Page 1

INSTALLATION & INSTRUCTION

MANUAL

SP3000

FLOW COMPUTER

DOC#: MN-3000.DOC

Page 2

2

- WARNING -

This instrument contains electronic components that are susceptible to damage by static electricity.

Please observe the following handling procedures during the removal, installation, or handling of the

internal circuit boards or devices.

HANDLING PROCEDURES

1. Power to unit must be removed.

2. Personnel must be grounded, via wrist strap or other safe, suitable means, before any printed

circuit board or other internal device is installed, removed, or adjusted.

3. Printed circuit boards must be transported in a conductive bag or other conductive container.

Boards must not be removed from protective enclosure until the immediate time of installation.

Removed boards must be placed immediately in protective container for transport, storage, or

return to factory.

COMMENTS

This instrument is not unique in its content of EDS (electrostatic discharge) sensitive components. Most

modern electrical designs contain components that utilize metal oxide technology (NMOS, CMOS, etc.).

Experience has proven that even small amounts of static electricity can damage or destroy these devices.

Damaged components, even though they appear to function properly, exhibit early failure.

*** SPONSLER, INC. STRONLY RECOMMENDS THOROUGH UNDERSTANDING AND REVIEW OF

THIS MANUAL PRIOR TO INSTALLATION.

Page 3

3

TABLE OF CONTENTS

INTRODUCTION 4

1.1 GENERAL DESCRIPTION 4

1.2 FEATURES 4

1.3 APPLICATION 5

1.4 GENERAL SPECIFICATIONS 6

1.5 INPUT S PEC I F ICATIONS 6

1.51 ANALOG INPUTS 6

1.52 RTD TEMPERATURE INPUTS 7

1.53 DIGITAL FLOW INPUT 7

1.6 OUTPUT SPECIFICATIONS 8

1.61 ANALOG OUTPUT 8

1.62 DIGITAL FLOW PULSE OUTPUT 8

1.63 RELAY OUTPUTS 9

1.64 AUXILIARY POWER OUTPUT 9

1.7 RS-232 COMMUNICATIONS PORT 9

1.8 DATA DISPLAY AND KE YPAD 10

INSTALLATION 10

2.1 MOUNTING THE INSTRUMENT 10

2.2 CONNECTING INPUTS AND OUTPUTS 11

PROGRAMMING CONSIDERATIONS 18

3.1 FRONT PANEL KEYPAD OPERATION 19

3.2 SETTING COMPUTATIONS 20

3.3 SELECTING THE ENGINEERING UNITS 22

3.4 SETTING THE HARDWARE 22

3.5 SETTING THE VARIABLES 24

3.51 SETTING THE PRESSURE VARIABLES 24

3.52 SETTING THE TEMPERATURE VARIABLES 25

3.53 SETTI NG T H E FLOW VARIABLES 26

3.54 FLOWCHART: DIGITAL PULSE -LINEAR 26

3.55 FLOWCHART: DIGITAL PULSE - SIXTEEN POINT 27

3.551 DIGITAL PULSE – SIXTEEN POINT PROGRAMMING 28

3.6 ANALOG LINEAR INPUT SETTINGS

3.7 ANALOG ORIFICE/PITOT INPUT SETTINGS 33

3.8 SETTING THE FLOW OUTPUT VARIABLES 34

CLEARING THE TOTALIZER: RESETTING THE TOTALIZER TO 0.000 34

CHECKING THE ALARM: VIEW THE MOST RECENT ALARM CONDITION 36

REAL TIME CLOCK 39

RUNNING MODE 40

8.1 SHOW DATA 41

8.2 PRINT LIST (RS-232 OPTION) 42

8.3 PRINT SYSTEM SETUP (RS-232 OPTION) 42

8.4 EXAMINE HARDWARE 43

8.5 EXAMINE COMPUTATIONS 43

8.6 EXAMINE VARIABLES 43

8.7 CHECK ALARM 44

8.8 LOCK/UNLOCK 45

PRINCIPLES OF OPERATION 46

9.1 GENERAL 46

9.2 TEMPERATURE CALCULATIONS 46

9.3 PRESSURE CALCULATIONS 46

9.4 FLOW CALCULATIONS 46

Appendix i 48

Appendix ii 51

Appendix iii 51

Appendix iv 52

Appendix v Troubleshooting Guide 52

RS-232 OPERATING INSTRUCTIONS 53

3.552 PROGRAMMING EXAMPLE 29 31

3.61 ANALOG 16 POINT INPUT SETTINGS 32

8.1.1 DISPLAY DATA SE TUP 41

Page 4

4

MODEL SP3000 MASS FLOW COMPUTER

INTRODUCTION

1.1 GENERAL DESCRIPTION

The Model SP3000 is a microprocessor based instrument designed to measure and compensate

flow in an industrial environment. Three inputs - temperature, pressure, and flow – are provided

for calculating the flow at standard conditions. Special signal conditioning circuitry is included to

allow direct connection of 2, 3, or 4 wire platinum Resistance Temperature Detectors (RTDs),

voltage inputs or current loops. A high speed digital input is provided for interfacing with the

meter mounted SP714 Pulse Amplifier. A 32 terminal strip on the rear panel provides easy

connection to the instrument.

The Model SP3000 is powered by 50 or 60 Hz, 110 or 220 VAC, switch selectable, or can be

ordered for 24 VDC power.

The Model SP3000 is designed to provide continuous, on-line, compensation for true flowrate

from volumetric flow transducers. All volumetric, mass, or heat flow calculations are taken with

permission from the Flow Measurement Engineering Handbook written by R.W. Miller. Steam

(100% quality, saturated, or superheated to 850

Steam tables.

Operator interface is through a 16 key keypad and a 2 line by 20 character liquid crystal display.

(The Model SP3000 may also be set up entirely through the optional RS-232 port). Range

selection, input filtering characteristics, scaling factors, etc. are selected through the front panel

keypad or RS-232 interface. There is no need to disassemble the unit or set any dip switches.

Scaled digital and 4-20mA analog current outputs, that represent compensated flow, are standard

for use in remote monitoring of flow. Two form C relays provide isolated flow or

temperature/pressure alarm outputs.

There is a single precision voltage reference in the unit used for all analog measurements. A

single multi-turn potentiometer is provided for factory calibration. No field adjustments are

necessary.

1.2 FEATURES

The Model SP3000 is designed to provide accurate and low cost compensated flow

measurement for industrial applications. The instrument can be set up to display volumetric,

mass, or heat flow, as well as totalized flow, with an overall accuracy of 0.25%.

Fully programmable from the front keypad, the microprocessor-based Model SP3000 Flow

Computer provides the operator with prompts to set up the operating parameters of the

instrument.

The Flow Computer offers the following features:

* Front Panel 16 key programming keypad

* 2 line 20 character liquid crystal display

* Compensates gas & steam flowrates for

temperature and pressure

* Compensates liquid flowrates for temperature

* Direct input of 100 ohms RTD

* Can display flow and heat flowrates and totals

* Scaleable 5V output pulse

* Analog output of 4-20mA proportional to

compensated flowrate

* 12 bit input resolution for A/D conversion

o

F) computations are based on the 1967 ASME

* Non-volatile RAM memory

* Self diagnostics of instrument

* Supervisory lockout of keypad

* Provides 24 VDC excitation at 100mA

* English and metric engineering units selectable via

front keypad

* Flowrate and temperature/pressure alarms via two

SPDT relays

* Real time clock and calendar (not battery backed)

* Optional 16 point linearization of input signal

* Optional RS-232 communications

Page 5

5

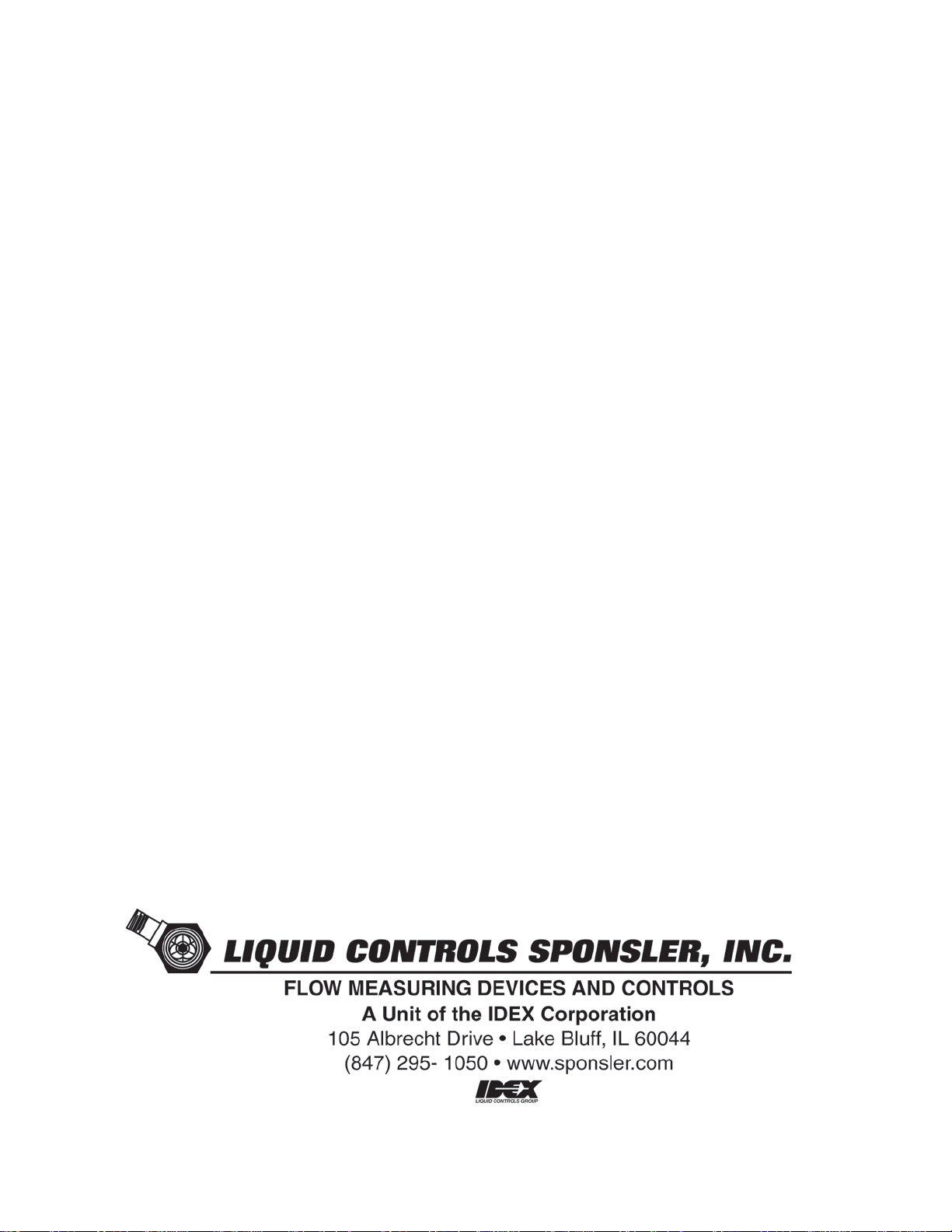

1.3 APPLICATION

P

Pulse Output

RS232 Output

4-20mA Output

TRANSDUCER

AMPLIFIER

100 OHMS RTD

FLOWMETER

COMPUTER

TOTALIZER

PRINTER

PRESSURE

SP714 PULSE

SP3000

MASS FLOW

BELL

LIGHT

Alarm Outputs

1 2 3 4 5 6

REMOTE

* Pressure Transducer sends 4-20mA signal to Model SP3000

* 100 ohms RTD direct hook-up to Model SP3000

* Meter Mounted SP714 Pulse Amplifier sends digital signal to Model SP3000

* Model SP3000 calculates flow and sends out signals

* 5V pulse out to remote totalizer in supervisory area

* 4-20mA out to stripchart recorder tracks trends

* RS-232 out to printer for data logging

* Alarm relays activate bell and/or light as needed

*

Page 6

6

1.4 GENERAL SPECIFICATIONS

1.5 F

12

11

A/D

92 K

Operating Temperature: 32

Storage Temperature: -10

o

to 122o F (0o to 50o C)

o

to 160o F (-32o to 71o C)

Humidity: 0 to 90% Non-Condensing

Front Bezel: NEMA 4X

Case: ABS Plastic

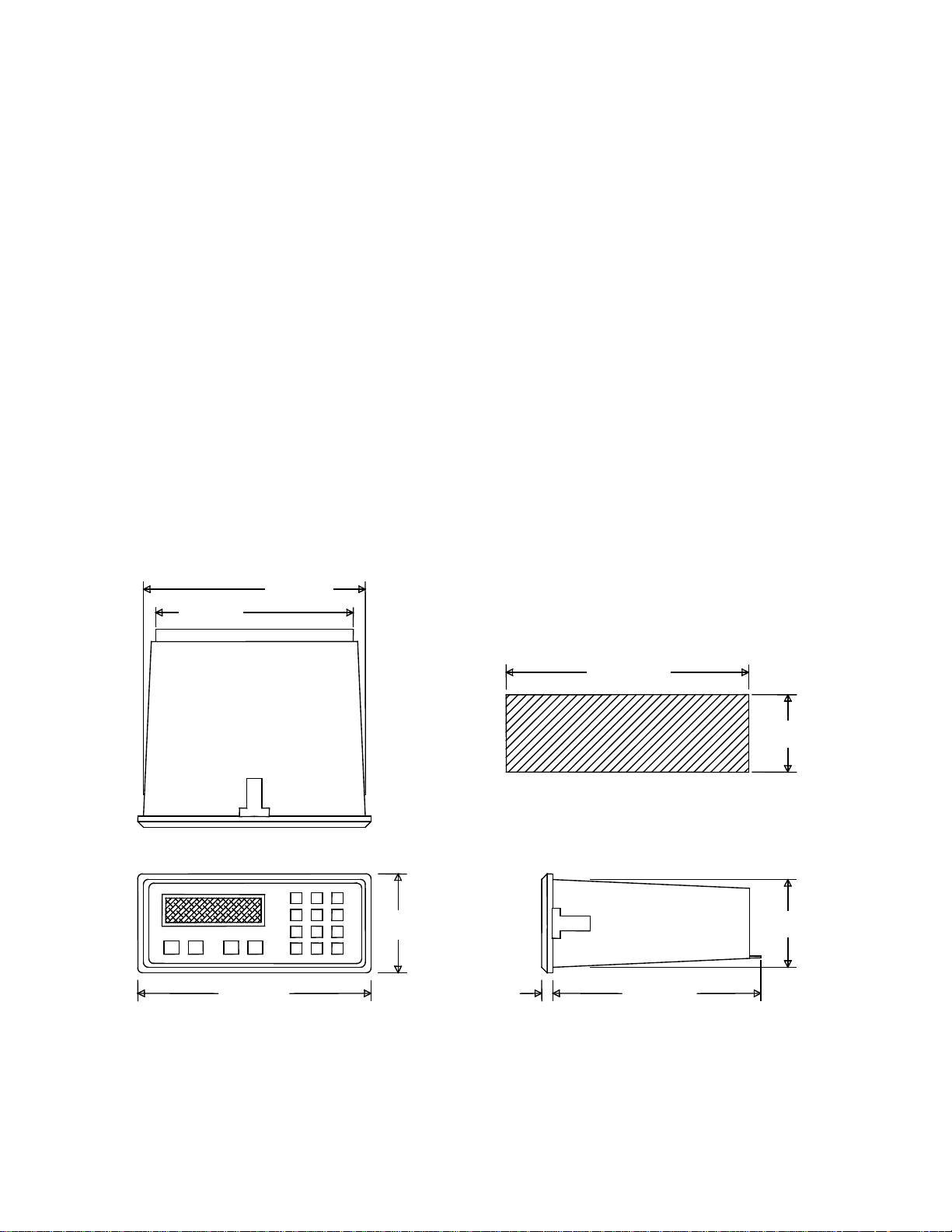

Dimensions: See page 2-1, fig 2-1

Voltage: 115 or 230 VAC +/- 15% (Switch Selectable)

50/60 Hz, 24 VDC +/- 20%

Power Consumption: 10 Watts max.

