Page 1

Page 2

Page 3

Preface

This Repair Manual is designed to facilitate competent repair of the engines listed herein.

The pictures and relevant descriptions show typical work that may not always be applicable to the engine in

hand, which nevertheless does not mean that they are not correct.

In such cases the repair work is to be planned and carried out in a similar way.

Please note that all jobs described in this Repair Manual were carried out on an engine which was not installed.

The expert knowledge necessary for handling Diesel engines was taken for granted when this publication

was compiled.

Note:

Only use fuel, coolants and lubricants in accordance with MAN regulations, otherwise the manufacturer’s warranty will not apply!

For basic information on the fuels see the publication “Fuels, Lubricants and Coolants for MAN

Diesel Engines”.

You can find the approved products on the Internet at:

−http://www.man-mn.com/ " Products & Solutions " E-Business−

Any repair of components such as injection pump, alternator etc. ought to be left to our or the manufacturer’s service department.

Yours faithfully,

MAN Nutzfahrzeuge Aktiengesellschaft

Nuremberg Works

We reserve the right to make technical modifications in the course of further development.

© 2004 MAN Nutzfahrzeuge Aktiengesellschaft

Reprinting, copying or translation, even in the form of excerpts, is forbidden without the written permission

of MAN. MAN expressly reserves all rights in accordance with the law on copyright.

MTDB Technical status: 11.2004 51.99598−8157

1

Page 4

Instructions

Important instructions which concern technical safety and protection of persons are emphasised as shown

below.

Danger:

This refers to working and operating procedures which must be complied with in order to rule out

the risk to persons.

Caution:

This refers to working and operating procedures which must be complied with in order to prevent

damage to or destruction of material.

Note:

Explanations useful for understanding the working or operating procedure to be performed.

Fitting flat seals / gaskets

Flat seals / gaskets are often inserted with sealing agents or adhesives to make fitting them easier or to

achieve better sealing. Flat seals may slip in operation due to the “sewing-machine” effect, in particular if

they are used between parts with different rates of linear expansion under heat (e.g. aluminium and cast

iron), and leaks may then occur.

Example:

the cap of the front crankshaft seal. If a sealing agent or an adhesive is used here the flat seal will move

inwards in the course of time as a result of the different expansion rates of the materials. Oil will be lost, for

which the shaft seal may be thought to be responsible.

Flat seals / gaskets can be fitted properly only if the following points are observed:

D Use only genuine MAN seals/gaskets.

D The sealing faces must be undamaged and clean.

D Do not use any sealing agent or adhesive − as an aid to fitting the seals a little grease can be used if

necessary so that the seal will stick to the part to be fitted.

D Tighten bolts evenly to the specified torque.

2

Page 5

Contents

Engine type classification 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety instructions 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting table 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General notes on engine overhaul 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commissioning after engine overhaul 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine views D 2842 LE 620 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine lubrication schedule 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel diagram 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic diagram of cooling system 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel system

Check the base fitting of the high−pressure pump 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the high-pressure lines 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing high-pressure pump 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the rail 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the rail pressure sensor, pressure relief valve 31 . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the injectors 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel prefilter with water separator 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel filter, exchanging filter cartridge 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flame-starter sheathed-element glow plug, removing and installing 39 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling system

Draining and filling coolant 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing thermostats 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing coolant pump 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repairing coolant pump with high-temperature and low-temperature parts 44 . . . . . . . . . . . . . . . . . . . . .

Cleaning cooling system 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication

Changing oil filter 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the oil cooler 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing, repairing oil pump 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil injection nozzle 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel / Crankshaft seal

Removing and fitting vibration damper, replacing front crankshaft gasket 61 . . . . . . . . . . . . . . . . . . . . . .

Removing and installing flywheel,replacing starter gear ring 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing crankshaft seal (flywheel end) 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the bearing race 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft gaskets 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intake / exhaust system

Removing and installing intake manifold 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing exhaust pipe 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger, trouble shooting 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the charge-air pressure 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing turbocharger 75

Checking axial and radial clearance of turbocharger rotor shaft 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder head

Removing and installing the cylinder head 78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the valve clearance 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dismantling and assembling the rocker arm mechanism 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing valves 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing valve guides 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing valve seat insert 94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reworking valve seat 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refacing valves 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Page 6

Contents

Valve timing

Removing and installing the gear case 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing camshaft 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and fitting camshaft bearing bushes 105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the valve timing 114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankgear, pistons

Removing and installing crankshaft 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing pistons with conrods 118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing pistons from conrod and fitting, checking − replacing conrod 121 . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing piston rings 123 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing cylinder liners 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring piston protrusion 129 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attachments

Removing and installing starter motor 130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V−belts 131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tensioning and changing V−belt 132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing speed pickup 133 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Data

Specifications 136 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankcase 137 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder liner 137 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 138 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel and starter gear ring 141 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conrods 142 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pistons 143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder head 144 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve gear 146 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine lubrication D 2842 LE 620 149 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling system 151 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repairing coolant pump with high−temperatureand low−temperature parts 151 . . . . . . . . . . . . . . . . . . . .

Turbocharger 152 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel system 153 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter motor 154 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque guide values 155 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special tools 161 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 174 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Page 7

All the engines dealt with here are related in terms of their design and make up a family.

The type classification, which is made up of a series of letters and numbers, reveals some of the features

of the engine in question provided the reader is familiar with the underlying nomenclature.

The system is explained below using the model type D 2842 LE 620 as an example:

D The “D” at the start of the type classification stands for “Diesel”

28 The numbers “28” indicates that the power plant in question has a bore of 128 mm

4 The “4” means 142 mm stroke

2 The “2” indicates that there are 12 cylinders. If there is a “0”, this is a 10−cylinder engine

L This letter stands for “charge−air cooling” (German: Ladeluftkühlung)

E The “E” stands for “fitted engine” (German: Einbaumotor) and is intended to distinguish MAN

vehicle engines

620 This is a factory-internal development number

5

Page 8

Safety instructions

General information

This brief overview summarises important instructions and is structured into areas of main concern in order

to impart the knowledge necessary to prevent accidents involving injury to persons, damage to the engine

or other property and harm to the environment. Additional notes are included in the operator’s manual for

the engine.

Important:

If despite all safety precautions an accident occurs as a result of contact with caustic acids, penetration of

fuel into the skin, scalding with hot oil, anti-freeze splashes into the eyes etc, consult a doctor immedi-

atel.

1. Instructions for preventing accidents with injury to persons

Checks, setting jobs and repair work must be carried out by authorised skilled personnel only.

D When carrying out maintenance and repair work, ensure that the engine cannot be

accidentally started from the bridge by unauthorised persons.

D The engine must be started and operated by authorised personnel only.

D When the engine is running, do not get too close to revolving components.

Wear tight-fitting working clothes.

D Do not touch hot engine with bare hands: risk of burning yourself.

D Keep engine vicinity, ladder and steps free of oil and grease. Accidents resulting from

slipping may have serious consequences.

D Work only with tools that are in good condition. Worn spanners slip: risk of injuries.

D Persons must not stand under an engine suspended from a crane hook.

Keep lifting gear in good order.

D Open coolant circuit only after the engine has cooled down. If opening the coolant

circuit while the engine is hot is unavoidable, observe the instructions in the chapter

“Maintenance and care” in the Operator’s Manual.

D Neither retighten nor open pressurised pipelines and hoses (lube oil circuit, coolant

circuit and downstream hydraulic oil circuit if fitted): risk of injuries resulting from

emerging fluids.

D When checking the injection nozzles, do not hold your hands in the fuel jet.

Do not inhale fuel mist.

6

Page 9

Safety instructions

D When working on the electrical system, unplug earth cable from battery first and

reconnect it last to avoid short-circuits.

D Observe the manufacturer’s instructions for handling batteries.

Caution:

Battery acid is toxic and caustic. Battery gases are explosive.

D When carrying out welding work, observe the “Information sheets for welders”.

2. Instructions for preventing damage to the engine and premature wear

D Prior to repairing the engine, clean it thoroughly. Ensure that dirt, sand or foreign matter will

not get into the engine during repair work.

D In the event of operational faults immediately identy the cause and rectify to prevent more serious

damage.

D Always use genuine MAN parts only. Installation of “equally” good parts from other suppliers may cause

severe damage for which the workshop carrying out the work is responsible.

D Never operate the engine while it is dry, i.e. without lubricant or coolant.

Use a suitable label to mark engines not ready for operation.

D Only use operating materials (fuel, engine oil, antifreeze and anticorrosion agents) approved by MAN.

Ensure that everything is kept clean. Diesel fuel must be free of water.

D Do not fill up with engine oil above the max. notch on the dipstick. Do not exceed the engine’s

maximum permissible operating inclination.

Non-compliance with these instructions may cause severe engine damage.

D Control and monitoring devices (charge check, oil pressure, coolant temperature) must work faultlessly.

D Observe the instructions for operating the alternator; see chapter “Maintenance and care” in the

Operator’s Manual.

7

Page 10

Safety instructions

3. Instructions for preventing environmental damage

Engine oil and filter cartridges and elements, fuel / fuel filters

D Take old oil to an old oil disposal point only.

D Ensure without fail that oil and Diesel fuel will not get into the sewerage system or the ground.

Caution:

Danger of contaminating potable water!

D Treat filter elements and cartridges as special waste.

Coolant

D Treat undiluted anticorrosion and / or antifreeze agents as special waste.

D The regulations of the relevant local authorities are to be observed for the disposal of spent coolants.

4. Instructions for handling used engine oil *

Prolonged or repeated contact of any kind of engine oil with the skin causes the skin to degrease, which

may result in dryness, irritation or inflammation. Old engine oil also contains hazardous substances which

in animal experiments have caused skin cancer. Handling old engine oil does not pose any health hazard if

the basic safety and hygiene related regulations are observed.

Health and safety regulations:

D Avoid prolonged, excessive or repeated contact of old engine oil with the skin.

D Use a suitable skin protection agent or wear protective gloves.

D Clean the skin that has been in contact with engine oil.

− Wash yourself thoroughly with soap and water. A nailbrush is an effective aid.

− Special hand cleaning agents facilitate cleaning soiled hands.

− Do not use petrol, Diesel fuel, gas oil, fluxes or solvents as cleaning agents.

D After washing apply moisturising handcream to your skin.

D Change oil-soaked clothes and shoes.

D Do not put any oil-soaked cloths into pockets.

Pay meticulous attention to the proper disposal of old engine oil.

− Old oil is a water hazard −

Therefore, do not pour any old oil into the ground, the drains or the sewerage system. Any violation of this

rule is punishable.

Collect and dispose of old engine oil properly. For information concerning collection points, contact seller,

supplier or the local authorities.

∗ Based on the “Information sheed for handling used engine oil”

(Notes on how to handle old engine oil).

8

Page 11

Safety regulations

5. Special instructions when working on the common rail system

Accident protection

D Risk of injury!

Fuel jets can cut through skin.

The atomisation of fuel creates a fire risk.

− When the engine is running never loosen the screw connections on the fuel’s high-

pressure side of the common rail system (injection line from the high-pressure pump

to the rail, on the rail and on the cylinder head to the injector)

− Keep away from the engine when it is running

D Risk of injury!

When the engine is running the lines are constantly under a fuel pressure of up

to 1600 bar.

− Wait at least a minute until the pressure in the rail has dropped before loosening a

screw connection

− If necessary check the pressure drop in the rail with MAN-Cats

D Risk of injury!

− People with pacemaker must keep at least 20 cm away from the running engine

− Do not touch live parts on the electric connection of the injectors when the engine is

running

9

Page 12

Safety regulations

Cleanliness

Today modern components of diesel injection consist of high-precision parts which are exposed to extreme

stresses. The high-precision technology requires the utmost cleanliness during all work on the fuel system.

Even a particle of dirt over 0.2 mm can lead to the failure of components.

The measures described as follows are therefore essential before work begins:

Risk of damage from penetration of dirt!

D Before working on the clean side of the fuel system clean the engine and the engine

compartment (high-pressure cleaner). During cleaning the fuel system must be closed

D Carry out visual inspection for any leakage or damage to the fuel system

D Do not spray the high-pressure cleaner direct onto the electric components, or alternati-

vely keep them covered

D Do not carry out any welding or sanding work in the engine compartment during mainte-

nance / repair

D Avoid air movements (any swirling of dust when starting engines)

D The area of the still closed fuel system must be cleaned and dried with the aid of com-

pressed air

D Remove detached particles of dirt such as paint chippings and insulation material with a

suitable extractor (industrial type vacuum cleaner)

D Cover areas of the engine compartment from which dust particles could be detached

with clean foil

D Wash your hands and put on clean work clothes before starting the disassembly work

D Clean tools and working materials before starting to work

10

Page 13

Safety regulations

When carrying out the work it is essential to comply with the following measures:

Risk of damage from penetration of dirt!

