Page 1

Descriptive Technical

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Documentation

- Model-dependent -

DTD no. 521-7135

Model(s): PT 7135 C, PT 7136, PT 5135 C,

PT 5136

Page 2

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Page 3

Descriptive Technical Documentation

DTD no. 521-7135 1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Contents

General Information

A Warning and Safety Instructions

B Modification History

C Technical Data

D Layout of Electrical Components

Function Groups

020 Door

2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 020-2

2.1 Door lock (A2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 020-2

030 Drum, bearing, sensors, heater bank

1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 030-2

2 Function

2.1 Heating control (R1, R2, R3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 030-4

2.2 Temperature limiter (F2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 030-4

2.3 NTC temperature sensor - Fill ring (1R30) . . . . . . . . . . . . . . . . . . 030-4

2.4 NTC temperature sensor - Heater bank (2R30) . . . . . . . . . . . . . . 030-4

2.5 Light - Drum (H3/6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 030-5

040 Drive

1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 040-2

2 Function

2.1 Motor - Air flow and drum drive (M5) . . . . . . . . . . . . . . . . . . . . . . 040-3

2.2 Motor - Air flow and drum drive (M5) . . . . . . . . . . . . . . . . . . . . . . 040-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 030-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 040-3

070 Condensate pump (M5)

2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 070-2

2.1 Level sensing - Float switch - Condensate (B8/7) . . . . . . . . . . . . 070-2

080 Fascia panel

1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-2

2 Function

2.1 Overriding time control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-3

2.2 No-load recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-3

2.3 Insufficient air flow measurement . . . . . . . . . . . . . . . . . . . . . . . . . 080-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-3

Page 4

Descriptive Technical Documentation

2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

2.4 Time of day programmable function . . . . . . . . . . . . . . . . . . . . . . . 080-3

2.5 Extended cooling phase programmable function. . . . . . . . . . . . . 080-4

2.6 Residual moisture level adjustment programmable function. . . . 080-4

2.7 Clean the airways warning modification programmable

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-5

2.8 Automatic programmable function. . . . . . . . . . . . . . . . . . . . . . . . 080-5

2.9 Clean filters programmable function . . . . . . . . . . . . . . . . . . . . . . 080-5

2.10 Clean heat exchanger programmable function . . . . . . . . . . . . . 080-6

2.11 Residual moisture level display programmable function . . . . . . . 080-6

2.12 Cool air free programmable function, with payment system

operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-6

2.13 Payment system programmable function . . . . . . . . . . . . . . . . . . . 080-7

2.14 Operator code programmable function . . . . . . . . . . . . . . . . . . . . . 080-7

2.15 Signal to payment system socket (X1/1) pin 7 programmable

function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-7

2.16 Overriding time control modification programmable function

with payment system operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 080-8

2.17 Programme lock programmable function with payment system

operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-8

2.18 Cool air timed programme maximum duration setting

programmable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-8

2.19 Warm air timed programme maximum duration setting

programmable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-9

2.20 Delay start programmable function . . . . . . . . . . . . . . . . . . . . . . . . 080-9

2.21 Language programmable function . . . . . . . . . . . . . . . . . . . . . . . . 080-9

2.22 Standard settings programmable function . . . . . . . . . . . . . . . . . . 080-9

3 Fault Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-10

3.1 Warning indication: Clean filter . . . . . . . . . . . . . . . . . . . . . . . . . . 080-10

3.2 Warning indication: Clean heat exchanger. . . . . . . . . . . . . . . . . 080-11

3.3 Warning indication: Adjust the load – The drum is empty or the

laundry too dry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-12

3.4 Demonstration mode active. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-13

3.5 Fault indication: Drain fault – Check the drain path . . . . . . . . . . 080-13

3.6 Fault indication: Clean the airways . . . . . . . . . . . . . . . . . . . . . . . 080-14

3.7 Fault indication: Technical fault . . . . . . . . . . . . . . . . . . . . . . . . . . 080-15

3.8 Fault code F1, heater bank NTC sensor short-circuited . . . . . . . 080-16

3.9 Fault code F2, heater bank NTC sensor open-circuited . . . . . . . 080-16

3.10 Fault code F3, fill ring NTC sensor short-circuited . . . . . . . . . . . . 080-17

3.11 Fault code F4, fill ring NTC sensor open-circuited . . . . . . . . . . . . 080-18

3.12 Fault code F41, faulty EEPROM / data fault . . . . . . . . . . . . . . . . . 080-18

3.13 Fault code F43, model type not programmed. . . . . . . . . . . . . . . . 080-19

3.14 Fault code F45, faulty flash RAM/ data fault. . . . . . . . . . . . . . . . . 080-19

3.15 Fault code F46, display fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-20

3.16 Fault code F47, communication fault between selection module

(EW) and power-programme module (ELP). . . . . . . . . . . . . . . . . 080-20

3.17 Fault code F50, motor stationary and heating operates for 5 s . . 080-21

3.18 Fault code F55, overriding time limit exceeded (approx. 180

min) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-21

3.19 Fault code F66, air leakage fault . . . . . . . . . . . . . . . . . . . . . . . . . . 080-23

4 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-24

4.1 Programming mode summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-24

4.2 Programming mode summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-29

4.3 Demonstration mode activation / deactivation . . . . . . . . . . . . . . . 080-33

4.4 Demonstration mode activation / deactivation . . . . . . . . . . . . . . . 080-34

4.5 Service mode summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-35

Page 5

Descriptive Technical Documentation

DTD no. 521-7135 3

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

4.6 Service mode summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 080-38

090 Electrical components

2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 090-2

2.1 Mains terminal strip (X3/1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 090-2

2.2 Payment system socket (X1/1) . . . . . . . . . . . . . . . . . . . . . . . . . . . 090-2

2.3 Payment system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 090-2

2.4 Central control via RS 232 interface with 9-pole plug . . . . . . . . . 090-3

4 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 090-4

4.1 Fitting payment system on machine lid. . . . . . . . . . . . . . . . . . . . . 090-4

4.2 Payment system (programme operation) . . . . . . . . . . . . . . . . . . . 090-5

4.3 Payment system (timed operation) . . . . . . . . . . . . . . . . . . . . . . . . 090-6

4.4 Central control via RS 232 interface . . . . . . . . . . . . . . . . . . . . . . . 090-7

Page 6

Descriptive Technical Documentation

4 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Page 7

Descriptive Technical Documentation

DTD no. 521-7135 A-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

A Warning and Safety Instructions

1 General information

Service and repair work should only be carried out by suitably qualified persons in

accordance with all appropriate local and national safety regulations.

Servicing, modification, testing and maintenance of electrical appliances should

only be carried out in accordance with all appropriate legal requirements, accident

prevention regulations and valid standards.

All regulations of the appropriate utility supply companies and standards relating

to safety (not limited to electrical safety) are to be complied with.

Before any service work is commenced, the machine must be disconnected from

the mains.

Even with the machine switched off, mains power may be applied to some

components.

A general visual check should always be carried out.

Page 8

Descriptive Technical Documentation

A-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

2 Risk of injury due to sharp edges

There may be a risk of injury due to sharp edges.

Protective gloves should be worn and the edge protection, Mat. no. 05057680,

should be used.

Page 9

Descriptive Technical Documentation

DTD no. 521-7135 A-3

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

3 Electrical connection via plug connector

It is always recommended to make electrical connection via a plug and socket so

that electrical safety checks, e.g. during repair or service work, can be carried out

easily.

The socket must be accessible after machine installation. This also applies even

if an on-site mains switch is also already provided.

For models with a total connected load greater than 9 kW, an additional on-site

mains switch must also be provided.

Electrical connection must be carried out in accordance with all appropriate legal

requirements, accident prevention regulations and valid standards.

Page 10

Descriptive Technical Documentation

A-4 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

4 Touch current measurement

x

Note

On machines with an earth connection, touch current leakage measurements

should be carried out on all accessible conductive parts that are not connected

to the earth.

Warning!

Touch current measurement should only be carried out after the earth

connection of the unit under test has been checked and found to be satisfactory!

Dangerous voltages may exist on defective machines as well as on accessible

conductive parts that are not connected to earth!

Note

Touch current measurement should be carried out on the following accessible

conductive parts:

• None.

Page 11

Descriptive Technical Documentation

DTD no. 521-7135 B-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

B Modification History

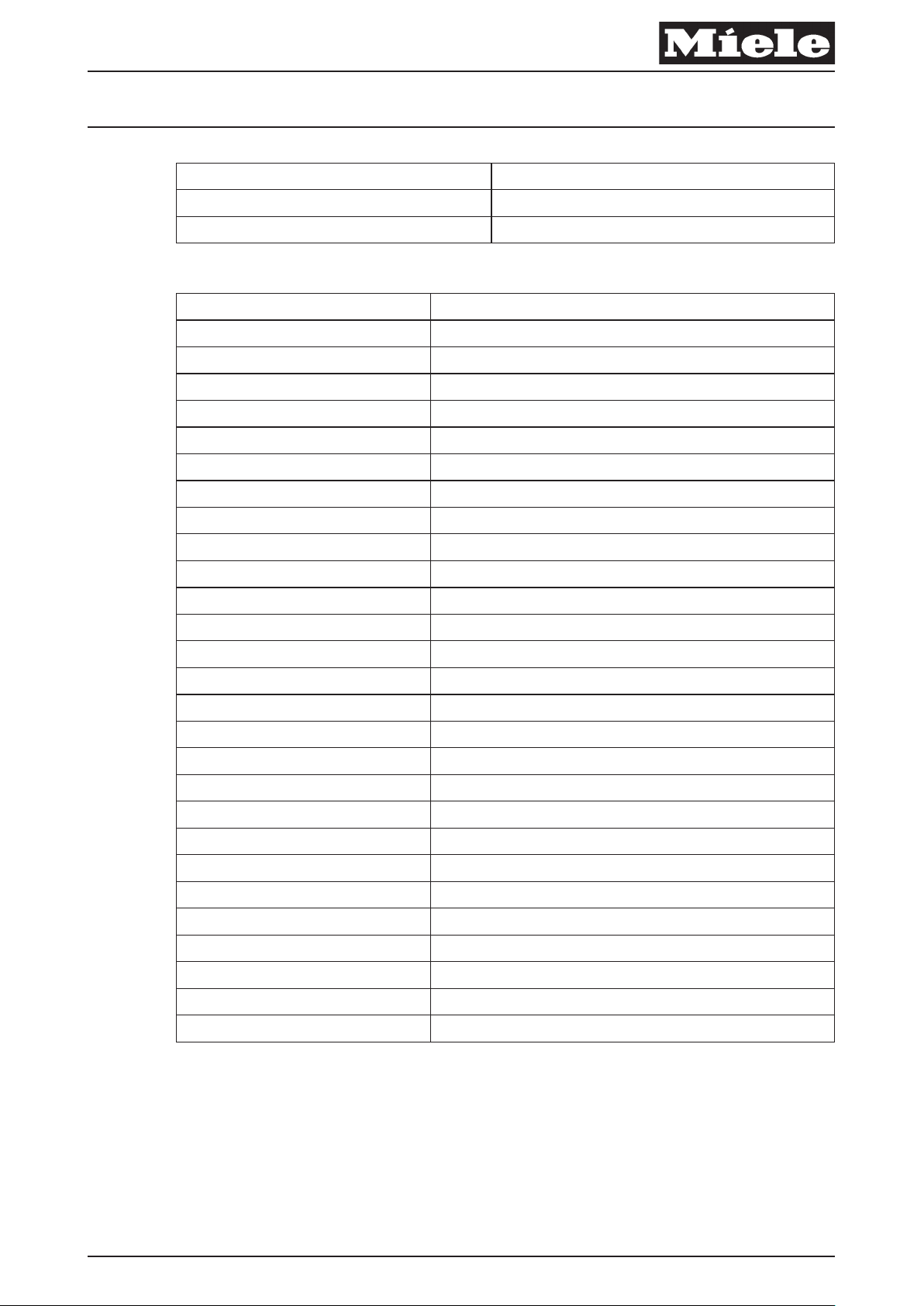

When? Who? What?

