MAXDATA Server PLATINUM 1500 IR M5

User’s Manual

2 Contents

Contents

1 Setting up the System 7

Server Position ........................................................................................................................................7

Connecting the System ...........................................................................................................................8

Back Panel Connectors ......................................................................................................................8

Standard Control Panel ............................................................................................................................9

2 Server Board Features 11

Connector and Header Locations ..........................................................................................................13

Configuration Jumpers ..........................................................................................................................14

Hardware Requirements .......................................................................................................................15

Processor .........................................................................................................................................15

Memory ............................................................................................................................................15

Memory Sparing and Mirroring ........................................................................................................16

Optional Hardware ................................................................................................................................17

Intel® Management Module .............................................................................................................17

Local Control Panel ...........................................................................................................................17

3 Server Chassis Features 19

Component Identification ......................................................................................................................20

Internal Components ........................................................................................................................20

Local Control Panel ................................................................................................................................21

Back Panel Features ..............................................................................................................................22

Peripheral Devices .................................................................................................................................23

Hard Disk Drives ....................................................................................................................................23

4 Hardware Installations and Upgrades 25

Before You Begin ..................................................................................................................................25

Tools and Supplies Needed ..............................................................................................................25

System References ..........................................................................................................................25

Removing and Installing the Chassis Cover ..........................................................................................25

Removing the Chassis Cover ...........................................................................................................25

Removing and Installing the Front Bezel ...............................................................................................26

Removing the Front Bezel .....................................................................................................................26

Installing the Front Bezel .......................................................................................................................26

Installing and Removing a Hard Disk Drive ...........................................................................................27

Installing Hot-swap Hard Disk Drive .................................................................................................27

Removing Hot-swap Hard Disk Drive ....................................................................................................28

Installing and Removing a PCI Riser Connector ....................................................................................29

Installing a PCI Riser Connector .......................................................................................................29

Installing and Removing a PCI Add-in Card ...........................................................................................31

Installing a PCI Add-in Card ..............................................................................................................31

Installing and Removing Memory ..........................................................................................................33

Installing DIMMs ..............................................................................................................................33

Installing or Replacing the Processor ....................................................................................................34

Installing the Processor ....................................................................................................................34

Installing the Heat Sink(s) .................................................................................................................35

Removing a Processor .....................................................................................................................36

RJ45 Serial Port Configuration ..............................................................................................................37

Replacing the Backup Battery ...............................................................................................................38

3MAXDATA Server PLATINUM 1500 IR M5

5 Server Utilities 41

Using the BIOS Setup Utility .................................................................................................................41

Starting Setup ...................................................................................................................................41

If You Cannot Access Setup .............................................................................................................41

Setup Menus .................................................................................................................................... 41

Clearing the Password ..........................................................................................................................43

Clearing the CMOS ...............................................................................................................................43

6 Troubleshooting 45

LED Information ....................................................................................................................................45

BIOS POST Beep Codes .......................................................................................................................46

7 Technical Reference 47

Power Supply Specifications .................................................................................................................47

500-W Single Power Supply Input Voltages ..................................................................................... 47

500-W Single Power Supply Output Voltages .................................................................................. 47

System Environmental Specifications ...................................................................................................47

8 Regulatory and Integration Information 49

Product Regulatory Compliance ............................................................................................................49

Product Safety Compliance ..............................................................................................................49

Product EMC Compliance ....................................................................................................................49

Product Regulatory Compliance Markings ............................................................................................49

Electromagnetic Compatibility Notices .................................................................................................50

FCC (USA) ........................................................................................................................................50

Europe (CE Declaration of Conformity) ............................................................................................50

Installation Precautions .........................................................................................................................50

Installation Requirements ......................................................................................................................51

Prevent Power Supply Overload ......................................................................................................51

Place Battery Marking ......................................................................................................................51

Use Only for Intended Applications .......................................................................................................51

4 Contents

Figures

1. Back Panel Connectors .....................................................................................................................8

2. Standard Control Panel Features ....................................................................................................... 9

3. Server Board Connector and Component Locations .......................................................................13

5. Internal Component Locations ........................................................................................................20

6. Local Control Panel Features ...........................................................................................................21

7. Chassis Back ...................................................................................................................................22

8. Chassis Back ...................................................................................................................................23

9. Removing the Chassis Cover ..........................................................................................................25

10. Standard Front Bezel .......................................................................................................................26

11. Local Control Panel Front Bezel ....................................................................................................... 26

12. Removing a Hot-swap Hard Drive Carrier from Chassis .................................................................27

13. Removing the Retention Device from a Hot-swap Drive Carrier .....................................................27

14. Removing the PCI Riser Assembly from the Chassis .....................................................................29

15. Installing an Add-in Card Connector into the PCI Riser Assembly ..................................................30

16. Installing the PCI Riser Assembly into the Chassis .........................................................................30

17. Removing the PCI Riser Assembly from the Chassis .....................................................................31

18. Installing an Add-in Card to the PCI Riser Assembly .......................................................................31

19. Installing the PCI Riser Assembly into the Chassis .........................................................................32

20. Installing Memory ............................................................................................................................33

21. Opening Socket Lever .....................................................................................................................34

22. Inserting Processor ........................................................................................................................35

23. Installung Heat Sink .........................................................................................................................35

24. Changing the Serial Port Configuration ...........................................................................................37

25. Replacing the Backup Battery .........................................................................................................39

Tables

1. NIC LEDs ........................................................................................................................................... 8

2. Standard Control Panel Features ....................................................................................................... 9

3. Front Panel LED Description ...........................................................................................................10

4. Server Board Features .....................................................................................................................11

5. Configuration Jumper ...................................................................................................................... 14

6. DIMM Module Memory Capacity Support ......................................................................................15

7. Server Chassis Features ..................................................................................................................19

8. Local Control Panel Features ...........................................................................................................21

9. Keyboard Commands ......................................................................................................................42

10. LED Information ..............................................................................................................................45

11. POST Error Beep Codes ..................................................................................................................46

12. Error Beep Codes Provided by Intel® Management Modules .........................................................46

13. 500-W Power Supply System Output Capability .............................................................................47

14. Environmental Specifications ..........................................................................................................47

15. Product Certification Markings ........................................................................................................49

5MAXDATA Server PLATINUM 1500 IR M5

6

1 Setting up the System

Server Position

Please take note of the following criteria for creating a practical and safe workplace when setting up

your computer:

The system can be used anywhere the temperature is suitable for people. However, rooms

with humidity over 70%, and dusty or dirty areas are not appropriate. In addition, do not

expose the server to any temperatures over +30 °C or under +10 °C.

Make sure that the cables connecting the server to peripheral devices are not tight.

Make sure that all power and connection cables are positioned so that they are not trip

hazards.

When you save data to your server‘s hard disks or to a floppy disk, they are stored as

magnetic information on the media. Make sure that they are not damaged by magnetic or

electromagnetic fields.

Because the electronics in your computer can be damaged by jarring, no mechanical devices

should be placed on the same surface as the server. This is especially important for impact

printers whose vibrations could damage the hard disk.

Please take care to ensure a free air flow to the server at all times. Do not block the ventilation

slots of the server case and particularly the power supplies. An insufficient air flow may

damage the server and / or it’s components.

ATTENTION

In order to fully separate the server from current, the power cord must be removed from the wall

outlet.