D When the clean side of the fuel system has been opened it is not permissible to use

compressed air for cleaning

D During assembly work loose dirt must be removed with the aid of suitable extractors

(industrial type vacuum cleaners)

D Use only fluff-free cleaning cloths on the fuel system

D Only tools without any damage may be used (cracked chrome coatings)

D When removing and installing components do not use materials such as cloths, cardbo-

ard or wood since these could shed particles and fine fibres

D If any paint chips / flakes off when connections are loosened (from possible over-coa-

ting) these chippings must be carefully removed before finally loosening the screw connection

D The connection openings of all removed parts on the clean side of the fuel system are

to be closed immediately with suitable caps (see special tools, page 172)

D These caps / stoppers must be packed protected from dust prior to use and after being

used once they must be disposed of

D Following this all the components must be carefully stored in a clean, closed container

D Never use used cleaning or testing liquids for these components

D New parts must not be removed from their original packing material until directly before

use

D Work on removed components may be carried out only at a workplace specially equip-

ped for it

D If removed parts are shipped always use the original packing material of the new part

11

Page 14

Troubleshooting table

Faults and possible causes

We recommend

Repair work is to be considered complete only after the damage which has occurred and the possible

causes have been eliminated. Ascertaining the causes of damage is frequently more difficult than eliminating the damage caused. For this reason we recommend you have the operational fault exactly described to

you before removal or disassembly work is commenced. Then, track down the probable causes by asking

specific questions, examining and eliminating these causes one by one with the aid of the table and your

own experience. This helps to reduce repairs to those necessary and counter complaints about “premature” exchange of parts and expensive working and downtimes.

Remark:

The subsequent list is meant to be a memory aid so that no causes of damage will be overlooked in the

elimination of faults. The precondition for this, however, is that you are familiar with the Repair Manual for

the engine and the relevant Operator’s Manual as well as the publication “Fuels, Lubricants, Coolants for

MAN Diesel Engines”.

12

Page 15

Fault table

1. EDC self-diagnosis

2. Starter motor turns over engine slowly or not at all

3. Starter motor turns, engine fails to start, engine fails to start / difficult to start when cold

4. Engine stalls (dies) during operation, no longer starts (starter motor turns),

engine fails to start / difficult to start when hot

5. Sudden, temporary engine shutdown, engine does not reach full revs

6. Engine runs at idle speed only, no throttle response

7. Engine runs at increased idle speed only, no throttle response

8. Rated engine speed significantly reduced (even at no load)

9. Reduced power output in all ranges

10. Irregular engine operation, loss of traction

11. Unstable idle speed, engine surges, misfiring, engine knocking

12. Engine judder

13. Unusual combustion noises

14. Excessive smoke emission: white smoke / blue smoke

15. Excessive smoke emission: black smoke

16. Engine temperature too high (coolant loss)

17. Fuel consumption too high

18. Lubrication oil pressure too low

19. Lube oil pressure too high

20. Lube oil consumption too high

21. Engine too “loud” / mechanical noises

22. Idle speed cannot be adjusted with idle speed operating unit

Possible causes

x x Battery flat, battery lead connections loose or corroded, break in power circuit

x Crankshaft drive blocked

x x Starter solenoid switch sticks (clicks) / damaged, cable connection loose or dam-

x x Starter motor / starter interlock relay defective (carbon brushes worked loose /

x x x x Engine oil viscosity unsuitable, not suitable for ambient temperature, lube oil qual-

x x Oil level in oil pan too high

x Oil level in pan too low, oil in oil pan too thin (mixed with condensate or fuel)

x Engine temperature too high

x Oil filter clogged

x x Oil pressure gauge defective

x Safety valve in the oil circuit defective (does not close, spring fatigued or broken)

x x Heavy bearing wear

x Oil pump gears heavily worn

x x x Engine cold

x Lube oil entering combustion chamber (piston rings worn, piston rings broken) −

x Safety valve in oil circuit defective (does not open), oil lines / oil galleries clogged

x x Piston rings heavily worn, broken

x x Piston pins or crankshaft bearings loose

x x x Valve clearance not correct

x x Valves jammed

x x x x Compression deficient, or more than 3−4 bar pressure difference between individ-

x x x Valve seats leaking

o x x Increased power input due to defective secondary loads / consumers such as

x x x x x Air filter fouled or clogged, charge air system leaking, air intake / exhaust lines

x x x x x x x x x Fuel low pressure system: fuel tank, prefilter, water trap faulty / clogged / mould /

x x x x x x x x Fuel low pressure system: fuel lines leaking, broken, clogged

aged

worn, winding damaged, short to ground)

ity does not comply with specifications

x Timing gears worn, tooth flank backlash too great

valve stem guide worn − overpressure in crankcase (crankcase breather

clogged)

x Leaks in lube oil circuit, particularly at turbocharger and oil cooler

x Valve stems heavily worn, bent

ual cylinders

hydraulic pumps, fan etc., power take-off engaged

clogged / leaking

fungal attack, fuel unsuitable / contaminated (paraffin added)

13

Page 16

Fault table

1. EDC self-diagnosis

2. Starter motor turns over engine slowly or not at all

3. Starter motor turns, engine fails to start, engine fails to start / difficult to start when cold

4. Engine stalls (dies) during operation, no longer starts (starter motor turns),

engine fails to start / difficult to start when hot

5. Sudden, temporary engine shutdown, engine does not reach full revs

6. Engine runs at idle speed only, no throttle response

7. Engine runs at increased idle speed only, no throttle response

8. Rated engine speed significantly reduced (even at no load)

9. Reduced power output in all ranges

10. Irregular engine operation, loss of traction

11. Unstable idle speed, engine surges, misfiring, engine knocking

12. Engine judder

13. Unusual combustion noises

14. Excessive smoke emission: white smoke / blue smoke

15. Excessive smoke emission: black smoke

16. Engine temperature too high (coolant loss)

17. Fuel consumption too high

18. Lubrication oil pressure too low

19. Lube oil pressure too high

20. Lube oil consumption too high

21. Engine too “loud” / mechanical noises

22. Idle speed cannot be adjusted with idle speed operating unit

Possible causes

x x x x x x x Fuel low pressure system: air in system (turn on ignition when bleeding system)

x x x x x x x x x Fuel low pressure system: feed pump, main filter

x x x x x o x x Fuel high pressure system: injectors defective / clogged / leaking / coked

x x x x o Fuel high pressure system: pressure lines − constriction, cavitation, leaking

x x o x x x x o Fuel high pressure system: high-pressure pump worn

x x x x x o Pedal value sensor (driving lever signal) defective: connection lines, short circuit,

x x EDC rpm sensor defective, lead defective

x x o EDC rpm sensor, polarity reversed

x x x x o o o o EDC detects incorrect engine speed (interference signal on rpm sensor lead)

x x x EDC boost pressure sensor: faulty, incorrect, implausible with atmospheric pres-

x x o x Exhaust turbocharger leaking or defective

x Intercooler leaking, defective

x o x x o x EDC coolant temperature sensor: faulty, line fault

x x x EDC charge-air temperature sensor: faulty, line fault

o x x Radiator fouled or failure of cooling system (temperatures too high)

x Coolant level too low, air in the coolant circuit

x V-belt for coolant pump drive not tensioned correctly

x x Incorrect V-belt tension

x Coolant pump leaking, defective / thermostat defective, does not open

x Coolant lines leaking, blocked or twisted

x Coolant entering combustion chamber (cylinder head / gasket leaking)

x x x o o Power supply to EDC control unit interrupted or battery voltage too low

x o o o EDC control unit defective (internal fault)

x Incorrect EDC control unit (check MAN part number)

x Afterrunning not completed

x x Thermostat defective

x Engine bearings worn

interruption

sure sensor, line fault

x Turbine and compressor wheel in the turbocharger soiled (running off balance)

14

Page 17

General notes on engine overhaul

The service life of an engine is influenced by very different factors. It is therefore not possible to specify

certain fixed numbers of operating hours for general overhauls.

In our view, it is not necessary to open up and engine or perform a general overhaul

as long as the engine has good compression values and the following operating values have not changed

significantly in relation to the values measured on commissioning the engine:

D Charging pressure

D Exhaust temperature

D Coolant and lubricant temperature

D Oil pressure and oil consumption

D Smoke emissions

The following criteria greatly influence the length of the engine service life:

D Correct power output setting according to the type of application

D Technically correct installation

D Inspection if installation by authorised personnel

D Regular maintenance as per maintenance plan

D Choice and quality of lube oil, fuel and coolant in accordance with the publication

“Fuels, Lubricants and Coolants for MAN Diesel Engines”

15

Page 18

Commissioning after engine overhaul

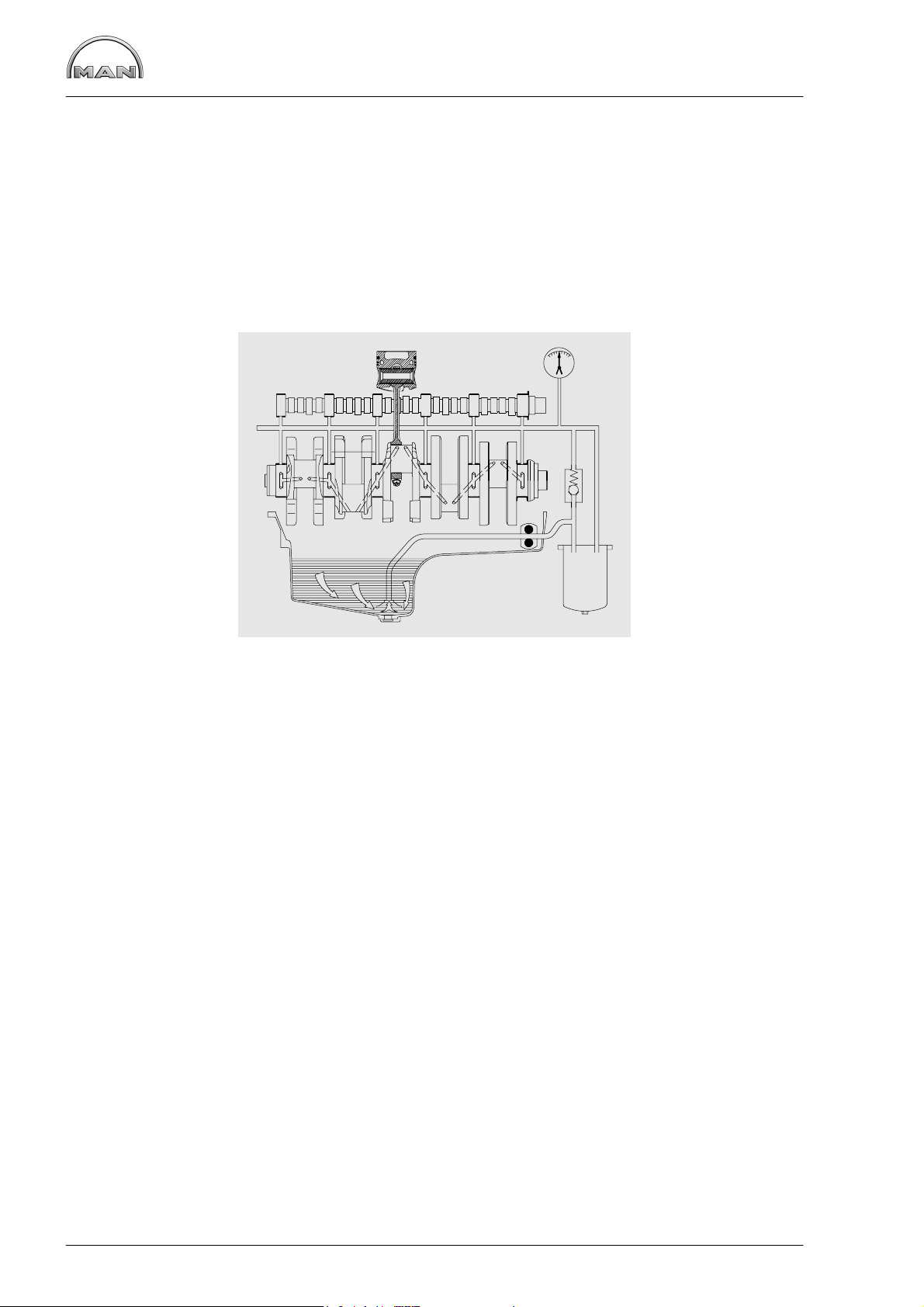

Pressurisation

It is extremely important for internal combustion engines (following the completion of repair work, i.e. in

their dry state) to be pressurised with lube oil before being recommissioned. This procedure can also be

used for ascertaining damage and its causes.

