (E-W) -

Intake and Exhaust Manifolds

7. INTAKE AND EXHAUST MANIFOLDS

REMOVAL AND INSTALLATION <SOHC-CARBURETOR>

1

3

4

11A-7-1

8

17 Nm

30 Nm

7

5

2

17 Nm

29 Nm

6

Removal steps

1. Engine hanger

2. Intake manifold stay

3. Intake manifold

4. Intake manifold gasket

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

5. Exhaust manifold cover

6. Engine hanger

7. Exhaust manifold

8. Exhaust manifold gasket

Page 50

11A-7-2

4G1 ENGINE (E-W) -

Intake and Exhaust Manifolds

REMOVAL AND INSTALLATION <SOHC-MPI>

1

17 Nm

17 Nm

21 Nm

2

3

44 Nm

4

5

9

8

17 Nm

7

29 Nm

6

Removal steps

1. Engine hanger

2. Intake manifold stay

3. Intake manifold

4. Intake manifold gasket

5. Oxygen sensor (vehicles for Hong

Kong only)

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

6. Exhaust manifold cover

7. Engine hanger

8. Exhaust manifold

9. Exhaust manifold gasket

Page 51

4G1 ENGINE (E-W) -

Intake and Exhaust Manifolds

11A-7-2a

REMOVAL AND INSTALLATION <SOHC 16-VALVE-MPI-REAR WHEEL DRIVE>

17 Nm

17 Nm

5Nm

1

21 Nm

6

9Nm

7

2

4

5

29 Nm

11

9

10

3

19 Nm

Removal steps

1. Boost sensor

2. Engine hanger

3. Intake manifold stay

4. Intake manifold

5. Intake manifold gasket

6. Solenoid valve assembly <Without

catalytic converter>

17 Nm

8

29 Nm

7. Solenoid valve assembly <With catalytic converter>

8. Engine hanger

9. Exhaust manifold cover

10. Exhaust manifold

11. Exhaust manifold gasket

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 52

11A-7-2b

4G1 ENGINE (E-W) -

Intake and Exhaust Manifolds

REMOVAL AND INSTALLATION <SOHC-CARBURETOR FOR CENTRAL AMERICA>

5

17 Nm

11

8

1

3

4

2

13 Nm

10

11 Nm

54 Nm

9

7

8

12

6

83 Nm

29 Nm

30 Nm

17 Nm

Removal steps

1. Engine hanger

2. Intake manifold stay

3. Intake manifold

4. Intake manifold gasket

5. Air hose

6. Exhaust manifold cover

E

E

Nov. 1995Mitsubishi Motors Corporation

July 1999Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-B

"AA

"AA

7. Air pipe

8. Reed valve and bracket

9. Reed valve

10. Reed valve bracket “A”

11. Reed valve bracket “B”

12. Exhaust manifold

Page 53

4G1 ENGINE (E-W) -

Intake and Exhaust Manifolds

REMOVAL AND INSTALLATION <DOHC>

1

3

4

17 Nm

11A-7-3

8

9

17 Nm

21 Nm

2

Removal steps

1. Engine hanger

2. Intake manifold stay

3. Intake manifold

4. Intake manifold gasket

5. Oxygen sensor

6

17 Nm

29 Nm

44 Nm

5

29 Nm

7

6. Exhaust manifold cover

7. Engine hanger

8. Exhaust manifold

9. Exhaust manifold gasket

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 54

11A-7-4

4G1 ENGINE (E-W) -

Intake and Exhaust Manifolds

Reed valve and bracket

Pipe nut (reed valve side)

Air pipe

Reed valve

bracket “B”

Pipe nut (exhaust

manifold side)

Pipe clamp bolt

INSTALLATION SERVICE POINTS

"AA

(1) Insert the lower end of the air pipe into the exhaust

(2) Fit the upper end of the air pipe to the reed valve a n d

(3) Attach the reed valve and bracket assembly to the reed

(4) Tighten the nutson both ends of the air pipe to thespecified

(5) Tighten the reed valve and bracket mounting bolts to

(6) Tighten the pipe clamp bolt.

