Page 1

972K

Wheel Loader

Engine Buckets

Engine Model Cat

Max. Net Power (1,800 rpm) – ISO 9249 215 kW 288 hp Weights

Max. Net Power (1,800 rpm) – SAE J1349 215 kW 288 hp Operating Weight 26 212 kg 57,770 lb

®

C9.3 ACERT™ Bucket Capacities 2.9 m3-9.9 m3 3.75 yd3-13.0 yd

• For 4.8 m

3

(6.3 yd3) general purpose buckets with bolt-on cutting edges.

3

Page 2

972K Features

Performance Series Buckets

With standard Performance Series Buckets,

operators bene t from reduced dig times and

better material retention; ultimately translating

into signi cant productivity and fuel ef ciency

improvements.

Load Sensing Hydraulics

Load sensing hydraulics produce ow and pressure

for the implement system upon demand and only

in amounts necessary to perform the needed work

functions, enhancing machine productivity and

fuelef ciency.

Operator Environment

The new four post ROPS cab provides enhanced

comfort, visibility, and productivity resulting in a

more ef cient operator. New features include an

ergonomic electro-hydraulic (EH) joystick steering

system with position control and force feedback

(speed sensitive), automatic climate control,

viscous mounts to reduce noise and vibration

levels, post mounted membrane switches,

and a convex windshield giving the operator

apanoramicview.

Cat® C9.3 ACERT™ Engine

The innovative Cat C9.3 ACERT engine is optimized

for maximum fuel ef ciency and increased

powerdensity while meeting Tier 4 Interim/

StageIIIBemission standards.

Powershift Transmission

The K Series™ transmissions incorporate a new

shifting strategy that delivers smoother shifts,

faster acceleration, and increased travel speed

when climbing a grade.

Fuel Ef ciency

The 972K wheel loader has been integrated as a

system; from the linkage and work tool carrying

the payload, to the engine, transmission and torque

converter moving the machine, the system has

been optimized to achieve the lowest cost per ton.

Contents

Reliability ..............................................................3

Durability ..............................................................4

Productivity ..........................................................5

Versatility ..............................................................6

Operator Environment ........................................8

Serviceability .....................................................10

Sustainability .....................................................11

Customer Support .............................................11

Owning Costs .....................................................12

Operating Costs .................................................13

Wheel Loader Speci cations .........................14

Standard and Optional Equipment .................30

The Cat® 972K was designed to improve operator

comfort, performance, and productivity, all while

meeting Tier 4 Interim/Stage IIIB emission standards.

ThePerformance Series Buckets enhance visibility

anddecrease cycle times. Theunmatched, revolutionary

world-class cab creates a comfortable, ef cient, safe,

and productive operator environment. Theinnovative

CatC9.3 ACERT engine is optimized for maximum fuel

efciency and increased power density while meeting

Tier 4 Interim/Stage IIIB emission standards. Thereliability,

durability, and versatility of the972Kresult in a machine

that is better built to meet yourneeds. Allday. Every day.

Page 3

Reliability

Tested and Proven. Ready to Work.

Structures

The K Series™ features many of the components designed

andproven reliable over generations of product design.

Strata Precleaner

The system removes 93% of the dust particles before the

air has reached the primary engine air lter. As air enters

theprecleaner, stationary vanes cause the incoming air to

spin. Theresulting centrifugal force spins dust and dirt to

the outer walls where they are ejected out into the exhaust

stream, while the clean air ows down the center of the tube

and continues into the primary air lter. The primary bene t

is extended lter life.

Cold Start/High Altitude Package

A new optional cold start package includes a fan pump

bypass, transmission pump bypass, additional battery

capacity, and an engine heater plug/cord. The bypass

systems reduce the parasitic load on the engine, while the

additional battery capacity increases the cold cranking

revolutions during startup. With the new optional coldstart

package available on K Series, starting capability hasbeen

dramatically improved in cold weather conditions. Thesystem

also improves starting capability at high altitudes.

Monitoring Programs

Monitoring product health is key to maintaining reliability of

any equipment. Many programs offered by Caterpillar make

the tracking of the customer’s machine health quick and

easy. These programs include Product Link, VisionLink™,

and S·O·S

SM

Services.

Renowned Cat Dealer Support

From helping you choose the right machine to knowledgeable

support, Cat dealers provide the best when it comes to sales

and service. Manage costs with preventive maintenance

programs like Scheduled Oil Sampling (S·O·SSM) analysis

orelaborate Customer Support Agreements. Stay productive

with best-in-class parts availability. Cat dealers can even

help you with operator training to help boost your pro ts.

Andwhen it’s time for machine rebuild, your Cat dealer can

help you save even more with Genuine Cat Reman parts.

Receive the same warranty and reliability as new products

atcost savings of 40 to 70 percent for power train and

hydraulic components.

3

Page 4

Durability

Better Built to Meet Your Needs

Frames

The robotically welded two-piece structural frame design

provides a rugged and reliable foundation for the machine

that improves stability, performance, and serviceability.

Arobust articulating hitch system joins the front and rear

frames improving durability. Enhanced lines routings across

the hitch joint streamline the manufacturing process and

improve reliability and durability.

Engine

The new Cat C9.3 ACERT engine was designed to optimize

power density. It uses a combination of technologies to reduce

regulated emissions while ensuring high performance and

excellent fuel efciency. An upgraded ADEM™ 4 electronic

control module manages the combustion process and a

newhigh-pressure common rail fuel system allows precise

injection timing for a clean, efcient fuel burn. Therugged

Cat Clean Emissions Module is securely rubber mounted

onits own platform above the engine and contains a

DieselOxidation Catalyst, Diesel Particulate Filter and

CatRegeneration System. Regeneration, the process by

which soot is removed from the Diesel Particulate Filter,

iscompletely automatic and does not interrupt the

machine’swork cycle.

Emissions

The 972K features a Cat C9.3 ACERT engine and a

CatClean Emissions Module to deliver the performance

andefciency that customers demand, while meeting

Tier4Interim/Stage IIIB emission standards. The six-cylinder

electronic engine is turbocharged and aftercooled.

ACERT™Technology is a combination of building blocks

that includes electronics, fuel systems, airmanagement

systems and aftertreatment components. The system is

optimized based on engine size, the type of application and

the geographic location in which it will work. The technologies

are applied systematically and strategically to meet high

customer expectations for productivity, fuel ef ciency,

reliability andservice life.

Axles

The 972K axles are designed to handle extreme applications

resulting in reliable performance and extended life. The front

axle is rigidly mounted to the frame in order to withstand

internal torque loads and still maintain support for the wheel

loader. The rear axle can oscillate to ±13 degrees helping to

ensure all four wheels stay on the ground providing stability

even in the roughest terrain.

4

Page 5

Productivity

Move More. All Day. Every Day.

Z-bar Linkage

The proven Z-bar linkage with Performance Series Buckets offer excellent penetration into the pile, high breakout forces, good

roll back angles, and faster dig times. The results are improved tire life, superior fuel efciency, and exceptional production

capabilities; all helping to enable asustainable solution for your business.

Load Sensing Hydraulics

Load sensing hydraulics produce ow and pressure for the implement system upon demand and only in amounts necessary to

perform the needed work functions, enhancing machine productivity and fuel efciency. Implement controllability is improved

through simultaneous implement operation and repeatable ne modulation, enabling greater operator comfort through ease

ofoperation.

Ride Control

Ride control provides the operator with a smoother ride over rough terrain, enabling a more comfortable ride at higher speeds.

The benet is reduced cycle times, higher productivity and better fuel efciency while performing load and carry applications.

