Marantz NB1, NB2 Service Manual

Service

LC3050 /N1B

Manual

SECTION PAGE

PRODUCT SPEC. ....................................................................................................................... 1

SAFETY PRECAUTIONS ............................................................................................................ 2

SERVICING PRECAUTIONS ...................................................................................................... 3

DISASSEMBLY PROCEDURE .................................................................................................... 4

PARTS LIST ............................................................................................................................... 10

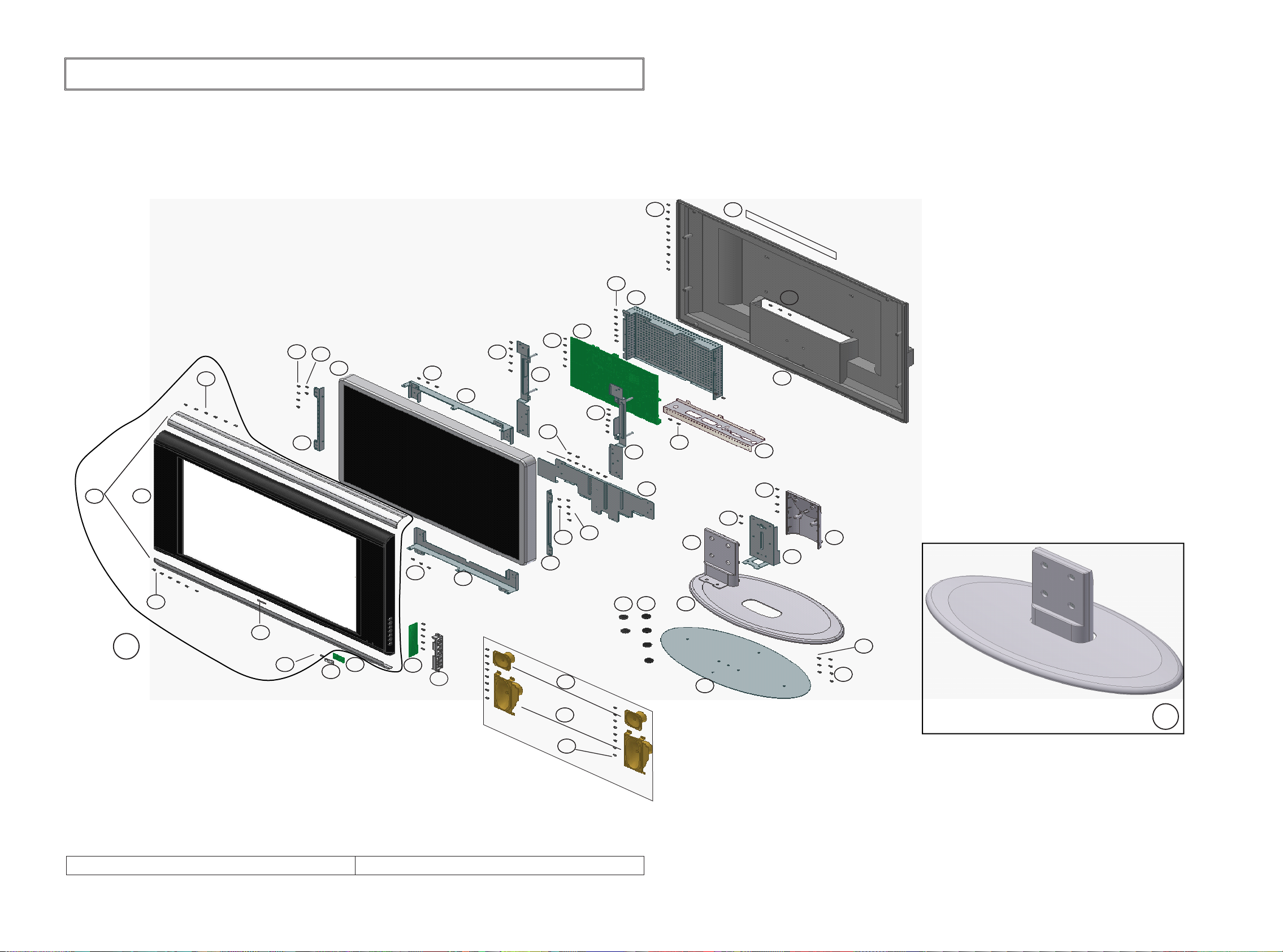

MECHANICAL EXPLODED VIEW ..............................................................................................11

TROUBLE SHOOTING .............................................................................................................. 12

WIRE DRESSING ...................................................................................................................... 17

ADJUSTMENT INSTRUCTION WITH DEFAULT FACTORY DATA........................................... 19

PCB LAYOUT ............................................................................................................................ 22

SCHEMATIC DIAGRAM ............................................................................................................ 27

BLOCK DIAGRAM ..................................................................................................................... 28

CONNECTION DIAGRAM ......................................................................................................... 29

WAVE FORM ............................................................................................................................. 30

FACTORY SPARE PARTS LIST ................................................................................................ 41

LCD TV

TABLE OF CONTENTS

Please use this service manual with referring to the user guide (D.F.U) without fail.

LC3050

LC3050

Part no. 90M47AW855010

First Issue 2004.05

ecm

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

it is famous.

Parts for your

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

1100 MAPLEWOOD DRIVE

ITASCA, IL. 60143

USA

PHONE : 630 - 741 - 0300

FAX : 630 - 741 - 0301

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

43-53 Bridge Rd.,

STANMORE NSW 2048

AUSTRALIA

PHONE : +61 - (0)2 - 9519 - 0900

FAX : +61 - (0)2 - 9519 - 0600

THAILAND

MRZ STANDARD CO., LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

CANADA

MARANTZ CANADA INC.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

HONG KONG

Jolly ProAudio Broadcast Engineering Ltd.

UNIT 2, 10F, WAH HUNG CENTRE,

41 HUNG TO ROAD, KWUN TONG, KLN.,

HONG KONG

PHONE : 852 - 21913660

FAX : 852 - 21913990

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

No.1 JALAN KILANG TIMOR

#08-03 PACIFIC TECH CENTRE

SINGAPORE 159303

PHONE : +65 6376 0338

FAX : +65 6376 0166

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

2ND FLOOR BANGUNAN INFINITE CENTRE

LOT 1, JALAN 13/6, 46200 PETALING JAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE : +60 - 3 - 7954 8088

FAX : +60 - 3 - 7954 7088

JAPAN

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

Technical

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

040401ECM

PRODUCT SPEC.

Model LC3050

Horizontal size 850 mm Thickness 244.6 mm

Main body

Height 540 mm Weight 14.6 kg

Power requirements DC 24V/6.0A

Television system

Television programme VHF: 2~13 UHF: 21~69 Cable: S1~S41

LCD Panel 30” wide TFT LCD panel

Power consumption MAX. 130W

External antenna impedance 75Ω

Audio output 10W + 10W

External IN/OUT ports

AC Power Adaptor

*1 Compatible with HDCP.

Supported Signals

•640 x 480P @ 60Hz

•1280 x 720P @ 50/60Hz

•1920 x 1080I @ 50/60Hz

•720 x 480P @ 60Hz

•720 x 576P @ 50Hz

Note: In some cases a signal on the LCD TV may not be displayed properly. The

problem may be an inconsistency with standards from the source equipment (DVD,

Set-top box, etc...). If you do experience such a problem please contact Marantz

Service Center, Inc. and also the manufacturer of the source equipment.

PAL-BG, I, DK/ SECAM-BG, DK, L

• DVI-IN 1

*1

• HEADPHONE JACK 1 • PC IN 1

• PC AUDIO IN 1 • SCART 2

• POWER IN 1 • ANTENNA IN 1

• SUB WOOFER OUT 1

AC 100-240V, 5.0A, 50/60Hz,

OUTPUT : 24VDC., 6.0A

• S-VIDEO IN 1

SERVICE MANUAL

PAGE:1

SAFETY PRECAUTIONS

!! Import ant Safety Notice !!

