Page 1

ENGINE

4D68

CONTENTS

11A-0-1

GENERAL INFORMATION 11A-0-3

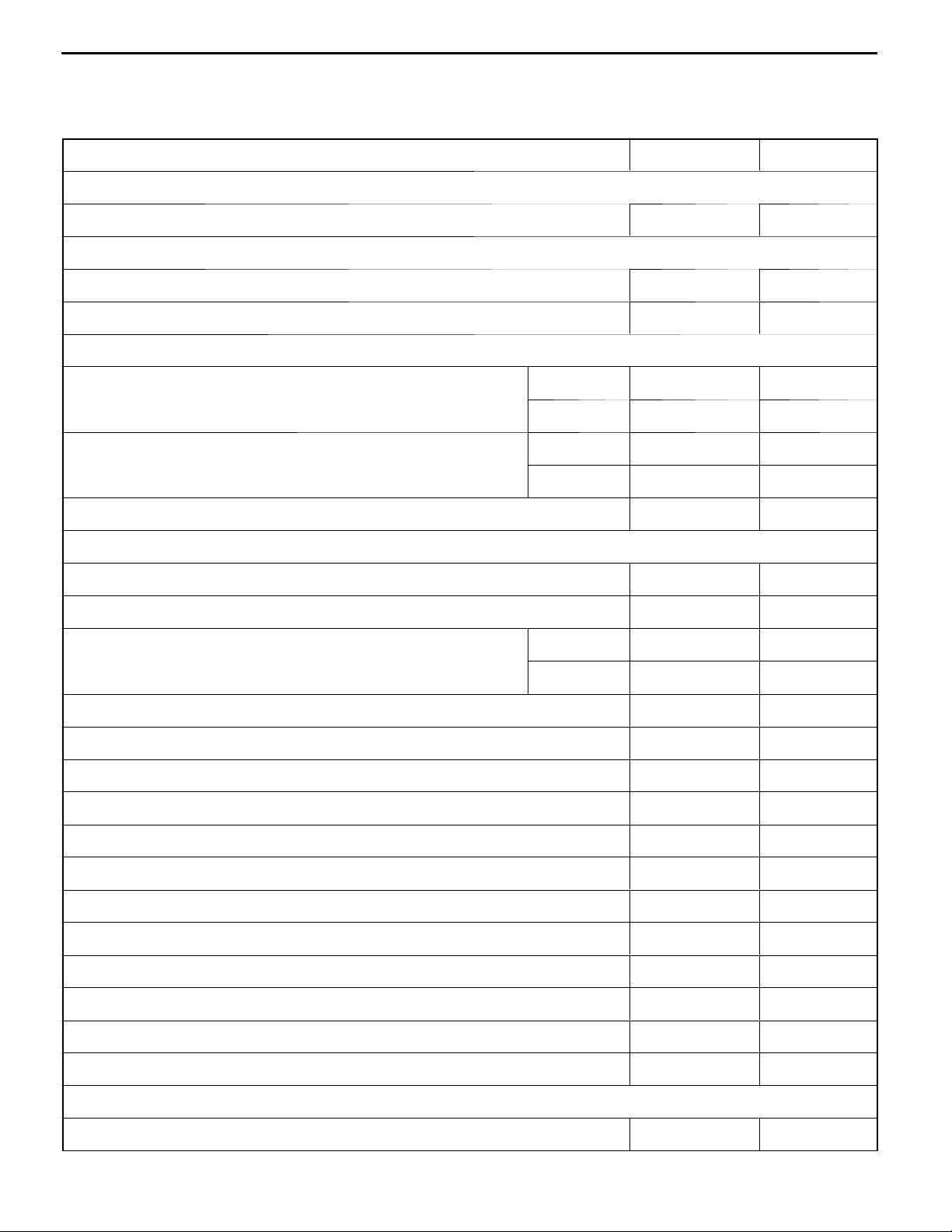

1. SPECIFICATIONS 11A-1-1

SERVICE SPECIFICATIONS 11A-1-1

REWORK DIMENSIONS 11A-1-3

TORQUE SPECIFICATIONS 11A-1-4

NEW TIGHTENING METHOD - BY USE OF BOLTS

TO BE TIGHTENED IN PLASTIC AREA 11A-1-7

SEALANT 11A-1-7

FORM-IN-PLACE GASKET 11A-1-8

2. SPECIAL TOOLS 11A-2-1

3. DRIVE BELT AND GLOW PLUG 11A-3-1

4. TIMING BELT 11A-4-1

5. GLOW PLUG, FUEL INJECTION PUMP

AND INJECTION NOZZLE 11A-5-1

6. INTAKE AND EXHAUST MANIFOLDS 11A-6-1

7. WATER PUMP, THERMOSTAT, HOSE AND PIPES 11A-7-1

.................................................

...............................................

.....................................

..........................................

............................

.................................

.............................

................

..............................

..........................................

..........................

................................

....................

......

8. ROCKER ARMS, ROCKER SHAFT AND CAMSHAFT 11A-8-1

9. CYLINDER HEAD, VALVES AND VALVE SPRINGS 11A-9-1

10. FRONT CASE, COUNTERBALANCE SHAFTS

AND OIL PAN 11A-10-1

11. PISTONS AND CONNECTING RODS 11A-11-1

12. CRANKSHAFT, CYLINDER BLOCK AND FLYWHEEL 11A-12-1

E

Dec. 1996Mitsubishi Motors Corporation

...............................................

.....................

PWEE9609

...

.....

...

Page 2

11A-0-2

NOTES

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 3

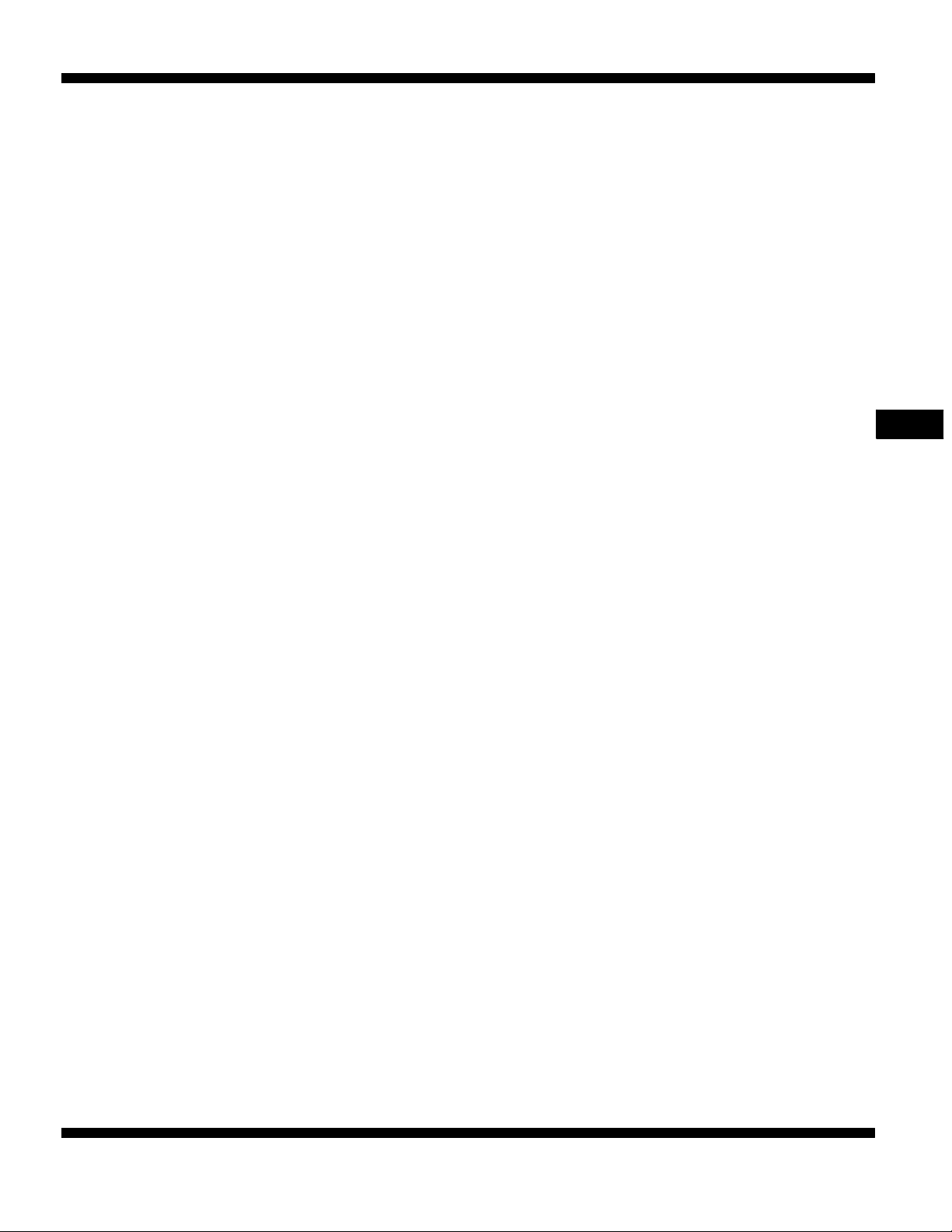

4D68 ENGINE (E-W) -

GENERAL INFORMATION

SECTIONAL VIEW OF ENGINE

General Information

11A-0-3

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

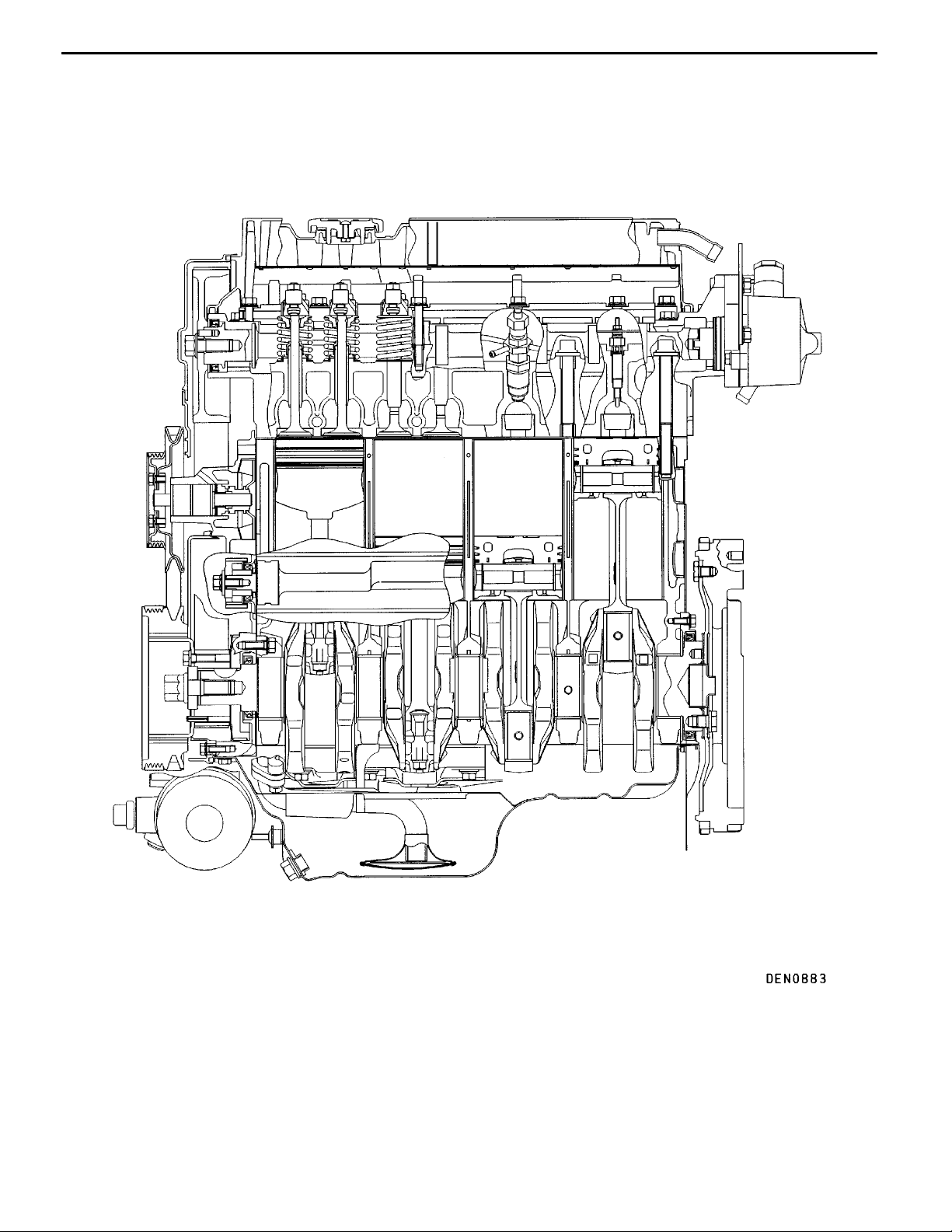

Page 4

11A-0-4

4D68 ENGINE (E-W) -

SECTIONAL VIEW OF ENGINE

General Information

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 5

4D68 ENGINE (E-W) -

General Information

GENERAL SPECIFICATIONS

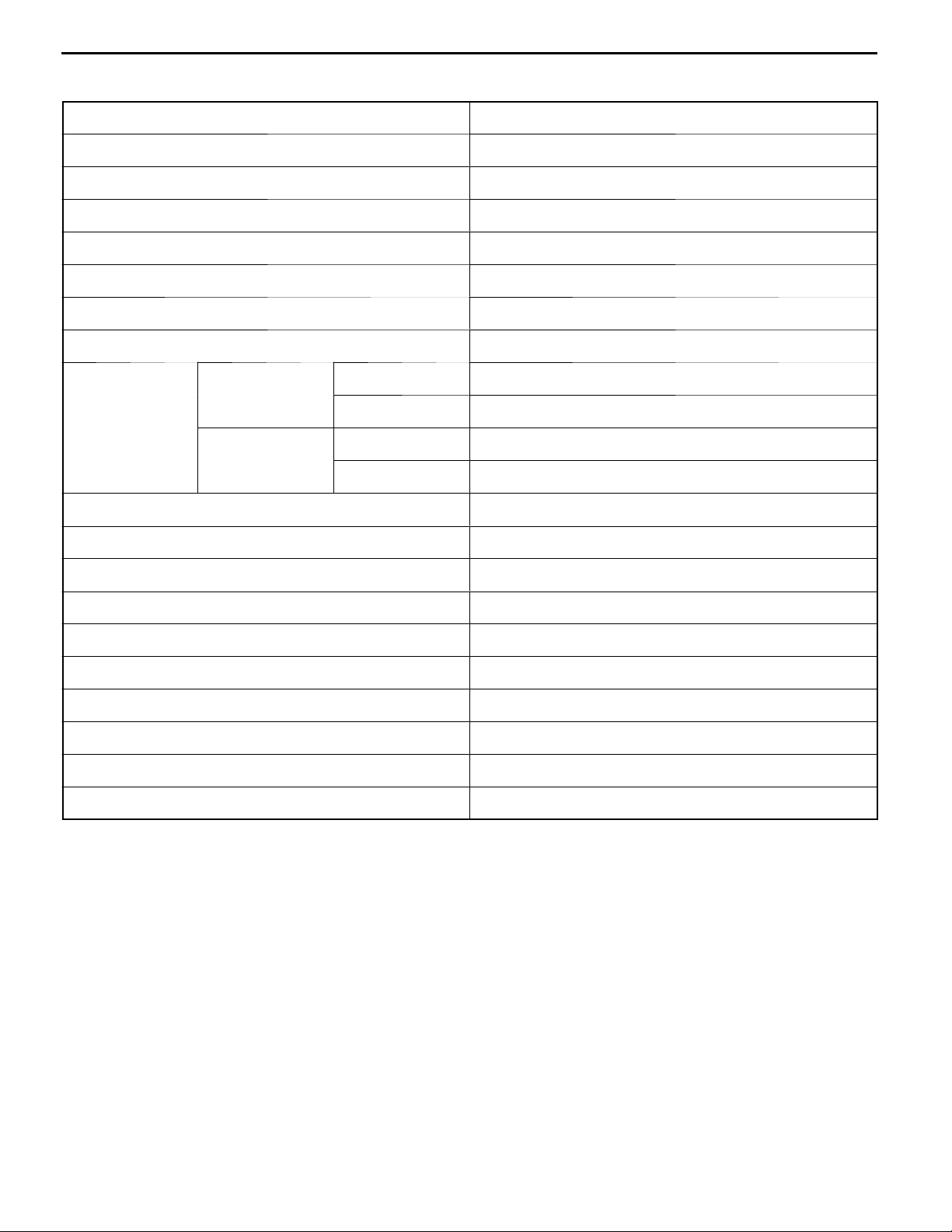

Descriptions Specifications

Type Diesel engine

Number of cylinders 4 in-line

Combustion chamber Swirl chamber

11A-0-5

Total displacement dm

Cylinder bore mm 82.7

Piston stroke mm 93

Compression ratio 22.4

V alve timing Intake valve Opens (BTDC) 20°

Lubrication system Pressure feed, full-flow filtration

Oil pump type External gear type

Cooling system Water-cooled

Water pump type Centrifugal impeller type

EGR type Single type

Fuel system Electronic control distributor-type injection pump

3

Closes (ABDC) 48°

Exhaust valve Opens (BBDC) 54°

Closes (ATDC) 22°

1.998

Supercharging Turbocharger

Rocker arm Roller type

Adjusting screw Elephant foot type

Oil lever sensor Provided

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 6

4D68 ENGINE (E-W) -

Specifications

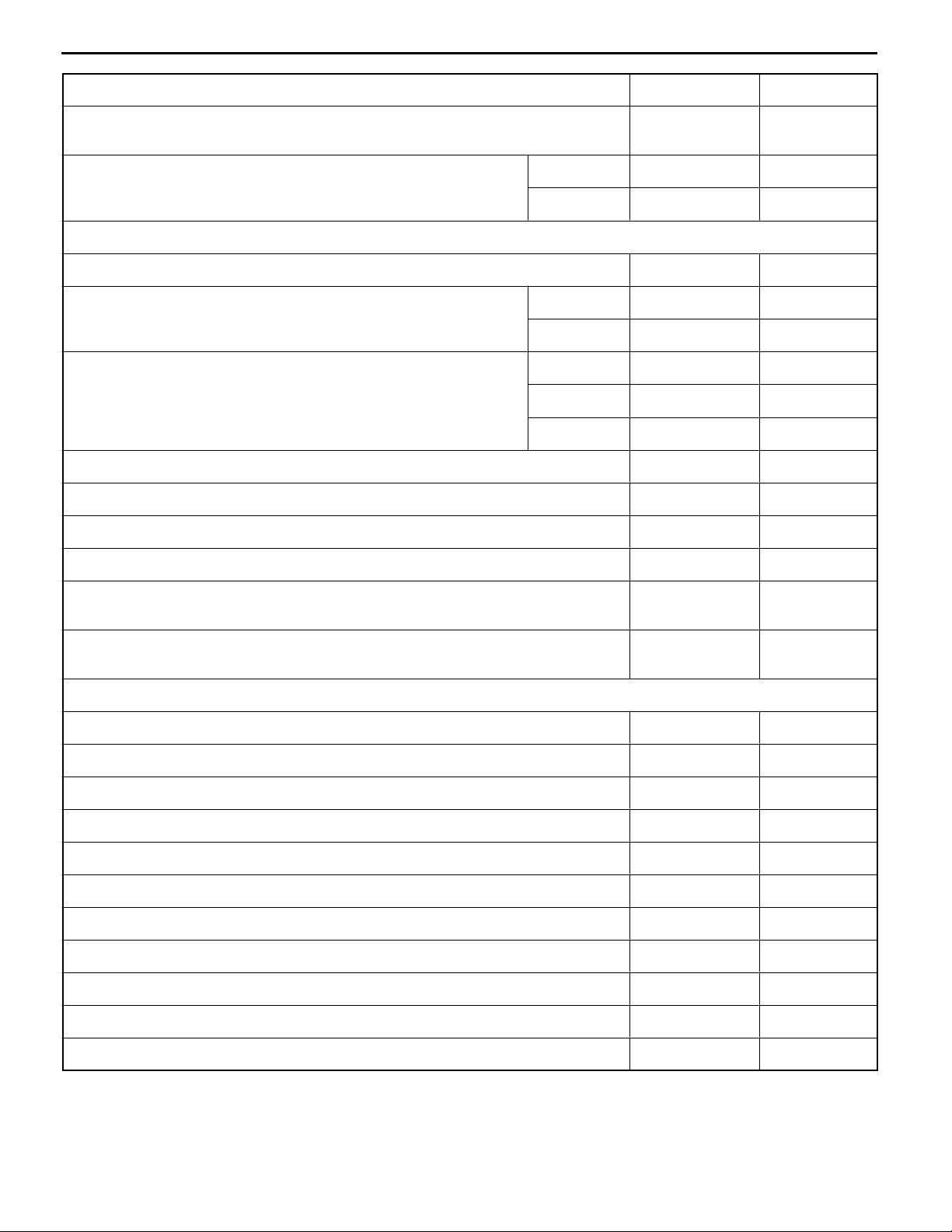

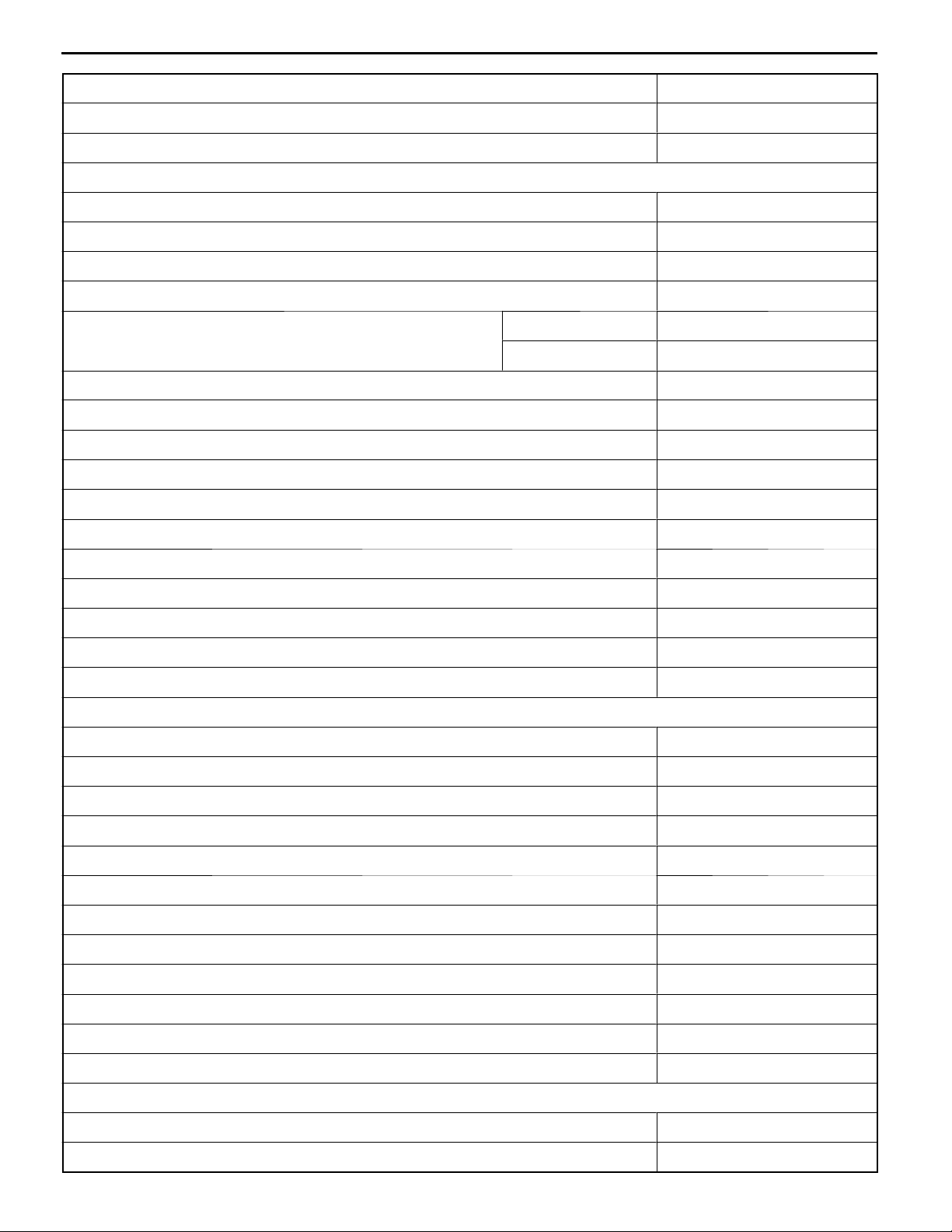

1. SPECIFICATIONS

SERVICE SPECIFICATIONS

Item Standard value Limit

Drive belt and glow plug

Glow plug resistance W 0.5 -

Timing belt

Timing belt deflection mm 4.0- 5.0 -

Timing belt “B” deflection mm 5.0- 7.0 -

Rocker arms, rocker shaft and camshaft

Camshaft cam height mm Intake 41.90 41.40

Exhaust 41.96 41.46

Valve clearance (on cold engine) mm Intake 0.25 -

Exhaust 0.35 -

11A-1-1

Camshaft journal O.D. mm 30.0 -

Cylinder head, valves and valve springs

Cylinder head gasket surface flatness mm Within 0.03 0.2

Cylinder head overall height mm 86.9- 87.1 -

Valve overall length mm Intake 114.05 113.55

Exhaust 113.80 113.30

Thickness of valve head (margin) mm 1.5 0.7

Valve stem O.D. mm 6.0 -

Valve face angle 45° - 45.5° -

V alve stem to guide clearance mm 0.05- 0.09 0.15

V alve spring free length mm 49.1 48.1

V alve load/installed height N/mm 240/37.9 -

V alve spring out-of-squareness 2° or less Max. 4°

Valve seat valve contact width mm 0.9- 1.3 -

V alve stem projection mm 43.45 43.95

Valve guide I.D. mm 8.0 -

V alve guide projection from cylinder head upper surface mm 15 -

Cylinder head bolt shank length mm - 119.7

Front case, counterbalance shafts and oil pan

Oil cooler by-pass valve dimension (L) [Normal temperature] mm 34.5 -

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 7

11A-1-2

Item LimitStandard value

4D68 ENGINE (E-W) -

Specifications

Oil cooler by-pass valve dimension (L) [by-pass hole closing temperature

(97 - 103°C or more)] mm

Oil pump side clearance Drive gear 0.08 - 0.14 -

Driven gear 0.06- 0.12 -

Pistons and connecting rods

Piston O.D. mm 82.7 -

Piston ring to piston ring groove clearance mm No. 1 0.05- 0.07 0.15

No. 2 0.05- 0.07 0.15

Piston ring end gap mm No. 1 0.20- 0.32 0.8

No. 2 0.35- 0.50 0.8

Oil ring 0.10 - 0.30 0.8

Piston pin O.D. mm 25.0 -

Crankshaft pin oil clearance mm 0.02 - 0.05 0.1

Connecting rod big end side clearance mm 0.10- 0.25 0.4

Connecting rod bushing I.D. mm 25.015- 25.025 -

40.0 -

Connecting rod bushing bend (Parallelism between big end center line and small

end center line) mm

Connecting rod bushing twist (Deflection between big end center line and small

end center line) mm

Crankshaft, cylinder block and flywheel

Crankshaft end play mm 0.05- 0.18 0.25

Crankshaft journal O.D. mm 57.0 -

Crankshaft pin O.D. mm 45.0 -

Crankshaft journal oil clearance mm 0.02- 0.04 0.1

Cylinder block gasket surface flatness mm 0.05 0.1

Cylinder block overall height mm 235 -

Cylinder bore I.D. mm 82.70- 82.73 -

Cylinder conicity mm 0.01 -

Piston to cylinder clearance mm 0.03- 0.05 -

Cylinder sleeve press-fitting force N 2,200 or more -

0.05 -

0.1 -

Piston projection mm 0.823 -

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 8

4D68 ENGINE (E-W) -

Specifications

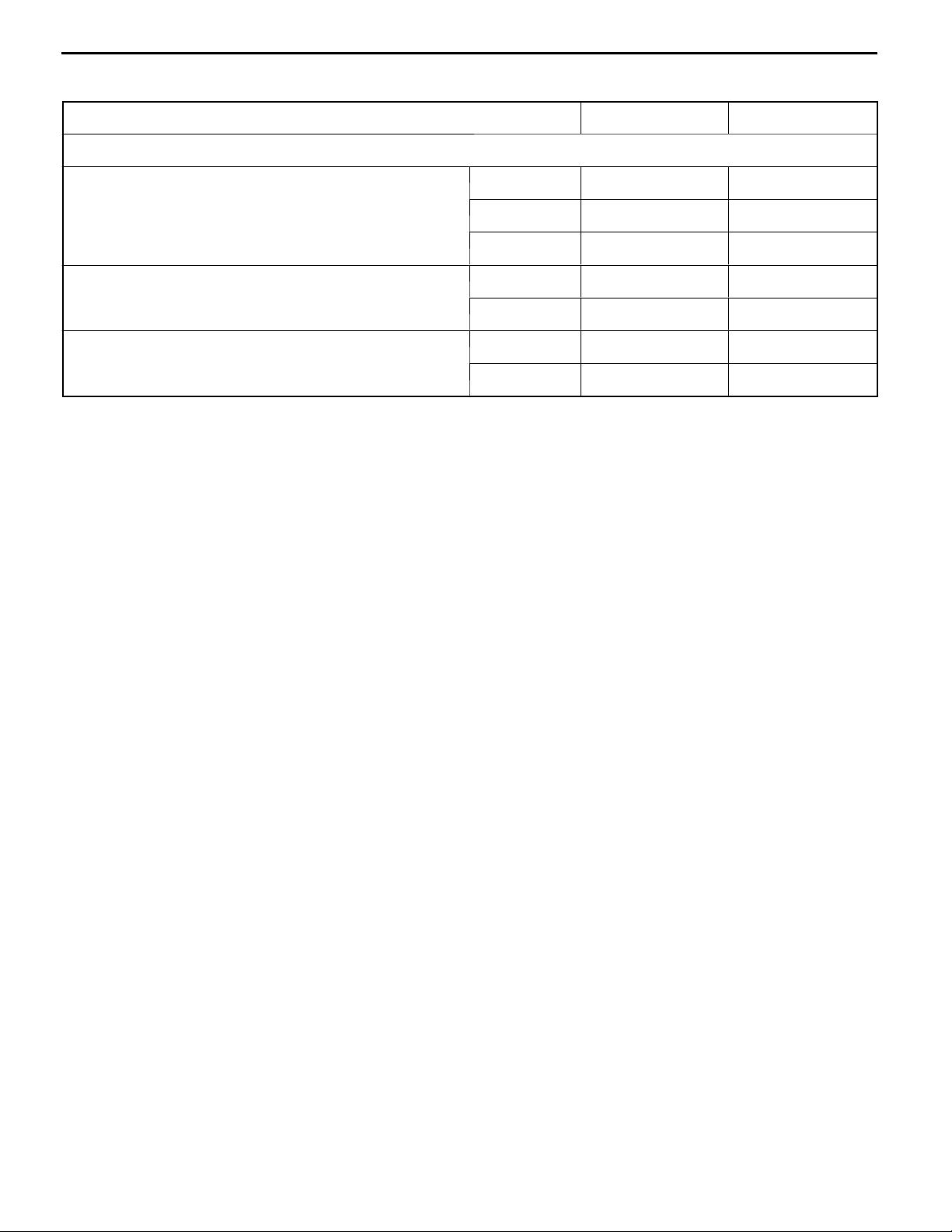

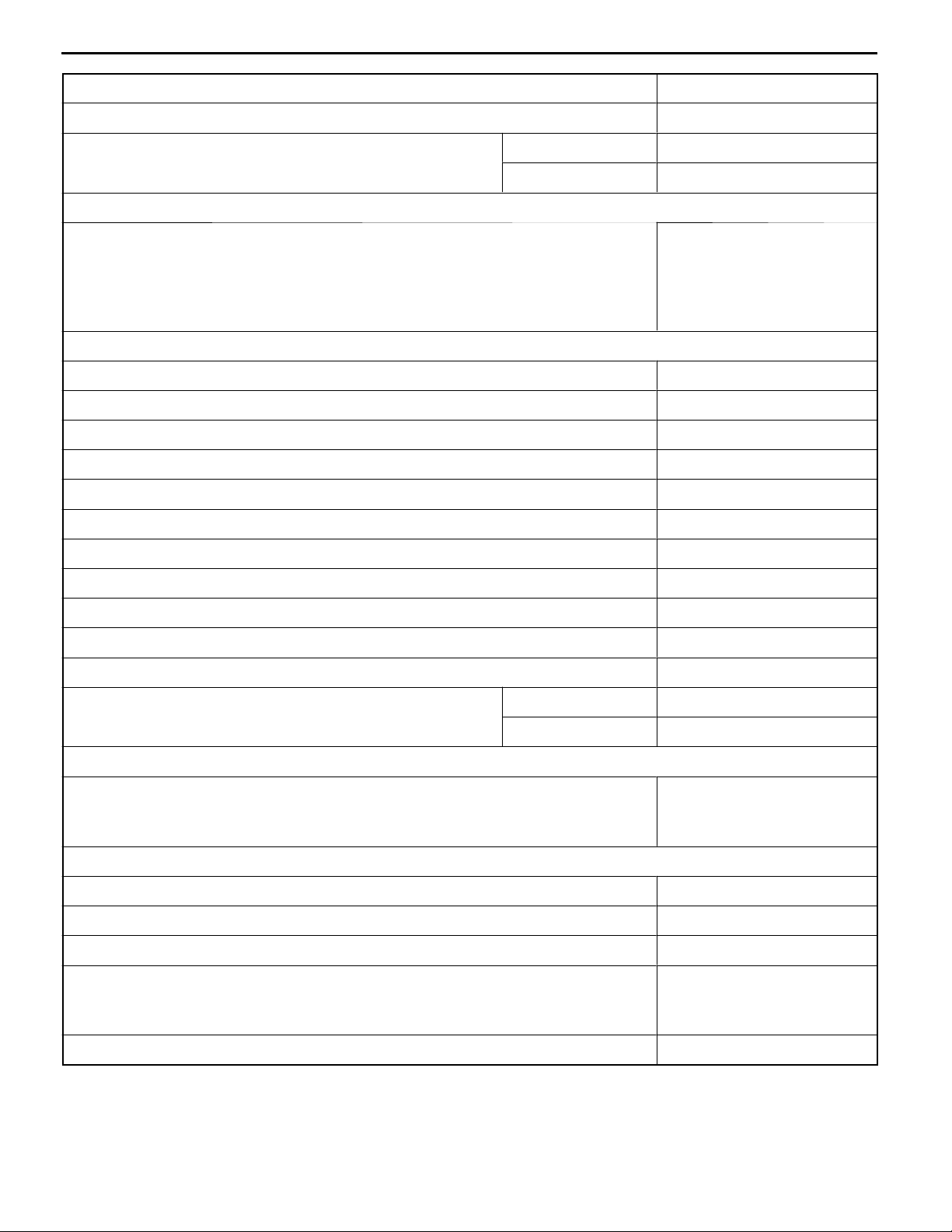

REWORK DIMENSIONS

Item Standard value Limit

Cylinder head, valves and valve springs

Cylinder head oversize valve guide hole 0.05 O.S. 13.050- 13.068 (both intake and exhaust) mm

0.25 O.S. 13.250- 13.268 -

0.50 O.S. 13.500- 13.518 -

Cylinder head oversize intake valve seat ring hole mm 0.3 O.S. 38.300 - 38.325 -

0.6 O.S. 38.600 - 38.625 -

Cylinder head oversize exhaust valve seat ring hole mm 0.3 O.S. 34.300 - 34.325 -

0.6 O.S. 34.600 - 34.625 -

NOTE

O.D.: Outer diameter

I.D.: Inner diameter

O.S.: Oversize diameter

11A-1-3

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 9

11A-1-4

4D68 ENGINE (E-W) -

Specifications

TORQUE SPECIFICATIONS

Items Nm

Drive belt and glow plug

Oil level gauge guide bolt 13

Pulley bolt (for power steering pump drive) 9

Alternator brace bolt 23

Lock bolt 23

Adjusting bolt 10

Alternator pivot nut 44

Crankshaft pulley bolt 25

Glow plug 18

Glow plug nut 1.8

Timing belt

Timing belt cover Flange bolt 11

Washer bolt 9

Crankshaft position sensor bolt 9

Timing belt tensioner bolt 48

Tensioner spring bolt 13

Timing belt idler pulley bolt 48

Camshaft sprocket bolt 88

Injection pump sprocket flange bolt 9

Injection pump sprocket nut 83

Crankshaft bolt 118

Oil pump sprocket nut 54

Tensioner “B” bolt 18

Counterbalance shaft sprocket bolt 45

Timing belt rear cover bolt 11

Engine support bracket bolt and nut 49

Glow plug, fuel injection pump and injection nozzle

Injection pipe 29

Injection pipe clamp bolt 5

Fuel pipe bolt 13

Engine hanger bolt 18

Fuel injection pump bolt 23

Fuel injection pump nut 18

Fuel injection pump stay bolt 35

Fuel return pipe nut 29

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 10

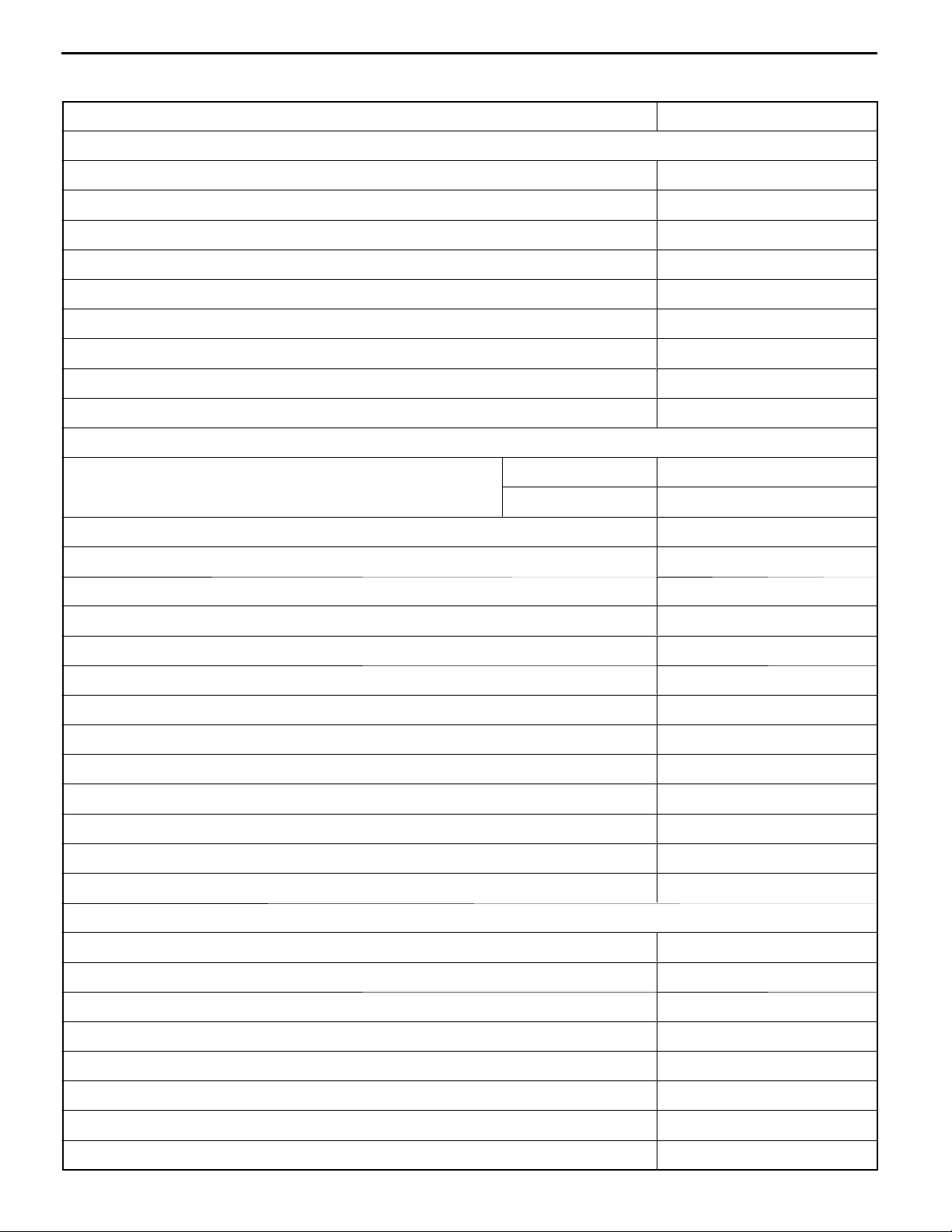

4D68 ENGINE (E-W) -

Items Nm

Injection nozzle 54

Fuel injection pump bracket nut 23

Intake and exhaust manifold

Air temperature sensor 14

Air intake fitting bolt 17

EGR valve bolt 24

EGR pipe bolt and nut 17

Turbocharger heat protector bolt M8 13

Exhaust fitting heat protector bolt 13

Water pipe “A” and “B” eye bolt 30

Water pipe “A” and “B” bolt 10

Oil pipe eye bolt 16

Specifications

M6 11

11A-1-5

Exhaust fitting bolt and nut 59

Oil return pipe bolt 9

Heat protector front and rear bolt 13

Turbocharger assembly bolt 59

Exhaust manifold bolt and nut 29

Alternator brace stay bolt 23

Intake manifold bolt and nut 17

Water pump, thermostat, hose and pipe

Oil pipe eye bolt 16

Oil return pipe eye bolt 17

Oil return pipe bolt 9

Engine coolant temperature sensor 35

Engine coolant temperature gauge unit 11

Cover bolt 19

Water pump bolt 13

Water inlet pipe bolt 12

V acuum pump bolt 22

Water inlet fitting bolt 23

Water outlet fitting bolt 12

Thermostat housing bolt 23

Rocker arms, rocker shaft and camshaft

Rocker cover bolt 6

Rocker shaft bolt 29

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 11

11A-1-6

Items Nm

Adjusting nut 15

Camshaft bearing cap bolt M8 ¢ 25, M8 ¢ 40 20

Cylinder head, valves and valve springs

Cylinder head bolt 90

Front case, counterbalance shafts and oil pan

Drain plug 39

Oil level sensor bolt 9

Oil pan bolt 7

Oil screen bolt 19

4D68 ENGINE (E-W) -

Specifications

M8 ¢ 55 29

¯

Fully loosen

¯

40 + 90° +90°

Oil cooler by-pass valve 54

Oil pressure switch 10

Relief plug 44

Oil filter bracket bolt 18

Plug 23

Flange bolt 36

Front case bolt 24

Oil pump cover Bolt 16

Screw 10

Pistons and connection rods

Connecting rod cap nut 20

¯

+90° - 100°

Crankshaft, cylinder block and flywheel

Flywheel bolt 132

Rear plate bolt 11

Oil seal case bolt 11

Bearing cap bolt 25

Check valve 15

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

¯

+90° - 100°

Page 12

4D68 ENGINE (E-W) -

Specifications

11A-1-7

NEW TIGHTENING METHOD - BY USE OF BOLTS TO BE TIGHTENED IN PLASTIC AREA

A new type of bolts, to be tightened in plastic area, is currently used some parts of the engine. The

tightening method for the bolts is different from the conventional one. Be sure to observe the method

described in the text when tightening the bolts.

Service limits are provided for the bolts. Make sure that the service limits described in the text are strictly

observed.

D Areas where the bolts are in use:

(1) Cylinder head bolts

(2) Main bearing cap bolts

(3) Connecting rod cap bolts

D Tightening method

After tightening the bolts to the specified torque, tighten them another 90° or 180° (twice 90°). The

tightening method varies on different areas. Observe the tightening method described in the text.

SEALANT

Items Specified sealant Quantity

Thermostat housing Mitsubishi Genuine Part No. MD970389 or equivalent As required

Engine coolant temperature

gauge unit

Oil pressure switch 3M ATD Part No. 8660 or equivalent As required

Water outlet fitting Mitsubishi Genuine Part No. MD970389 or equivalent As required

Oil pan Mitsubishi Genuine Part No. MD970389 or equivalent As required

Oil seal case Mitsubishi Genuine Part No. MD970389 or equivalent As required

Cover Mitsubishi Genuine Part No. MD970389 or equivalent As required

Camshaft bearing cap 3M ATD Part No. 8660 or equivalent As required

3M Nut Locking Part No. 4171 or equivalent As required

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 13

11A-1-8

4D68 ENGINE (E-W) -

Specifications

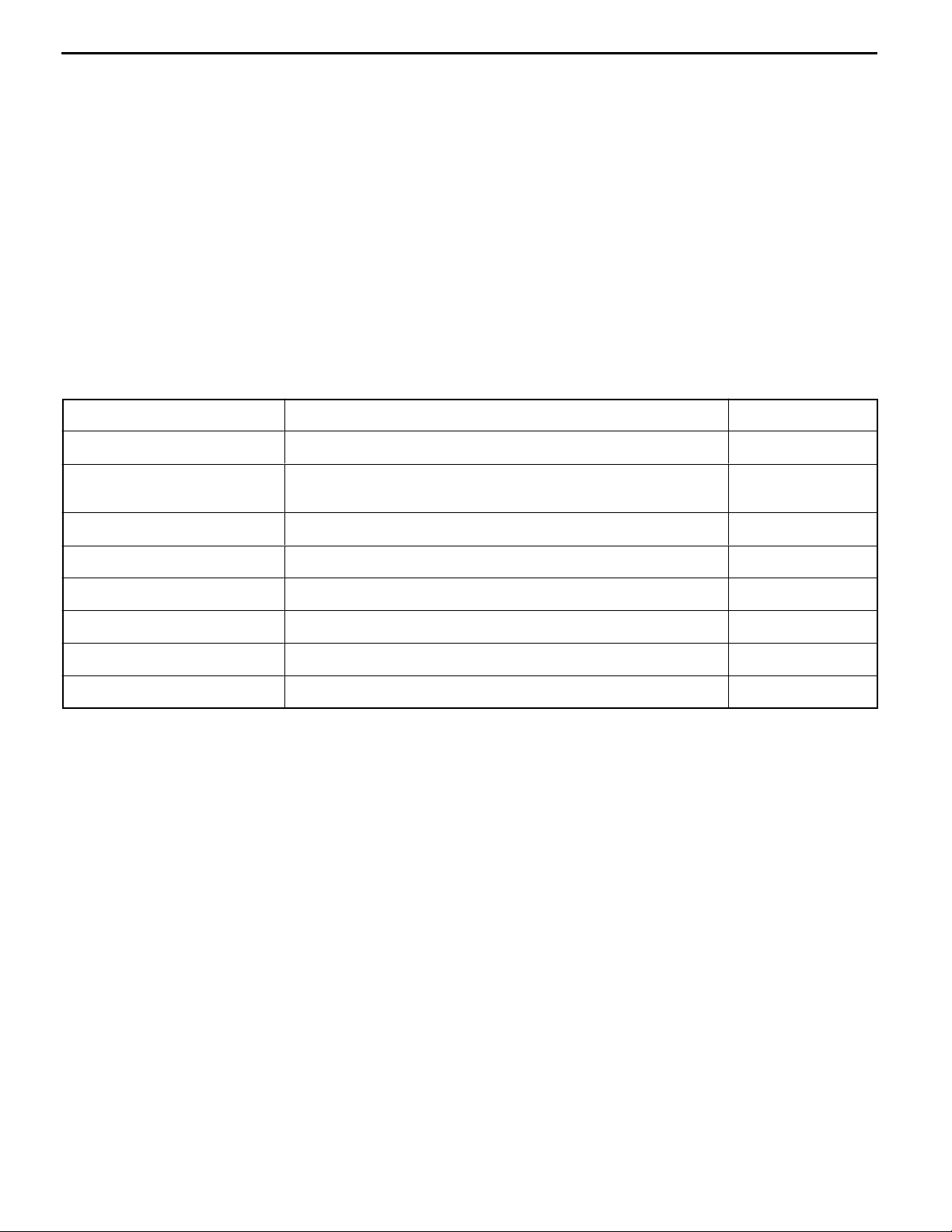

FORM-IN-PLACE GASKET

The engine has several areas where the form-in-place gasket (FIPG) is in use. To ensure that the gasket

fully serves its purpose, it is necessary to observe some precautions when applying the gasket. Bead

size, continuity and location are of paramount importance. Too thin a bead could cause leaks. Too thick

a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing of the

fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary to

apply the gasket evenly without a break, while observing the correct bead size.

The FIPG used in the engine is a room temperature vulcanization (RTV) type and is supplied in a 100-gram

tube (Part No. MD970389 or MD997110). Since the RTV hardens as it reacts with the moisture in the

atmospheric air, it is normally used in the metallic flange areas. The FIPG, Part No. MD970389, can

be used for sealing both engine oil and coolant, while Part No. 997110 can only be used for engine

oil sealing.

Disassembly

The parts assembled with the FIPG can be easily disassembled without use of a special method. In

some cases, however, the sealant between the joined surfaces may have to be broken by lightly striking

with a mallet or similar tool. A flat and thin gasket scraper may be lightly hammered in between the

joined surfaces. In this case, however, case must be taken to prevent damage to the joined surfaces.

For removal of the oil pan, the special tool “Oil Pa n Remover” (MD998727) is available. Be sure to use

the special tool to remove the oil pan.

Surface Preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper

or wire brush. Check to ensure that t he surfaces to which the FIPG is to b e applied is flat. Make sure

that there are no oils, greases and foreign substances deposited on the application surfaces. Do not

forget to remove the old sealant remained in the bolt holes.

Form-In-Place Gasket Application

When assembling parts with the FIPG, you must observe some precautions, but the procedures is very

simple as in the case of a conventional precut gasket.

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the

bolt hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is

hardened. While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When

the parts are mounted, make sure that the gasket is applied to the required area only. In addition, do

not apply any oil or water to the sealing locations or start the engine until a sufficient amount of time

(about one hour) has passed after installation is completed.

The FIPG application procedure may vary on different areas. Observe the procedure described in the

text when applying the FIPG.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 14

4D68 ENGINE (E-W) -

Special Tools

2. SPECIAL TOOLS

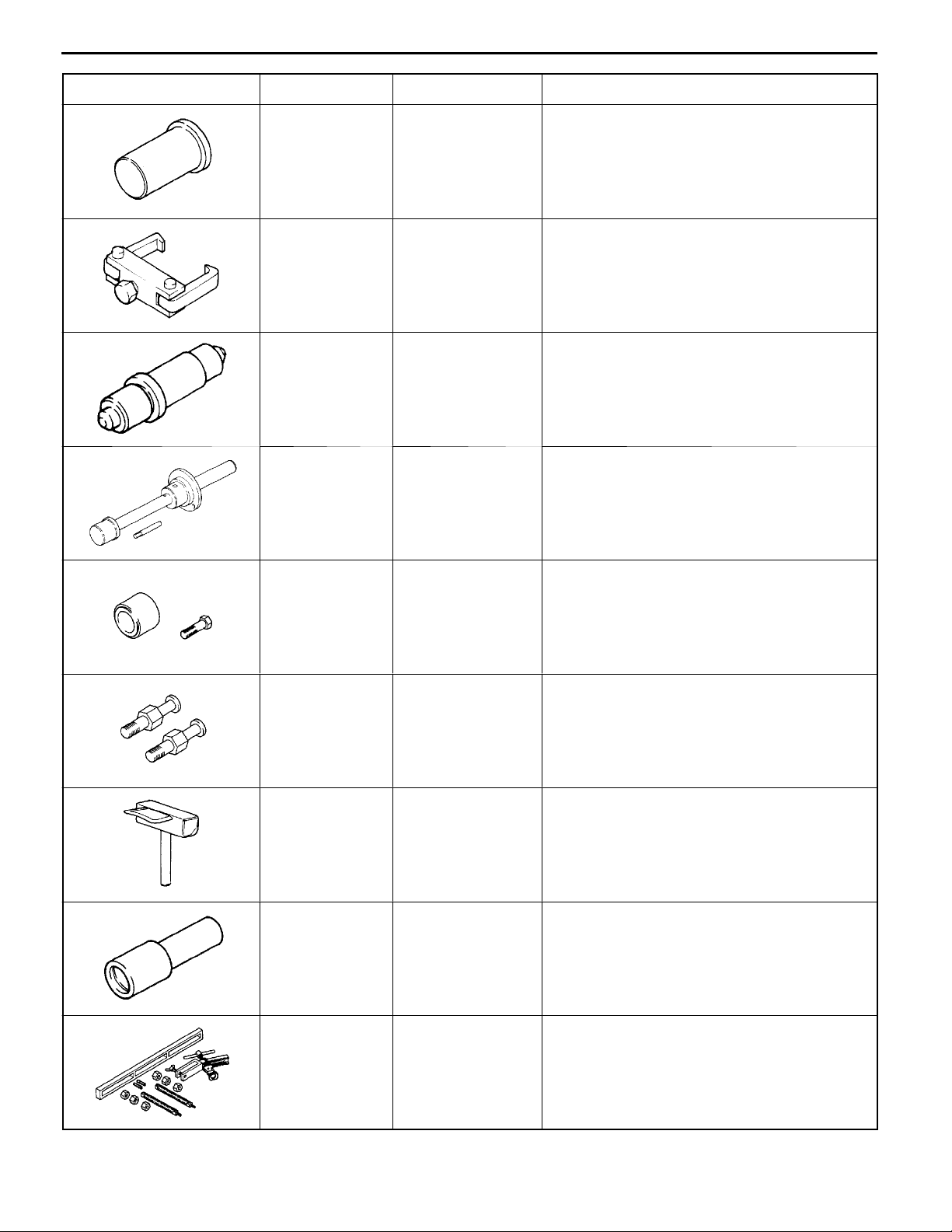

Tool Number Name Use

MB990767 End yoke holder Holding camshaft sprocket or fuel injection

11A-2-1

pump when loosening or tightening bolts.

Use with MD998719

MB991603 Bearing installer

stopper

MD990938 Handle Installation of crankshaft rear oil seal

MB991654 Cylinder head bolt

wrench

MD9981 15 Valve guide

installer

A guide for removal and installation of

counterbalance shaft left rear bearing

(Use with MD998776)

Tightening and loosening of cylinder head bolt

Removal and installation of valve guide

MD998162 Plug wrench Removal and installation of front case cap plug

(Use with MD998783)

MD998285 Crankshaft front oil

seal guide

MD998371 Silent shaft bearing

puller

MD998372 Silent shaft bearing

puller

Guide for installation of crankshaft front oil seal

Removal of counterbalance shaft front bearing

Removal of counterbalance shaft rear bearing

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 15

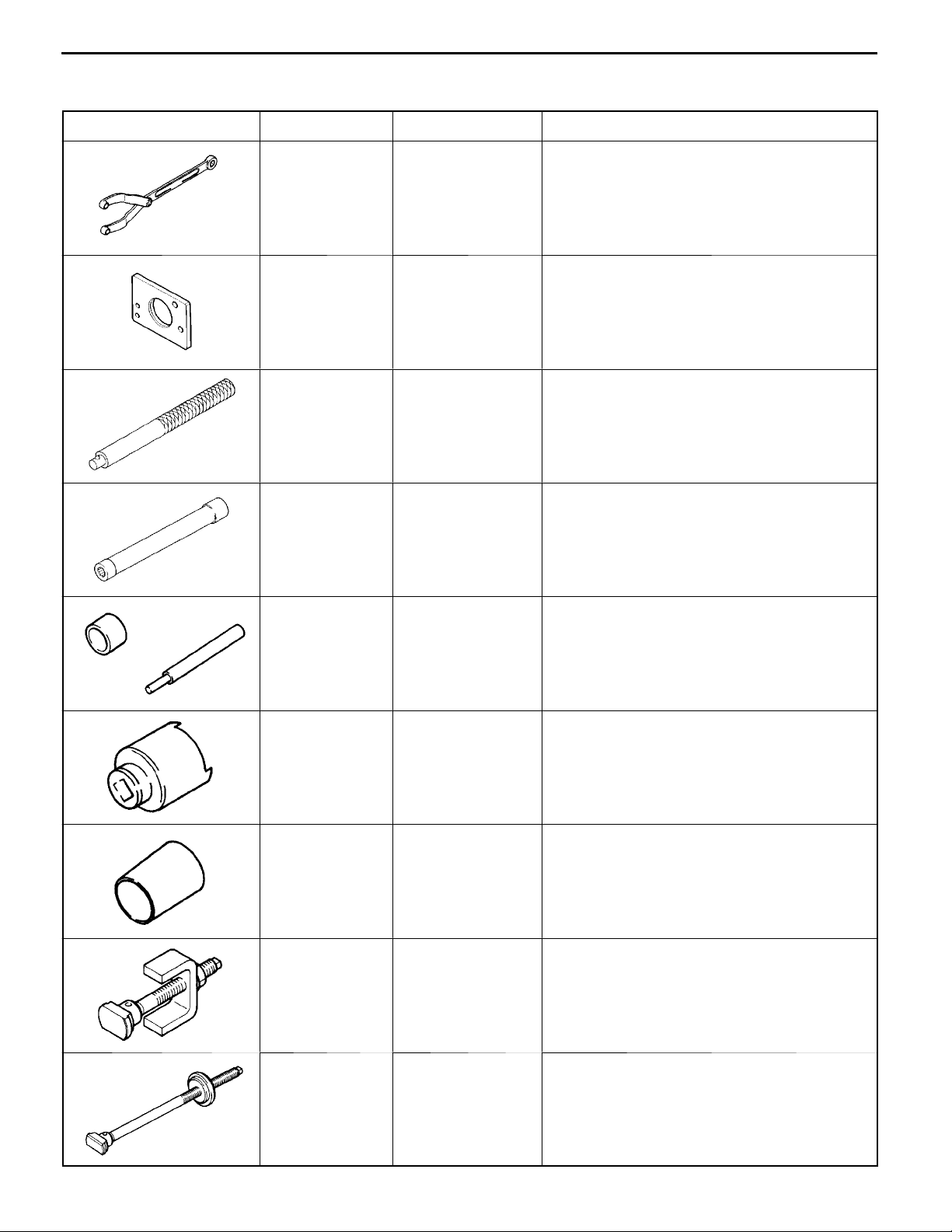

11A-2-2

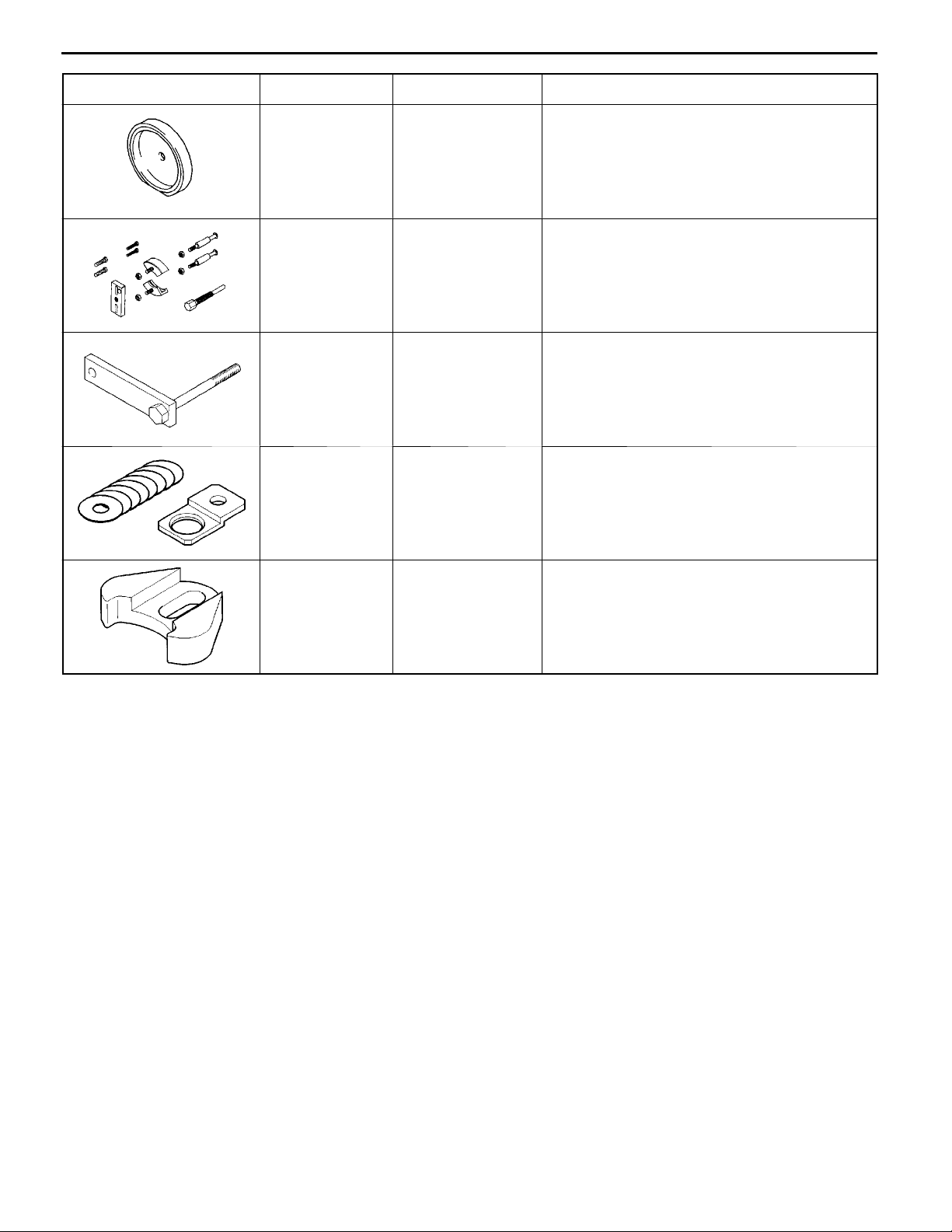

Tool UseNameNumber

4D68 ENGINE (E-W) -

Special Tools

MD998375 Crankshaft front oil

seal installer

MD998388 Injection pump

sprocket puller

MD998702 Connecting-rod

small-end bushing

replacement tool

MD998705 Silent shaft bearing

installer

Installation of crankshaft front oil seal

Removal of injection pump sprocket

Replacement of connecting-rod small-end

bushing

Installation of counterbalance shaft bearing

MD998713 Camshaft oil seal

installer

MD998719 Pulley holder pin

(2)

MD998727 Oil pan sealer

cutter

MD998729 Valve stem seal

installer

Installation of camshaft oil seal

Use with MB990767

Removal of oil pan

Installation of valve stem seal

MD998772 Valve spring

compressor

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Compression of valve spring

Page 16

4D68 ENGINE (E-W) -

Tool UseNameNumber

Special Tools

11A-2-3

MD998776 Crankshaft rear oil

seal installer

MD998778 Crankshaft

sprocket puller

MD998781 Flywheel stopper Holding of flywheel and drive plate

MD998783 Plug wrench

retainer

Installation of crankshaft rear oil seal

(Use with MB990938)

Removal of crankshaft sprocket

Removal and installation of front case cap plug

(Use with MD998162)

MD998785 Sprocket stopper Holding of counterbalance shaft sprocket

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 17

4D68 ENGINE (E-W) -

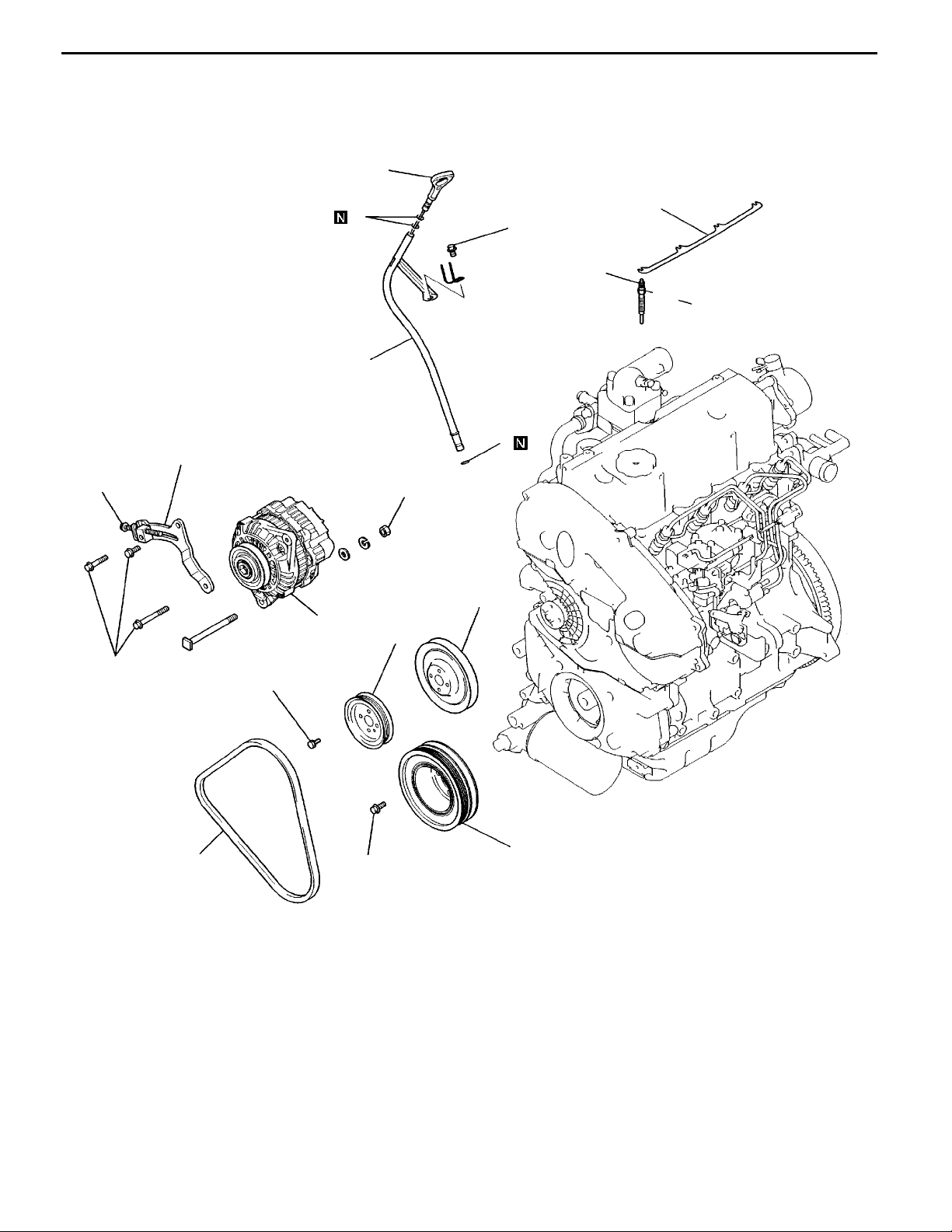

Drive Belt and Glow Plug

3. DRIVE BELT AND GLOW PLUG

REMOVAL AND INSTALLATION

1

11A-3-1

10 Nm

2

13 Nm

1.8 Nm

12

18 Nm

3

4

8

11

44 Nm

7

9

6

23 Nm

9Nm

5

Removal steps

1. Oil level gauge

2. O-ring

3. Oil level gauge guide

4. O-ring

5. Drive belt (V-type)

6. Pulley (for power steering pump

drive)

25 Nm

10

AA""AA

DEN0885

7. Water pump pulley

8. Alternator brace

9. Alternator

10. Crankshaft pulley

11. Glow plug plate

12. Glow plug

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 18

11A-3-2

4D68 ENGINE (E-W) -

REMOVAL SERVICE POINTS

AA"

(1) When removing the glow plug, you may loosen using

INSTALLATION SERVICE POINTS

"AA

(1) When installing the glow plug, screw in one thread or

Drive Belt and Glow Plug

GLOW PLUG REMOVAL

a tool up to the point where o n e or more threads are

left in engagement. Beyond this point, loosen with fingers.

Caution

D

Do not reuse a glow plug that has been dropped

from a height of 10 cm or more.

GLOW PLUG INSTALLATION

more with fingers and then tighten with a tool.

Caution

D

Do not reuse a glow plug that has been dropped

from a height of 10 cm or more.

DEL034

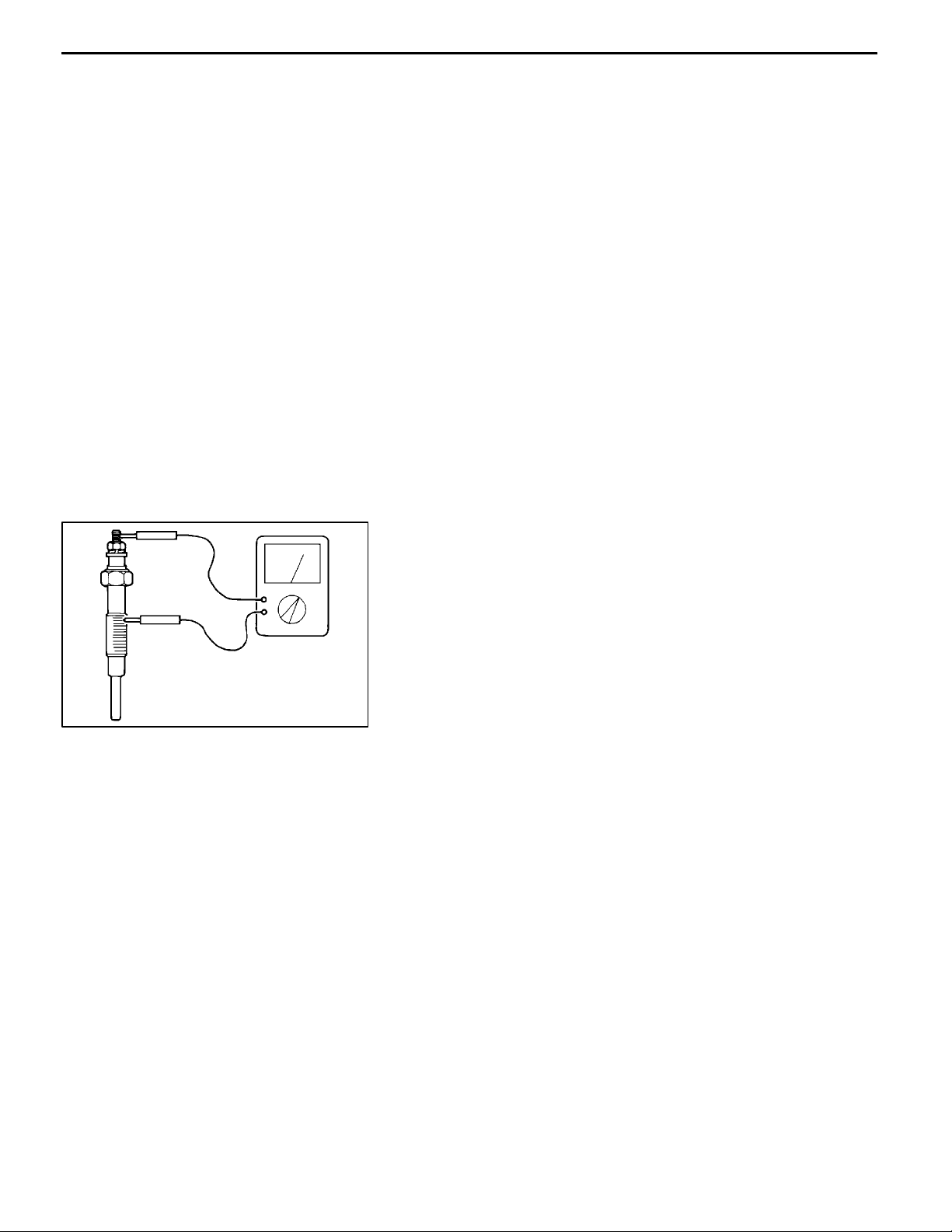

INSPECTION

GLOW PLUG

(1) Check the glow plugs for continuity between the terminal

and the body as shown. Replace the glow plugs which

show no continuity or too large a resistance.

Standard value: 0.5

W

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 19

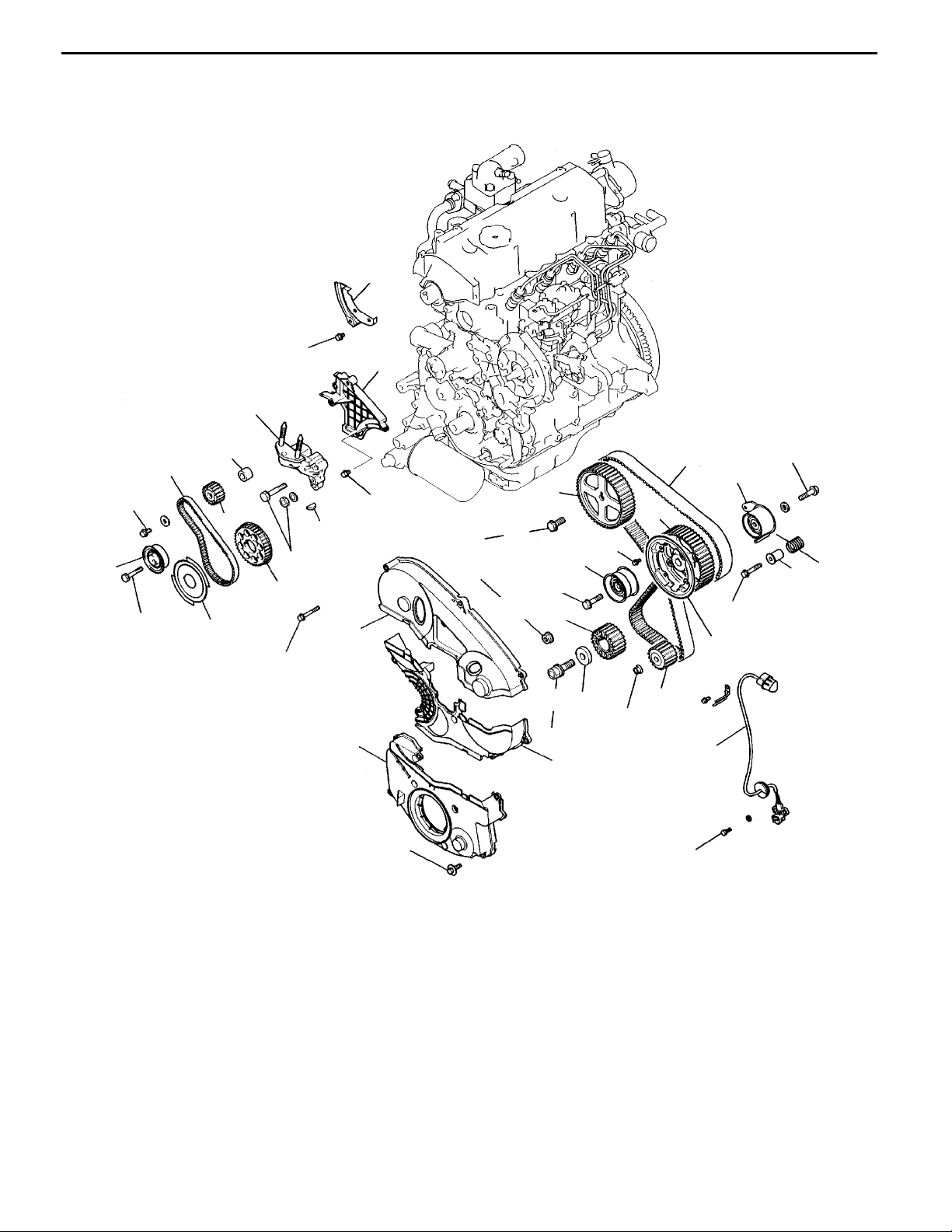

4D68 ENGINE (E-W) -

4. TIMING BELT

REMOVAL AND INSTALLATION

11 Nm

28

27

26

Timing Belt

11A-4-1

45 Nm

20

18 Nm

21

18

23

22

49 Nm

24

11 Nm

25

11 Nm

1

3

9Nm

88 Nm

83 Nm

10

48 Nm

13

11

9

17

15

16

118 Nm

2

9Nm

14

54 Nm

19

9Nm

5

12

4

6

13 Nm

48 Nm

8

7

DEN0886

AA""IA

"HA

AB""GA

AC""FA

AD"

E

Removal steps

1. Timing belt front upper cover

2. T iming belt front center cover

3. Timing belt front lower cover

4. Crankshaft position sensor

5. Timing belt

6. Timing belt tensioner

7. Tensioner spacer

8. Tensioner spring

9. Timing belt idler pulley

10. Camshaft sprocket bolt

11. Camshaft sprocket

12. Flange

13. Injection pump sprocket nut

14. Injection pump sprocket

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

AE""EA

AF"

AG""DA

AH""CA

AI""BA

"AA

AJ"

15. Crankshaft bolt

16. Special washer

17. Crankshaft sprocket

18. Crankshaft sensing blade

19. Oil pump sprocket

20. Tensioner “B”

21. T iming belt “B”

22. Counterbalance shaft sprocket

23. Spacer

24. Crankshaft sprocket “B”

25. Key

26. T iming belt rear center cover

27. T iming belt rear right cover

28. Engine support bracket

Page 20

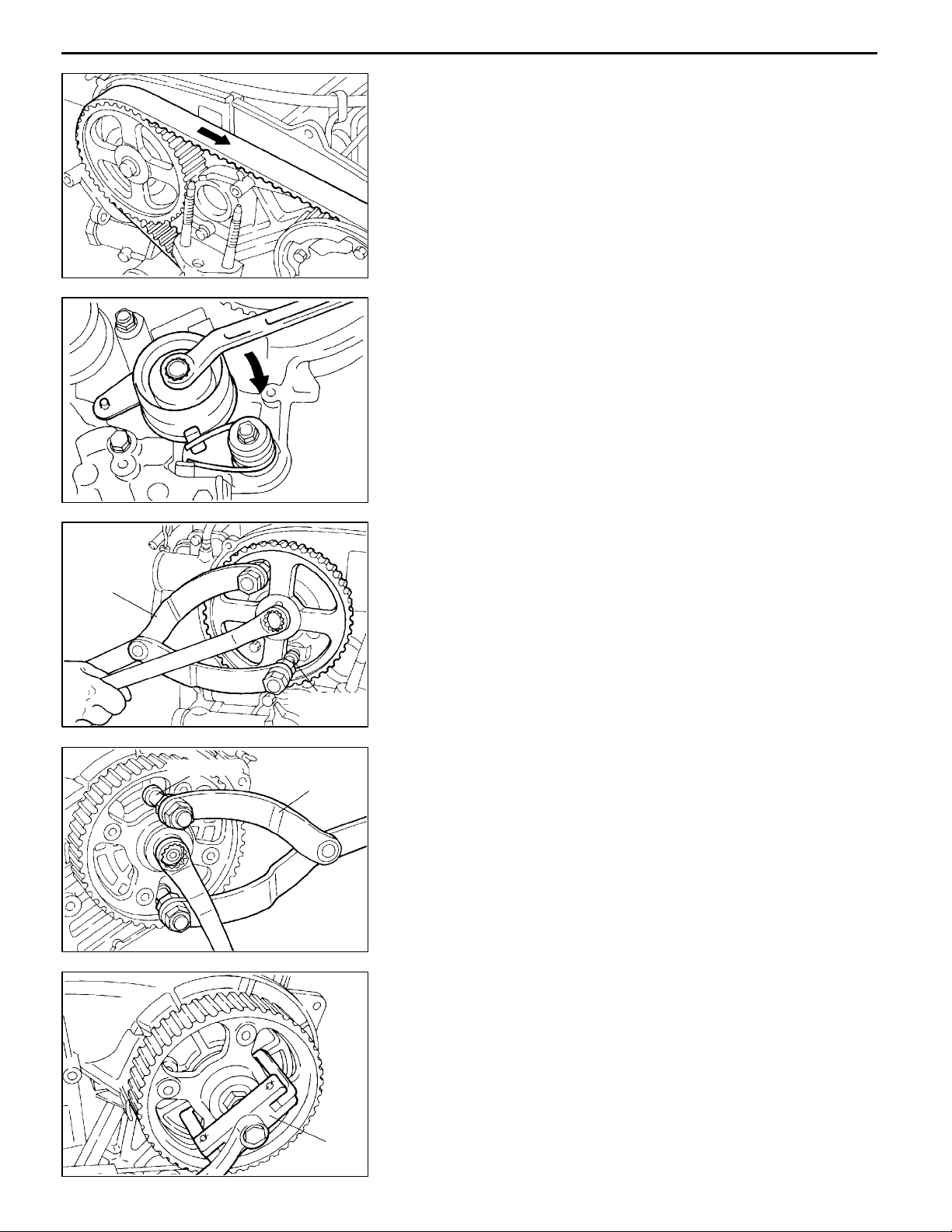

11A-4-2

4D68 ENGINE (E-W) -

REMOVAL SERVICE POINTS

AA"

(1) Using chalk, etc., mark an arrow on the back of the timing

DEN0739

(2) Attach a bolt to the front end face of the timing belt

(3) Remove the timing belt.

DEN0838

TIMING BELT REMOVAL

belt to indicate the direction of rotation. This is to ensure

correct installation of the belt in case it is reused.

tensioner. Fit an offset wrench onto the bolt and turn the

wrench downward as shown to tighten the tensioner

mounting bolt temporarily.

Caution

D

Use such a short bolt as would not come into

contact with the timing belt tensioner mounting

bolt at the rear end face when it is tightened.

Timing Belt

MB990767

MB998719

MD998719

DEN0741

MB990767

DEN0742

AB"

AC"

AD"

CAMSHAFT SPROCKET BOLT LOOSENING

INJECTION PUMP SPROCKET NUT LOOSENING

INJECTION PUMP SPROCKET REMOVAL

(1) Do not strike the sprocket and drive shaft to remove these

parts.

MD998388

DFU0625

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 21

4D68 ENGINE (E-W) -

Timing Belt

11A-4-3

MD998781

Plug

DEN0743

MD998778

DEN0744

Screwdriver

6EN05646EN0563

AE"

AF"

AG"

CRANKSHAFT BOLT LOOSENING

CRANKSHAFT SPROCKET REMOVAL

OIL PUMP SPROCKET REMOVAL

(1) Before loosening the oil pump sprocket nut (flange nut),

remove the timing belt and then the plug at the left side

of the cylinder block and insert a Phillips screwdriver [shank

diameter 8 mm] through the plug hole to keep the left

counterbalance shaft in position.

Caution

D

If the nut is loosened without removing the timing

belt, the force produced by loosening the nut will

be borne by the belt and can cause damage to

the belt cogs.

AH"

TIMING BELT “B” REMOVAL

(1) Using chalk, etc., mark an arrow on the back of the timing

belt to indicate the direction of rotation. This is to ensure

correct installation of the belt in case it is reused.

NOTE

(1) Water or oil on the belt shortens its life drastically,

so the removed timing belt, sprocket, an d tensioner

must be free from oil and water. Do not immerse parts

in cleaning solvent.

DEN0745

(2) If there is oil or water on any part, check the front

case oil seals, camshaft oil seal and water pump for

leaks.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 22

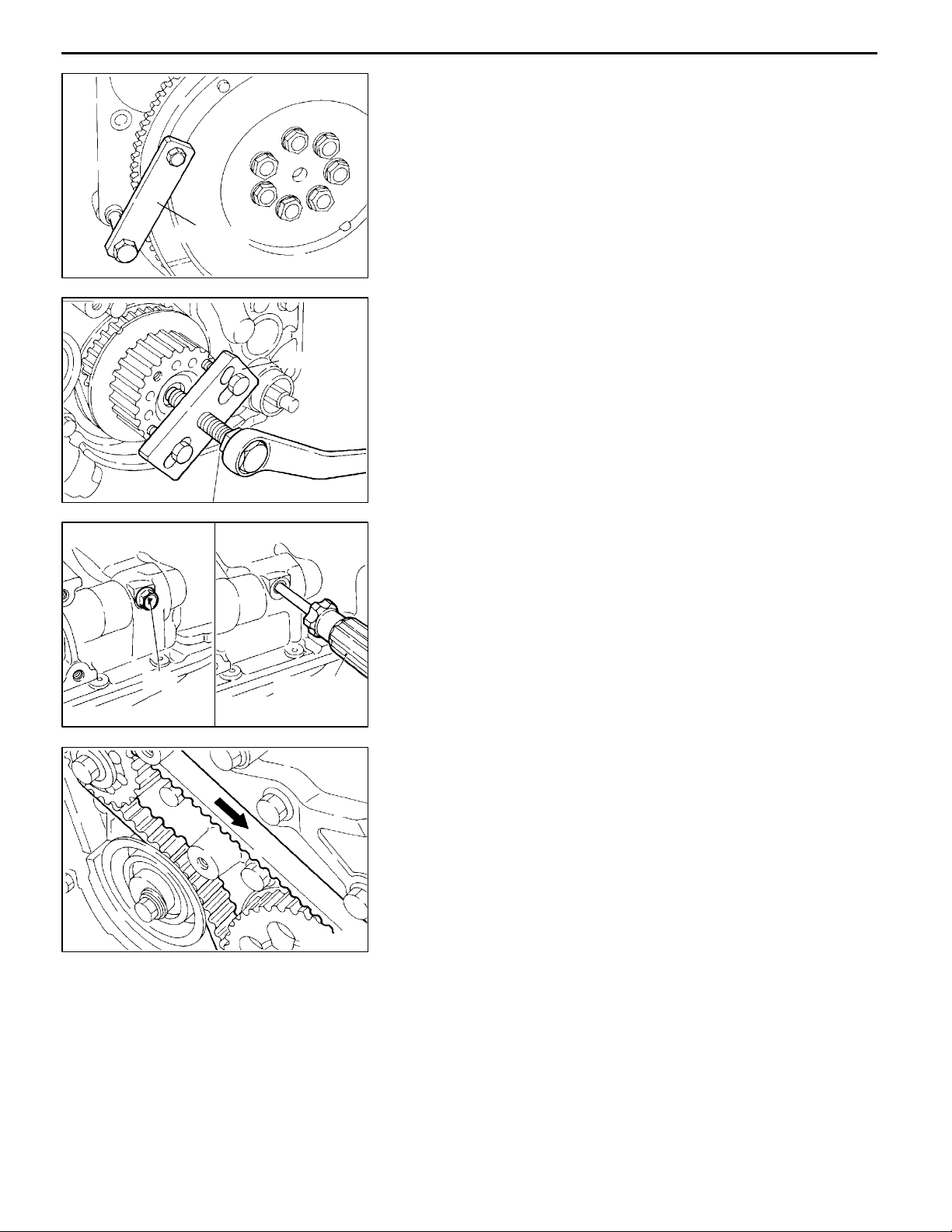

11A-4-4

4D68 ENGINE (E-W) -

Timing Belt

MD998785

MD998778

DEN0746

DEN0747

AI"

AJ"

COUNTERBALANCE SHAFT SPROCKET

REMOVAL

CRANKSHAFT SPROCKET “B” REMOVAL

Spacer

Sharp

edge

Chamfer

Silent

shaft

MD998785

6EN0615

DEN0746

Timing

mark

Oil

seal

INSTALLATION SERVICE POINTS

"AA

(1) Install the spacer with the chamfered end toward t he oil

"BA

"CA

(1) Align the timing marks on the crankshaft sprocket “B”

(2) Install the timing belt “B” on the crankshaft sprocket “B”

SPACER INSTALLATION

seal.

COUNTERBALANCE SHAFT SPROCKET

INSTALLATION

TIMING BELT “B” INSTALLATION

and sprocket with the marks on the front case respectively.

and counterbalance shaft sprocket. There should be no

slack on the tension side.

Timing mark

E

DEN0839

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 23

Tensioner “B”

Tensioner pulley

center

4D68 ENGINE (E-W) -

(3) Make sure that the pulley center and the bolt center are

Timing belt “B”

DEN0749

(4) More the tensioner “B” in the direction of arrow while lifting

Timing Belt

11A-4-5

located as shown in the illustration.

with a finger to give a sufficient tension to the tension

side of the timing belt. In this condition, tighten the bolt

to secure tensioner “B”. When the bolt is tightened, use

care to prevent the shaft from turning together. If the shaft

is turned together, the belt will b e overtensioned.

5-7mm

Phillips screwdriver

DEN0750

DEN0751

6EN0564

(5) Check to ensure that the timing marks on the sprockets

and the front case are in alignment.

(6) Press with index finger the center of span on the tension

side of timing belt “B”. The bolt must deflect 5 to 7 mm.

"DA

OIL PUMP SPROCKET INSTALLATION

(1) Keep the counterbalance shaft in position in the same

way as when it was loosened.

(2) Install the oil pump sprocket.

(3) Apply a minimum quantity of engine oil to the bearing

surface of the nut.

(4) Tighten the nuts to the specified torque.

"EA

MD998781

DEN0743

E

Dec. 1996Mitsubishi Motors Corporation

CRANKSHAFT BOLT TIGHTENING

PWEE9609

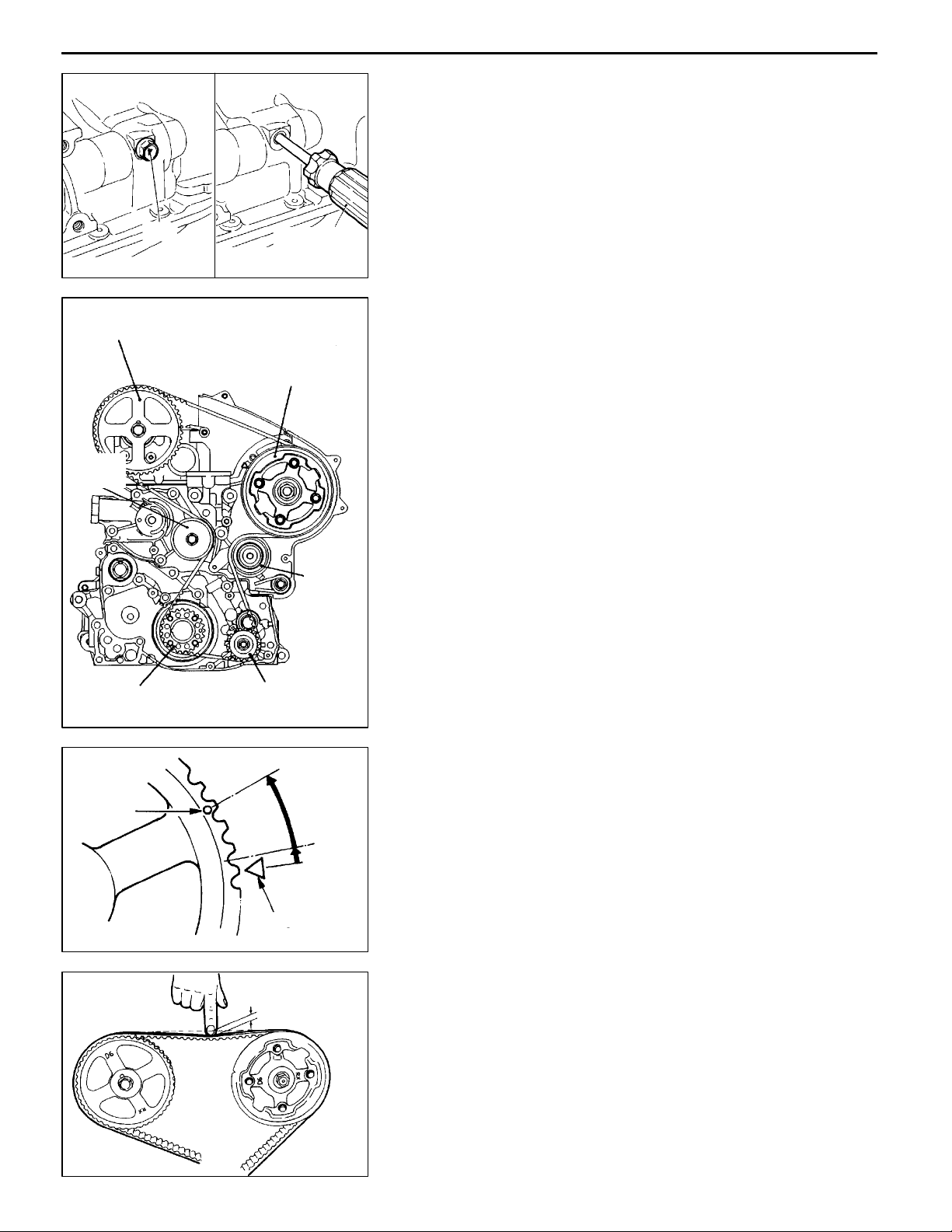

Page 24

11A-4-6

4D68 ENGINE (E-W) -

Timing Belt

MB990767

Camshaft

sprocket

Timing mark

Timing

mark

Oil pump sprocket

MD998719

MB990767

MD998719

Injection

pump

sprocket

DEN0754

DEN0755

DEN0838

"FA

"GA

"HA

INJECTION PUMP SPROCKET NUT TIGHTENING

CAMSHAFT SPROCKET BOLT TIGHTENING

TIMING BELT TENSIONER INSTALLATION

(1) Set the tensioner spring ends against the tensioner bracket

and the projection of the injection pump bracket.

(2) Attach a bolt to the front end face of the timing belt

tensioner. Fit an offset wrench onto the bolt and turn the

wrench downward as shown to tighten the tensioner

mounting bolt temporarily.

Caution

D

Use such a short bolt as would not come into

contact with the timing belt tensioner mounting

bolt at the rear end face when it is tightened.

"IA

TIMING BELT INSTALLATION

(1) Temporarily fix the tensioner at the most lower position

in the injection pump bracket slot.

(2) Turn the crankshaft to bring the No. 1 piston at the top

dead center on the compression stroke.

(3) Align the timing marks of all sprockets with their mating

marks as shown.

NOTE

If the injection pump sprocket is released, it turns about

one tooth in a counterclockwise direction. Therefore, the

timing mark of the injection pump sprocket should be

aligned when the timing belt is installed.

Timing mark

E

Camshaft

sprocket

Timing

mark

Dec. 1996Mitsubishi Motors Corporation

DEN0756

PWEE9609

Page 25

Plug

Camshaft sprocket

Timing

belt idler

4D68 ENGINE (E-W) -

(4) Remove the plug on the cylinder block and insert a Phillips

Screwdriver

6EN05646EN0563

(5) Install the timing belt on the sprockets in the following

Injection pump

sprocket

Timing Belt

11A-4-7

screwdriver [shank diameter 8 mm] through the hole.

If it can be inserted as deep as 60 mm or more, the timing

marks are correctly aligned. If the inserted depth is only

20 - 2 5 mm, turn the oil pump sprocket one turn and

realign the timing marks. Then check to ensure that the

screwdriver can be inserted 60 mm or more. Keep the

screwdriver inserted until installation of the timing belt

is finished.

sequence while taking care so that the belt is not slack

between sprockets or between sprocket and pulley.

1 Crankshaft sprocket

2 Timing belt idler

3 Camshaft sprocket

4 Injection pump sprocket

5 Oil pump sprocket

6 Turn the crankshaft in the reverse direction by 1/2

tooth of the camshaft sprocket to remove theslackenss

of the belt on the idler side.

7 Timing belt tensioner

Crankshaft sprocket

Timing

mark

Oil pump

sprocket

Timing mark

4-5mm

Timing

belt

tensioner

DEN0840

2-1/2

teeth

1/2 teeth

DEN0732

NOTE

To install the timing belt on the injection pump sprocket,

use an o ffset wrench or a similar tool and align the injection

pump sprocket timing mark with the mark in the engine.

(6) Loosen the tensioner mounting bolt 1/4 - 1/3 turn and

allow the spring tension to move the tensioner against

the belt.

(7) Turn the crankshaft counterclockwise by three teeth of

the cam sprocket from the timing mark and hold this

position. Check that the belt is in complete mesh with

the sprockets.

(8) Fix the tensioner.

(9) Turn the crankshaft clockwise to align t he timing marks.

(10)Check that the belt deflects 4 - 5 mm when its midpoint

is pushed by index finger.

(11)Check that the timing marks of all sprockets are aligned.

DEN0694

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 26

11A-4-8

4D68 ENGINE (E-W) -

INSPECTION

TIMING BELTS

The timing belts must be checked closely. Should the following

defects be evident, replace the belt with a new one.

(1) Hardened back surface rubber

Glossy, non-elastic, and so hard that no mark is produced

even when scratched by fingernails.

8EN0066

Timing Belt

Separation

Tooth bottom

Crack

Rounded edge

Abnormal wear

(loose core wire)

Canvas worn

exposing rubber

Stripped

teeth

Crack

Cracked

side

8EN0044

8EN0067

(2) Cracked back surface rubber

(3) Cracked or separated canvas

(4) Cracked tooth bottom

(5) Cracked side

(6) Abnormal wear on side

NOTE

Normal belt should have clear-cut sides as if cut by a

sharp knife.

(7) Abnormal wear in teeth

Initial stage:

Canvas on load side tooth flank worn (Fluffy canvas

fibers, rubber gone and color changed to white, and

unclear canvas texture)

Final stage:

Canvas on load side tooth flank worn down and rubber

exposed (tooth width reduced)

(8) Missing tooth

8EN0068

TENSIONER PULLER, IDLER PULLEY

(1) Check the pulley for smooth rotation, excessive play,

abnormal noise. Replace it if necessary.

DEN0911

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 27

4D68 ENGINE (E-W) -

Glow Plug, Fuel Injection Pump And Injection Nozzle

5. GLOW PLUG, FUEL INJECTION PUMP AND INJECTION NOZZLE

REMOVAL AND INSTALLATION

5Nm

5Nm

1

3

11A-5-1

4

19

10

11

29 Nm

54 Nm

17

18

16

29 Nm

13

2

29 Nm

14

15

5

18 Nm

9

6

13 Nm

7

23 Nm

18 Nm

8

13 Nm

AA""DA

AA""DA

AA""DA

AA""DA

AB"

E

23 Nm

Removal steps

1. Injection pipe No.1

2. Injection pipe No.2

3. Injection pipe No.3

4. Injection pipe No.4

5. Fuel hose

6. Fuel hose

7. Fuel hose

8. Fuel pipe

9. Engine hanger

10. Fuel injection pump

Dec. 1996Mitsubishi Motors Corporation

12

PWEE9609

AC""CA

AD""BA

"AA

"AA

35 Nm

DEN0887

11. Key

12. Fuel injection pump stay

13. Fuel return pipe nut

14. Fuel return pipe

15. Fuel return pipe gasket

16. Injection nozzle

17. Holder gasket

18. Nozzle gasket

19. Fuel injection pump bracket

Page 28

11A-5-2

4D68 ENGINE (E-W) -

Glow Plug, Fuel Injection Pump And Injection Nozzle

Delivery

holder

Nut

DEN0759

REMOVAL SERVICE POINTS

AA"

(1) When loosening the union nuts on the injection pump,

(2) When loosening the union nuts on the injection nozzles,

AB"

(1) Do not hold the injection pump by the accelerator lever

INJECTION PIPE REMOVAL

hold the delivery valve holder on the fuel injection pump

head with a spanner to prevent it from rotating along with

the union nut.

Caution

D

If the injection pipe has been removed, plug the

delivery valve holder to prevent foreign matter

from entering the injection pump.

hold the hexagon nut of the fuel return pipe with a spanner

to prevent it from rotating along with the union nut.

FUEL INJECTION PUMP REMOVAL

or the fast idle lever. These levers must not be removed.

DEN0760

AC"

FUEL RETURN PIPE NUT REMOVAL

(1) When removing the fuel return pipe nut, hold the hexagon

nut of the fuel return pipe with a spanner.

DEN0761

Deep socket wrench

AD"

(1) Write the cylinder number on the injection nozzle that

INJECTION NOZZLE REMOVAL

has been removed.

Caution

D

Cover the opening with an appropriate cap to

prevent entry of dust, water and foreign material

into the fuel passage and combustion chamber.

DEN0762

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 29

4D68 ENGINE (E-W) -

Holder gasket

Nozzle

gasket

DFU616

Glow Plug, Fuel Injection Pump And Injection Nozzle

11A-5-3

INSTALLATION SERVICE POINTS

"AA

(1) Clean nozzle holder installation areas of the cylinder head.

(2) Fit a new nozzle gasket and holder gasket into the nozzle

NOZZLE GASKET / HOLDER GASKET

INSTALLATION

holder hole in the cylinder head.

Deep socket wrench

Delivery

valve holder

Nut

DEN0763

DEN0761

"BA

"CA

INJECTION NOZZLE INSTALLATION

FUEL RETURN PIPE NUT INSTALLATION

(1) While holding the fuel hexagon nut of the fuel return pipe

with a wrench, tighten the fuel return pipe nut to the

specified torque.

"DA

INJECTION PIPE INSTALLATION

(1) When tightening the injection pipe nuts, hold the delivery

valve holder with a spanner in order to prevent it from

rotating along with the nut.

DEN0759

(2) When tightening the injection pipe nuts, hold the hexagon

nut of the return pipe with a spanner in order to prevent

it from rotating along with the nut.

DEN0760

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 30

4D68 ENGINE (E-W) -

Intake and Exhaust Manifolds

6. INTAKE AND EXHAUST MANIFOLDS

REMOVAL AND INSTALLATION

11A-6-1

17 Nm

13 Nm

14 Nm

11 Nm

13 Nm

34

30 Nm

59 Nm

29 Nm

11 Nm

14

35

13

12

16

27

15

36

28

59 Nm

17 Nm

16 Nm

10 Nm

17

19

59 Nm

33

59 Nm

9Nm

18

25

9

22

32

24

26

24 Nm

11

23

30

10

16 Nm

20

21

30 Nm

10 Nm

7

8

17 Nm

3

1

4

2

14 Nm

5

6

38

39

"CA

"BA

"BA

23 Nm

37

13 Nm

31

13 Nm

Removal steps

1. Air temperature sensor

2. Air temperature sensor gasket

3. Air intake fitting

4. Intake fitting gasket

5. Throttle body

6. Intake fitting gasket

7. EGR valve

8. EGR valve gasket

9. EGR pipe gasket

10. EGR pipe

11. EGR pipe gasket

12. T urbocharger heat protector

13. Exhaust fitting heat protector

14. Eyebolt

15. Gasket

16. W ater pipe “A”

17. W ater hose

18. Eyebolt

19. Gasket

20. Eyebolt

30

29

"AA

DEN0888

21. Gasket

22. Oil pipe

23. Eyebolt

24. Gasket

25. W ater pipe “B”

26. W ater hose

27. Exhaust fitting

28. Exhaust fitting gasket

29. Oil return pipe

30. Oil return pipe gasket

31. Heat protector, rear

32. T urbocharger assembly

33. T urbocharger gasket

34. Heat protector, front

35. Engine hanger

36. Exhaust manifold

37. Alternator brace stay

38. Intake manifold

39. Intake and exhaust manifold gasket

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 31

11A-6-2

Projection

4D68 ENGINE (E-W) -

Oil return pipe

DEN0843

Intake and Exhaust Manifolds

INSTALLATION SERVICE POINTS

"AA

(1) Install the oil return pipe gasket in such a way that its

OIL RETURN PIPE GASKET INSTALLATION

projection is located at the illustrated position.

Exhaust fitting

EGR pipe

Exhaust fitting

heat protector

Projection

DEN0844

"BA

EYEBOLT INSTALLATION

(1) Before installing the oil pipe eyebolt (at top of the

turbocharger), fill the turbocharger with clean engine oil.

"CA

EGR PIPE GASKET INSTALLATION

(1) Install the EGR pipe gasket in such a way that its projection

is located at the illustrated position.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 32

4D68 ENGINE (E-W) -

Water Pump, Thermostat, Hose and Pipes

7. WATER PUMP, THERMOSTAT, HOSE AND PIPES

REMOVAL AND INSTALLATION

16 Nm

1

2

17

3

11A-7-1

15

14

12 Nm

45 Nm

16

4

9Nm

5

18

22 Nm

8

23 Nm

19

7

11 Nm

6

10

23 Nm

22

9

35 Nm

20

12 Nm

21

11

12

19 Nm

13

13 Nm

Removal steps

1. Eyebolt

2. Gasket

3. Oil pipe

4. Gasket

5. Eyebolt

6. Gasket

7. Oil return pipe

8. Oil return hose

"FA

"EA

E

9. Engine coolant temperature sensor

10. Engine coolant temperature gauge

unit

11. Cover

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

"DA

"DA

"DA

"CA

"BA

"AA

12. W ater pump

13. Water pump gasket

14. O-ring

15. Water inlet pipe

16. O-ring

17. Vacuum pump

18. O-ring

19. Water inlet fitting

20. Thermostat

21. Water outlet fitting

22. Thermostat housing

DEN0889

Page 33

11A-7-2

4D68 ENGINE (E-W) -

DEN0768

Water Pump, Thermostat, Hose and Pipes

INSTALLATION SERVICE POINTS

"AA

(1) Apply a 3 mm bead of form-in-place gasket (FIPG) to

THERMOSTAT HOUSING INSTALLATION

the mounting surface.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent.

DEN0769

Jiggle valve

DEN0770

"BA

WATER OUTLET FITTING INSTALLATION

(1) Apply a 3 mm bead of form-in-place gasket (FIPG) to

the mounting surface.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent.

"CA

THERMOSTAT INSTALLATION

(1) Install th e thermostat with t h e jiggle valve up as shown

in the illustration.

"DA

WATER INLET PIPE / O-RING INSTALLATION

(1) Wet the O-ring (with water) to facilitate assembly.

Caution

D

Keep the O-ring free of oil or grease.

D

Secure the water pipe after the thermostat housing

has been installed.

Back side of cover

E

"EA

COVER INSTALLATION

(1) Apply a 3 mm bead of form-in-place gasket (FIPG) to

the mounting surface.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or

equivalent.

DEN0846

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 34

4D68 ENGINE (E-W) -

Water Pump, Thermostat, Hose and Pipes

11A-7-3

DEN0890

"FA

ENGINE COOLANT TEMPERATURE GAUGE UNIT

INSTALLATION

(1) If the water temperature sensor is to be reused, apply

the specified sealant to its thread.

Specified sealant:

3M Nut Locking Part No. 4171 or equivalent.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 35

4D68 ENGINE (E-W) -

Rocker Arms, Rocker Shaft and Camshaft

8. ROCKER ARMS, ROCKER SHAFT AND CAMSHAFT

REMOVAL AND INSTALLATION

6Nm

29 Nm

7

15 Nm

20 Nm

29 Nm

12

8

12

5

4

6

12

20 Nm

29 Nm

2

11

11A-8-1

1

10

9

12

Removal steps

1. Breather hose

2. Rocker cover

3. Rocker cover gasket

4. Rocker shaft

5. Rocker shaft spring

6. Rocker arm

7. Adjusting nut

8. Rocker arm adjusting screw

9. Front camshaft bearing cap

10. Camshaft front oil seal

11. Rear camshaft bearing cap

12. Camshaft bearing cap

13. Camshaft

13

"AA

"BA

"BA

"CA

"DA

"EA

3

Apply engine oil to all

moving parts before

installation.

DEN0891

Installation steps

13. Camshaft

12. Camshaft bearing cap

11. Rear camshaft bearing cap

9. Front camshaft bearing cap

8. Rocker arm adjusting screw

7. Nut

6. Rocker arm

5. Rocker shaft spring

4. Rocker shaft

10. Camshaft oil seal

3. Rocker cover gasket

2. Rocker cover

1. Breather hose

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 36

11A-8-2

4D68 ENGINE (E-W) -

Rocker Arms, Rocker Shaft and Camshaft

Camshaft

sprocket side

Identification

number

Front

DEN658

DEN0905

Within 1 mm

INSTALLATION SERVICE POINTS

"AA

(1) Install the bearing caps in the designated position

"BA

(1) Apply sealant to the locations shown in the illustrations.

"CA

(1) Do not screw the adjusting screw so far that its flange

CAMSHAFT BEARING CAP INSTALLATION

confirming the identification numbers stamped o n the cap

front. The No.5 cap has no identification number stamped.

FRONT, REAR CAMSHAFT BEARING CAP

INSTALLATION

Specified sealant:

3M ATD Part No. 8660 or equivalent

ROCKER ARM ADJUSTING SCREW

INSTALLATION

may come into contact with the rocker arm. Leave some

distance (within 1 mm) between them.

Depression

Bearing cap

E

MD998713

Dec. 1996Mitsubishi Motors Corporation

DEN0848

DEN0803

DEN0773

"DA

ROCKER SHAFT SPRING INSTALLATION

(1) Hook the rocker shaft spring to the depression of the

bearing cap.

"EA

CAMSHAFT OIL SEAL INSTALLATION

(1) Using the special tool, install a new camshaft oil seal

into the front bearing cap.

PWEE9609

Page 37

Camshaft

sprocket

4D68 ENGINE (E-W) -

Timing mark

DEN0605

Rocker Arms, Rocker Shaft and Camshaft

11A-8-3

VALVE CLEARANCE ADJUSTMENT

(1) Turn the crankshaft clockwise an d align the timing mark

on camshaft sprocket with that on the injection pump

bracket.

(2) Adjust the valve clearance at the points shown in the

illustration.

Exhaust

No.1

Intake

No.1

Intake

No.2

Exhaust

No.3

DEN0774

DEN0775

Adjusting

screw

Pad

(3) Loosen the adjusting screw lock nut.

(4) Using a thickness gauge, adjust the valve clearance by

turning the adjusting screw.

Standard value (on cold engine):

Intake 0.25 mm

Exhaust 0.35 mm

NOTE

Before insertion of a thickness gauge, provide clearance

for inserting the gauge by pushing the pad with a standard

screwdriver or the like from the opposite side.

Standard screwdriver

or the like

Pad

E

Thickness

gauge

Thickness

gauge

Dec. 1996Mitsubishi Motors Corporation

DEN0718

If an attempt is made to insert the thickness gauge without

providing the clearance for it in advance by pushing the

pad with a standard screwdriver or the like, the pad will

tilt as shown in the illustration, preventing insertion of the

thickness gauge.

DEN0719

PWEE9609

Page 38

11A-8-4

4D68 ENGINE (E-W) -

Exhaust

No.2

Intake

No.3

Exhaust

No.4

Intake

No.4

DEN0776

Rocker Arms, Rocker Shaft and Camshaft

(5) While holding the adjusting screw with a screwdriver,

tighten the lock nut.

(6) Rotate clockwise the crankshaft one complete turn (360

degrees).

(7) Adjust the valve clearance at the points shown in the

illustration.

(8) Repeat steps (3) to (5) to adjust the valve clearance of

the remaining valves.

NOTE

With the engine mounted on vehicle, warm up the engine.

Then, check for valve clearance on hot engine and adjust

if necessary.

9EN0058

INSPECTION

CAMSHAFT

(1) Measure the cam height.

Standard value:

Intake 41.90 mm

Exhaust 41.96 mm

Limit:

Intake 41.40 mm

Exhaust 41.46 mm

ROCKER ARM SHAFT

(1) Check the oil holes for clogging and clean if clogged.

(2) Check the outer circumference of the portion where the

rocker arm is installed and replace if damage or seizure

is evident.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 39

4D68 ENGINE (E-W) -

Cylinder Head, Valves and Valve Springs

9. CYLINDER HEAD, VALVES AND VALVE SPRINGS

REMOVAL AND INSTALLATION

11A-9-1

AA""EA

"DA

AB""CA

"BA

E

Removal steps

1. Cylinder head bolt

2. Cylinder head assembly

3. Cylinder head gasket

4. Valve spring retainer lock

5. Valve spring retainer

6. Valve spring

7. Intake valve

8. Exhaust valve

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

AC""AA

Apply engine oil to all

moving parts before

installation.

DEN0777

9. Valve stem seal

10. Spring seat

11. Intake valve guide

12. Exhaust valve guide

13. Intake valve seat

14. Exhaust valve seat

15. Cylinder head

Page 40

11A-9-2

4D68 ENGINE (E-W) -

MB991654

DEN0778

Cylinder Head, Valves and Valve Springs

REMOVAL SERVICE POINTS

AA"

(1) Using a 12 mm - 12 points socket wrench, loosen the

CYLINDER HEAD BOLT REMOVAL

cylinder head bolts.

MD998772

DEN0779

DEN0793

AB"

RETAINER LOCK REMOVAL

(1) Store removed valves, springs and other parts, tagged

to indicate their cylinder No. and location for reassembly.

AC"

VALVE STEM SEAL REMOVAL

(1) Do not reuse removed stem seals.

E

Painted

end

MD998729

DEN0780

Spring retainer

Stem seal

Spring seat

6EN0437

Dec. 1996Mitsubishi Motors Corporation

INSTALLATION SERVICE POINTS

"AA

(1) Install the valve spring seat.

(2) The special tool must be used to install valve stem seals.

"BA

(1) Direct the valve spring end with identification color toward

VALVE STEM SEAL INSTALLATION

Improper installation could result in oil leaks past the valve

guide.

Caution

D

Do not reuse removed valve stem seals.

VALVE SPRING INSTALLATION

the spring retainer.

PWEE9609

Page 41

4D68 ENGINE (E-W) -

Cylinder Head, Valves and Valve Springs

11A-9-3

MD998772

Identification mark

Rank A Rank B Rank C

12345678

Reference for measurement

Protrusion measuring locations

(with each piston at top dead center)

Protrusion

DEN0779

DEN0796

DEN0797

DEN0798

"CA

RETAINER LOCK INSTALLATION

(1) The valve spring, if excessively compressed, causes the

bottom end of the retainer to be in contact with, a n d

damage, the stem seal.

"DA

CYLINDER HEAD GASKET INSTALLATION

(1) In case any of the cylinder block, piston, connecting rod

and crankshaft has not been replaced, install the gasket

of the same rank as before which can be identified by

the mark shown in the illustration a t left.

(2) In case any of the cylinder block, piston, connecting rod

and crankshaft have been replaced, reselect and install

the gasket in accordance with the following procedure.

1 With each piston held at the top dead center, measure

its protrusion from the upper block surface at the

locations shown in the illustration at left (total of eight

locations). Be sure to take measurements on the

crankshaft center line.

2 Using the average of the eight measurements, select

the gasket rank (A, B or C) in accordance with the

table given below. If, however, the maximum protrusion

at any one location exceeds the protrusion tolerance

shown for any rank in the following table, use the

gasket one rank higher that rank.

mm

Rank

A 0.641 - 0.700 0.750 1.40±0.05

B 0.700 - 0.760 0.810 1.45±0.05

C 0.760 - 0.823 - 1.50±0.05

Average value

of piston

protrusions

Protrusion

tolerance for

each rank

Thickness of

selected gasket

(when tightened)

"EA

CYLINDER HEAD BOLT INSTALLATION

(1) When installing the cylinder head bolts, check that the

shank length of each bolt meets t h e limit. If the limit is

exceeded, replace the bolt.

Limit: max. 119.7 mm

(2) Apply engine oil to the bolt threads and washers.

Shank length

6EN0782

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 42

11A-9-4

4D68 ENGINE (E-W) -

Timing belt side

DEN0781

90

°

90

°

Paint mark

6AE0297

Cylinder Head, Valves and Valve Springs

(3) Using the special tool (MB991654) and according to the

tightening sequence, tighten the bolts to the specified

torque.

Tightening torque: 90 Nm

(4) Loosen all bolts fully.

(5) Retighten the loosened bolts to a torque of 40 Nm in

the specified tightening sequence.

(6) Make paint marks on the cylinder head bolt heads and

cylinder head.

(7) Give a 90° turn to the cylinder head bolts in the specified

tightening sequence.

(8) Give another 90° turn to the cylinder head bolts and make

sure that the paint mark on the head of each cylinder

head bolt and that on the cylinder head are on the same

straight line.

Caution

D

If the bolt is turned less than 90°, proper fastening

performance may not be expected. When

tightening the bolt, therefore, be careful to give

a sufficient turn to it.

D

If the bolt is overtightened, loosen the bolt

completely and then retighten it by repeating the

tightening procedure from step (1).

INSPECTION

CYLINDER HEAD

(1) Before cleaning the cylinder head, check it for water leaks,

gas leaks, cracks, and other damage.

(2) Remove all oil, water scale, sealant, and carbon. After

cleaning the oil passages, blow air through them to verify

that they are not blocked.

(3) Check for distortion in the cylinder head gasket surface

using a straight edge and thickness gauge. If distortion

DEN0794

E

Dec. 1996Mitsubishi Motors Corporation

exceeds the specified limit, replace the cylinder head.

Gasket surface distortion

Standard value: 0.05 mm or less

Limit: 0.2 mm

PWEE9609

Page 43

Valve seat

contact

4D68 ENGINE (E-W) -

Margin

6EN0542

Cylinder Head, Valves and Valve Springs

11A-9-5

VALVE

(1) Check the valve face for correct contact. If incorrect, reface

using a valve refacer. Valve seat contact should be

maintained uniform at the center of valve face.

(2) If the margin is smaller than the service limit, replace

the valve.

Standard value: 1.5 mm

Limit: 0.7 mm

(3) Measure the overall height of the valve. If the specified

limit is exceeded, replace the valve.

Standard value:

Intake 114.05 mm

Exhaust 113.80 mm

Limit:

Intake 113.55 mm

Exhaust 113.30 mm

Guide I.D.

Stem O.D.

Free

height

1EN0264

6EN0279

VALVE SPRING

(1) Measure the free height of the spring and, if it is smaller

than the limit, replace.

Standard value: 49.1 mm

Limit: 48.1 mm

(2) Measure the squareness of the spring and, if the limit

is exceeded, replace.

Standard value: 2°or less

Limit: Max. 4

°

VALVE GUIDE

(1) Measure the clearance between the valve guide and valve

stem. If the limit is exceeded, replace the valve guide

or valve, or both.

Standard value: 0.05 - 0.09 mm

Limit: 0.15 mm

VALVE SEAT

(1) Check the valve seat for trace of overheat and contact

with valve surface.

Standard value: 0.9 - 1.3 mm

Valve contact

width

1EN033

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 44

11A-9-6

4D68 ENGINE (E-W) -

Cylinder Head, Valves and Valve Springs

0.9 - 1.3 mm

65

°

15

°

44

Valve stem end

(2) Install the valve and, while pressing the valve against

the valve seat, measure the valve stem projection between

the valve stem end and the valve spring seat seating

Valve stem

projection

surface.

Standard value: 43.45 mm

Limit: 43.95 mm

Spring seat seating

surface

DEN0212

VALVE SEAT RECONDITIONING PROCEDURE

0.9 - 1.3 mm

65

°

44

°

°

15

°

1EN0105

(1) Before correcting the valve seat, check the clearance

between the valve guide and valve. If necessary, replace

the valve guide.

(2) Using the appropriate special tool or seat grinder, correct

the valve seat to achieve the specified seat width and

angle.

(3) After correcting the valve seat, lap the valve and valve

seat using lapping compound. Then, check the valve stem

projection (refer to 5. VALVE SEAT in INSPECTION).

Cut

away

Height of

seat ring

0.5 - 1.0 mm

Oversize I.D.

0.5 - 1.0 mm

1EN0274

1EN0275

VALVE SEAT REPLACEMENT PROCEDURE

(1) Cut the valve seat to be replaced from the inside to thin

the wall thickness. Then, remove t h e valve seat.

(2) Rebore the valve seat hole in the cylinder head to a selected

oversize valve seat diameter.

Intake valve seat hole diameter

0.30 O.S.: 38.300 - 38.325 mm

0.60 O.S.: 38.600 - 38.625 mm

Exhaust valve seat hole diameter

0.30 O.S.: 34.300 - 34.325 mm

0.60 O.S.: 34.600 - 34.625 mm

(3) Before fitting the valve seat, either heat the cylinder head

up to approximately 250°C or cool the valve seat using

cooling spray, to prevent the cylinder head bore from

galling.

(4) Using a valve seat cutter, correct the valve seat to the

specified width and angle.

See “VALVE SEAT RECONDITIONING PROCEDURE”.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 45

4D68 ENGINE (E-W) -

Cylinder Head, Valves and Valve Springs

11A-9-7

Removal

Installation

Press

Press

Push rod

contained in

MD998115

Valve guide

MD998115

Valve guide

6EN0543

6EN0543

VALVE GUIDE REPLACEMENT PROCEDURE

(1) Using the special tool and a press, remove the valve guide

toward the cylinder head gasket surface.

(2) Rebore the valve guide hole to the new oversize valve

guide outside diameter.

Valve guide hole diameter

0.05 O.S.: 13.050 - 13.068 mm

0.25 O.S.: 13.250 - 13.268 mm

0.50 O.S.: 13.500 - 13.518 mm

NOTE

Do not install a valve guide of the same size again.

(3) Using the special tool, press-fit the valve guide, working

from the cylinder head top surface.

(4) After installing valve guides, insert new valves in them

to check for sliding condition.

(5) When valve guides have been replaced, check for valve

contact and correct valve seats as necessary.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 46

4D68 ENGINE (E-W) -

Front Case, Counterbalance Shafts and Oil Pan

11A-10-1

10. FRONT CASE, COUNTERBALANCE SHAFTS AND OIL PAN

REMOVAL AND INSTALLATION

30

29

Apply engine oil to all

moving parts before

installation.

20

27

31

54 Nm

18 Nm

10 Nm

8

14

24 Nm

28

21

19

25

9

15

24

22

23

10 Nm

16 Nm

9Nm

17

26

16

18

23 Nm

36 Nm

24 Nm

5

13

11

12

6

19 Nm

4

7

10

44 Nm

39 Nm

2

3

7Nm

1

DEN0892

AA""LA

"KA

AB""JA

E

Removal steps

1. Oil filter

2. Drain plug

3. Drain plug gasket

4. Oil level sensor

5. Oil pan

6. Oil screen

7. Oil screen gasket

8. Oil cooler bypass valve

9. Oil pressure switch

10. Relief plug

11. Gasket

12. Relief spring

13. Relief plunger

14. Oil filter bracket

15. Oil filter bracket gasket

16. Plug

17. O-ring

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

AC""IA

"HA

"GA

"GA

"FA

"EA

"DA

AD""CA

AE""BA

AE""AA

18. Flange bolt

19. Front case

20. Front case gasket

21. Oil pump cover

22. Oil pump driven gear

23. Oil pump drive gear

24. Crankshaft front oil seal

25. Counterbalance shaft oil seal

26. Oil pump oil seal

27. Counterbalance shaft, right

28. Counterbalance shaft, left

29. Counterbalance shaft front bearing

30. Counterbalance shaft rear bearing,

right

31. Counterbalance shaft rear bearing,

left

Page 47

11A-10-2

MD998727

4D68 ENGINE (E-W) -

6EN0698

Front Case, Counterbalance Shafts and Oil Pan

REMOVAL SERVICE POINTS

AA"

(1) Knock the special tool deeply between the oil pan and

(2) Hitting the side of the special tool, slide the special tool

OIL PAN REMOVAL

the cylinder block.

along the oil pan to remove it.

Plug

MD998162

MD998783

6EN0909

Screwdriver

6EN05646EN0563

AB"

PLUG REMOVAL

(1) If the plug is too hard to loosen, tap on the plug several

times with a plastic hammer, then remove it using the

special tool.

AC"

FLANGE BOLT REMOVAL

(1) When loosening the oil pump driven gear flange bolt, first

insert a Phillips screwdriver [shank diameter 8 mm] into

the plug hole on the left side of the cylinder block to block

the silent shaft.

(2) Loosen the flange bolt.

6EN0565

AD"

COUNTERBALANCE SHAFT FRONT BEARING

REMOVAL

(1) Using t he special tool, remove the front bearing from the

cylinder block.

NOTE

Be sure to remove the front bearing first. If it has not

been removed, the Rear Bearing Puller cannot be used.

Front

bearing

MD998371

E

Dec. 1996Mitsubishi Motors Corporation

3EN0166

PWEE9609

Page 48

4D68 ENGINE (E-W) -

Front Case, Counterbalance Shafts and Oil Pan

11A-10-3

MB991603

MD998732

MB991603

MD998705

6EN0207

6EN0208

AE"

RIGHT COUNTERBALANCE SHAFT REAR

BEARING / LEFT COUNTERBALANCE SHAFT

REAR BEARING REMOVAL

(1) Using the special tool, remove two rear bearings from

the cylinder block.

(2) To remove the left rear bearing, install the special tool,

Silent Shaft Bearing Installer Stopper, to the front of the

cylinder block, then remove the bearing using the special

tool, Silent Shaft Bearing Puller.

INSTALLATION SERVICE POINTS

"AA

(1) Install the special tool in the cylinder block.

(2) Apply engine oil to the rear bearing outer circumference

(3) Using the special tool, install the bearing.

LEFT COUNTERBALANCE SHAFT REAR

BEARING INSTALLATION

and bearing hole in the cylinder block.

NOTE

The left side bearing is provided with no oil hole.

MB991603

Ratchet ball

MD998705

Rear bearing

Guide pin

Rear bearing (right)

6EN0578

6EN0774

Oil

hole

"BA

RIGHT COUNTERBALANCE SHAFT REAR

BEARING INSTALLATION

(1) Install the guide pin of the special tool to the threaded

hole of the cylinder block as illustrated.

(2) Install the bearing to the special tool, aligning the ratchet

ball of the special tool with the oil hole of the rear bearing.

(3) Apply engine oil to the outer circumference of the bearing

and to the bearing hole of the cylinder block.

6EN324

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 49

11A-10-4

MD998705

4D68 ENGINE (E-W) -

Guide pin

6EN0775

MD998705

Front Case, Counterbalance Shafts and Oil Pan

(4) Insert the installer aligning with the guide pin and install

the bearing.

Guide pin

Rear bearing

installer

6EN0776

6EN0777

6EN0774

"CA

COUNTERBALANCE SHAFT FRONT BEARING

INSTALLATION

(1) Remove the rear bearing installing portion from the special

tool.

(2) Install the guide pin of the special tool to the threaded

hole of the cylinder block as illustrated.

Ratchet ball

E

Front bearing

Dec. 1996Mitsubishi Motors Corporation

Oil

hole

6EN324

(3) Install the bearing to the special tool, aligning the ratchet

ball of the special tool with the oil hole of the front bearing.

(4) Apply engine oil to the outer circumference of the bearing

and to the bearing hole of the cylinder block.

PWEE9609

Page 50

MD998705

4D68 ENGINE (E-W) -

Guide pin

6EN0775

Front Case, Counterbalance Shafts and Oil Pan

11A-10-5

(5) Insert the installer aligning with the guide pin and install

the bearing.

Oil seal

Oil seal

6EN0778

Socket

wrench

Front case

6EN0494

Socket wrench

Front case

6EN0580

"DA

"EA

OIL PUMP OIL SEAL INSTALLATION

COUNTERBALANCE SHAFT OIL SEAL

INSTALLATION

Oil seal

E

MD998375

Front case

Dec. 1996Mitsubishi Motors Corporation

6EN0579

"FA

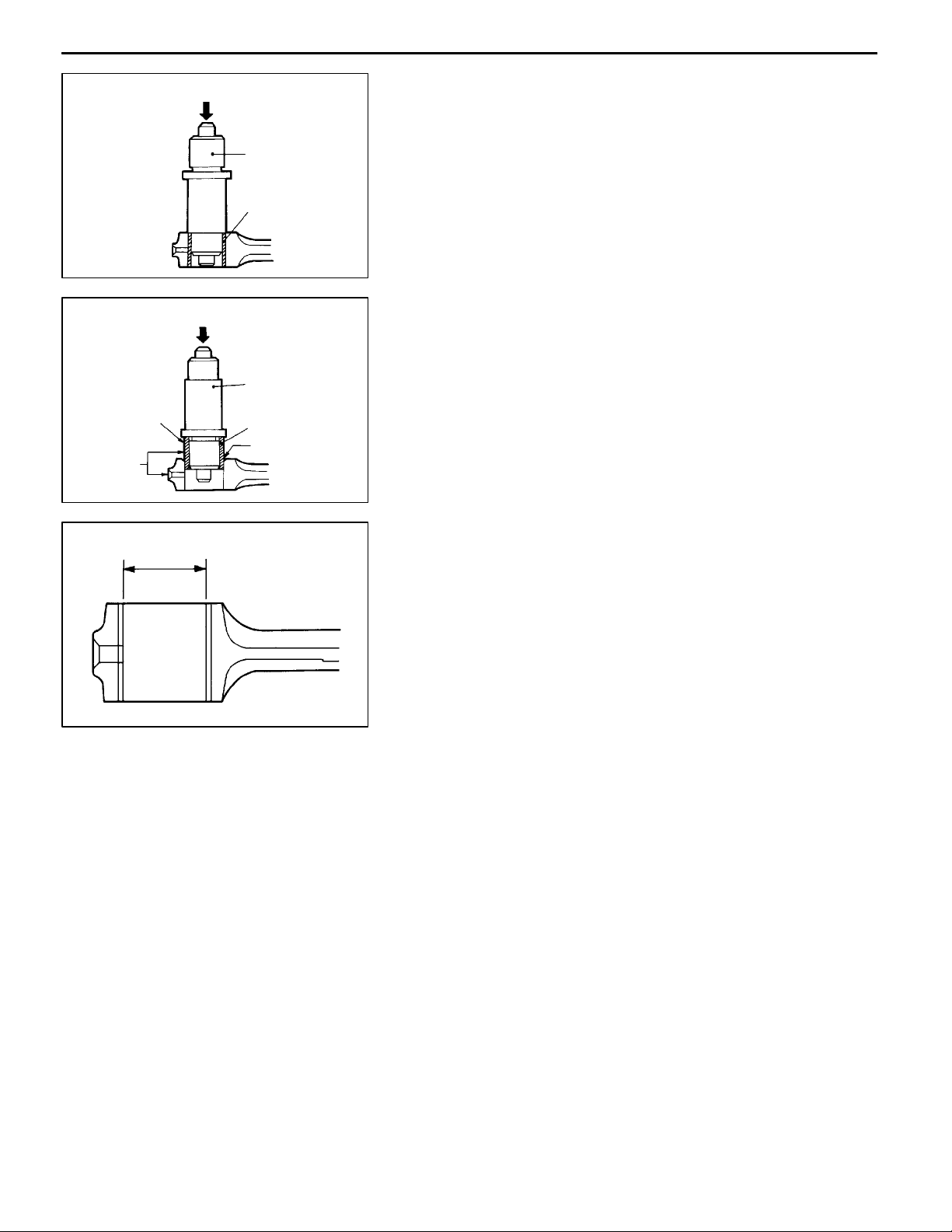

CRANKSHAFT FRONT OIL SEAL INSTALLATION

(1) Using the special tool, install the crankshaft front oil seal

into the front case.

PWEE9609

Page 51

11A-10-6

4D68 ENGINE (E-W) -

Front Case, Counterbalance Shafts and Oil Pan

MD998285

Alignment mark

6LU0015

6EN0746

"GA

OIL PUMP DRIVEN GEAR / OIL PUMP DRIVE

GEAR INSTALLATION

(1) Apply engine oil amply to the gears and line up the

alignment marks.

"HA

FRONT CASE INSTALLATION

(1) Install the special tool at the front end of the crankshaft

and apply a thin coat of engine oil to the outer

circumference. In case an oil seal has been installed to

the front case, be sure to use the guide.

(2) Install the front case assembly via a new front case gasket

and temporarily tighten the flange bolts (other than those

for tightening the filter bracket.)

(3) Install the oil filter bracket via the oil filter bracket gasket

and temporarily tighten four bolts with washers.

(4) Tighten the front case bolts to the specified torque.

MD998285

Phillips

screwdriver

6EN0747

6EN0564

"IA

FLANGE BOLT INSTALLATION

(1) Insert a Phillips screwdriver [shank diameter 8 mm] into

the plug hole on the left side of the cylinder block to block

the counterbalance shaft then tighten the flange bolt.

6EN0565

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 52

4D68 ENGINE (E-W) -

Front Case, Counterbalance Shafts and Oil Pan

11A-10-7

MD998162

MD998783

6EN0909

9EN0094

"JA

PLUG INSTALLATION

(1) Fit a new O-ring in the front case.

(2) Tighten the plug to the specified torque using the special

tool.

"KA

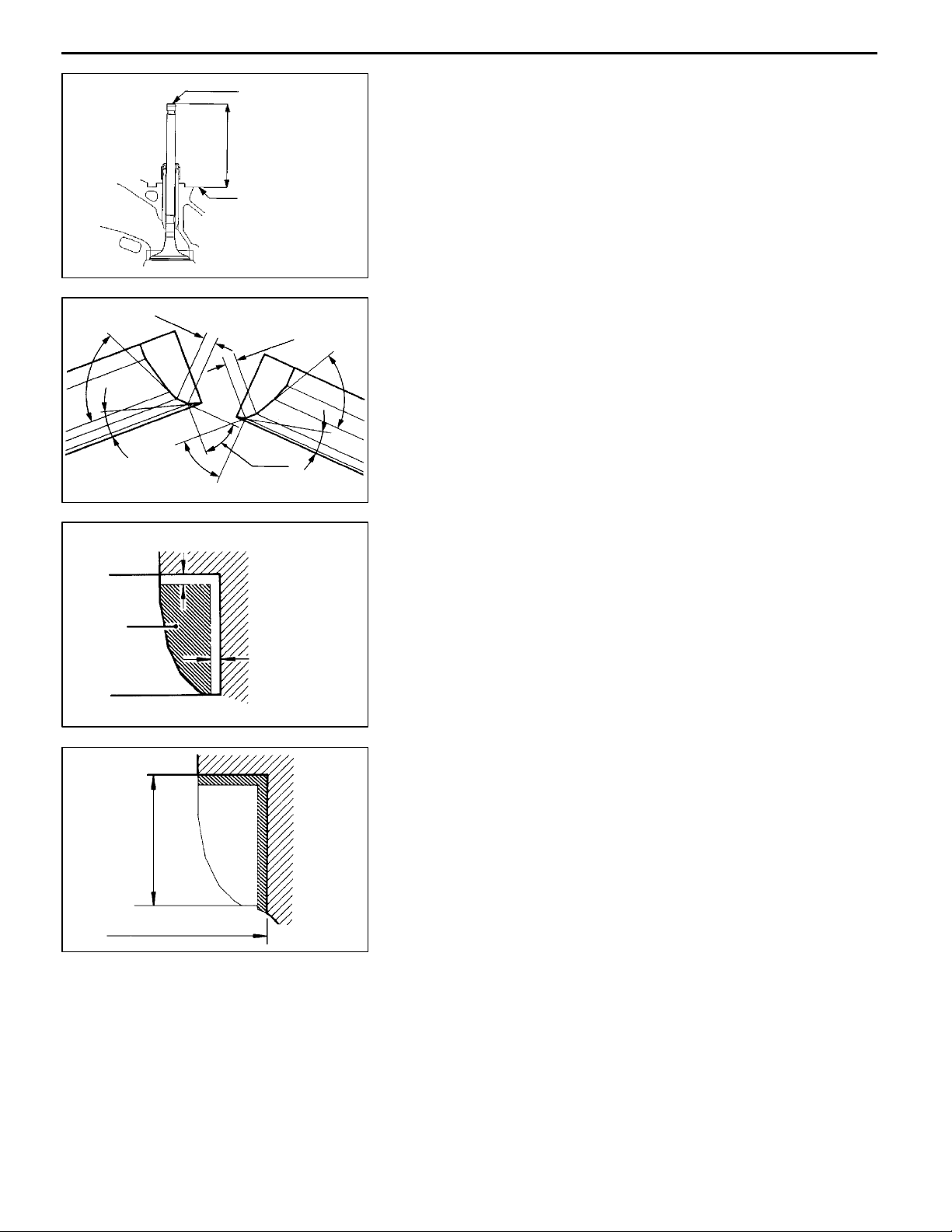

OIL PRESSURE SWITCH INSTALLATION

Specified sealant: 3M ATD Part No. 8660 or equivalent

Caution

D

Keep the end of the thread portion clear or sealant.

D

Avoid an overtightening.

"LA

OIL PAN INSTALLATION

(1) Clean both mating surface of oil pan and cylinder block.

(2) Apply a 4 mm wide bead of sealant to the entire

circumference of the oil pan flange.

Bolt

hole

portion

Crankshaft pulley side

8 mm bolts

Oil pan viewed from lower side

Groove

portion

6EN0213

6EN0449

Specified sealant:

MITSUBISHI GENUINE PART No. MD970389 or

equivalent

(3) The oil pan should be installed in 15 minutes after

application of sealant.

(4) Note the difference in bolt lengths at the location shown.

INSPECTION

FRONT CASE

(1) Check the oil holes for clogging and clean if necessary.

(2) Check the left silent shaft front bearing section for wear,

damage and seizure. If there is anything wrong with the

section, replace the front case.

(3) Check the front case for cracks and other damage. Replace

cracked or damaged front case.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 53

11A-10-8

Valve

4D68 ENGINE (E-W) -

DEN0711

Front Case, Counterbalance Shafts and Oil Pan

COUNTERBALANCE SHAFT

(1) Check the oil holes for clogging.

(2) Check the journals for seizure, damage, and contact with

bearing. If there is anything wrong with the journal, replace

the counterbalance shaft, bearing or front case assembly.

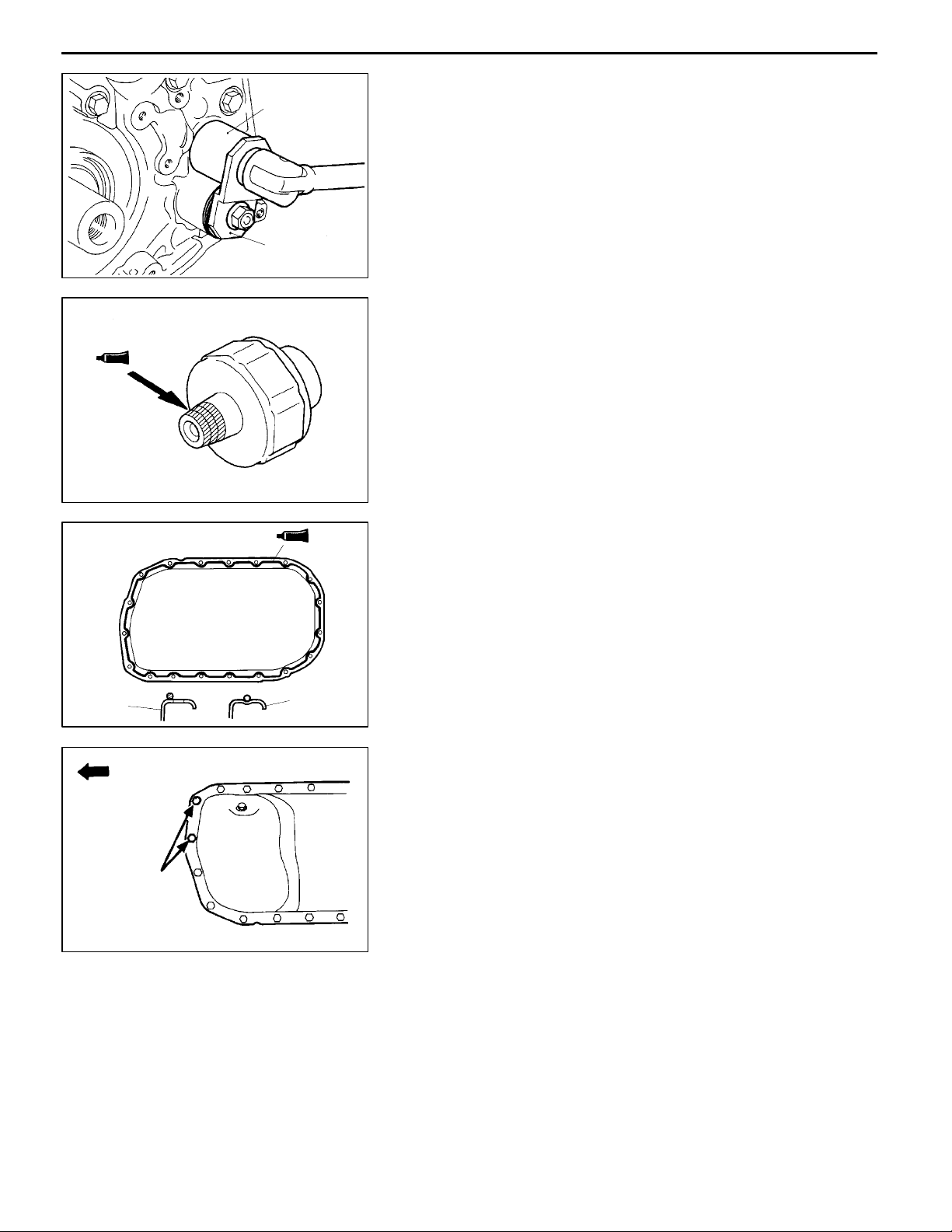

OIL COOLER BYPASS VALVE

(1) Make sure that the valve moves smoothly.

(2) Ensure that the dimension L measures the standard value

under normal temperature and humidity.

Dimension L: 34.5 mm

(3) The dimension must be the standardvalue when measured

after the valve has been dipped in 100°C oil.

Dimension L: 40 mm or more

6EN0589

6LU0013

OIL PUMP

(1) Assemble the oil pump gear to the front case and rotate

it to ensure smooth rotation with no looseness.

(2) Ensure that there is no ridge wear on the contact surface

between the front case and the gear surface of the oil

pump cover.

(3) Check the side clearance.

Standard value:

Drive gear 0.08 - 0.14 mm

Driven gear 0.06 - 0.12 mm

OIL SEAL

(1) Check the oil seal lip for wear and damage. Replace the

oil seal if necessary.

(2) Check the oil seal lip for deterioration. Replace oil seal

if necessary.

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 54

4D68 ENGINE (E-W) -

Pistons and Connecting Rods

11. PISTONS AND CONNECTING RODS

REMOVAL AND INSTALLATION

11A-11-1

"FA

AA""EA

"CA

"DA

"CA

"BA

"BA

E

Removal steps

1. Connecting rod cap nut

2. Connecting rod cap

3. Connecting rod bearing

4. Piston and connecting rod assembly

5. Connecting rod bearing

6. Piston ring No.1

7. Piston ring No.2

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

"AA

"AA

"AA

Apply engine oil to all

moving parts before

installation.

DEN0771

8. Oil ring

9. Snap ring

10. Piston pin

11. Piston

12. Connecting rod

13. Bushing

14. Connecting rod bolt

Page 55

11A-11-2

4D68 ENGINE (E-W) -

Cylinder No.

DEN0050

Front mark

(Identification

mark)

Front mark

DEN0784

Pistons and Connecting Rods

REMOVAL SERVICE POINTS

AA"

(1) Mark the cylinder number on the side of the connecting

CONNECTING ROD CAP REMOVAL

rod big end for correct reassembly.

INSTALLATION SERVICE POINTS

"AA

(1) Assemble the piston and connecting rod, directing the

(2) Insert the piston pin. The pin should be inserted by hand.

PISTON PIN / PISTON / CONNECTING ROD

INSTALLATION

front marks in the same direction.

Replace if there is a play.

“T” identification mark

“2T” identification mark

No. 1

No. 2

No. 3

E

Side mark

No. 1

No. 2

9EN0524

Location of identification

colors

No. 4

6EN0700

Dec. 1996Mitsubishi Motors Corporation

"BA

PISTON RING NO. 2 / PISTON RING NO. 1

INSTALLATION

(1) Using a ring expander, fit ring No. 2 and ring No. 1 with

their identification marks facing upward (on the piston

crown side).

Identification marks:

No. 1 ring: T

No. 2 ring: 2T

NOTE

Piston rings are stamped with size marks as follows:

Size Size mark

STD None

0.50 mm O.S. 50

1.00 mm O.S. 100

"CA

CONNECTING ROD BEARING INSTALLATION

(1) When the bearings are replaced, select and install them

according to th e identification colors on the crankshaft.

Crank pin O.D.

identification color

Yellow 1

None 2

White 3

PWEE9609

Connecting rod bearing

identification mark

Page 56

4D68 ENGINE (E-W) -

Pistons and Connecting Rods

11A-11-3

Coil expander joint No. 1

Timing

belt side

No. 2

Timing belt

side

Piston pin

Oil ring

Cylinder No.

6EN0549

DEN0054

"DA

PISTON AND CONNECTING ROD ASSEMBLY

INSTALLATION

(1) Liberally coat engine oil on the circumference of the piston,

piston ring, and oil ring.

(2) Arrange the piston ring and oil ring gaps as shown in

the illustration.

(3) Rotate the crankshaft so that the crank pin is on the center

of the cylinder bore.

(4) Use suitable thread protectors on the connecting rod bolts

before inserting the piston and connecting rod assembly

into the cylinder block. Care must be taken not to nick

the crank pin.

(5) Using a suitable piston ring compressor tool, install the

piston and connecting rod assembly into the cylinder block.

Caution

D

Direct the front mark (arrow) on the piston top

towards the engine front (timing belt side).

"EA

CONNECTING ROD CAP INSTALLATION

(1) Verifying the mark made during disassembly, install the

bearing cap to the connecting rod. If the connecting rod

is new with no index mark, make sure that the bearing

locking notches come on the same side as shown.

Notches

DEN0051

(2) Make sure that the connecting rod big end side clearance

meets the specification.

Standard value: 0.10 - 0.25 mm

Limit: 0.4 mm

6EN0621

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 57

11A-11-4

4D68 ENGINE (E-W) -

Pistons and Connecting Rods

Paint

mark

90°- 100

"FA

CONNECTING ROD CAP NUT INSTALLATION

Caution

D

If the cylinder head has been installed before installing

the connecting rod cap nut, be sure to remove the

spark plugs.

(1) Since the connecting rod cap bolts and nuts are torqued

using the plastic area tightening method, the bolts should

be examined BEFORE reuse. If the bolt threads are

“necked down”, the bolt should be replaced.

Necking can be checked by running a nut with fingers

to the full length of the bolt threads. If the nut does not

run down smoothly, the bolt should be replaced.

(2) Before installation of each nut, apply engine oil to the

thread portion and bearing surface of the nut.

(3) Install each nut to the bolt and tighten it with fingers. Then

tighten the nuts alternately to install the cap properly.

(4) Tighten the nuts to a torque of 20 Nm.

°

Paint mark

(5) Make a paint mark on the head of each nut.

(6) Make a paint mark on the bolt end at the position 90°

to 100° from the paint mark made on the nut in the direction

of tightening the nut.

(7) Give a 90° to 100° turn to the nut and make sure that

the paint mark on the nut and that on the bolt are in

alignment.

Nut

Bolt

6AE0298

Caution

D

If the nut is turned less than 90°, proper fastening

performance may not be expected. When

tightening the nut, therefore, be careful to give

a sufficient turn to it.

D

If the nut is overtightened (exceeding 10 0°), loosen

the nut completely and then retighten it by

repeating the tightening procedure from step (1).

E

Dec. 1996Mitsubishi Motors Corporation

PWEE9609

Page 58

Piston

4D68 ENGINE (E-W) -

5EN0066

Thickness gauge

Pistons and Connecting Rods

11A-11-5

INSPECTION

PISTON RING

(1) Check for side clearance.

If the limit is exceeded, replace t he ring or piston, or both.

(2) In the case of semi-keystone type piston rings, check

the ring to ring groove clearance as illustrated.

Standard value:

No. 1 0.05 - 0.07 mm

No. 2 0.05 - 0.07 mm

Limit:

No. 1 0.15 mm

No. 2 0.15 mm

Press down ring

with piston

Piston ring

End gap

DEN259

6EN0548

1EN0246

(3) Insert the piston ring into the cylinder bore. Force it down

with a piston, its crown being in contact with the ring,

to correctly position it at right angles to the cylinder wall.

Then, measure the end gap with a thickness gauge. If

the end gap is excessively, replace the piston ring.

Standard value:

No. 1 0.20 - 0.32 mm

No. 2 0.35 - 0.50 mm

Oil 0.10 - 0.30 mm

Limit: 0.8 mm

CRANKSHAFT PIN OIL CLEARANCE (PLASTIC GAUGE

METHOD)

(1) Remove oil from the crankshaft pin and the connecting

rod bearing.