Page 1

374D L

Hydraulic Excavator

Engine

Engine Model Cat

Net Power – ISO 9249 355 kW 476 hp

Net Power – SAE J1349 355 kW 476 hp

Weights

Operating Weight – Long Undercarriage 71 132 kg 156,819 lb

®

C15 ACERT® (ATAAC)

Drive

Maximum Travel Speed 4.1 km/h 2.6 mph

Maximum Drawbar Pull – Long Undercarriage 492.5 kN 110,718 lb

Page 2

374D L Features

Performance

High level of sustained production, improved

trenching and pipe-laying performance, improved

reliability and durability increase your productivity

and lower your operating costs.

Engine

The Cat® C15 engine uses ACERT® Technology

to meet U.S. EPA Tier 3 emission regulations,

with exceptional performance capabilities

and proven reliability.

Operator Station

Superior cab comfort and visibility provides

an excellent working environment. The monitor

is a full-color, graphical display with enhanced

functionality to provide a simple, comprehensive

machine interface.

Maximum Versatility

A variety of work tools, including buckets, are

available for applications such as demolition,

site clean-up, scrap processing, breaking up road

surfaces and bedrock through Cat® Work Tools.

Service and Maintenance

Fast, easy service has been designed in with

long service intervals, advanced filtration,

convenient filter access and user-friendly

electronic diagnostics for increased productivity

and reduced maintenance costs.

Contents

Hydraulics ............................................................3

Operator Station ..................................................4

Engine ...................................................................5

Control System ....................................................6

Structures.............................................................7

Undercarriage .....................................................8

Front Linkage .......................................................9

Buckets and Teeth ............................................10

Work Tools ..........................................................11

Environment .......................................................12

Service and Maintenance ...............................13

Complete Customer Support ...........................14

374D L Hydraulic Excavator Specifications ..15

374D L Standard Equipment ............................21

374D L Optional Equipment ..............................22

Notes ...................................................................23

The 374D L Series Excavator has excellent control,

high stick and bucket forces, impressive lift capacity,

simplified service and a comfortable operator station

to increase your productivity and lower operating costs.

2

Page 3

Hydraulics

Cat hydraulics deliver power and precise control to keep material moving

Main Pumps

The hydraulic system includes three pumps with an

independent swing circuit. The hydraulic circuit utilizes a

load-sensing system to ensure high hydraulic system efciency

and excellent productivity with little hydraulic loss.

• Large, heavy-duty main pumps and a separate swing

pump provide quick cycle times during multi-function

operation.

Reverse Swing Dampening Valve

Swing dampening valves reduce swing wag and produce

smooth swing stops.

Advanced Features

The following are hydraulic system features of the 374D L.

• The electric re-generation system is incorporated into

the hydraulic system to improve productivity and lower

fuel consumption.

• The main pump ow has increased 10 percent to provide

shorter cycle times.

• The main implement pressure has been increased

9 percent. This also provides shorter cycle times with

higher digging forces, increased bucket ll factors.

• Stick cylinder diameter for mass and reach congurations

has been increased along with the bucket cylinder diameter

on the reach stick. These increases produce 17 percent

higher digging forces.

Proportional Priority Pressure Compensation (PPPC)

Hydraulics

Load-sensing, PPPC system, with Caterpillar-developed

electronic actuation, provides high efciency and excellent

controllability.

• Cylinder speed is directly related to operator’s movement

of joystick from feathering to full speed.

• Flow to cylinders during multifunctional operation is

directly controlled by the operator and is not dependent

on loads.

• Controller reduces pump output to minimum to save

power when joysticks are in neutral position.

3

Page 4

Operator Station

374D L is designed for simple, easy operation and comfort

Cab Design

The spacious cab provides visibility and ergonomics.

The monitor is a full-color graphical display to provide

the operator with easy-to-read, comprehensive machine

information. The cab provides a comfortable environment

for the operator.

Hydraulic Activation Control Lever

The hydraulic activation control lever deactivates hydraulic

functions during engine start-up and prevents unintentional

machine operation.

Cab Exterior

Utilizes thick steel tubing along the bottom perimeter of

the cab, improving the resistance of fatigue and vibration.

The cab structure allows the FOGS to be bolted directly

to the cab, at the factory or as an attachment.

Cab Mounts

The cab shell is attached to the frame with viscous rubber

cab mounts, which dampen vibrations and sound levels while

enhancing operator comfort.

Additional Features

The 374D L operator station has many features for

operator comfort.

• Premium KAB seats with adjustable height consoles.

• A rear view camera is offered as an attachment.

The monitor functions as the display screen for the

camera, providing added safety for the operator

and surrounding work area.

• HID (High Intensity Discharge) lights are available as an

attachment with time delay for the boom and cab lights.

• A two-way radio ready option is available.

• Automatic climate control for the air conditioner,

heater and defroster.

• Fuel consumption can be displayed numerically

on the monitor.

4

Page 5

Engine

ACERT® Technology optimizes engine performance

Cat® C15 Engine

The Cat C15 engine with mechanically actuated electronic fuel injection (MEUI) powers the 374D L.

The C15 has ACERT® Technology, a series of Caterpillar engineered innovations which provide advanced

electronic control, precision fuel delivery and rened air management compliance.

Increased Power

The maximum power is 355 kW (476 hp), 18 percent more power than the 365C. The Power Management

System (PMS) is also available to manage productivity and fuel economy.

Improved Fuel Efficiency

The 374D L fuel maps provide additional power and performance with optimized fuel consumption

through exible power settings incorporated into ADEM™ controller.

Improved Reliability

The titanium-aluminum alloy rotor in the turbocharger improves reliability/durability and contributes

to faster response of the turbocharger.

Hydraulic Cooling Fan

The 374D L uses a variable speed, hydraulically-driven fan for quieter operation and reduced fuel

consumption during cooler ambient conditions.

Reversible Fan

A reversible fan option is offered as an attachment. The reverse function is operated through the

monitor. By selecting this function, the fan rotates in the opposite direction for a preset time to help

clean the cooling package for increased uptime and reduced service cost.

5

Page 6

Control System

Electronic management

Monitor Display Screen

The monitor is a full color, 400 × 234 pixels Liquid Crystal

Display (LCD). A master caution lamp blinks ON and OFF

when one of the critical conditions below occurs:

• Engine oil pressure low

• Coolant temperature high

• Hydraulic oil temperature high

Under normal conditions or the default condition, the monitor

display screen is divided into four areas: clock and throttle

dial, gauge, event display and multi-information display.

Gauge Display

Three analog gauges, fuel level, hydraulic oil temperature

and coolant temperature are displayed in this area.

Electronic Joysticks

Electronic joysticks provide features not possible

with hydraulic pilot valves:

• Eliminate pilot lines in cab for quieter operation

• Simple pattern change through the monitor

Operator Gain/Response

This is used to suit the operator preference or application.

• Quicker for fast response

• Slower, for more precision

• Contains three preset settings with 21 available

Pattern Control Changer

The standard hand control pattern changer can be accessed

through the monitor, to utilize either the standard excavator

control pattern (SAE) or Backhoe Loader pattern (BHL).

Alternator

The alternator is 24 volt with 75 amp capacity and is driven

by a serpentine belt off the front pulley. A snorkel pulls cool,

clean air from the outside for increased service life.

Product Link

Product Link is standard on the 374D L. Product Link

transmits diagnostic information from the machine back

to Caterpillar, Cat dealers and customers.

6

Page 7

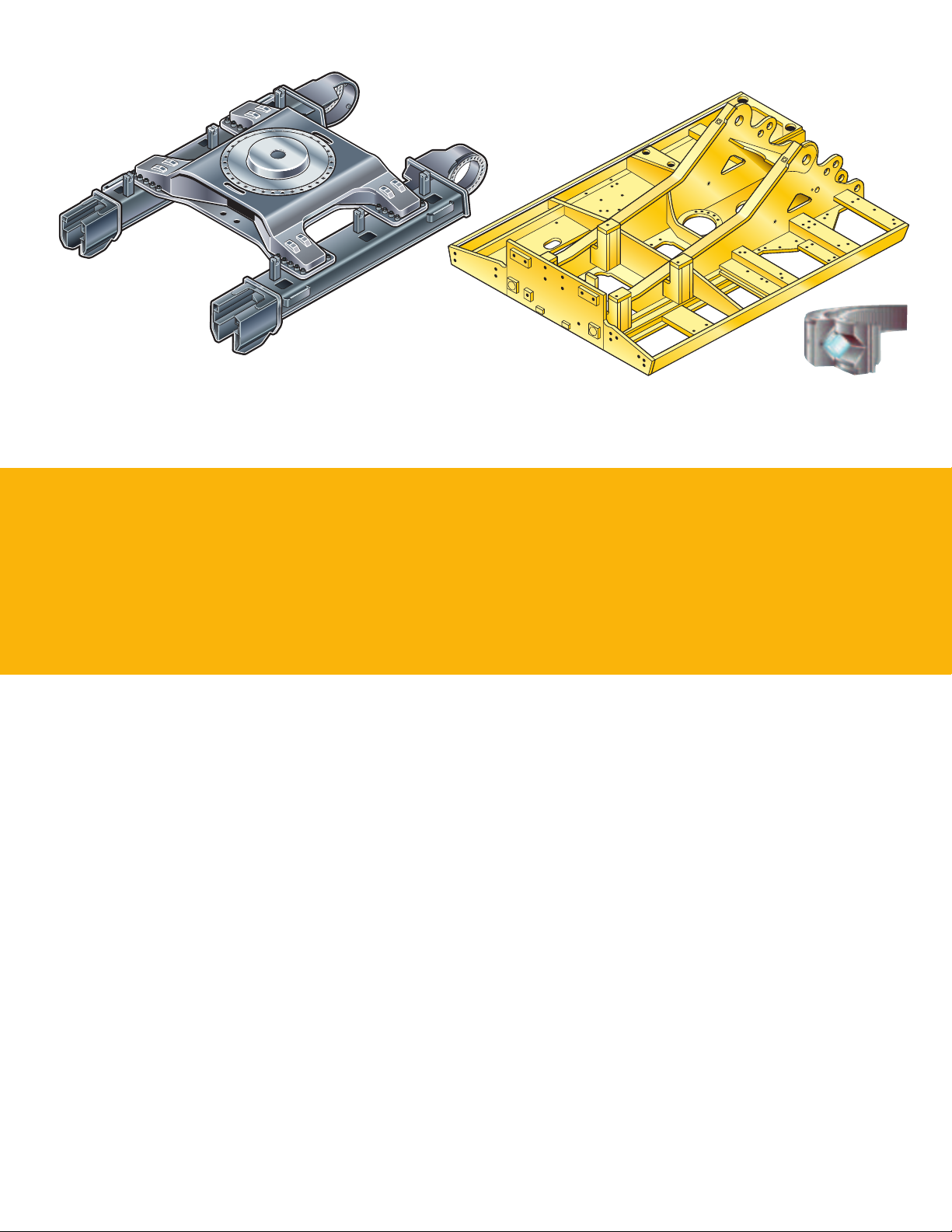

Structures

Rugged structures designed for maximum durability

Variable Gauge Undercarriage

The long variable gauge undercarriage is standard, providing a wide, stable base for operating, or a narrow gauge for reduced

shipping width. The undercarriage gauge in working position has been increased by 160 mm (6.3 in) for improved stability.

Upper Frame

The upper frame is designed for maximum durability and efcient use of materials. The boomfoot, skirt and counterweight

mounting area have been strengthened for longer service life and increased durability.

• Outer frame utilizes curved side rails, which are die-formed, for excellent uniformity and strength through the length

• Box section channels improve upper frame rigidity under the cab

• Boom tower and one piece main rails are constructed of solid, high-tensile strength steel plates

Catwalk

The catwalk width has been increased by 110 mm (4.3 in) from the 365C L. Catwalks are provided on both sides of the skirt

for easy access of the maintenance points. Slip resistant plates are used on the full length of the catwalks.

Cross Roller Bearing

The 374D L swing bearing is a cross roller type, with 54 mm (2.13 in) diameter rollers. The cross rollers have a much greater

contact area than ball bearing, providing increased stability and longer life.

Track Roller Frames

The track roller frame is made of thick, steel plate that is bent into a U-shape and welded to the bottom plate to create a box

structure. The box structure design provides increased rigidity and impact resistance.

7

Page 8

Undercarriage

The link that transmits the reaction forces from digging to the ground

Undercarriage

The undercarriage supports the swing bearing and upper structure and is the link that transmits

the reaction forces from digging to the ground. The strength of the undercarriage plays a major factor

in machine stability and durability.

Track Roller Frame

The track roller frame has been improved by installing a longer stroke recoil spring and lowering

the front idler. The longer recoil spring improves durability and service life of the undercarriage while

the offset idler increases the stability of the machine while working over the front.

Positive Pin Retention 2 (PPR2)

Track links with the PPR2 are provided as standard on the 374D L. The PPR2 track link is designed

to prevent looseness of the track pin in the track link and to reduce stress concentrations. The PPR2

system eliminates pin walking for increased service life.

Carrier Rollers

The carrier rollers use a oating “Duo-Cone” seal. The Duo-Cone seal protects the moving parts

in the carrier roller from water and dirt, and makes lubrication maintenance-free.

