Page 1

Warranty Period : 1 year

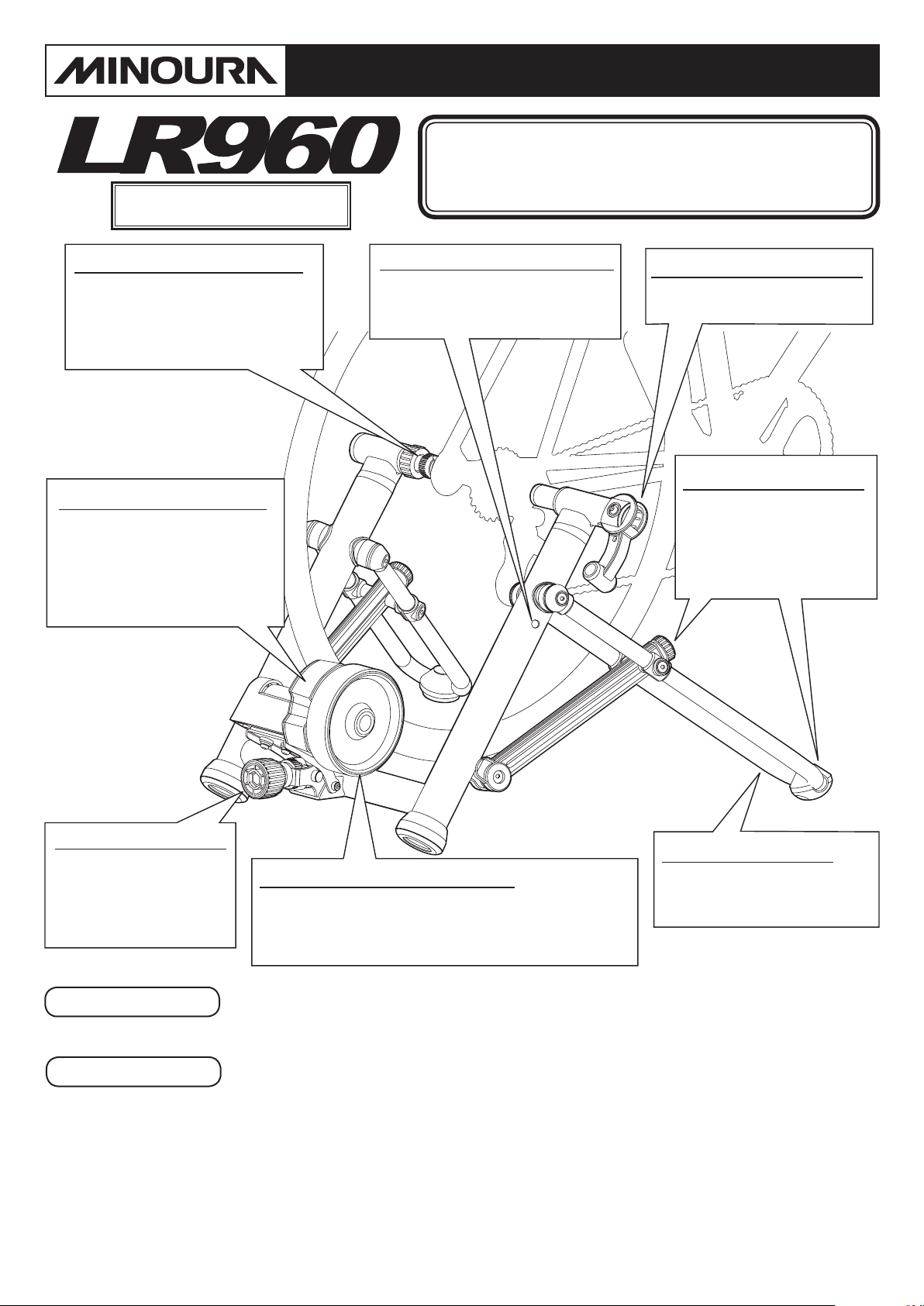

LiveRide

Applicable Tire Size Capacity:

any 24-inch – 700 x 40c

(Max Tire Outer Diameter = 712mm)

LR960

instructions manual

(ETRTO 42-622)

(ver.1.1 2013/8)

Bolt Type Left Side Coupling

Fits 120 – 145 mm standard hub

width. For quick release type hub

only. For xed nut hub, replace

to the optional "Longer Left Side

Coupling Bolt" (SKU:400-1285-00).

