Page 1

Operating Instructions

Diesel Engine

D 2866 E

D 2866 TE

D 2866 LE

D 2866 LXE

Page 2

Page 3

Preface

Dear Customer

These Operating Instructions are intended to familiarize you with your new MAN Diesel

engine and how it operates.

This manual is supplemented by the publication “Fuels, Lubricants and Coolants for MAN

Diesel Engines” and the “Service record”.

Note:

All three publications belong to the engine and must always be kept ready to hand

near the engine in the engine room.

Please read this Manual and the “Instructions for the installation of MAN Diesel Engines”

before you put the new engine into operation.

Comply in full with instructions relating to operation, prevention of accidents and environmental protection.

MAN Diesel engines are developed and manufactured in line with the latest state of the

art. However, trouble-free operation and high performance can only be achieved if the

specified maintenance intervals are observed and only approved fuels, lubricants and

coolants are used.

It is imperative and in your own interest to entrust your MAN Local Service Centre with

the removal of any disturbances and with the performance of checking, setting, and repair work.

Yours faithfully,

MAN Nutzfahrzeuge Aktiengesellschaft

Werk Nürnberg

Subject to change to keep abreast with technological progress.

2001 MAN Nutzfahrzeuge Aktiengesellschaft

No parts of this publication may be reproduced or translated without prior written permission of MAN. MAN explicitly reservs all rights according to copyright law.

MTDA Technical status: 11.1998 51.99493–8264

1

Page 4

Index

Declaration 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nameplates 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety regulations 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical information 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine views 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engines 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine lubrication 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel system 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intercooler 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air cleaner 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical equipment 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commissioning and operation 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparations 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running in 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

During operation 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutting down 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temporary decommissioning of engines 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance and care 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine lubrication 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel system 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intercooler 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air cleaner 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking and setting 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To check and set the start of delivery 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To check and adjust valve clearance 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder head bolts 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V-belts 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical data 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Page 5

Declaration

Declaration

In accordance with Article 4, paragraph 2, in conjunction with Appendix II, section B, of

Directive 89/392/EEC, version 93/44/EEC

MAN Nutzfahrzeuge Aktiengesellschaft,

hereby declares that the engine described below is destined for installation in a machine

as defined in the EC directive on machines.

Engine model:

Design:

For data see original declaration

Engine number:

Rating / speed:

Note:

The manufacturer of the complete ready-to-use machine in which this engine is to be

installed must take the further action necessary in the context of indirect safety-related engineering and provision of instructions to ensure that the ready-to-use machine complies with the requirements of the EC directive on machines.

The engine must not be put into operation until the complete machine satisfies the

conditions laid down in the EC directive on machines 89/392/EEC, most recently

amended by 93/44/EEC, or the latest amendment of said directive.

If required this declaration is

enclosed with the delivery note.

MAN Nutzfahrzeuge Aktiengesellschaft

Vogelweiherstraße 33

D–90441 Nürnberg

3

Page 6

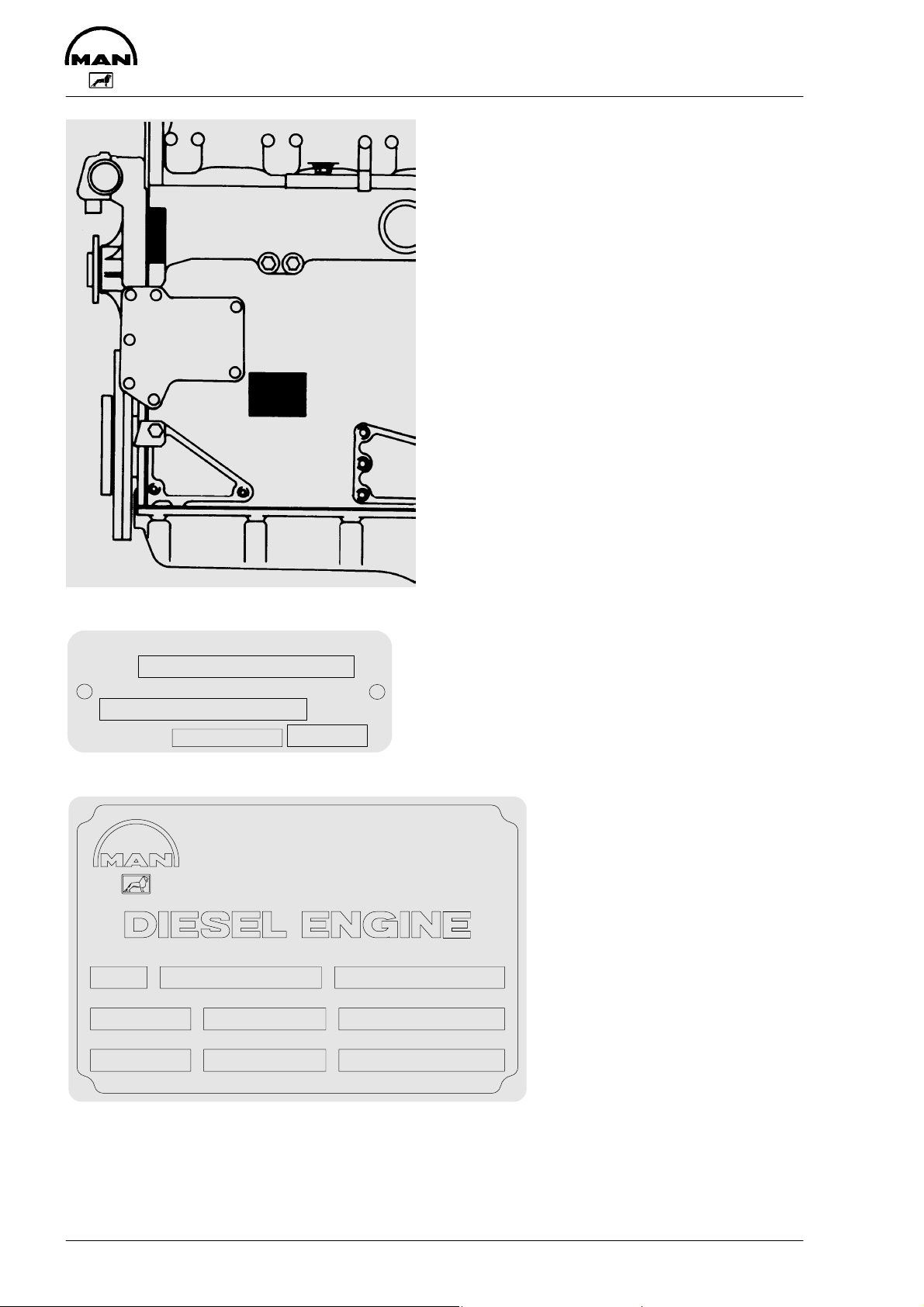

Nameplates

Model

......................................................................

delivered on

......................................................................

installed on

......................................................................

MAN Nutzfahrzeuge Aktiengesellschaft

Typ

Motor-Nr. / Engine No.

NI/II

MAN Nutzfahrzeuge AktiengesellscMAN Nutzfahrzeuge Aktiengesellschaft

Werk Nürnberg Germany

:

Motor–Nr.TypBauj.

In all your correspondence please always

quote engine model, serial number and job

number (Order number).

Enter 14-digit serial number (is used in the

spare parts catalog to distinguish between

spare parts).

Enter 14-digit engine serial

number.

Enter 6-digit job number

(Order number).

Serial NoModelYear

Temp. C

°

Job No Rating kW

Leistung kWWerk–Nr.

Drehz. 1/min

Aufstellhohe m uNNLeistg. PS

:

Speed rpm

:

Altitude mRating BHP

4

–0219

Page 7

Safety regulations

General notes

Handling diesel engines and the necessary resources is no problem when the personnel commissioned with operation and maintenance are trained accordingly

and use their common sense.

This summary is a compilation of the most important regulations. These are broken down

into main sections which contain the information necessary for preventing injury to persons, damage to property and pollution. In addition to these regulations those dictated by

the type of engine and its site are to be observed also.

Important:

If, despite all precautions, an accident occurs, in particular through contact with caustic

acids, fuel penetrating the skin, scalding from hot oil, anti-freeze being splashed in the

eyes etc., consult a doctor immediately.

Regulations designed to prevent accidents with injury to persons

During commissioning, starting and operation

D Before putting the engine into operation for the first time, read the operating instruc-

tions carefully and familiarize yourself with the “critical” points. If you are unsure, ask

your MAN representative.

D For reasons of safety we recommend you attach a notice to the door of the engine

room prohibiting the access of unauthorized persons and that you draw the attention

of the operating personal to the fact that they are responsible for the safety of persons

who enter the engine room.

D The engine must be started and operated only by authorized personnel.

Ensure that the engine cannot be started by unauthorized persons.

D When the engine is running, do not get too close to the rotating parts. Wear close-fit-

ting clothing.

D Do not touch the engine with bare hands when it is warm from operation – risk of

burns.

D Exhaust gases are toxic. Comply with the instructions for the installation of MAN Die-

sel engines which are to be operated in enclosed spaces. Ensure that there is adequate ventilation and air extraction.

D Keep vicinity of engine, ladders and stairways free of oil and grease.

Accidents caused by slipping can have serious consequences.

5

Page 8

Safety regulations

During maintenance and care

D Always carry out maintenance work when the engine is switched off. If the engine has

to be maintained while it is running, e.g. changing the elements of change-over filters,

remember that there is a risk of scalding. Do not get too close to rotating parts.

D Change the oil when the engines is warm from operation.

Caution:

There is a risk of burns and scalding. Do not touch oil drain plugs or oil filters with bare

hands.

D Take into account the amount of oil in the sump. Use a vessel of sufficient size to en-

sure that the oil will not overflow.

