Page 1

Engine

Engine Model Cat®C32 ACERT™

Gross Power – SAE J1995 782 kW 1,050 hp

Net Power – SAE J1349 708 kW 950 hp

• Cat®engine with ACERT™ Technology – U.S. EPA Tier 2,

EU Stage II compliant

Buckets

Bucket Capacities 12.2-23.7 m

3

16-31 yd

3

Operating Specifications

Operating Weight 133 637 kg 294,800 lb

Breakout Force 709.2 kN 159,562 lb

Static Tipping Load, 71 667 kg 158,026 lb

Full Turn

993K

Wheel Loader

®

®

Page 2

2

993K Wheel Loader

K-Series Wheel Loaders – the Next Generation in Performance

Keeping with the legacy of Caterpillar

®

quality and reliability, the wheel loader

line has expanded with the new Cat 993K.

The 993K offers greater productivity,

improved safety and enhanced operator

comfort for your toughest digging

applications.

High Lift Arrangement Optional

Attachment

• Optional High Lift Arrangement is

the pass match loader for the Cat 785

Off-Highway Truck

• Standard Lift Arrangement is the

pass match loader for the Cat 777

Off-Highway Truck pg. 18

Owning and Operating Costs

• Machine features extend machine life

and minimize downtime

• Centralized service center and ground

level access minimizes serviceability

• Cat dealers offer total customer

support unmatched in the industry

pg. 16

Safety

• Key features to improve all around

machine visibility

• Standard and optional features that

allow operators to safely get on and

off the machine

• Ergonomics improve operator

environment. pg. 8

Performance

• Lower your cost per ton by delivering

maximum payloads

• Developed to optimize pass match

with key size class trucks and job site

requirements

• Improved system design gives the

993K optimal productivity. pg. 6

Reliability/Durability

• High rebuild hours and structure life

increase 993K reliability

• Machine systems that ensure minimal

downtime and maximum availability

• Easy serviceability minimizes daily

checks with quick routine maintenance

turnaround pg. 4

Page 3

3

Buckets and Work Tools

• Numerous bucket options meet your

application needs

• Ground Engaging Tools with Cat

®

K Series™ Tips increase machine

productivity pg. 14

Operator Comfort

• Best-in-class working environment for

operator comfort and functionality

• Ease of operation for improved

operator efficiency

• Ergonomic standards for long shift

hours pg. 12

Serviceability

• Centralized service centers for

convenient maintenance

• Convenient access to service points

• Monitoring systems and dealer

support reduce unexpected downtime

pg. 10

Page 4

• Proven components and high hour

rebuild and machine life standards

provide proven reliability

• Machine systems working together

in the harshest environments

• Diagnostic programs are available

to monitor machine health and

maintain uptime

MACHINE LIFE. The 993K is designed

to meet customer rebuild requirements

and a high hour structure life. This is

accomplished through design emphasis

put on key components:

Caterpillar Designed Components.

Components used to build Cat Wheel

Loaders are designed and manufactured

to Caterpillar quality standards to

ensure maximum performance even

in extreme operating conditions.

• Linkage. The 993K features the field

proven Z-bar linkage design with new

maintenance-free sleeve bearing (SB)

pins. A key benefit of the SB pins is

when maintenance is required, customers

can schedule change out of pins on a

planned maintenance day. Design of the

SB pins allows this planned downtime

due to the fact it has low risk of

consequential damage. In addition,

significant growth in width for support

of the Z-bar linkage further increases

strength and durability.

• Cat Planetary Power Shift

Transmission. The 993K has increased

strength and reliability by utilizing a

similar planetary gear group used in

the Cat 994F.

• Front and Rear Frames. The front and

rear frames are spread further apart

for improved bearing life. A key

differentiator from competitive machines

is the box section rear frame and four

plate loader tower. The box section

absorbs torsional forces generated in a

loading cycle, maintaining alignment

for hitch pins and drive line. The fourplate loader tower resists shock and

torsional loads maintaining hitch and

loader linkage pin alignment.

• Axle Shaft Service Brake. Sharing

similar components with the Cat D9R,

this service brake provides improved

retarding capabilities and better braking

ability. Positive oil flow and brake oil

cooling result in improved brake disc

durability. Additionally, the 993K

third gear run out stopping distance

is greatly reduced.

4

Reliability, durability, uptime of the machine – it’s what you expect for your bottom line.

Reliability/Durability

Page 5

• Next Generation Modular Radiator

(NGMR). Utilizing 14 parallel flow

system modular cores, the NGMR

increases cooling performance by only

drawing cooler ambient air through the

radiator system.

PROVEN ENGINE TECHNOLOGY.

The 993K utilizes the Cat

®

C32 engine

which fully meets U.S. EPA Tier 2/EU

Stage II emissions requirements.

This Mechanically Actuated Electronically

Controlled Unit Injection (MEUI) diesel

engine shares a common platform with

the Cat 777F, 854K, 992K and Dll.

DIAGNOSTIC PROGRAMS.

Monitoring product health is key to

maintaining reliability of any equipment.

Many programs are available on the 993K,

both as standard and optional features,

to help you track machine condition.

VIMS Monitoring System with Enhanced

Display. Monitoring over 100 machine

parameters, VIMS records these

parameters for maintaining and optimizing

the machine. VIMS features System

Events and Data Events, giving

notification from machine malfunction

to changes in pre-programmed

machine settings.

Product Link. Product Link is a stateof-the-art satellite technology based

product that provides an information

flow between machine on-board systems

and the Caterpillar operations center.

Multiple types of information can be

collected and tracked – from machine

location and service meter hours to

health and productivity information.

Equipment Manager. With a subscription

to Equipment Manager through the

Cat Dealer StoreFront, the information

collected through Product Link can be

transmitted to a computer. With fast,

easy-to-access machine information,

you can optimize asset utilization, reduce

security risks, improve maintenance

management and implement beforefailure repair strategies.

S·O·S

SM

Services. Keep minor repairs

from becoming major ones and avoid

complete failures. By regularly taking

samples from the ports provided, your

Cat dealer tracks wear of components

and parts, oil performance and oil

condition and uses that data to predict

wear-related problems before they happen.

5

Page 6

• Move more tons of material with

the increased productivity of this

25 ton loader

• Improved system design gives the

993K optimum productivity

• Pass match the 993K with the right

truck for improved job site efficiencies

MOVE MORE TONS. Lower your cost

per ton by delivering maximum

payload. This 25 ton rated loader can

help your bottom line with increased

productivity. This is accomplished

through additional power, improved

cycle time and continuously high

bucket fill factors on every dig cycle.

OPTIMUM PRODUCTIVITY. The 993K

has designed a number of key systems

and features to achieve the maximum

power for a machine of this size class.

Increased breakout force, more rimpull

coupled with fill factor and increased

power gives the 993K optimum

productivity.

Positive Flow Control (PFC). PFC

ensures faster hydraulic implement

response, giving the operator improved

feel and control of the bucket. With PFC,

customers see a decrease in cycle time.

Impeller Clutch Torque Converter

(ICTC)/Rimpull Control System.

Mixing new with a current validated

system, customers can maintain hydraulic

balance while digging and loading by

utilizing the ICTC/Rimpull Control

System. The ICTC enables the operator

to finely modulate rimpull for smooth

machine operation.

Steering System. Load sensing steering

reduces the demand on the hydraulic

system when steering is not activated.

By delivering only the power draw that

is needed, engine power is reserved for

productive work.

Double Reduction Final Drives.

The 993K final drives are built off the

D11 design platform and tailored for

wheel loader applications. The double

reduction final drives enable the increase

in rimpull. Additional benefits include

significantly reducing power train stresses

resulting in longer overall power train

life, durability and ease of service.

Linkage Pins. The 993K features durable,

service-free,oil filled and sealed-for-life

Cat Sleeve Bearing (SB) pins. The SB

pins eliminate the need for daily greasing

of the front linkage and requires no

routine maintenance for continued uptime.