11.05.2005 Olaf Meyer zu Drewer Initial compilation

Page 12

Descriptive Technical Documentation

B-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Page 13

Descriptive Technical Documentation

DTD no. 521-7135 C-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

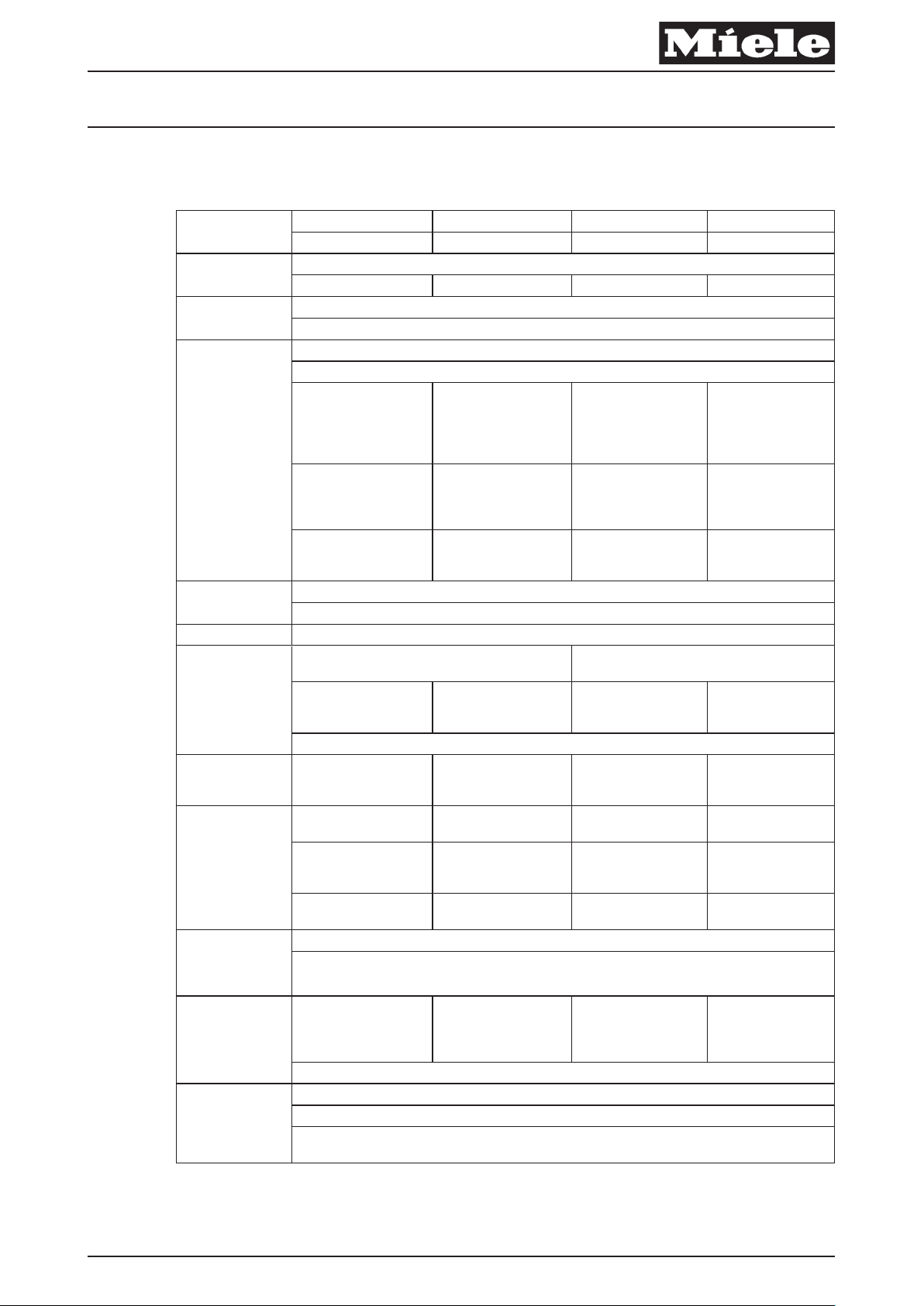

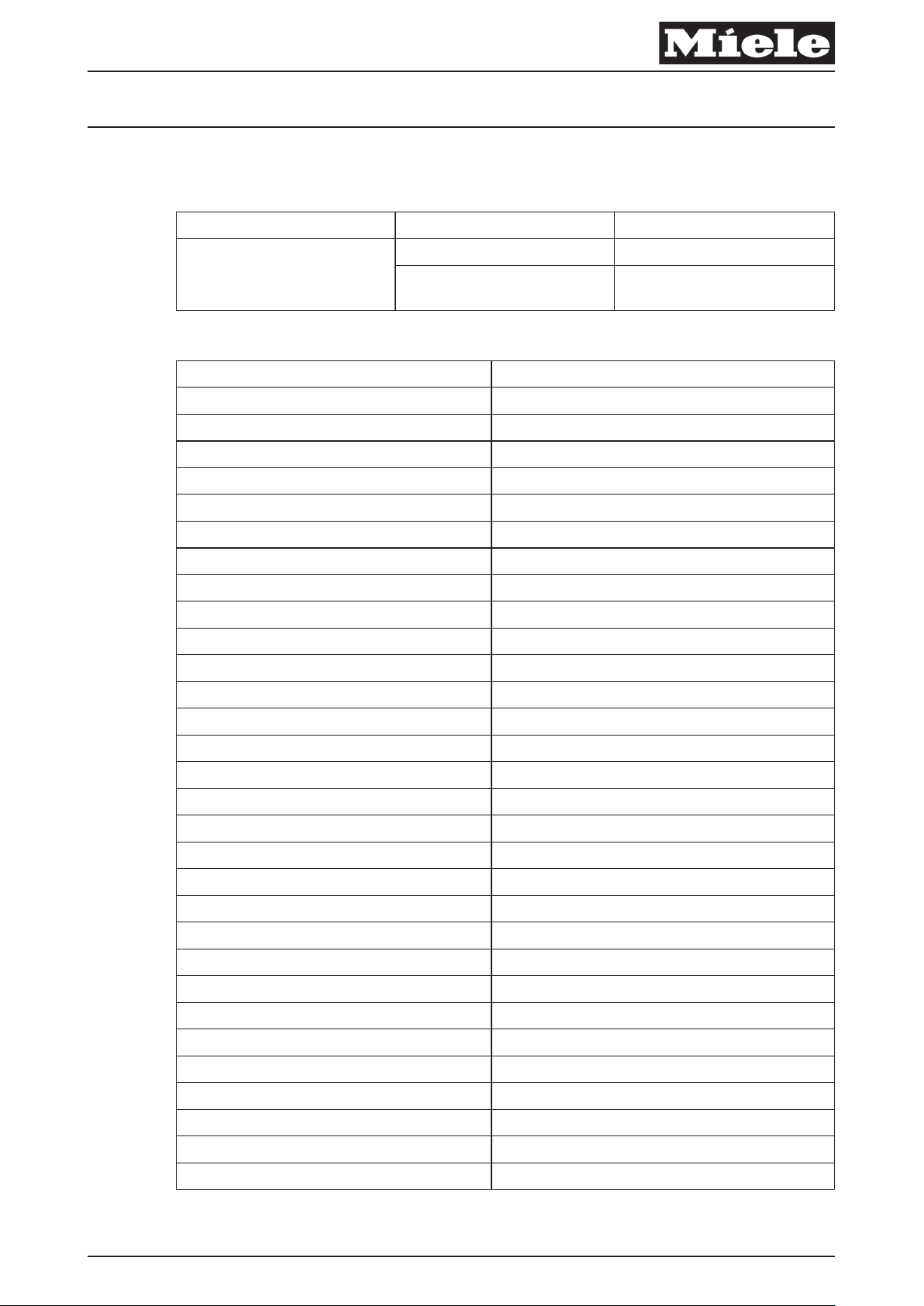

C Technical Data

Semi-commercial

machines

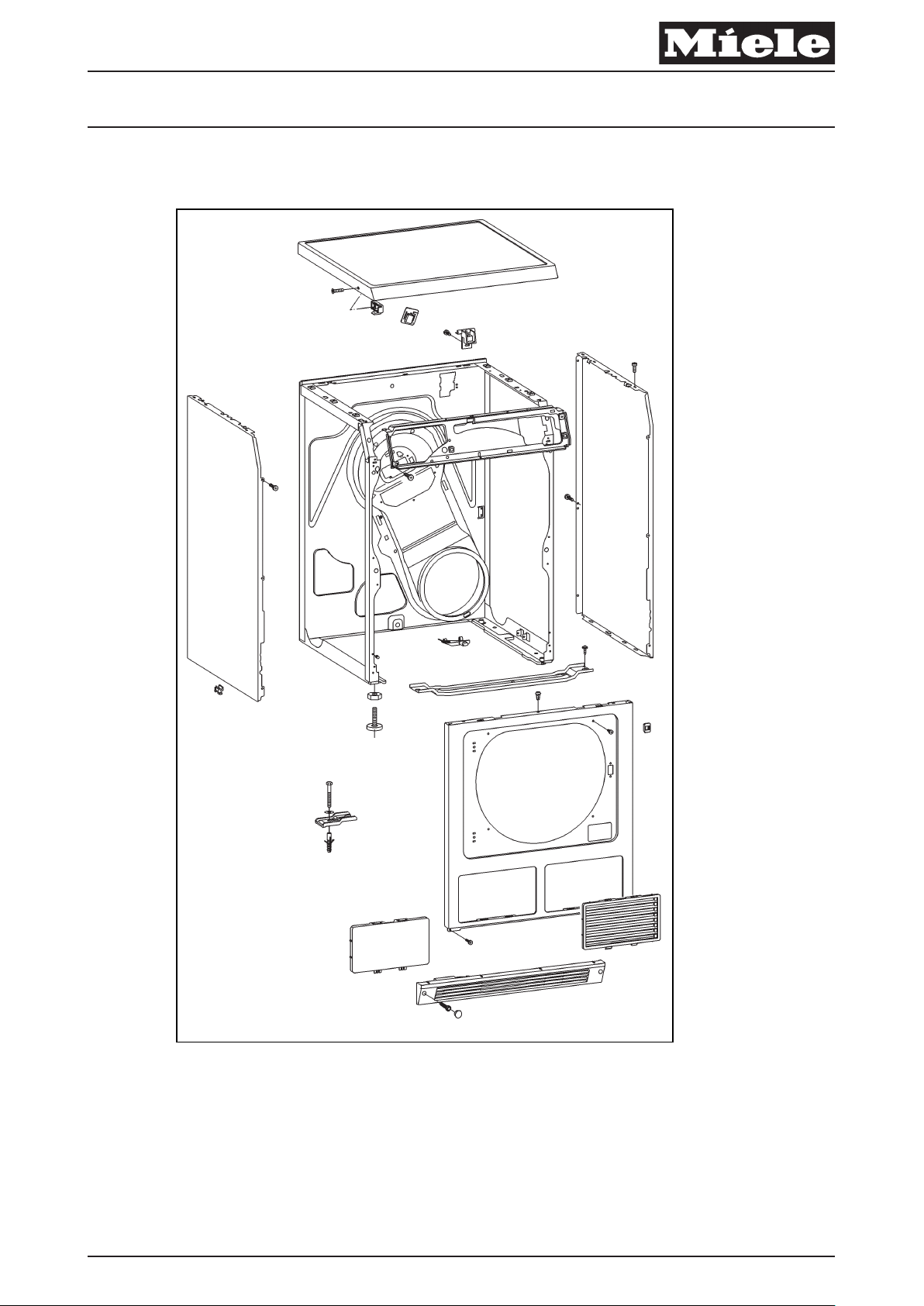

Casing Generation 2000, spaceframe construction

Door Door opened mechanically via pushbutton switch with Bowden cable

Drum, bearing,

sensors, heater

bank

Fill ring / Air guide Drying air NTC temperature sensor in fill ring, 1R30

Drive, fan Motor for air flow and drum drive (M5). Power consumption approx. 250 W

