Page 1

THE MclNTOSH MC 2155 SOLID STATE STEREO

POWER AMPLIFIER

Reading Time: 31 Minutes

Price $2.00

Page 2

VARIOUS REGULATORY AGENCIES REQUIRE THAT WE BRING THE FOLLOWING

INFORMATION TO YOUR ATTENTION. PLEASE READ IT CAREFULLY.

WARNING: TO PREVENT FIRE OR SHOCK

HAZARD, DO NOT EXPOSE THIS UNIT TO

RAIN OR MOISTURE.

The Mclntosh you have purchased is a Model

MC 2155. It has a serial number located on the rear panel

of the chassis. Record that serial number here:

Serial Number

The model, serial number and purchase date are im-

portant to you for any future service. Record the purchase date here:

Purchase date

Upon application, Mclntosh Laboratory provides a

Three-Year Service Contract. Your Mclntosh authorized

Service Agency can expedite repairs when you provide

the Service Contract with the instrument for repair. To

assist, record your Service Contract number here:

Service Contract Number

Page 3

Your MC 2155 Stereo Power Amplifier

will give you many years of pleasant

and satisfactory performance. If you

have any questions, please contact:

CUSTOMER SERVICE

Mclntosh Laboratory Inc.

2 Chambers Street

Binghamton, New York 13903-9990

Phone: 607-723-3512

Take Advantage of 3 years

of Contract Service...

Fill in the Application NOW.

Contents

SERVICE 1

INSTALLATION 2

HOW TO CONNECT 4

FRONT PANEL INFORMATION 9

REAR PANEL INFORMATION 11

PERFORMANCE LIMITS AND RATINGS 12

PERFORMANCE CHARTS 13

TECHNICAL DESCRIPTION 15

BLOCK DIAGRAM 17

MclNTOSH THREE YEAR SERVICE CONTRACT

An application for A THREE YEAR SERVICE CONTRACT is included with this manual.

The terms of the contract are:

1. Mclntosh will provide all parts, materials

and labor needed to return the measured

performance of the instrument to the

original performance limits. The SERVICE CONTRACT does not cover any

shipping costs to and from the authorized service agency or the factory.

2. Any Mclntosh authorized service agency

will repair Mclntosh instruments at nor-

mal service rates. To receive service

under the terms of the SERVICE CONTRACT, the SERVICE CONTRACT CERTIFICATE must be presented when the

instrument is taken to the service agency.

3. Always have service done by a

Mclntosh authorized service agency. If

the instrument is modified or damaged

as a result of unauthorized repair, the

SERVICE CONTRACT will be cancelled.

Damage by improper use or mishan-

dling is not covered by the SERVICE

CONTRACT.

4. The SERVICE CONTRACT is issued to

you as the original purchaser. To protect you from misrepresentation, this

contract cannot be transferred to a second owner.

5. To receive the SERVICE CONTRACT,

your purchase must be made from a

Mclntosh franchised dealer.

6. Your completely filled in application for

the SERVICE CONTRACT must be post-

marked within 30 days of the date of

purchase of the instrument.

7. To receive the SERVICE CONTRACT, all

information on the application must be

filled in. The SERVICE CONTRACT will

be issued when the completely filled in

application is received by Mclntosh

Laboratory Incorporated in Binghamton,

New York.

8. Units in operation outside the United

States and Canada are not covered by

the Mclntosh Factory Service Contract,

irrespective of the place of purchase.

Nor are units acquired outside the

U.S.A. and Canada, the purchasers of

which should consult with their dealer

to ascertain what, if any, service contract or warranty may be available locally.

Copyright 1981 © by Mclntosh Laboratory Inc. 1

Page 4

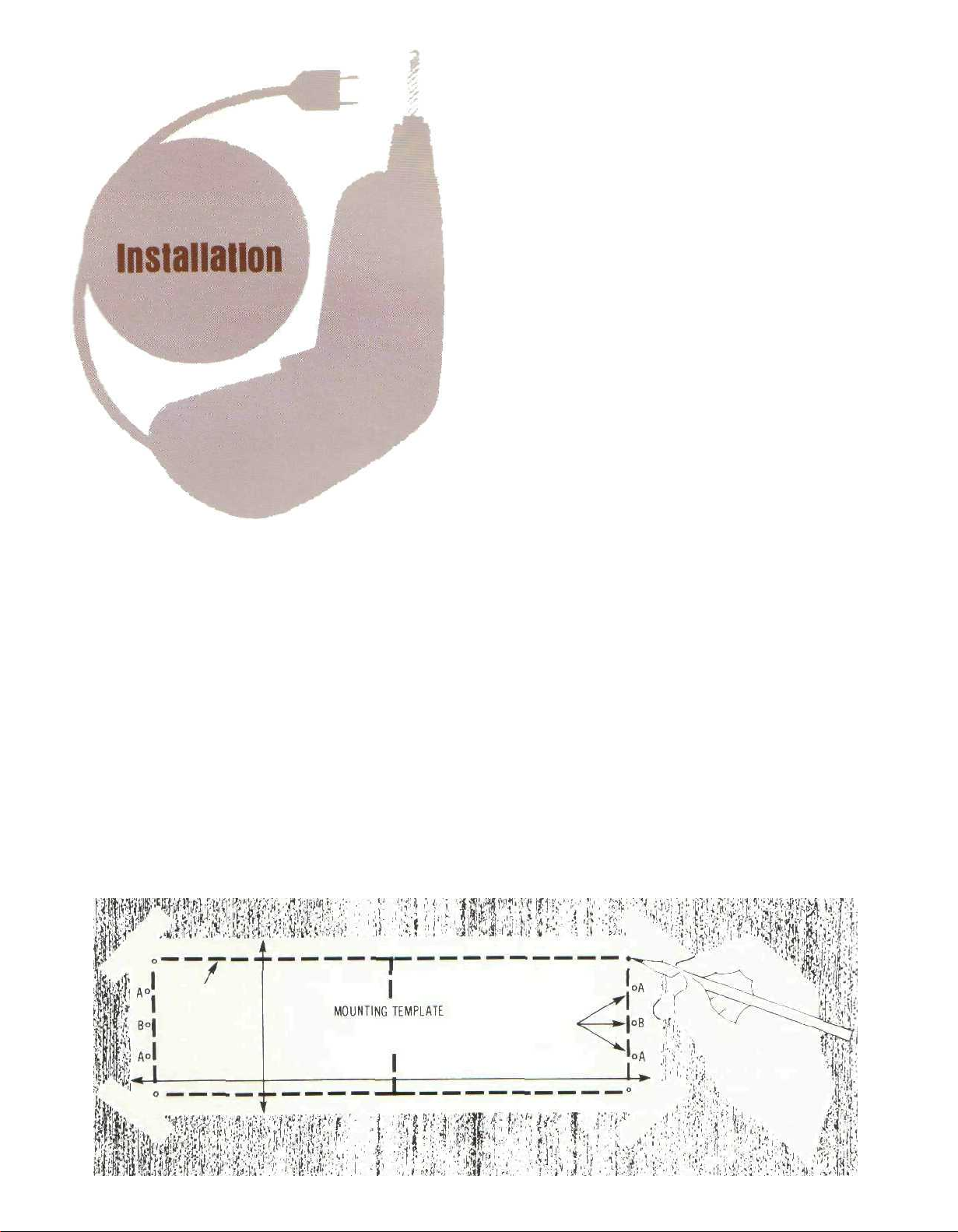

tion the instrument can be mounted in any position.

The recommended minimum space for installation

is 15 inches (38.1 cm)deep, 17 inches (43.2 cm) wide,

and 6 inches (15.2 cm) high.

To install the instrument in a Mclntosh cabinet,

follow the instructions that are enclosed with the

cabinet for any other type of installation, follow

these instructions:

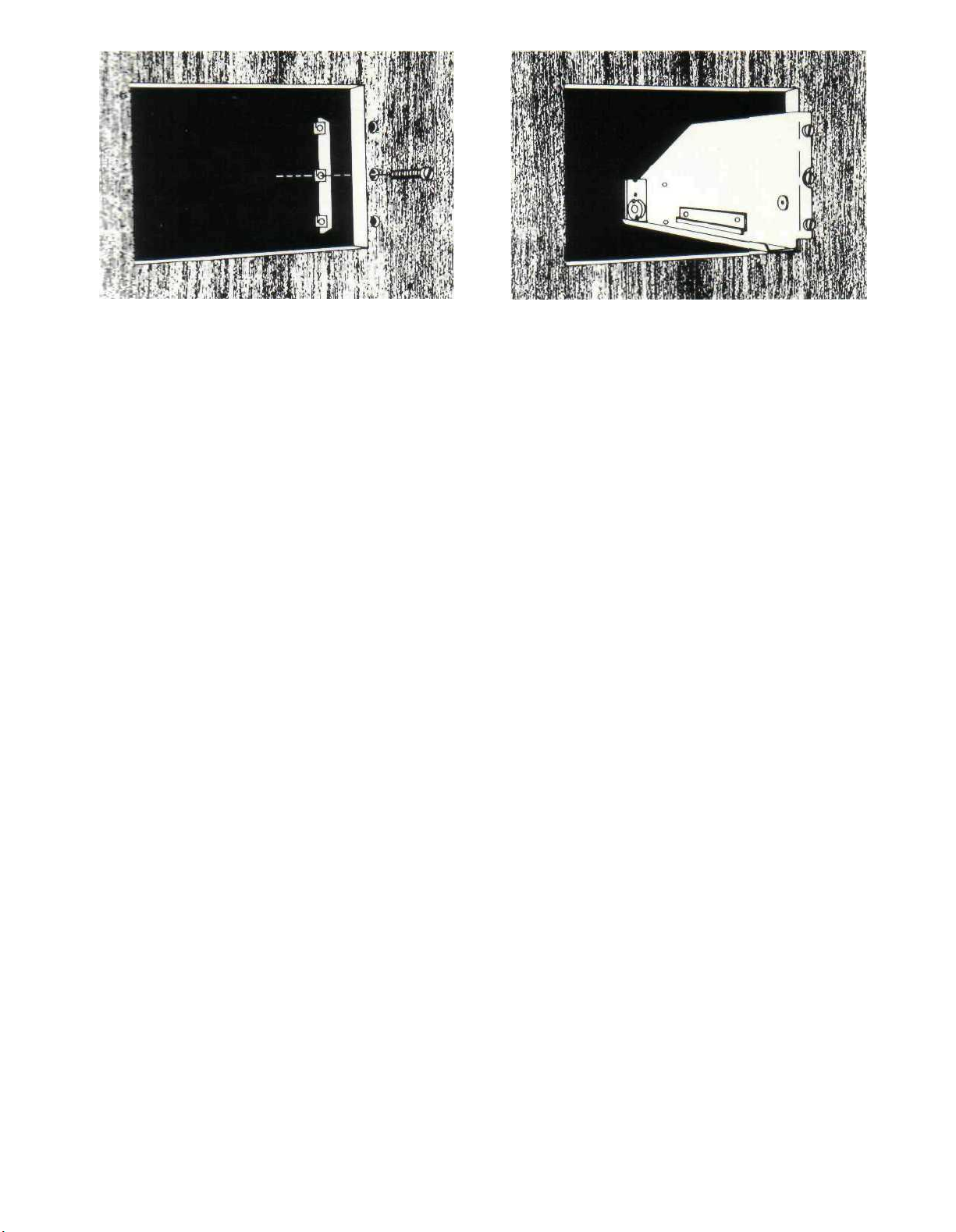

1. Open the carton and remove the PANLOC brackets, hardware package and mounting template. Remove the MC 2155 from the plastic bag and place it

upside down on the shipping pallet then unscrew

the four plastic feet from the bottom of the chassis.

2. Mark the cabinet panel

Place the mounting template in the position on the

cabinet pane! where the instrument is to be install-

ed, and tape it in place. The broken lines that represent the outline of the rectangular cutout also repressent the outside dimensions of the chassis. Make

sure these lines clear shelves, partitions or any

equipment. With the template in place, first mark the

six A and B holes and the four small holes that

locate the corners of the cutout. Then, join the four

corner markings with pencil lines using the edge of

the template as a straight edge.

The PANLOC system of installing equipment conveniently and securely is a direct result of Mclntosh

research. By depressing the two PANLOC buttons

on the front panel, the instrument either can be locked firmly in place or it can be unlocked so that the

chassis can slide forward, giving you easy access to

the top and rear panels.

The trouble-free life of an electronic instrument is

greatly extended by providing sufficient ventilation

to prevent the build-up of high internal temperatures

that cause deterioration. Allow enough clearance so

that cool air can enter at the bottom of the cabinet

and be vented from the top. With adequate ventila-

3. Drill Holes

Use a drill with a 3/16 inch bit held perpendicular to the

panel and drill the six A and B holes. Then, using a drill

bit slightly wider than the tip of your saw blade, drill

one hole at each of two diagonally opposite corners.

The holes should barely touch the inside edge of the

penciled outline. Before taking the next step, make

sure that the six A and 8 holes have been drilled.

4. Saw the Panel Cutout

Saw carefully on the inside of the penciled lines.

First make the two long cuts and then the two short

cuts. After the rectangular opening has been cut out.

use a file to square the corners and smooth any

irregularities in the cut edges.

2

Page 5

5 Install the Mounting Strips

In the hardware package you will find two mounting

strips and two sets of machine screws. For panels

that are less than ½ inch thick, use the ¾ inch

screws: for panels that are more than ½ inch thick,

use the 1 ¼ inch screws.

Starting at the right-hand side of the panel, insert

a screw of proper length into the center hole in the

panel. marked B on the template. On the back of the

panel, align a mounting strip with the holes in the

panel and tighten the screw until the screwhead is

pulled slightly into the wood.

Repeat this procedure to attach the mounting

strip to the left side of the panel.

6. Attach the PANLOC Brackets

Using two screws of proper length in the A holes on

each side, attach the PANLOC brackets to the cabinet panel; the short flange is mounted against the

front (face) of the cabinet panel. The screws pass

through the PANLOC bracket flange, the cabinet

panel, and then through the mounting strips

previously mounted.

7. Install the Instrument

Guide the AC power cord through the panel opening

to the back of the cabinet; then, slide the instrument

into the opening carefully so that the rails on the

bottom of each side of the chassis engage the

tracks on the mounting brackets. Continue to slide

the instrument into the cabinet until it is stopped by

the adjust position latches. Press the latches inward, this permits the instrument to slide into the

cabinet until its front panel is flush with the cabinet

panel. Depress the PANLOC buttons at the lower left

and right corners of the instrument panel to lock the

unit firmly in the cabinet. Depressing the PANLOC

buttons again will unlock the instrument so that it

can slide forward to the adjust position; if you press

inward on the adjust position latches then you can

remove the instrument from the cabinet.

3

Page 6

How to Connect

INPUT

STEREO OPERATION

Use shielded cables to connect the signal from

the preamplifier or signal source to the power

amplifier. To minimize the possibilty of hum the

shielded cables should be run parallel to each other

or loosely twisted together. Locate the cables away

from speaker leads and AC power cords. All connections are made on the back panel of the MC 2155.

For stereo operation, the left output of the

preamplifier should be plugged into the Left input

jack of the power amplifier. The right output of the

preamplifier should be plugged into the Right

(Mono) input jack of the power amplifier.

In stereo operation the MODE SWITCH must be in

the STEREO position.

MONOPHONIC OR SINGLE CHANNEL OPERATION

A shielded cable from the signal source is plug-

ged into the Right (Mono) input jack of the MC 2155

only. The MODE SWITCH on the back panel of the

amplifier must be placed in one of the MONO positions. In the MONO positions the output of the right

channel input amplifier is fed to both left and right

power amplifiers. The Left INPUT is disconnected.

Only the signal fed into the Right (MONO) input will

be amplified.

Be certain that the MC 2155 is never operated in

the stereo mode with the outputs connected for

monophonic operation. Should the MODE SWITCH

be left in the STEREO position and the outputs remain strapped for a mono parallel load, one channel

will attempt to drive the other which causes high circulating currents and overheating.

duction for which the loudspeakers have been de-

signed. If undersize wire is used, resistance is added

to the amplifier/loudspeaker combination which

adversely affects the performance. Added resistance causes depreciation of damping characteristics, modification of frequency response and reduction in power output.

Use lamp cord or wire with similar insulation to

connect the speakers to the amplifier. In all cases,

the leads to and from the speaker should be twin

conductor or twisted together. When using 8 ohm

speakers and for the normally short distances of

under 30 feet between the amplifier and speaker, #

18 wire or larger can be used. For distances over 30

feet use larger diameter wire. Select the correct size

wire from the chart below. It is recommended that

the DC resistance of the speaker leads be less than

5% of the speaker impedance. Resistance of the

leads should be computed for the length of wire both

to and from the speaker or speakers.

For multiple speaker operation, run separate

leads from the amplifier to the speakers.

MAXIMUM WIRE LENGTHS

Wire

Gauge

18

16

14

12

10

For 4 Ohm Load

Feet

15

25

40

60

100

Meters

4.57

7.62

12.19

18.29

30.48

For 8 Ohm Load

Feet

30

50

80

120

200

Meters

9.14

15.24

24.38

36.58

60.96

Wire lengths above represent the wire resistance

equal to 5% of the speaker impedance.

OUTPUT

Be certain the loudspeakers connected to the MC

2155 are capable of handling the power output of the

amplifier.

Selection of the proper gauge wire to connect the

loudspeakers preserves the quality of sound repro-

STEREO OPERATION

Check the impedance of the speaker which is

usually identified on the speaker itself or in the

owner's manual. Connect a lead from the common

terminal of the left speaker to the amplifier LEFT

OUTPUT terminal strip COMmon screw. Connect

4

Page 7

another lead from the other terminal of the

loudspeaker to the left output terminal marked for

the impedance of the speaker on the LEFT OUTPUT

terminal strip. The right channel speaker is connected in the same manner to the RIGHT OUTPUT

terminal strip.

When multiple speakers are to be connected to

either or both outputs, the combined load im-

pedance must be calculated. The load must be con-

nected to the appropriate impedance tap. Use this

table to aid in selecting the correct impedance

match:

Load

impedance

in ohms

0.8 to 1.6

1.6 to 3.2

3.2 to 6.4

6.4 and up

Connect for:

1 ohm output

2 ohm output

4 ohm output

8 ohm output

For monophonic operation using the MONO

PARALLEL mode, output impedances of ½, 1,2, and

4 ohms are accomodated. Connect as listed below.

The common output terminal is at ground potential.

Load Impedance

In Ohms

½

1

2

4

Connect - Speaker

Lead To:

Either Left or Right

Common Terminal

Either Left or Right

Common Terminal

Either Left or Right

Common Terminal

Either Left or Right

Common Terminal

Connect + Speaker

Lead To:

Both Left and Right

1 Ohm Terminals

Both Left and Right

2 Ohm Terminals

Both Left and Right

4 Ohm Terminals

Both Left and Right

8 Ohm Terminals

FOR MONOPHONIC CONSTANT VOLTAGE LINE

OPERATION

For output

voltage of

Connected for:

If a load impedance is used that is lower than the

output impedance tap, then reduced power and possible distortion will result. If a load impedance is used that is higher than the output impedance tap,

then neither the signal nor the amplifier will be

harmed but the power available is reduced.

FOR STEREO CONSTANT VOLTAGE OPERATION:

For output

voltage of

25 volts

Connect for:

4 ohms

MONOPHONIC OR SINGLE CHANNEL OPERATION

When the MC 2155 is used as a monophonic or

single channel power amplifier the two channels are

combined to produce output up to 300 watts. The

outputs must be connected as described below.

For monophonic operation using the MONO

BRIDGE mode, output impedances of 2, 4, 8, and 16

ohms are accomodated. Output connections are

made by connecting to the output terminals as

fisted below. Note that neither output terminal is at

ground potential.

25 volts

2 ohm output (mono)

Be certain that the MC 2155 is never operated in

the stereo mode with the outputs connected for

monophonic operation. Should the MODE SWITCH

be left in the STEREO position and the outputs remain strapped for a mono parallel load, one channel

will attempt to drive the other which causes high circulating currents and overheating.

AC POWER

The MC 2155 operates on 120 volts 50/60 Hz. The

auxiliary AC OUTLET on the MC 2155 is not fused or

switched.

Load Impedance

In Ohms

2

4

8

16

Connect - Speaker

Lead To:

Left 1 Ohm Terminal

Left 2 Ohm Terminal

Left 4 Ohm Terminal

Left 8 Ohm Terminal

Connect + Speaker

Lead To:

Right 1 Ohm Terminal

Right 2 Ohm Terminal

Right 4 Ohm Terminal

Right 8 Ohm Terminal

5

Page 8

Stereophonic

Connections

PROGRAM SOURCE

—

+

LEFT

SPEAKER

—

+

MUST BE IN STEREO

POSITION FOR

STEREO PROGRAMS

RIGHT

SPEAKER

6

Page 9

Mono-Bridge

Connections

PROGRAM SOURCE

(CONNECTIONS FOR

8 OHM SPEAKER

ILLUSTRATED)

— +

CONNECTIONS SHOWN FOR MONO

WHEN MODE SWITCH

IS IN THE MONO-BRIDGE POSITION

SPEAKER

7

Page 10

Mono-Parallel

Connections

PROGRAM SOURCE

(CONNECTIONS FOR

4 OHM SPEAKER

ILLUSTRATED)

—

+

CONNECTIONS SHOWN FOR MONO

WHEN MODE SWITCH

IS IN THE MONO-PARALLEL POSITION

SPEAKER

8

Page 11

The Front Panel Controls and

How to Use Them

METERS

Output power monitor meters indicate the output

power of each channel. Each meter has two primary

scales: WATTS and DECIBELS. When the METER

RANGE switch is in one of the decibel (dB) positions, peak signal readings are indicated on the

lower DECIBEL scale. When the METER RANGE

switch is in the WATTS position, direct power in

watts is read from the upper watts scale. The meters

are calibrated to read average watts. The intermediate markings between the calibrations represent, beginning with 150 watts, 60 watts, 30 watts,

the indicated 15 watts, 6 watts, 3 watts, the indicated 1.5 watts, 0.6 watt, 0.3 watt, the indicated

0.15 watt, 0.06 watt, 0.03 watt, the indicated 0.015

watt, 0.006 watt, 0.003 watt, the indicated 0.0015

watt, 0.0006 watt and 0.0003 watt. Although the

meter calibrations are in average watts for a sine

wave signal, the meters electrically respond to

signal peaks. The meters are voltage actuated and

indicate power accurately when the amplifier is

operated into rated output load impedances.

The meters respond to the peak output of each

channel. Ordinary meters lack the capability of indicating the short interval information in a sound

wave. The mass of the meter movement is too great

to respond to the nearly instantaneous changes in

music program material. Short interval information

can have a duration as short as half a thousandth of

a second. Ordinarily, a meter pointer moving over its

scale in such a short time would not be seen.

Mclntosh has developed circuits that drive the

meters to respond to the short interval information

in a sound wave to an accuracy of 90%. The electrical pulse that drives the meter pointer is time

stretched long enough so that the peak position of

the pointer can register in the persistence of vision

characteristic of the retina of the human eye.

LEFT GAIN

The LEFT GAIN control adjusts the volume in the

left channel to the desired listening level. Turn the

control clockwise to increase the volume.

RIGHT/MONO GAIN

The RIGHT/MONO GAIN control adjusts the

volume in the right channel to the desired listening

level. Turn the control clockwise to increase the

volume. When the output of MC 2155 is connected

for monophonic operation and the rear panel MODE

SWITCH is in the MONO position the volume is con-

trolled by the RIGHT/MONO GAIN control only.

METER RANGE

The METER RANGE switch has five positions.

9

Page 12

WATTS

POWER

In the WATTS position the meter's primary calibration is from .0015 watts (one and a half milliwatts),

up to 150 watts, the rated power output of the MC

2155. The meter is calibrated for 300 watts at the

right hand end of the meter scale. While the MC2155

cannot reach this power level continuously, it is

possible for short interval peaks to exceed, con-

siderably, the 150 watt continuous rating.

HOLD

In the HOLD position, the meter indicates WATTS

and locks to the highest power peak in a sequence

of peaks. The meter will be driven to maximum

power and electronically held there until a higher

peak passes through the amplifier. If no further

peaks are reached the meter needle will very slowly

return to its rest position (decay rate: 6 dB per

minute).

DECIBELS

In the other three positions of the METER RANGE

switch the meters will indicate the output of each

channel in DECIBELS relative to 150 watts or any

other chosen reference.

0dB In this position of the switch, if the

amplifier delivers 150 average watts, the

meter indicates 0 dB; at 75 average watts

the meter indicates -3 dB. If the amplifier

is overdriven to +2 dB the indicated output would be 238 watts.

-10dB In this position of the switch, if the

amplifier delivers 15 average watts, the

meter indicates 0 dB; at 7.5 average watts

the meter indicates -3 dB.

-20dB In this position of the switch, if the

amplifier delivers 1.5 average watts, the

meter indicates 0 dB; at .75 average watts

the meter indicates -3 dB.

HEADPHONES

The output of the front panel HEADPHONE jack

has been designed to feed low impedance dynamic

stereo headphones.

The HEADPHONE output is not affected by the

SPEAKER switch.

SPEAKERS

OFF: The loudspeakers are turned off when the

SPEAKER switch is in the OFF position. You can listen to headphones in private.

THE SPEAKER SWITCH MUST BE IN THE "ON" POSITION TO HEAR MUSIC FROM THE LOUDSPEAKERS.

ON: Music will be heard through the loudspeakers.

Use this as the normal listening position.

The power switch turns the MC 2155 ON or OFF.

The switch does not control the power outlet on the

back panel. If you wish to control the AC power from

a preamplifier control center leave the switch in the

ON position. Be sure the AC cord of the MC 2155 is

plugged into the controlled outlets on the rear of the

preamplifier control center.

OFF: In the OFF position the AC power to the

amplifier is turned off.

POWER GUARD

POWER GUARD assures that the MC 2155 cannot

be overdriven, thus amplifier output clipping is

eliminated. Clipping is caused when an amplifier is

asked to produce more power output than it can

deliver with low distortion. Amplifiers are capable of

delivering large quantities of highly distorted power

when they are driven to clipping. The extra energy

content of the clipped signal will damage most

speakers. Mclntosh's Power Guard circuit protects

your speakers from this kind of damage. The MC

2155 has a built in "waveform comparator" that

compares the wave shape of the output signal to the

input signal. If the disparity between the two

signals, due to overdrive, exceeds 0.5% (equivalent

to 0.5% total harmonic distortion) a red LIMIT

indicator illuminates. With any further increase in

distortion the Power Guard circuit operates to

limit the amplifier input dynamically so that the

amplifier cannot be overdriven. Power Guard

eliminates amplifier output clipping. As long as the

amplifier operates without

overload the NORMAL indicator illuminates.

NEW AUTOMATIC TEST

SYSTEM

The MC 2155 contains a

new automatic test circuit.

When AC line power is applied, an LED digit illuminates to indicate which test

is being performed. Starting with the numeral 7, it

makes the required measurement and verifies if it is

within tolerance by lighting the "normal" Power

Guard green lights. It then counts down to six, performs and verifies the next test, then five, four, three,

etc. until it reaches "1" and then the speakers turn

on. A "beep" tone is heard each time a test is per-

formed. If a circuit should fail, the red "limit" lights

will come on and the sequence will stop at that

point. Speaker turn on will not occur until the fault

has been corrected; thereby protecting your system

from any further damage.

There are two user controls associated with the

auto test circuit. They are located on the amplifier

top panel. Two switches control the speed of the

countdown (SLOW or FAST) and the presence of the

beep tone (ON-OFF).

10

Page 13

Rear Panel Information

MODE SWITCH

The MC 2155 will operate in three modes, Stereo,

Mono Bridge, and Mono Parallel. The Mono modes

differ in the loads they will drive and the connection

sequence to the speaker terminals.

LEFT and RIGHT OUTPUT TERMINALS

For stereo operation, output impedances of 1, 2, 4

and 8 ohms have been provided on a secure, screw

type barrier strip. For monophonic operation proper

interconnection provides 0.5, 1, 2, 4, 8, and 16 ohms

from the same barrier strips. See page 5 for connecting instructions.

INPUT JACKS

In the stereo mode of operation, both input jacks

accept signal. In the mono mode of operation only

the Right (MONO) channel input jack accepts signal

and the Left channel input jack is disconnected.

INPUT LEVEL

The Input sensitivity of the MC 2155 is 0.75 volts or

2.5 V depending on the position of the INPUT LEVEL

switch. All Mclntosh preamplifiers have been designed to deliver 2.5 volts output with rated input.

For the best signal to noise ratio when using Mclntosh

source equipment, place the INPUT LEVEL switch in

the 2.5 V position and the front panel LEFT and

RIGHT/MONO GAIN controls in the fully clockwise

position. If more gain is desired the 0.75 V position

may be used. For source equipment other than

Mclntosh, set the switch in the position nearest to

the stated output rating of the source equipment.

AC POWER

The input to the MC 2155 is 120 volts 50/60 Hz at

up to 6 amps. The primary circuit is protected by an 8

Amp Fuse.

11

Page 14

Performance Limits

PERFORMANCE GUARANTEE

Performance Limits are the maximum deviation

from perfection permitted for a Mclntosh instrument. We promise you that when you purchase a

new MC 2155 from a Mclntosh franchised dealer, it

will be capable of or can be made capable of performance at or exceeding these limits or you can return

the unit and get your money back. Mclntosh is the

only manufacturer that makes this statement.

PERFORMANCE

Mclntosh audio power ratings are in accordance

with the Federal Trade Commission Regulation of

November 4, 1974 concerning power output claims

for amplifiers used in home entertainment products.

POWER OUTPUT

STEREO

150 watts minimum sine wave continuous average

power output, per channel, both channels operating

into 1 ohm, 2 ohms, 4 ohms, or 8 ohms load impedance, which is:

12.2 volts RMS across 1 ohm

17.3 volts RMS across 2 ohms

24.5 volts RMS across 4 ohms

34.6 volts RMS across 8 ohms

MONO

300 watts minimum sine wave continuous average

power output into 0.5 ohm, 1 ohm, 2 ohms, 4 ohms, 8

ohms, or 16 ohms load impedance, which is:

12.2 volts RMS across 0.5 ohm

17.3 volts RMS across 1 ohm

24.5 volts RMS across 2 ohms

34.6 volts RMS across 4 ohms

49.0 volts RMS across 8 ohms

69.3 volts RMS across 16 ohms

OUTPUT LOAD IMPEDANCE

STEREO

1 ohm, 2 ohms, 4 ohms, and 8 ohms; separate ter-

minals are provided for each output.

MONO-PARALLEL

0.5 ohm, 1 ohm, 2 ohms, and 4 ohms; obtained by

connecting together the appropriate terminals of

both channels.

MONO-BRIDGED

2 ohms, 4 ohms, 8 ohms, or 16 ohms, balanced to

common connections.

RATED POWER BAND

20 Hz to 20,000 Hz

TOTAL HARMONIC DISTORTION

STEREO

0.02% maximum harmonic distortion at any power

level from 250 milliwatts to 150 watts from 20 Hz to

20,000 Hz both channels operating.

MONO

0.02% maximum harmonic distortion at any power

level from 250 milliwatts to 300 watts from 20 Hz to

20,000 Hz.

INTERMODULATION DISTORTION

STEREO

0.02% maximum if instantaneous peak power output is 300 watts or less per channel with both channels operating for any combination of frequencies.

20 Hz to 20,000 Hz.

MONO

0.02% maximum if instananeous peak power output

is 600 watts or less for any combination of frequencies, 20 Hz to 20,000 Hz.

FREQUENCY RESPONSE (at one watt output)

20 Hz to 20,00 Hz +0 -0.25 dB.

10 Hz to 100,000 Hz + 0.25 - 1 dB.

NOISE AND HUM

95 dB below rated output.

RATINGS

DAMPING FACTOR

Greater than 30

INPUT IMPEDANCE

50,000 ohms.

INPUT SENSITIVITY

Switchable: 0.75 volt or 2.5 volts—level control provided for higher input voltages.

POWER GUARD

Clipping is prevented and THD does not exceed 2%

with up to 20 dB overdrive at 1 kHz.

GENERAL INFORMATION

POWER REQUIREMENTS

120 volts 50/60 Hz 0.7 to 12 amps.

SEMICONDUCTOR COMPLEMENT

81 silicon transistors

47 silicon rectifiers and diodes

14 integrated circuits

MECHANICAL INFORMATION

SIZE

Front panel measures 16 inches wide (40.6 cm) by

5-7/16 inches high (13.8 cm). Chassis measures 15 inches wide (38.1 cm) by 5 inches high (12.7 cm) by

14-1/2 inches deep (36.8 cm), including connectors.

Knob clearance required is 1-1/2 inches (3.8 cm) in

front of mounting panel.

FINISH

Front panel is anodized gold and black with special

gold/teal nomenclature illumination. Chassis is

chrome and black

WEIGHT

65 pounds (29.5 kg) net, 77 pounds (35 kg) in shipping

carton.

12

Page 15

Performance Charts

13

PERFORMANCE CHARTS ARE

FOR ONE STEREO CHANNEL

WITH BOTH CHANNELS OPERATING.

MONO OPERATION IS IDENTICAL

EXCEPT POWER IS DOUBLED

FOR THE SINGLE MONO OUTPUT.

Page 16

14

Page 17

Technical Description

INPUT AMPLIFIER

Each channel input contains a complete seven

transistor low power amplifier. A differential transistor pair provides high input impedance and low

noise. The differential signals are combined in a current mirror circuit which drives a class A amplifier

3tage. The following output stage is a complimentary pair of transistors with class AB biasing. The

output signal drives the metering circuit, headphone

jack, and the high power output amplifier. This

discrete transistor amplifier design was selected for

low noise, low distortion, adequate power output

capability to drive headphones, and freedom from

turn on and turn off transients.

The INPUT LEVEL selector and GAIN controls are

passive attenuators which precede the input

amplifier circuitry. Therefore, the input system to the

amplifier cannot be overloaded when the controls

are correctly set.

In the MONO mode of operation the input signal

feeds only the right input amplifier via the

RIGHT/MONO GAIN control. The output of the right

input amplifier feeds both output power amplifier

sections. When MONO BRIDGE MODE is selected

the left channel input amplifier is used as a phase inverter before the left output amplifier. The output

channels are therefore 180° out of phase with

respect to each other which is the correct arrangement for bridge output connections. When MONO

PARALLEL MODE is selected the channels operate

in phase. The channels, of course, also operate in

phase for the STEREO MODE.

The first stage of the output power amplifier is a

differential transistor pair biased for best linearity.

The offset to the differential pair is adjustable. Cor-

rect adjustment allows the lowest possible distor-

tion at low frequencies. A current mirror circuit com-

bines the differential outputs into one signal which

is then amplified by a following class A voltage

amplifier. Both the differential transitors and the

voltage amplifier are supplied by active current

sources. The results are lower distortion and cleaner

turn-on characteristics.

The driver stage consisting of a complimentary

pair of power transitors biased class AB follow the

voltage amplifier. Next, two complimentary pairs of

rugged power transistors make up the power output

stage. All power transistors are mounted on conservatively sized anodized aluminum heat sinks.

Because of a unique connection of the bias network,

the output transistors operate class B and exhibit no

crossover distortion often associated with class B

operation. The heat sinks, therefore remain cool

when there is no output.

The amplifier output signal is fed to the output terminals through the output autotransformer. The

Mclntosh designed interleaved multifilar wound

autotransformer is used to properly match the

amplifier to stereo output load taps for 1, 2, 4 and 8

ohms. The MC 2155 will deliver full power over the

entire audio frequency range at any of these Impedances. The autotransformer also protects

speakers from damage in the event of amplifier

failure. Should a direct current component appear in

the output it is shunted by the autotransformer and

DC cannot damage the speaker.

OUTPUT POWER AMPLIFIER

The power amplifier inputs are coupled to the In-

put amplifier outputs through an electronic switch.

The switch eliminates turn-on and turn-off transients

and is used for speaker switching. A junction FET

and LED/light dependent resistor network make up

the switch. This combination allows the lowest

possible distortion when the amplifier is on and high

isolation when the output power amplifier is off. The

control signal to the switch is held off for the auto

test countdown time. Therefore, transients that may

come into the amplifier from source equipment will

not be amplified or reach the loudspeaker. Since the

HEADPHONE output and meters are powered by the

input amplifier, their operation is not affected by the

SPEAKER switch or turn on delay system.

A Mclntosh patented Sentry Monitoring circuit

constantly monitors the output signal and instantly

reacts to prevent overload of the output transistors.

At signal levels up to rated output this circuit has

high impedance and has no effect upon the output.

If the power output exceeds design maximum, the

Sentry Monitoring circuit operates to limit the signal

to the output transistors. In the event of a short circuit across the amplifier output or severe impedance mismatch the Sentry Monitoring circuit will

protect the output transistors from failure. Both

positive and negative halves of the output signal are

monitored and protected independently.

POWER GUARD PROTECTION CIRCUIT

The Mclntosh patented Power Guard circuit

eliminates amplifier clipping due to overdrive. The

15

Page 18

circuit also illuminates red LIMIT indicator lamps

when the amplifier is driven beyond its maximum

output capacity. Power Guard prevents loudspeaker

damage and eliminates harsh output distortion

caused by amplifier clipping.

The Power Guard circuit consists of a waveform

comparator which monitors the wave shape of the

amplifier input and output signals. Normally there is

no disparity between these signals and the comparator produces no output. When the amplifier is

driven beyond its maximum power capacity a difference will develope. If the disparity exceeds 0.5%

(equivalent to 0.5% total harmonic distortion) the

comparator output causes the red LIMIT indicators

to light. If there is a further increase in the disparity

the comparator output controls an electronic attenuator at the amplifier input to reduce the

amplifier gain, thus holding the amplifier output to

its maximum undistorted value regardless of the

degree of overdrive to the amplifier. The amplifier

may be overdriven by 20 dB before the output distortion exceeds 2%.

The comparator is an especially compensated

operational amplifier integrated circuit. Its output is

detected by a full wave bridge that feeds signals to

the control circuitry for the LIMIT and NORMAL in-

dicators and to the electronic attenuator at the

amplifier input. The attenuator is a light emitting

diode/light dependent resistor network selected

especially for its low distortion and time constant

characteristics.

SYSTEM TEST CIRCUIT

When AC line power is applied to the MC 2155 the

System Test circuit functions to verify operating

potentials at 7 test locations within the amplifier.

Upon applying power a digital display lights with the

number 7. The digit is driven by a counter that steps

down at a 1 second or .4 second rate. Each time the

digit changes electronic switches select the outputs

of various voltage comparators connected to test

points in the amplifier. If voltages are normal the

green NORMAL Power Guard indicator lights, there

is an audible beep produced by an internal sounder,

and the display decreases to the next test number.

When the count passes number 1 the loudspeakers

connect and the display blanks off. If a fault condi-

tion exists the counter stops. The digit displayed in-

dicates the circuit at fault. Servicing the amplifier is

thereby simplified.

this amplifier and goes directly to the full wave rectifiers through an attenuator which is controlled by

the METER RANGE switch.

The logarithmic amplifier consists of a high gain

operational amplifier with a bipolar connected silicon diode pair as feedback elements. These diodes

have a uniform logarithmic characteristic over an 80

dB range. Only 60 dB of this logarithmic range is used in the MC 2155.

The full wave rectifier circuit uses an operational

amplifier with silicon diode feedback networks. This

amplified diode circuit has nearly perfect rectification characteristics. One rectifier detects only positive signals. The other responds only to negative

signals and produces a positive output. The outputs

of the rectifiers are combined at the operational

amplifier output, so the highest signal, either

positive or negative, is the one that is indicated by

the meters. Gate diodes are used to charge a low

leakage capacitor which attains and holds a charge

during signal peaks. The operational amplifier pro-

vides a large amount of current so the capacitor can

charge suddenly. The charge on the peak holding

capacitor is amplified in a two transistor DC

amplifier which is used to drive the meter. From the

output of this amplifier there is a DC feedback net-

work that connects back to the detector to assure

excellent overall linearity and frequency response.

The current drive to the meters has a peaking

capacitor to accelerate the upscale response of the

meter needle. The meters also have a parallel shunt

resistor to correctly damp their action. In the WATTS

mode the discharge of the peak holding capacitor is

controlled by a resistor current source. In WATTS

HOLD, the resistor is disconnected so the peak

reading is retained. The rate of decay is about 6 dB

per minute.

POWER SUPPLY

The power supply is a conventional full wave

bridge rectifier arrangement providing plus and

minus 50 volts DC. Electronic regulators step down

and regulate plus and minus 15 volt sources for low

level circuits and plus 5 volts for the logic circuits.

Thermistors are used in the power transformer

primary circuit to limit the turn-on current.

The test circuit uses logic counter, BCD decoder,

lamp driver, and voltage comparator integrated cir-

cuits,

METER CIRCUIT

The meter circuit has three basic sections: a loga-

rithmic amplifier, a full wave rectifier, and a DC amp-

lifier. In the WATTS ranges, the logarithmic amplifier

is used. In the DECIBEL ranges, the signal bypasses

16

Page 19

Block

Diagram

17

MclNTOSH MC 2155 STEREO POWER AMPLIFIER

Page 20

MclNTOSH LABORATORY INC.

2 CHAMBERS ST., BINGHAMTON, N.Y. 13903-2699

607-723-3512

The continuou s improvemen t of its products is the policy of

Mclntosh Laboratory Incorporate d who reserve the right to

improve desig n without notice.

Printed in U.S.A.

039478

Loading...

Loading...