1.5 INPUT SPECIFICATIONS

The following applies to all inputs in all modes. Inputs are referenced to the signal ground. All ground terminals are

connected internally. The exception is the RTD input which is differential but is referenced to ground.

Transient Protection: 100V 5nsec

Note: In the event of the specified fault conditions, unit may temporarily malfunction, but no permanent

damage will occur.

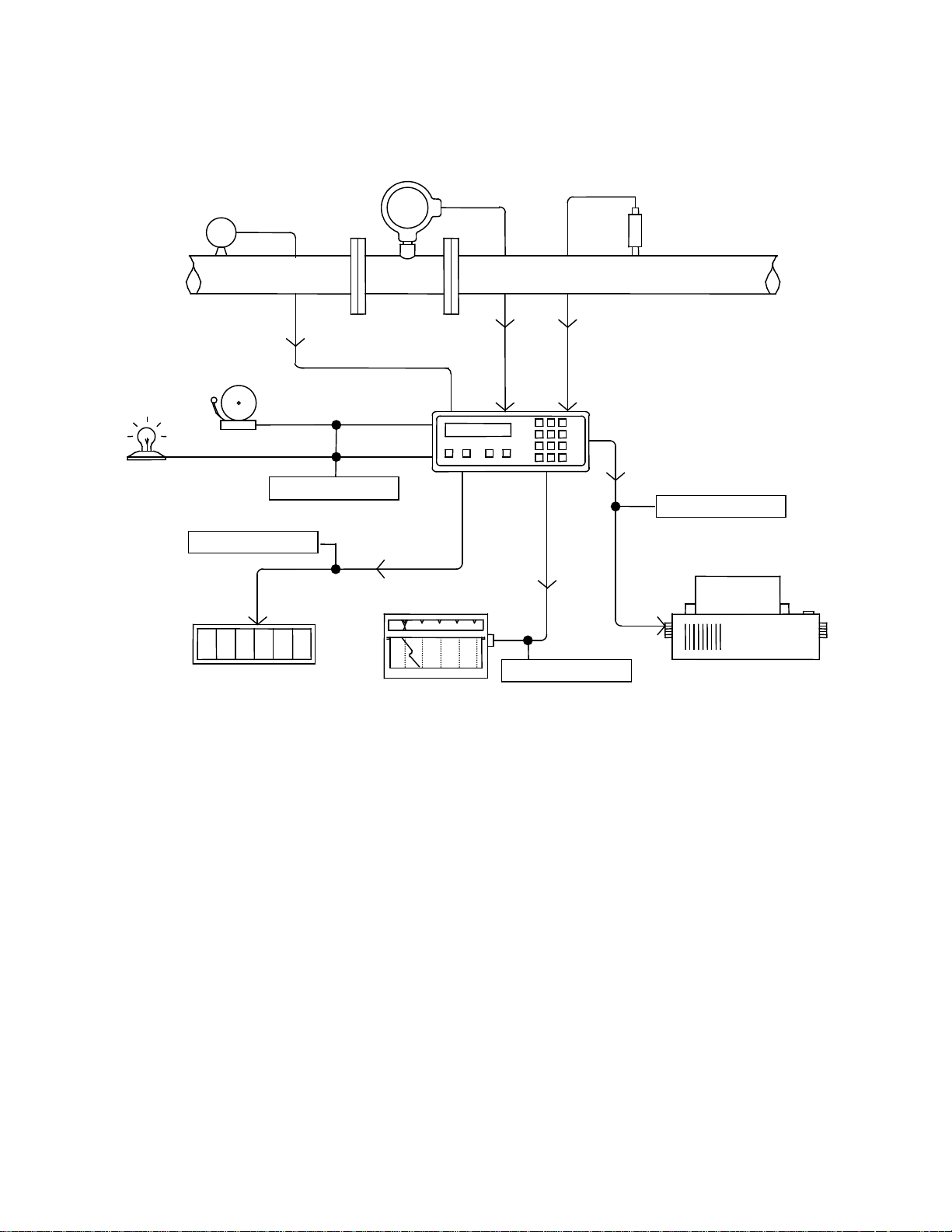

1.51 ANALOG INPUTS

Temperature, Pressure, and Flow (1 each)

* Current Input

Input Impedance: 100 ohms

Range: 0-20mA, 4-20mA

Maximum sustained input voltage: 5VDC (Fault Condition)

100

22.9 K

A/D

1.5 F

13

14

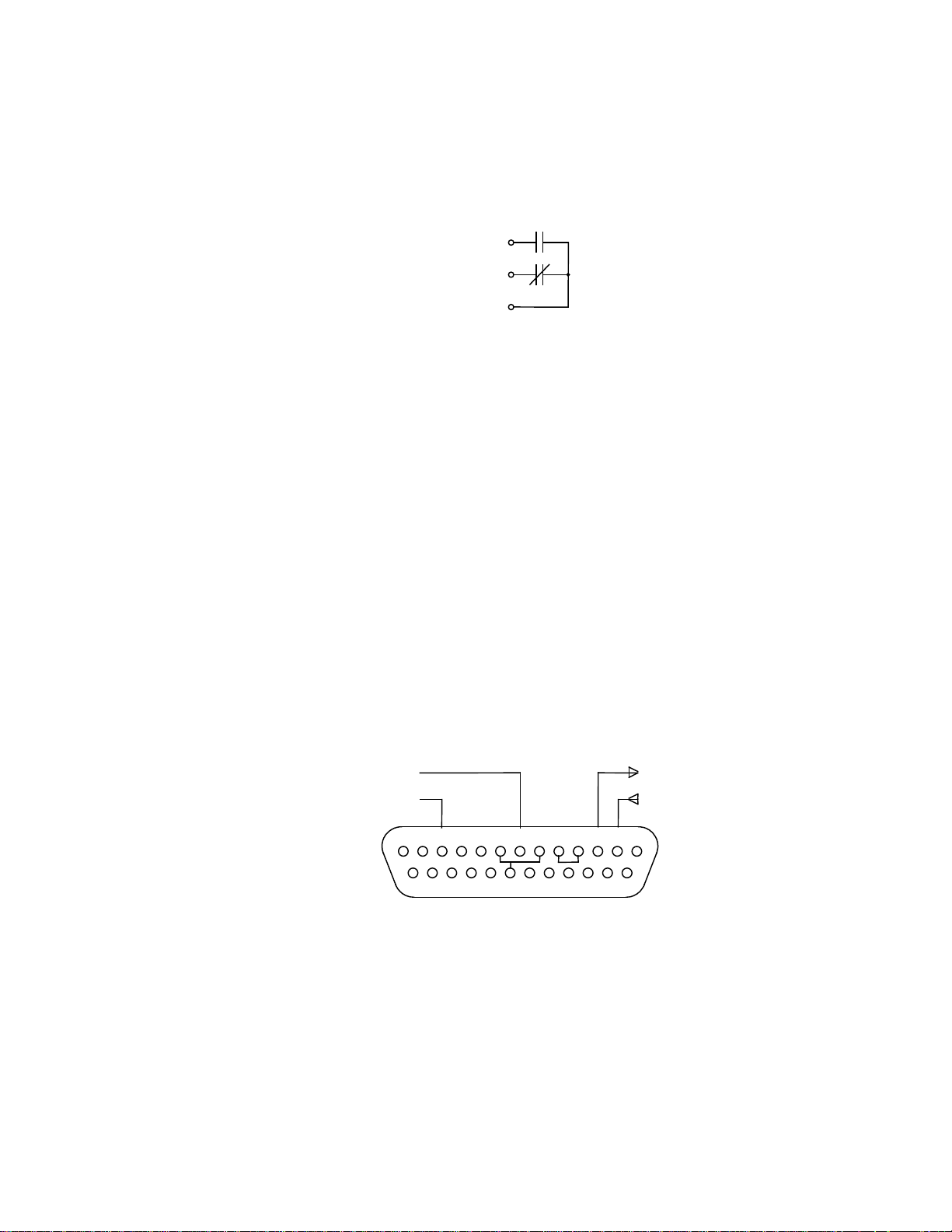

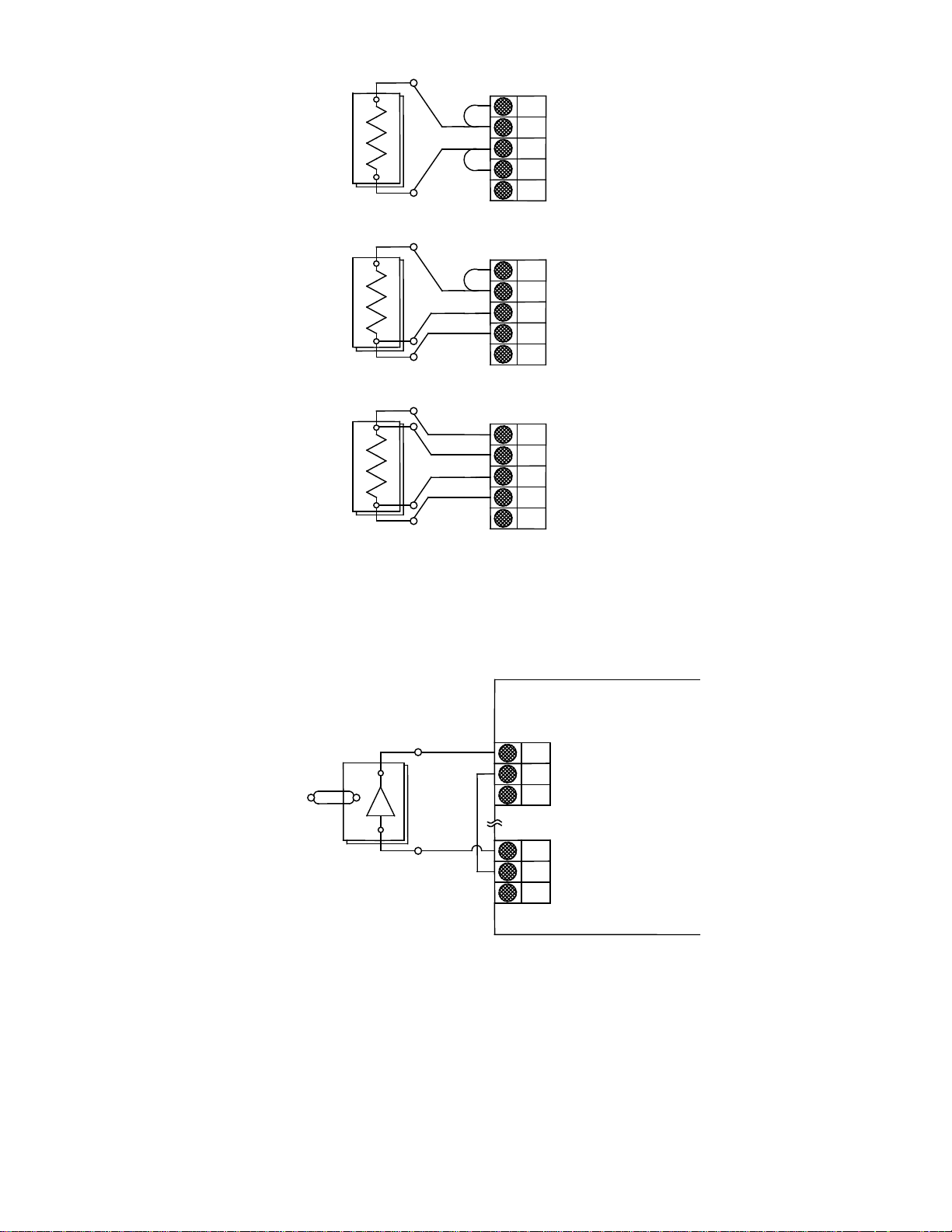

Typical Current Input Schematic:

* Voltage Input

Input Impedance: 100K ohms

Range: 0-5V, 0-10V

Typical Voltage Input Schematic:

