Page 1

Operating instructions

f or the W 1930i

Washing Machine

To prevent accidents and reduce

the risk of damaging the machine,

read the Operating Manual

before installing or using

the machine. M.-Nr. 04 612 680

ö

Page 2

Contents

Contents

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preparation for use

Help protect our environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions

Economical usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preparing the Laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

End of Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Changing the program sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adding detergent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Adding fabric softener or starch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Program selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Program sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Textile care symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Additional options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Delay start/Time remaining indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

User-Maintenance Instructions

Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Problem solving guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

After-sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installation Instructions

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Programmable functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

T e c h nical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2

Page 3

Guide to the machine

Guide to the machine

1 Supply cable

2 High pressure inlet hoses

3 Flexible drain hose, with detachable

swivel elbow

4 Detergent dispenser drawer

5 Control panel

6 Adapter strips

7 Inner door panel

8 Four height adjustable legs

9 Access panel for lint filter and drain

pump

10 Access panel for emergency drain

and door release

3

Page 4

Guide to the machine

Guide to the machine

Detergent dispenser drawer

Compartment i - for the pre-wash.

Compartment j - for the main wash.

b “Delay start” button.

c Time display “h mins”.

Compartment

softener or starch.

p (with lid) - for fabric

f Pushbuttons for additional functions.

g SPIN SPEED SELECTOR switch.

d “Door” button;

opens the drum door.

e “ON/OFF” button;

to turn machine on or off or

to interrupt a program.

The “On” lamp illuminates.

4

h PROGRAM SEQUENCE indicators

(LED indicator lamps).

i PROGRAM SELECTOR switch.

Page 5

Important safety instructions

Important safety instructions

WARNING – To reduce the risk of

fire, electric shock, or injury to persons when using your appliance, follow basic precautions, including the

following:

1. Read all instructions before using

the appliance.

2. Do not wash articles that have

been previously cleaned in,

washed in or soaked in gasoline,

dry-cleaning solvents, or other

flammable or explosive substances. They give off vapors that

could ignite or explode.

3. Do not allow children to play on or

in the appliance. Close supervision is necessary when the appliance is used near children.

4. Before the appliance is removed

from service or discarded, remove

the door to the washing compartment.

9. Do not add gasoline, dry-cleaning solvents, or other flammable

or explosive substances to the

wash water. These substances

give off vapors that could ignite or

explode.

10. Under certain conditions, hy-

drogen gas may be produced in a

hot water system that has not

been used for 2 weeks or more.

HYDROGEN GAS IS EXPLOSIVE.

If the hot water system has not

been used for such a period, before using the washing machine,

turn on all hot water faucets and

let the water flow from each for

several minutes. This will release

any accumulated hydrogen gas.

As the gas is flammable, do not

smoke or use an open flame during this time.

SA VE THESE INSTR UCTIONS

5. Do not reach into the appliance if

the drum is moving.

6. Do not install or store this ap-

pliance where it will be exposed

to weather.

7. Do not tamper with the controls.

8. Do not repair or replace any part of

the appliance, or attempt any servicing unless specifically recommended in the user-maintenance

instructions or in published userrepair instructions that you understand and have the skills to carry

out.

Refer to the Electrical Connection Section for grounding and installation instructions.

5

Page 6

OPERATING INSTRUCTIONS Help protect our environment

OPERATING INSTRUCTIONS Help protect our environment

Warning - To reduce the risk of fire,

electric shock, or injury to persons,

read the IMPORTANT SAFETY INSTRUCTIONS before operating this

appliance.

Disposal of the packing

material

The transport and protective packing is

mostly manufactured from the following

recycled or recyclable materials:

– corrugated paper/cardboard

– polystyrene - CFC-free

– polystyrene foil (transparent)

– Untreated wood

– Polypropylene (PP) strapping

Rather than throwing these materials

away, please take them to your community recycling center.

Disposal of your old machine

Old machines contain materials which

can be recycled. Please contact your

recycling center or scrap merchant before disposing of the appliance, and

render the machine inoperative as per

the “Warning and Safety Instructions”

6

Page 7

Economical usage

The key to good wash results is finding

the correct combination of detergent

and temperature, and then allowing the

washing machine to optimize their

usage through its programming. Program lengths can vary for this reason.

With the “Hydromatic” system, the

drum can revolve at various speeds.

Faster and slower agitation speeds,

along with pauses for soaking, combine to ensure excellent results.

The automatic load control feature ensures the correct water level for the

type of fabric and load being washed

(even though it may appear as if there

is too little water in the drum!).

Because of the accurately balanced

drum and special sound insulation, machine noise is minimal while operating.

The fully electronic controls offer a combination of simple operation with many

optional features. For instance, since a

main wash generally gives good results

for a normal load, the pre-wash cycle

has been made a user selectable option, saving time,water and energy over

older full cycle machines.

Economical usage

Economy

For optimum economical usage, remember the following tips:

– The automatic load control feature

will adjust the water level for loads

up to 11 lbs (5 kg). Washing with the

maximum load specified for each

program uses water and energy to

the best advantage.

– Use only the correct amount of deter-

gent required for the water hardness

in your area. Miele recommends the

use of powder detergents, as their

characteristics allow them to perform

better in this machine than liquid

detergents.

If the wash is not heavily stained, select

a lower temperature than indicated on

the wash care label.

7

Page 8

Preparing the Laundry

Preparing the Laundry

The headings numbered (

show the operating sequence and can

be used as a brief guide.

1,2,3,...)

Before washing

1 Prepare the wash load

Dark fabrics often contain “excess dye”

and should be washed separately several times before being included in a

mixed load.

Delicate fabrics should be washed separately using a delicates program.

Only wash wool or wool mixtures if they

are labeled machine washable on the

textile care label.

Pre-treat the laundry

Badly soiled areas (e.g. collars and

cuffs) and water soluble stains can be

pre-treated with bar soap, stain

remover, or detergent mixed into a solution or paste.

Do not use detergents containing solvents in the machine.

Empty all pockets.

Foreign objects left in pockets (e.g.

nails, coins, paper clips, etc.) can

cause damage to clothes and the

machine.

