Page 1

Page 1 of 18

No.

Article no.

Article designation

IC

1

2.850.3040

850 Professional IC AnCat - MSMHC - MCS

2

2.850.9010

IC Conductivity Detector

1

6.6059.232

MagIC Net™ 2.3 Professional CD 1 License

VA 1 2.797.0010

797 VA Computrace

1

2.843.0140

843 Pump Station

2

2.800.0010

800 Dosino

1

6.2148.010

Remote box MSB

1

6.2141.290

Cable 843 - 838

1

6.2055.100

Double flask holder

2

6.1608.050

Glass bottle GL45 100 mL

2

6.1618.060

Thread adaptor GL45/GL45

2

6.1819.010

PTFE tube

2

6.3032.120

2 mL Dosing Unit 807 glass

Sample

processor &

Liquid handling

1

2.858.0020

858 Professional Sample Processor

Pump

1

6.1826.020

PVC pump tubing (blue/blue)

1

6.1602.150

Bottle neck attachment / GL 45 – 3

× UNF 10/32

1

6.1608.070

Eluent bottle / 2 L / GL 45

2

2.800.0010

800 Dosino

2

6.3032.210

10 mL Dosing Unit 807 glass

1

6.2057.040

Dosino holder for 838

1

6.2846.000

ZrO2 needle 1/8 in for IC/VA 151

mm

2

6.2148.050

USB RS converter for 900

1

6.2134.100

Cable RS232 (DB9)-IBM PC (DB9)

5 m

1

6.2841.100

Rinsing station for IC

1

6.2041.450

Sample Rack 56x11 mL+56x50 mL:

VA 1 6.2747.010

Sample tubes 50 mL 25x

Application Bulletin 356

Installation instruction for «VoltIC pro I»

The «VoltIC pro I» combines a Professional AnCat IC

system with an automated VA system and shared sample

handling. «VoltIC pro I» is an all-in-one solution for the fully

automated analysis of anions, cations and heavy metals.