Fascia panel,

control module

Condenser box Condenser dryer

only

Condensate pump

(M13) - Condenser

dryer only

Electrical

connection German standard

models only

Drying technology Tangle prevention: Reversing cycle times via random generator

PT 7135 C PT 7136 PT 5135 C PT 5136

Condenser dryer Vented dryer Condenser dryer Vented dryer

- Filter flap / Cover - Filter flap / Cover

Door lock contact switch (A2)

Maximum load, dry laundry, 6.5 kg

Drum volume 130 l

Heater bank (R1, R2,

R3), 3-filament,

2-phase 3.45 kW

(1.94 kW + 0.71 kW,

0.8 kW)

Temperature limiter (F2),

170°C, manual reset

Drum light (H3/6). Bulb: 230 V,15 W. Activation via relay on power module.

Graphic LCD display, 240 x 64 lines, multifunction

selector

Electronic selection

module (2N1): EW 421

Fine-wire fuse (F7) 6.3 A, slow-blow

- Finger safety switch

Time- and

level- controlled

Max. drain pump head

height 1 m, max. drain

hose length 3 m

Power consumption

approx. 25 W

Connection cable length 1.6 m

Relay - Heating (K1), single armature relay, load rating 16 A, solenoid: 12 V DC, 200 Ω

Electronic powerprogramme module

(1N1), ELP 320 with

ID966

Can be updated via serial optical PC interface

Residual moisture indication: Laundry conductivity measurement process, time-left correction

Air path blockage monitoring via heater bank temperature sensor (2R30) behind perforated rear

drum panel and fill ring temperature sensor (1R30)

Heater bank (R1, R2,

R3), 3-filament,

3-phase 6.14 kW

(1.94 kW + 2.1 kW,

2.1 kW)

NTC temperature

sensor in heater bank

behind perforated rear

drum panel (2R30)

Temperature limiter

(F2), 175°C, manual

reset

Electronic selection

module (2N1): EW 421

(S32) on the fluff filter

flap

- Time- and level-

- Max. drain pump head

- Power consumption

Electronic powerprogramme module

(1N1), ELP 321 with

ID966

Heater bank (R1, R2,

R3), 3-filament,

2-phase 3.45 kW

(1.94 kW + 0.71 kW,

0.8 kW)

NTC temperature

sensor in heater bank

behind perforated rear

drum panel (2R30)

Temperature limiter

(F2), 170°C, manual

reset

Graphic LCD display, 132 x 48 lines, rotary

selector switch

Electronic selection

module (2N1): EW 391

- -

controlled

height 1 m, max. drain

hose length 3 m

approx. 25 W

Electronic powerprogramme module

(1N1), ELP 390 with

ID966

Heater bank (R1, R2,

R3), 3-filament,

3-phase 6.14 kW

(1.94 kW + 2.1 kW,

2.1 kW)

NTC temperature

sensor in heater bank

behind perforated rear

drum panel (2R30)

Temperature limiter

(F2), 175°C, manual

reset

Electronic selection

module (2N1):

EW 391

-

-

-

Electronic powerprogramme module

(1N1), ELP 391 with

ID966

Table 1: Semi-commercial tumble dryer (KG-TR), 2000 series

Page 14

Descriptive Technical Documentation

C-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Page 15

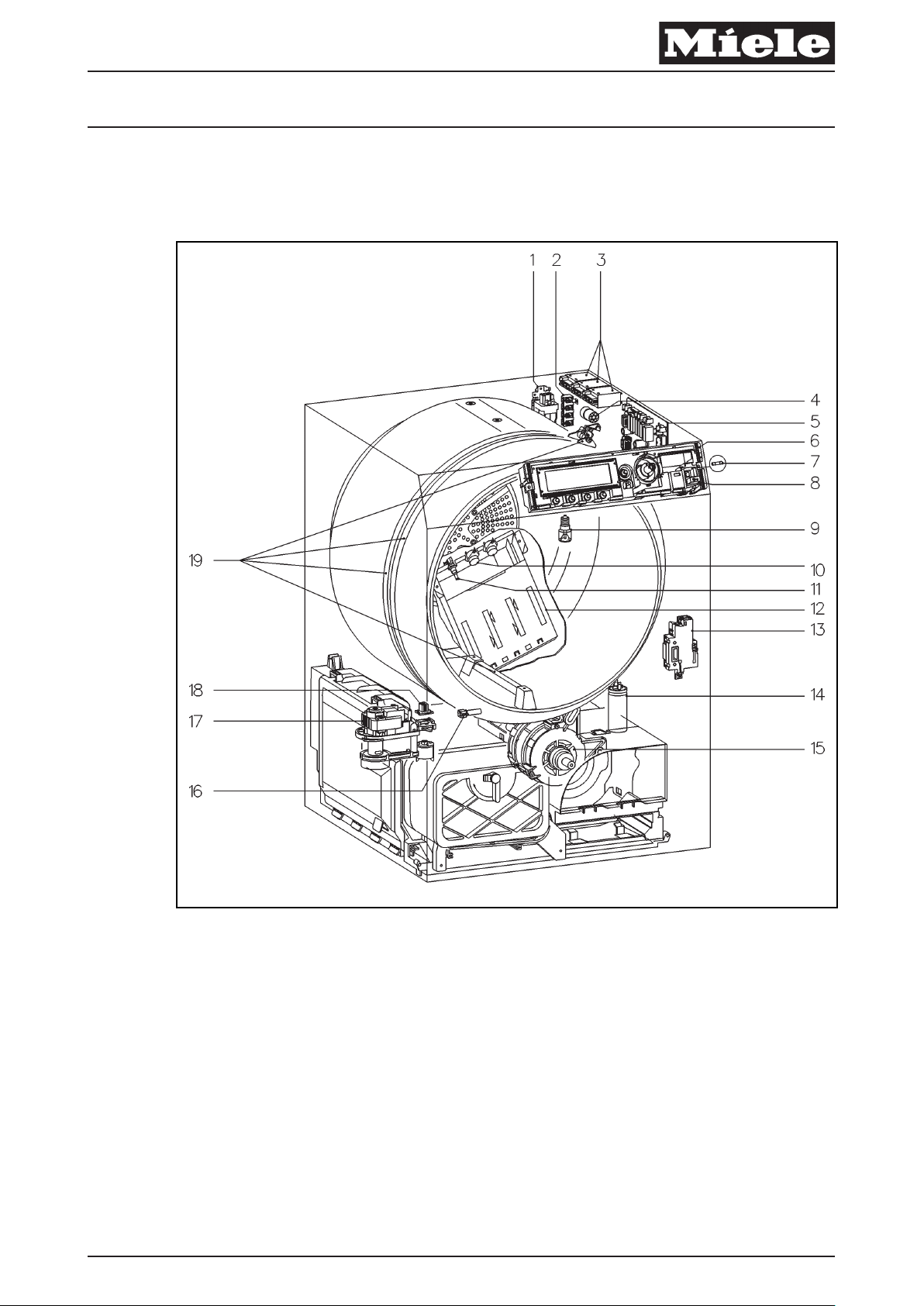

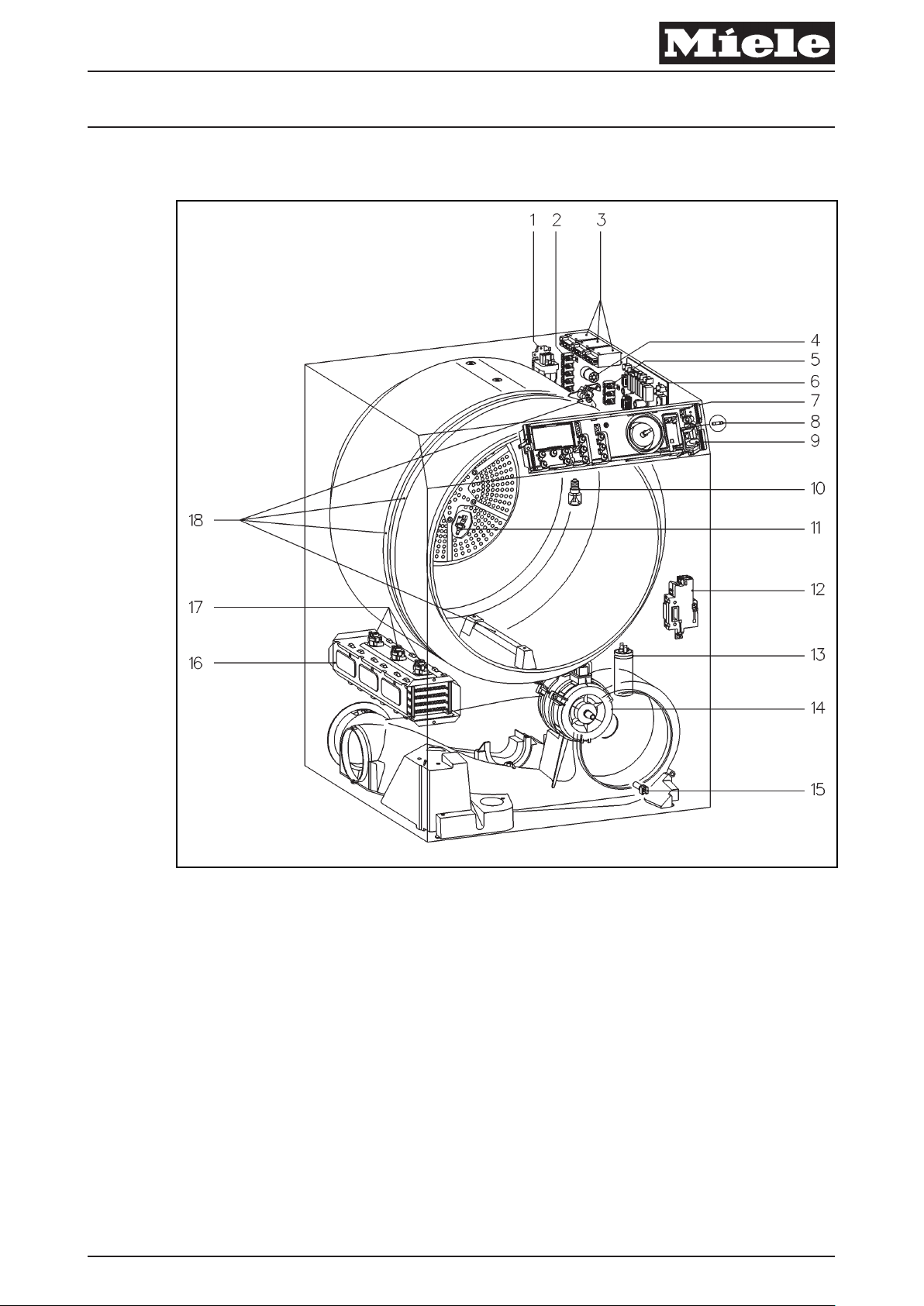

Layout 1

1 (Z1) Interference suppression capacitor

2 X3/1 Mains terminal strip

3 (1K1/1, 2K1/1, 3K1/1) Heating relay

4 (X1/1) Payment system socket

P6 Payment system – Programme unit

P8 Payment system – Time unit

5 (1N1) Power-programme module (ELP)

