Operating instructions

Gas hob

KM 81-2

It is essential to read these

operating instructions before

installing or using the machine,

to avoid the risk of accident

or damage to the machine. M.-Nr. 04 647 380

Q\

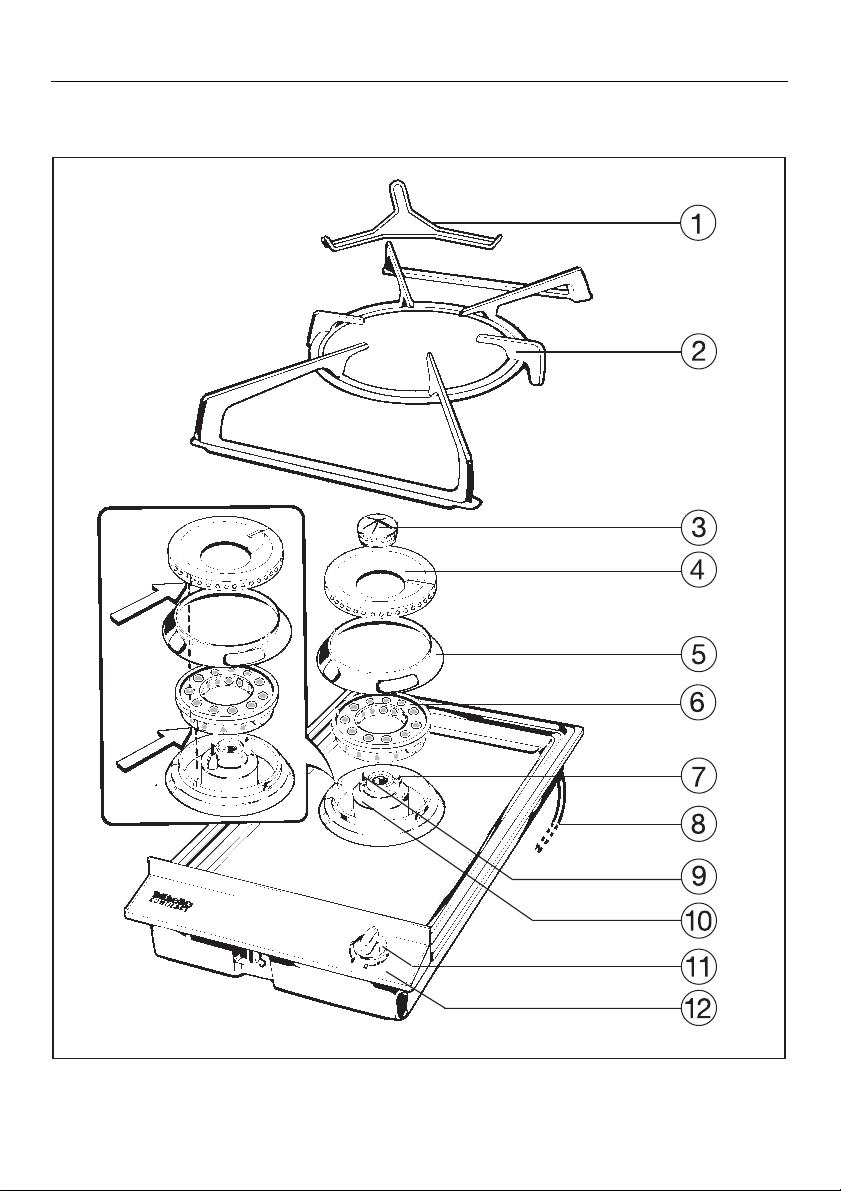

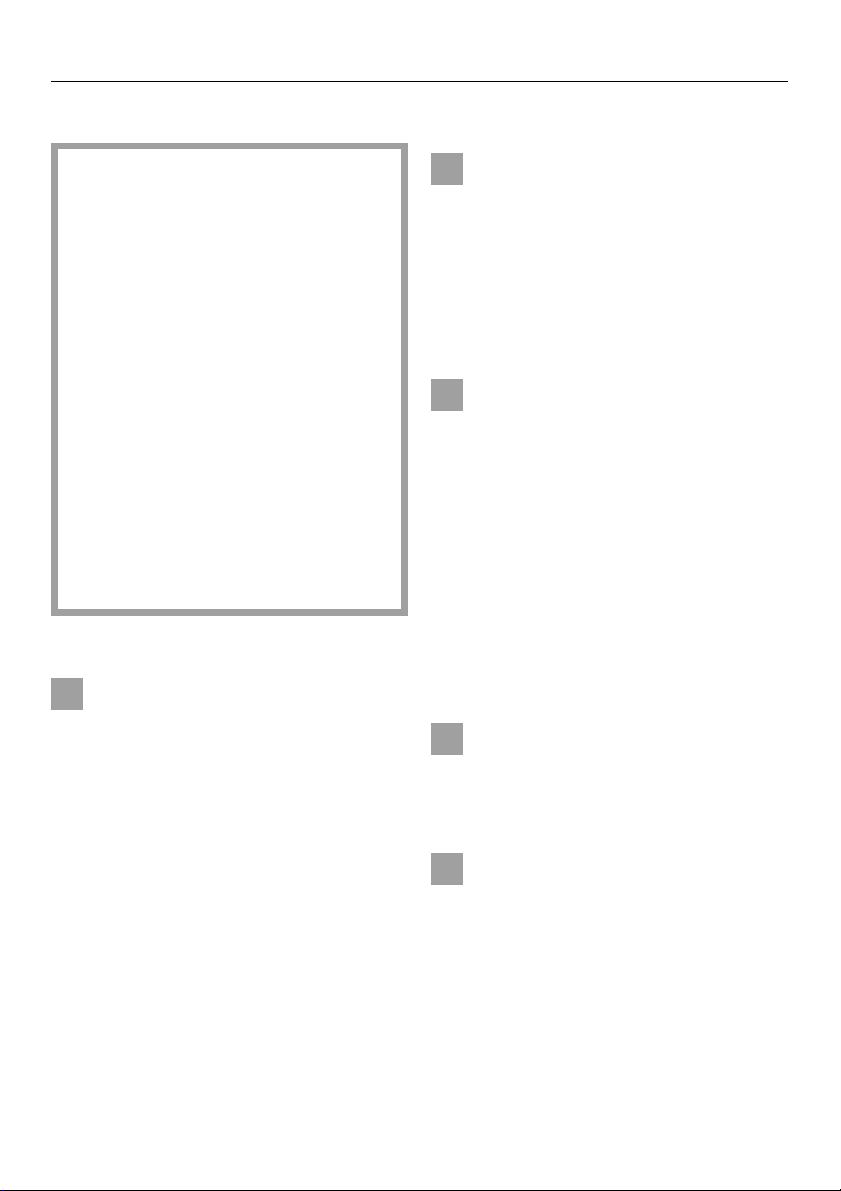

Description of the appliance

Description of the appliance

KM 81-2

2

Description of the appliance

KM 81-2

b Trivet

c Wok/pan support

d Small burner cap

eLarge burner cap

f Burner collar ring

Large burner cap base

g

h Ignitor

i Cable for connection

to electrical supply approx. 3.6 ft

(1.10 m) long.

j Ignition safety control

k Burner base

l Control for burner

m Control panel

Description of the appliance

Data plate

Because the data plate is no longer

visible once the appliance has been

built in, a 2nd data plate is supplied

which should be placed into the space

provided in these instructions under

"After Sales Service".

Special accessories

Special accessories are available from

your Miele Dealer or from the Spare

Parts Department.

Stainless steel cover-EA 80

A stainless steel cover is available for

the KM 81-2 hob. Check availability in

each country.

For installation of the cover, a minimum

distance of 650 mm is required between the work surface and wall units.

Note:

The wok/pan support should be

removed before the cover is closed

down over the hob.

Do not install the DA 8-2 directly

next to the gas hob.

3

Contents

Contents

Warning and Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

For the user

Description of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Gas safety / Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Gas burner unit

Burner control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Instructions for using the gas burner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Suitable pans and woks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning and Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Problem solving guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

After Sales Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

For the installer / electrician / engineer

Electrical connection, GB / IRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Gas connection GB / IRL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Appliance dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Instructions for building-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Clearance above and around the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Conversion to alternative types of gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4

Gas safety Environment

Gas safety Environment

WARNING:

