Page 1

INSTALLATION & OPERATION

MANUAL

SP712-2 REV. C

Loop Powered 4-20mA

Transmitter

DOC#: MN-712-C

Page 2

Sponsler, Inc.

SP712-2 Transmitter

pg

2

DOC#: MN-712-C

Temperature:

Input Voltage:

Minimum = 7 V + (20mA X RL)

Frequency 0-10 KHz

4mA @ 0 Hz, 20mA @ desired full scale frequency

Features:

Mounts directly on flowmeter

Enclosure:

FM Approved, CSA Certified

Weight 1.7 lbs.

SPECIFICATIONS

Operating -40 to 85°C

Storage -65 to 125°C

Maximum = 28 V + (4mA X RL)

Protected against polarity reversal

Signal Input:

Amplitude 50 mV – 35 V sine or square wave

Sensitivity field adjustable

Impedance 50K

Analog Output

Full scale range -- 100 Hz-10 KHz selectable

Response time -- 95% of change in 1 second

Linearity -- .3% F/S

Tempco -- < 2% of reading over entire temperature range

Class I Groups B, C, D

Class II Groups E, F, G

The SP712-2 is a 2-wire loop powered analog transmitter designed to linearly convert a

frequency input to an equivalent 4-20mA current output. When it incorporates with a turbine

flowmeter a current representation proportional to flow is obtainable. Data transmission in a

current format exhibits excellent noise immunity and the capability of long distance

transmission.

A full-scale frequency range of 100 Hz-10 KHz is selectable, via S1. The span adjustment

establishes the frequency point at which a 20mA output is achieved. The sensitivity adjustment

permits the SP712-2 to discriminate between a signal input and noise by increasing (CCW) or

decreasing (CW) the input signal amplitude necessary to process a valid signal. ‘Test’ S2 when

depressed, illuminates D1 if loop voltage and input signal both are present.

Installation of the SP712-2 requires only 2 wires because it is a true 2-wire transmitter: input

power and signal output utilizes the same wires.

Page 3

Sponsler, Inc.

SP712-2 Transmitter

pg

3

DOC#: MN-712-C

A)

Connect DMM positive lead to power supply positive, connect DMM negative lead to J1-3,

set DMM function to mA DC

B)

Connect power supply negative lead to 250 Ω resistor, connect other r esist or leg to J1-5

C)

Connect frequency generator posit ive & negat ive leads to J1 -1,2; respectively. Set output

to sinewave & amplitude to zero

D)

Set S1 for desired freq uency range

Turn power supply & frequency generator ‘ON’, DMM should indicate approximately

4.00mA

F)

Adjust ‘ZERO’ (R25) for 4.00mA DMM indication (record data)

G)

Set ‘Sensitivity’ adjust (R1) fully clockwise

Adjust signal amplitude of f r equency generator to 50mv & freq uency to m aximum desir ed

point (full scale frequency) ( r ecor d data)

I)

J)

Reduce signal amplitude of freq uency g ener ator to zero, adjust ‘ZERO’ (R25) for 4. 00mA

DMM indication if necessary

Adjust signal amplitude of f r equency generator to 50mv, adjust ‘SPAN’ (R19) for 20.00mA

DMM indication if necessary

L)

Adjust frequency of frequency generator to exactly 50% of maximum frequency point in

frequencies(record dat a)

6 + 4 = 10; DMM should indicate 10.00mA @ 750 Hz input

O

S1

1

0

Power

12-28 VDC

Frequency

DMM

mA

-

-

+ + - +

5 4 3 2 1

250 Ω

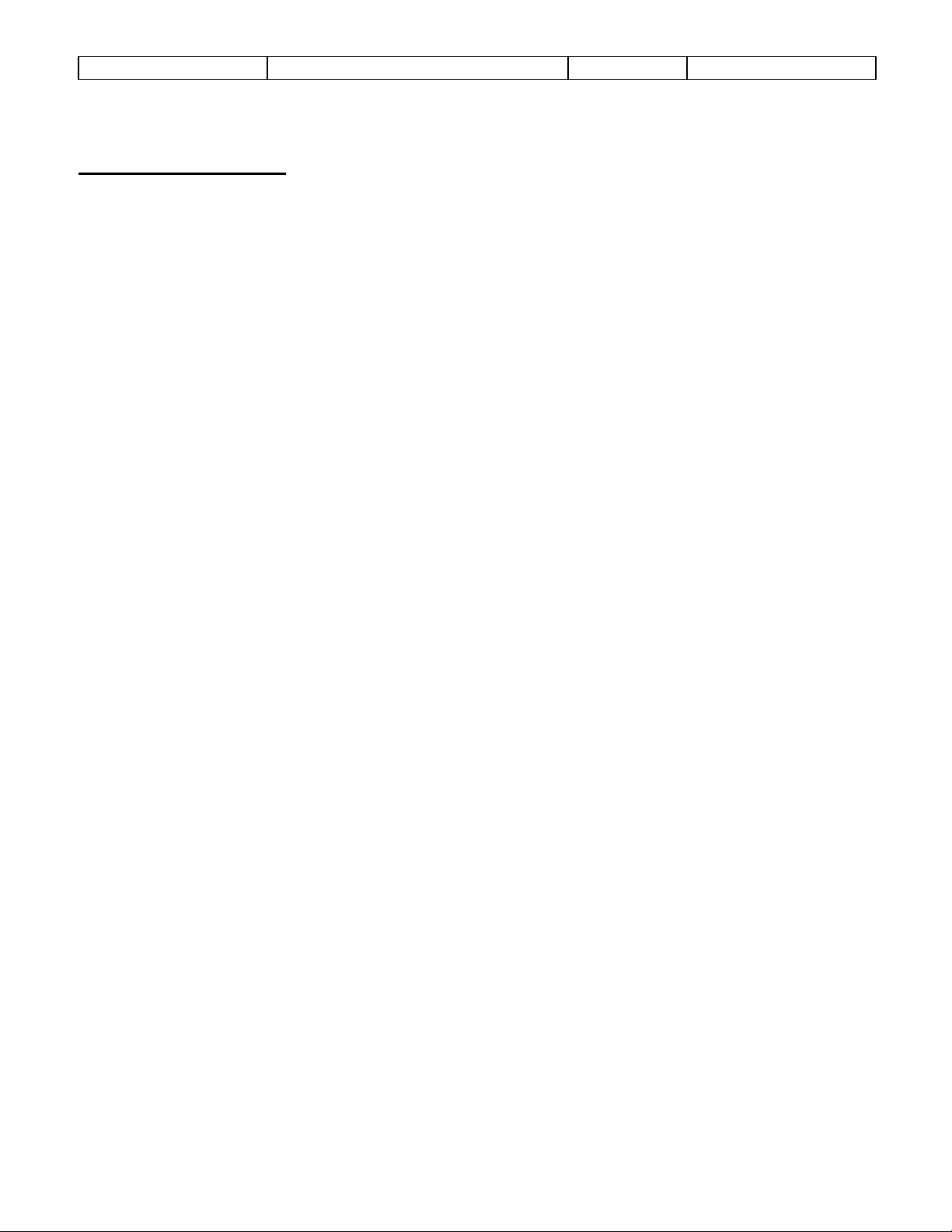

B ENCH TEST CALIBRATION PROCEDURE

Required Equipment: Power Supply 12-28v, Digital Multimeter (DMM), Frequency Generator, &

Frequency Counter

Test Procedure:

Gen/Ctr

0 = 100-1000Hz

1 = 1 KHz-10KHz

SENSITIVITY

Z

E

R

S

P

SP712-2

A

R1

N

Supply

~

DC

E)

H)

Adjust ‘SPAN’ (R19) for 20.00mA DMM indication (record data)

K)

step H, DMM should indicate 12.00mA ± .06. Repeat for 25% & 75% full scale

To check linearity @ any frequency point, incorpor at e t he following formula:

(F/F

X 16) + 4 = mA

max

(Where F = Flowrate frequency in Hz)

(F

= Frequency in Hz at which 20mA is set)

max

Ex. Assume maximum frequency point = 2000 Hz (20.00mA) Check for linearity @ 750

Hz point

750/2000 = .375

16 X .375 = 6

Page 4

Sponsler, Inc.

