Page 1

Engine

Engine Model Cat®3516B HD EUI

Gross Power – SAE J1995 1176 kW 1,577 hp

Operating Specifications

Operating Weight 195 434 kg 430,858 lb

Rated Payload – Standard 35 tonnes 38 tons

Rated Payload – High-Lift 32 tonnes 35 tons

Rated Payload – Super High Lift 32 tonnes 35 tons

994F

Wheel Loader

®

®

Page 2

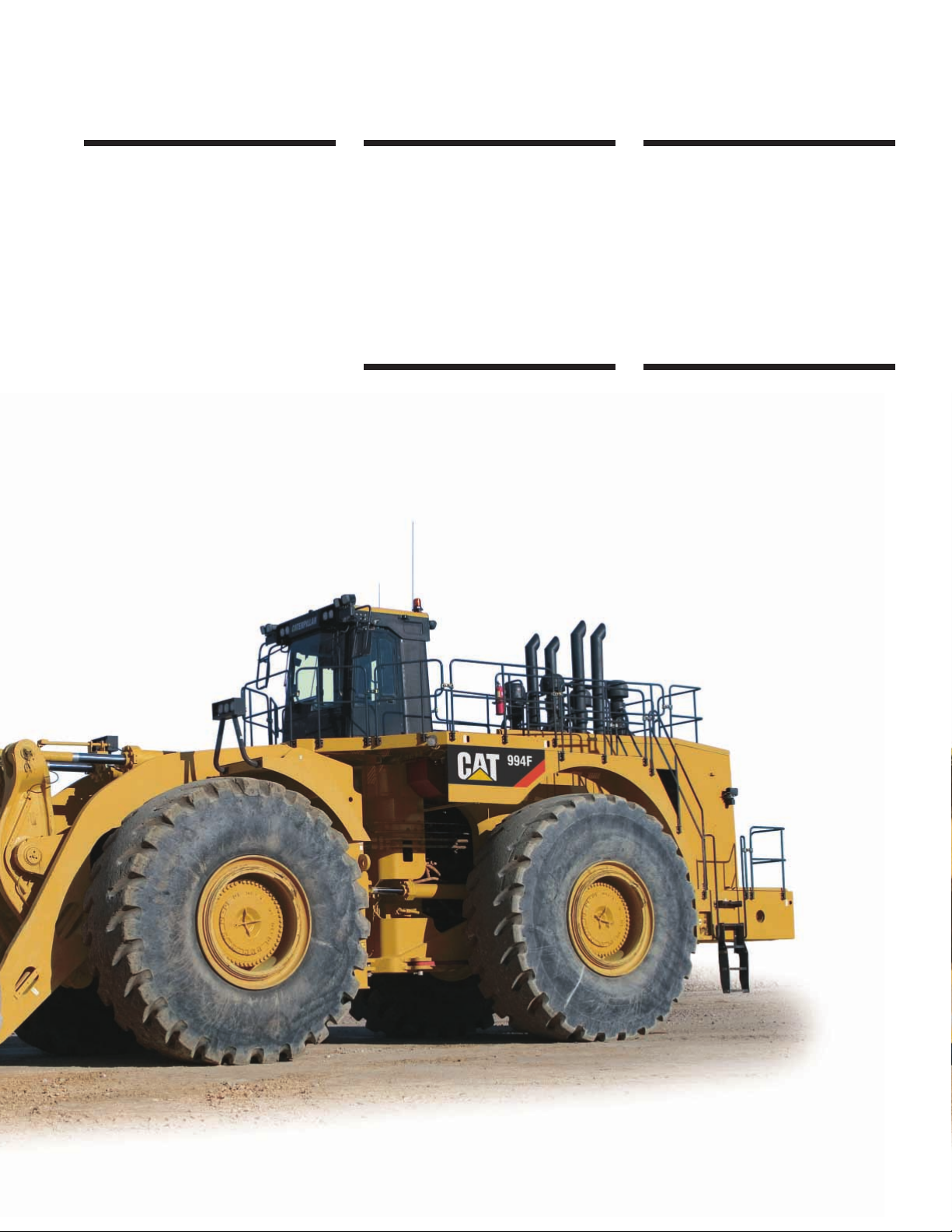

2

994F Wheel Loader

Powerful, responsive and rugged, the 994F sets the standard for high productivity

and durability.

Designed for maximum productivity, the

994F builds on its productive tradition

with innovations that enhance performance,

reliability, durability and operator comfort,

to lower your cost-per-ton.

Customer Support

Your Cat dealer offers a wide range

of services that can be set up under a

customer support agreement when you

purchase your equipment. To help you

get the best return on your investment,

the dealer will help you choose a plan

that can cover everything from machine

and work tool selection to replacement.

pg. 15

Serviceability

The 994F is designed for quick and

easy service. Most routine service can

be accomplished from ground level and

diagnostic ports have been clustered

to improve efficiency. pg. 14

Hydraulics

Powerful Cat hydraulics deliver the

power and control needed to keep

material moving. Technologically

advanced system provides precise,

low-effort control and trouble-free

operation. Unique filtration system

prevents cross contamination. pg. 8

Structures

Structural components are the backbone

of the 994F’s durability. The heavy

duty box-section loader frame creates

a durable, rugged machine. Solid steel

lift arms resist twisting for maximum

durability and reliability. pg. 6

Power Train

The Cat®3516B HD EUI engine

delivers high horsepower to maximize

productivity. Field proven for reliable

performance in the most demanding

applications, the 3516B HD EUI

offers superior fuel efficiency, lower

emissions, reduced engine noise and

lower operating costs. pg. 4

Page 3

3

Safety

Caterpillar has been and continues

to be proactive in developing mining

machines that meet or exceed safety

standards. Safety is an integral part

of all machine and systems designs.

