Page 1

Operating and installation instructions

Ventilation System

DA 229-2

To prevent accidents

and machine damage,

read these instructions

before installation or use. M.-Nr. 05 603 730

V

Page 2

Table of Contents

Warning and Safety instructions

Guide to the appliance

Functional description

Operation

Main power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Turning on the fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Selecting the power level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Delayed Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Turning off the fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Turning the lighting on / off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grease filter timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Checking the grease filter timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reprogramming the grease filter timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning and Care

Cleaning the casing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Grease filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Changing the light bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

After Sales Service

Installation instructions

2

Page 3

Warning and Safety instructions

Read these Operating Instructions carefully before installing or

using the Ventilation System.

This appliance is designed to vent

This appliance is intended for resi

dential use only. Use the appliance

only for its intended purpose. The

manufacturer cannot be held re

sponsible for damages caused by

improper use of the hood.

This appliance complies with current

safety requirements. Improper use of

the appliance can lead to personal

injury and material damage.

Read all instructions before installing

or using for the first time.

Keep these operating instructions in

a safe place and pass them on to

any future user.

SAVE THESE INSTRUCTIONS

AND REVIEW THEM

PERIODICALLY

-

-

cooking smoke / odors only.

Be certain your appliance is prop

erly installed and grounded by a

qualified technician.

To guarantee the electrical safety of this

appliance, continuity must exist be

tween the appliance and an effective

grounding system. It is imperative that

this basic safety requirement be met. If

there is any doubt, have the electrical

system of the house checked by a

qualified electrician. The manufacturer

cannot be held responsible for damages caused by the lack, or inadequacy of, an effective grounding system.

Before connecting the appliance to

the power supply make sure that

the voltage and frequency listed on the

data plate correspond with the household electrical supply. This data must

correspond to prevent machine dam

age. Consult a qualified electrician if in

doubt.

-

-

-

CAUTION

For General Ventilating Use Only.

Do Not Use To Exhaust Hazardous

Or Explosive Materials And Vapors.

Installation work and repairs should

only be performed by a qualified

technician in accordance with all appli

cable codes and standards. Repairs

and other work by unqualified persons

could be dangerous and the manufac

turer will not be held responsible.

-

-

3

Page 4

Warning and Safety instructions

This equipment is not designed for

maritime use or for use in mobile

installations such as caravans or air

craft. However, under certain conditions

it may be possible for an installation in

these applications. Please contact the

nearest Miele dealer or the Miele Tech

nical Service Department with specific

requirements.

Before servicing, disconnect the

power supply by either removing

the fuse, unplugging the unit or manu

ally "tripping" the circuit breaker.

Before discarding an old appli

ance, unplug it from the power

supply and remove the power cord and

any doors to prevent hazards.

-

-

-

-

Use

Do not allow children to play with

or operate the appliance or its controls. Supervise its use by the elderly or

infirm.

Be careful when preparing a

flambé beneath the hood.

Flames may be drawn up into the hood

by the suction or grease filters may

catch fire.

Never operate gas burners without

pots.

Do not leave cooking surfaces un

attended while in use. Overheated

food, oil and grease can catch fire.

-

Do not use the hood without the

grease filters in place.

Clean the grease filters regularly.

Dirty filters are a fire hazard.

Do not use a steam cleaner to

clean the hood. Steam could pene

trate electrical components and cause

a short circuit.

In areas subject to infestation by

cockroaches or other pest, keep

the appliance and its surroundings

clean at all times. Any damage caused

by cockroaches or other pest will not

be covered under warranty.

Installation

When installing the hood, make

sure that the following minimum

safety distances between Miele

cooktops and the hood are maintained.

– 22" (55 cm) above electric cooktops

– 26" (65 cm) above gas cooktops

–

26" (65 cm) above an open grill

For non-Miele cooking appliances

maintain the safety distances recom

mended by the cooktop manufacturer

in their installation and operating in

structions.

If there is more than one appliance be

neath the hood and they have different

minimum safety distances always se

lect the greater distance.

-

-

-

-

-

4

Page 5

Warning and Safety instructions

Do not use an extension cord to

connect the appliance to electricity.

Extension cords do not guarantee the

required safety of the appliance, (e.g.

danger of overheating).

Do not install this hood over

cooktops burning solid fuel.

Any fittings, sealant, or materials

used to install the ductwork must

be made of approved non-flammable

materials.

Never connect an exhaust hood to

an active chimney, dryer vent, vent

flue, or room ventilating ductwork. Seek

professional advice before connecting

an exhaust hood vent to an existing, inactive chimney or vent flue.

Make sure that the airflow in the

room is sufficient for combustion

and exhausting of all non-electric heating appliances (water heaters, gas

cooktops, gas ovens, etc.), otherwise

backdrafts may occur. Follow the heating manufacturer’s guidelines and

safety standards or those published by

the National Fire Protection Association

(NFPA), or the American Society for

Heating, Refrigeration and Air Condi

tioning Engineers (ASHRAE). If in

doubt, consult an experienced profes

sional.