D Open the coolant circuit only when the engine has cooled down. If opening while the

engine is still warm is unavoidable, comply with the instructions in the chapter entitled

“Maintenance and Care”.

D Neither tighten up nor open pipes and hoses (lube oil circuit, coolant circuit and any

additional hydraulic oil circuit) during the operation. The fluids which flow out can

cause injury.

D Fuel is inflammable. Do not smoke or use naked lights in its vicinity. The tank must be

filled only when the engine is switched off.

D When using compressed air, e.g. for cleaning the radiator, wear goggles.

D Keep service products (anti-freeze) only in containers which can not be confused with

drinks containers.

D Comply with the manufacturer’s instructions when handling batteries.

Caution:

Accumulator acid is toxic and caustic. Battery gases are explosive.

When carrying out checking, setting and repair work

D Checking, setting and repair work must be carried out by authorized personnel only.

D Use only tools which are in satisfactory condition. Worn open-end wrench slip, which

could lead to injury.

D When the engine is hanging on a crane, no-one must be allowed to stand or pass

under it. Keep lifting gear in good condition.

D When working on parts which contain asbestos, comply with the notes at the end of

this chapter.

6

Page 9

Safety regulations

D When checking injectors do not put your hands under the jet of fuel. Do not inhale ato-

mised fuel.

D When working on the electrical system disconnect the battery earth cable first.

Connect it up again last in order to prevent short circuits.

D When welding comply with the “Instructions for welders”.

Regulations designed to prevent damage to engine and premature wear

Do not demand more from the engine than it is able to supply in its intended application.

Detailed information on this can be found in the sales literature. The injection pump must

not be adjusted without prior written permission of MAN Nürnberg.

If faults occur, find the cause immediately and have it eliminated in order to prevent more

serious damage.

Use only genuine MAN spare parts. MAN will accept no responsibility for damage resulting from the installation of other parts which are supposedly “just as good”.

In addition to the above, note the following points:

D Never let the engine run when dry, i.e. without lube oil or coolant.

D When starting do not use any additional starting aids (e.g. injection with starting pilot).

D Use only MAN-approved service products (fuel, engine oil, anti-freeze and anti-cor-

rosion agent). Pay attention to cleanliness. The Diesel fuel must be free of water. See

“Maintenance and care”.

D Have the engine maintained at the specified intervals.

D Do not switch off the engine immediately when it is warm, but let it run without load for

about 5 minutes so that temperature equalization can take place.

D Never put cold coolant into an overheated engine. See “Maintenance and care”.

D Do not add so much engine oil that the oil level rises above the max. marking on

the dipstick. Do not exceed the maximum permissible tilt of the engine.

Serious damage to the engine may result if these instructions are not adhered to.

D Always ensure that the testing and monitoring equipment (for battery charge, oil pres-

sure, coolant temperature) function satisfactorily.

7

Page 10

Safety regulations

D Comply with instructions for operation of the alternator. See “Commissioning and oper-

ation”.

D Do not let the raw water pump run dry. If there is a risk of frost, drain the pump when

the engine is switched off.

Regulations designed to prevent pollution

Engine oil and filter elements / cartridges, fuel/fuel filter

D Take old oil only to an old oil collection point.

D Take strict precautions to ensure that no oil or Diesel fuel gets into the drains or the

ground.

The drinking water supply could be contaminated.

D Filter elements are classed as dangerous waste and must be treated as such.

Coolant

D Treat undiluted anti-corrosion agent and / or antifreeze as dangerous waste.

D When disposing of spent coolant comply with the regulations of the relevant local auth-

orities.

Notes on safety in handling used engine oil ∗

Prolonged or repeated contact between the skin and any kind of engine oil decreases the

skin. Drying, irritation or inflammation of the skin may therefore occur. Used engine oil

also contains dangerous substances which have caused skin cancer in animal experiments. If the basic rules of hygiene and health and safety at work are observed, health

risks are not to the expected as a result of handling used engine oil.

Health precautions:

D Avoid prolonged or repeated skin contact with used engine oil.

D Protect your skin by means of suitable agents (creams etc.) or wear protective gloves.

D Clean skin which has been in contact with engine oil.

– Wash thoroughly with soap and water. A nailbrush is an effective aid.

– Certain products make it easier to clean your hands.

– Do not use petrol, Diesel fuel, gas oil, thinners or solvents as washing agents.

8

Page 11

Safety regulations

D After washing apply a fatty skin cream to the skin.

D Change oil-soaked clothing and shoes.

D Do not put oily rags into your pockets.

Ensure that used engine oil is disposed of properly

– Engine oil can endanger the water supply –

For this reason do not let engine oil get into the ground, waterways, the drains or the

sewers. Violations are punishable.

Collect and dispose of used engine oil carefully. For information on collection points

please contact the seller, the supplier or the local authorities.

∗ Adapted from “Notes on handling used engine oil”.

Note on parts containing asbestos

D Certain parts of the engine (gaskets) may contain asbes-

tos. Spare parts and, where necessary, their packaging

is marked accordingly (see illustration below).

D When parts that contain asbestos are machined fine as-

bestos dust may be released. To prevent possible damage to health please take appropriate safety precautions

and follow the advice given below:

D Wherever possible work in the open air or in well venti-

lated rooms.

D If possible use hand-operated or slow-running machines,

if necessary with a dust trap. If fast-running machines are

used they ought always to have such a device.

D Wet the material before cutting or drilling it.

a

ACHTUNG

ENTHÄLT

ASBEST

Gesundheits-

gefährdung bei

Einatmen von

ATENÇÃO

CONTEM

AMIANTO

Respirrar po de

amianto é perîgroso

Asbeststaub

Sicherheits-

vorschriften

CONTIENT DE

Langvarig eller gjentatt

påvirkning øker risikoen

Bruk egnet vemeutstyr

para a saúde

Consulte as normas

de segurança

beachten

ATTENTION

L’AMIANTE

Respirer la

poussière d’amiante

est dangereux

pour la santé

Suicre les consignes

de sécurite

INNEHOLDER

ASBEST

Innånding av stov

fra dette materialet

kan forårske kreft

VAROITUS

SISÄLTÄÄ

ASBESTIA

Asbestipölyn

hengittäminen on

terveydelie

vaarallistta

Noudattakaa

turvaohjeita

ARTIKELN

INNEHÅLLER

ASBEST

Dammet är

farligt vid inandning

Innehåller

Asbest

WARNING

CONTAINS

ASBESTOS

Breathing asbestos

dust is dangerous

to health Follow

safety Instructions

VOORZICHTIG

BEVAT

ASBEST

Het inademen van

asbeststof

is schadelijk voor

de gezondheit

Houdt u aan de

veiligheids-

voorschriften

ATTENZIONE

CONTIENE

AMIANTO

Resirare polvere di

amiento é

pericoloso

per la salute

Seguire le norme

di sicurezza

PRECAUCIÓN

:CONTIENE

AMIANTO

Evitese ta

generación

de polvo

D Wet the dust, put it into a tightly closing container and have it disposed of as danger-

ous waste.

9

Page 12

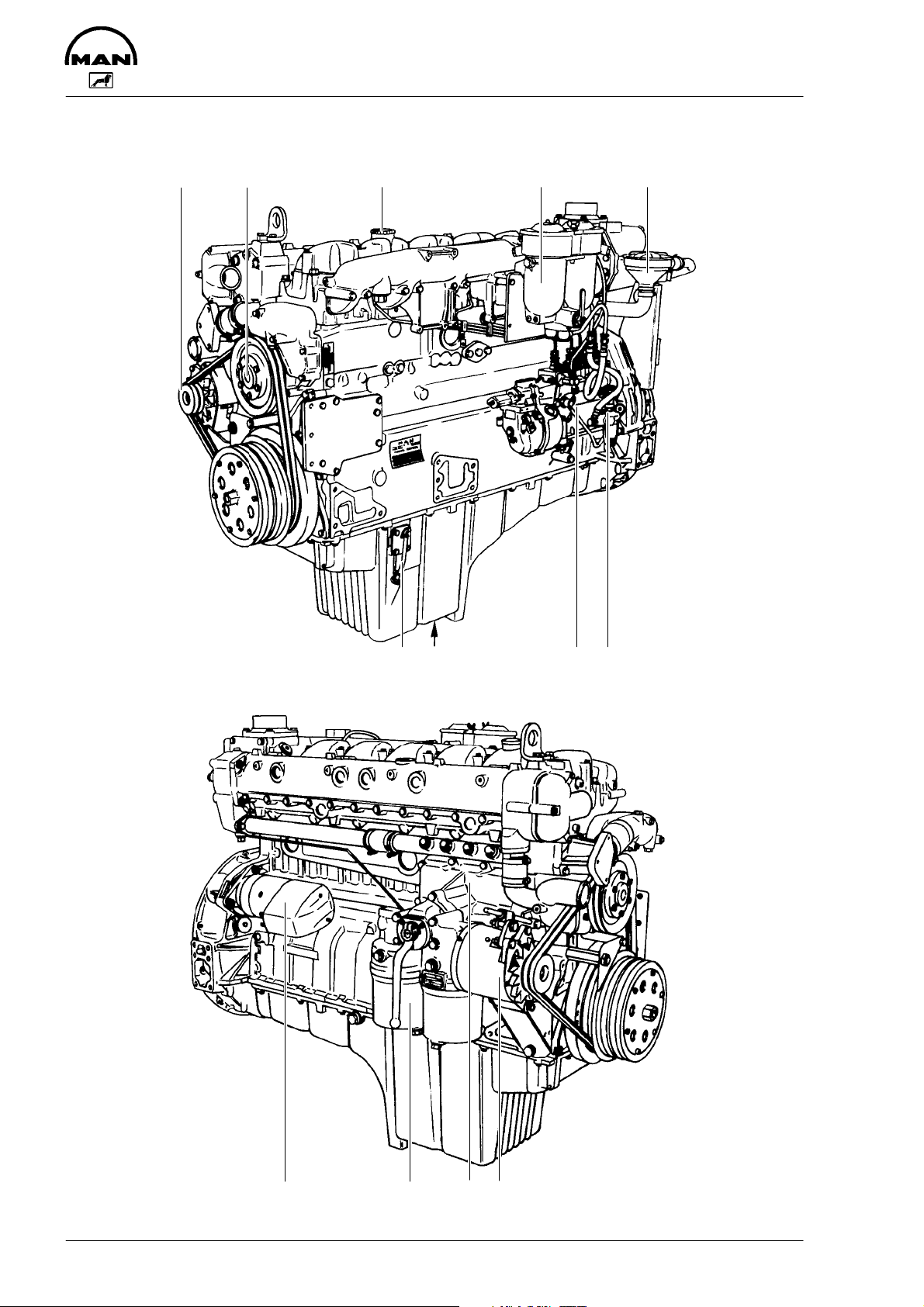

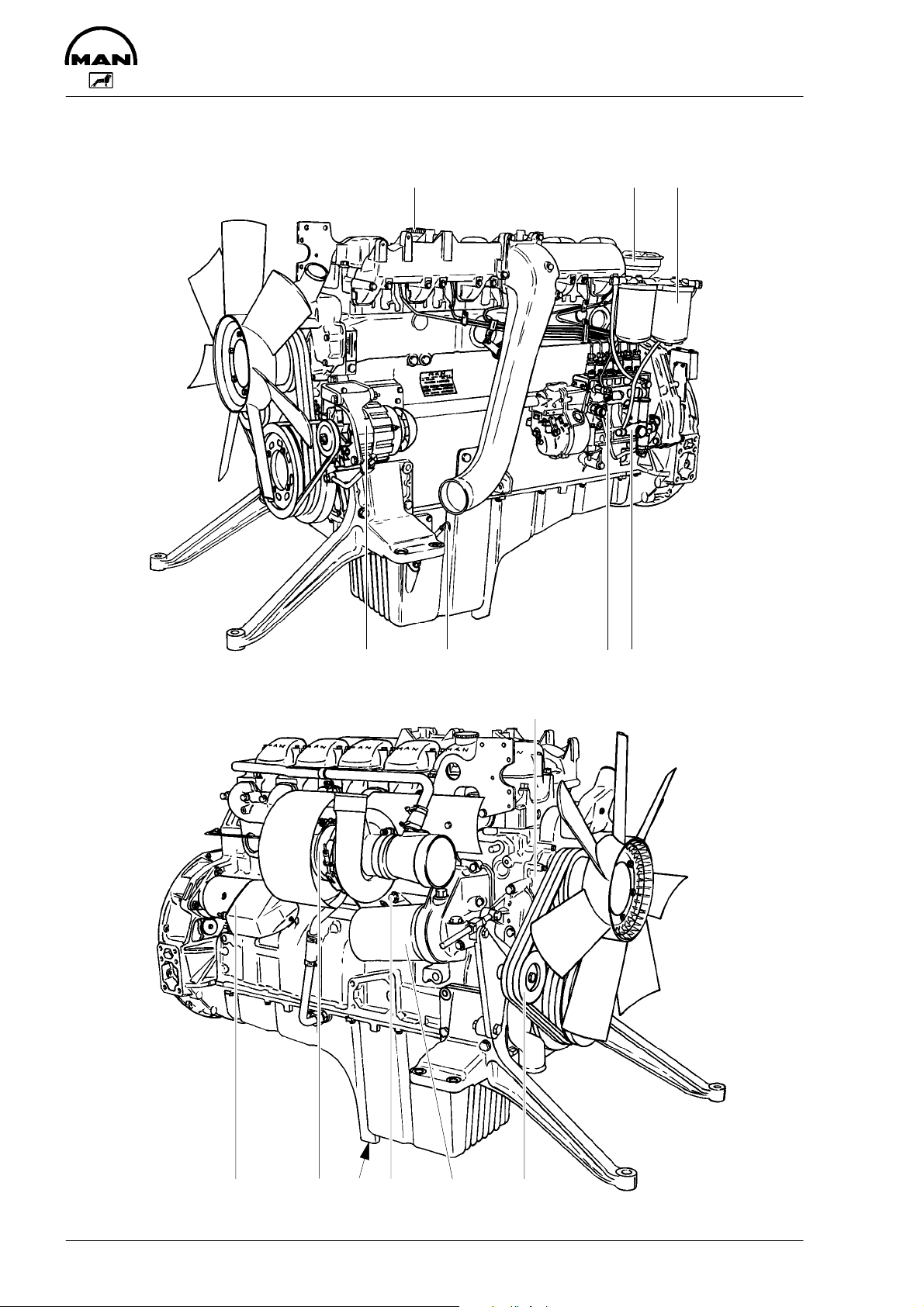

Engine views D 2866 E

12 3 4 5

Technical information

7689

10

10111213

Page 13

Technical information

1 Tensioning pulley

2 Water pump

3 Oil filler neck

4 Tandem fuel filter

5 Oil separator valve for crankcase breather

6 Fuel lift pump with prestrainer

7 Injection pump

8 Oil drain plug

9 Oil dipstick

10 Alternator

11 Oil cooler

12 Oil filter

13 Starter motor

11

Page 14

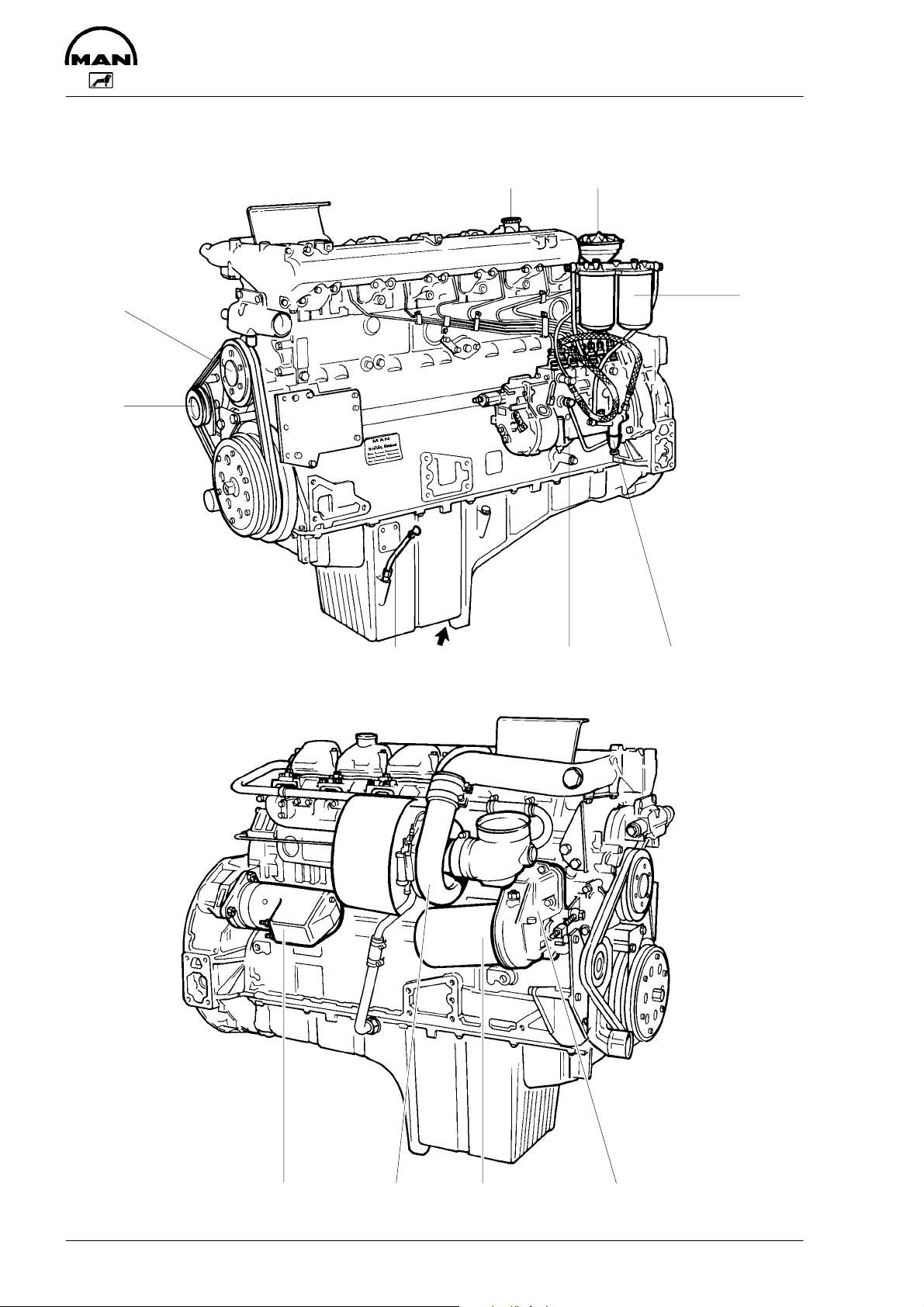

Engine views D 2866 TE

Technical information

3

2

1

4

5

6789

12

10111213

Page 15

Technical information

1 Tensioning pulley

2 Water pump

3 Oil filler neck

4 Oil separator valve for crankcase breather

5 Tandem fuel filter

6 Fuel lift pump with prestrainer

7 Injection pump

8 Oil drain plug

9 Oil dipstick

10 Oil cooler

11 Oil filter

12 Turbocharger

13 Starter motor

13

Page 16

Technical information

Engine views D 2866 LE, LXE

123

4567

8

14

91011121314

Page 17

Technical information

1 Oil filler neck

2 Oil separator valve for crankcase breather

3 Tandem fuel filter

4 Fuel lift pump with prestrainer

5 Injection pump

6 Oil dipstick

7 Alternator

8 Water pump

9 Tensioning pulley

10 Oil filter

11 Water drain plug

12 Oil drain plug

13 Turbocharger

14 Starter motor

15

Page 18

Technical information

Engines

The engines D 2866 E / TE / LE / LXE are in-line vertical liquid-cooled 6-cylinder fourstroke Diesel engines with direct injection. D 2866 E is a naturally aspirated engine.