7MAXDATA Server PLATINUM 1500 IR M5

Connecting the System

TP00762

A

F

C

D

E

G

H

B

I

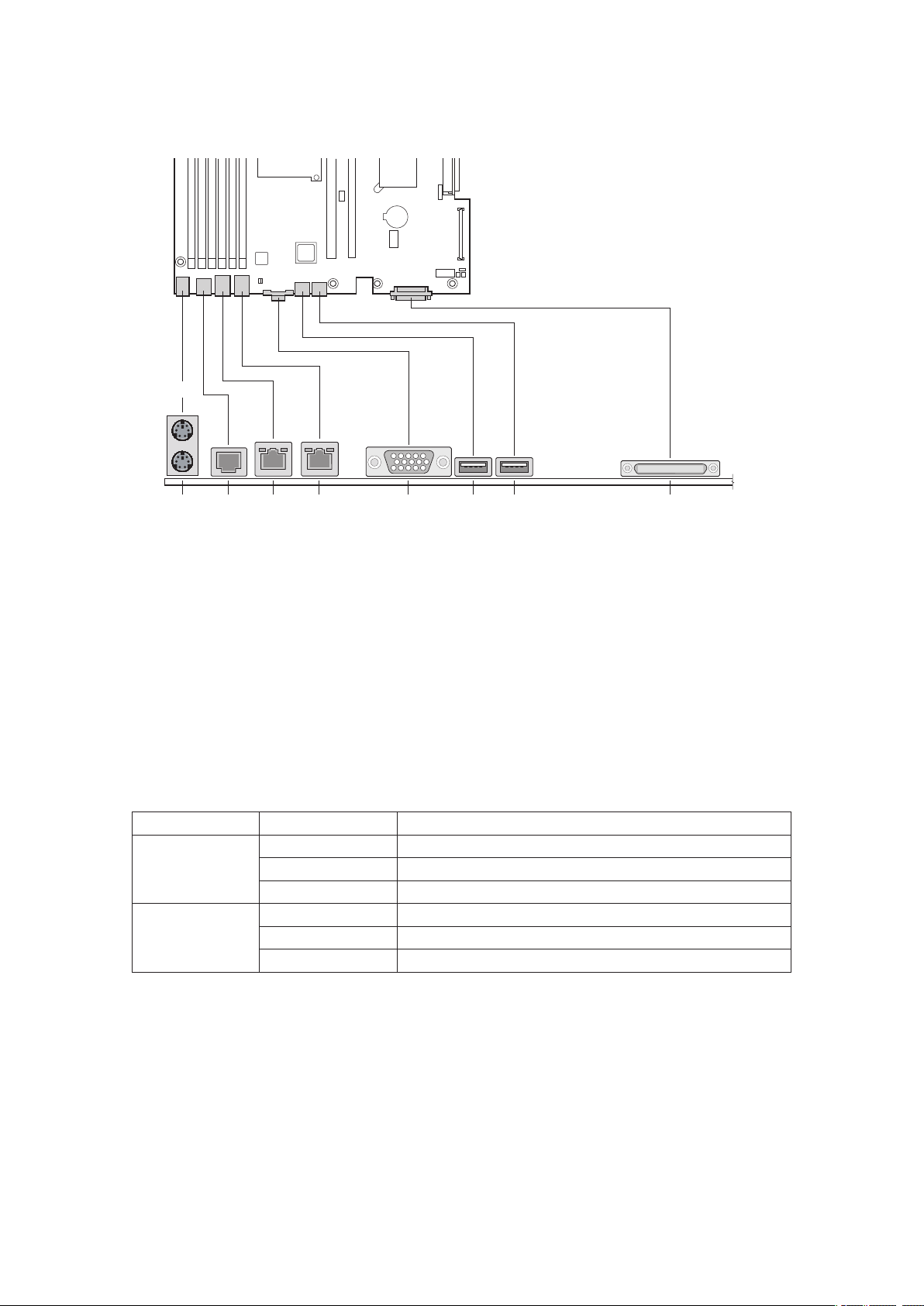

Back Panel Connectors

a

Figure 1. Back Panel Connectors

A. PS/2 mouse F. Video

B. PS/2 keyboard

C. Serial Port B H. USB port 2

D. NIC port 1 (1 Gbps)

E. NIC port 2 (1 Gbps)

Table 1. NIC LEDs

LED Color LED State Description

Left LED Off

Solid Amber

Blinking Amber Transmit/receive activity

Right LED Off 10 Mbps connection (if left LED is on or blinking)

Solid Amber 100 Mbps connection

Solid Green 1000 Mbps connection

No network connection

Network connection in place

G. USB port 1

I. SCSI channel B

8 Setting up the System

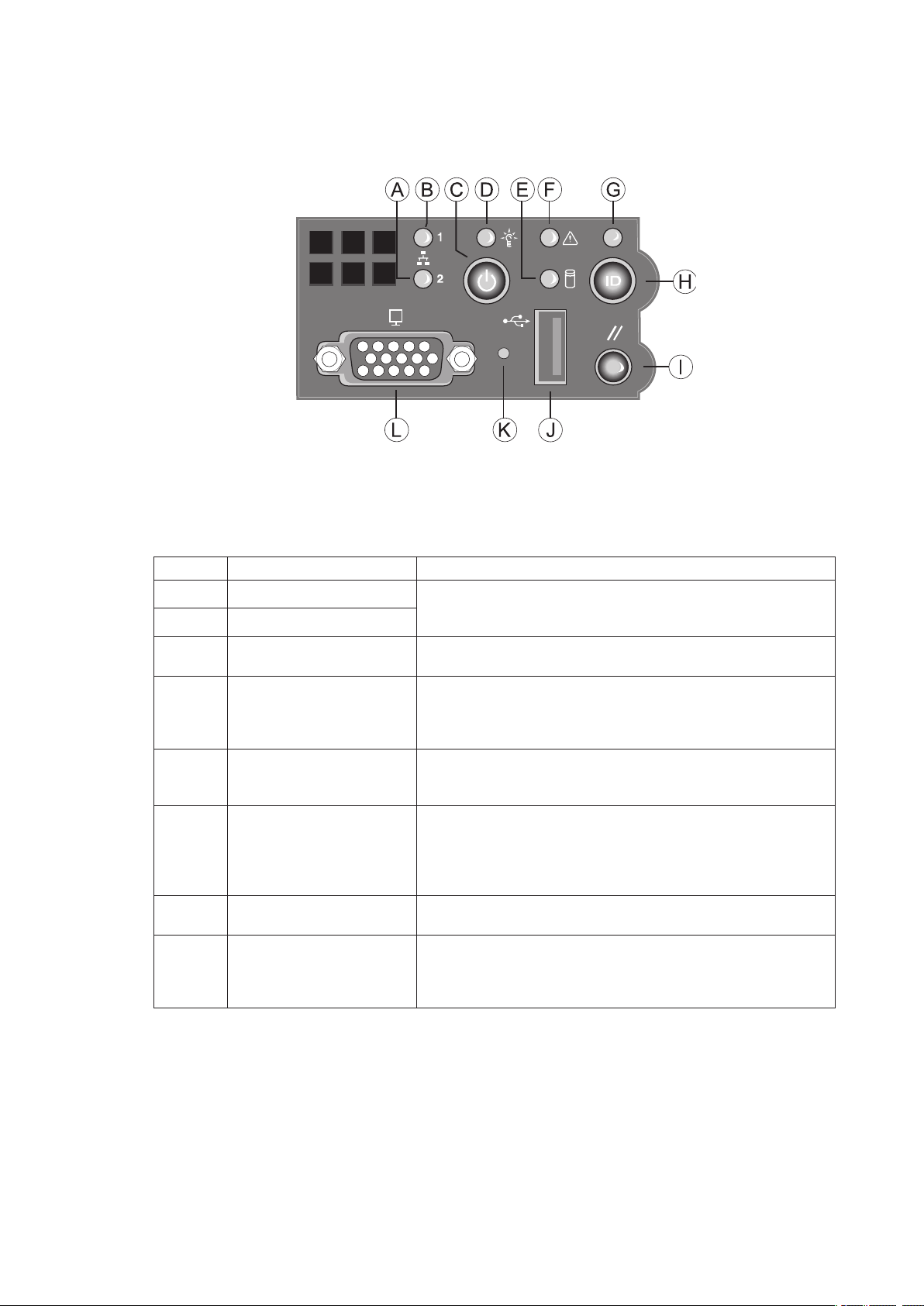

Standard Control Panel

The diagram below shows the features available on the Standard Control Panel. The Standard Control

Panel is one of two required control options that can be selected. The other option is the Local Control

Panel.

a

Figure 2. Standard Control Panel

Table 2. Standard Control Panel Features

Callout Feature Function

A NIC 2 activity LED Continuous green light indicates a link between the system

B NIC 1 activity LED

C Power/Sleep button Toggles the system power on/off. Sleep button for ACPI

D Power/Sleep LED Continuous green light indicates the system has power

E Hard disk drive activity

LED

F System Fault LED Solid green indicates normal operation

G System Identification LED Solid blue indicates system identification is active

H System Identification

button

and the network to which it is connected.

Blinking green light indicates network activity.

compatible operating systems.

applied to it. Blinking green indicates the system is in S1

sleep state.

No light indicates the power is off / is in ACPI S4 or S5 state.

Random blinking green light indicates hard disk drive activity

(SCSI or SATA).

No light indicates no hard disk drive activity.

Blinking green indicates degraded performance

Solid amber indicates a critical or non-recoverable condition

Blinking amber indicates a non-critical condition

No light indicates POST is running or the system is off.

No light indicates system identification is not activated

Toggles the front panel ID LED and the baseboard ID LED

on and off. The baseboard LED is visible from the rear of the

chassis and allows you to locate the server from the rear of a

rack of systems.

(Continued)

9MAXDATA Server PLATINUM 1500 IR M5

Standard Control Panel Features (Continued)

I Reset button Reboots and initializes the system.

J USB 2.0 port Allows you to attach a USB component to the front of the

chassis.

K NMI button Puts the server in a halt-state for diagnostic purposes.

L Video port Allows you to attach a video monitor to the front of the

chassis. The front and rear video ports cannot be used at

the same time.

Descriptions of the front panel LEDs are listed in the following table.

Table 3. Front Panel LED Description

LED Name Color Condition Description

Power/Sleep LED

Status

Hard Drive

Activity

NIC 1 Activity

NIC 2 Activity

ID LED (rack

only)

Green ON Power On

Green BLINK Standby/Sleep (S1)

OFF Off (also Sleep S4)

Green ON System Ready

Green BLINK System ready, but degraded: some CPU fault, DIMM killed

Amber ON Critical alarm: Critical power module failure, critical fan

failure, voltage (power supply), voltage and thermal fault

Amber BLINK Non-critical failure: Redundant fan failure, redundant power

failure, non-critical power and voltage

OFF System not ready: Post error / NMI event / PCI or terminator

missing

Green BLINK Hard drive activity

Amber ON Fault

OFF No activity

Green ON Linked

Green BLINK LAN activity

OFF Idle

Green ON Linked

Green BLINK LAN activity

OFF Idle

Blue BLINK Server identification; Toggled by ID button or software

OFF Server identification; Toggled by ID button or software

10 Setting up the System

2 Server Board Features

This chapter briefly describes the main features of the MAXDATA PLATINUM Server Board. This

chapter provides a list of the server board features, and diagrams showing the location of important

components and connections on the server board.

Table 4 summarizes the major features of the server board.

Table 4. Server Board Features

Feature Description

®

Processors Support for up to two Intel

and frequencies starting at 2.8 GHz.

Memory Memory mirroring and memory sparing options Six DIMM slots supporting DDR

266 MHz or DDR 333 MHz memory

Chipset Intel® E7520 chipset, including:

• E7520 MCH

I/O Control

• PXH

• Intel

External connections:

®

82801ER I/O Controller Hub 5-R (ICH-5R)

• Stacked PS/2 ports for keyboard and mouse

• RJ45 Serial B port

• Two RJ45 NIC connectors for 10/100/1000 Mbps connections

• Two USB 2.0 ports

• U320 high-density 80-pin SCSI connector (channel B)

Internal connections:

• Two USB port headers, each of which supports two USB 2.0 ports

• One DH10 Serial A header

• One Ultra320 80-pin SCSI connector (Channel A)

• Two SATA-150 connectors with integrated RAID 0/1 support

• One ATA-100 connector

• SSI-compliant 34-pin, high-density 100-pin, and alternate 50-pin control panel

headers

®

• Intel

Management Module 120-pin connector, supporting the optional

Professional and Advanced server management modules

Add-in Card • One low-profile riser slot that supports a riser card capable of supporting upto

three low-profile PCI-X 66 / 100 MHz add-in cards.

• One full-height riser slot, utilizing Intel® Adaptive Slot technology. Capable of

supporting riser cards that follow either PCI-X or PCI-Express® specifications.

The riser cards can support upto three full-height, full-length PCI-X 66 /

100 MHz, PCI-X 133, or PCI-Express

used.

®

Video On-board ATI

RAGE XL video controller with 8 MB SDRAM

Xeon™ Processors with an 800 MHz front side bus

®

add-in cards, depending on the riser card

(Continued)

11MAXDATA Server PLATINUM 1500 IR M5

Server Board Features (Continued)

Hard Drive, Optical

Drive, and Floppy

Drive

Floppy Support:

• Single Floppy channel accessed through either of two connectors. When

integrated with either the SATA or SCSI backplanes in the MAXDATA

PLATINUM 1500 IR or 2200 IR, the floppy controller signals are routed

through the 100-pin flex cable. Other server configurations can use the legacy

24-pin connector. Use of both interfaces in a common server configuration is

not supported.

Ultra ATA/100 support:

• Two IDE channels, each capable of supporting up to two drives. The primary

channel routes through a 100-pin flex cable to the backplane providing Optical

Drive support.

SATA support:

• Two SATA ports

• RAID level 0/1 support

SCSI support:

• Dual-channel LSI Logic

- Implements LSI Logic

- Supports LSI Logic

®

53C1030 Ultra320 SCSI controller

®

Fusion-MPT architecture

®

Integrated Mirroring and Striping technology

• Zero-channel RAID supporting the RUBI-2 specification

LAN Dual Intel® 82546GB 10/100/1000 NICs

Fans • Two 3-pin SSI compliant single speed processor fan connectors

• One 3-pin system fan connector with fan speed control.

• One 20-pin fan connector providing fan speed control and monitoring for

system fans in the MAXDATA PLATINUM 1500 IR and 2200 IR

Server

Management /

Diagnostics

• On-board Platform Instrumentation using the National Semiconductor

PC87431M mini-Baseboard Management Controller (mBMC) (Default).

• Support for optional Intel

®

Management Module - Advanced Edition or

Professional Edition

• Support for Intel® Server Management 8.x

®

• Intel

Light-Guided Diagnostics on all field replaceable units (FRUs)

12 Server Board Features

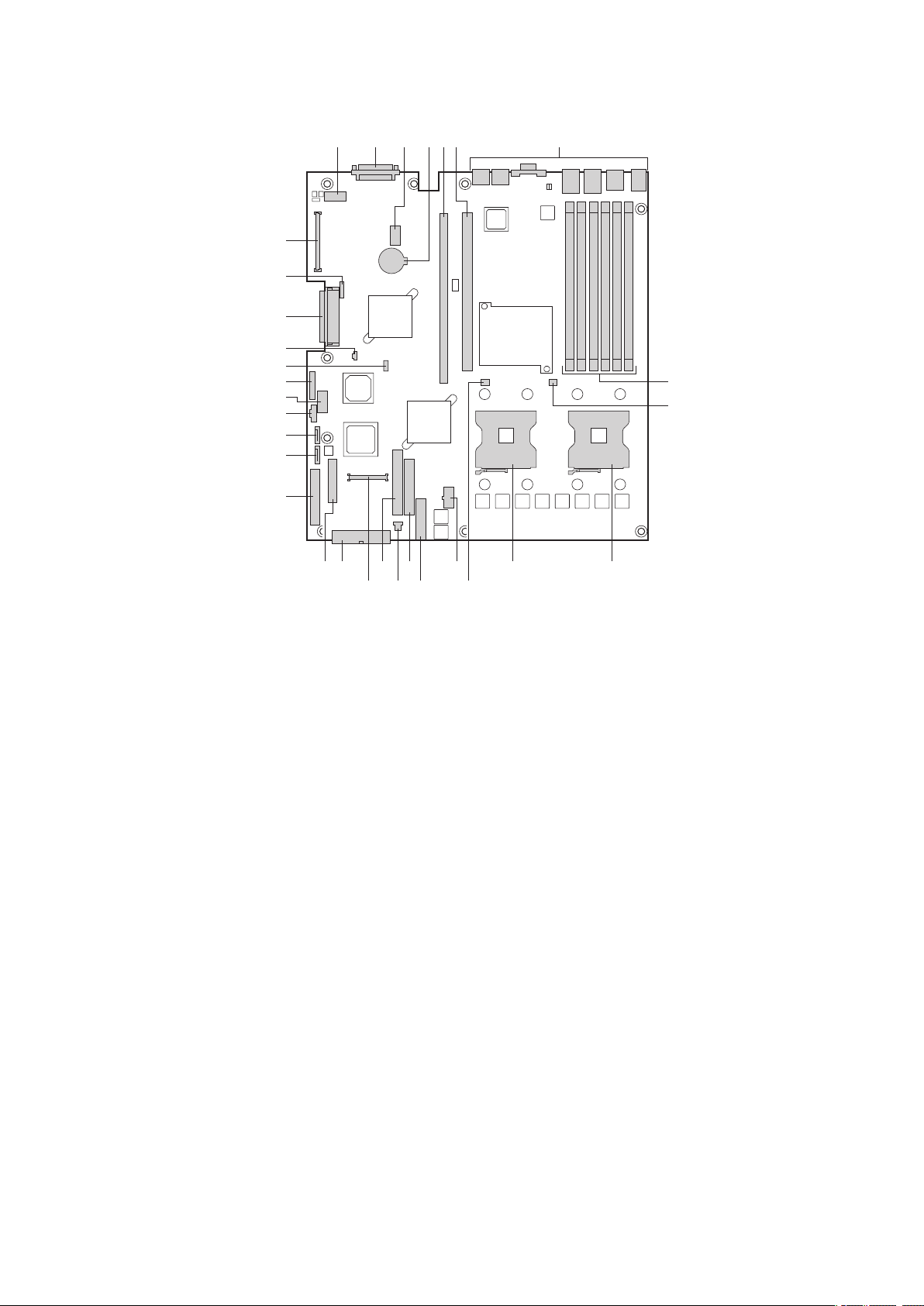

Connector and Header Locations

TP00757

A C DB E F G

H

I

JK

R

M

LN

ST

EE

CC

X

U

V

W

Z

Y

AA

DD

BB

QPO

a

Figure 3. Server Board Connector and Component Locations

A. Serial Port A L. Processor 2 fan header W. SATA port 2

B.

SCSI Channel B M. +12V processor power X. Power supply signal cable

C. 8-pin OEM connector N. Fan board connector Y. USB header (DH-10)

D. Battery O.

E. Full-height riser slot P. System fan 3-pin header AA. IPMB connector

F. Low-profile riser slot

G. Back panel I/O ports

H. DIMM sockets S. 24-pin SSI power connector DD. ICMB connector

I. Processor 1 fan header T. 50-pin control panel connector EE. 120-pin connector for optional

J. Processor socket 1 U.

K. Processor socket 2 V. SATA port 1

Floppy connector Z. USB header (1 x 10)

Q. Secondary IDE channel BB. IDE power connector

R. Control panel 100-pin

connector

34-pin SSI control panel

connector

CC. SCSI channel A

Intel® Management Module

13MAXDATA Server PLATINUM 1500 IR M5

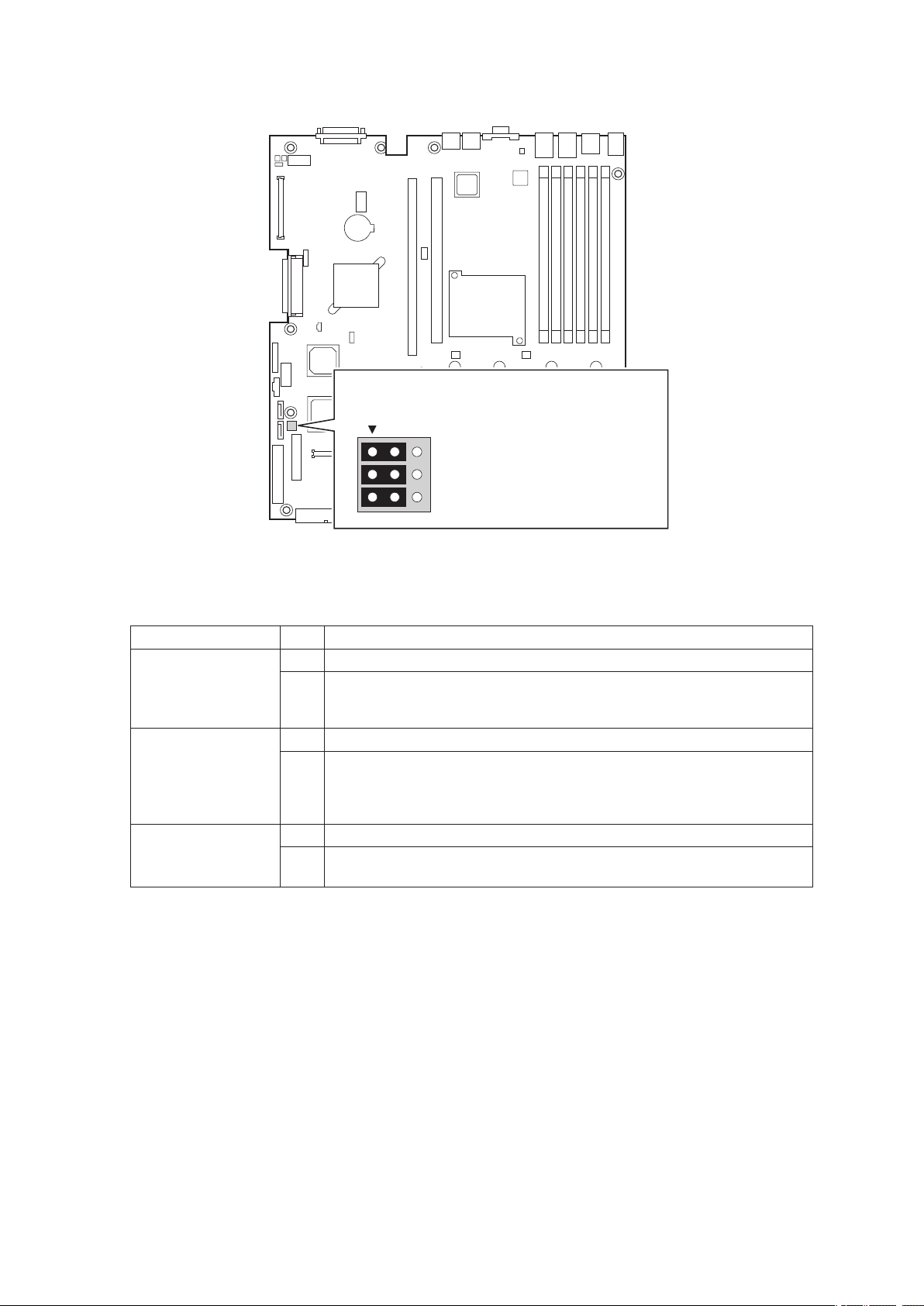

Configuration Jumpers

TP00759

3

2

C1-C2: CMOS Clear by BMC

1-2: Default setting for each jumper set

C2-C3: CMOS Clear Force Erase

B1-B2: Recovery Boot Disable (Normal Boot)

B2-B3: Recovery Boot Enable

A1-A2: Password Clear Protect

A2-A3: Password Clear Erase

A

B

C

a

Figure 4. Configuration Jumper Location

Table 5. Configuration Jumper

Jumper Name Pins What happens at system reset…

Password Clear (line

“A” in figure above)

1 - 2 These pins should be jumpered for normal system operation.

2 - 3 If these pins are jumpered, administrator and user passwords will be

cleared on the next reset. These pins should not be jumpered for normal

operation.

Recovery Boot (line

“B” in figure above)

1 - 2 These pins should be jumpered for normal system operation.

2 - 3 If these pins are jumpered, the system will attempt to recover the BIOS

by loading the BIOS code into the flash device from a floppy disk. This

jumper is typically used when the BIOS has become corrupted. These

pins should not be jumpered for normal operation.

CMOS Clear (line

“C” in figure above)

1 - 2 These pins should be jumpered for normal system operation.

2 - 3 If these pins are jumpered, the CMOS settings will be cleared on the

next reset. These pins should not be jumpered for normal operation.

14 Server Board Features

Hardware Requirements

Processor

One or two Intel® Xeon™ Processors with an 800 MHz front side bus must be installed. Processor

frequencies form 2.8 GHz to 3.6 GHz are supported.

Memory

The server board provides six DIMM sockets across two channels, Channel A and Channel B. Channel

A consists of DIMM sockets 1A, 2A, and 3A. Channel B consists of DIMM sockets 1B, 2B, and 3B.

If six DIMMs are installed, the following maximum capacitites are possible:

• For DDR266 DIMMS: Maximum capacity of 24 GB

• For DDR333 DIMMS: Maximum capacity of 16 GB

A minimum of one 256 MB DIMM is required in DIMM socket 1A or 1B. This uses single-channel

interleave. However, for dual-channel interleave, providing optimum performance, a minimum of two

DIMMs should be installed in DIMM sockets 1A and 1B. Except for the option of installing a single

DIMM in socket 1A or 1B, DIMMs must be installed in pairs and populated as follows:

• DIMM 1A and DIMM 1B: Populate these two sockets together first

• DIMM 2A and DIMM 2B: Populate these sockets in addition to DIMM 1A and DIMM 2A if four

DIMMs are to be used.

• DIMM 3A and DIMM 3B: Populate these sockets after DIMM 1A, DIMM 1B, DIMM 2A, and

DIMM 2B have been populated.

DIMMs must meet the following requirements:

• Use only registered DDR DIMM modules

• DDR266 and DDR333 memory can be mixed on the server board, but when mixing DIMM

types, DDR333 memory will be treated as DDR266.

• Use only DIMMs with DIMM organization of x72 ECC

• Use only DIMMs with the capacities outlined in the following table can be used

Table 6. DIMM Module Memory Capacity Support

SDRAM Parts, SDRAM

Technology

X8, single row 128 MB 256 MB 512 MB 1 GB

X8, double row 256 MB 512 MB 1 GB 2 GB

X4, single row 256 MB 512 MB 1 GB 2 GB

X4, stacked, double row 512 MB

128 MB 256 MB 512 MB 1 GB

1 GB 2 GB 4 GB

NOTE

When using Dual Rank (Double Row) DDR-333 DIMM technologies, a maximum of four loads per

memory channel is supported. When all DIMMs used in the system match either of these technologies,

a maximum of four DIMMs can be populated.

In determining your memory requirements, the need for memory sparing or memory mirroring must

be considered.

15MAXDATA Server PLATINUM 1500 IR M5

Memory Sparing and Mirroring

The Intel® E7520 chipset includes hardware that supports memory mirroring and memory on-line

sparing. Both memory mirroring and memory on-line sparing provide a way to prevent data loss in

case a DIMM fails.

With memory mirroring the system maintains two copies of all data in the memory subsystem. If a

DIMM fails, the data is not lost because the second copy of the data is available from the mirrored

DIMM in the opposite channel. The system will not fail due to memory error unless both the primary

and the mirrored copy of the data become corrupt at the same time.

In a mirrored system, the maximum usable memory is one-half of the installed memory, with four

identical DIMMs installed in sockets 1A, 1B, 2A, and 2B. Since the data is duplicated across DIMMs,

it means that up to one-half of the installed DIMMs are actively in use at any one time. The remaining

DIMMs are used for mirroring:

– If the DIMM in socket 1A fails, the DIMM in socket 2B takes over.

– If the DIMM in socket 1B fails, the DIMM in socket 2A takes over.

For memory on-line sparing, one DIMM per channel is used as the memory spare. The spare DIMM is

not available for use, but is kept in reserve. If a DIMM begins to fail, the content of the failing DIMM

is copied to the spare DIMM in that channel. When all of the data is copied to the spare DIMM, the

primary DIMM is removed from service and the spare DIMM takes its place.

When memory on-line sparing is used, the spare DIMMs must be equal to or larger than the largest

in-service DIMM in that channel.

NOTE

Memory mirroring and memory sparing are mutually exclusive. Only one can be active at a time.

16 Server Board Features

Optional Hardware

Intel® Management Module

Two versions of the Intel® Management Module are available to provide enhanced server management

features.

®

• The Intel

that plugs into the server board.

• The Intel

10/100 Mbps NIC mezzanine card, and cables.

Management Module - Professional Edition: contains a hardware mezzanine card

®

Management Module - Advanced Edition: includes a hardware mezzanine card,

Local Control Panel

The Local Control Panel provides enhanced system control by utilizing a LCD display, which provides

additional controls and indicators beyond the standard control panel.

NOTE

Use of this feature requires the installation of either Intel® Management Module, Professional Edition

or Advance Edition.

17MAXDATA Server PLATINUM 1500 IR M5

18

3 Server Chassis Features

This chapter briefly describes the main features of the MAXDATA PLATINUM 1500 IR Server Chassis.

It provides a list of the server features, and diagrams showing the location of important components

and connections on the server chassis.

Table 7 summarizes the major features of the server chassis.

Table 7. Server Chassis Features

Feature Description

Dimensions • 1.703 inches high

• 16.930 inches wide

• 26.457 inches deep

Hard Drives (dependent

on option selected)

Peripherals (dependent

on option selected)

Fans Support for up to seven system fans, including two fans in the power

Control Panel

(dependent on option

selected)

LEDs and displays

(dependent on option

selected)

• Up to three fixed or hot-swap SATA or SCSI drives

• Slimline bay for CD-ROM, DVD-ROM drive, or floppy drive

• Kit to convert one hard drive bay into a floppy drive bay (optional

accessory)

• PCI riser card bracket

supply

Standard Control Panel:

Local Control Panel (requires installation of an optional Management

Module)

With Standard Control Panel:

• NIC1 Activity

• NIC2 Activity

• Power / Sleep

• System Status

• System Identification

• Hard Drive Activity

With Local Control Panel:

• additional LCD Display

Power Supply One 500 W power supply

System Security • Lockable front bezel (optional accessory)

• Chassis intrusion switch

• Lock attach point for chassis cover

Fans • Four 40 x 40 x 56 mm dual-rotor fans

• One 40 x 40 x 28 mm single rotor fan

• Two 40 x 40 x 28 mm fans in the power supply

USB (dependent on

option selected)

Video • One front panel video port (available only with Standard Control Panel)

• One front panel USB port with Standard Control Panel

• Two front panel USB ports with Local Control Panel

• Two back panel USB ports

• One rear panel video port

19MAXDATA Server PLATINUM 1500 IR M5

Component Identification

A

B

C

D

E

F

G

H

I

J

Internal Components

The diagram below shows the server chassis with a server board installed into it.

a

Figure 5. Internal Component Locations

A. Slimline drive bay (drive not included) F. Server board

B. Backplane (optional component)

C. Power supply air baffle H. Fan module

D. Power supply

E. PCI add-in card riser assembly J. Hard drive bays (drives not included)

G. Processor air duct

I. Control panel (Standard Control Panel shown)

20 Server Chassis Features

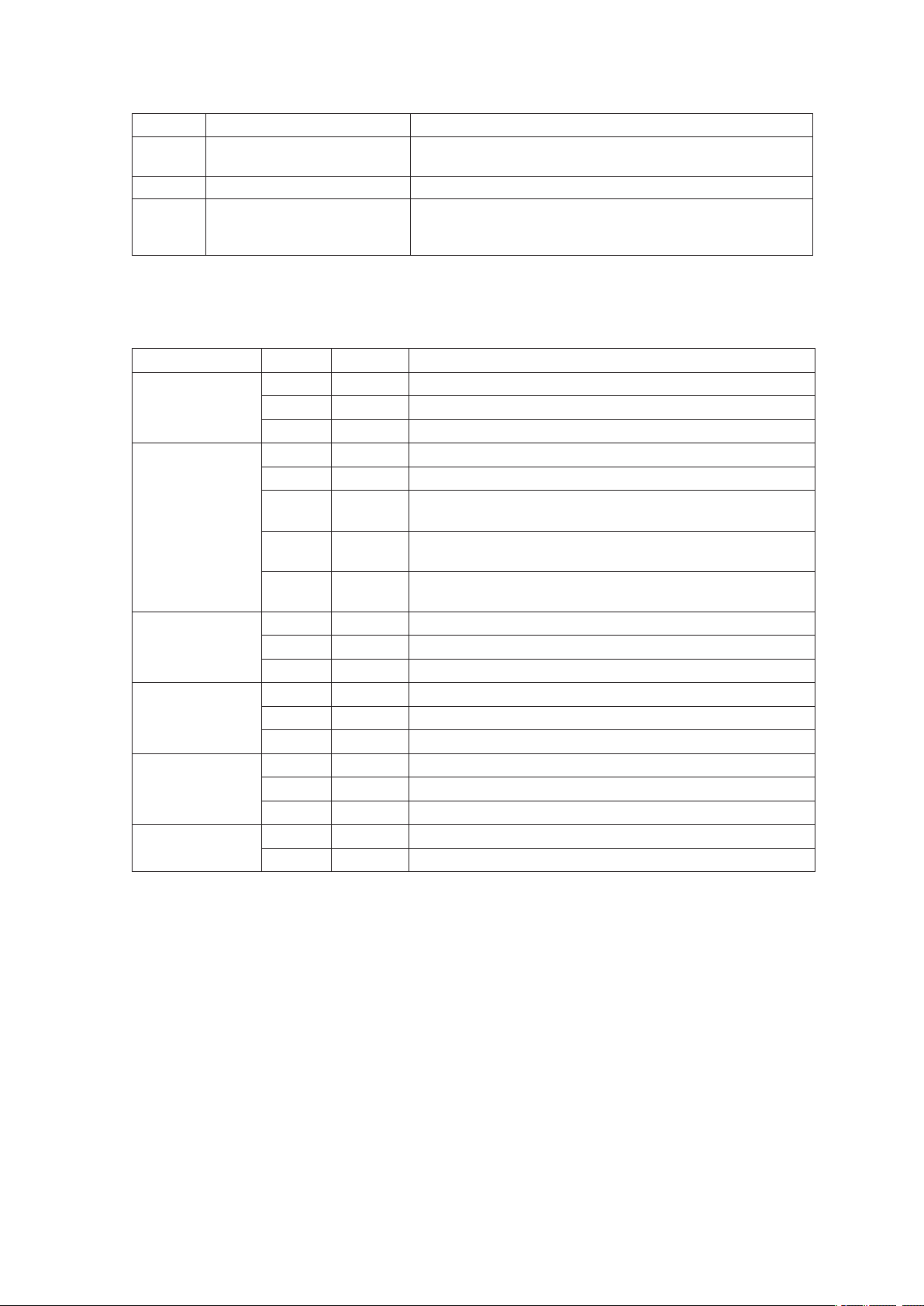

Local Control Panel

The diagram below shows the features available on the Local Control Panel. The Local Control Panel

is one of two required control options that can be selected. The other option is the Standard Control

Panel.

NOTE

This control panel requires the installation of a Management Module, Professional Edition or Advanced

Edition.

a

Figure 6. Local Control Panel

Table 8. Local Control Panel Features

Callout Feature Function

A USB 2.0 port Allows you to attach a USB component to the front of

the chassis.

B LCD display Screen on which system information is displayed.

C Menu control button, scroll up Scroll up one option at a time.

D Menu control button, scroll down Scroll down one option at a time.

E Menu control button, scroll left Move to the previous option.

F Menu control button, scroll right Move to the previous page.

G System Identification LED Solid blue indicates system identification is active. No

light indicates system identification is not activated.

21MAXDATA Server PLATINUM 1500 IR M5

Local Control Panel Features (Continued)

H Power/Sleep LED Continuous green light indicates the system has power

I Power/Sleep button Toggles the system power on/off. Sleep button for ACPI

J System Status LED Solid green indicates normal operation. Blinking green

L

K

M Hard disk drive status LED Random blinking green light indicates hard disk drive

N Reset button Reboots and initializes the system.

O USB 2.0 port Allows you to attach a USB component to the front of

NIC 1 activity LED

NIC 2 activity LED

Back Panel Features

applied to it. Blinking green indicates the system is in

S1 sleep state. No light indicates the power is off / is in

ACPI S4 or S5 state.

compatible operating systems.

indicates degraded performance. Solid amber indicates

a critical or non-recoverable condition. Blinking amber

indicates a non-critical condition. No light indicates

POST is running or the system is off.

Continuous green light indicates a link between the

system and the network to which it is connected.

Blinking green light indicates network activity.

activity. No light indicates no hard disk drive activity is

taking place.

the chassis.

a

Figure 7. Chassis Back

A. Low-profile add-in card bracket C. AC power receptacle

B. Full-height add-in card bracket D. I/O ports (see note)

NOTE

See the board section of the documentation for port identification.

22 Server Chassis Features

Peripheral Devices

The chassis provide locations and hardware for installing hard drives, a floppy drive, CD-ROM drive,

or DVD-ROM drive. The following figure shows the available options.

a

Figure 8. Optional Peripherals

A. Slimline floppy drive / DVD-ROM drive / CD-ROM drive

B. Hard drive bays (3)

Hard Disk Drives

The chassis ships with three drive carriers for installing three SCSI drives. One left drive bay can be

converted to be used as a floppy bay.

23MAXDATA Server PLATINUM 1500 IR M5

24

4 Hardware Installations and Upgrades

Before You Begin

Before working with your server product, pay close attention to the safety instructions at the beginning

of this manual.

Tools and Supplies Needed

• Phillips (cross head) screwdriver (#1 bit and #2 bit)

• Needle-nosed pliers

• Antistatic wrist strap and conductive foam pad (recommended)

System References

All references to left, right, front, top, and bottom assume the reader is facing the front of the chassis

as it would be positioned for normal operation.

Removing and Installing the Chassis Cover

Removing the Chassis Cover

The Server Chassis must be operated with the top cover in place to ensure proper cooling. You will

need to remove the top cover to add or replace components inside of the platform. Before removing

the top cover, power down the server and unplug all peripheral devices and the AC power cable.

None of the components inside of the chassis is hot-swappable.

NOTE

A nonskid surface or a stop behind the chassis may be needed to prevent the chassis from sliding

on your work surface.

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord.

4. Remove the shipping screw if it is installed. See letter “A” in the figure below.

5. While holding in the blue button at the top of the chassis in (see letter “B”), slide the top cover

back until it stops (See letter “C”).

6. Lift the cover upward to remove it.

Figure 9. Removing the Chassis Cover

a

25MAXDATA Server PLATINUM 1500 IR M5

Removing and Installing the Front Bezel

Two front bezel options are available. One is used for the Standard Control Panel and the other is

used with the Local Control Panel. Note the orientation in the figures below – the control panel is at

the right. If you are installing a bezel on your chassis, make sure you position it as shown.

Figure 10. Standard Front Bezel

a

Figure 11. Local

Control Panel Front Bezel

a

Removing the Front Bezel

1. Disconnect any cables attached to the control panel.

2. Pull the bezel out from the chassis.

Installing the Front Bezel

1. At each end of the bezel, line up the center notch on the bezel with the center guide on the

rack handles.

2. Push the bezel onto the front of the chassis until it clicks into place.

26 Hardware Installations and Upgrades

Installing and Removing a Hard Disk Drive

�

Installing Hot-swap Hard Disk Drive

1. Remove the front bezel if it is installed

2. Press in on the green latch at the front of the hard drive carrier. See letter “A” in the figure

below.

3. Pull out on the black lever and slide the carrier from the chassis. See letter “B” in the figure

below.

Figure 12. Removing a Hot-swap Hard Drive Carrier from Chassis

a

4. Remove the four screws that attach the plastic retention device or the previously installed hard

drive to the drive carrier. Two screws are at each side of the retention device or the hard drive.

Store the plastic retention device for future use.

Figure 13. Removing the Retention Device from a Hot-swap Drive Carrier

a

27MAXDATA Server PLATINUM 1500 IR M5

5. Remove the hard drive from its wrapper and place it on an antistatic surface.

6. Set any jumpers and/or switches on the drive according to the drive manufacturer’s

instructions.

7. With the drive circuit-side down, position the connector end of the drive so that it is facing the

rear of the drive carrier. See Error! Reference source not found.

8. Align the holes in the drive to the holes in the drive carrier and attach it to the carrier with the

screws that were attached to the plastic retention device.

9. With the black lever in the fully open position, slide the drive assembly into the chassis. The

green latch at the front of the drive carrier must be to the right. Do not push on the black drive

carrier lever until the lever begins to close by itself.

10. When the black drive carrier lever begins to close by itself, push on it to lock the drive

assembly into place.

Removing Hot-swap Hard Disk Drive

1. Remove the front bezel if it is installed.

2. Press in on the green latch at the front of the hard drive carrier.

3. Pull out on the black lever to slide the carrier from the chassis.

4. Remove the four screws that attach the hard drive to the drive carrier. Lift the drive from the

carrier. Store the drive in an anti-static bag.

5. If you are not installing a new drive, place the plastic retention device into the drive carrier,

using the four screws you removed from the hard drive.

6. Insert the screws that held the drive in the carrier into the screw locations on the carrier for

future use.

7. With the black lever in the fully open position, slide the drive carrier into the chassis. The green

latch must be to the right. Do not push on the black lever until the lever begins to close by

itself.

NOTE

For proper airflow, the hard drive carrier must be replaced in the chassis, even if no hard drive is

installed in it.

8. When the black lever begins to close by itself, push on it to lock the drive carrier into place.

28 Hardware Installations and Upgrades

Installing and Removing a PCI Riser Connector

A

B

You received your server chassis with your choice of one of two PCI riser connectors:

®

• A full-height PCI-Express riser with one PCI-Express

• A full-height PCI-X riser with one PCI-X slot

CAUTION

PCI riser connectors are NOT hot swappable. Before removing or replacing the riser connector, you

must first take the server out of service, turn off all peripheral devices connected to the system,

turn off the system by pressing the power button, and unplug the AC power cord from the system

or wall outlet.

Installing a PCI Riser Connector

To install the PCI riser connector, use the following instructions.

1. Observe the safety and ESD precautions at the beginning of this book.

2. Power down the server and unplug all peripheral devices and the AC power cable.

3. Remove the chassis cover.

4. Pull up on the two latches on the assembly. See letter “A” in the figure below.

5. Lift the PCI riser assembly from the chassis.

x8 slot

Figure 14. Removing the PCI Riser Assembly from the Chassis

a

29MAXDATA Server PLATINUM 1500 IR M5

6. Line up the screws on the riser assembly with the slot and the large hole on the riser

A

B

C

connector.

7. Press and hold the blue riser locking lever. See letter “A” in the figure below.

8. Place riser connector onto the retention pins

9. Slide the riser connector to the right to lock it into place.

10. Release the blue locking lever.

Figure 15. Installing an Add-in Card Connector into the PCI Riser Assembly

a

11. Install a PCI add-in card, if desired. For instructions, see “Installing a PCI Add-in Card.”

12. Position the riser assembly over the PCI sockets on the server board (see letter “A” in the

figure below), lining up the four hooks at the rear of the riser assembly (see letter “B”) with

the four slots in the rear of the chassis (see letter “C”).

13. Push the riser assembly down until the assembly is securely seated.

Figure 16. Installing the PCI Riser Assembly into the Chassis

a

14. Install the chassis cover.

15. Plug all peripheral devices and the AC power cable back into the server.

30 Hardware Installations and Upgrades

Installing and Removing a PCI Add-in Card

A

B

Installing a PCI Add-in Card

In the slots provided by the PCI riser connector, you can install either one or two add-in cards. Use

the following instructions to install an add-in card.

1. Observe the safety and ESD precautions at the beginning of this book.

2. Power down the server and unplug all peripheral devices and the AC power cable.

3. Remove the chassis cover.

4. Pull up on the two latches on the assembly. See letter “A” in the figure below.

5. Lift the PCI riser assembly from the chassis.

Figure 17. Removing the PCI Riser Assembly from the Chassis

a

6. Open the PCI retention clip on the PCI riser card assembly. See letter “A” in the figure below.

7. Remove the filler panel at the back of the riser assembly. See letter “B” in the figure below.

8. Insert the add-in card until it seats in riser card connector. Make sure the bracket inserts into

the matching slot. See letter “C”.

9. Close the retention clip. See letter “A” in the figure.

Figure 18. Installing an Add-in Card to the PCI Riser Assembly

a

31MAXDATA Server PLATINUM 1500 IR M5

10. Position the riser assembly over the PCI sockets on the server board (see letter “A” in the

A

B

C

figure below), lining up the four hooks at the rear of the riser assembly (see letter “B”) with

the four slots in the rear of the chassis (see letter “C”).

11. Push the riser assembly down until the assembly is securely seated.

Figure 19. Installing the PCI Riser Assembly into the Chassis

a

12. Install the chassis cover.

13. Plug all peripheral devices and the AC power cable back into the server.

32 Hardware Installations and Upgrades

Installing and Removing Memory

The silk screen on the board for the DIMMs displays DIMM 1B, DIMM 1A, DIMM 2B, DIMM 2A,

DIMM 3B, DIMM 3A starting from the edge of the board.

Installing DIMMs

To install DIMMs, follow these steps:

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord from the server.

4. Remove the chassis cover and locate the DIMM sockets.

a

Figure 20. Installing Memory

5. Make sure the clips at either end of the DIMM socket(s) are pushed outward to the open

position.

6. Holding the DIMM by the edges, remove it from its anti-static package.

7. Position the DIMM above the socket. Align the small notch in the bottom edge of the DIMM

with the key in the socket.

8. Insert the bottom edge of the DIMM into the socket.

9. When the DIMM is inserted, carefully push straight down on the top edge of the DIMM until

the retaining clips snap into place. Make sure the clips are firmly in place.

10. Replace the chassis cover and reconnect the AC power cord.

33MAXDATA Server PLATINUM 1500 IR M5

Installing or Replacing the Processor

CAUTIONS

Processor must be appropriate: You may damage the server board if you install a processor that

is inappropriate for your server.

ESD and handling processors: Reduce the risk of electrostatic discharge (ESD) damage to the

processor by doing the following: (1) Touch the metal chassis before touching the processor or server

board. Keep part of your body in contact with the metal chassis to dissipate the static charge while

handling the processor. (2) Avoid moving around unnecessarily.

Installing the Processor

To install a processor, follow these instructions:

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord from the server.

4. Remove the chassis cover and locate the processor sockets.

5. Locate the processor socket and raise the socket handle completely.

a

Figure 21. Opening Socket Lever

6. Align the pins of the processor with the socket, and insert the processor into the socket.

NOTE

Make sure the alignment triangle mark and the alignment triangle cutout align correctly (see Figure

on next page).

7. Lower the socket lever completely.

34 Hardware Installations and Upgrades

a

TP00774

Figure 22. Inserting Processor

Installing the Heat Sink(s)

1. The heat sink has Thermal Interface Material (TIM) located on the bottom of it. Use caution

when you unpack the heat sink so you do not damage the TIM.

2. Set the heat sink over the processor, lining up the four captive screws with the four posts

surrounding the processor.

3. Loosely screw in the captive screws on the heat sink corners in a diagonal manner. Do not fully

tighten one screw before tightening another.

4. Gradually and equally tighten each captive screw until all screws are tight.

a

Figure 23. Installung Heat Sink

5. Reinstall and reconnect any parts you removed or disconnected to reach the processor

sockets.

6. Replace the server’s cover and reconnect the AC power cord. See the documentation that

accompanied your server chassis for instructions on installing the server’s cover.

35MAXDATA Server PLATINUM 1500 IR M5

Removing a Processor

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Remove the AC power cord from the server.

4. Remove the chassis cover.

5. Unplug the processor fan cable from the server board.

6. Loosen the four captive screws on the corners of the heat sink.

7. Twist the heat sink slightly to break the seal between the heat sink and the processor.

8. Lift the heat sink from the processor. If it does not pull up easily, twist the heat sink again. Do

not force the heat sink from the processor. Doing so could damage the processor.

9. Lift the processor lever.

10. Remove the processor.

11. If installing a replacement processor, see “Installing the Processor.” Otherwise, reinstall the

chassis cover.

36 Hardware Installations and Upgrades

RJ45 Serial Port Configuration

The RJ45 serial port connector can be configured to support either a DSR signal or a DCD signal.

As the server board is shipped, it is configured to support DSR signals. To change the configuration

to support DCD signals a jumper on the board must be changed. Use the following instructions to

configure your server board to support DCD signals.

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord from the server.

4. Remove the server’s cover.

5. Locate the jumper block for the serial port. See figure 24.

6. Move the jumper from the default position covering pins 1 and 3 to cover pins 2 and 4.

Figure 24. Changing the Serial Port Configuration

aa

37MAXDATA Server PLATINUM 1500 IR M5

Replacing the Backup Battery

The lithium battery on the server board powers the RTC for up to 10 years in the absence of power.

When the battery starts to weaken, it loses voltage, and the server settings stored in CMOS RAM in

the RTC (for example, the date and time) may be wrong. Contact your customer service representative

or dealer for a list of approved devices.

WARNING

Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent

type recommended by the equipment manufacturer. Discard used batteries according to

manufacturer’s instructions.

WARNUNG

Wenn eine ungeeignete Batterie eingesetzt wird oder die Batterie falsch eingesetzt wird,

besteht Explosionsgefahr. Ersetzen Sie verbrauchte Batterien nur durch Batterien gleichen

oder äquivalenten Typs, der vom Hersteller empfohlen wurde. Entsorgen Sie die verbrauchte

Batterie entsprechend den Anweisungen des Herstellers.

AVERTISSEMENT

Danger d’explosion en cas de remplacement incorrect de la pile. Remplacez-la uniquement

par une pile du même type ou d’un type équivalent recommandé par le fabricant. Mettez au

rebut les piles usagées en vous conformant aux instructions du fabricant.

OSTRZEŻENIE

Nieprawidłowa wymiana baterii grozi eksplozją. Wymieniać tylko na taki sam lub

równoważny typ, zalecany przez producenta. Zużyte baterie utylizować zgodnie z instrukcjami

producenta.

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering. Udskiftning må kun ske med batteri

af samme fabrikat og type. Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare. Ved utskifting benyttes kun batteri som anbefalt av

apparatfabrikanten. Brukt batteri returneres apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte. Använd samma batterityp eller en ekvivalent typ

som rekommenderas av apparattillverkaren. Kassera använt batteri enligt fabrikantens

instruktion.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu. Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

38 Hardware Installations and Upgrades

1. Observe the safety and ESD precaution.

TP00760

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord from the server.

4. Remove the server’s cover and locate the battery. See the documentation that accompanied

your server chassis for instructions on removing the server’s cover.

5. Insert the tip of a small flat bladed screwdriver, or an equivalent, under the tab in the plastic

retainer. Gently push down on the screwdriver to lift the battery.

6. Remove the battery from its socket.

a

Figure 25. Replacing the Backup Battery

7. Dispose of the battery according to local ordinance.

8. Remove the new lithium battery from its package, and, being careful to observe the correct

polarity, insert it in the battery socket.

9. Close the chassis.

10. Run Setup to restore the configuration settings to the RTC.

39MAXDATA Server PLATINUM 1500 IR M5

40

5 Server Utilities

Using the BIOS Setup Utility

This section describes the BIOS Setup Utility options, which is used to change server configuration

defaults.

Starting Setup

You can enter and start BIOS Setup under several conditions:

• When you turn on the server, after POST completes the memory test

• When you have moved the CMOS jumper on the server board to the “Clear CMOS” position

(enabled)

In the two conditions listed above, during the Power On Self Test (POST), you will see this prompt:

Press <F2> to enter SETUP

In a third condition, when CMOS/NVRAM has been corrupted, you will see other prompts but not

the <F2> prompt:

Warning: CMOS checksum invalid

Warning: CMOS time and date not set

In this condition, the BIOS will load default values for CMOS and attempt to boot.

If You Cannot Access Setup

If you are not able to access BIOS Setup, you might need to clear the CMOS memory. For instructions

on clearing the CMOS, see “Clearing the CMOS”.

Setup Menus

Each BIOS Setup menu page contains a number of features. Except for those features that are

provided only to display automatically configured information, each feature is associated with a

value field that contains user-selectable parameters. These parameters can be changed if the user

has adequate security rights. If a value cannot be changed for any reason, the feature’s value field

is inaccessible.

41MAXDATA Server PLATINUM 1500 IR M5

Table 9 describes the keyboard commands you can use in the BIOS Setup menus.

Table 9. Keyboard Commands

Press Description

<F1> Help - Pressing F1 on any menu invokes the general Help window.

← →

↑

↓

F5/- Change Value - The minus key or the F5 function key is used to change the value

F6/+ Change Value - The plus key or the F6 function key is used to change the value

<Enter> Execute Command - The Enter key is used to activate submenus when the

<Esc> Exit - The ESC key provides a mechanism for backing out of any field. This key

The left and right arrow keys are used to move between the major menu pages.

The keys have no affect if a submenu or pick list is displayed.

Select Item up - The up arrow is used to select the previous value in a menu

item’s option list, or a value field pick list. Pressing the Enter key activates the

selected item.

Select Item down - The down arrow is used to select the next value in a menu

item’s option list, or a value field pick list. Pressing the Enter key activates the

selected item.

of the current item to the previous value. This key scrolls through the values in

the associated pick list without displaying the full list.

of the current menu item to the next value. This key scrolls through the values

in the associated pick list without displaying the full list. On 106-key Japanese

keyboards, the plus key has a different scan code than the plus key on the other

keyboard, but it has the same effect.

selected feature is a submenu, or to display a pick list if a selected feature has a

value field, or to select a sub-field for multi-valued features like time and date.

If a pick list is displayed, the Enter key will undo the pick list, and allow another

selection in the parent menu.

will undo the pressing of the Enter key. When the ESC key is pressed while

editing any field or selecting features of a menu, the parent menu is re-entered.

When the ESC key is pressed in any submenu, the parent menu is re-entered.

When the ESC key is pressed in any major menu, the exit confirmation window

is displayed and the user is asked whether changes can be discarded.

<F9> Setup Defaults - Pressing F9 causes the following to appear:

Setup Confirmation

Load default configuration now?

[Yes] [No]

If “Yes” is selected and the Enter key is pressed, all Setup fields are set to their

default values. If “No” is selected and the Enter key is pressed, or if the ESC

key is pressed, the user is returned to where they were before F9 was pressed

without affecting any existing field values.

<F10> Save and Exit - Pressing F10 causes the following message to appear:

Setup Confirmation

Save Configuration changes and exit now?

[Yes] [No]

If “Yes” is selected and the Enter key is pressed, all changes are saved and

Setup is exited. If “No” is selected and the Enter key is pressed, or the ESC key

is pressed, the user is returned to where they were before F10 was pressed

without affecting any existing values.

42 Server Utilities

Clearing the Password

If the user or administrator password(s) is lost or forgotten, moving the password clear jumper into

the “clear” position clears both passwords. The password clear jumper must be restored to its

original position before a new password(s) can be set. The password clear jumper is shown on the

line labeled “A” in figure 4.

1. Power down the system and disconnect the AC power.

2. Open the server chassis.

3. Move the jumper from the normal operation position, Password Clear Protect, at pins 1 and 2

to the Password Clear Erase position, covering pins 2 and 3.

4. Reconnect the AC power, power up the system.

5. Power down the system and disconnect the AC power.

6. Return the Password Clear jumper to the Password Clear Protect position, covering pins 1 and 2.

7. Close the server chassis.

8. Reconnect the AC power and power up the server.

Clearing the CMOS

If you are not able to access the BIOS setup screens, the CMOS Clear jumper will need to be used to

reset the configuration RAM. The CMOS Clear jumper is shown on the line labeled “C” in figure 4.

1. Power down the system and disconnect the AC power.

2. Open the server.

3. Move the jumper from the normal operation position, CMOS Clear by BMC, at pins 1 and 2

to the CMOS Clear Force Erase position, covering pins 2 and 3 as indicated in the following

diagram.

4. Reconnect the AC power, power up the system.

5. When the system begins beeping, power it down and disconnect the AC power.

6. Return the CMOS Clear jumper to the CMOS Clear by BMC location, covering pins 1 and 2.

7. Close the server chassis.

8. Reconnect the AC power and power up the system.

43MAXDATA Server PLATINUM 1500 IR M5

44

6 Troubleshooting

This chapter helps you identify and solve problems that might occur while you are using the

system.

LED Information

The MAXDATA PLATINUM Server Board includes LEDs that can aid in troubleshooting your system.

A table of these LEDs with a description of their use is listed below.

Table 10. LED Information

LED Name Function Location Color Notes

ID Aid in server iden-

tification from the

back panel

System fault Visible fault

warning

ATA drive activity ATA drive activity

Memory fault 1–6

Diagnostic LEDs.

1–4 (LSB, bit1,

bit2, MSB)

CPU 1 & 2 Fan

Fault

CPU 1 & 2 Fault

5v Standby

Power LED

Identify failing

memory module

Displays port 80

POST codes

Identify fan failure Front center board Amber On = Fault

Identify processor

failure

Identify 5v

standby power on

state

Identify the

power state of the

system

Control panel and

board rear left

corner

Control panel and

board rear left

corner

Control panel Green Blinking = Activity.

DIMM end rear of

board

Center back edge

of board

1” behind processor socket

Front left board

Control Panel

Blue Press ID LED

button or user

Server Manage

ment software to

turn on the LED.

Green or Amber • Green = No

Fault

• Green Blink =

degraded

• Amber = critical

error or nonrecoverable

• Amber blink =

non-critical

No action

required.

Amber On = Fault

Each LED can be

Off, Green, Amber,

Red

Amber On = Fault

Amber On = 5v standby

Green • Off = Power is

See the POST

code table

power on

off (off or S5)

• On = Power on

or S0)

• Slow Blink =

Low power

state (S1 – S3)

-

45MAXDATA Server PLATINUM 1500 IR M5

BIOS POST Beep Codes

The table below lists the POST error beep codes. Prior to system video initialization, the BIOS uses

these beep codes to inform users of error conditions. Please note that not all error conditions are

supported by BIOS beep codes.

Table 11. POST Error Beep Codes

Number of Beeps Reason for the beeps and action to take

1, 2, or 3 Memory error. Reseat the memory or replace the DIMMs with known good

modules.

4 – 7 or 9 – 11 Fatal error indicating a possible serious system problem. Remove all add-in

cards and re-start the system. If the error still occurs, contact your system

manufacturer. If the beep codes are not generated after the add-in cards are

removed, insert the cards one at a time, booting the system between each

card addition, until the beeps again occur to reveal the malfunctioning card.

8 Replace or reseat the system video add-in card. If on-board video is bing

used, the server board may be faulty.

In addition to the beep codes above, additional beep codes are provided if an Intel® Management

Module is installed. The Intel® Management Modules provide the following additional beep codes.

Table 12. Error Beep Codes Provided by Intel® Management Modules

Beep Code Reason for the beeps and action to take

1 Control panel CMOS clear has been initiated.

1-5-1-1 Processor failure. Reseat or replace the failed processor.

1-5-2-1 No processor is installed or the CPU 1 socket is empty. Reseat or replace the

failed processor.

1-5-2-3 Processor configuration error or CPU 1 socket is empty. Reseat or replace the

failed processor. In a two-processor system, make sure the processors are

identical.

1-5-2-4 Front-side bus select configuration error.

1-5-4-2

1-5-4-3

1-5-4-4 Power control failure.

DC power unexpectedly lost.

Chipset control failure.

46 Troubleshooting

7 Technical Reference

Power Supply Specifications

500-W Single Power Supply Input Voltages

• 100-127 V~ at 50/60 Hz; 8.2 A max.

• 200-240 V~ at 50/60 Hz; 4.1 A max.

500-W Single Power Supply Output Voltages

The table below lists the total wattage available from the power subsystem for each voltage.

Table 13. 500-W Power Supply System Output Capability

Voltage Maximum Current

+3.3 V 16 A

+5.0 V 12 A

+5 V Standby 2 A

+12.0 35 A

–12.0 V 0.5 A

CAUTION

Do not exceed a combined power output of 90 Watts for the +5 V and +3.3 V outputs. Exceeding

a combined 90 Watts will overload the power subsystem and may cause the power supplies to

overheat and malfunction.

System Environmental Specifications

Table 14. Environmental Specifications

Temperature Non-operating –40 °C to 70 °C.

Operating 10 °C to 30 °C; derated 0.5 °C for every 1000 ft

(305 m) to a maximum of 10,000 ft.

Humidity Non-operating 90 % relative humidity (non-condensing) at 30 °C.

Acoustic noise 7 Bels in sound power for a typical office ambient

temperature (18–24 °C). The selection of peripherals

may change the noise level.

47MAXDATA Server PLATINUM 1500 IR M5

48

8 Regulatory and Integration Information

Product Regulatory Compliance

Product Safety Compliance

The server board complies with the following safety requirements:

• EN 60 950 (European Union)

• IEC60 950 (International)

• CE – Low Voltage Directive (73/23/EEC) (European Union)

Product EMC Compliance

The mainboard has been tested and verified to comply with the following electromagnetical

compatibility (EMC) regulations when installed in a compatible MAXDATA host system.

• EN55022 (Class A) – Radiated & Conducted Emissions (European Union)

• EN55024 (Immunity) (European Union)

• CE – EMC Directive (89/336/EEC) (European Union)

Product Regulatory Compliance Markings

This product is marked with the following Product Certification Markings:

Table 15. Product Certification Markings

CE Mark

49MAXDATA Server PLATINUM 1500 IR M5

Electromagnetic Compatibility Notices

FCC (USA)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment to an outlet on a circuit other than the one to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications not expressly approved by the grantee of this device could void the

user’s authority to operate the equipment. The customer is responsible for ensuring compliance of

the modified product.

Only peripherals (computer input/output devices, terminals, printers, etc.) that comply with FCC Class

A or B limits may be attached to this computer product. Operation with noncompliant peripherals is

likely to result in interference to radio and TV reception. All cables used to connect to peripherals must

be shielded and grounded. Operation with cables, connected to peripherals, that are not shielded and

grounded may result in interference to radio and TV reception.

Europe (CE Declaration of Conformity)

This product has been tested in accordance to, and complies with the Low Voltage Directive (73/23/

EEC) and EMC Directive (89/336/EEC). The product has been marked with the CE Mark to illustrate

its compliance.

Installation Precautions

When you install and test the server board, observe all warnings and cautions in the installation

instructions.

To avoid injury, be careful of:

• Sharp pins on connectors

• Sharp pins on printed circuit assemblies

• Rough edges and sharp corners on the chassis

• Hot components (like processors, voltage regulators, and heat sinks)

• Damage to wires that could cause a short circuit

Observe all warnings and cautions that instruct you to refer computer servicing to qualified technical

personnel.

50 Regulatory and Integration Information

Installation Requirements

CAUTION

Follow these guidelines to meet safety and regulatory requirements when installing this board

assembly.

Read and adhere to all of these instructions and the instructions supplied with the chassis and

associated modules. If the instructions for the chassis are inconsistent with these instructions or

the instructions for associated modules, contact the supplier’s technical support to find out how you

can ensure that your computer meets safety and regulatory requirements. If you do not follow these

instructions and the instructions provided by chassis and module suppliers, you increase safety risk

and the possibility of noncompliance with regional laws and regulations.

Prevent Power Supply Overload

Do not overload the power supply output. To avoid overloading the power supply, make sure that the

calculated total current loads of all the modules within the computer is less than the output current

rating of each of the power supplies output circuits.

Place Battery Marking

There is insufficient space on this server board to provide instructions for replacing and disposing of

the battery. For system safety certification, the following statement or equivalent statement may be

required to be placed permanently and legibly on the chassis near the battery.

CAUTION

Risk of explosion if battery is incorrectly replaced.

Replace with only the same or equivalent type recommended by the manufacturer. Dispose of used

batteries according to the manufacturer’s instructions.

Use Only for Intended Applications

This server board was evaluated as Information Technology Equipment (I.T.E.) for use in computers

that will be installed in offices, homes, schools, computer rooms, and similar locations. The suitability

of this product for other applications or environments, (such as medical, industrial, alarm systems,

test equipment, etc.) may require further evaluation.

51MAXDATA Server PLATINUM 1500 IR M5

Loading...

Loading...