Many electrical and mechanical parts in this chassis have special safety-related

characteristics.

These parts are identified by in the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components

as recommended in this manual to prevent Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

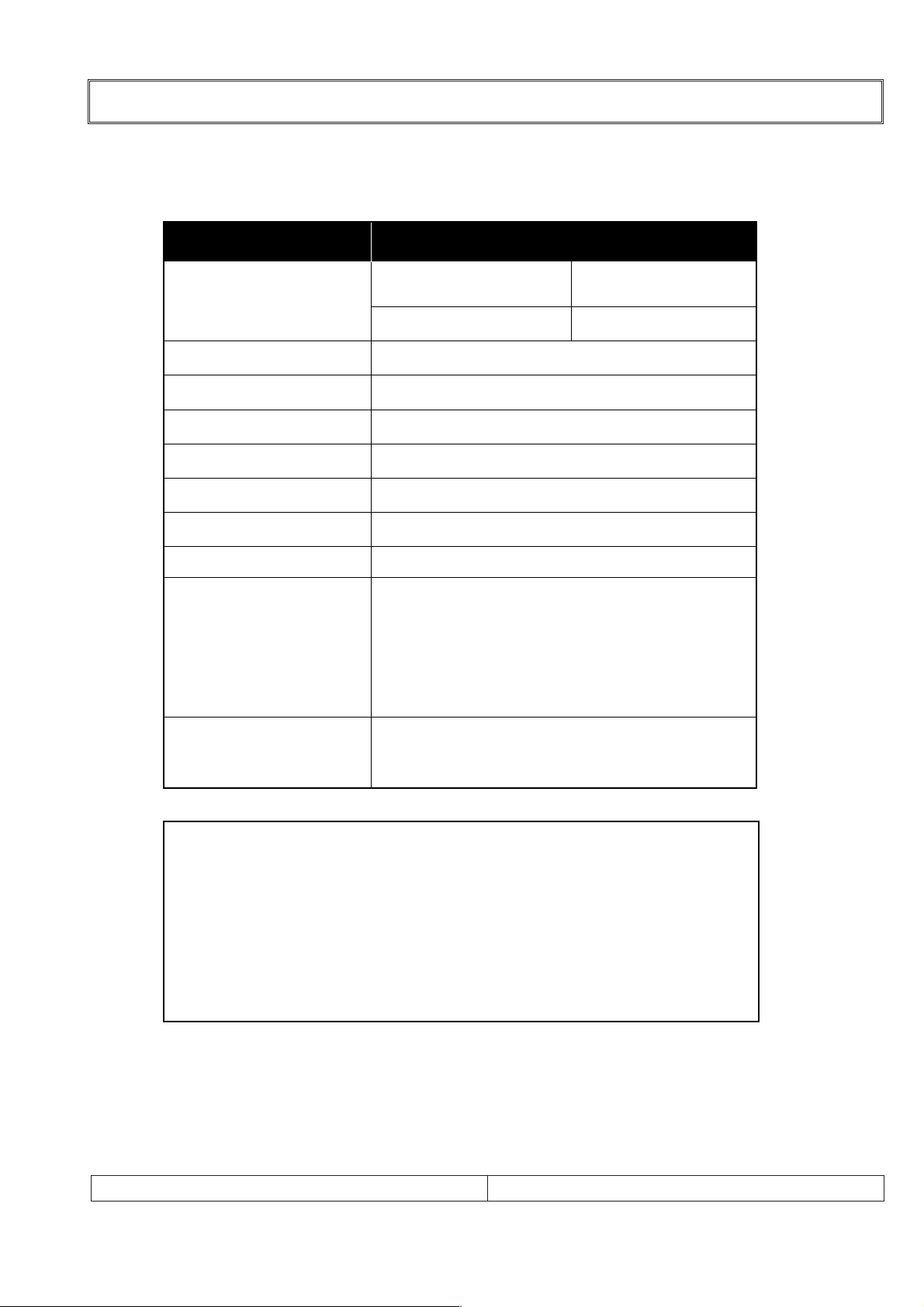

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor between a known good earth

ground (Water Pipe, Conduit, etc.) and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter with 1000 ohms/volt or more

sensitivity.

Reverse plug of the AC cord into the AC outlet and repeat AC voltage measurements for each

exposed metallic part. Any voltage measured must not exceed 0.75 volt RMS, which is,

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is possibility of shock hazard and

the set must be checked and repaired before it is returned to the customer.

Leakage Current Hot Check circuit

SERVICE MANUAL

PAGE :2

SERVICING PRECAUTIONS

CAUTION! !

Before servicing receivers covered by this service manual, read and follow the SAFETY

PRECAUTIONS on page 2 of this publication.

General Servicing Precautions

1.Always unplug the receiver AC power cord from AC power source before;

Removing or reinstalling any component, circuit board module or any other receiver assembly.

a.

Disconnecting or reconnecting any receiver electrical plug or other electrical connection.

b.

Connecting a test substitute in p

c. arallel with an electrolytic capacitor in the receiver.

CAUTION! ! A wrong part substitution or incorrect polarity installation of electrolytic capacitors

may result in an explosion harzard.

2.Do not spray chemicals on or near this receiver or any of its assemblies.

3.Do not defect any plug/socket voltage interlocks with which receivers covered by this service

manual might be equipped.

4.Always connect the test receiver ground lead to the receiver chassis ground before

connecting the test receiver positive lead. Always remove the test receiver ground lead last.

5.Do not connect the test fixture ground strap to power supply heatsink in this receiver

Electrost atically Sensitive(ES) Devices

Some semiconductor(solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive(ES) Device.Examples

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit board will weaken the adhesive

that bonds the foil to the circuit board causing the foil th separate from or “lift-off” the board.

The following guidelines and procedures should be flollowed whenever this condition is

encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the following procedure to install a

jumper wire on the copper pattern side of the circuit board.(Use this technique only on IC

connections.)

1.Carefully remove the damaged copper pattern with a sharp knife.(Remove only as much

copper as absolutely necessary.)

2.Carefully scratch away the solder resist and acrylic coating(if used) from the end of the

remaining coopper pattern.

3.Bend a small “U” in one end of a small guage jumper wire and carefully crimp it around the IC

pin.

4.Route the jumper wire along the path of the out-away copper pattern and let it overlap the

previously scraped end of the good copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