-

-

WARNING

TO REDUCE THE RISK OF INJURY

TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:

Smother flames with a close fitting

lid, cookie sheet, or metal tray, then

turn off the burner.

Be careful to prevent burns.

If the flames do not go out immediately,

evacuate and call the fire depart

ment.

Never pick up a flaming pan -

You may be burned.

Do not use water, including wet

dishcloths or towels - a violent

steam explosion will result.

Use an extinguisher

only if:

– You know you have a Class ABC ex-

tinguisher, and you already know

how to operate it.

–

The fire is small and contained in the

area where it started.

–

The fire department is being called.

–

You can fight the fire with your back

to an exit.

-

The manufacturer cannot be held lia

ble for damage caused by non-com

pliance with these Warning and

Safety instructions.

-

-

5

Page 6

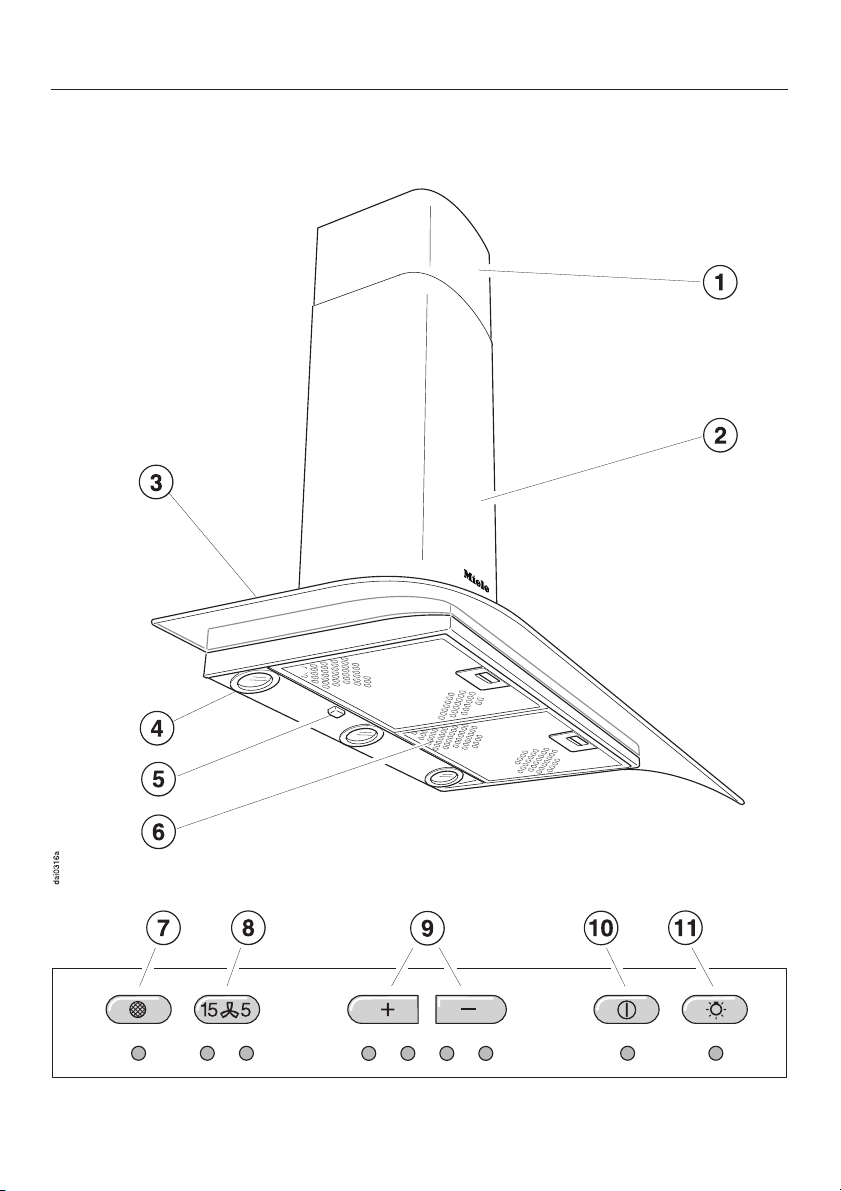

Guide to the appliance

6

Page 7

Guide to the appliance

Chimney extension

Chimney

Canopy

Overhead lighting

Main power switch

Grease filter

Grease filter button

The indicator below the grease filter

button lights when the grease filters

need to be cleaned.

This button is also used:

to reset the grease filter timer after

–

cleaning the grease filters (see

"Cleaning and Care").

to show how long the grease filter

–

has been in use (see "Operation /

Grease filter timer").

to change the number of hours

–

counted by the grease filter timer

(see "Operation / Reprogramming the

grease filter timer").

Delayed Shut Down

This button activates the Delayed Shut

Down feature. The fan can be set to

turn off automatically after either 5 or 15

minutes.

Fan power level buttons

Four fan speed selection.

On/Off button

Light button

7

Page 8

Functional description

The ventilation hood works by air ex

traction. The air is drawn in and

cleaned by the grease filters and di

rected outside.

The hood comes equipped with a

non-return flap. This flap automatically

closes when the hood is turned off so

that no exchange of outside air and

room air can occur. When the hood is

turned on, the air pressure of the ex

haust fan automatically opens the flap

blowing the inside air and cooking

odors outside.

-

-

-

8

Page 9

Operation

Main power switch

Press the main power switch to "I". The

fan and the lighting can now be oper

ated.

If the appliance is not going to be used

for a long period of time (e.g. while va

cationing) turn the appliance off by

pressing the main power switch to "0".

The next time it is turned on, the hood

will operate at the level previously used.

-

-

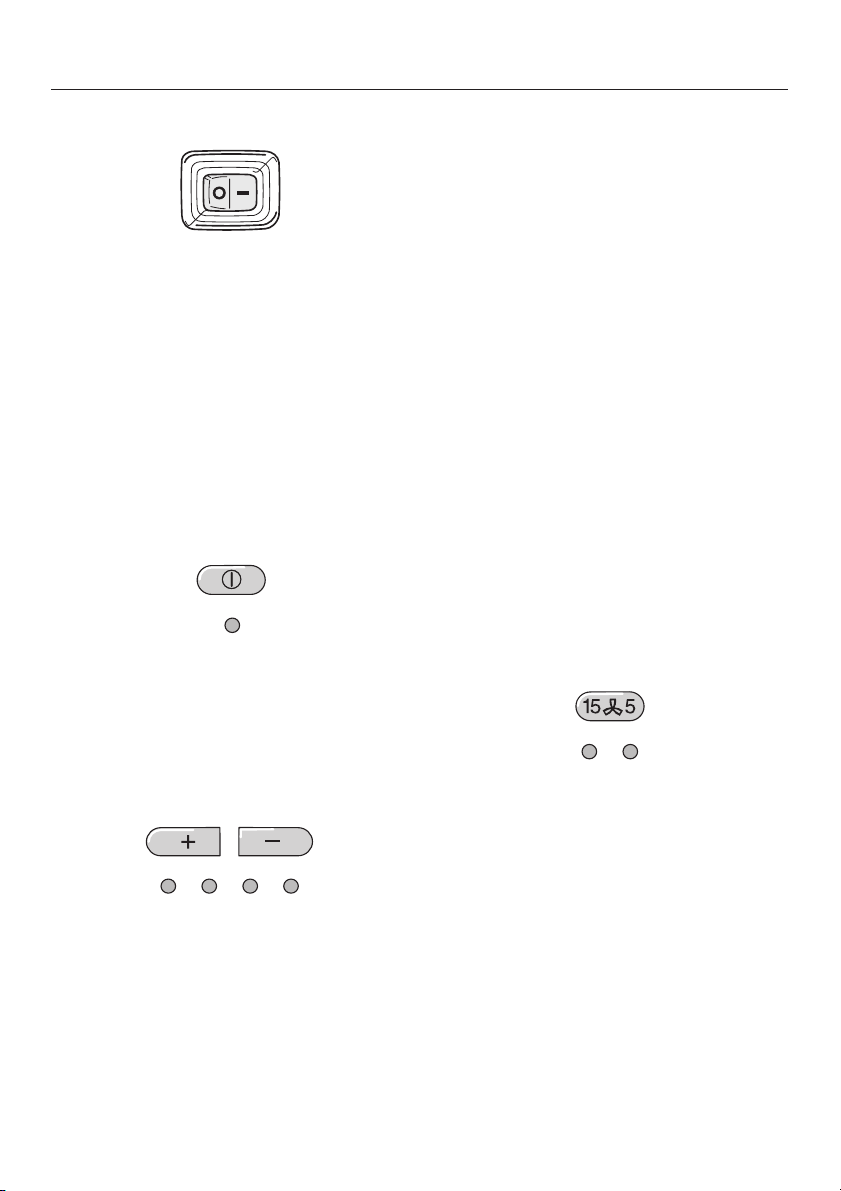

Turning on the fan

^ Press the On/Off button.

The fan runs at power level "2".

The On/Off indicator lights.

Intensive setting

Level "4" (yellow indicator) should be

used for a short period when frying or

cooking food with a strong aroma.

Fan performance

The maximum air flow capacity is

625 cfm. Factors such as narrow duct

diameter and bends will affect this

value.

Level 1 operates at 40% capacity

Level 2 operates at 60% capacity

Level 3 operates at 80% capacity

Level 4 operates at 100% capacity

Delayed Shut Down

If odors or smoke remain in the kitchen

after cooking has been completed, the

Delayed Shut Down feature can be selected to allow the hood to continue

running for either 5 or 15 minutes.

Selecting the power level

^

Use the pm controls to select the

desired power level.

p = increases the fan speed

m = decreases the fan speed

Level "1" to "3" (green indicators) are

usually sufficient for normal cooking.

^

Press the Delayed Shut Down button

while the fan is still running.

Press once = 5 minute delay

(left indicator lights)

Press twice = 15 minute delay

(right indicator lights)

To cancel the Delayed Shut Down fea

ture press the button again.

-

9

Page 10

Operation

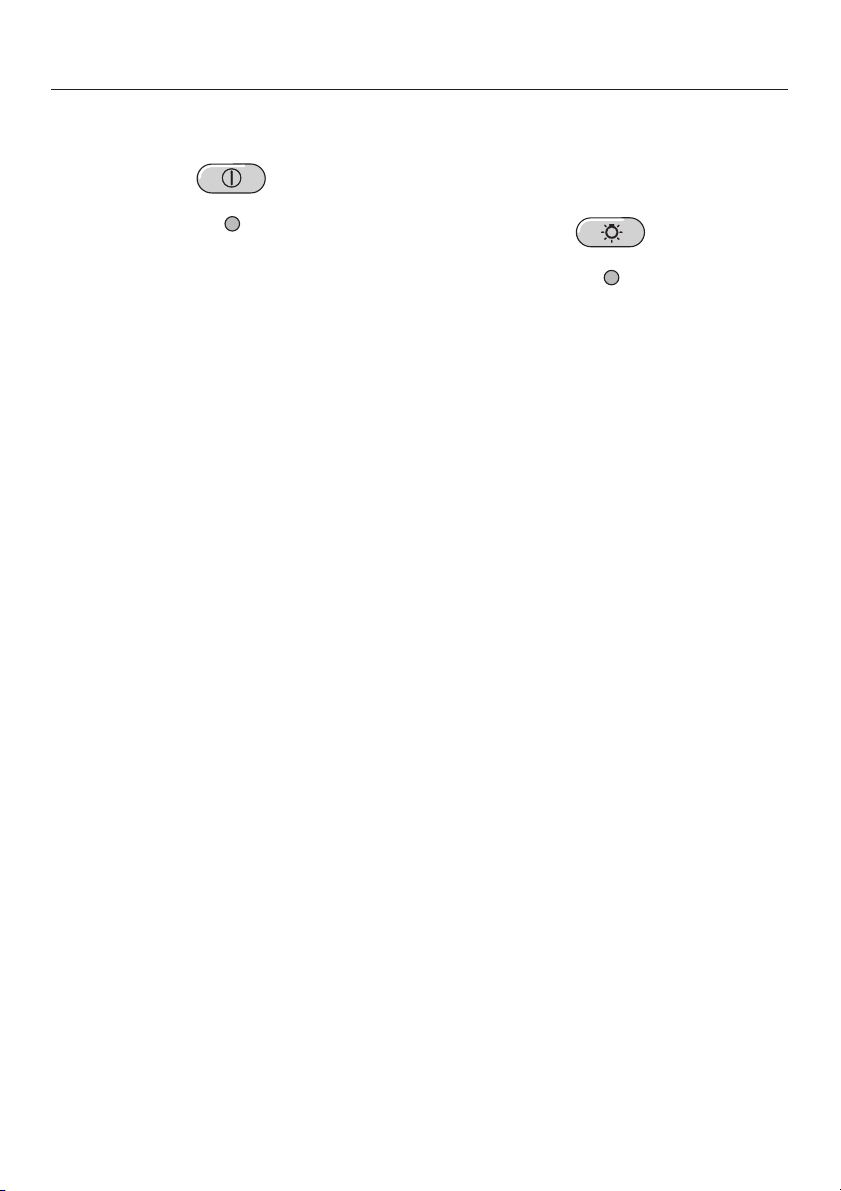

Turning off the fan

Press the On/Off button to turn the

^

fan off.

The indicator goes out.

Automatic Safety Shut Off

The fan will be turned off automatically

10 hours after the last button was acti

vated. The lighting however, will remain

on.

^ Press the On/Off button to turn the

fan back on.

Turning the lighting on / off

The overhead lighting can be turned on

and off independently of the fan.

Press the light button to turn on the

^

lighting.

The light button indicator illuminates.

Press the light button again to turn off

^

-

the lighting.

10

Page 11

Operation

Grease filter timer

A timer monitors the hours of fan opera

tion. The indicator for the grease filter

will light after 30 hours of operation. The

grease filters must then be cleaned.

After the grease filters have been

cleaned and put in place, the grease fil

ter timer must be reset.

To do this, press the grease filter but

^

ton for about 3 seconds.

The indicator will go out.

Checking the grease filter timer

To check the percentage of time al

ready used:

Press the On/Off button to turn the

^

fan on.

-

^ Press the grease filter button.

The number of flashing pm indicators show the percentage of programmed hours that have been used.

-

1 indicator = less than 25 %

2 indicators = less than 50 %

3 indicators = less than 75 %

4 indicators = less than 100 %

This information will remain stored in

memory in the event of a power failure.

11

Page 12

Operation

Reprogramming the grease filter

timer

The grease filter timer is preset to 30

hours. This time can be lengthened or

shortened to 20, 30, 40 or 50 hours.

A time of 20 hours should be pro

–

grammed in kitchens with frequent

pan or deep frying.

A time of 20 hours should also be

–

programmed if the kitchen is only

used occasionally. Otherwise grease

which has accumulated over a long

period of time will harden on the fil

ters making cleaning more difficult.

-

The indicator for the grease filter and

one of the pm indicators will flash.

The lit pm indicator shows the pro

grammed time:

1st indicator from the left = 20 hours

2nd indicator from the left = 30 hours

3rd indicator from the left = 40 hours

4th indicator from the left = 50 hours.

-

Use the p or m button to select

^

the desired time.

-

^ Press the On/Off button to turn off the

fan.

^

Press the Delayed Shut Down and

grease filter buttons at the same time.

12

^ Store the selection by pressing the

grease filter button.

If the procedure is not stored within

4 minutes of programming, the hood

will automatically default to the "old"

data.

Page 13

Cleaning and Care

Before cleaning or servicing the

hood, disconnect it from the power

supply by either removing the fuse,

unplugging it from the outlet or man

ually "tripping" the circuit breaker.

Cleaning the casing

Warning: Never use abrasive clean

ers, scouring pads, steel wool or

caustic (oven) cleaners on the hood.

They will

All external surfaces and controls can

^

be cleaned with warm water and liquid dish soap applied with a soft

sponge.

^ Wipe dry using a soft cloth.

Do not use too much water when

cleaning the controls. Water could

penetrate into the electronics and

cause damage.

damage the surface.

Stainless steel

Stainless steel surfaces can be cleaned

using a non-abrasive stainless steel

-

cleaner.

To help prevent resoiling, a conditioner

for stainless steel can also be used.

Apply sparingly with even pressure.

-

Stainless steel colored controls

These controls may become discol

ored or damaged if not cleaned reg

ularly.

Do not use a stainless steel cleaner

on these controls.

-

-

^

Glass surfaces can be cleaned using

glass cleaner.

Avoid:

–

cleaning agents containing soda, ac

ids or chlorides,

–

abrasive cleaning agents e.g. pow

der or cream cleansers,

–

abrasive sponges, e.g. pot scourers

or sponges which have been previ

ously used with abrasive cleaning

agents.

These will damage the surface.

-

-

-

13

Page 14

Cleaning and Care

Grease filters

The reusable metal grease filters re

move solid particles from the vented

kitchen air (grease, dust, etc).

The grease filters should be cleaned

every 3-4 weeks or whenever the

grease filter indicator lights.

A dirty filter is a fire hazard.

-

To remove the grease filters press the

^

locking clips in towards the middle of

the filter. Holding carefully, lower and

remove the filter.

^ Clean the filters

- by hand: use a scrub brush in

warm water with a mild detergent.

- in a dishwasher: place the filters in

the lower basket, making sure that

the spray arm is not blocked.

Depending on the detergent, cleaning the grease filters in a dishwasher

may cause permanent discoloration

of the filter surface. Performance of

the filter will not be affected by this

discoloration.

14

^

After cleaning, the filters can be

placed on a towel to air dry.

^

While the filters are removed, clean

any dirt or grease from the filter cas

ing to prevent the risk of fire.

-

Page 15

When putting the grease filters back

make sure that the locking clips are vis

ible facing down towards the cooking

surface.

If a filter is incorrectly installed, insert a

small screwdriver into the slit along its

edge to disengage it from the casing.

After returning the grease filters,

^

press the grease filter button for

3 seconds to reset the timer. The indi-

cator light will go out.

^ If the grease filters are cleaned be-

fore the timer has reached its maxi-

mum, the grease filter button should

be pressed for 6 seconds to reset the

counter to zero.

Cleaning and Care

-

15

Page 16

Cleaning and Care

Changing the light bulb

Before changing the light bulbs, dis

connect the hood from the power

supply by either removing the fuse,

unplugging it, or manually "tripping"

the circuit breaker.

When in use halogen bulbs become

extremely hot, and they can burn

your hands. Do not attempt to

change the bulbs until they have

had sufficient time to cool down.

Do not touch the bulb surface. Fingerprints or body oils deposited on

the bulb will decrease the life of the

bulb. Please follow the bulb manufacturer’s instructions.

-

To change the halogen bulb first re

^

move the lamp cover, a.

^ Pull the bulb, b, out of its socket and

replace with a new one.

^ Return the lamp cover, a.

Never use the lighting without the

lamp cover, a, in place. The glass is

specially made to filter harmful light

rays.

-

16

Page 17

In the event of a fault which you cannot

correct yourself please contact:

Your Miele Dealer

–

or

The Miele Technical Service

–

Department

USA 1-800-999-1360

techserv@mieleusa.com

CDN 1-800-565-6435

service@miele.ca

When contacting the Technical Service

Department, please quote the model

and serial number of your appliance.

These are shown on the data plate

which is visible when the grease filters

are removed.

After Sales Service

17

Page 18

18

Page 19

Installation instructions

Page 20

Table of Contents

Caring for the environment

Installation accessories

Plywood backing

Electrical data

Appliance dimensions

Installation

Retaining plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Attaching the canopy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Inserting the non-return flap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Exhaust connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Attaching the chimney extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Attaching the chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Air extraction

20

Page 21

Caring for the environment

Disposal of packing material

The cardboard box and packing materi

als protect the appliance during ship

ping. They have been designed to be

biodegradable and recyclable. Please

recycle.

Ensure that any plastic wrappings,

bags etc. are disposed of safely and

kept out of the reach of children. Dan

ger of suffocation!

-

-

Disposal of an old appliance

Old appliances may contain materials

that can be recycled. Please contact

your local recycling authority about the

possibility of recycling these materials.

Before discarding an old appliance,

unplug it from the outlet and cut off

its power cord and remove any

doors to prevent hazards.

See the Warning and Safety instruc

tions.

-

21

Page 22

Installation accessories

22

Page 23

a 2 protective shields

prevent scratches to the chimney dur

ing installation.

Installation accessories

-

b 2 hose clips for securing the

ducting.

c 1 reducing collar

for use with 5" (125 mm) exhaust

ducting.

d 1 non-return flap

e Upper retaining plate B secures

the chimney extension.

f Middle retaining plate C for addi

tional stability of the chimney.

g Lower retaining plate A secures

the canopy and the motor assembly.

6 screws 5 x 60 mm

10 large headed screws 5 x 40 mm

(S8 wall anchors included in the pack

aging are not for use in USA/CDN.)

-

2 M 6 locking nuts for securing the

motor assembly.

4 screws 3.9 x 7.5 mm for securing the

chimney and the chimney extension.

-

CAUTION:

During the installation process,

please be careful of sharp edges

that can cause harm.

23

Page 24

Plywood backing

The majority of the weight of the in

stalled ventilation system will be

supported by retaining plate A. It

must be firmly attached to the stud

framing behind

are not available in the required lo

cations, a plywood backing (min.

(13 mm) thick) spanning at least two

studs must

adequately support the weight as

stated may result in the ventilation

system falling off the wall, causing

personal injury and property dam

age.

the drywall. If studs

be installed. Failure to

wall so that the marks are visible

Hold retaining plate A against the

^

through the holes of the plate (see

"Installation / Retaining plate A").

Draw a line around the plate’s perim

-

1

/2"

eter, then set aside the plate.

Make a cutting line 3" (76 mm) above

^

-

and 3" (76 mm) below the outline of

plate "A".

Find the studs to the left and right of

^

the mounting location by tapping the

-

wall or using a stud finder.

Mark a vertical cutting line along the

^

center of each stud.

(If plywood backing is not needed, proceed to "Attaching the retaining plates

to the wall." )

To install a plywood backing board

^

Make a mark, S + 16

3

/4" (425 mm)

above the cooktop and on the center

line.

^

Make a second mark 12

3

/4"

(324 mm) underneath the first one.

Be careful not to damage any wiring

or plumbing that may be located behind the wall. Make sure that the

power supply to the area where this

installation is being performed has

been turned off at the breaker panel

before cutting into the wall.

^ Remove the drywall between the cut-

ting lines and replace it with plywood

of a matching thickness (min.

(13 mm) thick). Tape the joints and

refinish the wall.

^

Proceed to "Attaching the Retaining

plates to the wall" to complete the in

stallation.

-

1

/2"

-

24

Page 25

Electrical data

All electrical work should be per

formed by a qualified electrician in

strict accordance with national and

local safety regulations.

Installation, repairs and other work

by unqualified persons could be

dangerous. The manufacturer can

not be held responsible for unautho

rized work.

Ensure that power to the appliance

is OFF while installation or repair

work is performed.

Verify that the voltage, load and circuit

rating information found on the data

plate (located behind the grease filters), match the household electrical

supply before installing the hood.

If there is any question concerning the

electrical connection of this appliance

to your power supply, please consult a

licensed electrician or call Miele’s Tech-

nical Service Department.

USA 1-800-999-1360

CDN 1-800-565-6435

-

-

Important

The hood comes equippped with a 5 ft

(1.5 m) power cord with a NEMA 5-15

molded plug for connection to a

120 VAC, 60 Hz, 15 A power outlet.

Maximum load . . . . . . . . . . . . . . 410 W

Lighting . . . . . . . . . . . . . . . . . . 3 x 20 W

Voltage . . . . . . . . . . . . . . . . . . . . . 120 V

Frequency . . . . . . . . . . . . . . . . . . 60 Hz

Circuit rating. . . . . . . . . . . . . . . . . . 15 A

WARNING:

THIS APPLIANCE MUST BE

GROUNDED

25

Page 26

Appliance dimensions

26

Page 27

Appliance dimensions

Do not install this exhaust hood over

cooktops burning solid fuel.

When installing the hood, make sure

that the following minimum dis

-

tance (S) between the top of a Miele

cooking surface and the bottom of

the hood is:

- 22" (55 cm) above electric cooktops

- 26" (65 cm) above gas cooktops

- 26" (65 cm) above an open grill

For non-Miele cooking appliances

maintain the safety distances recom

mended by the cooktop manufacturer in their installation and operating instructions.

If there is more than one appliance

beneath the hood and they have different minimum safety distances always select the greater distance.

See "Warning and Safety instructions" for further information.

Standard unit height H:

DA 229-2. . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . (740 - 1070 mm)

To fit the chimney, distance A between

the top of the chimney and the ceiling

must be at least

7

/8" (20 mm).

Cut out area in wall or ceiling for

entrance of 6" (150 mm)

ductwork or 5" (125 mm)

ductwork with a reducing collar.

If the standard unit height H is not suit

able to the kitchen’s ceiling height, lon

ger optional chimney extensions are

available from your Miele dealer or

Miele’s Technical Service Department.

Extension available for this model:

DATK 229-650. . . . . . . . . 42

. . . . . . . . . . . . . . . 1070 mm - 1350 mm

1

/8" - 421/8"

1

/8" - 533/4"

-

-

26" (65 cm) is recommended for all in

stallations to allow for optimum work

space under the hood.

Read the entire installation procedures

and determine height S before begin

ning the installation.

If the hood is fitted flush to the ceiling

make sure that the remaining distance

to the ceiling is not greater or less than

appliance height H.

-

27

Page 28

Installation

Retaining plates

The ventilation system will be mounted to

the wall through the use of retaining

plates. Plate A is installed first, followed

by plate B. Plate C should ony be used if

the distance between plate A and plate B

is greater than 14

3

/8" (365 mm).

Attaching the retaining plates

to the wall

^ Before fitting the retaining plate draw

a vertical line centrally above the

cooktop on the rear wall.

^ Mark measurement S from the

cooktop surface upwards (see "Appli

ance dimensions"). This marks the

height of the lower rim of the hood.

-

28

Page 29

Retaining plate A

1

Drill two

^

3" (75 mm) and one at S + 15

/8" (3 mm) holes, one at S +

3

/4"

(400 mm) on the center line (see "Ap

pliance dimensions").

^ Lightly secure retaining plate A into

position using 5 x 40 mm screws

through the two holes and use the

notches to align with the center line.

Installation

-

Screw four 5 x 40 mm screws into the

^

upper and lower set of holes to se

cure retaing plate A.

-

^

Drill 6 more

1

/8" (3 mm) holes through

the now fitted retaining plate.

29

Page 30

Installation

Retaining plate B

Hold retaining plate B to the wall and

^

push up until it is directly below the

ceiling. Use the notches and the center line to align it horizontally. Mark

the 2 drill holes on the wall.

1

^ Drill two

/8" (3 mm) holes into the

wall.

^ Secure the retaining plate with two

5 x 40 mm screws.

Retaining plate C

Retaining plate C should only be used

if dimension Y is greater than 14

3

/8"

(365 mm). It provides additional stability for the chimney extension.

^ At a maximum distance of 14

3

/8"

(365 mm) from the ceiling hold retaining plate C against the wall and use

the notches to align it with the center

line. Mark the two drill holes.

^

Drill two

1

/8" (3 mm) holes into the

wall.

30

^

Secure retaining plate C with two

5 x 40 mm screws.

Page 31

Installation

Attaching the canopy

^ Hang the canopy on the angled

brackets on retaining plate A.

^ Secure the canopy with two screws

5 x 60 mm.

Adjusting the canopy

If the canopy is not perpendicular to the

wall it can be adjusted.

^ Loosen the two securing screws, a.

^ Slightly loosen the adjusting screws,

b.

^

Adjust the canopy so that it is level

and perpendicular to the wall.

^

Tighten the adjusting screws, b and

the securing screws, a.

31

Page 32

Installation

Inserting the non-return flap

If a non-return flap is not present in

^

the venting system, the non-return

flap supplied must be fitted into the

exhaust connection on the motor. The

flaps must open upwards.

^ The hood is designed for 6" (150 mm)

exhaust ducting. If 5" (125 mm) exhaust ducting is used the reducing

collar must be fitted into the exhaust

connection on the motor (see "Air extraction").

Attaching the motor assembly

First loosely screw the two locking

^

nuts onto the threaded bolts on retaining plate A.

Leave a gap of

ing the motor on.

1

/8" (3 mm) for hang-

32

^

Fit the motor assembly onto the

hooks on retaining plate A and slide

down behind the nuts.

^

Tighten the nuts.

Page 33

Installation

Electrical connection

Before connecting the appliance

read the "Warning and Safety In

structions" and the "Electrical data"

sections.

^ Plug the connectors on the canopy

into the corresponding receptacles

left and right of the motor assembly.

-

Exhaust connection

Conect the ductwork to the exhaust

^

connection using whatever means

are appropriate for the type of

ductwork being installed (hose

clamp, duct tape, etc.).

^ Direct the duct through the back wall

or ceiling.

See "Air extraction" for further details.

Insert the 4 prong connector into the

receptacle left of the motor assem

bly.

Insert the 6 prong connector into the

receptacle right of the motor assem

bly.

^

Secure the cords with the ties, as

shown above.

^

Plug in the power cord.

-

-

33

Page 34

Installation

Attaching the chimney

extension

The use of a chimney extension, allows

the hood to be installed at various dis

tances from the ceiling.

Remove the protective foil from the

^

chimney extension.

-

Secure the chimney extension to the

^

upper retaining plate with two

3.9 x 7.5 mm screws.

^ Bend the top hanging tabs 45° in-

wards. This will make installing the

chimney extension easier. Be careful

of sharp edges.

^

Pull the chimney extension slightly

outwards and snap over the upper

retaining plate B.

34

^

Fold the protective shield at the top.

^

Remove the adhesive backing from

the shield.

^

Stick the shield to the chimney exten

sion so that it is smooth and flush

with the bottom.

-

Page 35

Attaching the chimney

^ Remove the protective foil from the

chimney.

Installation

Secure the chimney to retaning plate

^

A on both sides with two 3.9 x 7.5

mm screws.

Remove the protective foil from the

^

canopy.

If the chimney is not tall enough an

optional chimney extension can be

ordered. See "Appliance dimensions".

^ Pull the chimney apart slightly

slide it over the chimney extension.

Do this carefully to prevent scratching the two pieces.

^

Slide the chimney down about

(2 cm) into the canopy.

^

Align and adjust the chimney.

^

Remove the protective shields.

and

3

/4"

^

Before using the appliance remove

the grease filter and remove the pro

tective foil from the filter frame. Re

turn the filter.

-

-

35

Page 36

Air extraction

Danger of toxic fumes.

Gas cooking appliances release

carbon monoxide that can be harm

ful or fatal if inhaled. The exhaust

gases extracted by the hood

should be vented outside of the

building only

.

Do not terminate the exhaust

ducts in attics, garages,

crawlspaces, etc.

Please read and follow the "Warning

and Safety Instructions" to reduce the

risk of personal injury. Follow all local

building codes when installing the

hood.

Exhaust ducting and connections

– The ducting should be as short and

straight as possible, and the number

of sharp bends should be minimized.

-

Use smooth or flexible pipes made

–

from approved non-flammable mate

rials for exhaust ducting.

Where the ductwork is horizontal, it

–

must slope away from the hood at

1

least

/8" per foot (1cm per meter) to

prevent condensation dripping into

the appliance.

If the exhaust is ducted through an

–

outside wall, a Miele Telescopic Wall

Vent can be used.

-

– For most efficient air extraction, the

diameter of the ductwork should not

be less than 6" (150 mm). Use of flat

ducts also reduces the air extraction

efficiency.

–

Noise levels of the hood will increase

if flat ducts or round ducts of less

than 6" (150 mm) in diameter are

used.

WARNING

To reduce the risk of fire, only use

metal ductwork.

CAUTION

To reduce risk of fire and to properly

exhaust air, be sure to duct air out

side. Do not vent exhaust air into

spaces within walls or ceilings or

into attics, crawl spaces, or garages.

36

–

If the exhaust is ducted into an inac

tive flue, the air must be expelled

parallel to the flow direction of the

flue.

-

Page 37

Never connect an exhaust hood to

an active chimney, dryer vent, vent

flue, or room venting ductwork. Seek

professional advice before connect

ing an exhaust hood vent to an exist

ing, inactive chimney or vent flue.

Ductwork with a diameter of less

than 6" (150 mm) should only be

used when absolutely necessary. As

duct diameter decreases, the hood’s

performance and sound levels will

be affected.

Important:

If the ductwork runs through rooms,

ceilings, garages, etc. where temperature variations exist, it may need to be

insulated to reduce condensation. In

some cases, a condensate trap may

also be required to collect and evaporate any condensate which may occur.

Air extraction

-

-

When installing a condensate trap,

ensure that it is positioned vertically

and if possible directly above the ex

haust outlet.

-

373839

Page 38

Page 39

Page 40

Alteration rights reserved / 000 CDN - 1801

This paper consists of cellulose which has been bleached without the use of chlorine.

Loading...

Loading...