Page 1

8 Bit Microcontroller

TLCS-870/C Series

TMP86FH47BUG

Page 2

© 2011 TOSHIBA CORPORATION

All Rights

Reserved

Page 3

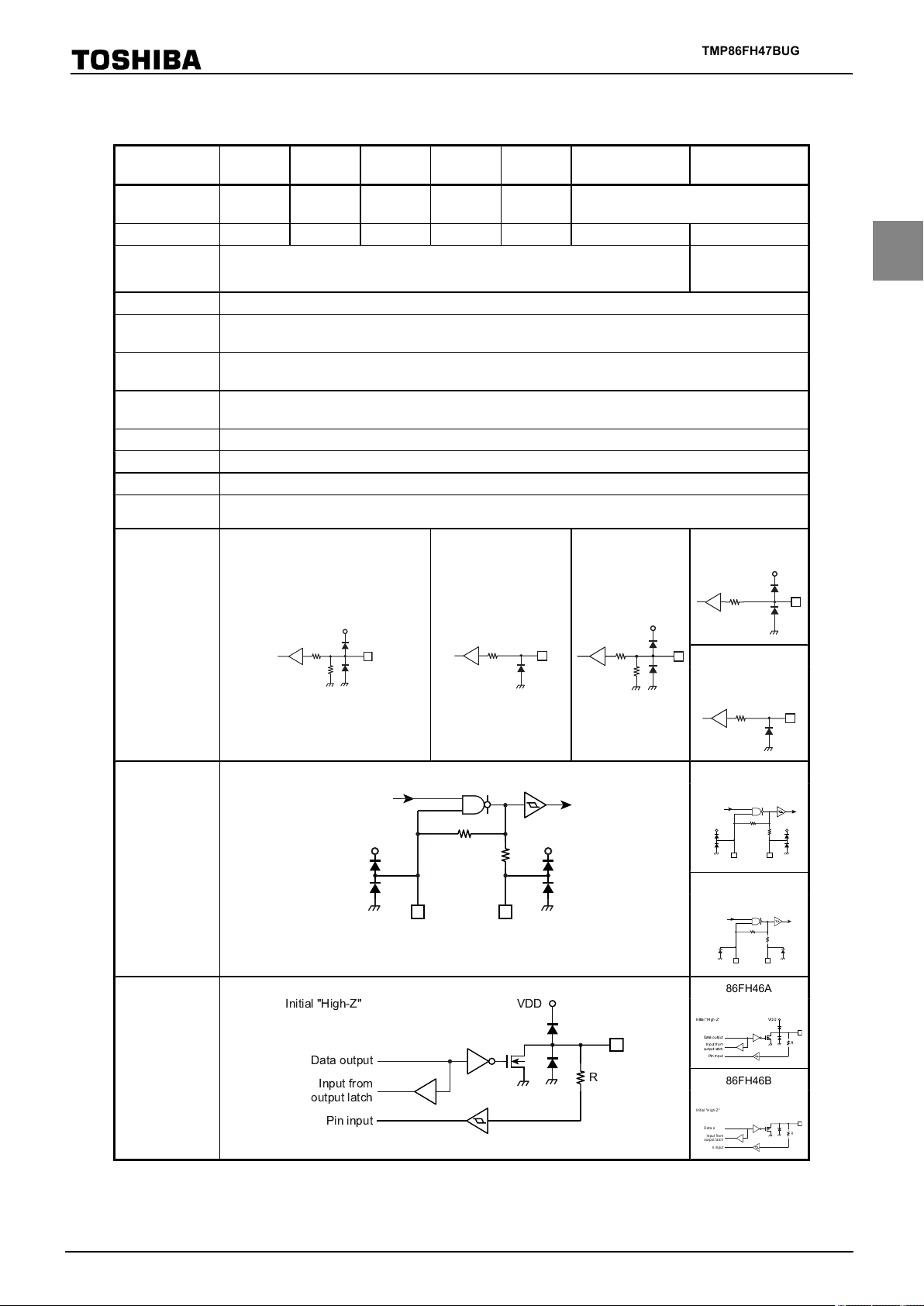

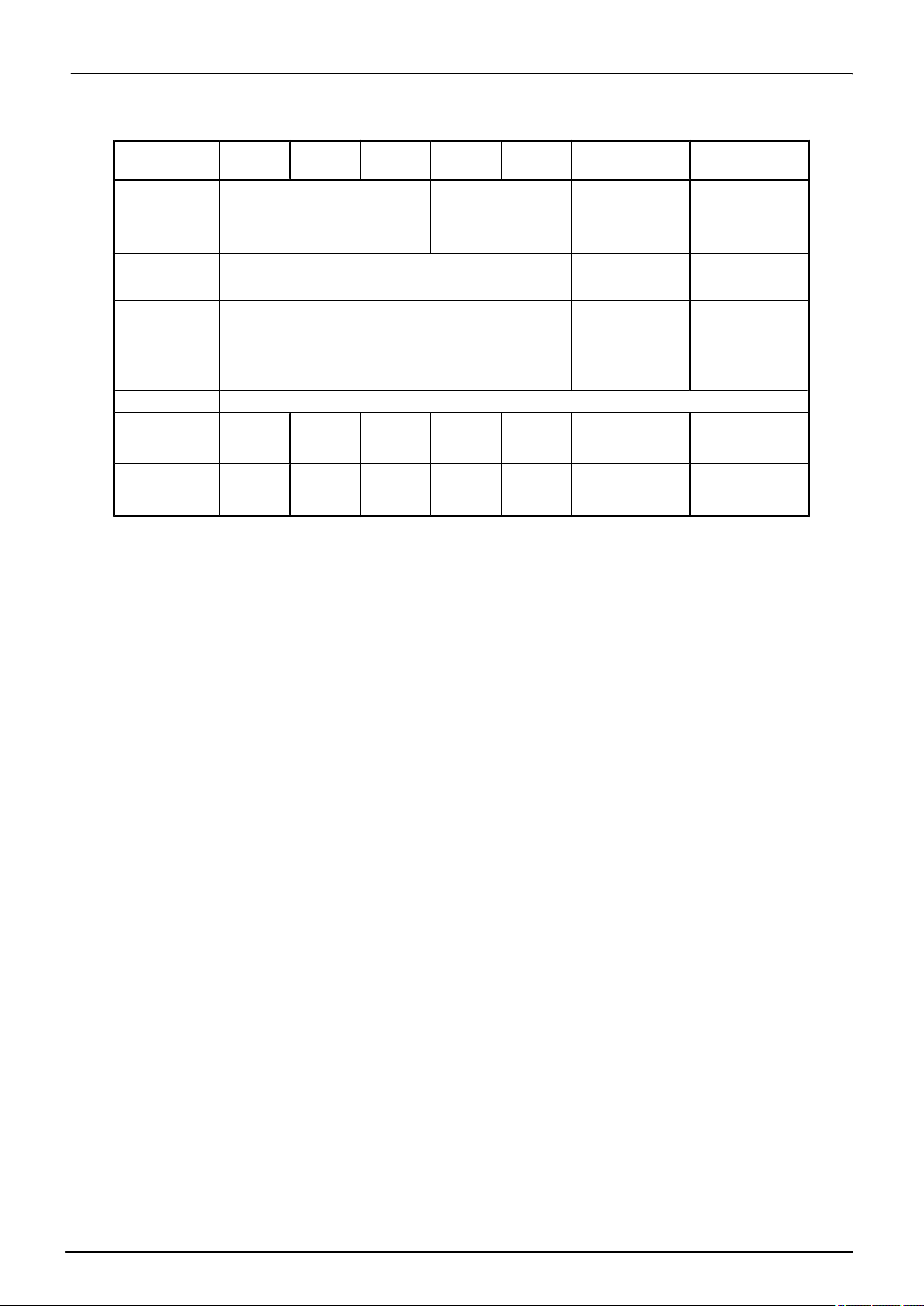

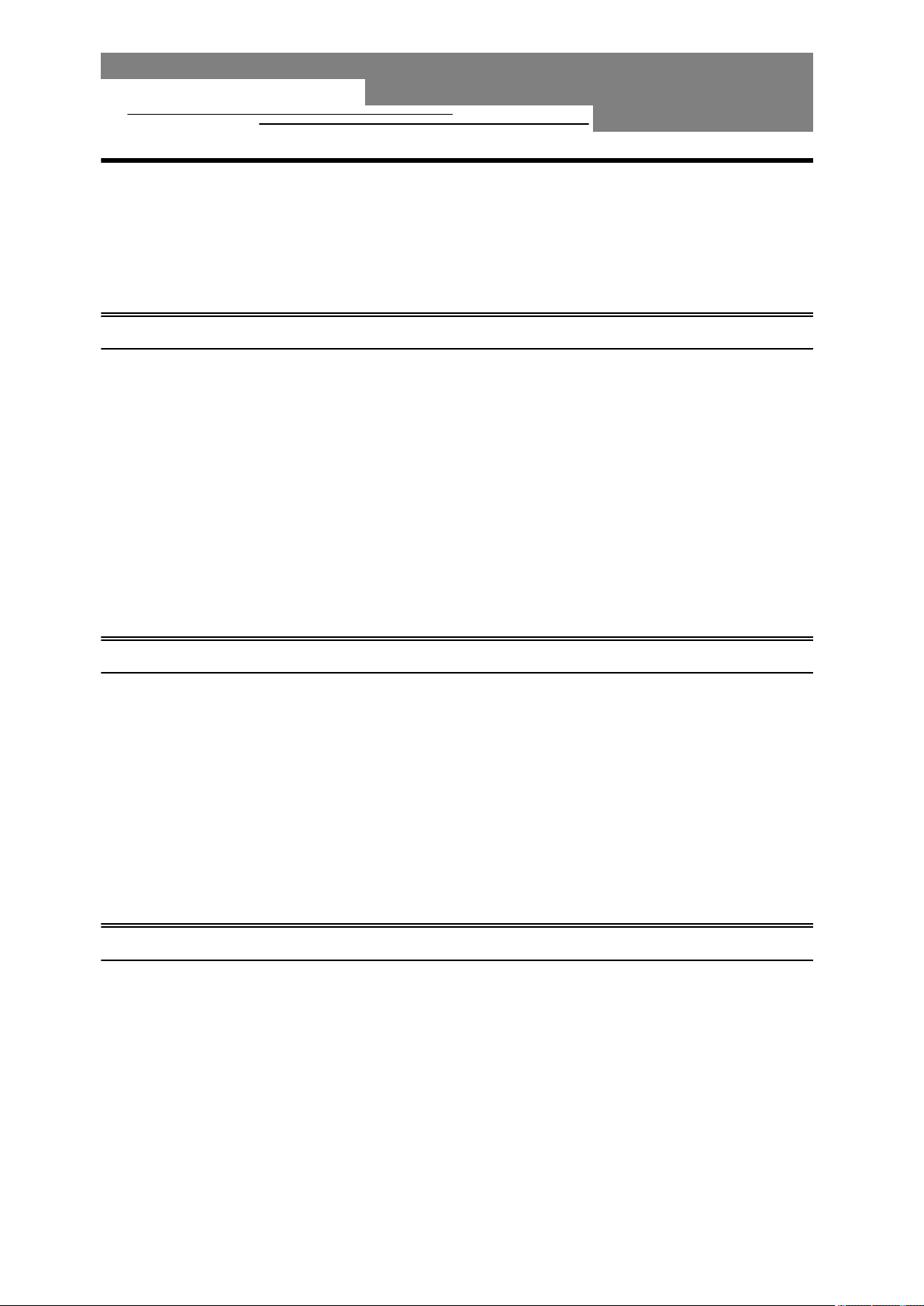

Difference among product (TMP86xx46 Series)

VDD

R

IN

R

R

without pull

down resister

without protect diode

on the VDD side

VDD

R

IN

R

R

VDD

without pull

down resister

R

without pull

down resister

without protect diode

on the VDD side

fs

Rf

R

O

Osc. enable

XTIN

XTEN

XTOUT

VDDVDD

fs

Rf

R

O

Osc. enable

XTIN

XTEN

XTOUT

VDDVDD

fs

Rf

R

O

Osc. enable

XTIN

XTEN

XTOUT

Initial "High-Z"

Input from

output latch

Data output

Pin input

R

TMP86FH47BUG

86C846

ROM

8192bytes

(MASK)

86CH46

86CH46A

16384bytes

(MASK)

86CM46

86CM46A

32768bytes

(MASK)

86PH46

16384bytes

(OTP)

86PM46

86PM46A

32768bytes

(OTP)

86FH46

16384bytes

(FLASH)

RAM 512bytes 512bytes 1024bytes 512bytes 1024bytes 512bytes 512bytes

DBR(note1) -

I/O 33pins

Large current out-

put

Interrupt

Timer counter

(External : 6 Internal : 12)

19pins

(LED direct

drive)

18interrupt sources

16-bit timer counter : 1ch

8-bit timer

counter : 2ch

UART 8-bit UART : 1ch

SIO High-Speed SIO : 1ch

Key-on wakeup 4ch

10-bit AD convert-

er

Analog-input : 8ch

86FH46A

86FH46B

128bytes (Flash con-

trol register

con-

tained)

86FH46A

Structure

pin

of TEST

Structure

of XTIN,XTOUT

Structure

port

of P2

86FH46B

86FH46A

86FH46B

86FH46A

86FH46B

Page 4

TMP86FH47BUG

86C846

Number of guaran-

teed writes

flash memory

Terminal for SERI-

AL PROM

Flash Security N.A. Read protect

Emulation Chip TMP86C947XB

to

MODE

(note2)

Package SDIP42-P-600-1.78

86CH46

86CH46A

- - 100 Times

86CM46

86CM46A

-

86PH46

86PM46

86PM46A

86FH46

BOOT1/RXD(P10)

BOOT2/TXD(P11)

86FH46A

86FH46B

(a)86FH46A

100 Times

(b)86FH46B

Times

1000

BOOT/RXD(P02)

TXD(P03)

(a)86FH46A

Read protect

(b)86FH46B

/ Write

Read

protect

Note 1: The products with Flash memory (86FH46,86FH46A,86FH46B) contain the Flash control register (FLSCR) at 0FFFH

DBR area. The products with mask ROM or OTP and the emulation chip do not have the FLSCR register. In

in the

these devices,therefore, a program that accesses the FLSCR register cannot function properly (executes differently

as in the case of a Flash product).

Note 2: The TXD and RXD pins to be used in Serial PROM mode differ between the 86FH46 and the 86FH46A,86FH46B.

Take this into consideration in your board design when you replace the product. Details of the function refer to the chapter of the 86FH46,86FH46A,86FH46B data sheet.

Note 3: P21,P22 combine XTIN,XTOUT and port.

