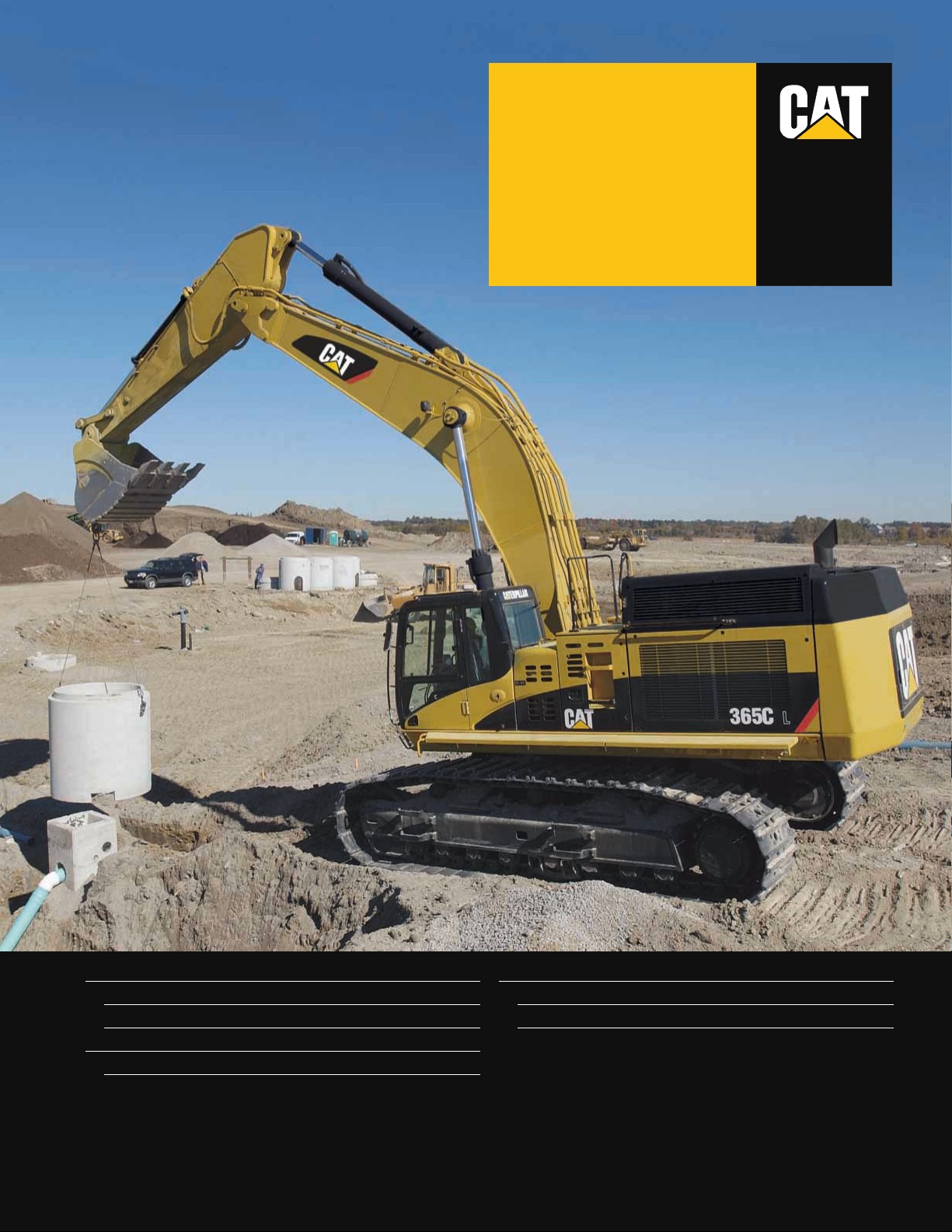

Milton CAT 365C L User Manual

Engine

Engine Model Caterpillar®C15 ATAAC

Net Flywheel Power 302 kW 404 hp

Weights

Operating Weight – 65 960 kg 145,430 lb

Long Undercarriage

• Reach Boom, R3.6 (11'10") stick, 1025 mm (40") Bucket,

and 650 mm (26") shoes.

Drive

Maximum Travel Speed 4.1 kph 2.6 mph

Maximum Drawbar Pull – 462 kN 103,767 lb

Long Undercarriage

365C L

Hydraulic Excavator

®

®

2

365C L Hydraulic Excavator

High performance and rugged durability combine to maximize your productivity.

High level of sustained production,

higher deep trenching and pipe-laying

performance, improved reliability and

durability increase your productivity

and lower your operating costs.

Buckets

A variety of work tools, including

buckets, couplers, hammers, and shears

are available through Cat Work Tools.

pg. 12

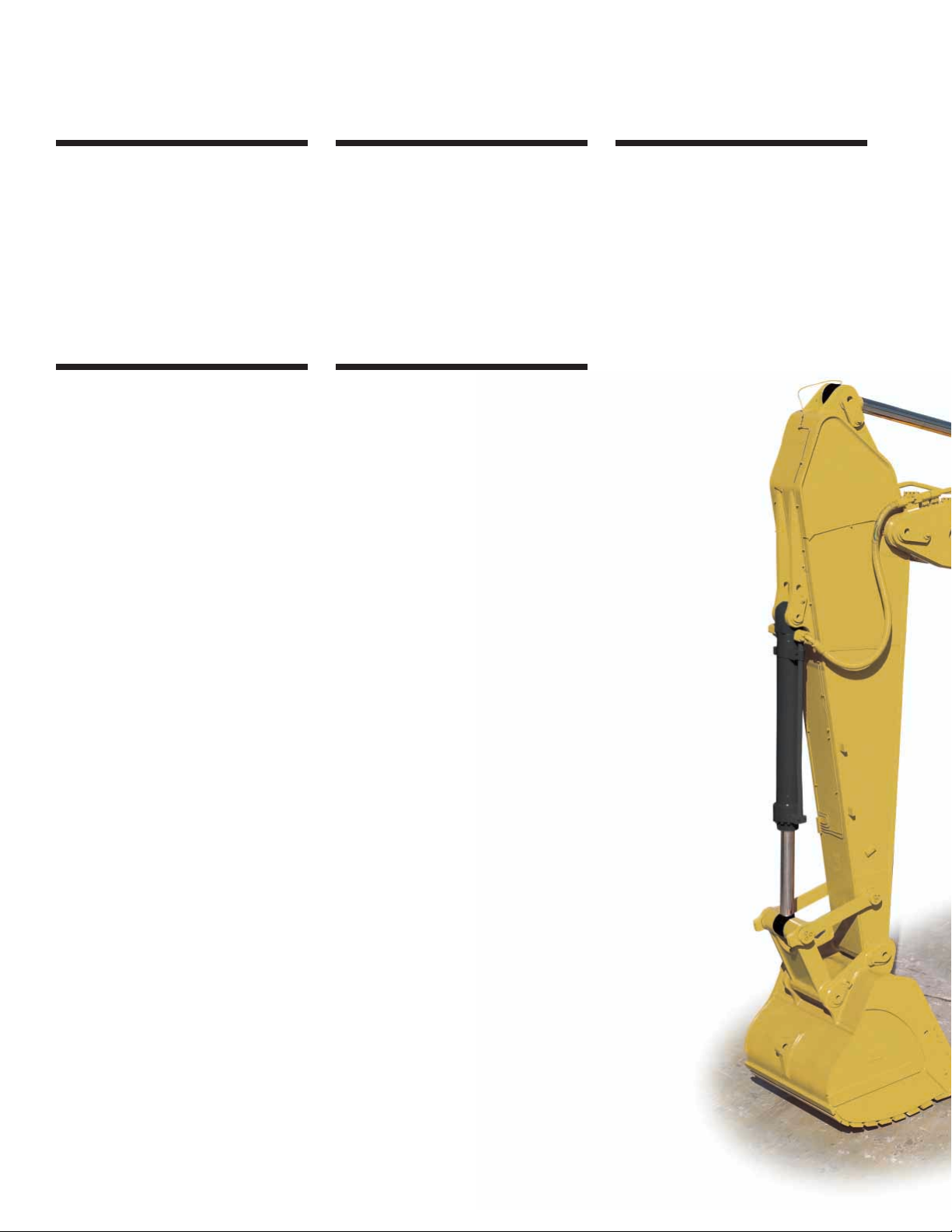

Front Linkage

Caterpillar excavator booms and sticks

are built for performance and long

service life. Two types of booms and

six lengths of sticks are available,

offering a range of configurations

suitable for a wide variety of applications.

All booms and sticks are stress relieved.

pg. 11

✔

Operator Station

An all-new cab provides improved

visibility and comfort. The new monitor

is a full-color graphical display with

enhanced functionality to provide simple,

comprehensive machine interface. pg. 6

✔

Hydraulics

Proportional Priority Pressure

Compensated (PPPC) system with

state-of-the-art electronic control

ensures hydraulic system efficiency

and excellent productivity. pg. 5

Engine

The Cat®C15 engine has state-of-the-art

ACERT®technology to meet U.S. EPA

Tier 3 emission regulations, with

exceptional performance capabilities

and proven reliability. pg. 4

✔

✔ New Feature

3

Complete Customer Support

Your Cat dealer offers a wide range

of services that can be set up under a

customer support agreement when you

purchase your equipment. The dealer

will help you choose a plan that can

cover everything from machine

configuration to eventual replacement.

pg. 14

Service and Maintenance

Fast, easy service has been designed

in with extended service intervals,

advanced filtration, convenient filter

access and user-friendly electronic

diagnostics for increased productivity

and reduced maintenance costs.

pg. 13

Structures

Caterpillar design and manufacturing

techniques assure outstanding durability

and service life from these important

components. The 365CL uses thicker

plates at the boom foot area to improve

rigidity. pg. 10

Undercarriage

Cat designed excavator undercarriage

is stable, durable and low maintenance.

The undercarriage is a long, variable

gauge type for good machine stability

and transportability. pg. 9

✔

Electronic Control System

Engine and machine Electronic Control

Modules maximize fuel efficiency and

performance by maintaining the optimum

balance between engine speed and

hydraulic demand. pg. 8

Diesel Engine. The Caterpillar C15,

with ACERT technology, is a 15.2 liter,

six-cylinder, 302 kW (404 hp) engine

with mechanically actuated electronic

fuel injection (MEUI) and overhead

camshaft. ACERT technology provides

outstanding engine performance through

advanced electronic control, precision

fuel delivery, and refined air management.

Fuel Consumption. The Advanced

Diesel Engine Management (A4)

controller uses sensors throughout the

engine to manage engine load and

performance. The A4 controller is the

muscle behind engine responsiveness,

self-diagnostics, controlling emissions,

and fuel economy.

Fuel System. C15 engine uses a

mechanically actuated electrically

controlled unit injection (MEUI) system.

The MEUI system combines highpressure injection and electronic control

in a single compact unit. The electronic

unit injector is an integral part of the

C15 fuel system. Computerized electronic

control provides precise metering and

timing of fuel injection.

Cooling System. High capacity,

side-by-side cooling system allows

operation in ambient temperatures up to

52 degree C (126 degree F). The Electric

Power Control (EPC) controls the fan

speed based on coolant temperature

and hydraulic oil temperature for

optimized cooling.

Turbocharger. The C15 engine uses a

water-cooled, center-section waste gated

turbocharger for improved performance.

This turbocharger controls the air volume

to the cylinders and works efficiently

during low and high load conditions.

Emissions. ACERT Technology is a

differentiated technology that reduces

emissions at the point of combustion.

The technology capitalizes on proven

Caterpillar leadership in three core

engine systems: fuel, air and electronics.

Cold Weather Starting Kit. The kit

consists of two additional batteries,

heavy-duty harness, large capacity

starting motor, and the ether starting

aid. With this kit, the 365C has the

capability to start at –32 degree C

(–25.6 degree F).

4

Engine

A combination of innovations working at the point of combustion, ACERT technology

optimizes engine performance while meeting EPA Tier 3 emission regulations.

PPPC Hydraulics. Load sensing,

Proportional Priority Pressure

Compensation (PPPC) system,

with Caterpillar-developed electronic

actuation, provides high efficiency

and excellent controllability.

• Cylinder speed is directly related

to operator’s movement of joystick

from feathering to full speed.

• Flow to cylinders during

multifunctional operation is

directly controlled by the operator

and is not dependent on loads.

• Controller reduces pump output

to minimum to save power when

joysticks are in neutral position.

Main Pumps. Large, heavy-duty main

pumps and a separate swing pump

provide quick cycle times during

multi-function operation.

Reverse Swing Damping Valve.

Swing dampening valves reduce swing

wag and produce smooth swing stops.

Auxiliary Hydraulic Valve. The auxiliary

valve is standard on the 365C L.

The auxiliary valve is used with optional

control arrangements to operate tools

such as hammers and shears.

5

Hydraulics

Cat hydraulics deliver power and precise control to keep material moving.

6

Designed for simple, easy operation and comfort, the 365C L allows the operator to focus

on production.

Operator Station

Cab Design. The workstation has

been designed to be spacious, quiet and

comfortable for the operator, assuring

high productivity throughout the entire

workday. Switches are conveniently

located for easy access. The new monitor

is located to provide excellent visibility

and access.

Seat. The 365C L seat provides a

variety of adjustments, including

fore/aft, height and weight to suit the

operator. Also included are adjustable

armrests and a retractable seat belt.

For additional comfort, a new heated

air suspension seat is available as an

attachment.

Hydraulic Activation Control Lever.

The hydraulic activation control

lever deactivates hydraulic functions

during engine start-up, and prevents

unintentional machine operation.

Climate Control. Positive filtered

ventilation with a pressurized cab comes

standard on the 365C L. Fresh air or

re-circulated air can be selected with

a switch on the left console.

Windows. To maximize visibility,

all glass is affixed directly to the cab

eliminating the use of window frames.

The upper front windshield opens,

closes and stores on the roof above the

operator with a one-touch action release

system. The lower front windshield

features a rounded design to maximize

downward visibility and improves

wiper coverage.

Wipers. Pillar-mounted parallelogram

wiper, including a washer nozzle,

increases the operator’s viewing area and

offers continuous and intermittent modes.

Skylight. An enlarged skylight with

sunshade provides excellent visibility

and good ventilation.

Monitor. The compact, full-color,

graphical display monitor is new with

the 365C L. The monitor has functions

to display machine, maintenance,

diagnostic and prognostic information.

The angle of the monitor can be adjusted

to face the operator and prevent sun glare.

Consoles. Redesigned consoles feature

a simple, functional design to reduce

operator fatigue, ease of switch operation

and excellent visibility. Both consoles

have attached armrests and allow the

height of the armrests to be adjusted.

Cab Exterior. The exterior design uses

thick steel tubing along the bottom

perimeter of the cab, improving the

resistance of fatigue and vibration.

This design allows the FOGS to be

bolted directly to the cab, at the factory

or as an attachment later, enabling the

machine to meet specifications and job

site requirements.

Cab Mounts. The cab shell is attached

to the frame with viscous rubber cab

mounts, which dampen vibrations

and sound levels while enhancing

operator comfort.

Standard Cab Equipment. To enhance

operator comfort and productivity,

the 365C L cab includes a lighter,

drink holder, coat hook, service meter,

literature holder, magazine rack and

storage compartment. The cab also

comes equipped with two, 12V-7 Amp

electrical sockets to provide additional

electrical resources.

Machine Security. An optional Machine

Security System (MSS) is available

from the factory on the 365C L.

MSS uses a special Caterpillar key

with an embedded electronic chip for

controlling unauthorized machine

operation.

Product Link. The 365C L is “Product

Link Ready” from the factory.

7

Monitor Display Screen. The monitor

is a full color 400 234 pixels Liquid

Crystal Display (LCD) graphic display.

The Master Caution Lamp the action

lamp blinks ON and OFF when one of

the critical conditions below occurs:

• Engine oil pressure low

• Coolant temperature high

• Hydraulic oil temperature high

Under normal conditions or the default

condition, the monitor display screen

is divided into four areas; clock and

throttle dial, gage, event display and

multi-information display.

Clock and Throttle Dial Display.

The clock, throttle dial and gas-station

icon with green color are displayed in

this area.

Gage Display. Three analog gauges,

fuel level, hydraulic oil temperature

and coolant temperature, are displayed

in this area.

Event Display. Machine event

information is displayed in this area

along with the icon and language.

Multi-information Display. This area

is reserved for displaying information

that is convenient for the operator.

The “CAT” logo mark is displayed when

no information is available to display.

Operator Gain/Response. This is used

to suit the operators preference or

application.

• Quicker, for fast response and more

production

• Slower, for more precision

• Three preset settings with 21 available

Pattern Control Changer. The standard

hand control pattern changer can be

accessed through the monitor, to utilize

either the standard excavator control

pattern (SAE) or Backhoe-loader

pattern (BHL).

Electronic Joysticks. Electronic

joysticks provide features not possible

with hydraulic pilot valves:

• Eliminate pilot lines in cab for

quieter operation

• Simple pattern change through

the monitor

8

Electronic Control System

Manages the engine and hydraulics for maximum performance.

Undercarriage Components.

Large, Caterpillar designed and built

undercarriage components offer

heavy-duty performance and durability.

Sealed and Lubricated Rollers.

Track rollers, carrier rollers and idlers

are sealed and lubricated for excellent

service life.

Idler Guards and Track Guides.

Idler guards and center track guides used

to maintain track alignment are standard

on the 365C L. Optional two-piece

full-length track guiding guards are

available for additional protection on

steep side slopes.

Track. The 365C L comes standard with

the new grease lubricated track called

GLT4. The track links are assembled

and sealed with grease to decrease

internal bushing wear, reduce travel

noise and extend service life lowering

operating costs.

Travel Motor. Two-speed axial piston

hydraulic motors provide the 365C L

drive power and automatic speed selection

when the high-speed position is selected.

This enables the machine to automatically

change between computer-controlled

high and low speeds depending on

drawbar-pull requirements.

Final Drives. The final drives are the

three-stage reduction planetary type.

This design results in a complete

drive/brake unit that is compact and

delivers excellent performance and

reliability.

9

Undercarriage

Durable undercarriage absorbs stresses and provides excellent stability.

Loading...

Loading...