Page 7

7

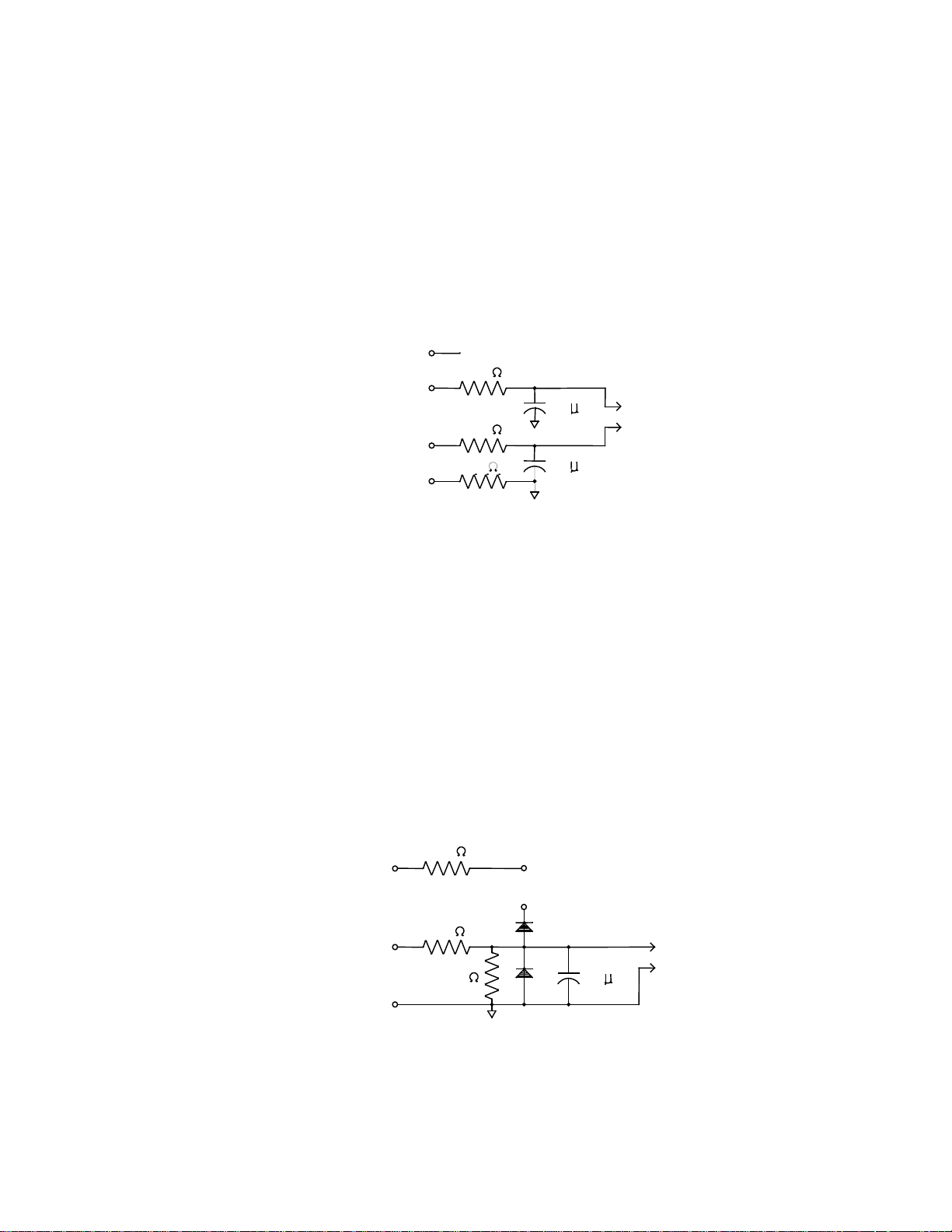

1.52 RTD TEMPERATURE INPUTS

2.2 VDC @ 2mA

1.5 F

1.5 F

20K

20K

100K

1.5 F

5 VDC

@ 0.9 mA

5.6 K

39 K

100 K

+5 VDC

+5 VDC

16

1718COUNTER

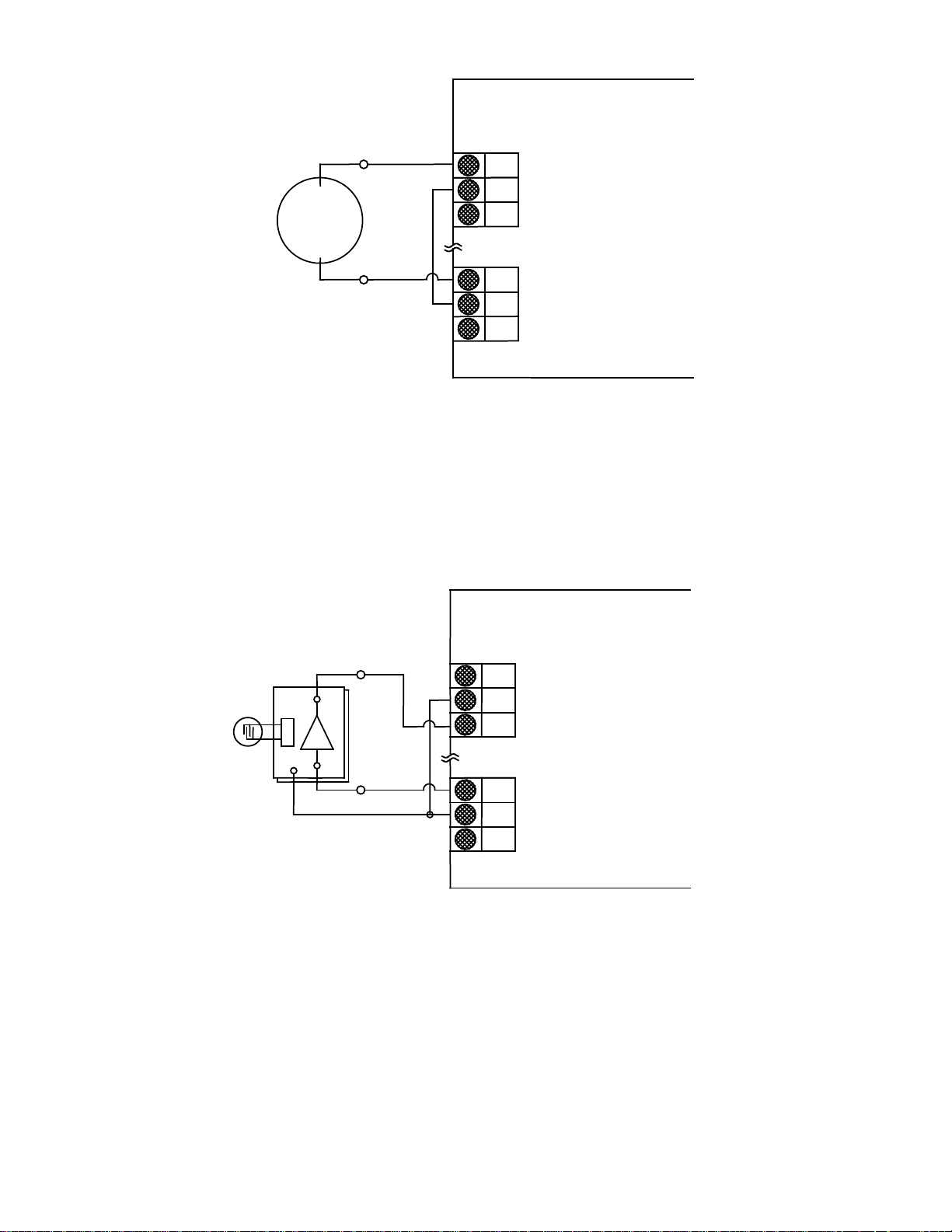

Compatible RTD type: 100 ohms Platinum

(a=0.00385; DIN 43-760 Calibration)

Configuration: 2, 3, or 4 wire

Excitation Current: 2mA typical

Max Fault Current: 15mA

Max Voltage on Sense Inputs: 50 VDC

Rejection of 50-60Hz signal: 40 dB (minimum)

(Automatically based on line frequency)

Raw Accuracy: 0.2% FS RTI

Temperature Range: -323.5

(-197.5

Typical RTD Schematic:

o

to +1378.7o F

1

2

3

4

o

to +748.1o C)

~

A/D

1.53 DIGITAL FLOW INPUT

Range: 3-30 VD C Pu ls e

Type: Dry contact, opto-isolated or

voltage source

Max Input Frequency: 40kHz

Min. Pulse Width: 10µsec (with 40kHz filter)

Thresholds: OFF is less than 2.0V/ ON is

greater than 2.5V

Input Impedance: Less than 30K ohms to ground

Excitation Voltage: 5VDC through 5.6K ohms resistor

Min. Frequency to maintain rate display: 1 Hz

Note: Totalizer counts all pulses down to 0 Hz

Typical Digital Pulse Input & Schematic:

Page 8

8

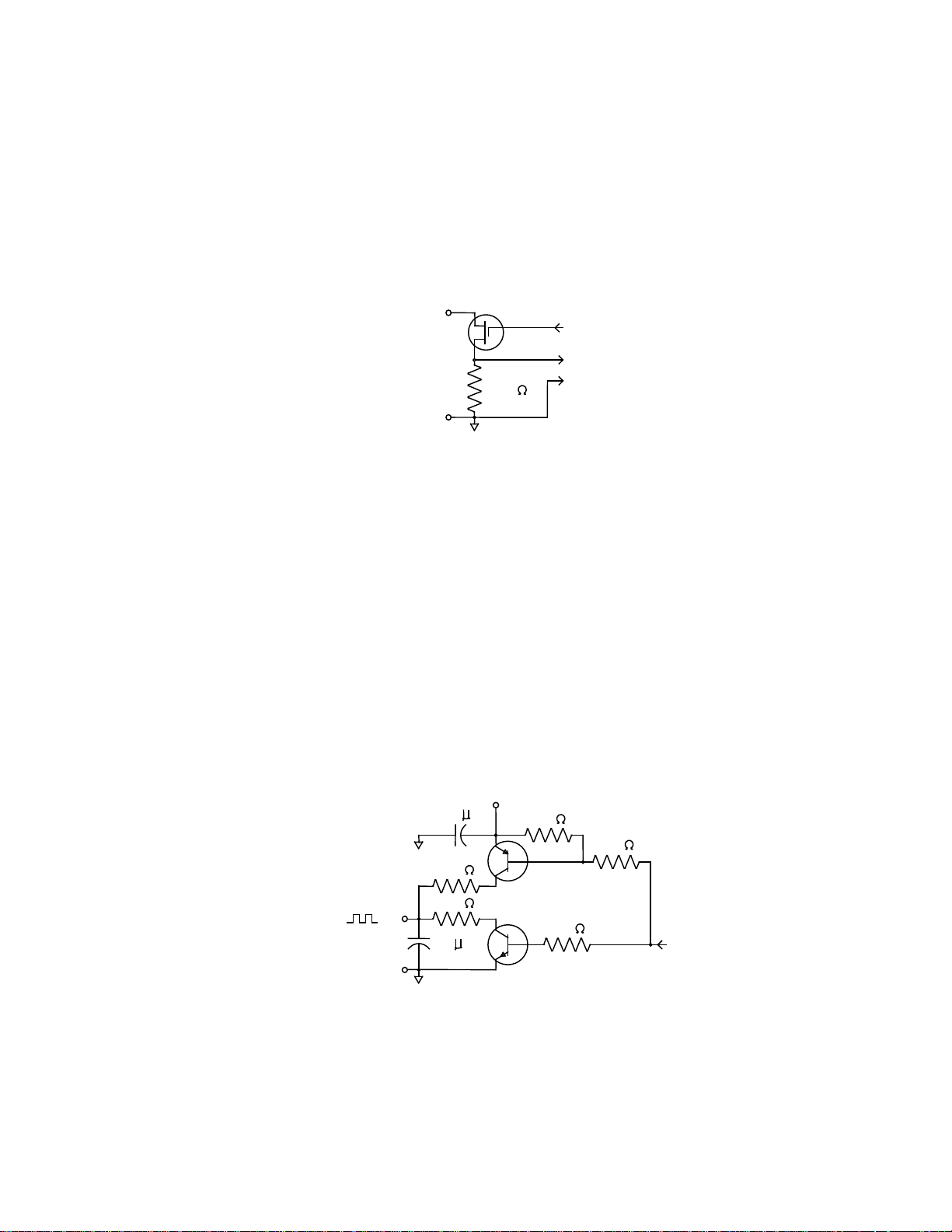

1.6 OUTPUT SPECIFICATIONS

~

.001 F

1.5 F

TTL 5 VDC

@ 21mA

+ 5 VDC

CPU

3.3 K

3.3 K

3.3 K

220

220

21

20

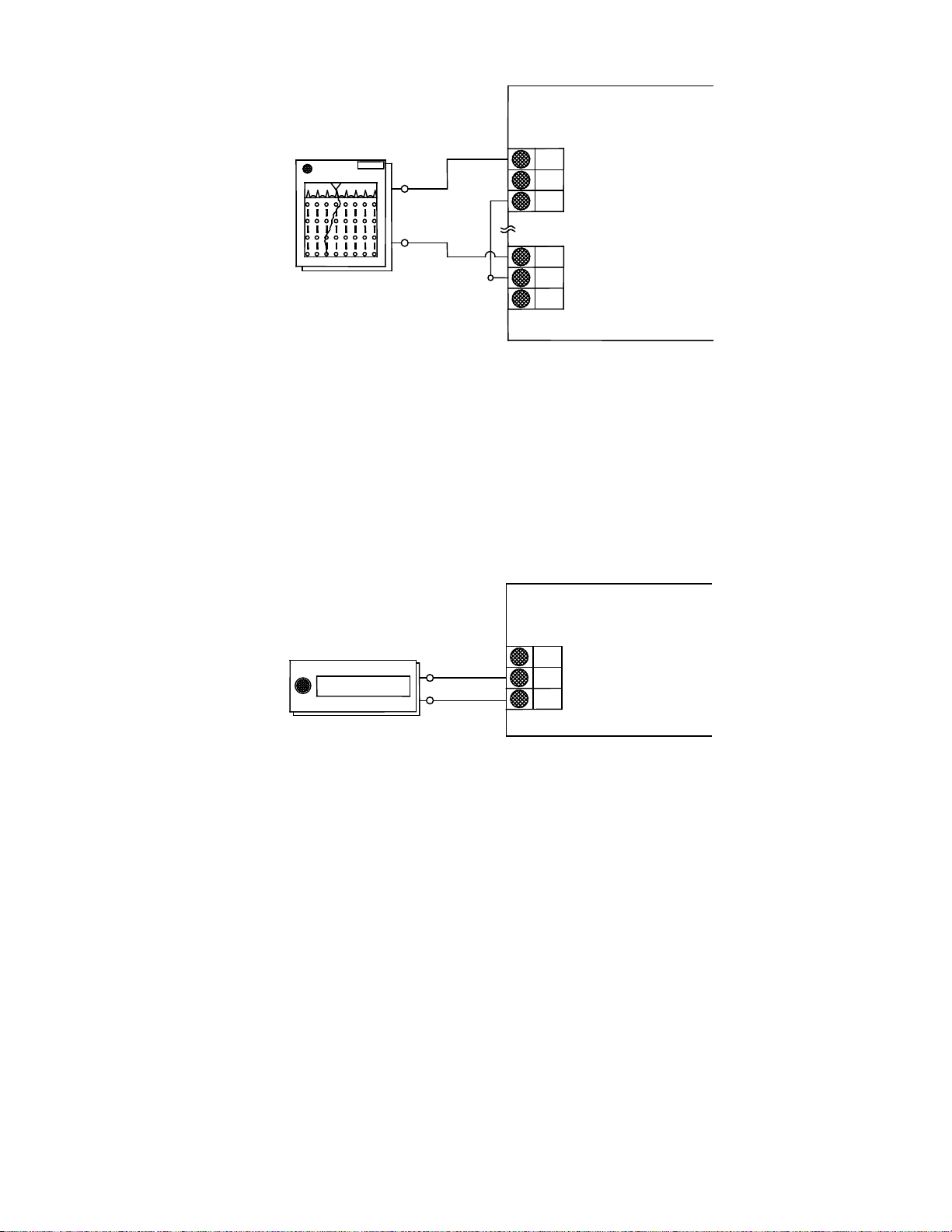

1.61 ANALOG OUTPUT

Number: 1

Range: 4-20mA DC, sink only

Compliance Voltage Range: 3.0-24 VDC

Load Type: Non-Inductive

Accuracy: +/- 100 µA

Update Rate: 1 Hz

Analog Output Schematic:

1.62 DIGITAL FLOW PULSE OUTPUT

This output is intended to drive a counter with a minimum input impedance of 1000 ohms. It is also

compatible with TTL, LSTTL, and 5V CMOS logic inputs. It is slew rate limited to help prevent RFI.

Number: 1

Output High Voltage No Load: 4.5 Volts min.

4.0mA source: 4.5 Volts min.

Output Low Voltage No Load: 0.2 Volts max.

4.0mA sink: 1.0 Volts max.

Output Waveform: Symmetric square wave above 1Hz

100msec pulse below 1Hz

Max Output Slew Rate: 27 Volts/µsec

Sustained Fault Voltage for

no permanent damage: 7 Volts

Transient Protection: 1500V 50µsec

Pulse Output Schematic:

19

CPU

A/D

100

18

Page 9

9

1.63 RELAY OUTPUTS

Ground (7)

One relay is provided as a flow alarm and a second is provided for the other alarm conditions.

