Page 1

NIRS

Vision – Diagnostics

Manual

8.105.8013EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@Metrohm.com

www.Metrohm.com

NIRS

Vision – Diagnostics

Manual

8.105.8013EN 2014-06-20 / fpe

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@Metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please send us your comments using the

address given above.

Page 5

▪▪▪▪▪▪▪

Table of contents

1 Overview ........................................................................................................................ 5

1.1 Vision Diagnostics Screen Display ................................................................. 9

2 Performance Test ......................................................................................................... 12

2.1 Overview .................................................................................................... 12

2.2 Noise Test ................................................................................................... 14

2.3 Bandwidth: Wavelength Accuracy and Precision ........................................ 16

2.4 Model 5000 and 6500 ................................................................................ 16

2.5 Wavelength Accuracy / Precision Measurement on the XDS ....................... 17

2.6 Operational Qualification ............................................................................ 18

2.7 Performance Test Timer.............................................................................. 19

3 Wavelength Certification .............................................................................................. 20

3.1 Run Wavelength Certification ..................................................................... 20

3.2 Setting up a User-Defined Wavelength Standard ........................................ 23

4 Reference Standardization ........................................................................................... 24

4.1 Creating a Reference Standard ................................................................... 25

4.2 Loading a Reference Standard .................................................................... 28

4.3 Reset Reference Standard ........................................................................... 28

5 Create Blank Correction ............................................................................................... 29

6 Window Correction ...................................................................................................... 31

7 Low-Flux Test ............................................................................................................... 32

8 Instrument Self-Test ..................................................................................................... 34

9 Wavelength Linearization ............................................................................................. 35

9.1 Wavelength Linearization on Model 5000 and 6500 .................................. 35

9.2 Wavelength Linearization on XDS Instruments ........................................... 36

9.3 Special Note on Wavelength Linearization of Process Instruments ............. 37

10 Gain Adjust ................................................................................................. 38

10.1 Autogain ..................................................................................................... 38

10.2 Manual Gain ............................................................................................... 39

11 Photometric Test ........................................................................................ 40

12 IPV Setup .................................................................................................... 44

13 Diagnostic Database ................................................................................... 46

13.1 View Diagnostic Database .......................................................................... 46

13.2 Backup and Restore Diagnostic Database ................................................... 46

13.3 Archive Diagnostic Database Information ................................................... 47

13.4 Export and Import Diagnostic Database Information .................................. 48

13.5 Diagnostics Timers ...................................................................................... 49

13.6 Maintenance Log ........................................................................................ 51

13.7 Show Status ................................................................................................ 52

14 Instrument Configuration ........................................................................... 53

15 Instrument Calibration (XDS instruments only) ........................................... 54

16 USP Tests .................................................................................................... 56

3

Page 6

▪▪▪▪▪▪▪

16.1 Full USP Test .............................................................................................. 56

16.2 USP Noise .................................................................................................. 57

16.3 Usp Low-Flux Noise Test ............................................................................ 57

16.4 Usp Wavelength Accuracy .......................................................................... 58

USP Photometric Linearity Test ................................................................................... 59

16.5 Photometric Linearity Setup ....................................................................... 61

16.6 Show USP Test Results ............................................................................... 61

17 Troubleshooting Tips ................................................................................. 62

17.1 Instrument Error: Run Wavelength Linearization........................................ 62

17.2 Weak Signal ............................................................................................... 62

17.3 Increasing Noise ......................................................................................... 63

4

Page 7

▪▪▪▪▪▪▪

1 Overview

Vision provides a complete set of diagnostics functions to test whether the Metrohm instrument

performs according to the manufacturer’s specifications. Instrument performance tests verify the

reliability of NIRSystems spectrophotometers, which insures the linearity, limits of detection, and

precision of NIR methods.

The Vision software drives all Metrohm spectrophotometers. There are differences in the

performance and diagnostic testing associated with the instruments. For the Model 5000 and 6500

instruments, please refer to the Instrument Performance Test Guide for further explanation on

performance tests. For the XDS instruments, there are additional set-up and evaluation diagnostics,

with slight differences for the various analyzers. Proper application of these tests is recommended to

ensure instrument matching and the seamless transfer of calibration methods developed on the XDS.

There are specific requirements for process instruments as well. Refer to the instrument manual for

your particular instrument. For tests that require the use of external standards, be careful that the

correct standards are used depending on your instrument type. Please be sure to follow the correct

section in this manual for your particular instrument type.

More detailed information about XDS Analyzers can be found in the installation and user manuals

provided with the analyzer:

• 8.921.8001EN Manual NIRS XDS RapidContent and RCA Solids Analyzer

• 8.921.8004EN Manual NIRS XDS SmartProbe Analyzer

• 8.921.8005EN Manual NIRS XDS RapidLiquid Analyzer

• 8.921.8006EN Manual NIRS XDS Interactance OptiProbe Analyzer

• 8.928.8001EN Manual NIRS XDS Process Analyzer – MicroBundle

5

Page 8

▪▪▪▪▪▪▪

Instrument model

Module

Standards

Numbering

5000 or 6500

Liquid Analyzer, Sample

AP-0220 Transmission

TSS3xxxx

5000 or 6500

InTact

AP-0230 Single Tablet

TSS2xxxx

5000 or 6500

MultiTab

AP-0240 Multi Tablet

TSS2xxxx

XDS

RCA, Rapid Solids Module,

XC-1010 Reflectance

RSS1xxxx

XDS

Rapid Liquid Analyzer

XC-1310 Transmission

TSS3xxxx

5000 or 6500 RCA, DCA, Smart Probe,

Sample Transport

(Reflectance), etc.

Transport (Transmission.)

Smart Probe, OptiProbe

(reflectance)

NIST traceable standards for use on the Metrohm NIR spectrophotometers

AP-0200 Reflectance

Standards

Standards

Standards

Standards

Standards

standards

RSS1xxxx

6

Page 9

▪▪▪▪▪▪▪

Vision SP includes enhanced Diagnostics, designed specifically to meet the needs of users in regulated

industries who must maintain complete instrument records of performance over time, including

conformance to photometric and\ wavelength standards. Among the features are the following:

• Diagnostic Database structure to support multiple instruments, multiple sampling

configurations

• Built-in table with acceptance specifications for all current, standard Metrohm NIRSystems

instrument and sampling modules, applied by instrument configuration

• Recallable test results, with control charts to show performance changes over time

• Control charts offer both calculated control limits and manufacturer’s tolerances

• A unique screen display to show data in various formats, permitting enlargement of each area

for better interpretation

• Test timer supports all available tests, prompts operator when tests are due

• Instrument Self-Test (similar to NSAS Self-Test)

• Photometric Certification tests for supported reflectance and transmission standards

• Wavelength Certification for supported (and user-defined) wavelength standards

• Instrument Performance Verification (IPV) for regular user tests of photometric performance

• Low-Flux Test in support of pharmaceutical requirements

• Reference Standardization for users of reflectance instruments

• Instrument maintenance log with comment fields

• Blank Correction (for XDS transmission measurements)

• Instrument Calibration (for ensuring calibration transfer between XDS instruments)

• Window Correction (For XDS process systems)

• USP tests including Noise, Low-Flux Noise, Wavelength Accuracy and the Photometric

Linearity Test – with results displayed according to the USP chapter <1119>.

7

Page 10

▪▪▪▪▪▪▪

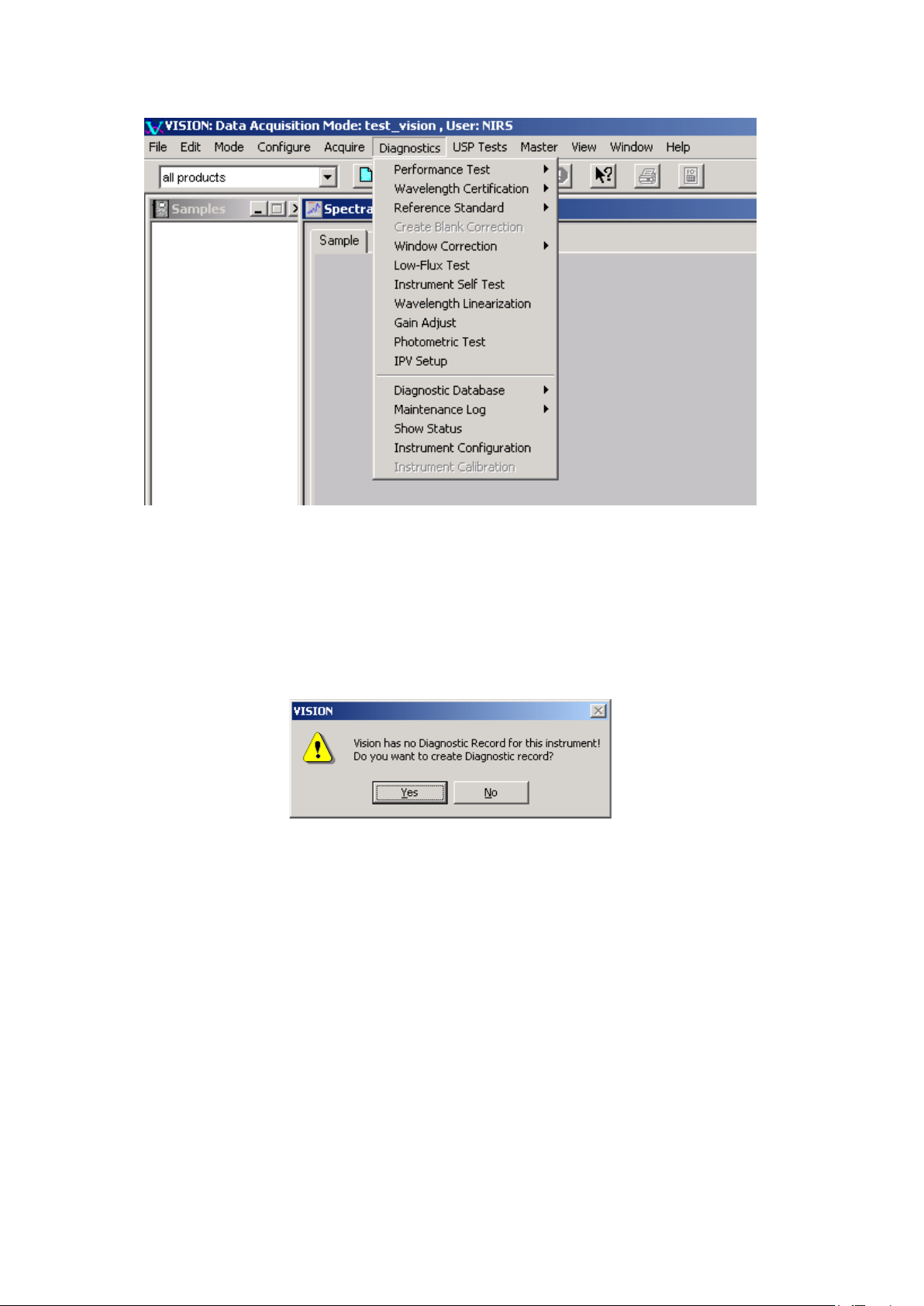

The tests in this manual are listed in the order in which they appear in the Vision software drop down

menus. More information on the order of running tests can be found in the Installation and user

manuals for the particular instrument being used.

When an instrument is first connected to Vision, Vision will determine whether there is a diagnostic

record for this instrument configuration. In order to establish the correct instrument record in the

Diagnostic Database, choose the option to create the diagnostic record when the initial screen

appears telling that a Diagnostic Record does not exist for this instrument.

Saying “yes” will not initialize the testing, but will enter the instrument configuration information in

the Diagnostic Database.

An instrument configuration is defined as a given monochromator and it assembled sampling

components, including fiber-optics, if used. Where fiber-optics are used, the sampling tip type, fiber

material and fiber length all constitute part of the monochromator configuration.

For most users with a single instrument, the configuration may never change, and is thus not an

overriding issue in diagnostics. Other users may operate several instruments from one computer, or

may change sampling modules based upon the sample characteristics. Diagnostic test results must be

maintained separately for each configuration, to assure use of correct tolerances, and for correct

information in control charts.

8

Page 11

▪▪▪▪▪▪▪

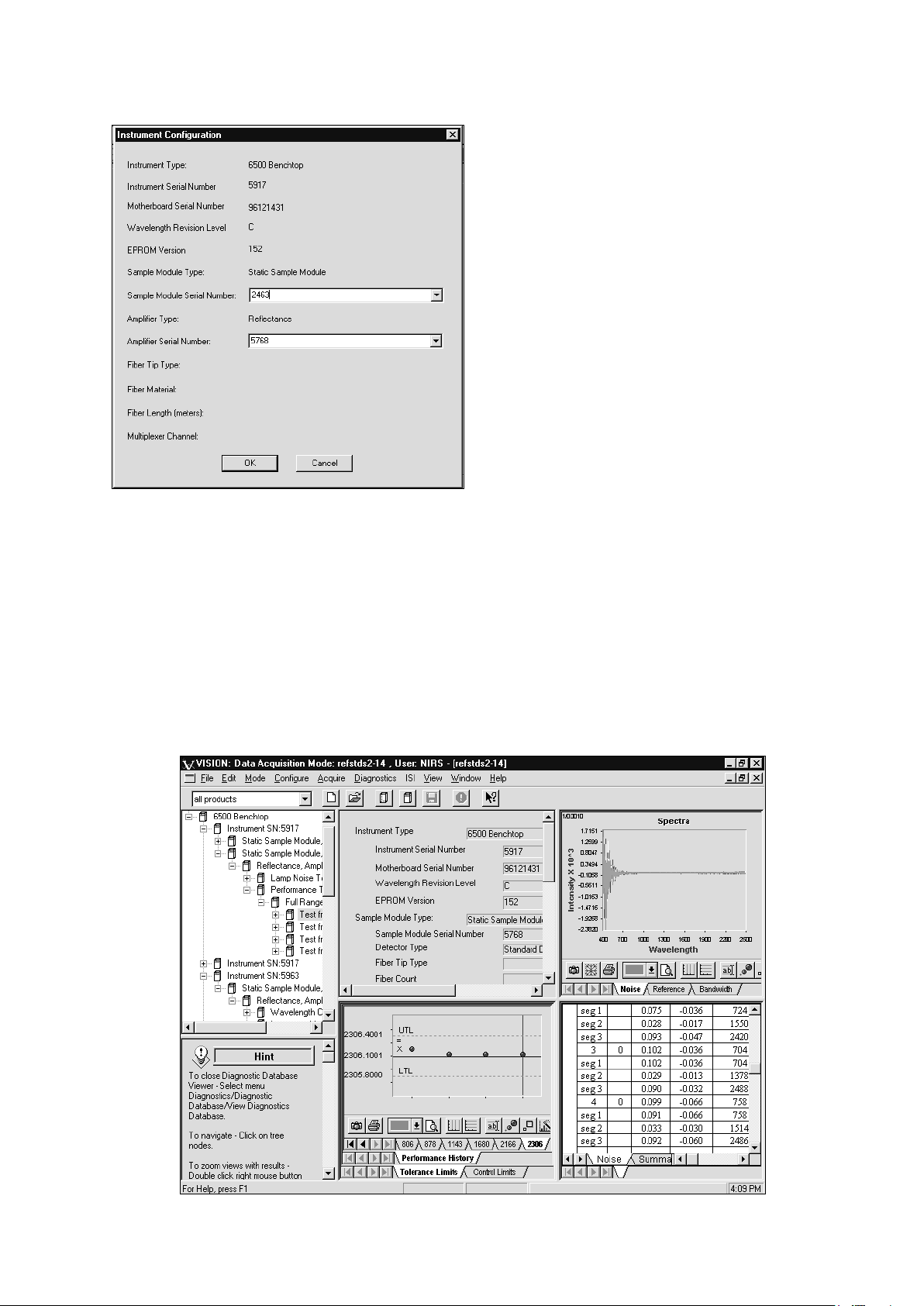

Confirmation of Instrument configuration

If the instrument configuration is not

recognized upon connection, Vision prompts

for full instrument configuration information,

including serial numbers of the

monochromator and modules. A typical screen

for a simple configuration is shown.

For instruments with fiber-optic sampling

devices, the tip, material, and fiber length are

required. For multiplexed process systems,

enter this information for each channel.

Vision builds a database of diagnostic

information for the instrument. It is vital to

enter correct information, to assure

application of correct tolerances for tests and

for accurate tracking of test results.

Tools for export, import and archiving of information in case of computer upgrades, changes, or

instrument moves, are explained under Diagnostic Database.

1.1 Vision Diagnostics Screen Display

Vision Diagnostics use a split-screen display to provide as much information as possible to the user.

This is a screen displayed during the Performance Test; other tests use the same display format.

Because each part of the screen may be used at different points during the test, all are displayed in

small size, and can easily be enlarged for better viewing. Each part of the screen is discussed in the

section following.

Vision Diagnostics Screen Display

9

Page 12

▪▪▪▪▪▪▪

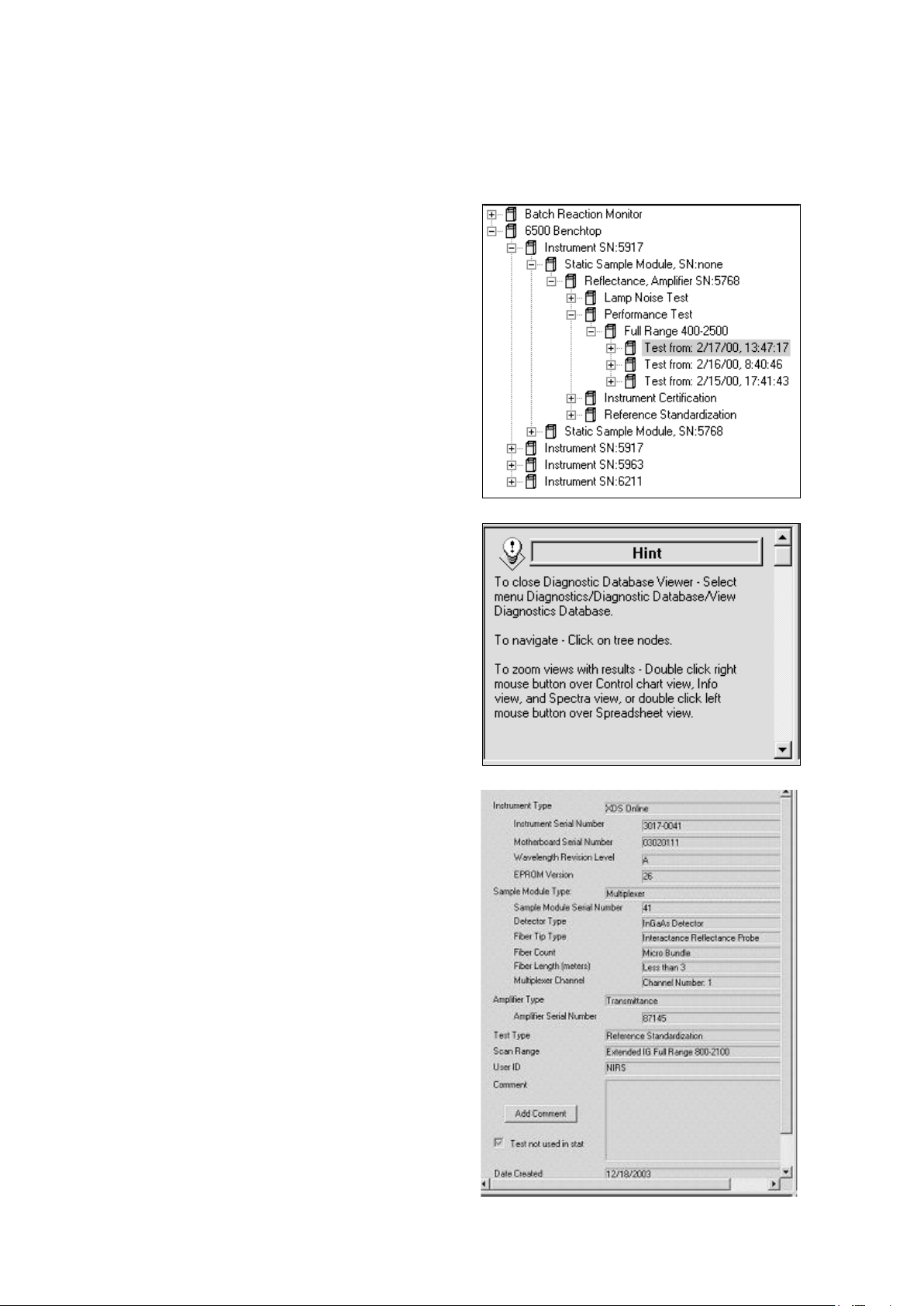

The instrument selection tree lists all instruments for

The Hint box tells how to zoom each of the four

The user may size the boxes manually using the mouse to move the partitions left, right, up or down.

The configuration box, spectrum box, and control chart boxes are all a double right-click to enlarge

or restore. After enlargement, double-click is repeated to return to the original display mode.

which information is stored in the database.

Click on the “+” sign beside each node to see all

items underneath. Each instrument lists all stored

configurations, tests, along with the date and time

of each test.

boxes, along with other useful suggestions.

The hint box is useful throughout Vision, and

suggests steps to the user to help navigate Vision

most efficiently.

The upper middle box lists the full instrument

configuration. The box shown is for a process

system, which includes fiber-optic probes.

With process systems, the “Sampling Module Type”

is integral to the instrument, and carries the same

serial number as the instrument.

Comments can be added for individual test results

by clicking on the “Add Comment” combo box.

The upper right box shows spectra where

applicable. In this case, noise spectra for a tested

instrument are displayed.

10

Page 13

▪▪▪▪▪▪▪

Other information displayed is the reference scan, or

the polystyrene/didymium spectra used for

The lower left quadrant shows control charts, when

The lower right box shows tabular data. Click on the

wavelength linearization.

A left-click on the spectrum gives a cursor which

gives wavelength and absorbance information for a

selected spectrum, as throughout Vision. The

selected spectrum is identified by a color bar above

the wavelength and absorbance.

When this window is active the user may click on

the camera icon to copy the spectral image to the

clipboard. The user may click on the printer icon to

print spectra.

enough data is stored for a given instrument

configuration to plot control charts.

The top row of tabs is for selection of test (RMS

noise is shown). Other choices are Peak-to-Peak,

Bias, Bandwidth, and the Wavelength Linearization

peaks.

The bottom tabs select between tolerances or

control limits. Control limits are calculated on one

specific instrument and give an excellent insight into

any changes that may occur over time. Trends may

be noted and acted upon before the parameter has

gone outside of tolerance.

tabs at the bottom to see each view. The options

are Noise, Summary, Wavelength, and OpQual

(Operational Qualification). The OpQual tabs provide

a summary of the actual instrument performance

versus specification values.

A double right click on the table takes the user to

Formula One Worksheet mode, which permits easy

cut-and-paste export of results to other

Windows™-based programs. When finished with

Formula One, click on the “X” to close.

11

Page 14

▪▪▪▪▪▪▪

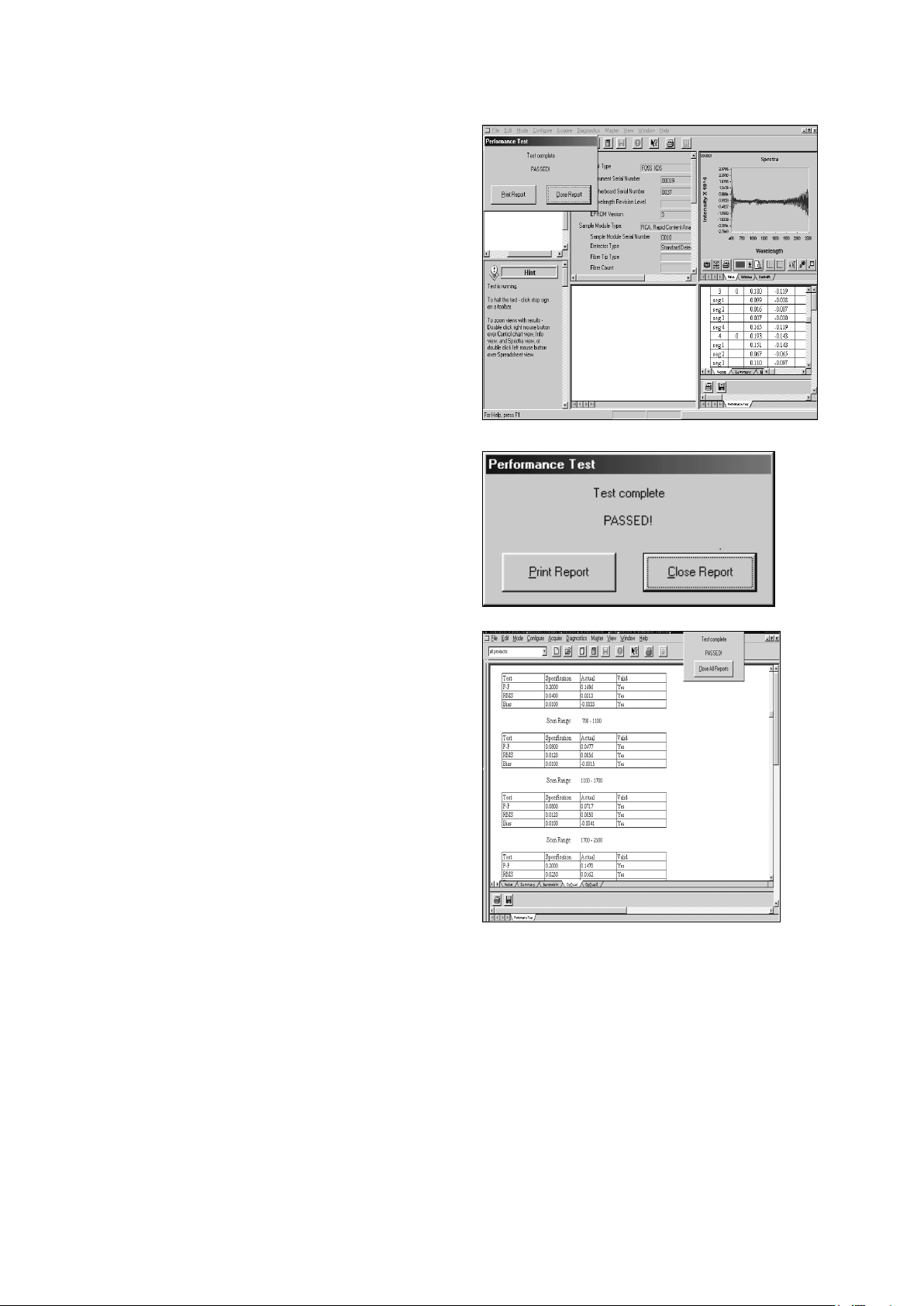

Select Performance Test from the Diagnostics

All diagnostic test results are stored in the

2 Performance Test

2.1 Overview

Performance Test is a comprehensive test of instrumental performance, and is the final assurance that

the instrument is ready to run samples. The key items verified during this test are:

• Instrument Noise in several wavelength regions depending on the instrument type and

configuration

• Internal Wavelength Performance (wavelength positions on non-traceable, internal reference

materials)

• Internal Wavelength Precision (Repeatability)

• NIR Gain

• Visible Gain (where applicable)

menu. Click on Run Performance Test. The test

will commence immediately.

Performance Test takes approximately 15-25

minutes to run depending upon settings,

instrument status and instrument type.

The test co-averages the results of 32 scans, irrespective of DCM settings for the number of scans.

This assures correct application of acceptance specifications and consistent comparison of test results

to initial factory test results.

The samples per test are set to a default of 10, but this can be changed under Performance Tests,

Configure Test Parameters. Use the default settings unless there is a compelling reason to change

them.

Diagnostic Database, regardless of which project

the user is logged into while performing the

tests. The user may store results in Excel format

using the drop-down menu shown. Test results in

the Diagnostic Database can be recalled at a later

time.

12

Page 15

▪▪▪▪▪▪▪

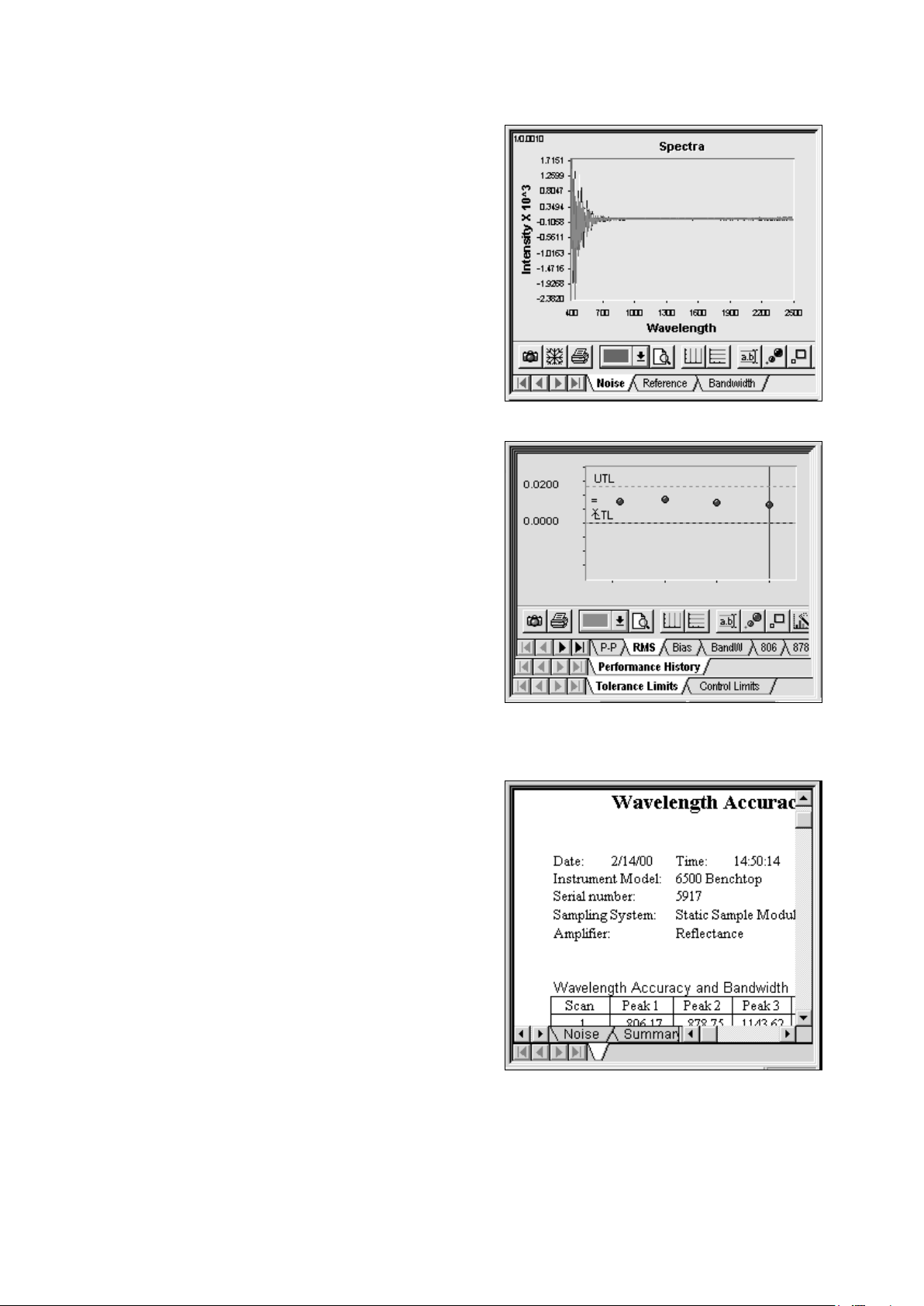

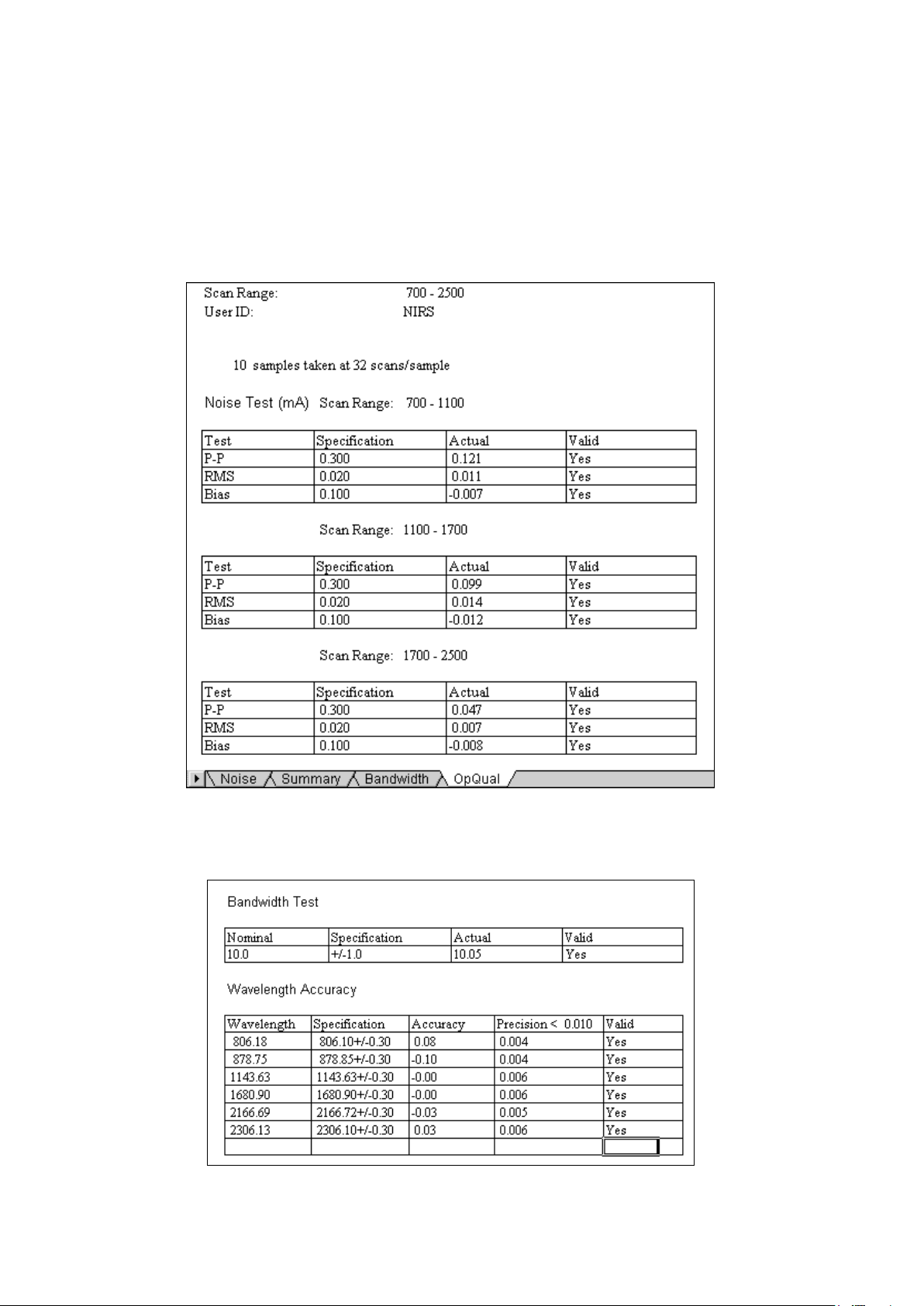

As the test runs, a screen like that shown to the

left is displayed. When finished, a message box is

Before clicking “Close All Reports”, the user is

To enlarge the tabular display of results, place

displayed to indicate test completion and status.

At the end of the Performance Test, all measured

values are compared with acceptance criteria

stored in Vision. If all results meet acceptance

criteria, the test is successful and this dialog box

is displayed.

directed to the tabular display in the lower right

quadrant.

the cursor over the tabular display in the lower

right quadrant and double-click twice. Now click

on the OpQual tab, near the bottom of the

screen to see a summary of noise test results.

The OpQual tab brings up the display shown.

This shows results of the Noise Test for each of

the up to four wavelength regions. The results

are shown along with the specification values

and a column to show if the test results are valid.

For each wavelength region, results are given for:

• Peak-to-Peak Noise (P-P)

• Root-Mean-Square Noise (RMS)

• Bias (A measure of baseline energy changes)

Each of these parameters is described in more detail in the next section and in the Instrument

Performance Test Guide supplied with the Metrohm instrument. If the test is reported as “Passed” the

user may proceed with sample analysis.

13

Page 16

▪▪▪▪▪▪▪

A note on Wavelength Linearization:

Sometimes when initiating Performance Test, Vision will report “Instrument Error: Run Wavelength

Linearization”. The error report is posted near the end of the first set of 32 co-averaged scans, as

Vision processes the data. This error occurs when an instrument configuration has been changed, the

lamp is not on, the reference is not in the correct position, or due to a beam blockage. A

troubleshooting table is provided at the end of Diagnostics to assist you in solving this issue.

2.2 Noise Test

The tabular output of the instrument Noise portion of Performance Test provides a wealth of

information about the instrument. Instrument noise should appear as random spectral variability.

Structure in the noise spectrum or high noise is often caused by changes in environment but also may

be indicative of instrument problems. The Noise Test is the most sensitive diagnostic test used to

determine instrument performance. The display provides information about noise and amplifier gain.

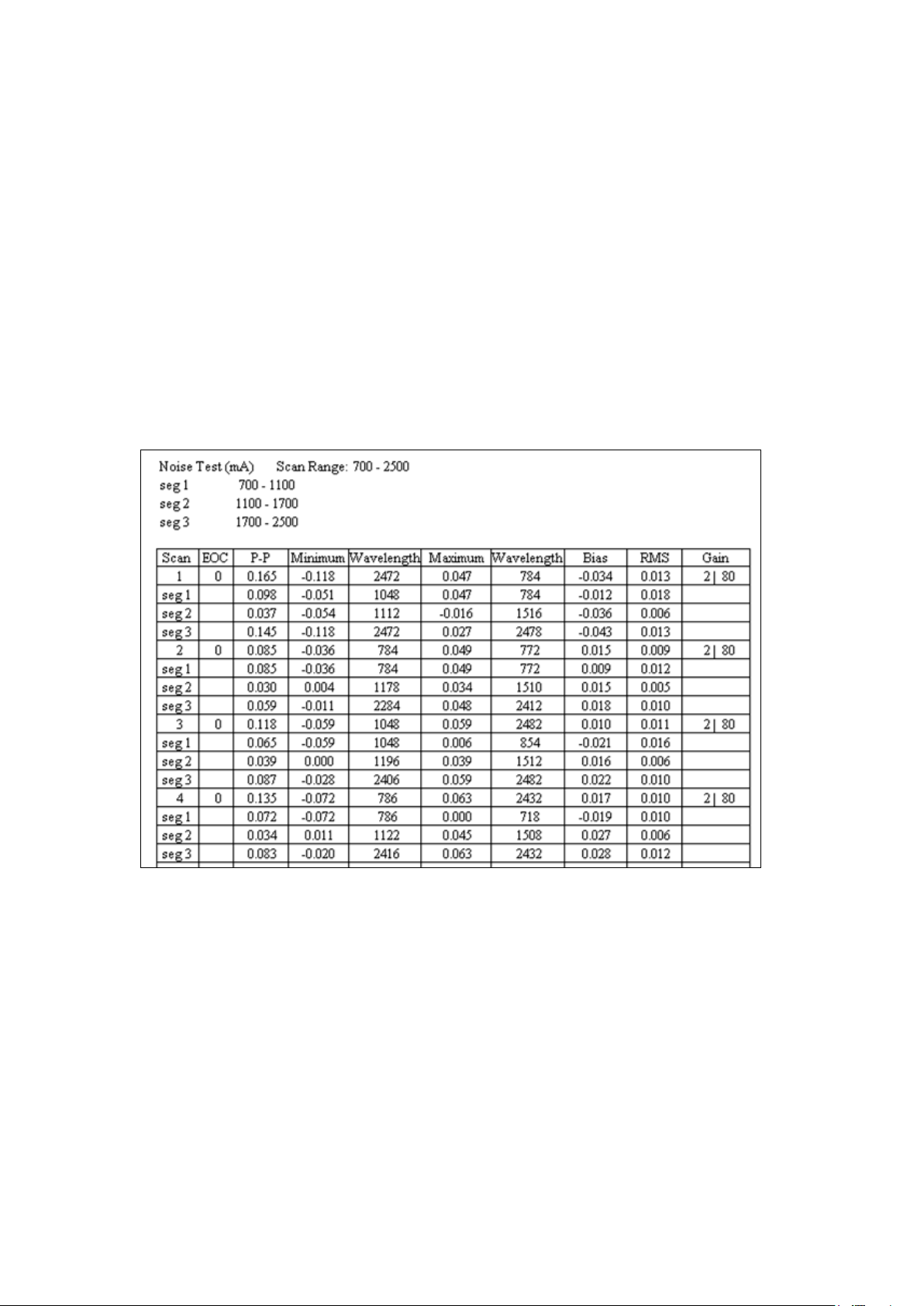

Instrument Noise (Displayed at lower right quadarant during Performance Test)

Vision breaks each instrument test up into segments (wavelength regions), based upon the

instrument configuration. Acceptance specifications are applied to each segment. Segments can be

adjusted by the user under Tests Params (under Data Collection Method) prior to acquisition of any

spectra. Unless there is a reason to change segments, the user is encouraged to use the defaults.

Laboratory instruments generally use a ceramic reference in reflectance, or air in transmission.

Process instruments offer the option of reference vs. reference, sample vs. sample, or sample vs.

reference. Each result column in the noise test is explained:

SCAN#

Identifies which of the 10 sets of sample scans is being reported. A sample scan is defined as 32 sets

of co-averaged reference vs. reference scans for a laboratory instrument.

14

Page 17

▪▪▪▪▪▪▪

EOC

End of convert. Communications failures during the instrument scan and with the computer are

reported here. This number should be zero, and if not the source of communication errors should be

investigated. Occasionally, EOC failures are due to random electrical noise or unexplained

disturbance, and if not frequently repeated they are not considered a problem.

P-P

Peak-to-Peak noise is the difference between the largest and smallest value in the noise spectrum.

(There may be a round-off error of .001 due to the mathematical algorithm.) The unit of measure is

milliabsorbance units, or one-thousandth of one absorbance unit. For example, .139 equals 0.000139

absorbance units. The number may also be expresses verbally as microabsorbance units, or “139”.

Peak-to-peak noise may be thought of as the greatest variation from one scan to the next scan of the

noise spectrum across all measured wavelengths.

Minimum

This is the highest intensity negative peak height, in milliabsorbance units, of the noise spectrum. The

wavelength where the minimum occurs is reported in the next column.

Wavelength

The wavelength where the peak minimum occurred.

Maximum

This is the maximum peak height, in milliabsorbance units, of the noise spectrum. The wavelength

where the maximum occurs is reported in the next column.

Wavelength

The wavelength where the peak maximum occurred.

Bias

The bias is the average absorbance value of all points in the noise spectrum. Immediately after the

instrument is turned on, the bias is quite high, and as the instrument warms up, bias settles to near

zero with slight random excursions above and below. In normal operation, fully warmed-up, the bias

should run in a range of +/-0.100 milliabsorbance units.

RMS

The Root Mean Square of the noise across the full spectral region in milliabsorbance units is reported.

Each sampling configuration has acceptance specifications programmed in Vision. These are applied

automatically. As with peak-to-peak noise, RMS is commonly referred to in microabsorbance units.

th

(One-million

of an absorbance unit.) In this case, 20 microabsorbance units is equivalent to 0.020

milliabsorbance units.

Gain

The “gain factor” for Autogain amplifiers is shown. For full-range instruments the NIR gain is shown

first, then the visible gain. Metrohm’ instruments use a system of gain optimization called

“AutoGain,” which uses the first scan of each data collection to adjust the gain level for the best

resolution of signal.

The detector picks a gain factor to optimize signal. The gain factor depends upon the sample

absorbance, requiring no user adjustment. This can be helpful when troubleshooting. For example, if

15

Page 18

▪▪▪▪▪▪▪

the instrument reference is not in place, gain factors may climb to the maximum value, and may also

explain why RMS noise and P-P are outside of bounds.

2.3 Bandwidth: Wavelength Accuracy and Precision

Bandwidth is measured during the Performance Test on non-XDS instruments and during the

Wavelength Certification test for XDS instruments. Metrohm instrument contains internal wavelength

reference materials, which are used as a means to maintain monochromator wavelength

measurement. These internal wavelength materials are protected and are moved by software

command, transparent to the user. When Performance Test is run, the relative wavelength positions

and repeatability of these wavelength materials are monitored and reported.

2.4 Model 5000 and 6500

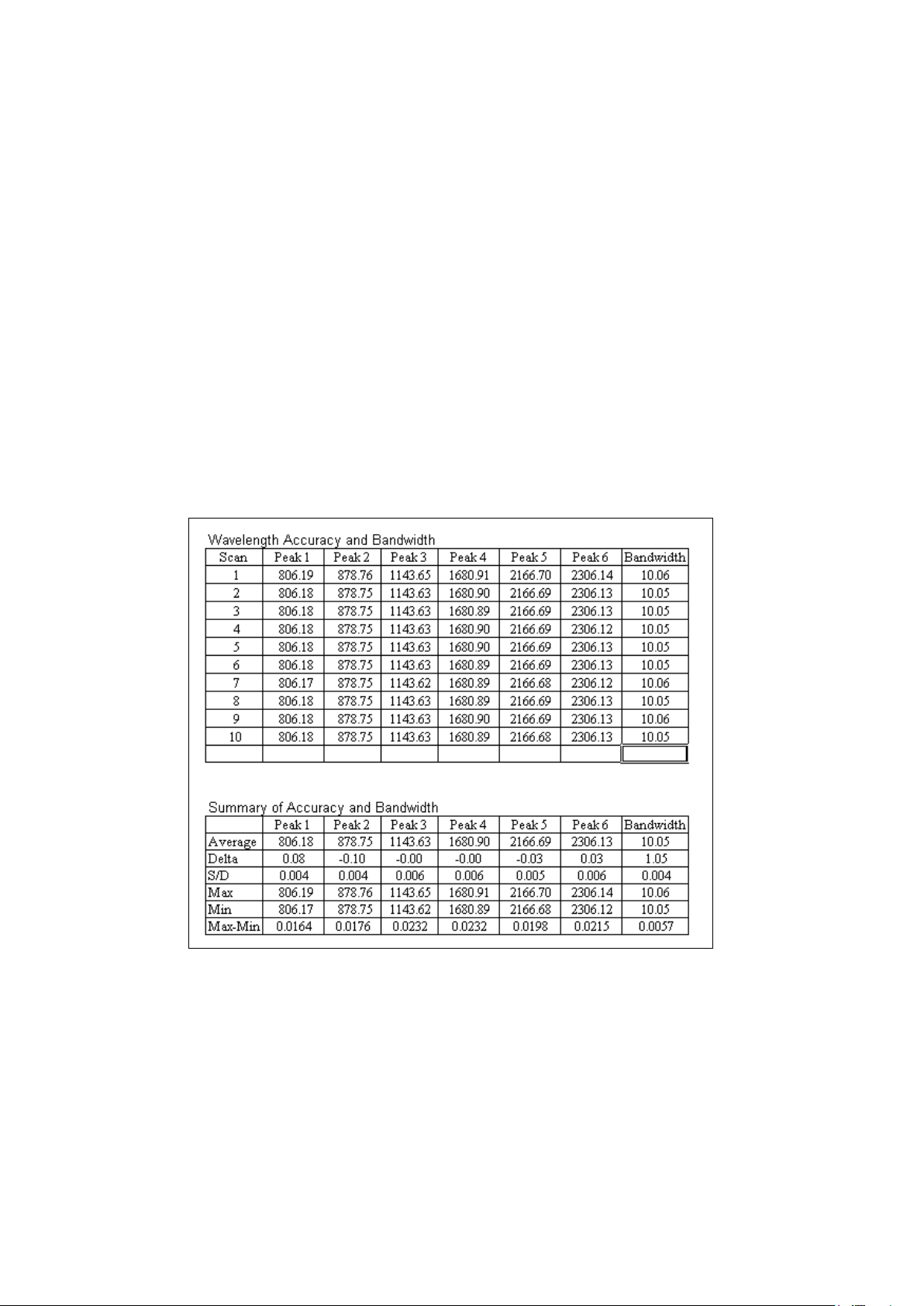

The Bandwidth tab shows instrument bandwidth as well as wavelength accuracy and precision. In the

NIR region, an internal polystyrene reference is analyzed by transmission measurement under

software control. 10 replicate scans of the polystyrene standard are used to calculate these

parameters.

The polystyrene absorbances which nominally occur at 806.10, 878.75, 1143.63, 1680.90 2166.72

and 2306.10 nm (Rev. C) are used to calculate wavelength accuracy and precision. A peak-finding

algorithm is applied to the polystyrene spectra to determine the peak maxima. The average peak

position obtained for 10 replicates determines the wavelength accuracy, and the standard deviation

of those values determines measurement precision.

Delta is the difference between the accepted nominal values, and those reported by the instrument.

The specification for reported vs. nominal is +/- 0.30 nm (+/- 0.50 for process instruments). Therefore,

any peak found to be within 0.30 nm is considered acceptable. The software flags any peak outside

the acceptance range and suggests that Wavelength Linearization be performed.

S/D is the standard deviation of the 10 replicates. This measures the stability of peak positions and

16

Page 19

▪▪▪▪▪▪▪

bandwidth. With respect to peak position, the specification on S/D is 0.015 nm or less, depending

upon instrument model and type.

The instrument bandpass (bandwidth) is calculated using the ratio of the absorbance at the

polystyrene peak at 2167 nm and the valley at approximately 2154 nm (after an offset correction.)

The S/D test is also run in the 400-1100 area of the spectrum on models 5500 and 6500. In this area,

didymium/polystyrene is used for two of the peaks, at 806.10 and 878.85 nm. Bandwidth is not

calculated in the 400-1100 nm area.

Process instruments (and certain laboratory instruments) cannot use the polystyrene peak at 2306.10

nm due to attenuation of the signal in the fiber-optics, or limitations in wavelength range. On such

instruments the tests will not report values for the 2306.10 peak, and will perform wavelength tests

on peaks within the wavelength response of the instrument.

Note: Wavelength positions are empirically determined, and have been set based upon the best

measurements possible given the technology available. As instrumental or standardization

breakthroughs lead to greater precision in setting nominal peak positions, Metrohm reserves the right

to issue revised nominals.

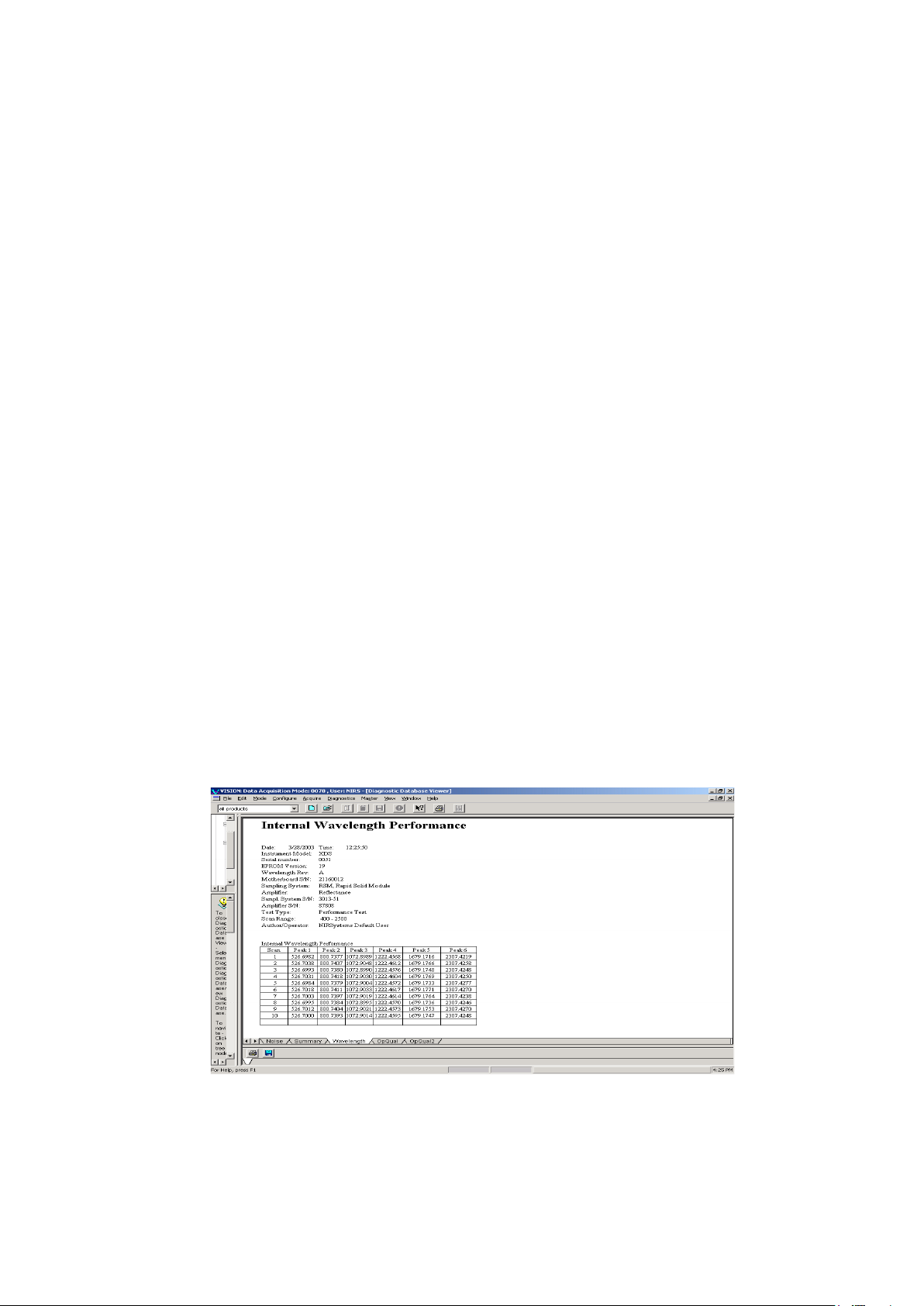

2.5 Wavelength Accuracy / Precision Measurement on the XDS

The XDS instrument, like the model 5000 and 6500, uses an internal wavelength reference material.

When Performance Test is run, the relative wavelength positions and repeatability of these

wavelength materials are monitored and reported. The internal standard for the XDS is comprised of

polystyrene, erbium oxide and samarium oxide and six peaks across the range from 500-2310nm are

used to determine the internal wavelength performance of the instrument.

Note that these internal wavelength materials need not be precisely on the assigned nominals. These

nominals are arbitrary. The internal wavelength materials are a method to assure stable readings on

the external wavelength standard, measured at the sample plane during Instrument Calibration and

Wavelength Certification.

17

Page 20

▪▪▪▪▪▪▪

2.6 Operational Qualification

A summary of noise results is available in the OpQual (Operational Qualification) screens. This screen

gives specifications (for a given instrument configuration), the average of measured values, and an

indication of whether the result is valid for that configuration. The measured values are the average

result for 10 sets of scans, covering each wavelength region. Many users find this screen easier to

interpret, and more concise, than the tabulated data for each set of scans.

Operational Qualification Summary Screen: Noise Test

The OpQual2 tab contains summary information on wavelength accuracy and precision. For Model

5000 and 6500 instruments it also contains information on the bandwidth, as shown:

Operational Qualification Summary Screen: Bandwidth, Wavelength Results

18

Page 21

▪▪▪▪▪▪▪

2.7 Performance Test Timer

The Performance Test Timer permits the user to

automatically set the instrument to run the

Performance Test unattended. It may be set for

a time interval or on a daily basis at a preset

time. Use military time for time of day, i.e.,

20:45 for 8:45 p.m. Be sure the instrument is

left on with the reference in the correct position

for Performance Test.

If the specified time has passed, Performance Test begins immediately upon successful connection

with the instrument.

Note that there is a Diagnostic Timer under Diagnostic Database, where many functions can be set

up for timed testing and storage of results. See Diagnostic Database for more information.

19

Page 22

▪▪▪▪▪▪▪

Click on Diagnostics, Wavelength

It may be read using the A: drive, or may be

3 Wavelength Certification

Wavelength Certification uses an external standard, with known peak positions, to verify the

wavelength scale of the instrument. The program is designed to run a certified Wavelength Standard

available from Metrohm. For reflectance measurements the standards are traceable to SRM-1920,

supplied by NIST. The standard for XDS reflectance instruments is SRM-1920 plus talc. For liquid

transmission systems the wavelength standard is polystyrene-didymium (XC-1310/XC1320) or

SRM-2035 (XC-1330). Vision also offers the option of a user-defined wavelength standard, with

appropriate tools for peak-finding and tolerances.

3.1 Run Wavelength Certification

Certification, Run Wavelength

Certification.

The Number of samples should be

10, as shown. Select the correct

standard for the instrument type

being used from the drop down

menu.

Click “OK” when ready.

Vision requests the Standard File for the

wavelength standard. This file is located on the

diskette or CD packed with the 6-piece standard

set.

copied into the C:\Vision directory as shown

here.

The file name will be similar to that shown

below.

Click “Open” to proceed.

20

Page 23

▪▪▪▪▪▪▪

RSS1xxxx

Reflectance

Reflectance

TSS2xxxx

Tablets (MultiTab,

Transmission

When prompted by the software, insert the

The wavelength standard is scanned, and a

400 600 800 1000 1200 1400 1600 1800 2000 2200 2400

-0.42

-0.39

-0.36

-0.33

-0.30

-0.27

-0.24

-0.21

-0.18

-0.15

-0.12

-0.09

-0.06

-0.03

0.00

0.03

0.06

Spectrum of SRM 1920

Wavelength (nm)

Absorbance log(1/R)

File

Sample Type Detector

Name

InTact)

TSS3xxxx Transmission Transmission

The standard file contains spectra of standards taken on the appropriate Metrohm master

instrument. It is important to use a certified wavelength reference that has been checked and verified

for correct wavelength response.

appropriate standard into the sample drawer. The

label should face the user when inserting the

standard.

If the standard file chosen is for the wrong type of standards, Vision will inform the user of the error.

Since Wavelength Certification is run regularly, the user may copy the standards file from the diskette

to the C:\Vision directory of the computer for simplicity. This file must be updated upon

recertification of the standard set.

peak-finding algorithm locates the peaks

produced by the standard material. The

horizontal axis is wavelength, and the vertical axis

is absorbance. These peaks must be measured

within the tolerance defined in Vision to be

considered valid or acceptable.

After the test is complete, a spectrum of the

standard is shown in the upper right quadrant of

the screen. An example of the spectrum of

SRM-1920 measured on an RCA is shown.

21

Page 24

▪▪▪▪▪▪▪

A tabular report is shown in the lower right

quadrant, giving each peak, its nominal position

and its measured position. The difference from

nominal and the repeatability of position are

calculated. This is a sample report for an XDS

analyzer.

This report is stored in the Diagnostic Database

and can be accessed from the Diagnostic

Database Viewer at a later time.

For XDS instruments, the Wavelength Certification also tests certain measured instrument profile

peaks in the wavelength standard. These peaks are used to set the “Instrument Wavelength Profile,”

and one peak is used for bandwidth calculation.

When running Wavelength Certification on the XDS, the test may pass, but give a recommendation

to re-run the instrument calibration to improve instrument performance. For the XDS, there is a tab

at the bottom of the test results for the Instrument Calibration Verification results, which has much

tighter tolerances. If the peak positions measured during the Wavelength Certification are outside of

these tolerances, yet still acceptable for Wavelength Certification, it is recommended that the user

re-run Instrument Calibration to ensure instrument matching and seamless calibration transfer.

If Wavelength Certification fails on an XDS instrument, run Instrument Calibration under Diagnostics,

then repeat the Wavelength Certification Test. If it fails on model 5000 or 6500 instruments, run

Wavelength Linearization under Diagnostics, then repeat the Wavelength Certification. If the system

fails the test again, contact Metrohm Technical Support.

22

Page 25

▪▪▪▪▪▪▪

3.2 Setting up a User-Defined Wavelength Standard

Click on “Setup Custom Wavelength Standard” to create a user-defined wavelength standard to be

used to verify wavelength axis repeatability. (The material must have sharp, well-defined peaks, and

be very stable to serve as a wavelength reference.) Name the standard. Collect a reference scan on

the instrument reference, typically a ceramic for reflectance, air for transmission. Scan the

user-defined wavelength standard when prompted. An example is shown for illustration:

Set up Custom Wavelength Standard

To select peaks, click on the vertical line, draw it to a peak, and then release the mouse button. A

small “+”denotes the peak. A peak-finding algorithm is applied for accuracy in peak assignment. The

Peak Position is shown in the table. Up to 16 peaks may be selected. The default tolerances are

+/- 0.15nm, which may be edited by the user. To delete a peak, highlight the box in the table and

click Del. When finished, click “Done”.

To use the custom wavelength standard, select Run Wavelength Certification. Select the standard you

created from the drop-down box. Peak positions and tolerances defined for that wavelength

standard during setup are applied.

23

Page 26

▪▪▪▪▪▪▪

Instrument must stabilize before data acquisition:

Run performance test after wavelength linearization:

4 Reference Standardization

Reference Standardization is used in reflectance, with all laboratory instruments and all XDS process

instruments. The purpose of Reference Standardization is to minimize any differences in

instrument-to-instrument response that could be attributed to differences in the reflectance reference

material supplied with the instrument.

To use the Reference Standardization feature, the user must go to Options and click on Reference

Standardization. All new Data Collection Methods (DCMs) created for this project will be reference

standardized. This can be verified when a DCM is created and the Reference Standardization box in

the upper right of the DCM screen is checked.

Reference Standardization is a method to provide a virtual 100% reflectance reference at each data

point, to serve as a true spectroscopic reference with no character attributable to the physical

reference used. This is important to achieve a high-quality spectrum on each instrument, and to

enhance transferability between instruments. Reference Standardization should always be used when

working with an XDS analyzer.

A photometric standard of known reflectivity (as measured on an absolute reflectance scale) is

scanned on the instrument. The internal ceramic standard is scanned. The differences of the ceramic

standard from 100 % reflectivity are mapped, and a photometric correction is generated. This

correction is then applied to every spectrum taken on the instrument, to make each spectrum appear

as if taken with a reference of a 100 % reflectance. This assures that bright samples do not saturate

the instrument, or produce negative absorbance values.

Vision software stores the Reflectance Standard file, which is downloaded to the instrument, and is

applied as a correction to each spectrum. Please refer to the Installation and User manuals on how to

perform Reference Standardization on XDS Process Analytics Instruments.

To set the “Options” for a given Project, click on Configure, Options.

This prevents spectral acquisition if the instrument is

cold.

Performance Test must pass before data acquisition:

This prevents the user from taking data on a

non-functional instrument.

Forces user to run tests sequentially. This is not

necessary with XDS, but may be used for other

models.

24

Page 27

▪▪▪▪▪▪▪

Use Auto-Linearization:

The instrument should be fully warmed-up,

Vision software stores the

Maintains correct wavelength registration automatically, using internal wavelength materials to keep

instrument in precise adjustment over time.

Reference Standardization:

Used to create a virtual 100% reflectance reference, using a traceable photometric standard. This is

explained in the next section. This feature must be used to assure method transferability on XDS

instruments, and to aid in transfer on other models run in reflectance.

Blank Correction:

This is used to create a correct transmission reference on transmission systems (such as the XDS

Rapid Liquid Analyzer). With this option chosen, the system takes a scan of the sample chamber and

the reference chamber, then applies a correction factor. It is explained more fully in the XDS RLA

manual. It is recommended for Calibration Transfer.

Master Standardization:

This method is typically not used.

Use Instrument Calibration (XDS only):

This is a method to adjust the instrument wavelength profile to an external, traceable wavelength

standard. This feature must be used on the XDS to assure method transferability.

Use Window Correction (XDS only):

Select this when using the XDS Process instrument with either Transmission Pair, or Interactance

Immersion probes. This option should not be used with Interactance Reflectance.

4.1 Creating a Reference Standard

tested and operating correctly when creating a

reference standard, to eliminate any chance of

error. Click on Create Reference Standard

Reference Standard file, which is

downloaded to the instrument,

and is applied as a correction to

each spectrum. Please refer to the

Installation and User manuals on

how to carry out Reference

Standardization on XDS Process

Analytics Instruments.

Follow these steps to create a

reference standard for laboratory

instruments:

Select Diagnostics, Reference Standard, Create Reference Standard.

25

Page 28

▪▪▪▪▪▪▪

Before Reference Standardization begins Vision

Vision requests that the user place the ceramic

The file is named “RSSxxxxx.da”. Click on the file, and then

must establish the instrument configuration and

have it verified by the user. This assures that test

data is sent to the correct location in the

Diagnostic Database.

This screen is shown:

If the Sample Module Serial Number field is

empty, locate the sample module serial number

on the side or back of the module. Record the

serial number and enter it in this field.

Click “OK” to accept the instrument

identification.

reference into position. If working with the RCA

or XDS RCA, make sure the cover is closed after

placing reference standard in position.

Click on “OK”. The status bar indicates scan

progress.

Vision requests that the Certified 80%

Reflectance Reference be placed in the sampling

area. For consistency, place the standard with

the calibration label parallel to the holder (RCA

and Sample Transport or other straight line

inside the module.

Note the position of the Certified Reflectance Standard and always use this position.

Place the standard, and click on “OK”.

The Certified 80% Reflectance Reference has been run on the Metrohm master reflectance

instrument. After it is created and loaded, the information is used to apply a correction to the

instrument reference.

Vision requests the Standard File for the Certified 80%

Reflectance Reference. This file is on the diskette or CD

packed with the standards, and may be copied to the

Vision directory for ease of use, as shown here.

click “Open”.

26

Page 29

▪▪▪▪▪▪▪

For the Smart Probe the Certified 99% Reflectance

Reference is used. It comes with a diskette or CD, which

Vision takes a spectrum of the Certified

The Certified 80% Reflectance Reference is

The correction spectrum represents the amount

must be used during Reference Standardization of the

Smart Probe or OptiProbe.

Place the standard onto the Smart Probe, hold in place,

and click on “OK”.

Vision prompts the user to rotate the Certified 99% Reflectance Reference. This is done to minimize

the directional effects of the standard, and provide best consistency. Note the label on the standard,

and rotate 90 degrees at each prompt.

Reflectance Reference, as indicated by the status

bar on screen. When finished, Vision plots a

spectrum of the ceramic instrument reference,

as shown.

Click “OK” to plot a spectrum of the Certified

Reflectance Reference.

shown with the spectrum of the ceramic

instrument reference.

Click “OK” to plot a correction spectrum.

of spectral correction required to provide a

virtual 100% reflectance reference at each data

point.

27

Page 30

▪▪▪▪▪▪▪

A final spectrum (green when plotted on-screen)

is plotted to verify that the corrected spectrum

produces the same results as the Certified

Reflectance Reference.

Click “Close Report” to continue. The correction

is automatically downloaded, and is saved in the

Diagnostic Database. The correction will be

applied in real time to all spectra taken with a

DCM where “Reference Standardization” is

checked.

Note that cleanliness of the sample window and probe tip is very important when this program is

run. If the window or probe tip is not extremely clean, the character of the window contamination

will be imparted to the reference correction. Therefore, maintain a clean window and probe tip at all

times.

4.2 Loading a Reference Standard

The reference standardization file is stored in the Diagnostic Database, attached to the record for the

instrument configuration under which it was taken. If the instrument configuration is changed, then

returned to the original configuration, the reference standardization file must be re-loaded to the

instrument. Click on Load Reference Standard to download the correction to the instrument. A

confirmation of successful download appears. From this point, any spectrum taken in a reference

standardized project will have the correction applied.

The database supports multiple reference standards, such as one for each reflectance configuration.

The instrument, however, only can hold one reference standardization file at a time. Therefore, when

the instrument configuration is changed, the reference standardization file must be reloaded. The

model 5000 and 6500 instruments, however, can only hold one reference standardization file at a

time. Therefore, for model 5000 or 6500 instruments only, when the instrument configuration is

changed, the reference standardization file must be reloaded as given in the next section. For XDS

instruments, up to nine sets of reference standardization and instrument calibration data are stored

on the motherboard of the instrument. When the XDS instrument configuration is changed, the

software recognizes it, and the appropriate Reference Standardization files are applied.

4.3 Reset Reference Standard

(not applicable to xds analyzers)

When a sampling module is changed on a model 5000 or 6500 instrument, new reference

standardization is required for the module being used. (Only one is stored in the instrument.) First,

change the module; perform Wavelength Linearization, then Performance Test. If these tests are

successful, click on Reset Reference Standard to remove the existing correction from the instrument.

Click on Create Reference Standard, then Load Reference Standard to download the new file to the

instrument.

28

Page 31

▪▪▪▪▪▪▪

5 Create Blank Correction

Upon selection of Blank Correction from the

When instructed, insert the correct spacer into

This option is applicable only to the XDS Rapid Liquid Analyzer. Refer to the XDS Rapid Liquid

Analyzer Installation and User Manual (PN 720-750-1300) for further details.

The option of “Blank Correction” provides an optimum photometric match between XDS Rapid Liquid

Analyzers. This must be selected in Project Options. A software algorithm applies the correction to

each spectrum automatically.

Blank Correction has been shown to substantially minimize slight photometric differences between

XDS Rapid Liquid Analyzers, permitting simplified transfer of equations from one instrument to

another. It must be applied for each cuvette size that is being used, as the correction is based on the

spacer for a given cuvette.

Select “Create Blank Correction” from the menu. Vision gives on-screen, step-by-step instructions for

the creation.

The menu selection for Blank Correction is available when the option is selected in This Project’s

Options, and the Data Collection Method (DCM) has the Blank Correction box checked. This is

explained under Reference Standardization and Project Options.

Diagnostics menu, Vision takes an instrument

reference. Next, this dialog box prompts the

user to remove any cuvettes, and verify

placement of the proper spacer.

the sample drawer and tighten the knurled knob

fully. Be sure to use the right spacer for the

cuvette size, or the Blank Correction will give the

wrong spectral correction.

Click “OK” when the spacer is in position. Vision

will scan the sample area.

After the sample area is scanned, a dialog box

prompts that Vision is ready to plot the Blank

Correction. Click “OK” to proceed.

29

Page 32

▪▪▪▪▪▪▪

This spectrum is a Blank Correction, and is a

When finished, click on “Close Report” to

typical shape. The shape may vary slightly,

depending upon the spacer used. Vision applies

the correction automatically to all subsequent

spectra taken with this Data Collection Method

(DCM).

proceed.

Because the correction is tied to a particular DCM, it is suggested that a separate project or DCM be

used for samples taken with different size cuvettes or vials. If the DCM is used for a different size

cuvette, Blank Correction must be repeated with the new spacer.

30

Page 33

▪▪▪▪▪▪▪

6 Window Correction

Window Correction is applicable to XDS process instruments used with Interactance Immersion and

Transmission Probes only. Further information on this can be found in the XDS Process Analytics

Instrument Installation and User Manual (PN 720-750-2400). It is a method that permits the user to

calibrate the fiber-optics using an Interactance Reflectance probe, then to insert the fibers into the

probe that will be used in the process, and map the optical difference in response between the two

geometries.

From the Diagnostics menu select Create Window Correction.

Note: The menu selection for Window Correction is available when the option is selected in This

Project’s Options, and the Data Collection Method (DCM) has the Window Correction box checked.

Selecting Project Options is explained under Reference Standardization and Project Options.

31

Page 34

▪▪▪▪▪▪▪

To initiate the Low-Flux Test, follow this

7 Low-Flux Test

Low-Flux Test is included for users who must run this test in support of regulatory requirements such

as the United States Pharmacopoeia (USP) General Information Chapter on Near-Infrared

Spectroscopy, <1119>. It can be run either on its own or in a truncated fashion as part of the USP

tests. The reported values and specification limits are different between the two types of Low-Flux

Test, with the USP test tolerances being much broader.

Low-Flux Test uses a nominal 10% reflectance standard in the sample position. (Reflectance

Standards contain a 10% reflectance standard (R101xxxx), which may be used for this test.) A noise

test is run using this standard. Because the reflectivity is less than the instrument standard, the test is

considered a good method for testing instrument noise in the range of reflectivity of many common

sample absorptions. This test verifies that the instrument is working properly at higher levels of

absorbance.

The Low-Flux Test is performed in reflectance and may use the 10% Certified Reflectance Standard

used in IPV Setup and the Photometric Test. If the user substitutes another 10% sample, it should be

of fairly flat spectral character, and be as close to 10% reflectance as possible. If the sample chosen is

too dark (less than 10% reflectance) the test will be unnecessarily severe, and the instrument may fail

the test. The acceptance specifications loaded into Vision are for the Certified 10% Reflectance

Standards and the internal screen that can be used on the XDS instruments.

The XDS instrument has an internal 10% neutral density (transmittance) screen, triggered by

software, which can be used in place of an external 10% reflectance standard. This screen gives

equivalent results during the Low-Flux Test, and minimizes the possibility of operator error in placing

the standard.

sequence:

From the Diagnostics menu bar, select Low-Flux

Test.

32

Page 35

▪▪▪▪▪▪▪

On the XDS instrument, Vision asks if the user

wishes to use an external sample (standard) for

When doing the Low-Flux Test on non-XDS

In the tabular result in the lower right quadrant

the test. Click “Yes” to use an external 10%

reflectance standard.

instruments the following window will appear.

The 10 % reflectance standard should be

positioned and the test runs.

If the user clicks “No” to the external standard (on the XDS only), then Vision will automatically

trigger the 10 % internal screen for this test. No user action is required. Vision runs the Low-Flux

Test, which takes about 20 minutes. At the end, the results are displayed.

Results from a typical run are shown:

of the screen, click on the tab marked

“Summary” to see the summarized results as

compared to acceptance specifications. Vision

reports a pass or fail based upon successful test

completion. Results are stored in the Diagnostic

Database for later recall. The user may print

results, or click “Close” to complete the test.

33

Page 36

▪▪▪▪▪▪▪

8 Instrument Self-Test

The Instrument Self-Test is a test of major components of the instrument. It tests and verifies the

status of each item listed, and serves as a way to know if something has failed. Vision operates each

component through defined tests and can flag major problems.

Instrument Self-Test Screen

The instrument tested in the illustration above did not have a Transmission Amplifier, indicated by the

message “Amp is not installed.”

This test should be performed with the instrument reference in place. To run the test a single time,

check Once under Test Type. The test will ask if the instrument fan is operating on laboratory

instruments, which can be verified by checking for airflow at the instrument fan filter.

At the conclusion of the test click Print for a hard copy.

34

Page 37

▪▪▪▪▪▪▪

9 Wavelength Linearization

9.1 Wavelength Linearization on Model 5000 and 6500

Wavelength scale registration of the instrument is an important characteristic. Metrohm instruments

are designed to provide wavelength response consistent with NIST-defined wavelength standards. To

this end, an internal polystyrene/didymium paddle is inserted into the instrument beam upon

software command, and selected peak positions of each material are used to maintain accuracy. The

peak positions required to achieve correct wavelength registration of the instrument are called

“nominals”. Wavelength Linearization provides long-term wavelength accuracy and precision for all

Metrohm instruments.

Wavelength Linearization Constants

A polystyrene standard (4 peaks) is used in the 1100-2500 nm region, and a polystyrene-didymium

standard (3 peaks) is used in the 400-1100 nm region. Actual peak positions are compared with

nominal peak positions stored in a software table. Differences between nominal and actual peak

positions are calculated, and corrections are made by instrument software, which are applied to all

subsequent sample spectra. The tolerance is +/- 0.3 nm for laboratory instruments, and 0.5 nm for

process instruments. If the test is successful, Vision asks if the operator wishes to apply the

linearization constants to the instrument. Click on OK to send linearization constants to the

instrument.

The Wavelength Linearization procedure can be performed automatically (“Auto-linearization”)

whenever a reference is scanned, to update the wavelength correction at each reference scan. This is

also performed as part of regular Performance Test. To apply Auto-linearization (recommended)

select Configure, Options, then click on Auto-linearization. When this is checked, wavelength

correction will be applied to every reference and sample scan. Auto-linearization adds a slight

amount of time to each scan.

Wavelength Linearization should be performed manually whenever a module is changed on a

laboratory instrument, as well as after a lamp change. Once this has been performed manually,

35

Page 38

▪▪▪▪▪▪▪

The NIR wavelength positions of these peaks

The “visible” portion of the spectrum is similar.

Auto-linearization will maintain correct wavelength registration.

On instruments using fiber-optics (and certain other models) Wavelength Linearization cannot use the

2306.1 peak due to attenuation in the fiber-optics. Vision will perform the linearization using peaks

available within the useable wavelength range of the instrument.

9.2 Wavelength Linearization on XDS Instruments

Wavelength Linearization for XDS instruments should only be performed at setup, after a lamp

change, or after instrument repair and then followed by Reference Standardization, Instrument

Calibration, Performance Test, and IPV Setup. Running Wavelength Linearization after Instrument

Calibration can interfere with the alignment obtained under Instrument Calibration.

Wavelength Linearization uses an internal wavelength standard set to determine a set of internal,

arbitrary peak positions that the instrument will use to maintain repeatability of wavelength response.

appear as shown. The scale of this display is

marked in encoder pulses, which do not relate

to nanometers directly. From the peaks, a

linearization is performed, which allows

assignment of nanometer values for the

wavelength axis.

A linearization is applied to this portion of the

spectrum as well. Minor artifacts appear in these

raw spectra due to detector crossover and other

spectroscopic reasons. After linearization these

artifacts are minimal or not evident, some being

beyond the usable range of the instrument.

These peak positions are not meant to be traceable, as the wavelength calibration of the XDS

instrument is done on an external standard, traceable to NIST. The internal wavelength standards are

used to maintain the external wavelength registration by use of software adjustment for any external

effects on the instrument.

36

Page 39

▪▪▪▪▪▪▪

Select Wavelength Linearization from the

Diagnostics menu. The instrument will scan the

Click “Yes” to send the linearization to the

reference.

The results screen shown below is typical. Peak

positions for the reference materials are located

using a peak-finding algorithm. These “found”

peaks are compared to the nominals.

instrument.

You will twice be asked to send constants to the

instrument for the linearization of the forward

and backward movement of the grating.

Indicate “Yes”.

After the linearization constants are successfully

sent to the instrument, this message confirms the

transfer.

Click “OK” to proceed.

9.3 Special Note on Wavelength Linearization of Process

Instruments

When a process instrument is first installed, a manual Wavelength Linearization must be performed

for each channel, including reference and all sample channels (with no sample in the beam). From

this time forward, Vision adjusts the wavelength registration of each sample channel based upon the

response of the reference channel, maintaining proper wavelength registration throughout the

system.

It is acceptable to manually perform Wavelength Linearization of the Reference channel from time to

time during normal operation. DO NOT perform Wavelength Linearization on the sample channel(s)

when there is sample (or residue) in the beam, as this will cause an incorrect Wavelength

Linearization to be stored in the instrument.

Manually perform Wavelength Linearization on process instruments on all sample channels at normal

maintenance shutdowns, or immediately after lamp change. Provide adequate time for instrument

warm-up following system power-up.

37

Page 40

▪▪▪▪▪▪▪

To start Gain Adjust, click on Diagnostics,

Run Gain Adjust with the instrument

10 Gain Adjust

Instrument amplifiers automatically adjust gain level based upon sample absorbance. The gain is

“turned up” for highly absorbing samples, and “turned down” for spectroscopically bright samples.

The “gain factor” range is between 1 and 80 for NIR and 1 and 8000 for visible detectors, with some

isolated exceptions. The gain factor is reported in the Performance Test for Autogain instruments; the

Gain Adjust test is not normally part of customer-run diagnostics.

Gain factor is a measure of gain multiplication for a given sample. The test is run with the instrument

reference (ceramic in reflectance, air in transmission). The gain factor reported in Vision should be

consistent over time, with a given module configuration.

The detector module electronics are set at the factory for optimum resolution and gain settings. Do

not attempt to adjust these settings unless operating a manual gain instrument (manufactured before

1995).

10.1 Autogain

The Gain Adjust feature can be a useful diagnostic tool, though it is not required for normal

operation. Gain is never user-adjusted on the AutoGain instruments. The name of the test comes

from a capability required with older systems.

then Gain Adjust.

The instrument must be connected and in

communication for this to function.

Click on Gain Adjust to see the Gain Factor

on Autogain instruments, and to verify that

the instrument is reading within the correct

range on the instrument reference.

The display gives the current reading, along with minimum and maximum allowable voltage.

reference in the correct position.

Click between NIR and Visible with the

button provided.

Exit when finished. Gain Factor is reported

as part of the Performance Test and is

stored in the Diagnostic Database.

38

Autogain Display

Page 41

▪▪▪▪▪▪▪

The display shown on the above is for NIR on a Static Sample module, and shows a Gain Factor of 2.

With XDS, this program reports gain information for the

Other instrument configurations operate at other gain factors, all the way up to 4000 and beyond in

the visible area of the spectrum. The Gain Factor is a function of the specific sampling configuration,

and should remain relatively constant over time. A dramatic change may signal a block sample beam,

a missing reference, or other significant problems.

NIR and visible regions.

When running the Gain Adjust on the XDS the screen on

the left appears.

The view above shows a fairly typical XDS Rapid Content

Analyzer. The gain program sets the internal reference

paddle over the sample opening, and takes gain readings

for both NIR and Visible regions.

Gain Factor is a measure of signal amplification. In the NIR region (1100-2500nm) it occurs in steps of

1, 2, 4, 10, 20, 40 and 80. In the Visible region (400-1100nm) the gains range from 1 to 80,000.

Gain Adjust can be helpful when troubleshooting an instrument. For example, a gain of 80 in NIR and

80,000 in Visible is a sign that the lamp is burned out, or some other sort of failure. Note that the

gain factors are reported in Performance Test, and can be called up from the Diagnostic Database.

This permits the user to see if the gain factor has changed significantly over time.

10.2 Manual Gain

Gain Adjust provides a method to adjust the gain potentiometers on manual gain instruments,

manufactured before 1995. When a manual gain system is detected, the screen switches to a

detailed diagram with adjustment arrows and feedback on gain status for the technician. A sample of

the manual adjustment screen is shown for reference:

Manual Gain Display and Instructions

Users with manual gain instruments will use this program to adjust their detectors for optimum

response. An upgrade to AutoGain is available from authorized service locations worldwide.

39

Page 42

▪▪▪▪▪▪▪

11 Photometric Test

Photometric Test provides a method to verify ongoing photometric performance of the instrument.

This is a requirement for pharmaceutical users. Before the Photometric Test can be run, a file must be

established using IPV Setup, described fully in the next section (D-54).

The IPV Setup file is acquired when the instrument is known to be operating properly, such as at

installation, or immediately after service. It is automatically stored in the C:\Vision directory with a file

name RSSVxxxx.da for reflectance standards.

Click on Diagnostics, IPV Setup to create an initial file for comparison. If more than one module is

used with a monochromator, IPV Setup must be done for each module, and a separate RSVxxxx file

created.

The test uses the same standards used in IPV Setup. Photometric Test compares current spectra of

each standard to those stored during IPV Setup. If any differences exceed normal tolerance values,

the instrument can be assumed to have changed in some manner, and may need service. This

method of instrument photometric testing is one means to demonstrate that the instrument is “in

control” from a regulatory standpoint.

Because the calibrated photometric standards are the link to previous photometric performance, the

standards should always be stored in their wooden box, and protected from fingerprints, dropping,

or other damage. If any cup is opened, dropped, or otherwise altered, Photometric Test results may

fail.

Photometric Test results are stored in the Diagnostic Database, and may be accessed at any time.

Control charts are plotted (after several tests have been stored) to provide an ongoing record of

performance.

During the test, the standards are checked at wavelengths where the response of the standards is

very flat, to eliminate the effect of minor spectral character on the measurement. The regions used

give a good overall picture of instrument performance and repeatability.

Acceptance tolerances are applied based on the type of instrument and sampling system. As long as

the instrument responds within the allowable range, it is assumed to be operating correctly on the

absorbance scale. If the instrument fails the test, the user should investigate the cause, and should

consider requesting a service call on the instrument.

NIRStandards are manufactured from a very stable material, and are certified on the Metrohm master

instrument, calibrated using procedures and materials traceable to the National Institute of Standards

and Technology (NIST) in the US. Each set of standards comes with a certificate of calibration, and

must be recalibrated once per year to assure consistent response, and to verify that no damage has

occurred that could alter the response of the standards. A wavelength standard, for use in

Wavelength Certification, is also included in the set.

40

Page 43

▪▪▪▪▪▪▪

To run Photometric Test, select it from the

Diagnostics menu.

Click on the RSSVxxxx.da file as shown. (The

Select this file and click “Open”.

Vision requests a “Standard File”. For

Photometric Test, use the RSSVxxxx.da file

stored in the Vision directory. This file was

created during IPV Setup. If you have more than

one module be sure to choose the correct file

for the module in use. Current photometric

readings will be compared to that initial file.

serial number will be different, of course.) Click

“Open”.

Do not use the file on the standards diskette for

Photometric Test, as it will cause Vision to return

an error message.

Vision requests a tolerance file. If running an

XDS instrument, the tolerance file was loaded in

the

C:\Vision directory, and is an “XDA” formatted file. For other instruments use the tolerance file

(*.DAT) on the diskette or CD supplied with reflectance standards.

41

Page 44

▪▪▪▪▪▪▪

Vision displays the wavelength regions for test.

Select the requested standard from the set.

When the 99% standard has been scanned, the

For Number of Replicates, retain the default

setting of 1, unless using the SmartProbe, in

which case 4 replicates should be used.

Click on “OK”.

Vision will begin to take an instrument reference

scan, if the instrument is operating in Reference

Standardized mode.

The red progress bar at the bottom of the screen indicates status. If operating in Reference

Standardized mode, Vision requests the 99% standard from the set. If not operating in Reference

Standardized mode, Vision requests the 80% standard, which is used in place of the internal

instrument reference.

Labels on the back of each standard identify the

reflectance value.

result will be plotted as shown.

In this picture, the upper and lower spectra are

tolerances from the initial IPV Setup spectrum.

The IPV Setup spectrum is the dark spectrum in

the middle, displayed in black on screen.

The lighter spectrum in the middle (red on screen) is the current spectrum. It should be within the

upper (blue) and lower (green) spectra as shown.

After each standard is run, Vision plots the comparison for each wavelength area as shown.

Tolerances are automatically applied, and a “Pass” or “Fail” indication is given. Continue to follow the

on-screen prompts for each standard. Vision requests the 40%, 20%, 10%, and 2% standards.

42

Page 45

▪▪▪▪▪▪▪

When Vision has completed the test, the

tabulated results may be printed. They are also

The control chart view is shown at right. The top

stored in the Diagnostic Database for later

recall.

When the test is complete, click “Close

Window”.

row of tabs is for selection of wavelength range

for viewing, as described above. The middle row

of tabs selects the standard. The 2% reflectance

is shown in this illustration.

The bottom tabs select between tolerance limits

(defined by Metrohm NIRSystems) or control

limits that are calculated on the specific

instrument being tested. Normally the control

limits will give the best indication of

performance.

43

Page 46

▪▪▪▪▪▪▪

IPV Setup is run as follows:

12 IPV Setup

IPV Setup is provided as a method to record initial instrument response to calibrated photometric

reflectance standards. This is normally performed upon initial installation, immediately after

Instrument Performance Certification (IPC), when a lamp has been changed, or when standards have

been re-certified.

When the standards are scanned during IPV Setup, a file is generated, and is stored in the Vision

directory. This file has the same format as the standards file, but a “V” is placed into the fourth

character of the file name. This indicates that it is a “verification” file. For example, if the standard set

has the serial number RSS10301, the IPV Setup file is named RSSV10301. If more than one module is

being used with the same set of standards, a separate IPV setup must be done for each. It is

recommended that after completion of the first IPV Setup, the user change the file name form

RSSVxxxx.da in the Windows Explorer to a name that will help in identifying the module i.e.

RSSVRCAxxxx.da. On completion of the IPV setup for subsequent modules, the same procedure for

file renaming can be followed.

With the IPV Setup file stored, the user can run Photometric Test to check the repeatability of

instrument performance. This is detailed in the previous section of this manual and in XDS manual,

under “Evaluation Diagnostics.” Photometric Test compares the current performance of the

instrument to the file stored during IPV Setup, and reports differences. If the instrument differences

exceed established tolerance limits, the test reports that, so corrective action may be initiated.

It is important that IPV Setup, and later Photometric Test, both be run with the same options selected

under Configure, Options. That is, if the IPV Setup file is acquired with Reference Standardization

switched on, and with Window Correction switched off, then

Photometric Test should be performed using the same settings. The System Manager should pay

particular attention to this. If options are not consistently applied, there will be a bias in the results of

Photometric Test. The bias may be enough to cause test failure, depending upon selections.

Because Metrohm spectrophotometers are sensitive instruments, they can detect differences in

temperature of the standards, and results may be affected slightly. To minimize this effect, be sure

the standards are at a stable temperature before use. If lab temperatures vary, the user may place the

standards inside the RCA cover for some time to let them equilibrate to a stable temperature.

Select IPV Setup from the Diagnostics menu.

Vision requests a “Standard File”. This is provided on

a floppy diskette or CD, packed in the wooden box

with the standards.

44

Page 47

▪▪▪▪▪▪▪

Insert this diskette into the A: drive, select that drive

in the dialog box, and click on the RSS1xxxx.da file

Click on “OK”.

When finished with IPV Setup, the user can now use

as shown. (The serial number will be different, of

course.) Click “Open”.

The standard file is “NSAS File” format (*.da), which

refers to an older software package. This format is

used where it aids in file transfer.

Vision displays the wavelength regions for the test.

For Number of Replicates, retain the default setting

of 1, unless using the SmartProbe, in which case 4

replicates should be used, with a 90-degree rotation

of the standard between replicates.

Vision will begin to take an instrument reference

scan, if the instrument is operating in Reference

Standardized mode. The red progress bar at the

bottom of the screen indicates status. If operating in

Reference Standardized mode, Vision requests the

99% standard from the set. If not operating in

Reference Standardized mode, Vision requests the

80% standard, which is used in place of the internal

instrument reference.

Select the requested standard from the set. Labels

on the back identify each standard. Note the

diskette that contains the “Standards File”. This file

is used only during IPV Setup.

the Photometric Test for regular verification of

photometric response.

The System manager should establish a schedule of regular Photometric Testing based upon

instrument usage. The generally accepted interval for heavy users is 1-2 times per week, or less often

for infrequent usage.

45

Page 48

▪▪▪▪▪▪▪

Click on Diagnostic Database to access the information

Upon opening the Diagnostic Database a “tree” opens

Simply click on Backup Diagnostic Database and

13 Diagnostic Database

stored about tested instrument(s).

Select the View Diagnostic Database option, which lists

each instrument, configuration, test, and date/time of

the test.

This menu offers options to back up and restore the