pg. 17

Matched Systems

An efficient loading/hauling system

starts with a perfect match. Your Cat

dealer can help you build an optimum

system to maximize truck payloads,

minimize loading time, and lower your

cost-per-ton. pg. 16

VIMS®Vital Information

Management System

Intelligent Caterpillar®designed machine

monitoring system, provides critical

machine health and payload data to keep

the 994F performing at top production

levels. pg. 12

Operator’s Station

The ergonomically designed cab

promotes a new level of operator

spaciousness and comfort, while

making it easier for the operator to

achieve maximum productivity over

extended shifts. Controls are positioned

within easy reach for superior control

and reduced fatigue. pg. 10

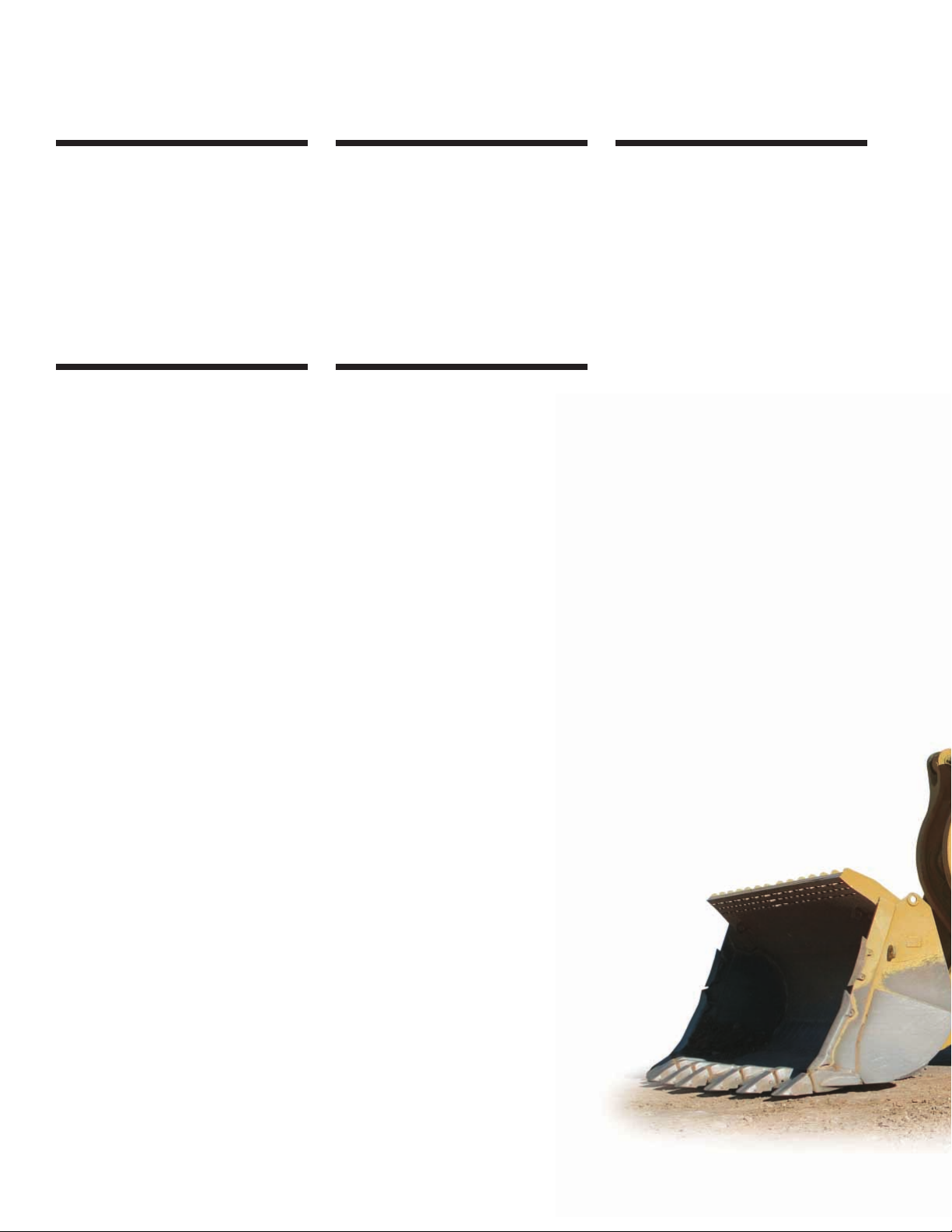

Buckets and Ground Engaging Tools

Aggressive Cat buckets are designed

for optimal loadability and structural

reliability. A wide selection of buckets

and ground engaging tools provide

a match for every application and

material condition to maximize

productivity. pg. 9

Page 4

Engine. Field-proven Cat®3516B HD

EUI (High Displacement) turbocharged

and aftercooled diesel engine delivers

high power and reliability in the world’s

most demanding mining applications.

The 3516B is a 16-cylinder, four-stroke

design and uses long, effective power

strokes for more complete fuel

combustion and optimum efficiency.

Engine Features.

• Three-ring, two-piece pistons with

high strength forged steel crowns

and lightweight aluminum skirts.

• Steel-backed, copper-bonded

aluminum bearings.

• Uniflow cylinder head design with

four alloy steel valves per cylinder.

• High carbon steel alloy crankshafts

with hardened journals.

• Pressure lubrication with full-flow

filtered oil and heat exchanger

oil cooler.

• Direct-electric 24-volt charging

system.

High Torque Rise. With 32% torque

rise, the 3516B HD EUI delivers high

lugging forces during digging and

acceleration in high rimpull conditions

for maximum efficiency and fast cycle

times.

Enhanced Life. High displacement, low

rpm rating and conservative horsepower

ratings mean more time in the field and

less time in the shop.

Electronic Control Module (ECM).

The ECM is the electronic “brains” of

the power system. Computerized system

senses operating conditions and power

requirements and adjusts engine for

most efficient operation at all times.

Electronic Unit Injection (EUI).

The electronically controlled unit

injection fuel system senses operating

conditions and regulates fuel delivery

for optimum fuel efficiency.

High Displacement (HD). The high

displacement engine has a longer

stroke, high power range and better

fuel efficiency.

4

Cat®power train delivers smooth, responsive performance and reliability in tough

conditions.

Power Train

Page 5

Advanced Diesel Engine Management.

ADEM™ system controls fuel injector

solenoids to start and stop fuel injection

for superior performance, greater

reliability, cold start protection, automatic

altitude compensation and air filter

restriction indication.

Separate Circuit Aftercooler.

Allows aftercooler circuit to operate

cooler than jacket water temperature

for a denser air charge and greater

combustion.

Ether Starting Aid. Ensures reliable

start-up in extreme cold operating

conditions.

Cat Planetary Power Shift

Transmission. Features heavy duty

components to handle the toughest

jobs. Electronic controls allow smooth

shifting for greater productivity,

durability and longer component life.

Impeller Clutch Torque Converter (ICTC).

Electronically controlled impeller clutch

torque converter provides maximum

flexibility in regulating optimum rimpull

in all conditions for smoother operation.

Inching Capability. Left brake pedal

operation allows the operator to reduce

rimpull to 25% then brake for more

precise inching when approaching a

truck or making directional changes.

Rimpull Control. Allows operator to

adjust maximum rimpull from 100%

down to 90, 85, 75 and 65% using a

four-position dial while in first gear.

Matching rimpull to job conditions

provides greater traction in slippery or

rough conditions for better performance

and longer tire life.

Stable Design. Low mounted heavyduty power train components ensure

a stable machine.

Proven Reliability. The 994F power

train has proven itself with the most

reliable and durable components in

the industry for the lowest operating

cost-per-ton.

Torque. Torque is developed at the

wheel, generating less stress and wear

on the axle shafts.

Axles. The front axle is fixed, and the

rear axle oscillates ±10°, which allows

either rear wheel to rise or fall 677 mm

(26.7 in) while all wheels remain on the

ground for maximum stability, greater

traction and a more comfortable ride.

Differentials. Standard conventional

differentials allow one tire to spin faster

than the other, keeping developed

torque out of the axles.

Axle Shafts. Free-floating axle shafts

can be removed independently of the

wheels and planetaries for quick and

easy servicing.

U-Joints. Permanently lubricated for

greater durability and long service life.

Only the slipjoint requires manual

lubrication.

Oil-Cooled Disc Brakes. Four-wheel,

fully hydraulic oil-cooled multiple

disc brakes are completely sealed and

adjustment free. Two brake pedals

allow standard braking with right pedal

plus rimpull modulation braking with

left pedal.

Brake Cooling. The brake oil cooler

provides additional cooling to the brake

discs for greater durability.

Filtration. Screens on the brake circuit

minimize the risk of contamination.

Parking/Secondary Brake. Manual,

spring-applied, multiple dry-disc brake

is located on the front driveline for

protection from contamination.

Monitoring system alerts operator if

transmission is engaged while parking

brake is applied, and if the pressure

drops, the parking brake is

automatically applied.

Engine Cooling. New Generation

Modular Core Radiator (NGMR)

significantly improves heat rejection

through the use of copper cooling cores

and improved flow characteristics.

Final Drives. The all-wheel drive design

features four planet carrier gears with

planetary double reduction in each wheel

for superior reliability. Planetaries can

be removed independently of the wheels

and brakes for quick and easy servicing.

Duo-Cone®Seals. Seals out dirt and

contamination to extend component life.

5

Page 6

Robust Structures. The 994F front

loader frame features robust structural

components for outstanding durability

in the toughest loading conditions.

The frame is the backbone of the 994F’s

durability and is specifically designed

and manufactured to withstand the higher

forces required by the machine’s

increased payload rating.

Frame. The box-section rear frame,

articulation hitch and four-plate loader

tower are designed to resist torsional

shocks, twisting forces and stresses

generated during the loading cycle

while protecting driveline and hydraulic

system components.

1) Axle Mounting Area. Thicker axle

pad castings joined by a box-boom

structure provides added strength and

stiffness in the axle mounting area.

2) Pivot Mount Castings. Castings in the

lift arm pivot mounting area have been

redesigned to better disperse stress

loads for increased structural integrity.

3) Steering Cylinder Mounts. Steering

cylinder mounts are thicker to more

efficiently transmit steering loads into

the frame.

Hitch Plate. The lower articulation

hitch plate is larger for greater structural

durability.

Z-bar Loader Linkage. Proven Z-bar

loader linkage geometry delivers

maximum productivity. Fewer pivot

point and moving parts are designed

to reduce maintenance costs.

Tilt Links. The pin joints at both ends

of the tilt links have been changed to a

greased pin designed that is connected

to autolube system. This will increase

the reliability of these joints.

Breakout Force. Increased breakout

force allows the loader to aggressively

penetrate the bank.

Rackback. High rackback angle ensures

greater material retention and less

spillage.

