Page 1

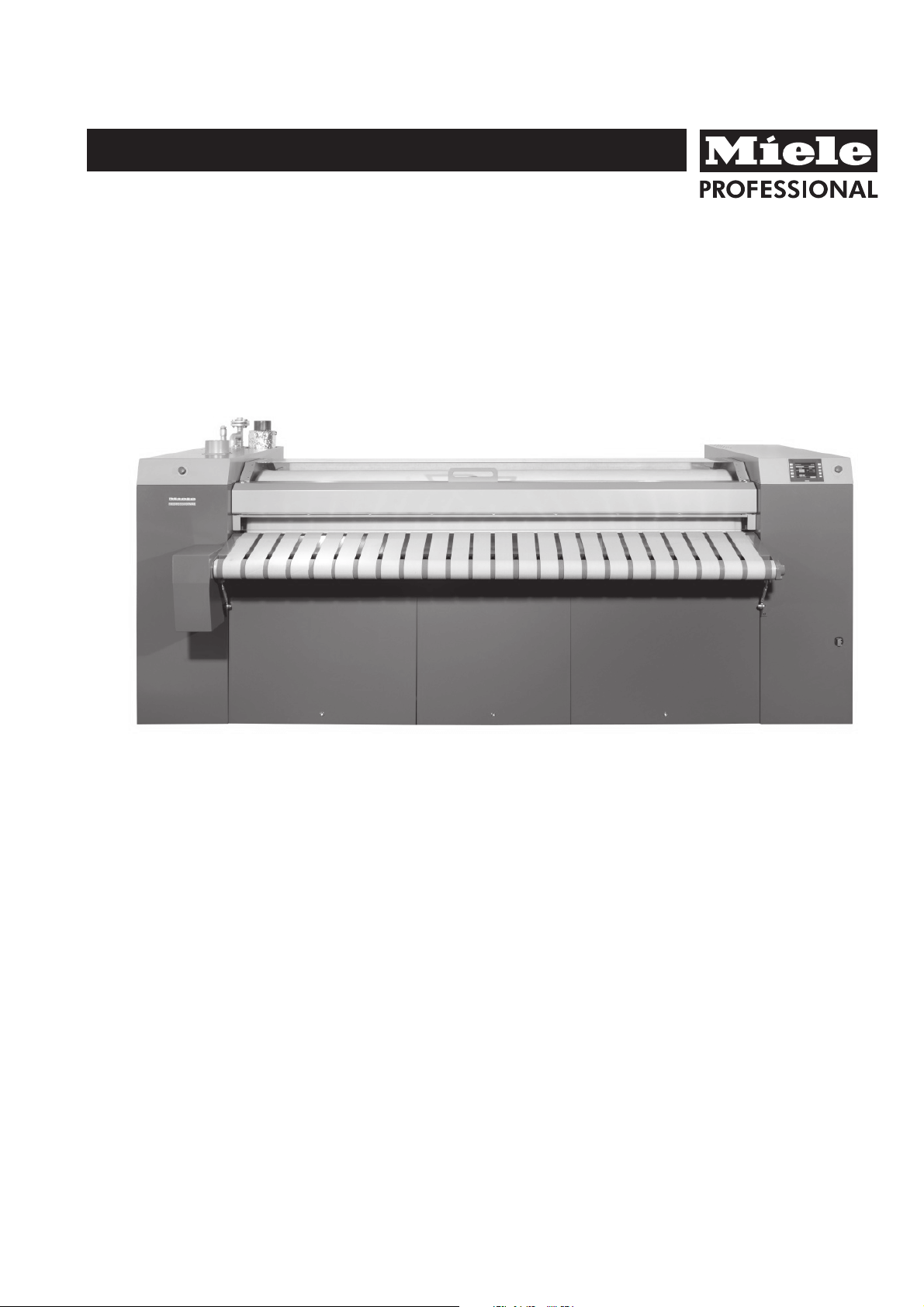

Operating instructions

Rotary ironer

PM 1621

PM 1625

PM 1630

PM 1635

PM 1825

PM 1830

PM 1835

To avoid the risk of accidents or damage to the machine it is

essential to read these instructions before installing,

commissioning and using it for the first time.

en-GB

M.-Nr. 09 404 660

Page 2

2

Page 3

Contents

Warning and Safety instructions...............................................................4

Caring for the environment ...................................................................7

Guide to the machine ........................................................................8

Preparing the laundry.......................................................................12

Condition of laundry .........................................................................12

Preparing the flatwork........................................................................12

Operation .................................................................................13

Preparation for use ..........................................................................13

Language...............................................................................13

Ironing....................................................................................13

Forward roller movement .....................................................................15

Using residual heat..........................................................................15

Stop clock function (optional) ..................................................................15

After ironing: ...............................................................................15

Notes ....................................................................................16

Protecting the padding .......................................................................16

Emergency release if there is a power cut whilst ironing .............................................16

Menu structure .............................................................................17

Cleaning and care ..........................................................................19

Cleaning and waxing the heater plate ...........................................................19

Maintenance ..............................................................................20

Disconnecting (securing) the roller .............................................................20

Leaf-type roller padding ......................................................................21

Heating system .............................................................................22

Wax trap ..................................................................................22

Bearing: ..................................................................................22

Condensate ...............................................................................22

Heat transfer oil for the heater plate.............................................................

Air filter ...................................................................................22

Service ...................................................................................23

Notes for the installer .......................................................................24

Storing the machine .........................................................................24

Operating conditions ........................................................................24

Installing the machine........................................................................24

Electrical connection ........................................................................24

Exhaust ducting for vapour extraction ...........................................................25

Exhaust air volume setting ....................................................................25

Gas connection.............................................................................26

Exhaust ducting ............................................................................26

Steam connection ...........................................................................27

External compressed air connection ............................................................27

Ventilation ducting for the oil reservoir ...........................................................27

Technical data .............................................................................28

22

The rotary ironer must be installed and commissioned by a Miele

service technician or by a Miele authorised Service Dealer.

3

Page 4

Warning and Safety instructions

It is essential to read these instructions.

~

This rotary ironer complies with all relevant safety

requirements. Improper use can, however, lead to

personal injury and damage to property.