SP712-2 Transmitter

pg

4

DOC#: MN-712-C

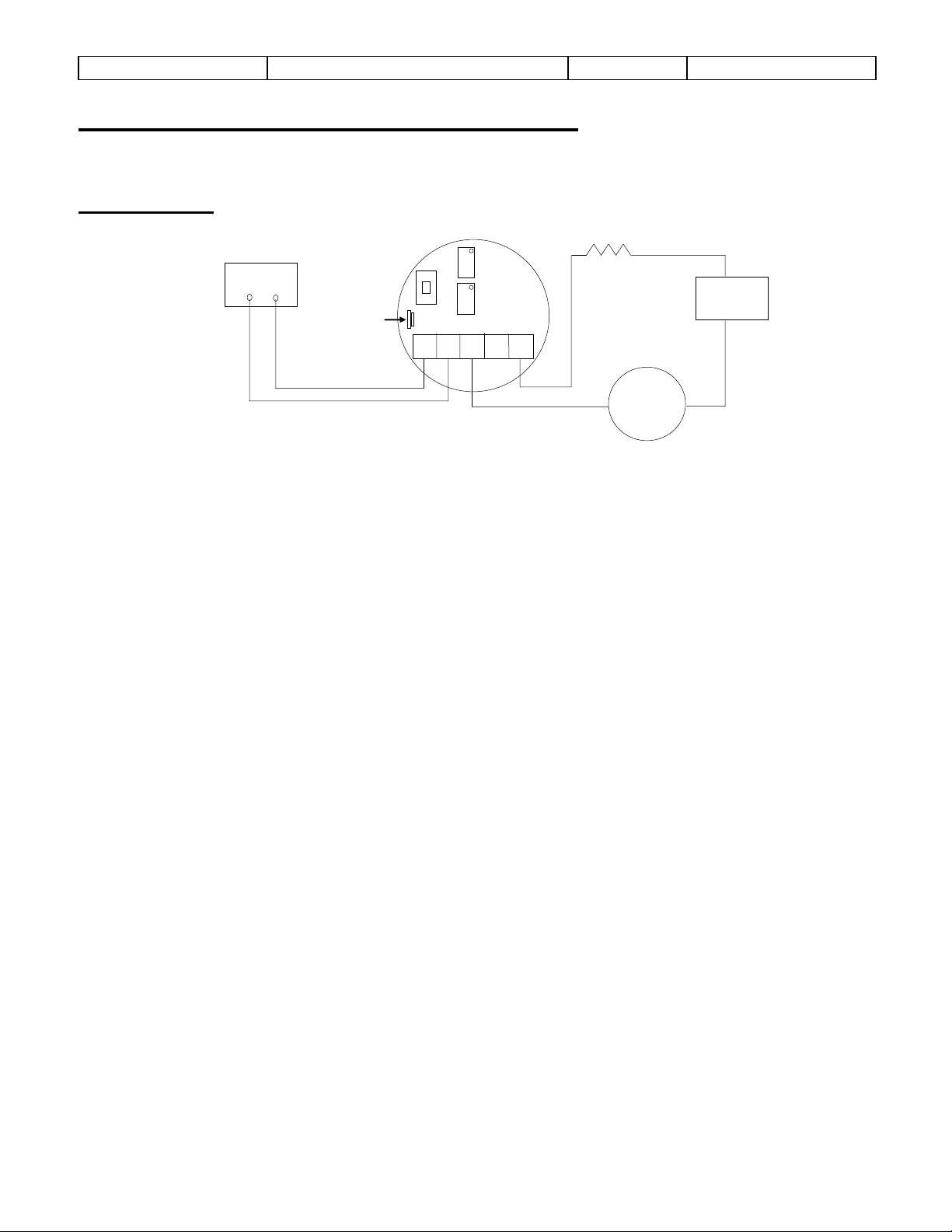

J1-3

SP712-2

J1-5

+

+

-

RSENSE

J1-3

SP712-2

J1-5

+

RSENSE

J1-3

SP712-2

J1-5

+

-

RLOAD

12-28 VDC

-

+

-

J1-3

SP712-2

J1-5

+

-

RLOAD

12-28 VDC

-

+

-

TYPICAL LOOP CONFIGURATIONS

POWER

SUPPLY

POWER

SUPPLY

Page 5

Sponsler, Inc.

SP712-2 Transmitter

pg

5

DOC#: MN-712-C

2.40 DP.

3.75 DIA.

1.40

3/4-14 FNPT

5-5-97

TN

NONE

DRAWING NUMBER

MATERIAL

SPONSLER, INC.

SCALE

DRAWN BY

DATE

APPR. BY

DATE

REVIEWED BY

DATE

DESCRIPTIO

REV. #

FILE

COD

REVCKDR

AUTH

REVISION RECORD

DATE

SIGNAL IN -

SIGNAL IN +

5

4

3

2

1

TERMINAL LOCATION

SENSITIVITY

NOTE: DIMENSIONS ARE IN INCHE S

.90

J1-1

234

5

+

+

+

+

+

+

CR4

R27

R29

C5

REV C

SP712-2

R2

R3

C2

C1

CR3

C12

A2

Q1

R15

C10

C11

CR2

CR1

C4

C3

R5R4R7

R6

R10

Z1

JU1

R1

S1

0

1

C8

C6

R17

C7

D1

R18

R16

R19

R26

R24

S2

Q2Q3A1

C9

R25

R14

R13

R12

R11

R9

R22

R23R8R21

R20

5.60

FREQUENCY SELECT

`0' @ 100-1000 Hz

`1' @ 1 KHz-10 KHz

LOOP IN +

N/C

LOOP IN -

\ELECT\SP712.DWG

SP712-2 LOOP POWERED

4-20mA TRANSMITTER

EM SP712-2

3.00 DIA.

D1 WILL ILLUMINATE IF

SIGNAL AND POWER BOTH

PRESENT WHILE S2 IS

DEPRESSED

Page 6

Sponsler, Inc.

SP712-2 Transmitter

pg

6

DOC#: MN-712-C

Page 7

Sponsler, Inc.

SP712-2 Transmitter

pg

7

DOC#: MN-712-C

Page 8

©2009

Pub. No. MN-712-C

(09/09)

Loading...

Loading...