Dump Speed. Controlled dumping

speed protects the front linkage from

excessive wear.

6

Designed for maximum strength and durability in the harshest operating environments.

Structures

2

3

1

Page 7

Lift Arms. The 994F’s solid steel lift

arms absorb high stresses generated

during loading without sacrificing

strength or durability. The linkage

design provides an excellent view of

the bucket edges, corners, and work

area, allowing the operator to focus on

productivity. The cross sectional area

of the lift arms has been increased in

several areas to improve durability.

1) Lift Arm Cross Member. A heat-treated

lift arm cross member and improved

weld procedures provide greater

reliability and durability.

2) Lift Arm Mounting. Lift arm to front

frame area has been redesigned to permit

the use of a larger pin. The casting in

this area of the front frame has been

optimized to reduce stresses. The bolted

joint at the lift arm to bucket pin location

has been removed to improve reliability.

3) Stress-Relieved Lift Arms. Lift arms

are stress relieved to eliminate residual

stresses created during manufacturing

and increase durability.

4) Auto Lube. Bucket to lift arm joint

(B-pin) is automatically lubricated

to increase reliability and reduce

daily servicing.

7

Page 8

Hydraulic System. Completely enclosed

hydraulic system uses separate circuits

for lift and tilt, steering and brake

control. Separate circuits provide

increased cooling and elimination of

cross-contamination, resulting in less

downtime and greater productivity.

Lift and Tilt System. Three dedicated

fixed displacement piston pumps and a

fourth electronically controlled variable

displacement piston pump deliver high

reliability, efficiency and performance

to the lift and tilt system. The variable

displacement pump is only activated

when additional hydraulic speed

is needed.

Pilot Controls. Low-effort, pilot-operated

finger-tip controls provide smooth,

precise control of lift and tilt functions.

Automatic lift kickout and return to

dig detents deliver fast cycle times.

Steering System. The 994F features a

load-sensing steering system with variable

displacement piston pump for smooth,

precise control. The revolutionary

steering system integrates steering and

transmission control functions into a

single controller. Simple side-to-side

movement of the STIC steer lever turns

the machine right or left. Center point

frame articulation allows the machine

to articulate 40° to the left or right,

permitting precise positioning in

tight areas.

Filtration System. Advanced filtration

system consists of additional screens

and filters throughout the lift/tilt, steering

and brake systems to maintain cleanliness,

and prevent downstream contamination.

All are monitored electronically through

VIMS™ system to simplify diagnostic

troubleshooting and reduce downtime.

• Lift/tilt high pressure screens

• Steering high pressure screens

• Lift/tilt case drain filters

• Steering case drain filters

• Hydraulic case drain filters

• Front pump drive lube filter

• Front and rear brake oil screens

8

Hydraulics

Cat hydraulics deliver the power and control needed to keep material moving.

Page 9

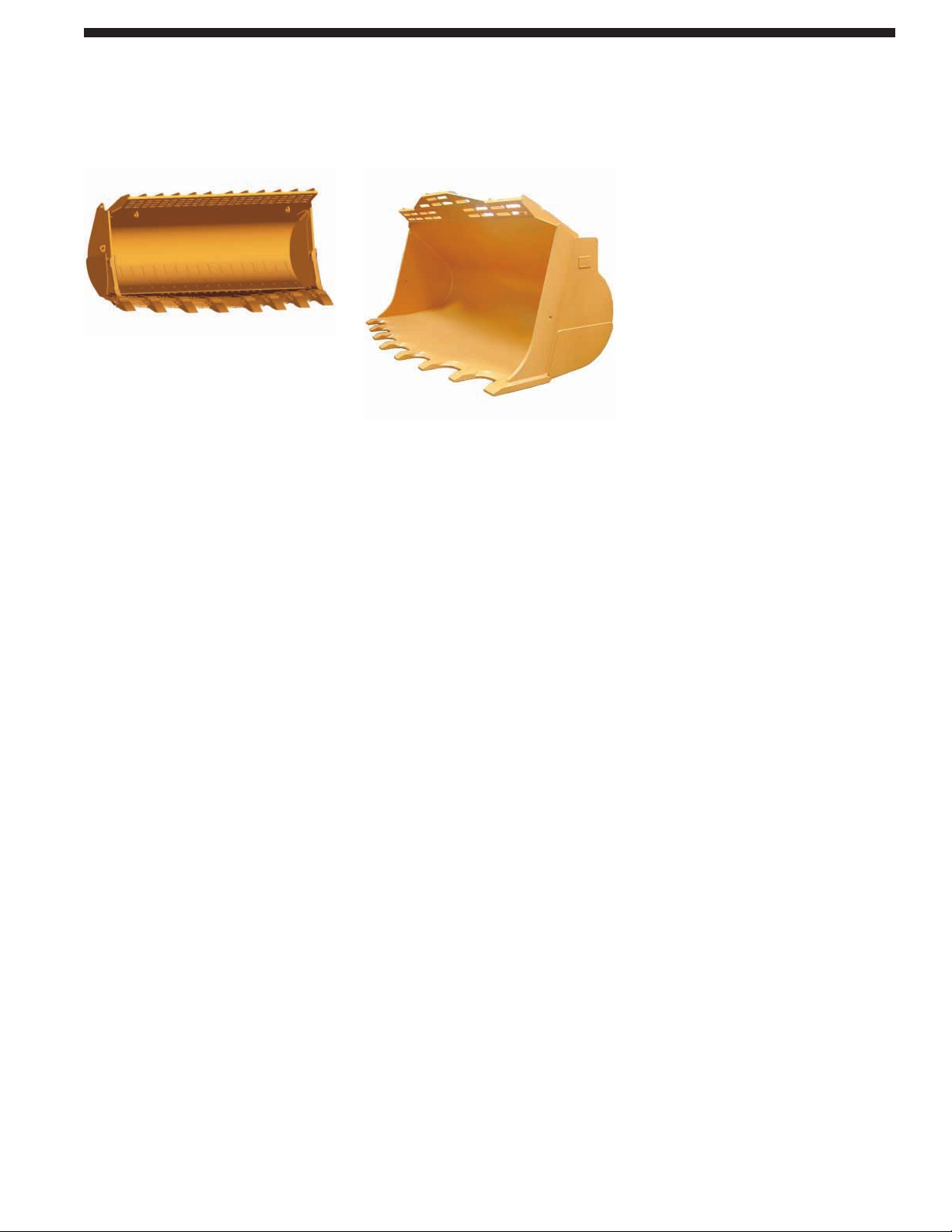

High Productivity. Aggressive Cat

bucket designs deliver unmatched

productivity in the most demanding

applications. 994F buckets have been

redesigned for optimal loadability and

structural reliability.

Rugged Design. Cat buckets are

manufactured using shell-tine

construction to resist twisting and

distortion. A more aggressive spade

edge increases bucket penetration and

fill factors and provides better retention

of loose material. An integral rock

guard helps retain big loads for greater

fill factors and optimum truck loading.

Spade Edge Rock Buckets. Spade edge

rock buckets with bolt-on segments are

designed to penetrate through the pile

while leaving a smooth work floor.

Shouldered, double-strap adapters allow

easy change-out and bolt-on segments

extend base edge life.

Serrated Edge Coal Bucket.

Serrated edge bucket is recommended

for low abrasion material loading

where greater penetration is required.

It does not use GET, thus eliminating

the risk of iron falling into crushers.

Replaceable serrated or straight edge

is available if needed. Serrated edge

is standard for the 36 m3(47 yd3) coal

bucket, but can be added to the smaller

buckets upon request.

Bucket Protection. Cat Ground Engaging

Tools (G.E.T.) provide superior bucket

protection for long life in the most

punishing conditions. Built to absorb

shock, impact, and abrasion, G.E.T.

work and wear as a system to boost

productivity and lower costs.

Tips. Tips extend bucket life in high

wear applications.

Sidebar Protectors. Protects bucket

corner and sides from wear in abrasive

materials. Pin-on sidebars are reversible

to extend wear life.

Edge Protectors. Protects bucket edge

from wear in materials with high wear

rates. Independently pinned for easy

replacement without removing tips

or adapters.

Wear Plates. Replaceable wear plates

protect the bucket bottom. Bolt-on and

weld-on wear plates protect the rear

base edge from damage.

Tips. Tips extend bucket life in high

wear applications.

