Page 1

T

ECHNICAL INFORMATION

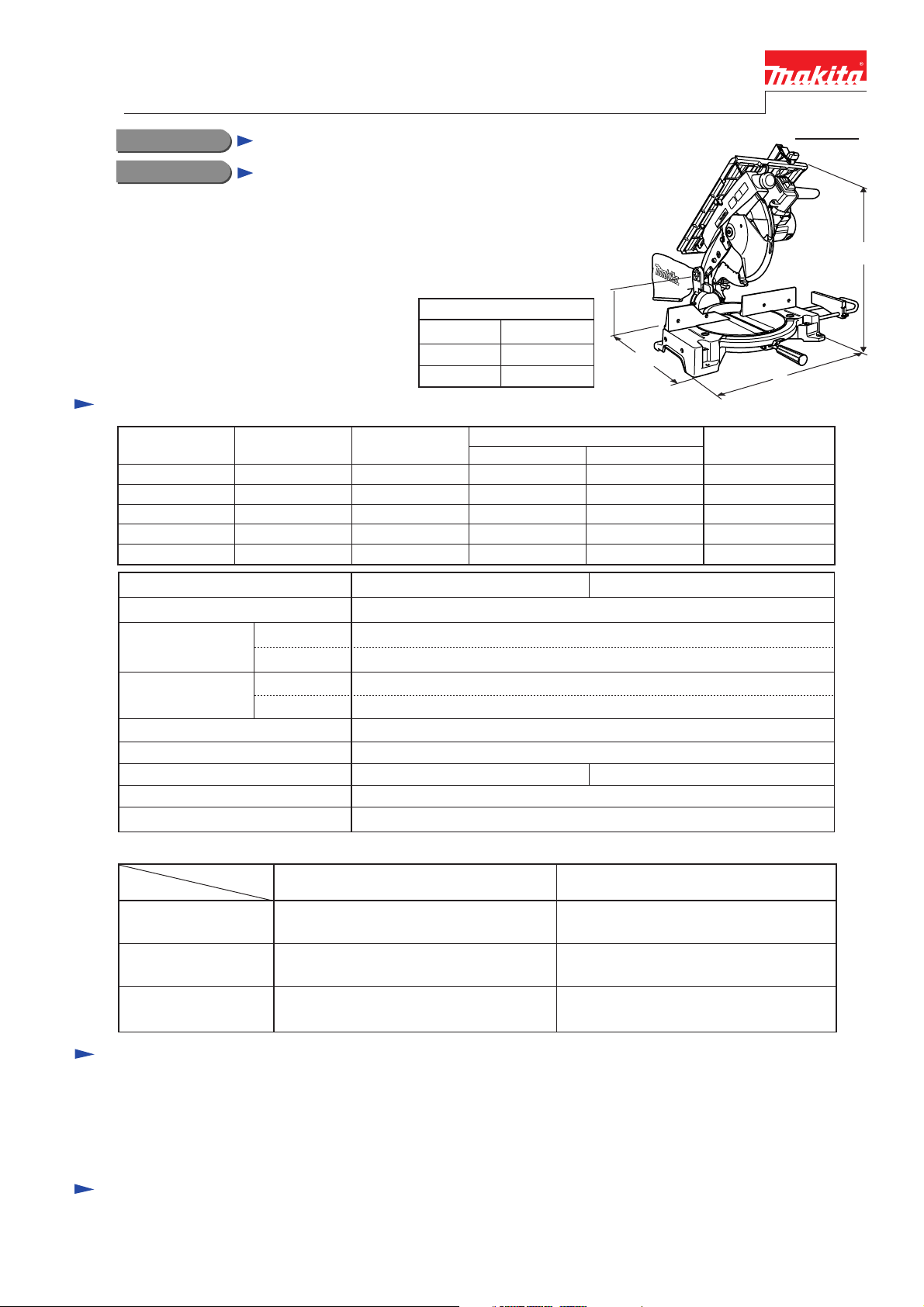

Models No.

LH1040, LH1040F

PRODUCT

P 1 / 20

Description

Table Top Miter Saw 260mm (10-1/4")

CONCEPT AND MAIN APPLICATIONS

Models LH1040 and LH1040F have been

developed as multi-purpose miter saws.

Installation of a table on Model LS1040

has enabled miter saw and table saw to be

packed in one tool for great versatility.

LH1040F features LED built-in job light

for accurate tracing of ink line in dark places.

Specification

Voltage (V) Cycle (Hz)

110 15 1,650

120

220

230

240

Model No.

No load speed: min-1 = rpm.

Saw blade: mm (")

Capacity: mm (")

(with 260 mm saw)

Protection against electric shock

Electric brake

LED job light

Cord length: m (ft)

Net weight: kg (lbs)

Current (A)

15 2,30050 / 60

7.9 1,650 1,000 2,30050 / 60

7.5 1,650 1,000

7.2 1,650 1,000 2,30050 / 60

Diameter

Hole diameter

Table saw

Miter saw

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

LH1040

15.88 (5/8) 30.0 ( for European countries)

No Yes

530 (20-7/8)

476 (18-3/4)

535 (21)

Continuous Rating (W)

Input Output

1,650

4,800

255 - 260 (10 - 10-1/4 )

40 (1-9/16 )

See the table below.

Double insulation

Yes

2.5 ( 8.2 )

13.7 (30.2 )

L

1,000

1,000

H

W

Max. Output(W)

2,30050 / 60

2,30050 / 60

LH1040F

Cutting capacity as Miter Saw

Miter angle

45

45

° Right

Bevel angle

90

°

° Left

69mm x 130mm (2-3/4" x 5-1/8")

93mm x 95mm (3-5/8" x 3-3/4")

69mm x 85mm (2-3/4" x 3-3/8")

93mm x 67mm (3-5/8" x 2-5/8")

69mm x 85mm (2-3/4" x 3-3/8")

93mm x 67mm (3-5/8" x 2-5/8")

90°

Standard equipment

TCT saw blade 260mm .......... 1 pc

Dust bag ................................. 1 pc

Holder set ............................... 1 pc

Sub plate ass'y ........................ 1 pc

Note: The standard equipment listed above may differ from country to country.

Socket wrench 13 ....................... 1 pc

Ring 16 (adaptor for saw blades

with 25mm hole diameter) ......... 1 pc

Triangular rule ............................ 1 pc

Optional accessories

Vertical vise

Horizontal vise

Holder set

Assorted TCT saw blades

45

° Left bevel

35mm x 130mm (1-3/8" x 5-1/8")

53mm x 95mm (2-1/16" x 3-3/4")

35mm x 65mm (1-3/8" x 2-9/16")

49mm x 42mm (1-15/16" x 1-5/8")

35mm x 91mm (1-3/8" x 3-5/8")

49mm x 67mm (1-15/16" x 2-5/8")

Set plate ................................... 1 pc

Blade cover .............................. 1 pc

Push stick ................................. 1 pc

Guide rule rule ........................ 1 pc

Page 2

P 2 / 20

Repair

CAUTION: For your safety, before maintenance or repair, be sure to;

1. Disconnect the machine from the power source.

2. Remove the saw blade from the machine.

[1] NECESSARY REPAIRING TOOLS

Tool No./ Description Use for

1R035/ Bearing Setting Plate 15.2 Press-fitting Ball bearings

1R045/ Gear Extractor (large) Disassembling Gear housing cover and Bearing box

1R208/ 90 Degrees Set Square Squaring Saw blade with Base

1R229/ 1/4" Hex shank bit for M5 Removal/Installation of screws that fasten Bearing box

1R235/ Round Bar for Arbor 6-100* (2 pcs) Disassembling Blade case

1R269/ Bearing Extractor Removing Ball bearings

1R291/ Retaining Ring S and R Pliers Removal/Installation of the Retaining ring

1R306/ Ring Spring Removing Jig** Disassembling Blade case

1R340/ Wrench for Bearing Retainer

*Note: Disassembling can be done also using two Phillips screwdrivers of 6.5X100mm or larger size instead.

**Note: Disassembling can be done also using 1R201/ Jig for Retaining Ring.

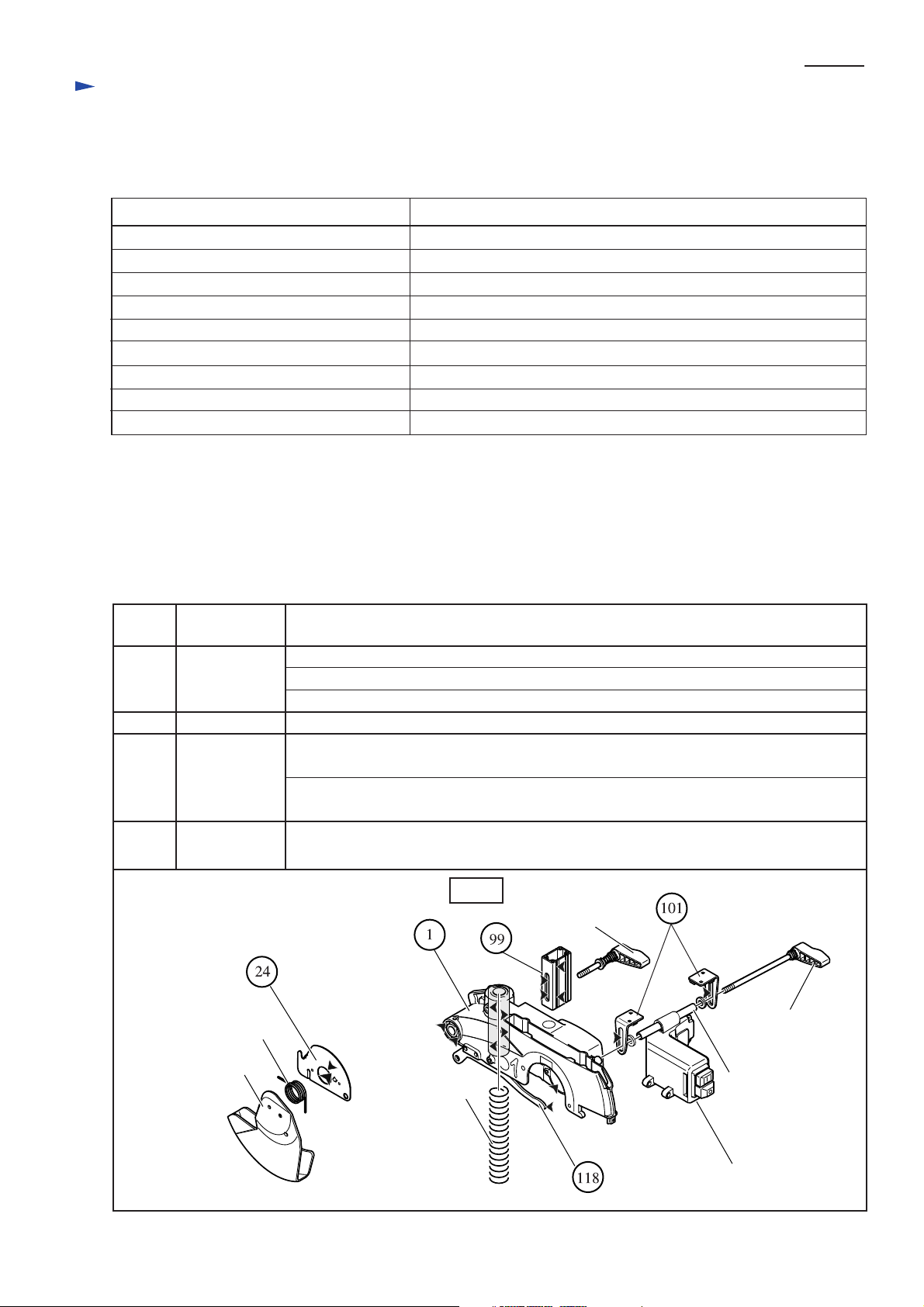

[2] LUBRICATION

1) Apply 12g of Makita grease N No.1 to the gear portion.

2) Apply an appropriate amount of Makita grease N No.1 to each of the listed below.

Although these slide surfaces are factory-greased with Makita grease N No.1, you apply other type of grease such as

Makita grease N No.2 or the like.

Removal/Installation of Bearing retainer

Position

No. Parts item Portion to be lubricated

Gear portion

1

101

Safety cover

Blade case

Center cover24

Table support99

Support plate

Torsion

spring 36

Accepting hole for compression spring 27

The pivotal portion where arm contacts

The portion where torsion spring 36 contacts

The elliptic punched hole where lever 54 contacts, when table support

is slidden up and down.

The side where (1) Blade Case contacts, when table support

is slidden up and down.

The elliptic punched hole where pipe 9-126 contacts, when support plates

are slidden up and down.

Fig.1-1

Compression

spring 27

The appropriate amount is 12g.

Lever 54

Lever 54

Pipe 9-126

Switch box

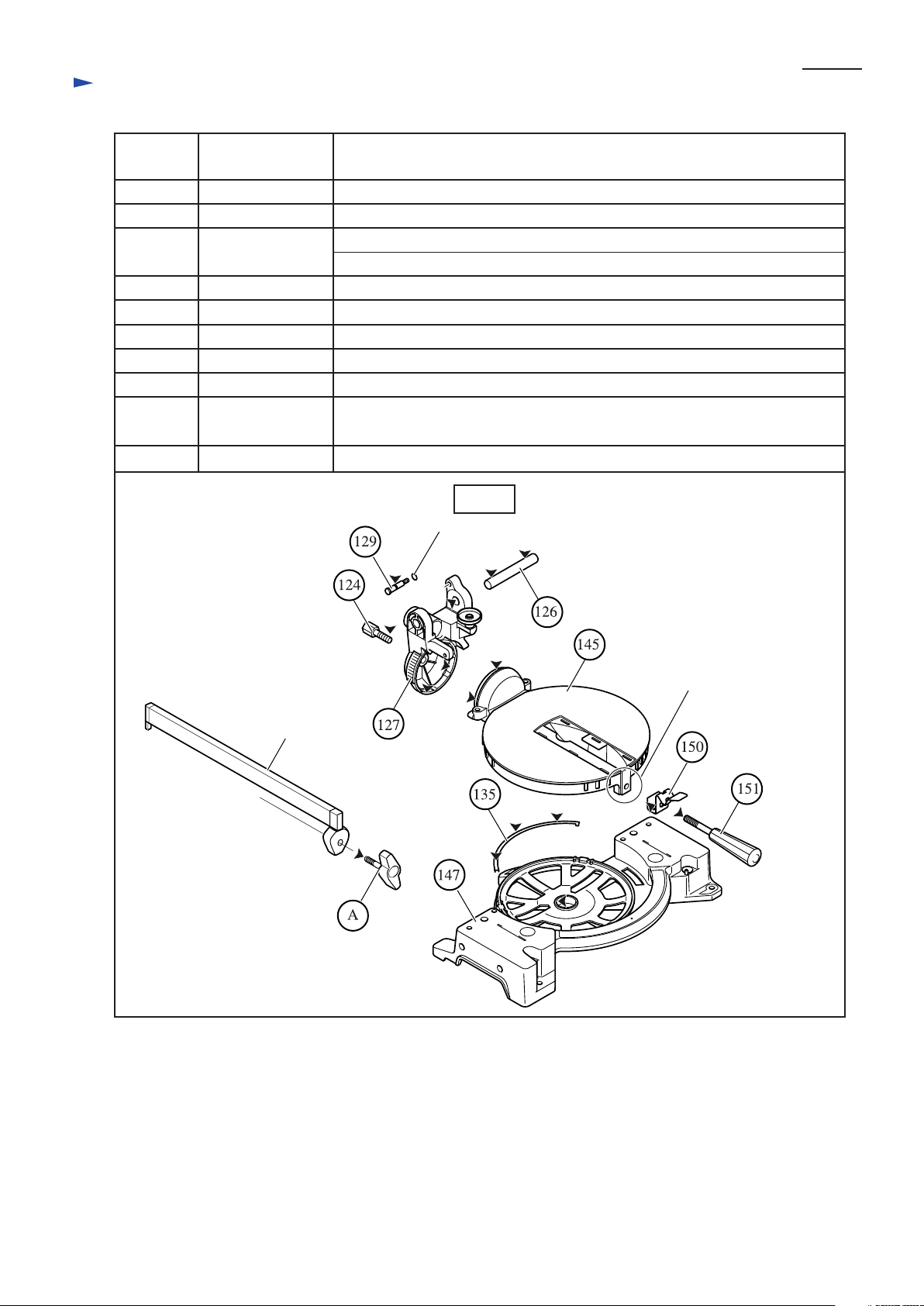

Page 3

Repair

[2] LUBRICATION

Position

No.

124

126

127

Parts item

Hex bolt M10 Threaded portion

Rod 16 The surface where (127) Arm Complete contacts.

Arm complete

Stopper pin129

Slide plate135

Turn base145

Base complete147

Knock spring150

P 3 / 20

Portion to be lubricated

The portion where (145) turn base contacts, when arm complete pivoting.

Accepting portion for pivoting (1) Blade Case

The groove to which O ring 5 is mounted.

The surface where (145) turn base contacts

Accepting portion for pivoting (127) Arm Complete

Accepting boss for the shaft of (145) Turn Base

Both edge which contacts its accepting portion of (145) Turn Base

151

A Tip of the threaded portion

Grip 32

Thumb screw

Tip of the threaded portion with which (150) Knock spring is pushed toward

(145) Turn Base

Fig.1-2

O ring 5

Rip fence

Accepting portion

for (150) Knock Spring

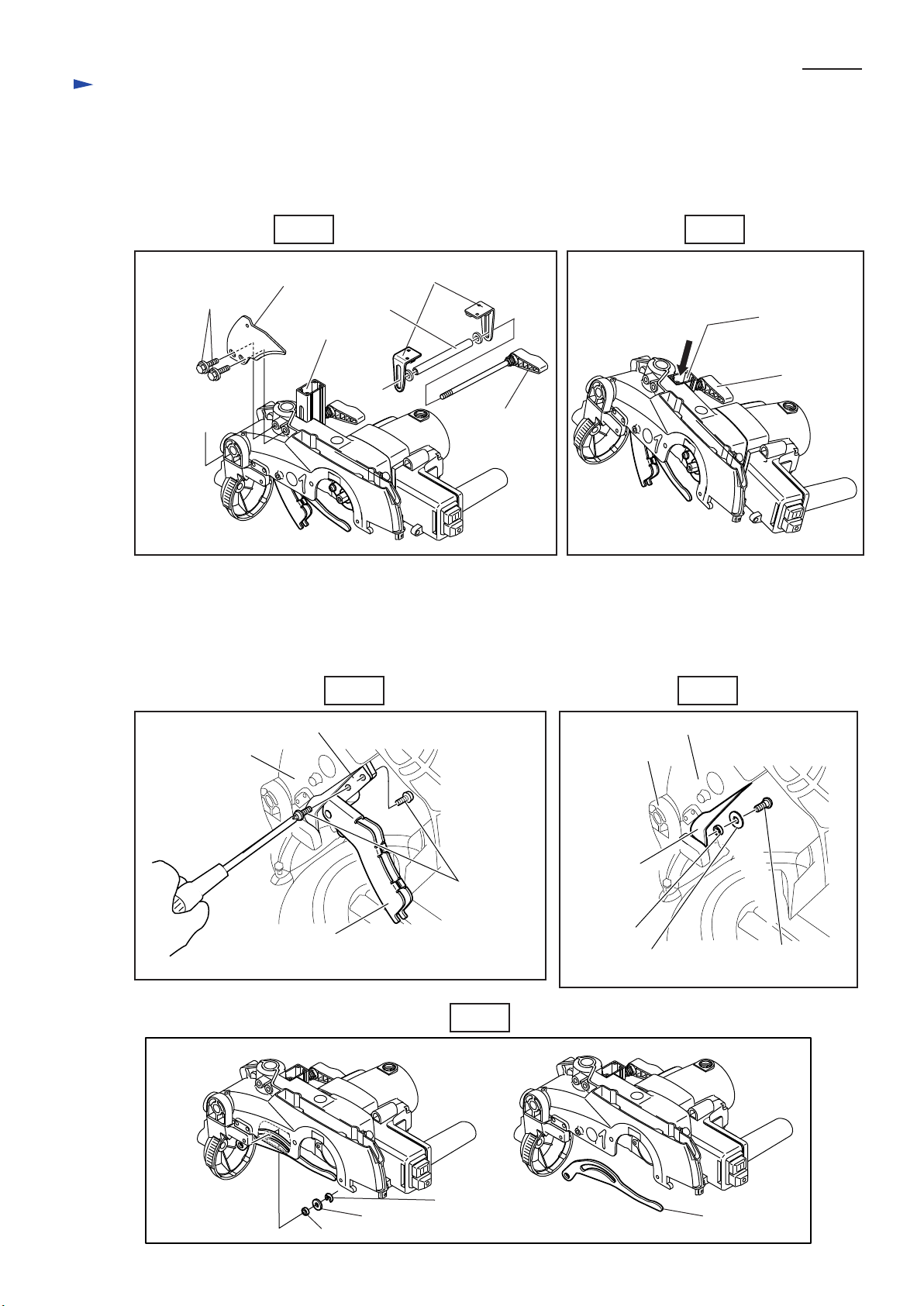

Page 4

Repair

< 3 > Removing table

1. Lift up table by loosening two 54 levers which are equipped under the table. See Fig.2-1.

2. Lift up the table to the highest level. See Fig.2-1.

3. Remove pan head screw M5x16 and remove cover complete from riving knife. See Fig.2-2.

4. Remove 8 M5x16 countersunk head screws. Then, table can be removed from blade case. See Fig.2-2.

And remove compression spring 27 from blade case. See Fig.2-2.

(In case of model LH1040 without fluorescent job light)

4A. While lifting up the table, remove light circuit from the table. Then, table can be removed from blade case.

And remove compression spring 27 from blade case. See Fig.2-2.

(In case of model LH1040F with fluorescent job light)

Fig.2-1

Table

Lever 54

P 4 / 20

Fig.2-2

Pan head

screw M5x16

Riving knife

Hex lock nut M5-8

Cover complete

Countersunk head

screw M5x16 (8 pcs.)

Table

Compression

spring 21

< 4 > Mounting table

1. Secure table with 8 M5x16 countersunk head screws. Refer to Fig.2-2.

2. While lifting up table to the highest level, mount compression spring 21 by inserting it from the side.

3. Take the left step with referring to the above Figs.

Table

Page 5

Repair

< 5 > Removing blade case section

1. Remove living knife. See Fig.3-1.

2. Remove lever 54, support plate and pipe 9-126. See Fig.3-1.

The pipe 9-126 removed in this step, is used as a jig for removing rod 16 which functions as a pivot for blade case.

3. Loosen lever 54 and press table support down to the surface of blade case. See Fig.3-2.

Fig.3-1 Fig.3-2

P 5 / 20

Hex flange

head bolt M8x20

Rod 16

4. Remove two M5x16 pan head screws. Now guard with guard holder can be removed from blade case. See Fig.3-3.

5. Remove hex socket button head screw M6 (adhesive type), flat washer 7 and ring 7. Now the linkage of link plate with

arm complete has been disconnected. See Fig.3-4.

6. Remove stop ring E-5, flat washer 6 and ring 6. then, link plate can be removed from blade case. See Fig.3-5.

Living knife

Table support

Support plate

Pipe 9-126

Fig.3-3

Table support

Lever 54

Lever 54

Fig.3-4

Blade case

Guard holder

Guard

Pan head

screw M5x16

Fig.3-5

Arm complete

Link plate

Ring 7

Flat washer 7

Blade case

Hex socket button

head screw M6

Ring 6

Flat washer 6

Stop ring E-5

Link plate

Page 6

Repair

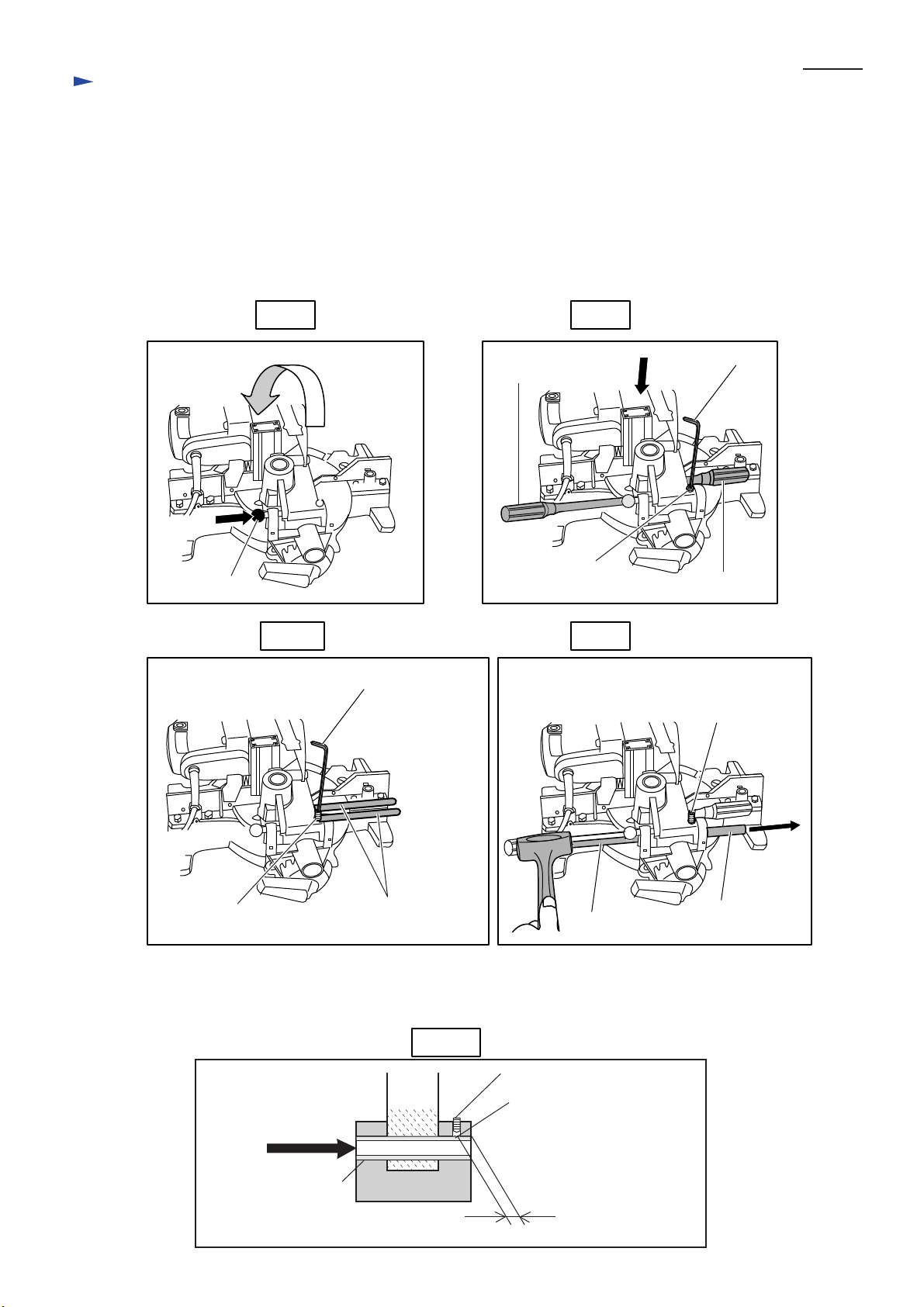

< 5 > Removing blade case section

7. Lower the blade case section to the possible lowest position, and lock it at the same position with stopper pin.

See Fig.3-6.

8. While further pressing the blade case section, insert two screwdrivers into the side hole of blade case.

See Fig.3-7. Or insert No.1R238 "Round Bar for Arbor" as illustrated in Fig.3-7A.

9. Loosen hex socket head bolt M6x10 with hex wrench. See Fig.3-7.

10. Apply pipe 9-126 on rod 16, and remove it by striking the pipe with plastic hammer toward the side of hex

socket head bolt M6x10. See Fig.3-8. Now blade case section can be separated from arm complete.

P 6 / 20

Stopper pin

Fig.3-6

Fig.3-7A

Hex wrench

Screwdriver

Hex socket

head bolt M6x10

Fig.3-7

Hex wrench

Screwdriver

Fig.3-8

Hex socket

head bolt M6x10

Hex socket

head bolt M6x10

<Note>

In order to minimize scratch on the accepting holes for rod 16, remove it toward

the side of hex socket head bolt M6x10. See Fig.3-8A.

Direction for

removing rod 16

Rod 16

The scratch on the accepting holes

is minimized to this area.

No.1R238

Round Bar for Arbor

Fig.3-8A

Blade

case

Arm complete

Pipe 9-126

Hex socket head bolt M6x10

The portion scratched with

hex socket head bolt M6x10

Rod 16

Page 7

Repair

< 5 > Removing blade case section

11. Put the removed blade case section on the turn base of arbor press, And set 1R306 "Ring Spring Removing Jig"

between the two screwdrivers, inserted in the step of Fig.3-7. See Fig.3-9.

12. Press down 1R306 "Ring Spring Removing Jig" with arbor press. So, spring holder is pressed down and

the screwdrivers can be pulled out from blade case.

Fig.3-9

P 7 / 20

No.1R306

Ring Spring Removing Jig

13. Put the removed blade case section on the turn base of arbor press, And set 1R306 "Ring Spring Removing Jig"

between the two screwdrivers, inserted in the step of Fig.3-7. See Fig.3-9.

14. Press down 1R306 "Ring Spring Removing Jig" with arbor press in order to lower spring holder,

while holding the blade case section firmly, so that it does not tilt or wobble.

15. Slowly lessen the pressure to 1R306 "Ring Spring Removing Jig", while holding the blade case section

firmly, so that it does not tilt or wobble. See Fig.3-10.

16. Remove spring holder and compression spring 27 from blade case, when the jig gets free from the force

of compression spring. See Fig.3-10.

Fig.3-10

Arbor press

Screwdriver

Blade case section

No.1R306

Ring Spring

Removing Jig

Slowly lessen the

pressure to the jig.

Spring holder

Compression spring 27

Blade case section

Page 8

Repair

< 5 > Mounting blade case section

1. Take the reverse step of removing, while paying attention to the following matters.

A. Scrape off the scratched portion of rod 16 with file, before mounting.

Mount rod 16 from the side of hex socket head bolt M6x10 . See Fig.4-1.

B. When pulling out two screwdrivers in the final step, press the blade case section down to the possible

lowest position. Then, at the same time, spring holder is mounted to the original position automatically.

C. Apply the adhesive to hex socket button head screw M6 with which link plate is secured to arm complete.

Refer to Fig.3-4.

Fig.4-1

P 8 / 20

Hex socket

head bolt M6x10

Blade

case

Arm complete

Direction for

mounting rod 16

Rod 16

The portion scratched with

hex socket head bolt M6x10,

has to be scraped off, before

mounting.

< 6 > Disassembling safety cover section

1. Loosen hex flange head bolt M8x12. Remove socket head flange screw M6 with hex wrench, inserted through

the punched hole of safety cover. Now safety cover section can be separated from blade case. See Fig.5-1.

2. The safety cover section can be disassembled by unscrewing pan head screw M5x12. See Fig.5-2.

Fig.5-1 Fig.5-2

Blade case section

Socket head

flange screw M6

Flat washer 5

Pan head

screw M5x12

Center cover

Center plate

Torsion spring 36

Safety cover

Hex flange head

bolt M8x12

Safety cover

Hex wrench

Tapping screw

bind PT3x8

No need to remove socket head flange screw M6

from center cover, for easy reassembling.

< 7 > Assembling safety cover section

1. In case of the disassembling as illustrated in Fig.5-2, tapping screw bind PT3x8 has to be

removed from safety cover before reassembling.

2. Drive tapping screw bind PT3x8 again, after mounting torsion spring 36, center cover and center plate.

Refer to Fig.5-2.

Page 9

Repair

< 8 > Disassembling motor section

1. Remove carbon brush. See FIg.6-1.

And then, remove table from blade case section as illustrated in Fig.2-1 and Fig.2-2.

2. Remove lever 54 and support plate. See Fig.6-2.

3. After removing four M6x60 pan head screws, motor section can be separated from blade case. See Fig.6-3.

<Note>

Compression spring 9 for shaft lock falls off easily from the machine, when separating motor section

from blade case. Be careful, not to lose this spring.

P 9 / 20

Carbon brush

Brush holder cap

Fig.6-1

Shaft lock

Brush

holder cap

Carbon brush

Fig.6-2

Support plate

Lver 54

Fig.6-3

Pan head screw M6x60

Pan head

screw M6x60

Compression spring 9

< 9 > Assembling motor section

1. Putting shaft lock into the notch of motor housing, mount armature to motor housing. See Fig.7-1.

2. While pushing shaft lock to the direction designated with black arrow, mount the motor section

to blade case in order to avoide piching of shaft lock between motor housing and blade case. See Fig.7-2.

3. Take the reverse step of disassembling after the above process.

Fig.7-1 Fig.7-2

Notch for shaft lock slide

Armature

Shaft lock

Shaft lock

Compression spring 9

Page 10

Repair

< 10> Disassembling safety block mechanism

1. Lock the blade case section at the possible highest position, with stopper pin.

2. Remove lock lever by unscrewing 2 M4x10 pan head screws. Then, lock lever can be removed from lock pin.

See Fig.8-1.

3. Remove motor section as shown in <8> Disassembling motor section, when removing lock pin 8. See Fig.8-2.

P 10 / 20

Pan head screw M4x10

Fig.8-1

Lock pin 8

Lock pin 8

Lock lever

Fig.8-2

Torsion spring 9

<11> Assembling safety block mechanism

1. Pass lock pin 8 through torsion spring 9, and hold its tail with switch box. See Fig.9-1.

2. While sliding lock lever to switch button side, tighten lock lever with one M4x10 pan head screw preliminarily.

See Fig.9-2.

3. Nip the hooked tail of torsion spring 9 and put it on lock lever. See Fig.9-3.

Lock pin 8

Hold this side

with switch box.

Torsion spring 9

Fig.9-1

Switch box

Torsion spring 9

Lock pin 8

Lock lever

Switch box

Slide lock lever to

switch button side,

when preliminary

tightening.

Fig.9-3

Switch box

Fig.9-2

Switch box

Switch button

Preliminary tightening

with one M4x10 pan

head screw

Hooked tail of torsion

spring 9, put on lock lever

Page 11

Repair

<11> Assembling safety block mechanism

4. Adjust the position of lock lever so that the distance between lock lever and safety cover is approx. 1mm.

See Fig.9-4. And then, finally tighten lock lever with 2 Mx10 pan head screws.

Fig.9-4

Lock lever

Safety cover

Approx. 1mm

P 11 / 20

<12> Removing turn base

1. Remove grip 32. From the bottom side of base, unscrew pan head screw M5x12. Now knock spring can be removed.

See Fig.10-1.

2. After removing guide fence, lever up kerf board with screwdriver to remove them. See Fig.10-2.

3. Remove hex lock nut M8x13 and flat washer 8. Now turn base can be removed from base. See Fig.10-3.

Fig.10-1 Fig.10-2

Hex bolt M8x30

Guide fence

Hex bolt M8x30

Kerf board

Turn base

Pan head screw M5x12

Grip 32

Knock spring

Screwdriver

Page 12

Repair

<12> Removing turn base

3. Remove hex lock nut M8x13 and flat washer 8. Now turn base can be removed from base. See Fig.10-3.

Fig.10-3

Hex lock nut M8x13

Socket wrench 13

which comes

with the product.

Turn base

Flat washer 8

Base

P 12 / 20

<13> Mounting turn base

1. Mount turn base and flat washer 8, and tighten hex lock nut M8x13 with socket wrench 13.

The hex lock nut M8x13 has to be so tightened, that turn base can move without wobbling.

2 Take the reverse step of disassembling after the above process.

<14> Angle adjustment of saw blade

1. Adjusting to 90° to turn base,

While applying 1R208 "90-degree Set Square", turn Hex bolt M8x28 of motor housing side,

until both saw blade and turn base contact the jig closely. See Fig.11-1.

2. Adjusting to 45° to turn base,

While applying 1R207 "45-degree Set Square", turn Hex bolt M8x28 of saw blade side,

until both saw blade and turn base contact the jig closely. See Fig.11-2.

Fig.11-1

Hex bolt M8x28

of motor housing side

Turn base

Fig.11-2

1R209

45-degree Set Square

Turn base

1R208

90-degree Set Square

Hex bolt M8x28

of saw blade side

Page 13

Repair

<15> Squaring adjustment of guide fence

P 13 / 20

1. Set the bevel angle 90

2. Provisionally tighten M8x30 hex bolt (B) into the smaller screw hole on the left side of guide fence

when viewed from operator's position.

3. While checking the angle of guide rule to saw blade using 90 Degrees set square (No.1R208), pivot the guide fence

by moving its right end until the angle is 90 degrees

4. After completion of squaring adjustment, securely tighten four M8x30 hex bolts; first A and D, then B and C.

°.

Hex bolt M8x30

A

Guide fence

90 Degrees set square

(No.1R208)

Fig.12-1

Screw hole smaller

than the other 3 screw holes.

B

Saw blade

Operator's position

.

Hex bolt M8x30

C

When adjusting,

move this side.

D

<16> Repairing switch section

Handle cover can not be separated from switch box without removing lock lever of safety lock mechanism.

Remove lock lever as illustrated in Fig.8-1.

1. Remove handle cover, Now relay can be replaced. See Fig.13-1.

Fig.13-1

Handle cover

Switch box

2. Do not forget to mount clamp plate and felt ring 6, when assembling switch section. And do not remove sponge

sheet from handle cover, when mounting it to switch box. Because these three parts protect the machine

against saw dust. See Fig.13-2.

Motor housing

Fig.13-2

Switch box

Felt rig 6

Pin

Relay

Handle cover

Sponge sheet

Clamp plate

Pin

Switch button OFF

Switch button ON

Page 14

Circuit diagram

(1) LH1040F with fluorescent job light for

* High voltage area in Europe,

* High voltage area in Saudi Arabia

* Cyprus

* Kuwait

* Bhutan

Color index of lead wires' sheath

Black

White

Red

Yellow

Orange

Blue

Purple

Brown

Gray

P 14 / 20

Switch for light

41 31 1 3 A1

42 32 2 4 A2

**Noise suppressor

*Main switch

(Relay)

Light switch box

Light circuit

Sponge

Brush holder

(Turn base side)

Varnish tetron

tube

Terminal

block

Circuit for

soft start

Power supply

cord

Switch box

*Main switch

(Relay): Its terminal No. 31, 3, 42,

2 and A2 are equipped with

receptacle sleeves.

**Noise suppressor: The product is supplied without equipping

noise suppressor for some countries.

Brush holder

(Table side)

Motor housing

Page 15

Circuit diagram

(2) LH1040F with fluorescent job light

for Low voltage in Great Britain

Color index of lead wires' sheath

Black

White

Red

Orange

Noise suppressor

Blue

Purple

Brown

Yellow

P 15 / 20

Switch for light

41 1 A1

3 5

64242

Light switch box

Light circuit

Line filter

Varnish tetron

tube

Terminal

block

A2

*Main switch

(Relay)

*Main switch

(Relay): Its terminal No. 42, 4, 5

and A2 are equipped with

receptacle sleeves.

Switch box

Sponge

Brush holder

(Table side)

Brush holder

(Turn base side)

Circuit for

soft start

Power supply

cord

Motor housing

Page 16

Circuit diagram

(1) LH1040 without fluorescent job light, for

* High voltage area in Europe,

* High voltage area in Saudi Arabia

* Cyprus

* Kuwait

* Bhutan

Color index of lead wires' sheath

Black

White

Red

Yellow

Orange

Purple

Gray

P 16 / 20

Varnish tetron

tube

41 31 1 3 A1

*Main switch

(Relay)

42 32 2 4 A2

**Noise suppressor

Switch box

*Main switch

(Relay): Its terminal No. 31, 3, 42,

2 and A2 are equipped with

receptacle sleeves.

**Noise suppressor: The product is supplied without equipping

noise suppressor for some countries.

Sponge

Brush holder

(Table side)

Brush holder

(Turn base side)

Terminal

block

Circuit for

soft start

Power supply

cord

Motor housing

Page 17

Circuit diagram

(2) LH1040 without fluorescent job light

for Low voltage in Great Britain

Color index of lead wires' sheath

Black

White

Red

Orange

Noise suppressor

Blue

Purple

Brown

Yellow

P 17 / 20

41 1 A1

3 5

A2

64242

*Main switch

(Relay)

*Main switch

(Relay): Its terminal No. 42, 4, 5

and A2 are equipped with

receptacle sleeves.

Sponge

Line filter

Brush holder

(Turn base side)

Varnish tetron

tube

Terminal

block

Circuit for

soft start

Power supply

cord

Switch box

Brush holder

(Table side)

Motor housing

Page 18

Wiring diagram

under Housing Cover

Housing cover

Terminal block

Motor housing

P 18 /20

Insulated connector

Lead wire of

soft start circuit

Punched hole

Do not push insulated connector

into motor housing through the

punched hole.

Motor housing

Soft start circuit

Rib

Lead holder

Lead wire of soft start

circuit has to be held

with the lead holder.

Varnish tetron

tube

The lead wires which are put

on the edge of field, have to

be bundled with varnish tetron

tubes by separating in two groups.

And max. four lead wires have to

be in each bundle.

Field

Varnish tetron

tube

Page 19

Wiring diagram

P 19 /20

Under clamp plate

Rib A

Before securing clamp plate,

put the lead wires

between rib A and B.

Rib B

When line filter is used, pass the following

lead wires through line filter.

* Field lead wire

(orange)

* Soft start lead wire

(Purple)

Clamp plate

Line filter

Field lead wire

(orange)

Soft start lead wire

(Purple)

Put line filter in the space illustrated

above. (exclusively for low voltage

in Great Britain)

Field lead wire

(orange)

Soft start lead wire

(Purple)

In switch box

Be careful, not to pinch the lead wires of light circuit

between rib B and relay, when fluorescent job light is installed.

When putting lead wires onto relay,

do not put them on this area.

Switch button

Rib B

Relay

Rib A

Put the insulated connectors into

the space between relay and inner wall,

or

push into the punched hole.

Hole for

pipe 9-126

Inner wall

Punched hole

for lead wires

Noise suppressor

Put the lead wires, connected to relay

through punched hole, between boss

and rib A.

Boss

Put noise suppressor

into the space between

relay and inner wall,

or

push it into the punched

hole, when it is used.

Page 20

Wiring diagram

Light Switch Box

Cord of light circuit

Light switch box

Put lead wires in

the lead holder.

P 20 / 20

Switch for light circuit

Lead holder

Insulated connector

Put insulated terminal in

the space shown in the

above illustration.

Loading...

Loading...