If engines are not pressurised, the risk of premature damage to bearing surfaces is very high because it

takes a relatively long period of time for the lube oil drawn in from the oil pan via the oil pump to reach the

individual bearings.

Such incipient damage need not necessarily lead to immediate bearing failure, but may impair the proper

functioning of the bearings and reduce their service lives.

Diagram of the oil flow with unpressurised engines

16

Page 19

Commissioning after engine overhaul

Pressurising an engine affords the following advantages:

D All engine parts are lubricated before engine startup; a lubricating film can be built up inside the bear-

ings as early as after the first few rotations of the crankshaft, thereby preventing damage to the bearing

races

D Any loss of oil, be it the result of excessively large bearing play or leaks from the crankcase or from

crankcase bores which may not be plugged, can be detected immediately. For this purpose, mount the

engine on an assembly dolly, remove the oil pan and install a suitable oil collector under the crankcase

in such a way that the bearings are visible

Performance of pressurisation:

At least 30% of the total oil quantity is forced from the pressurisation container into the engine oil circuit.

The operating pressure serves as the yardstick for the pressure to be forced in and must not be exceeded.

The pressurisation container is connected up to the engine oil circuit at the oil filter (screw plug).

17

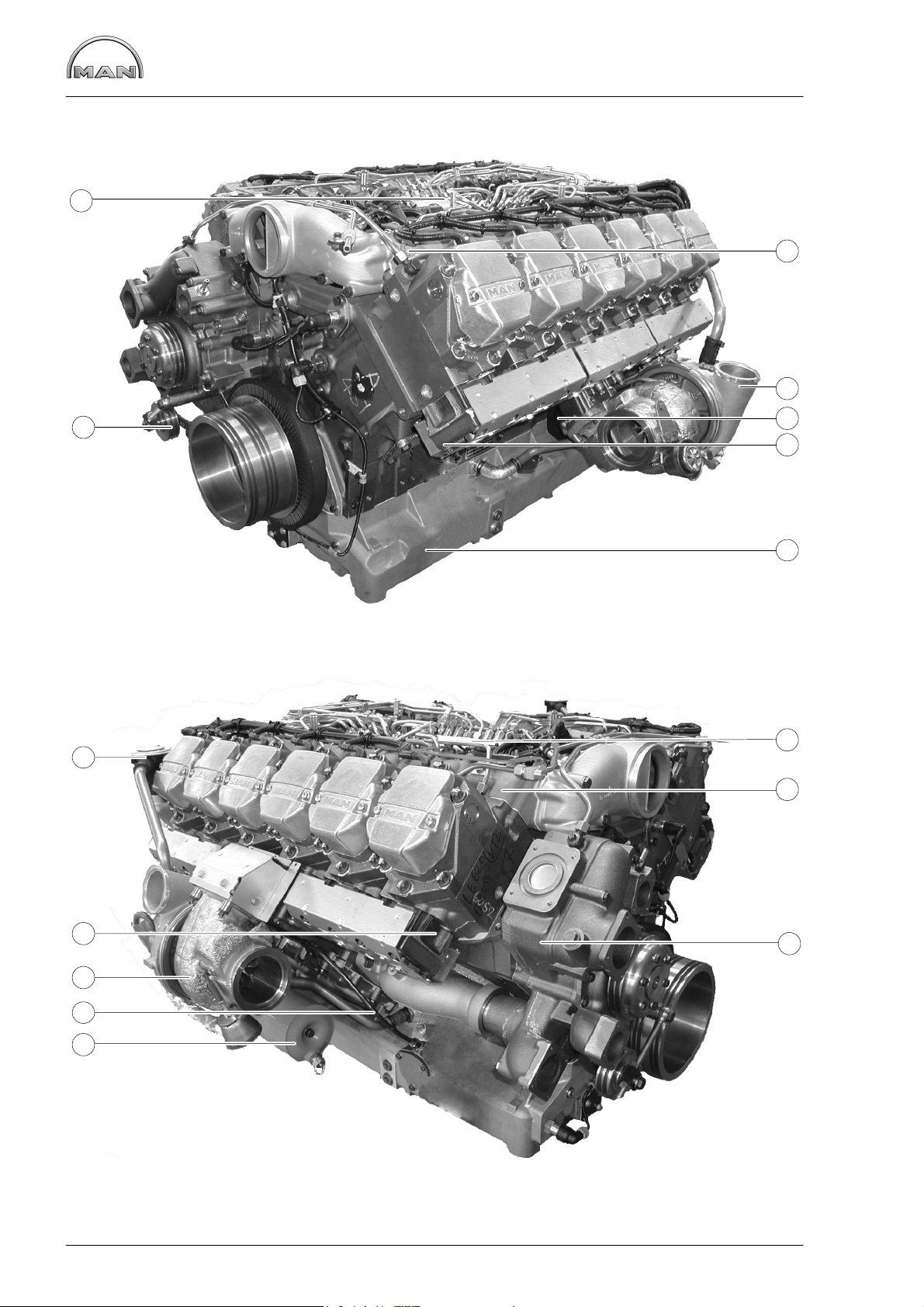

Page 20

Engine views D 2842 LE 620

7

1

2

6

11

3

4

5

7

1

4

2

10

9

8

18

Page 21

À In take pipe

Á Turbocharger

Starter motor

à Exhaust manifold

Ä Oil sump

Å Tension pulley

Æ Rail

Ç Coolant pump

È Oil filter

É Oil dipstick

Engine views D 2842 LE 620

11

Oil separator valve for crankcase breather

19

Page 22

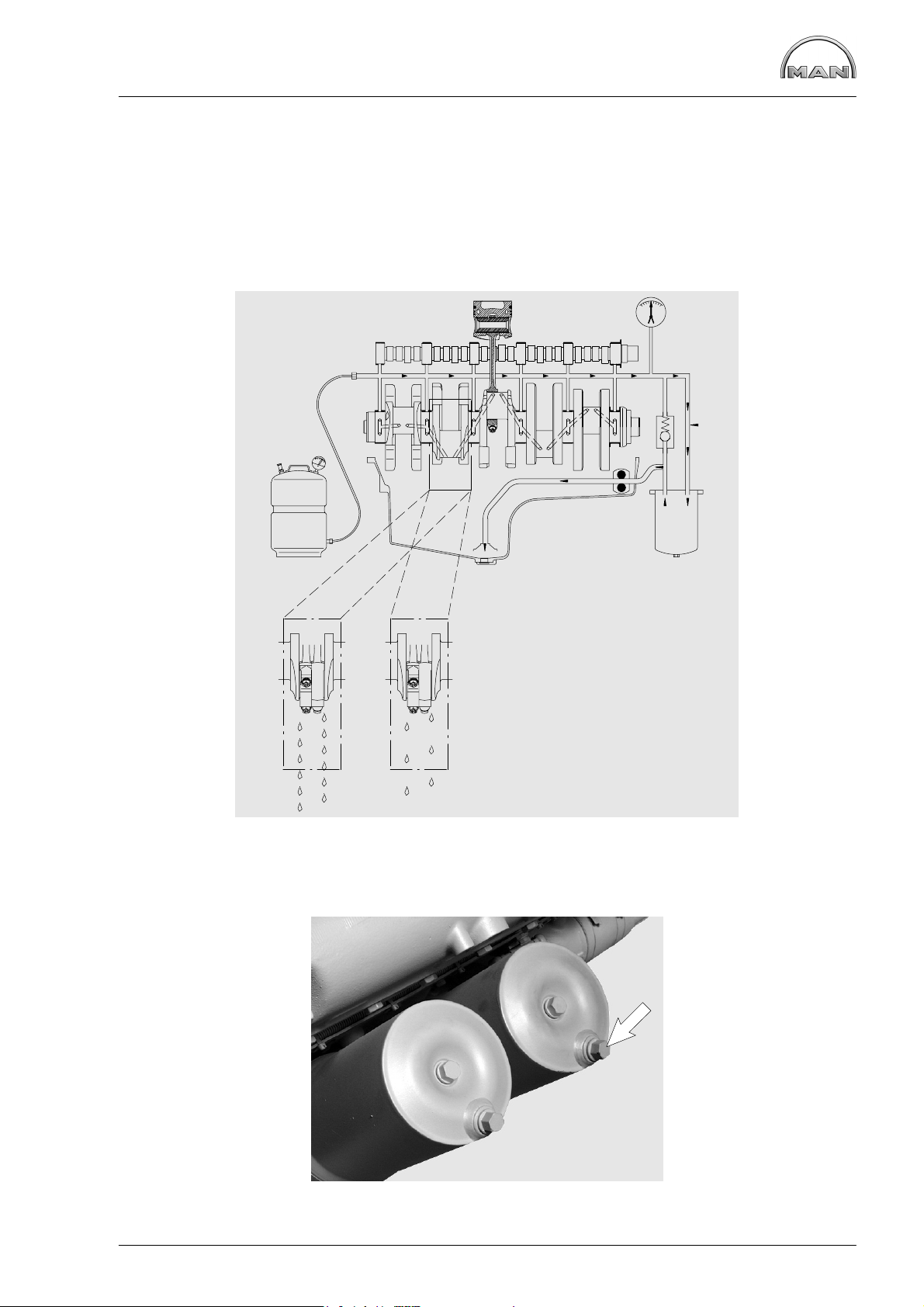

Engine lubrication schedule

1 2 3

4

5

À Oil line to crankshaft

Á High−pressure pump lubrication

Lubricating oil lines to exhaust turbochargers

à Oil return line from exhaust turbochargers

5

67789

Å Oil pump with oil pressure relief valves

Æ Holes for conrod bearing lubrication

Ç Oil drain screw

È Oil intake pipe

Ä Holes for main bearing lubrication

20

Page 23

Engine lubrication schedule

11

10

1 1

2

3

4

8

À Lubricating oil lines to exhaust turbochargers

Á Rocker arm lubrication

Piston pin lubrication

à Spray nozzles for piston cooling and

cam lubrication

Ä Camshaft bearing lubrication

5

79

6

Å Oil intake pipe

Æ Oil pressure relief valves

Ç Oil cooler

È Bypass valve

É Oil filter

11

Main oil galleries

21

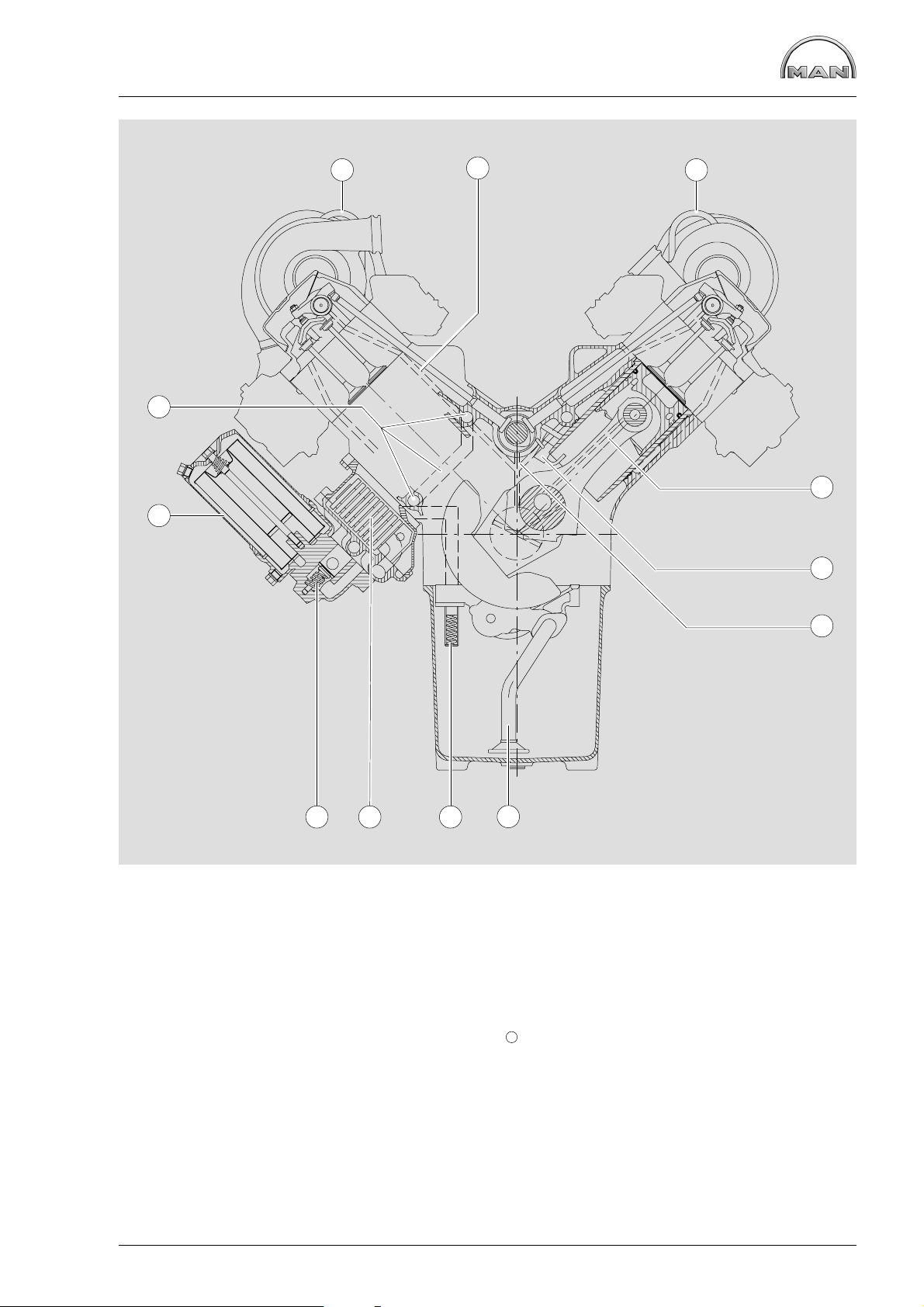

Page 24

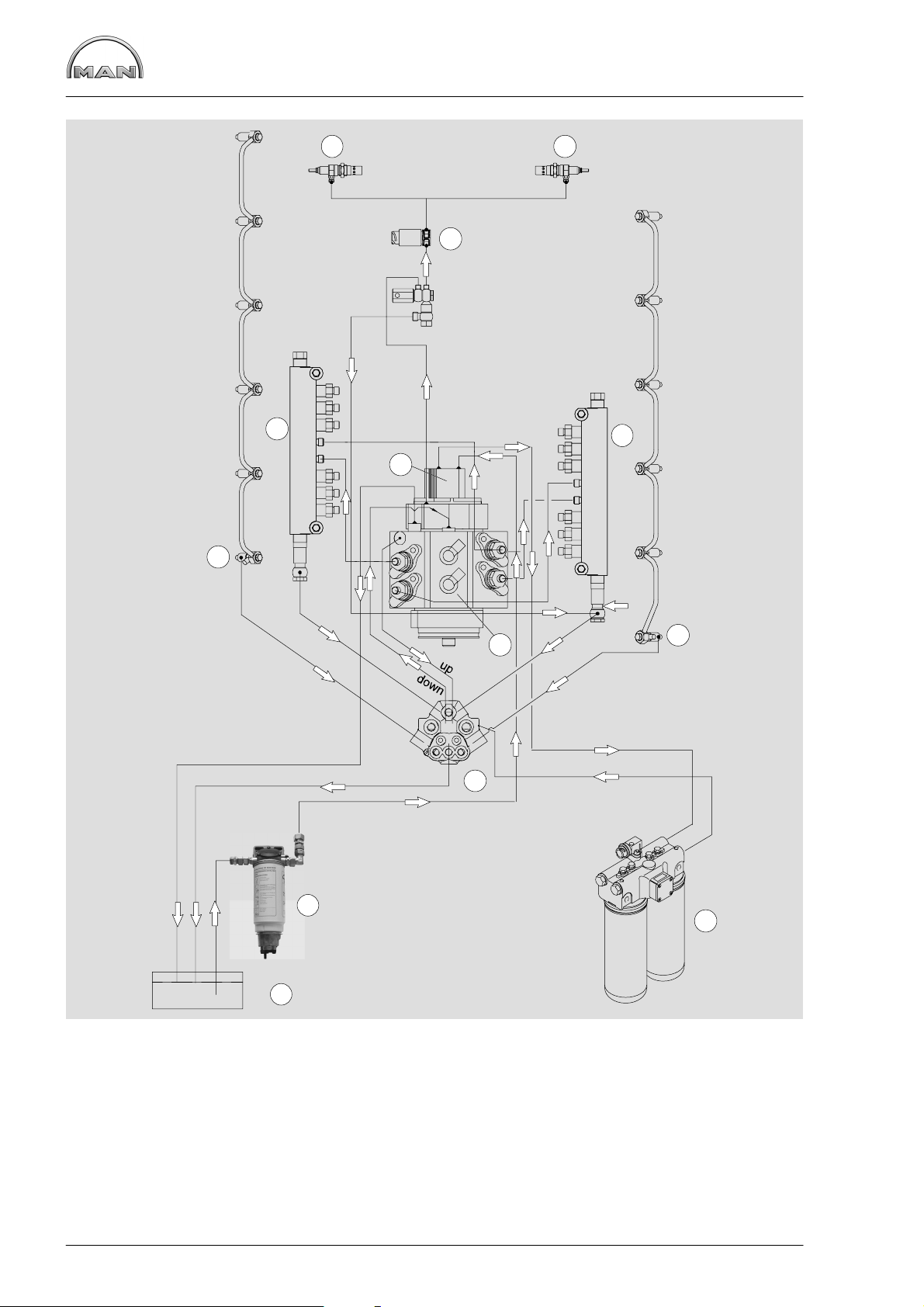

Fuel diagram

9

1010

4

4

6

3

3

14

2

5

3

8

2

1

À Tank

Á Fuel prefilter with water separator

Injector

à Rail

Ä High pressure pump

7

Å Fuel pump

Æ Fuel filter

Ç Fuel distributor

È Solenoid valve

É Glow plug

22

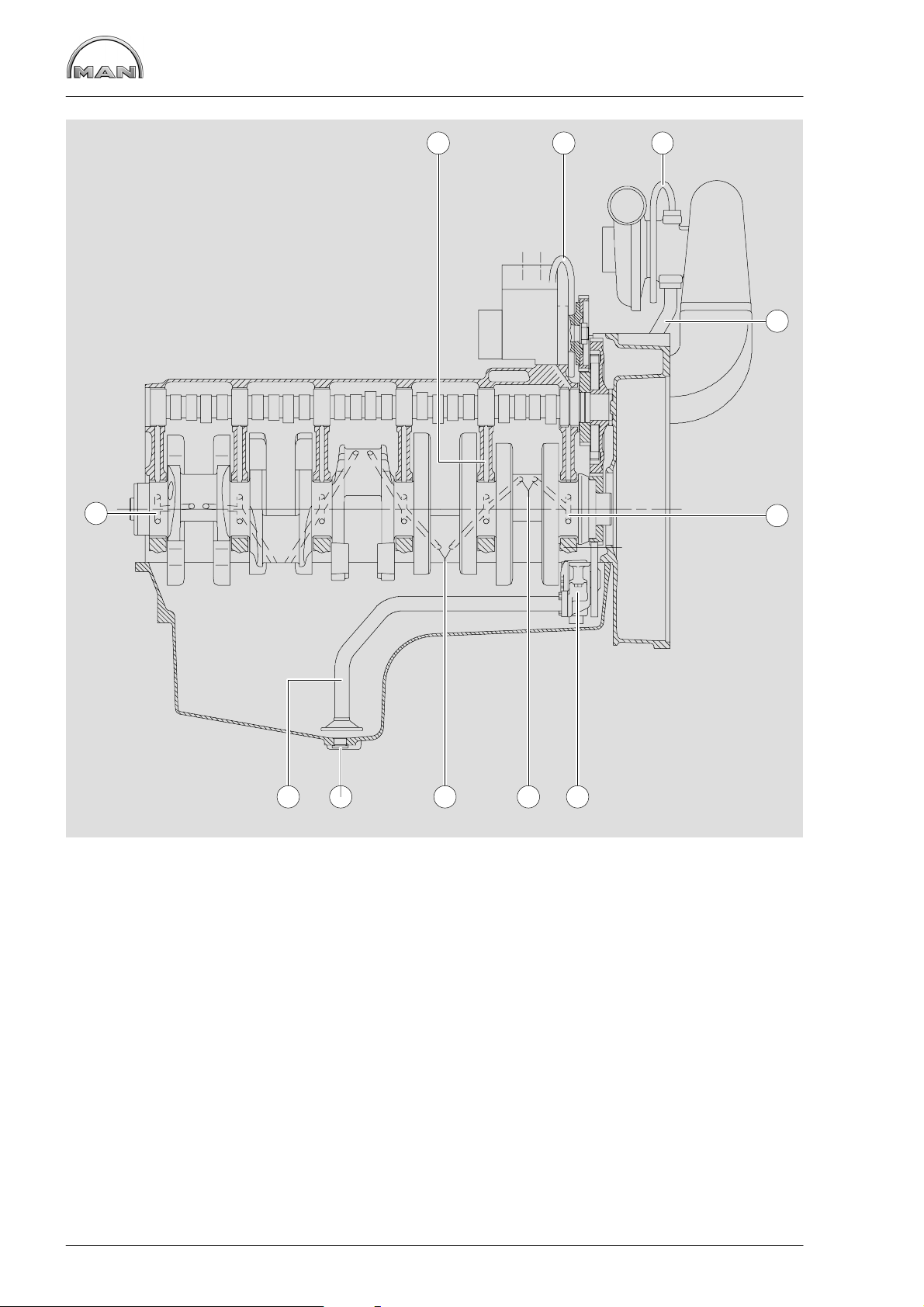

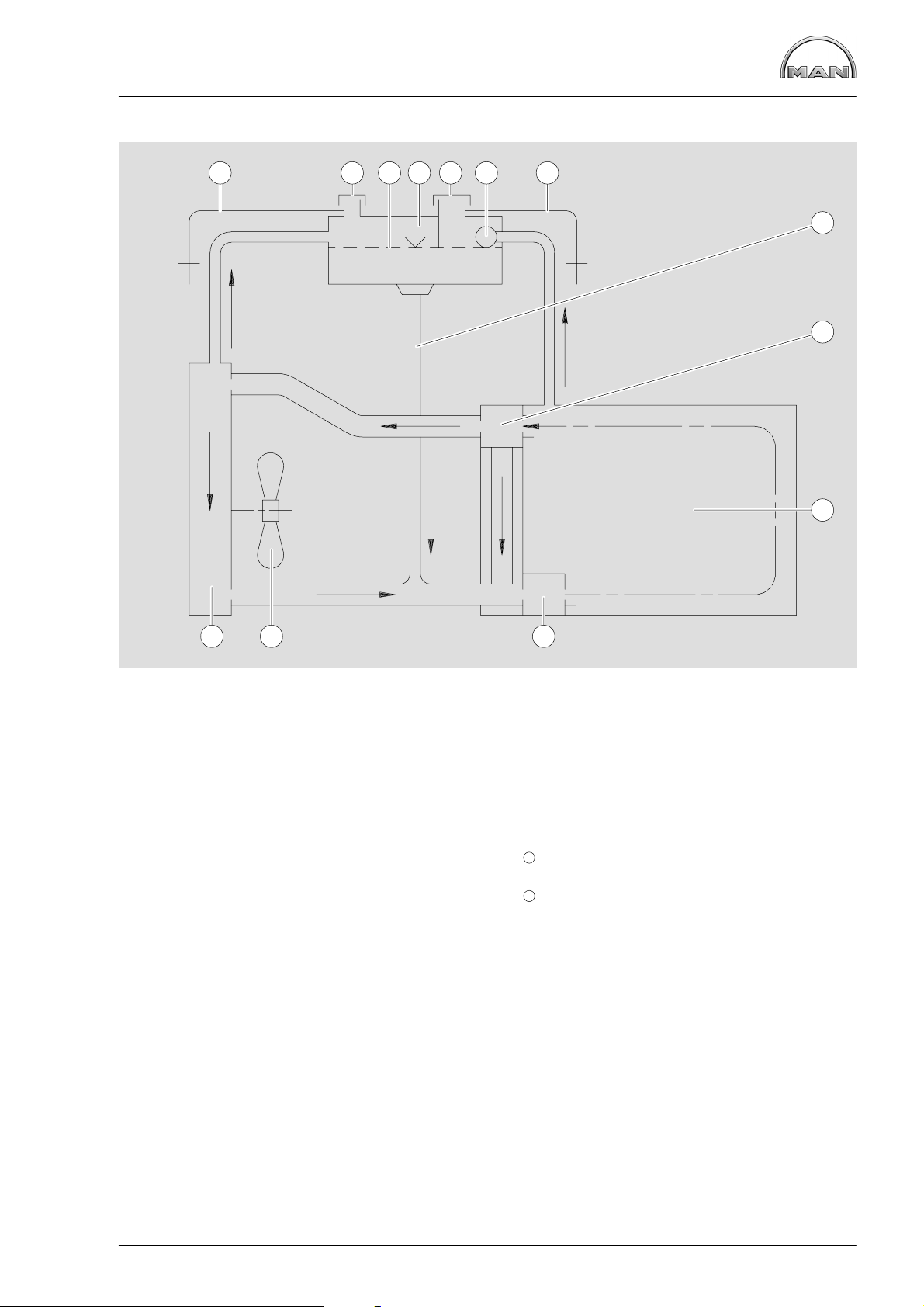

Page 25

Schematic diagram of cooling system

1 12 3 4 5

6

7

8

9

12

À Overflow and vent pipe Æ Filler pipe

Á Positive pressure / negative pressure valve Ç Thermostat

Coolant level in surge tank È Engine / crankcase

à Surge tank É Water pump

Ä Coolant filler neck

Å Degassing system

1011

11

Fan

12

Radiator / intercooler

23

Page 26

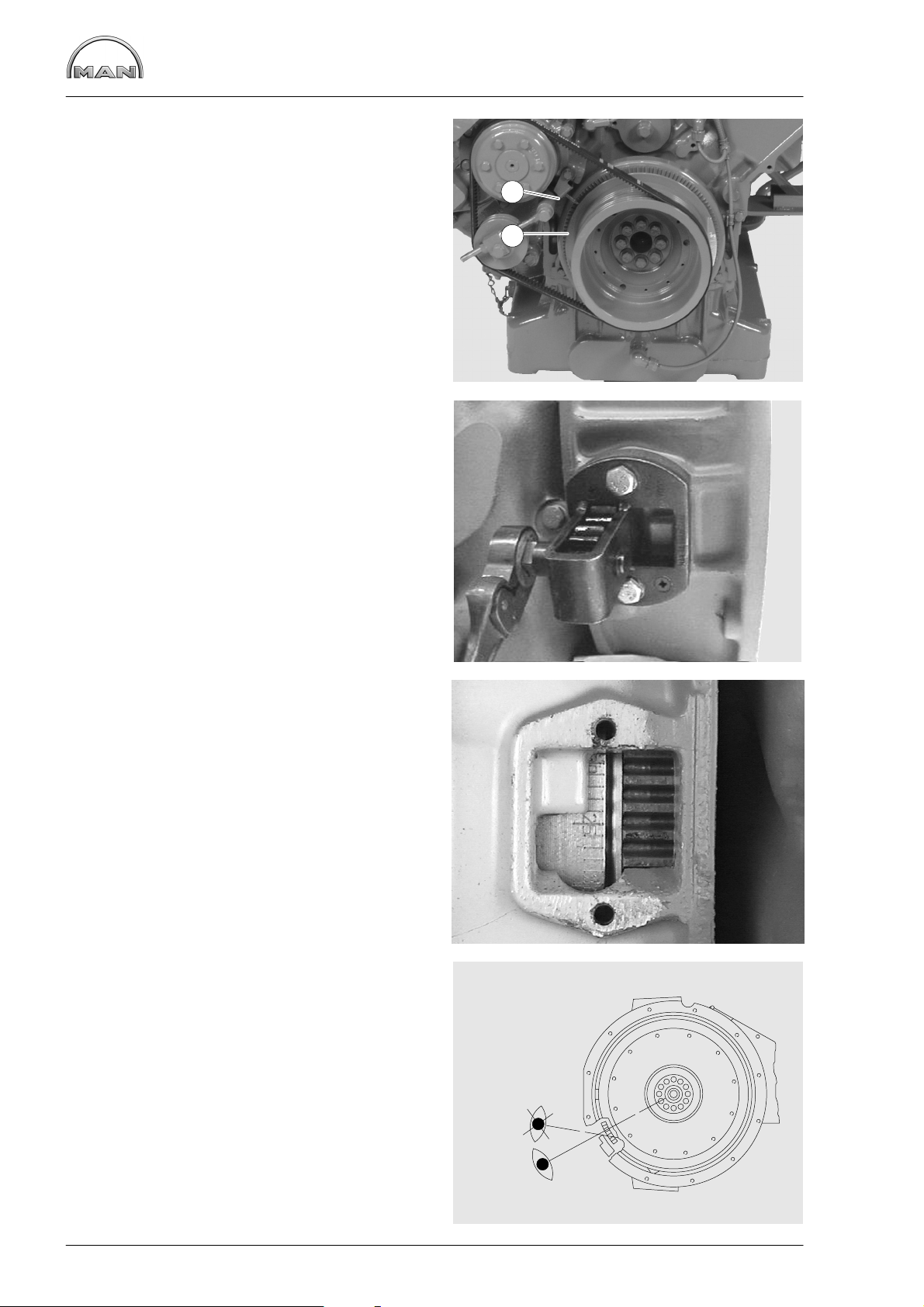

Check the base fitting of the high−pressure pump

Check the base fitting of the high−

pressure pump

Fig. 1 and Fig. 2

For the purpose of checking the start−of−delivery

setting, an “OT” (= TDC) mark and a scale from

10...50° before TDC are engraved on a disc Á

fitted in front of the torsional vibration damper.

The scale marks are read against an indicator À

fitted to the crankcase.

To turn the engine over manually during the setting

work, a plate with a central hexagon bolt must be

located on the front side of the crankshaft pulley.

For this purpose, the speed pickup together with

the plate is to be previously detached.

1

2

1

Fig. 3

The graduated scale on the flywheel, which is visible through the inspection hole in the flywheel

housing, is often difficult to access. However it

must be used to readjust the indicator after the

vibration damper has been removed or replaced.

For this purpose, before the vibration damper with

scale disc is installed, the engine must be set to

“TDC” using the flywheel marking.

The indicator must then be aligned so that its

measuring edge points exactly to the “TDC” mark

on the scale disc.

Fig. 4

To avoid read−off errors, always look over the

notch on the flywheel housing vertically to the

centre of the flywheel.

The marking on the graduated scale must be on

the imaginary “notch − flywheel centre” line.

2

3

24

4

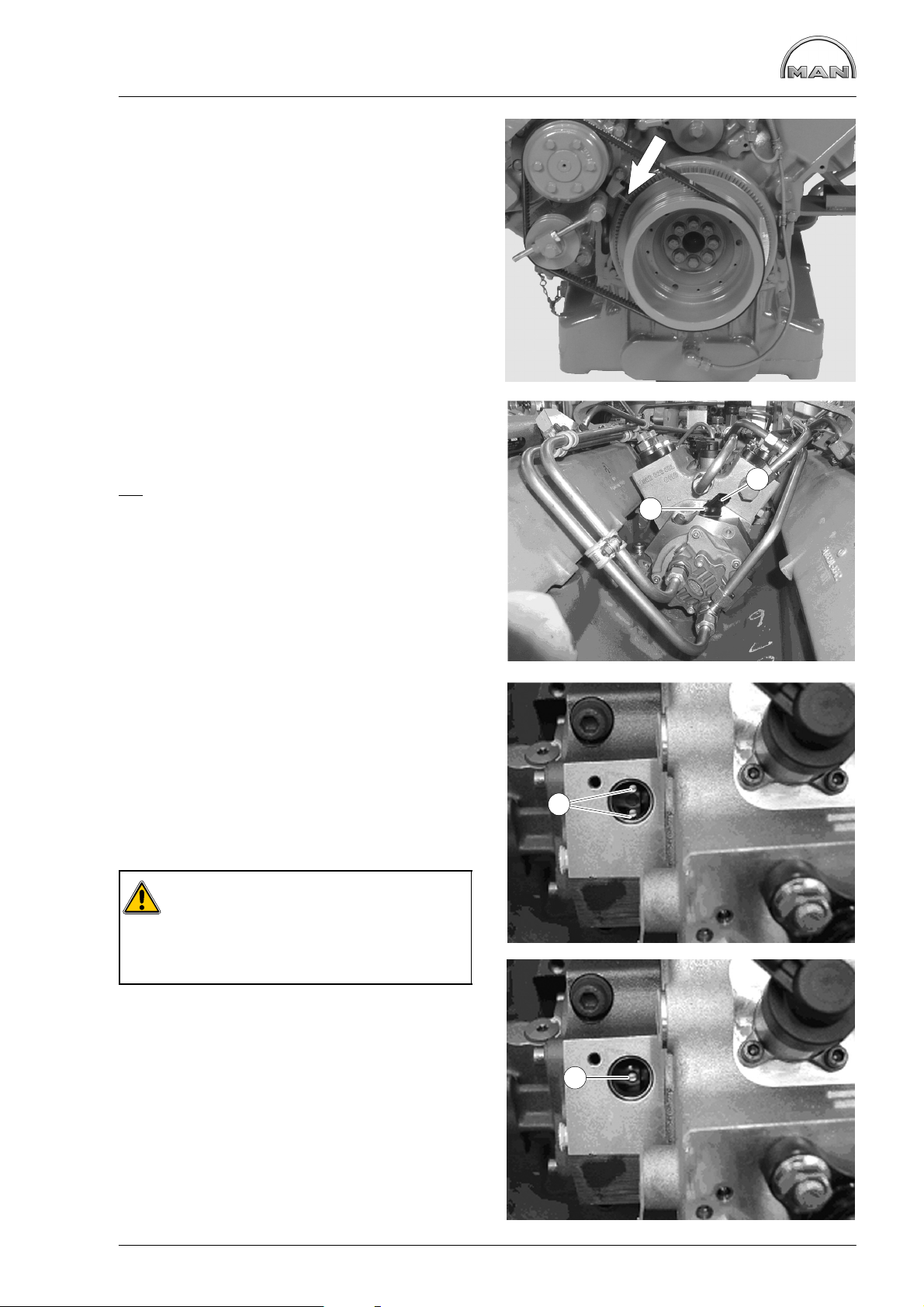

Page 27

Check the base fitting of the high−pressure pump

Fig. 5

The indicator (arrow) must then be aligned so that

its measuring edge points exactly to the “TDC”

mark on the scale disc.

Turn engine to ignition TDC 1.

Fig. 6

Pull the connector off the rpm sensor Á.

Unscrew the mounting bolt À of the rpm sensor Á

and pull out the rpm sensor.

marking may be visible.

No

Fig. 7

If the engine is now turned back to 69° before

TDC, 2 markings À must be visible.

If both markings are visible, then fit the rpm sensor

and tighten the mounting bolt with 9 Nm.

Reconnect the control unit.

5

2

1

7

1

Fig. 9

Caution:

If only 1 marking is visible, the high−pres-

sure pump has been fitted and twisted by

180° towards ignition TDC engine cylinder 1.

In this case, the high-pressure pump has to be removed.

8

1

9

25

Page 28

Removing and installing the high-pressure lines

Danger:

Before starting the work, comply with “Special instructions when working on the common rail system” (see page 9).

Caution:

All connections and removed parts are to be closed immediately with suitable caps!

Dirt in the injection system causes:

D injectors to jam

D the high-pressure pump drive to break

The lines contain fuel.

Catch escaping fuel in a suitable container.

