Milton CAT 972H User Manual

Engine

Engine Model Cat®C13 ACERT™

Gross Power – SAE J1995 232 kW 311 hp

Net Power – ISO 9249 214 kW 287 hp

• Caterpillar engine with ACERT™ Technology –

EPA Tier III, EU Stage III Compliant

Buckets

Bucket Capacities 3.8-4.6 m

3

5.0-6.0 yd

3

Weights

Operating Weight 25 148 kg 55,451 lb

• For 4.6 m3(6.0 yd3) general purpose bucket with BOCE

Operating Specifications

Static Tipping Load, Full Turn 16 903 kg 37,271 lb

• For 4.6 m3(6.0 yd3) general purpose bucket with BOCE

972H

Wheel Loader

®

®

2

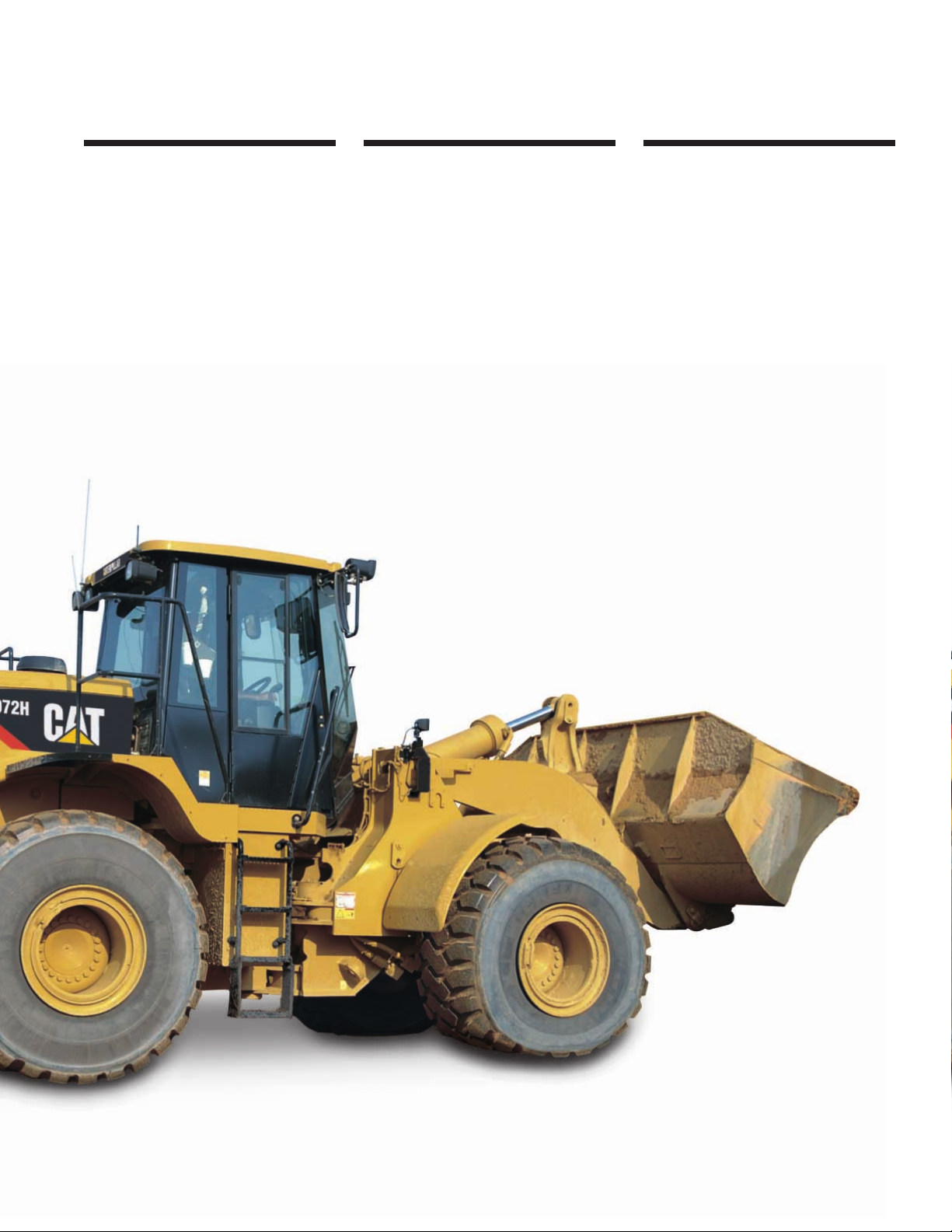

972H Wheel Loader

Cat®H-Series Wheel Loaders – The New Standard For Midsize Loaders

Performance you can feel with the capability

to work in the most demanding applications.

Unmatched operator comfort and efficiency in

a world class cab. Revolutionary electronics

and hydraulics for low-effort operation.

Increased productivity with lower owning

and operating costs.

SERVICEABILITY

• Service Centers For Convenient

Maintenance

• Exceptional Access To Service Points

• Monitoring Systems And Dealer Support

Reduce Unexpected Downtime pg. 16

PRODUCTIVITY

• Improved Cycle Times With LoadSensing Hydraulic System

• Constant Net Horsepower Through

The Operating Range

• Aggregate Autodig Automates The

Loading Process pg. 8

DURABILITY

• ACERT™ Technology Maintains

Performance, Efficiency And Durability

While Meeting Emissions Regulations

• Heavy Duty Components Stand Up To

All Operating Conditions

• Strong, Solid Structures Built To Last

pg. 6

RELIABILITY

• Proven Components And Technology

Equal Proven Reliability

• Diagnostic Systems Monitor Product

Health To Ensure Reliability

• Unmatched Parts Availability And

Dealer Support pg. 4

3

OWNING AND OPERATING COSTS

• Proven Fuel Efficiency

• Superior Maintenance

• Electronic Systems Monitor Product

Health And Performance

• Complete Dealer Support pg. 14

OPERATOR COMFORT

• Easy Entry And Exit

• Excellent Visibility

• Comfortable Environment With

Controlled Vibration

• Choice Of Steering And Implement

Control Systems pg. 12

VERSATILITY

• Special Machine Arrangements For

Specialized Applications

• Large Variety Of Cat®Work Tools

pg. 10

• Proven components and technology

provide proven reliability

• Electronic systems monitor vital

machine components

• Excellent uptime from the best dealer

support network in the industry

• Unmatched genuine Cat parts

availability

PROVEN RELIABILITY. The 972H features

many of the components designed and

proven in previous 972 models – all

contribute to the reliability of the 972H:

• Frames

• Axles

• Planetary powershift transmission

• Free wheel stator torque converter

• Separated cooling system

• Cab

ACERT™ TECHNOLOGY. Since March

2003, ACERT Technology has been

proving itself in on-highway trucks.

More recently it has proven itself again

in field tests of off-highway equipment.

This technology allows Cat engines to

meet durability and reliability expectations

without sacrificing fuel economy or

performance.

CATERPILLAR DESIGNED COMPONENTS.

Components used to build Cat Wheel

Loaders are designed and manufactured

to Caterpillar quality standards to ensure

maximum performance even in extreme

operating conditions.

Engine electronic control modules and

sensors are completely sealed against

moisture and dust. Deutsche connectors

and electrical wire braiding ensure that

electrical connections resist corrosion

and premature wear.

Hoses are engineered and manufactured

for high resistance to abrasion, excellent

flexibility and easy installation and

replacement.

Caterpillar

®

couplings use o-ring face

seals to provide positive sealing for

durable leak-free connections.

Heavy duty components reduce the risk

of leaks, corrosion and premature wear

increasing uptime and helping to protect

the environment.

MONITORING PROGRAMS. Monitoring

product health is key to maintaining

reliability of any equipment. Many

programs are available on the 972H –

both as standard and optional features –

to help you track machine condition.

Caterpillar Monitoring System. The 972H

is equipped with the Cat Monitoring

System (CMS) that keeps watch over the

health of your loader. CMS monitors

critical engine system functions and will

derate the engine to protect itself from

damage if needed. Depending on which

of the following six critical conditions

arise, the CMS monitor or front panel

will display warning lights and sound

audible alarms.

• High coolant temperature

• High air inlet temperature

• Low engine oil pressure

• High fuel pressure

• Low fuel pressure

• Engine over-speed

Product Link. Product Link is a state-ofthe-art satellite technology based product

that provides two-way information flow

between machine on-board systems and

the Caterpillar network operations center.

Multiple types of information can be

collected and tracked – from machine

location and service meter hours, to

health and productivity information.

EquipmentManager. With a subscription

to EquipmentManager through the

Cat Dealer Storefront the information

collected through Product Link can be

transmitted to a computer. With fast,

easy-to-access machine information,

you can optimize asset utilization,

reduce security risks, improve

maintenance management and

implement before-failure repair

strategies. The result is more uptime,

lower operating costs and a higher

overall return on equipment investment.

4

The Cat 972H – Tested And Proven – Ready To Work

RELIABILITY

S•O•SSMServices. Keep minor repairs

from becoming major ones and avoid

complete failures. By regularly taking

samples from the ports provided, your

Cat dealer tracks wear of components

and parts, oil performance, and oil

condition and uses that data to predict

wear-related problems before they

happen. Often a simple adjustment or

replacement of a part, based on S•O•S

reports, can keep a small problem from

turning into a major repair – allowing

your machine to be running when you

need it, not waiting in the shop for service.

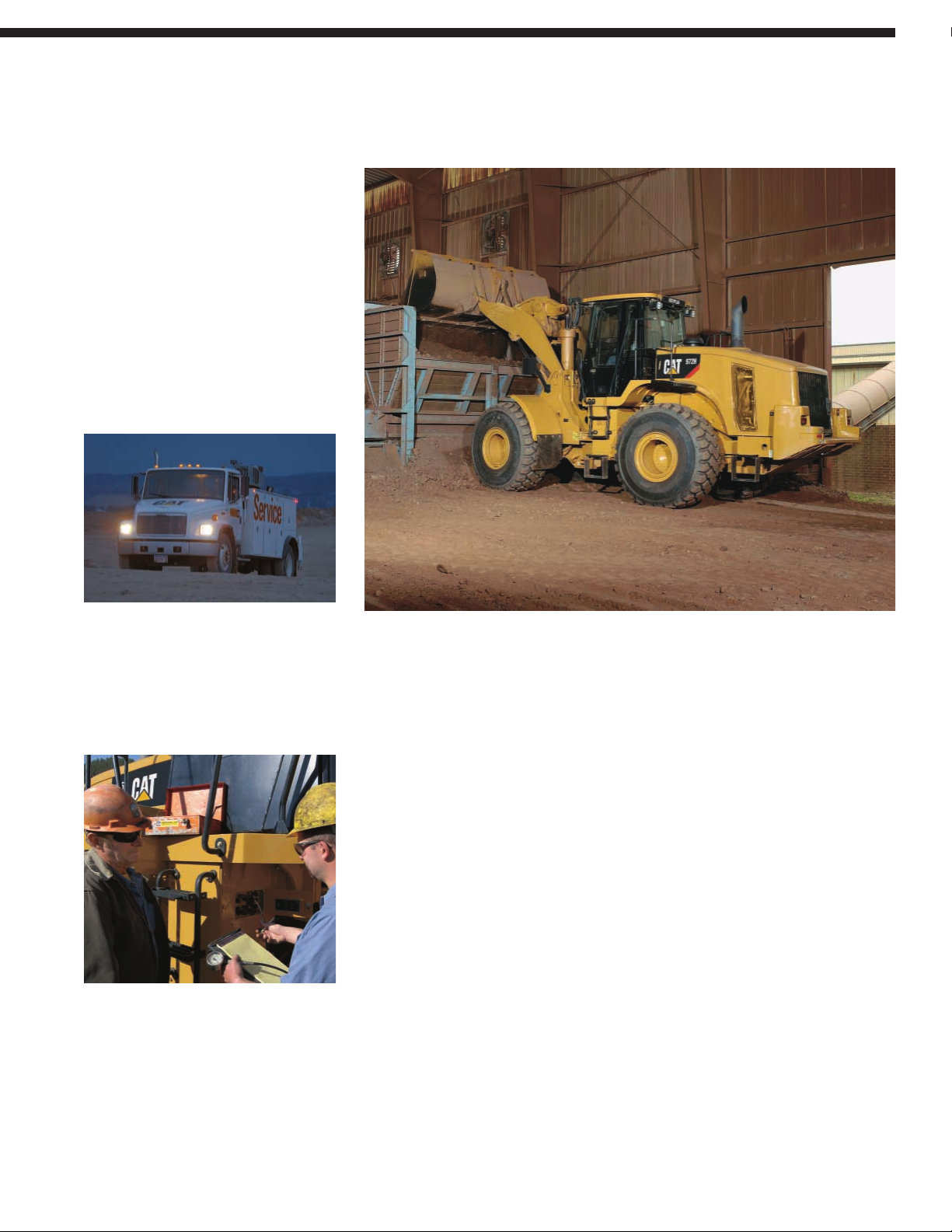

DEALER SUPPORT. The Caterpillar global

network of independently-owned dealers

is the best in the world at providing

support to keep your loader up and

running. Known for parts availability

and technical expertise, Cat dealers

are partners in your business.

Service Capabilities. Cat field service

technicians have the experience and tools

necessary to service your loader on site.

Field service trucks are fully loaded with

state-of-the-art tools and diagnostic

equipment as well as specifications

and schematics for every Cat machine.

Technical experts at the dealership and

at Caterpillar are available to provide

assistance to field service technicians

when needed.

When on-site repair isn’t enough, Cat

dealerships are fully-equipped to service

your loader quickly.

PARTS AVAILABILITY. Caterpillar

provides an unsurpassed level of

personalized service for your wheel

loader. With parts distribution centers

throughout the world, most parts can

be delivered in 24 hours.

REMANUFACTURED PARTS. Cat engines

and major components are designed to be

remanufactured and provide multiple life

cycles. The Cat Reman program is more

extensive than most rebuild programs.

Components are actually remanufactured

in the factory to original specifications

with necessary product updates.

Strict reuse guidelines and unparalleled

quality control ensure that reman products

provide the reliability and durability that

you expect from Caterpillar. Reman

products are stocked in distribution

centers around the world and are ready to

install to minimize downtime, maintain

productivity and profitability.

5

• ACERT™ Technology maintains

engine performance, efficiency and

durability while reducing emissions

• Heavy duty components withstand

all operating conditions

• Strong, solid structures built to last

EPA TIER III, EU STAGE III COMPLIANT

C13 ENGINE. ACERT Technology

combines proven systems with

innovative new technologies to precisely

deliver fuel to the combustion chamber.

It maintains engine performance,

efficiency and durability while

dramatically reducing emissions.

The Cat C13 with ACERT technology

is a 12.5 L displacement, 6-cylinder,

electronically governed engine.

Electronic fuel injection is provided

through the well-proven Caterpillar

mechanically actuated, electronically

controlled unit injection (MEUI) system.

A wastegate turbocharger, equipped with

a titanium wheel for improved durability,

combined with air-to-air aftercooling

(ATAAC) provides consistent high

horsepower with increased altitude

capability.

Electronic Controller. The engine is

governed by an electronic control module

designated the A4:E4V2. The controller

continually adjusts engine output based

on load demand using a series of sensors

located on the machine and engine.

Mechanically Actuated Electronic Unit

Injectors (MEUI). The MEUI system has

been at work in Cat engines across the

product line with a proven track record of

consistent, durable, reliable performance.

Engine Block and Pistons. The gray,

cast iron engine block is made of the

same material as the cylinder heads.

Wall diameters are thicker than in

previous designs while adjustments have

been made to reduce sound levels and

increase rigidity. One-piece all-steel

pistons are housed within a wet,

replaceable cast iron cylinder liner

constructed of high-strength, heat-treated

castings. Steel-forged connecting rods

are larger in diameter and are connected

to the crankshaft with two bolts.

RADIATOR. Brazed aluminum

construction provides a stronger joint

for maximum durability and resistance

to leaks. The 6-fins-per-inch, squarewave core design decreases the chance

of blockage and plugging.

POWERSHIFT TRANSMISSION.

The 972H continues to use heavy-duty

powershift transmission technology

proven on previous models and currently

used up through the largest wheel loader

built by Caterpillar – the 994F.

The planetary powershift transmission

features heavy-duty components to handle

the toughest applications. Built-in

electronic controls enhance productivity

and durability.

Control Throttle Shifting. Control Throttle

Shifting regulates engine speed during

high-energy directional changes for

smoother shifting and longer

component life.

Electronic Clutch Pressure Control.

Electronic Clutch Pressure Control

(ECPC) system modulates clutches

individually to improve shift quality,

component life and operator comfort.

Adjustment is simplified with all solenoid

valves externally mounted on top of the

transmission housing.

AXLES. The 972H axles are designed by

Caterpillar for durability in all operating

conditions. The front axle is rigidly

mounted to the frame to support the

weight of the wheel loader and withstand

internal torque loads as well as external

forces encountered throughout operation.

The rear axle is designed to allow ± 13°

oscillation. All four wheels remain on

the ground over uneven terrain providing

excellent stability and traction.

Integrated Braking System. The Cat

exclusive Integrated Braking System

reduces axle oil temperatures and

improves transmission neutralizer

smoothness. IBS has a direct impact

on durability of the axles and brakes

especially in applications involving

long distances and/or heavy braking.

6

Built Strong And Tough

DURABILITY

STRUCTURES. The articulated frame

design of the 972H features a durable

box-section engine frame and rigid fourplate loader tower that is robotically

welded. Robotic welding creates frame

joints with deep plate penetration welds

and excellent fusion for maximum

strength and durability.

Engine End Frame (EEF). A full boxsection engine end frame with hitch plates

at the front end provides a strong, rigid

structure that resists twisting and impact

loads. The result is an extremely solid

mounting platform for the engine,

transmission, axle, ROPS and other

accessories.

Spread Hitch. The distance between

the upper and lower hitch plates is

an important contributor to machine

performance and component life.

The Caterpillar spread hitch design

provides excellent load distribution and

bearing life. Both the upper and lower

hitch pins pivot on double tapered roller

bearings – improving durability by

distributing both vertical and horizontal

loads over a larger surface area.

The wide opening also provides

excellent service access.

Non-Engine End Frame (NEEF).

The non-engine end frame provides a

solid mounting base for the front axle,

lift arms, lift cylinders and tilt cylinders.

The fabricated, four-plate loader tower

absorbs the forces associated with

loading, twisting and penetration.

Counterweight. The one-piece

counterweight is integrated into the

972H design and styling. This 5,849 lb

(2653 kg) counterweight incorporates the

rear lights into the top of the structure.

Linkage. The 972H linkage is a singletilt Z-bar design. Z-bar linkage generates

excellent breakout force and good rack

back angle for better bucket loading and

load retention.

Lift arms are solid steel, providing

superior strength with an excellent front

end viewing area. The proven design

offers excellent dump clearance and

reach for exceptional matching to both

on- and off-highway trucks.

Rotary sensors, for the tilt lever and lift

circuit allow the operator to electronically

set detent positions from the cab. A guard

covers the sensor to protect it from

damage.

7

• Hydraulics are easy to control with

low effort

• Maximum fuel efficiency and

flexibility in idle speeds

• Consistent horsepower regardless

of conditions

• Standard and optional features that

maximize productivity

LOAD SENSING HYDRAULICS. The 972H

features a load sensing hydraulic system

that automatically adjusts to operating

conditions to provide only the hydraulic

flow required by the implement for

improved fuel efficiency.

With the new M3PC Priority Proportional

Pressure Compensation Valve, implement

control is improved over the previous

system – raise/lower and rack back/dump

can be operated simultaneously and fine

modulation is repeatable for improved

productivity.

Operators will notice enhanced ease of

operation, more rimpull into the pile

and a 20% increase in lift force.

Electrohydraulic Implement Controls.

Electrohydraulic implement controls on

the 972H provide the operator with incab programmable kickouts to prevent

material spillage – improving productivity.

The implement control console features

an optional Forward/Neutral/Reverse

switch allowing fast, easy directional

changes to reduce cycle times.

CONSTANT NET HORSEPOWER. On many

competitive machines, gross horsepower

is constant, meaning that net engine

power available for actual work will vary

based on demands made from parasitic

sources, such as air conditioning or

cooling fans.

The Cat C13 engine is electronically

configured to provide constant net

horsepower at full parasitic load

enhancing productivity and

improving fuel efficiency.

On-Demand Fan. With electronic control

of the variable speed on-demand fan,

temperature levels of the engine coolant,

transmission oil, hydraulic oil and air

inlet manifold are constantly monitored.

This data is used to control and maintain

fan speed at the level necessary to

maintain normal system temperatures.

Controlled fan speed improves fuel

efficiency, lowers noise levels and

reduces radiator plugging.

Separated Cooling System.

Many competitive loaders use cooling

systems that pull air in from the sides,

through the engine compartment and

exhaust it out the rear of the machine.

The 972H cooling system is isolated

from the engine compartment by a nonmetallic shield. The hydraulically driven,

variable speed fan draws in clean air from

the rear of the machine and exhausts it

out the sides and top of the hood. The end

results are optimal cooling efficiency,

increased fuel efficiency, less radiator

plugging and reduced operator sound

levels.

PLANETARY POWERSHIFT

TRANSMISSION. The electronic planetary

powershift transmission with automatic

shift capability is designed and built by

Caterpillar. The very responsive, fullpower speed and directional changes

provide excellent cycle times and

productivity.

VARIABLE SHIFT CONTROL.

Match transmission shifting patterns

to machine application requirements.

Variable Shift Control (VSC) improves

shift quality and fuel efficiency in certain

applications by allowing the transmission

to upshift at lower engine RPMs.

RIDE CONTROL. The optional Ride Control

System improves ride, performance and

load retention when traveling over rough

terrain. Operators gain confidence moving

at higher speeds in load and carry

operations decreasing cycle times

and increasing productivity.

PAYLOAD CONTROL SYSTEM.

Scales, designed specifically for Cat

machines allow on-the-go weighing of

material in the bucket. Operators load

trucks more accurately and efficiently.

Loading trucks right the first time equates

to quicker cycles for the operator and

more productivity for your operation.

8

Work Smart And Move More

PRODUCTIVITY

Payload Control is offered as a factoryinstalled option. Driver tickets and a

variety of reports can be printed with

the addition of the optional printer.

AUTOLUBE. The optional Caterpillar

Autolube System provides precise,

automatic lubrication of pins and

bushings – during loader operation.

Automatic lubrication reduces time spent

on daily maintenance and downtime for

unplanned repairs due to inadequate

greasing – improving productivity.

AGGREGATE AUTODIG. Well-received

by both experienced and novice operators,

the optional Aggregate Autodig automates

the loading process.

Aggregate Autodig provides smoother

loading cycles, consistently full payloads

and eliminates tire spin – all without

touching the controls.

9

Loading...

Loading...