1. Scope of delivery

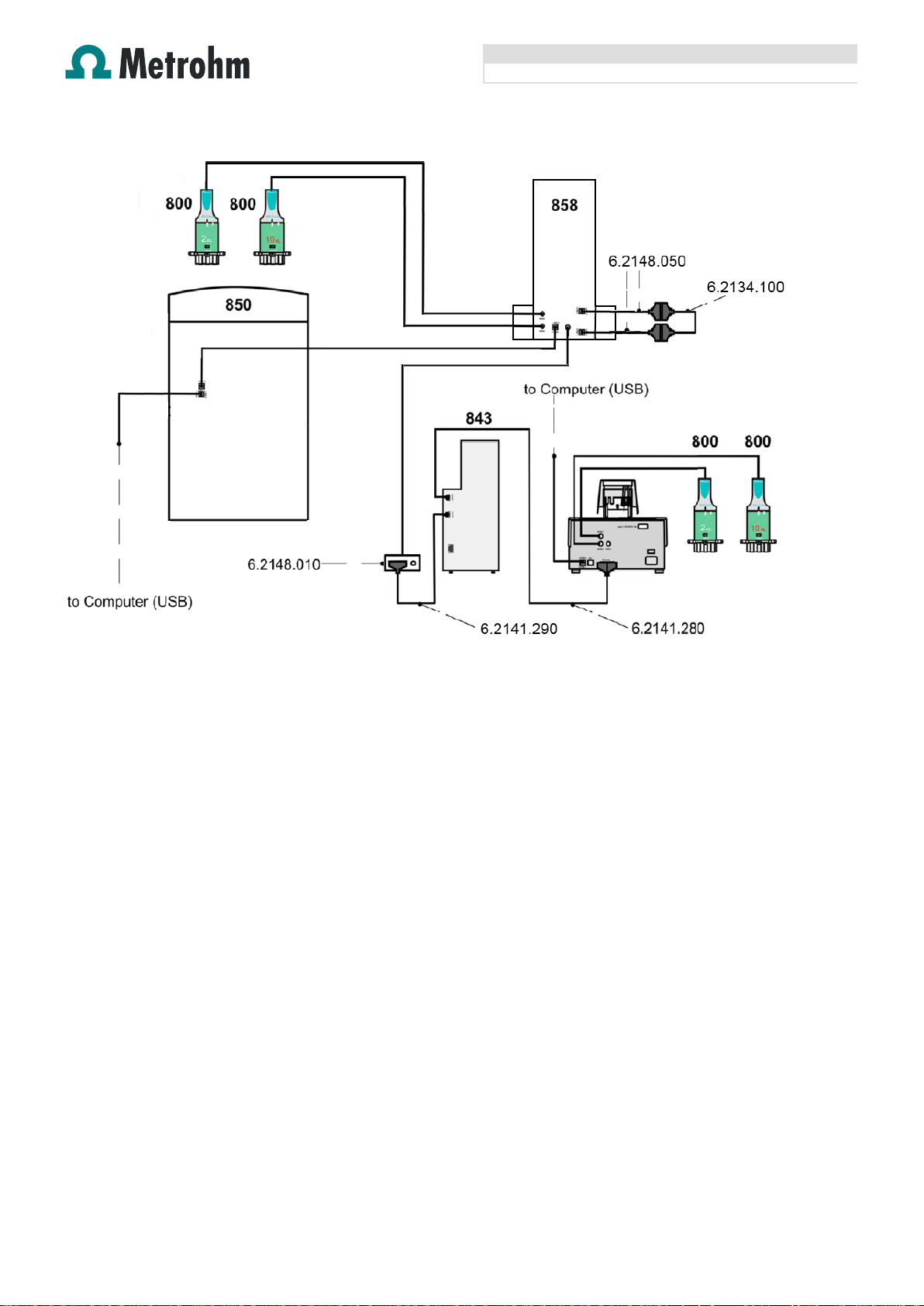

Fig.: VoltIC pro I system

Table of contents

1. Scope of delivery ...................................................... 1

2. Installation ................................................................ 2

2.1 Electrical connections ............................................... 2

2.2 850 Professional IC .................................................. 3

2.3 797 VA Computrace ................................................. 5

2.4 858 Professional Sample Processor ......................... 6

2.5 Connection of devices .............................................. 7

3 Software ................................................................... 8

3.1 Installation of an Serial port (RS) printer ................... 8

3.2 Installation of MagIC NetTM ..................................... 11

3.3 Configuration of MagIC NetTM ................................. 11

3.4 Installation of 797 VA Computrace software ........... 13

3.5 Configuration of 797 VA Computrace software ....... 13

3.6 Starting a determination ......................................... 14

4 Exemplary measurement ........................................ 15

5 Appendix ................................................................ 17

5.1 Time Program ......................................................... 17

Page 2

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 2 of 18

1

6.2743.057

Sample tubes 11 mL 200x

1

6.2743.077

Stopper with perforation 200x

1

6.1808.280

Adapter Dosino Port 4 / M6

1

6.1805.530

FEP tube connection M6 200

1

6.1831.070

PEEK Cap. 1/16 In/0.75 mm 70 cm

1

6.1803.150

PTFE capillary 1/16 In/0.25 mm 1 m

1

6.1822.410

PEEK connection capillary

1

6.5620.000

Connecting set to Dosing Unit: port

4 1 6.1608.030

Bottle Colourless Glass 1 L / GL 45

1

6.2744.034

Coupling nozzle – UNF 10/32, 2

pieces

1

6.2744.070

Pressure screw short, 5 pieces

3

6.2744.080

Coupling Outer M6/UNF

1

6.1803.030

PTFE capillary 0.5 mm i.d. / 3m

Optional

1

6.6059.208

MagIC Net™ 2.x Progessional

Upgrade Multi - 3 licenses

1

6.1006.520

Metrosep A Supp 5 - 150/4.0

1

6.1006.500

Metrosep A Supp 4/5 Guard/4.0

1

6.1050.410

Metrosep C 4 - 100/4.0

1

6.1050.500

Metrosep C 4 Guard/4.0

2. Installation

We strongly recommend that the individual steps are carried

out in the order given below.

2.1 Electrical connections

In order to install the VoltIC pro I you have to establish

following connections mentioned below:

858 to 850: Connect «controller» output of 858 to USB

serial port of 850

800 Dosino (10 mL) to 858: Connect by MSB (Port 2)

800 Dosino (10 mL) to 858: Connect by MSB (Port 3)

2 x 800 Dosinos (2 mL) to 797 VA Computrace:

Connect by MSB (Port 1, Port 2)

797 VA Computrace to 843 Pump Station: Connect by

remote cable 6.2141.280

843 Pump Station to Remote box: Connect by remote

cable 6.2141.290

Remote box to 858: Connect to MSB 1

850 to computer: Connect 850 to USB serial port of PC

797 VA Computrace to computer: Connect USB serial

port of 797 VA Computrace to USB serial port of PC

Null modem cable: Attach the two USB RS converters

(6.2148.050) to the available USB ports of the 858 and

connect both using the RS232 cable (6.2134.100)

Page 3

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 3 of 18

Fig.: Electrical connection diagram for the VoltIC pro I system

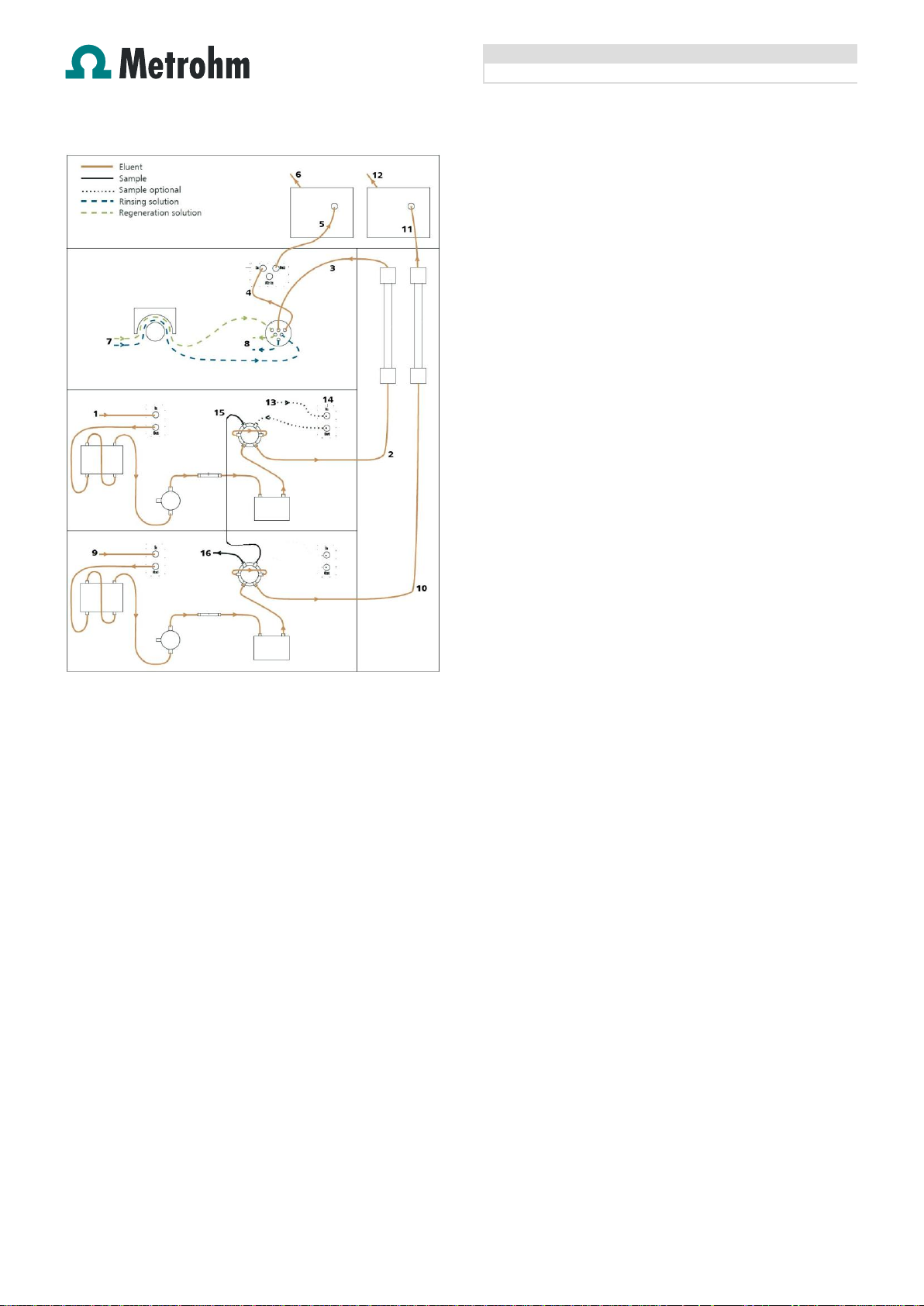

2.2 850 Professional IC

In order to install the Professional IC you have to perform

the following steps: Remove rollers and handle, place the

detector blocks in the instrument and connect the detector

cables, remove transport locking screws, connect the leak

sensor cable, connect the drainage tubing, and set up the

eluent bottles. Please refer to the 850 Professional IC

manual for a detailed description (chapters 2.6 and 2.8).

Capillaries are connected according to the following list and

the diagram below (also see manual chapters 2.14 to 2.18)

1. Connection to the eluent bottle for anion determination

2. Capillary to anion separation column

3. MSM inlet capillary – labeled with Eluent

4. MSM outlet capillary – labeled with Detector, which can

be connected to the MCS or directly to the detector.

The MCS air aspiration capillary is connected to the

CO2-absorber cartridge.