REED VALVE, BRACKET AND AIR PIPE

INSTALLATION

manifold, then tighten the pipe nut temporarily.

bracket assembly, then tighten the pipe nut temporarily.

valve bracket “B” and tighten the mounting bolts

temporarily.

torque.

Caution

The tightening torque of the reed valve side nut and

that of the exhaust manifold side nut are different

from each other.

Be sure to tighten each nut correctly to the specified

torque.

the specified torque.

E

E

Nov. 1995Mitsubishi Motors Corporation

July 1999Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-B

Page 55

NOTES

Page 56

4G1 ENGINE (E-W) -

Rocker Arms and Camshafts

8. ROCKER ARMS AND CAMSHAFTS

REMOVAL AND INSTALLATION <SOHC 12-VALVE>

1

3

4

2

5

7

6

4Nm

14

11A-8-1

9

31 Nm

10

11

12

13

19

20

21

15 Nm

18

17

16

22

15

Apply engine oil to all

moving parts before

8

installation.

Removal steps

1. Breather hose

2. P.C.V. hose

3. P.C.V. valve

4. P.C.V. valve gasket

5. Oil filler cap

6. Rocker cover

7. Rocker cover gasket

"FA

"EA

"EA

E

E

8. Camshaft oil seal

9. Rocker arm and shaft assembly

10. Rocker arm and shaft assembly

11. Rocker arm A

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

"CA

12. Rocker arm spring

13. Rocker arm B

14. Rocker arm shaft

15. Rocker arm C

16. Wave washer

17. Spacer

18. Rocker arm D

19. Rocker arm shaft

20. Adjusting screw

21. Nut

22. Camshaft

Page 57

11A-8-1a

4G1 ENGINE (E-W) -

Rocker Arms and Camshafts

REMOVAL AND INSTALLATION <SOHC 16-VALVE>

4

1

2

5

35 Nm

31 Nm

3

6

14

10

11

7

18

13

12

19

20

9Nm

15

16

9Nm

8

9

17

21

Apply engine oil to all

moving parts before

installation.

Removal steps

1. Breather hose

2. P.C.V. hose

3. Oil filler cap

4. P.C.V. valve

5. P.C.V. valve gasket

6. Rocker cover

7. Rocker cover gasket

8. Oil seal

"FA

"EA

"EA

E

E

9. Oil seal

10. Rocker arms and rocker arm shaft

IN

11. Rocker arms and rocker arm shaft

EX

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

"DA

"CA

"DA

"CA

12. Rocker arm B

13. Rocker arm A

14. Rocker arm shaft

15. Adjusting screw

16. Nut

17. Rocker arm C

18. Rocker arm shaft

19. Adjusting screw

20. Nut

21. Camshaft

Page 58

4G1 ENGINE (E-W) -

Rocker Arms and Camshafts

11A-8-1b

Intentionally blank

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 59

11A-8-2

4G1 ENGINE (E-W) -

Rocker Arms and Camshafts

REMOVAL AND INSTALLATION <DOHC>

Apply engine oil to all

moving parts before

installation.

2

1

10

4Nm

7

11 Nm

11

12

3

5

4

6

9

24 Nm

8

13

14

15

Removal steps

1. Breather hose

2. P.C.V. hose

3. P.C.V. valve

4. P.C.V. valve gasket

5. Oil filler cap

"HA

E

E

6. Rocker cover

7. Rocker cover gasket A

8. Rocker cover gasket B

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

"GA

"FA

"BA

"AA

"AA

9. Semi-circular packing

10. Camshaft oil seal

11. Bearing cap

12. Camshaft

13. Camshaft

14. Roller rocker arm

15. Lash adjuster

Page 60

4G1 ENGINE (E-W) -

INSPECTION

1. CAMSHAFT

(1) Measure the cam heights and replace the camshaft if

Rocker Arms and Camshafts

any height exceeds the specified limit.

