Page 1

Service

BD7004

BD7004 /

U1B

Manual

SECTION PAGE

1. TECHNICAL SPECIFICATIONS............................................................................................1

2. SERVICE HINTS AND TOOLS .............................................................................................4

3. WARNING AND LASER SAFETY INSTRUCTION ...............................................................5

4. LASER BEAM SAFETY PRECAUTIONS .............................................................................6

5. IMPORTANT SAFETY PRECAUTIONS ...............................................................................7

6. STANDARD NOTES FOR SERVICING ................................................................................9

7. CABINET DISASSEMBLY INSTRUCTIONS .......................................................................13

8. HOW TO INITIALIZE THE BLU-RAY DISC PLAYER ........................................................ 17

9. FIRMWARE RENEWAL MODE ..........................................................................................18

10. FIRMWARE RENEWAL MODE (Network Update) ..............................................................20

11. SERVICE MODE ..................................................................................................................21

12. TRAY LOCK MODE .............................................................................................................23

13. TROUBLESHOOTING .........................................................................................................24

14. BLOCK DIAGRAMS ............................................................................................................32

15. SCHEMATIC DIAGRAMS / CBA AND TEST POINTS .......................................................38

16. WAVEFORMS ......................................................................................................................97

17. WIRING DIAGRAM .............................................................................................................98

18. LEAD IDENTIFICATIONS .................................................................................................. 99

19. EXPLODED VIEW AND PARTS LIST ...............................................................................101

BLU-RAY DISC Player

TABLE OF CONTENTS

S0053-1V02DM/DG1004

Please use this service manual with referring to the user guide (D.F.U.) without fail.

修理の際は、必ず取扱説明書を準備し操作方法を確認の上作業を行ってください。

BD7004

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver. 2

Please refer to the

MODIFICATION NOTICE.

Page 2

MARANTZ DESIGN AND SERVICE

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

KOREA

D&M SALES AND MARKETING KOREA LTD.

CHUNG JIN B/D., #1001,

53-5, WONHYORO 3 GA, YONGSAN-GU,

SEOUL, 140-719, KOREA

PHONE : +82 - 2 - 323 - 2155

FAX : +82 - 2 - 323 - 2154

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

JAPAN

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

D&M Holdings Inc.

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL

NO.1600 NANJING (WEST) ROAD, SHANGHAI,

CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

company has created the ultimate in stereo sound.

product will continue to perform to the specications for

which it is famous.

Parts for your

MARANTZ

ORDERING PARTS :

equipment are generally available to our National Marantz Subsidiary or Agent.

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specied.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

NOTE ON SAFETY :

Symbol Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol .

Any other component substitution (other than original type), may increase risk of re or electrical shock hazard.

安全上の注意:

がついている部品は、安全上重要な部品です。必ず指定されている部品番号のものを使用して下さい。

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary

AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the face or Front Panel of

product and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and veried before it is return to the user/customer.

Ref. UL Standard No. 60065.

In case of difculties, do not hesitate to contact the Technical

Department at above mentioned address.

080702MZ

Page 3

1.TECHNICALSPECIFICATIONS

SIGNALSYSTEM

NTSCcolor

APPLICABLEDISCS

(1) BD/DVD-VideoDiscs

1-layer12cmsingle-sideddiscs,2-layer12cm

single-sideddiscs,2-layer12cmdouble-sideddiscs

(1layerperside)

(2) BD-RE/BD-R(RecordedinBDMVformat)

1-layer12cmsingle-sideddiscs,2-layer12cm

single-sideddiscs

1-layer8cmsingle-sideddiscs,2-layer8cmsinglesideddiscs

(3) DVD-R

1-layer12cmsingle-sideddiscs,2-layer12cm

single-sideddiscs

1-layer8cmsingle-sideddiscs,2-layer8cmsinglesideddiscs

(4) DVD-RW

1-layer12cmsingle-sideddiscs

1-layer8cmsingle-sideddiscs

(5) Compactdiscs(audioCD)

12cmdiscs,8cmdiscs

(6) CD-RW/-R

12cmdiscs,8cmdiscs

APPLICABLEMEMORYCARDS

(1) SDMemoryCard

(2) SDHCMemoryCard

(3) miniSDCard

(4) microSDCard

VIDEOOUTPUT

Youtputlevel:1Vp-p(75Ω/ohms)

Outputconnectors:Pinjack,1set

COMPONENTOUTPUT

Youtputlevel:1Vp-p(75Ω/ohms)

PB/CBoutputlevel:0.648Vp-p(75Ω/ohms)

PR/CRoutputlevel:0.648Vp-p(75Ω/ohms)

Outputconnectors:Pinjacks,1set

HDMIOUTPUT

Outputjack:19-pinHDMIterminal,1set

HDMIver.1.3a(DeepColor,DolbyDigitalPlus,DolbyTrueHD,

DTS-HD)

NETWORKTERMINAL

10BASE-T/100BASE-TX

ANALOGAUDIOOUTPUT

Outputlevel:2Vrms(10kΩ/kohms)

2channel(L,R)outputconnector:Pinjacks,1set

Multichannel(FL,FR,C,SL,SR,SBL,SBR,SW):Pinjacks,1set

AUDIOOUTPUTPROPERTIES

(1) Frequencyresponse

1 BDs(linearPCM) :20Hzto22kHz(48kHzsampling)

:20Hzto44kHz(96kHzsampling)

:20Hzto88kHz(192kHzsampling)

2 DVDs(linearPCM) :20Hzto22kHz(48kHzsampling)

:20Hzto44kHz(96kHzsampling)

3 CDs :20Hzto20kHz

(2) S/Nratio:115dB

(3) Totalharmonicdistortion:1kHz0.004%

(4) Dynamicrange :100dB(BD/DVD)/98dB(CD)

DIGITALAUDIOOUTPUT

Coaxialdigitaloutput:Pinjack,1set

POWERSUPPLY

AC120V,60Hz

POWERCONSUMPTION

30W(Standby:0.8W,Powersaving:0.75W)

MAXIMUMEXTERNALDIMENSIONS

W:440mm(17-3/8")

H:105mm(4-3/16")

D:324mm(12-13/16")

(includingprotrudingparts)

MASS

4.9kg(10.9lbs)

REMOTECONTROL:RC004BD

Infraredpulsetype

Supply:DC3V,2R6/AAbatteries

Externaldimensions:

W:52mm(2-1/16")

H :227mm(8-15/16")

D :30mm(1-3/16")

Mass :138g(0.3lbs)(includingbatteries)

1

Page 4

About Discs

ENGLISH

Introduction Connections Playback Function Setup Others

ENGLISH

Introduction Connections Playback Function Setup Others

Readable cards Playable files / data

SD Memory Card (8MB - 2GB) AVCHD, MP3, Windows Media™

Audio, JPEG, Picture-in-picture

commentary, subtitles or other

extras for BD-ROM ver. 2 (Profile

2.0/ Profile 1.1)

SDHC Memory Card (4GB - 8GB)

miniSD Card (8MB - 2GB)

microSD Card (8MB - 2GB)

Note for SD Memory Cards

• Do not remove the SD Memory Card or turn the unit to the

standby mode while the contents of the card is in playback. It

may result in malfunction or loss of the card’s data.

• Please keep the SD Memory Cards in their cases when you are

not using them.

• Do not try to open or modify the card.

• Do not touch the terminal surface with your fingers or any

metals.

• Do not attach additional labels or stickers to cards.

• Do not remove the label of the SD Memory Cards.

• This unit supports SD Memory Card with FAT12/FAT16 file

system, and SDHC Memory Card with FAT32 file system.

• This unit may not read the SD Memory Cards formatted on

computer. If that is the case, please reformat the SD Memory

Cards on this unit and try again.

• This unit does not support mini SDHC and micro SDHC

Memory Card.

• For miniSD Card and microSD Card adapter is necessary.

• Portions of this product are protected under copyright law

and are provided under license by ARIS/SOLANA/4C.

miniSD Card

Adapter

miniSD Card

microSD Card

Adapter

microSD Card

Introduction Introduction

Playable files Logos Media

AVCHD

DVD-RW/-R

SD Memory Card

(including SDHC)

miniSD Card

microSD Card

DivX

®

BD-RE/-R

DVD-RW/-R

CD-RW/-R

MP3

BD-RE/-R

DVD-RW/-R

CD-RW/-R

SD Memory Card

(including SDHC)

miniSD Card

microSD Card

Windows Media™

Audio

JPEG

Note

• ABOUT DIVX VIDEO: DivX® is a digital video format created by

DivX, Inc. This is an official Divx Certified device that plays

DivX video. Visit www.divx.com for more information and

software tools to convert your files into DivX video.

• ABOUT DIVX VIDEO-ON-DEMAND: This DivX Certified

®

device

must be registered in order to play DivX Video-on-Demand

(VOD) content. To generate the registration code, locate the

DivX VOD section in the device setup menu. Go to

vod.divx.com with this code to complete the registration

process and learn more about DivX VOD.

• Discs containing the DivX® files with the DivX®GMC (Global

Motion Compensation) playback feature, which is DivX

®

supplemental function, cannot be played back on this unit.

• This unit cannot play back the disc contents protected by

Windows Media™ Digital Rights Management (DRM).

• “WMA” (Windows Media™ Audio) is an audio codec

developed by Microsoft® in the United States of America.

—

—

Readable cards Playable files / data

SD Memory Card (8MB - 2GB) AVCHD, MP3, Windows Media™

SDHC Memory Card (4GB - 8GB)

miniSD Card (8MB - 2GB)

microSD Card (8MB - 2GB)

Note for SD Memory Cards

• Do not remove the SD Memory Card or turn the unit to the

standby mode while the contents of the card is in playback. It

may result in malfunction or loss of the card’s data.

• Please keep the SD Memory Cards in their cases when you are

not using them.

• Do not try to open or modify the card.

• Do not touch the terminal surface with your fingers or any

metals.

• Do not attach additional labels or stickers to cards.

• Do not remove the label of the SD Memory Cards.

• This unit supports SD Memory Card with FAT12/FAT16 file

system, and SDHC Memory Card with FAT32 file system.

• This unit may not read the SD Memory Cards formatted on

computer. If that is the case, please reformat the SD Memory

Cards on this unit and try again.

• This unit does not support mini SDHC and micro SDHC

Memory Card.

• For miniSD Card and microSD Card adapter is necessary.

• Portions of this product are protected under copyright law

and are provided under license by ARIS/SOLANA/4C.

miniSD Card

Adapter

miniSD Card

Disc Handling

• Handle the discs so that fingerprints and dust do not adhere to

the surfaces of the discs.

• Always store the disc in its protective case when it is not used.

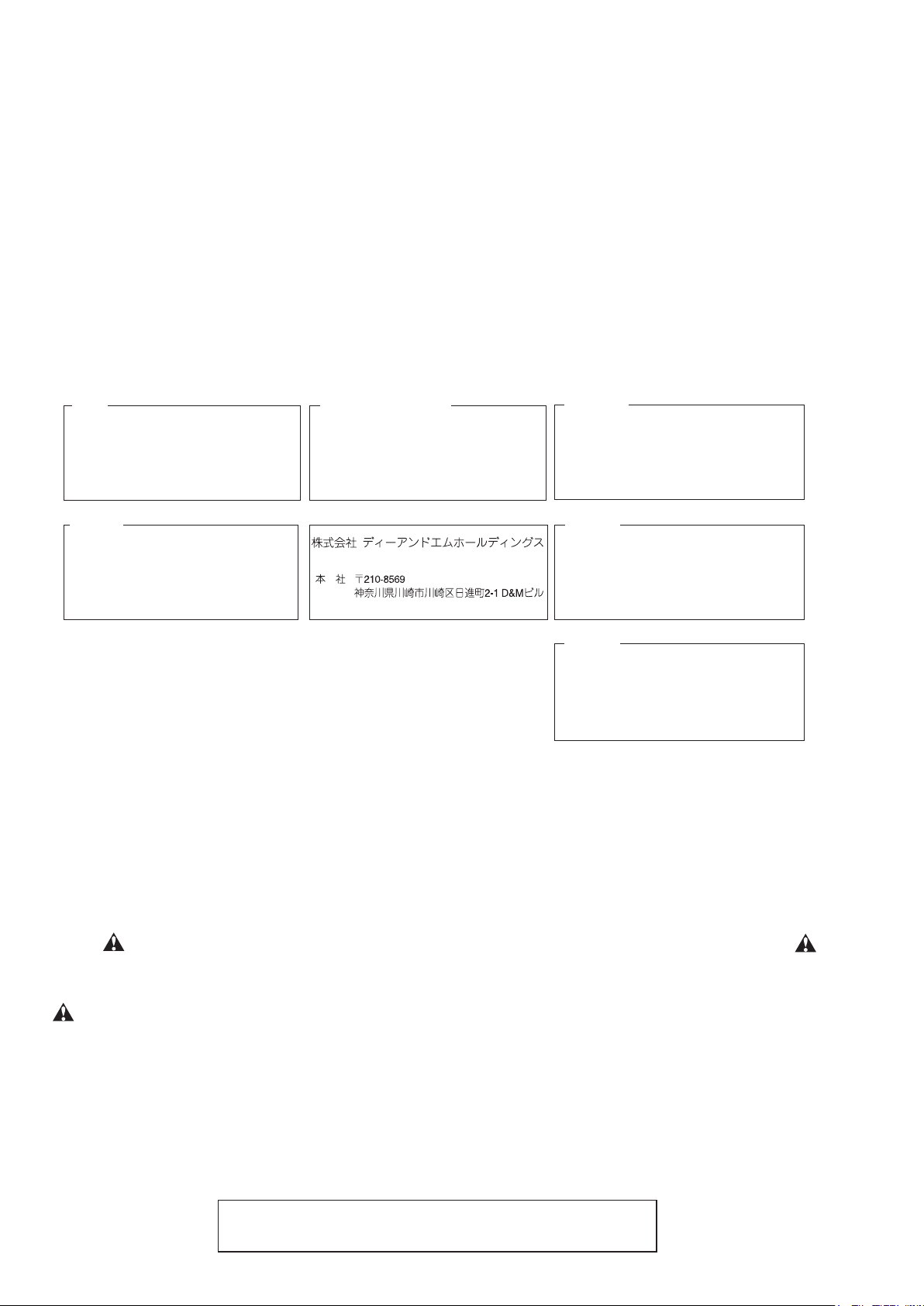

Playable files Logos Media

DVD-RW/-R

SD Memory Card

AVCHD

(including SDHC)

miniSD Card

microSD Card

• Note that discs with special shapes cannot be played on this

product. Do not attempt to play back such discs, as they may

damage the unit.

Cleaning Discs

• When a disc becomes dirty, clean it with a cleaning cloth. Wipe

the disc from the center to out. Do not wipe in a circular motion.

• Do not use solvents such as benzine, thinner, commercially

available cleaners, detergent, abrasive cleaning agents or

antistatic spray intended for analog records.

Playable Discs and Files

This unit is compatible to play back the following discs.