Sidebar Protectors. Protects bucket

corner and sides from wear in abrasive

materials. Pin-on sidebars are reversible

to extend wear life.

Edge Protectors. Protects bucket edge

from wear in materials with high wear

rates. Independently pinned for easy

replacement without removing tips

or adapters.

Wear Plates. Replaceable wear plates

protect the bucket bottom. Bolt-on and

weld-on wear plates protect the rear

base edge from damage.

9

Buckets and Ground Engaging Tools

Cat buckets provide the flexibility to match the machine to the material and conditions.

Page 10

10

Ergonomically designed for operator comfort, superior control and high productivity.

Operator’s Station

Page 11

Spacious Cab Design. The 994F sets the

standard for productivity with advanced

controls and greater operator comfort.

Features include outstanding visibility,

excellent cab ventilation, interior sound

levels below 75 dBA, trainer seat, cup

holder, storage bin, radio ready and

more. Improvements made for increased

operator maneuverability and productivity.

Steering and Transmission Integrated

Control System (STIC). Combines

directional selection, gear selection and

steering into a single lever for maximum

responsiveness. Simple side-to-side

motion turns machine right or left.

Transmission shifting (forward/neutral/

reverse) is controlled by the operator’s

fingers, and gear selection is controlled

by the thumb. The integrated control

system delivers low effort controls for

smoother, faster cycles with less

operator fatigue.

Left Brake Pedal. Allows the impeller

clutch torque converter to modulate

rimpull from 100% to 25%. After 25%

is achieved, the brakes are engaged

for improved control and smoother

directional shifts. This improves speed

control when approaching the truck.

Cat Comfort Series Seat. With air

suspension and retractable seat belt

is designed for comfort and support.

Seat cushions reduce pressure on the

lower back and thighs while allowing

unrestricted arm and leg movement.

The seat is six-way adjustable and the

retractable seat belt remains off the

floor and is easy to reach for the operator.

Armrests are height and tilt adjustable.

Trainer seat. The trainer seat consists

of a padded seat and back with lap style

seat belt. When the trainer seat is not in

use, the back can be folded down and

used as a drink tray and there is a storage

compartment (room for a large lunch

cooler) under the seat.

Seat Mounted Pilot Hydraulic Controls

and Armrests. Provide low effort, control

for enhanced comfort and stability.

Controls and arm rests are fore, aft

and height adjustable to accommodate

operators of any size in a comfortable

operating position. The levers are

ergonomically designed for improved

operator comfort.

Vital Information Management System.

VIMS™ system is the standard display

system that provides information on

the machine’s major components and

systems. Gauge displays fuel tank level

and temperatures for engine coolant,

power train and hydraulic oil. Tachometer

is an analog gauge with digital readout

for gear selection. The Payload Control

System is included in VIMS system.

Automatic Kickouts. Lift, lower and

bucket tilt automatic kickouts are

adjustable electronically from the cab.

Throttle Lock. Allows the operator

to preset the engine speed, resulting

in faster cycle times and increased

productivity.

Rimpull Control System (RCS). Allows

operator to match rimpull settings to

job conditions with four-position dial.

Operator can adjust maximum rimpull

from 100% down to 90, 85, 75 and 65%

while in first gear. Matching rimpull to

job conditions provides greater traction

in slippery or rough conditions for

better performance and longer tire life.

Rimpull Control System Switch.

Turns RCS on and off.

Other Features.

• outstanding viewing area

• excellent cab ventilation

• interior sound levels below 75 dB(A)

• standard coat hook

• intermittent wet-arm wipers

(front and rear)

• radio-ready

• CAES ready

• rear vision camera ready

• Product Link ready

• VIMS wireless ready

11

Page 12

For the operator. VIMS system

establishes a two-way communication

between the operator and the machine.

Real-time machine information allows

the operator to make informed decisions

that directly affect their safety, machine

availability, and ultimately the

productivity of the mine.

Maintenance. VIMS system provides

maintenance personnel an overview

of operator and machine performance.

This allows maintenance managers and

technicians the information necessary

to maximize component life, reduce

catastrophic failures, minimize

unscheduled downtime and improve

a mine’s asset management.

Production. VIMS system collects the

information a manager needs to

determine equipment usage, future

machine requirements, personnel

performance, and productivity levels.

Payload information can also be used

as an accounting tool, an indicator of

cycle time efficiency and truck over

loading or under loading.

Integrated System Monitoring. Sensors

located throughout the machine systems

enable VIMS system to quickly exchange

and monitor information from all machine

systems for efficient, high performance

operation.

Advanced Diagnostics. VIMS system

simplifies troubleshooting, reduces

downtime and lowers operating costs

by identifying abnormal conditions

before they cause extensive damage.

Data Access. Monitoring and diagnostic

information is stored on-board until

it can be downloaded for analysis.

Data can be accessed through the

message center, transmitted via

optional radio and downloaded onto

a computer for detailed analysis.

Machine Management. Maintenance

and Production personnel can download

data and generate reports for better

machine management. Data can be used

to improve effectiveness of scheduled

maintenance programs, maximize

component life, improve machine

availability, increase production and

lower operating costs.

12

Vital machine information at your fingertips.

VIMS™ Vital Information Management System

VIMS

PC

9

ET

1 Gauge Cluster

2 Message Center and Keypad

3 ADEM III Engine Control Module

21

108

4 CAT Data Link

5 Action Alarm

6 Action Lamp

7 Radio System (optional)

8 Data Port (VIMS-PC)

VIMS

7

6

5

4

3

12

9 Service Lamp

10 Diagnostic Connector (ET)

11

11 Transmission ECM

12 Implement

Page 13

Gauge Cluster. Conveniently located

gauge cluster maintains a constant display

of vital machine functions, including:

• engine coolant temperature

• transmission oil temperature

• hydraulic oil temperature

• fuel level

Speedometer/Tachometer Module.

Monitors three systems: engine speed,

ground speed and actual gear.

Keypad. Provides operator or service

technician immediate access to current

machine information, gauge values

and stored data through the message

center display.

Message Center. Displays payload

bucket weights and messages requested

by operator and advises operator of

abnormal machine conditions.

Alert System. Three-category warning

system alerts operator of abnormal

machine health conditions.

Categories.

• Category I – Machine or system

needs attention.

• Category II – Requires operator to

evaluate and correct situation before

continuing work.

• Category III – Immediate shutdown

required to prevent serious damage

to machine or system.

Production Management. The Wheel

Loader payload system displays the

current bucket weights along with

the target of the truck is being loaded

resulting in the ability to manage

payloads. Also has the ability to track

material and trucks for production

analysis.

Data Storage. VIMS system stores up

to 1200 cycles that would include: Date,

Time, Truck ID, Operator ID, Material

Description, Load Site Description,

Blast #, Fuel Used, Bucket Weight,

Bucket Status, Machine Status.

VIMS PC Software. VIMS PC software,

the off-board reporting software program,

allows service personnel to download a

complete record of machine health and

productivity data to a laptop computer

for diagnosis and analysis. Easy-to-use

software enables service technicians

and mine management to generate

health and payload reports for more

effective machine management.

VIMS Supervisor. On sites with multiple

VIMS machines and where VIMS PC

software is used to download all data,

the use of VIMS Supervisor can aid

in quick analysis of VIMS data.

VIMS Supervisor can generate Health

and Production report summaries for

a single machine or an entire fleet.

VIMS Supervisor is the drill down

tool for fleet analysis using an existing

“VIMS.mdb” database.

13

Page 14

Easy Servicing. The 994F is designed

for quick, easy servicing. Simplified

access to service areas allows for quick

servicing and ensures routine maintenance

procedures are performed on time.

Ground-Level Access. Ground-level

access to centralized lubrication points

makes lube service quick and easy.

Air Cleaners. Dry-type air cleaners

with primary and secondary elements,

automatic dust ejector, and service

indicator are positioned above the

hood for easy access.

Pressure Test Ports. Hydraulic pressure

test ports enable fast troubleshooting

of major hydraulic circuits.

Next Generation Modular Radiator

(NGMR). Modular design with removable

cores for easy replacement and

maintenance.

On-Board Diagnostics. Diagnostic

connector allows quick troubleshooting

of starting and charging functions.