6 (2N1) Selection module (EW)

7 (F7) Fine-wire fuse

8 (S4) Pushbutton - Door (Bowden cable)

9 (H3/6) Light - Drum

10 (1F2, 2F2) Temperature limiter

Descriptive Technical Documentation

DTD no. 521-7135 D-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

D Layout of Electrical Components

PT 7135 C

x

Page 16

Descriptive Technical Documentation

D-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

11 (2R30) Drying air NTC temperature sensor - In heater bank

behind perforated rear drum panel

12 (R1, R2, R3) Heater bank

13 (A2) Door lock

14 (C5) Capacitor - Drum drive

15 (M5) Motor - Air flow and drum drive

16 (1R30) Drying air NTC temperature sensor - Fill ring

17 (M13) Motor - Condensate pump

18 (B8/7) Float switch - Condensate

19 (B3/1) Sensor - Residual moisture

Page 17

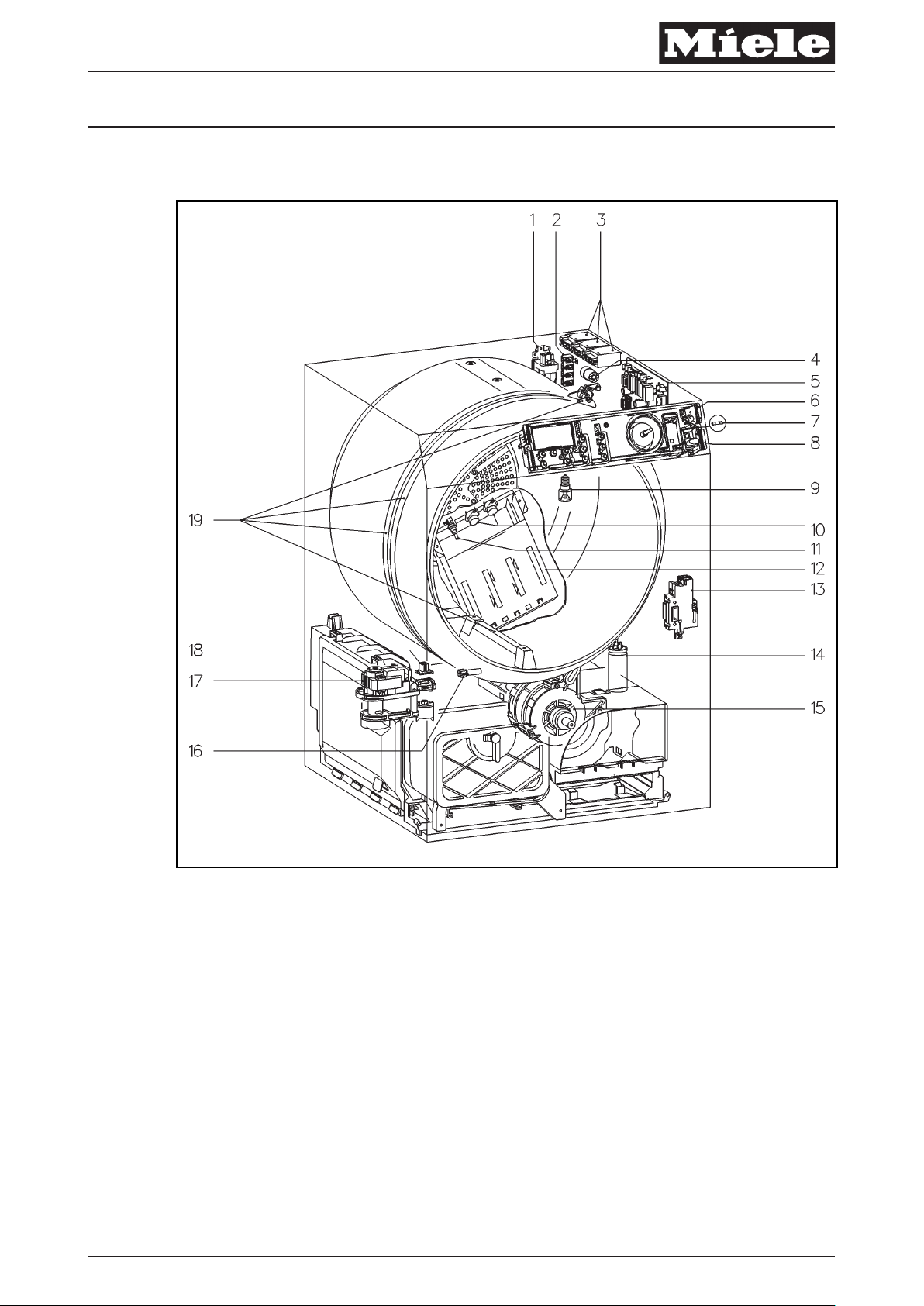

Layout 2

1 (Z1) Interference suppression capacitor

2 X3/1 Mains terminal strip

3 (1K1/1, 2K1/1, 3K1/1) Heating relay

4 (X1/1) Payment system socket

P6 Payment system – Programme unit

P8 Payment system – Time unit

5 (1N1) Power-programme module (ELP)

6 (2N1) Selection module (EW)

7 (F7) Fine-wire fuse

8 (S4) Pushbutton - Door (Bowden cable)

9 (H3/6) Light - Drum

10 (1F2, 2F2) Temperature limiter

11 (2R30) Drying air NTC temperature sensor - In heater bank

behind perforated rear drum panel

Descriptive Technical Documentation

DTD no. 521-7135 D-3

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

PT 5135 C

x

Page 18

Descriptive Technical Documentation

D-4 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

12 (R1, R2, R3) Heater bank

13 (A2) Door lock

14 (C5) Capacitor - Drum drive

15 (M5) Motor - Air flow and drum drive

16 (1R30) Drying air NTC temperature sensor - Fill ring

17 (M13) Motor - Condensate pump

18 (B8/7) Float switch - Condensate

19 (B3/1) Sensor - Residual moisture

Page 19

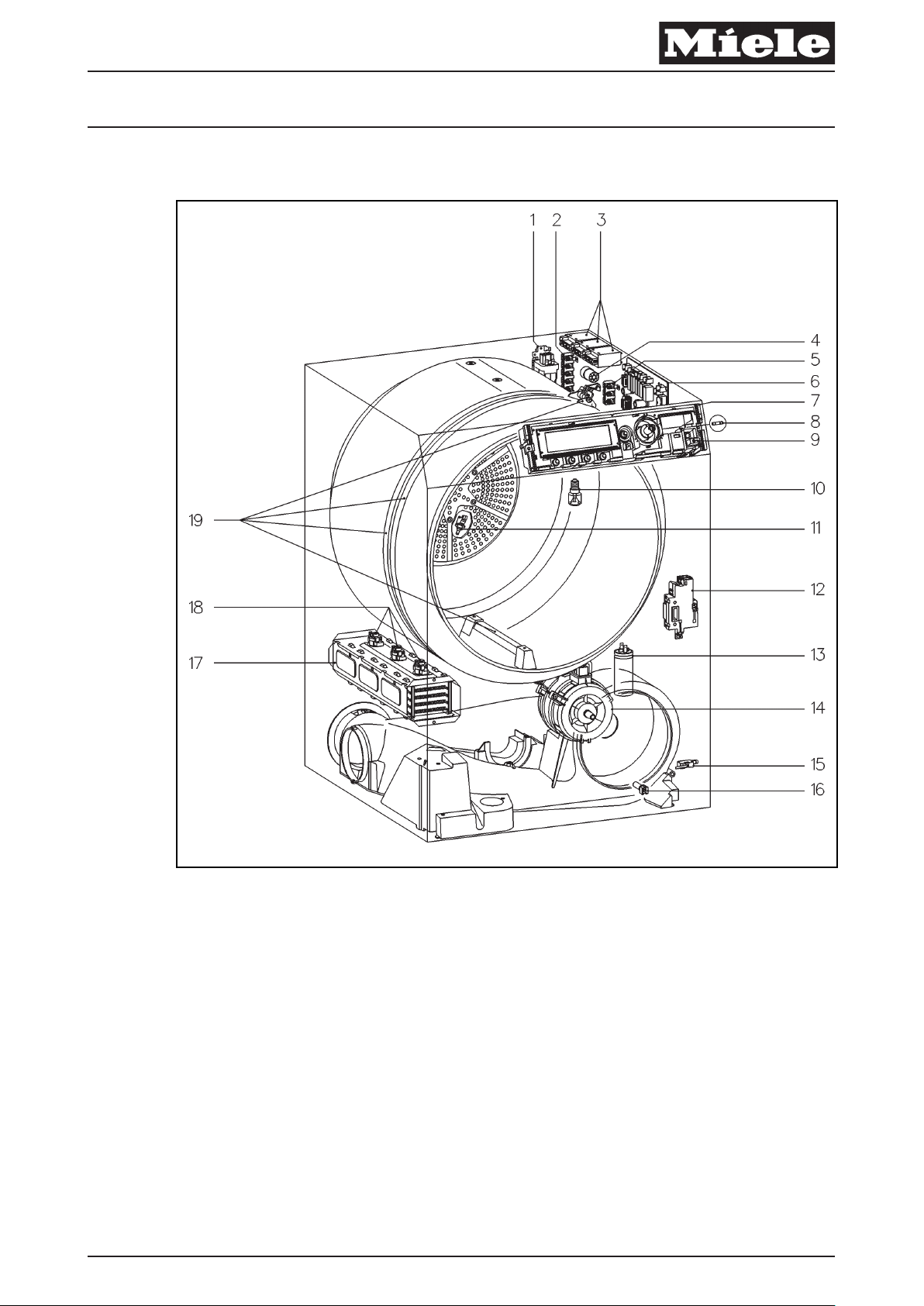

Layout 3

1 (Z1) Interference suppression capacitor

2 (X3/1) Mains terminal strip

3 (1K1/1, 2K1/1, 3K1/1) Heating relay

4 (X1/1) Payment system socket

P6 Payment system – Programme unit

P8 Payment system – Time unit

5 (M2) Fan (additional external cooling fan for Sweden)

6 (1N1) Power-programme module (ELP)

7 (2N1) Selection module (EW)

8 (F7) Fine-wire fuse

9 (S4) Pushbutton - Door (Bowden cable)

