Man D2868 LE433, D2862 LE453, D2862 LE433, D2862 LE423, D2862 LE463 Operating Instructions Manual

...Page 1

Operating Instructions

MAN Marine Diesel Engines

D2868 LE433

D2862 LE433/453

D2862 LE423/443/463

51.99493-8578 “Translation of the original operating instructions”

Page 2

Information and Copyright

Subject to technical alterations in the interests of further development.

Reprinting, copying or translating of these instructions, even in part, is forbidden without written permission

from MAN. All legal copyrights remain the exclusive property of MAN.

© 2011

MAN Truck & Bus AG

Vogelweiherstraße 33

90441 Nürnberg

Germany

Tel.: +49 911 / 420-1745

Fax: +49 911 / 420-1930

E-Mail: engines.components@de.man-mn.com

Internet: www.man-engines.com

Editorial: EMDGG, Technical status: 07.2010

51.99493-8578

2

Page 3

Contents

Information and Copyright 2.................................................................

Contents 3................................................................................

Preface 4.................................................................................

Instructions 5..............................................................................

Declaration 6..............................................................................

Nameplates 7.............................................................................

Safety regulations 8........................................................................

Commissioning and operation 14..............................................................

Engine views V8-1200 (D2868 LE433) 14...................................................

Engine views V12-1800 (D2862 LE433) / V12-1650 (D2862 LE453) 16..........................

Engine views V12-1550 (D2862 LE423) / V12-1400 (D2862 LE443) / D2862 LE463) 18............

First commissioning 20....................................................................

Commissioning 22........................................................................

Starting 23..............................................................................

Operation monitoring system 24............................................................

Shutting down 98.........................................................................

Page

Maintenance and care 99....................................................................

Lubrication system 99.....................................................................

Fuel system 104..........................................................................

Cooling system 108........................................................................

Alternator 115.............................................................................

Temporary decommissioning of engines 115..................................................

Technical data 116...........................................................................

Troubleshooting table 128.....................................................................

Index 130...................................................................................

3

Page 4

Preface

Dear Customer,

these Operating Instructions are intended to familiarize you with your new MAN Diesel engine and how it

operates.

This manual is supplemented by the publication “Fuels, Lubricants and Coolants for MAN Diesel Engines"

and the “Service record book".

Note:

All three publications belong to the engine and must always be kept ready to hand near the en

gine in the engine room.

Comply in full with instructions relating to operation, prevention of accidents and environmental

protection.

MAN Diesel engines are developed and manufactured in line with the latest state of the art. However,

trouble-free operation and high performance can only be achieved if the specified maintenance intervals

are observed and only approved fuels, lubricants and coolants are used.

Note:

Only use fuels, lubricants etc. in accordance with MAN's regulations.

Otherwise the manufacturer's liability for defects will not apply!

For basic information on the fuels see the publication “Fuels, Lubricants and Coolants for MAN

Diesel Engines".

You can find the approved products in the internet under:

https://mmrepro.mn.man.de/bstwebapp/BSTServlet

It is imperative and in your own interest to entrust your MAN Local Service Centre with the removal of any

disturbances and with the performance of checking, setting, and repair work.

Yours faithfully,

MAN Truck & Bus AG

Werk Nürnberg

4

Page 5

Instructions

Important instructions which concern technical safety and protection of persons are emphasised as shown

below.

Danger:

This refers to working and operating procedures which must be complied with in order to rule out

the risk to persons.

Caution:

This refers to working and operating procedures which must be complied with in order to prevent

damage to or destruction of material.

Note:

Explanations useful for understanding the working or operating procedure to be performed.

5

Page 6

Declaration

6

Page 7

Nameplates

In all your correspondence please always quote en

gine model, serial number and job number (Order

number).

For this reason it is advisable to read off the data

from the engine type plates before putting the engine

into operation and to enter them in the appropriate

spaces.

The engine type plates are on the crankcase (see

illustration).

MAN Nutzfahrzeuge Aktiengesellschaft

Type

Engine No. / Engine No.

NI/II

Model

......................................................................

delivered on

......................................................................

installed on

......................................................................

Engine serial number

......................................................................

Order number

......................................................................

Temp. C

°

MAN Nutzfahrzeuge AktiengesellscMAN Nutzfahrzeuge Aktiengesellschaft

Nürnberg Works, Germany

Job No Rating kW

Power kWWorks No.

:

Engine No.TypeYear of manufacture.

Eng. speed 1/min

Operating altitude m uNNPower. PS

:

Speed rpm

:

Altitude mRating BHP

7

Serial NoModelYear

−0219

Page 8

Safety regulations

General notes

Handling diesel engines and the necessary resources is no problem when the personnel commis

sioned with operation and maintenance are trained accordingly and use their common sense.

This summary is a compilation of the most important regulations. These are broken down into main sec

tions which contain the information necessary for preventing injury to persons, damage to property and pol

lution. In addition to these regulations those dictated by the type of engine and its site are to be observed

also.

Important:

If, despite all precautions, an accident occurs, in particular through contact with caustic acids, fuel penetrat

ing the skin, scalding from hot oil, anti‐freeze being splashed in the eyes etc., consult a doctor immedi

ately.

1. Regulations designed to prevent accidents with injury to persons

During commissioning, starting and operation

D Before putting the engine into operation for the first time, read the operating instructions

carefully and familiarize yourself with the “critical" points. If you are unsure, ask your

MAN representative.

D For reasons of safety we recommend you attach a notice to the door of the engine

room prohibiting the access of unauthorized persons and that you draw the attention of

the operating personal to the fact that they are responsible for the safety of persons

who enter the engine room.

D The engine must be started and operated only by authorized personnel.

Ensure that the engine cannot be started by unauthorized persons.

D When the engine is running, do not get too close to the rotating parts. Wear close‐fitting

clothing.

D Do not touch the engine with bare hands when it is warm from operation - risk of burns.

D Exhaust gases are toxic. Comply with the instructions for the installation of MAN Diesel

engines which are to be operated in enclosed spaces. Ensure that there is adequate

ventilation and air extraction.

D For safety reasons a separate, functioning red emergency‐stop‐button for each

engine must be installed at every bridge (the engine must stop immediately when

the button is pressed once).

8

Page 9

Safety regulations

ËË

ËË

D Electrical accessories and equipment from other manufactures may only be

connected without the approval of MAN to the connections provided for the cu

stomer or shipyard.

The control of the engine may be adversely affected and thus may lead to property

damage or personal injury and is therefore not permitted.

MAN assumes no liability for any property damage or personal injury.

Connections to the following MAN components are prohibited:

- EDC engine control unit (K-Line, CAN-Bus)

- MAN internal or external throttle lever control system (CAN-Bus)

- Emergency steering control (serial, CAN-Bus)

- Display systems for alarms (serial, CAN-Bus)

Approved connectors on terminal box: X4, X8 and X9.

D Keep vicinity of engine, ladders and stairways free of oil and grease.

Accidents caused by slipping can have serious consequences.

During maintenance and care

D Always carry out maintenance work when the engine is switched off.

If the engine has to be maintained while it is running, e.g. changing the elements of

change‐over filters, remember that there is a risk of scalding. Do not get too close to ro

tating parts.

D Change the oil when the engines is warm from operation.

Caution:

There is a risk of burns and scalding. Do not touch oil drain plugs or oil filters with bare

hands.

D Take into account the amount of oil in the sump. Use a vessel of sufficient size to en

sure that the oil will not overflow.

D Open the coolant circuit only when the engine has cooled down.

If opening while the engine is still warm is unavoidable, comply with the instructions in

the chapter entitled “Maintenance and Care".

D Neither tighten up nor open pipes and hoses (lube oil circuit, coolant circuit and any ad

ditional hydraulic oil circuit) during the operation.

The fluids which flow out can cause injury.

D Fuel is inflammable. Do not smoke or use naked lights in its vicinity. The tank must be

filled only when the engine is switched off.

D When using compressed air, e.g. for cleaning the radiator, wear goggles.

D Keep service products (anti‐freeze) only in containers which can not be confused with

drinks containers.

9

Page 10

Safety regulations

D Comply with the manufacturer's instructions when handling batteries.

Caution:

Accumulator acid is toxic and caustic. Battery gases are explosive.

2. Regulations designed to prevent damage to engine and premature wear

Do not demand more from the engine than it is able to supply in its intended application. Detailed informa

tion on this can be found in the sales literature.

If faults occur, find the cause immediately and have it eliminated in order to prevent more serious damage.

Use only genuine MAN spare parts. MAN will accept no responsibility for damage resulting from the install

ation of other parts which are supposedly “just as good".

In addition to the above, note the following points:

D Never let the engine run when dry, i.e. without lube oil or coolant.

D When starting do not use any additional starting aids (e.g. injection with starting pilot).

D Use only MAN‐approved service products (fuel, engine oil, anti‐freeze and anti‐corrosion agent). Pay at

tention to cleanliness. The Diesel fuel must be free of water. See “Maintenance and care".

D Have the engine maintained at the specified intervals.

D Today modern components of diesel injection consist of high‐precision parts which are exposed to ex

treme stresses. The high‐precision technology requires the utmost cleanliness during all work on the

fuel system.

Even a particle of dirt over 0,2 mm can lead to the failure of components.

D Do not switch off the engine immediately when it is warm, but let it run without load for about 5 minutes

so that temperature equalization can take place.

D Never put cold coolant into an overheated engine. See “Maintenance and care".

D Do not add so much engine oil that the oil level rises above the max. marking on the dipstick.

Do not exceed the maximum permissible tilt of the engine.

Serious damage to the engine may result if these instructions are not adhered to.

D Always ensure that the testing and monitoring equipment (for battery charge, oil pressure, coolant tem

perature) function satisfactorily.

D It is advisable to switch off the engine if an alarm of any kind is displayed in the engine monitoring and

diagnostic system. If this is not possible for any reason, the engine should be run no faster than 1200

rpm until the fault is remedied, see page 24.

D Comply with instructions for operation of the alternator. See “Maintenance and care".

D Do not let the seawater pump run dry. If there is a risk of frost, drain the pump when the engine is

switched off.

10

Page 11

Safety regulations

3. Regulations designed to prevent pollution

Engine oil and filter elements / cartridges, fuel / fuel filter

D Take old oil only to an old oil collection point.

D Take strict precautions to ensure that no oil or Diesel fuel gets into the drains or the ground.

Caution:

The drinking water supply could be contaminated.

D Filter elements are classed as dangerous waste and must be treated as such.

Coolant

D Treat undiluted anti‐corrosion agent and / or anti‐freeze as dangerous waste.

D When disposing of spent coolant comply with the regulations of the relevant local authorities.

