Operating Instructions

Laboratory Glassware Washer

PLW 8617

To prevent accidents and machine damage,

read these instructions before installation or

use.

en - US, CA

M.-Nr. 11 463 470

2

Contents

Guide to the manual ........................................................................................................ 6

Proper use........................................................................................................................ 7

User profiles..................................................................................................................... 8

Machine description........................................................................................................ 9

Machine overview.............................................................................................................. 9

Control elements on the display........................................................................................ 11

Main menu..................................................................................................................... 11

Program start display .................................................................................................... 13

IMPORTANT SAFETY INSTRUCTIONS .......................................................................... 18

Symbols on the machine................................................................................................... 23

Main menu........................................................................................................................ 24

Main menu......................................................................................................................... 24

Actions in theMain menu.............................................................................................. 24

Changing the display language ................................................................................. 25

Login........................................................................................................................... 25

Logout ........................................................................................................................... 26

Printing documentation ................................................................................................. 26

Opening and closing the door....................................................................................... 26

Application technology ................................................................................................... 27

General information........................................................................................................... 27

Transfer trolley ............................................................................................................... 27

Load carriers ................................................................................................................. 27

Arranging the wash items.............................................................................................. 28

Preparing the wash items.............................................................................................. 29

Before starting a program ............................................................................................. 31

At the end of a program ................................................................................................ 31

Laboratory glassware and utensils .................................................................................... 32

Program overview.............................................................................................................. 33

General program information ............................................................................................ 34

Programs for specific soiling ............................................................................................. 35

Programs for specific wash items ..................................................................................... 36

Additional programs.......................................................................................................... 37

Service program................................................................................................................ 37

Chemical processes and technology ............................................................................ 38

Dispensing liquid process chemicals............................................................................ 42

Dispensing systems .......................................................................................................... 42

Containers for process chemicals................................................................................. 43

Filling containers with process chemicals..................................................................... 43

Filling the dispensing system ........................................................................................ 44

Operation.......................................................................................................................... 45

Switching the machine on and off..................................................................................... 45

Loading the wash cabinet ................................................................................................. 45

Selecting a program .......................................................................................................... 46

Selecting a load carrier.................................................................................................. 46

Selecting programs from Favorites ............................................................................... 47

Starting a program ............................................................................................................ 48

3

Contents

Program sequence ............................................................................................................ 48

End of program.................................................................................................................. 49

Canceling a program......................................................................................................... 49

Program cancellation with manual disinfection ............................................................. 49

Delay start ......................................................................................................................... 50

Network connection........................................................................................................ 51

Network connection .......................................................................................................... 51

Network protocols............................................................................................................. 52

Process documentation .................................................................................................... 52

System settings ............................................................................................................... 53

System .............................................................................................................................. 53

Network connections ........................................................................................................ 53

Changing the PIN .......................................................................................................... 54

Granting write permissions............................................................................................ 55

Configuring the printer .................................................................................................. 56

Configuring the network................................................................................................ 57

Machine functions ............................................................................................................. 58

Automatic system test................................................................................................... 58

Carrying out self-disinfection (optional)......................................................................... 59

Starting the continuous program................................................................................... 60

Filling the dispensing system ........................................................................................ 61

Dispensing system setup .............................................................................................. 61

Calibrating the conductivity meter ................................................................................ 63

Carrying out a program test .......................................................................................... 64

Restarting .......................................................................................................................... 66

Opening the data plate Menu............................................................................................ 66

Managing favorites............................................................................................................ 67

Maintenance measures................................................................................................... 68

Maintenance...................................................................................................................... 68

Routine checks.................................................................................................................. 69

Cleaning the filters in the wash cabinet ............................................................................ 70

Cleaning the spray arms.................................................................................................... 71

Cleaning the machine........................................................................................................ 73

Locking the display ....................................................................................................... 73

Checking mobile units, modules, and inserts ................................................................... 75

Built-in printer (optional) .................................................................................................... 76

Replacing the paper roll ................................................................................................ 76

Thermal paper ............................................................................................................... 77

Fault messages and instructions................................................................................... 78

Representation of faults on the display............................................................................. 78

In the main menu........................................................................................................... 78

In the program sequence .............................................................................................. 78

Technical faults on the machine ........................................................................................ 79

List with active messages ............................................................................................. 79

Troubleshooting............................................................................................................. 80

Technical faults without fault number............................................................................ 81

After sales service........................................................................................................... 82

4

Contents

Electrical connection ...................................................................................................... 83

Electromagnetic compatibility (EMC) ................................................................................ 84

Plumbing .......................................................................................................................... 85

Technical details .............................................................................................................. 86

Disposing of your old machine ...................................................................................... 88

Appendix .......................................................................................................................... 90

User rights in theMain menu ............................................................................................ 90

User rights in the Systemmenu ........................................................................................ 91

Power levels of the programs/mobile units/module combinations ................................... 92

Optional extras .................................................................................................................. 95

5

Guide to the manual

Warnings

Information which is important for safety is highlighted in a thick

framed box with a warning symbol. This alerts you of potential danger of injury to people or damage to property.

Read these warning notes carefully and observe the instructions

and codes of practice described.

Notes

Notes contain information that is particularly important to follow.

They are highlighted by a thickly framed box.

Additional information and comments

Additional information and comments are contained in a simple

frame.

Operating steps

Operating steps are indicated by a black square bullet point.

Example:

Select an option using the arrow buttons and save your choice with

OK.

Display

Certain functions are shown in display messages using the same font

as used for the function itself in the display.

Example:

Menu Settings .

6

Proper use

The PLW 8617Laboratory Glassware Washer is designed to reprocess laboratory glassware, utensils, and similarly categorized components using water-based media.

Appropriate use

Reprocessing encompasses the cleaning, rinsing, and – where necessary – thermal disinfection and drying of the following wash items:

- Vessels such as beakers, flasks, cylinders, and test tubes

- Measuring vessels such as measuring cylinders, volumetric flasks,

and pipettes

- Dishes such as petri dishes and watch glasses

- Plates such as slides and sequencing plates

- Small items such as lids, magnetic stirring rods, spatulas, and stoppers

- Other items such as boxes, plastic flasks and containers, metal

parts, pipe and hose pieces, and funnels

The Laboratory Glassware Washer is generally referred to as “the machine” in these operating instructions. The term “wash items” is used

wherever the items to be reprocessed are not defined in any further

detail. The term “wash water” is used for the mixture of water and

process chemicals.

Reprocessing is carried out in conjunction with:

- Process chemicals which are tailored to the result of the reprocessing

- Load carriers which are tailored to the wash items

Observe the information issued by the manufacturer of the wash

items.

Inappropriate use

The PLW 8617Laboratory Glassware Washer may not be used for

any purposes other than the appropriate use described. This applies

in particular to:

- The reprocessing of medical devices suitable for reprocessing

- Use in the restaurant industry

- Residential or household use

7

User profiles

User administration

Access to the machine is restricted to a certain group of people. Authorized users are entered in User management via the machine’s

web interface. User managementis described in the programming

manual.

A User ID and PIN are required for the user Login on the machine.

User actions such as starting a reprocessing program are saved. User

data is read out on the Reprocessing report, for example.

User profiles

Day-to-day use

Service work

Administration

For day-to-day use, operators must be instructed on the basic functions and how to load the machine and must also be trained regularly.

They must have a basic knowledge of machine reprocessing of laboratory glassware and utensils.

Day-to-day work is carried out using the following user levels:

- Without message

- Automatic

- Operator

Modifications to the machine, such as on-site conditions, require additional specific knowledge of the machine.

They are carried out using the following user levels:

- Technician

- Administrator

Changes to the reprocessing process and performance testing also

require specialist knowledge about machine reprocessing of laboratory glassware and utensils, and about process technology.

They are carried out using the following user level:

- Administrator

8

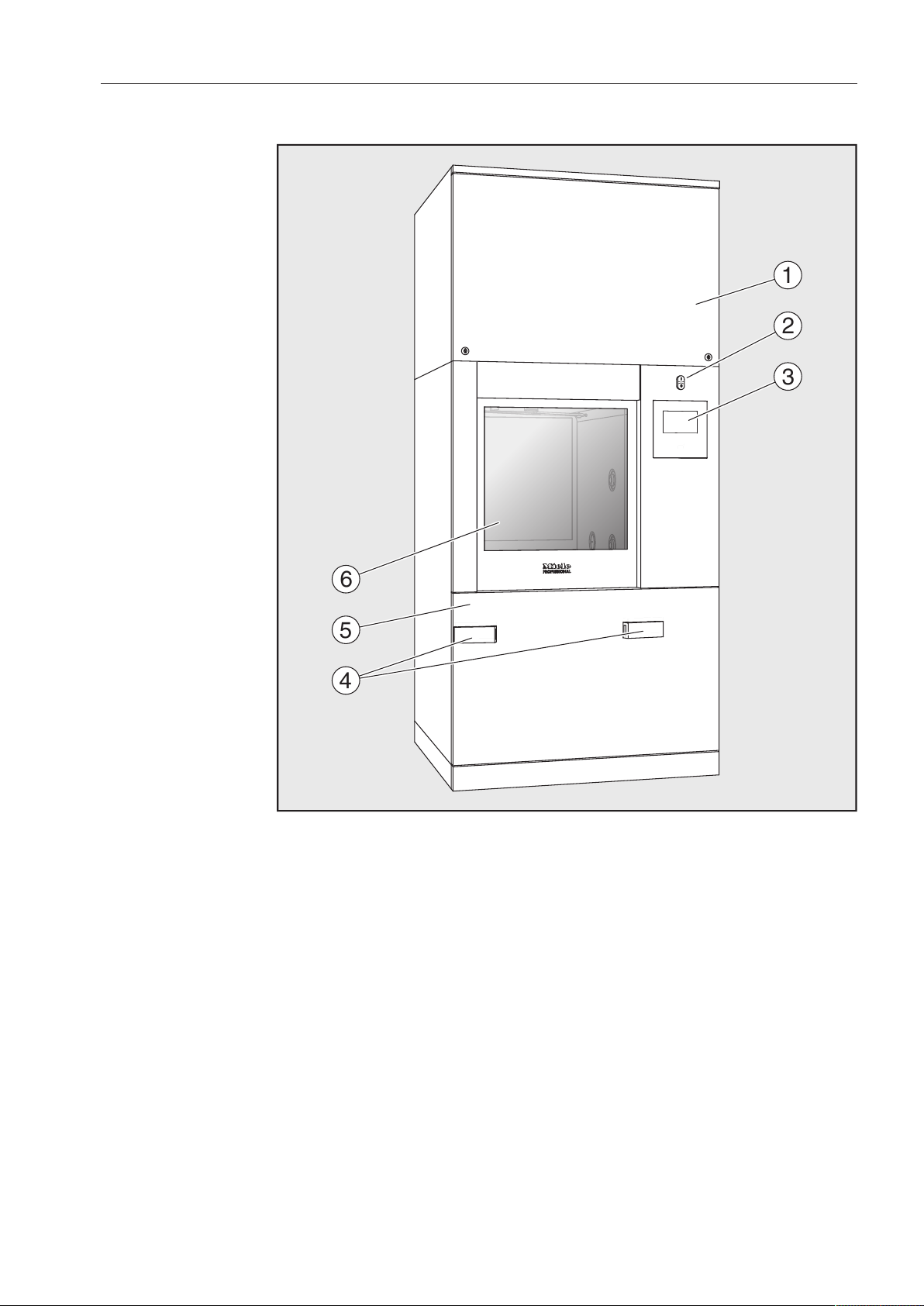

Infeed and out-

1

2

3

5

6

4

feed side

Machine description

Machine overview

a

Service cover for Miele Technical Service

b

I/0 power switch

c

Display

d

Docking system for transfer trolleys,

service cover lock

e

Service cover

f

Door closed

9

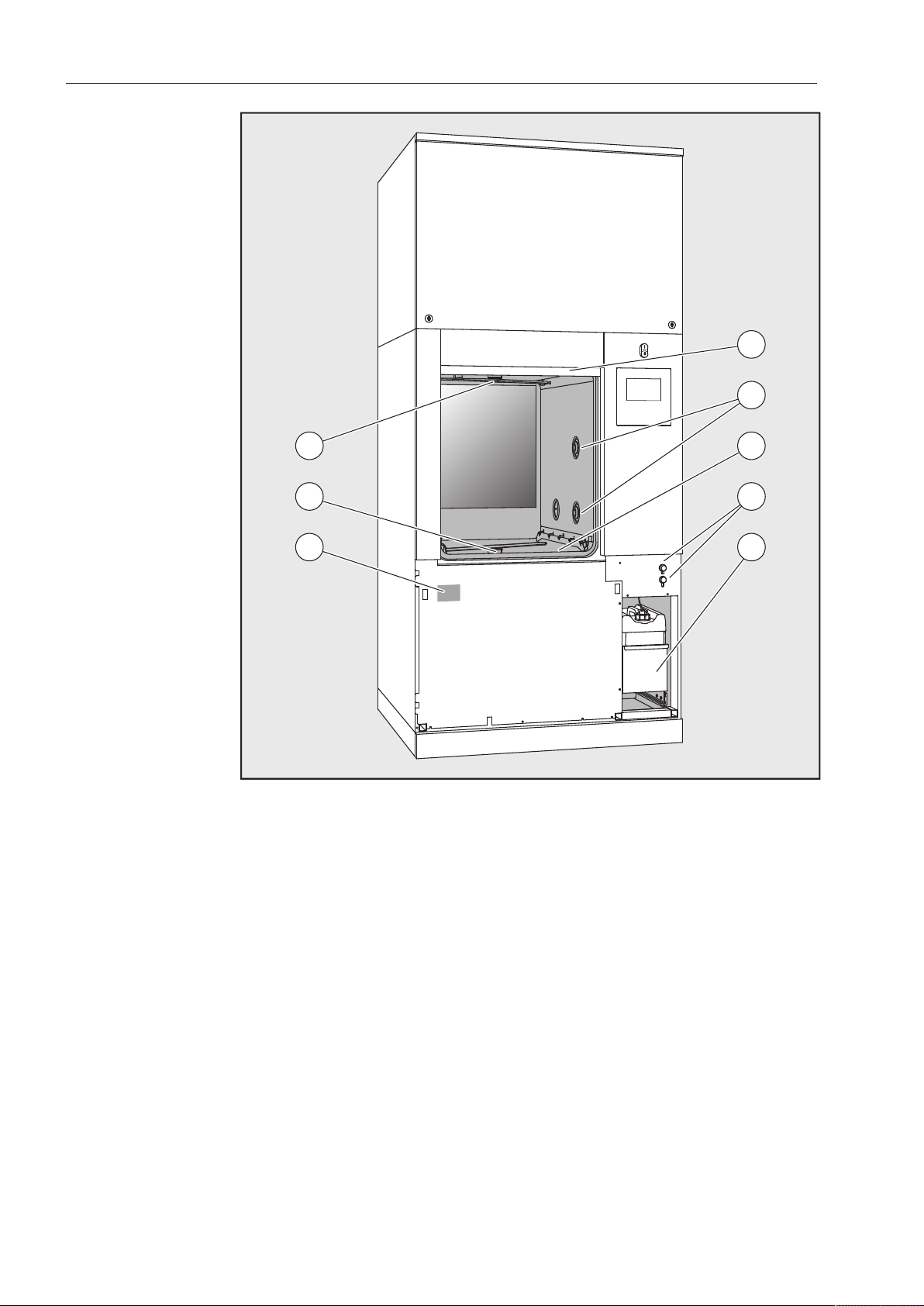

Machine description

1

2

3

4

7

8

56

Infeed and outfeed side without

service cover

a

Door open

b

Water supply for load carriers

c

Filter combination

d

Connections for Miele Technical Service

e

Drawer with containers and connections for process chemicals

f

Data plate

g

Lower machine spray arm

h

Upper machine spray arm

10

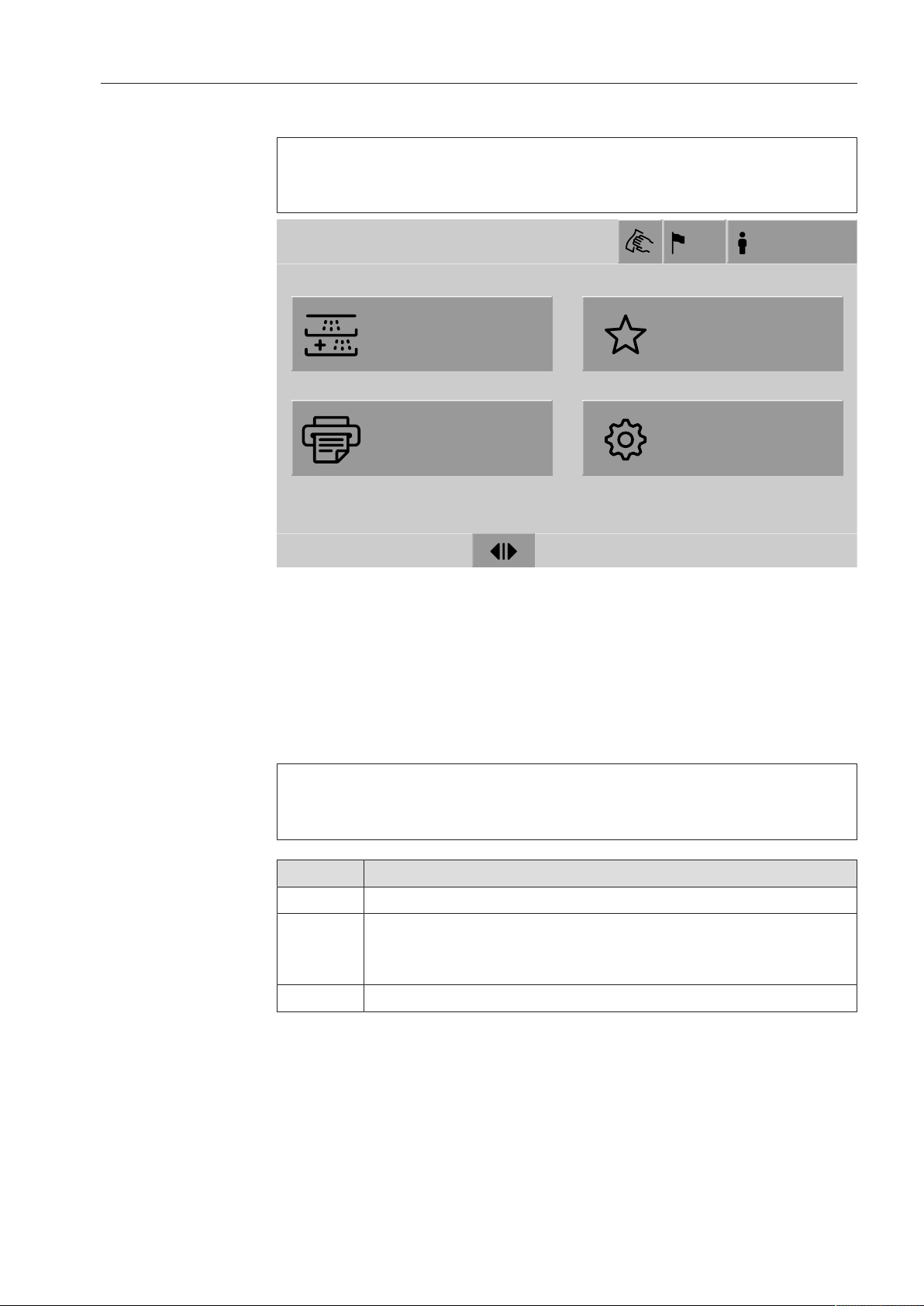

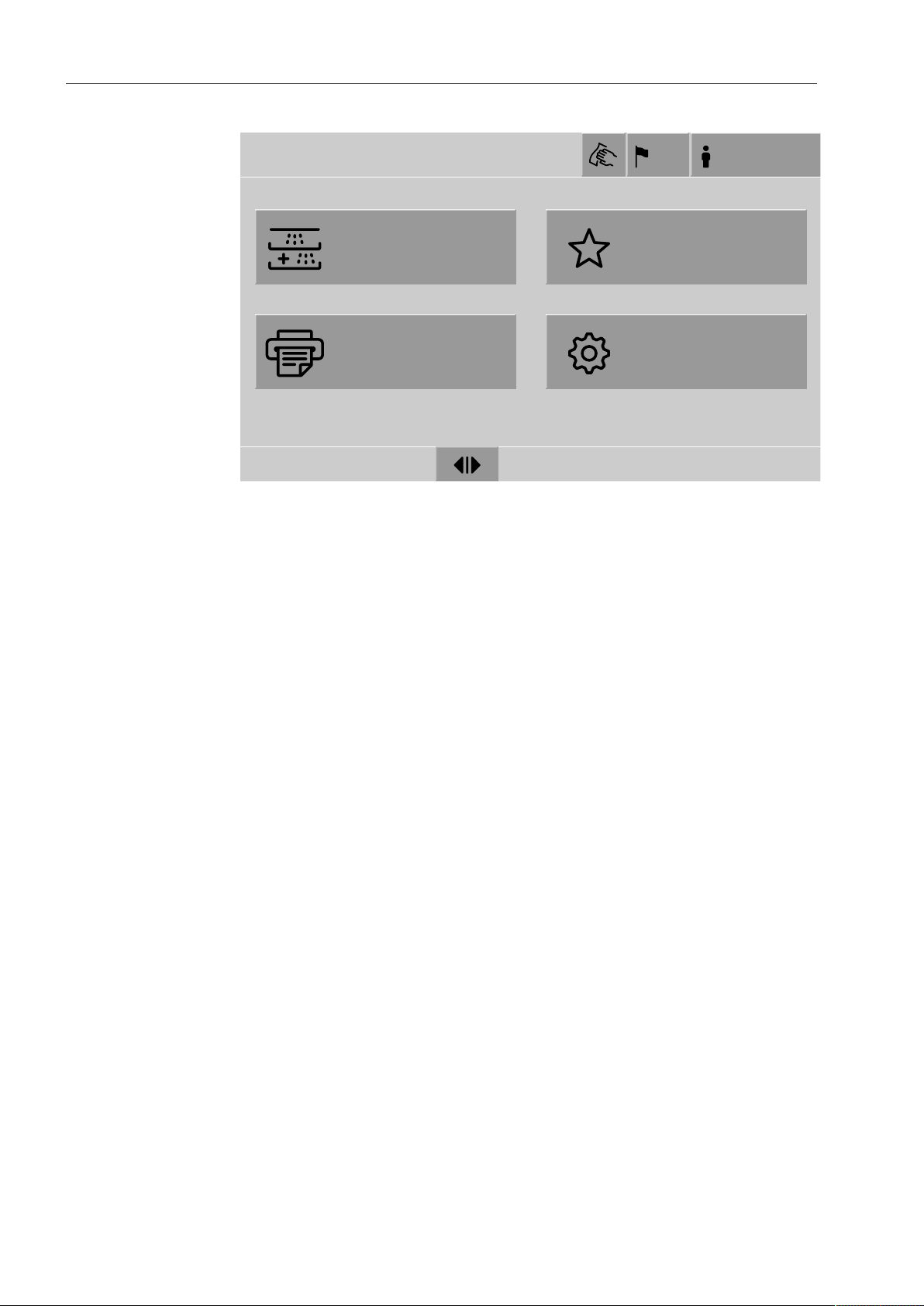

Control elements on the display

Reprocessing

Favorites

Documentation

System

Main menu

US

Login

18.06.2018 15:05

Machine description

Main menu

The machine display shows the control panel light on a black background. In these operating instructions, the display is shown as

black on a light background in order to improve legibility.

a

Header

b

Display language selected

c

Current user

d

Buttons to call up sub-menus

e

Footer

Buttons in the main menu/ header

Buttons for all enabled actions are displayed in the footer.

If a menu is split across several pages, a scroll bar will be displayed

above the footer. Swipe the display or tap the scroll bar to scroll between the pages.

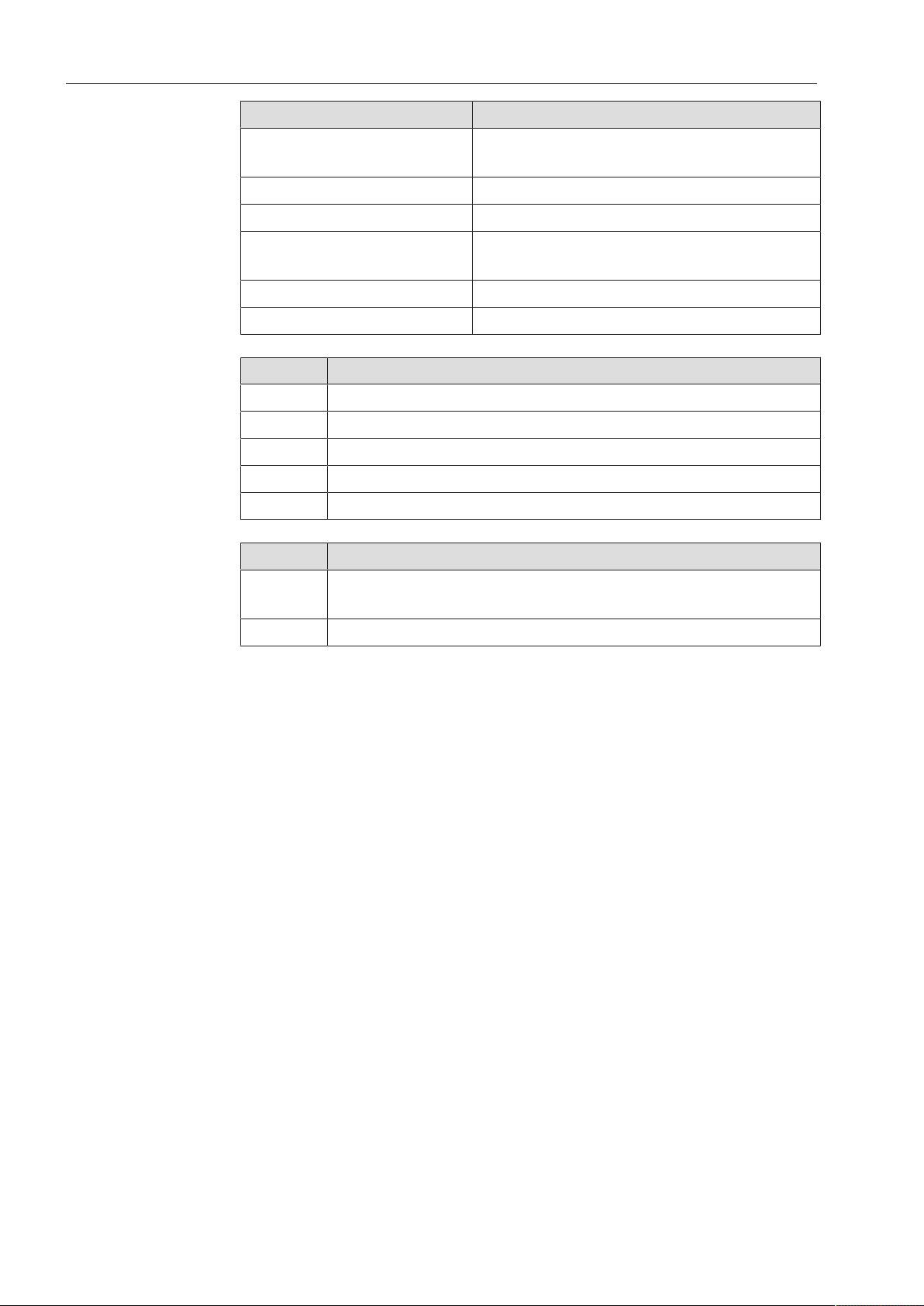

Symbol Description/function of the button

Locks the display, e.g., for surface disinfection

Opens the Select display languagemenu.

Opens the login or logout dialog, e.g., to switch users

The language currently set is indicated after the symbol,

e.g., US

11

Machine description

Symbols in the

main menu

Buttons in the main menu/ footer

Buttons in the submenus/

footer

Symbol Description/function of the button

Reprocessing

Favorites Opens the list of favorites

Documentation Opens the list of available wash reports

System

Information

Please wait – screen is loading

Symbol Description/function of the button

Warning present, opens the Messageslist

Fault present, opens the Messageslist

Opens the door

Closes the door

The door is locked

Symbol Description/function of the button

Leaves menu, goes back to previous menu level, does not

save entries

Opens the list of reprocessing programs

which are assigned to the load carrier

Opens the configuration menu, e.g., for

network settings or to change the PIN

OK Confirms entries

12

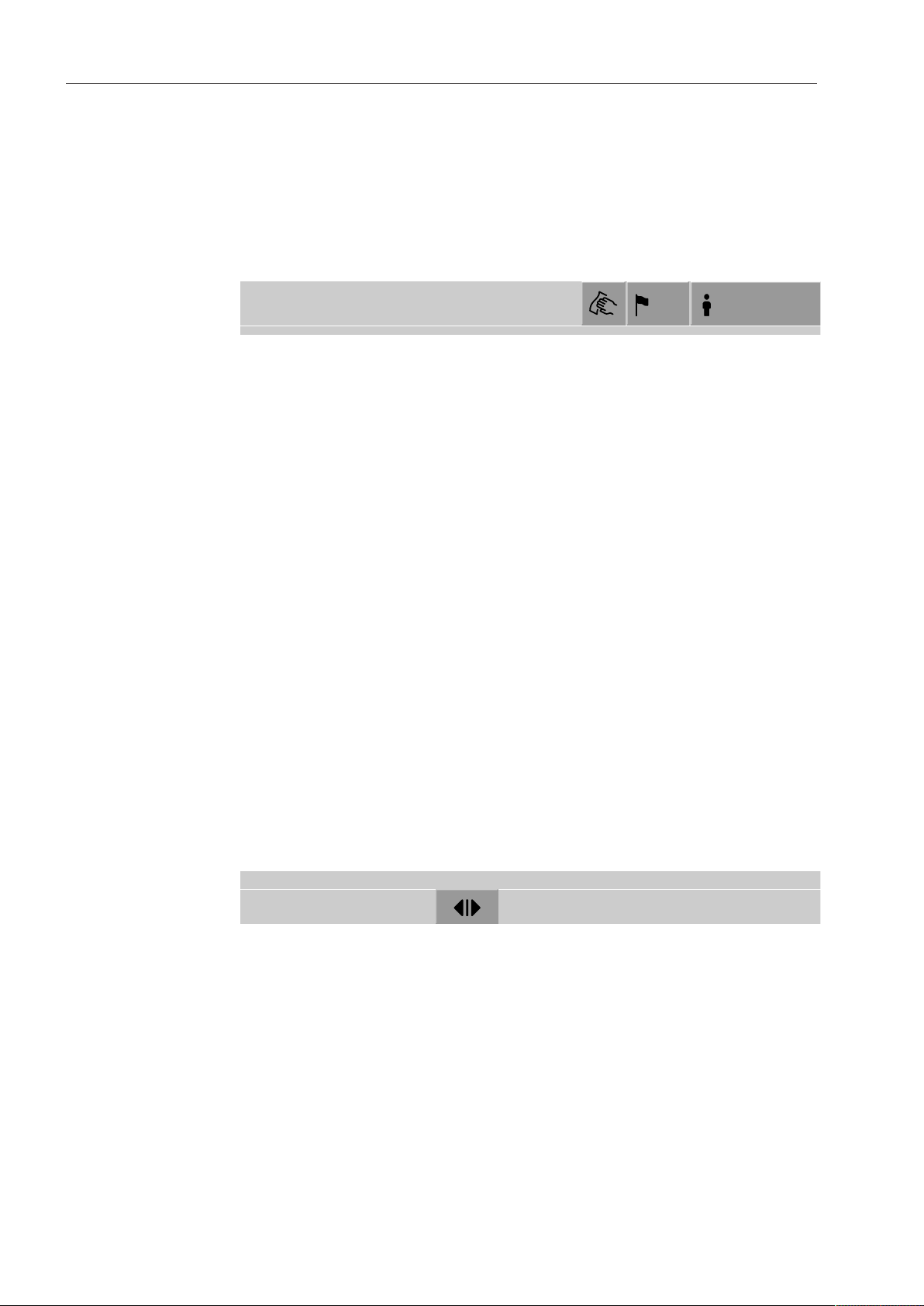

Machine description

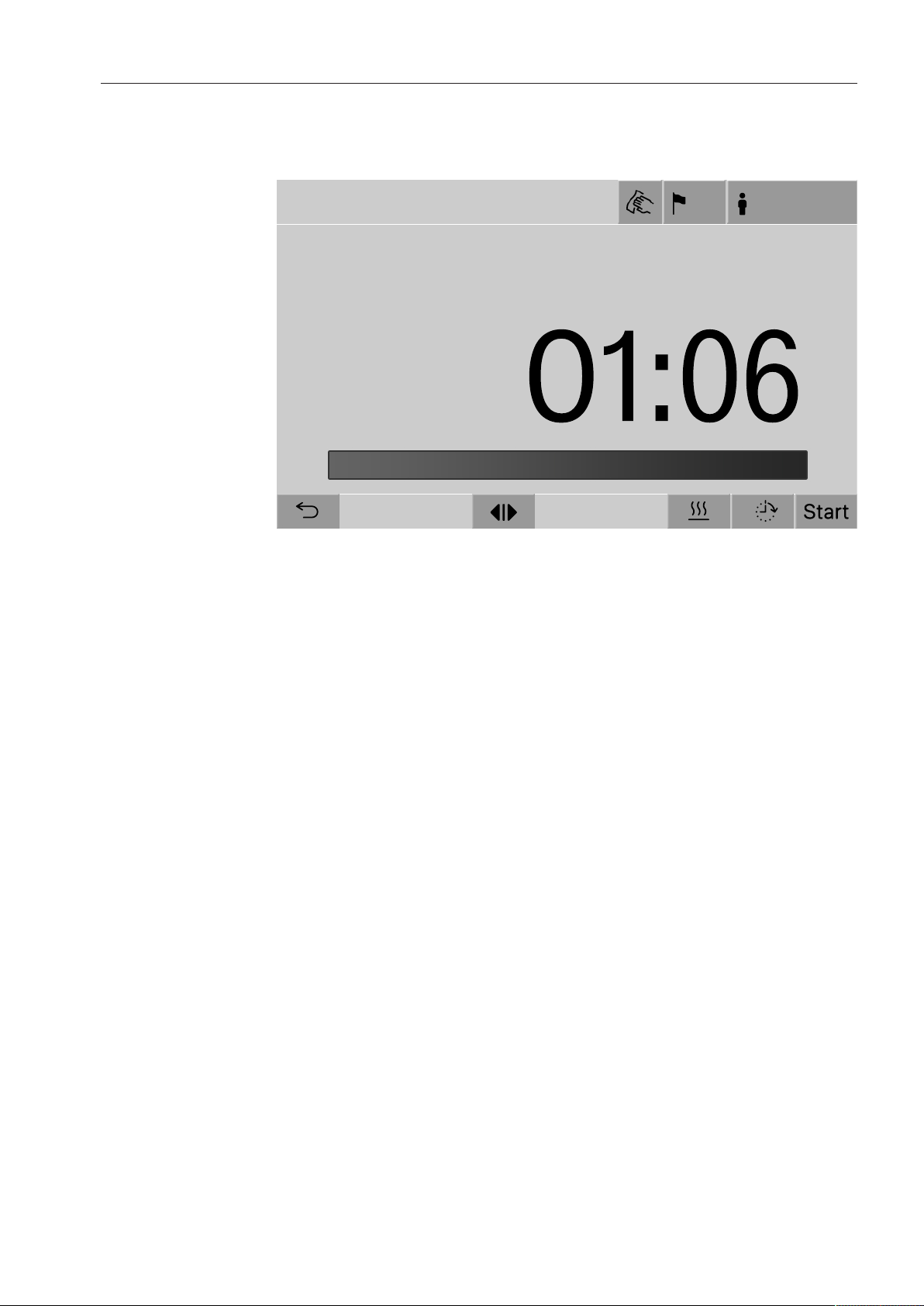

1:06

user/

18.06.2018 15:05

US

BED

Universal

Time left

Program start display

Once the A 500load carrier, for example, has been selected in the

Reprocessingmenu and the associated Universalreprocessing program has been confirmed, the following is displayed:

The pictogram of the load carrier and the selected reprocessing program are displayed in the header.

The duration and a progress bar are shown on the display.

The color of the progress bar corresponds to the current machine

status:

- Black for ready for operation

- White for an ongoing reprocessing program

- Green for a reprocessing program that has been successfully completed

- Yellow for warnings

- Red for faults

13

Machine description

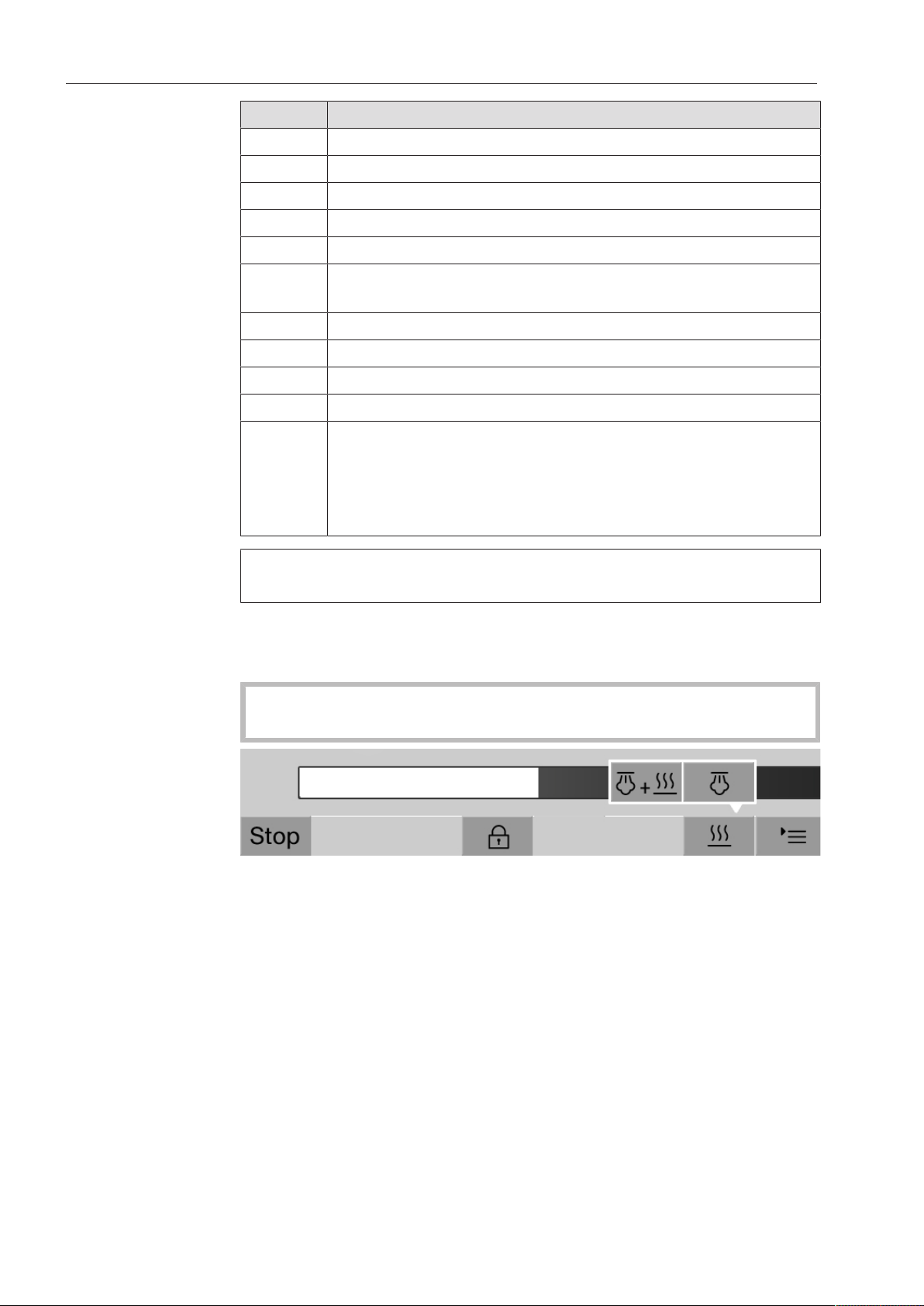

Program start/program sequence

buttons/symbols

Heat-up

context menu (optional)

Symbol Description/function of the button

Program start

Program cancellation

Opens the input screen for selecting the start time

Door locked

Shows the program sequence display in the default view

In/Out

Displays the program sequence as a diagram

Selects the steam heating method

Selects the electric heating method

+ Selects the electric and steam heating method

(next to

the

progress

bar)

This context menu is only available in machines where it is possible

to switch the energy supply from electric to steam.

The energy source for heating can be changed before and during the

program sequence. The selected setting is used for heating up the

wash water and the DI water in the DI water tank.

Schematic program sequence display, contains information for Miele Technical Service

Displays the current faults and warnings in the progress

bar

The selected setting is applied permanently in the machine controls.

Press the button to open the context menu.

14

Machine description

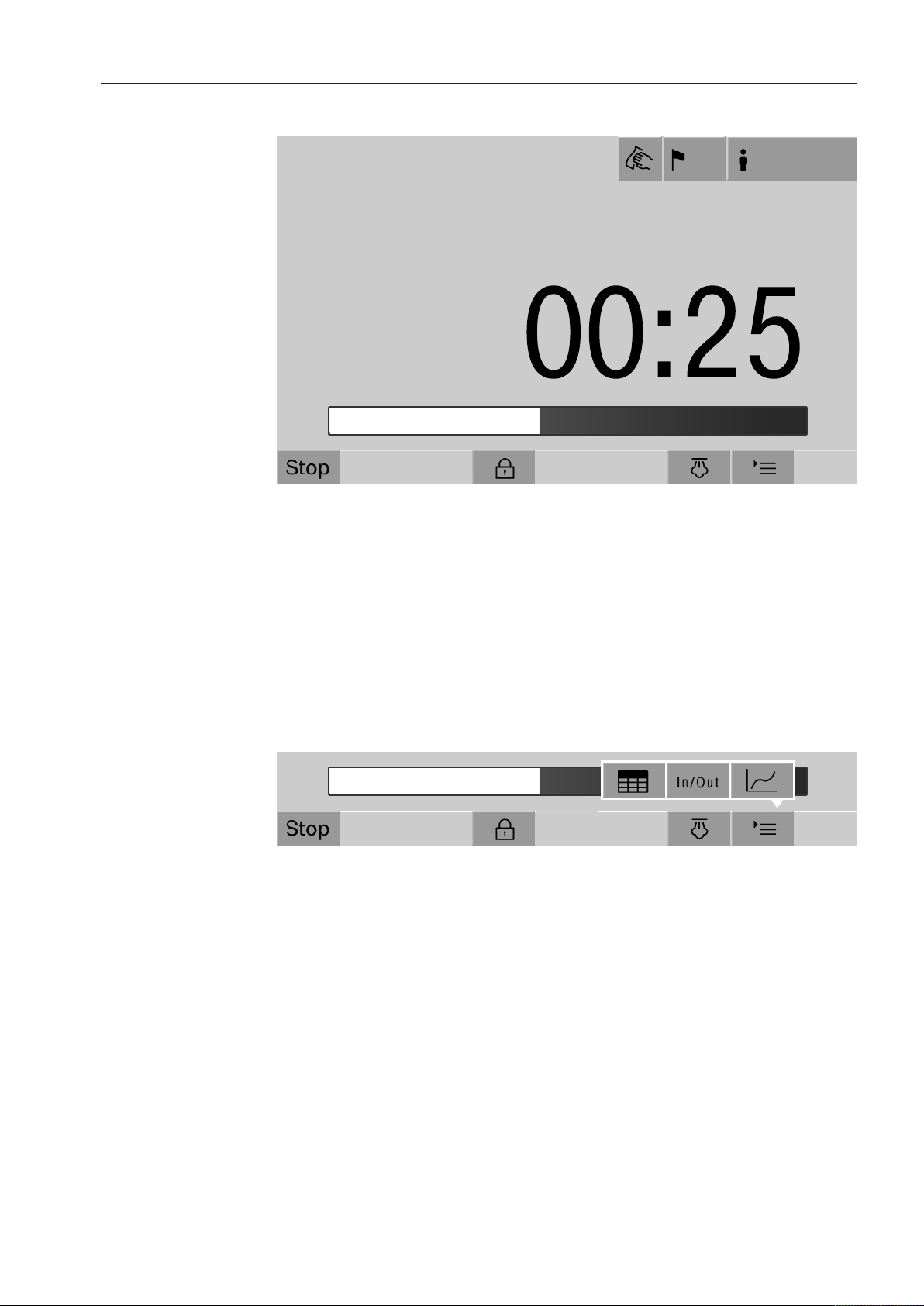

0:25

°C

167 °F

Duration

Universal

user/

18.06.2018 15:05

BED

US

Program block

Temperature

Main wash 1

Example of a program sequence

display

After the program has started, the following display is shown:

The current program phase and the temperature reached are also

shown on the display.

The progress bar indicates the ratio between the duration and the

time left.

Program sequence display context menu

During the program sequence, you can choose between 4views:

- Standard –

- Table –

- In/Out chart – In/Out

- Graphical –

Press the button to open the context menu.

15

Machine description

Program cycle display – table view

Once you have switched to the table view using the button, the

following data is displayed:

- Block name

- Program phase countdown

- Holding time

- Program parameters with the associated target and actual values

and the minimum and maximum values reached

It is possible to scroll to other pages using the scroll bar.

The maximum possible program parameters are:

- Material number and Date of manufacture of the mobile unit

- Cycle number

- User information: First name, Last name, User level

- Temperature of the wash water, sensor 1 and 2 measured values

- Temperature in the dispensing phases 1–3, sensor 1 and 2 measured values

- Temperature of the air during internal drying in phases 1 and 2

- Temperature of the air during external drying in phases 1 and 2

- Water volumes in the program step and the program phase

- Dispensing quantities of the used dispensing systems

- A0-Value

- Conductivity in the water intake and drainage

- Wash pressure for the internal wash water circuit and the PowerPulseCleaning

- Spray arm speeds

16

Machine description

Program sequence display – In/Out chart

Program sequence display – graphical view

The In/Out chart – In/Out contains information about the input signals

(page1), the output signals (page2), and individual sensor measured

values:

- Wash water temperature

- Air temperature

- Wash pressure at the circulation pump

- Conductivity

This information is used by Miele Technical Service and is not explained in these operating instructions.

Once you have switched to the graphical view using the button,

the following values are displayed as curves:

- Wash water temperature [W]

- External air/drying temperature [EA]

- Internal air/drying temperature [IA]

- Internal wash pressure [P]

17

IMPORTANT SAFETY INSTRUCTIONS

Risk to health and risk of damage if the operating instructions

are not followed.

Failure to follow the operating instructions – and in particular the

safety instructions and warnings they contain – may result in persons being seriously injured or property being seriously damaged.

Read these operating instructions carefully before using the machine. This will help prevent the likelihood of both personal injury

and damage to the machine.

Keep these operating instructions in a safe place.

Proper use

Use of the machine is only approved for the applications stated in

the operating instructions. Conversions, modifications, and any other

use are not permitted and could be dangerous.

The cleaning and disinfection processes are only designed for laboratory glassware and utensils which are designated as reprocessable

by the manufacturer. The information provided by the manufacturer of

the wash items must be observed.

This machine is intended for indoor use in a stationary location

only.

The machine is equipped with a special lamp to cope with particu-

lar conditions (e.g., temperature, moisture, chemical resistance, abrasion resistance, and vibration). This special lamp must only be used

for the purpose for which it is intended. It is not suitable for room

lighting. Replacement bulbs may only be installed by Miele Technical

Service.

Risk of injury

Please pay attention to the following notes to avoid injury.

This machine must be commissioned, serviced and repaired by a

Miele authorized and trained service technician only. To ensure compliance with Good Laboratory Practice guidelines, Miele repair and

maintenance contracts are recommended. Unauthorized repairs can

pose considerable risks to the user.

Do not install the machine in an area where there is any risk of ex-

plosion or of freezing conditions.

The electrical safety of the machine can only be guaranteed when

correctly grounded. It is essential that this standard safety requirement is observed and regularly tested. If in any doubt, please have

the electrical installation inspected by a qualified electrician.

18

A damaged or leaking machine could be dangerous and compro-

mise your safety. Disconnect the machine from the electrical supply

immediately and contact Miele Service.

IMPORTANT SAFETY INSTRUCTIONS

Label machines which have been taken out of operation and lock

them to prevent them being switched on again without authorization.

The machine may only be put back into operation once it has been

successfully repaired by Miele Technical Service.

Personnel operating the machine should be trained regularly. Un-

trained personnel must not be allowed access to the machine or its

controls.

Use caution when handling process chemicals. These may contain

irritant, corrosive or toxic ingredients.

Please observe the process chemical manufacturer's safety instructions and safety data sheets.

Wear protective gloves and goggles.

The machine is designed for operation with water and recom-

mended additive process chemicals only. Organic solvents and

flammable liquid agents must not be used as this could cause an explosion, damage rubber or plastic components in the machine and

cause liquids to leak out of it.

The water in the wash cabinet is NOT safe to drink!

Be careful when sorting wash items with sharp, pointed ends. Po-

sition them in the machine so that you will not hurt yourself or create

a danger for others.

Broken glass can result in serious injury when loading or unload-

ing. Damaged glass wash items must not be processed in the machine.

When operating the machine, beware of the high temperatures in-

volved. If you bypass the electrical lock to open the door, there is a

risk of scalding or chemical burns.

Where there is a risk of toxic or chemical substances occurring in

or leaking into the chamber wash water during cleaning (e.g., aldehyde in the disinfecting agent), it is essential to regularly check door

seals and make sure that the steam condenser is functioning correctly.

Opening the machine door during a program interruption carries particular risks in such circumstances.

Should personnel accidentally come into contact with toxic vapors

or process chemicals, follow the emergency instructions given in the

manufacturer's safety data sheets.

After drying with the drying unit, leave the door open at first to al-

low the wash items, mobile unit, modules, and inserts to cool down.

Allow mobile units, modules, inserts, and the load to cool down

before removing them. Any water remaining in containers should be

emptied into the chamber before removing items.

19

IMPORTANT SAFETY INSTRUCTIONS

Steam heating is permissible up to a pressure of 145 psi

(1000kPa). This corresponds to a water steam temperature of 355°F

(180°C).

Never clean the machine with a water hose or a pressure washer.

The machine must be disconnected from the electrical supply be-

fore any maintenance or repair work is carried out.

Quality assurance

The following points should be observed to assist in maintaining

quality standards when processing laboratory glassware and

utensils and avoid damage to the loads being cleaned.

If it is necessary to interrupt a program, as an exception only, this

may only be done by authorized personnel.

The cleaning standard must be routinely confirmed by the user.

The process should be validated on a regular basis, and checked

against documented control results.

For thermal disinfection, use temperatures and temperature holding

times to achieve the required infection prophylaxis in accordance with

current health and safety regulations.

Make sure items being washed are suitable for machine reprocess-

ing and are in good condition. Plastic items must be thermally stable.

Nickel plated items and aluminum items can be machine processed

using special procedures only.

Items containing iron, and soiling containing residual rust must not be

placed in the cabinet.

Process chemicals can, in certain circumstances, cause damage to

the machine. Always follow the recommendations of the process

chemical manufacturer.

In case of damage or doubt about compatibility, please contact

Miele.

Cleaning detergents containing chlorine can damage the elas-

tomers of the machine.

If the use of process chemicals containing chlorine is required, a

maximum temperature of 167°F (75°C) in the “Cleaning” program

phases is recommended (see program chart).

In machines equipped with special oil-resistant elastomers (from the

factory) for oil and grease applications, cleaning detergents containing chlorine may not be used!

20

Pre-treatments with cleaning agents can create foam, as can cer-

tain types of soiling and process chemicals. Foam can have an adverse effect on the cleaning result.

Processes must be set up such that foam cannot escape from the

wash cabinet. It would hinder the correct functioning of the machine.

IMPORTANT SAFETY INSTRUCTIONS

The process used must be monitored on a regular basis by the su-

pervisor to check foaming levels.

To avoid the risk of damage to the machine and its accessories

caused by process chemicals, soiling, and any reaction between the

two, please read the notes in “Chemical processes and technology”.

Even when a process chemical, e.g., detergent, is recommended,

the machine manufacturer takes no responsibility for the effect of

such chemicals on the wash items.

Please note that changes in product formulation, storage conditions,

etc., which are not announced by manufacturers of process chemicals may impair the quality of cleaning results.

When using process chemicals, always consult the instructions is-

sued by individual manufacturers. Process chemicals must only be

used for the purpose they are designed for by the manufacturer to

avoid any material damage or the occurrence of very strong chemical

reactions, such as an oxyhydrogen explosion.

Always follow the manufacturer's instructions on storage and dis-

posal of process chemicals.

Particles ≥200μm are removed by the filters in the wash chamber.

Smaller particles may find their way into the circulation system.

In critical applications where very stringent requirements have to

be met, it is strongly recommended that all the relevant factors for the

process, such as process chemicals, water quality, etc., are discussed with Miele.

If the cleaning result is subject to particularly stringent require-

ments, e.g., in chemical analysis, regular quality control should be

carried out by the operator to ensure that required standards of

cleanliness are being achieved.

The mobile units, modules, and inserts that hold the wash items

must be used only as intended.

The interior of lumened wash items must be thoroughly flushed

through with wash water.

Secure small and light items with cover nets or place in a mesh

tray for small items, so that they do not block the spray arms.

Empty any containers or utensils before loading them.

The amount of residual solvents and acids on items going into the

cabinet should be minimal.

There should be no more than a trace of any solvents with a flash

point of below 70°F (21°C).

Chloride solutions, in particular hydrochloric acid, must not be

placed in the cabinet.

21

IMPORTANT SAFETY INSTRUCTIONS

Ensure that solutions or steam containing chlorides or hydrochloric

acid do not come into contact with the stainless steel outer casing of

the machine in order to avoid any damage through corrosion.

After any plumbing work, the water pipework to the machine will

need to be primed. If this is not done, components can be damaged.

Follow the installation instructions in the operating and installation

instructions.

Using components and accessories

Only Miele accessories should be connected to this machine. They

must be suitable for the application they are used for. Consult Miele

for details on the type of accessories that can be used.

Only use Miele Mobile Units, Modules, and Inserts. Using mobile

units and inserts made by other manufacturers or making modifications to Miele accessories can result in unsatisfactory cleaning and

disinfection results. Any resultant damage would not be covered by

the warranty.

Only use process chemicals which have been approved by their

manufacturer for the relevant application. The manufacturer of the

process chemicals is liable for any negative influences on the material

of the wash items and the machine.

22

IMPORTANT SAFETY INSTRUCTIONS

Symbols on the machine

Attention:

Observe the operating instructions!

Attention:

Danger of electric shock!

Warning: Hot surfaces:

It can be very hot inside the wash chamber

when the door is opened!

Disposal of your old machine

Please note that, depending on the application, the machine may

be contaminated with blood and other bodily fluids, pathogens, facultative pathogens, or genetically modified material, etc., and must be

decontaminated before disposal.

For environmental and safety reasons, dispose of all process chemical residues in accordance with safety regulations and the manufacturer’s safety data sheets (wear safety goggles and gloves).

Remove or disable the door so that children cannot become trapped

inside. Then make appropriate arrangements for safe disposal of the

machine.

For machines with a tank system, the water in the tank must be removed beforehand.

Before disposal, all personal data saved in the machine must be

deleted, such as user names.

23

Main menu

Reprocessing

Favorites

Documentation

System

Main menu

US

Login

18.06.2018 15:05

Main menu

Actions in

theMain menu

The main menu of the machine is split into headers and footers and

4menus. The following actions can be performed using the buttons:

- Lock the display, e.g., for surface cleaning (see “Maintenance, locking machines”)

- Change the display language

- Log a user in and out

- Close popups with messages depending on the user level and the

type of message, warning, or fault message (see “Fault messages

and instructions”)

- Open the list of active messages (see “Fault messages and instructions”)

- Select and start a reprocessing program depending on the settings

in the Program controlmenu in the web interface (see “Operation”)

- Call up and start reprocessing programs stored asFavorites depending on the settings in the System, Manage favoritesmenu (see

“Operation”)

- Print outReprocessing reports

24

- Open the Systemmenu to adjust the machine settings depending

on theUser level (see “System settings”)

- Open and close the loading door

- Open and close the unloading door after the end of a program depending on the “Authentification - End of program”setting in the

web interface

Main menu

Changing the display language

Login

Manual login

Changing the display language has no impact on the set system language. Reports and printouts are issued in the system language.

Press the button in the header of the display.

The Select display languagemenu is displayed.

Press the button for the language you want.

The machine controls return to the previous menu; the selected language is set.

Press the button to exit the language selection menu if you do

not want to change the set language.

Access to the machine display is restricted to a certain group of

users. Every user must be entered in the User managementvia the

web interface (see programming manual, “User administration”).

Press the button in the header to open the entry window for user

login.

Enter the user ID and press OK to confirm.

Enter the PIN and press OK to confirm.

The functions on the machine display are enabled.

When a user logs in for the first time, they will be prompted to assign

a new PIN.

If the PIN has expired, this prompt will be displayed for the user. The

validity of the PIN can be set in the web interface under “System,

Identification”.

25

Main menu

Logout

Manual logout

Printing documentation

The logged-in user is automatically logged out after 24hours if no

button has been pressed on the display in that time, or if the machine

carries out an automatic restart.

The automatic restart can be set in the web interface under “System,

Automatic restart”.

A user who is logged in can log out manually, e.g., to protect the machine from access without authorization.

Press the button in the header to log out.

Confirm the confirmation prompt with Yes.

The functions on the machine display are disabled.

The last 200 reprocessing reports saved in the machine controls are

shown on the display. The most recent reprocessing report is the first

on the list. When the number of saved reprocessing reports exceeds

200, the oldest from the list is deleted.

If no external software for process documentation is connected to the

machine, the reprocessing reports can be printed out using an external printer connected via the network.

Opening and closing the door

Press the Documentationbutton.

A list of the reprocessing reports is displayed.

Press the button in the Printcolumn to activate the required repro-

cessing reports.

Press the OK button in the footer to start printing.

Press the button in the Printcolumn again to deactivate the selec-

tion.

The reprocessing report is printed out on the external printer.

The status of the machine door is shown in the footer of the display.

- The door has been released and can be opened.

- The door is open and can be closed.

- The door is locked.

Press the button with the symbol to open the door.

26

The door will move up.

Press the button with the symbol to close the door.

The door will move down.

General information

Application technology

Transfer trolley

Load carriers

A TT86 transfer trolley is required for transporting load carriers from

preparation areas to machines and from machines to checking and

packing tables.

In order to use MF27/28-1 transfer trolleys, the machine needs to be

equipped with the conversion kit RFMF27/28.

Transfer trolleys are supplied with their own operating instructions.

MF-1 transfer trolleys must not be used.

The machine can be fitted with a variety of load carriers, which can

be combined with a variety of modules and inserts depending on the

type and shape of items requiring cleaning.

Select load carriers and other equipment, such as rinsing fittings,

that are appropriate for the application.

Information on the individual areas of application can be found on the

following pages, as well as in the operating instructions for the load

carriers.

Miele offers suitable load carriers for all areas of application defined

in “Appropriate use”, such as mobile units, modules, inserts, and special rinsing fittings. More information can be obtained from Miele.

E9xx load carriers

Pictograms for manual program selection

Load carriers with the designation E9xx can be used in the machine

if they have a production date from 2007 onwards.

A857 retrofit kits for the mobile units are available from Miele.

When you select a program manually on the machine, you must select the relevant mobile unit first. Pictograms representing the mobile

units are shown on the display. The pictograms assigned to the mobile units in the A5xx model range are listed in the operating instructions for the mobile units.

Mobile unit/module combinations from the A5xx model range

The pictogram and name of the mobile unit can be found on a strut

on the front of the mobile unit. The model shown is the mobile unit

without modules inserted.

For different module combinations in the A500 and A503 mobile

units, several pictograms can be displayed (see operating instructions

for the mobile unit).

Fixed mobile units from the A5xx model range

The pictogram and name of the mobile unit can be found on the front

of the mobile unit.

27

Application technology

Arranging the wash items

Only items which have been declared by their manufacturer as suitable for machine reprocessing may be processed. The manufacturer’s specific reprocessing instructions must be observed.

Contaminated items pose a health risk.

Contaminated items can result in various hazards to health, which

can lead to infections, poisoning, injuries, and more depending on

the type of contamination.

When working with contaminated items, ensure that all necessary

measures are taken to protect personnel.

Wear protective gloves and use suitable aids.

- Arrange the wash items so that wash water can access all surfaces.

This ensures that they get properly cleaned.

- Do not place wash items to be cleaned inside other pieces where

they may be concealed.

- Do not place wash items so close together that cleaning is hampered.

- The interior of lumened wash items must be thoroughly flushed

through with wash water. Depending on the wash item, special rinsing fittings may be required for this, such as nozzles, irrigation

sleeves, or adapters.

- Ensure that wash items with long, narrow, hollow sections can be

flushed through properly before placing them in inserts or connecting them to a rinsing fitting.

- Lumened instruments should be inverted and placed in the correct

mobile units, modules, and inserts to ensure that wash water can

flow in and out of them unrestricted.

- Deep-sided wash items should be placed at an angle to make sure

the wash water runs off them freely.

- Tall, narrow lumened instruments should be placed in the center of

the mobile units if they are not going to be sprayed directly. This

ensures the insides of the lumened instruments are more easily accessed by the water jets.

- Take apart any wash items which can be dismantled according to

the manufacturer’s instructions and reprocess the individual parts

separately from each other.

- Lightweight wash items should be secured with a cover net to prevent them from spinning around in the wash cabinet and blocking

the spray arms.

28

- Only reprocess small items and micro components in special inserts, mesh trays with lids, or mesh inserts.

- The spray arms must not be blocked by wash items which are too

tall or which hang down in their path.

Application technology

- Broken glass can result in serious injury when loading or unloading.

Damaged glass wash items must not be reprocessed in the machine.

- Nickel and chrome-plated wash items and wash items made of aluminum are not generally suitable for machine reprocessing. Special

process conditions are required for these wash items.

- When cleaning items that are made entirely or partially out of plastic , the maximum thermal stability of the item must be considered.

Select an appropriate program or adjust the temperature of the program accordingly.

Preparing the wash items

Danger of explosion due to flammable gases.

Flammable solvents with a flash point below 70°F (21°C) outgas

and can generate a flammable mix of gases.

Only load the machine with wash items which have traces of sol-

vents at most.

Start the reprocessing program as soon as the machine has been

loaded with the wash items.

Risk of damage due to solvents.

Solvents with a flash point above 70°F (21°C) can damage elas-

tomers and plastics. The machine could leak as a result of this.

Only load the machine with wash items which have traces of sol-

vents at most.

Start the reprocessing program as soon as the machine has been

loaded with the wash items.

Risk of damage due to corrosion.

Chloride solutions, particularly hydrochloric acid, and ferrous mate-

rials that can rust or corrode cause corrosion on the stainless steel

of the machine and the load carrier.

Do not introduce any chloride solutions into the machine.

Do not introduce any ferrous materials that can rust or corrode into

the machine.

Risk of infection.

Microbiological material, pathogens, facultative pathogens, and ge-

netically modified material can cause infections or environmental

damage.

Before washing by machine, decide whether the wash items contaminated in this way need to be sterilized.

29

Application technology

Empty all wash items before loading into the machine, paying par-

ticular attention to relevant regulations.

Remove non-water soluble residues such as paint, adhesives, and

polymer compounds using appropriate solvents.

Rinse wash items which have been in contact with solvents, chlo-

ride solutions, or hydrochloric acid thoroughly with water and drain

very well. Start the reprocessing program immediately after loading

the machine.

Scoop nutrient media (agar) out of petri dishes.

Shake out any blood residues and remove any clots.

If necessary, rinse the wash items briefly with water to prevent

larger quantities of dirt from entering the machine.

Remove all stoppers, corks, labels, sealing wax residue, etc.

Sort small items such as stoppers and taps in suitable baskets for

small parts in order to secure them.

Remove any aids and additives which are difficult to get rid of and

contaminate the wash items in addition to the original soiling in advance. These include grease, paper labels, and other labels.

30

Application technology

Before starting a program

At the end of a program

Carry out a visual check before starting every program:

- Is everything correctly loaded/connected for cleaning?

- Can the wash water consistently permeate wash items with 2openings, such as pipettes and viscometers?

- Are the spray arms clean and do they rotate freely?

- Is the filter combination clean?

Remove any coarse soiling and clean the filter combination if necessary.

- Is the mobile unit correctly connected to the water supply?

- Are the removable modules, nozzles, irrigation sleeves, and other

rinsing fittings securely connected?

- Are all process chemical containers sufficiently filled?

The following must be checked at the end of every program:

- Are the nozzles and connectors securely held in position in the mobile unit, module, or insert?

- Are all lumened wash items still attached to the appropriate nozzles?

- Have any of the wash items on the load carriers moved during

cleaning?

If any of the wash items move during cleaning, this can have a negative effect on the wash result.

Assess whether wash needs to be repeated: for example, if petri

dishes have overturned or glass beakers have fallen over.

- Carry out a visual check of the wash items for cleanliness.

- Can wash water access the insides of wash items with 2openings?

- If the machine is equipped with a drying unit, carry out a visual

check of the wash items for dryness.

31

Application technology

Laboratory glassware and utensils

...wide-neck

...narrow-neck

Wash items with wide necks, such as glass beakers, wide-neck Erlenmeyer flasks, and petri dishes, or cylindrical items such as test

tubes, can be cleaned and rinsed inside and out using rotating spray

arms.

To do this, the wash items are positioned in inserts and placed in an

empty mobile unit with a spray arm.

Wash items with narrow necks, such as narrow-neck Erlenmeyer

flasks, round flasks, measuring cylinders, and pipettes, require special load carriers.

Load carriers are supplied with their own operating instructions.

When loading please note:

- Place petri dishes or similar items in the appropriate insert with the

dirty side facing downward.

- Place pipettes with the pointed end facing downward.

- Arrange inserts at least 1" (3cm) away from the edge of the load

carrier.

- Position inserts for test tubes in the center above the spray arm to

leave the corners of the load carrier free.

- Use a cover net to avoid breakages if required.

32

Application technology

Program overview

At delivery, the reprocessing programs are assigned to the A 503mobile unit. The following modules can be used in various combinations:

- A 612

- A 620

- A 621

- A 622

Exceptions to this are the Vials and Pipettesprograms (see table).

In order to use other mobile units, new load carriers must be set up in the web interface

under “Load carrier management”. “Load carrier management” is described in the programming manual.

Power levels

The mobile units in the modular loading concept can be fitted with modules in different

ways. Depending on the type and number of modules used, different volumes of water and

pump speeds are required to achieve a similar wash pressure. The individual reprocessing

programs are therefore available with different power levels. The higher the power level of a

reprocessing program, the higher the volume of water and the pump speed.

The program structure and the following parameters, which are relevant to performance,

are identical in the different power levels:

- Water quality

- Temperature

- Holding time

- Dispensed process chemical in %

- Drying temperature

- Drying duration

(see appendix: “Power levels/mobile units/module combinations” table)

33

Application technology

General program information

Program Area of application Mobile

unit

Mini - Very short program for barely soiled wash items and very low

rinse requirements

- For a wide range of soiling

- Not suitable for denatured residues such as protein

- Not suitable for inorganic, acid-soluble residues such as metallic salts

- In 2power levels

Standard - Short program for lightly soiled wash items and low rinse re-

quirements

- For a wide range of soiling

- Not suitable for denatured residues such as protein

- Not suitable for inorganic, acid-soluble residues such as metallic salts

- In 2power levels

Universal - Program for lightly soiled to moderately soiled wash items and

moderate rinse requirements

A 503

A 503

A 503

- For removing organic residues

- Suitable to a limited extent for inorganic, acid-soluble residues,

such as metallic salts

- In 2power levels

Intensive - Program for moderately soiled to heavily soiled wash items and

moderate to high rinse requirements

- For removing organic residues

- Suitable to a limited extent for inorganic, acid-soluble residues,

such as metallic salts

- In 2power levels

A 503

34

Application technology

Programs for specific soiling

Program Area of application Mobile

unit

Inorganic - Program for lightly soiled to moderately soiled wash items and

moderate to high rinse requirements

- For removing inorganic, acid-soluble residues such as metallic

salts

- In 2power levels

Organic - Program for moderately soiled to heavily soiled wash items

and moderate rinse requirements

- For removing concentrated organic residues, e.g., fats, waxes,

and stubborn dried-on or thermally adhered organic residues

- Not suitable for inorganic, acid-soluble residues such as

metallic salts

- In 2power levels

Oil - Program for heavily soiled wash items and moderate rinse re-

quirements

- For removing oils, greases, and in some cases waxes

- Not suitable for inorganic, acid-soluble residues such as

metallic salts

A 503

A 503

A 503

- In 2power levels

Agar - Program for moderately soiled to heavily soiled wash items

and moderate rinse requirements

- For removing agar

- In 2power levels

A 503

35

Application technology

Programs for specific wash items

Program Area of application Mobile

unit

Plastics - Program for lightly soiled to moderately soiled plastics and

moderate rinse requirements

- For heat-sensitive laboratory equipment, e.g., plastic bottles

that are resistant to temperatures of up to 130°F (55°C)

- In 2power levels

Vials - Program for lightly soiled to moderately soiled small wash

items and moderate to high rinse requirements

- For vials, centrifuge tubes, and test tubes

- In 2power levels

Pipettes - Program for lightly soiled to moderately soiled pipettes and

moderate to high rinse requirements

- For measuring and volumetric pipettes

- In 3power levels

A 503

A 503

+

A 605

A 503

+

A 613

36

Application technology

Additional programs

Program Area of application Mobile

unit

Laboratory

Special

- Program for cleaning and thermal disinfection at 199°F (93°C)

and 10min holding time in the first program phase; wash water is only pumped out after the disinfection process

- In 2power levels

Rinse cold water

- Program for rinsing wash items with cold water, e.g., to remove:

- Heavy soiling

- Disinfectant residue

or

- To prevent soiling from drying and becoming encrusted on

wash items before the start of a reprocessing program

Rinse DI water - Program for rinsing wash items with DI water, e.g., to remove:

- Heavy soiling

- Disinfectant residue

or

- To prevent soiling from drying and becoming encrusted on

wash items before the start of a reprocessing program

A 503

A 503

A 503

Drying - Program for drying temperature-stable wash items

A 503

- Not suitable for heat-sensitive wash items

Service program

Program Area of application Mobile

unit

Tank emptying Program for emptying the tank, e.g., for long downtimes; the

1)

Manual disinfection

wash cabinet must be empty

Program to drain the wash cabinet when the wash water needs

to be decontaminated by adding disinfecting agent in the event

of a program cancellation (see “Operation, program cancellation”)

1) Depending on the configuration of the Standby parameter in the web interface under

Water intake/DI water tank, the tank is automatically replenished at the end of the program

(see the programming manual, “System, appliance configuration, water intake”).

Zero

A 503

37

Chemical processes and technology

In this section you will find a description of the causes of common issues which can occur

between different types of soiling, process chemicals and the components of the machine,

along with their solutions as necessary.

This section is intended as a guide. If unforeseen interactions occur during reprocessing,

or if you have any questions on this subject, please contact Miele.

General information

Problem Solution

If elastomers (seals and hoses) and plastic

components in the machine are damaged,

this can lead to, for example, swelling,

shrinking, hardening or brittleness of materials, causing tears and cracks to develop.

Components cannot function correctly and

this generally leads to leaks.

A heavy build-up of foam during the program sequence will impair the cleaning and

rinsing effect on the wash items. Foam escaping from the wash cabinet can cause

damage to the machine.

When foam develops, the cleaning process

is not standardized or validated in principle.

Corrosion to stainless steel in the wash

cabinet and to accessories can give them a

different appearance:

- rust (red marks/discoloration)

- black marks/discoloration

- white marks/discoloration (etched surface)

- Determine and remedy the cause of the

damage.

See information regarding “Associated

process chemicals”, “Soiling”, and “Reaction between process chemicals and soiling” in this section.

- Determine and remedy the cause of the

foam build-up.

- Check the process used regularly to monitor foaming levels.

See information regarding “Associated

process chemicals”, “Soiling”, and “Reaction between process chemicals and soiling” in this section.

- Determine and remedy the cause of corrosion.

See information regarding “Associated

process chemicals”, “Soiling”, and “Reaction between process chemicals and soiling” in this section.

Corrosive pitting can lead to the machine

not being water-tight. Depending on the application, corrosion can affect cleaning and

rinsing results (laboratory analysis) or cause

corrosion to stainless steel wash items.

38

Chemical processes and technology

Associated process chemicals

Problem Solution

The ingredients in process chemicals have

a significant impact on the longevity and

functionality (throughput) of dispensing systems.

Process chemicals can damage elastomers

and plastics in the machine and accessories.

Hydrogen peroxide can release large

amounts of oxygen.

- Follow the process chemical manufacturer’s instructions and recommendations.

- Carry out regular visual inspections of the

dispensing system to check for signs of

damage.

- Check the throughput of the dispensing

system regularly.

- Ensure that the regular cycle of maintenance is observed.

- Contact Miele for advice.

- Follow the process chemical manufacturer’s instructions and recommendations.

- Carry out a regular visual check of any accessible elastomers and plastics for damage.

- Only use validated processes.

- The wash temperature must be lower than

158°F (70°C) when using hydrogen peroxide.

The following process chemicals can cause

large amounts of foam to build up:

- Cleaning agents and rinsing agents containing surfactants

Foam can occur:

- in the program phase in which the

process chemical is dispensed

- in the subsequent program phase if it has

been spilt

- in the subsequent program if rinsing agent

has been spilt during dispensing

- Contact Miele for advice.

- Process parameters in the wash program,

such as dispensing temperature and

dosage concentration, must be set to ensure the whole process is foam-free or

very low-foaming.

- Please observe the process chemical

manufacturer’s instructions.

39

Chemical processes and technology

Associated process chemicals

De-foaming agents, especially siliconebased ones, can cause the following:

- a build-up of deposits in the wash cabinet

- a build-up of deposits on the wash items

- De-foaming agents should be used as an

exception only; for instance, when they

are essential for the process.

- Clean the wash cabinet and accessories

periodically without any wash items and

- damage to elastomers and plastics in the

machine

- damage to certain plastics, e.g., polycar-

without de-foaming agent using the Or-

ganicprogram

- Contact Miele for advice.

bonate and plexiglass, in the wash items

being processed

Soiling

Problem Solution

The following substances can damage the

elastomers in hoses and seals, as well as

the plastics in the machine:

- oil, wax, aromatic and unsaturated hydrocarbons

- emollients

- cosmetics, hygiene and skincare products

such as creams

- Depending on usage, wipe the lower door

seal on the machine periodically with a

lint-free cloth or sponge.

- Clean the wash cabinet and accessories

without any wash items using the Or-

ganicprogram.

- Use the Oilprogram or a special program

that dispenses pH-neutral emulsifiers

containing surfactants in the pre-rinse.

The following substances can lead to a

heavy build-up of foam during washing and

rinsing:

- some disinfection agents, dishwashing

cleaning agents, etc.

- reagents for analysis, e.g., for microtiter

plates

- cosmetics, hygiene and skincare products

such as shampoos and creams

- active foaming agents such as surfactants

The following substances may cause corrosion to stainless steel in the wash cabinet

and on accessories:

- hydrochloric acid

- other substances containing chlorides,

such as sodium chloride

- concentrated sulfuric acid

- Thoroughly rinse wash items in water beforehand.

- Select a cleaning program with at least

one short pre-rinse in cold or hot water.

- Depending on the application, use defoaming agents that do not contain silicone oils.

- Thoroughly rinse wash items in water beforehand.

- Put the drip-dry wash items into mobile

units, modules, and inserts and place

these in the wash cabinet.

- Start a program as soon as possible after

placing them in the machine.

- chromic acid

- particles of iron and shavings

40

Chemical processes and technology

Reaction between process chemicals and soiling

Problem Solution

Natural oils and fats can be emulsified with

alkaline process chemicals. This can lead to

a heavy build-up of foam.

Soiling containing high protein levels can

cause a heavy build-up of foam when processed with alkaline process chemicals.

Non-precious metals such as aluminum,

magnesium, and zinc can release hydrogen

when processed with very acidic or alkaline

process chemicals (oxyhydrogen reaction).

- Use the Oilprogram.

- Use a special program that dispenses pHneutral emulsifiers containing surfactants

in the pre-rinse.

- Depending on the application, use defoaming agents that do not contain silicone oils.

- Select a cleaning program with at least

one short pre-rinse in cold water.

- Please observe the process chemical

manufacturer’s instructions.

41

Dispensing liquid process chemicals

Unsuitable process chemicals pose a health risk.

Using unsuitable process chemicals will generally cause an unsat-

isfactory wash result and can pose a health risk or cause damage

to property.

Only use process chemicals designed specifically for use in laboratory glassware washers and follow the manufacturer’s instructions

on how to use them.

Please follow any instructions relating to non-toxic residues.

Process chemicals pose a health risk.

Some process chemicals may be corrosive and irritant.

Observe the relevant safety codes and safety data sheets issued

by the process chemical manufacturers when handling process

chemicals.

Take all protective measures required by the process chemical

manufacturer, e.g., wear protective goggles and protective gloves.

Dispensing systems

The machine is fitted with 2dispensing systems for liquid detergent

and neutralizing agent as standard. Up to 4additional internal dispensing systems can be installed.

The dispensing systems and suction wands must be color-coded.

Stickers are supplied in the following colors:

- blue

- white

- red

- green

- yellow

- black

Enter the process chemicals used and the relevant color in the table

below if an additional dispensing system has been installed. When

containers with process chemicals are connected, the color coding

makes it easier to assign the relevant suction wand.

Dispensing

system

Color code Process chemical

42

1 blue

2

3 red

4

5

6

Dispensing liquid process chemicals

1

2

4external dispensing systems can be connected instead of the 4optional internal dispensing systems.

If a dispensing system is to dispense different process chemicals,

the chemicals must be changed by Miele Technical Service or an

authorized technician.

Containers for

process chemicals

Filling containers with process chemicals

The drawer for containers with process chemicals is located behind

the service cover. There is enough space in the drawer for 4containers with a 10l capacity.

Additional containers must be placed outside the machine.

The drawer is equipped with supports. The supports ensure that the

containers are slightly inclined. The containers must sit on the supports in such a way that the suction wand is located on the lower

side.

Always place the 4containers in the drawer, even if fewer process

chemicals are required. This will prevent the containers from falling

over when the drawer is opened or closed.

Fill the containers for process chemicals or replace them with a full

container if a corresponding message is displayed, e.g., Fill supply

container Dispensing system 1.

Unlock the service cover on the machine .

Tilt the service cover forward , lift it up, and lift it out of its lower

brackets.

Pull out the drawer with the containers for liquid process chemicals.

Take the corresponding container out of the drawer.

Unscrew and remove the suction wand.

Fill the process container with the required process chemical or re-

place it with a new container.

Observe the color coding for the dispensing system and the suction wand to ensure that the process chemicals do not get mixed

up.

43

Dispensing liquid process chemicals

Push the suction wand into the neck of the container and screw it

into place.

Place the container in the drawer.

The suction wand must be located on the lower side of the support.

Push the drawer into the machine.

Filling the dispensing system

Insert the service cover into the lower brackets of the machine and

press on it.

Lock the service cover.

Acknowledge the message Fill container for dispensing system “x”

with the OK button.

Each time a container is filled or replaced, the Fill dispensing sys-

temfunction must be carried out to remove any air from the dis-

pensing system.

A dispensing system must be filled when:

- The corresponding container has been filled or replaced with a new

one.

- The process chemicals have been changed.

A dispensing system can only be primed if there are no load carriers in the wash cabinet.

Open the Systemmenu.

Open the Machine functionsoption.

44

Open the Fill dispensing systemoption.

Press the button for the corresponding dispensing system, e.g.,

DOS 1.

The dispensing system will be filled.

Operation

Switching the machine on and off

The I/0 power switch disconnects the machine from the power supply. The switch is located above the display.

Press the I power switch to switch the machine on.

Once the boot process has finished, the machine is ready for operation.

Press the 0 power switch to switch the machine off.

The machine controls are shut down and the machine is disconnected from the power supply.

Loading the wash cabinet

The load carrier is pushed into the machine wash cabinet from the infeed side.

Press the button to open the door on the infeed side.

Push the load carrier from the transfer trolley into the machine wash

cabinet.

The markings on the load carrier and in the wash cabinet need

to be flush with one another.

Press the button to close the machine door.

45

Operation

Select load carrier

A 503 A 503 + A 603

A 500 + A 613 A 505

US

BED

user/

Selecting a program

The reprocessing programs are assigned to certain load carriers.

Therefore, a load carrier must be selected first with the help of a pictogram.

Selecting a load carrier

Press the Reprocessingbutton.

The menu for selecting the load carrier via a pictogram is displayed.

If more than 4load carriers are available, you will be able to scroll

through several pages in the selection menu.

Press the button for the required load carrier, e.g., A503.

The pictogram of the selected load carrier is displayed in the header,

e.g., Reprocessing.

The reprocessing programs which can be selected are listed.

Press the button for the required reprocessing program.

The program start screen is displayed.

46

Operation

US

BED

user/

Favorites

Universal

Agar Plus

Pipettes 1

Universal Plus

Selecting programs from

Favorites

If reprocessing programs have been defined in the System, Man-

age favoritesmenu, the program can be selected using the Favoritesbutton.

Press the Favoritesbutton.

The Select load carriermenu is displayed.

Press the button for the required load carrier, e.g., A503.

The pictogram of the selected load carrier is displayed in the header,

e.g., Favorites.

The reprocessing program defined as a favorite is displayed; Univer-

sal in this example.

Press the button for the required reprocessing program.

The program start screen is displayed.

47

Operation

1:06

user/

18.06.2018 15:05

US

BED

Universal

Time left

Starting a program

Check whether the right reprocessing program for the load carrier

is displayed in the header.

With the button, you can open the menu for selecting the reprocessing programs if you wish to choose a different reprocessing

program.

Press the button.

The reprocessing program starts.

It is only possible to start a reprocessing program when the machine

doors are closed and there are no fault messages.

If the symbol is displayed in the footer, you must work through

the list of active messages first (see “Fault messages and instructions”).

Program sequence

The program will run automatically once it has been started. You can

find detailed information about the program sequence and the program parameters on the machine display (see “Machine description”,

“Control panel on the display”).

48

Operation

End of program

After the program has ended, the following is displayed:

- Cycle number

- time elapsed since the end of the program

- Result of the wash process

- Program finishedmessage

The progress bar changes from white to green.

The wash cabinet lighting can be switched on automatically depending on the pre-setting.

Canceling a program

A reprocessing program can be canceled at any time. The wash water

is drained, then the door on the infeed side is released.

Press the button.

A confirmation prompt is displayed:

Cancel program?.

Program cancellation with manual

disinfection

Manual program cancellation

Confirm the confirmation prompt with Yes.

Once the water has finished draining, the following message will appear on the display:

Program cancelled.

The progress bar is red and the following fault message is displayed:

Program aborted by user.

Once the fault message has been acknowledged, the program can be

restarted.

For programs with the Drainage after disinfection parameter activated,

additional steps may be necessary for program cancellation. If there

has been no thermal disinfection, the wash water must be decontaminated manually.

During the first program phase:

Press the button and confirm the confirmation prompt Cancel

program? with Yes.

The fault messageProgram aborted by user is displayed.

There is wash water in the wash cabinet; it is not drained.

Program cancellation due to fault

Manual disinfection

If the program is canceled due to a fault during the initial program

phase, the wash water is not drained. The required steps are described under “Manual disinfection”.

Press OK to acknowledge the fault message in the list.

Press OK to acknowledge the program cancellation.

The message Please unload appears in the program sequence display.

49

Operation

Open the door on the infeed side.

Decontaminate the wash water by adding disinfecting agent.

Close the infeed side door.

Select the load carrier.

Select and start the Manual disinfectionprogram from the list of pro-

grams assigned to the load carrier.

The wash water is drained; another fault message is displayed.

Press OK to acknowledge the fault message in the list.

The infeed side door can be opened.

Delay start

The start of a program can be delayed. The delay start period can be

set to the exact minute.

If soiling is left to dry on the wash items for a long time, the reprocessing result can be adversely affected. There is also a risk of corrosion for stainless steel wash items.

To set the delay start, press the button in the footer.