Each has the following specifications:

Type: Dry contact, Form C

Contac t Rat ing: 10A at 115/230 VAC/28 VDC

Typical Relay Output Schematics:

22

23

24

1.64 AUXILIARY POWER OUTPUT

Voltage: 24 VDC regulated and filtered

Isolation: 230 VAC max

Current: 0 to 100 mA

Protection: Short Circuit Proof

1.7 RS-232 COMMUNICATIONS PORT

(Refer to RS-232 Addendu m supplied with RS-232 option)

Connector: 25 Pin Sub-D

Input Impedance: 3000 ohms to 7000 ohms

Compliance Voltage:

Output: -25 to –5 (Mark); 5 to 25 (Space); Volts

Input: -25 to –3 (Mark); 3 to 25 (Space); Volts

Protection: Short Circuit Proof

Protocol: 8 bits, 1 stop bit

Parity: None (Not Monitored)

Available Baud Rates: 300, 1200, 9600

RS-232 Connector Pin Out:

Printer Busy (11)

Transmit (3)

Recieve (2)

12345678910111213

25

Pins 6, 8, and 20 are jumpered together

Pins 4 and 5 are ju m pered together

24 23

22 212019

18 17

16 15

14

Page 10

10

1.8 DATA DISPLAY AND KEYPAD

7.055 (179.2)

2.495 +/- .010

7.365 +/- .010

.525

6.000 (152.4)

2.480

3.305

(207.5)

8.170

Internal 2 line by 20 character dot matrix LCD display. Sealed, 16 key panel featuring numeric keys 0-9,

plus the following keys:

A Advance through menus

B Back up through menus

C Cancel current menu selection

D Decimal point key

ENT General purpose enter or recall data key

CLR Data clear key

INSTALLATION

2.1 MOUNTING THE INSTRUMENT

The Model SP3000 can be mounted in a user panel greater than 0.047” (1.2mm) and less than 0.187”

(4.7mm) thick. Figure 2-1 shows the cutout dimensions, bezel size, and depth needed for the instrument.

Be sure to provide additional space for cabling and connections behind the instrument (approximately 1.0”).

Additionally, all wiring to the back of the instrument should have sufficient service loops to allow for the

easy removal of the instrument from the panel.

Slip the gasket provided over the rear of the instrument case and slide it forward until it engages the inner

surface of the front bezel, slide the instrument into the panel opening. Install the screws provided in the

mounting brackets and insert in the slots located on all four sides of the instrument. Tighten the screws to

firmly secure the bezel and gask et up against the pa nel .

CAUTION: Do not over tighten mounting screw brackets

7.349 (186.7)

(187.0 +/- .25)

(63.4 +/- .25)

PANEL CUTOUT DIMENSIONS

321

654

987

DCBA

C0E

(83.9)

(13.5)

(62.9)

Figure 2-1

Dimensional Layout

Page 11

11

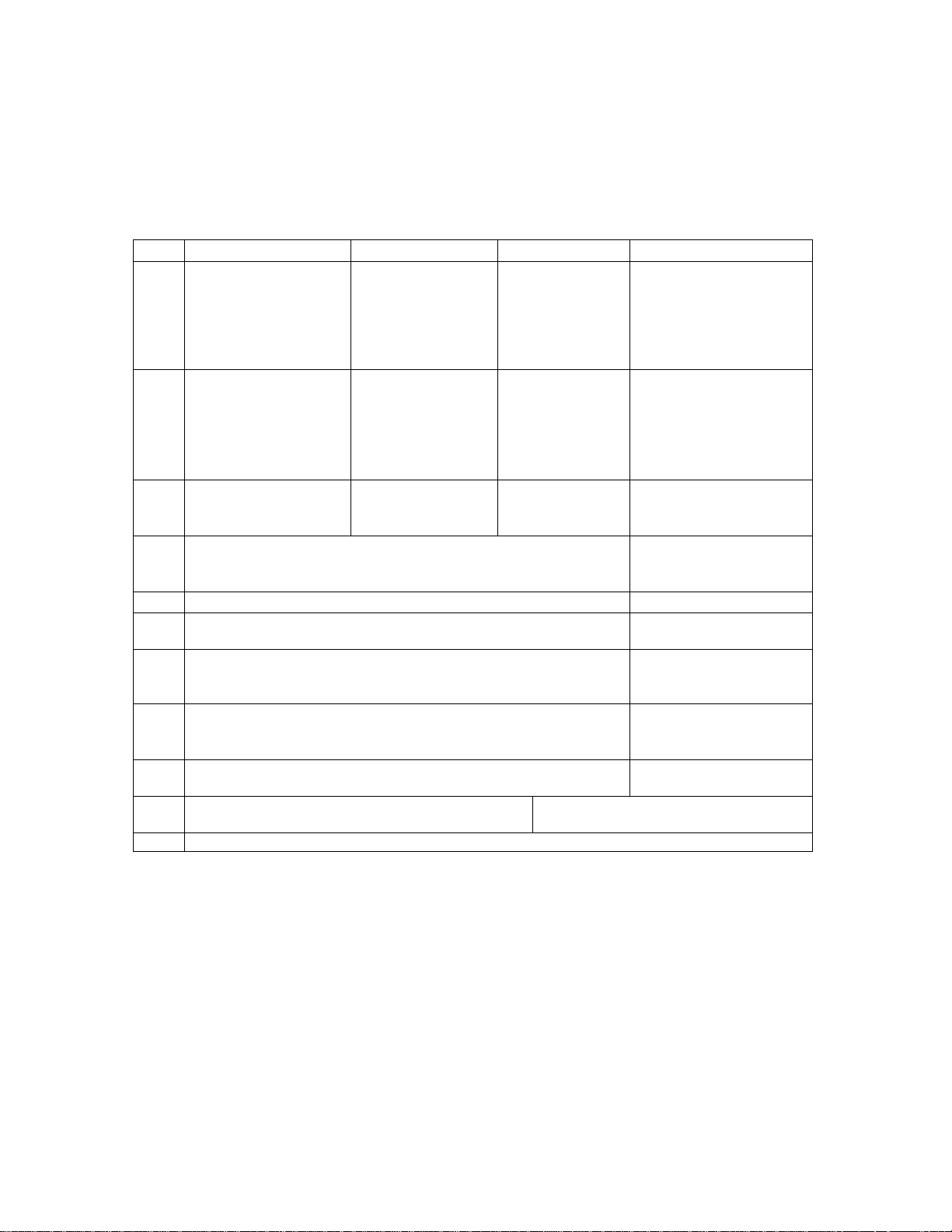

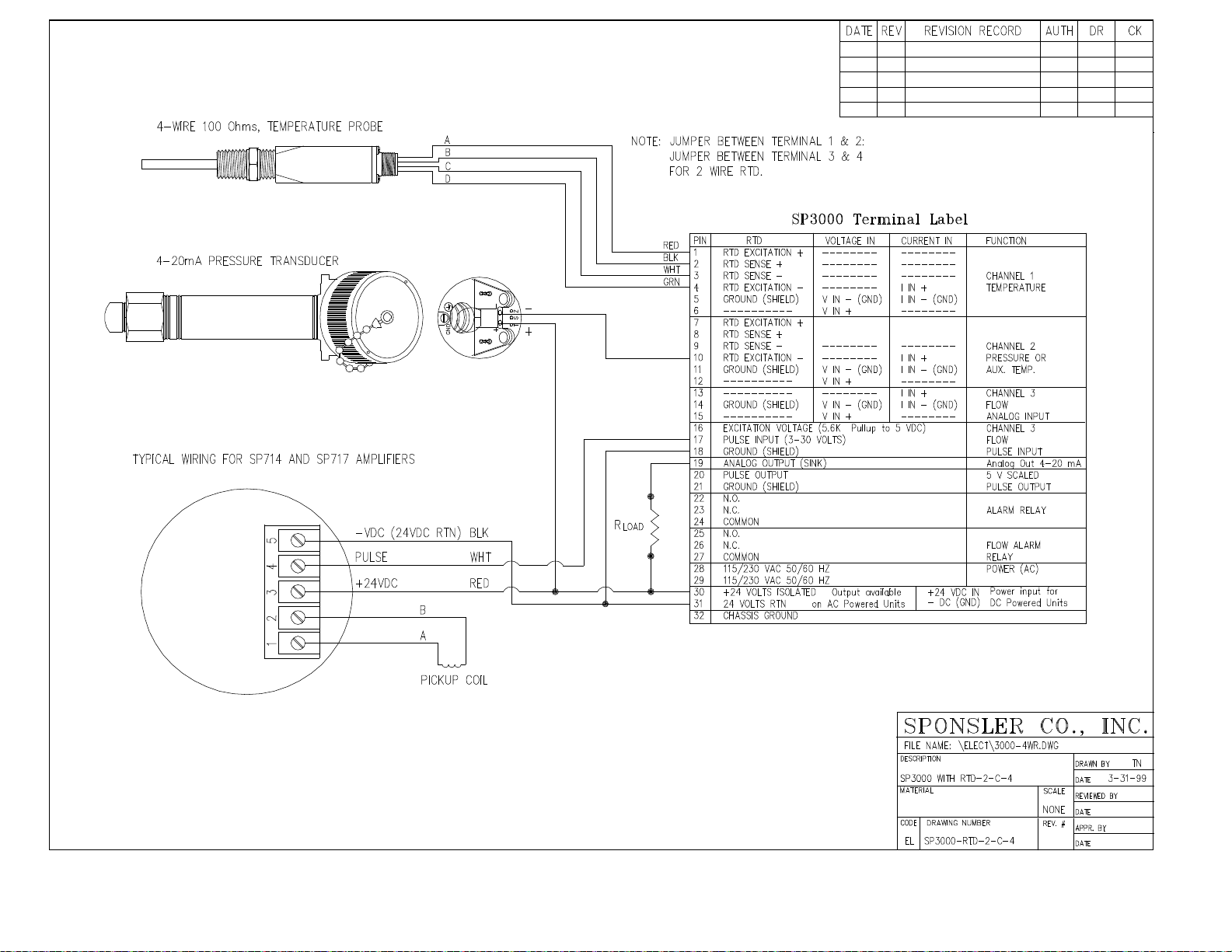

2.2 CONNECTING INPUTS AND OUTPUTS

PIN

RTD

VOLTAGE IN

CURRENT IN

FUNCTION

1

6

RTD EXCITATION +

----------------------------

-------------------------

V IN +

----------------------

----------------------

GROUND (SHIELD)

20

21

PULSE OUTPUT

GROUND (SHIELD)

5 V SCALED

PULSE OUTPUT

24

COMMON

25

N.O.

28

29

115/230 VAC 50/60 HZ

115/230 VAC 50/60 HZ

POWER (AC)

30

31

+24 VOLTS ISOLATED Output available

24 VOLTS RTN on AC Powered Units

+24 VDC IN Power input for

-- DC (GND) DC Powered Units

32

CHASSIS GROUND

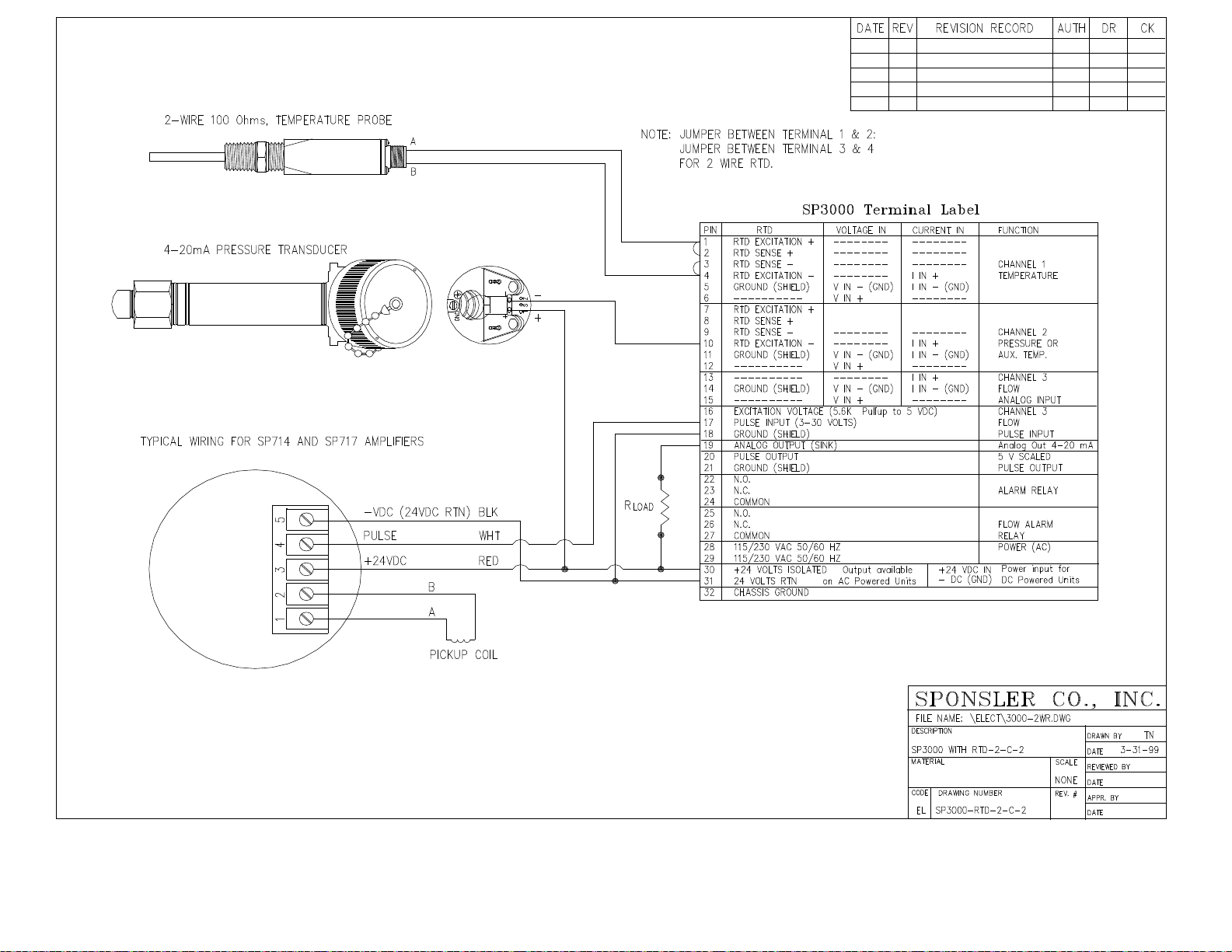

Make sure all power is disconnected before making any electrical connections. All connections are

completed at the rear terminal strips as indicated in the external wiring diagram. If cables are in areas with

heavy electrical fields, shielding will be required for noise immunity. One end of the shielding should be

connected to earth ground. Figures 2-2 though 2-9 show the input, output and power wiring locations for

the 32 point terminal block on the back of the instrument.

