MITEL 1A255 Datasheet

PRODUCT INFORMATION

Europe: Tel (46) 8 58 02 45 00 Fax (46) 8 58 02 01 10

Tel (44) 1291 436180 Fax (44) 1291 436771

America: Tel 1-800-96MITEL Fax (613) 592-6909

Asia: Tel (65) 293 5312 Fax (65) 293 8527

12090.11 1994-09-20

Baseband Video

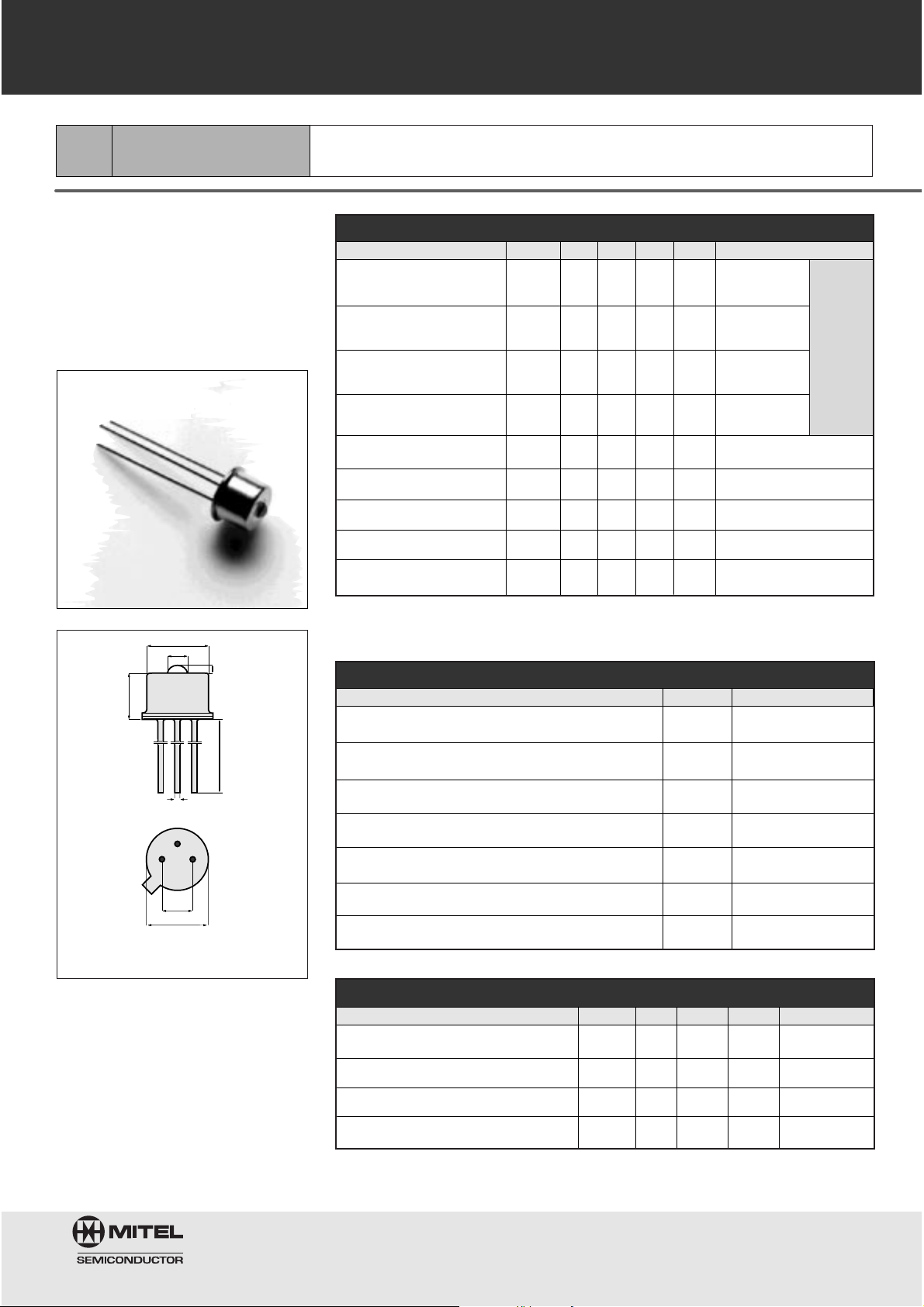

860nm

0.6

14

Ø1.5

Ø4.7

3.7

0.4

5.4

2.5

CASE

ANODE

CATHODE

BOTTOM VIEW

The anode is in electrical contact with the case.