If the information in this manual

is not followed exactly, a fire or

explosion may result causing

property damage, personal injury

or death.

WHAT TO DO IF YOU SMELL GAS

– If you smell gas you must act

immediately.

– Extinguish any flames.

– Do not create any electrical

sparks, e.g. do not insert or withdraw any electrical plugs or operate electrical switches such as

lights and door bells.

– Do not enter a room with an open

light when there is a smell of gas.

Disposal of the packing material

The transport and protective packing

has been selected from materials

which are environmentally friendly for

disposal and can normally be recycled.

Rather than just throwing these materials away, please ensure they are offered for recycling.

Disposal of your old

machine / appliance

Old machines / appliances contain materials which can be reclaimed or recycled. Please contact your dealer,

your local waste collection centre or

scrap merchant about potential recycling schemes, before disposing of the

machine/ appliance. Ensure that it presents no danger to children.

See the appropriate section in the

Warning and Safety instructions.

– Do not light cigarettes or matches.

– Do not smoke.

– Open all windows and doors.

– Close any shut-off valves at the

gas connection or mains supply

immediately.

– Shut off the gas valve next to the

machine.

– If all gas valves are closed but

there is still a smell of gas in the

room you should call your local

gas supplier immediately.

5

Warning and Safety Instructions

Warning and Safety Instructions

Important safety instructions

This appliance complies with all relevant legal safety requirements. Improper use of the appliance can,

however, present a risk of both personal injury and material damage.

Before installing and using the appliance for the first time, read the

operating instructions carefully.

They give information on safety, on

the operation and care of the appliance. This way you will avoid the

risk of accidents and damage to the

appliance.

Do not let children access the appliance or its controls. Supervise its

use by the elderly or infirm.

Keep these instructions in a safe

place and pass them on to any future user.

Correct usage

This appliance is intended for do-

mestic use, and in particular to

cook, fry or reheat food. Any other

usage is at the owner’s risk and could

be dangerous. The manufacturer cannot be held responsible for damage

caused by improper use of the appliance.

Technical safety

the information on the data plate.

You should find out details about the

type of gas and calorific value from

your Gas supplier and compare this information with the type of gas quoted

on the data plate.