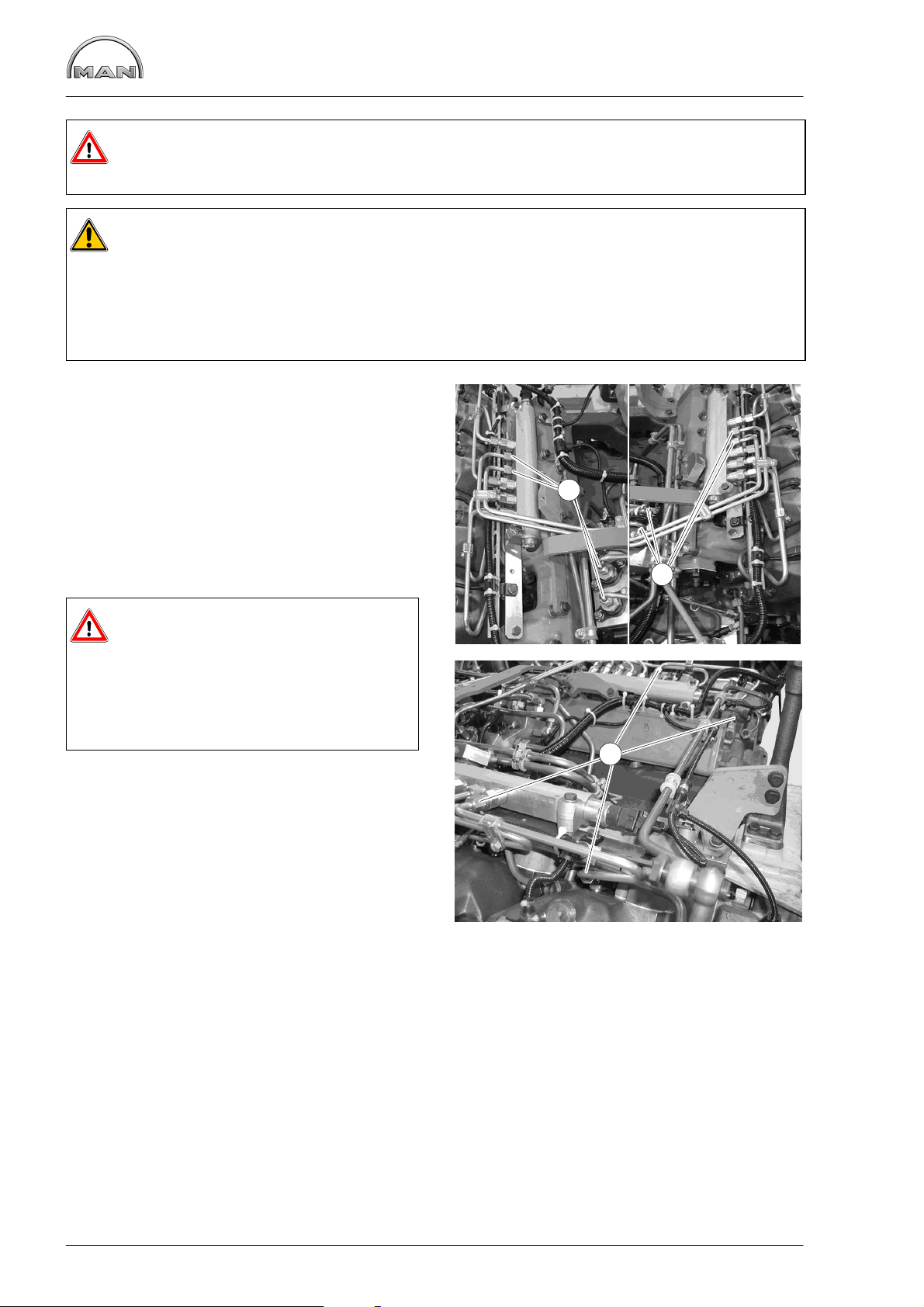

Fig. 1

Unscrew the union nuts À of the high-pressure

lines between the rail and high-pressure pump.

Fig. 2

Unscrew the union nuts Á of the high-pressure

lines between the rail and injectors.

The lines are installed in reverse order.

Danger:

High-pressure lines with WAF 17 union

nuts must be replaced!

High-pressure lines with WAF 19 union

nuts may be reused!

Injection lines must be fitted without tension.

Tightening torques for high-pressure lines:

Initial fit:

Pretightening 10 Nm

Final tightening 60°

Reuse:

Pretightening 10 Nm

Final tightening 30°

1

1

1

2

2

26

Page 29

Removing and installing high-pressure pump

Removing high-pressure pump

D Remove the high-pressure lines between the high-pressure pump and rail, see page 26

Note:

The subsequent reinstallation of the high-pressure pump is rendered considerably easier if before

its removal the engine has been turned to ignition TDC cylinder 1(see page 24).

Danger:

Before starting the work, comply with ”Special instructions when working on the common rail system” (see page 9).

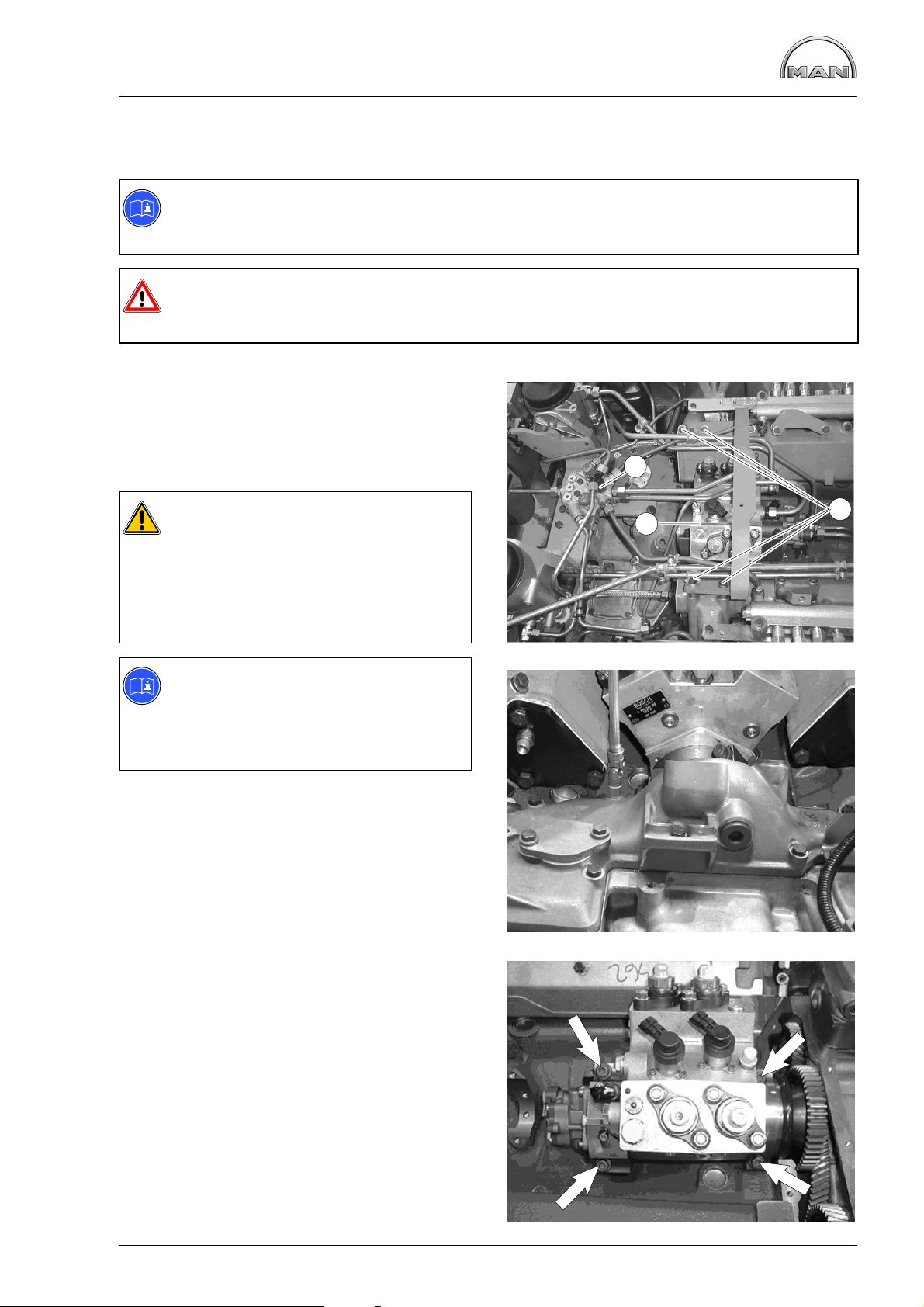

Fig. 1

Unscrew and remove all fuel and oil lines to the

high-pressure pump Á and to fuel distributor Â.

Undo all the electrical connections to the highpressure pump.

3

Caution:

All connections and removed parts are to

be closed immediately with suitable

caps!

The lines contain fuel!

Catch escaping fuel in a suitable container.

Note:

To facilitate reassembly, memorise or

mark down in a drawing or photo the

positions of the brackets, pipe clamps

and spacer sleeves etc.

To remove the injection pump, the high-pressure

pump drive must be made accessible.

For this purpose the fuel distributor must be detached.

Close shutoff valve from tank to engine.

Fig. 2

Remove timing case cover.

2

1

1

2

The injection pump drive can now be seen.

Fig. 3

Remove mounting bolts from high-pressure pump

(arrow).

Take off high-pressure pump.

3

27

Page 30

Removing and installing high-pressure pump

Installing high-pressure pump

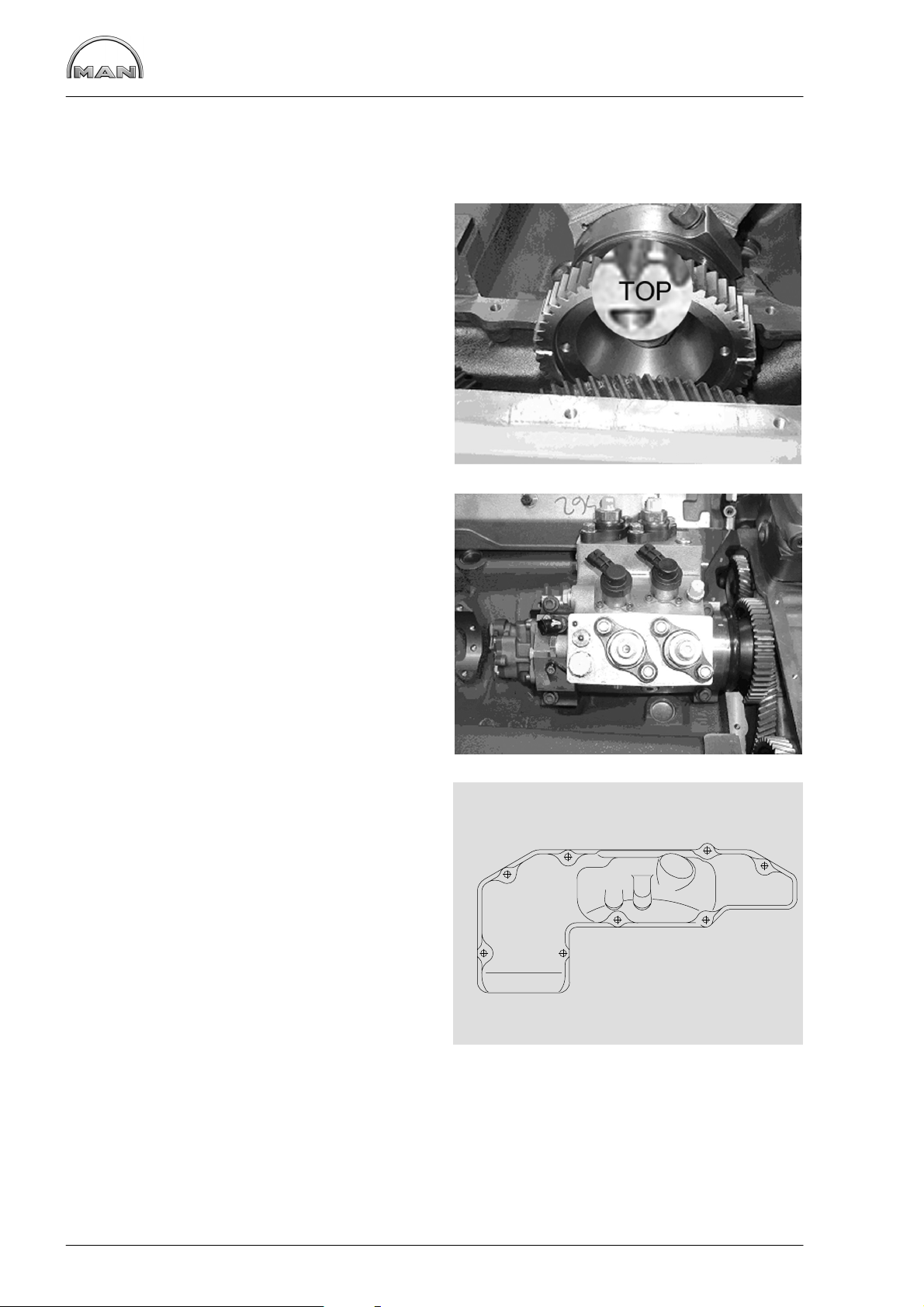

D Turn engine to ignition TDC 1.

Fig. 4

Turn mark “TOP” on the high-pressure pump drive

gear in the middle to pump.

Insert high-pressure pump.

Fig. 5

4

Tighten the mounting bolts in the sequence and

method specified (pos. 1−4).

Order of tightening: 1−2−3−4 in the steps:

1. Initial torque: 10−15 Nm

2. final torque: 65−70 Nm

Check the base fitting of the high-pressure pump,

see page 24.

Fig. 6

Tighten bolts on timing case cover to the torque

and in the sequence specified.

Tightening torque: 25 Nm

Refit all components previously removed.

3

2

5

1

5

42

87

1

4

3

6

28

6

Page 31

Removing and installing the rail

Danger:

Before starting the work, comply with “Special instructions when working on the common rail system” (see page 9).

Caution:

All connections and removed parts are to be closed immediately with suitable caps.

Dirt in the injection system causes:

D injectors to jam

D the high-pressure pump drive to break

The lines contain fuel.

Catch escaping fuel in a suitable container.

Fig. 1

D Close shutoff valve from tank to engine

Caution:

Before the high-pressure lines are removed

it is necessary to clean the CR system again.

7

Unscrew the union nuts Æ of the high-pressure

lines between the rail and injectors.

Fig. 2

Unscrew the union nuts Ç of the high-pressure

lines between the rail and high-pressure pump.

Fig. 3

Remove fuel pipe for rail return.

Take out rail É.

1

8

8

2

29

10

10

3

Page 32

Removing and installing the rail

Install rail

Install the filter in reverse order:

D Install rail and fuel pipe for rail return

D Fit high-pressure pipes

Danger:

High-pressure lines with WAF 17

union nuts must be replaced.

High-pressure lines with WAF 19

union nuts may be reused.

Injection lines must be fitted without

tension.

Tightening torques for high-pressure lines:

Initial fit:

Pretightening: 10 Nm

Final tightening:60°

Reuse:

Pretightening: 10 Nm

Final tightening:30°

D Install intake neck and bleed pipes

D Vent the fuel system, see page 38

30

Page 33

Removing and installing the rail pressure sensor,

pressure relief valve

Danger:

Before starting the work, comply with “Special instructions when working on the common rail system” (see page 9).

Caution:

All connections and removed parts are to be closed immediately with suitable caps!

Dirt in the injection system causes:

D injectors to jam

D the high−pressure pump drive to break

The lines contain fuel.

Catch escaping fuel in a suitable container.

Fig. 1

Remove the rail pressure sensor À or pressure

relief valve Á from the rail. Undo the electrical connection of the rail pressure sensor.

1

Fit the rail pressure sensor À or pressure relief

valve Á on the rail.

Tightening torque:

Rail pressure sensor À 70 Nm

Pressure relief valve Á 100 Nm

Reconnect the rail pressure sensor.

2

2

31

Page 34

Removing and installing the injectors

Danger:

Before starting the work, comply with ”Special instructions when working on the common rail system” (see page 9).

Caution:

All connections and removed parts are to be closed immediately with suitable caps!

Dirt in the injection system causes:

D injectors to jam

D the high-pressure pump drive to break

The lines contain fuel!

Catch escaping fuel in a suitable container.

Removing injectors

D Close shutoff valve from tank to engine

D Removing rail, see page 29

D Draining off coolant, see page 40

Fig. 1

Remove the cylinder head covers.

Fig. 2

Remove the cable lugs on the injector.

Caution:

There are small copper washers under the

cable lugs; these could fall into the en-

gine!

Fig. 3

1

2

Remove the valve cover seal.

Remove mounting bolts from carrier for injector

cable harness and slew carrier to one side.

3

32

Page 35

Removing and installing the injectors

Fig. 4

Remove coolant bleed pipe, rail carrier and leak-oil

pipe.

Fig. 5 and Fig. 6

Unscrew the mounting bolt Á of the connector fitting and pull the pressure pipe fittings  out of the

cylinder head.

4

Fig. 7

Unscrew the mounting bolt of the pressure flange

(see item À Fig. 6).

5

1

2

3

6

33

7

Page 36

Removing and installing the injectors

Fig. 8

Use a support bridge À and extractor tool Á (see

page 172) to pull out the injector and pressure

flange.

D Push the extractor tool Á through the support

bridge À over the injector, making sure that

the clamping sleeve is turned back far enough

D Tension the clamping sleeve and pull the injec-

tor with knurled nut out of the cylinder head

Danger:

Injectors must not be opened!

Caution:

Immediately close off the connection

openings of the injector with suitable caps

(see page 172) and place in the storage

sleeve.

Clean the injector seat in the nozzle bushing.

1

2

8

1

2

Fitting injectors

Fig. 9

Insert new O-ring À and new copper sealing ring

Â.

Grease the O-ring.

Figs. 10 and 11

Insert the injector with pressure flange into the

nozzle bushing in such a way that the feed bore

hole Á (see also item Á on Fig. 9) points to the

bore hole for the pressure pipe À in the cylinder

head.

Press in the injector by hand as far as it will go.

Pretighten the mounting bolt for pressure flange

with 1.5 Nm.

3

9

10

1

11

34

2

3

Page 37

Removing and installing the injectors

Fig. 11 and Fig. 12

Caution:

Removed pressure pipes must be replaced.

Insert pressure pipe into the cylinder head.

Caution:

The thin end of the pressure pipe points

towards the injection nozzle.

Replace the O-ring and apply a light coating of

grease.

Insert the connector fitting and align in such a way

that the high-pressure line can be connected without tension (see also item Á Fig. 6).

Pretightening: 10 Nm

Fully tighten the mounting bolt for pressure flange

(see also item À Fig. 6).

Final tightening: 25 Nm

Angle tightening: 905

12

Fully tighten the mounting bolt for connector fitting

(see also item À Fig. 6).

Final tightening: 20 Nm

Angle tightening: 905

Check tightness of injector, pressure

pipe and leak-oil line

Caution:

After the injectors have been installed, always check to ensure that the injectors,

pressure pipes and leak-off oil lines do not

leak.

Note:

The check for leaks can only be performed for one row of cylinders at a time.

Fig. 13 and Fig. 14

D Remove the high-pressure lines to the individ-

ual cylinders on the rail or on the connector fitting

D Connect test device Á up to the ring piece of

the leak-oil pipe À

D Pump approx. 2 bar pressure to fuel system

The pressure must not drop for a period of 3 minutes.

If there is a leak in the fuel system, the injectors

have to be removed once again. Check the removed parts for damage or soiling - replace if

necessary and then refit, observing the greatest

possible cleanliness.

13

14

1

1

2

35

Page 38

Removing and installing the injectors

Fig. 15

Install rail carrier, coolant bleep pipe and cable harness for injector.

Connect cable harness to the injectors.

Tightening torque: 1.5 Nm

Fig. 16

Fit valve cover with seal and

tighten mounting bolts.

D Installing rail, see page 30

D Fill coolant, see page 40

15

16

36

Page 39

Fuel prefilter with water separator

Fuel pre-filter with water separator

Fig. 1

Draining water:

D Open drain screw À and let off water

D Close drain screw À again

Changing filter element

Only when the engine is switched off

Close shut-off valves between engine, pre-filter

and tank.

D Disconnect plug

D Remove filter bowl Á and filter element Â

D Wet seal on new filter with fuel

D Screw on filter  and filter bowl Á

D Connect plug

D After this, bleed the fuel system

D Check filter for leaks

Caution:

Used fuel filters are classed as dangerous waste and must be disposed of accordingly.

3

2

1

1

37

Page 40

Fuel filter, exchanging filter cartridge

Changing fuel filter cartridge

Only when the engine is swiched off.

Close shut-off valves between engine, pre-filter

and tank.

Fig. 1

D Loosen filter cartridge by means of tape

wrench, unscrew it by hand and take it off

D Moisten the seals on the new filter cartridge

with fuel

D Screw on the filter cartridges and tighten them

vigorously by hand

D Bleeding the fuel system

D Check filter for leaks

Caution:

Used fuel filters are classed as dangerous waste and must be disposed of accordingly.

1

Bleeding the fuel system

To bleed the fuel system follow the instructions of the vehicle manufacturer.

38

Page 41

Flame-starter sheathed-element glow plug,

removing and installing

Removing sheathed-element glow plug

Fig. 1

Disconnect the electric connections from the

sheathed-element glow plug.

Remove fuel line carefully.

Loosen counter nut on sheathed-element glow

plug and remove glow plug.

Installing sheathed-element glow plug

Fig. 2

Turn counter nut on sheathed-element glow plug

upwards until it stops and apply “Curil T” sealant to

threaded portion.

Screw in sheathed-element glow plug with new

sealing ring until it stops at the counter nut and

align it with fuel line.

1

Connect up fuel line and electric connection.

Tighten counter nut.

Checking solenoid valve for leaks

Remove fuel line from flame glow plug.

When the engine is running and hot, no fuel must

emerge.

Removing solenoid valve

Fig. 3

D Detach fuel lines. Ensure that insulation el-

ement does not burst.

D Remove electric connection from valve

D Remove the two hex bolts and take off valve

The valve cannot be repaired.

Exchange the defective valves.

Fitting solenoid valve

2

3

D Screw valve to holder

D Screw on electric connection

D Refit fuel lines with new seals. Ensure that in-

sulation element does not burst.

4

39

Page 42

Draining and filling coolant

Draining coolant

Danger:

When draining hot coolant, there is a

danger of scalding!

Drain coolant as follows when cooling system has

cooled down:

Caution:

Collect the drained coolant and dispose

of it in accordance with regulations!

Fig. 1 and Fig. 2

1

1

To let off pressure briefly open cap on filler neck of

expansion tank.

Observe the vehicle manufacturer’s instructions.

Open drain plug in crankcase À or in the oil cooler

housing

Catch emerging coolant in a suitable container.

Á.

2

2

Fill / bleed the cooling system (only when engine has cooled down)

The cooling system of the engine is to be filled with a mixture of drinking water from the mains and antifreeze based on ethylene glycol and / or anticorrosion additive.

See Publication “Fuels, Lubricants and Coolants for MAN Diesel Engines”.

Coolant must be poured in according to the vehicle manufacturer’s filling specifications.

Do not pour any cold coolant into an engine which is still warm.

Ensure that the mixing ratio “water-antifreeze” is preserved.

D Pour in coolant slowly until the correct coolant level is reached (max. 10 ltr./min.)

D Run the engine briefly and then check coolant level once more

Danger:

If, in exceptional cases, the coolant level on warm engines has to be checked or the cooling circuit

opened, observe the vehicle manufacturer’s safety regulations.

40

Page 43

Removing and installing thermostats

Fig.1

D Draining off coolant, see page 40

Remove the three mounting bolts from the coolant

neck and take off coolant neck.

Fig. 2

Take out short-circuit inserts / thermostats.

Check the function of the thermostats as follows.

D Suspend the thermostat in a bowl of water

D Heat up the water

D Use suitable thermometer to ascertain the

opening start and compare it with the set-point

value given in “Service Data”.

D If necessary, measure the opening stroke

1

Replace defective thermostats.

Insert thermostat inserts ball valve facing upwards

(“TOP”) with new O-ring seal and new seal.

Caution:

Never let engine run without thermostats

or short-circuit inserts.

2

41

Page 44

Removing and installing coolant pump

Note:

Exchange or repair coolant pump only if it has been found to be leaky.

The design of the coolant pump mechanical cassette seal permits small amounts of coolant to

pass through it. This coolant passing through results in a trace of drained coolant below the drain

bore. The coolant pump need not be exchanged or repaired because of this trace of permeating

coolant.

For this reason before exchanging or repairing a coolant pump ascertain

D whether the cooling circuit shows visible and recurring signs of coolant loss; if yes

D whether the coolant loss is caused by spillage from the expansion tank (e.g. too full) or by

other leakages from hoses, radiator etc.

Coolant pumps must be exchanged only if coolant drips visibly while the engine is in operation or

after the engine has been switched off.

Removing coolant pump

D Draining off coolant, see page 40

D Remove the thermostats, see page 41

Fig. 1

Take V-belt off coolant pump, see page 132

Fig. 2

Remove the mounting bolts from coolant pump

Take off coolant pump and delivery start indicator

1

42

2

Page 45

Removing and installing coolant pump

Installing coolant pump

Fig. 3

Clean the sealing faces on coolant pump and engine housing.

Fit coolant pump with new seal.

Fit the mounting bolts.

Fig. 4

Coolant pumps with high-temperature and

low-temperature sections

To aid in assembly pins (special tool, see page

171, no. 43) can be screwed into the crankcase

(arrows, Fig. 3). The water pump can then be fixed

to the protruding pins.

3

Fit the mounting bolts.

There is a screw for removing the pins (special

tool, see page 171, no. 42).

This screw has a left-handed thread and is

screwed into the pin. In this way the two can be

screwed out together.

Fit remaining mounting bolts.

Fig. 5

Tighten the mounting bolts with the prescribed

torque.

Screw coolant hose pipe on to oil cooler.

Install short-circuit inserts / thermostats, , see

page 41.

Refit and tension V-belt, see page 132.

Filling up with coolant, see page 40.

4

5

43

Page 46

Repairing coolant pump with high-temperature

and low-temperature parts

Coolant pump for three thermostats

Fig. 1 and 2

1 Pump housing HT (high-temperature part)

2 Pump housing LT (low-temperature suction

part)

3 Hub

4 Bolt DIN 931−M8x155,

hex nut DIN 934−M8

5 Bolt DIN 933−M8x35−8.8

6 Mechanical seal 51.06520−0085

7 Impeller for coolant pump, HT circuit

8 Mechanical seal 51.06520−0099

9 Counterring complete 51.06520−0100

10 Impeller for coolant pump, LT circuit

11 Splash shield

12 Mechanical seal 51.06520−0096

13 Coolant pump bearing

14 Drive shaft for coolant pump

15 Circlip

16 Coolant pump seal

17 Grooved ball bearing 6003

18 Cap

1

2

3

5

4

1

18

6

7

17

8

9

10

11

16

12

13

Disassembling water pump

Fig. 3

Removing the water pump, see page 42.

Clamp water pump in a vice, use protective jaws.

Pull off boss with three-arm puller.

Fig. 4

Unclip the circlip from the coolant pump housing.

15

2

3

14

44

4

Page 47

Repairing coolant pump with high-temperature

and low-temperature parts

Fig. 5

Knock out cover by driving a suitable mandrel

under it (Fig. 1, item 3) at notch (arrow).

Fig. 6

Pull impeller off coolant pump shaft.

For this purpose four threaded bores M8 are provided.

5

Fig. 7

Note:

Remove bolt from low-temperature part

(Fig. 1, item 5).

Align water pump housing on a suitable and stable

surface.

Use a suitable mandrel to press the water pump

shaft together with bearing out of the housing.

Take off mechanical seal.

The high-temperature part and the low-temperature suction part are now separated.

Remove axial face seals and grooved ball bearing

from high-temperature part if they are still in the

housing.

6

7

45

Page 48

Repairing coolant pump with high-temperature

Reassembling coolant pump

Fig. 8

Press in water pump bearing.

Fit the circlip.

Note:

If you change the seals always install a

new shaft and axial face seals.

Fig. 9

Press boss flush on to bearing shaft.

and low-temperature parts

8

Fig. 10

Turn water pump housing over Press in new mechanical seal with press-fitting sleeve (special tool)

until it stops.

Observe installation note for seal on page 50.

Fig. 11

Press in counterring (arrow) with a suitable pressing tool (may be possible by hand).

Install mechanical seal while “wet”, i.e. to install it,

coat holding sleeve and water pump shaft with a

mixture of either 50% water and 50% cleaning

spirit or 40% to 50% antifreeze agent as per MAN

324 and water.

9

10

11

46

Page 49

Fig. 12

Repairing coolant pump with high-temperature

and low-temperature parts

Note:

Brace the bearing shaft.

Slowly press impeller on to bearing shaft to ensure

correct gap (0,5

Fig. 13

Press in new mechanical seal (pos. 8) with pressfitting sleeve (special tool) until it stops.

Observe installation note for seal on page 50.

+0,4

).

12

13

Fig. 14

Lay coolant pump gasket on pump housing.

Fig. 15

Carefully fit low-temperature suction part to hightemperature pump housing.

To make assembly easier insert 2 pins in opposite

sides of HT part (see Fig. 14)

Do not use force (hammer etc.) and note the 3

centring features (see arrows in Fig. 14).

14

Screw in bolt (Fig. 1, item 5).

Bolt LT and HT parts together with 2 bolts and nuts

on opposite sides (Fig. 1, item 4).

15

47

Page 50

Repairing coolant pump with high-temperature

and low-temperature parts

Fig. 16

Note:

For subsequent steps brace the bearing

shaft.

Press grooved ball bearing 6003 into position using

special tool.

Fig. 17

Press in new mechanical seal (pos. 6) with pressfitting sleeve (special tool) until it stops.

Observe installation note for seal on page 50.

16

Fig. 18

Slowly press impeller on to bearing shaft to ensure

correct gap.

Fig. 19

For this purpose an inspection hole closed up with

a screw plug (M16x1.5) is provided on the bottom

of the water pump housing.

1 Impeller

2 Coolant pump housing

17

18

2

1

19

48

Page 51

Repairing coolant pump with high-temperature

and low-temperature parts

Fig. 20

Fit new pump cover and press it into housing,

using a suitable pressing tool.

Attach water pump with new seal, see page 42.

20

49

Page 52

Repairing coolant pump with high-temperature

and low-temperature parts

Installation note for mechanical seal:

Install mechanical seal while “wet”, i.e. to install it, coat holding sleeve and water pump shaft with a mixture

of either 50% water and 50% cleaning spirit or 40% to 50% antifreeze agent as per MAN 324 and water.

Other antiseize agents must not be used.

Because the seal on collar Á is coated with sealing paint, no sealing paint needs to be applied if the locating bore in the coolant pump housing is in perfect condition.

If the bore shows even the slightest scoring or other minor damage, a sealing bead of Dirko-Transparent,

Part No. , must be applied to collar Á.

Fit the seal with a plastic transportation cap onto shaft À and use installation tool to press it in until the tool

contacts the housing. Remove the plastic cap.

1 2 3 4

5

Note:

Tests have shown that most cases of damage to the coolant pump can be attributed to the use of

unsuitable coolants.

Only the anticorrosion and antifreeze agents expressly approved by MAN Nutzfahrzeuge AG as

per MAN norm 324 (see brochure “Fuels, Lubricants, Coolants for and MAN Diesel Engines”)

guarantee faultless operation

50

Page 53

Cleaning cooling system

Cleaning inside of cooling system

Tests have shown that in many cases the poor condition of the coolant and / or the cooling system accounts for damage to the coolant pump seal. The poor condition of the cooling system is normally due to

the use of unsuitable or no antifreeze or corrosion inhibitor or to defective caps for filler necks and service

valves which are not punctually replaced.

If the coolant pump of an engine develops leaks twice in short succession or the coolant is heavily contaminated (cloudy, brown, mechanically contaminated, grey or black signs of leakage on the coolant pump

housing, after the defect on the oil cooler), clean the cooling system prior to removing the faulty coolant

pump as follows:

a) Drain coolant

b) Open the thermostats positively (use bypass inserts) so that the entire cooling circuit is flushed immedi-

ately during the cleaning operation

c) Fill coolant circuit with a mixture of hot water (min. 50°C) and Henkel P 3 neutrasel 5265 detergent

(1.5% by volume) (−5266, −5225, Kluthe Hakopur 316), refer to Publication ”Fuels, Lubricants ...”

d) Warm up the engine under load. After a temperature of 60°C is reached, run the engine for a further 15

minutes

e) Drain cleaning fluid

f) Repeat steps c) and d)

g) Flush the cooling circuit; to this effect

h) Open the drain valve slightly

i) Fill the cooling circuit with hot water

k) Run the engine at idle for 30 minutes. At the same time, continuously replenish the water emerging

through the drain valve by adding fresh water at the filler neck

l) Drain off cleaning fluid and close the drain valve

Only now should the coolant pump be repaired. On completion of repairs, fill the cooling system with coolant, refer to publication “Fuels, Lubricants ...”.

Note:

Only sediments and suspended particles can be removed by this cleaning method. If rust and lime

deposits are detected, proceed following the instructions set out in the section below:

51

Page 54

Cleaning cooling system

Removing lime deposits in cooling system

Proceed as follows:

D Drain coolant

D Fill the system with undiluted original pickling fluid (lithsolvent acid or engine pickling fluid RB-06). Keep

the engine running for approx. 8 hours with this fluid in the system (also in normal operation)

D Drain the pickling fluid and flush the system thoroughly with tap water

D If necessary, refill the system with fresh pickling fluid and pickle the system for a further 8 hours

D Drain the pickling fluid, fill the system with tap water, and run the engine at idle for 5 minutes to flush out

all fluid; then drain the water

D Fill the system with soda solution (1%). Drain the soda solution after running the engine at idle for 5 min-

utes, and flush with tap water until the discharging water runs clear

D Fill cooling circuit with a mixture of potable tap water and anti−freeze with at least 40% by volume, refer

to Publication ”Fuels, Lubricants ...”

Filler caps and service valves of cooling system

The rubber seals on the filler caps and service valves (negative pressure and positive pressure valves) of

the cooling system are subject to natural ageing.

To prevent leakages in the cooling system together with the associated loss of pressure and its consequences through to serious engine damage, replace the filler caps and service valves at the same time as

changing the coolant (every two years at the latest).

Waste water treatment

Drained and spent cleaning and pickling fluid should be brought up to a pH value of 7.5 to 8.5 with the aid

of caustic soda. Once the precipitation has settled to the bottom of the container, the clear fluid above can

be tipped into the sewer system. To be sure, it is advisable to consult the local authorities for more information on waste water rules and restrictions. The sludge at the bottom must be taken to a special waste

dump.

52

Page 55

Changing oil filter

Caution:

Used oil and oil filters are classed as dangerous waste and must de disposed of

accordingly. Note instructions for preventing environmental damage.

Fig. 1

Open oil drain plug on oil filter can and use container to catch oil that may emerge.

Danger:

Oil filter can and oil filter are filled with hot

oil.

Risk of burns and scalding.

Fig. 2

Remove mounting bolt of filter bowl.

1

Take off filter bowl and clean it internally.

Fig. 3

Insert new filter element and fit filter bowl with new

seals.

Refit oil drain plug with new seal.

Observe tightening torque for mounting bolt.

Note:

To prevent the seal from twisting hold the

filter bowl firmly when tightening the tensioning screw.

Top up with engine oil, let engine run briefly and

then check for leaks.

2

3

Check oil level.

53

Page 56

Removing and installing the oil cooler

D Draining off coolant, see page 40

D Removing the oil filter, see page 53

Caution:

Old oil and used oil filters are hazardous

waste.

Observe safety instructions for the prevention of environmental damage.

Fig. 1

Remove oil filter head (5 screws).

Remove filter head gasket.

Fig. 2

Unscrew oil cooler housing cover with fitted oil

cooler.

The 10 marked screws hold the oil cooler. Only

loosen these screws after removing the housing

cover.

Fig. 3

Check both oil cooler for damage and if necessary

replace them. Fit oil cooler with new gaskets.

1

2

Fig. 4

Tighten the mounting bolts with the prescribed

torque.

D Screw on oil cooler housing cover with fitted oil

cooler

D Attach oil filter head and oil filter with new

seals, see also page 53

D Fill engine oil and check for leaks after a short

engine run

D Check oil level

D Filling up with coolant

3

4

54

Page 57

Removing and installing, repairing oil pump

Drain engine oil

Danger:

The oil is hot, risk of scalding! Do not

touch the oil drain plug with bare fingers.

Oil is an environmental hazard. Handle

with care!

Fig. 1 and Fig. 2

With the engine at operating temperature, remove

the oil drain plugs on the oil sump and the oil filter

bowl and allow the old oil to drain off completely.

Use a suitable container of sufficient capacity here

to prevent oil from overflowing.

Caution:

Old oil is hazardous waste.

Observe safety instructions for the prevention of environmental damage.

1

Remove oil pan

Caution:

Oil pans are awkward to handle and

heavy.

They may contain residual amounts of

engine oil.

Use lifting gear or work with a helper.

Fig. 3

Remove the mounting bolts from oil pan.

Take off oil pan.

Removing oil pump

Fig. 4

Remove the mounting bolts from the bracket and

from the oil pump.

2

3

Take off oil suction pipe.

Measure backlash between oil pump drive gear

and crankshaft gear and compare value with the

nominal value.

Replace worn gears.

4

55

Page 58

Removing and installing, repairing oil pump

Fig. 5

Unscrew the mounting bolts of the pressure relief

valve and oil pump.

Take off overpressure valve and oil pump.

The overpressure valve is encapsulated.

Opening pressure, see “Service Data”.

Note:

Depending on the engine model and oil

pan variant, various oil pump versions are

possible.

Repairing oil pump

Fig. 6

Fit the oil pump in a vice (use protective jaws).

5

Remove oil pump cover.

Fig. 7

Pull the driven oil pump wheel from the casing.

Check the toothed wheels and pump casing for

wear (see “Service Data”).

Fig. 8

6

7

Remove oil pump drive gear.

To do this, lay pump on suitable support and press

off drive gear using a mandrel.

To install it, put drive gear on shaft, supporting

facing shaft end.

Press on the drive wheel, observing the prescribed

gap (see “Service Data”).

8

56

Page 59

Removing and installing, repairing oil pump

Fig. 9

Fit on the cover.

Tighten the mounting bolts with the prescribed

torque.

Grind or exchange heavily worn covers.

Checking the axial clearance of the

pump wheels

Fig. 10

Position dial gauge and push shaft up to the stop

in one direction and set dial gauge to ”0”.

Push the shaft in the opposite direction and read

off the needle deflection on the dial gauge.

Installing oil pump

Fig. 11

Tighten the mounting bolts with the prescribed

torque.

D Before installing, check whether the oil pump

run smoothly and then fit it / them free of ten-

sion

D Fit oil suction line À with seal in a tension−free

manner

D Screw on pressure−relief valve Á without seal

10

9

1

2

Before fitting the oil pan, run the engine to check

that the crankshaft drive and oil pumps are running

smoothly and easily.

Attaching oil pan

Fig. 12

Fit an oil pan seal.

Fit oil pan to crankcase and screw in the mounting

bolts.

Tighten the mounting bolts with the prescribed

torque.

11

12

57

Page 60

Removing and installing, repairing oil pump

Filling with engine oil

Caution: