Marantz SD-4050 Service Manual

Service

SD4050 /N1B, /U1B, /F1B

Manual

Cassette Deck

TABLE OF CONTENTS

1. TECHNICAL SPECIFICATION ...............................................................................1

2. BLOCK DIAGRAM ..................................................................................................2

3. WIRING DIAGRAM.................................................................................................3

4. ADJUSTMENT PROCEDURE ................................................................................ 5

5. SCHEMATIC DIAGRAM AND PARTS LOCATION ............................................... 10

6. MICROPROCESSOR AND IC DATA....................................................................17

7. EXPLODED VIEW AND PARTS LIST...................................................................19

8. ELECTRICAL PARTS LIST...................................................................................22

Please use this service manual with referring to the user guide (D.F.U) without fail.

SD4050

Printed in Japan

- SD4050 -

286W855010 AO

3120 785 22012

First Issue:1999.08

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

it is famous.

Parts for your

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

USA

MARANTZ AMERICA, INCMARANTZ AMERICA, INC.

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AMERICAS

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

MARANTZ BRAZIL

CAIXA POSTAL 21462

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

SINGAPORE

WO KEE HONG (S) PTE LTD

WO KEE HONG CENTRE

NO.23, LORONG 8, TOA PAYOH

SINGAPORE 319257

PHONE : +65 2544555

FAX : +65 2502213

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

NO. 102 JALAN SS 21/35, DAMANSARA

UTAMA, 47400 PETALING JAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE : +60 3 - 7184666

FAX : +60 3 - 7173828

JAPAN

MARANTZ JAPAN, INC.

Technical

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 748 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

990729A.O

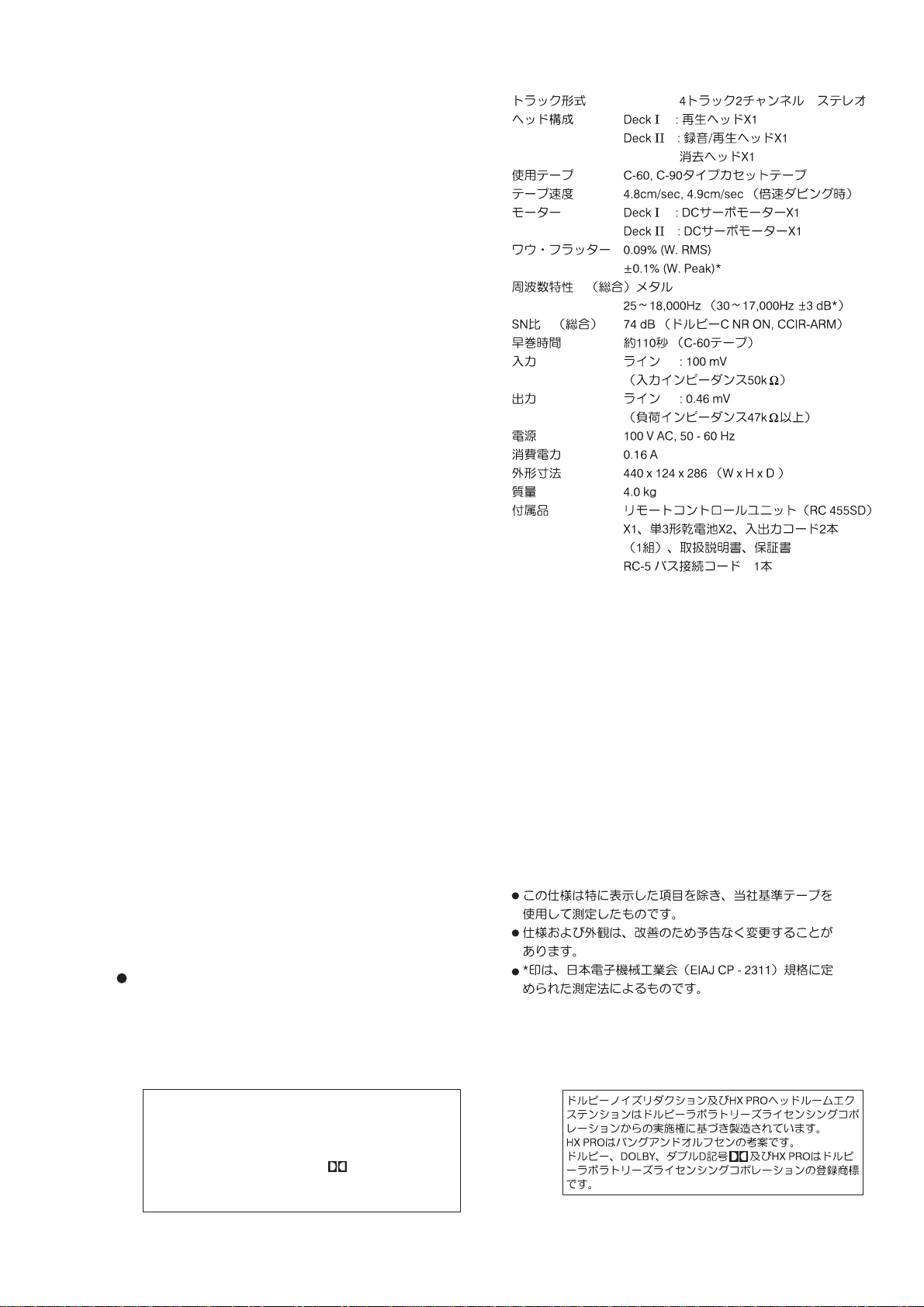

1. TECHNICAL SPECIFICATION

Track System : 4-track, 2-channel stereo

Heads : Deck I ; 1 Playback (Rotating)

Deck II ; 1 Erase and 1 Record/

Playback (Rotating)

Type of Tape : Cassette tape C-60 and C-90 (Philips

type)

Tape Speeds : 4.8 cm/sec, 4.9 cm/sec (When high

speed dubbing)

Motors : DC servo motor x 2

Wow and Flutter : 0.09 % RMS, +/- 0.1 %w. peak

Frequency response (Overall, -20 dB) :

25-18,000Hz +/- 3 dB (at -20 dB, metal

tape)

Signal-to-Noise Ratio (Overall) :

More than 74 dB (CCIR/ARM); Dolby

C NR on

Fast Winding Time : Appopox. 110sec with a C60 cassette

Inputs : 100 mV/50k ohm input level at

maximum

Outputs : 460 mV/47k ohm maximum

(0 dB : 200 nWb/mm)

Power Requirements :

120 V AC, 60 Hz

(U.S.A./Canada model)

230 V AC, 50 Hz (Europe model)

Power Consumption :

0.16 A

Dimensions (W x H x D) :

440 x 124 x 286 m/m (W x H x D)

Weight : 4.0 kg

Standard Accessories :

Remote control unit (RC455SD) x 1

(U.S.A. /Canada model only), Battery

(SUM-3, “AA”, “R6” type) x 2 (U.S.A. /

Canada model only),

Input-output connection cord x 1

Remote control cable x 1

Recording Bias : Apporox. 100 kHz

Channel Separation :More than 40 dB (at 1 kHz)

Phones : 0.95 mW (load impedance 8 ohm to

1.2k ohm)

Improvements may result in specification or feature changing without notice.

Dolby noise reduction and HX Pro headroom extension

manufactured under license from Dolby Laboratories

Licensing Corporation. HX Pro originated by Bang &

Olufsen.

“DOLBY”, the double-D symbol and “HX PRO” are

trademarks of Dolby Laboratories Licensing

Corporation.