The system works by using an accumulator to dampen the linkage motion, acting as a shock absorber.

Torque Converter

The 972K torque converter has been optimized to improve fuel efciency and deliver more power to the ground. The 10% increase

to rimpull delivers a performance and fuel efciency boost in all applications.

Transmission

The K series transmissions incorporate a new shifting strategy that delivers smoother shifts, faster acceleration, and better

performance climbing a grade. When placing the transmission into forward gear, the machine will automatically start in second

gear. With the further enhancement of a torque based 2 to 1 downshift, the downshift will only occur based on machine load.

Owners and operators will fully benet from utilizing the automatic 1-4 transmission mode, which results in lower fuel

consumption and optimal machine performance.

5

Page 6

Versatility

Work Tool Options to Meet Your Needs

Work Tools for Many Job Site Requirements

An extensive range of work tools and bucket styles are

available for the 972K to customize the machine for your

operation. The list includes: Performance Series Buckets;

Specialty Buckets (Multipurpose, Side Dump, Waste Handling,

Woodchip); Pallet Forks, Log and Lumber Forks, Rakes

(with or without top clamps); and Plows (angleor V-style).

Each is available either with pin on or quick couplerinterface.

Performance Series Buckets:

Load Easy, Fuel Efcient, Carry More

Performance Series Buckets utilize a system-based approach

to balance bucket shape with the machine’s linkage, weight,

lift and tilt capacities. Operators benet from reduced dig

times and better material retention; ultimately translating

into signicant productivity and fuel ef ciency improvements.

Lower Operating Costs

Performance Series Buckets feature a longer oor that easily

digs through the pile and provides excellent visibility for the

operators to see when the bucket is full. Less time digging

in the pile results in lower fuel consumption and improved

tire life. A unique spill guard protects the cab and linkage

components from material over ow.

Higher Productivity

Performance Series Buckets achieve higher ll factors –

ranging from 100% to 115% depending on the machine

application and material type. The buckets feature optimized

geometry with a bucket opening matched to the machine’s

linkage and incorporate a curved side prole to maximize

material retention. The optimized design results in unsurpassed

production capabilities.

Performance Series Bucket Styles

Performance Series Buckets are available for General Purpose,

Material Handling, Rock andCoal style buckets.

6

Page 7

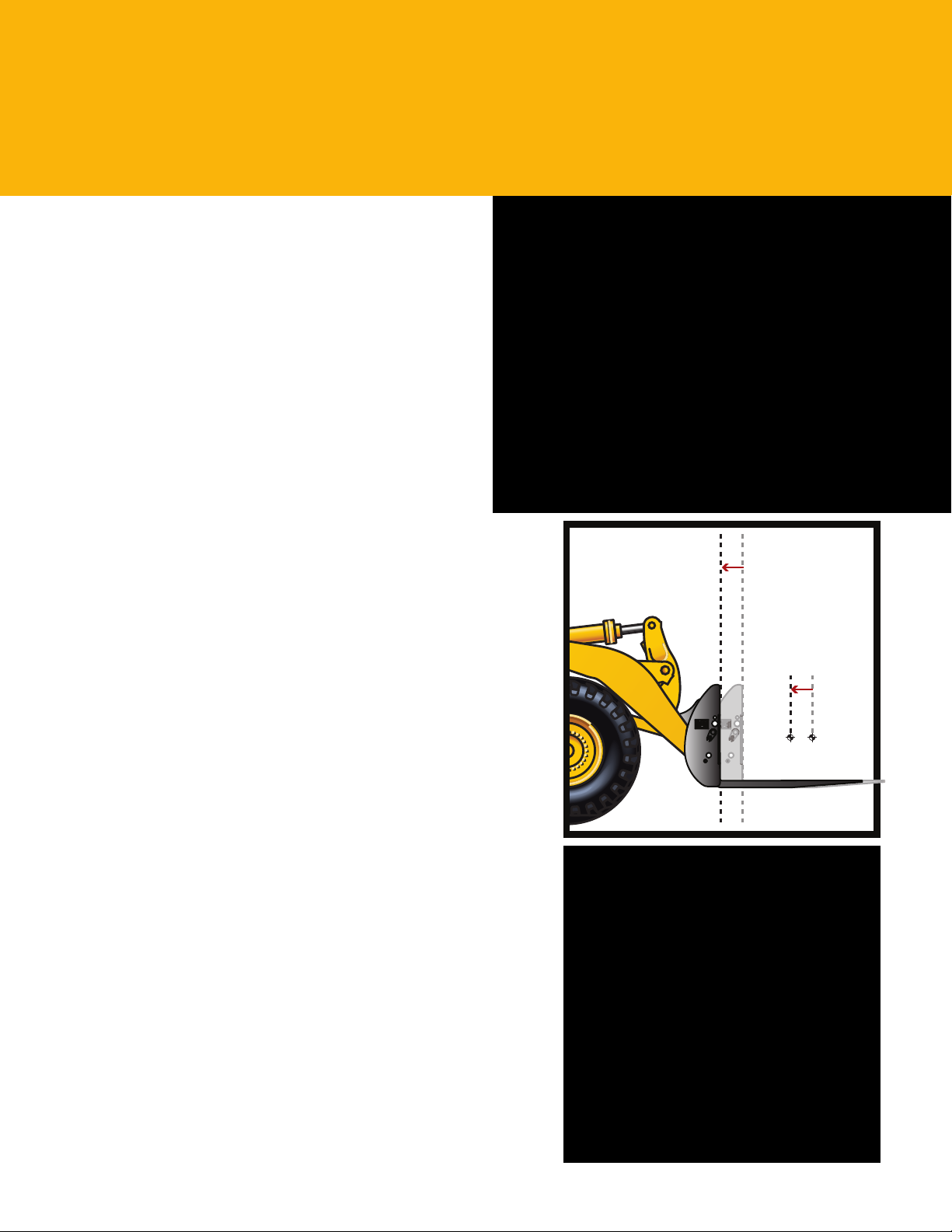

Fusion Quick Coupler

Improved Machine Performance

Fusion™ is the patented wheel loader coupler system

from Caterpillar. The Fusion Coupler System provides

performance virtually identical to pin on – with all the

exibility of a quick coupler system. The Fusion Coupler

sits back, close-in to the loader arms – minimizing offset

andincreasing the machine’s performance.

No Loss of Performance

Imagine lifting a hundred pound box with your arms fully

extended. Now imagine lifting that same load close to your

body. That’s the genius of Fusion: designed to integrate

the work tool and the machine by pulling the coupler and

tool closer in to the loader. As a result, the center of gravity

is moved inward, towards the machine. This translates

to increased lifting ability when compared to machines

equipped with other coupler systems.

Unsurpassed Durability

An advanced wedging mechanism creates a tight, rattlefree t. This patented lock up system eliminates play and

wear – resulting in a long service life. Wedges pull the

attachment tight to the machine in two directions – in and

down. Constant hydraulic pressure on the coupler wedges

compensate for wear, assuring a tight t through the life of

the coupler. Tight t gives better tool control and increased

productivity. Coupler durability is substantially increased

over traditional couplers.

Fusion™ eliminates

coupler offset...

...with

substantial

improvements in

center of gravity.

Enhanced Visibility

An open coupler frame design clears sight lines from the

operator’s seat, making it easier than ever before to engage

and disengage attachments with certainty. Offset tines and

other design changes to Fusion Pallet Forks, working in

conjunction with the Fusion Coupler, enhance visibility

substantially at ground level and truck bed height when

compared to traditional coupler and fork combinations.