5. Capillary from MCS to anion detector, long PEEK

pressure screws (6.2744.090) are used for the MCS

connection

6. Detector outlet capillary to waste

7. Regeneration solution aspiration capillaries (PTFE, 0.97

mm ID), connected to two bottles with ultrapure water

and 50 mmol/L sulfuric acid respectively via peristaltic

pump tubing with orange/yellow stoppers (6.1826.320)

8. MSM regeneration solution outlet capillaries – labeled

with Waste – to waste

9. Connection to the Eluent bottle for cation determination

10. Capillary to cation separation column

11. Capillary from cation separation column to cation

detector

12. Detector outlet capillary to waste

13. Sample inlet capillary (PTFE, 90 cm, d=0.25 mm),

connected to the anion valve (position 1)

14. Optional sample degasser

Capillary connection (PTFE, 40 cm, d=0.5 mm) between

anion valve (position 2) and cation valve (position 1)

15. Connection capillary anion channel valve to cation

channel valve

16. Capillary to the waste

Page 4

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 4 of 18

Prepare and degas two eluents suitable for the anion and

cation columns you want to use (see column manuals). For

Metrosep A Supp 5 a solution of 3.2 mmol/L Na2CO3 / 1.0

mmol/L NaHCO3 is adequate. For Metrosep C 4 a solution

of 1.7 mmol/L HNO3 / 0.7 mmol/L dipicolinic acid (DPA, 2,6Pyridinedicarboxylic acid) is adequate.

Provide regeneration solutions for the MSM Suppressor

(ultrapure water and 100 mmol/L sulfuric acid).

Page 5

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 5 of 18

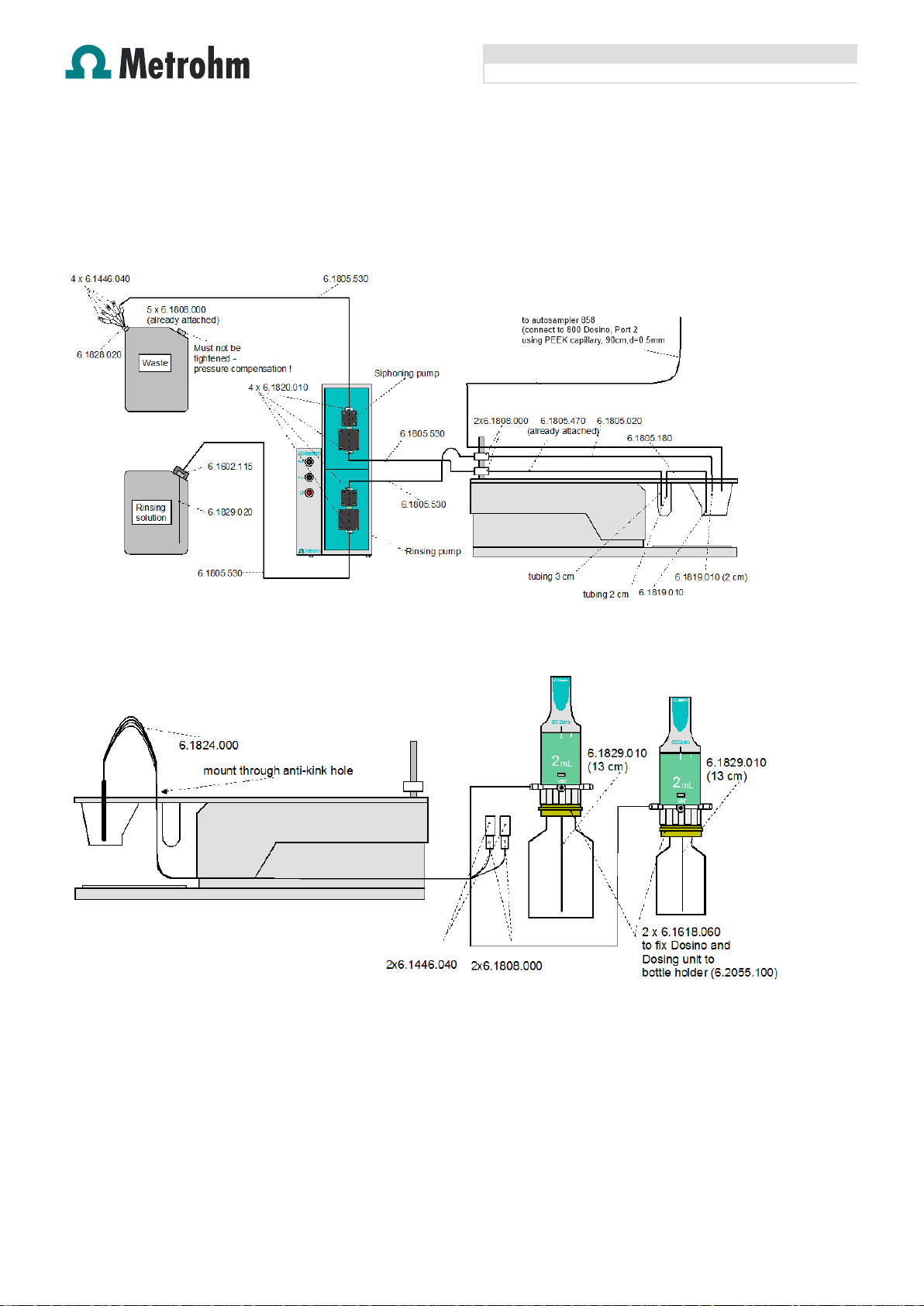

2.3 797 VA Computrace

Following steps have to be done to install the MVA-3

system:

a) Establish the following tubing connections between the system components

b) Establish the tubing connections for 800 Dosinos for the addition of solutions:

Page 6

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 6 of 18

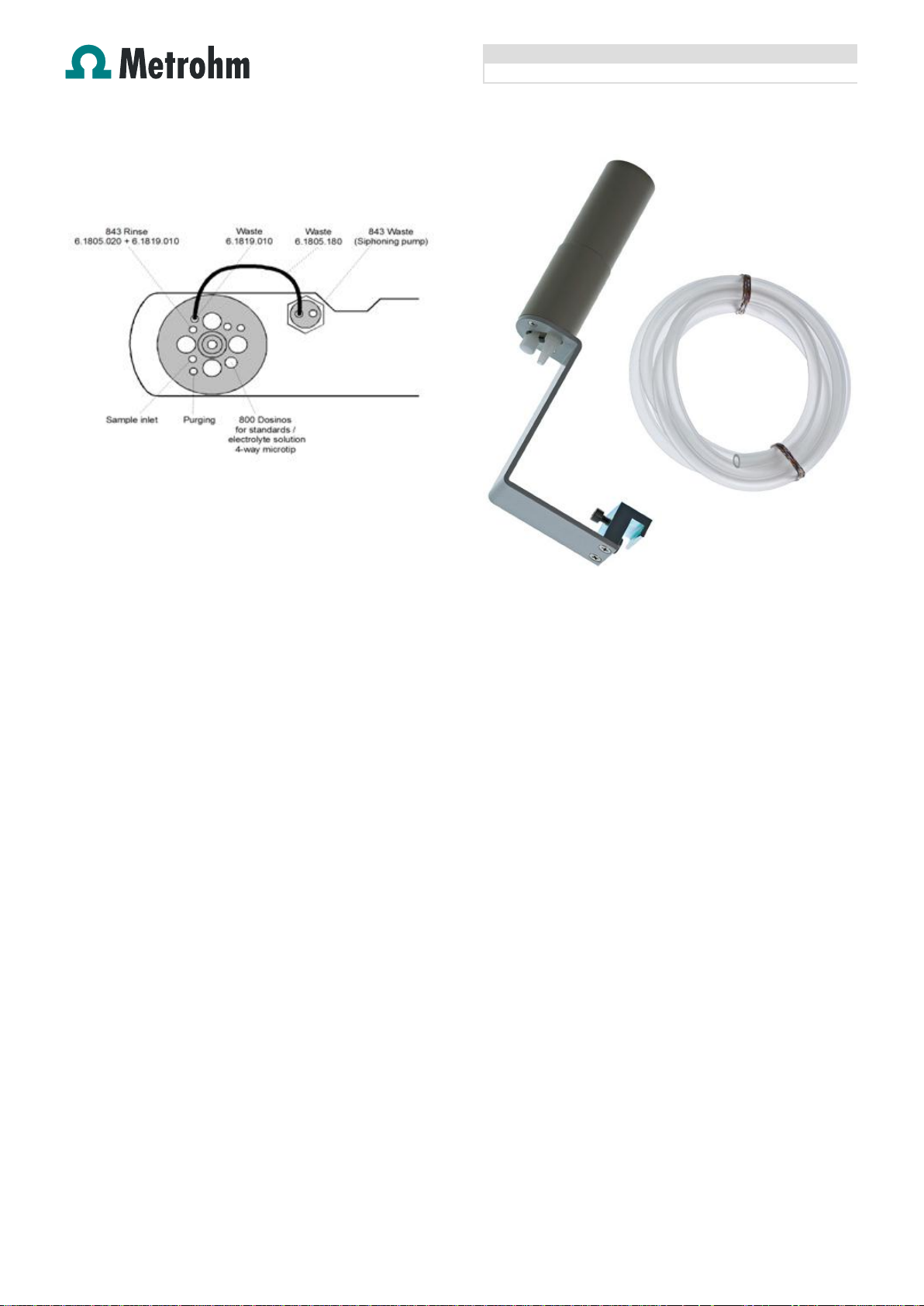

c) Establish the tubing connections at the measuring

head of the 797 VA Computrace:

2.4 858 Professional Sample Processor

For a detailed description, please refer to the 858

Professional Sample Processor manual. In general, you will

have to do the following: Plug in the Swing Head connection

cable, and plug in the power supply cable. The sample

processor initializes and lifts its Swing Head, once it is

connected to the IC device and the MSB connection is

recognized. Afterwards, it is possible to mount the retaining

plate (manual chapters 3.2 - 3.4).

Mount the Dosino holder (6.2057.040) on the side of the

tower and attach a 10 mL Dosing Unit (6.3032.210) and a

800 Dosino (2.800.0010) to it.

A rinsing station is mandatory for this setup.

The rinsing station is mounted onto the sample processor,

which is easiest when the rack is temporarily removed. The

exact position can be adjusted by directing the needle into

the rinsing station with the manual control (in the window

manual). The inner compartment approximately relates to a

swing head angle of ~116°, the outer one approximately

relates to ~110°. Memorize your angle settings.

Fig.: Rinsing station parts

A tubing is fixed at the bottom of the rinsing station to drain

the waste water. A bottle of ultrapure water is needed as

reservoir for the rinsing solution. The rinsing solution is

transported by one channel of the peristaltic pump of the

sample processor.

Mount the rinsing station on the sample processor.

Connect ultrapure water reservoir with the peristaltic pump

(via pump tubing (6.1826.360) and PEEK screws / tubing

olives) using a PTFE capillary (part of 6.1803.030). Then

connect the peristaltic pump (via pump tubing and PEEK

Screws / tubing olives) to the inner compartment of the

rinsing station also using a PTFE capillary (part of

6.1803.030).

The outer compartment of the rinsing station is connected to

the waste container.

Page 7

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 7 of 18

2.5 Connection of devices

The 858 Professional Sample Processor, the 850

Professional IC AnCat system and the 797 VA Computrace

are connected with each other via the 800 Dosino with a 10

mL Dosing Unit mounted on the 858 Professional Sample

Processor.

Connect the sample needle to Port 3 of the 10 mL Dosing

Unit at the 800 Dosino using a PEEK capillary (70 cm,

d=0.75 mm, 6.1831.070). The 850 Professional IC AnCat

system is connected to the Dosing Unit at Port 1 using a

PTFE capillary (90 cm, d=0.25 mm, part of 6.1803.150). The

sample inlet capillary (PEEK, 90 cm, d=0.5 mm, part of

6.1822.410) of the 797 VA Computrace is connected to the

Dosing Unit at Port 2. Port 4 of the Dosing Unit is equipped

with an adapter (6.1808.280) and a FEP tube (6.1805.530)

and connected to the waste.

The second 10 mL Dosing Unit with an 800 Dosino is

connected to one capillary of the fourfold micro tip and is

used to dilute the sample for the VA measurement

automatically (solution j).

Fig.: Capillary connections to and from rinsing station

Page 8

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 8 of 18

Fig.: schematic configuration of the VoltIC pro I system

a) PEEK, 70 cm, d=0.75 mm, 6.1831.070 / b) PTFE, 90 cm, d=0.25 mm, part of 6.1803.150 / c) PEEK, 90 cm, d=0.50 mm, part of 6.1822.410 /

d) FEP tube, 6.1805.530 / e) Fourfold micro tip, 6.1824.000 / f) FEP tube, 6.1805.530 / g) PTFE, 40 cm, d=0.50 mm, part of 6.1803.030 / h)

Heavy metal multistandard solution / i) buffer solution pH 4.6 / j) ultrapure water / k) rinsing solution for VA / l) anion eluent / m) cation eluent / n)

rinsing solution for rinsing station

3 Software

3.1 Installation of an Serial port (RS) printer

The data generated in the VA Computrace software is being

transferred to MagIC Net™ via a generic text printer. The

following steps describes how a generic text printer is being

installed under Windows 7.

Check the newly created COM-ports in your system after

connecting the null modem cable and USB RS adapters

(refer 2.1): Start Control Panel Device Manager

Under Ports (COM&LPT) the newly created USB serial ports

are visible (e.g. COM14 and COM15):

Page 9

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 9 of 18

Check and – if necessary – adjust the «Port Settings» to the

following parameters of both COM ports under «Properties»

by double-clicking on each COM port:

Create a generic text printer under: «Start» «Devices and

Printers» «Add a Printer»

Add a local printer by using the first newly created COM port

(e.g. COM 14) and select the «Generic / Text only» printer

driver. Use the current version of the driver. Rename the

printer to «RS Printer».

Page 10

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 10 of 18

Do not share this printer, do not print a test page and finish

the printer wizard.

Configure the newly created «RS Printer» go to «Start»

«Devices and Printers», right-click on the «RS printer» and

select «Printer properties»

Check the selected COM-port and the settings under

«Ports» and «Configure Port…»

Check the settings under «Advanced»:

Page 11

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 11 of 18

Enter «stopp» in the field «End Print Job» under «Printer

Commands»

3.2 Installation of MagIC NetTM

All programs must be shut down first. Install MagIC NetTM

(MagIC NetTM CD). All the standard directories proposed by

the program should be accepted. Restart windows.

Connected USB devices are automatically recognized when

MagIC Net™ is started. The Microsoft Installation Wizard is

accepted and executed. After confirmation of the

automatically generated request, the devices are stored in

the configuration. The devices are predefined as «850

Professional IC 1» and «858 Professional Sample

Processor 1». Name them accordingly, if other names

appear in your configuration (e.g. due to changed setting on

your computer).

3.3 Configuration of MagIC NetTM

In the window configuration, the 850 Professional IC, the

858 Professional Sample Processor and the columns

Metrosep A Supp 5 - 150/4.0 and Metrosep C 4 - 100/4.0

are visible. Add and define the eluents and the suppressor

solutions.

The settings for the rack require a «work position» fitting to

the respective rack (e.g. 125 mm for rack 6.2041.450).

Click «Apply» and «OK».

Also define an «External 1» position to access the rinsing

station for rinsing the needle. The needle position is in the

inner compartment which corresponds to an angle of ~116°

and a work position of 120 mm. The exact angle depends

on your installation (see chapter 2.4).

For the outer compartment, an external position 2 can be

defined with an angle of ~110° and a work position of 60

mm. The external position 2 could be used as drain position

(e.g. to expel sample directly to the waste), however, it is

not carried out during the time program of method VoltIC pro

I.

Page 12

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 12 of 18

For the data transfer from the VA Computrace software to

MagIC Net™ an RS 232 device must be added to the device

list as follows:

Go to the Configuration window in MagIC Net™ and select

«New» from the «Edit» button in the Device window. Select

the «RS 232 Device» from the «Miscellaneous» list:

Rename the device «797 RS232 Printer». Enter «1» in the

field «serial number».

Make the following settings under «RS 232»:

(Attention: the second newly generated COM port by the

null modem cable has to be selected as «COM Port», e.g.

COM 15 !)

Enter «stopp» in the field «Terminator for receive».

In the window method, import the method for VoltIC pro I

from the installation CD: Go to File → method manager and

choose your method group. Afterwards, click on edit →

import and choose the pathway on the installation CD

(MagICnet\examples\methods\VoltICpro.imet).

The method carries out a parallel determination of cations

and anions. Immediately after starting the anion

determination, the cation determination (of the same

sample) is initialized. Samples could be taken from the

same vial, or from two vials with one of them containing the

acidified sample solution for cation determination. Both

measurements are recorded in the same data file. In order

to measure samples from two different vial please select

method «VoltICpro_mod.imet» from the same folder.

In the window method, open the VoltICpro method and

assign the following equipment: Assign the column

Page 13

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 13 of 18

Metrosep A Supp 5 - 150/4.0 to the analysis anion, assign

the column Metrosep C 4 - 100/4.0 to the analysis cation,

assign the two eluents to their respective IC pump, match

the two suppressor solutions to the IC peristaltic pump, and

define the rack of the connected sample processor. Adjust

the temperature of the column oven to 30°C. Save the

method.

In order to start the equilibration, go to the window work

place, load your method, and press «Start HW». Before

inserting the columns, flush the system for about 10 minutes

and get rid of air bubbles (by using the purge valve and

syringe), then insert and rinse the precolumns for 10

minutes, and only afterwards put the analytical columns into

the flow (see also 850 manual).

3.4 Installation of 797 VA Computrace software

Install the software. All the standard directories proposed by

the program should be accepted. Restart windows.

Connected USB devices are automatically recognized when

VA Computrace software is started.

3.5 Configuration of 797 VA Computrace software

Make the following general settings in the main window

under «Settings» «General Settings»s” and click «OK»:

Load method «Det of Zn Cd Pb Cu_IC_VA.mth», modify or

create a new method.

Click on «Dosinos» in the «Working Method Specifications»

window and make following settings:

Page 14

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 14 of 18

3.6 Starting a determination

The hyphenated analysis of IC and VA follows the cycle

described below:

All sample information (sample ID, dilution factor, etc…) is

programmed in MagIC NetTM.

MagIC NetTM triggers VA Computrace software by remote

signal.

VA Computrace software will feeds back information to

MagIC NetTM after preparing the measuring cell (before

sample transfer) and after VA analysis has been finished

and the cell has been prepared for the next analysis.

Please follow the steps below for system startup:

Close all applications

Turn on all instruments (843 Pump Station should be

switched on after the 797 VA Computrace, otherwise

pumps start pumping)

Start MagIC NetTM and check if all hardware

components have been recognized and available in the

configuration window.

Load method «VoltICpro.imet» in MagIC NetTM

Start VA Computrace and check if hardware

components have been recognized

Load «Det of Zn Cd Pb Cu_IC_VA.mth» in VA

Computrace software

Under «Settings» «General Settings»

«Automation» activate «Remote Start» and «End of

Sample» and click «OK» (This must be done with

every restart of VA Computrace software as these

settings are not saved!)

Prepare both systems:

Ion chromatograph

o Equilibrate the system («Start HW»)

o Check for stable system pressure (+/- 0.1

MPa) on both channels; remove air bubbles

manually if necessary

o Check for stable baselines (anion channel:

~0.9 µS/cm, cation channel: ~680 µS/cm for

the mentioned eluents, refer 2.2)

VA

o Check working electrode and reference

electrode; refill if necessary

o Check nitrogen pressure, performance of

working electrode (create new drops)

o Perform electrode check

Start the VA method (VA will wait for trigger signal from

MagIC NetTM)

Enter the amount of standards and standard

concentrations in MagIC NetTM

Enter sample table in MagIC NetTM

For quantitative analysis, samples subjected to cation

analysis are normally acidified, whereas anion analysis is

normally carried out with unmodified samples. Method

«VoltICpro.imet» includes only one sample for anion, cation

and heavy metal analysis. Method «VoltICpro_mod.imet»

includes 2 sample vials on the rack for each sample (an

unmodified one for anion determination and an acidified one

for cation and heavy metal determination). According to the

method «VoltICpro_mod.imet» the position of the vial for

anion determination should be defined in the column

«sample position» and the position of the vial for cation and

heavy metal determination is the subsequent one.

Both methods «VoltICpro.imet» and «VoltICpro_mod.imet»

include variable sample volume for VA analysis (0.2 mL –

10 mL). The desired sample volume is entered as «Value 1»

(see sample table below).

As the VA Computrace software calculates with a fixed

sample volume of 10 mL, the difference to 10 mL is dosed

by the optional Dosino (ultrapure water) directly into the VA

vessel.

Page 15

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 15 of 18

Correlation

coefficient

Relative standard

deviation [%]

Lithium

0.999984

0.761

Sodium

0.999947

1.347

Ammonium

0.999939

1.371

Potassium

0.999776

2.904

Calcium

0.999864

1.813

Magnesium

0.999973

0.890

Correlation

coefficient

Relative standard

deviation [%]

Fluoride

0.999954

1.594

Chloride

0.999988

0.786

Nitrite

0.999992

0.650

Bromide

0.999993

0.584

Nitrate

0.999993

0.587

Phosphate

0.999997

0.408

Sulfate

0.999992

0.616

The recalculation to the actual sample volume used (Value

1) takes place after the VA analysis in MagIC NetTM.

Therefore, your sample table might look like the following

one:

Fig.: Sample table excerpt showing the use of «VoltICpro.imet»

For evaluation and after recording the first chromatogram,

check the retention times of your compounds. Since they

depend on the performance of your column, you may have

to adjust them in your method.

4 Exemplary measurement

An exemplary measurement was performed, including the

ions fluoride, chloride, nitrite, bromide, nitrate, phosphate,

sulfate, lithium, sodium, ammonium, potassium, calcium,

and magnesium (1000 µg/L each), zinc, cadmium, lead and

copper. Anions and cations were measured from separate

sample vials with the sample for cation measurement being

acidified with 50 µL nitric acid (2 mol/L) per 50 mL sample.

The two following chromatograms were recorded in parallel.

For the calibration, the average peak areas of 3 injections

were evaluated. Within the concentration range of 20 – 1000

µg/L, a quadratic curve type was used for evaluation of

anions, and a linear curve type was used for evaluation of

cations. Correlation coefficients and standard deviations are

listed in the following table. The calibration curves for

chloride and sodium are shown as examples.

Fig.: Statistical data of a six-point cation calibration from 20 µg/L to

1000 µg/L

Fig.: Standard chromatogram cations, 1000 µg/L

Fig.: Standard chromatogram anions, 1000 µg/L

Fig.: Statistical data of a six-point anion calibration from 20 µg/L to

1000 µg/L

Fig.: Chloride calibration curve from 20 µg/L to 1000 µg/L

Page 16

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 16 of 18

Fig.: Sodium calibration curve from 20 µg/L to 1000 µg/L

Fig.: Example of a combined report for IC and VA results in the

MagIC Net™ database

Fig.: Example voltammogramm of Zn, Cd, Pb and Cu determination

Fig.: Standard addition graphs of Zn, Cd, Pb and Cu determination

(sample: table water, Add 1)

Page 17

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 17 of 18

5 Appendix

5.1 Time Program

Time program «VoltICpro.imet»

Page 18

Application Bulletin 356

Installation instruction for «VoltIC pro I»

Page 18 of 18

Loading...

Loading...