2

RTD SENSE +

3

RTD SENSE –

4

RTD EXCITATION –

5

GROUND (SHIELD)

7

RTD EXCITATION +

8

RTD SENSE +

9

RTD SENSE –

10

RTD EXCITATION –

11

GROUND (SHIELD)

12

----------------------------

13

----------------------------

14

GROUND (SHIELD)

15

----------------------------

16

EXCITATION VOLTAGE (5.6K Ω PULLUP TO 5 VDC)

17

PULSE INPUT (3-30 VOLTS)

18

19 ANALOG OUTPUT (SINK) ANALOG OUT 4-20mA

-------------------------

-------------------------

------------------------V IN – (GND)

-------------------------

------------------------V IN – (GND)

V IN +

------------------------V IN – (GND)

V IN +

----------------------

---------------------I IN +

I IN – (GND)

---------------------I IN +

I IN – (GND)

---------------------I IN +

I IN – (GND)

----------------------

CHANNEL 1

TEMPERATURE

CHANNEL 2

PRESSURE OR

AUX TEMP

CHANNEL 3

FLOW

ANALOG INPUT

CHANNEL 3

FLOW

ANALOG INPUT

22

N.O.

23

N.C.

26

N.C.

27

COMMON

Figure 2-2

Terminal Designation Label

ALARM RELAY

FLOW ALARM

RELAY

Page 12

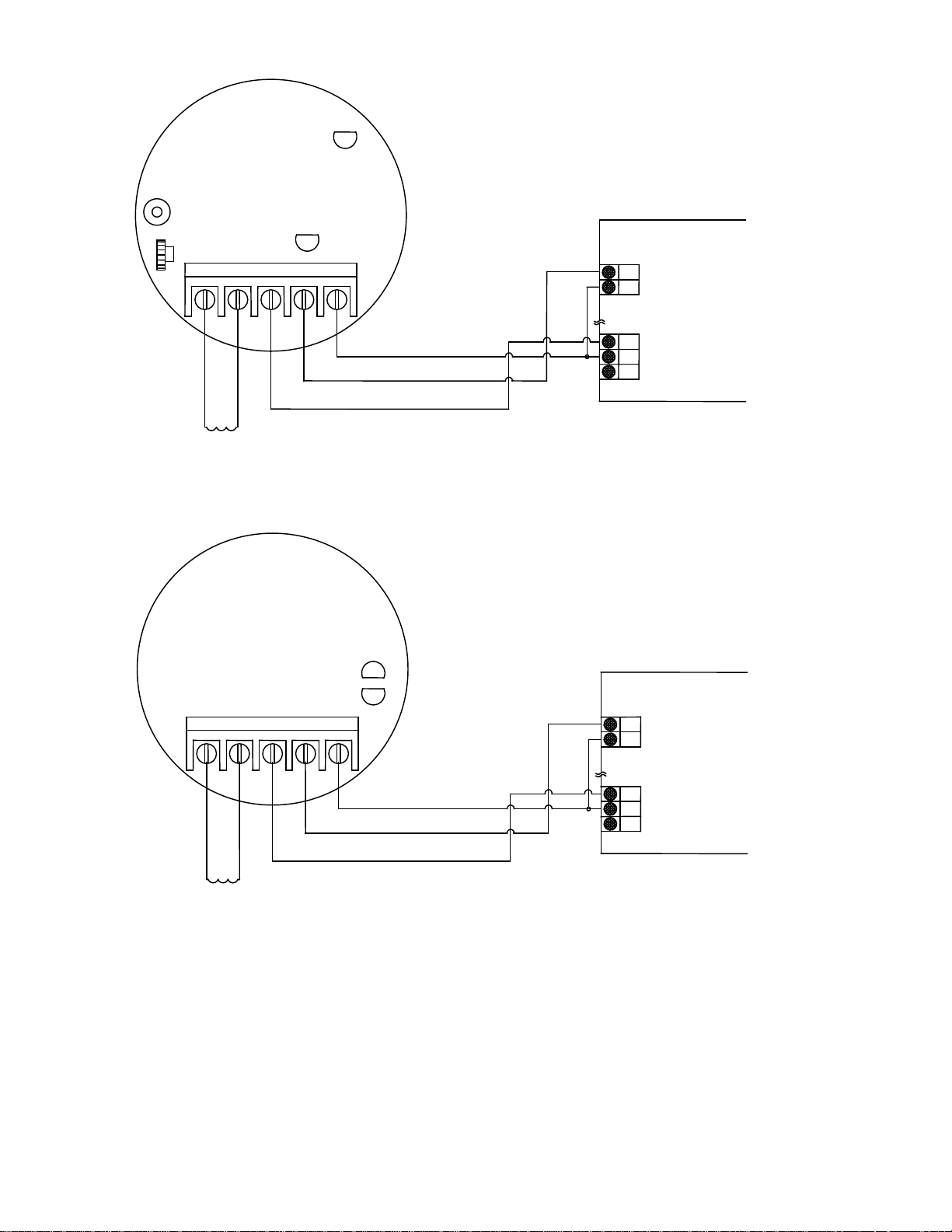

12

12345

17

183031

32

171830

31

32

12345

SP714 REV B

POWER

D1

TEST

SENS

S1

R1

J1

OUTPUT SIGNAL

D2

- DC (GND)

SIGNAL OUT +

+24 VDC

PICKUP COIL

A SIG IN +

B SIG IN -

FLOW COMPUTER

PULSE INPUT

GROUND (SHIELD)

+ 24 V

24 V RETURN

CHASSIS GROUND

PULSE INPUT CONNECTION

FLOW COMPUTER

PULSE INPUT

GROUND (SHIELD)

+ 24 V

24 V RETURN

CHASSIS GROUND

PULSE INPUT CONNECTION

J1

- DC (GND)

SIGNAL OUT +

+24 VDC

PICKUP COIL

A SIG IN +

B SIG IN -

(JU1 INSTALLED)

D1

SP717 REV A

(JU1 INSTALLED)

OUTPUT SIGNAL

D2

Figure 2-3

SP714 & SP717 Pulse Amplifiers Wiring Diagram

Page 13

13

2 WIRE CONNECTION

RTD EXCITATION +

GROUND (SHIELD)

4 WIRE CONNECTION

RTD WIRING DIAGRAMS

I IN +

CHASSIS GROUND

456

303132

3 WIRE CONNECTION

1

2 3 4 5 1 2 3 4 5

RTD SENSE +

RTD SENSE -

RTD EXCITATION GROUND (SHIELD)

1 2 3 4 5

RTD SENSE +

RTD SENSE -

RTD EXCITATION GROUND (SHIELD)

RTD EXCITATION +

RTD SENSE +

RTD SENSE -

RTD EXCITATION -

4-20mA T/C

TRANSMITTER

TEMPERATURE TRANSMITTER

4-20mA CONNECTION

FLOW COMPUTER

GROUND (SHIELD)

V IN +

+ 24 V

24 V RETURN

Figure 2-4

Temperature Transmitter Input Wiring Diagrams

Page 14

14

+

10

-

-

I IN +

GROUND (SHIELD)

V IN +

+ 24 V

24 V RETURN

CHASSIS GROUND

FLOW COMPUTER

4-20Ma PRESSURE

TRANSMITTER

11

12

30

31

32

4-20mA CONNECTION

10

I IN +

GROUND (SHIELD)

V IN +

+ 24 V

24 V RETURN

CHASSIS GROUND

FLOW COMPUTER

5 VOLT PRESSURE

TRANSMITTER

11

12

30

31

32

0-5 VOLT CONNECTION

Figure 2-5

Pressure Transmitter

Analog Input Wiring Diagrams

Page 15

15

FLOW COMPUTER

192021

30

31

32

STRIP CHART

192021

COUNTER

12345678

RECORDER

-

+

ANALOG OUTPUT CONNECTION

SINK (4-20mA)

PULSE OUT

GROUND (SHIELD)

+ 24 V

24 V RETURN

CHASSIS GROUND

Figure 2-6

Analog Output Wiring Diagram

FLOW COMPUTER

REMOTE ELECTRONIC

+

-

PULSE OUTPUT CONNECTION

SINK (4-20mA)

PULSE OUT

CHASSIS GROUND

Figure 2-7

Pulse Output Wiring Diagram

Page 16

16

Figure 2-8: Wiring Diagram-2-wire Probe

Page 17

17 Figure 2-8: Wiring Diagram-2-wire Probe

Page 18

18

PROGRAMMING CONSIDERATIONS

Run? Allows crossover from Setup to Run

Go To Standby? Allows crossover from Run to

made

Programming the SP3000 Flow Computer for the desired operation is very simple. All programming

selections and data entry are accomplished via the 16 keys located and labeled on the front panel. The

software in the unit contains two Top Level Menus: “Setup” Menu and “Running” Menu. The “Setup” Menu

allows the selection of operating parameters and entry of data variables. The “Computation” selection sets

the formulas used to process the raw input data into meaningful information. The “Engineering Units”

selection establishes the measuring system that is used for entry and display of the data. The “Hardware”

selection sets the type of input data and activates the proper input terminals on the rear of the unit. The

unit will automatically determine the setup parameter requirements based on the “Computation” and

“Hardware” selections. Prompts are displayed for entry of the required data as the operator progresses

through the setup menu. To aid in the setup, a calibration worksheet is provided. Fill out the worksheet

before beginning setup. Review this section for setup procedures and follow the worksheet for data to be

entered.

The “Running” menu allows the setup of the data display and examination of the programmed operating

parameters. The parameters may not be changed in the “Running” menu.

Either menu allows checking the alarm, clearing the totalizer, or accessing the lock.

Structural Division of the two Top Level Menus:

SETUP MODE RUNNING MODE

Sponsler V6.13 MS197

Run?

Set Computations?

Engineering Units?

Set Hardware?

Set Variables?

Clear Totalizer?

Check Alarm?

Lock/Unlock?

Real Time Clock?

Serial Interface?

Running...

Show Data?

Go To Standby?

Setup Data Display?

Setup Print List?

Print System Setup?

Clear Totalizer?

Examine Hardware?

Examine Comps?

Examine Variables?

Check Alarm?

Lock/Unlock?

When in this mode, the operating

parameters of the instrument may be set

up or changed

In either mode, check alarm, clear totalizer, or the lock may be accessed.

NOTE: Locking the unit in either mode prevents crossover to the other mode.

Setup

When in this mode, the operating parameters

may be examined, but no changes may be

Page 19

19

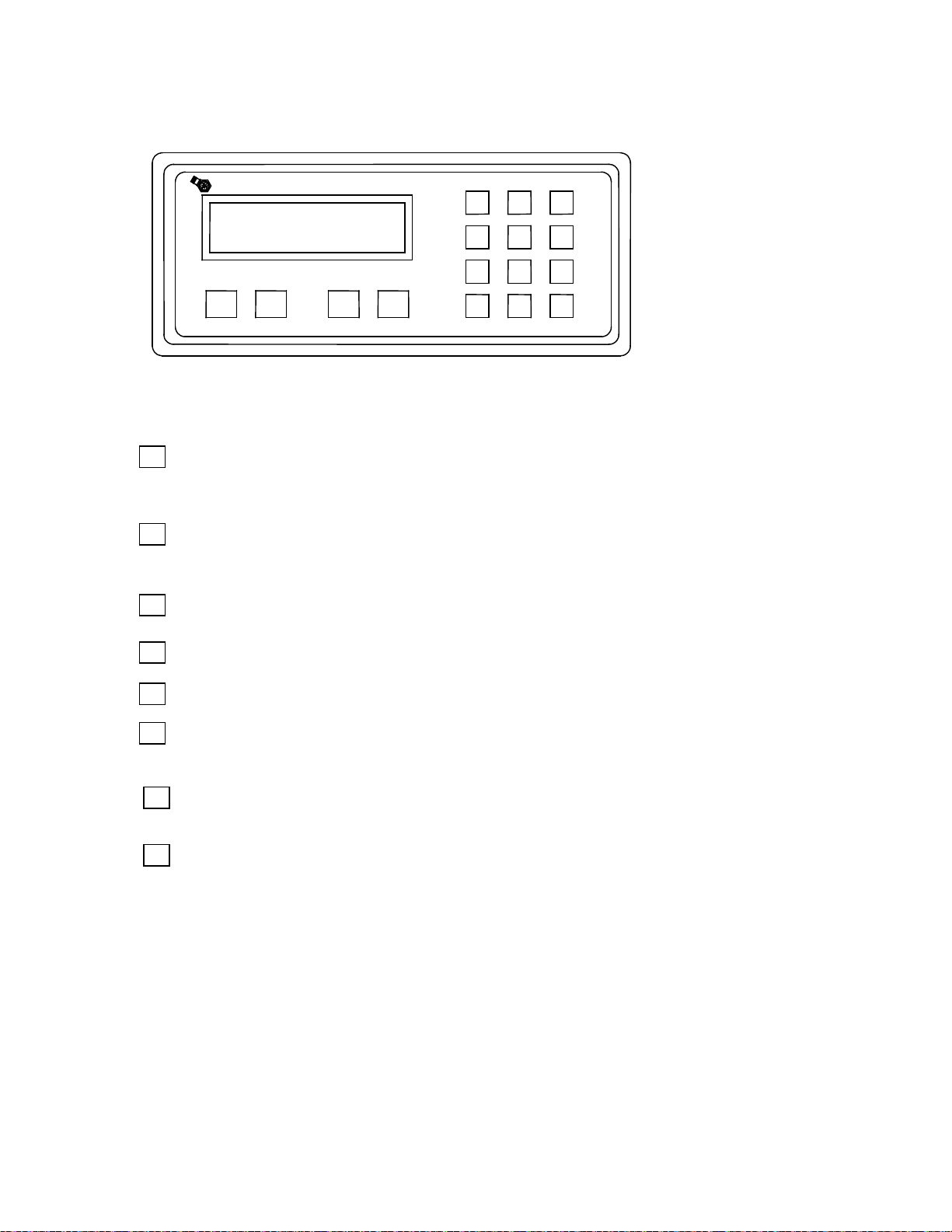

3.1 FRONT PANEL KEYPAD OPERATION

SPONSLER CO., INC.

123

473

6

9

8

0

SP3000

A

B C D

0

9

DEC. PT.

CANCEL

BACKUP

ENT

CLR

Programming is accomplished via the 16 keys labeled and located on the front panel.

Sponsler V6.13 MS197

Run?

ADVANCE

BACKUP CANCEL DEC PT

A B C D

ENT CLR

The function of each key is described below:

ADVANCE

Advances to the next item in the menu or sub-menu. If the last item in the menu is displayed,

pressing this button will have no effect on the display. The display will not wrap around to the top

of the menu.

Backs up to the previous item on the menu or sub-menu. If the first item in the menu is displayed,

pressing this button will have no effect on the display. The display will not wrap around to the

bottom of the menu.

Cancels current operation and goes back to the top of the menu or sub-menu. From any point in

the menu structure, pressing “Cancel” twice will always return to Run? Or Show Data? Option.

Inserts a decimal point in the numerical value being entered.

THRU

Keys used to enter numbers. Numerical values appear from left to right as keys are pressed.

When entering numerical values, pressing this key will erase the last digit typed. If a previously

entered value is displayed, pressing this key will erase the entire value.

Enters a selection or displayed value. If a parameter prompt is displayed, pressing this key will

display the value presently in memory. If there is no default or previously stored value, an error

message will be displayed.