SERVICE MANUAL

PAGE :3

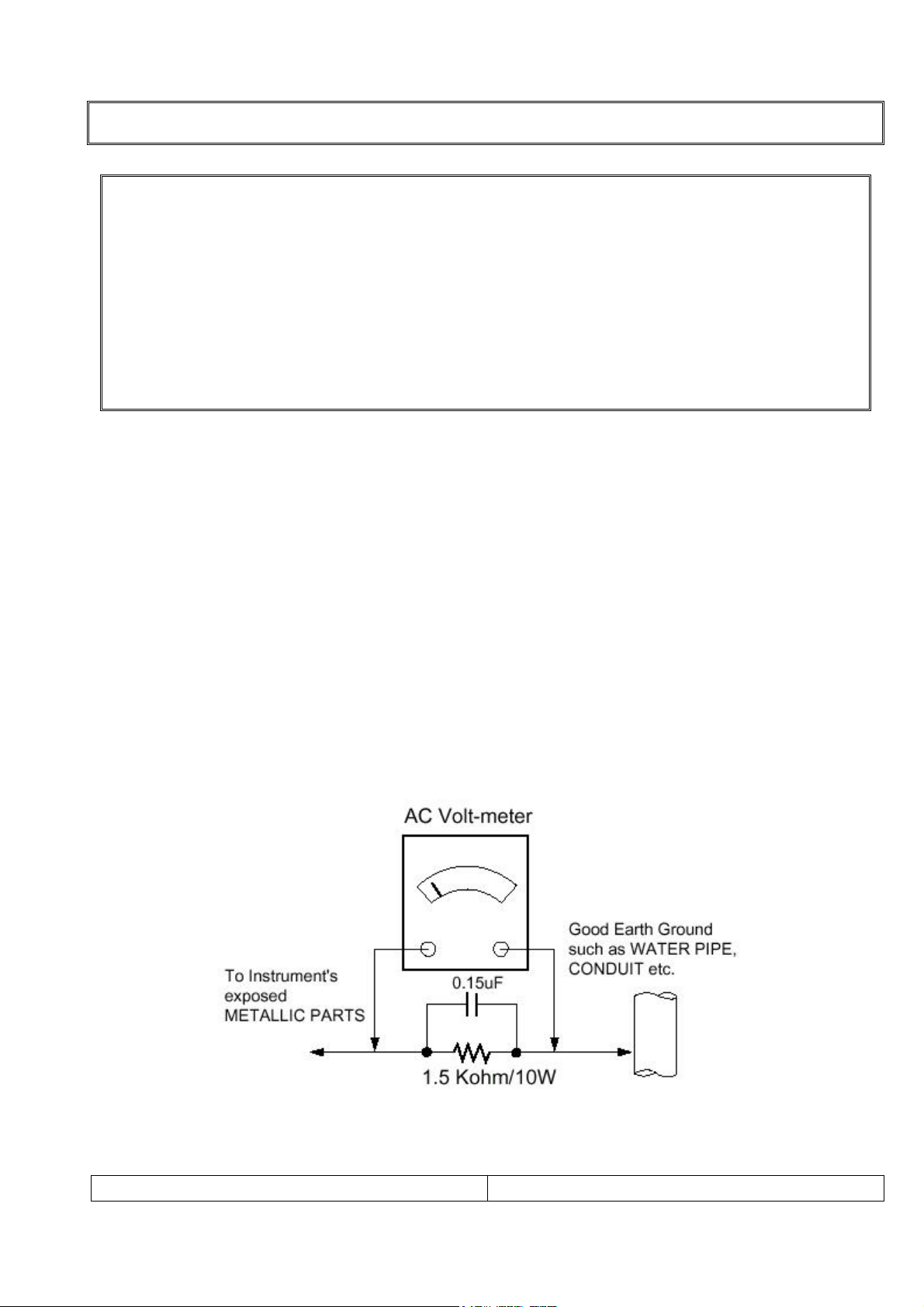

Disassembly procedure

1).Back cover

DISASSEMBLY PROCEDURE

Remove 4 screws

Remove 13 screws

SERVICE MANUAL

PAGE:4

DISASSEMBLY PROCEDURE

2).Metal plate & Rear chassis

Remove 4

Removal of rear metal chassis...

1. Remove 2

2. Slide away the

metal plate

Removal of Terminal metal plate

SERVICE MANUAL

PAGE:5

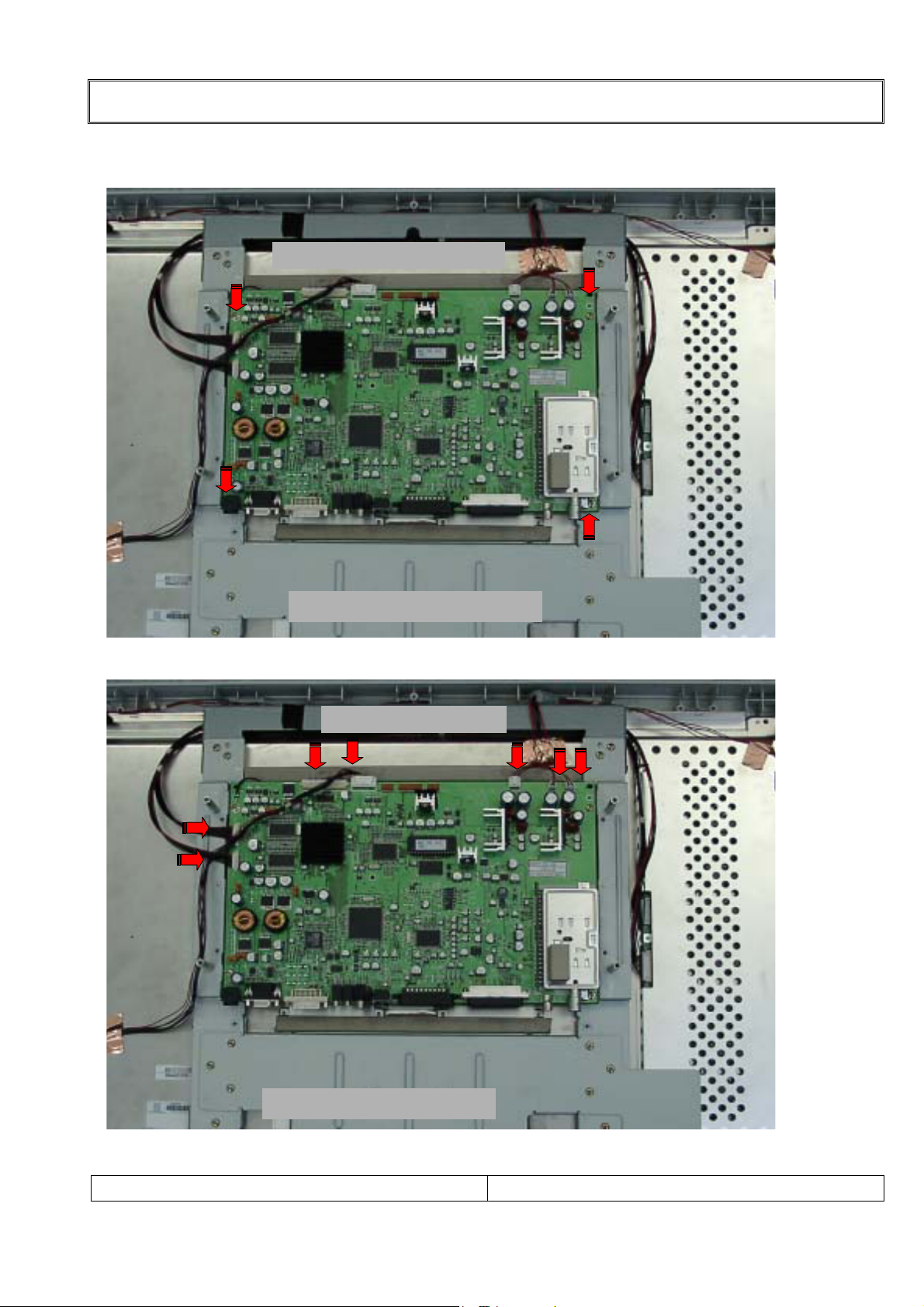

DISASSEMBLY PROCEDURE

3).Main PWB & Connectors

Remove 4 Main

Remove 4 Main

CB screws

CB screws

Removal of Main P

Removal of Main P

Remove 7

Remove 7

C

C

...

...