To play back a BD or DVD, make sure that it meets the

®

DivX

MP3

Windows Media™

Audio

JPEG

—

—

BD-RE/-R

DVD-RW/-R

CD-RW/-R

BD-RE/-R

DVD-RW/-R

CD-RW/-R

SD Memory Card

(including SDHC)

miniSD Card

microSD Card

requirements for region codes and color systems as described on

page 5. You can play back discs that have the following logos on

the disc. Other disc types are not guaranteed to play back.

Playable discs Logos

Blu-ray Disc

- BD-Video

- BD-RE (ver.2.1)

(Recorded in BDMV format)

- BD-R (ver.1.1/1.2/1.3)

(Recorded in BDMV format)

(Unclosed discs may not be played back.)

DVD-Video

Note

• ABOUT DIVX VIDEO: DivX® is a digital video format created by

DivX, Inc. This is an official Divx Certified device that plays

DivX video. Visit www.divx.com for more information and

software tools to convert your files into DivX video.

• ABOUT DIVX VIDEO-ON-DEMAND: This DivX Certified

must be registered in order to play DivX Video-on-Demand

(VOD) content. To generate the registration code, locate the

DivX VOD section in the device setup menu. Go to

vod.divx.com with this code to complete the registration

process and learn more about DivX VOD.

• Discs containing the DivX® files with the DivX®GMC (Global

Motion Compensation) playback feature, which is DivX

®

device

®

supplemental function, cannot be played back on this unit.

DVD-RW (Finalized discs only)

• This unit cannot play back the disc contents protected by

Windows Media™ Digital Rights Management (DRM).

• “WMA” (Windows Media™ Audio) is an audio codec

DVD-R

DVD-R DL

CD-DA (audio CD)

CD-RW

CD-R

Kodak Picture CD

(Finalized discs only)

DTS-CD (5.1 Music Disc)

—

developed by Microsoft® in the United States of America.

Readable cards Playable files / data

SD Memory Card (8MB - 2GB) AVCHD, MP3, Windows Media™

SDHC Memory Card (4GB - 8GB)

miniSD Card (8MB - 2GB)

microSD Card (8MB - 2GB)

Note for SD Memory Cards

• Do not remove the SD Memory Card or turn the unit to the

standby mode while the contents of the card is in playback. It

Audio, JPEG, Picture-in-picture

commentary, subtitles or other

extras for BD-ROM ver. 2 (Profile

2.0/ Profile 1.1)

may result in malfunction or loss of the card’s data.

• Please keep the SD Memory Cards in their cases when you are

not using them.

• Do not try to open or modify the card.

• Do not touch the terminal surface with your fingers or any

metals.

• Do not attach additional labels or stickers to cards.

• Do not remove the label of the SD Memory Cards.

• This unit supports SD Memory Card with FAT12/FAT16 file

system, and SDHC Memory Card with FAT32 file system.

• This unit may not read the SD Memory Cards formatted on

computer. If that is the case, please reformat the SD Memory

Cards on this unit and try again.

• This unit does not support mini SDHC and micro SDHC

Memory Card.

• For miniSD Card and microSD Card adapter is necessary.

miniSD Card

Adapter

miniSD Card

microSD Card

Adapter

microSD Card

• Portions of this product are protected under copyright law

and are provided under license by ARIS/SOLANA/4C.

2

Page 5

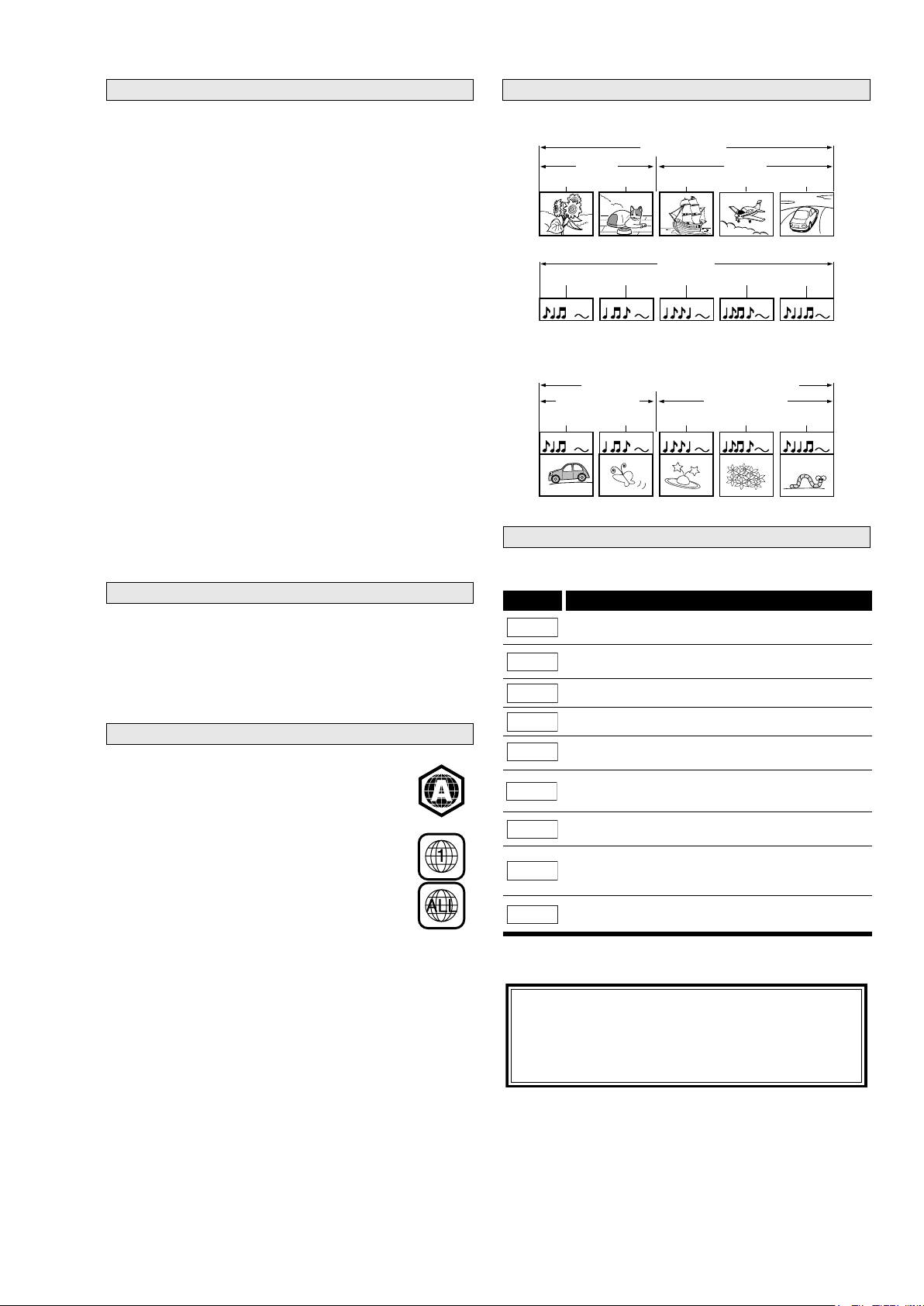

To specify for which media type each function is, we put the

following symbols at the beginning of each item to operate.

If you do not find any of the symbols listed above under the

function heading, the operation is applicable to all media.

Symbols Used in this User Guide

Symbol Description

Description refers to BD-Video and BD-RE (ver. 2.1)/

BD-R (ver.1.1/1.2/1.3) recorded in BDMV format

Description refers to DVD-Video and DVD-RW/-R

recorded in video mode

Description refers to DVD-RW/-R recorded in VR mode

Description refers to audio CD and DTS-CD

Description refers to DVD-RW/-R and SD Card with

AVCHD files

Description refers to BD-RE/-R, DVD-RW/-R and

CD-RW/-R with DivX

®

files

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with MP3 files

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with Windows Media™ Audio

files

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with JPEG files

BD-V

DVD-V

DVD-VR

CD

AVCHD

DivX

®

MP3

WMA

JPEG

About the button names in this explanation

< > : Buttons on the main unit

[ ] : Buttons on the remote control

Button name only:

Buttons on the main unit and remote control

This unit has been designed to play back BD with

region A and DVD-Video with region 1. You cannot

play back BD or DVD-Video that are labeled for other

regions. Look for the symbols on the right on your BD

or DVD-Video. If these region symbols do not appear

on your BD or DVD-Video, you cannot play back the

disc in this unit. The letter or number inside the

globe refers to region of the world. A BD or

DVD-Video labeled for a specific region can only play

back on the unit with the same region code.

To specify for which media type each function is, we put the

following symbols at the beginning of each item to operate.

If you do not find any of the symbols listed above under the

function heading, the operation is applicable to all media.

Region Codes

BD-Video

DVD-Video

Symbols Used in this User Guide

Symbol Description

Description refers to BD-Video and BD-RE (ver. 2.1)/

BD-R (ver.1.1/1.2/1.3) recorded in BDMV format

Description refers to DVD-Video and DVD-RW/-R

recorded in video mode

Description refers to DVD-RW/-R recorded in VR mode

Description refers to audio CD and DTS-CD

Description refers to DVD-RW/-R and SD Card with

AVCHD files

Description refers to BD-RE/-R, DVD-RW/-R and

CD-RW/-R with DivX

®

files

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with MP3 files

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with Windows Media™ Audio

files

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with JPEG files

BD-V

DVD-V

DVD-VR

CD

AVCHD

DivX

®

MP3

WMA

JPEG

About the button names in this explanation

< > : Buttons on the main unit

[ ] : Buttons on the remote control

Button name only:

Buttons on the main unit and remote control

To specify for which media type each function is, we put the

following symbols at the beginning of each item to operate.

Symbols Used in this User Guide

Symbol Description

Description refers to BD-Video and BD-RE (ver. 2.1)/

BD-R (ver.1.1/1.2/1.3) recorded in BDMV format

Description refers to DVD-Video and DVD-RW/-R

recorded in video mode

Description refers to DVD-RW/-R recorded in VR mode

Description refers to audio CD and DTS-CD

BD-V

DVD-V

DVD-VR

CD

Introduction Introduction

This unit uses NTSC, so BD or DVD you play back must be recorded

This unit has been designed to play back BD with

region A and DVD-Video with region 1. You cannot

play back BD or DVD-Video that are labeled for other

regions. Look for the symbols on the right on your BD

or DVD-Video. If these region symbols do not appear

on your BD or DVD-Video, you cannot play back the

disc in this unit. The letter or number inside the

globe refers to region of the world. A BD or

DVD-Video labeled for a specific region can only play

back on the unit with the same region code.

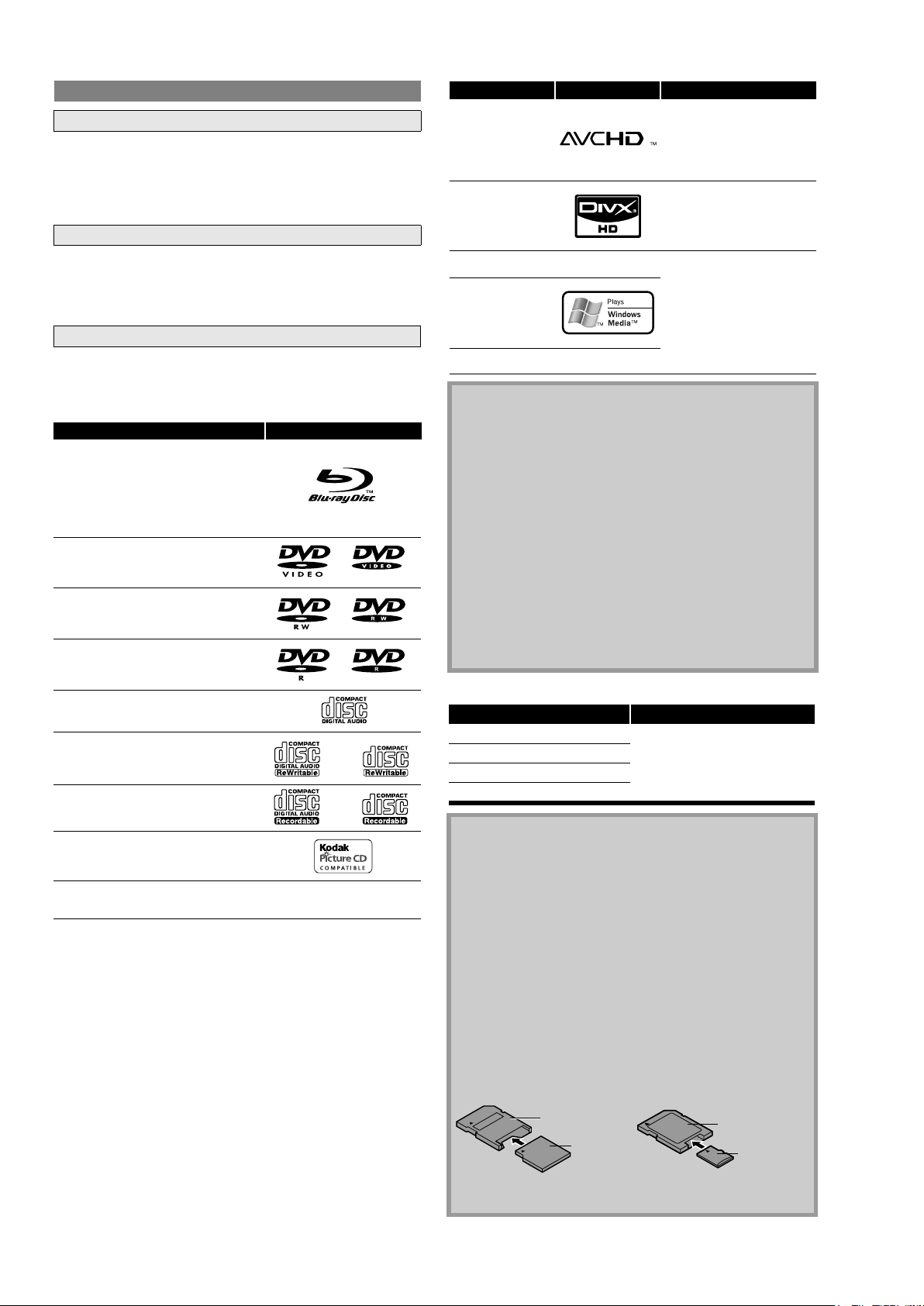

The contents of disc are generally divided into titles. Titles may be

further subdivided into chapters.

To specify for which media type each function is, we put the

following symbols at the beginning of each item to operate.

If you do not find any of the symbols listed above under the

function heading, the operation is applicable to all media.

Unplayable Discs

Region Codes

Structure of Disc/SD Memory Card Contents

BD-Video

DVD-Video

title 1 title 2

chapter 1 chapter 2 chapter 1 chapter 2 chapter 3

BD/DVD/AVCHD

audio CD

Audio CD

track 1 track 2 track 3 track 4 track 5

Audio CDs are divided into tracks.