Tandem Magnet Type Unit

A world's rst. Primary magnet

is engaged for the rst 7 levels

then the second magnet kicks in

for the next 6 levels.

Gives you the widest range of

resistance of any trainer.

U-Leg Hole for Smaller Wheel

Use this hole for all 24", 26", and

650c wheels to keep the bike

horizontal.

Quick Release Hub Clamp

Mounts/dismounts your bike in

seconds.

Micro-Adjustable Legs

By turning the dial, the legs

can be adjusted +/- 10 mm

to accommodate uneven

surfaces for complete

trainer stability.

Roller Pressure Knob

Double-threaded system

enables quick and easy

operation to engage/

release the roller to/from

the rear tire.

Please Note

Contact

Lighter Flywheel = More Power

Our patented ywheel weighs less for greater

portability but performs as well as a ywheel weighing

35% more. The key is the inside stair-step design for

perfect power transmission when you need it.

This trainer must be used with a completely smooth (no knobs or raised tread) tire.

Failure to do so will ruin the mag unit, your tire, and void any possible warranty.

If you need help, please contact the shop first where you originally purchased this product

or call the distributors in your country. The distributors list can be found on our web site.

When you cannot get enough service, you can contact us;

Tubular U-shape Leg

Not just for unique design, but

reduces weight and provides

great stability.

MINOURA NORTH AMERICA MINOURA JAPAN HEADQUARTERS

(for U.S. residents ONLY)

Phone: 1-510-538-8599 (8 am - 5 pm, Mon - Fri, PST) 1197-1 Godo, Anpachi, Gifu 503-2305 Japan

Fax: 1-510-538-5899 Phone: +81-584-27-3131

Email: support@minourausa.com Fax: +81-584-27-7505

Email: minoura@minoura.jp

Web: www.minoura.jp

(for ALL customers)

