Page 1

Operating instructions

Professional

cleaning machine

IR 6002

To avoid the risk of accidents or

damage to the machine it is

essential to read these instructions

before it is installed, commissioned

and used for the first time.

en-GB

M.-Nr. 06 828 452

Page 2

Contents

Description of the machine..........................................5

Areas of application.................................................5

Cleaning process...................................................5

Water recovery.....................................................5

Guide to the machine ..............................................7

Warning and Safety instructions .....................................9

Correct application ...............................................9

Symbols on the machine .........................................13

Opening and closing the door ......................................14

Electric door lock ..................................................14

To open the door with the emergency release ...........................14

Water softener ...................................................15

Setting the water softener ...........................................15

Reactivation display................................................15

Reactivating the water softener .......................................16

Filling the salt container ..........................................16

Position the salt container as follows ................................16

Run the reactivation programme ...................................17

Automatic mobile unit recognition (AWK) (optional) ....................18

Mobile unit coding .................................................18

Mobile unit coding strip ..........................................19

Setting mobile unit coding ........................................19

Areas of application...............................................21

Cover plate ......................................................21

Baskets .........................................................21

Special cleaning applications ........................................21

Cleaning programmes ..............................................22

Water connection spring adapter .....................................23

Height adjustable top basket.........................................23

Electronics .......................................................24

Printed circuit boards ............................................24

Fluxing agents and soldering paste ................................24

Soldering frames ................................................25

Metal cleaning ....................................................26

Glass cleaning ....................................................27

Baskets and inserts .............................................27

Particle decontamination ............................................28

2

Page 3

Contents

Chemical processes and technology.................................29

Dispensing liquid chemical agents ..................................34

Preparing the dispensing system .....................................34

Fill the containers with the relevant agent ............................35

Venting the dispensing system .......................................36

Dispensing system maintenance......................................36

External Dispensing systems.........................................36

Operation .......................................................37

Switching on .....................................................37

Changing the operating level ........................................37

Starting a programme ..............................................37

Programme sequence ..............................................39

Switching off .....................................................39

Cancelling a programme ............................................39

Interrupting a programme ...........................................40

Data transfer.....................................................41

Maintenance .....................................................42

Maintenance and care..............................................42

Routine checks ...................................................42

Maintenance .....................................................43

Cleaning the filters in the wash cabinet.................................43

Cleaning the coarse filter .........................................43

Cleaning the flat and micro-fine filters ...............................43

Cleaning the spray arms ............................................44

Cleaning the control panel...........................................45

Cleaning the front of the machine .....................................45

Cleaning the wash cabinet ..........................................45

Cleaning the door seals.............................................45

Mobile units, baskets and inserts .....................................46

Drying unit (TA) ...................................................47

Changing the coarse filter ........................................47

Exchanging the HEPA filter........................................48

Problem solving .................................................49

Thermal cut-out ...................................................49

Cleaning the filters in the water inlet ...................................50

After sales service ................................................51

3

Page 4

Contents

Installation ......................................................52

Electrical connection .............................................53

Plumbing........................................................54

Connection to the water inlet .........................................54

Drainage ........................................................56

Vent at the rear ...................................................56

Technical data ...................................................57

Disposal of your old machine.......................................58

4

Page 5

Description of the machine

Areas of application

This professional cleaning machine is

particularly suitable for use in high-tech

industrial production plants where very

high reproducible standards of

cleaning are required for complex

items.

Areas of application include:

Electronic components such as

–

printed circuit boards and soldering

frames,

Metal cleaning,

–

– Glassware cleaning,

– Decontamination of boxes and trays.

Cleaning process

This machine uses the fresh water

principle. The batch time for cleaning,

rinsing etc. is between 20 and 60

minutes. Drying takes place in an

integrated drying unit. Drying times will

vary depending on the heat retention

properties of the items being

processed as well as the amount of

contact water left on them after

cleaning. An additional drying time of

between 15 - 45 minutes should be

calculated.

This machine can be equipped with

baskets and inserts to suit the

application it will be used for.

Application specific programmes can

also be added.

Each application requires its own

cleaning programme. These are not

supplied as standard.

Water recovery

The IR 6002 is supplied with a two-part

drainage system and a pump for

recovering process water from the

machine for re-use. This water must be

stored in a recycling tank (not supplied)

situated next to the professional

cleaning machine.

This machine, together with the

recycling tank as applicable, can be

used as follows:

1. Fresh water system:

The whole process is carried out with

fresh water. Once used the water is

drained into the mains drainage

system, or into a special water disposal

unit.

2. Recyling the rinse water:

Water from the last two rinses, for

example, is recovered and used for the

cleaning and neutralising stages of the

next batch. Used water from the

cleaning and neutralising stages is then

drained into the mains drainage system

or into a special water recycling unit.

3. Recyling the cleaning water:

Used water from the cleaning stage is

recovered and used for the cleaning

stage of the next batch. Used water

from the remaining rinse stages is then

drained into the mains drainage system

or into a special water recycling unit.

5

Page 6

Description of the machine

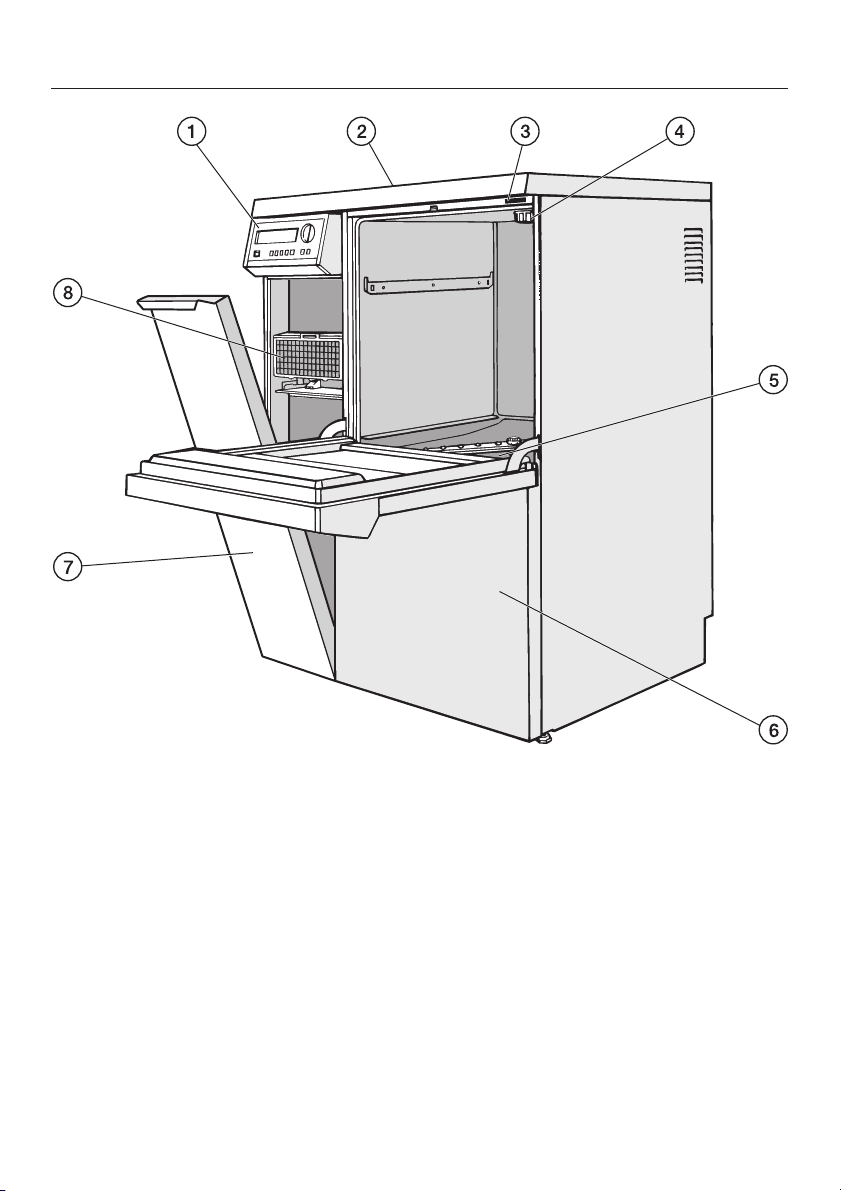

a Electronic controls

b Serial interface, at the back of the

machine (top left behind the cover

panel)

c Test point for validation

d Salt reservoir connection point

(for the water softener)

e Filter combination

f Service panel

6

g Service panel

h Drying unit (TA)