Common Interface Compatibility

The Fusion Coupler System gives Caterpillar customers one

common interface – eliminating the need for many different

couplers across the entire range of small and medium wheel

loaders. This expanded machine compatibility not only allows

one machine to use a range of work tools, but also allows one

work tool to be picked up by machines of many different sizes.

The Fusion coupler interface is designed to work on 924

through 972 machines. Each machine will have its own optimal

bucket and fork recommendations. However, cross-machine

compatibility gives you additional exibility and eet options

not found with any other wheel loader coupler.

7

Page 8

Operator Environment

Safe. Comfortable. Ef cient.

Electro-Hydraulic (EH) Joystick Steering with

ForceFeedback (Speed Sensitive)

The industry leading EH joystick steering system combines

operator comfort and precision control to provide a

sustainable work environment for the operator. The system

incorporates a force feedback motor that automatically adjusts

the effort needed to tilt the ergonomic joystick based on

ground speed, resulting in superior control in all applications

and climates. For customers who prefer a steering wheel, an

electro-hydraulic steering wheel is available as an option.

Implement Controls (EH)

Seat mounted single axis implement control levers provide

the operator with precise control of the work tool, all

while moving with the seat for maximum comfort. In cab

programmable kick-outs and automatic cylinder snubbing

maximize operator comfort and productivity throughout

their shift. Optional implement joysticks are available

for2Vand 3V hydraulics.

Seat

The Cat Optimized Seating System is 6-way adjustable to

accommodate operators of all sizes. The seat has a one piece

high back that supports the lumbar area of the back up

through the shoulders. Both armrests are large and can be

adjusted up, down, fore, and aft to enhance comfort and

convenience. An optional feature for the cab seat is a heated

backrest andcushion.

Sound and Vibration

New viscous cab mounts connect the cab to the frame of

the machine, decreasing noise and vibration the operator is

subjected to. This contributes to a well-rested operator, who

remains efcient and productive. All Day. Every Day.

Information Display

The central display panel has a large text box, ve analoglike gauges, and LED warning indicators. The large textbox

provides in-language information about machine operation,

feature activation and system troubleshooting and calibration.

With the 5 large analog-type gauges the operator can easily

identify if key systems are within normal operating range.

Aresettable trip totals function has been incorporated to

display information for average fuel consumed, total fuel

consumed, idle fuel, idle time, operating hours, odometer,etc.

The navigation buttons are located on the side of the screen

and help assist with set up and other various functions.

8

Page 9

Automatic Climate Control and Air Quality

The new climate control system automatically adjusts the air

temperature and fan speed to maintain the operator’s preferred

climate setting. The cab air ltration system recirculates 90%

of the cab air and is now serviced from outside the cab,

enabling maximum air quality and cab cleanliness. The new

air conditioning sealing system keeps refrigerant contained

preventing system shutdown. Combined together, the operator

remains efcient and productive all shift long due to a

sustainable work environment.

Entry and Exit

Well-placed grab bars and a ladder inclination angle of

10-degrees forward makes the walk into the cab feel more like

a staircase than a ladder. The new wider front hinged door can

be opened and closed while seated, greatly improving ingress

and egress. Two new left-hand and right-hand sliding windows

can also be opened and closed with one hand while seated for

comfortable communication to personnel on the ground.

Visibility

Visibility has been enhanced by removing the steering wheel,

adding a convex windshield, and eliminating two cabposts.

The cab has a clean and clear panoramic view for safe operation

of the machine. External rearview mirrors are mounted on the

cab to provide all around visibility. The external mirrors fold

horizontally to provide fast, safe access to clean the window

from the front platform. Optional heated and powered mirrors

are available to further improve visibility in cold climates.

Rearview Camera

With the new standard rearview camera, visibility is greatly

enhanced. The camera is located in a pocket on the grill to

protect it from damage and the elements. The camera can

be set to activate only when the transmission is in reverse to

help eliminate distractions in the cab, especially when in dark

environments. Two rear work lights are located in the rear

grill and can be activated to illuminate the area behind the

machine in low light conditions.

Control Panels and Park Brake Switch

Two control panels located on the front right ROPS post

consist of large membrane switches making them easy to

activate while wearing gloves. The membrane switches contain

LED’s to denote activation/mode and have a positive feel and

“click” to signal activation. The ISO symbols located on each

membrane switch are molded all the way through to ensure

the image will not wear off over time. A new “help” feature

explains the function of each membrane switch. Atwo position

rocker switch activates the electro-hydraulic park brake and

is automatically applied upon machine shutdown.

9

Page 10

Serviceability

Easy to Maintain. Easy to Service.

Electrical Service Center

The electrical service center provides grouped ground level

access to numerous electrical features, enhancing safety

and convenience for operators and service technicians. It

is conveniently located beneath the left platform for access

before entering the cab and contains the maintenance free

batteries, a fuse relay panel, main disconnect switch, ground

level engine shutdown switch, hood tilt switch, and the jump

start receptacle.

Engine Access

The K Series retains the Cat sloped “one-piece” tilting

hood, which has become one of our brand’s hallmarks and

provides industry-leading access to the engine, Cat Clean

Emissions Module (CEM) and other components but with

fresh new styling clearly distinct from the H Series. New to

the loaders is a rear clamshell hood design that allows quick

access to the engine oil dipstick and ll, fuel ll port, and

cooler cores.

Cooling System

The cooling system is readily accessible for clean out

and maintenance. With six cooling ns per inch and a

perforated grill, most airborne debris entering the system

passes through the cooler cores. The cooler cores swing out

providing easy access for cleaning; an option variable pitch

fan is available to automatically purge the cooler cores by

periodically reversing the air ow.

Hydraulic Service Center

The hydraulic components are all conveniently located

behind the hinged right side access ladder at a single ground

level service center enhancing safety and reducing service

time. Accessible from the service center are the transmission

and hydraulic oil lters, brake accumulators, pressure test

ports, etc.

10

Page 11

Sustainability

Conserving Resources

The 972K is designed to compliment your business plan,

reduce emissions and minimize the consumption of

naturalresources.

• Improved fuel efciency – less fuel consumed results

inlower emissions.

• Machine is built with a 96% recyclability rate

(ISO16714) to conserve valuable natural resources

andfurther enhance machine end-of-life value.

• Engine air lter life doubled to reduce cost and waste.

• Improved operator efciency through enhanced visibility

and reduced noise/vibration levels.

• Product Link family of products and solutions that collect,

communicate, store and deliver product and job-site

information to maximize productivity and reducecosts.

• Major components are rebuildable, eliminating waste

and saving money by giving the machine and/or major

components a second – and even third – life.

Customer Support

Ready to Help. Anytime. Anywhere.

Machine Selection

Cat dealers are ready to help evaluate machine options;

fromnew or used machine sales, to rental or rebuild

options, Cat dealers can provide an optimal solution

tomeet customer business needs.

Product Support

Cat dealers are with customers every step of the way

tomaximize machine uptime by providing unsurpassed

worldwide parts support, trained technicians and

customer support agreements.

Operation

To help maximize the return on your investment,

Catdealers offer various training resources to improve

operating techniques.

Financing

Cat dealers offer nancing options to meet a variety

ofcustomer needs.

Page 12

Owning Costs

Proven Best Investment

Customer Support Agreements

A Customer Support Agreement (CSA) is an arrangement

between you and your Cat dealer that helps you lower

your total cost per ton. CSAs are exible, allowing them

to be tailored to your business needs. They can range from

simple Preventive Maintenance Kits to elaborate Total Cost

Performance Guarantees. Having a CSA with your Cat dealer

enables more time for you to do what you do best –run

yourbusiness.

Monitoring Systems

Monitoring product health is key to optimizing the life

ofaninvestment into a Cat Wheel Loader.