Removal of Main PCB

Removal of Main PCB

SERVICE MANUAL

PAGE:6

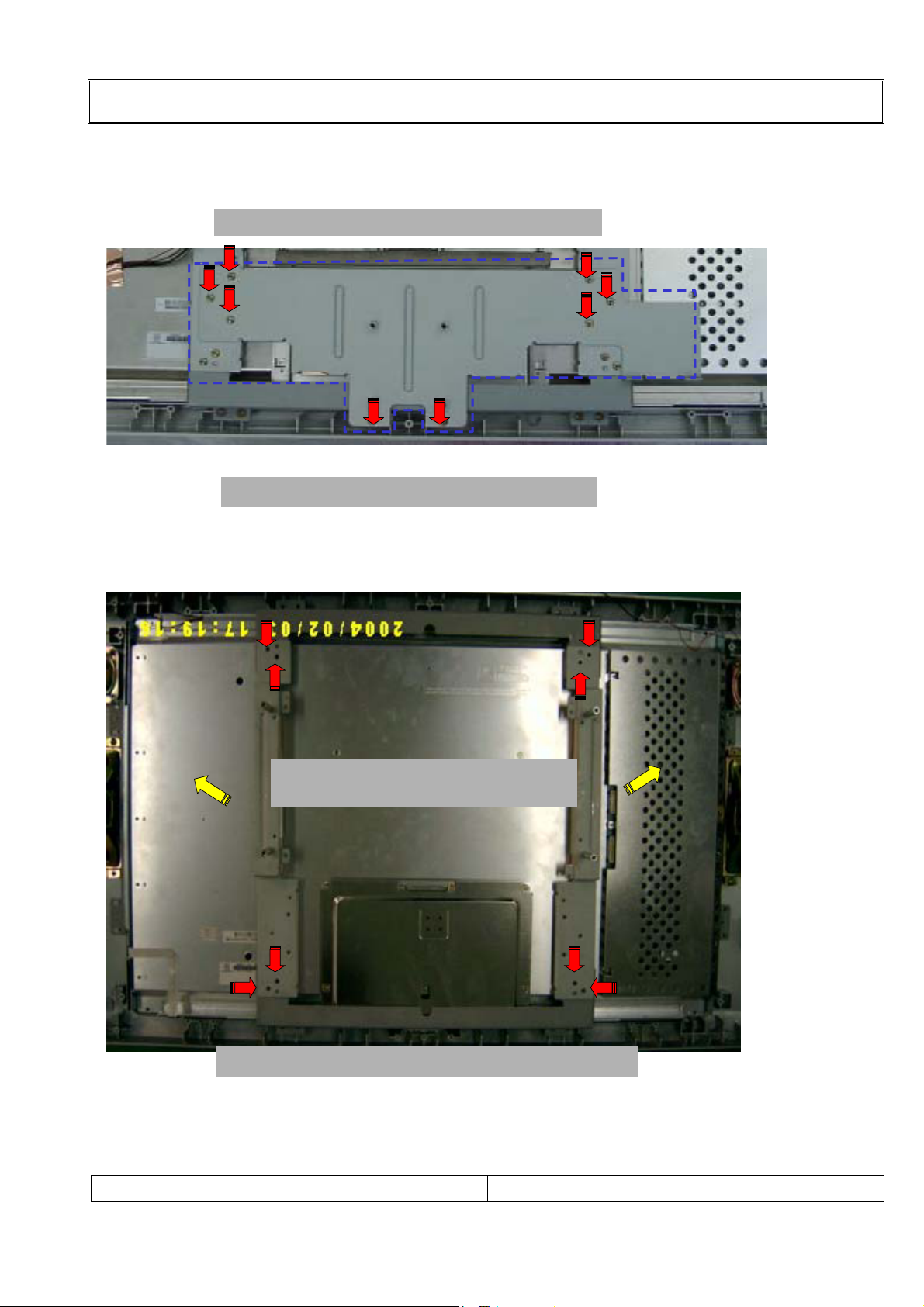

4).LCD Panel chassis

Remove 8 screws, then take off sub-

DISASSEMBLY PROCEDURE

metal

Removal of LCD Module sub-bracket

Remove 8 screws, then take off two

vertical mountmetal brackets

Removal of LCD Module vertical brackets

SERVICE MANUAL

PAGE:7

5-1). LCD Moul

DISASSEMBLY PROCEDURE

Remove18 screw

Removal of LCD Module brackets

Remove 4 brackets, then lift out LCD Module

(move all wire looms away which are attached to the module)