Page 7

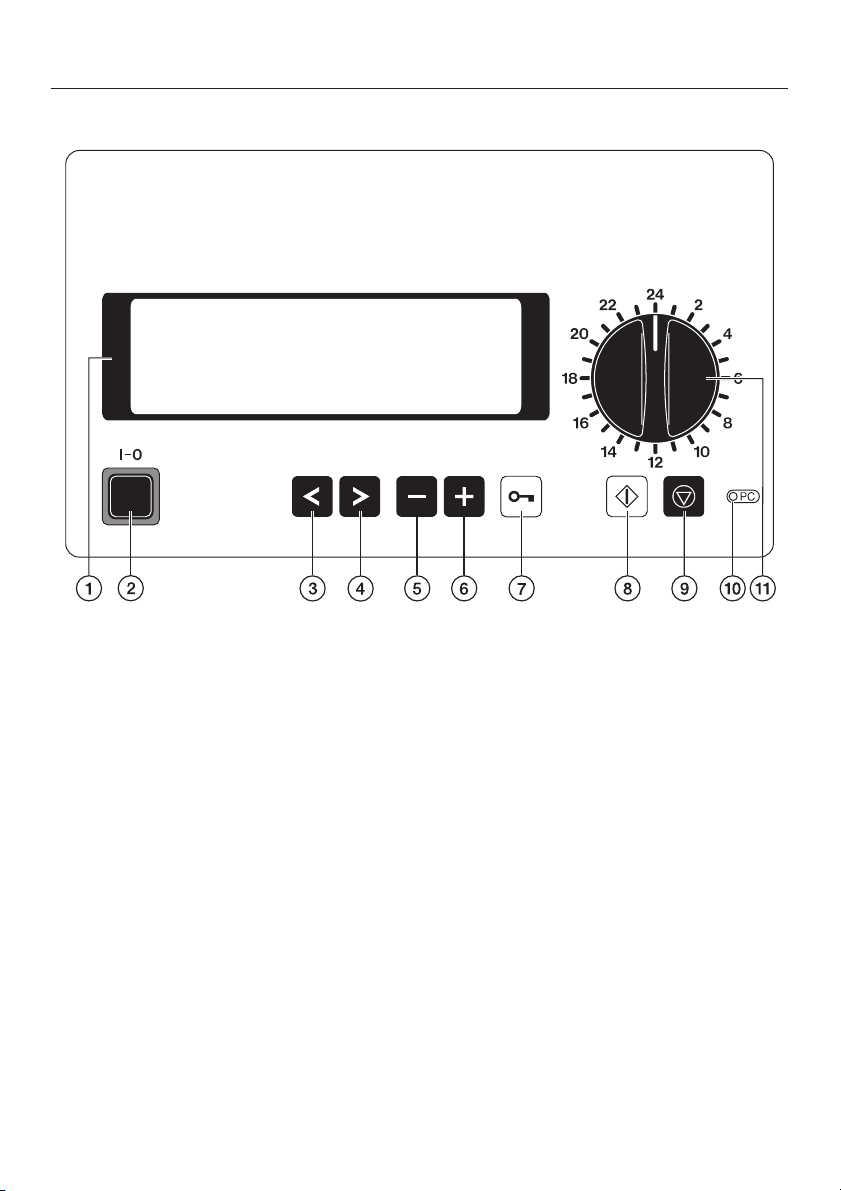

Electronic controls

Guide to the machine

a Display

with screen saver;

i.e. background lighting switches off

automatically after 15 mins.

Press any button to switch the

display back on again.

b On/Off button (I-0)

c Cursor button: left 1

Moves the cursor to the left:

- to the previous menu point

- to the previous parameter

- to the previous input position

d Cursor button: right 2

Moves the cursor to the right:

- to the next menu point

- to the next parameter

- to the next input position

e Minus button 3

– Selects programmes from position

24 upwards

– Scrolls back page by page in

menus

– Is used for entering numbers and

letters

– Alters pre-settings e.g. service

parameters

f Plus button 4

– Selects programmes from position

24 upwards

– Scrolls forward page by page in

menus

– Is used for entering numbers and

letters

– Alters pre-settings e.g. service

parameters

g Door switch 5

7

Page 8

Guide to the machine

h Start button 6

– Starts programmes

– Activates input mode

– Confirms activated values and

settings

– Confirms menu points for entry

into the relevant sub-menu

i Stop button 7

– Cancels a programme

– Exits from input screen without

saving

– Exits from menu screen

j Service interface 8

kProgramme selector

Selects programme places 1-23

8

Page 9

This machine complies with all

current safety requirements.

Inappropriate use can, however,

lead to personal injury and damage

to property.

To avoid the risk of accidents and

damage to the machine, please

read these instructions carefully

before starting to use it. Keep these

instructions in a safe place for

reference, and pass them on to any

future user.

Correct application

Warning and Safety instructions

Please pay attention to the following

notes to avoid injury and damage.

This machine should be installed,

~

commissioned and then maintained by

a Miele authorised and trained service

technician or other suitably qualified

and competent approved person.

Repairs and other work by unqualified

persons could be dangerous. The

manufacturer cannot be held liable for

unauthorised work.

Do not install the machine in an area

~

where there is any danger of explosion

or of freezing conditions.

This machine is designed for use as

~

described in these operating

instructions only. Alterations or

conversions to the machine, or using it

for purposes other than those for which

it is designed, are not permitted and

could be dangerous.

The manufacturer cannot be held liable

for damage caused by improper or

incorrect use or operation.

This machine is intended for land

~

based stationary, indoor use only. It

must not be installed in mobile sites

such as ships or military containers etc.

The electrical safety of this machine

~

can only be guaranteed if connected to

a correctly installed on-site earthing

system which complies with local and

national safety regulations. It is most

important that this basic safety

requirement is present and regularly

tested, and where there is any doubt,

the on-site wiring system should be

inspected by a qualified electrician.

The manufacturer cannot be held liable

for damage or injury caused by the lack

of or inadequacy of an effective

earthing system (e.g. electric shock).

A damaged or leaking machine is

~

dangerous. Disconnect the machine

from the mains immediately and call the

Miele Service Department.

Personnel operating the machine

~

should be trained regularly. Untrained

personnel must not be allowed access

to the machine or its controls.

9

Page 10

Warning and Safety instructions

Take care when handling chemical

~

agents such as cleaning agent,

neutralising agent, rinsing agent etc.

These may contain irritant or corrosive

ingredients.

Please follow the manufacturer's safety

instructions. Wear protective gloves

and goggles. With all chemical agents,

the manufacturer's safety instructions

and safety data sheets must be

observed.

The machine is designed for

~

operation with water and recommended

additive chemical agents only. Organic

solvents and flammable liquid agents

must not be used in this machine.

These could cause an explosion,

damage rubber and plastic

components in the machine, and cause

liquids to leak out of the machine.

The water in the cabinet must not be

~

used as drinking water.

Do not sit or lean on an open door.

~

The machine could tip up and be

damaged or cause an injury.

Be careful when sorting items with

~

sharp pointed ends and positioning

them in the machine that you do not

hurt yourself or create a danger for

others. Sharp knives etc. should be

placed in baskets with the pointed ends

facing downwards.

When using this machine in the

~

higher temperature ranges, be

especially careful not to scald or burn

yourself or come into contact with

irritant substances when opening the

door. Where disinfecting agents are

used there is a danger of inhaling toxic

vapours.

Where there is a risk of toxic or

~

chemical substances occuring in the

suds solution (e.g. aldehyde in the

disinfecting agent), it is essential to

regularly check door seals and make

sure that the steam condensor is

functioning correctly.

Opening the machine door during a

programme interruption carries

particular risks in such circumstances.

Should personnel accidentally come

~

into contact with toxic vapours or

chemical agents, follow the emergency

instructions given in the manufacturer's

safety data sheets.

Mobile units, modules, inserts and

~

the load must be allowed to cool down

before unloading the machine. Any

water remaining in containers could still

be very hot. Empty them into the wash

cabinet before taking them out.

After using the hot air drying unit,

~

open the door to allow the everything in

the cabinet from the load itself to the

mobile units, modules and inserts to

cool down.

10

Do not touch the heating elements if

~

you open the door during or directly

after the end of a programme; you

could burn yourself. They remain hot for

some time after the end of the

programme.

Page 11

Warning and Safety instructions

Do not clean the machine or near

~

vicinity with a water hose or a pressure

washer.

The machine must be disconnected

~

from the mains electricity supply before

any maintenance or repair work is

carried out. Do not reconnect it until the

maintenance or repair work has been

successfully completed.

The following points should be

observed to assist in maintaining

quality standards, to protect users,

and to avoid damage to the machine

and items being cleaned.

Chemical agents could, under

~

certain conditions, cause damage to

the machine. Please only use agents

recommended by Miele. In the event of

any damage or material deterioration

please contact your Miele application

specialist.

Pre-treatments with cleaning or

~

disinfecting agents can create foam, as

can certain types of soiling and

chemical agents. Foam can have an

adverse effect on the cleaning process.

Foam must not be able to escape

~

from the wash cabinet. It would hinder

the correct functioning of the machine.

Check the process used regularly to

~

monitor foaming levels.

To avoid the risk of damage to the

~

machine and any accessories used

with it caused by chemical agents,

soiling and any reaction between the

two, please read the notes in "Chemical

processes and technology".

Where a chemical additive is

~

recommended on technical application

grounds (e.g. a cleaning agent), this

does not imply that the manufacturer of

the machine accepts liability for the

effect of the chemical on the items

being cleaned.

Please be aware that changes in

formulation, storage conditions etc.

which may not be publicised by the

chemical manufacturer, can have a

negative effect on the cleaning result.

When using cleaning agents and

~

specialised products it is essential that

the manufacturer's instructions are

followed. Chemicals must only be used

for the purpose they are designed for

and in the situation specified, to the

exclusion of other chemicals, to avoid

such dangers as chemical reactions

(e.g. oxyhydrogen reaction) and

material damage.

In critical applications where very

~

stringent requirements have to be met,

it is strongly recommended that all the

relevant factors for the process, such

as chemical agents, water quality etc.

are discussed with the Miele

Application Technology specialists.