11A-8-3

Intake SOHC

12-VALVE

SOHC

16-VALVE

DOHC 34.67 34.17

Exhaust SOHC

12-VALVE

SOHC

16-VALVE

DOHC 34.26 33.76

Standard value

mm

38.78 38.28

36.99 36.49

39.10 38.60

36.85 36.35

Limit mm

2. LASH ADJUSTERS

Caution

1. The lash adjusters are precision-engineered

mechanisms. Do not allow them to become

contaminated by dirt or other foreign substances.

2. Do not attempt to disassemble the lash adjusters.

3. Use only fresh diesel fuel to clean the lash

adjusters.

(1) Prepare three containers and approximately five liters

To clean

outside

To clean

inside

To fill

diesel fuel

of diesel fuel. Into each container, pour enough diesel

fuel to completely cover a lash adjuster when it is standing

upright. Then, perform the following steps with each lash

adjuster.

A

B

C

(2) Place the lash adjuster in container A and clean its outside

surface.

NOTE

Use a nylon brush if deposits are hard to remove.

Diesel fuel

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 61

11A-8-4

MD998442

4G1 ENGINE (E-W) -

(3) While gently pushing down the internal steel ball using

Diesel fuel

Rocker Arms and Camshafts

special tool MD998442, move the plunger through 5 to

10 strokes until it slides smoothly. In addition to eliminating

stiffness in the plunger, this operation will remove dirty

oil.

Caution

The steel ball spring is extremely weak, so the lash

adjuster’s functionality may be lost if the air bleed

wire is pushed in hard.

NOTE

If the plunger remains stiff or the mechanism appears

otherwise abnormal, replace the lash adjuster.

Diesel fuel

MD998442

MD998442

Diesel fuel

MD998442

(4) Removal the lash adjuster from the container. Then, push

down thesteel ball gently and push the plunger to eliminate

diesel fuel from the pressure chamber.

Caution

Makesuretheoilholeinthesideof thebody ispointing

towardcontainerA. Donotpointtheoil hole atyourself

or other people.

(5) Place the lash adjuster in container B. Then, gently push

down the internal steel ball using special tool MD998442

and move the plunger through 5 to 10 strokes until it

slides smoothly. This operation will clean the lash

adjuster’s pressure chamber.

Caution

The steel ball spring is extremely weak, so the lash

adjuster’s functionality may be lost if the air bleed

wire is pushed in hard.

(6) Remove the lash adjuster from the container. Then, push

down thesteel ball gently and push the plunger to eliminate

diesel fuel from the pressure chamber.

Caution

Makesuretheoilholeinthesideof thebody ispointing

towardcontainerB. Donotpointtheoil hole atyourself

or other people.

Diesel fuel

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 62

4G1 ENGINE (E-W) -

(7) Place the lash adjuster in container C. Then, gently push

Rocker Arms and Camshafts

11A-8-5

down the internal steel ball using special tool MD998442.

Caution

Do not use container C for cleaning. If cleaning is

performed in container C, foreign matter could enter

the pressure chamber when chamber is filled with

diesel fuel.

MD998442

MD998442

Diesel fuel

(8) Stand the lash adjuster with its plunger at the top, then

push the plunger downward firmly until it moves through

its greatest possible stroke. Return the plunger slowly,

then release the steel ball and allow the pressure chamber

to fill with diesel fuel.

Diesel fuel

(9) Remove the lash adjuster from the container, then stand

the lash adjuster with its plunger at the top. Push the

plunger firmly and check that it does not move. Also,

check that the lash adjuster’s height matches that of a

new lash adjuster.

NOTE

If lash adjuster contracts, perform the operations (7)

through (9) again to fill it with diesel fuel completely.

Replace the lash adjuster if it still contracts after performing

these steps.

MD998440

E

E

Lash

adjuster

Division = 1 mm

Lash adjuster

Nut

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

(10)Set the lash adjuster on the special tool MD998440 (leak

down tester).

(11)Remove the bolt from the tester, then adjust the height

as illustrated.

(12)After the plunger has moved downward slightly (0.2 to

0.5 mm), measure the time taken for it to move downward

by a further 1 mm.