TO-46 Package With Lens

All dimensions in mm

The low thermal droop of this device

allows baseband video transmission

with minimum distortion. The double-lens optical system provides for

optimum coupling of power into the

fiber.

1A255

High-Performance LED

Thermal Characteristics

Fiber:

62.5/125mm

Graded

Index

NA=0.275

Optical and Electrical Characteristics

(25°C Case Temperature)

Absolute Maximum Ratings

Note 1: Measured at the exit of 100 meters of fiber.

Note 2: Transientdecline in optical power due to self-heating.

PARAMETER SYMBOL MIN. TYP. MAX. UNIT TEST CONDITION

Fiber-Coupled Power P

fiber

80 120 mW IF=80 mA

(Fig.1,2,&3) (Table1) (Note 1)

Rise and Fall Time tr,t

f

68nsI

F

=80 mA

(10-90%) (no bias)

Bandwidth f

c

55 MHz IF=80 mA

(3dBel)

Thermal Droop

(nonlinearity)

(Note 2)

lDPl 2%I

F

=80 mA

Peak Wavelength l

p

840 860 880 nm IF=80 mA

Spectral Width(FWHM) Dl 50 nm IF=80 mA

Forward Voltage (Fig.5) V

F

1.8 2.2 V IF=80 mA

Reverse Current I

R

20 mA VR=1V

Capacitance C 250 pF VR=0V, f=1MHz

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