MP3, WMA, JPEG, DivX®

group(folder)1 group(folder)2

DivX®/MP3/Windows Media™ Audio/JPEG

folder (group) 1 folder (group) 2

file (track) 1 file (track) 2 file (track) 3 file (track) 4 file (track) 5

Data discs or SD Memory Cards containing DivX® (in discs only)/

MP3/Windows Media™ Audio/JPEG are divided into folders, and

the folders are subdivided into files.

Symbols Used in this User Guide

Symbol Description

Description refers to BD-Video and BD-RE (ver. 2.1)/

BD-R (ver.1.1/1.2/1.3) recorded in BDMV format

Description refers to DVD-Video and DVD-RW/-R

recorded in video mode

Description refers to DVD-RW/-R recorded in VR mode

Description refers to audio CD and DTS-CD

Description refers to DVD-RW/-R and SD Card with

AVCHD files

Description refers to BD-RE/-R, DVD-RW/-R and

CD-RW/-R with DivX

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with MP3 files

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with Windows Media™ Audio

files

Description refers to BD-RE/-R, DVD-RW/-R, CD-RW/-R

and SD Memory Card with JPEG files

BD-V

DVD-V

DVD-VR

CD

AVCHD

DivX

®

MP3

WMA

JPEG

About the button names in this explanation

< > : Buttons on the main unit

[ ] : Buttons on the remote control

Button name only:

Buttons on the main unit and remote control

The following discs will not play back on this unit.

• BD-RE (ver.1.0) (BD-disc with cartridge)

• BD-RE (ver.2.1) (Recorded in BDAV format)

• BD-R (ver.1.1/1.2/1.3) (Recorded in BDAV format)

• BD that contains AVCHD files

• Multi-session burn BD/DVD with DivX

• Multi-session burn BD-RE/-R with MP3/Windows Media™ Audio/

JPEG files

• BD/DVD hybrid disc (e.g. Total Hi Def hybrid disc)

• BD-Video that does not include “A” on its region code.

• DVD-Video that does not include either “1” nor “ALL” on its

region code.

• DVD-ROM/RAM (For DVD-ROM discs, data files in DivX

5.x and 6.x can be played)

• DVD-RW/-R recorded in non-compatible recording format

• CD-ROM (Data files in DivX

• CDV (Only the audio part can be played)

• CD-G (Only the audio signals can be output)

• Compact Disc-Interactive (CD-I)

• Video Single Disc (VSD)

• Video CD, Super Video CD

• Super audio CD (Only the sound on the CD layer can be heard.

The sound on the high-density super audio CD layer cannot be

heard.)

• DVD-Audio

• HD DVD

• Disc with recording area less than 55mm in diameter

• Unauthorized disc (Pirated disc)

• Unfinalized disc

®

3.11, 4.x, 5.x and 6.x can be played)

®

files

®

3.11, 4.x,

Structure of Disc/SD Memory Card Contents

The contents of disc are generally divided into titles. Titles may be

further subdivided into chapters.

BD/DVD/AVCHD

title 1 title 2

chapter 1 chapter 2 chapter 1 chapter 2 chapter 3

Audio CDs are divided into tracks.

track 1 track 2 track 3 track 4 track 5

Data discs or SD Memory Cards containing DivX® (in discs only)/

MP3/Windows Media™ Audio/JPEG are divided into folders, and

the folders are subdivided into files.

DivX®/MP3/Windows Media™ Audio/JPEG

folder (group) 1 folder (group) 2

group(folder)1 group(folder)2

file (track) 1 file (track) 2 file (track) 3 file (track) 4 file (track) 5

Audio CD

audio CD

MP3, WMA, JPEG, DivX®

Color Systems

BD and DVD are recorded in different color systems throughout

the world. The most common color system is NTSC (which is used

primarily in the United States and Canada).

in the NTSC system. You cannot play back BD or DVD recorded in

other color systems.

Region Codes

This unit has been designed to play back BD with

region A and DVD-Video with region 1. You cannot

play back BD or DVD-Video that are labeled for other

regions. Look for the symbols on the right on your BD

or DVD-Video. If these region symbols do not appear

on your BD or DVD-Video, you cannot play back the

disc in this unit. The letter or number inside the

globe refers to region of the world. A BD or

DVD-Video labeled for a specific region can only play

back on the unit with the same region code.

BD-Video

DVD-Video

3

Page 6

2.SERVICEHINTSANDTOOLS

SERVICE HINTS

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc (PAL) 4822 397 10131

DVD test disc (NTSC) ALMEDIO TDV-540

4

Page 7

3.WARNINGANDLASERSAFETYINSTRUCTION

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

D

WARNUNG

I

WAARSCHUWING

AVVERTIMENTO

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tous les IC et beaucoup d’autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution

n’est prise a leur manipulation.

Lors de réparations, s’assurer de bien être

relié au même potentiel que la masse de

l’appareil et enfiler le bracelet serti d’une

résistance de sécurité.

Veiller a ce que les composants ainsi que les

outils que l’on utilise soient également a ce

potentiel.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell’apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora siano anche a

questo potenziale.

F

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seu ls habilités à

réparer votre appareil en panne.”

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should remove the cover or attempt to service this

device, due to possible eye injury.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURE OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Æ

TTELSE FOR STRÅLING

5

030804ecm

Page 8

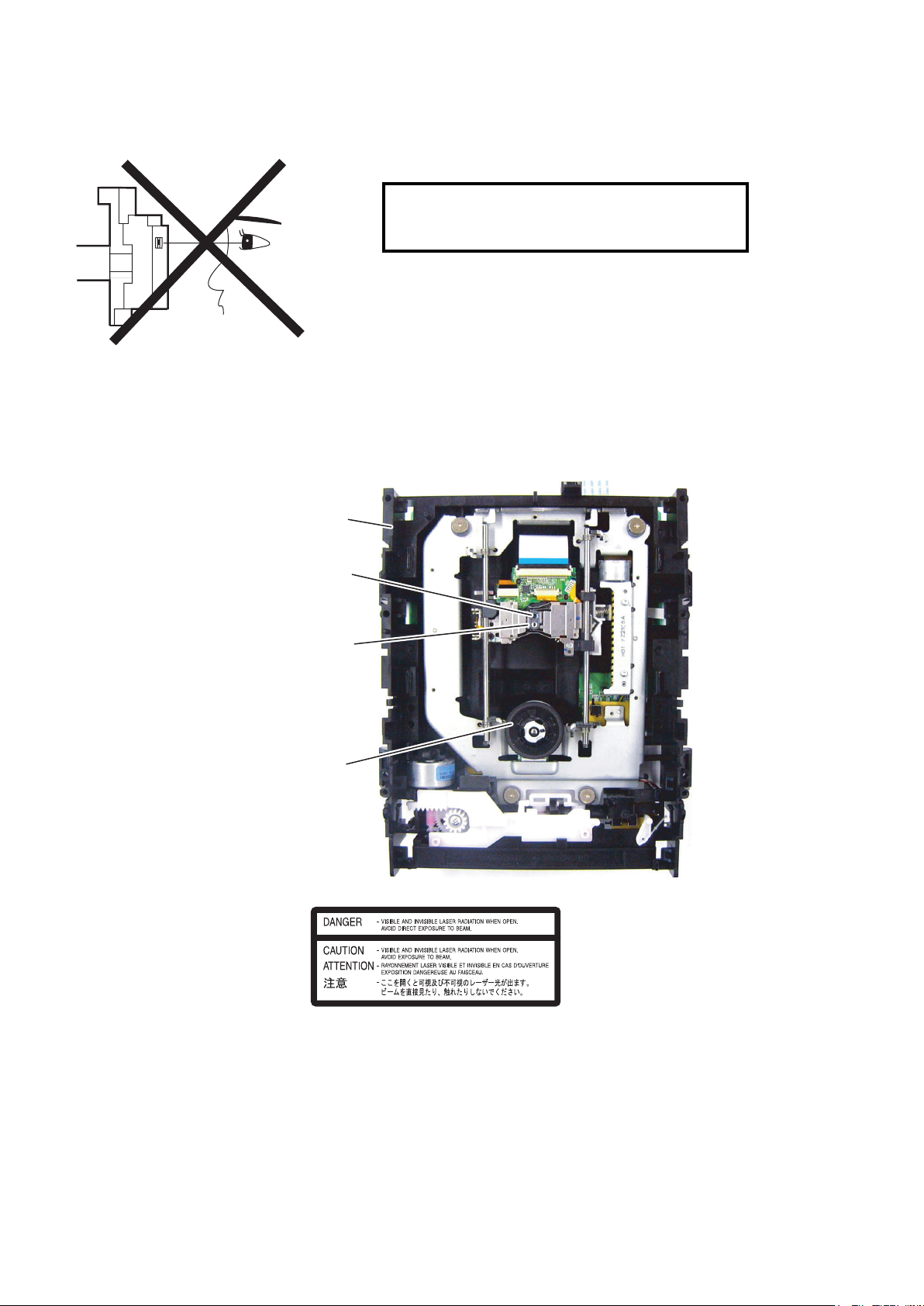

4.LASERBEAMSAFETYPRECAUTIONS

LASER BEAM SAFETY PRECAUTIONS

This BD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mechanism Assembly

from the pickup or allow it to strike against your

skin.

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of BD mechanism.

6

Page 9

5.IMPORTANTSAFETYPRECAUTIONS

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a ! on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review

continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are carefully inspected to confirm

with the recognized product safety and electrical

codes of the countries in which they are to be sold.

However, in order to maintain such compliance, it is

equally important to implement the following

precautions when a set is being serviced.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

Precautions during Servicing

A. Parts identified by the ! symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation tape

2) PVC tubing

3) Spacers

4) Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

7

Page 10

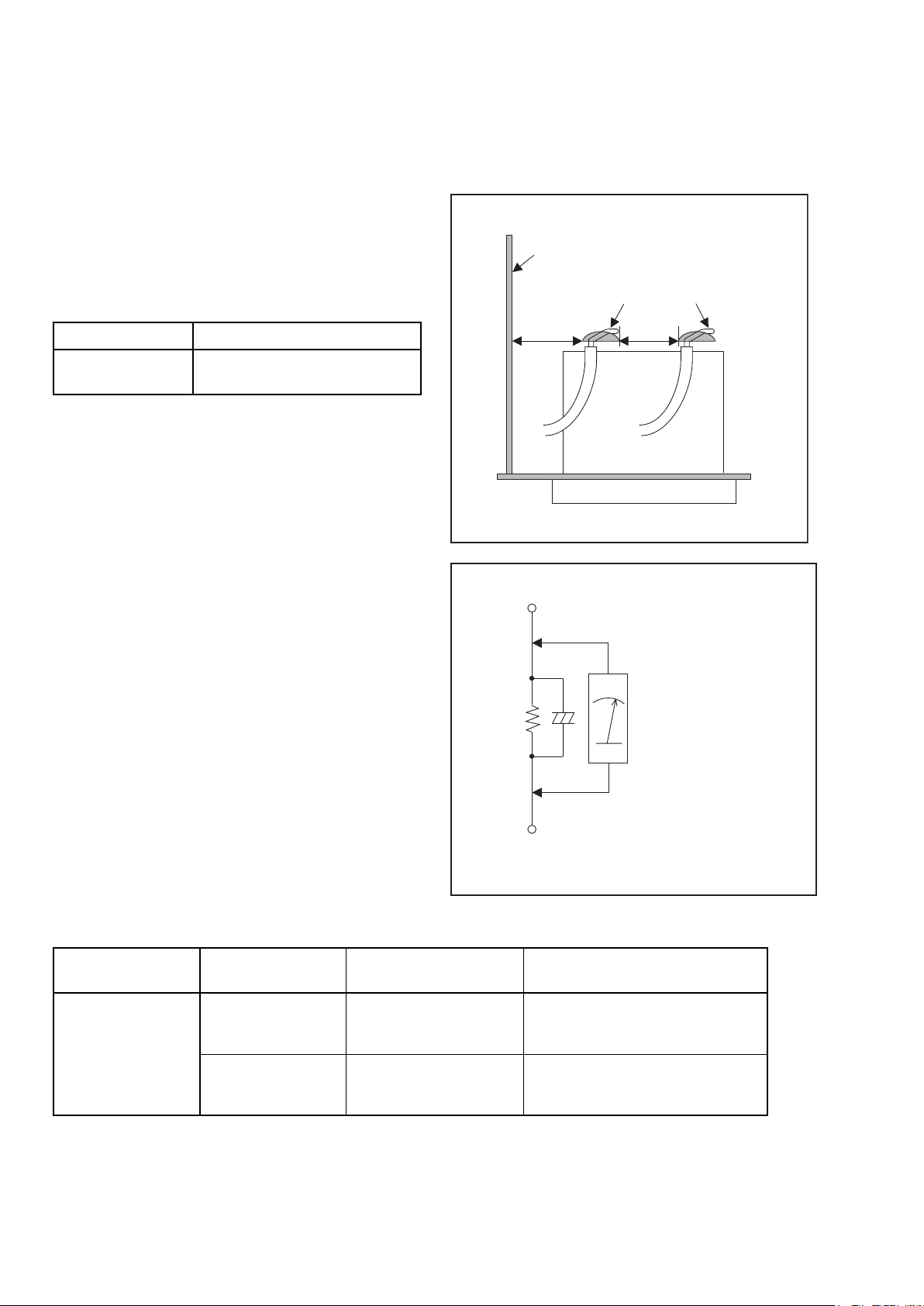

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Clearance Distance (d), (d’)

120 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

≥ 3mm(d)

≥ 4mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

d' d

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

Fig. 1

AC Voltmeter

(High Impedance)

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

2kΩ RES.

Connected in

parallel

120 V

50kΩ RES.

Connected in

parallel

Note:This table is unofficial and for reference only. Be sure to confirm the precise values.

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

8

One side of power cord plug

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

Fig. 2

Page 11

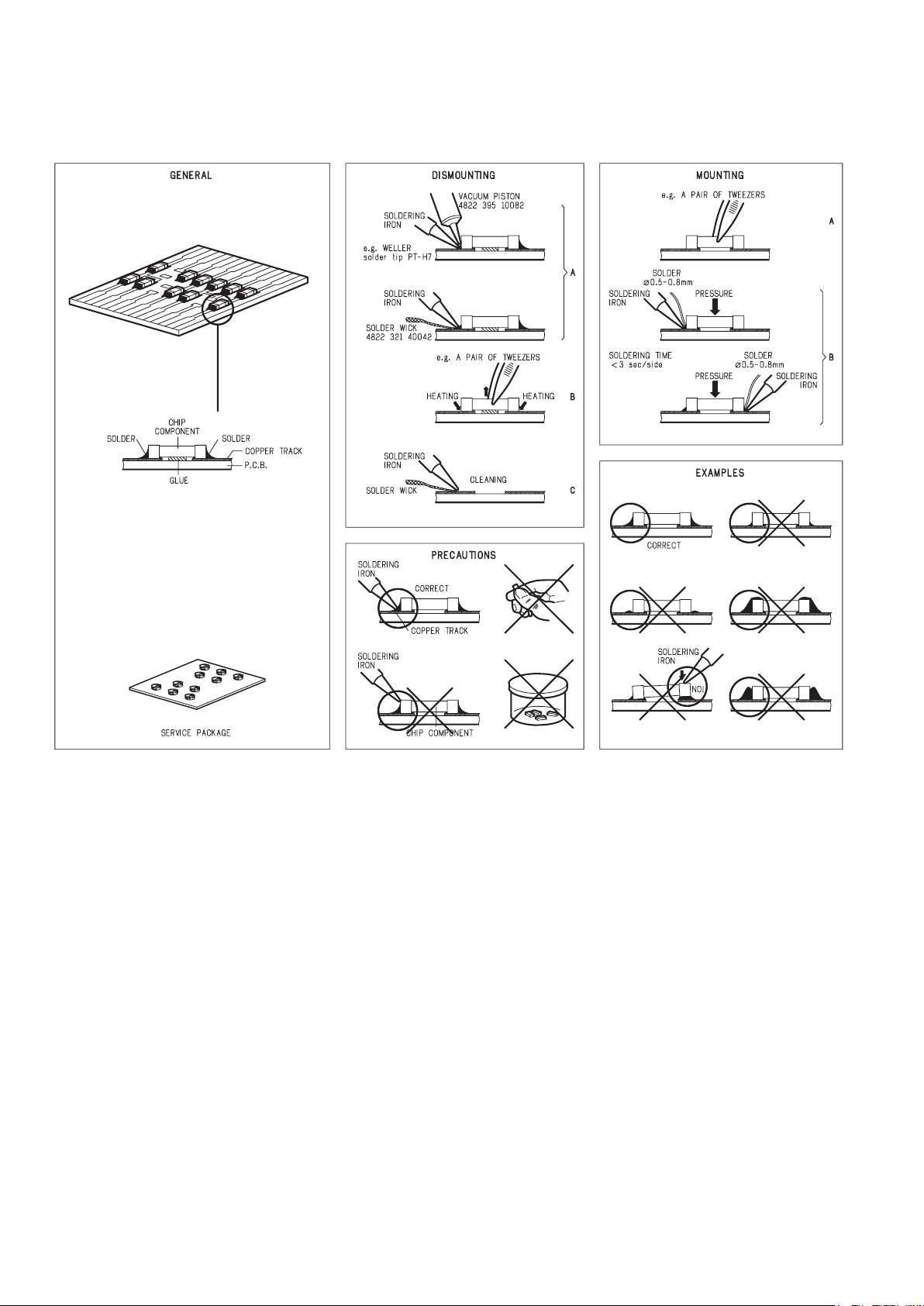

6.STANDARDNOTESFORSERVICING

STANDARD NOTES FOR SERVICING

Circuit Board Indications

Pb (Lead) Free Solder

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

In

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Input

Connector

CBA

Bottom View

5

10

When soldering, be sure to use the Pb free solder.

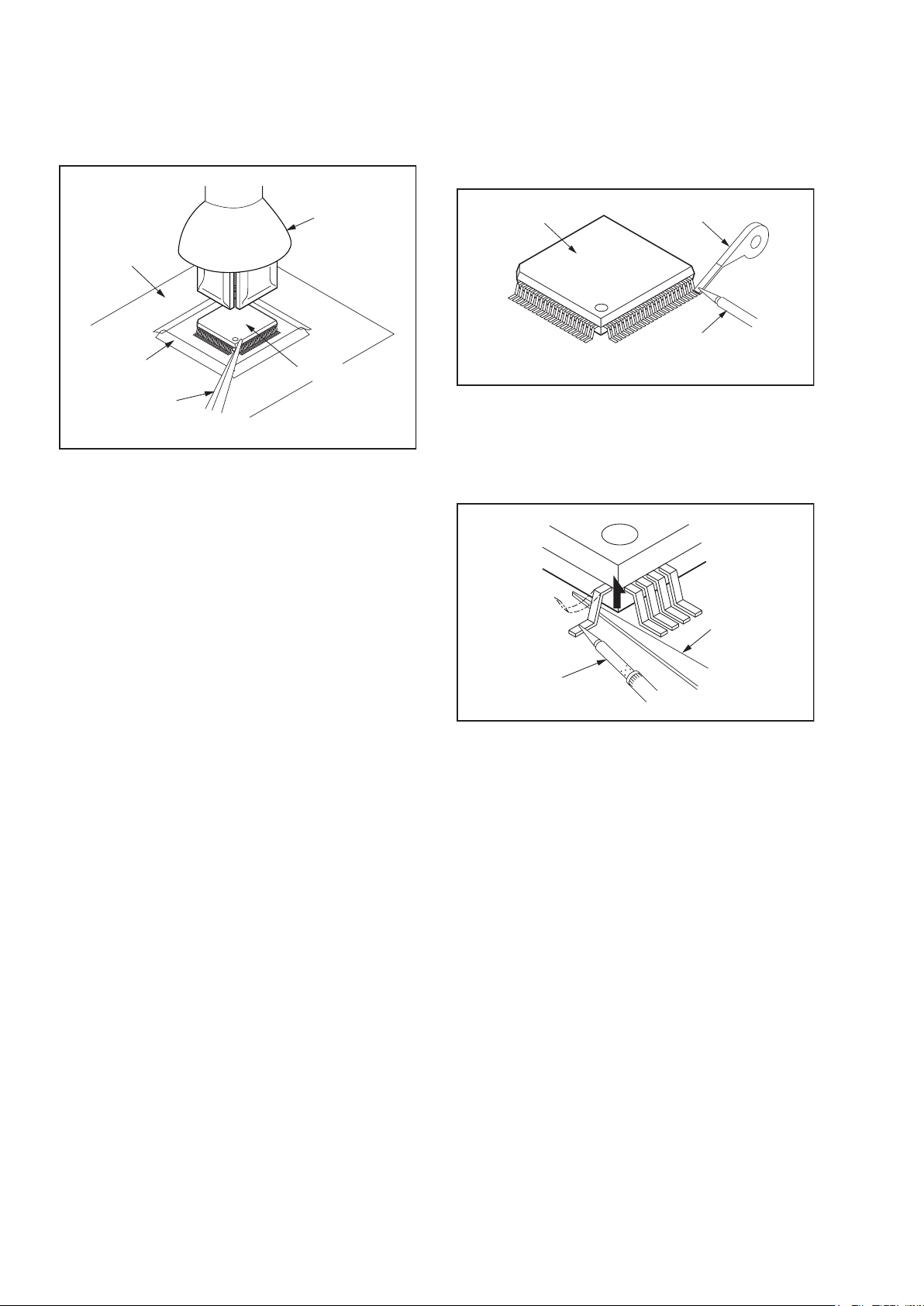

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

* Be careful to avoid a short circuit.

