Page 1

Installation instructions

Steam-Sterilizer

PS 1201B V1.0

PS 1202B V1.0

en-CA

M.-Nr. 09 490 990 - 03 /

2015-02-05

Page 2

Contents

Items supplied...................................................................................................................... 3

Unpacking the machine ...................................................................................................... 4

Connecting to services / Ambient conditions................................................................... 5

Connections and installation notes ....................................................................................... 5

Ambient conditions................................................................................................................ 5

Installation notes ................................................................................................................. 6

Back of the machine.............................................................................................................. 6

Water drainage ...................................................................................................................... 6

Mains water ........................................................................................................................... 7

Electrical connection ............................................................................................................. 7

Installation............................................................................................................................ 8

2

Page 3

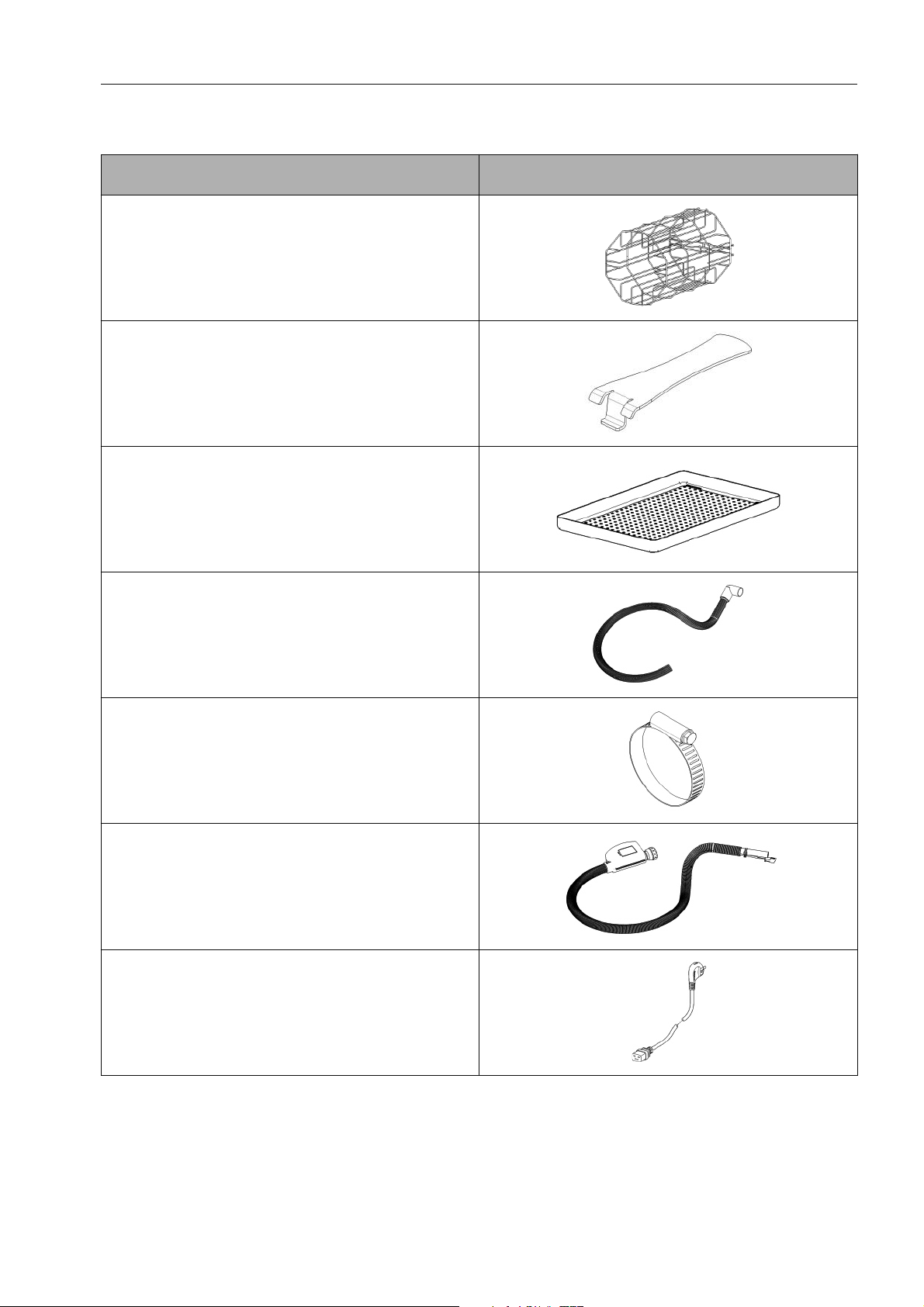

Items supplied

The machine is supplied with the following standard equipment which is packed in the

pressure chamber or included with the transport pack.

Description Illustration

Rack for trays

Tray handle

3 trays

Drain hose

2 hose clips for drain hose

Water inlet hose with water protection de‐

vice (fixed in position)

Power cable

3

Page 4

Unpacking the machine

The steam-sterilizer is supplied in transport packaging. The machine is mounted on a pal‐

let.

ĺ Remove the transport straps from the packaging.

ĺ Lift the lid off the box.

ĺ Remove the wooden frame.

ĺ Remove the outer cardboard sleeve from the machine.

ĺ Remove the cardboard corners.

ĺ Remove the polystyrene corners.

ĺ Remove the protective cover.

Useful tip: With the help of at least one other person, lift the sterilizer out of the remaining

packaging. The machine weighs approx. 63 kg. This is the weight when empty, as the ma‐

chine has not yet been filled with water and / or a load.

Please retain the original packing material after you have unpacked the machine. This

could be useful should you need to move the machine to another location at a later date.

The pressure chamber door is not completely closed during transportation.

ĺ After you have unpacked the machine, remove the tape securing the door.

ĺ Remove the foam from the door.

ĺ Open the door and take the accessories out of the pressure chamber.

The chamber must be empty for the commissioning process.

Do not remove the protective film from the display of a new machine until it has been

connected to the electrical and water supplies.

4

Page 5

Connecting to services / Ambient conditions

Connections and installation notes

Please connect the machine in accordance with the connection data in the following chart:

Installation data

Total connected load 3,200 W

Fuse rating 20 A (surge-proof)

Voltage 208 VAC (+/- 6 %)

Frequency 60 Hz

Water inlet hose

Threaded union 3/4"

Hose length 1.50 m

Flow pressure 150 - 600 kPa (22 - 87 psi)

Drain hose

Connection / Pipe coupling Ø 22.5 mm

Hose length 1.50 m

ɘ The machine must only be connected to the electrical supply with the supplied

NEMA L6-20P plug via a suitable switched socket with an earthing connector. The sock‐

et must be easily accessible after installation in order to disconnect the steam-sterilizer

from the electricity supply.

The drain hose must not exceed 5 metres in length and must be laid at a constant gradient

without kinks. The on-site drainage point must be at least 20 cm below the drain hose con‐

nection point on the machine. To avoid any water damage, please close the faucet at the

end of the working day.

Ambient conditions

Permissible ambient temperature /

Air humidity

Permissible storage temperature /

Air humidity

Maximum height above

sea level

+5 °C to +40 °C / 0 % - 80 %

-10 °C to +60 °C / 0 % - 80 %

2000 m

Minimum air pressure

(ambient pressure)

The machine should not be installed or operated in any area where there is a risk of ex‐

plosion or of freezing conditions existing.

80 kPa (12 psi)

5

Page 6

Installation notes

Back of the machine

Safety valve cover

Mains connection (machine plug connector)

Water inlet (with WPS system) *

Drainage (socket)

*) The fixed water protection device (WPS - Waterproof System) is located at the other end

of the hose.

The drain hose must not exceed 5 meters in length and must be laid at a constant gradi‐

ent without kinks. The on-site drainage point must be at least 20 cm below the drain

hose connection point on the machine.

Water drainage

The drain hose connection point is located at the back of the machine.

ĺ Take the drain hose supplied and push the angled rubber grommet onto the drainage

socket on the machine.

ĺ Secure the drain hose using the clip supplied.

ĺ Connect the drain hose to the on-site drain connection.

Ensure that the drain hose is properly connected and secured to the on-site drainage

point.

6

Page 7

Installation notes

Mains water

The mains water connection point is located at the back of the machine. The machine is

supplied with the water inlet hose already connected.

ĺ Connect the inlet hose to the on-site supply.

Do not use a hose extension. The connection hose is fitted with a special valve that is part

of the machine's waterproof system (WPS). Ensure that the inlet hose is correctly attached

and that the on-site shut-off valve is open.

The steam-sterilizer has an integrated water preparation unit (reverse osmosis unit). This

produces demineralized water for the steam generator.

On no account should the inlet hose be connected to a demineralized water or reverse

osmosis unit. If a water softening unit is being used, make sure it complies with the onsite connection. The grey water inlet must connected to mains water only. The conduc‐

tance level of the mains water must not exceed 375 μS/cm.

Using water containing sediment, particulate matter etc. or water with a high mineral con‐

tent will reduce the performance and useful life of the reverse osmosis unit.

Electrical connection

The electrical connection point is located at the back of the machine.

ĺ Connect the cable to the socket provided on the machine.

ĺ Connect the plug to the on-site socket and ensure that the cable is not twisted or

crimped.

Only use the electrical cable supplied with the machine. Do not use an extension lead.

The machine can be completely disconnected from the electrical supply by withdrawing

the plug from the socket. This should be done prior to cleaning, maintenance or commis‐

sioning of the steam-sterilizer.

ĺ To do this, unplug the power cable from the on-site socket.

The on-site electrical installation must conform to current national standards for the coun‐

try in which the machine is being operated. It must be operated on its own electrical circuit.

Note that the sterilizer may not be connected to a switchable outlet (e.g. Smart Home).

ɘ The machine must be connected to the electrical supply via a suitable switched

socket with earthing connector; otherwise this can result in a electric shock when touch‐

ing the machine casing. The manufacturer cannot accept any responsibility or warranty

claims for incorrect installation.

It is recommended that the machine is connected to a separate spur socket with its own

separate RCD (residual current device). This RCD should be checked regularly by the

operator.

The steam-sterilizer must only be connected to the electrical supply when the casing is

closed.

7

Page 8

Installation

– Install the machine in a well-ventilated room.

– Do not position it beside a sink as splashes of water could cause the machine to short

circuit.

– Keep the machine away from sources of heat.

– The steam-sterilizer must not be installed in areas which are accessible to patients.

– The steam-sterilizer must be installed in the clean area of the preparation room.

– The ventilation grilles in the rear panel must not be covered.

– The service panel must not be blocked.

– The mains switch must be accessible at all times.

– There must be a gap of at least 2 cm between the steam-sterilizer and surrounding surfa‐

ces both above and to the sides.

– Do not place any objects directly next to the cabinet in order to ensure that air can circu‐

late around it freely. Ensure that there is a gap of 7 cm between the back of the machine

and the wall behind it.

Place the steam-sterilizer on a smooth, level surface such as a table or worktop. The sur‐

face it is placed on must be water resistant and heat-resistant to 80 °C. Please note that

the steam-sterilizer when filled and loaded can weigh approx. 80 kg.

Pressure release valve

ɘ The machine must be set up in such a way that no one can stand near the back of

the machine in the event of the pressure release valve being activated. Danger of burn‐

ing and scalding.

Do not use the outer casing of the machine as a resting place for utensils or other ob‐

jects.

8

Page 9

V

Canada

Importer

Miele Limited

Professional Division

161 Four Valley Drive

aughan, ON L4K 4V8

Phone:

Fax:

www.mieleprofessional.ca

professional@miele.ca

Miele Professional Technical Service

Phone:

Fax:

serviceprofessional@miele.ca

1-888-325-3957

1-800-803-3366

1-888-325-3957

1-800-803-3366

Alteration rights reserved / Publication date: 2015-02-05 M.-Nr. 09 490 990 - 03 / 2015-02-05 / 03

Manufacturer

Miele Werk Bürmoos GmbH,

Mielestraße 1, 5111 Bürmoos

Austria

Loading...

Loading...