Page 1

Operating Instruction

LABORATORY GLASSWARE

WASHER

PLW 8505

To avoid the risk of accidents or damage to the

machine, it is essential to read these instructions

before it is installed and used for the first time.

en – CA, US

Page 2

CONTENT

Content

1.GENERAL RULES ............................................................................................................................ 5

1.1

Limits of manufacturer’s liability .............................................................................................. 5

1.2

Manual validity, contents and conservation ............................................................................ 5

2.PRODUCT INFORMATION .............................................................................................................. 6

2.1

Intended use, improper use .................................................................................................... 7

2.2

Safety instructions ................................................................................................................... 8

Correct application .............................................................................................................. 8

Risk of injury ........................................................................................................................ 8

Quality assurance ................................................................................................................ 9

Safety with children ........................................................................................................... 10

Using accessories ............................................................................................................. 11

Disposing of your old machine .......................................................................................... 11

Safety signal used ............................................................................................................. 11

2.3

Recommendations for proper operation ............................................................................... 12

Training .............................................................................................................................. 13

User profiles ...................................................................................................................... 13

3.INSTALLATION............................................................................................................................... 14

3.1

Water connection .................................................................................................................. 14

Inlet water quality .............................................................................................................. 14

Information......................................................................................................................... 15

3.2

Electrical connection ............................................................................................................. 16

3.3

Adding and dispensing cleaning agents ............................................................................... 17

Presence sensor of cleaning agent ................................................................................... 17

3.4

Replacement or refill of cleaning agent ................................................................................. 17

3.5

Warning ................................................................................................................................. 18

3.6

Connecting the drain hose .................................................................................................... 19

Drain cooling ...................................................................................................................... 20

3.7

Ambient ventilation requirements .......................................................................................... 20

4.CHECKS PRIOR TO START-UP .................................................................................................... 21

4.1

Introduction ........................................................................................................................... 21

4.2

Checks of safety systems ..................................................................................................... 21

4.3

General controls .................................................................................................................... 21

5.USING THE MACHINE ................................................................................................................... 22

5.1

Checking consumption ......................................................................................................... 22

5.2

Opening and closing the door ............................................................................................... 22

Opening the door using the emergency release device ................................................... 23

5.3

Switching on and off .............................................................................................................. 23

REV.0.04_COD.610078_A4 Page 2

Page 3

CONTENT

5.4

Preparation ............................................................................................................................ 24

6.CONTROL PANEL AND SYMBOLS USED .................................................................................... 25

6.1

Buttons .................................................................................................................................. 25

BUZZER ............................................................................................................................. 26

6.2

Display ................................................................................................................................... 26

7.PROGRAMS ................................................................................................................................... 29

7.1

Program blocks ..................................................................................................................... 29

7.2

Program chart ........................................................................................................................ 30

7.3

Start the program .................................................................................................................. 33

8.MACHINE STATUS ........................................................................................................................ 34

8.1

Ready for operation ............................................................................................................... 34

8.2

Program status ...................................................................................................................... 34

8.3

Power failure .......................................................................................................................... 34

8.4

Reset procedure .................................................................................................................... 35

9.MENU ............................................................................................................................................. 36

9.1

Accessing the menu .............................................................................................................. 36

9.2

Entering password ................................................................................................................. 37

9.3

Buzzer volume setting ........................................................................................................... 37

9.4

Date and time setting ............................................................................................................ 38

9.5

Selecting a language ............................................................................................................. 38

9.6

Changing user name ............................................................................................................. 39

9.7

Parameter overview ............................................................................................................... 40

10.CLOCK ...................................................................................................................................... 41

11.HISTORICAL DATA ................................................................................................................... 41

12.ALARMS AND EVENTS LIST ..................................................................................................... 42

12.1Description of alarm messages ............................................................................................. 42

12.2List of alarm messages .......................................................................................................... 42

12.3List of warning messages ...................................................................................................... 43

13.USB PORT ................................................................................................................................. 43

14.MAINTENANCE ......................................................................................................................... 44

14.1General recommendations on maintenance ......................................................................... 44

Machine status .............................................................................................................. 44

14.2Maintenance request ............................................................................................................. 44

14.3Routine maintenance ............................................................................................................. 44

14.4Table of routine maintenance tasks ...................................................................................... 45

14.5Special maintenance ............................................................................................................. 50

Table of special maintenance tasks .............................................................................. 50

15.PROBLEMS – CAUSES – REMEDY .......................................................................................... 51

15.1Introduction ........................................................................................................................... 51

15.2Problems (P.) – Causes (C.) – Remedy (R.) ........................................................................... 51

REV.0.04 _COD.610078_A4 Page 3

Page 4

CONTENT

16. TECHNICAL DATA .................................................................................................................... 53

17. DISPOSING OF YOUR OLD MACHINE .................................................................................... 55

REV.0.04_COD.610078_A4 Page 4

Page 5

1. GENERAL RULES

1.1 Limits of manufacturer’s liability

The manufacturer shall not be held liable for failures or problems which arise due to

tampering and/or incorrect applications and/or improper use of the machine.

The user must comply with all instructions set forth in the user's manual:

Always work within the allowable limits for the use of the machine

Always carry out constant and diligent maintenance

Allow use of the machine by persons with proper skills and abilities for their role and

purpose who have been properly trained and instructed

Use only manufacturer original spare parts

Any modifications, adaptation or the like which may be made to machines which are

subsequently placed on the market do not oblige the manufacturer to intervene on previously

supplied machines, nor to consider the machine and the related user's manual lacking and

inadequate.

The installation, maintenance and operating instructions given in the following pages have

been prepared to ensure the long life and outstanding performance of the appliance.

The instructions in this manual do not replace but rather are in addition to employer

requirements to adhere to current legislation on standards of prevention and safety.

GENERAL RULES

1.2 Manual validity, contents and conservation

It is important to keep this instruction manual with the machine for future reference.

If the machine is sold or transferred, the manual must be handed over to the new owners or

user in order for them to become acquainted with its functioning and the relative warnings.

Read the warnings carefully before installing and using the machine.

REV.0.04 _COD.610078_A4 Page 5

Page 6

PRODUCT INFORMATION

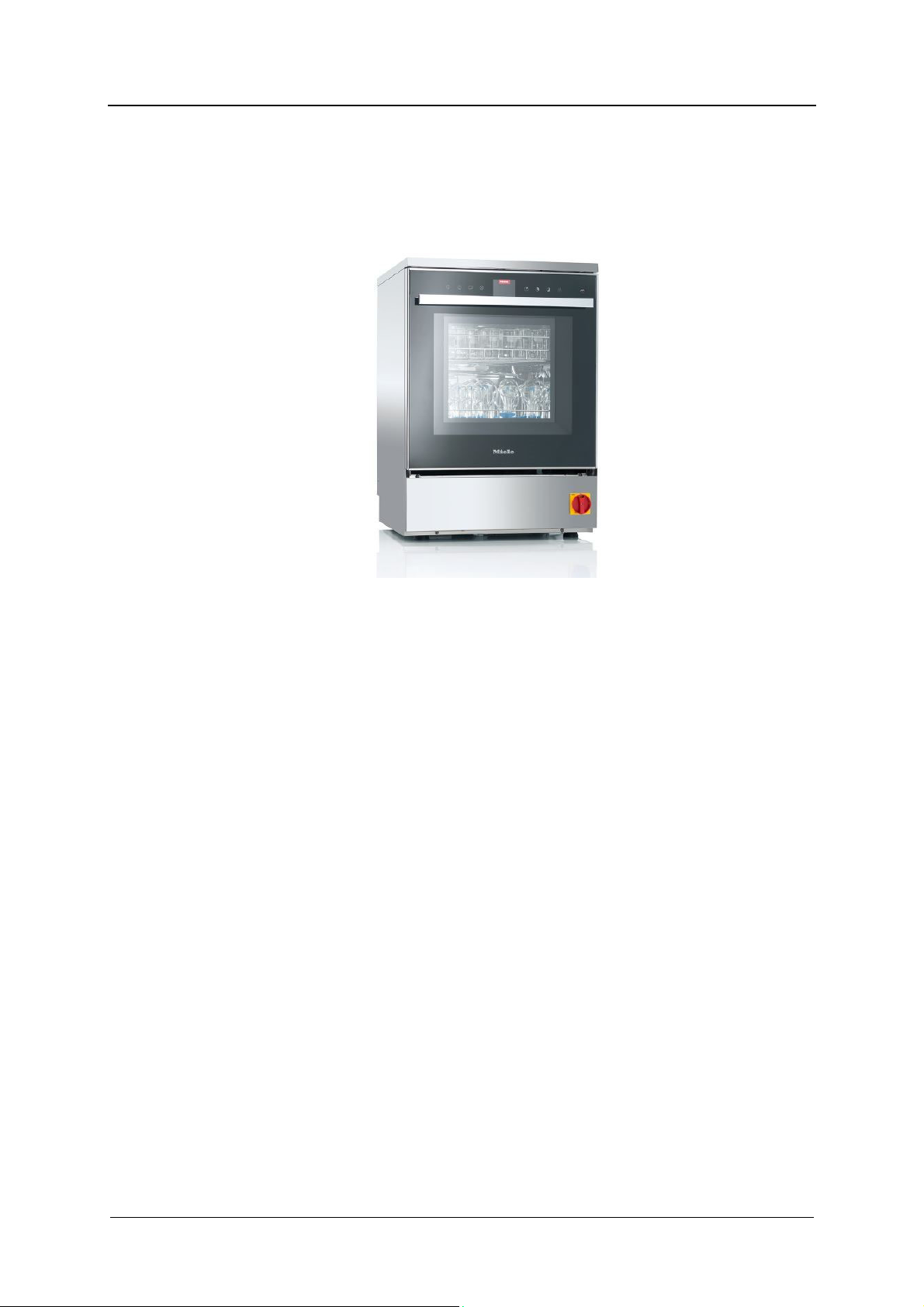

2. PRODUCT INFORMATION

Before starting work, the user must be completely familiar with the functions and proper

operation of the machine. The user must know the precise function of all command and

control devices of the machine.

PLW 8505

REV.0.04_COD.610078_A4 Page 6

Page 7

2.1 Intended use, improper use

This laboratory glassware washer is designed for washing laboratory glassware and

laboratory utensils with water based media. It is designed for use in laboratories in schools,

colleges and universities.

The process includes cleaning, rinsing and drying.

Due to the wide variety of laboratory glassware and laboratory utensils on the market, it may

be necessary in some cases to establish whether it is suitable for cleaning in a laboratory

glassware washer.

This will depend on its use and the type of soiling present. Please also observe information

provided by the manufacturer of the laboratory glassware and laboratory utensils.

Laboratory glassware and laboratory utensils suitable for cleaning include, for example:

Vessels such as test tubes, beakers, flasks, cylinders, etc.

Measuring vessels such as measuring cylinders, volumetric flasks, etc.

Dishes such as petri dishes, watch glasses, etc.

Small items such as lids, spatulas, magnetic stirring rods, stoppers, etc.

Other items such as funnels

Laboratory glassware and laboratory utensils for cleaning are referred to as the wash load if

they are not more specifically defined.

Processing conditions must be suitable for the wash load and for the type of soiling.

Cleaning agents must be suitable for the type of soiling and for methods of analysis being

used.

The use of a suitable carrier (mobile unit, basket, module, insert, etc.) is important to ensure

adequate processing of the load.

PRODUCT INFORMATION

WARNING

Inappropriate use can, however, lead to personal injury and material

damage.

Miele cannot be held liable for damage caused by improper or incorrect

use or operation of the machine.

If the appliance is used in a manner not specified by the manufacturer,

protection of the appliance may be compromised.

REV.0.04 _COD.610078_A4 Page 7

Page 8

PRODUCT INFORMATION

2.2 Safety instructions

This machine complies with all statutory safety requirements. Inappropriate use can,

however, lead to personal injury and material damage.

Read these instructions carefully before using it for the first time to avoid the risk of

accidents and damage to the machine.

Keep these instructions in a safe place where they are accessible to users at all times.

Correct application

This lab washer is designed for use with the applications described in these operating

instructions only. Alterations or conversions to the machine, or using it for purposes other

than those for which it was designed, are not permitted and could be dangerous. This lab

washer must only be used for cleaning laboratory glassware and utensils if the

manufacturer has stated that they are suitable for machine cleaning.

Manufacturer's cleaning and maintenance instructions must also be observed.

Miele cannot be held liable for damage caused by improper or incorrect use or operation

of the machine.

This machine is intended for indoor use only.

Risk of injury

Please pay attention to the following notes to avoid injury

Do not install the machine in an area where there is any risk of explosion or of freezing

conditions.

In order to reduce the risk of water damage, the area around the machine should be

limited to furniture and fittings that are designed for use in commercial environments.

Some metal parts pose a risk of injury/being cut. Wear cut-resistant protective gloves

when transporting and setting up the machine.

If the machine is built under, it must only be installed under a continuous countertop

which is firmly secured to adjacent units to improve stability.

The electrical safety of this machine can only be guaranteed when correctly grounded. It

is essential that this standard safety requirement is met. If in any doubt, please have the

on-site wiring system tested by a qualified electrician. Miele cannot be held liable for the

consequences of an inadequate grounding system (e.g., electric shock).

A damaged or leaking machine could be dangerous and compromise your safety.

Disconnect the machine from the power supply immediately and call the Miele Service

Department or an authorized and trained service technician.

Personnel operating the machine should be trained regularly. Untrained personnel should

not be allowed to use the machine.

Only use cleaning agents which have been approved by their manufacturer for use in the

application you are using. The cleaning agent manufacturer is responsible for any

negative influences on the material the load is made from and for any damage they may

cause to the machine.

Take care when handling cleaning agents. These may contain irritant, corrosive or toxic

ingredients.

Please observe the cleaning agent manufacturer's safety instructions and safety data

sheets. Wear protective gloves and goggles.

The machine is designed for operation with water and recommended additive cleaning

agents only.

REV.0.04_COD.610078_A4 Page 8

Page 9

Organic solvents and flammable liquid agents must not be used in the machine. This

could cause an explosion, damage rubber or plastic components in the machine and

cause liquids to leak out of it.

The water in the cabinet must not be used as drinking water.

Do not lift the machine by protruding parts such as the control panel or the opened

service flap as these could be damaged or torn off.

Do not sit or lean on the opened door. This could cause the machine to tip up and be

damaged or cause an injury.

Be careful when sorting items with sharp pointed ends and positioning them in the

machine that you do not hurt yourself or create a danger for others.

Broken glass can result in serious injury when loading or unloading. Broken glass items

must not be processed in the machine.

When using this machine in the higher temperature ranges, be especially careful not to

scald or burn yourself or come into contact with irritant substances when opening the

door.

Should personnel accidentally come into contact with toxic vapors or cleaning agents,

follow the emergency instructions given in the manufacturer's safety data sheets.

Mobile units, baskets, modules, inserts and the load must be allowed to cool down

before they are unloaded. Any water remaining in containers could still be very hot.

Empty them into the wash cabinet before taking them out.

Never clean the machine or near vicinity with a water hose or a pressure washer.

The machine must be disconnected from the power supply before any maintenance or

repair work is carried out.

Quality assurance

The following points should be observed to assist in maintaining quality standards

when processing laboratory glassware and utensils to avoid damage to the loads being

cleaned.

If it is necessary to interrupt a program, this may only be done by the designated user.

The standard of cleaning should be routinely confirmed by the user.

Make sure items being washed are suitable for machine cleaning and are in good

condition. Plastic items must be thermally stable. Nickel-plated items and aluminium

items can be machine processed using special procedures only.

Items containing iron and soiling containing residual rust must not be placed in the

cabinet.

Cleaning agents can, in certain circumstances, cause damage to the machine. Always

follow the recommendations of the cleaning agent manufacturer.

In case of damage or doubt about compatibility, please contact Miele.

Do not use bleach in the washer.

Abrasive substances must not be placed in the machine as they could cause damage to

the mechanical components of the water circuit. Any residues of abrasive substances on

items to be washed must be removed without trace before cleaning in the machine.

Pre-treatments with cleaning agents can create foam, as can certain types of soiling.

Foam can have an adverse effect on the cleaning result.

Foam can cause leakage and damage to the washer.Therefore do not use cleaning

agents that foam and set up the processes such that no foaming occurs.

PRODUCT INFORMATION

REV.0.04 _COD.610078_A4 Page 9

Page 10

PRODUCT INFORMATION

Where a cleaning agent is recommended on technical application grounds (e.g., a

cleaning agent), this does not imply that the manufacturer of the machine accepts liability

for the effect of the chemical on the items being cleaned.

Please be aware that changes in formulation, storage conditions, etc., which may not be

advertised by the chemical manufacturer can have a negative effect on the cleaning

result.

When using a cleaning agent it is essential that the manufacturer's instructions are

followed. The cleaning agent must only be used for the application it is designed for and

in the situation specified to avoid material damage and such dangers as a severe

explosive chemical reaction (e.g., an explosive oxyhydrogen gas reaction).

Always follow the relevant manufacturer's instructions on storage and disposal of

cleaning agents.

In critical applications where very stringent requirements have to be met, it is strongly

recommended that all the relevant factors for the process, such as cleaning agents,

water quality, etc., are discussed with the Miele Application Technology specialists.

The mobile units, baskets, modules and inserts that hold the load must be used only as

intended.

Hollow items must be thoroughly cleaned, internally and externally.

Secure small and light items with cover nets or place in a mesh tray for small items, so

that they do not block the spray arms.

Empty any containers or utensils before loading them.

The amount of residual solvents and acids on items going into the cabinet should be

minimal.

There should be no more than a trace of any solvents with a flash point of below

70°F (21 °C).

Ensure that solutions or steam containing chlorides or hydrochloric acid do not come into

contact with the wash cabinet, accessories and stainless-steel outer casing of the

machine in order to avoid any damage through corrosion

After any plumbing work the water pipework to the machine will need to be vented. If this

is not done, components can be damaged.

The gaps between a built-in machine and adjacent cabinetry must not be filled, e.g., with

silicone sealant as this could compromise the ventilation to the circulation pump.

Follow the installation instructions in the operating and installation instructions.

Safety with children

Children must be supervised in the vicinity of the machine. Do not allow children to play

with the machine. They could get locked inside it.

Children must not use the machine.

Keep children away from cleaning agents. These can cause burning in the mouth, nose

and throat if swallowed, or inhibit breathing. Keep children away from the machine when

the door is open. There could still be residual cleaning agent in the cabinet. Observe the

safety data sheets for the cleaning agent and seek medical advice immediately if a child

has swallowed cleaning agent or got it in the eyes.

REV.0.04_COD.610078_A4 Page 10

Page 11

Using accessories

Only designated accessories should be connected to this machine. They must be

suitable for the application they are required for. Consult Miele for details on the type of

accessories that can be used.

Only use designated mobile units, baskets, modules and inserts with this lab washer.

Using mobile units, baskets, modules and inserts made by other manufacturers, or

making modifications to the original accessories can cause unsatisfactory cleaning

results, for which Miele cannot be held liable. Any resultant damage would not be

covered by the guarantee.

Disposing of your old machine

For environmental and safety reasons ensure the machine is completely drained of any

residual water, chemical residues and cleaning agent. Observe safety regulations and

wear safety goggles and gloves.

Make the door lock inoperable so that children cannot accidentally shut themselves in.

Then make appropriate arrangements for its safe disposal.

Safety signal used

To inform personnel operating on the machines of obligations of behavior and residual risks,

adequate safety signals (as set forth by 92/58 EEC) are applied to the machine and near the

workplace.

GENERIC SAFETY SIGNALS:

In particular, labels with signals of obligation, prohibition and danger contained in this manual

and pertinent to this machine and most commonly used are:

PRODUCT INFORMATION

Warning

Danger of electrical

shock!

PERSONAL PROTECTIVE EQUIPMENT:

The evaluation of risks for the health and safety of users carried out in the workplace and on any

equipment used, as well as the evaluation of residual risks as indicated, allow the employer to evaluate

the need to adopt the individual protection gear which is most suitable and appropriate to be provided

to users.

Considering the type of machine, it is felt that the individual protection gear should be provided to staff.

Observe the operating

Warning

instructions

Warning

Hot Surface

SAVE THESE INSTRUCTIONS

Miele cannot be held liable for damage caused by non-compliance with these safety

instructions.

REV.0.04 _COD.610078_A4 Page 11

Page 12

PRODUCT INFORMATION

2.3 Recommendations for proper operation

The machine may never be left unattended while in operation.

When the machine is running do not interrupt the cycle.

Use recommended detergents and cleaning agents only. The use of other products

may damage the machine.

Do not introduce any items with substances that must not be discharged in sewage

system (in accordance with local legislation).

Recommending cleaning agents does not make the manufacturer responsible for any

damage to the materials and cleaned items.

Check that type of cleaning agent is suitable for the specific washing program used.

Follow the manufacturer's instructions when using cleaning agents and use them for

the foreseen use only.

Follow the manufacturer’s instructions and local and national requirements and

guidelines, on how to clean their items by machine.

The machine was designed for use with water and cleaning agents.

Do not use organic or other types of solvents as this may result in the risk of explosion

or the rapid deterioration of certain machine parts.

Acids, particularly hydrochloric acid, can damage steel. Contact should be avoided.

Use original accessories only.

Never use powder detergents.

Never use foaming detergent.

Accessories which are not approved by the manufacturer may compromise the results

achieved as well as user safety.

Never use cleaning agents based on chlorides and hypochlorites (bleaches, sodium

hypochlorite, hydrochloric acid and so on). These kinds of cleaning agents irreparably

damage the machine and jeopardize the integrity of materials and objects treated.

The user must carry out a general check-up and clean the appliance regularly as

indicated in the maintenance chapter.

Connection to the water supply should be easily accessible so that the water supply

can be turned off when necessary.

The manufacturer declines all responsibility for personal injury or material damage resulting

from non-compliance with the above rules.

REV.0.04_COD.610078_A4 Page 12

Page 13

Training

Instructions for use of the machine will be provided by Miele Service or an authorized

representative during machine commissioning.

It will be the duty of the employer to check that the degree of staff training is suitable for

assigned duties.

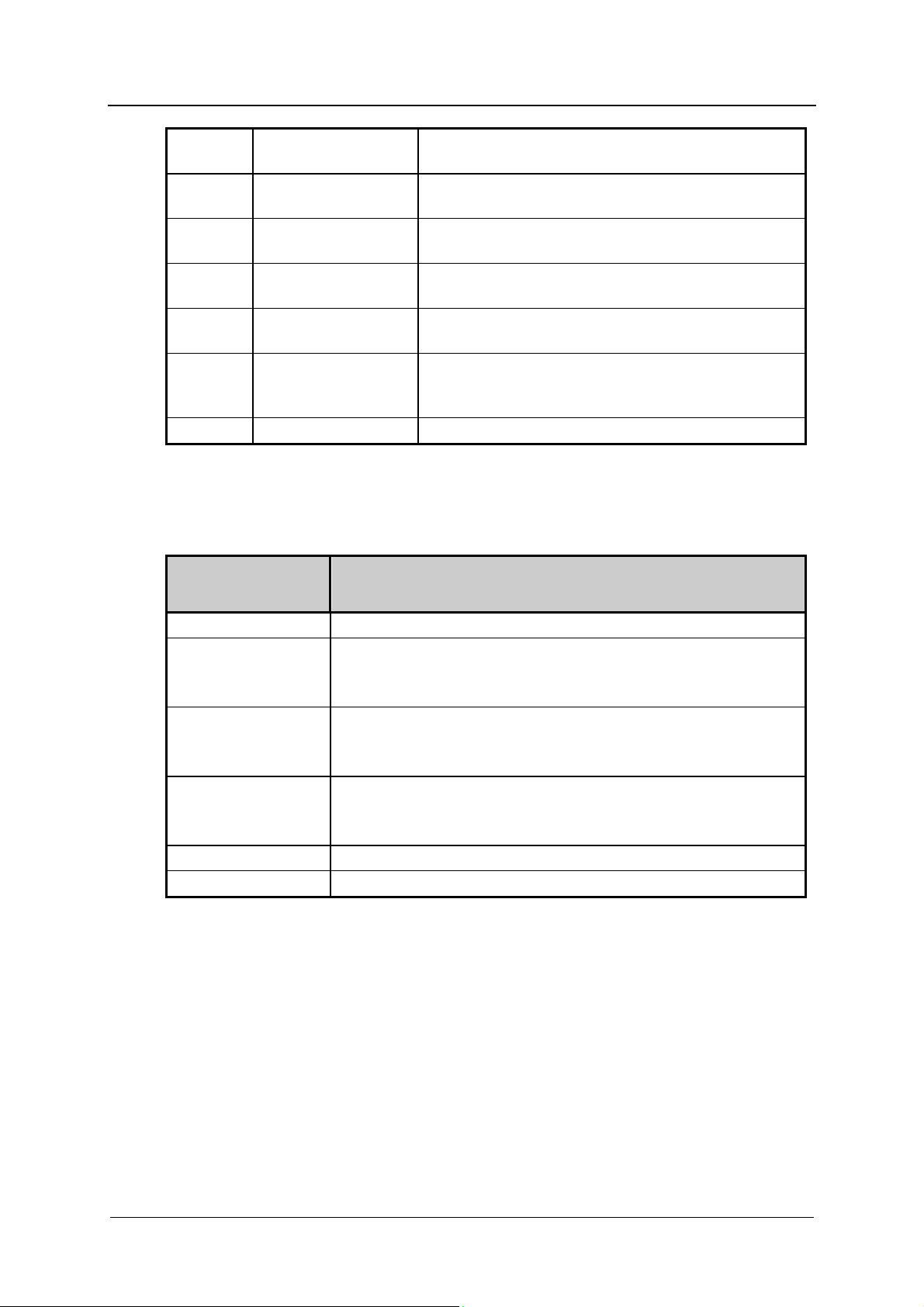

User profiles

Depending on the difficulty of certain installation operations and of the operation and

maintenance of the system, user profiles are identified as follows:

SERVICE Installation and repair technican.

ADMIN Responsible authority for the machine in the workplace:

USER Machine user:

PRODUCT INFORMATION

More advanced tasks, e.g., interrupting or canceling a program, require more

detailed knowledge about the machine cleaning of laboratory glassware and

laboratory untensils.

Alterations or adaptations of the lab washer, e.g., accessories used or on-site

conditions require additional specific knowledge of the lab washer.

We recommend only designated qualified personnel be allowed to operate

the washer.

REV.0.04 _COD.610078_A4 Page 13

Page 14

INSTALLATION

3. INSTALLATION

3.1 Water connection

Inlet water quality

The quality of the water used in all the cleaning stages is important to have good results.

The water used in each stage must be compatible with:

The material of which the machine is made.

The chemicals used in the process.

Process requirements for the various stages of the process.

In order to achieve good cleaning results, the machine needs to operate with soft water. Hard

water results in the build-up of calcium deposits on the load and in the machine.

If the mains water hardness level is more than 7 °fH (0.7 mmol/l or 4°dH), a water softening

system should be provided on site.

Note: It is the user’s responsibility to supply the machine with suitable water.

ATTENTION

Water from the wash cabinet must not be consumed.

The lab washer must be connected to the water supply in strict accordance with current local

and national water authority regulations.

The water used must be drinking-water quality. If the water supply has a high iron content

there is a danger of corrosion occurring on items being cleaned in the lab washer, as well as

the appliance itself. If the chloride content of the water exceeds 100 mg/l the risk of corrosion

to items being cleaned in the lab washer will be further increased.

In certain regions (e.g., mountainous areas) the water composition may cause precipitates to

form, requiring the use of softened water in the steam condenser.

The lab washer is supplied as standard for connection to cold water (blue coded) and hot

water up to max. 140 °F (red coded). Connect the inlet hoses to the water valves for cold and

hot water.

If there is no hot water supply available, the inlet hose coded red must also be connected to

the cold water supply.

The minimum flow pressure for cold water, hot water and for DI water connection is 14.5

psi (100 kPa).

Recommended flow pressure for cold and hot water connections is ≥ 29 PSI pressure and

for DI water connection ≥ 29 PSI pressure, to avoid excessively long water intake times.

The maximum permissible static water pressure is 116 psi (800 kPa) pressure.

If it is below 14.5 psi (100 kPa) dynamic pressure, you will need to install a pressure

increase pump. If the pressure is higher than 145 psi (1000 kPa) a pressure reducer

must be installed.

If the water pressure does not fall into the stated range, contact Miele Service or an

authorized and trained service technician for advice.

A water valve with a ¾" threaded union must be provided on site. It should be easily

accessible so that the water supply can be turned off when the machine is not in use.

REV.0.04_COD.610078_A4 Page 14

Page 15

Information

INSTALLATION

IMPORTANT

Do not overtighten the threaded unions on the hoses!

The back flow prevention system is already installed inside the machine according to

IEC61770;

If the connection of hot and cold water is not available, the two corresponding supply

pipes must be connected together;

The manufacturer declines all responsibility for damage or injury caused by improper

installation.

If you do not comply with the conditions above, the deriving damages will not

warranty.

ATTENTION

When the machine is not in operation, always close the water valves.

REV.0.04 _COD.610078_A4 Page 15

Page 16

INSTALLATION

3.2 Electrical connection

ATTENTION

Connection of the machine to the electrical to the electrical supply must be

made by qualified, skilled personnel.

Make sure that the power supply voltage reading corresponds to the voltage indicated

on the data tag

Check that the power supply voltage does not differ by more than 10% from its

nominal value.

The frequency of the power supply voltage must not differ by more than 1% of its

value.

Connection of the machine to the power supply must be provided with a ground

connection and an equipotential circuit as set forth by current standards.

Make sure that the electrical systems are efficiently grounded.

The ground conductor is to be connected to the ground terminal identified

by the standard symbol.

The machine is equipped with a terminal identified by the relative symbol for

equipotential connections between appliances (see rules for electrical

plants).

Connect the machine and the relative dedicated disconnection device (not supplied)

by using a power cable compatible with the electrical characteristics of the machine.

In case of prolonged take up of the machine it is recommended that you execute the

disconnection procedure of the electrical connection by placing the dedicated

disconnection device in "OFF" state.

The upstream electrical power line must be dimensioned and protected in accordance

with current local regulations.

ATTENTION

Please refer to the installation plan provided.

REV.0.04_COD.610078_A4 Page 16

Page 17

3.3 Adding and dispensing cleaning agents

The dosing system of cleaning agents is composed of:

1 dosing pump for detergent

1 dosing pump for neutralizing agent

Level sensor cleaning agent

Presence sensor of cleaning agent

Each dosing pump is combined with a sensor that confirms the presence of cleaning agent

inside the container. In case of product lack, the electronic control system of the machine

indicates a message in the display.

3.4 Replacement or refill of cleaning agent

To replace the cleaning agent container perform the following procedure:

Have a new container with cleaning agents ready.

Take the empty container.

Remove the siphon and place it on a chemical-resistant and easy-to-clean surface.

Insert the siphon into the new container.

Wipe up any spillages.

Place the cleaning agent container in the area for the storage of chemical substances.

Venting Dosing System by execute the Fill DOS1 program for detergent or Fill DOS2

program for neutralizer.

INSTALLATION

ATTENTION

Only use cleaning agents designed specifically for use in the machine and

follow the manufacturer's instructions on their application.

Caution when using cleaning agents. Some agents may be corrosive and

irritant. The relevant safety regulations and the cleaning agent

manufacturer's safety data sheets must be observed. Wear protective

goggles and gloves.

REV.0.04 _COD.610078_A4 Page 17

Page 18

INSTALLATION

3.5 Warning

For the maximum amount of cleaning agent which can be used per washing cycle,

follow the instructions for the cleaning agent you are using.

To ensure the efficiency of the chemical dosing system it is recommended to consider

the table of routine maintenance tasks; see the “Maintenance” chapter.

Use liquid cleaning agents only. Do not use powder detergent.

Always follow the relevant manufacturer's instructions on storage and disposal of

cleaning agents.

Check that the type of cleaning agents is suitable for the specific washing program

used.

ATTENTION

Before undertaking any sort of movement of the machine, ensure the

machine is completely drained of any residual water, chemical residues

and cleaning agent if necessary.

This procedure must be carried out, in order to prevent contact of the

cleaning agents with body parts and machine components that can be

damaged.

REV.0.04_COD.610078_A4 Page 18

Page 19

3.6 Connecting the drain hose

The drain hose connection should be checked carefully.

The machine is equipped with a drain hose with a diameter indicated on the

installation plan.

The choice of materials relating to the ventilation circuit for drainage operations must

take into account the same requirements as for piping that comes into direct contact

with drain fluids; it must be taken into consideration that these may give off harmful

(corrosive, toxic, etc.) vapors that may involve the output/input point of the duct.

CAUTION

If the drain system is clogged take great care when processing the water

and avoid contact with hands, eyes, etc., in the case of contact rinse the

parts concerned with plenty of water.

The drain hose is connected to the sewer network in the following manner:

Identify the drain pipe and relative fittings, and assemble them.

Make sure the seal gasket is installed correctly.

Identify the drain manifold and connect the hose via the union and ring nut. Tighten

the ring nut firmly.

Insert the drain hose and clamp it in place.

Insert the other end of the hose into the drain unit, installing it properly and locking it

in position.

It is necessary to follow these instructions for drain connection:

Drain hose must be connected by using a clamp.

Drain hose must not present angles or irregular curving in its course.

Drain point must be placed at the same height of the machine drain point or on the

floor.

INSTALLATION

Carefully follow these instructions as a wrong drain connection can cause the block of

machine.

The diameter of main drain must be as indicated on the installation plant.

Avoid drain pipe extension.

ATTENTION

Drainage must be done following international rules.

The manufacturer cannot be held responsible if an inaccurate if

inaccurate machine use causes pollution.

If the drain system is clogged take great care when processing the water

and avoid contact with hands, eyes, etc. In the case of contact rinse the

parts concerned with plenty of water.

When the machine is connected to an exhaust ventilation system, the

drain hose should be positioned outside the building, protected from any

animal access, and make sure that it not causes any hazard.

REV.0.04 _COD.610078_A4 Page 19

Page 20

INSTALLATION

Drain cooling

The machine is equipped by a system of drain cooling, which can be useful in order to reduce

the temperature from the standard temperature of 200° to 140°F (93° to 60°C).

3.7 Ambient ventilation requirements

During normal operation, the machine warms up itself dispersing heat and humidity.

Therefore, in order to guarantee a comfortable environment with good temperature and

humidity for the user, it is necessary to prepare an air conditioning or air circulation system

capable to balance the emissions reported in the installation plan.

Only when toxic detergents are used and/or it is expected that it is not possible to guarantee

acceptable levels of temperature and humidity in the installation environment, the air exhaust

of the equipment must be connected to a venting system.

The air that is expelled from the chamber must not be re-circulated so as to protect the user

from any undesired emissions produced by the machine or by the chemical products present

within the work area.

The machine connections are shown in detail on the

installation plan and electrical wiring diagram.

REV.0.04_COD.610078_A4 Page 20

Page 21

CHECKS PRIOR TO START-UP

4. CHECKS PRIOR TO START-UP

4.1 Introduction

The preliminary adjustments and controls are performed by a skilled technician who has been

specifically trained for this purpose.

4.2 Checks of safety systems

Indicative list of adjustments and checks of safety systems and devices to be carried out:

Check the mains supply voltage

Check the efficiency of the emergency and machine shutdown devices (circuit

breaker)

Check the efficiency of the door opening safety microswitch

Check the operation of machine controls, especially the START and STOP

commands

4.3 General controls

Indicative list of general adjustments and checks to be made:

Check proper execution of general supplies of the machine (electrical and plumbing)

Ensure that the user is trained for its use

Check that the motors installed on the machine rotate in the correct direction (only for

machines equipped with three-phase power supply motors)

REV.0.04 _COD.610078_A4 Page 21

Page 22

USING THE MACHINE

5. USING THE MACHINE

5.1 Checking consumption

Check consumption regularly by checking the fill levels in the supply containers and replace

containers in a timely manner before they are completely empty. Otherwise the dispensing

system will need repriming.

Wear appropriate individual protection gear (personal protection equipment).

Follow the instruction in the „ADDING AND DISPENSING CLEANING AGENTS”

section.

ATTENTION

Take care when handling cleaning agents. These may contain irritating,

corrosive or toxic ingredients.

Prior to use, carefully read the safety information provided by the

cleaning agent supplier and the label applied to the package.

5.2 Opening and closing the door

Pull on handle to open door.

The glass door is insulated, however it may be hot. Use caution when opening not to touch it.

ATTENTION

Keep hold of the door during opening and closing. Jerking the door open

or slamming it shut may break the glass.

Insert the basket with care into the wash chamber to avoid the risk of

breaking glass.

Before opening the door, check that the opening area is free from

obstacles.

The machine is equipped with an electric door lock in order to prevent it from being opened

when the machine is running.

REV.0.04_COD.610078_A4 Page 22

Page 23

USING THE MACHINE

Opening the door using the emergency release device

ATTENTION

The emergency release may only be used when it is no longer possible to

open the door normally, e.g., in the event of a power failure.

If the emergency release is operated during a program cycle, hot water

and cleaning agents can escape.

There is a risk of burning, scalding or chemical burns.

If a program is cancelled, the items in the lab washer must be cleaned

again.

1. An emergency release device is located above the

door, labelled accordingly.

2. Insert the tool into the emergency release opening.

3. Keep pushing the tool. In this moment the door is

unlocked and it is possible to open it.

4. To close the door, keep pushing the tool as

described above while pushing the door at the

same time.

5.3 Switching on and off

The machine is switched on and off by turning the main switch at the bottom right

REV.0.04 _COD.610078_A4 Page 23

Page 24

USING THE MACHINE

5.4 Preparation

Make sure that the items can be cleaned inside the machine and verify the

compatibility with the cleaning agents used during the cycles.

Place the items to be washed inside the machine and position them carefully on the

holder and in the rack.

Items should not overlap.

Items should be positioned so that liquids can flow out easily.

Tall or heavy items should be placed towards the middle of the basket if possible to

facilitate washing.

Make sure that nothing is blocking the arms and that they turn freely.

Place the load uniformly in the basket.

The mobile units, baskets, modules and inserts that hold the load must be used only

as intended.

Empty any containers or utensils before loading them.

Take apart any items which can be dismantled according to the manufacturer's

instructions and process the individual parts separately from each other.

Do not place items to be cleaned inside other pieces where they may be concealed.

Do not place items so close together that cleaning is hampered.

Arrange the load so that water can access all surfaces.

Only clean small items and micro components in special inserts, mesh trays with lids

or mesh inserts.

Plastic items must be thermally stable.

ATTENTION

The maximum load for each cycle is 44lbs (20 kg) (basket included).

Never use the machine without basket.

Before starting to use the machine, please make sure that all the routine checks have been

made. Verify the wash arms and their rotation.

ATTENTION

Never empty any solid waste into the machine.

This will block the drain system with pump and destroy the machine.

Noncompliance, even in part, of the rule here indicated, can cause

dangerous leakage of water from the door.

REV.0.04_COD.610078_A4 Page 24

Page 25

CONTROL PANEL AND SYMBOLS USED

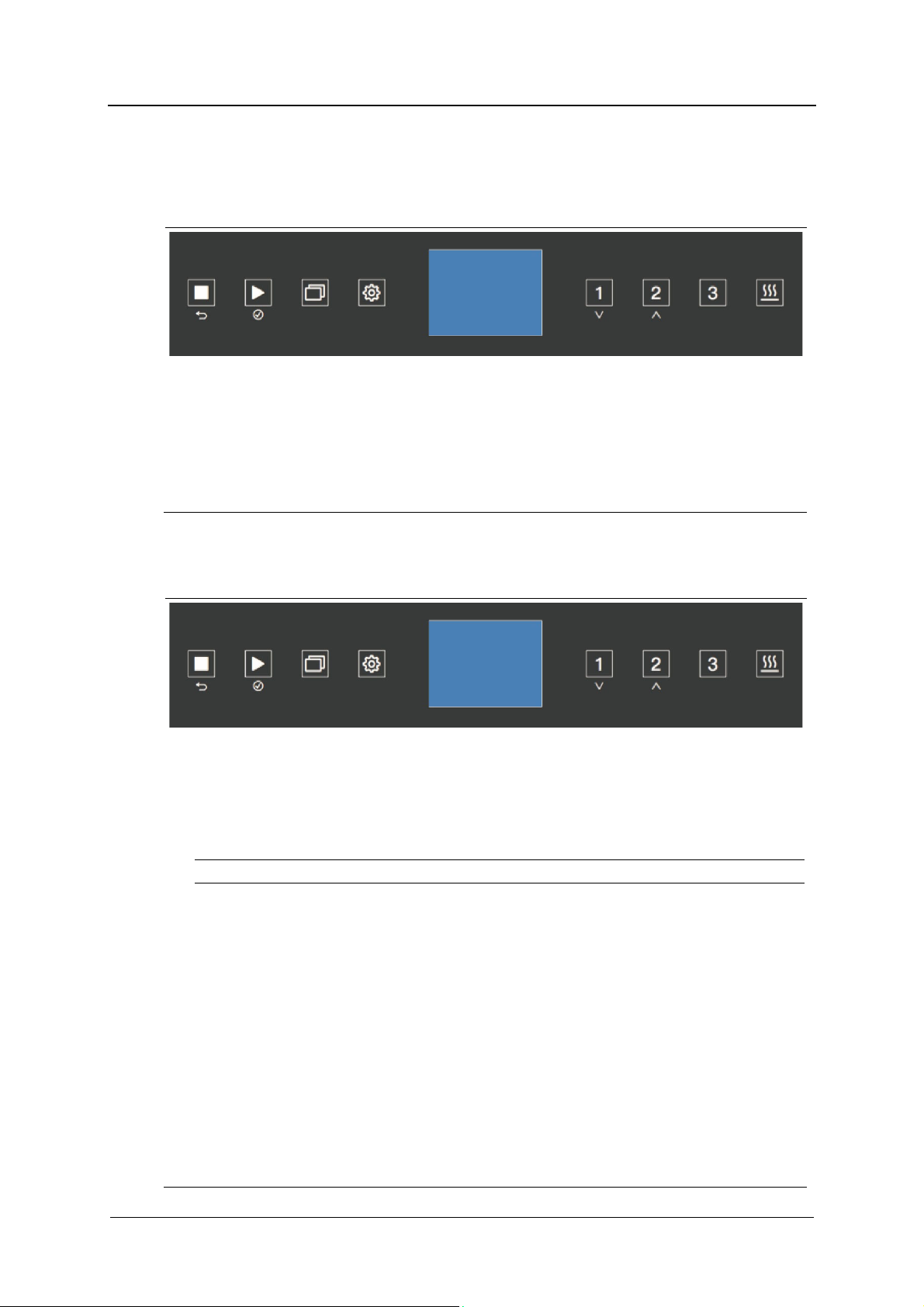

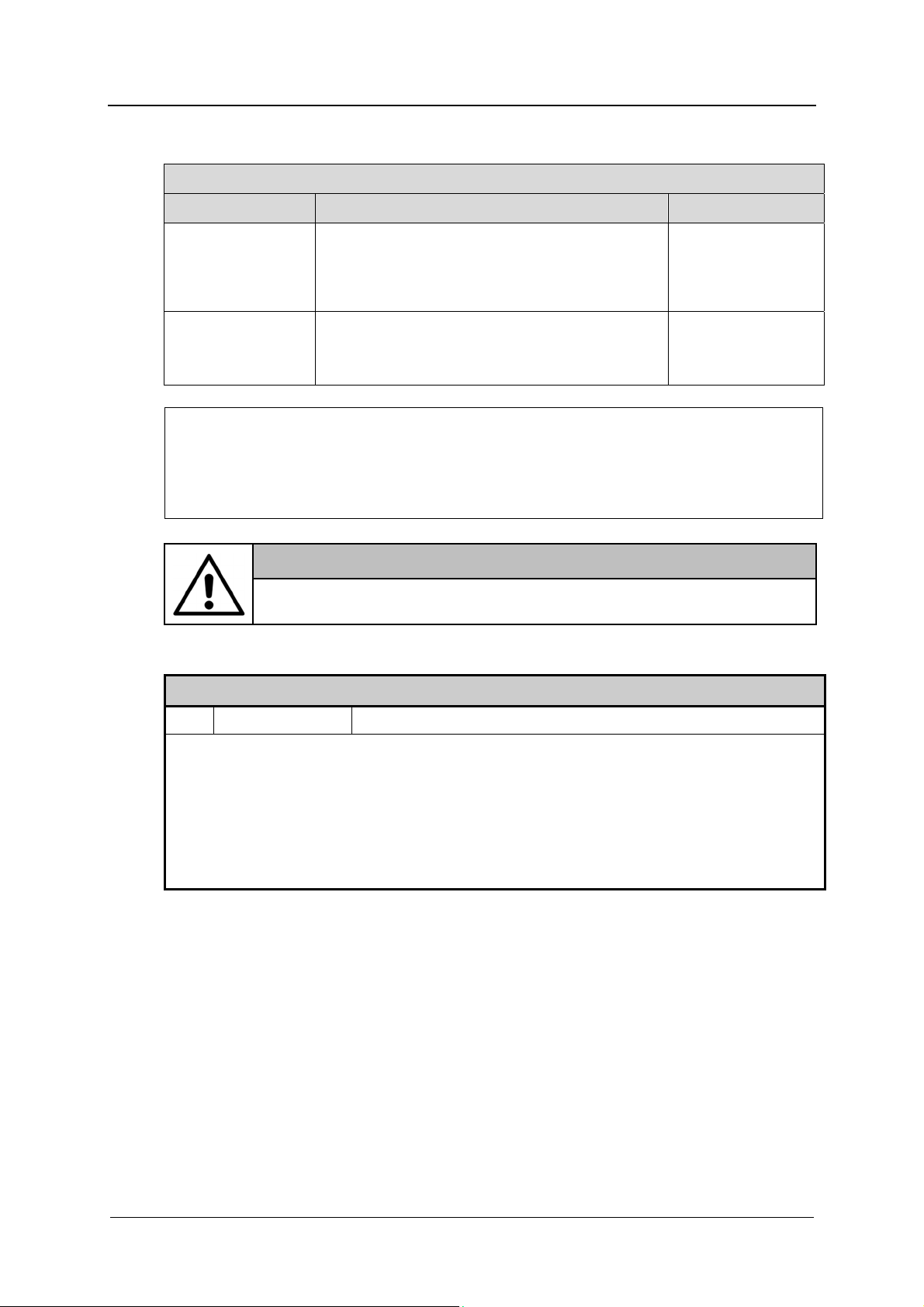

6. CONTROL PANEL AND SYMBOLS USED

The control panel with liquid crystal display is illustrated in the image.

This panel makes the machine easy to use, as it indicates the cycle phases in progress and

the temperature reached during each cycle phase; besides, it displays any error messages.

A

6.1 Buttons

The buttons of the glass display are touch-sensitive and backlit (LED). There are 8 buttons

available with the following functions:

B

C

D

Display

E

F

G

H

BUTTON DISCRIPTION

One press for interrupting a program.

The display advices the disinfection lack and the “manual

stop” message appears, the door remains locked and, if

necessary, it indicates the temperature inside the chamber.

By pressing START, the machine restarts the cycle execution

from the point, in which it had been stopped.

Two presses for canceling a program.

The machine returns to the stand-by condition and the door

is unlocked.

For canceling a process.

Starting a program.

For selecting or confirming entries in the user interface.

For accessing the list of all additional programs.

The menu incorporates all relevant functions.

During standby: Press the button for 5 seconds to access the menu.

Short program

For navigating within the display.

Standard program

For navigating within the display.

A

B

C

D

E

F

STOP

(cancel)

START

(confirm)

P+

PRG

P1

(down)

P2

(up)

G

H

REV.0.04 _COD.610078_A4 Page 25

P3

DRY

Intensive program

Drying function.

Before starting a program, it is possible to add additional drying time

or to deactivate the drying function.

The standard drying setting is 20 minutes on each program.

By pressing the button once, an additional 5 minutes is added to the

drying time, for a total drying time of 25 minutes.

By pressing the drying button twice, the drying step will be

deactivated.

Page 26

CONTROL PANEL AND SYMBOLS USED

BUZZER

The buzzer sounds each time a button is pressed and intermittently in the case of a machine

shutdown (see “MALFUNCTION” section).

6.2 Display

1

8

2

3

4

9

5

6

7

PIC.1

PIC.1

Display the following information:

1. Date and time

2. Selected program and program position

3. Current program phase

4. Temperature in chamber (Sensor 1) with A0 value

5. Target temperature for current program phase

6. Remaining time

7. Warning message

8. Cycle counter

9. Temperature in chamber (Sensor 2) with A0 value

At the beginning, while the machine is in the stand-by status, it displays the type of program

selected, temperature, date and time.

By pressing one of the program button (P1 , P2 or P3 ), the display shows the

program associated to the key and at the left bottom the following message: "press start" or

"door open".

By pressing the P+ button, it is possible to scroll all the available programs.

REV.0.04_COD.610078_A4 Page 26

Page 27

CONTROL PANEL AND SYMBOLS USED

PIC. 2

During the cycle, by pressing the PRG button it

is possible to display the screen showing the

various machine temperatures (Pic. 2).

PIC. 3

By pressing PRG button twice a screen with

alarms and warnings is displayed (Pic. 3).

PIC. 4

In case of an error, a window appears indicating

the identification alarm code and a brief description

as shown in Pic.4.

In case of failure, which does not lead to a block (such as lack of chemical) a message is shown

at the left bottom of the screen (Pic.1 point 7) or by pressing twice the PRG button as shown

in Pic.3.

REV.0.04 _COD.610078_A4 Page 27

Page 28

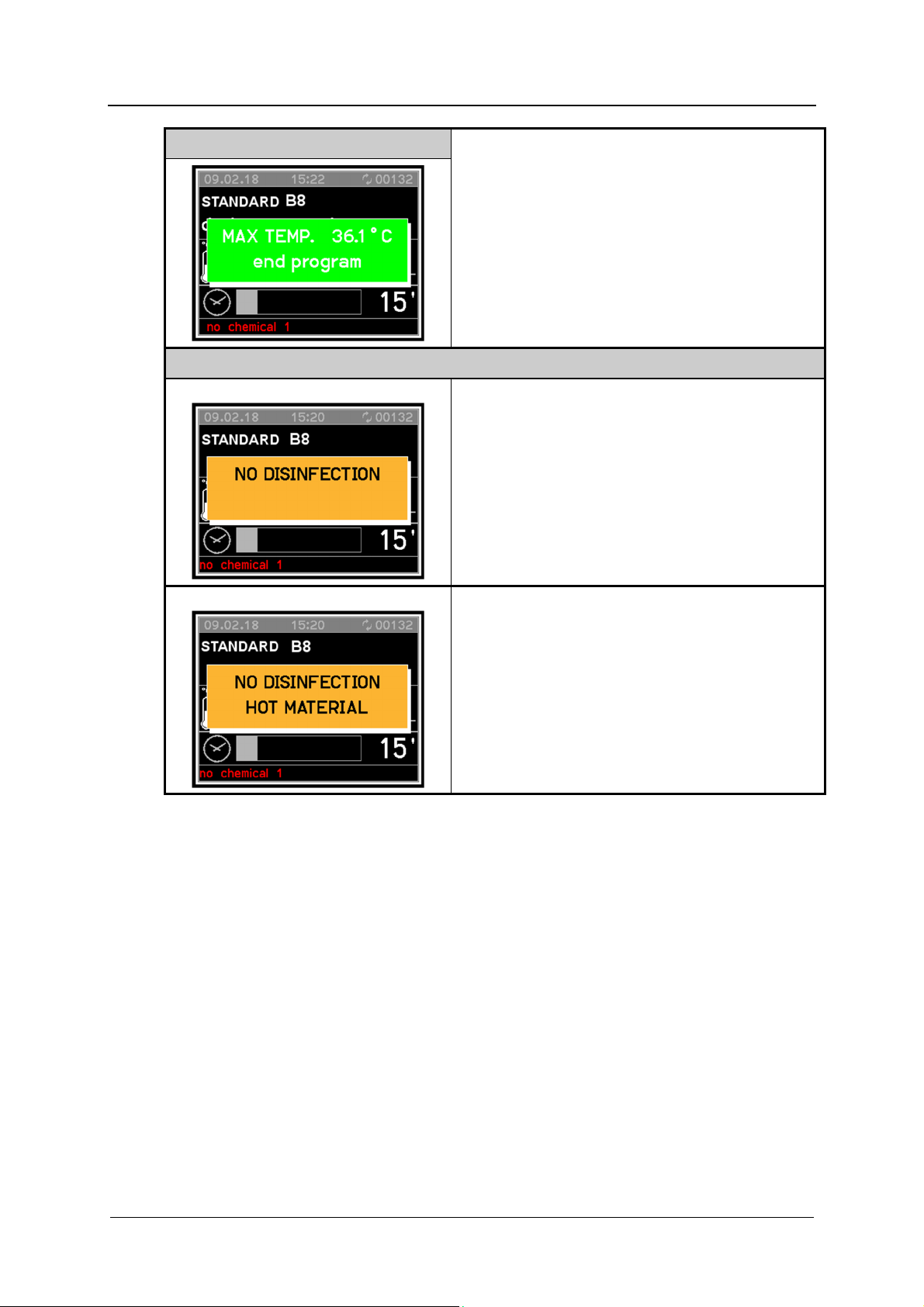

CONTROL PANEL AND SYMBOLS USED

PIC. 5

At the end of the cycle, a window appears as

displayed in Pic.5.

PIC. 6

Pic.6.A

In case a cycle was interrupted, a window appears

with a message warning the disinfection lack

(Pic.6.A).

In case of cycles without desinfection, this window

appears by pressing STOP only once.

Pic.6.B

If the temperature in a cancelled program was

149°F (65°C) or lower, the message shown in Fig.

6.A is displayed.

If the temperature was above 149°F (65°C), the

message shown in Fig. 6.B is displayed.

REV.0.04_COD.610078_A4 Page 28

Page 29

7. PROGRAMS

7.1 Program blocks

Drain

For draining wash water.

Pre-wash

A pre-wash removes coarse soiling and foaming agents.

Main wash

Depending on load, cleaning generally occurs at temperatures between 113°F (45 °C)

and 149°F (65 °C) with the addition of appropriate cleaning agent.

Interim rinse

In the interim rinse stages, the cleaning agents from the previous wash blocks are

rinsed off and neutralized where necessary by the addition of appropriate neutralizing

agents.

Final rinse

To avoid deposits and corrosion on the load, demineralized (AD) water should

preferably be used, if available, for the final rinse.

Drying

PROGRAMS

REV.0.04 _COD.610078_A4 Page 29

Page 30

PROGRAMS

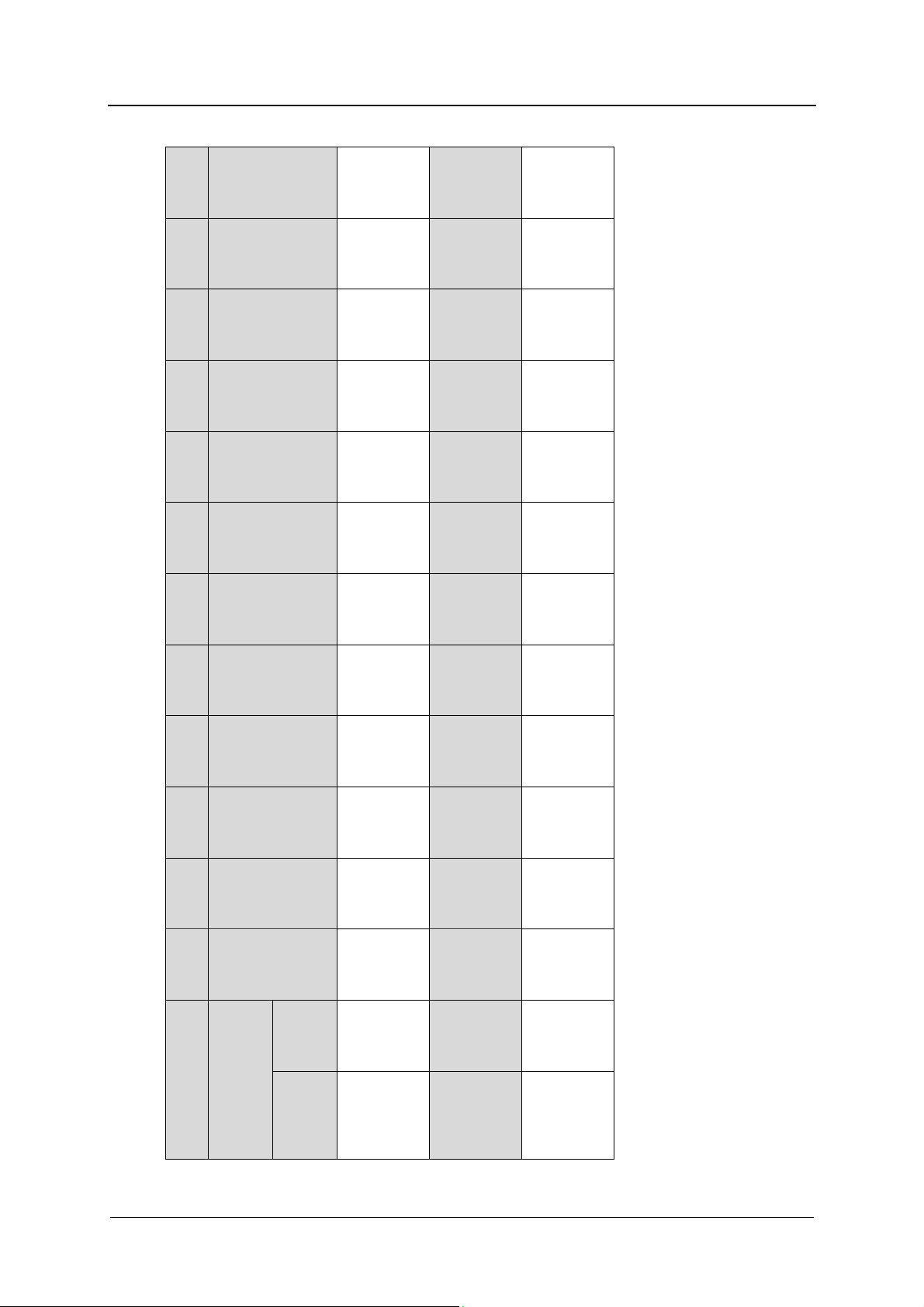

7.2 Program chart

Drying

Wash

Wash

Wash

Wash

Wash

Wash

Drying

2

Final

rinse

1

Final

rinse

rinse

Interim

rinse

Interim

2

rinse

Interim

2

-zation

Neutrali

4

3

DI

140°F

(60°C)

DI

1 Min

140°F

(60°C)

DI

1 Min

HW

140°F

(60°C)

DI

1 Min

DI

1 Min

140°F

(60°C)

DI

1 Min

HW

1 Min

1 Min

140°F

(60°C)

1 Min

Wash

Wash

Wash

Wash

Wash

1

-zation

Neutrali

2

Main

wash

1

Main

wash

Pre-

wash

1

Pre-

wash

Function

2

1

rinse

Interim

HW

HW

Button

DOS2

DOS1

122°F

(50°C)

HW

2 Min

HW

3 Min

CW

DOS2

DOS1

3 Min

3 Min

140°F

(60°C)

2 Min

HW

HW

HW

CW

DOS2

DOS1

DOS1

2 Min

3 Min

158°F

(70°C)

3 Min

140°F

(60°C)

2 Min

HW

HW

CW

DOS2

DOS1

1 Min

3 Min

149°F

(65°C)

2 Min

HW

HW

DOS2

DOS1

2 Min

3 Min

131°F

(55°C)

Block

REV.0.04_COD.610078_A4 Page 30

Program

Short

Standard

Intensive

Analytic

Plastic

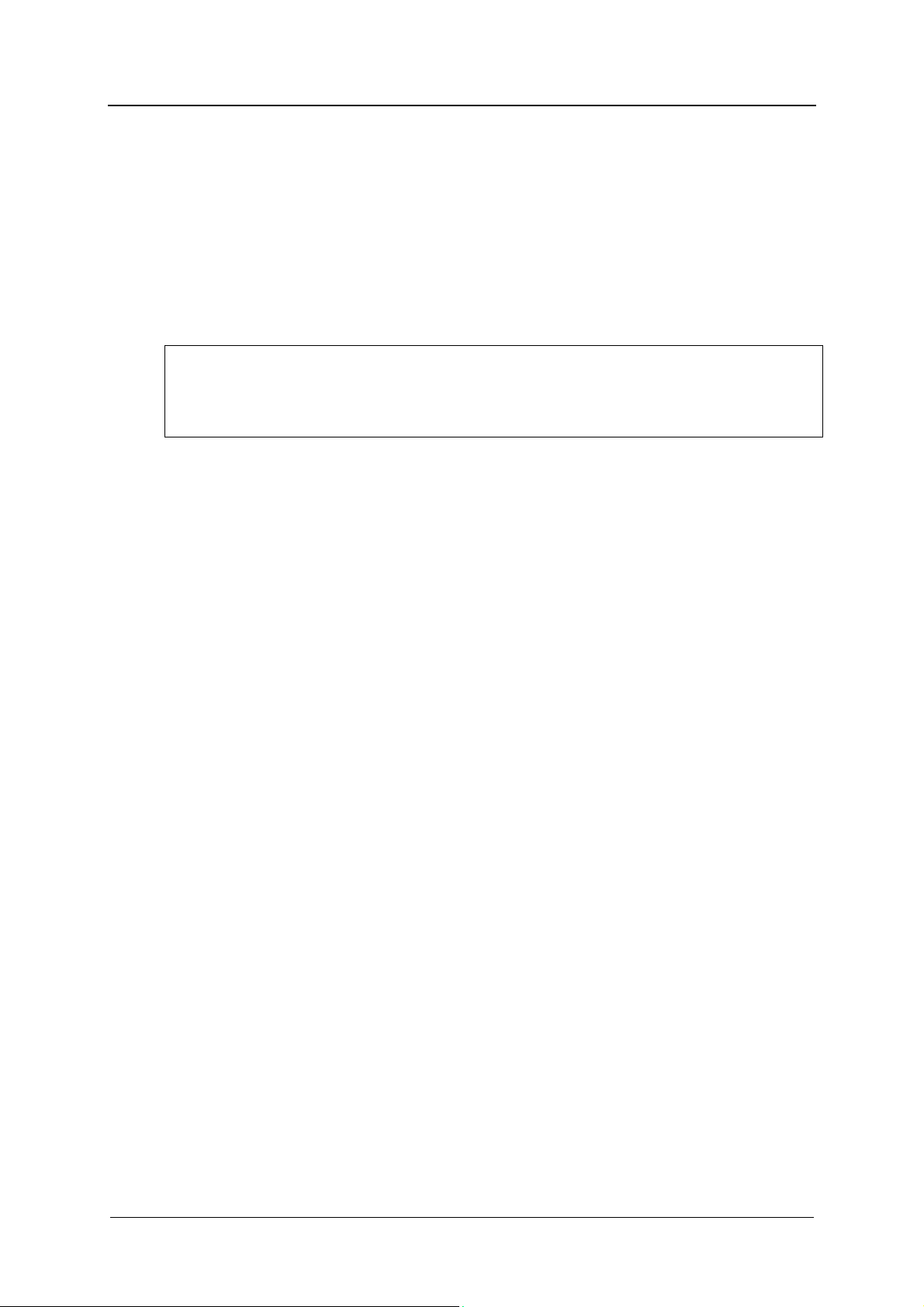

Page 31

PROGRAMS

Drying

Wash

Wash

Wash

Wash

Wash

Wash

Drying

2

Final

rinse

1

Final

rinse

4

rinse

Interim

3

rinse

Interim

2

rinse

Interim

2

-zation

Neutrali

DI

HW

167°F

(75°C)

1 Min

1 Min

DI

140°F

(60°C)

DI

1 Min

DI

1 Min

140°F

(60°C)

1 Min

(90°C)

1 Min

3 Min

CW

5 Min

Wash

Wash

Wash

Wash

Wash

1

-zation

Neutrali

2

Main

wash

1

Main

wash

2

Pre-

wash

1

Pre-

wash

1

rinse

Interim

DI

DOS2

DI

194°F

DOS1

Function

Button

HW

HW

CW

DOS2

DOS1

122°F

(50°C)

*)

HW

1 Min

HW

3 Min

CW

2 Min

DOS2

DOS1

1 Min

3 Min

149°F

(65°C)

2 Min

*)

Block

Program

Microbiol.

Prewash

Customer

specific 1

Customer

specific 2

REV.0.04 _COD.610078_A4 Page 31

Page 32

PROGRAMS

Drying

Wash

Wash

Wash

Wash

Wash

Wash

Drying

2

Final

rinse

1

Final

rinse

4

rinse

Interim

3

rinse

Interim

2

rinse

Interim

2

-zation

Neutrali

Wash

Wash

Wash

Wash

Wash

1

-zation

Neutrali

2

Main

wash

1

Main

wash

2

Pre-

wash

1

Pre-

wash

1

rinse

Interim

HW

HW

10 s

10 s

DOS1

Function

Button

HW

HW

10 s

10 s

DOS2

HW

HW

10 s

10 s

DOS 3

CW = Cold water

HW = Hot water

DI = Demineralized water, fully demineralized water, demineralized water

Min = Holding time in minutes

DOS1 = Detergent

Block

Program

Fill DOS1

Fill DOS2

Fill DOS3

DOS2 = Neutralizer

REV.0.04_COD.610078_A4 Page 32

*) Customizable programs with pre-set vaules to be adjusted.

Page 33

7.3 Start the program

In order to start, follow the procedure as described below:

Select a program.

Press START button.

PROGRAMS

REV.0.04 _COD.610078_A4 Page 33

Page 34

MACHINE STATUS

8. MACHINE STATUS

8.1 Ready for operation

The machine is ready for operation.

The diagnostics are active. If necessary the display indicates that the door is open or it gives

warning messages: lack of chemicals, memory full (historical data) or high temperature inside

chamber.

When the machine is ready for operation and the door is closed, it is possible to press the

START button.

8.2 Program status

The cycle performs a defined series of program stages.

The user interface displays the current program stage in progress and the temperature in the

chamber.

The display indicates that the door is open as appropriate or it issues warning messages, e.g.

lack of chemicals.

8.3 Power failure

In the event of a brief power failure during a running program, the current program phase is

repeated and the program continued.

REV.0.04_COD.610078_A4 Page 34

Page 35

8.4 Reset procedure

In the event of a malfunction during a cycle in progress, the door remains closed and locked.

To acknowledge the error message, it is necessary to carry out a procedure on the keyboard

as follows:

Press the STOP and START buttons together and keep pressed for 5 seconds.

Press the program P2 button followed by the program P1 button.

The machine is reset and returns to ready for operation and it’s possible to open the

door.

Note:

If the machine shutdown persists due to a fault in one of its components (e.g., faulty probe,

etc.), the door is released and the machine remains inactive.

In case this situation happens, seek technical assistance.

MACHINE STATUS

REV.0.04 _COD.610078_A4 Page 35

Page 36

MENU

9. MENU

The menu incorporates all administrative processes and settings. The menu can only be

accessed by using a password, which is issued by Miele Service or an authorized service

technician.

The programming access and the menu are protected by two password levels:

st

level: Machine user (USER) password – allow the access to the program and time

1

selection, historical and USB menu access (view and printing, not historical deletion)

nd

2

If the password is lost, contact Miele Service or an authorized service technician.

9.1 Accessing the menu

To access the menu keep the PRG button pressed for 5 seconds

Press the P1 and P2 buttons to scroll through the menu

Press START button to confirm selection

Press STOP button to exit the menu and return to “Ready for operation” or

Main Menu

level: Responsible Authority (ADMIN) password – allow the access to all menus

but with limited modification possibility

“Malfunction” mode

Basic Programs

Allows the pre-set programs to be viewed and copied

Customer programs

Allows the creation of new customized programs

Program selection

Allows the activation and deactivation of memorized programs

Setting

Allows access to all programming functions

REV.0.04_COD.610078_A4 Page 36

Page 37

9.2 Entering password

If a selected function is password-protected, a window appears in the display. This window

contains a series of asterisks.

Each asterisk represents a character of the password.

Use buttons P1 and P2 to select symbols and press START to confirm

individual entries.

The protected menu appears once the correct password is entered.

An error message appears in the display if the password entered is incorrect.

This error message must be confirmed by pressing

STOP . The error message window then disappears.

MENU

9.3 Buzzer volume setting

Hold PRG pressed for 5 seconds.

Use buttons P1 and P2 to scroll through the menu to the following options.

Each value must be confirmed individually by pressing START :

'Setting'

"Parameter"

Entering password

'System'

Select one of the following parameters using buttons P1 and P2 :

o Parameter 1.07:

Keypad tone volume

o Parameter 1.08:

Buzzer volume at end of program

o Parameter 1.09:

Warning ringtone volume

Confirm selection by pressing START .

Use buttons P1 and P2 to select the volume. Select '0' to switch off the

buzzer.

Save the selected volume by pressing START .

Exit the menu by pressing STOP .

REV.0.04 _COD.610078_A4 Page 37

Page 38

MENU

9.4 Date and time setting

The controls have a real-time clock. Times are saved to historical data.

Hold PRG pressed for 5 seconds.

Use buttons P1 and P2 to scroll through the menu to the following options.

Each value must be confirmed individually by pressing START :

'Setting'

'Clock'

Entering password

The hours, minutes and the date can be set using buttons

P1 and P2 .

Each value must be confirmed individually by pressing

START .

Exit the menu by pressing STOP .

9.5 Selecting a language

Use the following parameters to select the display output language.

Hold PRG pressed for 5 seconds.

Use buttons P1 and P2 to scroll through the menu to the following options.

Each value must be confirmed individually by pressing START :

'Setting'

"Parameter"

Entering password

'System'

Select one of the following parameters using buttons P1 and P2 :

o Parameter 2.04:

Language selection

Confirm selection by pressing START .

Use buttons P1 and P2 to select a language and press START to confirm.

The language will be changed immediately.

Exit the menu by pressing STOP .

REV.0.04_COD.610078_A4 Page 38

Page 39

9.6 Changing user name

User names can be changed using the following parameters. Contact Miele Service to

administer user profiles.

Hold PRG pressed for 5 seconds.

Use buttons P1 and P2 to scroll through the menu to the following options.

Each value must be confirmed individually by pressing START :

'Setting'

"Parameter"

Entering password

'System'

Select the following parameters using buttons P1 and P2 :

o Parameter 1.01:

User name selection

Confirm selection by pressing START .

Use buttons P1 and P2 to select a user and press START to confirm.

User names can consist of up to 16 characters. Each character must be selected

individually with buttons P1 and P2 and confirmed by pressing START .

A user name can consist of numbers, letters and spaces.

Exit the menu by pressing STOP after entering the last character.

MENU

REV.0.04 _COD.610078_A4 Page 39

Page 40

MENU

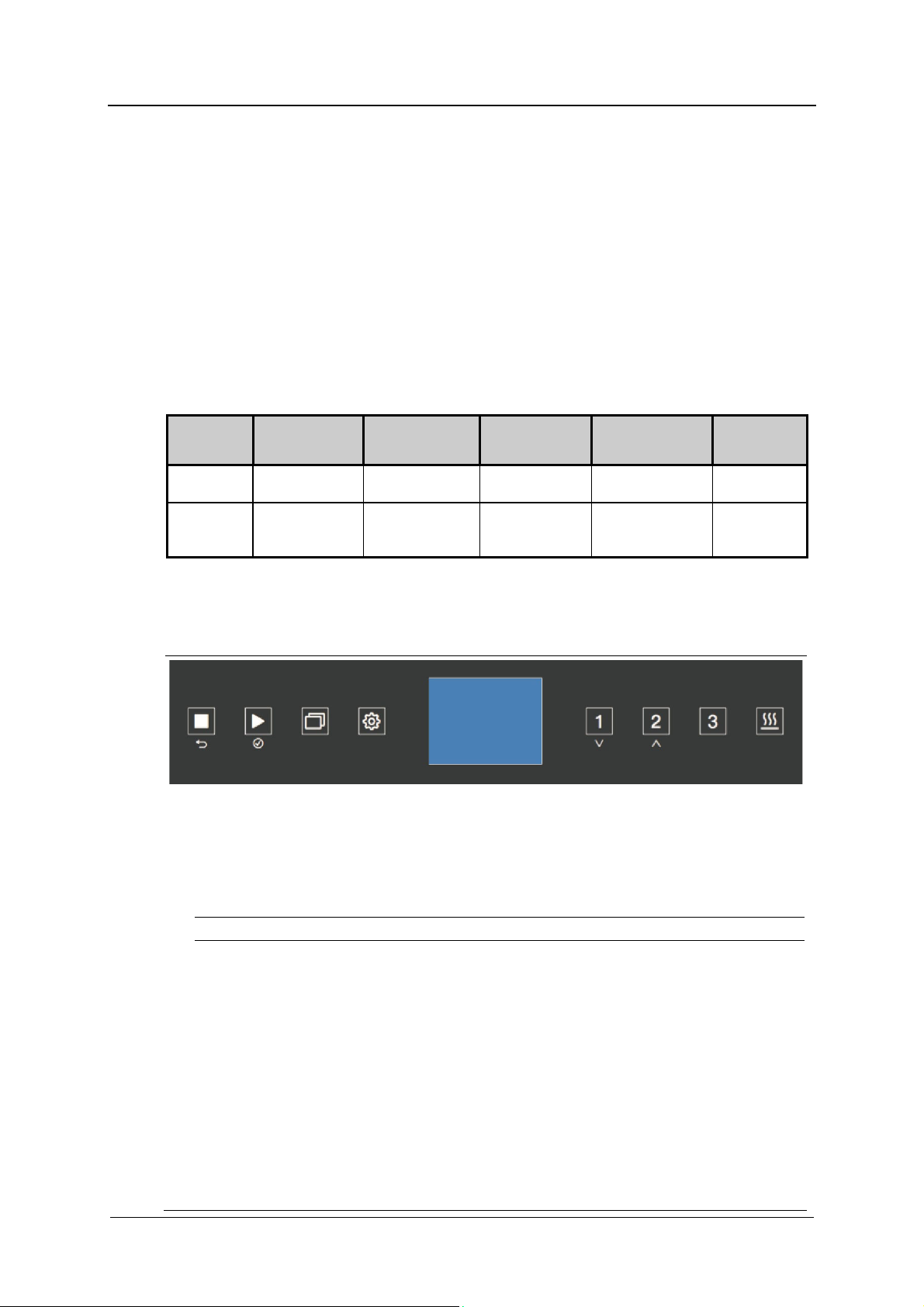

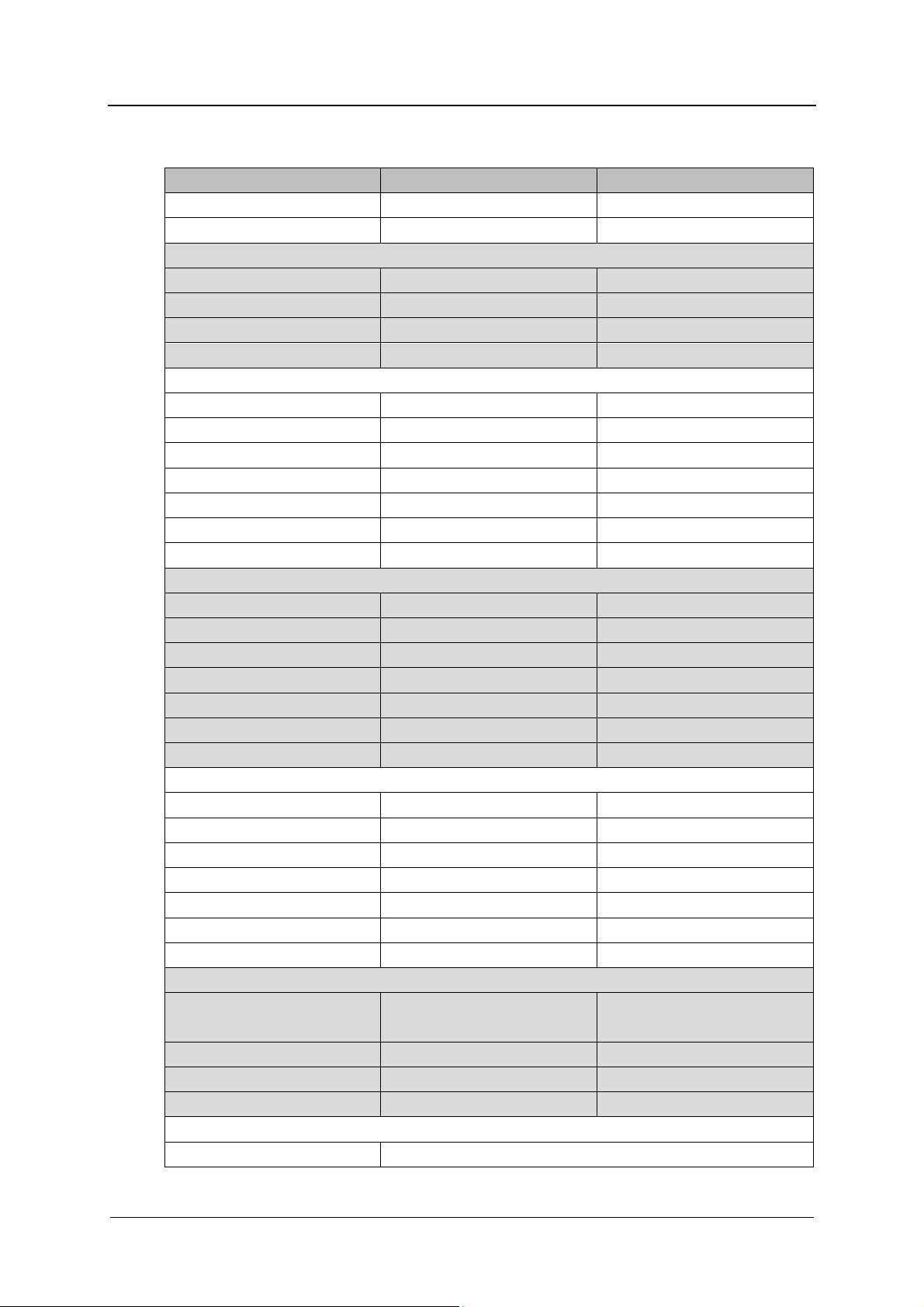

9.7 Parameter overview

CATEGORY

MACHINE

PRINTOUT

PRINTOUT

KEYBOARD

KEYBOARD

KEYBOARD

KEYBOARD

KEYBOARD

SECTION

1 01

1 04

1 05

1 07

1 08

1 09

1

13

1

16

DESCRIPTION

MIN.

MAX.

UDM

PARAMETER

SYSTEM DATA

User name (16 characters) ‚ ~ CHAR_STR

Graphic printout at the end of the

cycle

(0: No print out, 1: Graphic printout

2: Tabular printout, 3: Print to USB)

Printout of results of current cycle;

0=disabled 1=enabled

Buzzer volume - loading side

(0: buzzer switched off)

Buzzer volume - end of cycle

Buzzer alarm volume

(0: buzzer switched off)

Show A0 value in display 0=disabled

1=enabled

Historical cycles memory full (0=no

warning, 1=warning, 2=warning and it

is not possible to start a cycle)

0

0

0

50 NUM

0

50 NUM

0

50 NUM

0

0 2

3

NUM

1

SEL

1

SEL

SEL

MACHINE DATA

KEYBOARD

2 04

Selecting a language

0

7

SEL

REV.0.04_COD.610078_A4 Page 40

Page 41

10. CLOCK

The control has a real-time clock.

Time reading is also used when recording historical data.

11. HISTORICAL DATA

During the working cycle, the machine memorizes all working data of the wash cycles that

have been performed on a card.

The card is able to record the fields described below for up to max. 200 cycles in the

permanent memory.

The fields given in the example below are recorded for each cycle:

CLOCK

DATE START TIME PROGRAM MAX °F (°C)

12/12/2018 12.00 Short 140°F (60°C) 60 seconds 01

12/12/2018 13.05 Standard 140°F (60°C) 180 seconds 01

When 95% of the memory is full the dump memory message appears on the display.

To deactivate the recurring message follow the steps below.

Hold PRG pressed for 5 seconds.

Use buttons P1 and P2 to scroll through the menu to the following options.

Each value must be confirmed individually by pressing START :

HOLD >185°F

(85°C)

FAULTS

'Setting'

"Parameter"

Entering password

“System”

Select one of the following parameters using buttons P1 and P2 :

o Parameter 1.16

Confirm selection by pressing START .

Select one of the following options with buttons P1 and P2 :

o 0 = No warning

If the memory is full, the oldest report is overwritten

o 1 = Warning

o 2 = Warning and it is not possible to start a cycle

Confirm selection by pressing START .

Exit the menu by pressing STOP .

REV.0.04 _COD.610078_A4 Page 41

Page 42

ALARMS AND EVENTS LIST

12. ALARMS AND EVENTS LIST

12.1 Description of alarm messages

During machine operation, the user is aided by ALARMS or ALARM MESSAGES which

make use of visual signals on the operator display panel to advise of possible anomalies in

progress and machine alarms which have intervened.

Intervention of an ALARM during operation of the system is signaled to the user by a

message on the operator panel.

The alarm which appears on the panel remains active until the cause of intervention is

removed.

The intervention of an alarm stops the wash cycle currently in progress.

12.2 List of alarm messages

Possible alarms which may intervene during a work cycle are shown on the control panel

display.

The message includes the number of the alarm that has intervened and its name.

A complete list of possible alarm messages follows.

ALARM

E 2 open load. door Door open and/or unlocked during cycle.

E 4 load.door fail. Door blocked but open (discrepancy).

E 7 unblock.door 1

E 9 unlocking 1fail. Overtime unlock door.

E11 no cold water Timeout cold water filling level

E12 no hot water Timeout hot water filling level

E13 no demin. water Timeout demineralized water filling level

E23 drain problem Timeout minimum water level during the drain.

E26 prewash max°C

E27 tank probe lim°C Chamber temperature above maximum value.

E30 tank probe

E31 tank probe 2

E34 check temp.

DISPLAY

MESSAGE

DESCRIPTION

Door problems:

Overtime lock door.

During block door, the door has been

opened.

Chamber temperature exceeded selected value

during pre-wash.

Temperature sensor defective - Operation sensor

(sensor 1)

Defective temperature sensor - Redundant sensor

(sensor 2)

Appears when all the following conditions are met:

Chamber temperature above selected value.

Temperature difference between the two

probes is greater than 35.6°F (2°C).

Chamber heating failure.

REV.0.04_COD.610078_A4 Page 42

Page 43

USB PORT

E35 Serial 1 load

E37 CAN serial

E39 no tank heating

E44 levels steamcond

E45 pump steam cond.

E46 pump

E60 Time Maximum time exceeded in main wash

12.3 List of warning messages

DISPLAY

MESSAGE

No connection between master PCB and loading

control panel PCB.

No connection between master and slave PCB

(CANbus).

No heating in chamber. No temperature increase

during allocated time.

Max steam condenser level enabled and min steam

condenser level disabled.

Max and min steam condenser level enabled:

probable drain pump failure.

Circulation pump ON; Pressure switch closecircuited.

Circulation pump rotates in wrong direction.

DESCRIPTION

press start It is possible to start a cycle during a stand-by state.

The cleaning agent associated to dosing pump 1 is used up.

no chemical 1

no chemical 2

no chemical 3

open door Indicates that door is open.

wait Generic warning to wait before a new action.

Diagnostics with dosing pump enabled:

Pressure switch state with pressure switch presence;

The cleaning agent associated to dosing pump 2 is use up.

Diagnostics with dosing pump enabled:

Pressure switch state with pressure switch presence;

The cleaning agent associated to dosing pump 3 is used up.

Diagnostics with dosing pump enabled:

Pressure switch state with pressure switch presence;

13. USB PORT

Testing and transmission point for Miele Technical Service.

REV.0.04 _COD.610078_A4 Page 43

Page 44

MAINTENANCE

14. MAINTENANCE

14.1 General recommendations on maintenance

Maintenance operations for the machine described in this manual can be divided into "Routine

Maintenance" and "Special Maintenance".

Machine status

The machine must be turned off and the dedicated disconnection device must be in the OFF

position. The person performing the task must ensure that there is no-one around the

machine during this operation.

14.2 Maintenance request

The machine displays the “MAINTENANCE” warning after a specified time or after a

specified number of working hours.This warning does not affect the normal use of the

machine.

14.3 Routine maintenance

Routine maintenance includes all the operations aimed at keeping various parts of the

machine clean and functional. It must be performed on a regular basis or when it is

considered necessary due to incorrect performance of a washing cycle.

Since these are simple cleaning operations, they are normally performed by the machine user

on his own liability. The following table shows the various routine maintenance tasks, their

frequency, who is to perform them and the reference to the specific intervention form.

Each single task is fully explained in the single reference forms.

REV.0.04_COD.610078_A4 Page 44

Page 45

14.4 Table of routine maintenance tasks

CLEANING AND CHECKING OPERATIONS

FREQUENCY ACTION OPERATOR

MAINTENANCE

EVERY DAY - Cleaning the filters in the wash cabinet

USER

- Check the fill level of the chemical containers

regulary based on the usage, at least once a

day

EVERY WEEK - Spray arms: Check for free rotation. Open the

USER

cleaning caps and wash inside. Check and, if

necessary, clean the nozzle

Note:

Routine maintenance tasks must be performed within the intervals set forth in the table and

in accordiance to the daily routine controls check list.

It is however advisable to carry out single cleaning tasks anytime you feel they may be

necessary.

WARNING

Never clean the machine or and its immediate surrounding area with a water hose

or a pressure washer.

CLEANING THE EXTERNAL BODY OF THE MACHINE

METHOD OF CLEANING EXTERNAL BODY:

Operator: USER Frequency: once a day

Use a damp cloth to clean the external body of the machine. Only use neutral detergents. Do

not use abrasive detergents or solvents and/or thinners of any kind.

METHOD OF CLEANING CONTROL PANEL:

Clean the control panel using only a soft cloth dampened with a product for the cleaning of

plastic materials.

REV.0.04 _COD.610078_A4 Page 45

Page 46

MAINTENANCE

Operator: USER Frequency: every day

METHOD OF INTERVENTION:

Clean the washing chamber drain filters in the following manner:

Open the washing chamber door and remove the basket.

CLEANING OF FILTERS IN THE WASH CABINET

Warning:

Hot surface

Remove the drain water filtering assembly from the chamber.

Unscrew the threaded pin and remove the cover of the drain water filter basket.

REV.0.04_COD.610078_A4 Page 46

Page 47

MAINTENANCE

Clean the drain water filter basket. Remove residues deposited during various

washing cycles.

Remove and clean any deposits and incrustations from the washing chamber drain.

Place back the clean filter on the washing chamber drain.

Put the cover for the drain water filter back in place. Lock it in position with the

threaded pin.

Put the drain water filter group back in the wash chamber.

REV.0.04 _COD.610078_A4 Page 47

Page 48

MAINTENANCE

CLEANING OF WASHING CHAMBER THERMOSTAT PROBE

Operator: USER Frequency: 6 months

METHOD OF INTERVENTION:

Clean the washing chamber thermostat probe in the following manner:

Open the wash chamber door and remove the basket.

Visually check the washing chamber thermostat probe.

If deposits or lime incrustations can be seen clean thermostat probe using a damp

cloth and an appropriate detergent.

Take care not to damage or move the probe.

REV.0.04_COD.610078_A4 Page 48

Page 49

MAINTENANCE

CLEANING OF SPRAY ARMS

Operator: USER Frequency: every week

METHOD OF INTERVENTION: clean the spray arms as follows:

Open the wash chamber door and remove the basket.

Warning:

Hot surface

Unscrew the fastening pin of the two rotors and remove them from the chamber.

Unscrew the closure plug of the rear part of the nozzle and remove it.

Carefully clean and remove any incrustations from the washing rotor nozzles using

appropriate detergents.

Put the plugs back in place at the ends of the spray arms.

Make sure the gasket is properly positioned and in good condition. Replace it if

necessary.

Put the rotors back in the machine.

Lock them in place with the previously removed fastening pin.

REV.0.04 _COD.610078_A4 Page 49

Page 50

MAINTENANCE

14.5 Special maintenance

All special maintenance work is to be performed only by qualified, skilled personnel.

If your machine shows a functional anomaly so as to require a special maintenance, please

contact Miele Service.

Table of special maintenance tasks

Cleaning and checking operations

Frequency

Special

maintenance tasks

must be carried out

by Miele Service

after 1000

operating hours

or every 12

months

Action

Water solenoid filters: Check, clean and in case

Maintenance of dosing systems.

Temperature probes

Safety thermostat: sensor verfication.

Water solenoid valves: Check for any leakage.

Drain pump: Check for any leakage.

Check of pressure switches.

Check of piping and seals.

replace them.

Operator

SERVICE

REV.0.04_COD.610078_A4 Page 50

Page 51

PROBLEMS – CAUSES – REMEDY

15. PROBLEMS – CAUSES – REMEDY

15.1 Introduction

This chapter includes possible problems which may occur during machine operation, along

with their cause and solution.

If the inconveniences continue or take place frequently even after having carried out all the

instructions stated in this chapter, please contact Miele Service.

15.2 Problems (P.) – Causes (C.) – Remedy (R.)

P. MACHINE WILL NOT START:

C. Circuit breaker de-activated.

R. Place it in the "ON" working position.

C. Main switch de-activated

R. Place it in the "ON" working position

P. WASHING CYCLE DOES NOT START:

C. The door is not correctly closed or locked.