9

Page 12

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

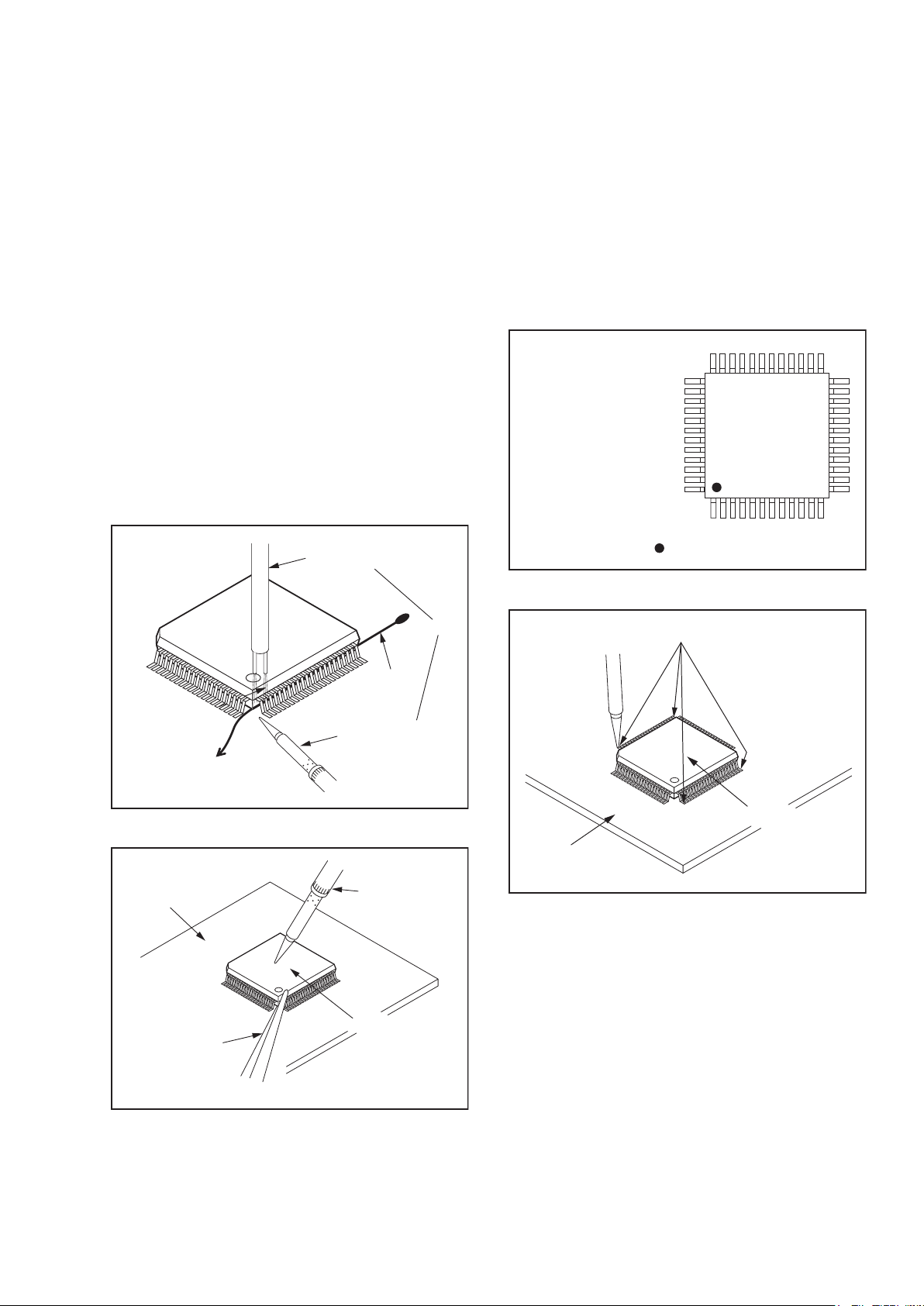

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

Fig. S-1-4

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

10

Page 13

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

11

Page 14

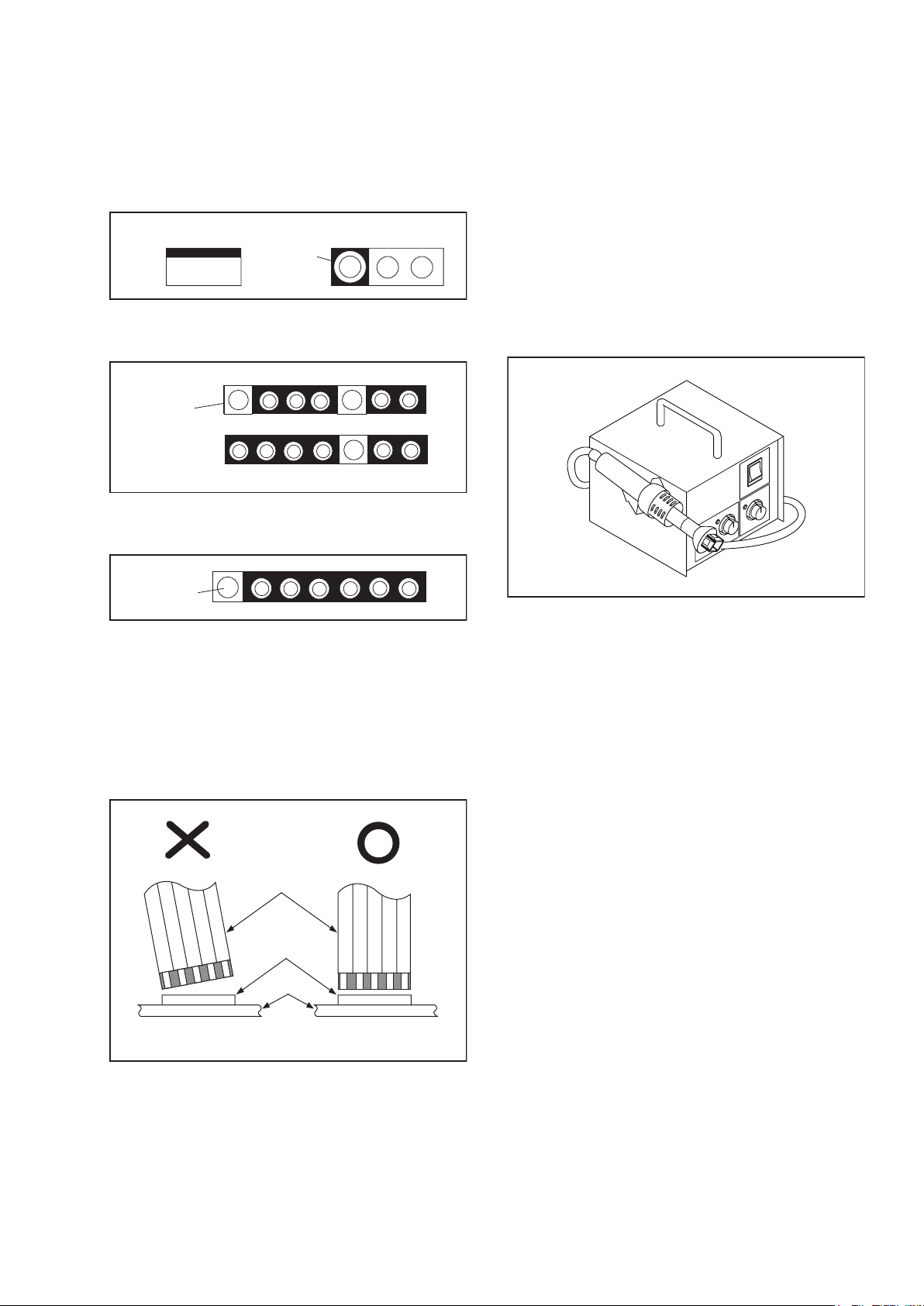

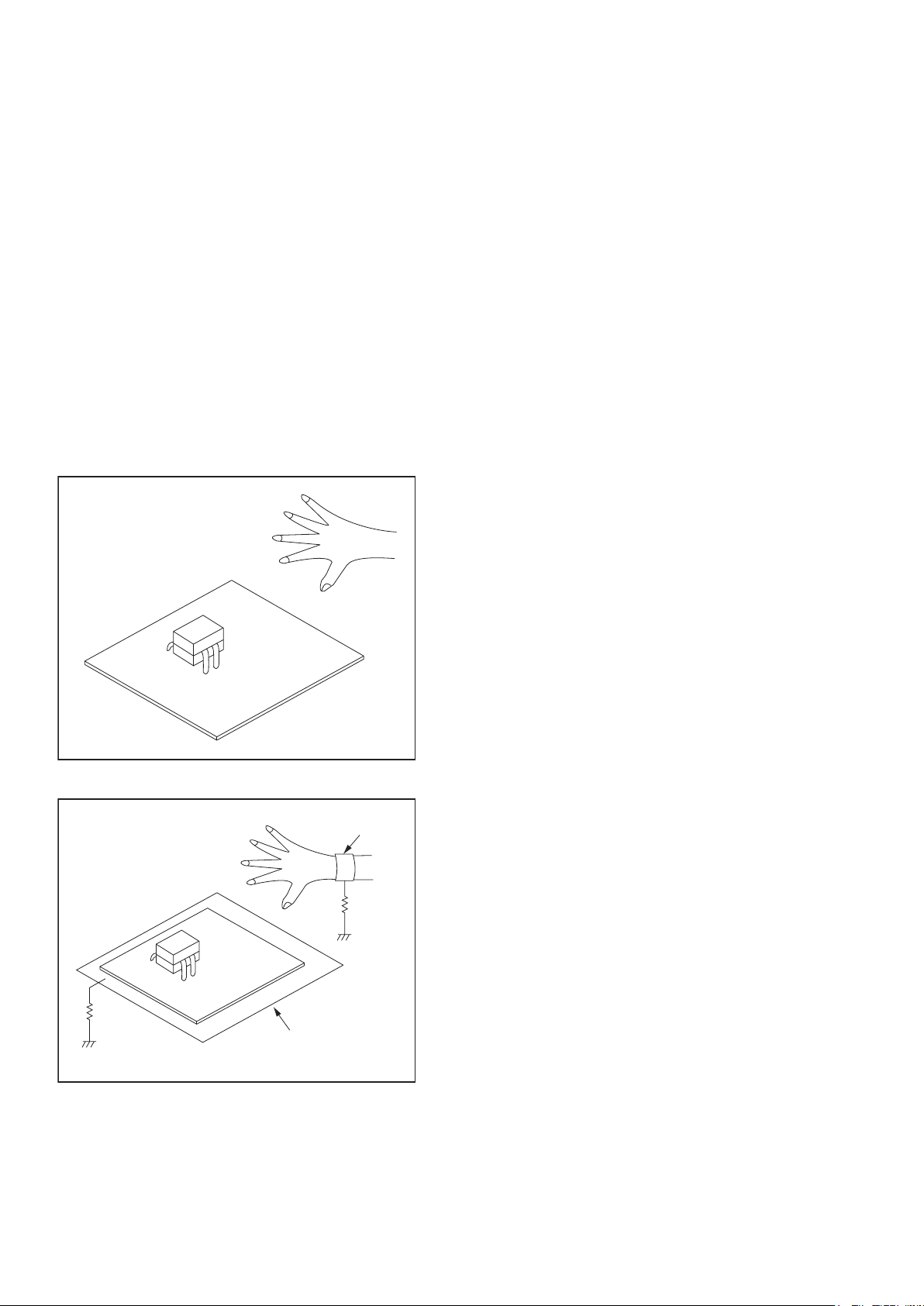

Instructions for Handling Semi-

conductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

12

Page 15

7.CABINETDISASSEMBLYINSTRUCTIONS

CABINET DISASSEMBLY INSTRUCTIONS

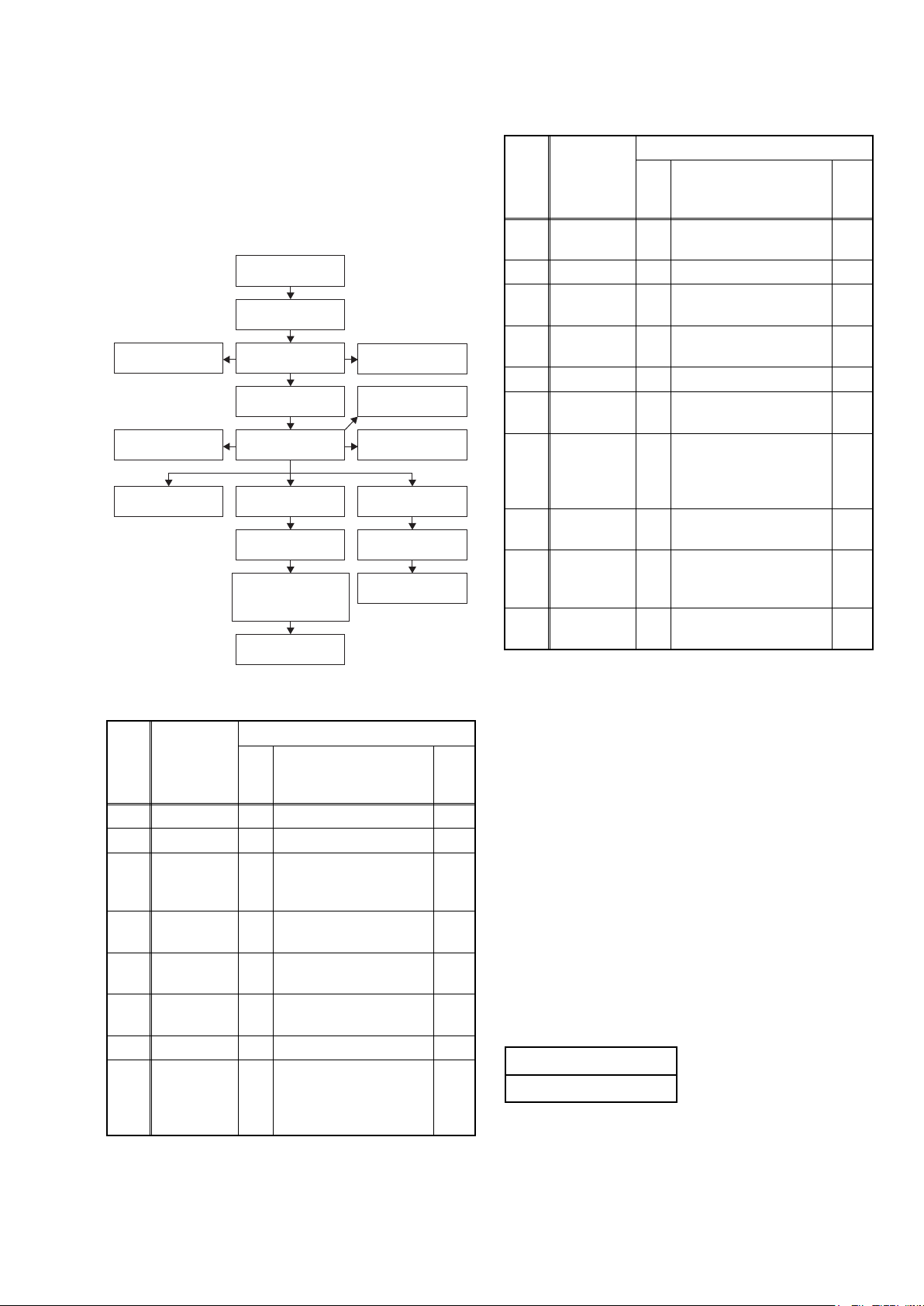

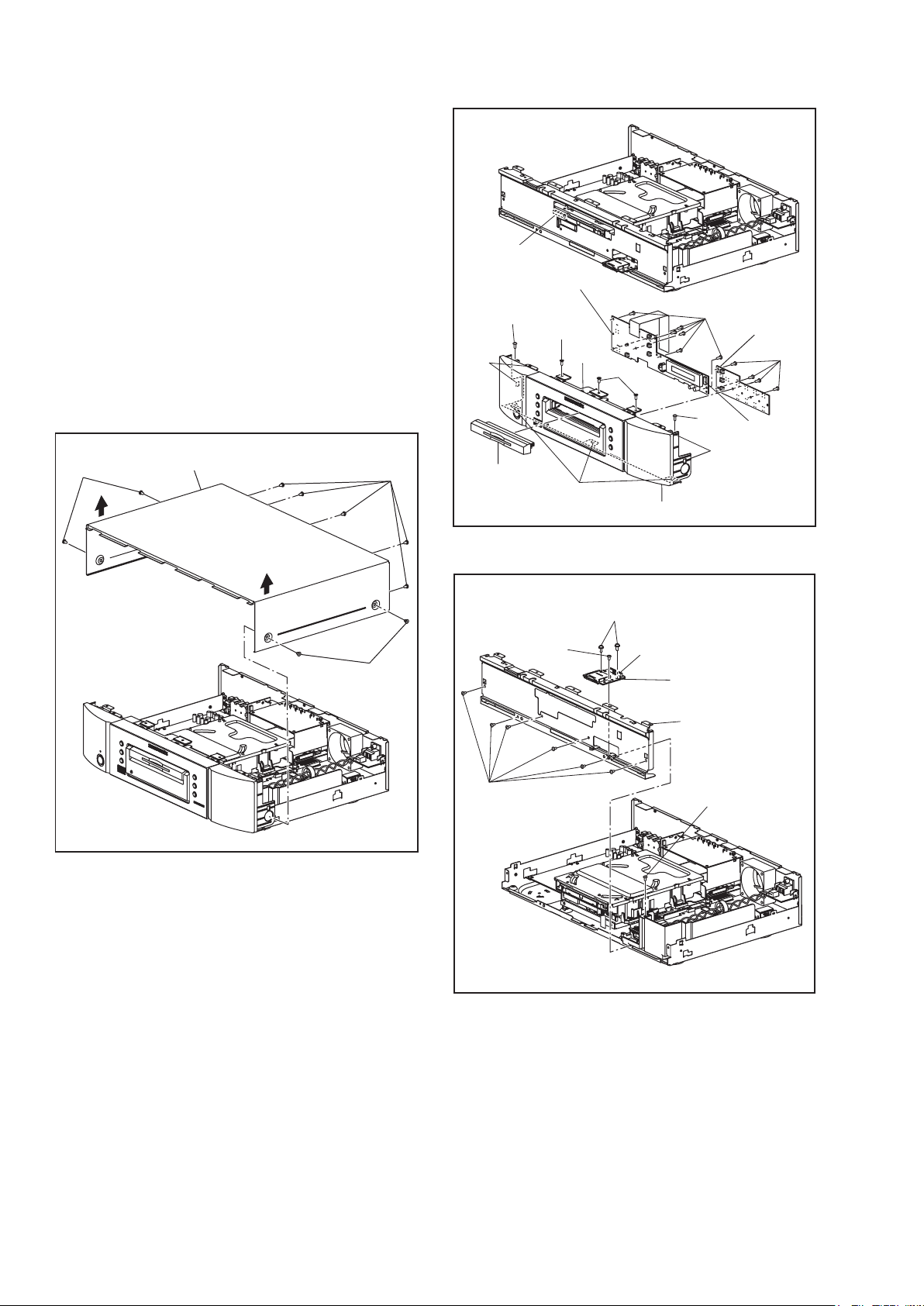

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[5] Front B CBA

[11] RS232C

CBA

[12] Audio CBA

[1] Top Cover

[2] Tray Panel

[6] Front Bracket

[8] Rear Panel

[13] Video CBA

[14] AV PCB

Bracket

[15] BD Main CBA

& BD Mechanism

Assembly

[16] Loader

Bracket

2. Disassembly Method

ID/

Loc.

No.

[1] Top Cover D1 9(S-1) --[2] Tray Panel D2 --------------- 1

[3]

[4]

[5]

[6]

[7]

[8] Rear Panel D4

Part

Front

Assembly

Front A

CBA

Front B

CBA

Front

Bracket

SD CBA

Fig.

No.

D2

D2 *CN3001 ---

D2 --------------- ---

D3 7(S-5), (S-6) ---

D3 2(S-7), *CN5001 ---

[3] Front

Assembly

[4] Front A CBA

[10] Inlet CBA

[7] SD CBA

[17] Power

Supply CBA

[18] Power

Holder

Removal

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

*5(L-1), *3(L-2),

2(S-2), 3(S-3),

10(S-4), *CN2002

5(S-8), (S-9), 2(S-10),

(S-11), (S-12),

11(S-13), 2(S-14),

2(S-15), *CN1006

[9] Motor

DC Fan

Note

2

---

ID/

Loc.

No.

[9]

[10]

[11]

Part

Motor DC

Fan

Inlet CBA

RS232C

CBA

Fig.

No.

[12] Audio CBA D5

D4 --------------- ---

D4 *CN1001 ---

D4 *CN5501 ---

5(S-16), *CN2005,

*CN2007, *CN2008

Removal

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

Note

---

[13] Video CBA D6 4(S-17), *CN7101 ---

AV PCB

[14]

Bracket

D6 4(S-18) ---

BD Main

[15]

CBA & BD

Mechanism

4(S-19), *CN6001,

D6

*CN7601

Assembly

Loader

[16]

Bracket

D6 6(S-20) ---

Power

[17]

Supply

D7 3(S-21), 2(S-22) ---

CBA

Power

[18]

↓

(1)

Holder

↓

(2)

D7 3(S-23) ---

↓

(3)

↓

(4)

(5)

Note:

(1) Identification (location) No. of parts in the figures

(2) Name of the part

(3) Figure Number for reference

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5) Refer to “Reference Notes.”

About tightening screws

When tightening screws, tighten them with the

following torque.

Torque

0.45 ± 0.05 N·m

3

↓

13

Page 16

Reference Note

1. How to remove tray panel

1) Connect the wall plug to an AC outlet and press

the [ A] button to open the tray.

2) To lift up, the tray panel is removed.

3) Press the [ A] button again to close the tray.

4) Press the [POWER ON/STANDBY] button to

turn the power off.

5) Unplug an AC cord.

2. CAUTION 1: Locking Tabs (L-1) and (L-2) are

fragile. Be careful not to break them.

3. The BD Main CBA & BD Mechanism Assembly

is adjusted as a unit at factory. Therefore, do

not disassemble it. Replace the BD Main CBA

& BD Mechanism Assembly as a unit.

