Page 1

MAN GUIDELINES TO

FITTING BODIES

Series TGL/TGM

Edition 2018 V2.0

Page 2

P U B L I S H E R

MAN Truck & Bus AG

(hereinafter referred to as MAN)

Engineering Vehicle Truck

Application Engineering

Dachauer Str. 667

D-80995 Munich

E-Mail: info.manted@man.eu

Fax: + 49 (0) 89 1580 4264

www.manted.de

This English version is a translation.

In case of doubt or conict the valid German language original will govern.

We reserve the right to make technical modications in the course of further development.

© 2018 MAN Truck & Bus AG

Not to be reprinted, duplicated by any means whatsoever or translated – in whole or in part – without the prior

written consent of MAN Truck & Bus AG. All rights, especially those deriving from copyright law, are expressly

reserved by MAN.

®

Trucknology

If names constitute trademarks, they are also recognised as protected by the relevant owner without use of

the appropriate symbols (® ™).

Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

and MANTED® are registered trademarks of MAN Truck & Bus AG.

Page 3

Content

I. Applicability and legal agreements ............................................... 1

1.0 General ..............................................................................................2

2.0 Legal agreements ..............................................................................2

2.1 Requirements .................................................................................... 2

2.2 Responsibility .................................................................................... 3

2.3 Registration of the vehicle ................................................................. 4

3.0 Liability .............................................................................................. 7

3.1 Liability for material defects .............................................................. 7

3.2 Product liability ..................................................................................7

3.3 Limitation of liability for accessories/spare parts ..............................8

3.4 Operational and road safety ..............................................................8

3.5 Instructions from body-building and conversion companies ............9

4.0 Quality assurance ............................................................................10

5.0 Approvals ........................................................................................11

5.1 Body approval ................................................................................. 11

5.2 Manufacturer Conrmation .............................................................13

5.3 Trademarks......................................................................................14

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 I

Page 4

Contents

II. Product identication ................................................................... 17

1.0 General ............................................................................................18

2.0 Terms ...............................................................................................18

2.1 Model range .................................................................................... 18

2.2 Model number ................................................................................. 18

2.3 Tonnage class .................................................................................20

2.4 Power rating .................................................................................... 20

2.5 Type of suspension .........................................................................20

2.6 Wheel conguration ........................................................................21

2.7 Sufx ...............................................................................................22

2.8 Cabs ................................................................................................ 23

3.0 Door designation .............................................................................25

4.0 Variant descriptor ............................................................................ 25

5.0 Base vehicle number .......................................................................26

6.0 Vehicle identication number and vehicle production number ....... 26

II Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 5

Contents

III. Chassis ........................................................................................... 29

1.0 General ............................................................................................30

1.1 Obtaining technical vehicle data ..................................................... 30

1.2 Standards, guidelines, regulations, tolerances ...............................30

1.3 Quality of execution ........................................................................31

1.3.1 Corrosion protection .......................................................................31

1.3.2 Welding work on the vehicle ...........................................................31

1.3.3 Drill holes, riveted and bolted connections ..................................... 35

1.4 Fire-protection measures for vehicle bodies and modications ..... 38

1.4.1 General ............................................................................................38

1.4.2 Statutory requirements ....................................................................38

1.4.3 Measures in the vicinity of the engine and exhaust system ...........39

1.4.4 Measures on the air intake system .................................................39

1.4.5 Electric wiring/ttings ......................................................................40

2.0 Overall vehicle ................................................................................. 41

2.1 General ............................................................................................41

2.2 Terms, dimensions and weights ...................................................... 41

2.2.1 Theoretical wheelbase ....................................................................41

2.2.2 Theoretical and permitted overhang lengths ..................................43

2.2.3 Permissible axle load ......................................................................44

2.2.4 Permissible gross weight ................................................................44

2.2.5 Permissible gross train weight ........................................................ 45

2.2.6 Axle overload ..................................................................................46

2.2.7 Wheel-load difference .....................................................................47

2.2.8 Minimum front-axle load .................................................................49

2.2.9 Calculating the axle load and weighing procedure ......................... 51

2.2.10 Rolling circumference and difference in rolling circumference .......51

2.3 Modications to the overall vehicle ................................................. 52

2.3.1 Modications to the wheelbase ...................................................... 52

2.3.2 Modifying the frame overhang ........................................................ 58

2.3.3 Modifying the wheel conguration .................................................. 62

2.3.4 Changing the tyre type ....................................................................63

2.3.5 Changing the vehicle type and interchangeable operation as

semitrailer .......................................................................................63

tractor/truck ....................................................................................63

2.3.6 Retrotting additional units, attachments and accessories ............ 64

2.4 Homologated vehicle components / vehicle components

relevant to safety .............................................................................65

3.0 Cab ..................................................................................................66

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 III

Page 6

Contents

3.1 General ............................................................................................66

3.2 Cabs ................................................................................................ 67

3.3 Spoilers, roof extensions, roofwalk ................................................. 68

3.4 Roof sleeper cabs ........................................................................... 71

3.5 Fastening of warning plates to the front ap .................................. 74

4.0 Chassis frame .................................................................................75

4.1 General ............................................................................................75

4.2 Frame materials...............................................................................75

4.3 Frame proles .................................................................................76

5.0 Frame attachments ......................................................................... 77

5.1 General ............................................................................................77

5.2 Front underride protection ..............................................................78

5.3 Side underride protection ...............................................................79

5.4 Rear underride protection ............................................................... 83

5.5 Fuel tanks ........................................................................................85

5.5.1 Mounting fuel tanks .........................................................................87

5.5.2 Modications to fuel lines ............................................................... 88

5.6 Coupling devices.............................................................................91

5.7 Front-mounted attachments ...........................................................92

6.0 Engine and driveline ........................................................................94

6.1 General ............................................................................................94

6.2 Engine versions ............................................................................... 95

6.2.1 Type codes for MAN engines .......................................................... 96

6.3 Engine environment ........................................................................97

6.3.1 Modications to the engine ............................................................. 97

6.3.2 Modication to the air intake ........................................................... 97

6.3.3 Modications to the engine cooling system ................................. 103

6.3.4 Modications to engine encapsulation, noise insulation .............. 105

6.3.5 Compressed-air supply .................................................................105

6.3.5.1 Basic principles ............................................................................. 105

6.3.5.2 Routing lines .................................................................................105

6.3.5.3 Connecting auxiliary consumers ................................................... 108

6.3.5.4 Loss of compressed-air pressure .................................................109

6.3.5.5 External air supply ......................................................................... 110

6.4 Exhaust system ............................................................................. 113

6.4.1 Modications to the exhaust routing ............................................113

6.4.2 AdBlue-System ............................................................................. 121

6.4.2.1 Basic principles and structure of the AdBlue system ................... 121

6.4.2.2 AdBlue line set ..............................................................................125

IV Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 7

Contents

6.4.2.3 AdBlue tank ...................................................................................135

6.4.2.4 AdBlue supply module .................................................................. 138

6.4.2.5 AdBlue cable harness ................................................................... 140

6.4.2.6 Parts list ........................................................................................159

6.5 Gearbox and propshafts ...............................................................163

6.5.1 Basic principles ............................................................................. 163

6.5.2 Propshaft congurations ............................................................... 164

6.5.3 Forces in the propshaft system .....................................................168

6.5.4 Modifying the propshaft conguration .......................................... 168

6.5.5 Fitting other manual or automatic gearboxes and transfer cases 169

6.6 PTOs .............................................................................................169

6.7 Brake system ................................................................................170

6.7.1 Basic principles ............................................................................. 170

6.7.2 Installing and fastening brake lines ............................................... 170

6.7.3 ALB, EBS brake system ................................................................ 170

6.7.4 Retrotting continuous brakes ...................................................... 170

7.0 Running gear .................................................................................171

7.1 General ..........................................................................................171

7.2 Modications to the running gear ................................................. 172

7.3 Equipment-related notes ...............................................................172

8.0 Electrical/electronic system (on-board network) ...........................173

8.1 General ..........................................................................................173

8.1.1 Electromagnetic compatibility .......................................................174

8.1.2 Static discharge ............................................................................174

8.1.3 Radio equipment and aerials ........................................................ 174

8.1.4 Diagnostics concept and parameterisation using MAN-cats ....... 177

8.2 Cables ........................................................................................... 178

8.2.1 Routing cables ..............................................................................178

8.2.2 Ground cable.................................................................................179

8.2.3 Wiring harnesses for wheelbase extensions ................................. 179

8.2.4 Cable harnesses for rear position lamps, additional rear

position lamps, trailer sockets, side marker lamps and

supplementary ABS sockets ......................................................... 183

8.2.5 Supplementary wiring diagrams and cable-harness drawings ..... 188

8.2.6 Battery cable ................................................................................. 188

8.3 Interfaces on the vehicle, preparations for the body ....................189

8.3.1 Tapping into the engine-on (D+) signal ......................................... 190

8.3.2 Electrical interface for liftgate........................................................190

8.3.3 Engine-Start-stop system ............................................................. 193

8.3.4 Tapping into the speed signal ....................................................... 193

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 V

Page 8

Contents

8.3.5 Tapping into the reverse gear signal .............................................194

8.3.6 Interfaces for intermediate speed control with VMC/PTM and

CSM (ISC interfaces) .....................................................................194

8.3.7 Interface for reversing-camera preparation ..................................197

8.4 Additional consumers ...................................................................203

8.4.1 Notes on charging balance ...........................................................208

8.5 Batteries ........................................................................................ 210

8.5.1 Handling and maintaining batteries .............................................. 210

8.5.2 Handling and care of maintenance-free batteries ........................211

8.6 Lighting installations .....................................................................212

8.7 Display and instrumentation concept ........................................... 213

8.8 Safety and assistance systems ..................................................... 214

8.8.1 Yaw-rate sensor ............................................................................ 214

8.8.2 Radar sensor ................................................................................. 216

8.8.3 Multi-functional camera ................................................................219

8.9 Electrical Boxes on the chassis frame .......................................... 222

VI Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 9

Contents

IV. Body..............................................................................................225

1.0 General requirements .................................................................... 226

1.1. Requirements ................................................................................ 226

1.2 Accessibility and clearance ...........................................................226

1.3 Handling characteristics and driving resistances .........................228

1.4 Vibration ........................................................................................229

1.5 Special feature of vehicles with lifting axles..................................229

1.6 Vehicles with outriggers ................................................................230

1.6.1 Outrigger operation with the wheels in contact with the ground .. 230

1.6.2 Outrigger operation with the wheels not in contact with

the ground ..................................................................................... 231

1.7 Tolerances ..................................................................................... 231

1.8 Assembly .......................................................................................231

1.9 Corrosion protection of bodywork ................................................232

1.10 Standards, directives and regulations ...........................................233

1.10.1 Machinery Directive (2006/42/EC).................................................233

1.10.2 Securing of cargo .......................................................................... 235

1.10.3 Contour markings .........................................................................235

1.10.4 Radio Equipment Directive 2014/53/EU .......................................236

2.0 Body and auxiliary-frame design .................................................. 239

2.1 General requirements .................................................................... 239

2.2 Body with auxiliary frame .............................................................. 241

2.2.1 Permissible materials .................................................................... 241

2.2.2 Auxiliary-frame design ..................................................................241

2.2.3 Connection to chassis frame ........................................................ 244

2.2.4 Equipment-specic notes and restrictions ...................................245

2.3 Body without auxiliary frame .........................................................249

2.4 Attaching auxiliary frames and bodies .......................................... 251

2.5 Bolt connections and riveted joints ............................................... 252

2.6 Flexible connection ....................................................................... 254

2.6.1 General requirements for exible body fasteners .........................254

2.6.2 Implementations of exible body fasteners .................................. 256

2.7 Rigid connection ........................................................................... 261

3.0 Bodies ........................................................................................... 264

3.1 Semitrailer tractors ........................................................................264

3.1.1 Chassis and equipment ................................................................264

3.1.2 Requirements for bodies ...............................................................264

3.2 Platform and box bodies ...............................................................266

3.3 Swap body ttings ........................................................................267

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 VII

Page 10

Contents

3.3.1 Chassis and equipment ................................................................267

3.3.2 Requirements to be met by the body ...........................................267

3.4 Liftgates ........................................................................................268

3.5 Tank and container bodies ............................................................ 279

3.5.1 Chassis and equipment ................................................................279

3.5.2 Requirements to be met by the body ...........................................279

3.6 Refuse-collector body ...................................................................282

3.6.1 Chassis and equipment ................................................................282

3.6.2 Requirements to be met by the body ...........................................282

3.7 Tippers ..........................................................................................283

3.7.1 Chassis and equipment ................................................................283

3.7.2 Requirements to be met by the body ..........................................284

3.8 Set-down and roll-off skip loaders ................................................286

3.9 Loading crane ...............................................................................287

3.9.1 Chassis and equipment ................................................................287

3.9.2 Requirements to be met by the body ...........................................289

3.9.3 Requirements to be met by auxiliary frames for loading cranes ...291

3.10 Transport mixers ........................................................................... 298

3.10.1 Chassis and equipment ................................................................298

3.10.2 Requirements to be met by the body ...........................................299

3.11 Cable winch ..................................................................................300

3.12 Single-pivot body .......................................................................... 300

VIII Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 11

Contents

V. Calculations ................................................................................. 303

1.0 General ..........................................................................................304

1.1 Speed ............................................................................................ 304

1.2 Efciency .......................................................................................306

1.3 Tractive force .................................................................................308

1.4 Gradeability ................................................................................... 309

1.4.1 Distance travelled on uphill or downhill gradients ........................ 309

1.4.2 Angle of uphill or downhill gradient ............................................... 310

1.4.3 Calculating the gradeability ........................................................... 311

1.5 Torque ...........................................................................................315

1.6 Power output .................................................................................317

1.7 Rotational speeds for power take-offs on the transfer case .........319

1.8 Driving resistances ........................................................................ 320

1.9 Turning circle ................................................................................. 323

1.10 Axle-load calculation .....................................................................326

1.10.1 Performing an axle-load calculation ............................................. 326

1.10.2 Calculation of weight with trailing axle lifted ................................. 333

1.11 Support length for body without auxiliary frame ........................... 335

1.12 Coupling devices...........................................................................336

1.12.1 Trailer coupling for steerable drawbar trailer (D value) .................. 336

1.12.2 Trailer coupling for rigid drawbar trailer/ center-axle trailer

(D

value, V value) .........................................................................337

C

1.12.3 Trailer coupling for semi-trailer (D value) ....................................... 339

1.13 Theoretical wheelbase and permissible overhang length ............. 341

If not otherwise specied: all dimensions are in mm, all weights and loads are in kg.

