Page 1

T

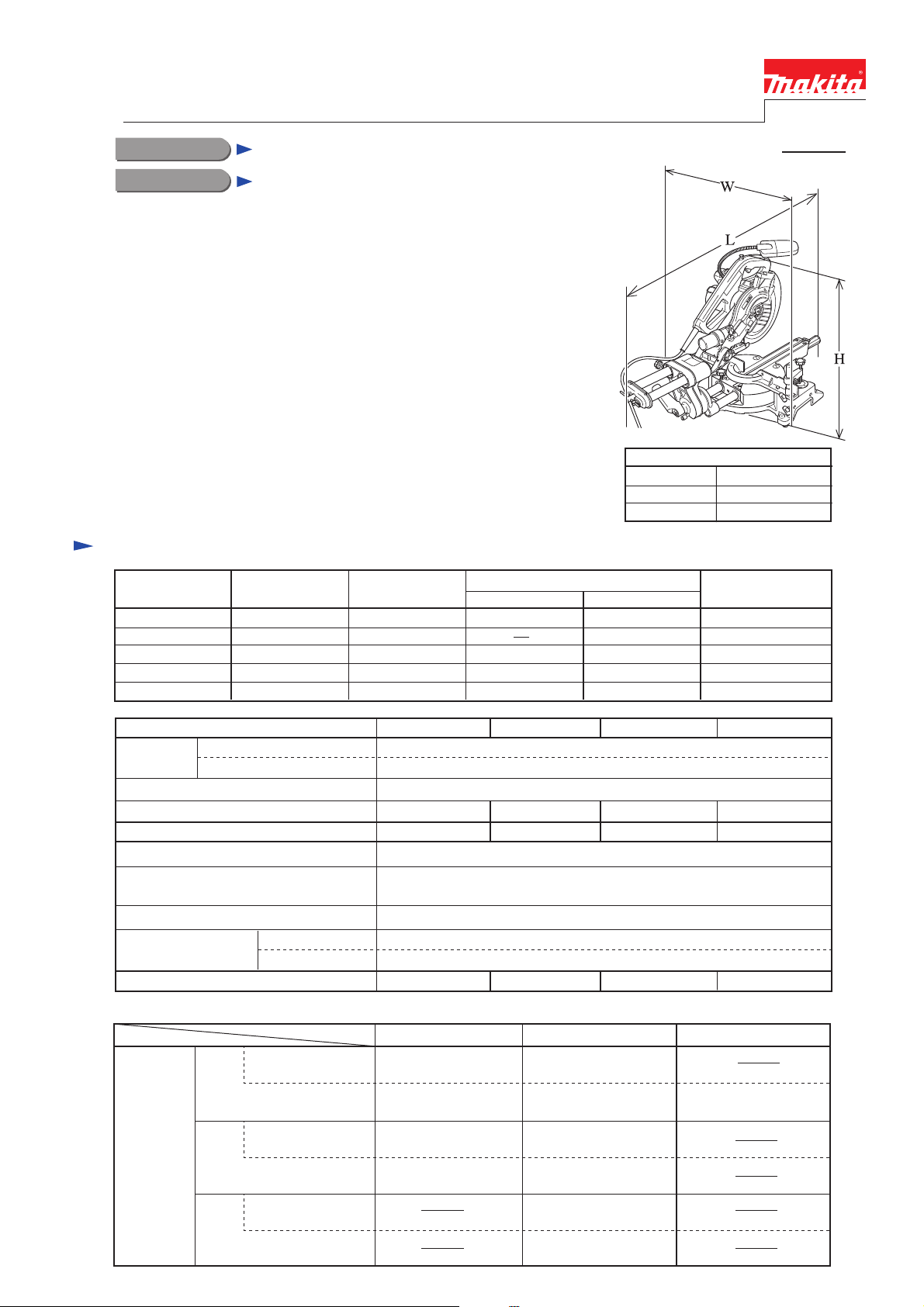

ECHNICAL INFORMATION

Models No.

LS0714, LS0714F, LS0714FL, LS0714L

PRODUCT

P 1 / 26

Description

Slide Compound Saw 190mm (7-1/2")

CONCEPT AND MAIN APPLICATIONS

New slide compound saw model LS0714 has been developed to

improve cost-effectiveness by removing electronic circuit for soft start &

constant speed from model LS0713.

The primary use is for making/modifying interior decorations in apartment

building. Model LS0714's compact design and light weight are

convenient to carry to workplace.

The LS0714 series is available in the following variations:

*LS0714:With neither Fluorescent job light nor Laser marker

*LS0714F:With Fluorescent job light for cutting workpiece in dark places

*LS0714FL:With Fluorescent job light and Laser marker for easy trace of

cutting line

*LS0714L:With Laser marker

Specification

Voltage (V) Cycle (Hz)

110

120

220

230

240

Current (A)

9.7

10.0

4.8

4.6

4.4

50 / 60

50 / 60

50 / 60

50 / 60

50 / 60

Length ( L )

Width (W )

Height ( H )

Continuous Rating (W)

Input Output

1,010

1,010

1,010

1,010

450

450

450

450

Dimensions : mm ( " )

670 (26-3/8)

430 (17)

458 (18)

Max. Output(W)

1,200

1,200500

1,200

1,200

1,200

Model No.

Saw blade

No load speed: min-1= rpm.

Fluorescent job light

Laser marker

Lock-off botton for trigger switch

Electric brake

Protection against electric shock

Power supply

cord: m ( ft )

Net weight: kg ( lbs )

Cutting capacity: mm ( " )

Miter angle

Diameter: mm ( " )

Hole diameter: mm ( " )

Australia

Except Australia

Bevel angle

With a 20mm

auxiliary wood fence

90°

With a 15mm

auxiliary wood fence

45°

Left and Right

With a 10mm

auxiliary wood fence

57° Right

LS0714

20 (13/16) [Canada, Chile, Colombia, Mexico, Panama, USA: 15.88 (5/8)]

No

No No

12.5 (27.6) 12.8 (28.2) 13.1 (28.9)

45°

Left

45 x 265

(1-3/4 x 10-3/8)

40 x 300

(1-9/16 x 11-3/4)

45 x 185

(1-3/4 x 7-1/4)

40 x 212

(1-9/16 x 8-3/8)

LS0714F LS0714FL

190 (7-1/2)

6,000

Yes Yes

Yes

Yes

No

( for Canada and USA: Yes)

Double insulation

2.0 (6.6)

2.5 (8.2)

90°

60 x 265

(2-3/8 x 10-3/8)

52 x 300

(2-1/16 x 11-3/4)

60 x 185

(2-3/8 x 7-1/4)

52 x 212

(2-1/16 x 8-3/8)

60 x 145

(2-3/8 x 5-3/4)

52 x 163

(2-1/16 x 6-3/8)

LS0714L

No

Yes

12.8 (28.2)

5°

Right

40 x 300

(1-9/16 x 11-3/4)

Page 2

Standard equipment

T.C.T. Saw blade 190mm ............................... 1 pc

Socket wrench 10 ........................................... 1 pc

Dust bag ........................................................ 1 pc

Vertical vise ................................................... 1 pc

Note: The standard equipment for the tool shown may differ from country to country.