Thermal Resistance- Infinite Heat Sink R

thjc

100 8C/W

Thermal Resistance- No Heat Sink R

thja

400 8C/W

Temperature Coefficient- Optical Power dP/dT

j

-0.5 %/8C

Temperature Coefficient-Wavelength dl/dT

j

0.3 nm/8C

PARAMETER SYMBOL LIMIT

Storage Temperature T

stg

-55 to +1258C

Operating Temperature (derating: Fig.4) T

op

-55 to +1258C

Electrical Power Dissipation(derating: Fig.4) P

tot

250 mW

Continuous Forward Current (f<10 kHz) I

F

110 mA

Peak Forward Current (duty cycle<50%, f>1 MHz) I

FRM

180 mA

Reverse Voltage V

R

1.5 V

Soldering Temperature (2mm from the case for 10 sec) T

sld

2608C

860nm

Core Diameter/Cladding Diameter

Numerical Aperture

50/125mm 62.5/125mm 100/140mm 200/230 m m

0.20 0.275 0.29 0.37

Table 1

Typical Fiber-Coupled Power

60mW 120mW 250 mW 400mW

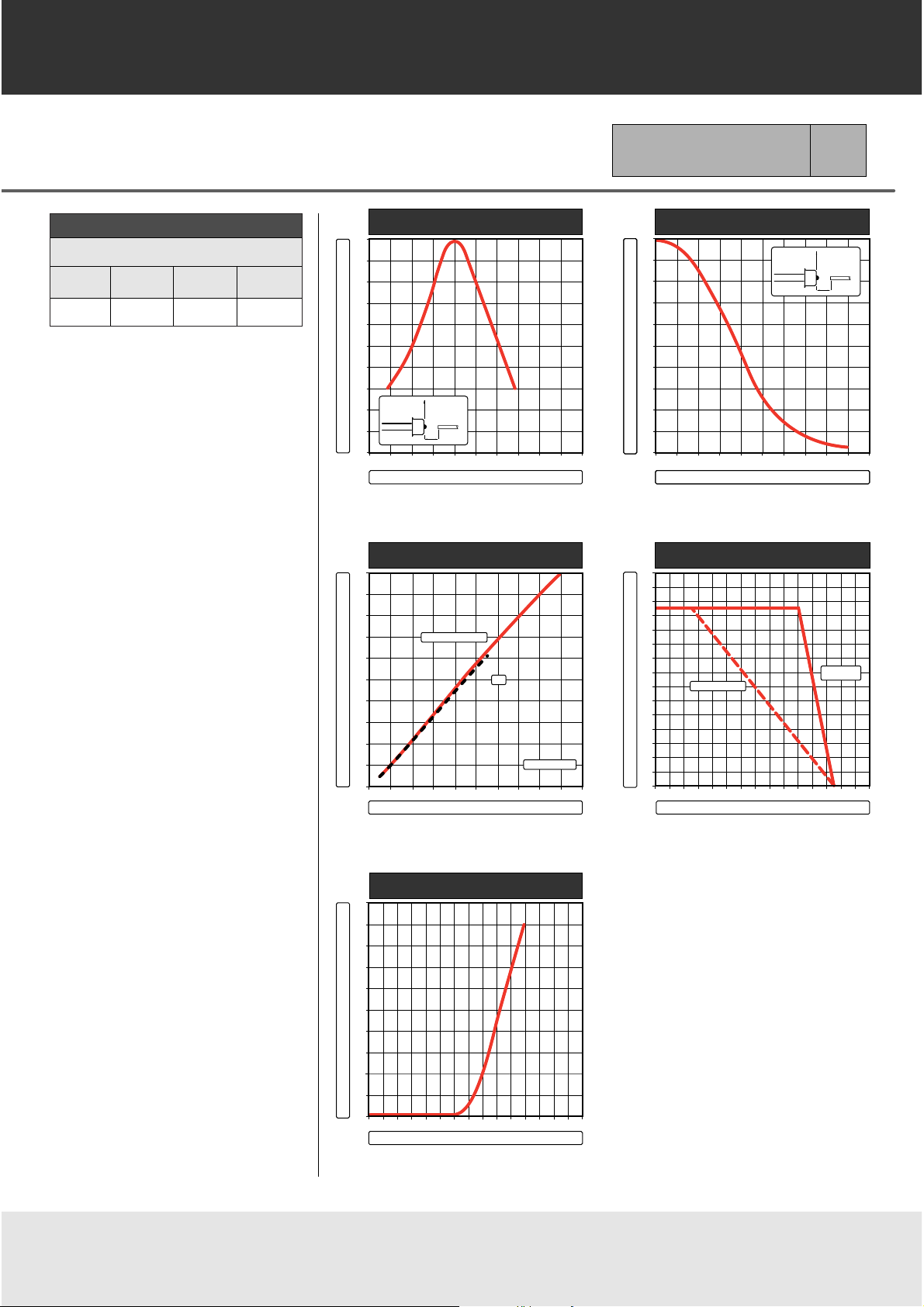

z - AXIAL DISPLACEMENT OF FIBER

RELATIVE FIBER-COUPLED POWER

0

20

40

60

80

100

%

0.5

1.0 1.5

2.0

2.5

3.0

mm

r

r = opt.

Øc = 62.5ʵm

z

FIGURE 1

0

20

40

60

80

100

%

0

20 40

60

80

100

µm

r - RADIAL DISPLACEMENT OF FIBER

RELATIVE FIBER-COUPLED POWER

r

z = opt.