11

Page 12

Warning and Safety instructions

If cleaning and rinsing results are

~

subject to particularly stringent

requirements (e.g. chemical analysis,

specialised industrial processes etc.), a

regular quality control test must be

carried out by the user to ensure that

the required standards of cleanliness

are being achieved.

Mobile units, modules and inserts

~

should only be used for the purpose

they are designed for.

Empty any containers or utensils

~

before arranging them in the machine.

Do not allow any remains of acids or

~

solvents, and in particular hydrochloric

acid or chloride solutions, to get into

the wash cabinet. Similarly avoid any

materials with a corrosive effect. The

presence in compounds of any solvents

should be minimal (especially those in

hazard class A1).

Please ensure that any water

~

drained into the public mains drainage

system complies with all local and

national water regulations. To prevent

pollution to the waterways please

ensure that accepted tolerance levels

are adhered to.

Do not process items in this

~

machine if they have, for example,

filings or metal shavings on them.

Depending on the type and shape of

filings, shavings etc. there is a risk of

them causing damage to the circulation

pump and also of causing contact

corrosion.

Ensure that solutions or steam

~

containing hydrochloric acid do not

come into contact with the steel outer

casing of the machine, to avoid any

corrosion damage.

After carrying out any work on the

~

mains water system, the water supply

system to the machine must be vented.

Otherwise, components of the machine

may become damaged.

12

Please follow the advice on

~

installation in these instructions and the

separate Installation Instructions.

Page 13

Warning and Safety instructions

Using accessories

Only use genuine Miele original

~

accessories with this machine and only

use them for the purposes they are

designed for. Consult Miele on the type

and application of such equipment.

Only use Miele mobile units, baskets

~

and inserts in this machine. Using

accessories, mobile units and inserts

made by other manufacturers, or

making modifications to Miele

accessories, can result in

unsatisfactory cleaning results, for

which Miele cannot be held liable. Any

resultant damage would also invalidate

the machine guarantee.

Only use chemical agents which

~

have been approved by their

manufacturer for use in the application

you are using. The chemical agent

manufacturer is responsible for any

negative influences on the material the

load is made from and for any damage

they may cause to the machine.

Disposing of your old machine

Please note that the machine may

~

have contamination from dangerous,

toxic or infectious substances in it and

must be decontaminated before

disposal.

For environmental and safety reasons

ensure the machine is completely

drained of any residual water and

process chemicals. Observe safety

regulations and wear safety goggles

and gloves.

Make the door lock inoperable, so that

children cannot accidentally shut

themselves in. Then make appropriate

arrangements for its safe disposal.

For tank system machines ensure that

any water is emptied out of the tank.

The manufacturer cannot be held

liable for damage caused by

non-compliance with these Warning

and Safety instructions.

Symbols on the machine

Warning:

Observe the operating

instructions.

Warning:

Danger of electric shock.

13

Page 14

Opening and closing the door

Electric door lock

This machine is equipped with an

electric door lock.

The door can only be opened when:

the electricity supply to the machine

–

is switched on,

the master switch I-0 is pressed in,

–

and

a cleaning programme is not in

–

progress.

To open the door

^ Press the 5 door button, and holding

onto the door grip open the door.

Do not touch the heating

,

elements if you open the door during

or directly after the end of a

programme: you could burn

yourself. They remain hot for some

time after the end of the programme.

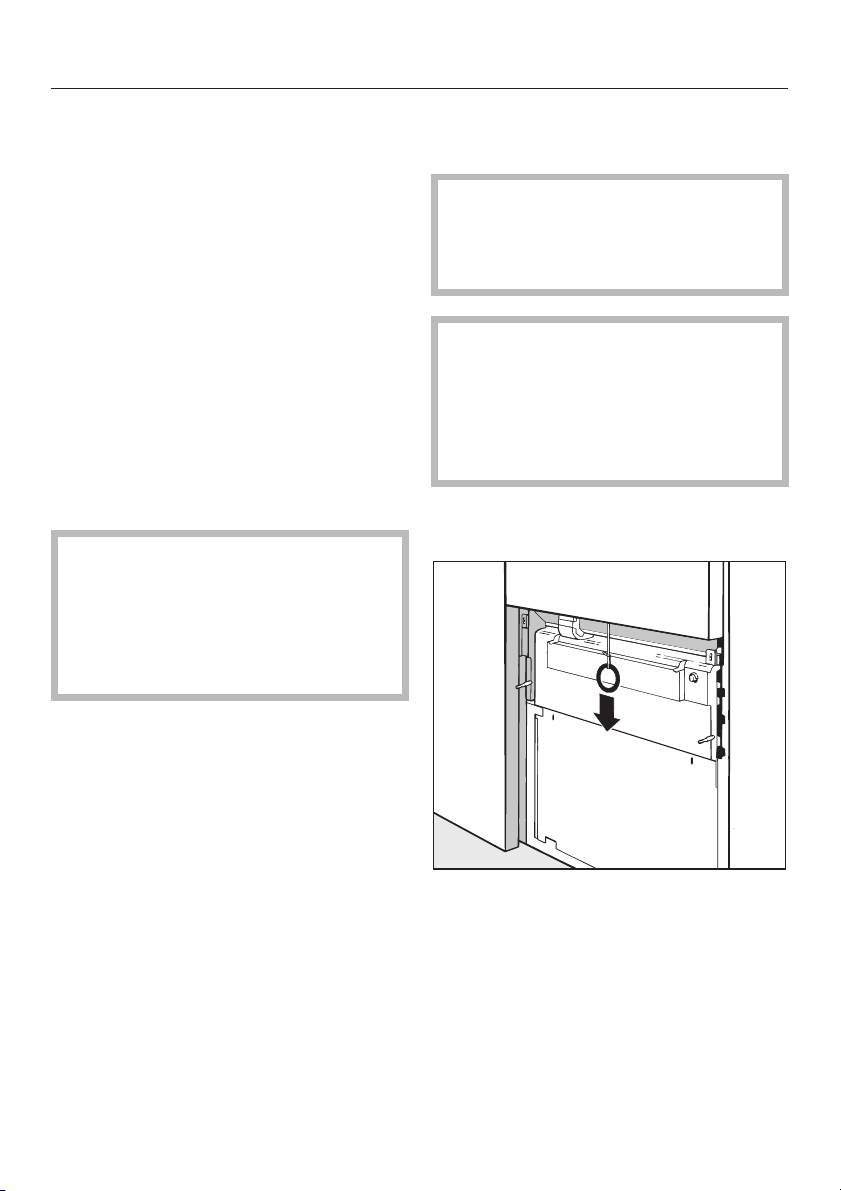

To open the door with the

emergency release

The emergency release should

,

only be used when the door cannot

be opened normally, e.g. in the

event of a power failure.

If there is a lot of hot water in the

,

wash cabinet when the programme

is interrupted and the door is then

closed quickly, hot water can

escape.

Danger of burning or scalding.

^ Switch the machine off with the I-0

button.

To close the door

^

Lift the door upwards and push until

it clicks shut.

14

^

The emergency release cable is

located at the bottom of the machine

behind the service panel. Pull it

downwards to open the door.

Page 15

In order to achieve good cleaning

results, the machine needs to operate

with soft water. Hard water results in the

build-up of calcium deposits on the

load and inside the wash cabinet.

Mains water with a hardness level

higher than 0.7 mmol/l (4 °d – German

scale) needs to be softened. This takes

place automatically in the integrated

water softener.

The water softener requires

–

reactivation salt.

The machine must be programmed

–

to correspond to the water hardness

in your area.

Water softener

Enter your water hardness level here:

°dH or mmol/l

Setting the water softener

When the machine is first

commissioned the Miele service

technician has to set the machine for

your local water hardness level (see

Programme manual, Operating

information/Reactivation).

– Your local water authority will be able

to advise you on the water hardness

in your area.

The water softener unit is set at the

factory for a water hardness level of

19 °dH (3.4 mmol/l).

If the water supply is harder or softer

than this (including below 0.7 mmol/l

or 4 °dH) the factory setting will

need to be reprogrammed via the

electronic controls.

For fluctuating levels, e.g.8-17°dH

(1.4 - 3.1 mmol/l), set the water softener

to the highest setting; in this example,

to 17 °dH (3.1 mmol/l).

The built-in water softener has

settings from 1 °dH - 60 °dH (0.2 -

10.8 mmol/l).

For future servicing it is useful to make

a note of your water hardness level.

Reactivation display

After a certain number of cycles the

message REACTIVATION will appear in

the display to warn you that the water

softener is depleted and cannot supply

any more softened water. As soon as

the programme has finished

reactivation salt will need to be

replenished.

If this cannot be done immediately, and

further cleaning cycles have been

carried out, the reactivation process will

need to be carried out twice in

succession.

15

Page 16

Water softener

Reactivating the water softener

Please only use special coarse grained

reactivation salt with granules of

approx. 1-4 mm. Do not use other types

of salt, e.g. table salt, agricultural or

gritting salt. These could contain

components which are insoluble in

water which could result in damage to

the water softener.

The salt container holds approx. 2 kg of

salt.

If only fine grained reactivation salt

is available please consult the Miele

Spare Parts Department for advice.

Salt with granules ü 4 mm must not

be used in this machine.

,

Inadvertently filling the salt

reservoir with cleaning agent can

cause serious damage to the water

softener and damage the filter insert,

and cause pressure to build-up in

the salt container. To avoid the risk

of injury please exercise caution

when removing the salt container as

there may be irritant alkaline

solutions present.

