Page 1

THE MCINTOSH MC 2105 SOLID STATE STEREO POWER AMPLIFIER

Reading Time: 28 Minutes

Price $1.25

Page 2

Page 3

Your MC 2105 Stereo Power Amplifier

will give you many years of pleasant

and satisfactory performance. If you

have any questions, please contact:

CUSTOMER SERVICE

Mclntosh Laboratory Inc.

2 Chambers Street

Binghamton, New York 13903

Phone: 607-723-3512

WARNING: TO PREVENT FIRE OR SHOCK

HAZARD, DO NOT EXPOSE THIS UNIT TO

RAIN OR MOISTURE.

Take Advantage of 3 years

of FREE Factory Service . . .

Fill in the Application NOW.

CONTENTS

SERVICE CONTRACT 1

INSTALLATION 2,3

HOW TO CONNECT 4,5

HOW TO USE THE DYNAMIC

PEAK LOCKING METERS ... 6

FRONT PANEL INFORMATION ... 8

PERFORMANCE LIMITS

AND RATINGS 9

TYPICAL PERFORMANCE CHARTS .. 10

TECHNICAL DESCRIPTION 11

BLOCK DIAGRAM 12

THREE YEAR FACTORY SERVICE CONTRACT

An application for a FREE THREE YEAR FACTORY SERVICE CONTRACT is included with this manual.

The terms of the contract are:

1. Mclntosh will provide all parts, materials and

labor needed to return the measured performance of the instrument to the original performance limits free of any charge. The

SERVICE CONTRACT does not cover any shipping costs to and from the authorized service

agency or the factory.

2. Any Mclntosh authorized service agency will

repair all Mclntosh instruments at normal

service rates. To receive the free service under

the terms of the SERVICE CONTRACT, the

SERVICE CONTRACT CERTIFICATE must accompany the instrument when taken to the

service agency.

3. Always have service done by a Mclntosh

authorized service agency. If the instrument

is modified or damaged, as a result of unauthorized repair the SERVICE CONTRACT

will be cancelled. Damage by improper use

or mishandling is not covered by the SERVICE CONTRACT.

4. The SERVICE CONTRACT is issued to you as

the original purchaser. To protect you from

misrepresentation this contract cannot be

transferred to a second owner.

5. For your protection Mclntosh selects its

dealers carefully. Only one dealer in ten

qualifies for a Mclntosh franchise. To receive

the SERVICE CONTRACT your purchase must

be made from a Mclntosh franchised dealer.

6. Your completely filled in application for a

SERVICE CONTRACT must be postmarked

within 30 days of the date of purchase of

the instrument.

7. To receive the SERVICE CONTRACT all information on the application must be filled

in. The SERVICE CONTRACT will be issued

when the completely filled in application

is received at Mclntosh Laboratory Incorporated in Binghamton, New York.

Copyright © 1970 By Mclntosh Laboratory Inc.

1

Page 4

Adequate ventilation extends the trouble-free

life of electronic instruments. It is generally found

that each 10° centigrade (18° F) rise in temperature reduces the life of electrical insulation by one

half. Adequate ventilation is an inexpensive and

effective means of preventing insulation breakdown

that results from unnecessarily high operating tem-

peratures. The direct benefit of adequate ventila-

tion is longer, trouble-free life.

Allow at least 15 inches deep x 17 inches wide

x 8 inches high for mounting the MC2105. Always

allow for air flow by either ventilation holes or

space next to the bottom of the amplifier and a

means for a warm air to escape at the top. With

adequate ventilation the amplifier can be mounted

in any position.

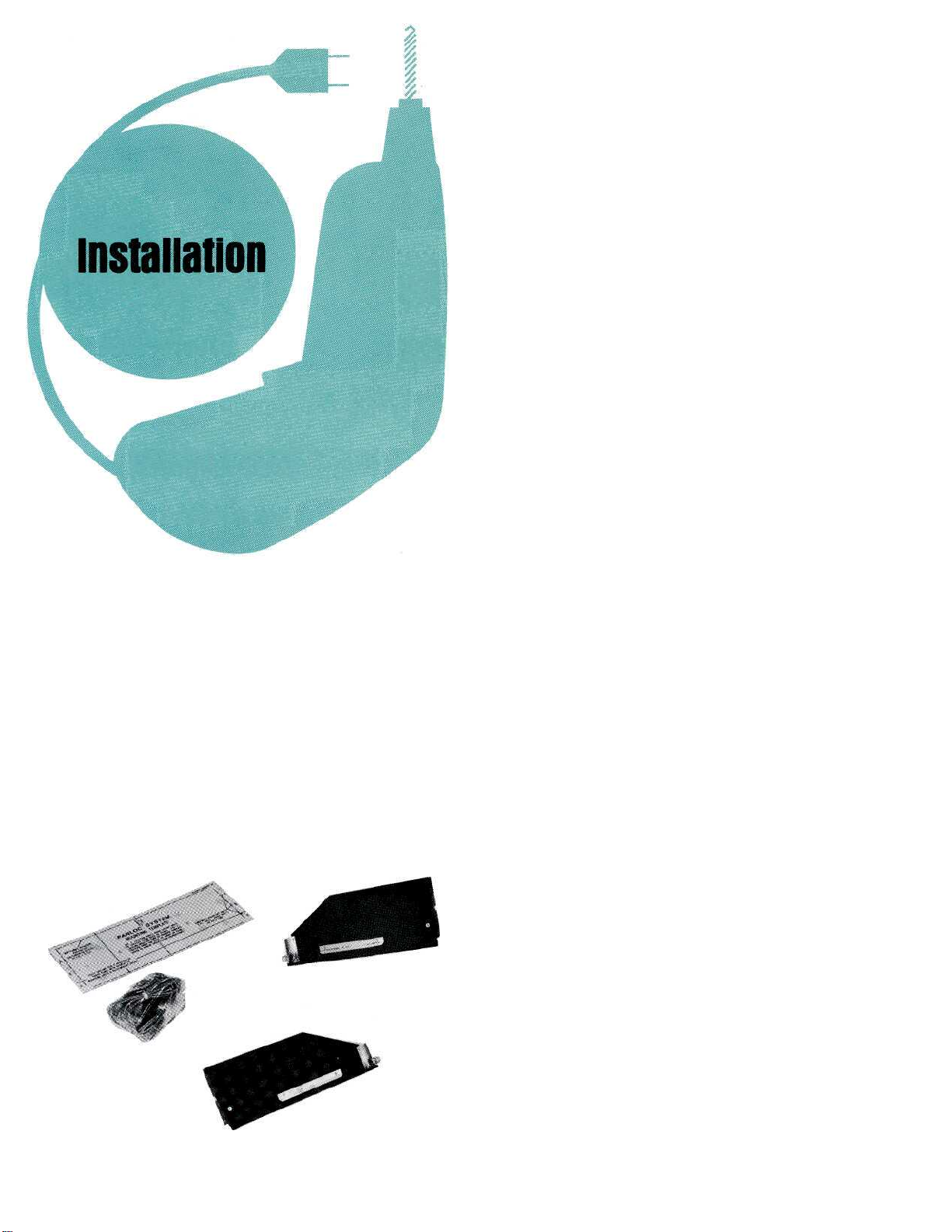

To prepare the MC 2105 for installation remove

the plastic protective covering. Turn it upside down

so that it rests on its top on the shipping pallet.

Remove the four plastic feet fastened to the bottom of the chassis.

Next, place the mounting brackets, the parts

bag and the mounting template at hand.

The PANLOC professional mounting design

eliminates the need for any shelf or bracket to

support the MC 2105. It is completely supported

by its own mounting brackets.

The design of the mounting template allows you

to position or locate the cutout from the front or

rear of the panel to which the instrument is to be

mounted. Position the plastic mounting template

over the area of the panel to be cut out for installation.

If the cutout is to be located from the front of

the panel, begin at 2. If the cutout is to be located

from the rear of the panel, begin here.

1. On the back of the cabinet panel, scribe a

vertical centerline through the exact center of

the area in which the cutout is to be made.

Place the template against the back of the

panel and match the template centerline with

the centerline on the cabinet panel.

Make sure that there is at least ¼ inch clearance between the bottom of the dashed line of

the cutout area on the template and any shelf

or brace below the proposed cutout.

Mark the two locating holes ("C" holes on

the mounting template).

Drill the two locating holes. Be certain the

drill is perpendicular to the panel.

Now position the template on the front of the

panel by aligning the "C" locating holes on the

template with the drill holes.

2. If the cutout is to be located from the front of

the panel:

With the template in place against the cabinet

panel, mark the "A" and "B" drill holes and

the four small holes that identify the corners

of the cutout. Join the corner marks with a pen-

cil. The edge of the template can be used as a

straight edge.

IMPORTANT: DRILL THE 6 HOLES BEFORE

MAKING THE CUTOUT.

Accurately drill the three holes on each side of

the cutout area with a 3/16 inch drill.

With the saw on the INSIDE OF THE PENCIL

LINES carefully cut out the rectangular opening.

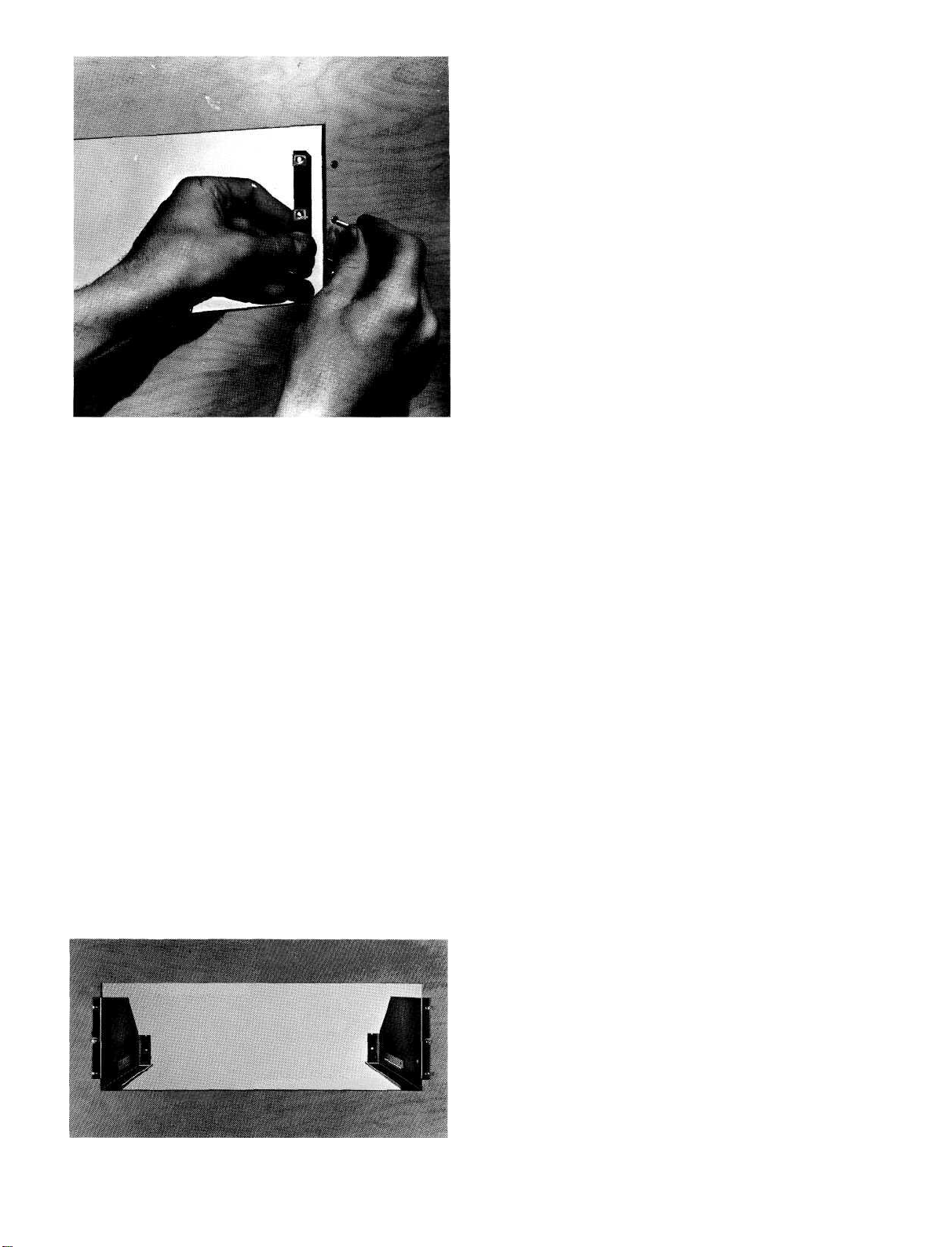

Secure the mounting strips to the rear of the

cabinet panel using two screws from the hardware

package.

Insert the screws in the center holes of the cabi-

net panel ("B" holes on the template) and tighten.

The screw head should pull into the wood slightly.

(Use two % inch long screws for panels under ½

inch, or two 1¼ inch long screws for panels ½ inch

thick and larger.)

2

Page 5

Attach the mounting brackets to the cabinet

panel using four screws.

Place the template over the mounting screws.

The mounting screws should be centered in the

"A" and "B" holes on the template. The sides of

the mounting brackets should match the vertical

dash lines on the template. If necessary, loosen the

screws and push the brackets into alignment and

retighten.

Insert the power cord through the opening. Carefully slide the MC 2105 into the opening so the rails

on the bottom of the equipment slide in the track

of the mounting brackets. Slide the instrument in

until it stops at the adjust position latches. Press

the latches in and continue to slide the instrument

in until the front panel is against the cabinet panel.

At the bottom front corners of the PANLOC instru-

ments are the PANLOC buttons. Depressing the

PANLOC buttons will lock the instrument firmly in

the installation. Depressing the PANLOC buttons

a second time (as with a ballpoint pen) will release

the instrument. You can then slide the instrument

forward to the inspection-adjustment position. Depressing the inspection-adjustment position latches

will allow the instrument to be slid completely out

of the installation.

3

Page 6

HOW to Connect

INPUT STEREO

The shielded cable from the left output of the

Mclntosh preamplifier is plugged into the left jack.

The shielded cable from the right output of the

Mclntosh preamplifier is plugged into the right

jack.

SPEAKERS

Speakers are connected at the barrier strips

marked OUTPUT on the back panel of the amplifier. Use lamp cord, bell wire, or wire with similar

type of insulation to connect the speakers to the

amplifier. For the normally short distances of under

50 feet between the amplifier and speaker, #18

wire or larger can be used. For distances over 50

feet between the amplifier and speaker use larger

wire.

The loudspeaker impedance is usually identified

on the loudspeaker itself. Connect one of the leads

from the left loudspeaker to the screw marked

COM on the LEFT OUTPUT barrier strip. Connect

the other lead from the left loudspeaker to the

screw marked with the number corresponding to

the speaker impedance on the LEFT OUTPUT

barrier strip. Connect one of the leads from the

right loudspeaker to the screw marked COM on the

RIGHT OUTPUT barrier strip. Connect the other

lead from the right loudspeaker to the screw

marked with the number corresponding to the

speaker impedance on the RIGHT OUTPUT barrier

strip.

The only adverse effect on the operation of a

Mclntosh amplifier when it is improperly matched

is a reduction in the amount of distortion-free

power available to the loudspeaker. Close impedance matching is desirable for maximum distortion-free power.

SPEAKER CONNECTIONS

Use this table to determine proper speaker con-

nection.

Connect the

If the speaker impedance speaker leads

is between: between COM and:

3.2 to 6.5 ohms 4 ohms

6.5 to 13 ohms 8 ohms

13 to 26 ohms 16 ohms

Connect as follows:

Connect one

right speaker

Connect one lead to the

If the left speaker to

speaker screw LEFTimped- COM and

ance is: other to:

4 ohms LEFT-4

8 ohms LEFT-8

16 ohms LEFT-16

DO NOT CONNECT A MONOPHONIC LOUDSPEAKER TO BOTH TERMINALS. THE LOUDSPEAKER CAN BE DAMAGED.

For 25 volt line operation connect one of the left

leads to the screw marked COM on the LEFT OUTPUT barrier strip. The other left lead is connected

to the screw marked 8W on the LEFT OUTPUT

barrier strip. Connect the right leads in the same

manner on the RIGHT OUTPUT barrier strip.

AC POWER:

The MC 2105 operates on 117 to 130 volt, 50/60

Hz. The amplifier will be turned on and off if its

power cord is plugged in one of the auxiliary AC

power outlets on the program source.

screw marked

RIGHT-COM

and the other

to:

RIGHT-4

RIGHT-8

RIGHT-16

4

Page 7

5

Page 8

HOW to Use the

Dynamic Peak

Locking Meters

Ordinary meters lack the capability of indicating

the short interval power in a sound wave. The

mass of the meter movement is too great to respond to instantaneous changes in music program

material. Mclntosh superior engineering has developed new circuitry that permits the meters on

the MC 2105 to respond to the short interval power

in a sound wave to an accuracy of 98% of the true

value. This is another Mclntosh development that

represents a major step forward in the use of

power level meters.

There are two circuits that give these meters

the indicating capability of the short interval power

in a sound wave. The first circuit is an accelerating

circuit that compensates for the inertia characteristics of the meter movement. Because the short

interval power fluctuation is so rapid, the eye

might not perceive the instantaneous power reading. This caused the development of the second

circuit, which is a "time stretching" circuit. The

time stretching circuit delays the movement of the

meter needle at peak reading for a few milli-

seconds.

With the aid of the CBS test record STR1000 the

frequency response of your phono cartridge can

be measured. The graph on page 7 shows the

ideal RIAA curve using the CBS record STR100.

Follow these steps to plot the performance of

your phonograph cartridge.

A tape recorder can be checked in the same

fashion.

1. Use a standard frequency response tape

as the signal source.

2. Complete all steps outlined for phono cart-

ridges.

3. You now have a graph of the playback characteristics of your tape recorder.

To find the record characteristics of the tape

recorder follow this procedure:

1. Record the CBS Test Record STR1000 on

your tape recorder. Adjust the record volume

only on the 1000 Hz signal for proper recording level. DO NOT ADJUST THE RECORD

VOLUME CONTROL DURING THE RECORD-

ING.

2. Play back the tape just recorded. Complete

all steps outlined for tape playback characteristics.

3. A comparison of the two curves will give the

recording characteristics of your tape re-

corder. A deviation of 3 dB is acceptable.

Similar checks can be made on all program

sources in your stereo system. Follow the same

general procedure for any program source for

which a standard reference is available.

1. Set the "METER RANGE SWITCH" to the

-20 position.

2. Play the 1000 Hz test tone recorded on the

CBS Test Record STR100 on your phono-

graph.

3. Turn the LEFT GAIN control until the left

meter indicates "0."

4. Turn the RIGHT GAIN control until the right

meter indicates "0."

5. Write down the meter indication at each fre-

quency as the record plays.

6. Transfer the readings by frequency to the

graph.

7. The graph shows the ideal RIAA response

curve using the CBS STR1000 test record.

Compare your curve with the curve on the

graph. A deviation of 3 dB from the ideal is

acceptable. By making this check at regular

intervals, (for instance, every 6 months) any

deterioration in the cartridge or system will

be quickly detected.

6

Page 9

IDEAL RIAA SYSTEM RESPONSE USING CBS STR 100 TEST RECORD

4

2

0

-2

-4

IN dB

-6

-8

-10

-12

RELATIVE OUTPUT LEVEL

-14

-16

20

100

1,000

10,000

-18

-20

20,000

4

2

0

-2

-4

IN dB

-6

-8

-10

-12

RELATIVE OUTPUT LEVEL

14

-16

-18

20

100

1,000

FREQUENCY IN Hz

-20

20,00010,000

7

Page 10

Front Panel information

LEFT GAIN

Use the left gain control to adjust the volume in the

left channel to the desired listening level. Turn the

control clockwise to increase the volume.

RIGHT GAIN

Use the right gain control to adjust the volume in the

right channel to the desired listening level. Turn the

control clockwise to increase the volume.

METER RANGE

The meter switch has four positions. The first position

is OFF. With the switch in the OFF position there is

no indication on the meters.

-0 In this position of the meter range switch, the

amplifier will deliver 100 watts when the meter indicates +3dB, with meter indication of "0", the amplifier delivers 50 watts, with a meter indication of —3dB,

-10 In this position of the meter range switch, the

amplifier will deliver 5 watts output when the meter

indicates "0". With a meter indication of —3dB, the

amplifier delivers 2½ watts output and a -10dB meter

indication, the amplifier delivers ½ watt.

-20 In this position of the meter range switch, the

amplifier will deliver ½ watt (500 milliwatts) when the

meter indicates "0". With a meter indication of —3dB,

the amplifier delivers ¼ watt (250 milliwatts) and a

-10dB meter indication the amplifier delivers 50

milliwatts.

the amplifier delivers 25 watts; and a meter indication

of -10dB, the amplifier delivers 5 watts.

(A meter reading of +3.2dB indicates 105 watts power

output.)

HEADPHONE

Use the jack for low impedance stereo headphones.

The headphone jack is on at all times.

SPEAKERS

OFF: The loudspeakers are turned off when the

SPEAKER switch is in the OFF position. You can

listen to headphones in private.

THIS SWITCH MUST BE IN THE "ON" POSITION

TO HEAR MUSIC FROM THE LOUDSPEAKERS.

ON: Music will be heard through the loudspeakers.

Use this as the normal listening position.

POWER

The power switch turns the MC2105 on or off. The

switch does not control the power outlet on the back

panel. If you wish to control the operation of the

on/off switch from a preamplifier control center leave

the switch in the ON position. In this case be sure to

plug the AC cord of the MC 2105 into the controlled

outlets on the rear of the preamplifier control center.

OFF: In the OFF position the AC to the amplifier is

turned off.

8

Page 11

Performance Limits and Ratings

PERFORMANCE GUARANTEE

Performance Limits are the maximum deviation from

perfection permitted for a Mclntosh instrument. We

promise you that the MC 2105 you buy must be capable

of performance at or exceeding these limits or you get

your money back. McIntosh is the only manufacturer

that make this guarantee.

PERFORMANCE

McIntosh audio power ratings are in accordance with

the Federal Trade Commission Regulation of November 4, 1974 concerning power output claims for amplifiers used in home entertainment products,

POWER OUTPUT

105 watts minimum sine wave continuous

average power output, per channel, both

channels operating into 4 ohms, 8 ohms,

or 1.6 ohms load impedance, which is:

20.5 volts RMS across 4 ohms

29.0 volts RMS across 8 ohms

41.0 volts RMS across 16 ohms

OUTPUT LOAD IMPEDANCE

4 ohms, 8 ohms, or 16 ohms; separate terminals are provided for each output

RATED POWER BAND

20 Hz to 20,000 Hz

TOTAL HARMONIC DISTORTION

0.25% maximum harmonic distortion at

any power level from 250 milliwatts to 105

watts per channel from 20 Hz to 20,000

Hz, both channels operating

INTERMODULATION DISTORTION

0.25% if instantaneous peak power output is 210 watts

or less per channel with both channels operating for

any combination of frequencies 20 Hz to 20,000 Hz

FREQUENCY RESPONSE

20 Hz to 20,000 Hz +0 -0.25 dB

10 Hz to 100,000 Hz +0 -3.0 dB at one watt output

NOISE AND HUM

90 dB below rated output

OUTPUT POWER MONITOR METER

Meter is calibrated to read +3 dB when amplifier produces 105 watts. Meter range switch is provided to

increase meter sensitivity by 10 dB or 20 dB

Calibration accuracy at 0 dB reading is ±2% at all

frequencies; meter range accuracy is ±5%

RATINGS

OUTPUT VOLTAGES

25 volts for distribution lines

DAMPING FACTOR

13 at 8 ohms output

18 at 4 ohms output

10 at 16 ohms output

INPUT IMPEDANCE

200.00 ohms

INPUT SENSITIVITY

0.5 volt. Level control provided for higher input voltage

GENERAL INFORMATION

POWER REQUIREMENTS

120 volts 50 60 Hz, 75 watts at zero signal output,

430 watts at rated output

SEMICONDUCTOR COMPLEMENT

34 silicon transistors

18 silicon rectifiers and diodes

MECHANICAL INFORMATION

SIZE

Front panel measures 16 3/16 inches wide (41,12 cm)

by 7 1/8 inches high (18,1 cm). Chassis measures 15

inches wide (38,1 cm) by 6 9/16 inches high (16.67 cm)

by 14½ inches deep (36.83 cm), including connectors.

Knob clearance required is 1½ inches (3.81 cm) in

front of mounting panel

FINISH

Front panel is anodized gold and black with special

gold teal nomenclature illumination. Chassis is chrome

and black

MOUNTING

Exclusive Mclntosh developed professional PANLOC

WEIGHT

65 pounds (29.48 kg) net, 77 pounds (34,93 kg) in shipping carton

SPECIAL FEATURES

The amplifier is completely stable when connected to

any loudspeaker system or even to any reactive loads;

The MC 2105 has special circuits to prevent damage

by short circuit or open circuit of the output loads, or

by any amount of output impedance mismatch,

Thermal cutouts are mounted on the output transistor

heat sinks to provide protection in the event of inade-

quate ventilation.

Peak reading - peak locking meters feature special cir-

cuit to respond to peak value of complex input signal.

9

Page 12

Page 13

Technical Description

A two stage amplifier with three transistors in

each channel increases the input voltage 16 dB.

There are 13 transistors in each power amplifier

section. The two stage preamplifier is fed to a pair

of matched transistors arranged as an emitter

coupled amplifier with two inputs and one output.

The signal from the preamplifier section connects

to one of these inputs. Both AC and DC negative

feedback are applied to the other input. This large

quantity of feedback is used to reduce noise and

distortion. The signal is then fed to a voltage amplifier. The voltage amplifier is followed by two driver

transistors.

The output section is arranged as a series pushpull amplifier. The power transistors used in the

output section of your MC 2105 are selected for

their high power dissipation capability, wide frequency response, and large "safe operating area."

In addition, each power transistor is given four

separate tests before it is put in your MC 2105. This

additional testing makes sure your MC 2105 will

deliver its rated power from 20 to 20 kHz with low

distortion and complete reliability.

The power transistors are mounted on oversized

anodized heat sinks. The heat sinks assure that

under normal operation the transistors will operate

at a low temperature. If temperatures increase due

to a shorted speaker, or restricted ventilation, an

automatic temperature sensing device turns off the

MC 2105. The device operates automatically at a

preset temperature. The MC 2105 will turn on again

when the temperature has returned to normal

limits. This additional feature gives your MC 2105

complete reliability under the most extreme operating conditions.

The output stages are matched to the load by

the Mclntosh autoformer. The Mclntosh autoformer

is carefully wound using Mclntosh trifilar winding

and interleaving techniques. Trifilar winding and

interleaving gives the transformers exceptional

bandwidth. The autoformers properly match the

power transistors to 4, 8, and 16 ohm loads at all

audio frequencies.

The use of the Mclntosh designed trifilar autoformer makes the Mclntosh solid state amplifiers

the only amplifiers that deliver FULL POWER AT

ALL SPEAKER IMPEDANCES. You have not been

power penalized for your choice of loudspeakers

when using the Mclntosh MC 2105.

Another of the advantages of the autoformers

is the 25 volt output for a constant voltage distribution system. With the MC 2105 several sets of

speakers can be operated independently throughout your home.

To further insure reliability a special power output SENTRY MONITORING CIRCUIT prevents failure of the power output transistors due to exces-

sive mismatch of the output. When your MC 2105

operates normally the SENTRY MONITORING CIRCUIT has no effect on signals passing through the

power amplifier. If the power dissipation should

rise above normal operation, the SENTRY MONITORING CIRCUIT restricts the drive to the output

transistors. The SENTRY MONITORING CIRCUIT

acts instantaneously for any input signal or load

combination. This arrangement assures complete

circuit reliability. Only Mclntosh gives you this de-

gree of protection.

POWER SUPPLY SECTION

There are three separate power supply sections.

One positive and one negative high current supply

is used for the output stages. The other positive

supply is used for the driving amplifier stages. All

supplies are full wave and use silicon rectifiers.

Adequate filtering is used to assure an absolute

minimum of hum. The power output stage filter

capacitors have very high capacity, which allows

full power output below 20 Hz. The power transformer is generous in size and runs cool, even

under heavy use.

11

Page 14

Block

Diagram

12

Page 15

Page 16

MCINTOSH LABORATORY INC.

2 CHAMBERS ST., BINGHAMTON, N. Y. 13903

607-723-3512

Design subject to change without notice.

Printed in U.S.A.

038-799

Loading...

Loading...