Page 1

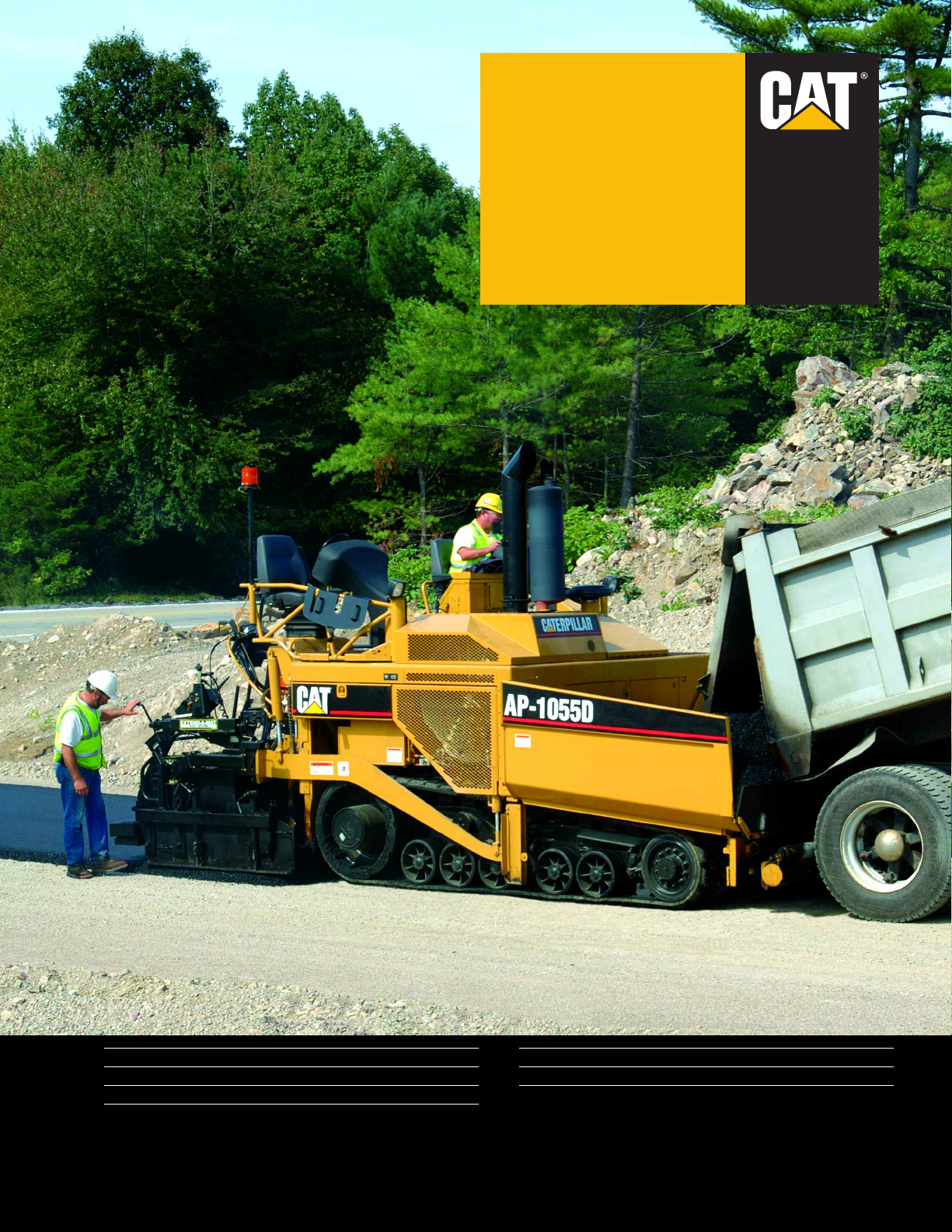

AP-1055D

Asphalt Paver

Cat®C7 Engine with ACERT®Technology

oss Power (SAE J1995)

Gr

Standard Paving Width 3.05 m (10')

Hopper Capacity 6.1 m3(13.2 tonne)

167 kW (224 hp)

215 ft3(14.5 ton)

Tractor Weight

AP-1055D with Mobil-trac™

AP-1055D with Steel Track 16 601 kg (36,600 lb)

17 601 kg (37,580 lb)

Page 2

Productivity and Reliability in a Durable Package

The AP-1055D Asphalt Paver with ACERT®Technology offers fuel efficiency, high

performance, speed and job versatility to maximize productivity.

C7 Engine with ACERT®Technology

✔

ACERT®Technology works at the

point of combustion to optimize engine

performance. ACERT®Technology

incorporates an electronic controller to

precisely deliver multiple injections of

fuel. These multiple injections are

combined with a refined air

management system in order to

generate fewer emissions and optimize

fuel combustion while meeting U.S.

EPA Tier 3 and E.U. Stage IIIa engine

emission regulations. The C7 engine is

a turbocharged, 6-cylinder diesel

engine that provides 167 kW (224 hp)

of gross power (SAE J1995) at

2200 rpm with a maximum torque of

872 N-m (643 ft/lb).

Page 4

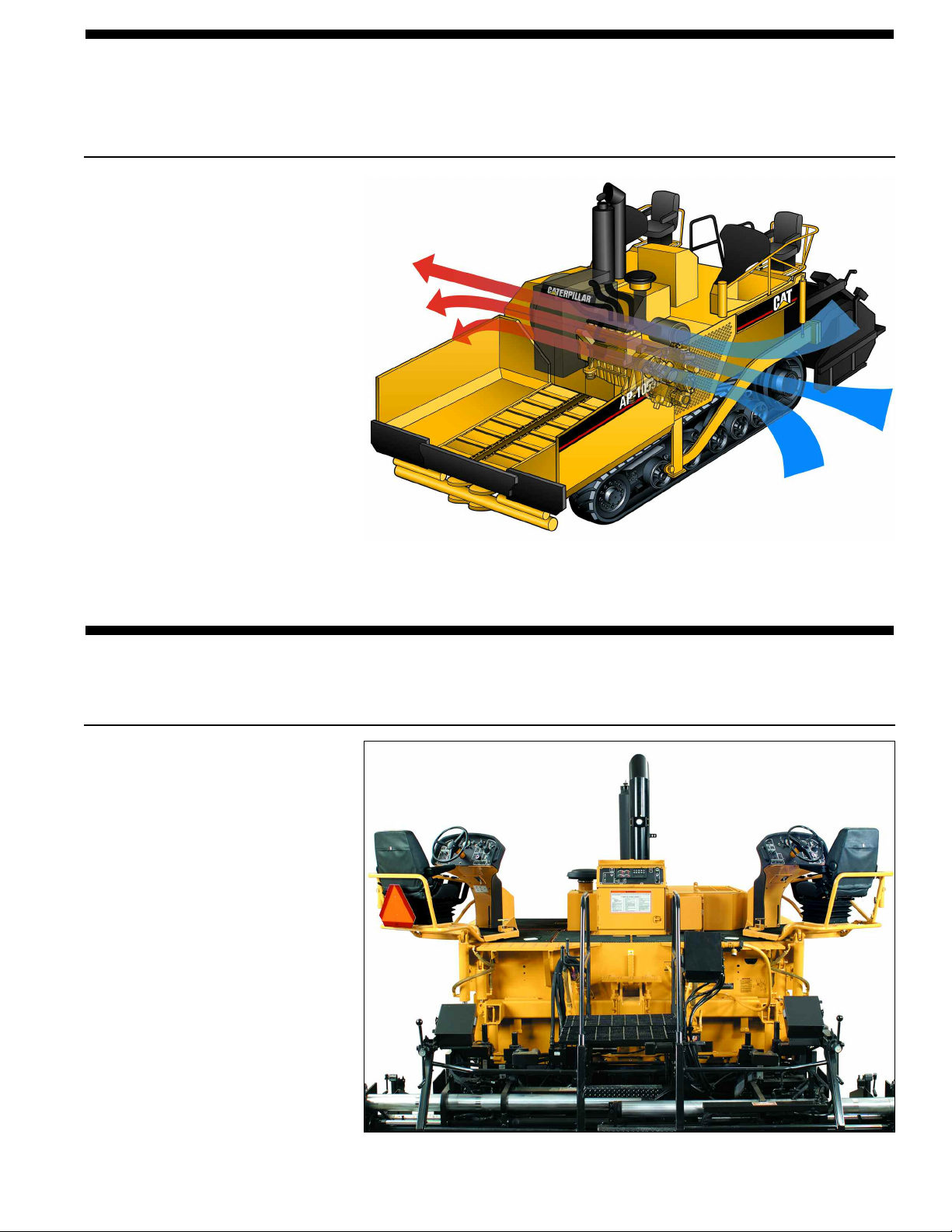

High Capacity Cooling System

✔

The high capacity cooling system

performs efficiently in high ambient

temperatures. The variable speed fan

draws air across the engine

compartment and exhausts it away

from the operator and engine

compartment in order to provide a

cooler working environment for the

tractor and screed operators.