Standard value:

3 - 20 second/1 mm [with diesel fuel at 15 - 20_C

(59 - 68_F)]

PWEE9520

PWEE9520-A

Page 63

11A-8-6

MD998442

4G1 ENGINE (E-W) -

(13)Place the lash adjuster in container C again, then gently

(14)Stand the lash adjuster with its plunger at the top, then

Diesel fuel

Rocker Arms and Camshafts

NOTE

Replace the lash adjuster if the time measurement is

out of specification.

push down the internal steel ball using special tool

MD998442.

push the plunger downward firmly until it moves through

its greatest possible stroke. Return the plunger slowly,

then release the steel ball and allow the pressure chamber

to fill with diesel fuel.

(15)Remove the lash adjuster from the container, then stand

the lash adjuster with its plunger at the top. Push the

plunger firmly and check that it does not move. Also,

check the lash adjuster’s height matches that of a new

lash adjuster.

NOTE

If lash adjuster contracts, perform the operations (13)

through (15) again to fill it with diesel fuel completely.

Replace the lash adjuster if it still contracts after performing

these steps.

(16)Stand the lash adjuster upright to prevent diesel fuel from

spilling out. Do not allow the lash adjuster to become

contaminated by dirt or other foreign matter. Fit the lash

adjuster onto the engine as soon as possible.

INSTALLATION SERVICE POINTS

"AA

Slit

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

(1) Apply engine oil to the camshaft journals a nd cams before

CAMSHAFT INSTALLATION

installation. Ensure that the intake-side and exhaust-side

camshafts are not reversed.

NOTE

There is a 4 mm-wide slot in the rear end of the

exhaust-side camshaft.

PWEE9520

PWEE9520-A

Page 64

4G1 ENGINE (E-W) -

Rocker Arms and Camshafts

11A-8-7

"BA

BEARING CAP INSTALLATION

(1) Position the camshaft dowel pins as shown.

NOTE

With the camshaft dowel pins in this position, the camshaft

notches for tightening cylinder head bolt are correctly

positioned.

(2) Bearing caps Nos. 2 to 5 are the same shape. Be sure

to install them in order of their cap numbers and check

the identification marks to ensure that the intake and

exhaust sides are not reversed.

Identification marks:

I: Intake

E: Exhaust

(3) Apply the specified sealant to the surfaces that are to

mate with the cylinder head. Then, tighten the bearing

cap bolts - for the middle caps first, then for the outer

caps, and soon. Tighten the bolts a little at a time such

that each bolt is tightened to the specified torque in the

final sequence.

Specified sealant:

3M ATD Part No. 8660 or equivalent

(4) Check that the rocker arms are installed correctly.

Chamfer

E

E

Oil holes

1 mm or less

"CA

(1) Install provisionally the screw to the rocker arm. Insert

ADJUSTING SCREW INSTALLATION

it so that the end of the screw is flush with the edge

of the rocker arm or projects slightly (1 mm or less).

"DA

ROCKER ARM SHAFT INSTALLATION

(1) Place the end with the larger chamfered side toward the

flywheel side. <SOHC 12-VALVE>

Place the end with the larger chamfered side toward the

timing belt side. <SOHC 16-VALVE>

NOTE

The rocker arm shaft for intake valves have eight oil holes.

(2) Place the section of the shaft with the oil holes toward

the cylinder head.

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 65

11A-8-8

4G1 ENGINE (E-W) -

Rocker Arms and Camshafts

SOHC 12-VALVE

Timing belt side

Identification mark

SOHC 16-VALVE

Timing belt side

Identification

mark

SOHC

MD998713

"EA

ROCKER ARM / ROCKER SHAFT ASSEMBLY

INSTALLATION

(1) Assemble the rocker arms and rocker shaft, paying

attention to the identification marks. Then mount the

assembly on the cylinder head.

"FA

CAMSHAFT OIL SEAL INSTALLATION

DOHC

E

E

MD998713

Sealant

"GA

(1) Apply the specified sealant to the area shown.

SEMI-CIRCULAR PACKING INSTALLATION

Specified sealant:

3M ATD Part No. 8660 or equivalent

DEN0053

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 66

4G1 ENGINE (E-W) -

Rocker Arms and Camshafts

11A-8-9

Timing belt side

"HA

ROCKER COVER INSTALLATION

(1) Apply the specified sealant to the area shown, then fit

the rocker cover.