Holder set (2 pcs. in set) ......................................... 1 set

Triangular rule ........................................................ 1 pc

Hex wrench 2.5 (LS0714FL/ LS0714L only).......... 1 pc

Switch button ........................................................... 2 pcs

Optional accessories

Horizontal vise

Holder assembly

Set plate assembly

Various TCT saw blades

Holder assembly for supporting long stock

Fluorescent tube for LS0714F and LS0714FL

P 2 / 26

Page 3

P 3 / 26

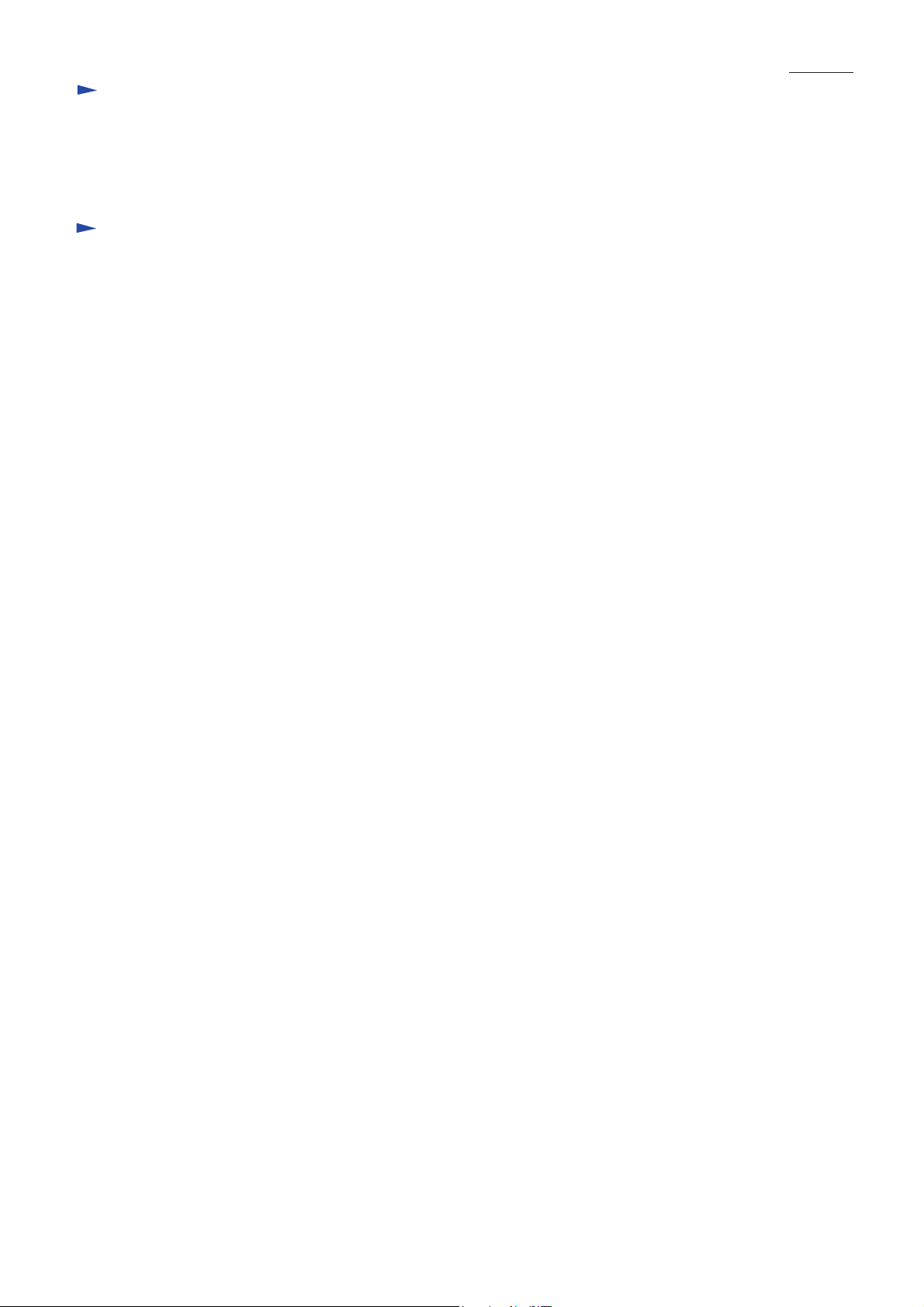

Repair

WARNING: Be sure to unplug the tool before maintenance or repair.

See the instruction manual on how to handle the tool.

Remove the following parts from the machine for safety before repair/ maintenance:

*Saw Blade *Inner Flange *Outer Flange *Dust Nozzle

[1] Lubrication

1. Apply Makita grease N. No.1 to the following portions designated by black triangle to protect parts and product from

unusual abrasion. See Fig. 1.

Item No. Parts description

Blade case

16

136

139

145

158

159, 161

Fig. 1

Arm complete

Stopper plate

Front arm complete

O ring 5153

Pipe 16-90155

Arm holder156

Screw M10

Flat washer 10

Thrust needle gauge 1024 160

Linear ball bearing, factory-assembled

Portion to lubricate

Apply 6g to the gear room if the room has been washed for cleaning.

Both pivot portions where front arm (item No. 145) contacts

Inside of hole which accepts arm holder's (156) rib portion.

Linear ball bearing in which pipe portion of front arm (145) slides

Surface to which inner wall of arm holder (156) contacts

Pivot portion where blade case (16) contacts

Whole

Pipe ends to which axis holes of front arm complete (145) contact

Swivel portion where arm complete (136) contacts

Threads

Surfaces where thrust needle gauge 1024 (160) contacts

Head and reverse side to which washers 10 (159 and 161) contact

Stopper pin

Helical gear 47

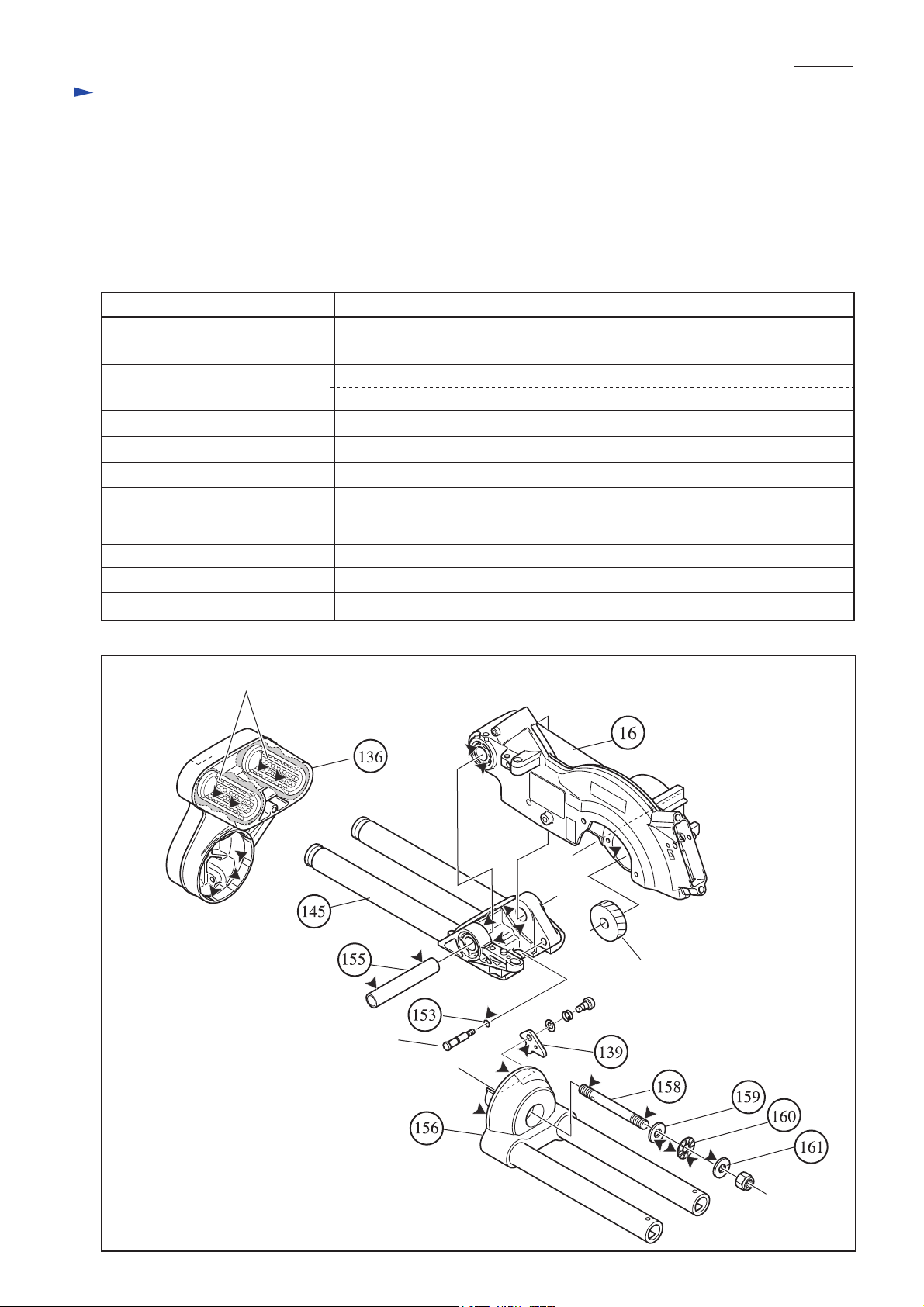

Page 4

P 4 / 26

Repair

2. Apply Makita grease N. No.1 to the following portions designated by black triangle to protect parts and product from

unusual abrasion. See Fig. 2.

Item No. Parts item Portion to lubricate

Spiral spring 26 Whole

17

21 Center plate Portion where center cover contacts

27

173

190

194

195, 196

Fig. 2

Link plate

Turn base

Grip 32

Base

Slide plate The surface on which (173) turn base's edge slides

Tip round portion

Axis

Linear ball bearing in which arm holder's (156) pipe slides

Threads

The boss for accepting (173) turn base's axis

Factory-assembled

linear ball bearing

Axis of turn base

Center cover

Boss for accepting

the turn base's axis

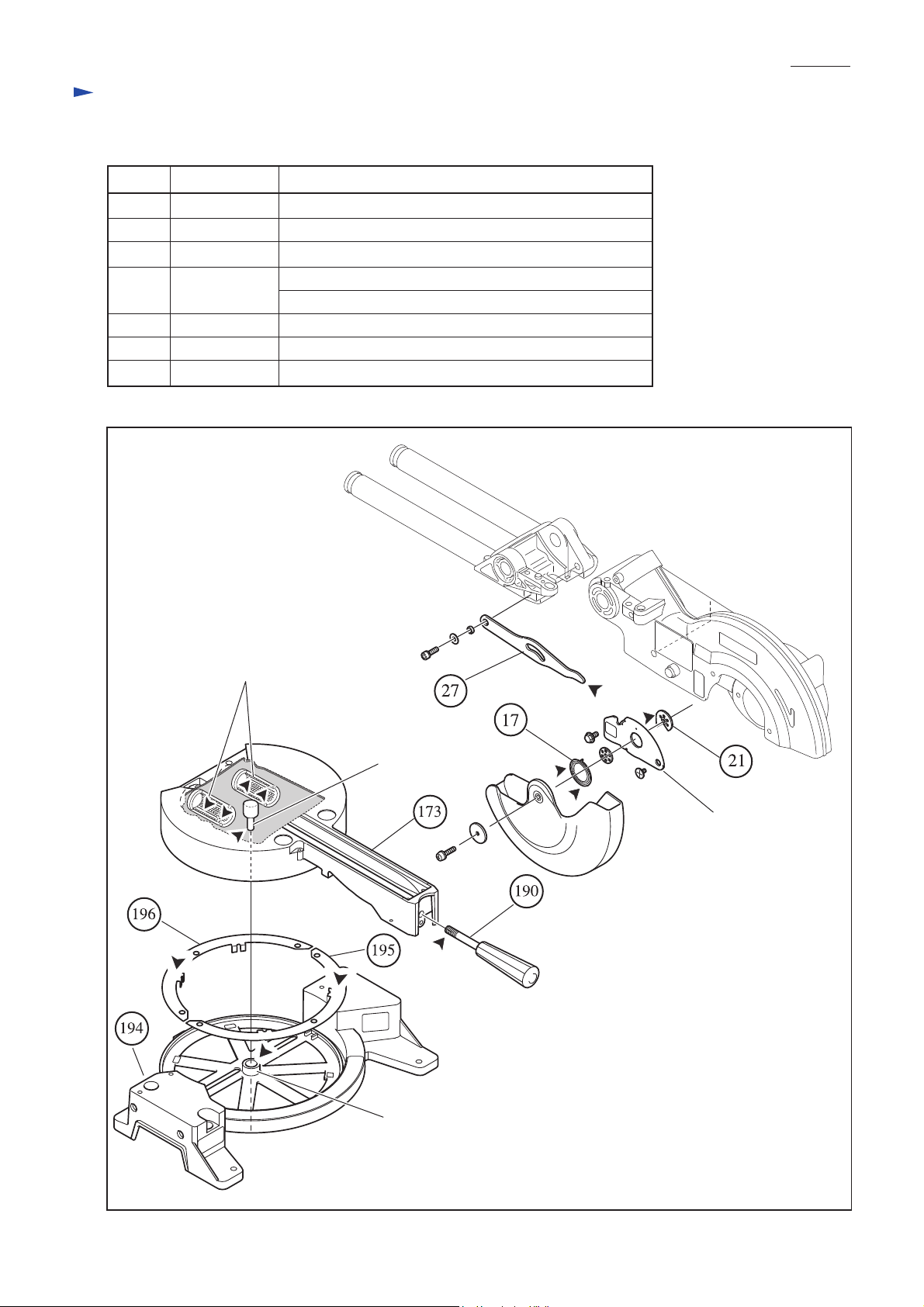

Page 5

P 5 / 26

Repair

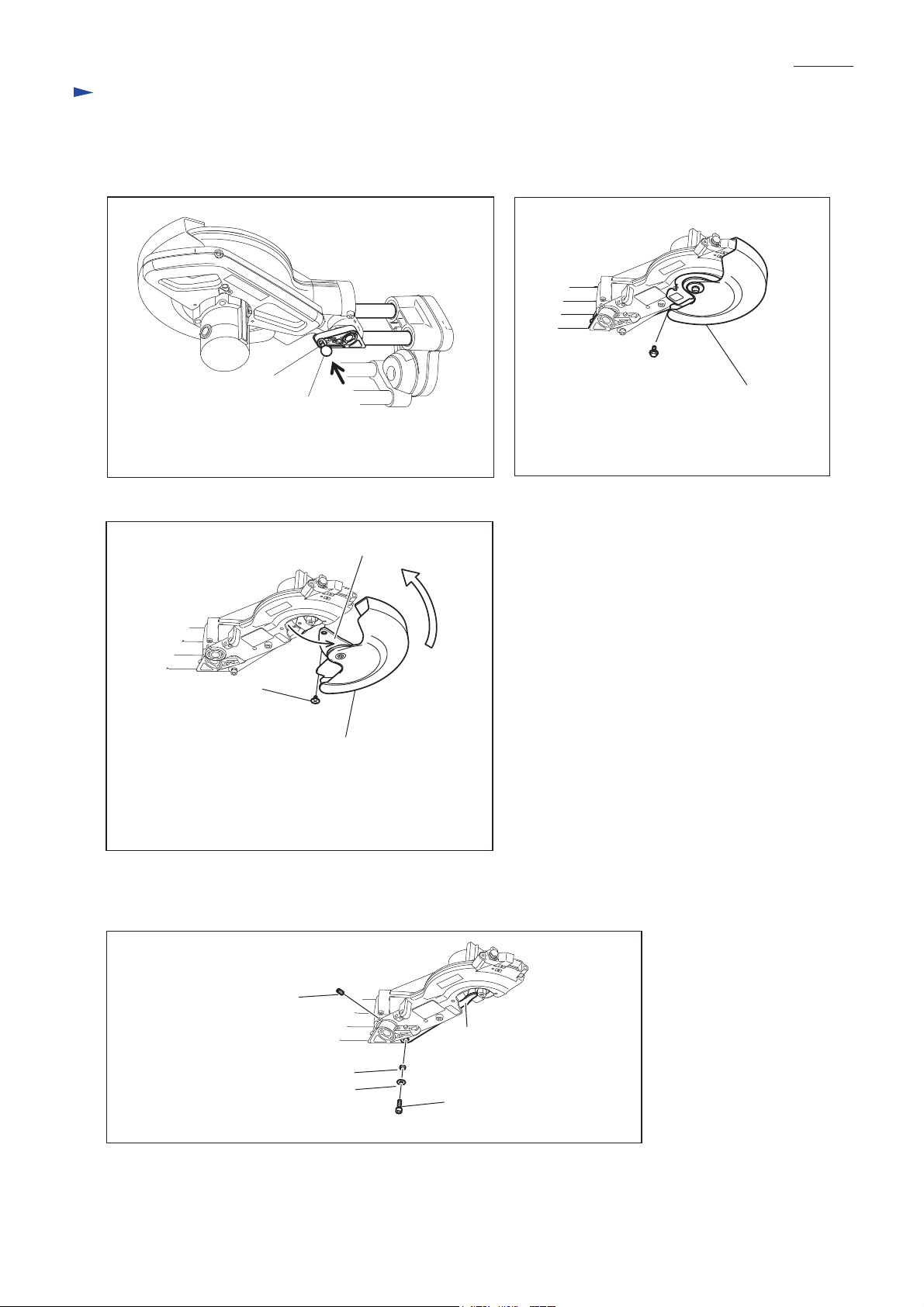

[2] Removing motor unit (blade case, motor housing, handle etc.) from front arm complete

1. Remove safety cover section from blade case as illustrated in Fig. 3-1, Fig.3-2 and Fig.3-3.

Fig. 3-1 Fig. 3-2

Stopper pin

Knob 20

Lock the motor unit by pushing knob 20 for stopper pin

while keeping the motor unit at the rest position.

Fig. 3-3

Center cover

+ Flat head screw M5

Safety cover

Turn safety cover and then open center cover as illustrated

above. + flat head screw M5 comes into sight at that time.

The safety cover section can be separated from motor unit

by removing the + flat head screw M5.

Hex bolt M6x14

Center cover

Remove hex bolt M6x14 from center cover.

2. Remove the screws in Fig. 3-4 to disconnect the linkage of motor unit and front arm complete.

Fig. 3-4

Hex socket headbolt M6x10

(for securing pipe16-90)

Link plate

Ring 6

Flat washer 6

Hex socket head bolt M6x20

(for fixing link plate)

Page 6

P 6 / 26

Repair

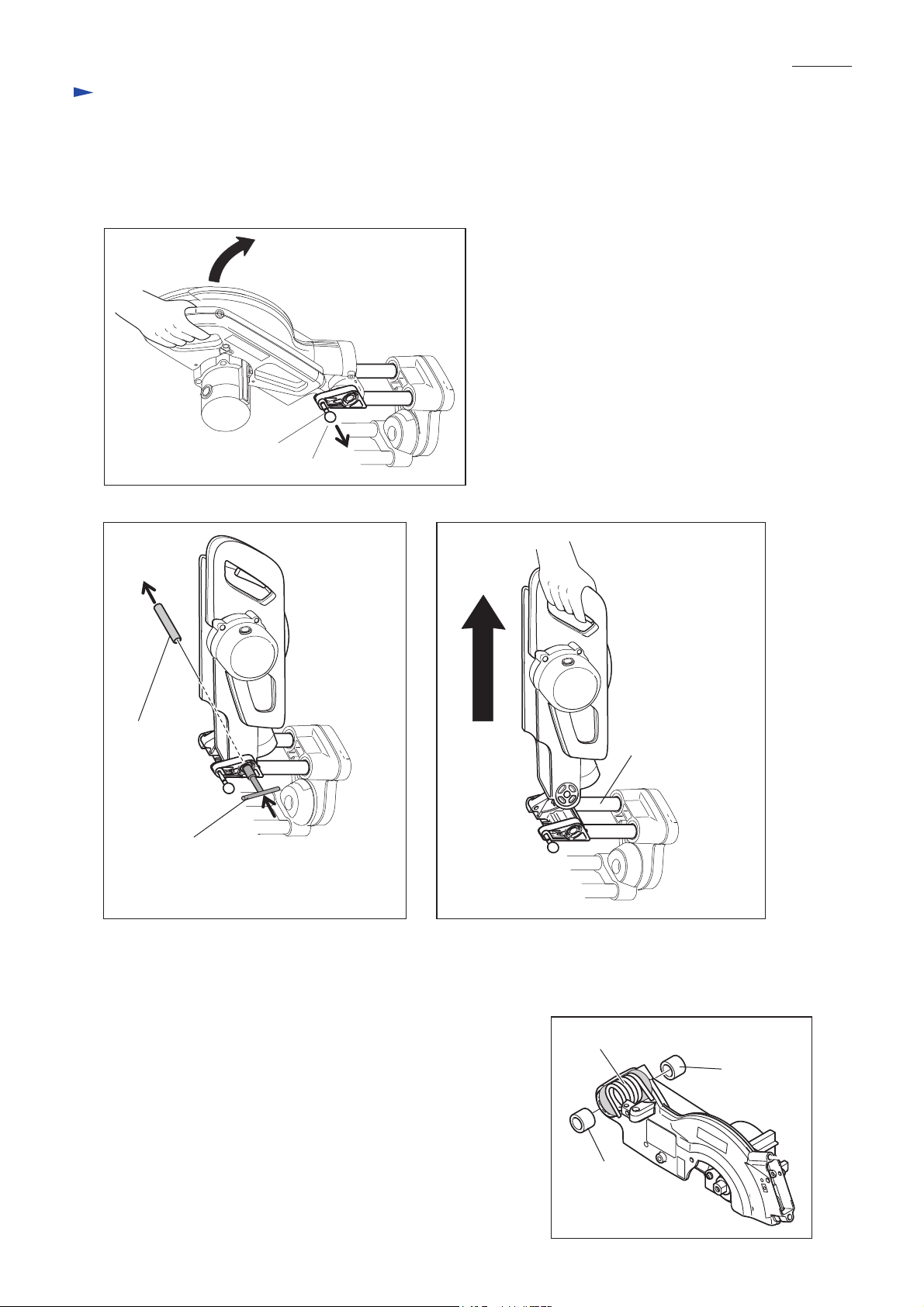

3. While holding the motor unit with your hand, pull out knob 20 for stopper pin to release the lock of motor unit, and

lift up the motor unit slowly until it comes to the free point from return force of torsion spring 28. See Fig. 3-5.

4. Remove pipe 16-90 by pushing it out using socket wrench 10. See Fig. 3-6.

5. Remove motor unit from front arm complete. See Fig. 3-7.

Fig. 3-5

Stopper pin

Knob 20

Fig. 3-6

Pipe 16-90

Socket wrench 10

Push out pipe 16-90 using socket wrench 10

as illustrated above.

Fig. 3-7

Front arm complete

[3] Mounting motor unit (blade case, motor housing, handle etc.) to front arm complete

1. Insert two sleeves 17 into torsion spring 28. See Fig. 4.

2. Mount the motor unit to front arm complete. Refer to Fig. 3-7.

3. Pass pipe 16-90 through the holes of front arm and blade case.

Refer to Fig. 3-6.

4. While keeping motor unit in the rest position, push knob 20 for

stopper pin toward the blade case side. Refer to Fig. 3-5.

5. Secure link plate with hex socket head bolt M6x20, and secure

the pipe 16-90 with ring 6, flat washer 6 and hex socket head screw

M6x10. Refer to Fig. 3-4.

Fig. 4

Torsion spring 28

Sleeve 17

Sleeve 17

Page 7

P 7 / 26

Repair

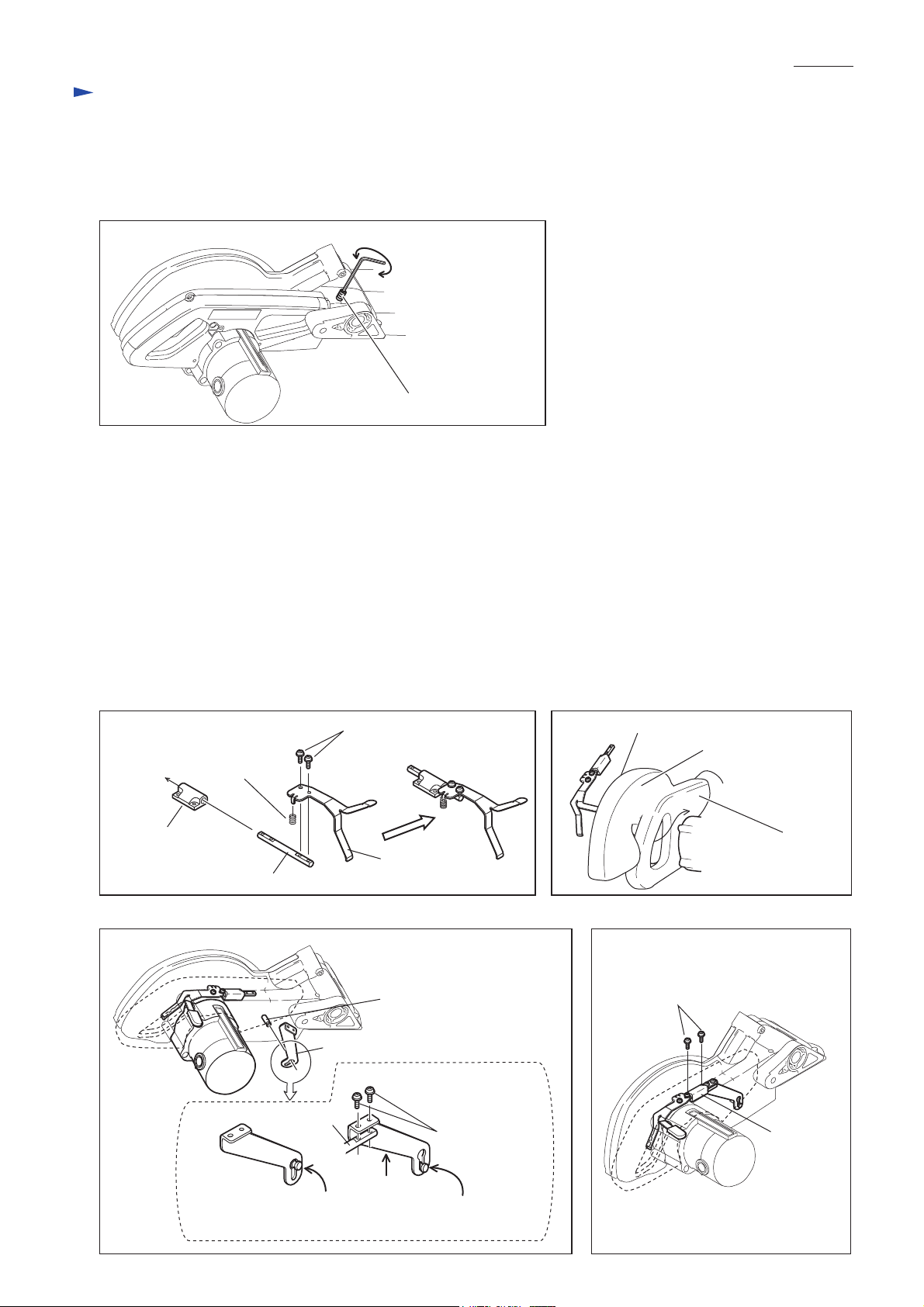

[5]Adjusting the return force of torsion spring 28

1. Torsion spring 28 should be adjusted so that motor unit can smoothly return to the initial raised position from any

other place.

Turning hex socket head set screw M6x16 with hex wrench allows to adjust the return force. See Fig. 5.

Fig. 5

Return force: Weak

Return force: Strong

Hex socket head set screw M6x16

[6] Assembling safety lock mechanism

Note: The products for the following countries are equipped with safety lock mechanism.

* Europe * South Africa * China

1. Assemble the component parts of safety lock mechanism as illustrated in Fig. 6-1.

2. Holding the mounted compression spring 7 to lock lever, pass the lock lever through the loop portion of handle,

and bring the safety lock mechanism between handle and blade case complete. See Fig. 6-2.

3. Pass lock pin through the large hole of lock plate.And lift up lock plate in order to align its screw holes with those

of rod 8.Then, the lock pin's head comes to the keyhole slot of lock plate.And secure lock plate with pan head

screw M4x10 to rod 8. See Fig. 6-3.

4. Secure rod holder with tapping screw bind CT 4x16, while pressing it toward blade case complete in order to

make rod 8 parallel to handle as Fig. 6-4. Make sure that safety cover is locked with safety lock mechanism when

lock lever is in the original position.

Compression

spring 7

Rod holder

Rod 8

Rod 8

Pan head screw M4x10

Lock lever

Lock pin

Lock plate

Pan head screw

Fig. 6-2Fig. 6-1

Lock lever

Blade case complete

Handle

Fig. 6-4Fig. 6-3

Tapping screw

bind CT 4x16

Rod holder

Lock pin's head unlocked

in keyhole slot

Lock pin's head locked

in the keyhole slot

Page 8

Repair

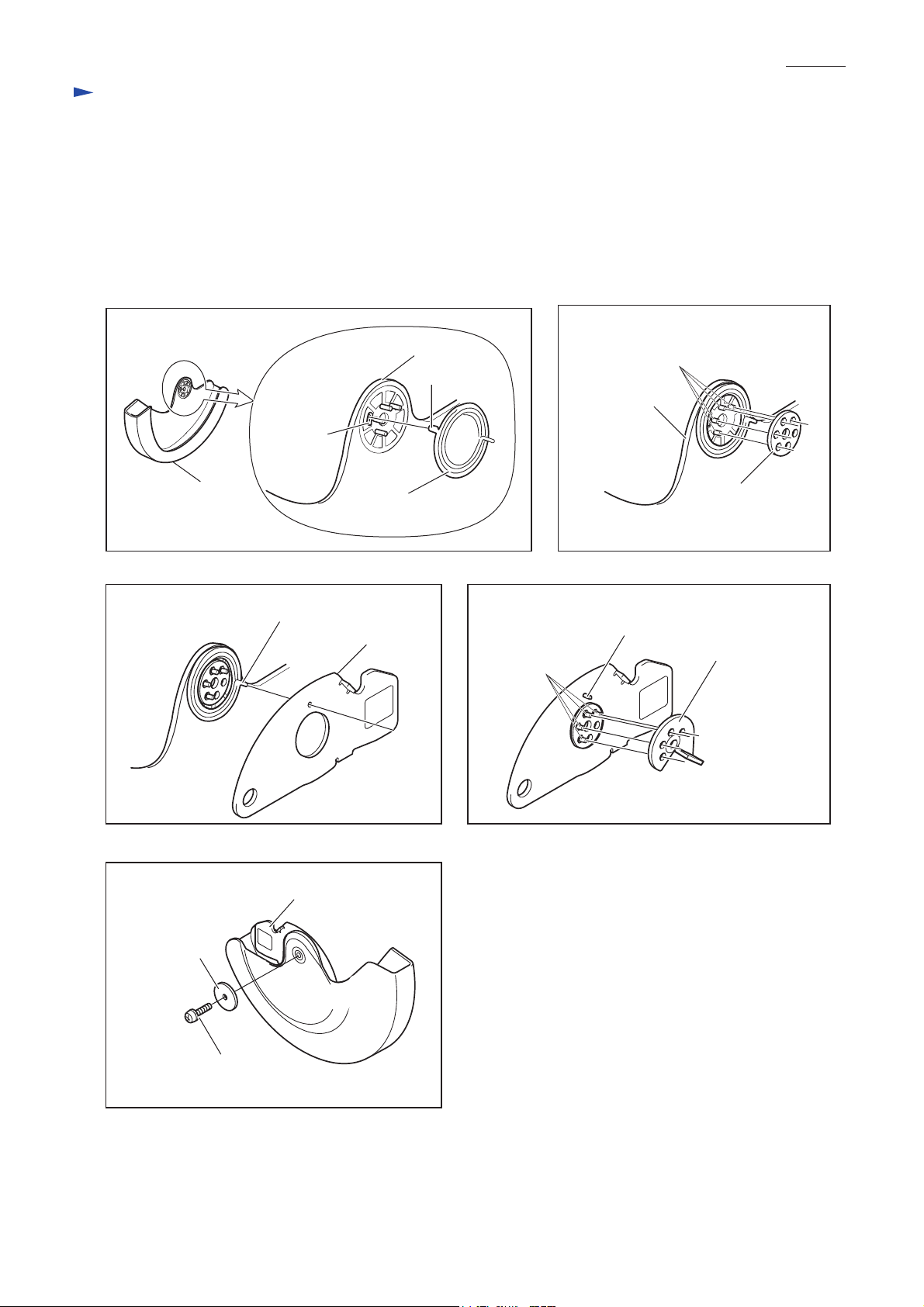

[7] Assembling safety cover section

1. Insert the tail portion of spiral spring 26 into the elliptical hole of safety cover. See Fig. 7-1.

2. Mount center washer to safety cover by aligning its holes with four bosses of safety cover. See Fig. 7-2.

3. Mount center cover by inserting the another tail portion of spiral spring 26 into the center cover's hole.

See Fig. 7-3.

4. Mount center plate to safety cover by fitting four bosses of safety cover into center plate's holes.

See Fig. 7-4.

5. Fix the assembled parts with pan head screw M5x18. See Fig. 7-5.

P 8/ 26

Fig. 7-1

Fig. 7-3

Safety cover

Elliptical

hole

Safety cover

Another tail portion of spiral spring 26

Spiral spring 26

Center cover

Tail portion

Fig. 7-4

Four Bosses

Fig. 7-2

Four Bosses

Safety cover

Center washer

Another tail portion

of spiral spring 26

Center plate

Fig. 7-5

Flat washer 5

Center cover

Pan head screw

M5x18

Page 9

P 9/ 26

Repair

[8] Removing turn base from base

1. Remove guide fence and kerf board. See Fig. 8-1.

2. Remove hex lock nut M8-13 using socket wrench.And then, remove turn base from base while pushing lock lever in

the direction designated with arrow. See Fig. 8-2.

Fig. 8-1

Hex socket headbolt M6x25

Guide fence

Tapping screw bind CT 4x12

Kerf board

Kerf board

Tapping screw bind

CT 4x12

Fig. 8-2

Turn base complete

Socket wrench

Hex lock nut M8-13

Flat washer 8

Base

Lock lever

Remove turn base from base complete

while pushing down lock lever.

Page 10

P 10/ 26

Repair

[9] Mounting turn base to base

1. Apply grease to slide plate and boss for accepting the turn base's axis. Refer to Fig. 2.

2. Fasten hex lock nut M8-13 so that the turn base can move smoothly without wobbling. Refer to Fig. 8-2.

[10] Mounting square rod and securing ring 26

1. Setting ring 26 to pipe 25-235 of arm holder complete, mount arm holder complete to turn base. See Fig. 9-1.

2. Slide arm holder complete so that each end of the two pipes come nearer to the axis of turn base. See Fig. 9-2.

3. Secure square rod to pipes of arm holder complete with hex bolt M5x30.

Fig. 9-1 Fig. 9-2

< Note > Rubber pin has to face

Pipe 25-235 of

arm holder complete

Ring 26

Hex bolt M5x30

arm mounted side.

Rubber pin

Hex bolt M5x30

Square rod

Turn base

Arm holder complete

<Note>

For easy mounting, slide ring 26 closely

to arm mounted side in this step.

4. Slide ring 26 toward turn base and align the following holes for thumb screw M6x33 and hex socket head bolt M4x10.

* Screw hole of turn base (upper side)

* Screw holes of ring 26

* Screw hole of turn base (bottom side)

And tighten thumb screw M6x33 to secure ring 26 to turn base. See Fig. 9-3.

5. Tighten hex socket head bolt M4x10 from the bottom side of turn base.

Then ring 26 is completely secured to turn base.

Fig. 9-3

Arm is mounted here.

Thumb screw M6x33

Axis of turn base

Arm is mounted

here.

Arm holder complete

Screw hole of turn base (upper side)

Screw hole of ring 26

Screw hole of turn base (bottom side)

Ring 26

Hex socket head bolt M4x10

Page 11

P 11/ 26

Repair

[11] Disassembling positive lock mechanism of turn base

1. Remove grip 32.

2. Separate lock lever plate and lock lever from turn base by removing tapping screw bind CT 4x16. See Fig. 10-1.

3. Turn lock pin in order to face pin 3 to vertical direction. And remove pin 3 while pushing compression spring 6

toward the grip side. See Fig. 10-2.

4. By pulling off lock pin from turn base, compression spring 6 can be removed from lock pin.

Fig. 10-1 Fig. 10-2

Grip 32

Lock lever plate

Lock lever

Tapping screw

bind CT 4x16

Pin 3

Compression

spring 6

Lock pin

[12] Assembling positive lock mechanism of turn base

Do the reverse of disassembling procedure with the following attention:

1. The protrusion of lock lever plate has to face the grip side.

2. Apply grease to the threaded portion of the grip.

See Fig. 11.

Fig. 11

Grip 32

Apply grease here.

Tapping screw bind CT 4x16

Projection of lock lever plate

Lock lever plate

Lock lever

Screw holes

Push compression spring in the direction

designated with arrow (toward grip side).

Page 12

Repair

[13] Mounting stopper plate to arm holder

Mount stopper plate as illustrated in Fig. 12.

Fig. 12

P 12/ 26

Arm holder

Stopper plate

Flat washer 6

Insert this tail into the small hole

of stopper plate.

Pan head screw M5

Torsion spring 8

[14] Mounting ring 26 and set screw M4x8

1. Insert ring 26 into the hole of arm. See Fig. 13.

2. Drive set screw M4x8 into the screw hole of arm by screwing thumb screw M6x33 with hex wrench.

Stop driving the set screw at the same time it reaches surface A.

Fig. 13

Thumb screw M6x33

Hex wrench

Screw hole for

thumb screw M6x33

Arm

Ring 26

Set screw M4x8

Arm holder

Stopper plate

Flat washer 6

Torsion

spring 8

Pan head

screw M5

Hex wrench

Set screw M4x8

Screw hole of

arm

Surface A

Ring 26

Arm

[15] Adjusting arm for smooth pivot action

1. Adjust hex lock nut M10x17 so that arm can pivot smooth without backlash. See Fig. 14-1.

2. Mount lever 100 and the relevant parts to arm with keeping the lever angle in lock position as Fig. 14-2.

Fig. 14-1 Fig. 14-2

Arm

Flat washer 10

Arm

Hex lock nut

M10-17

Arm holder

Approx 10° against

horizontal plane

Lever 100

Compression spring 5

Hex nut M10-17

Pan head screw M4x10

Page 13

Repair

[16] Angle adjustment of saw blade

1. Adjust the angle of saw blade at 90° against

While keeping this condition, fix the angle by adjusting 0

2. As for 45

After that the fix the angle by adjusting 0

° degrees adjusting, use 45 degrees set square as Fig. 15-3.

turn base using 90 degrees set square (Makita Part No.1R208). See Fig. 15-1.

° degrees bevel angle adjusting bolt

° degrees bevel angle adjusting bolt at the side of arm as Fig. 15-4.

P 13/ 26

at the side of arm. See Fig. 15-2.

Fig. 15-1

Fig. 15-3

45

°

1R208 : 90 degrees set square

90

°

1R207 : 45 degrees set square

Fig. 15-2

Arm

0

degrees bevel angle adjusting bolt

(Hex bolt M6x16)

Fig. 15-4

Arm

45

degrees bevel angle adjusting bolt

(Hex bolt M6x16)

90

°

45

°

[17] Adjustment for max. cutting capacity

Do the following steps to obtain the max. cutting capacity.

1. Pull the motor unit to your side until it stops.

2. Lower the motor unit until it stops.

3. And then adjust the Ø190mm saw blade so that it comes to the position shown in Fig. 16.

Note: The saw blade must not contact kerf boards and base, when the motor unit is in the lowest position.

4. Tighten hex bolt M6x16 using socket wrench 10.

Fig. 16

Socket wrench 10

(Standard equipment)

Hex bolt M6x16

ø190mm saw blade

Kerf board

Page 14

P 14/ 26

Repair

[18] Angle adjustment of guide fence

1. Provisionally tighten a M6x25 hex bolt into screw hole A on the operator's left side of guide fence as Fig. 17.

2. While checking the angle of guide rule to saw blade using 90 degrees set square (No.1R208), adjust the guide fence

by moving its right end until the angle sets at 90 degrees

3. After completion of squaring adjustment, securely tighten three M6x25 hex bolts in order of C, B, A.

Fig. 17

Hex bolt M6x25

.

C

Move this side.

Screw hole A is smaller

than Screw hole B/C.

A

90 degrees set square

(No.1R208)

B

Saw blade

Operator's position

[19] Disassembling laser section (exclusively for LS0714FL/ LS0714L)

1. Remove lock lever from rod 8 before disassembling laser section.

Refer to the chapter < 6 > "Assembling safety lock mechanism".

2. After removing thumb screw M5x24, remove top cover by taking off tapping screw bind CT4x20. See Fig. 18-1.

3. Take off laser line label which adheres on blade case, and remove shoulder screw M5 with which laser section is

secured on blade case.

Fig. 18-1

Tapping screw bind CT4x20

Flat washer 5

Thumb screw M5x24

Shoulder screw M5

Laser line label

4. Remove lead cover holder by unscrewing tapping screw bind CT4x20. Then, lead coverA and lead cover B can be

removed from blade case. See Fig. 18-2.

5. Disconnect socket unit of laser circuit from connector of lead unit.

6. Then, laser section can be removed from blade case.

Fig. 18-2

Lead cover holder

Lead cover B

Connector of

lead unit

Socket unit of

laser circuit

Tapping screw bind CT4x20

Lead cover A

Laser section

(Laser circuit, block B,

block C, etc.)

< Caution >

Be careful not to touch the lens for laser beam.

The laser beam irradiated through the smeared

lens becomes indistinct.

Top cover

Tapping screw bind CT4x20

Page 15

Repair

7. Laser section can be disassembled as shown in Fig. 18-3.

Fig. 18-3

1) Unscrewing pan head screw M3x10 allows

to remove torsion spring 9 and laser circuit.

Block C

Torsion spring 9

P 15/ 26

Block B

Pan head screw M3x10

2) Remove torsion spring 9 and block C

by unscrewing pan head screw M3x10.

Pan head screw

M3x10

Laser circuit

Torsion spring 9

[20] Assembling laser section (exclusively for LS0714FL/ LS0714L)

1. Mount torsion spring 9 and block B to block C and secure them with pan head screw M3x10. Refer to Fig. 19-1.

Make sure that block C and block B can move in torsional direction.

2. Mount torsion spring 9 and laser circuit to block B, and secure them with pan head screw M3x10. Refer to Fig. 18-3.

Make sure that block B and laser circuit can move in torsional direction. See Fig. 19-2.

Fig. 19-1

Block C

Torsion spring 9

Fig. 19-2

Block C

Block B

Pan head screw M3x10

3. For easy adjustment of irradiated angle of laser beam from now on, drive hex socket set screws M4x6 until their

head portions come to the same level with the surfaces of block C and laser circuit. See Fig. 19-3.

4. Hold the lead wires of laser circuit between two ribs of block C. See Fig. 19-4.

Fig. 19-3

Block C

Block C

Hex socket

set screw M4x6

Hex socket

set screw M4x6

Laser circuit

Block B

Hex socket

set screw M4x6

Laser circuit

Torsion spring 9

Laser circuit

Fig. 19-4

Ribs

Block C

Laser circuit

Page 16

P 16/ 26

Repair

WARNING: Special attention should be taken to the adjustment because plugging the tool is

required. Don't turn on the main switch for cutting operation of the tool while

adjusting the laser line position. Turn on the switch of laser beam only.

Never look into the laser beam. Direct laser beam may injure your eyes.

(1) Mechanism for adjustment of the position of laser line

1.Adjustment of the position of laser line can be made with the following screws which are under laser line label.

* Hex socket set screw M4x6 (A): for adjusting 90° to turn base See Fig.20-A

* Hex socket set screw M4x6 (B): for adjusting 90° to guide fence See Fig. 20-B

Fig. 20-1

Saw blade

By sliding the position of thumb screw M5x24, user can

select that the laser line is put down either the right side

Laser line

of blade or the left side.

Laser line label

Fig. 20-A Fig. 20-B

Hex socket set screw M4x6 (A)

The position of laser line

adjusted to 90° against

guide fence

Turn base

< Note > The position of laser line is factory adjusted in advance within 1mm from the sidesurface of blade.

(2) Precise adjustment of laser line

1. Lock the motor unit at the initial position.Mount "Jig for laser line adjustment" (Makita part No. 1R315) to spindle

and drive hex bolt M6x18 into the screw hole of spindle head. See Fig. 20-2.

Fig. 20-2

Hex socket set screw M4x6 (B)

Guide fence

The position of laser line

adjusted to 90° against

guide fence

Hex bolt M6x18

(for securing saw blade)

Jig for laser line adjustment (1R315)

Page 17

P 17/ 26

Repair

2. Make precise adjustment so that the laser line should be aligned with the line of jig for laser line adjustment (1R315)

when lowering the jig until it reaches the pan head screw M5x16 of link plate side. See Fig. 20-3.

Fig. 20-3

Link plate

Link plate

Pan head screw

M5x16 of link plate side

3.When lifting up the jig for laser line adjustment (1R315) until it reaches the pan head screw M5x16 of the laser box side,

be sure to make precise adjustment as Fig. 20-4.

Fig. 20-4

Jig for laser line

adjustment (1R315)

Line of jig for laser

line adjustment (1R315)

laser line should be aligned

with the line of jig.

Bearing box

Bearing box

Jig for laser line

adjustment (1R315)

Laser box

Line of jig

laser line should be aligned

with the line of jig for laser

line adjustment.

Pan head screw

M5x16 of laser

box side.

Page 18

P 18/ 26

Repair

(3) Adjustment of laser beam positioning (exclusively for LS0714FL/ LS0714L)

For safety and easy adjusting work, remove saw blade, safety cover section, flanges (outer and inner) and dust

nozzle.

1. Mount Jig for laser line adjustment (1R315) to spindle. See Fig. 20-2.

2. Tear away a part of laserline label until hex socket head set screws M4x6 (A and B) come into your sight as Fig.20-5.

3. Connect the machine with power source, and turn on the switch of laser. See Fig. 20-5.

4. Slide the position of thumb screw M5x24 to the center point for the movable range in order to reserve the adjustment

range to be wide. After that, drive the thumb screw M5x24 to fix the laser section.

Fig. 20-5

Switch of

laser beam

Laser line label

Slide the position of

thumb screw M5x24

to the center point for

the movable range.

Hex socket set

screw M4x6 (A)

5. Lower the jig until it reaches the pan head screw M5x16 of link plate side. See Fig. 20-3.

6. Move the laser line to the closest position to the line of jig by adjusting with hex socket set screw M4x6(A).

See Fig. 20-6.

Fig. 20-6

Hex socket set

screw M4x6 (A)

Be sure to turn hex wrench

Line of jig

clockwise and slowly in

order to avoid backlash.

Hex socket set

screw M4x6 (B)

Laser line at the closest

position to the line of jig.

Page 19

Repair

7. Lift up the jig until it reach the pan head screw M5x16 of laser box side. See Fig. 20-4.

8.Adjust the laser line so as to parallel the line of jig by turning hex socket set screw M4x6 (B). See Fig. 20-7.

Fig. 20-7

Laser box

Hex socket set

screw M4x6 (B)

Be sure to hex wrench

clockwise and slowly in

Line of jig for laser line

adjustment (1R315)

Laser line adjusted so as to

parallel the line of jig

order to avoid backlash

of screw.

P 19/ 26

9. In order to move the laser line onto the line of jig for laser line adjustment, slide the position of thumb screw M5x24

to left or right as Fig. 20-8. Finally driveThumb screw M5x24 to fix the laser section.

Fig. 20-8

Thumb screw M5x24

Line of jig for

laser line adjustment (1R315)

Laser line aligned

with the line of jig

Page 20

Repair

10. Lower the jig again until it reaches the pan head screw M5x16 of link plate side. See Fig. 20-6.

11. Align the laser line with the line of jig by turning hex socket set screw M4x6 (A). See Fig. 20-9.

Fig. 20-9

Hex socket head

set screw M4x6 (A)

Line of jig for laser line

adjustment (1R315)

Laser line aligning

with the line of jig

Be sure to turn hex wrench

clockwise and slowly in order

to avoid backlash of screw.

12. Lift up the jig again until it reaches the pan head screw M5x16 of laser box side. See Fig. 20-7.

13. Align the laser line with the line of jig by turning hex socket set screw M4x6 (B). See Fig. 20-10.

P 20/ 26

Fig. 20-10

Hex socket set screw M4x6 (B)

Line of jig for laser

line adjustment (1R315)

Laser line aligning

with the line of jig

Be sure to turn hex wrench

clockwise and slowly in order

to avoid backlash of screw.

14. Repeat the steps 9, 10, 11, 12 and 13, until the laser line aligns with the line of jig as illustrated in Fig. 20-3 and

Fig. 20-4.

Caution: Laserline label should be pasted again after adjustment.

This prevents dust from invading into the laser circuit and hex socket set screws M4x6 (A and B).

Page 21

Wiriing of Lead Wire to Terminal Block

(For all the subject models)

P 21/ 26

When connecting power supply cord with electrical

parts in handle, strip the power supply cord to expose

50mm up to 70mm of one inner lead wire for

connecting with Terminal as illustrated to right.

Terminal block

Circuit diagram

LS0714FL (with Fluorescent light and laser marker)

Color index of lead wires' sheath

Black

White

Red

(1) (2)

Orange

Blue

(3)

(4)

Powers supply cord

50-70mm

Brush

holder A

Brush

holder B

(5)

(9)

(10)

(1) Power supply cord

(2) Main switch

(3) Insulated connector

(4) Noise suppressor

Laser section

(11)

Power source

(5)Terminal block

(6) Connectors

(7) Light assembly

(8) Support complete

(Red or purple)

(6)

(12)

(9) Laser switch

(10) Receptacle

(11) Transformer

(12) Printed wiring board

(8)

(7)

(13)

(6)

(13) Laser circuit

Page 22

Wiring diagram in Handle L

LS0714FL (with Fluorescent light and laser marker)

P 22/ 26

Receptacles for connecting

to laser switch

Main switch

Noise suppressor

Printed wiring board

Rib B

Rib A

TransformerInsulated connector

Rib D

Connector

Punched

hole

Power supply cord

Rib C

Terminal block

Motor housing

1

Pass the lead wires (black and red) of wiring board

through the punched hole.

The following lead wires for connecting insulated

2

connector should be put into lead wire holder so that

insulated connector does not rise from handle L.

* Lead wire (red) to switch

* Lead wire (blue) to transformer

* Lead wire (blue) to light assembly

* Field lead wire (orange)

* Lead wire (white) of noise suppressor

Transformer must be mounted so that lead wires

3

(black and white) face the side of handle R and

are in the side of motor housing.

If these lead wires go over Rib A/B, these are pinched

between the Rib A/B and handle R.

Therefore, fix them with full attention.

4 When putting the lead wires into lead wire holders,

the thin lead wires have to be put under the thick

lead wires so as not to rise from the original position.

5

Power supply cord should be put so that its sheath

portion is between Rib C and the wall of housing L.

When putting handle R on housing L,

6

be careful not to go over lead wires on Rib D.

Otherwise it will happen pinching.

7

When connecting receptacles to laser switch,

be sure to face its wire-accepting side to handle R.

The receptacle with blue colored lead wire should

be close to I mark on the laser switch.

The receptacle with black colored lead wire should

be close to O mark on the laser switch.

See illustration below.

Wire-accepting side

Handle R

Lead wire

(blue)

Lead wire

(black)

Receptacles

Laser

switch

Page 23

Circuit diagram

LS0714F (with Fluorescent light)

Color index of lead wires' sheath

Black

White

Red

P 23/ 26

Orange

Blue

(1) (2)

(5)

(1) Power supply cord

(2) Main switch

(3) Insulated connector

(4) Noise suppressor

Wiring diagram in handle L

LS0714F (with Fluorescent light)

Main switch

(3)

(6)

(5) Terminal block

(6) Connectors

(4)

(7)

Brush

holder A

(8)

(7) Light assembly

(8) Support complete

Power supply cord

Brush

holder B

Noise suppressor

Boss

Insulated

connector

The following lead wires for connecting insulated connector

should be put into lead wire holder so that insulated connector

does not rise from handle L.

* Lead wire (red) to switch

* Lead wire (blue) to light assembly

* Field lead wire (orange)

* Lead wire (white) of noise suppressor

All lead wires have to be put on the right side of boss.

2

Rib C

Terminal block

Motor housing

Put field lead wires (orange) into lead wire holder

3

so that their wires do not sag in the motor housing.

4

When putting the lead wire into lead wire holders,

the thin lead wires have to be put under the thick

wires so as not to rise from the original position.

5

Power supply cord should be put so that its sheath

portion is between Rib C and the wall of housing L.

Page 24

Circuit diagram

LS0714 (without Fluorescent light and laser)

Color index of lead wires' sheath

Black

White

Orange

(1) Power supply cord

(2) Main switch

(3) Noise suppressor

(4) Support complete

Brush

holder A

P 24/ 26

Brush

holder B

Wiring diagram in handle L

LS0714 (without Fluorescent light and laser)

Main switch

Noise suppressor

Boss

Power supply cord

Rib C

Motor housing

All lead wires have to be put on the right side of boss.

1

2

Put field lead wires (orange) into lead wire holder so that their wires do not sag in the motor housing.

These lead wires have to be put into lead wire holder.

3

Power supply cord should be put so that its sheath portion is between Rib C and the wall of housing L.

4

Page 25

Circuit diagram

LS0714L (with laser marker)

Color index of lead wires' sheath

Black

White

Red

P 25/ 26

Orange

Blue

(1) (2)

(5)

(9)

(10)

(1) Power supply cord

(2) Main switch

(3) Insulated connector

(4) Noise suppressor

(5) Terminal block

(6) Connectors

(8) Support complete

Laser section

(11)

Power source

(12)

(4)

(3)

(6)

(9) Laser switch

(10) Receptacle

(11) Transformer

(12) Printed wiring board

Brush

holder A

Brush

holder B

(8)

(13)

(13) Laser circuit

Page 26

Wiring diagram in Handle L

LS0714L (with laser marker)

P 26/ 26

When connecting power supply cord with electrical

parts in handle, strip the power supply cord to expose

50mm up to 70mm of one inner lead wire for

connecting with Terminal as illustrated to right.

Printed wiring board

Rib D

Main switch

Noise suppressor

Connector

Punched

hole

Rib B

Rib A

Powers supply cord

Terminal block

50-70mm

Receptacles for connecting

to laser switch

Power supply cord

Rib C

Terminal block

Insulated connector

Pass the thin lead wires (black and red) with connector

1

of wiring board through the punched hole.

The following lead wires for connecting insulated

2

connector should be put into lead wire holder so thati

nsulated connector does not rise from handle L.

* Lead wire (red) to switch

* Lead wire (blue) to transformer

* Field lead wire (orange)

* Lead wire (white) of noise suppressor

Transformer must be mounted so that lead wires

3

(black and white) face the side of handle R and

are in the side of motor housing.

If these lead wires go over Rib A/B, these are pinched

between the Rib A/B and handle R.

Therefore, fix them with full attention.

4

When putting the lead wires into lead wire holders,

the thin lead wires have to be put under the thick

lead wires so as not to rise from the original position.

Transformer

Motor housing

5

Power supply cord should be put so that its sheath

portion is between Rib C and the wall of housing L.

6 When putting handle R on housing L,

be careful not to go over lead wires on Rib D.

Otherwise it will happen pinching.

7

When connecting receptacles to laser switch,

be sure to face its wire-accepting side to handle R.

The receptacle with blue colored lead wire should

be close to I mark on the laser switch.

The receptacle with black colored lead wire should

be close to O mark on the laser switch.

See illustration below.

Wire-accepting side

Handle R

Lead wire

(blue)

Lead wire

(black)

Receptacles

Laser

switch

Loading...

Loading...