10 (H3/6) Light - Drum

11 (2R30) Drying air NTC temperature sensor - In heater bank

behind perforated rear drum panel

Descriptive Technical Documentation

DTD no. 521-7135 D-5

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

PT 7136

x

Page 20

Descriptive Technical Documentation

D-6 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

12 (A2) Door lock

13 (C5) Capacitor - Drum drive

14 (M5) Motor - Air flow and drum drive

15 (S32) Safety switch - Finger protection

16 (1R30) Drying air NTC temperature sensor - Fill ring

17 (R1, R2, R3) Heater bank

18 (1F2, 2F2, 3F2) Temperature limiter (vented operation)

19 (B3/1) Sensor - Residual moisture

Page 21

Layout 4

1 (Z1) Interference suppression capacitor

2 (X3/1) Mains terminal strip

3 (1K1/1, 2K1/1, 3K1/1) Heating relay

4 (X1/1) Payment system socket

P6 Payment system – Programme unit

P8 Payment system – Time unit

5 (M2) Fan (additional external cooling fan for Sweden)

6 (1N1) Power-programme module (ELP)

7 (2N1) Selection module (EW)

8 (F7) Fine-wire fuse

9 (S4) Pushbutton - Door (Bowden cable)

10 (H3/6) Light - Drum

11 (2R30) Drying air NTC temperature sensor - In heater bank

behind perforated rear drum panel

Descriptive Technical Documentation

DTD no. 521-7135 D-7

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

PT 5136

x

Page 22

Descriptive Technical Documentation

D-8 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

12 (A2) Door lock

13 (C5) Capacitor - Drum drive

14 (M5) Motor - Air flow and drum drive

15 (1R30) Drying air NTC temperature sensor - Fill ring

16 (R1, R2, R3) Heater bank

17 (1F2, 2F2, 3F2) Temperature limiter

18 (B3/1) Sensor - Residual moisture

Page 23

Descriptive Technical Documentation

DTD no. 521-7135 020-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

020 Door

x

Page 24

Descriptive Technical Documentation

020-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

2 Function

2.1 Door lock (A2)

Door release via Bowden cable.

An open door is registered via a microswitch in the door lock.

Microswitch in door lock (A2): Drum door open = Contact open.

Page 25

Descriptive Technical Documentation

DTD no. 521-7135 030-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

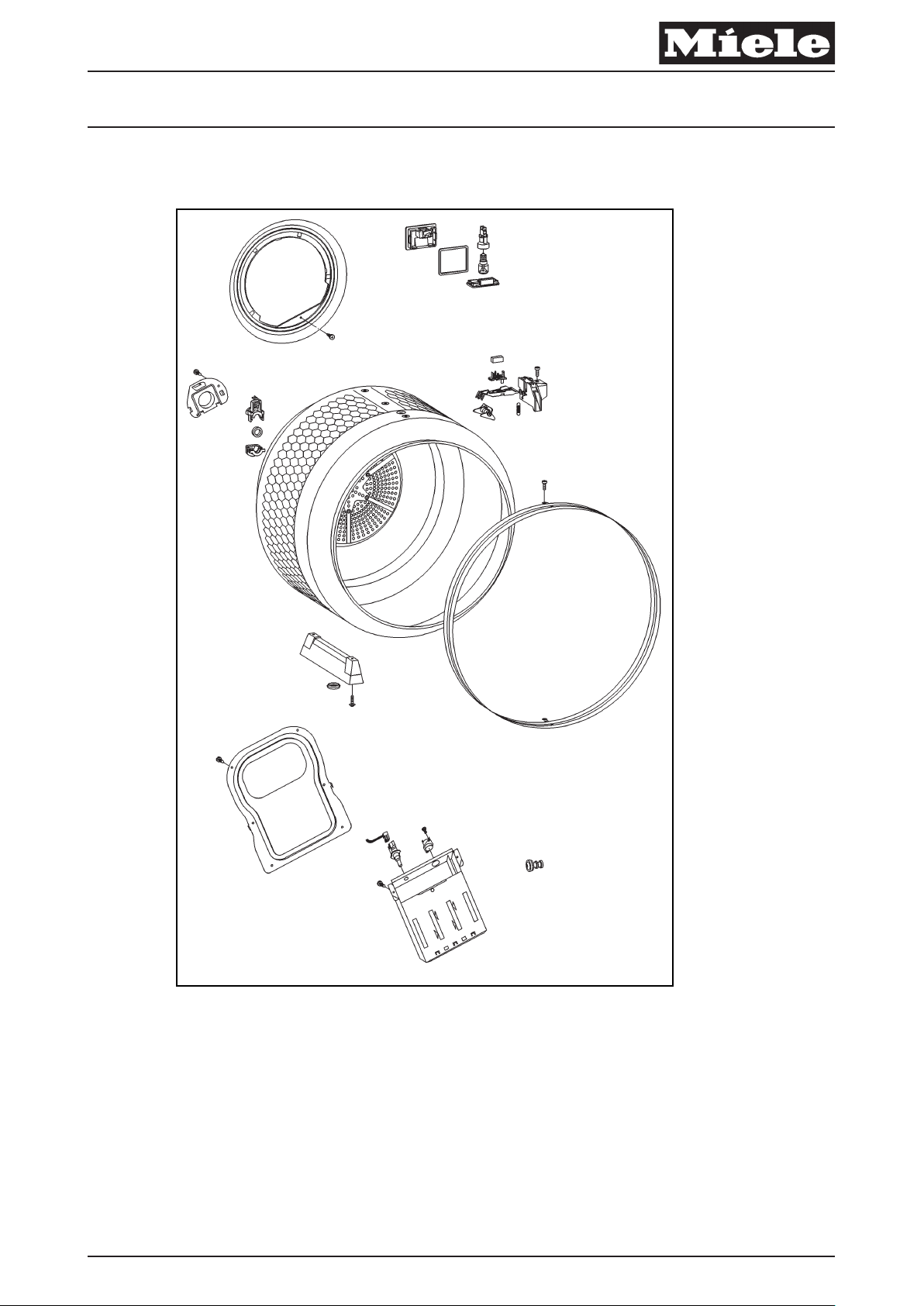

030 Drum, bearing, sensors, heater bank

x

Page 26

Descriptive Technical Documentation

030-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

1 Technical Data

Heater bank (R1, R2, R3) Condenser dryer Vented dryer

Heater rating with 230 V

connection

Table 1: Heater bank (R1, R2, R3)

Temperature (°C) Resistance (kΩ)

0 340

5 261

10 203

15 159

20 126

25 100

30 80.2

35 64.8

40 52.7

45 43.1

50 35.5

55 29.4

3-filament, 2-phase 3-filament, 3-phase

1.94 kW + 0.71 kW + 0.8 kW =

3.45 kW

1.94 kW + 2.1 kW + 2.1 =

6.14 kW

60 24.5

65 20.5

70 17.3

75 14.6

80 12.5

85 10.6

90 9.13

93 8.34

95 7.86

100 6.80

110 5.14

120 3.95

130 3.07

140 2.41

150 1.92

160 1.55

170 1.26

180 1.03

Page 27

Descriptive Technical Documentation

DTD no. 521-7135 030-3

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Temperature (°C) Resistance (kΩ)

190 0.852

200 0.710

Table 2: NTC temperature sensor - Heater bank (2R30) - Resistance values

Temperature (°C) Resistance (kΩ)

0 38.0

5 29.7

10 23.4

15 18.6

20 14.9

25 12.0

30 9.73

35 7.96

40 6.55

45 5.42

50 4.52

55 3.78

60 3.19

65 2.70

70 2.29

75 1.96

80 1.68

85 1.45

90 1.25

93 1.15

95 1.09

100 1.06

110 0.73

120 0.569

130 0.449

140 0.358

150 0.289

Table 3: NTC temperature sensor - Fill ring (1R30) - Resistance values

Page 28

Descriptive Technical Documentation

030-4 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

2 Function

2.1 Heating control (R1, R2, R3)

Safety features:

If the fill ring temperature sensor (1R30) is defective, the heating is not activated.

The heating is switched off as soon as the heating relay is switched on for more

than 5 s without the fan relay being activated.

The heating has a reswitch-on delay of 10 s and is switched off before, during and

after a reversing pause.

2.2 Temperature limiter (F2)

Vented dryer:

Three 3/4 inch temperature limiters, 175°C, with manual reset via pushbutton,

located in the heater channel next to the heater bank.

Condenser dryer:

Two closed 3/4 inch temperature limiters, 170°C, with manual reset via

pushbutton, located on the heater bank.

2.3 NTC temperature sensor - Fill ring (1R30)

If the fill ring temperature sensor registers a drying air temperature less than 15°C or greater than 160°C, it is assumed to be defective.

2.4 NTC temperature sensor - Heater bank (2R30)

An open circuit at the heater bank temperature sensor (2R30) can only be

registered with a temperature greater than 14°C. As during operation lower

temperatures can exist, the sensor is only checked when the heating has

operated for at least 1 min.

If a short circuit exists at the heater bank temperature sensor (2R30), this is

equivalent to a temperature of 250°C and the heating is immediately switched off.

Page 29

Descriptive Technical Documentation

DTD no. 521-7135 030-5

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

2.5 Light - Drum (H3/6)

Lighting is time-controlled. It is switched on approx.1 s after the door is opened.

Switch of f delay: 5 min.

When the door is closed, the lighting is always switched off.

Page 30

Descriptive Technical Documentation

030-6 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Page 31

Descriptive Technical Documentation

DTD no. 521-7135 040-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

040 Drive

x

Page 32

Descriptive Technical Documentation

040-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

1 Technical Data

Cooling fan flow rate Condenser dryer Vented dryer

Cooling air 300 m

Drying air 120 m

Table 1

3

/ h –

3

/ h 300 m3/ h. With 20 m vent duct

> 200 m

3

/ h

Page 33

Descriptive Technical Documentation

DTD no. 521-7135 040-3

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

2 Function

2.1 Motor - Air flow and drum drive (M5)

PT 7135 C, PT 5135 C

The motor drives the drum, drying air fan and cooling air fan at the same time.

2.2 Motor - Air flow and drum drive (M5)

PT 7136, PT 5136

The motor drives the drum and drying air fan at the same time.

Page 34

Descriptive Technical Documentation

040-4 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Page 35

Descriptive Technical Documentation

DTD no. 521-7135 070-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

070 Condensate pump (M5)

PT 7135 C, PT 5135 C

x

Page 36

Descriptive Technical Documentation

070-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

2 Function

2.1 Level sensing - Float switch - Condensate (B8/7)

Level sensing is via a reed switch.

Page 37

Descriptive Technical Documentation

DTD no. 521-7135 080-1

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

080 Fascia panel

x

Page 38

Descriptive Technical Documentation

080-2 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

1 Technical Data

PT 7135 C

and PT 7136

Extra dry

Normal + - 2% 0% -2%

Normal 0% 2% 0% 2% 0% 2% 0%

Hand iron r 8% 8% 8% 8% 8% 8%

Hand iron rr 12%

Machine iron 20%

Table 1: Standard residual moisture levels

PT 5135 C

and

PT 5136

Extra dry

Normal + - 2% 0% - 2% - 2%

Normal 0% 2% 0% 2% 0% 0% 0%

Hand iron r 8% 8% 8% 8% 8% 8%

Machine

iron

Table 2: Standard residual moisture levels

Cottons Minimum

iron

Cottons Minimum

iron

20%

Automatic Outerwea Shirts Denim Proofing

Automatic Outer wear Shirts Denim Proofing Towelling

Residual moisture level adjustment programmable function, see 080 2.6 Residual

moisture level adjustment programmable function.

