Page 1

Service

DR2100/N1S, /C1S

Manual

STANDBY

STANDBY

POWER

SOURCE

ON

OFF

REMARK : This service manual explains them by extracting specifications designed for the

model DR2100 only. The explanation for CD-R module “MAR775” ( Loader : CDL4009’ +

CD-R Main board ) is not mentioned on this seevice manual.

The CD-R module information is described in the service manual of CD-R modules

<MAR770/MAR775>.

MAIN UNIT

1. SERVICING THE DR2100 ......................................................................................1

2. TECHNICAL SPECIFICATION ...............................................................................3

3. WARNINGS ............................................................................................................4

4. SERVICE HINTS AND TOOLS ...............................................................................5

5. SERVICE MODE ....................................................................................................6

6. DIAGNOSTIC SOFTWARE .................................................................................... 7

7. FAULTFINDING TREES ....................................................................................... 11

8. FAULTFINDING GUIDE........................................................................................17

9. WIRING DIAGRAM............................................................................................... 30

10. BLOCK DIAGRAM ................................................................................................33

11. SCHEMATIC DIAGRAM AND PARTS LOCATION...............................................35

12. EXPLODED VIEW AND PARTS LIST...................................................................41

13. ELECTRICAL PARTS LIST...................................................................................44

CD Recorder

OPEN/CLOSE

OPEN/CLOSE

MULTI JOG

+

PUSH

REC TYPE

REC

STOP

PLAY/PAUSE

ERASE

FINALIZE

OPEN/CLOSE OPEN/CLOSE

STOP

PLAY/PAUSE

DISPLAY

CANCEL/DELETE

MENU/STORE

TABLE OF CONTENTS

ENTER

PROGRAM

MAR1250 ( CD MODULE )

2.1 WIRING DIAGRAM............................................................................................. 2-1

2.2 SCHEMATIC DIAGRAM ..................................................................................... 2-3

2.3 PARTS LOCATION ............................................................................................ 2-11

2.4 EXPLODED VIEW AND PARTS LIST............................................................... 2-15

2.5 ELECTRICAL PARTS LIST............................................................................... 2-17

Please use this service manual with referring to the user guide (D.F.U) without fail.

DR2100

DR2100DR2100

399K855010 AO

3120 785 22510

First Issue:2001.03

Page 2

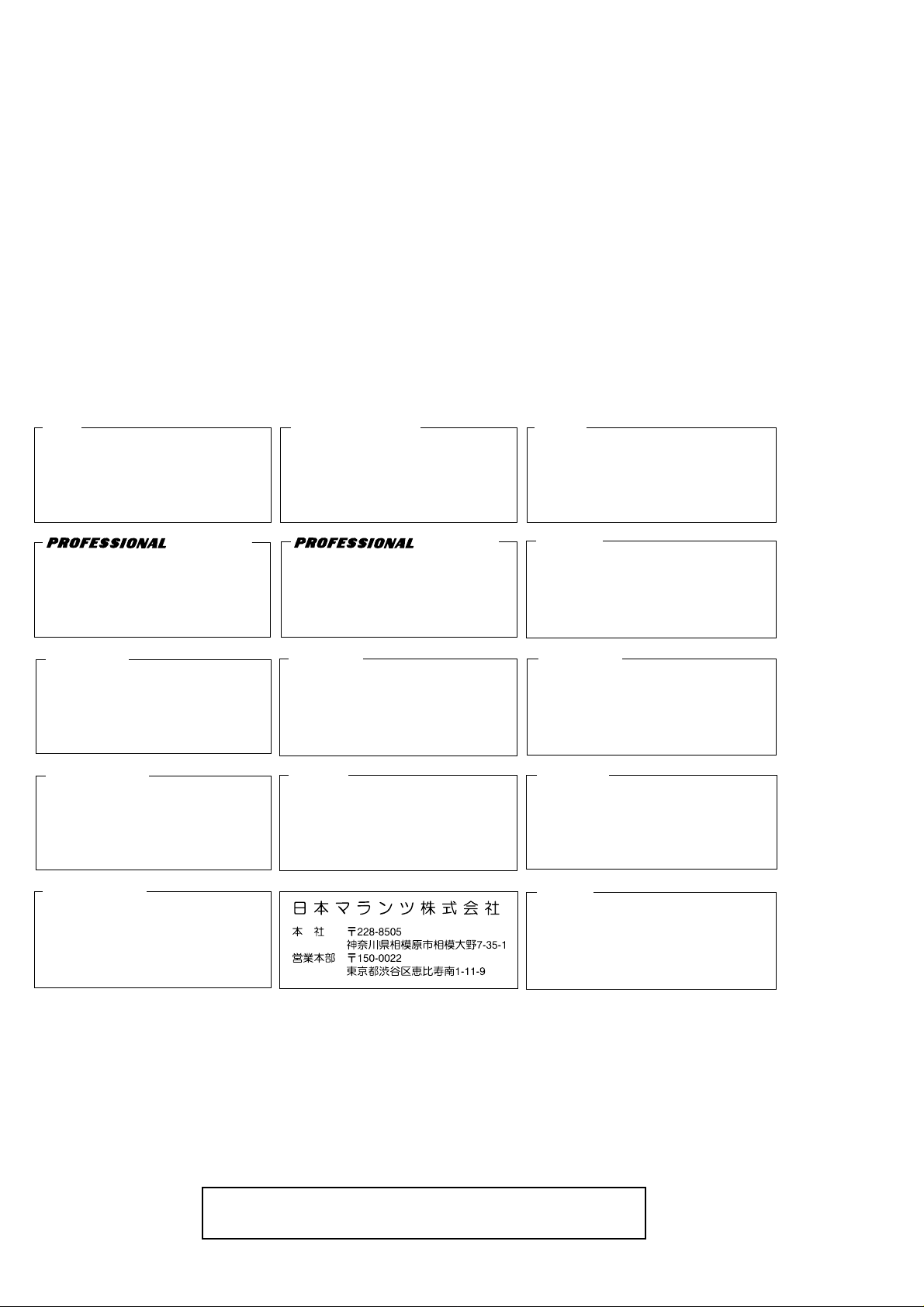

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

it is famous.

Parts for your

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

USA

MARANTZ AMERICA, INCMARANTZ AMERICA, INC.

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIPS DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

130 JOO SENG ROAD

#03-02 OLIVINE BUILDING

SINGAPORE 368357

PHONE : +65 858 5535 / +65 381 8621

FAX : +65 858 6078

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

Technical

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

001120 A.O

Page 3

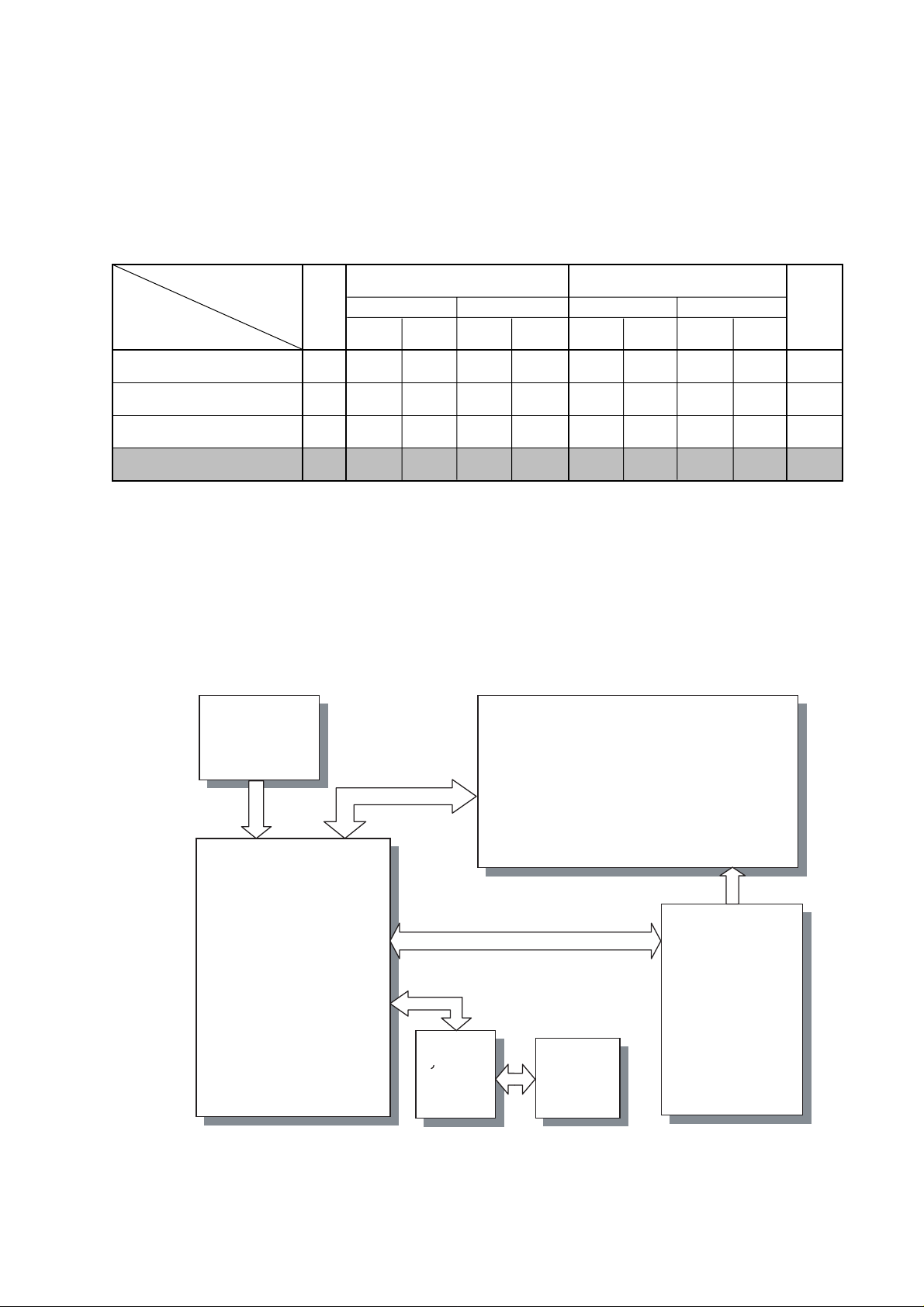

1. Servicing the DR2100

1.1 INTRODUCTION:

The DR2100 is the consumer version of a CD recorder, this means that the SCMS (Serial Copy Management System) is

included. The DR2100 can only record on the Audio CDRs (Consumer Use).

The DR2100 is suitable for recording and playback of CD-RW discs (CD-Re Writable disc).

Playback & Recording and Disc

Disc

Player/Recorder

Audio CD Player

Current products Ex:CD-17

Audio CD Player

CD-RW playback Ex:CD-17MK II

CD-RW Recorder

For Professional Ex:CDR630/640

CD-RW Recorder

For Consumer Ex:DR2100

CDR

CD

Consumer Disc

Finalized

non

Finalized

Professional Disc

Finalized Finalized

non

Finalized

Consumer Disc

Finalized

PP no P no no no no no -

PP no P no P no P no -

P P P/R P P/R P/R P/R P/R P/R no

P P P/R P P P/R P/R P YES

CD-RW

non

Finalized

Professional Disc

non

Finalized

P

SCMS

Consumer : For Digital Audio

Professional : For General use (Including PC)

P : Playback

R : Recording

1.2 OPENING THE PRODUCT:

The product can be opened by removing the top cover (6 screws). Once the product is opened one can have access to the

several PCB's and the main module.

Power Supply

PCB

CDR Module

MAR775

u-COM

PCB

DISPLAY

PCB

Below the several PCB's and it function and service policy will be discussed:

Rear Terminal

PCB

CD

Loader

MAR1250

1

Page 4

1.2.1 CDR loader (CDR main module CDL4009 or MAR775):

This complete CDR loader is considered as not repairable in the field. therefore this module will be repaired centrally. A

module exchange procedure will be set up for this purpose. The module can be removed from the product by removing 4

screws and the transformer and loosing the connectors.

This module is the complete CD recorder, it contains the following parts:

CD Mechanism (CDM4009'). Underneath this mechanism a PCB is mounted which is adjusted to the mechanism (laser

current settings are stored in EEPROM).

Loader Assy. This mechanical assy takes care for the tray control.

Main PCB. This PCB takes care that the (analog or digital) signal to be recorded is converted into a suitable signal which

can be recorded on the disc.

Digital signals with an other sampling frequency then 44.1kHz will be converted in the sample rate converter (DASP) to

44.1kHz.

Analog signals will be first converted into a digital converter by the AD converter.

This PCB also takes care that the signal from the CD (playback) is converted into a suitable digital signal (or analog via

the DA converter).

The main microprocessor controls the several functions of this PCB.

1.2.2 Power Supply PCB.

This PCB contains the Power SW, which is jointed the Power bottom on the front panel. This PCB consists of power supply

part. The power suppluy part delivers the several voltages for the diffrent PCB in the DR2100. On this power supply one

fuse (primary side) is mounted on this PCB. All parts are available as spare parts.

1.2.3 Terminal PCB.

This PCB coutaius input and output terminals. All parts are available as spare parts.

1.2.4 Display Board.

This PCB contains the Display, which informs the user about the status of the recording/playback process and it also takes

care for scanning the keys on the front panel. The information from the keys is fed via a I C connection to the main

microprocessor on the CDR loader module. Information which needs to be displayed is also fed via this I C line from the

main microprocessor on the CDR loader module to the display controller.

The parts for this PCB are available as service parts so this PCB can be repairable up to component level.

2

2

IMPORTANT

In case of replace the CD-R module "MAR775", the initialization is necessary.

Please initialize the CD-R module with following orders.

1. Press the POWER button (POWER ON) while depressing FINALIZE button and REC

TYPE button together.

2. LCD Display shows;

WAIT

PGM PROTOCOL

PGM PORT END

3. Press the POWER button (POWER OFF).

Then the CD-R module set up to DR2100 own status.

2

Page 5

2 TECHNICAL SPECIFICATIONS

GENERAL

System .................................................................................................... Compact disc digital audio

Number of channels ................................................................................ 2 (stereo)

Applicable discs ...................................................................................... CD, CD-R (digital audio), CD-RW (digital audio)

Power Requirement

Power Consumption................................................................................ 20 W

Operating Temperature .......................................................................... 5 - 35 °

Dimension (MAX)

Width ................................................................................................. 420 mm

Height................................................................................................ 76 mm

Depth ................................................................................................ 309 mm

Weight................................................................................................ 4.4 kg

AUDIO

Frequency Response.............................................................................. 20 Hz - 20 kHz

Playback S/N .......................................................................................... 100 dB

Playback Dynamic Range....................................................................... 96 dB

Playback Total Harmonic Distortion ........................................................ 0.003 %

Recording S/N......................................................................................... 90 dB

Recording Dynamic Range ..................................................................... 92 dB

Recording Total Harmonic Distortion ...................................................... 0.006 %

Digital Coaxial Output ............................................................................. 0.5 V (p-p) / 75 ohms

Analog Output Voltage ............................................................................ 2 V RMS

Digital Optical Output .............................................................................. - 20 dBm

............................................................................... AC 110 V - 240V 50 / 60 Hz

C

Recording values for line input

Digital Coaxial Input (automatic sample rate conversion)....................... 11 - 56 kHz

Digital Optical Input (automatic sample rate conversion)........................ 11 - 56 kHz

Analog Input ............................................................................................ 600 mVrms / 50 kohms

Specifications subject to change without prior notice.

3

Page 6

3. WARNINGS

WARNING

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically.

When repairing, make sure that you are connected with the

same potential as the mass of the set via a wristband with

resistance. Keep components and tools at this potential.

ATTENTION

Tous les IC et beaucoup d´autres semi-conducteurs sont

sensibles aux décharges statiques (ESD). Leur longévite

pourrait être considérablement écourtée par le fait qu´aucune

précaution nést prise à leur manipulation.

Lors de réparations, s´assurer de bien être relié au même

potentiel que la masse de l´appareil et enfileer le bracelet

serti d´une résistance de sécurité.

Veiller à ce que les composants ainsi que les outils que l´on

utilise soient également à ce potentiel.

WARNUNG

Alle ICs und viele andere Halbleiter sind empfindlich

gegenüber elektrostatischen Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kann die

Lebensdauer drastisch reduzieren.

Sorgen Sie dafür, daß sie im Reparaturfall über ein Pulsarmband mit Widerstand mit dem Massepotential des

Gerätes verbunden sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls auf diesem

Potential.

AVAILABLE ESD PROTECTION EQUIPMENT :

anti-static table mat large 1200x650x1.25mm 4822 466 10953

anti-static wristband 4822 395 10223

connection box (3 press stud connections, 1M ) 4822 320 11307

extendible cable (2m, 2M , to connect wristband to connection box) 4822 320 11305

connecting cable (3m, 2M , to connect table mat to connection box) 4822 320 11306

earth cable (1M , to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

wristband tester 4822 344 13999

ESD

WAARSCHUWING

Alle IC´s en vele andere halfgeleiders zijn gevoelig voor

electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de levensduur

drastisch doen vermindern. Zorg ervoor dat u tijdens reparatie

via een polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat.

Houd componenten en hulpmiddelen ook op ditzelfde potentiaal.

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili alle scariche

statiche (ESD).

La loro longevità potrebbe essere fortemente ridatta in caso di

non osservazione della più grande cauzione alla loro

manipolazione. Durante le riparationi occorre quindi essere

collegato allo stesso potenziale che quello della massa

delápparecchio tramite un braccialetto a resistenza.

Assicurarsi che i componenti e anche gli utensili con quali si

lavora siano anche a questo potenziale.

small 600x650x1.25mm 4822 466 10958

Safety regulations require that the set be restored to its

original condition and that parts which are identical with

those specified be used.

Safety components are marked by the symbol

Les normes de sécurité exigent que l`appareil soit remis

à l`état d`origine et que soient utilisées les pièces de

rechange identiques à celles spécifiées.

Les composants de sécurité sont marqués

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten. Der Originalzustand des Gerätes

darf nicht verändert werden. Für Reparaturen sind Originalersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol markiert.

U : VERSION N : VERSION

DANGER: Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Varning !

Advarsel !

Osynlig laserstrålning när apparaten är öppnad och

spärren är urkopplad. Betrakta ej strålen.

Usynlig laserstråling ved åbning når sikkerhedsafbrydere

er ude af funktion. Undgå udsaettelse for stråling.

CLASS III b

LASER PRODUCT

SAFETY

Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkeliijke toestand wordt teruggebracht en dat

onderdelen, identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

Le norme di sicurezza estigono che l´apparecchio venga

rimesso nelle condizioni originali e che siano utilizzati i

pezzi di ricambiago identici a quelli specificati.

Componenty di sicurezza sono marcati con

CLASS 3B

LASER PRODUCT

Varoitus !

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen !

After servicing and before returning the set to customer

perform a leakage current measurement test from all

exposed metal parts to earth ground, to assure no

shock hazard exists.

The leakage current must not exceed 0.5mA.

"Pour votre sécurite, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

4

Page 7

4. SERVICE HINTS AND TOOLS

SERVICE TOOLS

The tools listed below are standard test tools that can be used for repairing and testing Marantz

CD Players & Recorders.

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

Hexagon socket screw button (No. 1.5)

5

Page 8

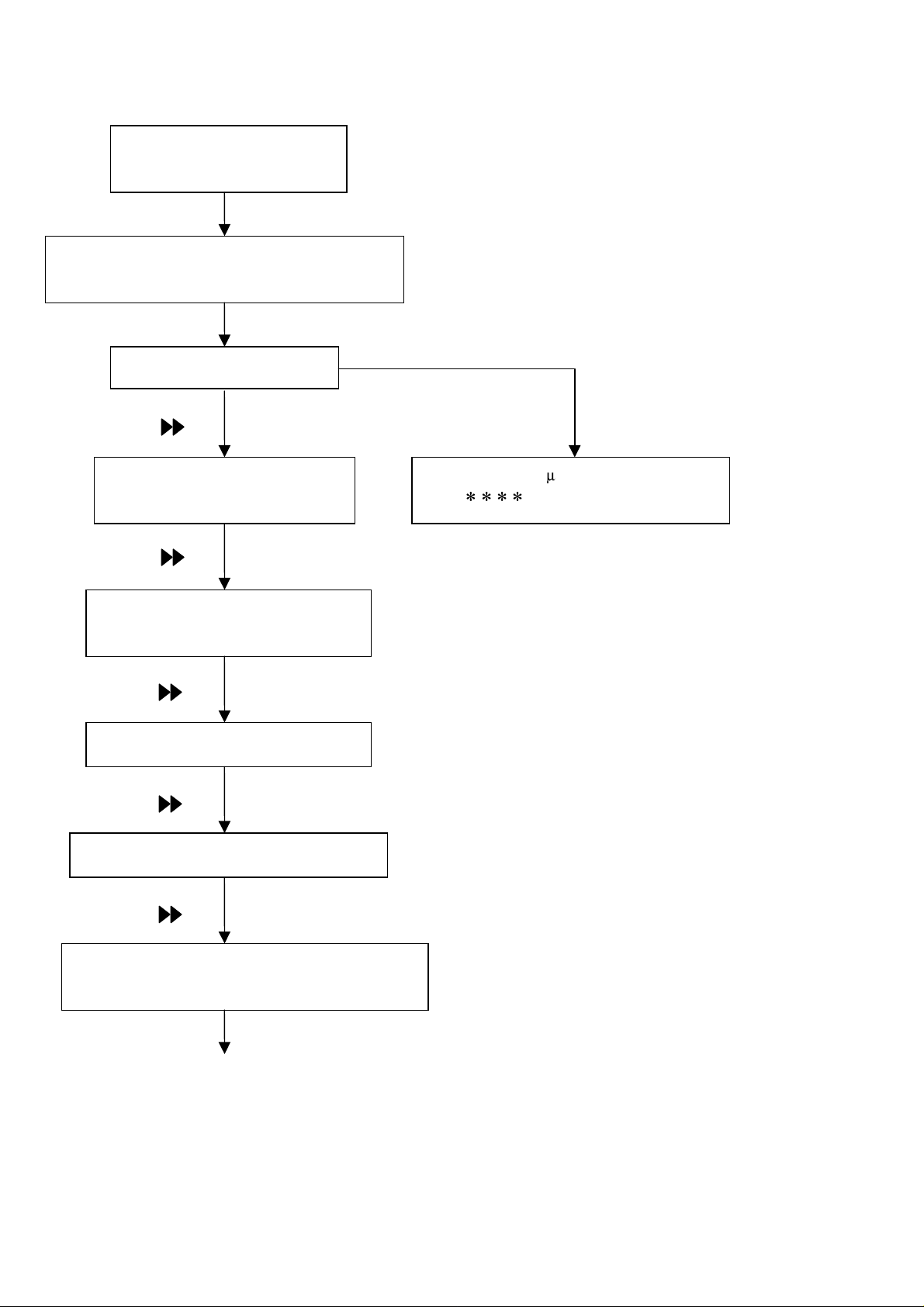

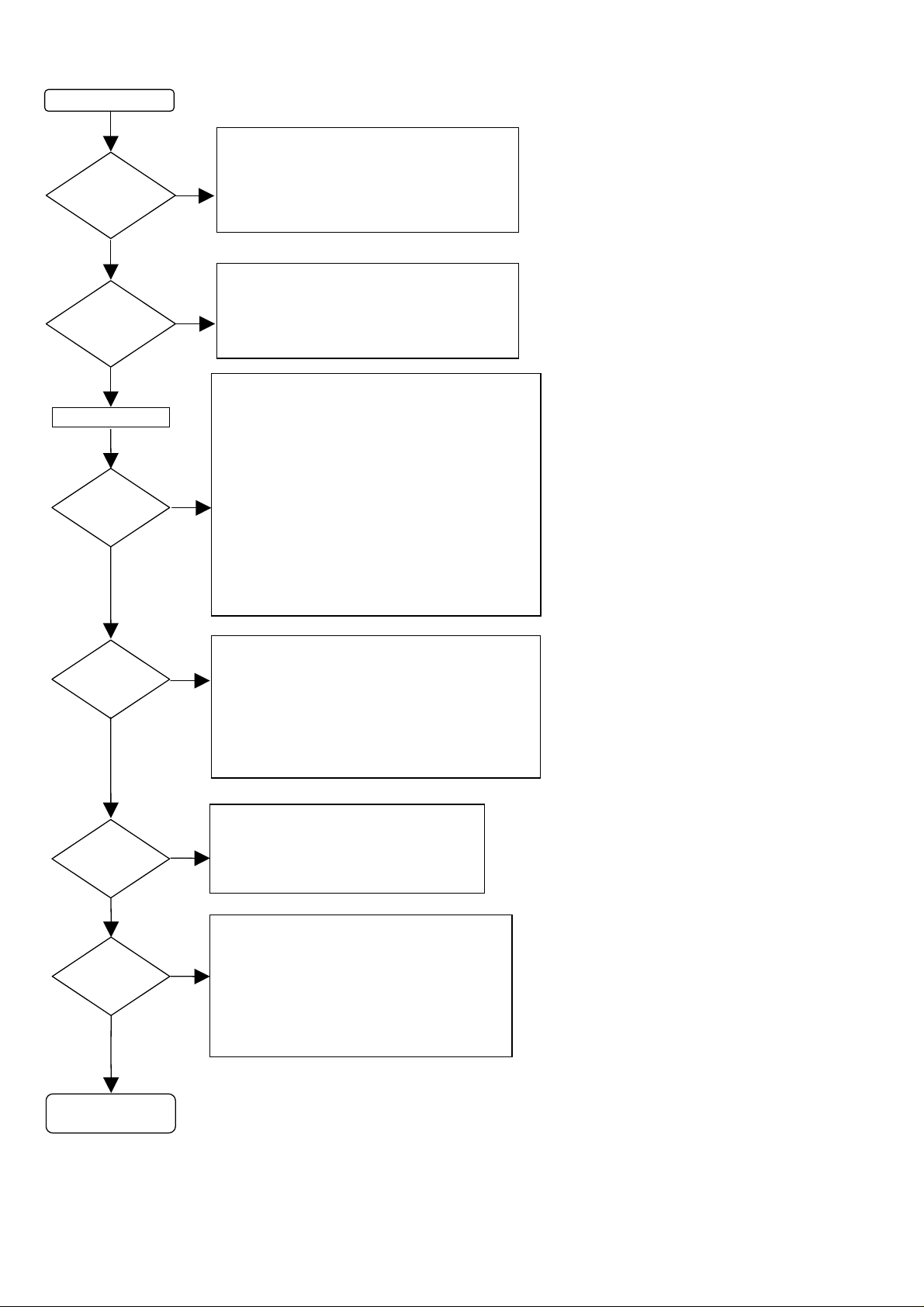

5. SERVICE MODE

The plug is in the socket

Turn off the POWER

Press<POWER>while pressing

<ENTER>and<PLAY/PAUSE> of CD player

“SERVICE_1” is displayed

Press< >

STANDBY LED Light on RED

“POWER_LED” is displayed

Press< >

STANDBY LED Light on GREEN

“POWER_LED” is displayed

Press< >

All parts of LCD is turned on

Press< >

Press<ENTER>and<PLAY/PAUSE> of CD Player

Version of MAIN

“VER

-COM is displayed

” is displayed

Each Segment is displayed one by one

Press< >

Check of key

When key is depressed,key name is displayed

Shut off the power

6

Page 9

6. DIAGNOSTICS SOFTWARE

6.1 Dealer mode

The purpose of the dealer mode is to prevent people taking out

the CD inside the player at exhibitions, showrooms etc.. This

mode disables the open/close function of the player.

The dealer mode can be switched on and off pressing keys

[OPEN/CLOSE] and [STOP] of the CDR player simultaneously

while switching on the unit. The dealer mode is stored in the

flash memory and can only be changed by executing the above

actions.

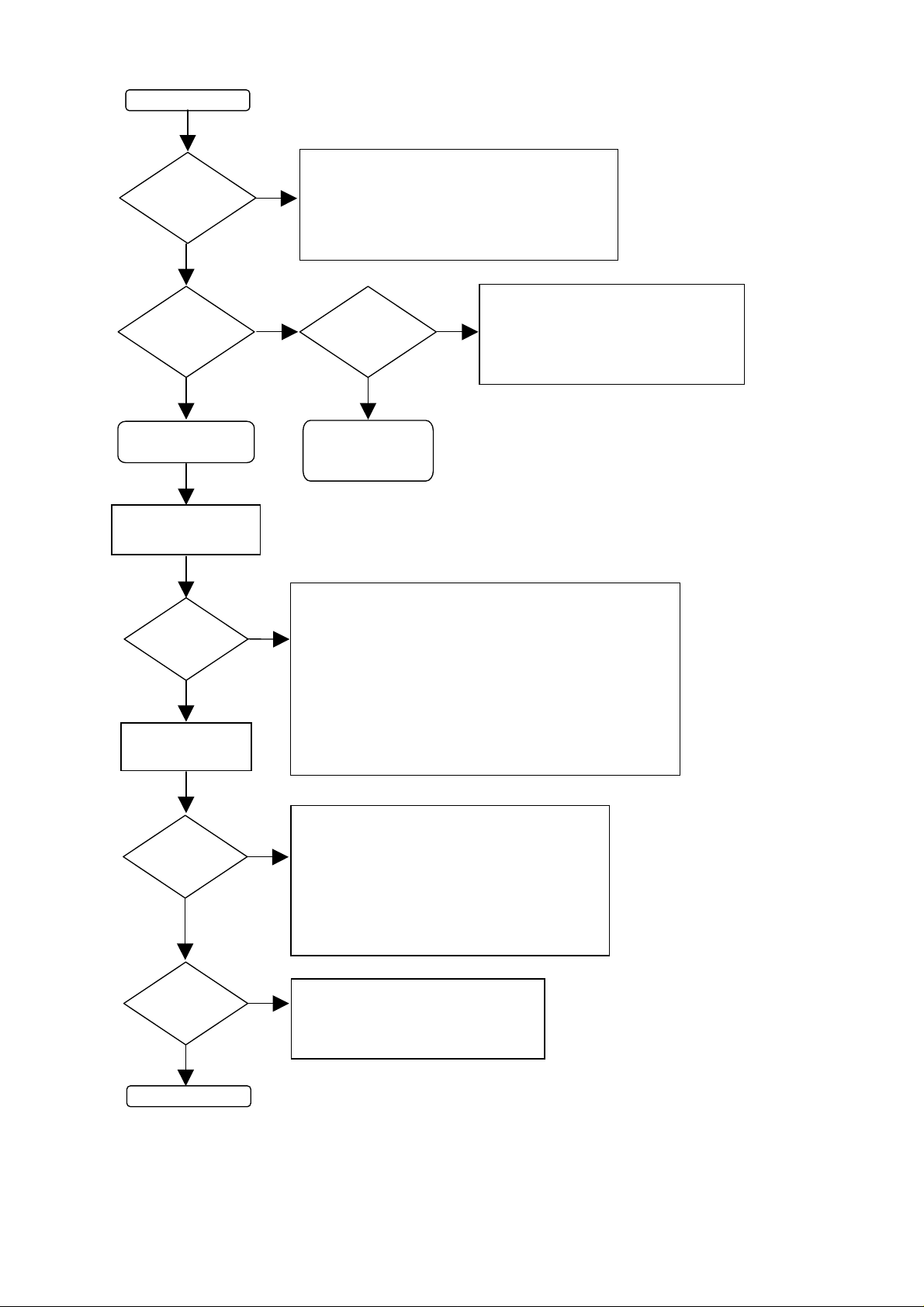

6.2 Dealer diagnostics

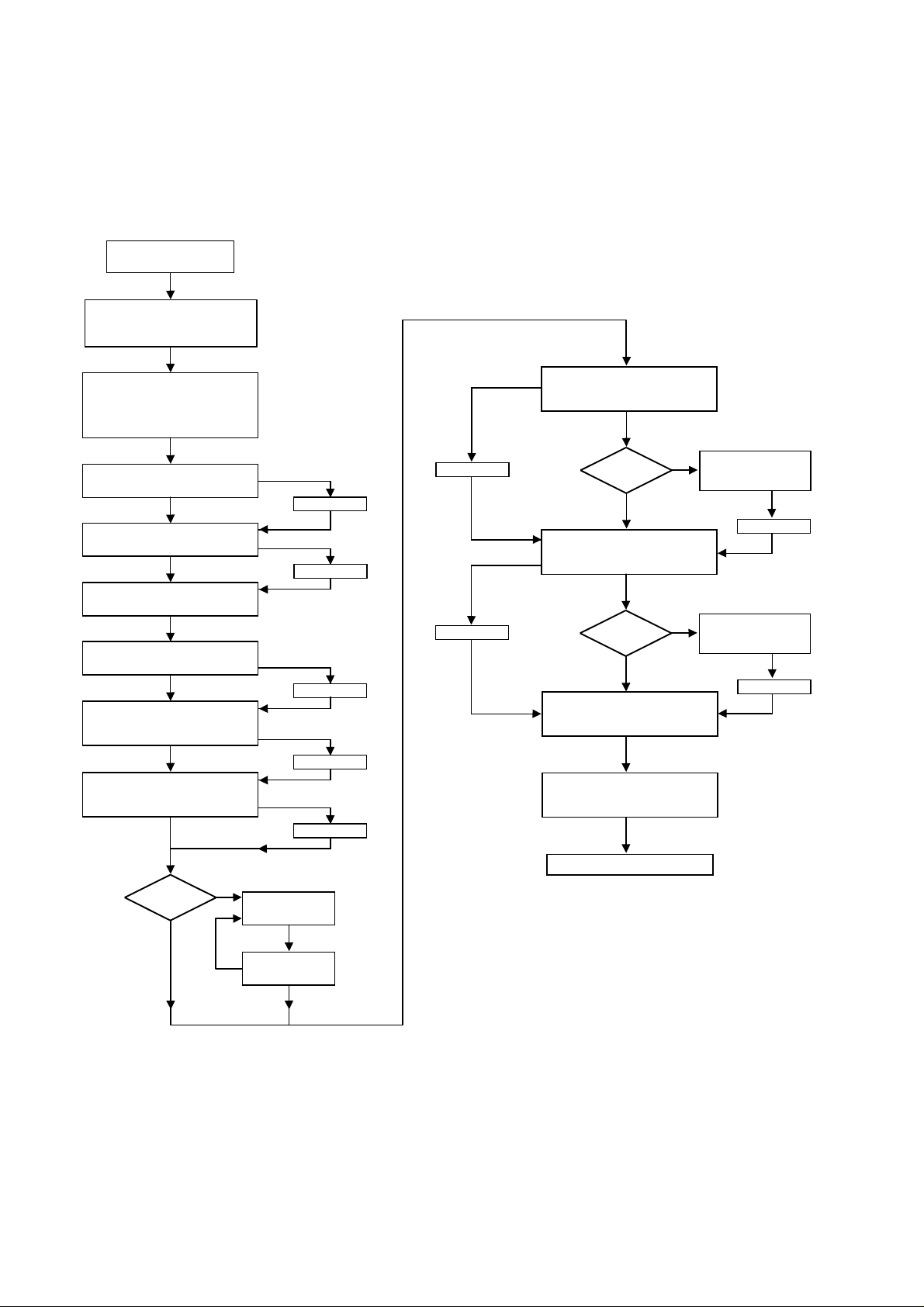

DEALER DIAGNOSTICS

(status of player)

If power ON,

switch power OFF

Press <ENTER> + <FFWD>

simultaneously and switch

ON unit

6.2.2 Requirements to perfo rm the test

Working keyboard to start up the test.

Working local display to check the output messages.

Display blinks

“BUSY”

during test

NO

Set OK?

YES

Set displays

“

PASSED

To end test, switch OFF unit

6.2.1 Description

The intention of the dealer diagnostics is to give an indication

of the CDR player status. An inexperienced, even nontechnical dealer will/can perform the test. Tests are executed

automatically without need for external tools or disassembly of

the unit. This test checks the CDR main board using the same

tests as the electrical service diagnostics program. Only the

result of the test, "PASSED" or "ERROR", will be shown on the

display. Pressing keys [F FWD] and [REWIND] simultaneously

while switching on the unit, starts the test. Switching off the uni t

ends the test.

”

Figure 6-1

Set displays

“ERROR”

CL96532086-024.eps

090999

7

Page 10

6.3 Electrical service diagnostics

ELECTRICAL SERVICE DIAGNOSTICS

(software versions, test for defective components)

If power ON,

switch power OFF

Load CD-DA disc (SBC444A)

Press <ENTER> + <CD STOP>

simultaneously and switch ON unit

PLAYER

INFORMATION

Display :

"PLAYER ID"

"SW VERSION BACK END"

"SW VERSION CDR LOADER"

"SW VERSION CD LOADER"

CDR MAIN

BOARD TEST

Display :

"DTST1"

DRAM test (7702)

PASS OR FAIL

Display :

"DTST2"

FLASH CHECKSUM test (7702)

PASS OR FAIL

Display :

"DTST3"

FLASH ERASE test (7702)

PASS OR FAIL

Display :

"DTST4"

CODEC test (7702)

PASS OR FAIL

Display :

"DTST5"

CDR LOADER

COMMUNICATION test

PASS OR FAIL

Display :

"DTST6"

CD LOADER

COMMUNICATION test

PASS OR FAIL

*

ABORT TEST

ABORT TEST

ABORT TEST

ABORT TEST

ABORT TEST

Press <F FWD>

Press <F FWD>

Press <F FWD>

Press <F FWD>

Press <F FWD>

ABORT TEST

Press <F FWD>

ABORT TEST

Press <F FWD>

LOADER TESTS

CDR LOADER TEST

CD-DA disc must be loaded

Display shows current disc time

Test OK?

YES

CD LOADER TEST

CD-DA disc must be loaded

Display shows current disc time

Test OK?

YES

DISPLAY TEST

DISPLAY TEST

Display segments blink at f=1kHz

KEYBOARD &

RC TEST

KEYBOARD & RC TEST

Display shows name of pressed keys

Press <F FWD>

NO

NO

Display :

or

or

Display :

or

or

"BERR1"

"NO CDDA"

"NO DISC"

Press <F FWD>

"BERR2"

"NO CDDA"

"NO DISC"

Press <F FWD>

Tests OK?

YES

NO

Display :

"DERRn"

n = failed test

Display next

failed test

Figure 6-2

8

To end test, switch OFF unit

CL 96532086_025.eps

080999

Page 11

6.3.1 Description

The intention of the electrical service diagnostics is to show the

software versions present in the player and to direct the dealer

towards defective internal units. The units are : the CDR main

board, the CDR loader, the CD loader in case of a DR6050 and

the keyboard/display board. A sequence of tests is executed

automatically. Some of the te sts can be aborted or skipped

without the result being taken into account. External tools or

disassembly of the unit is not necessary to get the diagnostic

information. Pressing keys [ENTER] and [CD STOP].

simultaneously while switching on the unit, starts the test.

Switching off the unit ends the test.

6.3.2 Requirements to perform the test

Working keyboard t o st art up the test.

Working loc al display to check the output messages.

A CD-DA disc with a minimum of 3 tracks in all trays to

perform the disc test.

6.3.3 Description of the tests

disc test is executed to check focus control, disc motor control,

radial control and jump grooves control. The d isc test is

performed by audio play-back of 5 seconds at the beginning,

middle and end of the disc.

CDR loader test

During the test, the current disc time is shown. In case of an

error the message "BERR1" will be displayed and the [F FWD]

key must be pressed to continue with the following test.

Pressing the [F FWD] key also aborts this test.

CD loader test

During the test, the current disc time is

shown.

In case of an error the message "BERR2" will be

displayed and the [F FWD] key must be pressed to continue

with the following test. Pressing the [F FWD] key also aborts

this test.

Display test

All segments will blink at a frequency of 1 Hz. Pressing the [F

FWD] key will start the next test because the user has to check

for himself if all segments work properly.

Player information

In this part of the test the following important information can be

checked without removing the cover :

Recorder ID.

SW-version back end of player.

SW-ver sion CDR loader.

SW-version CD loader.

CDR main board test

[F FWD] key. The message "DERRn" will be displayed with n

indicating the faulty test number.

If one of the tests is aborted with the [F FWD] key, no error

message will be displayed for this test. The flash data erase

test ("DTST3") can not be aborted !

The CDR main board test consists out of :

DRAM test

Display : "DTST1". The DRAM used for buffer management is

tested by writing, reading and verifying test patterns.

Flash checksum test

Display : "DTST2". This test checks the checksum of the

player's SW stored in the flash.

Flash data erase

Display : "DTST3". During this test, all temporary information

(CDtxt) in the flash is erased.

CODEC (ADC/DAC) test

Display : "DTST4". This test checks the CODEC IC by writing,

reading and verifying test patterns.

CDR communication test

Display : "DTST5". The communication between the host

processor (DASP) and the CDR loader via the DSA-R-bus is

tested.

Keyboard and remote control tests

The test will give the user the ability to test every key without

executing the function assigned to it. Therefore, the user needs

to press every key on the keyboard and the remote control. The

display will show the name of the key being pressed. Pressing

more than one key at once will give an unpredictable result

except for the service combinations : [ENTER] + [DISPLAY],

[ENTER] + [CD STOP], [ENTER] + [F FWD], [ENTER] +

[MENU], [ENTER] + [CANCEL], [ENTER] + [CD PLAY].

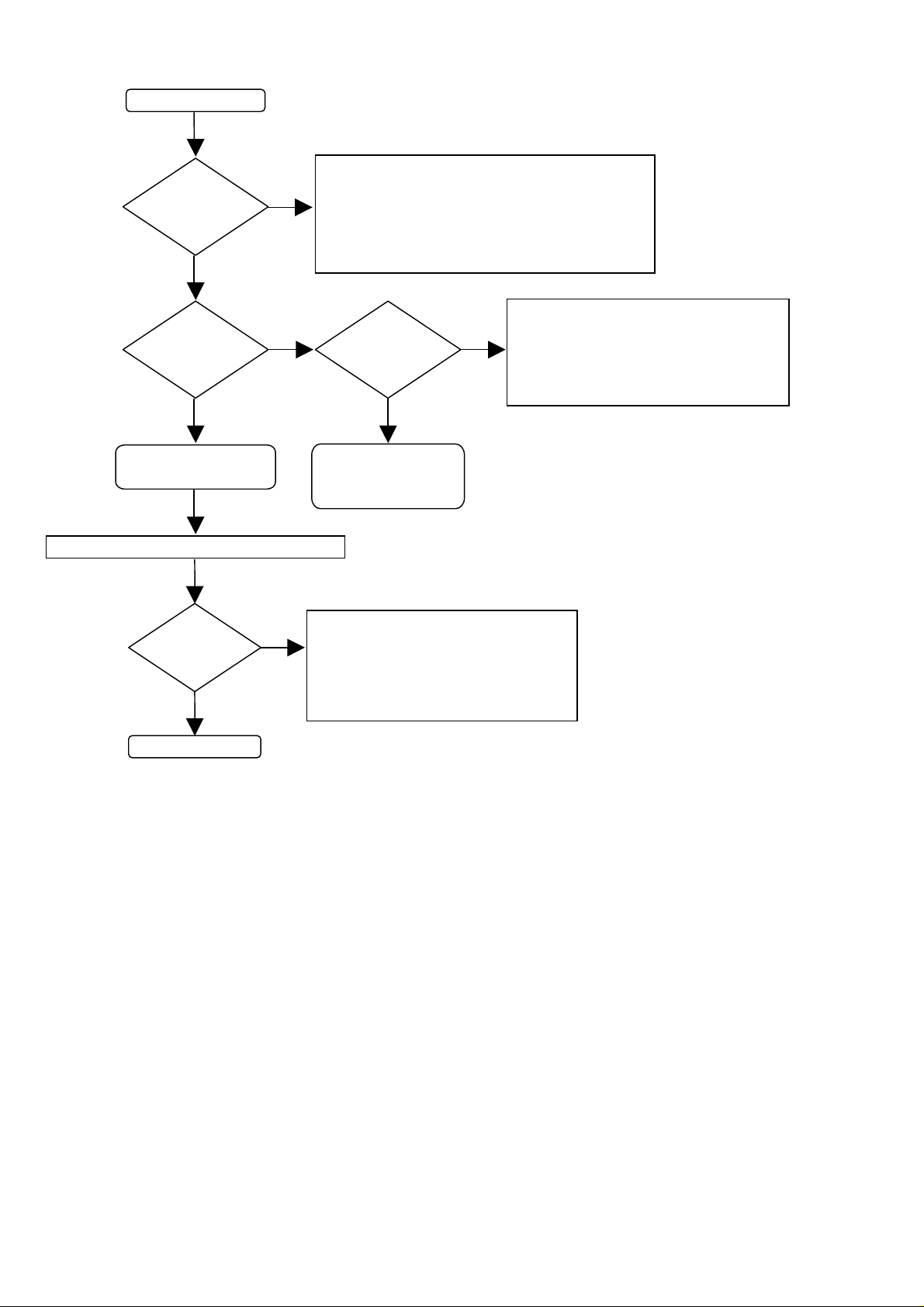

6.4 Mechanical service diagnostics

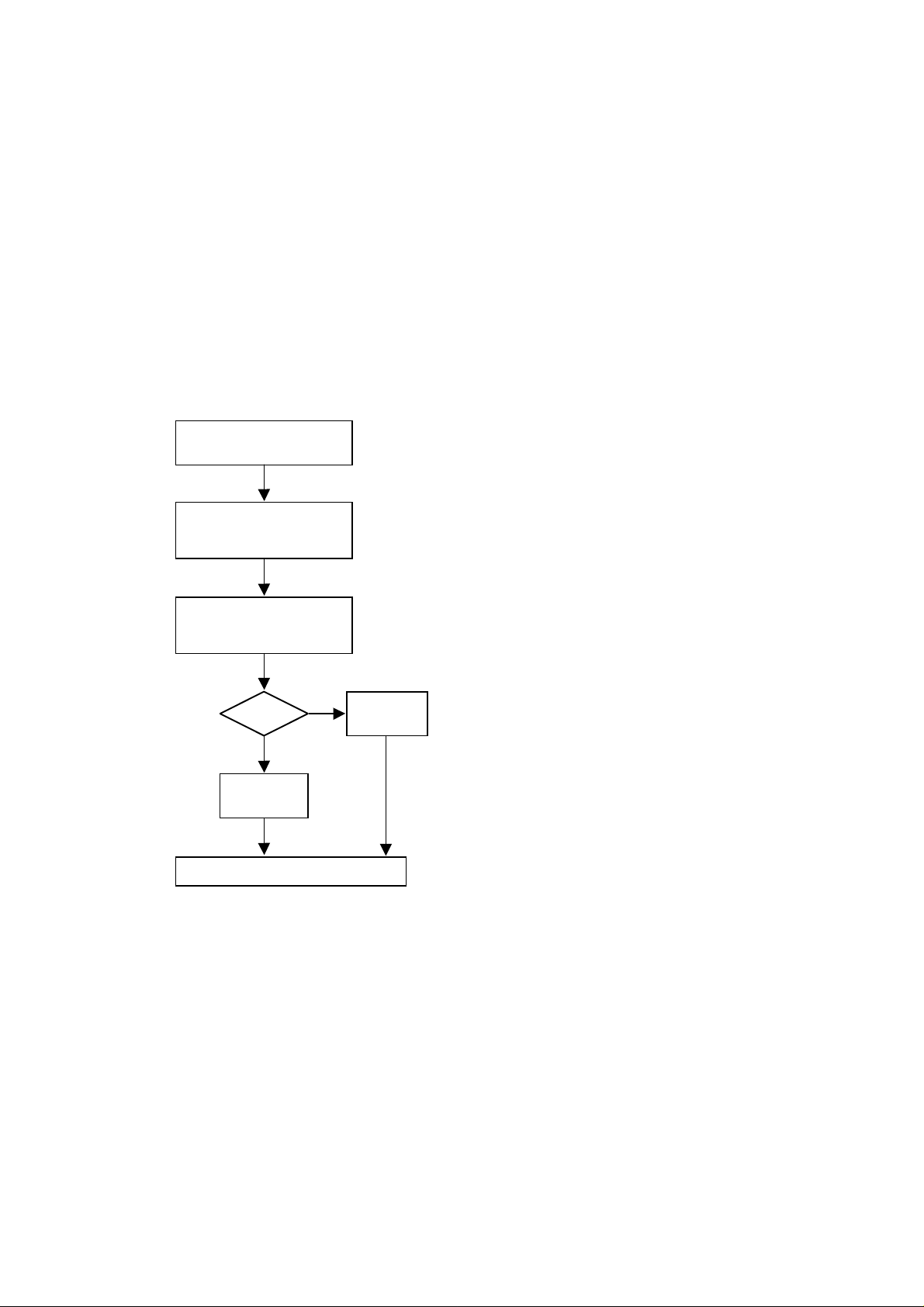

MECHANICAL SERVICE DIAGNOSTICS

(test for defective components)

If power ON,

switch power OFF

Press <ENTER> + <DISPLAY>

simultaneously and switch

ON unit

FOCUS TEST

Display shows

To end test, switch OFF unit

6.4.1 Description

“BUSY”

Visual inspection

SLEDGE TEST

Visual inspection

Display shows

<FWD><REWIND>

“BUSY”

Figure 6-3

CL96532086_026.eps

080999

CD communication test

Display : "DTST6"). The communication between the host

processor (DASP) and the CD loader is tested.

Loader tests

These tests determine if the CDR loader and the CD loader in

case of a DR2100 work correctly. A CD-DA disc with a

minimum of 3 tracks needs to be inserted in both loaders. A

No external tools are required to perform this test. The cover

needs to be removed because the user has to check the

movements of the tray, focus and sledge visually. Pressing

keys [ENTER] and [DISPLAY] simultaneously while

switching on the unit, starts the test. Switching off the unit ends

the test. In case of a DR2100, one can check the CD loader

mechanics in the same way by pressing the above key

combination on the CD player keys.

9

Page 12

6.4.2 Requirements to perform the test

6.5.1 Description

Working keyboard to cycle through the tests and to start up

the test.

Working local display to check the output messages.

6.4.3 Description of the tests

Focus control test

The focussing lens is continuously moving up and down. The

display reads "BUSY".

Sledge control test

After pressing [F FWD] the sledge continuously moves up and

down. Pressing [REWIND] stops the sledge at the position it is

in and the focus control test resumes. The display reads

"BUSY".

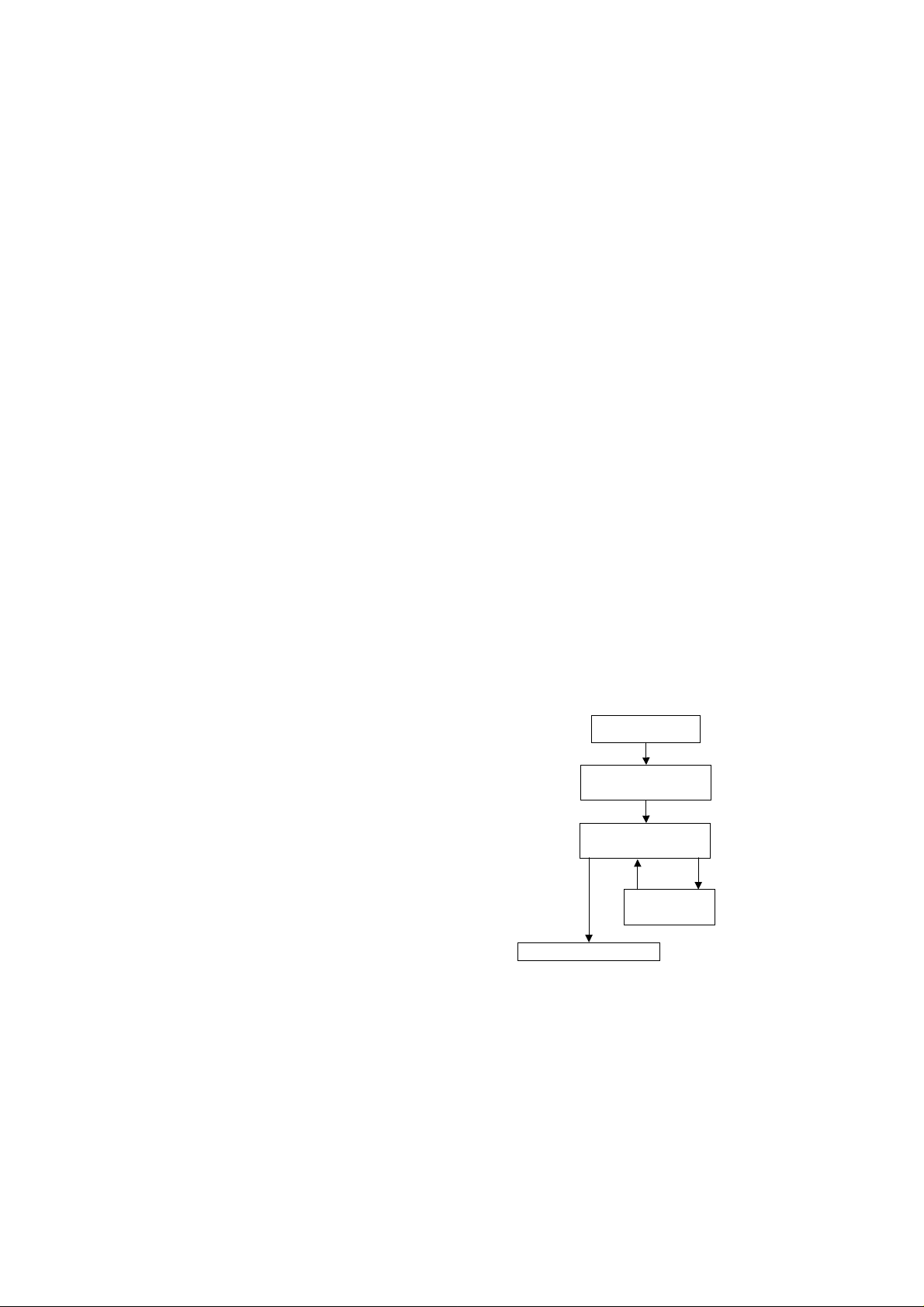

6.5 DC-er ase se rvice mode

DC ERASE SERVICE MODE

(erasement of complete CD-RW)

Load CD-RW disc

Press

<ENTER> + <MENU/STORE>

simultaneously and switc h

ON unit

This test is initiated by pressing [ENTER] and [MENU/STORE]

simultaneously while switching on the unit. The player will

erase a complete CD-RW disc (including PMA and ATIP lead

out area) at speed N=2. The display shows the countdown of

the remaining time required for the operation to complete. The

format is "ER mm:ss", where "mm" are the remaining minutes

and "ss" the remaining seconds. After completion the message

"PASSED" is shown, and the player has to be switched off and

on again to start up in normal operating mode. Switching off the

unit before completion of the test, leaves the disc in an

unpredictable state. In such case only a complete DC-erase

procedure can recover the CD-RW disc.

6.5.2 Requirements to perform the test

Functional CDR player.

A CD-RW audio disc must be present in the tray.

Display shows:

mm

ER mm:ss

“

:remaining minutes

”

ss :remaining seconds

TOTAL

and

REM

are also

illuminated

Display shows:

“

PASSED

”

when the erase function is

completed

ERROR

“

”

if DC ERASE fails

To end test, switch OFF unit

CL96532086_027.eps

Figure 6-4

080999

10

Page 13

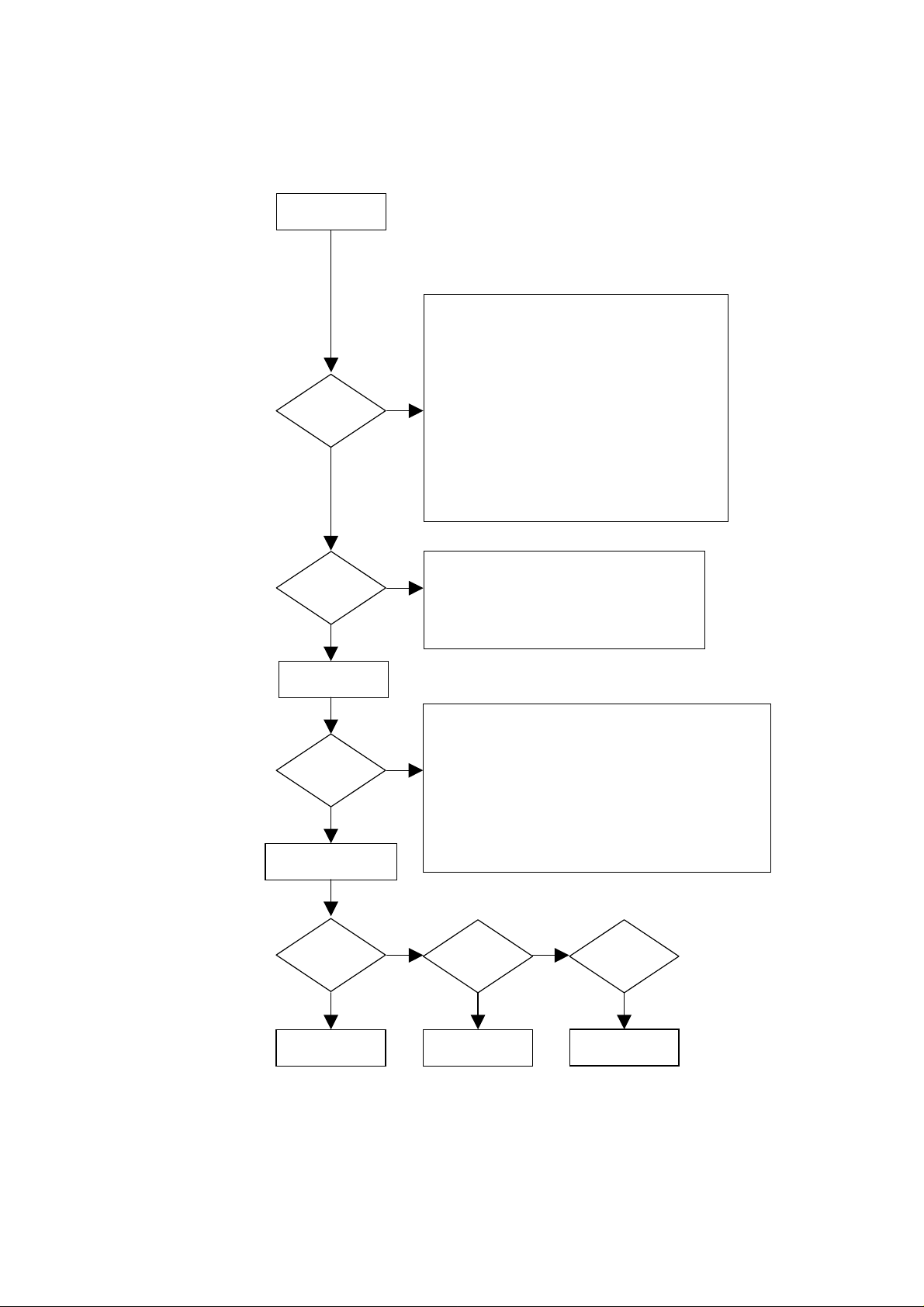

7. Faultfinding trees

7.1 C DR-Module (MAR775)

NO DISC LOADED

SWITCH ON POWER

DISPLAY?

YES

NO

CHECK:

MAINS, MAINS CABLE

POWER SUPPLY (SEE FAULT FINDING GUIDE PSU)

DISPLAY (SEE FAULT FINDING GUIDE DISPLAY BOARD)

WIRING

ON/OFF SWITCH

FUSES

VOLTAGES

WIRING

SUPPLY VOLTAGES

CLOCK SIGNAL 8MHz

CONTROL SIGNALS

KEYBOARD

STANDBY LED

ELECTRICAL SERVICE DIAGNOSTICS:

DISPLAY TEST, KEYBOARD TEST

DISPLAY:

"INSERT DISC"

YES

PRESS

<OPEN/CLOSE>

TRAY?

YES

INSERT DISC

PRESS <OPEN/CLOSE>

CD-DA DISC

LOADED?

CHECK:

NO

NO

WIRING

POWER SUPPLY VOLTAGE S

ELECTRICAL SERVICE DIAGN O STICS:

REPLACE CDR MODULE IF

OR

"BERRn"

CHECK:

DISPLAY BOARD (SEE FAULT FINDING GUIDE DISPLAY BOARD)

MECHANICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF ERROR OCCURS

CD-R DISC

LOADED?

YESYES

ERROR OCCURS

WIRING

SUPPLY VOLTAGES

CLOCK SIGNAL 8MHz

CONTROL SIGNALS

KEYBOARD

ELECTRICAL SERVICE DIAGNOSTICS:

DISPLAY TEST, KEYBOARD TEST

NONO

"DERRn"

CD-RW DISC

LOADED?

YES

SEE CD-DA DISC

FAULT FINDING

SEE CD-R DISC

FAULT FINDING

Figure 7-1

11

SEE CD-RW DISC

FAULT FINDING

CL 96532076_016.eps

290799

Page 14

CD-DA DISC LOADED

DISC

DETECTION &

READING?

YES

DISPLAY:

“CD”

&

T.O.C. INFO?

NO

NO

CHECK:

WIRING

POWER SUPPLY VOLTAG E S

ELECTRICAL SER VICE DIAG N O STICS:

REPLACE CDR MODULE IF

OR

"BERRn"

CHECK:

DISC: DIRT, SCRATCHES, DAMAGED...

ELECTRICAL SER VICE DIAG N O STICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

ERROR OCCURS

"DERRn"

"DERRn"

YES

PRESS <PLAY>

ANALOG

AUDIO

OUT?

YES

DISTORTION?

NO

HEADPHONE?

YES

DIGITAL

AUDIO

OUT?

YES

NO

YES

NO

NO

CHECK:

AUDIO CONNECTIONS & CABLES

REAR TERMINAL BOARD

W651 CONNECTION

FLEX CONNECTION

+5V (pin 8 conn. JJ01)

KILL VOLTAGE (pin 7 conn. JJ01):

-8V DURING PLAY

KILL TRANSISTORS QN51 - QN52

PLAY AUDIO SIGNAL S DI SC TRACK 15 :

SIGNAL OF 5.4 VPP ON PINS 1 AND 3 OF CONN.

JJ02

ELECTRICAL SER VICE DIAG N O STICS:

REPLACE CDR MODULE IF

OR

"BERRn"

CHECK:

AUDIO CONNECTIONS & CABLES

REAR TERMINAL BOARD

ELECTRICAL SER VICE DIAG N O STICS:

REPLACE CDR MODULE IF

OR

"BERRn"

CHECK:

WIRING OF HEADPHONE/IR BOARD

ELECTRICAL SER VICE DIAG N O STICS:

REPLACE CDR MODULE IF

OR

"BERRn"

CHECK:

AUDIO CONNECTIONS & CABLES

REAR TERMINAL BOARD

ELECTRICAL SER VICE DIAG N O STICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

FLEX CONNECTION

+5V (pin 8 conn. JJ01)

ERROR OCCURS

ERROR OCCURS

FLEX CONNECTION

+5V (pin 8 conn. JJ01)

DIGITAL OUT TRANSFORMER LT02, Q311

ERROR OCCURS

"DERRn"

"DERRn"

"DERRn"

"DERRn"

PLAY BACK OF CD-DA

DISCS OK

Figure 7-2

CL 96532076_017.eps

290799

12

Page 15

CD-R DISC LOADED

DISC

DETECTION &

READING?

YES

DISPLAY:

“CD R”

OPC INFO?

&

YES

NO

NO

CHECK:

WIRING

POWER SUPPLY VOLTAG ES

ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

CHECK:

DISPLAY:

“CD”

&

T.O.C. INFO?

NO

YES

DISC: DIRT, SCRATCHES, DAMAGED...

ELECTRICAL SER VICE DI AGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

CD-R DISC PARTIALLY

RECORDED OR EMPTY

START MANUAL

RECORDING FROM

ANALOG SOURCE

LEVEL

ADJUSTABLE?

YES

START RECORDING

FROM DIGITAL

SOURCE

DIGITAL IN?

OPTICAL IN?

YES

NO

NO

FINALISED CD-R DISC

LOADED

SEE CD-DA DISC

FAULT FINDING

CHECK:

AUDIO CONNECTIONS & CABLES

DISPLAY BOARD (SEE FAULT FINDING GUIDE DISPLAY BOARD)

EASY JOG KNOB

I2C COMMUNICATION

ELECTRICAL SERVICE DIAGNOSTICS:

KEYBOARD TEST

ELECTRICAL SER VICE DI AGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

CHECK:

AUDIO CONNECTIONS & CABLES

I/O BOARD

FLEX CONNECTION

+5V (pin 8 conn. JJ01)

Q311, OPTICAL RECEIVER J301

ELECTRICAL SER VICE DI AGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

RECORDING

SUCCESSFUL?

YES

SET OK

NO

CHECK:

ELECTRICAL SERVICE DIAGNOSTICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

Figure 7-3

13

CL 96532076_018.eps

290799

Page 16

CD-RW DISC LOADED

DISC

DETECTION &

READING?

YES

DISPLAY:

“CD RW”

&

OPC INFO?

YES

NO

NO

CHECK:

WIRING

POWER SUPPLY VOLTAGES

ELECTRICAL SERVICE DIAGNOS TICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

CHECK:

DISPLAY:

“CD”

&

NO

T.O.C. INFO?

YES

DISC: DIRT, SCRATCHES, DAMAGED...

ELECTRICAL SERVICE DIAGNOS TICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

CD-RW DISC PARTIALLY

FINALISED CD-RW DISC

RECORDED OR EMPTY

START ERASING OF LAST RECORDED TRACK

CHECK:

ERASING

NO

SUCCESSFUL?

YES

SET OK

LOADED

SEE CD-DA DISC

FAULT FINDING

ELECTRICAL SERVICE DIAGNOS TICS:

REPLACE CDR MODULE IF

OR

"BERRn"

ERROR OCCURS

"DERRn"

IF DISC CORRUPTED TRY DC ERASE

Figure 7-4

CL 96532076_019.eps

290799

14

Page 17

7.2 CD Module

CD MODULE

NO DISC

POWER ON

DISC

DETECTION

STARTS?

YES

DISPLAY?

YES

PRESS

<OPEN/CLOSE>

NO

NO

CHECK FLEX CONNECTION FROM CDR MAIN BOARD

POWER SUPPLY

+5V, +12V AT TESTPOINTS 28 AND 27

+5V AT CONN. 1000 PINS 1 AND 3

+5V AT IC7005 PIN 14

+3V3 AT IC7000 PINS 5,17,21,57, CHECK SAFETY RESISTORS

+5V AT IC7020 PIN 25

+10V AT IC7020 PINS 26, 27, 28

+12V AT IC7021 PIN 5, CHECK SAFETY RESISTOR R3131

+12V AT IC7022 PIN 5, CHECK SAFETY RESISTOR R3154

+5V AT IC7025 PIN 16

+5V AT IC7202 PIN 38, CHECK SAFETY RESISTOR R3308

+3V3 AT IC7309 PINS 4 AND 13, CHECK SAFETY RESISTORS R3215, R3216

+12V AT IC7120 PIN 8, CHECK SAFETY RESISTOR R3263

CLOCKS

8.4672MHz AT TESTPOINT 7

12MHz AT TESTPOINTS 29 AND 30

11.2896 AT TESTPOINT 10

2.1168MHz AT TESPOINT 20

44.1kHz AT TESTPOINT 21

DISPLAY

SEE FAULTFINDING GUIDE DISPLAY BOARD

MICROPROCESSOR 7202

NO

TRAY?

YES

LOAD DISC

(CD-DA OR PARTIALLY

RECORDED CD-R/CD-RW)

PRESS <OPEN/CLO S E >

NO

TOC?

YES

SEE NEXT PAGE:

PLAYBACK

DIAGNOSTIC SOFTWARE : MECHANICAL SERVICE DIAGNOSTICS CD LOADER : TRAY TEST

CHECK TRAY MOTOR VOLTAGES

MICROPROCESSOR 7202

CHECK T RAY MOTOR DRIVER IC7021

REPLACE OR REPAIR CD LOADER ASSY:

TRAY MOTOR ASSY 02, BELT 11

DIAGNOSTIC SOFTWARE : MECHANICAL SERVICE DIAGNOSTICS CD LOADER :

CHECK WIRING TO CDM

CHECK POWER DRIVERS 7021, 7022, 7020

CHECK VOLTAGES ON POWER DRIVERS (SEE CIRCUIT DIAGRAMS)

TESTPOINTS 4, 5, 6 : PULSE DENSITY MODULATED SIGNALS

HF PATH

TESTPOINTS 1, 2, 3, 9 : EYEPATTERN

CHECK

CDRW DISC. EYEPATTE RN OF CDRW DISC WI LL BE AMP LIFIED (

EYEPATTERN OF CDDA DISC WILL BE ATTENUATED(

CHECK

TESTPOINTS 20, 21, 22: I2S

REPLACE OR REPAIR CD LOADER ASSY (CDM MECHANISM)

RW

S1,S2

FOCUS TEST & SLEDGE TEST

AT TESTPOINT 8 : HIGH FOR CDDA AND CDR DISC, LOW FOR

AT TESTPOINTS 25 AND 26 (SEE CIRCUIT DIAGRAMS)

TRAY+, TRAY-

DATA, WCLK, SCLK

»

X 0.8)

»

X 2.5).

CL 96532086_030.eps

080999

Figure 7-5

15

Page 18

CD MODULE PLAYBACK

PRESS <PLAY>

DAC 7309

AUDIO?

YES

NO

OPAMP 7120

TESTPOINTS 20, 21, 22 : I2S AT INPUT OF DAC 7309

CHECK POWER SUPPLY PINS 4, 13

CHECK CLK11 AT PIN 6 : 11.2896MHz

PIN 11 : MUTE HIGH?

TESTPOINTS 23, 24 : ANALOG OUTPUT?

REP LACE DAC 7309

TESTPOINTS 23, 24 : ANALOG OUTPUT?

POWER SUPPLY: PIN 8 12V

REP LA CE OPAMP 7120

DISTORTION?

NO

AUDIO

CD OUT PCB?

YES

PLAYBACK CD

MODULE OK

YES

NO

DAC 7309

OPAMP 7120

FLEX TO CDR MAINBOARD

FLEX TO CD OUT BOARD

CHECK I/O BOARD, CD OUT BOARD

Figure 7-6

CL 96532086_031.eps

080999

16

Page 19

Dimmer Control

The -controller, MB90F553A/MB90553A adjust the brightness of LCD back light by receiving

signal from IR or SYSTEM BUS.

Mode LCD_DIM (1Pin) LCD_BL (2Pin)

Backlight OFF Low Low

Backlight ON Low High

Dimmer ON High Low

8. Faultfinding Guide

8.1 D isplay Boar d

8.1.1 Description of display board

General description

The display board has three major parts : the LCD (Liguid

Crystal Display), the display controller and the

The display controller is controlled by the DASP master

processor on the CDR main board. The communication

protocol used is I2C. So all the information between DASP and

display controller goes via the SDA or I2C DATA and SCL or

I2C CLK lines. Communication is always initiated by the DASP

on the CDR main board. Unlike the previous generations of

CDR players, the interrupt generated by the display controller

at key-press or reception of remote control is not used. Instead,

the DASP polls the display controller for these events.

B

lock Diagram around µ-Com

keyboard.

MB90550A

LCD DISPLAY

LCD

Control

Line

LED

on/stadby/timer

LED

Drive

Lines

LCD DRV.

Keyboard

KEY

SW.

Control

Lines

LCD DRV.

Control

Line

Extra

Extra Key

SW.

Keyboard

HOST

DASP

IIC Bus

Front

u-COM

Control

Lines

RC-5/SYSTEM

Bus in

Resister

Matrix

Player

Type

Select

Lines

Easyjog

Control

Lines

EASYJOG

RC-5

SYSTEM

Bus in/out

SYSTEM

Bus out

Key Input

Each key is detected by changing the voltage level shown below.

3.5V <4.5V 2.5V <3.5V 1.5V <2.5V 0.5V <1.5V <0.5V

KEY0 (P38) PROGRAM CANCEL/DELITE MENU/STORE DISPLAY DOOR OPEN

KEY1(P39) CD

PLAY/PAUSE

KEY2(P40) SOURCE REC TYPE REC CDR STOP

KEY3(P41) CDR

PLAY/PAUSE

If this recorder is STANDBY state, the power will be recovered when the key is pressed.

Stop Key can be work to select either CDR or CD.

CD STOP

CD/CDR FF CD/CDR REW CD TRAY

(CD SELECT)

(CDR SELECT)

ERASE FINALISE CDR

OPEN/CLOSE

OPEN/CLOSE

STAND BY

TRAY

ENTER

P20/A16

P21/A17

P22/A18

P23/A19

P24/A20

P25/A21

P26/A22

P27/A23

P30/ALE

P31/RD

P32/WRL

P33/WRH

P34/HRQ

P35/HAK

P36/RDY

P37/CLK

P40/SCK

P41/SOT

P42/SIN

P43/SCK1

P44/SOT1

P45/SIN1

P46/ADTG

P47/SCK0

P50/SDA0/SOT0

P51/SCL0/SIN0

P52/SDA1

Pin Configuration

P17/AD15

100

1

2

3

4

5

6

7

8

9

10

11

V

SS

12

13

14

15

16

17

18

19

20

21

22

V

CC

23

24

25

26

C

27

28

29

30

31323334353637383940414243444546474849

P53/SCL1

P16/AD14

P15/AD13

P14/AD12

P13/AD11

P12/AD10

P11/AD09

P10/AD08

P07/AD07

P06/AD06

P05/AD05

P04/AD04

P03/AD03

P02/AD02

P01/AD01

P00/AD00

P64/AN4

P65/AN5

P66/AN6

P67/AN7

VCCX1X0V

MD0

P70/IRQ0

P71/IRQ1

99989796959493929190898887868584838281

CC

AV

P55/SCL2

P54/SDA2

AVRH

AVRL

SS

AV

P60/AN0

P61/AN1

P62/AN2

P63/AN3

SS

V

(FPT-100P-M06)

SS

50

MD1

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

PA4/CKOT

PA3

PA2

RST

PA1/OUT3

PA0/OUT2

P97/PPG5

P96/PPG4

P95/PPG3

P94/PPG2

P93/PPG1

P92/PPG0

P91/OUT1

P92/OUT0

P87/IN3

P86/IN2

P85/IN1

P84/IN0

P83/TOT1

P82/TOT0

P81/TIN1

P80/TIN0

P77/IRQ7

P76/IRQ6

P75/IRQ5

P74/IRQ4

P73/IRQ3

P72/IRQ2

HST

MD2

-COM DESCRIPTION

Pin PORT SIGNAL I/O DESCRIPTION

1 P20/A16 LCD_DIM O LCD back light of DIMMER Control See DIMMER Control

2 P21/A17 LCD_BL O LCD backlight ON/OFF See DIMMER Control

3 P22/A18 POWER_LED O Power ON LED Active H

4 P23/A19 STB_LED O Standby LED Active H

5 P24/A20 SYS_SW I When Bus Switch SYSTEM bus = H

6 P25/A21 SYS_MUTE O SYSTEM LINE OUT OF MUTE Active H

7 P26/A22 STB_MUTE O Power On < - > MUTE when STANDBY

8 P27/A23 CDR/Through O To switch AUDIO OUT DR; H, Through; L

9 P30/ALE N.C. I

10 P31/RD N.C. I

11 VSS GND

12 P32/WRL N.C. I

13 P33/WRH N.C. I

14 P34/HRQ N.C I

15 P35/HAK N.C. I

16 P36/RDY POWER_ON O Power Control Power ON; H

17 P37/CLK N.C. I

18 P40/SCK TCK. I/O To connect Flash Writer

19 P41/SOT SYS_OUT

20 P42/SIN SYS_IN

21 P43/SCK1 N.C. I

22 P44/SOT1 N.C. I

23 VCC +5STB -- VCC

24 P45/SIN1 N.C. I

25 P46/ADTG N.C. I

26 P47/SCK0 N.C. I

27 CC

28 P50/SDA0/SOT0 ROM_SDA I/O SERIAL DATA to EEPROM

29 P51/SOL0/SIN0 ROM_SCL O SERIAL DATA to EEPROM

30 P52/SDA1 IIC_DATA I/O DATA Communication to CDR Module

31 P53/SCL1 IIC_CLK I/O CLK Communication to CDR Module

32 P54/SDA2 N.C. I

33 P55/SCL2 N.C. I

34 AVCC +5STB -- VCC

35 AVRH +5STB -- VCC

36 AVRL GND

37 AVSS GND

38 P60/AN0 KEY_IN_0 I KEY_0 INPUT

39 P61/AN1 KEY_IN_1 I KEY_1 INPUT

40 P62/AN2 KEY_IN_2 I KEY_2 INPUT

41 P63/AN3 KEY_IN_3 I KEY_3 INPUT

42 VSS GND

43 P64/AN4 N.C. I

44 P65/AN5 N.C. I

45 P66/AN6 N.C. I

46 P67/AN7 N.C. I

47 P70/IRQ0 LT1 I RESET signal from CDR Active H

48 P71/IRQ1 N.C. I

49 MD0 TMODE I To changing CPU Mode PULL UP

50 MD1 MD1 I To changing CPU Mode PULL UP

51 MD2 TAUX3 I To changing CPU Mode PULL DOWN

52 HST HST I STANDBY input signal by hardware PULL UP

53 P72/IRQ2 D_MOTOR_REV O Door REV Motor ON Active H

54 P73/IRQ3 D_MOTOR_FWD O Door FWD Motor ON Active H

55 P74/IRQ4 D_OPEN_SW I Door Open Active L

56 P75/IRQ5 D_CLOSE_SW I Door Close Active L

57 P76/IRQ6 JOG_A I JOG A

58 P77/IRQ7 JOG_B I JOG B

59 P80/TIN0 INT. I INTERRUPT signal from CDR Module

60 P81/TIN1 N.C. I

61 P82/TOT0 N.C. I

62 P83/TOT1 N.C. I

63 P84/IN0 IR_IN I Control bus INPUT either IR/RC5 or

64 P85/IN1 IN_SW I CDR, CD trey hardware SW. Active : H / Passive : L

65 P86/IN2 CDR_IN I CDR Trey IN Active L

66 P87/IN3 CD_IN I CD Trey IN Active L

67 P90/OUT0 N.C. I

68 P91/OUT1 N.C. I

69 P92/PPG0 N.C. I

70 P93/PPG1 N.C. I

71 P94/PPG2 N.C. I

72 P95/PPG3 N.C. I

73 P96/PPG4 N.C. I

74 P97/PPG5 N.C. I

75 PA0/OUT2 N. C. I

76 PA1/OUT3 N. C. I

77 RST CPU_RST I CPU RESET signal Low (PULL UP)

78 PA2 N.C. I

79 PA3 N.C. I

80 PA4/CKOT N.C. I

81 VSS GND

82 X0 8MHz X’tal

83 X1 8MHz X’tal

84 VCC +5STB -- VCC

85 P00/AD00 TAUX I To Flash Writer

86 P01/AD01 --- I To change CPU mode PULL UP

87 P02/AD02 RST O LCD Driver RESET Active L

88 P03/AD03 LCD_/WR O WR OUTPUT to LCD Driver Active L

89 P04/AD04 LCD_/RD O RD OUTPUT to LCD Driver Active L

90 P05/AD05 A0 O LCD Driver mode See NJU6450 Data Sheet

91 P06/AD06 N.C. I

92 P07/AD07 N.C. I

93 P10/AD08 D0 I/O To LCD Driver

94 P11/AD09 D1 I/O To LCD Driver

95 P12/AD10 D2 I/O To LCD Driver

96 P13/AD11 D3 I/O To LCD Driver

97 P14/AD12 D4 I/O To LCD Driver Active L

98 P15/AD13 D5 I/O To LCD Driver Active L

99 P16/AD14 D6 I/O To LCD Driver Active L

100 P17/AD15 D7 I/O To LCD Driver See NJU6450 Data Sheet

TRXD

TTXD

is activate

O SYSTEM Control bus OUTPUT

To connect Flash Writer

I SYSTEM Control bus or IR/RC5 Input

To connect Flash Writer

IIC Interface

IIC Interface

SYSTEM

Active H

Figure 8-1

17

18

Page 20

RST

D

0~D7

A

E (RD)

R/W (RD)

Block Diagram

NJU6450A

Reset

0

MPU Interface

Instruction

Status

BF

Bus

Holder

Decoder

Page Address

Multiplexer

Register

Com. Address

Register

Counter

Com. Address

Staet Line Register

I / O Buffer

Page Address Decoder

Display

2560 bit

Data RAM

Culumn Decoder

0b1b2b3b4b5b6b7

b

Line Decoder

Line Counter

Displey

Timing

Generator

V

DD

V1V2V3V4V

Display Data Latch

5

. V

4

. V

1

, V

DD

V

Common

Timing

Generator

5

. V

3

. V

2

, V

DD

V

5

V

SS

Driver

Segment

Driver

Common

SEG

0

~SEG

COM0~COM

60

15

VSS

D0

D1

D2

D3

D4

D5

D6

D7

VDD

RST

FR

V

5

V3

V2

M/S

V

4

V1

COM0

COM1

COM2

COM3

COM4

COM5

COM6

Pin Configuration

R/W (WR)

E (RD)

OSC2OSC1A0SEG0

SEG1

SEG2

76

100

SEG3

SEG4

SEG5

NJU6450A

2

2

FR

M/S

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

5175

50

26

251

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

SEG36

SEG37

SEG38

SEG39

SEG40

SEG41

SEG42

SEG43

SEG44

OSC

OSC

COM7

COM8

COM9

COM10

COM11

COM12

COM13

COM14

COM15

SEG60

SEG59

SEG58

SEG57

SEG56

SEG55

SEG54

SEG53

SEG52

SEG51

SEG50

SEG49

SEG48

SEG47

SEG46

SEG45

19 20

Page 21

8.1.2 Test instructions

Clock signal

As clock driver for the display controller, a resonator of 8 MHz

(XY01) is used. The signal can be measured at pins 8 and 9 of

the display controller : 8 MHz ±5%.

I2C DATA/I2C CLK

These lines connect to the DASP master processor via

respectively pin 5 and pin 7 of conn. JU02

. When there is no

communication, they should have the high level (+5V). The

oscillogram below gives an indication of how these signals

should look like.

IR receiver - remote control

In the DR2100 the IR receiver RPM6934 (ZY83, ZY84) is

mounted on the display board. In all versions the IR receiver

connects to the display controller. The signal coming from the

receiver can be checked at pin 3 of conn. JU05. This

signal is

normally high (+5V). When the remote control is being

operated, pulses mixed in with the +5V can be measured. The

oscillogram gives an indication of how the signal looks like with

the RC being operated.

+5V

I2C DATA

0V

+5V

I2C CLK

0V

CH1! 2. 00 V =

CH2 2 V= M TB10.0ms ch 1+

CL 96532076_025.eps

Figure 8-2 ‘I2C signals’

290799

+5V

+5V

0V

-35V

0V

1

CH1! 2.00 V= MT B20. 0ms ch 1+

Figure 8-3 ‘IR receiver signal’

CL 96532076_021.eps

290799

21

Page 22

8.1.3 Display board troubleshooting guide

SWITCH POWER ON,

EXIT STAND BY

MODE

DISPLAY?

NO

YES

CHECK :

SUPPLY VOLTAGES

+5V

5 % at conn. JU04-1

CLOCK SIGNAL

8Mhz at pins 82, 83 of QU01

CONTROL SIGNALS

RESET IN 3V3 (high) at conn. JU02-4 after start up

I2C DATA at conn. JY01-5

I2C CLK at conn. JY01-7

ELECTRICAL SERVICE DIAGNOSTICS - Local display test

KEY

NO

FUNCTIONS?

YES

REMOTE

NO

CONTROL?

YES

FRONT, MAIN u-COM BOARD

OK

CHECK:

KEY LINES

ELECTRICAL SERVICE DIAGNOSTICS – Keyboard test

EASY JOG KNOB

CHECK:

IR RECEIVER signal at pin 63 of QU01

ELECTRICAL SERVICE DIAGNOSTICS – Remote control test

CL 96532076_020.eps

290799

Figure 8-4 Display board troubleshooting’

22

Page 23

8.2 Power Supply Unit P816

8.2.1 Troubleshooting P816

Chec

k fuse F820 and

replace if necessary

OK

Check DC voltages

5VM, 5VU, +12V, -8V

NO

Disconnect power supply unit from CDR main board,

Main u-com board and REAR TERMINAL board.

Connect resistor 1k ohm at pin 3 of conn. J852 and ground

These voltages might be somewhathigher than specified

Check : Waveform of D804 at anode

Turn input voltage up and check voltageacross C821,

this voltage should be

t

Check DC voltages

5VM, 5VU, +12V, -8V

R830, R825, R826, R890 is not shorted.

Q825 works properly.

NO

Connect the mains inlet to a mains

isolated variac

1.41 x Vin AC

OK

OK

OK

OK

NO

Power supply unit OK

Power supply is OK

Check : - CDR main board

- Main u-com board

-C

D main board

- REAR TERMINAL board

Check the path of the other faulty voltage(s)

+5VM: check D856, C857, L856, C859, Q851

+5VU : check CR890, D866, L867, Q852, C853, C858, C867

+12V : check D866, C867, L867, Q861, R861, R862, C863

Check the functionality of the following components :

F820, R819, C820, L820, D802

OK

Power supply OK?

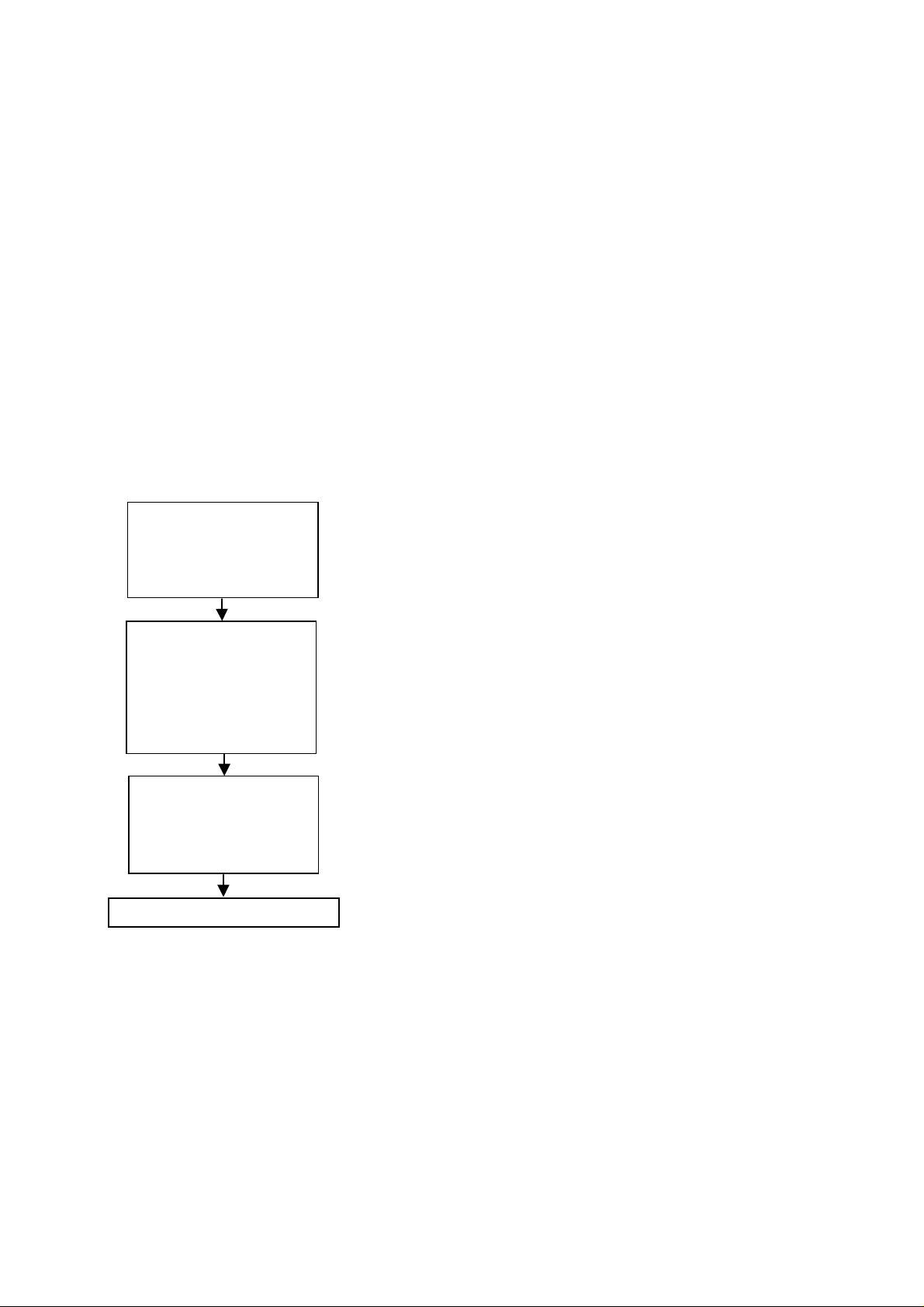

8.3 CD Main Board

The CD main board is built around the compact disc

mechanism MAR1250 and a loader 1250. The CDM delivers

diode signals and an unequalised high frequency signal. These

signals are necessary inputs for the decoder CD10. Based on

these signals the decoder will control the disc. The decoder is

able to control the sledge, focus motor, radial motor and turn

table. When everything is "locked", the decoder delivers a

digital output according to IEC958 standard, subcode to the

microprocessor and I2S for reproducing analog audio signals

by means of a D/A converter.

Check :

YES

Load on secondary output

Overvoltage protection : L832, D814, C814, R814, R815, R816

Oscillator voltage on pin 10 of Q810 :

check C802, R810 replace Q810

Drive circuit : gate voltage of MOSFET Q825

components R812, R813, C813, R825

Regulation circuit

- Measure voltage on pin 6 of Q810 with oscilloscope

- If > 2.5V check the regulation circuit : Q810, D881

R881- R885, C881, C882, R804 - R806, R809, C804, C809

Figure 8-5

The microprocessor controls the CD10 and is slave of the

master processor on the CDR main board in the DR2100. Both

processors communicate via a DSA connection (data, strobe

and acknowledge).

23

Page 24

CDM VAM1250

Trig enta

HF amp.

Diode signals

Radial, focus

Motor, sledge

CD10

SERVO

DECODER

Loader assy

PROCESSOR

UDA1320

DAC

Figure 8-6

8.3.1 Supply Voltages

Description

The CD main board receives +5V and +12V from the CDR main

board via respectively pin 16 and pin 15 of connector 1208. The

+5V is split up into +5VHF and +5V. The +5VHF is used mainly

for the diode currents and the HF-amplifier. The +5V is used for

the digital part of the board. On the board a +3V3 is made from

the +5V for the decoder CD10 and an A3V3 for the DAC

UDA1320. The +12V is split up into A12V for the audio output

stage and +12V for the power drivers of the CDM.

Measurements

Connect following supplies to next pins :

+5V + 5% to pin 16 of connector 1208.

+12V + 5% to pin 15 of connector 1208.

Ground reference to pin 17 of connector 1208.

Keep microprocessor 7202 in reset by forcing pin 7 of

connector 1208 to +5V. Check the following voltages :

Point Voltage

Position 1000 pins 1,3

Position 7000 pins 5,17,21,57

Position 7005 pin 14

Position 7020 pins 25

Position 7020 pins 26,27,28

Position 7021 pin 5

Position 7022 pin 5

Position 7025 pin 16

Position 7202 pin 38

Position 7309 pins 4,13

Position 7120 pin 8

+5V

+3.

+5V

+5V

+10

+12V

+12V

+5V

+5V

+3V

+12V

±

5%

3V± 5%

±

5%

±

5%

±

10%

±

10

±

10

±

5%

±

5% ( ot

3 ± 5%

±

10

her appl. 3V3 possible)

Figure 8-7

8.3.2 Clock Signals

Description

The microprocessor has its own Xtal or resonator of 12MHz.

The CD10 needs a clock of 8.4672MHz + 100ppm. This speed

also relates to the disc speed. To avoid locking proble m s

between the two drives in the CDR775, both drives run on the

same clock. Therefore the CD main board gets the clock for the

decoder from the CDR main board via pin 2 of connector 1208.

The DAC needs a system clock to drive its internal digital filters

and to clock the I2S signals from the decoder. In our case this

is 11.2896MHz (CL11) generated by the CD10.

Measurements

Connect the power supply as described above in "1.1.1.

Supply Voltages".

DSA

IIS, DOBM

ANA OUT

CL96532086_048.eps

CL96532086_049.eps

080999

Connect on pin 2 of position 1208 a clock signal of 8.4672

MHz ( 100ppm minimum rise time of 50ns and at TTL level

(0V and +5V).

Keep microproces sor 7202 in reset by forcing pin 7 at

position 1208 to +5V.

Release the reset. Now, the processor will reset the CD10

for at least 75

µs.

The output clock CL11 should be available now at pin 42 of

the CD10.

Check the following frequencies :

080999

Point Frequency

Position 7000 pin 16

Position 7202 pins 14,15

Position 7309 pin 6

Position 7309 pin 1

Position 7309 pin2

8.4672 MHz

12MHz

11.2896 MHz

2.1168 MHz

44.1kHz

Figure 8-8

8.3.3 CD10 Decoder/Servo SAA7324 (7000)

Description

The CD10 is a single chip combining the functions of a CD

decoder, digital servo and bitstream DAC. The decoder/servo

part is based on the CD7. The decoding part supports a full

audio specification and can operate at single speed (n=1) and

double speed (n=2).

Block Diagram

V

V

SSA2

DDA2

V

V

DDA1

4 14 5 17 33 50 58 52 57

PRE-

PROCESSING

DIGITAL

PLL

EFM

SRAM

RAM

VERSATILE PINS

INTERFACE

63 34 61 62 32

V1

V2/V3V4 V5 KILL

V

SCL

SDA

RAB

SILD

HFIN

HFREF

ISLICE

TEST1

TEST2

TEST3

SELPLL

CRIN

CROUT

CL16

CL11/4

SBSY

SFSY

SUB

RCK

STATUS

RESET

D1 D2 D3 D4

8910

12

R1

13

R2

V

7

GENERATOR

40

39

41

42

2

1

FRONT

3

6

25

31

44

24

16

15

TIMING

26

49

48

47

46

45

43

CONTROLLER

38

END

TEST

DECODER

INTERFACE

ref

MICROCONTROLLER

MICRO-

RIN

I

ref

ADC

INTERFACE

V

SSA1

11

DEMODULATOR

ADDRESSER

SUBCODE

PROCESSOR

Figure 8-9

V

SSD2

SSD1VSSD3

CONTROL

PART

AUDIO

PROCESSOR

PEAK

DETECT

±

5%

±

CONTROL

FUNCTION

KILL

±

100ppm

±

100ppm

±

100ppm

100ppm

V

DDD1(P)VDDD2(C)

CONTROL

CORRECTOR

INTERFACE

INTERFACE

(LOOPBACK)

INTERFACE

BITSTREAM

CL96532086_050.eps

OUTPUT

STAGES

MOTOR

ERROR

FLAGS

EBU

SERIAL

DATA

SERIAL

DATA

DAC

CL96532086_051.eps

080999

54

55

56

64

59

60

53

51

30

29

28

27

37

35

36

20

21

18

19

22

23

080999

RA

FO

SL

LDON

MOTO1

MOTO2

CFLG

DOBM

EF

SCLK

WCLK

DATA

SCLI

WCLI

SDI

V

neg

V

pos

LN

LP

RN

RP

24

Page 25

Pin Configuration

Figure 8-10

8.3.4 TDA7073A Power Drivers (7021, 7022)

Description

The TDA7073A is a dual power driver circuit for servo systems

with a single supply. In this configuration it is used to drive the

sledge, tray, focus and radial.

Measurements

Keep microprocessor 7202 in reset by forcing pin 7 of

connector 1208 to +5V. Connect the power supply as

described above in "1.1.1. Supply Voltages". Check the

following voltages :

Figure 8-11

Figure 8-12

8.3.5 BA6856FP Turn Table Motor Driver (7020)

Description

This component is a 3 phase, full wave pseudo linear driving

system with inbuilt Hall Bias circuit and 3 phase parallel output.

Measurements

Keep processor 7202 in reset by forcing pin 7 of connector

1208 to +5V. The outputs 9, 10, 11 of connector 1006 are 0V.

Pin 21 of the motor driver 7020 is 2.5V 10%.

Pin 22 of the motor driver 7020 is 2.5V 10%.

Pin 23 of the motor driver 7020 is 0V.

Pin 19 of the motor driver 7020 is 5V

10%.

Put the processor out of reset to continue the measurement.

Check MOT1 at pin 59 of CD10. The duty cycle of the output

should be 50%. Check wave form at pin 11 of 7005-D :

amplitude 5V + 5% duty cycle 50%.

The motor driver 7020 can be measured dynamically by

connecting a hall motor to the application panel. Apply a pulse

of 1V 10Hz and 15% duty cycle to pin 22 (Ec) as input value

with reference to pin 21 (Ecr=2.5V). Measure the output signals

on the driver. This will give as response a square wave on pin

17 and pin 18. When a positive voltage is applied, the square

wave on pin 17 will go ahead of the square wave on pin 18.

All signals will have a value as shown in the truth table. Check

the following output signals :

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

171819202122232425262728293031

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

514950

52

53

54

55

56

57

58

59

60

61

62

63

64

HFREF

HFIN

ISLICE

V

SSA1

V

DDA1

I

ref

V

RIN

D1

D2

D3

D4

R1

R2

V

SSA2

CROUT

CRIN

VDDA2

LN

LP

V

neg

V

pos

RN

RP

SELPLL

TEST1

CL16

RA

FO

SL

DOBM

SAA7324

V

SSD3

MOTO1

SFSY

SBSY

RCK

SUB

V

SSD1

V5

V4

V2/V3

KILL

EF

DATA

WCLK

V

DDD1(P)

SCLK

TEST3

CL11/4

RAB

SCLI

TEST2

SDI

WCLI

V

SSD2

SILD

MOTO2

STATUS

V

DDD2(C)

CFLG

V1

RESET

LDON

SDA

SCL

CL96532086_052.eps

080999

Pin Location Value

5 7021

12V

10%

5 7022

12V 10%

1 7022

1.65V

10%

2 7022

1.65V 10%

6 7022

1.65V 10%

7 7022

1.65V 10%

1 7021

5.0 10%

2 7021

5.0 10%

6 7021

1.65V 10%

7 7021

1.65V

10%

CL96532086_053.eps

080999

Pin Location Value DC

9 7022 FOC

5.8V

± 10%

12 7022 FOC 5.8V

13 7022 RAD 5.8V

16 7022 RAD 5.8V

9 7021 SLE 5.8V

12 7021 SLE 5.8V

13 7021 TRAY- 5.8V

16 7021 TRAY+ 5.8V

CL96532086_054.eps

080999

25

Page 26

Motor controller truth table

Input conditions conn 1006 pin Outputs conn 1006 Test points on driver

684 732 9 10 11 18 17 16

U+ U- V+ V- W+ W- UCOIL VCOIL WCOIL HALL_U HA LL_V HALL_W

L M H M M M 6V 0V 0V 0V 5V

H M L M M M 0V 6V 6V 5V 0V

M M L M H M 0V 6V 0V 0V 5V

M M H M L M 6V 0V 6V 5V 0V

H M M M L M 0V 0V 6V 5V 0V

L M M M H M 6V 6V 0V 0V 5V

CL96532086_055.eps

Figure 8-13

Hall-elements input signal voltage

levels

Input voltage Level Tolerance Unit

H2.80.1V

M2.50.1V

L2.20.1V

CL96532086_056.eps

Figure 8-14

8.3.6 Tray Control

080999

080999

Description

The tray control consists of a TDA7073A power driver (7021)

controlled by the processor 7202 via pin 19 TRAYIN and pin 20

TRAYOUT. If pin 20 is low and pin 19 high, the TRAY+ signal

at pin 16 of 7021 is forced to +8V and the TRAY- signal at pin

13 of 7021 to GND : the tray will open. If pin 20 is high and pin

19 low, TRAY+ becomes GND and TRAY- becomes +8V : the

tray will close. If pin 19 and 20 of the processor have the same

value, TRAY+ and TRAY- will have the same value as well : the

tray stops moving.

Measurements

Keep procesor 7202 in reset by forcing pin 7 of connector 1208

to +5V. Connect a load of 15 , 7W between pin 3 and 4 of

connector 1002. Check the voltage over the load with TRAY+

(pin 3) as positive reference. Check also the levels of pins 19

and 20 of the processor.

U TRAY+,TR AY- = <100mV

Pin 20 = +5V

Pin 19 = +5V

Force pin 20 of the processor to ground, and check the

voltages.

U TRAY+,TRAY- = -6.5V( 10%

Pin 20 = +0V

Pin 19 = +5V

Force pin 19 of the processor to ground as well and check the

levels again.

U TRAY+,TR AY- = <100mV

Pin 20 = +0V

Pin 19 = +0V

Release pin 20 of the processor and check the levels.

U TRAY+,TRAY- = 6.5V( 10%

Pin 20 = +5V

Pin 19 = +0V

Release pin 19 of the processor and check the levels again:

U TRAY+,TR AY- = <100mV

Pin 20 = +5V

Pin 19 = +5V

26

Page 27

8.3.7 HF Path

Description

The pre-amplified HF-signal is presented to both n=1 and n=2

amplifier circuits. The mux/demux switches via software and

micro processor controlled S1 and S2 lines between either one

of the amplified n=1 or n=2 signals. The signal will then follow

another amplification and filtering circuit. The filtering again is

controlled by the S1 and S2 lines, dependant on whether the

disc starts up (speed n=1, S1 and S2 Low), disc plays at speed

n=1 (S1 Low, S2 High) or disc plays at speed n=2 (S1 and S2

High).

E AMP

n-dependant filtering

n=1 AMP

3174

3173

430R

430R

F157

2

2140

HFGND

2143

330p

n=2 AMP

3191

430R

3192

430R

2164

180p

2162

HFGND

180p

100p

+5VHF

3188

3203

+5VHF

2K7

7009

BFS20

2K7

HFGND

3169

3180

2K7

7023

BFS20

2K7

HFGND

HFGND

DUAL 4 CHANNEL

MUX/DEMUX

+5VHF

HFGND

2141

2n2

2146

1n5

16

7

8

1

5

2

4

12

14

15

11

74HCT4052D

VCC

VEE

GND

0

1

2

3

+5VHF

HFGND

390p

2149

680p

2130

100n

HF

47u

22n

2160

HFGND

HFGND

1K

3196

HF

BC848B

BC858B

7010

HFGND

2161

7007

HFGND

7025

10

0

0

4x

9

3

1

6

G4

22n

HFGND

3

2137

HFGND

HF

F156

9

3189

13

F313

390R

22n

HFGND

HFIN

3178

2138

1K

S1

S2

HFGND

HFGND

2142

22n

F310

2150

47n

3

7000

SAA7324

F309

1 HFREF

2145

2 HFIN

47p

3181

3 ISLICE

22K

F159

5

VSSA14

VDDA1

FRONT

END

HF

3193

180R

10K

3205

CL96532086_057.eps

080999

DC Settings

Set the power and reset connections as described above in

"1.1.1. Supply Voltages". Check the following voltages :

Force Pin Location Measure

Emitter 7006 2.4 10%

S1 and S2 “HIGH” Collector 7010 1.9 10%

S1 and S2 “LOW” Collector 7010 1.9 10%

S1 and S2 “HIGH” 13 7025 1.6 10%

S1 and S2 “LOW” 13 7025 1.6 10%

S1 and S2 “HIGH” 3 7025 3.2 10%

S1 and S2 “LOW” 3 7025 3.2 10%

CL96532086_058.eps

Figure 8-16

Figure 8-15

080999

27

Page 28

Transfer Characteristics

Set the power and reset connections as described above in

"1.1.1. Supply Voltages". Connect a function generator via a

serial resistor of 1k5 to pin 4 of connector 1000. Use the

S1 and S2 “low” S1 and S2 “high”Frequencies

Input V

AC

Pin 2 at 7000 Input V

300 Hz 200mV < 100mV ± 20% 200mV < 100mV ± 20%

10 kHz 200mV 295mV ± 20% 200mV 330mV ± 20%

100 kHz 200mV 310 mV ± 20% 200mV 330 mV ± 20%

300 kHz 200mV 385 mV ± 20% 200mV 335 mV ± 20%

800 kHz 200mV 655 mV ± 20% 200mV 485 mV ± 20%

1.5 MHz 200mV 1. 1V ± 20% 200mV 760 mV ± 20%

3MHz 200mV 1.1V ± 20% 200mV 1.1V ± 20%

Figure 8-17

function generator as a sine wave generator with output level

of 1Vtt. Check this AC value with an AC mV-meter connected

to the input (pin 2) of the CD10 (7000) :

AC

Pin 2 at 7000

CL96532086_059.eps

080999

HFDET Setting

Set the power and reset connections as described above in

"1.1.1. Supply Voltages". Connect a function generator via a

serial resistor of 1k5 to pin 4 of connector 1000. Use the

Location Voltage DC Voltage AC

No HF HF

F190 4.8V± 20% 4.8V± 20% 175mV± 20%

F192 < 100mV 1.1V± 20% F206 4.9V± 20% 150mV± 20% -

8.3.8 Audio Part - DAC

Description

The DAC used, is the UDA1320 bit stream, continuous

calibration. I2S signals from various formats can be entered at

pins 1,2 and 3. If these signals are in phase with the delivered

system clock at pin 6, the DAC will reproduce analog output

signals at pins 14 and 16. 0dB level is 0.85Vrms. These analog

signals are at 1.65Vdc level.

The DAC has features which can be checked on the input pins.

Mute will switch off the analog signals. De-emphasis is not

used, since this is done in the decoder. Attenuation of -12dB is

not used because this is also done in the decoder.

I2S

I2S is a kind of digital audio format, consisting out of 3 lines :

CLOCK, WORDSELECT and DAT A.

Figure 8-18

WS

function generator as a sine wave generator with output level

of 500 kHz, 1Vtt. Check this AC value with an AC mV-meter :

CL96532086_060.eps

080999

signal is in phase with the WS-signal. Transition of the WS

always happens on a falling edge of the CLK.

DATA

DATA contains all data-bits. Data bits are set by the

transmitting device, and read by the receiving device. The

position of the DATA-bits within the WS-signal is very

important. There are several formats for this. In our case we

always use Philips I2S format, no Japanese or Sony format.

The number of data-bits per channel depends on the used

devices.

Timing of the I2S-bus, in case of Philips I2S is shown in the

next figure :

LEFT SAMPLE RIGHT SAMPLE

WORD-SELECT

Word select (WS) indicates whether the data-sample is from

the left or the right audio-channel. It has the same frequency as

the sample rate of the digital audio signal. This can be 32, 44.1

or 48kHz. Normal polarity is low for a left sample and high for a

right sample. So within the low state of the WS-line the data bits

for the left channel are transferred, and within the high state the

data bits of the right channel are transferred.

CLOCK

The CLOCK signal (CLK) indicates when DataTips must be

set, and when DataTips must be read. The frequency depends

on the speed of the I2S-bus, but is always a factor of the

frequency of the WS-signal. It can be 48x, 64x, 96, 128x... .In

our case it is 48x the sample rate frequency = 2.1168MHz. The

28

CLK

DATA

Figure 8-19

MSBMSB

CL96532086_061.eps

080999

Page 29

Measurements

IIS

22

DAC AMPLIFIER

CLK 11

25

NMUT E

Keep processor 7202 in reset by forcing pin 7 of connector

1208 to +5V. This puts the processor outputs in tristate. Check

the reset at pin 4 of processor 7202 to make sure that the

processor is in reset.

Now, force port 0-4 pin 33 at 7202 to 0V to set the decoder

outputs (SCLK, WCLK, DATA, and CL11).

Check the MUTE pin 11 at 7309 : this pin should be low.

Connect via an I2S generator I2S-signals to the DAC :

Pin 1 at 7309: SLCK.

Pin 2 at 7309: WCLK.

Pin 3 at 7309: DATA.

Connect also the SYSCLK pin 6 at position 7309 to a clock

±

signal of 11.2896 MHz

Generate an I2S signal equivalent with a sine wave of 1kHz at

0dB for both left and right channels.

Check if 0.8 VRMS at pins 14 and 16 at location 7209 with a

DC of 1.65VDC.

Check if 1.7 VRMS

1209.

Force MUTE Pin 11 at 7309 high.