B

r

a

k

e

s

(

2

0

%

R

i

m

p

u

l

l

)

100% Rimpull

Selected

Left Pedal

20% Rimpull

Selected

6

Delivery of performance is critical to your bottom line. When it comes to high productivity,

the 993K is designed with just that thought in mind.

Performance

Page 7

Cat Planetary Power Shift

Transmission. The 993K planetary

power shift transmission assists in the

increased rimpull. This transmission is

electronically controlled and features

three forward and three reverse speeds.

Transmission features include:

• Integrated shifting/steering control

with F/N/R rocker switch and

upshift/downshift switches.

• Transmission clutch control for

improved shift quality, component

life and operator comfort.

• ICTC for improved rimpull control

and transmission clutch durability.

Truck Pass Match. It is not always

about working harder, but working

smarter – optimize the wheel loader

to the trucks. This is accomplished

through even passes when loading and

optimizing operation for efficiencies.

The 993K was developed to optimize

pass match with key trucks in this size

class and job site requirements.

7

993K Pass Match

777 4 Pass

785 6 Pass

Page 8

• Good visibility for a safe work

environment

• Get your operator safely on and off

the 993K

• Daily and routine maintenance

features allow your service technician

to safely service the machine

IMPROVED VISIBILITY. Good visibility,

whether it is an operator needing front

viewing for positioning to a truck or

side viewing for vehicles or people in

the work area, is key to a safe work

environment. With a 14 percent increase

in cab space and a .6 m (2 ft) increase

in cab height, the operator has one of

the best viewing capabilities in the

industry for this wheel loader class size.

Additional standard visibility features

that enhance safety include:

• Long life LED tail lights

• Articulated wiper/washer system

with intermittent feature on front

and rear windows

Optional Rear Vision Camera with

In-Cab Monitor. An optional rear vision

camera with 178 mm (7 in), in-cab, color

display monitor is available to give a

close view of behind the wheel loader.

Working 24 Hours a Day. Any time

of the day and in all types of weather,

the 993K has a number of features

to ensure safe visibility. Rear heated

mirrors are available for quick defrost

and good visibility in winter conditions.

The optional High Intensity Discharge

(HID) lights provide exceptional lighting

for night work. Rotating warning beacons

are also available as a safety feature.

ACCESS and EGRESS. Getting on and

off the machine is one of the leading

causes of injury on a jobsite. The new

993K has several standard and optional

features that help to ensure your operators

get safely on and off the machine.

Wider Platform Access Stairs. Both left

and right stairways are standard and

have increased in width to provide

additional room, 600 mm (23.6 in),

for operators and service technicians to

access the cab and to perform platform

maintenance procedures. Optional

roading fenders are available to prevent

mud and debris build up on the steps

and rails.

8

People are the backbone of your business and keeping them safe and productive is the

number one priority. At Caterpillar, we have designed the 993K with your most important

asset in mind.

Safety

Page 9

Rear Access Egress System (RAES)

Attachment. An optional manlift

replaces the left hand ladder and lifts or

lowers the operator or service technician,

personal belongings and tools safely on

and off the platform.

MAINTENANCE SAFETY. Daily and

routine maintenance should not pose a

safety hazard to your operator or service

technician. With the 993K, design effort

was taken to group service points with

convenient access. With the standard

service or optional deluxe service center,

technicians can plan daily maintenance

by checking fluid levels and machine

parameters. This allows the technician

to prep for required maintenance and

take all material on the bumper platform

at one time rather than make trips on

and off the machine to get required

maintenance components or fluids.

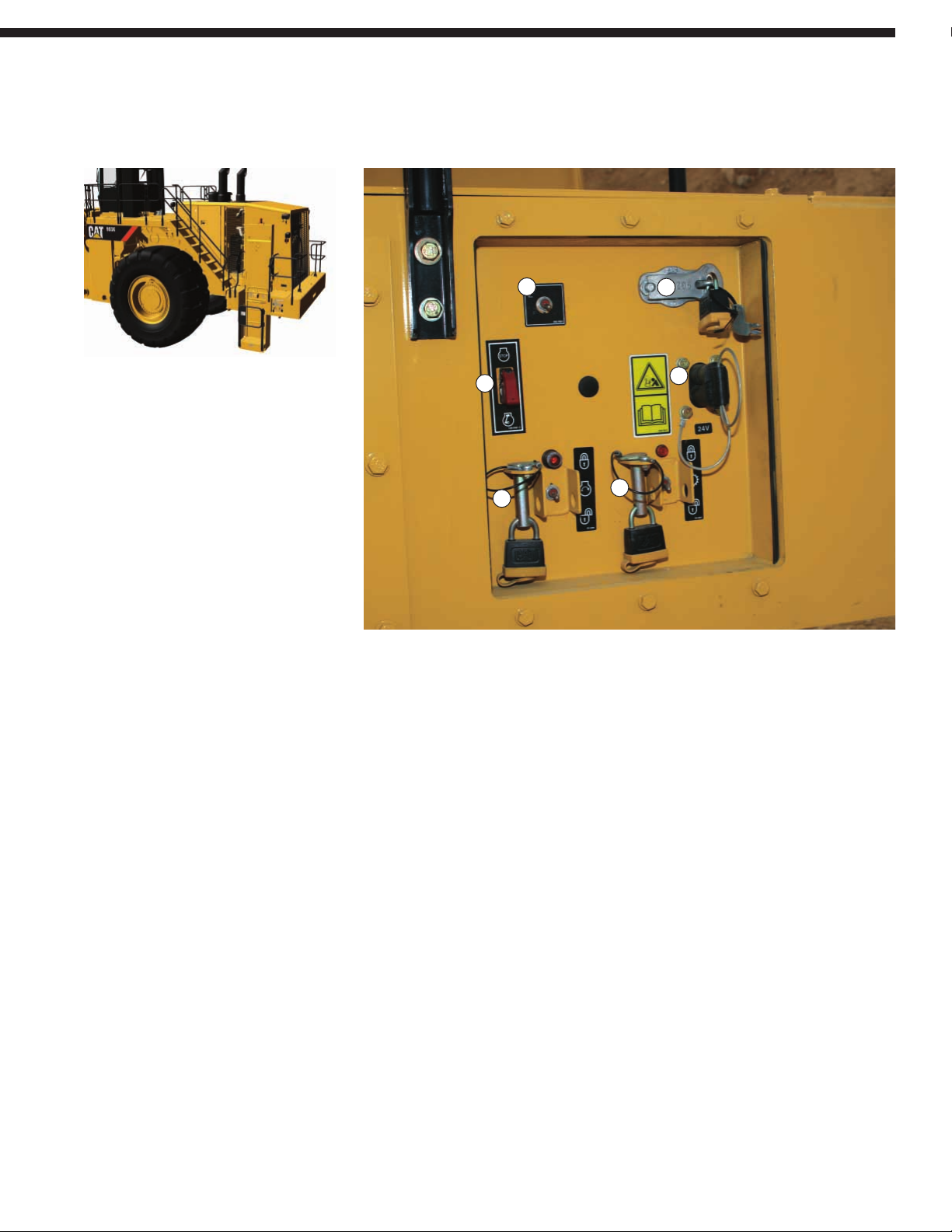

Bumper Service Center. Another key

safety service point is the Bumper

Service Center. A centralized service

center located at ground level on the left

hand, rear side of the 993K includes a

lockable battery disconnect (1), auxiliary

jump start receptacle (2), stairway light

switch (3) and engine shutdown switch

(4). This center also contains lockout

switches allowing your service technician

to perform routine maintenance while

ensuring the machine stays static.

Starter Lockout Switch (5). Key to

safety, another feature on the bumper

service center is a starter lockout that

stops the ability to start the machine,

which is often needed during service

procedures. The machine will still have

electrical power, however, the engine

cannot be started.

Transmission Lockout Switch (6).

The transmission lockout switch does

not allow the transmission to shift out

of neutral, even if running. This feature

is designed for service procedures that

requires machines to be running but

need the transmission disabled for

added safety.

SAFETY IN OPERATOR ENVIRONMENT.

The operator and safety go hand-in-hand.

Many features that enhance operator

comfort also aid in keeping your operator

safe from lowering noise levels to

design features that lower vibration and

repetitive motion. Key standard features

that aid operator safety include low

effort implement controls integrated

with the seat for ease of adjustment by

the operator, front windshield cleaning

platform with handrails and a seat belted

trainer’s seat for convenient operator

training on the job site. Additional safety

features include a cab filtration system

that removes dust and debris from the

cab air. Optional for dusty applications

is a cab pre-cleaner that reduces the

amount of dust prior to reaching the

cab filter.

SAFETY.CAT.COM™.

9

1

2

3

4

5

6

Page 10

• Minimize service time and

maximize production through key

ground level access points and

grouped service centers

• Monitoring the machine and

forewarning of machine trouble

allows you to plan daily maintenance

and schedule downtime to ensure

continued job site productivity

SERVICE ACCESS. Ground level access

service points, as well as grouped

serviced points, lead to easier

servicing, minimizing service time and

maximizing production. The 993K

offers five centralized service centers

located throughout the machine.

This allows a service technician to

perform a variety of service procedures

often ground level or platform from

access to the VIMS advisor to grease

fittings for the frame.

Standard Service Center. The 993K

offers one point of service for manual

grease points or AutoLube fast fill

(optional), implement and steering

hydraulic oil ecology drains, Cat

Electronic Technician, VIMS connection

points, 12-volt battery supply, key switch

to power ECMs, tray for computer and

a light for nighttime servicing.

Deluxe Service Center (Optional).

The optional deluxe service center

offers all the features of the Standard

Service Center and these additional

features:

• Indicator lights for add level on the

fuel, windshield fluid, engine oil,

engine coolant, implement oil,

transmission oil, steering oil,

Oil Renewal System (ORS) and

AutoLube, if equipped

• Fluid drain and fill for the engine,

engine coolant, hydraulic tank,

transmission, steering and brake

hydraulic oils, ORS reservoir and

AutoLube Quick Fill

• VIMS messenger display and power

switch (advisor display in the cab)

Bumper Service Center. The bumper

service center features safety service

controls including starter, transmission

lockouts, emergency engine shutdown

and battery disconnect. The bumper

service center also features an auxiliary

starting receptacle and stairway

light switch.

REMOTE DIAGNOSTIC PRESSURE PORTS.

Front Frame Hydraulic Center. The front

frame hydraulic center is accessible

from the ground level right side and

provides one location to monitor

implement pump pressures.

Rear Frame Hydraulic Center. The rear

frame service center is accessible from

the cab platform and provides one

location to monitor rear frame pressures

like fan pump, steering pump, brake

accumulator, impeller clutch torque

convertor, lock up clutch and

transmission pressures.

Hydraulic and Engine Service Area.

On top of the platform are access panels

for the hydraulic implement filters,

fuel filters, implement pilot filter,

fuel water separator and implement

tank breaker relief.

Electronic Service Center. A centralized

electronic service center is located on

the right side of the cab and provides

one service point for transmission

implements, ECMs, breakers and fuses.

It is isolated from machine vibration

and sealed against weather elements.

10

The 993K is designed to ensure minimal downtime through ground level access, grouped

service points and attention to key serviceable areas on the machine, so the 993K spends

its time working, not being worked on.

Serviceability

Page 11

AutoLube System Option. The AutoLube

System provides precise, automatic

lubrication of pins and bushings while

the machine is in operation. Automatic

lubrication reduces time spend on daily

maintenance and downtime for unplanned

repairs due to insufficient greasing.

DIAGNOSTICS. The 993K offers

customers the ability to troubleshoot,

monitor machine information, customize

operator settings for continuity of

operation and set machine configuration.

A number of these tasks are accomplished

through the new VIMS advisory

monitoring system that monitors over

100 machine parameters. VIMS Advisor

is bigger and allows for more descriptive

text displays. Additional capabilities

include alerting the operator to

malfunction in machine systems

or a change in machine settings.

S·O·SSMServices. Keep minor repairs

from becoming major ones and avoid

complete failures. By regularly taking

samples from the ports provided, your

Cat dealer tracks and predicts wear of

components and parts, oil performance

and oil condition.

ADDITIONAL SERVICE SUPPORT.

Product Link. Product Link is a state-

of-the-art satellite technology based

product that provides an information

flow between machine on-board systems

and the Caterpillar operations center.

Equipment Manager. With a subscription

to Equipment Manager through the

Cat Dealer StoreFront, the information

collected through Product Link can be

transmitted to a computer.

DEALER SUPPORT. The Cat global

network of independently owned dealers

is the best in the world at providing

support to keep your loader up and

running. Known for parts availability

and technical expertise, Cat dealers

are partners in your business.

Service Capabilities. Cat field service

technicians have the experience and

tools necessary to service your loader

on site. Field service trucks are fully

loaded with state-of-the-art tools

and diagnostic equipment as well as

specifications and schematics for every

Cat machine. Technical experts at the

dealership and Caterpillar are available

to provide assistance to field service

technicians when needed.

When on-site repair isn’t enough,

Cat dealerships are fully equipped

to service your loader quickly.

PARTS AVAILABILITY. Caterpillar

provides an unsurpassed level of

personalized service for your wheel

loader. With parts distribution centers

throughout the world, most parts can

be delivered in 24 hours.

REMANUFACTURED PARTS. Cat engines

and major components are designed to

be remanufactured and provide multiple

life cycles. The Cat Reman program

is more extensive than most rebuild

programs. Components are actually

remanufactured in the factory to the

original specifications with necessary

product updates. Reman products are

stocked in distribution centers around

the world and are ready to install

to minimize downtime, maintain

productivity and profitability. You receive

the same warranty and reliability as

new products at a cost savings of

40 to 70 percent.

11

Page 12

• Best-in-class working environment

for this wheel loader size class

• Greater control and ease of

operation for your operator

• Ergonomically designed for the

health and safety of your operator

OPERATING ENVIRONMENT. The 993K

cab has been ergonomically designed to

offer operators the best in working class

environment.

Seat. The Cat Comfort air suspension

seat, standard in the 993K, is built strong

and durable and is six-way adjustable

to accommodate operators of all sizes.

The seat features an automotive-style

lumbar support for maximum comfort.

The right hand armrest with integrated

implement controls adjusts for

comfortable, convenient operation.

A heated seat option is available for

additional comfort.

Operator Training. A 14 percent increase

in cab size allows room for a trainer

seat with 76.2 mm (3 in) seat belt.

This allows for a safe method to properly

train your operator.

Entry and Exit. Wider stairways and

two side access points are just two

features added to the 993K to assist

the operator in getting on and off

the machine.

Another key option is the powered

Rear Access Egress System (RAES)

that assists in access from the groundto-stairway platform.

12

The new 993K has been ergonomically designed to enhance operator comfort – contributing

to a more productive job site.

Operator Comfort

Page 13

Ease of Operation. The main control

panel on the 993K is located to the right

of the operator’s seat, keeping everything

within reach of the operator. All switches

and controls are conveniently placed

to allow efficiency and improved

productivity all while minimizing

operator fatigue.

Special attention was paid to implement

control effort and location. The implement

controls are fully adjustable and seat

mounted to allow the operator to set

the controls to their size. With operator

repetitive motions, fatigue is minimized

with low-effort implement controls.

VISIBILITY. The 993K provides excellent

visibility to both the front and rear of

the machine. The cab has been raised

two feet for better visibility to the truck

body. Wipers with intermittent feature

on both front and back keep the windows

clean in any condition. The cab roof has

channels that direct rain off the corners

of the cab, helping keep windows clear.

Rear Vision Camera. An optional rear

vision camera is available to clearly

monitor movement behind the

wheel loader.

Windshield Cleaning Package.

A windshield cleaning package

provides additional steps and handrails

to provide easy access for cleaning

the front windows.

Additional optional features that

enhance visibility include high intensity

discharge (HID) lighting package and

rotating warning beacons.

ERGONOMICS. Caterpillar understands

that wheel loaders work in some of the

harshest environments. By controlling

normal machine vibrations and sound

levels, operator efficiency and productivity

are improved. From the ground up, the

Cat 993K is designed with many features

(standard and optional) that reduce

vibration.

• When working, the noise inside

and outside the 993K cab has been

lowered with an operator sound

level of 72 dB(A)

• Ride Control is an option designed

to reduce jolting and bouncing

during load and carry operations.

An accumulator acts as a shock

absorber to reduce machine pitching

and provide a smoother ride over

rough terrain

• Electronically controlled, automatic

kickouts provide a smooth modulated

cylinder stop throughout the

digging cycle.

• Air suspension seat-mounted

implement controls reduce vertical

vibrations that come up through

the floor

All these features minimize operator

fatigue, resulting in operator comfort

and productivity.

13

Page 14

CAT BUCKETS. Cat buckets and

Ground Engaging Tools (GET) provide

versatility on any job site. Proper bucket

and application match delivers increased

stability and maximum productivity.

To better match your 993K to material

conditions, contact your Cat dealer for

specialty bucket needs.

Buckets. For the 993K, bucket capacities

range in size from 12.2-14.5 m

3

(16-19 yd3). The following information

highlights bucket specifications and

available buckets.

Heavy Duty Rock Bucket. For use in

extremely aggressive applications such

as face loading tightly compacted pit

material. Intended for use in materials

where moderate abrasion and impact

is encountered.

High Abrasion Bucket. For use in

extremely aggressive applications such

as face loading iron ore. Intended for

use in materials where high abrasion

and moderate impact is encountered

and a smooth floor is desired.

Coal Bucket. A 23.7 m

3

(31 yd3) bucket

for use in coal or other light density

non-abrasive materials.

Custom Buckets. Cat

®

Work Tools can

design a bucket for your specific needs

and material densities. Contact your

Cat dealer for more information.

Ground Engaging Tools (GET). Cat GET

increase machine productivity and protect

the expensive structural components

of your bucket.

Bucket Wings (optional). Bucket wings

provide additional tire protection by

deflecting rocks away from the path

of the tire. Bucket wings can be added

to all buckets.

Moderate and Abrasive. Key GET

utilized in these types of applications

include:

• Bucket tips

• Bolt-on segments

• Top wear plates

• Sidebar protectors

• Base edge wear plates

• Mechanically Attached Wear

Plates (MAWPS)

• Weld-on heel shrouds

Sidebar Protector

Extreme Applications. For use in extreme

applications such as face loading granite,

GET recommendations include:

• Half-arrow segments

• Adapter covers

• Top wear plates

• Dual (4) sidebar protectors

• Base edge wear plates

• Bucket wings

• Inner and outer liners

• Bucket wings

14

The combination of the right bucket and Ground Engaging Tools with the right machine

will provide the best possible performance in your application.

Buckets and Work Tools

Page 15

Cat®K Series™ Tips. The newest

generation of GET works harder and

lasts longer. K Series GET offers:

• Hammerless installation and removal

• Tips are held in place with a

one-piece, vertical retainer

• Sleeker, sharper digging profile

provides better penetration

Heavy Penetration. Recommended for

high abrasive and impact conditions,

especially shot rock

• Excellent penetration and wear

material stays sharp

Heavy Abrasion. Recommended for

high abrasive, low-to-moderate impact,

easier-to-penetrate materials

• Excellent wear material,

less penetration

General Duty. Recommended for general

applications with up to moderate impact

and abrasive conditions

• Good penetration, self-sharpening

cavities

Extra Duty. Recommended for general

applications requiring more wear material

in moderate-to-high impact conditions

• Good wear material, good penetration

Penetration. Recommended for harderto-penetrate, moderate-to-high impact,

lower abrasive materials

• Very good penetration, less wear

material stays sharp

15

Fill Factor kg/m3(lb/yd3)m

100% 22.7 (25.0) 12.2 (16) 2834 (3,125)

110% 24.9 (27.5) 12.2 (16) 3118 (3,438)

90% 20.4 (22.5) 12.2 (16) 2551 (2,813)

100% 22.7 (25.0) 12.9 (17) 2667 (2,941)

110% 24.9 (27.5) 12.9 (17) 2934 (3,235)

90% 20.4 (22.5) 12.9 (17) 2400 (2,647)

100% 22.7 (25.0) 13.8 (18) 2519 (2,778)

110% 24.9 (27.5) 13.8 (18) 2772 (3,056)

90% 20.4 (22.5) 13.8 (18) 2268 (2,500)

100% 22.7 (25.0) 14.5 (19) 2387 (2,632)

110% 24.9 (27.5) 14.5 (19) 2626 (2,895)

90% 20.4 (22.5) 14.5 (19) 2148 (2,368)

Payload Bucket Capacity Material Density

3

(yd3) kg/m3(lb/yd3)

Page 16

• Machine design features that extend

machine life and minimize downtime

keep the 993K in production

• Ease of serviceability for the 993K

includes centralized service centers

and ground level access. Less service

time means more working time

• Key machine monitoring allows for

key or standard maintenance to be

scheduled around your production

schedule

• Cat dealers offer total customer

support that’s unmatched in the

industry

MACHINE AND COMPONENT LIFE.

With a high hour structure life and key

life of major components, the 993K is

a leader in durability and structural life.

Additionally, commonality of components

with other Cat machines such as the

994F transmission and the C32 engine

used on the D11 and 777F, ensure proven,

field tested components that give

maximum life.

Sleeve Bearing Linkage Pins. The new

sleeve bearing linkage pins feature an

innovative design that virtually eliminates

any galling that can occur. Additionally,

with any pin failures, an early predictor

allows the customer to maintain machine

production and schedule downtime on

a regular maintenance day. Longer life

and predictable wear mean you get

maximum performance at the lowest

possible operating cost.

EASE OF SERVICEABILITY. Less downtime

means more working time. Centralized

service centers were designed for

ease of access which leads to easier

serviceability.

16

The 993K is engineered to provide durability, reliability, ease of serviceability and maximum

productivity for minimal downtime and machine life...putting more to your bottom line.

Owning and Operating Costs

Page 17

Key Service Centers. Service points

are clustered in five centralized service

centers, most of which can be accessed

safely from ground level. The five key

service centers are:

• Standard Service Center offering

one point of service for a number of

key service features. Available as an

option is the Deluxe Service Center

with the same features of the Standard

Service Center, as well as additional

fluid indicator lights, fluid drain

and fill connections and VIMS

Messenger Display

• Bumper Service Center with a

number of safety service controls

• Remote Diagnostic Ports front and

rear frame

• Hydraulic and Engine Service Area

• Electronic Service Center

MACHINE MONITORING. Monitoring the

machine and forewarning of machine

trouble allows you to schedule downtime

and ensure job site productivity.

VIMS Advisory Monitoring System.

Allows you to monitor over 100 machine

parameters and alerts the operator to

malfunctions in machine systems or

a change in machine settings.

CAT DEALER. Your Cat dealer offers a

wide range of services that can be set

up under a customer support agreement

when you purchase your equipment.

Your dealer will help you choose a plan

that will cover everything from machine

and work tools selection to replacement

so you get the best return on your

investment.

Selection. Make detailed comparisons

of the machines you are considering

before you buy. How long do components

last? What is the cost of preventive

maintenance? What is the cost of lost

production? Your Cat dealer can give

you precise answers to these questions.

Purchase. Look past initial price.

Consider the financing options available

as well as day-to-day operating costs.

This is also the time to look at dealer

services that can be included in the cost

of the machine to yield lower equipment

owning and operating costs over the

long run.

Operation. Improving operating

techniques can boost your profits.

Your Cat dealer has training videos,

literature and other ideas to help you

increase production.

Product Support. You will find nearly

all parts at our dealer parts counter.

Cat dealers utilize a world-wide computer

network to find in-stock parts to minimize

machine downtime. You can save money

with remanufactured parts and get the

same warranty and reliability as new

products but with a 40 to 70 percent

cost savings.

17

Page 18

High Lift Arrangement. Provides up to

645 mm (2.1 ft) more dump clearance

at full lift and 45 degree discharge and

100 mm (3.94 in) in additional reach

than the standard 993K lift arrangement.

Truck Match.

• The 993K standard lift arrangement

is recommended for use with the

Cat 777 Off-Highway Truck.

• The 993K optional high lift

arrangement is designed to match

the Cat 785 Off-Highway Truck.

NOTE. 1 and 3 dump clearance at full

lift and 45° dump. 2 and 4 reach at full

lift and 45° dump.

18

The 993K will meet your needs with a standard lift arrangement or the optional high lift

arrangement.

High Lift Arrangement Optional Attachment

777 Truck

1 3

High Lift Arrangement Standard Lift Arrangement

785 Truck

High Lift Arrangement Standard Lift Arrangement

2 4

1 3

2 4

Page 19

19

993K Wheel Loader specifications

Service Refill Capacities

Fuel Tank 2063 L 545 gal

Cooling System 318 L 84 gal

Crankcase 120 L 32 gal

Transmission 170 L 45 gal

Differentials and 493 L 130 gal

Final Drives – Front

Differentials and 485 L 128 gal

Final Drives – Rear

Hydraulics – Lift/Tilt 475 L 126 gal

Hydraulics – Steering/Brake 185 L 49 gal

Buckets

Bucket Capacities 12.2-23.7 m316-31 yd

3

Coal Bucket 23.7 m

3

31 yd

3

Brakes

Brakes Meet SAE J1473, OCT90

and ISO 3450:1992

Cab

Cab – ROPS/FOPS Meets SAE and

ISO standards

• Cat cab with integrated Rollover Protective Structure (ROPS)

are standard in North America and Europe

• ROPS meets SAE J1040 APR88 and ISO 3471:1994 criteria

• Falling Objects Protective Structure (FOPS) meets SAE J231

JAN81 and ISO 3449:1992 Level II criteria

• The operator sound pressure level measured according to

the procedures specified in ISO 6394:1998 is 72 dB(A) for

the cab offered by Caterpillar, when properly installed and

maintained and tested with the doors and windows closed

• Hearing protection may be needed when operating with an

open operator station and cab (when not properly maintained

or doors/windows open) for extended periods or in noisy

environments

Engine

Engine Model Cat®C32 ACERT™

Gross Power – SAE J1995 782 kW 1,050 hp

Net Power – SAE J1349 708 kW 950 hp

• Cat engine with ACERT™ Technology – U.S. EPA Tier 2,

EU Stage II compliant

Operating Specifications

Rated Payload 22.7 tonnes 25 tons

Operating Weight 133 637 kg 294,800 lb

Breakout Force 709.2 kN 159,562 lb

Static Tipping Load, Full Turn 71 667 kg 158,026 lb

• For 13 m3(17.0 yd3) bucket

Transmission

Converter Drive – Forward 1 6.9 km/h 4.3 mph

Converter Drive – Forward 2 11.9 km/h 7.4 mph

Converter Drive – Forward 3 20.1 km/h 12.5 mph

Converter Drive – Reverse 1 7.6 km/h 4.7 mph

Converter Drive – Reverse 2 13.2 km/h 8.2 mph

Converter Drive – Reverse 3 22.1 km/h 13.7 mph

Direct Drive – Forward 1 Lock-up disabled

Direct Drive – Forward 2 12.4 km/h 7.7 mph

Direct Drive – Forward 3 21.9 km/h 13.6 mph

Direct Drive – Reverse 1 7.7 km/h 4.8 mph

Direct Drive – Reverse 2 13.7 km/h 8.5 mph

Direct Drive – Reverse 3 24.2 km/h 15 mph

• Based on two percent rolling resistance and 50/65-51 tires

Hydraulic Cycle Time

Rackback 2.4 Seconds

Raise 9.4 Seconds

Dump 2.1 Seconds

Lower Float Down (Empty) 6.7 Seconds

Power Down 5.1 Seconds

Page 20

20

993K Wheel Loader specifications

Loader Hydraulic System

Relief Valve Setting 29 500 kPa 4,278 psi

Cylinders, Double Acting: 266.7 mm 10.5 in

Lift, Bore and Stroke 1882 mm 84 in

Cylinder, Double Acting: Tilt, 235 mm 9.3 in

Bore and Stroke 1040 mm 41 in

• Pumps (3), fully variable E/H displacement control –

180 cc (1) and 250 cc (2)

Tires

Tires Choose from a variety

of tires to meet your

application

• Choice of:

- 50/65R51, VSDL BS L5 Bridgestone

- 50/65-51,62PR BS DL L5 Bridgestone

- 50/65 R51, MX L5 Michelin

• NOTE: In certain applications (such as load and carry)

the loader’s productive capabilities might exceed the tires’

tonnes-km/h (ton/mph) capabilities. Caterpillar recommends

that you consult a tire supplier to evaluate all conditions

before selecting a tire model

Page 21

21

993K Wheel Loader specifications

Dimensions

All dimensions are approximate.

8

1

2

3

4

1 Height to top of ROPS 6000 mm (19.7 ft) 6000 mm (19.7 ft)

2 Height to top of stack 5448 mm (17.9 ft) 5448 mm (17.9 ft)

3 Height to top of hood 4252 mm (14.0 ft) 4252 mm (14.0 ft)

4 Height to top of bumper 1791 mm (5.9 ft) 1791 mm (5.9 ft)

5 Height to center axle 1535 mm (5.0 ft) 1535 mm (5.0 ft)

6 Bumper clearance 1180 mm (3.9 ft) 1180 mm (3.9 ft)

7 Ground clearance 590 mm (2.0 ft) 590 mm (2.0 ft)

8 Reach at 45° dump (tooth tip) 2503 mm (8.2 ft) 2612 mm (8.6 ft)

9 Clearance at 45° dump (tooth tip) 4654 mm (15.3 ft) 5299 mm (17.4 ft)

10 Bucket pin height at full lift 7002 mm (23.0 ft) 7647 mm (25.1 ft)

11 Maximum overall height

Bucket raised 9789 mm (32.1 ft) 10 433 mm (34.0 ft)

12 Wheel base 5890 mm (19.4 ft) 5890 mm (19.3 ft)

13 Maximum overall length 15 214 mm (50.0 ft) 15 846 mm (52.0 ft)

6

5

993K Standard Lift 993K High Lift

50/65R51 Tires 50/65R51 Tires

7

12

13

11

10

9

Tire used is a 50/65R51 Bridgestone 2** with static radial 1347 mm (4.4 ft)

Page 22

22

993K Wheel Loader specifications

Operation/Bucket Specifications – Standard Lift

Bridgestone 2** Bridgestone 2** Bridgestone 2** Bridgestone 2**

Bucket Type Rock Rock Rock Rock

Ground Engaging Tools Teeth & Segments Teeth & Segments Teeth & Segments Teeth & Segments

Cutting Edge Type Spade Spade Spade Spade

Bucket Part No. (Group Level) 303-3270 303-3310 303-3260 303-3330

Standard High Standard High

Rock Abrasion Rock Abrasion

Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift

Rated capacity (§)m

Struck capacity (§)m

Heaped capacity (§)m

3

13.0 13.0 13.0 13.0 12.0 12.0 12.0 12.0

3

17.0 17.0 17.0 17.0 16.0 16.0 16.0 16.0

yd

3

10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0

3

13.1 13.1 13.1 13.1 13.1 13.1 13.1 13.1

yd

3

13.0 13.0 13.0 13.0 12.0 12.0 12.0 12.0

3

17.0 17.0 17.0 17.0 16.0 16.0 16.0 16.0

yd

Width (§) mm 5080 5080 5160 5160 5080 5080 5160 5160

ft 16.7 16.7 16.9 16.9 16.7 16.7 16.9 16.9

Dump clearance at full lift and

45° discharge (§) mm 4654 5299 4721 5366 4744 5389 4769 5414

ft 15.3 17.4 15.5 17.6 15.6 17.7 15.6 17.8

Reach at full lift and

45° discharge (§) mm 2503 2612 2507 2616 2413 2522 2459 2568

ft 8.2 8.6 8.2 8.6 7.9 8.3 8.1 8.4

Reach with lift arms horizontal

and bucket level mm 4922 5438 4878 5394 4794 5310 4810 5326

ft 16.1 17.8 16.0 17.7 15.7 17.4 15.8 17.5

Digging depth (§) mm 246 313 231 298 246 313 231 298

in 9.7 12.3 9.1 11.7 9.7 12.3 9.1 11.7

Overall length (§) mm 15 214 15 846 15 158 15 792 15 086 15 718 15 090 15 724

ft 49.9 52.0 49.7 51.8 49.5 51.6 49.5 51.6

Overall height with bucket

at full raise (§) mm 9789 10 433 9762 10 407 9680 10 325 9680 10 325

ft 32.1 34.2 32.0 34.1 31.8 33.9 31.8 33.9

Loader clearance circle with bucket

in carry position (§) mm 11 018 11 312 11 021 11 315 11 019 11 313 11 003 11 296

ft 36.1 37.1 36.2 37.1 36.2 37.1 36.1 37.1

Static tipping load straight †(§) kg 84 525 70 917 83 129 69 597 84 691 71 113 83 728 70 165

lb 186,378 156,372 183,300 153,460 186,743 156,803 184,620 154,714

Static tipping load at full

40° turn

††

(§) kg 73 327 61 061 71 956 59 759 73 509 61 269 72 542 60 318

lb 161,687 134,639 158,663 131,769 162,087 135,097 159,956 133,002

Static tipping load at full

††

43° turn

(§) kg 71 667 59 599 70 299 58 301 71 851 59 809 70 884 58 858

lb 158,026 131,417 155,010 128,553 158,431 131,879 156,299 129,782

Breakout force ††(§) kN 709.2 708.5 725.1 724.4 753.1 752.4 751.6 750.8

lb 159,562 159,416 163,147 162,980 169,437 169,282 169,113 168,940

Operating weight †(§) kg 133 637 134 603 134 620 135 586 133 374 134 340 134 174 135 140

lb 294,670 296,800 296,838 298,968 294,091 296,221 295,855 297,985

Rock Rock

(§)

Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers. SAE Standards

J732C govern loader ratings and are denoted in the text by

† Static tipping load and operating weight shown are based on standard machine configuration with a full fuel tank, coolant, lubricants

and operator.

†† Measured 102 mm (4.0"): behind tip of segments with bucket hinge pin as pivot point in accordance with SAE J732C.

(§).

Page 23

23

993K Wheel Loader specifications

Bridgestone 2** Bridgestone 2** Michelin Michelin Michelin Michelin

Rock Rock Rock Rock Rock Rock

Teeth & Segments Teeth & Segments Teeth & Segments Teeth & Segments Teeth & Segments Teeth & Segments

Spade Spade Spade Spade Spade Spade

303-3280 303-3290 303-3270 303-3310 303-3260 303-3330

Standard Standard Standard

Rock Rock Rock

High Standard High

Abrasion Rock Abrasion

Rock Rock

Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift

13.8 13.8 14.5 14.5 13.0 13.0 13.0 13.0 12.0 12.0 12.0 12.0

18.0 18.0 19.0 19.0 17.0 17.0 17.0 17.0 16.0 16.0 16.0 16.0

11.0 11.0 12.0 12.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0

14.4 14.4 15.7 15.7 13.1 13.1 13.1 13.1 13.1 13.1 13.1 13.1

14.0 14.0 14.5 14.5 13.0 13.0 13.0 13.0 12.0 12.0 12.0 12.0

18.3 18.3 19.0 19.0 17.0 17.0 17.0 17.0 16.0 16.0 16.0 16.0

5080 5080 5080 5080 5080 5080 5160 5160 5080 5080 5160 5160

16.7 16.7 16.7 16.7 16.7 16.7 16.9 16.9 16.7 16.7 16.9 16.9

4555 5200 4555 5200 4675 5320 4742 5387 4765 5410 4790 5435

14.9 17.1 14.9 17.1 15.3 17.5 15.6 17.7 15.6 17.8 15.7 17.8

2602 2711 2602 2711 2501 2610 2505 2614 2411 2520 2457 2566

8.5 8.9 8.5 8.9 8.2 8.6 8.2 8.6 7.9 8.3 8.1 8.4

5062 5578 5062 5578 4920 5436 4876 5392 4792 5308 4808 5324

16.6 18.3 16.6 18.3 16.1 17.8 16.0 17.7 15.7 17.4 15.8 17.5

246 313 246 313 225 292 210 277 225 292 210 277

9.7 12.3 9.7 12.3 8.9 11.5 8.3 10.9 8.9 11.5 8.3 10.9

15 354 15 986 15 354 15 986 15 198 15 832 15 142 15 778 15 070 15 704 15 074 15 710

50.4 52.4 50.4 52.4 49.9 51.9 49.7 51.8 49.4 51.5 49.5 51.5

9789 10 433 9918 10 563 9810 10 454 9783 10 428 9701 10 346 9701 10 346

32.1 34.2 32.5 34.7 32.2 34.3 32.1 34.2 31.8 33.9 31.8 33.9

11 054 11 352 11 054 11 352 11 016 11 311 11 019 11 314 11 017 11 312 11 002 11 295

36.3 37.2 36.3 37.2 36.1 37.1 36.2 37.1 36.1 37.1 36.1 37.1

83 351 69 907 83 573 70 031 83 938 70 400 82 544 69 081 84 104 70 596 83 141 69 649

183,788 154,145 184,278 154,418 185,083 155,232 182,008 152,323 185,450 155,665 183,327 153,576

72 228 60 109 72 404 60 197 72 809 60 604 71 439 59 304 72 991 60 813 72 024 59 862

159,262 132,540 159,650 132,735 160,544 133,633 157,523 130,765 160,945 134,092 158,814 131,996

70 578 58 656 70 747 58 739 71 159 59 152 69 792 57 854 71 343 59 362 70 376 58 411

155,625 129,337 155,998 129,520 156,905 130,430 153,892 127,568 157,312 130,893 155,179 128,797

665.7 665.0 664.5 663.9 710.9 710.1 726.8 726.0 754.8 754.0 753.4 752.5

149,771 149,633 149,509 149,371 159,941 159,773 163,533 163,343 169,837 169,659 169,511 169,315

134 088 135 054 134 263 135 229 132 877 133 843 133 860 134 826 132 614 133 580 133 414 134 380

295,665 297,795 296,051 298,181 292,995 295,125 295,162 297,292 292,415 294,545 294,179 296,309

Page 24

24

993K Wheel Loader specifications

Operation/Bucket Specifications – High Lift

Michelin Michelin Bridgestone 62 PR Bridgestone 62 PR

Bucket Type Rock Rock Rock Rock

Ground Engaging Tools Teeth & Segments Teeth & Segments Teeth & Segments Teeth & Segments

Cutting Edge Type Spade Spade Spade Spade

Bucket Part No. (Group Level) 303-3280 303-3290 303-3270 303-3310

Standard Standard Standard High

Rock Rock Rock Abrasion

Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift

Rated capacity (§)m

Struck capacity (§)m

Heaped capacity (§)m

Width (§) mm

3

14.0 14.0 14.5 14.5 13.0 13.0 13.0 13.0

3

yd

18.0 18.0 19.0 19.0 17.0 17.0 17.0 17.0

3

11.0 11.0 12.0 12.0 10.0 10.0 10.0 10.0

3

yd

14.4 14.4 15.7 15.7 13.1 13.1 13.1 13.1

3

14.0 14.0 14.0 14.0 13.0 13.0 13.0 13.0

3

yd

18.3 18.3 18.3 18.3 17.0 17.0 17.0 17.0

5080 5080 5080 5080 5080 5080 5160 5160

ft

16.7 16.7 16.7 16.7 16.7 16.7 16.9 16.9

Dump clearance at full lift and

45° discharge (§) mm

4576 5221 4576 5221 4719 5364 4786 5431

ft

15.0 17.1 15.0 17.1 15.5 17.6 15.7 17.8

Reach at full lift and

45° discharge (§) mm

2600 2709 2600 2709 2503 2612 2507 2616

ft

8.5 8.9 8.5 8.9 8.2 8.6 8.2 8.6

Reach with lift arms horizontal

and bucket level mm

Digging depth (§) mm

Overall length (§) mm

5060 5576 5060 5576 4922 5438 4878 5394

ft

16.6 18.3 16.6 18.3 16.1 17.8 16.0 17.7

225 292 225 292 181 248 166 233

in

8.9 11.5 8.9 11.5 7.1 9.7 6.5 9.7

15 338 15 972 15 338 15 972 15 163 15 803 15 107 15 748

ft

50.3 52.4 50.3 52.4 49.7 51.8 49.6 51.7

Overall height with bucket

at full raise (§) mm

9810 10 454 9939 10 584 9854 10 498 9827 10 472

ft

32.2 34.3 32.6 34.7 32.3 34.4 32.2 34.4

Loader clearance circle with bucket

in carry position (§) mm

Static tipping load straight †(§) kg

11 053 11 351 11 053 11 351 11 014 11 310 11 017 11 313

ft

36.3 37.2 36.3 37.2 36.1 37.1 36.1 37.1

82 767 69 393 82 987 69 515 84 525 70 917 83 129 69 597

lb

182,502 153,012 182,986 153,281 186,378 156,372 183,300 153,460

Static tipping load at full

40° turn

††

(§)kg

71 713 59 655 71 886 59,742 73 327 61,061 71,956 59 759

lb

158,126 131,540 158,510 131,731 161,687 134,639 158,663 131,769

Static tipping load at full

††

43° turn

(§) kg

Breakout force ††(§) kN

Operating weight †(§)kg

70 074 58 211 70 240 58 293 71 667 59 599 70 299 58 301

lb

154,512 128,356 154,880 128,535 158,026 131,417 155,010 128,553

667.2 666.5 666.1 665.4 714.3 713.3 730.3 729.3

lb

150,130 149,970 149,867 149,708 160,713 160,503 164,317 164,088

133 328 134 294 133 503 134 469 133 637 134 603 134 620 135 586

lb

293,989 296,119 294,375 296,505 294,670 296,800 296,838 298,968

Rock

(§)

Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers. SAE Standards

J732C govern loader ratings and are denoted in the text by

† Static tipping load and operating weight shown are based on standard machine configuration with a full fuel tank, coolant, lubricants

and operator.

†† Measured 102 mm (4.0"): behind tip of segments with bucket hinge pin as pivot point in accordance with SAE J732C.

(§).

Page 25

25

993K Wheel Loader specifications

Bridgestone 62 PR Bridgestone 62 PR Bridgestone 62 PR Bridgestone 62 PR

Rock Rock Rock Rock

Teeth & Segments Teeth & Segments Teeth & Segments Teeth & Segments

Spade Spade Spade Spade

303-3260 303-3330 303-3280 303-3290

Standard High

Rock Abrasion

Rock

Standard Standard

Rock Rock

Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift Std. Hi-Lift

12.0 12.0 12.0 12.0 14.0 14.0 14.5 14.5

16.0 16.0 16.0 16.0 18.0 18.0 19.0 19.0

10.0 10.0 10.0 10.0 11.0 11.0 12.0 12.0

13.1 13.1 13.1 13.1 14.4 14.4 15.7 15.7

12.0 12.0 12.0 12.0 14.0 14.0 14.0 14.0

16.0 16.0 16.0 16.0 18.3 18.3 18.3 18.3

5080 5080 5160 5160 5080 5080 5080 5080

16.7 16.7 16.9 16.9 16.7 16.7 16.7 16.7

4809 5454 4834 5479 4620 5265 4620 5265

15.8 17.9 15.9 18.0 15.2 17.3 15.2 17.3

2413 2522 2459 2568 2602 2711 2602 2711

7.9 8.3 8.1 8.4 8.5 8.9 8.5 8.9

4794 5310 4810 5326 5062 5578 5062 5578

15.7 17.4 15.8 17.5 16.6 18.3 16.6 18.3

181 248 166 233 181 248 181 248

7.1 9.7 6.5 9.7 7.1 9.7 7.1 7.1

15 035 15 675 15 039 15 680 15 303 15 943 15 303 15 943

49.3 51.4 49.3 51.4 50.2 52.3 50.2 52.3

9745 10 390 9745 10 390 9854 10 498 9983 10 628

32.0 34.1 32.0 34.1 32.3 34.4 32.8 34.9

11 015 11 311 11 000 11 294 11 051 11 349 11 051 11 349

36.1 37.1 36.1 37.1 36.3 37.2 36.3 37.2

84 691 71 113 83 728 70 165 83 351 69 907 83 573 70 031

186,743 156,803 184,620 154,714 183,788 154,145 184,278 154,418

73 509 61 269 72 542 60 318 72 228 60 109 72 404 60 197

162,087 135,097 159,956 133,002 159,262 132,540 159,650 132,735

71 851 59 809 70 884 58 858 70 578 58 656 70 747 58 739

158,431 131,879 156,299 129,782 155,625 129,337 155,998 129,520

758.5 757.5 757.0 755.9 670.5 669.6 669.3 668.4

170,653 170,431 170,320 170,083 150,860 150,661 150,598 150,399

133 374 134 340 134 174 135 140 134 088 135 054 134 263 135 229

294,091 296,221 295,855 297,985 295,665 297,795 296,051 298,181

Page 26

26

993K Wheel Loader specifications

Serviceability

3

7

Standard Service Center (1)

Ground Level Access

Access to VIMS

Cat ET and Comm2 Connectors

12V Power Converter Power Switch

Implement and Steering Oil

Ecology Drains

Drop Down Laptop Platform

Work Light

Fill, if equipped

Power-up Switch

Deluxe Service Center (option)

Includes Standard features plus:

Fast Fill and Evac Quick

Disconnect Ports

Transmission Oil

Steering and Hydraulic Oil

Oil Renewal System Fill (if equipped)

AutoLube Fill, if equipped

Engine Oil

Engine Coolant

Implement and Steering Ecology

Drain Connectors

Important Service Add Level Indicators

VIMS Messenger Screen

2 5 6

4

1

Hydraulic and Engine Service Area (2)

Platform Access

Hydraulic Implement Filter

Fuel Filters

Implement Pilot Filter

Fuel Water Separator

Shunt Tank Fill

S•O•SSMPort

Implement Breaker Relief

Bumper Service Center (3)*

Ground Level Access

Jump Start Receptacle

Transmission Lockout

Starter Lockout

Battery Disconnect

Engine Shutdown

Stair Lamp Switch

Remote Diagnostic Pressure Ports

Front Frame (4)

Ground Level Access

Lift and Lower Circuit

Dump and Rackback Circuit

Right Implement

Left Implement

Implement Pilot/Axle Motor

Pilot Supply

Manual Lower Valve

Rear Frame (5)

Platform Access

Left Steering Cylinder

Right Steering Cylinder

Diagnostic Pressure Taps

Steering Pump Discharge

Fan Drive

Brake Accumulator

Torque Converter Inlet

Impeller Clutch

Lock-up Clutch

Transmission Lube

Directional Clutch

Speed Clutch

Transmission Control Inlet

Electrical Service Center (6)

Platform Access

Breakers

Fuse

Electronic Control Modules

Battery Box Center (7)

Two access doors for batteries

Main Machine Breaker

Main Machine Relay

Starter Breaker

Starter Relay

* This center offers a number of features that

assist in maintaining a safe environment while

servicing the 993K.