Specified sealant:

3M ATD part No. 8660 or equivalent

VALVE CLEARANCE ADJUSTMENT

<SOHC 12-VALVE>

(1) Position the No. 1 cylinder at top dead center on the

compression stroke.

(2) Adjust the valve clearance at the points shown in the

illustration.

(3) Loosen the adjusting screw locknut.

(4) Using a feeler gauge, adjust the valve clearance by turning

the adjusting screw.

Timing belt side

Thickness gauge

Standard value: on cold engine

Intake 0.09 mm

Exhaust 0.17 mm

(5) While holding the adjusting screw with a screwdriver,

tighten the lock nut.

(6) Rotate clockwise the crankshaft one complete turn (360

degree).

(7) Adjust the valve clearance at points as shown in the

illustration.

(8) Repeat steps (3) to (5) to adjust the valve clearance

of remaining valves.

(9) With the engine mounted on vehicle, warm up the engine.

Then, check for valve clearance on hot engine and adjust

if necessary.

Standard value: on hot engine

Intake 0.20 mm

Exhaust 0.25 mm

_

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 67

11A-8-10

4G1 ENGINE (E-W) -

Rocker Arms and Camshafts

Timing belt side

Timing belt side

Thickness gauge

<SOHC 16-VALVE>

(1) Position the No. 1 cylinder at top dead center on the

compression stroke.

(2) Adjust the valve clearance at the points shown in the

illustration.

(3) Loosen the adjusting screw locknut.

(4) Using a feeler gauge, adjust the valve clearance by turning

the adjusting screw.

Standard value: on cold engine

Intake 0.09 mm

Exhaust 0.17 mm

(5) While holding the adjusting screw with a screwdriver,

tighten the lock nut.

(6) Rotate clockwise the crankshaft one complete turn (360

degree).

(7) Adjust the valve clearance at points as shown in the

illustration.

(8) Repeat steps (3) to (5) to adjust the valve clearance

of remaining valves.

(9) With the engine mounted on vehicle, warm up the engine.

Then, check for valve clearance on hot engine and adjust

if necessary.

_

Standard value: on hot engine

Intake 0.20 mm

Exhaust 0.25 mm

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 68

4G1 ENGINE (E-W) -

Cylinder Head and Valves

9. CYLINDER HEAD AND VALVES

REMOVAL AND INSTALLATION <SOHC 12-VALVE>

11A-9-1

1

2

9

10

4

22

5

6

13

11

15

16

18

14

17

21

12

19

7

20

8

3

AA""DA

AB""CA

"BA

AB""CA

"BA

E

E

Apply engine oil to all

moving parts before

installation.

Removal steps

1. Cylinder head bolt

2. Cylinder head assembly

3. Cylinder head gasket

4. Retainer lock

5. Valve spring retainer

6. Valve spring

7. Intake valve (primary)

8. Intake valve (secondary)

9. Retainer lock

10. Valve spring retainer

11. Valve spring

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

AC""AA

AC""AA

PWEE9520

PWEE9520-A

12. Exhaust valve

13. Valve stem seal

14. Valve spring seat

15. Valve stem seal

16. Valve spring seat

17. Intake valve guide

18. Exhaust valve guide

19. Intake valve seat (primary)

20. Intake valve seat (secondary)

21. Exhaust valve seat

22. Cylinder head

Page 69

11A-9-1a

4G1 ENGINE (E-W) -

Cylinder Head and Valves

REMOVAL AND INSTALLATION <SOHC 16-VALVE>

1

4

5

9

8

10

14

6

17

15

2

12

13

16

20

19

11

18

3

7

AA""DA

AB""CA

"BA

AB""CA

"BA

Removal steps

1. Cylinder head bolt

2. Cylinder head assembly

3. Cylinder head gasket

4. Retainer lock

5. Valve spring retainer

6. Valve spring

7. Exhaust valve

8. Retainer lock

9. Valve spring retainer

10. Valve spring

AC""AA

AC""AA

Apply engine oil to all

moving parts before

installation.