Page 39

Descriptive Technical Documentation

DTD no. 521-7135 080-3

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

2 Function

2.1 Overriding time control

After programme start, an overriding time control of approx. 180 min applies to all

residual moisture drying programmes.

After this time has expired, the dr ying programme is cancelled and the cooling

stage for faults is activated. The anti-crease action phase is cancelled.

The fault is saved and can be called up in the service mode.

2.2 No-load recognition

No-load recognition and registration of very dry laundry can only take place with

residual moisture drying programmes.

The programme is cancelled, a cooling phase is started and the buzzer sounds

intermittently.

2.3 Insufficient air flow measurement

During warming up, the temperature increase at the heater bank temperature

sensor (2R30) is monitored.

If the air path is blocked, this temperature increases rapidly and a fault is

registered. The fault indication Insufficient air/Leakage is displayed.

2.4 Time of day programmable function

This is used to set the time of day display.

Page 40

Descriptive Technical Documentation

080-4 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

2.5 Extended cooling phase programmable function

An extended cooling phase means that the laundry temperature is lower at the

end of the programme.

A lower laundry temperature reduces the perception of dampness in the load.

Extended cooling has no effect with timed programmes.

2.6 Residual moisture level adjustment programmable function

The standard residual moisture levels can be modified to make them dryer or

damper.

PT 7135 C and PT 7136: Standard residual moisture levels, see 080 Table 1.

PT 5135 C and PT 5136: Standard residual moisture levels, see 080 Table 2.

x

Display bar 1 2 3 4 5 6 7

Residual

moisture

adjustment

Damper 3 Damper 2 Damper 1 Normal Dryer 1 Dryer 2 Dryer 3

Table 3: Residual moisture level adjustment - Cottons

Display bars 1 2 3 4 5 6 7

Residual

moisture

adjustment

Table 4: Residual moisture level adjustment - Minimum iron

Display bars 1 2 3 4 5 6 7 8 9 10 11

Residual

moisture adjustment

Table 5: Residual moisture level adjustment - Cottons, machine iron

Damper 3 Damper 2 Damper 1 Normal Dryer 1 Dryer 2 Dryer 3

26% 25% 24% 23% 22% 21% 20% 19% 18% 17% 16%

Damper Normal Dryer

Page 41

Descriptive Technical Documentation

DTD no. 521-7135 080-5

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

2.7 Clean the airways warning modification programmable function

This function can be used to modify the circumstances under which the Clean the

airways warning is displayed to suit individual requirements, see the operating

instructions or programming mode.

PT 7135 C and PT 7136: Service Dept. programming mode, see Programming

mode summary, 080 4.1.

PT 7136 vented dryer: The warning is reset via the finger protection safety switch

(S32) after opening the fluff filter flap.

PT 5135 C and PT 5136: Service Dept. programming mode, see Programming

mode summary, 080 4.2.

2.8 Automatic programmable function

PT 7135 C, PT 7136, PT 5135 C, PT 5136

This function can be used to add the Automatic programme to the programme

list.

2.9 Clean filters programmable function

PT 7136

When drying laundry which develops high levels of fluff, frequent cleaning of the

large surface area filter is necessary.

With a vented dryer this warning is shown at intervals and indicates that the filters

must be cleaned regularly.

This function can be used to modify the circumstances under which the Clean

filters warning is displayed to suit individual requirements, see the operating

instructions or programming mode.

Service Dept. programming mode, see Programming mode summary, 080 4.1.

Page 42

Descriptive Technical Documentation

080-6 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

2.10 Clean heat exchanger programmable function

PT 7135 C, PT 5135 C

With a condenser dryer this warning is shown at intervals and indicates that the

heat exchanger must be cleaned regularly.

This function can be used to modify the circumstances under which the Clean

heat exchanger warning is displayed to suit individual requirements, see the

operating instructions or programming mode.

PT 7135 C: Service Dept. programming mode, see Programming mode summary,

080 4.1.

PT 5135 C: Service Dept. programming mode, see Programming mode summary,

080 4.2.

2.11 Residual moisture level display programmable function

PT 7135 C, PT 7136

This function can be used to programme the machine to display the current

residual moisture level of the load being dried in percent.

2.12 Cool air free programmable function, with payment system

operation

With payment system operation, this function can be set to provide the Cool air

programme at no charge.

The Cool air free programmable function is only available with payment system

operation.

Page 43

Descriptive Technical Documentation

DTD no. 521-7135 080-7

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

2.13 Payment system programmable function

This is used to set the type of payment system. The appropriate operating

procedure is shown in the display.

For payment system details, see 090 2.3 Payment system.

PT 7135 C and PT 7136 only: For central control via RS 232 interface,

see 090 2.4 Central control via RS 232 interface with 9-pole plug

2.14 Operator code programmable function

With installation in a launderette, the domestic operation programmable functions

can be blocked.

Option code not required (domestic use):

Domestic programmable functions are freely available.

Supervisor programmable functions are not accessible.

Option code required (supervisor):

Access to domestic and supervisor programmable functions via code entry.

The code is freely selectable. If the code is no longer known to the supervisor,

then it can be reset to 000 by resetting all programmable functions to the standard

settings.

2.15 Signal to payment system socket (X1/1) pin 7 programmable

function

In order to reset an external payment system at the end of a programme, the

machine provides a mains voltage signal for 5 s applied to the payment system

connection socket (X1/1), pin 7 (payment system contact).

Page 44

Descriptive Technical Documentation

080-8 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

2.16 Overriding time control modification programmable function with

payment system operation

To reduce the possibility of unauthorised manipulation with payment system

operation, the overriding time can be reduced.

For overriding time control details, see 080 2.1 Overriding time control.

2.17 Programme lock programmable function with payment system

operation

To reduce the possibility of unauthorised manipulation with payment system

operation, the programme lock feature can be activated.

Depending on the set options, the programme will be locked immediately the

programme is started or after a certain period.

If the door is opened when the programme is locked, the programme will be

cancelled and the payment already made will be lost.

To ensure that laundry can still be added, the programme lock can be set to

become active after a certain time has elapsed.

2.18 Cool air timed programme maximum duration setting

programmable function

This is used to set the maximum duration of the Cool air timed programme.

PT 7135 C and PT 7136: The programme duration can be reduced via the

multifunction selector switch but cannot be increased again.

PT 5135 C and PT 5136: The programme duration can be reduced via the + / buttons, but cannot be increased again.

Page 45

Descriptive Technical Documentation

DTD no. 521-7135 080-9

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

2.19 Warm air timed programme maximum duration setting

programmable function

This is used to set the maximum duration of the Warm air timed programme.

PT 7135 C and PT 7136: The programme duration can be reduced via the

multifunction selector switch but cannot be increased again.

PT 5135 C and PT 5136: The programme duration can be reduced via the + / buttons, but cannot be increased again.

2.20 Delay start programmable function

This is used to activate the delay start feature.

If the delay start feature is deactivated, the display shows the time of day in the

style that has been set with the time of day programmable function.

2.21 Language programmable function

PT 7135 C, PT 7136

International:

Multilingual start screen, e.g. for multilingual countries and camp sites.

The desired language is selected before the basic programme menu and is

applicable for only one programme.

The Sort language programmable function is available to select and sort four

favourite languages for international installations.

2.22 Standard settings programmable function

To reset all programmable functions to standard settings.

The code no. for accessing the supervisor level will be reset to 000.

Page 46

Descriptive Technical Documentation

080-10 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

3 Fault Repair

3.1 Warning indication: Clean filter

PT 7136

Cause

This warning is given at certain intervals as a reminder that the filters must be

cleaned.

Remedy

x

Note

Clean the fluff filters regularly, see the operating instructions.

A Clean both parts of the large surface area filter behind the service panel and

the filters in the door opening.

Cause

Clean filter warning shown too soon/late.

Remedy

A The circumstances under which the Clean filters warning is displayed can be

modified to suit individual requirements, see the operating instructions or

programming mode.

A Service Dept. programming mode, see Programming mode summary,

080 4.1.

Page 47

Descriptive Technical Documentation

DTD no. 521-7135 080-11

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

3.2 Warning indication: Clean heat exchanger

PT 7135 C, PT 5135 C

Cause

With a condenser dryer this warning is shown at intervals and indicates that the

heat exchanger must be cleaned regularly.

Remedy

x

Note

Clean the heat exchanger regularly, see the operating instructions.

A Clean the heat exchanger.

Cause

Clean heat exchanger warning shown too soon/late.

Remedy

A The circumstances under which the Clean heat exchanger warning is

displayed can be modified to suit individual requirements, see the operating

instructions or programming mode.

A PT 7135 C: Service Dept. programming mode, see Programming mode

summary, 080 4.1.

A PT 5135 C: Service Dept. programming mode, see Programming mode

summary, 080 4.2.

Page 48

Descriptive Technical Documentation

080-12 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

3.3 Warning indication: Adjust the load – The drum is empty or the

laundry too dry

Symptom

This warning can only be displayed with residual moisture drying programmes

(i.e. not timed drying).

The programme is cancelled, a cooling phase is started and the buzzer sounds

intermittently.

This warning is cancelled when the door is opened.

Cause

The drum is empty or loaded with a few small items only.

The residual moisture sensing circuit has high resistance and the sensing system

registers no load (no load recognition). This is not a technical fault.

Remedy

A Modify the load or select a timed drying programme.

Cause

Residual moisture sensor (B3/1) defective.

Residual moisture sensor check

A PT 7135 C and PT 7136: Check the residual moisture sensor circuit for low

resistance (continuity), see the service mode Service mode summar y, 080

4.5.

A PT 5135 C and PT 5136: Check the residual moisture sensor circuit for low

resistance (continuity), see the service mode Service mode summar y,

080 4.6.

A No load recognition, see 080 2.2 No-load recognition.

Page 49

Descriptive Technical Documentation

DTD no. 521-7135 080-13

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

3.4 Demonstration mode active

Symptom

A programme start is not possible and the programming and service modes

cannot be accessed.

Cause

The demonstration mode is active.

Remedy

A PT 7135 C and PT 7136: Demonstration mode deactivation, see

Demonstration mode activation / deactivation, 080 4.3.

A PT 5135 C and PT 5136: Demonstration mode deactivation, see

Demonstration mode activation / deactivation, 080 4.4.

3.5 Fault indication: Drain fault – Check the drain path

Symptom

Applicable to condenser dryer only.

The programme is cancelled, a cooling phase is started and the buzzer sounds

intermittently.

This warning is cancelled when the door is opened.

Cause

Float switch - Condensate (B8/7) in the condensate pump housing is defective

(short-circuited).

Remedy

A Check the float switch - Condensate (B8/7). Exchange it if necessary.

A PT 7135 C and PT 7136: Service mode, see Service mode summary, 080 4.5.

A PT 5135 C and PT 5136: Service mode, see Service mode summary, 080 4.6.

Cause

Condensate pump (M13) defective.

Page 50

Descriptive Technical Documentation

080-14 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Remedy

A Check the condensate pump (M13). Exchange it if necessary.

A PT 7135 C and PT 7136: Service mode, see Service mode summary, 080 4.5.

A PT 5135 C and PT 5136: Service mode, see Service mode summary, 080 4.6.