8

Page 9

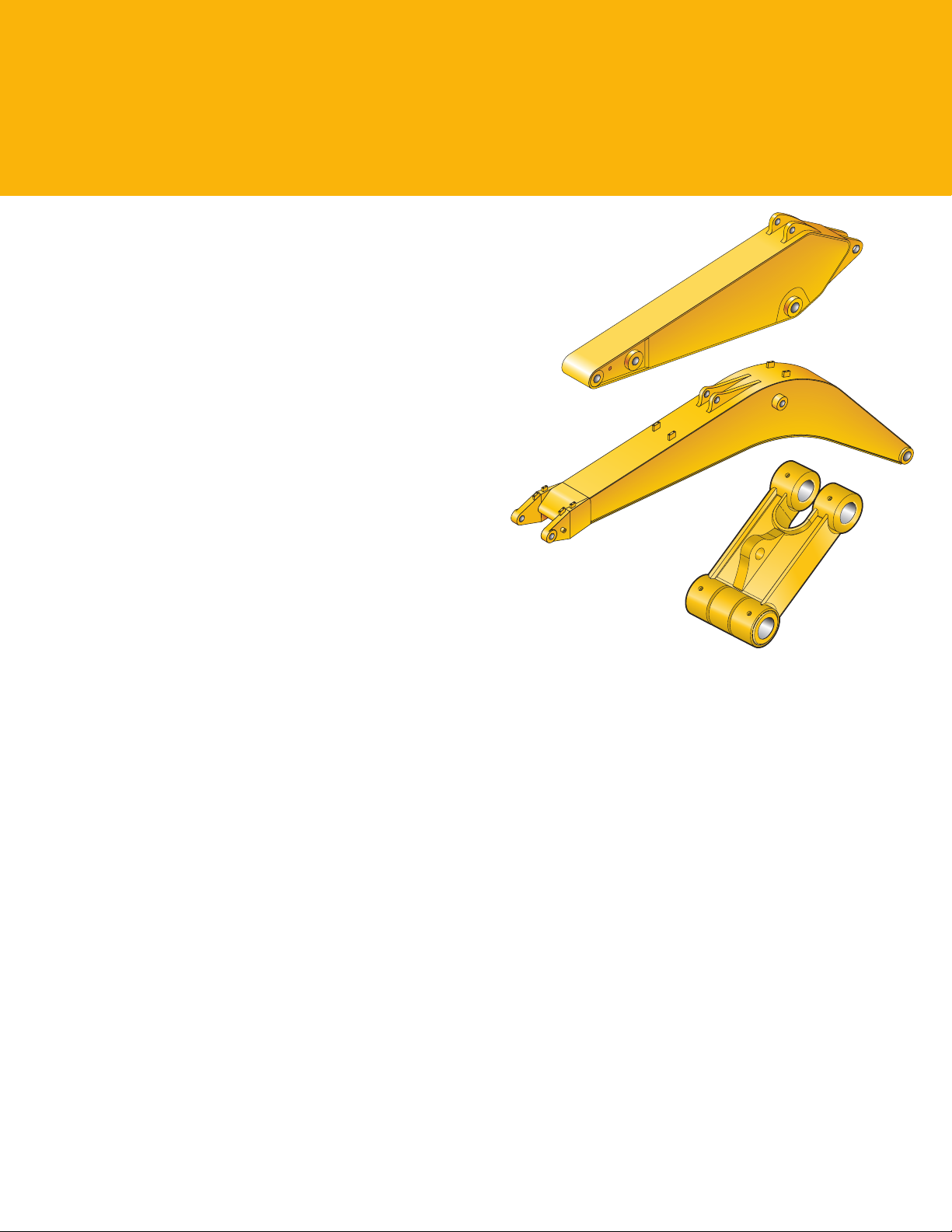

Front Linkage

Designed for flexibility and high productivity

Front Linkage

Cat excavator booms and sticks are built for performance

and long service life.

• Castings and forgings are used at high stress areas such

as boom nose, boom foot, boom cylinder and stick foot.

• All booms and sticks are stress-relieved for optimal life

and durability, while minimizing weight for improved

performance.

• All booms and sticks are ultrasonic inspected.

Bucket Linkage

Two bucket linkages are available for the 374D L.

Both linkages are available with or without a lifting eye

on the power link.

• The VB2 bucket linkage is for use with the reach sticks

and VB2-family buckets

• The WB2 bucket linkage is for use with the mass sticks

and WB2-family buckets

Boom Construction

374D L booms feature a large cross-section to improve

strength and reduce weight. Bafe plates reinforce the boom

interior for higher rigidity. Booms are designed for strength

and maximum payload.

Stick Construction

Sticks are made of high-tensile strength steel in a boxsection design, making them strong and light. All sticks

are reinforced with a thick bafe plate for added rigidity.

The connection between stick and boom is made of forged

steel, and a thick steel plate is used at the bucket connecting

location for increased strength and rigidity at load-bearing

points. An additional wear plate is added to the working side

of the stick for protection. All mass sticks include additional

wear bars on the working side to protect the structure during

operation. There are four reach sticks and two mass sticks

available to meet your application needs.

Linkage Pins

Bucket cylinder pin and idler to stick pin diameter for the

reach boom have been increased. The pins have thick chrome

plating for high wear resistance and long life.

9

Page 10

1 2

3 4

Buckets and Teeth

Designed and built for total system performance

Optimized Package

Caterpillar offers a wide range of buckets, each designed and eld tested to function as an integral part

of your excavator. All Cat Buckets feature K Series™ GET (Ground Engaging Tools). Buckets are

available in four levels of durability and are built to take full advantage of the machine’s power.

General Duty (GD)

General Duty buckets are designed for use in low impact, lower abrasion materials such as dirt, loam

and mixed compositions of dirt and ne gravel.

Heavy Duty (HD)

Heavy Duty buckets are the most popular and a good “centerline” choice. This bucket style is a good

starting point when application conditions are not known. Heavy Duty buckets are designed for a wide

range of impact and abrasion conditions including mixed dirt, clay and rock.

Severe Duty (SD)

Severe Duty buckets are designed for higher abrasion conditions such as shot granite. When compared

to the Heavy Duty bucket, wear bars and wear plates are substantially thicker and larger for added

protection.

Extreme Duty (XD)

Extreme Duty buckets are designed for very high abrasion conditions such as granite quarries.

Corner shrouds have been added and side wear plates are larger for added protection.

1) Severe Duty 2) Heavy Duty 3) General Duty 4) Extreme Duty

10

Page 11

Work Tools

Solutions for your business

Increase Machine Versatility

The Cat combination of machine and tool provides a total

solution for just about any application. Work tools can be

mounted directly to the machine or a quick coupler can be

added, making it quick and easy to release one work tool

and pick up another.

Couplers

Caterpillar offers two quick coupler styles: dedicated

and pin grabber. Each allows quick tool changes.

Center-Lock™ Pin Grabber Coupler

Center-Lock is the Caterpillar pin grabber style coupler

and features a patent pending locking system. A highly visible

secondary lock clearly shows the operator when the coupler

is engaged or disengaged from the bucket or work tool.

Work Tools

An extensive range of Cat Work Tools for the 374D L

includes buckets, hammers, grapples, shears, multi-processors

and rippers. Each are designed to optimize the versatility and

performance of your machine. Cat Work Tools and couplers

are ready to work in a variety of applications, such as site

and structure demolition, debris clean-up, truck loading,

scrap processing, breaking road surfaces and bed rock.

Hydraulic Kits

Caterpillar offers eld-installed hydraulic kits designed

to simplify the process of ordering and installing the right

kit. Modular kit designs integrate Cat Work Tools with

Cat Hydraulic Excavators. Every kit is easy to install.

Hoses are pre-made, tubes are pre-bent and pre-painted

and there are comprehensive instructions.

11

Page 12

Environment

374D L meets a wide range of environmental requirements

Emissions

ACERT® Technology is a differentiated technology that reduces emissions at the point of combustion.

The technology capitalizes on proven Caterpillar leadership in three core engine systems: fuel, air

and electronics.

Electro Magnetic Compliance

The 374D L meets the following EMC (Electro Magnetic Compliance) requirements:

• ISO 13766 Earth Moving Machinery – Electromagnetic compliance

• EU Directive 89/336/EEC

• Aus EMC Framework

Fluid Management

Several serviceability elements are designed into the 374D L to limit uid spillage while performing

routine maintenance.

Ecology Drains

Ecology drains are provided for the fuel and hydraulic tanks, allowing uids to be captured

in a container when draining the tanks.

12

Page 13

Service and Maintenance

Fast, easy service has been designed into the 374D L

Service Intervals

Long service intervals reduce maintenance costs. Engine oil,

oil lter and fuel lters are at 500 hours.

Oil Sample and Pressure Ports

Oil sample and pressure ports provide easy checking

of machine condition and are standard on every machine.

Hydraulic Capsule Filters

The return lters or capsule lters for the hydraulic system

are located beside the hydraulic tank. The lter elements

are removable without spilling hydraulic oil.

Service Points

Service points are centrally located with easy access

to facilitate routine maintenance.

Pilot Hydraulic System Filter

Pilot hydraulic system lter keeps contaminants from

the pilot system and is located in the pump compartment.

Remote Greasing Block

A concentrated remote greasing block on the boom delivers

grease to hard-to-reach locations.

Radial Seal Cleaner

Radial seal main air cleaner with precleaner has a doublelayered lter element for more efcient ltration. No tools

are required to change the element.

Fuel-Water Separator

The water separator removes water from fuel, even when under

pressure, and the water level can be monitored in the cab.

13

Page 14

Complete Customer Support

Cat dealer services help you operate longer with lower costs

Product Support

Cat dealers utilize a worldwide computer parts network

to minimize machine downtime. Save money with Cat

remanufactured components.

Machine Selection

Make detailed comparisons of machines you are considering.

What are job requirements and machine attachments?

What production is needed? Your Cat dealer can provide

recommendations.

Purchase

Consider nancing options and day-to-day operating costs.

Look at dealer services that can be included in the machine’s

cost to yield lower owning and operating costs over time.

Customer Support Agreements

Cat dealers offer a variety of product support agreements

and work with you to develop a plan to meet specic

needs. These plans can cover the entire machine, including

attachments, to help protect your investment.

Operation

Improving operating techniques can boost your prots.