Before filling the salt container make

sure that you have picked up the

right packet of reactivation salt.

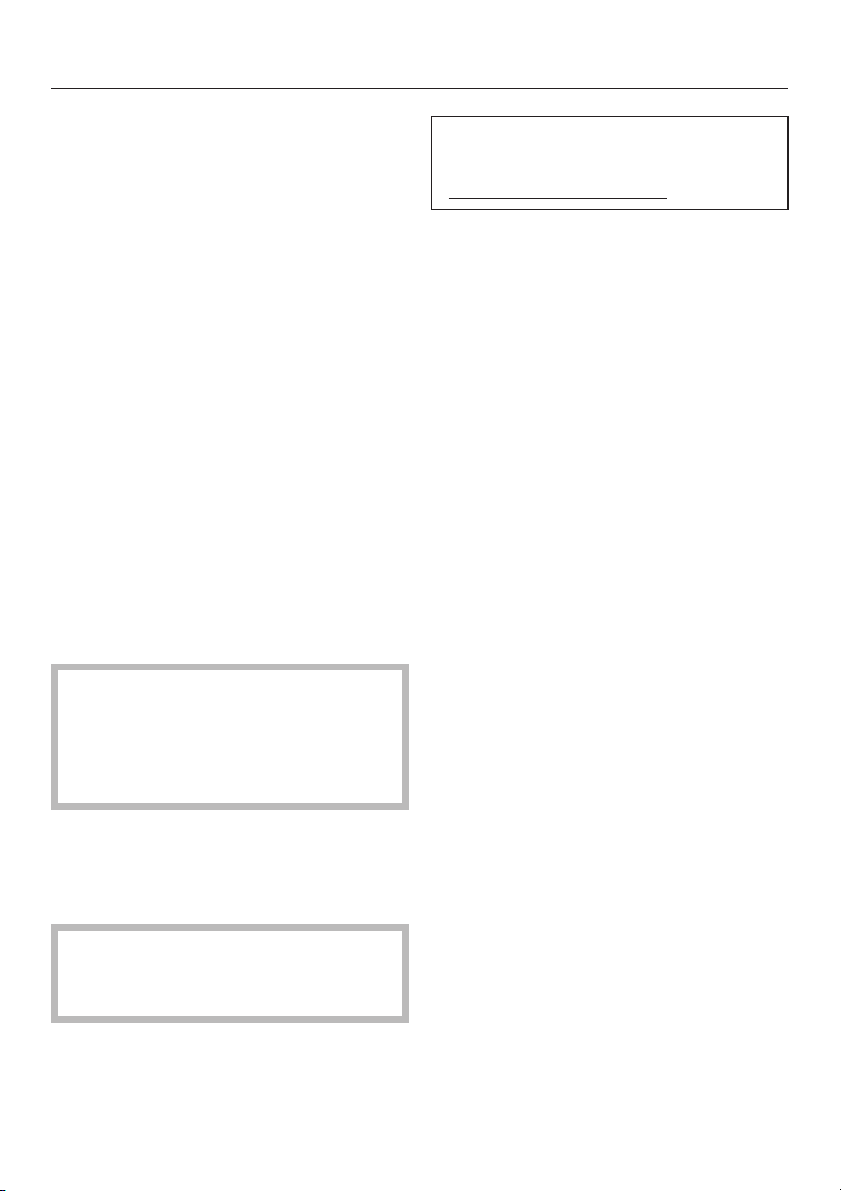

Filling the salt container

Unscrew the filter insert from the salt

^

container and remove.

^ Fill the salt container with reactivation

salt and screw the filter insert back in

place.

Position the salt container as follows

16

^

Remove any mobile units from the

cabinet.

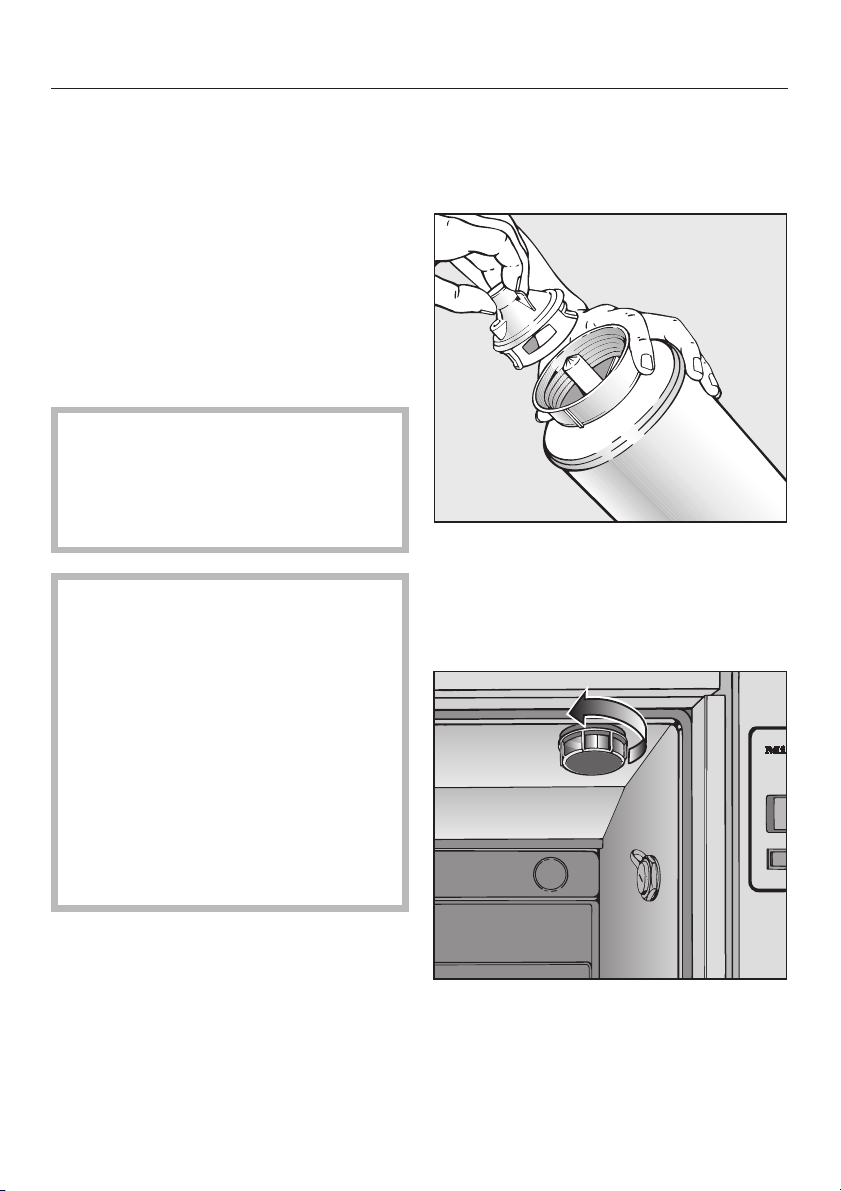

^

Unscrew the plastic cap situated in

the top right-hand side of the cabinet.

Page 17

There will be a small amount of

,

residual water in the cap. Take care

as it may be hot from the previous

programme.

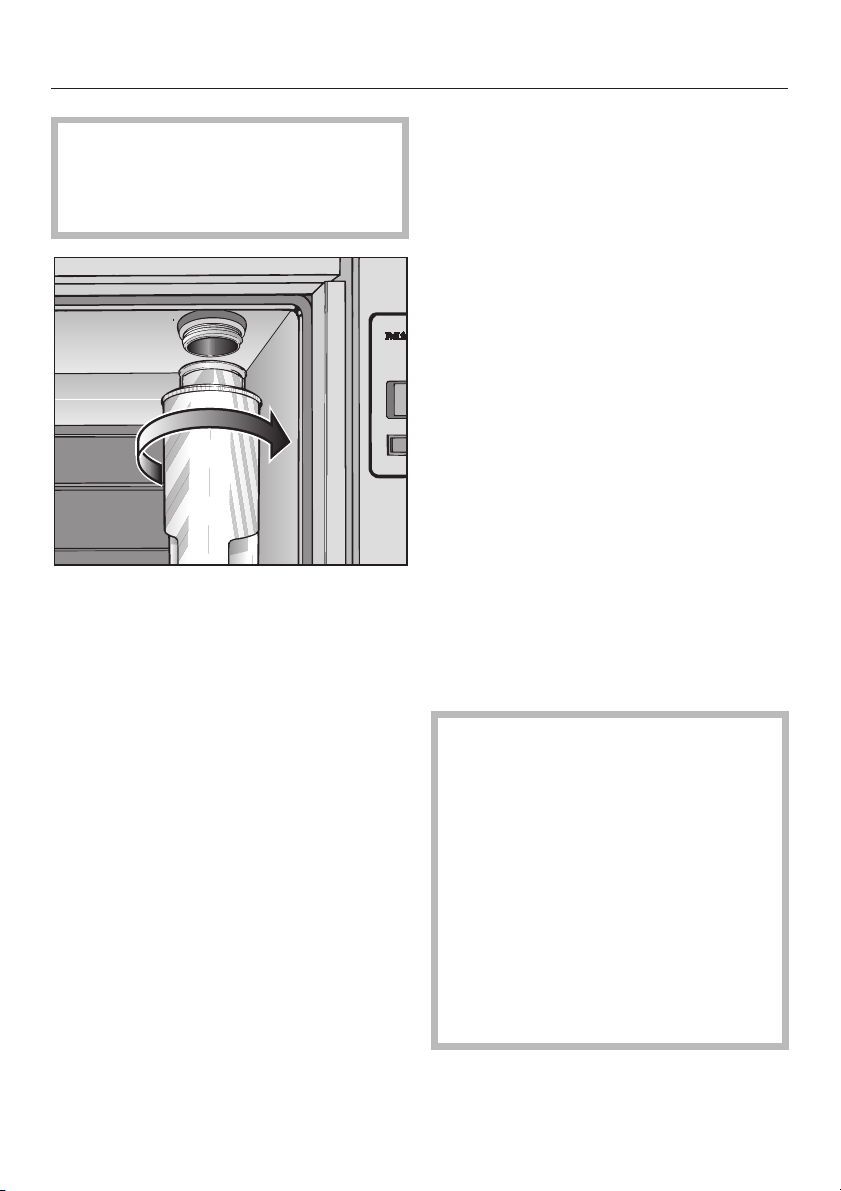

^ Screw the salt container firmly onto

the socket.

