Page 1

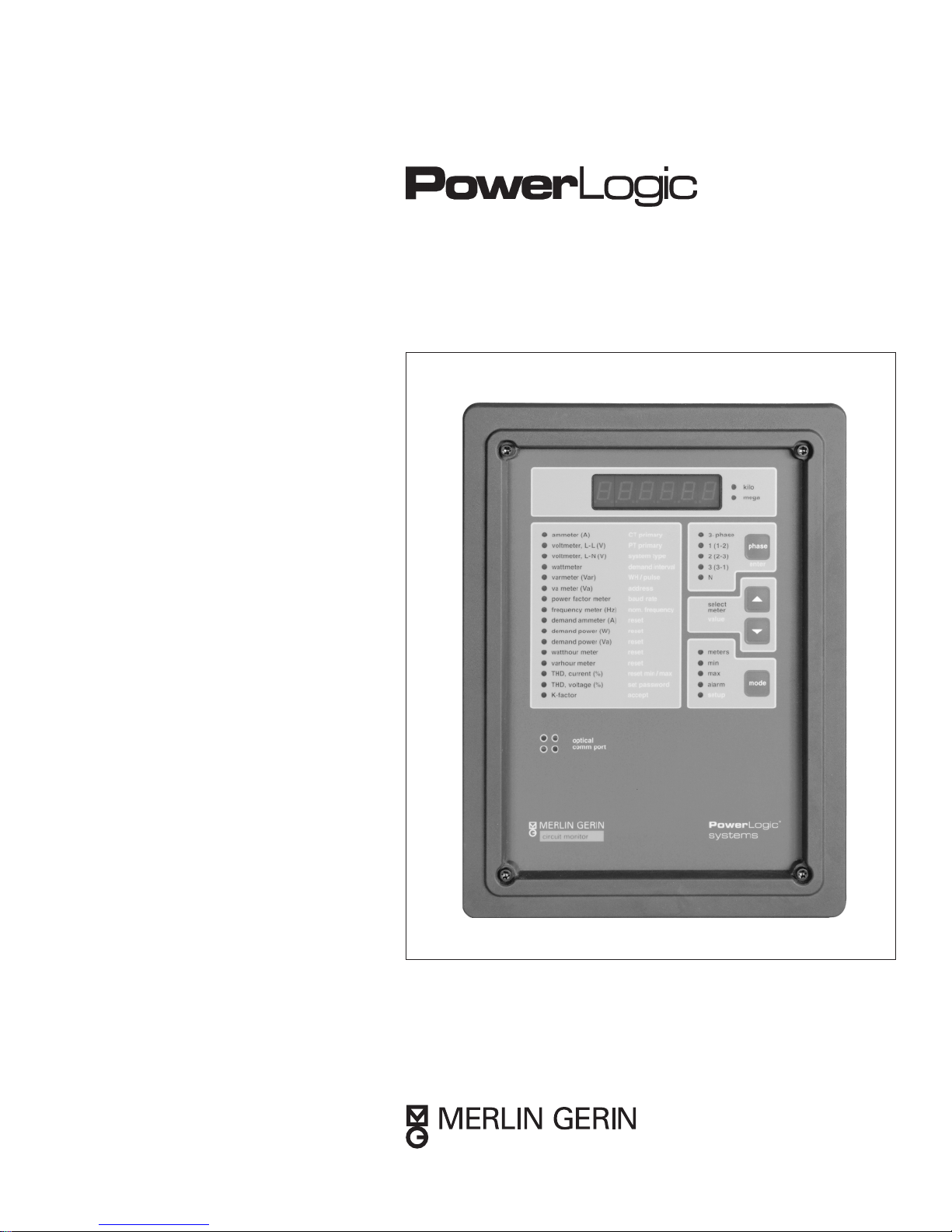

Installation and Operation

Circuit Monitor

Series 2000

3020IB9814

December 1998

Page 2

NOTICE

Read these instructions carefully and look at the equipment to become familiar with the device before trying

to install, operate, or maintain it. The following special messages may appear throughout this bulletin to warn

of potential hazards or to call attention to information that clarifies or simplifies a procedure.

DANGER

!

Used where there is hazard of serious injury or death. Failure to

follow a “DANGER” instruction

!

Used where there is hazard of serious injury or death. Failure to

follow a “WARNING” instruction

!

will

result in death or serious injury.

WARNING

can

result in death or serious injury.

CAUTION

Used where there is hazard of equipment damage. Failure to follow a

“CAUTION” instruction can result in damage to equipment.

Note: Provides additional information to clarify or simplify a procedure.

PLEASE NOTE: Electrical equipment should be serviced only by qualified electrical maintenance personnel,

and this document should not be viewed as sufficient for those who are not otherwise

qualified to operate, service, or maintain the equipment discussed. Although reasonable care

has been taken to provide accurate and authoritative information in this document, no

responsibility is assumed by Square D for any consequences arising out of the use of this

material.

FCC NOTICE: This equipment complies with the requirements in Part 15 of FCC rules for a Class A

computing device. Operation of this equipment in a residential area may cause unacceptable

interference to radio and TV reception, requiring the operator to take whatever steps are

necessary to correct the interference.

TECHNICAL SUPPORT

For technical support, please contact your Schneider Electric representative, who will

contact the Power Management Operation Technical Support Center. The Technical Support

Center will respond to your questions by telephone, fax, or mail.

POWERLOGIC, SY/MAX, SY/NET, SY/LINK, POWER-ZONE, VISI-VAC, ISO-FLEX and are Registered Trademarks of Square D Company.

SYSTEM MANAGER and CIRCUIT TRACKER are Trademarks of Square D Company.

Windows, Windows NT, and Windows 95 are Registered Trademarks of Microsoft Corporation.

Other names are trademarks or service marks of their respective companies.

1998 Square D Company All Rights Reserved

Page 3

Contents

CONTENTS

CHAPTER 1—INTRODUCTION......................................................................................................................1

What is the Circuit Monitor? ................................................................................................................................. 1

Expanded Memory.................................................................................................................................................. 3

Requirements for Using.................................................................................................................................. 4

Identifying the Series and Firmware Revisions .......................................................................................... 4

Model Numbers ............................................................................................................................................... 4

Upgrading Existing Circuit Monitors........................................................................................................... 5

Memory Options Summary ........................................................................................................................... 5

Safety Precautions ................................................................................................................................................... 6

Using This Bulletin .................................................................................................................................................. 6

Notational Conventions.................................................................................................................................. 6

Topics Not Covered Here............................................................................................................................... 7

Related Documents ................................................................................................................................................. 7

Reference Manual ............................................................................................................................................ 8

CHAPTER 2—HARDWARE DESCRIPTION ..................................................................................................9

Front Panel................................................................................................................................................................ 9

Rear Connections ................................................................................................................................................... 11

CHAPTER 3—INSTALLATION .....................................................................................................................13

CE Compliance ...................................................................................................................................................... 14

Mounting the Circuit Monitor ............................................................................................................................. 15

Wiring CTs, PTs, and Control Power ................................................................................................................. 17

Wiring Multiple Circuit Monitors to a Single Set of PTs/CPT ............................................................... 25

Deriving Control Power from Phase PT Inputs ........................................................................................ 26

Grounding the Circuit Monitor .......................................................................................................................... 27

Communications Wiring ...................................................................................................................................... 28

Connecting to a System Display.................................................................................................................. 29

Connecting to a Personal Computer........................................................................................................... 30

Connecting to a POWERLOGIC Ethernet Gateway................................................................................. 31

Connecting to a POWERLOGIC Network Interface Module ................................................................. 32

Connecting to a SY/MAX Programmable Controller .............................................................................. 33

Length of the Communications Link .......................................................................................................... 34

Daisy-Chaining POWERLOGIC Devices ................................................................................................... 35

Terminating the Communications Link ..................................................................................................... 36

Biasing the Communications Link .............................................................................................................. 37

CHAPTER 4—FRONT PANEL OPERATION ...............................................................................................39

The Setup Mode ..................................................................................................................................................... 40

The Configuration Option............................................................................................................................ 40

The Resets Option.......................................................................................................................................... 40

The Alarm/Relay Option ............................................................................................................................. 40

The Diagnostics Option ................................................................................................................................ 40

Choosing a Setup Option ............................................................................................................................. 41

How the Buttons Work ................................................................................................................................. 41

i

Page 4

Bulletin No. 3020IB9814

December 1998

Configuring the Circuit Monitor ......................................................................................................................... 42

Configuring the Circuit Monitor (cont.)

Performing Resets Using the Resets Option ...................................................................................................... 56

Setting Up Alarm/Relay Functions .................................................................................................................... 58

Viewing Active Alarms ........................................................................................................................................ 63

Viewing the Priority 1 Log ................................................................................................................................... 64

Clearing the Priority 1 Log ................................................................................................................................... 65

Factory Defaults ............................................................................................................................................. 42

General Configuration Procedure ............................................................................................................... 42

Viewing Configuration Data in Protected Mode ...................................................................................... 45

Setting the Master Password........................................................................................................................ 46

Setting the CT Ratios ..................................................................................................................................... 47

Setting the PT Ratio ....................................................................................................................................... 48

Setting the System Type ............................................................................................................................... 48

Setting the Demand Interval ........................................................................................................................ 49

Setting the Watthour/Pulse Output ........................................................................................................... 51

Setting the Device Address .......................................................................................................................... 52

Setting the Baud Rate .................................................................................................................................... 53

Setting the Nominal Frequency ................................................................................................................... 54

Resetting Demand, Energy, and Min/Max Values .................................................................................. 55

General Setup Procedure.............................................................................................................................. 59

Detailed Setup Procedure............................................................................................................................. 60

CHAPTER 5—MAINTENANCE AND TROUBLESHOOTING ......................................................................67

Maintenance ........................................................................................................................................................... 67

Battery-Backed RAM..................................................................................................................................... 67

Troubleshooting..................................................................................................................................................... 68

Getting Technical Support ................................................................................................................................... 69

APPENDICES

Appendix A—Circuit Monitor Dimensions ...................................................................................................... 71

Appendix B—Specifications ................................................................................................................................ 73

Appendix C—Installing Terminal Strip Covers ............................................................................................... 75

FIGURES

2-1 Circuit monitor front panel ...................................................................................................................... 10

2-2 Back of the circuit monitor ....................................................................................................................... 11

3-1 Example of disconnect breaker for CE compliance ..............................................................................14

3-2 Panel preparation ...................................................................................................................................... 16

3-3 Circuit monitor mounted in electrical panel ......................................................................................... 16

3-4 3-phase, 3-wire delta connection ............................................................................................................. 18

3-5 3-phase, 4-wire wye, ground connection ............................................................................................... 19

3-6 3-phase, 4-wire wye, ground connection, metered neutral ................................................................. 20

3-7 3-phase, 4-wire wye, 3-wire load ............................................................................................................ 21

3-8 2-1/2 element metering system type 42 (calculated neutral).............................................................. 22

3-9 2-1/2 element metering system type 43 ................................................................................................. 23

ii

Page 5

Contents

3-10 DC control power connections ................................................................................................................ 24

3-11 Circuit monitors connected to one set of PTs and one CPT ................................................................ 25

3-12 Deriving L-L control power from phase PT inputs .............................................................................. 27

3-13 Deriving L-N control power from phase PT inputs .............................................................................27

3-14 Grounding the circuit monitor ................................................................................................................ 28

3-15 Circuit monitors connected to a system display for circuit monitors................................................ 29

3-16 POWERLOGIC devices connected directly to a personal computer ................................................. 30

3-17 POWERLOGIC devices connected to an Ethernet gateway ............................................................... 31

3-18 POWERLOGIC devices connected to a PNIM ......................................................................................32

3-19 POWERLOGIC devices connected to a SY/MAX programmable controller................................... 33

3-20 Daisy-chaining the RS-485 communications terminals........................................................................ 35

3-21 Terminator placement when last device on the link is a circuit monitor .......................................... 36

3-22 Multipoint communications adapter connected to PNIM .................................................................. 37

4-1 Choosing a Setup option .......................................................................................................................... 41

4-2 Flowchart for front panel configuration................................................................................................. 44

4-3 Flowchart for performing resets using the Resets option.................................................................... 57

4-4 Alarm/Relay setup.................................................................................................................................... 59

A-1 Circuit monitor dimensions ..................................................................................................................... 71

A-2 Circuit monitor dimensions with Input/Output and Voltage/Power Modules............................. 72

A-3 Circuit monitor with Input/Output Module ........................................................................................ 72

C-1 Installing terminal strip covers ................................................................................................................ 75

TABLES

1-1 Summary of circuit monitor instrumentation ......................................................................................... 3

1-2 Class 3020 circuit monitors......................................................................................................................... 3

1-3 Circuit monitor feature comparison ......................................................................................................... 3

3-1 Typical circuit monitor mounting locations .......................................................................................... 15

3-2 Supported system wiring connections ................................................................................................... 17

3-3 Maximum distances of comms link at different baud rates ................................................................ 34

4-1 Factory defaults for front panel configuration parameters ................................................................. 42

4-2 Supported system type system code selections .................................................................................... 48

4-3 Maximum distances of comms link at varying baud rates ................................................................. 53

iii

Page 6

Chapter 1—Introduction

CHAPTER 1—INTRODUCTION

CHAPTER CONTENTS This chapter offers a general description of the circuit monitor, describes

important safety precautions, tells how to best use this bulletin, and lists

related documents. Topics are discussed in the following order:

What is the Circuit Monitor?................................................................................. 1

Expanded Memory ...................................................................................................3

Requirements for Using ...............................................................................4

Identifying the Series and Firmware Revisions........................................4

Model Numbers ............................................................................................4

Upgrading Existing Circuit Monitors ........................................................ 5

Memory Options Summary.........................................................................5

Safety Precautions................................................................................................... 6

Using This Bulletin ................................................................................................. 6

Notational Conventions ......................................................................... 6

Topics Not Covered Here ...................................................................... 7

Related Documents ................................................................................................. 7

Reference Manual ...................................................................................... 8

Note: This edition of the circuit monitor instruction bulletin describes features available

in series G4 or later and firmware version 17.009 (or higher). Series 2000 circuit

monitors with older series numbers or firmware versions will not include all features

described in this instruction bulletin.

not have the latest firmware version and you want to upgrade their firmware,

contact your local Schneider Electric representative for information on purchasing

the Class 3020 Type CM-2000U Circuit Monitor Firmware Upgrade Kit.

