Page 1

Service

CC3000 /N1B, /U1B, /K1B, /N2B, /U2B, /K2B

CC4000 /U1B, /K1B, /F1B, /U2B, /K2B, /F2B

Manual

CC4000F /U1B, /K1B, /U2B, /K2B

5Disc CD Changer

COMPACT

DIGITAL AUDIO

CC3000/4000

TABLE OF CONTENTS

Variation Table.............................................................................................................. 1-1

Location of pc boards & Technical Specifications ........................................................ 1-2

Service Aids, Chip Handling ........................................................................................ 1-3

ESD, Safety Instruction, etc.......................................................................................... 1-4

Disassembly Instructions & Service positions.............................................................. 3-1

Service Test Programs ................................................................................................. 3-3

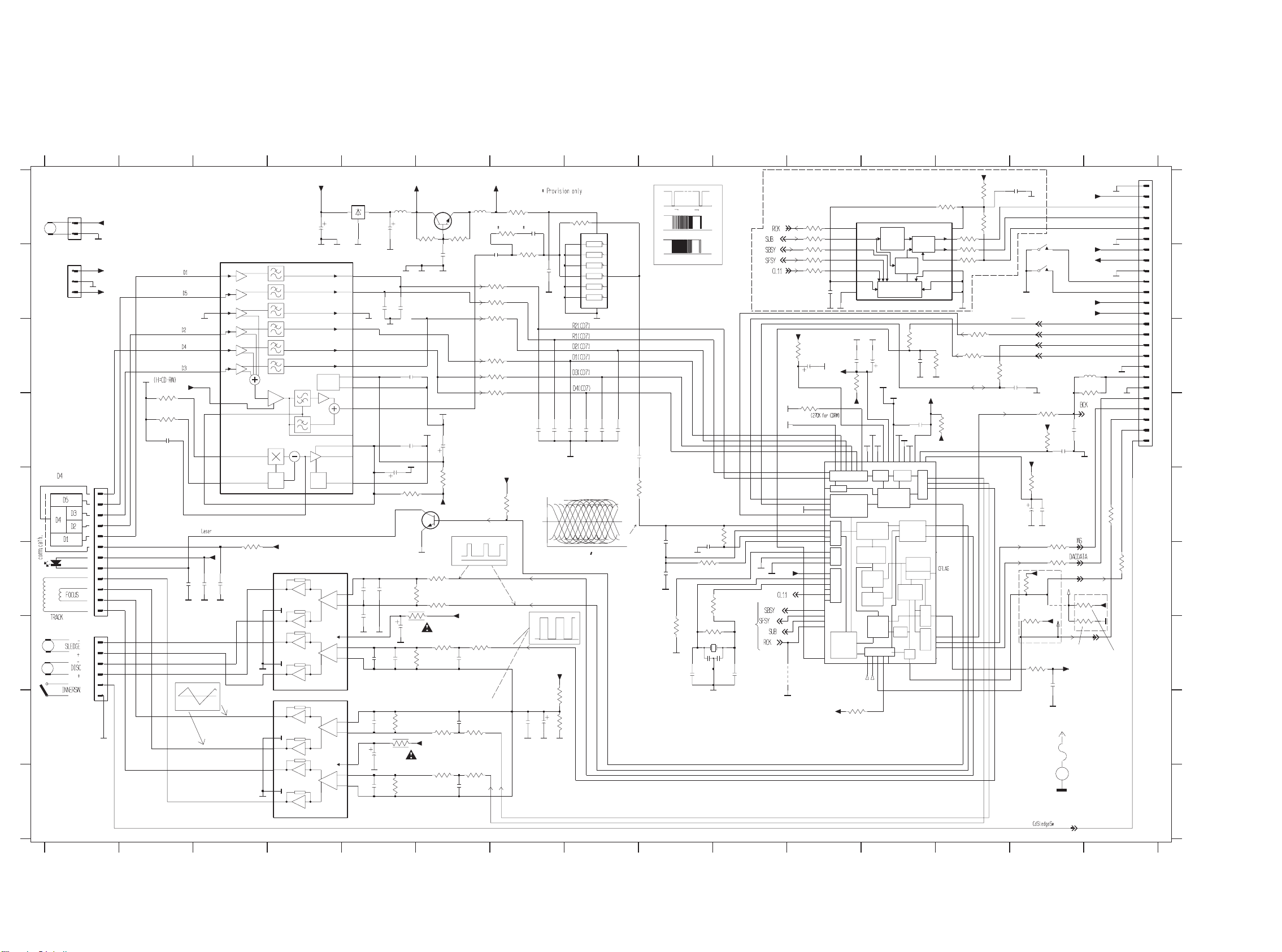

Set Block diagram ............................................................................................................4

Set Wiring diagram...........................................................................................................5

Supply & Headphone Boards...........................................................................................6

Front Board ......................................................................................................................7

Servo/Decoder Board ......................................................................................................8

DAC/AF Board..................................................................................................................9

Mechanical Exploded views & parts list .........................................................................10

Please use this service manual with referring to the user guide (D.F.U) without fail.

- CC3000 / CC4000 / CC4000OSE -

278W855010 ACT

3120 785 22010

First Issue:1999.08

R

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original

it is famous.

Parts for your

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

USA

MARANTZ AMERICA, INCMARANTZ AMERICA, INC.

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

MARANTZ BRAZIL

CAIXA POSTAL 21462

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

SINGAPORE

WO KEE HONG (S) PTE LTD

WO KEE HONG CENTRE

NO.23, LORONG 8, TOA PAYOH

SINGAPORE 319257

PHONE : +65 2544555

FAX : +65 2502213

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

NO. 102 JALAN SS 21/35, DAMANSARA

UTAMA, 47400 PETALING JAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE : +60 3 - 7184666

FAX : +60 3 - 7173828

JAPAN

Technical

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 748 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

990805ACT

Page 3

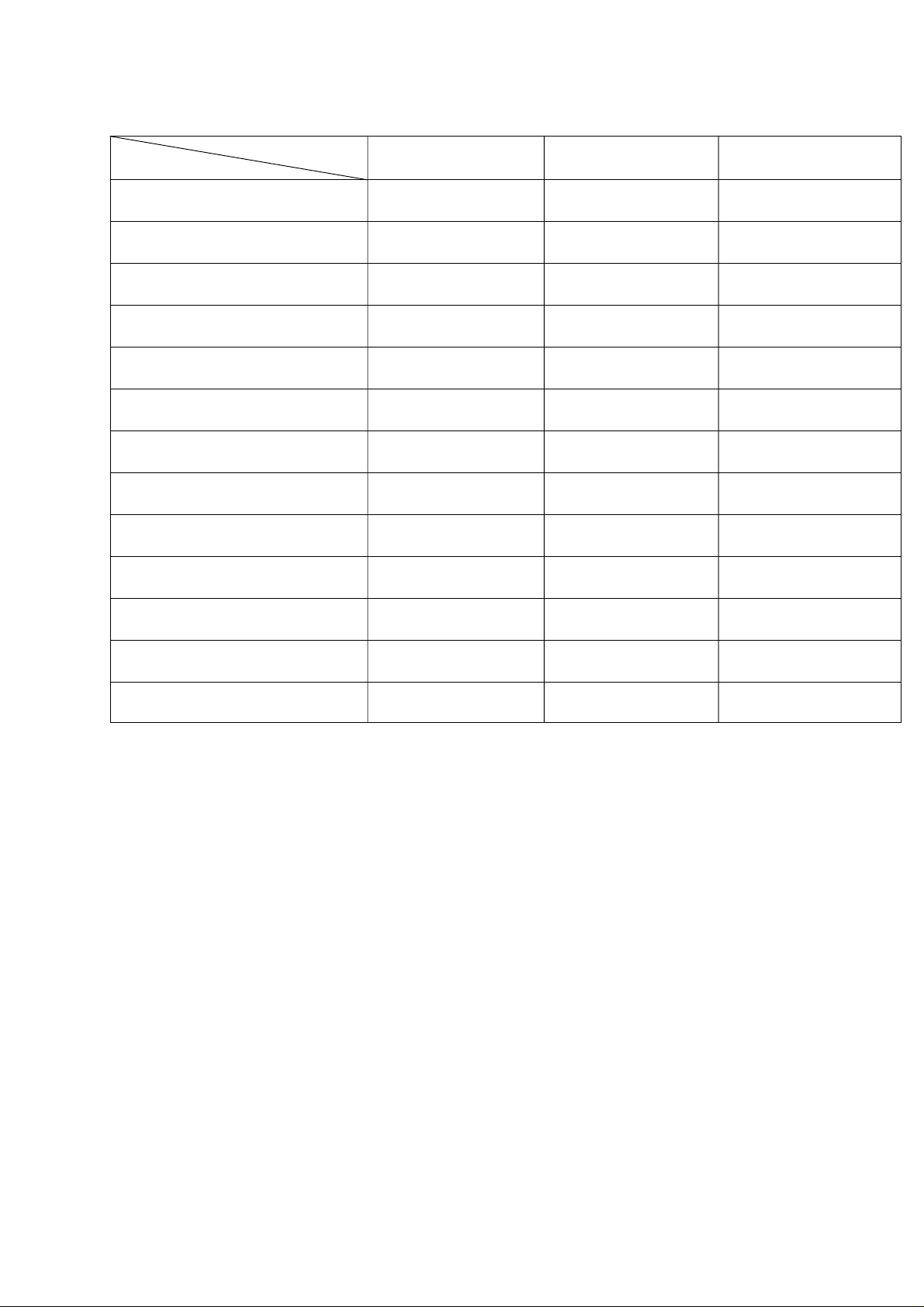

1-1

V ARIA TION TABLE

Type: CC3000 CC4000 CC4000F

Features: (CC4000OSE)

Headphone - X X

CC-DAC(Non-bitstream) X - TDA1545A T/N2

BCC-DAC(Bitstream) - X X

TDA1549T/N1

OP-AMP NJM4560D NJM21 14D NJM21 14D

for LPF

Mains Transformer Type EI-48 EI-54 EI-54

(Except /K)

Special ELE.CAP. - - *1

for DAC/AF BOARD

Special ELE.CAP. - - *2

for SUPPLY BOARD

Additional Bottom Plate - - X

Remote Control (RC4000CC) X X X

RC5 In/Out X X X

Digital Out (COAX) X X X

CD Text - - -

CDRW(Play Rewritable Disc) X X X

*1

(1) Item2895/2896 Elcap R20 50V S 10uF PM20 A (2020 012 93203)

(2) Item2897 Elcap ROA 50V S 47uF PM20 A (2020 012 93432)

(3) Item2899 Elcap ARS 25V S 47uF PM20 A (4822 124 12023)

(4) Item2902 Elcap ARS 25V S 47uF PM20 A (4822 124 12023)

(5) Item2905/2906 Elcap S 47uF 6V3 BIP (ELNA) A (4822 124 80954)

*2

Item2510 Elcap R20 16V S 2200uF PM20 (4822 124 40723)

Page 4

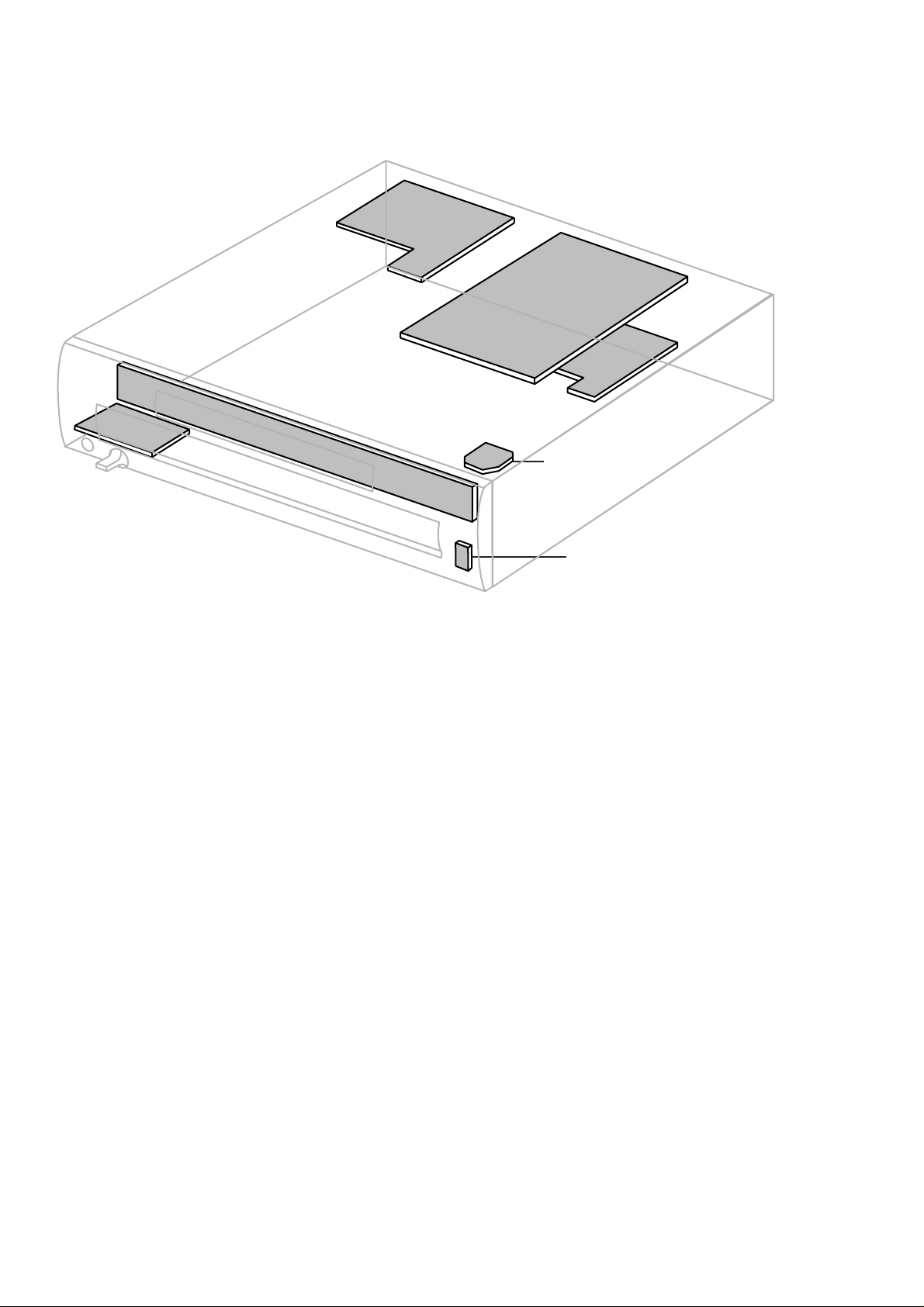

LOCATION OF PC BOARDS

1-2

SUPPLY BOARD

DAC / AF

BOARD

SERVO /

DECODER BOARD

H/P BOARD

FRONT BOARD

SPECIFICATIONS

GENERAL:

Mains voltage : 100V for /F

110-127V/220-240V Switchable for /K

120V for /U

220-230V for /N

Mains frequency : 50/60Hz

Power consumption : < 12W at Play mode

Dimension (WxDxH) : 435 x 380 x 119mm

Load/QP Board

Open/close Board

AUDIO PERFORMANCE:

Output level : 2Vrms ± 2dB @ 47kohm

Frequency response within ± 0.4dB: 20Hz - 20kHz

Dynamic range at 1kHz : > 90dB

Signal/Noise ratio at 1kHz : > 98dB

Total Harmonic Distortion at 1kHz : < 0.004%

Channel unbalance at 1kHz : < 1dB

Channel separation at 1kHz : > 95dB

Headphone impedance : 30 - 600 ohm

Headphone output (e.m.f.) : 4.5Vrms ± 2dB

Digital Output at 75ohm : 0.5V

1)

with 13th order Filter eg. 4822 395 30204

1)

1)

1)

Page 5

SERVICE AIDS

1-3

Service Tools:

Universal Torx driver holder .................................. 4822 395 91019

Torx bit T10 150mm ............................................. 4822 395 50456

Torx driver set T6 - T20......................................... 4822 395 50145

Torx driver T10 extended ...................................... 4822 395 50423

Compact Disc:

SBC426/426A Test disc 5 + 5A ............................ 4822 397 30096

SBC442 Audio Burn-in Test disc 1kHz ................. 4822 397 30155

SBC429 Audio Signals disc .................................. 4822 397 30184

Dolby Pro-logic Test Disc...................................... 4822 395 10216

Eccentricity Disc, 150µm....................................... 4822 397 30279

Others:

13th Order Filter .................................................... 4822 395 30204

ESD Equipment:

Anti-static table mat - large 1200x650x1.25mm ... 4822 466 10953

Anti-static table mat - small 600x650x1.25mm..... 4822 466 10958

Anti-static wristband .............................................. 4822 395 10223

Connector box (1MΩ) ............................................ 4822 320 11307

Extension cable

(to connect wristband to conn. box).................. 4822 320 11305

Connecting cable

(to connect table mat to conn. box) .................. 4822 320 11306

Earth cable (to connect product to mat or box) .... 4822 320 11308

Complete kit ESD3

(combining all above products) ......................... 4822 320 10671

Wristband tester .................................................... 4822 344 13999

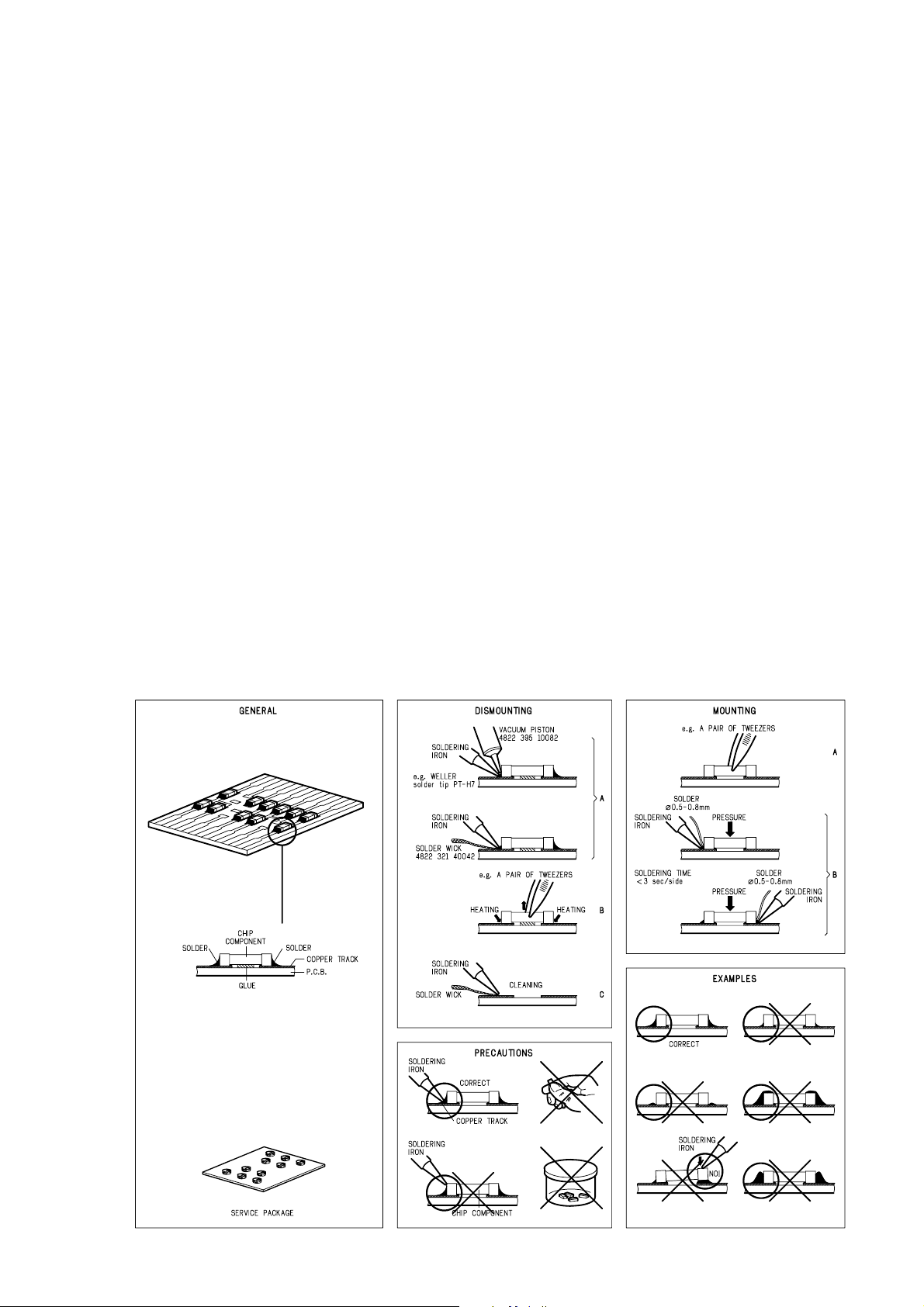

HANDLING CHIP COMPONENTS

PCS 101 006

Page 6

WARNING

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

1-4

ESD

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

WAARSCHUWING

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

“Pour votre sécurité, ces documents

doivent être utilisés par des spécialistes agréés, seuls habilités à réparer

votre appareil en panne”.

CLASS 1

LASER PRODUCT

GB

Invisible laser radiation when open.

Avoid direct exposure to beam.

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

Warning !

S

Varning !

3122 110 03420

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

"After servicing and before returning set to customer perform a

leakage current measurement test from all exposed metal parts to

earth ground to assure no shock hazard exist. The leakage current

must not exceed 0.5mA."

PCS 101 007

Varoitus !

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK Advarse !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

Page 7

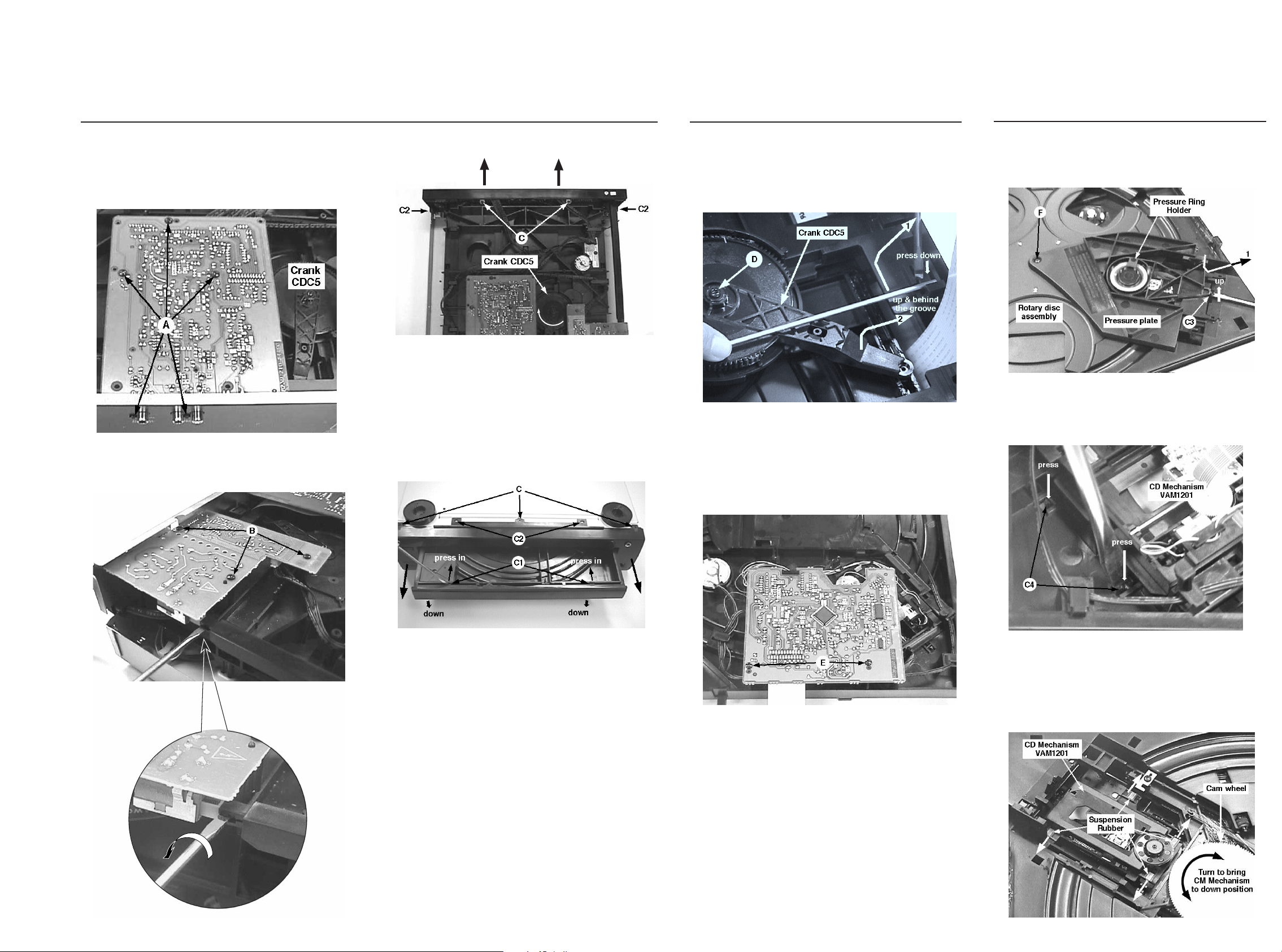

DISMANTLING INSTRUCTIONS

3-1 3-1

Dismantling of the DAC/AF board, Supply board and Front Panel Assembly

1) Remove the Top Cover (pos 151) by 8 screws.

- 2 screws on each side

4) Turn the crank CDC5 (pos 96) clockwise to slide out the

tray assembly.

- 4 screws from the rear

2) Remove the DAC/AF board by 5 screws A. Be careful not

to damage flex cable.

5) With the set upside-down, release the 2 catches C1 and

remove the tray cover as indicated.

6) Loosen the Front Panel assembly from the bottom bracket

(pos 181) by 5 screws C and 4 catches C2 as indicated.

- 2 screws on top

3) Remove the Supply board by 3 screws B and disconnect

- 3 screws from the bottom side

the Lever Power button (pos 6) as indicated.

Tray moves out

Turn

Dismantling of the Tray Assembly and Servo board

1) Remove the Metal rod (pos 152) as indicated.

2) Loosen the Crank CDC5 (pos 96) with screw D and lift the

crank arm out of the groove on the tray assembly. The

complete tray assembly can be pulled out of the Frame

(pos93).

3) Remove the Servo board by 2 screws E.

4) Protect the CD mechanism's Laser against ESD by shortcircuiting the flexfoil with a paper clip immediately upon

disconnection from the flexfoil connector.

(See Warning for more details)

Dismantling of the CD Mechanism

1) Loosen the Pressure ring holder (pos 90) by relasing catch

C3 as indicated.

2) Remove the Pressure plate (pos 89) and Rotary disc

assembly (pos 100) by 1 screw F.

3) Turn the Tray assembly upside-down and remove the

CDM Lock (pos 99) by using a "minus" screw-driver to

release 2 catches C4 as indicated.

4) With the Tray assembly facing up again, turn the cam

wheel (pos 116) to bring the CD mechanism (pos 98) to the

down position. Remove the CD mechanism by sliding out

the 4 rubber suspension (pos 104 to 107).

PCS 101 015

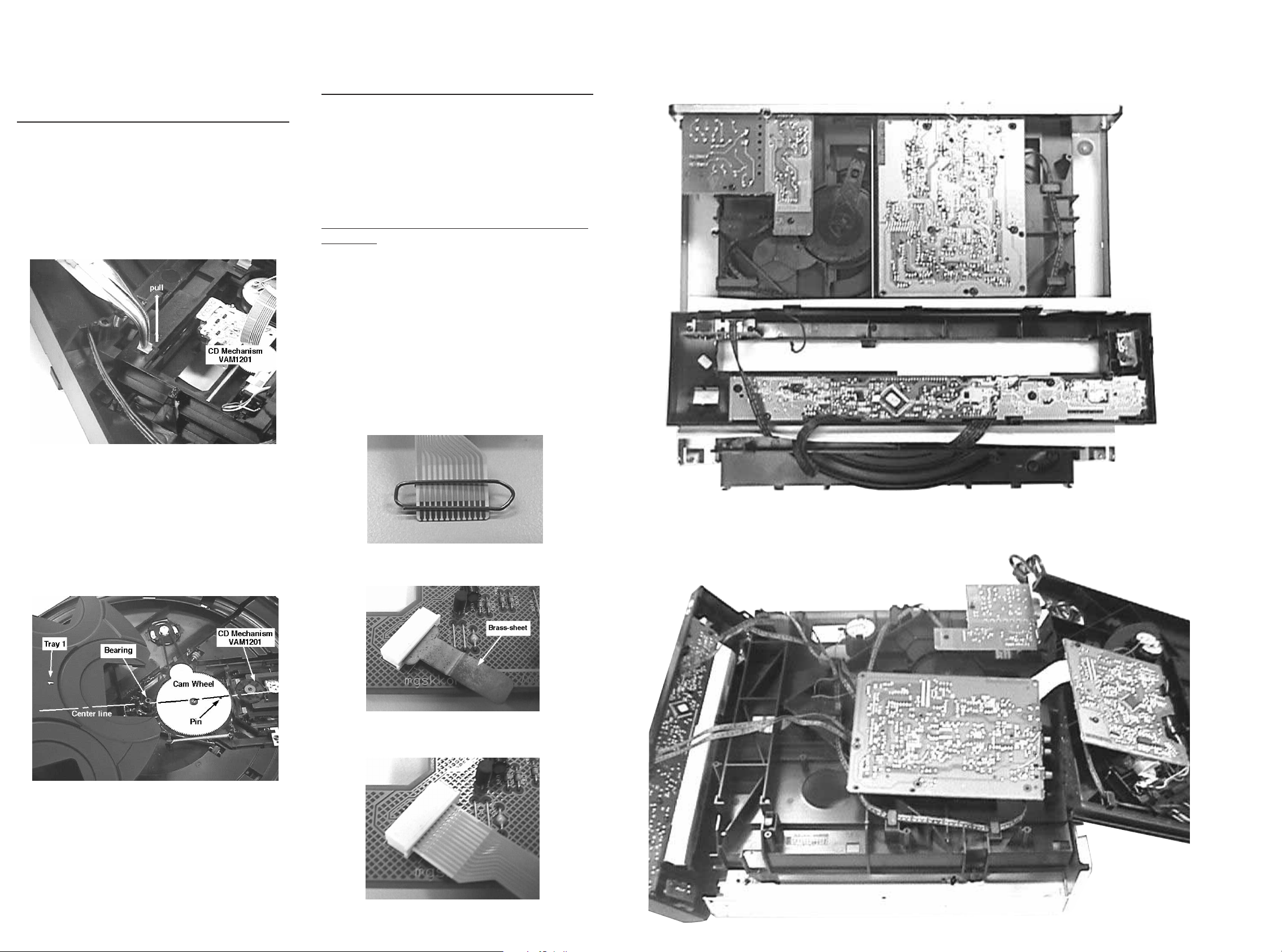

Page 8

3-2 3-2

Assembly of the CD mechanism and Rotary disc CDC5

1) Remove the 4 rubber suspension (pos 104-107) from the

Support bracket (pos 114) and attached them on to the

CD mechanism.