Monitoring System. VIMS system

notifies operator and service technicians

of problems before failure and identifies

location to minimize troubleshooting

and reduce downtime. Features:

• Three-level warning system

• Data recording system

• Payload Control System

• Off-board analysis system

Autolube. Standard automatic lubrication

system reduces maintenance time by

automatically lubricating bearings in:

• lift and tilt cylinders

• upper and middle bucket tilt levers

• bucket pins

• steering cylinders

• rear axle trunnions

• fan drive and belt tightening pulleys

• upper and lower articulation hitch

Lubrication timing and duration can

be easily set using the VIMS keypad.

14

Serviceability

Less time spent on maintenance means more time on the job.

Page 15

Machine Selection. Make detailed

comparisons of the machines you

are considering before you buy.

Purchase. Look past initial price.

Consider the financing options

available, as well as day-to-day

operating costs. This is also the time

to look at dealer services that can be

included in the cost of the machine

to lower equipment owning and

operating costs over the long run.

Financing. Your dealer is expert at

arranging affordable financing options

for all Caterpillar products.

Customer Support Agreements.

Cat dealers offer a variety of product

support agreements, and work with

customers to develop a plan that meets

specific needs. These plans can cover

the entire machine, including work

tools, to help protect your investments.

Product Support. You will find nearly

all parts at your dealer parts counter.

Cat dealers use a worldwide computer

network to find in-stock parts to minimize

machine downtime. Cat reman parts

offer the same warranty and reliability

as new products at cost savings of 40

to 70 percent.

Operation. Improving operating

techniques can boost your profits.

Your Cat dealer has training videotapes,

literature, and equipment training

courses to help you increase productivity.

Maintenance Services. Choose from

your dealer’s range of maintenance

services when you purchase your

machine. Repair option programs

guarantee the cost of repairs up front.

Diagnostic programs such as S•O•S

SM

coolant sampling and technical analysis

help you avoid unscheduled repairs.

Replacement. Repair, rebuild or replace?

Your Cat dealer can help you evaluate

the cost involved so you can make the

right choice.

www.cat.com. For more complete

information on Cat products, dealer

services, and industry solutions,

visit us on the web at www.cat.com.

15

Customer Support

Caterpillar®dealers have what it takes to keep mining machines productive.

Page 16

Application Match. The standard 994F

is sized to load the 150-ton 785C in

four passes. The 994F high-lift loads

the 195-ton 789C in six passes and

the 240-ton 793C in seven passes.

The 994F Super High-Lift loads the

195 ton 789C coal body in six passes

and the 240 ton 793C coal body in

seven passes.

Efficient Combination. For full truck

payloads with minimum loading time,

an efficient loading/hauling system

starts with a perfect match. Cat Wheel

Loaders are matched with Cat C-Series

Mining Trucks to maximize volume of

material moved at the lowest operating

cost-per-ton.

Bucket Selection. Selection of the right

bucket width depends on penetration

requirements and the loading target.

Bucket sizes are matched to truck bed

capacities for optimum loading efficiency

and greater productivity.

Narrow Bucket. The narrower 5650 mm

(222 in) buckets are optimally matched

to load the Cat 785C, and are also sized

for the 789C.

Wide Bucket. The wider 6220 mm

(244 in) buckets are optimally matched

to load the larger Cat 789C, and are also

sized for the 793C.

16

Matched Systems

An efficient loading/hauling system starts with a perfect match.

994F Standard Lift

Pass Match

785C 4

994F High Lift

Pass Match

789C 6

994F Super-High Lift

Pass Match

789C Coal body 6

789C 5 793C 7 793C Coal body 7

Page 17

Product Safety. Caterpillar has been and

continues to be proactive in developing

mining machines that meet or exceed

safety standards. Safety is an integral

part of all machine and systems designs.

SAE and ISO Standards. The 994F is

designed to national and international

standards, and has been tested and

self certified to comply with applicable

SAE and ISO safety standards.

Integral ROPS/FOPS Cab. Mounted to

the main frame to provide rollover and

falling object protection. ROPS structure

is designed as an extension of the

loader frame.

Ladder/Secondary Egress. Two wide,

stationary stairways with handrails on

both sides allow three-point contact

access to and from the machine.

Brake Systems. Four corner oil-cooled

braking system provides excellent control

in slippery conditions. The service brakes

are actuated by modulated hydraulic

pressure, while secondary and parking

brake functions are spring applied and

hydraulic released. This system assures

braking in the event of complete

hydraulic failure.

Steering System. A twin double-acting

cylinder steering system is designed to

deliver precise control under all loading

and underfoot conditions. The steering

hydraulic system is separate from the

main hydraulic system to prevent crosscontamination and overheating from

other sources.

Supplemental Steering System.

Provided using a ground driven pump is

standard on the 994F. Backup steering

system allows the operator to maintain

control of the loader in the event of a

failure in the main steering system.

Rear Vision Camera (optional). Located

on top of the radiator in the center.

Provides the operator 115° of field

vision via a colored monitor located in

the cab. Enables operator to see directly

behind the loader.

Trainer Seat. The trainer seat makes

training new operators in the correct

operation of the loader easier. In addition

observing operational issues is easier.

Lock-out Panel. The panel is conveniently

located on the left-hand side bumper in

front of the ladder allowing the operator/

serviceman to reach the switches from

ground level. In addition to the shutoff

and lockout switches described below,

this panel contains a VIMS port, stairway

lights and hood lights switches.

Engine Shutoff Switch. An engine

shutoff switch is located in the rear

ground level lockout panel for

immediate shutdown.

Transmission Lockout. A transmission

lockout switch is located in the rear

ground level lockout panel. Enables to

lockout machine transmission to prevent

gear engagement while the operator is

not in the cab.

Starter Lockout. A starter lockout

switch, when enabled, prevents the

starter from being activated while

service is being performed.

Toe Kicks. Toe kicks have been added

to the rear platform. Prevents tools from

falling off while servicing the machine.

Electrical System Disconnect. A battery

disconnect switch, which is conveniently

located near the left stairs, provides

lockout of the electrical system for

service work.

Service Center. Located at ground level

allowing easy access for filling and

draining machine fluid compartments.

Payload Policy. Safety is integral to

maintaining the highest productivity in

mining machine operation. Caterpillar’s

10/10 Payload Policy assures that

steering and braking systems have

sufficient capacity to perform at a

10% overload. VIMS, which is standard

on the 994F, includes a payload indicator

system. VIMS notifies the operator

when the bucket is overloaded.

Standard Safety Features.

• Slip resistant surfaces

• Retractable, 75 mm (3 in) wide

seat belts

• Wide-angle mirrors

• Hand rails

• Low interior sound level

• Trainer seat

SAFETY.CAT.COM™.

17

Safety

Caterpillar mining machines and systems are designed with safety as their first priority.

Page 18

18

994F Wheel Loader specifications

Transmission

Transmission Type Cat planetary power shift

Forward 1 7.7 km/h 4.8 mph

Forward 2 13.4 km/h 8.3 mph

Forward 3 22.5 km/h 14 mph

Reverse 1 8.5 km/h 5.3 mph

Reverse 2 13.2 km/h 8.2 mph

Reverse 3 24.8 km/h 15.4 mph

Direct Drive – Forward 1 Lock-up disabled

Direct Drive – Forward 2 13.7 km/h 8.5 mph

Direct Drive – Forward 3 24 km/h 14.9 mph

Direct Drive – Reverse 1 8.5 km/h 5.3 mph

Direct Drive – Reverse 2 13.5 km/h 8.4 mph

Direct Drive – Reverse 3 25.6 km/h 16 mph

• Travel speeds based on two percent rolling resistance and

53.5/85-57 tires in converter drive.