Dual Operator Stations

✔

The AP-1055D incorporates dual

operator stations that can be rotated to

four different positions. The stations

have fully equipped consoles with

meter per minute (feet per minute)

gauges, adjustable suspension seats,

armrests and retractable seat belts. The

operator stations can be positioned

beyond the machine frame. Extending

beyond the frame provides the operator

with good visibility when paving wider

than 3.05 m (10 ft). This is important

when matching a joint or when

working along existing structures

where precise paving control is

required.

Page 5

Undercarriage Selection

✔

The AP-1055D can be purchased with

either the Mobil-trac™ undercarriage

or the steel track undercarriage. The

Mobil-trac

traction and flotation benefits of a

crawler undercarriage with the

mobility, speed, and ride characteristics

of a wheel paver. The steel track

undercarriage incorporates track rollers

and a rear bogey system in order to

provide a smooth ride.

Page 6, 7

™ system combines the

Page 5

✔ New feature

Performance and reliability you can

depend on.

Based upon the industry-proven reputation of the

Caterpillar

AP-1055D establishes new standards for productivity and reliability in the asphalt

paver industry.

Durable, field proven powertrain, propel system and material handling system along

with the world’s largest and most dedicated dealer support system ensure the

AP-1055D will provide maximum return on investment.

2

®

AP-1050B and AP-1055B Asphalt Pavers, the

Page 3

Hydrostatic Drive System

The hydrostatic drive system

eliminates chains and other mechanical

linkages between the diesel engine and

final drive components.

hydrostatic propel system incorporates

pave, travel and maneuver modes for

maximum efficiency and versatility.

The speed control system maintains

preset paving speeds throughout the

job. The machine controller provides

accurate control of the steering and

propulsion systems, and ensures

straight-line tracking.

Page 7

A closed-loop

Gateless Feeder System

The AP-1055D provides precise mix

delivery through the most advanced

material handling system. This

exclusive feature reduces component

wear and minimizes the potential for

mix segregation.

Page 8, 9

Generator (Optional)

The generator is integrated within the

machine frame and is located below

the operator platform, between the dual

operator stations.

generator provides power to the

electrically heated screed and the

auxiliary power panel. A single control

switch located on the tractor’s center

control console activates the generator.

Page 10

Auxiliary Power Panel (Optional)

The optional auxiliary power panel is

available for simultaneous use with the

electric screed. The auxiliary power

panel supplies power to four, 120-volt

and two, 240-volt receptacles. The

120-volt receptacles are protected with

ground fault circuit interruption

(GFCI).

Page 10

This integrated

Serviceability

Simplified service means more paving

time and less maintenance time. Large

swing-open doors and panels provide

convenient access to service areas.

ransverse engine mounting provides

T

ground-level access to hydraulic pumps

and the engine cooling system.

Color-coded and numbered wiring

simplifies troubleshooting of the

electrical systems. The standard

500-hour engine oil change interval

increases machine

up-time.

Page 12

3

Page 4

Cat®C7 Engine with ACERT®Technology

ACERT®Technology incorporates a series of innovations working at the point of

combustion to optimize engine performance while meeting U. S. EPA Tier 3 and

E. U. Stage IIIa engine emission regulations.

urbocharged and Air-To-Air

T

Aftercooling (ATAAC)

The turbocharged air-to-air aftercooling

system provides high horsepower with

increased response time while keeping

exhaust temperatures low for long

hours of continuous operation.

Air-to-air aftercooling keeps air intake

temperatures down, maximizing fuel

efficiency and minimizing emissions.

Cat®C7 Engine with ACERT®Technology

The C7 engine provides a full-rated

gross power (SAE J1995) of 167 kW

(224 hp) at 2200 rpm with a torque of

872 N-m (643 ft/lb). The combination

of large displacement and high torque

allow the AP-1055D to perform under

the toughest conditions.

HEUI Fuel Injection

The HEUI™ fuel system is unique and

combines the technical advancement of

an electronic control system with the

simplicity of HEUI fuel injection. The

HEUI fuel system excels in its ability to

control injection pressure over the entire

engine operating speed range. These

features allow the C7 engine to have

complete control over injection timing,

duration and pressure.

Multiple Injection Fuel Delivery

Multiple injection fuel delivery involves

a high degree of precision. Precisely

shaping the combustion cycle lowers

combustion chamber temperatures,

which generates fewer emissions,

optimizes fuel combustion and

translates into more work output for

your fuel cost.

High Cylinder Pressures

High cylinder pressures combined with

tightly controlled tolerances promote

extremely efficient fuel burn, less

blow-by and lower emissions.

C7 Cylinder Block

The C7 engine’s cylinder block offers

increased tensile strength. It features

improved sealing with gaskets to ensure

fewer leaks. This new design supports

the engine’s higher compression ratios

and increases its power density. The

incorporation of straight-thread “O” ring

connection points reduce the loss of

engine oil and fluids.

Sound Reduction Features

The C7 engine sound reduction features

include composite valve covers with a

fully isolated base, a steel oil pan and a

cast iron front cover. The HEUI™ fuel

systems rate-shaping technology also

provides control of sound and vibration

levels.

Service, Maintenance and Repair

Easier service, maintenance and repair

is accomplished by monitoring key

functions and logging critical indicators.

Advanced electronic diagnostic

capabilities are possible using CAT

echnician.

Electronic

T

®

ADEM™ A4 Electr

The ADEM A4 electronic control

module manages fuel delivery, valve

timing and airflow to get the most

performance per liter (gallon) of fuel

used. The control module provides

flexible fuel mapping, allowing the

engine to respond quickly to varying

application needs. The control module

also monitors engine and machine

conditions while keeping the engine at

peak efficiency.

onic Control Module

4

Page 5

High Ambient Temperature Cooling System

The standard, high-capacity cooling system provides efficient operation in high ambient

temperatures. The new system design also provides quiet operation that benefits the

operator and the surrounding environment.

flow

Air

The airflow design draws ambient air

across the engine compartment and

through the radiator. This new design

allows the exhaust air to exit the right

side of the machine in order to provide

a cooler engine compartment and

operator platform.

High Capacity Cooling Package

The high capacity cooling system

allows the fan to run slower, reducing

power demand while extending

component life.

Variable Speed Fan

The variable speed fan is electronically

controlled and hydraulically driven to

provide on-demand cooling. This

on-demand operation reduces engine

power demand and provides quiet

operation.

Dual Operator Stations

The dual operator stations provide complete control and good visibility from either side of

the operating platform.

Dual Operator Stations

The dual operator stations incorporate

fully equipped consoles with meter per

minute (feet per minute) gauges,

adjustable suspension seats, armrests

and retractable seat belts.

Operator Visibility

The dual operator stations can be

positioned in one of four dif

locations to provide optimum visibility.

The stations can extend beyond the

machine frame for good visibility when

joint matching or while paving other

applications where precise control is

required.

Center Control Console

The center control console includes

analog gauges, switches and a digital

display for machine functions. The

center console also houses a majority

of the electrical components for fast,

easy service.

ferent

5

Page 6

Mobil-trac™ Undercarriage

The Mobil-trac undercarriage provides superior durability while delivering unmatched

mobility and traction.

Mobil-trac™ Under

The Mobil-trac undercarriage combines

the flotation and traction benefits of a

crawler suspension with the mobility

and ride quality of a wheel-type paver.

Durable Mobil-trac™ Belt

The Mobil-trac system includes a

durable, high strength rubber track belt

with a thick outer cover and five

internal layers of flexible steel cable.

Large Ground Contact Area

The Mobil-trac’s ground contact area is

3020 mm (119") long and 457 mm

(18") wide. This large footprint

provides even weight distribution over

the entire length of the belt.

Two Speed Planetary Drive

A fixed displacement motor drives a

two-speed planetary providing quick

mobility around the job site.

Friction Drive

A hydraulic tensioning cylinder with an

accumulator maintains friction between

the Mobil-trac belt and the drive wheel

in order to provide drive traction.

Manual adjustment of track tension is

not required.

carriage

Rubber Coated Steel Mid-Wheels

The fully bogied undercarriage

provides low maintenance and long

life.

Belt Tensioning

System

Mobil-trac™ Belt

Two-Speed

Planetary

Friction Drive

Wheel

Fully Bogied

Undercarriage

Rubber-Coated

Steel Mid-Wheel

6

Page 7

Steel Track Undercarriage

The steel track undercarriage provides even weight distribution, good tractive effort and

dependable performance.

Quad Rear Bogey

A special quad bogey is positioned

near the rear of the steel track in order

to evenly distribute the load. The steel

track system includes hydraulic

cylinders to provide automatic

tensioning.