Made in Japan

Page 2

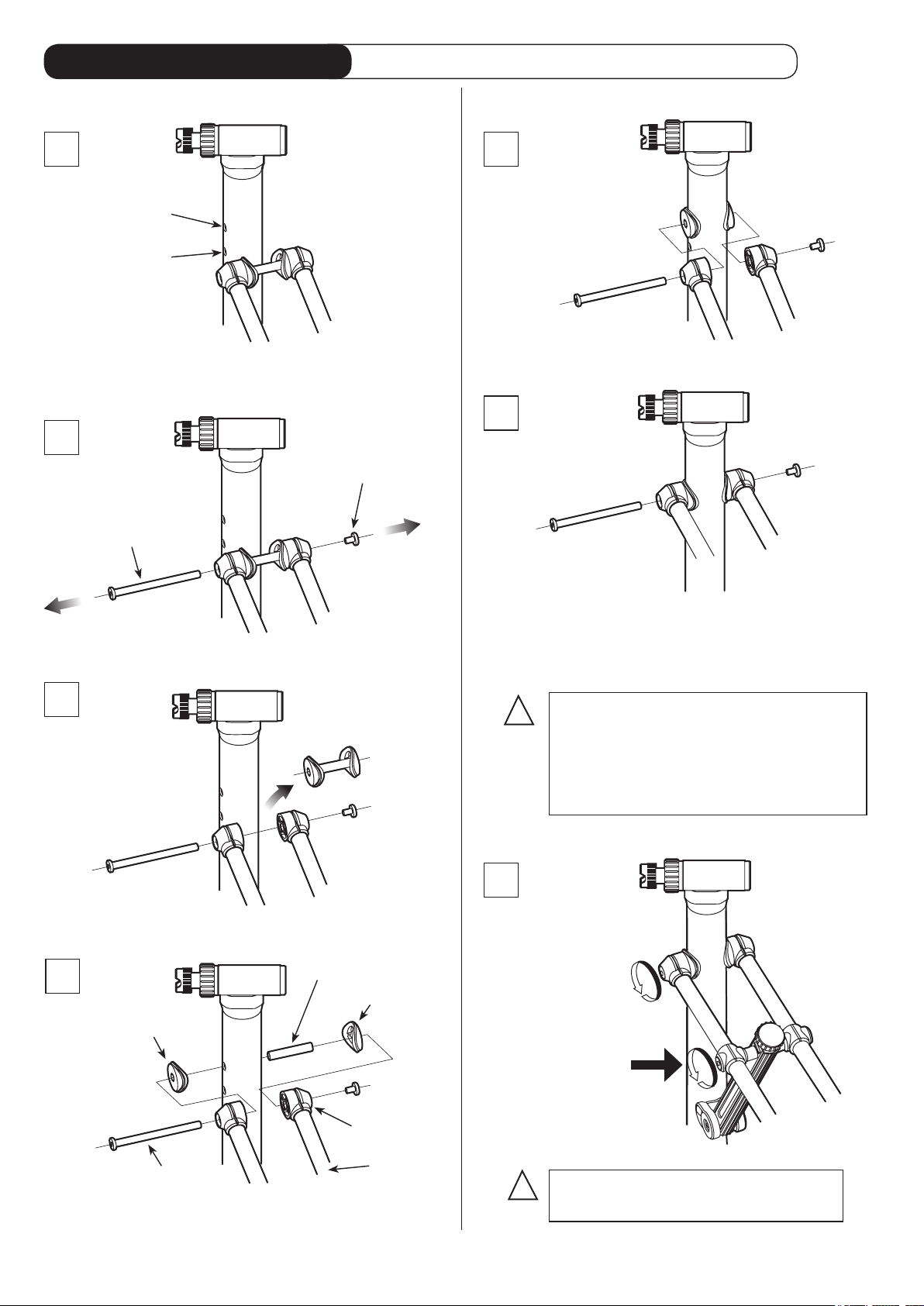

How To Assemble U-Leg

Required Tools: 2 x 5mm Hex Wrench (supplied)

1

for 700C

for 22"~26"

Choose the pivot hole of the U-Leg for your

bike size on the main pillar.

2

Pivot Bolt

(Nut Side)

650C

Pivot Bolt

(Screw Side)

(Fig. A)

5

(Fig. E)

Attach the U-Leg to the main pillar.

6

(Fig. F)

Disassemble the pivot bolt.

3

Remove the alloy sleeve and plastic washers.

4

Plastic Washer

Alloy Sleeve

Plastic Washer

(Fig. B)

(Fig. C)

End Plug

Check that the plastic end plugs on the U-Leg are

fully inserted and lined up with the hole.

Then insert the pivot bolt and fully tighten the

screw with using the supplied M5 hex wrenches.

!

Be sure you fully insert the plastic

end plugs to the U-Leg before

putting the pivot bolt through them.

Failure to do so may cause the legs

to be positioned at different heights.

7

The center

guide bolt is

intentionally

left loose when

packaged at the

factory.

Tighten it slightly

and check to

see that each leg

moves smoothly.

(Fig. G)

Pivot Bolt

U-Leg

(Fig. D)

Insert the alloy sleeve into the selected hole,

and put the plastic washers on both sides.

- 2 -

You do not need to disassemble

!

the center guide bolt. Just tighten.

