Page 1

WATO EX-65 Anesthesia

Machine

Operator’s Manual

Page 2

Page 3

CE Marking

The product bears CE mark indicating its conformity with the provisions of the Council

Directive 93/42/EEC concerning medical devices and fulfils the essential requirements of

Annex I of this directive.

The product is in radio-interference protection Group I Class B in accordance with EN55011.

The product complies with the requirement of standard EN60601-1-2 “Electromagnetic

Compatibility – Medical Electrical Equipment”.

Revision History

This manual has a revision number. This revision number changes whenever the manual is

updated due to software or technical specification change. Contents of this manual are subject

to change without prior notice. Revision 1.0 is the initial release of the document.

Revision number: 1.0

Release time: 2009-1

© Copyright 2009 Shenzhen Mindray Bio-Medical Electronics Co., Ltd. All rights reserved.

WARNING

z Federal Law (USA) restricts this device to sale by or on the order of a physician.

I

Page 4

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

Mindray) owns the intellectual property rights to this product and this manual. This manual

may refer to information protected by copyrights or patents and does not convey any license

under the patent rights of Mindray, nor the rights of others.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the written

permission of Mindray is strictly forbidden. Release, amendment, reproduction, distribution,

rental, adaption and translation of this manual in any manner whatsoever without the written

permission of Mindray is strictly forbidden

, and WATO are the registered trademarks or trademarks owned by

Mindray in China and other countries. All other trademarks that appear in this manual are

used only for editorial purposes without the intention of improperly using them. They are the

property of their respective owners.

Contents of this manual are subject to changes without prior notice.

II

Page 5

Manufacturer’s Responsibility

All information contained in this manual is believed to be correct. Mindray shall not be liable

for errors contained herein nor for incidental or consequential damages in connection with

the furnishing, performance, or use of this manual.

Mindray is responsible for the effects on safety, reliability and performance of this product

only if:

all installation operations, expansions, changes, modifications and repairs of this product

are conducted by Mindray authorized personnel; and

the electrical installation of the relevant room complies with the applicable national and

local requirements; and

the product is used in accordance with the instructions for use.

Warranty

This warranty is exclusive and is in lieu of all other warranties, expressed or implied,

including warranties of merchantability or fitness for any particular purpose.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or

other charges or liability for direct, indirect or consequential damages or delay resulting from

the improper use or application of the product or the use of parts or accessories not approved

by Mindray or repairs by people other than Mindray authorized personnel.

This warranty shall not extend to

Any Mindray product which has been subjected to misuse, negligence or accident; or

Any Mindray product from which Mindray's original serial number tag or product

identification markings have been altered or removed; or

Any product of any other manufacturer.

III

Page 6

Return Policy

In the event that it becomes necessary to return a unit to Mindray, follow the instructions

below.

1. Return authorization.

Contact the Customer Service Department and obtain a Customer Service Authorization

number. This number must appear on the outside of the shipping container. Returned

shipments will not be accepted if the number is not clearly visible. Please provide the model

number, serial number, and a brief description of the reason for return.

2. Freight policy

The customer is responsible for freight charges when this product is shipped to Mindray for

service (this includes customs charges).

3. Return address

Please send the part(s) or equipment to the address offered by the Customer Service

Department.

Contact Information

Manufacturer: Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Address: Mindray Building, Keji 12th Road South, Hi-tech Industrial Park,

Nanshan, Shenzhen 518057 P.R. China

Tel: +86 755 26582479 +86 755 26582888

Fax: +86 755 26582934 +86 755 26582500

Website: www.mindray.com

EC-Representative: Shanghai International Holding Corp. GmbH (Europe)

Address: Eiffestraße 80, Hamburg 20537, Germany

Tel: 0049-40-2513175

Fax: 0049-40-255726

IV

Page 7

Preface

Manual Purpose

This manual contains the instructions necessary to operate the product safely and in

accordance with its function and intended use. Observance of this manual is a prerequisite for

proper product performance and correct operation and ensures patient and operator safety.

This manual is based on the maximum configuration and therefore some contents may not

apply to your product. If you have any question, please contact us.

This manual is an integral part of the product. It should always be kept close to the equipment

so that it can be obtained conveniently when needed.

Intended Audience

This manual is geared for clinical professionals who are expected to have a working

knowledge of medical procedures, practices and terminology as required for monitoring of

critically ill patients.

Illustrations

All illustrations in this manual serve as examples only. They may not necessarily reflect the

setup or data displayed on your anesthesia machine.

Conventions

Italic text is used in this manual to quote the referenced chapters or sections.

[ ] is used to enclose screen texts.

→ is used to indicate operational procedures.

V

Page 8

FOR YOUR NOTES

VI

Page 9

Contents

1 Safety................................................................................................................................. 1-1

1.1 Safety Information ..........................................................................................................1-1

1.1.1 Dangers .............................................................................................................. 1-2

1.1.2 Warnings............................................................................................................. 1-2

1.1.3 Cautions ............................................................................................................. 1-3

1.1.4 Notes .................................................................................................................. 1-4

1.2 Equipment Symbols ........................................................................................................ 1-5

2 The Basics ......................................................................................................................... 2-1

2.1 System Description ......................................................................................................... 2-1

2.1.1 Intended Use....................................................................................................... 2-1

2.1.2 Contraindications ............................................................................................... 2-1

2.1.3 Components ....................................................................................................... 2-2

2.2 Equipment Appearance ................................................................................................... 2-3

2.2.1 Front View.......................................................................................................... 2-3

2.2.2 Rear View ........................................................................................................... 2-7

2.3 Batteries ........................................................................................................................ 2-12

3 System Controls and Basic Settings................................................................................ 3-1

3.1 Display Control ............................................................................................................... 3-1

3.2 Display Screen ................................................................................................................ 3-3

3.3 Basic Settings.................................................................................................................. 3-5

3.3.1 Adjust Screen Brightness ................................................................................... 3-5

3.3.2 Adjust Sound Volume......................................................................................... 3-5

3.3.3 Set System Time................................................................................................. 3-6

3.3.4 Set Language...................................................................................................... 3-6

3.3.5 Set Unit .............................................................................................................. 3-6

3.3.6 Restore Default Configurations.......................................................................... 3-6

3.3.7 Set the IP Address of Anesthesia Information System (CIS) ............................. 3-7

4 Operations and Ventilation Setup................................................................................... 4-1

4.1 Turn on the System ......................................................................................................... 4-1

4.2 Turn off the System.........................................................................................................4-1

4.3 Input Fresh Gas ............................................................................................................... 4-2

4.3.1 Set O

4.3.2 Set Anesthetic Agent .......................................................................................... 4-3

4.4 Set Ventilation Mode....................................................................................................... 4-4

4.4.1 Set Manual Ventilation Mode............................................................................. 4-4

4.4.2 Make Settings before Starting Mechanical Ventilation Mode............................ 4-5

O and Air Inputs................................................................................. 4-2

2, N2

1

Page 10

4.4.3 Volume Control Ventilation (VCV).................................................................... 4-5

4.4.4 Pressure Control Ventilation (PCV) ................................................................... 4-8

4.4.5 Synchronized Intermittent Mandatory Ventilation (SIMV)...............................4-11

4.4.6 Pressure Support Ventilation (PSV) ................................................................. 4-17

4.5 Start Mechanical Ventilation ......................................................................................... 4-21

4.6 Set the Timer ................................................................................................................. 4-22

4.6.1 Start the Timer.................................................................................................. 4-22

4.6.2 Stop the Timer .................................................................................................. 4-22

4.6.3 Reset the Timer ................................................................................................ 4-22

4.7 Stop Mechanical Ventilation ......................................................................................... 4-23

5 User Interface and Parameter Monitoring .................................................................... 5-1

5.1 Screen Layout ................................................................................................................. 5-1

5.1.1 Standby Screen................................................................................................... 5-2

5.1.2 Normal Screen.................................................................................................... 5-3

5.1.3 Special Screen .................................................................................................... 5-4

5.2 Screen Setup.................................................................................................................... 5-5

5.3 Parameter Monitoring ..................................................................................................... 5-5

5.3.1 O2 Concentration Monitoring ............................................................................ 5-5

5.3.2 Anesthetic Agent (AA) Concentration Monitoring ............................................ 5-7

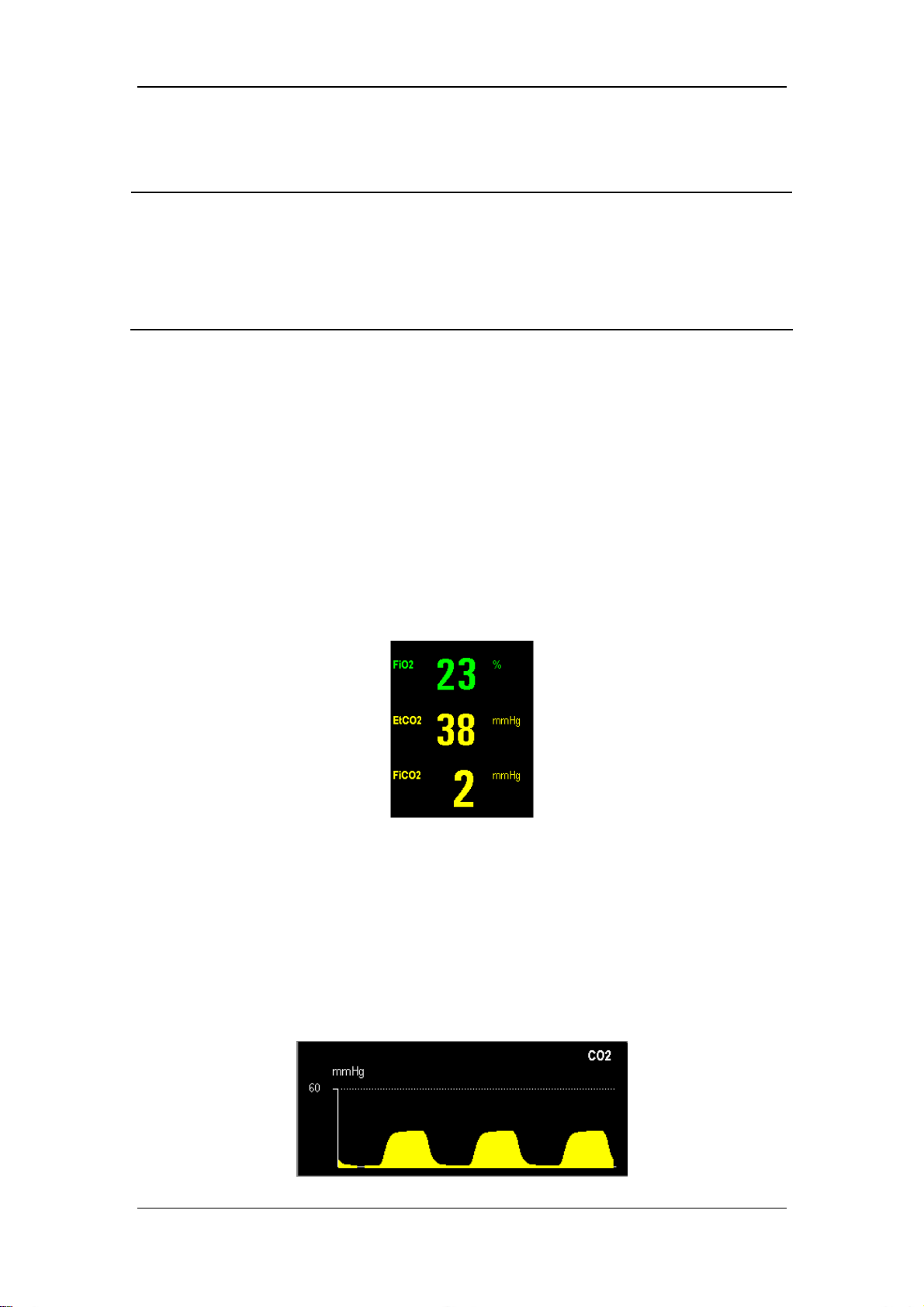

5.3.3 CO2 Concentration Monitoring ......................................................................... 5-8

5.3.4 Pressure Monitoring ........................................................................................... 5-9

5.3.5 Tidal Volume Monitoring ................................................................................. 5-10

5.3.6 Tidal Volume Compensation ............................................................................ 5-12

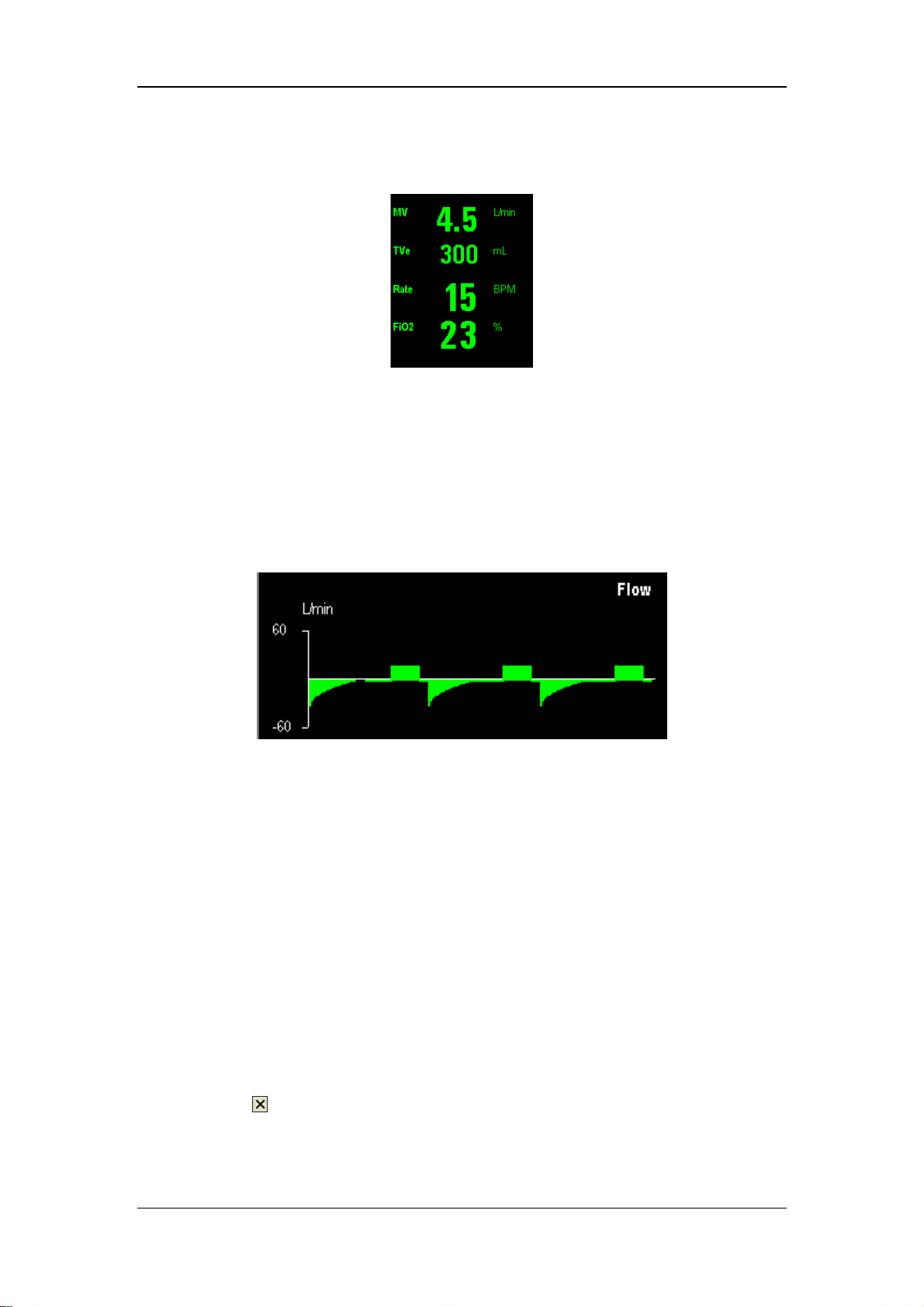

5.3.7 Volume Monitoring .......................................................................................... 5-13

5.3.8 Breath Rate Monitoring.................................................................................... 5-13

5.3.9 BIS Monitoring ................................................................................................ 5-14

5.4 Display Electronic Flowmeter....................................................................................... 5-16

5.5 Spirometry Loop ........................................................................................................... 5-16

6 Preoperative Test.............................................................................................................. 6-1

6.1 Preoperative Test Schedules............................................................................................ 6-1

6.1.1 Test Intervals ...................................................................................................... 6-1

6.2 Inspect the System ..........................................................................................................6-2

6.3 Power Failure Alarm Test................................................................................................ 6-2

6.4 Pipeline Tests .................................................................................................................. 6-3

6.4.1 O2 Pipeline Test ................................................................................................. 6-3

6.4.2 N2O Pipeline Test .............................................................................................. 6-4

6.4.3 Air Pipeline Test................................................................................................. 6-4

6.5 Cylinder Tests.................................................................................................................. 6-4

6.5.1 Check the Cylinder in Full Status....................................................................... 6-4

6.5.2 O2 Cylinder High Pressure Leak Test ................................................................ 6-5

6.5.3 N2O Cylinder High Pressure Leak Test ............................................................. 6-5

6.6 Flow Control System Tests ............................................................................................. 6-5

2

Page 11

6.6.1 Without O2 Sensor ............................................................................................. 6-5

6.6.2 With O2 Sensor .................................................................................................. 6-7

6.7 Vaporizer Back Pressure Test.......................................................................................... 6-8

6.8 Breathing System Tests ................................................................................................... 6-9

6.8.1 Bellows Test ....................................................................................................... 6-9

6.8.2 Breathing System Leak Test in Mechanical Ventilation Status ........................ 6-10

6.8.3 Breathing System Leak Test in Manual Ventilation Status................................6-11

6.8.4 APL Valve Test..................................................................................................6-11

6.9 Alarm Tests.................................................................................................................... 6-12

6.9.1 Prepare for Alarm Tests .................................................................................... 6-12

6.9.2 Test the O2 Concentration Monitoring and Alarms.......................................... 6-13

6.9.3 Test the Low Minute Volume Alarm ................................................................ 6-13

6.9.4 Test the Apnea Alarm ....................................................................................... 6-14

6.9.5 Test the Sustained Airway Pressure Alarm....................................................... 6-14

6.9.6 Test the High Paw Alarm.................................................................................. 6-14

6.9.7 Test the Low Paw Alarm .................................................................................. 6-15

6.9.8 Test the AG Module Alarm .............................................................................. 6-15

6.10 Preoperative Preparations............................................................................................ 6-15

6.11 Inspect the AGSS ........................................................................................................ 6-16

7 User Maintenance............................................................................................................. 7-1

7.1 Repair Policy................................................................................................................... 7-1

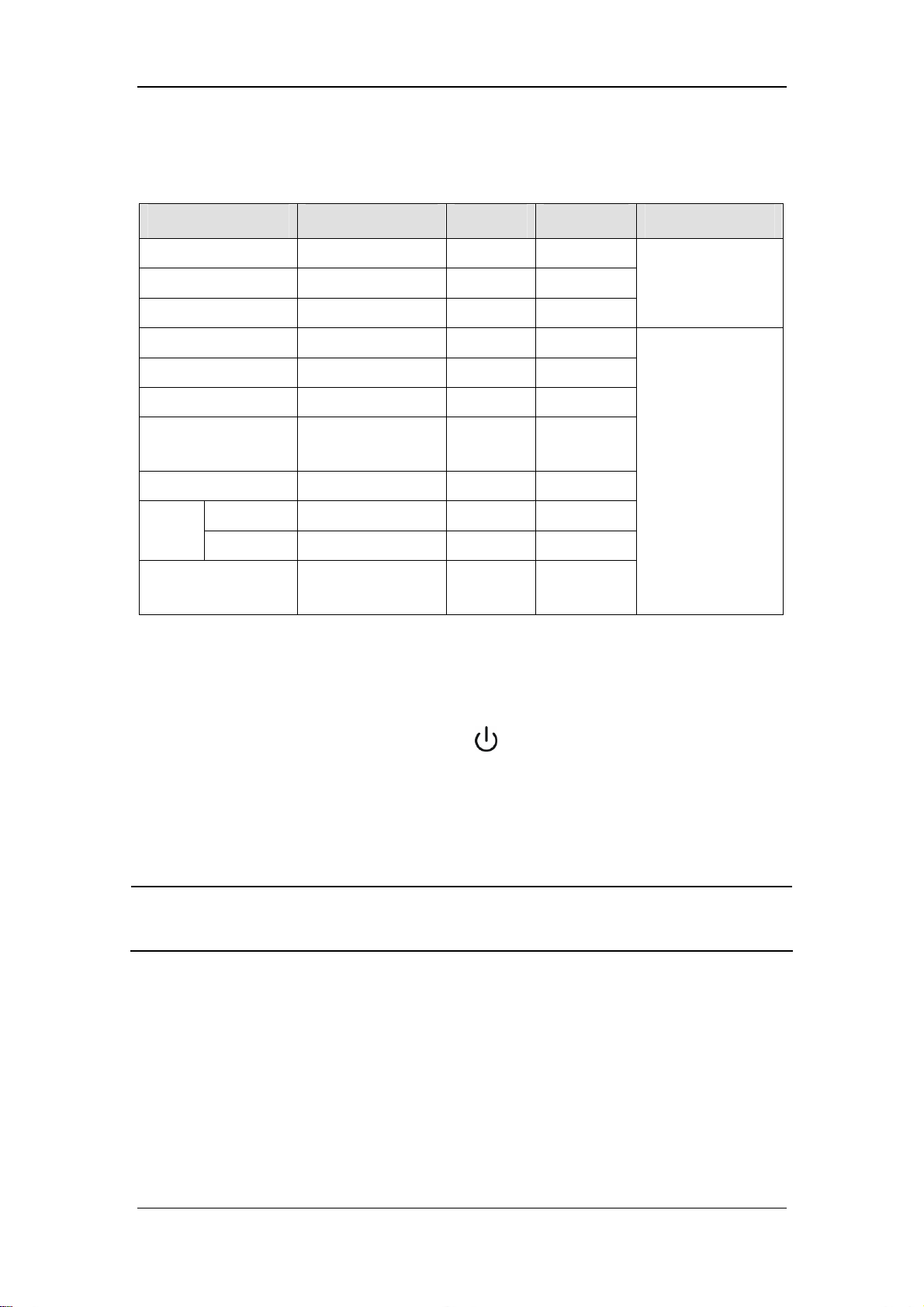

7.2 Maintenance Schedule .................................................................................................... 7-2

7.3 Breathing System Maintenance....................................................................................... 7-3

7.4 Flow Sensor Calibration.................................................................................................. 7-3

7.5 O2 Sensor Calibration..................................................................................................... 7-5

7.5.1 21% O2 Calibration............................................................................................ 7-5

7.5.2 100% O2 Calibration.......................................................................................... 7-6

7.6 Water Build-up in the Flow Sensor ................................................................................. 7-7

7.6.1 Prevent Water Build-up ...................................................................................... 7-7

7.6.2 Clear Water Build-up.......................................................................................... 7-8

7.7 Airway Pressure Gauge Zeroing ..................................................................................... 7-8

7.8 AGSS Transfer Tube Maintenance................................................................................ 7-10

8 CO2 Monitoring............................................................................................................... 8-1

8.1 Introduction..................................................................................................................... 8-1

8.2 Identify CO2 Module ...................................................................................................... 8-2

8.3 Use a Sidestream CO2 Module ....................................................................................... 8-3