Your Cat dealer has videos, literature and other ideas

to help you increase productivity, and Caterpillar offers

certied operator training to help maximize the return

on your investment.

Maintenance Services

Repair option programs guarantee repair costs up front.

Diagnostic programs such as Scheduled Oil Sampling,

Coolant Sampling and Technical Analysis help you avoid

unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you

evaluate the cost involved so you can make the right choice.

14

Page 15

374D L Hydraulic Excavator Specifications

Engine

Engine Model Cat® C15 ACERT®

(ATAAC)

Net Flywheel Power 355 kW 476 hp

Net Power

– ISO 9249

Net Power

– SAE J1349

Net Power

– EEC 80/1269

Bore 137 mm 5.4 in

Stroke 171 mm 6.75 in

Displacement 15.2 L 928 in

• The 374D L meets worldwide Tier 3

emission requirements.

• No engine power derating required below

2300 m (7,500 ft) altitude.

• Net power advertised is the power available

at the ywheel when the engine is equipped

with fan, air cleaner, mufer and alternator.

355 kW 476 hp

355 kW 476 hp

355 kW 476 hp

3

Weights

Operating Weight –

Long Undercarriage

• Reach Boom, R3.6 (11'10") stick, 3.8 m

(5.0 yd3) Bucket, and 650 mm (26") shoes.

71 132 kg 156,819 lb

3

Track

Standard with

Long Undercarriage

Optional for

Long Undercarriage

Optional for

Long Undercarriage

Number of Shoes

Each Side – Long

Undercarriage

Number of Track

Rollers Each Side –

Long Undercarriage

Number of Carrier

Rollers Each Side

900 mm 36 in

750 mm 30 in

650 mm 26 in

47

8

3

Drive

Maximum Travel

Speed

Maximum Drawbar

Pull – Long

Undercarriage

Hydraulic System

Main System

– Maximum Flow

(Total)

Swing System

– Maximum Flow

Maximum Pressure

– Equipment

– Normal

Maximum Pressure

– Travel

Maximum Pressure

– Swing

Pilot System

– Maximum Flow

Pilot System –

Maximum Pressure

Boom Cylinder

– Bore

Boom Cylinder

– Stroke

Stick Cylinder

– Bore

Stick Cylinder

– Stroke

VB2-Family Bucket

Cylinder – Bore

VB2-Family Bucket

Cylinder – Stroke

WB2-Family Bucket

Cylinder – Bore

WB2-Family Bucket

Cylinder – Stroke

4.1 km/h 2.6 mph

492.5 kN 110,718 lb

880 L/min 232 gal/min

360 L/min 95 gal/min

35 000 kPa 5,076 psi

35 000 kPa 5,076 psi

29 400 kPa 4,264 psi

87 L/min 23 gal/min

4120 kPa 600 psi

190 mm 7.5 in

1792 mm 70.6 in

210 mm 8.3 in

2118 mm 83.4 in

190 mm 7.5 in

1443 mm 56.8 in.

200 mm 7.9 in.

1457 mm 57.4 in.

Service Refill Capacities

Fuel Tank Capacity 935 L 247 gal

Cooling System 95 L 25 gal

Engine Oil 65 L 17 gal

Swing Drive (each) 12 L 3.2 gal

Final Drive (each) 15 L 4 gal

Hydraulic System

(including tank)

Hydraulic Tank 310 L 82 gal

670 L 177 gal

Sound Performance

Performance ANSI/SAE J1166

OCT98

• When properly installed and maintained,

the cab offered by Caterpillar, when tested

with doors and windows closed according

to ANSI/SAE J1166 OCT98, meets OSHA

and MSHA requirements for operator

sound exposure limits in effect at time

of manufacture.

• Hearing protection may be needed when

operating with an open operator station

and cab (when not properly maintained

or doors/windows open) for extended

periods or in a noisy environment.

Standards

Brakes SAE J1026 APR90

Cab/FOGS SAE J1356 FEB88

ISO 10262

Swing Mechanism

Swing Speed 6.4 rpm

Swing Torque 214.8

kN·m

158,428

lb ft

15

Page 16

374D L Hydraulic Excavator Specifications

Dimensions

All dimensions are approximate

3

9

6

7

8

1

4

5

2

Reach Boom Mass Boom

7.8 m (25'7") 7.0 m (23'0")

Stick R4.67 m R4.15 m R3.6 m R2.84 m M3.0 m M2.57 m

(15'4") (13'7") (11'10") (9'4") (9'10") (8'5")

Shipping Height 4950 mm 4620 mm 4480 mm 4250 mm 4700 mm 4610 mm

1

(16'3") (15'2") (14'8") (13'11") (15'5") (15'1")

Shipping Length 13 230 mm 13 310 mm 13 320 mm 13 430 mm 12 630 mm 12 670 mm

2

(43'5") (43'8") (43'8") (44'1") (41'5") (41'7")

Tail Swing Radius 4015 mm 4015 mm 4015 mm 4015 mm 4015 mm 4015 mm

3

(13'2") (13'2") (13'2") (13'2") (13'2") (13'2")

Length to Center of Rollers 4705 mm 4705 mm 4705 mm 4705 mm 4705 mm 4705 mm

4

(15'5") (15'5") (15'5") (15'5") (15'5") (15'5")

Track Length 5870 mm 5870 mm 5870 mm 5870 mm 5870 mm 5870 mm

5

(19'3") (19'3") (19'3") (19'3") (19'3") (19'3")

Ground Clearance 840 mm 840 mm 840 mm 840 mm 840 mm 840 mm

6

(2'9") (2'9") (2'9") (2'9") (2'9") (2'9")

Track Gauge (Shipping) * 2750 mm 2750 mm 2750 mm 2750 mm 2750 mm 2750 mm

7

(9'0") (9'0") (9'0") (9'0") (9'0") (9'0")

Transport Width ** 3500 mm 3500 mm 3500 mm 3500 mm 3500 mm 3500 mm

8

(11'6") (11'6") (11'6") (11'6") (11'6") (11'6")

Cab Height 3540 mm 3540 mm 3540 mm 3540 mm 3540 mm 3540 mm

9

(11'7") (11'7") (11'7") (11'7") (11'7") (11'7")

* Track gauge in extended (working) position: 3410 mm (11'2").

** Transport width shown for 750 mm (30 in) .

Add 150 mm (6 in) for 900 mm (36 in) shoes.

Subtract 100 mm (4 in) for 650 mm (26 in) shoes.

16

Page 17

Working Ranges

3

4

2

6

1

5

Reach Boom Mass Boom

7.8 m (25'7") 7.0 m (23'0")

Stick R4.67 m R4.15 m R3.6 m R2.84 m M3.0 m M2.57 m

(15'4") (13'7") (11'10") (9'4") (9'10") (8'5")

Bucket GP GP GP GP HDR HDR

Maximum Digging Depth 9660 mm 9140 mm 8590 mm 7830 mm 7650 mm 7230 mm

1

3

(3.8 m

) (3.8 m3) (3.8 m3) (3.8 m3) (4.6 m3) (4.6 m3)

(31'8") (30'0") (28'2") (25'8") (25'1") (23'9")

Maximum Reach at Ground Line 14 230 mm 13 690 mm 13 170 mm 12 530 mm 11 850 mm 11 460 mm

2

(46'8") (44'11") (43'3") (41'1") (38'11") (37'7")

Maximum Loading Height 8990 mm 8640 mm 8410 mm 8240 mm 7240 mm 7070 mm

3

(29'6") (28'4") (27'7") (27'0") (23'9") (23'2")

Minimum Loading Height 2230 mm 2750 mm 3300 mm 4060 mm 3060 mm 3480 mm

4

(7'4") (9'0") (10'10") (13'4") (10'0") (11'5")

Maximum Depth Cut for

5

2240 mm (8') Level Bottom

Maximum Vertical Wall Digging Depth 8450 mm 7750 mm 7050 mm 6580 mm 4330 mm 3960 mm

6

9550 mm 9020 mm 8460 mm 7680 mm 7510 mm 7070 mm

(31'4") (29'7") (27'9") (25'2") (24'8") (23'2")

(27'9") (25'5") (23'2") (21'7") (14'2") (13'0")

Bucket Digging Force (SAE) 297.5 kN 297.5 kN 296.9 kN 295.3 kN 342.1 kN 347.0 kN

(66,881 lb-f) (66,881 lb-f) (66,746 lb-f) (66,386 lb-f) (76,907 lb-f) (78,009 lb-f)

Bucket Digging Force (ISO) 339.4 kN 339.4 kN 338.6 kN 336.8 kN 384.0 kN 389.8 kN

(76,300 lb-f) (76,300 lb-f) (76,120 lb-f) (75,716 lb-f) (86,327 lb-f) (87,631 lb-f)

Stick Digging Force (SAE) 227.1 kN 245.6 kN 269.4 kN 299.7 kN 296.5 kN 322.7 kN

(51,054 lb-f) (55,213 lb-f) (60,564 lb-f) (67,375 lb-f) (66,656 lb-f) (72,546 lb-f)

Stick Digging Force (ISO) 234.0 kN 253.9 kN 279.3 kN 312.1 kN 305.0 kN 332.9 kN

(56,605 lb-f) (57,079 lb-f) (62,789 lb-f) (70,163 lb-f) (68,567 lb-f) (74,839 lb-f)

17

Page 18

374D L Hydraulic Excavator Specifications

Operating Weight and Ground Pressure

900 mm (36 in) Shoes 750 mm (30 in) Shoes 650 mm (26 in) Shoes

kg (lb) kPa (psi) kg (lb) kPa (psi) kg (lb) kPa (psi)

Reach Boom 7.8 m (25'7")

3

GP Bucket 3.8 m

R4.67 m (15'4") 73 221

R4.15 m (13'7") 73 010

R3.60 m (11'10") 72 859

R2.84 m (9'4") 72 686

Mass Boom 7.0 m (23'0")

HDR Bucket 4.6 m

M3.00 m (9'10") 75 596

M2.57 m (8'5") 75 422

(5.00 yd3)

3

(6.00 yd3)

(161,425)

78.0 (11.3) 72 172

77.8 (11.3) 71 961

(160,959)

77.6 (11.3) 71 810

(160,627)

77.4 (11.2) 71 637

(160,245)

80.5 (11.7) 74 547

(166,661)

80.4 (11.7) 74 373

(166,277)

(159,112)

(158,647)

(158,314)

(157,933)

(164,348)

(163,964)

Track

92.3 (13.4) 71 494

92.0 (13.3) 71 283

91.8 (13.3) 71 132

91.6 (13.3) 70 959

95.3 (13.8) 73 869

95.1 (13.8) 73 695

(157,617)

105.5 (15.3)

105.2 (15.2)

(157,152)

104.9 (15.2)

(156,819)

104.7 (15.2)

(156,438)

109.0 (15.8)

(162,853)

108.7 (15.8)

(162,470)

Major Component Weights

kg lb

Base machine with counterweight and 750 mm (30 in) shoes (without front linkage) 57 700 127,229

Two boom cylinders 1400 3,087

Counterweight

Removal type 10 200 22,491

Non-removal type 10 960 24,167

Boom (includes lines, pins, stick cylinder)

Reach Boom 7.8 m (25'7") 6730 14,840

Mass Boom 7.0 m (23'0") 6900 15,215

Stick (includes lines, pins, bucket cylinder and linkage)

R4.67 m (15'4") 4000 8,820

R4.15 m (13'7") 3790 8,357

R3.60 m (11'10") 3670 8,092

R2.84 m (9'4") 3470 7,651

M3.00 m (9'10") 4070 8,974

M2.57 m (8'5") 4240 9,349

18

Page 19

Reach Boom Lift Capacities

➤

Load Point Height Load at Maximum Reach Load Radius Over Front Load Radius Over Side

➤

➤

➤

Boom – 7.8 m (25 ft 7 in) Coupler – N/A Bucket – None

Stick – R4.67 m (15 ft 4 in) Shoes – 900 mm (36 in) double grouser (HD)

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft 9.0 m/30.0 ft 10.5 m/35.0 ft 12.0 m/40.0 ft

➤

➤

10.5 m kg *11 750 *11 750 *10 800 *10 800 9.20

35.0 ft lb *24,000 *24,000 29.69

9.0 m kg *12 450 *12 450 *10 200 *10 200 10.33

30.0 ft lb *27,350 *27,350 *22,500 *22,500 33.58

7.5 m kg *12 750 *12 750 *12 250 11 900 *9900 *9900 11.14

25.0 ft lb *27,800 *27,800 *26,550 25,450 *21,850 *21,850 36.36

6.0 m kg *13 450 *13 450 *12 500 11 700 *9850 9650 11.70

20.0 ft lb *29,300 *29,300 *27,350 25,050 *21,700 21,350 38.28

4.5 m kg *26 500 *26 500 *20 000 *20 000 *16 550 *16 550 *14 450 *14 450 *13 050 11 400 *10 400 9100 *10 000 9000 12.04

15.0 ft lb *43,050 *43,050 *35,800 *35,800 *31,350 31,300 *28,400 24,450 *22,000 19,900 39.48

3.0 m kg *23 050 *23 050 *18 300 *18 300 *15 450 13 950 *13 600 11 050 *12 050 8900 *10 350 8650 12.20

10.0 ft lb *49,700 *49,700 *39,550 39,450 *33,550 30,050 *29,600 23,700 *22,750 19,100 *22,700 19,100 40.00

1.5 m kg *25 350 24 100 *19 750 17 450 *16 350 13 400 *14 100 10 700 12 100 8750 *10 850 8550 12.16

5.0 ft lb *54,800 51,900 *42,750 37,600 *35,450 28,900 *30,600 23,000 *23,900 18,850 39.89

Ground

kg *17 300 *17 300 *26 500 23 200 *20 650 16 800 *16 950 13 000 *14 350 10 450 *11 700 8700 11.93

Line

lb *39,900 *39,900 *57,300 49,900 *44,700 36,200 *36,700 28,000 *31,100 22,450 *25,800 19,150 39.14

–1.5 m kg *12 500 *12 500 *22 700 *22 700 *26 400 22 750 *20 800 16 450 *17 000 12 750 *14 200 10 300 *12 450 9100 11.50

–5.0 ft lb *28,200 *28,200 *51,950 *51,950 *57,200 48,950 *45,000 35,400 *36,800 27,400 *30,600 22,150 *27,400 20,050 37.71

–3.0 m kg *15 350 *15 350 *19 700 *19 700 *30 800 *30 800 *25 250 22 650 *20 100 16 300 *16 350 12 650 *13 250 10 300 *12 450 9900 10.85

–10.0 ft lb *34,350 *34,350 *44,450 *44,450 *70,400 *70,400 *54,650 48,750 *43,450 35,150 *35,250 27,250 *28,200 22,200 *27,400 21,800 35.50

–4.5 m kg *28 450 *28 450 *29 000 *29 000 *22 850 *22 850 *18 300 16 450 *14 600 12 750 *12 250 11 300 9.92

–15.0 ft lb *64,350 *64,350 *62,700 *62,700 *49,300 49,200 *39,350 35,400 *31,150 27,550 *26,900 25,050 32.37

–6.0 m kg *29 550 *29 550 *23 450 *23 450 *18 800 *18 800 *14 800 *14 800 *11 550 *11 550 8.63

–20.0 ft lb *63,150 *63,150 *50,100 *50,100 *40,050 *40,050 *31,200

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

*31,200 *25,200 *25,200 28.01

➤

m

ft

Boom – 7.8 m (25 ft 7 in) Coupler – N/A Bucket – None

Stick – R4.15 m (13 ft 7 in) Shoes – 900 mm (36 in) double grouser (HD)

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft 9.0 m/30.0 ft 10.5 m/35.0 ft

➤

➤

10.5 m kg *12 450 *12 450 8.47

35.0 ft lb *27,700 *27,700 27.25

9.0 m kg *13 350 *13 350 *11 750 *11 750 9.68

30.0 ft lb *29,400 *29,400 *25,950 *25,950 31.45

7.5 m kg *13 550 *13 550 *11 800 11 750 *11 400 *11 400 10.55

25.0 ft lb *29,600 *29,600 *25,200 *25,200 34.41

6.0 m kg *15 800 *15 800 *14 200 *14 200 *13 150 11 600 *11 400 10 450 11.14

20.0 ft lb *34,250 *34,250 *30,900 *30,900 *28,800 24,900 *25,100 23,150 36.44

4.5 m kg *21 300 *21 300 *17 400 *17 400 *15 100 14 450 *13 600 11 350 *11 600 9750 11.50

15.0 ft lb *62,050 *62,050 *45,900 *45,900 *37,700 *37,700 *32,800 31,100 *29,600 24,350 *25,550 21,500 37.69

3.0 m kg *24 200 *24 200 *19 050 18 150 *16 050 13 900 *14 100 11 050 *12 100 9350 11.66

10.0 ft lb *52,200 *52,200 *41,250 39,150 *34,800 29,950 *30,600 23,700 *26,550 20,600 38.24

1.5 m kg *26 150 23 900 *20 350 17 400 *16 850 13 400 *14 450 10 750 12 750 9250 11.62

5.0 ft lb *56,500 51,550 *44,050 37,450 *36,450 28,900 *31,350 23,100 28,100 20,350 38.13

Ground

kg *16 850 *16 850 *26 850 23 200 *21 000 16 850 *17 250 13 050 *14 550 10 550 13 050 9400 11.38

Line

lb *39,000 *39,000 *58,100 49,950 *45,450 36,300 *37,300 28,150 31,450 22,650 28,700 20,700 37.34

–1.5 m kg *13 350 *13 350 *24 050 *24 050 *26 350 22 900 *20 850 16 550 *17 050 12 850 *14 100 10 450 *13 250 9900 10.93

–5.0 ft lb *30,200 *30,200 *55,050 *55,050 *57,100 49,300 *45,200 35,700 *36,900 27,700 *30,350 22,500 *29,200 21,800 35.83

–3.0 m kg *22 100 *22 100 *31 450 *31 450 *24 750 22 950 *19 850 16 500 *16 100 12 850 *13 200 10 850 10.24

–10.0 ft lb *49,800 *49,800 *68,300 *68,300 *53,550 49,350 *42,850 35,600 *34,650 27,700 *29,100 24,000 33.50

–4.5 m kg *32 500 *32 500 *27 200 *27 200 *21 850 *21 850 *17 550 16 700 *13 650 13 050 *12 900 12 650 9.25

–15.0 ft lb *73,600 *73,600 *58,750 *58,750 *47,050 *47,050 *37,650 36,050 *28,700 28,250 *28,350 28,100 30.16

–6.0 m kg *20 850 *20 850 *17 000 *17 000 *13 000 *13 000 *11 850 *11 850 7.85

–20.0 ft lb *44,450 *44,450 *36,000 *36,000 *26,750 *26,750 *25,850 *25,850 25.40

Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity *

standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Lifting capacities are based on the machine standing on a rm,

uniform supporting surface.

Weight of all lifting accessories must be deducted from the above lifting capacities.

Lifting point for all charts is stick nose.

Always refer to the appropriate Operation and Maintenance Manual for specic product information.

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

m

ft

19

Page 20

374D L Hydraulic Excavator Specifications

Reach Boom Lift Capacities

➤

Load Point Height Load at Maximum Reach Load Radius Over Front Load Radius Over Side

➤

➤

➤

Boom – 7.8 m (25 ft 7 in) Coupler – N/A Bucket – None

Stick – R3.6 m (11 ft 10 in) Shoes – 900 mm (36 in) double grouser (HD)

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft 9.0 m/30.0 ft 10.5 m/35.0 ft

➤

➤

10.5 m kg *14 850 *14 850 7.75

35.0 ft lb *33,100 *33,100 24.84

9.0 m kg *14 350 *14 350 *13 900 *13 900 9.06

30.0 ft lb *30,700 *30,700 29.39

7.5 m kg *15 450 *15 450 *14 300 *14 300 *13 500 12 600 9.98

25.0 ft lb *33,600 *33,600 *31,300 *31,300 *29,750 28,100 32.54

6.0 m kg *19 600 *19 600 *16 650 *16 650 *14 850 14 750 *13 800 11 450 *13 450 11 250 10.60

20.0 ft lb *42,300 *42,300 *36,100 *36,100 *32,350 31,750 *29,600 24,900 34.68

4.5 m kg *22 500 *22 500 *18 200 *18 200 *15 650 14 250 *14 050 11 250 *13 700 10 400 10.98

15.0 ft lb *48,500 *48,500 *39,400 *39,400 *34,050 30,750 *30,650 24,100 *30,150 23,000 35.99

3.0 m kg *25 150 24 700 *19 700 17 950 *16 500 13 800 *14 450 10 950 *13 750 10 000 11.15

10.0 ft lb *54,250 53,300 *42,600 38,650 *35,800 29,700 *31,350 23,550 *30,250 22,000 36.57

1.5 m kg *26 650 23 650 *20 750 17 250 *17 150 13 350 *14 650 10 700 13 650 9900 11.11

5.0 ft lb *57,650 50,950 *44,950 37,150 *37,150 28,750 *31,800 23,050 30,000 21,750 36.45

Ground

kg *26 850 23 100 *21 150 16 800 *17 350 13 050 *14 550 10 550 *13 900 10 100 10.86

Line

lb *34,650 *34,650 *58,200 49,750 *45,750 36,200 *37,550 28,100 *31,350 22,750 *30,600 22,200 35.63

–1.5 m kg *24 650 *24 650 *25 900 23 000 *20 700 16 600 *16 900 12 900 *13 900 10 700 10.39

–5.0 ft lb *56,500 *56,500 *56,150 49,450 *44,800 35,750 *36,500 27,850 *30,650 23,550 34.04

–3.0 m kg *24 250 *24 250 *29 550 *29 550 *23 850 23 100 *19 250 16 650 *15 500 13 000 *13 750 11 900 9.65

–10.0 ft lb *54,750 *54,750 *64,150 *64,150 *51,600 49,700 *41,550 35,850 *33,150 28,000 *30,300 26,250 31.58

–4.5 m kg *29 150 *29 150 *24 750 *24 750 *20 350 *20 350 *16 350 *16 350 *13 200 *13 200 8.60

–15.0 ft lb *63,150 *63,150 *53,500 *53,500 *43,850 *43,850 *34,900 *34,900 *28,950 *28,950 28.01

–6.0 m kg *14 450 *14 450 *11 400 *11 400 7.07

–20.0 ft lb *30,200 *30,200 *24,700 *24,700 22.79

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

m

ft

Boom – 7.8 m (25 ft 7 in) Coupler – N/A Bucket – None

Stick – R2.84 m (9 ft 4 in) Shoes – 900 mm (36 in) double grouser (HD)

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft 9.0 m/30.0 ft 10.5 m/35.0 ft

➤

➤

10.5 m kg *17 550 *17 550 6.81

9.0 m kg *16 300 *16 300 *16 050 *16 050 8.28

30.0 ft lb *35,850 *35,850 *35,600 *35,600 26.78

7.5 m kg *16 700 *16 700 *15 500 14 800 *15 400 14 050 9.27

25.0 ft lb *36,400 *36,400 *34,000 31,750 *34,000 31,350 30.21

6.0 m kg *28 400 *28 400 *21 300 *21 300 *17 800 *17 800 *15 800 14 550 *15 050 12 350 9.94

20.0 ft lb *60,550 *60,550 *45,900 *45,900 *38,600 *38,600 *34,400 31,300 *33,200 27,400 32.51

4.5 m kg *24 100 *24 100 *19 200 18 450 *16 450 14 100 *14 900 11 400 10.35

15.0 ft lb *51,900 *51,900 *41,550 39,800 *35,700 30,400 *32,850 25,150 33.91

3.0 m kg *26 300 24 150 *20 450 17 650 *17 100 13 650 *14 900 10 950 *14 850 10 900 10.5

10.0 ft lb *56,750 52,100 *44,250 38,150 *37,050 29,450 *32,750 24,000 34.52

1.5 m kg *27 050 23 350 *21 200 17 100 *17 500 13 300 *14 850 10 800 10.48

5.0 ft lb *58,600 50,350 *45,900 36,850 *37,900 28,700 *32,700 23,750 34.40

Ground

kg *26 500 23 100 *21 150 16 800 *17 350 13 100 *14 800 11 100 10.22

Line

lb *57,500 49,700 *45,850 36,150 *37,600 28,250 *32,600 24,400 33.52

–1.5 m kg *23 400 *23 400 *24 900 23 150 *20 250 16 700 *16 450 13 050 *14 650 11 900 9.71

–5.0 ft lb *54,350 *54,350 *54,100 49,750 *43,800 36,000 *35,450 28,200 *32,250 26,200 31.82

–3.0 m kg *26 200 *26 200 *22 250 *22 250 *18 150 16 900 *14 150 13 450 8.92

–10.0 ft lb *57,100 *57,100 *48,150 *48,150 *39,150 36,400 *31,150 29,800 29.17

–4.5 m kg *20 850 *20 850 *17 900 *17 900 *13 900 *13 900 *12 900 *12 900 7.76

–15.0 ft lb *45,000 *45,000 *38,300 *38,300 *28,900 *28,900 *28,200 *28,200 25.25

Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity *

standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Lifting capacities are based on the machine standing on a rm,

uniform supporting surface.

Weight of all lifting accessories must be deducted from the above lifting capacities.

Lifting point for all charts is stick nose.

Always refer to the appropriate Operation and Maintenance Manual for specic product information.

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

m

ft

2

20

Page 21

Mass Boom Lift Capacities

➤

Load Point Height Load at Maximum Reach Load Radius Over Front Load Radius Over Side

➤

➤

➤

Boom – 7.0 m (23 ft 0 in) Coupler – N/A Bucket – None

Stick – M3.0 m (9 ft 11 in) Shoes – 900 mm (36 in) double grouser (HD)

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft 9.0 m/30.0 ft

➤

➤

9.0 m kg *13 850 *13 850 7.35

30.0 ft lb *30,750 *30,750 23.67

7.5 m kg *16 250 *16 250 *13 100 *13 100 8.45

25.0 ft lb *35,600 *35,600 *28,950 *28,950 27.50

6.0 m kg *19 550 *19 550 *17 050 *17 050 *15 700 14 300 *12 900 *12 900 9.18

20.0 ft lb *42,300 *42,300 *37,050 *37,050 *28,500 *28,500 *28,450 *28,450 30.01

4.5 m kg *30 350 *30 350 *22 250 *22 250 *18 350 *18 350 *16 150 14 000 *13 150 12 500 9.62

15.0 ft lb *65,000 *65,000 *48,000 *48,000 *39,750 *39,750 *35,150 30,050 *28,900 27,650 31.52

3.0 m kg *24 850 24 800 *19 700 17 800 *16 750 13 550 *13 750 11 850 9.81

10.0 ft lb *53,600 53,400 *42,700 38,350 *36,400 29,150 *30,200 26,150 32.18

1.5 m kg *26 450 23 700 *20 700 17 150 *17 200 13 200 *14 800 11 700 9.76

5.0 ft lb *57,200 51,050 *44,850 36,950 *37,250 28,400 *32,500 25,800 32.04

Ground

kg *29 000 *29 000 *26 700 23 150 *20 950 16 750 *17 100 12 950 *15 950 12 100 9.48

Line

lb *67,300 *67,300 *57,800 49,800 *45,400 36,050 *36,900 27,950 *35,150 26,600 31.10

–1.5 m kg *23 900 *23 900 *32 900 *32 900 *25 550 23 000 *20 200 16 600 *16 050 13 100 8.93

–5.0 ft lb *53,950 *53,950 *71,500 *71,500 *55,400 49,500 *43,700 35,750 *35,300 28,950 29.26

–3.0 m kg *35 400 *35 400 *28 850 *28 850 *22 900 *22 900 *17 850 16 800 *15 800 15 300 8.06

–10.0 ft lb *77,150 *77,150 *62,600 *62,600 *49,400 *49,400 *38,100 36,250 *34,750 33,900 26.35

–4.5 m kg *22 350 *22 350 *17 550 *17 550 *14 600 *14 600 6.76

–15.0 ft lb *47,800 *47,800 *37,050 *37,050 *31,950 *31,950 21.91

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

m

ft

Boom – 7.0 m (23 ft 0 in) Coupler – N/A Bucket – None

Stick – M2.57 m (8 ft 5 in) Shoes – 900 mm (36 in) double grouser (HD)

1.5 m/5.0 ft 3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft 9.0 m/30.0 ft

➤

➤

9.0 m kg *16 700 *16 700 6.82

30.0 ft lb *37,100 *37,100 21.91

7.5 m kg *17 200 *17 200 *15 700 *15 700 8.00

25.0 ft lb *37,750 *37,750 *34,650 *34,650 26.00

6.0 m kg *20 600 *20 600 *17 800 *17 800 *15 450 14 850 8.77

20.0 ft lb *44,550 *44,550 *38,750 *38,750 *34,050 32,950 28.65

4.5 m kg *23 200 *23 200 *19 000 18 500 *16 700 13 950 *15 750 13 350 9.23

lb *50,050 *50,050 *41,200 39,850 *36,450 29,900 *34,650 29,550 30.23

15.0 ft

3.0 m kg *25 550 24 550 *20 250 17 750 *17 150 13 550 *16 500 12 650 9.43

10.0 ft lb *55,200 52,950 *43,800 38,250 *37,300 29,200 *36,300 27,900 30.92

1.5 m kg *26 800 23 600 *21 000 17 150 *17 400 13 250 *16 650 12 500 9.38

5.0 ft lb *58,000 50,850 *45,550 36,950 *37,750 28,550 *36,700 27,550 30.78

Ground

kg *26 950 *26 950 *26 650 23 200 *21 050 16 800 *17 000 13 100 *16 750 12 950 9.08

Line

lb *63,150 *63,150 *57,750 49,900 *45,550 36,200 *36,950 28,550 29.79

–1.5 m kg *31 500 *31 500 *25 100 23 200 *19 900 16 750 *16 750 14 200 8.50

–5.0 ft lb *55,000 *55,000 *68,600 *68,600 *54,400 49,850 *43,000 36,150 *36,900 31,300 27.86

–3.0 m kg *31 000 *31 000 *27 100 *27 100 *21 900 *21 900 *16 650 *16 650 *16 250 *16 250 7.59

–10.0 ft lb *67,800 *67,800 *58,750 *58,750 *47,150 *47,150 *35,750 *35,750 24.78

–4.5 m kg *19 700 *19 700 *15 150 *15 150 *14 350 *14 350 6.18

–15.0 ft lb *42,000 *42,000 *31,200 *31,200 20.00

Indicates that the load is limited by hydraulic lifting capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity

*

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

m

ft

standard ISO 10567:2007. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Lifting capacities are based on the machine standing on a rm,

uniform supporting surface.

Weight of all lifting accessories must be deducted from the above lifting capacities.

Lifting point for all charts is stick nose.

Always refer to the appropriate Operation and Maintenance Manual for specic product information.

21

Page 22

374D L Hydraulic Excavator Specifications

374D L Bucket Specications and Compatibility

Width Capacity Weight Fill ME boom 7.0 m GP boom 7.8 m

Linkage

Without Quick Coupler

General Duty (GD) VB2 1525 60 2.9 3.9 3205 7,064 100%

VB2 1900 75 3.8 5.0 3622 7,982 100%

VB2 1900 75 3.8 5.0 3720 8,198 100%

WB2 2000 79 4.6 6.0 4016 8,851 100%

WB2 2100 83 5.0 6.5 4167 9,184 100%

General Duty XL (GDXL) VB2 2000 79 4.6 6.0 4077 8,986 100%

Heavy Duty (HD) VB2 1220 48 2.2 2.9 2892 6,373 100%

VB2 1700 66 3.3 4.3 3529 7,778 100%

VB2 1900 75 3.8 5.0 3881 8,553 100%

VB2 1900 75 3.8 5.0 3782 8,336 100%

WB2 2100 83 5.0 6.5 4345 9,576 100%

WB2 2250 89 5.3 7.0 4591 10,119 100%

Severe Duty (SD) VB2 1100 43 1.9 2.5 2840 6,259 90%

VB2 1525 60 2.9 3.9 3453 7,610 90%

VB2 1700 66 3.3 4.3 3653 8,051 90%

VB2 1900 75 3.8 5.0 4016 8,851 90%

WB2 1800 71 3.7 4.8 4667 10,286 90%

WB2 1900 75 4.0 5.25 4825 10,634 90%

WB2 2000 79 4.4 5.75 4982 10,980 90%

WB2 2100 83 4.6 6.0 5141 11,331 90%

WB2 2200 87 5.0 6.5 5341 11,772 90%

Extreme Duty (XD) WB2 2000 79 4.4 5.75 5785 12,750 90%

WB2 2100 83 4.6 6.0 5982 13,184 90%

WB2 2200 87 5.0 6.5 6212 13,691 90%

mm in m3 yd3 kg lb % M2.57WB2 M3.0WB2 R2.84VB2 R3.6VB2 R4.15VB2 R4.67VB2

Maximum dynamic load pin-on (payload + bucket) kg 12 150 11 260 10 650 9610 8860 8070

lb 26,779 24,817 23,473 21,180 19,527 17,786

With Quick Coupler (CW-70)

General Duty (GD) VB2 1900 75 3.8 5.0 3668 8,084 100%

Severe Duty (SD) WB2 1900 75 4 5.25 4802 10,584 90%

WB2 2000 79 4.4 5.75 4959 10,930 90%

Extreme Duty (XD) WB2 2000 79 4.4 5.75 5797 12,777 90%

Maximum dynamic load with CW coupler (payload + bucket) kg 13 470 12 580 11 970 10 930 10 180 9390

The above gures are based on maximum recommended dynamic working weights

with front linkage fully extended at ground line with bucket curled. They do not exceed

a stability ratio of 1.25.

Capacity based on ISO 7451.

Bucket weights include General Duty tips.

22

lb 29,688 27,726 26,382 24,090 22,437 20,696

1800 kg/m

1500 kg/m3 (2,500 lb/yd3)

1200 kg/m

Not Recommended

3

(3,000 lb/yd3) or greater

3

(2,000 lb/yd3)

Page 23

Standard equipment may vary. Consult your Cat dealer for details.

374D L Standard Equipment

ELECTRICAL

Alternator – 75 ampere

Lights

Cab interior

Cab lights, halogen, time delay

Boom lights, halogen

Signal/warning horn

ENGINE/POWER TRAIN

Automatic engine speed control

Automatic swing parking brake

Automatic travel parking brakes

®

C15 with ACERT® Technology

Cat

Altitude capability to 2300 m (7,500 ft)

Electric fuel priming pump

High ambient cooling capability

Side-by-side cooling system with

separately mounted AC condenser

and variable speed fan

Two speed travel

Water separator, with level indicator,

for fuel line

GUARDS

Heavy duty bottom guards on upper frame

Heavy duty swivel guard on undercarriage

Heavy duty travel motor guards

on undercarriage

Track guiding guards, center section

OPERATOR STATION

Air conditioner, heater and defroster

with automatic climate control

Ashtray and 24 volt lighter

Beverage/cup holder

Coat hook

Console mounted electronic type joysticks

with adjustable gain and response

Floor mat

Instrument panel and gauges

with full color graphical display

Literature compartment

Neutral lever (lock out) for all controls

Positive ltered ventilation

Pressurized cab

Retractable seat belt 75 mm (3") width

Sunshade for windshield and skylight

Travel control pedals with removable

hand levers

Windshield wipers and washers

(upper and lower)

UNDERCARRIAGE

Double grouser 900 mm (35")

Grease lubricated track

Hydraulic track adjusters

Long, variable gauge

Steps – four

OTHER STANDARD EQUIPMENT

Auxiliary hydraulic valve

for hydro-mechanical tools

Caterpillar one key security system

with locks for doors, cab and fuel cap

Cat walks – left side and right side

Cross-roller type swing bearing

Drive for auxiliary pump

Hand control pattern changer

Mirrors – left and right

SM

quick sampling valves

S·O·S

for engine oil and hydraulic oil

Steel rewall between engine

and hydraulic pumps

Product Link

23

Page 24

374D L Optional Equipment

Optional equipment may vary. Consult your Cat dealer for details.

FRONT LINKAGE

Booms

Mass excavation 7.0 m (23'0")

with two working lights

Reach 7.8 m (25'7")

with two working lights

Sticks

M 2.57WB (8'5") for mass boom

M 3.0WB (9'10") for mass boom

R2.84VB (9'4") for reach boom

R3.6VB (11'10") for reach boom

R4.15VB (13'7") for reach boom

R4.67VB (15'4") for reach boom

Bucket Linkages

VB2-family for VB2 sticks

(available with or without lifting eye)

WB2-family for WB2 sticks

(available with or without lifting eye)

Buckets – see chart

Tips, sidecutters and edge protectors

TRACK

Double grouser 650 mm (26")

Double grouser 750 mm (30")

Double grouser 900 mm (35")

GUARDS

FOGS (Falling Object Guard System)

including overhead and windshield guards

Track guiding guards

– Full length

– Center section

Vandal guards for windshield

Wire mesh screen for windshield

AUXILIARY CONTROLS AND LINES

Basic control arrangements

Single action – one-way high pressure

for hammer application

Combined function – one-way high pressure

circuit for hammer application function for

one-way or two-way high pressure.

Quick coupler circuit

Quick coupler lines for booms

Quick coupler lines for sticks

Auxiliary boom lines

High pressure for reach and mass booms

Auxiliary stick lines

High pressure lines for reach

and mass sticks

MISCELLANEOUS OPTIONS

Adjustable high-back heated seat

with mechanical suspension

Adjustable high-back seat

with air suspension and heater

Boom lowering control device

Counterweight removal system

Starting aid for cold weather with ether

Stick lowering control device

Straight travel pedal

Cab front rain protector

Converter, 10 amp – 12 volt

with two sockets

HID, boom lights

HID, cab lights, time delay

Jump start terminals

Reversible cooling fan including

protective screen

Operator Compartment

Joysticks

Four button joystick for standard machine

or single action auxiliary control

Thumb wheel modulation joystick

for use with combined auxiliary control

Lunch box storage with lid

Radio

AM/FM radio mounted in right hand

console with antenna and two speakers

Radio ready mounting at rear location

including 24 volt to 12 volt converter

speakers, antenna

Two-way radio ready

WAVES ready

24

Page 25

Notes

25

Page 26

Notes

26

Page 27

27

Page 28

374D L Hydraulic Excavator

For more complete information on Cat products, dealer services, and industry solutions,

visit us on the web at www.cat.com

© 2010 Caterpillar Inc.

All rights reserved

Materials and specifications are subject to change without notice. Featured machines

in photos may include additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow”

and the “Power Edge” trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

28

AEHQ6064-01 (08-2010)

Loading...

Loading...