4. Notes on safety in handling used engine oil ∗

Prolonged or repeated contact between the skin and any kind of engine oil decreases the skin. Drying, irrit

ation or inflammation of the skin may therefore occur. Used engine oil also contains dangerous substances

which have caused skin cancer in animal experiments. If the basic rules of hygiene and health and safety

at work are observed, health risks are not to the expected as a result of handling used engine oil.

Health precautions:

D Avoid prolonged or repeated skin contact with used engine oil.

D Protect your skin by means of suitable agents (creams etc.) or wear protective gloves.

D Clean skin which has been in contact with engine oil.

- Wash thoroughly with soap and water. A nailbrush is an effective aid.

- Certain products make it easier to clean your hands.

- Do not use petrol, Diesel fuel, gas oil, thinners or solvents as washing agents.

D After washing apply a fatty skin cream to the skin.

D Change oil‐soaked clothing and shoes.

D Do not put oily rags into your pockets.

Ensure that used engine oil is disposed of properly

- Engine oil can endanger the water supply -

For this reason do not let engine oil get into the ground, waterways, the drains or the sewers. Violations are

punishable.

Collect and dispose of used engine oil carefully. For information on collection points please contact the

seller, the supplier or the local authorities.

∗ Adapted from “Notes on handling used engine oil".

11

Page 12

Safety regulations

5. Special instructions when working on the common rail system

Accident protection

D Risk of injury!

Fuel jets can cut through skin.

The atomisation of fuel creates a fire risk.

- When the engine is running never loosen the screw connections on the fuel's

high‐pressure side of the common rail system (injection line from the high‐pressure

pump to the rail, on the rail and on the cylinder head to the injector)

- Keep away from the engine when it is running

D Risk of injury!

When the engine is running the lines are constantly under a fuel pressure of up

to 1600 bar.

- Wait at least a minute until the pressure in the rail has dropped before loosening a

screw connection

- If necessary check the pressure drop in the rail with MAN‐Cats

D Risk of injury!

- People with pacemaker must keep at least 20 cm away from the running engine.

- Do not touch live parts on the electric connection of the injectors when the engine is

running.

Cleanliness

Today modern components of diesel injection consist of high‐precision parts which are exposed to extreme

stresses. The high‐precision technology requires the utmost cleanliness during all work on the fuel sys

tem.

Even a particle of dirt over 0,2 mm can lead to the failure of components.

The measures described as follows are therefore essential before work begins:

Risk of damage from penetration of dirt!

D Before working on the clean side of the fuel system clean the engine and the engine

compartment. During cleaning the fuel system must be closed.

D Carry out visual inspection for any leakage or damage to the fuel system

D Do not spray the high‐pressure cleaner direct onto the electric components, or alternati

vely keep them covered

D Do not carry out any welding or sanding work in the engine compartment during mainte

nance / repair

12

Page 13

Safety regulations

D Avoid air movements (any swirling of dust when starting engines)

D The area of the still closed fuel system must be cleaned and dried with the aid of com

pressed air

D Remove detached particles of dirt such as paint chippings and insulation material with a

suitable extractor (industrial type vacuum cleaner)

D Cover areas of the engine compartment from which dust particles could be detached

with clean foil

D Wash your hands and put on clean work clothes before starting the disassembly work

When carrying out the work it is essential to comply with the following measures:

Risk of damage from penetration of dirt!

D When the clean side of the fuel system has been opened it is not permissible to use

compressed air for cleaning

D During assembly work loose dirt must be removed with the aid of suitable extractors (in

dustrial type vacuum cleaners)

D Use only fluff‐free cleaning cloths on the fuel system

D Clean tools and working materials before starting to work

D Only tools without any damage may be used (cracked chrome coatings)

D When removing and installing components do not use materials such as cloths, cardbo

ard or wood since these could shed particles and fine fibres

D If any paint chips/flakes off when connections are loosened (from possible over‐coating)

these chippings must be carefully removed before finally loosening the screw connec

tion

D The connection openings of all parts removed from the clean side of the fuel system

must be immediately closed up with suitable caps/stoppers

D These caps/stoppers must be packed protected from dust prior to use and after being

used once they must be disposed of

D Following this all the components must be carefully stored in a clean, closed container

D Never use used cleaning or testing liquids for these components

D New parts must not be removed from their original packing material until directly before

use

D Work on removed components may be carried out only at a workplace specially equip

ped for it

D If removed parts are shipped always use the original packing material of the new part

13

Page 14

Commissioning and operation

Engine views V8-1200 (D2868 LE433)

2

3

4

10

5

6

7

1

9

8

3

8

11

12

10

14

Page 15

(1) Poly-V-belt guard

(2) Air filter

(3) Coolant filler neck

(4) Main fuse for voltage supply

(5) Oil drain valve engine

(6) Oil drain valve gearbox

(7) Oil filler neck

Commissioning and operation

(8) Oil filter

(9) Oil dipstick

(10) Fuel filter

(11) Sea water pump

(12) Engine terminal box EDC

15

Page 16

Commissioning and operation

Engine views V12-1800 (D2862 LE433) / V12-1650 (D2862 LE453)

2

3

4

5

6

1

9

8

7

3

8

10

11

12

10

16

Page 17

(1) Poly-V-belt guard

(2) Air filter

(3) Coolant filler neck

(4) Main fuse

(5) Oil drain valve gearbox

(6) Oil drain valve engine

(7) Oil filler neck

Commissioning and operation

(8) Oil filter

(9) Oil dipstick

(10) Fuel filter

(11) Sea water pump

(12) IEngine terminal box EDC

17

Page 18

Commissioning and operation

Engine views V12-1550 (D2862 LE423) / V12-1400 (D2862 LE443) / D2862 LE463)

2

3

4

5

6

1

9

8

7

3

8

11

10

12

18

Page 19

(1) Poly-V-belt guard

(2) Air filter

(3) Coolant filler neck

(4) Oil drain valve gearbox

(5) Main fuse

(6) Oil drain valve engine

(7) Oil filler neck

Commissioning and operation

(8) Oil filter

(9) Oil dipstick

(10) Fuel filter

(11) Sea water pump

(12) IEngine terminal box EDC

19

Page 20

Commissioning and operation

First commissioning

When putting a new or overhauled engine into operation for the first time pay attention to the “Installation

instructions for MAN marine diesel engines" without fail.

It is recommended that new or overhauled engines should not be operated at a load higher than about 75%

maximum load during the first few hours of operation. Initial run-in should be at varying speeds. After this

initial run-in, the engine should be brought up to full output gradually.

Caution:

Use only approved fuels, lubricants etc. (see brochure Fuels, lubricants etc."). Otherwise the liab

ility for defects will become null and void!

Filling with fuel

Caution:

Fill the tank only when the engine is switched off. Pay attention to cleanliness. Do not spill fuel.

Use only approved fuels, see brochure Fuels, lubricants etc.".

Filling-in of coolant

Fill the cooling system of the engine with a mixture of drinkable tap water and anti-freeze agent on the

ethylene glycole basis or anti-corrosion agent.

See Publication “Fuels, Lubricants and Coolants for MAN Diesel Engines".

D Pour in coolant slowly via expansion tank, see page 110

D Coolant filling quantity - see “Technical data", from page 101

20

Page 21

Commissioning and operation

Seawater pump

Do not let seawater pump run dry!

Make sure that all valves / cocks in the seawater

circuit are open.

If there is a risk of frost, drain the seawater pump.

Refilling with oil

The engines are as a rule supplied without oil.

Pour oil into engine via filler neck, see page 103.

Caution:

Do not add so much engine oil that the oil

level rises above the max. marking on the

dipstick. Overfilling will result in damage

to the engine.

Oil filling quantity - see “Technical data", from

page 101.

21

Page 22

Commissioning and operation

Commissioning

Before daily starting the engine, check fuel level, coolant level and engine oil level and replenish, if neces

sary.

Caution:

Use only approved fuels, lubricants etc. (see brochure Fuels, lubricants etc."). Otherwise the liab

ility for defects will become null and void!

Checking oil level

Check engine oil level only approx. 20 minutes

after the unit has been switched off.

DPull out dipstick (arrow)

D wipe it with a clean, lint-free cloth

D and push it in again up to the stop

D Pull out dipstick again

The oil level should be between the two notches in

the dipstick and must never fall below the lower

notch.

Caution:

Do not add so much engine oil that the oil

level rises above the max. marking on the

dipstick. Overfilling will result in damage

to the engine.

Ensure utmost cleanliness when handling fuels,

lubricants and coolants.

Oil

?

MAX

MIN

22

Page 23

Commissioning and operation

Starting

Danger:

Before starting make sure that no-one is in the engine's danger area.

Caution:

When starting do not use any additional starting aids (e.g. injection with starting pilot).

There are two possibilities to start the engine: using the ignition lock or using the Start" button.

Starting via the ignition lock:

Ensure that the gearbox is in neutral.

Insert the ignition key and turn it to position I". Readiness for operation is indicated by an indicator lamp

lighting up.

Turn ignition key on until stop (position “III" depending on starter lock) starter is activated.

Lube oil pressure must build up at the oil pressure gauge. If it does not, switch off the engine immediately.

Do not operate starter for longer than 10 seconds at a time.

After ignition of the engine, release the starter button and adjust control lever for desired speed.

If engine fails to start, release the key, wait about 30 seconds, then operate starter again.

For repeated starting turn the key back to “0".

If the engine is kept idling for long periods it may cool down and thus start to emit white or blue smoke.

We therefore recommend that you do not let the engine idle for more than 5 minutes.

It is well known that with any internal combustion engine wear is higher during idling.

Prolonged idling is harmful to the environment.

Starting via the button:

Ensure that the gearbox is in neutral.

Press the “IGN ON/OFF“ button. Readiness for operation is indicated by an indicator lamp lighting up.

Actuate “Engine Start“ button. Starter runs up and the control light goes out.

Lube oil pressure must build up at the oil pressure gauge on the display. If it does not, switch off the engine

immediately.

Do not operate starter for longer than 10 seconds at a time.

After starting the engine, let go of the Start button and set the adjustment lever to the desired speed.

If the engine has not started, wait approx. 30 seconds before pressing the Start" button again to operate

the starter motor.

If the engine is kept idling for long periods it may cool down and thus start to emit white or blue smoke.

We therefore recommend that you do not let the engine idle for more than 5 minutes.

It is well known that with any internal combustion engine wear is higher during idling.

Prolonged idling is harmful to the environment.

23

Page 24

Commissioning and operation

Operation monitoring system

Caution:

Do not exceed the maximum permissible engine tilt. If faults occur, find their cause immediately

and have them eliminated in order to prevent more serious damage!

If an engine / gearbox alarm is displayed on the monitoring devices, the engine is to be turned off

or, i.e. operated at low load at max. 1200 rpm.

When the following alarms are displayed

- engine oil pressure / reduction of lubrication oil pressure

- engine coolant temperature / overheating of engine coolant

- engine charge-air temperature

the engine is to be turned off immediately and the cause of the fault properly remedied, i.e. in a

specialist workshop.

Do not put this engine into operation again until the fault has been eliminated.

The engine is equipped as series standard with a monitoring and diagnostic system MAN-Marine-Dia

gnose-System (MMDS.

On the control console and alternatively on other control consoles, the following display devices are avail

able for monitoring operation:

1. Engine room panel, see page 26

CAN bus-controlled display devices:

2. CAN-Bus round instruments, see page 29

3. Display device MMDS-CLC 6.5, see page 33

4. MMDS-CLC 6.5 ship's alarm display, see page 48

Display units supported by PC:

5. Display device MMDS-CMS, see page 55

For operation and speed adjustment, MAN provides the following equipment:

6. Drive lever control system Marine Power Control (MPC), see page 75

6.1. Mobile navigating console, see page 88

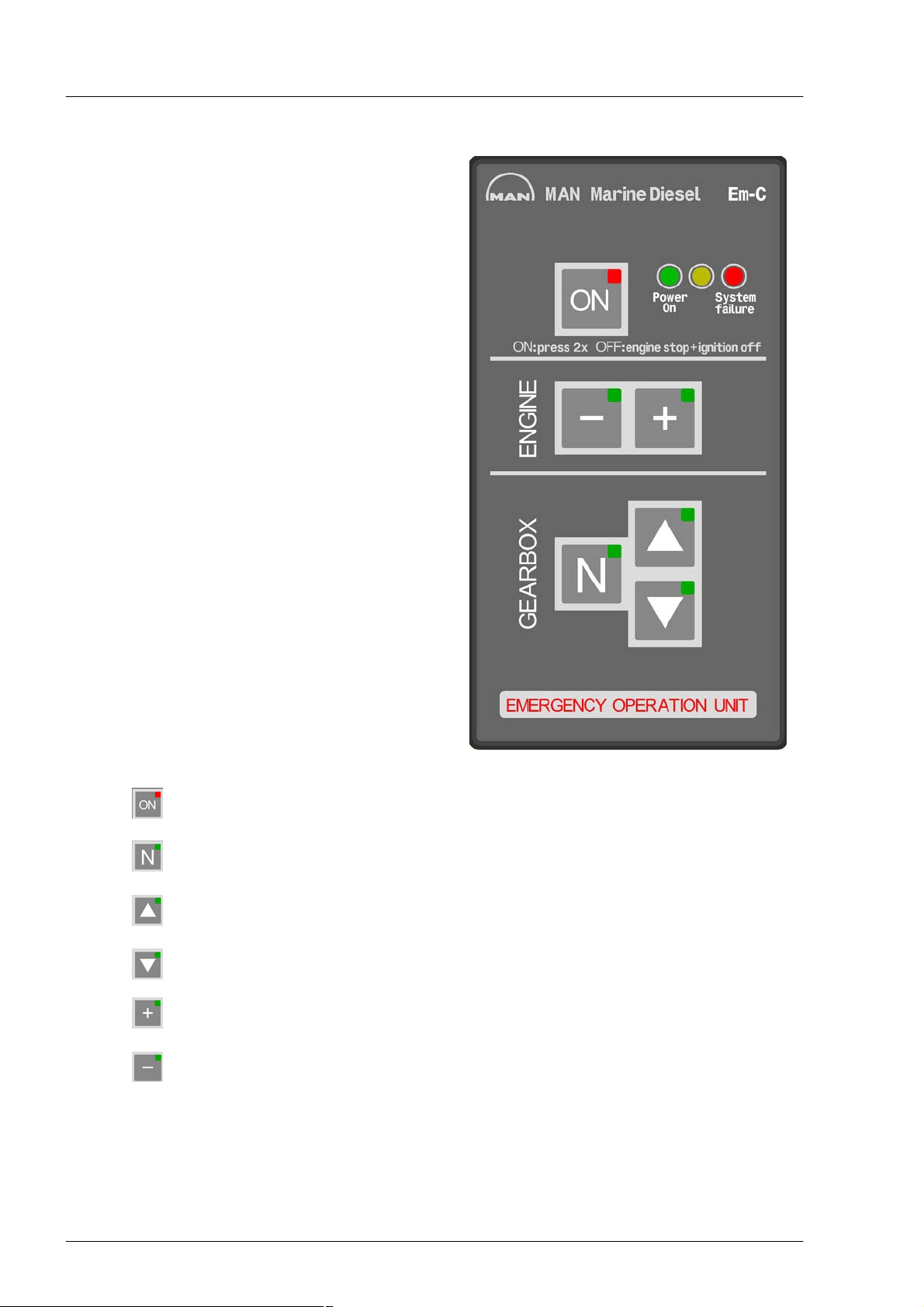

7. Optional: emergency unit Em (Emergency), see page 92

7.1. Override button for MMDS-CR and MMDS-BE3 systems, see page 96

24

Page 25

Commissioning and operation

Differences in operating parameters of engines and gearboxes

Differences in parameters can be observed on identical engines, irrespective if they are installed in one

boat or in different boats (boat series), such as

D pressures

D temperatures

D speeds

D fuel consumption

D injection quantity

D Load

D relative load

D control head signal

D oil level of engine and gearbox

D engine coolant level

D battery and charging voltage

The same applies to a single V-engine (e.g. exhaust temperatures before turbine, l.h. and r.h. side cylinder

banks).

These differences may be caused by

D component tolerances of the mechanical and electrical engine components

D design-related influences on engines (this applies especially to the exhaust temp.)

D external influences such as fuel supply, air supply and coolant supply

D installation conditions, hull characteristic and flow, exhaust system

D differences in the propeller and stern gear.

Under normal conditions this does not have any negative impact on the engine's operating safety. If the op

erating parameters are in an impermissible range, this is indicated by appropriate alarms of the diagnostic

system.

The same applies to the gearbox parameters.Please note that especially differences in the oil temperature

may arise on gearboxes running in clockwise or anticlockwise direction.

25

Page 26

Commissioning and operation

1. Engine room panel (integrated LC display “IGN ON/OFF"-button,

Start"-button, “Set+ Set-"-button and emergency stop switch)

The engine room panel is optionally available and serves to display engine and gearbox data, as well as

system information. In order to obtain the full functionality of an engine room panel, as well as the display

additional function buttons are integrated for the control of the ignition. starting the engine and for engine

speed adjustment.

5

1

4

2

3

(1) Set +

(2) Set -

(3) Emergency stop

Function “Ignition ON/OFF" (5) (yellow button)

After activated ignition at the control console, the ignition in the engine room is switched on and off with the

yellow buttons “IGN ON/OFF" (5).

If the ignition is not activated at the bridge or flybridge, the button has no function.

(4) Start

(5) ING (Ignition)

Activation of the ignition is indicated by the internal yellow lighting of the button. Only when the ignition has

been activated at the bridge is the yellow button “IGN ON/OFF" (5) of the engine room panel enabled.

Caution:

Ignition off ⇒ engine stop

26

Page 27

Commissioning and operation

Function “Start" (4) (green button)

With the ignition switched on, the engine can be started by pressing the green button “Start" (4).

The button lights up green when the ignition is switched on.

Function “Stop" (5) (yellow button)

Actuation of the yellow button “IGN ON/OFF" (5) stops the engine.

Function “Emergency stop“ (3)

Pressing the emergency stop switch (3) in the cover of the terminal box shuts the engine down immedi

ately. To unlock the emergency stop switch (3), turn the cap of the switch clockwise.

Then the ignition must be switched off and on again, in order to restart the engine.

Engine speed adjustment:

Function “Set +" (1)

By actuating the button “Set +" (1) with the engine running, the engine speed is increased.

Function “Set -" (2)

By actuating the button “Set -" (2) with the engine running, the engine speed is reduced.

Activation of the intermediate speed function:

Press “Set +" and “Set -" simultaneously, until both buttons flash.

To confirm, press both buttons again. Both buttons now light continuously.

Deactivation of the intermediate speed function:

By actuating the yellow button “IGN ON/OFF" (5) the intermediate engine speed function is terminated.

The intermediate engine speed function is carried out in similar fashion on the emergency unit, see

page 92.

27

Page 28

Commissioning and operation

Optional

External LC display of the ship-vehicle management computer (SFFR) in the cover of the engine

terminal box

Alarms and their codings can be indicated via the external LC display of the ship-vehicle management com

puter and communicated to our customer service organisation.

If an active MMDS alarm occurs the corresponding MMDS alarm page will be indicated automatically and

can be exited only after confirmation.

Flashing light , Indication of EDC, SFFR fault with high priority.

Permanent light , Indication of EDC, SFFR fault with low priority.

Flashing light Active, non-confirmed MMDS alarm

Permanent light Active, confirmed MMDS alarm

Operation of the external LC display of the ship-vehicle management computer

Operating button for calling up menu if no active, non-confirmed MMDS alarm is indic

ated.

For navigating in the menu, for indicating next or previous fault.

Confirmation of selection.

Acoustic acknowledgement of all monitoring devices connected to the same CAN bus.

For visual acknowledgement of an MMDS alarm.

For sending a resetting signal to the central MMDS unit.

28

Page 29

Commissioning and operation

CAN bus-controlled display devices:

2. CAN-Bus round instruments, rev counter with information display and buttons

D Rev counter (0-3000 rpm) with integrated LCD display for the following parameters and buttons for pa

ging:

- Engine oil pressure

- Gearbox oil pressure

- Coolant temperature

- Engine oil temperature

- Engine exhaust temperature

- Charge air temperature

- Boost pressure

- Load

- Hours of operation

- Fuel consumption

- Battery voltage

D Oil pressure engine 0-10 bar

D Gearbox oil pressure 0-25 bar

D Oil temperature engine 50--150°C

D Coolant temperature engine 40-120°C

D Exhaust temperature engine 100-900°C

D Battery voltage 18-32 V

29

Page 30

Commissioning and operation

Tachometer CAN-Master

The VDO Ocean Link Tachometer (CAN-Bus Tachometer)

The VDO Ocean Link tachometer is a multifunctional instrument for

indicating engine data, and is intended for use in navigation of sports

ships. The tachometer shows the actual engine speed in operation,

on the analogue scale. Further values and operating aids appear in

the LC display.

The instrument has a push-button on the front side, with which all

the functions can be selected. Handling of the instrument is thus

easy and uncomplicated.

LC‐Display Push button key

Main Functions

The main functions of the VDO Ocean Link can be called up by pressing the push-button. Each time the

button is pressed, the next measured value is displayed.

- Engine oil pressure - Charge air temperature

- Gearbox oil pressure - Charge air pressure

- Coolant temperature - % Load

- Engine oil temperature - Running time

- Exhaust gas temperature b. turbine 1 - Current fuel consumption

- Exhaust gas temperature b. turbine 2 - Battery voltage

- Exhaust gas temperature after turbine

The exhaust temperature to be displayed must be set when the display messages (Screen on / off).

30

Page 31

Commissioning and operation

Setting possibilities

Further settings can be made by pressing the button:

D Selection of illumination intensity in 8 steps

D Selection of display unit in metric or English units

D Selection of transmitters for the analogue inputs

Selection of illumination intensity

If you keep the push-button pressed for 4 seconds, the scroll bar for the illumination setting appears.

By repeatedly pressing the key, you can change the illumination of the tachometer and the connected bus

display in 8 steps. The display jumps back to the normal operating mode 8 seconds after the last time the

button is pressed. The illumination setting is retained even after switching the power supply off and on

again. Please note that setting of the illumination is possible only if external illumination is set to “Internal"

in the settings menu, see page 32.

Basic Settings

The basic settings necessary for perfect operation can be selected in the settings. These are obtained by

pressing and holding the button while switching on the power supply of the display.

Display Units: Selection of display unit

Screens on / off: Selection of display

Simulator Mode: activation of simulator mode

Exit Setup: exits the setting menu

In order to change a value (e.g. from NO to YES) press the button briefly.

In order to not change a value, keep the button pressed until the set value flashes once. Then release the

button immediately. This adopts the displayed setting. If the button is not pressed, the displayed setting is

automatically adopted after 10 seconds.

Selection of the display units)

The values for temperatures and pressures can be displayed alternatively in the units °C/bar

(METRIC) or °F/psi (ENGLISH). Selection of the units is carried out as follows:

In the example shown the unit is changed from METRIC to ENGLISH.

DISPLAY UNITS

Press key

METRIC

DISPLAY UNITS

ENGLISH

31

Page 32

Commissioning and operation

Setting the illumination (external illumination)

Select here whether illumination of the tachometer and the connected bus instruments are to be connected

internally or externally.

EXTERNAL: The illumination is switched on and off through an input of the 14-pin plug.

Dimming of the illumination is thus not possible.

INTERNAL: The illumination is regulated in the normal operating mode by pressing and

holding the push-button key in 8 steps.

Selection of the displays (Screen on / off)

Select here which measured values are to be displayed in the normal operating mode.

YES: Here all measured values, with their ISO symbol, are displayed. By selecting

NO", the measured value can be removed from the normal operating mode.

If the measured value is to be displayed again, select YES" when the ISO

symbol of the measured value is displayed

NO: No change in the setting are made.

Activation of the simulation mode (simulator mode)

Select here whether the simulation mode is to be switched on.

YES: The simulation mode is switched on. The display now generates random va

lues for all measuring channels and displays these. The measured values are

also transmitted to the bus instruments.

NO: The simulation mode is switched off.

Please note that the simulation mode still remains after switching off and switching on again, if it has not

been switched off by selecting NO.

Setting of the number of exhaust gas temperature measured values (Charge Boost Amount)

Select here whether one or two measured values are to be displayed for the exhaust gas temperature be

fore the turbine.

1: One exhaust gas temperature measured value.

2: Two exhaust gas temperature measured values. (V-engines)

Ending the settings (exit setup)

Select here whether the settings are to be exited.

YES The settings are exited, the display restarts in the normal operating mode.

NO The settings are restarted.

32

Page 33

Commissioning and operation

3. MMDS-CLC 6.5 display device (colour display)

Introduction

This document describes how the MMDS-CMS 6.5 colour display with MMDS-CLCB 6.5 remote control op

erates and is used in its application as an engine display to monitor engine operation. Fitting, mounting and

installation are explained in separate instructions for the unit.

The engine and gearbox data are shown on the colour display in the form of dials and digital displays.

LED symbols are used to display alarms; these are complemented by a table which lists all alarms present

with more detailed information.

A logo which will be displayed on all pages may be activated when installed. The shipyard can select this

logo selection itself (see page 47).

Function

The colour display is automatically activated when the supply voltage is applied. It can then be switched on

and off manually using the “Power" button . The other alarm functions such as the alarm relay

and the internal buzzer and the acknowledge button remain operative.

The engine speed display incorporates a damping algorithm to simulate mechanical instruments.

This means that small variations do not lead to an unstable display, which could irritate the officer con

trolling the ship.

33

Page 34

Commissioning and operation

Pre-Start page

The display is activated by switching the ignition on and the following Pre-Start page is displayed.

Pre-Start page

If a button is actuated or the engine started, the display switches to the basic display.

Pre-Start page with active acknowledged alarms

Should active acknowledged alarms arise, these are indicated by a red triangle. The number corresponds

to the number of alarms that have arisen.

34

Page 35

Commissioning and operation

Pre-Start page in the warning and alarm range.

If a value represented on the Pre-Start page reaches the warning or alarm range, the colour of the picto

graph changes to red. In the example shown the gearbox is not in the neutral position.

35

Page 36

Commissioning and operation

Basic display

On starting the engine the start page is called up automatically, indicating engine speed, coolant temperat

ure and oil pressure in the form of round instruments and also in digital format. The calculated fuel con

sumption is represented bottom, right.

Basic display

Engine and gearbox data are represented as digital display values or bar displays on three further pages.

The pages are selected with the buttons and

Page 2

Page 2

36

Page 37

Commissioning and operation

Page 3

The exhaust gas temperature values “Exhaust gas v. Turbo", and the operating hours counter are presen

ted on page 3.

Page 3

Page 4

Page 4 displays the daily fuel consumption counter “Trip".

Page 4

37

Page 38

Commissioning and operation

Buttons

Figure: Numbering of the operating buttons

1

2

3

4

5

6

Operational functions and configuration

The operation of the system and the display adjustment is carried out with the display buttons or the re

mote control MMDS-CLCB 6.5.

The following functions are incorporated:

Standard function: Call the alarms table, or browse to further alarm pages.

Additional function: If pressed longer than 5 seconds ⇒ Switches configuration menu on and off.

Standard function: Page back to the previous page

Additional dimming function: On simultaneous actuation of the buttons (4) and (3)

the brightness is reduced.

Additional function in the menu: Change parameter / reduce value.

Standard function: page up to the next page.

Additional dimming function: On simultaneous actuation of the buttons (4) and (2)

the brightness is increased.

Additional function in the menu: Change parameter / increase value.

Standard function: Acoustic and optical acknowledgement of all monitoring devices connected to

the same CAN-Bus.

Additional dimming function: Adjustment of the brightness on simultaneous actuation of the but

tons and .

Test function: If currently no alarm is on, or if all alarms have previously been optically acknowled

ged, after an actuation for longer than 5 seconds a horn test is carried out, i.e. the internal sum

mer and the horn relay are activated for the duration of the button press.

38

Page 39

Commissioning and operation

Standard function: A reset signal is sent via the CAN bus to the engine monitoring and diagnostic

system control unit (engine terminal box) or to a data station. As long as the appropriate criteria

are fulfilled, the engine slow down or shutdown alarms arising are reset.

Additional function in the menu: Accept change and pass to the next parameter.

Function (Actuation for approx. 3 seconds): Switch-on and switch-off of the display (display only,

not on remote operation).

Additional display function (Brief actuation): Insertion of the info. display for approx. 5 seconds

39

Page 40

Commissioning and operation

Alarms

Definition of alarm condition

An alarm is triggered when a monitored value exceeds or fails to reach its set limit value.

Should an alarm condition occur, an alarm table is automatically displayed. This lists all advance warnings,

alarms and sensor fault alarms. An internal buzzer and the horn relay are activated at the same time.

The collective alarm relay issues a repeat pulse if another alarm was already active. In this way, it is pos

sible to activate a visual call system for each new alarm or to send a telephone message if the ship is not

occupied. Acoustic acknowledgement with the (4) button switches the internal buzzer off and the

horn relay drops out.

Alarm acknowledgements and reset signals are sent on the CAN bus to the engine monitoring and dia

gnostic system Diagnostics unit and to all the monitoring devices subscribing to the same CAN bus. All the

equipment thus has the same alarm status.

So long as the values are displayed in white, the values are in their “normal ranges". On reaching a prelim

inary alarm the digital value flashes orange, with a main alarm red, and in the case of a sensor fault a yel

low flashing “SE" appears. On pressing the optical acknowledgement (Button (4)) all the flashing

displays revert to a continuously lit condition. When the fault has been eliminated and both acoustically and

optically acknowledged (button (4)), the alarm display reverts to the “Normal condition".

Normal Advance war

Figure: Example of the display of the engine oil pressure with alarm indication

The engine monitoring and diagnostic system control unit monitors all important sensors for plausibility.

If a sensor fault alarm occurs, the value is cleared from the digital displays and the pointer is removed from

the dials.

In the case of alarms, which have led to the automatic stopping or speed reduction of the engine

Alarm Sensor failure

via the central MMDS unit, the button (5) must also be actuated. In the case of a stop alarm,

this function is released on engine shutdown and with a reduce alarm below an engine speed of

800 1/min.

Alarm acknowledgements and reset signals are sent via the CAN bus to the engine monitoring and dia

gnostic unit and to all the monitoring devices connected to the same CAN bus.

40

Page 41

Commissioning and operation

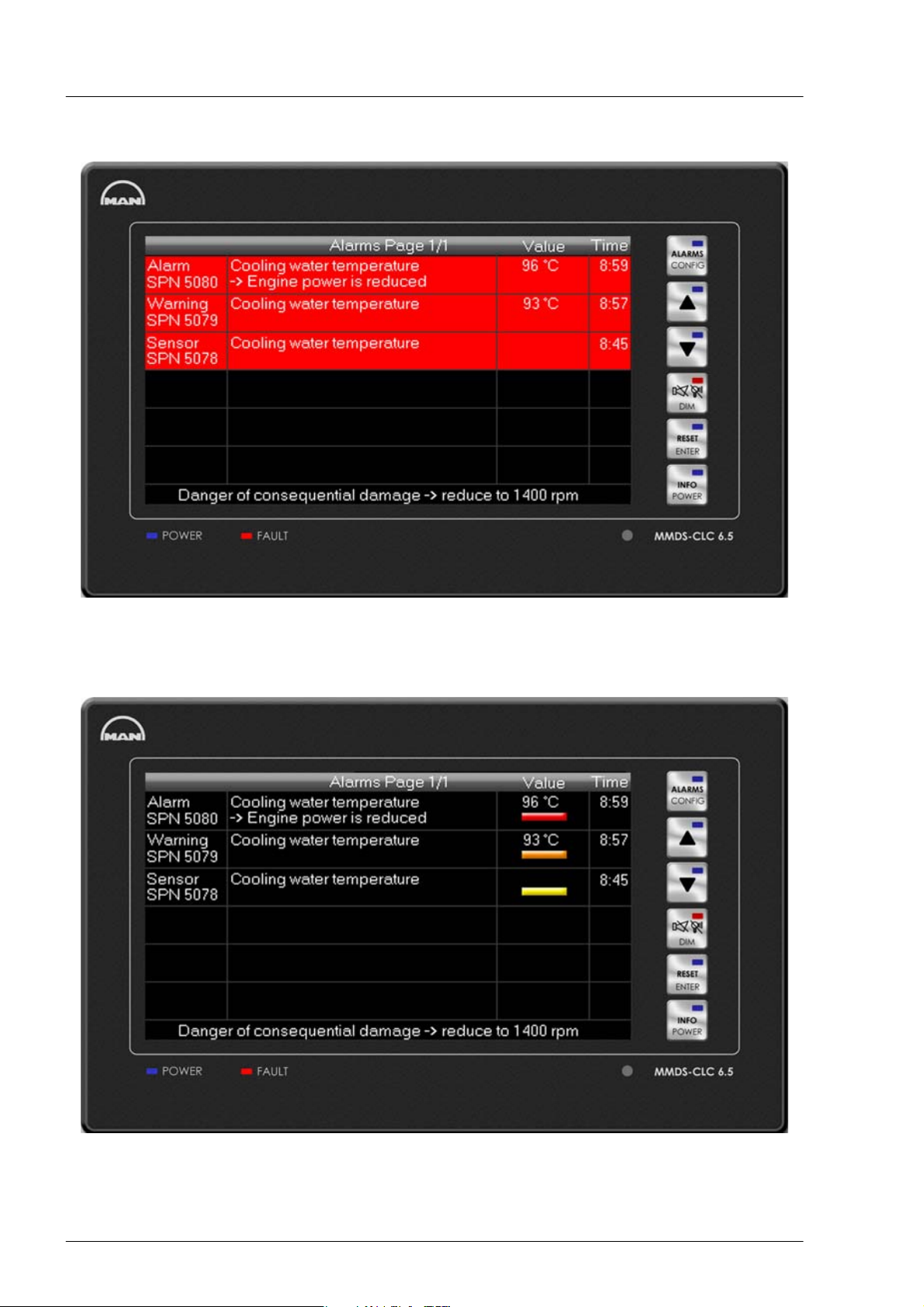

Alarms table

This table is automatically called when an alarm condition occurs, or can be called manually by pressing

the “Alarms" button (1) It shows all existing alarm messages, i.e. those that have not been acknow

ledged or reset. Each entry contains a measuring point text, the current measured value, the time when the

alarm occurred, the unit of measurement and the type of alarm. The following labels are used for the type

of alarm:

Text Meaning

Warning Advance warning

Alarm Alarm

Sensor Sensor fault alarm

A new alarm always appears in the top line. This is highlighted in flashing red until it is visually acknow

ledged. Older messages are automatically displaced one line downwards. If there are more than 6 entries,

further alarm pages are automatically presented for selection. In this event, pressing the “Alarms" button

(1) switches on to the next available alarm page. When the first page reappears, or if the display

remains the same after pushing that key, there are no further alarms. The numbering of the displayed

alarm page is shown at the bottom right of the page.

A message generally remains active until it has been acoustically and visually acknowledged (button

(4)) and the fault has been rectified. Shutdown and engine slow down alarms must also be reset using the

button (5).

Note:

The alarm texts are presented in the selected display language.

41

Page 42

Active alarm page

Commissioning and operation

Acknowledged alarm page

Figure: Alarms table

42

Page 43

Commissioning and operation

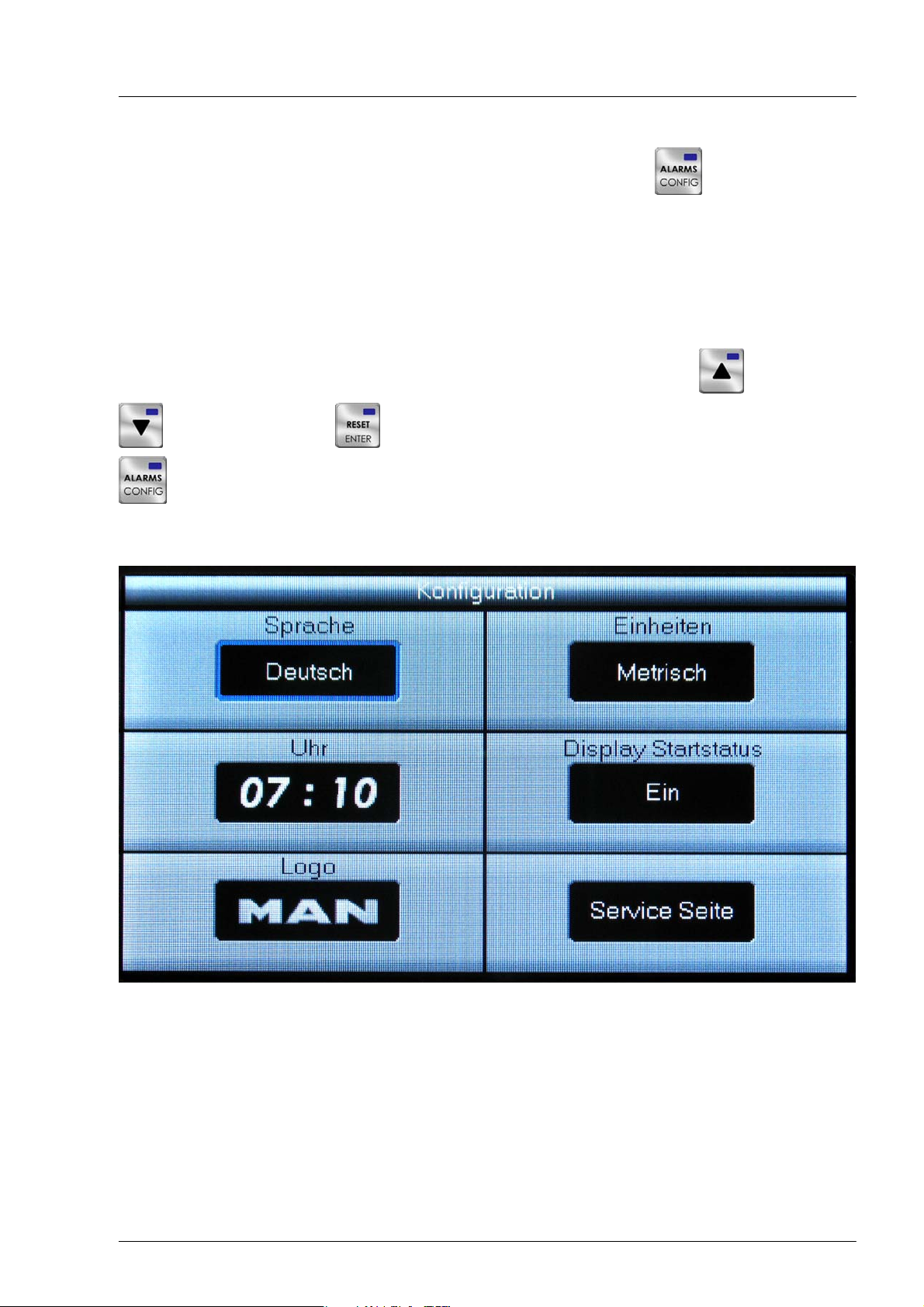

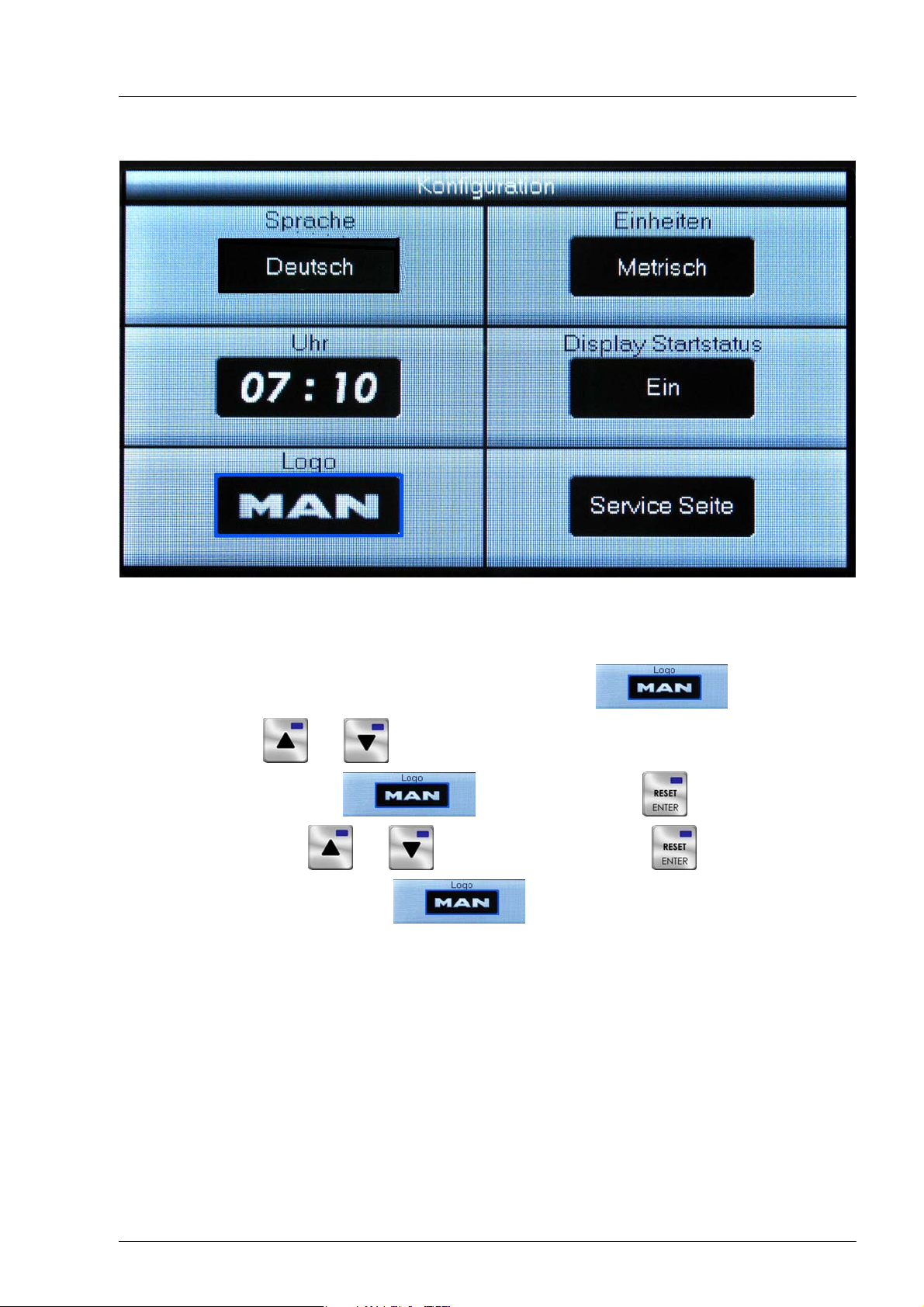

Menu functions

The display unit provides a number of setting options. Activation of the button (1) for approx.

3 seconds activates the menu page. The page contains the following configuration points:

DSelection of the presentation in German, English, Italian, Spanish and French

D Setting the time

D Selection of the logo

D Selection of the display in metric/non-metric units

D Activation of display start status

D Activation of the service page

The menu point in the respective blue marked field can be changed with the buttons (2) and

(3). Pressing the button (5) switches the marking to the next field. Pressing the button

(1) again for approx. 3 seconds causes the set values to be accepted and the menu is exited.

The display switches to the alarm table.

Figure: Menu for setting the display

43

Page 44

Commissioning and operation

Service page

The engine and gearbox data and the alarm conditions of all measuring stations are displayed in a table on

the service page. This page is accessed and exited on selecting the menu item and

changing the page via the buttons (2) and (3).

44

Page 45

Service page

tank

ture

ture

Water level in fuel filter 1

Engine oil pressure

Water level in fuel filter 2

0.0 mV

4.8 bar

0.0 mV

Commissioning and operation

Engine oil pressure at the oil filter

Engine oil temperature

Engine oil level

Crankcase pressure

Coolant temperature

Cool.temperature. in cool.exp.

Cool.press coolant pump

Coolant level in expansion tank

Gearbox oil pressure

?? %

78 _C

?? bar

3.8 V

?? mbar

81 _C

?? bar

0.5 bar

?? bar

Gearbox oil pressure at the filter

12.5 bar

Temp. exh. b. turbine 1

Temp. exh. a. turbine

Failure EDC

Failure SFFR

Temp. exh. b. turbine 2

510 _C

512 _C

420 _C

???? SPN

Remote slow-down

???? SPN

Override

Emergency stop

Alarm throttle control

?? mV

Safety system failure

Safety system alarm

Engine number

Engine type

12345678

D286X LE4XX

Water pre−filter 1

Water pre−filter 2

Oil press. engine

Oil press.eng.b.filtr

Service page 1/2

63 %

80 %

?? m/h

1200 1/min

Engine speed

Throttle

Load/Torque

Relative load

Oil temp. engine

Oil level engine

Crankcase press.

Coolant temp.

Cool. press. exp. t.

25.2 V

120 l/h

Fuel consumption

24.1 V

4.5 bar

4.4 bar

Fuel press. pump1

Pow. supply PIN15

Generator D+

Fuel press. pump2

Cool. press.wat. p.

Coolant level

Oil press. gearbox

Oil press.gbox.b.fil

Exhaust temp. 1

Service page 2/2

30 _C

250 mbar

100 mbar

Fuel press.handp.

Fuel press.return l.

23.5 mV

1200 rpm

Fuel temperature

Inject. pipe leak

Engine speed

Exhaust temp. 2

Exh.temp.aft.turbo

EDC−failure

SFFR−failure

Remote slow down

Override

?? %

78 _C

Oil temp. gearbox

?? _C

Oil level gearbox

Bearing temp.gear

?? bar

?? l/min

Seawater flow

Seawater press.

Emergency stop

Alarm throttle cont

Safety syst. fail

Alarm safety syst.

?? _C

58 _C

25 mbar

Charge air temp.

Seawater temp.

Air intake pressure

?? _C

2.5 bar

Boost pressure

Temp. MMDS int.

Engine number

Engine type

?? _C

30 mbar

Temp. plug X1

Exh. back press.

Engine speed

Throttle lever

Load

Relative load

Fuel consumption

Voltage, term. 15

Fuel press. pump1

Voltage, Gen. D+

Fuel press. pump2

Fuel press. handp.

Fuel temperature

Fuel press. return

Injection pipe leak

45

Engine speed

Gearbox oil tempera-

Oil level gearbox

Bearing temp.gearb.

Seawater flow

Seawater press.

Charge air tempera-

Seawater temp.

Boost press.

Temp. MMDS

Temp. plug X1

Exh. back press.

Page 46

Commissioning and operation

The table has 3 columns for each measuring point. Each entry contains an abbreviation of the designation

of the measuring point, the current measured value and the unit of measurement. The alarm status is

presented via LED symbols. As long as the LED is green the value is in the normal range. If the initial alarm

is reached the colour changes to orange and with a main alarm to red. A flashing LED indicates that the

alarm has not yet been visually acknowledged. If there is a sensor failure, the LED goes out.

Automatic dimming

A photo element is integrated in the front plate of the display unit. This registers the brightness of the envir

onment and the background lighting is automatically adapted to the circumstances. When the light condi

tions get darker the brightness of the display is reduced; if there is more light it is increased.

The automatic dimming can be adjusted to one's own requirements. By simultaneously activating the but

tons (4) and (2) or (3) the darkest point of the display lighting can be set.

46

Page 47

Selection of the logo

Commissioning and operation

Configuration

The logo to be blended in is selected on the logo page. This is displayed at the centre of all pages of the

display. This page is opened or closed on selection of the menu item and changing the

page via the buttons and .

After selection of the menu item by actuating the button an available logo can

be selected via the buttons and . After activation of the button for approx. 3 seconds,

the selection is accepted and the menu is closed.

LED displays

There are two LEDs beneath the display. A green Power" LED is activated by applying the supply voltage.

The red error" LED flashes when there is no communication on the CAN data bus. The displays of the en

gine and gearbox data then all show the value 0".

47

Page 48

Commissioning and operation

4. MMDS-CLC 6.5 ship's alarm display, operation

Introduction

This document describes how the MMDS-CLC 6.5 colour display with MMDS-CLCB 6.5 remote control op

erates and is used as a ship's alarm display. Fitting, mounting and installation are explained in separate in

structions for the unit.

The data monitored on the ship is visualised by the corresponding symbols and displays on the colour dis

play. LED symbols and a table that lists all active alarms with detailed information indicate states of alarm.

For commissioning and service, there is a service page where all the measured values as well as alarm

states of all sensors can be viewed at a glance.

To optimise adjustment to the user's requirements, five languages and display of the data in either metric

or non-metric units can be selected.

Buttons

1

2

3

4

5

6

MMDS-CLC 6.5 ship's alarm display

Operational functions and configuration

The operation of the system and the display adjustment is carried out with the display buttons or the re

mote control MMDS-CLCB 6.5.

The following functions are implemented:

Standard function: Call the alarms table, or browse to further alarm pages.

Additional function: If pressed longer than 5 seconds ⇒ Switches configuration menu on and off.

Standard function: Page back to the previous page

Additional dimming function: On simultaneous actuation of the buttons (4) and (3)

the brightness is reduced.

Additional function in the menu: Change parameter / reduce value.

48

Page 49

Commissioning and operation

Standard function: page up to the next page.

Additional dimming function: On simultaneous actuation of the buttons (4) and (2)

the brightness is increased.

Additional function in the menu: Change parameter / increase value.

Standard function: Acoustic and optical acknowledgement of all monitoring devices connected to

the same CAN-Bus.

Additional dimming function: Adjustment of the brightness on simultaneous actuation of the but

tons and .

Test function: If currently no alarm is on, or if all alarms have previously been optically acknowled

ged, after an actuation for longer than 5 seconds a horn test is carried out, i.e. the internal sum

mer and the horn relay are activated for the duration of the button press.

Standard function: A reset signal is sent via the CAN bus to the engine monitoring and diagnostic

system control unit (engine terminal box) or to a data station. As long as the appropriate criteria

are fulfilled, the engine slow down or shutdown alarms arising are reset.

Additional function in the menu: Accept change and pass to the next parameter.

Actuate the function (approx. 3 seconds): Switch-on and switch-off of the display (display only,

not on remote operation).

Display additional function (long actuation): Info. display appears for approx. 5 seconds

Function

The colour display is automatically activated when the supply voltage is applied. It can then be switched on

and off manually using the “Power" button (6). The other alarm functions such as the alarm relay

and the internal buzzer and the acknowledge button remain operative. There are two screen pages for dis

playing the most important engine and gearbox data. Alarms are displayed in an alarm table.

Graphical display of measured values data

When the device is switched on, page 1 is shown automatically.

Normally, the following is displayed:

Figure: start page with fuel tank levels, bilge status and door monitoring

49

Page 50

Commissioning and operation

a) Fuel tank: (configuration depending on boat type and tank shape)

D Fill level display and digital value

D with approx. 10% of the tank content, an alarm is issued (dependent on customer wish)

b) Water tank: (configuration depending on boat type and tank shape)

D Fill level display and digital value

D with approx. 10% of the tank content, an alarm is issued (dependent on customer wish)

c) Time: can be set on menu page

d) Illustration of the boat type: adapted at the request of the customer to specification.

e) Bilge alarms: with high fill level, an alarm is triggered. (rear, engine room, front end, others are possible)

f) Miscellaneous, e.g. lower bathing ladders, rear gate open (depending on boat type and configuration)

The sensors for the tank and water level as well as the switches for the bilge fill levels and miscellaneous

others are to be connected to the serial substation (e.g. IO 12 ). There must be harmonisation here with re

gard to configuration (tank curves) and possible signal inputs.

Page 2:

Normally, the following is displayed:

Figure: page 2 with digital display elements and bar displays

g) Trim flap position:

here is an instrument in the middle of the display that indicates the trim flap position of the port and star

board trim flaps. For each speed, the trim flap position is suggested by means of a green rectangle. This

proposal is generated from a trim curve integrated in the software that is recorded during the commis

sioning journey.

The trim flap sensors are read in at the serial substation.

h) Rudder position:

The rudder position is displayed in the upper area. The sensors for the rudder position are read in at the

serial substation.

i) GPS speed:

The speed recorded by the GPS is displayed at the right-hand edge of the screen.

The GPS is connected to the serial interface on the back of the CLC ship display.

j) Current fuel consumption:

The fuel consumption is shown at the bottom right.

The value is transferred from the MMDS-CLC 6.5 engine display per data line.

The fuel consumption can only be shown on ships with electronically controlled engines.

50

Page 51

Commissioning and operation

k) Range:

The range of the ship is displayed on the right.

This is a value calculated from the current fuel consumption, GPS speed and current fuel tank content.

The range can be displayed in nautical or standard miles, which can be selected in the menu.

Furthermore, the fuel consumption and e.g. the position of the bathing ladders are often displayed on

page 2.

The (2) and (3) keys can be used to switch back and forth between the two graphical

pages. If the alarm table is activated, the last displayed page is opened.

All sensors and switch inputs connected to the serial substation must be provided by the shipyard and

tested for proper function as well as conformity with the serial substation. Furthermore, the serial substation

must have been configured. The same applies to the GPS system that is connected directly to the CLC

ship.

Alarms

Should an alarm condition occur, an alarm table is automatically displayed. This lists all advance warnings,

alarms and sensor fault alarms. An internal buzzer and the horn relay are activated at the same time.

The collective alarm relay issues a repeat pulse if another alarm was already active. In this way, it is pos

sible to activate a visual call system for each new alarm or to send a telephone message if the ship is not

occupied. Acoustic acknowledgement with the (4) Alarm acknowledgements and reset signals are

sent on the CAN bus to the engine monitoring and diagnostic unit and to all the monitoring devices connec

ted to the same CAN bus. All the equipment thus has the same alarm status.

Alarm display on the graphics pages

On reaching an alarm condition, e.g. full bilge, the associated red LED flashes. By actuating the optical ac

knowledgement button (button (4)) all the flashing displays revert to a continuously lit condition.

When the fault has been eliminated and both acoustically and optically acknowledged (Button (4)),

the alarm display reverts to the “Normal condition".

Sensor failure

All the important sensors are monitored for plausibility. If a sensor error alarm occurs, then the measured

value on the corresponding instrument disappears.

51

Page 52

Commissioning and operation

Alarms table

This table is automatically called when an alarm condition occurs, or can be called manually by pressing

the button (1) It shows all existing alarm messages, i.e. those that have not been acknowledged or

reset. Each entry contains a measuring point text, the current measured value, the time when the alarm oc

curred, the unit of measurement and the type of alarm. The following labels are used for the type of alarm:

Text Meaning

Warning Advance warning

Alarm Alarm

Sensor Sensor fault alarm

A new alarm always appears in the top line. This is highlighted in flashing red until it is visually acknow

ledged. Older messages are automatically displaced one line downwards. If there are more than 10 entries,

further alarm pages are automatically presented for selection. In this event, pressing the “Alarms" button

(1) causes paging on to the next available alarm page. If the first page appears again, or if the dis

play remains unchanged on pressing the button, then no further alarms are present. The numbering of the

alarm pages presented is displayed on the page, lower right. In general a message remains active until it

has been acoustically and optically acknowledged (Button (4)) and the fault has been eliminated.

Figure: Alarms table

52

Page 53

Commissioning and operation

Menu functions

The display unit provides a number of setting options. Activation of the button (1) for approx.

3 seconds activates the menu page. The page contains the following configuration points:

D Setting the time

D Selection of the presentation in German, English, Italian, Spanish and French

D Selection of the display in metric/non-metric units

D Activation of the service page

The menu point in the respective red marked field can be changed with the buttons (2) and

(3). Pressing the button (5) switches the marking to the next field. Pressing the button

(1) for approx. 3 seconds results in the set values being accepted and the menu is closed.

The display switches to the alarm table. The selection of the language has no influence on the menu and

the service page. These pages are always displayed in English.

Figure: Menu for setting the display

53

Page 54

Selection of the logo

Commissioning and operation

Configuration

The logo to be blended in is selected on the logo page. This is displayed at the centre of all pages of the

display. This page is opened or closed on selection of the menu item and changing the

page via the buttons and .

After selection of the menu item by actuating the button an available logo can

be selected via the buttons and . After activation of the button for approx. 3 seconds,

the selection is accepted and the menu is closed.

LED displays

There are two LEDs beneath the display. A green “Power" LED is activated by applying the supply voltage.

The red “error" LED flashes when there is no communication on the CAN data bus. The displays of the ship

data then all show the value “0".

54

Page 55

Commissioning and operation

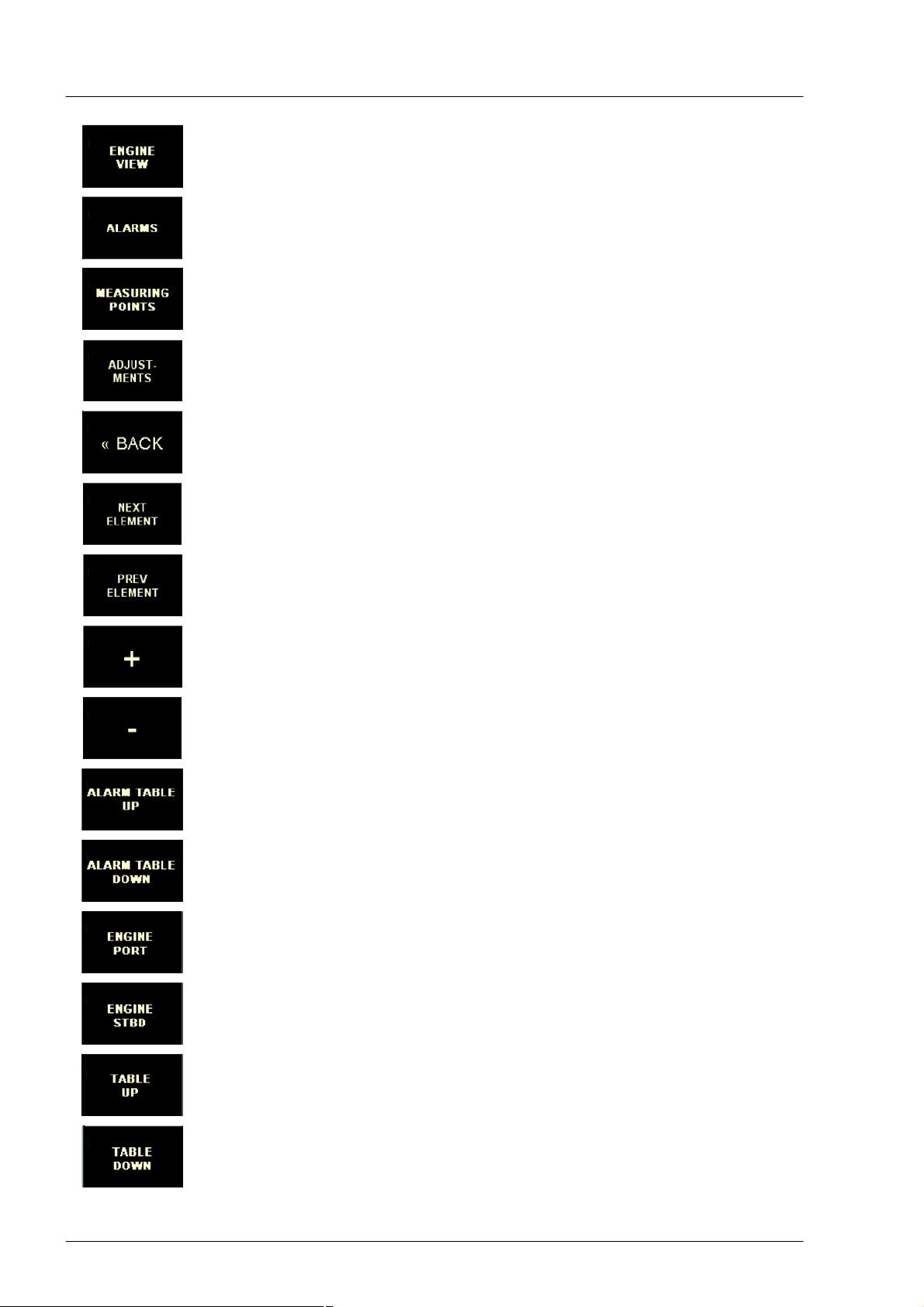

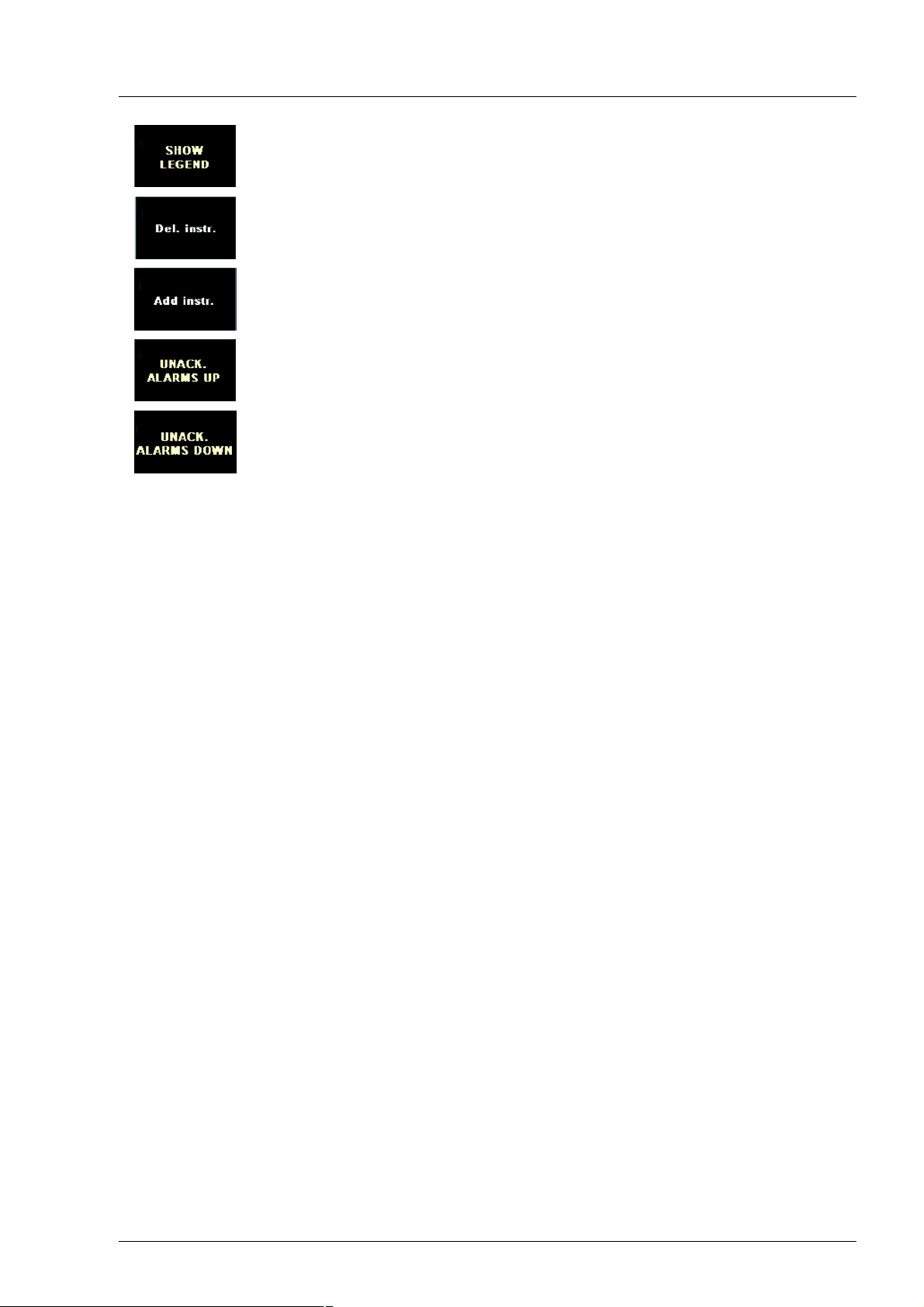

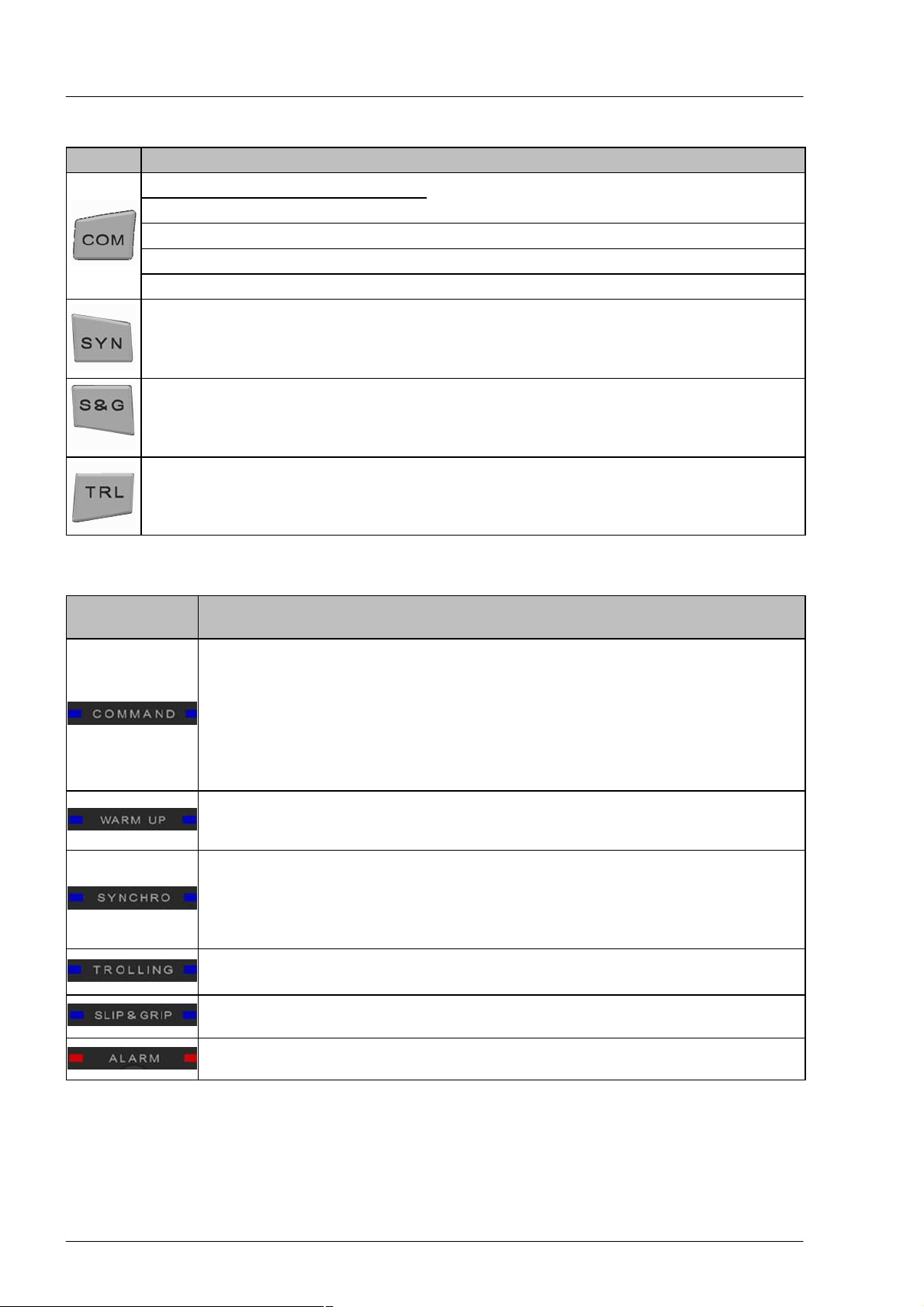

5. MMDS-CMS display device

The visualisation of engine operating data, general ship's messages and alarms is an important part of

modern alarm and safety systems on ships. The amount of information is steadily increasing and must be

registered and evaluated quickly. Alarms and / or warnings are to be recorded and reported quickly and

precisely. Clear and user-friendly displays are a precondition for safe operation of any ship.

The MAN Monitoring System represents a new component of the proven alarm, safety and diagnostic sys

tem MMDS, which offers a variety of new functions and display formats. The PC-based system is used to

display operating data of several engines and general ship messages.

The 10" / 15" MMDS-CMS 10 / 15 TFT monitor is part of the system. Data that has previously been pro

cessed by the corresponding software is shown on the display. The software is controlled using integrated

function keys that are located on the left of the display. The assigned functions are shown on the left edge

of the display. There is a choice of various forms of display. These can be pages with digital displays, ana

logue instruments, visual engine graphics and tabular displays. There are also two keys at the bottom right

for visual and acoustic alarm acknowledgement. The keys above these are for setting the display by means

of an “on screen display" menu.

55

Page 56

Commissioning and operation

Function and operation

Display functions

The display is switched on and off using the Power button (top right). Underneath this, there are four sys

tem keys for adjustment of the display illumination and for maintenance of the display. Usually, only the ar

row keys are important. The “Menu" and “Store" keys are for controlling the OSD menu.

Function: Switching the display on and off.

Functions: Activation and deactivation of the OSD menu and switching to the next

higher menu level.

Standard func

tion:

Standard func

tion:

Functions: Selecting menu items and saving parameter values.

Software operation

The MMDS-CMS 10/15 monitor serves to display and control visualisation software that is installed on the

PC. This software is adapted to the overall system and is explained in a system description. Ten function

keys are arranged on the left of the display for operation of the software. The assigned functions are shown

at the edge of the display.

For the control of software functions, there are also two keys at the bottom right for visual and acoustic

alarm acknowledgement.

Decrease display brightness.

Additional functions if the OSD menu is shown: shifting the selection field

for the menu items upwards and increasing parameter values.

Increasing display brightness

Additional functions if the OSD menu is shown: shifting selection field for

the menu items downwards and decreasing parameters.

Example of a function key with the assigned function to call up analogue

display.

Standard function:

Additional function:

Standard function:

Additional function:

Acoustic acknowledgement of all monitoring devices contained in the

system.

If a Windows communication box appears, this key (TAB) enables

selection control.

Visual acknowledgement, which means that all flashing alarms switch to

continuous light if they have previously been acknowledged acoustically.

All other monitoring devices contained in the system are acknowledged

as well.

If a Windows communication box appears, this key (ENTER) enables

acknowledgement.

56

Page 57

Commissioning and operation

Software description

Introduction

Processing engine data, general ship data and alarms is an important part of modern alarm and safety sys

tems on ships. The amount of information is steadily increasing and must be registered and evaluated

quickly.

The MAN Monitoring System MMDS-CMS belongs to the Alarm, Safety and Diagnostic Unit MMDS.

It offers a variety of functions and types of display, which are mainly defined by the visualisation software.

It is fully installed and configured on the compact PC MMDS-CMS S which is part of the system.

Measured values and alarms are displayed in different forms on the monitoring system. Alongside a preset

page with displays of analogue or digital instruments, there is a page that can be freely configured by the

user. In addition, the engines are represented graphically. In the event of a fault, the source of the problem

can be recognised easily. A further special feature is the dynamic display of speed-dependent variables.

The limit value changes directly with the speed so that the distance between an actual value and the cor

responding alarm limit value is easily recognisable at any time. All alarm and measuring point lists are avail

able in tabular form. The displays are operated using the integrated function keys or by means of an ex

ternal mouse or trackball.

This documentation is intended to make the user acquainted with the operation of the software and to

provide an overview of the system at a glance. Please note that this description is a minimum configuration

of the monitoring system. Extension options are documented separately. The devices belonging to the sys

tem are also documented extensively in the individual device descriptions.

57

Page 58

Commissioning and operation

Scope of services

The monitoring system registers, evaluates and displays engine and gearbox data of MAN ship's diesel en

gines. The measured values are registered via the MMDS diagnostic units, one of which is placed each of

the engine terminal boxes. Data interchange between the devices takes place via the separate CAN bus

lines, CAN Engine 1 and CAN Engine 2. The compact PC, which is part of every display, processes the

data and makes it available on a CMS 15" / 10" display with the help of visualisation software.

Display

The data is shown on the 10"/15" display MMDS-CMS 10" or the smaller MMDS-CMS 15". Ten function

keys are integrated in each of the monitors. This enables functions such as page selection or scrolling.

On connection of mouse and keyboard, one of the pages can be freely configured. On the Custom page,

the selection of data and its displays can be adapted to the user's needs by means of a few mouse-clicks.

Extension options

The MMDS-CMS alarm system can be extended to form a comprehensive ship and engine alarm system.

A large number of analogue and binary sensors can be integrated on connection of one or more data sta

tions (e.g. MMDS IO12) in order to, e.g., monitor the filling levels of fuel tanks or the condition of position

lanterns. Further route-specific information can be calculated by connecting a GPS receiver that uses

sensor data, for example the range resulting from the current fuel consumption and speed.

58

Page 59

Operation

Commissioning and operation

1

1

2

3

4

5

6

7

2

3

4

5

8

9

10

The displays are activated automatically when the power supply is switched on. They can be switched on

and off individually by pressing “Power" button Ê.

The computers can be switched on and off when the power supply is switched on. The startup procedure of

the operating system Windows XP, as well as of the visualisation software, takes approx. one minute and

is visible on the displays.

6

7

Control with the function keys

The (1) - (10) function keys to the left of the display are used to control the software. Operation is dynamic,

i.e., the assigned functions change depending on the page displayed. The currently possible functions are

explained in a specifically assigned section of the display located to the right of each key. Insofar as a field

is empty, the assigned key does not have any function.

Menu functions are selected using the function keys or per mouse-click on the menu text. The following list

shows all the functions available in the program. They can be used to select a specific page, to scroll within

tables or perform other functions.

Function: opens the start page, which exclusively shows digital displays (see page 62,

Main Menu).

Function: opens a page which displays data as analogue instruments (see page 64,

Analogue display).

Function: opens a page which displays data digitally (see page 65, Digital display).

Function: opens a page on which the user can customise the display interface ac

cording to his / her own wishes (see page 67, User-defined display).

59

Page 60

Commissioning and operation