Sort the laundry

Most garments have a Fabric care

label in the collar or side seam. Sort the

laundry by care label and color.

Only wash items that are labeled machine washable by the manufacturer.

8

Page 9

Preparing the Laundry

2 Press the “Door” button to open

the door

3 Load the machine

Unfold the laundry and place it in the

drum. For best results we recommend

washing mixed loads consisting of both

large and small items. This improves

the washing effectiveness and helps

distribute the load evenly to keep the

machine stable and reduce noise during spinning.

Recommended load sizes are noted

below:

COTTONS . . . . . . . . . . 11.0 lbs (5.0 kg)

PERMANENT PRESS. . 4.5 lbs (2.5 kg)

FINE/DELICATES . . . . . 2.0 lbs (1.0 kg)

WOOLENS. . . . . . . . . . . 2.0 lbs (1.0 kg)

FINE RINSE. . . . . . . . . 11.0 lbs (5.0 kg)

Preparing the Laundry

To start a program

1 Turn the program selector

to Finish / Start

2 Press the “ON/OFF” button

3 Press any additional option

buttons desired

(See the “Delay start” section if this feature is desired.)

4 Select spin cycle speed

5 Turn the program selector to the

desired program

The program selector can be turned to

the left or the right.

With curtains: Remove lead weights

and strips.

Woolens and knitted garments should

be turned inside out if recommended

by the manufacturer.

3 Close the machine door

Make sure there are no clothes caught

between the drum door and seal.

4 Add detergent

See section “Adding detergent” for details.

9

Page 10

End of Program

End of Program

After washing

1 Turn the program selector switch

to “Finish/Start”

2 Press the “ON/OFF” button.

3 Press the “Door” button.

Do not attempt to remove laundry

from the machine if the drum is

turning. You may seriously injure

yourself. If the drum turns with

the door open, contact the Miele

Service Department.

4 Remove the wash.

5 Check the folds in the door seal

for any small articles such as buttons or nails which may be lodged

there.

Make sure the drum is empty by

manually turning it completely

around or, during the next use,

items may be damaged (e.g. shrink)

or cause other laundry to discolor.

10

6 Close the drum door.

Page 11

Changing the program sequence

To cancel a program:

Turn the program selector to “Finish/Start”.

Changing the program sequence

To omit a program stage:

A program stage must first be reached

to be omitted:

To interrupt a program:

Press the “ON/OFF” buttton.

To continue the program, turn the machine back on.

To change an incorrectly selected

program:

Turn the program selector switch to

“Finish/Start”.

When only the “On” lamp is lit, a new

program can be selected.

To change a program which has been

“locked” using the Child Safety feature,

see the “Programmable functions” section.

Turn the program selector to

“Finish/Start”

As soon as the program sequence indicator lamp for the stage you wish starts

flashing:

Turn the program selector switch to

the desired program.

11

Page 12

Adding detergent

Adding detergent

Powder detergent should be added to

compartment j (main wash) and compartment i (pre wash, if necessary) at

the beginning of each wash cycle. Due

to the Miele “Eco-System”,

manufacturer’s recommended amount

of detergent is generally sufficient for

excellent wash results.

1

/3 to 1/2 the

It is important to add the correct amount of detergent, because...

...too little detergent can result in:

– gray laundry

– grease/stains not being removed

Do not use chlorine bleach!

Water is taken in through compartment

j during the main wash. If your water

is extremely hard (above 400 ppm calcium carbonate)

compartment j is insufficient for the

amount of detergent needed, a Service

Technician can reprogram the machine

so that water and detergent can also

be taken in through compartment i.

For small loads:

– Gradually reduce the amount of

detergent used with each small load.

– Check the wash results and the con-

dition of the laundry.

– If the laundry is not clean or if it is

gray or hard to the touch, add

slightly more detergent the next time

you use the machine.

and the capacity of

– lime deposits on the heater elements

and drum (in hard water areas).

...too much detergent can result in:

– excessive foam

– low level of agitation

– poor cleaning and rinsing results.

Water Softeners

If you wish to use a water softener to

cut down on detergent usage in hard

water areas:

– add the amount of detergent necess-

ary for a soft water area.

– Add the specified amount of water

softener per the manufacturers re-

commendation.

Always add the detergent first, in compartments i and j followed by the

softener, to ensure that both are

properly dispensed.

12

Page 13

Adding fabric softener or starch

Adding fabric softener or starch

If fabric softener is desired, it will work

more effectively and be gentler on the

clothes if it is dispensed in the final

rinse cycle of the wash, rather than in

the tumble dryer through the use of softener sheets. To automatically dispense

fabric softener:

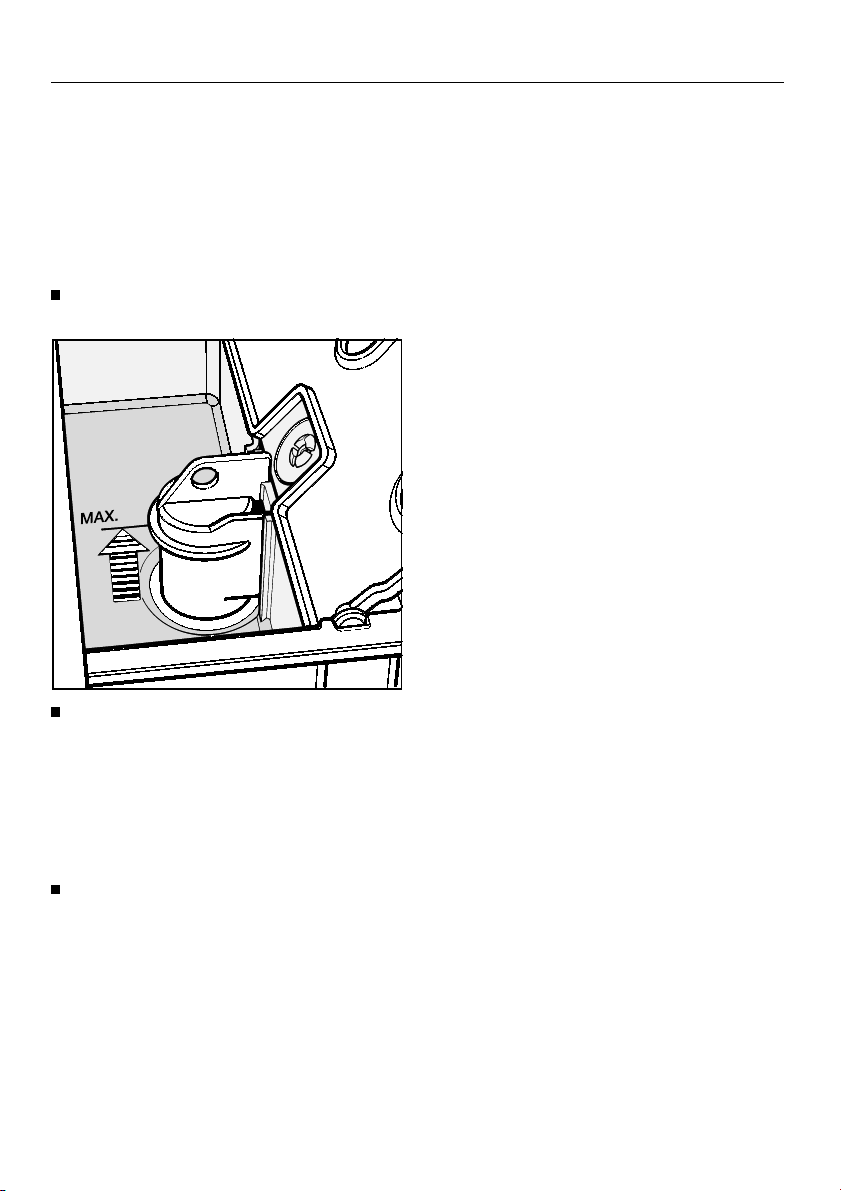

Open the lid of compartment p.

Pour an amount of liquid fabric softener into compartment p according

to the manufacturer’s instructions.

Do not exceed the maximum fill level

marked inside the compartment, as

any excess will prematurely activate

the siphon and be wasted.

Close the compartment lid and push

in the dispenser drawer.

The softener will automatically be dispensed during the last rinse cycle.

dispenser drawer was opened during

the last rinse cycle, thereby interrupting

the distribution of fabric softener. In this

case, the siphon tube should be

cleaned as described on Page 21.

Starch

Starching can be done as a separate

cycle (see below) or can be included in

any wash program during the final rinse.

Never mix fabric softener and starch

together in compartment p. This can

cause the overflow system to malfunction.

If starch is used for shirts, blouses,

table cloths, napkins, etc., pour the

liquid starch into compartment p (use

the same procedure as for fabric softener).

Using the “Starch” program to dispense liquid starch.

– Prepare the starch solution in accor-

dance with the manufacturer’s instructions and pour it into compartment p.

– Use the normal water level (Water

Plus button “out”) when starching so

that the solution will have the maximum effect.

“Without final spin” can be selected to

reduce fabric creasing.

At the end of the program a small

amount of water will normally remain in

compartment p. A high water level in

this compartment, however, may indicate that the siphon is clogged or the

13

Page 14

Program selection

Program selection

Program Temperature range Fabric

COTTONS

For cotton fabrics without

special finishes.

PERMANENT PRESS

For cotton blends, polyester

blends and synthetics such

as acrylic, nylon and ramie.

FINE/DELICATES

For synthetics, machine

washable silks, lace or

crocheted (non-woolen)

items, curtains and knits.

WOOLENS

For all machine washable

woolens and wool blends.

Also suitable for silks.

Starch cold For tablecloths, napkins, aprons and shirts.

Spin For spinning wet items not washed in the

Drain For use when the laundry is to be removed

85 - 105°F

105 - 120°F

140 - 170°F

85°

105 - 120°F

140°F

cold - 85°F

105 - 120°F

140°F

cold - 105°F For all colors of wool and silk.

For dark colored items.

For light colored items.

Exclusively white items.

For dark fabrics which are a blend or 100%

synthetic fabrics.

For light colored cotton or synthetic items.

For white polyester/cotton items.

For dark colored silks and all synthetic items

(lingerie).

For light colored silks and lace tablecloths.

For white cotton lace and crocheted items.

(There is no Pre-wash option in this

proram).

machine (hand washed). Such items must

be suitable for machine spinning.

wet for drip drying. Normally used in

conjunction with “Without final spin”.

Fine rinse For hand washed items that can be gently

rinsed, and if desired, spun.

14

Page 15

max. load Additional options

11 lbs Pre-wash

Gentle wash

available

Water plus

Normal wash cycle Rapid wash

cycle

Available Available

4.5 lbs Pre-wash

Water plus

Gentle wash

2 lbs Pre-wash

Gentle wash

2 lbs Available Available

11 lbs Available Available

11 lbs Available Available

Available Available

Available Available

Available Available

Available Available

15

Page 16

Program sequence

Program sequence

COTTONS PERMANENT

Pre-wash Selectable

Main wash ß

Interim rinse ßß–

Graduated rinse –

No. of rinses 4 3 3

Rinse and interim spin

Graduated spin rpm max. 900

Final spin rpm max. 1600 max. 900

Rinse & hold ßßß

Anti-crease spin ß

Wash rhythm normal normal normal

Water level – wash

– rinse

Approx. running time (Normal cycle) 1h 49 min 1 h 12 min 1h 00 min

Explanations:

(1)

(1)

ß ––

(3)

(2)

(1)

low

(1)

low

PRESS

Selectable

(1)

(1)

ß

ßß

––

(3)

(2)

ß

(1)

low

high

FINE/

DELICATES

Selectable

ß

(2)

ß

high

high

(3)

max. 600

(1)

ß Cycle included

– Cycle not included

Interim rinse:

Additional water flows into the drum, and the suds is cooled slightly.

Graduated rinse:

The suds is cooled at the end of the wash cycle by incoming water, and drained in intervals. This

minimizes the danger of creasing by avoiding sudden temperature changes.

(1) Increased water level:

The water level can be increased from the normal level to a higher level by pressing the “Water

plus” button.

(2) The “Gentle wash” option can also be selected in this program.

(3) Maximum spin speed is automatically set by the machine.

16

Page 17

WOOLENS Starch Spin Fine rinse

–

ß ––

ß –––

––––

––––

3––2

––––

––––

max. 900

(3)

max. 1600 max. 1600 max. 900(3)

ßß– ß

– ß ––

Woolens normal – –

low

high

47 min – – –

Graduated spin:

The speed is gradually increased, until the final spin speed is reached.

Final spin:

The maximum spin speed is held constant for a fixed period of time.

In the program PERMANENT PRESS, WOOLENS and Fine rinse the spin speed is automatically

limited to 900 rpm and in the FINE/DELICATES program to 600 rpm, even if the selector has been

set to a higher speed. A lower speed can also be selected.

Woolens:

Wool is susceptible to damage when it is wet. Agitation times during the program are shorter,

and the drum rotates slower.

“Without final spin”:

At the end of the final rinse the wash remains suspended in water if the SPIN SPEED SETTING is

set to “Without final spin”. This helps reduce creasing if the laundry will not be removed immediately at the end of the cycle.

low

–

–

–

–

high

17

Page 18

Textile care symbols

Textile care symbols

Some clothing manufactures have

started placing textile care symbols on

their products. The following is an explanation of some of these symbols.

/ Hand wash

h do not wash

ABC dry clean only

Washing (°C)

987 COTTONS

4321 PERMANENT PRESS

21 FINE/DELICATES

a@ WOOLLENS

The significance of the bar beneath the

wash tub is:

no bar normal (maximum) agitation

e used in the Cottons program

bar reduced (medium) agitation,

f used in the Permanent Press,

Gentle wash, or Delicates

program.

broken minimal agitation

bar used in the Woolens program

g

Te mperature Conversion Chart

D do not dry clean

y suitable for chlorine

bleaching

z not suitable for chlorine

bleaching

Tumble dry

q at normal temperature

r at low temperature

s do not tumble dry

Ironing

I hot iron

H medium hot iron

G cool iron

J do not iron

18

°C

°F

30 40 50 60 65 70 75

85 105 120 140 150 160 170

Page 19

Additional options

Additional options

By selecting one or more pushbutton

functions, basic programs can be tailored to the type of laundry being

washed.

When the “Door” button is pressed, all

the other buttons spring out, and the

additional options are cancelled.

“Pre-wash”

Use for heavily soiled or stained

laundry items.

Available in the “COTTONS”, “PERMANENT PRESS” and “DELICATES”

programs.

Add the reguired amount of detergent

to compatment i.

The “Water plus” option is available in

the following programs:

The wash and rinse cycles for COTTONS.

The wash cycle for PERMANENT

PRESS.

“Gentle wash”

For gentle washing of slightly soiled

laundry items, or delicate fabrics

which tend to pill.

Drum movement is reduced by half.

Available in the “COTTONS”, “PERMANENT PRESS” and “FINE DELICATES”

programs.

“Rapid wash”

Offers a quick wash cycle (approx.

37 minutes)

Can be used with or without a pre-

wash.

To operate:

“Water plus”

This increases the normal water level to

a slightly higher level:

For particularly delicate fabrics in addition to the “Gentle wash” option,

In hard water areas, if more water is

required for dispensing the detergent,

In softwater areas to enhance washing and rinsing results.

For people who are skin sensitive to

detergents.

1 Push in the ON/OFF button to turn on

the machine.

2 Push in the Pre-wash button if desired.

3 Push in the Rapid wash button. No-

tice the thick grey ring surrounding

the button. This grey ring corre-

sponds to the grey ring surrounding

the COTTONS, PERMANENT

PRESS, DELICATES and WOOLENS

programs on the Selector switch.

Choose the desired program and the

machine will start.

19

Page 20

Delay start/Time remaining indicator

Delay start/Time remaining indicator

Time display “H:min”

The Time display has a dual function.

The Delayed start is activated by

pressing the button, or;

It shows the time remaining in the

wash program.

Delay Start

If the “Delay start” lamp is blinking, the

start of the program can be delayed up

to 9 hours and 30 minutes.

Entering the start delay:

– Press the button to the left of the

“Delay start” lamp as many times as

necessary until the desired delay

time appears. Each time the button

is pressed, the time of delay will increase by 30 minutes.

Select the program

Remaining time

The remaining time for program completion is shown in hours and minutes

as soon as:

– A program is selected.

– The time delay reaches zero.

The display counts backwards in 1

minute increments.

– The display will begin counting the

delayed time backwards in one

minute increments.The “Delay start”

lamp will remain lit.

Program start

– When the delay time reaches zero,

the “Time remaining” lamp illuminates, and the “Delay start” lamp

goes out. The duration of the selected program will be shown on the

display.

Deleting the start delay

– When the display reaches “9 h 30

min”, press the button to the left of

the “Delay start” lamp and the start

delay will be deleted.

20

Page 21

USER MAINTENANCE INSTRUCTIONS Cleaning and care

USER MAINTENANCE INSTRUCTIONS Cleaning and care

Cleaning the washing machine

Clean the casing with a mild nonabrasive detergent or soap and

water, and wipe dry with a soft cloth.

Clean the control panel with a damp

cloth.

The drum can be cleaned using a

stainless steel cleaner according to

the manufacturer’s instructions.

A stainless steel cleaner specially formulated for use in washing machines is available from the Miele

Parts Department.

Do not use abrasive cleaners or solvents.

Cleaning the detergent drawer.

Should the detergent drawer become

clogged or dirty, it can be cleaned as

follows:

Pull out the drawer until it stops.

Clean the dispenser compartments

and the fabric softener duct.

Press down the red release lever

and, at the same time, pull the

drawer out of the machine.

Remove the siphon tube from com-

partment p and rinse in warm water.

21

Page 22

Cleaning and care

Cleaning and care

Cleaning the drain pump and

lint trap.

Occasionally small objects, (buttons,

coins, etc.), may find their way into the

lint trap. It is a good idea to occasionally check the lint trap to ensure that it

is free of foreign objects.

To clean the lint trap, remove the tool

from behind the detergent dispenser

drawer.

Open the machine door.

Place a 2 quart capacity container

underneath the drain tube.