Page 5

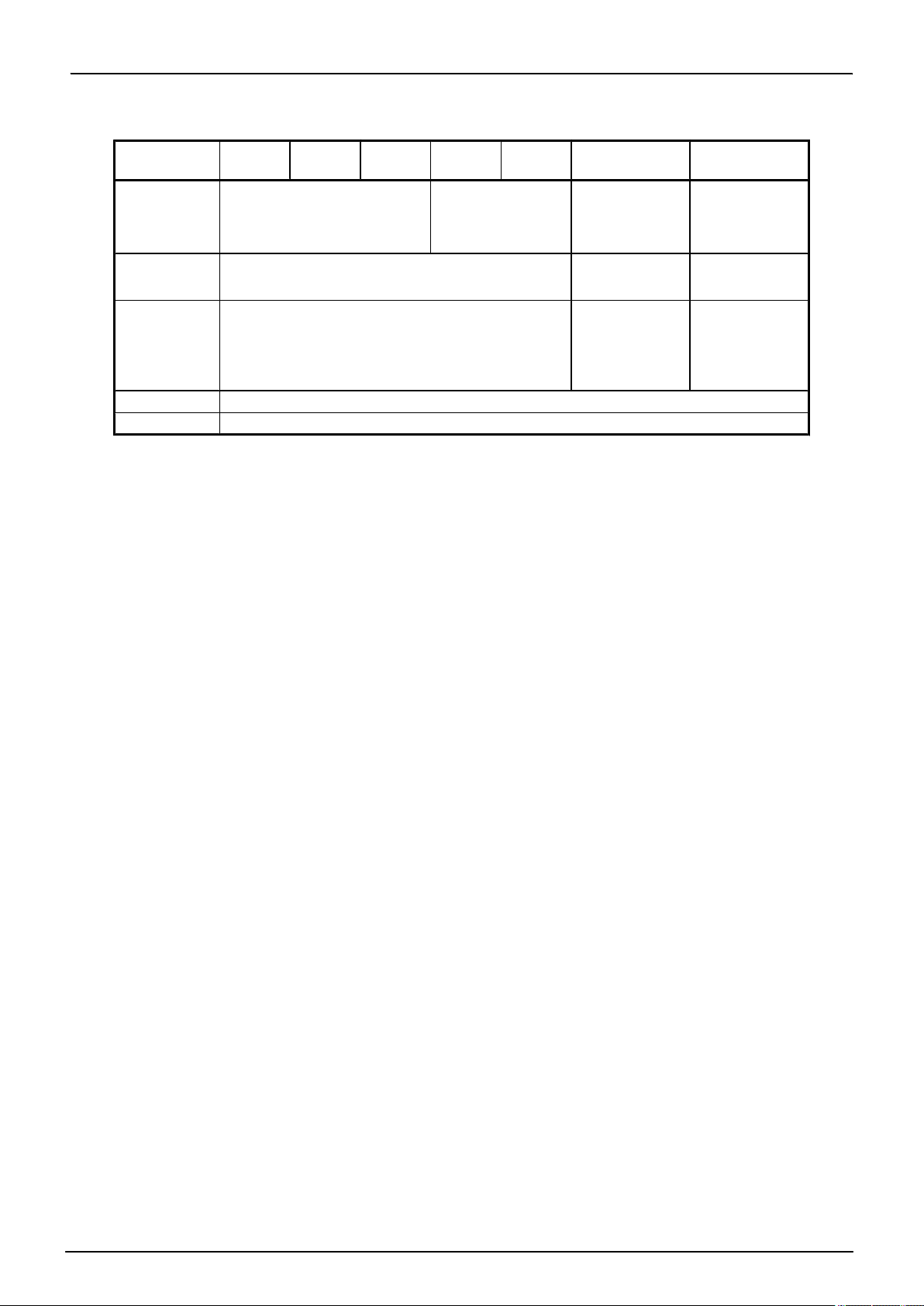

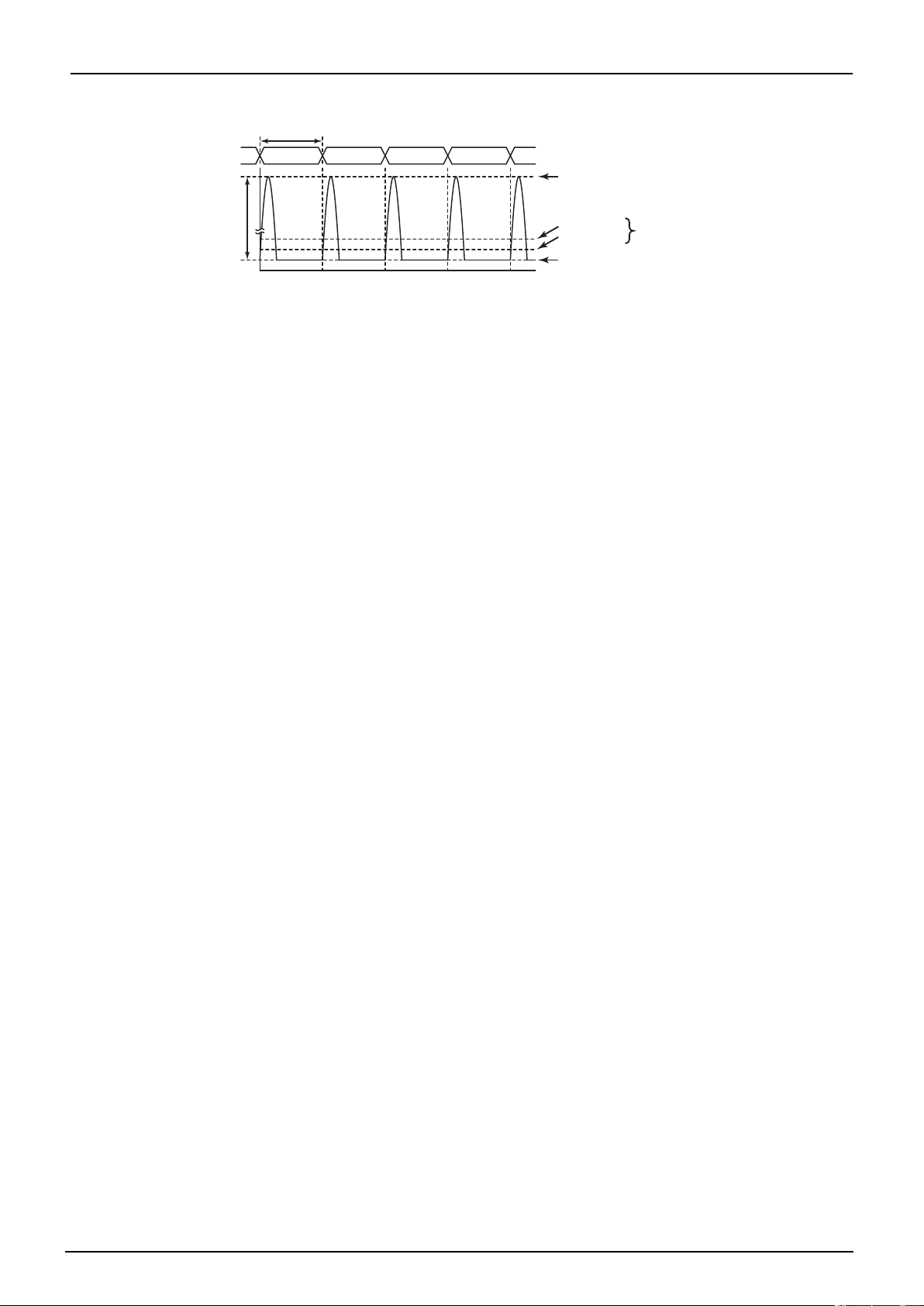

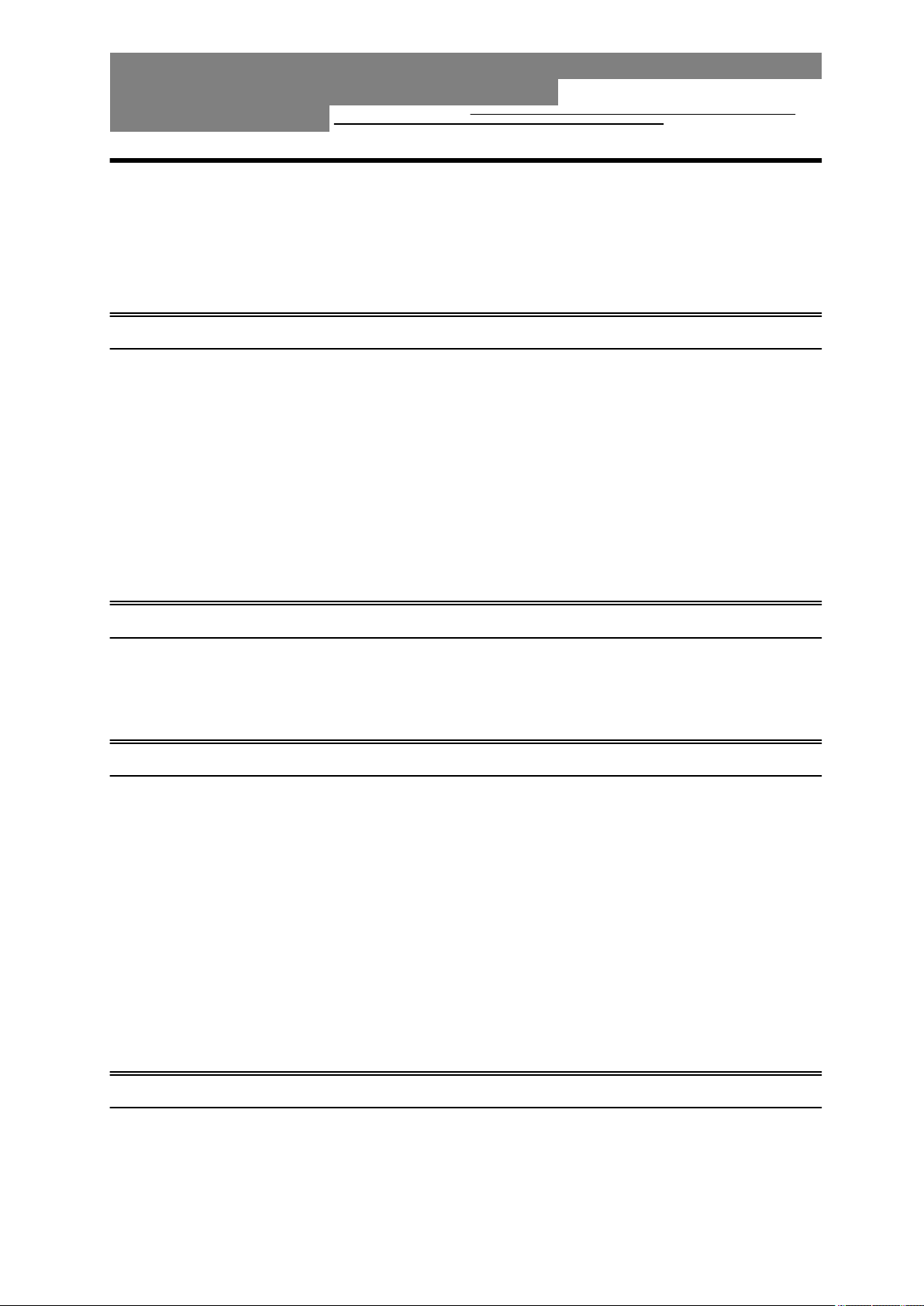

Difference among product (TMP86xx47 Series)

VDD

R

IN

R

R

without pull

down resister

without protect diode

on the VDD side

VDD

R

IN

R

R

VDD

without pull

down resister

R

without pull

down resister

without protect diode

on the VDD side

fs

Rf

R

O

Osc. enable

XTIN

XTEN

XTOUT

VDDVDD

fs

Rf

R

O

Osc. enable

XTIN

XTEN

XTOUT

VDDVDD

fs

Rf

R

O

Osc. enable

XTIN

XTEN

XTOUT

Initial "High-Z"

Input from

output latch

Data output

Pin input

R

TMP86FH47BUG

86C847

ROM

8192bytes

(MASK)

86CH47

86CH47A

16384bytes

(MASK)

86CM47

86CM47A

32768bytes

(MASK)

86PH47

16384bytes

(OTP)

86PM47

86PM47A

32768bytes

(OTP)

86FH47

16384bytes

(FLASH)

RAM 512bytes 512bytes 1024bytes 512bytes 1024bytes 512bytes 512bytes

DBR(note1) -

I/O 35pins

Large current out-

put

Interrupt

Timer counter

(External :

19pins

(LED direct

drive)

18interrupt sources

6 Internal : 12)

16-bit timer counter : 1ch

8-bit timer

counter : 2ch

UART 8-bit UART : 1ch

SIO High-Speed SIO : 1ch

Key-on wakeup 4ch

10-bit AD convert-

er

Analog-input : 8ch

86FH47A

86FH47B

128bytes (Flash con-

trol register

con-

tained)

86FH47A

Structure

pin

of TEST

Structure

of XTIN,XTOUT

Structure

port

of P2

86FH47B

86FH47A

86FH47B

86FH47A

86FH47B

Page 6

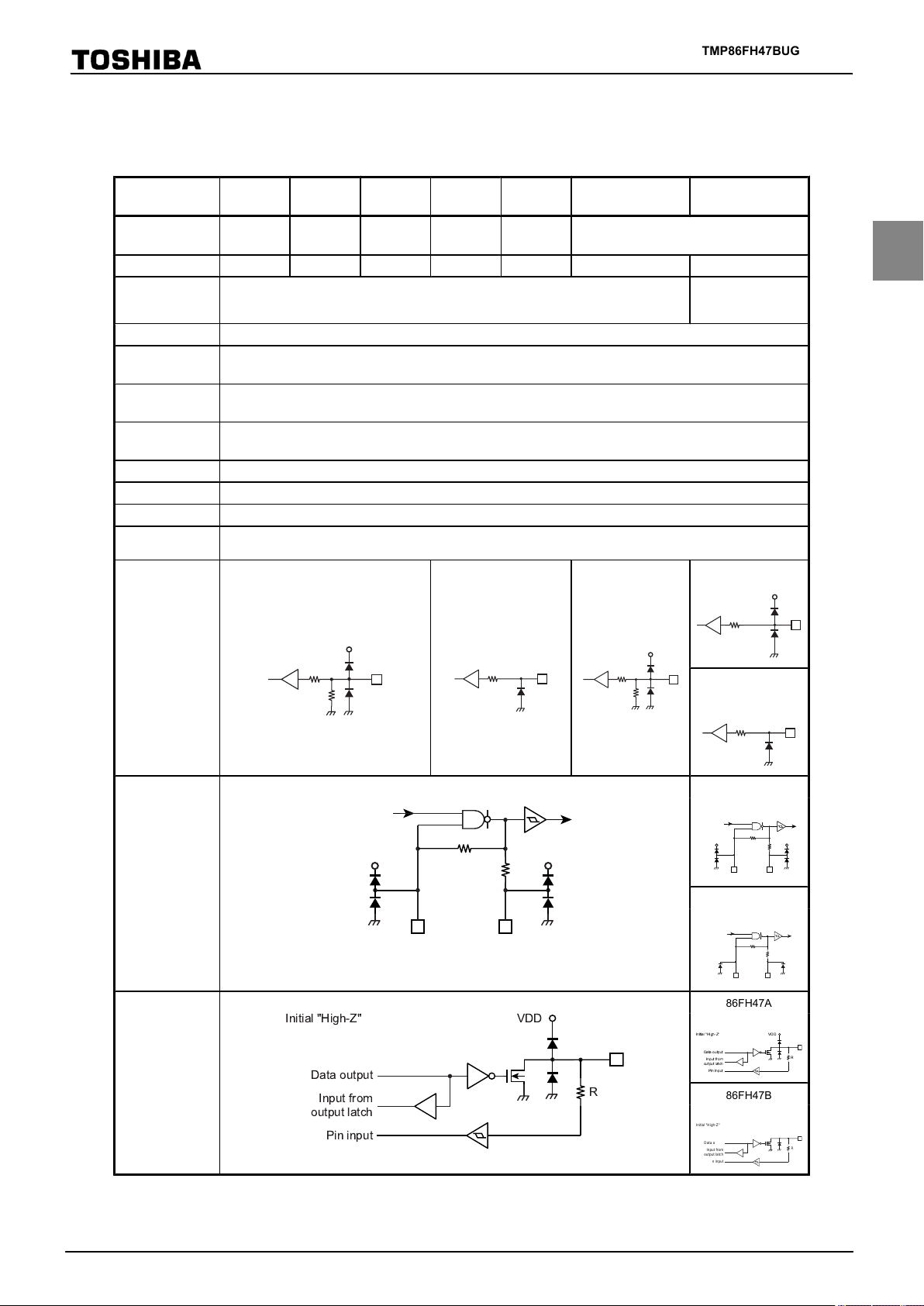

TMP86FH47BUG

86C847

Number of guaran-

teed writes

flash memory

Terminal for SERI-

AL PROM

Flash Security N.A. Read protect

Emulation Chip TMP86C947XB

(LQFP44-

P-1010-0.80A)

(LQFP44-

P-1010-0.80B)

to

MODE

(note2)

Package

Available

Package

N.A.

86CH47

86CH47A

- - 100 Times

Available

(86CH47)

Available

(86CH47A)

86CM47

86CM47A

-

Available N.A. Available Available N.A.

N.A. Available N.A. N.A. Available

86PH47

86PM47

86PM47A

86FH47

BOOT1/RXD(P10)

BOOT2/TXD(P11)

86FH47A

86FH47B

(a)86FH47A

100 Times

(b)86FH47B

1000

BOOT/RXD(P02)

TXD(P03)

(a)86FH47A

Read protect

(b)86FH47B

Read

protect

Times

/ Write

Note 1: The products with Flash memory (86FH47,86FH47A,86FH47B) contain the Flash control register (FLSCR) at 0FFFH

DBR area. The products with mask ROM or OTP and the emulation chip do not have the FLSCR register. In

in the

these devices,therefore, a program that accesses the FLSCR register cannot function properly (executes differently

as in the case of a Flash product).

Note 2: The TXD and RXD pins to be used in Serial PROM mode differ between the 86FH47 and the 86FH47A,86FH47B.

Take this into consideration in your board design when you replace the product. Details of the function refer to the chapter of the 86FH47,86FH47A,86FH47B data sheet.

Note 3: P21,P22 combine XTIN,XTOUT and port.

Page 7

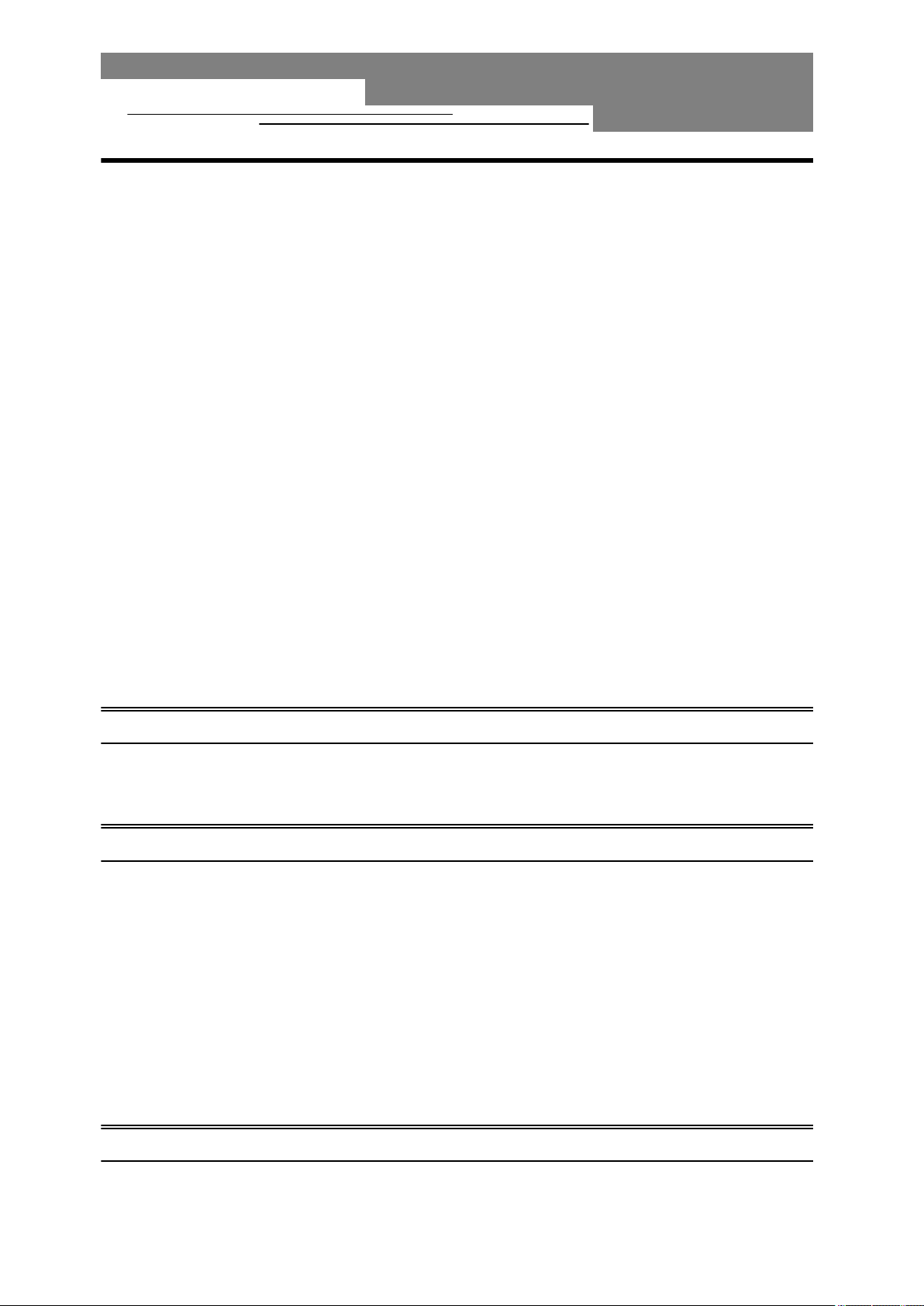

Differences in Electrical Characteristics (TMP86xx46 Series)

5.5

4.5

2.7

1.8

1 4.2 8 16 [MHz]

[V]

(a)

5.5

4.5

2.7

1.8

2.0

0.030

0.034

1 4.2 8 16 [MHz]

[V]

(a)

(b)

(Note1)

5.5

4.5

2.7

1.8

1 4.2 8 16 [MHz]

[V]

(a)

5.5

4.5

3.0

2.7

1.8

0.030

0.034

1 4.2 8 16

(a)

(b)

(Note2)

[MHz]

[V]

5.5

4.5

2.7

1.8

0.030

0.034

1 4.2 8 16 [MHz]

[V]

(a)

5.5

4.5

2.7

1.8

2 4 8 16 [MHz]

[V]

(a)

5.5

4.5

2.7

1.8

0.030

0.034

2 4.2 8 16 [MHz]

[V]

(a)

TMP86FH47BUG

Operating condition

(MCU

mode)

Read/

Fetch

Erase/

Program

86C846 / 86CH46 / 86CM46

86CM46A

86PM46

86PH46

86CH46A

(a) 1.8V to 5.5V (-40 to 85 °C) (a) 2.0V to 5.5V (-40 to 85 °C)

(b) 1.8V

to 2.0V (-20 to 85 °C)

- - -

86FH46

(a) 2.7V to 5.5V (-40 to 85 °C)

86FH46A

86FH46B

TMP86FH46A

(a) 3.0V

to 5.5V (-40 to 85 °C)

(b) 2.7V to 3.0V (-20 to 85 °C)

TMP86FH46B

(a) 2.7V to 5.5V (-40 to 85 °C)

Operating condition

(Serial PROM

mode)

Supply voltage

(Absolute Maxi-

mum

Ratings)

Operating current

Note 1: With The 86CH46A,PH46 the operating temperature (Topr) is -20 °C to 85 °C when the supply voltage VDD is less

2: With The 86FH46A, the operating temperature (Topr) is -20 °C to 85 °C when the supply voltage VDD is less than

Note

Note 3: With The 86FH46A,86FH46B when a program is executing in the Flash memory or when data is being read from the

Note 4: About the measurement condition of supply current, VIN level of TEST pin is deffrent between 86FH46B and the oth-

(a) 4.5V to 5.5V (-10 to 40 °C)

- -

(a) 4.5V to 5.5V (20 to 30 °C) (a) 4.5V to 5.5V (-10 to 40 °C)

86FH46A

−0.3 ~ 6.5

(a)−0.3 ~

6.5

86FH46B

(a)−0.3 ~ 6.0

Operating current varies with each product. For details, refer to the datacheet (electrical chracteristics) of each product.(Note4)

(Note3)

than 2.0V.

3.0V.

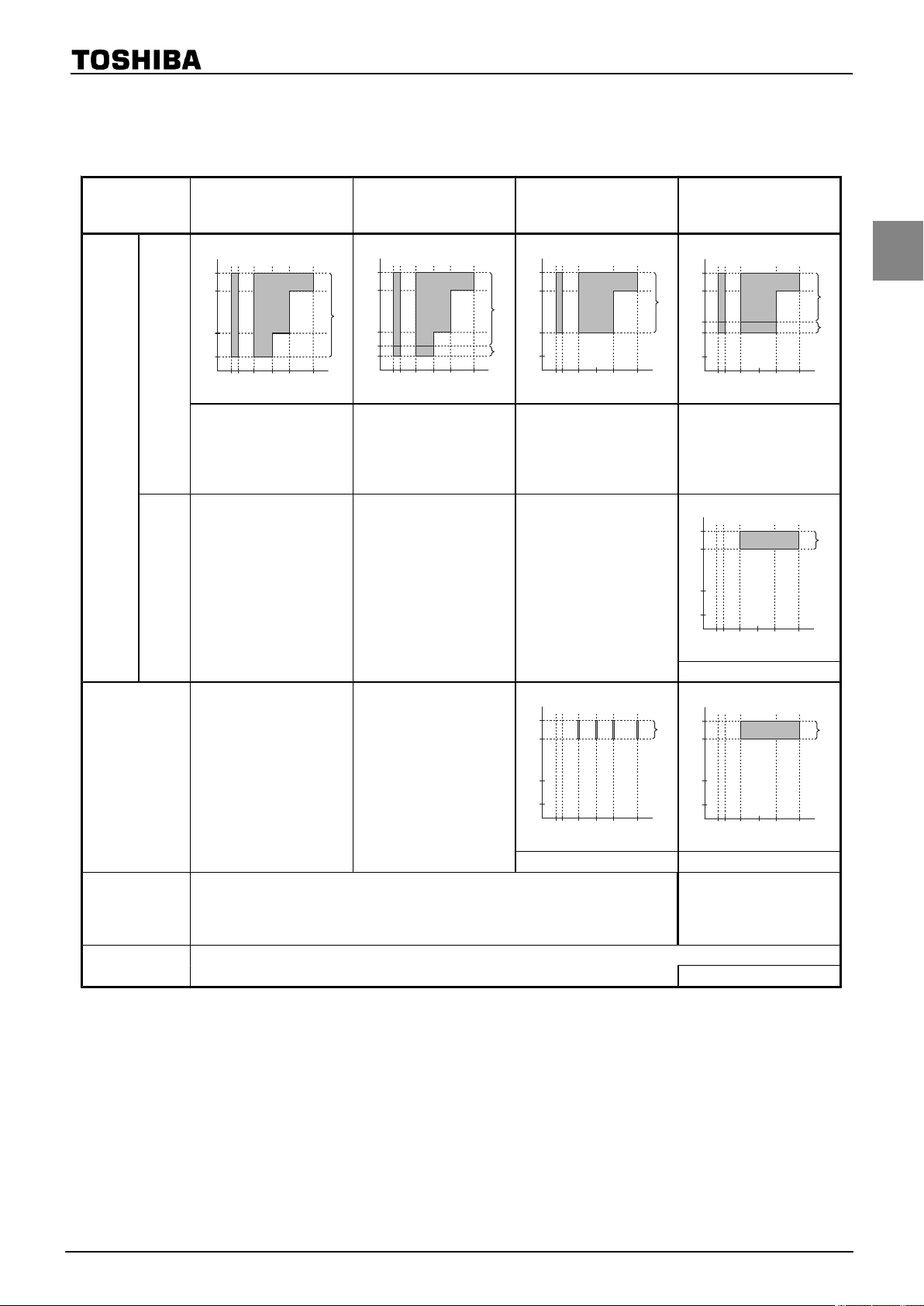

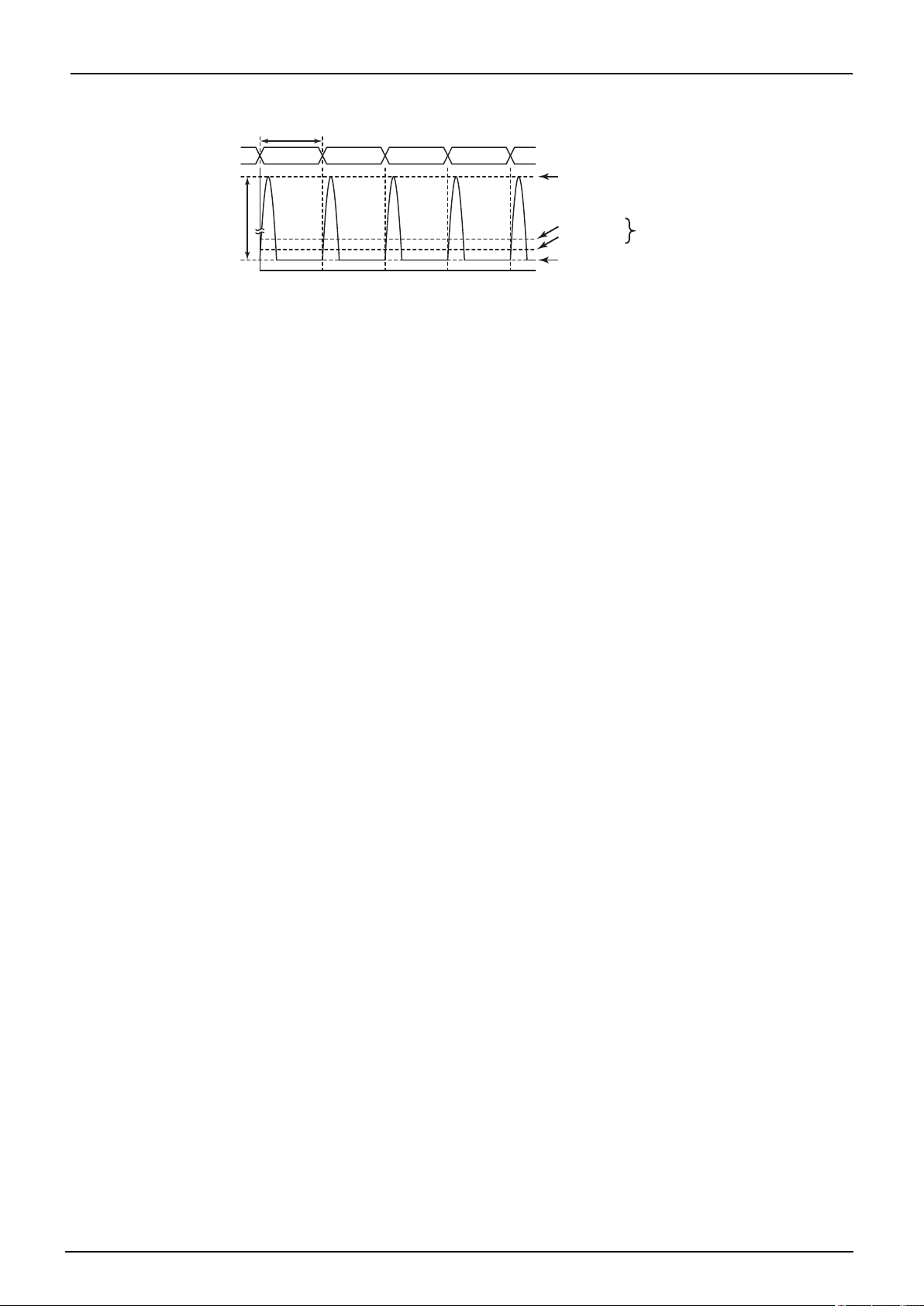

Flash memory, the Flash memory operates in an intermittent manner causing peak currents in the Flash memory momentarily, as shown in Figure. in this case, the supply current IDD(in NORMAL1,NORMAL2 and SLOW1 mode) is defined as the sum of the average peak current and MCU current.

er 86xx46 series MCUs. The supply current is defined as follows; VIN of TEST pin: VIN ≤ 0.1V(86FH46B), VIN ≤ 0.2V(others) It is described in the section "Electrical characteristics" of TMP86FH46B in detail.

Page 8

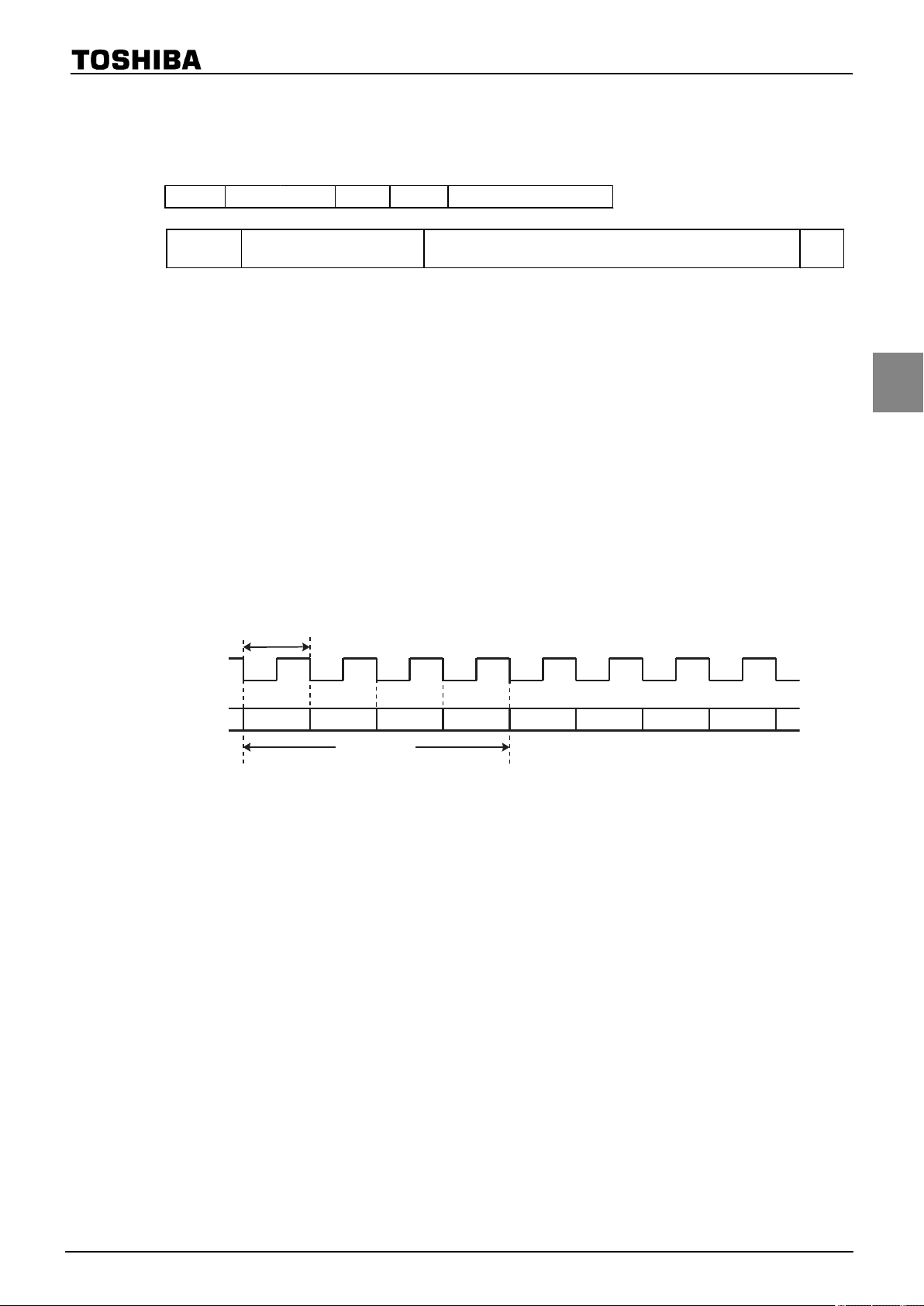

n

Program counter (PC)

n+1 n+2 n+3

1 machine cycle(4/fc or 4/fs)

MCU current

I

[mA]

DDP-P

Typ. current

Momentary Flash current

Max. current

Sum of average momentary

Flash current and MCU curren

t

Intermittent Operation of Flash Memory

TMP86FH47BUG

Page 9

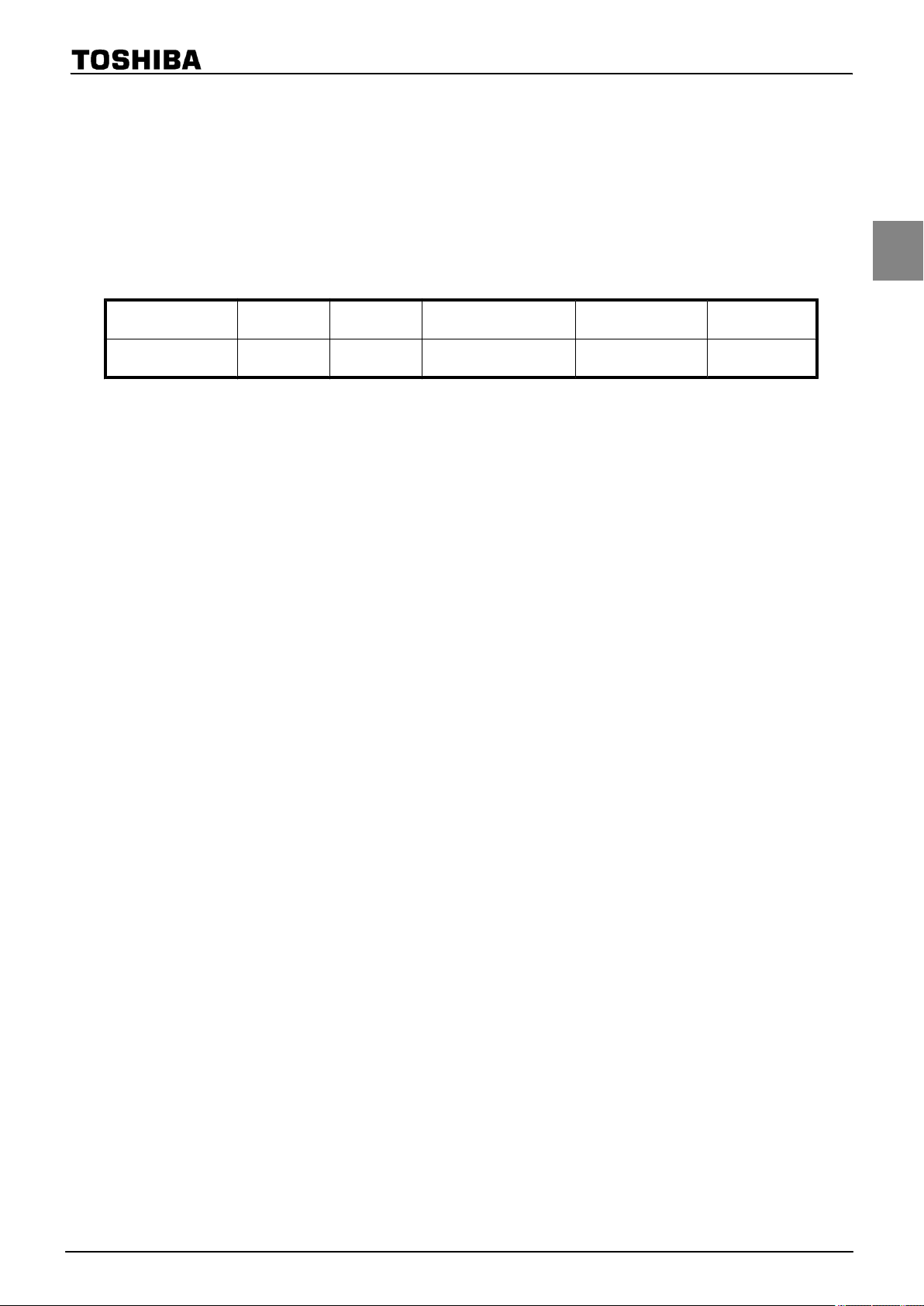

Differences in Electrical Characteristics (TMP86xx47 Series)

5.5

4.5

2.7

1.8

1 4.2 8 16 [MHz]

[V]

(a)

5.5

4.5

2.7

1.8

2.0

0.030

0.034

1 4.2 8 16 [MHz]

[V]

(a)

(b)

(Note1)

5.5

4.5

2.7

1.8

1 4.2 8 16 [MHz]

[V]

(a)

5.5

4.5

3.0

2.7

1.8

0.030

0.034

1 4.2 8 16

(a)

(b)

(Note2)

[MHz]

[V]

5.5

4.5

2.7

1.8

0.030

0.034

1 4.2 8 16 [MHz]

[V]

(a)

5.5

4.5

2.7

1.8

2 4 8 16 [MHz]

[V]

(a)

5.5

4.5

2.7

1.8

0.030

0.034

2 4.2 8 16 [MHz]

[V]

(a)

TMP86FH47BUG

Operating condition

(MCU

mode)

Read/

Fetch

Erase/

Program

86C847 / 86CH47 / 86CM47

86CM47A

86PM47

(a) 1.8V to 5.5V (-40 to 85 °C)

- - -

86PH47

86CH47A

(a) 2.0V to 5.5V (-40 to 85 °C)

(b) 1.8V

to 2.0V (-20 to 85 °C)

86FH47

(a) 2.7V to 5.5V (-40 to 85 °C)

86FH47A

86FH47B

86FH47A

(a) 3.0V

to 5.5V (-40 to 85 °C)

(b) 2.7V to 3.0V (-20 to 85 °C)

86FH47B

(a) 2.7V to 5.5V (-40 to 85 °C)

Operating condition

(Serial PROM

mode)

Supply voltage

(Absolute Maxi-

mum

Ratings)

Operating current

Note 1: With The 86CH47A, PH47 the operating temperature (Topr) is -20 °C to 85 °C when the supply voltage VDD is less

2: With The 86FH47A, the operating temperature (Topr) is -20 °C to 85 °C when the supply voltage VDD is less than

Note

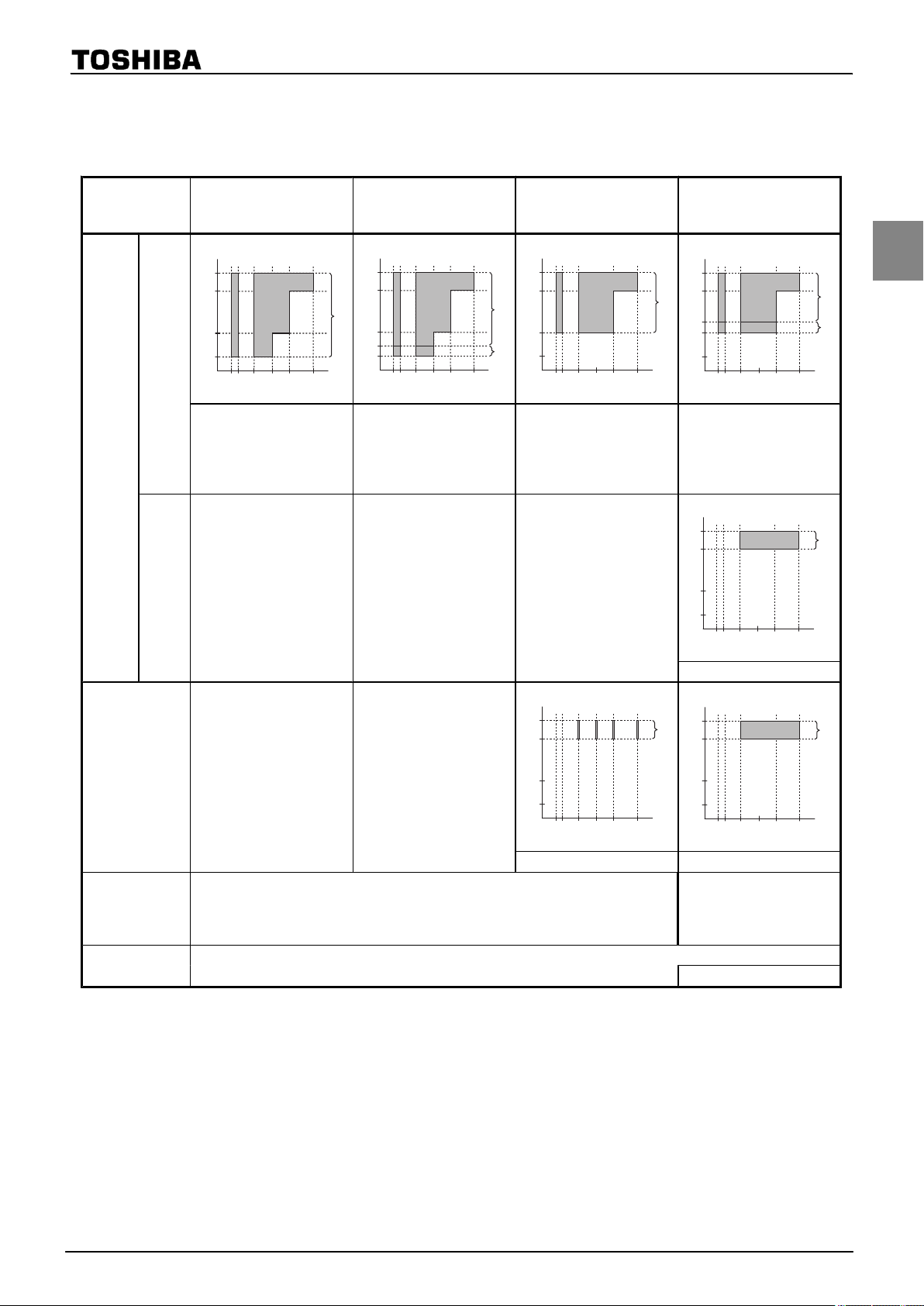

Note 3: With The 86FH47A,86FH47B when a program is executing in the Flash memory or when data is being read from the

Note 4: About the measurement condition of supply current, VIN level of TEST pin is deffrent between 86FH47B and the oth-

(a) 4.5V to 5.5V (-10 to 40 °C)

- -

(a) 4.5V to 5.5V (20 to 30 °C) (a) 4.5V to 5.5V (-10 to 40 °C)

86FH47A

−0.3 ~ 6.5

(a)−0.3 ~

6.5

86FH47B

(a)−0.3 ~ 6.0

Operating current varies with each product. For details, refer to the datacheet (electrical chracteristics) of each product.(Note4)

(Note3)

than 2.0V.

3.0V.

Flash memory, the Flash memory operates in an intermittent manner causing peak currents in the Flash memory momentarily, as shown in Figure. in this case, the supply current IDD(in NORMAL1,NORMAL2 and SLOW1 mode) is defined as the sum of the average peak current and MCU current.

er 86xx47 series MCUs. The supply current is defined as follows; VIN of TEST pin: VIN ≤ 0.1V(86FH47B), VIN ≤ 0.2V(others) It is described in the section "Electrical characteristics" of TMP86FH47B in detail.

Page 10

n

Program counter (PC)

n+1 n+2 n+3

1 machine cycle(4/fc or 4/fs)

MCU current

I

[mA]

DDP-P

Typ. current

Momentary Flash current

Max. current

Sum of average momentary

Flash current and MCU curren

t

Intermittent Operation of Flash Memory

TMP86FH47BUG

Page 11

Revision History

Date

2010/7/23 Tentative 1 1st Release of Tentative

2010/10/6 1 First Release

2011/5/10 2 Contents Revised

Revision Comment

Page 12

Page 13

Table of Contents

Difference among product (TMP86xx46 Series)

TMP86FH47BUG

1.1 Features......................................................................................................................................1

1.2 Pin Assignment..........................................................................................................................3

1.3 Block Diagram...........................................................................................................................

1.4 Pin

Names

Functions..........................................................................................................5

and

4

2. Operational Description

2.1 CPU Core Functions ................................................................................................................7

2.1.1 Memory Address Map .......................................................................................................................................................7

2.1.2 Program Memory (Flash) ...................................................................................................................................................7

2.1.3 Data Memory

(RAM) .........................................................................................................................................................7

2.2 System Clock Controller ..........................................................................................................8

2.2.1 Clock Generator .................................................................................................................................................................8

2.2.2 Timing Generator .............................................................................................................................................................10

2.2.2.1 Configuration of timing generator

2.2.2.2 Machine cycle

2.2.3 Operation Mode Control Circuit ......................................................................................................................................11

2.2.3.1 Single-clock mode

2.2.3.2 Dual-clock mode

2.2.3.3 STOP mode

2.2.4 Operating Mode Control ..................................................................................................................................................16

2.2.4.1 STOP mode

2.2.4.2 IDLE1/2 mode and SLEEP1/2 mode

2.2.4.3 IDLE0 and SLEEP0 modes (IDLE0, SLEEP0)

2.2.4.4 SLOW mode

2.3 Reset Circuit ...........................................................................................................................29

2.3.1 External Reset Input .........................................................................................................................................................29

2.3.2 Address trap reset .............................................................................................................................................................30

2.3.3 Watchdog timer reset .......................................................................................................................................................30

2.3.4 System clock reset ............................................................................................................................................................30

3. Interrupt Control Circuit

3.1 Interrupt latches (IL15 to IL2)

...............................................................................................31

3.2 Interrupt enable register (EIR) ...............................................................................................32

3.2.1 Interrupt master enable flag (IMF) ..................................................................................................................................32

3.2.2 Individual interrupt enable flags (EF15 to EF4) .............................................................................................................32

3.3 Interrupt Source Selector (INTSEL).......................................................................................35

3.4 Interrupt Sequence ................................................................................................................35

3.4.1 Interrupt acceptance processing is packaged as follows. ................................................................................................35

3.4.2 Saving/restoring general-purpose registers ......................................................................................................................36

3.4.2.1 Using PUSH and POP instructions

3.4.2.2 Using data transfer instructions

3.4.3 Interrupt return .................................................................................................................................................................38

i

Page 14

3.5 Software Interrupt (INTSW) ..................................................................................................39

3.5.1 Address error

3.5.2 Debugging ........................................................................................................................................................................39

detection ....................................................................................................................................................39

3.6 Undefined Instruction Interrupt (INTUNDEF) ......................................................................39

3.7 Address Trap Interrupt (INTATRAP) ...................................................................................39

3.8 External Interrupts ..................................................................................................................39

4. Special Function Register (SFR)

4.1 SFR..........................................................................................................................................43

4.2 DBR.........................................................................................................................................45

5. Time Base Timer (

TBT)

5.1 Time Base Timer.....................................................................................................................47

5.1.1 Configuration.....................................................................................................................................................................47

5.1.2 Control...............................................................................................................................................................................47

5.1.3 Function.............................................................................................................................................................................48

5.2 Divider Output (DVO)............................................................................................................49

5.2.1 Configuration.....................................................................................................................................................................49

5.2.2 Control...............................................................................................................................................................................49

6. Watchdog Timer (WDT)

6.1 Watchdog Timer Configuration .............................................................................................51

6.2 Watchdog Timer Control .......................................................................................................52

6.2.1 Malfunction Detection Methods Using the

6.2.2 Watchdog Timer Enable ..................................................................................................................................................53

6.2.3 Watchdog Timer Disable .................................................................................................................................................54

6.2.4 Watchdog Timer Interrupt (INTWDT) ............................................................................................................................54

6.2.5 Watchdog Timer Reset .....................................................................................................................................................55

6.3 Address Trap ..........................................................................................................................56

6.3.1 Selection of Address Trap in Internal RAM (ATAS) .....................................................................................................56

6.3.2 Selection of Operation at Address Trap (ATOUT) .........................................................................................................56

6.3.3 Address Trap Interrupt (INTATRAP)...............................................................................................................................56

6.3.4 Address Trap Reset...........................................................................................................................................................57

Watchdog Timer .........................................................................................52

7. I/O Ports

7.1 Port P0 (P07 to P00)

7.2 Port P1 (P17 to P10)...............................................................................................................61

7.3 Port P2 (P22 to P20)...............................................................................................................62

7.4 Port P3 (P37 to P30)...............................................................................................................63

7.5 Port P4 (P47 to P40)...............................................................................................................65

...............................................................................................................60

8. 16-Bit Timer/Counter 1 (TC1)

8.1 Configuration...........................................................................................................................67

8.2 Timer/Counter Control............................................................................................................68

ii

Page 15

8.3 Function...................................................................................................................................70

8.3.1 Timer mode........................................................................................................................................................................70

8.3.2 External Trigger Timer

8.3.3 Event Counter Mode.........................................................................................................................................................74

8.3.4 Window Mode...................................................................................................................................................................75

8.3.5 Pulse Width Measurement Mode......................................................................................................................................76

8.3.6 Programmable Pulse Generate (PPG) Output Mode........................................................................................................79

Mode...........................................................................................................................................72

9. 8-Bit TimerCounter (TC3, TC4)

9.1 Configuration ..........................................................................................................................83

9.2 TimerCounter Control.............................................................................................................84

9.3 Function...................................................................................................................................89

9.3.1 8-Bit Timer Mode (TC3

9.3.2 8-Bit Event Counter Mode (TC3, 4).................................................................................................................................90

9.3.3 8-Bit Programmable Divider Output (PDO) Mode (TC3, 4)...........................................................................................90

9.3.4 8-Bit Pulse Width Modulation (PWM) Output Mode (TC3, 4)......................................................................................93

9.3.5 16-Bit Timer Mode (TC3 and 4)......................................................................................................................................95

9.3.6 16-Bit Event Counter Mode (TC3 and 4).........................................................................................................................96

9.3.7 16-Bit Pulse Width Modulation (PWM) Output Mode (TC3 and 4)..............................................................................96

9.3.8 16-Bit Programmable Pulse Generate (PPG) Output Mode (TC3 and 4).......................................................................99

9.3.9 Warm-Up Counter Mode.................................................................................................................................................101

9.3.9.1 Low-Frequency Warm-up Counter Mode

(NORMAL1 → NORMAL2 → SLOW2 → SLOW1)

9.3.9.2 High-Frequency Warm-Up Counter Mode

(SLOW1 → SLOW2 → NORMAL2 → NORMAL1)

and 4)........................................................................................................................................89

10. Synchronous Serial Interface (SIO)

10.1 Configuration ......................................................................................................................103

10.2 Control.................................................................................................................................104

10.3 Function...............................................................................................................................106

10.3.1 Serial clock....................................................................................................................................................................106

10.3.1.1 Clock source

10.3.1.2

10.3.2 Transfer bit direction.....................................................................................................................................................108

10.3.2.1 Transmit mode

10.3.2.2 Receive mode

10.3.2.3 Transmit/receive mode

10.3.3 Transfer modes..............................................................................................................................................................109

10.3.3.1 Transmit mode

10.3.3.2 Receive mode

10.3.3.3 Transmit/receive mode

Shift edge

11. Asynchronous Serial interface (UART)

11.1 Configuration ......................................................................................................................121

11.2 Control ................................................................................................................................ 122

11.3 Transfer Data Format

11.4 Transfer Rate.......................................................................................................................126

11.5 Data Sampling Method........................................................................................................126

11.6 STOP Bit Length................................................................................................................. 127

11.7 Parity....................................................................................................................................127

11.8 Transmit/Receive Operation................................................................................................127

11.8.1 Data Transmit Operation...............................................................................................................................................127

11.8.2 Data Receive Operation.................................................................................................................................................127

..........................................................................................................125

iii

Page 16

11.9 Status Flag........................................................................................................................... 128

11.9.1 Parity Error....................................................................................................................................................................128

11.9.2 Framing Error................................................................................................................................................................128

11.9.3 Overrun Error................................................................................................................................................................128

11.9.4 Receive Data Buffer Full..............................................................................................................................................129

11.9.5 Transmit Data Buffer Empty.........................................................................................................................................129

11.9.6 Transmit End Flag

.........................................................................................................................................................130

12. 10-bit AD Converter (ADC)

12.1 Configuration ......................................................................................................................131

12.2 Register configuration.........................................................................................................132

12.3

12.4 STOP/SLOW Modes during AD Conversion.....................................................................137

12.5 Analog Input Voltage and AD Conversion Result.............................................................138

12.6 Precautions about AD Converter........................................................................................139

Function..............................................................................................................................135

12.3.1 Software Start Mode......................................................................................................................................................135

12.3.2 Repeat Mode..................................................................................................................................................................135

12.3.3 Register Setting............................................................................................................................................................136

12.6.1 Analog input pin voltage range.....................................................................................................................................139

12.6.2 Analog input shared pins...............................................................................................................................................139

12.6.3 Noise Countermeasure...................................................................................................................................................139

13. Key-on Wakeup (KWU)

13.1 Configuration.......................................................................................................................141

13.2 Control.................................................................................................................................141

13.3 Function...............................................................................................................................141

14. Flash Memory

14.1 Flash Memory Control........................................................................................................144

14.1.1 Flash Memory Command Sequence Execution Control (FLSCR<FLSMD>)............................................................144

14.2 Command

14.2.1 Byte Program.................................................................................................................................................................145

14.2.2 Sector Erase (4-kbyte Erase).........................................................................................................................................145

14.2.3 Chip Erase (All Erase)..................................................................................................................................................146

14.2.4 Product ID Entry...........................................................................................................................................................146

14.2.5 Product ID Exit..............................................................................................................................................................146

14.2.6 Security Program...........................................................................................................................................................146

14.3 Toggle Bit (D6)...................................................................................................................147

14.4 Access to the Flash Memory Area......................................................................................148

14.4.1 Flash Memory Control in the Serial PROM Mode......................................................................................................148

14.4.1.1 How to write to the flash memory by executing the control program in the RAM area (in the RAM loader mode within the

14.4.2 Flash Memory Control in the MCU mode...................................................................................................................150

14.4.2.1 How to write to the flash memory by executing a user write control program in the RAM area (in the MCU mode)

Sequence............................................................................................................145

serial PROM mode)

15. Serial PROM Mode

15.1 Outline.................................................................................................................................153

15.2 Memory Mapping................................................................................................................153

15.3 Serial PROM Mode Setting................................................................................................154

iv

Page 17

15.3.1 Serial PROM Mode Control Pins.................................................................................................................................154

15.3.2 Pin Function...................................................................................................................................................................154

15.3.3 Example Connection for

15.3.4 Activating the Serial PROM Mode...............................................................................................................................156

On-Board Writing.................................................................................................................155

15.4 Interface Specifications for UART.....................................................................................157

15.5 Operation Command...........................................................................................................158

15.6 Operation Mode...................................................................................................................158

15.6.1 Flash Memory Erasing Mode (Operating command: F0H).........................................................................................160

15.6.2 Flash Memory Writing Mode (Operation command: 30H).........................................................................................162

15.6.3 RAM Loader Mode (Operation Command: 60H)........................................................................................................165

15.6.4 Flash Memory SUM Output Mode (Operation Command: 90H)................................................................................167

15.6.5 Product ID Code Output Mode (Operation Command: C0H).....................................................................................168

15.6.6 Flash Memory Status Output Mode (Operation Command: C3H)..............................................................................170

15.6.7 Flash Memory security program Setting Mode (Operation Command: FAH)............................................................172

15.7 Error Code...........................................................................................................................174

15.8 Checksum (SUM)................................................................................................................174

15.8.1 Calculation Method.......................................................................................................................................................174

15.8.2 Calculation data.............................................................................................................................................................175

15.9 Intel Hex Format (Binary)...................................................................................................176

15.10 Passwords..........................................................................................................................176

15.10.1 Password String...........................................................................................................................................................177

15.10.2 Handling of Password Error........................................................................................................................................177

15.10.3 Password Management during Program Development..............................................................................................177

15.11 Product ID Code................................................................................................................178

15.12 Flash Memory Status Code...............................................................................................178

15.13 Specifying the Erasure Area..............................................................................................180

15.14 Port Input Control Register...............................................................................................180

15.15 Flowchart...........................................................................................................................182

15.16 UART Timing...................................................................................................................183

16. Input/Output Circuitry

16.1 Control Pins.........................................................................................................................185

16.2 Input/Output Ports...............................................................................................................186

17. Electrical Characteristics

17.1 Absolute Maximum Ratings................................................................................................187

17.2 Operating Conditions...........................................................................................................188

17.2.1 Serial

17.2.2 MCU mode (Except Flash Programming or erasing) .................................................................................................188

17.2.3 MCU mode (Flash Programming or erasing) ..............................................................................................................189

PROM mode.......................................................................................................................................................188

17.3 DC Characteristics ..............................................................................................................190

17.4 AD Characteristics...............................................................................................................192

17.5 AC Characteristics...............................................................................................................193

17.6 Flash Characteristics............................................................................................................194

17.6.1 Write Characteristics.....................................................................................................................................................194

17.7 Oscillating Conditions.........................................................................................................195

17.8 Handling Precaution............................................................................................................195

18. Package Dimensions

v

Page 18

vi

Page 19

CMOS 8-Bit Microcontroller

TMP86FH47BUG

TMP86FH47BUG

The TMP86FH47BUG

is a single-chip 8-bit high-speed and high-functionality microcomputer incorporating

16384 bytes of Flash Memory. It is pin-compatible with the TMP86CH47AUG/TMP86C847UG (Mask ROM version). The TMP86FH47BUG can realize operations equivalent to those of the TMP86CH47AUG/TMP86C847UG

by programming the on-chip Flash Memory.

Product No.

TMP86FH47BUG

ROM

(FLASH)

16384

bytes

RAM Package MASK ROM MCU Emulation Chip

512

bytes

P-LQFP44-1010-0.80B

TMP86CH47AUG/

TMP86C847UG

TMP86C947XB

1.1 Features

1. 8-bit single

- Instruction execution time :

- 132 types & 731 basic instructions

2. 18interrupt sources (External : 6 Internal : 12)

chip microcomputer TLCS-870/C series

0.25 μs (at 16 MHz)

122 μs (at 32.768 kHz)

3. Input / Output ports (35 pins)

Large current output: 19pins (Typ. 20mA), LED direct drive

4. Prescaler

- Time base timer

- Divider output function

5. Watchdog Timer

6. 16-bit timer counter: 1 ch

- Timer, External trigger, Window, Pulse width measurement,

Event counter, Programmable pulse generate (PPG) modes

7. 8-bit timer counter : 2 ch

- Timer, Event counter, Programmable divider output (PDO),

Pulse width modulation (PWM) output,

Programmable pulse generation (PPG),

16bit mode (8bit timer 2ch combination) modes

8. Serial Interface

- High-Speed 8-bit SIO: 1ch

9. 8-bit UART : 1 ch

This product uses the Super Flash® technology under the licence of Silicon Storage Technology, Inc. Super Flash® is registered trademark of Silicon Storage

Technology, Inc.

Page 1

RA000

Page 20

1.1 Features

TMP86FH47BUG

10. 10-bit successive approximation type AD converter

- Analog input:

8 ch

11. Key-on wakeup : 4 ch

12. Clock operation

Single clock mode

Dual clock mode

13. Low power consumption operation

STOP mode: Oscillation stops. (Battery/Capacitor back-up.)

SLOW1 mode: Low power consumption operation using low-frequency clock.(High-frequency clock

stop.)

SLOW2 mode: Low power consumption operation using low-frequency clock.(High-frequency clock os-

cillate.)

IDLE0 mode: CPU stops, and only the Time-Based-Timer(TBT) on peripherals operate using high fre-

quency clock. Release by falling edge of the source clock which is set by TBTCR<TBTCK>.

IDLE1 mode: CPU stops and peripherals operate using high frequency clock. Release by interruputs

(CPU restarts).

IDLE2 mode: CPU stops and peripherals operate using high and low frequency clock. Release by inter-

ruputs. (CPU restarts).

SLEEP0 mode: CPU stops, and only the Time-Based-Timer(TBT) on peripherals operate using low fre-

quency clock.Release by falling edge of the source clock which is set by TBTCR<TBTCK>.

SLEEP1 mode: CPU stops, and peripherals operate using low frequency clock. Release by interruput.

(CPU restarts).

SLEEP2 mode: CPU stops and peripherals operate using high and low frequency clock. Release by inter-

ruput.

14. Wide operation voltage:

4.5 V to 5.5 V at 16MHz /32.768 kHz

2.7 V to 5.5 V at 8 MHz /32.768 kHz

RA000

Page 2

Page 21

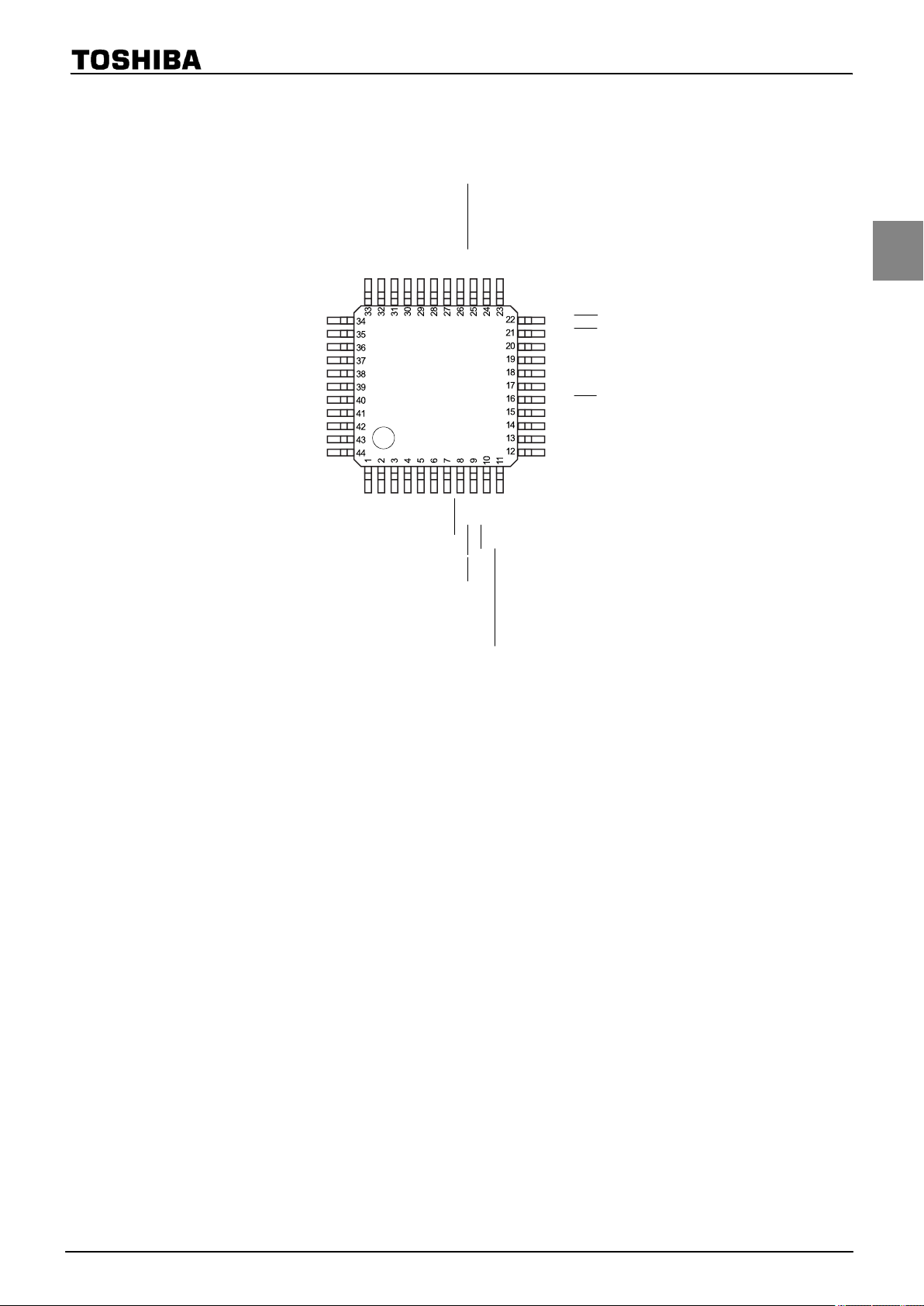

1.2 Pin Assignment

PDO3/PWM3/TC3)

P37 (AIN7/STOP5)

P36 (AIN6/STOP4)

P35 (AIN5/STOP3)

P34 (AIN4/STOP2)

P33 (AIN3)

P32 (AIN2)

P31 (AIN1)

P30 (AIN0)

P10 (

P11 (INT1)

P12 (INT2/TC1)

VAREF P13 (DVO)

AVDD P14 (PPG)

AVSS P15 (INT3)

P40 P16

P41 P17

P42 P07 (INT4)

P43 P06 (

P44 P05 (SI)

P45 P04 (SO)

P46 P03 (TXD)

P47 P02 (RXD/BOOT)

SCK)

TMP86FH47BUG

XIN

VSS

TEST

XOUT

VDD

(XTIN) P21

(XTOUT) P22

RESET

INT5/STOP) P20

(

INT0) P00

(

(PDO4/PWM4/PPG4/TC4) P01

Figure 1-1 Pin Assignment

RA000

Page 3

Page 22

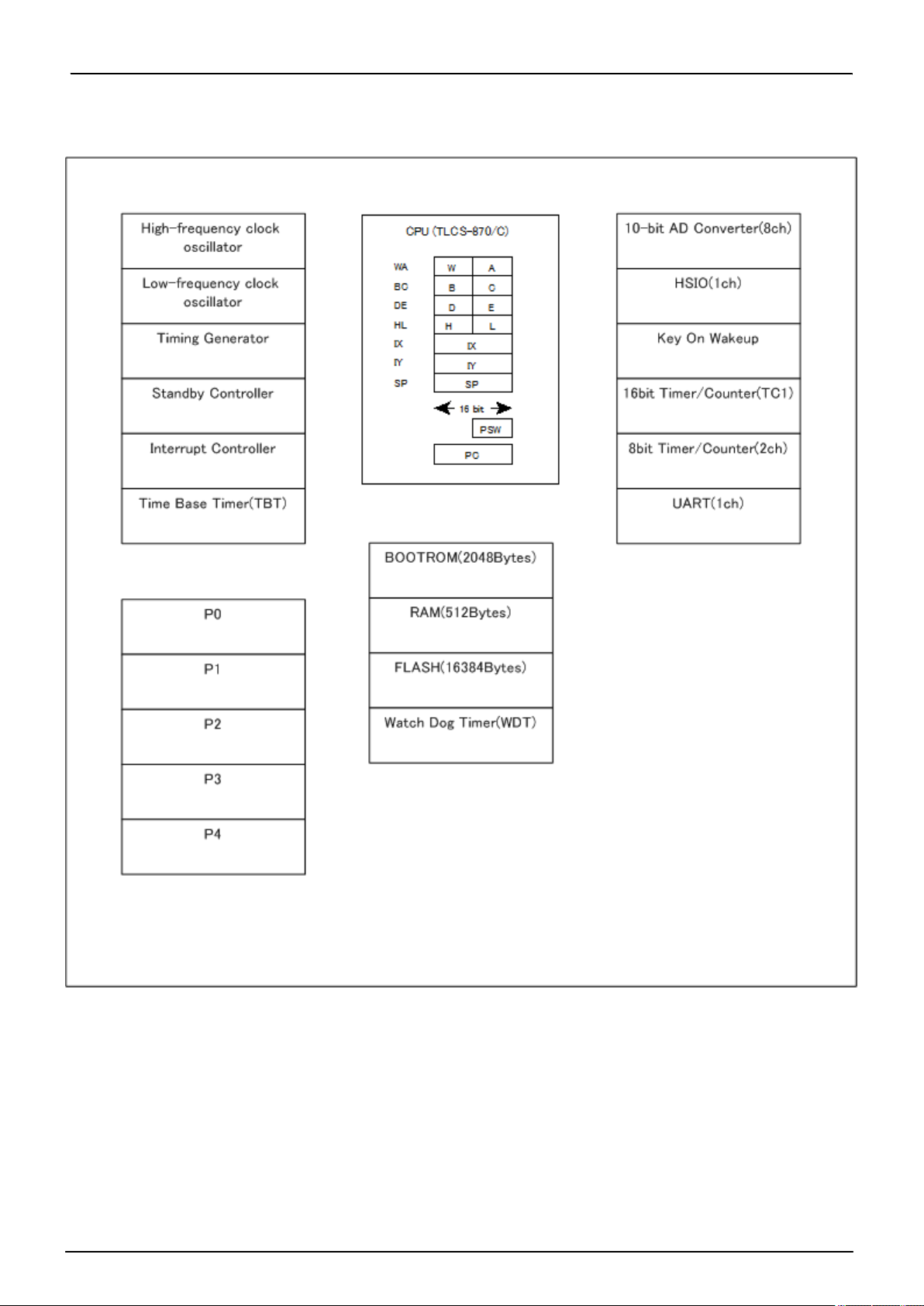

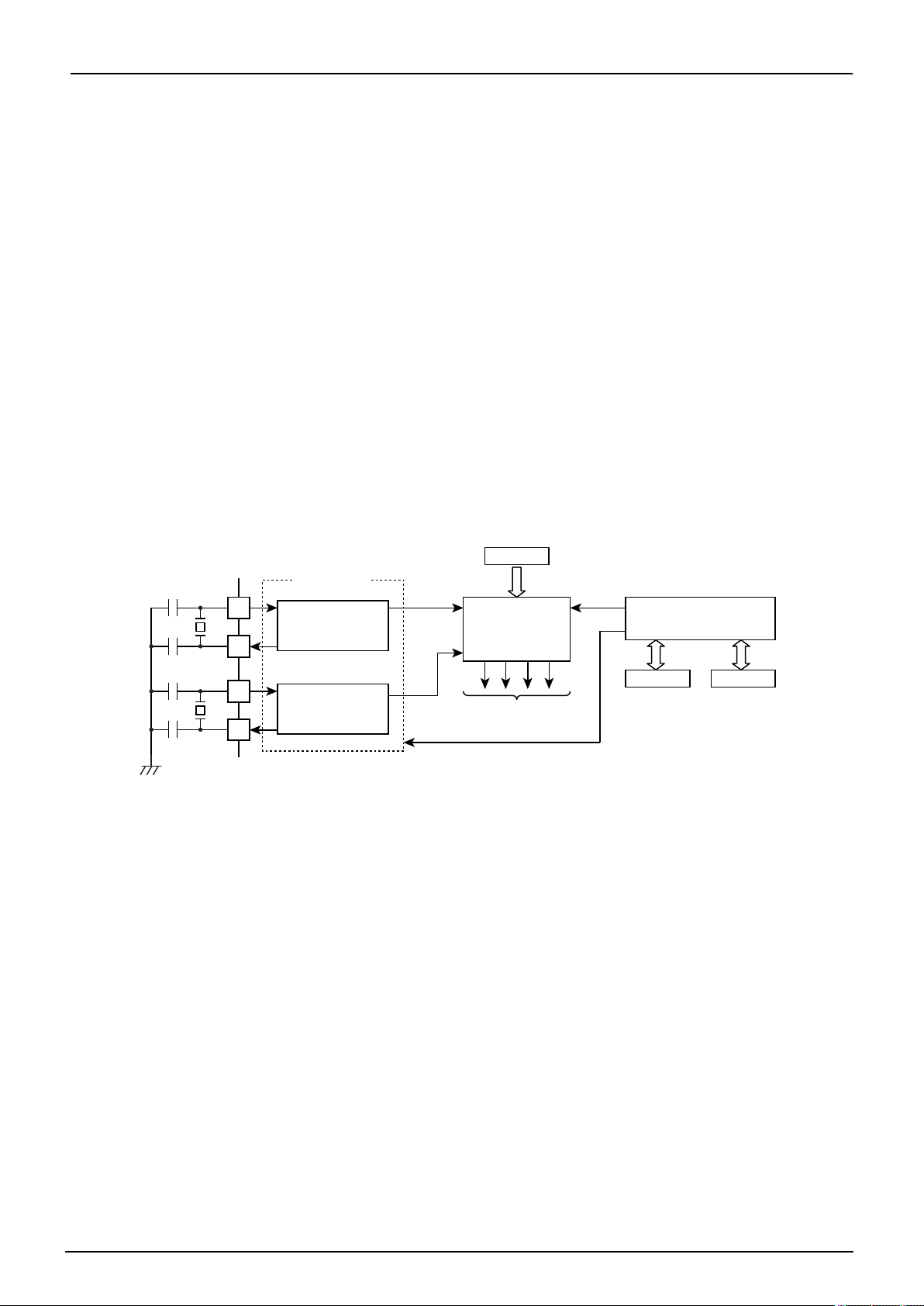

1.3 Block Diagram

1.3 Block Diagram

TMP86FH47BUG

RA000

Figure 1-2 Block Diagram

Page 4

Page 23

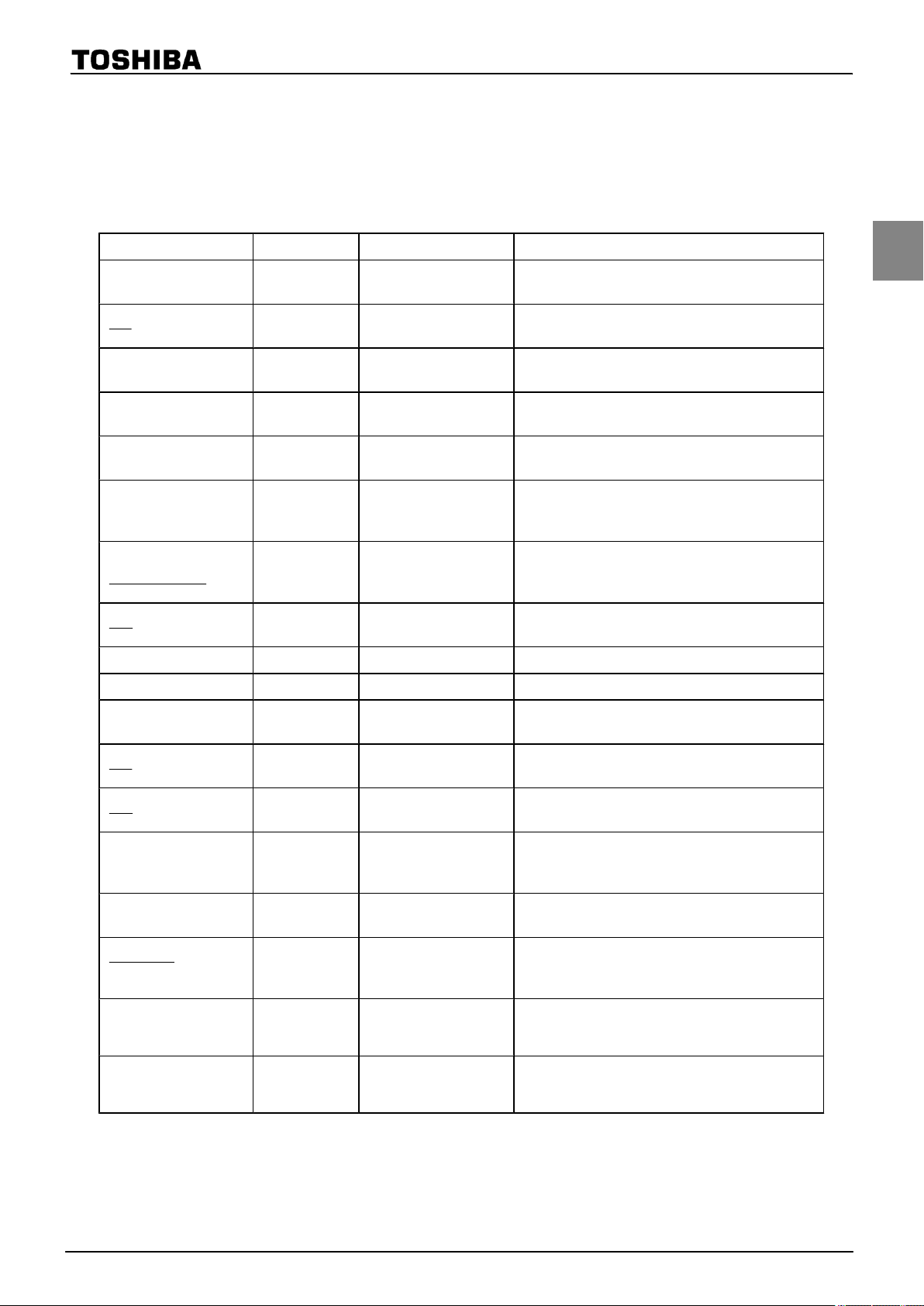

1.4 Pin Names and Functions

TMP86FH47BUG

The TMP86FH47BUG

has MCU mode, parallel PROM mode, and serial PROM mode. Table 1-1 shows the

pin functions in MCU mode. The serial PROM mode is explained later in a separate chapter.

Table 1-1 Pin Names and Functions(1/3)

Pin Name

P07

INT4

P06

SCK

P05

SI

P04

SO

P03

TXD

P02

RXD

BOOT

P01

TC4

PDO4/PWM4/PPG4

Pin Number Input/Output Functions

17

16

15

14

13

12

11

IOIPORT07

External interrupt

IOIOPORT06

Serial clock

IOIPORT05

Serial data

IOOPORT04

Serial data

IOOPORT03

UART data

IO

PORT02

I

UART data

I

Serial PROM mode control input

IO

PORT01

I

TC4 input

O

PDO4/PWM4/PPG4

input/output

input

output

output

input

4 input

output

P00

INT0

P17 18 IO PORT17

P16 19 IO PORT16

P15

INT3

P14

PPG

P13

DVO

P12

INT2

TC1

P11

INT1

P10

PDO3/PWM3

TC3

P22

XTOUT

10

20

21

22

23

24

25

7

IOIPORT00

External interrupt

IOIPORT15

External interrupt

IOOPORT14

PPG output

IOOPORT13

Divider Output

IO

PORT12

I

External interrupt

TC1 input

I

IOIPORT11

External interrupt

IO

PORT10

O

PDO3/PWM3 output

I

IO

O

input

TC3

PORT22

Resonator connecting

nal clock

0 input

3 input

2 input

1 input

pins(32.768kHz) for inputting exter-

RA000

P21

XTIN

PORT21

6

IO

Resonator connecting

I

nal clock

pins(32.768kHz) for inputting exter-

Page 5

Page 24

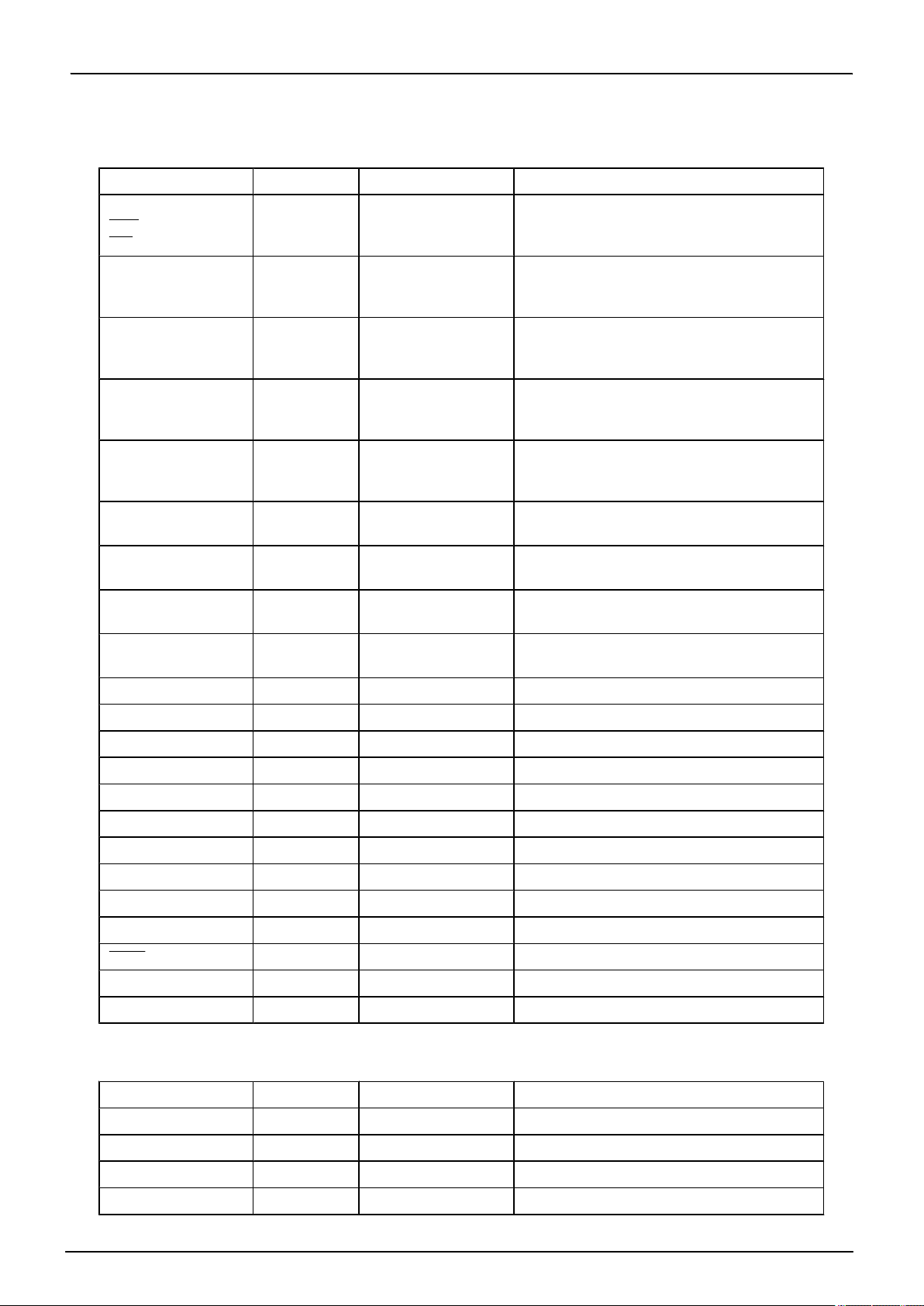

1.4 Pin Names and Functions

Table 1-1 Pin Names and Functions(2/3)

TMP86FH47BUG

P20

STOP

INT5

P37

AIN7

STOP5

P36

AIN6

STOP4

P35

AIN5

STOP3

P34

AIN4

STOP2

P33

AIN3

P32

AIN2

P31

AIN1

Pin Name

Pin Number Input/Output Functions

IO

PORT20

9

33

32

31

30

29

28

27

I

STOP mode

External interrupt 5 input

I

IO

PORT37

I

Analog Input7

I

STOP5

IO

PORT36

I

Analog Input6

I

STOP4

IO

PORT35

I

Analog Input5

I

STOP3

IO

PORT34

I

Analog Input4

I

STOP2

IOIPORT33

Analog Input3

IOIPORT32

Analog Input2

IOIPORT31

Analog Input1

release signal input

input

input

input

input

P30

AIN0

P47 44 IO PORT47

P46 43 IO PORT46

P45 42 IO PORT45

P44 41 IO PORT44

P43 40 IO PORT43

P42 39 IO PORT42

P41 38 IO PORT41

P40 37 IO PORT40

XIN 2 I Resonator connecting pins for high-frequency clock

XOUT 3 O Resonator connecting pins for high-frequency clock

RESET 8 IO Reset signal

TEST 4 I Test pin for out-going test. Normally, be fixed to low.

VAREF 34 I Analog Base Voltage Input Pin for A/D Conversion

26

IOIPORT30

Analog Input0

Table 1-1 Pin Names and Functions(3/3)

Pin Name Pin Number Input/Output Functions

AVDD 35 I Analog Power Supply

AVSS 36 I Analog Power Supply

VDD 5 I +5V

VSS 1 I 0(GND)

Page 6

RA000

Page 25

2. Operational Description

TMP86FH47BUG

2.1 CPU

Core Functions

The CPU core consists of a CPU, a system clock controller, and an interrupt controller.

This section provides a description of the CPU core, the program memory, the data memory, and the reset circuit.

2.1.1 Memory Address Map

The TMP86FH47BUG memory is composed Flash, RAM, DBR(Data buffer register) and SFR(Special function register). They are all mapped in 64-Kbyte address space. Figure 2-1 shows the TMP86FH47BUG memory address map.

SFR

RAM

DBR

0FFF

C000

Flash

FFC0

FFDF

FFE0

FFFF

0000

H

003F

H

0040

H

023F

H

0F80

H

H

H

H

H

H

H

64 bytes

512

bytes

128

bytes

16384

bytes

SFR:

Vector table for vector call instructions

(32 bytes)

Vector table for interrupts

(32 bytes)

Special function register includes:

I/O ports

Peripheral

Peripheral status registers

System control registers

Program status word

RAM:

Random access memory includes:

Data memory

Stack

DBR: Data buffer register includes:

Peripheral control

Peripheral status registers

Flash: Program memory

control registers

registers

Figure 2-1 Memory Address Map

2.1.2 Program

The TMP86FH47BUG has a 16384 bytes (Address C000H to FFFFH) of program memory (Flash).

Memory (Flash)

2.1.3 Data Memory (RAM)

The TMP86FH47BUG has 512bytes (Address 0040H to 023FH) of internal RAM. The first 192 bytes

(0040H to 00FFH) of the internal RAM are located in the direct area; instructions with shorten operations

are available against such an area.

Page 7

Page 26

2. Operational Description

2.2 System Clock Controller

The data memory contents become unstable when the power supply is turned on; therefore, the data memory should be initialized by an initialization routine.

Example :Clears RAM to “00H”. (TMP86FH47BUG)

SRAMCLR: LD (HL), A

2.2 System Clock Controller

TMP86FH47BUG

LD HL, 0040H ; Start address setup

LD A, H ; Initial value (00H) setup

LD BC, 01FFH

INC HL

DEC BC

JRS F, SRAMCLR

The system clock controller consists of a clock generator, a timing generator, and a standby controller.

Timing generator control register

TBTCR

0036

H

Timing

generator

System clocks

Standby controller

0038

H

0039

System control registers

XIN

XOUT

XTIN

XTOUT

Clock

generator

fc

High-frequency

clock oscillator

fs

Low-frequency

clock oscillator

Clock generator control

Figure 2-2 System Clock Control

2.2.1 Clock Generator

The clock generator generates the basic clock which provides the system clocks supplied to the CPU core

and peripheral hardware. It contains two oscillation circuits: One for the high-frequency clock and one for

the low-frequency clock. Power consumption can be reduced by switching of the standby controller to low-power operation based on the low-frequency clock.

H

SYSCR2SYSCR1

The high-frequency (fc) clock and low-frequency (fs) clock can easily be obtained by connecting a resonator between the XIN/XOUT and XTIN/XTOUT pins respectively. Clock input from an external oscillator is also possible. In this case, external clock is applied to XIN/XTIN pin with XOUT/XTOUT pin not connected.

Page 8

Page 27

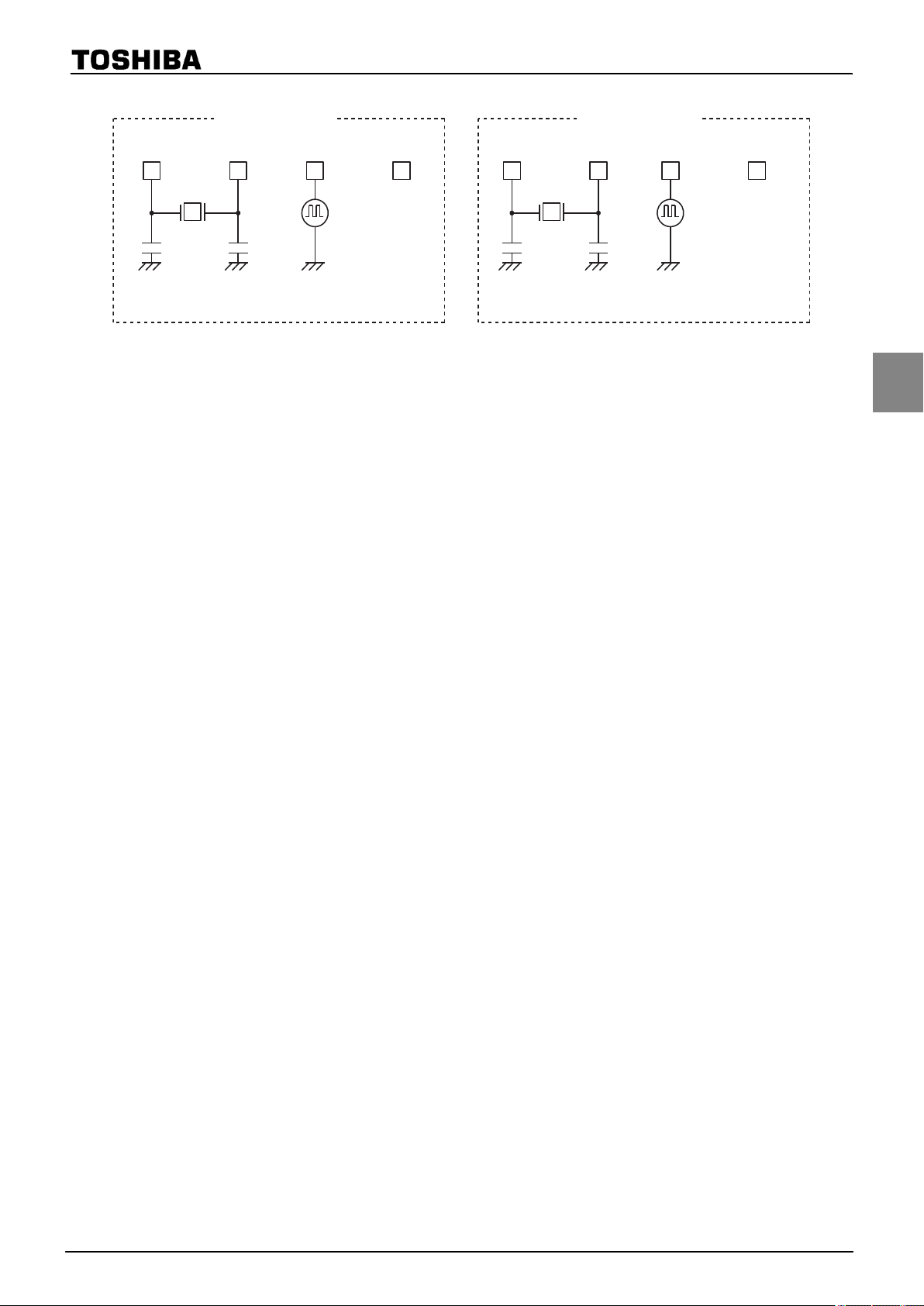

TMP86FH47BUG

(a) Crystal/Ceramic

resonator

Note:The function to monitor the basic clock directly at external is not provided for hardware, however,

High-frequency clock

XOUTXIN

(b) External oscillator

XOUTXIN

(Open)

XTIN

(c) Crystal (d) External oscillator

Low-frequency clock

XTOUT

XTIN

XTOUT

(Open)

Figure 2-3 Examples of Resonator Connection

with disabling all interrupts and watchdog timers, the oscillation frequency can be adjusted by monitoring the pulse which the fixed frequency is outputted to the port by the program.

The system to require the adjustment of the oscillation frequency should create the program for the adjustment in advance.

Page 9

Page 28

2. Operational Description

2.2 System Clock Controller

2.2.2 Timing Generator

The timing generator generates the various system clocks supplied to the CPU core and peripheral hardware from the basic clock (fc or fs). The timing generator provides the following functions.

TMP86FH47BUG

1. Generation of main system clock

2. Generation of divider output (DVO) pulses

3. Generation of source clocks for time base timer

4. Generation of source clocks for watchdog timer

5. Generation of internal source clocks for timer/counters

6. Generation of warm-up clocks for releasing STOP mode

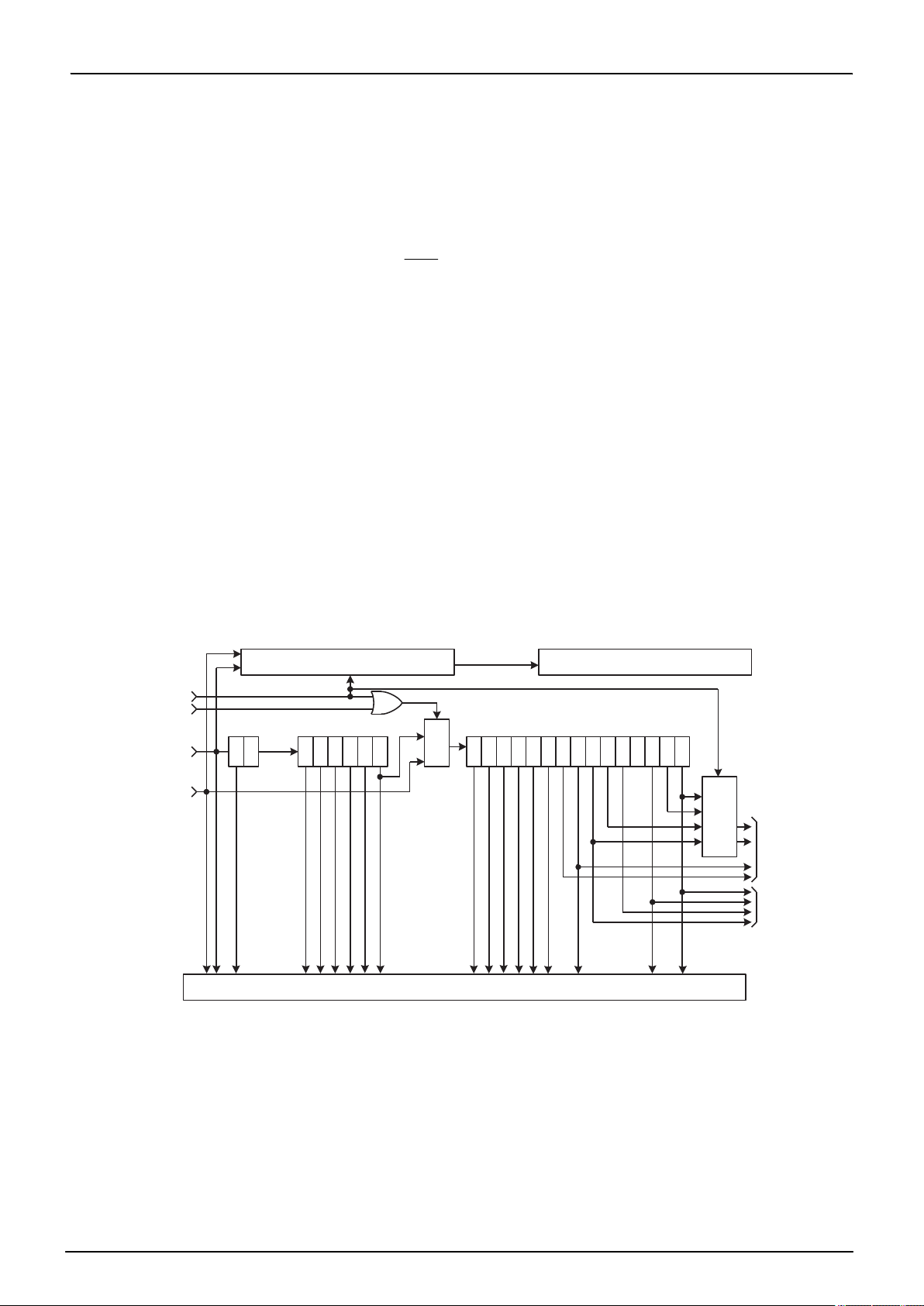

2.2.2.1 Configuration of timing generator

The timing generator consists of a 2-stage prescaler, a 21-stage divider, a main system clock generator,

and machine cycle counters.

An input clock to the 7th stage of the divider depends on the operating mode, SYSCR2<SYSCK> and

TBTCR<DV7CK>, that is shown in Figure 2-4. As reset and STOP mode started/canceled, the prescaler

and the divider are cleared to “0”.

SYSCK

DV7CK

High-frequency

clock fc

Low-frequency

clock fs

fc/4

1 21 432 87 109 1211 1413 1615

5 6 17 18 19 20 21

S

A

Y

B

Multi-

plexer

fc or fs

Machine cycle countersMain system clock generator

Divider

B0

B1

A0

A1

S

Y0

Y1

Multiplexer

Warm-up

controller

Watchdog

timer

Timer counter, Serial interface, Time-base-timer, divider output, etc. (Peripheral functions)

Figure 2-4 Configuration of Timing Generator

Page 10

Page 29

Timing Generator Control Register

TMP86FH47BUG

TBTCR

(0036H)

Note 1: In single clock mode, do not set DV7CK to “1”.

Note 2: Do not set “1” on DV7CK while the low-frequency clock is not operated stably.

Note 3: fc: High-frequency clock [Hz], fs: Low-frequency clock [Hz], *: Don’t care

Note 4: In SLOW1/2 and SLEEP1/2 modes, the DV7CK setting is ineffective, and fs is input to the 7th stage of the divider.

Note 5: When STOP mode is entered from NORMAL1/2 mode, the DV7CK setting is ineffective during the warm-up period af-

7

(DVOEN)

DV7CK

ter release of STOP mode, and the 6th stage of the divider is input to the 7th stage during this period.

6 5 4 3 2 1 0

(DVOCK) DV7CK (TBTEN) (TBTCK) (Initial value: 0000 0000)

Selection of input to the 7th stage

of the divider

0: fc/28 [Hz]

1: fs

2.2.2.2 Machine cycle

Instruction execution and peripheral hardware operation are synchronized with the main system clock.

The minimum instruction execution unit is called an “machine cycle”. There are a total of 10 different

types of instructions for the TLCS-870/C Series: Ranging from 1-cycle instructions which require one machine cycle for execution to 10-cycle instructions which require 10 machine cycles for execution. A machine cycle consists of 4 states (S0 to S3), and each state consists of one main system clock.

R/W

1/fc or 1/fs [s]

Main system clock

State

Machine cycle

Figure 2-5 Machine Cycle

2.2.3 Operation Mode Control Circuit

The operation mode control circuit starts and stops the oscillation circuits for the high-frequency and low-frequency clocks, and switches the main system clock. There are three operating modes: Single clock mode, dual clock mode and STOP mode. These modes are controlled by the system control registers (SYSCR1 and

SYSCR2). Figure 2-6 shows the operating mode transition diagram.

2.2.3.1 Single-clock mode

Only the oscillation circuit for the high-frequency clock is used, and P21 (XTIN) and P22 (XTOUT)

pins are used as input/output ports. The main-system clock is obtained from the high-frequency clock. In

the single-clock mode, the machine cycle time is 4/fc [s].

S3S2S1S0 S3S2S1S0

(1) NORMAL1 mode

In this mode, both the CPU core and on-chip peripherals operate using the high-frequency clock.

The TMP86FH47BUG is placed in this mode after reset.

Page 11

Page 30

2. Operational Description

2.2 System Clock Controller

TMP86FH47BUG

(2) IDLE1 mode

In this mode, the internal oscillation circuit remains active. The CPU and the watchdog timer are hal-

ted; however

on-chip peripherals remain active (Operate using the high-frequency clock).

IDLE1 mode is started by SYSCR2<IDLE> = "1", and IDLE1 mode is released to NORMAL1

mode by an interrupt request from the on-chip peripherals or external interrupt inputs. When the

IMF (Interrupt master enable flag) is “1” (Interrupt enable), the execution will resume with the acceptance of the interrupt, and the operation will return to normal after the interrupt service is completed.

When the IMF is “0” (Interrupt disable), the execution will resume with the instruction which follows the IDLE1 mode start instruction.

(3) IDLE0 mode

In this mode, all the circuit, except oscillator and the timer-base-timer, stops operation.

This mode is enabled by SYSCR2<TGHALT> = "1".

When IDLE0 mode starts, the CPU stops and the timing generator stops feeding the clock to the peripheral circuits other than TBT. Then, upon detecting the falling edge of the source clock selected

with TBTCR<TBTCK>, the timing generator starts feeding the clock to all peripheral circuits.

When returned from IDLE0 mode, the CPU restarts operating, entering NORMAL1 mode back

again. IDLE0 mode is entered and returned regardless of how TBTCR<TBTEN> is set. When IMF

= “1”, EF6 (TBT interrupt individual enable flag) = “1”, and TBTCR<TBTEN> = “1”, interrupt processing is performed. When IDLE0 mode is entered while TBTCR<TBTEN> = “1”, the INTTBT interrupt latch is set after returning to NORMAL1 mode.

2.2.3.2 Dual-clock mode

Both the high-frequency and low-frequency oscillation circuits are used in this mode. P21 (XTIN) and

P22 (XTOUT) pins cannot be used as input/output ports. The main system clock is obtained from the highfrequency clock in NORMAL2 and IDLE2 modes, and is obtained from the low-frequency clock in

SLOW and SLEEP modes. The machine cycle time is 4/fc [s] in the NORMAL2 and IDLE2 modes, and

4/fs [s] (122 μs at fs = 32.768 kHz) in the SLOW and SLEEP modes.

The TLCS-870/C is placed in the single-clock mode during reset. To use the dual-clock mode, the lowfrequency oscillator should be turned on at the start of a program.

(1) NORMAL2 mode

In this mode, the CPU core operates with the high-frequency clock. On-chip peripherals operate us-

ing the high-frequency clock and/or low-frequency clock.

(2) SLOW2 mode

In this mode, the CPU core operates with the low-frequency clock, while both the high-frequency

clock and the low-frequency clock are operated. As the SYSCR2<SYSCK> becomes "1", the hardware changes into SLOW2 mode. As the SYSCR2<SYSCK> becomes “0”, the hardware changes into NORMAL2 mode. As the SYSCR2<XEN> becomes “0”, the hardware changes into SLOW1

mode. Do not clear SYSCR2<XTEN> to “0” during SLOW2 mode.

(3) SLOW1 mode

This mode can be used to reduce power-consumption by turning off oscillation of the high-frequency clock. The CPU core and on-chip peripherals operate using the low-frequency clock.

Page 12

Page 31

TMP86FH47BUG

Switching back and forth between SLOW1 and SLOW2 modes are performed by

SYSCR2<XEN>. In SLOW1 and SLEEP modes, the input clock to the 1st stage of the divider is stopped; output

from the 1st to 6th stages is also stopped.

(4) IDLE2 mode

In this mode, the internal oscillation circuit remain active. The CPU and the watchdog timer are halted; however, on-chip peripherals remain active (Operate using the high-frequency clock and/or the

low-frequency clock). Starting and releasing of IDLE2 mode are the same as for IDLE1 mode, except that operation returns to NORMAL2 mode.

(5) SLEEP1 mode

In this mode, the internal oscillation circuit of the low-frequency clock remains active. The CPU,

the watchdog timer, and the internal oscillation circuit of the high-frequency clock are halted; however, on-chip peripherals remain active (Operate using the low-frequency clock). Starting and releasing of SLEEP mode are the same as for IDLE1 mode, except that operation returns to SLOW1

mode. In SLOW1 and SLEEP1 modes, the input clock to the 1st stage of the divider is stopped; output from the 1st to 6th stages is also stopped.

(6) SLEEP2 mode

The SLEEP2 mode is the idle mode corresponding to the SLOW2 mode. The status under the

SLEEP2 mode is same as that under the SLEEP1 mode, except for the oscillation circuit of the highfrequency clock.

(7) SLEEP0 mode

In this mode, all the circuit, except oscillator and the timer-base-timer, stops operation. This

mode is enabled by setting “1” on bit SYSCR2<TGHALT>.

When SLEEP0 mode starts, the CPU stops and the timing generator stops feeding the clock to

the peripheral circuits other than TBT. Then, upon detecting the falling edge of the source clock selected with TBTCR<TBTCK>, the timing generator starts feeding the clock to all peripheral circuits.

When returned from SLEEP0 mode, the CPU restarts operating, entering SLOW1 mode back

again. SLEEP0 mode is entered and returned regardless of how TBTCR<TBTEN> is set. When

IMF = “1”, EF6 (TBT interrupt individual enable flag) = “1”, and TBTCR<TBTEN> = “1”, interrupt processing is performed. When SLEEP0 mode is entered while TBTCR<TBTEN> = “1”, the

INTTBT interrupt latch is set after returning to SLOW1 mode.

2.2.3.3 STOP mode

In this mode, the internal oscillation circuit is turned off, causing all system operations to be halted.

The internal status immediately prior to the halt is held with a lowest power consumption during STOP

mode.

STOP mode is started by the system control register 1 (SYSCR1), and STOP mode is released by a inputting (Either level-sensitive or edge-sensitive can be programmable selected) to the

warm-up period

is completed, the execution resumes with the instruction which follows the STOP mode

STOP pin. After the

start instruction.

Page 13

Page 32

2. Operational Description

2.2 System Clock Controller

TMP86FH47BUG

IDLE1

mode

(a) Single-clock mode

IDLE2

mode

SLEEP2

mode

SLEEP1

mode

(b) Dual-clock mode

SYSCR2<TGHALT> = "1"

SYSCR2<IDLE> = "1"

Interrupt

SYSCR2<XTEN> = "0"

SYSCR2<IDLE> = "1"

Interrupt

SYSCR2<SYSCK> = "0"

SYSCR2<IDLE> = "1"

Interrupt

SYSCR2<XEN> = "1"

SYSCR2<IDLE> = "1"

Interrupt

Note 2

IDLE0

mode

NORMAL1

mode

NORMAL2

mode

SLOW2

mode

SLOW1

mode

Reset release

Note 2

SYSCR1<STOP> = "1"

STOP pin input

SYSCR2<XTEN> = "1"

SYSCR1<STOP> = "1"

STOP pin input

SYSCR2<SYSCK> = "1"

SYSCR2<XEN> = "0"

SYSCR1<STOP> = "1"

STOP pin input

SYSCR2<TGHALT> = "1"

RESET

STOP

SLEEP0

mode

Note 1: NORMAL1 and NORMAL2 modes are generically called NORMAL; SLOW1 and SLOW2 are called SLOW;

IDLE0, IDLE1 and IDLE2 are called IDLE; SLEEP0, SLEEP1 and SLEEP2 are called SLEEP.

Note 2: The mode is released by falling edge of TBTCR<TBTCK> setting.

Figure 2-6 Operating Mode Transition Diagram

Table 2-1 Operating Mode and Conditions

Operating Mode

Single clock

Dual clock

Oscillator

High

Frequency

RESET

NORMAL1 Operate Operate

IDLE1

STOP Stop Halt -

NORMAL2

IDLE2 Halt Halt

SLOW2

SLEEP2 Halt Halt

SLOW1

SLEEP1

STOP Stop Halt Halt -

Oscillation

Oscillation

Stop

Low

Frequency

Stop

Oscillation

CPU Core WDT TBT

Reset Reset Reset Reset Reset

Operate

Halt HaltIDLE0

Operate with

High-freq.

Operate with

Low-freq.

Operate with

Low-freq.

Halt HaltSLEEP0

Operate with

High or Low-

freq.

Operate with

Low-freq.

Operate with

Low-freq.

Operate

AD

Converter

Operate Operate

Halt Halt

Operate

Halt 4/fs [s]

Peripherals

Other

Operate

Halt

Machine Cy-

cle Time

4/fc [s]

4/fc [s]

Page 14

Page 33

System Control Register 1

TMP86FH47BUG

SYSCR1

(0038H) STOP RELM RETM OUTEN WUT (Initial value: 0000 000*)

7 6 5 4 3 2 1

STOP STOP mode start

RELM

RETM

OUTEN Port output during STOP mode

WUT

Release method for STOP

mode

Operating mode after STOP

mode

Warm-up time at releasing

STOP mode

0: CPU core and peripherals remain active

core and peripherals are halted (Start STOP mode)

1: CPU

0: Edge-sensitive release

1: Level-sensitive

0: Return to NORMAL1/2 mode

1: Return

0: High impedance

1: Output

Return to NORMAL mode Return to SLOW mode

000

010

100

110

*01

*11

release

to SLOW1 mode

kept

3 x 216/fc

216/fc

3 x

214/fc

3 x 210/fc

210/fc

214/fc

0

3 x 213/fs

213/fs

3 x

26/fs

26/fs

3 x 26/fs

26/fs

Note 1: Always set RETM to “0” when transiting from NORMAL mode to STOP mode. Always set RETM to “1” when transit-

ing from

Note 2: When STOP mode is released with

Note 3: fc:

SLOW mode to STOP mode.

RESET pin input, a return is made to NORMAL1 regardless of the RETM contents.

High-frequency clock [Hz], fs: Low-frequency clock [Hz], *; Don’t care

Note 4: Bits 1 in SYSCR1 are read as undefined data when a read instruction is executed.

Note 5: As the hardware becomes STOP mode under OUTEN = “0”, input value is fixed to “0”; therefore it may cause exter-

nal interrupt request on account of falling edge.

Note 6: When the key-on wakeup is used, RELM should be set to "1".

Note 7: Port P20 is used as

comes High-Z

STOP pin. Therefore, when stop mode is started, OUTEN does not affect to P20, and P20 be-

mode.

Note 8: The warming-up time should be set correctly for using oscillator.

R/W

R/W

R/W

R/W

R/W

System Control Register 2

SYSCR2

(0039H)

7

XEN XTEN SYSCK IDLE TGHALT (Initial value: 1000 *0**)

XEN High-frequency oscillator control

XTEN Low-frequency oscillator control

SYSCK

IDLE

TGHALT

Note 1: A reset is applied if both XEN and XTEN are cleared to “0”, XEN is cleared to “0” when SYSCK = “0”, or XTEN is

cleared to

Note 2: *: Don’t care, TG: Timing generator, *; Don’t care

Note 3: Bits 3, 1 and 0 in SYSCR2 are always read as undefined value.

Note 4: Do not set IDLE and TGHALT to “1” simultaneously.

Note 5: Because returning from IDLE0/SLEEP0 to NORMAL1/SLOW1 is executed by the asynchronous internal clock, the pe-

riod of IDLE0/SLEEP0 mode might be shorter than the period setting by TBTCR<TBTCK>.

6 5 4

Main system clock select (Write)/

main system

(Read)

CPU and watchdog timer control (IDLE1/2

modes)

TG control (IDLE0 and SLEEP0

modes)

clock monitor

and SLEEP1/2

“0” when SYSCK = “1”.

3

0: Turn off oscillation

1: Turn

0: Turn off oscillation

1: Turn

0: High-frequency clock (NORMAL1/NORMAL2/IDLE1/IDLE2)

1: Low-frequency

0: CPU and watchdog timer remain active

1: CPU

modes)

0: Feeding clock to all peripherals from TG

1: Stop

(Start IDLE0 and SLEEP0 modes)

2

on oscillation

on oscillation

and watchdog timer are stopped (Start IDLE1/2 and SLEEP1/2

feeding clock to peripherals except TBT from TG

1 0

clock (SLOW1/SLOW2/SLEEP1/SLEEP2)

R/W

R/W

Page 15

Page 34

2. Operational Description

2.2 System Clock Controller

Note 6: When IDLE1/2 or SLEEP1/2 mode is released, IDLE is automatically cleared to “0”.

Note 7: When

Note 8: Before setting TGHALT to “1”, be sure to stop peripherals. If peripherals are not stopped, the interrupt latch of periph-

2.2.4 Operating Mode Control

2.2.4.1 STOP mode

TMP86FH47BUG

IDLE0 or SLEEP0 mode is released, TGHALT is automatically cleared to “0”.

erals may be set after IDLE0 or SLEEP0 mode is released.

STOP mode is controlled by the system control register 1, the

put (STOP5

The

to STOP2) which is controlled by the STOP mode release control register (STOPCR).

STOP pin is also used both as a port P20 and an INT5 (external interrupt input 5) pin. STOP

STOP pin input and key-on wakeup in-

mode is started by setting SYSCR1<STOP> to “1”. During STOP mode, the following status is maintained.

1. Oscillations are

turned off, and all internal operations are halted.

2. The data memory, registers, the program status word and port output latches are all held in the

status in effect before STOP mode was entered.

3. The prescaler and the divider of the timing generator are cleared to “0”.

4. The program counter holds the address 2 ahead of the instruction (e.g., [SET (SYSCR1).7])

which started STOP mode.

STOP mode includes a level-sensitive mode and an edge-sensitive mode, either of which can be selected with the SYSCR1<RELM>. Do not use any key-on wakeup input (STOP5 to STOP2) for releasing

STOP mode in edge-sensitive mode.

Note 1: The STOP mode can be released by either the STOP or key-on wakeup pin (STOP5 to STOP2). How-

Note 2: During STOP period (from start of STOP mode to end of warm up), due to changes in the external in-

ever, because the STOP pin is different from the key-on wakeup and can not inhibit the release input, the STOP pin must be used for releasing STOP mode.

terrupt pin signal, interrupt latches may be set to “1” and interrupts may be accepted immediately after STOP mode is released. Before starting STOP mode, therefore, disable interrupts. Also, before enabling interrupts after STOP mode is released, clear unnecessary interrupt latches.

(1) Level-sensitive release mode (RELM = “1”)

In this mode, STOP mode is released by setting the

STOP2 pin

input which is enabled by STOPCR. This mode is used for capacitor backup when the

STOP pin high or setting the STOP5 to

main power supply is cut off and long term battery backup.

Even if an instruction for starting STOP mode is executed while

STOP pin input is high or

STOP5 to STOP2 input is low, STOP mode does not start but instead the warm-up sequence starts immediately. Thus,

gram to first confirm that the

ing two

methods can be used for confirmation.

to start STOP mode in the level-sensitive release mode, it is necessary for the pro-

STOP pin input is low and STOP5 to STOP2 input is high. The follow-

1. Testing a port.

2. Using an external interrupt input

INT5 (INT5 is a falling edge-sensitive input).

Page 16

Page 35

Example 1 :Starting STOP mode from NORMAL mode by testing a port P20.

LD (SYSCR1), 01010000B ; Sets up the level-sensitive release mode

SSTOPH: TEST (P2PRD). 0 ; Wait until the

JRS F, SSTOPH

DI ; IMF ← 0

SET (SYSCR1). 7 ; Starts STOP mode

STOP pin input goes low level

Example 2 :Starting STOP mode from NORMAL mode with an INT5 interrupt.

PINT5: TEST (P2PRD). 0 ; To reject noise, STOP mode does not start if

JRS F, SINT5 port P20 is at high

LD (SYSCR1), 01010000B ; Sets up the level-sensitive release mode.

DI ; IMF ← 0

SET (SYSCR1). 7 ; Starts STOP mode

SINT5: RETI

V

STOP pin

IH

TMP86FH47BUG

XOUT pin

NORMAL

operation

STOP

operation

Confirm by program that the

STOP pin input is low and start

STOP mode.

Warm up

STOP mode is released by the hardware.

Always released if the STOP

pin input is high.

NORMAL

operation

Figure 2-7 Level-sensitive Release Mode

Note 1: Even if the

Note 2: In this case of changing to the level-sensitive mode from the edge-sensitive mode, the release mode

is not switched until a rising edge of the

(2) Edge-sensitive release mode (RELM = “0”)

In this mode, STOP mode is released by a rising edge of the

cations where a relatively short program is executed repeatedly at periodic intervals. This periodic signal (for example, a clock from a low-power consumption oscillator) is input to the STOP pin. In the

edge-sensitive release mode, STOP mode is started even when the STOP pin input is high level. Do

not use any STOP5 to STOP2 pin input for releasing STOP mode in edge-sensitive release mode.

STOP pin input is low after warm-up start, the STOP mode is not restarted.

STOP pin input is detected.

STOP pin input. This is used in appli-

Example :Starting STOP mode from NORMAL mode