To avoid the risk of accidents and damage to the

machine, please read these instructions carefully

before using it for the first time. They contain

important information on its safety, use and

maintenance.

Technical and electrical safety

The machine must not be operated in the same

~

room as dry cleaning machines which use solvents

containing PERs or CFCs.

The ironer must only be operated in a room with a

~

low relative humidity level.

Any removable outer panels must be back in

~

place, and all heated, moving or electrical parts

shielded before the machine is switched on.

Do not damage, remove or bypass the safety

~

features, fixtures and control elements of the

machine.

Do not make any alterations to the machine,

~

unless authorised to do so by Miele.

Do not use a machine with damaged controls or

~

cables. These must be repaired before it is used

again.

Keep these instructions in a safe place and ensure

that they are made available to new users. They

must be made aware of these Warning and Safety

instructions.

Pass these instructions on to any future

users/owners of the machine.

Correct application

The rotary ironer must be used as described in these

instructions and must be checked on a regular basis

to make sure it is functioning correctly. Maintenance

must be carried out when necessary.

Only iron materials with this ironer which are

~

suitable for machine ironing and which were washed

in water.

If the ironer is used in a publically accessible

~

room, it is the supervisor's responsibility to ensure

that suitable measures are in place which enable

operators to use it safely.

The ironer is not intended for outdoor use.

~

Repairs to electrical appliances should only be

~

carried out by a suitably qualified and competent

person in strict accordance with current local and

national safety regulations. Repairs and other work by

unqualified persons could be dangerous. The

manufacturer cannot be held liable for unauthorised

work.

Faulty components must only be replaced by

~

genuine Miele original spare parts. Only when these

parts are fitted can the safety standards of the

machine be guaranteed.

The electrical safety of this machine can only be

~

guaranteed if connected to a correctly installed

earthing system on site. It is most important that this

basic safety requirement is observed and tested

regularly, and where there is any doubt the on-site

electrical system should be inspected by a qualified

electrician. The manufacturer cannot be held liable

for the consequences of an inadequate earthing

system (e.g. electric shock).

The machine is only completely isolated from the

~

electricity supply either when it is switched off at the

isolator switch or the mains fuse has been

disconnected.

4

Page 5

Warning and Safety instructions

Use

This ironer must not be left unattended during use.

~

Children and unauthorised people must be kept

~

away from the rotary ironer.

This machine is not a toy! To avoid the risk of

~

injury, keep children well away and do not allow them

to play on or near the rotary ironer or to operate it

themselves.

The machine can only be used by people with

~

reduced physical, sensory or mental capabilities, or

lack of experience or knowledge, if they are

supervised whilst using it or have been shown how to

use it in a safe way and understand the hazards

involved.

When the ironer is heated up with the heater plate

~

in position, there is an acute danger of burning, if the

edge of the heater plate is touched on the feed out

side.

When ironing double layered items, do not reach

~

in between the layers to straighten out the fabric. This

is extremely dangerous as you may not be able to

extract your hands in time. The same applies when

ironing garments with pockets.

Using accessories

Accessory parts may only be fitted when

~

expressly approved by Miele. If spare parts or

accessories from other manufacturers are used, this

will invalidate the guarantee, and Miele cannot

accept liability.

Notes on the use of this machine

– This ironer must be operated at all times in

accordance with the legal requirements of the

Health and Safety Acts.

– When working with the ironer, always wear close

fitting clothes and keep long hair tied back. Wide

sleeves, apron straps, scarves and ties etc. could

be taken in by the roller.

– Remove rings and bracelets before ironing.

– Smooth out folds as far away from the feed-in on

the feed-in table as possible. Feed pillow cases

and duvet covers into the ironer with the open end

first. Do not take hold of the corners from the

inside. Do not take hold of vest straps or apron

straps etc. from the inside.

Do not iron items with fringes, thin ties and straps

~

etc. These could get tangled in the feed-in belts and

cause a fault.

Ensure the room in which the ironer is being used

~

is sufficiently lit

Keep the area around the ironer free from clutter.

~

Always keep a fire extinguisher accessible in the

~

rare event of textiles igniting.

The ironer may only be used in mobile installations

~

such as ships if a risk assessment of the installation

has been carried out by a suitably qualified engineer.

It is imperative that all local and national safety

regulations concerning the use of this machine are

observed.

– Check daily that safety devices are correctly set.

This way you will avoid the danger of burns,

squashed fingers and even loss of hands.

– Check daily that safety devices are functioning

correctly.

– Make sure that safety features cannot be bridged.

– Before switching to reverse make sure that nobody

is endangered.

– With gas heated machines ensure the room has

sufficient ventilation.

– Switch the machine off before lubricating it.

5

Page 6

Warning and Safety instructions

Gas safety

Safety precautions to take if you smell gas (gas

heated ironers only):

Natural gas usually has no smell of its own. In the UK

a smell is added for safety reasons.

Turn off the gas emergency control valve

^

immediately. This is usually located near the gas

meter.

Warning and safety symbols on the machine

Read the operating instructions

^ Do not enter a room with an open flame where

there is the smell of gas.

^ Eliminate all sources of ignition in a safe manner.

Do not smoke, light cigarette lighters or matches.

^ Do not operate electrical lights or switches, i.e. do

not switch them “On” or “Off”.

^ Open all windows and doors to ventilate the area.

^ If the smell of gas persists, evacuate the building.

In the UK you must now: Call the Gas Emergency

Service on 0 800 111 999. For any gas work in

the UK always use a Gas Safe registered

engineer.

In other countries please follow relevant country

specific procedures on gas.

Read the instructions e.g.

installation instructions.

Caution, hot surfaces.

Caution, voltage up to 1000 Volts.

Earth

Danger of squashing

Important: When commissioning and before

concluding any maintenance, conversion or repair

work it is essential that a test for possible leakages

is carried out. All components which carry gas

must be checked, including the gas supply

stopcock and burner jets.

In the U.K. this must be carried out by a Gas Safe

registered engineer. Particular attention should be

paid to the measuring stubs on the gas valve and

the burner. Testing must be carried out with the

burner switched on and switched off.

All personnel working with this machine must be fully

trained in all aspects of its use and safety.

Keep these instructions in a safe and accessible

place.