Øc = 62.5ʵm

z

r - RADIAL DISPLACEMENT OF FIBER

RELATIVE FIBER-COUPLED POWER

FIGURE 2

0

20

40

60

80

100

%

0

40 80

120

160

200

mA

FORWARD CURRENT

RELATIVE FIBER-COUPLED POWER

50% DUTY CYCLE

DC

HEAT SINKED

FIGURE 3

FORWARD VOLTAGE

FORWARD CURRENT

mA

200

100

0

0

1 2

3

V

FIGURE 5

mW

300

200

100

0

0 50 100

150¡

C

NO HEAT SINK

OPERATING TEMPERATURE

MAX. ELECTRICAL POWER DISSIPATION

FIGURE 4

INFINITE

HEAT SINK

1A255

High-Performance LED

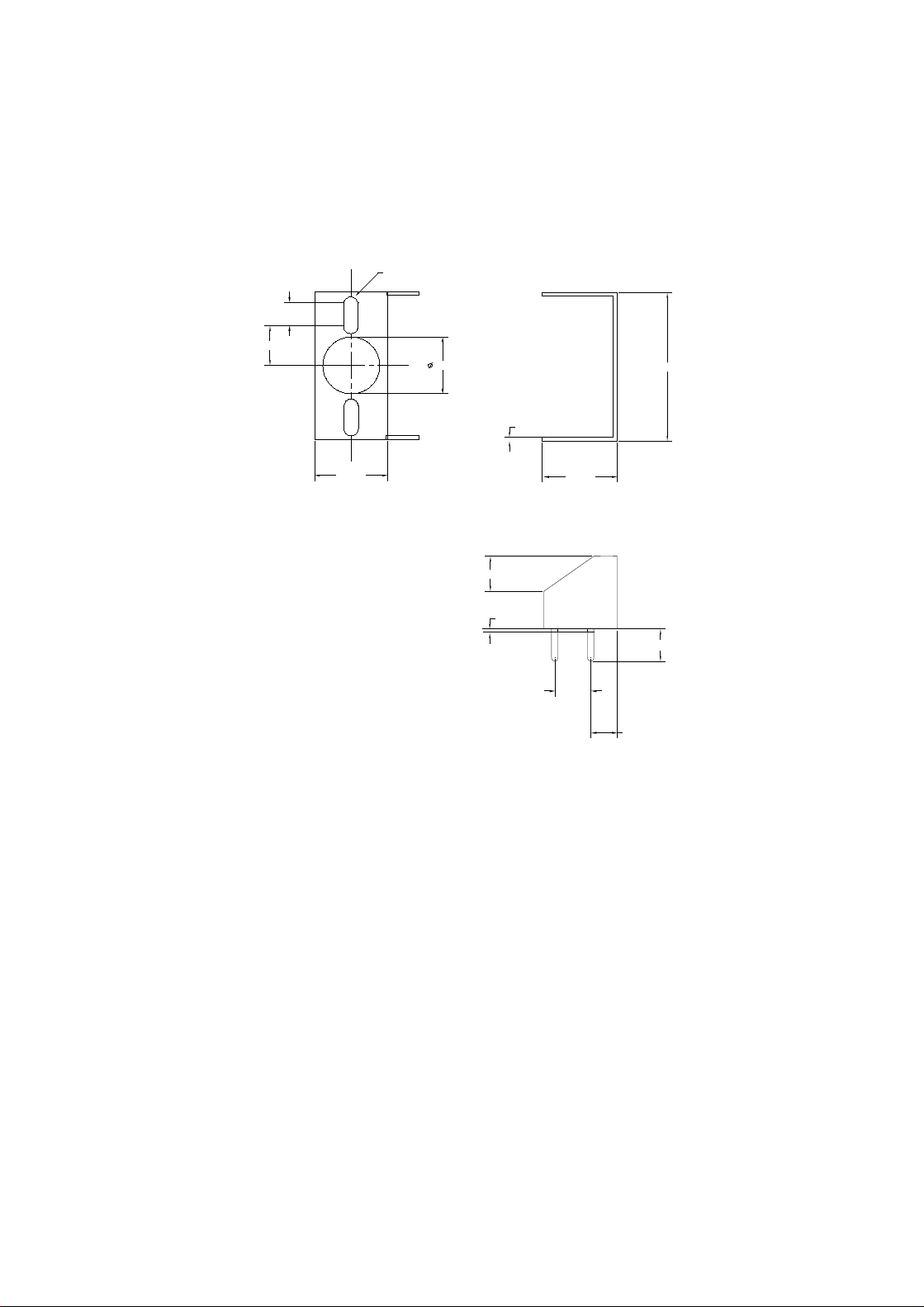

SHORT WAVELENGTH LED

5.6000

3.3000

Clip for SC-2A

R 1.00

80,000

0.5000

20.8200

10,2500

10.3000

4.9500

0.5000

4.5000

5.0800

3.6450

Loading...

Loading...