2) Place the CD mechanism with the rubber suspension

above the mounting 4 holes.

3) Hold the CD mechanism in position and pull the tips of the

rubber suspension through the holes in the Support

bracket.

Warning

Charged capacitors on the Servo board may damage the

CD drive electronics when connecting a new CD mechanism. That's why, besides the safety measures like

* Switch off power supply

* ESD protection

Additional actions must be taken by the repair technician.

The following steps have to be done when replacing the CD

Mechanism:

1) Disconnect the old CD mechanism flexfoil from printed

board.

2) Connect paperclip to CD mechanism flexfoil to short-

circuit flexfoil (fig.1).

3) Short-circuit printed board with brass-sheet (4822 321

11197) plugged into the flexfoil connector (fig. 2).

4) Remove the old CD mechanism.

5) Assemble the new CD mechanism into position.

5) Remove short-circuit from printed board connector.

6) Remove short-circuit from flexfoil of new CD mechanism.

7) Connect new flexfoil to print connector (fig. 3).

SERVICE POSITION 1

4) After assembly of the CD Mechanism, the Cam wheel (pos

116) and the Rotary disc (pos 100) must be re-aligned.

This is done by positioning the Bearing (pos 101), pin on

the Cam wheel and CD Mechanism in a straight line as

indicated.

5) Assemble the Rotary disc onto the Bearing with the "1"

printing mark facing the CD Mechanism.

Figure 1

SERVICE POSITION 2

Figure 2

PCS 101 016

Figure 3

Page 9

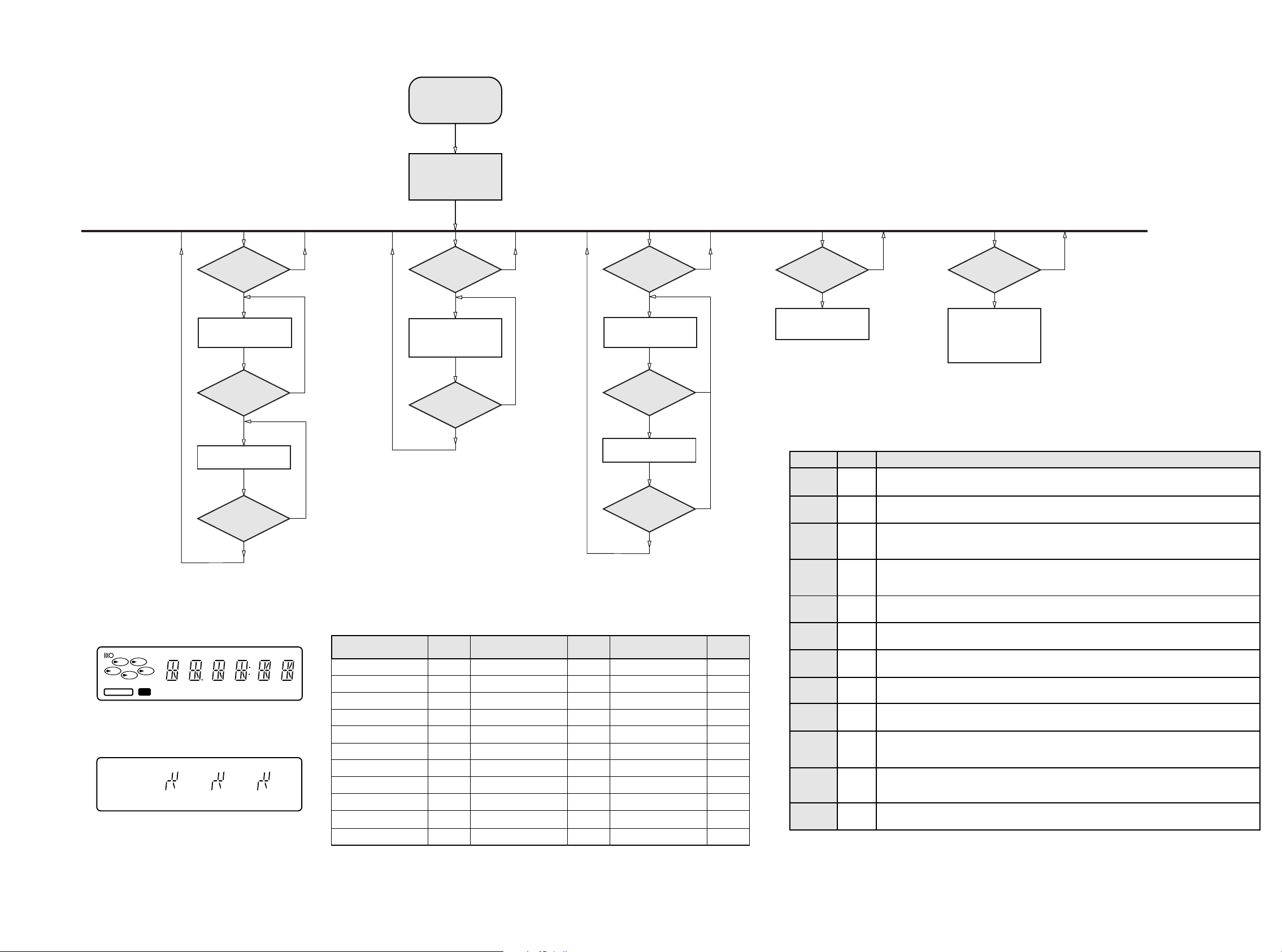

3-3 3-3

SERVICE TEST PROGRAM I

MAIN MENU

DISPLAY

TEST

TIME

Button pressed?

Y

Display shows

Figure 1

TIME

Button pressed?

Y

Display shows

Figure 2

STOP

Button pressed?

Y

TRACK PEAK TOT REM TRACK TIME

54

13

2

PROGRAM

FTS

SHUFFLE

Figure 1

TRACK TOT TRACK

SHUFFLE REPEAT DISC

Figure 2

VIDEO CD -I

CD

+

PAUSE

G

+

G

N

N

N

1

REPEAT DISC

Keys

activated

No Key pressed

Any Remote control key

Program

Scan

Repeat

Edit

Time

Fader

To start service test program

hold STOP & PLAY

depressed while

plugging in the mains cord

Display shows the

ROM version *

"S V yy"

(Main menu)

QUARTZ

TEST

PROGRAM

Button pressed?

Y

Display shows

8M

Output at (Front Board)

pin 80 of uP = 1,953.125Hz

STOP

Button pressed?

Y

Display

shows

--

RC

1

2

3

4

5

6

S refers to Service Mode.

V refers to Version.

yy refers to Software version number of ∝Processor.

(Counting up from 01 to 99)

KEY TEST

N

N

Keys

activated

Pause

Previous

Next

Stop

Play

Shuffle

Disc 1

Disc 2

Table 1

Display

shows

7

8

9

Exit

11

12

13

14

Button pressed?

Display shows "--"

Display according

Button pressed?

SHUFFLE

Y

Any Button

pressed?

Y

to Table 1

STOP

Y

Keys

activated

Disc 3

Disc 4

Disc 5

Open/Close

Quick Play

Load

CD

TEST

N

N

NEXT Button

pressed?

Y

FOR CD Test

see page 3-4

Error code

E1000

N

E1001

Type

W

W

N

Button pressed?

Set is in Service PLAY Mode.

This mode is intended for

- CD PLAY Test

The CD PLAY is intended to

detect intermittent or not reproducible failures.

This is done by continuously playing a disc.

In case of failures, error codes according

to table 2 will be displayed.

Error Description

Focus Error

Triggered when the focus lost for a certain time during play.

Radial Error

Triggered when the radial servo is not on track for a certain time during play.

PLAY

Y

SERVICE

PLAY MODE

N

Sledge In Error

The sledge did not reach its inner position (inner-switch is still close) before approximately 6 Sec. have

E1002

W

passed by. Inner-switch or sledge motor problem.

Sledge Out Error

The sledge did not come out of its inner position (inner-switch is still open) before approximately 250 mSec.

E1003

W

have passed by. Inner-switch or sledge motor problem.

Jump error

Triggered in normal play when the jump destination could not be found within a certain time.

E1005

W

Subcode Error

Triggered when a no valid subcode for a certain time during play.

Display

shows

15

16

17

18

19

20

E1006

E1007

E1008

E1020

E1070

E1071

W

PLL Error

The Phase Lock Loop could not lock within a certain time.

W

Turntable Motor Error

Generated when the CD could not reached 75% of speed during startup within a certain time. Discmotor problem.

W

Focus Search Error

The focus point has not been found within a certain time.

F

The carousel switch is not open within certain time. This can happen when either the switch is defective and

closed all the time, or when the carousel is blocked in between two disc positions.

W

The time-out is approximately 5 seconds.

The carousel position switch did not close within a certain time. This can happen when the switch is defective

W

and never closes electrically, or when the carousel is blocked in between two disc positions. The time-out is

approximately 5 Sec.

The drawer could not enter the inside position and is opening again. This can be caused because the drawer is

E1079

W

blocked by something and cannot go fully inside, or the drawer switch is defective and does not close.

F = Fatal error & the set stop play function W = Warning

Table 2

PCS 101 017

Page 10

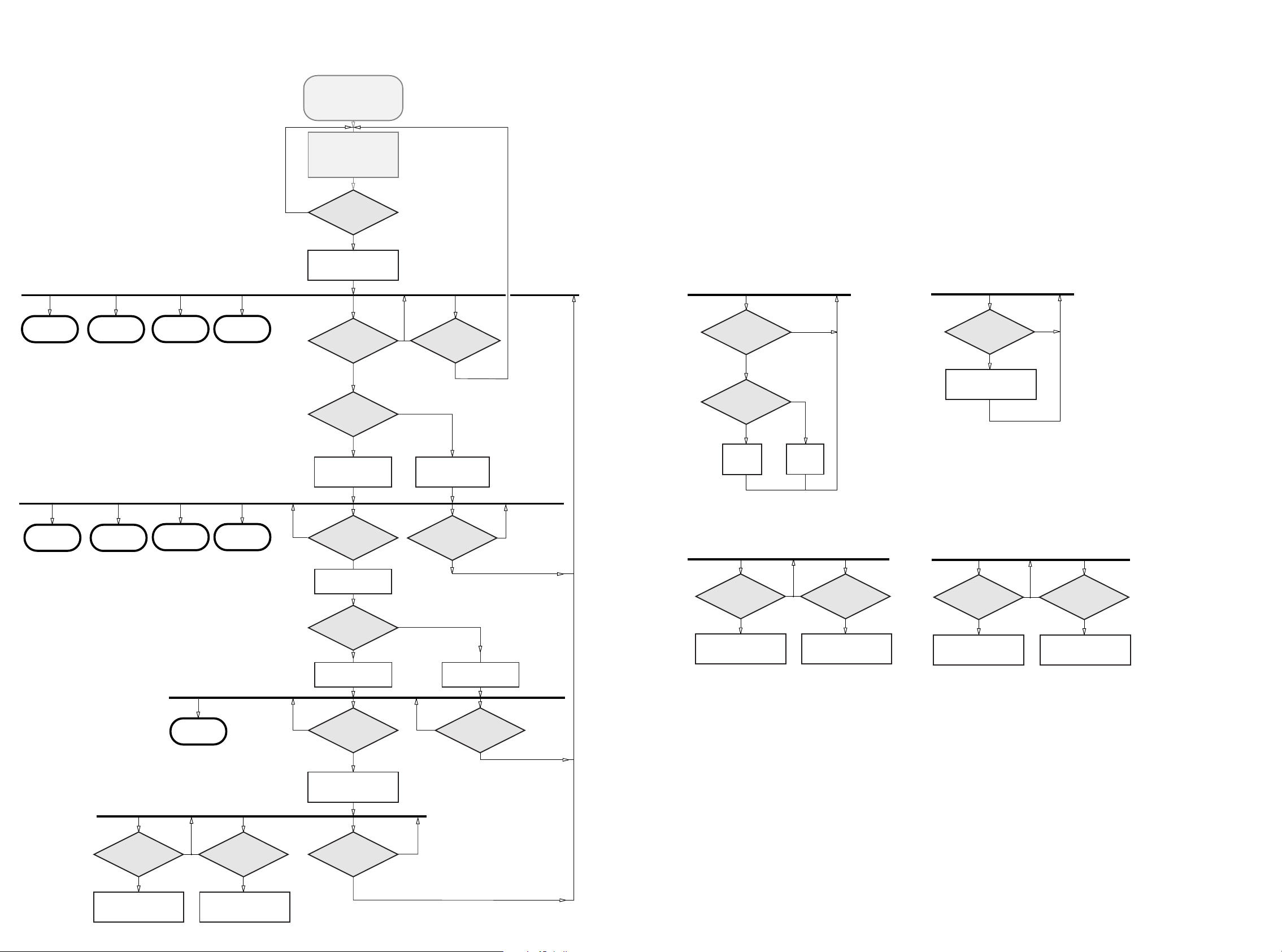

3-4 3-4

SERVICE TEST PROGRAM II

CD Menu

Tray

Motor Test

Changer

Mech. Test

Disc

Motor Test

Sledge

Motor Test

To start service test program

hold STOP & PLAY

depressed while

plugging in the mains cord

Display shows the

ROM version

"S V yy"

(Main menu)

N

NEXT

Button pressed?

Y

Display shows

"CD"

PLAY

Button pressed?

Y

Is FOCUS found?

Y

S refers to Service Mode.

V refers to Version.

yy refers to Software version

number of ∝Processor.

(Counting up from 01 to 99)

N

N

Button pressed?

N

Focus Servo Test

STOP

Tray Motor

Test

OPEN/CLOSE

Button pressed?

Is tray

closed?

Y

Y

Y

N

N

Changer

Mechanism

Test

CD_X #

Button pressed?

Y

Change to

selected disc

# CD_X refers to CD1, CD2 or CD3

N

Tray

Motor Test

Changer

Mech. Test

NEXT

Button pressed?

Y

Sledge jumps outward in

steps of 16-tracks

Disc

Motor Test

Sledge

Motor Test

N

Jump tracks Test

Sledge jumps inward in

Sledge

Motor Test

PREVIOUS

Button pressed?

Y

steps of 16-tracks

N

Button pressed?

Disc starts turning,

Display becomes

N

Button pressed?

Radial Servo Test

Button pressed?

Display shows

"FOC OK"

PLAY

Y

Display shows

"DISC"

is speed ok?

Y

"DISC OK"

PLAY

Y

Display shows

"RDL"

STOP

Y

Display shows

"FOC ERR"

STOP

Button pressed?

Y

N

Disc Servo Test

N

N

N

Display remains as

"DISC ERR"

STOP

Button pressed?

Y

Open Tray

Close Tray

Sledge Motor

Test

NEXT

Button pressed?

Y

Sledge moves outside

Display shows

"SLD 0"

In software version 15 and below there are some slight problems in the

Note:

Service Program for the CD Test which will be resolved by running change.

The problems are:

1) If the Tray Motor test is done with the Tray in the open position, the tray

will close only after the pressing the Open/Close button twice.

2) If this test is performed after the Tray Motor Test, the tray may not change

as selected. The test will resumed correctly if CD test is quit and restarted.

3) After performing the Sledge Motor Test or Disc Motor Test the set will

return automatically to the "CD Menu".

N

PREVIOUS

Button pressed?

Y

Sledge moves inside

Display shows

"SLD I"

Disc Motor

Test

SHUFFLE

Button pressed?

Y

Disc Motor turns Counter

Clockwise & Display shows

"CCW"

N

N

Button pressed?

Disc Motor turns

Clockwise & Display shows

PROGRAM

Y

"CW"

PCS 101 018

Page 11

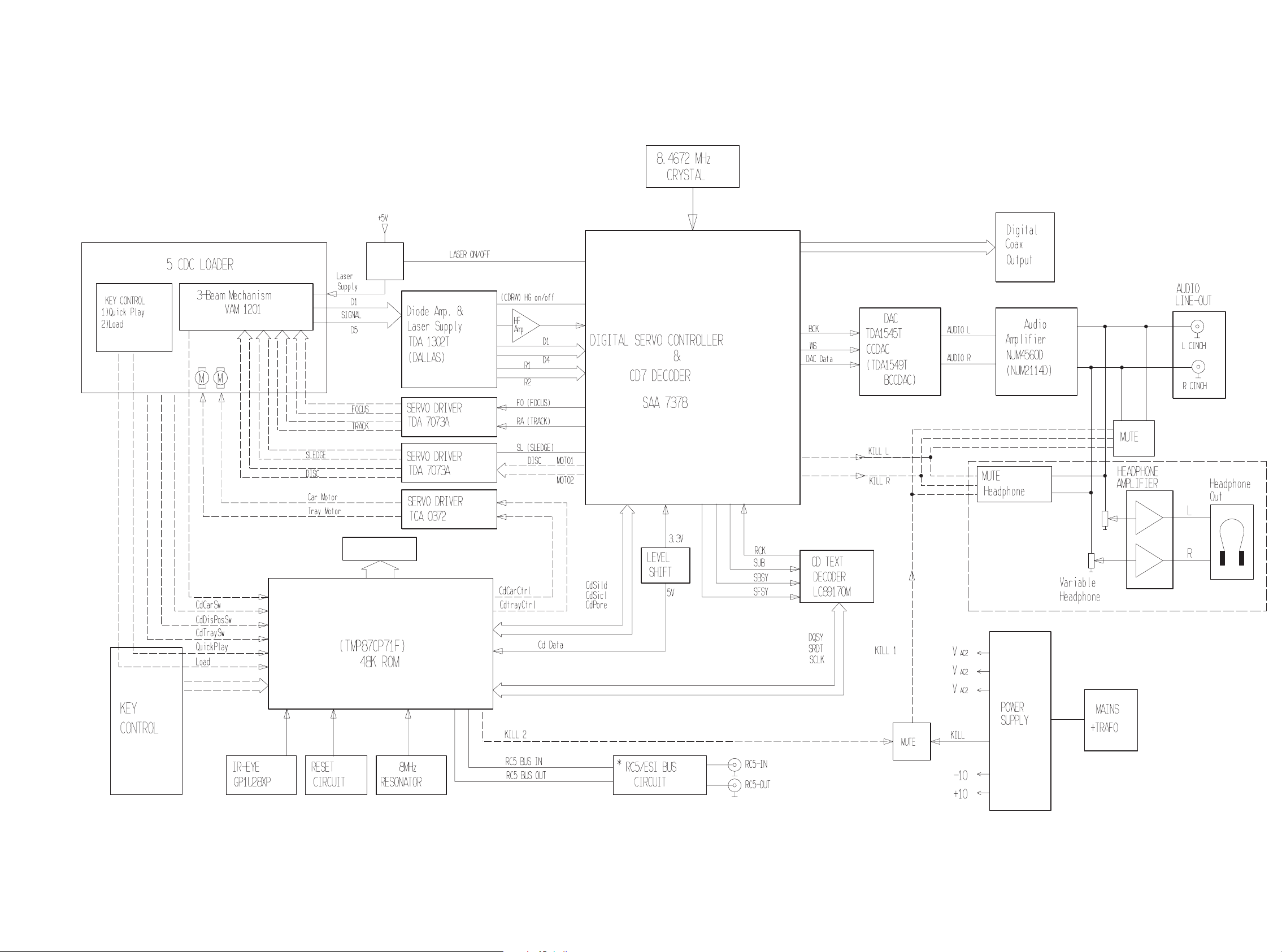

SET BLOCK DIAGRAM

4-1 4-1

FTD

µP

CC4000

CC4000F

only

Page 12

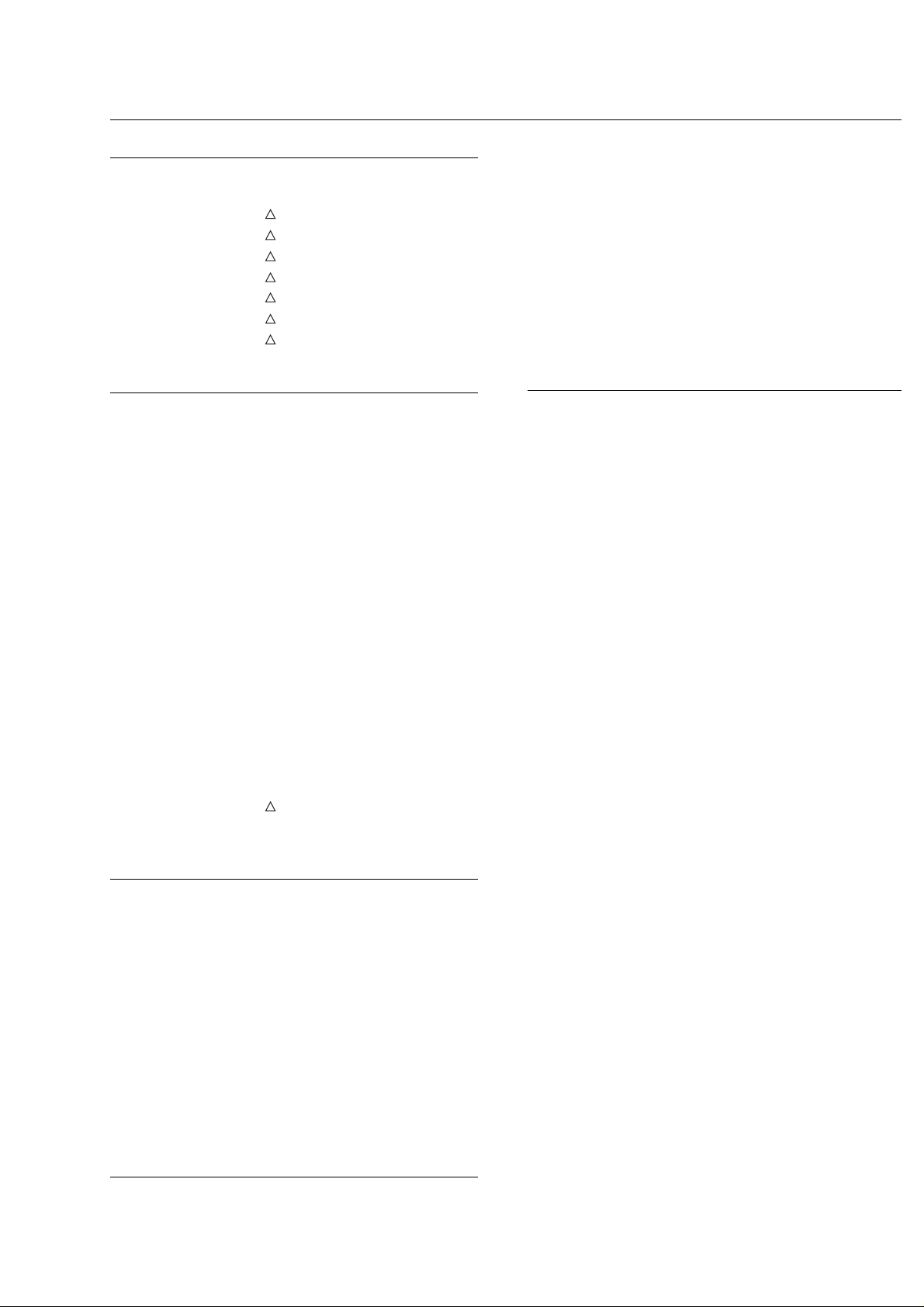

SET WIRING DIAGRAM

5-1 5-1

L

T

P

TRAY LOADER

TRANSFORMER

H

POWER SUPPLY

HP PANEL

CC4000 / CC4000F only

D

S

DAC/AF

C

CONTROL & DISPLAY PANEL

SERVO/DECODER

3139 119 30820 dd wk 852

Page 13

6-1 6-1

SUPPLY & HEADPHONE

BOARD

TABLE OF CONTENTS

Headphone part - Circuit ................................................. 6-1

Supply part - Circuit ......................................................... 6-2

Supply & Heaphone layout.............................................. 6-2

Electrical parts list............................................................ 6-3

HEADPHONE CIRCUIT DIAGRAM

1370 2

+10V

A

-10V

VHP R

B

GND

C

VHP L

D

CONN. 1370 TO CONN. 1301 ON DAC CIRCUIT

-

1370 1

-

1370 3

-

1370 4

-

1370 5

-

3380

3380

2380

22n

10k

10k

+10V

-10V

10k

10k

3384

15k

3382

3383

3381

15k

5

CC4000/CC4000F ONLY

45 6123

11372

-

21372

2383

100n

3386

2

3

6

+10V

-10V

NJM4556

8

4

NJM4556

1

7380

(A)

7

7380

(B)

120R

2381

10n

3385

120R

2382

10n

45 6123

L

R

* For Testing only

-

1371

2

3

1

3999*

3086_0283_2

1370 A 1

1370 A 1

1370 B 1

1370 C 1

1370 C 1

1371 B 6

1372 A 6

A

1372 A 6

2380 A 1

2381 B 5

2382 D 5

2383 A 6

3380 B 1

3380 D 1

3381 D 3

3382 B 3

3383 C 3

3384 A 3

3385 D 4

B

3386 B 4

3999 D 6

7380 B 4

7380 D 4

C

D

Page 14

6-2 6-2

POWER SUPPLY CIRCUIT DIAGRAM

A

9501

MAINS

1540 1

9502

-

B

3

9504

1

C

1543

4

9505

1502

/K

-

T100mA

x

x

-

x

x

x

2544

3n3 400V

1500

/U, /F

T200mA

x

-

-

x

-

x

-

D

1540 2

-

MAINS

E

F

G

1501

9506

VERSION VARIATIONS

XXX

/N

1501

T80mA

1502

-

1541

x

1542

-

1543

-

9501

-

9502

x

9503

-

9504

-

9505

x

9506

-

x - Item in used

1542-3

1541-1

1541-2

1542-4

2

5

1542-1

1542-2

1542-5

9503

1541-3

451 6789 1023

5500 (Mains Transformer)

0V

451 6789 1023

1503 2

1503 1

1503 3

28V

1503 6

8.6V

1503

1503 4

8.6V

HEADPHONE & SUPPLY BOARD LAYOUT

1005 D10

1005 E10

VAC2

VAC1

VFTD

GND

+10

-10

KILL

A

B

C

D

E

F

1005 F10

1005 C10

1005 B10

1005 B10

1005 A10

1500 D 2

1501 D 1

1502 E 2

1503 B 6

1503 A 6

1503 B 6

1503 E 6

1503 D 6

1503 D 6

1540 B 1

1540 D 1

1541 A 3

1541 B 3

1541 E 3

1542 A 3

1542 B 3

1542 C 3

1542 C 3

1542 D 3

1543 C 2

2500 D 7

2501 D 7

2502 D 9

2503 D 9

2504 B 6

2505 B 7

2506 D 9

2507 G 9

2508 C 8

2509 C 9

2510 E 7

2544 D 2

2560 F 9

3560 F 9

6500 D 7

6501 D 7

6502 D 8

6503 D 8

6504 B 7

6505 C 9

6506 B 9

6507 D 8

6508 D 8

6560 F 8

6561 F 8

6562 F 9

7500 B 8

9501 A 2

9502 B 2

9503 D 3

9504 C 2

9505 D 2

9506 E 1

A

B

C

D

04-22

4

3104 113 3086.

4

9

3381

1500

CONN.1005 TO CONN.1008

-

4.8V

-

2505

2504

22n

22n

-

6504

-36V

7500

MC7924

2

1N4003G

-3.9V

2508

220u

50V

2500

22n

6500

2501

22n

1N4003G

6501

1N4003G

5

0V

-

6507

1N4003G

6508

1N4003G

6502

1N4003G

6503

1N4003G

ON DECODER CIRCUIT

-19.5V

3

1

6505

BZX79C3V9

1

2502

22n

2503

22n

2

6506

BZV85-C7V5

-27V

2509

22u

50V

+10V

2506

6800u

16V

-10V

1005 7

1005 6

1005 5

1005 4

1005 1

1005 2

-

-

-

-

-

-

2510

2200uF

16V

6560

1

1N4003G

6561

2

1N4003G

2560

330u 16V

3560

1k

+3.9V

6562

BZX79C3V9

1005 3

-

2507

100n

G

Date: wk853.1

This assembly drawing shows a summary of all possible versions. For components

used in a specific version see schematic diagram and respective parts list.

123

CC4000 / CC4000F only

2560

2460

4

9

4

04-22

1005

1

3560

6508

6507

2510

2503

6503

6506

2509

1503

1

1540

3086.

4

3460

7460

T80mA

240V

1408

T80mA

T200mA

230V

117V

2506

2507

1370

1

2383

1372

2380

3380

2544

1542

7380

1

6

3

9000

9501

1

1541

9503

1

1543

3

1

4

5

2

3385

3383

3384

R

1371

9502

3386

2381

3382

GND

9504

1502

9505

L

1501

9506

2382

3999

1

1

6561

6502

2502

2504

6504

6560

9001

6562

2501

2500

2508

6501

6500

6505

3104 113 3086.

2505

7500

CBE

A

B

C

D

1005 A 3

1370 A 1

1371 A 2

1372 A 1

1408 A 3

1500 B 1

1501 B 2

1502 C 2

1503 D 3

1540 B 2

1541 B 1

1542 C 1

1543 D 1

2380 A 1

2381 A 2

2382 A 2

2383 A 1

2460 A 3

2500 C 3

2501 C 3

2502 C 3

2503 C 3

2504 C 3

2505 C 3

2506 C 3

2507 D 3

2508 D 3

2509 D 3

2510 C 3

2544 C 1

2560 B 3

3380 A 1

3381 A 1

3382 A 2

3383 A 1

3384 A 1

3385 A 1

3386 A 2

3460 A 2

3560 B 3

3999 A 2

6500 C 3

6501 C 3

6502 C 3

6503 C 3

6504 C 3

6505 D 3

6506 D 3

6507 B 3

6508 B 3

6560 B 3

6561 B 3

6562 B 3

7380 A 1

7460 A 2

7500 C 3

9000 A 1

9001 B 3

9501 B 1

9502 B 2

9503 C 1

9504 C 2

9505 C 2

9506 B 2

123

TRANSFORMER CONNECTIONS

/N VERSION

240V

220V-230V

0V

NOT SERVICEABLE

BLACK

BLUE

o

130 C

BROWN

THERMAL FUSE

RED

RED

BLUE

WHITE

GREEN

WHITE

ACF1

ACF2

VFTD

AC1

GND

AC2

BLUE

RED

RED

/U VERSION

BLUE

117V

BLACKBLUEBROWN

o

130 C

BROWN

0V

THERMAL FUSE

NOT SERVICEABLE

WHITEWHITE GREEN

RED

RED

BLUE

WHITE

GREEN

WHITE

ACF1

ACF2

VFTD

AC1

GND

AC2

BLUE BROWN

BLUE REDRED

WHITEWHITE GREEN

/K VERSION

240V

220V-230V

127V

110V

0V

NOT SERVICEABLE

BLACK

BLUE

RED

ORANGE

o

130 C

BROWN

THERMAL FUSE

RED

RED

BLUE

WHITE

GREEN

WHITE

ACF1

ACF2

VFTD

AC1

GND

AC2

ORANGE

BLUE

RED

BLUE

RED

BLACK

BROWN

RED

/F VERSION

BLUE

100V

o

130 C

BROWN

0V

THERMAL FUSE

NOT SERVICEABLE

WHITEWHITE GREEN

RED

RED

BLUE

WHITE

GREEN

WHITE

ACF1

ACF2

VFTD

AC1

GND

AC2

BLUE BROWN

BLUE REDRED

WHITEWHITE GREEN

Page 15

6-3

ELECTRICAL PARTS LIST - SUPPLY & HEADPHONE BOARD

MISCELLANEOUS

1371 482 2267 31453 Headphone Socket

for CC4000, CC4000F

1500 482 2276 13224 Power Switch

1501 482 2252 51167 FUSE T200mA 250V for /U

1501 482 2071 58009 FUSE T80mA 250V for /N

1501 482 2071 52001 FUSE T200mA 250V for /F

1502 482 2070 31001 FUSE T100mA 250V for /K

1540 482 2265 20723 Socket. Primary Winding

1543 482 2277 11237 Voltage Selector for /K

!

!

!

!

!

!

!

6503 482 2130 31878 1N4003G

6504 482 2130 31878 1N4003G

6505 482 2130 31981 BZX79-B3V9

6506 532 2130 32586 BZV85-C7V5

6507 482 2130 31878 1N4003G

6508 482 2130 31878 1N4003G

6560 482 2130 31878 1N4003G

6561 482 2130 31878 1N4003G

6562 482 2130 31981 BZX79-B3V9

CAPACITORS

2380 482 2126 11585 22nF+80-20% 25V

for CC4000, CC4000F

2381 482 2121 51387

2382 482 2121 51387

10nF20% 16V for CC4000, CC4000F

10nF20% 16V for CC4000, CC4000F

2383 482 2126 12882 100nF+80-20% 50V

for CC4000, CC4000F

2500 482 2126 11585 22nF+80-20% 25V

2501 482 2126 11585 22nF+80-20% 25V

2502 482 2126 11585 22nF+80-20% 25V

2503 482 2126 11585 22nF+80-20% 25V

2504 482 2126 11585 22nF+80-20% 25V

2505 482 2126 11585 22nF+80-20% 25V

2506 482 2124 12328 6800µF 16V

2507 482 2126 12882 100nF+80-20% 50V

2508 482 2124 11769 220µF 20% 50V

2509 482 2124 81151 22µF 50V

2510 482 2123 14025 2200U 20% 16V for CC4000

2510 482 2124 40723 2200µF 20% 16V

for CC3000, CC4000F

2544 482 2126 14504 3.3nF 20% 250V

!

2560 482 2124 40849 330µF 20% 16V

TRANSISTORS & INTEGRATED CIRCUITS

7380 482 2209 82362

NJM4556D for CC4000, CC4000F

7500 482 2209 31257 MC79L24ACP

Note: Only the parts mentioned in this list are normal

service spare parts.

RESISTORS

3380 482 2101 21199 10kX2 20%

for CC4000, CC4000F

3381 482 2116 83864

3382 482 2116 83864

3383 482 2116 52244

3384 482 2116 52244

3385 482 2116 52206

3386 482 2116 52206

10k 5% 0.5W for CC4000, CC4000F

10k 5% 0.5W for CC4000, CC4000F

15k 5% 0.5W for CC4000, CC4000F

15k 5% 0.5W for CC4000, CC4000F

120R 5% 0.5W for CC4000, CC4000F

120R 5% 0.5W for CC4000, CC4000F

3560 482 2050 11002 1k 1% 0.4W

3999 482 2116 52303 8k2 5% 0.5W for /U, /F

3999 482 2116 52297 68k 5% 0.5W for /N

3999 482 2116 52228 680R 5% 0.5W for /K

DIODES

6500 482 2130 31878 1N4003G

6501 482 2130 31878 1N4003G

6502 482 2130 31878 1N4003G

Page 16

7-1 7-1

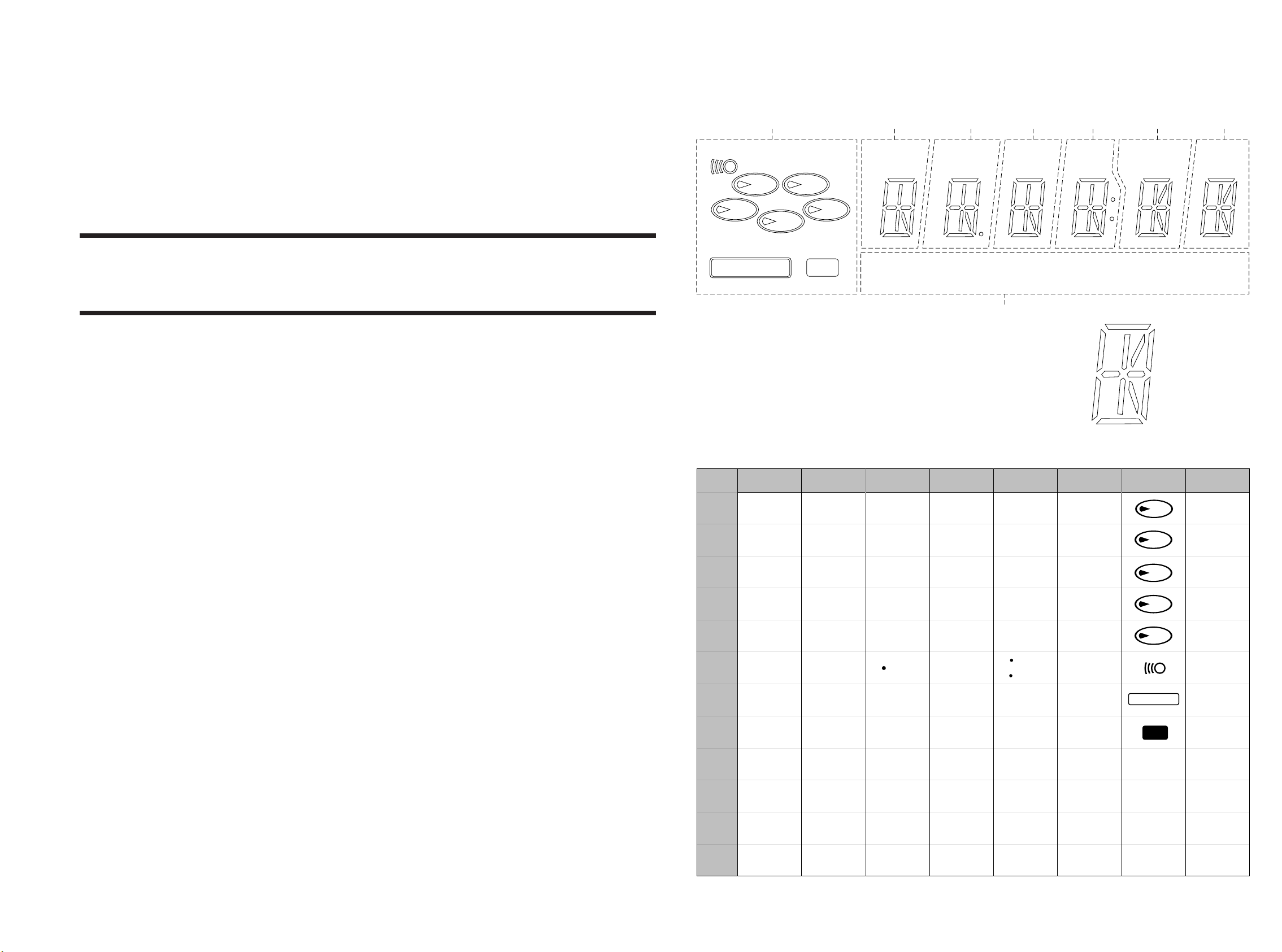

LCD DISPLAY PIN CONNECTIONS

FRONT BOARD

TABLE OF CONTENTS

7G

2

PROGRAM

54

FTS

3G4G5G6G

2G

1G

TRACK PEAK TOT REM TRACK TIME

13

SHUFFLE

VIDEO CD -I

8G

+

G

PAUSE

f

g

e

( 6G - 1G )

REPEAT DISC

a

k

j

b

g

p

c

n

d

1

LCD Pin connections ....................................................... 7-1

Circuit diagram - Main part .............................................. 7-2

Component & Chip layouts - Main part ........................... 7-3

Circuit diagram & layout - Open/Close part .................... 7-3

Electrical parts list............................................................ 7-4

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

1G 3G

TIME

a

b

f

j

k

g

c

e

p

2G 5G4G 6G 7G 8G

TRACK

a

b

f

j

k

g

c

e

p

REM

a

b

f

j

Dp

g

c

e

p

TOT

a

b

f

j

-

g

c

e

p

PEAK

a

b

f

j

Col

g

c

e

p

TRACK

a

b

f

j

-

g

c

e

p

1

2

3

4

5

PROGRAM

FTS

-

-

SHUFFLE

VIDEO

CD

-

I

+

G

PAUSE

REPEAT

1

DISC

-

P11

P12

n

d

n

d

n

d

n

d

n

d

n

d

-

-

-

-

PCS 101 024

Page 17

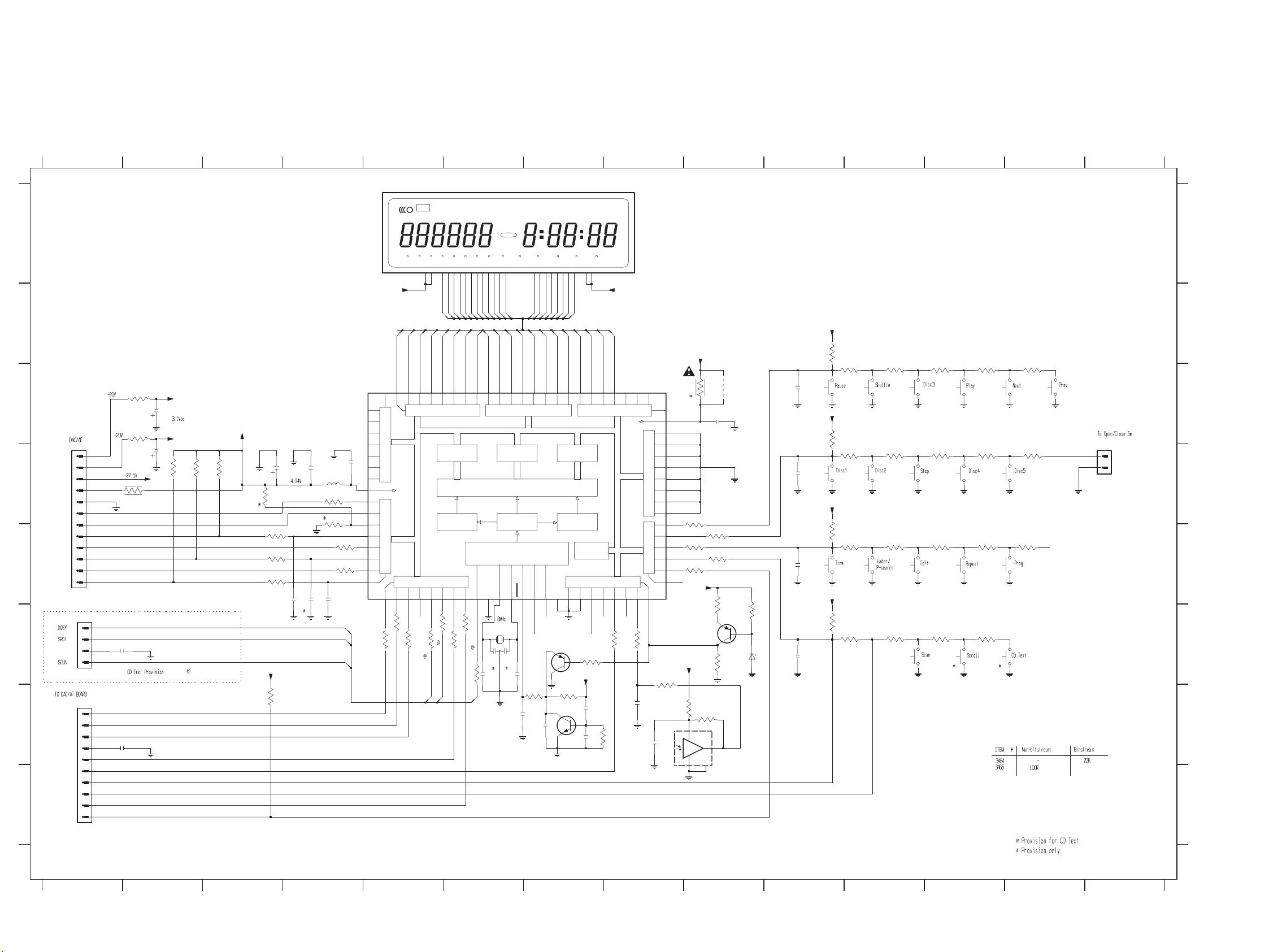

CIRCUIT DIAGRAM - MAIN PART

7-2 7-2

42 D14

1400 A5

1403 D1

1404 G1

1405 F1

1407 C11

1408 D11

1409 C12

1410 D10

1411 D11

1412 C11

1414 E10

1415 E11

1416 E11

1417 F11

1418 E12

1419 C13

1420 E12

1421 C12

1422 D12

1423 D12

1424 F12

1425 F12

1427 C10

2401 C2

2402 D2

2403 D3

2404 G1

2405 F6

2406 F6

2407 G6

2408 G7

2409 G7

2410 G7

2411 G8

2412 G8

2413 C9

2414 C10

2415 D10

2416 E10

2417 F10

2418 F1

2419 D4

2420 D4

2421 E4

2422 E4

2423 E4

3401 C2

3402 C2

3405 F8

3406 F8

3407 G9

3408 G9

3409 G7

3410 G7

3411 G7

3412 F8

3413 F6

3414 F6

3415 F6

3416 F5

3417 F5

3418 F5

3419 F5

3420 F5

3421 E3

3422 E4

3423 E3

3424 E4

3425 E3

3426 D4

3427 C9

3428 D9

3429 E9

3430 E9

3431 E9

3432 E9

3433 B10

3434 C11

3435 C11

3436 C12

3437 C10

3438 D11

3439 D11

3440 D12

3441 E10

3442 E11

3443 E11

3444 E12

3445 E12

3446 C13

3447 F10

3448 F11

3449 F11

3450 F12

3451 F12

3452 D13

3453 G3

3454 D12

3455 C12

3456 D2

3457 D2

3458 D3

3459 E13

3460 F9

3461 F9

3462 F9

3463 F7

3464 D3

3465 D4

3466 D2

5400 F6

5401 D4

6401 F9

7401 E4

7408 G7

7409 H9

7410 F9

7411 F7

9480 C9

1234567891011121314

1400

8-BT-213GK

A

B

3401

C

4R7

3402

1403

EH-B

1

VAC1

2

VAC2

3

D

E

F

-VFTD

+5B

D_GND

CdCarCtrl

CdDisDetect

CdDisPosSw

CdTrayCtrl

CdSledgeSw

CdTraySw

CdCarSw

4

5

6

7

8

9

10

11

12

1405

1

2

3

4

4R7

3466

3R3

2418

22n

EH-B

1404

CdData

1

CdSild

G

H

CdSicl

D_GND

CdPore

QuickPlay

Laod

RC5BusIn

RC5BusOut

2

3

4

5

Kill2

6

7

8

9

10

2404

22n

EH-B

2401

2402

-Vkk

F1

1u

3458

47K

CdCarCtrl

CdDisDetect

CdDisPosSw

CdTrayCtrl

CdSledgeSw

CdTraySw

CdCarSw

+5V

2419

1u

5401 2u2

3464

2403

22K

100u

3465

3425

100R

1K

3423

1K

3421

F2

1u

47K

47K

3457

3456

1K3426

3424

1K

3422

1K

2420

P6640

P6539

P6438

P6337

P6236

1u

P6135

P6034

VDD33

P0732

P0631

P0530

P0429

P0328

P0227

P0126

P0025

1K

2423

cdTxtIn

cdTxtClk

100n

cdTxD

7401

TMP87CN71

470R

3420

CdData

+5V

3453

22K

2421

100n

2422

10n

FTS TRACKTITLECHAPTERREPEATA-BSCANPAUSESHUFFLE

123456789

F2

P12

P11

P10

P09

G08

G07

G06

G05

G04

G03

44

P6741P7042P7143P72

I/O PORT 0 I/O PORT 6

24

470R

3419

CdSild

P7345P7446P7547P7648P7749P8050P8151P8252P8353P8454P85

I/O PORT 7 I/O PORT 9

DATA MEMORY

(RAM)

1024X8 BIT

VDD

16 BIT

TIMER/COUNTER

I/O PORT 3

P30

P3118P3219P3320P3421P3522P3623P37

17

1K

1K

1K

1K

3414

CdSicl

330R

3417

cdTxtIn

3416

cdTxtClk

3415

CdPore

3418

DVD

VCD

P08

P07

P06

P05

P04

P03

P01

P02

G02

G01

PROGR MEMORY

CONTROLLER

CLOCK/TIMING CONTROLLER

(I/O PORT 2)

VSS

XOUT

P20

16

15

14

CST

5400

3413

1K

33p

2405

RC5Bus

cdTxD

10 11 12 13 14

22 23 24 25 26 27 29 304567891 101112131415 1617 181922021

G01

G02

G03

G04

G05

G06

G07

P02

P01

P03

I/O PORT 8

(ROM)

48KX8 BIT

C P U

INTERRUPT

RESET

XIN

12

13

33p

2406

2407

P04

P05

11

3411

1K

100n

G08

P06

P07

P08

P09

55

P8656P8757P9058P9159P9260P9361P9462P9563P96

PROGRAM

COUNTER

8 BIT

TIMER/COUNTER

6 BIT A/D-

CONVERTER

P2110P22

TEST

8

9

BC857B

7411

+5V

3410

47K

BC847B

100n

2408

7408

3463

4K7

2409

2410

TIMEREMTOTALTRACK TRACKCHAPTERTITLE

15

P10

P11

I/O PORT 1

100n

10n

3409

F1

1K

100K

+

P12

KILL2

3412

VKK

1K

2411

P112P123P134P145P156P167P17

64

I/O PORT 4I/O PORT 5

P10

1

3405

2n2

P97 65

VKK 66

P40 67

P41 68

P42 69

P43

P44 71

P45 72

P46 73

P47 74

P50 75

P51 76

P52 77

P53 78

P54 79

P55 80

3406

1K

47n

70

3407

2

2412

34

-Vkk

1R

3428

1K

3430

1K

3432

1K

+5V

7410

BC857B

+5V

V

SUPPLY

GND

47R

3408

10K

OUT

3427

9480

2413

100n

3429

1K

3431

1K

1K

3461

22K

3460

1

7409

GP1U28XP

KeySet1

KeySet2

KeySet3

KeySet4

RC5BusOut

3462

6401

RC5BusOut

150R

BZX79-F3V3

220p

220p

220p

220p

2414

2415

2416

2417

QuickPlay

1427

1410

1414

3K9

+5V

3K9

+5V

3K9

+5V

3K9

A

+5V

3433

3434

680R

T

3435

820R

1407

1412

3436

1K2

1409

3455

2K2

1421

3446

4K7

1419

B

C

3437

3438

680R

3441

3442

680R

3447

3448

680R

T

3439

1411

T

3443

820R

1415

T

3449

820R

3440

1K2

1408

3444

1K2

1416

3450

1K2

1417

3454

2K2820R

1422

3445

2K2

1420

3451

2K2

1424

3452

4K7

1423

3459

4K7

1418

1425

42

1

2

DIPMATE

D

E

F

G

Load

H

123456789

10 11 12 13 14

Page 18

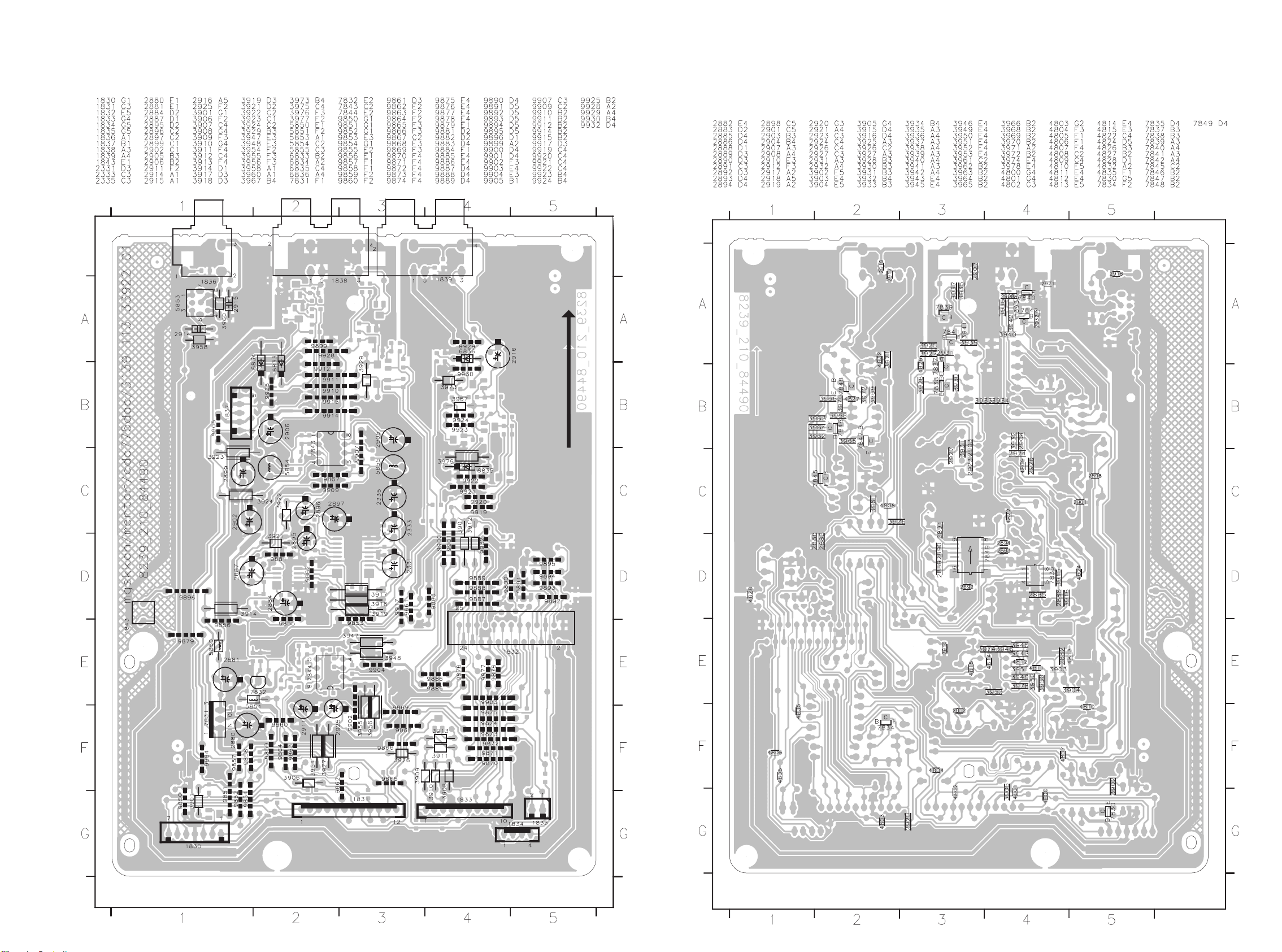

7-3 7-3

COMPONENT & CHIP LAYOUTS - MAIN PART

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

3387p2

3387p2

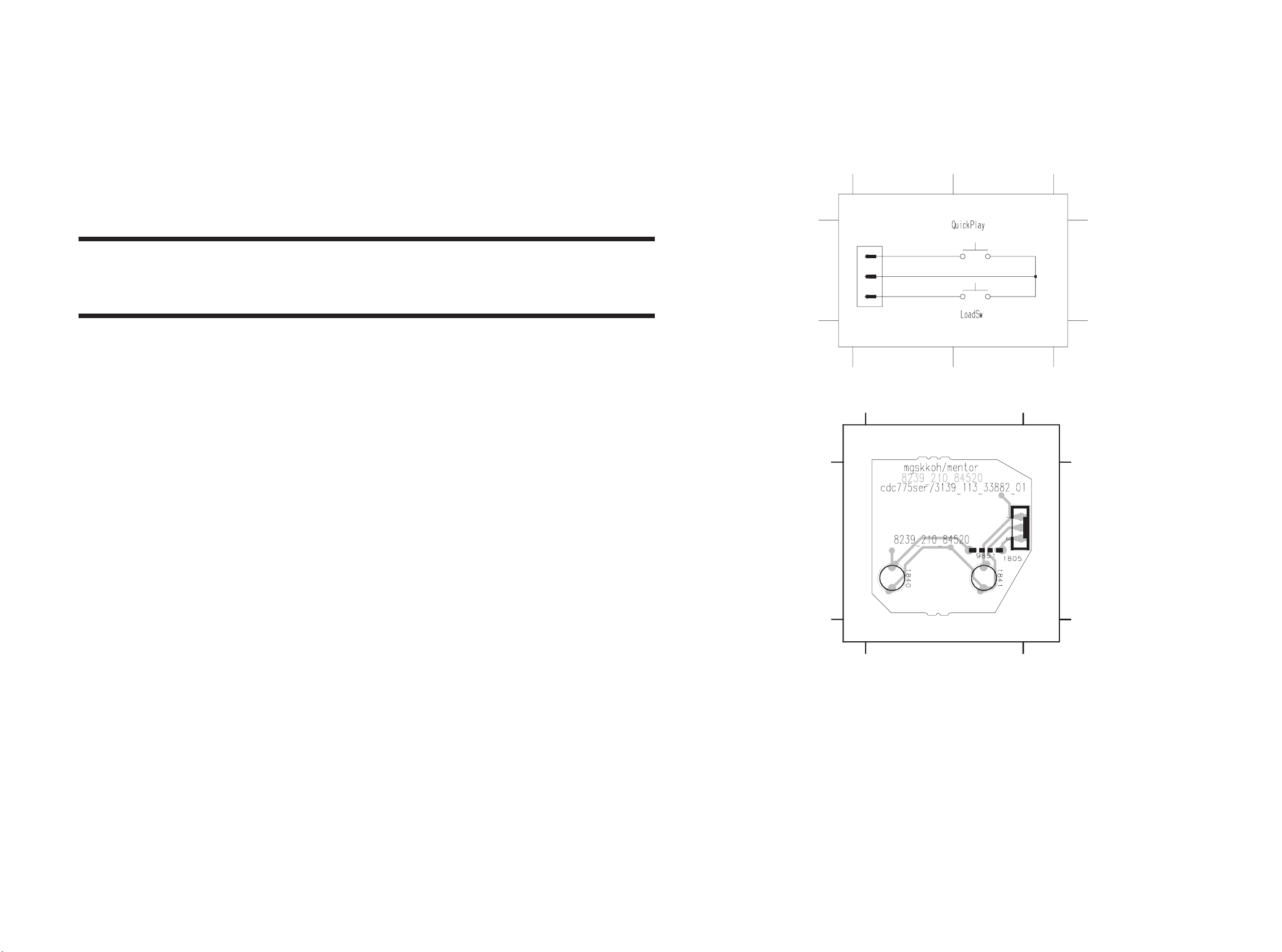

CIRCUIT & LAYOUT - OPEN/CLOSE PART

A

B

123

43

1

2

DIPMATE

1413

A

B

43 A1

1413 A

2

123

12

43 A2

1413 A

1

AA

12

Page 19

ELECTRICAL PARTS LIST - FRONT BOARD

MISCELLANEOUS

1400 3139 110 51990 FTD Display

1407 4822 276 13775 Tact Switch

1408 4822 276 13775 Tact Switch

1409 4822 276 13775 Tact Switch

1410 4822 276 13775 Tact Switch

1411 4822 276 13775 Tact Switch

1412 4822 276 13775 Tact Switch

1413 4822 276 13775 Tact Switch

1414 4822 276 13775 Tact Switch

1415 4822 276 13775 Tact Switch

1416 4822 276 13775 Tact Switch

1417 4822 276 13775 Tact Switch

1418 4822 276 13775 Tact Switch

1419 4822 276 13775 Tact Switch

1420 4822 276 13775 Tact Switch

1421 4822 276 13775 Tact Switch

1422 4822 276 13775 Tact Switch

1423 4822 276 13775 Tact Switch

1427 4822 276 13775 Tact Switch

CAPACITORS

2401 4822 124 22651 1µF 20% 50V

2402 4822 124 22651 1µF 20% 50V

2403 4822 124 42234 100µF 20% 6,3V

2404 5322 122 32654 22nF 10% 63V

2407 4822 126 14585 100nF 10% 50V

2408 4822 126 13838 100nF 20% 50V

2409 4822 126 13838 100nF 20% 50V

2410 4822 122 33177 10nF 20% 50V

2411 4822 122 33127 2,2nF 10% 50V

2412 4822 126 13751 47nF 10% 50V

2413 4822 126 13838 100nF 20% 50V

2414 4822 122 33575 220pF 5% 50V

2415 4822 122 33575 220pF 5% 50V

2416 4822 122 33575 220pF 5% 50V

2417 4822 122 33575 220pF 5% 50V

2418 5322 122 32654 22nF 10% 63V

2419 4822 126 14043 1µF 16V

RESISTORS

3401 4822 050 24708 4R7 1% 0,6W

3402 4822 050 24708 4R7 1% 0,6W

3405 4822 051 10102 1k 2% 0,25W

3406 4822 050 11002 1k 1% 0,4W

3407 4822 051 20479 47R 5% 0,1W

3408 4822 117 10833 10k 1% 0,1W

3409 4822 117 10837 100k 1% 0,1W

3410 4822 117 10834 47k 1% 0,1W

3411 4822 051 10102 1k 2% 0,25W

3412 4822 050 11002 1k 1% 0,4W

3413 4822 051 10102 1k 2% 0,25W

3414 4822 051 10102 1k 2% 0,25W

7-4 7-4

3415 4822 051 10102 1k 2% 0,25W

3416 4822 051 10102 1k 2% 0,25W

3417 4822 051 10102 1k 2% 0,25W

3418 4822 117 13577 330R 1% 0,25W

3419 4822 116 83883 470R 5% 0,5W

3420 4822 116 83883 470R 5% 0,5W

3421 4822 051 10102 1k 2% 0,25W

3422 4822 051 10102 1k 2% 0,25W

3423 4822 051 10102 1k 2% 0,25W

3424 4822 051 10102 1k 2% 0,25W

3425 4822 051 10102 1k 2% 0,25W

3426 4822 051 10102 1k 2% 0,25W

3428 4822 051 10102 1k 2% 0,25W

3429 4822 050 11002 1k 1% 0,4W

3430 4822 051 10102 1k 2% 0,25W

3431 4822 051 10102 1k 2% 0,25W

3432 4822 051 10102 1k 2% 0,25W

3433 4822 051 20392 3k9 5% 0,1W

3434 4822 117 10361 680R 1% 0,1W

3435 4822 117 11454 820R 1% 0,1W

3436 4822 051 20122 1k2 5% 0,1W

3437 4822 116 52276 3k9 5% 0,5W

3438 4822 117 10361 680R 1% 0,1W

3439 4822 117 11454 820R 1% 0,1W

3440 4822 116 52207 1k2 5% 0,5W

3441 4822 051 20392 3k9 5% 0,1W

3442 4822 117 10361 680R 1% 0,1W

3443 4822 117 11454 820R 1% 0,1W

3444 4822 051 20122 1k2 5% 0,1W

3445 4822 117 11449 2k2 1% 0,1W

3446 4822 051 20472 4k7 5% 0,1W

3447 4822 051 20392 3k9 5% 0,1W

3448 4822 117 10361 680R 1% 0,1W

3449 4822 117 11454 820R 1% 0,1W

3450 4822 051 20122 1k2 5% 0,1W

3451 4822 117 11449 2k2 1% 0,1W

3452 4822 051 20472 4k7 5% 0,1W

3453 4822 051 20223 22k 5% 0,1W

3454 4822 117 11449 2k2 1% 0,1W

3455 4822 116 52256 2k2 5% 0,5W

3456 4822 116 83884 47k 5% 0,5W

3457 4822 117 10834 47k 5% 0,1W

3458 4822 117 10834 47k 5% 0,1W

3459 4822 051 20472 4k7 5% 0,1W

3460 4822 051 20223 22k 5% 0,1W

3461 4822 051 10102 1k 2% 0,25W

3462 4822 117 10353 150R 1% 0,1W

3463 4822 051 20472 4k7 5% 0,1W

3464 4822 051 20223

3465 4822 051 20101 100R 5% 0,1W for CC3000

3466 4822 052 10338 3R3 5% 0,33W

4401 4822 051 20008 0R Jumper 0805

22k 5% 0,1W for CC4000, CC4000F

4402 4822 051 20008 0R Jumper 0805

4403 4822 051 20008 0R Jumper 0805

4404 4822 051 20008 0R Jumper 0805

4405 4822 051 20008 0R Jumper 0805

4406 4822 051 20008 0R Jumper 0805

4407 4822 051 20008 0R Jumper 0805

4408 4822 051 20008 0R Jumper 0805

4409 4822 051 20008 0R Jumper 0805

4410 4822 051 20008 0R Jumper 0805

4411 4822 051 20008 0R Jumper 0805

4412 4822 051 20008 0R Jumper 0805

4413 4822 051 20008 0R Jumper 0805

4414 4822 051 20008 0R Jumper 0805

4415 4822 051 20008 0R Jumper 0805

4416 4822 051 20008 0R Jumper 0805

4417 4822 051 20008 0R Jumper 0805

4418 4822 051 20008 0R Jumper 0805

4419 4822 051 20008 0R Jumper 0805

4420 4822 051 20008 0R Jumper 0805

4421 4822 051 20008 0R Jumper 0805

4422 4822 051 20008 0R Jumper 0805

4423 4822 051 20008 0R Jumper 0805

4424 4822 051 20008 0R Jumper 0805

4425 4822 051 20008 0R Jumper 0805

4426 4822 051 20008 0R Jumper 0805

4427 4822 051 20008 0R Jumper 0805

4428 4822 051 20008 0R Jumper 0805

4429 4822 051 20008 0R Jumper 0805

4430 4822 051 20008 0R Jumper 0805

4431 4822 051 20008 0R Jumper 0805

4432 4822 051 20008 0R Jumper 0805

4433 4822 051 20008 0R Jumper 0805

COILS & FILTERS

5400 4822 242 72066 Ceram Resonator 8MHz

5401 4822 157 11477 Coil 2,2µH 5%

DIODES

6401 4822 130 31981 BZX79-B3V9

TRANSISTORS & INTEGRATED CIRCUITS

7401 3139 110 52000 TMP87CP71F

7408 5322 130 60159 BC846B

7409 4822 130 10165 GP1U28XP

7410 4822 130 60373 BC856B

7411 4822 130 60373 BC856B

Note: Only the parts mentioned in this list are normal

service spare parts.

Page 20

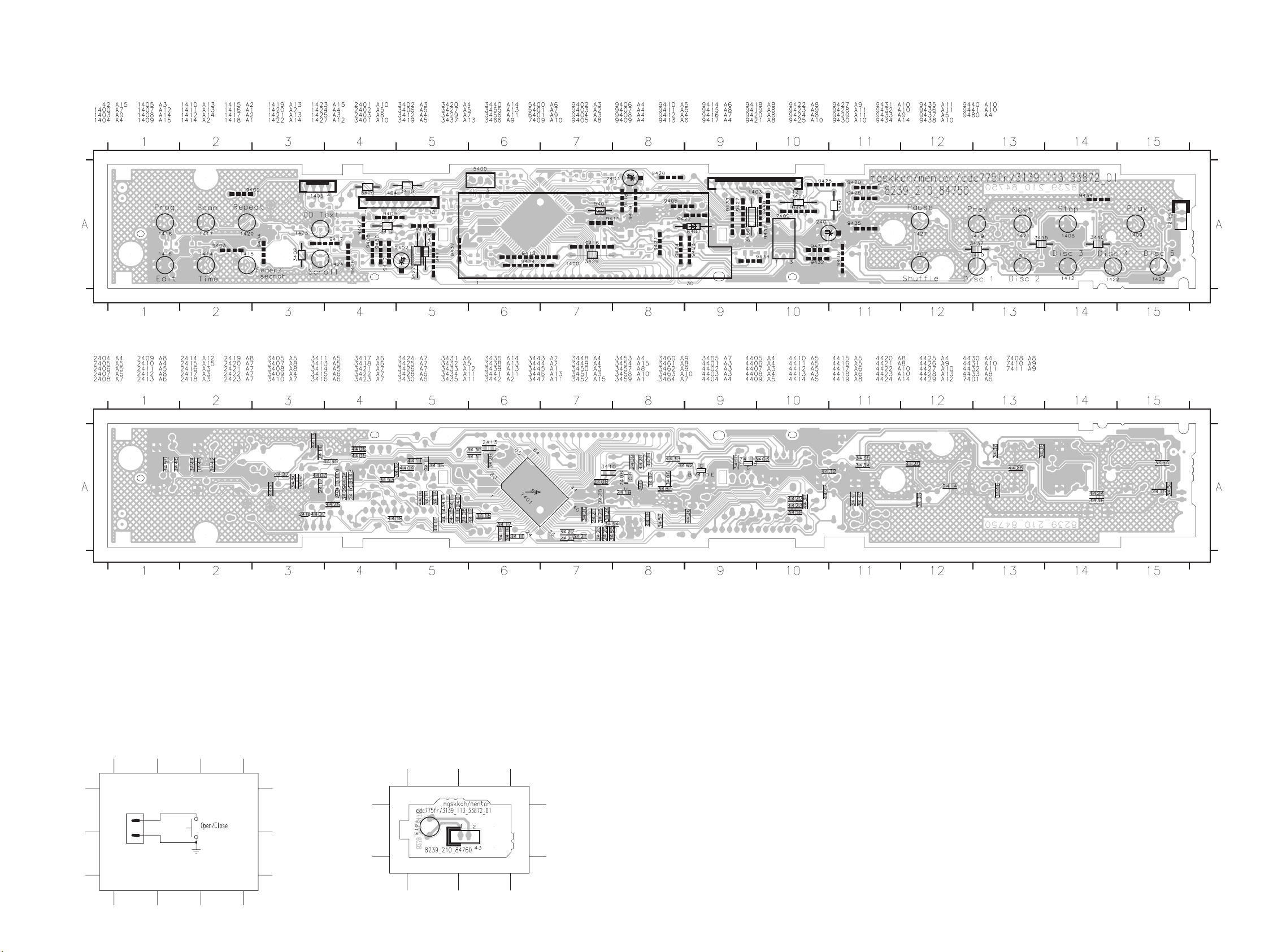

8-1 8-1

CIRCUIT DIAGRAM & LAYOUT - LOAD/QP PART

SERVO/DECODER BOARD

TABLE OF CONTENTS

Circuit diagram & layout - Load/Quick Play part ............. 8-1

Circuit diagram - Main part .............................................. 8-2

Component & Chip layouts - Main part ........................... 8-3

Electrical parts list............................................................ 8-4

A

A

1805

1

2

3

EH-B

12

1841

A

1840

12

1

A

1805 A1

1840 A2

1841 A2

1805 A1

1840 A1

1841 A1

9851 A1

3388p2

1

Page 21

CIRCUIT DIAGRAM - MAIN PART

8-2 8-2

1800 E1

1801 G1

1802 D15

1803 B1

1804 A1

1810 G10

1820 B14

1821 A14

2802 D6

2804 D2

2807 B5

2808 D8

2809 G5

2810 B5

2812 C5

2813 D5

2814 F2

2815 F3

2816 F3

2817 A4

2818 A5

2819 B6

2820 B7

2821 B7

2823 F9

2824 F9

2825 F9

2826 E14

2827 D14

2828 D12

2829 D8

2830 D8

2831 C12

2832 C11

2833 G10

2834 G9

2835 H7

2836 H7

2837 G5

2838 F5

2839 F5

2840 F5

2841 I6

2842 I5

2843 H5

2844 H6

2845 H5

2846 G6

2847 G5

2848 D8

2849 D7

2850 C12

2851 D7

2852 D8

2853 B11

2854 D14

2855 C11

2856 D14

2859 E14

2860 A14

2861 G14

2862 E5

2863 A7

3801 C7

3802 E6

3803 C7

3804 E5

3805 B7

3806 C7

3807 B7

3808 B7

3809 D2

3810 D2

3812 F3

3813 E7

3814 B7

3815 A8

3816 A6

3817 A6

3818 A7

3820 A11

3821 A11

3822 B11

3823 B11

3824 B11

3825 E8

3829 A13

3832 B13

3834 B13

3835 A13

3836 A13

3837 H7

3838 H7

3839 F6

3840 F6

3841 F6

3842 I6

3843 I6

3844 I5

3845 H6

3846 H6

3847 H5

3848 G6

3849 G6

3850 G6

3851 C11

3852 F6

3853 H5

3854 E14

3855 C12

3857 C12

3858 C13

3859 C13

3860 C13

3861 D14

3864 D14

3865 F14

3866 F14

3868 F14

3869 F15

3870 G15

3871 G14

3872 H11

3873 D13

3874 F9

3875 G10

3876 G9

3877 C11

3878 F9

3879 E10

3880 D11

3881 A13

3882 E15

3883 F15

3884 G14

3885 A7

3886 D15

5801 A5

5802 A6

5803 C15

7801 B4

7802 A8

7803 D11

7805 A12

7806 H5

7807 F4

7808 E5

7810 A6

7811 A5

9812 G11

9815 F14

123456789101112131415

S

M

D

D

3882

470R

3883

D

not for

opt_out version

5597-NAPB

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1802

470R

A

B

C

D

E

F

G

H

I

3881

4K7

14

VDD

13

12

11

10

SW2

9

SW1

8

TEST

22K

to servo drivers

(7806,7807)

at 3837

33R

3873

+4V

+4V

3.8V

3829 470R

470R3832

3834 470R

D

3859

470R

3858

470R

2860

47R

3836

10K

3835

D

47n

1821

1820

D

EBU

+10V

CarMotor

CdCarSw

CdDisPosSw

EBU_GND

Load

PORE

*

QuickPlay

SILD

SDA

SCL

+4V

9815

100R

3865

470R

3866

470R

100n

2854

2827

V1

only for

opt_out version

EBU

47p

5803

2u2

470R

3886

100p

D

KILLL

+4V

10K

3869

10K

3870

KILLR

to

dig. out circuitry

3860

470R

47p

2856

8.46MHz

3.8V

3.8V

+4V

47u

2826

176.4kHz

+4V

3868

kill circuitry

3871

D

3861

100R

3864

10R

3854

100n

2859

D

D

22K

+4V

22K

V2

3884

100R

2861

EBU_GND

DC voltages

V

measured in

play mode

+10V

2846

2844

2841

3845

3842

+4V

2820

3808

10K

3807

10K

3801

10K

3806

10K

3803

47n

3805

10K

10K

4V

3885

15K

560R

3818

3814

2.6V

2821

2851

L

220p

100n

PC74HCU04D

2849

220p

3815

22K

7802

14

VCC

1A

1Y

1

3

5

9

11

13

2848

220p

2

2A

2Y

4

3A

3Y

6

4A

4Y

8

5A

5Y

10

6A

6Y

12

GND

7

L

2830

2829

2808

220p

220p

2863

18p

10K

220p

5802

2u2

DA

+5V

EYE-PATTERN

4K7

3813

800mVpp

TB = 0.5us/div

LaserOn

4V

3848

8K2

0V

+4servo

1K

100n

3837

1K

47u

3838

2835

2836

D

D

D

1.9V

10K

10K

2852

3825

2n2

1K

CD-TEXT INFO

3.3ms

47p

2823

22n

2824

L

3876

D

L

10K

2834

4V

DQSY

SCLK

SRDT

2825

47n

3878 100K

3874

3875 1M

1810

CST 8M467

22p

D

only during

TOC-reading

22K

3879

To

330R

CD TEXT

DECODER

2833

Provision For CD Text

7805

470R3820

3821 470R

470R3822

3823 470R

3824

470R

11.29MHz

+4V

3851

33R

2832

4u7

3.8V

3880

DA

330K

DA

7803

SAA7378

D

D

SelPLL

D

22p

9812

For Non-CD Text Version

D

LC89170M

1

2

3

4

5

6

7

47n

2853

D

D

L

DA

2855

SelPLL

3877

+4V

457

10

3

63239495611216

8

9

ADC

11

VREF

GENERATOR

52

MICRO

51

PROCESSOR

53

INTERFACE

54

15

17

14

18

FRONT END

20

23

TEST

29

13

21

22

24

TIMING

25

50

35

36

38

37

58

DECODER

MICRO-

PROCESSOR

INTERFACE

57

to Kill circuitry

3872

V4

4K7

EXCK

SBSO

SCOR

WFCK

MCK

XMODE

GND

L

100n

2831

100R

L

DA

DIGITAL

PLL

EFM

DEMODULATOR

SRAM

RAM

ADDRESSER

SUBCODE

PROCESSOR

VERSATILE PINS

INTERFACE

6263 42 4140

V2

V1

32 x 8

2 PORT

RAM

TIMING & SYNC

PROTECTION

4u7

EBU_GND

D

L

19

PRE-

PROC.

CONTROL

PART

CRC

CHECK

D

CONTROL

FUNCTION

PROCESSOR

PEAK

DETECT

470R

D

D

MOTOR

CONTROL

CORRECTOR

AUDIO

KILL

D

2828

100n

3047 592

ERROR

FLAGS

43

CPU

INTERF

3855

2850

+4servo

3.8V

OUTPUT STAGES

EBU

DQSY

SRDT

SCLK

1n

3857

D

26

27

28

64

33

34

55

61

60

31

INTERFACE

48

46

45

INTERFACE

SERIAL DATA

44

10V

2807

2809

2845

2842

+5V

5801

2u2

47u

2818

L

1n5

2810

7810

5V

BC547B

3816

3817

4.7V

100R

560R

10n

2819

D

DA

L

560p

DA

47n

2812

L

47n

L

4u7

7808

47R

2802

L

3802

100R

0V

+5V

2813

4u7

2862

3804

BC337-40

4V

0V

L

0V

3840

2847

3847

3844

150K

6K8

3841

3839

3852

150K

3R3

47u

3849

8K2

22n

3850

470R

1n

3846

8K2

+10V

3843

8K2

1n

100n

10V

2837

S

100n

680R

3853

3R3

47u

TRACK

560R

C

7807

TDA7073

ON/

OFF

13

A

+10V

10V 5V

47u

2817

S

SUPPLY

VDD

VDD

L

7801

VDD

GND

VDDL

LDON

+

+

-

+

+

-

7811

L7805

O6

O5

O4

O3

O2

O1

RFE

RF

LO

TURNTABLE

1

2

3

4

5

6

7

8

TDA7073

1

2

3

4

5

6

7

8

2

L

2

5

1

3

6

4

18

15

9

10

8

16

7

100n

100n

S

SLIDE

1.9V

7806

FOCUS

1.9V

1.9V

1.9V

1.9V

1.9V

S

28402838

S

100n

A

10n

2843

10n

L

2839

5CDC-MG-RW SERVO/DECODER

A

Carousel

1804

Motor

To DM81

B

C

D

E

F

G

H

I

XH-B

1

2

1803

1

2

3

EH-B

D

CarMotor

M

QuickPlay

Load

TDA1302T

23

I6

6

20

I5

5

24

I4

L

L

4K7

V4

3810

120K

4

22

I3

3

I2

19

2

I1

21

1

HG

11

LS

12

3809

10n

1800

5597-NAPB

1801

EH-B

2804

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

2814

L

D

100n

+5V

2815

L

MI

17

ADJ

14

5V

2816

100n

100n

L

during Focus search

3812

IREF

VGAP

1K

+5V

16

15

14

13

OUT1-

12

11

10

S

9

16

15

14

13

OUT1-

12

11

10

S

9

PCS 101 029

1234567891011121314

15

Page 22

8-3 8-3

COMPONENT & CHIP LAYOUTS - MAIN PART

This assembly drawing shows a summary of all possible versions. For components

used in a specific version see schematic diagram and respective parts list.

This assembly drawing shows a summary of all possible versions. For components

used in a specific version see schematic diagram and respective parts list.

PCS 101 030

Page 23

ELECTRICAL PARTS LIST - SERVO/DECODER BOARD

MISCELLANEOUS

1800 4822 267 51453 Flex Socket 12Pin Hort.

1802 4822 265 11556 Flex Socket 25Pin Hort.

1810 4822 242 10566 X’tal Resonator 8.4672MHz

1820 4822 276 13106 Tact Switch

1821 4822 276 13106 Tact Switch

1840 4822 276 13775 Tact Switch

1841 4822 276 13775 Tact Switch

CAPACITORS

2802 4822 124 40769 4,7µF 20% 100V

2804 4822 122 33177 10nF 20% 50V

2807 5322 122 31865 1,5nF 10% 63V

2808 4822 122 33575 220pF 5% 50V

2809 4822 126 13296 100nF 10% 16V

2810 5322 116 80853 560pF 5% 63V

2812 4822 126 13751 47nF 10% 63V

2813 4822 126 13751 47nF 10% 63V

2814 4822 126 13296 100nF 10% 16V

2815 4822 126 13296 100nF 10% 16V

2816 4822 126 13296 100nF 10% 16V

2817 4822 124 80231 47µF 20% 16V

2818 4822 124 80231 47µF 20% 16V

2819 4822 122 33177 10nF 20% 50V

2820 4822 126 13751 47nF 10% 63V

2821 4822 126 13296 100nF 10% 16V

2823 4822 126 13692 47pF 1% 63V

2824 5322 122 32654 22nF 10% 63V

2825 4822 126 13751 47nF 10% 63V

2826 4822 124 80231 47µF 20% 16V

2827 4822 126 13296 100nF 10% 16V

2828 4822 126 13296 100nF 10% 16V

2829 4822 122 33575 220pF 5% 50V

2830 4822 122 33575 220pF 5% 50V

2831 4822 124 40769 4,7µF 20% 100V

2832 4822 124 40769 4,7µF 20% 100V

2833 5322 122 32658 22pF 5% 50V

2834 5322 122 32658 22pF 5% 50V

2835 4822 126 13296 100nF 10% 16V

2836 4822 124 80231 47µF 20% 16V

2837 4822 124 80231 47µF 20% 16V

2838 4822 126 13296 100nF 10% 16V

2839 4822 126 13296 100nF 10% 16V

2840 4822 126 13296 100nF 10% 16V

2841 5322 126 10511 1nF 5% 50V

2842 4822 122 33177 10nF 20% 50V

2843 4822 124 80231 47µF 20% 16V

2844 5322 126 10511 1nF 5% 50V

2845 4822 122 33177 10nF 20% 50V

2846 5322 122 32654 22nF 10% 63V

2847 4822 126 13296 100nF 10% 16V

2848 4822 122 33575 220pF 5% 50V

2849 4822 122 33575 220pF 5% 50V

8-4 8-4

2850 5322 122 34123 1nF 10% 50V

2851 4822 122 33575 220pF 5% 50V

2852 4822 122 33175 2,2nF 20% 50V

2854 5322 122 32531 100pF 5% 50V

2855 4822 126 13196 100nF 10% 25V

2856 4822 126 13692 47pF 1% 63V

2859 4822 126 13296 100nF 10% 16V

2861 4822 126 13692 47pF 1% 63V

2862 4822 124 40769 4,7µF 20% 100V

2863 4822 126 13689 18pF 1% 63V

3860 4822 051 20471 470R 5% 0,1W

3861 4822 051 20101 100R 5% 0,1W

3864 4822 051 20101 100R 5% 0,1W

3865 4822 051 20471 470R 5% 0,1W

3866 4822 051 20471 470R 5% 0,1W

3868 4822 116 52257 22k 5% 0,5W

3869 4822 116 83864 10k 5% 0,5W

3871 4822 116 52257 22k 5% 0,5W

3872 4822 116 52283 4k7 5% 0,5W

3873 4822 116 52191 33R 5% 0,5W

3874 4822 051 20331 330R 5% 0,1W

RESISTORS

3801 4822 116 83864 10k 5% 0,5W

3802 4822 051 20101 100R 5% 0,1W

3803 4822 116 83864 10k 5% 0,5W

3804 4822 051 20479 47R 5% 0,1W

3805 4822 117 10833 10k 1% 0,1W

3806 4822 117 10833 10k 1% 0,1W

3807 4822 116 83864 10k 5% 0,5W

3808 4822 116 83864 10k 5% 0,5W

3809 4822 051 20124 120k 5% 0,1W

3810 4822 051 20472 4k7 5% 0,1W

3812 4822 051 10102 1k 2% 0,25W

3813 4822 051 20472 4k7 5% 0,1W

3814 4822 116 83864 10k 5% 0,5W

3815 4822 051 20223 22k 5% 0,1W

3816 4822 051 20101 100R 5% 0,1W

3817 4822 051 20561 560R 5% 0,1W

3818 4822 116 52226 560R 5% 0,5W

3825 4822 050 11002 1k 1% 0,4W

3837 4822 051 10102 1k 2% 0,25W

3838 4822 051 10102 1k 2% 0,25W

3839 4822 051 20154 150k 5% 0,1W

3875 4822 051 20105 1M 5% 0,1W

3876 4822 117 10833 10k 1% 0,1W

3877 4822 051 20101 100R 5% 0,1W

3878 4822 051 20104 100k 5% 0,1W

3879 4822 051 20223 22k 5% 0,1W

3880 4822 051 20274 270k 5% 0,1W

3882 4822 051 20471 470R 5% 0,1W

3883 4822 051 20471 470R 5% 0,1W

3884 4822 051 20101 100R 5% 0,1W

3885 4822 051 20153 15k 5% 0,1W

3886 4822 051 20453 470R 5% 0,1W

4801 4822 051 20008 0R Jumper 0805

4802 4822 051 20008 0R Jumper 0805

4803 4822 051 20008 0R Jumper 0805

4805 4822 051 20008 0R Jumper 0805

4806 4822 051 20008 0R Jumper 0805

4809 4822 051 20008 0R Jumper 0805

4810 4822 051 20008 0R Jumper 0805

4813 4822 051 20008 0R Jumper 0805

4814 4822 051 20008 0R Jumper 0805

4815 4822 051 20008 0R Jumper 0805

4816 4822 051 20008 0R Jumper 0805

3840 4822 051 20154 150k 5% 0,1W

3841 4822 117 11507 6k8 1% 0,1W

3842 4822 117 10833 10k 1% 0,1W

3843 4822 051 20822 8k2 5% 0,1W

3844 4822 051 20561 560R 5% 0,1W

COILS & FILTERS

5801 4822 157 11477 Coil 2,2µH 5%

5802 4822 157 11477 Coil 2,2µH 5%

5803 4822 157 10586 Coil 2,2µH 10% 0805

3845 4822 117 10833 10k 1% 0,1W

3846 4822 051 20822 8k2 5% 0,1W

3847 4822 051 20681 680R 5% 0,1W

3848 4822 051 20822 8k2 5% 0,1W

3849 4822 051 20822 8k2 5% 0,1W

3850 4822 051 20471 470R 5% 0,1W

3851 4822 116 52191 33R 5% 0,5W

3852 4822 052 10338!3R3 5% 0,33W

!

3853 4822 052 10338

3R3 5% 0,33W

3854 4822 051 20109 10R 5% 0,1W

TRANSISTORS & INTEGRATED CIRCUITS

7801 4822 209 12636 TDA1302T/N1

7802 5322 209 11517 PC74HCU04T

7803 4822 209 12752 SAA7378GP/M1

7806 4822 209 32852 TDA7073A/N2

7807 4822 209 32852 TDA7073A/N2

7808 4822 130 41344 BC337-40

7810 4822 130 40959 BC547B

7811 4822 209 80817 L7805CV

3855 4822 051 20471 470R 5% 0,1W

3857 4822 051 20223 22k 5% 0,1W

3858 4822 116 83883 470R 5% 0,5W

Note: Only the parts mentioned in this list are normal

service spare parts.

3859 4822 116 83883 470R 5% 0,5W

Page 24

9-1 9-1

DAC/AF BOARD

Notes:

TABLE OF CONTENTS

Notes................................................................................ 9-1

Circuit diagram................................................................. 9-2

Component & Chip layouts.............................................. 9-3

Electrical parts list............................................................ 9-4

PCS 101 032

Page 25

CIRCUIT DIAGRAM

9-2 9-2

1830 A1

1831 B1

1832 H1

1833 H1

1834 G2

1835 A13

1836 C13

1837 D15

1838-A E15

1838-B E15

1839-A H15

1839-B H15

1843 D2

2331 C7

2333 C7

2335 C8

2880 A3

2881 A4

2882 B5

2883 D3

2884 F6

2885 F7

2886 G8

2887 G8

2888 D4

2889 C7

2890 C8

2891 C8

2892 C4

2893 E6

2894 E8

2895 E5

2896 E8

2897 E6

2898 E10

2899 E11

2901 E11

2902 E11

2903 D12

2904 F12

2905 E13

2906 F13

2907 E14

2908 F14

2910 B8

2911 A10

2912 B11

2914 B12

2915 C12

2916 H15

2917 I15

2918 B14

2919 I13

2920 I3

2921 B14

2923 E12

2924 F12

2925 B10

2926 G12

2927 D12

2931 D14

2932 D14

3901 B2

3902 B2

3903 B5

3904 B5

3905 C2

3906 D2

3907 D2

3908 H3

3909 H3

3910 H3

3911 H3

3912 D2

3913 I3

3914 F6

3915 F8

3916 F8

3917 C6

3918 C7

3919 C7

3921 E5

3922 E8

3923 E10

3924 E10

3925 D11

3926 G11

3927 C11

3928 F11

3929 D11

3930 G11

3931 D12

3932 G12

3933 E13

3934 F13

3935 E13

3936 F13

3937 E13

3938 F13

3939 C13

3940 D13

3941 D13

3942 D13

3943 A6

3945 A7

3946 B7

3947 A8

3948 A8

3949 A9

3950 B9

3951 A9

3952 B9

3953 B10

3954 A10

3955 A11

3956 A11

3958 C11

3960 B12

3961 H10

3962 H11

3963 I11

3964 H11

3965 H12

3966 H12

3967 H13

3968 I13

3969 H13

3970 H13

3971 H14

3972 H14

3973 G14

3974 B7

3975 I13

3976 H3

3977 B10

3978 B7

4828 H2

5850 A4

5851 A6

5853 B12

5854 G12

5855 D12

6833 D11

6834 G11

6835 I13

6836 H14

7830 A2

7831 A4

7832 A5

7834 H3

7835 G6

7837 D11

7838 G11

7839 E14

7840 F14

7841 D14

7842 D14

7843-A F12

7843-B E12

7844-A A10

7844-B A7

7845 H11

7846 H12

7847 H13

7848 H14

7849 D6

9893 G2

9894 G2

9895 G2

9902 A11

9904 A8

9907 E12

9919 H11

9920 H11

9923 H12

9924 G13

9930 H13

123456789101112131415

+10V

2889

3919

3R3

100n

6

5

3978

2331

15

VDDD

VREF

GND

GNDA

+S

-S

4K7

47u

14

VDDA

VSSD

VSSA

VDDO

VSSO

FILTCR

VOR

IREF

4

2

4

3974

12K

NC

7844-B

TCA0372

2333

11

12

10

9

6

7

13

7

3915

18K

6IOL

8IOR

9904

3948

3

3947

2910

100n

S

22R

CarMotor

1R

+5V

3950

+5V

12K

3952

3949

12K

3951

+S

7

8

12K

S

-S

1K

3954

3977

-10V

2

4

2911

2R2

7844-A

TCA0372

3953

12K

2925

47u

2R2

47u

M

S

1

3955

2912

M

S

S

22R

100n

+5V

9902

3956

1R

3958

EBU_GND

560R

2914

100n

KILL1

M

5853

7CHA

34

2

6

1

78

2915

22n

EBU_GND

1835

1

Tray Motor

2

XH-B

3960

10R

digital out circuitry

2

3

YKC21-3416

1836

2918

100n

1

3939

22K

22K

18K

22n

3970

47K

3969

47K

3975

D

10R

1K

3941

2K2

3942

2K2

3940

1K

3935

1K

3937

2K2

3938

2K2

3936

1K

9930

D

47u

2890

100n

2335

47u

GNDA

2891

100n

KILL_L

3925

47K

3927

10K

BC857B

7837

6833

3929

1N4148

220K

5855

10m

2927

150p

3K9

3931

220p

2894

GNDA

2886

GNDA