Removal of LCD Panel module mounting brackets

SERVICE MANUAL

PAGE:8

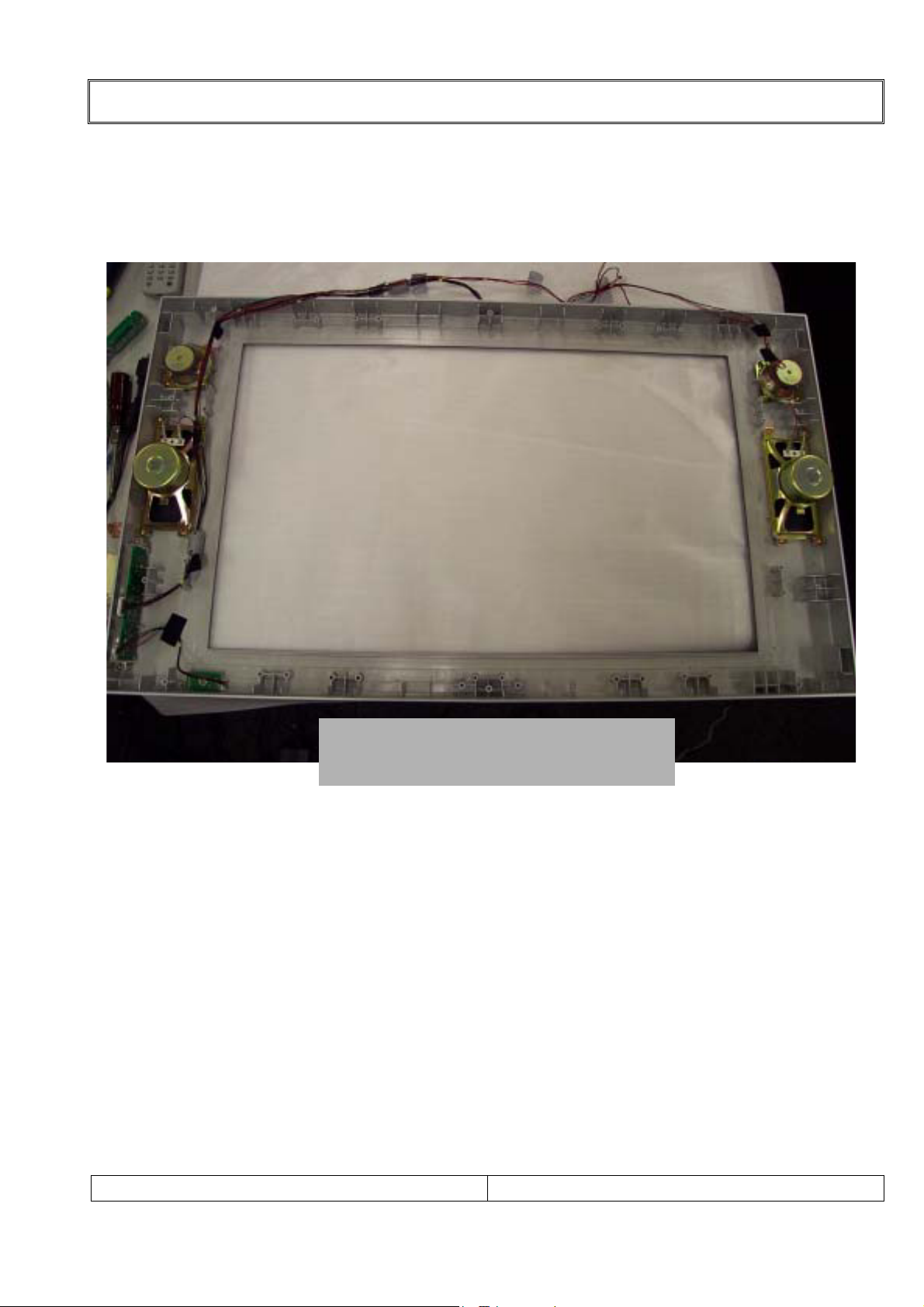

5-2).LCD Module

DISASSEMBLY PROCEDURE

Front mask remains after

removing LCD Module

SERVICE MANUAL

PAGE:9

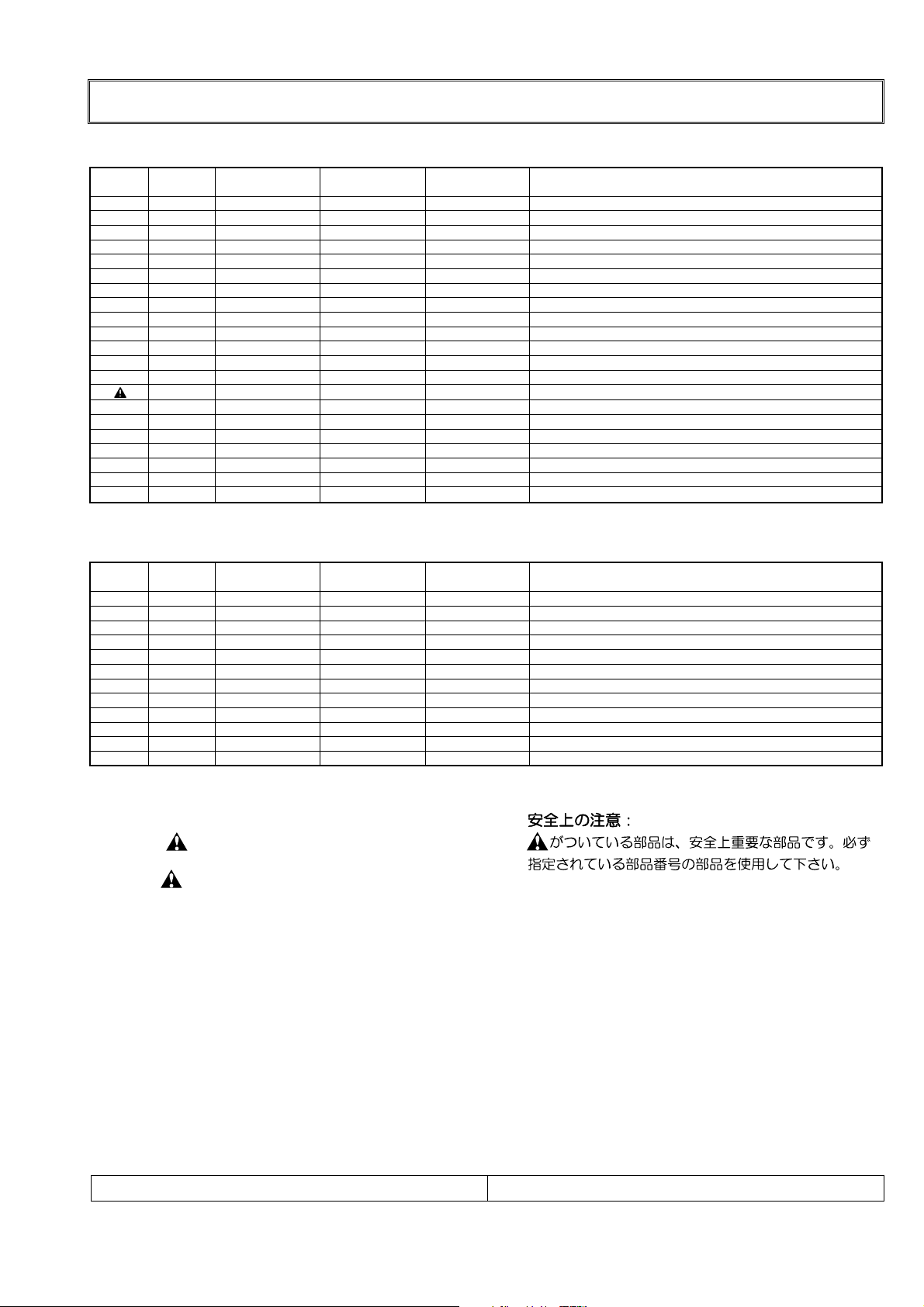

PARTS LIST

(

)

(

)

EXPLODED

POS. NO.

A

B

3

4

5

8

9

15

18

NOTE : “nsp” PARTS IS LISTED FOR REFERENCE ONLY, MARANTZ WILL NOT SUPPLY THESE PARTS.

ELECTRICAL PA

POS. NO.

P1001

P1002

P1003

P1006

P1007

P1008

P1009

P801

P901

P902

TU1001

VIEW PARTS L

VERS.

COLOR

/N1B

/N1B

/N1B

/N1B

/N1B

/N1B

/N1B

/N1B

/N1B

/N1B

/N1B

/N1B

/N1B

RTS LIST

VERS.

COLOR

IST

PART NO.

FOR EUR

00M47AW248510

00M47AW128510

90M-QK000120R

90M-QJ000020R

90M-ZZ002580R

90M47AW154010

90M-KZ000030R

90M-ZZ002590R

90M47AW248020

00M47AW851310

00MZK47AW0010

90M-AA000050R

90M-ZC000400R

nsp

nsp

nsp

nsp

nsp

PART NO.

(FOR EUR)

90M-YT003940R

90M-YT003940R

90M-YT003880R

90M-YT003900R

90M-YT003900R

90M-YT003870R

90M-YT003910R

90M-YT003920R

90M-YT003890R

90M-YT003930R

90M-AV000390R

PART NO.

MJI

00M47AW248510

00M47AW128510

90M-QK000120R

90M-QJ000020R

90M-ZZ002580R

90M47AW154010

90M-KZ000030R

90M-ZZ002590R

90M47AW248020

00M47AW851310

00MZK47AW0010

90M-AA000050R

90M-ZC000400R

00M47AW801010

90M47AW809010

90M47AW809020

90M47AW809030

90M47AW809040

PART NO.

(MJI)

90M-YT003940R

90M-YT003940R

90M-YT003880R

90M-YT003900R

90M-YT003900R

90M-YT003870R

90M-YT003910R

90M-YT003920R

90M-YT003890R

90M-YT003930R

90M-AV000390R

PANEL ASSY

STAND ASSY

SPEAKER

SPEAKER

PCB ASSY

KNOB

UNIT KIT

PCB ASSY

PANEL

PACKING

USER GUIDE

UNIT KIT

AC ADAPTER

MAINS CORD

NOT STANDARD

PACKING CASE

CUSHION

CUSHION

CUSHION

CUSHION

MAIN PCB

TERMINAL

TERMINAL

TERMINAL

TERMINAL

TERMINAL

TERMINAL

TERMINAL

TERMINAL

TERMINAL

TERMINAL

TUNER

DESCRIPTPARTS NAME ION

FRONT PANEL ASSY

STAND ASSY

10W 8OHM

20W 8OHM

CONTROL PCB ASSY & LED PCB ASSY

ON/OFF, MENU, CH, VOL, TV/AV

LCD PANEL 29" CMO V296W1-L**

MAIN PCB ASSY

REAR PANEL LT-30*EP/*LP

USER GUIDE/N1B

REMOTE CONTROLLER RC3050LC

24V/6.0A 1.8M

VDE KKP-4819R

SPARE PART

PACKING CASE LC3050/N1B

CUSHION TOP L

CUSHION TOP R

CUSHION BOTTOM L

CUSHION BOTTOM R

DISCRIPTPARTS NAME ION

RGB21PIN,VP 381-091B

RGB21PIN,VP 381-091B

RCA-1406(W/R)

ST-215

ST-215

WOOFER, RCA-103

S-VHS, PJ6046G

4P POWER

DAH-15RF-4B4

DVI-CON

2IN1 TAFD-S212D

AYCALT32A01K

AYSTLT32A01E

610-005B

610-005A

AYCOLT32A01B

404-004C

PANV296W1L01

AYMALT35A01E

AYBCLT32A01D

500-031B

510-004L

620-004A

621-001B

300-010U

310-009E

310-009F

310-010E

310-010F

0JASCART000D

0JASCART000D

0JAGE14060BD

0JAKKST215BD

0JAKKST215BD

0JAGN10300BD

0JAPK6046GBD

0JASYDC4P0BD

0JADM15RF00D

0JASYDVI29BD

0TULGS212DBD

NOTE ON SAFETY :

Symbol Fire or electrical shock hazard. Only original

parts should be used to replaced any part marked with

symbol . Any other component substitution (other

than original type), may increase risk of fire or electrical

shock hazard.

SERVICE MANUAL

PAGE:10

SERVICE MANUAL

PAGE:11

MECHANICAL EXPLODED VIEW

33

1

3

4

5

6

7

8

5

33

26

27

9

10

10

11

11

13

14

15

16

17

18

19

20

21

22

29

25

24

31

31

31

26

31

26

32

32

26

33

33

26

28

34

27

35

27

30

23

12

33

2

3333

11

33

44

55

66

77

8

55

3333

2626

2727

99

1010

1010

1111

1111

1313

1414

1515

1616

1717

1818

1919

2020

2121

2222

2929

2525

2424

3131

3131

3131

2626

3131

2626

3232

3232

2626

3333

3333

2626

2828

3434

3535

2727

3030

2323

1212

3333

22

3

4

26

3

4

26

3

4

26

3

4

26

A

B

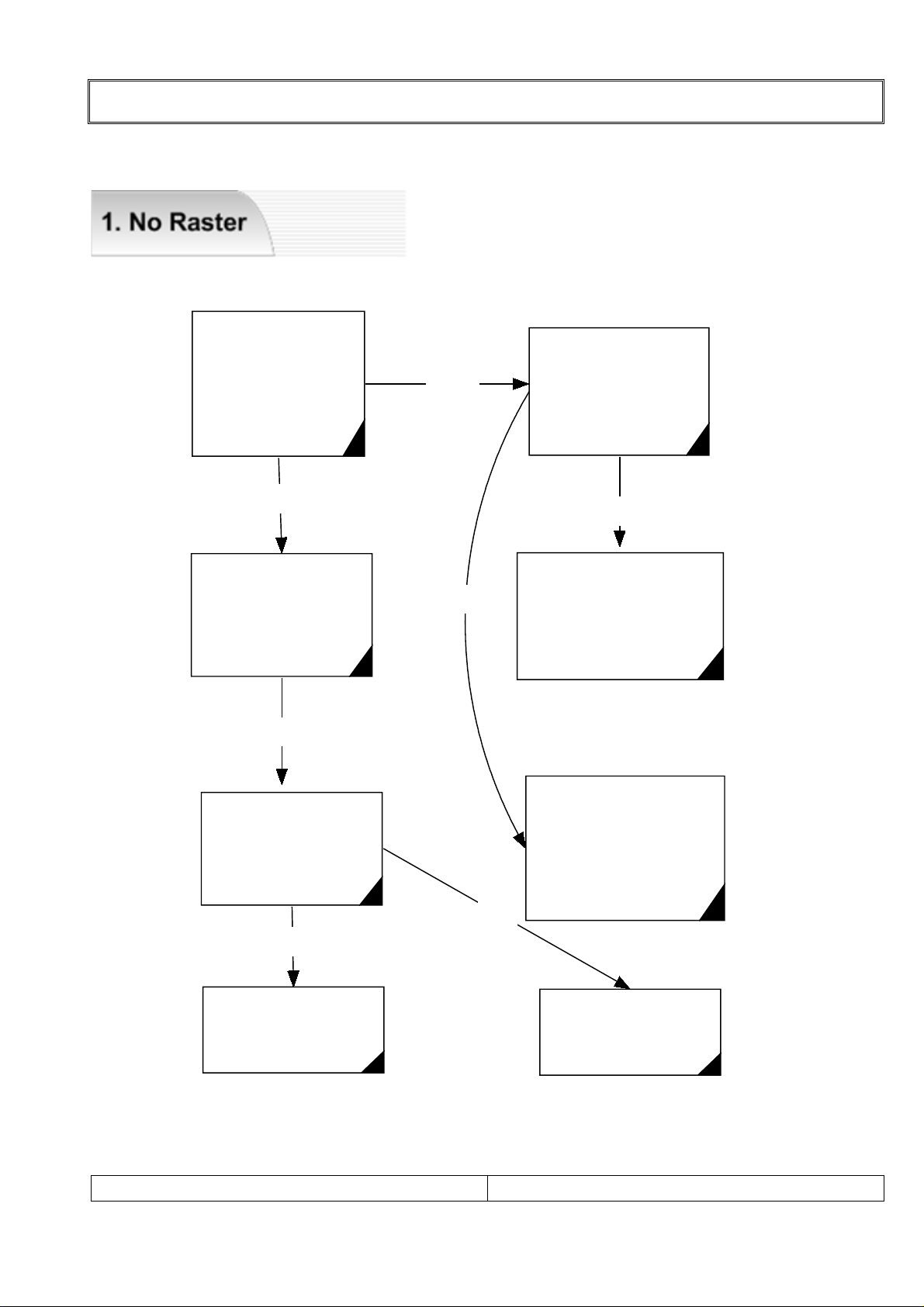

No Raster?

(Real Black?)

Check P441

Connector & Cable

OK?

YES

Check

P441 Pin #3~6

Panel VCC

Check P952,951

Pin #10~15 : VCC

Pin #4 : On/Off

OK?

Replace Inverter

Cable or module

NO

YES

Check appropriate

circuit

(Power suply

& u-Com control )

YES

Replace LCD module

NO

Check or Replace

I 803

YES

NO

TROUBLE SHOOTING

SERVICE MANUAL

C

PAGE:12

Is OSD OK?

Check

IC271 =1.8V Reg

IC272 =3.3V Reg

pin #32,39

H.V Sync OK?

YES

IC201

Each and all

video Input Check

Pin #78,80,82

=component

96 = RF CVBS

97 +A/v

100,102 =YC

NO

YES

Check IC101

Pin #378(clock)

Pin #326,301(Sync)

OK?

Check IC402

Pin #1,9,17,26,34,44

(vcc)

pin #31 =(Clock)

OK?

YES

NO

NO

Check

IC271,272 DC Reg

In/OuT Power Line

Fasten P441

Cable & Connector

YES

YES

Check

AL201 ~206&

A;L208 ~210 Oof

IC201Video Data out

OK?