11. Intake valve

12. Valve stem seal

13. Valve spring seat

14. Valve stem seal

15. Valve spring seat

16. Exhaust valve guide

17. Intake valve guide

18. Exhaust valve seat

19. Intake valve seat

20. Cylinder head

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 70

4G1 ENGINE (E-W) -

Cylinder Head and Valves

11A-9-1b

Intentionally blank

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Added

PWEE9520

PWEE9520-A

Page 71

11A-9-2

4G1 ENGINE (E-W) -

REMOVAL AND INSTALLATION <DOHC>

Cylinder Head and Valves

2

4

12

1

8

9

10

5

20

6

14

15

17

13

16

19

18

11

7

3

AA""DA

AB""CA

"BA

AB""CA

"BA

E

Apply engine oil to all

moving parts before

installation.

Removal steps

1. Cylinder head bolt

2. Cylinder head assembly

3. Cylinder head gasket

4. Retainer lock

5. Valve spring retainer

6. Valve spring

7. Intake valve

8. Retainer lock

9. Valve spring retainer

10. Valve spring

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

AC""AA

AC""AA

11. Exhaust valve

12. Valve stem seal

13. Valve spring seat

14. Valve stem seal

15. Valve spring seat

16. Intake valve guide

17. Exhaust valve guide

18. Intake valve seat

19. Exhaust valve seat

20. Cylinder head

Page 72

4G1 ENGINE (E-W) -

Cylinder Head and Valves

11A-9-3

SOHC

DOHC

SOHC

MB991653

MB991653

MD998772

REMOVAL SERVICE POINTS

AA"

AB"

(1) Tag removed valves, springs, and other components,

CYLINDER HEAD BOLT REMOVAL

RETAINER LOCK REMOVAL

noting their cylinder numbers and locations to facilitate

reassembly. Store these components safely.

DOHC

MD998772

MD998735

E

Nov. 1995Mitsubishi Motors Corporation

PWEE9520

Page 73

11A-9-4

4G1 ENGINE (E-W) -

Cylinder Head and Valves

Contact (must

be in center of

face)

Margin

6EN0542

AC"

VALVE STEM SEAL REMOVAL

INSPECTION

1. CYLINDER HEAD

(1) Before cleaning the cylinder head, check it for water leaks,

gas leaks, cracks, and other damage.

(2) Remove all oil, water scale, sealant, and carbon. After

cleaning the oil passages, blow air through them to verify

that they are not blocked.

(3) Check for distortion in the cylinder head gasket surface

using a straight edge and thickness gauge. If distortion

exceeds the specified limit, grind the gasket surface to

specification.

Gasket surface distortion

Standard value: 0.05 mm or less

Limit: 0.2 mm

Grinding limit: 0.2 mm

Cylinder head height (specification when new):

SOHC 12-VALVE: 106.9 - 107.1 mm

SOHC 16-VALVE: 119.9 - 120.1 mm

DOHC: 131.9 - 132.1 mm

Caution

No more than 0.2 mm of stock may be removed from

the cylinder head and cylinder block mating surfaces

in total.

2. VALVES

(1) Check the valve face for correct contact. If contact is

uneven or incomplete, reface the valve seat.

(2) If the margin is less than specified, replace the valve.

Standard value:

Intake

Exhaust: 1.5 mm

Limit:

Intake: 0.5 mm

Exhaust: 1.0 mm

1.0 mm

:

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 74

4G1 ENGINE (E-W) -

(3) Measure the valve’s total length. If the measurement is

Intake SOHC 12-VALVE 100.75 100.25

Exhaust SOHC 12-VALVE 101.05 100.55

Cylinder Head and Valves

less than specified, replace the valve.

Standard mm Limit mm

SOHC 16-VALVE 111.56 111.06

DOHC 106.35 105.85

SOHC 16-VALVE 114.71 114.21

DOHC 106.85 106.35

11A-9-5

Squareness

Free height

1EN0264

3. VALVE SPRINGS

(1) Measure the valve spring’s free height. If the measurement

is less than specified, replace the spring.

Standard mm Limit mm

SOHC Intake 46.1 45.6

12-VALVE

SOHC 16-VALVE 50.9 50.4

DOHC 49.1 48.6

Exhaust 46.8 46.3

(2) Measure the squareness of the spring. If the measurement

exceeds the specified limit, replace the spring.

Standard value: 2_or less

Limit: 4

_

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 75

11A-9-6

Valve

guide

Guide I. D.

4G1 ENGINE (E-W) -

Stem O. D.

1EN0279

Valve stem end

Cylinder Head and Valves

4. VALVE GUIDES

(1) Measure the clearance between the valve guide a n d valve

stem. If the clearance exceeds t h e specified limit, replace

either or both components.

Standard mm Limit mm

Intake SOHC 12-VALVE 0.020 - 0.050 0.10

SOHC 16-VALVE 0.020 - 0.047 0.10

DOHC 0.020 - 0.047 0.10

Exhaust SOHC 12-VALVE 0.050 - 0.085 0.15

SOHC 16-VALVE 0.030 - 0.062 0.15

DOHC 0.030 - 0.057 0.15

Valve projection

Spring seating

surface

5. VALVE SEATS

(1) Assemble the valve, then measure the valve stem

projection between the end of the valve stem an d the

spring seating surface. If the measurement exceeds the

specified limit, replace the valve seat.

Standard mm Limit mm

SOHC Intake 43.70 44.20

12-VALVE

SOHC Intake 53.21 53.71

16-VALVE

DOHC Intake 48.80 49.30

Exhaust 43.30 43.80

Exhaust 54.10 54.60

Exhaust 48.70 49.20

E

E

Nov. 1995Mitsubishi Motors Corporation

Dec. 1998Mitsubishi Motors Corporation Revised

PWEE9520

PWEE9520-A

Page 76

4G1 ENGINE (E-W) -

Cylinder Head and Valves

11A-9-7

0.9 - 1.3 mm

65

_

15

Cut away

Valve seat

height

_

44

_

0.5 - 1.0 mm

Oversize hole I. D.

0.9 - 1.3 mm

44

_

15

0.5 - 1.0 mm

_

1EN0274

1EN0275

65

VALVE SEAT CORRECTION SERVICE POINTS

(1) Before correcting the valve seat, check the clearance

_

between the valve guide and valve. If necessary, replace

the valve guide.

(2) Using the appropriate special tool or seat grinder, correct

the valve seat to achieve the specified seat width and

angle.

(3) After correcting the valve seat, lap the valve and valve

seat using lapping compound. Then, check the valve stem

projection (refer to 5. VALVE SEATS in INSPECTION).

VALVE SEAT REPLACEMENT SERVICE

POINTS

(1) Cut the valve seat to be replaced from the inside to reduce

the wall thickness. Then, remove the valve seat.

(2) Rebore the valve seat hole in the cylinder head to match

the selected oversize valve seat diameter.

Valve seat diameters

Standard mm

SOHC In- Primary 0.30 O.S. 27.300 - 27.325

12-VALVE take

Secondary 0.30 O.S. 32.300 - 32.325

Exhaust 0.30 O.S. 35.300 - 35.325

SOHC Intake 0.30 O.S. 28.300 - 28.321

16-VALVE

<4G13>

Exhaust 0.30 O.S. 26.300 - 26.321

SOHC Intake 0.30 O.S. 30.300 - 30.321

16-VALVE

<4G18>

Exhaust 0.30 O.S. 28.300 - 28.321

DOHC Intake 0.30 O.S. 31.300 - 31.325

Exhaust 0.30 O.S. 27.800 - 27.825

0.60 O.S. 27.000 - 27.625

0.60 O.S. 32.600 - 32.625

0.60 O.S. 35.600 - 35.625

0.60 O.S. 28.600 - 28.621

0.60 O.S. 26.600 - 26.621

0.60 O.S. 30.600 - 30.621

0.60 O.S. 28.600 - 28.621

0.60 O.S. 31.600 - 31.625