Page 1

Engine

Engine Model Cat®C18 ACERT

®

Gross Power 414 kW 555 hp

Flywheel Power 373 kW 501 hp

Operating Specifications

Operating Weight 49 546 kg 109,249 lb

Rated Payload 11.4 tonnes 12.5 tons

Buckets

Bucket Capacities 6.3 m3–7.0 m

3

8.2 yd3–9.2 yd

3

988H

Wheel Loader

®

®

Page 2

2

988H Wheel Loader

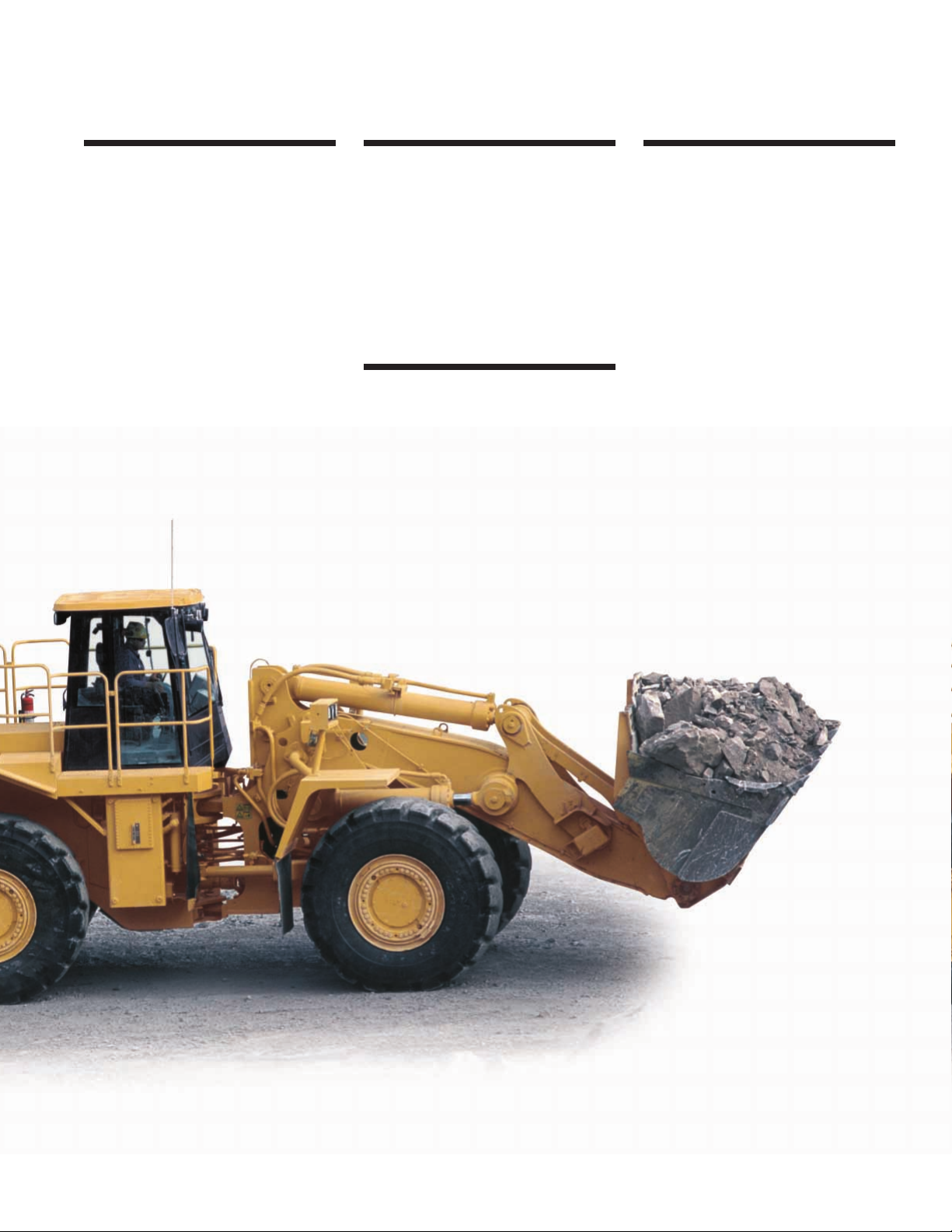

Improved performance and rugged durability combine with operator comfort

for maximum productivity.

Revolutionary design, Caterpillar

®

quality.

Electro-hydraulic controls, increased power

and torque rise, front linkage and unmatched

operator comfort work together for increased

performance and added durability to make

the 988H an innovative, 21st Century large

wheel loader geared for maximum production

in the toughest conditions.

Maintenance and Serviceability

Most daily maintenance checks are

performed from the machine’s left side,

facilitating quick start up. Case drain

filters for main hydraulic, steering and

fan pumps protect against contamination,

and remote pressure taps contribute to

improved serviceability. Easy access to

major components enhance serviceability

and increase uptime. pg. 15

Application Truck Match

Increased performance and good pass

matching make the 988H a versatile

performer. pg. 14

Hydraulics and Electronic Monitoring

Innovative electro-hydraulics play a

key role in performance of the 988H

and provide lower operator effort.

Increased hydraulic efficiency improves

lift and tilt cycle time for reduced overall

cycle time. The tradition of reliable,

high-performance Cat hydraulics

continues. pg. 8

Power Train

The Cat C18 engine with ACERT

®

Technology is U.S. EPA Tier 3/EU

Stage III compliant. The Cat transmission

and impeller clutch torque converter

offer smooth, consistent shifting with

fingertip control. Electronic controls

help increase productivity. pg. 6

✔

Structures and Fabricated Box Boom

The articulated frame design features a

high-torsion, compact, load-absorbing,

front frame and a large, box-section,

engine-end frame. Fabricated boom

and linkage geometry increase dump

clearance, provide improved breakout

and lift forces and increase the viewing

area to the bucket corners. pg. 4

Page 3

✔ New Feature

3

Customer Support

Your Cat dealer offers a wide range of

services that help you operate longer

with lower costs. pg. 16

Bucket Match

Improve machine performance and

increase stability by selecting the right

bucket for your application and material

density. pg. 13

Buckets and Ground Engaging Tools

(GET)

Choose between 6.3 m3(8.2 yd3) and

7.0 m3(9.2 yd3) capacity buckets, spade

edge and straight edge buckets and

various GET to match job conditions.

Cat buckets retain the proven shell-tine

construction design for unmatched

durability. pg. 12

Operator Station

Experience a high level of efficiency,

comfort and productivity with one-hand

STIC operation, a large cab, low-effort

fingertip lift and tilt controls, improved

operator visibility, reduced sound levels,

improved ventilation and easier entry

and exit. pg. 10

Page 4

Structures. Combine the use of robotic

welding and castings in critical highstress areas. More than 90 percent of

the 988H structure is robotically welded

to provide highly consistent welds and

increased strength. Castings are also

used in several areas to increase strength

by helping to spread the loads and reduce

the number of parts.

1 Full Box-Section Frame. Has been

improved for maximum strength and

minimum weight. The frame rail is now

extended further forward, improving

rail to hitch strength.

2 Box-Shaped Tower. Is designed

for improved resistance to twisting

for maximum strength. The tilt cylinder

tower’s high-strength steel plates direct

stress down to the lift cylinder case

mounting tube, absorbing impact and

loading forces. This design results in

a narrower tower which gives a better

operator viewing area.