NO

NO

Check External

Video Soure

Replace IC201

TROUBLE SHOOTING

SERVICE MANUAL

PAGE:13

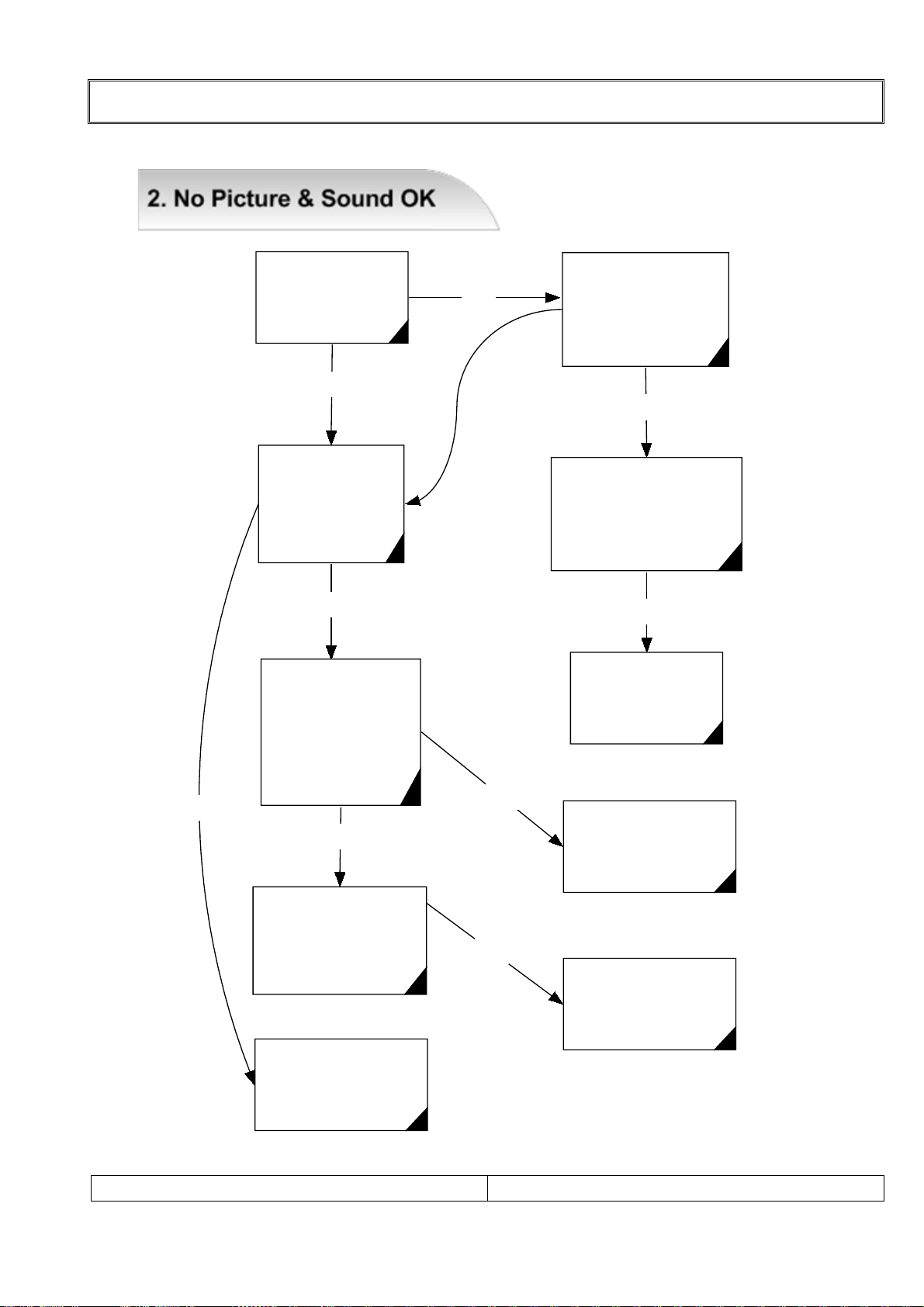

Check IC601

Audio Inputs

Pin#47.48=PC L.R

50.51=Compo L.R

56.57=A/V L.R

60=RF Mono

OK?

Check IC601 Outputs

Pin #27.28=L.R Out

30=Woofer Out

OK?

YES

Check IC651.652

Audio outputs

Each pin #7.#11

OK?

Check external

Input audio source

Check IC601 VCC

and Replacement

YES

NO

Check IC605

Pin #10 Vcc &

Pin #8 Mute

(Pin #8 Low=Mute)

and Replacement

YES

Check Speaker

and Replacement

NO

NO

TROUBLE SHOOTING

SERVICE MANUAL

PAGE:14

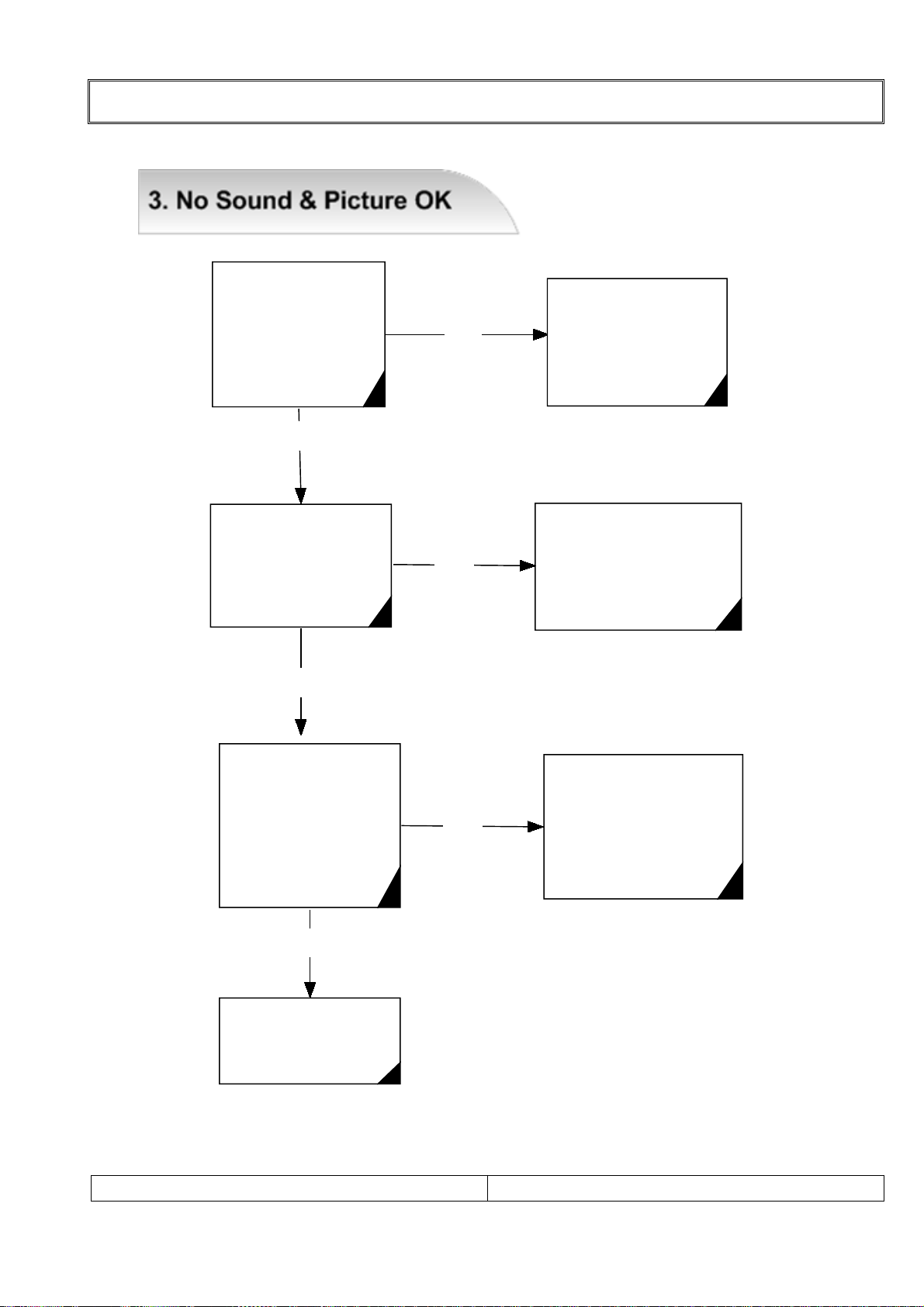

TROUBLE SHOOTING

Check IC601

Pin#21

(CVBS Sibnal)

OK?

Check Pin #57 ~ 60

of IC 101

(R,G,B FB)

YES

Check Pin #67,70,72

73 of IC201

(R,G,B FB)

Check CVBS Signal

from Pin #67 of IC201

to Pin #21 of IC101

Replace IC01

YES

NO

Check RF Source gain

NO

NO

SERVICE MANUAL

PAGE:15

TROUBLE SHOOTING

Check

IC271,272,821

In/Out Voltage

Check

AL201~206&

AL208~210

IC201 Video Data out

OK?

YES

Check

AL301~306

IC301 Video Data out

OK?

DC Reg

In/Out Power Line

Check & Replacement

IC201

Each and all

video Input Check

Pin #78,80,82=

Component

96=RF CVBS

98=A/V

100,102=Y/C

YES

NO

Replacement

IC101

YES

Check IC1151

Pin #1,2,12~15 (Sync)

& VCC

NO

Replace IC1151

Check VCC Line

& Replacement

NO

NO

IC301

Each and all

Input Signals Check

Pin #54,65,70 =

RGB input

32,33,35,36,38,39,

41,42 = DVI Input

YES

SERVICE MANUAL

PAGE:16

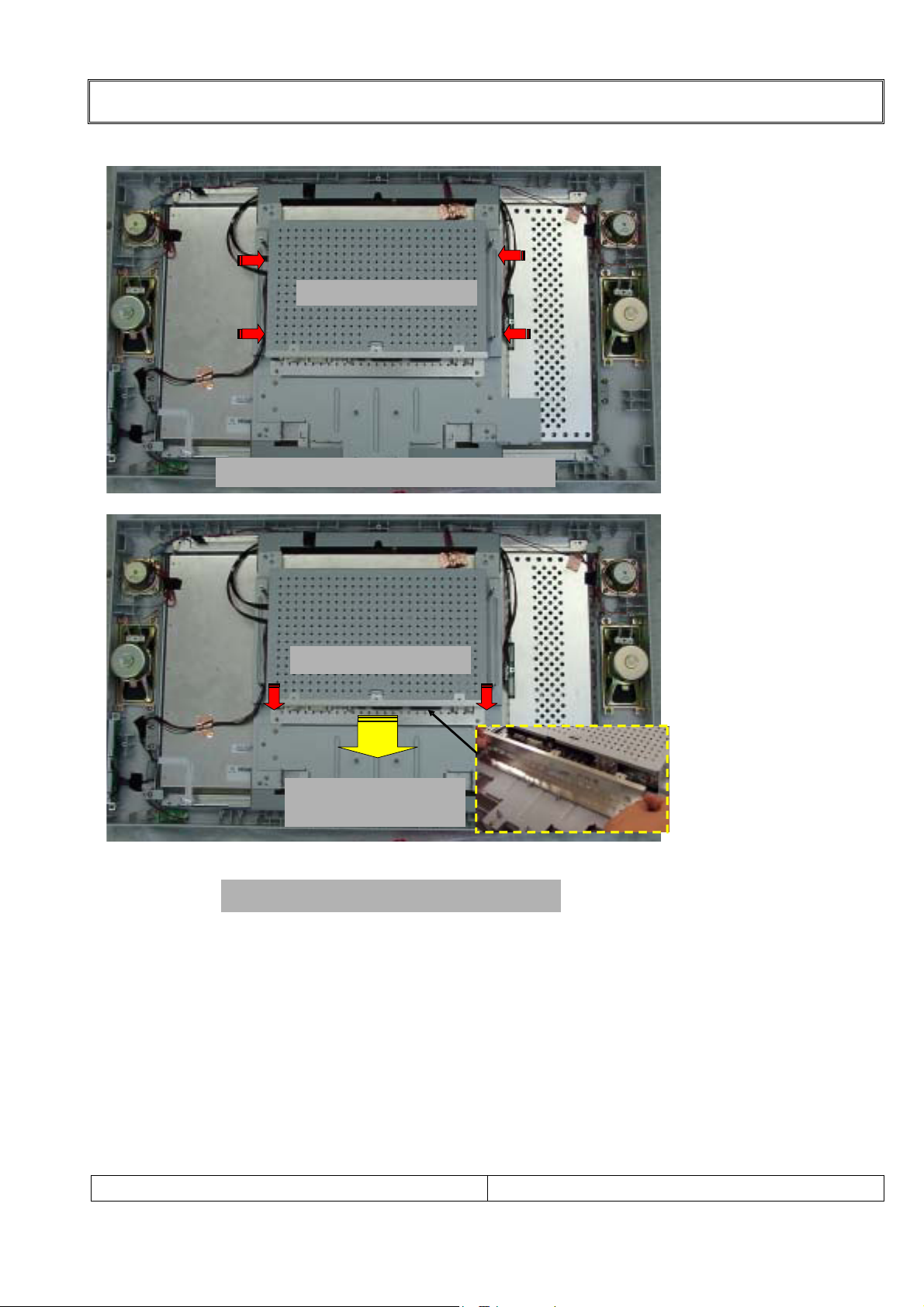

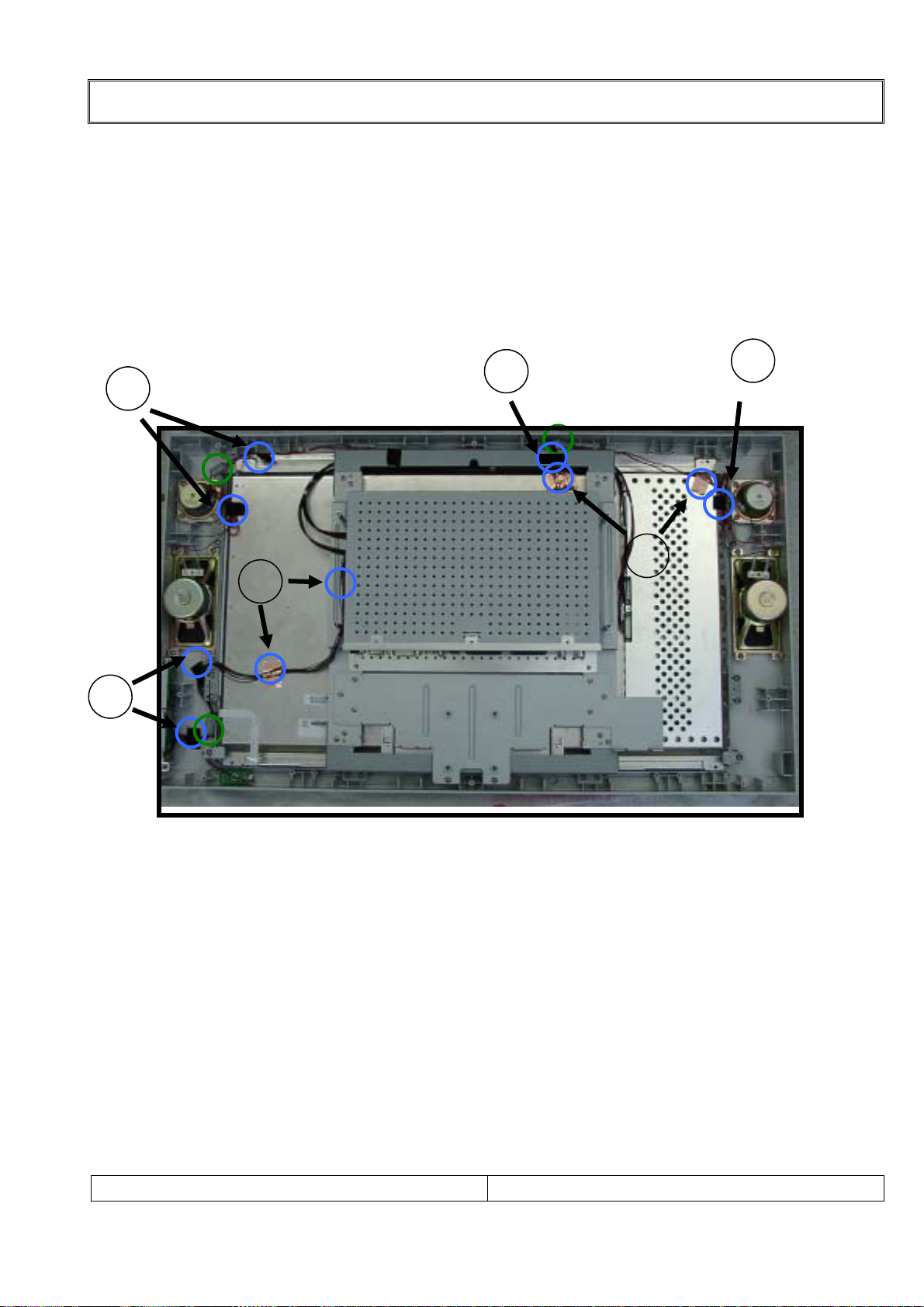

WIRE DRESSING

Wire Dressing

Note : Using Acetate Tape No1, No3, No4, No5.

Using Copper Tape No2, No6 (Conducted tape)

3

1

4

2

6

5

SERVICE MANUAL

PAGE:17

WIRE DRESSING

1) Wire Dressing for Left speaker & woofer speaker. ( No.1)

2) Wire Dressing for Right speaker & Woofer speaker. ( No.2 )

3) Wire Dressing for Key control & Power Indicator with IR receiver ( No.3 )

2

1

3

SERVICE MANUAL

PAGE:18

Loading...

Loading...