Water softener

Then:

Switch off the machine.

^

Carefully unscrew the salt container,

^

making sure any water pressure still

remaining can depressurise. Do not

use force!

If the container will not come off

manually please contact the Miele

Service Department.

Replace the cap.

^

Select and start the COLD WASH

^

programme to flush out any excess

salt from the softener unit and from

the cabinet.

^ Push the mobile unit back into the

cabinet.

^ Turn off the stopcocks.

^ Empty the salt container. Do not

empty it into the wash cabinet.

Run the reactivation programme

^ Close the door.

^

Open the stopcocks.

^

Select the REACTIVATION

programme.

The programme will run automatically.

^ Rinse the salt container and filter

insert with clean water.

The water pressure (flow pressure at

the take off point) must be at least

150 kPa (1.5 bar) for cold and hot

water.

If it is below150 kPa (1.5 bar) or if it

fluctuates a lot, the water softener

will not work properly. After

reactivation, salt remains may still be

found in the salt container.

To use up salt remains and to rinse

out the water softener, the

REACTIVATION programme must be

carried out again.

17

Page 18

Automatic mobile unit recognition (AWK) (optional)

In operating level C the automatic

mobile unit recognition system (AWK)

allocates programme places from 1 15 to mobile units with the correct

coding.

The unit coding (on the mobile unit) and

the programme place with the

corresponding programme (in the

electronic control unit) have to match

each other.

To do this:

Each mobile unit must be coded

^

before being used for the first time

(see "Coding the mobile unit"), and

^ The programme for which the mobile

unit is coded must be allocated to t

^ he correct programme place.

See "System function - Selector switch

organisation" in the Programming

manual for information on how to

change programme positions.

,

Before starting a programme it is

absolutely essential that you check

that the programme shown in the

display is the correct one for the

mobile unit being used.

Otherwise inadequate cleaning or

disinfection could be the result.

Please make sure, that the places

assigned for the programmes using

Automatic mobile unit recognition

are not changed around arbitrarily.

Mobile unit coding

The automatic mobile unit recognition

feature assigns a programme place to

a mobile unit. The mobile units must be

coded with a magnetic strip (via a Bit

combination).

In operating level C, the only

programme available for a coded

mobile unit is the one assigned to the

corresponding programme place.

After a coded mobile unit has been put

into the machine and the door closed,

the automatic mobile unit recognition

system will select the allocated

programme (as long as there are no

residues or particles on the magnetic

strip).

Make sure that there are no

,

small metallic objects or instrument

parts attracted to the magnetic strip,

in particular to the underside of it.

Any metallic objects on the strip can

result in the coding being incorrectly

read.

Press 6 to start the programme.

18

Page 19

Automatic mobile unit recognition (AWK) (optional)

Coding is effected through 5 Bits:

Bits 1 to 4 define the mobile unit

–

code,

Bit 5 serves as a control (Parity Bit).

–

Mobile unit coding strip

15 different codes can be set. They are

assigned to programme places 1 to 15.

Under "System function, Selector switch

organisation" the matching

programmes have to be put into the

first 15 programme places.

Programme

place

10

11

12

13

14

15

Bit 1 Bit 2 Bit 3 Bit 4 Bit 5

0

1

2

3

4

5

6

7

8

9

0

0

I

I

0

I

I

0

0

0

I

I

0

I

I

0

0

0

I

I

0

I

I

0

0

0

I

I

0

I

I

Parity

Bit

0

0

0

0

0

0

I

I

I

I

0

0

0

0

I

I

I

I

I

0

I

0

0

0

I

0

0

0

0

0

I

0

I

I

0

I

0

I

I

I

0

I

I

I

I

I

0

I

The coded total must be an even

number.

If the coded total gives an odd number

the message CHECK MOBILE UNIT

RECOGNITION appears.

If the mobile unit total equals 0, the

message NO MOBILE UNIT

RECOGNITION will appear. In neither

case can the programme be started,

The mobile unit recognition function

must be re-set.

Setting mobile unit coding

To set or alter the coding of a mobile

unit with automatic recognition (AWK),

proceed as follows:

^

Unscrew the track with AWK (using

an allen key) and remove from the

retainer.

19

Page 20

Automatic mobile unit recognition (AWK) (optional)

Remove the magnetic strip from the

^

track.

Put the magnetic strip back in the

^

track.

The magnetic strip must be placed

in the track such that the Bit coding

set out in the chart is visible through

the round windows in the track.

^

Set the programme place coding.

20

^

Place the track in the holder in the

mobile unit and screw firmly in place.

The magnetic strip must have grey

magnets.

Page 21

Areas of application

Cover plate

The machine is supplied with a baffle

fitted in front of the hot air outlet in the

rear wall of the wash cabinet.

This baffle has to be dismantled if

mobile units and baskets are used

which have a drying unit connection on

them.

^ Loosen both screws on the baffle.

Baskets

This machine can be fitted with wide

variety of baskets. There are too many

to describe them all here. Please

contact your Miele application

specialist for details of suitable baskets

and inserts for your requirements, or to

discuss the possiblity of having custom

built ones for your particular

application.

Special cleaning applications

It is possible to test particular cleaning

requirements. The machine may then

be used for other applications. Many

users carry out their own test washes.

Should the use of the machine change,

then the cleaning programme can also

be adapted. This applies in particular to

the cleaning agents used, the type of

load, and the type of soiling and

material from which the items are

made.

^ Take the baffle off.

21

Page 22

Areas of application

Cleaning programmes

The machine is supplied without

programmes. When creating

programmes account has to be taken

of the plumbing connections and any

buffer or recyling tank. Consideration

also has be taken of process chemicals

and any physical or chemical

properties of the items being cleaned

and the type of soiling being handled.

The following pages give some tips on

particular problems and ways of

dealing with them.

If you have any questions please

contact the following:

– The Miele Service Department

– Your Miele application specialist

– Your Miele Dealer

Before starting a programme you

should carry out a visual check on

the following:

Is everything correctly

–

loaded/connected for cleaning?

Are the spray arms clean and do

–

they rotate freely?

Are the filters clean? Remove any

–

coarse soiling and clean them

properly if necessary.

Is the adapter connecting the water

–

supply to the spray arms/jets

correctly connected?

– Are all chemical containers filled

sufficiently?

22

Page 23

Areas of application

Water connection spring

adapter

Make sure that the water connection

spring adapter engages correctly when

a basket or injector unit is inserted in

the machine. It must be 4-5 mm higher

than the water connection inlet in the

machine.

If it is not, adjust the adapter

accordingly.

^

Loosen lock ring a.

^

Push up adapter b.

^

Tighten lock ring c.

Height adjustable top basket

The top basket can be adjusted above

and below the middle position by 2 cm.

Depending on the position of the top

basket and the inserts used, the

baskets can accommodate vessels and

instruments of the following heights:

Example: Top basket O 188/1 and

bottom basket U 874/1 without

inserts:

Top basket

position

Top max. 15.5 max. 28.5

Middle max. 17.5 max. 26.5

Bottom max. 19.5 max. 24.5

The height available in the right

hand side of the top basket is limited

by the salt reservoir connection

point.

To adjust the top basket:

^

Pull out the top basket until a

resistance is felt; lift from the runners

and remove.

Top basket

height (cm)

Bottom

basket

height (cm)

^

Unscrew the roller bearings on both

sides of the basket with a suitable

spanner and reposition as required.

23

Page 24

Areas of application

Electronics

Depending on the soldering process

used and the application the products

are to be used for soldering frames

used in the production of electronic

components and printed circuit boards

can be cleaned in this machine.

Printed circuit boards

Resin or colophonium coated circuit

boards can be cleaned in this machine.

The results will be influenced by the

type of fluxing agent used. Please seek

the advice of your application specialist

if required. A tenside additive is

required for cleaning (0.5 - 0.7 % at

65 - 75 °C, process 1 or 2, see

"Description of the machine - Water

recovery") or a special cleaning agent

(20% at 50 °C, process 3, see

"Description of the machine - Water

recovery"). If the rinse water or the

special cleaning agent is to be re-used

a buffer or recycling tank is required.

Fully demineralised water is required

for the rinse.

Fluxing agents and soldering paste

Batch times for cleaning are approx.

30 - 40 min, and approx. 30 - 50 min for

drying, depending on the complexity

and quantity of items being processed.

The special baskets for circuit boards,

upper basket O 500 and bottom basket

U 500 are made from plastic coated

stainless steel. Each is designed to

process 73 europa size circuit boards

per batch.

Upper basket O 500

Residues from the soldering process

are water soluble and must be

removed. The cleaning process then

takes place in water only.

24

Page 25

Bottom basket U 500

Large quantities of small boards can be

processed using inserts such as the

E 402 or E 403 in conjunction with an

E 439. Lightweight or sensitive circuit

boards should be protected with a cover

net or grille.

Areas of application

Carrying out the final rinse on

aluminium soldering frames with fully

demeralised water will help to prevent

any material damage that might be

caused by the quality of the mains

water.

Example: 8 soldering frames approx.

475 mm x 430 mm x 45 - 50 mm (length

x width x thickness) can be cleaned

and dried in this machine in a batch

time of 30 minutes, if the machine is

connected to a 65 °C hot water supply.

Loading example:

Bottom basket U 874 with insert E 500

Soldering frames

Depending on the type of soiling (adipic

acid, colophonium etc.) cleaning should

be carried out using an alkaline cleaning

agent (0.3 - 0.5% at 50 - 75 °C, process

1 or 2, see "Description of the machine Water recovery") or a special cleaning

agent (1 - 3% at 50 - 75 °C, process 3,

see "Description of the machine - Water

recovery"). If the rinse water or the

special cleaning agent is to be re-used

a buffer or recycling tank is required.

Depending on the type of material used

to manufacture the soldering frames it

may be necessary to use an acidic

neutralising agent (0.1 - 0.2%) or a

rinsing agent (0.05 - 0.1%).

Insert E 500

25

Page 26

Areas of application

Metal cleaning

This machine can be used to degrease

and remove any dust and lapping

abrasives from metal components at

the end of the manufacturing process

or before they are lacquered or

galvanised.

Process 1 and 2 (see "Description of

the machine - Water recovery") are

frequently used for this where the items

are only lightly soiled with residues

(0.5-1.0% cleaning agent at 60-80 °C).

Process 3 (see "Description of the

machine - Water recovery") is frequently

used for this where the items are

heavily soiled with residues (1.0-3.0%

cleaning agent at 60-80 °C). If the rinse

water or the special cleaning agent is to

be re-used a buffer or recycling tank is

required.

The cleaning agent and process used

will depend on the iron, steel and

non-ferrous heavy metal content. With

lapping agents a test wash should be

carried out to ascertain cleaning levels.

Make sure that metal shavings

,

(from drilling, cutting etc) cannot get

into the wash cabinet. This is

particularly important with corrosive

iron materials.

The O 188 upper basket in conjunction

with the U 874 bottom basket are

recommended as standard baskets for

this machine, or the 4 level E 439 for

processing small components. Various

mesh trays and inserts are available for

processing very small items. The mesh

trays and inserts can be placed in

O 188/U 874 or E 439.

Depending on the material and rinse

results it is often necessary to carry out

a final rinse with fully demineralised

water.

26

Page 27

Glass cleaning

Technical and optical glassware can be

processed in this machine to remove

grease, dust and lapping abrasives

and to ensure a residue free final rinse.

A residue-free final result will depend

on the quality of the water used.

Technical advice should be sought

regarding the processing of very

sensitive glassware and fine grade

lapping abrasives.

Process 1 and 2 (see "Description of

the machine - Water recovery") are

frequently used for glassware cleaning

(0.5-1.0% cleaning agent at 60-80 °C).

If the rinse water is to be re-used a

buffer or recycling tank is required.

Baskets and inserts

Small glass lenses can be cleaned in

the machine using baskets O 188/U

874 and inserts E 402/403. For larger

glass lenses inserts E 118 and E 136

should be used. Small lenses can also

be processed using an E 403 in an

E 439.

Areas of application

Insert E 118

27

Page 28

Areas of application

Particle decontamination

This machine is particularly suitable for

particle decontamination of chip boxes,

wafer trays, semi-finished products,

assembly trays and computer parts.

Cleaning takes place using a water

based process only, using a very small

amount of special cleaning agent and

without the addition of solvents. The

cleaning process for this application

takes place using the highest grade

water only.

Chip boxes, wafer trays etc. are

cleaned using process 1 only

(see"Description of the machine Cleaning process").

28

Page 29

Chemical processes and technology

General notes

Problem How to resolve it

If elastomers (seals and hoses) and

plastics in the machine suffer damage,

this can cause swelling, shrinkage,

hardening and brittleness in materials

and cause cracks to occur in them.

They will then not function correctly.

This usually takes the form of them not

being water-tight.

Heavy foaming during a programme

affects cleaning and rinsing results.

Foam escaping from the wash cabinet

can cause damage to the machine.

Cleaning processes cannot be

regulated and validated where there

has been a build-up of foam..

Corrosion to stainless steel in the wash

cabinet and to accessories can give

them a different appearance:

– rust (red marks / discolouration),

– black marks / discolouration,

– white marks / discolouration (etched

surface).

Corrosive pitting can lead to the

machine not being water-tight.

Depending on application, corrosion

can influence cleaning and rinsing

results (laboratory analysis) or cause

corrosion to stainless steel items in the

cabinet.

Establish the cause of the damage

–

and put it right.

See information regarding "Chemical

agents", "Soiling" and "Reaction between

chemical agents and soiling".

Establish the cause of the foam and

–

put it right.

Check the process used regularly to

–

monitor foaming levels.

See information regarding "Chemical

agents", "Soiling" and "Reaction between

chemical agents and soiling".

– Establish the cause of the corrosion

and put it right.

See information regarding "Chemical

agents", "Soiling" and "Reaction between

chemical agents and soiling".

29

Page 30

Chemical processes and technology

Chemical agents

Problem How to resolve it

The ingredients in chemical agents

have a strong influence on the longevity

and functionality (throughput) of the

dispensing system. The dispensing

system (hoses and pumps) should be

set up for a particular type of chemical

agent.

General types:

alkaline to pH neutral products,

–

acidic to pH neutral products,

–

hydrogen peroxide.

–

Chemical agents can damage

elastomers and plastics in the machine

and accessories.

The following oxidising chemical agents

can damage elastomers (hoses and

seals) and plastics in the machine:

– nitric acid,

– peracetic acid,

–

products contain active chlorine.

Use Miele approved chemical agents

–

in this machine.

Carry out a regular visual check of

–

the dispensing system for any

damage.

Check the flow rate of the dispensing

–

system regularly.

– Use Miele approved chemical agents

in this machine.

– Carry out a regular visual check of

any accessible elastomers and

plastics for damage.

The wash temperature should be limited

to:

– 50 °C with nitric acid,

– 35 °C with peracetic acid,

–

80 °C with products containing active

chlorine.

The following chemical agents can

release large amounts of oxygen:

–

hydrogen peroxide,

–

peracetic acid.

30

–

Only use approved processes such

as OXIVARIO or OXIVARIO PLUS.

–

The wash temperature must be less

than 70 °C when using hydrogen

peroxide.

–

Please contact Miele Service or your

Miele Application Professional for

advice.

Page 31

Chemical processes and technology

Chemical agents

Problem How to resolve it

The following chemical agents can

cause large amounts of foam to build

up:

Cleaning agents and rinsing agents

–

containing tensides,

emulsifiers.

–

Foam can occur:

in the programme block in which the

–

chemical agent is dispensed,

in the following programme block if it

–

has been spilt,

– in the following programme with

rinsing agent if it has been spilt.

De-foaming agents, especially silicone

based ones can cause the following:

– deposits to build up in the cabinet,

– deposits to build up on the load,

– damage to elastomers and plastics in

the machine,

– damage to certain plastics (e.g.

polycarbonate and plexiglass) in the

load being processed.

Process parameters in the wash

–

programme, such as dispensing

temperature, dosage concentration

etc. must be set to ensure the whole

process is foam free or very low

foaming.

Please observe chemical agent

–

manufacturer's instructions.

– De-foaming agents should be used in

exceptional cases only, for instance

when absolutely essential for the

process.

– The wash cabinet and accessories

should be periodically cleaned

without a load and without

de-foaming agent using the

ORGANICA programme (if available)

or a special programme.

–

Please contact Miele Service or your

Miele Application Professional for

advice.

31

Page 32

Chemical processes and technology

Soiling

Problem How to resolve it

The following oxidising chemical agents

can damage elastomers (hoses and

seals) and plastics in the machine:

oil, wax, aromatic and unsaturated

–

hydrocarbons,

cooling lubricant, cutting/drilling oil and

–

emulsions,

emollients,

–

cosmetics, hygiene and care products

–

such as creams (analytical

applications).

The following substances can lead to a

heavy build-up of foam during washing

and rinsing:

– fluxing agent,

– cooling lubricant, cutting/drilling oil and

emulsions,

– agents such as disinfecting agent and

dishwashing detergent etc.

–

reagents for analysis e.g. for microtiter

plates,

–

cosmetics, hygiene and care products

such as shampoos and creams

(analytical applications),

–

active foaming agents such as

tensides.

The following substances cause corrosion

to stainless steel in the wash cabinet and

on accessories:

–

hydrochloric acid,

–

other substances containing chlorides

such as sodium chloride etc.,

–

concentrated sulphuric acid,

–

chromic acid,

–

particles of iron and swarf.

Depending on usage, wipe the

–

lower door seal on the machine

periodically with a lint-free cloth or

sponge.

Clean the wash cabinet and

accessories without a load using

the ORGANICA programme (if

available) or a special programme.

Prepare the load

–

using the "OIL" programme (if

available) or use a special

programme that dispenses

emulsifiers.

– Thoroughly rinse items in water

beforehand.

– Select a cleaning programme with

at least one short pre-rinse in cold

or hot water.

– Depending on application use

de-foaming agents that do not

contain silicone oils.

–

Thoroughly rinse items in water

beforehand.

–

Place items drip dried into mobile

units, baskets and inserts and then

place these in the wash cabinet.

32

Page 33

Chemical processes and technology

Reaction between chemical agents and soiling

Problem How to resolve it

Natural oils and fats can be emulsified

with alkaline chemical agents. This can

lead to a heavy build-up of foam.

Soiling containing high protein levels

such as blood can cause a heavy

build-up of foam when processed with

alkaline chemical agents.

Non-precious metals such as

aluminium, magnesium and zinc can

release hydrogen when processed with

very acidic or alkaline chemical agents

(oxyhydrogen reaction).

The following substances when used

with chemical agents can lead to a

heavy build-up of foam during washing

and rinsing:

–

flux,

–

cooling lubricant, cutting/drilling oil

and emulsions,

–

abrasive and polishing agents.

Where available use the "OIL"

–

programme.

This special programme dispenses

–

emulsifiers (pH neutral) in the

pre-rinse.

Depending on application use

–

de-foaming agents that do not

contain silicone oils.

Select a cleaning programme with at

–

least one short pre-rinse in cold

water.

– Please observe chemical agent

manufacturer's instructions.

– Depending on application, use

emulsifiers or de-foaming agents that

do not contain silicone oils.

33

Page 34

Dispensing liquid chemical agents

The correct amount of liquid agent etc.

Only use agents formulated

,

specifically for use in a water based

process in this professional cleaning

machine and make sure you follow

the manufacturer's instructions on

the packaging.

required for the application chosen will

be dispensed through these dispensing

systems.

The liquid agent containers are situated

next to the machine.

This machine is fitted with 2 dispenser

pumps as standard:

Dispensing system DOS 1 (blue) to

–

dispense a liquid alkaline agent. It

can dispense up to 120 ml/min.

Dispensing system DOS 3 (red) to

–

dispense a liquid acid agent such as

neutralising agent or rinsing agent. It

can dispense up to 105 ml/min.

Additional optional DOS modules:

– Dispensing system DOS 2 (white) to

dispense a liquid acid agent such as

neutralising agent. It can dispense

up to 105 ml/min.

–

Dispensing system DOS 4 (green) to

dispense a liquid alkaline agent. It

can dispense up to 120 ml/min.

Agents used must be non-foaming

or produce as little foam as possible

at dispensing temperature. Any

foam can affect the cleaning or final

rinse result.

Preparing the dispensing

system

The liquid agents can be filled into 5 10 litre plastic containers.

When first commissioning, or when the

message FILL DOS 1 and/or DOS 2, 3,

4 CONTAINER flashes in the display

after switching on or at the end of a

programme, fill the storage container

with the relevant liquid agent.

If the message CHECK DISPENSING

SYSTEM 1 and/or CHECK DISPENSING

SYSTEM 2, 3, 4 flashes in the display,

check the containers and the

dispensing tubes, and refill or

exchange the containers for full

containers if empty.

The programme will stop automatically.

34

Page 35

Dispensing liquid chemical agents

When first commissioning, or when

the message CHECK

DISPENSING SYSTEM... appears,

start the DOS-FILL programme to

vent the dispensing system (see

"Venting the dispensing system").

Take great care when handling

,

liquid agents and additives. These

may contain irritant or corrosive

ingredients.

Please follow the manufacturer's

instructions and wear protective

gloves and goggles.

Fill the containers with the relevant

agent

Switch the machine off.

^

^ Open the container and fill it with the

required agent.

^ Insert the siphon tube into the

container and securely tighten it.

Once the storage containers have been

filled the relevant message goes out.

Please remember to refill containers

in good time. Do not let them get

empty. It is best to refill them as

soon as the FILL DOS 1, 2, 3 or 4

CONTAINER message appears in

the display. If a container is not

being used, the level query for the

unused dispensing system can be

turned off to avoid the error

message (see "Machine

functions/Dispensing/Query

container" in the Programming

Manual supplied with the machine).

35

Page 36

Dispensing liquid chemical agents

Venting the dispensing system

Before the machine is first

commissioned, and later on if one or

more containers has been allowed to

run dry, the dispensing system(s) for

liquid media will need to be vented. To

do this:

Press the I-0 button.

^

Select operating level B.

^

Select as required:

^

Programme DOS1-FILL

Programme DOS2-FILL

Programme DOS3-FILL

Programme DOS4-FILL.

(See "Operation/B. Free programme

selection).

^ Press the Start button 6.

The DOS-FILL Service Programmes

are allocated to programme places

58-61 ex works, but can be

re-allocated to other programme

places, if preferred.

Dispensing system

maintenance

To ensure trouble-free operation, the

following maintenance should be

carried out by a Miele approved service

technician.

Every 12-18 months

Replace the hoses in the dispensing

system(s).

External Dispensing systems

If external pumps are used for

dispensing liquid agents, please

contact the Miele Service Department.

The instructions given in the

Programming Manual under "Machine

functions" will need to be observed.

36

Page 37

Operation

Switching on

Open the stopcocks (if turned off).

^

Press the I-0 button.

^

In operating levels A, B and D the most

recently selected PROGRAMME NAME

appears in the display and in operating

level C, AUTOMATIC MOBILE UNIT

RECOGNITION is displayed.

Changing the operating level

There are four operating levels

available on this machine:

A = Fixed and free access

programmes

B = Free programme selection

C = AWK – Automatic mobile unit

recognition (programme selection

via mobile unit coding) - optional

D = Programming / free programme

selection / change code

(see Programming manual)

^

Press 1 and 2 at the same time.

Operating levelsABCDareshown

in the display.

^

Select the operating level you want

using the 1 or 2 button.

^

Press 6 to confirm selection.

[0000] will appear

– Enter numbers using the 4 and

3 buttons

– Select number position with the

1 or 2 button

– To confirm the code press 6.

If you enter the wrong code:

FALSE CODE, ENTER AGAIN will

appear in the display

Close the door.

^

Selecting or changing your own

code See "System functions" in the

Programming Manual:

Code 1 for levels ABC

Code 2 for levels ABCD

Starting a programme

A. Fixed and free access

programmes

Programmes which you want to have

accessible in operating level A need to

be given free-access under operating

level D. See the programming manual

for details on how to do this.

^

Select operating level A.

^

Check in the display that the

programme shown is the one

required.

^

Enter code when requested by the

display.

The code is set ex-works to ü0000<.

To enter the code:

– Press the start button 6,

^

If several programmes have been

made freely accessible, select the

one required using the programme

selector.

^

Press the Start button 6.

37

Page 38

Operation

B and D. Free programme selection

Select operating level B or D.

^

In operating levels B and D there are

three ways of selecting a programme.

1. Programme places1-23canbe

selected using the Programme selector.

Turn the programme selector to the

^

required programme.

The programme name will appear in

the display.

2. Programmes above place 24 are

selected using the 4 and 3 keys.

^ Turn the programme selector to 24.

^ Press 4 (scrolls forwards) until the

required programme is shown.

^ Press 3 (scrolls back) until the

required programme is shown.

3. The PROGRAMME SURVEY menu

lists all stored programmes. A

programme can be selected from this

menu. To do this:

C. AWK – Automatic mobile unit

recognition (optional)

Select operating level C.

^

Push the coded mobile unit into

^

place (see "Automatic mobile unit

recognition").

Close the door.

^

Important

It is absolutely essential to check

that the programme required for

this mobile unit is the one shown in

the display before pressing the Start

button to start the programme.

Otherwise inadequate cleaning

could be the result.

Please make sure, that the places

assigned for the programmes using

Automatic mobile unit recognition

are not changed around arbitrarily.

^ Press the Start button 6.

^

Select Programme Survey with 1

and confirm with 6.

^

Select a programme using 1 or 2.

^

Press 6 to confirm selection.

This exits the Programme Survey, and

the selected programme is shown in

the display.

After selecting one of the three options

above:

^

Press the Start button 6; the

programme proceeds.

For further information on programme

selection see "Operating Level B" in the

Programming Manual.

38

Page 39

Operation

Programme sequence

The programme will start automatically

as soon as the Start button has been

pressed. It is finished when

PROGRAMME END appears in the

display and the background lighting

flashes (press any button to stop it

flashing).

See "System functions" in the

programming manual for further

information on switching it off.

Detailed information on programme

sequences is given in the appendix

to the Programming Manual.

The display background lighting

goes out automatically after approx.

15 mins. To bring it back on again,

press one of the buttons.

,

On machines with a built-in

printer you must not change the

colour ribbon cartridge or the paper

roll whilst a programme is in

progress.

Switching off

Press and release the I-0 button.

^

Turn off the stopcocks.

^

Cancelling a programme

A programme can only be cancelled

in operating level B or D.

In operating levels B or D

Press the 7 button. The programme

^

is interrupted.

^ If the water temperature is below

40 °C, CANCEL OR üCONTINUE<,

will appear in the display, and if it is

above 40 °C üCANCEL< will appear

in the display.

,

If there is a lot of hot water in the

wash cabinet when the programme

is interrupted and the door is then

closed quickly, hot water can

escape.

Danger of burning or scalding.

^

Use cursor button 1 to select

üCANCEL<; the ü < cursors will start

flashing.

^

Press the Start button 6. The

programme is cancelled and the

water drained away. WATER DRAIN

will appear in the display.

^

After the water has been pumped

away the required programme can

be selected and started again.

39

Page 40

Operation

Interrupting a programme

A programme can only be

interrupted in operating level B or D.

If you absolutely have to open the door,

e.g. because the load is obviously

unstable (conscious intervention):

1. In operating levels B or D

Press the Stop button 7. The

^

programme is interrupted.

If the water temperature is below

40 °C CANCEL OR üCONTINUE<

will appear in the display, and if it is

above 40 °C üCANCEL< will appear

in the display.

^ Open the door.

,

Caution. Water and items in the

machine may be hot. Danger of

burning or scalding.

Where a chemical disinfection

programme has been used, be

aware that steam may contain high

quantites of disinfecting agent.

If there is a lot of hot water in the

,

wash cabinet when the programme

is interrupted and the door is then

closed quickly, hot water can

escape.

Danger of burning or scalding.

If the water temperature is lower than

40 °C when the programme is

interrupted:

Press the Start button 6 to continue

^

the programme.

If the water temperature is higher than

40 °C when the programme is

interrupted:

^ Press the Start button 6.

The programme is cancelled and the

water pumped away. WATER DRAIN

will appear in the display.

^ Once the water has been pumped

away, the programme can be

restarted.

^

Rearrange the load. Follow infection

control regulations and wear

protective gloves.

^

Close the door carefully.

40

Page 41

Data transfer

There is a 9-pole sub-D socket on the

back of the machine for data transfer

between the Profitronic unit and an

external report printer or a PC.

The serial interface is RS 232

compatible.

For the interface configurations see

"PC/Printer Functions" in the

Programming manual.

Various printers can be used as

external printers:

Epson-compatible

–

(contact Miele for a list of suitable

models).

– HP Laserjet

Pin configuration in the 9-pole sub-D

connector at the back of the machine:

5 GND (base)

3 TXD (transmit)

2 RXD (receive)

1-4-6 (linked)

7-8 (linked)

A standard null-modem or laplink cable

can be connected.

The extension cable to the printer/PC

must not exceed 13 m.

Please note the following when

connecting a printer or PC:

Only use an industry-standard PC or

–

printer (e.g. in Germany TÜV, or VDE

approved),

The size of the printer or PC must be

–

taken into account when installing

the machine.

The report printer settings are

described in detail in the Programming

manual under "PC/Printer functions".

41

Page 42

Maintenance

Maintenance and care

This machine should be inspected in

accordance with local and national

safety regulations after every 1000

operating hours, or every 6 months by a

Miele approved service technician.

A service will cover the following:

Electrical safety tests

–

Door mechanism and door seal

–

Any screw connections and

–

connectors in the wash cabinet

Water inlet and drainage

–

– Internal and external dispensing

systems

– Spray arms

– Filter combination

– Sump including drain pump and

non-return valve

– Steam condenser

–

All mobile units, baskets and inserts

–

The drying unit

and where applicable:

–

Any printer connected to the

machine.

The following operational tests will be

carried out within the framework of the

maintenance:

A programme will be run as a test

–

run

Thermo electrical measurements will

–

be taken

Seals will be tested for water

–

tightness

All relevant measuring systems will

–

be safety tested including error

message displays.

– Safety devices.

Routine checks

Before the start of each working day,

the user must carry out a number of

routine checks.

The following need to be inspected:

– All filters in the wash cabinet

–

The spray arms in the machine and

in any mobile units or baskets

–

The wash cabinet and the door seal

–

Mobile units, baskets and inserts.

42

Page 43

Maintenance

Cleaning the filters in the wash

cabinet

This machine must not be used

,

without all the filters in place.

The filter combination in the base of

the wash cabinet should be

inspected regularly and cleaned if

necessary.

Caution

,

Watch out for glass splinters which

could cause injury.

Cleaning the coarse filter

Remove the fine filter from between

^

the coarse and the micro-fine filters.

^ To unscrew the micro-fine filter, take

hold of the two lugs and turn twice in

an anti-clockwise direction.

^

Press the two lugs together, remove

and clean the coarse filter.

^

Put the clean filter back in position

and press until it clicks in place.

Cleaning the flat and micro-fine

filters

^

Remove the coarse filter.

^

Then remove the micro-fine filter

together with the flat filter.

^

Clean the filters.

^

Replace the filters by carrying out the

above steps in the reverse order.

Ensure that the filters sit flat in the

base of the wash cabinet.

43

Page 44

Maintenance

Cleaning the spray arms

The spray arms can become blocked

and should therefore be checked every

day.

Use a sharp pointed object to push

^

particles into the spray arm jets, and

rinse well under running water.

Remove the spray arms as follows:

Take any baskets out of the wash

^

cabinet.

Spray arm on top basket or mobile unit

(if present):

^ Loosen the nut on the spray arm and

take the spray arm off.

Metal nuts have a left-hand thread.

Ceramic nuts have a right-hand

thread.

Unscrew the upper spray arm.

^

Loosen the knurled thumb nut to

^

unscrew the lower spray arm.

After cleaning the spray arms, fit or

^

screw them back into position.

After replacing the spray arms,

rotate them to make sure they move

freely.

44

Page 45

Cleaning the control panel

The control panel should only be

^

cleaned using a damp cloth or with a

proprietary cleaning agent for glass

or plastic surfaces.

An approved and listed disinfecting

agent can be used to wipe surfaces.

Do not use abrasive cleaners or

,

all-purpose cleaners.

Because of their chemical

composition they could cause

serious damage to plastic

components.

Cleaning the front of the

machine

Maintenance

Do not clean the machine or

,

near vicinity with a water hose or a

pressure washer.

Cleaning the wash cabinet

The wash cabinet is generally

self-cleaning.

However, should a build-up of deposits

occur in the cabinet please contact

Miele for advice.

Cleaning the door seals

The door seals should be cleaned

regularly with a damp cloth to remove

any soiling.

^ The front should be cleaned using a

damp cloth and a little washing-up

liquid, or with a non-abrasive

proprietary cleaning agent designed

for use on stainless steel.

^ To help prevent resoiling

(fingermarks etc.) a stainless steel

conditioning agent (available from

the Miele Spare Parts Department or

via the Internet, depending on

country) can also be used.

,

Do not use any cleaning agents

containing ammonia or thinners as

these can damage the surface

material.

Seals which are no longer tight or which

have suffered damage must be

replaced with new ones by an

approved Miele technician.

45

Page 46

Maintenance

Mobile units, baskets and

inserts

Mobile units, baskets and inserts

should be checked daily to make sure

they are functioning correctly.

The following need to be inspected:

Check that the guide rails on mobile

–

units/inserts are free of hindrance

and that they are secured to the

mobile units/inserts correctly.

Check that the mobile unit connector

–

is at the correct height and screwed

on correctly.

– Check that the locking caps in the

module connectors of modular

system mobile units are working

properly.

– Check that jets, sleeves and hose

adapters are securely held in

position in mobile units/inserts.

– Check that washing solution can flow

unhindered through all jets, sleeves

and hose adapters.

and where applicable:

Make sure that the spray arms rotate

–

freely.

Make sure the spray arm jets are free

–

of any blockages. See "Cleaning the

spray arms".

Make sure that there are no small

–

metallic objects sticking to the

magnetic strip on a mobile unit.

Check that the magnetic strip on

–

mobile units with automatic mobile

unit recognition is correctly screwed

into position.

–

Make sure caps and closures on

sleeves are correctly located.

46

Page 47

Drying unit (TA)

The CHANGE TA COARSE and

CHANGE TA FINE service

programmes have been allocated to

programme places 62 and 63

ex-works. If required, they can be

moved to other programme places.

See "System functions" in the

Programming manual.

Changing the coarse filter

The coarse filter should be changed

when the message CHANGE COARSE

FILTER flashes in the display.

^ Remove the service panel from the

control unit.

Maintenance

^ Replace the coarse filter. The soft

side of the filter must face the front.

^ Replace the filter grille and push it

upwards to secure it.

^ Refit the service panel.

After the coarse filter has been

changed, reset the operating hours

counter to zero, as follows:

^

Remove the filter grille from the

drying unit.

^ Select the Programme CHANGE TA

COARSE (see Operation: B - Free

programme selection).

^

Press the Start button 6.

When the service programme has

ended, a message will appear in the

display.

^

To üCONTINUE< press 6.

47

Page 48

Maintenance

Exchanging the HEPA filter

The HEPA filter should be changed

when the message CHANGE FINE

FILTER flashes in the display.

To ensure the machine operates

correctly, use original Miele HEPA

filters only (classification 13).

It is advisable to have the fine filter

changed whenever the machine is

serviced.

If it needs changing before this:

^ Remove the service panel from the

control unit.

Pull the HEPA filter out of it holder

^

and replace it with a new one.

^ Replace the coarse filter housing and

swing the securing screws back

downwards.