NOTE: The unit must be in the “Setup” mode to program or change operating parameters. On power up,

the unit will return to the mode in which it was operating when power was removed. If the unit was

operating in the “Running” mode, the unit will display operating data on the power up. To enter the “Setup”

mode:

Page 20

20

DISPLAY SHOWS

the Top Level Menu

A

A

ENT

A

B

C

C

PRESS

Operating Data Scroll

Running...

Show Data?

Running...

Go to Standby?

Sponsler V6.13 MS197

Run? (This display indicates that the unit is in the

“Setup” mode. If the unit was in the “Setup” mode

when the power was removed, the unit will return

to this display on power up)

The function keys allow entry to the menus and sub-menus for selecting operating options or entering

numerical parameters.

Press

Press

Press

Press

Press

Press

Press

ENT

ENT

ENT

ENT

To advance a menu or sub-menu

To backup a menu or sub-menu

To access a menu or sub-menu

To select a displayed option. When an option has

been selected, the unit will autom atical l y advanc e to

the next menu item

To view the previously entered value at any data entry

point.

To erase the last digit typed or to erase a previously

entered value

To cancel current operation and return to the top of the

menu or sub-menu. From any point in the menu

structure, pressing twice will return to the top of

3.2 SETTING COMPUTATIONS

The computation selects the formulas that are used to process the raw input data into meaningful

information. Section 9 details the formulas used in each computation.

Flow Computation Selection and Applications

Ideal Gas – Volume: uses volume, temperature and pressure to yield a compensated

Volumetric flow rate displayed in SCFM (Nm3/h) and total in SCF

(Nm3)

Ideal Gas – Mass: uses volume, temperature to yield a compensated a Mass flow

rate displayed in lbm/h (kg/h) and total lbm (kg)

Steam Tables – Mass: uses volume and temperature and/or pressure to yield a

compensated Mass flow rate displayed in lbm/h (kg/h) and total in

lbm (kg). The unit may be set up to follow saturated steam curve;

see SPECIAL NOTE on page 3-9. (Steam tables are saturated 1

PSIA to 3200 PSIA with super heated values up to 900

o

F. Higher

temperatures cause an alarm condition).

Page 21

21

Liquids – Mass: uses volume and temperature to yield a compensated Mass flow

A

ENT

A

B

ENT

rate displayed in lbm/min (kg/h) and total in lbm (kg).

Liquids – Volume: uses volume and temperature to yield a compensated Mass flow

rate displayed in GPM (1/s) and total in gallons (liters).

Heat – Gas: uses volume, pressure and temperature to yield a compensated

Mass flow rate displayed in lbm/h (kg/h) and total in lbm (kg) as

well as Heat flow rate displayed in Btu/h (kW, kcal/h, MJ/h) and

total in kBtu (kWh, Mcal, MJ).

Heat – Steam: uses volume and pressure and/or temperature to yield a

compensated Mass flow rate displayed in lbm/h (kg/h) and total in

lbm (kg) as well as Heat flow rate displayed in Btu/h (kW, kcal/h,

MJ/h) and total on kBtu (kWh, Mcal, MJ). (Unit may be set up to

follow saturated steam curve, see SPECIAL NOTE, pg. 3-9)

Heat – Liquid: uses volume and temperature to yield a compensated Mass flow

rate displayed in lbm/min (kg/h) and total in lbm (kg) as well as

Heat flow rate displayed in Btu/h (kW, kcal/h, MJ/h) and total in

kBtu (kWh, Mcal, MJ).

Del Heat – Liquids: uses volume and two temperatures to yield a compensated Mass

flow rate displayed in lbm/min (kg/h) and total in lbm (kg) as well

as Heat flow rate displayed in Btu/h (kW, kcal/h, MJ/h) and total in

kBtu (kWh, Mcal, MJ).

To access the Computation Menu:

Display Shows:

Press:

Sponsler V6.13 MS197

Run?

Sponsler V6.13 MS197

Set Computations?

Flow Computations: to advance the menu

Ideal Gas – Volume?

to backup menu

to select the displayed

computation

The nine options available in the Computations Menu are:

Ideal Gas – Volume?

Ideal Gas – Mass?

Steam Tables – Mass?

Liquids – Mass?

Liquids – Volume?

Heat – Gas?

Heat – Steam?

Heat – Liquid?

Del Heat – Liquids?

Page 22

22

3.3 SELECTING THE ENGINEERING UNITS

ENT

ENT

A

B

ENT

Engineering units establish the measuring system that is used for entry and display of the operating

parameters.

Four options are available to select the desired units for the application:

English (Imperial): Temperature

kPa (Metric): Temperature

2

Kg/cm

(Metric) Temperature oC; Pressure kg/cm2

bar (metric) Temperature

NOTE: The output data display units and the required variable units are determined by the

Computation and Engineering Units selected. A complete listing of input and output data units is given

in Appendix i.

To enter the Engineering Units Menu:

Display Shows:

Sponsler V6.13 MS197

Engineering Units?

Engineering Units? To advance menu

English?

To backup menu

To select displayed option

Engineering Units Menu:

Engineering Units:

English?

Engineering Units:

kPa (Metric)?

Engineering Units:

2

kg/cm

(Metric)?

Engineering Units:

bar (Metric)?

3.4 SETTING THE HARDWARE

The hardware selection determines the input terminals from which the unit will accept raw data. Internal

analog switches activate the proper terminals for the input type selected. Review the specification sheet for

each input device being used with the system to determine the required selection.

To access the Hardware Menu:

Display Shows:

Press:

Sponsler V6.13 MS197

Set Hardware?

o

F; Pressure PSI

o

C; Pressure kPa

o

C; Pressure bar

Press:

Page 23

23

Input Configuration:

A

ENT

A

A

ENT

ENT

ENT

Pressure? To advance Input Configuration

Menu

To access Pressure Input Type

Menu

Flowchart Representation of Hardware Menu:

Sponsler V6.13 MS197

Set Hardware?

ENT

Input Configuration? Input Configuration? Input Configuration?

Pressure? Temperature? Flow?

Input Type: Input Type: Input Type:

5 Volts? 5 Volts? 5 Volts?

10 Volts? 10 Volts? 10 Volts?

0-20mA? 0-20mA? 0-20mA?

4-20mA? 4-20mA? 4-20mA?

RTD (100 ohms) Digital Pulse

or*

Sub-Menu

Input Configuration:

Temperature two? Flowmeter Type:

Linear?

ENT

Orifice/Pitot?

Sixteen Point?

Input type:

5 Volts?

10 Volts?

0-20mA?

4-20mA?

RTD (100 ohms)?

* Channel 2 may be a pressure or temperature input depending on which computation is selected. The

pressure sub-menu is replaced by the temperature two sub-menu if the Del-Heat-Liquids Computation is

selected.

NOTE:

The pressure input is always the gage pressure of the line. Differential pressure is selected under the flow input type.

Input type “5 Volts?” is a 0 to 5 volt signal. 1 to 5 volt signals cannot be handled properly due to software constraints.

Input type “10 Volts?” is a 0-10 volt signal.

The flowmeter type sub-menu directly follows the flow input type.

Flowmeter types:

LINEAR is selected whenever the signal from the flowmeter is linear over the operating range.

ORIFICE/PITOT is the selection when the signal from the flowmeter represents a square law differential pressure. This

type is not available when Digital Pulse is selected as the input type.

SIXTEEN POINT is for compensating any other type on non-linear input sig nal s.

* * BE SURE THAT INPUT DEVICES ARE WIRED TO THE PROPER TERMINALS. IF HARDWARE SELECTION

DOES NOT MATCH WIRING, THE RESULT WILL B E ERRONEOUS READINGS.

Page 24

24

3.5 SETTING THE VARIABLES

At input = Minimum --

Enter the gage pressure value represent ed b y the

At input = Maximum --

Enter the gage pressure value represent ed b y the

10)

Atmospheric Pressure --

This value is added to the input gage pressure to

CLR

ENT

A

B

ENT

D

The variables determine how the input signals are interpreted by the software to display and output the

compensated flow. The parameters required for proper calculation are determined by the Computation,

Engineering Units, and Hardware Selections. The unit will automatically prompt for the required

parameters.

Use the numeric keypad to input the required variables. The key sets the decimal point when entering

a numerical value. The key acts as a backspace (erases the last digit typed) when entering a

numerical value. The key enters the data into memory.

To access the Variable Menu:

Display Shows:

Sponsler V6.13 MS197

Set Variables?

Select Setup Item: to advance Variable Menu

Pressure input

to backup menu

to access Pressure input

sub-menu

3.51 SETTING THE PRESSURE VARIABLES

The Pressure Variables determine how the input signals from channel 2 are interpreted. The

Pressure sub-menu is the same for all Computation and Hardware selections. The Engineering

units selected determine the pressure input units. The pressure input is always the gage pressure

of the line.

NOTE:

The Pressure sub-menu is replaced by a second temperature sub-menu if the Computation is DelHeat-Liquids.

The Pressure input is not required for Liquids-Mass or Volume computations. The functionality of

the input terminals and the sub-menu remain active and may be used if desired.

The Pressure Input Sub-menu & Definitions of Required Data:

Select Setup Item:

Pressure input?

ENT

Press:

ENT

Lo press?

Hi press?

Barometric?

lowest analog input (i.e. 4mA=10 PSIG. Enter 10)

highest analog input (i.e. 20mA=500 PSIG. Enter

calculate the absolute pressure value (i.e. 14.696

PSIA. Enter 14.696)

Page 25

25

Press alarm set point --

Lo alarm?

Enter Low Pressure value at which the unit activat es

Press alarm set point --

Enter High Pressure value at which the unit activates

PSIG)

NOTES

At input = Minimum --

Enter the temperature value repres en ted b y the

1

At input = Maximum --

Enter the temperature value repres en ted b y the

2

Base Reference --

Enter the temperature value at which the sp ecif ic

Temp alarm set point --

Enter Low Temperature value at which the unit

Temp alarm set point --

Enter High Temperature value at which the unit

0 0 0

ENT

an alarm relay (i.e. 5PSIG. Enter 5. Alarm relay is

activated when pressure input indicates 5 PSIG)

Hi alarm?

an alarm relay (i.e. 500 PSIG. Enter 500. Alarm

relay is activated when pressure input indicates 500

SPECIAL NOTE: To set the flow computer to follow the saturated steam curve with

1. Pressure and No temperature inputs: set Lo temp = 0.00 and Hi temp = 0.00. The

flow computer will use the pressure input to look up the corresponding temperature

on the saturated steam table for calculations and display.

2. Temperature and No pressure input: set Lo press = 0.00 and Hi press = 0.00.

The flow computer will use the temperature input to look up the corresponding

pressure on the saturated steam table for calculations and display.

3.52 SETTING THE TEMPERATURE VARIABLES

The temperature variables determine how the input signals from channel 1 * are interpreted. The

temperature sub-menu is determined by the Computation and Hardware selections.

NOTE:

* The Pressure sub-menu is replaced by Temperature 2 sub-menu if the Computation is Del-HeatLiquids. Follow the same setup procedure as outlined in this section.

Entering Negative Values:

A leading minus sign may be entered by pressing the key as the first keystroke when entering

a numerical temperature value.

Subsequent strokes of the key will enter zero into the number as usual. The key acts

conventionally in all other variab le su b-menus.

The Temperature Input Sub-menu & Definitions of Required Data:

Select Setup item:

Temperature input?

1

Lo temp?

Hi temp?

Temperature?

Lo alarm?

Hi alarm?

lowest analog output (i.e. 4mA=32o F. Enter 32)

highest analog input (i.e. 20mA=240oF. Enter 240)

gravity is measured (i.e. 60oF. Enter 60)

activates an alarm relay (i.e. 20o F. Enter 20. Alarm

relay is activated when temperature input indicates a

temperature of 20

o

F)

activates an alarm relay (i.e. 850o F. Enter 850.

Alarm relay is activated when pressure input

indicates a temperature of 850

o

F)

Page 26

26

NOTES

Pulses per unit vol.

Enter the K-Factor (Pulses per unit volume) from the

2

Specific gravity

Enter the specific gravity constant calculated at

3

Thermal Expansion

Enter the thermal coefficient of expansion for the

4

Mean

Enter the constant value for the ability of the liquid to

Cutoff: 0 to 40 KHz

Enter the highest pulse rate (frequency) at which the

width required

Flow alarm set point

Enter the low compensated flowrat e value at which

Flow alarm set point

Enter the high compensated flowrate va lu e at whic h

Notes:

1. These prompts do not appear if Hardware is RTD (100 ohms). The resistance input is

referenced to a look-up table to determine the temperature.

2. This prompt appears if a liquid computation is selected (Liquid-Mass, Liquid-Volume, Heat-

Liquid, Del Heat-Liquids).

3.53 SETTING THE FLOW VARIABLES

The Flow variables determine how the input signals from channel 3 are interpreted. The flow input

sub-menu will only prompt for the required variables as determined by the Computation and

Hardware selections. Flowcharts showing complete sub-menu prompts are given for each of the

Hardware selections. Use the flowchart corresponding to the Hardware selected and observe

notes as to which variables are required for the Computation selected.

HARDWARE SELECTIONS

Input Type Use Flow Chart

Page

Digital Pulse-Linear 3.54 3-10

Digital Pulse-Sixteen Point 3.55 3-11

Analog-Linear 3.6 3-15

Analog-Sixteen Point 3.61 3-16

3.54 FLOWCHART: DIGITAL PULSE-LINEAR

Select Setup item:

Flow input?

ENT

K-Factor?

1 Gas compressibility

Z Factor?

Gravity?

C(X10E-6)?

Spec Heat?

Input filter?

Lo alarm?

Hi alarm?

flowmeter calibration data sheet

Enter the Compressibility factor of the gas being

measured

Standard or the Base Reference Temperature for the

product being measured

liquid being measured

retain heat.

unit will accept pulses. Higher pulse rates are

ignored. NOTE: Also determines the minimum pulse

the flow alarm relay will activate

the flow alarm relay will activate

Page 27

27

NOTES:

NOTES

2

Specific gravity

Enter the specific gravity constant calculated at

3

Thermal Expansion

Enter the Thermal Coefficient of Expansion for the

Cutoff: 0 to 40 KHz

Enter the highest pulse rate (frequency) at which the

Flow alarm set point

Enter the high compensated flowrate va lu e at whic h

ENT

ENT

A

1. Used in Ideal Gas equation only.

2. Not used in Idea Gas-Volume or Steam equations.

3. Used in Liquids equations only.

4. Used in Heat-Gas, Del-Heat-Liquids and Heat-Mass equations only.

3.55 FLOWCHART: DIGITAL PULSE- SIXTEEN POINT

Select input item:

Flow input?

Linearize

16 Point?

Enter Point

Freq. 01?

** Refer to section 3.551 & 3.552 for

complete 16 point menu and

programming example

1 Gas Compressibility

Z Factor?

Gravity?

C(X10E-6)?

4 Mean

Spec Heat?

Input filter?

Flow alarm set point

Lo alarm?

Hi alarm?