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 IX

Page 12

NOTICE

X Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 13

These Guidelines to tting bodies aimed at professional bodybuilder.

Therefore, in this guideline, background knowledge is assumed.

It should be noted that some work may only be carried out by suitably qualied personnel in order to avoid the risk

of injury and to achieve the necessary quality for construction work.

Notational conventions

In this guideline the following notational conventions are used:

Information

This notice points out further information to you.

Important notice

This notice draws your attention to possible damage to the vehicle.

Environmental notice

An environmental notice provides you with tips for environmental protection.

Warning notice

A hazard warning notice points out possible risks of accident or injury to you and others.

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 XI

Page 14

NOTICE

XII Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 15

I. Applicability and legal agreements

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 1

Page 16

I. Applicability and legal agreements

1.0 General

The statements in these MAN guidelines to tting bodies are binding. Exceptions may only be approved by MAN

following a written request and provided such exceptions are technically feasible (for address see “Publisher”).

2.0 Legal agreements

2.1 Requirements

In addition to these guidelines to tting bodies the executing company must observe all of the following that apply

to the operation and bodywork of the vehicle:

• Legislation, rules and regulations

• Accident-prevention regulations

• Operating instructions

observed.

Standards are technical standards and thus contain minimum requirements. Failure to observe such minimum

requirements is a negligent act. Standards are binding if they are part of rules and regulations.

Information received from MAN in answer to telephone enquiries is non-binding unless conrmed in writing.

Enquiries must be directed to the MAN department responsible.

Information is based on conditions of use such as are typical in Europe. Dimensions, weights and other basic values

deviating therefrom must consequently be taken into account for the engineering design and attachment of

bodywork and the design of the auxiliary frame. The executing company must ensure that the entire vehicle is able

to sustain the conditions of use to be expected.

Various manufacturers have worked out specications for certain units, e.g. loading cranes, liftgates, cable winches

and so on. These are also to be observed if they contain requirements extra to the MAN guidelines to tting bodies.

Mentions of:

• Legal regulations

• Accident-prevention regulations

• Regulations issued by professional associations

• Standard operating procedures

• Other guidelines and sources

are by no means complete and are only for purposes of information. They are no replacement for due diligence on

the part of the particular company.

2 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 17

I. Applicability and legal agreements

2.2 Responsibility

Responsibility for professional

• Engineering Design

• Production

• tting of bodywork,

• modications to chassis

is always, and in full, that of the company producing or assembling the bodywork or carrying out the modication

(manufacturer’s liability). This also applies when MAN has expressly granted approval of the bodywork or

modication. Written approval of bodywork or modications by MAN does not release the bodywork

manufacturer from their responsibility for the product.

Should the executing company detect an error in the planning stage or in the intentions of the

• customers

• user

• its own personnel

• vehicle manufacturer

they will draw the attention of the particular party to it.

The company is responsible for ensuring that the

• Operational safety

• Road safety

• serviceability,

• Driving characteristics

of the vehicle are not negatively affected in any way.

In terms of road safety the company must construe and base:

• Engineering Design

• production of bodywork,

• tting of bodywork,

• modications to chassis

• instructions,

• Operating instructions

by the latest state of the art and recognized rules of the discipline. More difcult operating conditions are in addition

to be taken into consideration.

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 3

Page 18

I. Applicability and legal agreements

2.3 Registration of the vehicle

National laws and technical regulations with respect to the registration of modied vehicles are to be complied

with. Modication work carried out in on the chassis must be submitted to a Technical Service for assessment.

The executing company remains responsible even subsequent to the registration of the vehicle in the event of the

competent authorities having issued the vehicle registration in ignorance of the operational safety of the product.

EU multi-stage type-approval procedure as per Annex XVII 2007/46/EC

Process

Within the framework of the multi-stage process pursuant to Annex XVII of Directive 2007/46/EC, each manufacturer

shall bear independent responsibility for approval and conformity of production of all systems, components or

independent technical units that it manufactures or adds in an earlier stage of manufacturing.

The body manufacturer is the manufacturer of the second or additional production stage pursuant to 2007/46/EC.

Responsibilities

As a basic principle, the body builder is responsible for:

• modications it carried out on the base vehicle.

• objects granted approval at an earlier stage if, due to modications to the base vehicle, the approvals

granted are no longer applicable to this vehicle.

• ensuring that the modication carried out complies with the respective national/international statutory

regulations, in particular those of the destination country.

• submitting the modications it carried out to a technical service for assessment.

• documenting compliance with statutory regulations in appropriate form (test report and/or permit or

documents meeting the legal requirements of the destination country).

As a basic principle, MAN as manufacturer of the base vehicle is responsible for:

• providing the body builder with the homologation documentation (EU/EEC approvals) available for

the scope of delivery of the base vehicles in electronic form on request.

Identication of the vehicles

The respective vehicle shall receive a vehicle identication number (“VIN”), which identies MAN as manufacturer

of the incomplete base vehicle.

As a basic principle, the requirements laid down in Annex XVII to 2007/46/EU and the published associated

procedural instructions apply.

Conformity of production (COP)

As a basic principle, the requirements laid down in individual EU Directives and Annex X to 2007/46/EU as well as

the requirements laid down in Annex 2 to the EEC Agreement of 1958 apply.

Provision of documentation for registration/following stage

In accordance with Annex XVII to 2007/46/EU, MAN as manufacturer of the base vehicle provides the body builder

or builders the available EU/EEC system approvals and the Certicate of Conformity (CoC)1) for the base vehicle in

electronic form.

1)

Only in cases where the vehicle is EU-compliant and a Certicate of Conformity (CoC) has been printed by

the plant.

4 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 19

I. Applicability and legal agreements

Case I: Registration in Germany

In the case of MAN acting as general contractor (“single-invoice transaction”) the body builder/s as later-stage manufacturer/s undertake/s to provide the following documentation in electronic form:

a) The individual supplier conditions provide for an acceptance/approval and registration process

by the vehicle manufacturer (MAN).

1. In the case of an existing and valid whole vehicle type-approval in accordance

with 2007/46/EC for the manufacturing stages, a CoC. On request, existing EC/EEC system

approvals or technical reports must be submitted.

2. Alternatively to 1, the test reports and approval documentation required for national

individual approval procedures in accordance with Section 13 of the EC vehicle

approval Directive.

The latest time for submitting the above stated documentation in printable form is the day the

completed vehicle is returned to the contractually agreed place of delivery.

The documentation shall be sent to the following e-mail address documents@de.man-mn.com.

In cases where MAN receives a CoC from the bodybuilder, then original certicates may only

be generated by MAN on behalf of the bodybuilder.

b) The acceptance/approval and registration process is to be carried out by the contract partner or

by the manufacturer of the nal completion stage of the vehicle.

1. None.The registration process is the responsibility of the contract partner or the

manufacturer of the nal completion stage of the vehicle.

In all other cases the acceptance/approval and registration process is to be carried out by the manufacturer of the

nal completion stage of the vehicle or by the corresponding contract partner.

Case II: Registration outside Germany but inside the area of application of Directive 2007/46/EC

If MAN serves as general contractor then the bodybuilder is under an obligation, as the nal stage manufacturer, to

provide in electronic form, all the necessary approval/registration documentation for all modications made during

the subsequent manufacturing stages of the respective responsible sales organisation or importer which exceed

the scope of the basic vehicle.

Irrespective of any general contractor status of the importers, the acceptance/approval and registration process is

to be carried out by the manufacturer of the nal completion stage of the vehicle or by the corresponding contract

partner.

The importer in the respective country or the corresponding contract partner has the authority and responsibility for

the registration process.

MAN does not supply any national data for registration purposes exceeding that for incomplete vehicles set forth in

Annex IX to Directive 2007/46/EG in its current form and as amended from time to time. This also applies in

particular to national model codes and encrypted basic technical data.

MAN as a manufacturer reserves the right – following corresponding feasibility studies and economic

implementation – and after reaching corresponding specically applicable agreements with national sales

organisations and importers, to provide data for national registration which exceeds the scope of that set forth

above (e.g. vehicle’s manufacturing plates etc.). Enquiries in this regard shall be sent to the following e-mail address

documents@de.man-mn.com.

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 5

Page 20

I. Applicability and legal agreements

Non-disclosure agreement

The bodybuilder may not forward the approval documentation provided by MAN to any third parties without

obtaining prior, express permission from MAN.

The forwarding of documentation that is directly associated with the registration of the vehicle in question

to persons of the institutions listed below is excepted:

• MAN Sales partners

• Technical vehicle inspection centers or testing organisations

• Approval authorities

• Registration authorities or licensing centers acting for the government

Note on type approval / homologation for TiB, CiB, BiB, CKD, SKD and PKD vehicles

Where:

• TiB stands for “truck in the box”

• CiB stands for “chassis in the box”

• BiB stands for “bus in the box”

• CKD stands for “completely knocked down”

• SKD stands for “semi knocked down”

• PKD stands for “partly knocked down”

For these versions MAN is not considered to be the manufacturer within the meaning of Directive 2007/46/EC –

therefore, the responsibility for the homologation and registration process lies with the manufacturer of

these vehicles.

In principle, the substance of the contracts respectively concluded with MAN shall apply.

In principle, MAN does not provide registration-related data for completed vehicles. Exceptions include

homologation documentation for components subject to approval such as the engine, which MAN provides

in electronic form.

However, this does not exclude MAN as a manufacturer reserving the right – following corresponding feasibility

studies and economic implementation – and after reaching corresponding specically applicable agreements with

national sales organisations and importers, to provide data for national registration which exceeds the scope of that

set forth above (e.g. vehicle’s manufacturing plates etc.). Enquiries in this regard shall be sent to

MAN’s Homologation Department.

6 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 21

I. Applicability and legal agreements

3.0 Liability

3.1 Liability for material defects

Claims on liability for defects only exist within the contract of sale between the purchaser and the seller. The liability

for defects consequently rests with the seller of the article of sale. Claims may not be made of MAN if the reported

defect results from the following:

• Non-adherence to these body guidelines

• Selection of a chassis unsuitable for the intended purpose of the vehicle

• Damage to the chassis caused by:

- the body,

- the nature/execution of body installation,

- modication to the chassis,

- incorrect operation.

3.2 Product liability

Defects in workmanship detected by MAN are to be corrected. In as much as this is legally admissible, MAN will

bear no liability, in particular for consequential damages.

Product liability regulates:

• The liability of the manufacturer for their product or component of a product.

• The claim to compensation from the manufacturer of an integrated component of a product made by the

manufacturer claimed upon if the occurring damage results from a defect of this component of a product.

The company that executes the bodywork or modication to the chassis shall indemnify MAN from any claims for

liability made by its customers or other third parties, in as much as any damage results from the following:

• The company having failed to comply with the guidelines to tting bodies valid at the time.

• The bodywork or chassis modication has caused damage through faulty

- Engineering Design

- Manufacture

- Assembly

- instructions.

• The set principles were not complied with in any other way.

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 7

Page 22

I. Applicability and legal agreements

3.3 Limitation of liability for accessories/spare parts

Warning notice

Accessories and spare parts not manufactured by MAN or approved for use in its products can impair the

operational and road safety of the vehicle and lead to dangerous situations.

MAN Truck & Bus AG (or the seller) accepts no liability for claims of any kind resulting from a combination of the

vehicle together with an accessory that was made by another manufacturer. Excepted from the aforementioned are

cases in which MAN Truck & Bus AG (or the seller) itself offers the accessory for sale or ts it to the vehicle (or the

subject of the contract).

3.4 Operational and road safety

In order to ensure operational and road safety or to maintain the validity of any claims under the guarantee, the

bodybuilder must observe the instructions given in these guidelines to tting bodies exactly. MAN shall not be liable

for non-compliance.

Warning notice

Before commencing work on the body, making modications or starting installation work, the bodybuilder must

also have knowledge of the sections of the operator‘s manual that relate to the work he is completing. It will

otherwise be impossible to recognise risks and other persons may be endangered.

MAN cannot be liable for reliability, safety and suitability under the following circumstances.

• Bodies are not constructed and tted in accordance with these guidelines to tting bodies

• MAN Genuine Parts or approved parts and modications are replaced with other parts

• Unauthorised modications are made to the vehicle

Approvals by third parties, for example Technical Inspection Agencies or approvals from public authorities, shall not

be considered sufcient for precluding safety risks.

Companies handling and working on the vehicle are liable for any damages that result from decient functional and

operational safety or inadequate operating manuals. MAN consequently requires of the bodybuilder or modier:

• maximum state-of-the-art safety standards,

• comprehensible and adequately detailed operating instructions,

• easily visible, permanently afxed plates at points posing a risk to operators and/or third persons,

• adherence to necessary protective measures (e.g. against re and explosion risks),

• full details relating to toxicology,

• full details relating to ecology.

Safety has priority! Make use of all technical possibilities to avoid and eliminate insecure operation.

This applies equally to:

• Active safety = prevention of accidents. This includes:

- driving safety as a result of the overall concept of the vehicle with its bodywork

- conditional safety produced by minimal physical stress on occupants through vibration, noise,

climate, etc.

- assured perception, especially correct design of lighting ttings, warning devices, sufcient direct

and indirect visibility

- operational safety, including optimum operability of all devices and ttings, and those of

the bodywork

8 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 23

I. Applicability and legal agreements

• Passive safety = avoidance and containment of accident consequences. This includes:

- outer safety, e.g. design of the exterior of the vehicle/bodywork in terms of deformation, tting

of protective devices

- inner safety, including protection of the occupants of vehicles, but also cabs installed by

bodywork producers

Climatic and environmental conditions affect:

• Operational safety

• readiness for use,

• in-service performance,

• Service life

• cost-effectiveness,

Climatic and environmental inuences are, for example:

• effects of temperature

• Humidity

• aggressive substances,

• sand and dust,

• radiation.

Ensure sufcient clearance of all parts involved in movement, including all cables and leads. The operating manuals

for MAN vehicles provide information on the maintenance points on the vehicle. Regardless of the kind of bodywork,

ensure good access to these maintenance points in all cases. Maintenance must be possible unhindered by having

to remove any parts. Ensure adequate ventilation and/or cooling of sub-assemblies.

3.5 Instructions from body-building and conversion companies

In the event of a body atng added or modications to the vehicle atng carried out by a conversion company, the

operator of the vehicle is also entitled to receive the operating instructions. All the benets of a product are of no

use if the customer is unable to:

• handle it safely and true to its purpose,

• use it rationally and effortlessly,

• correctly service and maintain it,

• work with it expertly in all its functions.

Every bodybuilder and modier shall consequently ensure that their technical manuals exhibit:

• Comprehensibility

• Complete

• Accuracy

• Traceability

• Product-specic notes on safety

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 9

Page 24

I. Applicability and legal agreements

A poor or incomplete operating manual means considerable risk factors for the user. Possible consequences are:

• reduced value because product advantages go unrecognized;

• complaints, irritation and annoyance;

• failures and damage that are usually attributed to the chassis,

• unexpected and unnecessary extra costs through repairs and loss of time;

• a negative image and thus less inclination to purchase from the same source again.

Operating personnel is to be instructed in operation and maintenance for the particular vehicle body or modication.

Instruction must also include possible effects on the static and dynamic performance of the vehicle.

4.0 Quality assurance

To satisfy the high quality demands of our customers and comply with international product/producer liability,

continuous quality inspection is also needed to conduct retrots and in the production/tting of bodywork.

This calls for a properly functioning quality-assurance system.

The bodybuilder is advised to set up and provide evidence of a quality management system complying with general

requirements and accepted rules (e.g. EN ISO 9000 ff or VDA Vol. 8).

If MAN is the contracting body for the bodywork or modication, it will demand evidence of qualication. MAN Truck

& Bus AG reserves the right to conduct its own VDA Vol. 8 system audit of a supplier or appropriate examinations

of processes. VDA Vol. 8 is harmonised with the bodywork manufacturer associations ZKF (federal association of

bodywork and vehicle engineering), BVM (federal association of the metalworking trade) as well as with the ZDH

(federal association of skilled crafts).

Publications:

VDA Vol. 8: Aids to quality assurance for trailer, body and container manufacturers can be obtained from

the German Association of the Automotive Industry (VDA).

10 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 25

I. Applicability and legal agreements

5.0 Approvals

The “Approvals” section contains information on the approval of bodies and manufacturer’s conrmation.

The prerequisites, basic principles to be complied with when submitting applications and the options for obtaining

applications are described.

5.1 Body approval

General information

Body approval from MAN is not required if the bodies or modications are carried out in accordance with these

guidelines to tting bodies.

If MAN approves a body, this approval applies, in the case of bodies,

• to their basic compatibility with the respective chassis,

• to interfaces with the body (e.g. dimensioning and fastening the auxiliary frame).

The endorsement of approval entered by MAN in the submitted technical documents does not cover inspection of the:

• Function

• Engineering Design

• equipment of the body or the modication.

The endorsement of approval only concerns measures or parts to be seen or taken from the submitted technical

documents.

MAN reserves the right to refuse issue of an approval of bodywork, even if comparable approval was issued at an

earlier date. Technical advances rule out the possibility of cases atng fully identical. MAN furthermore reserves the

right to alter these guidelines at any time, or to issue instructions differing from those contained herein in the case

of single chassis.

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 11

Page 26

I. Applicability and legal agreements

Should a number of identical chassis have identical bodywork, MAN may issue a collective approval for the sake

of simplicity.

For an approval process to proceed swiftly, the following are required:

Template for inspection documentation

Documents should only be sent to MAN if bodies deviate from these guidelines to tting bodies. If this is the case,

technical documents enabling inspection must be sent to MAN (for address see “Publisher” above) before work on

the vehicle begins.

A rapid processing procedure requires:

• documents preferably submitted in the usual digital formats (e.g. PDF, DWG, DXF, STEP),

• complete technical data and documents,

• as few documents as possible.

The following details will be contained:

• Vehicle model (for model numbers see Chapter II, Section 2.2 “Model numbers”) with

- Cab version

- Wheelbase

- Frame overhang

• Vehicle identication number or vehicle production number (if already existing, see Chapter II, Section 6.0,

“Vehicle identication numbers and vehicle production numbers)

• Appropriate marking of departures from these guidelines in all documents!

• Loads and their points of application

- Forces from bodywork

• Axle load calculation

• Special conditions of use:

• Subframe

- Material and cross-section gures

- Dimensions

- Type of prole

- Cross member arrangement in auxiliary frame

- Particularities of auxiliary frame design

- Changes to cross-sections

- Supplementary reinforcements

- Kick-up, etc.

• Joining means:

- Positioning (with reference to chassis)

- Type

- Size

- Quantity

The following are not sufcient for inspection and approval:

• Parts lists

• Literature

• Photos

• Other non-binding information

Drawings are only of value under the number assigned them.

12 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 27

I. Applicability and legal agreements

5.2 Manufacturer Confirmation

General information

In the case of modications to vehicles, a manufacturer conrmation may become necessary. Upon special request,

MAN can issue an exception to existing technical stipulations. Manufacturer conrmations may only be issued if this

can be arranged with the functional, trafc and operational safety guidelines.

If MAN approves a chassis modication, this approval shall only relate to the basic constructive permissibility for

the relevant chassis.

Manufacturer conrmations can generally be issued in the following categories:

• Vehicle conrmations, e.g.

- Wheelbase modications

- Changing tyre types

- Optional deployment or conversion of truck/semi-trailer tractor

- Axle loads and gross weight

- Trailer load and gross trailer weight

• Factory automatic load-dependent brake force distribution and engine plates

• Documents supplied with the vehicle, e.g.

- COP document

- “Low noise vehicle” certication

• Approval documents, e.g.

- Data conrmation

A detailed overview of the available manufacturer conrmations is available at www.manted.de.

Application for manufacturer conrmations

Manufacturer conrmations may only be applied for outside Germany via the respective central import company.

The applicant is both the invoice recipient and the conrmation recipient, and must be one and the same person.

Manufacturer approvals can be applied for using the following options:

• Application via fax or email

- Obtaining the forms (templates) via www.manted.de → Guidelines and Forms

- Sending the completed application via fax or email to the contact address specied in the

application.

• Application via MANTED-online application

- can be found at www.manted.de →Services → MANTED-online application (additional registration required).

→ Create MANTED-online application → Select the corresponding application.

- Please complete all the required elds in the online application.

- Please see the help document in the online applications area for further information.

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 13

Page 28

I. Applicability and legal agreements

Note

It is a requirement that the conversion measure(s) are only carried out after the receipt of the corresponding

manufacturer conrmation(s) - as far as is necessary.

Such special approval issued by MAN is not binding on the competent authority.

MAN has no inuence on the issuance of exemptions by the competent authority.

Generally, every exemption must be checked and inspected by the ofcially recognised expert, as well as entered

in the ofcial vehicle documents by the responsible accreditation body. If the measure concerned is outside the

national legal provisions and regulations, an exemption must be obtained beforehand from the competent authority.

Compliance with these guidelines to tting bodies does not release the user from his responsibility for technically

exemplary implementation of the modication works.

MAN reserves the right to decline to grant approvals for modications, even if a comparable approval has been

granted before. Technical progress does not automatically allow for equal treatment. Furthermore, MAN reserves

the right to modify these guidelines to tting bodies at any time or, for individual chassis, to issue instructions which

deviate from these guidelines to tting bodies.

5.3 Trademarks

The MAN logo and MAN emblem are trademarks of MAN Truck & Bus AG and may not be removed or repositioned

without permission (for the contact address see “publisher” above).

MAN Truck & Bus AG reserves the right to prohibit the body manufacturer or vehicle modier from using the

MANtrademarks if they breach the Guideline To Fitting Bodies as amended. The body manufacturer or vehiclemodier

will then be required to remove all visible trademarks.

If changes are made that render approvals for the basic vehicle (e.g. type or system approval) invalid; these approvals

or evidence thereof must be reobtained by the body manufacturer or vehicle modier. The body manufacturer or

vehicle modier must afx the legally required markings to the vehicle, e.g. the additional plate in accordance with

Article 59 of the German Road Trafc Licensing Regulation (StVZO).

14 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 29

NOTICE

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 15

Page 30

NOTICE

16 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 31

II. Product identification

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 17

Page 32

II. Product identication

1.0 General

For purposes of internal and external communication, various vehicle designations have been introduced according

to certain classication criteria and adapted to suit requirements.

The most important designations are:

• Variant designation

• Door identication

• Base vehicle and model number

• Vehicle identication and vehicle production number

In addition, general information on MAN’s cab variants can also be found in this chapter.

2.0 Terms

Denitions of the terms used to describe MAN vehicles.

2.1 Model range

MAN’s “Trucknology Generation” is divided into four model ranges. An overview can be found in the following table.

Table 01-II: The “Trucknology Generation” model ranges

Series Explanation Tonnage [t]**

TGL Trucknology Generation L - Light range 7 - 12

TGM Trucknology Generation M - Medium range 12 - 26

TGS Trucknology Generation S - Heavy range with narrow cabs* 18 - 41

TGX Trucknology Generation X - Heavy range with wide cabs* 18 - 41

* For further information on the MAN range of cabs, see Chapter II, Section 2.8 “Cabs” and Chapter III,

Section 3.2 “Cab variants”

** Standard tonnage / permissible gross weight

2.2 Model number

A vehicle can only be uniquely identied on the basis of its model number, also known as model code number.

The model number comprises three characters and unambiguously classies different vehicle families and variants.

It identies the assignment to a model range, the tonnage and the type of suspension.

As a rule, it consists of a letter and two digits and together with the base vehicle number, it is also an element of

the vehicle identication number and the vehicle production number.

The tables below list the existing model code numbers for the TGL, TGM, TGS und TGX model ranges.

The designation shown in the table contains the standard wheel conguration. The given suspension type is

the basic suspension of the vehicle’s front- and rear-axle assemblies.

18 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 33

II. Product identication

Table 02-II: Model numbers and vehicle designations in the TGL model range

Type number Tonnage [t] Designation Suspension Note

N01 7,5 TGL 7.xxx 4x2 BB Leaf-Leaf Replaced by N03 in 2007

N02 8 TGL 8.xxx 4x2 BB Leaf-Leaf

N03 7 - 8 TGL 7.xxx 4x2 BB Leaf-Leaf

N04 10 - 12

TGL 10.xxx 4x2 BB

TGL 12.xxx 4x2 BB

Leaf-Leaf

TGL 12.xxx 4x2 BB

N05 10 - 12

TGL 10.xxx 4x2 BB

TGL 12.xxx 4x2 BB

Leaf-Leaf

N11 7,5 TGL 7.xxx 4x2 BL Leaf-Air Replaced by N13 in 2007

N12 8 TGL 8.xxx 4x2 BL Leaf-Air

N13 7 - 8 TGL 7.xxx 4x2 BL Leaf-Air

N14 10 - 12

N15 10 - 12

TGL 10.xxx 4x2 BL

TGL 12.xxx 4x2 BL

TGL 10.xxx 4x2 BL

TGL 12.xxx 4x2 BL

Leaf-Air

Leaf-Air

N49 12 TGL 12.xxx 4x2 BL-FOC Leaf-Air

N60 8 TGL 8.xxx 4x2 BB-TIB Leaf-Leaf

N61 10 - 12

TGL 10.xxx 4x2 BB-TIB

TGL 12.xxx 4x2 BB-TIB

Leaf-Leaf

Table 03-II: Model numbers and vehicle designations in the TGM model range

Type number Tonnage [t] Designation Suspension Note

N08 15 - 18

N16 12 - 15

TGM 15.xxx 4x2 BB

TGM 18.xxx 4x2 BB

TGM 12.xxx 4x2 BL

TGM 15.xxx 4x2 BL

Leaf-Leaf

Leaf-Air

TGM 15.xxx 4x2 BL

N18 15 - 19

TGM 18.xxx 4x2 BL

Leaf-Air

TGM 19.xxx 4x2 BL

TGM 12.xxx 4x2 LL

N26 12 - 22

TGM 15.xxx 4x2 LL

Air-Air

TGM 22.xxx 6x2-4 LL

N28 18 TGM 18.xxx 4x2 LL Air-Air

N34 13

TGM 13.xxx 4x4 BL

TGM 13.xxx 4x4 BL FW

Leaf-Air

N36 13 TGM 13.xxx 4x4 BL Leaf-Air

N37 13 TGM 13.xxx 4x4 BB Leaf-Leaf

N38 18 TGM 18.xxx 4x4 BB Leaf-Leaf

N44 26 TGM 26.xxx 6x2-4 LL Air-Air

N46 26 TGM 26.xxx 6x2-4 BL Leaf-Air

N48 26 TGM 26.xxx 6x4 BB Leaf-Leaf

N62 18 TGM 18.xxx 4x2 BB-CKD Leaf-Leaf

N63 15 TGM 15.xxx 4x2 BL-TIB Leaf-Air

N64 18 TGM 18.xxx 4x4 BB-TIB Leaf-Leaf

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 19

Page 34

II. Product identication

2.3 Tonnage class

The tonnage class corresponds to the design specication as per model-number list (see Chapter II, Section 2.2

“Model number”). It is the permissible gross weight for this vehicle model and may not be exceeded. More

information on permissible gross weight can be found in Chapter III, Section 2.2.4 “Permissible gross weight”.

2.4 Power rating

The stated power ratings generally round off the engine output power to the next ten hp. Engine technical data

sheets are an exception. More detailed information, for example on the exhaust-gas status (Euro standard) is not

contained.

2.5 Type of suspension

As standard there are three different combinations of suspension, depending on the type of operation for which the

vehicle is employed. The rst letter describes the front-axle assembly, the second describes the rear-axle assembly.

Table 04-II: Types of suspension for TGL/TGM and TGS/TGX

Abbreviation Explanation

BB Leaf suspension on front axle, leaf suspension on rear axle(s)

BL Leaf suspension on front axle, air suspension on rear axle(s)

LL Air suspension on front and rear axle(s)

20 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 35

II. Product identication

2.6 Wheel configuration

The wheel conguration identies the number of wheels, driven wheels and steered wheels.

The term “wheel conguration” is a common term but not standardised. It is “wheel locations” that are counted and

not the individual wheels. Twin tyres are therefore regarded as one wheel.

Here are two examples to explain the term wheel conguration:

Example of a three-axle vehicle with leading axle (wheel conguration))

6x2/4

6 Total number of wheel locations

x

2 number of driven wheels

/ leading axle in front of driven rear axle

4 number of steered wheels

Example of a three-axle vehicle with trailing axle (wheel conguration)

6x2-4

6 Total number of wheel locations

x

2 number of driven wheels

- trailing axle behind driven rear axle

4 number of steered wheels

The number of steered wheels is only stated if there are steered leading or trailing axles in addition to steered front

wheels.

A leading axle runs in front of a driven rear-axle unit; a trailing axle runs behind the driven rear-axle unit. The wheel

conguration identies these axles by means of a slash “/” in the case of a leading axle and a hyphen “-” in the case

of a trailing axle.

If a chassis is tted with both a leading and a trailing axle, the number of steered wheels follows the hyphen “-”.

For a hydrostatic front axle MAN HydroDrive, an “H” is added to the wheel conguration, e.g. 6x4H = front axle with

MAN HydroDrive, two rear axles, one of them driven.

The following wheel congurations are currently available ex works:

Table 05-II: Wheel congurations for TGL/TGM

Wheel conguration Description

4x2 Two-axle vehicle with one driven axle

4x4 Two axles with two driven axles "allwheel"

6x2-4 Three-axle vehicle with steered trailing axle

6x4 Three-axle vehicle with two driven and non-steered rear axles

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 21

Page 36

II. Product identication

2.7 Suffix

The sufx differentiates trucks from semitrailer tractors or describes special product features.

Semitrailer tractors are designated with an ‘S’ sufx. Trucks have no special designation.

Example of a semitrailer tractor:

TGS 33.440 6x6 BBS

S = semitrailer

Identication of special product features is added separated from the front part of the sufx by a hyphen “-”.

Example of special product features:

TGM 13.250 4x4 BL-FW

-FW = Fire engine chassis with all-wheel drive and low build height approved solely for

re ghting vehicle bodies

Table 06-II: Overview of sufxes

Abbreviation Explanation Example

S Semitrailer tractor TGS 33.440 6x6 BBS

-CKD

-TIB

-FW

-FOC Forward control chassis for omnibus superstructure TGL 12.xxx 4x2 BL-FOC

-TS Version optimised in weight for tank/silo TGS 18.350 4x2 BLS-TS

-WW Worldwide variant, can only be registered outside Europe TGS 33.360 6x4BB-WW

-EL Vehicles tted with Efcient Line equipment variant TGX 18.440 4x2 BLS-EL

-U Vehicle with low build height ("Ultra") TGX 18.400 4x2 LLS-U

Completely Knocked Down vehicle for assembly in an MAN

plant in the recipient country

Truck In The Box for assembly in an MAN plant in the recipient country

Fire-engine chassis with all-wheel drive and low build height

approved solely for re ghting vehicle bodies

TGM 18.280 4x2 BB-CKD

TGM 18.250 4x2 BB-TIB

TGM 13.250 4x4 BL-FW

22 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 37

II. Product identication

2.8 Cabs

Due to the wide range of transport tasks and uses of MAN vehicles, different cab versions are available.

At MAN, there are cabs assigned to each series. The following list provides an overview.

In general, MAN offers the following cabs (not assigned here to series):

• C, M, L, DK cab

- narrow cabs

- e.g. for short-haul and distribution transport

• LX cab

- narrow cab with high roof

- e.g. for special applications and national long-haul transport

• XLX, XXL cab

- wide cab

- e.g. for international long-haul transport

• XL cab

- wide cab

- e.g. for special applications in short-haul transport

- TGS/TGX cabs differ in their width

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 23

Page 38

Fig. 01-II: Cab variants

II. Product identication

Fahrerhaus

Cab

XXL

2 440 mm

XLX

XL

2440 mm

2240 mm

LX

Baureihe

Range

TGX

(18–41 t)

2 280 mm

2 280 mm

2 280 mm

TGS

(18–41 t)

2280 mm

TGM

(15–26 t)

2280 mm 2280 mm 2280 mm

TGM

(12–15 t)

TGL

(7,5–12 t)

L

M

Doka /

Double cab

C

2 240 mm

Fahrerhaus

Cab

Baureihe

Range

TGX

(22.5")

2280 mm 2280 mm 228 0 mm 2280 mm

188 0 mm

2785 mm 2785 mm 2785 mm

1620 mm 1620 mm 1620 mm

TGS

(22.5")

TGM

(22.5")

TGM

(19.5")

TGL

(17.5")

Further technical information can be found in Chapter III, Section 3.2 “Cab variants”

24 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 39

II. Product identication

3.0 Door designation

MAN’s door designation provides readily accessible information on the vehicle model with its tonnage and

power output.

The door designation consists of:

• Series

• Permissible gross weight

• Power rating (separated from the permissible gross weight by a full stop “.”)

Table 07-II: Examples of door designations

Series Permissible gross weight [t] Power rating [hp]

TGL 12 .220

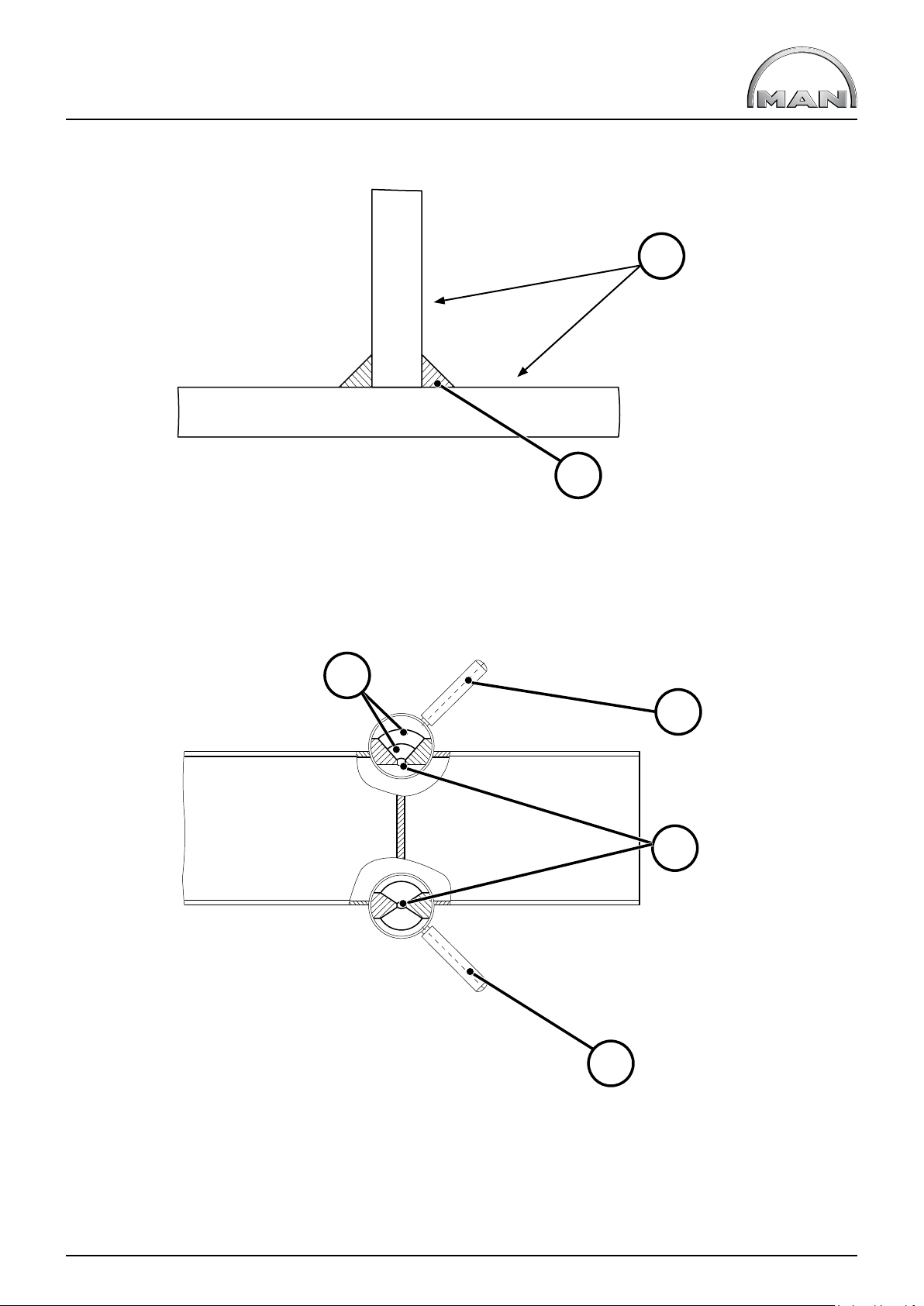

TGM 18 .340

TGM 26 .290

TGS 24 .480

TGS 18 .360

TGX 26 .540

4.0 Variant descriptor

The variant descriptor consists of:

• Series

• Permissible gross weight

• Power rating (separated from the permissible gross weight by a full stop “.”)

• Wheel conguration

• Suspension type

• Sufx

The terms used are explained in Chapter II, Section 2.0 “Terms”.

Table 08-II: Examples of variant descriptors

Series Permissible gross weight [t] Power rating [hp]

TGL 12 .220 4x2 BL

TGM 18 .340 4x2 BB -FW

TGM 26 .290 6x4 BB

TGS 24 .480 6x2-2 LL -U

TGS 18 .360 4x2 BL S-TS

TGX 26 .540 6x2-2 LL

Wheel

conguration

Suspension

type

Sufx

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 25

Page 40

II. Product identication

5.0 Base vehicle number

The eight-character base vehicle (“GFZ”) number was introduced in order to identify and better differentiate

between MAN vehicles.

The MAN base vehicle number describes an MAN vehicle (base vehicle) with certain technical features and dened

standard equipment.

Table 09-II: Examples of base vehicle numbers

Digit 1 2 3 4 5 6 7 8

Example L 0 6 X K G 3 1

Example L 2 1 S G F 3 8

Example L N 1 8 C E 0 8

L=Truck Typ number Sequential designation

The model number is an important element of the base vehicle number and occupies places 2- 4 in the base vehicle

number.

More information on model numbers can be found in Chapter II, Section 2.2 “Model number”.

6.0 Vehicle identification number and vehicle production number

The vehicle identication number and vehicle production number describe customer-specic vehicles with

corresponding scopes of equipment and technical characteristics.

Vehicle identication number

The vehicle identication number (VIN) is a 17-character internationally standardised alphanumeric string that

uniquely identies a vehicle.

Table 10-II: Example of a vehicle identication number

Digit 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Example W M A 0 6 X Z Z 9 7 K 0 0 1 4 6 4

ISO

3779

World manufacturer’s

code (MAN, for

example, is WMA)

Descriptive designation (places

4-6 are the model number)

Sequential designation

26 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 41

II. Product identication

As a rule, vehicle identication numbers for MAN chassis of the Trucknology Generation begin with the letters

“WMA”.

Exceptions are, amongst others, vehicles

• from CKD plants (these have their own manufacturer’s codes)

• of the Steyr brand (VAN)

• of the ÖAF brand (VA0)

• of the ERF brand (SAF).

The vehicle identication number contains the model number in places 4 – 6.

(see Chapter II, Section 2.2 “Model number”).

Note:

Stamped vehicle identication numbers must not be obscured by vehicle bodies or modications.

Vehicle production number

The vehicle production number consists of seven characters and describes the vehicle’s technical equipment.

It contains the model number in places 1 - 3 followed by a four-character alphanumeric code.

Table 11-II: Example of a vehicle production number

Digit 1 2 3 4 5 6 7

Example 0 6 X 0 0 0 4

Typ number Sequential designation

Table 12-II: Example of vehicle designation, model number, identication number, base vehicle number

and vehicle production number

Designation of vehicle

Model

number

Vehicle identication number

(VIN)

Base vehicle

number

Vehicle production

number

TGX 18.440 4x2 BLS 06X WMA06XZZ97K001464 L06XKG31 06X0004

TGS 26.410 6x2-4 LL 21S WMA21SZZ67M479579 L21SGF38 21S0002

TGM 18.330 4X2 BL N18 WMAN18ZZ16Y155852 LN18CE08 N180008

More information on model numbers can be found in Chapter II, Section 2.2 “Model number”.

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 27

Page 42

NOTICE

28 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 43

III. Chassis

MAN Guide to fitting bodies TGL/TGM Edition 2018 V2.0 29

Page 44

III. Chassis

1.0 General

To create the product a customer expects, under certain circumstances additional components may need to be

integrated, attached or modied. We recommend using MAN Genuine parts to the extent to which they are

compatible with the engineering design.

1.1 Obtaining technical vehicle data

Technical vehicle data enables selection of the optimal base vehicle for the intended purpose of the vehicle.

Information on MAN vehicles and vehicle components such as

• Cabs / bumpers

• Exhaust

• Frame side member

• Final cross member

• Gearboxes / power take-off systems

can be found at www.manted.de. Registration is required.

The following can be found at MANTED:

• Dimensions

• Weights

• Position of center of gravity for payload and body (minimum and maximum body lengths)

• Standard equipment

• Drawings

Information

The data published in MANTED refer to the series-production status of a vehicle. This may vary, depending on the

technical scope of delivery. What is decisive is the actual status of the built and delivered vehicle.

National and international specications take priority over technically admissible dimensions and weights if they

restrict the technically admissible dimensions and weights.

1.2 Standards, guidelines, regulations, tolerances

Applicable standards and guidelines / directives are technical standards and must therefore be complied with.

Standards are binding if they are part of rules and regulations. It cannot be assumed that all standards, regulations

and guidelines/directives mentioned in the context of the chapter are complete.

Please observe notes on:

• Legal regulations

• Other guidelines/directives.

All components installed in MAN vehicles comply with the respectively applicable national and European standards

and directives.

MAN‘s own standards are often considerably more stringent than national and international standards. In some

cases, MAN presupposes the application of its own standards for reasons of quality or safety. These are explicitly

stated in the corresponding sections. MAN works standard can be obtained at www.ptd.man.eu. Registration is

required.

Unless expressly stated otherwise, the general tolerances apply.

30 Edition 2018 V2.0 MAN Guide to fitting bodies TGL/TGM

Page 45

III. Chassis

1.3 Quality of execution

1.3.1 Corrosion protection

Surface and corrosion protection inuence the service life and appearance of the chassis. The coating quality of

add-on and modication parts should consequently be that of a series-production chassis. In order to ensure this

requirement, MAN works standards M3297 “Corrosion-protection and coating systems for non-MAN bodies” and

M3018 “Corrosion-protection and coating systems for purchased parts” are binding

Mechanical connecting elements (e.g. screws, nuts, washers, bolts) are to be optimally protected against corrosion.

In the event of non-compliance, MAN excludes liability for the consequences.

Series production MAN chassis are coated with environmentally friendly, water-based two-component chassis topcoat paints at approx. 80°C. To guarantee uniform coating, the following coating structure is required for all metal

component assemblies:

• Bare metal or blasted component surface (SA 2.5)

• Priming: two-component epoxy primer, approved in accordance with MAN works standard M3162-C or,

if possible, cathodic dip painting to MAN works standard M3078-2, with zinc phosphate pre-treatment.

• Top coat: two-component top-coat paint to MAN works standard M3094, preferably water-based;

if there are no facilities for this, then solvent-based paint is also permitted.

• Refer to the data sheets of the paint manufacturer for details of curing and drying times and temperatures.

In the selection and combination of different metals (e.g. aluminium and steel), the effect of standard electrode

potential for corrosion must be considered. The possible effects of the electrochemical series with regard