Page 1

IC Sit-Down Rider Trucks

SAFETY TIPS

and a guide to the

Information Plates,

Operation and Warning Decals

found on your truck

LINDE LIFT TRUCK CORP.

A MEMBER OF THE LINDE GROUP

161970 February 2003

Page 2

2

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Foreword

This Operator's Manual is not a training manual. It is a guide to help Operators safely

operate their equipment by pointing out the correct methods and procedures. The

Operator's Manual cannot cover every possible hazard or potential accident situation.

It is up to you, the Operator, to avoid or correct these potential dangers. It is important

that you know and understand the information in this manual as well as the equipment

you will be operating. Do not operate a damaged or malfunctioning truck. Practice

safe operation every time you use your lift truck so that we can join together to set

high standards for safety.

The lift truck is designed for lifting and transporting of pallets or loads of material. The

truck is designed for operation on smooth and dry surfaces. The truck has the ability

to climb or descend smooth and dry ramps with or without a load. Ensure you use the

truck only for the job it was intended to do.

NOTE:

The descriptions and specifications included in this manual were in effect at

the time of printing. Linde Lift Truck Corporation reserves the right to make

improvements and changes in specifications or design without notice and

without incurring obligation. Please check with your authorized Linde dealer

for information on possible updates or revisions.

Regular care and maintenance of your truck is not only important for full and efficient

truck life, it is essential for equipment and Operator safety. The importance of

maintaining the truck in a safe operating condition with regular planned servicing and

prompt repairs when necessary cannot be emphasized too strongly. Experience has

shown that powered industrial trucks can cause injury if improperly used or maintained.

To assist in keeping your truck in service and in good operating condition, a

Maintenance section is included in this manual.

The section outlines maintenance and inspection procedures to be done at regular

intervals. These procedures are considered essential to the life and safe performance

of your truck.

The following highlighted data and information are used in this manual to ensure safe

operating and maintenance procedures. Heed them.

Page 3

3

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

NOTE:

Indicates information or points of particular interest for more efficient and

convenient operation.

This manual contains operating and periodic maintenance instructions as well as

specifications for the lift truck. The manual is designed to assist in the proper care

and maintenance of your truck while providing maximum safety and efficient operation.

Consider this manual a special tool which, if properly applied, can help ensure years

of safe and efficient material handling. Your local dealer or the factory can arrange for

Operator training and/or maintenance instructions for your truck should you need

them.

Parts and Service

See your Linde dealer for genuine Linde parts (the only factory-authorized

replacements), factory-trained service personnel and manuals for your equipment.

General Safety Rules

Safety signs and messages are placed in this manual and on the truck to provide

instructions and identify specific areas where potential hazards exist and special

precautions should be taken. Know and understand the meaning of these instructions,

signs, and messages. Damage to the truck, death or serious injury to you or others

may result if these messages are not followe

d.

INDICATES A POTENTIALLY HAZARDOUS SITUATION, WHICH IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY ALSO

RESULT IN DAMAGE TO YOUR MACHINE.

INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH IF NOT AVOIDED

COULD RESULT IN DEATH OR SERIOUS INJURY.

DANGE

R

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH IF NOT AVOIDED

WILL RESULT IN DEATH OR SERIOUS INJURY.

You, as the Operator, are ultimately responsible for your own safety and the safety of

those around you. Read and Study this manual. Be sure to understand all the

operating procedures and safety precautions before operating the truck.

Page 4

4

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

The Occupational Safety and Health Act (OSHA) states, “The employer shall ensure

that each powered industrial truck operator is competent to operate a powered

industrial truck safely, as demonstrated by the successful completion of the training

and evaluation specified in this paragraph.” Do not attempt to operate this truck

unless you are fully trained and authorized.

Before Operation

Before using the truck, inspect your work area. Check that it is neat, well lit, adequately

ventilated, and free from hazardous material. Aisles and roadways should be

unobstructed and well marked.

Fire extinguishers and other emergency equipment should be visible and easy to

reach. Wear safety equipment when required. Don’t smoke in “No Smoking” areas,

when refueling. Don’t mix drugs or alcohol with your job.

The truck is designed for safety. Unauthorized additions or modifications without

Linde’s approval are prohibited. Do not remove or alter nameplates.

If you have any questions or concerns about lift truck safety, talk to your supervisor. If

an accident should occur, report it immediately.

Start the engine only when securely seated in the operator’s compartment.

Page 5

5

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Do not remove any safety guards or other safety devices. These include the Overhead

Guard, Load Backrest Extension, and if equipped by the Owner, alarm, lights and

mirrors.

The Overhead Guard is intended to provide protection to the Operator from falling

objects, but cannot protect from every possible impact.

OPERATOR’S DAILY CHECKLIST

At the beginning of each shift, inspect your truck by using the Linde Operator’s Daily

Checklist . Check for damage and maintenance problems. Have repairs made

before you operate the truck.

Checklist for IC Sit-down Trucks

Page 6

6

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Do not make repairs yourself. Lift truck mechanics are trained professionals. They

know how to make repairs. Periodic maintenance is vital to safe operation of the

truck. Adhere to a strict inspection, lubrication, and maintenance schedule. Allow

only authorized personnel to work on the truck.

Do not operate a damaged or defective lift.

If warning decals are damaged or missing, they must be replaced.

Know your Truck’s capacity. The capacity of your truck is listed on the Capacity Plate.

Read and understand the Capacity Plate. The capacity of your truck is listed on the

Data Plate. Never attempt to lift or transport a load exceeding the truck’s rated

capacity.

Never attempt to lift or transport a load exceeding the trucks rated capacity.

Page 7

7

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

PEDESTRIANS

Watch out for pedestrians. Always yield the right-of-way to pedestrians. Do not drive

the truck up to anyone standing in front of a rack or other fixed object. Do not pass

another truck traveling in the same direction at an intersection, blind spot or other

dangerous location. Sound horn at intersections and other locations where vision is

obstructed. Always look in the direction of travel.

If your vision is restricted, then operate the truck in reverse. Be sure to pivot in your

seat to the right to provide maximum visibility to the rear.

Page 8

8

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Do not engage in stunt driving or horseplay. Use lights in dark and dim areas. Always

ensure that there are no pedestrians in the trucks rear swing area before turning.

Watch for pedestrians beside the truck.

DANGE

R

Watch for people in your work area because they may not watch for you, even if you

have lights or alarms.

Page 9

9

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

149569

W

ARNING

KEEP HANDS CLEAR.

SERIOUS INJURY COULD RESULT.

OPERATING POSITION

Face the truck when mounting and dismounting. Maintain a three-point contact, one

foot and two hands with the truck when mounting or dismounting. Never exit a moving

truck. Never jump on or off the truck.

Operate the truck only when you are in the normal operating position. Keep hands

and feet inside the Operator’s Compartment.

Keep hands, feet and legs out of the upright.

Page 10

10

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

DANGE

R

Never allow anyone to walk under raised forks.

Wear your seat belt at all times when operating the truck.

Page 11

11

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Do not place yourself between the mast and the body of the truck. Do not use the

upright as a ladder. Do not transport personnel at any time. Do not lift personnel

using the forks of the truck, or with a work platform. The truck is not designed to lift

personnel.

Page 12

12

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

TRAVEL

The truck is designed for operation on smooth, and dry surfaces such as warehouse

and factory floors, loading docks or paved surfaces. Under all travel conditions, operate

the truck at a speed that will permit it to be brought to a stop in a safe manner.

Do not travel at excessive speeds; keep your truck under control at all times.

Travel with the load near the floor, tilted back to cradle the load whenever possible.

Never lift or lower the load when the truck is in motion. When handling bulky loads

that restrict your vision operate your truck in reverse to improve visibility. Unstable

loads are a hazard to you and to your fellow workers. Always make certain that the

load is well stacked, secured and evenly positioned across both forks. Never attempt

to lift a load with only one fork. Do not travel on an uneven surface. Watch for

overhead obstructions such as lights, wiring, pipes, sprinkler systems, doorways,

etc. Do not move railroad cars or trailers with this truck, or use to operate or close

railroad car doors.

Page 13

13

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Watch for slack chain condition. Slack chains mean rail or carriage hang-up. Raise

the forks before you move. Do not attemp to repair yourself, always get a trained

mechanic.

INCLINES, RAMPS, DOCKS, ELEVATORS

If you must travel on an incline, do so with caution. Do not operate truck on a wet

incline. Keep the load upgrade to maintain control when traveling up or down an

incline with a loaded truck

Be aware that when descending an incline your stopping distance will be greater than

when on a level surface. Reduce your speed, and ensure that there is adequate clear

space at the bottom of the ramp to stop and turn.

Page 14

14

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Keep the counterweight upgrade when traveling up or down an incline with an empty

truck

To avoid hazards associated with a dock, you should personally check that the trailer

brakes have been applied, wheel chocks are in place, and that any trailer-to-dock

locking systems are being utilized. The impact of moving in and out of a trailer may

cause the trailer to creep or move. Confirm that the driver will not move the trailer

until you are done.

Do not drive the truck onto an elevator without specific authorization. Verify that the

capacity of the elevator exceeds the weight of your truck and the weight of the load.

Page 15

15

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

DANGE

R

Never turn on an incline or ramp either loaded or unloaded. Travel straight up or

straight down.

Be especially cautious when driving the truck on ramps or bridge plates. Be sure to

maintain a safe distance from each edge. Before driving the truck over a ramp or

bridge plate, verify that their position is secured to prevent movement of the plates.

Page 16

16

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

TIP-OVER

Lateral tip over can occur with a combination of speed and sharpness of turn. This

condition of instability is even more likely with an unloaded truck. With the load raised,

lateral tipover can occur while turning and/or braking when traveling in reverse or

accelerating and turning while traveling forward. Lateral tip over can occur loaded or

unloaded by turning on a ramp. Longitudinal tip over can occur with a combination of

overloading and load elevated. This condition is even more likely with excessive

forward tilt, braking in forward travel or accelerating rearward.

DANGE

R

Lift truck tip over can cause serious injury or death if the operator is trapped between

the truck and the ground.

Page 17

17

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

DANGE

R

If your truck starts to tip over DO NOT JUMP! Make sure your seat belt is securely

fastened, stay in the seat, grip the wheel, lean away from impact and brace your feet.

Side tip over

can occur -

IN CASE OF

SIDE TIP OVER,

Follow these

instructions:

DON'T JUMP!

HOLD ON TIGHT

BRACE FEET

LEAN AWAY

149963

WARNING

Don't risk injury

or death,

SLOW DOWN

when turning.

FASTEN

SEAT BELT.

READ

OPERATOR’S MANUAL.

EVEN WHEN

UNLOADED.

Page 18

18

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Confirm the engine type before filling the tank with the recommended fuel.

NOTE:

Do not allow the lift truck to become low on fuel or completely run out of fuel. Sediment

or other impurities in the fuel tank could be drawn into the fuel system. This could

result in difficult starting or damage to components.

DO NOT fill the tank to the top. Fuel expands when it gets warm and may overflow.

Lift Trucks should be refueled only at designated safe locations. Safe outdoor locations

are preferable to those indoors. Never fill the tank near open flame or when the

engine is running. Explosive fumes may be present during refueling. DO NOT smoke

in refueling areas. Before fueling an internal combustion truck, turn the engine off and

leave the operator’s compartment. When filling, keep the funnel or fuel hose nozzle

in contact with the tank’s metal. This avoids the possibility of an electric spark igniting

the fuel.

After refueling, close the cap tight and wipe up any spilled fuel carefully and completely.

Verify that fuel tank cap has been replaced securely before restarting engine.

Page 19

19

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Only Trained, authorized personnel should fill or exchange LP-Gas tanks. Protective

clothing such as a face shield, long sleeves and gauntlet gloves should be worn.

Do not refuel or store LP-Gas powered life trucks near underground entrances,

elevator shafts, or other places where LP-Gas could collect in a pocket and cause

potential danger for an explosion.

Do not leave the lift truck, for even a short time, near equipment that generates high

temperatures. Oven and furnaces are examples. The heat may raise the pressure

of the fuel tank in place.

Close the service valve on the tank when LP-Gas fueled lift trucks are parked overnight

or stored for long periods indoors with the fuel tank in place. Close Valves on empty

tanks.

Never use an open flame to check the liquid level in the fuel tank, the condition of LP

Gas lines/connectors, or the electrolyte level of the battery. Examine LP-Gas tanks

before filling and before reuse. Look for damage to the valve, liquid gauge, fittings and

hand wheels. Check for dents, scrapes or other damage to the pressure vessel and

for dirt or debris in the openings.

Inspect the LP-Gas fuel lines and fittings with a soap solution after filling the tank or

when looking for leaks.

All defective or damaged LP-Gas tanks must be removed form service.

Page 20

20

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

Do not leave the engine running where there is poor ventilation. The engine exhaust

gas contains carbon monoxide. There is danger that this will cause gas poisoning

which may result is serious injury or death.

Immediately after using the lift truck, the engine coolant is at high temperature and

high pressure. Do not remove the radiator cap under these conditions. Hot water

may spurt out and cause burns.

When removing the radiator cap, turn it slowly to release the internal pressure.

When checking the coolant level, stop the engine and wait for the engine and radiator

to cool down before checking. For lift trucks equipped with a subtank or reservoir,

check the level in the subtank.

When adding water on lift trucks equipped with a subtank, add the water to the subtank.

Serious accidents can occur if LP-Gas tanks are not properly handled. To reduce the

risk of damage to tanks, use extreme care when transporting them.

Page 21

21

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

It is extremely dangerous if you or any tool touches or gets caught in the fan or fan

belt when the fan is rotating. Never touch the fan when it is rotating.

Always stop the engine before inspecting rotating parts.

When inspecting the areas around rotating parts, do not allow anything to come close

which may get caught.

If the tire inflation pressure is low, it will affect truck stability. However, do not inflate

the tires immediately. The inflation pressure may have gone down because of damage

to the rim. If the rim is damaged or cracked and the tires are inflated, there is danger

that the rim will break when the tire is under high pressure, and this may cause personal

injury or death.

For safety, when checking tire pressure, place your body in front of the tread face of

the tire. Do not check from the side face of the tire.

Suitable qualifications are needed for tire inflation work. Always have the work carried

out by properly qualified personnel.

The tire inflation pressure on a forklift truck is several times higher than the pressure

on an automobile. The use of an inflation cage, or some other safety device, helps

prevent serious injury. When the tires are being inflated, there is danger that dirt or

dust may be thrown up by the compressed air and enter your eyes, so always wear

safety glasses.

Page 22

22

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

PARKING

When you are finished with the truck, observe proper shutdown procedures.

· Never park on a grade

· Always come to a complete stop before leaving truck

· Place travel controls in Neutral.

· Lower forks fully to the floor and tilt forward

· Set Parking Brake

· Turn key to OFF position.

Do not park on a grade or incline. Do not park in areas which block emergency

equipment or routes, access to fire aisles or fire equipment, or stairways.

Failure to properly shutdown the truck may allow the truck to move causing injury to

pedestrians and damage to property.

Lower forks fully to the floor and tilt forward

Parking Brake

Neutral

Control

Lever

Key to OFF position

(3 Position) Directional Control

Lever (Option)

(Place in Neutral Position

as shown)

From Forward

Direction

From Reverse

Direction

Parking

Brake

Page 23

23

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

MODEL

TRUCK WGT.

(LESS ATTACH.

AND BATTERY)

A

S SHIPPED THIS TRUCK MEETS THE APPLICABLE REQUIREMENTS OF ASME B56.1

161599 1/03

LIFT TRUCK CORP.

A

MEMBER OF THE LINDE GROUP

lb

kg

lb

kg

BATTERY WEIGHT

MAX MIN

BATTERY

CAPACITY

V

AH

CAPACITY

TRUCK

TYPE

lb kg

BATTERY

TYPE

SALES #

DATA PLATE

1. Model designation of the truck

2. Truck serial number

3. Truck sales order number - the sales and serial numbers are assigned

to each specific truck and should be used when requesting any information

on the truck. Also, these numbers should be referenced when ordering service

parts from your authorized Linde dealer.

4. Truck weight - with removable attachment.

5. Truck type - the code letters in this block signify the type of construction

with safeguards against fire, shock hazards and explosion in classified and

nonclassified areas. Check with the proper authority before entering areas

containing flammable or explosive materials.

6. Not used, see Capacity Plate.

7*. Minimum battery weight required.

8*. System voltage of the truck

9*. Battery Type

* Used for Electric trucks only.

1

2

7

3

4

5

6

8

9

Page 24

24

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

ATTAC HM ENT (S)

AB

in. in.

mm

mm

LIFT TRUCK CORP.

A

MEMBER OF THE LINDE GROUP

A

FLOOR

B

C

D

in. in.

mm mm

DRIVE

TIRES

BACK

TILT

CAPACITY PLATE

1. Attachment (Sideshifter, Clamp, etc.) - if an attachment is installed on

the truck at the time of purchase, it will be indicated in this block.

2. Truck serial number

3. Truck capacity, load center and lifting height - these show the maximum

load capacity of the truck in relation to load centers and lift heights. Capacity

may be reduced when lifted above certain heights. Operators of this truck

need to be aware of these capacities. Personal injury or damage to the

truck can occur if these capacities are exceeded.

NEVER ATTEMPT TO LIFT A LOAD GREATER THAN THE MAXIMUM

CAPACITY LISTED ON THIS PLATE (#3 ABOVE).

4. Drive Tires- Size and type can affect the capacity of your truck. Ensure

truck is equipped with tires specified.

5. Back Tilt- Maximum.

1

2

3

4

5

Page 25

25

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

OPERATOR WARNING AND SAFETY DECALS

(continued)

Operator Warnings Decal

Read and understand the following before operating the truck:

139950 2/99

1. CHECK YOUR TRUCK -

2. KNOW YOUR TRUCK -

3. KEEP INSIDE -

4. PROTECT YOURSELF -

5. SEAT BELT -

6. LATERAL TIPOVER -

7. LONGITUDINAL T IPOVE R -

8. LATERAL OR LONGINTUDINAL TIPOVER -

9. DON'T JUMP OFF -

10. HIGH LOADS -

The truck should be checked daily before

being placed in service. If found to be in need of repair, defective, or in

any way unsafe it should be reported immediately to the proper authority

and removed from service until restored to a safe operating condition.

Do not operate this truck unless you have been

trained and authorized to do so. Read all warnings and instructions in the

Operator's manual on this truck; or obtain them from plant Safety Director

or the local Linde representative.

Operate truck only from designated operating position.

Operate the truck only when you are in the normal operating position and

seated in the Operator's seat. Never place any part of your body into the

mast structure, between the mast and the truck, or outside the truck.

Do not carry passengers.

Do not operate truck without overhead guard.

MAKE SURE YOUR SEAT BELT IS FASTENED

BEFORE OPERATING THE TRUCK.

Can occur loaded or unloaded by a combination

of speed and sharpness of turn. SLOW DOWN BEFORE TURNING. With

the mast raised, lateral tipover also can occur by turning and/or braking

when moving rearward, turning and/or accelerating forward or turning on

an incline or ramp. TRAVEL WITH THE MAST LOWERED. The potential

for lateral tipover will be further increased by overloading, excessive

rearward tilt or off-center positioning of the load. Don't risk injury or death.

Drive smart.

Can occur by driving with the load down

slope on an incline or ramp, overloading, excessive forward tilt or

aggressive braking when moving forward or accelerating rearward with

the mast elevated. TRAVEL WITH THE MAST LOWERED.

Don't risk injury or death. Drive smart.

Can occur if the truck is

driven over objects on the floor or ground, off the edge of improved

surf aces, or into potholes, or by i mpacting overhead obstacl es or collision

with other objects. Don't risk injury or death. Drive smart.

If your truck begins to tip over, DON'T JUMP.

Hold the steering wheel tightly, brace feet, and lean away from tip. Stay in

the seat to avoid being trapped between the truck and the ground.

Do not handle loads which are higher than the load

backrest or load backrest extension unless load i s secu red so that no pa rt

of it could fall backward.

SIT-DOWN RIDER TRUCK OPERATOR WARNINGS

Failure to comply with these warnings will create an unreasonable risk of injury to yourself and others.

11. STABILIZE YOUR LOAD -

12. CENTER YOUR LOAD -

13. NEVER OVERLOAD -

14. AVOID SUDDEN MOVEMENTS -

15. LOOK OVERHEAD -

16. MINIMUM TILT -

17. EYES AHEAD -

18. CARE ON RAMPS -

19. SLOW DOWN -

20. WATCH PEOPLE -

21. WORK PLATFORMS -

22. SHUT DOWN COMPLETELY -

Do not handle unstable or lo osely stacked

loads. Use special care when handling long, high, or wide loads to avoid

losing the load, striking bystanders, or tipping truck.

When using forks, space forks as far apart

as load will permit. Before lifting, be sure load is centered and forks are

completely under load.

Do not overload truck. Check capacity plate for

load weight and load center informa tion .

Start, stop, travel, steer, and brake

smoothly. Sudden movements can endanger yourself and others.

Elevate forks or other li fting mechanism only to

pick up or stack a load. Lift and lower with mast vertical or slightly back -

NEVER FORWARD. Watch out for obstructions, especially overhead.

Opera te tilti ng mechanism slowly and smoothly.

Do not tilt forward when elevated except to pick up or deposit a load.

When stacking use only enough backward tilt to stabilize load.

Travel with load or lifting mechanism as low as

possible and tilted back. Always look in direction of travel. Keep a clear

view, and when load interferes with visibility, travel with lifting mechanism

trailing (except when climbing ramps).

Use special care when operating on ramps -

travel slowly, and do not angle or turn. When truck is loaded, travel with

load uphill. When truck is empty, travel with lifting mechanism downhill.

Obser ve applicable traff ic re gula tions. Yield

right-of-way to pedestrians. Slow down & sound horn at cross aisles and

whenever vi sion is obstructed.

Do not allow anyone to stand or pass under lifting

mechanism, directly behind truck or within rear swing area when turning.

DO NOT LIFT OR CARRY PERSONNEL

USING THE FORKS OF THE TRUCK, not even with a work platform. The

truck is designed for transporting, warehousing and stacking of material,

not personnel.

Before getting off truck, neutralize

trav el control, fully lower lift ing mechanism and set the pa rking brake.

Also shut off power when leaving truck unattended. Block wheels if truck

is parked on an incline.

Page 26

26

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

OPERATOR WARNING AND SAFETY DECALS

(continued)

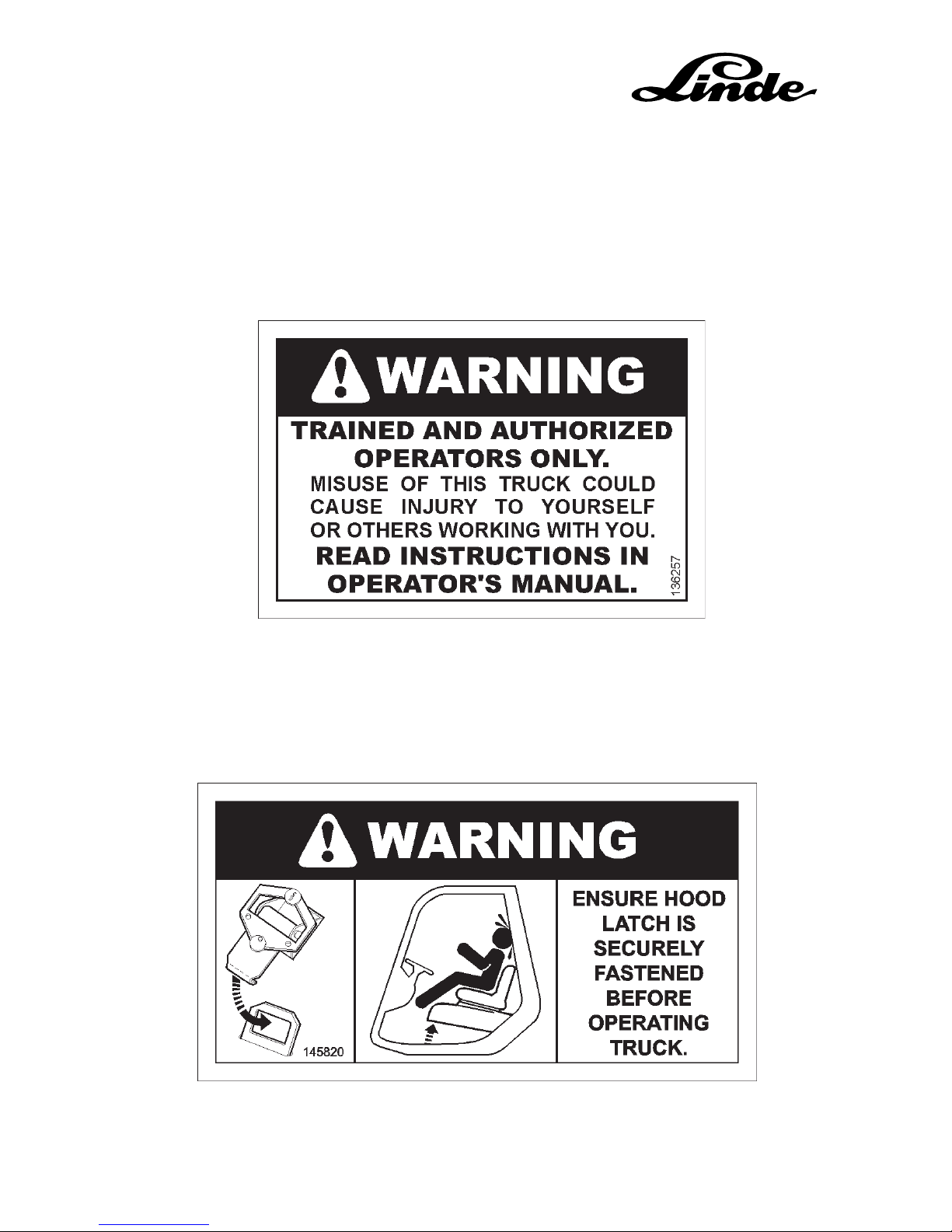

Trained Operator Warning Decal

This decal reinforces the requirement that only trained and authorized

personnel are to operate the truck.

Hood Latch Warning Decal

This decal reinforces that the Operator should verify that the Hood Latch is

securely fastened before operating the truck.

Page 27

27

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

OPERATOR WARNING AND SAFETY DECALS

(continued)

“Don’t Walk Under or Stand On Forks” Warning Decal

This decal is located on both sides of the Mast Uprights and warns both the

Operator and any pedestrians not to stand on or walk under a raised load at

any time.

Page 28

28

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

OPERATOR WARNING AND SAFETY DECALS

(continued)

Brake Warning Decal

This decal reinforces that the Operator should engage the Parking Brake

lever whenever necessary, as it is not automatically applied.

Personnel Warning Decal

This decal reinforces that the Operator should never use the Forks to lift

personnel for any reason.

Page 29

29

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

OPERATOR WARNING AND

SAFETY DECALS (continued)

Seat Belt / Tip-Over Warning Decal

This decal reinforces that the Operator should

read the Operator’s Manual and engage the Seat

Belt before operating the truck. It also instructs

the Operator on what to do in the event of a tipover of the truck.

Page 30

30

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

NOTES:

Page 31

31

SAFETY TIPSSAFETY TIPS

SAFETY TIPSSAFETY TIPS

SAFETY TIPS

NOTES:

Page 32

©2002 Linde Lift Truck Corporation

2450 West 5th North Street

Summerville, S.C. 29484

PHONE (843) 875-8000 FAX (843) 875-8329

LINDE LIFT TRUCK CORP.

A MEMBER OF THE LINDE GROUP

Page 33

With Diesel Engine

353 804 3001 GB

Linde Fork Lift Truck

H 50 - 02 / H 60 - 02 / H 70 - 02

H 80 - 02 / H 80/900 - 02

Operating Instructions

0702

d353-02/33

Page 34

Page 35

Linde - Your Partner

Linde AG Linde Material Handling Division

Linde, an enterprise operating

worldwide in the investment

and service sector, is one of

the large industrial enterprises in the EC with its three

business segments and six

divisions.

The Linde Material Handling

division is a leading manufacturer of industrial trucks and

hydraulics. It includes eight

manufacturing plants in the

Federal Republic of Germany ,

France and Great Britain, as

well as subsidiaries and branches in all economically important countries.

Linde industrial trucks enjoy a

worldwide reputation - thanks

to their high quality in engineering, performance and service.

Werk II, Aschaffenburg-Nilkheim

Werk I, Aschaffenburg

Lansing Linde Ltd., Basingstoke

Fenwick-Linde, Châtellerault

Werk III, Kahl am Main

Linde Heavy Truck Division Ltd., Merthyr Tydfil

Page 36

2

353 804 3001.0702

Description

Your Linde lift truck

offers the best in economy, safety and driving convenience.

Therefore it lies mainly in the hands of the operator to

preserve the qualities of the trucks for a long and profitable

service life and to make full use of their benefits on the job.

These operating instructions tell you all you need to know

about starting, operation, running, and servicing the truck.

For maintenance and repair work not described in these

operating instructions special technical skill and knowledge,

measuring equipment and special worshop tools are often

required. Please contact your authorised Linde dealer for this

service.

Only qualified persons authorised by Linde are allowed to

service the trucks.

For some options, follow the operating instructions supplied

with that equipment. Follow the operating instructions for your

truck and perform the services specified in the inspection and

maintenance schedule regularly, on time and with the specified oils and lubricants.

Keep a record of all maintenance services, otherwise your

warranty may become void.

The terms “front“, “rear“, “left“ and “right“ refer to the position

in which the item is installed in the truck, looking in the forward

travel direction of the truck.

Authorised applications

Your Linde truck is designed for transporting and lifting the

loads specified in the load capacity diagram.

In particular, we refer to the VDMA booklet "Rules for the

Normal and Proper Use of Industrial Trucks" supplied with

this manual, to accident prevention rules of your employer's

liability insurance and to the requirements of traffic regulations.

The rules for the normal and proper use of industrial trucks

must be followed under all circumstances by the responsible

persons, in particular by the operators and service personnel.

The user, and not the manufacturer Linde, is liable for any

hazards arising from unauthorised applications.

If you wish to use the truck for applications not mentioned in

these guidelines, please first contact your Linde distributor

before supplementing or retrofitting it for this purpose.

No changes, in particular no conversions or retrofits, may be

made to the truck without the prior permission of the manufacturer.

Page 37

3

353 804 3001.0702

Technical note

These operating instructions or excerpts thereof may only be

copied, translated or used by third parties after prior written

approval by the manufacturer.

Linde pursues a policy of continuous improvement in the

design and construction of its products. As a result, the

illustrations and technical details regarding design, equipment and engineering of trucks are subject to change or

modification as a result of technological progress.

Therefore, no liability based on the specifications, illustrations and descriptions contained in this operating manual will

be accepted.

Please submit all enquiries concerning your truck and all

orders for spare parts to your authorised distributor, making

sure to state your correct shipping address.

For repairs use only genuine Linde spare parts to ensure that

your truck will retain its original technical standard.

When ordering spare parts, specify the part numbers and also

the

Lift truck model: __________________________________

Manufacturer’s number/year built: ____________________

Takeover date: ___________________________________

Also state the manufacturer’s number of the engine and mast

when ordering parts for these assemblies.

Engine number: __________________________________

Mast number: ____________________________________

Mast lift height: ________________________________mm

When taking over the fork truck, transfer the data from the

assembly type plates into this manual.

Takeover inspection

Every fork lift truck undergoes careful inspection before

leaving the factory, in order to make sure that it will be in

satisfactory condition and fully equipped as ordered when

delivered to the customer. Authorised distributors are under

obligation to re-inspect the truck before delivery and to hand

it over in proper order.

With a view to avoiding later complaints, we request you to

check the condition of the truck, to make sure that it is

equipped as ordered, and to acknowledge the proper handing/taking over of the truck in the manufacturer’s certificate of

conformity.

The following technical documents belong to each fork lift

truck:

1 Operating instructions

1 Manufacturer’s declaration of conformity

(manufacturer declares that the industrial truck conforms

to the EC directives for machines)

1 Rules for the Normal and Proper use of Industrial Trucks

(VDMA)

Wishing you satisfactory operation,

Linde AG

Linde Material Handling Division

Aschaffenburg

Description

Page 38

4

353 804 3001.0702

Page 39

5

353 804 3001.0702

1

2

5

4

3

7

8

6

1 Manufacturer’s plate

2 Manufacturer

3 CE symbol

(The symbol certifies that the EC directives for machines

and all applicable guidelines are fulfilled.)

4 Serial number / year built

5 Weight of empty truck

6 Battery voltage

7 Rated capacity

8 Type

9 Lift mast number (stamped)

10 Chassis number (stamped on side)

11 Working hydraulics pump plate

12 Power steering pump plate

13 Traction hydraulics pump plate

14 Engine type plate

Type plates Description

1

9

10

11

12

13

14

d353-2/095

Page 40

6

353 804 3001.0702

Innovative technology,

easy and ergonomic operation,

energy-efficient, environment- and maintenance-friendly,

solid manufacture and

because almost all spares are of our own manufacture they

are readily available!

The success of a company

with about 9600 employees in eight manufacturing sites.

Fork lift truck models H 50 / H 60 / H 70 / H 80 / H 80/900 with Diesel engine Description

The driver’s position and operating features are designed using

the latest research in ergonomics. Each operating element is

designed in regard to position and operation to ensure the

driver’s convenience guaranteeing effortless and safe operation.

Of course, this also includes the easy hydrostatic power

steering with a kick-back safety, the proven double-pedal

travel control - forward with the right pedal, reverse with the

left - and only one main lever for all mast functions.

d353-02/33

Page 41

7

353 804 3001.0702

PagePagePage

Table of contents Description

Description .....................................................................2

Authorised applications ........................................................ 2

Technical note...................................................................... 3

Takeover inspection .............................................................3

Type plates........................................................................... 5

Technical data ................................................................... 10

Noise emission levels ....................................................... 12

Frequency characteristic for human body vibrations ...... 12

Technical description........................................................13

Engine ............................................................................13

Hydraulic system ........................................................... 13

Technical description .................................................... 13

Operation .......................................................................13

Lift mast ..........................................................................13

Brakes ............................................................................13

Steering .......................................................................... 13

Electrical system ............................................................ 1 3

General view of truck ........................................................1 4

Controls and indicators ..................................................... 15

Composite instrument .......................................................17

Beginning operation ................................................ 1 8

Safety rules ........................................................................ 1 8

Important safety information ............................................. 1 8

Handling fuels and lubricants .......................................... 18

Accident prevention check ................................................ 19

Operation of industrial trucks in the plant area................1 9

Diesel engine emissions .................................................. 19

Particle filter system inspection (option) .......................... 1 9

Running-in instructions.....................................................19

Services prior to first operation ......................................... 19

Daily checks ...................................................................... 19

Daily checks and servicing before operation .................. 20

Opening the bonnet .......................................................... 20

Closing the bonnet ............................................................ 20

Check the fuel level .......................................................... 20

Refuelling ..........................................................................2 1

Check the engine oil level ................................................ 2 1

Check the header tank coolant level ................................ 21

Check the tyre inflation pressure ...................................... 22

Applying the seat belt .......................................................2 3

Opening the seat belt........................................................2 3

Adjusting the operator seat ............................................... 23

Starting the engine ............................................................ 24

Cold start ........................................................................... 2 5

Stopping the engine ......................................................... 25

Malfunctions during operation ..........................................25

Operation ...................................................................... 26

Driving ............................................................................... 26

Driving forward .............................................................. 26

Reversing....................................................................... 2 6

Reversing the direction of travel ................................... 2 6

Stopping .........................................................................2 6

Single-pedal model .......................................................... 27

Steering .............................................................................30

Brakes................................................................................ 30

Service brake ................................................................. 3 0

Parking brake ................................................................. 30

Applying the parking brake ........................................... 3 0

Releasing the parking brake ......................................... 30

Central-lever control of lifting device and attachments ... 31

Tilting the mast forward .................................................3 1

Tilting the mast back......................................................3 1

Lifting the fork carriage ..................................................3 1

Lowering the fork carriage ............................................ 31

Operating the attachments ............................................ 3 1

Operating the sideshift .................................................. 31

Operating the clamp ...................................................... 31

Single-lever control of lifting device and attachments .....3 2

Installation of additional equipment ................................. 33

Turning on the lighting ......................................................3 3

Turning on the hazard warning light ................................ 3 3

Turning on the front working lights ...................................3 3

Turning on the working light (at rear)...............................3 3

Operating the intermittent front windscreen wiper ...........3 3

Operating the front windscreen wiper .............................. 3 3

Operating the front windscreen washer ........................... 3 3

Intermittent switch for rear and top windscreen wiper .....3 3

Operating the rear windscreen and top screen wipers ... 33

Operating the rear windscreen and top screen washer ..3 3

Operating the directional indicator lights ......................... 33

Turning on the dome light.................................................3 3

Heater ................................................................................3 4

Controls .......................................................................... 3 4

Fan motor fuse ...............................................................34

Operating the horn............................................................ 34

Check fuses, renew if required ......................................... 35

Before lifting a load ........................................................... 36

Loading ............................................................................. 3 7

Adjusting the fork spread ..................................................3 7

Loading ............................................................................. 3 7

Transporting a load ........................................................... 38

Depositing a load .............................................................. 38

Before leaving the lift truck unattended ........................... 3 8

Transport ........................................................................... 3 9

Transport with lorry or low-bed semi-trailer..................3 9

Hoisting the truck ..............................................................3 9

Hoisting the truck with a crane .........................................3 9

Hoisting the truck, wheel change ..................................... 40

Hoisting the truck with lifting eyes ....................................40

Wheel change ................................................................... 40

Mast removal, trailer coupling .......................................... 41

Mast removal .....................................................................4 1

Securing the moveable overhead guard ......................... 4 1

Trailer coupling ................................................................. 41

Towing instructions ........................................................... 42

Towing............................................................................ 42

Towing procedure ..........................................................4 2

Releasing the disc brake ............................................... 4 2

Opening the hydraulic by-pass valve ........................... 4 2

After towing .................................................................... 4 2

Making the brakes operational again ........................... 42

Emergency exit for trucks with rear windscreen ..............43

Taking the truck out of operation ......................................44

Measures before taking the truck out of operation .......... 4 4

Putting the truck back into operation ................................4 4

Maintenance ...............................................................44

General information .......................................................... 44

Servicing the mast and the front part of the truck ............45

Securing the mast against tilting back .............................4 5

Standard mast ................................................................... 45

Securing the raised standard mast .................................. 4 5

Maintenance after the first 50 service hours ....................4 5

Inspection and maintenance schedule ............................ 46

Page 42

8

353 804 3001.0702

Page 43

9

353 804 3001.0702

PagePagePage

Table of contents Description

Inspection and maintenance as required...... 48

Cleaning the lift truck ........................................................4 8

Cleaning and spraying the mast chain ............................ 4 8

Cleaning the air filter ......................................................... 4 9

Cleaning with compressed air ...................................... 49

Emptying the dust bowl in the air filter cover ...................5 0

Replacing the safety element ........................................... 5 0

Clean the pre-filter ............................................................ 50

Regenerate the particle filter ............................................5 1

Check wheel fastener for tightness .................................. 5 2

Check the tyres for damage and foreign objects ............. 5 2

Lubricate the steer axle, mast and tilt cylinder bearings . 5 2

Clean the radiator and engine oil, hydraulic oil and

fuel cooler, check for leaks ............................................5 3

Clean with compressed air ............................................ 5 3

Clean with a cold cleaner .............................................. 5 3

Drain the water separator in the fuel system ...................5 4

Check seat belt for condition and operation ....................5 5

500-hour inspection and maintenance...........5 6

Clean and lubricate the steer axle ...................................5 6

Grease the mast pivots .....................................................5 6

Grease the tilt cylinder and overhead guard pivots .........5 6

Check the engine mounting, movable overhead guard,

steer axle and drive axle hub differentials for tightness... 57

Check the forks and fork quick-releases .......................... 57

Check the mast, lift chains and stops for condition,

operation and security ................................................... 5 7

Adjust the lift chains .......................................................... 58

Lubricate with chain spray................................................ 58

Check the pre-tension of double hoses if attachments

are fitted .........................................................................5 8

Check and oil other pivots and joints ............................... 5 8

Check the engine cooling system for leaks ..................... 5 9

Check and oil the pedals, accelerator and

engine control linkage ................................................... 59

Renew the engine oil (at least every 12 months) ............ 6 0

Drain the engine oil .......................................................... 60

Renew the engine oil filter................................................ 60

Add engine oil ................................................................... 61

Check the hydraulic oil level ............................................ 6 1

Check the coolant concentration ...................................... 6 2

Check the particle filter system.........................................6 2

Check and tension V-belt drives ...................................... 6 3

Tighten V-belt drives .........................................................6 3

Drain the water separator in the fuel system ...................6 3

Clean the radiator, hydraulic oil and fuel cooler .............6 4

Clean with compressed air ............................................ 6 4

Clean with a cold cleaner .............................................. 6 4

Renew the drive axle hub differential oil and clean

the magnetic plug .......................................................... 64

Check the condition and security of electric cables,

connectors and cable connections ...............................6 5

Check the condition, electrolyte level and

specific gravity of the battery......................................... 65

1000-hour inspection and maintenance........ 66

Renew the hydraulic pressure, suction and

breather filters ................................................................ 66

Renew the pressure filter ..............................................6 6

Renew the suction filter .................................................6 6

Renew the breather filter............................................... 67

Renew the fuel filter canister ............................................6 7

Check the engine mounting for condition and tightness ..... 67

Renew and tension the V-belt drive .................................6 8

Check the exhaust system for leaks and tightness ......... 69

Check the hydraulic system, hydraulic pumps,

valves and lines for leaks .............................................. 69

Renew the air filter element, check the vacuum switch ...7 0

Check the parking brake ................................................... 7 0

Check the drive axle hub differential oil level

and for leaks .................................................................. 7 1

Check the particle filter system.........................................7 1

2000-hour inspection and maintenance........ 72

Check the particle filter system.........................................7 2

Check valve tip clearances ............................................... 7 2

Renew the safety element ................................................ 7 3

3000-hour inspection and maintenance........ 74

Renew the hydraulic oil .................................................... 74

Drive axle hub differential: Renew oil and

clean the magnetic plug ................................................ 75

Renew the coolant ............................................................ 7 6

Inspection and maintenance data .................................... 7 7

Fuel and oil recommendations ......................................... 78

Engine oils ..................................................................... 78

Diesel fuel ...................................................................... 79

Hydraulic oil ................................................................... 79

Gear oil .......................................................................... 79

Grease ............................................................................ 79

Coolant .......................................................................... 7 9

Battery grease ................................................................ 79

Chain spray ....................................................................7 9

Troubleshooting guide (Diesel engine) ........................... 80

Troubleshooting guide (hydraulic system) ...................... 83

Electric circuit diagram ...................................................... 8 4

Electric circuit diagram (Options) .....................................8 7

Particle filter wiring diagram .............................................9 0

Hydraulic circuit diagram ..................................................9 2

Index .................................................................................. 94

Page 44

10

353 804 3001.0702

Technical data Description

Notes:

1) Additional lifting mast heights; see table.

2) Aditional optional tyres upon request.

3) Values in brackets for double wheels 8.25 - 15/18 PR.

4) 1718 mm for double wheels 8.25 - 15.

5) With a free lift of 150 mm.

6) On short slopes, when crossing obstacles (refer to

section "Travel").

CharacteristicsWeightWheels and TyresDimensionsPerformanceIC engineOthers

1.1 Manufacturer (see page 1)

1.2 Model designation

1.3

Power unit: battery, diesel, petrol, LPG, mains power

1.4 Operation: manu., pedest., stand-on, seated, ord. pic.

1.5 Load capacity Q [t]

1.6 Load centre c [mm]

1.8 Axle centre to fork face x [mm]

1.9 Wheelbase y [mm]

2.1 Service weight [kg]

2.2 Axle load with load, front/rear [kg]

2.3 Axle load without load, front/rear [kg]

3.1

Tyres, front/rear (SE = CS superelastic, L = pneum.)

3.2 Tyre size, front

3.3 Tyre size, rear

3.5 Wheels, number front/rear (x = driven)

3.6 Track width, front b10 [mm]

3.7 Track width, rear b11 [mm]

4.1 Mast/fork carriage tilt, forward/backward degrees

4.2 Height of mast, lowered h1 [mm]

4.3 Free lift h2 [mm]

4.4 Lift h3 [mm]

4.5 Height of mast, extended h4 [mm]

4.7 Height of overhead guard (cabin) h6 [mm]

4.8 Height of seat/stand-on platform h7 [mm]

4.12 Tow coupling height h10 [mm]

4.19 Overall length l1 [mm]

4.20 Length to fork face l2 [mm]

4.21 Overall width b1/b2 [mm]

4.22 Fork dimensions s/e/l [mm]

4.23 Fork carriage to DIN 15173, class/form A, B

4.24 Width of fork carriage b3 [mm]

4.31 Ground clearance, mast m1 [mm]

4.32 Ground clearance, centre of wheel base m2 [mm]

4.33

Aisle width with pallets 1200x1000 across forks Ast [mm]

4.34 Aisle width with pallets 800x1200 along forks Ast [mm]

4.35 Turning radius Wa [mm]

4.36 Min. distance between the centres of rotation b13 [mm]

5.1 Travel speed, with/without load km/h

5.2 Lifting speed, with/without load m/s

5.3 Lowering speed, with/without load m/s

5.5 Tractive force, with/without load, 60 minute rating N

5.7 Climbing ability with/without load, 30 minute rating % 6)

5.9 Acceleration time with/without load (first 10 m) s

5.10 Service brake

7.1 Manufacturer of engine/type

7.2 Engine rated power to ISO 1585 kW

7.3 Rated rpm RPM

7.4 Number of cylinders / cc n/cc

7.5 Fuel consumption to VDI l/h kg/h

8.1 Type of drive control

8.2 Working pressure for attachments bar

8.3 Oil quantity for attachments l/min

8.4 Mean noise level at driver's ear dB (A)

8.5 Towing coupling, design/type DIN, no.

to VDI 2198

Data Sheet for Material Handling Equipment

VDI 2198

DFG

June 1999

Fork Lift Trucks

Designation VDI 2198

H 50 D

Diesel

seated

5.0

600

590

2160

9300

12200 / 2100

4450 / 4850

L (SE)

300 - 15/22 PR 2)

8.25 - 15/18 PR 2)

2x (4x) / 2 3)

1594 4)

1600

6 / 10

2730 1) 5)

150

3550 1)

4450 1)

2714

1432

810

4590

3390

1894 (2262) / 1850 3)

60 x 130 x 1200

4 A

1800

202

245

4850

5050

3060

975

22 / 22

0.53 / 0.53

0.50 / 0.50

61000 / 31000

45 / 28

4.7 / 4.3

hydrostatic

KHD / BF 6M 1012

85

2200

6 / 4800

5.3

hydrostatic transmission

260

-

-

-

H 60 D

Diesel

seated

6.0

600

590

2160

9550

13770 / 1780

4470 / 5080

L (SE)

355/65 - 15/24 PR 2)

8.25 - 15/18 PR 2)

2x (4x) / 2 3)

1594 4)

1600

6 / 10

2730 1) 5)

150

3550 1)

4450 1)

2714

1432

810

4590

3390

1948 (2262) / 1850 3)

60 x 130 x 1200

4 A

1800

202

245

4850

5050

3060

975

22 / 22

0.53 / 0.53

0.50 / 0.50

57000 / 33000

35 / 27

5.2 / 4.7

hydrostatic

KHD / BF 6M 1012

85

2200

6 / 4800

5,6

hydrostatic transmission

260

-

-

-

H 70 D

Diesel

seated

7.0

600

600

2160

10760

15650 / 2110

4770 / 5990

L (SE)

8.25 - 15/18 PR 2)

8.25 - 15/18 PR 2)

4x / 2

1748

1600

6 / 10

2730 1) 5)

150

3150 1)

4250 1)

2714

1432

810

4600

3400

2262 / 1850

70 x 150 x 1200

4 A

2180

202

245

4860

5060

3060

975

22 / 22

0.42 / 0.42

0.42 / 0.42

58000 / 35000

29 / 28

5.7 / 5.1

hydrostatic

KHD / BF 6M 1012

85

2200

6 / 4800

5.9

hydrostatic transmission

260

-

-

-

H 80 D

Diesel

seated

8.0

600

600

2160

11500

17160 / 2340

4730 / 6770

L (SE)

8.25 - 15/18 PR 2)

300 - 15/18 PR 2)

4x / 2

1748

1550

6 / 10

2730 1) 5)

150

3150 1)

4250 1)

2714

1432

810

4600

3400

2262 / 1850

75 x 150 x 1200

4 A

2180

202

245

4860

5060

3060

975

22 / 22

0.42 / 0.42

0.42 / 0.42

58000 / 35000

26 / 27

6.2 / 5.3

hydrostatic

KHD / BF 6M 1012

85

2200

6 / 4800

6.2

hydrostatic transmission

260

-

-

-

H 80 D/900

Diesel

seated

8.0

900

630

2510

12400

18200 / 2200

5400 / 7000

L (SE)

8.25 - 15/18 PR 2)

300 - 15/18 PR 2)

4x / 2

1748

1550

6 / 10

2730 1) 5)

150

2750 1)

4150 1)

2714

1432

810

5590

3790

2262 / 1850

70 x 200 x 1800

4 A

2180

202

240

5175

5375

3345

975

22 / 22

0.42 / 0.42

0.42 / 0.42

58000 / 42000

-

6.2 / 5.3

hydrostatic

KHD / BF 6M 1012

85

2200

6 / 4800

6.7

hydrostatic transmission

260

-

-

-

Page 45

11

353 804 3001.0702

Lifting capacity diagrams:

Safety distance “a” = 200 mm

Load capacities apply for SE tyres.

Mast and lifting height H 50, H 60 (in mm)

Lifting height h3 3550 4150 4550 5250 6050

Mast retracted (with 150 mm free lift for standard) h1# 2730 3030 3230 3580 3980

Mast extended h4 4450 5050 5450 6150 6950

Mast and lifting height H 70, H 80 (in mm)

Lifting height h3 3150 3750 4150 4850 5650

Mast retracted (with 150 mm free lift for standard) h1# 2730 3030 3230 3580 3980

Mast extended h4 4250 4850 5250 5950 6750

Mast and lifting height H80/900 (in mm)

Lifting height h3 2750 3350 3750 4450 5250

Mast retracted (with 150 mm free lift for standard) h1# 2730 3030 3230 3580 3980

Mast extended h4 4150 4750 5150 5850 6650

Technical data Description

Page 46

12

353 804 3001.0702

Noise emission levels

Determined in a test cycle in accordance with EN 12053 from

the weighted values in the operating modes DRIVING, LIFTING, IDLING.

Noise level at driver’s station

H 50 - H 80 L

PAZ

= 78 dB (A)

Uncertainty KPA= 4 dB (A)

Sound level at driver’s place

While lifting LPa= 8 0 dB (A)

While idling LPb= 6 5 dB (A)

While driving LPc= 8 3 dB (A)

Uncertainty KPA= 4 dB (A)

Acoustic power level

H 50 - H 80 L

WAZ

=100 dB (A)

Uncertainty KWA= 2 dB (A)

Acoustic power level

While lifting LWa=101 dB (A)

While idling LWb= 8 7 dB (A)

While driving LWc=105 dB (A)

Uncertainty KWA= 2 dB (A)

Guaranteed acoustic power level

Acc. to directive 2000/14/EC LWA=105 dB (A)

The directive legally requires this information. This value has

been calculated from the acoustic power levels for ”Lifting”

and ”Driving” and is only be used as a comparable value for

different trucks. For the determination of the real environmental

noise stress this value is less appropriate, as it is not

representative of normal truck operation, which includes

”Idling”.

NOTE

Higher or lower noise emissions can exist during operation of the truck, for example due to type of operation,

environmental influences and additional noise emission

sources.

Technical data Description

Frequency characteristic for human body

vibrations (preliminary values as only a

draft standard is available)

The values are determined in conformance with prEN 13059

on trucks with standard equipment according to the technical

data sheet (driving over test course with bumps).

Frequency characteristic acc. to EN 12096

Measured frequency characteristic a

w.zs

= 0.8 m/s²

Uncertainty K = 0.3 m/s²

Frequency characteristic given for hand and arm vibrations

Frequency characteristic < 2.5 m/s²

NOTE

The frequency characteristic for the human body can not

be used to determine the actual frequency load during

operation. This load depends on the working conditions

(condition of roadway, type of operation, etc) and must

therefore be determined at the site, if necessary.

The specification of hand and arm vibrations is required

by law, even if the values, as in this case, do not indicate

any danger.

Page 47

13

353 804 3001.0702

The 353 fork lift truck series is designed for loading and

spotting loads of up to 5 tons with the H 50, of up to 6 tons with

the H 60, of up to 7 tons with the H 70 and 8 tons with the

H 80 with a load centre distance of 600 mm.

The H 80 / 900 is designed for loading and spotting loads of

up to 8 tons with a load centre distance of 900 mm.

The trucks have a compact and low profile design.

The low centre of gravity and the optimum distribution of

weight ensures optimum stability under all operating conditions.

Engine

A water-cooled, 6-cylinder supercharged Diesel engine with

direct fuel injection is installed as power unit. It drives the

hydraulic pumps of the truck at load-dependent speed.

The combustion air is cleaned by dry air filter with a paper

element.

Hydraulic system

The drive system consists of one variable-displacement pump

for driving the two traction hydraulics variable-displacement

motors, one hydraulic pump each for the working and steering

hydraulics, and one hydraulic pump for boost pressure.

The variable-displacement hydraulic motors in the drive units

are supplied with pressure by the variable-displacement

pump. They power the traction wheels via two lateral drive

axle hub differentials.

Operation

The hydraulic pump and the speed are simultaneously controlled by the forward and reverse accelerator pedals. The

truck speed can be regulated by the hydrostatic power source

from a standstill up to the maximum speed with infinitely

variable control in both directions. The double pedal control

permits easy as well as safe and time-saving handling of the

lift truck.

Both hands are always free for steering and control of the

work movements. The net result is quick reversing and

energy-saving stacking.

There is only one control lever (main control lever) for controlling the work motions lifting, lowering and tilting. Additional

control levers are supplied for the operation of supplementary

attachments.

Lift mast

Overhead tilt cylinders are fitted for sensitive tilting and for

mast stabilisation. The LTS (Linde Torsion Support), also

functioning as overhead guard, ensures high strength against

torsion, i.e. easy working due to reduced torsional vibrations

of the mast and so a long service life.

For lifting the inner mast, there are two lift cylinders mounted

on the outer upright channel.

The fork carriage is lifted by two flyer chains running at the

inner upright channel.

Brakes

The hydrostatic transmission is used as service brake. The

two multiple disc brakes integrated in the compact axle are

utilised as a parking brake.

When the engine is stopped, the multiple disc brakes are

applied = automatic braking.

The brake pedal is also used as parking brake. To park the

truck, lock the brake pedal mechanically.

Steering

The steering is a hydrostatic power steering system, which

turns the rear wheels with the steering wheel via the steer

cylinder.

The steering system can also be operated when the engine is

stopped, but a greater effort is required to turn the steering

wheel.

Electrical system

The electrical system is supplied by a three-phase current

generator with 12 VDC. For starting the engine, a

12-volt battery is installed.

Technical description Description

Page 48

14

353 804 3001.0702

1 Steering wheel

2 Tilt cylinder

3 Driver’s seat

4 Cabin*

5 Counterweight

6 Bonnet

7 Steering axle

8 Electrical system cover

9 Foot steps

10 Left drive axle hub differential

11 Fork carriage

12 Lift cylinder

13 Forks

14 Fork quick-releases

15 Lift chain

16 Lifting mast

17 Control console

* Option

General view of truck Description

d353-02/34

12 3

4

5

6

7

89

1011

12

13

14

15

16

17

Page 49

15

353 804 3001.0702

1

23 4

56

7

8

9

10

1112

13

14

15

16

17

18

d353-02/35

1 Toggle switches for supplementary functions*

2 Parking brake lever

3 Steering wheel/hydrostatic power steering

4 Horn button

5 Ignition switch and key switch

6 Toggle switches for supplementary functions*

7 Composite instrument

8 Air outlet*

9 Control lever for supplementary hydraulics (attachments)*

10 Label for supplementary hydraulics*

11 Notice label

12 Load capacity diagram

13 Load capacity plate (attachment)*

14 Symbol label for working hydraulics

15 Control lever for working hydraulics

16 Forward accelerator pedal

17 Brake pedal

18 Reverse accelerator pedal

* Option

Controls and indicators Description

Page 50

16

353 804 3001.0702

Page 51

17

353 804 3001.0702

1

2

6

5

7

9

3

13

d353-2/071

4

10

8

11

12

Composite instrument Description

Indicator element Function Possible fault(s)

The composite instrument contains the following control and

indicator elements:

1 Hour meter

2 Hour meter on indicator light

3 Coolant temperature control indicator, coolant level indi-

cator

4 Particle filter warning light

5 Hydraulic oil temperature warning light

6 Engine oil pressure warning light

7 Pre-heating indicator light

8 Flasher indicator light

9 Battery charge indicator light

10 Fuel level warning light

11 Air filter restriction indicator light

* Option

Hour meter (1). The row of figures (13)

shows the full service hours, the last

figure (12) 1/10 of an hour

Hour meter ON indicator light (2)

Coolant temperature control indicator, coolant level indicator (3)

Particle filter warning light* (4)

Hydraulic oil temperature warning

light (5)

Engine oil pressure warning light (6)

Pre-heating indicator light (7)

Flasher indicator light* (8)

Battery charge indicator light (9)

Fuel level warning light (10)

Air filter restriction indicator light (11)

Indicates lift truck service hours. The

display serves as reference for

elapsed working hours and for the

required inspection and maintenance

activities

Indicates that the hour meter is running

Indicates that the coolant temperature is too high or that the coolant level is too low

Indicates that the particle filter must

be regenerated

Monitors the hydraulic oil temperature

Indicates low oil pressure of engine

lubrication

It is illuminated if the pre-heating

function is on

Indicates operation of flasher unit

when direction indicator is on

Indicates malfunctions in the electrical system

Indicates a fuel reserve of approx. 8.0

litres.

Indicates excessive accumulation of

dirt on air cleaner element

NOTE

The elapsed service hours should be recorded when replacing a defective hour

meter. Record data on durable tape and

affix next to hour meter

- Fan V-belt slack

- Dirt on the radiator

- Leak in the cooling system

- Low coolant level

- Regenerate the particle filter

- Dirt on oil cooler

- Oil filter blocked

- Oil level in hydraulic system is too low

- Oil not as specified

- Low oil level in crankcase

- Engine is overheating

- Oil not as specified

- Internal leakage in lubricating system

- V-belt broken or slipping

- Cables broken

- Alternator faulty

- Regulator or relay faulty

- Air filter element restricted

Page 52

18

353 804 3001.0702

The responsible persons, particularly the truck operator and

servicing personnel, must be instructed in the safety guidelines for the normal and proper use of industrial trucks

included with these operating instructions.

The employer must ensure that the operator has understood

all safety informations.

Please observe the guidelines and safety rules therein for

example:

- information on the operation of industrial trucks

- rules for roadways and work areas

- rights, duties and safety rules for the operator

- operation in special areas

- information related to starting, driving and braking

- service and repair information

- recurrent inspections, accident prevention check

- disposal of greases, oil and batteries

- remaining risks.

The operator (employer) or the responsible person must

ensure that all the guidelines and safety rules applicable for

your truck are observed.

When instructing a trained operator, acquaint him with the

- special features of the lift truck (double-pedal control,

main control lever, brake pedal)

- optional attachments

- special operating and working area characteristics,

by training and practicing driving, shifting and steering operations until they are completely mastered.

Only then start to practice shelf-stacking.

The stability of the truck in the work area is ensured if

employed properly. Should the truck tip over during an

unauthorised application or due to incorrect operation, always follow the instructions depicted below.

Safety rules Beginning operation

Handling fuels and lubricants

Always handle fuels and lubricants as required and

as specified by the manufacturer.

Only store fuels and lubricants in approved containers at

specified storage places. As they could be inflammable, do

not contact them with hot objects or a naked flame.