Cause

The condensate drainage path is blocked.

Remedy

A Check the drainage path for blockages. Repair as necessary.

3.6 Fault indication: Clean the airways

Symptom

The programme continues normally or is interrupted.

The fault is indicated at the end of the cooling down phase.

The fault is saved in the fault memory, see Fault code F66, air leakage fault, 080

3.19.

PT 7135 C and PT 7136: This warning is cancelled when the door is opened.

Cause

Air paths are clogged.

Insufficient air flow registered, see 080 2.3 Insufficient air flow measurement.

Remedy

x

Note

Check and clean the filters regularly, see the operating instructions.

A Clean the fluff filters in the door cap and door fill ring.

A Condenser dryer: Remove the heat exchanger and clean it.

A Check and clean the air paths.

Page 51

Descriptive Technical Documentation

DTD no. 521-7135 080-15

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Cause

Clean the airways warning shown too early/late.

Remedy

A The point at which the Clean the airways warning is shown can be adjusted

to suit the needs of the operator, see the operating instructions or

programming mode.

A PT 7135 C and PT 7136: For Service Dept. programming mode see

Programming mode summary, 080 4.1.

A PT 5135 C and PT 5136: For Service Dept. programming mode see

Programming mode summary, 080 4.2.

3.7 Fault indication: Technical fault

Symptom

In normal operation mode the display shows Technical fault.

Programme interruption, cooling down phase, intermittent buzzer operation.

This fault indication is deleted by pressing the multifunction selector switch.

Cause

The power-programme module (ELP) or selection module (EW) has registered a

fault.

The power-programme module (ELP) interrupts the programme.

The displayed fault is the reason for the programme interruption.

Remedy

A PT 7135 C and PT 7136: For fault memory check, see the Service mode,

Service mode summary, 080 4.5.

A PT 5135 C and PT 5136: For fault memory check, see the Service mode,

Service mode summary, 080 4.6.

A Check the Mat. nos. to verify that the correct selection module (EW) and

power-programme module (ELP) are fitted.

A Check the electrical connection between the power-programme module (ELP)

and selection module (EW).

Page 52

Descriptive Technical Documentation

080-16 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

3.8 Fault code F1, heater bank NTC sensor short-circuited

Symptom

In normal operation mode the display shows Technical fault.

Programme interruption, cooling down phase, intermittent buzzer operation.

Only the Cool air timed programme can be operated.

This fault indication is deleted by pressing the multifunction selector switch.

Cause

Heater bank temperature sensor (2R30) short-circuited (> 250°C).

Remedy

A Check the heater bank temperature sensor (2R30), its leads and its plug

connections for short or open circuit.

A Check the heater bank temperature sensor (2R30) for correct performance,

see 030 Table 2.

3.9 Fault code F2, heater bank NTC sensor open-circuited

Symptom

In normal operation mode the display shows Technical fault.

Programme interruption, cooling down phase, intermittent buzzer operation.

Only the Cool air timed programme can be operated.

This fault indication is deleted by pressing the multifunction selector switch.

Cause

Heater bank temperature sensor (2R30) open-circuited (< 20°C). Only registered

after the heating has been switched on for at least 1 min.

Remedy

A Check the heater bank temperature sensor (2R30), its leads and its plug

connections for short or open circuit.

A Check the heater bank temperature sensor (2R30) for correct performance,

see 030 Table 2.

Page 53

Descriptive Technical Documentation

DTD no. 521-7135 080-17

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Cause

Heater bank not heating.

Remedy

A Check the heater bank (R) for short or open circuit.

Cause

Heating relay (K1).

Remedy

A Check the heating relay (K1).

Cause

Temperature limiter (F2).

Remedy

A Check the temperature limiter F2 for continuity.

3.10 Fault code F3, fill ring NTC sensor short-circuited

Symptom

In normal operation mode the display shows Technical fault.

Programme interruption, cooling down phase, intermittent buzzer operation.

Only the Cool air timed programme can be operated.

This fault indication is deleted by pressing the multifunction selector switch.

Cause

Fill ring temperature sensor (1R30) short-circuited (> 160°C).

Remedy

A Check the fill ring temperature sensor (1R30), its leads and its plug

connections for short or open circuit.

A Check the fill ring temperature sensor (1R30) for correct performance, see

030 Table 3.

Page 54

Descriptive Technical Documentation

080-18 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

3.11 Fault code F4, fill ring NTC sensor open-circuited

Symptom

In normal operation mode the display shows Technical fault.

Programme interruption, cooling down phase, intermittent buzzer operation.

Only the Cool air timed programme can be operated.

This fault indication is deleted by pressing the multifunction selector switch.

Cause

Fill ring temperature sensor (1R30) open-circuited (< 15°C).

Remedy

A Check the fill ring temperature sensor (1R30), its leads and its plug

connections for short or open circuit.

A Check the fill ring temperature sensor (1R30) for correct performance, see

030 Table 3.

3.12 Fault code F41, faulty EEPROM / data fault

Symptom

The programme operates with default values.

In normal operation mode the display shows Technical fault.

Programme interruption, cooling down phase, intermittent buzzer operation.

This warning is cancelled when the door is opened.

Cause

Faulty EEPROM / data fault.

Remedy

A If there is no functional fault, a remedy is not required.

A Otherwise exchange the power-programme module (1N1, ELP).

Page 55

Descriptive Technical Documentation

DTD no. 521-7135 080-19

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

3.13 Fault code F43, model type not programmed

Cause

In normal operation mode this fault is not indicated via the display.

The selection module (EW) and power-programme module (ELP) do not match.

Remedy

A Check the Mat. nos. to verify that the correct selection module (EW) and

power-programme module (ELP) are fitted.

3.14 Fault code F45, faulty flash RAM/ data fault

Symptom

In normal operation mode the display shows Technical fault.

Programme interruption, cooling down phase, intermittent buzzer operation.

Cause

Faulty flash RAM/ data fault.

Remedy

A Check the Mat. nos. to verify that the correct selection module (EW) and

power-programme module (ELP) are fitted.

A Reset all programmable functions to standard settings. Then modify the

desired programmable functions.

A Exchange the power-programme module (ELP).

Page 56

Descriptive Technical Documentation

080-20 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

3.15 Fault code F46, display fault

Symptom

Programme interruption, cooling down phase, intermittent buzzer operation.

Cause

Internal display fault on selection module (EW). Display driver for LCD module

defective.

Remedy

A Exchange the selection module (EW).

3.16 Fault code F47, communication fault between selection module

(EW) and power-programme module (ELP)

Symptom

In normal operation mode the display shows Technical fault.

Programme interruption, cooling down phase, intermittent buzzer operation.

With operation with a payment system, the programme end signal is provided at

the payment system socket (X1/1) pin 7.

Cause

Selection module (EW) - Power-programme module (ELP) interface fault.

Remedy

A Check the electrical connection between the selection module (EW) and

power-programme module (ELP).

Page 57

Descriptive Technical Documentation

DTD no. 521-7135 080-21

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

3.17 Fault code F50, motor stationary and heating operates for 5 s

Symptom

The motor for air flow and drum drive (M5) is stationary.

This fault occurs in normal operating mode and the following occurs: Programme

interruption, cooling down phase, intermittent buzzer operation for 2 min.

This warning is cancelled when the door is opened.

Cause

The heating has operated for longer than 5 s with the motor stationary. This is a

power-programme module (ELP) fault.

Remedy

A Check the motor (M5).

A Exchange the power-programme module (ELP).

3.18 Fault code F55, overriding time limit exceeded (approx. 180 min)

Symptom

Only applicable to residual moisture programmes.

This fault occurs in normal operating mode and the following occurs: Programme

interruption, cooling down phase, intermittent buzzer operation for 2 min.

This warning is cancelled when the door is opened.

For the overriding time limit, see 080 2.1 Overriding time control.

Cause

Laundry too wet or dryer overloaded.

Remedy

A Spin the laundry more or reduce the quantity.

Cause

Electrically conductive item in load (e.g. zip).

Remedy

A Select a hot air drying programme.

Page 58

Descriptive Technical Documentation

080-22 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Cause

Air path clogged.

Remedy

A Check and clean the air paths.

Cause

Heater bank not heating.

Remedy

A Check the heater bank (R1) for short or open circuit.

Cause

Heating relay (K1/1).

Remedy

A Check the heating relay (K1/1).

Cause

Temperature limiter (F2).

Remedy

A Check the temperature limiter (F2) for continuity.

Cause

Residual moisture sensor (B3/1) defective.

Residual moisture sensor check

A PT 7135 C and PT 7136: Check the residual moisture sensor for high

resistance, see service mode Service mode summary, 080 4.5.

A PT 5135 C and PT 5136: Check the residual moisture sensor for high

resistance, see service mode Service mode summary, 080 4.6.

Page 59

Descriptive Technical Documentation

DTD no. 521-7135 080-23

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

3.19 Fault code F66, air leakage fault

Symptom

In normal operation mode the display shows Clean the airways.

Cause

Air path clogged.

Insufficient air flow registered, see 080 2.3 Insufficient air flow measurement.

Remedy

A Check and clean the air paths.

Page 60

Descriptive Technical Documentation

080-24 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

4 Service

4.1 Programming mode summary

PT 7135 C, PT 7136

Initial requirements

A Finish or cancel any programme in operation, including the demonstration

mode.

A Open the door.

A Disconnect the fill ring NTC temperature sensor (1R30) plug.

x

Note

If the fill ring NTC temperature sensor (1R30) plug is disconnected at the powerprogramme module (1N1), then power is also no longer supplied to the door lock

(A2). In this case the programming mode cannot be accessed.

A If the international multilingual start screen is shown, select the desired

language.

Accessing

x

Note

After it is begun, the accessing procedure must be completed within 10 s.

A Press and hold the Star t button.

A Close the door.

A As soon as the Start button flashes, release the Start button.

A Immediately press and release the Start button 5 times and at the 5th time

hold it pressed in until programmable functions are shown in the display.

Acknowledgement indicator

Successful accessing of the programming mode is indicated by rapid flashing

(5 Hz) of the Start button.

The display shows the Service Dept. programmable functions.

If the accessing procedure has been unsuccessful, the control automatically

reverts to the normal operating mode.

Page 61

Descriptive Technical Documentation

DTD no. 521-7135 080-25

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Options

The set option is indicated by a V next to it.

A Programmable function selection: Turn the multifunction selector switch to

mark the desired function and press the multifunction selector switch to

confirm the selection.

A Option selection: Turn the multifunction selector switch to mark the desired

option and press the multifunction selector switch to confirm the selection.

x

Note

Highlighted options are standard settings.

If an electronic module is supplied as a replacement part, the highlighted

options should be set to suit the machine in which the module is fitted!

Page 62

Descriptive Technical Documentation

080-26 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

x

Programmable function Option

Language Language for operating, programming and service modes

Sort language Select and sort four favourite languages for international installations

Anti-crease action Off

On

Buzzer Off

Normal

Loud

Clock display, see 080 2.4 Time of day

programmable function

Display contrast Standard contrast setting: Bar diagram level 4

Display brightness Standard brightness setting: Bar diagram level 5

Stand-by On: Display und backlight switched off automatically after 10 min

Extended cooling time, see 080 2.5

Extended cooling phase programmable

function

Save On: Save option available. Favourite programmes can be allocated to

Residual moisture level adjustment Cottons

Residual moisture level adjustment Minimum iron

Residual moisture level adjustment Machine iron

Clean the airways warning, see 080 2.7

Clean the airways warning modification

programmable function

Automatic programme, see 080 2.8

Automatic programmable function

24 h clock

12 h clock am/pm

No clock, 24 h Delay start

Not in programme in operation: Stand-by only before and after

programme but not while it is in operation

0 min

2 min

4 min

6 min

8 min

10 min

12 min

14 min

16 min

18 min

direct selection buttons.