Track Rails

The steel track system incorporates D3

dozer track rails. The sealed and

lubricated links include a split master

link for dependable performance.

Bonded Track Pads

The track pads contain a special rubber

compound in order to provide long life

and good traction. The pads are

attached with two bolts for easy

replacement.

Single Speed Planetary Drive

A variable displacement motor drives a

single-speed planetary in order to

provide infinitely variable speed

selection.

Bonded Track

Pads

Track Tensioning

System

D3 Track

Rails

Single

Speed

Planetary

Quad Rear

Bogey

Hydrostatic Drive System

Efficient hydrostatic drive system eliminates chains and other mechanical linkages between

the engine and final drive components.

Closed-Loop Hydrostatic Propel

System

The propel system incorporates pave,

travel and maneuver modes for

maximum versatility

Propulsion Control

The machine controller provides

accurate control of steering and

propulsion systems and ensures

straight-line tracking.

Speed Control

A speed control dial located on each

operator station allows the operator to

set a maximum travel speed. When the

propel lever is positioned in the

full-forward position the paver will

travel at the pre-set speed. Each station

includes a meters per minute

(feet per minute) gauge.

.

Propel Motors

Planetar

Drive

y

Machine

Controller

Hydraulic

ank

Oil T

Propel Pumps

Electrical

Junction Box

7

Page 8

Exclusive Material Delivery System

Productivity and quality enhancements are built-in features.

The AP-1055D provides precise mix delivery with minimal

operator monitoring through the most advanced material

handling system.

Left and right feeders in addition to the left and right augers

are controlled independently. The ability to control these four

components separately

eliminates the need for feeder gates.

In order to control mix delivery, the operator sets a speed rate

for each feeder that will maintain the desired mix level in the

left and right auger chambers.

, through a machine controller,

Outboard Feeder Drives

Increased live tunnel area

provides easy servicing.

The feeders have outboard mounted

motors, reducers and feeder drive

chains to maximize the live feeder

tunnel area and reduce center line

segregation. This design also provides

greater ease of servicing the feeder

drive system.

Once the feeder speeds are set, the ratio of feeder speed to the

maximum auger speed is automatically maintained by the

machine controller

the job progresses.

This ratio control capability is particularly helpful when

paving wider on one side of the machine than on the other

Each feeder can be set at a specified speed to deliver the

proper amount of mix that is needed.

, even though the propel rate may change as

.

Outboard Feeder

Drive Motors

Right Feeder and

Auger Drive Pumps

8

Page 9

Gateless Feeders

Variable speed feeders precisely control mix delivery while reducing wear and segregation.

The gateless feeders on the AP-1055D

always run full of mix regardless of the

speed required to fill the auger chamber.

This is typically a slower speed than

would be experienced with a paver

utilizing feeder gates to control mix

delivery rates. By not always having to

run at full speed, feeder component

wear is significantly reduced.

When changes in feeder speed are

required, delivery of mix to the augers is

immediate. This is in contrast to pavers

with gates, where any delivery rate

change is delayed for the length of time

it takes to clear the tunnel of mix from

the previous gate setting.

Running at slower speeds can also help

reduce the opportunity for segregation,

especially when working with larger

stone mixes that have more of a

tendency to segregate.

Feeder Design

Tunnel construction

improves mix flow.

The AP-1055D auger drive assembly is

independent of the tractor which allows

the distance between the two feeders to

be significantly reduced. Keeping the

feeders close together allows the flow

from both feeders to blend together

more easily as they discharge into the

auger cavity. The tunnel and auger

designs eliminate voids under the chain

case to minimize segregation.

Auger Drive Motors

Left Feeder and

Auger Drive

Pumps

Auger Assembly

Provides mat consistency while minimizing segregation.

The auger assembly height can be

hydraulically adjusted 192 mm (7.6").

The ability to raise the auger assembly

simplifies loading and unloading from a

transport vehicle. Also, when working

with larger stone mixes, segregation can

often be eliminated or minimized by

raising the augers to allow mix to flow

unrestricted under the auger assembly.

9

Page 10

Optional Generator System

The high capacity, integrated generator ensures peak performance and high reliability.

Industrial, Single-Phase Generator

The 24 kW generator is hydraulically

driven through a load-sensing,

pressure-compensating pump providing

quiet operation.

Single Control Switch

A single switch on the tractor’s

operating console activates the

generator. The generator operates at

1800 rpm and includes GFCI

protection.

Full Power

Full power is provided to the electric

screed and auxiliary power panel while

the engine is operating at low idle

A control manifold and internal

speed.

voltage regulator maintains constant

frequency and voltage at both high and

low idle.

Optional Auxiliary Power Panel

The auxiliary power panel provides efficient power for night-time lighting and other

job site power needs.

Optional Auxiliary Power Panel

The power panel provides 8 kW of

power and includes four 120-volt

receptacles protected by ground fault

circuit interruption (GFCI) and two

240-volt receptacles.

Power Needs

The auxiliary power panel can be used

to supply power for night-time lighting

and job site work tools.

Auxiliary Power Panel Door

The panel door can remain closed

while power cords are attached to the

receptacles providing effective

protection.

10

Page 11

Electric Heat Screeds

The AS-2301 and Extend-A-Mat®10-20B screeds are available with an electric heating

system.

Thermal Image of Electric Heat Screed Plate at Target Temperatures

Operator Friendly Environment

The electric screed plate heating

system eliminates the use of diesel fuel

burners, creating a user friendly

environment.

Fast Warm-Up Time

The electric screed provides a warm-up

time in 30 minutes or less to 122° C

(220° F) when ambient temperatures

are at or above 22° C (40° F).

Simple Operation

The screed control panel incorporates

touch-pad technology with high

intensity LED’s that promote

simplified use and diagnostic capability

with minimal operator training.

Multi-Zone Heating Elements

The heating elements are mounted to

the screed plates in a multi-zone

configuration to provide even heat

distribution.

Thermostatically Controlled

The screed plates incorporate

thermostatically controlled temperature

sensors in each screed section

including the extenders. The

temperature sensors provide inputs to

the screed controller.

* Refer to the Screed Specalogs for

more detailed information.

11

Page 12

Serviceability

Simplified service means more paving and less maintenance time.

Electronic Monitoring System (EMS-III)

EMS-III simplifies calibration of

hydraulic and electrical systems and is

compatible with CA

Technician (CAT ET).

Large Access Doors and Panels

Preventative maintenance points can be

accessed through the large swing open

access doors and panels.

Remote Lubrication Points

Grease fittings are grouped to provide

quick, routine service of bearings.

Quick-Connect Sampling Ports

The quick-connect ports simplify

retrieval of critical fluids for diagnosis.

Color-Coded and Numbered Electrical

System

Troubleshooting is efficient and

simplified with the color-coded and

numbered electrical system.

®

T

Electronic

Optional Equipment

Tractor Options

• Auger and Mainframe Extensions

• Oscillating Push Rollers

• Truck Hitch

• Generator

• Auxiliary Power Panel

• Ventilation System

• Decelerator Pedals

• Sonic Feeder Sensor or Proportional

Paddle Sensor

• Steering Guide

• Warning Beacon

• Umbrella

• Uptime Kit

• Washdown System

Controls and Grade References

• Automatic Grade and Slope Control

• Non-Contacting Sonic Grade Sensor

• Contacting Grade Sensor

• Outboard Leveler, 9.15 m (30') and

12.2 m (40')

• Inboard Leveler

• Mobile Stringline

• Fore ‘N Aft Leveler

• Sonic Averaging Beam

• Rigid Ski, 9.15 m (30') and 12.2 m

(40')

Screed Choices

• Extend-A-Mat®10-20B

(electric or diesel)

• Extend-A-Mat®10-20WB

(diesel only)

• AS-2301 (electric or diesel)

• Pavemaster 10B (diesel only)

* Reference Screed Specalogs for

detailed information.

12

Page 13

Engine

The Caterpillar®C7 engine with

ACERT®Technology is a six cylinder,

turbocharged, diesel engine. The

engine meets U.S. EPA Tier 3 and EU

Stage IIIa engine emission regulations.

Engine Cat®C7

Gross Power kW hp

SAE J1995 167 224

Net Power kW hp

ISO 9249 166 223

EEC 80/1269 166 223

SAE J1349 165 221

Specifications

Bore 110 mm 4.33"

Stroke 127 mm 5.0"

Displacement 7.24 L 441.7 in

• The power ratings apply at a rated

speed of 2200 RPM when tested

under the reference conditions for the

specific standard.

• The net power advertised is the

power available at the flywheel when

the engine is equipped with

alternator, air cleaner, muffler and fan

at minimum speed.

• The net power at the flywheel when

the fan is at maximum speed is

151 kW (202 hp) per the SAE J1349

reference conditions.

• Derating is not required up to an

altitude of 2134 m (7,000 ft).

Suspension

The high-speed Mobil-trac™

undercarriage consists of a durable,

high-strength rubber belt with a thick

outer cover that includes five internal

layers of flexible steel cable.

is 3023 mm (119") long and 457 mm

(18") wide. Drive traction is provided

by a hydraulic tensioning cylinder with

accumulator that maintains friction

between the belt and the drive wheels.

Rubber-coated steel mid-wheels

provide smooth ride and high traction

efficiency by distributing weight over

the entire length of the belt.

The steel track undercarriage consists

of four 241 mm (9.5") diameter track

rollers, a special rear, four roller

152 mm (6") diameter bogey, and two

3

152 mm (6") diameter single roller

return idlers per side. Rollers are

bogied in pairs and each pair is

articulated for optimum leveling

capability. Rollers ride on Caterpillar

D3 track rails. Track rails are sealed,

lubricated and include a split master

link for quick track removal and

installation. The 3048 mm (120")

tracks are fitted with 127 mm (5") by

356 mm (14") rubber bonded track

pads. Track tensioning is provided by a

parallel link swing arm design that

provides constant hydraulic pressure.

Track tension is maintained without

manual adjustment. Recoil forces are

controlled by check and relief valves.

The track

Drive System

The Mobil-trac™ drive system utilizes

two dual path hydrostatic pumps and

two fixed displacement motors. The

pumps are infinitely variable with

electronic displacement controls (EDC)

for steering and speed. Single speed

motors drive two speed planetary gear

boxes to provide two propel ranges.

The drive system is equipped with two

switches located at the operator

stations. The two switches are used as

manual overrides and are directly

linked to EDC’s.

The steel track drive system utilizes

two dual path hydrostatic pumps and

two variable displacement motors. The

pumps are infinitely variable with

electronic displacement controls (EDC)

for steering and speed. The two speed

motors drive single speed planetary

gear boxes to provide two propel

®

ranges. The drive system is equipped

with two switches located at the

operator stations. The two switches are

used as manual overrides and are

directly linked to EDC’s.

Forward Speed Ranges

Paving

Mobil-trac 0-67 mpm 0-220 fpm

Steel Track 0-78 mpm 0-255 fpm

Travel

Mobil-trac 0-15 km/hr 0-9 mph

Steel Track 0-8 km/hr 0-5 mph

Electrical System

The 24-volt electrical system utilizes

two 12-volt batteries and a 24-volt,

100-amp alternator. The wiring is

color-coded and number impregnated

for easy servicing. Electrical wiring is

protected by vinyl-coated nylon

braiding for greater durability. Circuit

breakers located on the front side of

the center console include manual

resets.

13

Page 14

Feeders and Augers

Dual feeders and augers are controlled

through variable speed hydrostatic

drives and operate independently of

forward speed. Right and left side

feeders operate independently of each

other. Feeder drive and drive chains are

located outside the mainframe for easy

accessibility.

Feeder flights are constructed of

heavy-duty bushed roller chain with

forged steel flight bars sliding over

replaceable, abrasion-resistant drag

pans with 360-440 Brinell hardness.

Long life auger system consists of

segmented, 406 mm (16") diameter,

cast Ni-Hard steel hemi-screw augers.

Auger and hanger bearings have builtin steel shields for greater protection.

Augers are driven independently by

two motors. Each auger is controlled

by an adjustable material flow switch.

Manual override is provided. Auger

height is hydraulically adjustable

192 mm (7.6").

Ventilation System

The ventilation system helps remove

asphalt gas, vapors and fumes from the

auger chamber area. The system

consists of a hydraulically driven

exhaust fan, ducts and exhaust stack to

vent asphalt gas, vapors and fumes

away from the operator and screed

areas. The design provides good

visibility to the feeders and a cooler

operating environment.

Operator Stations

The operator stations include dual

control consoles, each with lockable

vandal cover, steering wheel, meter per

minute (feet per minute) gauge, auger

raise/lower switch, hopper raise/lower

switch, left and right feeder

f/man switch, left and right

auto/of

feeder speed control dial, left and right

auger auto/off/man switch, manual

auger reverse switch, screed vibrator

switch, engine start switch, propel

forward/reverse control lever,

pave/travel/maneuver speed range

selection switch, horn, maximum speed

control dial, secondary brake switch,

screed lift switch up/down, extender

in/out switches and engine speed

switch.

The center control console includes the

power key switch, left and right

console selection switch, warning

beacon switch, working light switch,

generator switch, screed

counterbalance switch and the horn

button. Analog gauges are provided for

engine coolant temperature, engine oil

pressure, hydraulic oil temperature and

fuel level. An electronic monitoring

system (EMS-III) with horn and light

indicators monitor the left track

pressure, right track pressure, system

voltage, engine temperature, operator

error, hydraulic oil level, propel

system, charge filter, material feed and

screed plate heat. A digital display

provides engine rpm, service code

information, hour meter, gear selection

and meter per minute (feet per minute).

Service Refill Capacities

Liters Gallons

Engine Oil w/filter

Fuel Tanks (Dual) 462 122

Hydraulic Oil

Cooling System 36 9.5

Tank 149 39.4

26 6.8

Steering

Hydraulic power assist steering system

provides smooth, low effort steering by

means of a steering wheel. Electric

over hydraulic dual path differential

steering assures precise machine

control. Steering commands are

independent of propel speed.

Three steering modes including pave,

travel and maneuver are selectable at

the operator consoles. When in the

pave or travel mode, the steering range

is electrically reduced to minimize

abrupt steering movements. When in

maneuver mode, the steering system is

at full range, allowing the paver to

pivot-turn by counter-rotating the

tracks.

Inside Turning Radius:

914 mm (3')

Brakes

The service braking system consists of

a closed-loop, hydrostatic system that

provides dynamic braking.

14

The secondary braking system includes

a spring applied, hydraulically released

brake which is actuated by a switch on

each operator console.

Page 15

Dimensions

AP-1055D

A Tractor length w/push roller 4.77 m (15' 8")

B Length with push roller and screed

Length with truck hitch and screed 7.03 m (23' 1")

C Transport width with end gates and 10-20B screed (hopper raised) 3.33 m (10' 11")

Transport width with end gates and AS-2301 screed (hopper raised) 3.38 m (11' 1")

Transport width without end gates and 10-20B screed(hopper raised) 3.05 m (10')

ransport width without end gates and AS-2301 (hopper raised) 3.23 m (10' 7")

T

D Tractor operating width (hopper lowered) 3.31 m (10' 10")

E Operating height with ventilation system 3.55 m (11' 8")

F Transport height with muffler, fumes stack and seat lowered 2.82 m (9' 3")

G Truck dump height 658 mm (26")

H Push roller height 533 mm (21")

I Hopper length 2.00 m (6' 7")

J Truck entry width 3.22 m (10' 7")

I

E

6.54 m (21' 6")

F

G

H

A

B

D

J

C

Weights (approximate)

AP-1055D Mobil-trac

Tractor: (includes generator) 17 061 kg (37,580 lb) 16 601 (36,600)

with Extend-A-Mat®10-20B (diesel heat) 20 477 kg (45,130 lb) 20 044 (44,150)

with Extend-A-Mat 10-20B (electric heat, includes generator)

with AS-2301 (diesel heat) 20 621 kg (45,420 lb) 20 175 (44,440)

with AS-2301 (electric heat, includes generator) 20 602 kg (45,380 lb) 20 139 (44,400)

20 330 kg (44,780 lb)

AP-1055D specifications

AP-1055D Steel

19 867 (43,800)

T

rack

15

Page 16

Caterpillar offers a comprehensive line of Asphalt Pavers

Contact your local Caterpillar®dealer to learn more about the complete line of Caterpillar

Paving Products.

®

The AP-1000D Wheel Asphalt Paver

Gross power (SAE J1995) 167 kW 224 hp

Tractor weight* 14 741 kg 32,470 lb

Standard paving width 3.05 m 10'

* Tractor weight includes generator and auxiliary power panel.

The AP-655C Mobil-trac™ Asphalt Paver

Gross power

Tractor weight* 15 690 kg 34,560 lb

Standard paving width 2.44 m 8'

* Tractor weight includes generator and auxiliary power panel.

130 kW

174 hp

The AP-800D Wheel Asphalt Paver

Gross power 97 kW 130 hp

Tractor weight* 13 307 kg 29, 310 lb

Standard paving width 2.44 m 8'

* Tractor weight includes generator and auxiliary power panel.

The AP-650B Steel Track Asphalt Paver

Gross power

Tractor weight 13 917 kg 30,655 lb

Standard paving width 2.44 m 8'

97 kW

130 hp

QEHQ1114 (2/05)

© 2005 Caterpillar

All Rights Reserved.

Featured machines in photography may include optional equipment.

Materials and specifications are subject to change without notice.

www

.cat.com

Loading...

Loading...