Hydraulic System – Lift/Tilt

Lift/Tilt System – Circuit Open

Lift/Tilt System – Pump 3x Piston, fixed

displacement

Lift/Tilt – Pump 1x Variable, Piston

Max Flow at 1,710 rpm (3x) 1370 L/min 362 gal/min

Relief Valve Setting – Lift/Tilt 32 800 kPa 4,750 psi

Cylinders – Lift/Tilt Double-acting

Lift Cylinder – Bore 318 mm 13 in

Lift Cylinder – Stroke 1660 mm 65.4 in

Tilt Cylinder – Bore 267 mm 10.5 in

Tilt Cylinder – Stroke 1140 mm 44.9 in

Number of Lift/Tilt Pumps 4

Number of Lift Cylinders 2

Number of Tilt Cylinders 2

Hydraulic System – Pilot

Pilot System – Circuit Closed

Pilot System – Pump Gear

Max Flow at 1,710 rpm 154 L/min 40.7 gal/min

Relief Valve Setting – Pilot 2400 kPa 348 psi

Number of Pilot Pumps 1

Engine

Engine Model Cat®3516B HD EUI

Rated Speed 1,600 rpm

Gross Power – SAE J1995 1176 kW 1,577 hp

Net Power – EEC 80/1269 1092 kW 1,463 hp

Net Power – ISO 9249 1092 kW 1,463 hp

Net Power – SAE J1349 1180 kW 1,447 hp

Bore 170 mm 6.7 in

Stroke 215 mm 8.5 in

Displacement 78 L 4,875 in

3

Peak Torque @ 1,100 rpm 8499 N•m 6,289 lb ft

Torque Rise 32%

• Net power advertised is the power available at the flywheel

when the engine is equipped with fan, air cleaner, muffler,

and alternator.

• Net torque rise meets SAE J139.

• No engine derating required up to 3050 m (10,000 ft) altitude.

Operating Specifications

Operating Weight 195 434 kg 430,858 lb

Rated Payload – Standard 35 tonnes 38 tons

Rated Payload – High-Lift 32 tonnes 35 tons

Rated Payload – Super High Lift 32 tonnes 35 tons

Bucket Capacity Range 14-36 m

3

18.5-47 yd

3

Cat Truck Match – Standard 785C, 789C

Cat Truck Match – High-Lift 789C, 793C

Cat Truck Match – Super High Lift 789C, 793C

Articulation Angle 40º

q

ft-lb N•m

7000

6000

5000

4000

3000

Engine Torque

2000

1000

1000 1200 1400

1100 1300 1500 1600

Engine Speed

hp Bkw

1800

1600

1400

1200

1000

800

600

Engine Power

400

200

1000 1200 1400 1600

1100 1300 1500

Engine Speed

Net

Gross

1700

1700

9490

8134

6779

5423

4067

2711

1355

rpm

1342

1193

1043

rpm

894

745

596

447

298

149

ue

Engine Tor

Engine Power

Page 19

19

994F Wheel Loader specifications

Brakes

Brakes SAE J1473 OCT 90,

ISO 3450:1992

Cab

Air Conditioning Standard air conditioning

system contains

environmentally friendly

R134a refrigerant

Cab – ROPS/FOPS SAE J1394, SAE J11040

APR88, ISO 3471-1:1986,

ISO 3471:1994

Caterpillar cab with separate Rollover Protective Structure/

Falling Object Protective Structure (ROPS/FOPS) is standard

in North America, Europe and Japan.

• ROPS meets SAE J394, SAE J1040 APR 88, ISO 3471-01:1986

and ISO 3471:1994 criteria.

• FOPS meets SAE J231 JAN 81 and ISO 3449:1992 Level II

criteria.

Sound Performance ISO 6394:1998

The operator sound exposure Leq (equivalent sound pressure

level) measured according to the work cycle procedures

specified in ANSI/SAE J1166 OCT98 is 75 dB(A), for the cab

offered by Caterpillar, when properly installed, maintained

and tested with the doors and windows closed.

• Hearing protection may be needed when operating with an

open operator station and cab (when not properly maintained

or doors/windows open) for extended periods or in noisy

environment.

• The exterior sound pressure level for the standard machine

measured at a distance of 15 m (49.2 ft) according to the test

procedures specified in SAE J88 JUN86, mid-gear-moving

operation, is 87 dB(A).

• The sound power level is 115 dB(A) measured according

to the dynamic test procedure and conditions specified

in ISO 6395:1988/Amd. 1:1996 for a standard machine

configuration.

Vibration EC 89/392 EEC

Hydraulic System – Steering

Steering System – Circuit Closed

Steering System – Pump Piston, variable

displacement

Max Flow @ 1,710 rpm (6900 kPa) 884 L/min 234 gal/min

(2x)

Relief Valve Setting – Steering 3100 kPa 4,500 psi

Number of Steering Pumps 2

Hydraulic Cycle Time

Rackback 5.5 Seconds

Raise 11.3 Seconds

Dump 3.1 Seconds

Lower Float Down (Empty) 3.5 Seconds

Power Down 6.7 Seconds

Service Refill Capacities

Fuel Tank 3833 L 1,013 gal

Cooling System 490 L 129 gal

Crankcase 286 L 75.5 gal

Transmission 350 L 92 gal

Differentials and 621 L 164 gal

Final Drives – Front

Differentials and 621 L 164 gal

Final Drives – Rear

Differential/Final Drives (each) 621 L 164 gal

Hydraulics – Lift/Tilt 390 L 103 gal

Hydraulics – Brake Cooling 36 L 9 gal

Hydraulics – Steering/Brake 208 L 55 gal

Pump Drive – Front 7 L 2 gal

Hydraulic System (including tank) 893 L 235.91 gal

Dimensions

Hinge Pin Height at Full Lift – Std 8157 mm 26 ft 10 in

• Standard machine with 53.5/85-57 tires and 19 m3(24.5 yd3)

5639 mm (222 in) spade edge rock bucket with teeth and

segments.

• High-Lift machine with 53.5/85-57 tires and 18 m3(23.5 yd3)

6223 mm (245 in) spade edge rock bucket with teeth and

segments.

Buckets

Bucket Capacities 14 – 36 m318.5 – 47 yd

3

Axles

Maximum Single-Wheel Rise 677 mm 26.65 in

and Fall

Front Fixed

Rear Trunnion

Oscillation Angle ±10°

Page 20

20

994F Wheel Loader specifications

Page 21

21

994F Wheel Loader specifications

Bucket Capacity/Material Density Selection Guide

t

Rock Mining Applications only, for Coal Mining contact your Cat representative.

The following table provides a guideline for bucket selection based on various material densities and estimated fill factors.

Based on the new ratings, fill factors are expected to be 110-120% in cohesive materials with easy digging, 100-110% in

ypical shot rock loading, and 90-100% in poorly shot rock with large rocks and difficult penetration. For many mining

applications, the 994F standard lift is matched with the 19 m3(24.5 yd3) rock bucket and the high lift is matched with the

17 m3(22.5 yd3) rock bucket.

Bucket Capacity Bucket Fill Factor

3

m

19

17

yd

24.5

22.5

3

115% 95%

Standard

Changes in bucket weight, including field installed

15

19.5

1.4 1.6 1.8 2.0 2.2 2.4 2.6

2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4

Material Density

(Thousands)

kg/m

lb/yd

wear iron, can impact rated payload. Consult your

Caterpillar dealer for assistance in selecting and

3

configuring the proper bucket for the application.

3

The Caterpillar Large Wheel Loader Payload Policy

is a guideline intended to maximize wheel loader

structural and component life.

115% 95%

High-Lift

Page 22

22

994F Wheel Loader specifications

Operating Specifications – Standard Lift

For machines equipped with 53.5/85-57, 76 PR L-5 tires – see additional tables for other tire sizes

Coal Bucket

Narrow Bucket Wide Bucket (6200 mm/

(5640 mm/222 in) (6200 mm/244 in) 244 in)

Straight

Edge

Coal

Spade Edge Spade Edge Bucket

Rock Bucket Rock Bucket Teeth &

Teeth & Segment Teeth & Segment Segment

yd

3

3

14 15 17 19 18 19 31

18.5 19.5 22.5 25 23.5 25 41

ft/in 18' 6" 18' 6" 18' 6" 18' 6" 20' 4" 20' 4" 20' 4"

yd

3

3

11 12 14 15 14.5 15 27

14.4 15.7 18.3 19.6 19.0 19.6 35.3

in 4" 4" 4" 4" 4" 4" 2"

ft/in 54' 6" 54' 6" 54' 11" 55' 5" 54' 11" 55' 5" 55' 2"

lb 288,327 289,114 287,187 283,292 281,991 278,933 285,046

lb 254,993 254,709 237,173 222,336 238,289 223,685 218,964

lb 423,064 423,373 424,828 427,209 427,694 429,303 430,273

Rated capacity (§)m

Width (§) mm 5640 5640 5640 5640 6200 6200 6200

Struck capacity (§)m

Dump clearance at full lift mm 5771 5771 5663 5556 5663 5563 5635

and 45° discharge (§) ft/in 18' 11" 18' 11" 18' 7" 18' 3" 18' 7" 18' 3" 18' 6"