NOTES:

1. Used in Ideal Gas equations only.

2. Not used in Ideal Gas-Volume or Steam equations.

3. Used in Liquids equations only.

4. Used in Heat-Gas, Del Heat-Liquids, and H eat-Mass equations only.

Enter the compressibility factor of the gas being

measured

Standard or the Base reference temperature for the

product being measured

liquid being measured

Enter the constant value for the ability of the liquid to

retain heat

unit will accept pulses. Higher pulse rates are

ignored. NOTE: Also determines the minimum pulse

width required

Enter the low compensated flowrate value at which

the flow alarm relay will activate

the flow alarm relay will activate

Page 28

28

3.551 DIGITAL PULSE – SIXTEEN POINT PROGRAMMING

C

The 16 Point Linearization is used when the flowmeter gives a non-linear signal. The unit

uses up to 16 different frequency and K-Factor entries to form a curve for linearizing the

input signal.

SPONSLER, INC. STRONGLY RECOMMENDS THOROUGH REVIEW AND

UNDERSTANDING OF THIS SECTION PRIOR TO PROGRAMMING THE 16 POINT

MENU.

NOTES:

1 A minimum of three points must be set up.

2. If two consecutive input values or K-Factors are set to zero, extrapolation is taken from

the last two non-zero points to determine a K-Factor used for calculations.

3. If the input frequency is above the highest or below the lowest frequency programmed,

the unit will use the last two points to extrapolate the K-Factor and calculate the

resulting actual flow. Care must be taken that the K-Factor doesn’t extrapolate to zero.

If this happens, the unit will give erroneous readings. To avoid this occurrence,

program point 01 frequency at zero and point 01 K-Factor at the same K-Factor for the

lowest input frequency as listed in the flowmeter calibration sheet.

4. Frequencies must be entered in ascending order.

not

5. The 16 point option will

in the Flow Variables menu.

6. Press the button when the desired number of points are entered. This will exit the

16 Point Setup routine and return to “Set Variables?” heading. If all 16 points are

programmed, the unit will automatically advance to the next required Setup item.

override the cutoff Input Filter frequency entered elsewhere

Page 29

29

3.552 PROGRAMMING EXAMPLE: `Flowchart: Digital Pulse – Sixteen Point

Select Setup item:

Linearize

Enter point

Press 0

Freq 09? 834.0000

Press 2274834

Freq 01? 0.0000

Press 1383067

Enter point

Press 948

Enter point

Press 32

Freq 10? 958.0000

Press 2303039

Freq 02? 32.0000

Press 1383067

Enter point

Press 1058

Enter point

Press 148

Freq 11? 1058.0000

Press 2323958

Freq 03? 148.0000

Press 2160356

Enter point

Press 1290

Enter point

Press 259

Freq 12? 1290.0000

Press 2384127

Freq. 04? 259.0000

Press 2161185

Enter point

Press 1514

Enter point

Press 377

Freq 13? 1514.0000

Press 2417309

Freq 05? 377.0000

Press 2203285

Enter point

Press 1741

Enter point

Press 492

Freq 14? 1741.0000

Press 2440122

Freq 06? 492.000

Press 2224646

Enter point

Press 1966

Enter point

Press 601

Freq 15? 1966.0000

Press 2458372

Freq 07? 601.000

Press 2235430

Enter point

Press 2195

Enter point

Press 723

Freq 16? 2196.0000

Press 2479318

Freq 08? 732.0000

Press 2256791

Gas Compressibility

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

Flow input?

**NOTE: This is an example of 16 point programming using calibration data for turbine Serial No. 107221. (See

next page) Actual Calibration data must be entered for the specific turbine flowmeter used with the unit.

16 point?

ENT

Freq 01?

K-Factor 01?

Freq. 02?

K-Factor 02?

Freq 03?

K-Factor 03?

Freq 04?

K-Factor 04?

Freq 05?

Press

Press

Press

Press

Press

Press

Press

Press

Press

ENT

ENT

ENT

Enter point

Freq 09?

K-Factor 09?

Freq 10?

K-Factor 10?

Freq 11?

K-Factor 11?

Freq 12?

K-Factor 12?

Freq 13?

K-Factor 13?

Press 834

Press

ENT

Press

Press

Press

ENT

ENT

Press

Press

ENT

Press

Press

Press

Press

K-Factor 05?

Freq 06?

K-Factor 06?

Freq. 07?

K-Factor 07?

Freq 08?

K-Factor 08?

NOTE: To view the previously entered value at any data entry point, press ENT. The stored value will display. If the display value doesn’t need

to be changed, press ENT. The value will be retained and the unit will automatically advance to the next data entry point. If the value needs to

be changed, press CLR. Press the number keys to display the desired value to be entered, then press ENT. The value will be stored and the

unit will automatically advance to the next data entry point.

Press

Press

Press

Press

Press

Press

Press

ENT

ENT

ENT

ENT

Freq 14?

K-Factor 14?

Freq 15?

K-Factor 15?

Freq 16?

K-Factor 16?

Z Factor

Press

Press

Press

Press

Press

Press

ENT

ENT

ENT

ENT

ENT

Page 30

30

PT

16

0

MEAN TOTAL CYCLES (PER WEIGHT USED):

10

11

12

13

141516

1383067.5

1383067.5

2160356.1

2161185.6

2203285.3

2224646.2

2235430.4

2256791.3

2274834.0

2303038.7

2323984.8

2343271.9

2384127.2

2397400.0

2417309.2

2433070.7

2440121.9

2448624.8

2458372.0

2471437.4

2479318.1

32

148

259

377

492

601

723

834

948

1058

1176

1290

1398

1514

1637

1741

1861

1966

2087

2195

6669

10417

10421

10624

10727

10779

10882

10969

11105

11206

11299

11496

11560

11656

11732

11766

11807

11854

11917

11955

208.145

70.417

40.221

28.192

21.816

17.918

15.058

13.147

11.720

10.589

9.605

8.909

8.267

7.698

7.166

6.760

6.345

6.030

5.710

5.447

0.0014

0.0041

0.0072

0.0103

0.0133

0.0161

0.0192

0.0220

0.0247

0.0273

0.0301

0.0325

0.0350

0.0376

0.0404

0.0428

0.0456

0.0480

0.0507

0.0531

0.004822

65

0.9986

0.036022

0.30000

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

USA

WESTMINSTER S.C. 29693

2363 SANDIFER BLVD.

SPONSLER CO., INC.

1ea.

CRYO

17-4

304

107211

COIL NO.

:RF22M

BEARINGS:

ROTOR MATERIAL:

HOUSING MATERIAL:

SERIAL NO.:

MODEL NO.: MF40-CB-PH-1/4A-4RFX

HR

2

AIR

1

9334

CPFT3

"K"

FREQ. CPS

APPROX.

CYCLES

TOTAL

SECONDS

TIME

ACFM

RATE

ACFM

TRUE VOL.

DEG.FAR.

TEMP.

SP.GR.

(TRUE)

SP.GR.1.000

VOL.GALLONS

LBS.

WEIGHT

PT.

DATE: 13-Jan-92

CALIBR AT ED BY:

TEST STAND NO.:

FLUID:

CALIBRATION #:

WORK ORDER #:

SENSING ELEMENT CONSTANT (MEAN CYCLES/ACF):

09

08

07

06

05

04

03

02

01

*

NOTE: 16 Point Linearization frequency points must be in ascending order. Disregard the PT column on the left;

Calibration Data points are in descending order.

Establish the points that require linearization based on the flowrate range required and the non-linearity of the

specific meter.

* Point 01 frequency should be “0”, with K-Factor of lowest frequency listed.

Page 31

31

3.6 ANALOG LINEAR INPUT SETTINGS

NOTES

Select Setup item:

1

Gas compressibility

Enter the compressibility factor of the gas being

2

Specific gravity

Enter the specific gravity constant calculated at

At input = minimum

Enter the flow value at which the analog input is

At input = maximum

Enter the flow value at which the analog input is

Low flow

Enter the lowest flow value below which any

3

Thermal Expansion

Enter the Thermal Coefficient of Expansion for the

4

Mean

Enter the constant value for the ability of the liquid to

Flow alarm set point

Enter the low compensated flowrat e value at which

Flow alarm set point

Enter the high compensated flowrate value at which

Graphical representation of the Analog Linear sub-menu

Flow input?

ENT

Z Factor?

Gravity?

Lo flow?

Hi flow?

Cutoff?

C(X10E-6)?

Spec Heat?

measured

standard or the Base Reference Temperature for the

product being measured

lowest (i.e. no flow = 4.00mA. Enter 0)

highest (i.e. 300 m3/hr = 20.00mA. Enter 300)

calculations are unnecessary. For example, a small

leakage when valve is closed to be ignored

liquid being measured

retain heat

Lo alarm?

Hi alarm?

NOTES:

1. Used in Ideal Gas equations only.

2. Not used in Ideal Gas-Volume or Steam equations.

3. Used in Liquids equations only.

4. Used in Heat-Gas, Del Heat-Liquids, and H eat-Liquids equations only.

the flow alarm relay will activate

the flow alarm relay will activate

Page 32

32

3.61 ANALOG 16 POINT INPUT SETTINGS

NOTES

ENT

ENT

Select Setup item:

Flow input?

Linearize

16 Point?

1 Gas compressibility

Z Factor?

2 Specific gravity

Gravity?

At input = minimum

Lo flow?

At input = maximum

Hi flow?

Low flow

Cutoff?

3 Thermal Expansion

C(X10E-6)?

ENT

Enter Point

Actual 01?

Actual 01? 0.000

K-Factor 01?

Enter the compressibility factor of the gas being

measured

Enter the specific gravity constant calculated at

standard or the Base Reference Temperature for the

product being measured

Enter the flow value at which the analog input is

lowest (i.e. no flow = 4.00mA. Enter 0)

Enter the flow value at which the analog input is

highest (i.e. 300 m

3

/hr = 20.00mA. Enter 300)

Enter the lowest flow value below which any

calculations are unnecessary. For example, a small

leakage when valve is closed to be ignored

Enter the Thermal Coefficient of Expansion for the

liquid being measured

4 Mean

Spec Heat?

Flow alarm set point

Lo alarm?

Flow alarm set point

Hi alarm?

Enter the constant value for the ability of the liquid to

retain heat

Enter the low compensated flowrat e value at which

the flow alarm relay will activate

Enter the high compensated flowrate va lu e at whic h

the flow alarm relay will activate

NOTES:

1. Used in Ideal Gas equations only.

2. Not used in Ideal Gas-Volume or Steam equations.

3. Used in Liquids equations only.

4. Used in Heat-Gas, Del Heat-Liquids, and H eat-Liquids equations only.

Page 33

33

3.7 ANALOG ORIFICE/PITOT INPUT SETTINGS

NOTES

ENT

Graphical representation of the Analog Orifice/Pitot sub-menu

Select Setup item:

Flow input?

1 Gas compressibility

Z Factor?

2 Specific gravity

Gravity?

Meter compensation

Factor (K1)?

At input = minimum

Delta P lo?

At input = maximum

Delta P hi?

Low Flow

Cutoff?

3 Thermal Expansion

C(X10E-6)?

4 Mean

Spec Heat?

Flow alarm set point

Lo alarm?

Flow alarm set point

Hi alarm?

NOTES:

1. Used in Ideal Gas equations only.

2. Not used in Steam equations only.

3. Used in Liquids equations only.

4. Used in Heat-Gas, Del Heat-Liquids, and H eat-Liquids equations only.

Page 34

34

3.8 SETTING THE FLOW OUTPUT VARIABLES

Select Setup item:

Flow at 4mA out

Enter the compensated Flow Rate value to be represented by 4mA

Digital pulse out

Enter a multiplying factor for the 5V digital pulse output. This

increment of the flow totalizer (maximum Output rate is 50 kHz).

A A A A A

The Flow Output Variables determine how the output signals reflect the compensated flow. The Flow

Output sub-menu is the same for all Computation or Hardware Selections.

NOTE: It is not necessary to set up the Flow Output if it is not required.

Flow Output?

ENT

Min flow?

Flow at 20mA out

Max flow?

Scaling?

output

Enter the compensated Flow Rate value to be represented by

20mA output

factor multiplies the incremental counts of the flow totalizer and

outputs a pulse as required.

EXAMPLE:

Scaling factor of 0.1 outputs one pulse for every 10 increments of

the flow totalizer. Scaling factor of 10 outputs ten pulses for each

CLEARING THE TOTALIZER: RESETTING THE TOTALIZER TO 0.000

The totalizer can be cleared (reset to zero) in either of the two top-level menus: “Setup” or “Running”.

NOTE: The totalizer accumulates only while the unit is in the “Running” side of the menu.

To clear Totalizer in “Setup” menu:

Sponsler V6.13 MS197

Run?

Sponsler V6.13 MS197

Set Computations?

Sponsler V6.13 MS197

Engineering Units?

Sponsler V6.13 MS197

Set Hardware?

Sponsler V6.13 MS197

Set Variables?

Page 35

35

Sponsler V6.13 MS197

A

A A A

ENT

A

A

A

Clear Totalizer?

Totalizer Cleared This message is momentarily displayed to verify that the totalizer

Sponsler V6.13 MS197

Check Alarm?

* To Clear Totalizer in “Running” Menu:

Press

Running...

Show Data?

Running...

Go To Standby?

Running...

Setup Display?

Running...

Setup Print List?

Running...

Print System Setup?

Running...

Clear Totalizer?

Totalizer Cleared This message is momentarily displayed to verify that the totalizer

Running...

Show Data?

ENT

is cleared. The menu then advances to the next item

is cleared. The unit then returns to the top of the menu.

Page 36

36

CHECKING THE ALARM: VIEW THE MOST RECENT ALARM CONDITION

ENT

B

A

A

A

ENT B ENT

A

A

A

ENT

If the alarm should go off, the point which went into alarm most recently may be checked and quieted from

either of the Top-Level menus.

To Check the Alarm in “Setup” Menu:

Sponsler V6.13 MS197

Run?

Sponsler V6.13 MS197

Set Computations?

Sponsler V6.13 MS197

Engineering Units?

Sponsler V6.13 MS197

Set Hardware?

Sponsler V6.13 MS197

Set Variables?

Sponsler V6.13 MS197

Clear Totalizer?

Sponsler V6.13 MS197

Check Alarm?

The most recent alarm condition will be

Alarm Condition displayed on the top line. Pressing will

Press ENT to Quiet de-energize the corresponding alarm relay. If

The condition that caused the alarm still exists

When the unit is returned to “Running” mode,

The alarm relay will again energize.

Alarm Condition Momentarily displayed to indicate the alarm

Alarm Cleared has been cleared.

The unit automatically advances to the next

menu.

Sponsler V6.13 MS197 To check that no other alarm condition exists,

Lock/Unlock? press to backup to the check alarm option.

Sponsler V6.13 MS197

Check Alarm?

No Alarm Condition Momentarily displayed to indicate that no alarm conditions exist.

The unit will automatically advance to the next menu.

Sponsler V6.13 MS197

Lock/Unlock?

Page 37

37

LOCK/UNLOCK

Advance or Backup the menu until the display indicates:

Sponsler V6.13 MS197

or

Running...