If you have Series 2000 circuit monitors that do

WHAT IS THE The POWERLOGIC Circuit Monitor is a multifunction, digital

CIRCUIT MONITOR? instrumentation, data acquisition and control device. It can replace a variety

of meters, relays, transducers and other components. The circuit monitor is

equipped with RS-485 communications for integration into any power

monitoring and control system. However, POWERLOGIC System Manager

application software—written specifically for power monitoring and

control—best supports the circuit monitor’s advanced features.

The circuit monitor is a true rms meter capable of exceptionally accurate

measurement of highly nonlinear loads. A sophisticated sampling technique

enables accurate, true rms measurement through the 31st harmonic. Over 50

metered values plus extensive minimum and maximum data can be viewed

from the six-digit LED display. Table 1-1 on page 3 provides a summary of

circuit monitor instrumentation.

The circuit monitor is available in several models to meet a broad range of

power monitoring and control applications. Table 1-2 on page 3 lists the

circuit monitor models. Table 1-3 compares the features available by model.

Circuit monitor capabilities can be expanded using add-on modules that

mount on the back of the circuit monitor. A voltage/power module and

several input/output modules are available. See I/O Capabilities in the Circuit

Monitor Reference Manual for a description of the available I/O modules.

1

Page 7

Bulletin No. 3020IB9814

December 1998

What is the Circuit Monitor?

(cont.)

Using POWERLOGIC application software, users can upgrade circuit

monitor firmware through either the RS-485 or front panel optical communications ports. This feature can be used to keep all circuit monitors up to date

with the latest system enhancements.

Some of the circuit monitor’s many features include:

• True rms metering (31st harmonic)

• Accepts standard CT and PT inputs

• Certified ANSI C12.16 revenue accuracy

• High accuracy—0.2% current and voltage

• Over 50 displayed meter values

• Min/Max displays for metered data

• Power quality readings—THD, K-factor, crest factor

• Real time harmonic magnitudes and angles

• Current and voltage sag/swell detection and recording

• On-board clock/calendar

• Easy front panel setup (password protected)

• RS-485 communications standard

• Front panel, RS-232 optical communications port standard

• Modular, field-installable analog and digital I/O

• 1 ms time stamping of status inputs for sequence-of-events recording

• I/O modules support programmable KYZ pulse output

• Setpoint-controlled alarm/relay functions

• On-board event and data logging

• Waveform and event captures, user-selectable for 4, 12, 36, 48, or 60 cycles

• 64 and 128 point/cycle waveform captures

• High-speed, triggered event capture

• Programming language for application specific solutions

• Downloadable firmware

• System connections

– 3-phase, 3-wire Delta

– 3-phase, 4-wire Wye

– Metered or calculated neutral

– Other metering connections

• Optional voltage/power module for direct connection to 480Y/277V

•

Optional control power module for connecting to 18–60 Vdc control power

• Wide operating temperature range standard (-25 to +70°C)

• UL Listed, CSA certified, and CE marked

• MV-90TM billing compatible

• Pre-configured data log and alarms

2

Page 8

Chapter 1—Introduction

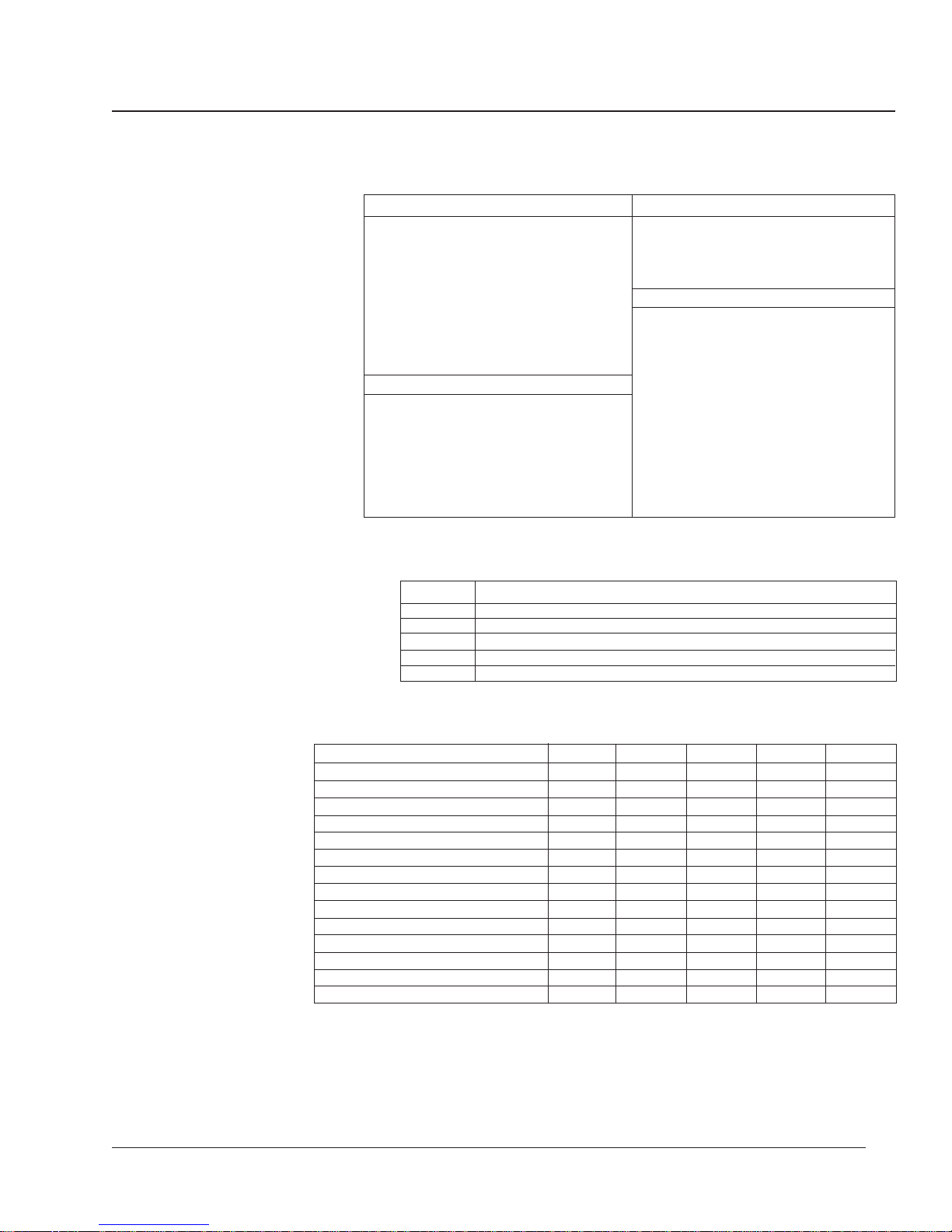

Table 1-1

Summary of Circuit Monitor Instrumentation

Real-Time Readings

•Current (per phase, N, G, 3Ø)

•Voltage (L-L, L-N)

•Real Power (per phase, 3Ø)

•Reactive Power (per phase, 3Ø)

•Apparent Power (per phase, 3Ø)

•Power Factor (per phase, 3Ø)

•Frequency

•Temperature (internal ambient)*

•THD (current and voltage)

•K-Factor (per phase)

Demand Readings

•Demand Current (per-phase present, peak)

• Demand Voltage (per-phase present, peak)*

•Average Power Factor (3Ø total)*

•Demand Real Power (3Ø total)

•Demand Reactive Power (3Ø total)*

•Demand Apparent Power (3Ø total)

•Coincident Readings*

•Predicted Demands*

• Accumulated Energy, Real

• Accumulated Energy, Reactive

• Accumulated Energy, Apparent*

• Bidirectional Readings*

• Crest Factor (per phase)

• K-Factor Demand (per phase)

• Displacement Power Factor (per phase, 3Ø)

• Fundamental Voltages (per phase)

• Fundamental Currents (per phase)

• Fundamental Real Power (per phase)

• Fundamental Reactive Power (per phase)

• Harmonic Power

• Unbalance (current and voltage)

• Phase Rotation

•

Harmonic Magnitudes & Angles (per phase)

* Available via communications only.

Energy Readings

Power Analysis Values*

Table 1-2

Class 3020 Circuit Monitors

Type Description

CM-2050 Instrumentation, 1% accuracy

CM-2150 Instrumentation, 0.2% accuracy, data logging, alarm/relay functions

CM-2250 Waveform capture, plus CM-2150 features

CM-2350 Instrumentation, waveform capture, 0.2% accuracy

CM-2450 Programmable for custom applications, plus-2350 features

Table 1-3

Circuit Monitor Feature Comparison

Feature CM-2050 CM-2150 CM-2250 CM-2350 CM-2450

Full Instrumentation ✘✘✘✘✘

RS-485 Comm Port ✘✘✘✘✘

Front Panel Optical Comm Port ✘✘✘✘✘

1% Accuracy Class ✘

0.2% Accuracy Class ✘✘✘✘

Alarm/Relay Functions ✘✘✘✘

On-board Data Logging ✘✘✘✘

Downloadable Firmware ✘✘✘✘

Date/Time for Each Min/Max ✘✘✘✘

Waveform Capture ✘✘✘

Extended Event Capture ✘✘✘

Extended Memory (up to 1.1 Meg.)* ✘✘✘✘

Sag/Swell Detection ✘✘

Programmable for Custom Applications ✘

* Standard memory: CM-2150, CM-2250, CM-2350, and CM-2450 = 100K; CM-2452 = 356K

EXPANDED MEMORY New Series G4 (or higher) circuit monitor models CM-2150 and higher now

are factory-equipped with 100 kilobytes (100K) of nonvolatile memory.

(Earlier Series G3 models CM-2150 and CM-2250 shipped with 11K of

memory, models CM-2350 and CM-2450 with 100K of memory.)

3

Page 9

Bulletin No. 3020IB9814

December 1998

EXPANDED MEMORY (cont.) For applications where additional memory is required, you can order a

circuit monitor with an optional 512K or 1024K memory expansion card,

resulting in 612K or 1124K, respectively, total nonvolatile memory (100K

base memory plus the expansion card memory). Memory upgrade kits are

also available for most earlier circuit monitors. See Upgrading Existing

Circuit Monitors, page 5.

Requirements for Using System Manager software version 3.02 with Service Update 1, 3.02a with

Expanded Memory Service Update 1, or 3.1 (or higher) is required to take advantage of expan-

sion card memory or the 100K of memory standard on G4 circuit monitors.

Earlier versions of System Manager software will recognize only 11K (the

Series G3 and earlier memory capacity) of available memory.

Also, your circuit monitor must be equipped with firmware version 17.008 or

later to take advantage of expanded memory. The following section tells how

to determine the firmware version shipped with your circuit monitor.

To determine if your circuit monitor firmware version has been updated

with downloadable firmware, see Viewing Configuration Data in Protected

Mode, page 45.

To obtain the latest available firmware revision contact your local Schneider

Electric representative (see Note, page 1.)

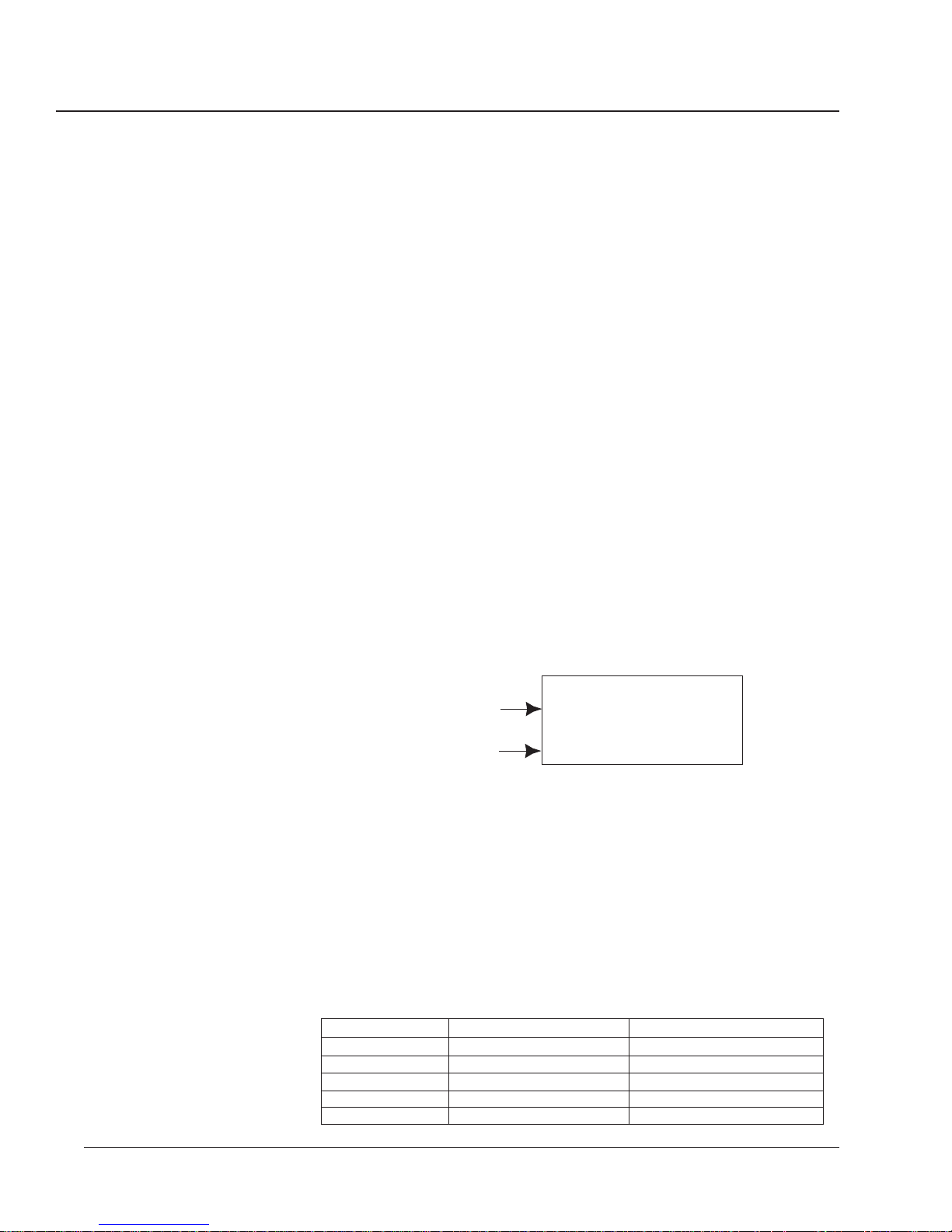

Identifying the Series and The circuit monitor series and firmware revision number are printed on a

Firmware Revisions sticker on the top of the circuit monitor enclosure. Figure 1-1 shows a sample

sticker.

63230-204-106

Series

Series: G2C

U6 REV: 16-16.007

Firmware Revision

Figure 1-1: Circuit monitor series/firmware revision sticker

U33 REV: 16.007

Model Numbers Circuit monitor models equipped with an optional memory expansion card

are differentiated from standard models by a suffix—either -512k or -1024k—

added to the model number (table 1-4). As shown in the table, the memory

expansion option is available for model numbers CM-2150, CM-2250,

CM-2350, and CM-2450. The CM-2452 circuit monitor is now obsolete and

has been replaced by the CM-2450-512k, which has more memory at a lower

price than the CM-2452. However, existing CM-2452 circuit monitors can be

upgraded as detailed on the following page.

Table 1-4

Circuit Monitor Model Numbers

Standard Models Models with 512k Option Models with 1024k Option

3020 CM-2050 N/A N/A

3020 CM-2150 3020 CM-2150-512k 3020 CM-2150-1024k

3020 CM-2250 3020 CM-2250-512k 3020 CM-2250-1024k

3020 CM-2350 3020 CM-2350-512k 3020 CM-2350-1024k

3020 CM-2450 3020 CM-2450-512k 3020 CM-2450-1024k

4

Page 10

Chapter 1—Introduction

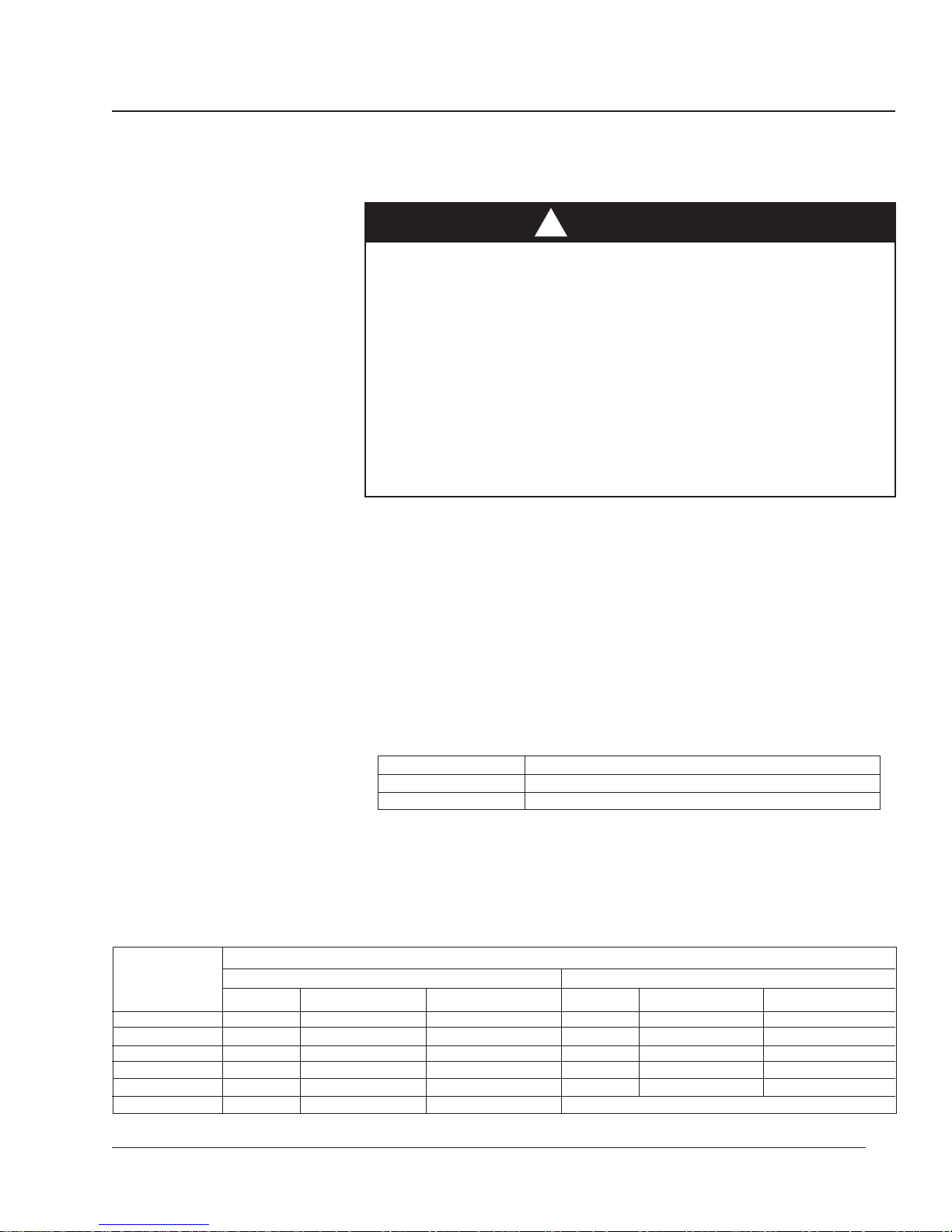

Upgrading Existing Memory upgrade kits are available for field installation by a qualified

Circuit Monitors electrician. No special tools are required.

DANGER

!

HAZARD OF ELECTRIC SHOCK, BURN, OR EXPLOSION

Only qualified electrical workers should install a memory upgrade kit

in a circuit monitor. Perform the upgrade only after reading the

installation instructions shipped with the upgrade kit. Before removing the cover of the circuit monitor to install the memory board:

• Disconnect all voltage inputs to the circuit monitor

• Short the CT secondaries

• De-energize the control power inputs

Failure to observe this precaution will result in death or

serious injury.

For Series G3 and earlier circuit monitors, the memory upgrade kit can be

installed only in circuit monitor models CM-2350 and CM-2450.

Note: Model CM-2452 was factory-equipped with 100K of memory and a 256K

memory expansion card, for a total of 356K of memory. The 256K card can be

removed and replaced with a 512K or 1024K expansion card, for total memory of

either 612K or 1124K.

The memory upgrade kit can be installed in Series G4 models CM-2150 and

higher. Memory upgrade kits are available with either the 512k or 1024k

memory card (see table 1-5). No special tools are required for installation.

Table 1-5

Memory Upgrade Kit Part Numbers

Part Number Description

3020 CM-MEM-512K 512K Memory Upgrade Kit for Series 2000 Circuit Monitors

3020 CM-MEM-1024K 1024K Memory Upgrade Kit for Series 2000 Circuit Monitors

Memory Options Summary Table 1-6 summarizes the memory options now available for Series 2000

Circuit Monitors. To obtain price and availability on circuit monitors with

expanded memory and circuit monitor memory upgrade kits, contact your

local sales representative.

Table 1-6

Series 2000 Circuit Monitor Memory Options

Total Memory Capacity

Model Number Series G3 or Earlier Series G4 or Later

Standard 512K Expansion 1024K Expansion Standard 512K Expansion 1024K Expansion

CM-2050 N/A N/A N/A N/A N/A N/A

CM-2150 11K N/A N/A 100K 612K 1124K

CM-2250 11K N/A N/A 100K 612K 1124K

CM-2350 100K 612K 1124K 100K 612K 1124K

CM-2450 100K 612K 1124K 100K 612K 1124K

CM-2452 356K 612K ➀ 1124K ➀ Obsolete

➀ CM-2452 256K memory expansion card removed and replaced with 512K or 1024K memory expansion card.

5

Page 11

Bulletin No. 3020IB9814

December 1998

SAFETY PRECAUTIONS

DANGER

!

HAZARD OF BODILY INJURY OR EQUIPMENT DAMAGE

• Only qualified electrical workers should install this equipment.

Such work should be performed only after reading this entire set

of instructions.

• The successful operation of this equipment depends upon proper

handling, installation, and operation. Neglecting fundamental

installation requirements may lead to personal injury as well as

damage to electrical equipment or other property.

• Before performing visual inspections, tests, or maintenance on this

equipment, disconnect all sources of electric power. Assume that

all circuits are live until they have been completely de-energized,

tested, grounded, and tagged. Pay particular attention to the

design of the power system. Consider all sources of power,

including the possibility of backfeeding.

Failure to observe this precaution will result in death, serious

injury or equipment damage.

USING THIS BULLETIN This document provides the information required to install and operate the

circuit monitor. The document consists of a table of contents, five chapters,

and three appendices. Chapters longer than a few pages begin with a chapter

table of contents. To locate information on a specific topic, refer to the table

of contents at the beginning of the document, or the table of contents at the

beginning of a specific chapter.

Notational Conventions This document uses the following notational conventions:

• Procedures. Each procedure begins with an italicized statement of the

task, followed by a numbered list of steps. Procedures require you to take

action.

• Bullets. Bulleted lists, such as this one, provide information but not

procedural steps. They do not require you to take action.

• Cross-References. Cross-references to other sections in the document

appear in boldface. Example: see Mounting the Circuit Monitor in

Chapter 3.

6

Page 12

Chapter 1—Introduction

Topics Not Covered Here Some of the circuit monitor’s advanced features, such as on-board data log

and event log files, must be set up over the communications link using

POWERLOGIC application software. This circuit monitor instruction bulletin

describes these advanced features, but does not tell how to set them up. For

instructions on setting up these advanced features, refer to the appropriate

application software instruction bulletin.

RELATED DOCUMENTS Several optional add-on modules are available for use with the circuit

monitor. Each module is shipped with an instruction bulletin detailing

installation and use of the product. Available add-on modules for the

circuit monitor are listed below.

Instruction Bulletin Title Reference No.

• POWERLOGIC Control Power Module (CPM-48) 3090IM9305

• POWERLOGIC Ride-Through Module 3090IM9701

• I/O Modules (IOM-11/44/18) 3020IM9304

• I/O Modules (IOM-4411/4444) 3020IM9401

• Voltage/Power Module 3090IM9302

• Optical Communications Interface (OCI-2000) 3090IM9303

• Ethernet Communications Module (ECM-2000/ECM-RM) 3020IB9818

➀

➀ Reference numbers listed are the original document numbers. If a document has been revised, the listed number will be followed by a

revision number, for example R10/97.

7

Page 13

Bulletin No. 3020IB9814

December 1998

Reference Manual This Installation and Operation manual provides the information necessary

to install and operate the circuit monitor. Additional information on the

circuit monitor’s advanced features is available in English only in the

POWERLOGIC Circuit Monitor Reference Manual. The reference manual

includes information on the following topics:

• Metering Capabilities

• Input/Output Capabilities

• Alarm Functions

• Logging

• Waveform Capture

• Disturbance Monitoring

• CM-2450 with Programming Language

• Advance Topics

• Communication Cable Pinouts

• Abbreviated Register Listing

• Calculating Log File Sizes

• Alarm Setup Information

• Reading and Writing Registers from the Front Panel

8

Page 14

Chapter 2—Hardware Description

CHAPTER 2—HARDWARE DESCRIPTION

FRONT PANEL The circuit monitor front panel is designed for maximum ease of use. The

circuit monitor has five modes of operation:

• METERS — for viewing real-time metered data

• MIN — for viewing the minimum of the selected metered value

• MAX — for viewing the maximum of the selected metered value

• ALARM — for viewing the status of on-board alarms

• [Setup] — for setting up the circuit monitor

The general procedure for displaying data is simple:

1. Press the MODE button to select one of the five available modes.

2. Press the SELECT METER buttons to select a metered value.

3. Press the PHASE button to select a phase.

In [Setup] mode, use the alternate descriptions in grey to the right of the

LEDs. In SETUP mode, the PHASE, MODE, and SELECT METER buttons

function differently than in the other display modes. For details see

Chapter 4—Front Panel Operation.

Figure 2-1 shows the front panel of the circuit monitor. A description of the

front panel follows.

➀ 6-Digit LED display. For local display of metered values.

➁ Kilo/Mega LEDs. The Kilo LED lights when the displayed value is in

Kilo units. The Mega LED lights when the displayed value is in Mega

units.

➂ Meter Indication LEDs. The lit LED indicates the value being displayed.

➃ Setup/Reset Parameters. These grey, bracketed values are used to set up

the circuit monitor and perform resets. Refer to these values when in

[Setup] mode.

➄ Phase Indication LEDs. Indicate the phase for the displayed value.

Note: If you select a metered value that does not provide a reading for

the selected phase, the circuit monitor automatically jumps to a phase for

which a reading exists. For example, assume that you are viewing Phase

A Power Factor, then change to Frequency; the circuit monitor

automatically jumps from Phase A to 3-Phase, since the circuit monitor

does not provide a Phase A Frequency reading.

➅ PHASE Select Button. Press to select the phase for the selected meter

value. Note: In [Setup] mode, press this button to move from one setup

parameter to the next. See Chapter 4—Front Panel Operation for details.

➆ SELECT METER buttons. Press to change the metered value being

displayed. Note: In [Setup] mode, press these buttons to change the value of

the displayed setup parameter. See Chapter 4—Front Panel Operation

for details.

9

Page 15

Bulletin No. 3020IB9814

December 1998

➇ Mode Indication LEDs. These LEDs indicate the present display mode.

The Alarm LED flashes when an alarm is active.

➈ MODE Select Button. Press to select the display mode.

➉ Optical Communications Port. This port allows the circuit monitor to

communicate to a portable computer using the optional optical

communications interface (Class 3090 Type OCI-2000). The OCI-2000

mounts magnetically to the circuit monitor and provides a standard

RS-232 interface. Anything that can be done over the RS-485

communications link—including circuit monitor setup—can also be done

using the optical communications port.

➀

➂

➃

➉

o AMMETER (A)

o VOLTMETER, L-L (V)

o VOLTMETER, L-N (V)

o WATTMETER (W)

o VARMETER (VAr)

o VA METER (VA)

o POWER FACTOR METER

o FREQUENCY METER (Hz)

o DEMAND AMMETER (A)

o DEMAND POWER (W)

o DEMAND POWER (VA)

o WATTHOUR METER

o VARHOUR METER

o THD, CURRENT (%)

o THD, VOLTAGE (%)

o K-FACTOR

Optical

Comm Port

CIRCUIT MONITOR

[CT Primary]

[PT Primary]

[Sys. Type]

[Dmd. Int.]

[WH/Pulse]

[Address]

[Baud Rate]

[Nom. Freq.]

[Reset]

[Reset]

[Reset]

[Reset]

[Reset]

[Rst. Min/Max]

[Set Password]

[Accept]

3-PHASE

A (A-B)

B (B-C)

C (C-A)

N

SELECT

METER

[Value]

METERS

MIN

MAX

ALARM

[Setup]

Kilo

Mega

PHASE

MODE

➁

➅

➄

➆

➇

➈

10

Figure 2-1: Circuit monitor front panel

Page 16

Chapter 2—Hardware Description

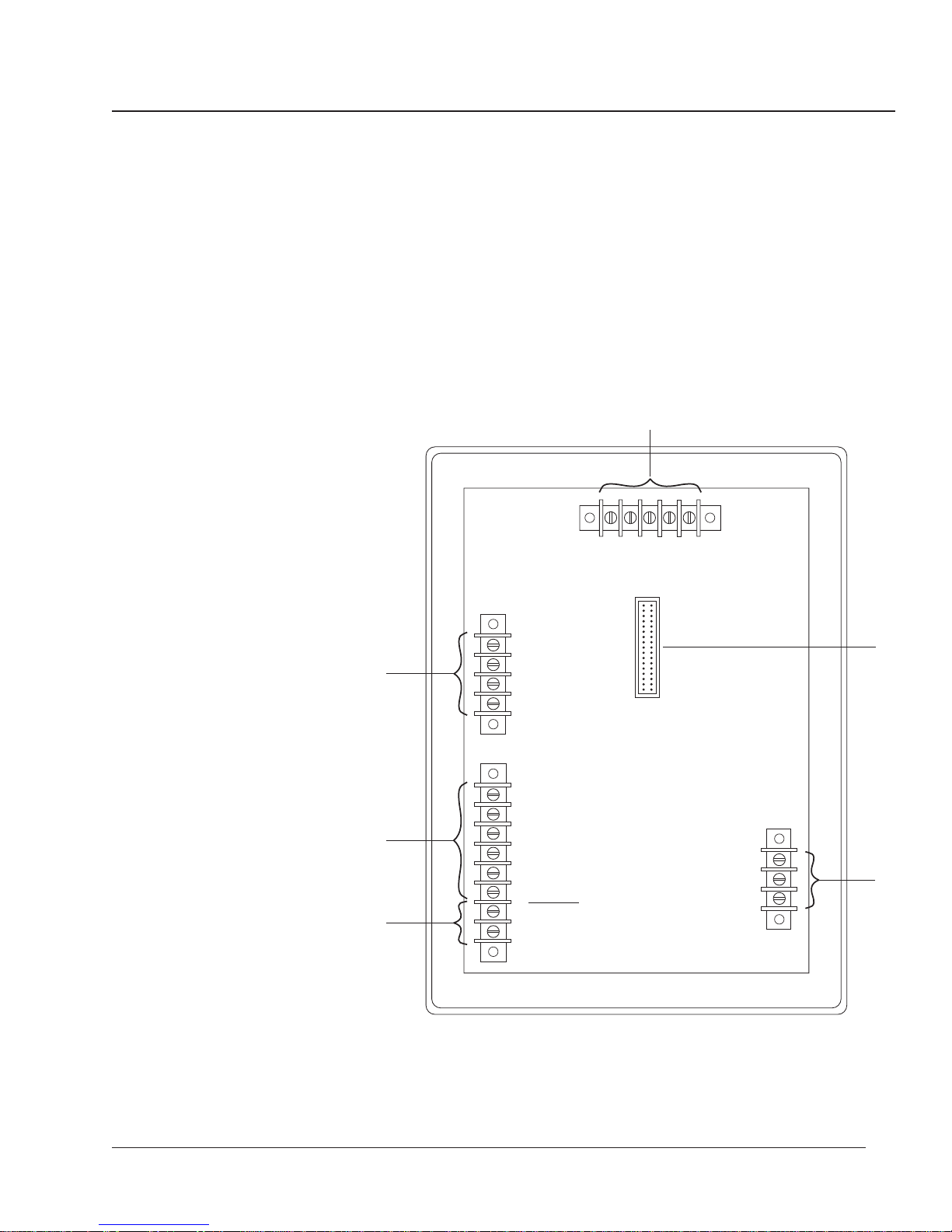

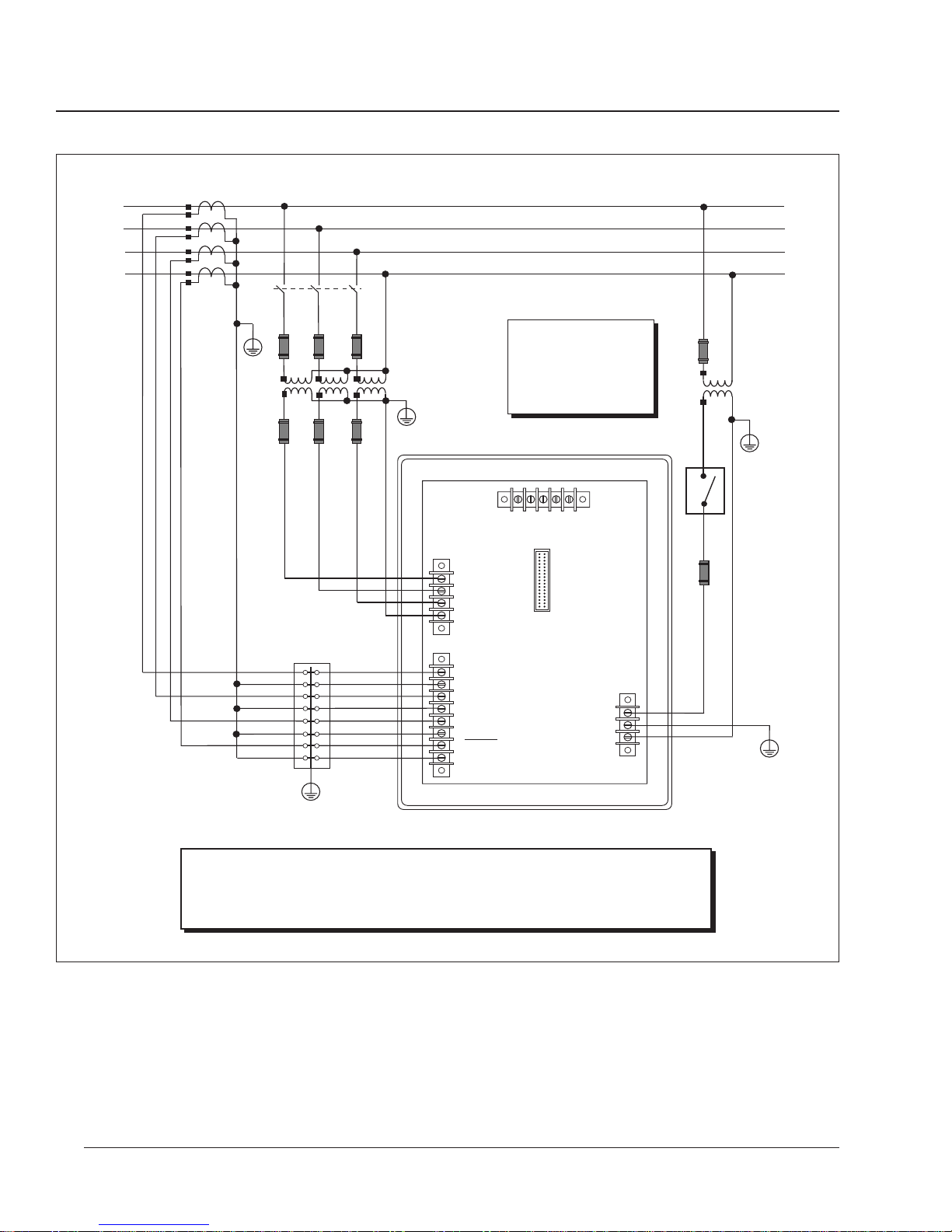

REAR CONNECTIONS Figure 2-2 shows the rear of the circuit monitor. Identified parts are as

follows:

➀ Auxiliary Current Inputs

➁ 3-Phase Current Inputs

➂ 3-Phase Voltage Inputs

➃ RS-485 Communications Terminals

➄ Input/Output Module Connector

➅ Control Power Terminals

Note: See Chapter 3—Installation for wiring instructions.

➃

➂

➁

➀

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

V

3 PHASE

b

VOLTAGE

V

INPUTS

c

120 VOLTS

V

NOMINAL

n

910111256781234

V

a+

I

a-

I

3 PHASE

CURRENT

b+

I

INPUTS

5 AMPS

b-

I

NOMINAL

c+

I

c-

I

AUXILIARY

n+

I

CURRENT

INPUTS

n-

5 AMPS

I

NOMINAL

20 21 22 23 24

IN+ IN- OUT+ OUT- SHLD

RS-485

DATA COMMUNICATIONS

CONTROL

POWER

(+)L G N(-)

➄

25 26 27

➅

Figure 2-2: Back of the circuit monitor

11

Page 17

Chapter 3—Installation

CHAPTER 3—INSTALLATION

CHAPTER CONTENTS This chapter tells how to mount and wire the circuit monitor. Refer to the

table of contents below to locate a specific topic.