Off: Save option not available

The standard residual moisture levels can be modified to make them up to

3 stages dryer or damper, see 080 2.6 Residual moisture level adjustment

programmable function

The standard residual moisture levels can be modified to make them up to

3 stages dryer or damper, see 080 2.6 Residual moisture level adjustment

programmable function

The standard residual moisture levels can be modified to make them dryer

or damper, see 080 2.6 Residual moisture level adjustment programmable

function

Off

Reduced sensitivity

Normal

Sensitive

On: Automatic programme included in programme list

Off: Automatic programme not included in programme list

Page 63

Descriptive Technical Documentation

DTD no. 521-7135 080-27

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Programmable function Option

Clean filters warning, vented dryers only,

see 080 2.9 Clean filters programmable

function

Clean heat exchanger warning, condenser

dryers only, see 080 2.10 Clean heat

exchanger programmable function

Residual moisture level display, see

080 2.11 Residual moisture level display

programmable function

Cool air free, with payment system

operation, see 080 2.12 Cool air free

programmable function, with payment

system operation

Payment system operation, see 080 2.13

Payment system programmable function

Supervisor level code, see 080 2.14

Operator code programmable function

Signal to payment system socket (X1/1)

pin 7, see 080 2.15 Signal to payment

system socket (X1/1) pin 7 programmable

function

Off

Display after 5 h

Display after 10 h

Display after 15 h

Display after 20 h

Display after 25 h

Display after 30 h

Display after 35 h

Display after 40 h

Display after 45 h

Display after 50 h

Display after 55 h

Off

Display after 100 h

Display after 200 h

Display after 300 h

Display after 400 h

Display after 500 h

Display after 600 h

Display after 700 h

Display after 800 h

Display after 1000 h

Display after 1200 h

Display after 1400 h

Display after 1600 h

Without percentage indication

With percentage indication

Yes

No

Off

Programme operation (MZK)

Timed operation (MZZ)

IK 6 (RS 232)

RS 232 interface active

Code not required. Domestic programmable functions can be

modified.

Code required. After code entry, domestic and supervisor programmable

functions can be modified.

At programme end

When Start button is released

When Start button is released and at programme end

Page 64

Descriptive Technical Documentation

080-28 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Programmable function Option

Overriding time control modification with

payment system operation, see 080 2.16

Overriding time control modification

programmable function with payment

system operation

Programme lock with payment system

operation after releasing the Start button,

see 080 2.17 Programme lock

programmable function with payment

system operation

Cool air timed programme maximum

duration, see 080 2.18 Cool air timed

programme maximum duration setting

programmable function

Warm air timed programme maximum

duration, see 080 2.19 Warm air timed

programme maximum duration setting

programmable function

Delay start, see 080 2.20 Delay start

programmable function

Language setting, see 080 2.21 Language

programmable function

Standard settings, see 080 2.22 Standard

settings programmable function

120 min

135 min

150 min

165 min

180 min

195 min

210 min

225 min

240 min

None

Immediately

1 min

2 min

3 min

4 min

5 min

10 min

20 min

30 min

40 min

50 min

60 min

70 min

80 min

90 min

100 min

110 min

120 min

15 min

20 min

25 min

30 min

35 min

40 min

45 min

50 min

55 min

60 min

90 min

120 min

Active

Inactive

National

International, additional welcoming menu (favourite languages)

Reset all programmable functions to standard settings

Table 6: Programming mode summary

Page 65

Descriptive Technical Documentation

DTD no. 521-7135 080-29

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Save and quit

x

Note

Confirmed programmable options are saved.

A Reconnect the fill ring NTC temperature sensor (1R30) plug.

4.2 Programming mode summary

PT 5135 C, PT 5136

Initial requirements

A Finish or cancel any programme in operation, including the demonstration

mode.

A Open the door.

A Disconnect the fill ring NTC temperature sensor (1R30) plug.

x

Note

If the fill ring NTC temperature sensor (1R30) plug is disconnected at the powerprogramme module (1N1), then power is also no longer supplied to the door lock

(A2). In this case the programming mode cannot be accessed.

A During initial commissioning only: Select the desired language.

Accessing

x

Note

After it is begun, the accessing procedure must be completed within 10 s.

A Press and hold the Star t button.

A Close the door.

A As soon as the Start LED flashes, release the Start button.

A Immediately press and release the Start button 5 times and at the 5th time

hold it pressed in until the Start LED flashes.

Acknowledgement indicator

Successful accessing of the programming mode is indicated by rapid flashing

(5 Hz) of the Start LED.

Page 66

Descriptive Technical Documentation

080-30 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

The display shows the Service Dept. programmable functions.

If the accessing procedure has been unsuccessful, the control automatically

reverts to the normal operating mode.

Options

A Programmable function selection: Press the + / - buttons as appropriate to

mark the desired function and press the OK button to confirm the selection.

The set option is indicated by a V next to it.

A Option selection: Press the + / - buttons as appropriate to mark the desired

option and press the OK button to confirm the selection.

x

Note

Highlighted options are standard settings.

If an electronic module is supplied as a replacement part, the highlighted

options should be set to suit the machine in which the module is fitted!

Programmable function Option

Language Language for operating, programming and service modes

Anti-crease action On

Off

Clock display, see 080 2.4 Time of day

programmable function

Supervisor level Code modification

Display contrast Standard contrast setting: Bar diagram level 4

Display brightness Standard brightness setting: Bar diagram level 5

Stand-by On: Display und backlight switched off automatically after 10 min

Buzzer Off

Extended cooling time, see 080 2.5

Extended cooling phase programmable

function

Residual moisture level adjustment Cottons

24 h clock

12 h clock am/pm

No clock, 24 h Delay start

Not in programme in operation: Stand-by only before and after

programme but not while it is in operation

Normal

Loud

0 min

2 min

4 min

6 min

8 min

10 min

12 min

14 min

16 min

18 min

The standard residual moisture levels can be modified to make them up to

3 stages dryer or damper, see 080 2.6 Residual moisture level adjustment

programmable function

Page 67

Descriptive Technical Documentation

DTD no. 521-7135 080-31

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

Programmable function Option

Residual moisture level adjustment Minimum iron

Residual moisture level adjustment Machine iron

Clean the airways warning, see 080 2.7

Clean the airways warning modification

programmable function

Clean heat exchanger warning, condenser

dryers only, see 080 2.10 Clean heat

exchanger programmable function

Cool air free, with payment system

operation, see 080 2.12 Cool air free

programmable function, with payment

system operation

Payment system operation, see 080 2.13

Payment system programmable function

Supervisor level code, see 080 2.14

Operator code programmable function

Signal to payment system socket (X1/1)

pin 7, see 080 2.15 Signal to payment

system socket (X1/1) pin 7 programmable

function

Overriding time control modification with

payment system operation, see 080 2.16

Overriding time control modification

programmable function with payment

system operation

The standard residual moisture levels can be modified to make them up to

3 stages dryer or damper, see 080 2.6 Residual moisture level adjustment

programmable function

The standard residual moisture levels can be modified to make them dryer

or damper, see 080 2.6 Residual moisture level adjustment programmable

function

Off

Reduced sensitivity

Normal

Sensitive

Off

Display after 100 h

Display after 200 h

Display after 300 h

Display after 400 h

Display after 500 h

Display after 600 h

Display after 700 h

Display after 800 h

Display after 1000 h

Display after 1200 h

Display after 1400 h

Display after 1600 h

Yes

No

Off (Delay start possible)

Programme operation (MZK)

Timed operation (MZZ)

RS 232 interface active

Code not required. User programmable functions can be modified.

Code required. After code entry, supervisor programmable functions can

be modified.

At programme end

When Start button is released

When Start button is released and at programme end

120 min

135 min

150 min

165 min

180 min

195 min

210 min

225 min

240 min

Page 68

Descriptive Technical Documentation

080-32 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Programmable function Option

Programme lock with payment system

operation after releasing the Start button,

see 080 2.17 Programme lock

programmable function with payment

system operation

Cool air timed programme maximum

duration, see 080 2.18 Cool air timed

programme maximum duration setting

programmable function

Warm air timed programme maximum

duration, see 080 2.19 Warm air timed

programme maximum duration setting

programmable function

Delay start, see 080 2.20 Delay start

programmable function

Automatic programme, see 080 2.8

Automatic programmable function

Standard settings, see 080 2.22 Standard

settings programmable function

None

Immediately

1 min

2 min

3 min

4 min

5 min

10 min

20 min

30 min

40 min

50 min

60 min

70 min

80 min

90 min

100 min

110 min

120 min

15 min

20 min

25 min

30 min

35 min

40 min

45 min

50 min

55 min

60 Min

90 min

120 min

Active

Inactive

On: Automatic programme included in programme list

Off: Automatic programme not included in programme list

Reset all programmable functions to standard settings

Table 7: Programming mode summary

Save and quit

x

Note

Confirmed programmable options are saved.

A Reconnect the fill ring NTC temperature sensor (1R30) plug.

Page 69

Descriptive Technical Documentation

DTD no. 521-7135 080-33

14.10.2005, DE_en This information should not be duplicated or passed on without Miele approval. All rights reserved.

4.3 Demonstration mode activation / deactivation

PT 7135 C, PT 7136

Initial requirements

A Finish or cancel any programme in operation.

A Open the door.

A If the international multilingual start screen is shown, select the desired

language.

Accessing

x

Note

After it is begun, the accessing procedure must be completed within 10 s.

A Press and hold the Star t button.

A Close the door.

A As soon as the Start button lights up constantly, after approx. 5 s, release

the Start button.

x

Note

During deactivation the Start button does not light up constantly.

A Immediately press and hold the Start button again until an appropriate

instruction is shown in the display (approx. 5 s).

A Follow the instruction shown in the display.

Acknowledgement indicator

The demonstration programme operates.

If the accessing procedure has been unsuccessful, the control automatically

reverts to the normal operating mode.

Options

The demonstration mode programme duration is approx. 90 s. After a short

pause, it starts again automatically.

x

Note

After an interruption in the mains supply, the demonstration mode programme

begins again automatically.

Page 70

Descriptive Technical Documentation

080-34 DTD no. 521-7135

This information should not be duplicated or passed on without Miele approval. All rights reserved. 14.10.2005, DE_en

Save and quit

A Demonstration programme deactivation: Repeat the accessing procedure.

4.4 Demonstration mode activation / deactivation

PT 5135 C, PT 5136

Initial requirements

A Finish or cancel any programme in operation.

A Open the door.

Accessing

x

Note

After it is begun, the accessing procedure must be completed within 10 s.

A Press and hold the Star t button.

A Close the door.

A As soon as the Start LED lights up constantly, after approx. 5 s, release the

Start button.

x

Note

During deactivation the Start button does not light up constantly.

A Immediately press and hold the Start button again until an appropriate

instruction is shown in the display (approx. 5 s).

A Follow the instruction shown in the display.

Acknowledgement indicator

The demonstration programme operates.