Page 3

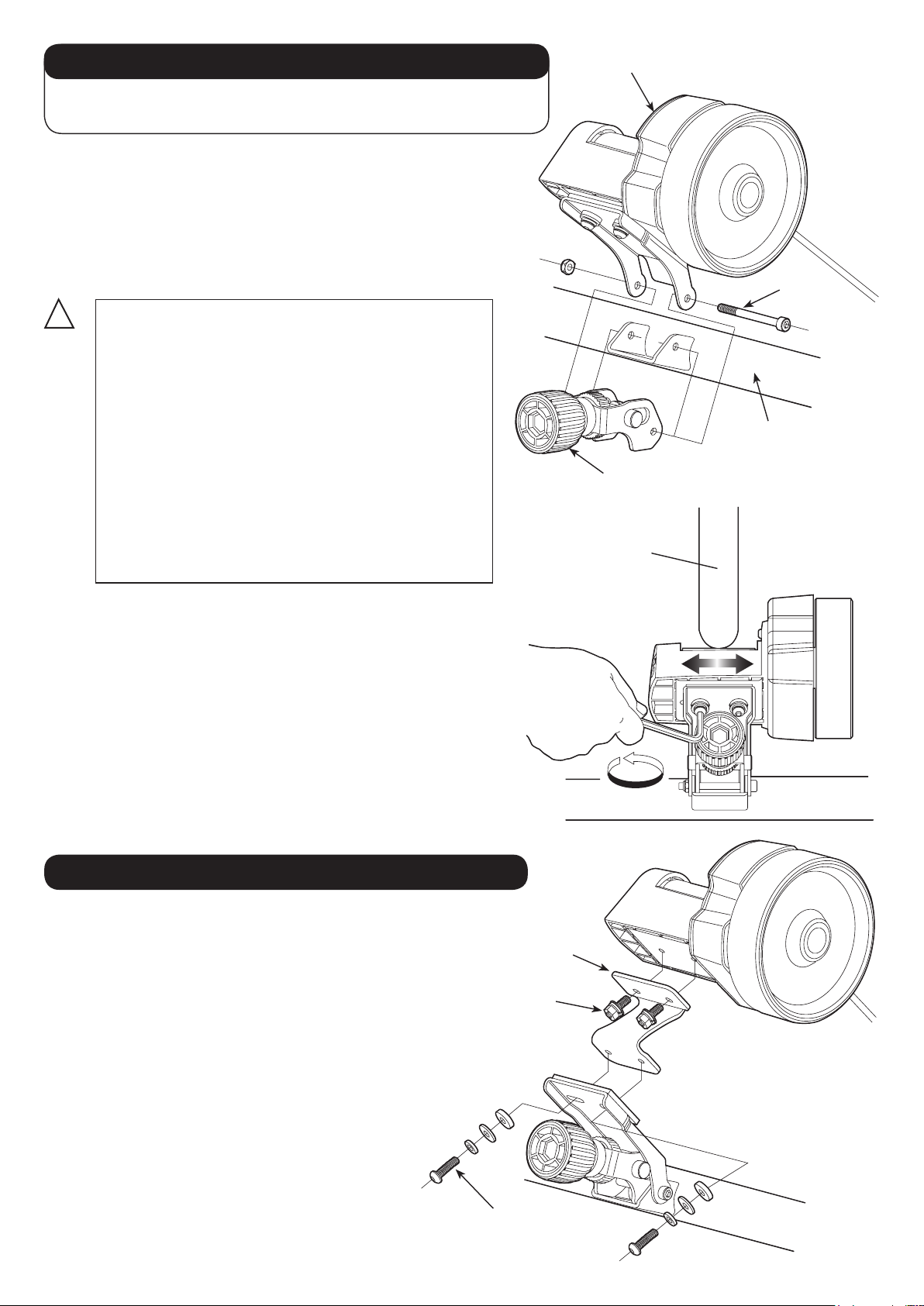

How To Install Mag Unit & Knob Set

Required Tools: 1 x 5mm Hex Wrench (supplied)

1 x 10mm Spanner (not supplied)

The Mag resistance unit and Roller Pressure Knob now

need to be installed to the frame.

First, attach the Knob onto the bracket on the Step-Bar.

Then place the Mag unit over the Knob, and tighten both

brackets together using the pivot bolt and M6 nut. (Fig. H)

Mag Resistance Unit

Pivot Bolt

!

Overtightening the pivot bolt will cause the

Knob to become inoperable.

Make sure you unscrew (loosen) the pivot

bolt by 1/4 - 1/2 turn once you completely

tightened it.

The Mag unit should be lowered towards the

ground by its own weight at this point.

If the pivot bolt is too loose, the Mag unit may

drop suddenly and come down on your hand

or ngers.

Make sure to adjust the torque properly to

insure proper operation.

Your bicycle tire should be as close to the center of the

roller as possible. (see Fig. I)

If the tire has been touching the plastic housing, damage

will occur to the Mag unit and your tire.

The base bracket has two sets of thread holes for mounting

the Mag unit. Choose the better holes.

Also it can be micro-adjusted and to do so, loosen the

backside screws and slide the Mag unit in the direction

needed to center the tire properly.

Tighten the screws when you have finished.

Roller Pressure Knob

Rear Tire

Step-Bar

(Fig. H)

(Fig. I)

How To Use Small Wheel Adaptor

If your tires are 26" or smaller and are less

than 1.75" in width, you will need to use the

supplied Z-shaped Small Wheel Adapter.

Your tire size should be clearly marked on the

tires sidewall.

The direction of the Z-adapter is fixed so

follow the arrow printed on the top and make

sure it's pointing toward the front (toward

your bike).

If the drive roller cannot reach the tire, make

sure the Z-adapter has been installed correctly.

Use the original round head bolts for the

Mount Base, and use the supplied hex head

bolts for the Mag unit. (see Fig. J)

Z-Adaptor

Hex Head Bolt

Round Head Bolt

- 3 -

(Fig. J)

Page 4

Placing LR960 on Floor

Fully open the legs and place on a flat and horizontal floor.