• Cat Product Link – Cat Product Link allows remote

monitoring of equipment to improve overall eetmanagement effectiveness. Product Link is deeply

integrated into machine systems. Events and diagnostic

codes, as well as hours, fuel, idle time and other detailed

information are transmitted to a secure web based

application, VisionLink™. VisionLink includes powerful

tools to convey information to users and dealers, including

mapping, working and idle time, fuel level and more.

• S·O·SSM Services – Helps manage component life and

decrease machine downtime, increasing productivity and

efciency. Regular uid sampling can help track what

is going on inside your machine. Wear related problems

are predictable and easily repairable. Maintenance can

be done to accommodate your schedule, resulting in

increased uptime and exibility in maintenance repairs

before failure.

12

Parts Availability

Caterpillar provides an unsurpassed level of personalized

service to help you work more cost effective and ef cient.

By utilizing a worldwide parts network Cat dealers help

minimize machine downtime and save money by delivering

replacement parts within 24 hours.

Resale Value

Owning quality equipment is an important factor in

maintaining resale value. Caterpillar is not only known for

machines that are better built, but provides product and

dealer support to maintain the reliability and durability

ofyour machine.

Page 13

Operating Costs

Save Time and Money by Working Smart

Data from customer machines show Cat wheel loaders are among the most fuel efcient machines in the industry.

Severalfeatures contribute to this excellent fuel ef ciency:

• Performance Series Buckets – Deliver faster ll times and better material retention, ultimately reducing cycle times while

improving productivity and fuel ef ciency.

• Load-Sensing Hydraulics – Provides only the hydraulic ow required by the implement and steering systems for improved

fuel efciency and greater rimpull.

• ACERT™ Engine – Power dense engine enables a more fuel-efcient method to meet emissions regulations.

• Fuel Management System (FMS) – Optimizes power for maximum fuel savings with minimal impact on production.

• Engine Idle Shutdown – Automatic engine and electrical system shutdown conserves fuel.

• Torque Converter – Transfers more power to the ground and optimizes fuel efciency in all applications.

• Shift Strategy – Reduced torque interruption increases driveline efciency, conserving fuel. Auto 1-4 transmission mode

keeps engine rpm low, reducing fuel consumption while delivering optimal machine performance.

Machine conguration, operator technique, and job site layout can impact fuel consumption by as much as 30 percent.

• Machine Con guration – Select the correct work tool and tire type based on machine application. Radial tires are preferred;

ensure proper ination pressures. Heavier tires burn more fuel. Keep engine rpm low by using auto 1-4 transmission mode.

• Job Site Layout – Spot loading targets in the right position. Avoid traveling more than twice the machine length during

short cycle loading. Reduce transport distance for load and carry cycles by optimizing job site layout.

• Loading Bucket – Load in rst gear and keep engine rpm low. Raise and tilt bucket smoothly and do not use a “pumping”

motion. Avoid lift lever detent and use of transmission neutralizer.

• Loading Truck or Hopper – Do not raise the work tool any higher than necessary. Keep engine rpm low and unload in

controlled manner.

• Idle – Set the parking brake to engage Engine Idle Management System.

13

Page 14

972K Wheel Loader Speci cations

Engine Operating Specications Hydraulic System

Engine Model Cat® C9.3 ACERT™ Static Tipping Load 16 317 kg 35,963 lb Steering System Piston

Max. Gross Power 237 kW 318 hp

(1,800 rpm) – Implement System– 340 L/min 90 gal/min

SAEJ1995 Static Tipping Load 17 642 kg 38,884 lb Maximum Pump

Max. Net Power 215 kW 288 hp

(1,800 rpm) – Implement System – 31 000 kPa 4,496 psi

ISO9249 Breakout Force 196 kN 44,075 lb Maximum Operating

Max. Net Power 215 kW 288 hp

(1,800 rpm) –

SAEJ1349

Max. Net Power 215 kW 288 hp

(1,800 rpm) –

EEC80/1269

Peak Gross Torque 1426 N·m 1,051 ft-lb

(1,400 rpm) – Hydraulic Cycle 5.9 Seconds

SAEJ1995 Time – Raise from

Peak Net Torque 1335 N·m 985 ft-lb

(1,400 rpm) – Hydraulic Cycle 2.0 Seconds

SAEJ1349 Time – Dump at

Bore 115 mm 4.5 in

Stroke 149 mm 5.9 in

Displacement 9.3 L 568 in

• Cat engine with ACERT™ Technology –

meets Tier 4 Interim/Stage IIIB emission

standards.

Weights

Operating Weight 26 212 kg 57,770 lb

• For 4.8 m

with BOCE.

3

(6.3 yd3) general purpose buckets

Buckets

Full 37° Turn – Pump Type

ISO14397-1*

Full 37° Turn – Output (2,275 rpm)

Rigid Tires**

3

• For 4.8 m

buckets with BOCE.

* Full compliance to ISO (2007) 14397-1

Sections 1 thru 6, which requires 2%

verication between calculations and testing.

** Compliance to ISO (2007) 14397-1

Sections 1 thru 5.

(6.3 yd3) general purpose

Pressure

Implement System– 300 L/min 79.3 gal/

Optional 3rd Function min

Maximum Flow

Implement System– 20 700 kPa 3,000 psi

Optional 3rd Function

Maximum Pressure

Transmission

Forward 1 7.0 km/h 4.4 mph

Forward 2 12.5 km/h 7.8 mph

Forward 3 21.4 km/h 13.3 mph

Forward 4 36.9 km/h 22.9 mph

Reverse 1 8.0 km/h 5.0 mph

3

Reverse 2 14.3 km/h 8.9 mph

Reverse 3 24.5 km/h 15.2 mph

Reverse 4 42.2 km/h 26.2 mph

• Maximum travel speed in standard vehicle

with empty bucket and standard L3 tires

with 826 mm (33 in) roll radius.

Carry Position

Maximum Raise

Hydraulic Cycle 2.4 Seconds

Time – Lower,

Empty, Float Down

Hydraulic Cycle 10.3 Seconds

Time – Total

• Cycle time with rated payload.

Brakes

Brakes Meet OSHA,

SAEJ1473 OCT90

and ISO 3450-1985

required standards

Bucket Capacities 2.90 m3- 3.75 yd3-

• Refer to bucket selection chart.

14

9.90 m

3

13.00 yd

3

Page 15

Axles Cab Service Rell Capacities

Front Fixed

Rear Oscillating

±13degrees

Maximum Single- 495 mm 19.5 in

Wheel Rise and Fall

Tires

• Choose from a variety of tires to match

your application.

• Choices include:

26.5R25 VLT BS E3 Radial

26.5R25 VJT BS E3/L3 Radial

26.5R25 VMT BS L3 Radial

26.5-25 SRG LD FS L3 Bias

750/65R25 XLD L3T MX L3 Radial

26.5R25 XHA2 MX L3 Radial

26.5R25 XLD D1 MX L4 Radial

26.5R25 VSNT BS E4/L4 Radial

26.5-25 SDT LD FS L5 Bias

26.5R25 VSDL BS L5 Radial

26.5R25 XLDD2 MX L5 Radial

26.5R25 X MINE D2 MX L5 Radial

Cat Flexport™

• NOTE: In certain applications (such as

load and carry), the loader’s productive

capabilities might exceed the tires’ tonneskm/h (ton-mph) capabilities. Caterpillar

recommends that you consult a tire supplier

to evaluate all conditions before selecting a

tire model. Other special tires are available

on request.

ROPS/FOPS Meets SAE and

ISOstandards

• Caterpillar cab with a four post integrated

Rollover Protective Structure (ROPS) are

standard in North America and Europe.

• ROPS meets SAE J1040 APR88 and

ISO3471:1994 criteria.

• Falling Objects Protective Structure (FOPS)

meets SAE J231 JAN81 and ISO:1992

Level II criteria.

Sound

• The sound values indicated below are

forspecic operating conditions only.

Machine and operator sound levels will

vary at different engine and/or cooling fan

speeds. Hearing protection may be needed

when the machine is operated with a cabin

that is not properly maintained, or when

the doors and/or windows are open for

extended periods or in a noisy environment.

• The operator sound pressure level for a

standard machine con guration, measured

according to the procedures speci ed

inISO6396:2008, is 71 dB(A) with the

cooling fan speed set at maximum value.

• The machine sound power level for a

standard machine con guration, measured

according to the procedures speci ed in

ISO6395:2008, is 111 dB(A) with the

cooling fan speed set at maximum value.

• The machine sound pressure level for

astandard machine con guration,

measured according to the procedures

specied in SAE J88:2006, is 76 dB(A).

Themeasurement was conducted under

thefollowing conditions: distance of 15 m

(49.2ft), moving forward in an intermediate

gear ratio, static hydraulic cycle (with no

payload) and with the cooling fan speed

setat maximum value.

• The operator sound pressure level for

amachine installed with a Low Sound

package, measured according to the

procedures specied in ISO6396:2008,

is69dB(A) with the cooling fan speed

setatmaximum value.

• The machine sound power level for a

machine installed with a Low Sound

package, measured according to the

procedures specied in ISO6396:2008,

is108 dB(A) with the cooling fan speed

setat maximum value.

Fuel Tank – 381 L 101 gal

Standard

Cooling System 66 L 17.4 gal

Crankcase 24.5 L 6.5 gal

Transmission 50 L 13.2 gal

Differentials and 64 L 16.9 gal

Final Drives – Front

Differentials and 64 L 16.9 gal

Final Drives – Rear

Hydraulic Tank 198 L 52.3 gal

15

Page 16

972K Wheel Loader Speci cations

Dimensions

All dimensions are approximate and based on L3 Michelin XHA2 tires.

1

2

3

10

15

11

5

12

13

14

9

4

8

6 7

Height to Top of ROPS 3547 mm 11'7"

1

Height to Top of Exhaust Pipe 3518 mm 11'6"

2

Height to Top of Hood 2828 mm 9'3"

3

Ground Clearance with 26.5R25 (See Tire Option Chart for Other Tires) 475 mm 1'6"

4

B-Pin Height – Standard 4456 mm 14'7"

5

B-Pin Height – High Lift 4792 mm 15'8"

Center Line of Rear Axle to Edge of Counterweight 2473 mm 8'1"

6

Wheelbase 3450 mm 11'3"

7

B-Pin Height @ Carry – Standard 689 mm 2'3"

8

Center Line of Rear Axle to Hitch 1725 mm 5'7"

9

Rack Back @ Maximum Lift 56 degrees

10

Dump Angle @ Maximum Lift 48 degrees

11

Rack Back @ Carry 50 degrees

12

Rack Back @ Ground 41 degrees

13

Height to Center Line of Axle 798 mm 2'7"

14

Lift Arm Clearance 3804 mm 12'6"

15

Lift Arm Clearance @ High Lift 4153 mm 13'6"

16

Page 17

Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

3

3

3

3

Bolt-On

Edges

4.20

5.49

3.70

4.84

3220

10'6"

3225

10'6"

1332

4'4"

2955

9'8"

103

4"

9129

30'0"

5937

19'6"

14 925

49'0"

18 770

41,371

20 088

44,274

16 396

36,138

17 706

39,024

210

47,189

26 223

57,795

General Purpose – Pin On

Teeth and Bolt-On Teeth and

Segments Teeth Edges Segments Teeth

4.20 4.00 4.40 4.40 4.20

5.49 5.23 5.75 5.75 5.49

3.70 3.50 3.80 3.80 3.60

4.84 4.58 4.97 4.97 4.71

3271 3271 3220 3271 3271

10'8" 10'8" 10'6" 10'8" 10'8"

3071 3071 3229 3076 3076

10'0" 10'0" 10'7" 10'1" 10'1"

1470 1470 1327 1465 1465

4'9" 4'9" 4'4" 4'9" 4'9"

3160 3160 2948 3153 3153

10'4" 10'4" 9'8" 10'4" 10'4"

103 73 103 103 73

4" 2.8" 4" 4" 2.8"

9353 9353 9122 9346 9346

30'9" 30'9" 30'0" 30'8" 30'8"

5937 5937 6230 6230 6230

19'6" 19'6" 20'6" 20'6" 20'6"

15 104 15 104 14 921 15 100 15 100

49'7" 49'7" 49'0" 49'7" 49'7"

18 589 18 840 18 817 18 636 18 885

40,971 41,523 41,474 41,074 41,622

19 903 20 157 20 147 19 962 20 215

43,866 44,427 44,405 43,996 44,554

16 213 16 447 16 437 16 253 16 485

35,734 36,251 36,227 35,822 36,334

17 521 17 757 17 758 17 573 17 807

38,616 39,138 39,140 38,731 39,248

208 223 211 209 224

46,880 50,138 47,419 47,109 50,397

26 361 26 198 26 229 26 367 26 203

58,099 57,740 57,807 58,111 57,752

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

17

Page 18

972K Wheel Loader Speci cations

Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

3

3

3

3

Bolt-On

Edges

4.60

6.02

4.00

5.23

3220

10'6"

3187

10'5"

1363

4'5"

3004

9'10"

103

4"

9178

30'2"

6195

20'4"

14 951

49'1"

18 658

41,124

19 985

44,048

16 289

35,901

17 608

38,808

202

45,482

26 284

57,929

General Purpose – Pin On

Teeth and Bolt-On Teeth and

Segments Teeth Edges Segments Teeth

4.60 4.40 4.80 4.80 4.60

6.02 5.75 6.28 6.28 6.02

4.00 3.80 4.10 4.10 3.90

5.23 4.97 5.36 5.36 5.10

3271 3271 3220 3271 3271

10'8" 10'8" 10'6" 10'8" 10'8"

3033 3033 3154 2999 2999

9'11" 9'11" 10'4" 9'10" 9'10"

1500 1500 1392 1528 1528

4'11" 4'11" 4'6" 5'0" 5'0"

3209 3209 3049 3254 3254

10'6" 10'6" 10'0" 10'8" 10'8"

103 73 103 103 73

4" 2.8" 4" 4" 2.8"

9402 9402 9223 9447 9447

30'11" 30'11" 30'4" 31'0" 31'0"

6195 6195 6031 6031 6031

20'4" 20'4" 19'10" 19'10" 19'10"

15 132 15 132 14 976 15 157 15 157

49'8" 49'8" 49'2" 49'9" 49'9"

18 476 18 733 18 683 18 500 20 705

40,722 41,288 41,179 40,775 45,634

19 799 20 059 20 017 19 830 22 448

43,638 44,210 44,118 43,705 49,475

16 104 16 343 16 317 16 132 18 062

35,494 36,021 35,963 35,554 39,810

17 422 17 662 17 642 17 455 19 773

38,398 38,927 38,884 38,471 43,580

201 214 196 194 207

45,173 48,227 44,075 43,766 46,655

26 422 26 258 26 212 26 350 26 186

58,233 57,873 57,770 58,074 57,714

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

18

Page 19

Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

General Purpose – Pin On

Bolt-On

Edges

3

5.00

3

6.54

3

4.30

3

5.62

3220

10'6"

3137

10'3"

1407

4'7"

3072

10'0"

103

4"

9246

30'4"

6284

20'8"

14 989

49'3"

18 779

41,390

20 115

44,334

16 414

36,177

17 739

39,097

198

44,634

26 325

58,019

Teeth and

Segments Teeth

5.00 4.80

6.54 6.28

4.30 4.10

5.62 5.36

3271 3271

10'8" 10'8"

2982 2982

9'9" 9'9"

1543 1543

5'0" 5'0"

3277 3277

10'9" 10'9"

103 73

4" 2.8"

9470 9470

31'1" 31'1"

6284 6284

20'8" 20'8"

15 170 15 170

49'10" 49'10"

18 595 18 832

40,984 41,507

19 927 20 166

43,919 44,447

16 228 16 449

35,767 36,254

17 551 17 772

38,683 39,171

197 210

44,325 47,205

26 463 26 299

58,323 57,963

General Purpose – Fusion QC

Bolt-On Teeth and

Edges Segments Teeth

4.20 4.20 4.00

5.49 5.49 5.23

3.70 3.70 3.50

4.84 4.84 4.58

3220 3271 3271

10'6" 10'8" 10'8"

3195 3041 3041

10'5" 9'11" 9'11"

1367 1504 1504

4'5" 4'11" 4'11"

3000 3205 3205

9'10" 10'6" 10'6"

103 103 73

4" 4" 2.8"

9175 9398 9398

30'2" 30'10" 30'10"

6036 6036 6036

19'10" 19'10" 19'10"

14 944 15 126 15 126

49'1" 49'8" 49'8"

18 260 18 079 18 430

40,246 39,848 40,621

19 563 19 379 19 746

43,118 42,711 43,520

15 906 15 723 16 058

35,057 34,653 35,393

17 205 17 020 17 369

37,920 37,513 38,282

203 201 215

45,615 45,306 48,375

26 600 26 738 26 574

58,625 58,929 58,569

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

19

Page 20

972K Wheel Loader Speci cations

Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

3

3

3

3

Bolt-On

Edges

4.40

5.75

3.80

4.97

3220

10'6"

3200

10'6"

1362

4'5"

2993

9'9"

103

4"

9167

30'1"

6205

20'5"

14 940

49'1"

18 263

40,252

19 578

43,150

15 902

35,049

17 213

37,937

203

45,788

26 642

58,718

General Purpose – Fusion QC

Teeth and Bolt-On Teeth and

Segments Teeth Edges Segments Teeth

4.40 4.20 4.60 4.60 4.40

5.75 5.49 6.02 6.02 5.75

3.80 3.60 4.00 4.00 3.80

4.97 4.71 5.23 5.23 4.97

3271 3271 3220 3271 3271

10'8" 10'8" 10'6" 10'8" 10'8"

3047 3047 3157 3003 3003

9'11" 9'11" 10'4" 9'10" 9'10"

1500 1500 1397 1535 1535

4'11" 4'11" 4'7" 5'0" 5'0"

3198 3198 3050 3255 3255

10'5" 10'5" 10'0" 10'8" 10'8"

103 73 103 103 73

4" 2.8" 4" 4" 2.8"

9391 9391 9224 9448 9448

30'10" 30'10" 30'4" 31'0" 31'0"

6205 6205 6211 6211 6211

20'5" 20'5" 20'5" 20'5" 20'5"

15 122 15 122 14 971 15 154 15 154

49'8" 49'8" 49'2" 49'9" 49'9"

18 082 18 439 18 113 17 931 18 282

39,853 40,639 39,921 39,520 40,293

19 393 19 767 19 425 19 239 19 606

42,742 43,566 42,812 42,403 43,212

15 719 16 060 15 761 15 577 15 912

34,645 35,396 34,738 34,332 35,072

17 028 17 383 17 070 16 884 17 233

37,530 38,312 37,622 37,212 37,982

202 216 195 194 207

45,479 48,572 43,941 43,632 46,510

26 780 26 616 26 700 26 838 26 675

59,022 58,662 58,847 59,151 58,791

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

20

Page 21

Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

3

3

3

3

Bolt-On

Edges

4.80

6.28

4.10

5.36

3220

10'6"

3130

10'3"

1419

4'7"

3085

10'1"

103

4"

9259

30'5"

6270

20'7"

14 991

49'3"

18 105

39,903

19 423

42,808

15 754

34,722

17 068

37,619

190

42,897

26 695

58,836

General Purpose – Fusion QC

Teeth and Bolt-On Teeth and

Segments Teeth Edges Segments Teeth

4.80 4.60 5.00 5.00 4.80

6.28 6.02 6.54 6.54 6.28

4.10 3.90 4.30 4.30 4.10

5.36 5.10 5.62 5.62 5.36

3271 3271 3220 3271 3271

10'8" 10'8" 10'6" 10'8" 10'8"

2975 2975 3106 2951 2951

9'9" 9'9" 10'2" 9'8" 9'8"

1555 1555 1440 1576 1576

5'1" 5'1" 4'8" 5'2" 5'2"

3290 3290 3117 3322 3322

10'9" 10'9" 10'2" 10'10" 10'10"

103 73 103 103 73

4" 2.8" 4" 4" 2.8"

9483 9483 9291 9515 9515

31'2" 31'2" 30'6" 31'3" 31'3"

6270 6270 6296 6296 6296

20'7" 20'7" 20'8" 20'8" 20'8"

15 174 15 174 15 009 15 193 15 193

49'10" 49'10" 49'3" 49'11" 49'11"

17 922 18 271 17 986 17 802 18 150

39,500 40,270 39,642 39,237 40,003

19 236 19 602 19 306 19 119 19 483

42,396 43,203 42,552 42,138 42,941

15 569 15 903 15 636 15 450 15 783

34,314 35,051 34,462 34,052 34,786

16 881 17 230 16 953 16 766 17 112

37,207 37,975 37,366 36,952 37,716

189 201 186 185 196

42,588 45,348 41,881 41,572 44,224

26 833 26 670 26 786 26 924 26 761

59,140 58,780 59,036 59,340 58,980

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

21

Page 22

972K Wheel Loader Speci cations

Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

Material Handling – Pin On

3

3

3

3

Bolt-On

Edges

4.60

6.02

3.90

5.10

Teeth and

Segments Teeth

3220

10'6"

3120

10'2"

1286

4'2"

3014

9'10"

103

4"

9188

30'2"

30'11" 30'11"

6162

20'3"

14 957

15 137 15 137

49'1"

18 595

40,983

19 901

43,862

16 235

35,782

17 534

38,646

18 413 18 653

40,582 41,111

19 715 19 958

43,453 43,988

16 051 16 274

35,376 35,869

17 349 17 573

38,237 38,732

201

45,174

26 279

57,918

44,865 47,882

26 417 26 253

58,222 57,862

4.60 4.40

6.02 5.75

3.90 3.70

5.10 4.84

3271 3271

10'8" 10'8"

2957 2957

9'8" 9'8"

1413 1413

4'7" 4'7"

3219 3219

10'6" 10'6"

103 73

4" 2.8"

9412 9412

6162 6162

20'3" 20'3"

49'8" 49'8"

199 213

Rock – Pin On***

Bolt-On Teeth and

Edges Segments Teeth

3.60 3.60 3.40

4.71 4.71 4.45

3.10 3.10 2.90

4.05 4.05 3.79

3252 3252 3252

10'8" 10'8" 10'8"

3336 3248 3248

10'11" 10'7" 10'7"

1420 1528 1528

4'7" 5'0" 5'0"

2964 3104 3104

9'8" 10'2" 10'2"

44 44 4

1.7" 1.7" 0.1"

9127 9272 9272

30'0" 30'6" 30'6"

6042 6042 6042

19'10" 19'10" 19'10"

14 978 15 061 15 061

49'2" 49'5" 49'5"

19 302 19 235 19 616

42,543 42,394 43,234

20 641 20 572 20 963

45,494 45,342 46,202

16 872 16 804 17 167

37,187 37,036 37,837

18 203 18 134 18 504

40,120 39,968 40,783

222 222 231

50,090

49,982 52,114

26 934 26 985 26 760

59,361 59,473 58,977

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

22

Page 23

Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

3

3

3

3

Rock – Pin On***

Bolt-On

Edges

4.00

5.23

3.50

4.58

3252

10'8"

3233

10'7"

1463

4'9"

3073

10'1"

44

1.7"

9236

30'4"

6159

20'3"

15 039

49'5"

19 183

42,281

20 544

45,281

16 744

36,905

18 098

39,889

204

45,999

27 081

59,685

Teeth and

Segments Teeth

4.00 3.80

5.23 4.97

3.50 3.30

4.58 4.32

3252 3252

10'8" 10'8"

3142 3142

10'3" 10'3"

1571 1571

5'1" 5'1"

3214 3214

10'6" 10'6"

44 44

1.7" 1.7"

9380 9380

30'10" 30'10"

6159 6159

20'3" 20'3"

15 123 15 123

49'8" 49'8"

19 114 19 459

42,128 42,887

20 474 20 829

45,125 45,907

16 674 17 016

36,750 37,503

18 027 18 376

39,733 40,501

204 212

45,886 47,764

27 132 26 907

59,797 59,301

Rock – Fusion QC***

Bolt-On Teeth and

Edges Segments Teeth

3.60 3.60 3.40

4.71 4.71 4.45

3.10 3.10 2.90

4.05 4.05 3.79

3252 3252 3252

10'8" 10'8" 10'8"

3310 3222 3222

10'10" 10'6" 10'6"

1455 1563 1563

4'9" 5'1" 5'1"

3008 3147 3147

9'10" 10'3" 10'3"

44 44 4

1.7" 1.7" 0.1"

9171 9315 9315

30'2" 30'7" 30'7"

6060 6060 6060

19'11" 19'11" 19'11"

14 996 15 081 15 081

49'3" 49'6" 49'6"

18 779 18 710 19 158

41,390 41,238 42,225

20 105 20 035 20 500

44,312 44,157 45,184

16 368 16 299 16 730

36,076 35,923 36,873

17 690 17 620 18 065

38,990 38,835 39,816

215 214 223

48,357 48,247 50,268

27 326 27 378 27 153

60,225 60,339 59,844

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

23

Page 24

972K Wheel Loader Speci cations

Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

Coal – PinOn Coal – Fusion QC

Bolt-On Bolt-On Change

Edges Edges inSpecs

3

3

3

3

7.10 7.10

9.29 9.29

6.20 6.20

8.11 8.11

3447 3447

11'3" 11'3"

2842 2819 335

9'3" 9'2" 1'1"

1544 1584 23

5'0" 5'2" 1"

3393 3438 273

11'1" 11'3" 0'10"

117 105 –4

4.6" 4.1" –0.1"

9578 9614 336

31'6" 31'7" 1'2"

6546 6581 336

21'6" 21'8" 1'2"

15 385 15 401 332

50'6" 50'7" 1'2"

17 394 16 779 –1558

38,337 36,983 –3,434

18 728 18 106 –1721

41,277 39,906 –3,794

15 072 14 465 –1391

33,220 31,882 –3,066

16 407 15 797 –1568

36,161 34,817 –3,457

154 149 –5

34,604 33,479 –1,327

26 946 27 506 85

59,387 60,622 186

High Lift

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

24

Page 25

Extended Capacity Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

3

3

3

3

Bolt-On

Edges

4.60

6.02

4.05

5.30

3220

10'6"

2978

9'9"

1400

4'7"

2857

9'4"

123

4.8"

8996

29'7"

5875

19'4"

14 787

48'7"

20 204

44,531

21 762

47,964

17 668

38,940

19 203

42,325

215

48,470

26 062

57,440

General Purpose – Pin On

Teeth and Bolt-On Teeth and

Segments Teeth Edges Segments Teeth

4.60 4.40 4.90 4.90 4.70

6.02 5.75 6.41 6.41 6.15

4.05 3.90 4.20 4.20 4.00

5.30 5.10 5.49 5.49 5.23

3271 3271 3220 3271 3271

10'8" 10'8" 10'6" 10'8" 10'8"

2824 2824 2920 2765 2765

9'3" 9'3" 9'6" 9'0" 9'0"

1537 1537 1448 1584 1584

5'0" 5'0" 4'9" 5'2" 5'2"

3062 3062 2933 3138 3138

10'0" 10'0" 9'7" 10'3" 10'3"

123 93 123 123 93

4.8" 3.6" 4.8" 4.8" 3.6"

9221 9221 9072 9297 9297

30'4" 30'4" 29'10" 30'7" 30'7"

5875 5875 6095 6095 6095

19'4" 19'4" 20'0" 20'0" 20'0"

14 961 14 961 14 827 15 001 15 001

49'1" 49'1" 48'8" 49'3" 49'3"

20 021 20 388 20 052 19 867 20 098

44,127 44,936 44,194 43,787 44,296

21 574 21 959 21 624 21 434 21 667

47,549 48,397 47,660 47,241 47,755

17 482 17 836 17 520 17 333 17 546

38,531 39,312 38,615 38,202 38,672

19 015 19 384 19 071 18 881 19 094

41,910 42,722 42,032 41,614 42,085

214 228 204 202 215

48,095 51,358 45,923 45,550 48,516

26 200 26 037 26 185 26 323 26 160

57,744 57,384 57,712 58,016 57,656

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

25

Page 26

972K Wheel Loader Speci cations

Extended Capacity Operating Specifications

Bucket Type

Edge Type

Capacity – Rated (§)

Capacity – Struck (§)

Width (§)

Dump Clearance at Maximum Lift and 45° Discharge (§)

Reach at Maximum Lift and 45° Discharge (§)

Reach at Level Lift Arm and Bucket Level (§)

Digging Depth (§)

Overall Length

Overall Height with Bucket at Maximum Lift

Loader Clearance Circle with Bucket at Carry Position (§)

Static Tipping Load, Straight (ISO)*

Static Tipping Load, Straight (Rigid Tire)*

Static Tipping Load, Articulated (ISO)*

Static Tipping Load, Articulated (Rigid Tire)*

Breakout Force** (§)

Operating Weight*

m

yd

m

yd

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

mm

ft/in

kg

lb

kg

lb

kg

lb

kg

lb

kN

lb

kg

lb

3

3

3

3

Bolt-On

Edges

4.60

6.02

4.05

5.30

3220

10'6"

2948

9'8"

1436

4'8"

2903

9'6"

122

4.8"

9041

29'8"

6039

19'10"

14 804

48'7"

19 674

43,362

21 217

46,763

17 155

37,809

18 681

41,173

208

46,886

26 508

58,424

General Purpose – Fusion QC

Teeth and Bolt-On Teeth and

Segments Teeth Edges Segments Teeth

4.60 4.40 4.90 4.90 4.70

6.02 5.75 6.41 6.41 6.15

4.05 3.90 4.20 4.20 4.00

5.30 5.10 5.49 5.49 5.23

3271 3271 3220 3271 3271

10'8" 10'8" 10'6" 10'8" 10'8"

2794 2794 2899 2744 2744

9'2" 9'2" 9'6" 9'0" 9'0"

1573 1573 1484 1621 1621

5'1" 5'1" 4'10" 5'3" 5'3"

3108 3108 2975 3180 3180

10'2" 10'2" 9'9" 10'5" 10'5"

122 92 115 115 85

4.8" 3.6" 4.5" 4.5" 3.3"

9267 9267 9108 9333 9333

30'5" 30'5" 29'11" 30'8" 30'8"

6039 6039 6126 6126 6126

19'10" 19'10" 20'2" 20'2" 20'2"

14 981 14 981 14 837 15 015 15 015

49'2" 49'2" 48'9" 49'4" 49'4"

19 491 19 844 19 574 19 389 19 752

42,959 43,738 43,141 42,734 43,534

21 029 21 404 21 141 20 952 21 335

46,350 47,176 46,596 46,178 47,023

16 969 17 308 17 052 16 865 17 213

37,400 38,147 37,584 37,171 37,937

18 493 18 850 18 603 18 413 18 777

40,759 41,545 41,001 40,583 41,385

207 220 198 196 209

46,513 49,589 44,570 44,204 47,022

26 646 26 483 26 598 26 736 26 573

58,728 58,368 58,622 58,926 58,567

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 26.5R25 XHA2 L3 Radial tires, full

fluids, operator, standard counterweight, cold start, roading fenders, Product Link, opendifferential axles (front/rear), power train guard,

secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 26.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including SAE

Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

26

Page 27

Bucket Selection Chart

Material Density

General

Purpose

Pin OnFusion QC

Material

Handling

Rock

Standard Linkage

Coal

General

Purpose

800kg/m

700

4.20 m (5.49 yd) 4.83 m (6.32 yd) 4.20 m (5.49 yd)

4.40 m (5.75 yd)

4.60 m (6.02 yd)

4.80 m (6.28 yd)

5.00 m (6.54 yd)

4.60 m (6.02 yd)

3.60 m (4.71 yd)

4.00 m (5.23 yd)

7.10 m (9.29 yd)

4.20 m (5.49 yd)

4.40 m (5.75 yd)

4.60 m (6.02 yd)

900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400

5.06 m (6.62 yd) 4.40 m (5.75 yd)

5.29 m (6.92 yd) 4.60 m (6.02 yd)

5.52 m (7.22 yd) 4.80 m (6.28 yd)

5.75 m (7.52 yd) 5.00 m (6.54 yd)

5.29 m (6.92 yd) 4.60 m (6.02 yd)

4.14 m (5.42 yd) 3.42 m (4.47 yd)

4.60 m (6.02 yd) 3.80 m (4.97 yd)

8.17 m (10.69 yd) 7.10 m (9.29 yd)

4.83 m (6.32 yd) 4.20 m (5.49 yd)

5.06 m (6.62 yd) 4.40 m (5.75 yd)

5.29 m (6.92 yd) 4.60 m (6.02 yd)

2500

4.80 m (6.28 yd)

5.00 m (6.54 yd)

Rock

Coal

Bucket Density

115% 110% 105% 100% 95%

All buckets are showing Bolt-On Edges.

Material Handling buckets are at oor buckets.

3.60 m (4.71 yd)

7.10 m (9.29 yd)

8.17 m (10.69 yd) 7.10 m (9.29 yd)

1,348

1,180lb/ydMaterial Density

1,517 1,685 1,854 2,022 2,191 2,359 2,528 2,696 2,865 3,033 3,202 3,370 3,539 3,707 3,876 4,044

5.52 m (7.22 yd) 4.80 m (6.28 yd)

5.75 m (7.52 yd) 5.00 m (6.54 yd)

4.14 m (5.42 yd) 3.42 m (4.47 yd)

4,213

27

Page 28

972K Wheel Loader Speci cations

Bucket Selection Chart

Material Density kg/m 800 900700 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

0 m (5.4

9 yd)

.40 m (5

4

4.2

.75 yd)

4.20 m (5.49 yd)

4.40 m (5.75 yd)

5.06

4.83 m

m (6.62

(6.32 yd)

yd)

General

Purpose

Pin On

Material

Handling

Rock

High Lift Linkage

Coal

General

Purpose

Fusion QC

Rock

4.60 m (6.02 yd)

4.80 m (6.28 yd)

5.00 m (6.54 yd) 5.7

4.60 m (6.02 yd) 5.29 m (6.92 yd)

3.60 m (4.71 yd)

4.00 m (5.23 yd) 4.60 m (6

7.10 m (9.29 yd) 8.17 m (10.69 yd) 7.10 m (9.29 yd)

4.20 m (5.49 yd)

4.40 m (5.75 yd)

4.60 m (6.02 yd)

4.80 m (6.28 yd)

5.00 m (6.54 yd)

3.60 m (4.71 yd) 4.14 m (5.42 yd)

5.75 m (

5.52 m

5 m (7.52 yd)

5.29 m

5.5

2 m (7.2

7.52 yd)

5.

29 m (6.92 yd)

(7.22 yd)

4.14

.02 yd)

4.

5.06 m (

(6.92 yd)

2 yd)

m (5.42 yd)

83 m (6.32 yd)

6.62 yd)

4.80 m

5.

00 m (6.54 yd)

4.60

4.

80 m (6.28

5.00 m (6.54 yd)

6.02 yd)

4.60 m (

)

(6.28 yd

4.60 m (6.02 yd)

3.80 m (4.397 yd)

4.20 m

4.40 m

(5.75 yd

m (6.02 yd)

yd)

3.42 m (4.47 yd)

.42 m (4.47 yd)

(5.49 yd)

)

Coal

Material Density lb/yd 1,3481,180 1,517 1,685 1,854 2,022 2,191 2,359 2,528 2,696 2,865 3,033 3,202 3,370 3,539 3,707 3,876 4,044 4,213

Bucket Density

115% 110% 105% 100% 95%

All buckets are showing Bolt-On Edges.

Material Handling buckets are at oor buckets.

7.10 m (9.29 yd) 8.17 m (10.69

yd) 7.10 m (9.29 yd)

28

Page 29

Bucket Selection Chart

Material Density kg/m 800 900 1000 1100 1200 1300700 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

e

n

General

ag

Purpose

Pin O

Link

QC n

General

Purpose

Extended Capacity

Fusio

Material Density lb/yd 1,3481,180 1,517 1,685 1,854 2,022 2,191 2,359 2,528 2,696 2,865 3,033 3,202 3,370 3,539 3,707 3,876 4,044 4,213

Bucket Density

115% 110% 105% 100% 95%

All buckets are showing Bolt-On Edges.

Material Handling buckets are at oor buckets.

4.60 m (6.02 yd) 5.29 m (6.92 yd) 4.60 m (6.02 yd)

4.90 m (6.41 yd) 5.64 m (7.38 yd) 4.90 m (6.41 yd)

4.60 m (6.02 yd) 5.29 m (6.92 yd)

4.90 m (6.41 yd) 5.64 m (7.38 yd)

4.60 m (6.02 yd)

4.90 m (6.41 yd)

Bucket Fill Factors

(as a % of ISO Rated Capacity)

Loose Material Performance Series Bucket

Earth/Clay

Sand and Gravel

Aggregate: 25-76 mm (1 to 3 in)

19 mm (0.75 in) and smaller

Rock

115

115

110

105

100

29

Page 30

972K Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

POWER TRAIN

Brakes, full hydraulic enclosed wet-disc

with Integrated Braking System (IBS)

Brake wear indicators

Diesel Particulate Filter (DPF)

Engine, Cat 9.3 meets Tier 4 Interim/

StageIIIB emission standards

Fan, radiator, electronically controlled,