Turn the lint trap lid counterclockwise

2 - 3 times. Do not remove it. Approx. 2 quarts of water will drain out

of the hose.

If the main drain hose is clogged, more

water will be retained in the machine

(max. 6.5 gal/25l). In this case, tighten

the lint trap lid and empty the dish before repeating the procedure as often

as necessary.

Open the lint trap door.

22

Caution: If laundry has been

washed at a high temperature, the

water draining out of the machine

will still be hot! Stop and allow it to

cool before proceeding.

Page 23

Cleaning and Care

Once the flow of water stops,

remove the lint trap and clean it.

Remove any foreign objects or lint.

Turn the drain pump impeller (in the

back of the chamber) by hand to

check that it rotates freely. Any

foreign objects should be removed.

Cleaning and Care

Clean inside of the lint trap housing.

Remove any detergent deposits or

foreign objects from the thread of the filter housing and filter unit before replacing the lint trap.

23

Page 24

Cleaning and care

Cleaning and care

Cleaning the water inlet filters.

The washing machine has two water

inlet filters to protect each inlet valve.

To clean the filter in the inlet hose:

Turn off the valve.

Carefully unscrew the inlet hose from

the valve by turning the connector

counterclockwise using a wrench if

necessary.

Remove the rubber seal from the

connector.

Inspect the inlet hose regularly. The

hose should be replaced if there are

small cracks in the surface, or if it has

been otherwise damaged or cut.

If a replacement is necessary, use only

a genuine Miele inlet hose as other

hoses may burst under pressure.

To clean the filter in the inlet valve:

Using a wrench, carefully loosen and

remove the plastic hose connector

on the inlet valve.

Using needle nose pliers, grasp the

plastic filter and pull it out of the

hose connector. Clean the filter

under running water and carefully

remove any large particles.

Replace the filter and seal and reconnect the hose. Slowly turn on the

valve and check for leaks.

24

Using needle nose pliers, withdraw

the plastic filter by pulling on the bar

(see illustration). Rinse under water

to clean, and then replace.

The two filters - one at the pressure

hose/valve connection and one at

the inlet connection to the solenoid

valve - must not be removed.

Page 25

Problem solving guide

Problem solving guide

Any work done on the electrical components of this appliance should only

be performed by a qualified and trained person in accordance with all

local and national codes and regulations. Unauthorized repairs may result

in personal injury and damage to the machine.

What to do if, . . . Cause . . . Remedy . . .

. . . The program does not

start?

. . . The “Check p / q” indi-

cator lamps are flashing?

There is no power.

The “ON” indicator lamp has

not lit up.

There is power and the “ON”

indicator lamp is on, but the

program selector has not been

turned to the “Finish / Start”

position.

The “Check p” indicator lamp

is flashing, and the program

has started.

The water inlet is blocked.

The “Check q” indicator lamp

is flashing.

The drain is blocked.

Check that..:

– the door is properly closed.

– the machine is plugged in.

– the fuse or circuit breaker has

not tripped.

– Turn the program selector to

the “Finish / Start” position.

– Select a program.

– The inlet valve is not opened

far enough.

– The inlet hose is kinked.

– The water pressure is too low.

Call the Service Dept.

– Clean the drain pump and lint

trap.

– Has the drain hose been

installed too high? (max drain

height = 4 feet)

25

Page 26

Problem solving guide

Problem solving guide

What to do if, . . . Cause . . . Remedy . . .

. . . the “Pre-wash”, “Main

wash” or “Rinse 1-2” indicator

lamp is flashing?

. . . The “Rinse & hold” indicator lamp is flashing?

. . . The “Final spin” indicator

lamp is flashing?

. . . The “ON” indicator lamp

is flashing?

. . . The wash is too wet after

the final spin?

. . . The machine shakes during the spin cycle?

There is an internal problem. Restart the program. If the

The spin speed selector has

been set to “Without final spin”.

The final spin has not taken

place. The machine detected

an imbalance.

indicator lamp starts flashing

again, call the Service Dept.

Select a spin speed setting.

– Redistribute the laundry load.

– Select a spin speed.

– Turn the program selector to

“Spin”.

The child-safety feature is

activated, and the program has

been changed.

The spin speed selected was

too low.

The load was not evenly

distributed in the drum, and the

laundry was spun at a reduced

speed to protect the machine.

The drain pump or lint trap is

clogged.

The four feet are not resting

evenly on the floor.

The shipping struts have not

been removed.

Go back to the program

originally selected.

Select a higher spin speed next

time.

Mix large and small items in a

load to avoid imbalance.

Clean the drain pump or lint

trap.

Level the machine (see

Installation Section).

Remove the shipping struts.

26

Page 27

Problem solving guide

Problem solving guide

What to do if, . . . Cause . . . Remedy . . .

. . . In spite of adequate water

supply, the water flows slowly

into the machine?

. . . Large residues of detergent remain in the dispenser

drawer?

. . Fabric softener is not completely dispensed or water remains in the p compartment?

. . . There is an excessive

build-up of foam?

. . . Lime deposits appear on

the drum surface?

A filter in the water inlet system

is blocked.

The water pressure is too low.

Detergent used with a water

softener tends to become sticky.

The dispenser drawer was not

pushed in when the fabric

softener was being dispensed.

The siphon tube is either

incorrectly positioned or

clogged.

Use only a low-sudsing

detergent at the appropriate

temperature.

Not enough detergent has been

used.

Clean the water inlet filters.

– Clean the filters in the water

inlet system.

– It may help to select “Water

plus”.

Pour detergent into the

dispenser before adding any

water softener.

Make sure the drawer is all the

way in.

Clean the siphon tube.

– Follow recommendations on

the package.

– Take the water hardness into

account.

– Use less detergent for lightly

soiled or small loads.

– Use a decalcifier suitable for

use in washing machines. A

product called “Quick” is

available from the Miele Parts

Department.

– Use the correct amount of

detergent for the water

hardness in your area.

27

Page 28

Problem solving guide

Problem solving guide

What to do if, . . . Cause . . . Remedy . . .

. . . Grey greasy particles

cling to washed laundry?

. . . Liquid detergent does not

give the required result?

. . . After washing pilling appears on the fabric?