Page 27

27

993K Wheel Loader specifications

Safety

Visibility Safety

Standard Features

Long-life LED taillights

Cab raised 0.6 m (2 ft) for better visibility to truck box

or hoppers

Articulated wiper/washer system with intermittent feature

on front and rear windows

Egress and Ingress Safety

Standard Features

Primary and secondary exits

Punch stamped tread plates

600 mm (23.6 in) wide right and left hand stairway access

with railings

Ground level nighttime lighting switch

Full perimeter railings on upper platform

Optional Features

Rear vision camera with in-cab monitor

High Intensity Discharge (HID) lighting package

Rearview heated mirrors

Warning beacon lights

Optional Features

Roading fenders

Rear Access Egress System (RAES)

Maintenance Safety

Standard Features

Battery lockout

Starter lockout

Hydraulic system lockout

Transmission lockout (both in-cab and ground level)

Ground level service center

Ground level sight gauges on all major systems

Operator Safety

Standard Features

Front windshield cleaning platform access with handrails

Easily adjusted implement controls affixed to Cat Comfort Seat

Low-effort implement controls

Cab filtration system

Optional Features

Ground level deluxe service center

Optional Features

Powered cab air pre-cleaner removes airborne dust before

it reaches cab air filter, increasing filter service interval

Page 28

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

POWER TRAIN

Brakes, oil-cooled, multi-disk, service and secondary

Demand fan

Drive line parking brake

Fuel priming pump (electric)

Ground level engine shutdown

Precleaner, engine air intake (above hood)

Radiator, Next Generation Modular NGMR)

Starting aid, ether, automatic

Throttle lock, electronic

Transmission, 533 mm (21 in ) planetary, powershift with

3F/3R, electronic control

OTHER STANDARD EQUIPMENT

Automatic bucket leveler

Automatic lift and lower bucket kickout

Axle ecology drain

Bumper Service Center

Grouped hydraulic pressure ports

Guards, crankcase and power train

Hitch, drawbar with pin

Impeller clutch

Implement lock lever, cab

Implement and steering ecology drains

Linkage pins, maintenance-free

Mufflers, under hood

Oil sampling valves

Positive flow control implement valve

Rims

Sight gauges

Steering oil level

Implement oil level

Transmission oil level

Stairway, left and right side

Starter lockout, bumper

Steering, load sensing

Steering and transmission lock lever, cab

Transmission lockout, bumper

ANTI-FREEZE

Premixed 50 percent concentration of Extended Life Coolant

with freeze protection to –34° C (–29° F)

ELECTRICAL

Alarm, back-up

Alternator, 150-amp brushless

Batteries, maintenance-free (4) 1400 CCA

Deutsch terminal connectors

Diagnostic connector starting and charging system

Electrical system, 24-Volt

Electronic transmission control

Lighting system, halogen (front and rear)

Starting and charging system (24-Volt)

Starter receptacle for emergency start

Starter and transmission lockouts in bumper

Electronic Service Center

OPERATOR ENVIRONMENT

Advisor Display

Displays real time operating information, performs

calibrations and customizes operator settings

Air condition

Air precleaner

Cab

Sound suppressed and pressurized, separate external

rollover protective structure (ROPS/FOPS), radio ready

for entertainment including antenna, speakers, 12-Volt

10-amp converter and power port

Cigar lighter and ashtray (12-Volt)

Coat hook (2) with straps

Controls, left and tilt function

Heater and defroster

Horn, electric

Instrumentation gauges

Engine coolant temperature

Hydraulic oil temperature

Fuel level

Power train oil temperature

Tachometer

Digital display on center console

Gear

Ground speed

Machine hours

Light, dome (cab)

Lunch box, beverage holders and manual holders

Rimpull Control System

Seat belt, retractable, 76 mm (3 in) wide

STIC system

Trainer seat with lap belt

VIMS

External data port, Integral Payload Control System

Wet-arm wipers and washers, front and rear

Intermittent front wipers

28

993K Wheel Loader specifications

Page 29

29

993K Wheel Loader specifications

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

STARTING AIDS

Heater, engine coolant, 120V

Heater, engine coolant, 240V

Roading fenders

Sound suppression arrangement

Axle oscillation limiting – recommended if customer adds

chains to rear tires

Computer Aided Earthmoving System, ready option

Low ambient coolant, –50° C (–58° F)

Buckets and GET – consult your Cat dealer for all options

ELECTRICAL

Camera, rear vision – WAVES

Light, warning beacons

Power converter – additional 10 amps with standard amp

Product Link – depends on geographic location

OPERATOR ENVIRONMENT

Radio, AM/FM, CD basic

Radio, satellite XM

Radio, satellite Sirius

Radio, satellite ready

Sunscreen, front and rear windows

Precleaner, turbine

POWER TRAIN

Oil Renewal System (ORS)

Ride Control

Page 30

Mandatory Equipment

Must choose from each category. Consult your Caterpillar dealer for more

information.

COOLING ARRANGEMENTS

Standard – for ambient temperatures 43°C (110°F),

standard filtration

Standard – for ambient temperatures 43°C (110°F),

deluxe filtration

High Ambient – for ambient temperatures 55°C (131°F),

standard filtration

High Ambient – for ambient temperatures 55°C (131°F),

deluxe filtration

SERVICE CENTER ARRANGEMENTS

Service center, standard

Service center, deluxe

Software, messenger (select language group)

REAR ACCESS

Standard steps and handrails

Powered, rear access/egress system

STEERING AND FILTRATION SYSTEMS*

Standard steering, standard filtration

Secondary steering, deluxe filtration

Secondary steering, standard filtration

Secondary steering, deluxe filtration

*Standard and deluxe filtration options cannot be mixed

and matched so please keep selections consistent when

selecting lift arrangement, cooling package and

steering system.

OPERATION AND MAINTENANCE MANUAL

English version (select language group)

Spanish version

TIRES

Consult your Cat dealer for current options

LIFT ARRANGEMENTS

Standard lift, standard filtration

Standard lift, deluxe filtration

High lift, standard filtration

High lift, deluxe filtration

LUBE ARRANGEMENTS

Line, grease, standard lubrication

AutoLube arrangement

ELECTRONICS

Advisor display software (select language group)

LIGHTING ARRANGEMENT

Lighting, standard

Lighting, premium

CAB WINDSHIELD

Glass, cab window (silicone sealed bond)

Glass, cab, rubber-mounted

OPERATOR SEAT

Seat, standard

Seat, heated

MIRROR ARRANGEMENT

Mirror, standard

Mirror, heated

TORQUE CONVERTER

Standard ICTC with housing

ICTC with housing and lock-up

Engine, standard

FUEL ARRANGEMENTS

Fuel arrangement, standard

Fuel arrangement, fast fill

Fuel arrangement, heated (fuel heater)

Fuel arrangement, fast fill, heated (fuel heater)

30

993K Wheel Loader specifications

Page 31

31

Notes

993K Wheel Loader specifications

Page 32

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2007 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, ACERT, SAFETY.CAT.COM, K SERIES, their respective logos,

“Caterpillar Yellow,” and the POWER EDGE trade dress, as well as corporate and product

identity used herein, are trademarks of Caterpillar and may not be used without permission.

AEHQ5922 (12-07)

993K Wheel Loader

R

Loading...

Loading...