CE Compliance........................................................................................................14

Mounting the Circuit Monitor ............................................................................ 15

Wiring CTs, PTs, and Control Power................................................................. 17

Wiring Multiple Circuit Monitors to a Single Set of PTs/CPT .......... 25

Deriving Control Power from Phase PT Inputs.................................... 26

Grounding the Circuit Monitor .......................................................................... 27

Communications Wiring ..................................................................................... 28

Connecting to a System Display ............................................................. 29

Connecting to a Personal Computer ...................................................... 30

Connecting to a POWERLOGIC Ethernet Gateway .............................. 31

Connecting to a POWERLOGIC Network Interface Module ............. 32

Connecting to a SY/MAX Programmable Controller ....................... 33

Length of the Communications Link ..................................................... 34

Daisy-Chaining POWERLOGIC Devices .............................................. 35

Terminating the Communications Link ................................................ 36

Biasing the Communications Link ......................................................... 37

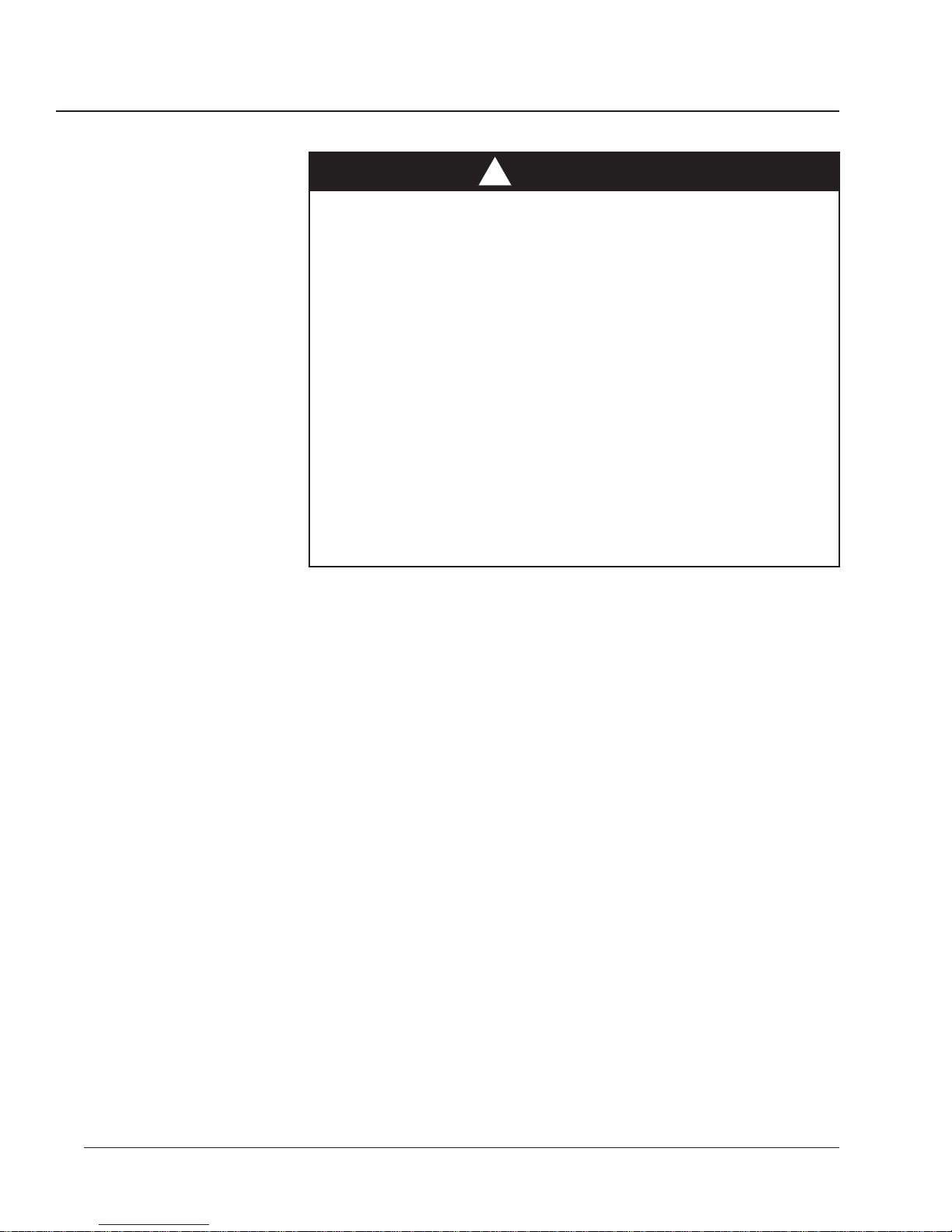

DANGER

!

HAZARD OF PERSONAL INJURY OR DEATH

Only qualified electrical workers should install and wire this

equipment. Such work should be performed only after reading this

complete set of instructions.

Failure to observe this precaution will result in death, serious

injury or equipment damage.

13

Page 18

Bulletin No. 3020IB9814

December 1998

CE COMPLIANCE To comply with CE Electromagnetic Compatibility requirements, the circuit

monitor must be installed in a metallic enclosure (switchgear, for example).

For CE compliance, Merlin Gerin Disconnect Breakers Type P25M #21104 or

IEC 947 equivalent must be connected directly to the metering voltage and

control power inputs (figure 3-1).

Note: The disconnect switch must be placed within reach of the circuit monitor

and labeled “Disconnect Switch for Circuit Monitor.”

Disconnect

Breaker

Metering Voltage Source

must

Note: The disconnect breaker

here

If control power is derived from the metering voltage source,

no additional disconnect device is necessary.

However, if control power is derived from a separate source,

an

additional

between the control power terminals and the control power

source.

(See inset box at right for detail of additional disconnect

breaker.)

disconnect breaker

V

a

V

b

V

c

V

n

be installed

must

be installed here

Control Power

Source

L

L

2

1

Note: See figures 3-4 through 3-10 for possible connection types.

Figure 3-1: Example of disconnect breaker for CE compliance

14

L

G

N

Page 19

Chapter 3—Installation

MOUNTING THE CIRCUIT The circuit monitor is a flush-mounted device that projects through the back

MONITOR of a panel or breaker cell door. Table 3-1 lists typical mounting locations in

various power equipment designs.

Note: Series 2000 circuit monitors use the same cutout dimensions and

hole patterns as the Series 100, 200 circuit monitors, but the required rear clearances

have increased.

When choosing a mounting location, consider the following points:

• Allow for easy access to the rear of the circuit monitor.

• Allow extra space for all wires, shorting blocks, or other components.

• Consider the depth of the circuit monitor. Include extra depth for add–on

modules that you might add in the future. See Appendix A for circuit

monitor dimensions.

• Be sure that ambient conditions fall within the acceptable range: operating

temperature –25°C to +70°C, relative humidity, 5–95% non-condensing.

For CE mounting requirements, see CE Compliance, page 14.

Note: Before preparing the cutout, refer to Appendix A and verify that the

required clearances exist.

To mount the circuit monitor, complete the following steps:

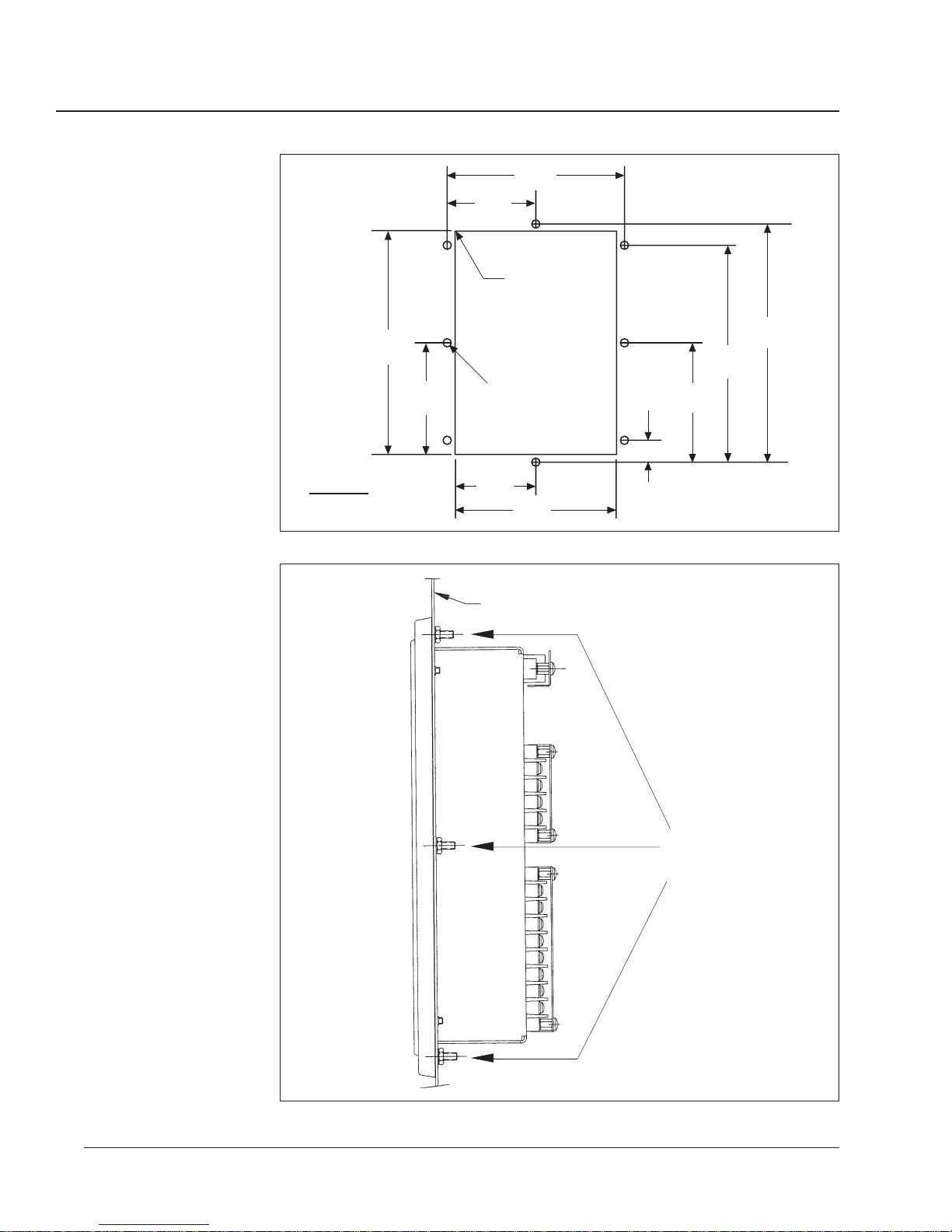

1. Prepare the cutout and mounting holes. Refer to figure 3-2 for exact

dimensions.

2. Insert the circuit monitor through the cutout from the front of the panel

or breaker cell door. Guide the circuit monitor mounting studs through

the holes in the panel.

3. Secure the circuit monitor to the panel using four #10-32 hex nuts

included in the circuit monitor hardware kit (63230-204-16). Figure 3-3

shows the circuit monitor mounted in an electrical panel.

Table 3-1

Typical Circuit Monitor Mounting Locations

Equipment Type Mounting Location

QED Switchboards, Model 6 MCCs Main Meter Location or Aux. Section

POWER-ZONE III Switchgear Main Instrument Compartment Door

HVL and VISI/VAC Switchgear 9-inch Front Panel or Instrument Door

Metal-Clad and Substation CBs Standard Relaying Locations

ISO-FLEX Medium Voltage MCCs Standard Relaying Locations

15

Page 20

Bulletin No. 3020IB9814

December 1998

10.41

264

5.21

132

4.06

104

R Typical

8 Holes

0.28

7

8.11

206

0.09

2

Diameter

5.52

140

10.10

256

11.03

280

Inches

Millimeters

3.71

94

7.41

188

0.93

Figure 3-2: Panel preparation

Panel

24

Secure to panel

using #10-32 hex

nuts (4 required)

16

Figure 3-3: Circuit monitor mounted in electrical panel

Page 21

Chapter 3—Installation

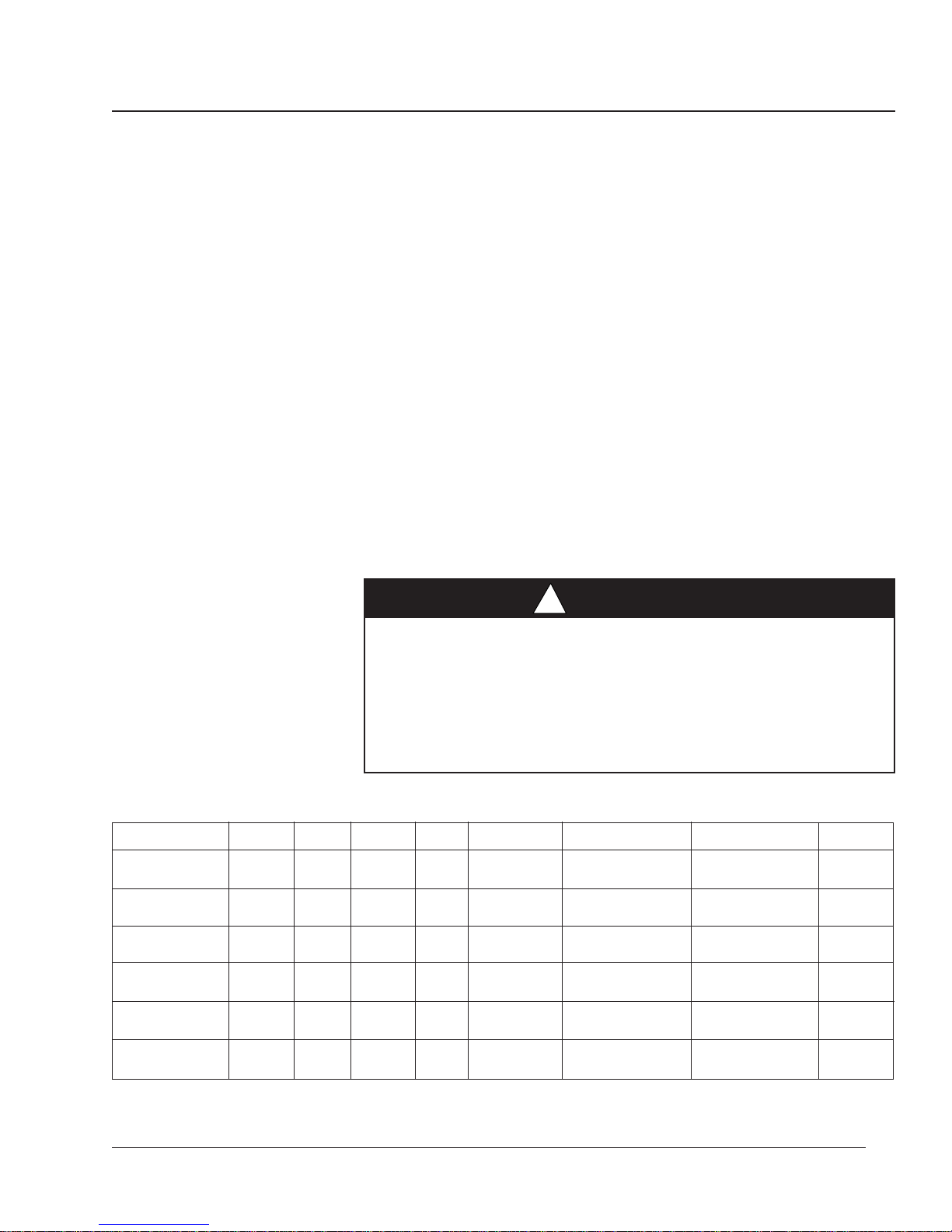

WIRING CTs, PTs, AND The circuit monitor supports a variety of 3-phase power system wiring

CONTROL POWER connections, including 3-wire delta, and 4-wire wye. Table 3-2 lists the

supported system connections. Figures 3-4 through 3-9 show CT, PT, and

control power wiring. Figure 3-10 on page 24 shows dc control power.

Notes:

• When wiring the circuit monitor, route wires outward to make room for

add-on modules that you might install in the future.

• Wiring instructions are also included in CM hardware kit.

• For CE wiring requirements, see CE Compliance, page 14.

To wire the circuit monitor, complete the following steps:

1. Using a suitable crimping tool, crimp the blue spade connectors included

with the circuit monitor onto the wires for the voltage, current, and

control power inputs.

2.

Connect the spade connectors to the circuit monitor terminals as shown in

the appropriate wiring diagram. (Figures 3-4 through 3-10 show wiring

connections.) Do not overtighten screws, but ensure that they are snug.

3. Ground the circuit monitor. See Grounding the Circuit Monitor in this

chapter for instructions.

4. Install protective terminal strip covers. See Appendix C for instructions.

DANGER

!

HAZARD OF PERSONAL INJURY OR DEATH

Only qualified electrical workers should install and wire this equipment.

Such work should be performed only after reading this complete set of

instructions. Follow proper safety procedures regarding CT secondary

wiring. Never open circuit the secondary of a CT.

Failure to observe this precaution will result in death, serious injury

or equipment damage.

Table 3-2

Supported System Wiring Connections

System Type Sys ID➀# CTs Aux. CT # PTs PT Conn. Currents Voltages Figure #

3∅, 3-wire 30 2 None 2 Open Delta A, B➁, C A-B, B-C, C-A

Delta

3∅, 4-wire 40 3 None 3 Wye-Wye A, B, C, N

Wye, Ground A-B➁, B-C➁, C-A

3∅, 4-wire 41 3 Neut 3 Wye-Wye A, B, C, N, G

Wye, Ground A-B➁, B-C➁, C-A

3∅, 4-wire 40 2 None 3 Wye-Wye A, B, C, N

Wye, Ground

3∅, 4-wire 42 3 None 2 Open Wye A, B, C, N

Wye, Ground A-B➁, B-C➁, C-A

3∅, 4-wire 43 3 Neut 2 Open Wye A, B, C, N, G

Wye, Ground A-B➁, B-C➁, C-A

➀ The System ID is used during setup to specify the system type.

➁ Indicates a value that is calculated rather than measured directly.

➂ For 3-wire loads only.

➂

➁

➁

➁

➁

➁

A-N, B-N, C-N 3-5

A-N, B-N, C-N 3-6

A-N, B-N, C-N 3-7

A-B➁, B-C➁, C-A

A-N, B-N➁, C-N 3-8

A-N, B-N➁, C-N 3-9

➁

➁

➁

➁

➁

➁

3-4

17

Page 22

Bulletin No. 3020IB9814

December 1998

Line

AØ

BØ

CØ

CTs (5 Amp Secondaries)

CT Shorting

Block

VDS

Fuses

OPEN DELTA PT

CONNECTION

(120 V L-L

Secondaries)

Fuses

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

V

b

V

c

V

n

910111256781234

V

a+

I

a-

I

b+

I

b-

I

c+

I

c-

I

n+

I

n-

I

Note: Control power can be drawn

from phase PT inputs. See

Deriving Control Power from

Phase PT Inputs

For DC control power connections,

see figure 3-10.

20 21 22 23 24

IN+ IN- OUT+ OUT- SHLD

DATA COMMUNICATIONS

3 PHASE

VOLTAGE

INPUTS

120 VOLTS

NOMINAL

3 PHASE

CURRENT

INPUTS

5 AMPS

NOMINAL

AUXILIARY

CURRENT

INPUTS

5 AMPS

NOMINAL

RS-485

in this chapter.

CONTROL

POWER

14 VA

Load

Fuses

CPT

(120 or 240 Vac

Secondary, 14 VA)

Disconnect

Switch

Fuse

(+)L G N(-)

25 26 27

True Earth

Ground

Notes:

• Pay close attention to polarity marks (■) when connecting CTs and PTs.

• Installation Category II

Figure 3-4: 3-phase, 3-wire delta connection

18

Page 23

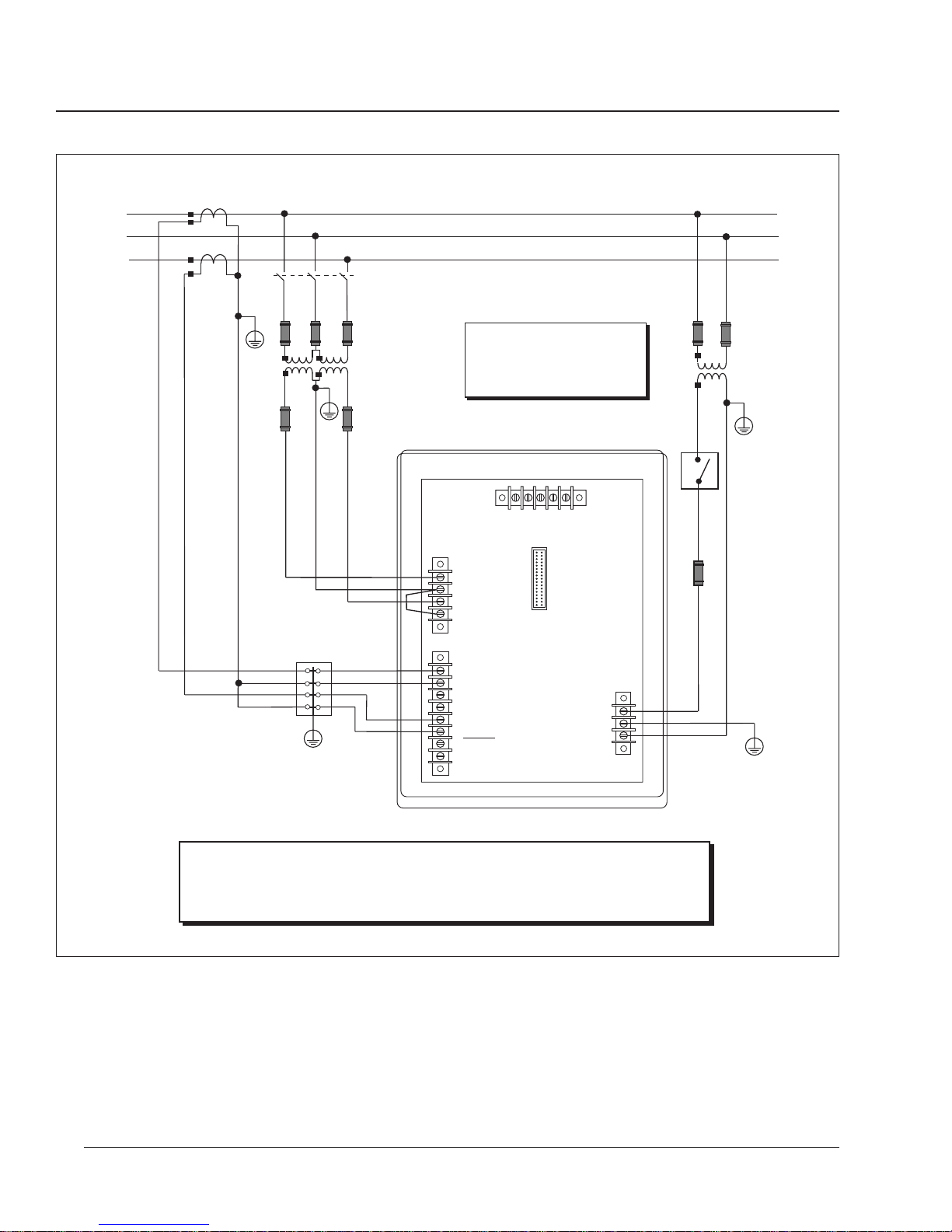

Chapter 3—Installation

Line

AØ

BØ

CØ

CTs (5 Amp Secondaries)

Load

N

VDS

Note: Control power can

be drawn from phase PT

Fuses

Fuses

WYE PT

CONNECTION

(120 V L-N

Secondaries)

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

V

3 PHASE

b

VOLTAGE

V

INPUTS

c

120 VOLTS

V

NOMINAL

n

910111256781234

V

inputs. See

Control Power from

Phase PT Inputs

chapter. For dc control

power connections, see

figure 3-10.

20 21 22 23 24

IN+ IN- OUT+ OUT- SHLD

DATA COMMUNICATIONS

RS-485

Deriving

in this

Fuse

Fuse

CPT

(120 or 240 Vac

Secondary, 14 VA)

Disconnect

Switch

CT Shorting

Block

a+

I

a-

I

3 PHASE

CURRENT

b+

I

b-

I

c+

I

c-

I

n+

I

n-

I

INPUTS

5 AMPS

NOMINAL

AUXILIARY

CURRENT

INPUTS

5 AMPS

NOMINAL

CONTROL

POWER

14 VA

(+)L G N(-)

25 26 27

Notes:

• Pay close attention to polarity marks (■) when connecting CTs and PTs.

• Installation Category II

Figure 3-5: 3-phase, 4-wire wye, ground connection

True Earth

Ground

19

Page 24

Bulletin No. 3020IB9814

December 1998

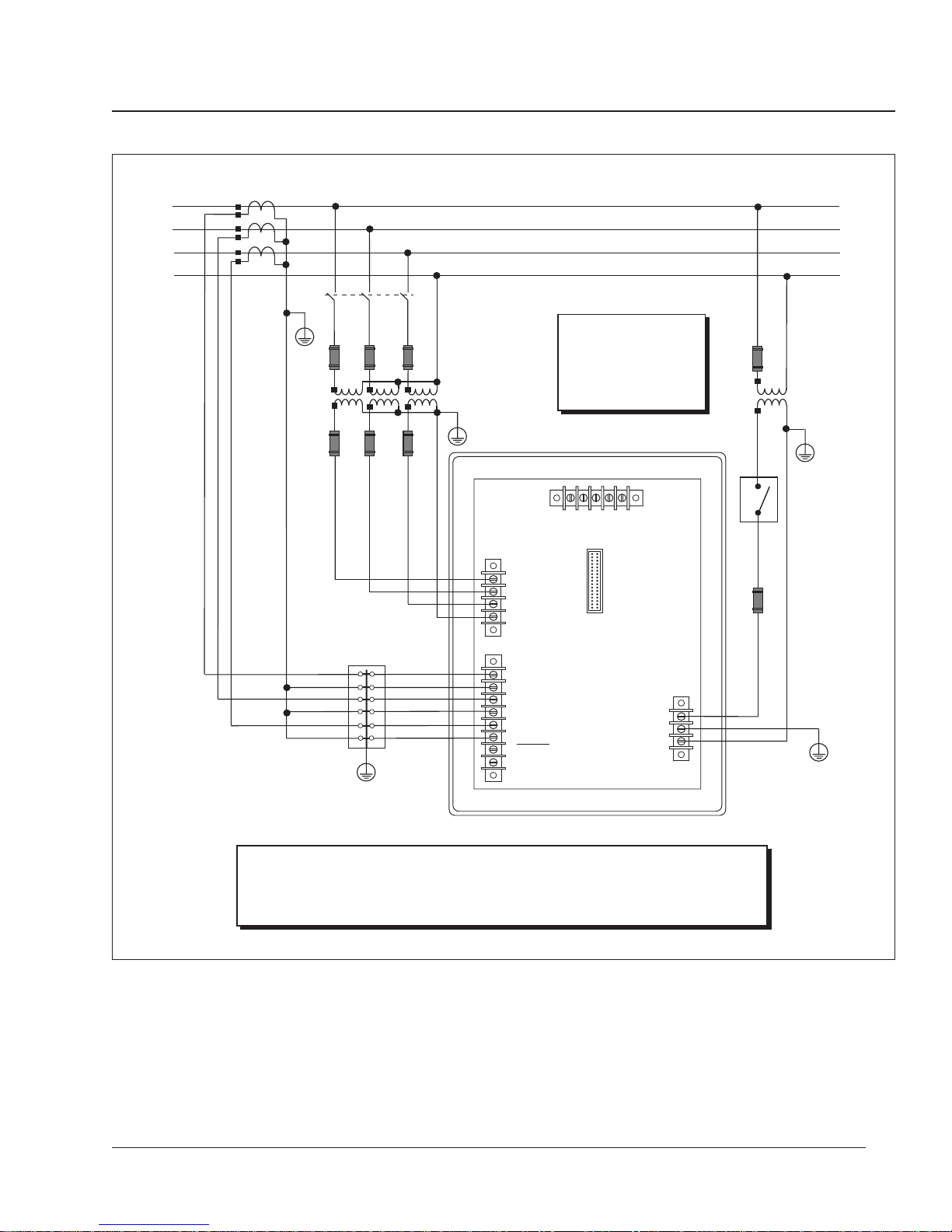

Line

AØ

BØ

CØ

CTs (5 Amp Secondaries)

Load

N

VDS

Note: Control power can

Fuses

Fuses

CT Shorting

Block

WYE PT

CONNECTION

(120 V L-N

Secondaries)

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

V

3 PHASE

b

VOLTAGE

V

INPUTS

c

120 VOLTS

V

NOMINAL

n

910111256781234

V

a+

I

a-

I

3 PHASE

CURRENT

b+

I

INPUTS

5 AMPS

b-

I

NOMINAL

c+

I

c-

I

AUXILIARY

n+

I

CURRENT

INPUTS

n-

5 AMPS

I

NOMINAL

be drawn from phase PT

inputs. See

Control Power from

Phase PT Inputs

chapter. For dc control

power connections, see

figure 3-10.

20 21 22 23 24

IN+ IN- OUT+ OUT- SHLD

DATA COMMUNICATIONS

RS-485

Deriving

CONTROL

POWER

14 VA

in this

(+)L G N(-)

Fuse

CPT

(120 or 240 Vac

Secondary, 14 VA)

Disconnect

Switch

Fuse

25 26 27

True Earth

Ground

Notes:

• Pay close attention to polarity marks (■) when connecting CTs and PTs.

• Installation Category II

Figure 3-6: 3-phase, 4-wire wye, ground connection, metered neutral

20

Page 25

Chapter 3—Installation

Line

AØ

BØ

CØ

CTs (5 Amp Secondaries)

3-Wire

Load

N

VDS

Note: Control power can

be drawn from phase PT

Fuses

WYE PT

CONNECTION

(120 V L-N

Secondaries)

inputs. See

Control Power from

Phase PT Inputs

chapter. For dc control

power connections, see

figure 3-10.

Deriving

in this

Fuse

CPT

(120 or 240 Vac

Secondary, 14 VA)

Fuses

CT Shorting

Block

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

1256781234

V

b

11

V

c

10

V

9

n

V

a

I

a-

I

b+

I

b-

I

c+

I

c-

I

n+

I

n-

I

3 PHASE

VOLTAGE

INPUTS

120 VOLTS

NOMINAL

3 PHASE

CURRENT

INPUTS

5 AMPS

NOMINAL

AUXILIARY

CURRENT

INPUTS

5 AMPS

NOMINAL

20 21 22 23 24

IN+ IN-

OUT- SHLD

OUT+

RS-485

DATA COMMUNICATIONS

CONTROL

POWER

14 VA

Fuse

(+)L G N(-)

25 26 27

Disconnect

Switch

True Earth

Ground

Notes:

• Pay close attention to polarity marks (■) when connecting CTs and PTs.

• Installation Category II

Figure 3-7: 3-phase, 4-wire wye, 3-wire load

21

Page 26

Bulletin No. 3020IB9814

December 1998

Line

AØ

BØ

CØ

CTs (5 Amp Secondaries)

Load

N

VDS

Note: Control power can

be drawn from phase PT

inputs. See

Control Power from

Phase PT Inputs

chapter. For dc control

power connections, see

figure 3-10.

20 21 22 23 24

IN+ IN- OUT+ OUT- SHLD

DATA COMMUNICATIONS

Deriving

in this

RS-485

Fuse

Fuse

CPT

(120 or 240 Vac

Secondary, 14 VA)

Disconnect

Switch

Fuses

Fuses

WYE PT

CONNECTION

(120 V L-N

Secondaries)

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

V

3 PHASE

b

VOLTAGE

V

INPUTS

c

120 VOLTS

V

NOMINAL

n

910111256781234

V

CT Shorting

Block

a+

I

a-

I

3 PHASE

CURRENT

b+

I

b-

I

c+

I

c-

I

n+

I

n-

I

INPUTS

5 AMPS

NOMINAL

AUXILIARY

CURRENT

INPUTS

5 AMPS

NOMINAL

CONTROL

POWER

14 VA

(+)L G N(-)

25 26 27

Notes:

• Pay close attention to polarity marks (■) when connecting CTs and PTs.

• Installation Category II

Figure 3-8: 2-1/2 element metering system type 42 (calculated neutral)

True Earth

Ground

22

Page 27

Chapter 3—Installation

Line

AØ

BØ

CØ

CTs (5 Amp Secondaries)

Load

N

VDS

Fuses

Fuses

CT Shorting

Block

WYE PT

CONNECTION

(120 V L-N

Secondaries)

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

V

3 PHASE

b

VOLTAGE

V

INPUTS

c

120 VOLTS

V

NOMINAL

n

910111256781234

V

a+

I

a-

I

3 PHASE

CURRENT

b+

I

INPUTS

5 AMPS

b-

I

NOMINAL

c+

I

c-

I

AUXILIARY

n+

I

CURRENT

INPUTS

n-

5 AMPS

I

NOMINAL

Note: Control power can

be drawn from phase PT

inputs. See

Control Power from

Phase PT Inputs

chapter. For dc control

power connections, see

figure 3-10.

20 21 22 23 24

IN+ IN- OUT+ OUT- SHLD

DATA COMMUNICATIONS

RS-485

Deriving

CONTROL

POWER

14 VA

in this

(+)L G N(-)

Fuse

CPT

(120 or 240 Vac

Secondary, 14 VA)

Disconnect

Switch

Fuse

25 26 27

True Earth

Ground

Notes:

• Pay close attention to polarity marks (■) when connecting CTs and PTs.

• Installation Category II

Figure 3-9: 2-1/2 element metering system type 43

23

Page 28

Bulletin No. 3020IB9814

December 1998

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

1256781234

V

b

11

V

c

10

V

9

n

V

a

I

a-

I

b+

I

b-

I

c+

I

c-

I

n+

I

n-

I

3 PHASE

VOLTAGE

INPUTS

120 VOLTS

NOMINAL

3 PHASE

CURRENT

INPUTS

5 AMPS

NOMINAL

AUXILIARY

CURRENT

INPUTS

5 AMPS

NOMINAL

20 21 22 23 24

IN+ IN-

DATA COMMUNICATIONS

OUT+

RS-485

OUT- SHLD

CONTROL

POWER

(+)L G N(-)

25 26 27

(+)

dc Control Power

(–)

120/250 Vdc Nominal

24

Note: Installation Category II

Figure 3-10: DC control power connections

Page 29

Chapter 3—Installation

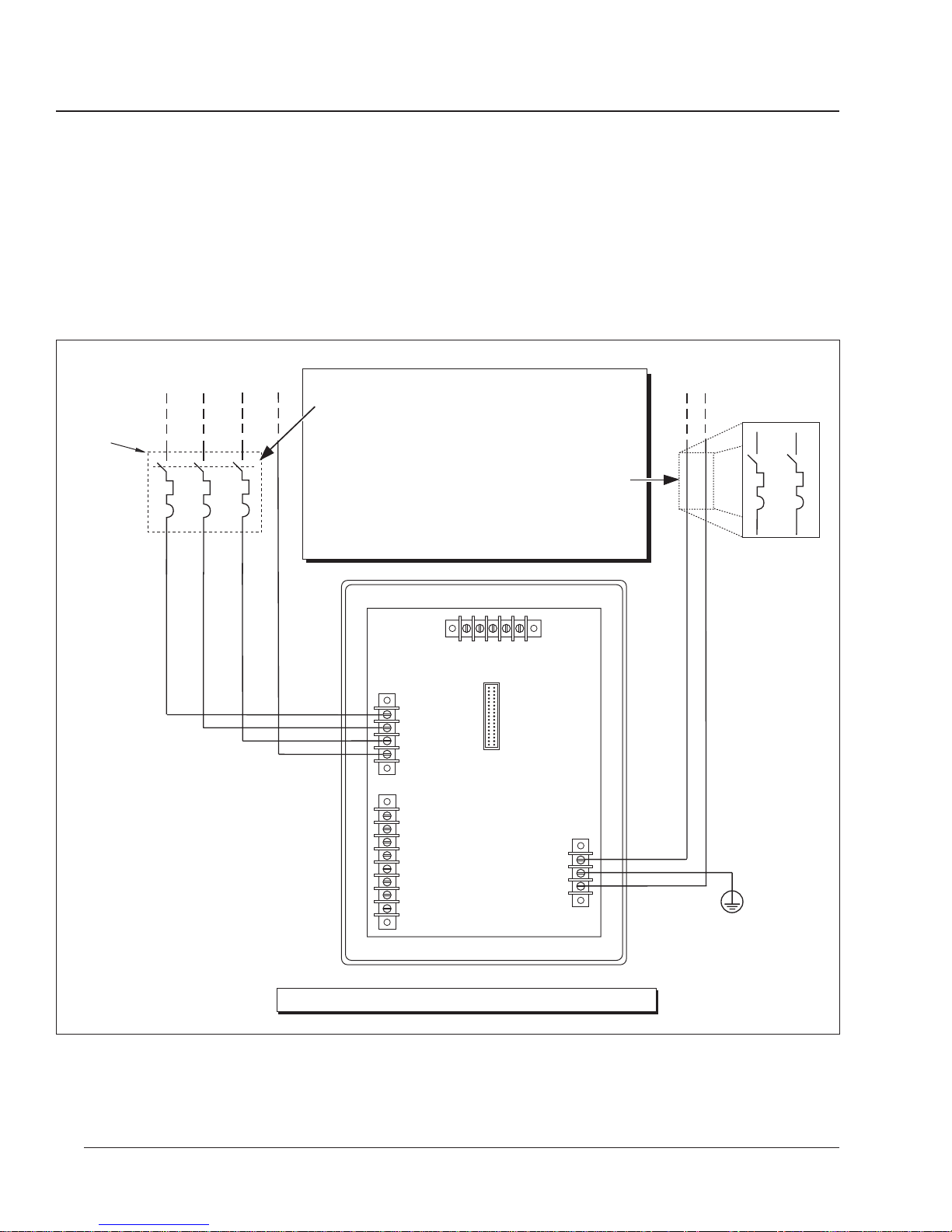

Wiring Multiple Circuit Multiple circuit monitors can share one set of 3-phase PTs. Also, multiple

Monitors to a Single Set circuit monitors can share a single control power transformer (CPT). In all

of PTs/CPT cases, each circuit monitor must use a separate set of CTs. Figure 3-11 shows

how to connect multiple circuit monitors to a single set of PTs and CPT.

Note: When using this wiring method, ground the PT secondaries in only one

location.

PTs

CPT

CM

CTs

CM

CTs

Figure 3-11: Circuit monitors connected to one set of PTs and one CPT

CTs CTs

CM CM

25

Page 30

Bulletin No. 3020IB9814

December 1998

Deriving Control Power Whenever possible, derive circuit monitor control power from a stable

from Phase PT Inputs voltage source. If such a source is unavailable, the circuit monitor can derive

control power from its phase PT inputs. Due to the wide range of permissible

control power inputs, the circuit monitor can accept either L-N or L-L control

power inputs up to 240 V nominal. Using the L-L control power option

increases the circuit monitor ride-through time and enables more reliable

operation during voltage disturbances.

Referring to figures 3-12 and 3-13, complete the following steps to derive control

power from phase PT inputs:

1. Connect the Va terminal (terminal 12) to the L terminal (terminal 25).

2. For L-N control power, connect the Vn terminal (terminal 9) to the N

terminal (terminal 27). For L-L control power, connect the Vc terminal

(terminal 10) to the N terminal (terminal 27).

3. Install protective terminal strip covers. See Appendix C for instructions.

CAUTION

!

HAZARD OF EQUIPMENT DAMAGE

When deriving control power from the phase PT inputs, the phase

PT used must have a VA rating sufficient for all connected burdens.

If the VA rating is exceeded, it could reduce the voltage transformer’s

accuracy or damage the PT.

Failure to observe this precaution can result in equipment

damage.

26

Page 31

Chapter 3—Installation

TYPE 1 ENCLOSURE

INDOOR USE ONLY

a

V

b

V

c

V

n

910111256781234

V

a+

I

a-

I

b+

I

b-

I

c+

I

c-

I

n+

I

n-

I

3 PHASE

VOLTAGE

INPUTS

120 VOLTS

NOMINAL

3 PHASE

CURRENT

INPUTS

5 AMPS

NOMINAL

AUXILIARY

CURRENT

INPUTS

5 AMPS

NOMINAL

20 21 22 23 24

IN+ IN- OUT+ OUT- SHLD

RS-485

DATA COMMUNICATIONS

CONTROL

POWER

TYPE 1 ENCLOSURE

INDOOR USE ONLY

aVbVcVnIa+Ia-Ib+Ib-Ic+Ic-In+In-

V

3 PHASE

VOLTAGE

INPUTS

120 VOLTS

NOMINAL

910111256781234

3 PHASE

CURRENT

(+)L G N(-)

25 26 27

INPUTS

5 AMPS

NOMINAL

AUXILIARY

CURRENT

INPUTS

5 AMPS

NOMINAL

20 21 22 23 24

IN+ IN- OUT+ OUT- SHLD

RS-485

DATA COMMUNICATIONS

CONTROL

POWER

(+)L G N(-)

25 26 27

Figure 3-12: Deriving L-L control power from phase PT inputs Figure 3-13: Deriving L-N control power from phase PT inputs

GROUNDING THE For optimal grounding, connect the circuit monitor to a true earth ground.

CIRCUIT MONITOR

To ground the circuit monitor, complete the following steps:

1. Connect the Ground terminal (terminal 26) to a true earth ground, using

#14 AWG wire or larger with spade connector (see figure 3-14).

2. Install protective terminal strip cover. See Appendix C for instructions.

DANGER

!

HAZARD OF ELECTRIC SHOCK

Ground the circuit monitor as described in these instructions. Failure

to properly ground the circuit monitor may allow hazardous voltages

to be present on the circuit monitor chassis, and may result in

equipment damage.

Failure to observe this precaution will result in death, serious

injury or equipment damage.

27

Page 32

Bulletin No. 3020IB9814

December 1998

a+

I

a-

I

3 PHASE

CURRENT

b+

I

56781234

b-

I

c+

I

c-

I

n+

I

n-

I

INPUTS

5 AMPS

NOMINAL

AUXILIARY

CURRENT

INPUTS

5 AMPS

NOMINAL

CONTROL

POWER

(+)L G N(-)

25 26 27

#14 AWG Wire

(or Larger)

True Earth

Ground

Figure 3-14: Grounding the circuit monitor

COMMUNICATIONS WIRING POWERLOGIC devices are equipped with RS-485 communications. The

RS-485 standard lets you daisy-chain up to 32 POWERLOGIC-compatible

devices to a single communications port. This document refers to a chain of

POWERLOGIC devices connected by communications cable as a

communications link.

A POWERLOGIC communications link can consist of up to 32

POWERLOGIC-compatible devices connected to a communications port on

one of the following:

• POWERLOGIC System Display

• Personal computer

• POWERLOGIC Network Interface Module

• SY/MAX programmable controller

• Other host devices with a POWERLOGIC-compatible port

Figures 3-15 through 3-19 show circuit monitors and other POWERLOGIC

compatible devices connected in typical systems. The accompanying text

describes important considerations for each connection alternative.

The figures also show the placement of communications adapters and

terminators. For additional information on using the communications

adapter and terminator, see Terminating the Communications Link and

Biasing the Communications Link in this chapter.

28

Page 33

Chapter 3—Installation

Connecting to a System • Connect up to 32 circuit monitors to the system display for Circuit

Display Monitors (Class 3050 Types SD-200, SD-220). See Length of the

Communications Link in this chapter for distance limitations at

varying baud rates.

• Connect circuit monitors to the RS-485 port on the bottom of the system

display.

• Configure the system display’s baud rate to match the baud rate of circuit

monitors on the communications link.

• Refer to the instruction bulletin for the system display for circuit monitors

(Class 3050 Types SD-200, SD-220) for detailed instructions on

configuring the system display.

System Display

To RS-485

communications port

BELDEN 8723

(or equivalent)

MCT-485

MCA-485

CAB-107

CAB-107

(see Appendix B

(See Appendix D

for cable pinouts)

for cable pinouts)

1–32 Circuit Monitors

Figure 3-15: Circuit monitors connected to a system display for circuit monitors

29

Page 34

Bulletin No. 3020IB9814

December 1998

Connecting to a • Connect up to 32 POWERLOGIC devices to a personal computer. See

Personal Computer Length of the Communications Link in this chapter for distance

limitations at varying baud rates.

• POWERLOGIC devices can be connected to a SY/LINK card installed in

the personal computer. To do this, connect the POWERLOGIC devices to

the RS-422 port (female DB-9 connector) of the SY/LINK card.

• POWERLOGIC devices can be connected to a serial COMM port on the

personal computer. To do this, the POWERLOGIC devices must be

connected to an RS-232 to RS-422/RS-485 converter which is connected

to the personal computer. POWERLOGIC offers a converter kit for this

purpose (Class 3090 Type MCI-101). Refer to the instruction bulletin

included with the MCI-101 for connection instructions.

Connected to RS-422 port of SY/LINK

Connected to RS-422 port of SY/LINK card

card or RS-422 PC serial port

BELDEN 8723

(or equivalent)

MCT-485

MCA-485

1–32 Devices (Circuit Monitors and other POWERLOGIC-compatible devices)

Figure 3-16: POWERLOGIC devices connected directly to a personal computer

CAB-107

CAB-107

(see Appendix B

(See Appendix D

for cable pinouts)

for cable pinouts)

30

Page 35

Chapter 3—Installation

Connecting to a POWERLOGIC

• There are two models of the POWERLOGIC Ethernet Gateway: a single

Ethernet Gateway (EGW) port version (EGW1) and a dual port version (EGW2).

• The serial port on the EGW1 can support up to 8 POWERLOGIC devices.

• Each serial port on the EGW2 can support up to 32 POWERLOGIC

devices on a daisy-chain, or up to 64 devices when a signal repeater

is used.

• Connection to the Ethernet can be made via a UTP or AUI port.

POWERLOGIC

Network Server

with Client

POWERLOGIC

Ethernet Gateway

(dual port version)

UNIT STATUS

Ethernet

Belden 8723

(or equivalent)

MCT-485

Transmit

Receive

Collision

UTP Link

UTP Parity

RS-232

UTP

RS-485

PORT 1 PORT 2

(AMBER•OK)

AUI

MCT-485

1–32 Devices (Circuit Monitors and Other

POWERLOGIC-Compatible Devices)

Figure 3-17: POWERLOGIC devices connected to an Ethernet gateway

1–32 Devices (Circuit Monitors and Other

POWERLOGIC-Compatible Devices)

31

Page 36

Bulletin No. 3020IB9814

December 1998

Connecting to a POWERLOGIC • Connect up to 32 POWERLOGIC devices to a PNIM. See Length of the

Network Interface Module Communications Link in this chapter for distance limitations at different

(PNIM) baud rates.

• Connect POWERLOGIC devices to PNIM port 0 (top RS-485 port) only.

• Configure PNIM port 0 for “POWERLOGIC” mode. (See side of PNIM for

instructions on setting dip switches.

• Configure the baud rate of PNIM port 0 to match the baud rate of the

POWERLOGIC devices on the communications link.

• Refer to the PNIM instruction bulletin for detailed instructions on

configuring the PNIM.

System Display

BELDEN 8723

(or equivalent)

MCT-485

1–32 Devices (Circuit Monitors and other

Figure 3-18: POWERLOGIC devices connected to a PNIM

POWERLOGIC

-compatible devices)

Connect Circuit Monitors

to top port (port 0) of

PNIM only.

MCA-485

CAB-107

CAB-107

(See Appendix D

(see Appendix B

for cable pinouts)

for cable pinouts)

PNIM

Remote PC

32

Page 37

Chapter 3—Installation

Connecting to a SY/MAX • Connect up to 32 POWERLOGIC devices to a programmable

Programmable Controller

controller. See Length of the Communications Link in this chapter for

distance limitations at different baud rates.

• Connect POWERLOGIC devices to the RS-422 port of the programmable

controller.

• The programmable controller must contain a program to access

POWERLOGIC device data.

• Configure the baud rate of the programmable controller’s port to match

the baud rate of the POWERLOGIC devices on the communications link.

• Refer to the programmable controller instruction manual for detailed

instructions on configuring the programmable controller.

Note: POWERLOGIC devices can be connected to other manufacturer’s

systems using available communication interfaces. For further information,

contact the POWERLOGIC Technical Support Center. See Getting Technical

Support in Chapter 5.

Programmable

Controller

Connect Circuit Monitors

to RS-422 port of

programmable controller.

BELDEN 8723

(or equivalent)

MCT-485

1–32 Devices (Circuit Monitors and other

POWERLOGIC

-compatible devices)

(See Appendix D

for cable pinouts)

MCA-485

CAB-107

CAB-107

(see Appendix B

for cable pinouts)

Figure 3-19: POWERLOGIC devices connected to a SY/MAX programmable controller

33

Page 38

Bulletin No. 3020IB9814

December 1998

Length of the The length of the communications link cannot exceed 10,000 feet (3,050 m).

Communications Link This means that the total length of the communications cable from the

PNIM, personal computer, system display, or processor, to the last device

in the daisy-chain, cannot exceed 10,000 feet. When 17 or more devices are

on a communications link, the maximum distance may be shorter,

depending on the baud rate. Table 3-3 shows the maximum distances at

different baud rates.

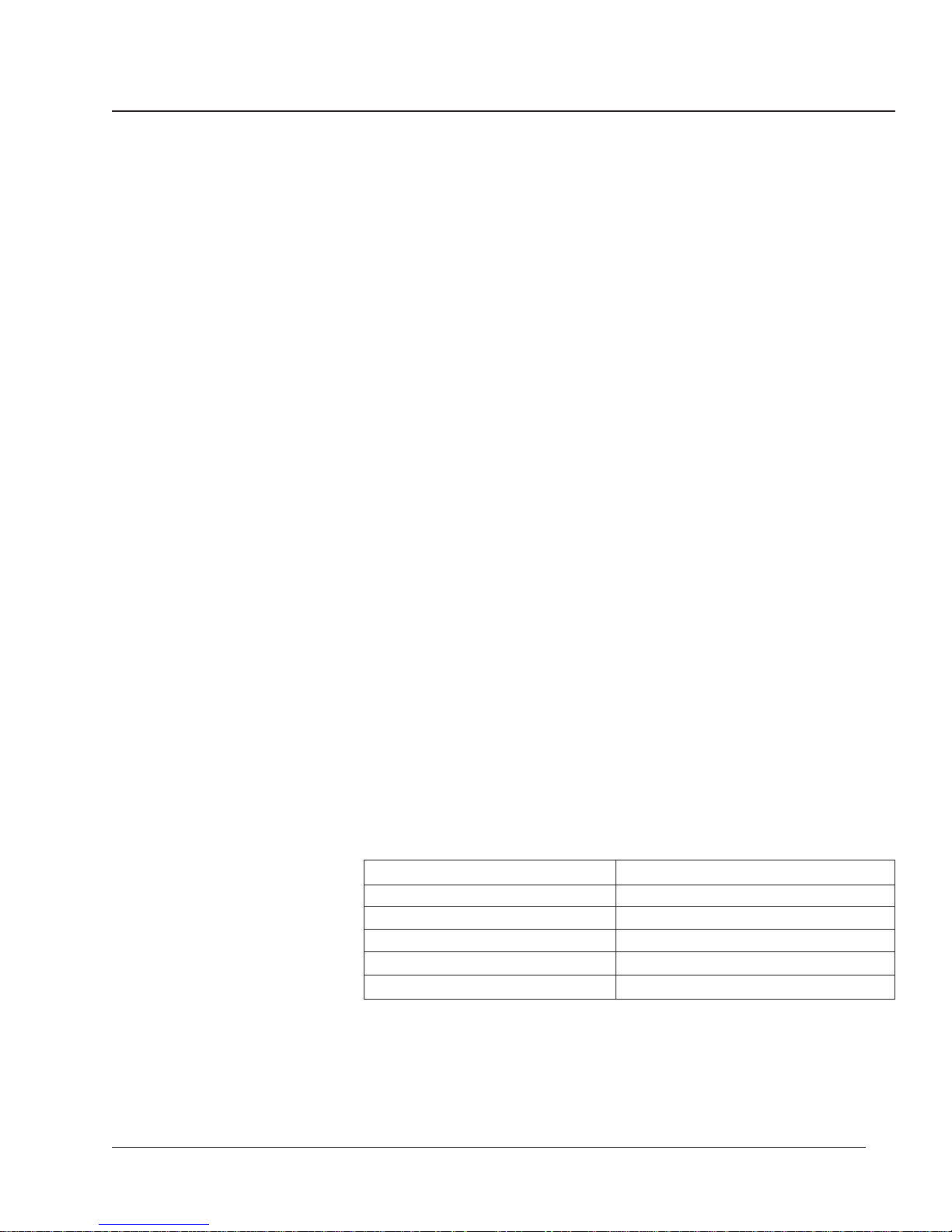

Table 3-3

Maximum Distances of Comms Link at Different Baud Rates

Maximum Distances

Baud Rate 1–16 devices 17–32 devices

1200 10,000 ft (3,050 m) 10,000 ft (3,050 m)

2400 10,000 ft (3,050 m) 5,000 ft (1,525 m)

4800 10,000 ft (3,050 m) 5,000 ft (1,525 m)

9600 10,000 ft (3,050 m) 4,000 ft (1,220 m)

19200 10,000 ft (3,050 m) 2,500 ft (762.5 m)

34

Page 39

Chapter 3—Installation

Daisy-Chaining

POWERLOGIC Devices

Note: To daisy-chain POWERLOGIC devices, use communications cable

containing two twisted-shielded pairs (Belden 8723 or equivalent). Connect the

wires to the circuit monitor’s terminals using the red spade connectors included

with the circuit monitor. Using a suitable crimping tool, crimp the red

connectors onto the communications wires.

Each communicating POWERLOGIC device has five RS-485 terminals for

connection to a POWERLOGIC communications link. On all devices, the

terminals are labeled IN+, IN-, OUT+, OUT-, and SHLD. On the circuit

monitor, the IN+, IN-, OUT+, OUT-, and SHLD terminals are numbered 20,

21, 22, 23, and 24, respectively.

To daisy-chain the circuit monitor to another POWERLOGIC device, wire the

circuit monitor’s RS-485 communications terminals to the matching

communications terminals of the next device. In other words, wire the IN+

terminal of the circuit monitor to the IN+ terminal of the next device, wire

IN- to IN-, OUT+ to OUT+, OUT- to OUT-, and SHLD to SHLD.

See Figure 3-20.

If the circuit monitor is the last device on the daisy-chain, terminate it. See

Terminating the Communications Link in this chapter for instructions. If

the circuit monitor is the first device on the daisy-chain, connect it to the

PNIM, personal computer, system display, or programmable controller using

a CAB-107 or equivalent cable and a Multipoint Communications Adapter.

See Biasing the Communications Link in this chapter for instructions. See

Communication Cable Pinouts in the Circuit Monitor Reference Manual for

the CAB-107 pinout.

or other POWERLOGIC-

Green*

White

To RS-485

Terminals of

next device

* Standard conductor color convention

Red

Black

Circuit Monitor

compatible Device

IN+

IN-

OUT+

OUT-

SHLD

Circuit Monitor

or other POWERLOGIC-

compatible Device

IN+

IN-

OUT+

OUT-

SHLD

Belden 8723

(or equivalent)

Circuit Monitor