Page 1

Service Training

Linde IC-Engined Fork Truck

H 50/60/70/80 D/T

H 50/60/70/80 D-02/T-02

H 50/60/70/80 D-03/T-03

Type 353

This training material is only provided for your use and remains the exclusive property of

LINDE MATERIAL HANDLING

Page 2

Page 3

Service Training

09.06

TABLE OF CONTENT

4 IC-engined fork truck H 50/60/70/80, Type 353 1

4.1 Engine drive 1

4.1.1 Engine model BF6M 1012 E 1

4.1.1.1 Engine specifications 1

4.1.1.1.1 Explanation of the engine number 2

4.1.1.2 Changing and tightening the drivebelt 3

4.1.1.3 Adjusting valve clearance 4

4.1.1.4 Adjusting the injection valve 7

4.1.1.5 Checking the compression pressure 9

4.1.1.6 Cylinder head 10

4.1.1.7 Adjusting the begin of delivery 12

4.1.8 Special tools 16

4.1.2 Engine model BF6M 2012 18

4.1.2.1 Overview of engine components 18

4.1.2.2 Engine specifications 20

4.1.2.2.1 Explanation of the engine number 11

4.1.2.3 Replacement of V-ripped belt 22

4.1.2.4 Adjusting valve clearance 23

4.1.2.5 Checking and adjusting leak-fuel-free injection nozzles 24

4.1.2.6 Thermostat 30

4.1.2.7 Checking the compression pressure 32

4.1.2.8 Cylinder head 33

4.1.2.9 Injection pump 35

4.1.2.9.1 Adjusting the begin of delivery 35

4.1.2.9.2 Replacement of the injection pump 37

4.1.2.10 Heater flange 43

4.1.2.11 Special tools 46

4.2 Transmission 1

4.2.1 Hydrostatic transmission 2

4.2.1.1 Schematic diagram of the drive 3

4.2.1.2 Transmission specifications 4

4.2.1.3 Hydraulic circuit diagram 6

4.2.2 Operation of the hydrostatic transmission 20

4.2.2.1 Travel control unit P 20

Page 4

09.04

Service Training

4.2.2.2 Operation of control valve block N = Power Limiter 23

4.2.2.3 Braking 24

4.2.2.4 Auxiliary brake 24

4.2.2.5 Lock-out logic - reversing lock 26

4.2.2.6 Flushing of the circuit and housing 28

4.2.3 Hydraulic remote control 30

4.2.3.1 Adjustments 31

4.2.3.1.1 Hydraulic neutral position 31

4.2.3.1.2 Primary adjustment of start of control 31

4.2.3.1.3 Mechanical limitation of the swashplate angle 31

4.2.3.1.4 Hydraulic remote control HPV 105 -02 32

4.2.3.1.5 Reversal lock (logic lock out) 34

4.2.3.1.6 Reducing the truck speed 34

4.2.4 Wheel drive 35

4.2.4.1 Reduction gearbox with disc brake (GR 80 -02/-03/-04) 36

4.2.4.2 Servicing the reduction gearbox (GR 80 -02/-03/-04) 38

4.2.4.3 Disc brake repairs 39

4.2.4.4 Reduction gearbox GR 80 -06 with multiple disc brake 40

4.2.4.5 Repair on the reducing gear GR 80 -06 41

4.2.5 Troubleshooting 48

4.2.5.1 Connecting diagram for troubleshooting 48

4.2.5.2 Tools and aids for measurements 50

4.2.5.3 Explanations to troubleshooting 52

4.2.5.4 Hydraulic speed control for the engine 53

4.2.5.4.1 Functional test 53

4.2.5.4.2 Troubleshooting 53

4.2.5.5 Hydraulic braking system 58

4.2.5.5.1 Functional test 58

4.2.5.5.2 Troubleshooting 58

4.2.5.6 Pressure equality and start of control 61

4.2.5.6.1 Functional test 61

4.2.5.6.2 Troubleshooting 61

4.2.5.7 Hydrostatic travel drive 65

4.2.6 Test and adjustment instructions for hydraulic primary and secondary control 77

4.2.6.1 Q

4.2.6.2 Q

4.2.6.3 Q

of variable displacement pump BPV 100 78

max

of hydraulic motors HMV 105 80

max

of hydraulic motors HMV 105 81

min

Page 5

Service Training

4.3 Chassis 1

4.3.1 Overhead guard - torsion mounting 2

4.3.1.1 Work on the overhead guard 3

4.4 Steering system 1

4.4.1 Power steering circuit diagram 2

4.4.2 Series 304 steering axle 4

4.4.2.1 Description 4

4.4.3 Steering axle removal 5

4.4.3.1 Steering axle installation 6

4.4.4 Steering axle repairs 6

4.4.4.1 Renewing the wheel bearings 7

4.4.4.2 Steering knuckle removal and installation 8

4.4.4.3 Steering cylinder removal and installation 10

4.4.4.4 Replacing the steering cylinder seals 12

4.4.4.5 Steering stop adjustment 13

09.04

4.5 Controls 1

4.5.1 Accelerator and brake pedal adjustment 2

4.5.2 Speed control 5

4.5.2.1 Speed control up to 10/95 5

4.5.2.2 Speed control from 11/95 7

4.5.3 Medium wheel speed 8

4.5.4 Start of drive wheel rotation 9

4.5.5 Brake shaft stop screws 10

4.5.6 Symmetry of the travel control 11

4.5.6.1 Drive wheel start of rotation 11

4.5.6.2 Engine speed increase 12

4.5.7 Pressure difference Δp13

4.5.8 Modification of engine acceleration 14

4.6 Electrical system 1

4.6.1 Wiring diagram 2

4.6.2 Wiring diagram for options 6

4.6.3 Wiring diagram, 353 -02 9

4.6.4 Wiring diagram for options, 353 -02 13

4.6.5 Wiring diagram, 353 -03 Diesel 17

4.6.6 Wiring diagram for options, 353 -03 21

Page 6

12.05

4.6.7 Electrical system circuit diagram, type 353 -03 LPG 25

4.6.8 Wiring diagram for options, 353 -03 29

4.6.9 Central electrical system 34

4.6.10 Central electrics of series 353 -03 36

4.6.10.1 Relay and fuses of 353 -03 Diesel 36

4.6.10.2 Relay and fuses of 353 -03 LPG 38

4.6.10.3 Relay and fuses for 353 -03 particulate trap 40

4.7 Working hydraulics 1

4.7.1 Working hydraulics circuit diagram 2

4.7.1.1 Explanation of the working hydraulics 3

4.7.2 Tilt cylinder 4

4.7.2.1 Tilt cylinder removal, installation, adjustment, sealing 5

4.8 Mast 1

4.8.1 Mast removal 2

4.8.2 Lift cylinder removal, installation 3

4.8.3 Sealing the lift cylinder 4

Service Training

4.9 LP gas model H 50/60/70/0, Type 353 1

4.9.1 Drive engine 1

4.9.1.1 Technical data on engine 1

4.9.1.1.1 Technical data on engine up to 12/2004 1

4.9.1.1.2 Technical data on engine from 01/2005 2

4.9.1.2 Note on the engine number 3

4.9.1.3 Changing and tensing V-belt 4

4.9.1.4 Checking and setting valve clearance 5

4.9.1.5 Removing and installing the cylinder head 6

4.9.2 Electrical system 9

4.9.2.1 Electronic ignition system 9

4.9.2.1.1 Electronic ignition system up to 12/2004 9

4.9.2.1.2 Electronic ignition system from 01/2005 14

4.9.2.1.2.1 Mechanical ignition timing 19

4.9.2.2 Electronic engine-speed control 23

4.9.2.3 Electrical system circuit diagram 26

4.9.2.3.1 Electrical system circuit diagram up to 12/2004 26

4.9.2.3.2 Electrical system circuit diagram from 01/2005 30

Page 7

Service Training

4.9.3 Propellant gas system 33

4.9.3.1 Diagram 33

4.9.3.2 Functional description of the propellant gas system 34

4.9.4 Inspections and adjustments 42

4.9.4.1 Ignition system 42

4.9.4.2 Installation of the engine speed control system 46

4.9.4.3 Inspection of the engine speed control system 48

4.9.4.4 Adjustment of the propellant gas mixers 53

12.05

Page 8

12.05

Service Training

Page 9

Service Training

09.04

4 IC-ENGINED FORK TRUCK H 50/60/70/80, TYPE 353

4.1 ENGINE DRIVE

4.1.1 ENGINE MODEL BF6M 1012 E

4.1.1.1 ENGINE SPECIFICATIONS

Engine model BF6M 1012 E

Displacement 4790 cc

Power 85 kW at 2250 rpm

Opening pressure of injection valve 260 bar

Compression ratio 17,5 : 1

Compression 28 - 33 bar

Maximum difference in pressure 4 bar

Firing order 1 - 5 - 3 - 6 - 2 - 4

+ 0,1

+ 0,1

mm

mm

Valve clearence (cold) inlet: 0,3

outlet: 0,5

+ 50

Lower idling speed 750

Upper idling speed 2300

rpm

+ 50

rpm

Oil pressure at lower idling speed

and 125 °C oil temperature min. 0,8 bar

Section 4.1

Page 1

Count the cylinders beginning at the flywheel end.

Page 10

Section 4.1

Page 2

4.1.1.1.1 EXPLANATION OF THE ENGINE NUMBER

09.04

Service Training

1 Manufacturer's plate with type and engine number

2 Engine number stamped on the crankcase

NOTE: A second type plate was affixed to the rocker cover by Linde.

EXPLANATION OF THE ENGINE NUMBER

B F 6 M 1012 E

external cooling

series

coolant/water

number of cylinders

aspirated engine

turbocharged

Page 11

Section 4.1

Service Training

4.1.1.2 CHANGING AND TIGHTENING THE DRIVEBELT

CHANGING THE DRIVEBELT

- Slacken the alternator and tensioner fastening screws (2).

- Turn the tensioning screw (3) anti-clockwise, press the alternator in and remove the drivebelt.

- Check the pulley for wear, renewing it if necessary.

- Install a new drivebelt.

TIGHTENING THE DRIVEBELT

- Turn the tensioning screw (3) clockwise until the required tension is obtained.

- Check the tension with a gauge (1), Part No. 000 941 9435.

- Tighten the screws (2) again.

Settings:

Initial installation 400

Check after 15 minutes Operation under load

and retighten the belt, if necessary 300 ± 50 N

With re-use 250 ± 50 N

+ 50

09.04

N

Page 3

Page 12

Section 4.1

Page 4

4.1.1.3 ADJUSTING VALVE CLEARANCE

The adjustment can be carried out when the engine is cool or warm after a cooling period of at least 30

minutes (oil temperature < 80 °C).

Valve clearance: Inlet 0.3 mm

Outlet 0.5 mm

VALVE CLEARANCE SCHEMATIC

09.04

Service Training

Crankshaft position 1

Turn the engine until the valve inlet and outlet of

cylinder 1 are just open.

adjustable

NOTE: When a new rocker cover is installed, increase the valve clearance by 0.1 mm. Adjust the valve

clearance to normal values after 50 service hours.

Crankshaft position 2

Turn the engine one full revolution (360 °).

not adjustable

Page 13

Section 4.1

Service Training

VALVE CLEARANCE ADJUSTMENT BY MEANS OF A TORQUE ANGLE GAUGE FROM SERIAL

NUMBER E1 X353 T 000268

In engines which are equipped with a thrust washer in the valve spring retainer (Fig. A1), the valve

clearance can only be adjusted by means of a torque angle gauge.

This method using a torque angle gauge may also be applied for the DEUTZ engines BF6M 1012 / 2012

installed in series 353 trucks up to now, which have so far been adjusted by means of the feeler gauge

method.

09.06

Page 5

Fig. A1 Valve gear with pressure disk

New method for checking and adjusting the valve clearance (with torque angle gauge)

Prerequisite: The engine must have cooled down for at least 30 minutes; oil temperature below 80 °C.

- Carry out the preparations (e.g. remove cylinder head cover).

- Turn crankshaft until valve overlap on cylinder no. 1 is reached. This means: Inlet valve starts opening,

outlet valve closes.

- Crankshaft position 1 in accordance with corresponding adjustment diagram (see "valve clearance

schematic").

- Fix magnet of torque angle gauge on cylinder head.

- Place torque anlge gauge 8190 with screw driver bit on setting screw. Use screw driver bit 8191.

Checking the valve clearance

- Put T-handle (4) on torque angle gauge (1) (Fig. 5).

- Loosen locknut (3) on rocker arm and support

setting screw (2) with T-handle against turning

(figure A5).

- Set torque angle gauge to 0 (zero) and suppport

setting screw (2) with T- handle against turning

(figure A4).

- Turn setting screw with screw driver bit clockwise

until rocker arm contacts thurst washer free from

clearance.

- Read the value (setting angle) on the torque angle

gauge.

Fig. A5

Page 14

Section 4.1

Page 6

Adjustment of valve clearance

- Set torque angle gauge to 0 (zero) (Fig. A4).

Take care not to turn the setting screw!

- Turn setting screw back (counterclockwise) until reaching the corresponding

setting angle.

Setting angle of inlet valve: 75°

outlet valve: 120°

Locknut tightening torque: 20 Nm

- Put T-handle on torque angle gauge (Fig.

A5).

- Support setting screw with T-handle and

tighten locknut with socket wrench (open

end). Observe instructions for tightening!

- Adjust valve clearance for the remaining

valves as described above.

- Remove tools.

09.06

Service Training

Fig. A 4 Valve clearance adjustment

(example: TCD 2012 2V with exhaust gas

recirculation)

1 = Torque angle gauge 8190

Tools required for adjustment

Deutz part number 8190 8191

The required special tools may be ordered from the address below.

Please quote the corresponding ordering number.

WILBÄR

Wilhelm Bäcker GmbH & Co. KG

Postfach 140580

D42826 Remscheid

E-Mail: info@wilbaer.de

Tel.: ++49 (0) 2191 9339-0

Page 15

Section 4.1

Service Training

4.1.1.4 ADJUSTING THE INJECTION VALVE

CHECKING THE OPENING PRESSURE

NOTE: Use only test oil acc. to ISO 4113 or diesel fuel for the test.

CAUTION: When checking injection nozzles, take care that the fuel jet does not hit the hands. Due to the

high pressure, the fuel can penetrate the skin and cause severe injuries.

- Install the injection nozzle on the nozzle tester.

- Press the lever down slowly. Read the pressure at the start of fuel ejection and adjust the pressure, if

necessary, by changing the shims.

09.06

Page 7

Specified pressure

New injection nozzles 260

Pressure for re-usability 255

ADJUSTING THE INJECTION NOZZLE OPENING PRESSURE

- Clamp the holder 110110 for the injection valve in a vise.

- Place the top part of the injection holder into the holder 110110 and unscrew the union nut.

Sequence of disassembly:

1. Union nut

2. Injection nozzle

3. Intermediate piece

4. Pressure spindle

5. Compression spring

6. Shims

7. Nozzle body

+8

bar

+8

bar

- Adjust the pressure by fitting the correct shim. The thicker the shim,

the higher the opening pressure will be. Re-assemble the injection

valve. Tighten the union nut to a torque of 40 - 50 Nm. Check the

injection valve with the nozzle tester.

Page 16

Section 4.1

Page 8

CHECKING FOR LEAKS

- Dry the nozzle and nozzle holder - blow dry with an air jet.

- Slowly press the tester hand lever down until a pressure approx. 20 bar under the previously obtained

opening pressure is reached.

- The nozzle does not leak if no drops of fuel show within 10 seconds.

If a drop of fuel leaks out, disassemble the injection valve and eliminate the leak by cleaning the injection

nozzle. If this does not remedy the leak, renew the injection valve.

Do not rework the valve.

BUZZING AND JET TEST

- Shut off the compression tester pressure gauge.

The buzzing test is an audible test for determining if the needle is moving easily in the nozzle body. New

injection nozzles have a different buzzing behaviour as opposed to used ones. Wear in the area of the

needle seat lets the buzzing behaviour deteriorate. A nozzle that does not buzz despite cleaning must be

replaced.

09.06

Service Training

A used injection valve must buzz audibly if the hand lever is operated quickly and it must produce a finely

atomized spray. The shape of the spray can vary greatly from that of a new injection valve.

INSTALLING THE INJECTION NOZZLE

- Using some grease, slide the seal onto the injection valve.

- Insert the injection valve.

- Put the clamping shoe in place.

- Torque the screws to 16

+ 5

N.

Page 17

Section 4.1

Service Training

4.1.1.5 CHECKING THE COMPRESSION PRESSURE

- Remove the injection nozzle.

- Check the valve clearance.

- Insert and fasten connector 100110 along with the special seal.

- Connect a compressometer and crank the engine with the starter.

Specified pressure 28 - 33 bar

Max. difference in pressure 4 bar

NOTE: The measured compression pressure depends on the RPM of the starter when the

measurement is carried out and on the altitude of the place the engine is operated in.

For this reason it is not possible to define exact limits. The compression pressure check is

only recommended as a means of comparing all cylinders in relation to each other. If the

difference in pressure exceeds 15 %, dismantle the appropriate cylinder unit and determine

the cause.

09.06

Page 9

Page 18

Section 4.1

Page 10

4.1.1.6 CYLINDER HEAD

REMOVING THE CYLINDER HEAD

- With the engine cool, slacken the cylinder head bolts evenly and in steps in the reverse order as given

in the schematic "Cylinder head bolt tightening sequence".

DETERMINING THE CYLINDER HEAD GASKET

NOTE: For the adjustment of the gap, there are 3 different cylinder head gaskets, which identifiable

by holes.

- Place the dial gauge along with spacers 10075C on the sealing surface of the cylinder block and set the

dial gauge to "0".

- Turn the piston to TDC and note the projecting length of the piston at the points of measurement.

- Select the correct cylinder head gasket according to the largest projecting length of the piston.

Projecting length Identification of

of piston cylinder head gasket

09.06

Service Training

0.43 - < 0.64 mm 1 hole

0.64 - < 0.74 mm 2 holes

0.74 - 0.85 mm 3 holes

Page 19

Section 4.1

Service Training

INSTALLING THE CYLINDER HEAD

NOTE: Sealing surfaces for cylinder head gaskets must be clean and free of oil. Pay attention to the

fitting sleeve.

- Check the cylinder head for warping.

- Put the cylinder head in place.

- Check the cylinder head bolts for stretching, see "Visual check".

- Lightly the oil and screw in the cylinder head bolts.

NOTE: Use the cylinder head bolts no more than 5 times.

- Insert the push rods.

- Mount the rocker arm bracket.

- Slightly oil and screw in the long cylinder head bolts.

- Torque the cylinder head bolts as specified and according to the tightening sequence.

Pre-tightening: 1st step 30 Nm

2nd step 80 Nm

Retightening: 90°

09.06

Page 11

CYLINDER HEAD BOLT TIGHTENING SEQUENCE

Manifold Side

Page 20

Section 4.1

Page 12

4.1.1.7 ADJUSTING THE BEGIN OF DELIVERY

If an injection pump must be replaced, the begin of delivery must be re-adjusted by determining the shim

thickness anew.

DETERMINING THE SHIM THICKNESS

The old injection pump and shim are not required for this procedure.

NOTE: From 4/95, the mounting depth of the injection pump has been increased by 10 mm so that the

EP code changes from 70 to 170 and the basic dimension L

mm to 119 mm.

The metod of determining the thickness of the shims for the old versions remains the same.

Proceed as follows:

In the column marked "EP", read the EP code for cylinder 3 on the type plate on the rocker cover,

e.g. 070 or 170 (reading sequence: line 1 = cylinder 1, line 2 = cylinder 2, etc.).

09.06

Service Training

of the injection pump from 109

0

Page 21

Section 4.1

Service Training

09.96

09.06

Page 13

Take the corrected injection pump installation dimension (EK) in Table 1a/1b according to the EP code,

e.g. 111.725 mm.

Table 1a: EP code beginning with '0'

E

K

(mm) (mm) (mm) (mm) (mm)

110.0 110.6 111.2 049 111.8 073 112.4 097

110.025 110.625 111.225 050 111.825 074 112.425 098

110.05 110.65 111.25 051 111.85 075 112.45 099

110.075 110.675 111.275 052 111.875 076 112.475 100

110.1 110.7 111.3 053 111.9 077 112.5 101

110.125 110.725 111.325 054 111.925 078 112.525 102

110.15 110.75 031 111.35 055 111.95 079 112.55 103

110.175 110.775 032 111.375 056 111.975 080 112.575 104

110.2 110.8 033 111.4 057 112.0 081 112.6 105

110.225 110.825 034 111.425 058 112.025 082 112.625 106

110.25 110.85 035 111.45 059 112.05 083 112.65

110.275 110.875 036 111.475 060 112.075 084 112.675

110.3 110.9 037 111.5 061 112.1 085 112.7

110.325 110.925 038 111.525 062 112.125 086 112.725

110.35 110.95 039 111.55 063 112.15 087 112.75

110.375 110.975 040 111.575 064 112.175 088 112.775

110.4 111.0 041 111.6 065 112.2 089 112.8

110.425 111.025 042 111.625 066 112.225 090 112.825

110.45 111.05 043 111.65 067 112.25 091 112.85

110.475 111.075 044 111.675 068 112.275 092 112.875

110.5 111.1 045 111.7 069 112.3 093 112.9

110.525 111.125 046 111.725 070 112.325 094 112.925

110.55 111.15 047 111.75 071 112.35 095 112.95

110.575 111.175 048 111.775 072 112.375 096 112.975

Code E

K

Code E

K

Code E

K

Code E

K

Table 1b: EP code beginning with '1'

Code

E

K

(mm) (mm) (mm) (mm) (mm)

120.0 120.6 121.2 149 121.8 173 122.4 197

120.025 120.625 121.225 150 121.825 174 122.425 198

120.05 120.65 121.25 151 121.85 175 122.45 199

120.075 120.675 121.275 152 121.875 176 122.475 200

120.1 120.7 121.3 153 121.9 177 122.5 201

120.125 120.725 121.325 154 121.925 178 122.525 202

120.15 120.75 131 121.35 155 121.95 179 122.55 203

120.175 120.775 132 121.375 156 121.975 180 122.575 204

120.2 120.8 133 121.4 157 122.0 181 122.6 205

120.225 120.825 134 121.425 158 122.025 182 122.625 206

120.25 120.85 135 121.45 159 122.05 183 122.65

120.275 120.875 136 121.475 160 122.075 184 122.675

120.3 120.9 137 121.5 161 122.1 185 122.7

120.325 120.925 138 121.525 162 122.125 186 122.725

120.35 120.95 139 121.55 163 122.15 187 122.75

120.375 120.975 140 121.575 164 122.175 188 122.775

120.4 121.0 141 121.6 165 122.2 189 122.8

120.425 121.025 142 121.625 166 122.225 190 122.825

120.45 121.05 143 121.65 167 122.25 191 122.85

120.475 121.075 144 121.675 168 122.275 192 122.875

120.5 121.1 145 121.7 169 122.3 193 122.9

120.525 121.125 146 121.725 170 122.325 194 122.925

120.55 121.15 147 121.75 171 122.35 195 122.95

120.575 121.175 148 121.775 172 122.375 196 122.975

Code E

K

Code E

K

Code E

K

Code E

K

Code

Page 22

Section 4.1

Page 14

09.96

09.06

Service Training

Read the code for the injection pump length (A) on the new injection pump, e.g. 53.

The basic dimension of the injection pump (L

) is 109/119 mm.

0

Determine the theoretical thickness of the shim (T

T

= EK - (L0 + A/100)

S

).

S

TS = 111.725 mm - (109 mm + 53/100 mm) or TS = 121.725 mm - (119 mm + 53/100 mm)

T

= 2.195 mm

S

Choose the thickness of the shim (SS) according to Table 2.

T

2.195 = SS 2.2 mm

S

Table 2

Theor. Thickness Shim Theor. Thickness Shim

" Thickness "Ts" Thickness

"T

S

(mm) (mm) (mm) (mm)

0.95 - 1.049 1.0 2.45 - 2.549 2.5

1.05 - 1.149 1.1 2.55 - 2.649 2.6

1.15 - 1.249 1.2 2.65 - 2.749 2.7

1.25 - 1.349 1.3 2.75 - 2.849 2.8

1.35 - 1.449 1.4 2.85 - 2.949 2.9

1.45 - 1.549 1.5 2.95 - 3.049 3.0

1.55 - 1.649 1.6 3.05 - 3.149 3.1

1.65 - 1.749 1.7 3.15 - 3.249 3.2

1.75 - 1.849 1.8 3.25 - 3.349 3.3

1.85 - 1.949 1.9 3.35 - 3.449 3.4

1.95 - 2.049 2.0 3.45 - 3.549 3.5

2.05 - 2.149 2.1 3.55 - 3.649 3.6

2.15 - 2.249 2.2 3.65 - 3.749 3.7

2.25 - 2.349 2.3 3.75 - 3.850 3.8

2.35 - 2.449 2.4

""S

"S

S

S

"

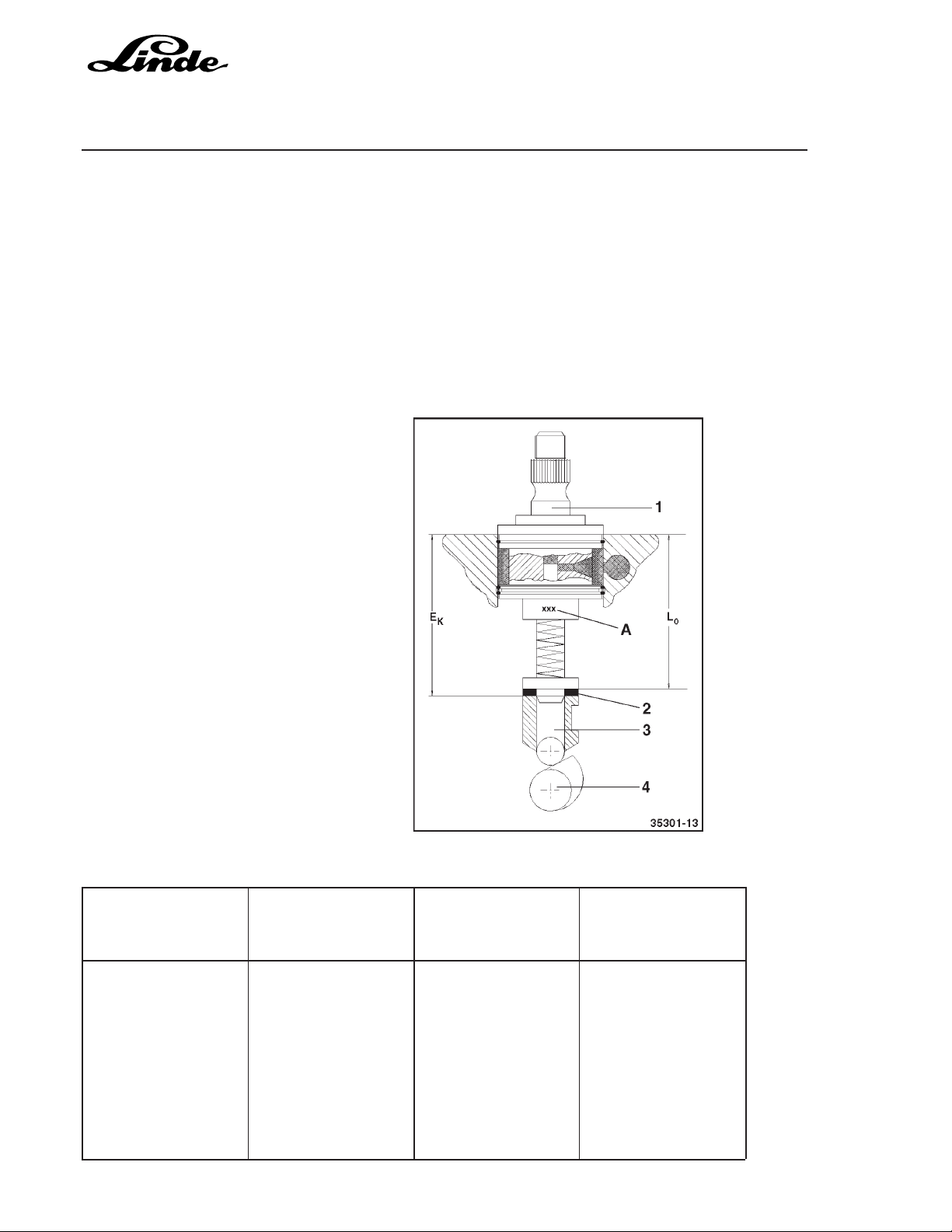

1 Injection pump

2 Shim thickness S

S

3 Roller shaft

4 Camshaft on base circle

A Code

E

Installation dimension

K

L0Basic dimension 109/119 mm

Page 23

Section 4.1

Service Training

INSTALLING THE INJECTION PUMP

- Place the required shim (2) on the roller shaft.

