MARANTZ SR5007 Service manual

Service

SR5007 /

N1SG,N1B

U1B,K1B

Manual

AV Surround Receiver

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

SR5007

S0679-0V05DM/DG1305

Copyright 2013 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver.5

Please refer to the

MODIFICATION NOTICE.

CONTENTS

ABOUT THIS MANUAL .............................................................3

What you can do with this manual ............................................3

Using Adobe Reader (Windows version) ..................................4

SAFETY PRECAUTIONS ..........................................................7

NOTE FOR SCHEMATIC DIAGRAM .........................................8

TECHNICAL SPECIFICATIONS ................................................9

DIMENSION ...............................................................................9

CAUTIONS IN SERVICING .....................................................10

Initializing AV Surround Receiver ............................................10

Service Jig ..............................................................................10

DISASSEMBLY ........................................................................ 11

1. FRONT PANEL ASSY .........................................................13

2. PCB MX PORT/PCB RS232C ...........................................14

3. PCB HDMI ...........................................................................15

4. POWER TRANS MAIN ........................................................16

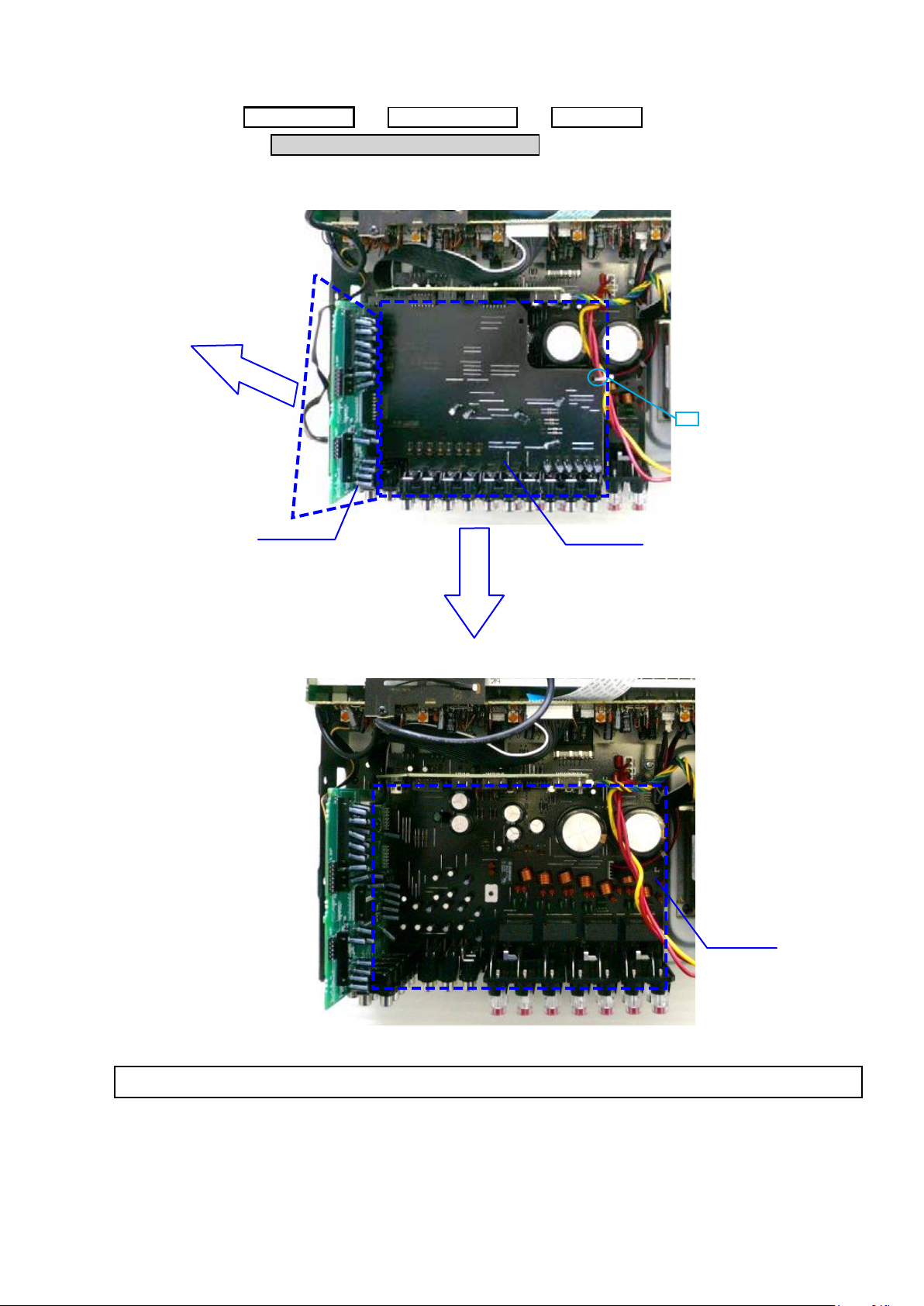

5. PCB VIDEO/PCB INPUT/PCB MAIN .................................17

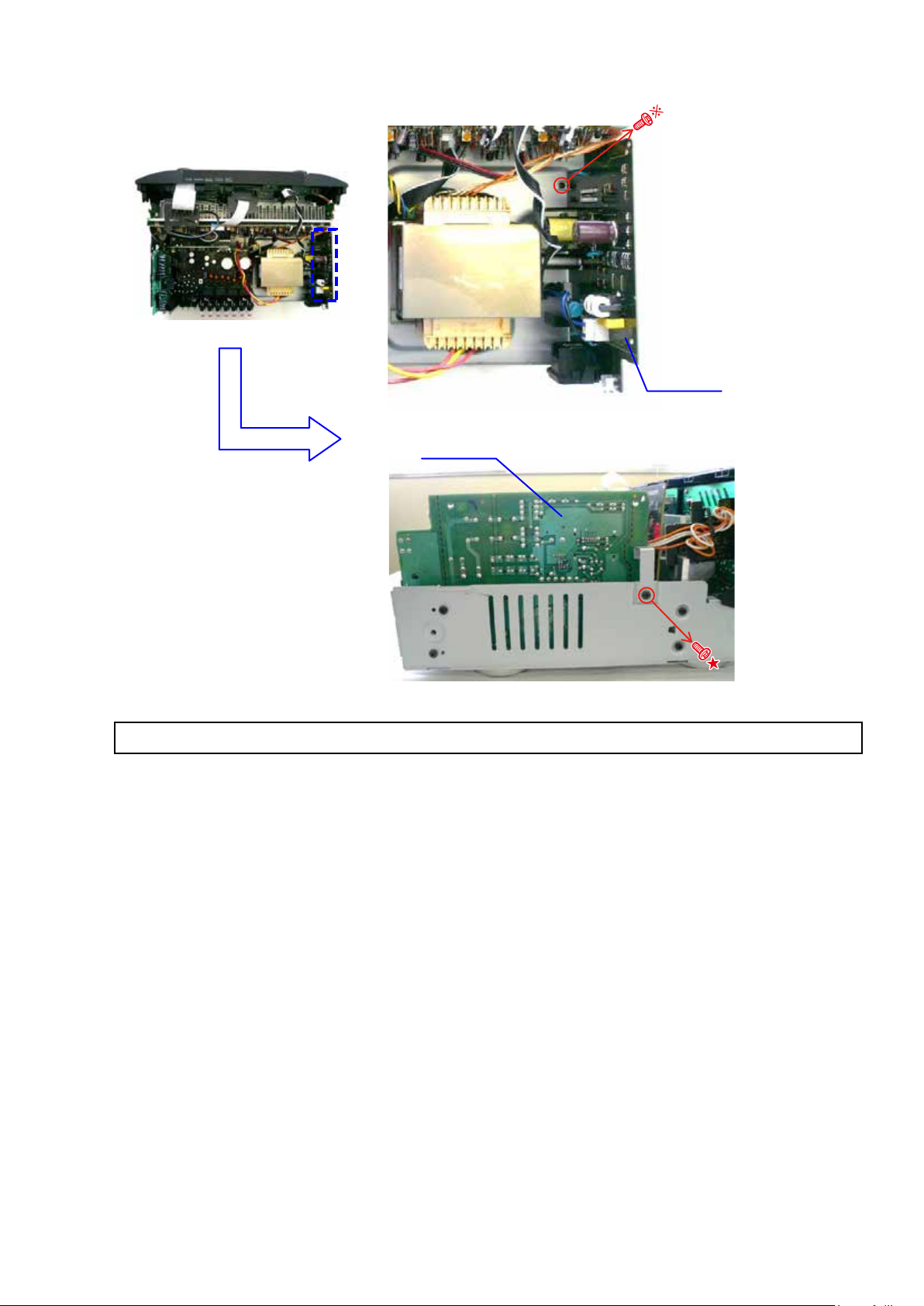

6. PCB FRONT CNT/PCB SMPS ............................................18

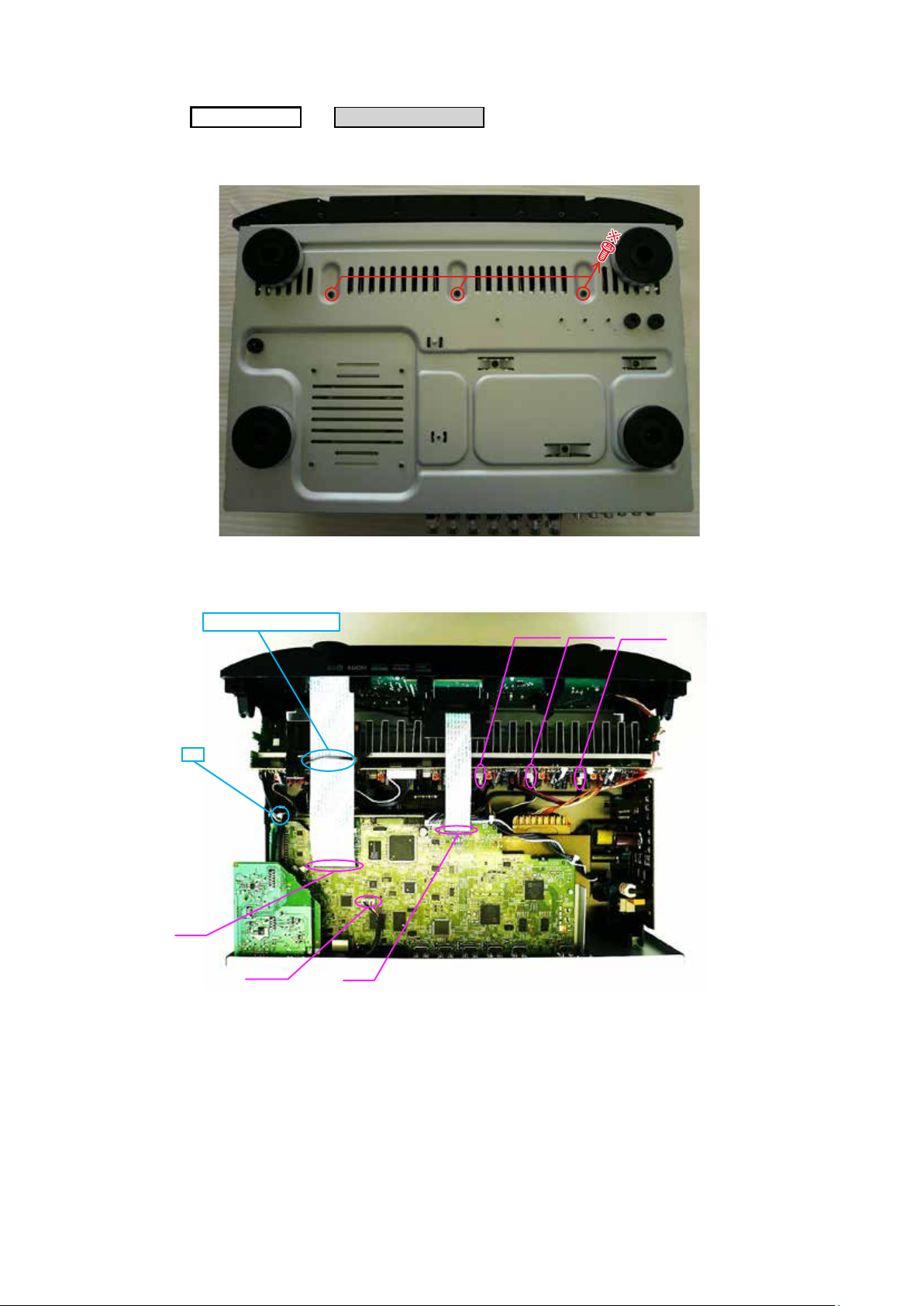

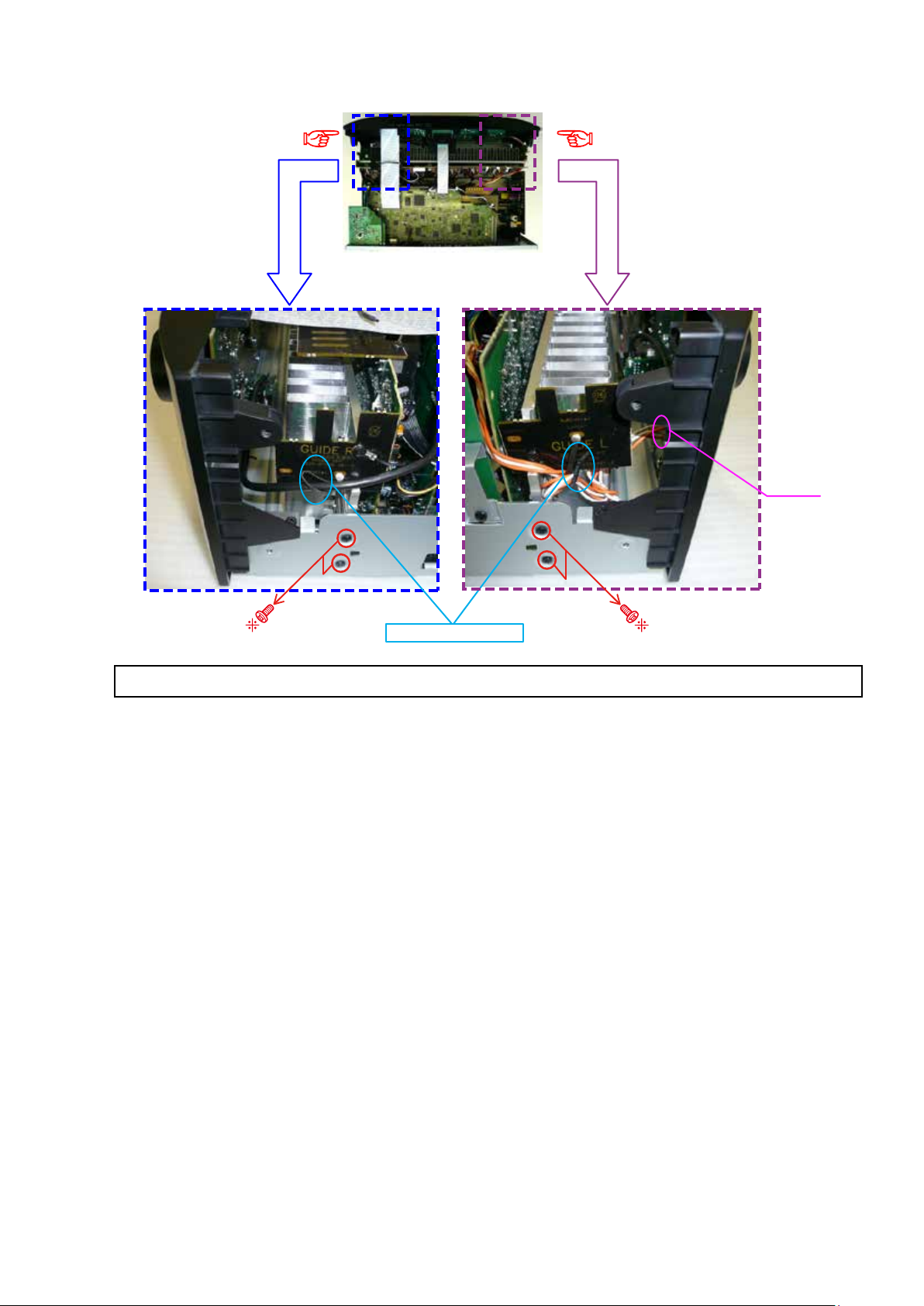

7. RADIATOR ASSY ................................................................20

SPECIAL MODE ......................................................................22

Special mode setting button ....................................................22

1. µcom/DSP Version display mode ........................................23

2. PANEL/REMOTE LOCK Selection mode ............................26

3. Service Related Selection mode ........................................27

4. DUAL BACKUP MEMORY ..................................................35

BLOCK DIAGRAM ...................................................................37

JIG FOR SERVICING ..............................................................53

WHEN THE MICROPROCESSOR IS REPLACED

WITH A NEW ONE ...................................................................56

PROCEDURE FOR UPGRADING THE VERSION

OF THE FIRMWARE ................................................................56

1. How to update by DFW .......................................................56

2. How to update by DPMS .....................................................60

3. How to update by USB Memory ..........................................67

ADJUSTMENT .........................................................................74

SURROUND MODES AND PARAMETERS ............................75

TROUBLE SHOOTING ............................................................79

1. POWER ...............................................................................79

2. Analog video ........................................................................80

3. HDMI/DVI ............................................................................86

4. AUDIO .................................................................................94

5. Network/USB .......................................................................97

6. SMPS ................................................................................100

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK ...........104

LEVEL DIAGRAM ..................................................................105

PRINTED WIRING BOARDS ................................................. 111

HDMI .................................................................................... 111

FRONT HDMI .......................................................................11 3

OPTIONAL CIRCUIT ............................................................113

RS232 ..................................................................................11 3

FRONT .................................................................................11 4

USB ......................................................................................11 6

TOP_GUIDE .........................................................................11 6

H/P ........................................................................................11 6

GUIDE L ...............................................................................116

GUIDE R ..............................................................................11 6

7CH AMP ..............................................................................117

VIDEO ..................................................................................11 8

FRONT CNT .........................................................................119

MAIN ....................................................................................121

SMPS ...................................................................................123

SCHEMATIC DIAGRAMS (1/27) ...........................................124

HDMI SW UNIT .....................................................................124

FRONT HDMI UNIT ..............................................................125

HDMI RX UNIT ......................................................................126

HDMI TX UNIT ......................................................................127

HDMI TX DDR UNIT .............................................................128

DSP UNIT ..............................................................................129

DIR/PLD UNIT .......................................................................130

MAIN DAC UNIT ...................................................................131

DM860A UNIT .......................................................................132

NET PHY UNIT .....................................................................133

CPU UNIT .............................................................................134

CPU LEVEL CHG UNIT ........................................................135

DIGITAL CNT UNIT ...............................................................136

D.SUPPLY UNIT ...................................................................137

7CH-AMP UNIT (1/2) ............................................................138

7CH-AMP UNIT (2/2) ............................................................139

SPK REG SMPS UNIT (1/4) .................................................140

SPK REG SMPS UNIT (2/4) .................................................141

SPK REG SMPS UNIT (3/4) .................................................142

SPK REG SMPS UNIT (4/4) .................................................143

INPUT UNIT ..........................................................................144

FRONT UNIT .........................................................................145

FRONT HDMI UNIT ..............................................................146

RS232 / OPTIONAL CIRCUIT UNIT ....................................147

VIDEO F/CNT UNIT (1/3) ......................................................148

VIDEO F/CNT UNIT (2/3) ......................................................149

VIDEO F/CNT UNIT (3/3) ......................................................150

WIRING DIAGRAM ...............................................................151

EXPLODED VIEW ..................................................................152

PARTS LIST OF EXPLODED VIEW .....................................153

PACKING VIEW ...................................................................156

PARTS LIST OF PACKING & ACCESSORIES ....................157

SEMICONDUCTORS .............................................................158

1. IC's ....................................................................................158

2. FL DISPLAY.......................................................................189

PARTS LIST OF PCB UNIT ..................................................190

7CH_AMP PCB UNIT ASS'Y .................................................190

MAIN PCB UNIT ASS'Y.........................................................195

VIDEO PCB UNIT ASS'Y ......................................................199

FRONT PCB UNIT ASS'Y .....................................................201

INPUT PCB UNIT ASS'Y .......................................................204

HDMI PCB UNIT ASS'Y ........................................................205

RS232 PCB UNIT ASS'Y.......................................................222

2

ABOUT THIS MANUAL

Read the following information before using the service manual.

What you can do with this manual

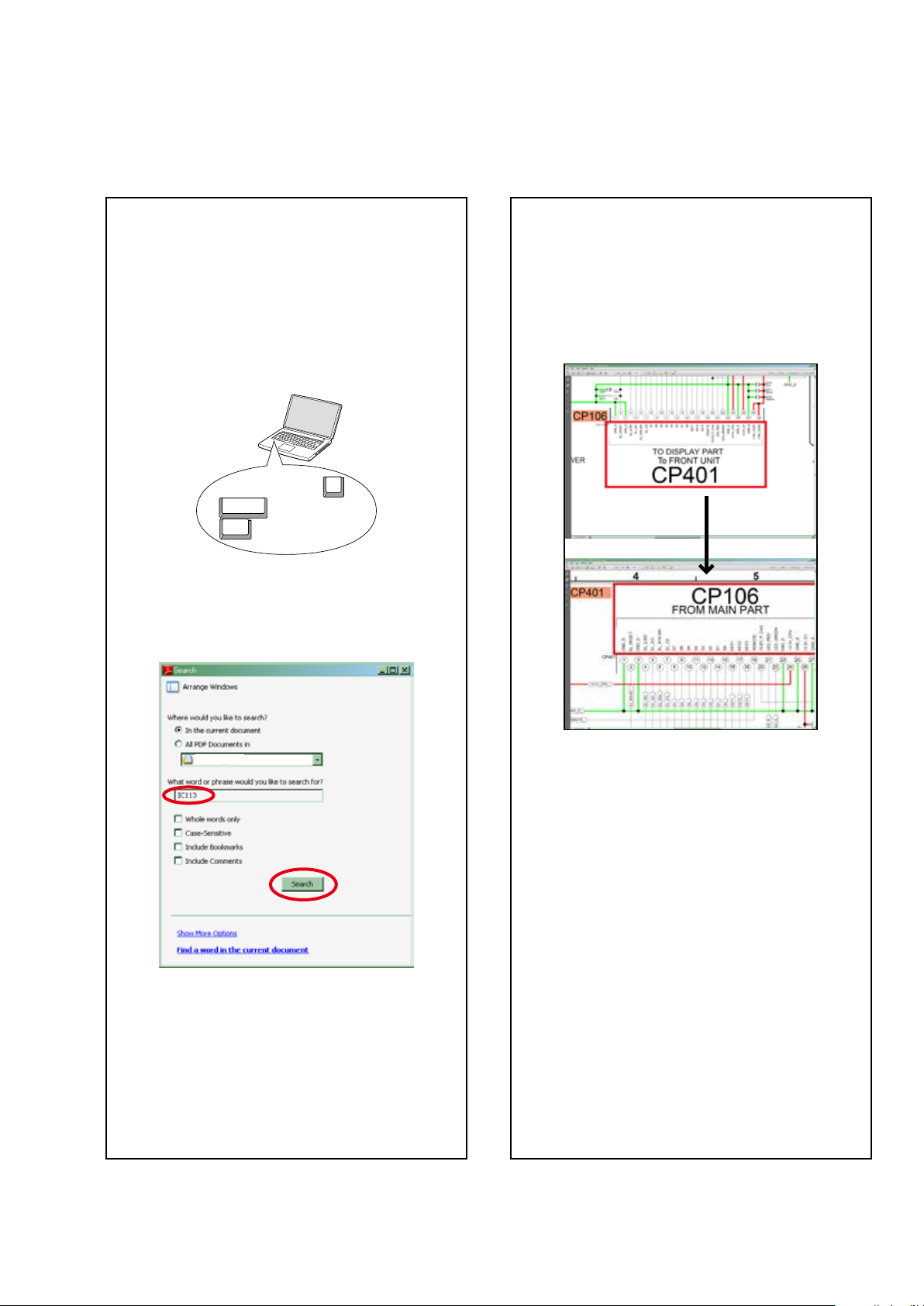

Search for a Ref. No. (phrase)

(Ctrl+Shift+F)

You can use the search function in Acrobat Reader to

search for a Ref. No. in schematic diagrams, printed

wiring board diagrams, block diagrams, and parts lists.

1.Press Ctrl+Shift+F on the keyboard.

• The Search window appears.

F

Shift

Ctrl

2.Enter the Ref. No. you want to search for in the

Search window, and then click the Search button.

• A list of search results appears.

Jump to the target of a schematic diagram

connector

Click the Ref. No. of the target connector in the red box

around a schematic diagram connector.

• The screen jumps to the target connector.

3.Click an item on the list.

• The screen jumps to the page for that item, and

the search phrase is displayed.

• Page magnification stays the same as before the

jump.

3

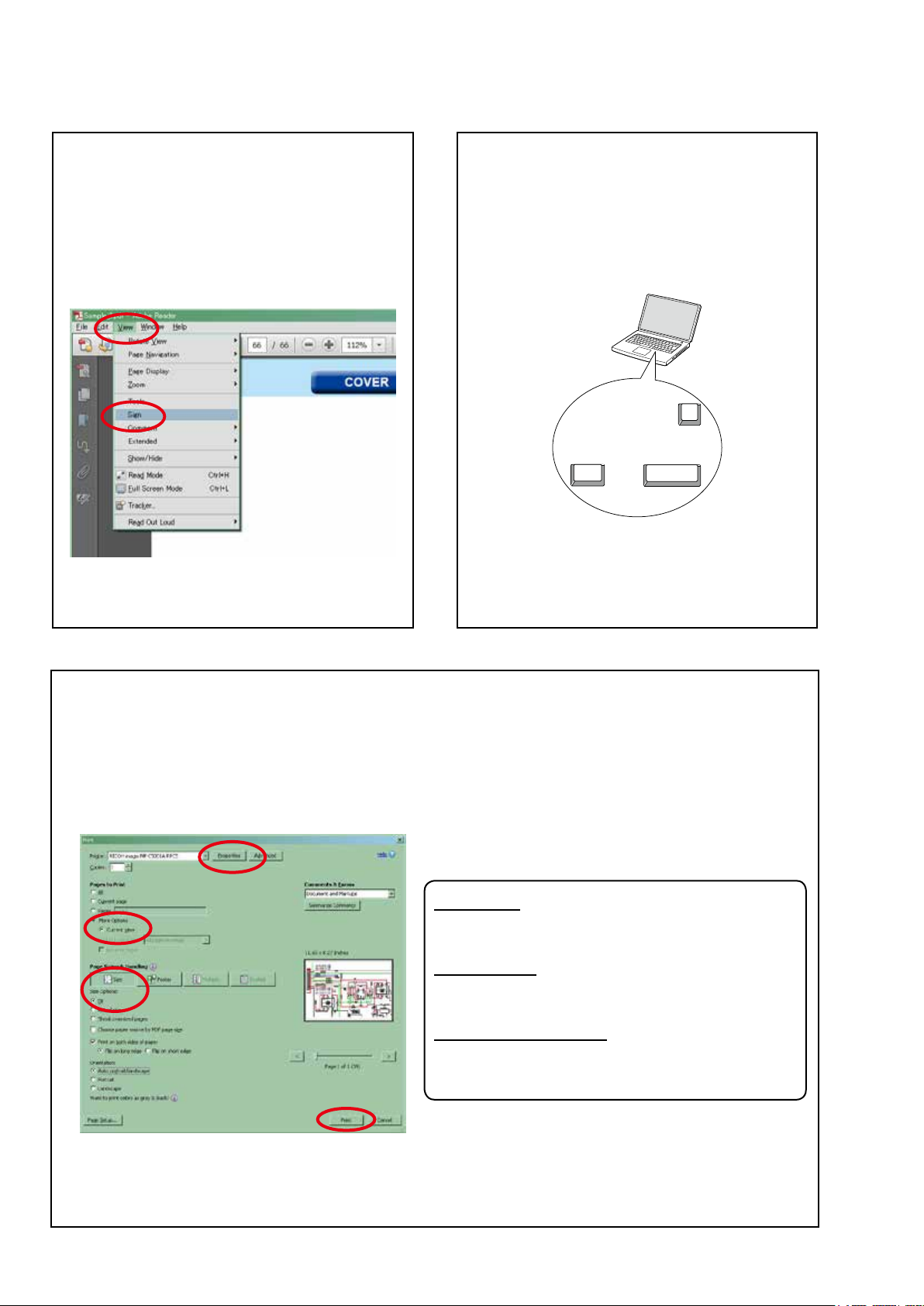

Using Adobe Reader (Windows version)

Add notes to this data (Sign)

The Sign function lets you add notes to the data in this

manual.

Save the le once you have nished adding notes.

[Example using Adobe Reader X]

On the "View" menu, click "Sign".

• The Sign pane appears.

[Example using Adobe Reader 9]

On the "Document" menu, click "Sign".

Magnify schematic / printed wiring board

diagrams - 1

(Ctrl+Space, mouse operation)

[Example using Adobe Reader 9,X]

Press Ctrl+Space on the keyboard and drag the

mouse to select the area you want to view.

• The selected area is magnied.

0

Ctrl Space

• When you want to move the area shown, hold down

Space and drag the mouse.

• When you want to show a full page view, press

Ctrl+0 on the keyboard.

Print a magnied part of the manual

The Properties dialog box and functions will vary depending on your printer.

1. Drag the mouse to magnify the part you want to print.

2. On the "File" menu, click "Print".

3. Congure the following settings in the Print dialog box.

• Properties

Click this button and check that the printer is set to a

suitable paper size.

• Page to print

Select the following checkbox.

"More Options" : "Current View"

• Page Sizing & Handling

Select the following checkbox.

"Size" / "Size Options" : "Fit"

4. Click the Print button to start printing.

4

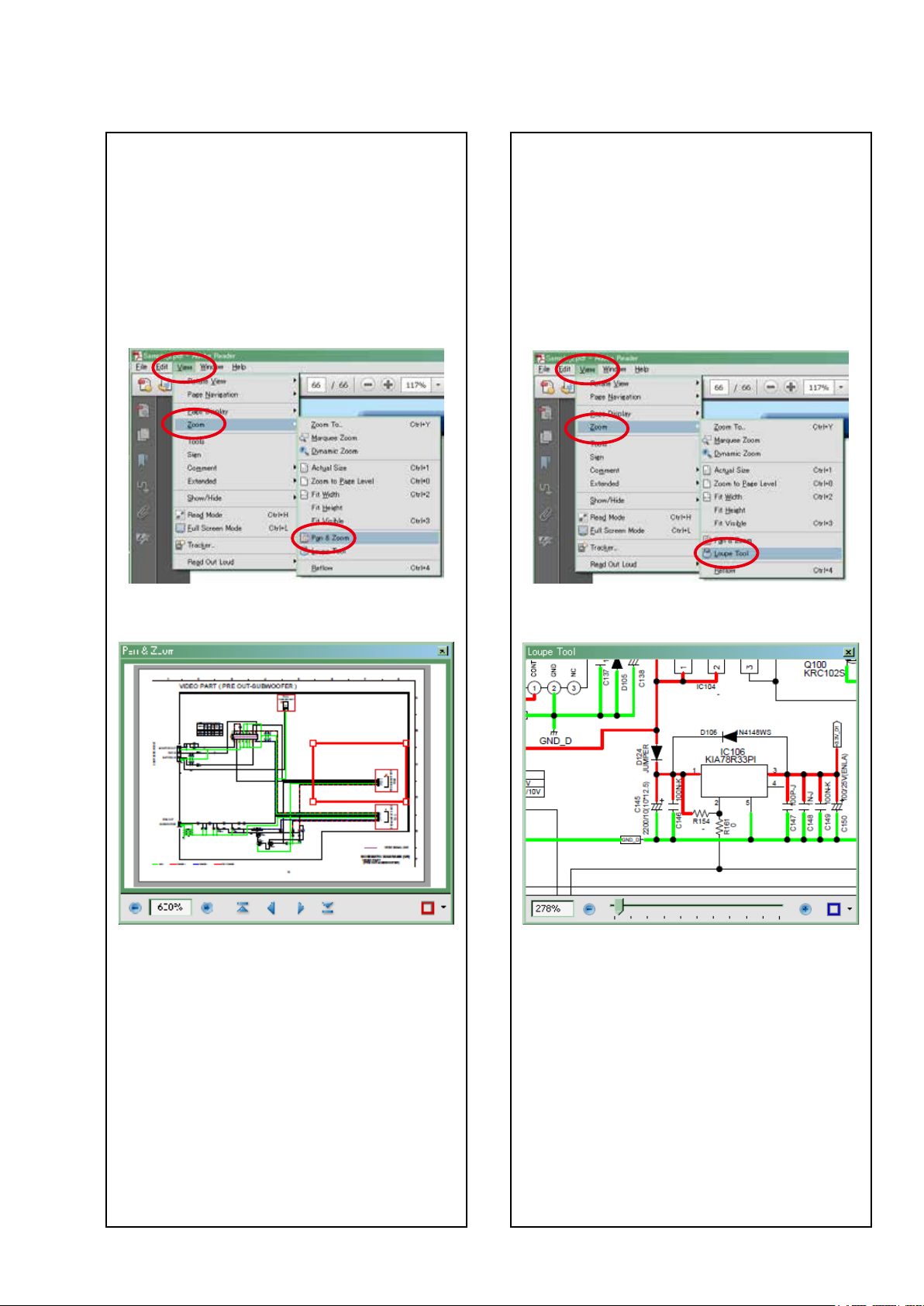

Magnify schematic / printed wiring board

diagrams - 2

(Pan & Zoom function)

The Pan & Zoom function lets you see which part of a

magnied diagram is being shown in a separate window.

Magnify schematic / printed wiring board

diagrams - 3

(Loupe Tool function)

The Loupe Tool function lets you magnify a specific

part of a diagram in a separate window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Pan & Zoom".

• The Pan & Zoom window appears on the screen.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Loupe Tool".

• The Loupe Tool window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select & Zoom", and

then click "Pan & Zoom Window".

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select & Zoom", and

then click "Loupe Tool Window".

5

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specications for

company has created the ultimate in stereo sound.

which it is famous.

Parts for your

MARANTZ

equipment are generally available to our National Marantz Subsidiary or agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specied.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

KOREA

D&M SALES AND MARKETING KOREA LTD.

2F,YEON BLDG.,

88-5, BANPO-DONG, SEOCHO-GU,

SEOUL KOREA

PHONE : +82 - 2 - 715 - 9041

FAX : +82 - 2 - 715 - 9040

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL

NO.1600 NANJING (WEST) ROAD, SHANGHAI,

CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

NOTE ON SAFETY :

Symbol z Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol z .

Any other component substitution (other than original type), may increase risk of re or electrical shock hazard.

安全上の注意:

がついている部品は、安全上重要な部品です。必ず指定されている部品番号のものを使用して下さい。

z

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary

AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the face or Front Panel of

product and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and veried before it is return to the user/customer.

Ref. UL Standard No. 60065.

In case of difculties, do not hesitate to contact the Technical

Department at above mentioned address.

6

091105DM/DG

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

LEAKAGE CURRENT CHECK

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state (on,

off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if

you touch internal metal parts when the set is

energized, you may get an electric shock. Avoid

getting an electric shock, by using an isolating

transformer and wearing gloves when servicing

while the set is energized, or by unplugging the

power cord when replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs

on the edges of parts. The burrs could cause injury if

ngers are moved across them in some rare cases.

Wear gloves to protect your hands.

◎Use only designated parts!

The set's parts have specic safety properties (re

resistance, voltage resistance, etc.). Be sure to use

parts which have the same properties for replacement.

The burrs have the same properties. In particular, for

the important safety parts that are indicated by the z

mark on schematic diagrams and parts lists, be sure to

use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or

other insulating materials, and some parts are mounted

away from the surface of printed circuit boards.

Care is also taken with the positions of the wires by

arranging them and using clamps to keep them away

from heating and high voltage parts, so be sure to set

everything back as it was originally placed.

◎Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in

their original positions, check that no serviced parts

have deteriorate the area around. Then make an

insulation check on the external metal connectors and

between the blades of the power plug, and otherwise

check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet,

disconnect the antenna, plugs, etc., and on the power.

Using a 500V insulation resistance tester, check that

the insulation resistance value between the inplug and

the externally exposed metal parts (antenna terminal,

headphones terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and the structural parts used in

the set have special safety properties. In most cases

these properties are difcult to distinguish by sight, and

the use of replacement parts with higher ratings (rated

power and withstand voltage) does not necessarily

guarantee that safety performance will be preserved.

Parts with safety properties are indicated as shown

below on the wiring diagrams and the parts list in this

service manual. Be sure to replace them with the parts

which have the designated part number.

(1) Schematic diagrams .......Indicated by the z mark.

(2) Parts lists .......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks, res or other dangerous

situations.

7

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identied and remedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

NOTE FOR PARTS LIST

1.

Parts indicated by "nsp" on this table cannot be supplied.

2.

When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3.

A part ordered without specifying its part number can not be supplied.

4.

Part indicated by "★" mark is not illustrated in the exploded view.

5.

General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

General-purpose Carbon Chip Resistors are not included are not included in the P.W.Board parts list.

(Refer to the Schematic Diagram for those parts.)

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

8

TECHNICAL SPECIFICATIONS

nAudio Section

• Power amplier

Rated output:

Front :

100 W + 100 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

Center :

100 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

Surround :

100 W + 100 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

Surround back:

100 W + 100 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

Maximum effective output power:

Front :

150 W + 150 W (6 Ω, 1 kHz with 10 % T.H.D.)

Center :

150 W (6 Ω, 1 kHz with 10 % T.H.D.)

Surround :

150 W + 150 W (6 Ω, 1 kHz with 10 % T.H.D.)

Surround back:

150 W + 150 W (6 Ω, 1 kHz with 10 % T.H.D.)

Output connectors: 6 – 8 Ω

• Analog

Input sensitivity/Input impedance: 200 mV/47 kΩ

Frequency response: 10 Hz – 100 kHz — +1, –3 dB (DIRECT mode)

S/N : 100 dB (IHF–A weighted, DIRECT mode)

nVideo section

• Standard video connectors

Input/output level and impedance: 1 Vp-p, 75 Ω

Frequency response : 5 Hz – 10 MHz — 0, –3 dB

• Color component video connector

Input/output level and impedance:

Y (brightness) signal — 1 Vp-p, 75 Ω

B / CB signal — 0.7 Vp-p, 75 Ω

P

R / CR signal — 0.7 Vp-p, 75 Ω

P

Frequency response : 5 Hz – 60 MHz — 0, –3 dB

nTuner section

[FM](Note: μV at 75 Ω, 0 dBf = 1 x 10

Receiving Range (for U model):

[FM] 87.5 MHz – 107.9 MHz

Receiving Range (for N, K model):

[FM] 87.5 MHz – 108.0 MHz

Usable Sensitivity:

[FM] 1.2 μV (12.8 dBf)

50 dB Quieting Sensitivity (for U model):

[FM] MONO 2.8 μV (20.2 dBf)

50 dB Quieting Sensitivity (for N, K model):

[FM] MONO 2.0 μV (17.3 dBf)

S/N (IHF-A) (for U model) :

[FM] MONO 70 dB(IHF–A weighted, DIRECT mode)

STEREO 67 dB(IHF–A weighted, DIRECT mode)

S/N (IHF-A) (for N, K model):

[FM] MONO 72 dB (DIRECT mode)

STEREO 67 dB (DIRECT mode)

Total harmonic Distortion (at 1 kHz) (for U model):

[FM] MONO 0.7 %

STEREO 1.0 %

Total harmonic Distortion (at 1 kHz) (for N, K model):

[FM] MONO 0.3 %

STEREO 0.7 %

–15

W)

nGeneral

Power supply (for U model) : AC 120 V, 60 Hz

Power supply (for N model) : AC 230 V, 50/60 Hz

Power supply (for K model) : AC 220 V, 50 Hz

Power consumption:

650 W

0.2 W (Standby)

0.5 W (CEC standby)

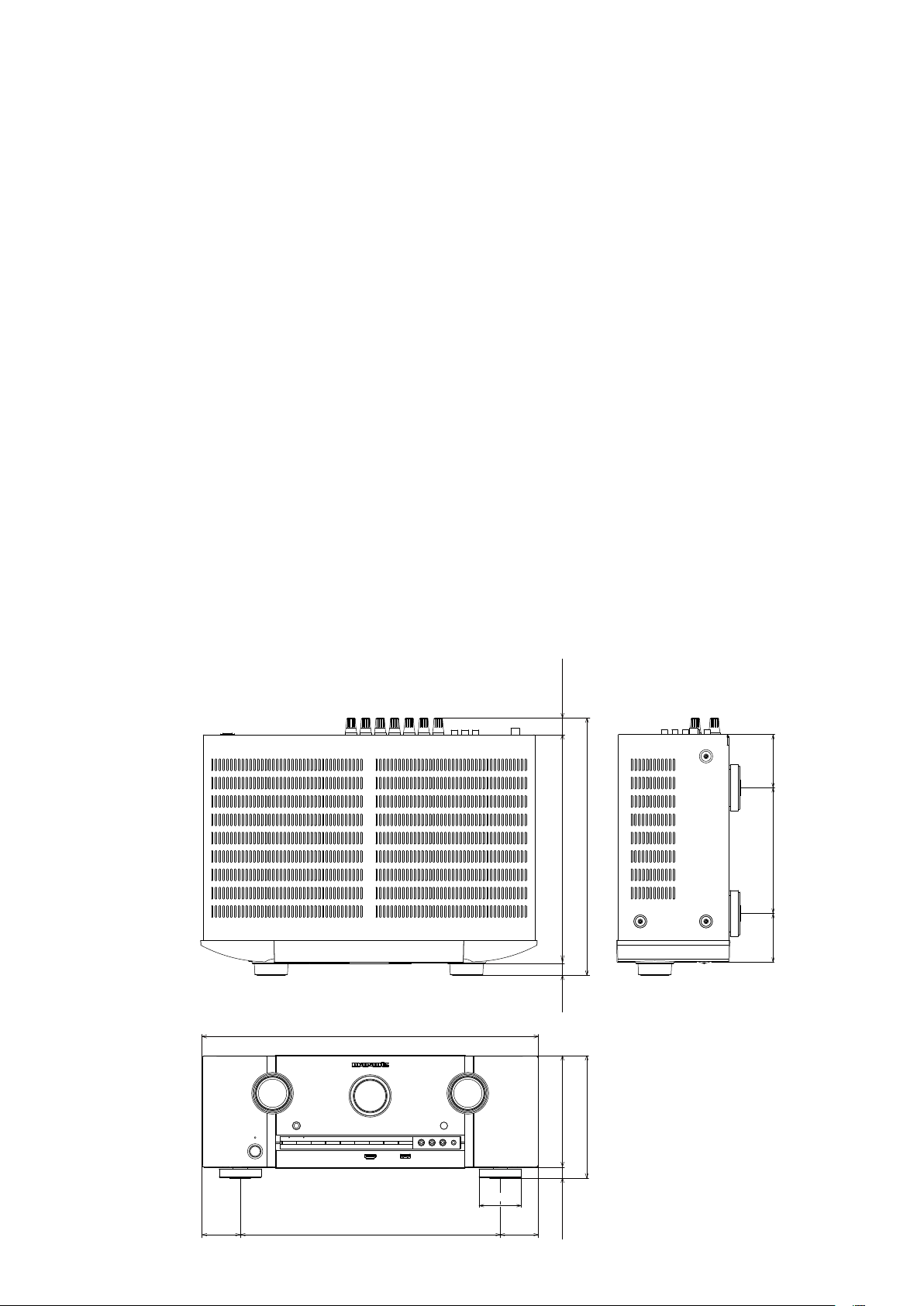

DIMENSION

440.0

21.5

298.0148.013.0 15.7

69.5164.564.0

335.2

50.0 50.0340.0

161.0

55.0

9

CAUTIONS IN SERVICING

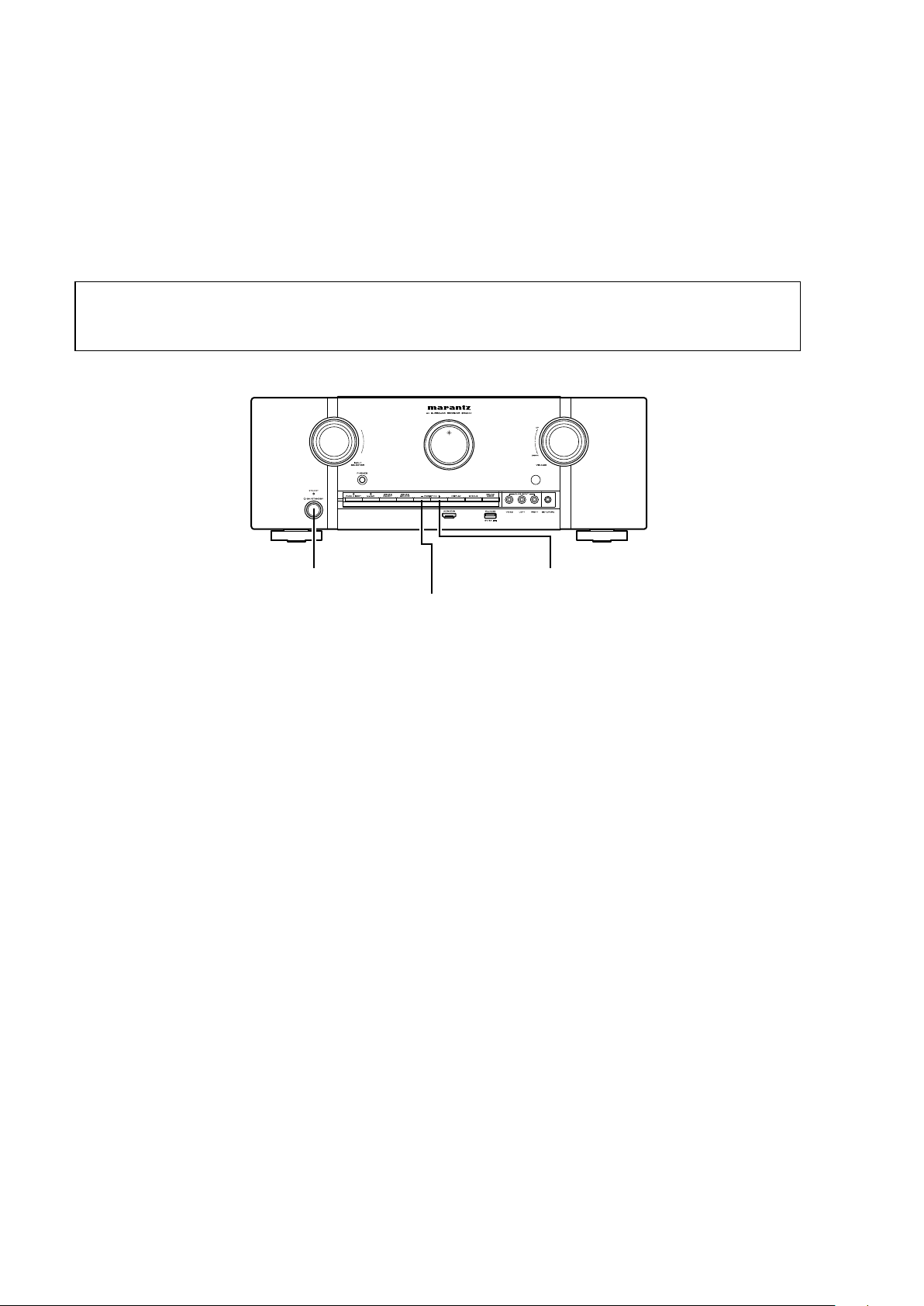

Initializing AV Surround Receiver

AV Surround Receiver initialization should be performed when the μcom, peripheral parts of μcom, and Digital PCB. were

replaced.

1. Turn off the power pressing "ON/STANDBY (X)" button.

2. Press "ON/STANDBY (X)" button while simultaneously while pressing "PRESET CH +" and "PRESET CH –" buttons.

3. Check that the entire display is ashing at intervals of about 1 second, and then release the 2 buttons.

The microprocessor will be initialized.

NOTE: • If step 3 fails, start over from step 1.

• All user settings will be lost and the factory setting will be recovered after the set is initialized.

So make sure to note down your setting beforehand for restoring after the initialization.

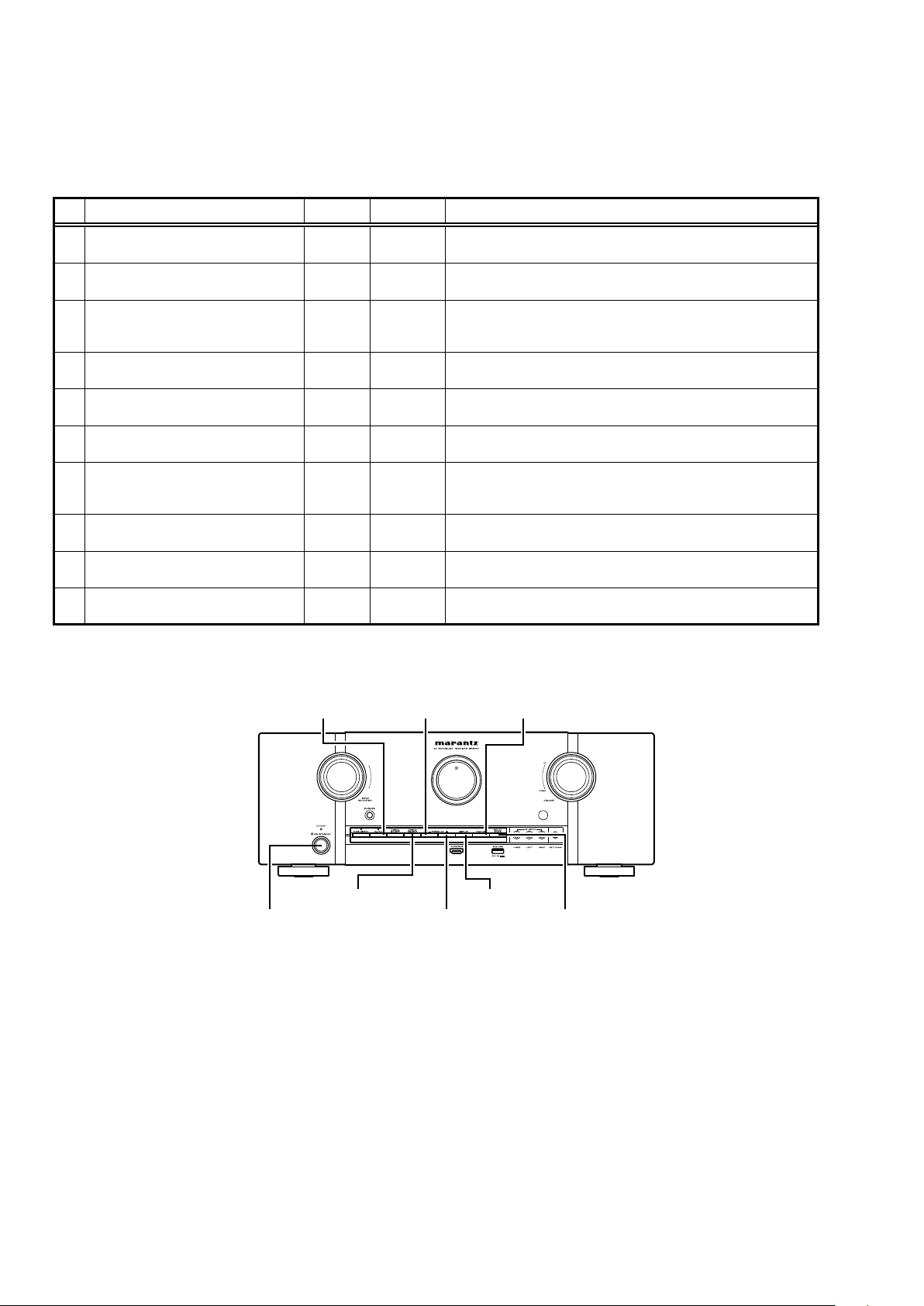

ON/STANDBY (X) PRESET CH +

PRESET CH -

Service Jig

When you repair the printing board, you can use the following JIG (Extension cable kit).

Please order it from Marantz Ofcial Service Distributor in your region if necessary.

8U-110084S : EXTENSION UNIT KIT : 1 Set

(Refer to 53 page.)

10

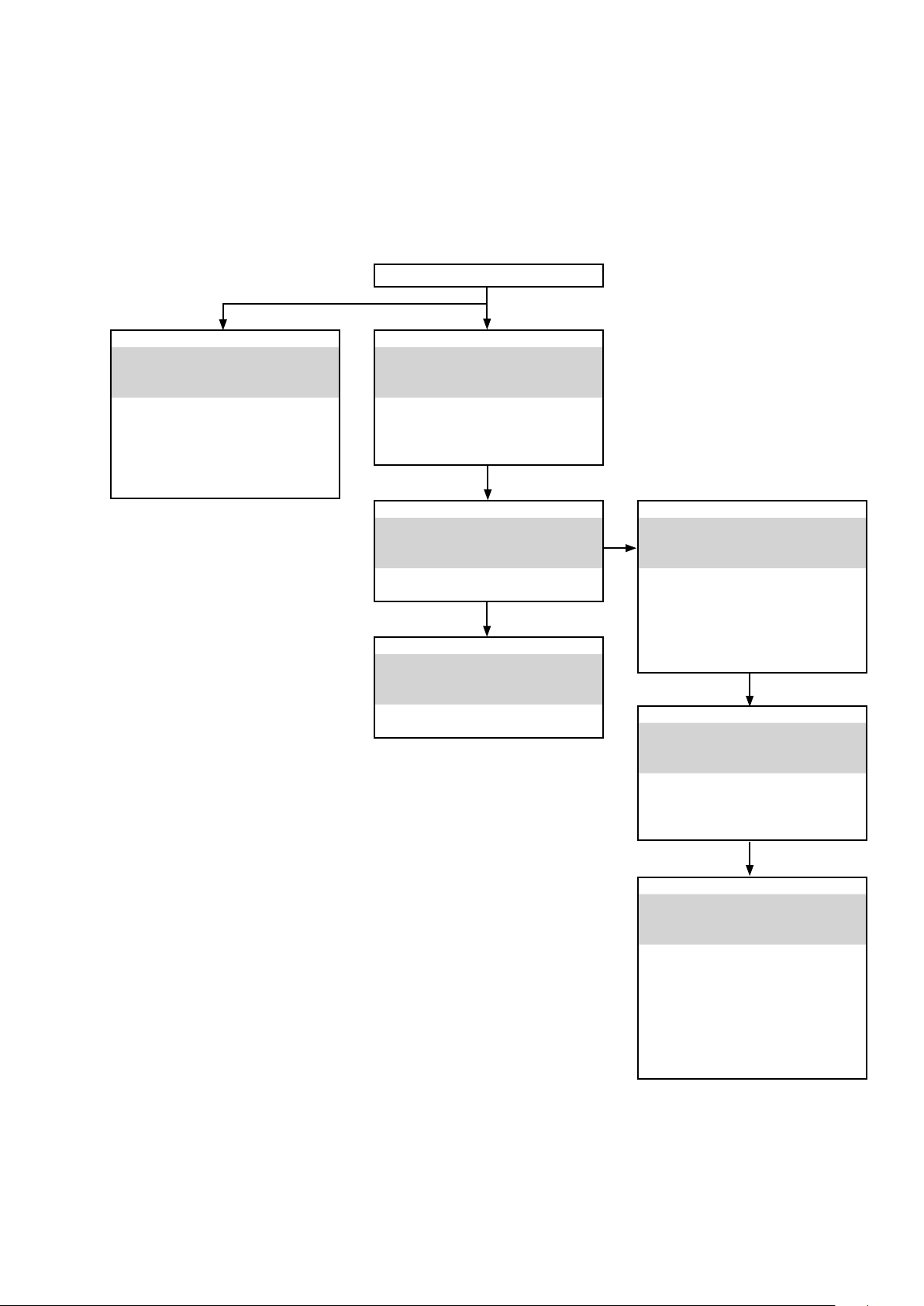

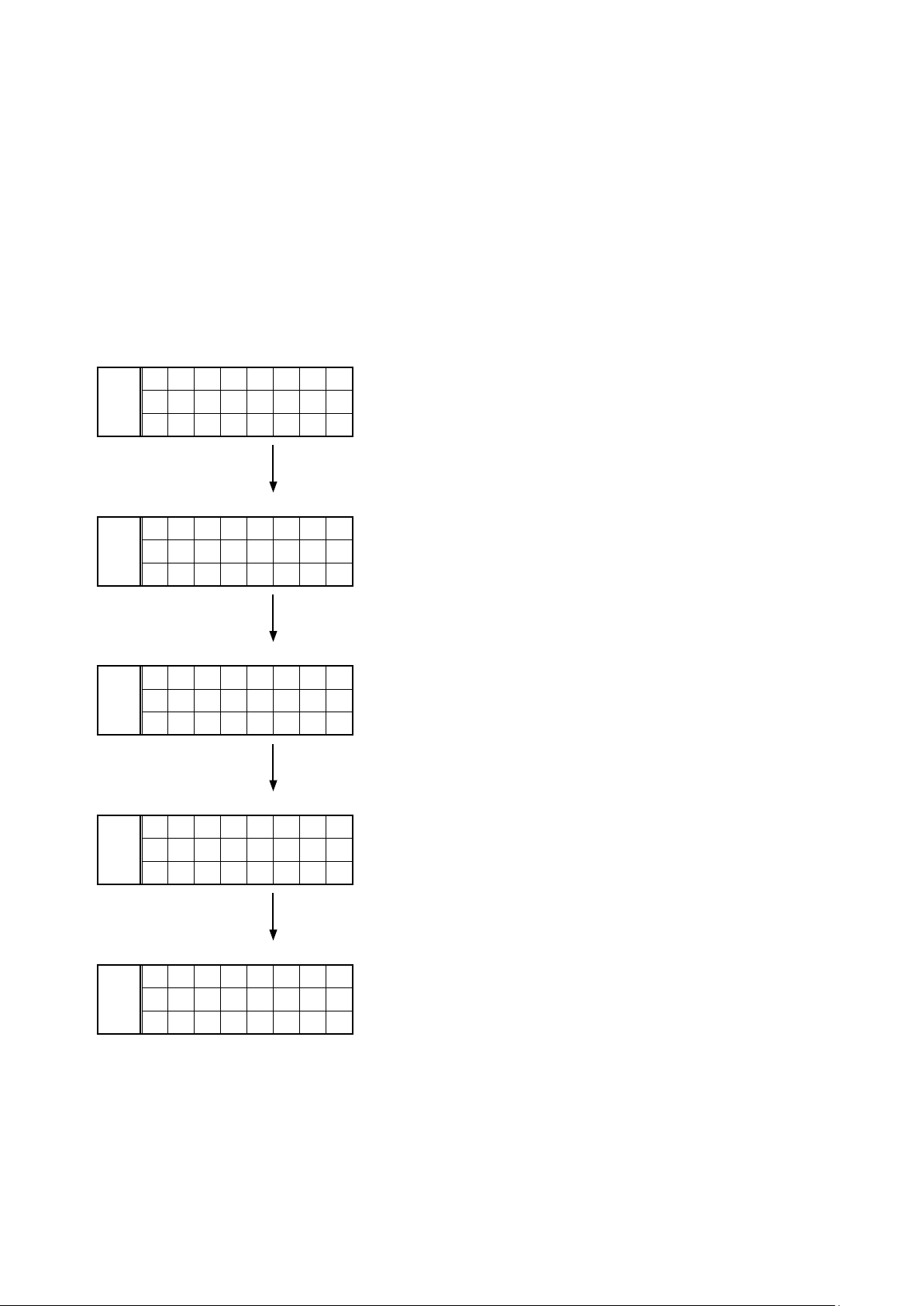

DISASSEMBLY

• Disassemble in order of the arrow in the following gure.

• In the case of the re-assembling, assemble it in order of the reverse of the following ow.

• In the case of the re-assembling, observe "attention of assembling".

• If wire bundles are untied or moved to perform adjustment or replace parts etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

FRONT PANEL ASSY

Refer to "DISASSEMBLY

1. FRONT PANEL ASSY"

and "EXPLODED VIEW"

PCB H/P ASSY

(Ref. No. of EXPLODED VIEW : P1)

PCB USB ASSY

(Ref. No. of EXPLODED VIEW : P3)

PCB FRONT ASSY

(Ref. No. of EXPLODED VIEW : P4)

PCB MX PORT/PCB RS232C

Refer to "DISASSEMBLY

2. PCB MX PORT/PCB RS232C"

and "EXPLODED VIEW"

PCB RS232C ASSY

(Ref. No. of EXPLODED VIEW : P15)

PCB RC5 MX

(Ref. No. of EXPLODED VIEW : P17)

PCB HDMI

Refer to "DISASSEMBLY

3. PCB HDMI"

and "EXPLODED VIEW"

PCB HDMI ASSY

(Ref. No. of EXPLODED VIEW : P16)

POWER TRANS MAIN

Refer to "DISASSEMBLY

4. POWER TRANS MAIN"

and "EXPLODED VIEW"

POWER TRANS

(Ref. No. of EXPLODED VIEW : 31)

PCB VIDEO/PCB INPUT/PCB MAIN

Refer to "DISASSEMBLY

5. PCB VIDEO/PCB INPUT/PCB MAIN"

and "EXPLODED VIEW"

PCB VIDEO ASSY

(Ref. No. of EXPLODED VIEW : P19)

PCB INPUT

(Ref. No. of EXPLODED VIEW : P13)

PCB MAIN

(Ref. No. of EXPLODED VIEW : P12)

PCB FRONT CNT/PCB SMPS

Refer to "DISASSEMBLY

6. PCB FRONT CNT/PCB SMPS"

and "EXPLODED VIEW"

PCB FRONT CNT

(Ref. No. of EXPLODED VIEW : P14)

PCB SMPS

(Ref. No. of EXPLODED VIEW : P18)

11

RADIATOR ASSY

Refer to "DISASSEMBLY

7. RADIATOR ASSY"

and "EXPLODED VIEW"

PCB GUIDE_R

(Ref. No. of EXPLODED VIEW : P7)

PCB AMP ASSY

(Ref. No. of EXPLODED VIEW : P8)

PCB GUIDE TOP

(Ref. No. of EXPLODED VIEW : P9)

PCB GUIDE_L

(Ref. No. of EXPLODED VIEW : P10)

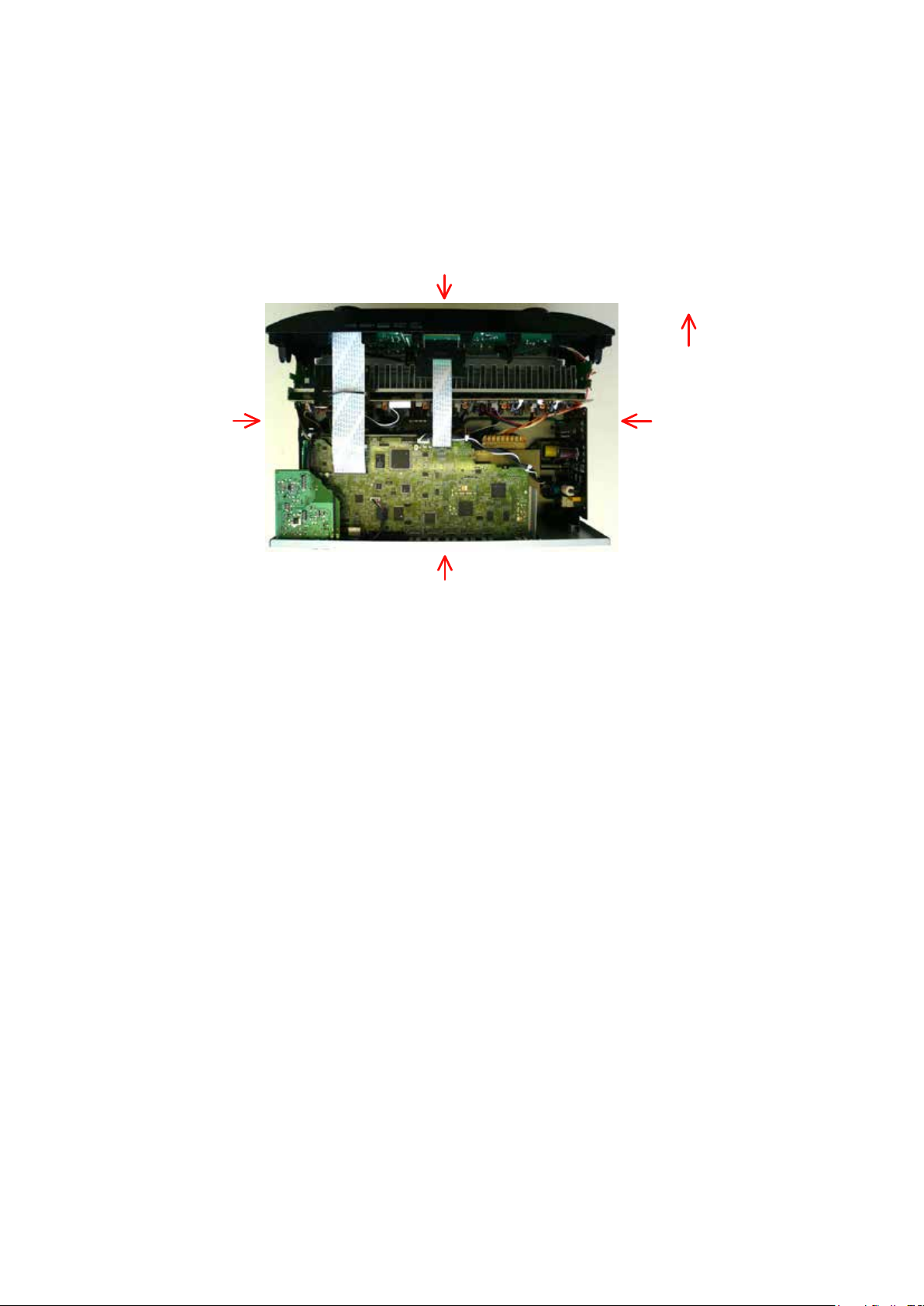

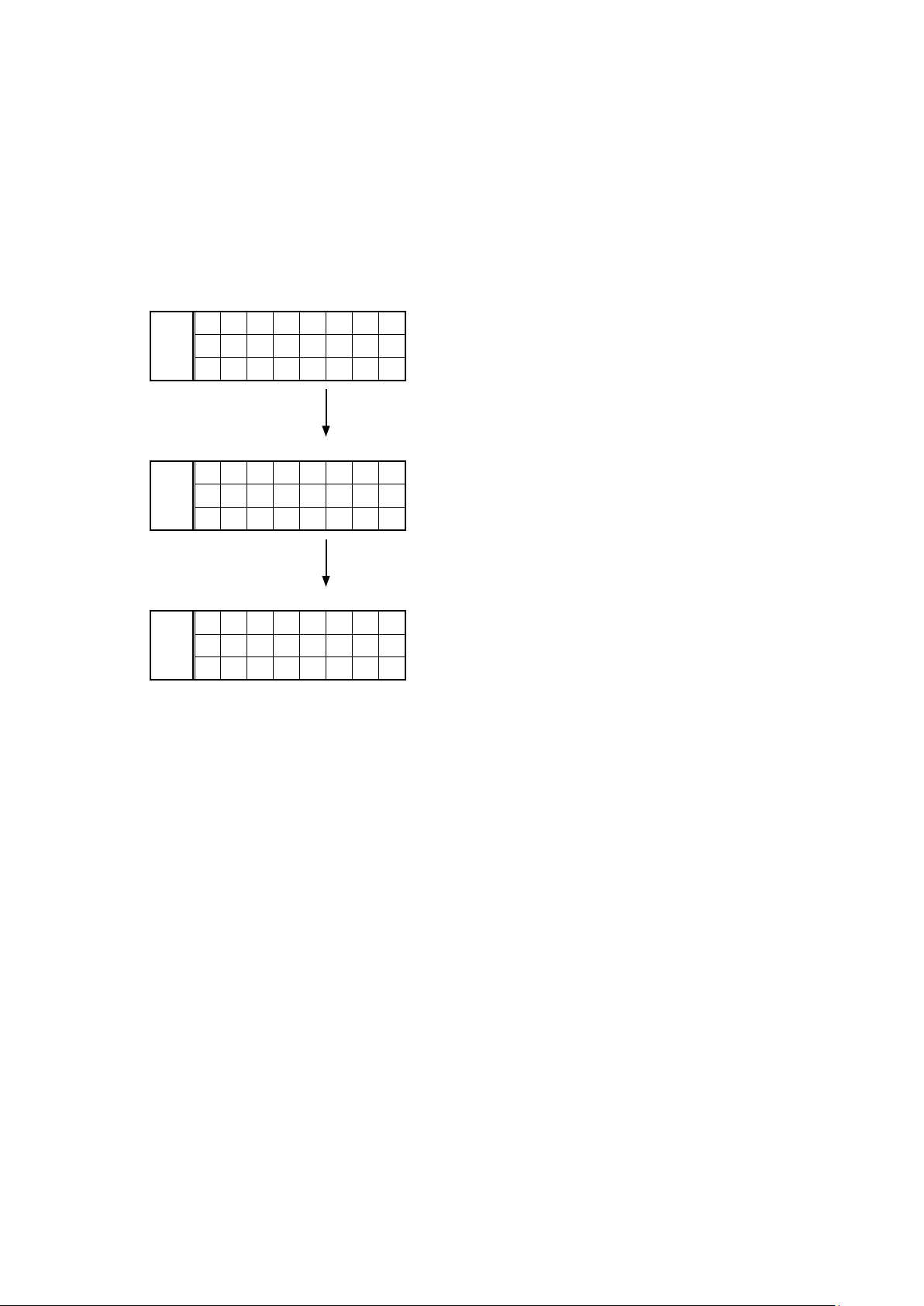

About the photos used for "descriptions of the DISASSEMBLY" section

• The shooting direction of each photograph used herein is indicated on the left side of the respective photograph as

"Shooting direction: ***".

• Refer to the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set..

The viewpoint of each photograph

(Shooting direction)

Shooting direction: B

[View from the top]

Front side

Shooting direction: DShooting direction: C

Shooting direction: A

12

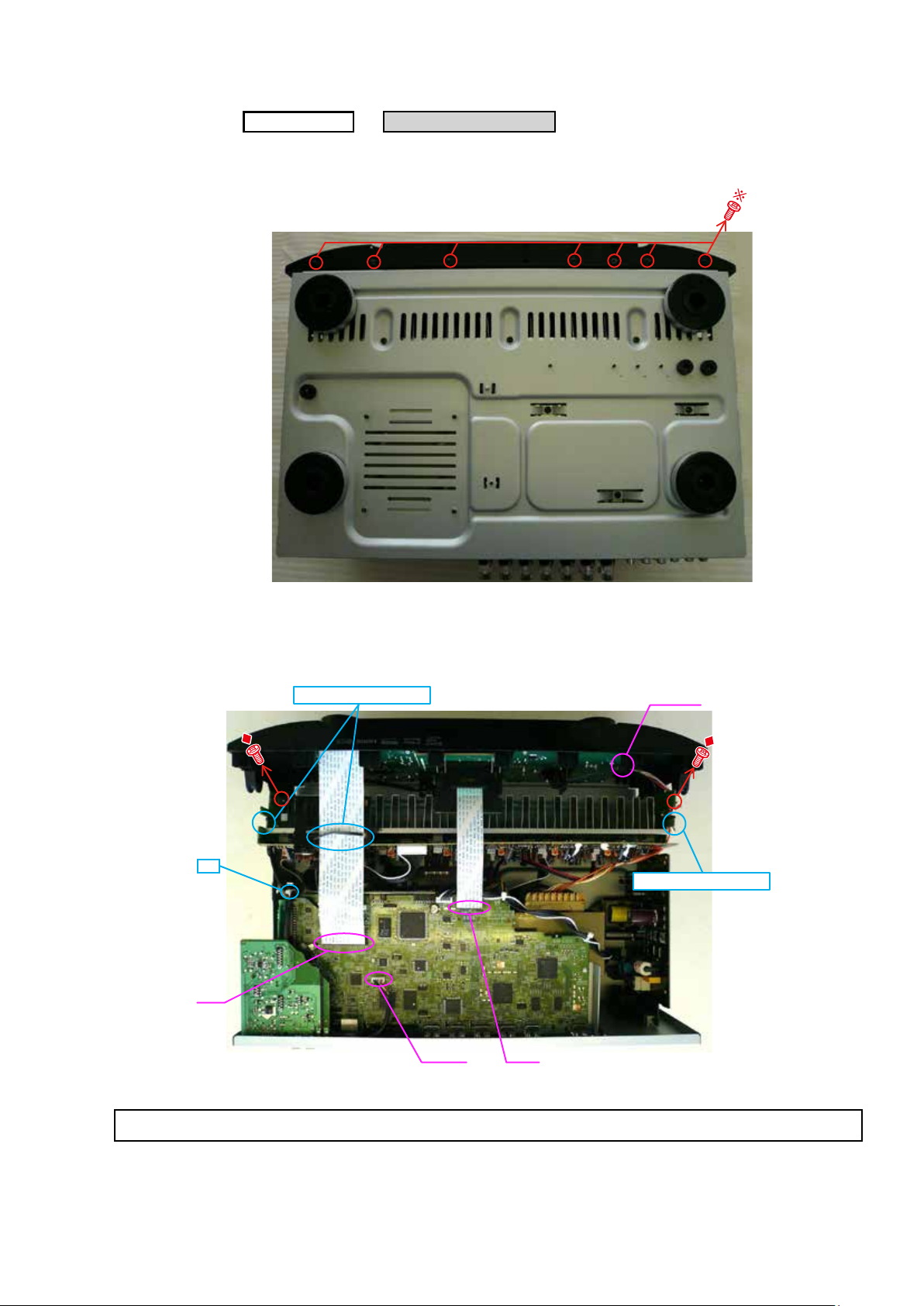

1. FRONT PANEL ASSY

Proceeding :

(1) Remove the screws.

View from the bottom

TOP COVER

FRONT PANEL ASSY

→

(2) Cut the wire clamp band, then disconnect the connector wires and FFC. Remove the screws.

STYLE PIN : Loosen

cut

FFC

N2801 FFC

CP4400

STYLE PIN : Loosen

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in FRONT PANEL ASSY.

13

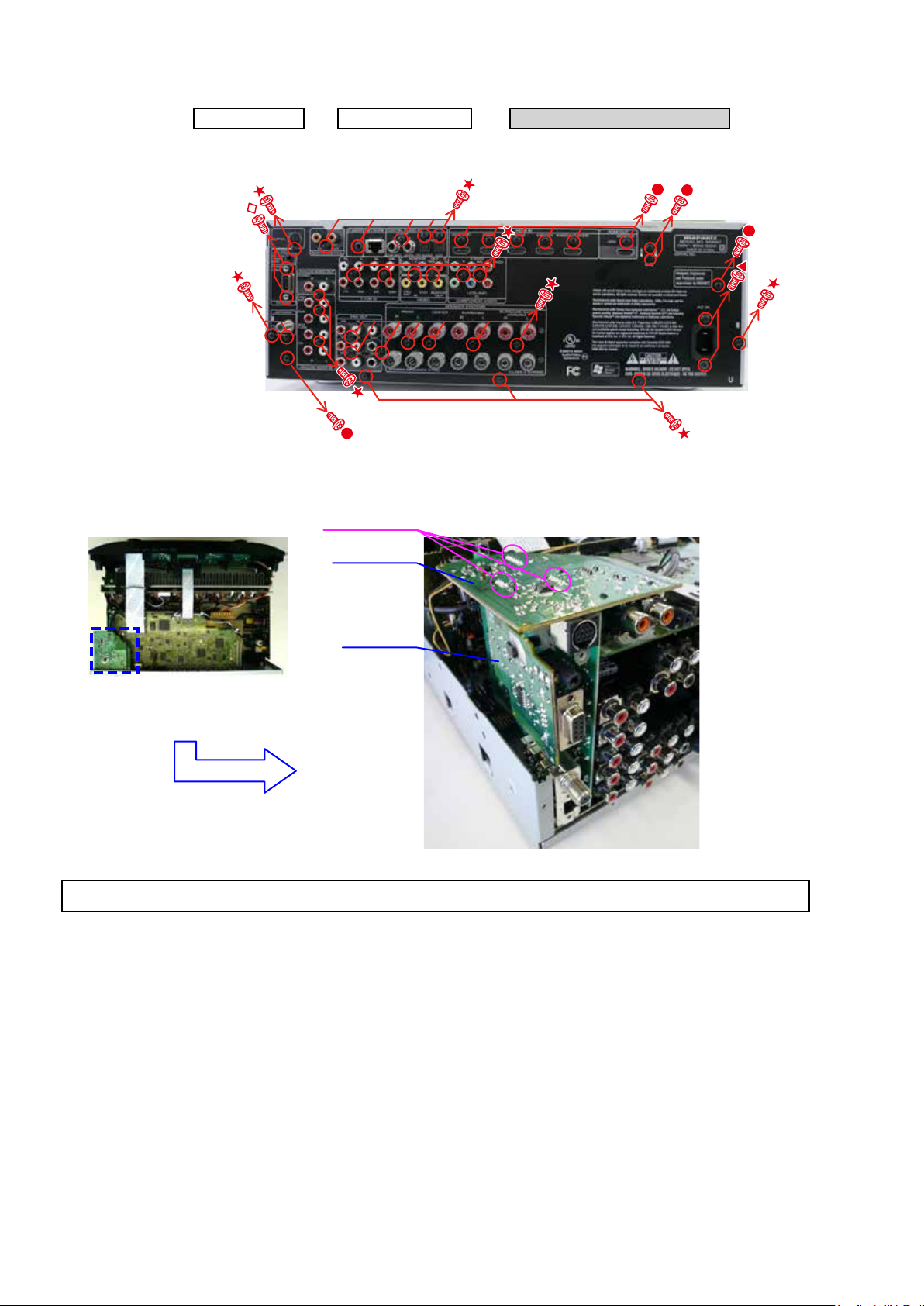

2. PCB MX PORT/PCB RS232C

Proceeding :

(1) Remove the screws.

Shooting of photograph: A

(2) Disconnect the connector board.

TOP COVER

BACK CHASSIS

→

Board to board

PCB RC5_MX

PCB MX PORT/PCB RS232C

→

PCB RS232

Please refer to "EXPLODED VIEW" for the disassembly method of PCB RC5_MX and PCB RS232C.

14

3. PCB HDMI

Proceeding :

(1) Remove the screws.

Shooting of photograph: A

(2) Cut the wire clamp band, then disconnect the connector wires and FFC, then disconnect the connector board and

HOLDER.

TOP COVER

BACK CHASSIS

→ →

cut

PCB HDMI

N3405 N3601

FFC

FFC cable

Board to board

cut

N2801

Board to board

15

HOLDER

4. POWER TRANS MAIN

→

Proceeding :

TOP COVER

BACK CHASSIS PCB HDMI

→ →

POWER TRANS MAIN

(1) Disconnect the connector wires, then remove the screws.

CP5003

CP4000

CP4400

STYLE PIN : Loosen

CP4142

cut

16

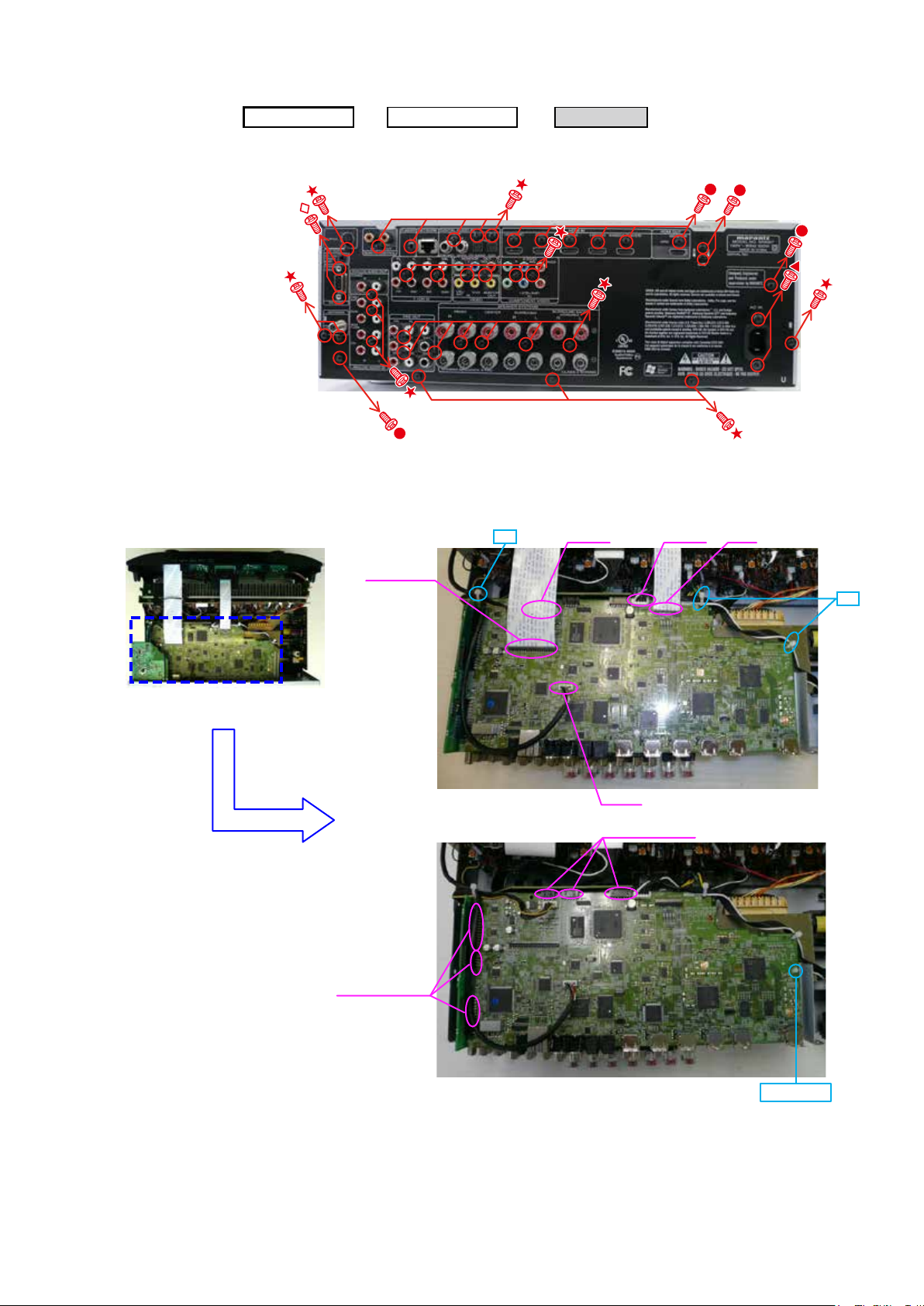

5. PCB VIDEO/PCB INPUT/PCB MAIN

→

Proceeding :

Proceeding :

TOP COVER

PCB VIDEO/PCB INPUT/PCB MAIN

(1) Disconnect the connector board.

PCB INPUT

BACK CHASSIS

→

→

PCB HDMI

cut

PCB VIDEO

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB.

17

PCB MAIN

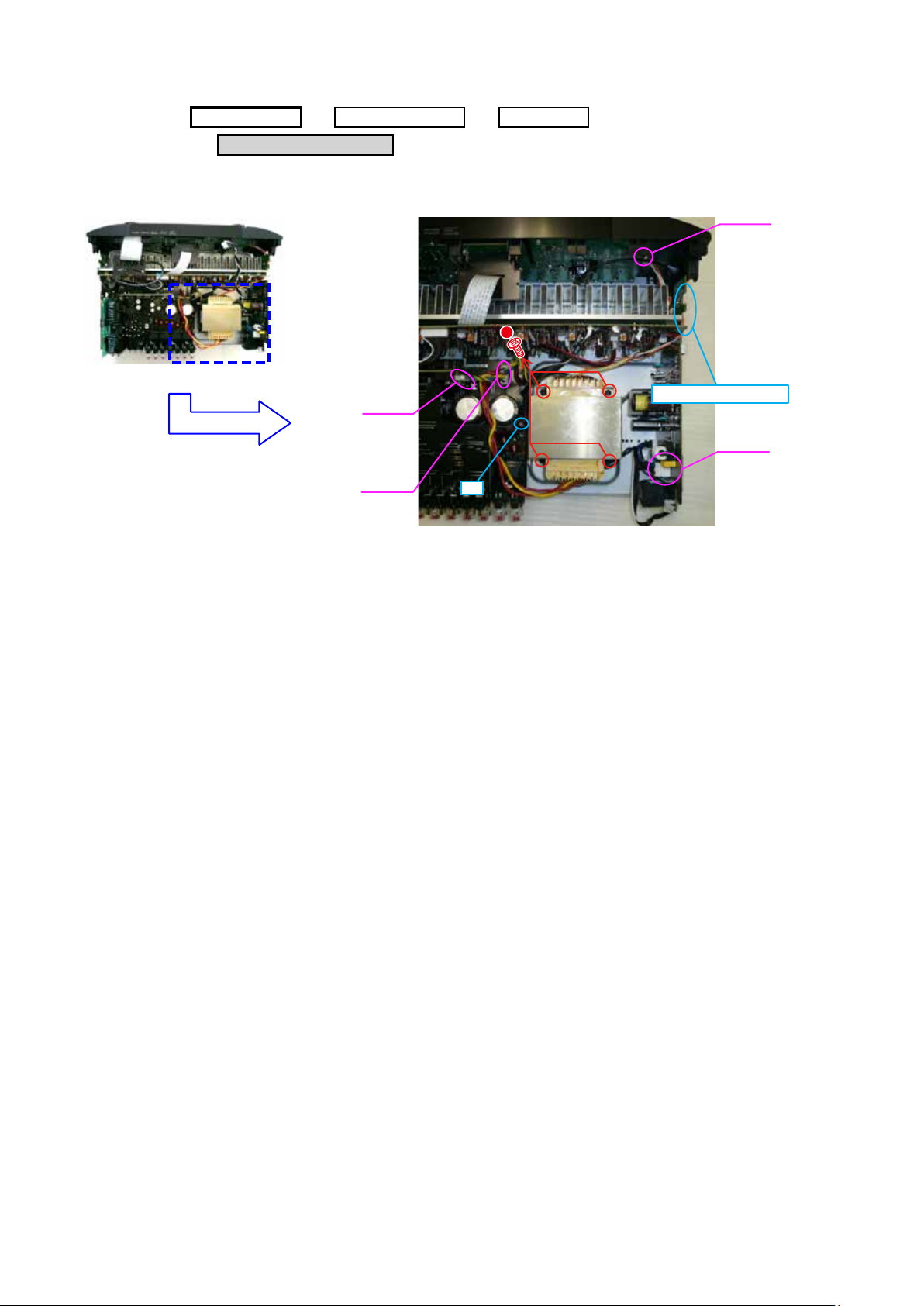

6. PCB FRONT CNT/PCB SMPS

→ →

Proceeding :

(1) Remove the screws.

View from the bottom

TOP COVER

PCB VIDEO

BACK CHASSIS

→ →

PCB FRONT CNT/PCB SMPS

PCB HDMI

(2) Disconnect the connector wire.

PCB FRONT CNT

CP5003

18

(3) Remove the screws.

PCB SMPS

PCB SMPS

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB.

19

7. RADIATOR ASSY

Proceeding :

(1) Remove the screws.

View from the bottom

TOP COVER

RADIATOR ASSY

→

(2) Cut the wire clamp band, then disconnect the connector wires and FFC.

STYLE PIN : Loosen

cut

FFC

N2801

FFC

CP402 CP403

CP405

20

(3) Remove the screws.

Shooting direction: C

STYLE PIN : Loosen

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in RADIATOR ASSY.

Shooting direction: D

CP4400

21

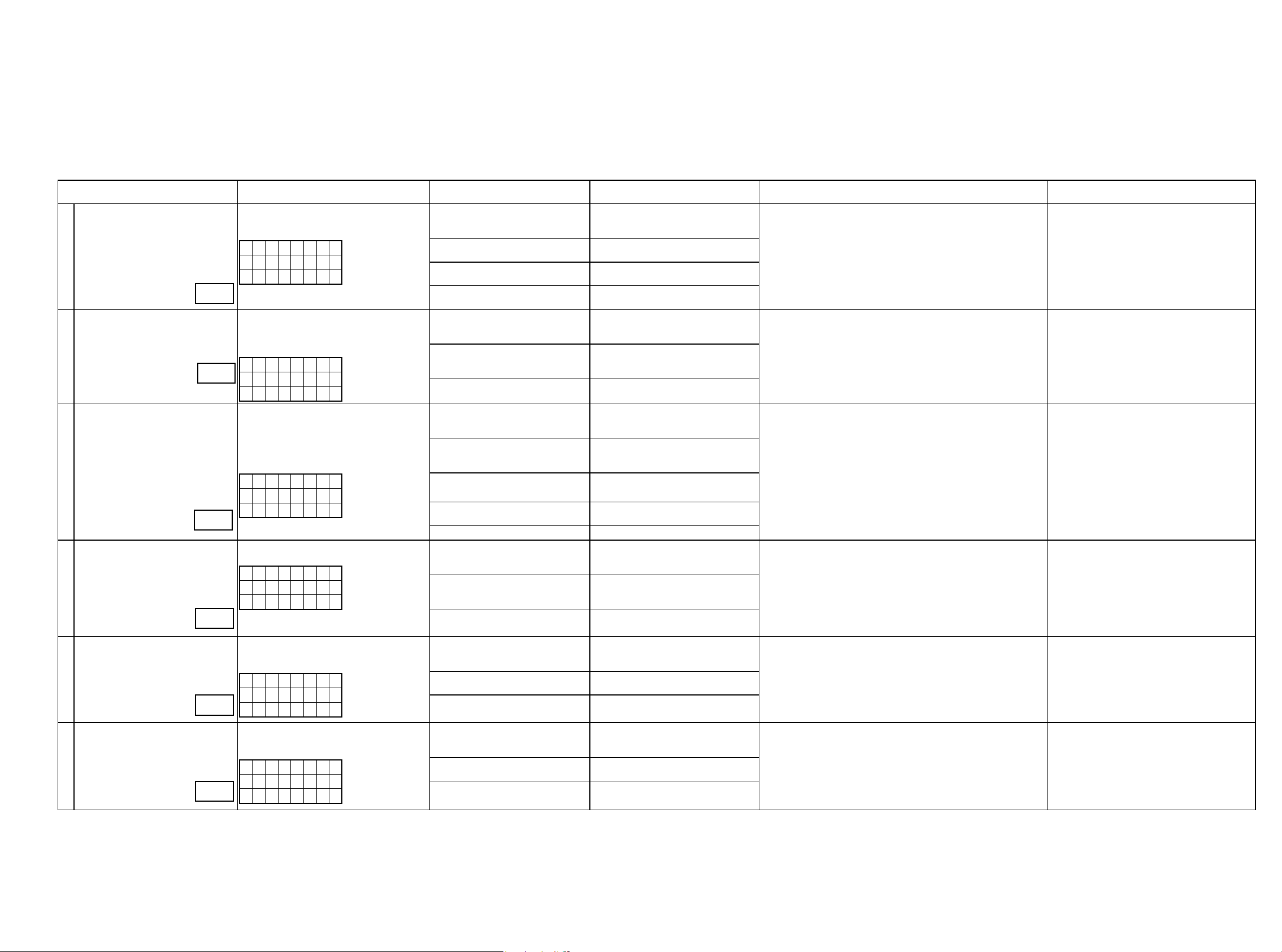

SPECIAL MODE

Special mode setting button

No.1 - 7 : Press the "ON/STANDBY (X)" button to turn on the power while pressing both the button A and the button B at the

b

No.8 - 10 : Turn on the power, then press and hold down the button A and button B for over 3 seconds.

b

No. Mode Button A Button B Contents

Version display

1

(μcom/DSP Error Display)

User Initialization mode

2

(Installer Setup settings are not initialized.)

Factory Initialization mode

3

(Installer Setup settings are also

initialized.)

4 PANEL/REMOTE LOCK Selection mode DISPLAY M-DAX

5 Service Related Selection mode

Mode for switching tuner frequency step

6

(U/N model only)

7 Installer Setup mode

8 Memory Backup

9 Memory Recovery

10 Memory Backup Clear

same time.

DISPLAY STATUS

ZONE2

SOURCE

PRESET

CH +

ZONE2

SOURCE

DISPLAY

SOUND

MODE

PRESET

CH +

PRESET

CH +

SOUND

MODE

M-DAX

PRESET

CH –

STATUS Selects the “Diagnostic mode” or “Displaying the protection history mode”.

PRESET

CH –

STATUS

PRESET

CH –

DISPLAY Recovery of DUAL BACKUP MEMORY is performed. (Refer to 35 page)

PRESET

CH –

Firmware versions such as Main or DSP are displayed in the FL Display.

Errors are displayed when they occur. (Refer to 23 page)

Backup data initialization is carried out.

(Installer Setup settings are not initialized.)

Backup data initialization is carried out.

(Installer Setup settings are also initialized.)

Selects to reject operations through panel buttons and the master volume

knob on the main unit and operations via the remote control.

Change tuner frequency step to FM:50kHz/200kHz

Access the Remote Maintenance mode via the internet.

Installer Setup is displayed on GUI/Option Menu.

Refer to AVR_RemoteMaintenance_.pdf of SDI.

b

Backup of DUAL BACKUP MEMORY is performed. (Refer to 35 page)

Backup of DUAL BACKUP MEMORY is cleared. (Refer to 35 page)

M-DAX

PRESET CH - STATUS

ZONE2 SOURCE

PRESET CH +ON/STANDBY (X)

DISPLAY

SOUND MODE

22

1. µcom/DSP Version display mode

1.1. Operation specications

µcom/DSP version display mode:

When the set is started up in this mode, the version information is displayed.

Starting up:

Press the "ON/STANDBY

Now, press the "STATUS" button to the display the 2nd item information on the FL Display.

When the version is displayed on the FL Display, the version list is also displayed on the GUI.

b

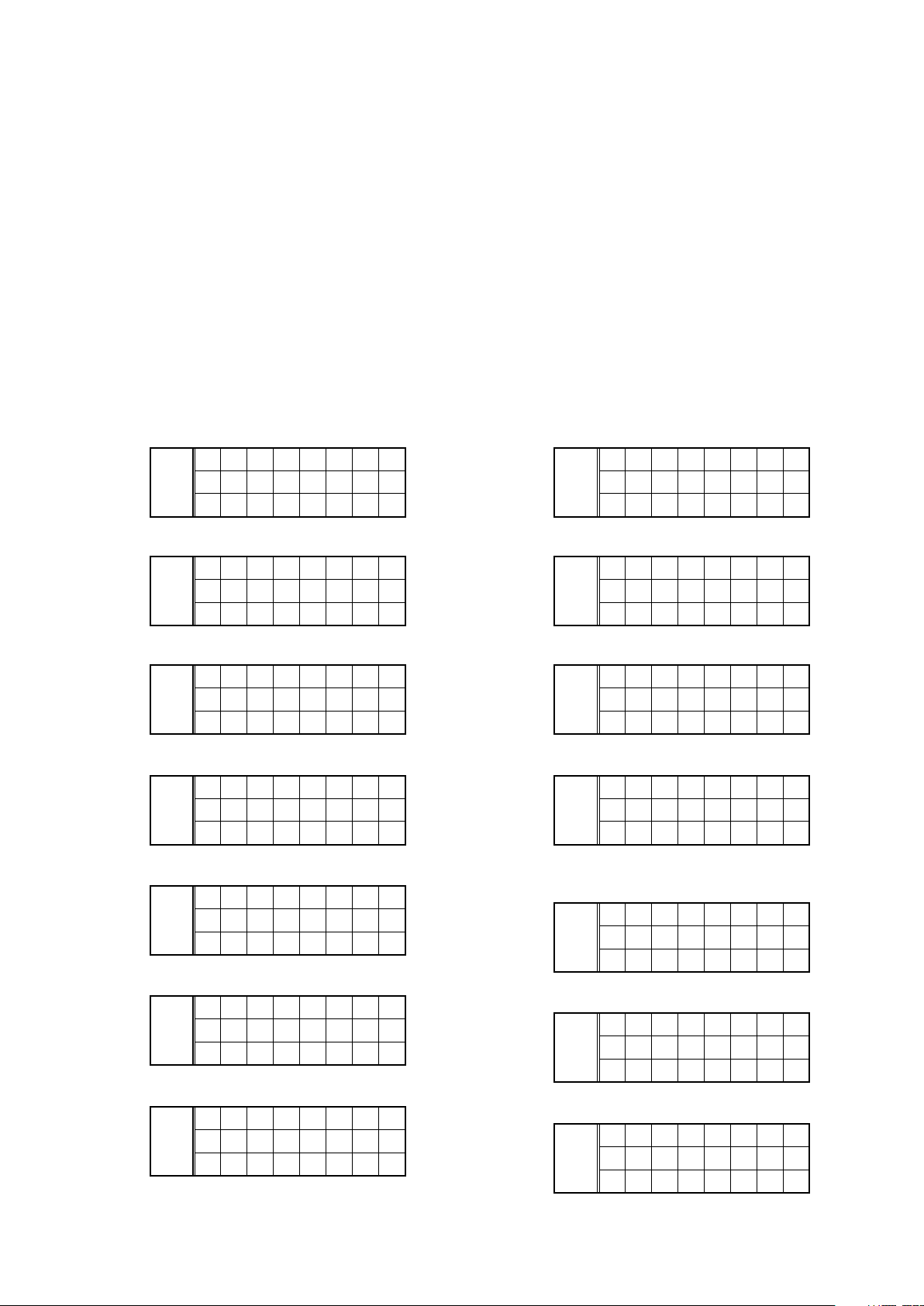

1.2. Display Order

Error information(Refer to 1.3. Error display) → q Model destination information → w Firmware Package Version

→ e Main μ-com / FBL(1st Boot Loader) Version → r DSP ROM Version → t Audio PLD Version

→ y GUI SFLASH Version → u Ethernet(DM860A) 1st Boot Loader, Hardware ID

→ i Ethernet(DM860A) 2nd Boot Loader, Rhapsody Flag → o Ethernet(DM860A) IMAGE

→ Q0 Ethernet(DM860A)MAC ADDRESS information

(X)

" button to turn on the power while pressing the "DISPLAY" and "STATUS" buttons.

Model destination information :

q

SR5007 U model

S R 5 0 0 7 U

FLD

S N - * * * *

* * * * * *

SR5007 N model

S R 5 0 0 7 N

FLD

S N - * * * *

* * * * * *

SR5007 K model

S R 5 0 0 7 K

FLD

S N - * * * *

* * * * * *

Firmware Package Version :

w

P A C K A G E

FLD

0 0 0 0

GUI S-FLASH Version :

y

SR5007 U model

G U I

FLD

1 4 2 1 * * * *

SR5007 N model

G U I

FLD

1 4 2 2 * * * *

SR5007 K model

G U I

FLD

1 4 2 5 * * * *

Ethernet(DM860A) 1st Boot Loader, Hardware ID :

u

N E T F B L

FLD

* * * * * *

- A A

Main µ-com / FBL(1st Boot Loader) Version :

e

M A I N

FLD

* * * * * * * *

B L - * * . * *

DSP ROM Version :

r

D S P

FLD

* * . * *

Audio PLD Version :

t

A . P L D

FLD

* * . * *

23

Ethernet(DM860A) 2nd Boot Loader, Rhapsody Flag

i

:

N E T S B L

FLD

* * * * * * * *

* * * * * - 0 A

Ethernet(DM860A) IMAGE :

o

N E T I M G

FLD

* * * * * * * *

* * * * *

Ethernet(DM860A) MAC ADDRESS information :

Q0

N E T M A C

FLD

* * * * * *

- * * * * * *

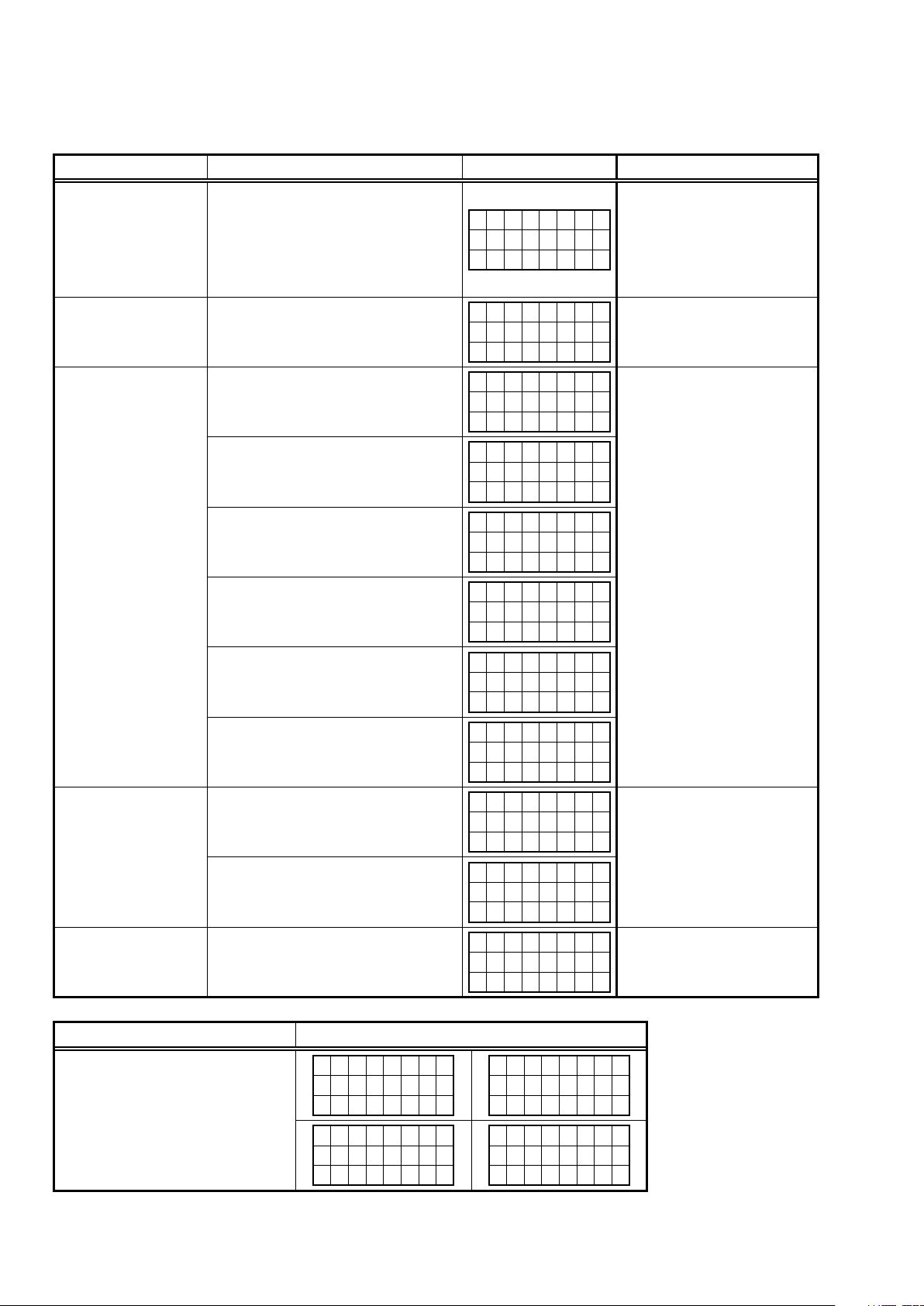

1.3. Error display

See the following table for each "Error information" display and its explanation (status).

Display order is q,w,e,r,t.

Condition Status FL Display Trouble shooting

q

Firm Check NG

w

DIR NG

e

DSP NG

Compared with the destination setting on

the board. This is displayed when the model

name or destination information written into

the rmware does not match. (b)

No response from DIR

When DSP code boot is performed, the DSP

FLAG0 port does not change to "H" even if

DSP reset is executed.

Before DSP command is issued, the DSP

BUSY port does not change to "L".

When DSP data read is performed,

executing WRITE="L" does not result in

ACK="H".

When DSP data read is performed, executing

REQ="L" does not result in ACK="L".

When DSP data writing is performed,

executing WRITE="H" does not result in

ACK="H".

F I R M

E R R O R

D I R

E R R O R

0 1

D S P

E R R O R

0 1

D S P

E R R O R

0 2

D S P

E R R O R

0 3

D S P

E R R O R

0 4

D S P

E R R O R

0 5

• Please check the destinationresistors (R773/R776, HDMI B'D).

• Please write the rmware of

correct destination.

• Please check DIR (IC21, HDMI

B'D) and around circuits.

• Please check DSP (U8, HDMI

B'D) and around circuits.

When DSP data writing is performed,

executing REQ="L" does not result in

ACK="L".

An error occurred in testing writing data

between IP SCALER and DRR.

r

IP SCALER NG

Testing writing data between IP SCALER

and DRR resulted in no response.

t

EEPROM NG

Status FL Display

b

The written Firmware and product settings

(model name, brand name, destination)

are compared. If Firmware that is not

designed for this product is written, ▲ is

displayed in the upper right column, as

shown on the right.

Error occurs in EEPROM checksum.

(*** is a block address number.)

M A I N

* * * * * * * *

L - * * . *

B

D S P

* * . *

D S P

E R R O R

0 6

I P

S C A L E R

E R R 0 1

I P

S C A L E R

E R R 0 2

E 2 P R O M

E R R O R

* * *

–

A . P L

*

–

G U I

* * * * * * * *

*

D

* * . *

• Please check IP SCALER (U1601,

HDMI B'D) and around circuits.

–

*

–

24

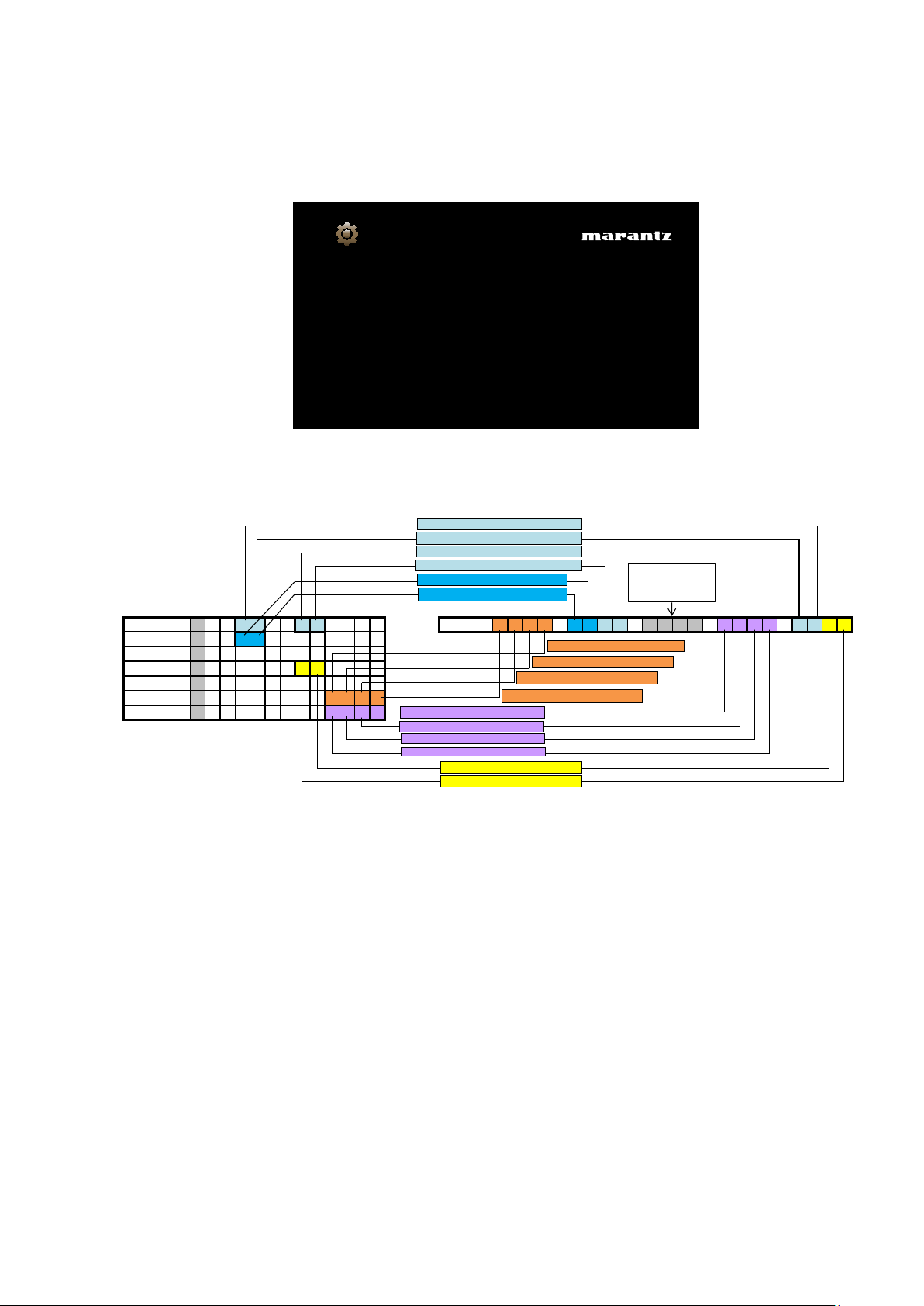

1.4. Version display on the Setup Menu

DM860 SBL

DM860 IMG

The 6th digit from the right for Main μcom

The 5th digit from the right for Main μcom

The 2nd digit from the right for Main μcom

The 1st digit from the right for Main μcom

The 2nd digit from the right for DSP

The 1st digit from the right for DSP

The 1st digit from the right for SBL

The 2nd digit from the right for SBL

The 3rd digit from the right for SBL

The 4th digit from the right for SBL

The 1st digit from the right for IMG

The 3rd digit from the right for IMG

The 4th digit from the right for IMG

The 1st digit from the right for GUI

The 2nd digit from the right for GUI

The 2nd digit from the right for IMG

Use the following procedure to display the rmware version.

(1) Press the “SETUP” button on the remote control.

(2) Select “General-Information-Firmware”.

A version with 20 digits is displayed as shown in the following image.

General/Firmware

Version

Displays system information

1490-0108-0000-2300-5336

GUI Image

The displayed 20 digits are derived from each device version as shown below.

Mainμcom 0 0 9 8 0 0 7 3

DSP 7 1 1 0

A.PLD 1 6 0 6

GUI 5 7 1 1 0 0 2 6

DM860 FBL 0 9 0 3 1 1

B 2 0 1 2 0 1 2 5 0 9 4 1

I 2 0 1 2 0 4 0 1 0 1 4 1

Info display

1 4 9 0 - 0 1 3 7 - 0 0 0 0 - 1 4 1 0 - 8 9 6 2

The shaded part

is not used.

This rmware version No. (xxxx-xxxx-xxxx-xxxx) is included in the service contact document.

b

These 20 digits are also included in the document.

25

2. PANEL/REMOTE LOCK Selection mode

2.1. Behavior specications

In this mode, you can switch between the PANEL LOCK MODE and the Mode for preventing remote control acceptance.

2.2. Starting up

Press the "ON/STANDBY (X)" button to turn on power while pressing the "DISPLAY" and "M-DAX" buttons.

Press the "PRESET CH +" button to select the mode and the "STATUS" button to conrm the selection.

2.3. Mode selection method and how each mode is displayed

Each time you press the "PRESET CH +" button, the mode displayed on the FL DISPLAY changes.

While the desired mode name is displayed on the FL DISPLAY, press the "STATUS" button. The set is restarted and the

selected mode takes effect.

The currently set item is marked with "*".

q

P / V L O C K

FLD

* O N

Operations using the main unit panel buttons and the master

volume knob are rejected.

w

F P L O C K

FLD

O N

Operations using the main unit panel buttons are rejected.

e

r

t

F P L O C K

FLD

O F F

Panel lock mode is cancelled.

R C L O C K

FLD

O N

Operations using the remote control are rejected.

R C L O C K

FLD

* O F F

RC lock mode is cancelled.

26

3. Service Related Selection mode

3.1. Behavior specications

In this mode, you can switch between the Diagnostic mode (SERVICE CHECK), the Displaying the protection mode

(PROTECTION) and the 232C clear mode (RS232C RESET).

3.2. Starting up

Press the "ON/STANDBY (X)" button to turn on power while pressing the "ZONE2 SOURCE" and "STATUS" buttons.

Press the "PRESET CH +" button to select the mode and press the "STATUS" button to restart the set and make the

setting take effect.

q

1 S E R V I C E

FLD

C H E C K

This mode is used for conrming the Video and Audio (signal)

paths. (Diagnostic mode)

The signal paths of the set can be easily conrmed after repair.

w

2 P R O T E C T

FLD

e

The protection history can be checked.

3 R S 2 3 2 C

FLD

R E S E T

The 232C standby mode is changed to the Normal standby mode.

3.3. Canceling diagnostic mode

Turn off the power by pressing the "ON/STANDBY (X)" button.

27

Personal notes:

28

3.4. DIAGNOSTIC MODE (Video/Audio (signal) path conrmation mode)

This mode is used for conrming the Video and Audio (signal) paths. (Troubleshooting)

Conrming the operation of unit can be easily done after repair.

Backup data will not be lost.

3.4.1. Operation

Use the remote control (RC014SR) that is supplied with the SRxx06 model. Press buttons on the remote control in the order indicated in the “Details of how to operate remote control” column in the following table to establish the conrmation path.

You will nd using another remote control unit with the macro functions very useful. To use the macro functions, program a macro function to output a remote control code in accordance with the steps in the table below.

3.4.2. Video system conrmation items

g.XX : Refer to the block diagram of the g.XXth.

Conrmation item Setting and display

Analog Video (signal) Path Video Convert (IP Scaler) : OFF

All ZONE : ON

Display:

1

V D V D

0 1

- - -

- - - -

-

d B

.

g.1

Analog or HDMI to HDMI (signal) Path Video Convert (IP Scaler) : ON

IP Scaler : Analog&HDMI

Resolution : Auto

2

GUI FUNCTION Video Convert (IP Scaler) : ON

3

Display:

g.2

V D V D

0 2

IP Scaler : Analog&HDMI

Resolution : Auto

Menu : ON

All ZONE :ON

Display:

- - -

.

- - - -

d B

V D V D

- - -

.

- - - -

d B

CEC FUNCTION

(Control Monitor : HDMI Monitor1)

0 2

g.3

HDMI Control : ON

Display:

V D V D

4

0 3

g.4

- - -

.

- - - -

d B

Details of how to operate remote

controller *a)

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [1/AUTO]

6.Press [Z2]

7.Press [POWER ON]

8.Press [AMP]

9.Press [DVD] twice

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [2/STEREO]

6.Press [DVD] twice

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [2/STEREO]

6.Press [Z2]

7.Press [POWER ON]

8.Press [AMP]

9.Press [DVD] twice

10.Press [AMP MENU]

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [3/M-DAX]

6.Press [DVD] twice

Output sequence of remote control codes

It is useful to form a macro program. *b)

※

ZONE2 POWER OFF ·Input : CVBS / Output : CVBS

q

KEY1/AUTO (Main Zone)

w

(Initialization & Video Convert All OFF)

ZONE2 POWER ON

e

DVD (Main Zone)

r

ZONE2 POWER OFF ·Input : CVBS / Output : HDMI

q

KEY2/STEREO (Main Zone)

w

(Initialization & Video Convert All OFF

& IP Scaler "Analog & HDMI")

DVD (Main Zone)

e

ZONE2 POWER OFF ·GUI Display / Output : HDMI

q

KEY2/STEREO (Main Zone)

w

(Initialization & Video Convert All OFF

& IP Scaler "Analog & HDMI")

ZONE2 POWER ON

e

DVD (Main Zone)

r

GUI MENU (Main Zone)

t

ZONE2 POWER OFF · When the power supply of a TV is put in the standby mode, make sure

q

KEY3/M-DAX (Main Zone)

w

(Initialization & CEC Control ON &

Select Control Monitor 1)

DVD (Main Zone)

e

·Input : Component / Output : Component

·Input : USB (Picture) / Output : CVBS

(

As the input source, you can switch from DVD to other ones.)

b

·Input : Component / Output : HDMI

·Input : HDMI / Output : HDMI

·Input : USB (Picture) / Output : HDMI

(b As the input source, you can switch from DVD to other ones.)

(b As the input source, you can switch from DVD to other ones.)

that the power supply of this unit is also put in the standby mode.

(b As the input source, you can switch from DVD to other ones.)

Contents of conrmation Remarks

Conrm the input pass one by one.

Because it becomes only the input of the highest

input becomes Convert/IP Scaler (signal) Path if it

inputs it at the same time.

HDMI Audio (signal) Path

(Audio : AMP)

5

HDMI Audio (signal) Path

(Audio : TV)

6

g.5

g.6

Audio : AMP(When checking the audio output

from AMP)

Display:

V D V D

0 5

Audio : TV(When checking the audio output

from TV)

Display:

- - -

.

- - - -

d B

V D V D

0 6

- - -

.

- - - -

d B

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [5/HT-EQ]

6.Press [DVD] twice

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [6/V.SEL]

6.Press [DVD] twice

ZONE2 POWER OFF ·Input : HDMI (Signal of PCM, DolbyDigital or DTS) / Output : Speakers

q

KEY5/HT-EQ (Main Zone)

w

(Initialization & Select Audio AMP)

DVD (Main Zone)

e

ZONE2 POWER OFF ·Input : HDMI (Signal of PCM, DolbyDigital or DTS) / Output : TV

q

KEY6/V.SEL (Main Zone)

w

(Initialization & Select Audio TV)

DVD (Main Zone)

e

·Input : HDMI (Signal of HD Audio) / Output : Speakers

(b As the input source, you can switch from DVD to other ones.)

(b As the input source, you can switch from DVD to other ones.)

29

3.4.3. Audio system conrmation items

g.XX : Refer to the block diagram of the g.XXth.

Conrmation item Setting and display

Analog (signal) Path Input Mode : Fixed ANALOG

SURROUND mode : DIRECT

Amp assign : NORMAL

1

g.7

DIGITAL (signal) Path

(MAIN)

2

g.8

HDMI (signal) Path Input Mode : Fixed HDMI

3

g.10

A/D (signal) Path

(Main Zone)

4

Display:

A D V D

0 1

Input Mode : Fixed DIGITAL

Amp assign : NORMAL

Display:

- - -

.

- - - -

d B

A D V D

0 2

Amp assign : NORMAL

Display:

- - -

.

- - - -

d B

A D V D

0 5

Amp assign : NORMAL

SURROUND mode : Multi ch STEREO

Vol -20dB

Speaker Cong : SSSSY

(Front/Center/Surround/SourroundBack :

Small, SW : Yes)

Display:

- - -

.

- - - -

d B

A D V D

g.11

0 6

- - -

.

- - - -

d B

Details of how to operate remote

controller

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [7/T.TONE]

6.Press [DVD] twice

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [8/CH LVL]

6.Press [DVD] twice

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [SURROUND]

6.Press [DVD] twice

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [PURE DIRECT]

6.Press [DVD] twice

Output sequence of remote control codes

It is useful to form a macro program.

b

ZONE2 POWER OFF ·Input : Analog / Output : Speakers (Front L/R)

q

KEY7/T.TONE (Main Zone)

w

(Initialization & Amp assign NORMAL&

Input Mode Fixed ANALOG &

SURROUND mode DIRECT)

DVD (Main Zone)

e

ZONE2 POWER OFF ·Input : Digital / Output : Speakers (Front L/R)

q

KEY8/CH LVL (Main Zone)

w

(Initialization & Amp assign NORMAL&

Input Mode Fixed DIGITAL)

DVD (Main Zone)

e

ZONE2 POWER OFF ·Input : HDMI / Output : Speakers (Front L/R)

q

SURROUND

w

(Initialization & Amp assign NORMAL &

Input Mode Fixed HDMI)

DVD (Main Zone)

e

ZONE2 POWER OFF ·Input : Analog / Output : Speakers (Front L/R)

q

PURE DIRECT

w

(Initialization & Amp assign ZONE2 &

SURROUND mode : Multi ch STEREO &

ZONE2 Volume -20dB)

DVD (Main Zone)

e

·Input : Analog / Output : Pre OUT(Front L/R)

(b As the input source, you can switch from DVD to other ones.)

·Input : Digital / Output : Pre OUT(Front L/R)

(b As the input source, you can switch from DVD to other ones.)

·Input : HDMI / Output : Pre OUT(Front L/R), SW(20Hz)

(b As the input source, you can switch from DVD to other ones.)

·Input : Analog / Output : Pre OUT(Front L/R), SW(20Hz)

(b As the input source, you can switch from DVD to other ones.)

Contents of conrmation Remarks

Analog Audio (signal) Path

(ZONE2)

5

Amp Assign (signal) Path

(Amp Assign : SPKR-C)

6

g.12

g.13

Amp assign : ZONE2

ZONE2 Function : Source

Zone2 Vol -20dB

Display:

A D V D

0 7

Amp assign : BiAMP

SURROUND mode : Multi ch STEREO

Vol -20dB

Display:

- - -

- - - -

-

d B

.

A D V D

1 1

- - -

.

- - - -

d B

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [P2]

6.Press [Z2]

7.Press [POWER ON]

8.Press [AMP]

9.Press [DVD] twice

1.Press [AMP]

2.Press [Z2]

3.Press [STANDBY]

4.Press [AMP]

5.Press [DISP]

6.Press [DVD] twice

ZONE2 POWER OFF ·Input : Analog / Output : Speakers (SURR BACK L/R)

q

P2

w

(Initialization & Amp assign ZONE2 &

SURROUND mode : Multi ch STEREO &

ZONE2 Volume -20dB)

ZONE2 POWER ON

e

DVD (Main Zone)

r

ZONE2 POWER OFF ·Input : Analog / Output : Speakers (SURR BACK L/R)

q

DISPLAY

w

(Initialization & Amp assign SPKR-C &

SURROUND mode : Multi ch STEREO &

Volume -20dB)

DVD (Main Zone)

e

·Input : Analog / Output : Pre OUT(ZONE2 L/R)

(b As the input source, you can switch from DVD to other ones.)

(b As the input source, you can switch from DVD to other ones.)

30

Loading...

Loading...