1

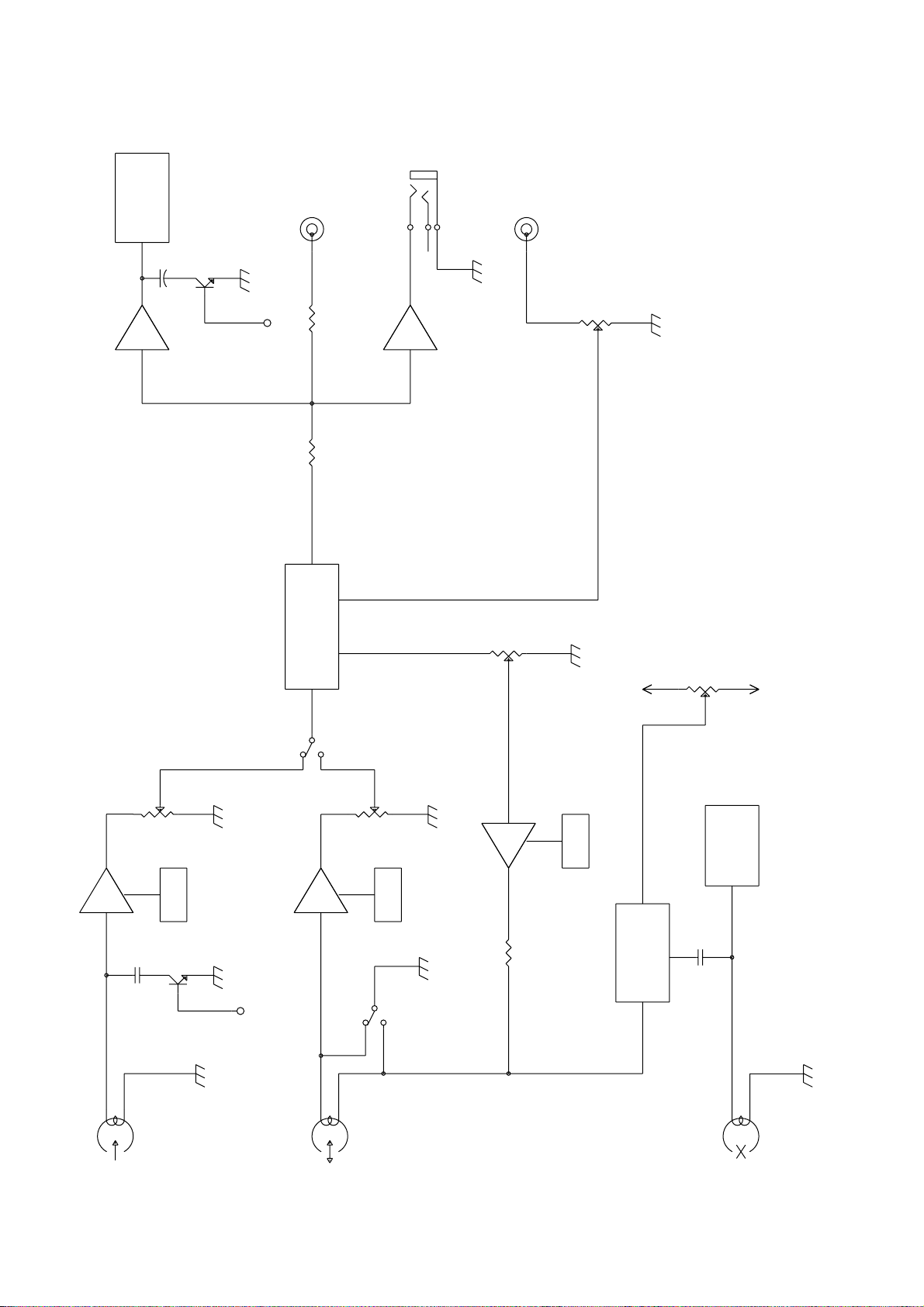

2. BLOCK DIAGRAM

FL DISPLAY

METER AMP

CPSPB AMP

OUTPUT

PHONES

INPUT

PHONES AMP

PB AMP

PB EQ

HI SPEED

DOLBY NR B,C

REC

PB EQ

PLAY

REC AMP

REC EQ

+V

HX PRO

BIAS ADJ.

BIAS

OSC

-V

DECK A

PLAY HEAD

DECK B

R/P HEAD

E HEAD

2

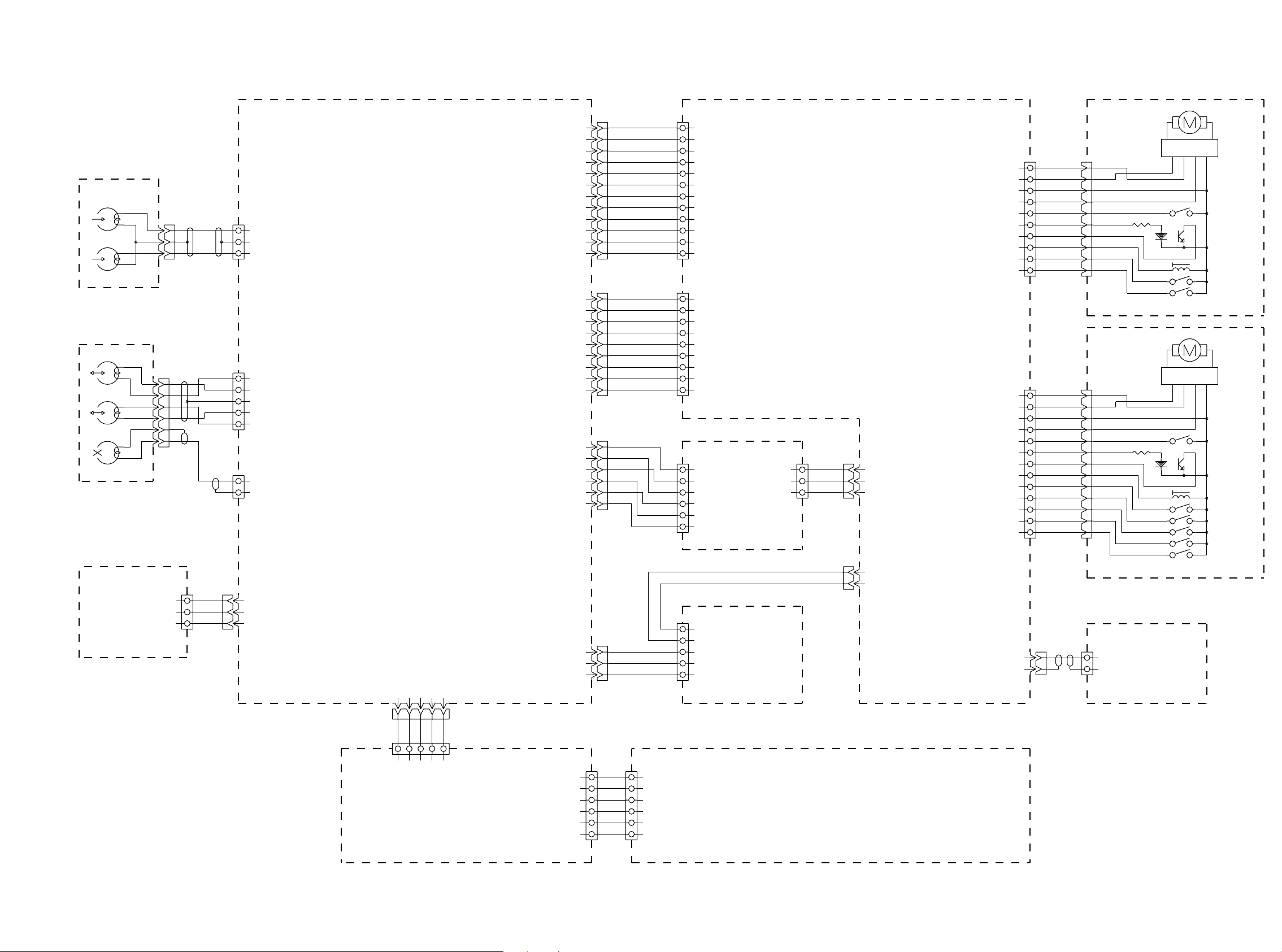

3. WIRING DIAGRAM

DECK I

PLAY HEAD

L

PLAY HEAD

R

DECK II

R/P HEAD

L

R/P HEAD

R

E HEAD

PCB PHONE

PCB MAIN

1

1

2

2

3

3

1

1

2

2

3

3

4

4

5

5

6

6

P301 470

3

2

1

P302

5

4

3

2

1

P303

2

1

P307

P308

P309

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

1

1

2

2

3

3

4

4

5

5

6

6

J307

1

2

3

4

5

6

7

8

9

10

11

12

J308

1

2

3

4

5

6

7

8

9

J311

1

2

3

4

5

6

PCB CONTROL

J503

1

2

3

1

2

3

1

2

3

P503

J319

1

2

3

4

5

6

7

8

9

10

J320

1

2

3

4

5

6

7

8

9

10

11

12

13

PCB VR

1

2

P318

P504

1

1

2

2

J306

1

2

3

1

2

1

2

3

P306

P305

J401

5

4

3

3

2

2

1

1

3

2

1

1

2

3

MECH I

1

2

3

4

5

6

7

8

9

10

MECH II

1

2

3

4

5

6

7

8

9

10

11

12

13

J504

1

2

470

+-AB

PLAY

SOL

CrO2

TAPE

+-AB

PLAY

SOL

CrO2

TAPE

F.REC

METAL

R.REC

P304

J304

12345

12345

12345

J501

1

2

3

4

5

6

P501

1

2

3

4

5

6

PCB TRANS B PCB REMOTE

PCB SLIDE PCB KEY

3 4

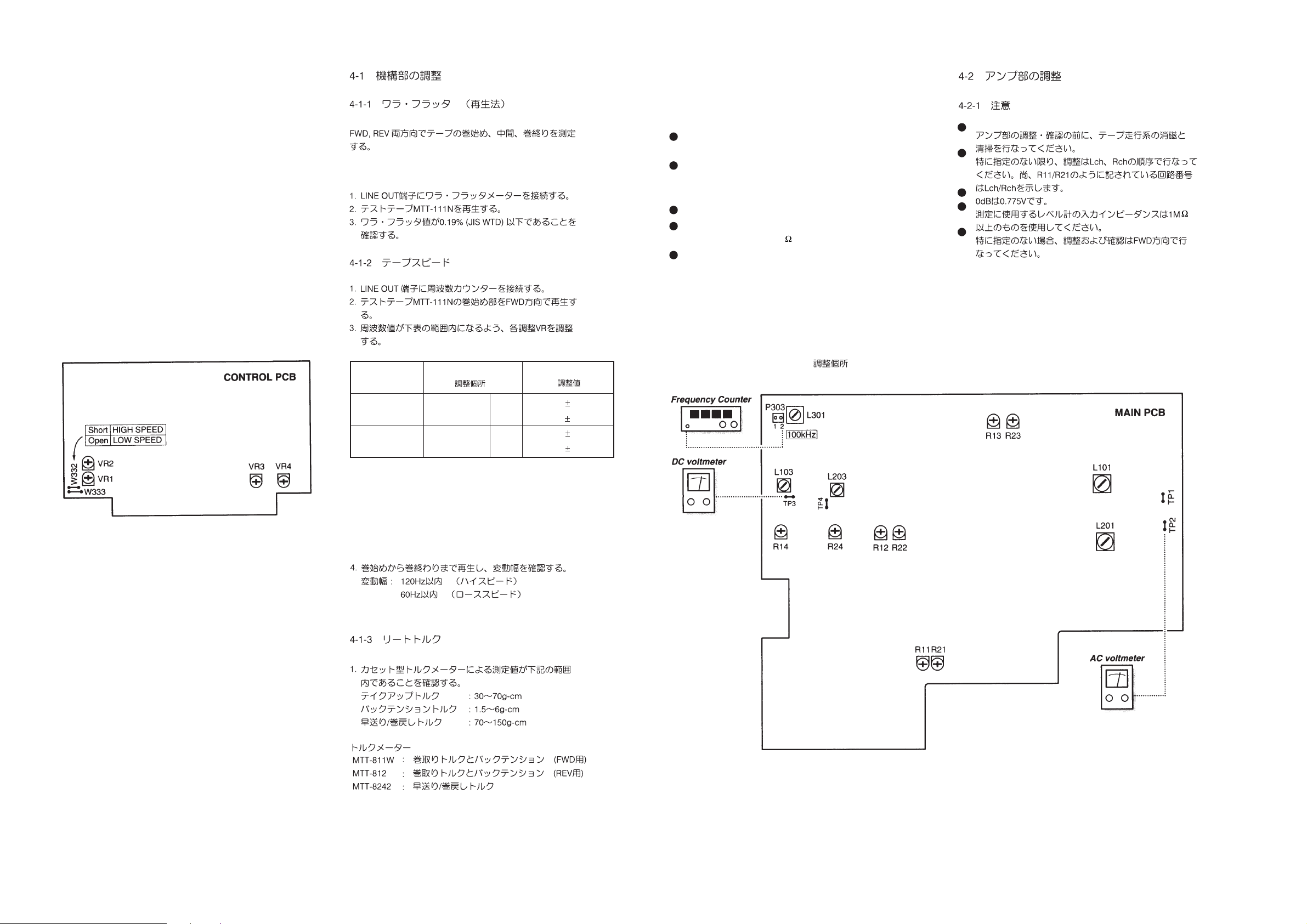

4. ADJUSTMENT PROCEDURE

4-1 MECHANICAL ADJUSTMENT

4-1-1 Wow and flutter (playback method)

In both FWD and REV play modes, these measurements

should be made at the beginning, middle, and the end of the

tape.

1. Connect a wow-and-flutter meter to the LINE OUT.

2. Load and play a TEAC MTT-111N test tape.

3. Check that readings on the wow-and-flutter meter is within

0.19% (JIS WTD).

4-1-2 Tape speed

1. Connect a frequency counter to the LINE OUT.

2. Load a TEAC MTT-111N test tape and play in FWD

direction the beginning of the test tape.

3. Adjust each variable resistor to get the following values.

Adjustment point Adjustment value

4-2 ELECTRICAL ADJUSTMENT

4-2-1 Precautions

Before performing adjustments and checks clean and

demagnetize the entire tape parh.

In general, adjustments and checks are made in the order

of Lch then Rch. Double REF. Nos. indicate Lch/Rch.

(Example ; R11/R21)

0dB is referenced to 0.775V.

The AC voltmeter used in the procedures must have an

input impedance of 1M or more.

Unless specified otherwise, adjustments and checks are

made in FWD direction.

4-2-2 Adjustment locations

Fig. 2-1

4. In play mode, check that the following values are obtained

at the beginning and end of the tape.

Speed drifting : Within 120 Hz (HIGH speed)

Within 60 Hz (LOW speed)

4-1-3 Reel torque

1. Load the cassette torque meter on the deck and read the

pointer indication on the dial scale for each tape transport

operation. The measured torque should be within the

following specified values.

Take-up : 30 to 70g-cm

Supply : 1.5 to 6g-cm

FF/REV : 70 to 150g-cm

Torque metter

MTT-8111W : Forward torque & back tension

MTT-8121W : Reverse torque & back tension

MTT-8242 : Fast forward & rewind static torque

PLAYBACK

REC/PLAY

HIGH speed VR2 6,000 30Hz

LOW speed VR1 3,000 20Hz

HIGH speed VR4 6,000 30Hz

LOW speed VR3 3,000 20Hz

Fig. 2-2

5

6

Loading...

Loading...