Page 1

L27/38S

Project Guide - Power Plant

Four-stroke GenSet

Page 2

Page 3

MAN Diesel & Turbo

Index

Page 1 (5)

Table of contents

Table of contents

L27/38S powerplant

I 00 Introduction

Introduction to project guide I 00 00 0 1643483-5.5

Key for engine designation I 00 05 0 1609526-0.8

Designation of cylinders I 00 15 0 1607568-0.2

Code identification for instruments I 00 20 0 1687100-5.6

Symbols for piping I 00 25 0 1655279-1.1

D 10 General information

List of capacities D 10 05 0 1689471-7.4

List of capacities D 10 05 0 1689472-9.4

Vibration limits and measurements D 10 24 0 3700395-8.3

Description of sound measurements D 10 25 0 1609510-3.5

Description of structure-borne noise D 10 25 0 1671754-6.2

Exhaust gas components D 10 28 0 1655210-7.3

Emission limits Worldbank II D 10 28 0 3700044-8.0

Moment of inertia D 10 30 0 1687148-5.2

Green Passport D 10 33 0 1699985-1.1

Overhaul recommendation, Maintenance and Expected life time D 10 35 0 3700340-7.1

Overhaul recommendation, Maintenance and Expected life time D 10 35 0 3700341-9.1

Overhaul recommendation, Maintenance and Expected life time D 10 35 0 3700342-0.1

Overhaul recommendation, Maintenance and Expected life time D 10 35 0 3700343-2.1

B 10 Basic diesel engine

General description B 10 01 1 1689477-8.1

Cross section B 10 01 1 1665740-7.3

Main particulars B 10 01 1 3700157-5.1

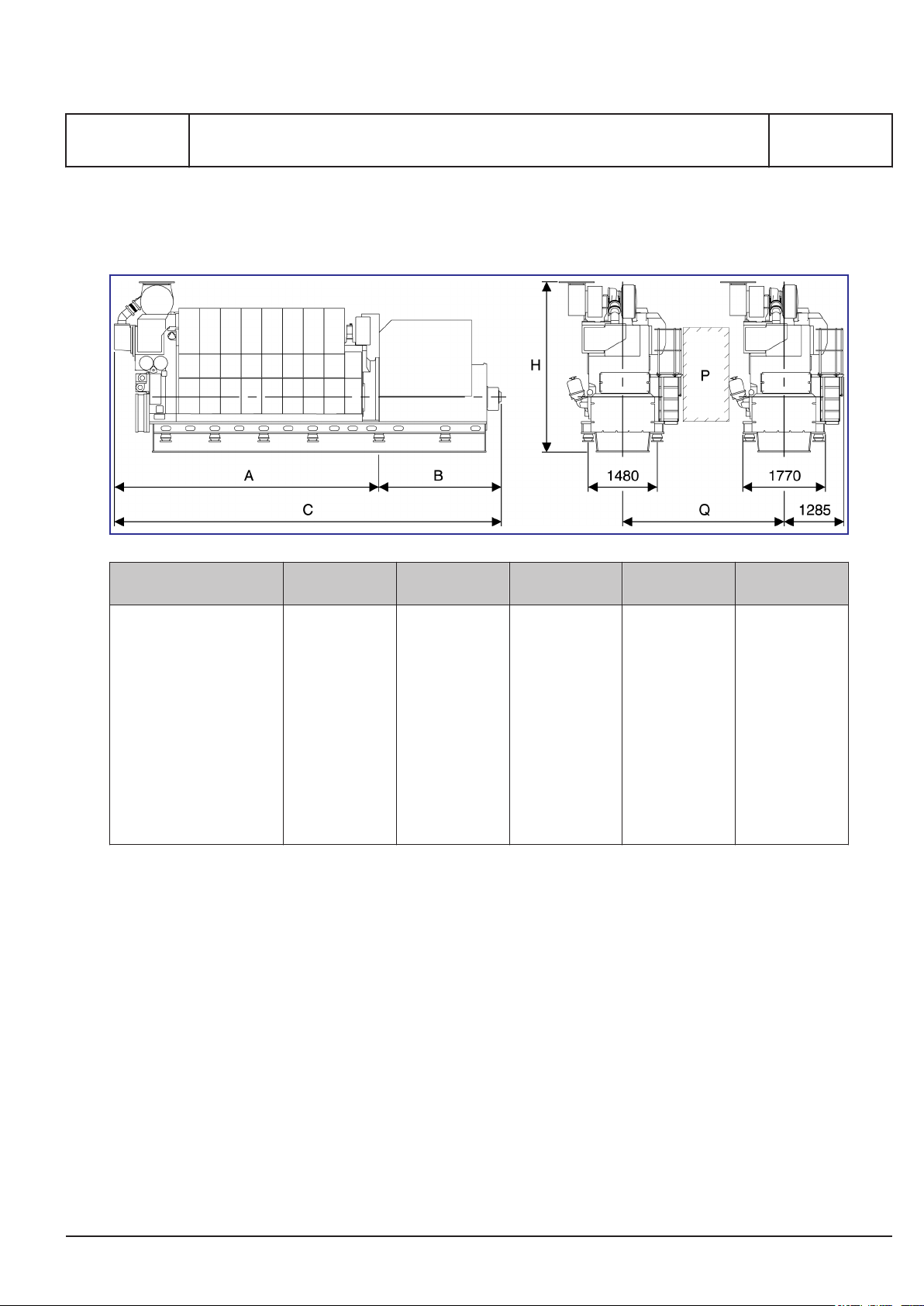

Dimensions and weights B 10 01 1 1689493-3.1

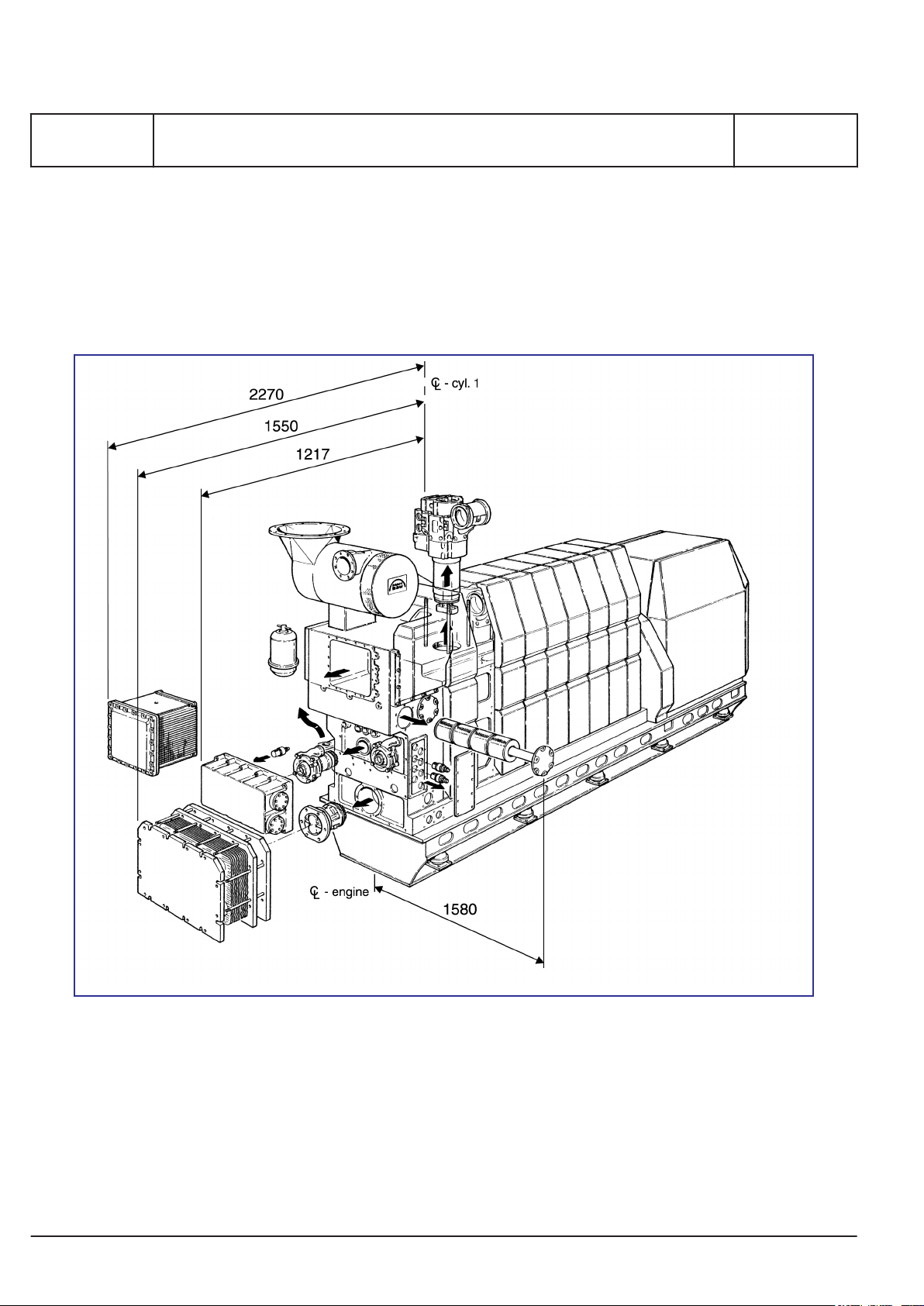

Centre of gravity B 10 01 1 1679708-8.2

Overhaul areas B 10 01 1 1665770-6.6

2018-04-13 - en

Page 4

MAN Diesel & Turbo

Table of contents

Firing pressure comparison B 10 01 1 3700366-0.0

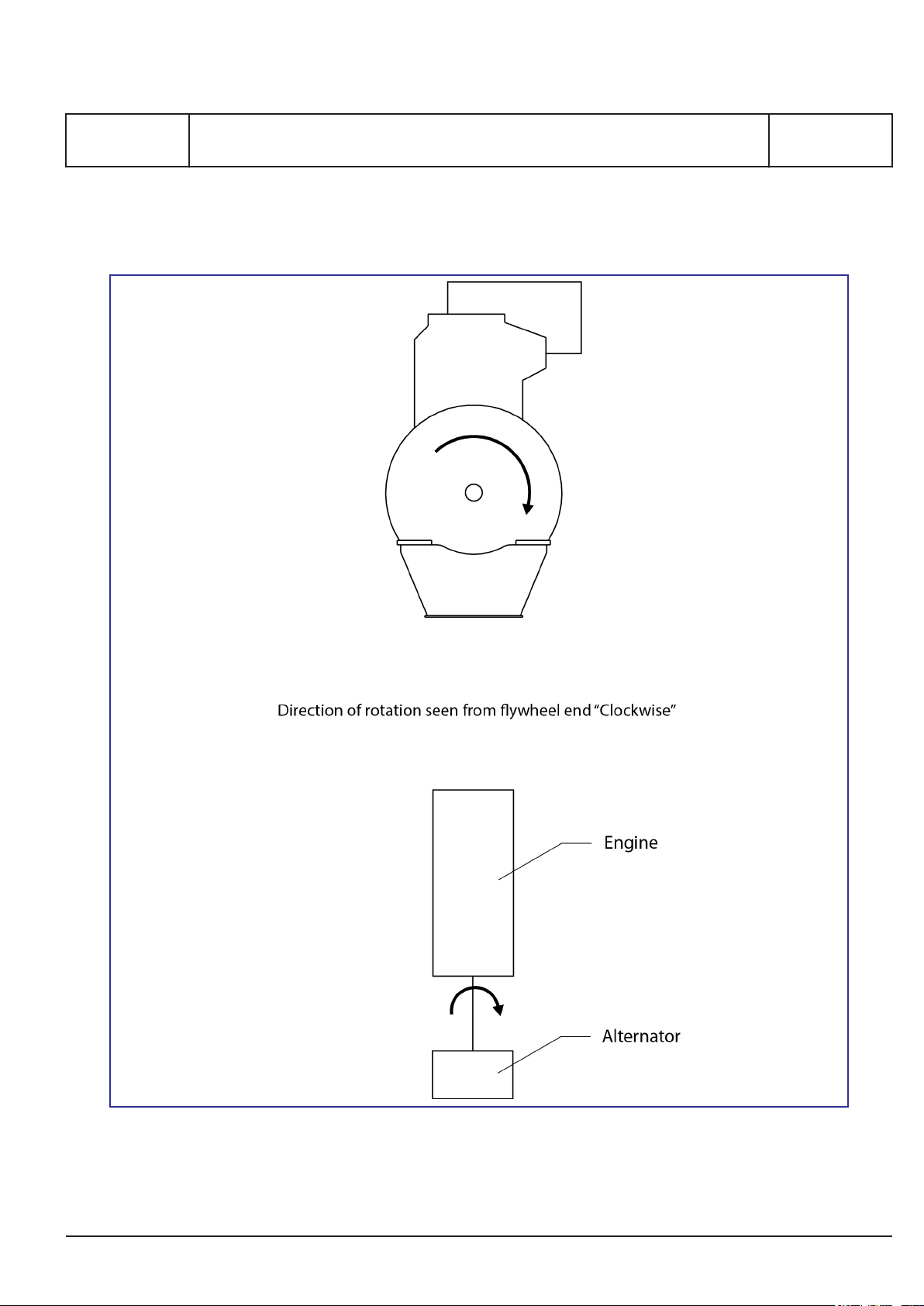

Engine rotation clockwise B 10 11 1 1607566-7.2

B 11 Fuel oil system

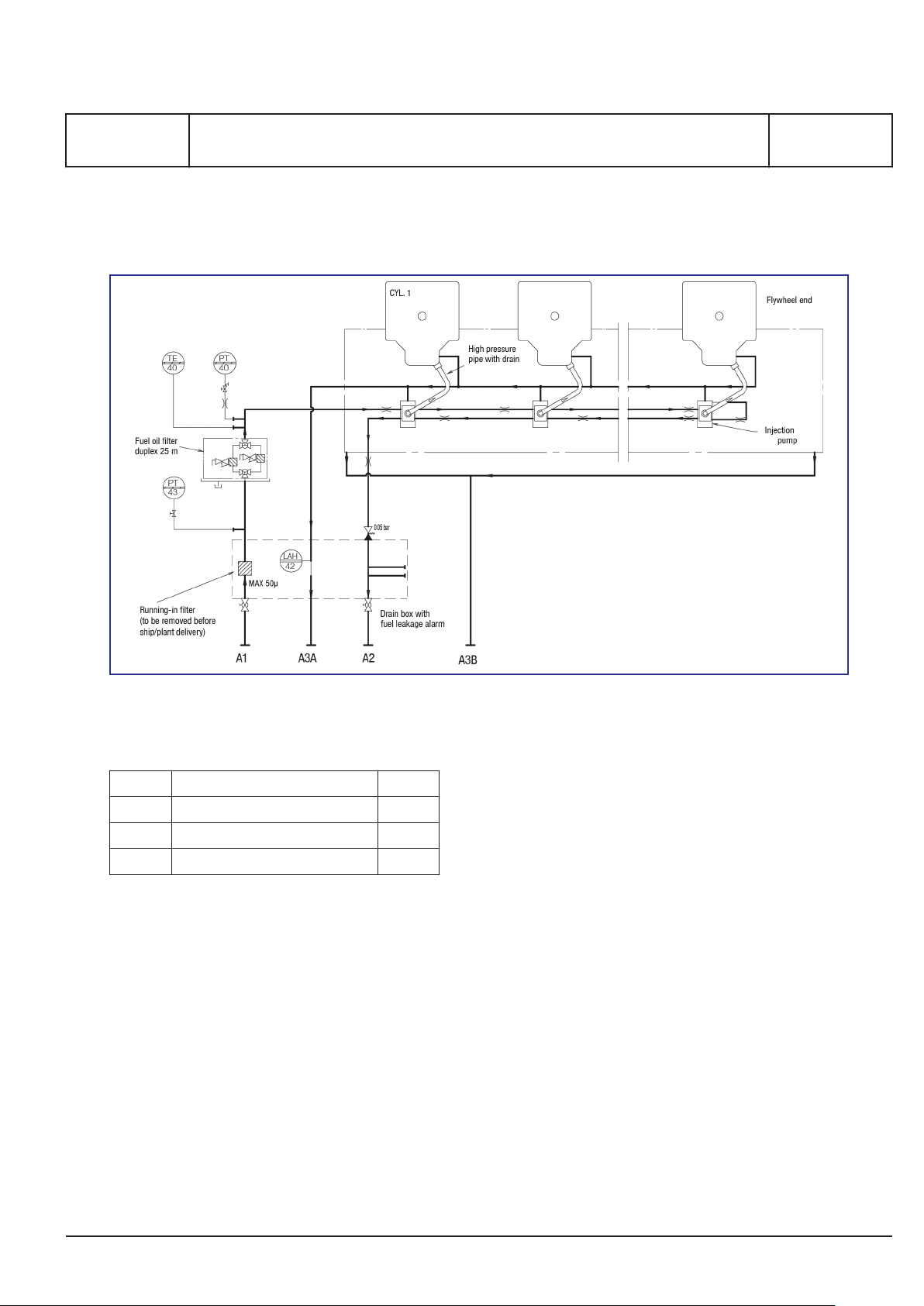

Internal fuel oil system B 11 00 0 3700163-4.1

Part-load optimisation - PLO B 11 00 0 3700499-0.1

Heavy fuel oil (HFO) specification 010.000.023-05

Marine diesel oil (MDO) specification 010.000.023-04

Gas oil / diesel oil (MGO) specification 010.000.023-01

Bio fuel specification 010.000.023-02

Explanatory notes for biofuel B 11 00 0 3700063-9.0

Crude oil specification B 11 00 0 3700246-2.0

Index

Page 2 (5)

Viscosity-temperature diagram (VT diagram) 010.000.023-06

Guidelines regarding MAN Diesel & Turbo GenSets operating on low sulphur

fuel oil

Calculation of specific fuel oil consumption (SFOC) B 11 01 0 3700405-6.2

Fuel oil consumption for emissions standard B 11 01 0 1693568-5.3

Fuel injection valve B 11 00 0 3700222-2.0

Fuel injection pump B 11 02 1 1683324-8.1

Fuel oil filter duplex E 11 08 1 1679744-6.7

MDO / MGO cooler E 11 06 1 1689458-7.3

HFO/MDO changing valves (V1 and V2) E 11 10 1 1624467-7.3

B 11 00 0 1699177-5.1

B 12 Lubricating oil system

Internal lubricating oil system B 12 00 0 1693562-4.4

Crankcase ventilation B 12 00 0 1699270-8.7

Prelubricating pump B 12 07 0 1655289-8.10

Lubricating oil (SAE 40) - Specification for heavy fuel operation (HFO) 010.000.023-11

Specification of lube oil (SAE 40) for operation with gas oil, diesel oil (MGO/

MDO) and biofuels

Specific lubricating oil system - SLOC B12150,

2018-04-13 - en

010.000.023-07

1607584-6.11

Page 5

MAN Diesel & Turbo

Index

Page 3 (5)

Treatment and maintenance of lubricating oil B12150,

Criteria for cleaning/exchange of lubricating oil B 12 15 0 1609533-1.7

Table of contents

1643494-3.11

B 13 Cooling water system

Specification of engine coolant 010.000.023-13

Coolants inspecting 010.000.002-03

Cooling water system cleaning 010.000.002-04

Quality of raw-water in cooling tower operation (additive and circulating

water)

Quality of water used in exhaust gas boiler plants B 13 00 0 1699251-7.0

Water specification for fuel-water emulsions 010.000.023-16

B 13 00 0 1699250-5.0

Internal cooling water system B 13 00 3 3700201-8.0

Internal cooling water system B 13 00 6 3700203-1.0

Design data for the external cooling water system B 13 00 0 1665774-3.7

Two string central cooling water system B 13 00 6 1699122-4.1

Expansion tank B 13 00 0 1613419-0.5

Preheater arrangement in high temperature system B 13 23 1 3700160-9.0

Expansion tank pressurized T 13 01 1 1671771-3.5

B 14 Compressed air system

Specification for compressed air 010.000.023-21

Compressed air system B 14 00 0 3700205-5.1

Compressed air system B 14 00 0 3700206-7.1

Compressed air system B 14 00 0 1655207-3.2

B 15 Combustion air system

Combustion air system B 15 00 0 1665736-1.7

Specifications for intake air (combustion air) 010.000.023-17

Engine room ventilation and combustion air B 15 00 0 1699110-4.1

Water washing of turbocharger - compressor B 15 05 1 1639499-6.0

B 16 Exhaust gas system

Exhaust gas system B 16 00 0 1655213-2.6

2018-04-13 - en

Page 6

MAN Diesel & Turbo

Table of contents

Pressure droop in exhaust gas system B 16 00 0 1624460-4.2

SCR (Selective Catalytic Reduction) B 16 00 0 3700467-8.1

Equipment to optimize performance B 16 00 0 3700546-9.0

Exhaust gas velocity B 16 01 0 3700152-6.2

Cleaning the turbocharger in service - turbine side B 16 01 3 3700418-8.1

Position of gas outlet on turbocharger B 16 02 0 1689481-3.2

B 17 Speed control system

Starting of engine B 17 00 0 1655204-8.8

Power Management - Alternator protection B 17 00 0 3700383-8.2

Engine operation under arctic conditions B 17 00 0 1689459-9.0

Actuators B 17 01 2 1689484-9.0

Index

Page 4 (5)

Actuators B 17 01 6 3700319-4.1

Actuators B 17 01 7 3700320-4.1

B 19 Safety and control system

Operation data & set points 3700061-5.9

System description V1.5

Communication from the GenSet 1.7

Modbus list B 19 00 0 3700054-4.0

Oil mist detector B 19 22 1 1699190-5.0

B 20 Foundation

Resilient mounting system for landbased generating sets B 20 00 0 1699989-9.5

B 21 Test running

Shop test programme for power plants B 21 01 1 1699986-3.2

E 23 Spare parts

Weight and dimensions of principal parts E 23 00 0 1689476-6.4

Spare parts for unrestricted service P 23 01 1 3700022-1.4

P 24 Tools

Introduction to spare part plates for tools P24000,

3700496-5.0

2018-04-13 - en

Page 7

MAN Diesel & Turbo

Index

Page 5 (5)

Standard tools (normal maintenance) P 24 01 1,

Additional tools P 24 03 9,

Hand tools P 24 05 1,

Table of contents

3700126-4.11

B 50 Alternator

Alternators for GenSets B 50 00 0 1699895-2.1

Alternator cable installation BG 50 00 0 1699865-3.4

Combinations of engine- and alternator layout BG 50 00 0 3700084-3.10

B 98 Preservation and packing

3700125-2.4

3700414-0.0

Lifting instruction P 98 05 1 1679796-1.2

2018-04-13 - en

Page 8

Page 9

MAN Diesel & Turbo

I 00 Introduction

Page 1 (1)

I 00 Introduction

2018-04-13 - en

Page 10

Page 11

MAN Diesel & Turbo

1643483-5.5

Page 1 (2)

Introduction to project guide

L23/30DF, L16/24S, L21/31S, L23/30S, L27/38S, L28/32S, L28/32S-DF, L28/32DF,

V28/32H, V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

Introduction

Our project guides provide customers and consultants with information and data when planning new plants

incorporating four-stroke engines from the current MAN Diesel & Turbo engine programme. On account of the

modifications associated with upgrading of our project guides, the contents of the specific edition hereof will

remain valid for a limited time only.

Every care is taken to ensure that all information in this project guide is present and correct.

For actual projects you will receive the latest project guide editions in each case together with our quotation

specification or together with the documents for order processing.

All figures, values, measurements and/or other information about performance stated in the project guides are

for guidance only and shall not be used for detailed design purposes or as a substitute for specific drawings

and instructions prepared for such purposes. MAN Diesel & Turbo makes no representations or warranties

either express or implied, as to the accuracy, completeness, quality or fitness for any particular purpose of the

information contained in the project guides.

MAN Diesel & Turbo will issue an Installation Manual with all project related drawings and installation instructions when the contract documentation has been completed.

The Installation Manual will comprise all necessary drawings, piping diagrams, cable plans and specifications of

our supply.

I 00 00 0

All data provided in this document is non-binding. This data serves informational purposes only and is especially not

guaranteed in any way.

Depending on the subsequent specific individual projects, the relevant data may be subject to changes and will be

assessed and determined individually for each project. This will depend on the particular characteristics of each

individual project, especially specific site and operational conditions.

If this document is delivered in another language than English and doubts arise concerning the translation, the English text shall prevail.

Original instructions

2016.01.06

Page 12

MAN Diesel & Turbo

I 00 00 0

Introduction to project guide

L23/30DF, L16/24S, L21/31S, L23/30S, L27/38S, L28/32S, L28/32S-DF, L28/32DF,

V28/32H, V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

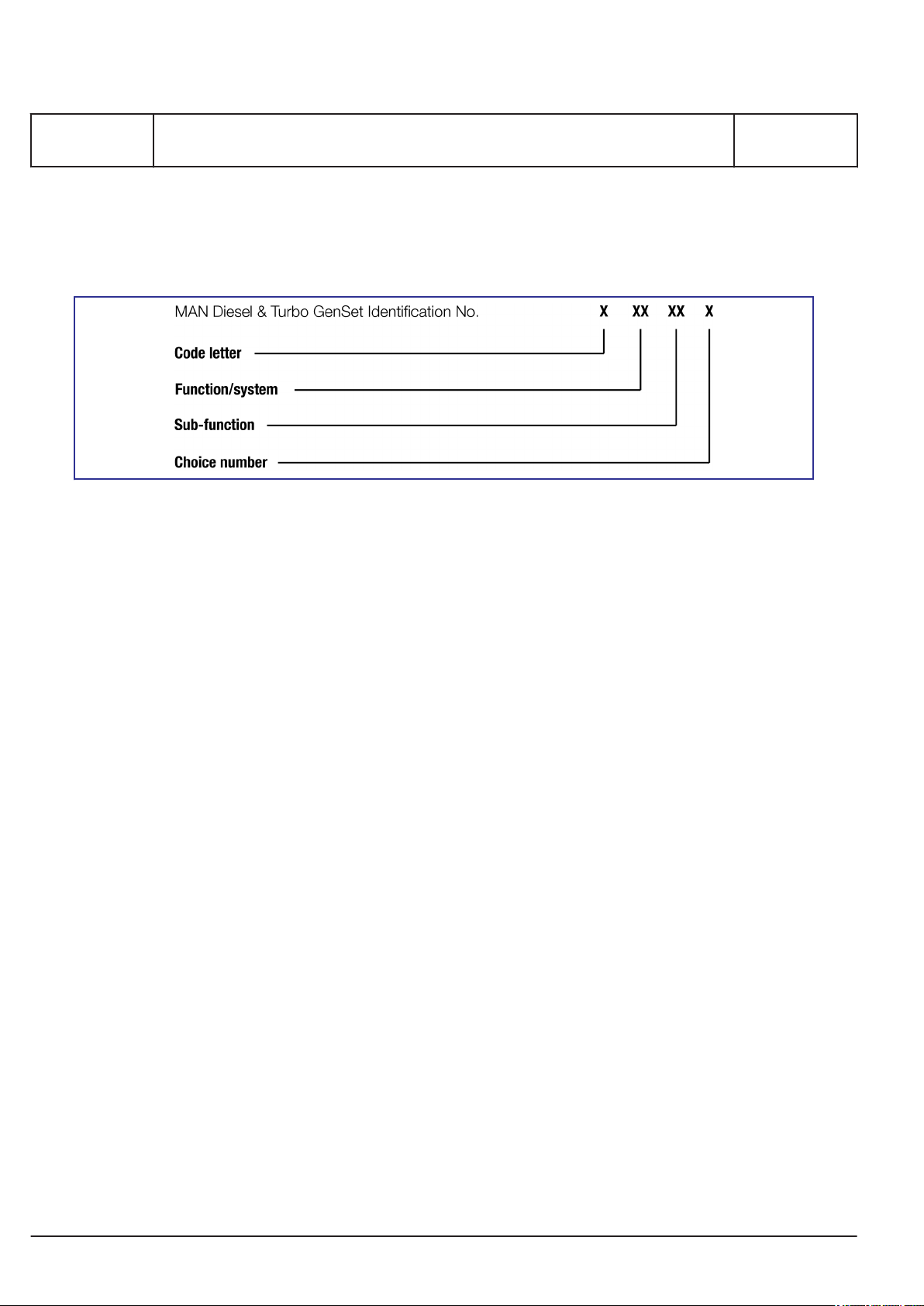

Code numbers

Code letter: The code letter indicates the contents of the documents:

B : Basic Diesel engine / built-on engine

D : Designation of plant

E : Extra parts per engine

G : Generator

I : Introduction

P : Extra parts per plant

1643483-5.5

Page 2 (2)

Function/system number: A distinction is made between the various chapters and systems, e.g.: Fuel oil system, monitoring equipment, foundation, test running, etc.

Sub-function: This figure occurs in variants from 0-99.

Choice number: This figure occurs in variants from 0-9:

0 : General information 1 : Standard

2-8 : Standard optionals 9 : Optionals

Further, there is a table of contents for each chapter and the pages follow immediately afterwards.

Drawing No: Each document has a drawing number including revision number i.e. 1643483-5.5.

Release date: The release date of the document Year.Month.Date. This is the date the document has been

created.

Notice: When refering to a document, please state both Drawing No including revision No and Release

date.

Copyright 2011 © MAN Diesel & Turbo, branch of MAN Diesel & Turbo SE, Germany, registered with the Danish

Commerce and Companies Agency under CVR Nr.: 31611792, (herein referred to as “MAN Diesel & Turbo”).

This document is the product and property of MAN Diesel & Turbo and is protected by applicable copyright laws.

Subject to modification in the interest of technical progress. Reproduction permitted provided source is given.

2016.01.06

Page 13

MAN Diesel & Turbo

1609526-0.8

Page 1 (1)

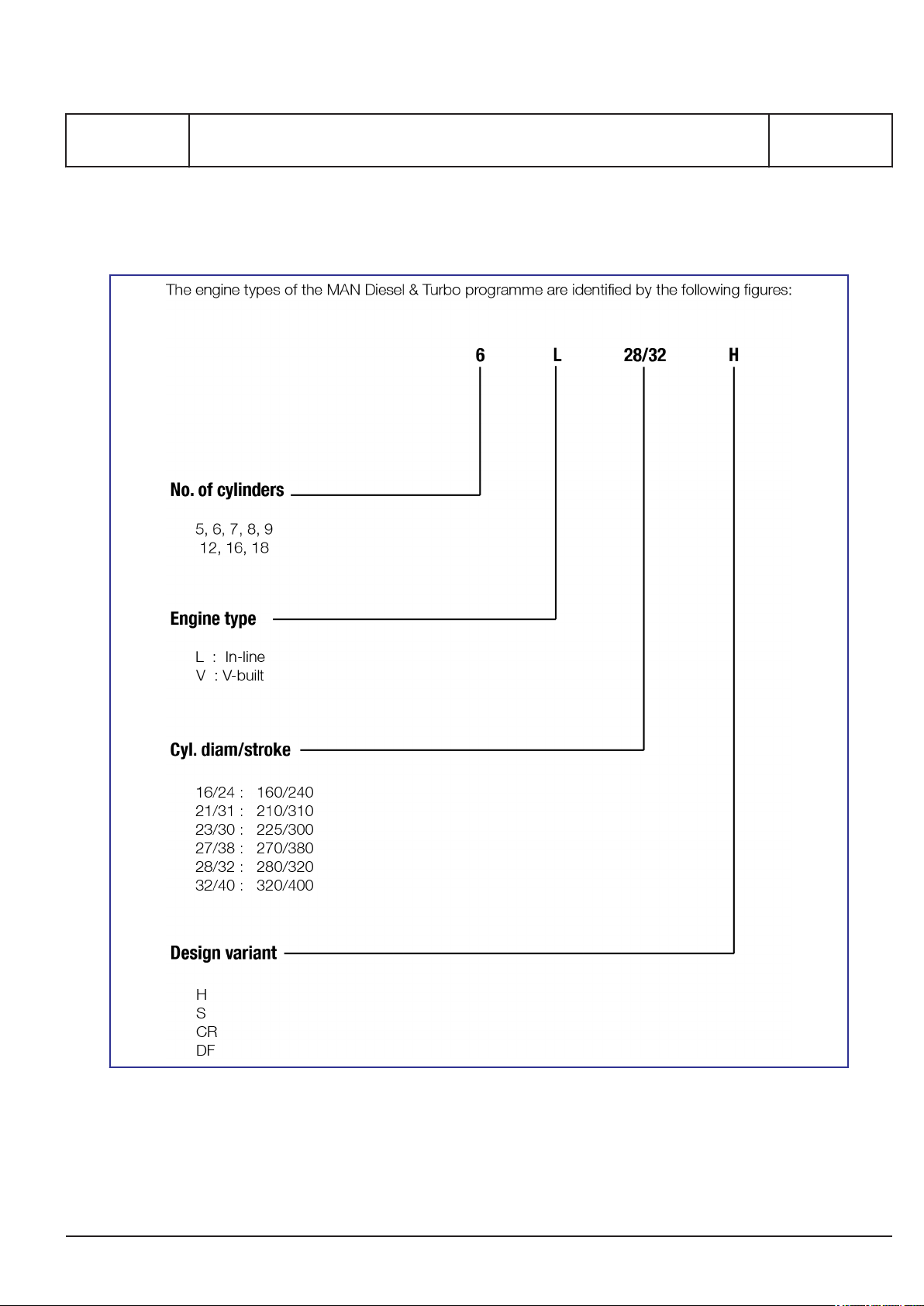

L27/38S, L16/24S, L21/31S, L23/30S, L28/32S, L23/30DF, L28/32DF, V28/32H,

Key for engine designation

Key for engine designation

V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

I 00 05 0

2015.11.27

Page 14

Page 15

MAN Diesel & Turbo

1607568-0.2

Page 1 (1)

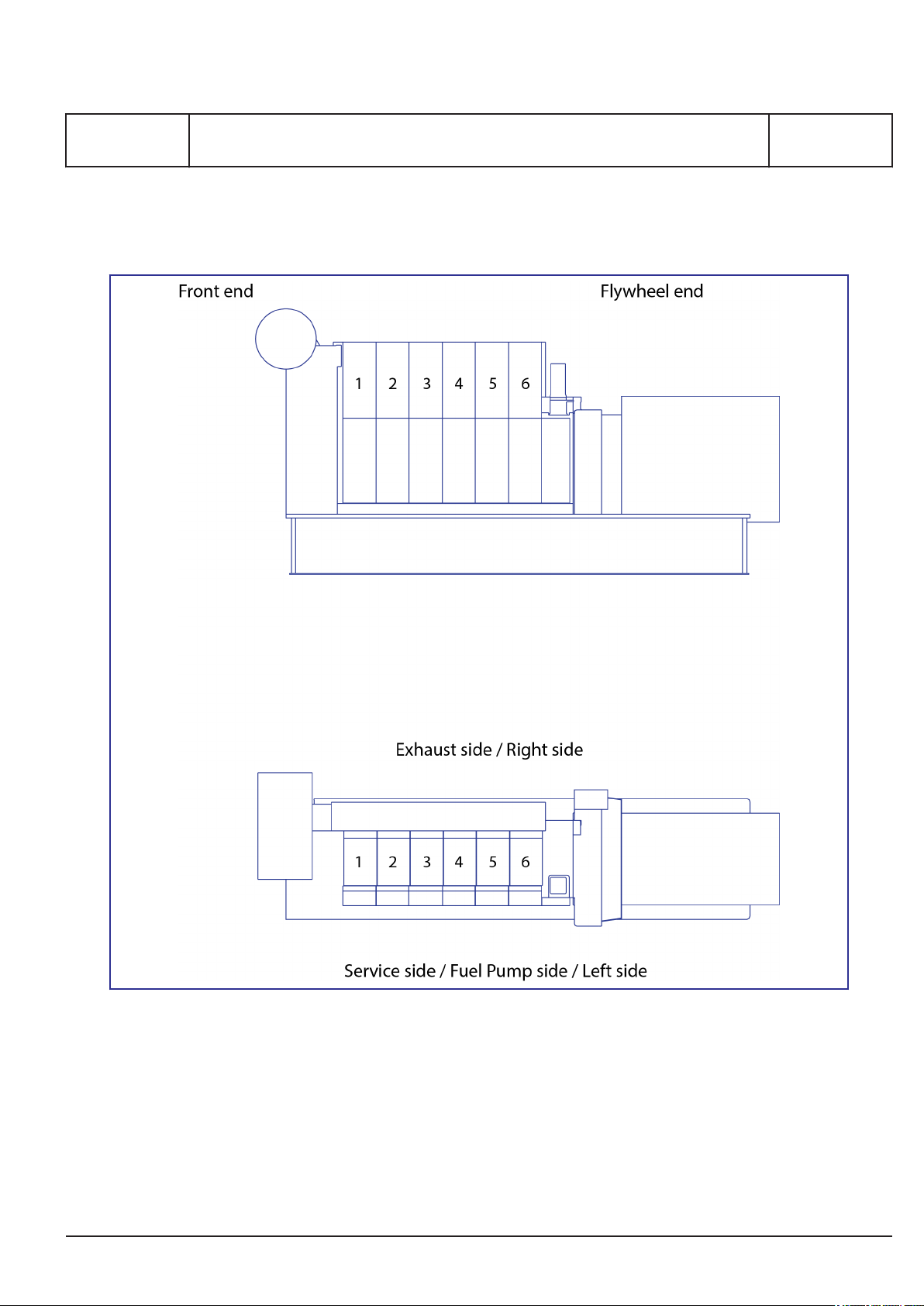

General

Designation of cylinders

I 00 15 0

L16/24S, L21/31S, L23/30S, L23/30DF, L28/32S, L27/38S, L28/32DF, L16/24,

L21/31, L23/30H, L27/38, L28/32H

2016.08.24

Page 16

Page 17

MAN Diesel & Turbo

1687100-5.6

Page 1 (3)

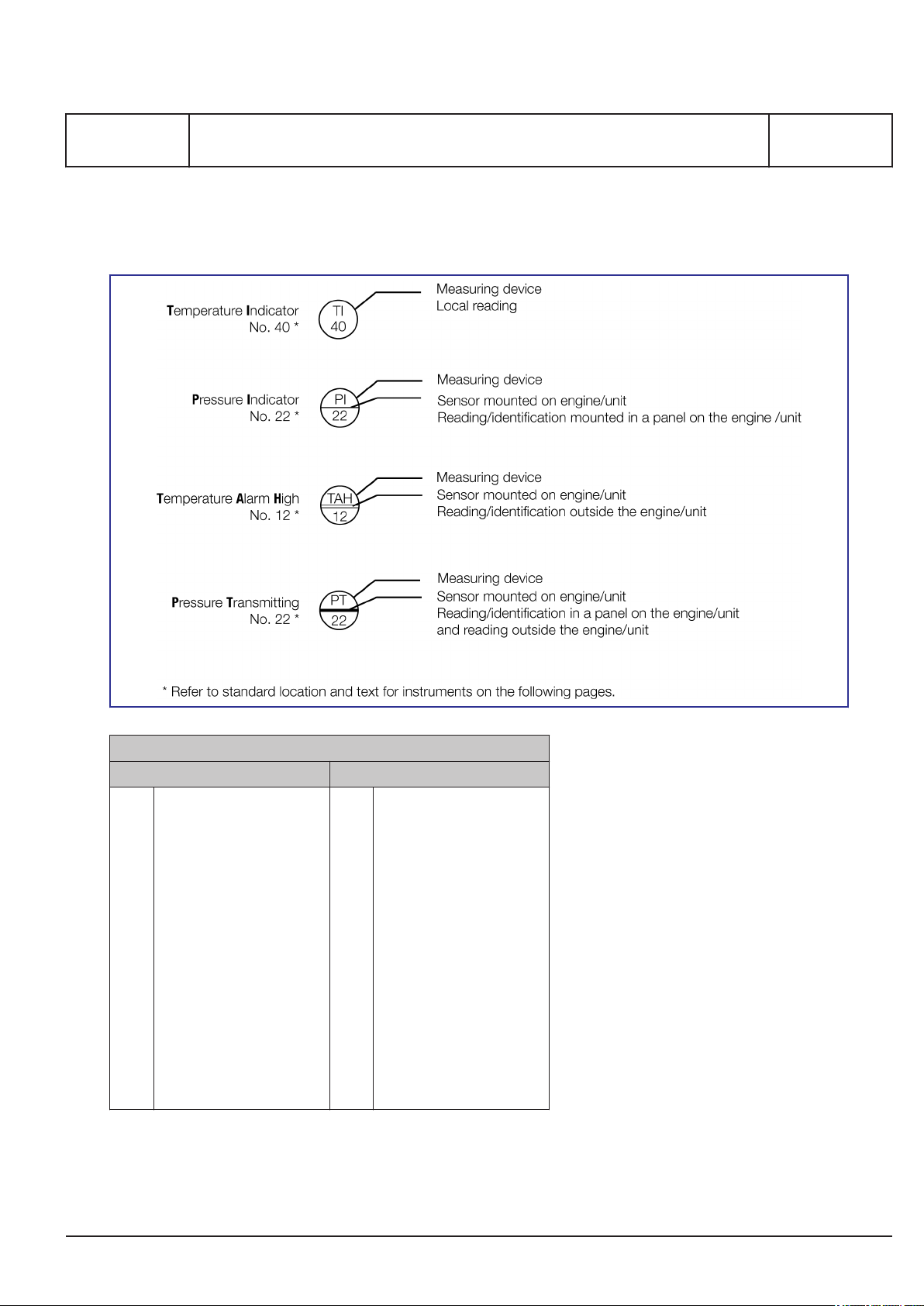

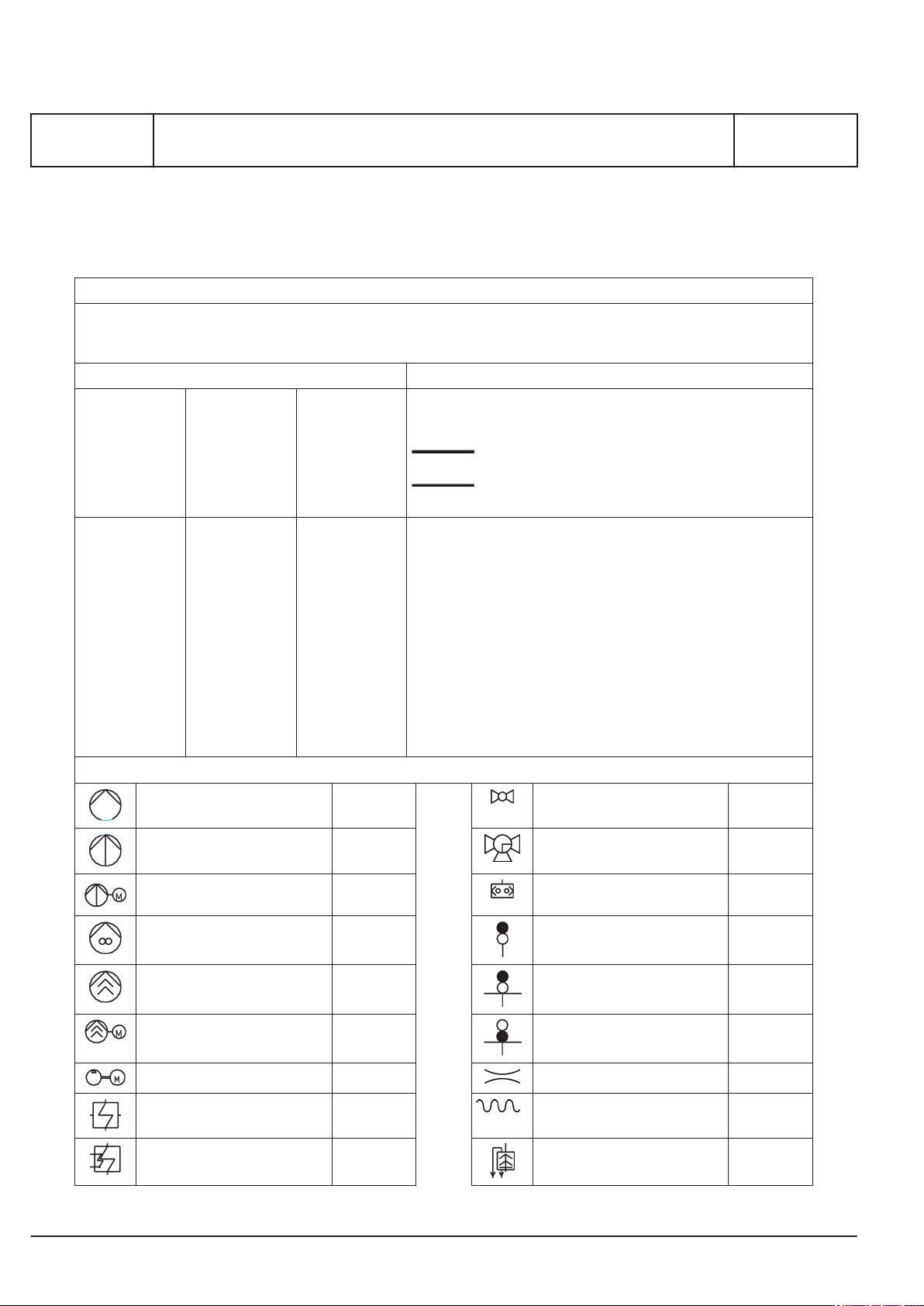

Explanation of symbols

Code identification for instruments

I 00 20 0

L16/24S, L27/38S, L21/31S, L23/30S, L23/30DF, L28/32S, L28/32DF, V28/32H,

V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

Specification of letter code for measuring devices

1st letter Following letters

F

Flow

L

Level

P

Pressure

S

Speed, System

T

Temperature

U

Voltage

V

Viscosity

X

Sound

Z

Position

A

Alarm

D

Differential

E

Element

H

High

I

Indicating

L

Low

S

Switching, Stop

T

Transmitting

X

Failure

V

Valve, Actuator

2018.03.27

Page 18

MAN Diesel & Turbo

I 00 20 0

Code identification for instruments

L16/24S, L27/38S, L21/31S, L23/30S, L23/30DF, L28/32S, L28/32DF, V28/32H,

V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

Standard text for instruments

Diesel engine/alternator

LT water system

01

inlet to air cooler

02

outlet from air cooler

03

outlet from lub. oil cooler

HT water system

10

inlet to engine

10A

FW inlet to engine

11

outlet from each cylinder

12

outlet from engine

13

inlet to HT pump

Lubricating oil system

04

inlet to alternator

05

outlet from alternator

06

outlet from fresh water cooler

(SW)

14

inlet to HT air cooler

14A

FW inlet to air cooler

14B

FW outlet from air cooler

15

outlet from HT system

16

outlet from turbocharger

07

inlet to lub. oil cooler

08

inlet to fresh water cooler

09

17

outlet from fresh water cooler

18

inlet to fresh water cooler

19

preheater

19A

inlet to prechamber

19B

outlet from prechamber

1687100-5.6

Page 2 (3)

20

inlet to cooler

21

outlet from cooler/inlet to filter

22

outlet from filter/inlet to engine

23

inlet to turbocharger

23B

outlet from turbocharger

Charging air system

30

inlet to cooler

31

outlet from cooler

32

jet assist system

33

outlet from TC filter/inlet to TC

compr.

Fuel oil system

40

inlet to engine

41

outlet from engine

42

leakage

43

inlet to filter

Nozzle cooling system

50

inlet to fuel valves

51

outlet from fuel valves

52

53

24

sealing oil - inlet engine

25

prelubricating

26

inlet rocker arms and roller

guides

27

intermediate bearing/alternator

bearing

34

charge air conditioning

35

surplus air inlet

36

inlet to turbocharger

37

charge air from mixer

44

outlet from sealing oil pump

45

fuel-rack position

46

inlet to prechamber

47

54

55

valve timing

56

injection timing

57

earth/diff. protection

2829level in base frame

main bearings

3839Ambient temperature

4849

5859oil splash

alternator load

Exhaust gas system

60

outlet from cylinder

61

outlet from turbocharger

62

inlet to turbocharger

63

combustion chamber

64

6869

65

66

67

2018.03.27

Page 19

MAN Diesel & Turbo

1687100-5.6

Page 3 (3)

Compressed air system

70

inlet to engine

71

inlet to stop cylinder

72

inlet to balance arm unit

73

control air

Load speed

80

overspeed air

81

overspeed

82

emergency stop

83

engine start

Miscellaneous

91

natural gas - inlet to engine

92

oil mist detector

93

knocking sensor

94

cylinder lubricating

Code identification for instruments

I 00 20 0

L16/24S, L27/38S, L21/31S, L23/30S, L23/30DF, L28/32S, L28/32DF, V28/32H,

V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

74

inlet to reduction valve

75

microswitch for turning gear

76

inlet to turning gear

77

waste gate pressure

84

engine stop

85

microswitch for overload

86

shutdown

87

ready to start

95

voltage

96

switch for operating location

97

remote

98

alternator winding

7879inlet to sealing oil system

88

index - fuel injection pump

89

turbocharger speed

90

engine speed

99

common alarm

100

inlet to MDO cooler

101

outlet to MDO cooler

102

alternator cooling air

2018.03.27

Page 20

Page 21

MAN Diesel & Turbo

1655279-1.1

Page 1 (10)

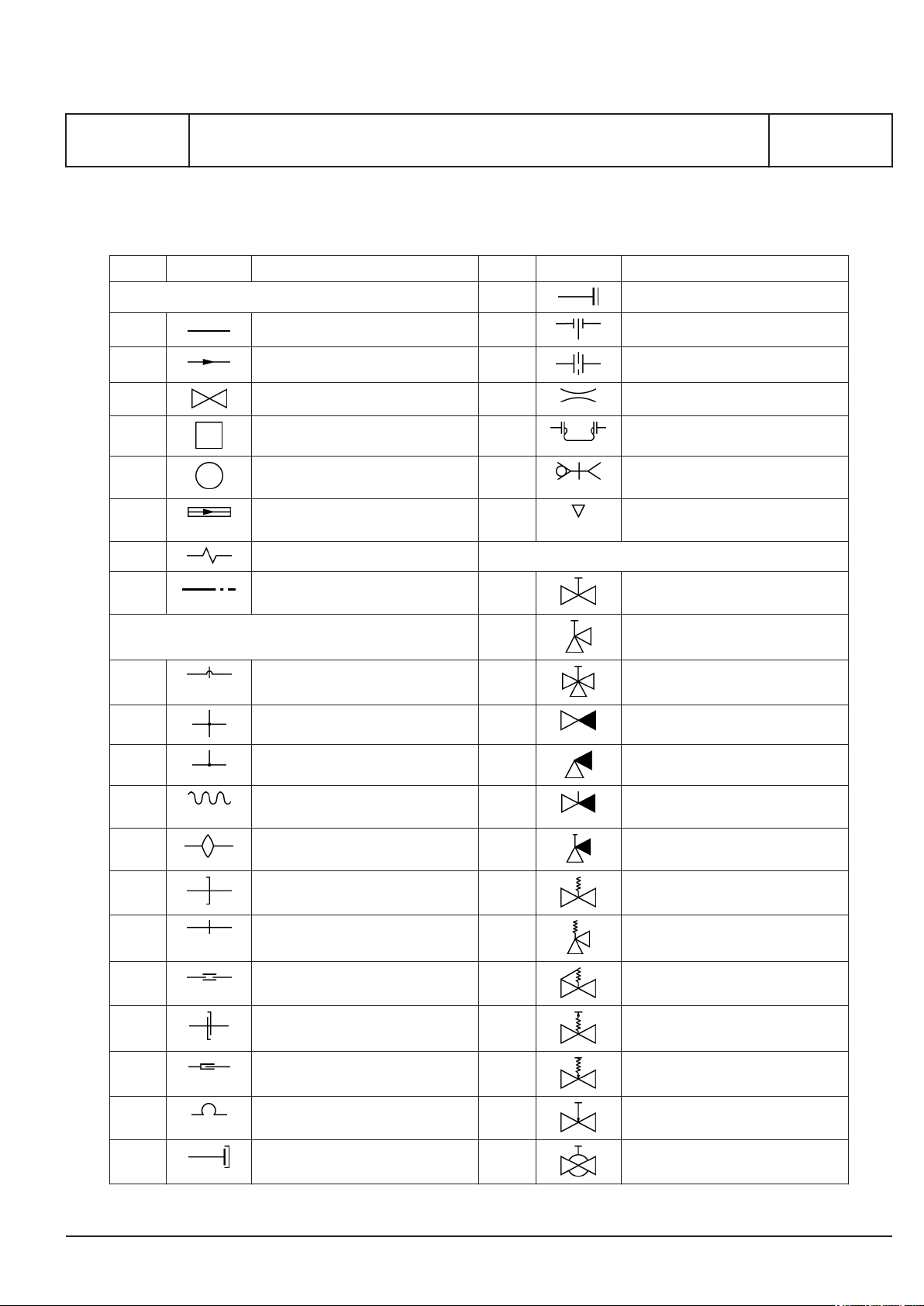

Symbols for piping

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

General

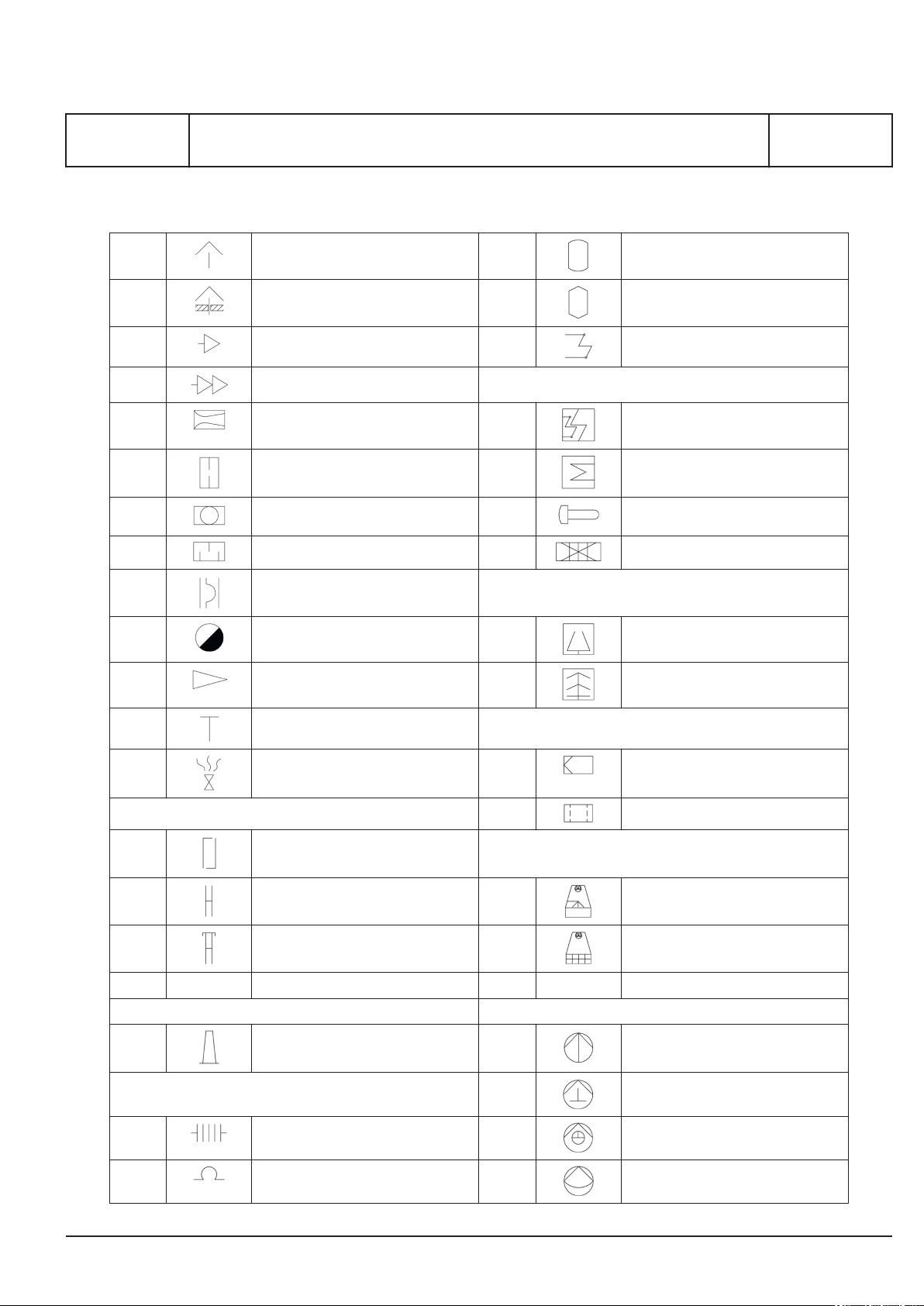

No Symbol Symbol designation No Symbol Symbol designation

1. GENERAL CONVENTIONAL SYMBOLS 2.13 Blank flange

1.1 Pipe 2.14 Spectacle flange

1.2 Pipe with indication of direction flow 2.15 Orifice

1.3 Valves, gate valves, cocks and flaps 2.16 Orifice

1.4 Appliances 2.17 Loop expansion joint

1.5 Indicating and measuring instruments

1.6 High-pressure pipe 2.19 Pneumatic flow or exhaust to

1.7 Tracing 3. VALVES, GATE VALVES, COCKS AND FLAPS

2.18 Snap coupling

I 00 25 0

atmosphere

1.8 Enclosure for several components

as-sembled in one unit

2. PIPES AND PIPE JOINTS 3.2 Valve, angle

2.1 Crossing pipes, not connected 3.3 Valve, three-way

2.2 Crossing pipes, connected 3.4 Non-return valve (flap), straight

2.3 Tee pipe 3.5 Non-return valve (flap), angle

2.4 Flexible pipe 3.6 Non-return valve (flap), straight

2.5 Expansion pipe (corrugated) general 3.7 Non-return valve (flap), angle, screw

2.6 Joint, screwed 3.8 Safety valve

2.7 Joint, flanged 3.9 Angle safety valve

2.8 Joint, sleeve 3.10 Self-closing valve

2.9 Joint, quick-releasing 3.11 Quick-opening valve

3.1 Valve, straight through

screw down

down

2.10 Expansion joint with gland 3.12 Quick-closing valve

2.11 Expansion pipe 3.13 Regulating valve

2.12 Cap nut 3.14 Ball valve (cock)

2015.11.17

Page 22

MAN Diesel & Turbo

I 00 25 0

Symbols for piping

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

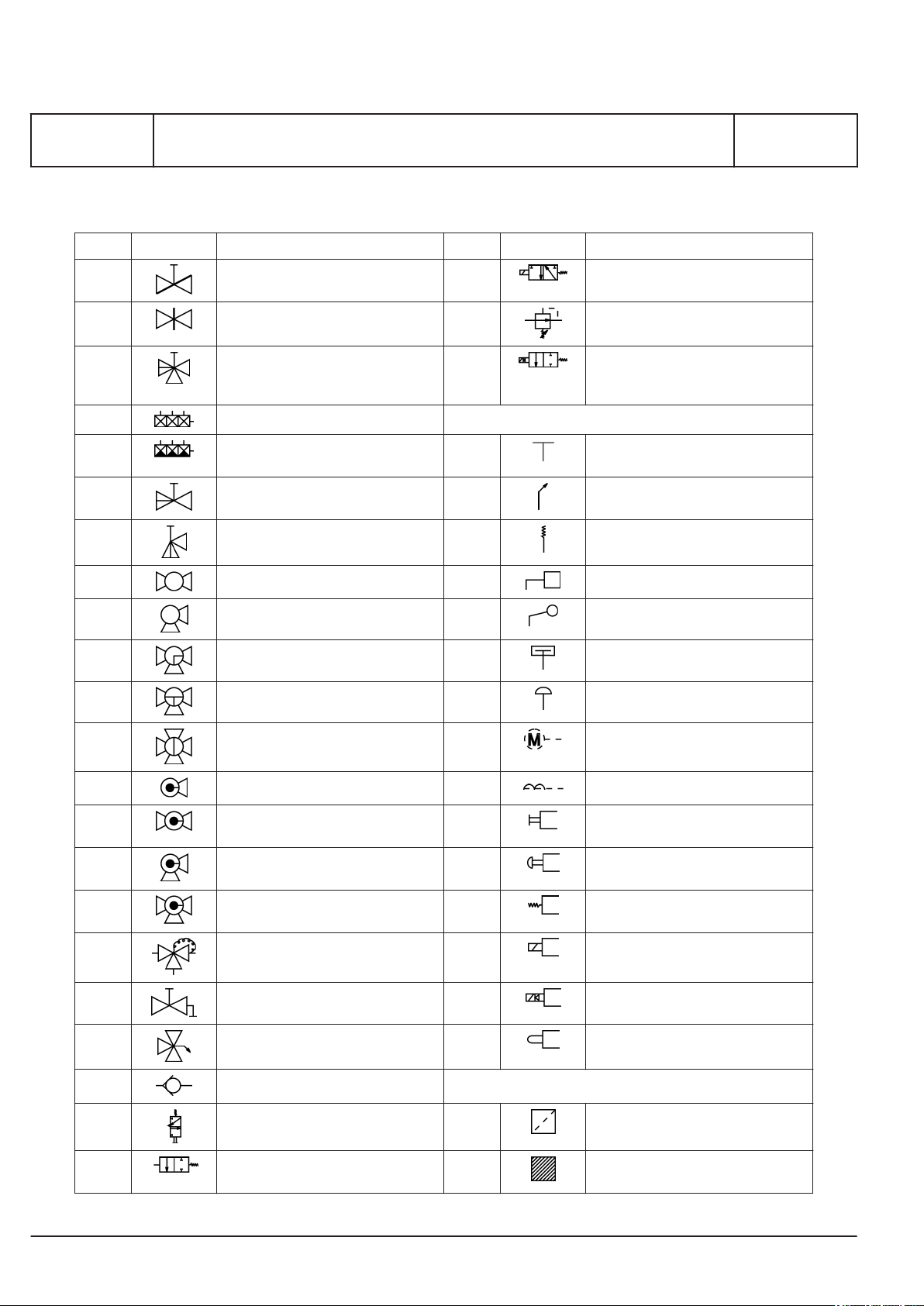

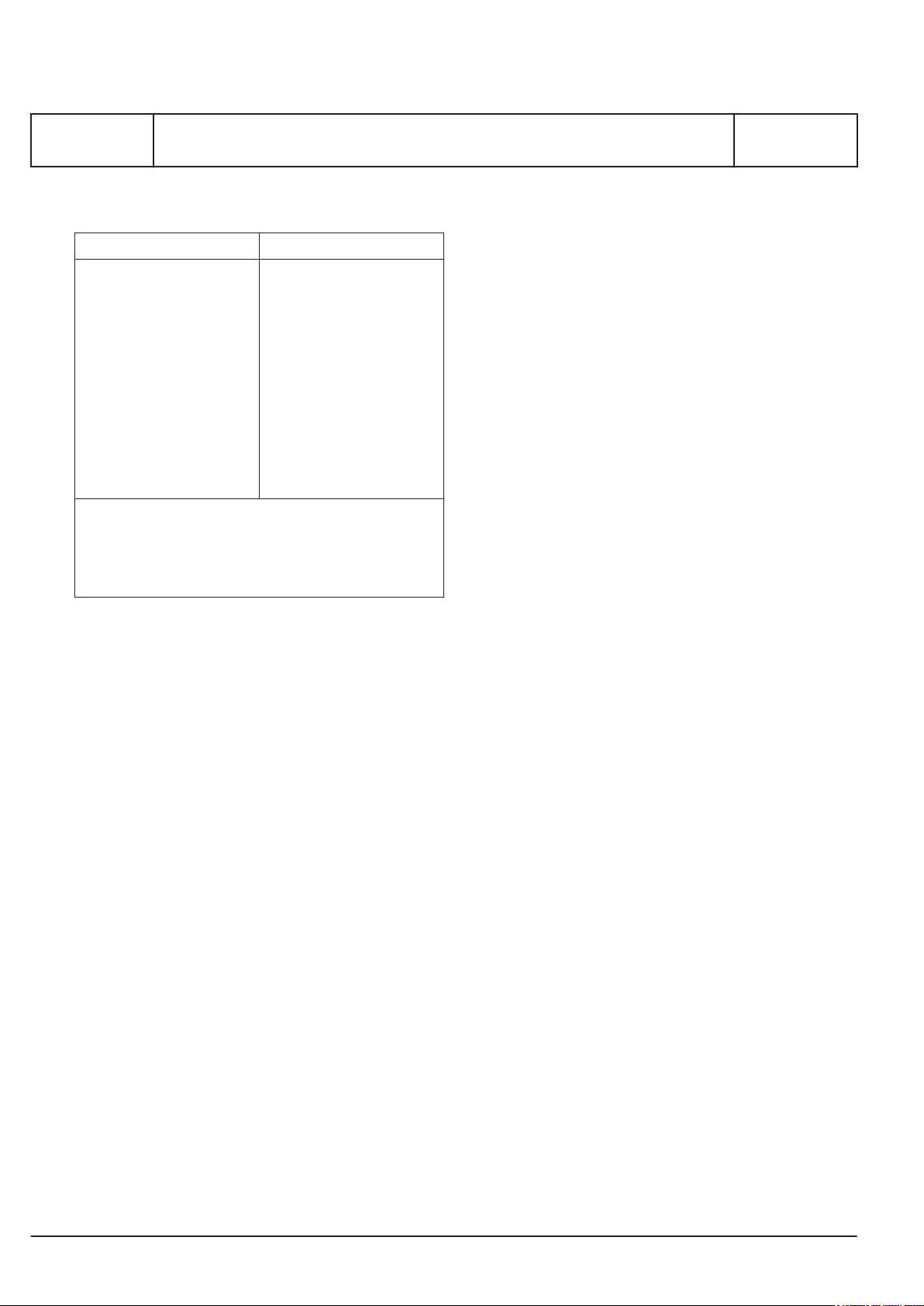

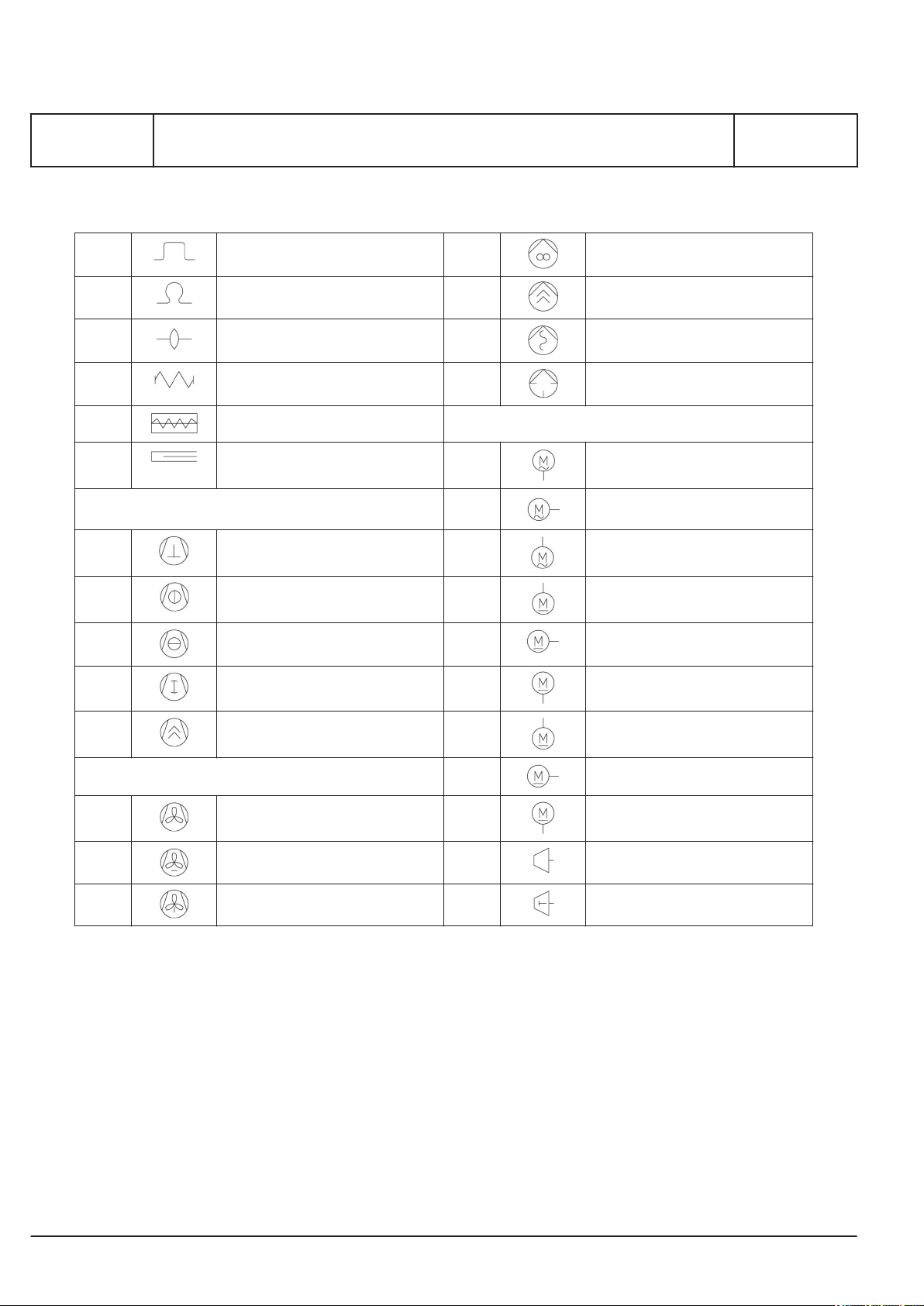

No Symbol Symbol designation No Symbol Symbol designation

3.15 Butterfly valve 3.37 3/2 spring return valve contr. by solenoid

3.16 Gate valve 3.38 Reducing valve (adjustable)

3.17 Double-seated changeover valve 3.39 On/off valve controlled by solenoid

and pilot directional valve and with

spring return

3.18 Suction valve chest 4. CONTROL AND REGULATION PARTS

3.19 Suction valve chest with non-return

valves

3.20 Double-seated changeover valve,

straight

3.21 Double-seated changeover valve,

angle

3.22 Cock, straight through 4.4 Mass

4.1 Fan-operated

4.2 Remote control

4.3 Spring

1655279-1.1

Page 2 (10)

3.23 Cock, angle 4.5 Float

3.24 Cock, three-way, L-port in plug 4.6 Piston

3.25 Cock, three-way, T-port in plug 4.7 Membrane

3.26 Cock, four-way, straight through in

plug

3.27 Cock with bottom connection 4.9 Electromagnetic

3.28 Cock, straight through, with bottom

conn.

3.29 Cock, angle, with bottom connec-

tion

3.30 Cock, three-way, with bottom con-

nection

3.31 Thermostatic valve 4.13 Solenoid

3.32 Valve with test flange 4.14 Solenoid and pilot directional valve

3.33 3-way valve with remote control

(actuator)

4.8 Electric motor

4.10 Manual (at pneumatic valves)

4.11 Push button

4.12 Spring

4.15 By plunger or tracer

3.34 Non-return valve (air) 5. APPLIANCES

3.35 3/2 spring return valve, normally

closed

3.36 2/2 spring return valve, normally

closed

5.1 Mudbox

5.2 Filter or strainer

2015.11.17

Page 23

MAN Diesel & Turbo

1655279-1.1

Page 3 (10)

Symbols for piping

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

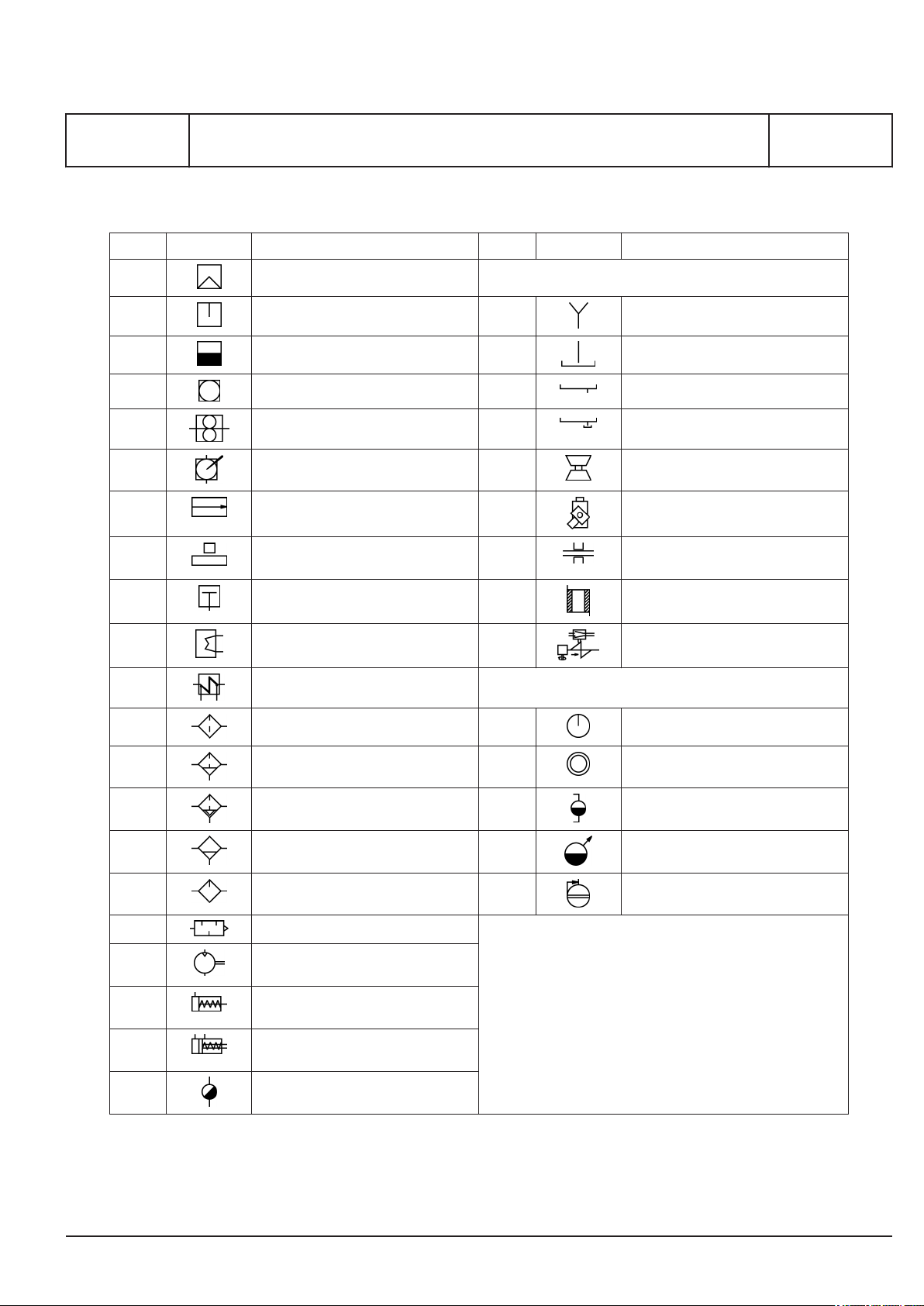

No Symbol Symbol designation No Symbol Symbol designation

5.3 Magnetic filter 6. FITTINGS

5.4 Separator 6.1 Funnel / waste tray

5.5 Steam trap 6.2 Drain

5.6 Centrifugal pump 6.3 Waste tray

5.7 Gear or screw pump 6.4 Waste tray with plug

5.8 Hand pump (bucket) 6.5 Turbocharger

5.9 Ejector 6.6 Fuel oil pump

5.10 Various accessories (text to be

added)

5.11 Piston pump 6.8 Water jacket

6.7 Bearing

I 00 25 0

5.12 Heat exchanger 6.9 Overspeed device

5.13 Electric preheater 7. READING INSTR. WITH ORDINARY DESIGNATIONS

5.14 Air filter 7.1 Sight flow indicator

5.15 Air filter with manual control 7.2 Observation glass

5.16 Air filter with automatic drain 7.3 Level indicator

5.17 Water trap with manual control 7.4 Distance level indicator

5.18 Air lubricator 7.5 Recorder

5.19 Silencer

5.20 Fixed capacity pneumatic motor

with direction of flow

5.21 Single acting cylinder with spring

returned

5.22 Double acting cylinder with spring

returned

5.23 Steam trap

2015.11.17

Page 24

MAN Diesel & Turbo

I 00 25 0

Symbols for piping

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

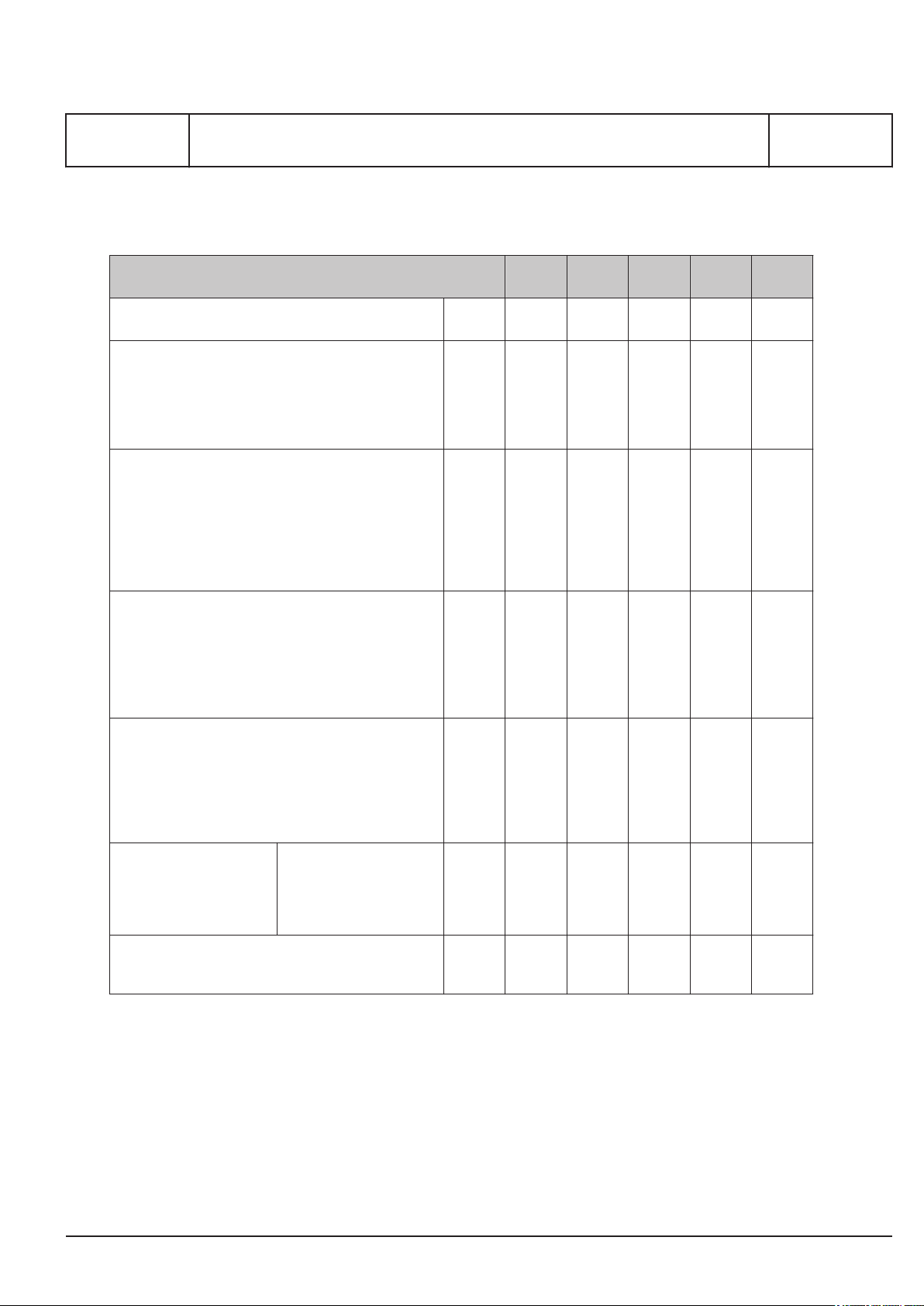

List of Symbols

Pipe dimensions and piping signature

Pipe dimenesions

A : Welded or seamless steel pipes. B : Seamless precision steel pipes or Cu-pipes.

Normal

Diameter

DN

15

20

25

32

40

50

65

80

90

100

125

150

175

200

General

Pump, general DIN 2481 Ballcock

Outside

Diameter

mm

21.3

26.9

33.7

42.4

48.3

60.3

76.1

88.9

101.6

114.3

139.7

168.3

193.7

219.1

Wall

Thickness

mm

In accordance

with classification or other

rules

Stated: Outside diameter and wall thickness i.e. 18 x 2

Piping

: Built-on engine/Gearbox

: Yard supply

Items connected by thick lines are built-on engine/ gearbox.

1655279-1.1

Page 4 (10)

General

Centrifugal pump DIN 2481 Cock, three-way, L-port

Centrifugal pump with electric

motor

Gear pump DIN 2481 Spectacle flange DIN 2481

Screw pump DIN 2481 Spectacle flange, open DIN 2481

Screw pump with electric

motor

Compressor ISO 1219 Orifice

Heat exchanger DIN 2481 Flexible pipe

Electric pre-heater DIN 2481 Centrifuge DIN 28.004

DIN 2481 Double-non-return valve DIN 74.253

DIN 2481 Spectacle flange, closed DIN 2481

2015.11.17

Page 25

MAN Diesel & Turbo

1655279-1.1

Page 5 (10)

Symbols for piping

I 00 25 0

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

Heating coil DIN 8972 Suction bell

Non-return valve Air vent

Butterfly valve Sight glass DIN 28.004

Gate valve Mudbox

Relief valve Filter

Quick-closing valve Filter with water trap ISO 1219

Self-closing valve Typhon DIN 74.253

Back pressure valve Pressure reducing valve (air) ISO 1219

Shut off valve Oil trap DIN 28.004

Thermostatic valve Accumulator

Pneumatic operated valve Pressure reducing valve with

pressure gauge

General

Specification of letter code for measuring devices

2015.11.17

Page 26

MAN Diesel & Turbo

I 00 25 0

Symbols for piping

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

1st letter Following letters

D : Density

E : Electric

F : Flow

L : Level

M ; Moisture

P : Pressure

S : Speed

T : Temperature

V : Viscosity

Z : Position

(ISO 3511/I-1977(E))

The presence of a measuring device on a schematic diagram does not necessarily indicate that the device is included in our scope of supply.

For each plant. The total extent of our supply will be stated

formally.

General

Specification of ID-no code for measuring signals/devices

1st digit 2nd digit

Refers to the main system to which the signal is related. Refers to the auxillary system to which the signal is rela-

1xxx : Engine x0xx : LT cooling water

2xxx : Gearbox x1xx : HT cooling water

3xxx : Propeller equipment x2xx : Oil systems (lub. oil, cooling oil, clutch oil, servo

4xxx : Automation equipment x3xx : Air systems (starting air, control air, charging air)

5xxx : Other equipment, not related to the propulsion

plant

x5xx :

x6xx : Exhaust gas system

x7xx : Power control systems (start, stop, clutch, speed,

x8xx : Sea water

x9xx : Miscellaneous (shaft, stern tube, sealing)

The last two digits are numeric ID for devices referring to the same main and aux. system.

A : Alarm

D : Difference

E : Transducer

H : High

I : Indicating

L : Low

N : Closed

O : Open

S : Switching, shut down

T : Transmitter

X : Failure

C : Controlling

Z : Emergency/safety acting

ted.

oil)

x4xx : Fuel systems (fuel injection, fuel oil)

pitch)

1655279-1.1

Page 6 (10)

Where dublicated measurements are carried out, i.e. multiple similar devices are measuring the same parameter,

the ID specification is followed by a letter (A, B, ...etc.), in order to be able to separate the signals from each other.

2015.11.17

Page 27

MAN Diesel & Turbo

1655279-1.1

Page 7 (10)

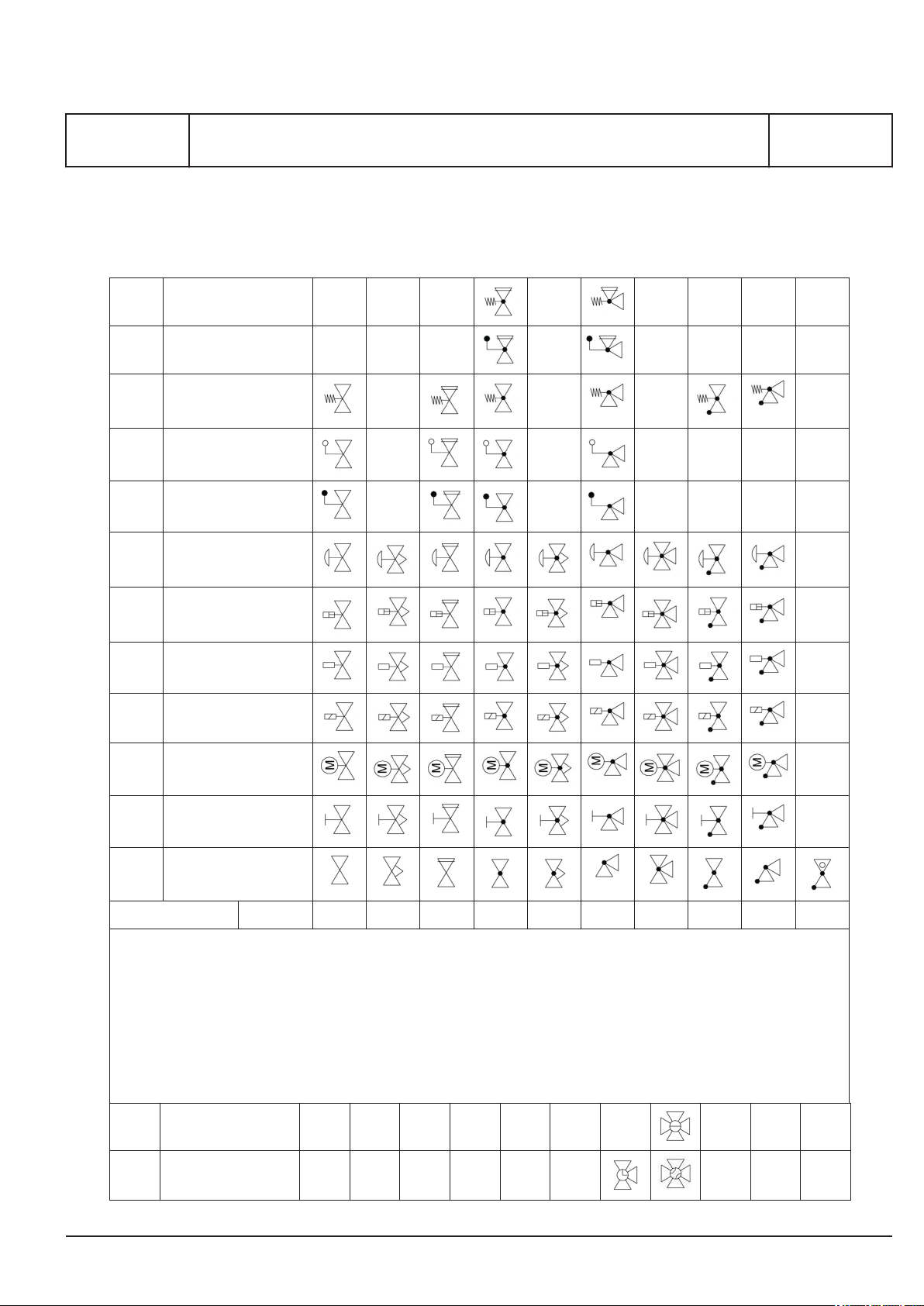

Basic symbols for piping

2237 Spring operated safety

valve

2238 Mass operated Safety

valve

2228 Spring actuator

2284 Float actuator

2229 Mass

2231 Membrane actuator

Symbols for piping

I 00 25 0

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

2230 Piston actuator

2232 Fluid actuator

2223 Solenoid actuator

2234 Electric motor actuator

2235 Hand operated

584: Valve general

585: Valve with continuous regulation

593: Valve with safety function

588:Straight-way valve

592: Straight-way valve with continuous regulation

590:Angle valve

591: Three-way valve

604: Straight-way non return valve

605: Angle non-return valve

579: Non-return valve, ball type

Basic Symbol

I - bored

Valves 584 585 593 588 592 590 591 604 605 579

L - bored

2015.11.17

Page 28

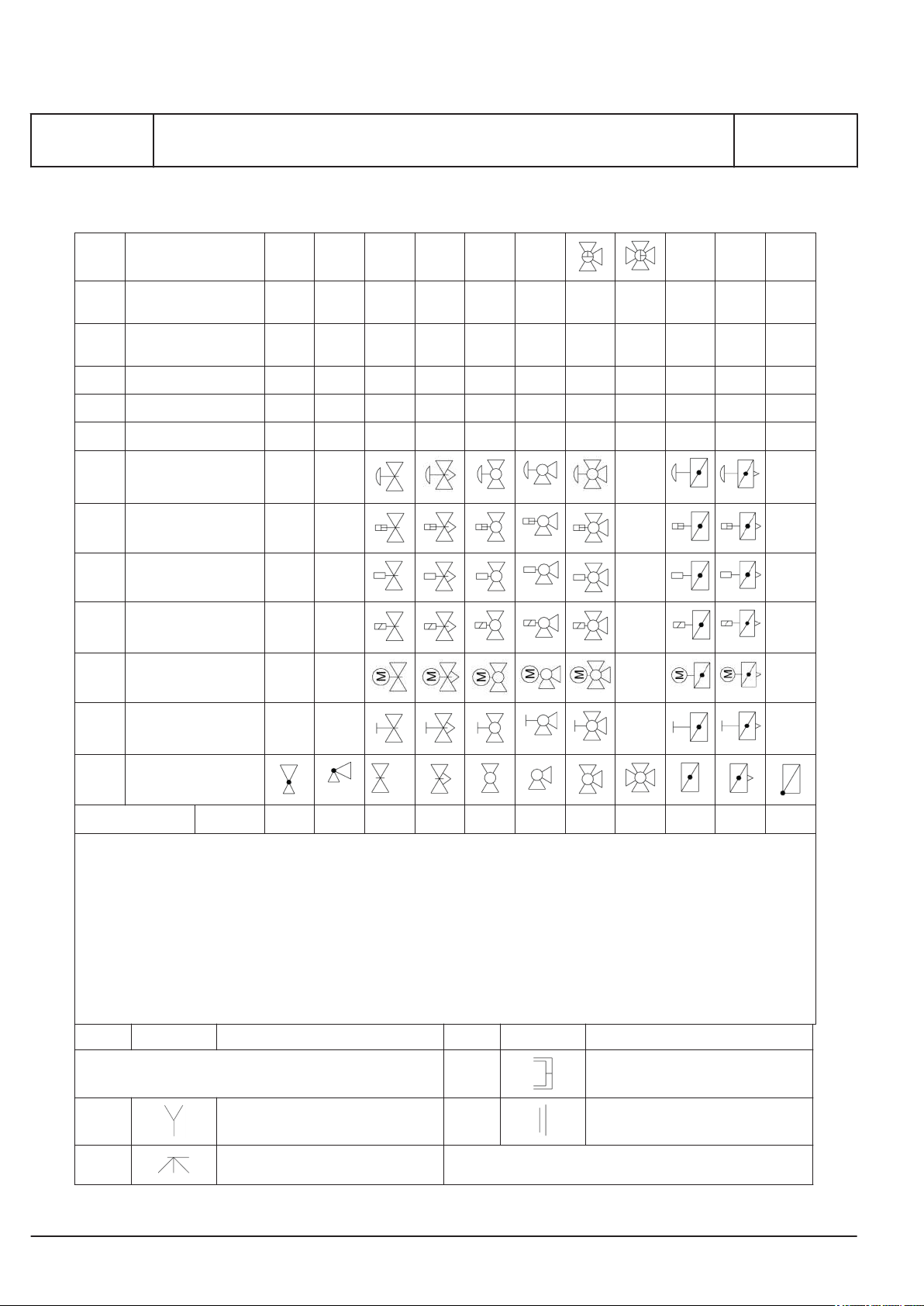

MAN Diesel & Turbo

I 00 25 0

Symbols for piping

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

T - bored

2237 Spring operated

safety valve

2238 Mass operated

Safety valve

2228 Spring actuator

2284 Float actuator

2229 Mass

2231 Membrane actuator

2230 Piston actuator

2232 Fluid actuator

1655279-1.1

Page 8 (10)

2223 Solenoid actuator

2234 Electric motor actua-

tor

2235 Hand operated

594: Straight-way reduction valve

595: Angle reduction valve

586: Gate valve

587: Gate valve with continuous regulation

599: Straight-way cock

600: Angle cock

601: Three-way cock

602: Four-way cock

607: Butterfly valve

608: Butterfly valve with continuous regulation

606: Non-return valve, flap type

Miscellaneous

Basic Symbol

Valves 594 595 586 587 599 600 601 602 607 608 606

No Symbol Symbol designation No Symbol Symbol designation

972 Pipe threaded connection

582 Funnel xxx Blind

581 Atomizer

Tanks

2015.11.17

Page 29

MAN Diesel & Turbo

1655279-1.1

Page 9 (10)

Symbols for piping

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

583 Air venting 631 Tank with domed ends

6.25 Air venting to the outside 771 Tank with conical ends

299 Normal opening/ closing speed yyy Electrical insert heater

300 Quick opening/ closing speed

613 Orifice with diffuser 8.03 Electrical preheater

612 Orifice 8.08 Heat exchanger

611 Sight glass 792 Nest of pipes with bends

615 Silencer 798 Plate heat exchanger

617 Berst membrane

Heat exchanger

Separators

I 00 25 0

629 Condensate relief 761 Separator

580 Reducer 764 Disc separator

589 Measuring point for thermo element

1298 Air relief valve 669 Air filter

Couplings/ Flanges

167 Coupling

955 Flanged connection 16.03 Cooling tower

971 Clamped connection 16.06 Radiator cooler

No Symbol Symbol designation No Symbol Symbol designation

Chimney Pumps

838 Chimney 708 Centrifugal pump

Filters

671 Fluid filter

Coolers

Expansion joints

2285 Expansion bellow 704 Piston pump - radial

4.1 Expansion pipe 700 Membrane pump

697 Piston pump

2015.11.17

Page 30

MAN Diesel & Turbo

I 00 25 0

Symbols for piping

L27/38S, L16/24, L16/24S, L21/31, L21/31S, L23/30H, L23/30S, L23/30DF,

L28/32H, L28/32S, V28/32H, V28/32S, L27/38, L28/32DF

4.1.1.1 Loop expansion joint 702 Gear pump

4.1.1.2 Lyra expansion joint 705 Screw pump

4.1.1.3 Lens expansion joint 706 Mono pump

4.1.1.4 Expansion bellow 703 Hand vane pump

4.1.1.5 Steel tube

4.1.1.6 Expansion joint with gland 13.14 Electrical motor AC

Compressors

716 Piston compressor 13.14 Electrical motor AC

Motors

13.14 Electrical motor AC

1655279-1.1

Page 10 (10)

725 Turbo axial compressor 13.15 Electrical motor DC

726 Turbo dial compressor 13.15 Electrical motor DC

720 Roots compressor 13.15 Electrical motor DC

722 Screw compressors 13.15 Electrical motor DC

Ventilators

637 Fan general 13.15 Electrical motor DC

638 Fan - radial 632 Turbine

639 Fan - axial 633 Piston engine

13.15 Electrical motor DC

2015.11.17

Page 31

MAN Diesel & Turbo

D 10 General

information

Page 1 (1)

D 10 General information

2018-04-13 - en

Page 32

Page 33

MAN Diesel & Turbo

1689471-7.4

Page 1 (2)

Capacities

5L27/38: 300 kW/cyl., 720 rpm,

6-9L27/38: 330 kW/cyl., 720 rpm

Engine output

Speed

Heat to be dissipated

Cooling water cylinder

Charge air cooler; cooling water HT

Charge air cooler; cooling water LT

Lubricating oil cooler

Heat radiation engine

Flow rates

4)

Internal (inside engine)

HT circuit (cylinder + charge air cooler HT stage)

LT circuit (lube oil + charge air cooler LT stage)

Lubrication oil

External (from engine to system)

HT water flow (at 40°C inlet)

LT water flow (at 38°C inlet)

Air data

Temperature of charge air at charge air cooler outlet

Air flow rate

Charge air pressure

Air required to dissipate heat radiation (eng.)

(t2-t1= 10°C)

Exhaust gas data

Volume flow (temperature turbocharger outlet)

Mass flow

Temperature at turbine outlet

Heat content (190°C)

Permissible exhaust back pressure

Permissible exhaust back pressure (SCR)

Pumps

External pumps

Diesel oil pump

Fuel oil supply pump

Fuel oil circulating pump

Starting air data

Air consumption per start,

incl. air for jet assist (IR/TDI)

3)

6)

8)

(5 bar at fuel oil inlet A1)

(4 bar discharge pressure)

9)

(8 bar at fuel oil inlet A1)

List of capacities

5 6 7 8 9

kW

rpm

kW

kW

kW

kW

kW

m3/h

m3/h

m3/h

m3/h

m3/h

°C

m3/h

kg/kWh

bar

m3/h

m3/h

t/h

°C

kW

mbar

mbar

m3/h

m3/h

m3/h

Nm

1500

720

256

466

178

224

63

58

58

64

16

58

50

5)

9137

6.67

4.01

20414

7)

19203

10.3

376

575

< 30

< 50

1.06

0.51

1.06

3

2.5 2.9 3.3 3.8 4.3

1980

720

330

594

216

279

83

58

58

64

20.2

58

53

12061

6.67

4.01

26895

25348

13.6

376

759

< 30

< 50

1.40

0.67

1.40

2310

720

385

675

242

325

97

58

58

92

23

58

55

14071

6.67

4.01

31431

29572

15.9

376

886

< 30

< 50

1.63

0.79

1.63

2640

720

440

750

268

372

111

58

58

92

25.5

58

56

16082

6.67

4.01

35968

33797

18.1

376

1012

< 30

< 50

1.87

0.90

1.87

D 10 05 0

L27/38S, L27/38

2970

720

495

820

297

418

125

58

58

92

28

58

57

18092

6.67

4.01

40504

38021

20.4

376

1139

< 30

< 50

2.10

1.01

2.10

2017.03.03 - 330 kW, 720 rpm

Page 34

MAN Diesel & Turbo

D 10 05 0

L27/38S, L27/38

Conditions

Reference condition : Tropic

Air temperature

LT water temperature inlet engine (from system)

Air pressure

Relative humidity

Temperature basis:

Set point HT cooling water engine outlet

Set point LT cooling water engine outlet

Set point lubrication oil inlet engine

Remarks to capacities

1)

HT cooling water flows first through HT stage charge air cooler, then through water jacket and cylinder head, water

temperature outlet engine regulated by mechanical thermostat.

2)

LT cooling water flows first through LT stage charge air cooler, then through lube oil cooler, water temperature

outlet engine regulated by mechanical thermostat.

3)

Tolerance: + 10% for rating coolers, - 15% for heat recovery.

4)

Basic values for layout of the coolers.

5)

Under above mentioned reference conditions.

6)

Tolerance: quantity +/- 5%, temperature +/- 20°C.

7)

Under below mentioned temperature at turbine outlet and pressure according above mentioned reference conditions.

8)

Tolerance of the pumps' delivery capacities must be considered by the manufactures.

9)

In order to ensure sufficient flow through the engine fuel system the capacity of the fuel oil circulation pumps must

be minimum 3 times the full load consumption of the installed engines

List of capacities

°C

°C

bar

%

1)

2)

°C

°C

°C

1689471-7.4

Page 2 (2)

45

38

1

50

79°C nominal

(Range of mech. thermostatic element 77-85°C)

35°C nominal

(Range of mech. thermostatic element 29-41°C)

66°C nominal

(Range of mech. thermostatic element 63-72°C)

High temperature alarms can occur for some

engine types running 100% MCR with SCR catalyst (50 mbar exhaust back pressure) and tropical condition (ambient air 45°C & LT-water

38°C).

2017.03.03 - 330 kW, 720 rpm

Page 35

MAN Diesel & Turbo

1689472-9.4

Page 1 (2)

Capacities

5L27/38: 320 kW/cyl., 750 rpm,

6-9L27/38: 330 kW/cyl., 750 rpm

Engine output

Speed

Heat to be dissipated

Cooling water cylinder

Charge air cooler; cooling water HT

Charge air cooler; cooling water LT

Lubricating oil cooler

Heat radiation engine

Flow rates

4)

Internal (inside engine)

HT circuit (cylinder + charge air cooler HT stage)

LT circuit (lube oil + charge air cooler LT stage)

Lubrication oil

External (from engine to system)

HT water flow (at 40°C inlet)

LT water flow (at 38°C inlet)

Air data

Temperature of charge air at charge air cooler outlet

Air flow rate

Charge air pressure

Air required to dissipate heat radiation (eng.)

(t2-t1= 10°C)

Exhaust gas data

Volume flow (temperature turbocharger outlet)

Mass flow

Temperature at turbine outlet

Heat content (190°C)

Permissible exhaust back pressure

Permissible exhaust back pressure (SCR)

Pumps

External pumps

Diesel oil pump

Fuel oil supply pump

Fuel oil circulating pump

Starting air data

Air consumption per start,

incl. air for jet assist (IR/TDI)

3)

6)

8)

(5 bar at fuel oil inlet A1)

(4 bar discharge pressure)

9)

(8 bar at fuel oil inlet A1)

List of capacities

5 6 7 8 9

kW

rpm

kW

kW

kW

kW

kW

m3/h

m3/h

m3/h

m3/h

m3/h

°C

m3/h

kg/kWh

bar

m3/h

m3/h

t/h

°C

kW

mbar

mbar

m3/h

m3/h

m3/h

Nm

1600

750

263

488

194

230

67

69

69

66

16.8

69

51

5)

9951

6.81

4.04

21710

7)

20546

11.2

365

589

< 30

< 50

1.13

0.54

1.13

3

2.5 2.9 3.3 3.8 4.3

1980

750

330

587

225

279

83

69

69

66

20.3

69

53

12314

6.81

4.04

26895

25426

13.9

365

729

< 30

< 50

1.40

0.67

1.40

2310

750

385

666

252

325

97

69

69

96

23

69

55

14367

6.81

4.04

31431

29664

16.2

365

850

< 30

< 50

1.63

0.79

1.63

2640

750

440

741

280

372

111

69

69

96

25.7

69

56

16419

6.81

4.04

35968

33901

18.5

365

972

< 30

< 50

1.87

0.90

1.87

D 10 05 0

L27/38S, L27/38

2970

750

495

811

307

418

125

69

69

96

28.2

69

57

18472

6.81

4.04

40504

38139

20.8

365

1093

< 30

< 50

2.10

1.01

2.10

2017.03.03 - 330 kW, 750 rpm

Page 36

MAN Diesel & Turbo

D 10 05 0

L27/38S, L27/38

Conditions

Reference condition : Tropic

Air temperature

LT water temperature inlet engine (from system)

Air pressure

Relative humidity

Temperature basis:

Set point HT cooling water engine outlet

Set point LT cooling water engine outlet

Set point lubrication oil inlet engine

Remarks to capacities

1)

HT cooling water flows first through HT stage charge air cooler, then through water jacket and cylinder head, water

temperature outlet engine regulated by mechanical thermostat.

2)

LT cooling water flows first through LT stage charge air cooler, then through lube oil cooler, water temperature

outlet engine regulated by mechanical thermostat.

3)

Tolerance: + 10% for rating coolers, - 15% for heat recovery.

4)

Basic values for layout of the coolers.

5)

Under above mentioned reference conditions.

6)

Tolerance: quantity +/- 5%, temperature +/- 20°C.

7)

Under below mentioned temperature at turbine outlet and pressure according above mentioned reference conditions.

8)

Tolerance of the pumps' delivery capacities must be considered by the manufactures.

9)

In order to ensure sufficient flow through the engine fuel system the capacity of the fuel oil circulation pumps must

be minimum 3 times the full load consumption of the installed engines

List of capacities

°C

°C

bar

%

1)

2)

°C

°C

°C

1689472-9.4

Page 2 (2)

45

38

1

50

79°C nominal

(Range of mech. thermostatic element 77-85°C)

35°C nominal

(Range of mech. thermostatic element 29-41°C)

66°C nominal

(Range of mech. thermostatic element 63-72°C)

High temperature alarms can occur for some

engine types running 100% MCR with SCR catalyst (50 mbar exhaust back pressure) and tropical condition (ambient air 45°C & LT-water

38°C).

2017.03.03 - 330 kW, 750 rpm

Page 37

MAN Diesel & Turbo

3700395-8.3

Page 1 (2)

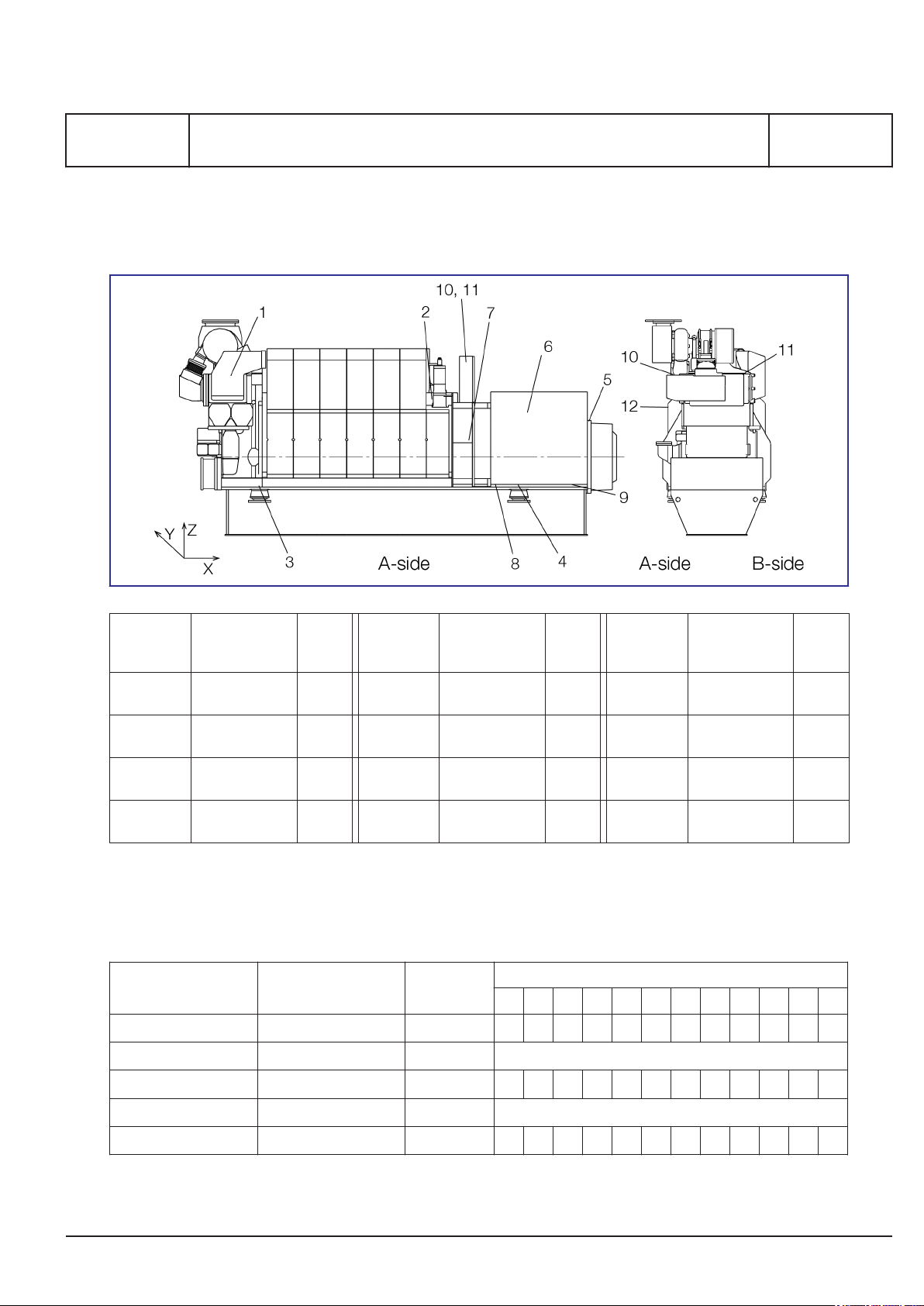

GenSet

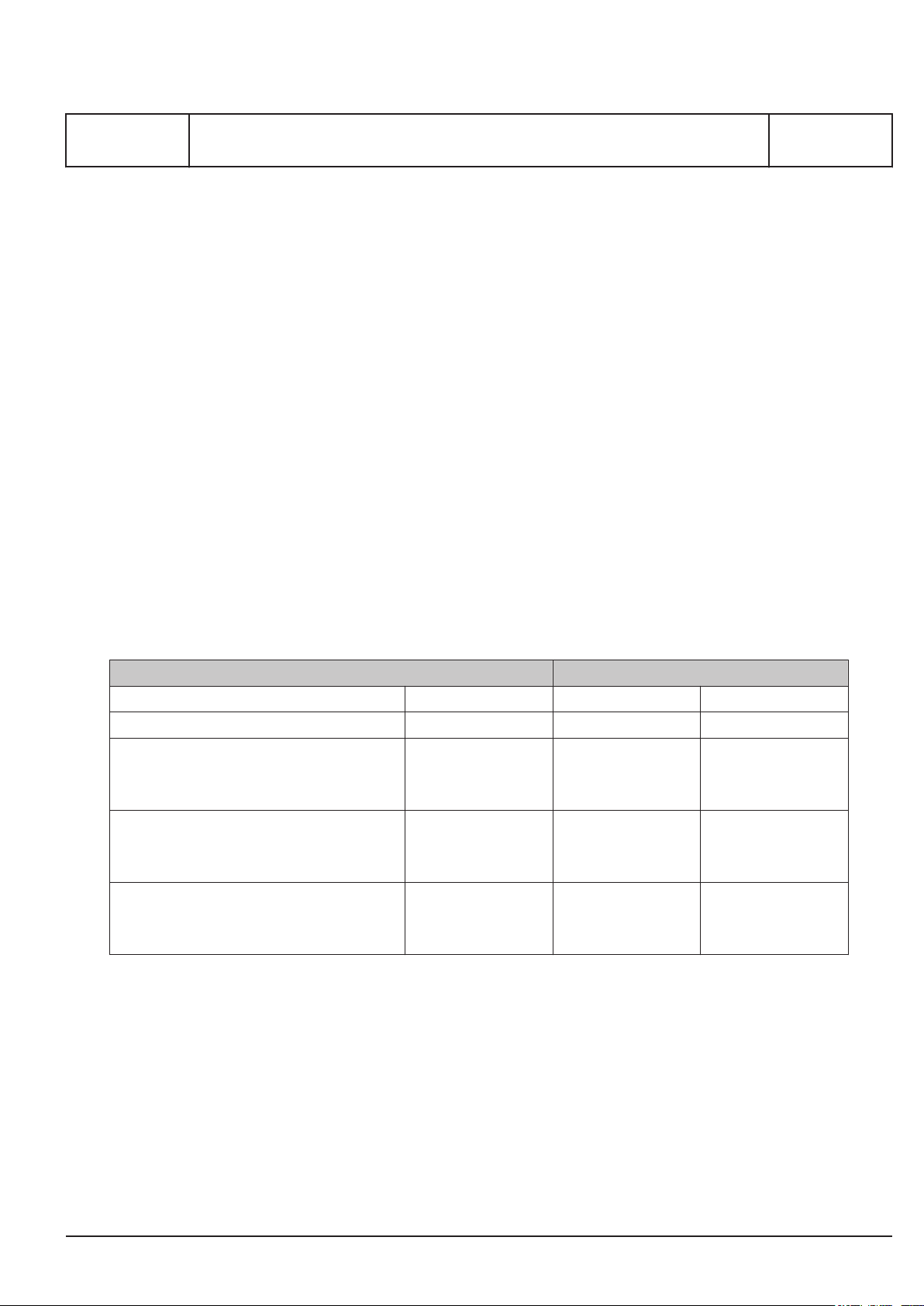

Vibration limits and measurements

D 10 24 0

L23/30DF, L28/32S-DF, L28/32S, L27/38S, L23/30S, L21/31S, L16/24S, L28/32DF,

V28/32H, V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

Measurement

point

1 TC fore 18

2 Governor/TC

3 Front support 18

4 Aft support 18

Engine: VDI 2063T

Alternator: ISO 8528-9, DIN 6280-11

Note: All measurements are specified as mm/s r.m.s.

Description Limit Measure-

ment

point

5 Aft alternator

18

aft

6 Alternator

7 Intermediate

8 Alternator foot See

Date Running

Hours

Description Limit Measure-

ment

point

18

25

18

bearing

cooler

bearing

below *

* Alternator

P ≤ 1250 kVA 20 24

P >1250 kVA 18 22

Value 1 or 2 are depending on alternator make

Load

%

100

1 2 3 4 5 6 7 8 9 10 11 12

Vertical (z)

Description Limit

9 Alternator foot See

below *

10 Automation box

A-side

11 Automation box

B-side

12 T&P panel 25

Value 1 Value 2

25

25

100

100

Crosswise (y)

Longitudinal (x)

2017.12.14

Page 38

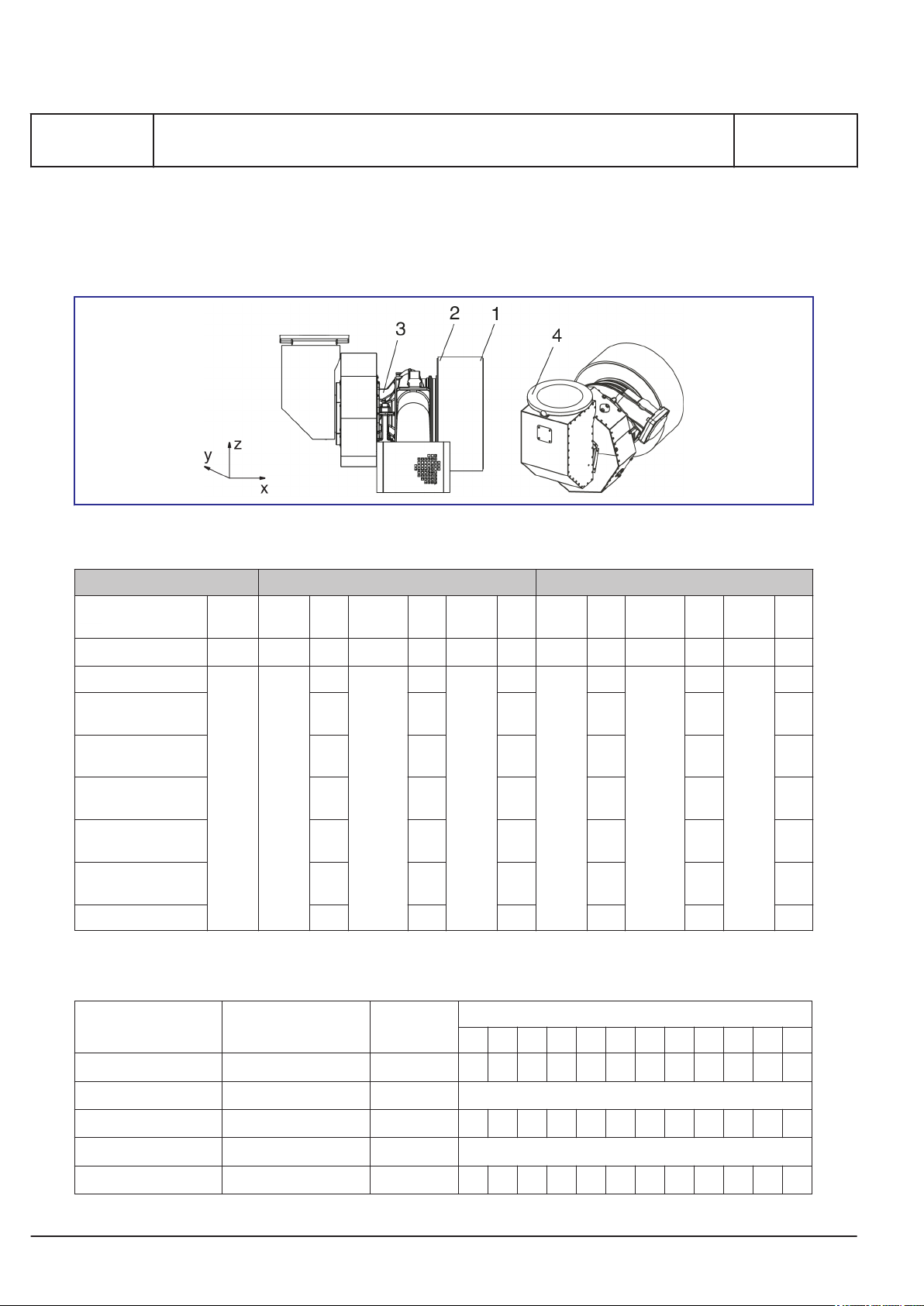

MAN Diesel & Turbo

D 10 24 0

Vibration limits and measurements

L23/30DF, L28/32S-DF, L28/32S, L27/38S, L23/30S, L21/31S, L16/24S, L28/32DF,

V28/32H, V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

Turbocharger

Vibration acceleration measuring point, see the project guide for turbocharger.

Turbocharger type

f (Hz) mm/s g mm/s g mm/s g mm/s g mm/s g mm/s g

Meas.

pt (1)

Recommendation

Meas.

pt (2+3)

Contact engine builder

Meas.

pt (4)

Meas.

pt (1)

Meas.

pt (2+3)

Meas.

pt (4)

3700395-8.3

Page 2 (2)

TCR10

TCR12

NR12

TCR14

NR14, NR15, NR17 2.0 1.6 2.0 4.5 2.2 4.0

TCR16

NR20

TCR18

NR20, NR24 1.4 1.1 1.4 3.2 1.6 2.9

TCR20

NR24, NR26 1.2 0.9 1.2 2.6 1.3 2.3

TCR22 0.9 0.7 0.9 1.9 1.0 1.7

3-300 45

2.9

2.6 2.0 2.6 5.8 2.9 5.2

1.7 1.4 1.7 3.8 1.9 3.5

35

2.2

45

2.9

100

6.4

50

3.2

90

Turbocharger vibration limit values - measuring point

Date Running

Hours

Shop test

Load

%

100

100

1 2 3 4 5 6 7 8 9 10 11 12

Vertical (z)

Crosswise (y)

5.8

100

Longitudinal (x)

2017.12.14

Page 39

MAN Diesel & Turbo

1609510-3.5

Page 1 (1)

Description of sound measurements

L28/32S, L23/30DF, L28/32S-DF, L27/38S, L23/30S, L21/31S, L16/24S, L28/32DF,

V28/32H, V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

General

Purpose

This should be seen as an easily comprehensible

sound analysis of MAN GenSets. These measurements can be used in the project phase as a basis

for decisions concerning damping and isolation in

buildings, engine rooms and around exhaust systems.

Measuring equipment

All measurements have been made with Precision

Sound Level Meters according to standard IEC

Publication 651or 804, type 1 – with 1/1 or 1/3

octave filters according to standard IEC Publication

225. Used sound calibrators are according to

standard IEC Publication 942, class 1.

Definitions

Sound Pressure Level: LP = 20 x log P/P0 [dB ]

D 10 25 0

Sound measuring "on-site"

The Sound Power Level can be directly applied to

on-site conditions. It does not, however, necessarily

result in the same Sound Pressure Level as measured on test bed.

Normally the Sound Pressure Level on-site is 3-5

dB higher than the given surface Sound Pressure

Level (Lpf) measured at test bed. However, it

depends strongly on the acoustical properties of the

actual engine room.

Standards

Determination of Sound Power from Sound Pressure measurements will normally be carried out

according to:

ISO 3744 (Measuring method, instruments, background noise, no of microphone positions etc) and

ISO 3746 (Accuracy due to criterion for suitability of

test environment, K2>2 dB).

where P is the RMS value of sound pressure in pascals, and P0 is 20 μPa for measurement in air.

Sound Power Level: LW = 10 x log P/P0 [dB]

where P is the RMS value of sound power in watts,

and P0 is 1 pW.

Measuring conditions

All measurements are carried out in one of MAN

Diesel & Turbo's test bed facilities.

During measurements, the exhaust gas is led outside the test bed through a silencer. The GenSet is

placed on a resilient bed with generator and engine

on a common base frame.

Sound Power is normally determined from Sound

Pressure measurements.

New measurement of exhaust sound is carried out

at the test bed, unsilenced, directly after turbocharger, with a probe microphone inside the

exhaust pipe.

Previously used method for measuring exhaust

sound are DS/ISO 2923 and DIN 45635, here is

measured on unsilenced exhaust sound, one meter

from the opening of the exhaust pipe, see fig.1.

Figure 1: .

2016.02.22

Page 40

Page 41

MAN Diesel & Turbo

1671754-6.2

Page 1 (1)

Description of structure-borne noise

L28/32S, L23/30DF, L28/32S-DF, L27/38S, L23/30S, L21/31S, L16/24S, L28/32DF,

V28/32H, V28/32S, L16/24, L21/31, L23/30H, L27/38, L28/32H

Introduction

This paper describes typical structure-borne noise

levels from standard resiliently mounted MAN GenSets. The levels can be used in the project phase

as a reasonable basis for decisions concerning

damping and insulation in buildings, engine rooms

and surroundings in order to avoid noise and vibration problems.

References

References and guidelines according to ISO 9611

and ISO 11689.

Operating condition

Levels are valid for standard resilient mounted GenSets on flexible rubber support of 55° sh (A) on relatively stiff and well-supported foundations.

D 10 25 0

Frequency range

The levels are valid in the frequency range 31.5 Hz

to 4 kHz.

Figure 1: Structure-borne noise on resiliently mounted GenSets

2016.02.22

Page 42

Page 43

MAN Diesel & Turbo

1655210-7.3

Page 1 (2)

Exhaust gas components

L23/30DF, L28/32S-DF, V28/32S, V28/32H, L28/32S, L27/38S, L23/30S, L21/31S,

L16/24S, L28/32DF, L16/24, L21/31, L23/30H, L27/38, L28/32H

Exhaust gas components of medium

speed four-stroke diesel engines

The exhaust gas is composed of numerous constituents which are formed either from the combustion

air, the fuel and lube oil used or which are chemical

reaction products formed during the combustion

process. Only some of these are to be considered

as harmful substances.

For the typical exhaust gas composition of a MAN

Diesel & Turbo four-stroke engine without any

exhaust gas treatment devices, please see tables

below (only for guidance). All engines produced currently fulfil IMO Tier II.

Carbon dioxide CO

Carbon dioxide (CO2) is a product of combustion of

all fossil fuels.

Among all internal combustion engines the diesel

engine has the lowest specific CO2 emission based

on the same fuel quality, due to its superior efficiency.

2

D 10 28 0

Hydrocarbons HC

The hydrocarbons (HC) contained in the exhaust

gas are composed of a multitude of various organic

compounds as a result of incomplete combustion.

Due to the efficient combustion process, the HC

content of exhaust gas of MAN Diesel & Turbo fourstroke diesel engines is at a very low level.

Particulate matter PM

Particulate matter (PM) consists of soot (elemental

carbon) and ash.

Sulphur oxides SO

Sulphur oxides (SOX) are formed by the combustion

of the sulphur contained in the fuel.

Among all propulsion systems the diesel process

results in the lowest specific SOx emission based

on the same fuel quality, due to its superior efficiency.

Nitrogen oxides NO

The high temperatures prevailing in the combustion

chamber of an internal combustion engine causes

the chemical reaction of nitrogen (contained in the

combustion air as well as in some fuel grades) and

oxygen (contained in the combustion air) to nitrogen

oxides (NOX).

X

X

Carbon monoxide CO

Carbon monoxide (CO) is formed during incomplete

combustion.

In MAN Diesel & Turbo four-stroke diesel engines,

optimisation of mixture formation and turbocharging

process successfully reduces the CO content of the

exhaust gas to a very low level.

2016.02.22

Page 44

MAN Diesel & Turbo

D 10 28 0

Exhaust gas components

L23/30DF, L28/32S-DF, V28/32S, V28/32H, L28/32S, L27/38S, L23/30S, L21/31S,

L16/24S, L28/32DF, L16/24, L21/31, L23/30H, L27/38, L28/32H

Main exhaust gas constituents

Nitrogen N

Oxygen O

Carbon dioxide CO

2

2

2

Steam H2O 5.9 - 8.6 260 - 370

Inert gases Ar, Ne, He ... 0.9 75

Total > 99.75 7,000

Additional gaseous exhaust gas constituents considered as pollutants

Sulphur oxides SO

Nitrogen oxides NO

Carbon monoxide CO

Hydrocarbons HC

1)

X

2)

X

3)

4)

Total < 0.25 26

approx. [% by volume] approx. [g/kWh]

74.0 - 76.0 5,020 - 5,160

11.6 - 13.2 900 - 1,030

5.2 - 5.8 560 - 620

approx. [% by volume] approx. [g/kWh]

0.07 10.0

0.07 - 0.10 8.0 - 10.0

0.006 - 0.011 0.4 - 0.8

0.01 - 0.04 0.4 - 1.2

1655210-7.3

Page 2 (2)

Additional suspended exhaust gas

constituents, PM

5)

approx. [mg/Nm3] approx. [g/kWh]

operating on operating on

Soot (elemental carbon)

6)

MGO

8)

50 50 0.3 0.3

HFO

7)

MGO

6)

HFO

Fuel ash 4 40 0.03 0.25

Lube oil ash 3 8 0.02 0.04

Note!

At rated power and without exhaust gas treatment.

1)

SOX, according to ISO-8178 or US EPA method 6C, with a sulphur content in the fuel oil of 2.5% by weight.

2)

NOX according to ISO-8178 or US EPA method 7E, total NOX emission calculated as NO2.

3)

CO according to ISO-8178 or US EPA method 10.

4)

HC according to ISO-8178 or US EPA method 25A.

5)

PM according to VDI-2066, EN-13284, ISO-9096 or US EPA method 17; in-stack filtration.

6)

Marine gas oil DM-A grade with an ash content of the fuel oil of 0.01% and an ash content of the lube oil of 1.5%.

7)

Heavy fuel oil RM-B grade with an ash content of the fuel oil of 0.1% and an ash content of the lube oil of 4.0%.

8)

Pure soot, without ash or any other particle-borne constituents.

7)

2016.02.22

Page 45

MAN Diesel & Turbo

3700044-8.0

Page 1 (1)

Emission limits Worldbank II

L28/32S, L23/30S, L16/24S, L21/31S, L27/38S, V28/32S

Emission limits

In general the engine is designed to fulfil the

emission limits according Worldbank II

(2007/2008) for plants ≤ 300 MWth and nondegraded airshed.

SOx and PM emissions are mainly influenced by the

fuel specification. The sulphur and the ash content

must be limited accordingly. The NOx emission is

influenced by the ambient conditions, fuel specifica-

tions and operating conditions of the engine.

Please contact MAN Diesel & Turbo at an early

stage for project specific emission calculations

(contact your sales representative).

Needed adaptions of the engine parameters to fulfil

project specific emission limits may in minor extent

affect the fuel oil consumption.

Worldbank II 2007/2008, only for liquid fuel (L16/24, L21/31, L27/38, V28/32S)

Bore size < 400

3 MWth < x ≤ 50 MW

50 MWth < x ≤ 300 MWthNon-degraded airshed:

NOx ≤ 1460 mg/Nm3 at

th

15% O

2

(NOx ≤ 1600 mg/Nm3 at

15% O2 to maintain higher

effic.)

NOx ≤ 1460 mg/Nm3 at

15% O

2

SOx : max. 1,5% sulphur in fuel

(up 3% exceptionell)

SOx ≤ 1170 mg/Nm3 at 15% O

or max. 2% sulphur in fuel

D 10 28 0

PM ≤ 50 mg/Nm3 at 15% O

(100 mg/Nm3 for econ. rea-

sons)

PM ≤ 50 mg/Nm3 at 15% O

2

2

2

Degraded airshed:

NOx ≤ 400 mg/Nm3 at

15% O

300 MWth < x Non-degraded airshed:

NOx ≤ 740 mg/Nm3 at

15% O

Degraded airshed:

NOx ≤ 400 mg/Nm3 at

15% O

SOx : max. 0.5% sulphur in fuel

2

SOx ≤ 585 mg/Nm3 at 15% O

2

or max. 2% sulphur in fuel

SOx : max. 0.2% sulphur in fuel

2

PM ≤ 30 mg/Nm3 at 15% O

PM ≤ 50 mg/Nm3 at 15% O

2

PM ≤ 30 mg/Nm3 at 15% O

2

2

2

2015.11.16

Page 46

Page 47

MAN Diesel & Turbo

1687148-5.2

Page 1 (1)

Moment of inertia

GenSet

Eng. type Moments of inertia Flywheel

Number of

cylinders

n = 720 rpm

5L27/38

6L27/38

7L27/38

8L27/38

9L27/38

n = 750 rpm

5L27/38

6L27/38

7L27/38

8L27/38

9L27/38

Continuous

rating

kW Kgm

1500

2100

2450

2800

3150

1600

2100

2450

2800

3150

Moments

required total

J

min

2

691

968

1129

1290

1451

679

892

1040

1189

1338

Engine +

damper

2

Kgm

207

264

291

353**)

381**)

207

264

291

353**)

381**)

Moments of

inertia

2

Kgm

403

403

403

403

403

403

403

403

403

403

D 10 30 0

L27/38S, L27/38

Mass Required

moment of

inertia after

flywheel *)

kg Kgm

1451

1451

1451

1451

1451

1451

1451

1451

1451

1451

2

81

301

435

534

667

69

225

346

433

554

*) Required moment of inertia after flywheel is based on 403 Kgm2 flywheel, and the most common damper.

The calucation is based on 42% engine acceleration.

Larger flywheel means lower alternator inertia demand, as total GenSet inertia is the final demand.

Selection of bigger flywheel for having lower alternator inertia demand, have to be approved by a torsional

vibration calculation.

The following flywheels are available:

J

J

J

=

=

=

403 Kgm

570 Kgm

801 Kgm

2

2

2

**) Incl. flexible coupling for two bearing alternator.

2015.11.27

Page 48

Page 49

MAN Diesel & Turbo

1699985-1.1

Page 1 (1)

V28/32S, V28/32H, L28/32S, L27/38S, L23/30DF, L23/30S, L16/24S, L21/31S,

Green Passport

In 2009 IMO adopted the „Hong Kong International

Convention for the Safe and Environmentally Sound

Recycling of Ships, 2009“.

Until this convention enters into force the recommendatory guidelines “Resolution A.962(23)” (adopted 2003) apply. This resolution has been implemented by some classification societies as “Green

Passport”.

MAN Diesel & Turbo is able to provide a list of hazardous materials complying with the requirements

of the IMO Convention. This list is accepted by classification societies as a material declaration for

“Green Passport”.

This material declaration can be provided on

request.

Green Passport

D 10 33 0

L28/32DF, L16/24, L21/31, L23/30H, L27/38, L28/32H

2015.11.26

Page 50

Page 51

MAN Diesel & Turbo

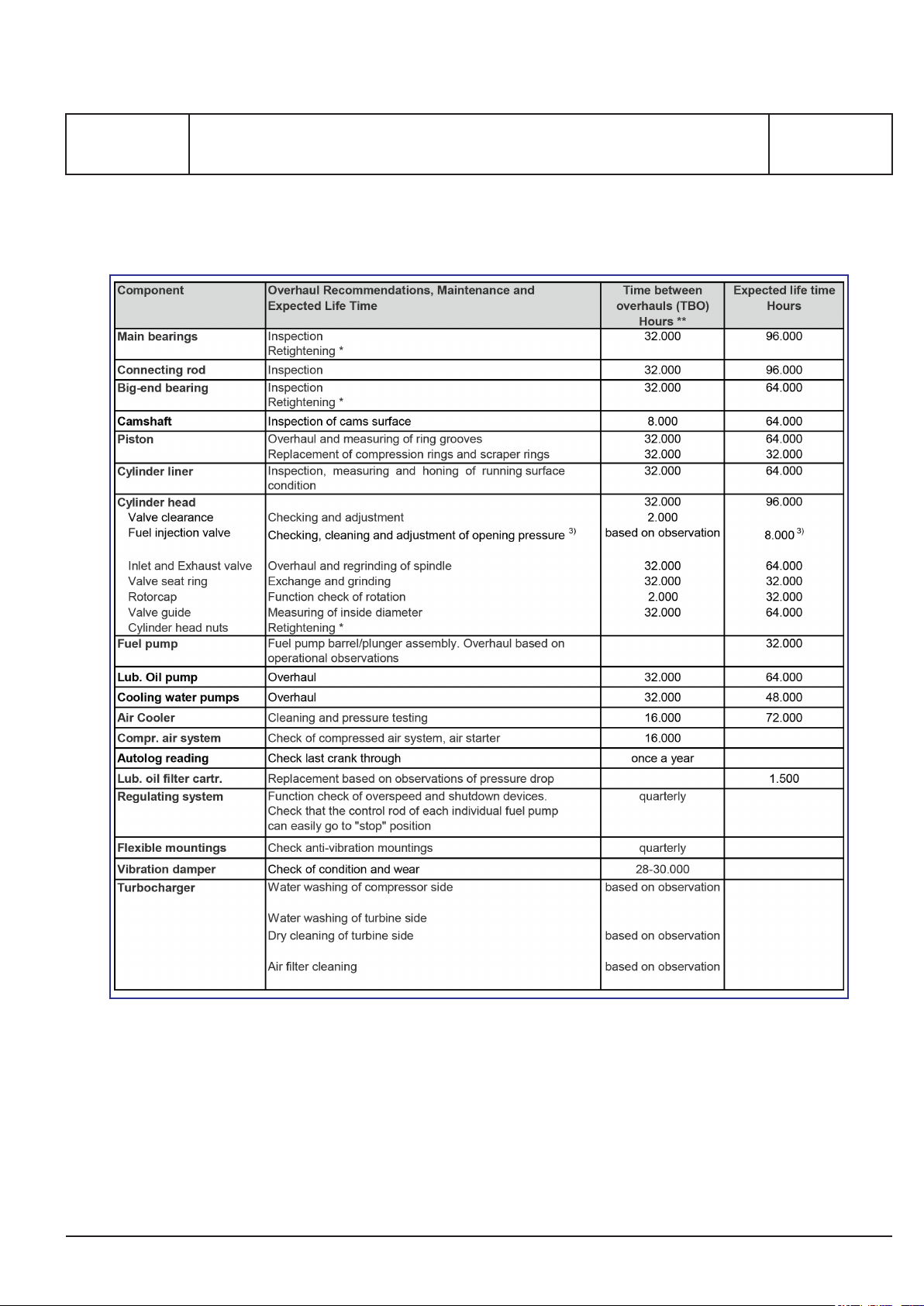

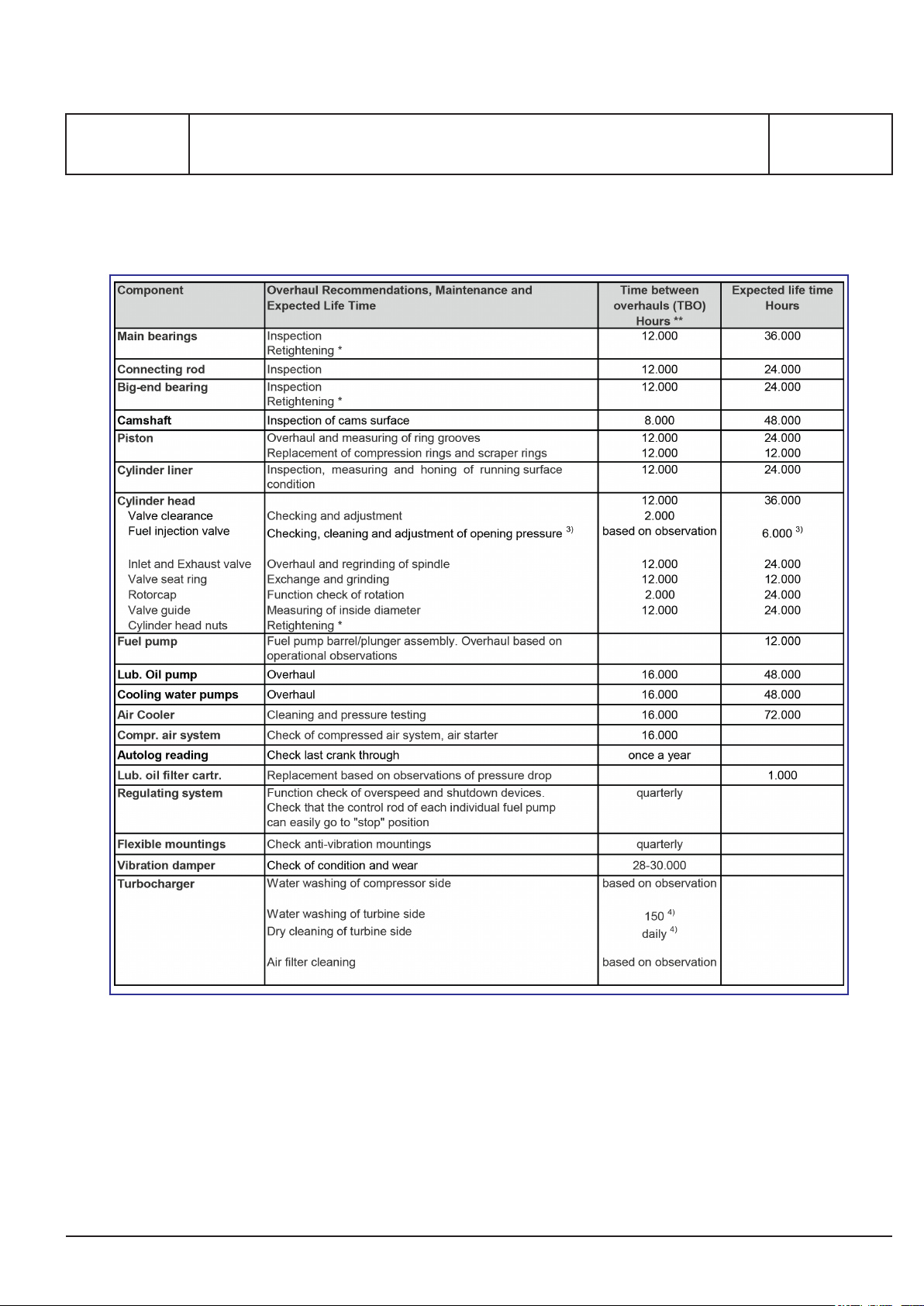

3700340-7.1

Page 1 (2)

Overhaul recommendation, Maintenance and Expected

D 10 35 0

life time

L27/38S, L27/38

* After starting up and before loading engine.

** Time between overhauls: It is a precondition for the validity of the values stated above, that the engine is oper-

ated in accordance with our instructions and recommendations for cleaning of fuel and lub. oil and original spare

parts are used.

2014.05.09 - MGO/MDO, Tier II, Stationary island mode 1)

In the Project Guide for GenSet, see Lub. Oil treatment, in section B 12 00 0 and Fuel oil specification in section

B 11 00 0 and section 14 000 for Propulsion.

In the Instruction Manual for GenSet and L21/31 Propulsion, see Lub. Oil treatment and Fuel oil specification in

section 504/604. For Propulsion L27/38, L23/30A, L28/32A see section 1.00.

Page 52

MAN Diesel & Turbo

D 10 35 0

L27/38S, L27/38

1) Island mode, max. 75 % average load.

2) Parallel running with public grid, up to 100 % load.

3) See working card for fuel injection valve in the instruction manual, section 514/614 for GenSet and section 1.20.

4) Time can be adjusted acc. to performance observations.

Note: Time between overhaul for Crude oil is equal to HFO

Time between overhaul for Biofuel is equal to MDO, except for fuel equipment case by case, depending on TAN

number

Overhaul recommendation, Maintenance and Expected

life time

3700340-7.1

Page 2 (2)

2014.05.09 - MGO/MDO, Tier II, Stationary island mode 1)

Page 53

MAN Diesel & Turbo

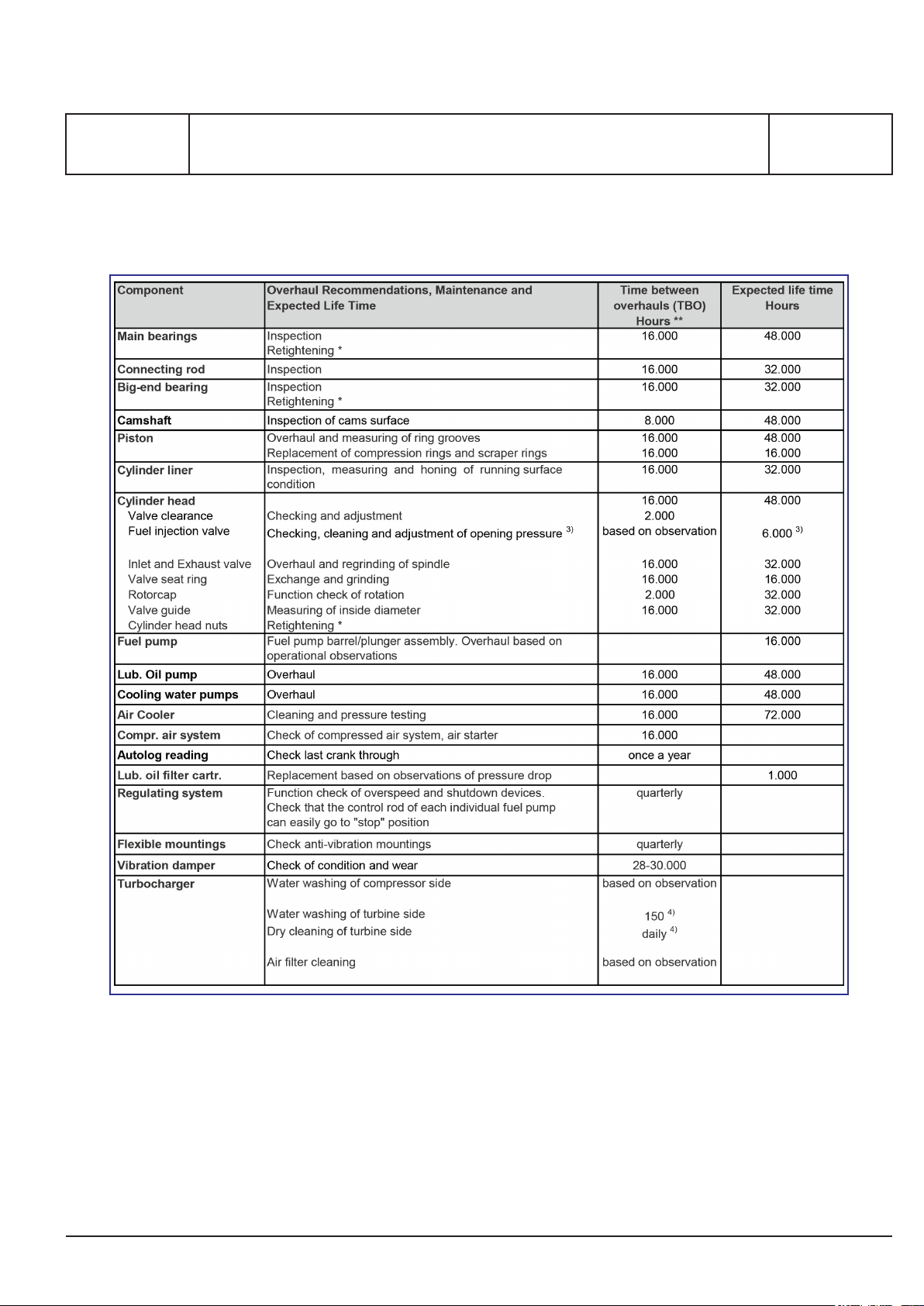

3700341-9.1

Page 1 (2)

Overhaul recommendation, Maintenance and Expected

D 10 35 0

life time

L27/38S, L27/38

* After starting up and before loading engine.

** Time between overhauls: It is a precondition for the validity of the values stated above, that the engine is oper-

ated in accordance with our instructions and recommendations for cleaning of fuel and lub. oil and original spare

parts are used.

2014.05.09 - HFO, Tier II, Stationary island mode 1)

In the Project Guide for GenSet, see Lub. Oil treatment, in section B 12 00 0 and Fuel oil specification in section

B 11 00 0 and section 14 000 for Propulsion.

In the Instruction Manual for GenSet and L21/31 Propulsion, see Lub. Oil treatment and Fuel oil specification in

section 504/604. For Propulsion L27/38, L23/30A, L28/32A see section 1.00.

1) Island mode, max. 75 % average load.

Page 54

MAN Diesel & Turbo

D 10 35 0

L27/38S, L27/38

2) Parallel running with public grid, up to 100 % load.

3) See working card for fuel injection valve in the instruction manual, section 514/614 for GenSet and section 1.20.

4) Time can be adjusted acc. to performance observations.

Note: Time between overhaul for Crude oil is equal to HFO

Time between overhaul for Biofuel is equal to MDO, except for fuel equipment case by case, depending on TAN

number

Overhaul recommendation, Maintenance and Expected

life time

3700341-9.1

Page 2 (2)

2014.05.09 - HFO, Tier II, Stationary island mode 1)

Page 55

MAN Diesel & Turbo

3700342-0.1

Page 1 (2)

Overhaul recommendation, Maintenance and Expected

D 10 35 0

life time

L27/38S

* After starting up and before loading engine.

** Time between overhauls: It is a precondition for the validity of the values stated above, that the engine is oper-

ated in accordance with our instructions and recommendations for cleaning of fuel and lub. oil and original spare

parts are used.

2014.08.12 - MGO/MDO, stationary public grid

In the Project Guide for GenSet, see Lub. Oil treatment, in section B 12 00 0 and Fuel oil specification in section

B 11 00 0 and section 14 000 for Propulsion.

In the Instruction Manual for GenSet and L21/31 Propulsion, see Lub. Oil treatment and Fuel oil specification in

section 504/604. For Propulsion L27/38, L23/30A, L28/32A see section 1.00.

1) Island mode, max. 75 % average load.

Page 56

MAN Diesel & Turbo

D 10 35 0

L27/38S

Note: Time between overhaul for Crude oil is equal to HFO

Overhaul recommendation, Maintenance and Expected

life time

2) Parallel running with public grid, up to 100 % load.

3) See working card for fuel injection valve in the instruction manual, section 514/614 for GenSet and section 1.20.

4) Time can be adjusted acc. to performance observations.

Time between overhaul for Biofuel is equal to MDO, except for fuel equipment case by case, depending on TAN

number

3700342-0.1

Page 2 (2)

2014.08.12 - MGO/MDO, stationary public grid

Page 57

MAN Diesel & Turbo

3700343-2.1

Page 1 (2)

Overhaul recommendation, Maintenance and Expected

D 10 35 0

life time

L27/38S

* After starting up and before loading engine.

** Time between overhauls: It is a precondition for the validity of the values stated above, that the engine is oper-

ated in accordance with our instructions and recommendations for cleaning of fuel and lub. oil and original spare

parts are used.

2014.05.09 - HFO, Stationary public grid 2)

In the Project Guide for GenSet, see Lub. Oil treatment, in section B 12 00 0 and Fuel oil specification in section

B 11 00 0 and section 14 000 for Propulsion.

In the Instruction Manual for GenSet and L21/31 Propulsion, see Lub. Oil treatment and Fuel oil specification in

section 504/604. For Propulsion L27/38, L23/30A, L28/32A see section 1.00.

1) Island mode, max. 75 % average load.

Page 58

MAN Diesel & Turbo

D 10 35 0

L27/38S

Note: Time between overhaul for Crude oil is equal to HFO

Overhaul recommendation, Maintenance and Expected

life time

2) Parallel running with public grid, up to 100 % load.

3) See working card for fuel injection valve in the instruction manual, section 514/614 for GenSet and section 1.20.

4) Time can be adjusted acc. to performance observations.

Time between overhaul for Biofuel is equal to MDO, except for fuel equipment case by case, depending on TAN

number

3700343-2.1

Page 2 (2)

2014.05.09 - HFO, Stationary public grid 2)

Page 59

MAN Diesel & Turbo

B 10 Basic diesel

engine

Page 1 (1)

B 10 Basic diesel engine

2018-04-13 - en

Page 60

Page 61

MAN Diesel & Turbo

1689477-8.1

Page 1 (7)

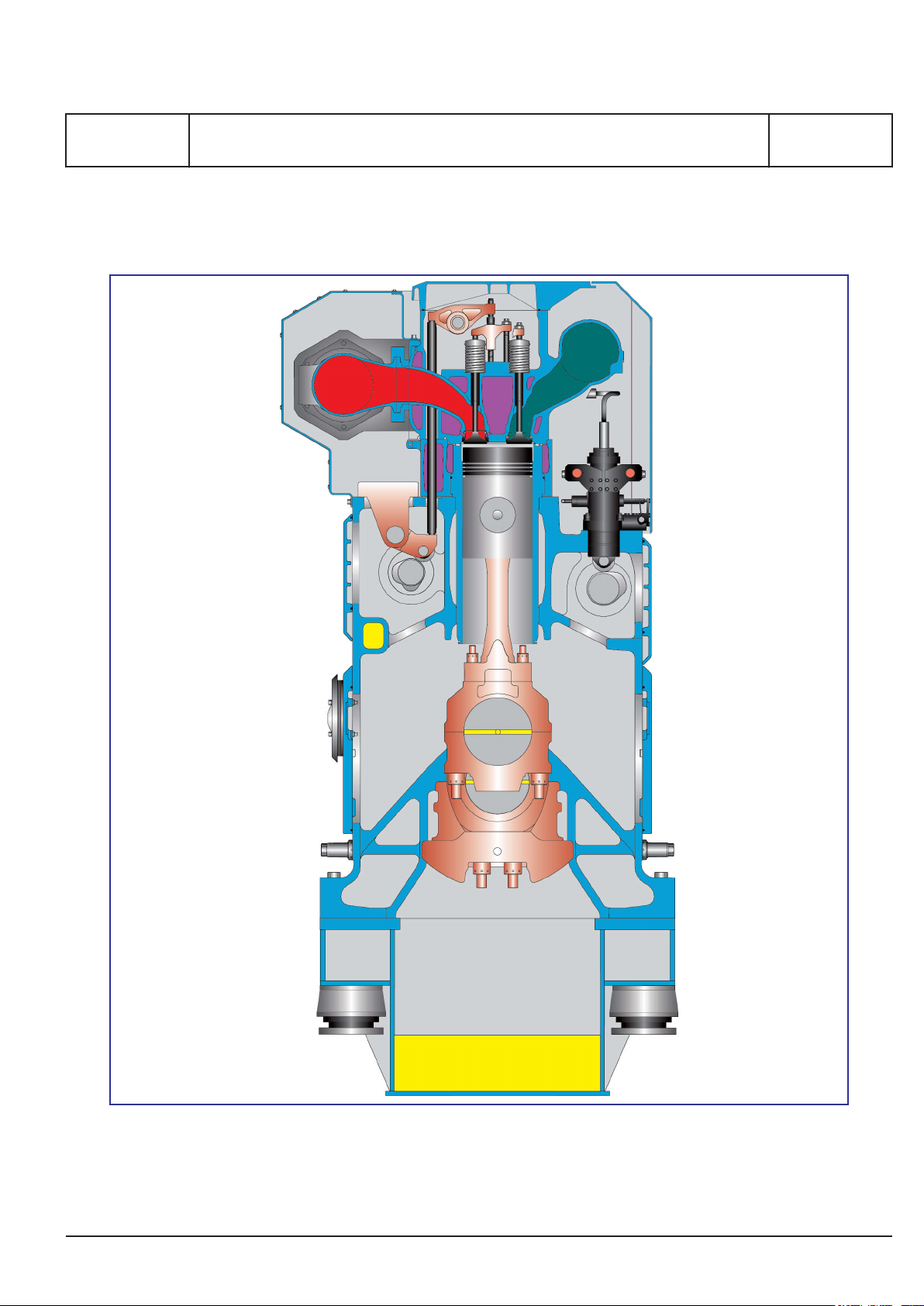

General

The engine is a turbocharged, single-acting fourstroke diesel engine of the trunk piston type with a

cylinder bore of 270 mm and a stroke of 380 mm.

The crank shaft speed is 720 or 750 rpm.

The engine can be delivered as an in-line engine

with 5 to 9 cylinders.

For easy maintenance the cylinder unit consists of:

the cylinder head, water jacket, cylinder liner, piston

and connecting rod which can be removed as complete assemblies with possibility for maintenance by

recycling. This allows shoreside reconditioning work

which normally yields a longer time between major

overhauls.

The engine is designed for an unrestricted load profile on HFO, low emission, high reliability and simple

installation.

General description

Engine frame

The monobloc cast iron engine frame is designed to

be very rigid. All the components of the engine

frame are held under compression stress. The

frame is designed for an ideal flow of forces from

the cylinder head down to the crankshaft and gives

the outer shell low surface vibrations.

Two camshafts are located in the engine frame. The

valve camshaft is located on the exhaust side in a

very high position and the injection camshaft is

located on the service side of the engine.

The main bearings for the underslung crankshaft

are carried in heavy supports by tierods from the

intermediate frame floor, and are secured with the

bearing caps. These are provided with side guides

and held in place by means of studs with hydraulically tightened nuts. The main bearing is equipped

with replaceable shells which are fitted without

scraping.

On the sides of the frame there are covers for

access to the camshafts and crankcase. Some

covers are fitted with relief valves which will operate

if oil vapours in the crankcase are ignited (for

instance in the case of a hot bearing).

B 10 01 1

L27/38S, L27/38

Figure 1: Engine frame.

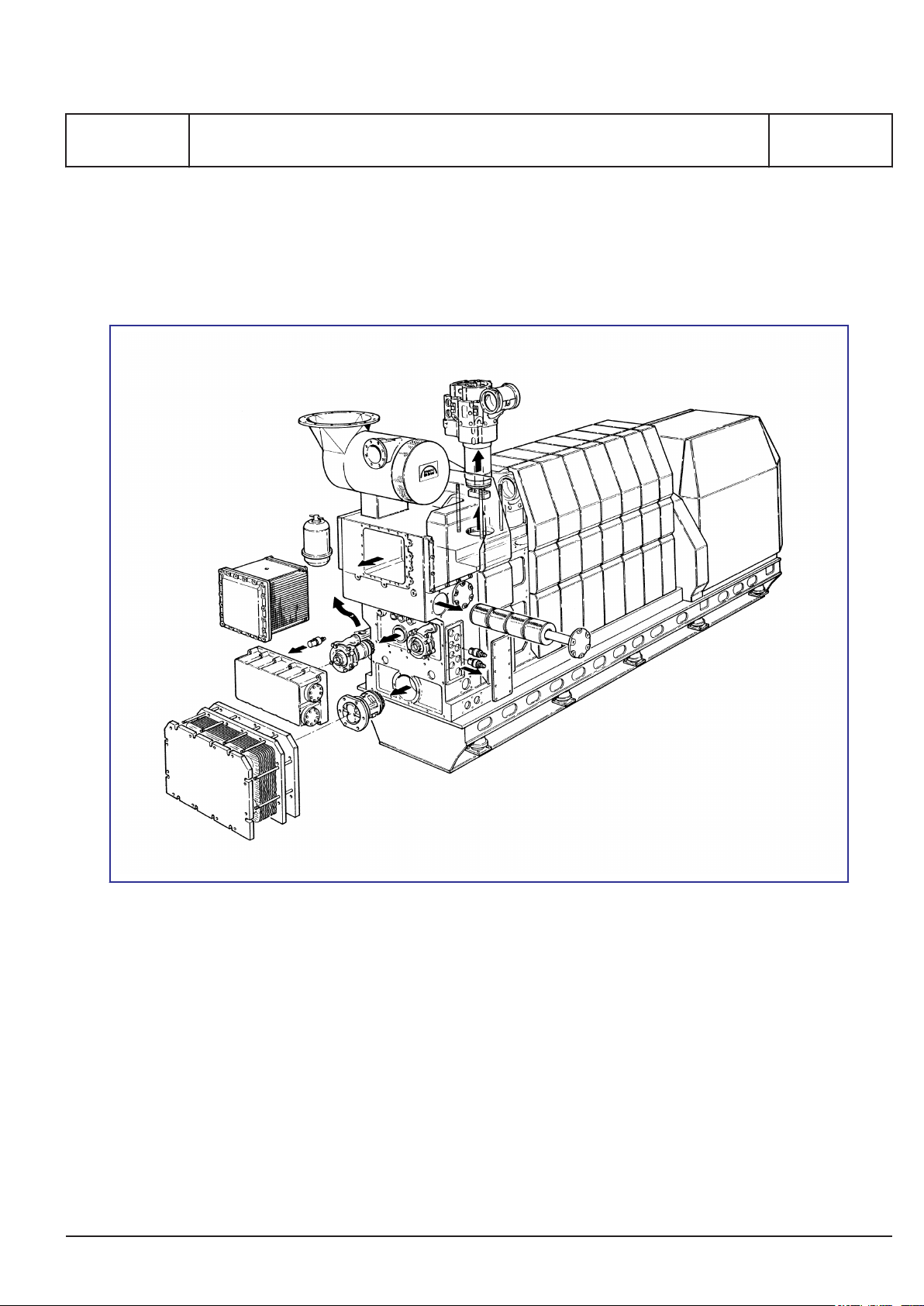

Base frame

The engine and alternator are mounted on a rigid

base frame. The alternator is considered as an integral part during engine design. The base frame,

which is flexibly mounted, acts as a lubricating oil

reservoir for the engine.

Cylinder liner

The cylinder liner is made of special centrifugal cast

iron and fitted in a bore in the engine frame. The

liner is clamped by the cylinder head and rests by

its flange on the water jacket.

2015.11.26

Page 62

MAN Diesel & Turbo

B 10 01 1

L27/38S, L27/38

General description

The cylinder head is tightened by means of 4 nuts

and 4 studs which are screwed into the engine

frame. The nuts are tightened by means of hydraulic

jacks.

The cylinder head has a screwed-on top cover. It

has two basic functions: oil sealing of the rocker

chamber and covering of the complete head top

face.

1689477-8.1

Page 2 (7)

Figure 2: Cylinder liner.

The liner can thus expand freely downwards when

heated during the running of the engine. The liner is

of the flange type and the height of the flange is

identical with the water cooled area which gives a

uniform temperature pattern over the entire liner

surface. The lower part of the liner is uncooled to

secure a sufficient margin for cold corrosion in the

bottom end. There is no water in the crankcase

area.

The gas sealing between liner and cylinder head

consists of an iron ring.

To reduce bore polishing and lube oil consumption

a slip-fit-type top land ring is arranged on the top

side of the liner.

Cylinder head

The cylinder head is of cast iron with an integrated

charge air receiver, made in one piece. It has a

bore-cooled thick walled bottom. It has a central

bore for the fuel injection valve and 4 valve cross

flow design, with high flow coefficient. Intensive

water cooling of the nozzle tip area made it possible

to omit direct nozzle cooling. The valve pattern is

turned about 20° to the axis and achieves a certain

intake swirl.

Figure 3: Cylinder head.

Air inlet and exhaust valves

The valve spindles are made of heat-resistant mate-

rial and the spindle seats are armoured with wel-

ded-on hard metal.

All valve spindles are fitted with valve rotators which

turn the spindles each time the valves are activated.

The turning of the spindles ensures even temperature levels on the valve discs and prevents deposits

on the seating surfaces.

The cylinder head is equipped with replaceable

valve seat rings. The exhaust valve seat rings are

water cooled in order to assure low valve temperatures.

The seat rings are made of heat-resistant steel. The

seating surfaces are hardened in order to minimize

wear and prevent dent marks.

2015.11.26

Page 63

MAN Diesel & Turbo

1689477-8.1

Page 3 (7)

Valve actuating gear

Drive of the push rod for the inlet and exhaust

valves is from the camshaft via inlet and exhaust

rocking levers supported on a joint pillow, with the

cam movements being transmitted via a follower.

The push rod movement is in the cylinder head

transmitted to short rockers, and from these to a

guided, spring-loaded yoke. This yoke operates two

equal valves each.

The pillow supporting the rocking levers (the rocking

lever casing) is bolted to the cylinder head.

Bearing bushes, ball pans and yokes are lubricated

by means of a fitting in the pillow.

Fuel injection system

The engine is provided with one fuel injection pump

unit, an injection valve, and a high pressure pipe for

each cylinder.

The injection pump unit is mounted on the engine

frame. The pump unit consists of a pump housing

embracing a roller guide, a centrally placed pump

barrel and a plunger. The pump is activated by the

fuel cam, and the volume injected is controlled by

turning the plunger.

The fuel injection valve is located in a valve sleeve in

the centre of the cylinder head. The opening of the

valve is controlled by the fuel oil pressure, and the

valve is closed by a spring.

The high pressure pipe which is led through a bore

in the cylinder head is surrounded by a shielding

tube.

The shielding tube also acts as a drain channel in

order to ensure any leakage from the fuel valve and

the high pressure pipe will be drained off.

The complete injection equipment including injection pumps and high pressure pipes is well

enclosed behind removable covers.

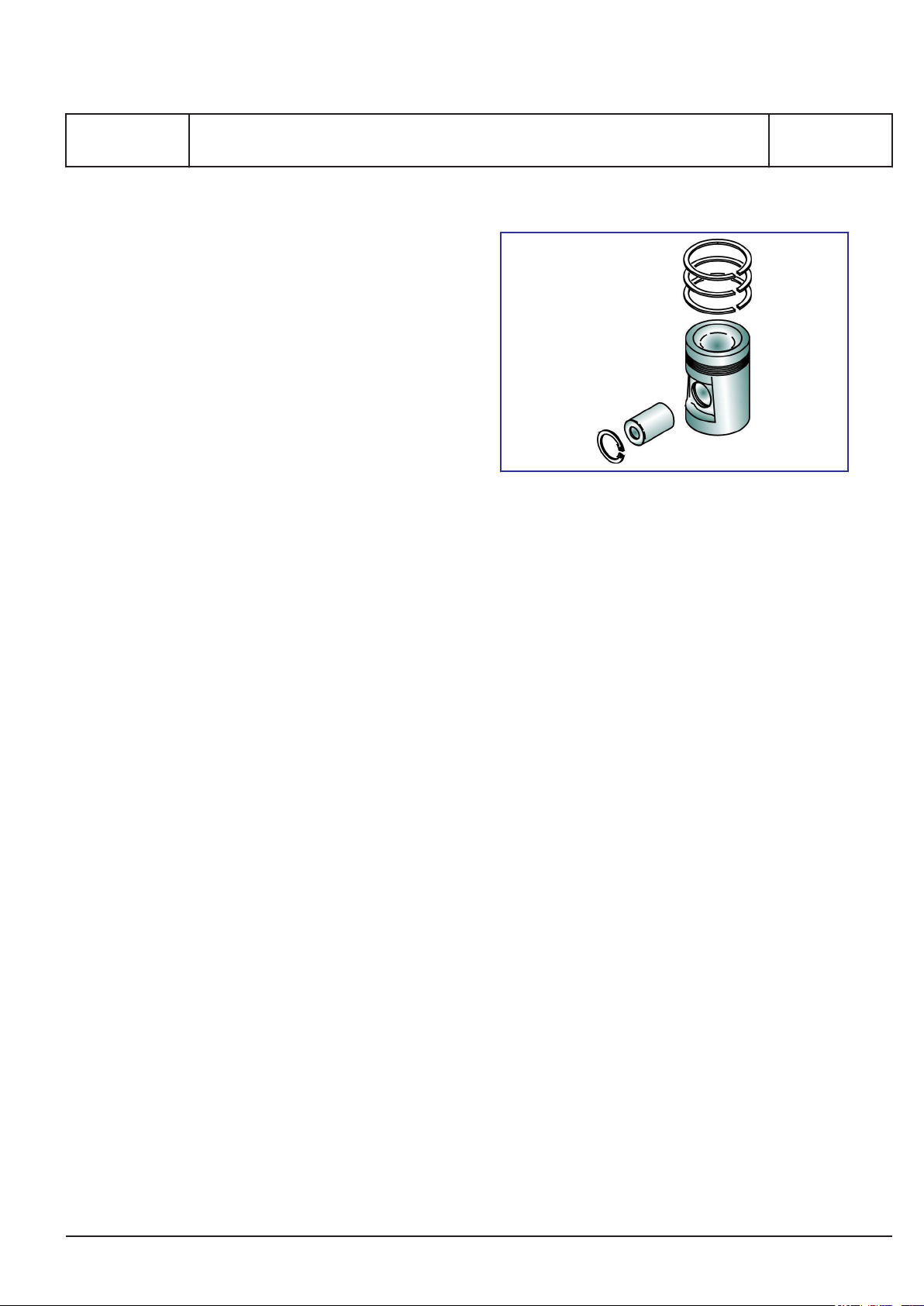

Piston

The piston, which is oil-cooled and of the composite type, has a body made of nodular cast iron and

a crown made of forged deformation resistant steel.

It is fitted with 2 compression rings and 1 oil scraper

ring in hardened ring grooves.

General description

Figure 4: Piston

By the use of compression rings with different barrelshaped profiles and chrome-plated running surfaces, the piston ring pack is optimized for maximum

sealing effect and minimum wear rate.

The piston has a cooling oil space close to the piston crown and the piston ring zone. The heat transfer, and thus the cooling effect, is based on the

shaker effect arising during the piston movement.

The cooling medium is oil from the engine's lubricating oil system.

Oil is supplied to the cooling oil space through

channels from the oil grooves in the piston pin

bosses. Oil is drained from the cooling oil space

through ducts situated diametrically to the inlet

channels.

The piston pin is fully floating and kept in position in

the axial direction by two circlips.

Connecting rod

The connecting rod is of the marine head type.

The joint is above the connecting rod bearing. This

means that the big-end bearing must not be

opened when pulling the piston. This is of advantage for the operational safety (no positional

changes/no new adaption), and this solution also

reduces the height dimension required for piston

assembly / removal.

Connecting rod and bearing body consist of CrMo

steel. They are die-forged products.

The bearing shells are identical to those of the

crankshaft bearing. Thin-walled bearing shells having an AISn running layer are used.

B 10 01 1

L27/38S, L27/38

2015.11.26

Page 64

MAN Diesel & Turbo

B 10 01 1

L27/38S, L27/38

The bearing caps and bearing blocks are bolted

together by waisted bolts.

General description

Camshaft and camshaft drive

The inlet and exhaust valves as well as the fuel

pumps of the engine are actuated by two cam-

shafts.

Due to the two-camshaft design an optimal adjustment of the gas exchange is possible without interrupting the fuel injection timing. It is also possible to

adjust the fuel injection without interrupting the gas

exchange.

The two camshafts are located in the engine frame.

On the exhaust side, in a very high position, the

valve camshaft is located to allow a short and stiff

valve train and to reduce moving masses.

1689477-8.1

Page 4 (7)

Figure 5: Connecting rod.

Crankshaft and main bearings

The crankshaft, which is a one-piece forging with

hardened bearing surfaces to achieve better wear

resistance, is suspended in underslung bearings.

The main bearings are of the trimetal type, which

are coated with a running layer. To attain a suitable

bearing pressure and vibration level the crankshaft

is provided with counterweights, which are attached

to the crankshaft by means of two hydraulic

screws.

At the flywheel end the crankshaft is fitted with a

gear wheel which, through two intermediate wheels,

drives the camshafts.

Also fitted here is a coupling flange for the connection of an alternator. At the opposite end (front end)

there is a gear wheel connection for lube oil and

water pumps.

Lubricating oil for the main bearings is supplied

through holes drilled in the engine frame. From the

main bearings the oil passes through bores in the

crankshaft to the big-end bearings and thence

through channels in the connecting rods to lubricate

the piston pins and cool the pistons.

Figure 6: Twin camshafts.

The injection camshaft is located at the service side

of the engine.

Both camshafts are designed as cylinder sections

and bearing sections in such a way that disassem-

bly of single cylinder sections is possible through

the side openings in the crankcase.

The two camshafts and the governor are driven by

the main gear train which is located at the flywheel

end of the engine. They rotate with a speed which

is half that of the crankshaft.

2015.11.26

Page 65

MAN Diesel & Turbo

1689477-8.1

Page 5 (7)

The camshafts are located in bearing bushes which

are fitted in bores in the engine frame; each bearing

is replaceable and locked in position in the engine

frame by means of a locking screw.

General description

B 10 01 1

L27/38S, L27/38

Figure 7: Front-end box.

The gear wheel for driving the camshaft as well as a

gear wheel connection for the governor drive are

screwed on to the aftmost section.

The lubricating oil pipes for the gear wheels are

equipped with nozzles which are adjusted to apply

the oil at the points where the gear wheels are in