!

To open the U-Leg, grab the main frame and the rubber cap on the U-Leg (see Fig. L).

Do NOT pull the Alloy Leg Guide directly, otherwise it may be bent or damaged.

Main Frame

Alloy Leg Guide

U-Leg

(Fig. L)

(Fig. K)

Adjuster Knob

Check that all 4 points are touching the floor

evenly. (see Fig. M)

If all 4 points are not touching the floor

evenly, the frame could be deformed and

cause damage to the trainer and possibly

your bike.

About Leg Height Adjuster

Each U-Leg height can be adjusted individually by

+/- 10 mm travel.

This adjuster allows for uneven floor or ground

compensation to help insure proper stability.

UP

DOWN

(Fig. M)

When using the adjuster, be sure to check and

make sure that all 4 points are touching the ground

evenly.

And the trainer should be positioned as close as

possible to the floor for better stability.

- 4 -

(Fig. N)

Page 5

How To Mount Your Bike

LR960's coupling position is pre-adjusted in the factory to fit the 125mm standard rear hub width.

If it is too loose or too tight to your bike, or if you use different width of rear hub like a track race

bike, adjust the left side coupling as precisely as possible for maximum stability.

Please note there is no adjustment on the right side (lever side) coupling.

Applicable Hub Width: 120 – 145mm

!

!

1

2

3

The coupling cone shape is designed to t the supplied quick release skewer perfectly.

We strongly recommend you to replace your rear wheel skewer with the supplied one.

We do NOT guarantee the stability while using LR960 with your own skewer.

If your bike's rear hub axle is NOT a quick release skewer type, but a hub nut type, you

don't need to use the supplied skewer.

The standard left side coupling bolt (UF-8) is too short to hold the hub nut type axle.

You must replace it to the optional longer one "Extended Left Side Coupling Bolt for Nut

Type Hub (SKU: 400-1285-00)" for your safety.

The following steps describe the micro adjustment of the left side coupling. This step is not always required

and once fixed in the proper position, you should not need to adjust again. Once adjusted to fit your bike,

simply operate the Quick Hub Handle Lever for a proper fit every time.

First, loosen the red Lock Ring by

turning it counter-clockwise.

The left side coupling is actually a bolt/

coupling combination.

Turn the coupling to adjust the position.

Raise the Quick Hub Clamp Lever up

to retract the right side coupling.

Lock Ring

Left Side Coupling

Right Side Coupling

Quick Hub

Clamp Lever

(Fig. O)

Insert the left side hub end (quick release

4

lever side) into the left side coupling cone.

In this position, place the other side of

5

the bike into the right side (rear cog side)

coupling cone. Make sure your derailleur

cable goes OVER the coupling.

Now, push down (lower) the Quick

6

Hub Clamp Lever until it fully engages

the skewer or axle nut.

Make sure the Quick Clamp Hub Lever

7

is lowered into its locked position and

cannot be lowered any further.

The frame may appear slightly open

but this is normal.

If the frame seems to be opened too

widely, re-mount your bike following

the instructions. Failure to do so could

damage your bike and/or the trainer.

Now, grab the saddle of your bike and rock the bike back and forth to make sure your bike is

8

securely in the trainer. Your bike should not move independently of the trainer where it is attached.

Quick Release Skewer

(Fig. P)

(Fig. Q)

(Fig. R)

Tighten the red Lock Ring firmly to fix the left side coupling position.

9

- 5 -

Page 6

Roller Pressure Adjustment

Fully turn the red knob counter-clockwise. (initial position)

1

Turn the silver dial counter-clockwise until the drive roller touches the tire surface.

2

Turn the red knob clockwise to compress the tire by the roller. (required depth = 3 – 4 mm)

3

(Fig. S) (Fig. T)

Turn the silver dial counter-clockwise Turn the red knob clockwise

Tire wearing must occur on any tire drive system. To minimize the tire wear and maintain the tire

life as long as possible, it's crucial that you precisely adjust the roller pressure against the tire.

Too much contact with the roller may deform the tire and cause premature tire wear or burst.

Too little contact will cause the tire to slip on the roller when you pedal and build up excessive heat

that may cause your tire to melt.

The correct pressure is the roller compresses the tire in the depth of 3 – 4 mm.

To remove the bike, loosen the red knob only.

4

same tire.)

もしダイヤルやノブが固くて回せないときは、赤い

!

ノブを手前に引っ張り(内蔵バネの力で戻ろうとし

ます)中心のボルト孔に指を挿入して保持してやる

ことで、意図的にダイヤルやノブをフリーにするこ

とができます。この状態で操作してみてください。

(You don't need to loose the silver dial whenever using

タイヤの空気圧が低いと「キュルキュル」という異

!

音が発生し、またタイヤの摩耗が早まります。

トレーナーで使用する際はタイヤの空気圧は通常よ

りも 1 割ほど上げるようにしてください。

またタイヤ表面の汚れは除去しておいてください。

- 6 -

(Fig. U)

緩めるのは赤いノブだけ

Page 7

How To Operate Remote Shifter

LR960 comes with a convenient remote shifter device.

By installing it on your handlebar or stem, you can adjust the

resistance level in 13 levels without getting off the bike.

The plastic band is soft enough to fit aero-shaped carbon handlebar

or round shaped stem as well as the standard round dimension

handlebars.

How to install the remote shifter

1) Wind the plastic band around the handlebar

2) Hook the tip to the gutter on the plastic shifter base (Fig. V-1)

3) Flip up the lever to lock (Fig. V-2)

How to increase the resistance level

Twist the shifter dial toward "H" symbol

How to reduce the resistance level

Twist the shifter dial toward "L" symbol

!

"L" is not zero resistance. There is still some resistance

at "L" level due to the roller compression to the tire.

The remote shifter is pre-adjusted to fit the standard handlebar

size; 22mm (7/8") diameter.

If it becomes loose or too tight, or you need to install the shifter

onto an oversized handlebar or stem, adjust the band length by

turning the plastic screw with an M4 hex wrench (see Fig. Y).

2

1

(Fig. V)

(Fig. W)

Decrease

Indicator

(white dot)

!

Do not overtighten the plastic screw. It will break the

plastic band. Release the hook before adjusting.

How To Adjust Remote Cable

If you cannot shift at L or H position, it's time to adjust the cable tension.

1) Set the remote shifter lever at "H" position and straighten the cable.

2) Pull off the black plastic cap on foot of the cable, then the adjusting

screw will appear. (Fig. Z)

3) While pushing the outer cable toward the shifter, push the adjusting

screw to the outer cable. (Fig. Z & AA)

4) Turn the lock nut until it touches the Mag unit. You shouldn't

overtighten the nut, otherwise you won't be able to set the shifter at

"L" position.

5) Insert the plastic cap again.

Adjusting Screw

Lock Nut

(Fig. X)

Increase

You must release the hook

for adjusting screw

(Fig. Y)

Cap

(Fig. Z)

- 7 -

(Fig. AA)

Tighten nut until it touchs housing

Page 8

LR960 Schematics

UF-9

UF-8

TM-1

GM-7

UF-6

UF-7

UF-18

UF-5

UF-2

UF-4

UF-13

UF-3

GM-26

TM-6

TM-2

TM-4

CAUTION

!

Do NOT touch TM-6 "Alloy Rotor" during

and 15 minutes after workout.

It's VERY HOT and may burn you.

UF-2 : U-Leg (Red painted) GM-1 : 2.7kgs Flywheel

UF-3 : Alloy Leg Guide GM-7 : Drive Roller Holder

UF-4 : Height Adjuster Cap GM-26 : Roller Pressure Knob

UF-5 : Height Adjuster Knob TM-1 : Remote Shifter (Twin)

UF-6 : Right Side Coupling & Clamp Lever (Red) TM-2 : Drive Roller

UF-7 : Clamp Lever Guide TM-4 : Main Housing

UF-8 : Left Side Coupling TM-6 : Alloy Rotor

UF-9 : Coupling Lock Ring (Red)

UF-13 : Ruber Cap

UF-18 : Main Frame

GM-1

Other Languages / Andere Sprachen / Autres Langues / Otros Idiomas

If you need the instructions manual written in different language(s) such as

GB

German, French or Spanish, check out the following web page.

Wenn Sie deutsches Versionsanweisungen-Handbuch brauchen, überprüfen Sie die

G

folgende Webseite bitte.

Pour télécharger les instructions en français, veuillez vous rendre sur la page Web

F

dont l'adresse figure ci-bas.

Si necesita el manual de instrucciones de versión español, compruebe la página web

ES

siguiente.

Loading...

Loading...