4

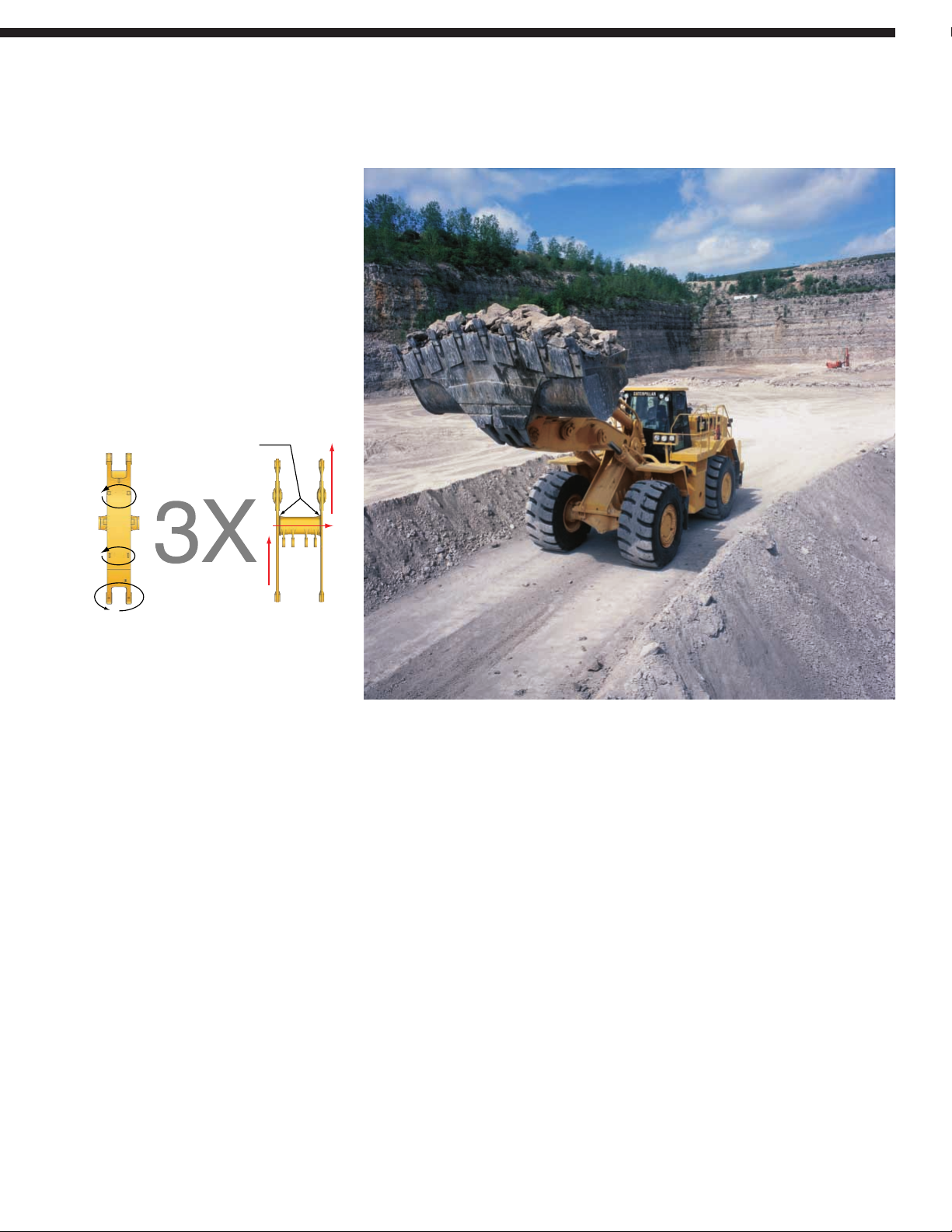

Superior design of structures, along with the bold, box-section front linkage

provide superior strength.

Structures and Fabricated Box Boom

Page 5

3 Upper and Lower Hitch Pins. Pivot on

double-tapered roller bearings. The hitch

plates are shaped to direct stress away

from the end of the weld, resulting in

a smoother transition of stress loads

into the frame.

4 Spread-Hitch Design. Increases the

spread 26 percent to help square-up the

frame and provide increased clearance

for access to the hitch and hydraulic lines.

5 Steering Cylinder Mounts. Are located

on the axle pads to provide efficient

transfer of steering loads to the axle.

6 Fabricated Box Boom. Replaces the

traditional steel plate lift arms found

on wheel loaders. This design features

forked ends for easier service, faster

assembly and increased reliability.

Castings in high stress areas smooth

the transition of stress distribution for

excellent service life. The boom and dual

bucket links work together for increased

breakout force, better torsional resistance

and higher lift capacity.

Fabricated Boom Box-Section Design.

Has more torsional stiffness than a Z-bar

design. With the parallel lift arm design,

corner loading the bucket sends stresses

up the lift arm, through the cross tube

welding and up the other lift arm.

The box-section design spreads stresses

over the full length and perimeter of the

boom, allowing stress transfer through

parent material. This resists twisting

and prevents stress paths that can

lead to cracking.

Weld Joint

Load Path

Load Path

(Full Length)

5

Page 6

1 Cat C18 Engine with ACERT

®

Technology. Is U.S. EPA Tier 3 and

EU Stage III compliant. It features

increased horsepower and efficient fuel

management for quick response, high

productivity and exceptional service life.

A new, sculptured cylinder block provides

greater strength and lighter weight.

988H Fuel Management System.

The Cat 988H Wheel Loader Fuel

Management System delivers solid

productivity and fuel savings of as much

as 15 percent in truck loading and more

in load in carry operations. By lowering

engine speed during all but the digging

portion of each cycle, the proprietary

system minimizes impact on productivity

while gaining significant fuel savings.

For maximum flexibility, the system

offers three different operating modes:

full power, balanced and maximum fuel

savings. The system allows the operator

to quickly adjust to changing production

demands by moving a single switch

mounted in the cab.

The Fuel Management System can

be retrofitted to 988H Wheel Loaders

already working in the field.

Mechanically Actuated, Electronic Unit

Injection (MEUI). Proven high-pressure,

direct injection fuel system electronically

monitors operator demands and sensor

inputs to optimize engine performance.

Air Cleaners. Are dry-type radial seal

with primary and secondary elements

and precleaner.

ADEM™ IV. Controls the fuel injector

solenoids to monitor fuel injection.

This system provides automatic altitude

compensation, air filter restriction

indication and it will not allow the

engine to fire until it has oil pressure,

acting as cold start protection and

a form of pre-lube.

Air-to-Air Aftercooler (ATAAC).

Provides a separate cooling system for

the intake manifold air. The ATAAC

system routes hot, compressed air from

the turbo and cools it with a single pass,

air-to-air aluminum heat exchanger.

The cooled compressed air greatly reduces

the emissions produced, meeting the

EPA Tier 3/EU Stage III requirements.

2 Separate Engine Cooling System.

Isolates the radiator and fan from the

engine compartment for more efficient

cooling and allows for a sloped hood

for an increased viewing area.

6

The Cat power train delivers top performance and durability in tough applications.

Changes to the aftercooler, injectors, bearings and pistons help improve startability,

response, power, emissions and fuel consumption.

Power Train

1

Page 7

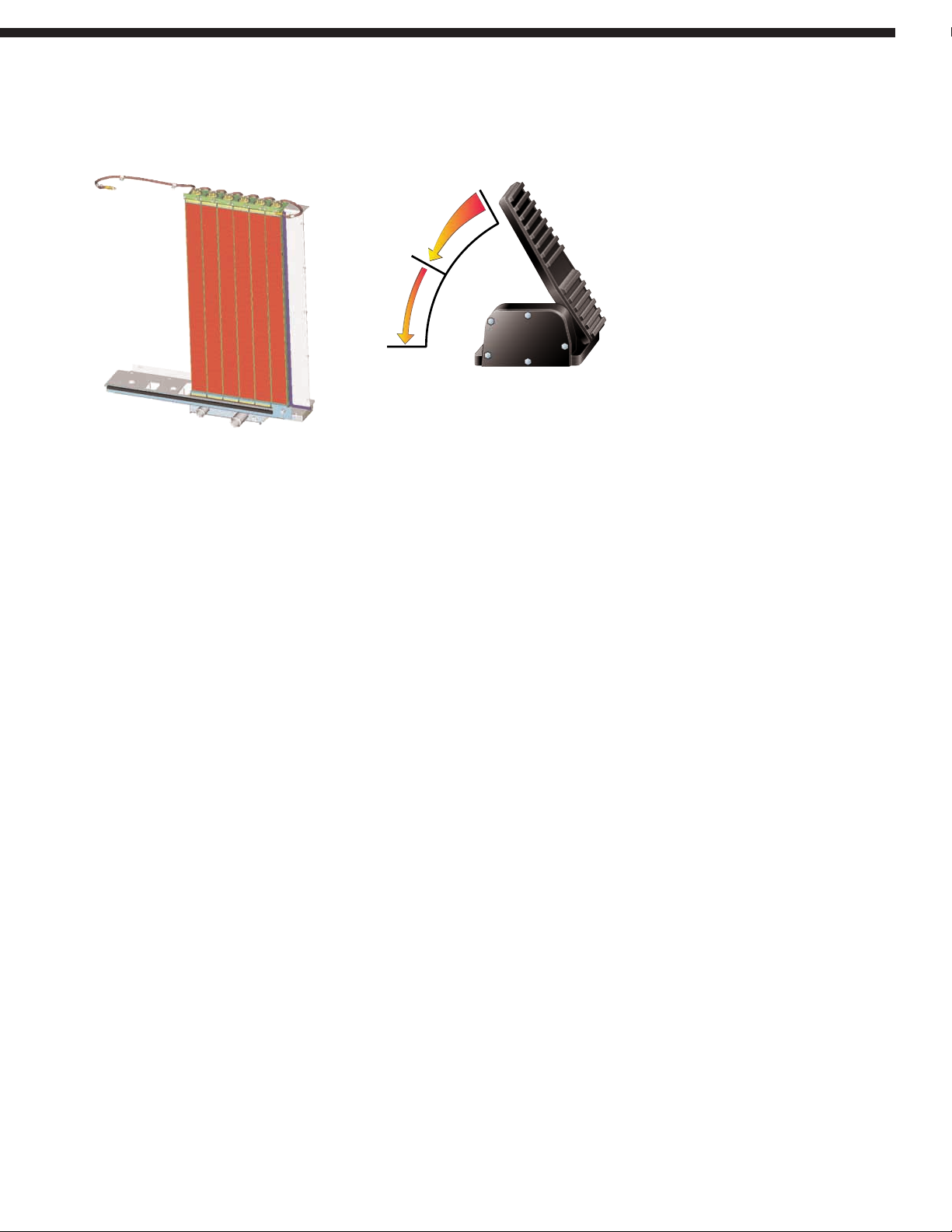

Next Generation Modular Radiator

(NGMR). Improves cooling capabilities

by using a parallel flow system with

six cores. Serviceability is improved

with NGMR since there is no top

tank to remove.

3 Electronically Controlled Cat

Planetary Power Shift Transmission.

Features perimeter-mounted, large

diameter clutch packs that control inertia

for smooth shifting and increased

component life.

Demand Fan. The Cat C18 electronic

engine continuously gathers information

to control the demand fan speed and

provides constant net horsepower

regardless of operating conditions.

This compensates for varying fan loads

and enables the machine to maintain

normal system temperatures and reduce

fuel consumption.

4 Impeller Clutch Torque Converter

(ICTC). Combined with the Rimpull

Control System (RCS) allows the

operator maximum flexibility in

modulating rimpull.

• Calibration procedure improved.

• Left pedal modulation improved.

• Wear compensated for by providing

the ability to recalibrate for optimum

left pedal modulation regardless of

torque converter wear.

• Left brake pedal modulates rimpull

from 100 to 25 percent for reduced

tire slippage and wear. After 25 percent

is achieved, further pedal travel

applies the brake.

• RCS allows operator to select from

four preset maximum rimpull settings,

other than 100 percent, that are

available in first gear (90, 80,

70 and 60 percent).

• A lock-up clutch torque converter

provides direct drive efficiency.

Translates into improved fuel

efficiency in certain applications.

Final Drives. Feature planetary reduction

at each wheel. Torque is developed at

the wheel, which offers less stress at the

axle shafts. The planetary units can be

removed independently from the wheels

and brakes.

5 Heavy-Duty Axles. Feature optional axle

oil coolers, permanently lubed universal

joints and stronger axle components in

both the differentials and final drives for

increased performance, serviceability

and durability. Conventional differential

is standard.

Free-Floating Axle Shafts. Can be

removed independent of the wheels

and planetaries for quick and easy

serviceability.

Optional Axle Oil Cooling System.

Features two circuits that circulate oil

from the differentials through an oilto-air cooler and filter and back to the

brakes. This system provides increased

oil life and improves component

performance and durability. The system

automatically turns on and off at a

preset oil temperature.

6 Axle-Shaft, Oil Disc Brakes.

Are adjustment-free, fully hydraulic

and completely sealed. Disc face

grooves provide cooling even when

brakes are applied for long, faderesistant service life.

• Location of the brakes improves

serviceability. The axle shaft brake

design allows brake service while

leaving the final drive intact.

• Axle-shaft brakes require less force

by operating on the low torque side

of the axle. Combined with improved

axle oil circulation for increased

cooling, the oil-enclosed, multipledisc brake design improves durability.

• Parking brake is spring-applied, oilreleased and dry disc. It is mounted

on the transfer gear output shaft.

Manual override is possible to allow

movement of the machine.

Secondary Brakes. Are fully modulated

and the front and rear service brake

circuits are isolated so one circuit

can operate if pressure drops in

the other circuit.

Service Brakes. Are four-wheel,

hydraulic, oil-dipped, multiple disc

brakes that are adjustment-free,

completely enclosed and allow

modulated engagement without

slack adjusters.

B

r

a

k

e

s

(

2

0

%

R

i

m

p

u

l

l

)

100% Rimpull

Selected

Left Pedal

20% Rimpull

Selected

7

Page 8

1 Electro-Hydraulic Control System.

Increases hydraulic efficiency and

enhances operator comfort through

low-effort, fingertip controls. XT-3™

and XT-5™ hose along with reliable

components reduce the risk of leaks

and blown lines, helping protect

the environment.

2 Lift and Tilt System. Consists of

larger bore lift and tilt cylinders and

a two position main hydraulic pump,

contributing to increased performance

and serviceability.

Two Position Main Hydraulic Pump.

Is controlled by the Electronic Control

Module (ECM). A solenoid valve

controls the pump displacement, allowing

the ECM to adjust hydraulic flow during

the loader cycle. This strategy results in

fast hydraulics and greater lift forces,

leading to optimized performance.

3 Load Sensing Steering. The STIC

control system integrates the steering

and transmission into a single controller.

A STIC operated, pilot valve controls the

flow to steering cylinders. The steering

system utilizes a variable displacement

pump for maximum machine performance

by directing power through the steering

system only when needed.

4 Case Drain Filtration. A total of

three filters for the main hydraulic,

steering and fan pumps protect against

contamination with easy access

for service.

8

Efficient, well-balanced hydraulics and low-effort electronic controls mean high

performance and exceptional durability.

Hydraulics and Electronic Monitoring

1

Page 9

5 Demand Fan. A speed controlled,

hydraulic fan provides maximum

cooling efficiency by directing the

appropriate amount of power through

the fan system based on the system’s

temperature.

Advanced Electronics. Play a major

role in the operation of the 988H.

Productivity improvements, enhanced

serviceability, increased operator

efficiency and lower costs are direct

benefits of the 988H advanced

electronics.

6 Caterpillar Monitoring System (EMS-III).

Continually monitors various machine

systems through three instrument clusters

and provides a three-level warning

system to alert the operator of immediate

or pending problems. It shares information

with the engine, hydraulic and transmission

controls that can be used during servicing

to simply service and troubleshooting.

The Caterpillar Monitoring System also

allows for new software to be uploaded

directly into the cab.

Optional Payload Control System.

Tracks data regarding the load in the

bucket. It also features a numeric keypad

and easy to view display. An available

printer makes onboard ticket printing

possible.

Optional Ride Control. Provides a

boom suspension system by placing

two accumulators in the boom circuit,

reducing fore and aft pitch over rough

terrain. This results in a smoother,

more comfortable ride, allowing higher

load and carry speeds, increased load

retention and component life.

Loose Material Mode. Provides maximum

hydraulic speed and efficiency for loading

in easily penetrated loose material.

9

6

Page 10

World Class Cab. Over 3.18 m3(112 ft3)

of volume incorporates innovations for

operator comfort, maneuverability and

productivity. Features include outstanding

viewing area, excellent cab ventilation,

interior sound levels below 77 dB(A),

standard coat hook, cup holder, storage

bin, intermittent wet-arm wipers, room

for a large lunch cooler and radio and

Cat Product Link ready.

10

An industry standard for comfort and efficiency.

Operator Station

15

5

8

16

6

4

3

2

1

Page 11

1 STIC Control System. Combines gear

selection and steering into one control

lever that requires less effort and

provides smooth shifting. Side-to-side

motions for steering, finger operator

direction control and thumb operator

buttons for gear selection combine to

provide a fluid motion that reduces

effort and allows the operator to work

the machine for long periods of time

with little or no fatigue.

2 Left Pedal. Operates the impeller

clutch torque converter/braking while

the right pedal operates standard braking.

3 Cat Comfort Seat. An ergonomic

design with thick foam in key parts

of the seat back, thick seat cushions

and an automotive-style lumbar support

translates into great operator comfort,

reduced fatigue and consistent

productivity throughout the work shift.

The six-way adjustable, air suspension

seat has a retractable seatbelt, headrest

and adjustable armrests for optimum

comfort.

4 Electro-Hydraulic Controls and

Armrests. Provide low effort, fingertip

control for enhanced comfort and

stability.

Floor-mounted controls and armrests

are fore, aft and height adjustable to

accommodate operators of any size in

a comfortable operating position.

5 Caterpillar Monitoring System

(EMS-III). Provides information on

machine’s major components and

systems.

• Gauge displays fuel tank level

and temperatures for engine coolant,

torque converter and hydraulic oil.

Tachometer is an analog gauge with

digital readout for gear selection and

ground speed.

• Alerts operator if transmission

is engaged while parking brake is

applied. If pressure drops, the parking

brake applies automatically.

Main module consists of 10 fault

indicators and one display panel. If any

critical engine condition is detected, the

engine will derate power.

6 Throttle Lock. Allows operator to

pre-set the engine speed for a variety

of applications, resulting in faster cycle

times and increased productivity.

7 Rimpull Control System (RCS).

Has four factory preset, reduced rimpull

settings (90, 80, 70 and 60 percent of

rimpull). Reduced rimpull settings can

be modified by your Cat dealer to better

match ground conditions.

8 Rimpull Control System (RCS) Switch.

Turns RCS on and off.

9 Kickout Positioner Control. Allows the

operator to set customized upper, lower

and bucket dig angle kickouts for

maximum operating efficiency.

10 Optional Ride Control Switch.

Turns ride control to off or automatic

position.

11 Autoshift. Allows the operator to

set the maximum gear into which the

transmission will be allowed to shift.

This feature contributes to additional

comfort and focus on the job. The switch

also offers a manual position for operator

controlled shifting.

12 Optional Lock-up Clutch Torque

Converter Switch. Activates the lock-up

clutch for direct drive efficiency.

13 Loose Material Operating Mode.

Tailors hydraulics to provide maximum

loose material loading efficiency.

14 Front and Rear Window

Wiper/Washer. Are within easy reach to

help maintain a clear field of vision.

15 Viewing Area. Bonded front windshield

eliminates distracting metal frames for

excellent bucket and work site operator

visibility. An internal ROPS improves

peripheral viewing by eliminating the

large structure outside the cab.

16 Electro-Hydraulic Lock-out Switch.

Disables hydraulic controls.

17 Optional Reversible Fan.

18 Optional Hazard Lights.

19 Optional Rotary Beacon.

20 Optional Autolube.

11

Upper Left Console

Upper Right Console

7

9

20 17

19

18

11

121014

14

13

Page 12

Buckets. Ranging from 6.3 m3(8.2 yd3)

to 7.6 m3(10 yd3) may be configured for

a variety of impact and abrasive

conditions. All buckets are built with

shell-tine construction (1) that resist

twisting and distortion and feature

replaceable, weld-on wear plates to

protect the bottom of the bucket.

The integral rock guard (2) helps retain

large loads while heavy-duty pins and

retainers (3) provide durability.

Spade Edge Rock Buckets. With bolt-on

segments, are available in 6.4 m

3

(8.33 yd3), 6.9 m3(9.0 yd3) and 7.6 m

3

(10 yd3). Each accepts up to two sets of

sidebar protectors (4), feature shouldered,

double-strap adapters, easily changed

bolt-on segments and several tip options.

Straight Edge Buckets. Are available

in 6.3 m

3

(8.2 yd3) Straight Edge Rock

as well as 7.0 m3(9.2 yd3) and 7.6 m

3

(10 yd3) General Purpose configurations.

The Straight Edge Rock bucket features

double strap adapters and accepts

two sets of sidebar protectors, bolt-on

segments and tips. The General Purpose

bucket is available with bolt-on cutting

edge, bolt-on adapters or bolt-on

adapters with segments.

High Abrasion Bucket. Is available

with 6.4 m3(8.33 yd3) capacity and is

recommended for use in face loading

where high abrasion and moderate

impact is encountered. This bucket

features additional wear protection

items including independently attached

edge and adapter covers, additional

liners and wear plates, one set of sidebar

protectors and a thicker base edge.

Heavy Duty Quarry Bucket. Is available

as a 6.4 m3(8.33 yd3) capacity bucket

and is recommended for use in face

loading where moderate abrasion and

high impact is encountered. It features

additional wear protection items

including four sidebar protectors (4),

thicker base edge and adapters (5),

additional liners and wear plates (6)

and bolt-on half arrow segments (7).

Bucket Controls. Feature electrohydraulic lift and tilt circuits for lower

lever effort.

Lift Circuit. Has four positions: raise,

hold, lower and float and can adjust

automatic upper and lower kickouts

from the cab.

Tilt Circuit. Features three positions:

tilt back, hold and dump. It can adjust

automatic bucket positioner to desired

loading angle from the cab and does

not require visual spotting.

Mechanically Attached Wear Plates

(MAWP). Are available as a Custom

attachment.

12

Buckets and Ground Engaging Tools (GET)

Cat buckets and GET provide the flexibility to match the machine to your application.

Page 13

Buckets and GET. The 988H offers a

variety of bucket types and available

GET configurations to properly configure

the machine based on material density,

impact and abrasion.

Depending on your material densities,

the 988H has available a 6.4 m3(8.33 yd3)

Spade Nose bucket with teeth and bolton segments for improved performance

and edge protection.

Increased full turn static tipping load,

horsepower and hydraulic capabilities

allow the 988H to effectively utilize the

6.6 m3(8.7 yd3) and 6.9 m3(9.0 yd3)

bucket size in lighter materials such

as limestone.

To better match your 988H to material

conditions, contact your Cat dealer for

specialty bucket needs.

13

Bucket Match

Proper bucket and application match deliver increased stability and peak performance.

Bucket Selection Guide and Matrix

3

3

yd

m

9.06.9

6.6

8.7

Bucket Size

6.4

8.33

2200

1300 1500 1700 1900

Changes in bucket weight, including field installed wear iron, can impact rated payload. Consult your Caterpillar dealer for

assistance in selecting and configuring the proper bucket for the application. The Caterpillar Large Wheel Loader Payload

Policy is a guideline intended to maximize wheel loader structural and component life.

3.88 and 4.25 Meter Linkage

110% 90%

2400 2600 2800 3000 3200 3400 lb/LCY

Material Density

NOTE: Percentages shown represent bucket fill factor

- Center point at 100% fill

100%

110% 90%100%

110%

100%

90%

2000

kg/LCM

Page 14

Performance. The 988H is an aggressive

first gear loader for face and bank

excavation. With increased dump

clearance, the 988H can easily load

37-63 tonnes (40-70 ton) off-highway

trucks. Increased performance and good

pass match make the 988H a versatile

performer with a cost per ton that will

help your bottom line.

The versatility of a material handler

is designed into this wheel loader.

With balanced rimpull and hydraulics,

the 988H is an aggressive loader and

gets the job done quickly and efficiently

in loose or stock-pile material and in

load and carry work.

14

Application Truck Match

Matched payloads and matched buckets ensure optimum performance.

Large Wheel Loader/Truck Application Match

988H Rated Payload: 11.4 metric ton (12.5 short ton)

4 pass

3 pass

988H Dump Clearance & Reach

3.4 m (11 ft 2 in) & 2.0 m (6 ft 10 in)

35 40 45 50 55 60

35

Truck Payload

769D = 36 Metric Tons (40 Short Ton) nominal payload

771D = 41 Metric Tons (45 Short Ton) nominal payload

773E = 54 Metric Tons (60 Short Ton) nominal payload

775E = 63 Metric Tons (70 Short Ton) nominal payload

5 pass

65 7040 45 50 55 60

Metric Tons

Short Tons

Page 15

15

Maintenance and Repair. Is easier

through monitoring key functions and

logging critical indicators. Electronic

diagnostic access is possible with a single

tool, the Cat Electronic Technician (ET).

In addition to the servicing features

built into the engine, the 988H includes:

• Daily Maintenance Checks. Most can

be performed from the left side of the

machine, making it part of an easy

pre-start routine. Routine maintenance

promotes long service life and durability.

• Next Generation Modular Radiator

(NGMR). Allows service technicians to

replace individual cores for enhanced

serviceability. Maintenance is also

simplified since NGMR is isolated

from the engine compartment.

• U-joints and Slipshaft. Are permanently

lubricated.

• Lube Points. Are centralized in

accessible locations. Fuel fill is located

on the left side. Both lube points and

fuel fill are accessible from ground

level, making lube and fuel service

quicker and easier.

• Swing-out Doors. On both sides of

the engine compartment provide easy

access to the engine oil dipstick and

filler spout, S·O·SSMport, fuel filters,

air conditioner compressor, engine oil

filters, alternator, starting receptacle, air

filter service indicator, coolant fill and

ether starting aid. The disconnect switch

and diagnostic connectors are located

on the rear platform.

• Hinged Doors. In the platform provide

access to the hydraulic tank fill, lift and

tilt and steering filters. The transmission

sight glass and filler spout are serviced

from the hitch area.

• Case Drain Filters. Protect the hydraulic

system from contamination and are

conveniently located behind the cab

in the service platform.

• Batteries (1,000 CCA). Sit in a built-in

battery box and are accessible through

tread plates on the right platform.

• Shock Resistant Lights.

Are replaceable by hand, not requiring

the use of any tools.

• Caterpillar Monitoring System

(EMS-III). Provides operators and

service technicians with diagnostic

information on the machine’s major

components and systems. It also allows

for a flashable software using a laptop

and Cat ET instead of replacing a chip

that contains the new software.

• Remote Mounted ECPC Pressure Taps.

Are easily accessible behind the cab

under the platform.

• 500 Hour Oil Change Interval.

Uptime and production are increased

with a longer time between engine

oil changes.

Easier maintenance and enhanced serviceability give you more time in the pile.

Maintenance and Serviceability

Page 16

16

Machine Selection. Make detailed

comparisons of the machines under

consideration before purchase. Cat dealers

can estimate component life, preventive

maintenance cost and the true cost

of lost production.

Purchase. Look past initial price.

Consider the financing options available

as well as the day-to-day operating

costs. Look at dealer services that can

be included in the cost of the machine

to yield lower equipment owning and

operating costs over the long run.

Customer Support Agreements.

Cat dealers offer a variety of product

support agreements and work with

customers to develop a plan that best

meets specific needs. These plans can

cover the entire machine, including

work tools, to help protect the

customer’s investment.

Product Support. You will find nearly

all parts at our dealer parts counter.

Cat dealers use a world-wide computer

network to find in-stock parts to minimize

machine down time. Save money with

genuine Cat Remanufactured parts.

You receive the same warranty and

reliability as new products but at a

cost savings of 40-70 percent.

Operation. Improving operator techniques

can boost your profits. Your Cat dealer

has training videotapes, literature,

classes and other ideas to help you

increase productivity.

Maintenance Services. More and more

equipment buyers are planning for

effective maintenance before buying

equipment. Choose from your dealer’s

wide range of maintenance services at

the time you purchase your machine.

Repair option programs guarantee the

cost of repairs up front. Diagnostic

programs such as S·O·SSMand Coolant

Sampling and Technical Analysis help

you avoid unscheduled repairs.

Replacement. Repair, rebuild or replace?

Your Cat dealer can help you evaluate

the cost involved so you can make the

right choice.

SAFETY.CAT.COM™.

Customer Support

Cat dealer services help you operate longer with lower costs.

Page 17

17

988H Wheel Loader specifications

Operating Specifications

Rated Payload 11.4 tonnes 12.5 tons

Operating Weight 49 546 kg 109,249 lb

Rated Payload – Standard 11.4 tonnes 12.5 tons

Transmission

Converter Drive – Forward 1 6.7 kph 4.2 mph

Converter Drive – Forward 2 11.8 kph 7.3 mph

Converter Drive – Forward 3 20.8 kph 12.9 mph

Converter Drive – Forward 4 36 kph 22.3 mph

Converter Drive – Reverse 1 7.6 kph 4.7 mph

Converter Drive – Reverse 2 13.5 kph 8.4 mph

Converter Drive – Reverse 3 23.7 kph 14.7 mph

Direct Drive – Forward 1 Lock-up disabled

Direct Drive – Forward 2 12.3 kph 7.7 mph

Direct Drive – Forward 3 21.9 kph 13.6 mph

Direct Drive – Forward 4 38.6 kph 24 mph

Direct Drive – Reverse 1 7.9 kph 4.9 mph

Direct Drive – Reverse 2 14.1 kph 8.8 mph

Direct Drive – Reverse 3 25.1 kph 15.6 mph

• Travel speeds based on two percent rolling resistance

and 35/65-33 tires.

Hydraulic Cycle Time

Raise 9.4 Seconds

Dump 2.4 Seconds

Lower Float Down (Empty) 3.8 Seconds

Total Hydraulic Cycle Time 15.6 Seconds

Service Refill Capacities

Fuel Tank 712 L 188 gal

Cooling System 103 L 27.2 gal

Crankcase 60 L 15.9 gal

Transmission 70 L 18.5 gal

Differentials and Final Drives 186 L 49 gal

– Front

Differentials and Final Drives 186 L 49 gal

– Rear

Hydraulic System (factory fill) 470 L 124.2 gal

Hydraulic System (tank only) 267 L 70.5 gal

Buckets

Bucket Capacities 6.3 m3–7.0 m38.2 yd3–9.2 yd

3

Max. Bucket Capacity 7 m

3

9.2 yd

3

Engine

Engine Model Cat C18 ACERT

®

Gross Power 414 kW 555 hp

Flywheel Power 373 kW 501 hp

Net Power – EEC 80/1269 373 kW 501 hp

Net Power – ISO 9249 373 kW 501 hp

Gross Power – ISO 3046-2 388 kW 520 hp

Bore 145 mm 5.7 in

Stroke 183 mm 7.2 in

Displacement 18.1 L 1,104.5 in

3

• These ratings apply at 1,800 rpm when tested under the

specific standard conditions for the specified standard.

• Power rating conditions based on standard air conditions

of 25° C (77° F) and 99 kPa (29.32 in Hg) dry barometer,

using 35° API gravity fuel having an LHV of 42 780 kJ/kg

(18,390 Btu/lb) when used at 30° C (86° F) [reference a fuel

density of 838.9 g/L (7.001 lb/gal)].

• Net power advertised is the power available when the

engine is equipped with alternator, air cleaner, muffler

and hydraulic fan drive.

• No derating required up to 3048 m (10,000 ft) altitude.

• Direct-electric, 24-volt starting system with 100 amp

alternator and four high performance maintenance-free

batteries with 1,000 cold cranking amps.

3000 2213

2800

•m)Engine Power (kW)

2600

2400

2200

2000

Engine Torque (N

1800

450

400

350

300

250

200

235

230

225

220

215

BSFC (gm/kW-hr)

210

205

Engine Speed (RPM)

Gross

Net

1600 1800 200014001000 1200

2066

1919

1771

1624

1476

1328

603

536

469

402

335

Engine Power (Bhp) Engine Torque (ft•lb)

268

0.385

0.377

0.369

0.361

0.353

BSFC (lb/Bhp-hr)

0.344

0.336

Page 18

18

988H Wheel Loader specifications

Steering

Steering Meets SAE and

ISO standards

Total Steering Angle 86°

• Full hydraulic, load-sensing steering system meets

SAE J1511 FEB94 and ISO 5010:1992 specified standards.

• Center point frame articulation.

• Front and rear wheels track.

Loader Hydraulic System

Main Hydraulic System Output 492 L/min 130 gal/min

at 2,010 rpm and 6900 kPa (1,000 psi)

Relief Valve Setting 31 000 kPa 4,500 psi

Cylinders, Double Acting: 220 × 8.7 ×

Lift, Bore and Stroke 911 mm 35.9 in

Cylinder, Double Acting: 220 × 8.7 ×

Tilt, Bore and Stroke 1770 mm 69.7 in

Pilot System, Gear-Type Pump 76 L/min 20.1 gal/min

Output at 2,010 rpm and

2500 kPa (363 psi)

Relief Valve Setting (low idle) 2400 kPa 348.1 psi

• With SAE 10W oil at 66° C (150° F).

Axles

Maximum Single-Wheel Rise 568 mm 22.4 in

and Fall

Front Fixed

Rear Oscillating ±13°

Brakes

Brakes Meet SAE ISO 3450:1996

Cab

Cab – ROPS/FOPS Meets SAE and

ISO standards

• Cat cab with integrated Rollover Protective Structure (ROPS)

and Falling Object Protective Structure (FOPS) is standard.

• ROPS meets SAE J1040 APR99 and ISO 3471:1994 criteria.

• FOPS meets SAE J231 JAN 81 and ISO 3449:1992 Level II

criteria.

Sound Performance

Meets ANSI, SAE and ISO standards

• The operator sound exposure Leq (equivalent sound

pressure level) measured according to the work cycle

procedures specified in ANSI/SAE J1166 OCT 98 is 76 dB(A),

for the cab offered by Caterpillar, when properly installed,

maintained and tested with the doors and windows closed.

• Hearing protection may be needed when operating with an

open operator station and cab (when not properly maintained

or doors/windows open) for extended periods or in noisy

environment.

• The exterior sound pressure level for the standard machine

measured at a distance of 15 m (49.2 ft) according to the test

procedures specified in SAE J88 JUN 86 mid-gear-moving

operation is 81 dB(A).

• The sound power level is 115 dB(A) measured according

to the dynamic test procedure and conditions specified

in ISO 6395:1998/AMD. 1:1996 for a standard machine

configuration.

• For “CE” marked configurations, the labeled sound

power level is 110 dB(A) measured according to the test

procedures and conditions specified in 2000/14/EC.

• For “CE” marked configurations, the operator sound

pressure level is 73 dB(A) measured according to the

test procedures and conditions specified in 2000/14/EC

Directive and ISO 6396:1992.

Page 19

19

988H Wheel Loader specifications

Dimensions

All dimensions are approximate.

1 Height to Top of Cab 4128 mm 13.54 ft

2 Height to Top of 4112 mm 13.49 ft

Exhaust Stacks

3 Height to Top of Air Cleaner 3382 mm 11.1 ft

4 Height to Top of Hood 3156 mm 10.35 ft

5 Center Line of Rear Axle 3132 mm 10.28 ft

to Edge of Rear Bumper

6 Center Line of Front Axle 2275 mm 7.46 ft

to Hitch

7 Wheel Base Length 4550 mm 14.93 ft

8 Length with Bucket on Ground

♦♦

9 Ground Clearance 549 mm 1.8 ft

10 Height to Center of Wheel 978 mm 3.21 ft

11 C-Pin Height 1009 mm 3.31 ft

899 mm* 2.95 ft*

12 Dig Depth 226 mm 0.74 ft

195 mm* 0.64 ft*

13 Rack Back Angle at Ground 47.8°

45.7°*

14 Rack Back Angle at Carry 56.5°

54°*

15 Clearance at Maximum 3879 mm 12.73 ft

Lift/Dump 3466 mm* 11.37 ft*

16 Height to Spillguard 5432 mm 17.82 ft

5019 mm* 16.47 ft*

17 B-Pin Height 5853 mm 19.2 ft

5440 mm* 17.85 ft*

18 Overall Height with

♦♦

Bucket Raised

♦

*

♦

*

19 Rack Back Angle 65°

at Maximum Lift 73°*

20 Dump Angle at Maximum Lift 45°

45°*

21 Reach

♦♦

*3.88 Meter Linkage

19

1

2

3

4

910

57

8

4.25 Meter Linkage

Dimensions vary with bucket. Refer to Operation/Bucket Specifications.

6

20

17

21

14

13

11

12

15

16

18

Page 20

Operation/Bucket Specifications

20

988H Wheel Loader specifications

3.88 Meter Linkage

Bucket Type Spade Wide

GET Teeth & Segments Teeth & Segments BOCE

Rated Capacity m3(yd3) 6.4 (8.33) 6.9 (9.0) 6.9 (9.0)

Struck Capacity m3(yd3) 5.3 (6.9) 5.7 (7.5) 5.7 (7.5)

Heaped Capacity m3(yd3) 6.4 (8.33) 6.9 (9.0) 6.9 (9.0)

Bucket Width mm (ft/in) 3810 (12'6") 3980 (13'1") 3964 (13'0")

Overall Height mm (ft/in) 7699 (25'3") 7772 (25'6") 7772 (25'6")

Dump Clearance at 45° dump

Bare mm (ft/in) 3742 (12'3") 3682 (12'1") 3638 (11'11")

Teeth mm (ft/in) 3466 (11'4") 3410 (11'2") —

Reach at 45° dump

Bare mm (ft/in) 1494 (4'11") 1554 (5'1") 1881 (6'2")

Teeth mm (ft/in) 2028 (6'8") 2084 (6'10") —

Overall Length

Bare mm (ft/in) 11 877 (39'0") 11 962 (39'3") 11 982 (39'4")

Teeth mm (ft/in) 12 215 (40'1") 12 294 (40'4") —

Turning Radius at SAE Carry

Bare mm (ft/in) 8543 (28'0") 8641 (28'4") 8644 (28'4")

Teeth mm (ft/in) 8597 (28'2") 8689 (28'6") —

Reach at 45° dump

and 2.13 m (7'0") HGT

Bare mm (ft/in) 2389 (7'10") 2427 (8'0") 2840 (9'4")

Teeth mm (ft/in) 2924 (9'7") 2957 (9'8") —

Reach with level boom level bucket

Bare mm (ft/in) 3435 (11'3") 3520 (11'7") 3972 (13'0")

Teeth mm (ft/in) 4198 (13'9") 4277 (14'0") —

Digging Depth – Bucket Level mm (in) 195 (7.7") 195 (7.7") 185 (7.3")

Full Dump at Maximum Lift degrees 51.4 51.4 51.4

Tipping Load

Straight kg (lb) 34 825 (76,776) 34 355 (75,740) 34 635 (76,357)

Articulated 43° kg (lb) 29 368 (64,745) 28 923 (63,764) 29 182 (64,335)

Breakout Force kN (lb-f) 378.4 (85,068) 360.6 (81,066) 383.9 (86,304)

Operating Weight kg (lb) 49 546 (109,230) 49 816 (109,825) 49 716 (109,605)

Weight Distribution at SAE Carry

Front kg (lb) 25 265 (55,700) 25 746 (56,760) 25 540 (56,306)

Rear kg (lb) 24 281 (53,530) 24 070 (53,065) 24 176 (53,299)

Rock Spade Spade

(Standard Bucket) Rock Rock

Page 21

21

988H Wheel Loader specifications

3.88 Meter Linkage

Straight Duty High General

Rock Quarry Abrasion Purpose

Teeth & Segments Teeth & Segments Teeth & Segments BOCE

Heavy

6.3 (8.2) 6.4 (8.33) 6.4 (8.33) 7.0 (9.2)

5.2 (6.8) 5.3 (6.9) 5.3 (6.9) 5.88 (7.7)

6.3 (8.2) 6.4 (8.33) 6.4 (8.33) 7.0 (9.2)

3800 (12'6") 3862 (12'8") 3926 (12'11") 3695 (11'2")

7699 (25'3") 7698 (25'3") 7699 (25'3") 7698 (25'3")

4011 (13'2") 3728 (12'3") 3811 (12'6") 3790 (12'5")

3735 (12'3") 3376 (11'1") 3447 (11'4") —

1526 (5'0") 1543 (5'1") 1577 (5'2") 1720 (5'8")

1765 (5'9") 2076 (6'10") 2047 (6'9") —

11 497 (37'9") 11 917 (39'1") 11 779 (38'8") 11 765 (38'7")

11 839 (38'10") 12 333 (40'6") 12 242 (40'2") —

8550 (28'0") 8605 (28'3") 8625 (28'4") 8573 (28'2")

8634 (28'4") 8678 (28'6") 8682 (28'6") —

2518 (8'3") 2401 (7'11") 2464 (8'1") 2729 (8'11")

2757 (9'1") 2934 (9'8") 2935 (9'8") —

3480 (11'5") 3535 (11'7") 3552 (11'8") 3751 (12'0")

3822 (12'6") 4295 (14'1") 4225 (13'10") —

195 (7.7") 225 (8.9") 195 (7.7") 191 (7.5")

51.4 51.4 51.4 51.4

35 257 (77,728) 32 650 (71,981) 33 833 (74,589) 35 026 (77,219)

29 816 (65,733) 27 239 (60,052) 28 383 (62,574) 29 568 (65,186)

467.4 (105,076) 360.7 (81,089) 389.2 (87,496) 433.1 (97,365)

49 261 (108,602) 51 181 (112,835) 51 016 (112,471) 49 401 (108,910)

24 616 (54,269) 28 161 (62,084) 27 367 (60,334) 24 988 (55,089)

24 645 (54,333) 23 020 (50,750) 23 649 (52,137) 24 413 (53,821)

Page 22

Operation/Bucket Specifications

22

988H Wheel Loader specifications

4.25 Meter Linkage

Bucket Type Spade Wide

GET Teeth & Segments Teeth & Segments BOCE

Rated Capacity m3(yd3) 6.4 (8.33) 6.9 (9.0) 6.9 (9.0)

Struck Capacity m3(yd3) 5.3 (6.9) 5.7 (7.5) 5.7 (7.5)

Heaped Capacity m3(yd3) 6.4 (8.33) 6 .9 (9.0) 6.9 (9.0)

Bucket Width mm (ft/in) 3810 (12'6") 3980 (13'1") 3964 (13'0")

Overall Height mm (ft/in) 8112 (26'7") 8186 (26'10") 8186 (26'10")

Dump Clearance at 45° dump

Bare mm (ft/in) 4155 (13'8") 4095 (13'5") 4051 (13'3")

Teeth mm (ft/in) 3879 (12'9") 3823 (12'7") —

Reach at 45° dump

Bare mm (ft/in) 1591 (5'3") 1652 (5'5") 1699 (5'7")

Teeth mm (ft/in) 2126 (7'0") 2182 (7'2") —

Overall Length

Bare mm (ft/in) 12 321 (40'5") 12 406 (40'8") 12 426 (40'9")

Teeth mm (ft/in) 12 658 (41'6") 12 738 (41'9") —

Turning Radius at SAE Carry

Bare mm (ft/in) 8731 (28'8") 8828 (29'0") 8803 (28'11")

Teeth mm (ft/in) 8787 (28'10") 8879 (29'2") —

Reach at 45° dump

and 2.13 m (7'0") HGT

Bare mm (ft/in) 2785 (9'2") 2825 (9'3") 2951 (9'8")

Teeth mm (ft/in) 3320 (10'11") 3355 (11'0") —

Reach with level boom level bucket

Bare mm (ft/in) 3805 (12'6") 3890 (12'9") 3947 (12'11")

Teeth mm (ft/in) 4568 (15'0") 4647 (15'3") —

Digging Depth – Bucket Level mm (in) 226 (8.9") 226 (8.9") 216 (8.5")

Full Dump at Maximum Lift degrees 48.5 48.5 48.5

Tipping Load

Straight kg (lb) 32 445 (71,529) 32 014 (70,579) 32 264 (71,130)

Articulated 43° kg (lb) 27 191 (59,946) 26 780 (59,040) 27 012 (59,551)

Breakout Force kN (lb-f) 409.2 (91,992) 390.1 (87,698) 415.3 (93,363)

Operating Weight kg (lb) 50 574 (111,497) 50 844 (112,092) 50 744 (111,871)

Weight Distribution at SAE Carry

Front kg (lb) 25 583 (56,401) 26 088 (57,514) 25 874 (57,042)

Rear kg (lb) 24 991 (55,096) 24 756 (54,578) 24 870 (54,829)

Rock Spade Spade

(Standard Bucket) Rock Rock

Page 23

23

988H Wheel Loader specifications

4.25 Meter Linkage

Straight Duty High General

Rock Quarry Abrasion Purpose

Teeth & Segments Teeth & Segments Teeth & Segments BOCE

Heavy

6.3 (8.2) 6.4 (8.33) 6.4 (8.33) 7.0 (9.2)

5.2 (6.8) 5.3 (6.9) 5.3 (6.9) 5.88 (7.7)

6.3 (8.2) 6.4 (8.33) 6.4 (8.33) 7.0 (9.2)

3800 (12'6") 3862 (12'8") 3926 (12'11") 3695 (11'2")

8112 (26'7") 8112 (26'7") 8112 (26'7") 8111 (26'7")

4424 (14'6") 4141 (13'7") 4225 (13'10") 4203 (13'9")

4148 (13'7") 3790 (12'5") 3860 (12'8") —

1623 (5'4") 1641 (5'5") 1674 (5'6") 1818 (6'0")

1863 (6'1") 2173 (7'2") 2145 (7'0") —

11 941 (39'2") 12 358 (40'7") 12 223 (40'1") 12 209 (40'1")

12 283 (40'4") 12 774 (41'11") 12 686 (41'7") —

8738 (28'8") 8795 (28'10") 8812 (28'11") 8763 (28'9")

8824 (28'11") 8871 (29'1") 8873 (29'1") —

2904 (9'6") 2801 (9'2") 2861 (9'5") 3114 (10'3")

3144 (10'4") 3334 (10'11") 3332 (10'11") —

3850 (12'8") 3905 (12'10") 3922 (12'10") 4121 (13'6")

4192 (13'9") 4665 (15'4") 4595 (15'1") —

226 (8.9") 256 (10.1") 226 (8.9") 222 (8.7")

48.5 48.5 48.5 48.5

32 867 (72,459) 30 346 (66,901) 31 421 (69,271) 32 650 (71,981)

27 628 (60,909) 25 130 (55,402) 26 172 (57,699) 27 394 (60,393)

505.1 (113,551) 390.5 (87,788) 421.6 (94,779) 468.3 (105,278)

50 289 (110,868) 52 209 (115,101) 52 044 (114,737) 50 429 (111,177)

24 907 (54,910) 28 634 (63,127) 27 811 (61,313) 25 293 (55,761)

25 382 (55,958) 23 575 (51,974) 24 233 (53,425) 25 136 (55,415)

Page 24

Tire Dimensions/Specifications

24

988H Wheel Loader specifications

Change in

Ground

Width over tires

mm inches mm inches mm inches kg lb kg lb

clearance

vertical

dimensions

Change in

operating

weight

Change

in full

turn static

tipping load

35/65R33 (L-4) Michelin XLDD1 3579 140.9 445 17.5 — — —— ——

35/65-33 42 PR (L-5) Bridgestone D-Lug 3541 139.4 544 21.4 –99 –3.9 2259 4980 1310 2888

35/65R33 (L-4) Bridgestone

V-Steel N Traction VSNT 3566 140.4 483 19.0 –38 –1.5 664 1464 385 849

35/65R33 (L-5) Bridgestone

V-Steel D-Lug VSDL 3566 140.4 498 19.6 –53 –2.1 1257 2772 729 1608

35/65-33 42PR (L-5) General LD 250 Belted 3487 137.3 506 19.9 –61 –2.4 1510 3328 876 1930

875/65R33 (L-4) Goodyear RL-4K Hi Stability 3487 137.3 506 19.9 –61 –2.4 552 1217 320 705

35/65R33 (L-5) Goodyear RL-5K 20 20 6S 3574 140.7 508 20.0 –64 –2.5 974 2148 565 1246

35/65-33 42PR (L-5) Goodyear NRL D/L 5A 3574 140.7 508 20.0 –64 –2.5 1646 3628 954 2104

875/65R33 (L-5) Goodyear RL-5K Hi Stability 3574 140.7 508 20.0 –64 –2.5 1486 3276 862 1900

35/65R33 (L-5) Michelin XLDD2 3579 140.9 463 18.2 –18 –0.7 648 1428 376 828

35/65R33 (L-5) Michelin XMINED2 3579 140.9 478 18.8 –33 –1.3 1404 3096 815 1796

NOTE: In certain applications (such as load-and-carry work), the loader’s productive capabilities might exceed the tires tonnes-km/f (ton-mph)

capabilities. Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model.

Other special tires are available on request.

Page 25

25

988H Wheel Loader specifications

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

Tilt and lift control system lock

Tinted glass

Transmission gear (indicator)

Wet-arm wiper/washers (front and rear)

Intermittent front wiper

Power Train

Brakes, full hydraulic, enclosed, wet multiple disc

service brakes

Case drain filtration

Demand fan

Electric fuel priming aid

Engine, Cat C18 MEUI Direct Injected Diesel with

ACERT®Technology and ADEM™ IV controller

Guard, three piece transmission

Parking brake

Precleaner, engine air intake

Radiator, Next Generation Modular Radiator (NGMR)

Remote Electronic Clutch Pressure Control (ECPC)

pressure taps

Separated cooling system

Starting aid (ether)/automatic

Throttle lock

Torque converter, impeller clutch with rimpull control system

Transmission, planetary, auto shift with 4F/3R speed

range control

Other Standard Equipment

Automatic bucket tilt/lift kickouts, electronically adjustable

from cab

Cab tilt support

Counterweight

Doors, service access (locking)

Engine, crankcase, 500 hour interval with CH4 oil

Ground level fuel fill

Hitch, drawbar with pin

Hydraulic oil cooler

Lower cab cover

Muffler (under hood)

Oil sampling valves

Stairway, left side rear access

Vandalism protection caplocks

Venturi stack

Tires, Rims and Wheels

An allowance for tires is included in the base machine price.

Tire selections are shown in the Tire/Supplemental

Specifications list.

Antifreeze

Premixed 50 percent concentration of extended life coolant

with freeze protection to –34° C (–29° F)

Electrical

Alarm, back-up

Alternator (100-amp)

Batteries, maintenance-free (four 1,000 CCA)

Deutsch terminal connectors

Diagnostic connector

Starting and charging system

Electrical converter, 12-volt

Electrical system, 24-volt

Lighting system, Halogen

(Front and Rear)

Starter, electric (heavy-duty)

Starter receptacle for emergency start

Operator Environment

Air Conditioner

Cab, sound-suppressed, pressurized

Internal four-post rollover protective structure

(ROPS/FOPS)

Radio ready for (entertainment) includes antenna,

speakers and converter (12-volt 15-amp)

12V cigar lighter, 12V power port and ashtray

Coat hook

Electro-hydraulic tilt and lift controls

Heater and defroster

Horn, electric

Lights, (interior cab)

Lunchbox and beverage holders

Loose Material Mode

Monitoring system (Caterpillar Monitoring System [EMS-III])

Action alert system, three category

Instrumentation, Gauges:

Engine coolant temperature

Fuel level

Hydraulic oil temperature

Transmission temperature

Speedometer/tachometer

Instrumentation, Warning Indicators:

Axle oil temperature (front/rear)

Brake oil pressure

Engine intake/combustion air temperature

Electrical system, low voltage

Engine oil pressure

Engine overspeed

Fuel pressure

Hydraulic oil filter status

Parking brake status

Transmission filter status

Mirrors, rearview (exterior mounted)

Seat (cloth), Cat Comfort, air suspension

Seat belt, retractable, 76 mm (3 in) wide

STIC control system with steering lock

Page 26

26

988H Wheel Loader specifications

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

Lights, HID

Linkage, 4.25 meter

Lock-up clutch

Mid-ambient cooling

No-SPIN differential, rear only

Oil change, high-speed

Payload Control System (PCS)

Product Link

QuickLube

Rear intermittent wiper

Rear chain clearance

Ride control

Right-hand stairway

Roading fenders, front and rear

Roof, extended

Secondary steering

Sound suppression, exterior

Steel mill configuration (Custom)

Tires

Auto Lube

Auxiliary lights

Axle oil-coolers

Block handler configuration (Custom)

Buckets

Bulk loader configuration (Custom)

Computer Aided Earthmoving System (CAES) ready

Directional lights

Engine Brake

Extended Life Coolant –50° C (–58° F)

Forestry configuration (Custom)

Fuel, fast fill

Fuel, heater

Fuel, fast fill and heater

Guards

Crankcase

Steering cylinders

Heater, engine coolant, 120-volt

Heater, engine coolant, 220-volt

High ambient cooling

Hydraulic, three valve

Page 27

988H Wheel Loader specifications

27

Notes

Page 28

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2007 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow”

and the POWER EDGE trade dress, as well as corporate and product identity used

herein, are trademarks of Caterpillar and may not be used without permission.

AEHQ5618-02 (10-07)

Replaces AEHQ5618-01

988H Wheel Loader

R

Loading...

Loading...