They must correspond.

when continuity is complete between

the appliance and an effective earthing

system.

It is imperative that this basic safety requirement be tested and where there is

any doubt, the electrical system of the

house should be checked out by a

qualified electrician. The manufacturer

cannot be held responsible for damage

such as electric shock caused by the

lack or inadequacy of an effective earthing system.

been built-in. This is necessary to ensure that all electric components are

shielded.

way that they do not touch any parts of

the appliance which become hot. This

could cause damage.

Please ensure that the domestic

electrical supply corresponds to

The electrical safety of this appliance can only be guaranteed

For safety reasons the appliance

must only be operated after it has

Ensure that the gas pipe and electrical cable are installed in such a

6

Warning and Safety Instructions

Warning and Safety Instructions

Installation work and repairs may

only be carried out by a suitably

qualified and competent person,e.g.

’Corgi’ registered for gas in G.B.

Repairs and other work by unqualified

persons could be dangerous.

The appliance is only completely

isolated from the electrical supply

when it is switched off at the wall

socket, or the mains fuse is withdrawn,

or the screw-out fuse is removed (in

countries where this is applicable). Do

not pull by the mains cable, but by the

plug when withdrawing the plug from

the socket.

Do not connect the appliance to the

mains electrical supply by an extension lead. Extension leads do not guarantee the required safety of the appliance.

Gas burners should only be used

in rooms with adequate ventilation.

Ensure that the worktop area around

the hob is clear of obstacles to allow

sufficient ventilation.

Important notes for the installer

Check that all parts of the burner

unit are correctly assembled before igniting the gas, otherwise the ignition could malfunction.

Please note the following, in cases

where the hob is on LPG supply:

Where this appliance is installed in

marine craft or in caravans, it shall not

be used as a space heater.

When installing the gas hob, the

following minimum dimensions

must be kept:

25 cm distance from any heat-sensitive material or surfaces, otherwise

some form of insulation must be

fitted.

65 cm between the hob and a wall

unit above it.

65 cm between the hob and a

cooker hood above it.

Wall sealing strips and any back-

moulding must be of heat resistant

material.

7

Warning and Safety Instructions

Warning and Safety Instructions

Important notes for the user

Do not let small children use the

appliance or touch it during operation. Not only do the cooking areas

heat up, but also the control panel.

Danger of burning. Keep all pans out of

the reach of children.

Make sure that there is a minimum

distance of 15 mm between the

pot or pan and the control panel. Never

place a pot on the control panel.

When using an electric socket

near the hob, care should be taken

that the cable of the electrical appliance does not come into contact

with the gas flames or the hot parts of

the hob.

Note that potential hazards may

exist with overhead cabinets.

The wok/pan support and trivet (if

supplied) heat up when the burners are in use. Do not touch them until

they have cooled down. The use of

oven gloves is recommended.

Do not let cooking grease or other

flammable materials accumulate

on the unit.

Never leave the hob unattended

when cooking with oil or fat. Very

hot oil can cause a fire. Always heat fat

slowly, watching as it heats.

Before removing pots and pans,

be sure to turn the control to “OFF”.

Allow sufficient time for the unit to

cool before touching or exposing

surface areas to flammable materials.

Always ensure that food is suffi-

ciently cooked or reheated.

Many factors will affect the overall cooking time, including the size and amount

of food, its temperature, changes to the

recipe and the shape and size of cooking container.

Some foods may contain micro organisms which are only destroyed by

thorough cooking, therefore when cooking or reheating foods, e.g. poultry, select a longer cooking or reheating time.

It is essential to ensure that food

has been evenly and sufficiently

heated. Turn or stir during cooking if

necessary, and check that it is thoroughly cooked.

Never use damp potholders.

Use only suitable cookware. Unsuit-

able cookware may break due to a

sudden temperature change.

Avoid allowing liquids or foods con-

taining salt to spill on to a stainless

steel hob. Should this happen, wipe up

any spillages containing salt immediately, otherwise discoloration could occur.

When frying foods, make sure that

the food is as dry as possible so

as to prevent moisture from causing hot

fat to bubble over.

When shallow or deep frying, do

not overfill the pan with oil.

8

Warning and Safety Instructions

Warning and Safety Instructions

When using a cooker hood over the

gas hob, ensure that any burners in

use are always covered with a pan.

Do not flambé under a cooker hood.

Otherwise flames could be drawn

up by the suction of the cooker

hood, parts of which could then be

damaged. Fat residues in the filter

could catch fire.

Do not use the gas hob to heat up

the room. The high temperatures of

the hob could cause inflammable objects in the vicinity to burn.

Do not use spray aerosols in the

vicinity of the appliance while it is

in operation.

Under no circumstance use a

steam-cleaning appliance to clean

the gas hob.

The steam could penetrate to live components and cause a short circuit.

Disposal of discarded appliances

Before disposing of an old ma-

chine / appliance, ensure that disconnection from the gas supply is

made by a suitably competent person.

Switch off at the mains, disconnect and

remove the appliance cable at both

ends and render useless. This is intended to prevent the discarded appliance from being a hazard.

The manufacturer cannot be held

liable for damage caused by noncompliance with safety instructions.

In countries which may be subject

to infestation by cockroaches or

other vermin, pay particular attention to

keeping the appliance and its surroundings in a clean condition at all times.

Any damage which might be caused

by cockroaches or other vermin will not

be covered by the appliance guarantee/warranty.

Spray canisters, aerosols or in-

flammable substances must not be

stored in a drawer beneath the hob.

Any cutlery trays must be made of a

heat resistant material.

9

Gas burner unit

Gas burner unit

Before using for the first time, take

heed of the “Warning and Safety

Instructions”.

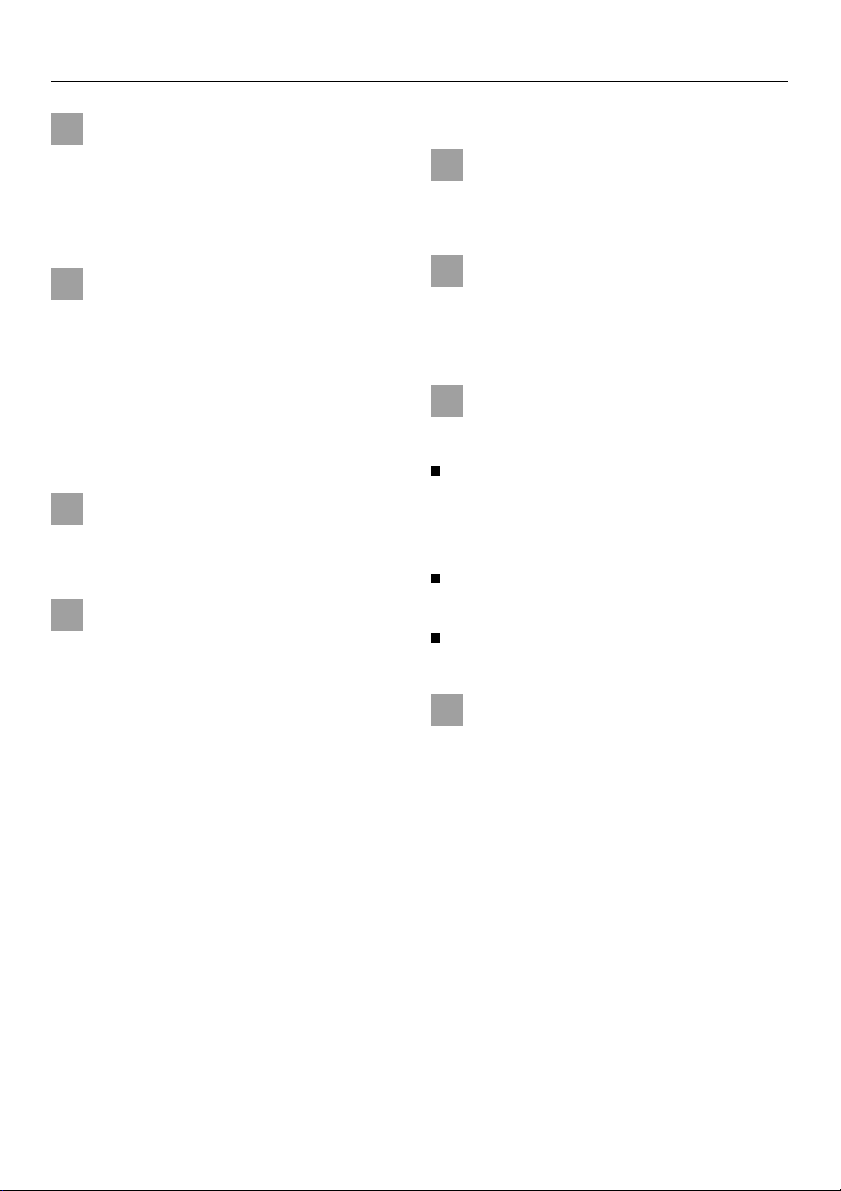

Burner control

The inner and outer burner are both

controlled by one knob.

The burner control knob may only

be turned anti-clockwise to switch

on and back in a clockwise direction to switch off. Otherwise the control could be damaged.

The gas flame is lit by electrical ignition.

When the burner control is pressed in the

strong flame position, a spark passes

from the electrode to the burner and ignites the gas to give a flame (see

page 11).

The burner is equipped with an ignition

safety device. If a gas flame goes out, for

example, if food boiled over, or if there

was a sudden draft, the ignition safety

control cuts off the supply of gas.

Instructions for using the hob

Place the wok or the pan on the

wok/pan support.

X Gas switched off

&

Strong flame (outer and inner rings

both produce high flames)

& Lower flame (outer ring on low)

& Intermediate state b (provides

ignition for outer ring from inner ring)

/ Very low flame

(inner ring on high, outer ring off)

/ Lowest flame

(inner ring on low, outer ring off)

10

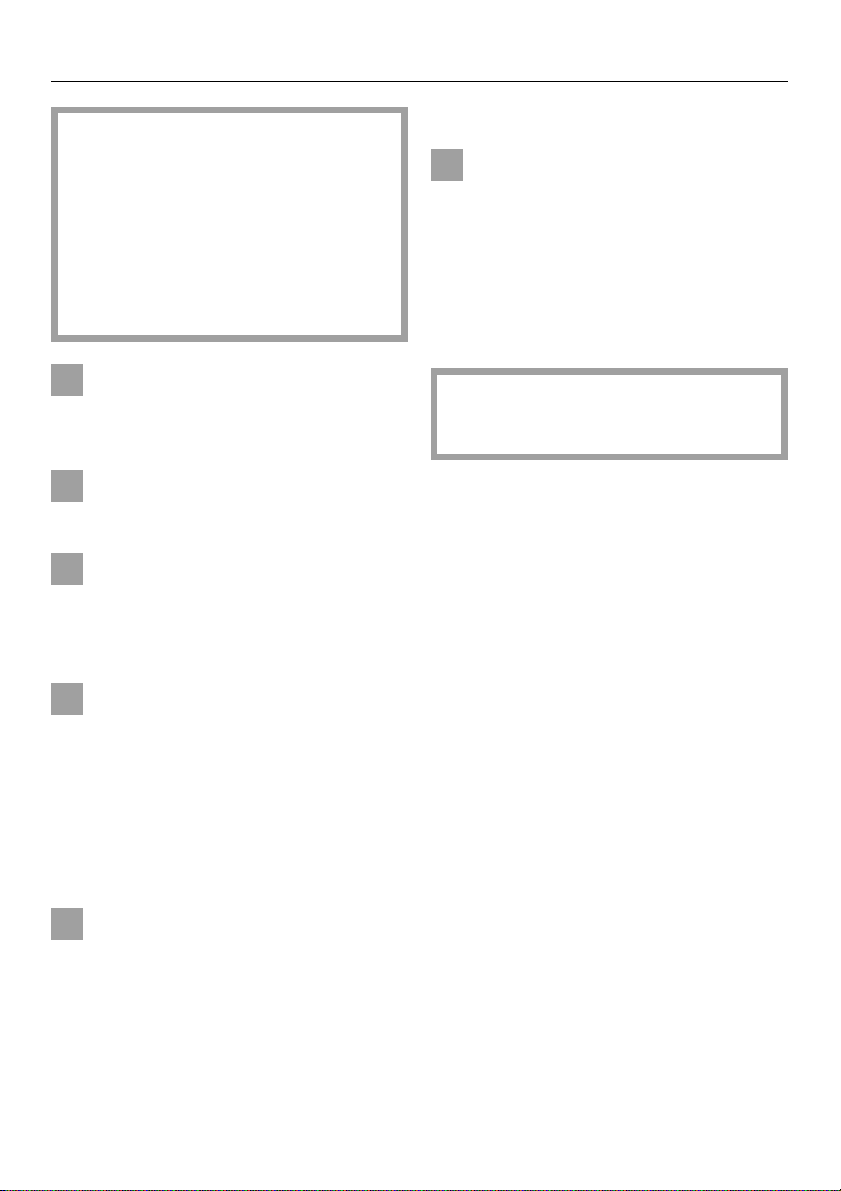

A trivet is supplied with the gas hob. It

is designed to sit on the wok/ pan support when using small pans. The trivet

should only be used on the burner with

the lowest setting. It should only be

used with pans with a diameter of less

than 10 cm.

Gas burner unit

Press in the control knob and turn

anti-clockwise to the high setting (largest flame symbol).

When the flame ignites, keep the control pressed in for 5-10 seconds, and

then press down once more firmly

before letting go.

Gas burner unit

Turn the control knob to the highest

setting for boiling or searing food,

the lower setting for continuing cooking and for keeping food warm.

Turn the control knob down to a lower

setting in good time in order to prevent

food from boiling over or burning.

If the flame goes out, repeat the procedure, keeping the control knob pressed

in for a few extra seconds.

If, after several attempts the gas still

does not burn, check whether the lugs

are correctly positioned, for the large

burner cap in the notch in the large

burner cap base, and for the large burner cap base in the notch in the burner

base.

To turn the heat down from the

highest to the lowest setting, turn the

control anti-clockwise until there is a

resistance, (intermediate stage

press in and continue to turn the

control anti-clockwise to the

desired setting.

To turn the heat up from the lowest to

the highest setting, turn the control

clockwise until there is a resistance,

(intermediate stage

continue to turn clockwise to the

high setting.

To switch the burner off, turn the control knob in a clockwise direction to

X

" position. The flame will go out.

the "

& b), press and

& b),

11

Gas burner unit

Gas burner unit

Power cut

If there is an interruption to the electrical supply, the gas can be ignited with

a match.

Light a match, press in the burner control and turn anti-clockwise to the highest setting (large flame).

With the control knob pressed in, ignite

the gas at the burner with a match.

Keep the control knob pressed in for

a further 5-10 seconds, and then

press firmly down once again before

letting go.

Important:

Only woks/pans with a max.

diameter of 280 mm should be used

on the gas hob.

If woks/pans have a larger diameter,

the flame may spread out to the sides

of the wok or the pan and damage or

burn the worktop or surrounding units.

The outer part of the gas flame is much

hotter than the centre. Therefore the

tips of the flame should be in contact

with the base of the pan and not

spread out to the sides. Flames which

spread out to the sides of the pan

merely warm up the air in the room.

When using the hob ensure the following minimum distances are maintained:

50 mm between the wok or the pan

and heat sensitive worktop or surrounds.

With too small a distance the flame

may spread out from the wok or the

pan and damage or burn the worktop or surrounding units.

15 mm between the wok or the pan

and the control panel.

Never place a pan on the control

panel.

12

Gas burner unit

Suitable woks, pots and pans

Material

Most woks and pans can be used for

cooking on gas.

Wok / Pan base

Bases do not need to be even for gas

cooking, in contrast to those used on

electric burners. Through the spreading action of the flame, heat reaches all

parts of the base.

Thin bases conduct heat to the food inside more quickly than thicker ones.

Since heat is not evenly distributed

over the pan base, there is a danger

that food may be overheated in places.

Therefore, when using saucepans with

thin bases, stir the food more often.

Thick bases lessen the risk of food

overheating in places, as better distribution of heat is possible.

Gas burner unit

Wide, flat pots are more suitable than

narrow, tall ones, since they heat up

more quickly.

Lids

Less heat is lost by cooking in a

covered pot.

Shape of woks, pots and pans

Using a small wok / pan on the strong

flame does not mean faster cooking

but simply results in wasteful gas consumption. The correct procedure is to

cook with small pots on the low flame

and large ones on the strong flame.

small pots = low flame

large pots = strong flame

13

Cleaning and care

Cleaning and care

In the event of a pan boiling over, clean

the burner and the hob surface immediately, to prevent the boiled over substance from burning on.

Burner unit

The burner unit can be dismantled for

cleaning when cold.

Burner caps

The burner caps and collar ring can be

cleaned with a solution of dishwashing

liquid.

Do not use any caustic cleaners,

scouring powders, knives or hard

brushes, as these will cause scratches.

With time and use, the surface of the

burner caps will become dull.

Reassembling the burner unit

Important: The burner must be correctly fitted together before it is lit,

otherwise the ignition device could

be damaged.

Electronic ignition

The ignition device electrodes on

the burner must always be dry,

otherwise they will not spark.

From time to time, the electrodes

should be wiped with a well wrung-out

cloth and wiped dry with a clean cloth.

Important: Do not damage the ignition electrodes and the thermo

element of the ignition safety device.

14

When fitting the large burner cap base

to the burner base, ensure that the locating lug fits exactly into the appropriate notch.

Place the burner collar ring onto the

large burner cap base.

Place the large burner cap onto the

large burner cap base, ensuring that

the locating lug fits exactly into the appropriate notch.

Fit the small burner cap.

Cleaning and care

Wok/pan support, trivet

Cleaning and care

Control panel / Control knob

Caution: the wok/pan support and

trivet become hot in use.

The wok/pan support and trivet can be

removed for cleaning, and cleaned in a

hot solution of washing up liquid.

Never use scouring agents as these

could scratch the surface.

Dry with a cloth.

Hob surface

Avoid allowing liquids or foods containing salt to spill on to the stainless steel hob. Should this happen,

wipe up any spillages immediately.

Otherwise discoloration could occur.

Remove dust, oils and fats, spillages of

foods and condensed water from pots

and pans immediately to prevent them

from drying on.

Do not use any scouring agents or

pads on the knob or control panel,

as these could cause damage.

Clean the control knob and the control

panel with hot water and a little dishwashing liquid.

After application, rub dry with a clean

cloth.

Under no circumstances use a

steam-cleaning appliance to clean

the gas hob. The steam could penetrate to live components and cause

a short circuit.

Dried on food residues are easier to

remove if they are first softened with

warm water.

Clean the hob surface using hot water

with a little dishwashing liquid.

Do not use any scouring agents or

pads, knives or hard brushes.

These will cause scratching.

Do not use cleaning agents containing acids.

A proprietary cleaning agent for stainless steel can be used on the stainless

steel hob surface.

15

Problem solving guide

Problem solving guide

Repairs to the gas and electrical

components of this appliance must

only be carried out by a suitably

qualified person. Repairs by unauthorized personnel could be dangerous.

However some minor problems can be

resolved as follows:

. . . the gas flame goes out after

being lit

Check whether the burner caps are

correctly positioned.

Follow the procedure on how to start

the flame from top left of page 11, do

not forget to press the control right in

before releasing after 5–10 seconds.

What to do if . . .

. . . the burner does not ignite after

several attempts

Check whether:

the burner caps are correctly positioned, and are dry and clean.

the gas supply tap is turned on.

a mains fuse has blown. In this case

call an electrician or the Miele Service Dept.

Use a match to light the gas

(see page 10).

. . . the shape and colour of the flame

are suddenly different from usual

Check whether the parts of the burner unit are correctly assembled.

. . . the electric spark ignition for the

gas burner no longer works

Check whether food residues or

cleaning agents have collected

between the ignition electrode and

the burner.

Clean these away carefully. Do not let

the electrode get wet.

Check, whether the orifices of the

small burner cap are clean, especially those toward the tip of the ignition electrode.

16

After Sales Service

After Sales Service

In the event of any fault which you cannot remedy yourself, please contact:

Your Miele Dealer

or

The Miele Service Department

The address of the nearest Service

Department is given on the back page.

When contacting the Service Department, please quote the Model and Serial No. of the appliance, both of which

can be found on the data plate.

Space for data plate

17

Electrical connection UK, IRL

Electrical connection UK, IRL

Electrical connection of the appliance should be undertaken by a

suitably competent person in strict

accordance with national and local

safety regulations.

The appliance is supplied with a mains

cable for connection to single phase

230-240 V, 50 Hz supply (GB), 220 V,

50 Hz (IRL). The fuse rating and rated

load are given on the data plate.

Connection should be made by a fused

connection unit or a switched socket

which complies with local and national

regulations and is accessible after the

appliance has been built-in.

For extra safety it is advisable to install

a residual current device (RCD), with a

trip current of 30 mA.

Important:

The wires in the mains lead are coloured in accordance with the following

code:

The wire which is coloured blue must

be connected to the terminal which is

marked with the letter N or coloured

black.

The wire which is coloured brown must

be connected to the terminal which is

marked with the letter L or coloured red.

WARNING

THIS APPLIANCE MUST BE

EARTHED.

Any replacement connection cable

must be 3 x 1 mm

2

.

Green/yellow = earth

Blue = neutral

Brown = live

As the colours of the wires in the mains

lead of this appliance may not correspond with the coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured green and

yellow must be connected to the terminal in the plug which is marked with the

letter E or by the earth symbol z or coloured green or green and yellow.

18

Electrical connection UK, IRL

Non rewireable plugs BS 1363

If this machine or appliance is fitted

with a non-rewireable plug, the following information applies:

If the socket outlets are not suitable for

the plug supplied with this product, it

must be cut off and an appropriate

plug fitted.

The plug cut from the flexible cord

should be disposed of and on no account be inserted into a socket elsewhere in the house (electric shock

hazard).

The fuse cover must be refitted when

changing the fuse, and if the fuse

cover is lost, the plug must not be used

until a suitable replacement is obtained. The colour of the correct replacement cover is that of the coloured

insert in the base of the plug, or the colour that is embossed in words in the

base of the plug (as applicable to the

design of plug fitted).

Electrical connection UK, IRL

The correct fuse rating of the replacement fuses that are ASTA approved to

BS 1362 should be fitted.

Replacement fuse covers may be purchased from your local electrical suppliers, or Miele Service Agent.

19

Gas connection

Gas connection

Connection to the gas supply, or

conversion from use on one type of

gas to another should only be

undertaken by an approved Corgi

registered fitter, who is responsible

for correct functioning of the appliance when installed.

The gas hob is suitable for natural gas

and LPG, and is supplied as standard

for connection to natural gas.

Check with your local Gas Supplier

for details about the type of gas and

calorific value and compare this information with the type of gas

quoted on the data plate.

For LPG consult your Miele-Dealer

or the Service Department for the

correct gas jet kit.

Instructions for conversion to alternative forms of gas can be found in the

following Section.

The gas connection must be installed so that it can be connected

either from inside or outside the kitchen unit and the stop-valve must

be easily accessible and visible, by

opening one of the furniture doors,

if necessary.

The appliance may only be connected

by a registered gas fitter (eg Corgi in

the UK), who is responsible for correct

functioning of the appliance when installed.

When the gas hob has been installed, it is essential to check that

neither the gas pipe nor the mains

cable are in contact with hot parts

of the appliance, otherwise temperature damage to the pipe and the

cable could occur.

Nominal rating for all types of gas at

the high setting:

Gas type kW

Burner Natural gas

Liquid gas

Nominal rating for all types of gas at

the low setting:

Gas type kW

Burner Natural gas

Liquid gas

Contact your local gas supplier if the

natural gas connection pressure is less

than 18 mbar or higher than 25 mbar.

5.75

5.40

0.20

0.20

An appropriate rigid or flexible connection can be used.

The gas connection must be in accordance with local and national regulations

and should be tested for possible leakage.

20

Appliance dimensions

KM 81-2

Appliance dimensions

Dimensions in mm:

Gas connection:

Gas connection:

21

Instructions for building-in

Instructions for building-in

There may be a wall at the rear and a

wall or tall unit at one side. On the other

side however, no unit or divider must

stand higher than the hob.

With kitchen cabinetry, the following

minimum dimensions must be kept:

– a distance of 250 mm from adjacent units if they are susceptible

to heat, otherwise some form of insulation must be installed.

– a distance of 650 mm between

the hob and any wall cabinet

installed above it unless building

regulations require otherwise.

– a distance of 650 mm between

the hob and cooker hood, unless

building regulations require otherwise.

All backmoulds must be of heat resistant material. With all kitchen cabinet

suppliers, please comply with their recommendations for distances.

If a drawer or shelf is installed

underneath the hob unit, ensure

that there is a distance of at least

80 mm between the base of the hob

unit and the upper edge of the

drawer or shelf.

Ensure that nothing rubs the gas

pipe when drawer, cabinet door,

etc. are moved.

22

Instructions for building-in

Prepare the worktop cut-out as illustrated.

Dimension “B” applies for a combination of appliances and is given on

the chart.

Instructions for building-in

2 zone Combiset

1 element

2 elements

3 elements

4 elements

5 elements

4 zone Combiset

1 elements

2 elements

3 elements

Combination

One 2 zone

+ one 4 zone

Two 2 zone

+ one 4 zone

Three 2 zone

+ one 4 zone

Depth

in

mm

490

490

490

490

490

490

490

490

490

490

490

Width

(=

Dimension B)

in mm

265

558

851

1144

1437

560

1143

1728

851

1143

1437

One 2 zone

+ two 4 zone

Two 2 zone

+ two 4 zone

Extractor (e.g. DA 8-2)

For building in between two appliances:

- Dimension B increases by 90 mm.

For building in at the end of a combination:

- Dimension B increases by 98 mm.

490

490

1436

1729

23

Instructions for building-in

Instructions for building-in

Stick the seal provided f under the

edge of the hob. Any sealing strip

still protruding should be cut off with

a sharp knife.

loosen

tighten

b Appliance

c Tensioning screw

Clamp

d

e Worktop

f Seal

Turn the tensioning screws c in the

direction of the arrow until the

clamps on the appliance

swung out.

Place the appliance in position, turn

the clamps and tighten the tensioning screws until the clamps hold the

worktop

Connect the appliance to the electrical supply.

When building-in more than one Combiset unit, a stainless steel spacer bar

(V 98 ) must be installed between each

unit. It is supplied with its own installation instructions.

e. Do not overtighten.

b can be

24

Clearance above and around the appliance

Clearance above and around the appliance

KM 93-2 (shown), KM 81-2 respectively

Shown area indicates protected

surface, which may be ceramic

tiles or other approved material.

If clearance between side and rear

walls and the periphery of the burner is

less than 200 mm, the walls must be

protected with a non-combustible

material. The protection must extend a

minimum distance of 150 mm above

the burner, refer - gas fitting regulations.

Cable for connection to electrical

supply with 3 pin plug.

25

Conversion to alternative types of gas

Conversion to alternative types of gas

The appliance is set up for natural gas.

for U.K.

When converting to alternative

types of gas (LP gas), (or back to

Natural gas), the main jet and the

small jets of the burner must be

changed. (Check with your dealer if

this option is available in your

country).

Turn off the gas main (if this appliance has already been installed),

turn off the electrical supply and

pull out the plug if fitted.

Remove the wok/pan support, the

large burner cap, the burner collar

ring and the large burner cap base.

With a suitable cross head screwdriver, unscrew the three screws.

Pull the controls for the gas burner

up and off.

Carefully raise the hob cover slightly

at the rear and pull forward. Then

carefully lift upwards and forwards.

Ensure that the earth lead which connects the hob and the control panel

is not damaged.

Main jetØSmall

jet

Ø

Natural gas 1.70

Nr. 34

Liquid gas 1.12

Nr. 7

The jet marking refers to 1/100mm of

the jet orifice.

0.74/0.36

0.52/0.23

Screw in the new jets acccording to

the table.

26

Conversion to alternative types of gas

Conversion to alternative types of gas

Changing the main jet for the outer

burner

(This applies only to liquid gas in the

U.K.)

Using a 10 mm socket spanner, loosen

the main jet from its holder, using a

13 mm spanner to counterhold.

Screw in the new main jet, once again

using the spanner to counterhold.

Changing the small jets

Natural gas

Liquid gas

The jets must be changed:

Small jet with smaller orifice

b

(e. g. for liquid gas: 0.23)

c Small jet with larger orifice

(e. g. for liquid gas: 0.52)

Using a small screwdriver, unscrew

both small jets in the gas fitting.

Pull the jets out with a pair of pointed

pliers.

Select the jets as shown in the table

and fit, reversing the procedure, and

secure.

27

Conversion to alternative types of gas

Conversion to alternative types of gas

Replacing the main jet for the inner

burner

e jet disc

f

air sleeve

air vent

g

Assemble removed parts in reverse

order and check for leaks by operating the wok burner without the hob

cover in place (ignite the flame using

a match).

Checking the first intake of air

Remove screw d from fitting c

using an 8 mm spanner and a

12 mm spanner to counterhold.

Then remove the screw fitting c

from b using a 12 mm spanner and

a second 12 mm spanner to counterhold.

Replace the jet disc e contained in

section

from the table of jets.

Turn the air sleeve f to adjust the

two air vents

illustrated (2 mm).

28

b with the correct jet disc

g to the opening

b Fastening screw

c Air sleeve

Gap X must measure:

6 mm for Natural gas

13 mm for Liquid gas

If this is not the case, loosen the secur-

ing screw, re-position the air jet and

then tighten the securing screw.

Re-assemble the hob in the reverse

order.

Conversion to alternative types of gas

Conversion to alternative types of gas

Important note:

When reassembling, it is important

of the

to ensure that the profile

control panel should grip the appropriate moulding

tective casing.

c on the lower pro-

b

After conversion

After converting the gas hob unit to

an alternative type of gas, place the

label supplied with the jet kit on to

the data plate over the type of gas

stated.

Check that there are no leakages.

Check that the burner is correctly

assembled.

Turn on the gas supply.

Turn on the electrical supply.

Light the burner:

When set at “low”, or when the control

knob is quickly turned from "high" to

"low", the flame should not go out.

When set at “high” the inner core of

the gas flame should be clearly

visible.

Screw the three screws into the burner base using a suitable crosshead screwdriver.

Put the large burner cap base, the

burner collar ring, the large burner

cap and the wok/pan support in

place.

Check whether the lug of the large

burner cap is correctly positioned in

the notch in the large burner cap

base and whether the lug of the

large burner cap base is correctly

positioned in the notch in the burner

base.

29

30

31

Alteration rights reserved / 22 GB, IRL 2797

This paper consists of cellulose which has been bleached without the use of chlorine.

Loading...

Loading...