D 2866 TE is turbocharged, and D 2866 LE / LXE are turbocharged and intercooled.

Engine block

The cylinder block is a single piece of alloy cast iron. To increase its stiffness, it is extended to a level below the crankshaft centre line. The engine has replaceable wet cylinder liners and individual cylinder heads with shrunk-in valve seat rings and replaceable

valve guides.

Piston / Conrod / Crank assembly

The forged crankshaft has screwed-on counterweights. Radial seals with replaceable

wearing rings on crankshaft and flywheel are provided to seal the crankcase penetrations.

The connecting rods are die-forged, diagonally split and can be removed through the top

of the cylinders together with the pistons. Crankshaft and connecting rods run in steelbacked lead bronze ready-to-fit type bearings.

16

Page 19

Technical information

Engine timing

Camshaft, oil pump and injection pump are driven by a gear train arranged at the flywheel end.

5

6

4

1

2

1 Crankshaft gear 4 Camshaft drive gear

2 Oil pump drive gear 5 Idler gear

3 Oil pump impeller gears 6 Injection pump drive gear

The crankshaft gear and camshaft gear are match-marked by “1” or “D”.

Valves

The overhead valves are actuated via chilled cast iron tappets, push rods and rocker

arms from the camshaft.

3

17

Page 20

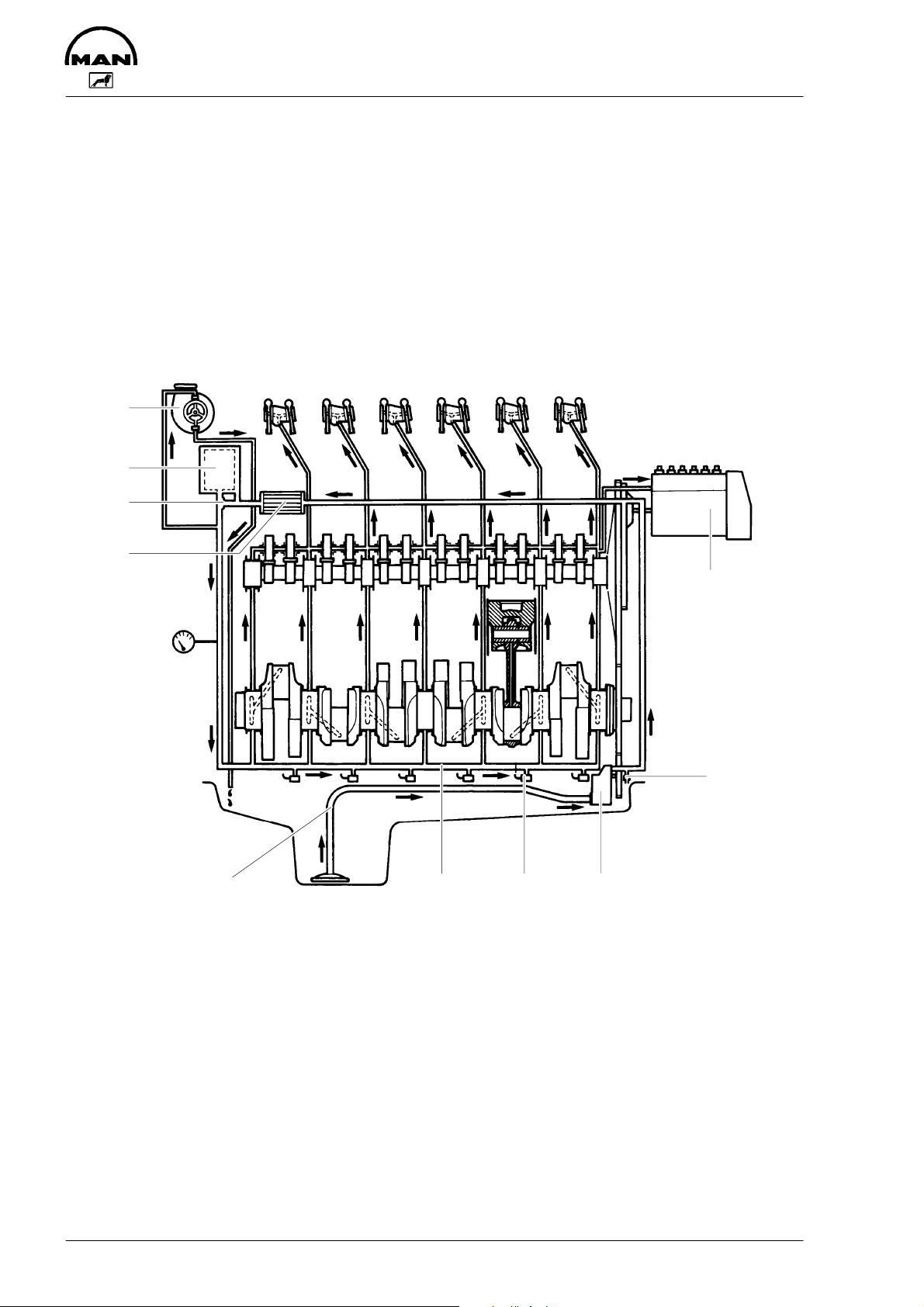

Technical information

Engine lubrication

The engine is equipped with force-feed lubrication.

The pressure is produced by a gear pump whose drive gear is in direct mesh with the

crankshaft gear at the flywheel end.

The oil pump draws the oil from the oil sump and delivers it through the oil cooler and oil

filter to the main distributor gallery and from there to the main bearings, big-end bearings

and camshaft bearings as well as to the small-end bearings and the rocker arms.

8

7

6

9

10

5

1234

1 Oil suction pipe 7 Oil filter

2 Main oil galleries 8 Turbocharger

3 Jets for piston cooling and cam lubrication (D 2866 TE / LE / LXE only)

4 Oil pump 9 Oil cooler

5 Oil relief valve 10 Injection pump

6 Bypass valve

18

Page 21

Technical information

The injection pump and the turbocharger are also connected to the engine lubricating

system.

The cylinder walls and timing gears are splash-lubricated.

Each cylinder has an oil jet provided for cooling the underside of the pistons.

The lube oil is cleaned in a full-flow oil filter.

Depending on the agreed extent of delivery and the design of the engine, the lube oil circuit can be equipped with oil pressure monitors (advance warning and cut-off function)

which shut the engine down in the event of a sudden loss of pressure.

Oil cooler

An oil cooler is provided between the oil filter and the crankcase. This cooler is of the flat

tube type with turbulence inserts and operated by the coolant.

19

Page 22

Technical information

Fuel system

The fuel is delivered by the fuel lift pump via the fuel filter to the injection pump and from

there to the injectors.

The fuel is sprayed into the cylinder through four-hole nozzles fitted in screw-fit injectors

in the cylinder heads.

Excessive fuel delivered and leak fuel from the injectors flow through the return pipe back

to the tank. A strainer and a hand pump are arranged ahead of the fuel lift pump.

45 48 67

10

1 Fuel tank

2 Fuel strainer

3 Fuel lift pump

4 Parallel fuel filter

5 Bleeder screw

6 Injection pump

7 Overflow valve

8 Injection nozzles

9 Suction line

10 Return line

3

2

9

1

Injection pump

The in-line injection pump is driven via gears from the crankshaft. It is connected to the

force-feed lubricating system of the engine and consequently maintenance-free.

The centrifugal governor flange-mounted on the pump casing is a variable range governor designed to keep the speed set by the control lever constant under conditions of

varying load.

The governor of the turbocharged engines has a full load stop controlled by the chargeair pressure and is designed to decrease the full load fuel quantity in the low speed

range from a certain (adjustable) charge-air pressure onwards.

20

Page 23

Technical information

Fuel filters

Before entering the suction chamber of the injection pump, the fuel is cleaned in a twostage, parallel or changeover filter.

Turbocharger (D 2866 TE, LE, LXE)

The exhaust gases of the engine are passed through the turbine rotor of the turbocharger. Air impeller mounted on the same shaft draws in fresh air and delivers it at a higher

pressure to the cylinders.

The turbocharger is air-cooled or liquid-cooled. Lubrication of the main bearing is by oil

under pressure from the engine lubricating system.

1

D

A

3

E

1 Compressor casing A Air inlet

2 Turbine casing B Gas outlet

3 Compressor wheel C Gas inlet

4 Turbine rotor D Oil inlet

E Oil return

2

4

B

C

21

Page 24

Technical information

Intercooler (D 2866 LE, LXE)

Before entering the cylinders the combustion air compressed in the turbocharger is

passed through a heat exchanger (intercooler).

Heat removal in the cooler is either by air (air-to-air intercooler) or, in case of the marine

application, by means of seawater (air-to-water intercooler) delivered by the raw water

pump.

It is important to provide a seawater filter ahead of the air-to-water intercooler.

In the case of extended standstills, cleaned seawater may be left in the intercooler, but

dirty water (brackish water) must definitely be discharged.

The seawater-operated intercooler must be regularly cleaned as required in order to

maintain its full cooling efficiency. If the engine output is found to drop, the reason may

be in a fouled-up intercooler. The intercooler has to be removed from the engine for

cleaning.

Cooling

The engine has a liquid-cooling system.

The water pump is a maintenance-free impeller pump driven by V-belts from the crankshaft pulley.

Depending on the agreed extent of delivery and the design of the engine, the coolant circuit can be equipped with temperature and level monitors which, in the event of overheating, will trigger an advance warning system or, in the event of loss of coolant, shut

the engine down.

Air cleaner

Air cleaner is mounted on the engine to purify the air for combustion.

The intervals at which the air cleaner requires servicing depend on the specific operating

conditions encountered. Clogged air filters may cause black smoke and reduce power.

A check should be made from time to time to see that the fastening elements securing

the air cleaner to the intake manifold seal the connection tightly. Any ingress of unfiltered

air is liable to cause a high rate of cylinder and piston wear.

22

Page 25

Technical information

Electrical equipment

Alternator

The alternator is fitted with integral silicon rectifiers.

A transistorized regulator mounted on the alternator limits the alternator voltage. The alternator should not be operated except with the regulator and battery connected in circuit

to avoid damage to the rectifier and regulator.

The alternator is maintenance-free. Nevertheless, it must be protected against dust and,

above all, against moisture.

Operate the alternator according to the instructions given in the chapter “Commissioning and operation”.

Starter motor

The sliding-gear starter motor is flanged to the rear of the flywheel housing on the righthand side.

As part of every engine overhaul, the starter pinion and ring gear should be cleaned with

a brush dipped in fuel and then a coat of grease should be applied again.

Always protect starter motor against moisture.

Warning:

Always disconnect the battery earth cable before starting work on the electrical system. Connect up the earth cable last, as there is otherwise a risk of short-circuits.

23

Page 26

Commissioning and operation

Preparations

At the time of initial commissioning of a

new or overhauled engine make sure to

have observed the “Technical Information

for the installation of MAN Diesel engines”.

1

1 Oil filler neck on valve cover

Before daily starting the engine, check

fuel level, coolant level and engine oil

level and replenish, if necessary.

D Thereafter fill up to maximum oil sump

capacity, wait about 1/2 hour and mark

maximum oil level visible on dipstick

D After refilling with oil, rotate the engine

with the starter and move the shutdown lever to “stop” at the same time

until the oil pressure warning light goes

out and the oil pressure gauge shows a

pressure. Then start the engine and

allow it to run at medium speed for a

few minutes. Check oil pressure and

tightness of system. Then shut down

the engine. After about 20 minutes,

check the oil level. The oil level should

now be at the upper notch of the dipstick, but not higher.

Add any necessary oil to the upper dipstick mark.

Caution:

Do not add so much engine oil that the

oil level rises above the max. marking

on the dipstick. Overfilling will result in

damage to the engine.

The notches in the dipstick indicate the

highest and lowest permissible oil levels.

Marking the dipstick

As a rule oil dipsticks of marine propulsion

engines are not marked by the manufacturer since the final installed position is

unknown. Therefore, they should be

marked after engine installation.

Proceed as follows:

D Fill with minimum oil quantity recom-

mended for the respective engine type.

After this initial filling wait about

1/2 hour until the entire oil has collected in the oil sump

D Pull out dipstick and mark minimum oil

level visible on dipstick

The oil required in the sump is specified in

the “Technical Data” at the end of these

Instructions.

Note:

The oil required to fill the oil filters and

pipes depends upon the engine equipment and use and must be determined

individually at the time of initial commissioning (Make a note of the determined quantity).

Ensure outmost cleanliness when handling fuels, lubricants and coolants.

Use only approved fuels, lubricants

etc. (see brochure “Fuels, lubricants

etc.”). Otherwise the manufacturer’s

warranty will become null and void.

24

Page 27

Commissioning and operation

Raw water pump

Do not let raw water pump run dry.

Make sure that all valves / cocks in the

raw water circuit are open.

If there is a risk of frost, drain the raw

water pump.

Starting

Insert key in starting lock.

Press starter button, moving control lever

against stop “maximum engine speed”.

Do not operate starter for longer than

10 seconds at a time.

After ignition of the engine, release the

starter button and adjust control lever for

desired speed.

If engine fails to start, release the key,

wait about 30 seconds, then operate

starter again.

Running in

It is recommended that new or overhauled

engines should not be operated at a load

higher than about 75% maximum load

during the first few hours of operation. Initial run-in should be at varying speeds.

After this initial run-in, the engine should

be brought up to full output gradually.

During operation

Do not overload the engine. Do not exceed the maximum permissible engine

tilt. If faults occur, find their cause immediately and have them eliminated in

order to prevent more serious damage!

During operation the oil pressure in the

engine lubrication system must be monitored. If the monitoring devices register a

drop in the lube oil pressure, switch off the

engine immediately.

Avoid running the cold engine for any

length of time since in any internal combustion engine this is liable to cause increased wear due to corrosion. Prolonged

idling is harmful to the environment.

Note:

On initial start of an overhauled engine

or after long periods without use, press

shut-down lever in “stop” position and

operate starter motor for a few seconds (max. 10) until oil pressure is

indicated. Only then the engine should

be started in the normal way.

The coolant temperature should be

approx. 80 to 85°C.

The charge warning light of the alternator

should go out when the engine is running.

25

Page 28

Commissioning and operation

Alternator

In order to avoid damage to the alternator,

observe the following instructions:

While the engine is running

D Do not de-energize the main battery

switch!

D Do not disconnect the battery or pole

terminals or the cables!

D If, durig operation, the battery charge

lamp suddenly lights up, stop the engine immediately and remedy the fault

in the electrical system!

D Do not run the engine unless the bat-

tery charge control is in satisfactory

order!

D Do not short-circuit the connections of

the alternator with those of the regulator or said connections with ground, not

even by briefly bringing the connections

into contact!

D Do not operate the alternator without

battery connection!

Shutting down

Disengage the gearbox clutch and move

the shut-down lever to “stop”. After the engine has been running at a high load

level, do not shut it down immediately but

allow it to idle about 5 minutes so that

temperatures may equalize.

Remove key from starting lock.

Caution:

Ensure that the engine can not be

started by unauthorized persons.

Temporary decommissioning of engines

Temporary anti-corrosion protection according to MAN works norm M 3069 is required for engines which are to be put out

of service for fairly long periods.

The works standard can be obtained from

our After-Sales Service department in Nuremberg.

26

Page 29

Maintenance and care

Engine lubrication

Oil level

Check the oil level in the engine sump

daily with a dipstick. The level should be

between the two notches cut into the dipstick and should never be allowed to drop

below the lower notch.

Caution:

Do not add so much engine oil that the

oil level rises above the max. marking

on the dipstick. Overfilling will result in

damage to the engine.

The oil level should be checked with the

engine horizontal and only after it has

been shut down for about 20 minutes.

Oil drainage

With the engine at operating temperature,

remove the oil drain plugs on the oil sump

and the oil filter bowl and allow the old oil

to drain off completely. Use a vessel of

sufficient size to ensure that the oil does

not overflow. Refit the oil drain plugs with

new gaskets.

Caution:

The oil is hot- risk of scalding. Do not

touch the oil drain plug with bare fingers. Oil is an environmental hazard.

Handle it with care!

1

1 Oil filler neck on valve cover

After refilling with oil, rotate the engine

with the starter and move the shut-down

lever to “stop” at the same time until the

oil pressure warning light goes out and

the oil pressure gauge shows a pressure.

Then start the engine and allow it to run at

medium speed for a few minutes. Check

oil pressure and tightness of system.

Then shut down the engine. After about

20 minutes, check the oil level. The oil

level should now be at the upper notch of

the dipstick, but not higher.

Add any necessary oil to the upper dipstick mark.

Note:

Refer to maintenance chart for compulsory oil change intervals and oil

quality for D 2866 TE engines having

higher ratings.

Lubricating oil filter

Refilling with oil

Refill with fresh engine oil at the oil filler

neck.

Cleaning of the lubricating oil is effected in

a full-flow oil filter with paper cartridges. A

bypass valve ensures continuity of oil supply if the filter elements should be

clogged.

After draining off the oil, release tie screw.

Remove filter bowl. Renew filter cartridge.

Thoroughly clean all other parts in cleaning fluid. Use new gaskets for re-assembly

27

Page 30

Maintenance and care

2 3

1 4 5

1 Oil drain plug

2 Oil filter bowl

3 Tie screw

4 Filter cartridge

5 Gasket

Observe positions of selector lever!

Continuous operation

(both filter halves

in operation)

Right-hand filter

cut out

Left-hand filter

cut out

Caution:

Do not leave selector lever in any intermediate position because this

would be liable to interfere with oil

supply.

5

4

2

1

3

1 Oil drain plug

2 Oil filter bowl

3 Tie screw

4 Filter cartridge

5 Gasket

Renewal of filter cartridges

D Allow the filter content to run off along

drain plugs. Hold a suitable vessel

under hole

Caution:

Oil is hot and under pressure!

D After releasing the clamping bolts re-

move filter bowls

D Renew filter cartridges. Thoroughly

clean all other parts in cleaning fluid

(do not allow cleaning fluid to enter the

oil circuit)

D Use new gaskets for reassembly of fil-

ter bowls

Note:

To prevent the seal from twisting hold

the filter bowl firmly when tightening the

tensioning screw

Every time an oil change is made, the two

oil filter cartridges should be renewed!

A changeover-type oil filter, the filter elements of which can be replaced even

during operation, can be fitted on request.

During continuous operation position the

selector lever that both filter halves are in

operation.

Caution:

Used oil filters are classed as dangerous waste and must be disposed of

accordingly.

28

Page 31

Maintenance and care

Fuel system

Fuel

If Diesel fuel which contains moisture is

used the injection system and the cylinder

liners / pistons will be damaged. This can

be prevented to same extent by filling the

tank as soon as the engine is switched off

while the fuel tank is still warm (formation

of condensation is prevented). Drain

moisture from storage tanks regularly. Installation of a water trap upstream of the

fuel filter is also advisable. Do not use any

additives to improve flow properties in

winter.

Injection pump

Fuel lift pump

The fuel lift pump is operated by the injection pump camshaft via the roller tappet.

Strainer

3

1

2

No alterations must be made to the injection pump. If the lead seal is damaged the

warranty on the engine will become null

and avoid.

Faults

We urgently recommend that you have

faults in the injection pump rectified only in

an authorised specialist workshop.

Bleeding the fuel system

Bleeding the fuel filters is by releasing the

bleed screws and operating the manual

primer (fit new seals).

The suction chamber of the injection

pump is continuously bled via the relief

valve during operation. If the suction

chamber is completely empty, e.g., when

fitting a new pump, filling and bleeding it is

by actuating the manual primer.

1 Fuel strainer

2 Filtering screen

3 Filter housing

After every 200 hours of operation the fuel

strainer connected upstream of the fuel lift

pump should be cleaned.

Fuel filter

After every 1000 hours of operation – or

earlier if loss of engine power indicates

clogging – the filter elements should be

renewed.

29

Page 32

Maintenance and care

Two-stage fuel filter

(replaced by parallel fuel filter)

In two filter housings connected in series

the fuel first passes through a felt tube element and then through a paper element.

5

3

1 Felt tube element (primary filter)

2 Paper element (secondary filter)

3 Vent plugs

4 Filler plug

5 Clamping screws

Replacement of filter elements

D Remove clamping bolts

D Take off filter bowls

D Take out filter elements

D Wash out filter bowls

D Install new filter cartridges

D Refit filter bowls using new gaskets

D Open vent plug for primary filter (felt

tube element). Fit new seals

D Operate manual fuel lift pump until fuel

is emitted without any bubbles

D Close vent plug on primary filter

D Bleed secondary filter in the same

manner

4

1

2

Parallel fuel filter with filter cartridges

(replaced by parallel filter with interchangeable filter)

The fuel passes through two filter elements connected in parallel.

2

3

1

1 Filter elements

2 Vent plugs

3 Filler plug

4 Clamping screws

Replacement of filter elements

D Remove clamping bolts

D Take off filter bowls

D Take out filter elements

D Wash out filter bowls

D Install new filter cartridges

D Refit filter bowls using new gaskets

D Open vent plug (fit new seals)

D Operate manual fuel lift pump until fuel

is emitted without any bubbles

D Close vent plug

4

1

30

Page 33

Maintenance and care

Parallel fuel filter with interchangeable

filter

The fuel flows through two parallel filters.

3

2

3

1

4

1 Filter cartridge

2 Screw plug

3 Bleed screw

4 Moisture drain plugs

Draining moisture:

Unscrew drain plugs at every oil change

until moisture has been discharged and

clean fuel flows out.

Replacement of filter elements:

After every 1000 hours of operation – or

earlier if loss of engine power indicates

clogging – the filter elements should be

renewed.

Caution:

Used fuel filters are classed as dangerous waste and must be disposed of

accordingly.

Change-over fuel filter with filter cartridges

(replaced by change-over fuel filter with

interchangeable filter)

Where the changeover-type filter is installed, the servicing procedure is for the

filter side requiring to be shut off with the

engine running. During continuous operation, the selector lever should be placed

in a position where both filter halves are in

operation.

9

8

1

11

7

3

5

2

4

10

6

12

1 Changeover type filter

2 Collecting vessel

3 Cover for collecting vessel

4 O-ring

5 Gasket

6 Fixing bolts for collecting vessel

7 Screw nut

8 Filler plug

9 Vent plug

10 Fixing nut

11 Sludge drain plug

(socket head width across flats 5)

12 Selector lever

31

Page 34

Maintenance and care

Caution:

Do not leave selector lever in any intermediate position because this

would be liable to interfere with fuel

supply. If in doubt stop the engine to

change the fuel filter.

Continuous operation

(both filter halves

in operation)

Right-hand filter

cut out

Left-hand filter

cut out

Change-over fuel filter with interchangeable filter

2

3

1

1 Filter cartridge

2 Bleed screw

3 Selector lever

To replace filter element

D Move selector lever to position where

filter side to be cleaned is cut out

D Slacken vent plug 1 or 2 turns (fit new

seals)

D Allow filter to drain through sludge drain

plug

D Take off filter cover on slackening fixing

nut

D Withdraw filter element and flush filter

chamber with clean fuel

D Install new element

D Fit filter cover using new gasket

D Fill filter bowl through filler opening with

fuel. Close vent plug

D Position selector lever so that both

filters are in circuit

Replacement of filter elements:

After every 1000 hours of operation – or

earlier if loss of engine power indicates

clogging – the filter elements should be

renewed.

Caution:

Used fuel filters are classed as dangerous waste and must be disposed of

accordingly.

32

Page 35

Maintenance and care

Injector maintenance

(by authorized specialist personnel)

2

4

5

1

6

7

8

9

1 Nozzle holder

2 Union screw

3 Washer

4 Compression spring

5 Thrust pin

6 Intermediate disc

7 Injection nozzle

8 Nozzle nut

9 Gasket

Removal, dismantling and cleaning

Unscrew delivery pipe at nozzle holder

and at the injection pump.

3

Remove leak-off pipe.

Release union screw of nozzle holder with

special wrench.

Remove nozzle holder with gasket from

the cylinder head.

Note for cleaning nozzles with Bosch

cleaning set KDEP 2900

Clean nozzle body externally from soot

and carbon. When cleaning several

nozzles at the same time, make sure

nozzle bodies and needles are not mixed

up. Visually inspect needle and body.

Cleaning is useless if the seat of the

needle is indented or the pintle is damaged and the nozzle should be replaced.

Clean annular groove with scraper over

full circumference. Wash out dislodged

carbon deposits and dirt.

The injectors are designed to spray the

fuel delivered by the injection pump directly into the spherical combustion

chamber in the piston crown.

The injector consists of the nozzle and the

nozzle holder.

A copper gasket fitted to the injector ensures gas-tight seating and good heat dissipation.

The opening pressure of the nozzle is adjusted by means of shims at the compression spring.

Scrape needle seat with cleaning cutter.

Dip cutter in test oil before use. The cutter

can also be clamped in a lathe.

Polish needle seat with wooden cleaning

tool, preferably by chucking the needle in

a lathe at the pintle end.

Clean the spray holes of hole nozzles

using the cleaner KDEP 2900/2 by chucking a cleaning needle of suitable diameter

in the collet. If the carbon deposits in the

spray holes cannot be removed by rotating and pressing, have the needle project

only slightly from the collet and drive out

the carbon by lightly tapping on the tool.

33

Page 36

Maintenance and care

Before reassembly thoroughly wash

nozzle body and needle in clean test oil.

Hold the needle at the pintle end only; to

avoid corrosion do not touch the lapped

surfaces of the needle with your fingers.

Thoroughly clean all other parts of the

nozzle holder with clean fuel.

Check nozzle discharge pressure in

nozzle tester.

The edge-type filter should not be pressed

into the nozzle holder by approx. 5 mm.

If this depth is exceeded the injector must

be replaced.

Caution:

Do not hold your hands under the fuel

jet, as there is a risk of injury. Do not

inhale the atomised fuel. If possible

work under an extraction system.

Installation

Clean seat in cylinder head.

Insert nozzle holder with new gasket.

Tighten union nut with 120 Nm.

Install injection lines free of constraint.

Install leak fuel lines.

Caution:

The injection lines are designed for

high operating pressures and should

thus be handled with particular care.

1

1 Edge-type filter

Check nozzle discharge pressure in

nozzle tester. Adjust the discharge pressure by inserting shims of suitable thickness under the compression spring.

D When mounting the pipes to the engine

take care of good fitness

D Do not bend pipes to permanent de-

formation (not for replacing the nozzles

either)

D Do not mount any heavily bent pipes

D Avoid bending the pipes at the ends by

more than 2 to 3 degrees

D In case of faults in the injection system

which might have resulted in excessive

operating pressures, not only the failed

part but also the injection line has to be

replaced

34

Page 37

Maintenance and care

Cooling

Fill the cooling system of the engine with a

mixture of drinkable tap water and antifreeze agent on ethylene glycole basis or

anti-corrosion agent.

See Publication “Fuels, Lubricants and

Coolants for MAN Diesel Engines”.

Filling-in of coolant

(only when engine has cooled down)

D Fill in the coolant slowly

D Make sure that all air can escape from

the cooling system

D Run the engine briefly and then check

coolant level once more

If, in an exceptional case, the coolant

level has to be checked in an engine that

has reached operating temperature, first

carefully turn the cap (large cap) with

safety valve to the first stop, let off pressure, then open carefully.

Draining of coolant

Drain plug in oil cooler housing cover (for

engines with liquid-cooled turbocharger)

Drain coolant as follows when cooling system has cooled down:

D Remove cover from filler neck of surge

tank

D Remove drain plug in crankcase, oil

cooler housing and exhaust manifold

Coolant must be added at the filler

neck only. Do not put cold coolant into an

engine which is warm from operation.

Ensure that the ratio of water to antifreeze is correct. Find the cause of the

loss of coolant and have it eliminated.

Warning:

If the cap with the working valves is

opened, there is the risk that it will not

close tightly again afterwards. The excess pressure required in the system

will then no longer build up. Premature

boiling occurs and coolant is lost. To

prevent damage to the engine open

this cap only in exceptional circumstances and fit a new one as soon as

possible.

Drain plug in oil cooler housing

35

Page 38

Maintenance and care

1

2

1 Working valve

2 Filler cap

Improper mixing of anti-freeze and corrosion inhibitors may lead to lime and corrosion deposits in the engine cooling system which can jeopardize cooling

efficiency.

In such cases it is necessary to clean the

cooling system at suitable intervals.

D Let the mixture work for 5 minutes

D Hose down the radiator with a straight

jet of tap water directly from the front.

In cases of stubborn dirt deposits remove the radiator and hose it down directly from behind. Do not use highpressure cleaners (steam sprayers may

be used)

Henkel P3-begesol contains no toxic or

corrosive substances and, if handled

properly, may be used without hesitation.

Cleaning the inside of the cooling system

(by authorized specialist personnel)

Investigations have shown that in many

cases the poor condition of the coolant

and / or the cooling system accounts for

damage to the water pump mechanical

seal. The poor condition of the cooling

system is normally due to use of unsuitable or no anti-freezing agents and corrosion inhibitor or defect, not early enough

replaced covers for filler neck and working

valves.

Cleaning the outside of the radiator

(wear goggles)

Extreme dirt deposits can clog the honeycombs so that the remaining surface no

longer ensures sufficient cooling. In such

cases, the insects, dust etc. should be removed from the honeycomb system of the

radiator block and the radiator itself then

cleaned with the cleansing agent HENKEL

P3-begesol. This cleansing agent is available from MAN in 10-kg cans under Part

No. 09.21002-0164.

Procedure:

D Mix P3-begesol with water, ratio 1:1

D Using a spray gun, spray the mixture in

as straight a jet as possible directly into

the radiator fins

If twice in a short time the water pump of

an engine develops leakes or the coolant

is heavily contaminated (dull, brown,

mechanically contaminated, grey or black

signs of a leakage on the water pump

casing, after the defect on the oil cooler)

clean the cooling system prior to removing that water pump as follows:

a) Drain coolant

b) Open thermostats positively (use short-

circuit inserts), so that the entire coolant circuit is flushed in the cleaning

operation

c) Fill coolant circuit with a mixture of hot

water (min. 50°C) and Henkel P 3 neutrasel 5265 detergent (1.5% by volume)

(-5266, -5225, Kluthe Hakopur 316),

see Publication “Fuels, Lubricants ...”

36

Page 39

Maintenance and care

d) Warm up engine under load. After a

temperature of 60°C is reached, run

engine for a further 15 minutes

e) Drain cleaning fluid

f) Repeat steps c) and d)

g) Flush cooling system. To this effect

h) Replace drain plug by drain plug with a

bore of 8 mm dia

i) Fill cooling system with hot water

k) Run engine at idle for 30 minutes. At

the same time continuously replenish

the water leaking from the bore in drain

plug by adding fresh water

Repair water pump only now. Thereafter,

fill the cooling system with approved cooling fluid. See Publication “Fuels, Lubricants ...”.

Note:

Only sediments and suspended particles can be removed by this cleaning

method. If corrosion and lime deposits

are found, proceed according to the

following section:

D Drain the pickling fluid, fill the system

with tap water, and run the engine at

idle for 5 minutes to flush out all fluid;

then drain the water

D Fill the system with a 1% soda solution.

Drain the soda solution after running

the engine at idle for 5 minutes, and

flush with tap water until the discharging water is clear

D Fill cooling circuit with a mixture of po-

table tap water and anti-freeze with at

least 40% by volume, refer to Publication “Fuels, Lubricants ...”

Note:

Older radiators may develop leaks

when such deposits are removed. The

surge tank should be filled only up to

the bottom edge as otherwise foaming

will cause the pickling fluid to spill over.

Cleaning the inside of tube bundles of

raw water heat exchangers

(by authorized specialist personnel)

Removal of lime deposits in the cooling system

(by authorized specialist personnel)

Procedure:

D Drain the coolant

D Fill the system with undiluted original

pickling fluid (Lithsolventsäure or en-

gine pickling fluid RB-06), see sources

of supply

D Let the engine run (also in normal oper-

ation) for approx. 8 hours with this fill-

ing in the cooling circuit

D Drain the pickling fluid and thoroughly

flush the system with tap water

D If necessary, refill the circuit again with

fresh pickling fluid and pickle the en-

gine for another 8 hours

Deposits building up inside the tube

bundle of the water-to-water heat exchanger can reduce the flow cross-section

of the individual tubes to the point where a

decrease in engine cooling occurs. This

condition will automatically lead to overheating of the engine with all of its accompanying effects. For this reason, it is recommendable to clean the tube bundle of

the water-to-water heat exchanger at the

first sign of high engine coolant.

Procedure:

D Remove and dismantle the heat ex-

changer (integrated in the coolant

surge tank)

D Place the removed tube bundle in a

suitable container made of plastic, such

as PE, PP, PVC, GFK

37

Page 40

Maintenance and care

D Fill the container with undiluted original

pickling fluid at room temperature (Lithsolventsäure or engine pickling fluid

RB-06) until the tube bundle is completely immersed

D Allow the pickling fluid to work approx.

10 hours. If this time is not sufficient,

continue the pickling process for up to

5 hours

D Pickling can be shortened by heating

up the fluid (max 50°C) and by occasionally moving the tube bundle

D After pickling thoroughly flush the

bundle with tap water and reinstall in

the heat exchanger

D Use new gaskets (O-seals)

D Mount the heat exchanger on the en-

gine and check for tightness

Note:

The variety of dirt deposits may also

create problems for the method of

pickling described above. In such

cases, we ask you to first of all submit

a specimen of the deposit for further

examination.

Damaged tube bundles may develop

leaks when dirt deposits are removed.

Filler caps and working valves of cooling system

The rubber gaskets of the filler caps and

working valves (negative pressure and

positive pressure valves) of the cooling

system are subject to natural aging.

To preclude leakages in the cooling system and tailing pressure drop and its

consequences up to severe engine damage, renew the filler caps and working

valves in line with the change of coolant

(every two years at the latest).

Waste water treatment

Drained and spent cleaning and pickling

fluid should be brought up to a pH value

of 7.5 to 8.5 with the aid of caustic soda.

Once the precipitation has settled to the

bottom of the container the clear fluid

above can be dumped into the sewer. The

sludge at the bottom should be taken to a

special waste dump. Anyway, it is recommended to consult the local authorities for

more information about waste water rules

or restrictions.

Sources of supply for pickling fluids

Lithsolventsäure

Keller & Bohacek

Liliencronstr. 54

D–40472 Düsseldorf

Phone: (02 11) 96 53 0

Motor pickling fluid RB–06

Reincolor-Chemie GmbH

Werkstr. 21

D–90518 Altdorf

Phone: (0 91 87) 97 03 0

38

Page 41

Maintenance and care

Turbocharger

Maintenance

(by authorized specialist personnel)

The turbochargers do not call for any specific maintenance.

The only points to be observed are the oil

pipes which should be checked at every

oil change for leakage and restrictions.

The air cleaners should be carefully serviced.

Furthermore, a regular check should be

kept on charge air and exhaust gas pipes.

Any leakages should be attended to at

once because they are liable to cause

overheating of the engine.

This precaution will enable any wear of

the bearings to be detected in good time

before serious damage is caused to the

rotor and bearings.

Measuring of axial clearance

A

When operating in highly dust or oil-laden

atmospheres, cleaning of the air impeller

may be necessary from time to time. To

do this, take compressor housing (Cau-

tion: do not tilt it so that it jams) and

clean it in solvent (diesel oil, petroleum

ether) using a brush.

If the air compressor should be badly

fouled, it is recommended that the wheel

be allowed to soak in a vessel with solvent

and to clean it then with a stiff brush. In

doing so, take care to see that only the

compressor wheel is immersed and that

the turbocharger is supported on the bearing casing and not on the wheel.

Special hints

A = Measuring point for dial gauge

Measuring of radial clearance

(The radial clearance will be determined

only at turbine end)

A

It is recommended that the radial and

axial clearances of the rotor be checked

after every 3000 hours operation.

A = Measuring point for dial gauge

39

Page 42

Maintenance and care

A

B

A = Point of support for dial gauge tip

B = Measuring capacity

Axial and radial clearances

D 2866

TE/LE/LXE

with liquid-

cooled exhaust

manifold

D 2866

TE/LE/LXE

with uncooled

exhaust manifold

KKK

model

K 36 0,16 0,58

4LGZ 0,20 0,65

axial

(mm)

radial

(mm)

Intercooler

Maintenance

(by authorized specialist personnel)

In order to maintain the heat transfer efficiency of the intercooler, it is necessary to

clean it at regular intervals which depend

on the quality of the coolant used.

For this purpose, dismantle the intercooler. In almost all cases, it will suffice to

clean the individual parts in a hot alkaline

solution, e.g. a 3 to 5% P3-FD solution.

Should hard and firmly adhering scale deposits continue to exist a second treatment should be made with a descaling

agent which will not corrode the cooler

core.

Use new gaskets when assembling the

cooler.

Be sure to clean the sealing surfaces

carefully before installing the gaskets.

Observe the specified pressure when

making the hydraulic test.

If excessive clearances are found, the

turbocharger should be replaced.

Test gauge pres-

sure

water side 4 bar

charge air

side

3 bar

40

Page 43

Maintenance and care

Air cleaner

Dry air cleaner

1 2 3 4 5 76

1 Connection port, fouling indicator

2 Cleaner housing

3 Clamp

4 Element

5 Hexagon nut

6 Cover

7 Dust bowl

Fouling Indicator

As the degree of clogging increases the

red indicator becomes more and more visible in the transparent section of the air

cleaner.

If the fouling indicator remains engaged,

i.e. it still shows completely red even with

the engine shut down, the filter cartridge

must be cleaned or replaced.

Filter operational

1 2

Service only when engine is switched off.

Dust collector

The dust collector must be emptied at regular intervals. The collector should never

be more than half full of dust.

When the two retainers have been folded

up the dust collector can be taken off.

Remove the lid of the dust collector and

empty the collector.

Ensure that the lid and the collector are

reassembled correctly. A lug on the collector fits into a recess in the edge of the lid.

If the filter is installed horizontally note the

“oben” (“top”) marking on the filter bowl.

Filter must be serviced

1 Red indicator

2 Reset button

After servicing the cartridge, press the

button to reset the fouling indicator.

41

Page 44

Maintenance and care

Changing the filter cartridge

Caution:

No dust must get to the clear air end.

Remove the hex hut, take out the contaminated cartridge and fit a new one.

Blowing out (wear goggles)

To do this fit a pipe to the compressed air

gun. The end of the pipe should be bent

by approx. 90°. The pipe must be long

enough to reach the bottom of the cartridge.

Blow the cartridge out from the inside with

dry compressed air (max. 5 bar) by moving the pipe up and down inside the cartridge until no more dust is released.

Clean the filter housing with a damp cloth,

especially at the sealing face for the cartridge.

Caution:

The engine must not be run without a

main cartridge.

Cleaning the cartridge

Caution:

The filter cartridge should normally be

changed. Clean it only in emergencies

(e.g. when no replacement is available).

Checking the cartridge

When a cartridge has been cleaned it

must be examined for damage before it is

refitted, e.g. damage to the paper bag and

rubber seals. Check also for compression

of or dents in the metal jacket.

Tears and holes in the paper bag can be

found by shining a torch into the bag.

42

Page 45

Maintenance and care

On no account re-use damaged cartridges. If in doubt fit a new cartridge.

Safety cartridge

Viscous air cleaner

When the main cartridge is being serviced

the safety cartridge remains in the filter

housing. The engine must not be run without the main cartridge.

Safety cartridges must be neither cleaned

nor re-used.

Safety cartridges must be changed:

D at the latest after being in use for two

years

D if, after the main cartridge has been

serviced (changed), the contamination

gauge responds again immediately

D if the main cartridge is defective

When the main cartridge has been removed the safety cartridge is accessible

and can be removed also.

The maintenance intervals for filters depend on the respective operating conditions.

As soon as a distinct layer of dust has

accumulated on the filter element, remove

air cleaner and wash in fuel or cleaning

oil.

Shake element out thoroughly to dry it.

Uniformly coat filter surface with a thin film

of engine oil.

Remove the hex nut.

Pull out the safety cartridge.

Insert a new safety cartridge. Refit and

tighten the hex nut.

43

Page 46

Checking and setting

To check and set the start of delivery with start of delivery marker

on injection pump hub

(by authorized specialist personnel)

2

1

3

1 Setting pointer

2 “OT” (top dead centre) mark and scale

3 Hexagon driver to rotate engine by

hand (Width across flats 32)

The pointer should then be aligned such

that its measuring edge exactly coincides

with the “OT” mark on the scale disc.

In order to enable the engine to be rotated

manually during adjustments, there is a

plate with a central hexagon driver fitted

to the front of the crankshaft pulley (barring device).

Checking

Remove screw plug for inspection hole in

mounting flage of the injection pump.

For the purpose of checking the start-ofdelivery setting, an “OT” (top dead centre)

mark and a scale from 10 ... 50° before

top dead centre are engraved on a disc

fitted in front of the torsional vibration

damper. The scale marks are read against

a pointer fitted to the crankcase.

There is another scale engraved on the

flywheel which can be read through an inspection hole in the flywheel housing but

access may be difficult. The scale should

be used for readjusting the pointer after

the vibration damper has been removed

or replaced.

In other words, before the vibration

damper with the scale disc is installed, the

engine should be positioned at “OT” (top

dead centre) by means of the scale on the

flywheel.

Then rotate engine so that mark on

pointer fitted to injection pump coincides

with mark on pump hub.

Read degrees on scale engraved on disc

on torsional vibration damper.

The reading should equal the specified

start-of-delivery setting (see “Technical

Data”).

If not, correct start-of-delivery setting.

44

Page 47

Checking and setting

Setting start of delivery

Correct start of delivery by turning the

pump hub in the slotted holes of the drive

gear.

Remove cover above the injection pump

drive gear

Rotate engine with barring device until the

pointer is on the specified start of delivery

(scale disc ahead of vibration damper).

Unscrew timing case cover. Remove fixing

screws of injection pump impeller. Turn

the hub of the injection pump accordingly

until the line marks (pointer and injection

pump hub) are in alignment. After every

adjustment carefully retighten fixing

screws.

Recheck start of delivery.

Use new gaskets when mounting cover

and screw plug.

To check and set the start of delivery with start of delivery indicator

in the governor housing

(by authorized specialist personnel)

2

1

3

1 Setting pointer

2 “OT” (top dead centre) mark and scale

3 Hexagon driver to rotate engine by

hand (Width across flats 32)

For the purpose of checking the start-ofdelivery setting, an “OT” (top dead centre)

mark and a scale from 10 ... 50° before

top dead centre is engraved on a disc

fitted in front of the torsional vibration

damper. The scale marks are read against

a pointer fitted to the crankcase.

There is another scale engraved on the

flywheel which can be read through an inspection hole in the flywheel housing but

access may be difficult. The scale should

be used for readjusting the pointer after

the vibration damper has been removed

or replaced.

Note:

The D 2866 LE / LXE engines with fancooled radiator are not equipped with

a scale disc in front of the torsional

vibration damper. Start of delivery in

these engines should be set by means

of the degrees scale on the flywheel.

In other words, before the vibration

damper with the scale disc is installed, the

engine should be positioned at “OT” (top

dead centre) by means of the scale on the

flywheel.

45

Page 48

Checking and setting

The pointer should then be aligned such

that its measuring edge exactly coincides

with the “OT” mark on the scale disc.

In order to enable the engine to be rotated

manually during adjustments, there is a

plate with a central hexagon driver fitted

to the front of the crankshaft pulley (barring device).

Checking

Remove screw plug (1) on governor housing. If fitted, take out blocking pin (2).

If the pointer is exactly in the centre of the

inspection hole, the pump plunger for cylinder no. 1 is at start of delivery. However,

it is possible to determine exactly whether

or not the pump is at start of delivery only

by means of the following special tools:

Connect up power supply of light signal

transmitter (red terminal = +). Turn engine

by hand so that piston in cylinder no. 1 in

the compression stroke comes close to

the start of delivery.

4

3

5 6

a. Light signal transmitter

80.99605-6002

21

Push light signal transmitter into socket in

governor housing. Ensure that the lug (3)

fits in the groove (4). Tighten the knurled

nut (5) by hand.

Lamp (A) comes on shortly before start of

delivery is reached.

Slowly turn the engine further until lamp

(B) comes on too. The injection pump is

now at start of delivery.

When the pump is in this position the degree scale on the flywheel housing must

also indicate the specified start of delivery.

46

Page 49

Checking and setting

Note:

If only lamp (B) comes on during this

test the engine has been turned past

the start of delivery. In this case turn

the engine back and repeat the procedure.

b. Sleeve

If a light signal transmitter is not available,

good measurement results can also be

achieved with a plug-in receptacle.

The receptacle is to be made of aluminium or steel in accordance with the drawing (figure 2259).

ø15

ø12

ø9

Setting start of delivery

If the start of delivery as determined in the

checks carried out in accordance with

method a) or b) is not correct, proceed as

follows:

Remove cover above the injection pump

drive gear. Losen the fixing bolts joining

the drive gear to the injection pump hub.

13

29

ø3

ø11

Set engine to start of delivery as described above.

Insert the sleeve into the governor housing up to the stop. The start of delivery is

set exactly when the pointer for start of

delivery is in the centre of the 3 mm bore

in the sleeve.

30

15

Set the engine so that the cylinder no. 1 is

at the specified number of degrees before

firing top dead centre (TDC).

Remove screw plug on governor housing.

The pointer for start of delivery must be

visible in the centre of the inspection hole.

Turn the injection pump camshaft to the

left or right as necessary until the conditions required for a) or b) (depending on

which method is being used) are obtained.

After every adjustment carefully retighten

fixing bolts.

Check start of delivery again.

Close up governor housing.

47

Page 50

Checking and setting

To check and adjust valve clearance

(by authorized specialist personnel)

The valve clearance for new and overhauled engines should be checked after

the first 10 to 20 hours of operation.

Then it should be adjusted every 400

hours of operation.

The valve clearance (see “Technical

Data”) should be adjusted so that the

feeler gauge can be moved between the

valves stem and the rocker arm with a

slight resistance being felt.

Adjustment is made with the adjusting

screw after releasing the lock nut.

2 3 1

1 Inlet valve

2 Exhaust valve

3 Feeler gauge

Rotate the crankshaft so that the piston of

the cylinder to be adjusted is at firing

TDC. This is the case when the valves of

the synchronous pistons are just rocking.

Valve rocking on cylinder

1

6

Adjust valves on cylinder

In order to enable the engine to be rotated

manually during adjustments, there is a

plate with a central hexagon driver fitted

to the front of the crankshaft pulley (barring device).

5 3 6 2 4

2 4 1 5 3

Cylinder head bolts

General notes

The engine may have either of the following two types of cylinder head bolt:

D Cylinder head bolts with

hex head tightened by the

angle-of-rotation method,

socket size 19

D Cylinder head bolts with

Torx head tightened by the

angle-of-rotation method,

Torx wrench size E18

Bolts to be used in event of repairs:

Bolts with hex head may be replaced by

bolts with Torx head if all the bolts on the