8.3.1 Prepare to Measure CO2 .................................................................................... 8-3

8.3.2 Make CO2 Settings ............................................................................................ 8-4

8.3.3 Measurement Limitations................................................................................... 8-6

8.3.4 Troubleshooting.................................................................................................. 8-6

8.3.5 Scavenge the Sample Gas .................................................................................. 8-7

8.3.6 Zero the Sensor .................................................................................................. 8-7

3

Page 12

8.3.7 Calibrate the Sensor ........................................................................................... 8-7

8.4 Use a Microstream CO2 Module .................................................................................... 8-8

8.4.1 Prepare to Measure CO2 .................................................................................... 8-8

8.4.2 Make CO2 Settings ............................................................................................ 8-8

8.4.3 Measurement Limitations..................................................................................8-11

8.4.4 Scavenge the Sample Gas .................................................................................8-11

8.4.5 Zero the Sensor ................................................................................................ 8-12

8.4.6 Calibrate the Sensor ......................................................................................... 8-12

8.4.7 Oridion Information ......................................................................................... 8-12

8.5 Use a Mainstream CO2 Module.................................................................................... 8-13

8.5.1 Prepare to Measure CO2 .................................................................................. 8-13

8.5.2 Make CO2 Settings .......................................................................................... 8-14

8.5.3 Measurement Limitations................................................................................. 8-16

8.5.4 Zero the Sensor ................................................................................................ 8-16

8.5.5 Calibrate the Sensor ......................................................................................... 8-16

9 AG and O2 Concentration Monitoring .......................................................................... 9-1

9.1 Introduction..................................................................................................................... 9-1

9.2 Understand MAC Values................................................................................................. 9-2

9.3 Identify AG Modules....................................................................................................... 9-3

9.4 Prepare to Measure AG................................................................................................... 9-3

9.5 Make AG Settings........................................................................................................... 9-5

9.5.1 Set Anesthetic Agent .......................................................................................... 9-5

9.5.2 Set Pump Rate.................................................................................................... 9-5

9.5.3 Set O2 Compensation......................................................................................... 9-5

9.5.4 Set Working Mode.............................................................................................. 9-5

9.5.5 Set CO2 Unit...................................................................................................... 9-6

9.5.6 Restore Defaults................................................................................................. 9-6

9.5.7 Set CO2 Waveform ............................................................................................ 9-6

9.6 Change Anesthetic Agent ................................................................................................ 9-6

9.7 Measurement Limitations................................................................................................ 9-7

9.8 Troubleshooting .............................................................................................................. 9-7

9.9 Scavenge the Sample Gas ............................................................................................... 9-8

9.10 Calibrate the AG Module .............................................................................................. 9-8

10 BIS Monitoring............................................................................................................. 10-1

10.1 Introduction................................................................................................................. 10-1

10.2 Identify the BIS Module.............................................................................................. 10-1

10.3 Safety Information ...................................................................................................... 10-2

10.4 Understand BIS Parameters ........................................................................................ 10-3

10.5 Prepare to Measure BIS .............................................................................................. 10-4

10.6 Continuous Impedance Check..................................................................................... 10-5

10.7 Cyclic Impedance Check............................................................................................. 10-6

10.8 BIS Sensor Check Window......................................................................................... 10-6

4

Page 13

10.9 Set BIS Smoothing Rate.............................................................................................. 10-7

10.10 Restore Defaults........................................................................................................ 10-7

10.11 Set BIS Related Waveforms ...................................................................................... 10-8

11 Alarms............................................................................................................................11-1

11.1 Introduction..................................................................................................................11-1

11.1.1 Alarm Categories.............................................................................................11-1

11.1.2 Alarm Levels ...................................................................................................11-2

11.2 Alarm Indicators...........................................................................................................11-2

11.2.1 Alarm Lamp.....................................................................................................11-2

11.2.2 Audible Alarm Tones .......................................................................................11-3

11.2.3 Alarm Message................................................................................................11-3

11.2.4 Flashing Alarm Numeric .................................................................................11-3

11.2.5 Alarm Status Symbols .....................................................................................11-3

11.3 Set Alarm Volume ........................................................................................................11-4

11.4 Set Alarm Limits ..........................................................................................................11-4

11.4.1 Set Ventilator Alarm Limits.............................................................................11-4

11.4.2 Set CO2 Alarm Limits.....................................................................................11-4

11.4.3 Set AG Alarm Limits.......................................................................................11-5

11.4.4 Set BIS Alarm Limits ......................................................................................11-5

11.5 Set Alarm Level............................................................................................................11-5

11.6 Set Cardiopulmonary Bypass (CPB) Alarm .................................................................11-5

11.7 Set MV&TVe Alarm.....................................................................................................11-6

11.8 Set Apnea Alarm...........................................................................................................11-6

11.9 Alarm Silence ...............................................................................................................11-7

11.9.1 Set 120 s Alarm Silence...................................................................................11-7

11.9.2 Cancel 120 s Alarm Silence.............................................................................11-7

11.10 When an Alarm Occurs ..............................................................................................11-7

12 Trend and Logbook...................................................................................................... 12-1

12.1 Trend Graph ................................................................................................................ 12-1

12.2 Trend Table.................................................................................................................. 12-2

12.3 Alarm Logbook ........................................................................................................... 12-3

13 Installations and Connections..................................................................................... 13-1

13.1 Install the Breathing System ....................................................................................... 13-1

13.1.1 Breathing System Diagrams........................................................................... 13-2

13.1.2 Circuit Adapter Diagram ................................................................................ 13-3

13.1.3 Install the Breathing system ........................................................................... 13-4

13.1.4 Install the Bag Arm ........................................................................................ 13-6

13.1.5 Install the Bellows.......................................................................................... 13-7

13.1.6 Install the Flow sensor.................................................................................... 13-9

13.1.7 Install the O2 Sensor .................................................................................... 13-10

13.1.8 Install the Sodalime Canister........................................................................ 13-12

5

Page 14

13.2 Install the Breathing Tubes........................................................................................ 13-19

13.3 Install the Manual Bag .............................................................................................. 13-20

13.4 Install the Vaporizer .................................................................................................. 13-21

13.4.1 Assemble the Vaporizer................................................................................ 13-21

13.4.2 Fill the Vaporizer.......................................................................................... 13-25

13.4.3 Drain the Vaporizer ...................................................................................... 13-27

13.5 Install/Replace the Gas Cylinder............................................................................... 13-29

13.6 Install Modules.......................................................................................................... 13-31

13.6.1 Install the CO2 Module................................................................................ 13-31

13.6.2 Install the AG Module.................................................................................. 13-31

13.6.3 Install the BIS Module ................................................................................. 13-32

13.7 Pneumatic Connectors............................................................................................... 13-32

13.7.1 Connect the Pipeline Gas Supplies............................................................... 13-33

13.7.2 Install the Gas Cylinder................................................................................ 13-34

13.8 CIS Connector........................................................................................................... 13-34

13.9 Scavenging................................................................................................................ 13-34

13.10 AGSS Transfer and Receiving System.................................................................... 13-35

13.10.1 Components................................................................................................ 13-35

13.10.2 Assemble the AGSS ................................................................................... 13-36

13.10.3 Waste Gas Disposal System ....................................................................... 13-37

14 Cleaning and Disinfection............................................................................................ 14-1

14.1 Clean and Disinfect the Anesthesia Machine Housing................................................ 14-2

14.2 Disassemble the Breathing System Cleanable Parts ................................................... 14-2

14.2.1 O2 Sensor....................................................................................................... 14-3

14.2.2 Manual Bag .................................................................................................... 14-4

14.2.3 Breathing Tubes ............................................................................................. 14-5

14.2.4 Airway Pressure Gauge .................................................................................. 14-6

14.2.5 Bag Arm ......................................................................................................... 14-6

14.2.6 Bellows Assembly.......................................................................................... 14-7

14.2.7 Flow Sensor.................................................................................................... 14-8

14.2.8 Expiratory Check Valve Assembly................................................................. 14-9

14.2.9 Inspiratory Check Valve Assembly ................................................................ 14-9

14.2.10 Sodalime Canister ...................................................................................... 14-10

14.2.11 Water Collection Cup ..................................................................................14-11

14.2.12 Breathing system........................................................................................ 14-12

14.2.13 AGSS Transfer and Receiving System....................................................... 14-13

14.3 Clean&Disinfect and Re-install the Breathing System ............................................. 14-15

14.3.1 Breathing system.......................................................................................... 14-17

14.3.2 Water Collection Cup ................................................................................... 14-17

14.3.3 Manual Bag .................................................................................................. 14-17

14.3.4 Breathing Mask ............................................................................................ 14-18

14.3.5 Inspiratory and Expiratory Check Valves Assembly.................................... 14-18

14.3.6 Bellows Assembly........................................................................................ 14-18

6

Page 15

14.3.7 Sodalime Canister ........................................................................................ 14-19

14.3.8 Breathing Tubes and Y Piece........................................................................ 14-20

14.3.9 Flow Sensor.................................................................................................. 14-20

14.3.10 O2 Sensor................................................................................................... 14-21

14.3.11 AGSS Transfer and Receiving System ....................................................... 14-21

15 Accessories.................................................................................................................... 15-1

A Theory of Operation....................................................................................................... A-1

A.1 Pneumatic Circuit System ............................................................................................. A-1

A.2 Electrical System Structure ........................................................................................... A-4

B Product Specifications.....................................................................................................B-1

B.1 Safety Specifications ......................................................................................................B-1

B.2 Environmental Specifications.........................................................................................B-2

B.3 Power Requirements.......................................................................................................B-2

B.4 Physical Specifications...................................................................................................B-3

B.5 Pneumatic Circuit System Specifications.......................................................................B-4

B.6 Breathing System Specifications....................................................................................B-5

B.7 Ventilator Specifications.................................................................................................B-7

B.8 Ventilator Accuracy ........................................................................................................B-9

B.9 Anesthetic vaporizer .....................................................................................................B-10

B.10 AGSS Transfer and Receiving System Specifications................................................B-10

B.11 O2 Sensor Specifications............................................................................................B-11

B.12 CO2 Module Specifications .......................................................................................B-14

B.13 AG Module Specifications .........................................................................................B-17

B.14 BIS Module Specifications.........................................................................................B-21

C EMC ................................................................................................................................ C-1

D Alarm Messages.............................................................................................................. D-1

D.1 Physiological Alarm Messages...................................................................................... D-1

D.2 Technical Alarm Messages............................................................................................ D-4

E Symbols and Abbreviations............................................................................................E-1

E.1 Symbols .......................................................................................................................... E-1

E.2 Abbreviations.................................................................................................................. E-3

F Factory Defaults...............................................................................................................F-1

F.1 CO2 Module.................................................................................................................... F-1

F.2 AG Module...................................................................................................................... F-2

F.3 BIS Module .....................................................................................................................F-3

F.4 Ventilator ......................................................................................................................... F-4

7

Page 16

FOR YOUR NOTES

8

Page 17

1 Safety

1.1 Safety Information

DANGER

z Indicates an imminent hazard that, if not avoided, will result in death or serious

injury.

WARNING

z Indicates a potential hazard or unsafe practice that, if not avoided, could result in

death or serious injury.

CAUTION

z Indicates a potential hazard or unsafe practice that, if not avoided, could result in

minor personal injury or product/property damage.

NOTE

z Provides application tips or other useful information to ensure that you get the

most from your product.

1-1

Page 18

1.1.1 Dangers

There are no dangers that refer to the product in general. Specific “Danger” statements may

be given in the respective sections of this manual.

1.1.2 Warnings

WARNING

z Before putting the system into operation, the operator must verify that the

equipment, connecting cables and accessories are in correct working order and

operating condition.

z The equipment must be connected to a properly installed power outlet with

protective earth contacts only. If the installation does not provide for a protective

earth conductor, disconnect it from the power line.

z Use AC power source before the batteries are depleted.

z To avoid explosion hazard, do not use the equipment in the presence of flammable

anesthetic agent, vapors or liquids.

z Do not open the equipment housings. All servicing and future upgrades must be

carried out by the personnel trained and authorized by us only.

z Do not rely exclusively on the audible alarm system for patient monitoring.

Adjustment of alarm volume to a low level may result in a hazard to the patient.

Remember that alarm settings should be customized according to different patient

situations and always keeping the patient under close surveillance is the most

reliable way for safe patient monitoring.

z The physiological parameters and alarm messages displayed on the screen of the

equipment are for doctor’s reference only and cannot be directly used as the basis

for clinical treatment.

z Dispose of the package material, observing the applicable waste control regulations

and keeping it out of children’s reach.

z To avoid explosion hazard, do not use flammable anesthetic agent such as ether

and cyclopropane for this equipment. Only non-flammable anesthetic agents which

meet the requirements specified in IEC 60601-2-13 can be applied to this

equipment. This anesthesia machine can be used with halothane, enflurane,

isoflurane, sevoflurane and desflurane. Only one of the five anesthetic agents can

be used at a time.

z Do not touch the patient, table, or instruments during defibrillation.

1-2

Page 19

WARNING

z Use appropriate electrodes and place them according to the instructions provided

by the manufacturer. The display restores to normal within 10 seconds after

defibrillation.

1.1.3 Cautions

CAUTION

z To ensure patient safety, use only parts and accessories specified in this manual.

z At the end o f its service life, the equipment, as well as its accessories, must be

disposed of in compliance with the guidelines regulating the disposal of such

products.

z Magnetic and electrical fields are capable of interfering with the proper

performance of the equipment. For this reason make sure that all external devices

operated in the vicinity of the equipment comply with the relevant EMC

requirements. Mobile phone, X-ray equipment or MRI devices are a possible

source of interference as they may emit higher levels of electromagnetic radiation.

z This system operates correctly at the electrical interference levels identified in this

manual. Higher levels can cause nuisance alarms that may stop mechanical

ventilation. Pay attention to false alarms caused by high-intensity electrical fields.

z Before connecting the equipment to the power line, check that the voltage and

frequency ratings of the power line are the same as tube indicated on the

equipment’s label or in this manual.

z Always install or carry the equipment properly to avoid damage caused by drop,

impact, strong vibration or other mechanical force.

z The anesthesia machine keeps stable with a 10º tilt in typical configuration. Do not

hang articles on both sides of the anesthesia machine for fear of getting tilted.

1-3

Page 20

1.1.4 Notes

NOTE

z Put the equipment in a location where you can easily see the screen and access the

operating controls.

z Keep this manual close to the equipment so that it can be obtained conveniently

when needed.

z The software was developed in compliance with IEC 60601-1-4. The possibility of

hazards arising from software errors is minimized.

z This manual describes all features and options. Your equipment may not have all

of them.

1-4

Page 21

1.2 Equipment Symbols

Attention: Consult

accompanying documents (this

manual)

Dangerous voltage

Alternating current

Battery

Operating state

Material description

Fuse

Equipotential

Autoclavable

Not autoclavable

Reset

Power On

Alarm silence key

Normal screen key

ACGO On

Power Off

Standby

MV&TVe alarm key

flush button

O

2

ACGO Off

Bag position/ manual

ventilation

Lock

Network connector

Mechanical ventilation

Unlock

Flow control

USB connector

Air supply connector

Upward (Pop-off valve)

O

sensor connector

2

N2O supply connector

Sample gas return port

(to the AGSS)

1-5

Page 22

VGA connector

supply connector

O

2

Table top light

Cylinder

AGSS outlet

PEEP outlet

Manufacture date

Manufacturer

Serial number

APL valve

Maximum level of the

sodalime canister

Vaporizer

Isolation transformer

European community

representative

CAUTION HOT

Lock or unlock as the

arrow shows

Gas input direction

Unlock the lifting device

Lock the lifting device

Approximate

Max. weight: 11.3 kg

Max. weight: 30 kg

Type BF applied part.

Defibrillation-proof protection

against electric shock.

Do Not Crush

Please align!

Pipeline

CE marking

The anesthesia machine

is driven by Air.

The following definition of the WEEE label applies to EU member states only.

This symbol indicates that this product should not be treated as household

waste. By ensuring that this product is disposed of correctly, you will help

prevent bringing potential negative consequences to the environment and

human health. For more detailed information with regard to returning and

recycling this product, please consult the distributor from whom you purchased

it.

* For system products, this label may be attached to the main unit only.

1-6

Page 23

2 The Basics

2.1 System Description

2.1.1 Intended Use

The anesthesia machine is intended to provide breathing anesthesia for adult, pediatric and

infant patients during surgery.

The anesthesia machine must only be operated by qualified anesthesia personnel who have

received adequate training in its use.

WARNING

z This anesthesia machine is intended for use by qualified anesthesia personnel only

or under their guidance. Anyone unauthorized or untrained must not perform any

operation on it.

z This anesthesia machine is not suitable for use in an MRI environment.

2.1.2 Contraindications

The anesthesia machine is contraindicated for use on patients who suffer pneumothorax or

severe pulmonary incompetence.

2-1

Page 24

2.1.3 Components

The anesthesia machine consists of a main unit, vaporizer (five optional anesthetic agents:

enflurane, isoflurane, sevoflurane, desflurane and halothane), anesthetic ventilator, electronic

flowmeter assembly, breathing system etc.

The anesthesia machine provides monitoring and displaying of respiratory mechanics (RM)

parameters (airway resistance and compliance) and spirometry loops as well. It is configured

with the following ventilation modes: volume control ventilation (VCV), pressure control

ventilation (PCV), pressure support ventilation (PSV), synchronized intermittent mandatory

ventilation—volume control (SIMV-VC) and synchronized intermittent mandatory

ventilation—pressure control (SIMV-PC).

The anesthesia machine can be externally connected to a patient monitor which is in

compliance with the requirements of relevant international standard and can be configured

with anesthesia information system (CIS).

The anesthesia machine features the following:

Automatic leak detection

Breathing system gas leak compensation and automatic compliance compensation

Cylinder and pipeline connections available for gas supplies

Electronic flowmeter and electronic PEEP

Timer which counts the duration between the start and end of an operation

Table top light

Information displayed in big numerics

User-adjustable display screen

Alarm events storage and review, fault status and maintenance information recording

Auxiliary O

N2O cut-off

Modular AG, CO2 and BIS modules

Sample gas return to the AGSS

Setting CPB alarm mode

supply and active anesthesia gas scavenging system (AGSS)

2

2-2

Page 25

2.2 Equipment Appearance

2.2.1 Front View

——Display and control panel

2-3

Page 26

1. Brake

2. Pipeline pressure gauge (s)

Displays the pipeline pressure or the cylinder pressure after relief.

3. Total flowmeter

The medium level of flowtube float indicates the current flow of the mixed gas.

4 Flow control (s)

When the system switch is set to the ON position:

Turn the control counterclockwise to increase the gas flow.

Turn the control clockwise to decrease the gas flow.

5 Electronic flowmeter

Displays the current flow of the corresponding gas.

6. Ventilator control panel

7. Control knob

8. Display

9. Vaporizer

A. Concentration control

Push and turn the concentration control to set the

concentration of anesthetic agent.

B. Locking lever

Turn the locking lever clockwise to lock the vaporizer

in position.

10. Gas supply connector (s)

O

O and AIR connectors are provided.

2 , N2

11. System switch

Set the switch to the position to enable gas flow and to turn on the system.

Set the switch to the position to disable gas flow and to turn off the system.

12. Cylinder pressure gauge (s)

High-pressure pressure gauge (s) that displays cylinder pressure before relief.

13. O

Push to supply high flows of O

flush button

2

to the breathing system.

2

14. Auxiliary electrical outlet

Three auxiliary electrical outlets are provided when the anesthesia machine is

configured with an isolation transformer.

15 Drawer lock

16. Worktable (with drawer)

2-4

Page 27

——Breathing system

2-5

Page 28

1. O

sensor connector

2

2. Inspiration connector

3. Expiration connector

4. Inspiratory check valve

5. Expiratory check valve

6. Bellows housing

7. Sample gas return port (to the AGSS)

8. Manual bag port

9. Bag/mechanical ventilation switch

Select the position to use bag for manual ventilation.

Select the position to use ventilator for mechanical ventilation.

10. APL (airway pressure limit) valve

Adjusts breathing system pressure limit during manual ventilation. The scale shows

approximate pressures. Above 30 cmH

O, you will feel clicks as the v turns. Turn

2

clockwise to increase.

11. O

sensor connector

2

12. Rotary handle

13. Sodalime canister

The sodalime inside the canister absorbs the CO

cyclic use of the patient exhaled gas.

the patient exhales, which enables

2

2-6

Page 29

2.2.2 Rear View

——Power supply

2-7

Page 30

1. Cylinder connector (s)

2. Equipotential stud

3. Fan

4. Mains inlet

5. Network connector

6. CIS 12 V power supply connector

7. Speaker

8. Auxiliary O2 supply

9. ACGO (Auxiliary Common Gas Outlet) switch

Set the switch to the position to stop mechanical ventilation. Then,

fresh gas is sent to the externally connected manual breathing system through the

ACGO outlet and the technical alarm of [ACGO On] is triggered. The system

monitors airway pressure and O

Set the switch to the position to apply mechanical or manual ventilation

concentration instead of volume.

2

to the patient through the breathing system.

10. Module slot

CO2, AG and BIS modules mentioned in this manual can be inserted into the slot and

identified. The CO

and AG modules cannot be used simultaneously.

2

11. AGSS outlet

12. AGSS Transfer and Receiving System

2-8

Page 31

——Anesthesia information system (CIS)

2-9

Page 32

This rear view is based on the situation that the anesthesia machine is configured with

anesthesia information system (CIS).

1. Display

2. Rail

3. Mounting bracket

4. Keyboard

5. CIS main unit

A

B

A. Reset key

B. CIS switch

: Press to switch on/off the CIS.

C. USB connector

D. Network connector

E. Electrical outlet

F. Display connector

: Press to restart the CIS.

F

D

E

C

C

2-10

Page 33

WARNING

z Connect to the AC mains in compliance with B.3 Power Requirements. Failure to

do so may cause damage to the equipment or affect its normal operation.

z Make sure that the jacket on the electrical outlet is already fixed to avoid power

cord off during surgery.

NOTE

z If the equipment cannot be powered by the AC mains, check if the fuse inside the

electrical outlet is normal. If AC mains supply still fails after the fuse is replaced,

contact the service personnel.

z When the auxiliary electrical outlet does not work normally, check if the

corresponding fuse is burned.

z Equipment connected to the auxiliary electrical outlet shall be authorized.

Otherwise, leakage current above the allowable limit will result, which may

endanger the patient or operator, and damage the anesthesia machine or externally

connected equipment. When the anesthesia machine is configured with only one

auxiliary electrical outlet, this electrical outlet is only used for connecting the

adapter for Desflurane vaporizer. When the anesthesia machine is configured with

multiple auxiliary electrical outlets, the equipment connected shall comply with the

voltage and current specifications of the auxiliary electrical outlets.

z All analog or digital products connected to this system must be certified passing the

specified IEC standards (such as IEC 60950 for data processing equipment and

IEC 60601-1 for medical electrical equipment). All configurations shall comply

with the valid version of IEC 60601-1-1. The personnel who are responsible for

connecting the optional equipment to the I/O signal port shall be responsible for

medical system configuration and system compliance with IEC 60601-1-1 as well.

2-11

Page 34

2.3 Batteries

NOTE

z Use batteries at least once every month to extend their life. Charge the batteries

before their capacities are worn out.

z Inspect and replace batteries regularly. Battery life depends on how frequent and

how long it is used. For a properly maintained and stored lithium battery, its life

expectancy is approximately 3 years. For more aggressive use models, life

expectancy can be shortened. We recommend replacing lithium batteries every 3

years.

z The operating time of a battery depends on equipment configuration and

operation. For example, starting module monitoring frequently will shorten the

operating time of the batteries.

z In case of battery failure, contact us or have your service personnel replace it. Do

not replace the battery without permission.

The anesthesia machine is designed to operate on battery power whenever AC power

becomes interrupted. When the anesthesia machine is connected to the AC power source, the

batteries are charged regardless of whether or not the anesthesia machine is currently on. In

case of power failure, the anesthesia machine will automatically be powered by the internal

batteries. When AC power source is restored within the specified time, power supply is

switched from battery to AC automatically to ensure continuous system use.

On-screen battery icon indicates the battery statuses as follows:

current charge level of the batteries in proportion to its maximum charge level.

The capacity of the internal battery is limited. If the battery capacity is too low, a high-level

alarm will be triggered and the [Low Battery Voltage!] message displayed in the technical

alarm area. In this case, apply AC power to the anesthesia machine.

: indicates that the batteries operate normally. The solid portion represents the

: indicates low battery and the batteries need to be charged.

: indicates too low battery and the batteries need to be charged immediately.

2-12

Page 35

3 System Controls and Basic Settings

3.1 Display Control

1. Alarm lamp

High level alarms: the lamp quickly flashes red.

Medium level alarms: the lamp slowly flashes yellow.

Low level alarms: the lamp turns yellow without flashing.

2. Menu shortcut key(s)

Push the menu shortcut key to access the corresponding menu.

3. Control knob

Push the control knob to select a menu option or confirm your setting. Turn the control

knob clockwise or counterclockwise to scroll through the menu options or change your

settings.

3-1

Page 36

4. MV&TVe alarm key

In case of manual ventilation mode: Push the key to switch off MV and TVe

overrange alarms and apnea alarm. Push the key again to switch on MV and TVe

overrange alarms and apnea alarm.

In case of mechanical ventilation mode: Push the key to switch off MV and TVe

overrange alarms. Push the key again to switch on MV and TVe overrange alarms.

5. Normal screen key

Push the key to close all menus displayed.

6. Standby key

Push the key to enter or exit standby mode.

7. Alarm silence key

To set alarm silence state, push this key to enter 120 s alarm silenced status. The

alarm silence symbol

and 120 s countdown time appear in the upper right

corner of the screen.

To clear alarm silence, push this key again.

8. Operating state LED

On: when the anesthesia machine is operating.

Off: when the anesthesia machine is turned off.

9. AC power LED

On: when the anesthesia machine is connected to the AC power source.

Off: when the anesthesia machine is not connected to the AC power source.

10. Battery LED

On: when the anesthesia machine is equipped with batteries and is connected to the

AC power source, and the batteries are being charged.

Off: when the anesthesia machine is not equipped with batteries or is switched off.

Flash: when the anesthesia machine is being battery powered.

11. Ventilator parameter setup shortcut key(s)

Push the parameter setup shortcut key to change the corresponding setting. Turn the

control knob to change the specific setting and push the control knob to activate the

selected setting.

12. Display screen

Refer to 3.2Display Screen for details.

3-2

Page 37

3.2 Display Screen

This anesthesia machine adopts a high-resolution color TFT LCD to display various

parameters and graphs, such as ventilation parameters and pressure/flow/volume waveforms.

Depending on how your anesthesia machine is configured, it may display gas module

parameters and waveforms, BIS parameters, BIS trend waveform, spirometry loops etc.The

following is a standard display screen. For descriptions of other screens, refer to5 User

Interface and Parameter Monitoring.

1

2 3 4 5

6

78

9

10

18

17

16

1. Ventilation mode prompt area

Displays the current ventilation mode. If manual ventilation is selected for the

bag/mechanical ventilation switch,

ventilation is selected for the bag/mechanical ventilation switch, the currently selected

mechanical ventilation mode is displayed.

is displayed in this area. If mechanical

11

12

13

14

15

2. Lung icon area

The icon

inspiration triggering is performed currently.

3. MV&TVe alarm off icon

Displays the MV&TVe alarm off icon when MV&TVe alarm is switched off.

is displayed when SIMV-VC or SIMV-PC mode is selected and

3-3

Page 38

4. Physiological alarm area

Displays physiological alarm messages.

5. Apnea alarm off icon area

Displays apnea alarm off icon

non-mechanical ventilation mode.

6. Alarm silence icon area

Displays alarm silence icon and 120 s countdown time.

7. System time area

Displays system time of the anesthesia machine.

8. Technical alarm area

Displays technical alarm messages. When multiple alarms occur, they are displayed

cyclically.

9. Power supply state icon area

Displays power source or battery icon.The icon

machine is powered by AC power source. The battery icon is displayed when the

anesthesia machine is battery powered to indicate battery capacity. For details, refer

to2.3 Batteries.

10. [Vent Mode] shortcut key Used to select mechanical ventilation mode.

11. [Alarm Setup] shortcut key

when apnea alarm is switched off in

is displayed when the anesthesia

Used to change the alarm settings for the anesthetic ventilator, gas modules or BIS

module.

12. [Screens] shortcut key

Used to set user screen.

13. [User Setup] shortcut key

Used to change the settings for TV compensation, O2 monitoring source, gas module,

BIS module, screen, sound etc.

14. [Maintenance] shortcut key

Used to perform leak test, calibrate O2 sensor and flow sensor, view trend graph, trend

table and alarm logbook, and set language, system time, pressure unit, IP address etc.

15. Timer setup shortcut key

Used to start, stop and reset the timer.

16. Parameter setup shortcut keys area

Used to set the parameters related to the selected mechanical ventilation mode. The

arrangement of the shortcut keys in this area varies depending on the selected

mechanical ventilation mode. For details, refer to 4 Operations and Ventilation Setup.

17 System prompt message area

3-4

Page 39

Displays information about system operating state.

18 Parameter&graph area

Displays the parameters, waveforms, spirometry loops, or electronic flowmeter graphs

which the anesthesia ventilator, gas module or BIS module monitors. Different types of

screens are displayed based on the actual system configuration or screen layout settings.

For details, refer to 5 User Interface and Parameter Monitoring.

3.3 Basic Settings

This chapter covers only general settings of the anesthesia machine, such as language, screen

brightness, system time etc. Parameter settings and other settings can be referred to in the

respective sections.

3.3.1 Adjust Screen Brightness

1. Select the [User Setup] shortcut key and select [Screen and Audio Setup >>].

2. Select [Screen Brightness] and select the appropriate value (ranging from 1 to 10) for

screen brightness. The value 10 is for the brightest and 1 the least bright. If the

anesthesia machine is battery powered, you can select less brightness to save battery

capacity.

3.3.2 Adjust Sound Volume

3.3.2.1 Key Sound Volume

1. Select the [User Setup] shortcut key and select [Screen and Audio Setup >>].

2. Select [Key Sound Volume] and select the appropriate value (ranging from 0 to 10) for

key sound volume. The value 0 is for audio off and 10 for the loudest.

3.3.2.2 Alarm Sound Volume

1. Select the [User Setup] shortcut key and select [Screen and Audio Setup >>].

2. Select [Alarm Sound Volume] and select the appropriate value (ranging from 1 to 10)

for alarm sound volume. The value 1 is for the lowest and 10 for the loudest.

3-5

Page 40

3.3.3 Set System Time

1. Select the [Maintenance] shortcut key → [User Maintenance >>] → [Set System

Time >>].

2. Set [Date] and [Time].

3. Select [Date Format] and toggle between [YYYY-MM-DD], [MM-DD-YYYY] and

[DD-MM-YYYY].

4. Select [Time Format] and toggle between [24 h] and [12 h].

CAUTION

z Changing date and time will affect the storage of trends and log information. It

may also cause loss of data.

3.3.4 Set Language

1. Select the [Maintenance] shortcut key and select [User Maintenance >>].

2. Select [Language] and select the desired language.

3. Restart the anesthesia machine to activate the language setting.

3.3.5 Set Unit

1. Select the [Maintenance] shortcut key and select [User Maintenance >>].

2. Select [Paw Unit] and toggle between cmH

If the anesthesia machine is configured with CO

of FiCO2 and EtCO2. For details, refer to 8 CO2 Monitoring.

O, hPa and mbar.

2

or AG module, you can set the display units

2

3.3.6 Restore Default Configurations

3.3.6.1 Restore the Factory Default Configuration of the Ventilator

To restore the factory default configuration of the ventilator, do as follows:

1. Select the [Maintenance] shortcut key → [User Maintenance >>] → [Ventilator

Defaults].

3-6

Page 41

2. Select [Ok] from the pop-up menu.

After [Ok] is selected, the following settings restore their default values:

User screen

Ventilator parameters

Alarm limits of ventilator-related parameters

O2 monitoring source

Alarm sound volume and key sound volume

Screen brightness

Paw display unit

3.3.6.2 Restore the Factory Default Configuration of the Gas Module

If the anesthesia machine is configured with CO

factory default configuration of the corresponding module. For details, refer to 8 CO2

Monitoring and 9 AG and O2 Concentration Monitoring.

or AG module, you can directly restore the

2

3.3.6.3 Restore the Factory Default Configuration of the BIS Module

If the anesthesia machine is configured with BIS module, you can directly restore the factory

default configuration of the corresponding module. For details, refer to 10 BIS Monitoring.

3.3.7 Set the IP Address of Anesthesia Information System

(CIS)

To set the IP address of anesthesia information system (CIS), do as follows:

1. Select the [Maintenance] shortcut key → [User Maintenance >>] → [Set IP

Address >>].

2. In the [Set IP Address] menu, set the correct IP address of the CIS.

3. Select [Ok] to activate the IP address setting.

3-7

Page 42

FOR YOUR NOTES

3-8

Page 43

4 Operations and Ventilation Setup

WARNING

z Before using this anesthesia machine on the patient, make sure that the system is

correctly connected and in good condition, and that all the tests described in 6

Preoperative Test are already completed. In case of test failure, do not use the

system. Have a qualified service representative repair the system.

4.1 Turn on the System

1. Connect the power cord to the AC power source. Make sure that the AC power LED is

illuminated.

2. Set the system switch to ON. Make sure that both the operating state LED and battery

LED are illuminated (the battery is being charged or fully charged).

3. The alarm lamp flashes yellow and red once in turn and then a beep is given.

4. The display shows the start-up screen and then enters the standby screen after half a

minute.

WARNING

z Do not use the anesthesia machine if it generates alarms during start-up or fails to

operate normally. Contact your service personnel or us.

4.2 Turn off the System

To turn off the system, do as follows:

1. Confirm that system use is finished.

2. Set the system switch to OFF.

NOTE

z For the first mechanical ventilation of each patient, do not exit the standby screen

if mechanical ventilation related parameters are not set properly. Adjust fresh gas

and anesthetic agent concentrations (if necessary) on the standby screen and set

ventilation parameters properly based on the patient’s conditions before applying

mechanical ventilation.

4-1

Page 44

4.3 Input Fresh Gas

4.3.1 Set O

O and Air Inputs

2, N2

1. Connect the gas supplies correctly and ensure adequate gas pressure.

2. You can control the O

O and Air flows in the fresh gas through the O

2, N2

flow controls. Readings of the gas flow can be seen on the respective electronic

flowmeter. On the left hand of the electronic flowmeters is the total flowmeter showing

the flow of the mixed gas.

The O

Turn the N

and N2O flow controls constitute a chain linkage:

2

O flow control counterclockwise to increase the N2O flow to some

2

extent. Then continuing turning the N

O flow control will cause the O2 flow control

2

to turn counterclockwise together to increase the O

flow, keeping the O2

2

concentration in the mixed gas above 25%.

Turn the O

continuing turning the O

clockwise together to decrease the N

flow control clockwise to decrease the O2 flow to some extent. Then

2

flow control will cause the N2O flow control to turn

2

O flow, keeping the O2 concentration in the

2

mixed gas above 25%.

O and Air

2, N2

NOTE

z This anesthesia machine can be used alone as a ventilator. You can adjust O2

concentration in the breathing system through the O2 flow control.

z The O2 concentration in the fresh gas may be quite different from that in the

breathing system.

z The total flowmeter is calibrated based on 100% O2. The accuracy of the

flowmeter may degrade with other gas or mixed gas.

z When viewing the readings on the total flowmeter, keep your visual angle at the

same level of the float. The reading of a same scale may vary when viewed at a

different angle.

z If the readings shown on the electronic flowmeters differ from that on the total

flowmeter, the former shall prevail and the latter is an approximate value.

4-2

Page 45

4.3.2 Set Anesthetic Agent

NOTE

z You do not need to perform this operation if inspiratory anesthetic agent is not

used.

z This anesthesia machine can be mounted with vaporizers corresponding with

halothane, enflurane, isoflurane, sevoflurane and desflurane. Only one of the five

vaporizers can be opened at a time because the vaporizers are featured with

interlock.

4.3.2.1 Select the Desired Anesthetic Agent

1. Determine the anesthetic agent to be used and then fill the vaporizer. For details, refer to

13.4.2 Fill the Vaporizer.

2. Mount the vaporizer filled with anesthetic agent onto the anesthesia machine. For details,

refer to 13.4 Install the Vaporizer.

4.3.2.2 Adjust the Concentration of Anesthetic Agent

Push and turn the concentration control on the vaporizer to set the appropriate concentration

of anesthetic agent.

NOTE

z Inspect the color of the sodalime in the canister before using the anesthetic agent.

Replace the sodalime immediately if obvious color change is detected.

z For details about how to use the anesthetic agent, refer to the Vaporizer

Instructions for Use.

4-3

Page 46

4.4 Set Ventilation Mode

4.4.1 Set Manual Ventilation Mode

1. Turn the APL valve control to adjust the pressure in the breathing system within the

appropriate range.

2. Set the bag/mechanical ventilation switch to the

prompt area displays the icon for manual ventilation mode. Besides, the system prompt

message area displays [Manual Vent.].

3. Push the O

In the manual ventilation mode, you can use the APL valve to adjust the breathing system

pressure limit and gas volume in the manual bag. When the pressure in the breathing system

reaches the pressure limit set for the APL valve, the valve opens to release excess gas.

The following figures show the Paw waveform and flow waveform in the manual ventilation

flush button to inflate the bag if necessary.

2

position. The ventilation mode

mode.

4-4

Page 47

NOTE

z When using the anesthesia machine on the patient, make sure that manual

ventilation mode is available.

4.4.2 Make Settings before Starting Mechanical Ventilation

Mode

1. Make sure that the system is Standby.

2. Set the appropriate Plimit value in the parameter setup shortcut keys area.

3. Check the ACGO switch to make sure that it is OFF.

4. Set the bag/mechanical ventilation switch to the

5. If necessary, push the O

flush button to inflate the bellows.

2

position.

NOTE

z The default mechanical ventilation mode of the anesthesia machine is VCV. Other

mechanical ventilation modes are optional. For the ventilation mode not configured

for your anesthesia machine, operations of the corresponding menu options are

disabled.

4.4.3 Volume Control Ventilation (VCV)

4.4.3.1 Description

Volume control ventilation (hereinafter referred to as VCV) mode is a basic fully-mechanical

ventilation mode. In the VCV mode, each time mechanical ventilation starts, gas is delivered

to the patient at a constant flow, which reaches the preset TV within the gas delivery time. To

ensure a certain amount of TV, the resulted airway pressure (Paw) changes based on patient

pulmonary compliance and airway resistance. In the VCV mode, as long as Paw is less than

Plimit and the gas delivery flow is kept constant, expirations starts immediately after Plimit is

reached.

In the VCV mode, you need to set [Plimit] to prevent high airway pressure from injuring the