CN2002

[4] Front A CBA

(S-2)

(S-3)

(L-1)

(L-1)

(S-3)

(S-4)

[5] Front B

CBA

(S-4)

(S-1)

[1] Top Cover

(S-1)

(S-1)

Fig. D1

[2] Tray Panel

(S-6)

(S-5)

(L-2)

[3] Front Assembly

(S-7)

CN5001

(S-2)

CN3001

(L-1)

Fig. D2

[7] SD CBA

[6] Front Bracket

(S-5)

14

Fig. D3

Page 17

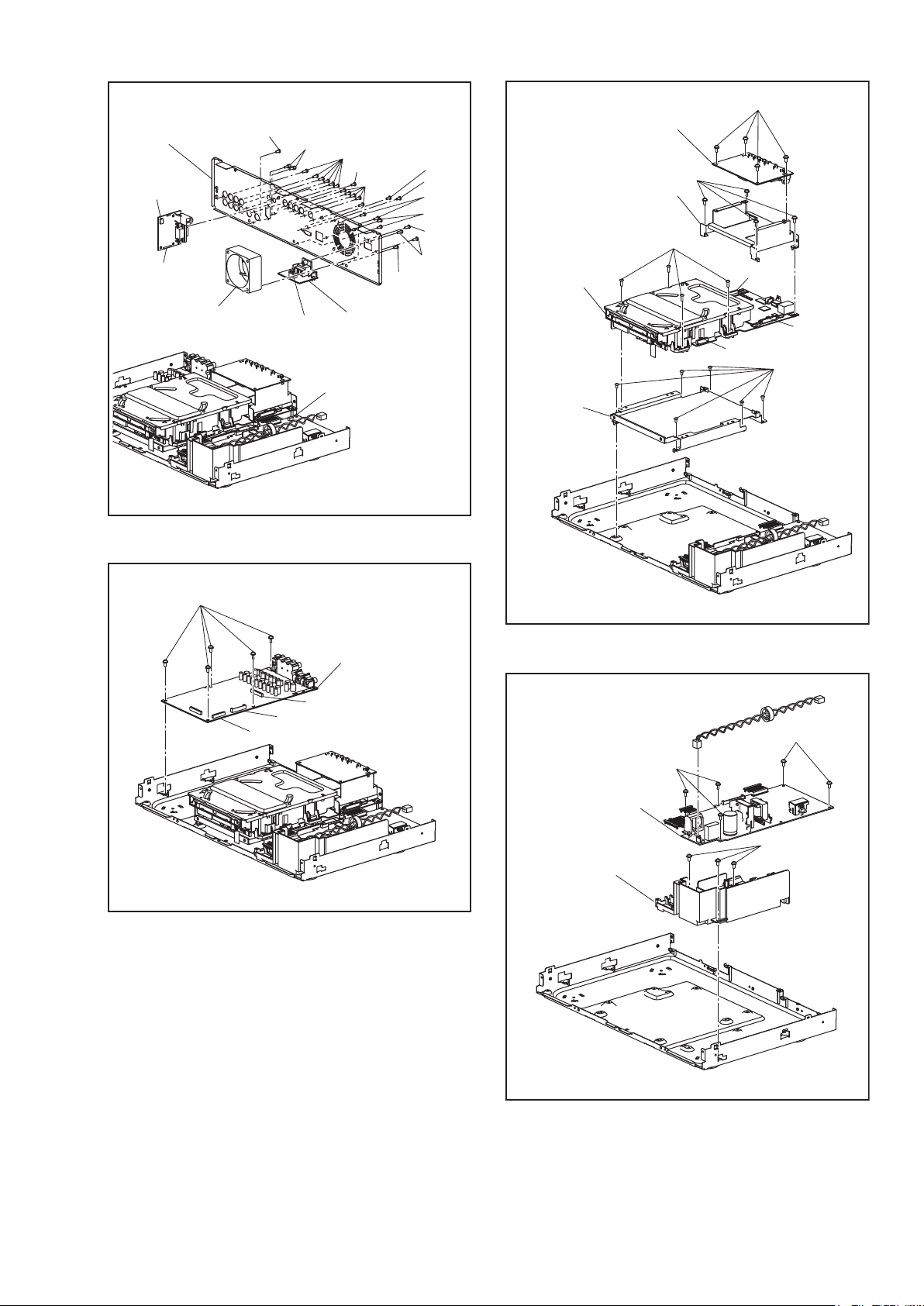

(S-17)

[8] Rear Panel

CN5501

[11] RS232C

CBA

[9] Motor DC Fan

(S-8)

(S-14)

CN1001

(S-13)

(S-8)

(S-13)

(S-8)

[10] Inlet CBA

CN1006

(S-12)

(S-11)

(S-15)

(S-8)

(S-9)

(S-10)

Fig. D4

[13] Video CBA

[14] AV PCB Bracket

[15] *BD Main CBA

& BD Mechanism

Assembly

[16] Loader

Bracket

(S-18)

(S-19)

CN7101

CN6001

CN7601

(S-20)

(S-16)

CN2008

CN2005

[12] Audio CBA

CN2007

Fig. D5

* See Reference Notes 3.

(S-21)

[17] Power Supply

CBA

[18] Power Holder

Fig. D6

(S-22)

(S-23)

15

Fig. D7

Page 18

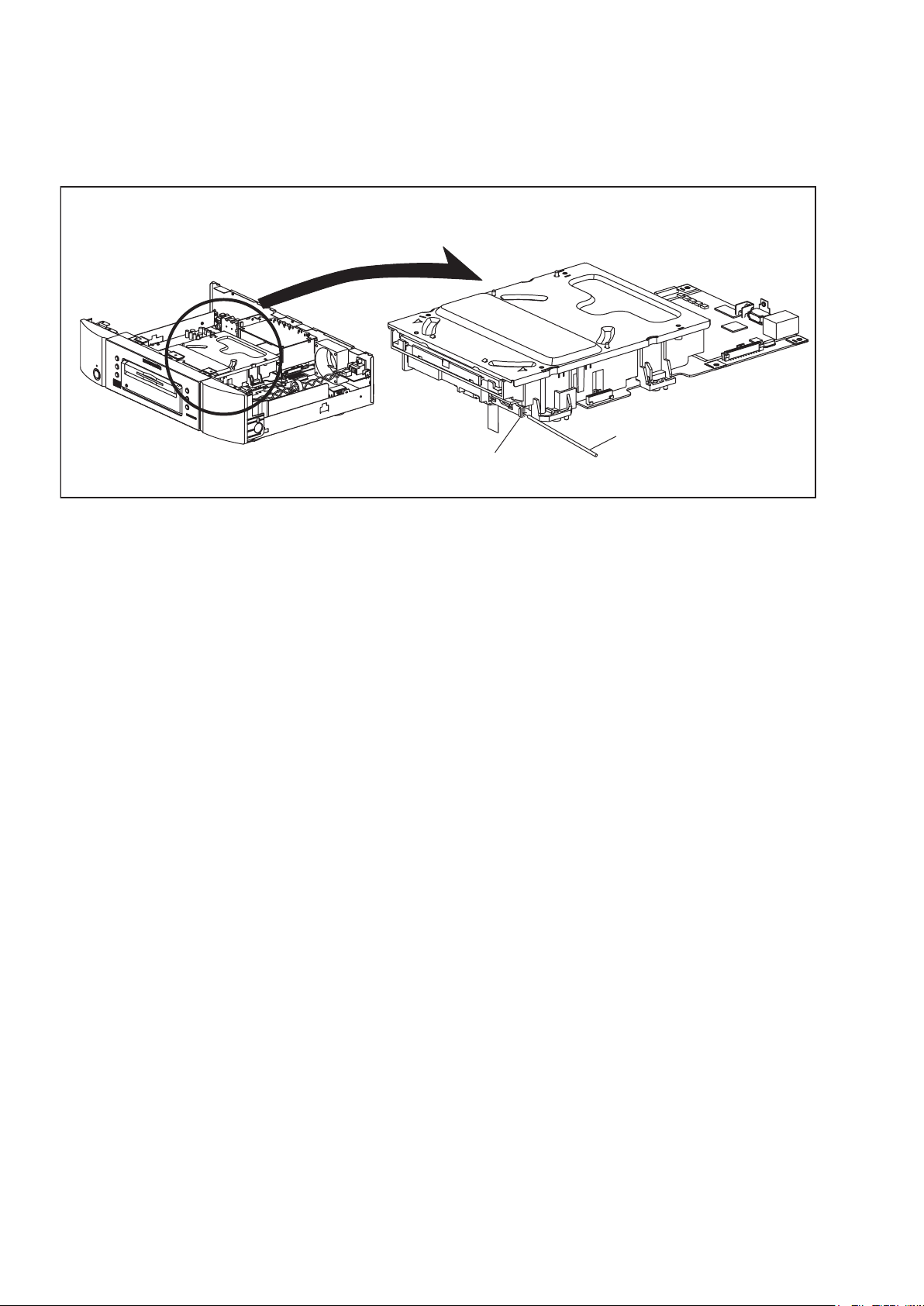

3. How to Eject Manually

1. Remove the Top Cover.

2. Insert a screwdriver, etc. into the straightly so that the Portion A is pushed.

3. Pull the tray out manually and remove a disc.

Portion A

Screwdriver,

hexagon wrench

16

Page 19

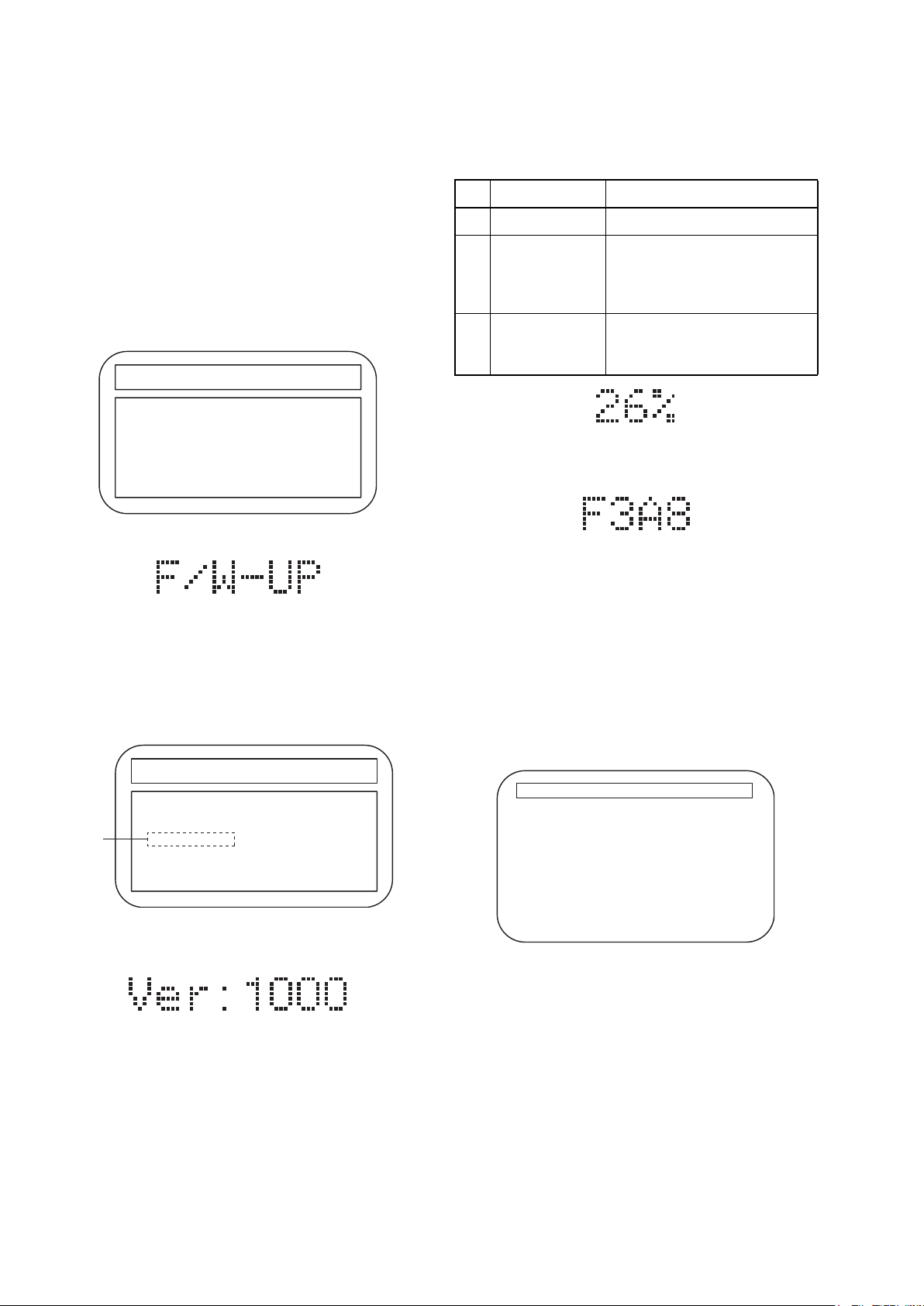

8.HOWTOINITIALIZETHEBLU-RAYDISCPLAYER

HOW TO INITIALIZE THE BLU-RAY DISC PLAYER

To put the program back at the factory-default,

initialize the BD player as the following procedure.

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. a appears on the screen.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

: *******

: *.***

: *-*

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. a

4. Press [ C ] button on the remote control unit.

Fig. b appears on the screen and Fig. c appears

on the VFD.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

EEPROM CLEAR : OK

: *******

: *.***

: *-*

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. b

Fig. c

5. To exit this mode, press [POWER OFF] button.

17

Page 20

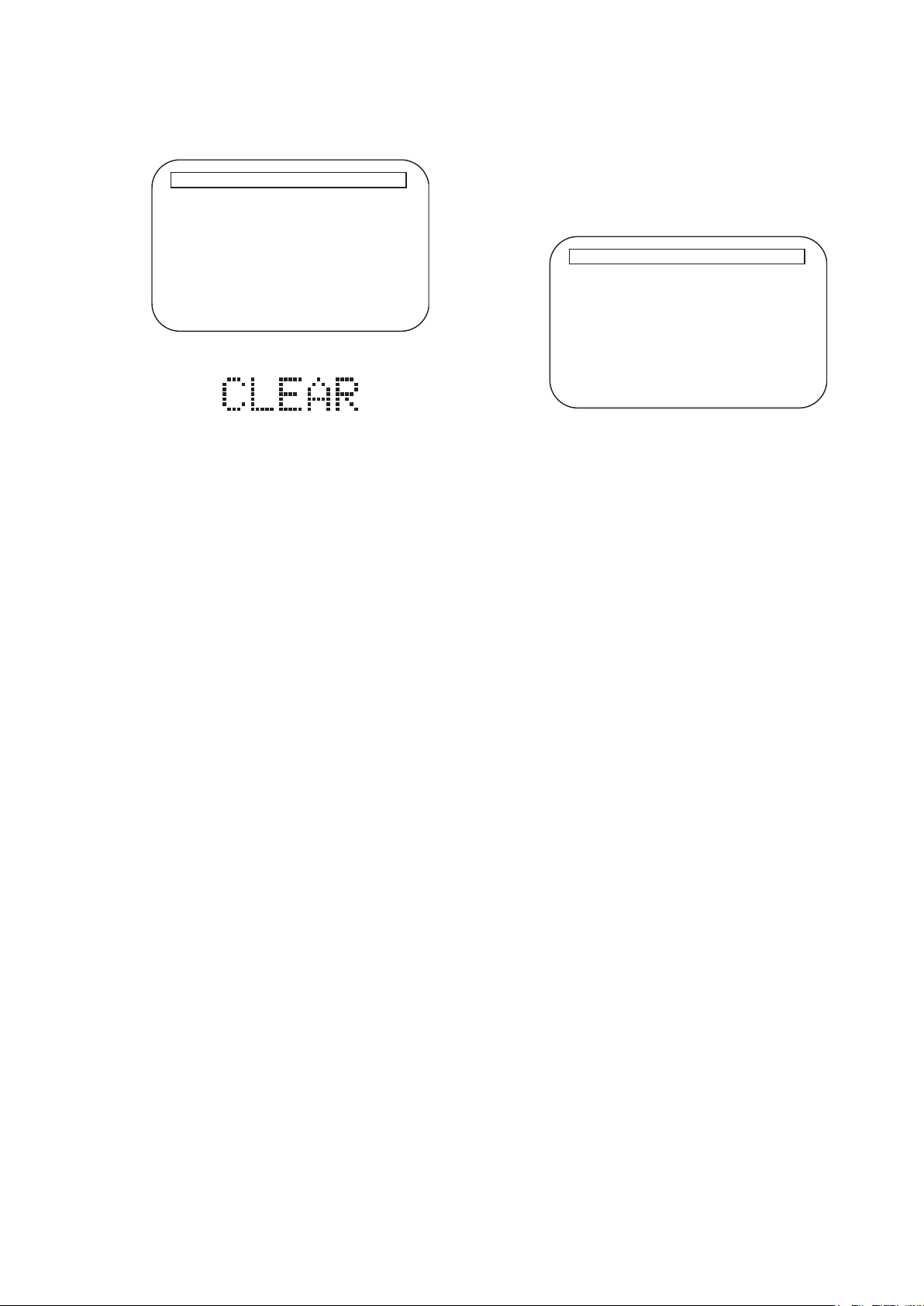

9.FIRMWARERENEWALMODE

FIRMWARE RENEWAL MODE

Note: The file extension of the available firmware is

“b20”.

1. Turn the power on and remove the disc on the tray

and close the tray.

2. To put the BD player into version up mode, press

[9], [8], [7], [6], and [POP UP MENU/MENU]

buttons on the remote control unit in that order.

The tray will open automatically.

Fig. a appears on the screen and Fig. b appears

on the VFD.

"

" differs depending on the models.

*******

F/W VERSION UP MODE F/W Name: ******* Ver. *.***

Please insert a Disc

for F/W Version Up

Fig. a Version Up Mode Screen

Fig. b VFD in Version Up Mode

3. Load the disc for version up.

4. The BD player enters the F/W version up mode

automatically. Fig. c appears on the screen and

Fig. d appears on the VFD. Make sure to insert the

proper F/W for the state of this model.

"

" differs depending on the models.

*******

F/W VERSION UP MODE F/W Name: ******* Ver. *.***

1. ALL

(*1)

Ver. *.*** ************A*.b20

Now Loading...

The appearance shown in (*1) of Fig. c is

described as follows:

No. Appearance State

1 Now Loading... Loading the disc

Sending files into the

2 Reading...

memory.

After reading, automatically

the tray opens.

Writing new version data,

3 See FL Display

the progress will be displayed

as shown in Fig. e.

Fig. e VFD in Vresion Up Mode

5. After programming is finished, the checksum on

the VFD (Fig. f).

VFD upon Finishing the Programming Mode (Example)

Fig. f

Checksum appears on the VFD then the tray will

open automatically. Remove the disc on the tray.

At this time, no button is available.

6. Unplug the AC cord from the AC outlet. Then plug

it again.

7. Turn the power on.

8. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. g appears on the screen.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

: *******

: *.***

: *-*

EXIT : POWER

Fig. c Programming Mode Screen (Example)

Fig. d VFD in Programming Mode (Example)

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. g

18

Page 21

9. Press [ C ] button on the remote control unit.

How to Verify the Firmware Version

Fig. h appears on the screen and Fig. i appears on

the VFD.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

: *******

: *.***

: *-*

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. j appears on the screen.

"

" differ depending on the models.

*******

Version Info

EEPROM CLEAR : OK

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. h

Fig. i

10. To exit this mode, press [POWER OFF] button.

F/W Name

Version

Region

: *******

: *.***

: *-*

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. j

4. To exit this mode, press [POWER OFF] button.

19

Page 22

10.FIRMWARERENEWALMODE(NetworkUpdate)s

FIRMWARE RENEWAL MODE (Network Update)

1. Press [SETUP] button on the remote control unit in

stop mode.

2. Use [

3. Use [

} / O] button to select “CUSTOM”, then

press [ENTER] button.

} / O] button to select “Other”, then press

[ENTER] button.

4. Use [

X / Y] button to select “Network Update”,

then press [ENTER] button.

Confirmation message will appear.

5. Use [

X / Y] button to select “Yes”, then press

[ENTER] button.

This unit will start checking for the latest firmware

How to Verify the Firmware Version

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. j appears on the screen.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

: *******

: *.***

: *-*

version.

NOTE:

If any error message concerning the network

environment appears, please confirm the

setting of your unit according to the error

message. If you need to change any of your

network environmental setting in order to

4. To exit this mode, press [POWER OFF] button.

Fig. j

execute the update, please contact to the

internet service provider.

6. Confirmation message will appear.

X / Y] button to select “Yes”, then press

Use [

[ENTER] button.

The unit will start downloading the latest firmware

version.

7. When the download completes, confirmation

message will appear.

Press [ENTER] button.

The unit will start updating the firmware version.

It may take a while to complete the updating.

(Please wait until “100%” appears on the front

panel display.)

8. After updating finishes, this unit will restart and

open the disc tray automatically.

EXIT <POWER>EEPROM CLEAR <STOP>

20

Page 23

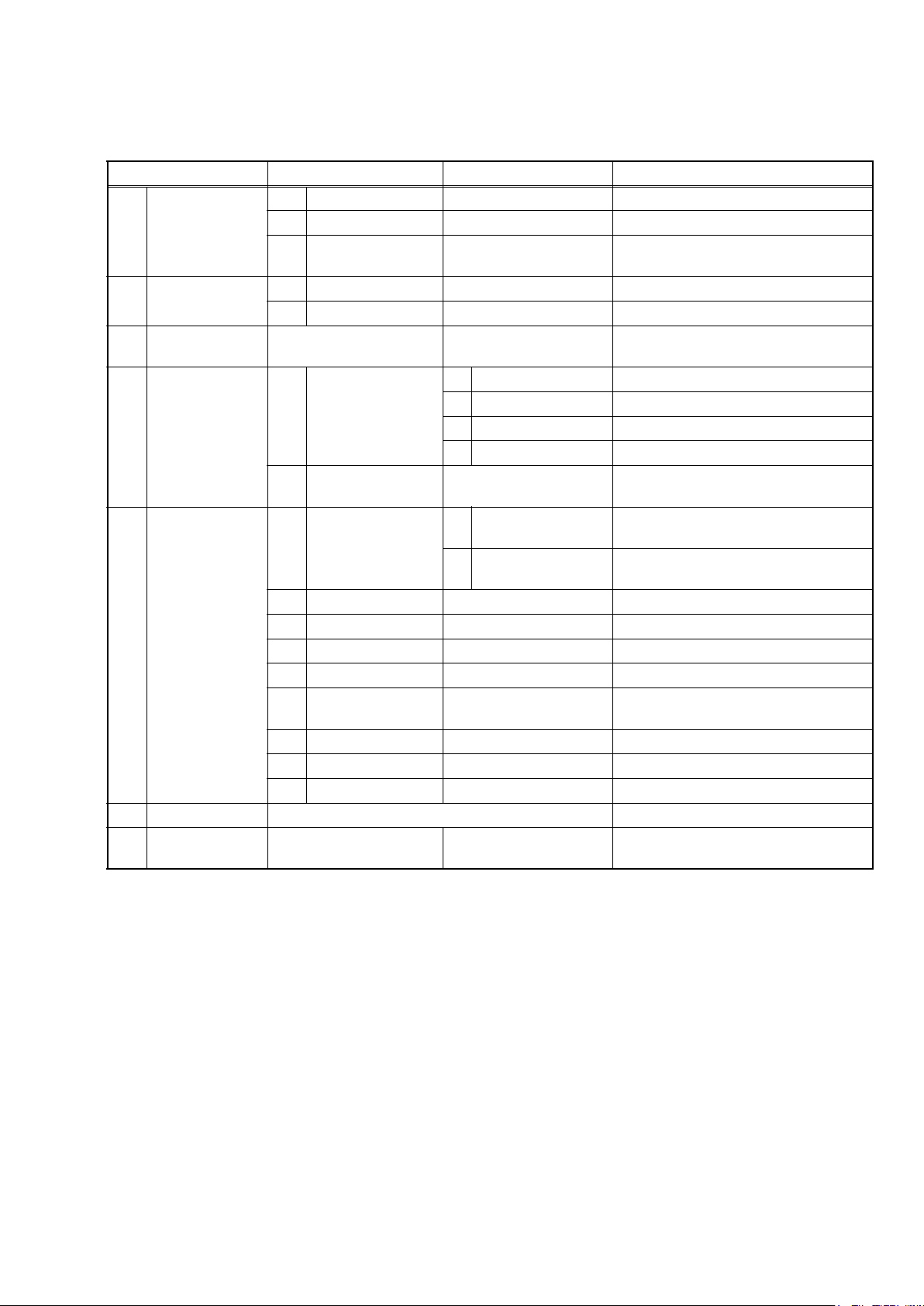

11.SERVICEMODE

SERVICE MODE

Service Mode

1 MECHA TEST

2 VFD/LED TEST

3 ERROR RATE

4 LD TEST

CHANNEL

5

TEST

6 SD CARD TEST

DEFAULT

7

SETTING

1st level 2nd level 3rd level Description

1 Tray Aging Aging of tray open/close

2 TOC Read TOC reading

3 Heat Run

1 All On Turning on all VFD

2 All Off Turning off all VFD

1 Off Turning off LD

1 LD Power

2 Operating Time

1 TEST TONE

2 Front Lch

3 Center

4 Front Rch

5 Surround Rch

Surround Back

6

Rch

7 Surround Back Lch

8 Surround Lch

9 Sub woofer

2 BD Turning on BD LD

3 DVD Turning on DVD LD

4 CD Turning on CD LD

Center/Subwoofer/

1

Front LR

Surround LR/

2

Surround Back LR

Tray close -> TT1 playback -> TT10

playback -> Tray open -> Tray close

Displaying Error rate, Jitter

during playback

Displaying LD Operation Time (with

clear function)

Default setting

Note: If some test are performed continuously, any error will occur

21

Page 24

Entering Service Mode

In power on condition, no discs and tray close, it will be entered into service mode by the following operation using

the remote controller. However, it will not be entered when Media Select Item is SD Memory.

Service Mode by using remote controller

Press the following buttons on the remote controller in power on condition, no discs and tray close;

[2]->[5]->[8]->[0]->[CLEAR]

Release from Service Mode

Press the [POWER OFF] button to turn off power.

Screen saver/Auto Power Off in Service Mode

These functions are not performed in Service Mode.

After entering, Fig. k appears on the screen and Fig. l appears on the VFD.

* Firmware Version differs depending on the

models, and this indication is one example.

SERVICE MODE

1: MECHA TEST

2: VFD/LED TEST

3: ERROR RATE MEASURE

4: LD TEST

5: CHANNEL TEST

6: SD CARD TEST

7: DEFAULT SETTING

F/W Name :******* Region

Release Ver. :*.***

ADSP1/2 Ver. :---/--- PLD Ver. :--FPGA Ver. :--- I/P Scaler Ver.:---

:*-*

Fig. k Service Mode (Main Menu)

Fig. I Service Mode

Available button in service mode

Button condition

ENTER Enter the next level

POWER Turn the power off (when the service mode is completed)

1~7 Enter the selected item (next level)

OTHER Not available

Note: Press the number key to select items. Or, press the cursor button (up/down) to select items and press

[ENTER] button.

INDICATION DESCRIPTION REMARK

F/W Name Model Name E5K***D, etc.

Region BD region - DVD region A-1, etc.

Release Ver. Release version D.jpp, etc.

22

Page 25

12.TRAYLOCKMODE

TRAY LOCK MODE

Tray Lock Mode prevents the tray opening or closing to

prevent disc theft in demo mode.

Enter this mode using the following procedure.

1. Confirm that the TV Monitor is connected.

2. With playback stopped, press [SETUP], [TOP

MENU], [3], [AUDIO], [0] and [SETUP] buttons on

the remote control unit in that order. "Trade-On"

appears in the upper right corner on the screen,

and Fig. a appears on the VFD for 2 seconds.

3. To exit this mode, press [SETUP], [TOP MENU],

[3], [AUDIO], [0] and [SETUP] buttons on the

remote control unit in that order. "Trade-Off"

appears in the upper right corner on the screen,

and Fig. b appears on the VFD for 2 seconds.

Fig. a

Fig. b

23

Page 26

13.TROUBLESHOOTING

TROUBLESHOOTING

FLOW CHART NO.1

The power cannot be turned on.

Is the fuse normal?

Is normal state restored when once unplugged

power cord is plugged again after several seconds?

Is the EV+5V line voltage normal?

Check each rectifying circuit of the secondary circuit

and service it if defective.

FLOW CHART NO.2

The fuse blows out.

Check the presence that the primary component

is leaking or shorted and service it if defective.

After servicing, replace the fuse.

FLOW CHART NO.3

When the output voltage fluctuates.

Yes

Yes

Yes

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuiting on the

primary circuit component, and service it if defective.

(D1007, D1008, D1011, D1012, D1023, D1024,

IC1002, Q1002, T1002, C1022, R1022)

Check the presence that the rectifying diode or

circuit is shorted in each rectifying circuit of

secondary side, and service it if defective.

Does the photo coupler circuit on the secondary

side operate normally?

Yes

Check D1021, IC1002, IC1004 and their periphery,

and service it if defective.

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is any short-circuit on the rectifying diode and the circuit in each rectifying circuit of the secondary

side, and service it if defective. (D1025, D1028, D1030, D1031, D1032, D1033, IC1008, IC1009, IC1010, Q1009,

Q1010, Q1011, Q1013, Q2636)

FLOW CHART NO.5

FL is not outputted.

Is 35V voltage supplied to the emitter of Q2602?

Yes

Is the "L" signal outputted to the collector of

Q2603?

Yes

Check Q2601, Q2602, D2603 and their periphery,

and service it if defective.

No

No

No

Check D1029, IC1004 and their periphery,

and service it if defective.

Check D1032, C1033 and periphery circuit,

and service it if defective.

Is the "H" signal inputted to the base of Q2603?

Yes

Replace Q2603.

Check FL-SW line and service

it if defective.

No

24

Page 27

FLOW CHART NO.6

P-ON+5V (1) is not outputted.

Is 5V voltage inputted to the emitter of Q1011?

Yes

Is 4.5V voltage inputted to the base of Q1011?

Yes

No

No

Check D1025, D1030, D1031, C1029, C1034 and

their periphery, and service it if defective.

Check Q1007 and PWSW4 line and service it if

defective.

Replace Q1011.

FLOW CHART NO.7

P-ON+5V (2) is not outputted.

Is 5V voltage inputted to the emitter of Q1009?

Yes

Is 4.5V voltage inputted to the base of Q1009?

Yes

No

No

Check D1025, D1030, D1031, C1029, C1034 and

their periphery, and service it if defective.

Check Q1007 and PWSW4 line and service it if

defective.

Replace Q1009.

FLOW CHART NO.8

P-ON+10.5V is not outputted.

Is 14V voltage inputted to the collector of Q1013?

No

Yes

Is 11V voltage inputted to the base of Q1013? Is 14V voltage inputted to the base of Q1006?

No

Check D1029, D1041, C1026, L1004

and

their periphery, and service it if defective.

Yes Yes No

Replace Q1013.

Check Q1006, D1046,

and their periphery, and

service it if defective.

Check Q1008,

and

PWSW4 line, and

service it if defective.

FLOW CHART NO.9

P-ON+1.2V is not outputted.

Is 5V voltage supplied to Pin(3) of IC1009?

Yes

Is the "L" signal inputted to the base of Q1015?

Yes

Check IC1009, Q1015

and their periphery, and

service it if defective.

FLOW CHART NO.10

P-ON+3.3V is not outputted.

Is 5V voltage supplied to Pin(1) of IC1008?

Yes

ls "L" signal outputted to the collector of Q1005?

Yes

Check IC1008, D1040 and their periphery circuit,

and service it if defective.

No

No

No

No

Check D1025, D1030, D1031, C1029, C1034 and

their periphery, and service it if defective.

Check PWSW2 line and service it if defective.

Check D1025, D1030, D1031, C1029, C1034 and

their periphery, and service it if defective.

Check Q1005 and PWSW1 line and service it if

defective.

25

Page 28

FLOW CHART NO.11

P-ON+1.8V is not outputted.

Is 5V voltage inputted to Pin(3) of IC1010?

Yes

ls "L" signal outputted to the base of Q1016?

Yes

Check IC1010, Q1016

and their periphery, and

service it if defective.

FLOW CHART NO.12

P-ON+14.5V is not outputted.

Is 15V voltage inputted to the emitter of Q1010?

Yes

Is 14V voltage inputted to the base of Q1010?

Yes

Replace Q1010.

FLOW CHART NO.13

The fluorescent display tube does not light up.

Is 3.3V voltage supplied to Pin(24) of FL3001?

No

No

No

No

No

Check D1025, D1030, D1031, C1029, C1034

and their periphery, and service it if defective.

Check PWSW2 line and their periphery, and service it

if defective.

Check D1028, C1026, L1003 and their periphery, and

service it if defective.

Check Q1008 and PWSW4 line and service it if

defective.

Check the EV+3.3V line and service it if defective.

Yes

Is 9V voltage supplied to Pin(1,2) of FL3001?

Yes

Is 5V voltage supplied to Pin(29,30) of FL3001?

Yes

Replace FL3001.

FLOW CHART NO.14

The key operation is not functioning.

Are the contact point and the installation state of

the key switches (SW3002, SW3004-SW3007,

SW3105, SW3107, SW3109) normal?

Yes

When pressing each switches (SW3002,

SW3004-SW3007, SW3105, SW3107, SW3109),

do the voltage of Pin(1, 62) of IC2000 increase?

Yes

Replace IC2000.

No

No

No

No

Is 10V voltage supplied to the emitter of Q2604?

Yes No

Is 9V voltage inputted

to the base of Q2604?

Yes No

Replace Q2604.

Check Q2603 and FL-SW

Check D1033, C1028, R1032,

R1033 and their periphery,

and service it if defective.

line

and service it if defective.

Check the F2

line and service it if defective.

Re-install the switches (SW3002, SW3004-SW3007,

SW3105, SW3107, SW3109) correctly or replace

the poor switch.

Check the switches (SW3002, SW3004-SW3007,

SW3105, SW3107, SW3109) and their periphery,

and service it if detective.

26

Page 29

FLOW CHART NO.15

No operation is possible from the remote control unit.(Operation is possible from the unit.)

Is 5V voltage supplied to Pin(2) of RS3001

No

Check EV+5V line and service it if defective.

(remote control receiver) ?

Yes

Is the "L" pulse sent out Pin(1) of RS3001 (remote

control receiver) when the remote control unit is activated?

Yes

Is the "L" pulse inputted to the Pin(27) of IC2000?

Yes

Replace IC2000.

No

No

Replace the RS3001 (remote control receiver) or

remote control unit.

Check the line between the

receiver)

and the

Pin(27) of IC2000,

defective.

FLOW CHART NO.16

The disc tray cannot be opened and closed. (It can be done using the remote control unit.)

Is the normal control voltage inputted to Pin(62) of

IC2000?

Refer to "FLOW CHART NO.14" <The key

No

Replace the "OPEN/CLOSE" switch (SW3101).

operation is not functioning.>

Yes

Replace the BD Main CBA & BD Mechanism

Assembly.

RS3001 (remote control

and service it if

FLOW CHART NO.17

The disc tray cannot be opened and closed.

[No Disc] indicated.

Both functions of picture and sound do not operate normally.

Yes

Replace the BD Main CBA & BD Mechanism

Assembly.

27

Page 30

FLOW CHART NO.18

Picture does not appear normally.

Set the disc on the disc tray, and playback.

Are the video signals outputted to each pin of

CN4000?

CN4000 3PIN VIDEO

CN4000 5PIN VIDEO-Y(I/P)

CN4000 7PIN VIDEO-Pb/Cb

CN4000 9PIN VIDEO-Pr/Cr

Yes

Are the video signals shown above inputted into

each pin of IC4000?

IC4000 3PIN VIDEO

IC4000 8PIN VIDEO-Y(I/P)

IC4000 10PIN VIDEO-Pb/Cb

IC4000 12PIN VIDEO-Pr/Cr

Yes

Are the video signals outputted to each pin of

IC4000?

IC4000 20PIN VIDEO-Y(I/P)

IC4000 17PIN VIDEO-Pb/Cb

IC4000 15PIN VIDEO-Pr/Cr

IC4000 25PIN VIDEO

Yes

Are the video signals outputted to the specific

output terminal?

Are the component video signals outputted to the

VIDEO OUT terminal (JK4002, JK4003, JK4005)?

Are the composite video signals outputted to

the VIDEO OUT terminal (JK4004)?

No

No

No

No

No

Replace the BD

Main CBA & BD Mechanism

Assembly.

Check the line between each pin of CN4000 and

each pin of IC4000, and service it if defective.

CN4000 3PIN → IC4000 3PIN VIDEO

CN4000 5PIN → IC4000 8PIN VIDEO-Y(I/P)

CN4000 7PIN → IC4000 10PIN VIDEO-Pb/Cb

CN4000 9PIN → IC4000 12PIN VIDEO-Pr/Cr

Is 5V voltage supplied to the Pin(7,21) of IC4000?

Yes

Replace IC4000.

Check VIDEO+5V line and

No

service it if defective.

Check the periphery of the VIDEO OUT terminal

(JK4002, JK4003, JK4005) from Pin(15,17,20) of

IC4000 and service it if defective.

Check

the periphery of the VIDEO OUT terminal

(JK4004)

from Pin(25) of IC4000

and service it if

defective.

28

Page 31

FLOW CHART NO.19

Audio is not outputted normally. (JK2200, JK2201)

Set the disc on the disc tray, and playback.

Are the analog audio signals outputted to each pin

of CN2007?

CN2007 22PIN AUDIO(L)

CN2007 24PIN AUDIO(R)

Yes

Are the analog audio signals inputted to each pin

of IC2200?

IC2200 6PIN AUDIO(L)

IC2200 2PIN AUDIO(R)

Yes

Is the "H" level mute signal outputted to CN2007?

CN2007 19PIN AUDIO(R)-MUTE

CN2007 20PIN AUDIO(L)-MUTE

Yes

Is the signal at Pin(24) of IC2000 "H" ?

Yes

Are the analog audio signals outputted to each pin

of IC2200?

IC2200 7PIN AUDIO(L)

IC2200 1PIN AUDIO(R)

Yes

Are the audio signals outputted to the audio

terminal (JK2200, JK2201)?

No

No

No

No

No

No

Replace the BD

Main CBA & BD Mechanism

Assembly.

Check each line between each pin of CN2007

and each pin of IC2200, and service it if detective.

CN2007 22PIN → IC2200 6PIN AUDIO(L)

CN2007 24PIN → IC2200 2PIN AUDIO(R)

Replace the BD

Main CBA & BD Mechanism

Assembly.

AUDIO-MUTE line, and

Check

service it if

detective.

Replace IC2200.

Check the periphery between Pin(1,7) of IC2200

and the audio terminal (JK2200, JK2201), and

service it if detective.

29

Page 32

FLOW CHART NO.20

Audio is not outputted. (JK2202, JK2203)

Set the disc (with 7.1ch Audio) on the disc tray, and playback.

Are the analog audio signals outputted to each pin

of CN2007?

CN2007 15PIN FRONT-AUDIO(L)

CN2007 17PIN FRONT-AUDIO(R)

CN2007 5PIN SURROUND(L)

CN2007 7PIN SURROUND(R)

CN2007 3PIN SURROUND BACK(L)

CN2007 1PIN SURROUND BACK(R)

CN2007 12PIN CENTER

CN2007 10PIN SUB WOOFER

Yes

Are the analog audio signals inputted to each pin

of IC2601, IC2602, IC2603 and IC2604?

IC2601 2, 6PIN FRONT-AUDIO(L/R)

IC2603 2, 6PIN SURROUND(L/R)

IC2604 2, 6PIN SURROUND BACK(L/R)

IC2602 2, 6PIN CENTER/SUB WOOFER

Yes

Are the analog audio signals outputted to each pin

of IC2601, IC2602, IC2603 and IC2604?

IC2601 1,7PIN FRONT-AUDIO(L/R)

IC2603 1,7PIN SURROUND(L/R)

IC2604 1,7PIN SURROUND BACK(L/R)

IC2602 1,7PIN CENTER/SUB WOOFER

Yes

Do the mute signals of CN2007 become to "H"

level?

FRONT-AUDIO(L) → CN2007 14PIN

FRONT-AUDIO(R) → CN2007 18PIN

SURROUND(L/R) → CN2007 8PIN

SURROUND BACK(L/R) → CN2007 4PIN

CENTER → CN2007 13PIN

SUB WOOFER → CN2007 9PIN

No

No

No

No

Replace the BD Main CBA & BD Mechanism

Assembly.

Check each line between each pin of CN2007

and each pin of IC2601, IC2602,IC2603 and IC2604

and service it if defective.

CN2007 15,17PIN → IC2601 2,6PIN FRONT-AUDIO(L/R)

CN2007 5,7PIN → IC2603 2,6PIN SURROUND(L/R)

CN2007 1,3PIN → IC2604 2,6PIN SURROUND BACK(L/R)

CN2007 10,12PIN → IC2602 2,6PIN CENTER/SUB WOOFER

Replace

ICs (IC2601, IC2602

, IC2603 or IC2604).

Replace the BD Main CBA & BD Mechanism

Assembly.

Yes

Is the analog audio signal of each line outputted to

each terminal of JK2202 and JK2203 (as shown

below) ?

IC2601 7PIN → JK2202 FRONT-AUDIO(L)

IC2601 1PIN → JK2202 FRONT-AUDIO(R)

IC2603 7PIN → JK2202 SURROUND(L)

IC2603 1PIN → JK2202 SURROUND(R)

IC2604 7PIN → JK2203 SURROUND BACK(L)

IC2604 1PIN → JK2203 SURROUND BACK(R)

IC2602 7PIN → JK2202 SUB WOOFER

IC2602 1PIN → JK2202 CENTER

No

Check each line and service it if defective.

30

Page 33

BD Mechanism Replacement Guidelines s

The guidelines describe how to determine whether a BD Mechanism Assembly is defective or not.

Confirm that the malfunction is eliminated after replacing the defective BD Mechanism Assembly with a new one.

*The BD Mechanism Assembly shall be acceptable when the following test disc can be played successfully;

BD-ROM BLX-201S3(SONY) chp12

*Select [4: LD Test] and select [2: Operating Time] in Service Mode.

If the Operating Time shows 3,000 hours or more, the BD Mechanism Assembly shall be determined that it has

reached the end of its life.

Replacement of BD Main CBA & BD Mechanism Assembly

1. Remove the Top Cover, Tray Panel, Front Assembly, Front Bracket, Video CBA and AV PCB Holder.

2. Disconnect Connectors and replace the BD Main CBA & BD Mechanism Assembly.

Refer to CABINET DISASSEMBLY INSTRUCTIONS.

BD Main CBA

& BD Mechanism Assembly

31

Page 34

BLOCK DIAGRAMS

14.BLOCKDIAGRAMS

System Control Block Diagram

RS232C-

CONNECTOR

3 RXD

2 TXD

CN5550

REMOTE

JK5550

-OUT

REMOTE

-IN

EV+3.3V

VFD

19 20 21 22

FL3001

FRONT A CBA

SENSOR

REMOTE

RS3001

D3005

STANDBY

DRIVE

Q3004

POWER

SW3002

CN3001

1

2

KEY-2

KEY-1

CN3101

1

2

KEY

KEY

SWITCH

SWITCH

FRONT B CBA

RS232C CBA

IC5500

RS232C

INTERFACE

CN5551

13

14

RS232C

I/F

11

12

1

IC5550

(PHOTO COUPLER)

4

BUFFER

Q5551, Q5552

-LED

2

12 12REMOTE

CN2002 CN3002

3

BUFFER

Q2002

274934

REMOTE

RS232C-RXD

15 SUB-TXD

21 MUTE1

22 MUTE2

46

SUB-RXD

SYS-RESET

3

16

Q2620, Q2621

Q2618

28 CEC-IN

30 CEC-OUT

SWITCHING

BUFFER

BUFFER

Q2619

(SUB MICRO CONTROLLER)

IC2000

CN2005

RS232C-TXD

45

3 3FL-SDA

33

FL-SDA

5 5FL-STB

4 4FL-SCL

FL-SCL

FL-STB

STANDBY

6 6FL-RESET

15 15KEY-2

18 18

1

60

50

KEY-2

FL-RESET

STANDBY-LED

16 16KEY-1

EV+3.3V

8MHz

X'TAL

X2000

RESET

IC2001

8

9

62

KEY-1

14

RESET

AUDIO-MUTE

24

AUDIO-MUTE

TO AUDIO

BLOCK

DIAGRAM

OSC1

OSC2

32 FL-SW

PWSW1

FL-SW

PWSW237PWSW4

PWSW1

4

44

PWSW2

PWSW4

TO POWER

SUPPLY

BLOCK

FAN-CONT1

25

63 FAN-LOCK

FAN-CONT1

FAN-LOCK

DIAGRAM

AUDIO CBA

REMOTE

RS232C-RXD

RS232C-TXD

1 1

5 5

4 4

CN4002

VIDEO CBA

BD MAIN CBA

REMOTE

6 6

CN4001

RS232C-RXD

RS232C-TXD

1 1

2 2

15 15MUTE1

14 14MUTE2

MUTE1

MUTE2

TO VIDEO

BLOCK

DIAGRAM