Insufficient detergent was used

to break down the particles of

grease in heavily soiled laundry.

Liquid detergents do not

contain bleaching agents. They

do not remove stains as well as

powdered detergents

containing non-chlorinated

bleaches.

This is a normal occurance of

everyday wear with some

fabrics.

– Add more detergent.

– Before washing the next load

run a COTTONS 120°F

program with detergent but

without a load to clean the

machine.

– Use a general purpose

powder detergent containing

a bleaching agent.

– Pre-treat stains with a stain

remover.

These fabrics must be handled

with care. Wash them using the

DELICATES program and/or

select “Gentle wash” in the

future.

28

Page 29

Problem solving guide

Problem solving guide

Opening the drum door in the

event of a power failure

Switch off the washing machine.

Remove the flap opener from behind

the detergent drawer facia panel.

Place a dish or bowl under the spout.

Point the drain hose into the con-

tainer.

Remove the stopper.

Caution: if laundry has been

washed at a high temperature water

draining out of the machine will still

be hot!

Open the flap (in the machine plinth).

The amount of water discharged depends on the drainage height. A delivery head (e.g. 1 m) will mean there is

more water to drain. The container will

need to be emptied several times.

When no more water drains out

place the stopper back in the hose.

29

Page 30

Problem solving guide

Problem solving guide

Pull the emergency door latch downwards using a spoon handle (see illustration). The machine door will

then open.

Please note that: on machines with left

hand hingeing the emergency door

latch is located behind a second access flap in the centre of the plinth.

To check water pressure

Place a bucket under the stopcock.

Turn on the stopcock.

If 5 litres of water flow into the bucket in

15 seconds the water pressure is correct.

Electric socket

If there is any doubt about the electricity supply socket, consult a qualified

electrician.blem solving guide

Always make sure the drum is stationary before reaching in to the machine to remove washing. Reaching

into a moving drum is extremely

dangerous.

30

Page 31

After sales service

If problems occur that cannot be easily

remedied, or if the appliance is under

warranty, please contact:

– Your Miele Dealer or

– The Miele Service Department (see

back cover).

When contacting the Service Department, please have the model and serial

numbers of your appliance available,

both of which can be found on the dataplate visible when the door front is

opend above the porthole glass.

After sales service

31

Page 32

INSTALLATION INSTRUCTIONS Installation

INSTALLATION INSTRUCTIONS Installation

Installation surface

Experience has shown that a concrete

floor is the most suitable surface for a

washing machine. Concrete floors are

far less prone to vibration during the

spin cycle than wooden floors.

Please note the following points:

The machine must be level and securely positioned.

Installation

Lift the machine from its shipping pallet

and move it to the installation site.

Please note:

Do not lift the machine by the drum

door.

Ensure that the machine feet and the

floor are dry to prevent slippage during the spin cycle.

To avoid vibrations during spinning,

the machine should not be installed

on soft floor coverings.

If installation must be on a wooden

joist floor, we recommend the use of

1

a plywood base at least 1

and 23

600mm X 600mm). Ideally the base

should be large enough to span several joists and should be anchored

to the joists and not just the floorboards.

As a general rule, we recommend

the installation of the machine (or

washer/dryer stack) in the corner of

a room where the stability of the floor

is at its greatest.

If the machine is installed on a

raised platform, it should be secured

using retaining clips (available from

the Miele Parts Dept.). If installed on

a masonary or concrete base, the

base should be provided with a rim

1/2" to 3/4" (12-20 mm) high.

5

/8" X 23 5/8" wide (30mm X

/4" thick

Removing the shipping struts

Using adjustable pliers, pull out the

retaining clips on the right and left of

the support plate.

32

Turn the left-side shipping strut 90°

counterclockwise.

Page 33

Installation

Turn the right-side shipping strut 90°

clockwise.

Installation

Plug the two holes with the plastic

caps supplied.

Movement of the machine without the

shipping struts in place should be kept

to a minimum.

Withdraw the two struts together with

the support plate.

The shipping struts should be

stored in a safe place for future use.

They must be reinstalled before the

machine is moved. Reinstallation

can be performed by reversing the

procedure.

33

Page 34

Installation

Installation

Levelling the machine

The machine must be perfectly level to

ensure safe and proper operation.

If necessary adjust the front and back

legs as follows:

Tighten the counternut using a

screwdriver, as shown.

Building in

This washing machine is specially designed for installation under a countertop, and comes with a protective cover

which replaces the machine lid.

Unscrew the feet until the machine

stands level.

Hold the foot tight using a wrench or

pliers.

34

For safety reasons the cover of the

machine should not be removed.

Page 35

Installation

Please note the following:

– The machine should never be oper-

ated without the front panel firmly in

place.

– The electrical outlet and water

faucets should be close to the machine and easily accessible.

– The slides provided with the ma-

chine will prevent damage to the

floor while moving the washer into

position.

Installation

Matching the control panel to

the adjacent washer fronts

The height of the control panel can be

adjusted in one of two ways:

by tightening or loosening the nuts to

raise or lower the adapter strips as

needed, or

by adding or removing adaper strips.

– For installation under countertops

7

that are 35

above the floor, one or more 2"

spacer frames, Part # 1542631, may

be required.

– Spacer frames (with installation in-

structions) can be purchased from

your Miele dealer or the Miele Parts

Department.

/16" (900 mm) or more

The attached adapter strips can be

compressed up to

ening the 4 nuts located under the bottom adapter strip. If the control panel

needs to be shortened by more than

3

/8" (10 mm), one or more adapter

strips can be removed.

The control panel height can be ex-

tended an additional 1" (25 mm) by adding additional adapter strips and extension bolts. These parts are available

from your Miele dealer or the Miele

Parts Department.

Important

After the final adjustment has been

made, cut the plastic bolt flush with the

bottom of the lowest adapter.

3

/8" (10 mm) by tight-

35

Page 36

Installation

Installation

Installing the front panel

A front panel must be installed on the

washer before it can be safely operated. It can be custom made to match

the surrounding cabinetry or furmiture.