Machine is unlocked

Enter a 5 digit code number (NOTE: Code may

Machine is unlocked

As soon as the fifth digit is entered, 5 “*”s will be

Machine is unlocked

Now confirm:

Enter the 5 digit code again

Machine is unlocked

As soon as the fifth digit is entered, 5 “8”s will be

Sponsler V6.13 MS197

Running...

After the lock has been initiated in the “Setup” mode, only “:Check alarm?” or “Lock/Unlock”

****Locked!!****

ENT

ENT

Lock is used to prevent unwanted changes to programming. No changes through the front panel or RS232 port can be made while the unit is locked. The lock may be initialized in either the “Setup” or “Running”

mode. Once the unit is locked, the operating mode can’t be changed. If unit is locked in “Setup” mode,

“Running” mode can’t be accessed. If the unit is locked in “Running” mode, “Setup” mode can’t be

accessed.

NOTE: Any 5 digit security code (except 00000) may be used to lock the unit. The same 5 digit code must

be entered to unlock the unit. Place the 5 digit security code used to lock the unit in a safe location for

future reference.

To Lock:

Lock/Unlock

Enter code:

Enter code: *****

Now confirm: *****

Real time clock? or

may be accessed. Any attempt to enter one of the programming menus or the “Running” mode

will display:

Push to continue

Press

Lock/Unlock?

NOT be 00000). As each digit is pressed an “*”

will appear on the display to verify that the digit

has been entered.

displayed momentarily. The unit will then

advance to “Now confirm:”

displayed momentarily. The unit will lock and

then advance to the next menu item.

Show Data?

In the “Running” mode the lock prevents access to “Go to Standby?” and “Clear Totalizer?”. All

other functions of the “Running” menu remain accessible.

Page 38

38

To Unlock:

Machine is locked

Enter the 5 digit code number. No confirming

Machine is locked

The unit will unlock and then advance to the next

Note:

This error message may display after the entry of the 5 digit code

ENT

Advance or Backup the menu until the display indicates:

Sponsler V6.13 MS197

Lock/Unlock

Enter code:

Enter code: *****

Sponsler V6.13 MS197

Real time clock? or

Bad lock code

Push to continue

in the lock/unlock procedure. Pressing enter will exit the

Lock/Unlock menu option and advance to the next menu item.

or

Press

Running...

Lock/Unlock?

ENT

step is required to unlock the unit.

menu item as soon as the correct code is

entered.

Running...

Show Data?

Page 39

39

REAL TIME CLOCK

Sponsler V6.13 MS197

Select item:

Enter time:

Enter the correct hour and minutes based on 24 hour c lock.

Select item:

Enter date:

Enter the correct date in the format: Month (1-12). Date (1-

Sponsler V6.13 MS197

The unit will automatically advance to the next menu item.

NOTE:

Bad Time value

Error messages indicating that the numerical value

or

Bad Date value

Syntax error

Error message indicating that the numerical values

ENT D ENT

ENT

ENT

D

D

ENT

The SP3000 has a real time clock and calendar that can be set from the front keypad while the unit is in

the “Setup” mode. The clock cannot be set while in the “Running” mode. The time and date are saved

upon power down: however, there is no battery backup to update the time and date during loss of power.

NOTE: The time must be in 24 hour format.

Advance “Setup” menu until display indicates:

Real time clock?

Set time?

Enter hours (00-23) and minutes (00-59) based on 24 hour clock.

Example: 2:32 p.m. must be entered as 14:32 (Decimal point must be entered between

hour and minutes).

Hr. Min?

Example: 14 32 (2:32 p.m.)

Press

ENT

Set date?

Mo. Da. Yr. ?

31). Year (00-99) Example: 4 23 92 (April 23,

1992)

Press

Serial Interface?

ENT

Push to continue

entered is invalid.

Push to continue

ENT

Push to continue

are not entered in the correct format.

Page 40

40

RUNNING MODE

Running...

Press to activate the live display of flow data

Running...

Press to access the “Setup” mode for setting variables

Running...

Press to program the order of the live display

Running...

Used with RS-232 option to select the items printed out the

Running...

Used with RS-232 option to print out all parameter values out

Running...

Press to reset the Totalizer to 0.000

Running...

Press to view the Hardware configurations for the

Running...

Press to view the Flow Computation selected

Running...

Press to view the input variables configurations

Running...

Press to view the most recent alarm condition

Running...

Press to access and change the lock function

ENT

ENT

ENT

ENT

ENT

The “Running” mode is the normal operating mode for the SP3000. Flow measurement is performed only

in the “Running” mode.

Top Level Running Menu:

Show Data?

Go to Standby?

Setup data display?

ENT

Setup print list?

Print System setup?

Clear Totalizer?

Examine Hardware?

Examine Comps?

Examine Variables?

Check Alarm?

Lock/Unlock?

serial port

the serial port

ENT

Temperature, Pressure, and Flow Inputs

ENT

ENT

Page 41

41

8.1 SHOW DATA

A

A

ENT

B

ENT

A

C

This menu item will start the data list scrolling on the LCD display. The order of display for up to 16 items

can be designated in the “Setup data display?” menu. Each item can be displayed more than once in the

scan list. Each item will be displayed for approximately two seconds. If an item requires longer display

time, it may be selected for consecutive display points.

The parameters available for display selection (from a total of 19) are dependent upon the Computation

and Hardware setup. The system automatically determines the data available for display based on the

programmed parameters.

DISPLAY DATA DESCRIPTIONS:

1. Time and Date Current time and date

2. Flow Rate Filtered & Compensated with engineer ing un its

3. Mass Flow Filtered & Compensated with engineering units

4. Heat Flow Filtered & Compensated with engineering units

5. Totalizer Compensated accumulated flow with engineering units

6. Totalizer (Mass) Compensated accumulated flow

7. Heat Totalizer Compensated accumulated heat flow

8. Temperature Filtered & Scaled temperature in degrees

9. Pressure Filtered & Scaled pressure in units of measurement

10. Uncompensated Flow Filtered but not compensated with engineering units

11. Raw Flow (Channel 3) Analog value of flow input

12. Raw Pressure (Channel 2) Raw analog value of pressure input

13. Raw Temperature (Channel 1) Raw analog value of temperature input

14. Raw RTD Input 1 Raw analog value of RTD input in mA

15. RTD Ohms (Channel 1) Resistance of RTD

16. Analog Output Output value in mA

17. Specific Volume Current specific volume from Steam Tables

18. Specific Heat Current specific heat from Steam Tables

19. Flow Frequency Raw input pulse frequency

8.1.1 DISPLAY DATA SETUP

Running...

Show Data?

Running...

Go to Standby?

Running...

Setup data display?

Select item #1

Time & Date? Press to advance the list of data available for display

Press to backup the list of data available for display

Press to select the data for display. The item # will increment as each selection is

Continue to advance or backup the list and select desired data for display

NOTE: Up to 16 display items may be selected. Pressing the button exits the routine and returns to “Show Data?”

made

when the desired number of display items is entered. If 16 items are entered, the unit exits the routine and

returns to “Show Data?” upon entering item 16.

(DISREGARD IF RS-232 OPTION IS NOT INSTALLED IN UNIT )

Page 42

42

8.2 PRINT LIST (RS-232 OPTION)

ENT

A

ENT

ENT

C A A

A

During normal operation, the instrument may be set up to print out, through the RS-232 port, the important

operating data such as flow rate, temperature, or pressure. The same data that is available for display can

be scanned and printed out the serial port of the instrument.

The operator can designate up to 16 items of this list that will be printed, and in which order they will be

printed. NOTE: Each item can be selected more than once in the print list even though there is no

advantage to doing this.

Use the same procedure and the same list to set up the list of items to print as used for setting up the

display list. (Refer to previous section 8-11)

(Select the item by pressing the key while the item is displayed.

For Example:

DISPLAY:

PRESS:

Select item #1

Flow Rate

Select item #2

Totalizer

Select item #3

Temperature

Select item #3

Pressure

Continue the process until a list of all the parameters to print while the instrument is running has been

established. Use the key to break out of the menu after the list is created. Make sure that the Print

Interval and the serial port have been activated in the Standby Menu for enabling this feature.

8.3 PRINT SYSTEM SETUP (RS-232 OPTION)

This feature is for use in documentation. When this menu item is selected, an entire print out of all the user

defined parameters is sent out the RS-232 port.

DISPLAY:

Running...

Show Data?

Running...

Go to Standby?

Continue Pressing until:

Running...

Print system setup?

A system dump of the parameters through the RS-232 serial communications port is performed.

ENT

PRESS:

ENT

Page 43

43

8.4 EXAMINE HARDWARE

A

A

ENT

A C A A A

A

ENT

A B C

This feature is used to examine how the hardware configuration of the unit has been set up.

DISPLAY:

Running...

Show data?

Continue Pressing until

Running...

Examine Hardware?

Once selected, use key to scroll through the hardware setup.

Use the key to return to “Show Data?”

8.5 EXAMINE COMPUTATIONS

This feature is used to examine which computation has been selected.

DISPLAY:

Running...

Show Data?

Continue Pressing until

Running...

Examine Comps?

Once selected, use key to return to “Show Data?”

8.6 EXAMINE VARIABLES

This feature is used to examine the various parameters and constants that have been entered.

DISPLAY:

Running...

Show Data?

Continue Pressing until

Running...

Examine Variables?

Once selected, use and keys to scroll through the parameters setup.

Use the or key to return to “Show Data?”

ENT

ENT

PRESS:

PRESS:

PRESS:

Page 44

44

8.7 CHECK ALARM

A

A A A

A A A

A

ENT

ENT

A

A

ENT

Press

Running...

Show Data?

Running...

Go to Standby?

Running...

Setup data display?

Running...

Setup print list?

Running...

Print system setup?

Running...

Clear Totalizer?

Running...

Examine Hardware?

Running...

Examine Comps?

Running...

Examine Variables?

Running...

Check Alarm?

Alarm Condition The most recent alarm condition will be

Press to quiet displayed on the top line. Press to de Energize the corresponding alarm relay. If

the condition that caused the alarm still exists,

the alarm will again energize.

Alarm Condition Momentarily displayed to indicate that the

Alarm Cleared alarm has been cleared.

Running... The unit will automatically advance to the top

Show Data? of the “Running” menu. This procedure must

be repeated until “No Alarm Condition” is

displayed.

Page 45

45

8.8 LOCK/UNLOCK

Running...

Press

Machine is unlocked

Enter a 5 digit code number (NOTE: Code may

Running...

After the unit is locked, any attempt to “Go to Standby?” (crossover to the “Setup” menu) or to

****Locked!!****

Advance or Backup the menu until the display indicates:

Running...

Press

Machine is locked

Enter the 5 digit code number. No confirming

ENT

ENT

ENT

Lock is used in the “Running” mode to prevent unwanted changes in the programming. Lock prevents

crossover to the “Setup” mode and the totalizer can not be reset to zero. All other functions in “Running”

mode remain operable.

NOTE: Any 5 digit security code (except 00000) may be used to lock the unit. The same 5 digit code must be entered to unlock the

unit. Place the 5 digit security code used to lock the unit in a safe location for future reference.

To Lock:

Advance or Backup the menu until the display indicates:

Lock/Unlock?

Enter code:

NOT be 00000). As each digit is pressed an “*”

will appear on the display to verify that the digit

has been entered.

Machine is unlocked

Enter code: *****

As soon as the fifth digit is entered, 5 “*”s will be

displayed momentarily. The unit will then

advance to “Now confirm:”

Machine is unlocked

Now confirm:

Machine is unlocked

Now confirm: *****

Enter the 5 digit code again

As soon as the fifth digit is entered, 5 “8”s will be

displayed momentarily. The unit will lock and

then advance to the next menu item.

Show Data?

“Clear Totalizer” will result in the following display:

Push to continue

All other functions of the “Running” mode remain accessible.

To Unlock:

ENT

Lock/Unlock?

Enter code:

Machine is locked

Enter code: *****

step is required to unlock the unit.

The unit will unlock and then advance to the next

menu item as soon as the correct code is

entered.

Running...

Show Data?

Note:

Bad lock code

Push to continue

This error message may display after the entry of the 5 digit code

in the lock/unlock procedure. Pressing enter will exit the

Lock/Unlock menu option and advance to the next menu item.

Page 46

46

PRINCIPLES OF OPERATION

9.1 GENERAL

This chapter explains in detail how the instrument calculates the mass flow based on specific data input.

Each parameter is updated at a 2Hz rate. Therefore, all references to the machine’s “interval” in the

following descriptions indicates a period of 0.4 seconds.

9.2 TEMPERATURE CALCULATIONS

If an RTD is used as a temperature transducer, the computer runs a constant current through both the RTD

and the internal semi-precision resistor in series with it. (See section 1.52) The computer measures the

voltage drop across each individually and calculates a ratio; thus, determining the actual resistance of the

RTD. A look-up table is used to linearize and convert the ohmic reading to temperature in degrees. This

value is checked against keyed in alarm limits and the alarm relay is activated if necessary.

Any other type of temperature transducer must present a voltage or current to Channel 1 of the computer.

This value is checked against a keyed in temperature parameters to calculate the actual temperature.

9.3 PRESSURE CALCULATIONS

Any pressure transducer must present a voltage or current to Channel 2 of the computer. The raw

pressure value is digitized from Channel 2 and then scaled according to the two keyed in pressure

parameters to calculate the actual pressure. The value is checked against keyed in alarm limits and the

alarm relay is activated if necessary.

9.4 FLOW CALCULATIONS

The value provided by the digital input pulse accumulator is divided by the K-Factor to find the

instantaneous flow over the interval. The result is then filtered according to the keyed in flow filter

parameter to get uncompensated flow.

The following definitions and calculations are used to determine Volumetric, Mass and Heat Flow.

Definition of Terms:

BR: Base Reference Temperature entered by user.

c: Thermal coefficient of expansion for the media (X 10

DENSITY: Density as calculated from parameters and inputs.

DP: Differential pressure in inches of water calculated from flow input.

FLOW: Uncompensated flow calculated from input.

HZ: Input frequency in cycles per seconds.

K: The meter calibration factor in pulses per cubic foot or gallon.

K1: Factor used in Orifice/Pitot calculations.

kPa: The absolute pressure (Gage pressure + Barometric pressure).

MASS: Mass flow rate calculated using temperature, pressure and flow. Del Heat equation uses

temp 1 for Mass calculations.

PSIA: The absolute pressure (Gage pressure + Barometric pressure).

PSIG: Upstream gage pressure calculated from input.

SG: Specific Gravity as entered by user with respect to Standard conditions or the Base

Reference temperature.

SH: Specific Heat as entered by user or from Steam Tables.

SV: Specific Volume from Steam Tables.

TEMP: Temperature as calculated from input.

UCFLOW: Uncompensated flow as determined by calculations.

VOL: Volumetric flow as determined by calculations.

Z: Gas compressibility factor as entered by user.

%: Percentage as a decimal point of full scale of the raw input.

-6

).

Page 47

47

FLOW INPUT CALCULATIONS:

Digital:

(Hz/K) x (60 sec/1 min) = UCFLOW

Analog-Linear:

Lo-Flow + (Hi Flow – Lo Flow) x (%) = UCFLOW

Analog-Orifice/Pitot: