Page 1

Service Manual

0070-01-0702-02_Acctr V srv color.indd 1 2/18/11 9:23 AM

Page 2

Service Manual

0070-02-0702-02_Acctr V srv b_w.indd 1 2/18/11 9:23 AM

Page 3

Accutorr® is a registered trademark of Mindray DS USA, Inc.

f

Masimo SET

®

Mindray

®

Nellcor

is a U.S. registered trademark of Tyco International Ltd.

SmarTemp

®

is a U.S. registered trademark of Masimo Corp.

is a trademark or a registered trademark of Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

™

is a trademark of Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Copyright © Mindray DS USA, Inc., 2009. All rights reserved. Contents of this publication may not be reproduced in any

orm without permission of Mindray DS USA, Inc.

Accutorr V Service Manual 0070-10-0702

Page 4

Table of Contents

Preface ....................................................................................................................................... v

Warnings, Cautions, and Notes..................................................................................................... vii

Warnings.................................................................................................................................... vii

Cautions ..................................................................................................................................... viii

Notes ......................................................................................................................................... x

Safety Designations ...................................................................................................................... xi

Product Limitations........................................................................................................................ xii

Unpacking................................................................................................................................... xiii

Symbols and Descriptions.............................................................................................................. xiii

Theory of Operation .........................................................................................................1 - 1

Introduction ................................................................................................................................. 1 - 2

Controls and Indicators ................................................................................................................. 1 - 2

System Overview .........................................................................................................................1 - 2

Hardware Structure ......................................................................................................................1 - 4

Main Board ..........................................................................................................................1 - 5

Power Board ......................................................................................................................... 1 - 6

Key and Displays Board .........................................................................................................1-7

Parameter Boards .................................................................................................................. 1 - 8

SpO

Module ................................................................................................................1 - 8

2

NIBP Module ................................................................................................................. 1 - 9

Optional Temperature Module .........................................................................................1 - 9

Recorder............................................................................................................................... 1 - 10

Bar Code Scanner .................................................................................................................1 - 10

Specifications.................................................................................................................... 2 - 1

Introduction ................................................................................................................................. 2 - 2

NIBP Measurement.......................................................................................................................2 - 2

Blood Pressure....................................................................................................................... 2 - 2

Static Accuracy .....................................................................................................................2 - 2

Maximum Cuff Pressure ..........................................................................................................2-2

Cuff Inflation ......................................................................................................................... 2 - 3

Maximum Leakage.................................................................................................................2 - 3

Deflation Rate........................................................................................................................2 - 3

Update Period .......................................................................................................................2 - 3

Initial NIBP Pressure Setup and Range ......................................................................................2 - 3

NIBP Measurement Cycle ..............................................................................................................2 - 4

Cuff Inflation Time.................................................................................................................. 2 - 4

Cuff Pressure Automatic Check Algorithm ..........................................................................2 - 4

Automatically Adjusted Inflation Value after First Measurement .................................................... 2 - 5

Pulse Rate .............................................................................................................................2 - 5

SpO2 Measurement...................................................................................................................... 2 - 6

DPM SpO2 Module Performance.............................................................................................2 - 6

SpO2 ...........................................................................................................................2 - 6

Pulse Rate ......................................................................................................................2 - 6

Alarm setting range ........................................................................................................ 2 - 6

Masimo MS-2013 SpO

Performance ......................................................................................2 - 7

2

Accutorr V Service Manual 0070-10-0702 i

Page 5

Table of Contents

SpO2 ............................................................................................................................2 - 7

Pulse Rate ......................................................................................................................2 - 8

Alarm Setting Range .......................................................................................................2 - 8

Nellcor NELL-3 SpO

SpO

............................................................................................................................2 - 9

2

Performance........................................................................................... 2 - 9

2

Pulse Rate ......................................................................................................................2 - 9

Alarm Setting Range .......................................................................................................2 - 9

Temperature ................................................................................................................................ 2 - 10

Display Area, Indicator, and Controller...........................................................................................2 - 10

Display Area.........................................................................................................................2 - 10

LCD ..............................................................................................................................2 - 10

7-Segment Digit Display ..................................................................................................2 - 11

Monochrome LED Indicator ..............................................................................................2 - 11

Power Indicator .............................................................................................................. 2 -11

Overlay and labeling .............................................................................................................2 - 11

Alarm Lamp .......................................................................................................................... 2 - 12

Keys..................................................................................................................................... 2 - 12

Patient Cable Connectors........................................................................................................2 - 13

Audio Indicator............................................................................................................................2 - 14

Pulse Tone Function................................................................................................................2 - 14

Multiple-Level Volume ............................................................................................................. 2 - 14

Real-time Clock ............................................................................................................................2 - 14

Standby Mode.............................................................................................................................2 - 15

Alarm Information ........................................................................................................................2 - 16

Basics...................................................................................................................................2 - 16

Alarm Notification ................................................................................................................. 2 - 16

Audio Alarm Pause, Audio Alarm Off, and Audio Alarm Silencing .............................................. 2 - 16

Configuration management ...........................................................................................................2 - 16

Barcode scanner .......................................................................................................................... 2 - 16

Troubleshooting................................................................................................................ 3-1

Introduction ................................................................................................................................. 3 - 2

Part Replacement..........................................................................................................................3 - 2

Monitor Status Check....................................................................................................................3 - 2

Technical Alarm Check .................................................................................................................3 - 3

Troubleshooting Guide..................................................................................................................3 - 4

Power On/Off Failures ..........................................................................................................3 - 4

Display Failure ...................................................................................................................... 3 - 4

LED Digital Display and Indication Lamp Failure ........................................................................3 - 4

Alarm Problems ....................................................................................................................3 - 5

Key Failure ..........................................................................................................................3 - 5

Recorder Failures...................................................................................................................3 - 6

Interface Failures ..................................................................................................................3 - 6

Power Supply Failures ............................................................................................................3 - 6

Network Related Problems .....................................................................................................3 -7

Software Upgrade Problems ...................................................................................................3 - 8

Bar Code Scanner Failures......................................................................................................3-8

ii 0070-10-0702 Accutorr V Service Manual

Page 6

Table of Contents

NIBP Measurement Failures.....................................................................................................3 -9

SpO

Measurement Failure .................................................................................................... 3 - 9

2

Temperature Measurement Failures .........................................................................................3 - 9

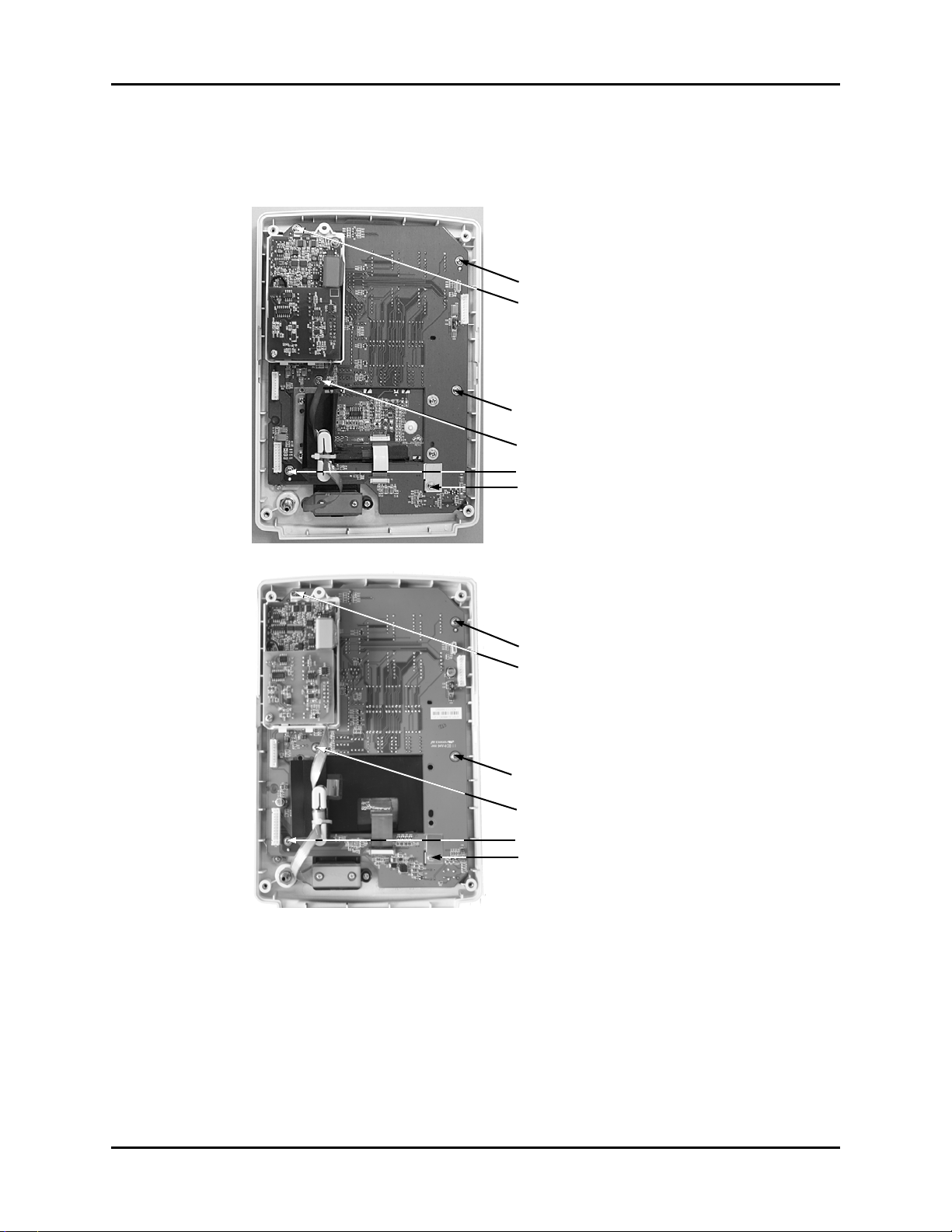

Repair and Disassembly ...................................................................................................4 - 1

Tools...........................................................................................................................................4 - 2

Preparation for Disassembly ..........................................................................................................4 - 2

Disassembly................................................................................................................................4 - 3

Separating the Front and Rear Halves of the Monitor ................................................................ 4 - 3

Disassembling the Front Housing Assembly ..............................................................................4 - 6

Removing the Main Rack Assembly .......................................................................................... 4 - 9

Removing NIBP Module .........................................................................................................4 -11

Removing the Main (CPU) Board ............................................................................................4 - 12

Removing the Power Board .....................................................................................................4 - 13

Removing the Battery Connector Assembly ................................................................................4 - 13

Removing the Fan and Speaker ...............................................................................................4 - 14

Removing the Power Socket ...................................................................................................4 - 15

Disassembling the Temperature Module....................................................................................4 - 16

Disassembling SpO

Disassembling a DPM SpO

Disassembling a Masimo SpO

Disassembling a Nellcor SpO

Modules .................................................................................................4 - 17

2

module .................................................................................4 - 17

2

module ............................................................................4 - 18

2

module .............................................................................4 - 19

2

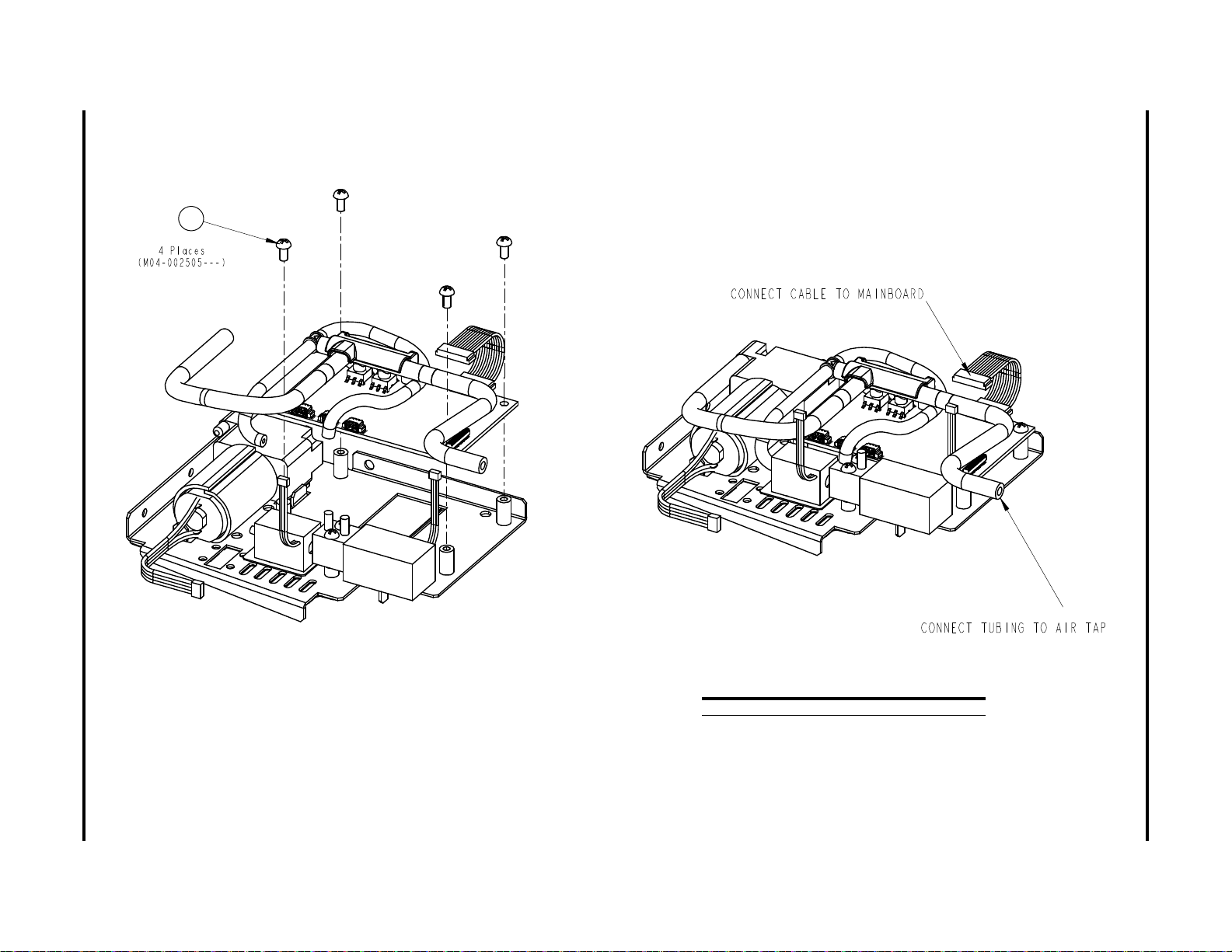

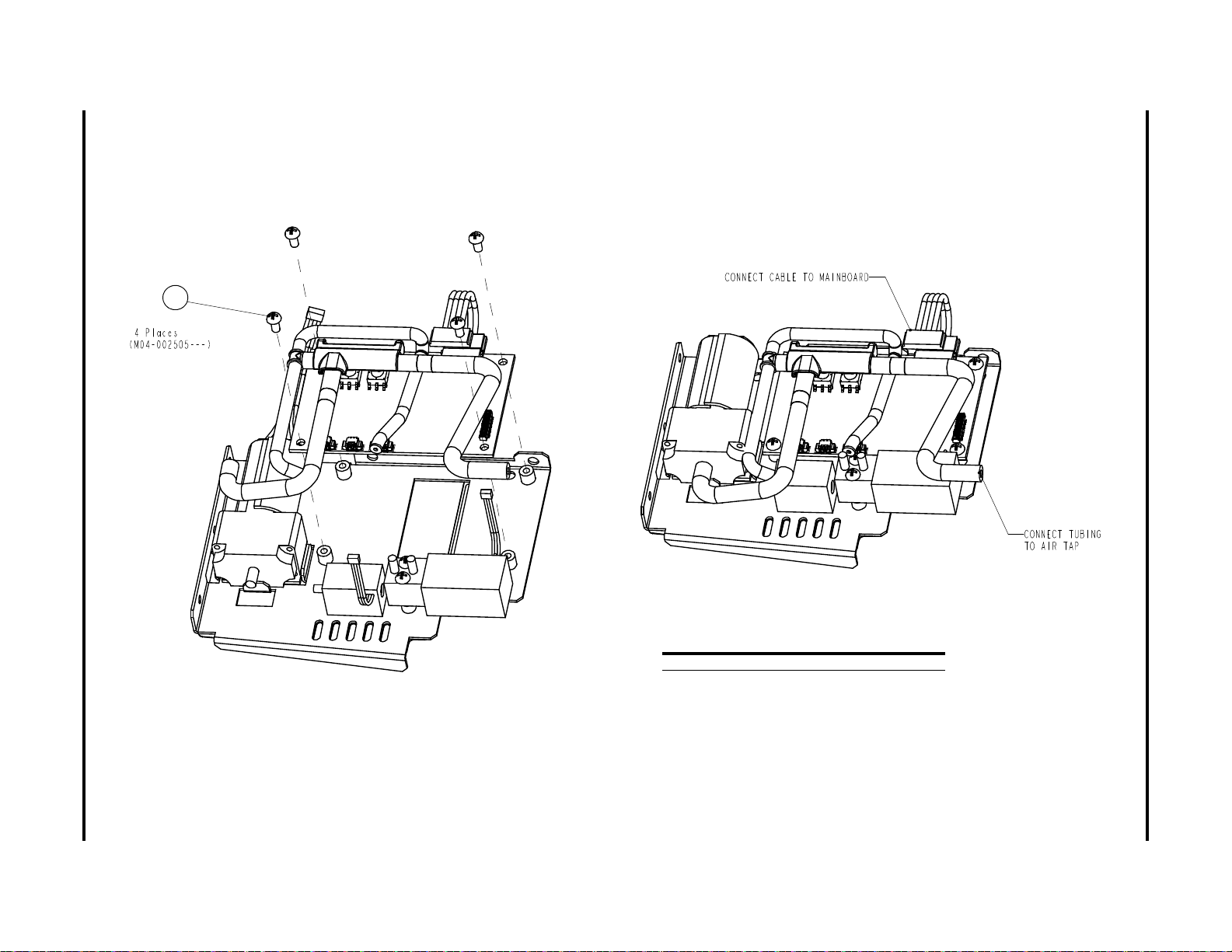

Disassembling the NIBP Module .............................................................................................. 4 - 20

Removing the NIBP Pump ................................................................................................4 - 20

Removing the NIBP Dump Valve ....................................................................................... 4 - 20

Removing the NIBP Bleed Valve .......................................................................................4 - 21

Parts ................................................................................................................................5 - 1

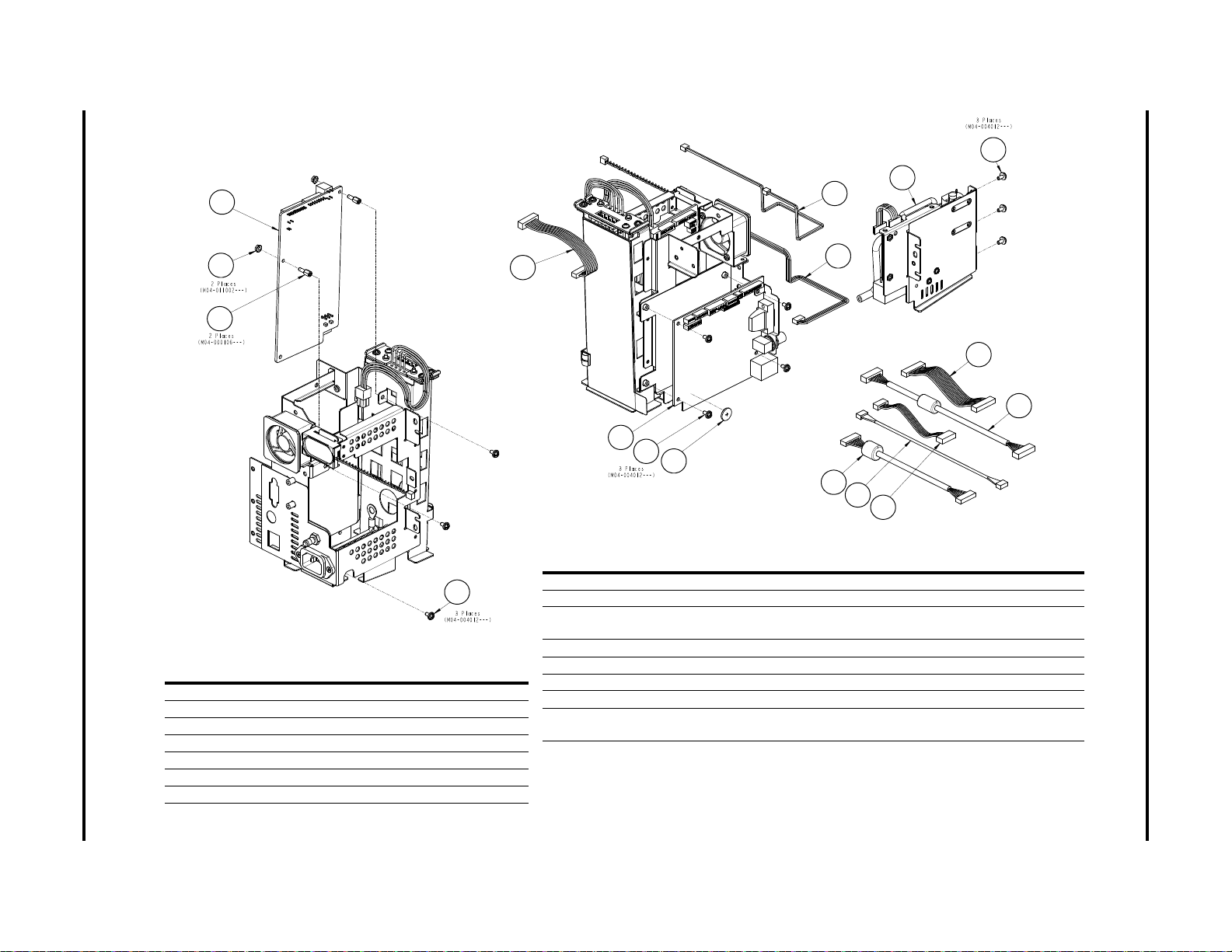

Main Assembly ............................................................................................................................5 - 2

Front Assembly (Color LCD) ...........................................................................................................5 - 3

Front Assembly (Black-and-White LCD) ............................................................................................5 - 7

Rear Housing Assembly.................................................................................................................5 - 11

Main Bracket Assembly.................................................................................................................5 - 12

NIBP Assembly (Pump M6Q-100003- - -).........................................................................................5 - 14

NIBP Assembly (Pump 082-000056-00).......................................................................................... 5 - 17

Temperature Module Subassembly .................................................................................................5-20

Temperature Power Module Subassembly........................................................................................ 5 - 22

Test and Calibration..........................................................................................................6 -1

Introduction ................................................................................................................................. 6 - 2

Test Report ............................................................................................................................6 - 2

Recommended Frequency .......................................................................................................6 - 2

Visual Test ................................................................................................................................... 6 - 4

Power-on Test...............................................................................................................................6 - 4

NIBP Calibration .......................................................................................................................... 6 - 5

NIBP Accuracy Test ...................................................................................................................... 6 - 9

NIBP Leakage Test .................................................................................................................6 - 10

Test ...................................................................................................................................6 - 13

SpO

2

Accutorr V Service Manual 0070-10-0702 iii

Page 7

SpO2 Test Under Normal Conditions .................................................................................6 - 13

SpO

Test in Motion Mode...............................................................................................6 - 13

2

Summary of Test Methods.................................................................................................6 - 14

DPM SpO

Nellcor SpO

Masimo SpO

..............................................................................................................6 - 14

2

..........................................................................................................6 - 14

2

.........................................................................................................6 - 14

2

Testing the Optional Temperature Module .................................................................................6 - 15

Nurse Call Performance Test....................................................................................................6-17

Bar Code Scanner Test ...........................................................................................................6 - 19

Electrical Safety Tests..............................................................................................................6 - 21

Enclosure Leakage Current Test .........................................................................................6 - 21

Earth Leakage Current Test ...............................................................................................6 - 21

Patient Leakage Current Test .............................................................................................6 - 22

Patient Auxiliary Leakage Current Test................................................................................6 - 22

Recorder Check .....................................................................................................................6 - 23

Software upgrade ..................................................................................................................6 - 24

1 - iv 0070-10-0702 Accutorr V Service Manual

Page 8

Preface Introduction

Preface

This manual provides detailed information about the assembling, disassembling, testing, and

troubleshooting of the equipment to support effective troubleshooting and repair. It is not

intended to be a comprehensive, in-depth explanation of the product architecture or technical

implementation. Observance of the manual is a prerequisite for proper equipment

maintenance and prevents equipment damage and personnel injury.

Refer to the Accutorr V Operating Instructions: P/N 0070-00-0699-XX for information for

operating this instrument.

This manual is based on the maximum configuration. Therefore, some contents may not be

applicable. For questions, contact Service.

This manual is for biomedical engineers, authorized technicians, or service representatives

responsible for troubleshooting, repairing, and maintaining the monitors.

Contents of this manual are subject to change without prior notice.

A password is required to access the service mode. The service password is 321.

The Accutorr V configurations are:

• Accutorr V with Nellcor® Pulse Oximetry—

includes NIBP, Nellcor SpO

• Accutorr V with Nellcor

includes NIBP, Nellcor SpO

a Trend Display, and Recorder

2,

®

Pulse Oximetry and SmarTemp™—

SmarTemp, a Trend Display, and Recorder

2,

• Accutorr V with Masimo SET® Pulse Oximetry—

includes NIBP, Masimo SpO2, a Trend Display, and Recorder

• Accutorr V with Masimo SET® Pulse Oximetry and SmarTemp™—

includes NIBP, Masimo SpO2, SmarTemp, a LCD, and Recorder

• Accutorr V with DPM Pulse Oximetry—

includes NIBP, DPM SpO2, a Liquid Crystal Display (LCD), and Recorder

• Accutorr V with DPM Pulse Oximetry and SmarTemp™—

includes NIBP, DPM SpO

SmarTemp, a Liquid Crystal Display (LCD), and Recorder

2,

• Accutorr V with DPM NIBP and SmarTemp™—

includes NIBP, SmarTemp, a Trend Display, and Recorder

• Accutorr V with DPM NIBP only—

includes NIBP, a LCD, and Recorder

All Accutorr V configurations can be upgraded with a barcode scanner.

Masimo Patents: This device (MASIMO SpO2 Module) is covered under one or more of the

following U.S. Patents 5,758,644, 5,823,950, 6,011,986, 6,157,850, 6,263,222,

6,501,975, and other applicable patents listed at: www.masimo.com/patents.htm.

Possession or purchase of this device does not convey any express or implied license to use

the device with replacement parts which would, alone, or in combination with this device,

fall within the scope of one or more of the patents relating to this device.

Accutorr V Service Manual 0070-10-0702 v

Page 9

Introduction Preface

Nellcor Patents: This device (Nellcor SpO2 Module) is covered under one or more of the

following U.S. Patents Patent No. 5,485,847, 5,676,141, 5,743,263, 6,035,223,

6,226,539, 6,411,833, 6,463,310, 6,591,123, 6,708,049, 7,016,715, 7,039,538,

7,120,479, 7,120,480, 7,142,142, 7,162,288, 7,190,985, 7,194,293, 7,209,774,

7,400,919, and 7,212,847. Possession or purchase of this device does not convey any

express or implied license to use the device with replacement parts which would, alone, or in

combination with this device, fall within the scope of one or more of the patents relating to

this device.

vi 0070-10-0702 Accutorr V Service Manual

Page 10

Warnings, Cautions, and Notes Introduction

Warnings, Cautions, and Notes

Read and adhere to all of the warnings and cautions listed throughout this manual.

A WARNING is provided to alert the user to potentially serious outcomes (death, injury or

serious adverse events) to the patient or the user.

A CAUTION is provided to alert the user that special care should be taken for the safe and

effective use of the device. They will include actions to be taken to avoid effects on patients

or users that will not be potentially life threatening or result in serious injury, but about which

the user should be aware.

A NOTE is provided when additional general information is available.

Warnings

WARNING: Internal Electrical Shock Hazard - This unit does not contain

any user-serviceable parts. Do not remove instrument

covers. Refer servicing to qualified personnel. When the

integrity of the protective earth conductor, in the installation

or its arrangement, is in doubt, the equipment should be

operated from its internal battery. Observe all CAUTION and

WARNING labels on the unit.

WARNING: Possible explosion hazard. Do not operate machine near

flammable anesthetic agents or other flammable

substances. Do not use flammable anesthetic agents (i.e.,

ether or cyclopropane.)

WARNING: Always place the unit on a flat, rigid surface or onto a

WARNING: To ensure proper performance and safety and to prevent

WARNING: Use only cuffs with approved quick connect type connectors.

WARNING: The Accutorr V is not intended for use in a magnetic

WARNING: Danger of explosion if battery is incorrectly replaced.

WARNING: Do not use a damaged or broken unit or accessory.

Mindray approved stable mounting bracket.

the voiding of the warranty, only use authorized parts and

accessories with the Accutorr V. Use of unauthorized

accessories may result in erroneous readings.

resonance imaging (MRI) environment and may interfere

with MRI procedures.

Replace only with the same or equivalent type

recommended by the manufacturer. Dispose of used

batteries according to the manufacturers instructions and

local regulations. Batteries used in this device may present a

risk of fire or chemical burn if mistreated. Do not incinerate

battery, possible explosion may occur.

WARNING: Operation of the Accutorr V below the minimum amplitude

or value of patient physiological signal may cause

inaccurate results.

Accutorr V Service Manual 0070-10-0702 vii

Page 11

Introduction Cautions

WARNING: Use of accessories, transducers, and cables other than those

WARNING: Perform the decontamination or cleaning process with the

WARNING: Electrical safety tests are a proven means of verifying the

WARNING: Commercially available test equipment such as a safety

WARNING: Electrical safety tests should meet the requirements of the

WARNING: These electrical safety tests do not supersede local

WARNING: All devices using the AC mains and connected to medical

specified in the manual may result in increased

Electromagnetic Emissions or decreased Electromagnetic

Immunity of the Accutorr V. It can also cause delayed

recovery after the discharge of a cardiac defibrillator.

unit powered down and power cord removed.

electrical safety of the monitor. They are intended for

determining potential electrical hazards. Failure to identify

these hazards in a timely manner may cause personnel

injury.

analyzer can be used for electrical safety tests. Verify that

the test equipment can be safely and reliably used with the

monitor before use. The service personnel should acquaint

themselves with the use of the test equipment.

latest editions of EN 60601-1 and UL 60601.

requirements.

equipment within patient environments must meet the

requirements of the IEC 60601-1-1 medical electrical

systems standard and should be put under electrical safety

tests at the frequency recommended for the monitor.

Cautions

CAUTION: Observe extreme caution when a defibrillator is in use. Do

not touch any part of the patient, table, or monitor when a

defibrillator is in use. The Accutorr V should not be used

adjacent to or stacked with other equipment. If adjacent or

stacked use is necessary, the Accutorr V should be observed

to verify normal operation in the configuration in which it

will be used.

CAUTION: The unit should be checked periodically for obstructed vents.

CAUTION: At the end of their life, dispose of the Accutorr V,

CAUTION: When equipped with Nellcor

CAUTION: When equipped with MASIMO

If an obstruction is found, refer the unit to qualified service

personnel.

accessories, and single use supplies in accordance with local

regulations. Dispose of packaging waste in accordance with

local regulations.

®

oxygen transducers including Nellcor

dedicated adhesive sensors. Use of other oxygen

transducers may cause improper oximeter performance.

oxygen transducers including MASIMO LNOP

®

LNCS

patient dedicated adhesive sensors and MASIMO PC

Series Patient Cable. Use of other oxygen transducers may

cause improper Oximetry performance.

SpO2, use only Nellcor®

®

Oxisensor® patient

®

SpO2, use only MASIMO®

®

and MASIMO

viii 0070-10-0702 Accutorr V Service Manual

Page 12

Cautions Introduction

CAUTION: Inaccurate readings may be caused by incorrect sensor

CAUTION: Route cables neatly. Ensure cables, hoses, and wires are

CAUTION: When cleaning sensors, do not use excessive amounts of

CAUTION: Recharge the Lithium ion battery while in the unit at room

application or use; significant levels of dysfunctional

hemoglobins (i.e. carbohemoglobins or methemoglobin); or

intra-vascular dyes such as indocyanine green or methylene

blue; exposure to excessive illumination, such as surgical

lamps (especially ones with a Xenon light source), bilirubin

lamps, fluorescent lights, infrared heating lamps, or direct

sunlight; excessive patient movement; venous pulsations;

electro-surgical interference; and placement of a sensor on

an extremity that has a blood pressure cuff, arterial

catheter, or intra-vascular line.

kept away from patient’s neck to avoid strangulation. Keep

floors and walkways free of cables to reduce risk to

hospital personnel, patients, and visitors. If the sensor or

patient cable is damaged in any way, discontinue use

immediately.

liquid. Wipe the sensor surface with a soft cloth, dampened

with the cleaning solution. To prevent damage, do not soak

or immerse the sensor in any liquid solution. DO NOT

ATTEMPT TO STERILIZE.

temperature. If using the Accutorr V in a hot environment,

the Lithium ion battery may not charge when the unit is

connected to the AC mains.

CAUTION: Remove the battery if the Accutorr V is not used for an

extended period of time.

CAUTION: The Communications Connectors on the Accutorr V are only

for use with IEC 60601-1-1 compliant equipment.

CAUTION: Never place fluids on top of this monitor. If fluid spills on the

unit, wipe clean immediately and refer the unit to qualified

service personnel.

CAUTION: Before disassembling the monitor, eliminate static charges.

CAUTION: Properly connect the cables or wires when reassembling the

CAUTION: All tests should be performed by qualified personnel only.

CAUTION: Disconnect the monitor from the patient and make sure that

When disassembling the parts labeled with static-sensitive

symbols, wear electrostatic discharge protection such as

antistatic wristband or gloves. Follow the correct sequence

to disassemble the monitor. Otherwise, the monitor may be

damaged permanently. Disconnect all the cables before

disassembling any parts. Take care not to damage any

cables or connectors.

monitor to avoid short circuit. When assembling the

monitor, select proper screws. If the wrong size screw is

tightened by force, the monitor may be damaged and the

screw or the part may not function as expected.

important data is saved before upgrading the monitor.

CAUTION: Do not shut down or power off the equipment when

upgrading the bootstrap program. Otherwise, it may cause

the equipment to break down.

Accutorr V Service Manual 0070-10-0702 ix

Page 13

Introduction Notes

CAUTION: Program upgrades should be performed by qualified

service personnel only.

Notes

NOTE: The Accutorr V should be operated only by trained and

qualified personnel.

NOTE: Use disposable and single use accessories only once.

NOTE: Place the equipment in a location where the screen can

easily be seen and the operating controls can easily be

accessed.

NOTE: The instructions in this manual are based on the maximum

configuration.

NOTE: The optional Temperature module kit must be installed only

by trained personnel, and proper ESD prevention methods

must be followed.

NOTE: Only devices specified by Mindray DS USA, Inc.

Bio-Medical Electronics Co. , Ltd shall be connecte

NOTE: When

NOTE: Disconnect the Accutorr V from the mains to isolate it from

the RS-232 connector is used for DIAP, barcode power

must be set to OFF.

the mains power during an emergency.

/Shenzhen Mindray

d the RS-232 port.

x 0070-10-0702 Accutorr V Service Manual

Page 14

Safety Designations Introduction

Safety Designations

Safety designations per IEC 60601-1 Standard:

Type of protection against electric shock Class 1 with internal electric power source.

Where the integrity of the external protective

earth (ground) in the installation or its

conductors is in doubt, the equipment shall be

operated from its internal electric power

source.

Degree of protection against electric shock Monitor - Type B applied part.

NIBP - Type BF defibrillation protected

applied part.

SpO

- Type BF protected applied part.

2

Temp - Type BF protected applied part.

Supply Connection 100 – 240 V

50/60 Hz

0.85 – 0.5 A

Mode of Operation Continuous

Protection Against Hazard of Explosion Not Protected (Ordinary)

Protection Against Ingress of Liquids IPX1

Degree of Electrical Connection Between

Equipment and Patient

Degree of Mobility Portable

Equipment designed for direct electrical and

non-electrical connection to the patient.

AC

Accutorr V Service Manual 0070-10-0702 xi

Page 15

Introduction Product Limitations

Product Limitations

Non-invasive blood pressure (NIBP) accuracy depends on the application of the proper cuff

size. See Chapter 3.0 of the Operating Instructions for detailed information.

The Accutorr V will not operate effectively on patients who are experiencing convulsions or

tremors.

The Accutorr V is a portable device intended for intra-hospital use.

If the pressure cuff is not placed at the patient’s heart level, the NIBP measurement may be

subject to error, due to the hydrostatic effect.

The pulse rate data displayed on the Accutorr V is computed from the measurement of

peripheral pulses (peripheral pulses taken only during a measurement cycle). The rate

measured by the Accutorr V may differ from the rate of an ECG monitor. This is because the

ECG is an electrical signal that may not always result in a peripheral pulse.

Administration of certain vasoconstrictor drugs (for example, norepinephrine), may reduce

peripheral perfusion to a level that prevents the Accutorr V from taking pulse rate

measurements.

Arterial compression, tricuspid regurgitation, or other conditions may reduce perfusion to a

level that prevents the Accutorr V from taking pulse rate measurements.

The presence of arrhythmias may increase the time required to complete a measurement and

may extend this time so that a measurement cannot complete.

The Accutorr V is not intended for use during CPR. The monitor uses an oscillometric

technique based on normal peripheral circulation to compute blood pressure.

xii 0070-10-0702 Accutorr V Service Manual

Page 16

Unpacking Introduction

T1

Unpacking

Remove the instrument from the shipping carton and examine it for signs of shipping

damage. Save all packing materials, invoice, and bill of lading. These may be required to

process a claim with the carrier. Check all materials against the packing list. Contact the

Customer Service Department (800) 288-2121 or (201) 265-8800 for prompt assistance in

resolving shipping problems.

NOTE: The Accutorr V should only be shipped in its original

packing materials to avoid shipping damage.

Symbols and Descriptions

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

Attention, Consult

Accompanying Documents /

Refer to Manual

Equipotentiality

Equipotential grounding

Alternating Current (AC) Adult

Predictive Thermometer

Connector

Type BF Equipment

Defibrillator-proof Type BF

Equipment

Pediatric/Child

SpO

SpO

2

Accutorr V Service Manual 0070-10-0702 xiii

Connector Neonate

2

Electrical connectors Operating on battery power

Battery Manufacturer

Connected to AC mains

NIBP Connector

Power On/Off – Standby Recycle

Serial number Up key

Page 17

Introduction Symbols and Descriptions

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

REF

Part Number Confirm key

Patient Information key Down key

Main menu key Deflate Cuff key

Set alarms key Patient Size key

Start NIBP key Alarm Silence key

Display Tabular Trends/Pleth

Wav e

NIBP interval key SP1

NC1 Nurse Call connector

RS-232 connector

(Serial Port 1)

Print key (front panel) CS1 Network connector

Print key (recorder)

Alarm Silenced indicator on

LCD display

Alarm Disabled indicator on

LCD display

Audio Alarm Off indicator on

LCD display

Classified by Underwriters Laboratories Inc. with respect to electric shock, fire and

mechanical hazards, only in accordance with UL 60601-1, CAN/CSA C22.2

NO.601-1, IEC 60601-1-1, IEC 60601-2-30, IEC 60601-2-49.

xiv 0070-10-0702 Accutorr V Service Manual

Page 18

1.0

Theory of Operation

Introduction.................................................................................................... 1 - 2

Controls and Indicators ................................................................................... 1 - 2

System Overview............................................................................................ 1 - 2

Hardware Structure......................................................................................... 1 - 4

Accutorr V Service Manual 0070-10-0702 1 - 1

Page 19

Introduction Theory of Operation

1.1 Introduction

The Accutorr V monitors the following patient vital signs: non-invasive blood pressure (NIBP),

pulse oxygen saturation (SpO2), pulse rate (PR), and temperature (Temp) for a single adult,

pediatric, or neonatal patient. Temperature is measured using the optional Temperature

Module.

1.2 Controls and Indicators

For information on controls, connectors, and indicators, refer to the Accutorr V Operating

Instructions, Part Number 0070-10-0699-02.

1.3 System Overview

FIGURE 1-1 shows the relationship of the Accutorr V monitoring system’s mechanical,

hardware, and software components.

FIGURE 1-2 shows the Accutorr V monitoring system’s PC board connections.

SYSTEM

MECHANICAL

MAIN UNIT

RECORDER

BATTERY

CHAMBER

TEMP

MODULE

CHAMBER

BARCODE

SCANNER

SUPPORT

HARDWARE

MAIN BOARD

POWER

BOARD

KEY &

DISPLAY

PAR AME TER

BOARDS

RECORDER

BOARD

BARCODE

SCANNER

SOFTWARE

FIGURE 1-1 System Mechanical, Hardware, and Software Overview

SYSTEM

SOFTWARE

PARAMETER

SOFTWARE

UPGRADE

SOFTWARE

PRINT

SOFTWARE

GATEWAY

SOFTWARE

1 - 2 0070-10-0702 Accutorr V Service Manual

Page 20

Theory of Operation System Overview

PARAMETER RECEPTACLE

J6

RECORDER

J2

J3

AC

INLET

J2

POWER

J4 J5

FAN

J1

J6

BATTERY

J2 J3 J4 J5

J1

J8 J9

J7

P3 P4

P5

KEY & DISPLAY

BOARD

P2

LCD

FIGURE 1-2 The System PCBA Connections

J1

SpO

2

J2

P2

ISOLATION

POWER BOARD

P1

MAIN BOARD

BDM

PORT

TEMP

ISOLATION

POWER BOARD

J10

SPEAKER

J2

NIBP

J4

J4

J3

J11 J12 J13

NETWORK CONNECTOR

NURSE CALL

J2

RS232

Accutorr V Service Manual 0070-10-0702 1 - 3

Page 21

Hardware Structure Theory of Operation

1.4 Hardware Structure

FIGURE 1-3 shows the Accutorr V’s Hardware Structure. The core of the system is the main

board, which supplies power for all parameter modules. The parameter modules directly

communicate with the main board. The the main board processes measurements and the

status of all modules, and displays them through the key and display board.

SpO

NIBP MODULE

MODULE

2

TEMP MODULE

ISOLATION

POWER BOARD

POWER BOARD

COMMUNICATIONS

/POWER SUPPLY

BATTERY

KEY &

DISPLAY

BOARD

LED &

KEY

LCD

POWER

SUPPLY

SPEAKER

COMMUNICATIONS

/POWER SUPPLY

RECORDER

ISOLATION

POWER BOARD

MAIN BOARD

FAN

ACCUTORR V

FIGURE 1-3 The Accutorr V’s Hardware Structure

NOTE: The SpO2 isolation power board does not apply to models

with DPM Pulse Oximetry.

ETHERNET

RS232

NURSE CALL

AC

1 - 4 0070-10-0702 Accutorr V Service Manual

Page 22

Theory of Operation Hardware Structure

1.4.1 Main Board

FIGURE 1-4 shows the main board, which provides resources and support for the overall

system. It controls the LCD, LED, keyboard, speaker, and recorder. It also communicates with

parameter modules and connectors. The main board also controls communication with the

speaker, the recorder, and all external connectors.

WATCHDOG

RTC E2 PROM

ETHERNET

NURSE CALL

SPEAKER

PHY RTL8201

CPU

AUDIO PROCESS

CIRCUIT

FLASHSDRAM

1.5V

LINEAR POWER

3.3V LCD

5.0V 12V LED KEY

SERIAL PORT 0

FPGA

RS232 IC

RS232

SERIAL PORT 1:

NIBP

SERIAL PORT 2:

SpO

2

SERIAL PORT 3:

TEMP

SERIAL PORT 4:

RECORDER

FIGURE 1-4 Main Board Principle Diagram

The main board communicates with all parameter modules and the recorder through an

FPGA extended serial port.

The main board supplies information using FPGA to the key and display board. It drives the

display, detects the keys, and implements the user interface.

The main board controls the alarm indicator using FPGA.

The main board controls the speaker to give audible alarms, key tones, and Pitch Tone.

The main board provides the nurse call connection, network connection, and R232

connection.

The real-time clock is implemented by the RTC chip. The RT clock is powered by the AC

mains, battery, or button cell on the main board. The button cell ensures the continuous

working of the clock in the event that the AC mains and batteries are not available.

SDRAM stores running program instructions and data temporarily. The system memory and

trend data memory is flashed. The device configuration memory is EEPROM.

Accutorr V Service Manual 0070-10-0702 1 - 5

Page 23

Hardware Structure Theory of Operation

1.4.2 Power Board

The power board, shown in FIGURE 1-5, converts the input power (AC mains or battery) to

different working voltages for other boards. It also charges the battery.

AC

INPUT

EMI

FILTER

RECTIFIER

& FILTER

PMW

CONTROLLER

FLYBACK

CONVERTER

CURRENT

DETECTION

COUPLER

FEEDBACK &

ISOLATION

CIRCUIT

FIGURE 1-5 Power Board Principle Diagram

RECTIFIER

& FILTER

0VP&0PP

16.8V

DC/DC

CONVERTER

DC/DC

CONVERTER

CHARGING

CIRCUIT

DC/DC

CONVERTER

SWITCH

CIRCUIT

PCON

0VP&0CP

BATTERY

0VP&0CP

12V

OUTPUT

5V

OUTPUT

3.3V

OUTPUT

The AC flows through the EMI filter and the rectifier and filter. The rectifier and filter converts

the AC to 16.8V DC voltage by the Flyback converter. The 16.8V DC voltage is the main

input to the DC/DC converters and charging circuit. The DC/DC converters convert 16.8V

DC to 12V, 5V, and 3.3V DC. The charging circuit charges the lithium battery. When the

Accutorr V is not connected to the AC mains, the battery supplies power to the DC/DC

converters.

The 16.8V DC output is protected against over-voltage and over-power. The 12V, 5V, and

3.3V DC outputs are protected against over-voltage, short-circuit, and over–current.

1 - 6 0070-10-0702 Accutorr V Service Manual

Page 24

Theory of Operation Hardware Structure

1.4.3 Key and Displays Board

The key and displays board, shown in FIGURE 1-6, provides the user interface. The board

contains the LCD module, 7-segment digital display, LED indication lamp, and keys.

LCD

SIGNAL

ADV

3.3V

VSB

FSTN LCD

MODULE

KEY MATRIX

3.3V

DISABLE

LED

CPLD

Switch

START-UP

CIRCUIT

LED&KEY

DETECTION

FIGURE 1-6 Key and displays Board Principle Diagram

The LCD module adjusts brightness and contrast (only for black-and-white LCD display).

NOTE: The monitor with color LCD does not have “Contrast ”

setting item in the common setup menu.

The 7-segment digit units display parameter data.

The AC indicator is driven by the ADV output from the power board, and the working status

indicator (built in the Power On/Off key) is driven by 3.3V voltage. The battery indicator is

jointly controlled by the flash control signal, ADV signal, and VBC signal.

The keypad contains the power ON/OFF key and the other 13 function keys.

Accutorr V Service Manual 0070-10-0702 1 - 7

Page 25

Hardware Structure Theory of Operation

1.4.4 Parameter Boards

1.4.4.1 SpO

FIGURE 1-7 shows the SpO2 module parameter board diagram.

WATC HDOG

DRIVE DAC

Module

2

LED DRIVE

CIRCUITRY

SENSOR

/RST

WDI

GAIN CONTROL

CIRCUITRY

PROGRAMMABLE

GAIN CIRCUITRY

CPU

OFFSET DAC

OFFSET

AMPLIFIER

DRAM

FLASH

ISOLATED SERIAL

IN/OUTPUT PORT

4KV ISOLATED

POWER SUPPLY

+3.3V

+5V

-5V

A/D

CONVERTER

HOST

+12V

FIGURE 1-7 SpO

The SpO

sensor collects the pulsing red and infrared light signals transmitting through the

2

Module Principle Diagram

2

finger or toe, and processes the collected signals to create the measured result. The SpO2

module controls the LED drive circuit and the amplifying circuit gain corresponding to the

finger or toe perfusions and transmittances.

1 - 8 0070-10-0702 Accutorr V Service Manual

Page 26

Theory of Operation Hardware Structure

1.4.4.2 NIBP Module

FIGURE 1-8 shows the NIBP module parameter board diagram.

CUFF

MANIFOLD

VALVES

AND PUMP

PRESSURE

SENSOR

FOR

PROTECT

PRESSURE

SENSOR

PRESSURE

SIGNAL

AMPLIFIER

CIRCUITS

FOR

PROTECT

VALV E

CIRCUIT

PRESSURE

SIGNAL

PRESSURE

SIGNAL

AMPLIFIER

CIRCUITS

MOTOR CONTROL

FEEDBACK SIGNAL

PUMP AND

CONTROL

OVER

PRESSURE

PROTECT

CIRCUIT

WATC HDOG

A/D

CONVERTER

FLASH DRAM

CPU

ASYCHRONOUS

SERIAL

COMMUNICATION

FIGURE 1-8 NIBP Module Principle Diagram

The Accutorr V calculates NIBP values using the oscillometric method of noninvasive blood

pressure measurement. These measurements correspond to comparisons with auscultatory

values, measured using the fifth Korotkoff sound within ANSI/AAMI SP10 standards for

accuracy.

1.4.4.3 Optional Temperature Module

FIGURE 1-9 shows the Temperature module parameter board diagram.

PROBE

RECOGNIZE

CIRCUIT

TEMPERATURE

DETECT

CIRCUIT

A/D

CIRCUIT

PROBE

HEAT

CIRCUIT

CPU SYSTEM

(ROM & RAM

WATCHDOG)

FIGURE 1-9 Optional Temperature Module Principle Diagram

The Temperature Module uses a thermistor as a sensor for measuring temperature. The

resistance of a given thermistor is nonlinearly relative to the temperature. The Temperature

Module measures the resistance of the thermistor and converts it into temperature.

Accutorr V Service Manual 0070-10-0702 1 - 9

POWER

&

SIGNAL

ISOLATE

CIRCUIT

MAIN

BOARD

Page 27

Hardware Structure Theory of Operation

1.4.5 Recorder

The recorder receives data from the main board and sends it to the thermal printhead for

printing. It has a button to start or stop printing and a green LED to indicate the presence or

absence of paper.

1.4.6 Bar Code Scanner

The bar code scanner reads one-dimensional and two-dimensional bar codes to simplify

admitting a patient. The bar code scanner communicates with the monitor. The serial port

supplies it with power. The scanner’s serial port is defined in the following table:

PIN DEFINITION

2Barcode_RX

3Barcode_TX

5GND

9VCC5VDC

The monitor’s serial port is defined in the following table:

PIN DEFINITION

2 Monitor_TX

3 Monitor_RX

5GND

9VCC5VDC

Basic settings of the bar code scanner are listed in the following table:

HOST PARAMETERS BAR CODE SCANNER FACTORY DEFAULT

Baud Rate 9600 9600

Data Bits 8 8

Stop Bits 1 1

Calibration bit 0 0

Handshaking None None

USER PARAMETERS BAR CODE SCANNER FACTORY DEFAULT

Beeper Tone Medium Medium

Beeper Volume Medium High

Trigger Mode Level Auto Aim

Parameter Scanning Disable Enable

DATA FORMAT BAR CODE SCANNER FACTORY DEFAULT

Prefix Value 7013 <CR><LF> 7013 <CR><LF>

Suffix 1 Value

Suffix 2 Value

Scan Data Transmission Format <PREFIX><DATA><SUFFIX 1><SUFFIX 2> Data only

7013 <CR><LF> 7013 <CR><LF>

1 - 10 0070-10-0702 Accutorr V Service Manual

Page 28

Theory of Operation Hardware Structure

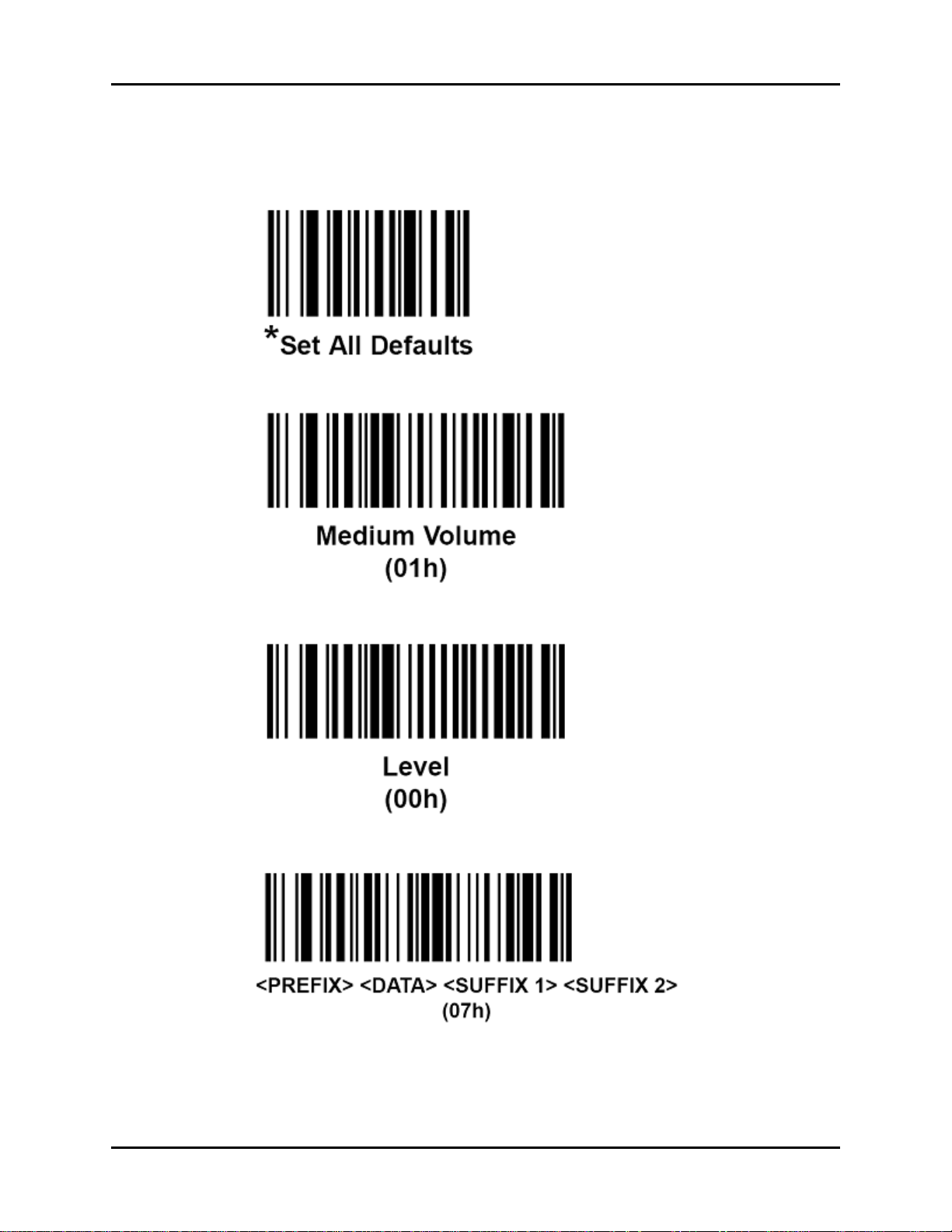

To change parameter settings, scan the following bar codes in sequence.

1. Set parameter defaults:

2. Set beeper volume:

3. Set trigger mode:

4. Set scan data transmission format:

Accutorr V Service Manual 0070-10-0702 1 - 11

Page 29

Hardware Structure Theory of Operation

5. Disable parameter scanning:

1 - 12 0070-10-0702 Accutorr V Service Manual

Page 30

2.0

Specifications

Introduction..............................................................................................2 - 2

NIBP Measurement ...................................................................................2 - 2

NIBP Measurement Cycle ..........................................................................2 - 4

SpO2 Measurement..................................................................................2 - 6

Temperature .............................................................................................2 - 10

Display Area, Indicator, and Controller .......................................................2 - 10

Audio Indicator ........................................................................................2 - 14

Real-time Clock ........................................................................................2 - 14

Standby Mode .........................................................................................2 - 15

Alarm Information.....................................................................................2 - 16

Configuration management .......................................................................2 - 16

Barcode scanner ......................................................................................2 - 16

Accutorr V Service Manual 0070-10-0702 2 - 1

Page 31

Introduction Specifications

2.1 Introduction

The Accutorr V monitors patient vital signs (including non-invasive blood pressure (NIBP),

pulse oxygen saturation (SpO2), and pulse rate (PR)) for a single adult, pediatric, or neonatal

patient. It also monitors oral or rectal mode temperature (Temp) for a single adult or pediatric

patient; or axillary mode temperature for a single neonate, adult, or pediatric patient using

the optional Temperature Module.

2.2 NIBP Measurement

The NIBP module is used to measure the systolic pressure, diastolic pressure, and mean

pressure in the neonatal, pediatric, and adult modes. The Accutorr V calculates NIBP values

using the oscillometric method of noninvasive blood pressure measurement. These

measurements correspond to comparisons with auscultatory values, measured using the fifth

Korotkoff sound within ANSI/AAMI SP10 standards for accuracy.

2.2.1 Blood Pressure

PARAMETER PATIENT SIZE RANGE

Systolic pressure measurement Adult

Pediatric

Neonate

Diastolic pressure measurement Adult

Pediatric

Neonate

Mean pressure measurement Adult

Pediatric

Neonate

Measurement accuracy Mean error: <±5 mmHg

Standard deviation: <±8 mmHg

Measurements outside of the stated ranges are not guaranteed to be accurate.

55 – 235 mmHg

55 – 160 mmHg

45 – 120 mmHg

30 – 200 mmHg

30 – 150 mmHg

20 – 100 mmHg

30 – 235 mmHg

30 – 160 mmHg

20 – 120 mmHg

2.2.2 Static Accuracy

Measurement range: 0 – 300 mmHg

Static pressure measurement accuracy: ±3 mmHg

2.2.3 Maximum Cuff Pressure

Normal Use Over Pressure Protection

In normal use, the over-pressure detection is controlled by software. Once the cuff pressure

exceeds the threshold, the software enables the system to deflate the cuff.

Adult 300 mmHg

Pediatric 200 mmHg

Neonate 150 mmHg

Single Fault Over-pressure protection

2 - 2 0070-10-0702 Accutorr V Service Manual

Page 32

Specifications NIBP Measurement

In single fault conditions, the hardware controls the cuff deflation to prevent the cuff

pressure from exceeding the following ranges:

Adult 330 mmHg

Pediatric 220 mmHg

Neonate 165 mmHg

2.2.4 Cuff Inflation

The Non-Invasive Blood Pressure inflation source brings a volume of 200 ccs to a pressure of

300 mmHg in less than or equal to 10 seconds

2.2.5 Maximum Leakage

The Non-Invasive Blood Pressure Cuff driver allows a pressure drop to be, at most, 1 mmHg

in 10 seconds as measured with a 200 cc volume at differential pressures of 250 mmHg,

150 mmHg, and 50 mmHg.

2.2.6 Deflation Rate

The Non-Invasive Blood Pressure Cuff venting mechanism in adult mode vents a volume of

500 cc, reduced from a pressure of 260 mmHg to a pressure of 15 mmHg in a maximum of

10 seconds.

The Non-Invasive Blood Pressure Cuff venting mechanism in neonatal mode vents a volume of

500 cc, reduced from a pressure of 150 mmHg to a pressure of 5 mmHg in a maximum of

5 seconds.

2.2.7 Update Period

The Non-Invasive Blood Pressure Parameter has an update period of one (1) second.

2.2.8 Initial NIBP Pressure Setup and Range

The initial pressure is adjustable, and should be set to the following default values:

PATIENT TYPE DEFAULT INITIAL PRESSURE ADJUST RANGE

Adult 180 mmHg 100 – 280 mmHg

Pediatric 140 mmHg 60 – 180 mmHg

Neonate 100 mmHg 40 – 120 mmHg

Manual pressure changes in increments of 5 mmHg.

Accutorr V Service Manual 0070-10-0702 2 - 3

Page 33

NIBP Measurement Cycle Specifications

2.3 NIBP Measurement Cycle

There are two different modes of measurement operation: manual and interval modes. The

manual mode requires the operator to initiate the measurement cycle.

The interval mode follows a configured plan of automatically initiated measurement cycles,

using the follow selections:

OFF (manual), STAT, or 1, 2, 3, 5, 10, 15, 20, 30, 60, 120, 240 minutes

NOTE: When the NIBP STAT interval is selected, the Accutorr V

takes back to back (one right after the other) blood pressure

readings. As a safety precaution, there is a five minute or

10 measurement limit for continuous NIBP measurements.

After 5 minutes or 10 measurements, the NIBP module

automatically switches to the mode in use before NIBP STAT

was selected. This reduces the chance of surface vessel

rupture (petechia).

The maximum adult and pediatric measurement cycle is 180 seconds.

The maximum neonatal measurement cycle is 90 seconds.

The NIBP module adjusts the inflation pressure automatically according to the systolic

pressure of the last measurement. If the first measurement is unsuccessful, the subsequent

inflation pressures change to 50 mmHg higher than the previous systolic pressure in adult or

pediatric mode, and 40 mmHg higher than the previous systolic pressure in neonate mode.

(The subsequent inflation pressure should be greater than the systolic pressure in the previous

measurement).

2.3.1 Cuff Inflation Time

If the cuff pressure does not attain 15 mmHg within 20 seconds for adult and pediatric

patients, or 15 mmHg within 10 seconds for neonate patients from the start of inflation, the

Accutorr V retries measuring up to three times. If the target pressure is not reached after three

retries, the cuff is deflated, and a status code displays.

2.3.1.1 Cuff Pressure Automatic Check Algorithm

If the monitor cannot inflate the cuff to the Pressure Threshold within the expected time period,

the monitor deflates the cuff, cancels the measurement, shuts off the pump, and displays the

message “Unable to Measure”. The cancellation occurs based on the following tables.

OPERATING MODE PRESSURE THRESHOLD DURATION

Adult and Pediatric 15 mmHg 20 sec. 3

Neonate 15 mmHg 10 sec. 3

NUMBER OF

RETRIES

OPERATING MODE

Adult, Pediatric, Neonate 60 mmHg 3

2 - 4 0070-10-0702 Accutorr V Service Manual

TARGET INFLATION

PRESSURE

NUMBER OF

RETRIES

Page 34

Specifications NIBP Measurement Cycle

2.3.2 Automatically Adjusted Inflation Value after First Measurement

In the Interval and Stat modes, the inflation value of the next measurement will be

automatically adjusted by the NIBP module based on the systolic value of the previous

reading. After the first unsuccessful measurement, the subsequent inflation value will be the

previous systolic pressure reading plus P2:

Adult Mode: P2 = 50

Pediatric Mode: P2 = 50

Neonate Mode: P2 = 40

2.3.3 Pulse Rate

Accuracy: ±3 BPM or ±3%, whichever is greater.

Resolution: 1 BPM

PATIENT TYPE PULSE RANGE

Adult 35 – 245 BPM

Pediatric 35 – 245 BPM

Neonate 70 – 245 BPM

Measurements outside of the stated ranges are not

guaranteed to be accurate.

±10 mmHg

±10 mmHg

±10 mmHg

Accutorr V Service Manual 0070-10-0702 2 - 5

Page 35

SpO2 Measurement Specifications

2.4 SpO2 Measurement

When configured with the DPM SpO2 module, NELLCOR NELL-3 SpO2 module, or MASIMO

MS-2013 SpO2 module, the Accutorr V can perform SpO2 measurements.

The SpO2 measurement function complies with the requirements of ISO9919.

2.4.1 DPM SpO2 Module Performance

The DPM SpO2 accuracy has been validated in human studies against arterial blood sample

reference measured with a CO-oximeter. Pulse oximeter measurements are statistically

distributed, and only about two-thirds of the measurements can be expected to fall within the

specified accuracy compared to CO-oximeter measurements.

2.4.1.1 SpO

2

Range: ........................................................................................... 0 – 100%

Resolution: .................................................................................... 1%

Accuracy in the static condition:

PATIENT TYPE

Adult or pediatric ±2 digits Undefined

Neonate ±3 digits Undefined

2.4.1.2 Pulse Rate

Range: ........................................................................................... 20 – 254 BPM

Resolution: .................................................................................... 1 bpm

Accuracy in the static condition:

PATIENT TYPE PR RANGE ACCURACY

Adult / Pediatric / Neonate 20 – 254 bpm ± 3 digits

RANGE

SPO

2

70% TO 100% 0 – 69%

2.4.1.3 Alarm setting range

SPO2 MODULE

DPM SpO

2 - 6 0070-10-0702 Accutorr V Service Manual

module 50 – 100% 0 – 254 bpm

2

SPO

2

PR

Page 36

Specifications SpO2 Measurement

2.4.2 Masimo MS-2013 SpO2 Performance

This section details the performance measurements of the Masimo MS-2013, which is

designed in accordance with the requirements of the interface of the Masimo MS-2013

board. The Accutorr V interface complies with the requirements of the Masimo MS-2013

board communication protocol.

2.4.2.1 SpO

Compatible Sensors:

See Section 6.6 for a list of compatible sensors.

Measurement range: 1 – 100%

Resolution:

Accuracy no motion conditions:

PATIENT TYPE

Adult ±2 digits Undefined

Pediatric ±2 digits Undefined

Neonate ±3 digits Undefined

Accuracy During motion conditions:

PATIENT TYPE

Adult ±3% Undefined

Pediatric ±3% Undefined

Neonate ±3% Undefined

2

1%

SPO

RANGE: 70% – 100% SPO2 RANGE: 1% – 69%

2

SPO

RANGE: 70% – 100% SPO2 RANGE: 1% – 69%

2

SpO

response time:

2

Under the condition that the PR is 75 BPM and the averaging is 8 seconds, the maximum

response time for the SpO

value to increase from 60% to 95% is 20 seconds.

2

Low Perfusion Performance:

LOW PERFUSION CONDITION

% LIGHT

TRANSMISSIBILITY

> 0.02% > 5% ± 2 digits ± 3 digits

Accutorr V Service Manual 0070-10-0702 2 - 7

SPO

2

ACCURACY

PR ACCURACYPULSE AMPLITUDE

Page 37

SpO2 Measurement Specifications

2.4.2.2 Pulse Rate

Resolution: 1 BPM

Update frequency: 1 Hz

Range and Accuracy:

PATIENT TYPE PR RANGE

Adult/Pediatric/Neonate 25 – 240 BPM ± 3 digits ± 5 digits

1 The Masimo MS-2013 pulse oximeter with an LNOP- Adt sensor was validated for no motion accuracy

in human blood studies on healthy adult volunteers in induced hypoxia studies in the range of 70% to

100% SpO

one standard deviation. Plus or minus one standard deviation encompasses 68% of the population.

2 The Masimo MS-2013 pulse oximeter with LNOP- Adt sensor has been validated for motion accuracy in

human blood studies on healthy adult volunteers in induced hypoxia studies while performing rubbing

and tapping motions at 2 to 4 Hz. At an amplitude of 1 to 2 cm and non-repetitive motion between 1 to

5 Hz at an amplitude of 2 to 3cm in induced hypoxia studies in the range of 70% to 100% SpO

a laboratory co-oximeter and ECG monitor. This variation equals plus or minus one standard deviation. Plus or minus one standard deviation encompasses 68% of the population.

3 The Masimo MS-2013 pulse oximeter with LNOP-Neo and Neo Pt sensors has been validated for neona-

tal motion accuracy in human blood studies on neonates while moving the neonate’s foot at 2 to 4 Hz

at an amplitude of 1 to 2 cm against a laboratory co-oximeter and ECG monitor. This variation equals

plus or minus one standard deviation. Plus or minus one standard deviation encompasses 68% of the

population.

4 The Masimo MS-2013 pulse oximeter has been validated for low perfusion accuracy in bench top test-

ing against a Biotek Index 2 simulator and Masimo’s simulator with signal strengths of greater then

0.02% and transmission of greater than 5% for saturations ranging from 70 to 100%. This variation

equals plus or minus one standard deviation. Plus or minus one standard deviation encompasses 68%

of the population.

against a laboratory co-oximeter and ECG monitor. This variation equals plus or minus

2

2.4.2.3 Alarm Setting Range

ACCURACY IN

STATIC

CONDITION

1

ACCURACY IN

MOTION

CONDITION

against

2

2,3,4

SPO2 MODULE

MS-2013 SpO

2 - 8 0070-10-0702 Accutorr V Service Manual

module 50 – 100 20 – 250 bpm

2

SPO

2

PR

Page 38

Specifications SpO2 Measurement

2.4.3 Nellcor NELL-3 SpO2 Performance

This section details the performance measurements of the NELL-3 pulse oximeter (integrated

OxiMax measurement technique), which is designed in accordance with the requirement of

the interface of the Nellcor NELL-3 board. The SHIP (Standard Host Interface Protocol) mode

is used.

2.4.3.1 SpO

Compatible Sensors:

See Section 6.6 for a list of compatible sensors

Measurement Range and Accuracy:

SENSOR

MAX-A, MAX-P, and MAX-I ± 2% Undefined

OxiCliq A, OxiCliq N, OxiCliq P and OxiCliq I ±2.5% Undefined

D-YS, DS-100A, OXI-A/N and OXI-P/I ± 3% Undefined

MAX-R, D-YSE and D-YSPD ± 3.5% Undefined

1 When sensors are used on neonatal subjects as recommended, the specified accuracy range

2 Neonatal accuracy specifications are based upon testing neonatal sensors on healthy adult volun-

2

ACCURACY

70% – 100% 0% – 69%

increases by ± 1 digit, to account for the theoretical effect on oximeter measurements of fetal

hemoglobin in neonatal blood.

teers in induced hypoxia studies, in the range of 70-100% SpO

into account published literature which predicts that there may be a small difference in % SpO

reported by the oximeter when measurements from adult and fetal blood with 100% fetal hemoglobin are compared. Fetal hemoglobin is present in concentrations varying from 10% to 90% in neonatal blood, and this percentage declines over time. As the percentage of fetal hemoglobin in

neonatal blood declines, the theoretical effect on accuracy due to this source is reduced

. The specified accuracy also takes

2

1,2

2

2.4.3.2 Pulse Rate

MEASUREMENT RANGE ACCURACY

20 – 250 BPM ±3 BPM

251 – 300 BPM Undefined

2.4.3.3 Alarm Setting Range

SPO2 MODULE SPO

Nell-3 SpO

Accutorr V Service Manual 0070-10-0702 2 - 9

module 50 – 100 20 – 250 bpm

2

2

PULSE RATE

Page 39

Temp er at ur e Specifications

2.5 Temperature

MODE

monitor 25

predict 35

MEASUREMENT

RANGE ACCURACY

º

C – 44

º

(77

F – 111.2º F)

º

C – 43

º

(95

F – 109.4º F)

º

C

º

C

º

C (77º F) – 32º C

25

º

(89.6

F), not including

º

C (89.6º F)

32

º

32

C (89.6º F) – 44ºC

º

(111.2

F), including

º

C (89.6º F)

32

Not defined typically 10 s – 12 s

º

±0.2

C (±0.4ºF) <60 s

º

±0.1

C (±0.2ºF)

2.6 Display Area, Indicator, and Controller

On the front panel of the Accutorr V, there are a panel display area, a red/yellow LED group

(on the top of the device), a set of buttons, and patient cable connectors. Refer to Chapter 2

of the Accutorr V Operating Instructions (P/N 0070-10-0699-XX).

2.6.1 Display Area

The display area includes 1 LCD, 7 groups of 7-segment digit display, and 7 groups of

monochrome LED indicators.

TYP ICAL

MEASUREMENT

TIME

from the moment

when temperature

“----” displays

dynamically

2.6.1.1 LCD

Monochrome FSTN Matrix: 320×160

Color TFT Matrix: 480×272

LCD type

SIZE AND

RESOLUTION DISPLAYED CONTENTS NOTE

2

2

The brightness

and contrast of

the LCD are

adjustable.

Only brightness

of LCD is

adjustable.

dot pitch: 0.24×0.24

dot pitch:

0.16125×0.16125

Startup screen, menus/

dialogs, time and date,

prompt messages, patient ID,

patient size, trend data

(including scroll bar), SpO

waveform, and time to the

next NIBP measurement

Startup screen, menus/

dialogs, time and date,

prompt messages, patient ID,

patient size, trend data

(including scroll bar), SpO

waveform, and time to the

next NIBP measurement

2 - 10 0070-10-0702 Accutorr V Service Manual

Page 40

Specifications Display Area, Indicator, and Controller

2.6.1.2 7-Segment Digit Display

Seven groups of 7-segment digit displays display the systolic pressure (red LED), diastolic

pressure (red LED), mean pressure/cuff pressure (red LED), SpO

temperature (red LED), and NIBP interval (red LED).

(green LED), PR (red LED),

2

2.6.1.3 Monochrome LED Indicator

Seven groups of monochrome LED indicators display or indicate the pulse strength (green

LED), ADULT–PEDIATRIC–NEO (patient type)–(green LED), Pulse Rate Source (SpO

NIBP)–(green LED), F/C (unit of temperature)–(red LED), silence function (yellow LED), NIBP

measurement status (green LED), and temperature measurement type (red LED).

2

or

2.6.1.4 Power Indicator

AC power indicator Green LED

Illuminates when the Accutorr V is connected to the AC

mains.

Battery indicator Green LED

On/Standby indicator Green LED

2.6.2 Overlay and labeling

• The front panel overlays are displayed in English and extended to other languages.

• The labeling is displayed only in English.

• Startup screen, menu fonts, and LCD prompting characters can be changed through a

software upgrade. The default start logo is Accutorr V.

• The format of the date can be set in the maintenance mode: Chinese style (year - month day), European style (day - month - year), American style (year - day - month).

• Display of NIBP data:

• The LCD display order is: systolic pressure data, diastolic pressure data, and mean

pressure data. For legibility, a “/” separates the data of the three pressures.

• Data displayed by LED digit displays: The systolic pressure data and diastolic pressure

data (in the same fonts) are displayed in parallel. The font of the mean pressure data is

smaller than the systolic pressure data and diastolic pressure data, and displays next

to them.

Illuminates when the unit is on and the battery is inserted.

Flashes when the battery voltage is too low.

Illuminates when the device is powered on or in standby

mode.

Darkens when the device is shut down.

Accutorr V Service Manual 0070-10-0702 2 - 11

Page 41

Display Area, Indicator, and Controller Specifications

2.6.3 Alarm Lamp

• The monitor provides 2 alarm priority levels: high level alarms or low level alarms.

• The Alarm lamp is on the front panel of the monitor. It is a group of (red/yellow) LED

indicators.

• During a high alarm, the red LED, of which the duty cycle is 50%, flashes at a frequency

of 1.4 – 2.8 Hz (84 times per minute).

• During a low alarm, the yellow LED illuminates continuously.

• In case a high alarm and a low alarm occur simultaneously, only the red LED flashes.

NOTE: The audio alarm indication complies with EN60601-1-8.

2.6.4 Keys

There are 14 keys on the front panel of the monitor.

KEYS DESCRIPTION

Turn the monitor on, off, or switch to standby. In the operating state,

press and hold for less than 1 second to switch the device to the

On/Standby indicator

Start NIBP

standby or press and hold for 2s to turn the device off.

Press to start an NIBP measurement.

Deflate

Print

Silence

Set Alarms

Interval

Menu

Display

Patient Info

Patient Size

Up Arrow

During an NIBP measurement, stops the measurement. Also, suspends

interval mode until the next time NIBP Start is pressed.

Start recording trend data/real-time waveform. Press again to stop

recording. When recording trend data, press and hold for less than 1

second to record the current data displaying on the LCD, or press and

hold for 2 seconds to record all data of the current patient.

This button has dual functions:

Press and hold for less than 1 second to pause an audio alarm

(parameters in alarm continue to flash).

Press and hold for 2 seconds to silence an alarm.

Sets alarm parameters.

Sets the measurement mode and time interval. Option: STAT mode,

Off, and interval mode (options: 1, 2, 3, 5,10, 15, 20, 30, 60, 120,

and 240 minute intervals). In the Off mode, perform measurement

manually.

Press to view the menu options.

Press to switch between the normal views, PLETH waveform.

Press to automatically create a patient ID.

Press to change patient size

Press to perform menu operations on the LCD.

OK

Down Arrow

2 - 12 0070-10-0702 Accutorr V Service Manual

Page 42

Specifications Display Area, Indicator, and Controller

2.6.5 Patient Cable Connectors

The patient cable connectors include the NIBP connector, SpO2 connector, and the optional

thermometer connector.

CABLE

CONNECTOR DESCRIPTION

NIBP Cuff

The NIBP cuff connector label is .

SpO

2

Temperature

probe

The SpO2 connector label is SpO2.

• Connects the DPM, Masimo, or Nellcor cable. The Label is SpO

manufacturer name.

with the

2

• Apply standard round DPM 6 pin connector (same as used on Trio) to the

monitor configured with the DPM SpO

board.

2