6

Page 7

Disposal of the packing material

The packaging is designed to protect the machine

during transportation. The transport and protective

packing has been selected from materials which are

environmentally friendly for disposal and should be

recycled.

Rather than just throwing these materials away,

please ensure that they are recycled. Ensure that any

plastic wrappings, bags, etc are disposed of safely

and kept out of the reach of babies and young

children. Danger of suffocation.

Disposing of your old machine

Electrical and electronic machines often contain

materials which, if handled or disposed of incorrectly,

could be potentially hazardous to human health and

to the environment. They are, however, essential for

the correct functioning of your appliance. If handled

or disposed of incorrectly they could be potentially

hazardous to human health and to the environment.

Please do not therefore dispose of it with your general

waste.

Caring for the environment

Please dispose of it at your local community waste

collection / recycling centre, or contact Miele for

advice. Please contact your dealer, your local waste

collection centre or scrap merchant about potential

recycling schemes.

Ensure that it presents no danger to children while

being stored for disposal.

7

Page 8

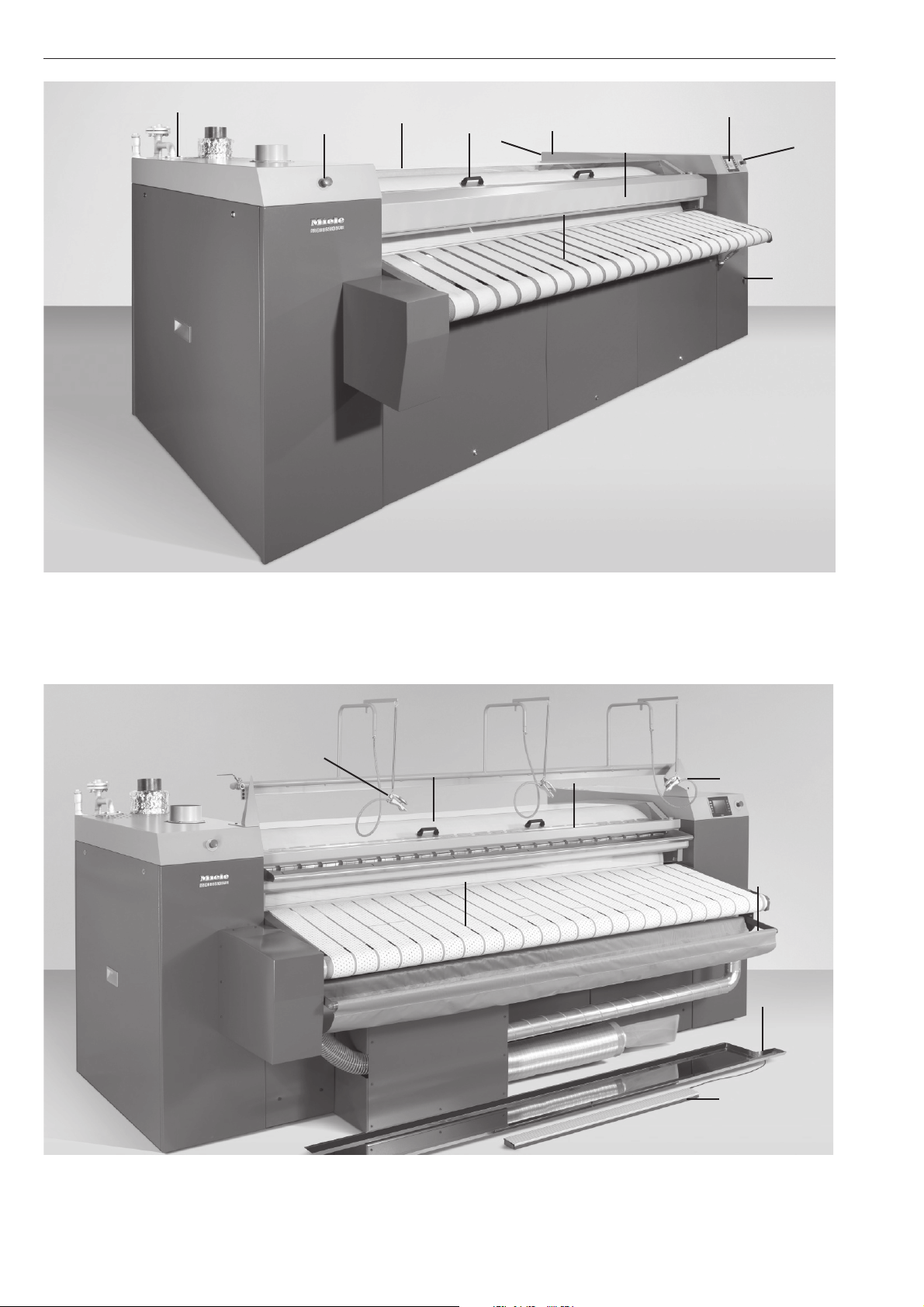

Guide to the machine

5

5

6

4

5

7, 8

3

1

5

2

9

1 Control panel 2 Feed-in table 3 Finger guard

4 Cover/Roller (optional) 5 Emergency stop switch 6 Out-table

7 Main switch 8 Service key switch 9 Compressed air valve

14

10

15

16

17

11

12

13

Optional: 10 Roller cover 11 Laundry table for small items 12 Hygiene guard 13 Foot control bar

14 Textile dampening 15 Return feed

17 Laser feed guide ¡

8

¢ 16 Feed-in table Plus with suction

Page 9

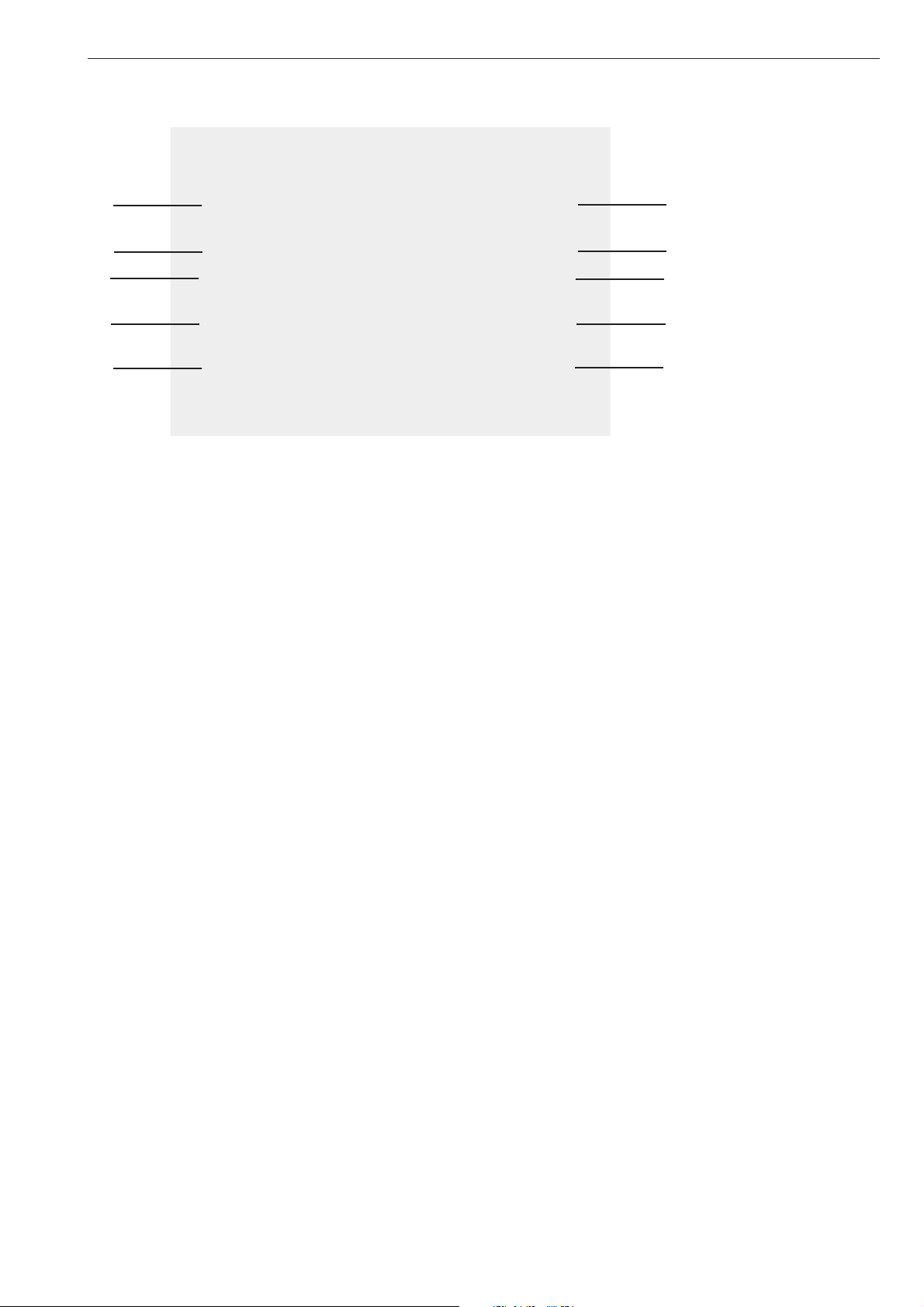

Buttons on the control panel

1 6

2 7

3 8

4 9

5 10

Guide to the machine

"Ironer speed" buttons1=+ 2=-

The revolution speed of the roller can be increased

using + and decreased using - in Universal mode .

The speed set and the actual speed are shown in the

display.

3 l "Start/Stop" button

When this button is pressed, the roller is lowered and

turns or is raised and stops.

4 ! button "Heating on/off"

Button symbols according to heating type:

Electric !

Gas *

When this button is pressed the heating is switched

on or off.

The status is shown in the display.

Steam h

On steam-heated machines, when the h "Steam"

button is pressed, steam pressure is shown in the

display or Automatic heat-up (optional) is activated.

6

# "Menu" button/ one level up in menu

7 X "Programme list" button:

The programme list shows all programmes which can

be selected directly.

8 J "Language" button

For selecting the desired user guidance language.

The language must be available and activated.

9 Y "Scroll down sub menu" button

10 Y "Scroll up sub menu" button

5 , "Quit" button

After a fault has occurred, it can be cleared by

pressing this button.

9

Page 10

Guide to the machine

Display

11 12

13 14

15 16

17 18

20 19 24

25

22

26 27 23

11 Menu

12 Time

13 Ironer

14 Ironer programme number

15 Ironer feed-in target speed

16 Ironer feed-in actual speed

17 Feed-in heater plate target temperature

18 Display heater plate actual temperature

19 Activate suction vacuum table (optional)

20 Activate laser-guided feed-in (optional)

21 Information text

22 User levels

23 Activate high pressure (optional)

24 Laundry return feed (optional)

25 Motor current (only in technician's level)

26 Stop time function (optional)

27 Forward roller movement

Additional symbols in the display:

¤

! Fault

name

programme name

Wax symbol

(please clean and wax the heater plate

10

Page 11

Guide to the machine

Safety features

Master switch

Switches the power supply for the rotary ironer on I or

off 0. This switch can be secured with a padlock if the

rotary ironer needs to be switched off in the event of a

fault or for maintenance work.

Emergency stop switch

Finger guard

If fingers slip between the laundry feed-in table and

the finger guard, the roller will stop turning and lift

immediately. The finger guard is not active if the roller

is running in reverse.

If the finger guard has been activated the machine

can only be restarted by quitting the fault using the

button , and by pressing the l "Start/Stop" button.

One on both the left and right hand columns on the

feed-in side and the output side.

As soon as an emergency stop switch is pressed, the

roller stops turning and lifts immediately.

Only use the emergency stop switch or finger

guard to stop the machine in the case of an

emergency, and not for normal switching off.

To reset an emergency stop switch after it has been

used, turn the switch clockwise.

The finger guard is a safety feature which must be

checked daily for proper functioning before the

machine is used.

Service key switch

During work on the rollers, the ironer or the

compressed air system the roller is lifted into the

repair position. See "Maintenance".

11

Page 12

Preparing the laundry

Condition of laundry

For a good finish the ideal residual moisture level lies

between 25 - 50 %, depending on the condition of the

fabric.

Rinsing the laundry using hot water in the final rinse

helps to reduce the residual moisture level, and the

residual heat in the laundry will help reduce

processing time, saving energy.

Preparing the flatwork

Before starting to iron, laundry should be sorted

according to size and type of fabric.

First iron articles made from:

perlon, nylon etc. temperature 100 - 110°C

then iron

woollens, silks temperature 111 - 150°C

then iron

cottons and linen fabric temperature 151 - 180°C

.

If you want to switch back to ironing at a lower

temperature, reduce the temperature setting and then

wait until the "Heating" indicator light comes on again.

Starched laundry should be ironed last to prevent any

starch residues on the heater plate from affecting

other items of laundry.

Items with buttons should be passed through the

ironer with the buttons facing into the roller padding.

If they face downwards there is a danger of them

being damaged or torn off when the item is passed

through the ironer.

A cloth should be placed over zips, metal buttons

and hooks to protect the heater plate during ironing.

Metal and plastic buckles and very bulky buttons

should not be passed through the ironer.

Warning. Before using the ironer you should

clean the heater plate by running a cloth through

the entire width of the roller.

12

Page 13

Operation

Preparation for use

Open site stopcock for compressed air.

^

Open site stopcock for gas (gas heating only).

^

Open site stopcock for steam (steam heating only)

^

very slowly and only a little way. This is not

necessary with Automatic heat-up.

If steam has accumulated, the stopcock to the

,

machine must only be opened very slowly in

several stages. Turning the steam stopcock

abruptly will damage the machine. This is not

necessary with Automatic heat-up.

^ Switch on the main power supply switch.

The following will appear in the display:

Finger guard test

Activate the finger guard

The following will appear in the display:

Operation

UNIVERSAL 0

Target value Actual value

m/min

°C

Switch heating on

7.4

180

m/min

°C

08:45:58

Operator

Language

If a different user guide language is to be selected:

^ Press J "Language" button

The display will appear in a different language with

each press of the button. The language must be

available and activated.

Ironing

^ Press the heating button.

Button symbols according to heating type:

Electric !, Gas *

(Steam h does not need to be pressed)

0.0

19

The finger guard is a safety feature which must be

checked daily for proper functioning before the

machine is used.

^ Push the finger guard in the direction of the roller.

The following will appear in the display:

Message

Finger guard function

OK

OK

^ Press OK.

The * heating and D fan symbols appear in the

display. The machine is heating up when these

symbols show constantly in the display.

The machine is ready to use when the temperature

set is reached.

The following appears in the display: Ironer ready for

use

^ Start the machine by pressing the l "Start/

Stop" button.

An acoustic signal sounds and the roller is lowered.

Allow the roller to rotate for about 5 minutes to enable

the heat to equalise between the heater plate and the

roller.

,

When the ironer is heated up with the heater

plate in position, there is an acute danger of

burning, if the edge of the heater plate is touched

on the feed out side.

13

Page 14

Operation

To select a programme press the X "Programme

^

list" button.

Programme shortcut

UNIVERSAL PROGRAMME 5

PROGRAMME 1 PROGRAMME 6

PROGRAMME 2 PROGRAMME 7

PROGRAMME 3 WAX PROGRAMME

PROGRAMME 4 PROGRAMME 9

Operator

09:25:55

^ Select the UNIVERSAL programme or select a

suitable programme for the type of laundry.

1/20

Temperature

Operation

UNIVERSAL 0

Target value Actual value

m/min

°C

Switch heating on

Press the display field "Target value °C" highlighted

^

7.4

180

m/min

°C

08:45:58

0.0

Operator

grey.

180

123

456

789

.0

# <=

OK

19

Temperature, ironer speed and pressure (optional)

can all be adjusted in the UNIVERSAL programme.

Temperature, ironer speed, pressure

These parameters can only be adjusted in the

Universal programme.

Target and actual values are shown in the display.

Adjust the heater plate temperature according to

laundry type.

Material Temperature range

Polyester / artificial silk 100 - 110°C

Silk / wool 111 - 150°C

Cottons / linen 151 - 180°C

^ Enter the required temperature into the input field

and confirm with OK.

The temperature cannot be altered for steam

heated ironers.

Temperature adjustment is optional.

Speed of ironer

^ Adjust the

ironer speed according to laundry type

and residual moisture using the + or - buttons.

The ironer speed can also be altered via the display

field "Ironer speed" highlighted grey.

^ Enter the required ironer speed into the input field

and confirm with OK.

Pressure

£ (optional)

Roller pressure can be increased by pressing the

control field in the display. The field will then turn

green.

14

Page 15

Operation

Laundry feed-in

Feed-in Plus table with suction (optional)

Feed-in belts make it easier to feed laundry into the

ironer.

^ Laundry should be placed parallel to the roller at

the start of the feed-in table. Make sure it lies flat

across the feed-in belts as it goes in.

Do not restrict ironing of smaller articles to any one

part of the roller. Make use of the whole roller width.

Forward roller movement

The forward roller movement (at the feed-in belts)

tensions the laundry as it is drawn in. Standard value

- 5%. Pressing the control field changes the forward

roller movement.

Equal

=

1 5%

2 10 %

3 15 %

Using residual heat

(not steam-heated machines)

The heating can be switched off before ironing is

finished to make use of residual heat in the heater

plate. To maintain the same standard of laundry

finish, the ironer speed is slowed down automatically.

Time remaining until the ironer switches off

automatically is shown in the display.

Stop clock function (optional)

By pressing the + "Stop clock" field, the stop clock

is started and the field turns green.

If the stop clock is stopped by pressing the

clock" field, the ironing process stopped or the

programme changed, the stopped time is saved.

Completed ironer times are shown on the 2nd display

page (X button) with date, time and programme.

The stop times can be deleted by pressing the

field.

+ "Stop

reset

Foot control bar (optional)

^ The foot control bar

of laundry or in the event of feed-in errors.

The roller will stop.

^ The roller starts again as soon as the foot control is

released.

The ironed laundry can be very hot when it comes

off the ironer.

Pick-off bands

can be used for smaller items

After ironing:

Allow the roller to run for approx. 5 minutes with the

heating switched off to allow the padding to dry out.

Switch the ironer off using the l "Start/Stop" button

^

For gas or steam-heated machines, close the

^

on-site stopcock.

^ Switch off at the main switch on the rear of the

right-hand column.

Allow the ironed laundry to cool down before

,

packing or stacking it. Hot laundry could self-ignite

and cause a fire.

The pick-off bands are used for picking laundry off

the roller.

15

Page 16

Notes

Protecting the padding

Switch the machine off during pauses in ironing to

prevent damage to the padding.

It is very important to avoid running the ironer

without passing laundry through it.

Do not restrict ironing smaller articles to any one part

of the roller; make use of the whole roller width. This

way an equal amount of heat is obtained from the

heater plate and the roller padding is protected from

uneven use.

Emergency release if there is a power cut

whilst ironing

The roller lifts automatically in the event of a power

cut.

Once power is restored, the ironer is switched back

on by pressing the l "Start/Stop" button.

16

Page 17

Menu structure

Notes

Main menu

via service key

Operation Heater

Messages Report history

Programmes Process programme

Reset programme

Statistics Operating hours

Report counter

(Number)

Service Parameters Interfaces

Data backup Programmes

Report counter

(Duration)

Set-up

Diagnosis Hardware

Event log

System log

Languages

Settings Display

Date / time

PIN

Info

Service level is PIN-protected and is accessible only to Miele service personnel.

Technician's level is also PIN-protected. The PIN is: 0189

17

Page 18

Notes

Access to the Technician's level

Operator

Service

Technician

^ Press Technician.

^ Input PIN (0189) and press OK.

The operation menu appears in the display:

Operation

UNIVERSAL 0

Target value Actual value

m/min

°C

Switch heating on

^ Press

# "Menu" button.

7.4

180

m/min

°C

08:45:58

Operator

The following menus are displayed:

Main menu

Operation

Messages

Programmes

Statistics

Service

Messages

– Message history

All messages are displayed here.

Programmes

– Process programme

Here you can give a programme a name and

number. Roller speed, roller lead, heater plate

temperature, pressure (optional) can be set.

– Reset programme

A programme can be deleted here.

Statistics

–

Operating hours

Total number of operating hours.

0.0

19

Service

Parameters

Interfaces

–

IP address, Subnet screen, Std. Gateway

Machine

–

Roller lead 5 %

Ironer off when foot switch operated for 180 s

Trough cleaning time interval 8 h

Data backup

– Programmes

Programmes saved to USB, Compact Flash

Diagnosis

– Hardware

Slots ST1-ST15forcontrol hardware in- and

outputs can be checked here.

Active slots are highlighted in green. If they are red,

there is an error.

– Event log

Technician actions carried out, e.g. "Password level 2

selected" are marked with date and time.

– System log

System messages are shown here which in the case

of a fault can be passed on to Miele Service.

Languages

The operating language is activated or deactivated

here.

Settings

– Display

Display brightness can be adjusted here.

– Date / time

Date, time and summer- and wintertime can be

adjusted here.

– PIN

The password for the Technician's level can be

changed here.

Info

Serial number of the machine, AR, software status,

version, node number, CPU temperature , control

battery status.

–

Report counter

Number of messages displayed, e.g. emergency

stop, finger guard, cover.

–

Report counter

Number and time of messages.

18

Page 19

Cleaning and care

Cleaning and waxing the heater plate

Regular cleaning and maintenance of the heater plate

is essential for ensuring consistent ironing results, as

well as for protecting the motor and the roller cover. It

also helps to prolong the life of the machine.

This machine is fitted with a steel heater plate.

Deposits (starch and detergent residues) can build

up on the heater plate.

Do not use any abrasive cleaning agents or

,

sandpaper .

The steel heater plate must only be cleaned using

cleaning agents approved by the manufacturer.

Use the cleaning set. It consists of a cleaning cloth, a

waxing cloth and wax. This set is available to order

from Miele as an accessory.

When the message

appears in the display (optional), select Waxing

programme 8. The wax symbol

display. It will go out again when the waxing

programme is finished.

Clean the heater plate before waxing.

Please clean and wax plate

¤ will appear in the

Feed-in direction

^ To wax, sprinkle wax into the pockets of the waxing

cloth

Use the wax sparingly to avoid the roller cover

becoming too smooth.

^ Fold over the top third of the cloth to close it.

^ Feed the wax cloth through the hot ironer.

^ Feed the cloth into the machine repeatedly, moving

along the whole width of the roller from left to

right.

If

Please clean and wax plate does not appear in the

display (optional):

Clean the heater plate at the start of the working day

and use the waxing cloth without wax.

Clean and wax the heater plate according to laundry

throughput.

^ Select the waxing programme.

(Temperature setting 180°C, low roller speed, high

contact pressure.)

Feed-in direction

^ Leave the waxing programme. Feed in a damp

cloth across the entire roller width using the

universal programme to remove any wax and

starch residues.

Pick-off bands

The tips of the pick-off bands need to be cleaned

occasionally to remove any build-up of residues such

as starch.

Important: Feed in the steel wool cleaning strips face

downwards, towards the heater plate.

^

Feed the cloth into the machine repeatedly, moving

along the whole width of the roller from left to

right.

The heater plate should always be waxed after it has

been cleaned.

^ Mark the position of the pick-off segment and

dismantle the pick-off segment. Do not use the

rotary ironer without the pick-off bands fitted.

Danger of crushing.

^

Relocate it to its original position after cleaning.

19

Page 20

Maintenance

Maintenance must be carried out only by Miele

,

Service or other authorised suitably qualified and

competent personnel.

Disconnecting (securing) the roller

During work on the roller, the ironer or the

compressed air system the roller is lifted into the

repair position leaving a space between the roller and

the heater plate.

^ Switch on the main power supply switch.

^ Set the service switch to I.

The following appears in the display on user level:

Open both service panels on the side columns.

^

The roller is in the raised position.

Set-up

m/min

5,0

Position

14:36

START

Operator

The roller is in the raised position.

Press

Position: Lower roller, raise roller.

Press START: The roller only rotates whilst this

control is touched.

In technician's level inputting the PIN brings up the

following in the display:

Set-up

14:36

^ Loosen the screws securing the safety bolts on

both sides.

^ Push the safety bolts into the holes and tighten the

screws back up again.

^ Remove the cover plate if necessary.

Work on the roller, heater plate or compressed air

system can now be carried out.

To secure the roller again:

20

m/min

START

5,0

Position

Rotation direction

Technician

^ Loosen the screws securing the safety bolts on

both sides.

^ Pull the safety bolts back out of the holes on both

sides and tighten the screws back up.

^ Close both service panels on the side columns.

Page 21

Maintenance must be carried out only by Miele

,

Service or other authorised suitably qualified and

competent personnel.

Roller diameter

PM 1621, PM 1625,

PM 1630, PM 1635

Maintenance

Max. diameter (with

cover) 600 mm

Removal and replacement of the roller

plate cover should be undertaken only by

Miele Service or other authorised,

suitably qualified and competent

personnel.

Leaf-type roller padding

Only iron articles up to max. 3 mm thick. Bulky

fabrics, protruding buttons, curtain weights etc.

could damage the leaf-type padding.

After commissioning

It is advisable approx. 40 operating hours after

commissioning to cut back the overlap of the roller

cover (which has occurred through stretching) to

about 30 mm, and then to brush out about 15 mm of

this using a wire brush.

This will help to prevent damp streaks and pressure

imprints. The roller padding must be the same

thickness across the whole width of the roller, and fit

firmly up to the heater plate.

PM 1825, PM 1830,

PM 1835

Max. diameter (with

cover) 800 mm

Discolouration of the roller cover

Some discolouration of the roller cover from light to

dark brown is normal.

To minimise discolouration:

– Always use the complete width of the roller.

– Space out smaller items, and do not always iron

them in the same place.

– Switch the machine off during pauses in ironing.

21

Page 22

Maintenance

Heating system

Errors or faults in the heating system are shown in the

display and must only be rectified by Miele Service or

other authorised, suitably qualified and competent

personnel.

Gas heated machines

The interior of the machine, the burner cavity and the

burner should be checked regularly for any build-up

of fluff and cleaned as required by a Miele service

technician or suitably qualified and competent

person.

To ensure the correct performance of the

,

machine and to prevent the risk of faults and fire

risk it is important to check the machine and carry

out maintenance on a regular basis.

Wax trap

The wax trap is located in the exhaust air ducting

connection for vapour extraction. Condensate and

wax flows back along a tube into a drip cup located

underneath the left-hand column.

Condensate

Accumulated condensate from the oil reservoir on the

left-hand column must be drained once a year.

2

1

^ To do this, open the drain valve (1) with an SW 11

spanner and collect the condensate.

Filling connection (2) for oil.

Heat transfer oil for the heater plate

An analysis of the heat transfer oil must be carried

out once a year.

^ Check the tube (see arrow) regularly for blockages.

^ Remove and check the drip cup. Dispose of any

wax in an environmentally friendly way.

Bearing:

Lubrication (applies for all bearings):

at least once a year.

Air filter

Air filter on the fan for the control box at the back of

the right-hand column.

^ Remove the grille sideways (see arrow) and clean

the paper insert once a week with a vacuum

cleaner.

22

Page 23

Service

In the event of any faults please contact the Miele

Service Department.

When contacting the Service Department, please

quote the Model, Serial number (SN:) and Material

number (M.Nr).

See data plate for details.

Only use spare Parts approved by the manufacturer.

When ordering spare parts please quote the Model,

Serial number (SN:) and Material number (M.Nr).

Maintenance

23

Page 24

Notes for the installer

The rotary ironer must be commissioned by a

Miele authorised service technician.

The machine must not be operated in the same room

as dry cleaning machines which use solvents

containing PERs or CFCs. Escaping vapours could

ignite on the motor and form hydrochloric acid which

can have dangerous consequences.

Storing the machine

The following conditions must be observed for

transport and storage:

Temperature: minimum -25°C to maximum 55°C

Air humidity: minimum5%tomaximum 75 %,

non-condensing

Maximum storage duration: 2 years

Electrical connection

Electrical connection may only be carried out by a

suitably qualified technician in strict accordance with

local and national safety regulations (BS 7671 in the

UK).

When installing a residual current device (RCD), a

type B (sutable for detecting high frequency AC and

DC earth leakage current) must be installed.

This ironer conforms to the requirements of

EN 60204-1.

The machine is supplied ex-works for

400 V~ 3N 50 Hz.

See data plate for details.

Connection should be made via a suitable isolator

which complies with local and national safety

regulations.

Operating conditions

Operating conditions as specified in EN 60204

generally apply.

Temperature and relative air humidity

Temperature: 5°C - 40°C

Relative air humidity: 10% - 85%

At an ambient temperature of 21°C (40°C) the

maximum permissible relative air humidity is 70%

(50%).

Installing the machine

This machine is classified as Class A. It can cause

radio interference if set up in living areas.

The machine is transported to the installation location

in packaging.

Remove all packaging prior to commissioning.

4 points for lifting gear such as straps and hooks are

located near the top of the side columns.

When setting the machine leave at least 600 mm

space at either side of the machine so that the side

panels are accessible.

For hard-wired machines, connection should be

made via a suitable mains switch with all-pole

isolation which when in the off position ensures a 3

mm gap between all open contacts. These include

circuit breakers, fuses and relays (IEC/EN 60947).

The socket connection or isolator switch should be

easily accessible for disconnecting the machine from

the electricity supply for service or maintenance work.

If the machine is isolated from the electrical supply

adequate measures must be taken to ensure that it

cannot be reconnected to the electrical supply until

all work has been carried out.

Leave a minimum of 1.5 m free space in front of and

behind the machine to prevent surrounding materials

(furnishings, walls) from becoming too hot. There

should be a minimum space of 1 meter above the

machine.

Levelling and securing the ironer

Use a spirit level and the adjustable feet to align the

machine.

Tighten the counter nuts on each foot up against the

machine columns.

24

The wiring diagram and connection box are located

in the right hand side column. Mains connection is via

the main switch which is located in the control box.

Equipotential bonding

The leakage current of this machine is more than 10

mA. Equipotential bonding should be carried out.

Connection should be made in accordance with

the wiring diagram, the installation diagram and

the installation. It is important to follow all of these

carefully to ensure the machine is connected

correctly.

Page 25

Notes for the installer

After connecting the machine

If the phase order of the electrical connection is

incorrect the exhaust fan in the left-hand column

turns in the wrong direction.

Disconnect the machine from the mains and change

two phases over.

Check the exhaust fan rotation. When looking at the

motor, the exhaust fan should turn in an

anti-clockwise direction.

To prevent the build-up of condensation and wax the

machine is fitted with a wax trap. The tube for

disposal of wax and condensate is located in the

left-hand column and must be checked regularly for

blockages.

Ensure that there is sufficient ventilation in the room

where the ironer is installed.

If the exhaust is ducted into the outside air, the end of

the duct should be protected against the elements.

An exhaust system ducted into the open air must be

situated in such a way that it does not cause a

nuisance.

The on-site ducting system and the exit point to the

outside must be checked on a regular basis for a

build-up of fluff and cleaned, if required.

Exhaust air volume setting

The exhaust air outlet is located in the left-hand

column

Exhaust ducting for vapour extraction

Follow the fitting instructions supplied.

The exhaust ducting must not be directed into any

chimney or flue which is used by gas, solid fuel or oil

fired appliances. It must also be kept separate from

any exhaust system leading from a tumble dryer.

The warm, moist exhaust air should be discharged to

the outside air by the shortest route possible.

Air throughput is greatest on the lowest screw setting

(see diagram) and can be reduced by turning the

screw to 90°. The ideal setting is reached when the

roller dries out sufficiently to leave no water spots

either on the covering or on flatwork with the lowest

throughput of air. If the air throughput is too high the

roller will cool down too much, thus reducing the

ironer's performance.

To ensure optimum flow, the ducting should be laid

with as few bends as possible and all connections

and joins should be airtight.

The connection point for the exhaust ducting is

located on the top of the left hand column and has a

diameter of 150 mm.

25

Page 26

Notes for the installer

Gas connection

Gas connection work must be carried out by an

authorised fitter in accordance with local and national

safety regulations including gas regulations, building

regulations and fire regulations. This must be a Gas

Safe registered technician in the UK.

The gas group to which the machine has been set at

the factory is given on the Gas Data label on the rear

of the machine.

Follow the fitting instructions supplied.

After setting up and connecting the machine

,

successfully ensure that all removable outer

panels are correctly fitted back into position.

Do not attempt to repair or work on gas-heated

,

appliances yourself. Repairs must only be carried

out by an authorised technician to ensure safety.

In the event of a fault please contact the Miele

Service Department.

Exhaust ducting

The exhaust ducting to be installed on site must not

be directed into any chimney which is used by gas,

solid fuel or oil fired appliances.

The connection point for the exhaust ducting is

located on the top of the left hand column and has a

diameter of 125 mm.

,Ensure that there is sufficient ventilation in the

room where the ironer is installed.

Follow the fitting instructions supplied.

26

Page 27

Notes for the installer

Steam connection

Steam connection must only be carried out by an

authorised installer.

To avoid unnecessary heat tension ensure that

heating up is even (no sudden bursts of steam). If

steam has accumulated, the stopcock to the machine

must only be opened very slowly in several stages

Turning the steam stopcock abruptly will

,

damage the machine.

Steam and condensation ducting connections

Machine connection flange DIN 2635, DN 32.

Minimum nominal diameter of the pipe (DIN 2402) is

DN40.

Follow the fitting instructions supplied.

External compressed air connection

The connection (10 mm) for the compressed air hose

is located on the front of the right-hand column. The

duct is located at the back of the right-hand column.

The air operating pressure in the compressed air

system of the machine must remain constant during

functional operation.

Min. 6 to max. 10 bar at 80 l/h consumption.

The compressor must exceed the consumption by

20-30%.

Ventilation ducting for the oil reservoir

Installation suggestion

1 Stop cock

2 Condensate drain

3 Dirt trap

4 Stop cock

Machine connection flange DIN 2633, DN 32.

5 Non-return valve

These components are installed on-site.

Lay the pipes so that the operating components of

the ironer remain accessible.

Insulate the pipes against heat loss (also serves as

personnel protection insulation). Protect insulation

material from moisture.

27

Page 28

Technical data

PM 1621E/G PM 1625E/G/D PM 1630E/G/D PM 1635E/G/D

Height in mm 1970/1970 1970/1970/1630 1970/1970/1630 1970/1970/1630

Width in mm 3290 3690 4190 4690

Depth in mm 1840 1840 1840 1840

Weight in kg 2390/2600 2550/2760/2600 2760/2970/2830 2950/3170/3050

Voltage See data plate

Connected load See data plate

Fuse rating See data plate

Test certificates

awarded

Max. load bearing

in operation in N

Steam pressure in bar 10

Gas pressure in mbar 14 - 300

Air pressure Min. 6 to max. 10 bar at 80 l/h consumption.

Product safety standard EN 60204-1, EN ISO 10472-1, EN ISO 10472-5

24000/26100 25600/27800/25600 27800/29900/27800 29700/31900/30000

See data plate

Emission sound

pressure level in

dB (A), EN ISO 11204

Sound power level in

dB (A), EN ISO 9614-2

PM 1825E/G/D PM 1830E/G/D PM 1835G/D

Height in mm 1970/1970/1630 1970/1970/1630 1970/1630

Width in mm 3690 4190 4690

Depth in mm 2044 2044 2044

Weight in kg 2990/3200/3280 3250/3470/3600 3730/3900

Voltage See data plate

Connected load See data plate

Fuse rating See data plate

Test certificates awarded See data plate

Max. load bearing

in operation in N

Steam pressure in bar 10

Gas pressure in mbar 14 – 300

Air pressure Min. 6 to max. 10 bar at 80 l/h consumption.

Product safety standard EN 60204-1, EN ISO 10472-1, EN ISO 10472-5

Emission sound pressure

level in

dB (A), EN ISO 11204

Sound power level in

dB (A), EN ISO 9614-2

30200/32300/32200 32800/35100/35400 37700/38300

66

66

28

Page 29

29

Page 30

United Kingdom:

Miele Co. Ltd.

Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW

Customer Contact Centre Tel.: 0330 160 6600

E-mail: mielecare@miele.co.uk

Internet: www.miele.co.uk

Alteration rights reserved/2615

M.-Nr. 09 404 660 / 03

Loading...

Loading...