- Turn the injection pump control lever to the stop position.

- Set the roller shaft (3) on the base circle.

- Slightly oil the O-ring and the hole for the ring.

- Remove the shut-off solenoid and replace by device 100830.

Bring the control rod to the stop position with device 100800 and lock it in this position.

- Insert the injection pump (1).

- Install the flange and tighten the bolts evenly to a torque of 5 Nm.

- Loosen the bolts by 60 °.

- Using socket head 110460 and the torque spanner, turn the injection pump several times clockwise and

anti-clockwise by 5 ° to 15 ° and determine the average friction torque (RM), e.g. 4.8 Nm.

- Turn the injection pump anti-clockwise as far as the stop with an average friction torque (RM) of 4.8 Nm

+ 1 Nm = 5.8 Nm and hold it in place.

Tighten the flange bolts alternately to a torque of 7 Nm, 10 Nm and 30 Nm.

- Remove device 100830 and, using a screwdriver, check the control rod for ease of movement by sliding

it back and forth.

- Reconnect the plug on the shut-off solenoid and switch on the ignition.

- Install the shut-off solenoid with a new seal.

09.96

09.06

Page 15

NOTE: Oil the seal lightly.

Tighten the screws to a torque of 21 Nm.

NOTE: The shut-off solenoid must click when the ignition is switched on and off.

Page 24

Section 4.1

Page 16

4.1.8 SPECIAL TOOLS

E 14 Torx socket heads, long version

E 20

51 Socket head, 15 mm, long version for injection valve

(union nut)

2461 Compression pressure tester

09.06

Service Training

7532 Torque spanner

7773 A Socket spanner 1/4 "

8189 Torx tool kit

91 107 V-belt tension gauge

100 110 Connector for compression pressure tester

Page 25

Service Training

100 400 Dial gauge M2T with locking ring

100 750 Dial gauge with spacers for measuring TDC and projecting

length of piston

110 110 Holder for injection valve, 11 mm

110 460 Socket head for turning the injection pump

09.96

09.06

Section 4.1

Page 17

114 010 Tool for connecting glow plug cables

142 710 Removal tool (hook) for crankshaft sealing rings

142 890 Assembly tool for rear crankshaft sealing ring

142 900 Assembly tool for crankshaft sealing ring

Clamping device for control rod

Address your order for special tools to:

Fa. Wilbär, P.O. Box 14 05 80, D-42826 Remscheid

Page 26

Section 4.1

Page 18

4.1.2 ENGINE MODEL BF6M 2012

4.1.2.1 OVERVIEW OF ENGINE COMPONENTS

09.06

Service Training

Page 27

Service Training

1 Generator

2 Oil filler hole

3 Heater flange

4 Coolant connection-recovery line

5 Fan pulley

6 Fuel lift pump

7 Coolant pump

8 V-belt pulley on crankshaft

9 Belt tensioner pulley

10 Mounting legs

11 Oil pan

12 Oil filling nozzle

13 Öil filter casing with engine oil cooler

14 Oil level dipstick

15 Provisions for attaching a compressor or hydraulic pump

16 Fuel filter cartridge

17 Öil filter cartridge

18 Lifting magnet

09.06

Section 4.1

Page 19

Page 28

Section 4.1

Page 20

09.06

Service Training

4.1.2.2 ENGINE SPECIFICATIONS

Engine model BF6M 2012 E

Displacement 6060 cc

Power 74.9 kW at 2200 rpm

Opening pressure of injection valve 260 bar

Compression ratio 19 : 1

Compression 30 - 38 bar

Maximum difference in pressure 4 bar

Firing order 1 - 5 - 3 - 6 - 2 - 4

+ 0,1

+ 0,1

mm

mm

Valve clearence (cold) inlet: 0,3

outlet: 0,5

Lower idling speed 800 rpm

+ 50

Upper idling speed 2300

rpm

Oil pressure at lower idling speed

and 125 °C oil temperature min. 0,8 bar

Count the cylinders beginning at the flywheel end.

Page 29

Service Training

4.1.2.2.1 EXPLANATION OF THE ENGINE NUMBER

09.06

Section 4.1

Page 21

1 Manufacturer's plate with type and engine number

2 Engine number stamped on the crankcase

NOTE: A second type plate was affixed to the cylinder head cover by Linde.

EXPLANATION OF THE ENGINE NUMBER

B F 6 M 2012 E

external cooling

series

coolant/water

number of cylinders

aspirated engine

turbocharged

Page 30

Section 4.1

Page 22

4.1.2.3 REPLACEMENT OF V-RIPPED BELT

Fit the V-ripped belt and tension it.

Pressh the belt tensioner pulley (1) in direction of the

arrow. Fit the V-ripped belt, and finally place it on pulley

(2). Loosen the belt tensioner pulley in opposite direction

to the arrow until the V-ripped belt is tensioned.

If the V-ripped belt is used again, make sure to observe

the wear limit.

Measure the distance "a" between the lug of the movable

tensioning arm and the stop of the fixed tensioner housing.

If the distance "a" is less than 3 mm, the V-ripped belt must

be replaced.

09.06

Service Training

The V-ripped belt is equipped with a spring-loaded belt

tensioner pulley that tensions automatically, and it is not

re-tightened.

Page 31

Section 4.1

Service Training

4.1.2.4 ADJUSTING VALVE CLEARANCE

The adjustment can be carried out when the engine is cool or warm after a cooling period of at least 30

minutes (oil temperature < 80 °C).

09.06

Page 23

Valve clearance: Inlet 0.3

Outlet 0.5

VALVE CLEARANCE SCHEMATIC

Crankshaft position 1

Turn the engine until the valve inlet and outlet of

cylinder 1 are just open.

+0.1

mm

+0.1

mm

adjustable

Crankshaft position 2

Turn the engine one full revolution (360 °).

not adjustable

NOTE: When a new rocker cover is installed, increase the valve clearance by 0.1 mm. Adjust the

valve clearance to normal values after 50 service hours.

ADJUST & CHECK THE VALVE CLEARANCE

- Unscrew the venting valve and swivel it to the side.

- Dismount the cylinder head cover.

- Crankshaft position as shown in adjusting diagram.

- Prior to a valve clearance adjustment the motor must

have cooled down for at least 30 minutes: Oil temperature

less than 80 °C.

- Check the valve clearance (1) between the rocker cog

(2) and the valve (3) with feeler gauge (6) (Gauge must

overcome slight resistance to be slid in).

For permissible valve clearance see above.

Tighten locknut: Demand value: 20 ±2 Nm

Page 32

Section 4.1

Page 24

4.1.2.5 CHECKING AND ADJUSTING LEAK-FUEL-FREE INJECTION NOZZLES

CHECKING THE OPENING PRESSURE

NOTE: Use only test oil acc. to ISO 4113 or diesel fuel for the test.

CAUTION: When checking injection nozzles, take care that the fuel jet does not hit the hands. Due to the

high pressure, the fuel can penetrate the skin and cause severe injuries.

- Install the injection nozzle on the nozzle tester.

- Press the lever down slowly. Read the pressure at the start of fuel ejection and adjust the pressure, if

necessary, by changing the shims.

NOTE: After checking and adjustment, the pressure in the spring chamber in the injection nozzle must

be reduced to zero before the injection nozzles are installed in the engine, in order to prevent

possible starting difficulties of the engine.

CAUTION! During the checking procedure, the tension nut must only be unscrewed and re-tightened

according to tightening instructions. Disassembling of the leakage fuel free injection nozzle

is not permitted during the warranty period.

09.06

Service Training

Page 33

Service Training

CHECK INJECTORS

The injectors are not equipped with bores for leak -off fuel.

The surplus fuel cannot be discharged and accumulates

in the space above the injector needle in the area of the

spring of the injector holder. Actuation of the manual lever

of the injector tester is no longer possible in this case.

For relieving the pressure in the area of the spring,

slacken the tensioning nut before each test and re-tighten

to the specified torque after the test.

- Slacken tensioning nut by approx. 180° and re-tighten.

Use dolly 110 110 for injector.

Specified tightening torque: 30 - 40 Nm

09.06

Section 4.1

Page 25

- Connect injector to nozzle tester 8008.

Caution

Beware of injection nozzle jet. The fuel

penetrates deeply into the skin and may cause

blood poisoning.

- With pressure gauge switched-on, slowly press lever of

nozzle tester 8008 down.

The pressure at which the gauge pointer stops or

suddenly drops is the opening pressure.

Opening pressure: 220 bar

NOTE: The pressure will build-up again in the area of

the spring after approx. 3 - 4 strokes. Slacken

the tensioning nut once again, re-tighten to

specified tightening torque and repeat the

test.

Page 34

Section 4.1

Page 26

SETTING OF INJECTORS

For a correction of the opening pressure:

- Remove injector from nozzle tester 8008. Remove

tensioning nut and uninstall all components. Use dolly

110 110 for the injector.

Sequence of parts disassembly and re-assembly

1. Tensioning nut

2. Nozzle

3. Adapter

4. Thrust pin

5. Compression spring

6. Shim

09.06

Service Training

- Adjust opening pressure by selecting appropriate shim.

A thicker shim will increase the opening pressure. Reassemble injector. Tighten tensioning nut.

Specified tightening torque: 30 - 40 Nm

- Check injector on nozzle tester 8008 once again.

Page 35

Service Training

LEAK TEST

- Dry nozzle and nozzle holder by compressed air.

- Press hand lever of tester slowly down until apressure

of approx. 20 bar below the previous opening pressure

reading is attained.

- The nozzle is leak proof if there is no dripping within

10 seconds.

09.06

Section 4.1

Page 27

- If there is dripping, dismantle the injector and clean to

remedy the leak. If this does not work, replace the

nozzle by a new one.

- No reworking allowed!

Page 36

Section 4.1

Page 28

BUZZING AND SPRAY PATTERN TEST

- Switch-off pressure gauge of tester.

- The buzzing test permits audible checking for ease of

movement of the nozzle needle in the nozzle body. New

injectors compared to used ones have a different buzzing

sound.

- This buzzing sound deteriorates by wear in the area of

the needle seat. If there is no buzzing of a nozzle despite

cleaning, it must be replaced by a new one.

- A used injector must produce an audible buzzing sound

upon rapid actuation of the hand lever and provide for a

weil atomised spray pattern. The spray pattern may

differ noticeably from that of a new injector.

RE-INSTALLATION OF INJECTORS

09.06

Service Training

- Place new slightly greased sealing rings onto injectors

and install injectors.

NOTE: This notch on the injectors must face away

from the claws.

- Place claws in place and tighten bolts hand tight.

Page 37

Service Training

- Attach new injection lines with sealing rubber elements.

Tighten cap screws finger-tight.

HINWEIS: When installing the injection lines make sure

that sealing cones are exactly aligned one on

top of the other.

Subsequent bending is not allowed. Injeetion

lines must not be re-used.

09.06

Section 4.1

Page 29

- Tighten bolts of claws.

Specified tightening torque: 16

- Pre-tension cap nuts of injection lines on injection pumps

and injection nozzles to a tightening torque of approx.

5 Nm. Then tighten cap nuts.

Specified tightening torque: 25

NOTE: Use claw grip wrench 8018.

+ 5

+3,5

Nm

Nm

Page 38

Section 4.1

Page 30

4.1.2.6 THERMOSTAT

REMOVAL

- Drain coolant, collect it, and dispose of it in accordance

with legal standards.

- Dismantle outlet connecting piece. Remove thermostat.

NOTE: Collect coolant and dispose of it in

accordance with legal standards.

- Attach new sealing ring to thermostat. Insert thermostat

together with new sealing ring.

09.06

Service Training

NOTE: Mind operating position of thermostat. Arrow

(venting notch) points to the top.

- Attach outlet connecting piece.

Required tightening torque: 30 Nm

Page 39

Service Training

CHECKING

Check thermostat in removed condition.

- Measure dimension „a“ on the thermostat.

NOTE: „a“ = stroke beginning at approx. 83 ± 2°C (T1)

„b“ = stroke ending at approx. 95°C (T2)

- Heat up thermostat in the water bath.

For a determination of the exact opening point, the

temperature reading should take place as closely as

possible to the thermostat, however, without contacting

the latter.

The water must be continuously stirred to arrive at a

uniform distribution of temperature. The rate of rise of

temperature should not exceed 1°C/ min. at a maximum

otherwise opening will be delayed correspondingly.

09.06

Section 4.1

Page 31

- Measure dimension „b“ on the thermostat.

Stroke length at indicated temperature (T2) 8 mm at

aminimum.

Page 40

Section 4.1

Page 32

4.1.2.7 CHECKING THE COMPRESSION PRESSURE

- Remove the injection nozzle.

- Check the valve clearance.

- Insert and fasten connector 100110 along with the special seal.

- Connect a compressometer and crank the engine with the starter.

Specified pressure 30 - 38 bar

Max. difference in pressure 4 bar

NOTE: The measured compression pressure depends on the RPM of the starter when the

measurement is carried out and on the altitude of the place the engine is operated in.

For this reason it is not possible to define exact limits. The compression pressure check is

only recommended as a means of comparing all cylinders in relation to each other. If the

difference in pressure exceeds 15 %, dismantle the appropriate cylinder unit and determine

the cause.

09.06

Service Training

Page 41

Section 4.1

Service Training

4.1.2.8 CYLINDER HEAD

REMOVING THE CYLINDER HEAD

- With the engine cool, slacken the cylinder head bolts evenly and in steps in the reverse order as given

in the schematic "Cylinder head bolt tightening sequence".

DETERMINING THE CYLINDER HEAD GASKET

NOTE: For the adjustment of the gap, there are 3 different cylinder head gaskets, which identifiable

by holes.

- Place the dial gauge along with spacers 100750 on

the sealing surface of the cylinder block and set the

dial gauge to "0".

- Turn the piston to TDC and note the projecting length

of the piston at the points of measurement.

09.06

Page 33

- Compare the largest value with the table and determine

the corresponding cylinder head gasket.

Projecting length Identification of

of piston cylinder head gasket

0.33 - < 0.55 mm 1 hole

0.56 - < 0.65 mm 2 holes

0.66 - 0.76 mm 3 holes

Page 42

Section 4.1

Page 34

INSTALLING THE CYLINDER HEAD

NOTE: Sealing surfaces for cylinder head gaskets must be clean and free of oil. Pay attention to the

fitting sleeve.

- Check the cylinder head for warping.

- Put the cylinder head in place.

- Check the cylinder head bolts for stretching, see "Visual check".

- Lightly the oil and screw in the cylinder head bolts.

NOTE: Use the cylinder head bolts no more than 5 times.

- Insert the push rods.

- Mount the rocker arm bracket.

- Slightly oil and screw in the long cylinder head bolts.

- Torque the cylinder head bolts as specified and according to the tightening sequence.

Pre-tightening: 1st step 30 Nm

2nd step 80 Nm

Retightening: 90°

09.06

Service Training

CYLINDER HEAD BOLT TIGHTENING SEQUENCE

Manifold Side

Page 43

Section 4.1

Service Training

09.06

Page 35

4.1.2.9 INJECTION PUMP

4.1.2.9.1 ADJUSTING THE BEGIN OF DELIVERY

If an injection pump must be replaced, the begin of delivery must be re-adjusted by determining the shim

thickness anew.

DETERMINING THE SHIM THICKNESS

The old injection pump and shim are not required for this procedure.

Proceed as follows:

In the column marked "EP", read the EP code for cylinder 3 on the name plate on the cylinder head cover,

e.g. 070 (reading sequence: line 1 = cylinder 1, line 2 = cylinder 2, etc.).

Take the corrected injection pump installation dimension (EK) in Table 1 according to the EP code,

e.g. 120.875 mm.

Table 1

E

K

(mm) (mm) (mm) (mm)

119,25 230 119,85 254 120,45 278 121,05 302

119,275 231 119,875 255 120,475 279 121,075 303

119,3 232 119,9 256 120,5 280 121,1 304

119,325 233 119,925 257 120,525 281 121,125 305

119,35 234 119,95 258 120,55 282 121,15 306

119,375 235 119,975 259 120,575 283 121,175 307

119,4 236 120,0 260 120,6 284 121,2 308

119,425 237 120,025 261 120,625 285 121,225 309

119,45 238 120,05 262 120,65 286 121,25 310

119,475 239 120,075 263 120,675 287 121,275 311

119,5 240 120,1 264 120,7 288 121,3 312

119,525 241 120,125 265 120,725 289 121,325 313

119,55 242 120,15 266 120,75 290 121,35 314

119,575 243 120,175 267 120,775 291 121,375 315

119,6 244 120,2 268 120,8 292

119,625 245 120,225 269 120,825 293

119,65 246 120,25 270 120,85 294

119,675 247 120,275 271 120,875 295

119,7 248 120,8 272 120,9 296

119,725 249 120,825 273 120,925 297

119,75 250 120,35 274 120,95 298

119,775 251 120,375 275 120,975 299

119,8 252 120,4 276 121,0 300

119,825 253 120,425 277 121,025 301

EP code E

K

EP code E

K

EP code E

K

EP code

Page 44

Section 4.1

Page 36

09.06

Service Training

Read the code for the injection pump length (A) on the new injection pump, e.g. 42.

The basic dimension of the injection pump (L

) is 117.5 mm.

0

Determine the theoretical thickness of the shim (T

TS = EK - (L0 + A/100)

T

= 120.875 mm - (117.5 mm + 42/100 mm)

S

TS = 2.955 mm

Choose the thickness of the shim (S

T

2.955 = SS 3.0 mm

S

) according to Table 2.

S

1 Injection pump

2 Shim thickness S

S

3 Roller shaft

4 Camshaft on base circle

A Code

E

Installation dimension

K

L0Basic dimension 117.5 mm

).

S

Table 2

Theor. Thickness Shim Theor. Thickness Shim

" Thickness "Ts" Thickness

"T

S

(mm) (mm) (mm) (mm)

0,95 - 1,049 1,0 2,45 - 2,549 2,5

1,05 - 1,149 1,1 2,55 - 2,649 2,6

1,15 - 1,249 1,2 2,65 - 2,749 2,7

1,25 - 1,349 1,3 2,75 - 2,849 2,8

1,35 - 1,449 1,4 2,85 - 2,949 2,9

1,45 - 1,549 1,5 2,95 - 3,049 3,0

1,55 - 1,649 1,6 3,05 - 3,149 3,1

1,65 - 1,749 1,7 3,15 - 3,249 3,2

1,75 - 1,849 1,8 3,25 - 3,349 3,3

1,85 - 1,949 1,9 3,35 - 3,449 3,4

1,95 - 2,049 2,0 3,45 - 3,549 3,5

2,05 - 2,149 2,1 3,55 - 3,649 3,6

2,15 - 2,249 2,2 3,65 - 3,749 3,7

2,25 - 2,349 2,3

2,35 - 2,449 2,4

"S

""S

S

"

S

Page 45

Service Training

4.1.2.9.2 REPLACEMENT OF THE INJECTION PUMP

This repair method is intended for a replacement of the injection pumps only.

Commercially available tools:

Claw grip wrench 8018

Torx tool kit 8189

Special tools:

Press-on device for control rod 100 830

Extractor pulling device 150 800

Extractor pulling device for

injection valve 110 030

- Remove pressure control valve and inspection cover.

Pull off cable connector from cut-off solenoid, governor

and temperature sensor. Swivel holding plate sideways.

09.06

Section 4.1

Page 37

- Remove engine cut-off device or lock cover.

- Press control rod into stop position using the stop lever.

Insert press-on device for control rod 100 830 and

tighten by bolts.

Page 46

Section 4.1

Page 38

- Press control rod into stop position using the knurled

lock bolt.

- Use press-on device for control rod 100 830.

NOTE: Tighten knurled lock bolt finger tight.

- Set cylinder of the injection pump to be removed to firing

TCD.

- Turn crankshaft by approx. 120° opposite to the direction

of rotation of the engine.

(Zünd OT - firing TCD)

09.06

Service Training

NOTE: As viewed in direction of the flywheel.

- Remove the corresponding injection line, injection pump

and injection valve.

NOTE: Use claw grip wrench 8018 for the injection

line.

Use extractor pulling device 150 800 with

puller 110 030 for injection valve if jammed.

Pull out O-ring if necessary, using extractor

120 680.

- Carefully extract shim with bar magnet..

Page 47

Service Training

- Read off ID number for injection pump length (dimension

A) for the new injection pump.

NOTE: Determining new shim.

- Place newly determined shim on roller tappet

.

09.06

Section 4.1

Page 39

- Turn injection pump steering lever to center position

more or less.

- Apply AP 1908 compound to location hole in crankcase

and to O-rings of injection pump. Mount injection pump

and insert injection pump steering lever carefully into

control rod.

NOTE: The roller tappet for the respective injection

pump must be on the base circle of the

camshaft.

Page 48

Section 4.1

Page 40

- Put on flange.

NOTE: Chamfered end must face injection pump

body.

- Slightly oil bolts and tighten to a tightening torque of

5 Nm.

09.06

Service Training

- Release bolts again by 60°.

- Carefully turn injection pump counter clockwise up to a

noticeable stop using serrated wrench 8117.

Page 49

Service Training

- Turn bolts in again by 60° and gradually tighten to a

tightening torque of 7 Nm, 10 Nm and 30 Nm.

NOTE: Start with the outer boit remotest from

flywheel.

- Turn knurled lock bolt back again.

Remove press on device 100 830.

NOTE: Check smooth movement of control rod from

stop position to start position. Actuate cut-off

lever to this end.

09.06

Section 4.1

Page 41

- Mount new O-ring.

NOTE: Slightly oil O-ring.

- Press control rod into stop position using the cut-off

lever and retain.

- Install engine shut-off device. Tighten bolts. Plug in

cable connector.

Specified tightening torque: 21 Nm

Page 50

Section 4.1

Page 42

- Siide sealing ring onto injection valve using some grease

and insert injection valve.

NOTE: The notch on the injection valve must face

away from the claw. Marking faces exhaust

gas end.

- Mount claws and tum in bolts loosely.

09.06

Service Training

- Fit new injection line with sealing rubber. Tighten cap nut

finger-tight.

NOTE: Sealing cones must be exactly in line when

mounting the injection line.

Re-bending is not allowed. Injection lines

must not be used twice.

- Tighten bolt of claws.

Specified tightening torque: 16

+5

Nm

Page 51

Service Training

4.1.2.10 HEATER FLANGE

POSITIVE POLE SCREW OF HEATER FLANGE

Special screw TN 0425 8628

09.06

Section 4.1

Page 43

NOTE: This special screw must be used

MOUNTING

Prior to mounting the special screw TN 0425 8628, the

heater flange must be removed from the engine, so that

countersupporting with a hollow hexagon wrench is

possible during the mounting of the special screw.

only once!

The hollow hexagon wrench (size 5) for counter support

must be inserted into the heater flange as shown on the

photograph.

Page 52

Section 4.1

Page 44

The hollow hexagon wrench must be swivelled in

anticlockwise direction.

09.06

Service Training

Page 53

Service Training

The hollow hexagon wrench must be swivelled between

the upper and the lower heating coil base to be able to

counter-support.

When tightening the special screw, always countersupport with the hollow hexagon wrench (in direction of

the arrow), in order to avoid bending of the heating coil.

Tightening torque for special screw: 38 Nm.

09.06

Section 4.1

Page 45

Page 54

Section 4.1

Page 46

4.1.2.11 SPECIAL TOOLS

No. Designation

8002 Hydraulic pressure pump for cooler leak test

8005 Compression tester

(by IVEKA Automotive Technologies Schanz GmbH,

Talweg 8, D-75417 Mühlacker-Lomersheim)

8008 Nozzle tester

09.06

Service Training

8012 Socket SW 15, long design for injection valve (union nut)

8018 Clay-grip wrench a/flats 17 for injection lines

8024 Valve sealing pliers

8113 Torx wrench sockets E14

8114 Torx wrench sockets E20, long version

8115 V-belt tension gauge

Page 55

Service Training

8117 Serrated wrench for tuming injection pump

8189 Torx tool kit

9017 Valve spring assembly lever

09.06

Section 4.1

Page 47

9090 Spring clamp pliers

100 110 Connector tor compression tester

(by IVEKA Automotive Technologies Schanz GmbH,

Talweg 8, D-75417 Mühlacker-Lomersheim)

100 320 Turning gear

100 330 Turning gear

100 400 Dial gauge M2T with locking ring

Page 56

Section 4.1

Page 48

100 750 Measuring bar with spacers tor gauging TDC and piston

projection

100 830 Press-on device tor control rod

100 890 Measuring device for base circle measurement

09.06

Service Training

101 910 Tightening angle dial indicator tor main bearing, big-end and

flywheel bolts, etc.

110 030 Extractor for injectors, to be used with tool 150 800

110 110 Dolly for injector a/flats 11

110 470 Assembly tool tor control rod sleeves

110 500 Special wrench for injection line

Page 57

Service Training

120 680 Extractor for sealing ring beneath injector

121 410 Sleeve for fitting valve stem seal

130 300 Piston ring pliers

09.06

Section 4.1

Page 49

130 440 Trapezoidal groove wear gauge

130 660 Piston ring compressor Ø 98 mm

Address your order for special tools to:

Fa. Wilbär, P.O. Box 14 05 80, D-42826 Remscheid

Page 58

Section 4.1

Page 50

09.06

Service Training

Page 59

Service Training

4.2 TRANSMISSION

Page 4.2

Section 1

Page 60

Page 4.2

Section 2

4.2.1 HYDROSTATIC TRANSMISSION

The transmission is composed of separate components consisting of a high pressure axial variabledisplacement pump with integrated control elements and 2 high pressure axial variable-displacement

motors. Each hydraulic motor is bolted to a 2-stage planetary hub reduction gear via an intermediate

housing that contains the disc brake so forming a compact drive unit for each traction wheel.

A flange-mounted tandem pump is connected to the shaft of the variable-displacement pump. The first

pump supplies boost pressure for the working hydraulics while the second one delivers the pressure for

the power steering system. A gear pump serving as delivery pump is driven via an auxiliary power takeoff on the engine.

With the proven double-pedal control, a travel control unit is used to select the travel directions, the control

pressures for regulating the variable-displacement pump (primary control) and the variable-displacement

motors (secondary control) as well as for adjusting the speed of the engine. The disc brakes can be operated

even when the engine is running by depressing the brake pedal located between the accelerator pedals.

A speed limiter prevents any overloading of the engine by the transmission. An engine stall during additional

loads by the working and steering hydraulics is prevented by the anti-stall device.

Service Training

When reversing the direction of travel, a lock-out logic ensures that the engine speed does not rise until

the truck starts moving in the new direction.

Page 61

Service Training

4.2.1.1 SCHEMATIC DIAGRAM OF THE DRIVE

Page 4.2

Section 3

1 Gear pump, 23 cc, due to transmission ration

1 engine revolution = 27 cc

2 Engine KHD BFM 6 1012 E

3 Axial piston pump BPV 100 S

4 Axial piston pump MPF 55 S

5 Gear pump, 27 cc

6 Traction wheels

7 Planetary hub reduction gearbox i = 17.45

8 Disc brake

9 Axial piston motor HMV 105 S

10 Suction filter

11 Oil tank

A Feed

B Working hydraulics

C Steering hydraulics

Page 62

Page 4.2

Section 4

Service Training

4.2.1.2 TRANSMISSION SPECIFICATIONS

VARIABLE DISPLACEMENT PUMP

Type: BPV 100 S

Definition of type designation: B = Series

P = Pump

V = Variable-displacement

100 = Max. delivery in cc/rev.

S = Swashplate

Number of pistons: 9

Piston diameter: 22.5 mm

Max. swashplate angle: 18 °

Max. operating pressure: 330 bar, H 50/60

390 bar, H 70/80

Boost/control pressure: 17.5 bar

Max. speed: 2250 RPM

Q

at n

max

Q

of feed pump: 60 l/min

max

: 225 l/min

max

Type of control: hydraulic

Operation: hydraulic remote control

Start/end of control: 4 - 10 bar

Overload protection: hydraulic power control, load-sensing

Pump drive: Curved teeth coupling

TANDEM PUMP

1 pump for working hydraulics

Type: MPF 55 S

Definition of type designation: M = Medium pressure

P = Pump

F = Fixed displacement

55 = Delivery 55 cc/rev.

S = Swashplate

1 gear pump for steering: 27 cc/rev.

Page 63

Service Training

WHEEL DRIVES

Two wheel drives bolted to frame

Each unit consists of:

1 variable-displacement hydraulic motor HMV 105 S

Definition of type designation: H = High pressure

M = Motor

V = Variable displacement

105 = Max. displacement in cc/rev.

S = Swashplate

Number of pistons: 9

Piston diameter: 21 mm

Swashplate angle/displacement: max. 20.8 °/105 cc

min. 8 °/40 cc

Start/end of delivery: 7 bar/10 bar

1 oil-pressure operated disc brake

Page 4.2

Section 5

- mounted on extended engine shaft

- fully encapsulated, running in oil

- required only as parking brake and emergency brake

1 planetary hub reduction gearbox i = 17.45

Page 64

Page 4.2

Section 6

4.2.1.3 HYDRAULIC CIRCUIT DIAGRAM

A WORKING HYDRAULICS

1 Control valve block consisting of:

2 Way valve (auxiliary hydraulics)

3 Shuttle valve

4 Way valve (auxiliary hydraulics)

5 Pressure holding valve

6 Way valve - tilting

7 Way valve - lifting

8 Pressure reducing valve

8a Restrictor

8b Restrictor

9 2/2-way valve (pressure balance)

10 Maximum pressure valve, 265 bar

11 Tilt cylinder

12 Slow down valve

13 Lift cylinder

Service Training

B STEERING CONTROL VALVE ASSEMBLY

14 Pressure relief valve

15 Make-up valve

16 Shock valve

17 Steering control valve

C STEERING CYLINDER

D SHUTTLE VALVE

E OIL COOLER

F COOLER BYPASS VALVE, 1 bar

Page 65

Service Training

G BOOST PRESSURE PUMP

18 Gear pump, 23 cc/rev.; i = 1.18, resulting in 27 cc/rev.

18a Way valve - auxiliary braking

18b Restrictor

18c Restrictor

H ENGINE

J ENGINE SPEED CONTROL CYLINDER

K VARIABLE-DISPLACEMENT PUMP BPV 100, ASSY.

19 Variable-displacement pump

20 3/2-way valve

Reversing lock

21 3/3-way valve

22 Control piston

22a Nozzles, 1.44 mm

23 4/3-way valve - pilot valve

24 Servo piston

25 Combined feed and pressure-relief valve 330

26 Boost pressure valve 17.5 bar

+20

bar (H 50/60)/390

Page 4.2

Section 7

+20

bar (H 70/80)

L WORKING HYDRAULICS PUMP

27 Axial piston pump MPF 55

M POWER STEERING PUMP

28 Gear pump 27 cc/rev

N POWER LIMITER

29 6/2-way valve

30 Pressure reducing valve

Page 66

Page 4.2

Section 8

31 High-pressure modulator

32 Nozzles

33 Pressure-relief valve

40 3/2-way valve

41 Nozzle

42 By-pass valve

O PRESSURE FILTER 10 microns

P TRAVEL CONTROL UNIT ASSEMBLY

43 Pressure reducing valve

44 Pressure-relief valve

45 Restrictor

46 4/2-way valve - brake actuation

47 2/2-way valve

48 4/3-way valve - direction of travel

49 3/2-way valve - signal for engine speed

Service Training

Q HYDRAULIC DRIVE UNIT ASSEMBLY

50 Pressure-relief valve

50a Restrictor

51 3/3-way valve

52 Hydraulic motors

53 4/2-way valve - pilot valve

53a Restrictor

53b Restrictor

54 Disc brakes

55 Control piston

R 3/2-WAY VALVE - EXTERNAL BRAKE RELEASE

S OIL TANK

56 Suction filter

57 Suction and pressurizing valve with filter 0.35

+0.15

bar

Page 67

Seite 9

Abschnitt 4.2

Service Training

HYDRAULIKSCHALTPLAN H 50/60/70/80, TYP 353

Page 68

Service Training

05.00

Abschnitt 4.2

Seite 10

HYDRAULIKSCHALTPLAN H 50/60/70/80 D-02, BAUREIHE 353

Page 69

Seite 11

Abschnitt 4.2

05.00

Service Training

HYDRAULIKSCHALTPLAN H 50/60/70/80 T-02, BAUREIHE 353

Page 70

Page 71

Service Training

05.00

Page 4.2

Section 13

Page 72

Page 4.2

Section 14

HYDRAULIC CIRCUIT DIAGRAM, TYPE 353 -03

A WORKING HYDRAULICS

1 Control valve block consisting of:

2 Way valve (auxiliary hydraulics)

3 Way valve (auxiliary hydraulics)

4 Way valve (tilting)

5 Way valve (lifting)

6 Restrictor

7 Pressure reducing valve

8 2/2-way valve (pressure balance)

9 Maximum pressure valve, 265

10 Shuttle valve

11 Pressure holding valve

12 Tilt cylinder

13 Slow down valve

14 Lift cylinder H 50/H 60

15 Line breakage protection

16 Lift cylinder H 70/H 80

09.04

+5

bar

Service Training

C STEERING CONTROL VALVE ASSEMBLY

17 Pressure relief valve

18 Make-up valve

19 Shock valve

20 Steering control valve

D STEERING CYLINDER

E BOOST PRESSURE PUMP

21 Restrictor

22 Gear pump, 23 cc/rev.

23 Way valve - auxiliary braking

Page 73

Service Training

F ENGINE

G ENGINE SPEED CONTROL CYLINDER

H VARIABLE-DISPLACEMENT PUMP HPV 105-02, ASSY.

24 Variable-displacement pump

25 3/2-way valve

Reversing lock

26 3/3-way valve

27 Control piston

28 4/3-way valve - pilot valve

29 Servo piston

30 Combined feed and pressure-relief valve

+15

- pressure-relief valve 285

- pressure-relief valve 305

- pressure-relief valve 360

- pressure-relief valve 420

31 Boost pressure valve 17.5 bar

bar (H50)

+15

bar (H60)

+15

bar (H70/80)

+15

bar (H80/900)

09.04

Page 4.2

Section 15

J WORKING HYDRAULICS PUMP

32 Axial piston pump MPF 55

K POWER STEERING PUMP

33 Gear pump 27 cc/rev

L POWER LIMITER

34 6/2-way valve

35 Nozzles

36 Pressure reducing valve

Page 74

Page 4.2

Section 16

37 Pressure-relief valve 13 bar

38 High-pressure modulator

39 3/2-way valve

40 By-pass valve

M TRAVEL CONTROL UNIT ASSEMBLY

41 3/2-way valve - signal for engine speed

42 Pressure reducing valve

43 Pressure-relief valve 11 bar

44 Restrictor

45 4/2-way valve - brake actuation

46 2/2-way valve 12 bar

47 4/3-way valve - direction of travel

48 Way valve - direction of travel (single pedal) (optional equipment)

09.04

Service Training

N OIL COOLER

O OIL FILTER

49 Filling device

P HYDRAULIC DRIVE UNIT ASSEMBLY

50 Pressure-relief valve

51 Restrictor

52 3/3-way valve

53 Hydraulic motor HMV 105

54 4/2-way valve - pilot valve

55 Control piston

56 Disc brakes

Q 3/2-WAY VALVE - EXTERNAL BRAKE RELEASE

R OIL TANK

57 Suction filter 0,25 bar

58 Suction and pressurizing valve with air breather filter 0.35 bar

59 Distributor kit

Page 75

Page 17

Section 4.2

09.04

Service Training

HYDRAULIC CIRCUIT DIAGRAMM H 50/60/70/80 D-03, TYPE 353

Page 76

Service Training

09.04

Section 4.2

Page 18

Page 77

Service Training

09.04

Page 4.2

Section 19

Page 78

Page 4.2

Section 20

09.04

Service Training

4.2.2 OPERATION OF THE HYDROSTATIC TRANSMISSION

The oil flow (20 L/min at n

1, 60 L/min at n

min

) generated by boost pressure pump G goes through filter

max

O to control valve block N entering it at port E1 and leaving at port E, from where it goes to port E of the

travel control unit P.

The oil flows through the restrictor (45) and leaves the travel control unit at port F to enter control valve block

N at port F, and then the feed valves (25) and the boost pressure valve (26), which stabilizes the boost

pressure at 17.5 bar.

4.2.2.1 TRAVEL CONTROL UNIT P

The way valve (47) which is pressurized to 12 bar and open at first is arranged in parallel to the restrictor

(45). After the boost pressure increases to 17.5 bar at F the valve is pushed to the closed position. The

pressure-relief valve (44), which is also arranged in parallel to the restrictor (45), ensures a constant

differential pressure of 11 bar between E and F. The feed and control pressure of 17.5 bar goes through

the way valve (48), travel direction, and the pressure reducing valve (43) to ports Y and Z and from there

to the servo piston (24) to which equal pressure is applied on each end. The pressure of 17.5 bar is applied

via way valve (46), the brake valve and port BR to the disc brakes as brake release pressure. This pressure

is also applied to the way valve (49), speed control valve as boost pressure for control of the engine. The

higher pressure with a differential pressure of 11 bar created by restrictor (45) and valve (44) is applied at

the pressure reducing valve (43) as boost pressure.

When an accelerator pedal is depressed, way valve (48) determines the direction of travel while valve (49)

and pressure reducing valve (43) establish the pilot pressures controlling engine speed and pump output.

When the stroke of the accelerator pedal creates a differential pressure of 4 bar between Y and Z, the pump

begins delivery and the truck starts to move. At the same time a pressure of 7 bar goes from valve (49)

through port VF to the speed control piston, increasing the engine speed to approx. 1200 rpm (jump in

speed). As the accelerator pedal is depressed further, the differential pressure between Y and Z rises to

approx. 10 bar, whereas the pressure at VF remains constant. The Q

of the pump (19) and Q

max

of the

min

hydraulic motors (52) is reached at a differential pressure of 10 bar (primary/secondary control) without

increasing the engine speed, however. Depressing the pedal still further modulates valve (49) and

increases the pressure in proportion to the pedal stroke to approx. 17.5 bar (end of pedal stroke). The engine

is brought to maximum RPM and the truck achieves maximum speed.

Depressing the brake pedal fully when an accelerator pedal is operated opens valve (46) so that the

pressure goes from F (feed pressure) to valve (43) as boost pressure. This reduces the differential pressure

between E and F; consequently the differential pressure between Y and Z drops to under 4 bar, causing

the pump to downstroke to zero output. At the same time port BR is connected via T2 to tank, reducing the

brake release pressure and so applying the brakes. A reduction in pressure to under 12 bar at port F (leak

in the closed circuit) opens valve (47). As a result restrictor (45) is bypassed and no differential pressure

can build between E and F, preventing an upstroking of the pump when the brake is applied.

Page 79

Service Training

09.04

Page 4.2

Section 21

Travel Control Unit

I Operation

Travel direction, swashplate angle, maximum rpm

II Operation

Brake

43 Pressure regulating valve - swashplate angle

44 Pressure-relief valve, 11 bar

45 Restrictor - for differential pressure

46 4/2-way valve - braking

47 2/2-way valve, 12 bar - brake protection

48 4/3-way valve - travel direction

49 3/2-way valve - signal for maximum rpm

Page 80

Page 4.2

Section 22

09.04

Service Training

Page 81

Service Training

09.04

4.2.2.2 OPERATION OF CONTROL VALVE BLOCK N = POWER LIMITER

Page 4.2

Section 23

Remote control

Feed

Travel control unit

Feed pump

Travel control

unit

HMV HMVHMV Travel control unitEngine speed

control cylinder

The feed pressure oil flows via E1 and E through control valve block N, goes through travel control unit P

from port E to F and returns to the control valve block through port F. The feed pressure valve (26) stabilizes

a pressure of 17.5 bar at port F, which is fed to the remote control of the hydraulic motors through an oil

line.

Valve (33), which is connected in parallel to ports E and F of the control valve block, opens at a differential

pressure of 13 bar. This allows a part of the oil flow to go to the travel control unit while the remainder

continues through valve (33) to the feed oil passage. The pressure at port E goes to the HMV hydraulic

motors via a line as pilot pressure. The setting of valve (29) is determined by the differential pressure

between Y and Z. If, due to the selection of a travel direction, a higher pressure exists at Z, valve (29) is

shifted to position (a) and the higher pressure Y goes to the pressure reducing valve (30). At the same time

the pressure applied through valve (40), which is switched to position b by the feed pressure, goes to the

hydraulic motor remote control through port X.

When the pressure ranges from 4 to 10 bar, the differential pressure between Y and Z modulates the pilot

valve (23) with the servo piston (24) and sets the pump from zero delivery to Q

The same pressure also adjusts the hydraulic motors from Q

max

to Q

when the pressure ranges from 7

min

with control piston (22).

max

to 10 bar.

Page 82

Page 4.2

Section 24

09.04

Service Training

POWER LIMITER, ANTI-STALL DEVICE

The drive is provided with a power limiter to prevent any overload on the engine by the travel drive.

This device controls the swashplate angle of the variable-displacement pump and the variable-displacement

motors depending on the high pressure so that the product of flow volume Q x working pressure P does

not exceed the available engine power at any time.

EXPLANATION

When an accelerator pedal is depressed, the higher pilot pressure at Z or Y goes via the activated

preselector valve (29) to pressure reducing valve (30), while the working pressure of the closed circuit

goes through valve (29) to the high-pressure modulator (31). After the selected engine power is achieved

(Q

and approx. 170 bar), valve (30) is activated via the high-pressure modulator (31), thus reducing the

max

differential pressure between Y and Z. This causes the pump to downstroke from Q

reducing the oil flow. At the same time the hydraulic motors stroke up from Q

min

max

to Q

towards Q

, increasing the

max

min

, thus

torque at the traction wheels.

Any additional power requirements by the working and steering hydraulics cannot be served by the power

limiter. This overloads the engine and, if the power requirement continues, reduces its speed. If the engine

speed drops until the differential pressure between Y and Z is reduced to 4 bar, the pump will downstroke

to zero delivery, thus preventing the engine from stalling.

4.2.2.3 BRAKING

When the accelerator pedal is released, the pressure for the engine speed control cylinder is first reduced

and then the differential pressure between Y and Z so that the hydraulic motors stroke from Q

and the pump from Q

to zero output. This reduces truck speed, braking the truck.

max

min

to Q

max

4.2.2.4 AUXILIARY BRAKE

Due to the reversal of power when braking (tractive power converted to pushing power), the hydraulic

motors drive the pump, which is coupled to the engine, so that the engine speed must rise as a result. When

a determined engine speed is reached, the auxiliary brake is applied, preventing the engine speed from

rising too high. The maximum braking force is determined by the pressure-relief valve in the high-pressure

circuit.

Page 83

Service Training

EXPLANATION

09.04

Page 4.2

Section 25

Tank

Feed

The oil flow from the feed pump (18) goes through restrictor (18c) and is fed through port P3 into the oil

circuit. Way valve (18a) is kept closed by a spring. Restrictor (18c) is used to measure a differential pressure

whose size is proportional to the flow, i.e. it varies with engine speed. The nearly constant pressure

upstream of the restrictor goes into the spring chamber of valve (18a), whereas the speed-dependent

pressure is applied against the spring pressure. When the engine speed reaches approx. 2250 rpm, valve

(18a) opens and sends the working pressure applied at port M through 18 b to port HB

Page 84

Page 4.2

Section 26

at the pressure balance in the working hydraulics way valve block. This causes the pressure balance to

close, thus increasing the pressure of the oil flow of the working hydraulic pump (27). The power required

from the engine prevents the rpm from rising too high during braking.

4.2.2.5 LOCK-OUT LOGIC - REVERSING LOCK

When the direction of travel is reversed quickly, the differential pressure changes from Y/Z to Z/Y faster

than the pump can follow. At the same time the speed signal is set by travel control unit P through port VF

to speed control cylinder J for maximum engine speed. Simultaneously, the signal for Q

X of the hydraulic motors.

d

As the inertia of the truck drives the engine via the hydraulic motors and pump and lets the engine

overspeed during braking, the braking distance would be very long. The specified braking delay is

achieved through the auxiliary braking and during reversing the reversing lock also becomes effective.

09.04

Service Training

is applied to port

min

EXPLANATION

When the pilot pressure for pump and engine control is preselected at Y by depressing the related

accelerator pedal, it goes to spring chamber (a) in the servo piston (24), while the constant feed pressure

is applied in spring chamber (b). This causes the spool to move to (b), shifting the pilot valve to position

(a) by means of the mechanical connection. This allows the constant pressure of 17.5 bar to go into spring

chamber (a) of the control piston (22) through valve (23). The piston shifts to (b), causing the pump to

upstroke and valve (21) to move to position (a). The pressure of 17.5 bar existing in spring chamber (b)

Page 85

Page 4.2

Service Training

09.04

Section 27

at piston (24) continues through open valve (21) to valve (20), which is shifted to position (b) by the 5 bar

spring and the feed pressure in the spring chamber. This connects the spring chamber of control cylinder

J via port N to the tank.

When the travel direction is reversed quickly, the pressure in spring chamber (a) of the servo piston (24)

drops to 17.5 bar, whereas in spring chamber (b) the pilot pressure will rise to a differential pressure of

approx. 10 bar. As the servo piston can only follow the change in pressure with a delay, valves (23) and

(21) and piston (22) are still in their original position. This causes the higher pressure in spring chamber

(b) of servo piston (24) to go through valve (21) to valve (20), shifting it to position (a). The pressure now

goes through the shifted valve to port N (spring chamber) of engine speed control cylinder J, pushing it

against the speed signal applied at port V3 so that the injection pump is set to lower idling speed.

HP Reverse

Power

Limiter

Power Limiter

Travel Control

Unit

HP Forward

This pressure is also sent to port N at control valve block N, shifting valve (40) to position (a). The 17.5 bar

pressure from the feed oil passage now goes through the open valve via port X to the remote control for

the hydraulic motors. Via ports F, the same pressure exists in the spring chamber of the control pilots as

at port X. Due to the pressure bias, the pilot is shifted so that the pressure applied at E goes to the rod end

of the control piston (55), while the piston end is connected to the tank. The shift of the piston cause the

motor to be regulated to Q

, thus increasing the braking force.

max

Page 86

Page 4.2

Section 28

4.2.2.6 FLUSHING OF THE CIRCUIT AND HOUSING

In order to prevent extremely high oil temperatures in the closed circuit, the drive is provided with circuit

flushing through an output control device. The temperature in the hydraulic units and the tank is also

approximated by flushing the pump and the motor housing.

CIRCUIT FLUSHING

Each hydraulic motor has an output control device consisting of valve (50), nozzle (50a) and valve (51).

If high pressure exists at P, valve (51) shifts to position (a). The low pressure at S goes through the open

valve (51) and the nozzle (50a) to the pressure-relief valve (50) set to 13 bar and to the opening valve into

the motor housing. A differential pressure of 7.5 bar exists between valve (50) and low pressure. Due the

size of the nozzle (50a), the quantity of oil emitted is fixed to 3 litres per hydraulic motor. The quantity of

oil leaving at the low pressure side is replaced by cool oil flowing in through the feed valves. This method,

together with the leakage caused by the high pressure, allows the entire circulating oil to be replaced several

times per minute.

HOUSING FLUSHING

09.04

Service Training

The cool oil delivered by pump G goes through filter O and travel control unit P to the feed valves (25). The

appropriate feed valve returns the same quantity of oil into the circuit as is lost due to leakage and removed

as output oil. The remaining quantity is blown off through the feed pressure valve (26) into the pump

housing, from where it flows back to the tank via port I.

The oil quantity removed from the closed circuit through the output device goes into the related motor