Front Panel Dimensions:

Height: 22

Width: 23

Thickness:

Using the provided template, layout

and drill the pilot holes for the mounting

brackets as follows:

7

/16" (+ 3/8" / -1")

570 mm (+ 10 / - 25 mm)

3

/16" – 23 1/2"

588 – 596 mm

3

/4" (19 mm) maximum

Tape the centered template to the

panel.

Lay the panel with the finished side

face down and the bottom edge toward you.

Align the bottom of the template with

the lower edge of the door.

Center the template on the panel by

using the four parallel lines located

at each corner. The panel is centered when the identical line on each

side aligns with the panel edge.

3

For example, if your panel is 23

/8"

wide, the second line from the center of

the template will align with both the

right and left edges.

Using a 3/8" (10 mm) drill bit, drill 1/2"

(12 mm) deep pilot holes at tem-

plate locations 1 and 2 only.

Remove the template from the panel.

36

Page 37

Installation

Installation

Right-hand hinge

Open the door and remove the lower

screw from the upper hinge.

Using the screws provided, loosely

attach the front panel th the machine

door through the now empty lower

hinge hole and the corresponding

hole on the unhinged side of the

door (see illustration).

Align the front panel and tighten the

two screws.

The remaining pilot holes can now

be drilled into the front panel through

the holes in the machine door.

Use the remaining screws to se-

curely mount the front panel to the

machine door.

Left-hand hinge

37

Page 38

Installation

Installation

Sizing the toekick

The appliance toekick visible below the

door can be partially conceated by installing a custom made toekick that

matches the adjacent cabinetry.

Please note: The depth of recess

and height of the appliance toekick

cannot be altered.

The lenght of the matching toekick

5

should be 23

toekicks heights are listed below.

Height from the

floor to the bottom of the

countertop

1

32

/4" (820 mm) none 3 15/16" (100 mm)

1

34

/4" (870 mm) 1 5 15/16" (150 mm)

1

36

/4" (920 mm) 2 7 7/8" (200 mm)

The matching toekick must be cut

out so that access to the emergency drain and door release panel

is not impeded.

/8" (600 mm). Maximum

Number

of

spacer

frames

rquired

Maximum

toekick height

Installing the toekick

Align and attach the two Velcro

strips to each other. Cut the strip into

three equal pieces.

Remove the protective backing from

one side of the three Velcro strips.

Press them into place on the washer

toekick.

Peel the protective backing off of the

second, exposed side of the Velcro

strip.

Align the matching toekick with the

machine toekick and press it fimly

into place.

Washer -Dryer stack

This Miele washing machine can be installed as a washer/dryer stack

together with a Miele tumble dryer. For

this purpose, a stacking kit, available

from the Miele Parts Dept., is needed.

A washer and dryer should never

be stacked without using the

proper stacking kit.

38

Page 39

Installation

Any residual water left in the

machine from the factory testing process can be flushed

out as follows:

Do not put any laundry in the machine.

Add a small amount of detergent to

compartment j.

Turn on the machine.

Press the “Rapid wash” button.

Turn the program selector to the

“COTTONS 140°F” program.

Any residual water will be flushed

out during water the program.

Installation

Water hardness reminder

The amount of detergent needed to

wash clothes depends on various factors, including the water hardness in

your area. You can set the water hardness dial in the detergent dispenser as

a reminder.

Turn the dial to the desired setting.

Use the tool supplied with the ma-

chine. It is located behind the deter-

gent drawer, on the left hand side

(see Cleaning and Care) water.

1 = soft, 4 = very hard

39

Page 40

Plumbing

Plumbing

Connect the cold water supply hose

(hose marked blue) to the cold water

valve and the hot water supply hose

(hose marked red) to the hot water

valve.

Turn on the valves and check for leaks.

The water pressure must be within

15-145 psi (1-10 bar). If the water

pressure is greater than 145 psi

(10 bar), a pressure reducer must be installed. If the water pressure is below

15 psi (1 bar), insufficient water may be

available for a complete fill.

The water supply hoses are equipped

with filters; please do not remove these

filters.

Special note

Connection to the drain system

The 5 ft. (1.5 m) drain hose may be connected as follows:

1. Directly into a sink: hook the hose

over the edge of the sink and secure

it firmly (e.g. by tying the hose to the

water faucet).

2. Connection t o a stand pipe: place the

drain hose into a 1

stand pipe and firmly secure it. (An

anti-siphoning device is not required

as there is one built into the machine.)

3. To a floor drain: if desired, the drain

hose may be extended to 15 ft.

(4.5 m) maximum.

1

/2" (38 mm)

If connecting the machine to a cold

water supply

adapter to connect both hoses to the

cold water valve, otherwise the correct functioning of the machine

could be impaired. The machine

should not be connected to hot

water only.

40

only, use the inc lud ed Y-

The machine drains using a pump with

a maximum delivery height of 4 ft.

(1.2 m).

Make sure there are no kinks in the

drain hose.

The machine is equipped with an airgap/anti-siphoning system so that no

minimum drain height is required.

Page 41

Electrical connection

GROUNDING INSTRUCTIONS

This appliance must be grounded.

In the event of a malfunction or breakdown, grounding will reduce the risk of

electric shock by providing a path of

least resistance for the electric current.

This appliance is equipped with a cord

having an equipment grounding conductor and plug. The plug must be

plugged into an poropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

Warning

Electrical connection

ELECTRICAL INSTRUCTIONS

This installation should be done by an

experienced and qualified person, in

most cases a licensed electrician, in accordance with local codes and regulations.

The washing machine is supplied with

a 5 ft long, 4 wire cord, ending in a

NEMA 14-20 P plug, ready for connection to a 120 V/240V (208 V) 60 Hz, AC

power supply.

The proper outlet can be purchased

from any electrical supply dealer or

from the Miele Parts Dept. Ask for a

NEMA 14-20 R receptacle.

Improper connection of the equipment-grounding conductor can result in the risk of electric shock.

Check with a qualified electrician or

serviceman if you are in doubt as to

whether the appliance is properly

grounded.

Do not modify the plug provided with

the appliance; if it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

“EASY INSTALLATION KIT”

If you don’t have a designated, 4 wire,

120 V/240 V (208 V)-15 Amp line for

this appliance, but you have a 3 wire,

240 V (208 V)-30 Amp line, you can

use an optional “Easy Installation Kit”,

which allows you to connect this appliance to that line.

For more information on the electrical

connection and the “Easy Installation

Kit” please contact

– your Miele dealer or

– the nearest Miele Service Depart-

ment.

41

Page 42

OPERATING INSTRUCTIONS Pr ogrammable functions

OPERATING INSTRUCTIONS Programmable functions

Warning - To reduce the risk of fire,

electric shock, or injury to persons,

read the IMPORTANT SAFETY INSTRUCTIONS before operating this

appliance.

Additional functions can be programmed into the machine if desired:

A High water level (only in

“Cottons” rinses)

Where rinse results are particularly important (e.g. Soap allergies).

B 5th Rinse in the “Cottons”

program

For soft water areas (up to 135 ppm calcium carbonate).

In soft water areas, a higher water level

can be selected in addition to a 5th

rinse cycle, if required.

C No water intake through

compartment i

The 10 second water intake through

compartment i during the main wash

is omitted.

vated, but the program will continue uninterrupted. This prevents children from

inadvertently changing or stopping a

wash program by playing with the dials.

If the program selector switch is turned

to its original position, the “On” lamp

will stop flashing.

To change a program onc e the Program

lock is activated:

Turn the program selector switch to

“Finish/Start”.

The sequence indicator lamps will start

flashing in succession after about 30

seconds. A new program can be selected as soon as the “On” lamp is the

only one remaining lit.

The functions described above can

be programmed by the Customer

using the steps shown on the follow-

ing pages.

There are other programmable func-

tions which are reserved for Miele

Service Engineers. They are not nor-

mally activated, and require access

to internal machine components.

E Additional rinse in Rapid

wash

D Program Lock

(Child safety feature)

When activated, the washing machine

will ignore any changes made after the

first three minutes of operation. For

example if the program selector switch

is moved to a different setting or an additional function is selected, the “On”

lamp will flash, notifying you that the

Child safety feature has been acti-

For soft water areas.

For an extra thorough rinse.

42

Page 43

Programmable functions

Programmable functions

Step 1:

Turn off the machine, close the door, and release all pushbuttons. Set the progam

selector switch to “Finish/Start”.

Step 2:

Step 3:

Carry out steps 2 and 3 within 4 seconds.

Press the “ON/OFF”

button

Press the “Water plus”

button 4 times (i.e.

press in and out twice)

The “ON” lamp will

illuminate and the “Prewash” and “Main wash”

lamps will flash.

43

Page 44

Programmable functions

Programmable functions

Step 4:

Desired function:

A High water level

B 5th rinse cycle

C No water intake

Select the function desired:

through compartment

i

Set the Program

selector to “Fine rinse”.

Continue with Step 5 to

activate.

Set the Program

selector to “Drain”.

Continue with Step 5 to

activate.

Set the Program

selector to “Starch”.

Continue with Step 5 to

activate.

D Program Lock

(Child safety feature)

44

Set the Program

selector to “WOOLENS

cold”. Continue with

Step 5 to activate.

Page 45

Programmable functions

E Additional rinse in

Rapid wash

Programmable functions

Set the Program selector

to “WOOLENS 85°”.

Continue with Step 5 to

activate.

Step 5:

Step 6:

activate the function

Press the “Water plus”

button twice (i.e. in

and out once) to toggle

the function “ON/OFF”.

The “Rinse 1-2” lamp will

illuminate when the

function is activated.

to store in memory

Press the “ON/OFF”

button.

45

Page 46

Programmable functions

Programmable functions

To check if the function has

been stored:

Carry out Steps 1 to 4.

If the “Rinse 1-2” lamp lights up, the

programmable function is activated.

Press the “ON/OFF” button. This finishes the check of the programmable function.

If, after Step 2, the selector switch is

accidentally turned to a setting

other than one of the three shown:

– If the “Rinse 1-2” indicator does

not light up - no function was activated

– If the “Rinse 1-2” indicator lights

up - proceed as in “Deleting the

additional functions”.

Exception: the “Rinse 1-2” indicator

will light up if the switch is set to

“COTTONS 170°F”.

Deleting the additional functions:

Follow the same instructions given

under “To activate the additional functions”, steps 1 to 4.

When the “Rinse 1-2” lamp goes out;

Press “ON/OFF”.

The additional function has now been

deleted.

46

Page 47

INSTALLATION INSTRUCTIONS Technical data

INSTALLATION INSTRUCTIONS Technical data

1.1 Dimensions

Height

Width

Depth

(including distance from wall)

1

33

1

23

24" (610 mm)

/2"+ 1/2"/–1/4" (850 mm +10/–0,5 mm)

/2" (600 mm)

Weight

Capacity

Rated load

Fuse rating

Water pressure

Maximun drain height

Drain hose diameter

Maximum drain length

Power supply

Max floor load

220 lbs. (99 kg)

11 lbs. (5 kg) dry laundry

2.8 kW

15 Amp

14.5-145 p.s.i. (1-10 bar)

4.0 ft. (1.2 m)

1" I.D. (25 mm)

15 ft. (4.5 m)

120 V/240 V ~ multi-phase

(208 V) 60 Hz, AC

1600 Newton

(360 lbs)

47

Page 48

Technical data

Technical data

1.2 Specifications

Hot and cold water hoses come equipped with

tions.

1

Drainage is via a 5 ft. long (1.5 m), 1

/4" OD hose.

This washing machine is supplied with a 5 feet long cable with plug for connection

to a 120/240 V (208 V) 60 Hz (3-pole-4 wire grounding) power supply.

Program duration (appro ximate):

Cottons without prewash

Rapid wash – Cottons (3.5 lbs)

Spin speed:

W 1930i

Detergent dispense r:

Automatic for:

3

/4" Female hose thread connec-

170°F 1 h 49 min

140°F 39 min

from 400 to 1600 rpm

Pre-wash

Main wash

Fabric softener or starch

T e mperature control:

48

Variable from cold to 170°F

Page 49

49

Page 50

50

Page 51

51

Page 52

Alteration rights reserved/000 3296

These instructions are printed on 100% recycled paper and are completely Biodegradable.

Loading...

Loading...