Page 1

Installation Plan

Tumble dryer

PT 7188 EL

en - AU

14.14 M.-Nr. 09 923 550

Page 2

M.-Nr. 09 923 550

2

Australia:

Miele Australia Pty. Ltd.

1 Gilbert Park Drive

KNOXFIELD

Victoria 3180

Tel. +61 3 97647-100

Fax +61 3 97647-129

Internet: www.miele.com.au

It is essential to read the operating and installation instructions before

installing, commissioning or using the machine.

This avoids the risk of accidents or damage.

All rights reserved

Page 3

Page 4

Page 5

Page 6

Page 7

Technical datasheet

Tumble dryer:

Heating:

PT 7188

Electric (EL)

Legend:

Abbreviations in bold type:

Connection required

en - AU

Abbreviations in circle with dashes:

Connection optional or required depending on model version

UM

Miele plinth

US 6008 (US = plinth with drawer)

Height

mm

320

Width

mm

692

Depth

mm

685

BS

Concrete plinth

Quality and density of concrete must comply with load. Concrete plinth must be firmly secured to floor!

Recommended height

mm

300

Minimum height

mm

70

Recommended width

mm

≥700

Recommended depth

mm

≥700

Electrical

connection

1. Standard voltage (as supplied)

V

1N AC 230 - 240

Frequency

Hz

50

Rated load

kW

5.78 – 6.24

Fuse rating

A

1 × 25

Supply lead cross-section

mm²

3 × 2.5

Length of supply lead

mm

2170

Supply lead with plug (supplied)

Electrical connection must comply with national regulations.

A wall socket or mains isolator must be easy accessible after

installation.

Reinstallation of the supply point, changes to the equipment

or checks on the protective conductor, including determination

of correct fuse rating, should only be performed by a properly

trained electrician.

Optional extras:

Machine connections:

Technical datasheet: PT 7188 EL

Date: 28.03.2014 Page: 7

Page 8

Vented

Nominal air throughput in vented mode

Max. permissible pressure loss

Waste air/gas temperature, max.

Connector on machine (int. diameter)

Connection pipe provided on site (ext. diameter)

Miele adapter, Mat. No. 6595070 (int. diameter 100 mm) for

flexible aluminium ducting and adapter, Mat. No. 915051,

(ext. diameter 110 mm) for connection to standard heatresistant plastic pipes supplied.

As relative humidity inside the vent ducting can be as high as

100%, suitable measures must be taken to prevent a backflow of condensate into the machine.

m³/h

Pa

°C

mm

mm

320

420

80

100

100

Air intake

Standard Connection:

Air intake from installation site

Min. air intake cross-section

(to prevent draughts in room)

A sufficient supply of fresh air should be ensured to replace

the air extracted.

cm² 237

Fittings (supplied)

Miele US 6008 plinth

4 × metal angled brackets

(to secure machine to plinth)

4 × screws DIN 571 (Ø × length)

mm

6 × 50

4 × rawl plugs (Ø × length)

mm

8 × 40

Machine must be bolted to the floor!

Fixing materials for a floating screed floor are to be provided

on site.

On concrete platform

2 × clamps

2 × screws DIN 571 (Ø × length)

mm

6 × 50

2 × rawl plugs (Ø × length)

mm

8 × 40

Machine must be bolted to the floor!

Fixing materials for a floating screed floor are to be provided

on site.

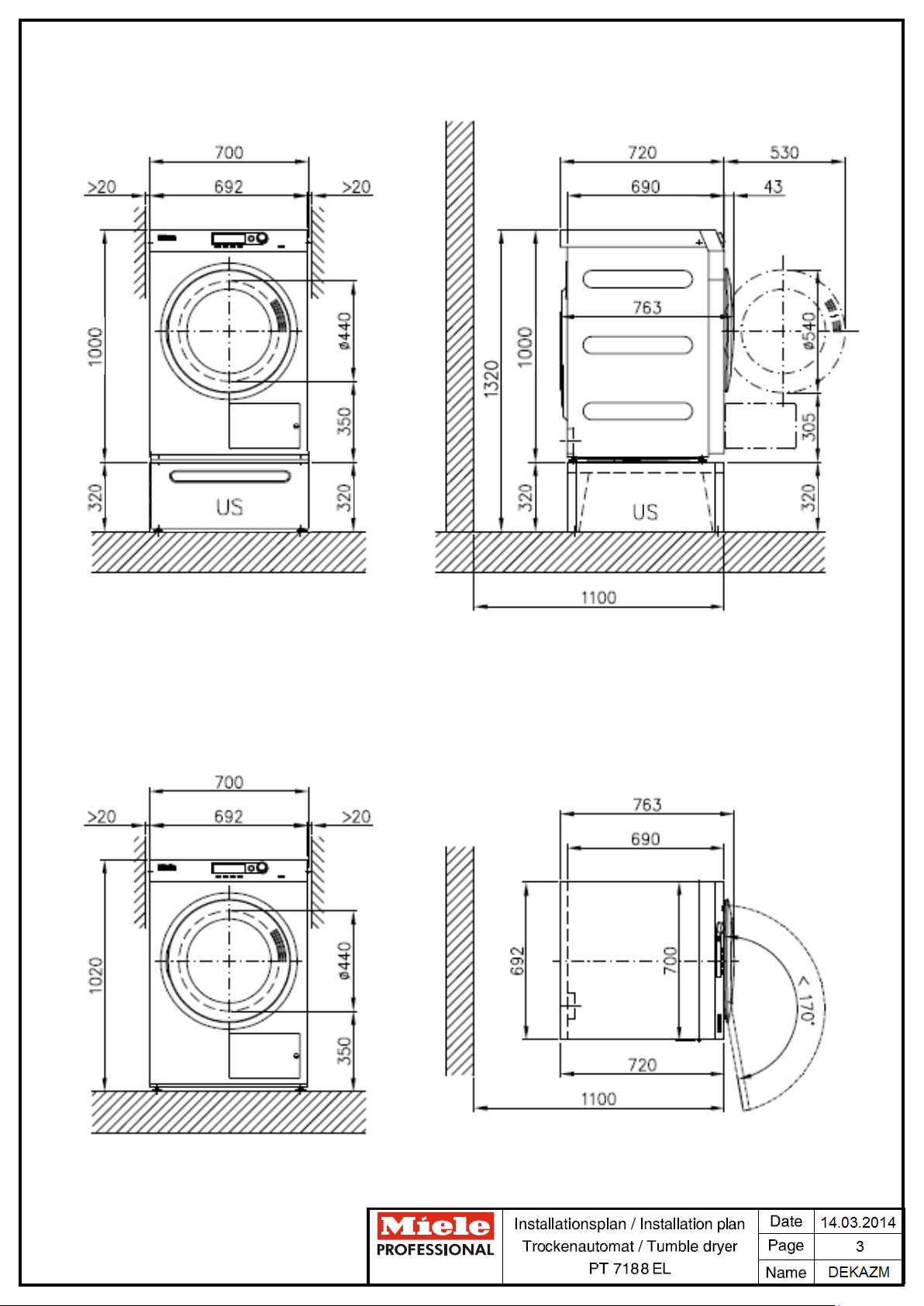

Machine data

Unit width

mm

700

Machine depth

mm

763

Unit height

mm

1020

Casing width

mm

692

Casing depth

mm

690

Minimum width of delivery access to installation site

mm

720

Minimum rear wall gap (measured to front of machine)

mm

1100

Wall gap (to front of machine)

Minimum gap ensures sufficient space for maintenance and

servicing.

mm

900

Net weight

kg

77

Dynamic floor load, max.

N

1000

Average heat dissipation

(dependent on ambient room temperature and programme

selected)

W

450

Sound pressure (re 20 mPA),

workplace-related (at distance of 1 m and height of 1.6 m)

dB (A)

<70

Installation should only be carried out by authorized fitters in accordance with valid regulations!

Observe installation instructions when installing machine! All rights reserved! Measurements in mm.

Technical datasheet: PT 7188 EL

Date: 28.03.2014 Page: 8

Loading...

Loading...