Reach at full lift mm 2071 2071 2160 2266 2160 2278 2306

and 45° discharge (§) ft/in 6' 9" 6' 9" 7' 1" 7' 5" 7' 1" 7' 6" 7' 6"

Reach with lift arms mm 4916 4916 5056 5206 5056 5210 5179

horizontal and bucket level ft/in 16' 1" 16' 1" 16' 7" 17' 0" 16' 7" 17' 1" 17' 0"

Digging depth (§) mm 108 108 108 108 108 108 63

Overall length (§) mm 16 604 16 604 16 744 16 894 16 744 16 898 16 830

Overall height with bucket mm 10 719 10 719 10 866 10 911 10 636 10 621 10 960

at full raise (§) ft/in 35' 2" 35' 2" 35' 7" 35' 9" 34' 11" 34' 10" 39' 11"

Loader clearance circle with mm 12 668 12 668 12 704 12 742 12 965 13 002 13 073

bucket in carry position (§) ft/in 41' 7" 41' 7" 41' 8" 41' 9" 42' 6" 42' 7" 42' 11"

Static tipping load straight** (§) kg 130 783 131 140 130 266 128 499 127 909 126 522 129 295

Static tipping load kg 113 391 113 684 112 784 111 091 110 539 109 241 111 719

at full 40° turn** (§) lb 250,188 250,835 248,849 245,113 243,895 241,032 246,298

Breakout force*** (§) kN 1134 1133 1055 989 1060 995 974

Operating weight** (§) kg 191 899 192 039 192 699 193 779 193 999 194 729 195 169

(§) Specifications rating conform to all applicable standards recommended by the Society of Automotive Engineers. SAE standard J732c governs loader ratings

and is denoted in the chart by (§).

* Dimensions are measured to the tip of the bucket teeth to provide accurate clearance data. SAE standard specifies the cutting edge.

** Static tipping load and operating weight shown are based on standard machine configuration with 53.5/85-57 tires, full fuel tank, coolant and lubricants.

*** Measured 102 mm (4 in) behind tip of cutting edge with the bucket hinge pin as pivot point in accordance with SAE J732c.

Page 23

23

994F Wheel Loader specifications

Changes in Standard Lift Specifications due to Tire Size

W

Dimensional changes

50/80-57 52/80-57 55/80R57 53.5/85-57 58/85-57

Dump clearance at full lift mm –136 –143 –89 0 +17

and 45° discharge in –5 –6 –4 0 +0.7

Reach at full lift and mm +118 +143 +68 0 –15

45° discharge in +5 +6 +3 0 –0.6

Reach with lift arms mm +118 +143 +68 0 –15

horizontal and bucket level in +5 +6 +3 0 –0.6

Digging depth mm +136 +143 +89 0 –17

in +5 +6 +4 0 –0.7

Overall length mm +105 +111 +70 0 –12

in +4 +4 +3 0 –0.5

Overall height with bucket mm –136 –143 –89 0 +17

at full raise in –5 –6 –4 0 +0.67

Total width over tires mm 5305 5302 5509 5460 5524

in 209 209 217 214 217

eight changes

50/80-57 52/80-57 55/80R57 53.5/85-57 58/85-57

Static tipping load straight kg –4234 –3339 +50 0 +327

lb –9,334 –7,361 +110 0 +721

Static tipping load kg –3738 –2953 +44 0 +285

at full 40° turn lb –8,241 –6,510 +97 0 +628

Operating weight kg –5388 –4256 +64 0 +416

lb –11,878 –9,383 +141 0 +917

Page 24

24

994F Wheel Loader specifications

Operating Specifications – High Lift

For machines equipped with 53.5/85-57, 76 PR L-5 tires – see additional tables for other tire sizes

Coal Bucket

Narrow Bucket Wide Bucket (6200 mm/

(5640 mm/222 in) (6200 mm/244 in) 244 in)

Straight

Edge

Coal

Spade Edge Spade Edge Bucket

Rock Bucket Rock Bucket Teeth &

Teeth & Segment Teeth & Segment Segment

yd

3

3

14 15 17 19 18 19 31

18.5 19.5 22.5 25 23.5 25 41

ft/in 18' 6" 18' 6" 18' 6" 18' 6" 20' 4" 20' 4" 20' 4"

yd

3

3

11 12 14 15 14.5 15 27

14.4 15.7 18.3 19.6 19 19.6 35.3

in 5" 5" 5" 5" 5" 5" 3"

ft/in 57' 0" 57' 0" 57' 6" 58' 0" 57' 6" 58' 0" 57' 10"

lb 239,631 240,140 238,344 234,887 233,641 231,033 236,044

lb 245,475 245,475 228,375 213,793 229,305 215,325 210,421

lb 429,094 429,403 430,858 433,239 433,724 435,333 436,303

Rated capacity (§)m

Width (§) mm 5640 5640 5640 5640 6200 6200 6200

Struck capacity (§)m

Dump clearance at full lift mm 6110 6110 6002 5895 6002 5902 5974

and 45° discharge (§) ft/in 20' 0" 20' 0" 19' 8" 19' 4" 19' 8" 19' 4" 19' 7"

Reach at full lift mm 2632 2632 2721 2827 2721 2839 2867

and 45° discharge (§) ft/in 8' 8" 8' 8" 8' 11" 9' 3" 8' 11" 9' 4" 9' 5"

Reach with lift arms mm 5556 5556 5696 5846 5696 5850 5819

horizontal and bucket level ft/in 18' 2" 18' 2" 18' 8" 19' 4" 18' 8" 19' 2" 19' 1"

Digging depth (§) mm 123 123 123 123 123 123 78

Overall length (§) mm 17 396 17 396 17 536 17 686 17 536 17 690 17 622

Overall height with mm 11 058 11 058 11 205 11 250 10 960 10 975 12 184

bucket at full raise (§) ft/in 36' 3" 36' 3" 36' 9" 36' 11" 36' 0" 36' 0" 40' 0"

Loader clearance circle with mm 12 959 12 959 12 993 13 030 13 249 13 285 13 285

bucket in carry position (§) ft/in 42' 6" 42' 6" 42' 7" 42' 10" 43' 6" 43' 7" 43' 7"

Static tipping load straight** (§) kg 108 695 108 926 108 111 106 543 105 978 104 795 107 068

Static tipping load kg 93 575 93 757 92 914 91 399 90 871 89 753 91 770

at full 40° turn** (§) lb 206,297 206,699 204,840 201,500 200,336 197,871 202,318

Breakout force*** (§) kN 1091 1091 1015 951 1020 957 936

Operating weight** (§) kg 194 634 194 774 195 434 196 514 196 734 197 464 197 904

(§) Specifications rating conform to all applicable standards recommended by the Society of Automotive Engineers. SAE standard J732c governs loader ratings

and is denoted in the chart by (§).

* Dimensions are measured to the tip of the bucket teeth to provide accurate clearance data. SAE standard specifies the cutting edge.

** Static tipping load and operating weight shown are based on standard machine configuration with 53.5/85-57 tires, full fuel tank, coolant and lubricants.

*** Measured 102 mm (4 in) behind tip of cutting edge with the bucket hinge pin as pivot point in accordance with SAE J732c.

Page 25

25

994F Wheel Loader specifications

Changes in High Lift Specifications due to Tire Size

W

Dimensional changes

50/80-57 52/80-57 55/80R57 53.5/85-57 58/85-57

Dump clearance at full lift mm –136 –143 –89 0 +17

and 45° discharge in –5 –6 –3.5 0 +0.7

Reach at full lift and mm +118 +143 +68 0 –15

45° discharge in +5 +6 +3 0 –0.6

Reach with lift arms mm +118 +143 +68 0 –15

horizontal and bucket level in +5 +6 +3 0 –0.6

Digging depth mm +136 +143 +89 0 –17

in +5 +6 +4 0 –0.7

Overall length mm +90 +94 +59 0 –12

in +4 +4 +2 0 –0.5

Overall height with bucket mm –136 –143 –89 0 +17

at full raise in –5 –6 –4 0 +0.7

Total width over tires mm 5305 5302 5509 5460 5524

in 209 209 217 214 217

eight changes

50/80-57 52/80-57 55/80R57 53.5/85-57 58/85-57

Static tipping load straight kg –3643 –2878 +43 0 +281

lb –8,031 –6,344 +95 0 +620

Static tipping load kg –3217 –2541 +38 0 +248

at full 40° turn lb –7,092 –5,602 +84 0 +548

Operating weight kg –5388 –4256 +64 0 +416

lb –11,878 –9,383 +141 0 +917

Page 26

26

994F Wheel Loader specifications

Operating Specifications – Super High Lift

Machines only equipped with 58/85-57 tires & Coal Bucket

Coal Bucket

(6500 mm/256 in)

Serrated Edge

Coal Bucket

yd

yd

3

3

3

36

47

39.2

ft/in 1' 0"

ft/in 63' 1"

lb 183,962

lb 155,925

lb 467,313

Rated capacity (§)m

Struck capacity (§)m330

Dump clearance at full lift mm 7336

and 45° discharge (§) ft/in 24' 0"

Reach at full lift mm 3386

and 45° discharge (§) ft/in 11' 1"

Reach with lift arms mm 7543

horizontal and bucket level ft/in 24' 9"

Digging depth (§) mm 299

Overall length (§) mm 19 504

Overall height with bucket mm 14 412

at full raise (§) ft/in 47' 3"

Loader clearance circle with mm 14 262

bucket in carry position (§) ft/in 46' 10"

Static tipping load straight** (§) kg 83 444

Static tipping load kg 69 748

at full 40° turn** (§) lb 153,768

Breakout force*** (§) kN 693

Operating weight** (§) kg 211 970

Width over tires mm 5524

58/85-57 in 217

(§) Specifications rating conform to all applicable standards recommended by the Society of Automotive Engineers. SAE standard J732c governs loader ratings

and is denoted in the chart by (§).

* Dimensions are measured to the tip of the bucket teeth to provide accurate clearance data. SAE standard specifies the cutting edge.

** Static tipping load and operating weight shown are based on standard machine configuration with 53.5/85-57 tires, full fuel tank, coolant and lubricants.

*** Measured 102 mm (4 in) behind tip of cutting edge with the bucket hinge pin as pivot point in accordance with SAE J732c.

Page 27

27

994F Wheel Loader specifications

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

POWER TRAIN

Brakes, oil-cooled, multi-disc, service/secondary

Driveline parking brake

Engine, 3516B HD EUI (SCAC) Diesel,

turbocharged/aftercooled

Fuel priming pump (electric)

Ground level engine shutoff

Precleaner, engine air intake (above hood)

Radiator, Next Generation Modular (NGMR)

Power train oil coolers (2) air to oil, (2) water to oil

Starting aid, ether, automatic

Throttle lock, electronic

Torque converter, Impeller Clutch (ICTC)

with LUC, Rimpull Control System

Transmission, planetary powershift, 3F/3R electronic control

OTHER

Air tank, ECC compliant (EN286)

Air line dryer

Automatic bucket lift kickout/positioner

Automatic lubrication system

Base machine price includes a rim allowance

Blower fan

Couplings, Caterpillar O-ring face seals

Doors, service access (locking)

Ecology drains for engine, radiator, hydraulic tank, steering

and brake tank, and brake cooling tank

Engine oil change system, high speed, Wiggins

Fast fill fuel system (Shaw-Aero)

Fuel tank, 4641 L (1,226 gal)

Hitch, drawbar with pin

Hoses, Caterpillar XT™

Hydraulic, steering and brake filtration/screening system

Improved Service Center

Mufflers (4)

Oil sampling valves

Premixed 50% concentration of extended life coolant with

freeze protection to –34° C (–29° F)

Rear access to cab and service platform

Steering, load sensing

Supplemental steering system

Vandalism protection caplocks

ELECTRICAL

Alarm, back-up

Alternator, dual 80 amp

Batteries, dry

Converter, 10/15 amp, 24V to 12V

Lighting system, (halogen, working lights, access and

service platform lighting)

Starting and charging system, 24V

Starter lockout in bumper

Transmission lockout in bumper

OPERATOR ENVIRONMENT

Air conditioner

Cab, sound suppressed and pressurized, separate external

rollover protective structure (ROPS/FOPS) Radio ready

for (entertainment) includes antenna, speakers and

converter (12-volt 5-amp) and power port

Cab, cleanout hose

Cigar lighter, ashtray

Coat hook

Controls, lift and tilt function

Heater, defroster

Horn, air

Instrumentation, gauges

Coolant temperature

Engine hour meter

Hydraulic oil temperature

Power Train oil temperature

Light, cab, dome

Lunchbox, beverage holders

Mirrors, rearview (externally mounted)

Rimpull Control System

Seat, Cat Comfort (cloth), air suspension, six-way adjustable

Seat belt, retractable, 76 mm (3 in) wide

STIC Control System

Tinted glass

Trainer seat with lap belt

Transmission gear indicator

Vital Information Management System (VIMS)

External data port, Integral Payload Control System

Message center, universal gauge

VIMS Keypad

Wet-Arm Wipers/Washers (front and rear)

Intermittent front and rear wipers

Page 28

28

994F Wheel Loader specifications

Optional Equipment

With approximate changes in operating weights.

Optional equipment may vary. Consult your Caterpillar dealer for specifics.

kg lb

BUCKETS

Spade Edge

NARROW – 5650 mm (222 in)

Rock – 14 m3(18.5 yd3) (J800) 18 338 40,429

Rock – 15 m3(19.5 yd3) (J800) 18 481 40,744

Rock – 17 m3(22.5 yd3) (J800) 18 217 40,162

Rock – 19 m3(25 yd3) (J800) 20 197 44,526

WIDE – 6220 mm (245 in)

Rock – 18 m3(23.5 yd3) (J800) 20 167 44,460

Rock – 19 m3(25 yd3) (J800) 20 444 45,072

Straight Edge

Coal – 32 m3(42 yd3) (J700) 20 167 44,460

Serrated Edge

Coal – 36 m3(47 yd3) (none) 20 444 45,072

GROUND ENGAGING TOOLS

BUCKET TIPS*

Heavy duty – long – rock (J800) 88 193

Heavy duty – abrasion – rock (J800) 105 232

Heavy duty – penetration – rock (J800) 97 214

Penetration – rock (J800) 54 120

Heavy duty – long – coal (J700) 51 113

Heavy duty – abrasion – coal (J700) 66 145

BUCKET WINGS

Low profile 350 772

kg lb

POWER TRAIN

Crankcase guard 300 662

Engine prelube 1 3

Engine oil renewal system 66 145

Sy-Klone turbine precleaner 11 25

RIMS

914 mm (36") wide 1813 3,996

1118 mm (44") wide

with 126 mm (6") flange 1925 4,245

1194 mm (47") wide

with 126 mm (6") flange 1930 4,255

ELECTRICAL

CAES, attachment ready 23 50

VIMS, wireless II 0 0

Camera, rear vision 2 4

OTHER

Cab precleaner 2 5

Product Link** 1 3

** Requires multiple quantities.

** Available mid-2005.

Mandatory Attachments (select one from each group)

Mandatory and optional equipment may vary. Consult your Caterpillar dealer for specifics.

kg lb

LIFT ARRANGEMENTS

Standard 0 0

High Lift 3186 7,024

Super High Lift 17 729 39,085

FUEL LINES

No heater 0 0

With heater 6 13

Cold weather starting 32 71

RIMS

914 mm (36") wide 0 0

1118 mm (44") wide

with 126 mm (6") flange 428 944

1194 mm (47") wide

with 126 mm (6") flange 459 1,012

STARTERS

Air start, turbine, Ingersoll 0 0

Air start, turbine, TDI 0 0

Electric- not recommended in ambient

temperatures below 0° C (32° F) 0 0

kg lb

Page 29

994F Wheel Loader specifications

29

Notes

Page 30

994F Wheel Loader specifications

30

Notes

Page 31

994F Wheel Loader specifications

31

Notes

Page 32

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2007 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow”

and the POWER EDGE trade dress, as well as corporate and product identity used

herein, are trademarks of Caterpillar and may not be used without permission.

AEHQ5640-02 (12-07)

Replaces AEHQ5640-01

994F Wheel Loader

R

Loading...

Loading...